Page 1

General Description

The MAX1836/MAX1837 high-efficiency step-down

converters provide a preset 3.3V or 5V output voltage

from supply voltages as high as 24V. Using external

feedback resistors, the output voltage may be adjusted

from 1.25V to VIN. An internal current-limited switching

MOSFET delivers load currents up to 125mA

(MAX1836) or 250mA (MAX1837).

The unique current-limited control scheme, operating

with duty cycles up to 100%, minimizes the dropout

voltage (120mV at 100mA). Additionally, this control

scheme reduces supply current under light loads to

12µA. High switching frequencies allow the use of tiny

surface-mount inductors and output capacitors.

The MAX1836/MAX1837 step-down converters with

internal switching MOSFETs are available in a 6-pin

SOT23 package, making them ideal for low-cost, lowpower, space-sensitive applications. For increased output drive capability, use the MAX1776 step-down

converter that uses an internal 24V switch to deliver up

to 500mA. For even higher currents, use the MAX1626/

MAX1627 step-down controllers that drive an external

P-channel MOSFET to deliver up to 20W.

________________________Applications

9V Battery Systems

Notebook Computers

Distributed Power Systems

Backup Supplies

4mA to 20mA Loop Power Supplies

Industrial Control Supplies

Hand-Held Devices

____________________________Features

♦ 4.5V to 24V Input Voltage Range

♦ Preset 3.3V or 5V Output

♦ Adjustable Output from 1.25V to V

IN

♦ Output Currents Up to 125mA (MAX1836) or

250mA (MAX1837)

♦ Internal P-Channel MOSFET

♦ Efficiency Over 90%

♦ 12µA Quiescent Current

♦ 3µA Shutdown Current

♦ 100% Maximum Duty Cycle for Low Dropout

♦ Current-Limiting and Overtemperature Protection

♦ Small 6-Pin SOT23 Package

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

________________________________________________________________ Maxim Integrated Products 1

19-1919; Rev 1; 01/02

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

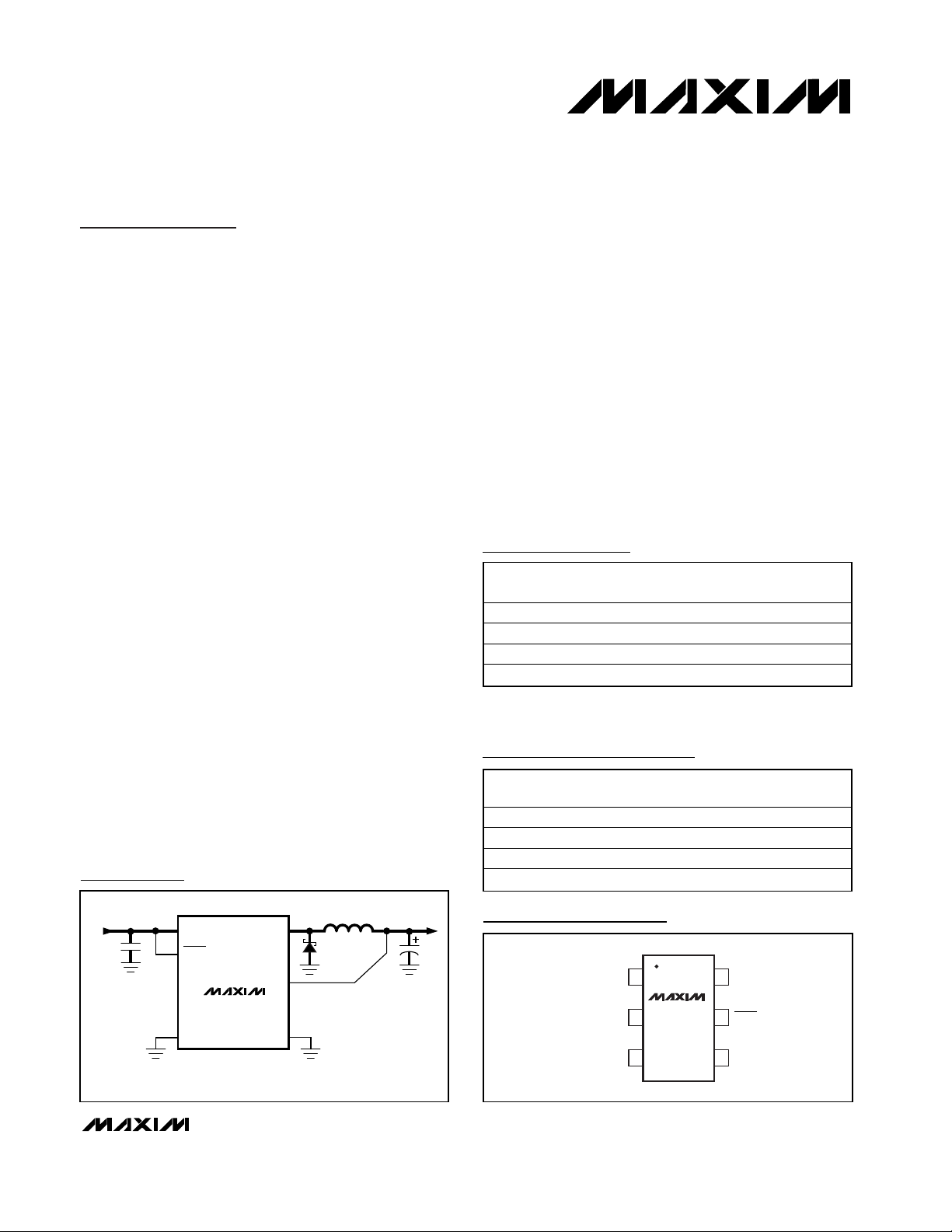

PART

PRESET OUTPUT

VOLTAGE (V)

LOAD

CURRENT (mA)

MAX1836EUT50 5 125

MAX1836EUT33 3.3 125

MAX1837EUT50 5 250

MAX1837EUT33 3.3 250

Selector Guide

MAX1836

MAX1837

IN

GND

LX

SHDN

FB

OUT

NOTE: HIGH-CURRENT PATHS SHOWN WITH BOLD LINES.

OUTPUT

3.3V OR 5V

INPUT

4.5V TO 24V

Typical Operating Circuit

GND

LXIN

16OUT

5 SHDN

FB

MAX1836

MAX1837

SOT23

TOP VIEW

2

34

Pin Configuration

Note: The MAX1836/MAX1837 require special solder temperature profile described in the Absolute Maximum Ratings.

PART

TEMP RANGE

PIN-

TOP

M ARK

MAX1836EUT50-T

AANW

MAX1836EUT33-T

AANY

MAX1837EUT50-T

AANX

MAX1837EUT33-T

AANZ

Ordering Information

PA C K A G E

-40°C to +85°C

-40°C to +85°C

-40°C to +85°C

-40°C to +85°C

6 SOT23-6

6 SOT23-6

6 SOT23-6

6 SOT23-6

Page 2

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, SHDN to GND ...................................................-0.3V to +25V

LX to GND.......................................................-2V to (V

IN

+ 0.3V)

OUT, FB to GND.......................................................-0.3V to +6V

Continuous Power Dissipation (T

A

= +70°C) (Note 1)

6-Pin SOT23 (derate 8.7mW/°C above +70°C)............696mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Note 1: Thermal properties are specified with product mounted on PC board with 1in

2

of copper area and still air.

)

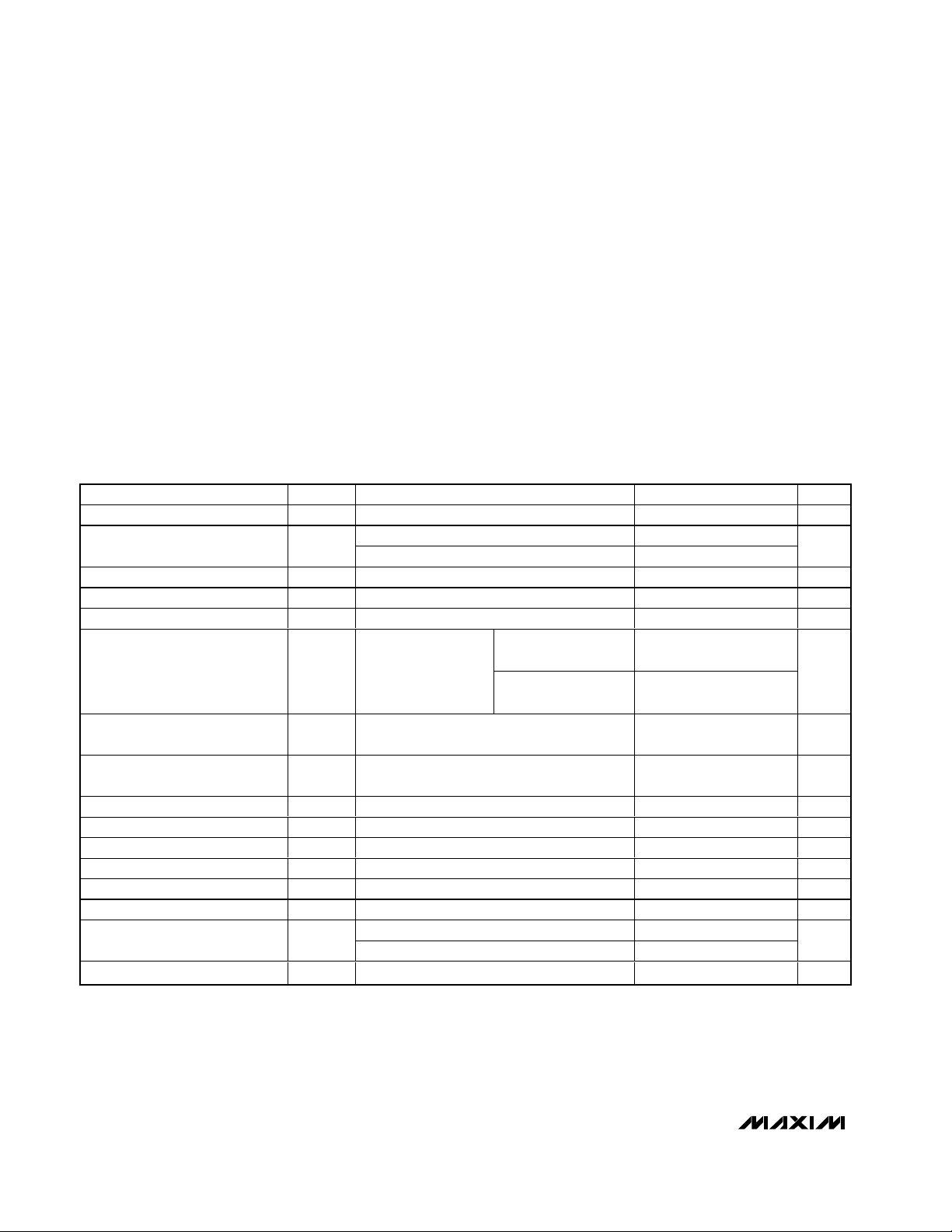

ELECTRICAL CHARACTERISTICS

(Circuits of Figures 1 (MAX1836) and 2 (MAX1837), VIN= 12V, SHDN = IN, TA= 0°C to +85°C. Typical values are at TA= +25°C,

unless otherwise noted.)

Dual Mode is a trademark of Maxim Integrated Products, Inc.

Input Supply Range V

Input Undervoltage Lockout

Threshold

Input Supply Current I

Input Supply Current in Dropout I

Input Shutdown Current SHDN = GND 3 7 µA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN

V

UVLO

IN

IN (D ROP) VIN

VIN rising 3.55 4.0 4.4

VIN falling 3.45 3.9 4.3

= 5V 18 µA

4.5 24 V

12 25 µA

V

FB = GND,

I

= 0 to 125mA

Output Voltage (Preset Mode) V

Output Voltage Range

(Adjustable Mode)

Feedback Set Voltage

(Adjustable Mode)

OUT Bias Current V

FB Bias Current I

FB Dual ModeTM Threshold VFB rising or falling 50 100 150 mV

LX Switch Minimum Off-Time t

LX Switch Maximum On-Time t

LX Switch On-Resistance R

LX Current Limit I

LX Zero-Crossing Threshold -75 +75 mV

OUT

V

OUT

V

FB

FB

OFF( M IN)

ON (M AX

LX

LIM

LOAD

(MAX1836) or

250mA (MAX1837)

(Note 2) 1.25 V

= 5V 2.5 7.4 µA

OUT

VFB = 0 or 1.25V, TA = +25°C -25 +25 nA

VFB = 1.3V 7 10 13 µs

VIN = 6V 1.1 2 Ω

MAX1836 250 312 450

MAX1837 500 625 850

MAX183_EUT50 4.80 5.00 5.20

MAX183_EUT33 3.168 3.30 3.432

IN

1.200 1.25 1.300 V

0.2 0.4 0.6 µs

V

V

mA

Page 3

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(Circuits of Figures 1 (MAX1836) and 2 (MAX1837), VIN= 12V, SHDN = IN, TA= 0°C to +85°C. Typical values are at TA= +25°C,

unless otherwise noted.)

)

ELECTRICAL CHARACTERISTICS

(Circuits of Figures 1 (MAX1836) and 2 (MAX1837), VIN= 12V, SHDN = IN, TA= -40°C to +85°C, unless otherwise noted.) (Note 4)

Zero-Crossing Timeout LX does not rise above the threshold 30 µs

LX Switch Leakage Current VIN = 18V, LX = GND, TA = +25°C1µA

Dropout Voltage V

Line Regulation VIN = 5V to 24V 0.05 %

Load Regulation

Shutdown Input Threshold V

Shutdown Leakage Current I

Thermal Shutdown 10°C hysteresis (typ) 160 °C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DROPOUTIOUT

SHDN

SHDN

= 100mA, VIN = 5V 120 mV

I

= 0 to 125mA (MAX1836) or 250mA

OUT

(MAX1837)

VIN = 4.5V to 24V (Note 3) 0.8 2.4 V

V

= 0 or 24V -1 +1 µA

SHDN

0.3 %

Input Supply Range V

Input Undervoltage Lockout

Threshold

Input Supply Current I

Input Shutdown Current SHDN = GND 7 µA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

4.5 24 V

V

25 µA

V

IN

UVLO

IN

VIN rising 3.55 4.4

VIN falling 3.45 4.3

FB = GND,

I

= 0 to 125mA

Output Voltage (Preset Mode) V

Output Voltage Range

(Adjustable Mode)

Feedback Set Voltage

(Adjustable Mode)

OUT Bias Current V

FB Dual Mode Threshold VFB rising or falling 50 150 mV

LX Switch Minimum Off-Time t

LX Switch Maximum On-Time t

LX Switch On-Resistance R

LX Current Limit I

OUT

V

OUT

V

FB

OFF( M IN)

ON (M AX

LX

LIM

LOAD

(MAX1836) or

250mA (MAX1837)

(Note 2) 1.25 V

= 5V 7.4 µA

OUT

VFB = 1.3V 7 13 µs

VIN = 6V 2 Ω

MAX1836 250 450

MAX1837 500 900

MAX183_EUT50 4.80 5.20

MAX183_EUT33 3.168 3.432

IN

1.200 1.300 V

0.2 0.6 µs

V

V

mA

Page 4

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

4 _______________________________________________________________________________________

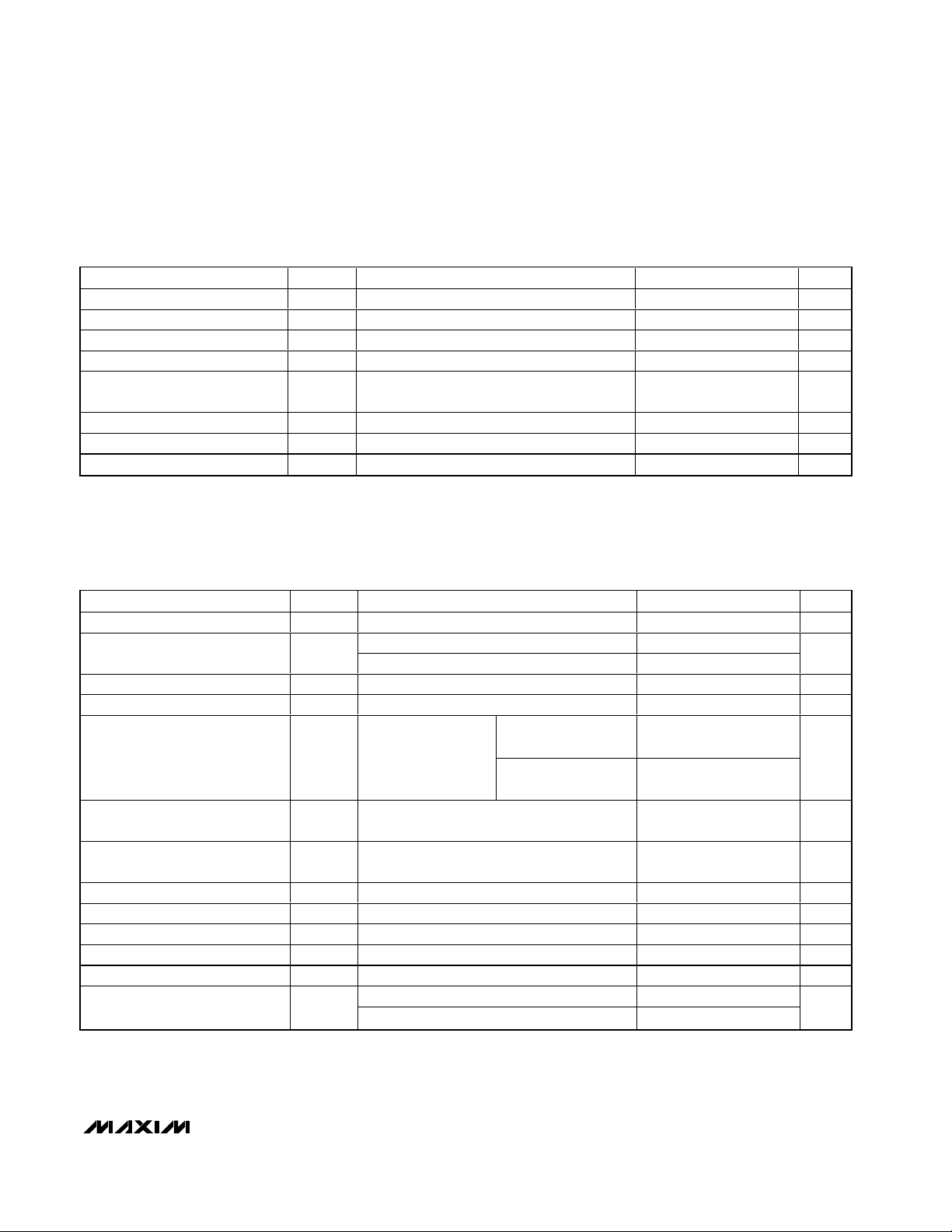

Typical Operating Characteristics

(Circuits of Figures 1 (MAX1836) and 2 (MAX1837), VIN= 12V, SHDN = IN, TA = +25°C.)

3.27

3.29

3.28

3.31

3.30

3.32

3.33

0 10050 150 200

MAX1836EUT33

OUTPUT VOLTAGE vs. LOAD CURRENT

MAX1836/7 toc01

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

VIN = 5V

VIN = 9V to 12V

FIGURE 1

100

95

90

85

80

70

0.1 10 1001 1000

MAX1836EUT33

EFFICIENCY vs. LOAD CURRENT

MAX1836/7 toc02

LOAD CURRENT (mA)

EFFICIENCY (%)

75

VIN = 9V

VIN = 12V

VIN = 5V

FIGURE 1

V

OUT

= 3.3V

3.27

3.29

3.28

3.31

3.30

3.32

3.33

0 150 20050 100 250 300 350

MAX1837EUT33

OUTPUT VOLTAGE vs. LOAD CURRENT

MAX1836/7 toc03

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

VIN = 9V

VIN = 5V

VIN = 12V

FIGURE 2

100

95

90

85

80

70

0.1 10 1001 1000

MAX1837EUT33

EFFICIENCY vs. LOAD CURRENT

MAX1836/7 toc04

LOAD CURRENT (mA)

EFFICIENCY (%)

75

VIN = 9V

VIN = 12V

VIN = 5V

FIGURE 2

V

OUT

= 3.3V

0

40

20

100

80

60

160

140

120

180

0 100 15050 200 250 300 350

MAX1837EUT33

SWITCHING FREQUENCY vs. LOAD CURRENT

MAX1836/7 toc05

LOAD CURRENT (mA)

FREQUENCY (kHz)

VIN = 9V

VIN = 5V

VIN = 12V

FIGURE 2

V

OUT

= 3.3V

3.27

3.29

3.28

3.31

3.30

3.32

3.33

0 4 8 12162024

MAX1837EUT33

OUTPUT VOLTAGE vs. INPUT VOLTAGE

MAX1836/7 toc06

INPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

I

OUT

= 10mA

I

OUT

= 200mA

FIGURE 2

V

OUT

= 3.3V

L1 = 47µH

Note 2: When using the shutdown input, the maximum output voltage allowed with external feedback is 5.5V. If the output voltage is

set above 5.5V, connect shutdown to the input.

Note 3: Shutdown input minimum slew rate (rising or falling) is 10V/ms.

Note 4: Specifications to -40°C are guaranteed by design, not production tested.

PARAMETER

CONDITIONS

UNITS

LX Zero-Crossing Threshold -75

mV

Shutdown Input Threshold

VIN = 4.5V to 24V (Note 3) 0.8 2.4 V

Shutdown Leakage Current I

SHDN

V

SHDN

= 0 or 24V -1 +1 µA

ELECTRICAL CHARACTERISTICS (continued)

(Circuits of Figures 1 (MAX1836) and 2 (MAX1837), VIN= 12V, SHDN = IN, TA= -40°C to +85°C, unless otherwise noted.) (Note 4)

SYMBOL

V

SHDN

MIN TYP MAX

+75

Page 5

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

_______________________________________________________________________________________ 5

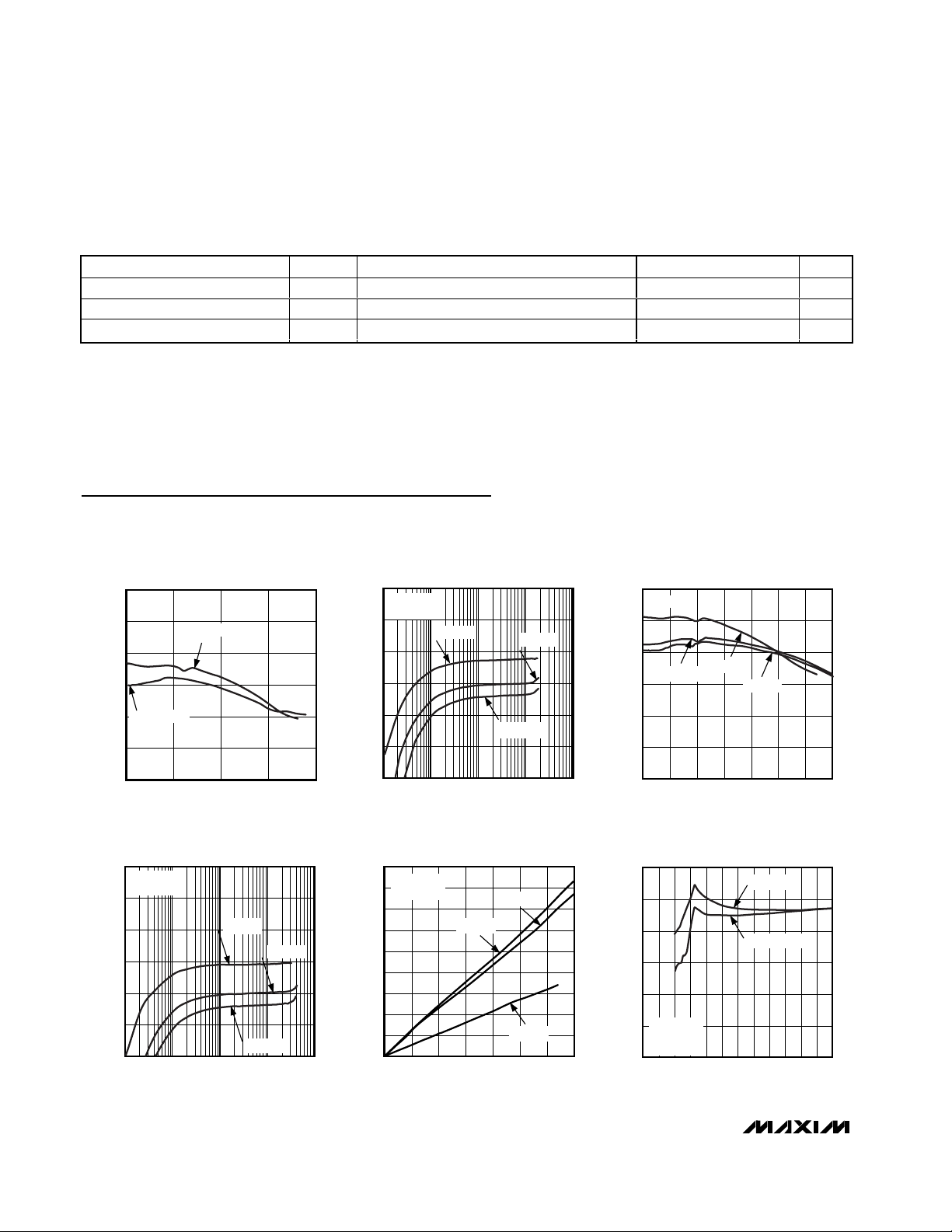

Typical Operating Characteristics (continued)

(Circuits of Figures 1 (MAX1836) and 2 (MAX1837), VIN= 12V, SHDN = IN, TA = +25°C.)

MAX1837EUT33

EFFICIENCY vs. INPUT VOLTAGE

100

V

I

OUT

OUT

L1 = 47µH

= 200mA

95

90

85

EFFICIENCY (%)

80

I

= 10mA

75

70

0 4 8 12162024

OUT

INPUT VOLTAGE (V)

OUTPUT VOLTAGE vs. LOAD CURRENT

5.04

VIN = 12V TO 24V

5.02

FIGURE 2

= 3.3V

MAX1836/7 toc07

MAX1837EUT50

VIN = 9V

SWITCHING FREQUENCY vs. INPUT VOLTAGE

100

10

FREQUENCY (kHz)

1

0812

MAX1837EUT33

4

INPUT VOLTAGE (V)

MAX1836/7 toc10

I

= 200mA

OUT

FIGURE 2

= 3.3V

V

OUT

L1 = 47µH

I

= 10mA

OUT

16 2420

MAX1837EUT50

EFFICIENCY vs. LOAD CURRENT

100

FIGURE 6

= 5V

V

OUT

95

VIN = 12V

90

PEAK INDUCTOR CURRENT vs. INPUT VOLTAGE

MAX1837EUT33

1000

FIGURE 2

= 3.3V

V

OUT

MAX1836/7 toc08

L1 = 47µH

800

600

400

PEAK INDUCTOR CURRENT (mA)

200

LIMITED BY

t

ON(MIN)

0

0 4 8 12162024

VIN = 9V

VIN = 7V

INPUT VOLTAGE (V)

LIMITED BY

MAX1836/7 toc11

I

OUT

I

= 200mA

I

LIM

OUT

MAX1836/7 toc09

= 10mA

5.00

OUTPUT VOLTAGE (V)

4.98

FIGURE 6

4.96

0 10050 150 200 250 300

VIN = 7V

LOAD CURRENT (mA)

MAX1837EUT50

DROPOUT VOLTAGE vs. LOAD CURRENT

400

FIGURE 6

= 5V

V

350

OUT

300

250

200

150

DROPOUT VOLTAGE (mV)

100

50

0

0 100 200 300

LOAD CURRENT (mA)

MAX1836/7 toc12

85

EFFICIENCY (%)

80

75

70

0.1 10 1001 1000

VIN = 18V

LOAD CURRENT (mA)

NO-LOAD SUPPLY CURRENT

vs. INPUT VOLTAGE

15

14

13

12

SUPPLY CURRENT (µA)

11

10

0 4 8 12 16 20 24

INPUT VOLTAGE (V)

VIN = 24V

MAX1836/7 toc13

Page 6

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuits of Figures 1 (MAX1836) and 2 (MAX1837), VIN= 12V, SHDN = IN, TA = +25°C.)

100µs/div

MAX1837EUT50

LOAD TRANSIENT

A: I

OUT

= 10mA to 250mA, 200mA/div

B: V

OUT

= 5V, 20mV/div

C: I

L

, 500mA/div

V

IN

= 12V, FIGURE 6

400mA

200mA

5.02V

0

B

A

C

MAX1836/7 toc14

5.00V

4.98V

750mA

250mA

0

400

µs/div

MAX1837EUT50

LINE TRANSIENT

A: VIN = 9V to 18V, 10V/div

B: V

OUT

= 5V, R

OUT

= 100Ω, 100mV/div

C: I

L

, 500mA/div

FIGURE 6

20V

10V

5.1V

0

B

A

C

MAX1836/7 toc15

5.0V

4.9V

500mA

0

400

µs/div

MAX1837EUT50

LINE TRANSIENT NEAR DROPOUT

A: VIN = 5V to 12V, 5V/div

B: V

OUT

= 5V, R

OUT

= 100Ω, 100mV/div

C: I

L

, 500mA/div

FIGURE 6

15V

10V

5.1V

5V

B

A

C

MAX1836/7 toc16

5.0V

4.9V

500mA

0

200

µs/div

MAX1837EUT50

STARTUP WAVEFORM

A: V

SHDN

= 0 to 2V, 2V/div

B: V

OUT

= 5V, R

OUT

= 100Ω, 2V/div

C: I

L

, 500mA/div

V

IN

= 12V, FIGURE 6

2V

0

2V

4V

B

A

C

MAX1836/7 toc17

0

500mA

0

Page 7

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

_______________________________________________________________________________________ 7

Detailed Description

The MAX1836/MAX1837 step-down converters are

designed primarily for battery-powered devices, notebook computers, and industrial control applications. A

unique current-limited control scheme provides high

efficiency over a wide load range. Operation up to

100% duty cycle allows the lowest possible dropout

voltage, increasing the useable supply voltage range.

Under no-load, the MAX1836/MAX1837 draw only

12µA, and in shutdown mode, they draw only 3µA to

further reduce power consumption and extend battery

life. Additionally, an internal 24V switching MOSFET,

internal current sensing, and a high switching frequency minimize PC board space and component cost.

Current-Limited Control Architecture

The MAX1836/MAX1837 use a proprietary current-limited control scheme that operates with duty cycles up to

100%. These DC-DC converters pulse as needed to

maintain regulation, resulting in a variable switching frequency that increases with the load. This eliminates the

high supply currents associated with conventional con-

Pin Description

Figure 1. Typical MAX1836 Application Circuit

Figure 2. Typical MAX1837 Application Circuit

PIN NAME FUNCTION

Dual-Mode Feedback Input. Connect to GND for the preset 3.3V (MAX183_EUT33) or 5.0V (MAX183_EUT50)

1FB

output. Connect to a resistive divider between the output and FB to adjust the output voltage between 1.25V

IN

, and connect the OUT pin to GND. When setting output voltages above 5.5V, permanently connect

and V

SHDN

to IN.

2 GND Ground

3 IN Input Voltage. 4.5V to 24V input range. Connected to the internal P-channel power MOSFET’s source.

4 LX Inductor Connection. Connected to the internal P-channel power MOSFET’s drain.

Shutdown Input. A logic low shuts down the MAX1836/MAX1837 and reduces supply current to 3µA. LX is

5

SHDN

high impedance in shutdown. Connect to IN for normal operation. When setting output voltages above 5.5V,

permanently connect

SHDN

to IN.

Regulated Output Voltage High-Impedance Sense Input. Internally connected to a resistive divider. Connect

6 OUT

to the output when using the preset output voltage. Connect to GND when using an external resistive divider

to adjust the output voltage.

INPUT

4.5V OR 12V

C

IN

10µF

25V

IN

SHDN

MAX1836

OUT

L1

LX

47µH

D1

OUTPUT

3.3V OR 5V

C

OUT

100µF

6.3V

INPUT

4.5V OR 12V

C

IN

10µF

25V

IN

SHDN

LX

OUT

MAX1837

L1

22µH

D1

OUTPUT

3.3V OR 5V

C

OUT

150µF

6.3V

GND

= TAIYO YUDEN TMK432BJ106KM

C

IN

L1 = SUMIDA CDRH5D28-470

= SANYO POSCAP 6TPC100M (SMALLER CAPACITORS CAN BE USED FOR 5V)

C

OUT

D1 = NIHON EP05Q03L

NOTE: HIGH-CURRENT PATHS SHOWN WITH BOLD LINES.

FB

GND

= TAIYO YUDEN TMK432BJ106KM

C

IN

L1 = SUMIDA CDRH5D28-220

= SANYO OS-CON 6SA150M (SMALLER CAPACITORS CAN BE USED FOR 5V)

C

OUT

D1 = NIHON ED05Q03L

NOTE: HIGH-CURRENT PATHS SHOWN WITH BOLD LINES.

FB

Page 8

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

8 _______________________________________________________________________________________

stant-frequency pulse-width-modulation (PWM) controllers that switch the MOSFET unnecessarily.

When the output voltage is too low, an error comparator

sets a flip-flop, which turns on the internal P-channel

MOSFET and begins a switching cycle (Figure 3). As

shown in Figure 4, the inductor current ramps up linearly, charging the output capacitor and servicing the

load. The MOSFET turns off when the current limit is

reached, or when the maximum on-time is exceeded

while the output voltage is in regulation. Otherwise, the

MOSFET remains on, allowing a duty cycle up to 100%

to ensure the lowest possible dropout voltage. Once

the MOSFET turns off, the flip-flop resets, diode D1

turns on, and the current through the inductor ramps

back down, transferring the stored energy to the output

capacitor and load. The MOSFET remains off until the

0.5µs minimum off-time expires and the inductor current ramps down to zero, and the output voltage drops

back below the set point.

Figure 4. Discontinuous-Conduction Operation

Figure 3. Functional Diagram

INPUT

4.5V OR 24V

C

IN

IN

SHDN

V

SENSE

QR

S

Q

MAXIMUM

MAX1836

MAX1837

MAXIMUM

OFF-TIME

Q

TRIG

ON-TIME

DELAY

DELAY

TRIG

V

SET

1.25V

100mV

OUT

GND

LX

FB

L1

D1

OUTPUT

3.3V OR 5V

C

OUT

10V

0

3.3V

500mA

0

CIRCUIT OF FIGURE 2, V

, 5V/div

A. V

LX

= 3.3V, 20mV/div, 200mA LOAD

B. V

OUT

C. INDUCTOR CURRENT, 500mA/div

4µs/div

IN

= 12V

A

B

C

Page 9

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

_______________________________________________________________________________________ 9

Input-Output (Dropout) Voltage

A step-down converter’s minimum input-to-output voltage differential (dropout voltage) determines the lowest

useable input supply voltage. In battery-powered systems, this limits the useful end-of-life battery voltage. To

maximize battery life, the MAX1836/MAX1837 operate

with duty cycles up to 100%, which minimizes the inputto-output voltage differential. When the supply voltage

approaches the output voltage, the P-channel MOSFET

remains on continuously to supply the load.

Dropout voltage is defined as the difference between

the input and output voltages when the input is low

enough for the output to drop out of regulation. For a

step-down converter with 100% duty cycle, the dropout

voltage depends on the MOSFET drain-to-source onresistance (R

DS(ON)

) and inductor series resistance;

therefore, it is proportional to the load current:

Shutdown (

SHDN

)

A logic-level low voltage on SHDN shuts down the

MAX1836/MAX1837. When shut down, the supply current drops to 3µA to maximize battery life, and the internal P-channel MOSFET turns off to isolate the output

from the input. The output capacitance and load current determine the rate at which the output voltage

decays. A logic-level high voltage on SHDN activates

the MAX1836/MAX1837. Do not leave SHDN floating. If

unused, connect SHDN to IN. When setting output voltages above 5.5V, the shutdown feature cannot be

used, so SHDN must be permanently connected to IN.

The SHDN input voltage slew rate must be greater than

10V/ms.

Thermal-Overload Protection

Thermal-overload protection limits total power dissipation in the MAX1836/MAX1837. When the junction temperature exceeds TJ= +160°C, a thermal sensor turns

off the pass transistor, allowing the IC to cool. The thermal sensor turns the pass transistor on again after the

IC’s junction temperature cools by 10°C, resulting in

a pulsed output during continuous thermal-overload

conditions.

Design Information

Output Voltage Selection

The feedback input features dual-mode operation.

Connect the output to OUT and FB to GND for the preset output voltage. The MAX1836/MAX1837 are supplied with factory-set output voltages of 3.3V or 5V. The

two-digit part number suffix identifies the output voltage

(see the Selector Guide). For example, the

MAX1836EUT33 has a preset 3.3V output voltage.

The MAX1836/MAX1837 output voltage may be adjusted by connecting a voltage divider from the output to

FB (Figure 5). When externally adjusting the output voltage, connect OUT to GND. Select R2 in the 10kΩ to

100kΩ range. Calculate R1 with the following equation:

where V

FB

= 1.25V, and V

OUT

may range from 1.25V to

VIN. When setting output voltages above 5.5V, the shutdown feature cannot be used, so SHDN must be permanently connected to IN.

Inductor Selection

When selecting the inductor, consider these four parameters: inductance value, saturation current rating,

series resistance, and size. The MAX1836/MAX1837

operate with a wide range of inductance values. For

most applications, values between 10µH and 100µH

work best with the controller’s switching frequency.

Calculate the minimum inductance value as follows:

where t

ON(MIN)

= 1.0µs. Inductor values up to six times

L

(MIN)

are acceptable. Low-value inductors may be

smaller in physical size and less expensive, but they

result in higher peak-current overshoot due to currentsense comparator propagation delay (300ns). Peakcurrent overshoot reduces efficiency and could exceed

the current ratings of the internal switching MOSFET

and external components.

Figure 5. Adjustable Output Voltage

V

DROPOUT OUT DS(ON) INDUCTOR

=× +

IR R

()

R1 R2

V

OUT

V

=

-

1

FB

(V - V )

L

(MIN)

IN(MAX) OUT ON(MIN)

=

I

LIM

t

R1

R2

OUTPUT

1.25V TO V

IN

C

OUT

INPUT

4.5V OR 24V

C

IN

NOTE: HIGH-CURRENT PATHS SHOWN WITH BOLD LINES.

IN

SHDN

GND

MAX1836

MAX1837

LX

FB

OUT

L1

D1

Page 10

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

10 ______________________________________________________________________________________

The inductor’s saturation current rating must be greater

than the peak switching current, which is determined

by the switch current limit plus the overshoot due to the

300ns current-sense comparator propagation delay:

where the switch current-limit (I

LIM

) is typically 312mA

(MAX1836) or 625mA (MAX1837). Saturation occurs

when the inductor’s magnetic flux density reaches the

maximum level the core can support, and the inductance starts to fall.

Inductor series resistance affects both efficiency and

dropout voltage (see the Input-Output Voltage section).

High series resistance limits the maximum current available at lower input voltages and increases the dropout

voltage. For optimum performance, select an inductor

with the lowest possible DC resistance that fits in the

allotted dimensions. Typically, the inductor’s series

resistance should be significantly less than that of the

internal P-channel MOSFET’s on-resistance (1.1Ω typ).

Inductors with a ferrite core, or equivalent, are recommended.

The maximum output current of the MAX1836/MAX1837

current-limited converter is limited by the peak inductor

current. For the typical application, the maximum output current is approximately:

Output Capacitor

Choose the output capacitor to supply the maximum

load current with acceptable voltage ripple. The output

ripple has two components: variations in the charge

stored in the output capacitor with each LX pulse, and

the voltage drop across the capacitor’s equivalent

series resistance (ESR) caused by the current into and

out of the capacitor:

The output voltage ripple as a consequence of the ESR

and output capacitance is:

where I

PEAK

is the peak inductor current (see the

Inductor Selection section). These equations are suit-

able for initial capacitor selection, but final values

should be set by testing a prototype or evaluation circuit. As a general rule, a smaller amount of charge

delivered in each pulse results in less output ripple.

Since the amount of charge delivered in each oscillator

pulse is determined by the inductor value and input

voltage, the voltage ripple increases with larger inductance but decreases with lower input voltages.

With low-cost aluminum electrolytic capacitors, the

ESR-induced ripple can be larger than that caused by

the current into and out of the capacitor. Consequently,

high-quality low-ESR aluminum-electrolytic, tantalum,

polymer, or ceramic filter capacitors are required to

minimize output ripple. Best results at reasonable cost

are typically achieved with an aluminum-electrolytic

capacitor in the 100µF range, in parallel with a 0.1µF

ceramic capacitor.

Input Capacitor

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple on the input caused by the circuit’s switching.

The input capacitor must meet the ripple-current

requirement (I

RMS

) imposed by the switching currents

defined by the following equation:

For most applications, nontantalum chemistries (ceramic, aluminum, polymer, or OS-CON) are preferred due

to their robustness with high inrush currents typical of

systems with low-impedance battery inputs.

Alternatively, two (or more) smaller-value low-ESR

capacitors can be connected in parallel for lower cost.

Choose an input capacitor that exhibits <+10°C temperature rise at the RMS input current for optimal circuit

longevity.

Diode Selection

The current in the external diode (D1) changes abruptly

from zero to its peak value each time the LX switch

turns off. To avoid excessive losses, the diode must

have a fast turn-on time and a low forward voltage. Use

a diode with an RMS current rating of 0.5A or greater,

and with a breakdown voltage >VIN. Schottky diodes

are preferred. For high-temperature applications,

Schottky diodes may be inadequate due to their high

leakage currents. In such cases, ultra-high-speed silicon rectifiers are recommended, although a Schottky

diode with a higher reverse voltage rating can often

provide acceptable performance.

(V - V )

I

=+I

PEAK LIM

II

IN OUT

L

1

OUT(MAX) PEAK

=

2

ns

300

VV V

RIPPLE RIPPLE(ESR) RIPPLE(C)

V ESR

RIPPLE(ESR) PEAK

V

RIPPLE(C)

≈+

I

=

LI

()

PEAK OUT

=

2C V

OUT OUT

-I

2

V

V-V

IN OUT

IN

II

RMS LOAD

VV-V

()

=

OUT IN OUT

V

IN

Page 11

MAX1836/MAX1837 Stability

Commonly, instability is caused by excessive noise on

the feedback signal or ground due to poor layout or

improper component selection. When seen, instability

typically manifests itself as “motorboating,” which is

characterized by grouped switching pulses with large

gaps and excessive low-frequency output ripple during

no-load or light-load conditions.

PC Board Layout and Grounding

High switching frequencies and large peak currents

make PC board layout an important part of the design.

Poor layout may introduce switching noise into the

feedback path, resulting in jitter, instability, or degraded performance. High-power traces, bolded in the typical application circuits (Figures 1 and 2), should be as

short and wide as possible. Additionally, the current

loops formed by the power components (CIN, C

OUT

,

L1, and D1) should be as tight as possible to avoid

radiated noise. Connect the ground pins of these

power components at a common node in a star-ground

configuration. Separate the noisy traces, such as the

LX node, from the feedback network with grounded

copper. Furthermore, keep the extra copper on the

board, and integrate it into a pseudoground plane.

When using external feedback, place the resistors as

close to the feedback pin as possible to minimize noise

coupling. The MAX1837 evaluation kit shows the recommended layout.

Applications Information

High-Voltage Step-Down Converter

The typical application circuits’ (Figures 1 and 2) components were selected for 9V battery applications.

However, the MAX1836/MAX1837 input voltage range

allows supply voltages up to 24V. Figure 6 shows a

modified application circuit for high-voltage applications. When using higher input voltages, verify that the

input capacitor’s voltage rating exceeds V

IN(MAX)

and

that the inductor value exceeds the minimum inductance recommended in the Inductor Selection section.

Inverter Configuration

Figure 7 shows the MAX1836/MAX1837 in a floating

ground configuration. By connecting what would normally be the output to the supply-voltage ground, the

IC’s ground pin is forced to regulate to -5V

(MAX183_EUT50) or -3.3V (MAX183_EUT33). Avoid

exceeding the maximum ratings of 24V between IN and

GND, and 5.5V between OUT and GND. Other negative

voltages may be generated by placing a resistive

divider across the output capacitor and connecting the

tap to FB in the same manner as the normal step-down

configuration.

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

______________________________________________________________________________________ 11

Table 1. Component Suppliers

INDUCTORS

Coilcraft 847-639-6400 847-639-1469 www.coilcraft.com

Coiltronics 561-241-7876 561-241-9339 www.coiltronics.com

Sumida USA 847-956-0666 847-956-0702 www.sumida.com

Toko 847-297-0070 847-699-1194 www.tokoam.com

CAPACITORS

AVX 803-946-0690 803-626-3123 www.avxcorp.com

Kemet 408-986-0424 408-986-1442 www.kemet.com

Panasonic 847-468-5624 847-468-5815 www.panasonic.com

Sanyo 619-661-6835 619-661-1055 www.secc.co.jp

Taiyo Yuden 408-573-4150 408-573-4159 www.t-yuden.com

DIODES

Central Semiconductor 516-435-1110 516-435-1824 www.centralsemi.com

International

Nihon 847-843-7500 847-843-2798 www.niec.co.jp

On Semiconductor 602-303-5454 602-994-6430 www.onsemi.com

Zetex 516-543-7100 516-864-7630 www.zetex.com

SUPPLIER PHONE FAX WEBSITE

310-322-3331 310-322-3332 www.irf.com

Page 12

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

12 ______________________________________________________________________________________

Figure 7. MAX1836/MAX1837 Inverter Configuration

Figure 6. High-Voltage Application

Chip Information

TRANSISTOR COUNT: 731

PROCESS: BiCMOS

INPUT

4.5V TO 24V

C

IN

10µF

25V

= TAIYO YUDEN TMK432BJ106KM

C

IN

L1 = SUMIDA CDRH5D28-470

= SANYO POSCAP 10TPC68M

C

OUT

D1 = NIHON EP05Q03L

NOTE: HIGH-CURRENT PATHS SHOWN WITH BOLD LINES.

IN

SHDN

GND

LX

OUT

MAX1837

FB

L1

47µH

D1

OUTPUT

5V

C

68µF

10V

OUT

INPUT

3.6V TO 18V

C

IN

10µF

NOTE: HIGH-CURRENT PATHS SHOWN WITH BOLD LINES.

IN

SHDN

MAX1836

MAX1837

LX

OUT

GND

FB

L1

47µH

D1

OUTPUT

-3.3V OR -5V

C

OUT

100µF

Page 13

MAX1836/MAX1837

24V Internal Switch, 100% Duty Cycle,

Step-Down Converters

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 13

© 2002 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages.)

6LSOT.EPS

Loading...

Loading...