Page 1

General Description

The low-cost MAX1873R/S/T provides all functions

needed to simply and efficiently charge 2-, 3-, or 4series lithium-ion cells at up to 4A or more. It provides a

regulated charging current and voltage with less than

±0.75% total voltage error at the battery terminals. An

external P-channel MOSFET operates in a step-down

DC-DC configuration to efficiently charge batteries in

low-cost designs.

The MAX1873R/S/T regulates the battery voltage and

charging current using two control loops that work

together to transition smoothly between voltage and

current regulation. An additional control loop limits current drawn from the input source so that AC adapter

size and cost can be minimized. An analog voltage output proportional to charging current is also supplied so

that an ADC or microcontroller can monitor charging

current.

The MAX1873 may also be used as an efficient currentlimited source to charge NiCd or NiMH batteries in multichemistry charger designs. The MAX1873R/S/T is

available in a space-saving 16-pin QSOP package. Use

the evaluation kit (MAX1873EVKIT) to help reduce

design time.

Applications

Notebook Computers

Portable Internet Tablets

2-, 3-, or 4-cell Li+ Battery Pack Chargers

6-, 9-, or 10-cell Ni Battery Pack Chargers

Hand-Held Instruments

Portable Desktop Assistants (PDAs)

Desktop Cradle Chargers

Features

♦ Low-Cost and Simple Circuit

♦ Charges 2-, 3-, or 4-Series Lithium-Ion Cells

♦ AC Adapter Input-Current-Limit Loop

♦ Also Charges Ni-Based Batteries

♦ Analog Output Monitors Charge Current

♦ ±0.75% Battery-Regulation Voltage

♦ 5µA Shutdown Battery Current

♦ Input Voltage Up to 28V

♦ 200mV Dropout Voltage/100% Duty Cycle

♦ Adjustable Charging Current

♦ 300kHz PWM Oscillator Reduces Noise

♦ Space-Saving 16-Pin QSOP

♦ MAX1873 Evaluation Kit Available to Speed

Designs

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

________________________________________________________________ Maxim Integrated Products 1

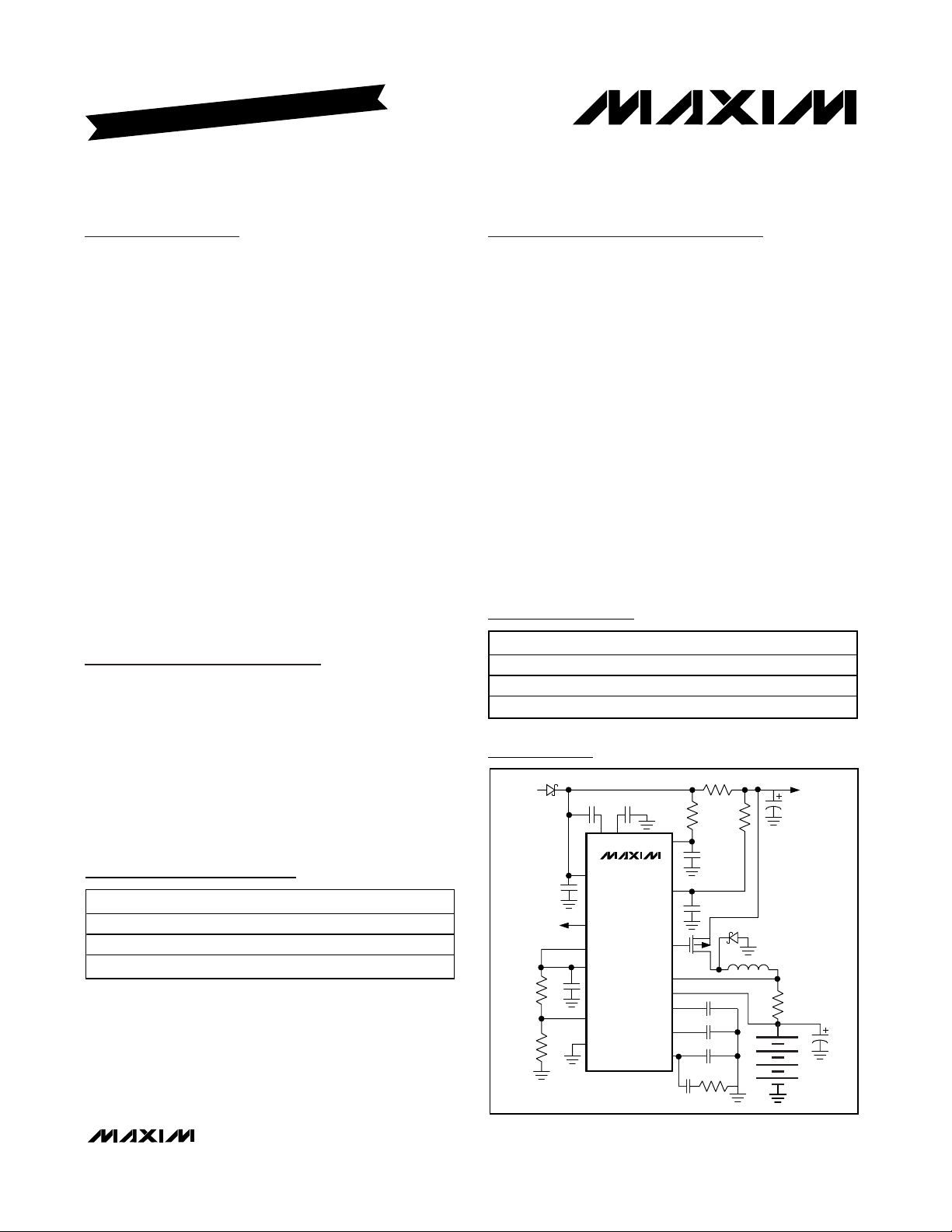

Ordering Information

19-2099; Rev 0; 7/01

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALU

ATIO

N

K

IT A

VA

ILA

BLE

Selector Guide

Typical Operating Circuit

Pin Configuration appears at end of data sheet.

PART TEMP. RANGE PIN-PACKAGE

MAX1873REEE -40°C to +85°C 16 QSOP

MAX1873SEEE -40°C to +85°C 16 QSOP

MAX1873TEEE -40°C to +85°C 16 QSOP

VIN 9V TO

28V

(9V MIN

FOR 2-

CELLS)

VH VL CSSP

SYSTEM

LOAD

MAX1873

PART SERIES CELLS TO CHARGE

MAX1873REEE

MAX1873SEEE

MAX1873TEEE 4-Cell Li+ 10-cell Ni Battery Packs

2-Cell Li+ or 5- or 6-cell Ni Battery

3-Cell Li+ or 7- or 9-cell Ni Battery

4V OUT PER

200mV ON R

DCIN

IOUT

CS

ICHG/EN

REF

VADJ

GND

CSSN

EXT

CSB

BATT

CCI

CCS

CCV

2- TO 4-CELL

Li+

Page 2

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

2 _______________________________________________________________________________________

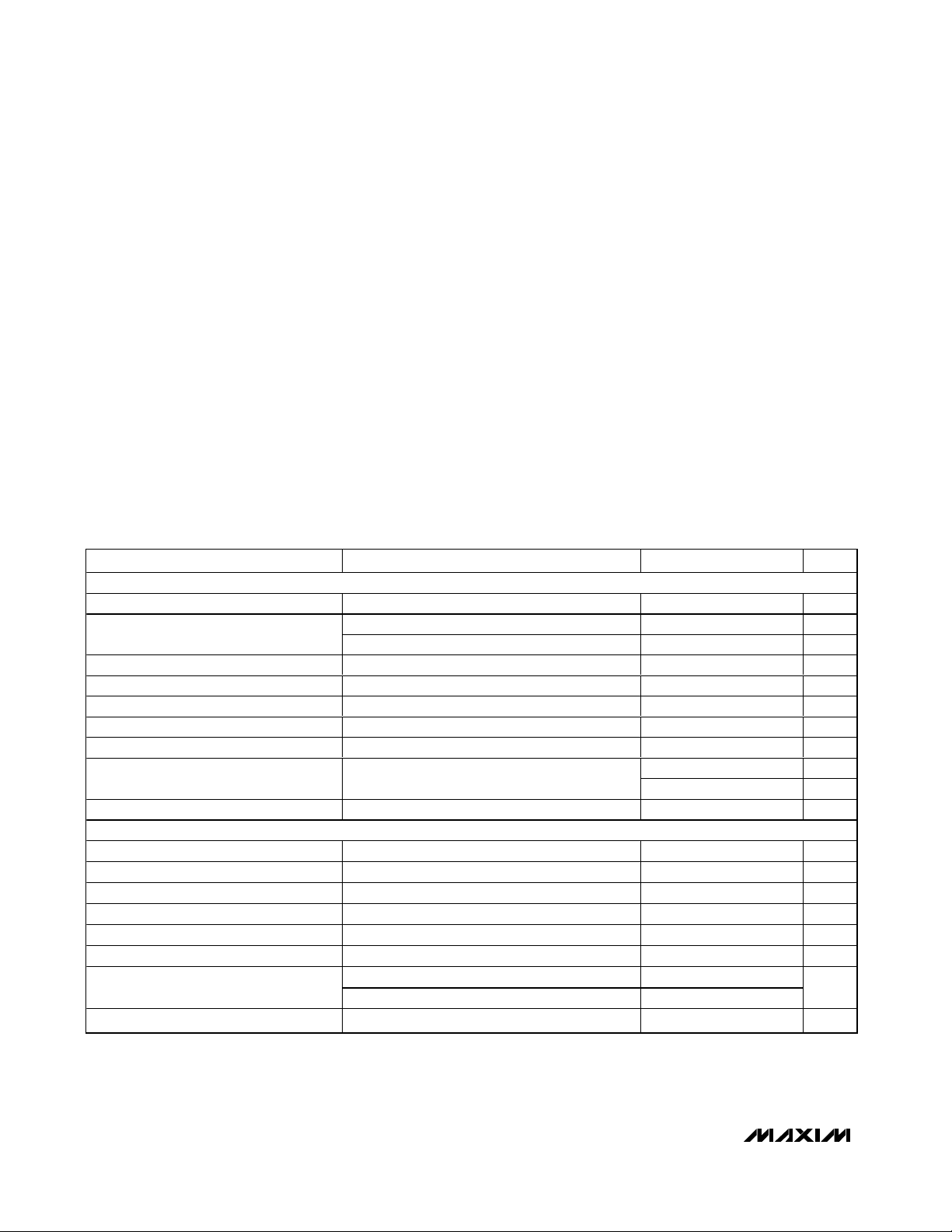

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

ICHG/EN

= V

REF

, V

VADJ

= V

REF

/2. MAX1873R: V

BATT

= V

CSB

= 8.4V;

MAX1873S: V

BATT

= V

CSB

= 12.6V; MAX1873T: V

BATT

= V

CSB

= 16.8V; TA= 0°C to +85°C. Typical values are at TA= +25°C, unless

otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

CSSP, CSSN, DCIN to GND ...................................-0.3V to +30V

VL, ICHG/EN to GND................................................-0.3V to +6V

VH, EXT to DCIN.......................................................-6V to +0.3V

VH, EXT to GND ......................................(V

DCIN

+ 0.3V) to -0.3V

EXT to VH .................................................................+6V to -0.3V

DCIN to VL..............................................................+30V to -0.3V

VADJ, REF, CCI, CCV, CCS,

IOUT to GND.............................................-0.3V to (VL + 0.3V)

BATT, CSB to GND.................................................-0.3V to +20V

CSSP to CSSN.......................................................-0.3V to +0.6V

CSB to BATT..........................................................-0.3V to +0.6V

VL Source Current ............................................................+50mA

VH Sink Current ................................................................+40mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C..........+667mW

Operating Temperature Range

MAX1873_EEE................................................-40°C to +85°C

Junction Temperature..................................................... +150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................ +300°C

INPUT SUPPLY AND REFERENCE

DCIN Input Voltage Range 628V

D C IN Qui escent S up p l y C ur r ent

DCIN to BATT Undervoltage Threshold CSSP = DCIN, input falling 0.05 0.175 V

DCIN to BATT Undervoltage Threshold CSSP = DCIN, input rising 0.22 0.38 V

VL Output Voltage 6.0V < V

VL Output Load Regulation IVL = 0 to 3mA 15 50 mV

REF Output Voltage I

REF Line Regulation 6.0V < V

REF Load Regulation I

SWITCHING REGULATOR

PWM Oscillator Frequency 270 300 330 kHz

EXT Driver Source On-Resistance 47Ω

EXT Driver Sink On-Resistance 2.5 4.5 Ω

VH Output Voltage DCIN - VH, 6V < V

CSSN/CSSP Input Current V

CSSN/CSSP Off-State Leakage V

BATT, CSB Input Current

BATT, CSB Input Current DCIN ≤ BATT (input power removed) 1.5 5 µA

PARAMETER CONDITIONS MIN TYP MAX UNITS

6.0V < V

DCIN ≤ BATT 0.1 10 µA

= 21µA (200kΩ load) 4.179 4.20 4.221 V

REF

= 0 to 1mA 6 13 mV

REF

CSSN/VCSSP

DCIN

ICHG/EN = 0 (charger disabled) 0.2 1

ICHG/EN = REF (charger enabled) 250 500

< 28V 4 7 mA

DCIN

< 28V 5.15 5.40 5.65 V

DCIN

< 28V

DCIN

= 28V, V

= V

SSN/VCSSP

<28V, IVH = 0 to 20mA 4.75 5.75 V

DCIN

= 28V 70 200 µA

DCIN

= 18V, V

BATT

= V

= 18V 1.5 5 µA

CSB

26mV

22 65 ppm/V

µA

Page 3

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

_______________________________________________________________________________________ 3

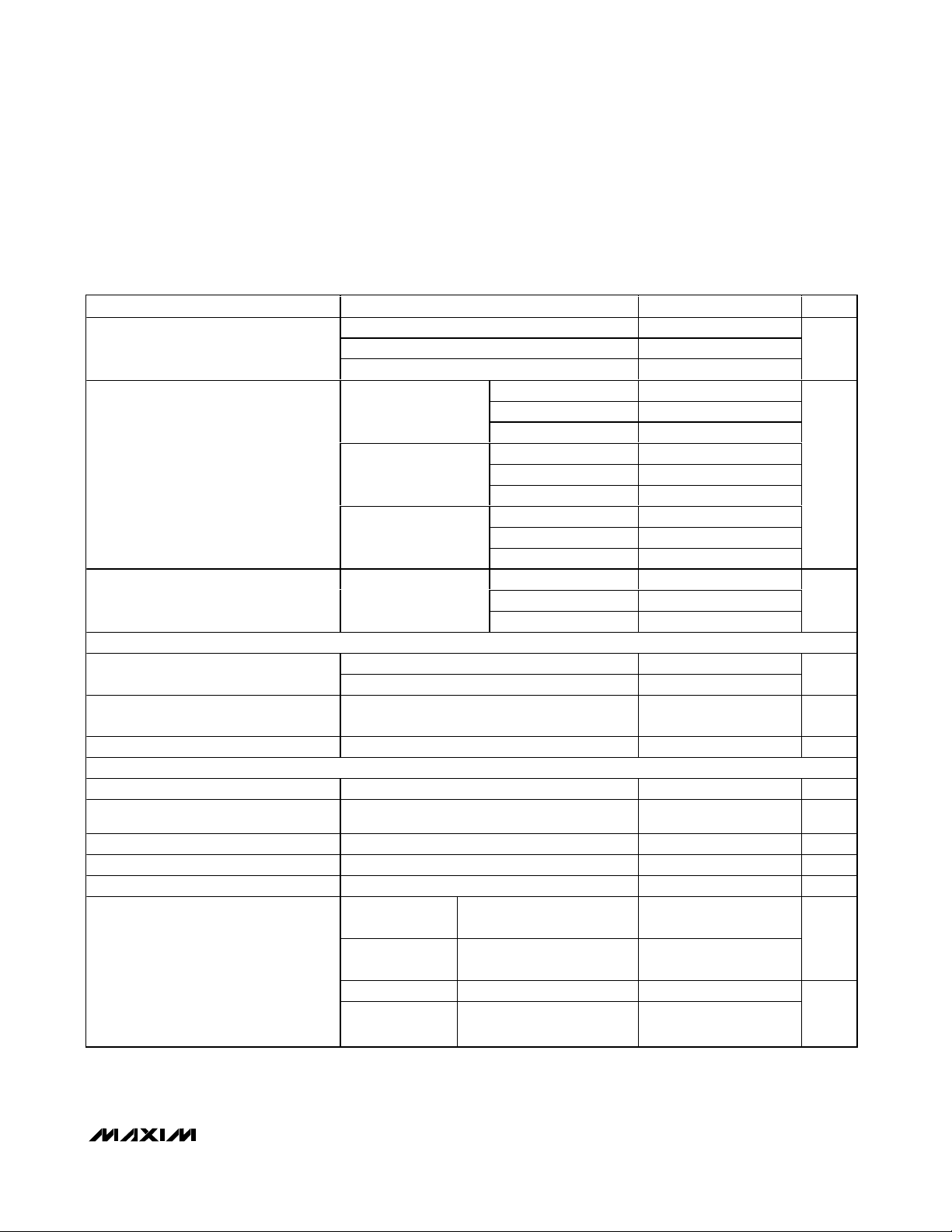

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

ICHG/EN

= V

REF

, V

VADJ

= V

REF

/2. MAX1873R: V

BATT

= V

CSB

= 8.4V;

MAX1873S: V

BATT

= V

CSB

= 12.6V; MAX1873T: V

BATT

= V

CSB

= 16.8V; TA= 0°C to +85°C. Typical values are at TA= +25°C, unless

otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Battery Regulation Voltage

BATT Undervoltage Threshold

CURRENT SENSE

CSB to BATT Battery Current-Sense

Voltage

CSB to BATT Current-Sense Voltage

when V

< 2.5V per Cell

BATT

CSSP to CSSN Current-Sense Voltage 6V < V

CONTROL INPUTS/OUTPUTS

ICHG/EN Input Threshold Includes 50mV of hysteresis 500 600 700 mV

ICHG/EN Input Voltage Range For

Charge Current Adjustment

VADJ Input Current V

ICHG/EN Input Current V

VADJ Input Voltage Range 0V

IOUT Voltage

2-cell version MAX1873R 10.45 11 11.55

3-cell version MAX1873S 15.675 16.5 17.325BATT Overvoltage Cutoff Threshold

4-cell version MAX1873T (Note 1) 17.575 18.5 19.425

V

= 0 7.898 7.958 8.018

MAX1873R

(2 Li+ cells)

MAX1873S

(3 Li+ cells)

MAX1873T

(4 Li+ cells)

VADJ

V

= V

/2 8.337 8.4 8.463

REF

= V

(Note 1) 8.775 8.842 8.909

REF

= 0 11.847 11.937 12.027

= V

/2 12.505 12.6 12.695

REF

= V

(Note 1) 13.163 13.263 13.363

REF

= 0 15.796 15.916 16.036

= V

/2 16.674 16.8 16.926

REF

= V

(Note 1) 17.551 17.684 17.817

REF

V

V

V

V

V

V

V

VADJ

VADJ

VADJ

VADJ

VADJ

VADJ

VADJ

VADJ

MAX1873R 4.8 5.0 5.2

For I

charge

V

V

CHG

ICHG/EN

ICHG/EN

/20 trickle

MAX1873S 7.2 7.5 7.8

MAX1873T 9.6 10 10.4

= V

REF

= V

/4 40 50 60

REF

190 200 210

51015mV

< 28V 90 100 110 mV

CSSP

700 V

= V

VADJ

ICHG/EN

Full scale

25% scale

Trickle charge V

No charge

current

/2 -100 100 nA

REF

= V

REF

V

- V

CSB

0 < I

OUT

V

- V

CSB

0 < I

OUT

- V

CSB

- V

V

CSB

= sinking 20µA

I

IOUT

= 200mV,

BATT

< 500µA

= 50mV,

BATT

< 500µA

= 10mV 75 200 325

BATT

= 0,

BATT

-100 100 nA

3.6 4.0 4.4

0.9 1.0 1.1

40 70 90

REF

REF

mV

mV

mV

V

V

V

V

V

Page 4

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

ICHG/EN

= V

REF

, V

VADJ

= V

REF

/2. MAX1873R: V

BATT

= V

CSB

= 8.4V;

MAX1873S: V

BATT

= V

CSB

= 12.6V; MAX1873T: V

BATT

= V

CSB

= 16.8V; TA= -40°C to +85°C. Typical values are at TA= +25°C,

unless otherwise noted.)

PARAMETER CONDITIONS MIN MAX UNITS

INPUT SUPPLY AND REFERENCE

DCIN Input Voltage Range 628V

D C IN Qui escent S up p l y C ur r ent

DCIN to BATT Undervoltage Threshold CSSP = DCIN, input falling 0.05 0.2 V

DCIN to BATT Undervoltage Threshold CSSP = DCIN, input rising 0.22 0.38 V

VL Output Voltage 6.0V < V

VL Output Load Regulation IVL = 0 to 3mA 50 mV

REF Output Voltage I

REF Line Regulation 6.0V < V

REF Load Regulation I

SWITCHING REGULATOR

PWM Oscillator Frequency 270 330 kHz

EXT Driver Source On-Resistance 7 Ω

EXT Driver Sink On-Resistance 4.5 Ω

VH Output Voltage DCIN - VH, 6V < V

CSSN/CSSP Input Current V

CSSN/CSSP Off-State Leakage V

BATT, CSB Input Current

BATT, CSB Input Current DCIN ≤ BATT (input power removed) 5 µA

BATT Overvoltage Cutoff Threshold

Battery Regulation Voltage

6.0V < V

< 28V 7 mA

DCIN

DCIN ≤ BATT 10 µA

< 28V 5.15 5.65 V

DCIN

= 21µA (200kΩ load) 4.179 4.221 V

REF

< 28V

DCIN

= 0 to 1mA 13 mV

REF

<28V, IVH = 0 to 20mA 4.75 5.75 V

DCIN

CSSN/VCSSP

= V

DCIN

SSN/VCSSP

= 28V, V

= 28V 200 µA

DCIN

= 18V V

BATT

= V

= 18V 5 µA

CSB

6mV

65 ppm/V

ICHG/EN = 0 (charger disabled) 1

ICHG/EN = REF (charger enabled) 500

2-cell version MAX1873R 10.45 11.55

3-cell version MAX1873S 15.675 17.325

4-cell version MAX1873T (Note 1) 17.575 19.425

V

= 0 7.898 8.018

MAX1873R

(2 Li+ cells)

MAX1873S

(3 Li+ cells)

MAX1873T

(4 Li+ cells)

VADJ

V

= V

/2 8.337 8.463

REF

= V

(Note 1) 8.775 8.909

REF

= 0 11.847 12.027

= V

/2 12.505 12.695

REF

= V

(Note 1) 13.163 13.363

REF

= 0 15.796 16.036

= V

/2 16.674 16.926

REF

= V

(Note 1) 17.551 17.817

REF

V

V

V

V

V

V

V

VADJ

VADJ

VADJ

VADJ

VADJ

VADJ

VADJ

VADJ

µA

V

V

Page 5

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

ICHG/EN

= V

REF

, V

VADJ

= V

REF

/2. MAX1873R: V

BATT

= V

CSB

= 8.4V;

MAX1873S: V

BATT

= V

CSB

= 12.6V; MAX1873T: V

BATT

= V

CSB

= 16.8V; TA= -40°C to +85°C. Typical values are at TA= +25°C,

unless otherwise noted.)

Note 1: While it may appear possible to set the Battery Regulation Voltage higher than the Battery Overvoltage Cutoff Threshold, this

cannot happen because both parameters are derived from the same reference and track each other.

Note 2: Specifications to -40°C are guaranteed by design, not production tested.

PARAMETER CONDITIONS MIN MAX UNITS

BATT Undervoltage Threshold

CURRENT SENSE

CSB to BATT Battery Current-Sense

Voltage

CSB to BATT Current-Sense Voltage

when V

< 2.5V per Cell

BATT

CSSP to CSSN Current-Sense Voltage 6V < V

CONTROL INPUTS/OUTPUTS

ICHG/EN Input Threshold Includes 50mV of hysteresis 500 700 mV

ICHG/EN Input Voltage Range for

Charge Current Adjustment

VADJ Input Current V

ICHG/EN Input Current V

VADJ Input Voltage Range 0V

IOUT Voltage

For I

CHG

/20 trickle

charge

V

V

ICHG/EN

ICHG/EN

CSSP

= V

VADJ

ICHG/EN

= V

= V

< 28V 90 110 mV

REF

= V

Full scale

25% scale

Trickle charge V

No charge

current

MAX1873R 4.8 5.2

MAX1873S 7.2 7.8

MAX1873T 9.6 10.4

REF

/4 40 60 mV

REF

190 210 mV

515mV

700 V

REF

/2 -100 100 nA

REF

V

- V

CSB

0 < I

OUT

- V

V

CSB

0 < I

OUT

- V

CSB

- V

V

CSB

I

= sinking 20µA

IOUT

= 200mV,

BATT

< 500µA

= 50mV,

BATT

< 500µA

= 10mV 75 325

BATT

= 0,

BATT

-100 100 nA

REF

3.6 4.4

0.9 1.1

40 90

mV

mV

V

V

V

Page 6

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

6 _______________________________________________________________________________________

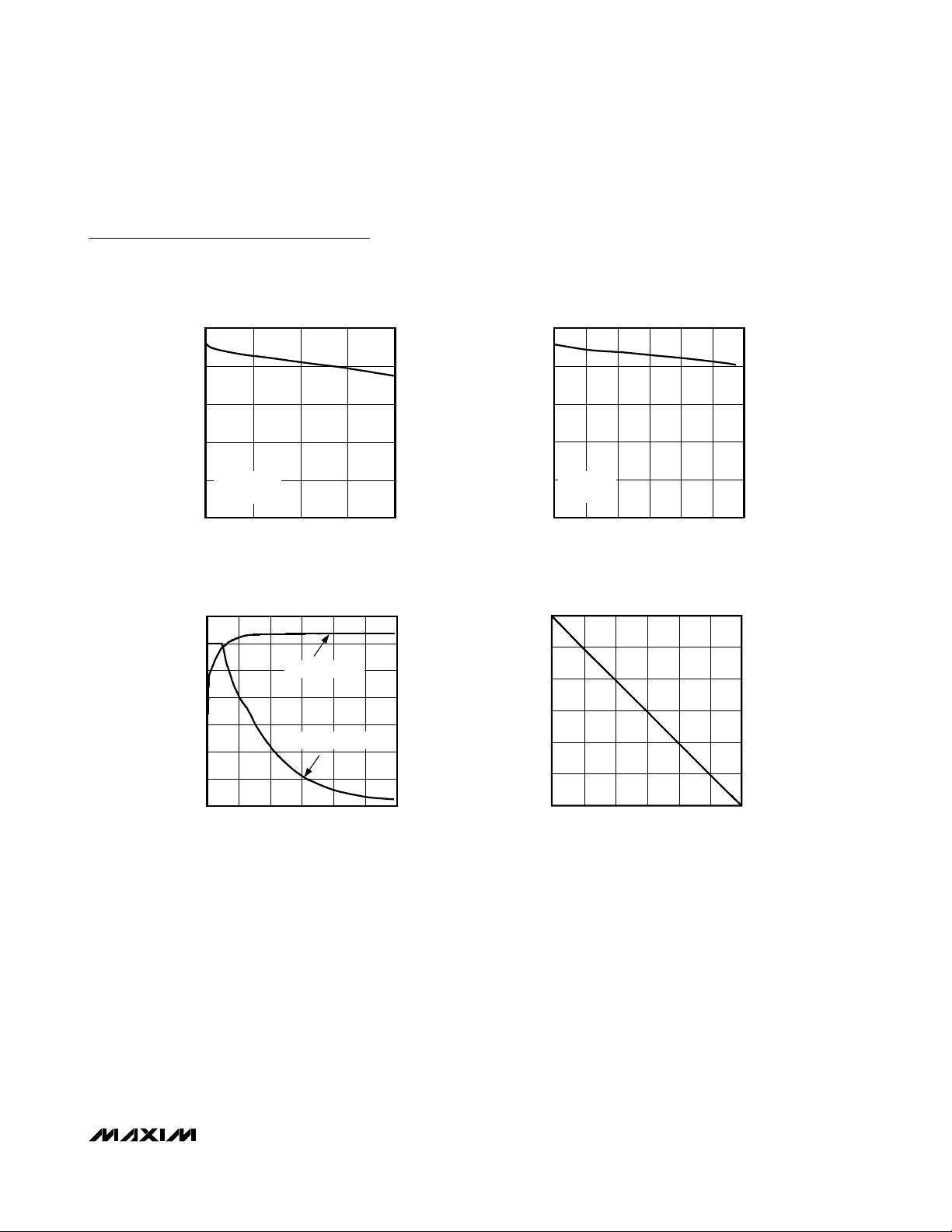

Typical Operating Characteristics

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

ICHG/EN

= V

REF

, V

VADJ

= V

REF

/2. MAX1873R: V

BATT

= V

CSB

= 8.4V;

MAX1873S: V

BATT

= V

CSB

= 12.6V; MAX1873T: V

BATT

= V

CSB

= 16.8V; TA= +25°C, unless otherwise noted).

0

5.0

2.5

10.0

7.5

15.0

12.5

17.5

0 1.0 1.50.5 2.0 2.5 3.0 3.5

MAX1873T (4-CELL)

BATTERY VOLTAGE vs. CHARGING CURRENT

MAX1873 toc01

CHARGING CURRENT (A)

BATTERY VOLTAGE (V)

R

CSB

+ 0.068Ω

0

1.0

0.5

2.5

2.0

1.5

4.0

3.5

3.0

4.5

010050 150 200 250

IOUT VOLTAGE

vs. CSB-BATT VOLTAGE

MAX1873 toc02

CSB-BATT VOLTAGE (mV)

IOUT VOLTAGE (V)

4.180

4.190

4.185

4.200

4.195

4.205

4.210

RECENT VOLTAGE

VS.

TEMPERATURE

MAX1873 toc04

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

-50 0 25-25 50 75 100

MAX1873T

15.5

16.0

17.0

16.5

17.5

18.0

021345

MAX1873T (4-CELL)

BATTERY REGULATION VOLTAGE

vs. VADJ VOLTAGE

MAX1873 toc03

VADJ VOLTAGE (V)

BATTERY REGULATION VOLTAGE (V)

4.180

4.195

4.190

4.185

4.200

4.205

4.210

0 0.40.30.1 0.2 0.5 0.6 0.7 0.8 0.9 1.0

RECENT VOLTAGE

VS. REFERENCE CURRENT

MAX1873 toc05

REFERENCE VOLTAGE (mA)

REFERENCE VOLTAGE (V)

MAX1873T

50

60

80

70

90

100

81612 20 24 28

MAX1873R (2-CELL)

EFFICIENCY vs. INPUT VOLTAGE

MAX1873 toc06

INPUT VOLTAGE (V)

EFFICIENCY (%)

V

BATT

= 7V

I

CHG

= 3A

Page 7

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

_______________________________________________________________________________________ 7

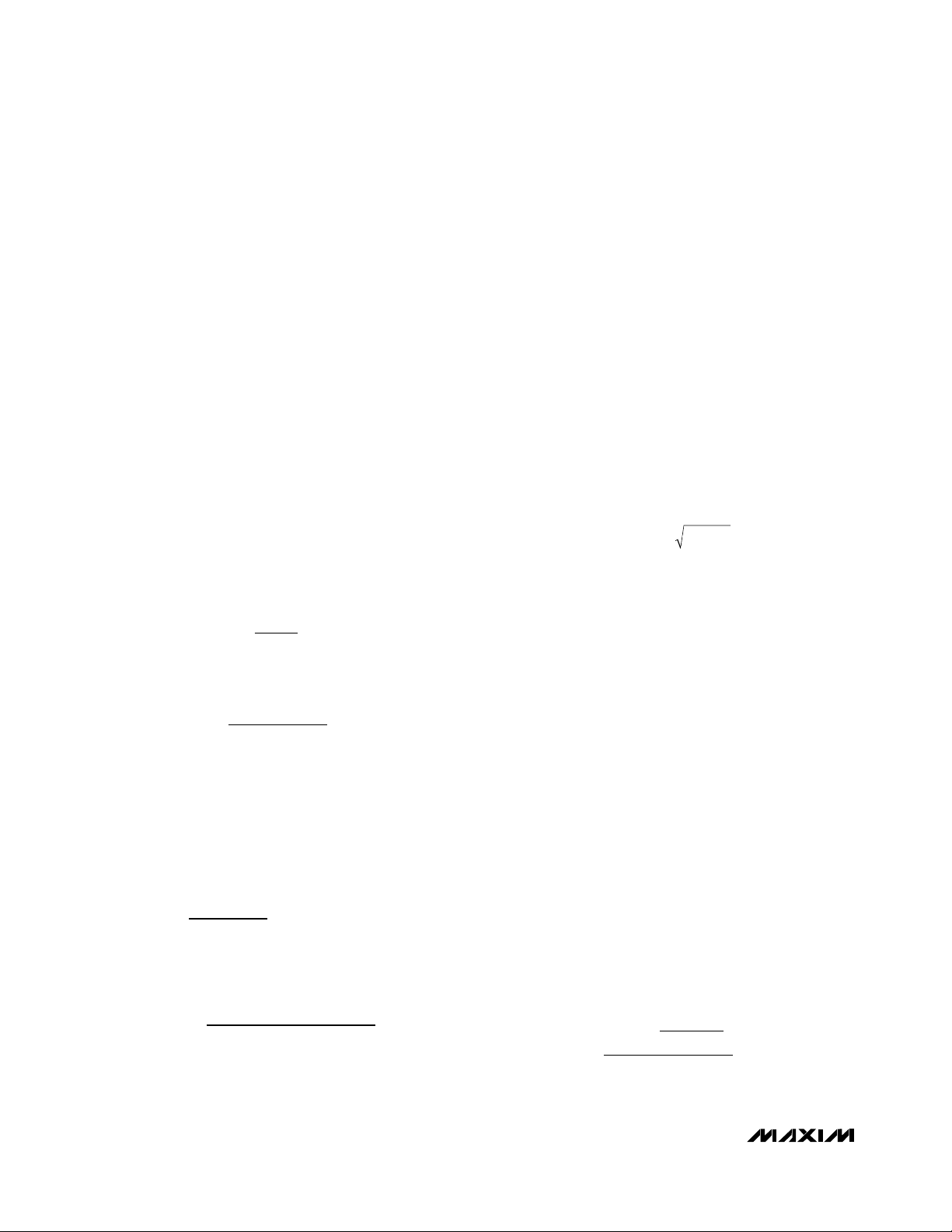

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

ICHG/EN

= V

REF

, V

VADJ

= V

REF

/2. MAX1873R: V

BATT

= V

CSB

= 8.4V;

MAX1873S: V

BATT

= V

CSB

= 12.6V; MAX1873T: V

BATT

= V

CSB

= 16.8V; TA= +25°C, unless otherwise noted).

100

90

80

70

EFFICIENCY (%)

60

50

18

16

14

12

10

BATTERY VOLTAGE (V)

8

6

EFFICIENCY vs. INPUT VOLTAGE

V

= 10.5V

BATT

= 3A

I

CHG

12 2016 24 28

4-CELL BATTERY VOLTAGE AND

CHARGING CURRENT vs. TIME

MAX1873S (3-CELL)

INPUT VOLTAGE (V)

BATTERY VOLTAGE

CHARGING CURRENT

MAX1873 toc07

3.5

3.0

MAX1873 toc09

2.5

2.0

1.5

1.0

0.5

MAX1873T (4-CELL)

EFFICIENCY vs. INPUT VOLTAGE

100

90

80

70

EFFICIENCY (%)

60

V

= 14V

BATT

+ 3A

I

CHG

50

16 2018 22 24 26 28

INPUT VOLTAGE (V)

CHARGING CURRENT

vs. SYSTEM LOAD CURRENT

3.0

2.5

2.0

1.5

1.0

CHARGING CURRENT (A)

CHARGING CURRENT (A)

0.5

MAX1873 toc08

MAX1873 toc10

4

0507525 100 125 150

TIME (MINUTES)

0

0

0 1.0 1.50.5 2.0 2.5 3.0

SYSTEM LOAD CURRENT (A)

Page 8

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

8 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 CSSN

2 CSSP Source Current-Sense Positive Input. Also used for input source undervoltage sensing.

3 CCS Input-Source-Current Regulation Loop Compensation Point

4 CCV

5 CCI Battery Charge Current Control-Loop Compensation Point

6 ICHG/EN

7 IOUT

8 VADJ

9 REF 4.2V Reference Voltage Output. Bypass to GND with a 1µF ceramic capacitor.

10 BATT

11 CSB Battery Current-Sense Positive Input

12 GND Ground

13 VH

14 EXT Drive Output for External PFET. EXT swings from V

15 DCIN

16 VL

Source Current-Sense Negative Input. Connect a current-sense resistor between CSSP and CSSN to

limit total current drawn from the input source. To disable input current sensing, connect CSSN to CSSP.

Battery Regulation Voltage Control-Loop Compensation Point. Pulling CCV high (to VL) through a 1.5kΩ

resistor disables the voltage control loop for charging NiCd or NiMH batteries.

Battery Charging Current Adjust/Shutdown Input. This pin can be connected to a resistive-divider

between REF and GND to adjust the charge current sense threshold between CSB and BATT. When

ICHG/EN is connected to REF, the CSB-BATT threshold is 200mV. Pull ICHG/EN low (below 500mV) to

disable charging and reduce the supply current to 5µA.

Charge Current Monitor Output. Analog Voltage Output that is proportional to charging current. V

= 20 (V

Battery Regulation Voltage Adjust. Set the battery regulation voltage from 3.979V per cell to 4.421V per

cell with 1% resistors. Output accuracy remains better than 0.75% even with 1% adjusting resistors

due to reduced adjustment range. For 4.2V, the voltage-divider resistors must be equal value

(nominally 100kΩ each).

Battery Voltage-Sense Input and Battery Current-Sense Negative Input. Bypass to GND with a 68µF for

MAX1873R, 47µF for MAX1873S, and 33µF for MAX1873T. Use capacitors with ESR < 1Ω.

Internal VH Regulator. VH internally supplies power to the EXT driver. Connect a 0.22µF ceramic

capacitor between VH and DCIN.

Power-Supply Input. DCIN is the input supply for charger IC. Bypass to GND with a 0.22µF ceramic

capacitor.

Internal VL Regulator. VL powers the MAX1873’s control logic at 5.4V. Bypass to GND with a 2.2µF or

larger ceramic capacitor.

CSB

- V

) or 4V for a 200mV current-sense voltage (maximum load capacitance = 5nF).

BATT

DCIN

to V

DCIN

- 5V.

IOUT

Page 9

Detailed Description

The MAX1873 includes all of the functions necessary to

charge 2-, 3-, or 4-series cell lithium-ion (Li+) battery

packs. It includes a high-efficiency step-down DC-DC

converter that controls charging voltage and current. It

also features input source current limiting so that an AC

adapter that supplies less than the total system current

in addition to charging current can be used without fear

of overload.

The DC-DC converter uses an external P-channel MOSFET switch, inductor, and diode to convert the input voltage to charging current or charging voltage. The typical

application circuit is shown in Figure 1. Charging current

is set by R

CSB

, while the battery voltage is measured at

BATT. The battery regulation voltage limit is nominally

set to 8.4V for the R version (2-cells), 12.6V for the S

version (3-cells), and 16.8V for the T version (4-cells),

but it can also be adjusted to other voltages for different Li+ chemistries.

Voltage Regulator

Li+ batteries require a high-accuracy voltage limit while

charging. The battery regulation voltage is nominally

set to 4.2V per cell and can be adjusted ±5.25% by

setting the voltage at VADJ between REF and ground.

By limiting the adjust range of the regulation voltage, an

overall voltage accuracy of better than ±0.75% is maintained while using 1% resistors.

An internal error amplifier maintains voltage regulation

to within ±0.75%. The amplifier is compensated at CCV

(see Figure 1). Individual compensation of the voltage

regulation and current regulation loops allows for optimal compensation of each. A typical CCV compensation network is shown in Figure 1 and will suffice for

most designs.

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

_______________________________________________________________________________________ 9

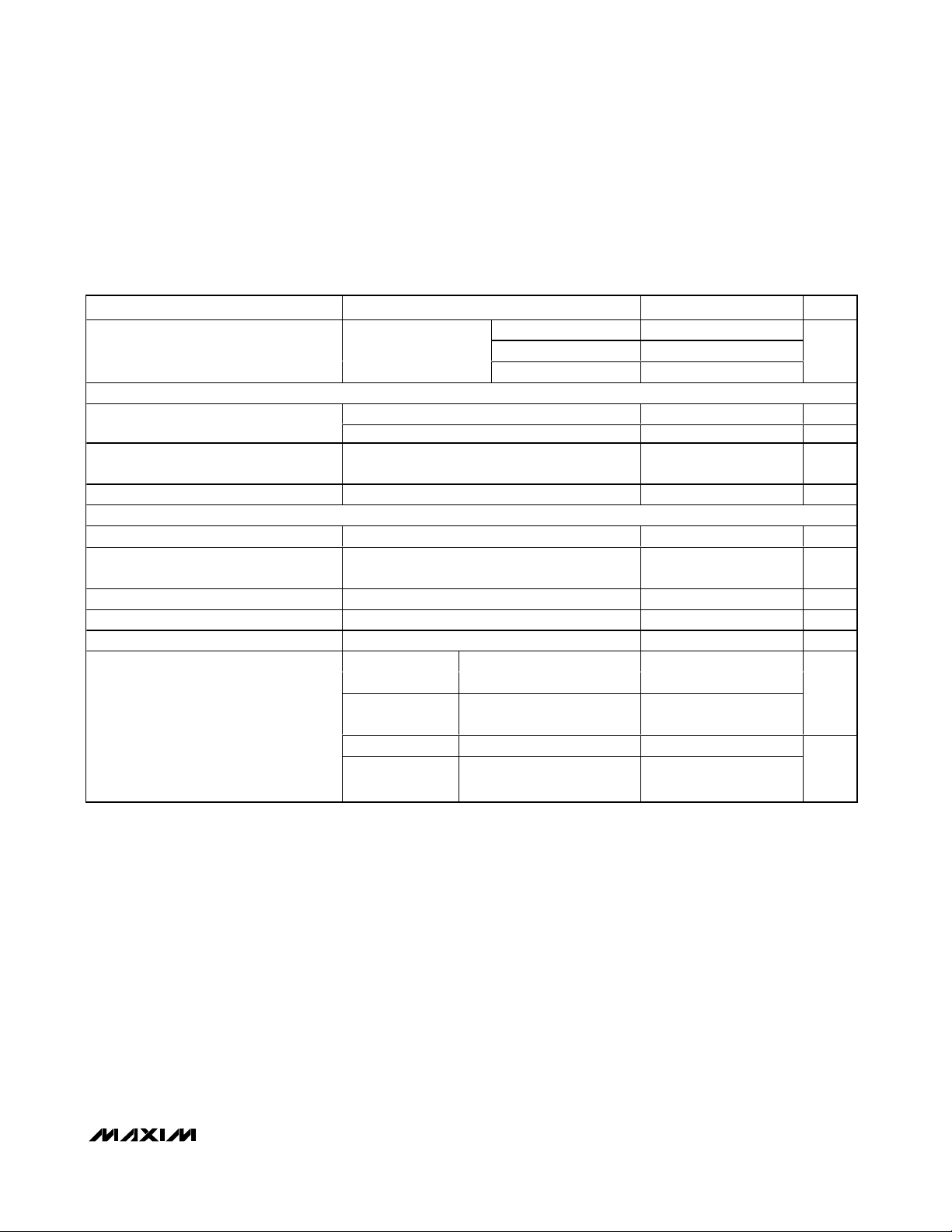

DISABLE

Figure 1. Typical Application Circuit

VIN 17V TO 28V

(9V MIN FOR 2- CELLS)

N

100kΩ

D1

MBR5340

C

VL

2.2µF

R

C

0.01µF

C

0.01µF

C

REF

1µF

4.7Ω

P

R

4.7Ω

N

P

R

CSS

0.033Ω

N

D2

MBR5340

P

L1

10µH

R1

R2

R

CSB

0.068Ω

C

L

47µF

C

BATT

68µF

BATTERY

(2- TO 4-CELLS)

SYSTEM

LOAD

LI+

C

DCIN

0.22µF

4V OUT PER

200mV ON R

C

CCVS

0.1µF

C

47nF

C

CCS

47nF

R

10kΩ

CSB

CC

CCV

C

VH

0.22µF

VH

DCIN

MAX1873

IOUT

ICHG/EN

CCI

CCS

CCV

CSSP

VL

CSSN

EXT

CSB

BATT

REF

VADJ

GND

C

CCVP

1nF

Page 10

MAX1873

Charging-Current Regulator

The charging-current regulator limits the battery charging current. Current is sensed by the current-sense

resistor (R

CSB

in Figure 1) connected between BATT

and CSB. The voltage on ICHG/EN can also adjust the

charging current. Full-scale charging current (I

CHG

=

0.2V / RCSB) is achieved by connecting ICHG/EN to

REF. See Setting the Charging-Current Limit section for

more details.

The charging-current error amplifier is compensated at

CCI (Figure 1). A 47nF capacitor from CCI to GND provides suitable performance for most applications.

Input-Current Regulator

The input-current regulator limits the source current by

reducing charging current when the input current

reaches the set input-current limit. In a typical portable

design, system load current will normally fluctuate as

portions of the system are powered up or put to sleep.

Without the benefit of input-current regulation, the input

source would have to be able to supply the maximum

system current plus the maximum charger-input current. The MAX1873 input-current loop ensures that the

system always gets adequate power by reducing

charging current as needed. By using the input-current

limiter, the size and cost of the AC adapter can be

reduced. See Setting the Input-Current Limit section for

design details.

Input current is measured through an external sense

resistor, R

CSS

, between CSSP and CSSN. The inputcurrent limit feature may be bypassed by connecting

CSSP to CSSN.

The input-current error amplifier is compensated at

CCS. A 47nF capacitor from CCS to GND provides suitable performance for most applications.

PWM Controller

The pulse-width modulation (PWM) controller drives the

external MOSFET at a constant 300kHz to regulate the

charging current and voltage while maintaining low

noise. The controller accepts inputs from the CCI, CCV,

and CCS error amplifiers. The lowest signal of these

three drives the PWM controller. An internal clamp limits

the noncontrolling signals to within 200mV of the controlling signal to prevent delay when switching between

the battery-voltage control, charging-current control,

and input-current regulation loops.

Shutdown

The MAX1873 stops charging when ICHG/EN is pulled

low (below 0.5V) and shuts down when the voltage at

DCIN falls below the voltage at BATT. In shutdown, the

internal resistive voltage-divider is disconnected from

BATT to reduce the battery drain. When AC-adapter

power is removed, or when the part is shut down, the

MAX1873 typically draws 1.5µA from the battery.

Source Undervoltage Shutdown (Dropout)

The DCIN voltage is compared to the voltage at BATT.

When the voltage at DCIN drops below BATT + 50mV,

the charger turns off, preventing drain on the battery

when the input source is not present or is below the

battery voltage.

A diode is typically connected between the input

source and the charger input. This diode prevents the

battery from discharging through the body diode of the

high-side MOSFET should the input be shorted to GND.

It also protects the charger, battery, and systems from

reversed polarity adapters and negative input voltages.

Simple Current-Limited Switch-Mode

Li+ Charger Controller

10 ______________________________________________________________________________________

Figure 2. Functional Block Diagram

CSSN

CSSP

CCS

CCV

CCI

ICHG

/EN

IOUT

9R

VADJ

A = 1

GND

SHUTDOWN

FOR ALL

BLOCKS

CONTROL

LOGIC

CURRENT

ERROR AMP

R

5.4

REGULATOR

UNDERVOLTAGE

COMPARATOR

BATT

VH

DRIVER

VOLTAGE

ERROR AMP

R

4.2V

REFERENCE

VL

DCIN

EXT

VH

GND

CSB

BATT

REF

Page 11

Charge-Current Monitor Output

IOUT is an analog voltage output that is proportional to

the actual charge current. With the aid of a microcontroller, the IOUT signal can facilitate gas-gauging, indicate percent of charge, or charge-time remaining. The

equation governing this output is:

where V

CSB

and V

BATT

are the voltages at the CSB and

BATT pins, and ICHG is the charging current. IOUT can

drive a load capacitance of 5nF.

Design Procedure

Setting the Battery-Regulation Voltage

For Li+ batteries, VADJ sets the per-cell battery-regulation voltage limit. To set the VADJ voltage, use a resistive-divider from REF to GND (Figure 1). For a battery

voltage of 4.2V per cell, use resistors of equal value

(100kΩ each) in the VADJ voltage-divider. To set other

battery-regulation voltages, see the remainder of this

section.

The per-cell battery regulation voltage is a function of

Li+ battery chemistry and construction and is usually

clearly specified by the manufacturer. If this is not

clearly specified, be sure to consult the battery manufacturer to determine this voltage before charging any

Li+ battery. Once the per-cell voltage is determined,

the VADJ voltage is calculated by the equation:

where V

BATTR

is the desired battery-regulation voltage

(for the total series-cell stack), N is the number of Li+

battery cells, and V

REF

is the reference voltage (4.2V).

Set V

VADJ

by choosing R1. R1 should be selected so

that the total divider resistance (R1+ R2) is near 200kΩ.

R2 can then be calculated as follows:

Since the full range of VADJ (from 0 to VREF) results in

a ±5.263% adjustment of the battery-regulation limit

(3.979V to 4.421V), the resistive-divider’s accuracy

need not be as tight as the output-voltage accuracy.

Using 1% resistors for the voltage-divider still provides

±0.75% battery-voltage-regulation accuracy.

Setting the Charging-Current Limit

The charging current ICHG is sensed by the currentsense resistor R

CSB

between CSB and BATT, and is

also adjusted by the voltage at ICHG/EN. If ICHG/EN is

connected to REF (the standard connection), the

charge current is given by:

In some cases, common values for R

CSB

may not allow

the desired charge-current value. It may also be desirable to reduce the 0.2V CSB-to-BATT sense threshold

to reduce power dissipation. In such cases, the

ICHG/EN input may be used to reduce the charge-current-sense threshold. In those cases the equation for

charge current becomes:

Setting the Input-Current Limit

The input-source current limit, IIN, is set by the inputcurrent sense resistor, R

CSS

, (Figure 1) connected

between CSSP and CSSN. The equation for the source

current is:

This limit is typically set to the current rating of the input

power source or AC adapter to protect the input source

from overload. Short CSSP and CSSN to DCIN if the

input-source current-limit feature is not used.

Inductor Selection

The inductor value may be selected for more or less

ripple current. The greater the inductance, the lower

the ripple current. However, as the physical size is kept

the same, larger inductance value typically results in

higher inductor series resistance and lower inductor

saturation current. Typically, a good tradeoff is to

choose the inductor such that the ripple current is

approximately 30% to 50% of the DC average charging

current. The ratio of ripple current to DC charging current (LIR) can be used to calculate the inductor value:

where f

SW

is the switching frequency (nominally

300kHz) and I

CHG

is the charging current. The peak

inductor current is given by:

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

______________________________________________________________________________________ 11

VVVor

=−

20

IOUT CSB BATT

VRI

OUT CSB CHG

()

=×

20

()

VVNV

=

95 9./

()

VADJ BATTR REF

RV V V R

[]

21=−

[]

()

VADJ REF VADJ

−

()

×/

IVVVR

CHG ICH EN REF CSB

IVR

= 02./

CHG CSB

=

02.//

()

/

IVR

= 01./

IN CSS

LV V V

=−

BATT DCIN MAX BATT

[]

{}

VfILIR

DCIN MAX SW CHG

()

[]

()

×× ×

/

Page 12

MAX1873

For example, for a 4-cell charging current of 3A, a

V

DCIN(MAX)

of 24V, and an LIR of 0.5, L is calculated to

be 11.2µH with a peak current of 3.75A. Therefore a

10µH inductor would be satisfactory.

MOSFET Selection

The MAX1873 uses a P-channel power MOSFET

switch. The MOSFET must be selected to meet the efficiency or power dissipation requirements of the charging circuit as well as the maximum temperature of the

MOSFET. Characteristics that affect MOSFET power

dissipation are drain-source on-resistance (

RDS(ON)

)

and gate charge. Generally these are inversely proportional.

To determine MOSFET power dissipation, the operating

duty cycle must first be calculated. When the charger is

operating at higher currents, the inductor current will be

continuous (the inductor current will not drop to 0). In

this case, the high-side MOSFET duty cycle (D) can be

approximated by the equation:

And the catch-diode duty cycle (D') will be 1 - D or:

where V

BATT

is the battery-regulation voltage (typically

4.2V per cell) and V

DCIN

is the source-input voltage.

For MOSFETs, the worst-case power dissipation due to

on-resistance (PR) occurs at the maximum duty cycle,

where the operating conditions are minimum sourcevoltage and maximum battery voltage. PRcan be

approximated by the equation:

Transition losses (PT) can be approximated by the

equation:

where tTRis the MOSFET transition time and fSWis the

switching frequency. The total power dissipation of the

MOSFET is then:

Diode Selection

A Schottky rectifier with a current rating of at least the

charge current limit must be connected from the MOSFET drain to GND. The voltage rating of the diode must

exceed the maximum expected input voltage.

Capacitor Selection

The input capacitor shunts the switching current from

the charger input and prevents that current from circulating through the source, typically an AC wall cube.

Thus the input capacitor must be able to handle the

input RMS current. At high charging currents, the converter will typically operate in continuous conduction. In

this case, the RMS current of the input capacitor can

be approximated with the equation:

where I

CIN

is the input capacitor RMS current, D is the

PWM converter duty cycle (typically V

BATT/VDCIN

), and

I

CHG

is the battery-charging current.

The maximum RMS input current occurs at 50% duty

cycle, so the worst-case input-ripple current is 0.5 x

I

CHG

. If the input-to-output voltage ratio is such that the

PWM controller will never work at 50% duty cycle, then

the worst-case capacitor current will occur where the

duty cycle is nearest 50%.

The impedance of the input capacitor is critical to preventing AC currents from flowing back into the wall

cube. This requirement varies depending on the wall

cube’s impedance and the requirements of any conducted or radiated EMI specifications that must be met.

Low ESR aluminum electrolytic capacitors may be

used, however, tantalum or high-value ceramic capacitors generally provide better performance.

The output filter capacitor absorbs the inductor-ripple

current. The output-capacitor impedance must be significantly less than that of the battery to ensure that it

will absorb the ripple current. Both the capacitance and

the ESR rating of the capacitor are important for its

effectiveness as a filter and to ensure stability of the

PWM circuit. The minimum output capacitance for stability is:

Simple Current-Limited Switch-Mode

Li+ Charger Controller

12 ______________________________________________________________________________________

PPP

II LIR

=+

PEAK CHG

12/

()

=+

TOT R T

V

BATT

D

≈

V

DCIN

VV

−

DCIN BATT

D

'≈

V

DCIN

V

BATT MAX

P

=××

R

()

V

DCIN MIN

()

RI

DS ON CHG

()

2

VIft

×××

DCIN CHG SW TR

P

=

T

3

II DD

≈−

CIN CHG

2

C

V

REF

>

OUT

VfR

BATT SW CSB

V

+

1

V

DCIN MIN

××

BATT

()

Page 13

where C

OUT

is the total output capacitance, V

REF

is the

reference voltage (4.2V), V

BATT

is the maximum battery

regulation voltage (typically 4.2V per cell), V

DCIN (MIN)

is the minimum source-input voltage, and R

CSB

is the

current-sense resistor (68mΩ for 3A charging current)

from CSB to BATT.

The maximum output capacitor ESR allowed for stability is:

where R

ESR

is the output capacitor ESR.

Compensation Components

The three regulation loops: input current limit, charging

current limit, and charging voltage limit are compensated separately using the CCS, CCI, and CCV pins,

respectively.

The charge-current loop error-amplifier output is

brought out at CCI. Likewise, the source-current erroramplifier output is brought out at CCS. 47nF capacitors

to ground at CCI and CCS compensate the current

loops in most charger designs. Raising the value of

these capacitors reduces the bandwidth of these loops.

The voltage-regulating loop error-amplifier output is

brought out at CCV. Compensate this loop by connecting a capacitor in parallel with a series resistor-capacitor from CCV to GND. Recommended values are shown

in Figure 1.

Applications Information

VL, VH, and REF Bypassing

The MAX1873 uses two internal linear regulators to

power internal circuitry. The outputs of the linear regulators are at VL and VH. VL powers the internal control

circuitry while VH powers the MOSFET gate driver. VL

may also power a limited amount of external circuitry,

as long as its maximum current (3mA) is not exceeded.

A 2.2µF bypass capacitor is required from VL to GND

to ensure stability. A 0.22µF capacitor is required from

VH to DCIN. A 1µF bypass capacitor is required

between REF and GND to ensure that the internal 4.2V

reference is stable. In all cases, use low-ESR ceramic

capacitors.

Charging NiMH and NiCd Cells

The MAX1873 may be used in multichemistry chargers.

When charging NiMH or NiCd cells, pull CCV high (to

VL) with a 1.5 kΩ resistor. This disables the voltage

control loop so the Li+ battery-regulation voltage set-

tings do not interfere with charging. However, the battery undervoltage-protection features remain active so

charging current is reduced when V

BATT

is less than

the levels stated in the BATT Undervoltage Threshold

line in the Electrical Characteristics Table. 5- or 6-series

Ni cells may be charged with the R version device, 7to 9-cells with the S version, and 10-cells with the T version.

The MAX1873 contains no charge-termination algorithms for Ni cells; it acts only as a current source. A

separate microcontroller or Ni-cell charge controller

must instruct the MAX1873 to terminate charging.

Chip Information

PROCESS: BiCMOS

TRANSISTOR COUNT: 1397

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

______________________________________________________________________________________ 13

Pin Configuration

RV

×

CSB BATT

<

V

REF

R

ESR

TOP VIEW

1

CSSN VL

CSSP

2

CCS

3

MAX1873R/S/T

4

CCV

CCI

5

ICHG/EN

6

IOUT

7

VADJ

8

16 QSOP

16

15

DCIN

14

EXT

13

VH

12

GND

CSB

11

10

BATT

9

REF

Page 14

MAX1873

Simple Current-Limited Switch-Mode

Li+ Charger Controller

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2001 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

QSOP.EPS

Loading...

Loading...