Page 1

General Description

The MAX1739/MAX1839 fully integrated controllers are

optimized to drive cold-cathode fluorescent lamps

(CCFLs) using the industry-proven Royer oscillator

inverter architecture. The Royer architecture provides

near sinusoidal drive waveforms over the entire input

range to maximize the life of CCFLs. The MAX1739/

MAX1839 optimize this architecture to work over a wide

input voltage range, achieve high efficiency, and maximize the dimming range.

The MAX1739/MAX1839 monitor and limit the transformer center-tap voltage when required. This ensures

minimal voltage stress on the transformer, which

increases the operating life of the transformer and

eases its design requirements. These controllers also

provide protection against many other fault conditions,

including lamp-out and buck short faults.

These controllers achieve 50:1 dimming range by

simultaneously adjusting lamp current and “chopping”

the CCFL on and off using a digitally adjusted pulsewidth modulated (DPWM) method. CCFL brightness is

controlled by an analog voltage or is set with an

SMBusTM-compatible two-wire interface (MAX1739).

The MAX1739/MAX1839 drive an external high-side

N-channel power MOSFET and two low-side N-channel

power MOSFETs, all synchronized to the Royer oscillator. An internal 5.3V linear regulator powers the MOSFET drivers and most of the internal circuitry. The

MAX1739/MAX1839 are available in space-saving

20-pin QSOP packages and operate over the -40°C to

+85°C temperature range.

________________________Applications

Notebook/Laptop Computers

Car Navigation Displays

LCD Monitors

Point-of-Sale Terminals

Portable Display Electronics

Features

♦ Fast Response to Input Change

♦ Wide Input Voltage Range (4.6V to 28V)

♦ High Power-to-Light Efficiency

♦ Minimizes Transformer Voltage Stress

♦ Lamp-Out Protection with 2s Timeout

♦ Buck Switch Short and Other Single-Point Fault

Protection

♦ Integrated Royer MOSFET Drivers Reduce

Transformer Pin Count

♦ Buck Operation Synchronized to Royer Oscillator

♦ Synchronizable DPWM Frequency

♦ Pin-Selectable Brightness Control Interface

♦ SMBus Serial Interface (MAX1739)

♦ Analog Interface (MAX1739/MAX1839)

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

________________________________________________________________ Maxim Integrated Products 1

Pin Configuration

19-1755; Rev 1; 3/01

For price, delivery, and to place orders, please contact Maxim Distribution at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

†

Patent pending

SMBus is a trademark of Intel Corp.

Ordering Information

Pin Configurations continued at end of data sheet.

PART TEMP. RANGE PIN-PACKAGE

MAX1739EEP -40°C to +85°C 20 QSOP

MAX1839EEP -40°C to +85°C 20 QSOP

TOP VIEW

REF

MINDAC

CCI

SH/SUS

CRF/SDA

CTL/SCL

CSAV

1

2

3

4

MAX1739

5

6

7

8

9

10

20

BATT

19

DH

18

LX

17

BSTCCV

VL

16

GND

15

14

CS

DL1MODE

13

12

DL2

11

SYNCCTFB

QSOP

Page 2

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

2 _______________________________________________________________________________________

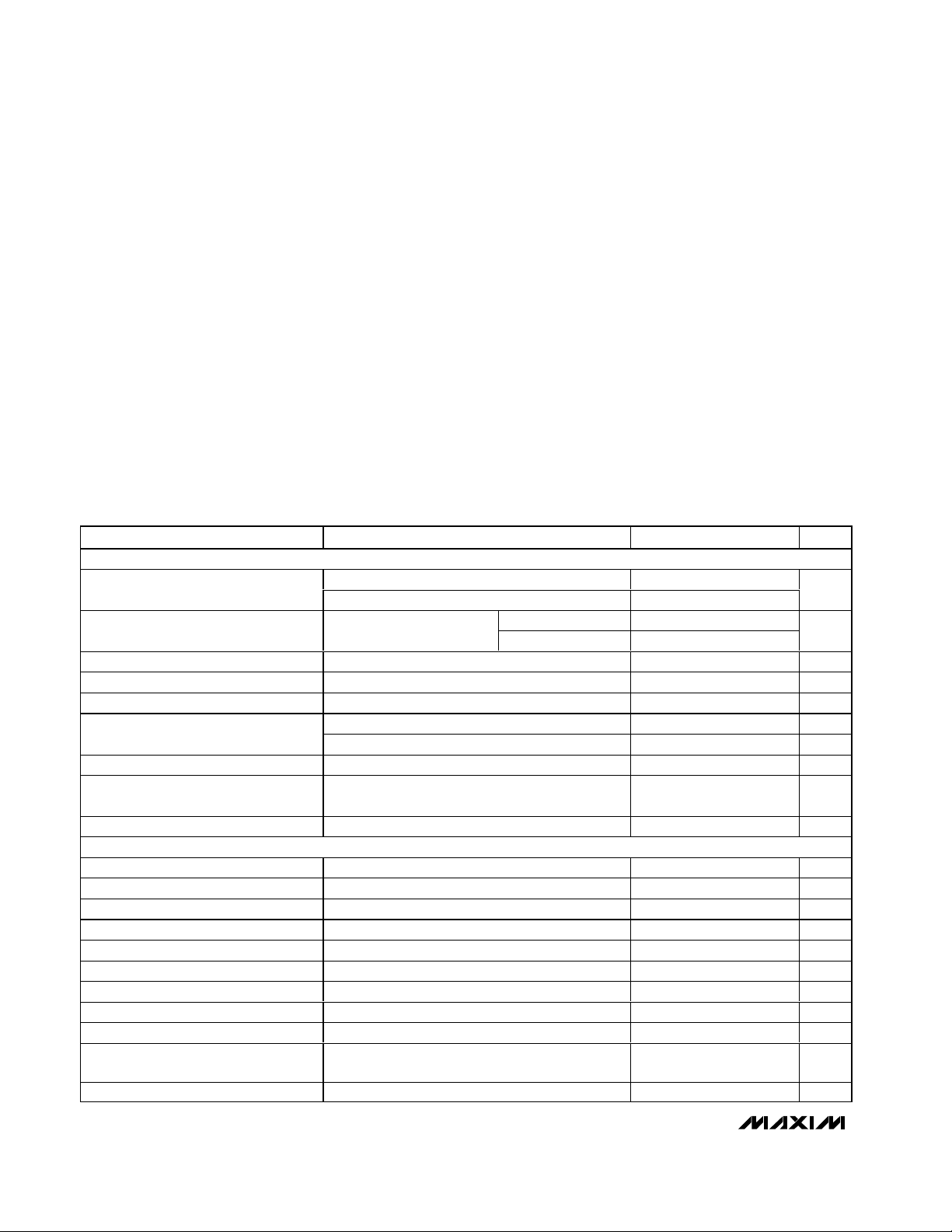

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V+ = 8.2V, VSH/SUS = VSH= 5.5V, MINDAC = GND, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VBATT to GND ...........................................................-0.3V to 30V

V

BST

, V

SYNC

to GND.................................................-0.3V to 34V

V

BST

to VLX.................................................................-0.3V to 6V

V

DH

to VLX.................................................-0.3V to (V

BST

+ 0.3V)

V

LX

to GND...................................................-6V to (V

BST

+ 0.3V)

VL to GND...................................................................-0.3V to 6V

V

CCV

, V

CCI

, V

REF

, V

DL1

, V

DL2

to GND .........-0.3V to (VL + 0.3V)

V

MINDAC

, V

CTFB

, V

CSAV

to GND ................................-0.3V to 6V

V

CS

to GND...................................................-0.6V to (VL + 0.3V)

V

MODE

to GND.............................................................-6V to 12V

V

CRF/SDA

, V

CRF

, V

CTL/SCL

, V

CTL

, V

SH/SUS

,

V

SH

to GND ............................................................-0.3V to 6V

Continuous Power Dissipation (T

A

= +70°C)

20-Pin QSOP (derate 9.1mW/°C above +70°C)...........727mW

Operating Temperature .......................................-40°C to +85°C

Storage Temperature.........................................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

SUPPLY AND REFERENCE

V

BATT

V

BATT

with Full Duty Cycle on DH

V

BATT

VL Output Voltage, Normal Operation

VL Output Voltage, Shutdown SH/SUS = SH = GND, no load 3.5 4.5 5.5 V

VL Undervoltage Lockout Threshold

VL Undervoltage Lockout Hysteresis 300 mV

REF Output Voltage, Normal

Operation

VL POR Threshold 0.9 2.7 V

SWITCHING REGULATOR

DH Driver On-Resistance 18 Ω

DL1, DL2 Driver On-Resistance 18 Ω

Minimum DH Switching Frequency 1/tDH, SYNC = CS or GND, not synchronized 49 56 64 kHz

DH Minimum Off-Time 250 375 500 ns

DH Maximum Duty Cycle 98 %

SYNC Synchronization Range Detect falling edges on SYNC 64 200 kHz

SYNC Input Current 0 < V

SYNC Input Threshold SYNC falling, referred to CS 400 500 600 mV

SYNC Input Hysteresis Referred to the SYNC input threshold 50 100 150 mV

SYNC Threshold Crossing to DL1,

DL2 Toggle Delay

CS Overcurrent Threshold 408 450 492 mV

PARAMETER CONDITIONS MIN TYP MAX UNITS

VL = V

Input Voltage Range

Quiescent Current, Operation

BATT

V

= open 6 28

L

DH = DL1 = DL2 = open

Quiescent Current, Shutdown SH/SUS = SH = GND 6 20 µA

6V < V

< 28V, 0 < I

BATT

VL rising (leaving lockout) 4.6

VL falling (entering lockout) 4.0 V

4.5V < VL < 5.5V, I

< 30V -2 2 µA

SYNC

V

= 0 to 5V, C

SYNC

50% point on SYNC to 50% point on DL1 or DL2

4.6 5.5

V

= 28V 3.2 6

BATT

= VL = 5V 3.2 6

V

BATT

< 15mA

LOAD

= 40µA 1.96 2.00 2.04 V

REF

DL_1

and C

DL_2

< 100pF,

5.0 5.35 5.5 V

120 ns

V

mA

Page 3

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

_______________________________________________________________________________________ 3

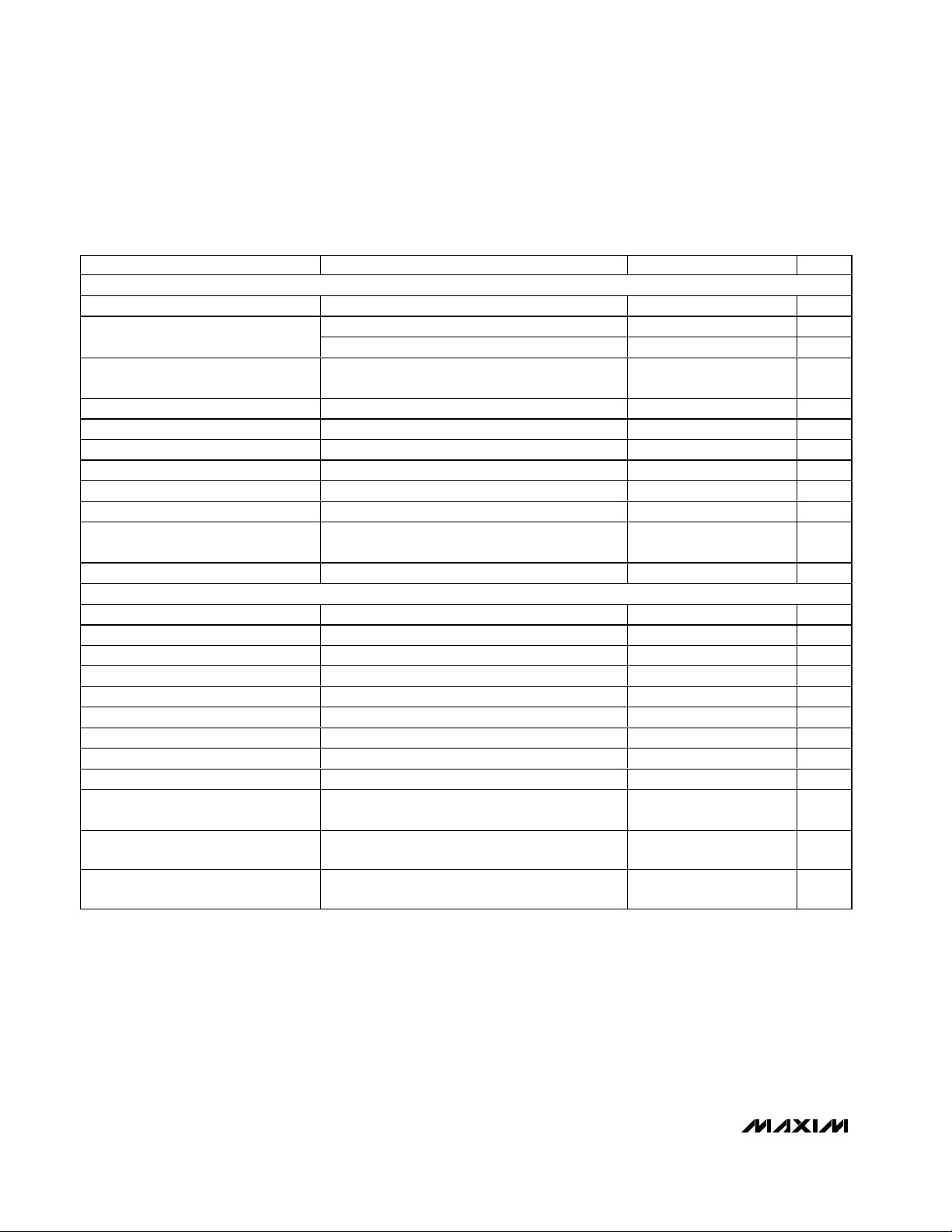

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 8.2V, VSH/SUS = VSH= 5.5V, MINDAC = GND, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

DAC AND ERROR AMPLIFIER

DAC Resolution Guaranteed monotonic 5 Bits

MINDAC Input Voltage Range 0 2 V

MINDAC Input Bias Current 0 < V

MINDAC Digital PWM Disable

Threshold

CSAV Input Voltage Range 0 0.8 V

CSAV Regulation Point

CSAV Input Bias Current -1 1 µA

CSAV to CCI Transconductance 1V < V

CTFB Input Voltage Range 0 2 V

CTFB Input Bias Current -1 1 µA

CTFB Regulation Point 570 600 630 mV

CTFB to CCV Transconductance 1V < V

TIMERS AND FAULT DETECTION

Chopping Oscillator Frequency No AC signal on MODE, not synchronized 24 28 32 kHz

Digital PWM Chop-Mode Frequency

MODE to DPWM Sync Ratio F

Lamp-Out Detection Timeout Timer

(Center-Tap Voltage Stuck at

Maximum) (Note 1)

CSAV Lamp-Out Threshold 50 75 100 mV

Fault-Detection Threshold on CCV (Note 2) 0.4 1 V

Shorted Buck-Switch Detection

Timeout Timer (UL1950 Protection)

(Note 3)

Lamp Turn-On Delay After SH/SUS or SH forces device on or SH rises 4 ms

MODE Operating Voltage Range -5.5 11 V

MODE = GND Threshold

(min Brightness = 0)

MODE = REF Threshold

(max Brightness = 0)

MODE = VL Threshold

(MAX1739 SMB Interface Mode)

MODE AC Signal Amplitude Peak to peak (Note 5) 2 V

MODE AC Signal Synchronization

Range

PARAMETER CONDITIONS MIN TYP MAX UNITS

< 2V -1 1 µA

MINDAC

MINDAC = VL 2.4 2.9 4 V

V

V

V

No AC signal on MODE 205 220 235

32kHz AC signal on MODE 250

100kHz AC signal on MODE 781

V

lamp-out

threshold

V

detection

threshold on CCV

To sync DPWM oscillator, not in shutdown

(Note 4)

To sync DPWM oscillator, not in shutdown

(Note 4)

To sync DPWM oscillator, not in shutdown

(Note 4)

Chopping oscillator synchronized to MODE AC

signal

= 0, DAC code = 11111 binary 188 194 200

MINDAC

= 0, DAC code = 00001 binary 2 6.25 16

MINDAC

= 1V, DAC code = 00000 binary 93 100 110

MINDAC

< 2.7V 100 µmho

CCI

< 2.7V 30 40 50 µmho

CCV

/ F

MODE

CSAV

CCV

DPWM

< CSAV

< fault-

No AC signal on MODE 2.06 2.33 2.73

32kHz AC signal on MODE 2.05

100kHz AC signal on MODE 0.66

No AC signal on MODE 332 291 259

32kHz AC signal on MODE 256

100kHz AC signal on MODE 82

1.4 2.6 V

VL - 0.6 V

32 100 kHz

mV

Hz

128

s

ms

0.6 V

Page 4

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

4 _______________________________________________________________________________________

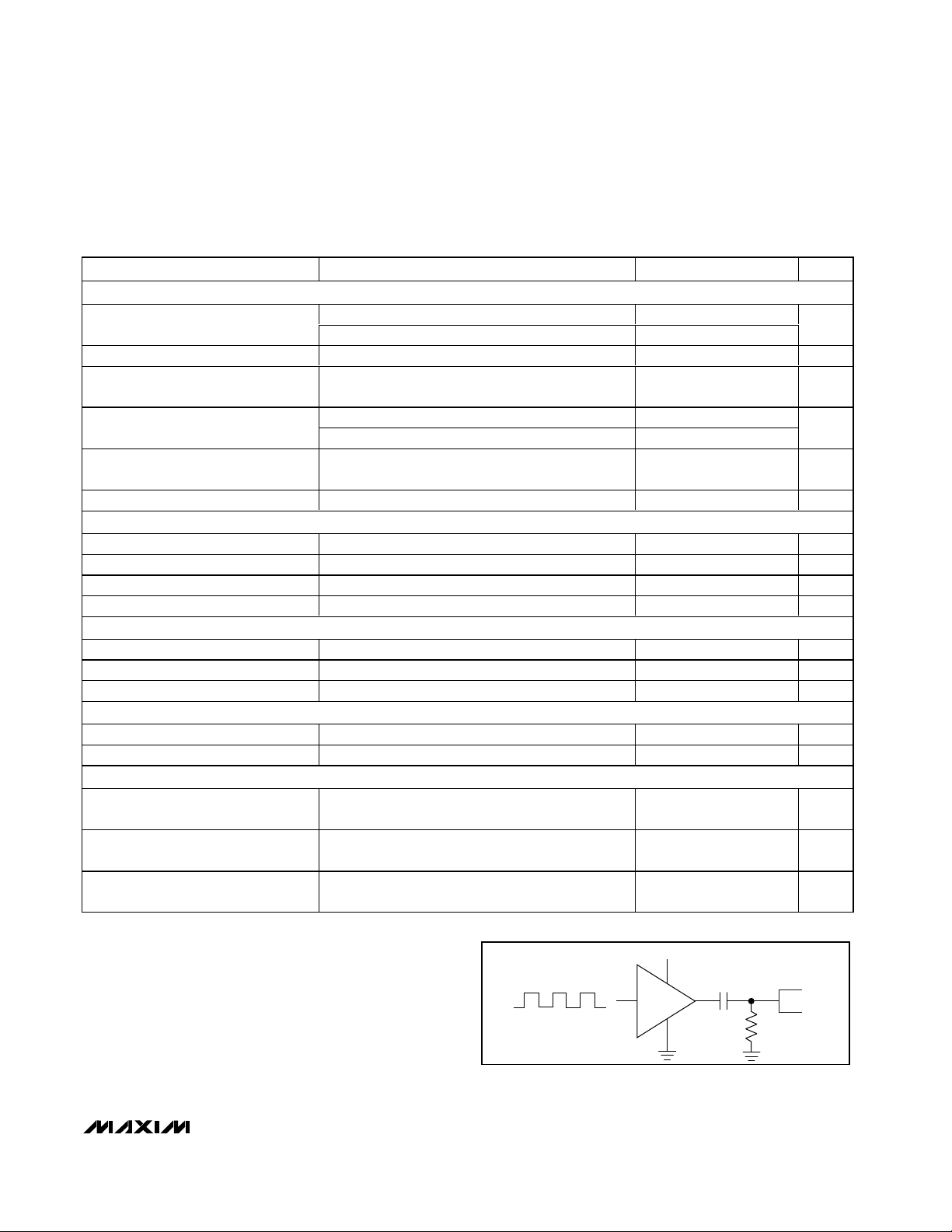

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 8.2V, VSH/SUS = VSH= 5.5V, MINDAC = GND, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

ANALOG INTERFACE BRIGHTNESS CONTROL (MODE connected to REF or GND )

CRF/SDA, CRF Input Range 2.7 5.5 V

CRF/SDA, CRF Input Current

CTL/SCL, Input Range MAX1739 0

CTL Input Range MAX1839 0 CRF V

CTL/SCL, CTL Input Current MODE = REF or GND -1 1 µA

ADC Resolution Guaranteed monotonic 5 Bits

ADC Hysteresis 1 LSB

SH Input Low Voltage 0.8 V

SH Input High Voltage 2.1 V

SH/SUS Input Hysteresis when

Transitioning In and Out of Shutdown

SH Input Bias Current -1 1 µA

SYSTEM MANAGEMENT BUS BRIGHTNESS CONTROL (MAX1739, MODE connected to VL, see Figures 12 and 13)

CRF/SDA, CTL/SCL, SH/SUS Input

CRF/SDA, CTL/SCL, SH/SUS Input

CRFSDA, CTLSCL Input Hysteresis 300 mV

CRF/SDA, CTL/SCL, SH/SUS Input

CRF/SDA Output Low Sink Current V

CTL/SCL Serial Clock High Period t

CTL/SCL Serial Clock Low Period t

Start Condition Setup Time t

Start Condition Hold Time t

C RF/S D A V al id to C TL/S C L Ri si ng E d g e

S etup Ti m e, S l ave C l ocki ng i n D ata

CTL/SCL Falling Edge to CRF/SDA

Transition

CTL/SCL Falling Edge to CRF/SDA

Valid, Reading Out Data

PARAMETER CONDITIONS MIN TYP MAX UNIT

= V

V

CRF/SDA

V

CRF/SDA

CRF/SDA

HIGH

LOW

SU:STA

HD:STA

t

SU:DAT

t

HD:DAT

t

DV

= 0.4V 4 mA

= 5.5V 20 µA

CRF

= V

= 5.5V, SH/SUS = SH = 0 -1 1 µA

CRF

150 mV

2.1 V

-1 1 µA

4µs

4.7 µs

4.7 µs

4µs

250 ns

0ns

CRF/

SDA

0.8 V

1µs

V

Page 5

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS

(V+ = 8.2V, VSH/SUS = VSH= 5.5V, MINDAC = GND, TA= -40°C to +85°C, unless otherwise noted.) (Note 6)

Note 1: Corresponds to 512 DPWM cycles or 65536 MODE

cycles.

Note 2: When the buck switch is shorted, V

CTFB

goes high

causing V

CCV

to go below the fault detection threshold.

Note 3: Corresponds to 64 DPWM cycles or 8192 MODE cycles.

Note 4: The MODE pin thresholds are only valid while the part is

operating. In shutdown, V

REF

= 0 and the part only

differentiates between SMB mode and ADC mode. In

shutdown with ADC mode selected, the CRF/SDA and

CTL/SCL pins are at high impedance and will not cause

extra supply current when their voltages are not at

GND or VL.

V

AMPLITUDE

> 2V

MODE

500pF

10k

Note 5: The amplitude is measured with the following circuit:

Note 6: Specifications from -40°C to +85°C are guaranteed by

design, not production tested.

SUPPLY AND REFERENCE

V

BATT

V

BATT

VL Output Voltage, Normal Operation

VL Undervoltage Lockout Threshold

REF Output Voltage, Normal

Operation

VL POR Threshold 0.9 2.7 V

SWITCHING REGULATOR

DH Driver On-Resistance 18 Ω

DL1, DL2 Driver On-Resistance 18 Ω

SYNC Synchronization Range Detect falling edges on SYNC 64 200 kHz

CS Overcurrent Threshold 408 492 mV

DAC AND ERROR AMPLIFIER

CSAV Regulation Point V

CTFB Regulation Point 560 640 mV

CTFB to CCV Transconductance 1V < V

ANALOG INTERFACE BRIGHTNESS CONTROL (MODE connected to REF or MODE connected to GND)

SH Input Low Voltage 0.8 V

SH Input High Voltage 2.1 V

SYSTEM MANAGEMENT BUS BRIGHTNESS CONTROL (MODE connected to VL)

CRF/SDA, CTL/SCL, SH/SUS Input

Low Voltage

CRF/SDA, CTL/SCL, SH/SUS Input

High Voltage

PARAMETER CONDITIONS MIN TYP MAX UNITS

VL = V

Input Voltage Range

Quiescent Current, Shutdown SH/SUS = SH = GND 20 µA

BATT

VL = open 6 28

6V < V

0 < I

VL rising (leaving lockout) 4.6

VL falling (entering lockout) 4.0

4.5V < VL < 5.5V, I

MINDAC

< 28V,

BATT

< 15mA

LOAD

= 40µA 1.95 2.05 V

REF

= 0, DAC code = 11111 binary 186 202 mV

< 2.7V 30 50 µmho

CCV

4.6 5.5

5.0 5.6 V

0.8 V

2.1 V

V

V

CRF/SDA Output Low Sink Current V

CRF/SDA

= 0.4V 4 mA

Page 6

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

6 _______________________________________________________________________________________

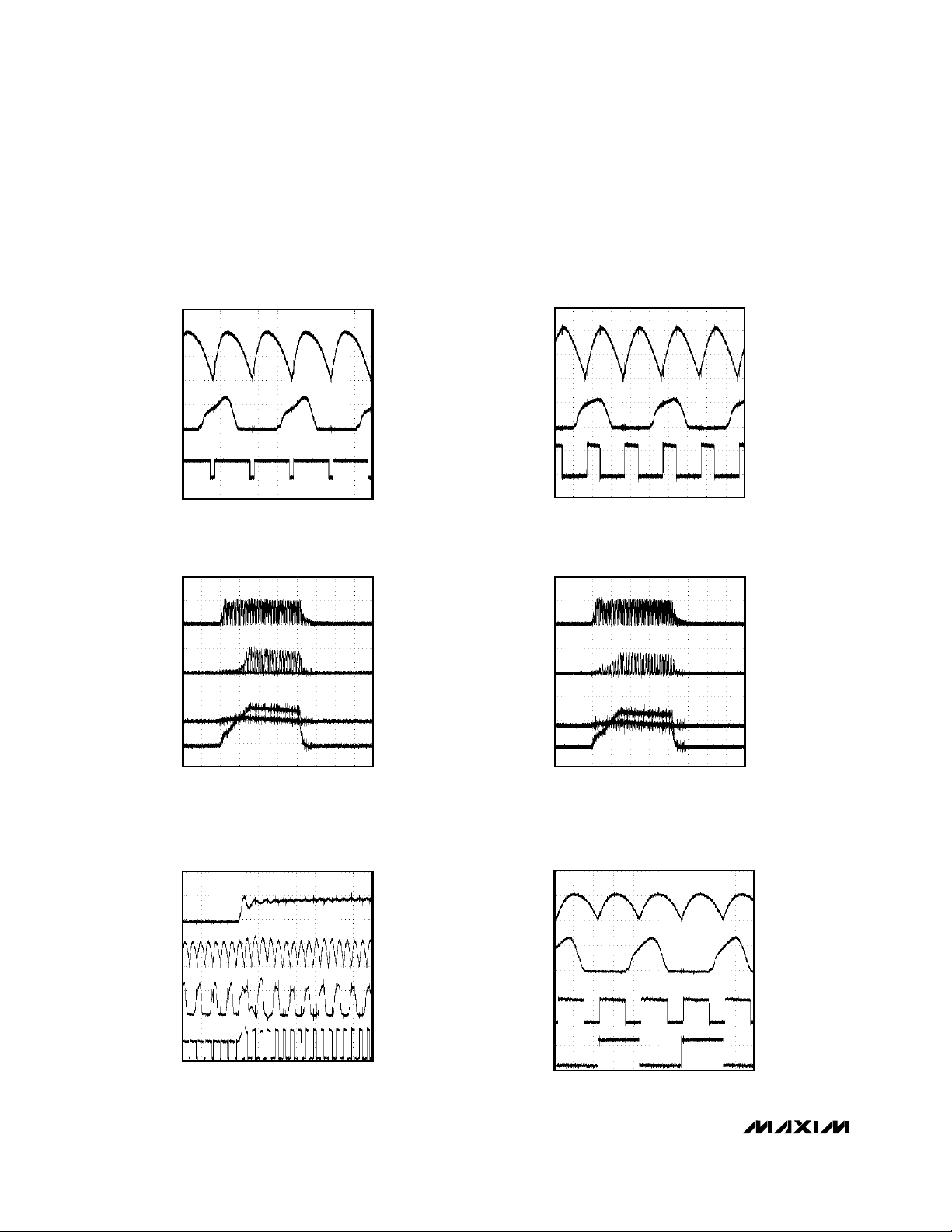

Typical Operating Characteristics

(VIN= 12V, V

CTL

= V

CRF

, V

MINDAC

= 1V, MODE = GND, Circuit of Figure 8.)

4µs/div

WIDE INPUT RANGE

(V

BATT

= 8V)

V

CSAV

500mV/div

V

CTAP

5V/div

V

DH

20V/div

MAX1739/1839 toc01

4µs/div

WIDE INPUT RANGE

(V

BATT

= 20V)

V

CSAV

500mV/div

V

CTAP

5V/div

V

DH

20V/div

MAX1739/1839 toc02

100µs/div

V

CCI

V

CCI

V

CCI

V

CCV

V

CCV

V

CCV

WIDE INPUT RANGE

(V

BATT

= 8V, DPWM = 9%, V

CTL

= 0)

V

CSAV

500mV/div

V

CTAP

10V/div

V

CCV, VCCI

200mV/div

1.2V

MAX1739/1839 toc03

100µs/div

V

CCI

V

CCI

V

CCI

V

CCV

V

CCV

V

CCV

WIDE INPUT RANGE

(V

BATT

= 20V, DPWM = 9%, V

CTL

= 0)

V

CSAV

500mV/div

V

CTAP

10V/div

V

CCV, VCCI

200mV/div

1.2V

MAX1739/1839 toc04

20µs/div

FEED-FORWARD COMPENSATION

V

CTAP

5mV/div

V

IN

20V

10V

V

CSAV

500mV/div

V

DH

20V/div

MAX1739/1839 toc05

4µs/div

SWITCHING WAVEFORMS

V

CSAV

500mV/div

V

CTAP

10V/div

V

DH

20V/div

V

DL

5V/div

MAX1739/1839 toc08

Page 7

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

_______________________________________________________________________________________ 7

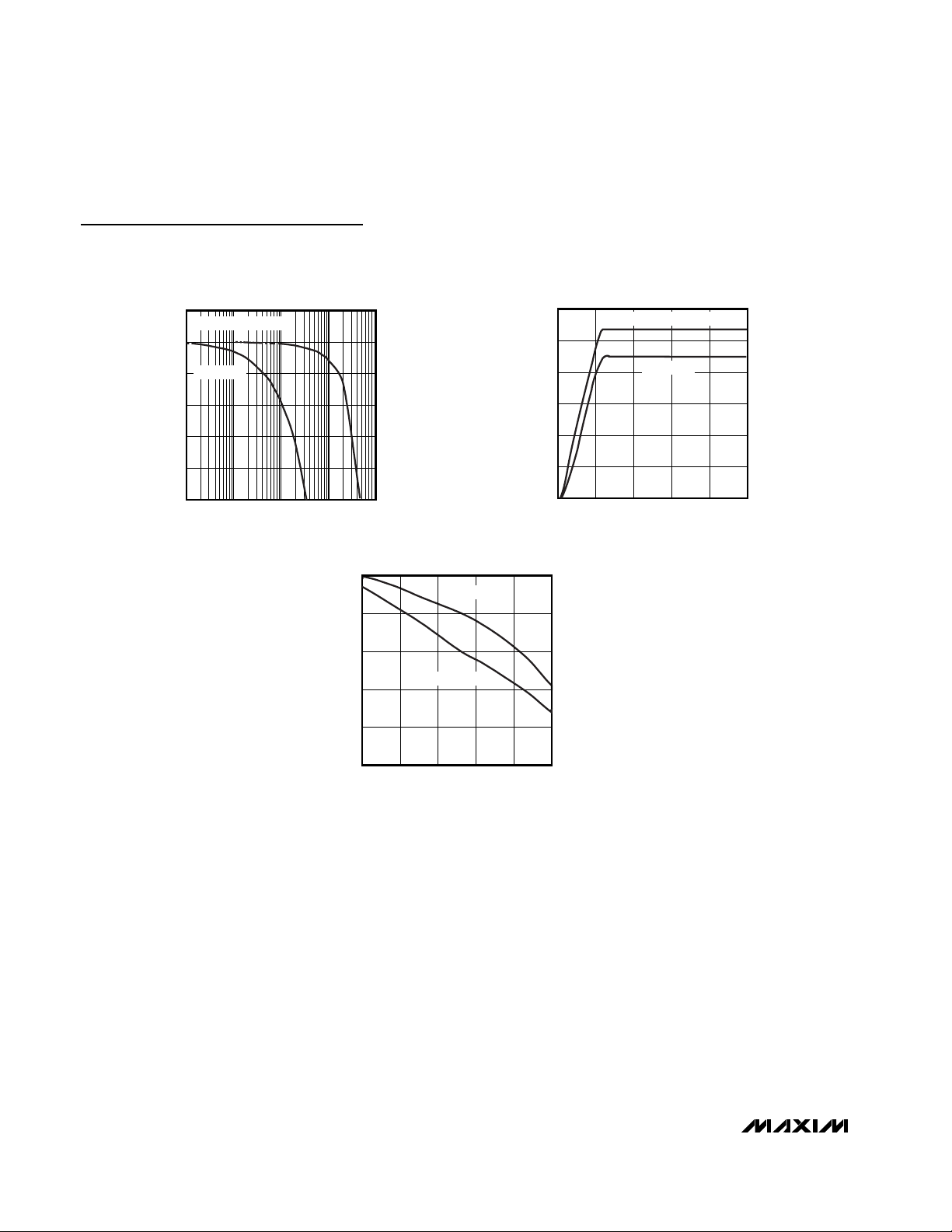

Typical Operating Characteristics (continued)

(VIN= 12V, V

CTL

= V

CRF

, V

MINDAC

= 1V, MODE = GND, Circuit of Figure 8.)

20ms/div

STARTUP

(ADC SOFT-START, MODE = GND)

V

CTAP

10V/div

V

BATT

V

CSAV

500mV/div

I

BATT

500mA/div

MAX1739/1839 toc09

12V

0

2ms/div

LAMP-OUT VOLTAGE LIMITING

V

SECONDARY

2kV/div

V

CTAP

5V/div

MAX1739/1839 toc10

1ms/div

SYNCHRONIZED DPWM

(f

MODE

= 100kHz, V

CTL

= V

CRF

/2)

V

CSAV

500mV/div

V

CTAP

5V/div

V

DH

20V/div

MAX1739/1839 toc07

1ms/div

SYNCHRONIZED DPWM

(f

MODE

= 32kHz, V

CTL

= V

CRF

/2)

V

CSAV

500mV/div

V

CTAP

5V/div

V

DH

20V/div

MAX1739/1839 toc06

400ms/div

LAMP-OUT VOLTAGE LIMITING

V

SECONDARY

2kV/div

V

CTAP

5V/div

MAX1739/1839 toc11

0

200

100

500

400

300

800

700

600

900

0105 152025

INPUT CURRENT vs.

INPUT VOLTAGE

MAX1739/1839 toc12

V

BATT

(V)

I

BATT

(mA)

0

2

1

5

4

3

8

7

6

9

SHUTDOWN CURRENT (µA)

SHUTDOWN

MINIMUM BRIGHTNESS

MAXIMUM BRIGHTNESS

Page 8

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

8 _______________________________________________________________________________________

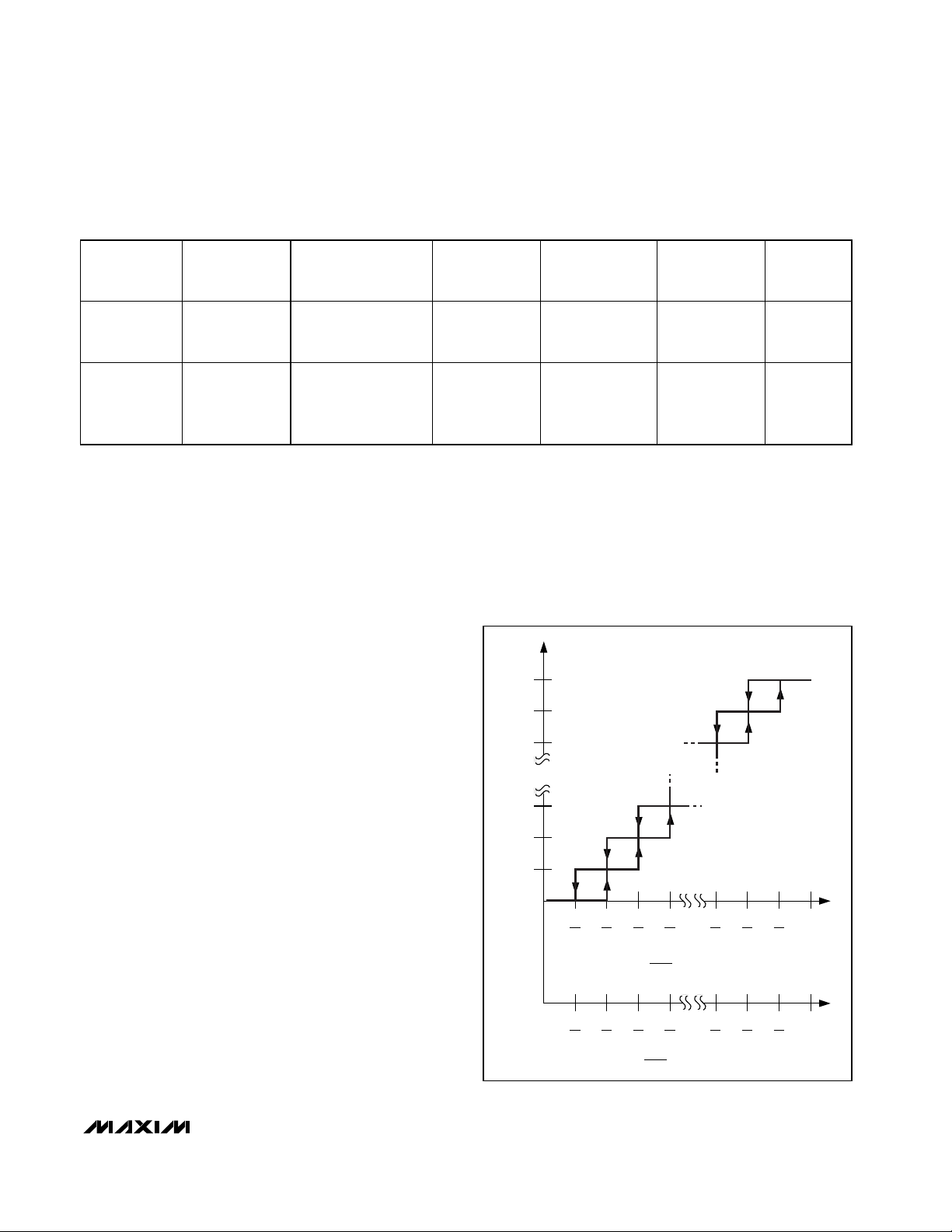

Typical Operating Characteristics (continued)

(VIN= 12V, V

CTL

= V

CRF

, V

MINDAC

= 1V, MODE = GND, Circuit of Figure 8.)

5.40

5.35

5.30

5.25

VL (V)

5.20

5.15

5.10

NORMAL OPERATION

SHUTDOWN

0.01 1 100.1 100

VL vs. I

VL

IVL (mA)

MAX1739/1839 toc13

5.36

5.35

5.34

VL (V)

5.33

VL vs. BATT VOLTAGE

NORMAL OPERATION

SHUTDOWN

0101552520

V

(V)

BATT

4.60

4.55

4.50

4.45

SHUTDOWN VL (V)

MAX1739/1839 toc14

4.6

4.5

4.4

4.3

SHUTDOWN VL (V)

4.2

4.1

4.0

VL vs. TEMPERATURE

SHUTDOWN

NORMAL OPERATION

VL (V)

MAX1739/1839 toc15

6

5

4

3

2

1

0

5.32

5.31

-40 10-15 356085

TEMPERATURE (°C)

4.40

4.35

Page 9

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

_______________________________________________________________________________________ 9_______________________________________________________________________________________

Pin Description

PIN

1 REF REF 2V Reference Output. Bypass to GND with 0.1µF. Forced low during shutdown.

2 MINDAC MINDAC

3 CCI CCI

4 CCV CCV

5 SH/SUS SH

6 CRF/SDA CRF

7 CTL/SCL CTL

8 MODE MODE

9 CSAV CSAV Current-Sense Input. Input to the GMI error amplifier that drives CCI.

10 CTFB CTFB Center-Tap Voltage Feedback Input. The average V

11 SYNC SYNC

12 DL2 DL2

13 DL1 DL1 Low-Side N-Channel MOSFET 1 Gate Drive

14 CS CS

15 GND GND System Ground

16 VL VL

17 BST BST

18 LX LX High-Side Driver Ground Input

19 DH DH High-Side Gate Driver Output. Falling edges on SYNC turn on DH.

20 BATT BATT Supply Input. Input to the internal 5.3V linear regulator that powers the chip.

MAX1739 MAX1839

NAME

DAC Zero-Scale Input. V

Disable DPWM by connecting MINDAC to VL.

GMI Output. Output of the current loop GMI amplifier that regulates the CCFL current.

Typically bypass to GND with 0.1µ F .

GMV Output. Output of the voltage loop GMV amplifier that regulates the maximum

average primary transformer voltage. Typically bypass to GND with 3300p F .

Logic Low Shutdown Input in Analog Interface Mode. SMBus suspends input in SMBus

interface mode (MAX1739 only).

5- Bi t AD C Reference Input in Anal og Inter face Mod e. Bypass to GN D wi th 0.1µF. SM Bus seri al

d ata i np ut/op en- d r ai n outp ut ( MAX 1739 onl y) i n S M Bus i nter face m od e.

CCFL Brightness Control Input in Analog Interface Mode. SMBus serial clock input

(MAX1739 only) in SMBus interface mode.

Interface Selection Input and Sync Input for DPWM Chopping (see Synchronizing the

DPWM Frequency). The average voltage on the MODE pin selects one of three CCFL

brightness control interfaces:

1) MODE = VL, enables SMBus serial interface (MAX1739 only).

2) MODE = GND, enables the analog interface (positive scale analog interface mode);

V

CTL/SCL

3) MODE = REF, enables the analog interface (negative scale analog interface mode);

V

CTL/SCL

Royer Synchronization Input. Falling edges on SYNC force DH on and toggle the DL1

and DL2 drivers. Connect directly to the Royer center tap.

Low-Side N-Channel MOSFET 2 Gate Drive. Drives the Royer oscillator switch. DL1 and

DL2 have make-before-break switching, where at least one is always on. Falling edges

on SYNC toggle DL1 and DL2 and turn DH on.

Current-Sense Input (Current Limit). The current-mode regulator terminates the switch

cycle when VCS exceeds (V

5.3V Linear Regulator Output. Supply voltage for most of the internal circuits. Bypass

with 1µF capacitor to GND. Can be connected to V

High-Side Driver Bootstrap Input. Connect through a diode to VL and bypass with 0.1µF

capacitor to LX.

= 0 means minimum brightness.

= 0 means maximum brightness.

MINDAC

REF

FUNCTION

sets the DAC’s minimum scale output voltage.

CTFB

- V

).

CCI

BATT

is limited to 0.6V.

if V

BATT

< 5.5V.

Page 10

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

10 ______________________________________________________________________________________

Detailed Description

The MAX1739/MAX1839 regulate the brightness of a

CCFL in three ways:

1) Linearly controlling the lamp current.

2) Digitally pulse-width modulating (or chopping) the

lamp current (DPWM).

3) Using both methods simultaneously for widest dimming range.

DPWM is implemented by pulse-width modulating the

lamp current at a rate faster than the human eye can

detect. Figure 1 shows the current and voltage waveforms for the three operating modes with the brightness

control set to 50% of full scale.

The MAX1739/MAX1839 include a 5.3V linear regulator

to power most of the internal circuitry, drivers for the

buck and Royer switches, and the synchronizable

DPWM oscillator. The MAX1739/MAX1839 are very flexible and include a variety of operating modes, an analog interface, an SMBus interface (MAX1739 only), a

shutdown mode, lamp-out detection, and buck-switch

short detection.

Figure 1. Brightness Control Methods

V

= 0

MINDAC

= V

V

CTL

(DAC SET TO MIDSCALE)

EFFECTIVE BRIGHTNESS IS:

50% IN CONTINUOUS AND DPWM CONTROL

25% IN COMBINED CONTROL

/2 or BRIGHT[4:0] = 10,000

CRF

DPWM CONTROL

V

CTAP

TRANSFORMER

VOLTAGE

V

CSAV

LAMP CURRENT

CONTINUOUS CURRENT CONTROL

V

CTAP

V

CSAV

CURRENT + DPWM CONTROL

Page 11

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

_______________________________________________________________________________________ 11

Voltage and Current Control Loops

The MAX1739/MAX1839 use two control loops. The current control loop regulates the average lamp current. The

voltage control loop limits the maximum average primaryside transformer voltage. The voltage control loop is

active during the beginning of DPWM on-cycles and in

some fault conditions. Limiting the transformer primary

voltage allows for a lower transformer secondary voltage

rating that can increase reliability and decrease cost of

the transformer. The voltage control loop acts to limit the

transformer voltage any time the current control loop

attempts to steer the transformer voltage above its limit as

set by V

CTFB

(see Sense Resistors).

The voltage control loop uses a transconductance

amplifier to create an error current based on the voltage between CTFB and the internal reference level

(600mV typ) (Figure 2). The error current is then used

to charge and discharge C

CCV

to create an error volt-

age V

CCV

. The current control loop produces a similar

signal based on the voltage between CSAV and its

internal reference level (see the Dimming Range section). This error voltage is called V

CCI

. The lower of

V

CCV

and V

CCI

is used with the buck regulator’s PWM

ramp generator to set the buck regulator’s duty cycle.

During DPWM, the two control loops work together to

limit the transformer voltage and to allow wide dimming

range with good line rejection. During the DPWM offcycle, V

CCV

is set to 1.2V and CCI is set to high imped-

ance. V

CCV

is set to 1.2V to create soft-start at the

beginning of each DPWM on-cycle in order to avoid

overshoot on the transformer primary. V

CCI

is set to

high impedance to keep V

CCI

from changing during the

off-cycles. This allows the current control loop to regulate the average lamp current only during DPWM oncycles and not the overall average lamp current.

Upon power-up, V

CCI

slowly rises, increasing the duty

cycle, which provides soft-start. During this time, V

CCV

,

which is the faster control loop, is limited to 150mV

above V

CCI

by the CCV-CLAMP

. Once the secondary

voltage reaches the strike voltage, the lamp current

begins to increase. When the lamp current reaches the

regulation point, V

CCI

reaches steady state. With MINDAC = VL (DPWM disabled), the current control loop

remains in control and regulates the lamp current.

With MINDAC between REF and GND, DPWM is

enabled and the MAX1739/MAX1839 begin pulsing the

lamp current. During the on-cycle, V

CCV

is at 150mV

above V

CCI

. After the on-cycle, V

CCV

is forced down to

1.2V to provide soft-start at the beginning of the next

on-cycle. Also, V

CCI

retains its value until the beginning

of the next on-cycle. When V

CCV

increases, it causes

the buck regulator duty cycle to increase and provides

soft-start. When V

CCV

crosses over V

CCI

, the current

control loop regains control and regulates the lamp current. V

CCV

is limited to 150mV above V

CCI

for the

remainder of the on-cycle.

In a lamp-out condition, V

CCI

increases the primary

voltage in an attempt to maintain lamp current regulation. As V

CCI

rises, V

CCV

rises with it until the primary

voltage reaches its set limit point. At this point, V

CCV

stops rising and limits the primary voltage by limiting

the duty cycle. Because V

CCV

is limited to 150mV

above V

CCI

, the voltage control loop is quickly able to

limit the primary voltage. Without this clamping feature,

the transformer voltage would overshoot to dangerous

levels because V

CCV

would take more time to slew

down from its supply rail. Once the MAX1739/MAX1839

sense less than 1/6 the full-scale current through the

lamp for 2 seconds, it shuts down the Royer oscillator

(see Lamp-Out Detection).

See the Sense Resistors section for information about

setting the voltage and current control loop thresholds.

Feed-Forward Control

Both control loops are influenced by the input voltage

feed-forward (V

BATT

) control circuitry of the MAX1739/

MAX1839. Feed-forward control instantly adjusts the

buck regulator’s duty cycle when it detects a change in

input voltage. This provides immunity to changes in

input voltage at all brightness levels. This feature

makes compensation over wide input ranges easier,

makes startup transients less dependent on input voltage, and improves line regulation for short DPWM ontimes.

The MAX1739/MAX1839 feed-forward control is implemented by varying the amplitude of the buck-switch’s

PWM ramp amplitude. This has the effect of varying the

duty cycle as a function of input voltage while maintaining the same V

CCI

and V

CCV

. In other words, V

BATT

feed

forward has the effect of not requiring changes in errorsignal voltage (V

CCI

and V

CCV

) to respond to changes in

V

BATT

. Since the capacitors only need to change their

voltage minimally to respond to changes in V

BATT

, the

controller’s response is essentially instantaneous.

Transient Overvoltage Protection

from Dropout

The MAX1739/MAX1839 are designed to maintain tight

control of the transformer primary under all transient

conditions. This includes transients from dropout,

where V

BATT

is so low that the controller loses regulation and reaches maximum duty cycle. Backlight

designs will want to choose circuit component values to

minimize the transformer turns ratio in order to minimize

primary-side currents and I2R losses. To achieve this,

Page 12

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

12 ______________________________________________________________________________________

Figure 2. Functional Diagram

REF

MINDAC

DPWM CONTROL

LAMP CURRENT AND

SMBus

CTL/SCL

CRF/SDA

VL

GND

DPWM OSC

MODE

BATT

REF

VL

PEAK

DETECTOR

VL

SUPPLY

GMI

SH/SUS

MINDAC = VL?

PWM

PK_DET_CLAMP

CCI

CSAV

REF

Y = 1, N = 0

RAMP

GENERATOR

CCV CLAMP

CCV

BUCK

0.6V

BST

ENABLE

BUCK REGULATOR

GMV

CTFB

LX

DH

PWM CONTROL

450mV

CS

500mV

DL1

CS

ROYER OSC

SYNC

DL2

CS

Page 13

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

______________________________________________________________________________________ 13

allow the circuit to operate in dropout at extremely low

battery voltages where the backlight’s performance is

secondary. All backlight circuit designs can undergo a

transient overvoltage condition when the laptop is

plugged into the AC adapter and V

BATT

suddenly

increases. The MAX1739/MAX1839 contain a unique

clamp circuit on V

CCI

. Along with the feed-forward circuitry, it ensures that there is not a transient transformer

overvoltage when leaving dropout.

The PK_DET_CLAMP circuit limits V

CCI

to the peaks of

the buck-regulator’s PWM ramp generator. As the circuit reaches dropout, V

CCI

approaches the peaks of

the PWM ramp generator in order to reach maximum

duty cycle. If V

BATT

decreases further, the control loop

loses regulation and V

CCI

tries to reach its positive sup-

ply rail. The clamp circuit on V

CCI

keeps this from hap-

pening, and V

CCI

rides just above the peaks of the

PWM ramp. As V

BATT

decreases further, the feed-forward PWM ramp generator loses amplitude and the

clamp drags V

CCI

down with it to a voltage below

where V

CCI

would have been if the circuit was not in

dropout. When VBATT is suddenly increased out of

dropout, V

CCI

is still low and maintains the drive on the

transformer at the old dropout level. The circuit then

slowly corrects and increases V

CCI

to bring the circuit

back into regulation.

Buck Regulator

The buck regulator uses the signals from the PWM

comparator, the current-limit detection on CS, and

DPWM signals to control the high-side MOSFET duty

cycle. The regulator uses voltage-mode PWM control

and is synchronized to the Royer oscillator. A falling

edge on SYNC turns on the high-side MOSFET after a

375ns minimum off-time delay. The PWM comparator or

the CS current limit ends the on-cycle.

Interface Selection

Table 1 lists the functionality of SH/SUS, CRF/SDA, and

CTL/SCL in each of the three interface modes of the

MAX1739/MAX1839. The MAX1739 features both an

SMBus digital interface and an analog interface, while

the MAX1839 features only the analog interface. Note

that MODE can also synchronize the DPWM frequency

(see Synchronizing the DPWM Frequency).

Dimming Range

Brightness is controlled by either the analog interface

(see Analog Interface) or the SMBus interface (see

SMBus Interface). CCFL brightness is adjusted in three

ways:

1) Lamp current control, where the magnitude of the

average lamp current is adjusted.

2) DPWM control, where the average lamp current is

pulsed to the lamp with a variable duty cycle.

3) A combination of the first two methods.

In each of the three methods, a 5-bit brightness code is

generated from the selected interface and is used to

set the lamp current and/or DPWM duty cycle.

The 5-bit brightness code defines the lamp current

level with ob00000 representing minimum lamp current

and ob11111 representing maximum lamp current. The

average lamp current is measured across an external

sense resistor (see Sense Resistors). The voltage on

the sense resistor is measured at CSAV. The brightness

code adjusts the regulation voltage at CSAV (V

CSAV

).

The minimum average V

CSAV

is V

MINDAC

/10, and the

maximum average is set by the following formula:

V

CSAV

= V

REF

✕

31 / 320 + V

MINDAC

/ 320

which is between 193.75mV and 200mV.

Note that if V

CSAV

does not exceed 100mV peak (which

is about 32mV average) for over 2 seconds, the

MAX1739/MAX1839 will assume a lamp-out condition

and shut down (see Lamp-Out Detection).

The equation relating brightness code to C

SAV

regula-

tion voltage is:

V

CSAV

= V

REF

✕

n / 320 + V

MINDAC

✕

(32 - n) / 320

where n is the brightness code.

To always use maximum average lamp current when

using DPWM control, set V

MINDAC

to V

REF

.

DPWM control works similar to lamp current control in

that it also responds to the 5-bit brightness code. A

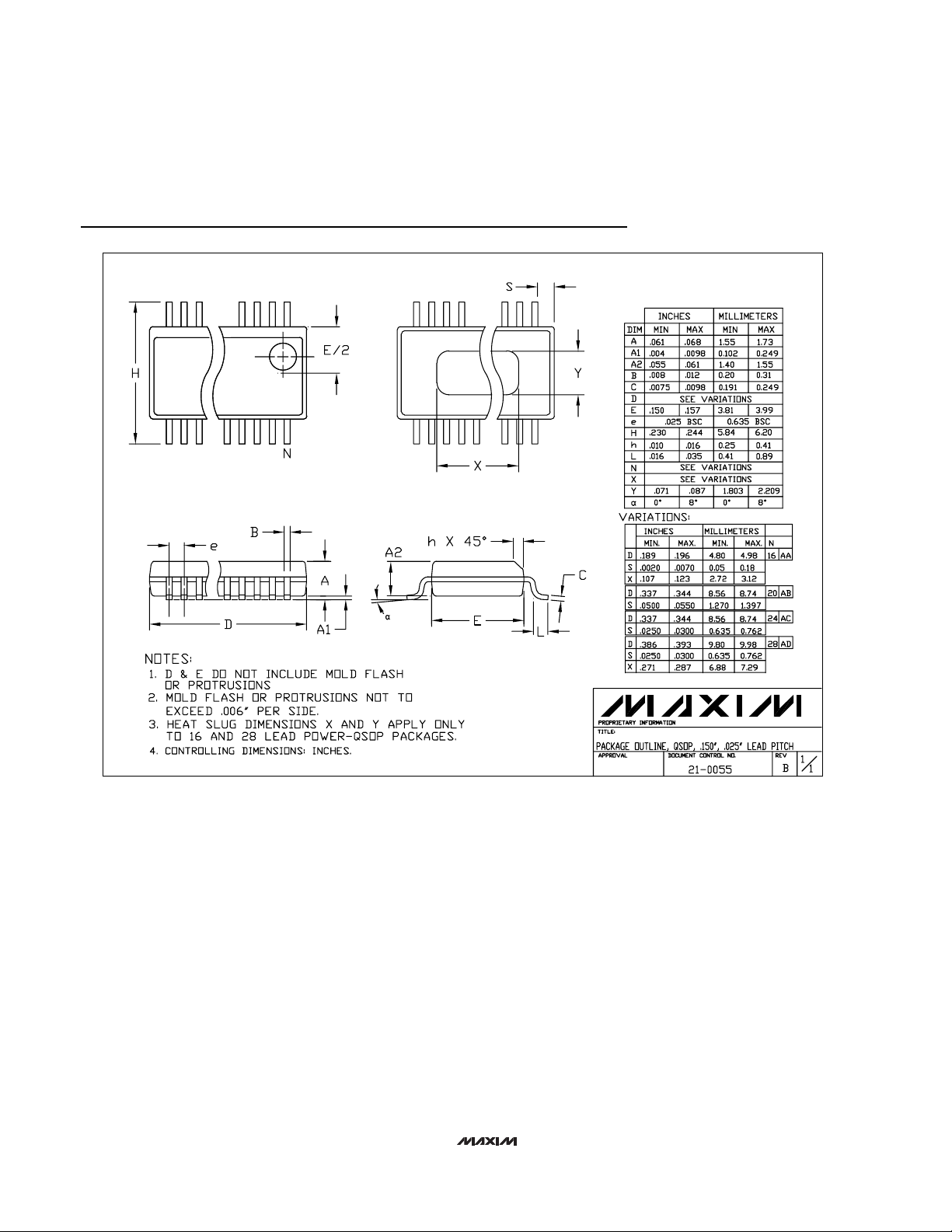

Table 1. Interface Modes

PIN

SH/SUS SMBus suspend Logic-level shutdown control input

CRF/SDA SMBus data I/O Reference input for minimum brightness Reference input for maximum brightness

CTL/SCL SMBus clock input Analog control input to set brightness (range from 0 to CRF/SDA)

DIGITAL

INTERFACE

MODE = VL

(MAX1739 only)

MODE = REF,

/SCL = 0 = maximum brightness

V

CTL

ANALOG INTERFACE

MODE = GND,

V

/SCL = 0 = minimum brightness

CTL

Page 14

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

14 ______________________________________________________________________________________

brightness code of ob00000 corresponds to a 9.375%

DPWM duty cycle, and a brightness code of ob11111

corresponds to a 100% DPWM duty cycle. The duty

cycle changes by 3.125% per step, except codes

ob00000 to ob00011 all produce 9.375% (Figure 3).

To disable DPWM and always use 100% duty cycle, set

V

MINDAC

to VL. Note that with DPWM disabled, the

equations above should assume V

MINDAC

= 0 instead

of V

MINDAC

= VL. Table 2 lists MINDAC’s functionality,

and Table 3 shows some typical settings for the brightness adjustment.

In normal operation, V

MINDAC

is set between 0 and

V

REF

, and the MAX1739/MAX1839 use both lamp current control and DPWM control to vary the lamp brightness (Figure 4). In this mode, lamp current control

regulates the average lamp current during a DPWM oncycle and not the overall average lamp current.

Analog Interface and Brightness Code

The MAX1739/MAX1839 analog interface uses an internal ADC with 1-bit hysteresis to generate the brightness

code used to dim the lamp (see Dimming Range).

CTL/SDA is the ADC’s input, and CRF/SCL is its reference voltage. The ADC can operate in either positivescale ADC mode or negative-scale ADC mode. In

positive-scale ADC mode, the brightness code increas-

es from 0 to 31 as V

CTL

increases from 0 to V

CRF

. In

negative-scale mode, the brightness scale decreases

from 31 to 0 as V

CTL

increases from 0 to V

CRF

(Figure 5)

.

The analog interface’s internal ADC uses 1-bit hysteresis to keep the lamp from flickering between two codes.

V

CTL

’s positive threshold (V

CTL(TH)

) is the voltage

required to transition the brightness code as V

CTL

increases and can be calculated as follows:

V

CTL(TH)

= (n + 2) / 33 V

CRF

(positive-scale ADC mode, MODE = GND)

V

CTL(TH)

= (33 - n) / 33 V

CRF

(negative-scale ADC mode, MODE = REF)

where n is the current selected brightness code. V

CTL

’s

negative threshold is the voltage required to transition

the brightness code as V

CTL

decreases and can be

calculated as follows:

V

CTL(TH)

= n / 33 V

CRF

(positive-scale ADC mode, MODE = GND)

V

CTL(TH)

= (31 - n) / 33 V

CRF

(negative-scale ADC mode, MODE = REF)

Figure 5 shows a graphic representation of the thresholds. CRF/SDA’s and CTL/SCL’s input voltage range is

2.7V to 5.5V.

Table 2. MINDAC Functionality

Figure 3. DPWM Settings

Figure 4. Combined Power Level

100

90

80

70

60

50

40

30

DPWM DUTY CYCLE (%)

20

10

0

01248 2016 24 28 32

DPWM SETTINGS

BRIGHTNESS CODE

COMBINED POWER LEVEL

(BOTH DPWM AND

100

90

80

70

60

50

40

30

COMBINED POWER LEVEL (%)

20

10

LAMP CONTROL CURRENT)

0

01248 2016 24 28 32

BRIGHTNESS CODE

MINDAC = VL

MINDAC = REF

0 ≤ V

MINDAC

< V

REF

DPWM disabled (always on 100% duty cycle). Operates in lamp current control only.

(Use V

DPWM control enabled, duty cycle ranges from 9% to 100%. Lamp current control is disabled

(always maximum current).

The device uses both lamp current control and DPWM.

= 0 in the equations.)

MINDAC

Page 15

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

______________________________________________________________________________________ 15

See Digital Interface for instructions on using the

SMBus interface.

Synchronizing the DPWM Frequency

MODE has two functions: one is to select the interface

mode as described in Interface Selection, and the other

is to synchronize the DPWM “chopping” frequency to

an external signal to prevent unwanted effects in the

display screen.

To synchronize the DPWM frequency, connect MODE

to VL, REF, or GND through a 10kΩ resistor. Then connect a 500pF capacitor from an AC signal source to

MODE as shown in Figure 6. The synchronization range

is from 32kHz to 100kHz, which corresponds to a

DPWM frequency range of 250Hz to 781Hz (128 MODE

pulses per DPWM cycle). High DPWM frequencies limit

the dimming range. See Loop Compensation for more

information concerning high DPWM frequencies.

Royer Oscillator MOSFET Drivers

The MAX1739/MAX1839 directly drive the two external

MOSFETs used in the Royer oscillator. This has many

advantages over the traditional method that uses bipolar switching and an extra winding on the transformer.

Directly driving the MOSFET eliminates the need for an

extra winding on the transformer, which reduces cost

and minimizes the size of the transformer. Also, driving

the switches directly improves commutation efficiency

and commutation timing. Using MOSFETs for the

switches typically improves overall inverter efficiency

due to lower switch drops.

The Royer topology works as a zero voltage crossing

(ZVC) detector and switches currents between the two

sections of the transformer primary windings. The two

windings work alternately, each generating a half wave

that is transferred to the secondary to produce the full-

wave sinusoidal lamp voltage and current. The

MAX1739/MAX1839 detect the zero crossing through

the SYNC pin; the threshold is set at 500mV referred to

CS and has a typical delay of 50ns. The active switching forces commutation very close to the ZVC point and

has better performance than the traditional windingbased ZVC switchover. Commutation can be further

Table 3. Brightness Adjustment Ranges (for 33:1 Dimming)

Note: The current-level range is solely determined by the MINDAC-to-REF ratio and is externally set.

Figure 5. Brightness Code

BRIGHTNESS

Maximum

Brightness

Minimum

Brightness

POSITIVE-

SCALE ADC

MODE = GND,

CTL/SCL

CRF/SDA

CTL/SCL

MINDAC

REF / 3

=

= 0,

=

V

V

MODE = GND,

V

V

V

NEGATIVE-

SCALE ADC

MODE = REF,

V

MODE = REF,

V

V

CTL/SCL

CTL/SCL

MINDAC

= 0

= V

= V

CRF/SDA

REF / 3

SMBus

Bright [4:0] =

ob11111

Bright [4:0] =

ob00000,

,

V

MINDAC

V

REF / 3

DAC

OUTPUT

Full-scale

DAC OUTPUT =

195.83mV

Zero-scale

=

DAC OUTPUT =

MINDAC

/ 10

V

31

30

29

3

BRIGHTNESS CODE

2

1

0

1332333334

32333133303329

V

V

DPWM DUTY

CYCLE

33

V

CTL

(MODE = GND)

V

CRF

33

CTL

(MODE = REF)

CRF

COMBINED

POWER

(%)

100 100

93

30

33

33323313301

LEVEL (%)

313332331

Page 16

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

16 ______________________________________________________________________________________

optimized using R14 and R15 as shown in Figure 7.

The resistor-divider can be used to force commutation

as close to the zero-crossing point as possible.

POR and UVLO

The MAX1739/MAX1839 include power-on reset (POR)

and undervoltage lockout (UVLO) features. The POR

resets all internal registers, such as DAC output, fault

conditions, and all SMBus registers. POR occurs when

VL is below 1.5V. The SMBus input logic thresholds are

designed to meet electrical characteristic limits for VL

as low as 3.5V, but the interface will continue to function down to the POR threshold.

The UVLO threshold occurs when VL is below 4.2V

(typ) and disables the buck-switch driver.

Low-Power Shutdown

When the MAX1739/MAX1839 are placed in shutdown,

all IC functions are turned off except the 5V linear regulator that powers all internal registers and the SMBus

interface (MAX1739). The SMBus interface is accessible in shutdown. In shutdown, the linear regulator output voltage drops to about 4.5V and the supply current

is 6µA (typ), which is the required power to maintain all

internal register states. While in shutdown, lamp-out

detection and buck-switch short-circuit detection latches are reset. The device can be placed into shutdown

by either writing to the MODE register (MAX1739

SMBus mode only) or with SH/SUS.

Lamp-Out Detection

For safety, during a lamp-out condition, the MAX1739/

MAX1839 limit the maximum average primary-side

transformer voltage (see Sense Resistors) and shut

down the lamp after 2s.

The lamp-out detection circuitry monitors V

CSAV

and

shuts down the lamp if V

CSAV

does not exceed 75mV

(typ) within 2 seconds. This circuitry ignores most pulses under 200ns. However, in some cases, a small

capacitor is needed at CSAV to prevent noise from tripping the circuitry. This is especially true in noisy environments and in designs with marginal layout.

Ideally, the voltage at CSAV is a half-wave rectified sine

wave. In this case, the CSAV lamp-out threshold is as

follows:

I

MIN

= I

MAX

/ 6

where I

MIN

is the CSAV lamp out threshold, and I

MAX

is

the maximum lamp current (see Sense Resistors). Note:

The formulas assume a worst-case CSAV lamp-out

threshold of 100mV and a maximum CSAV average

voltage of 200mV.

Use MINDAC or limit the brightness code to prevent

setting the lamp current below the CSAV lamp-out

threshold.

STATUS1 bit sets when the lamp-out detection circuit

shuts down the device.

Buck-Switch Short Fault Detection

and Protection

When the buck switch (N1) fails short, there is no voltage limiting on the transformer and the input forces

excessive voltage on the transformer secondary. This

Figure 6. DPWM Synchronization

Figure 7. Adjusting the ZVC Detection

ADC-

10k

SMBus

ADC+

500pF

DPWM

SYNCHRONIZATION

SIGNAL

VL

REF

MODE

GND

MAX1739

MAX1839

LX

MAX1739

MAX1839

SYNC

REF

CTFB

GND

L1

R14

R15

T1

R4

R5

Page 17

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

______________________________________________________________________________________ 17

Figure 8. Standard Application Circuit

increases the circuit’s demand for current but may not

be enough to blow the fuse. With the buck switch shorted, the center tap rises above its regulation point,

which causes the CCV amplifier’s output (V

CCV

) to go

low. To detect this, the MAX1739/MAX1839 check that

V

CCV

is below 1V at the end of every DPWM period. If

this condition persists for over 250ms (or 64 DPWM

pulses), the inverter switch commutation is stopped

with either DL1 or DL2 on. With the buck switch shorted, this will cause a short circuit with enough current to

blow the fuse. If the buck switch is not shorted, then the

inverter latches off as in a lamp-out condition.

Both buck-switch short and lamp-out detection will

clear the STATUS1 bit in the SMBus interface. STATUS1 does not clear immediately but will clear about 2

seconds after the inverter has been forced off (see

Digital Interface).

Note that once the inverter board fuse has blown,

SMBus communications with the part will cease since

the MAX1739 will then be without power.

Applications Information

As shown in the standard application circuit (Figure 8),

the MAX1739/MAX1839 regulate the current of a 4.5W

CCFL. The IC’s analog voltage interface sets the lamp

brightness with a minimum 20:1 power adjustment

range. This circuit operates from a wide supply-voltage

range of 7V to 24V. Typical applications include notebook, desktop monitor, and car navigation displays.

CCFL Specifications

To select the correct component values for the

MAX1739/MAX1839 circuit, several CCFL parameters

(Table 4) and the minimum DC input voltage must be

specified.

Royer Oscillator

Components T1, C6, C7, N2A, and N2B form the Royer

oscillator. A Royer oscillator is a resonant tank circuit

that oscillates at a frequency dependent on C7, the primary magnetizing inductance of T1 (LP), and the

impedance seen by the T1 secondary. Figure 8 shows

V

IN

(5V TO 28V)

C9

4.7µF

C2

C1

BATT

CCV

C3

CCI

MAX1739

MAX1839

REF

MINDAC

DHI

BST

SYNC

VL

N1 D2

LX

D1

C6

C4

C5 L1

T1

R4

C7

MODE

VL

CRF/SDA

DIMMING

CTL/SCL

ON/OFF

SH/SUS

CTFB

DL2

DL1

GND

CSAV

R5

N2B

D5

N2A

CS

R13

Page 18

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

18 ______________________________________________________________________________________

a proven application that is useful for a wide range of

CCFL tubes and power ranges. Table 5 shows the recommended components for a 4.5W application.

MOSFETs

The MAX1739/MAX1839 require three external switches

to operate: N1, N2A, and N2B. N1 is the buck switch;

select a logic-level N-channel MOSFET with low R

DSON

to minimize conduction losses (100mΩ, 30V typ). Also

select a comparable-power Schottky diode for D1.

N2A/N2B are the Royer oscillator switches that drive

the transformer primary; select a dual-logic-level Nchannel MOSFET with low R

DSON

to minimize conduc-

tion losses (100mΩ, 30V typ).

Sense Resistors

R4 and R5 sense the transformer’s primary voltage.

Figure 9 shows the relationship between the primary

and secondary voltage. To set the maximum average

secondary transformer voltage, set R5 = 10kΩ, and

select R5 according to the following formula:

where V

S

is the maximum RMS secondary transformer

voltage (above the strike voltage), and N is the turns

ratio of the transformer.

Table 4. CCFL Specifications

Table 5. Components for the Standard Application Circuit

SPECIFICATION SYMBOL UNITS DESCRIPTION

CCFL Minimum Strike

Voltage

(Kick-Off Voltage)

CCFL Typical Operating

Voltage

(Lamp Voltage)

V

S

V

L

V

V

RMS

RMS

S RMS

RR

45

()

N

1=−

V

15

.

Although CCFLs typically operate at <550V

(1000V

voltage is typically higher at cold temperatures and at the tube’s end

of life. This voltage is set by the combination of the maximum primary

voltage (center-tap voltage limit corresponding to

V

CTFB

Once a CCFL has been struck, the voltage required to maintain light

output falls to approximately 550V

little as 250V

constant, even as the tube’s brightness is varied.

and up) is required initially to start the tube. The strike

RMS

= 0.6V) and the transformer (T1) turns ratio.

. Short tubes may operate on as

. The CCFL operating voltage stays relatively

RMS

RMS

, a higher voltage

RMS

CCFL Maximum Operating

Current (Lamp Current)

CCFL Maximum Frequency

(Lamp Frequency)

DESIGNATION DESCRIPTION RECOMMENDED DEVICE MANUFACTURER

L1 47µH, 1.1A inductor CR104-470 Sumida

N1 30V, 0.1Ω N-channel MOSFET FDN361AN Fairchild

N2 30V, 95mΩ dual N-channel MOSFET FDC6561AN Fairchild

T1 8.7µH, 180:1 transformer 5371-T001 (CIUH842 style) Sumida

D1 30V, 1A Schottky diode CRS02 Toshiba

D2 0.1A Schottky diode BAT54 Fairchild

D3 0.1A dual Schottky diode MMBD4148SE Fairchild

C6 22pF, 3.1kV capacitor GHM1038-SL-220J-3K Murata

C7 0.1µF, 63V, low-dissipation capacitor SMD1812 WIMA

I

L

f

L

mA

RMS

kHz

The maximum RMS AC current through a CCFL is typically 5mA

DC current is not allowed through CCFLs. The maximum lamp current

is set by the sense resistor (R13) at the maximum brightness setting.

The maximum AC-lamp-current frequency. The MAX1739/ MAX1839

synchronize to the Royer oscillator frequency set by the external

components and are designed to operate between 32kHz and

100kHz.

RMS

.

Page 19

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

______________________________________________________________________________________ 19

The MAX1739/MAX1839 regulate the average current

through the CCFL. The current is sensed through the

sense resistor (R13) at CSAV. The voltage at CSAV is

the half-wave rectified representation of the current

through the lamp (Figure 10). The MAX1739/MAX1839

regulate the average voltage at CSAV (I

R13, AVG

✕

R13)

and are controlled by either the analog interface or the

SMBus interface. To set the maximum lamp current,

determine R13 as follows:

R13 = 0.4304 / I

L,RMS,MAX

where I

L,RMS,MAX

is the maximum RMS lamp current.

MINDAC and the wave shape influence the actual maximum RMS lamp current. Use an RMS current meter to

make final adjustments to R13.

Loop Compensation

C

CCI

sets the speed of the current control loop that is

used during startup, maintaining lamp current regulation, and during transients caused by changing the

lamp current setting. The standard C

CCI

value is

0.01µF. Larger values limit lamp current overshoot.

Smaller values speed up its response to changes in the

lamp current setting, but can lead to instability for

extremely small values. Very large values of C

CCI

increase the delay to strike voltage in DPWM and can

cause loss of regulation in the extreme case. Note that

very large C

CCV

can do the same thing.

C6not only affects loop compensation, but it also affects

the waveform shape, overall efficiency, and the maximum necessary secondary transformer voltage. Low values of C6improve loop stability, especially in systems

using a CCFL with a large difference between its restrike

voltage and its operating voltage (characteristic of long

narrow CCFLs) during DPWM. A low value of C6also

improves stability when the lamp’s operating voltage

drops with an increase in lamp current. However, low

values of C

6

increase the maximum necessary trans-

former voltage. C

7

interacts with C6and affects the

Royer frequency, Royer Q value, and overall efficiency.

C

CCV

sets the speed of the voltage control loop that

affects DPWM transients and operation in fault conditions. If DPWM is not used, the voltage control loop

should only be active during fault conditions. The standard value of C

CCV

is 3300pF. Use the smallest value

of C

CCV

necessary to set an acceptable fault transient

response and not cause excessive ringing at the beginning of a DPWM pulse. Note that the worst-case fault

Figure 9. Transformer Primary/Secondary Voltage Relationship Figure 10. Current-Sense Waveforms

R4

TO

CTFB

R5

V

π

CT

2

VOLTAGE (PIN 2)

T1 PRIMARY-TAP

VS = V

L1

T1

V

CT

VCT is the average DC voltage at center top

2

π

ω

= N ✕ 1.1 ✕ VCT

S(RMS)

N

N

P

S

T1 SECONDARY

N

P

N2BN2A

NπV

CT

2

-NπV

CT

2

VOLTAGE (PIN 10–PIN 6)

2

ω

N = N

π

S/NP

R13

I

I

L,PK

I

R13, AVG

T1

C6

I

L, RMS, MAX

2

π

ω

0.04304

=

R13

CCFL

LAMP

I

D5A

D5B

CSAV

R13

I

L,PK

-I

L,PK

2

π

ω

I

L,RMS

Page 20

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

20 ______________________________________________________________________________________

transient that C

CCV

is designed to protect against is

open tube at the beginning of DPWM pulses.

Large C

CCV

values reduce transient overshoots, but

can cause loss of regulation at low DPWM duty cycles

by increasing the delay to strike voltage. Smaller values

of C

CCV

allow quicker DPWM startups and faster

response to fault conditions. Very small values of C

CCV

make the circuit more susceptible to ringing, and in

extreme cases may cause instability. Some ringing is

expected between the Royer oscillator and the buck

inductor. Some of the ringing can be suppressed by

adding a capacitor in parallel with R5. This capacitor

should be chosen such that:

1 / (2 ✕π✕R5 ✕C) = ringing frequency

When using high DPWM frequencies and low DPWM

duty cycles, the DPWM on-time is reduced. In some

cases, this causes the lamp current transient to exceed

the DPWM on-time. In this case, the MAX1739/

MAX1839 lose regulation and the lamp current never

reaches the lamp current set point. Supply rejection

while operating in this condition is degraded. If the

DPWM on-time is short enough, the lamp current does

not have enough time to reach the lamp-out threshold

and causes a lamp-out detection. To prevent this,

decrease the turn-on transient duration (by lowering

C

CCV

), increase the DPWM duty cycle (by limiting the

brightness code), or decrease the DPWM frequency

(see Synchronizing the DPWM Frequency).

DPWM or other “chopping” methods can cause audible

noise from some transformers. The transformer should

be carefully designed to avoid such behavior.

Dimming Range

The external components required to achieve a dimming range are highly dependent on the CCFL used.

The standard application circuit uses a CCFL with stringent requirements. To achieve a 20:1 dimming range,

the standard circuit drops slightly more voltage across

C6 as it does across the CCFL at the full lamp current

setting. This ensures good stability in that circuit with

V

MINDAC

as low as 1V. To further increase the dimming

range when using this CCFL, C6 must be increased,

which increases the maximum secondary transformer

voltage and requires a transformer with a higher voltage rating. Other components (such as the primary

transformer inductance and C7) may also need to be

adjusted to maintain good waveforms, Royer efficiency,

and the desired Royer frequency.

Other Components

The high-side MOSFET driver is powered by the external boosting circuit formed by C5 and D2. Connect BST

through a signal-level Schottky diode to VL, and

bypass it to LX with a 0.1µF ceramic capacitor. This circuit delivers the necessary power to drive N1 as shown

in Figure 8. If a higher gate capacitance MOSFET is

used, the size of the bypass capacitor must be

increased. The current need at BST is as follows:

I

BST

= 1mA d + Q

T

✕

f

where d is the buck controller duty cycle (98% max),

QTis the MOSFET total gate charge, and f is twice the

Royer oscillator frequency.

The maximum current through D2 (ID) is:

ID= I

BST

/ (1 - d)

D5A and D5B are used to generate the current-sense

voltage across R13. The current through these diodes is

the lamp current; use a dual-series signal-level diode.

Bypassing and Board Layout

Connect C4 from VL to GND as close as possible with

dedicated traces that are not shared with other signal

paths. The ground lines should terminate at the GND

end of C4: quiet ground, power ground, and lamp current-sense ground. Quiet ground is used for REF, CCV,

R5, and MINDAC (if a resistor-divider is used). The

power ground goes from the ground of C4 directly to

the ground side of C9. Power ground should also supply the return path for D1, N2, and the buck currentsense resistor (from CS to GND, if used). The ground

path for R13 should be separate to ensure that it does

not corrupt quiet ground and it is not affected by DC

drops in the power ground. Refer to the MAX1739 EV

kit for an example of good layout.

Digital Interface (MAX1739)

With MODE connected to VL, the CRF/SDA and

CTL/SCL pins no longer behave as analog inputs;

instead, they function as SMBus-compatible 2-wire digital interfaces. CRF/SDA is the bidirectional data line,

and CTL/SCL is the clock line of the 2-wire interfaces

corresponding, respectively, to the SMBDATA and

SMBCLK lines of the SMBus. The MAX1739 uses the

write-byte, read-byte, and receive-byte protocols

(Figure 11). The SMBus protocols are documented in

System Management Bus Specification v1.08 and are

available at www.sbs-forum.org.

The MAX1739 is a slave-only device and responds to

the 7-bit address 0b0101101 (i.e., with the RW bit clear

indicating a write, this corresponds to 0x5A). The

MAX1739 has three functional registers: a 5-bit brightness register (BRIGHT4–BRIGHT0), a 3-bit shutdown

mode register (SHMD2–SHMD0), and a 2-bit status

register (STATUS1–STATUS0). In addition, the device

Page 21

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

______________________________________________________________________________________ 21

has three identification (ID) registers: an 8-bit chip ID

register, an 8-bit chip revision register, and an 8-bit

manufacturer ID register.

The CRF/SDA and CTL/SCL pins have Schmidt-triggered inputs that can accommodate slow edges; however, the rising and falling edges should still be faster

than 1µs and 300ns, respectively.

Communication starts with the master signaling the

beginning of a transmission with a START condition,

which is a high-to-low transition on CRF/SDA while

CTL/SCL is high. When the master has finished communicating with the slave, the master issues a STOP

condition (P), which is a low-to-high transition on

CRF/SDA while CTL/SCL is high (Figures 10, 11). The

bus is then free for another transmission. Figures 12

and 13 show the timing diagram for signals on the

2-wire interface. The address byte, command byte, and

data byte are transmitted between the START and

STOP conditions. The CRF/SDA state is allowed to

change only while CTL/SCL is low, except for the

START and STOP conditions. Data is transmitted in 8bit words and is sampled on the rising edge of

CTL/SCL. Nine clock cycles are required to transfer each

byte in or out of the MAX1739 since either the master or

the slave acknowledges the receipt of the correct byte

during the ninth clock. If the MAX1739 receives its correct

slave address followed by RW = 0, it expects to receive 1

or 2 bytes of information (depending on the protocol). If

the device detects a start or stop condition prior to clocking in the bytes of data, it considers this an error condition

and disregards all of the data. If the transmission is completed correctly, the registers are updated immediately

after a STOP (or RESTART) condition. If the MAX1739

receives its correct slave address followed by RW = 1, it

expects to clock out the register data selected by the previous command byte.

SMBus Commands

The MAX1739 registers are accessible through several

different redundant commands (i.e., the command byte

in the read-byte and write-byte protocols), which can

1b

ACK

1b7 bits

ADDRESS ACK

1b

WR

8 bits

DATA

1b

ACK P

8 bits

S COMMAND

Write-Byte Format

Receive-Byte Format

Slave Address Command Byte: selects

which register you are

writing to

Data Byte: data goes into the register

set by the command byte

1b

ACK

1b7 bits

ADDRESS ACK

1b

WR S

1b

ACK

8 bits

DATA

7 bits

ADDRESS1bRD

1b8 bits

/// PS COMMAND

Slave Address

Slave Address

Command Byte: sends command

with no data; usually used for oneshot command

Command Byte: selects

which register you are

reading from

Slave Address: repeated

due to change in dataflow direction

Data Byte: reads from

the register set by the

command byte

1b

ACK

7 bits

ADDRESS1bRD

8 bits

DATA

1b

/// PS

Data Byte: reads data from

the register commanded

by the last read-byte or

write-byte transmission;

also used for SMBus Alert

Response return address

S = Start condition Shaded = Slave transmission WR = Write = 0

P = Stop condition Ack= Acknowledged = 0 RD = Read =1

/// = Not acknowledged = 1

Figure 11. SMBus Protocols

1b

ACK

7 bits

ADDRESS1bWR

8 bits

COMMAND

1b

ACK P

S

Send-Byte Format

Read-Byte Format

Page 22

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

22 ______________________________________________________________________________________

be used to read or write the brightness, SHMD, status,

or ID registers.

Table 6 summarizes the command byte’s register

assignments, as well as each register’s power-on state.

The MAX1739 also supports the receive-byte protocol

for quicker data transfers. This protocol accesses the

register configuration pointed to by the last command

byte. Immediately after power-up, the data byte

returned by the receive-byte protocol is the contents of

the brightness register, left justified (i.e., BRIGHT4 will

be in the MSB position of the data byte) with the

remaining bits containing a 1, STATUS1, and STATUS0.

This gives the same result as using the read-byte protocol with a 0b10XXXXXX (0x80) command. Use caution

with shorter protocols in multimaster systems since a

second master could overwrite the command byte without informing the first master. During shutdown, the serial interface remains fully functional. The part also

supports limited read/write-word protocol. Read-word

works similar to read-byte except the second byte

returned is 0xFF. Write-word also works similar to writebyte. The second data byte is acknowledged and

updated after the first data byte is acknowledged and

updated.

Figure 12. SMBus Write Timing

Figure 13. SMBus Read Timing

SMBCLK

SMBDATA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

SMBCLK

AB CDEFG HIJ

t

LOWtHIGH

t

t

HD:STA

SU:STA

AB CDEFG H

t

t

HIGH

LOW

t

SU:DAT

t

HD:DAT

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

I = SLAVE PULLS SMBDATA LINE LOW

t

HD:DAT

K

t

SU:STO

J = ACKNOWLEDGE CLOCKED INTO MASTER

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION, DATA EXECUTED BY SLAVE

M = NEW START CONDITION

I

M

L

t

BUF

J

K

SMBDATA

t

SU:STAtHD:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

t

SU:DAT

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

t

HD:DAT

t

SU:DAT

I = ACKNOWLEDGE CLOCK PULSE

J = STOP CONDITION

K = NEW START CONDITION

t

SU:STO

t

BUF

Page 23

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

______________________________________________________________________________________ 23

Brightness Register

[BRIGHT4–BRIGHT0] (POR = 0b10111)

The 5-bit brightness register corresponds with the 5-bit

brightness code used in the dimming control (see

Dimming Range). BRIGHT4–BRIGHT0 = 0b00000 sets

minimum brightness, and BRIGHT4–BRIGHT0 =

0b11111 sets maximum brightness. The SMBus interface does not control whether the device regulates the

current by analog dimming, DPWM dimming, or both;

this is done by MINDAC (Table 2).

Shutdown-Mode Register

[SHMD2–SHMD0] (POR = 0b001)

The 3-bit shutdown-mode register configures the operation of the device when the SH/SUS pin is toggled as

described in Table 7. The shutdown-mode register can

also be used to shut off directly the CCFL, regardless

of the SH/SUS state (Table 8).

*The hexadecimal command byte shown is recommended for maximum forward compatibility with future MAXIM products.

Table 6. Commands Description

R OR W

PROTOCOL

Read and

Write

Read and

Write

Read

Only

Read

Only

Read and

Write

Read

Only

COMMAND

BYTE*

0x01

0b0XXX

XX01

0x02

0b0XXX

XX10

0x03

0b0XXX

XX11

0x04

0b0XXX

XX00

0x40

0b10XX

XXXX

0xFE

0b11XX

XXX0

POR

STATE

0x17 0 0 0

0xF9 STATUS1 STATUS0 1 1 1 SHMD2 SHMD1 SHMD0

0x96

0x00

0xBF

0x4D

BIT 7

(MSB)

ChipID71ChipID60ChipID50ChipID41ChipID30ChipID21ChipID11ChipID0

ChipRev70ChipRev60ChipRev50ChipRev40ChipRev30ChipRev20ChipRev10ChipRev0

BRIGHT4

(MSB)

MfgID70MfgID61MfgID50MfgID40MfgID31MfgID21MfgID10MfgID0

DATA REGISTER BIT ASSIGNMENT

BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1

BRIGHT4

(MSB)

BRIGHT3 BRIGHT2 BRIGHT1

BRIGHT3 BRIGHT2 BRIGHT1

BRIGHT0

(LSB)

1 STATUS1 STATUS0

BIT 0

(LSB)

BRIGHT0

(LSB)

0

0

1

Read

Only

0xFF

0b11XX

XXX1

0x96

ChipID71ChipID60ChipID50ChipID41ChipID30ChipID21ChipID11ChipID0

0

Page 24

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

24 ______________________________________________________________________________________

Status Register

[STATUS1–STATUS0] (POR = 0b11)

The status register returns information on fault conditions. If a lamp is not connected to the secondary of the

transformer, the MAX1739 will detect that the lamp current has not exceeded the CSAV detection threshold

and after 2 seconds will clear the STATUS1 bit (see

Lamp-Out Detection). The STATUS1 bit is latched; i.e.,

it will remain 0 even if the lamp-out condition goes

away. When STATUS1 = 0, the lamp is forced off. STATUS0 reports 1 as long as no overcurrent conditions

are detected. If an overcurrent condition is detected in

any given DPWM period, STATUS0 is cleared for the

duration of the following DPWM period. If an overcur-

rent condition is not detected in any given DPWM period, STATUS0 is set for the duration of the following digital DPWM period. Forcing the CCFL lamp off by

entering shutdown, writing to the mode register, or by

toggling SH/SUS sets STATUS1.

ID Registers

The ID registers return information on the manufacturer,

the chip ID, and the chip revision number. The

MAX1739 is the first-generation advanced CCFL controller, and its ChipRev is 0x00. Reading from the MfgID

register returns 0x4D, which is the ASCII code for “M”

(for Maxim); the ChipID register returns 0x96. Writing to

these registers has no effect.

Table 7. SHMD Register Bit Descriptions

Table 8. SH/SUS and SHMD Register Truth Table

Table 9. Status Register Bit Descriptions (Read Only/Writes Have No Effect)

X = Don’t care

BIT NAME

2 SHMD2 0

1 SHMD1 0

0 SHMD0 1

POR

STATE

SHMD2 = 1 forces the lamp off and sets STATUS1. SHMD2 = 0 allows the lamp to operate, though it

may still be shut down by the SH/SUS pin (depending on the state of SHMD1 and SHMD0).

When SH /SUS = 0, this bit has no effect. SH/SUS = 1 and SHMD1 = 1 forces the lamp off and sets

STATUS1. SH /SUS = 1 and SHMD1 = 0 allow the lamp to operate, though it may still be shut down

by the SHMD2 bit.

When SH /SUS = 1, this bit has no effect. SH /SUS = 0 and SHMD0 = 1 forces the lamp off and sets

STATUS1. SH /SUS = 0 and SHMD0 = 0 allows the lamp to operate, though it may still be shut down

by the SHMD2 bit.

DESCRIPTION

SH/SUS SHMD2 SHMD1 SHMD0 OPERATING MODE

0 0 X 0 Operate

0 0 X 1 Shutdown, STATUS1 set

1 0 0 X Operate

1 0 1 X Shutdown, STATUS1 set

X 1 X X Shutdown, STATUS1 set

BIT NAME

1 STATUS1 1

0 STATUS0 1

POR

STATE

DESCRIPTION

STATUS1 = 0 means that a lamp-out condition has been detected. The STATUS1 bit stays clear

even after the lamp-out condition has gone away. The only way to set STATUS1 is to shut off the

lamp by programming the mode register or by toggling SH/SUS.

STATUS0 = 0 means that an overcurrent condition was detected during the previous digital PWM

period. STATUS0 = 1 means that no overcurrent condition was detected during the previous digital

PWM period.

Page 25

MAX1739/MAX1839

†

Wide Brightness Range

CCFL Backlight Controllers

______________________________________________________________________________________ 25