Page 1

General Description

The MAX1820/MAX1821 low-dropout, pulse-width-modulated (PWM) DC-DC buck regulators are optimized to

provide power to the power amplifier (PA) in WCDMA

cell phones; however, they may be applied in many

other applications where high efficiency is a priority. The

supply voltage range is from 2.6V to 5.5V, and the guaranteed output current is 600mA; 1MHz PWM switching

allows for small external components, while skip mode

reduces quiescent current to 180µA with light loads.

The MAX1820 is dynamically controlled to provide varying output voltages from 0.4V to 3.4V. The circuit is

designed such that the output voltage settles in <30µs

for a full-scale change in voltage and current. The

MAX1821 is set with external resistors to provide any

fixed output voltage in the 1.25V to 5.5V range.

The MAX1820/MAX1821 include a low on-resistance

internal MOSFET switch and synchronous rectifier to

maximize efficiency and minimize external component

count; 100% duty-cycle operation allows for low dropout

of only 150mV at 600mA load, including the external

inductor resistance. The devices are offered in 10-pin

µMAX and tiny 3✕ 4 chip-scale (UCSP™) packages.

________________________Applications

WCDMA Cell Phone Power Amplifiers

PDA, Palmtop, and Notebook Computers

Microprocessor Core Supplies

Digital Cameras

PCMCIA and Network Cards

Hand-Held Instruments

Features

♦ Dynamically Adjustable Output from 0.4V to 3.4V

(MAX1820)

♦ Programmable Output from 1.25V to 5.5V

(MAX1821)

♦ SYNC to 13MHz External Clock (MAX1820X)

♦ SYNC to 19.8MHz External Clock (MAX1820Y)

♦ NO SYNC, Internal 1MHz Oscillator (MAX1820Z)

♦ Low Quiescent Current

180µA (typ) in Skip Mode

0.1µA (typ) in Shutdown Mode

♦ No External Schottky Diode Required

♦ 600mA Guaranteed Output Current

♦ 0% to 100% Duty-Cycle Operation

♦ 150mV Dropout at 600mA Load (Including R

DC

of External Inductor)

♦ µMAX or UCSP Packaging

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

________________________________________________________________ Maxim Integrated Products 1

19-2011; Rev 2; 7/02

EVALUATION KIT

AVAILABLE

Ordering Information

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configurations appear at end of data sheet.

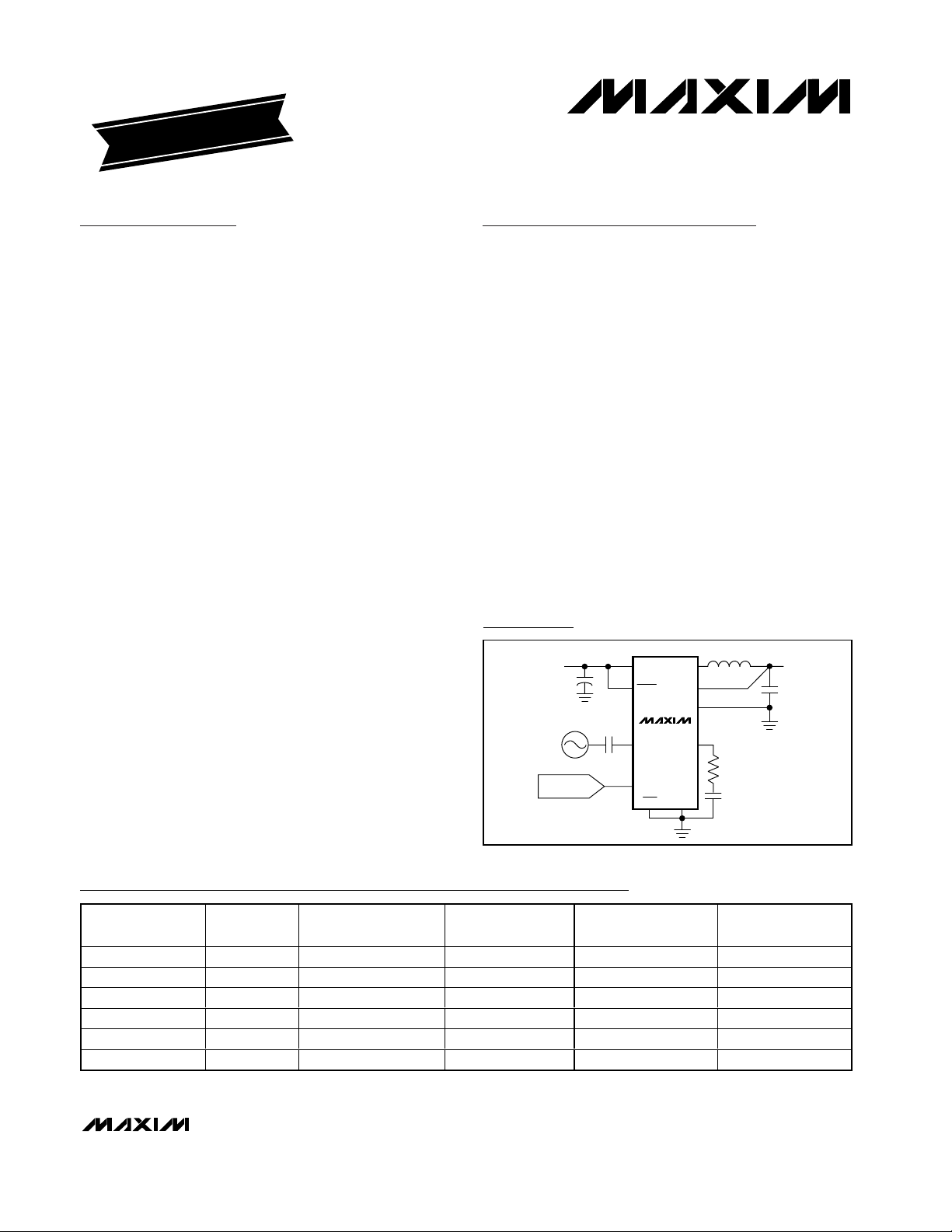

Typical Operating Circuits continued at end of data sheet.

SYNC

GND

SHDN

BATT

PGND

COMP

V

OUT

CONTROL

DAC

REF

LX

OUT

13MHz

OR

19.8MHz

MAX1820

SKIP

4.7µH

4.7µF

INPUT

2.6V TO

5.5V

DYNAMIC

OUTPUT

0.4V TO 3.4V

Typical Operating Circuits

*UCSP reliability is integrally linked to the user’s assembly methods, circuit board material, and environment. Refer to the UCSP

Reliability Notice in the UCSP Reliability section of this data sheet for more information.

UCSP is a trademark of Maxim Integrated Products, Inc.

Ordering Information continued at end of data sheet.

PART

MAX1820ZEBC*

MAX1820YEBC*

MAX1820XEBC*

MAX1820ZEUB

MAX1820YEUB

MAX1820XEUB

SYNC

FREQ (MHz)

No Sync

19.8

13

No Sync

19.8

13

OUTPUT VOLTAGE TEMP RANGE PIN-PACKAGE UCSP MARK

✕

4 UCSP AAB

✕

4 UCSP AAL

✕

4 UCSP AAM

Dynamic -40°C to +85°C3

Dynamic -40°C to +85°C3

Dynamic -40°C to +85°C3

Dynamic -40°C to +85°C 10 µMAX —

Dynamic -40°C to +85°C 10 µMAX —

Dynamic -40°C to +85°C10 µMAX —

Page 2

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

BATT, OUT (FB), SHDN, SYNC, SKIP,

REF to GND .......................................................-0.3V to +6.0V

PGND to GND .......................................................-0.3V to +0.3V

LX, COMP to GND...................................-0.3V to (V

BATT

+ 0.3V)

Output Short-Circuit Duration ............................................Infinite

Continuous Power Dissipation (T

A

= +70°C)

3

✕

4 UCSP (derate 10.4mW/°C above +70°C)............832mW

10-Pin µMAX (derate 5.6mW/°C above +70°C) ...........444mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Ranges

3

✕

4 UCSP ....................................................-40°C to +150°C

10-Pin µMAX ..................................................-65°C to +150°C

Solder Profile (UCSP) ......................................................(Note 1)

Lead Temperature (soldering, 10s) .................................+300°C

ELECTRICAL CHARACTERISTICS

(V

BATT

= 3.6V, SHDN = BATT, SKIP = SYNC = GND, V

REF

= 1.25V (MAX1820 only), TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 2)

Note 1: For UCSP solder profile information, visit www.maxim-ic.com/1st_pages/UCSP.htm.

Input BATT Voltage V

Undervoltage Lockout

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Threshold

Quiescent Current I

V

UVLO

IN

Q

Quiescent Current in Dropout

Shutdown Supply Current I

SHDN

ERROR AMPLIFIER

OUT Voltage Accuracy

(MAX1820)

OUT Input Resistance

(MAX1820)

V

R

OUT

OUT

V

rising, 1% hysteresis 2.20 2.35 2.55 V

BATT

SKIP = GND (MAX1820Z/MAX1821) 180 300

SKIP = BATT, no switching 450 2000

SKIP = GND (MAX1820Y, MAX1820X, and

MAX1821X)

SKIP = BATT, 1MHz switching 3300

SKIP = GND 530 1000

SKIP = BATT, no switching 550 1000

SHDN = GND 0.1 6 µA

V

= 1.932 ±0.005V, load = 0 to 600mA,

REF

SKIP = BATT or GND

V

= 0.227 ±0.005V, load = 0 to 30mA,

REF

SKIP = BATT, V

2.6 5.5 V

240 360

3.33 3.4 3.47

BATT

≤ 4.2V

0.35 0.40 0.45

250 400 kΩ

µA

µA

V

REF Input Current (MAX1820) I

FB Voltage Accuracy

(MAX1821)

FB Input Current (MAX1821) I

Transconductance g

REF

V

FB

FB

FB = COMP 1.225 1.25 1.275 V

V

= 1.4V 0.01 50 nA

FB

m

30 50 85 µS

0.1 1 µA

COMP Clamp Low Voltage 0.2 0.45 1.0 V

COMP Clamp High Voltage 2.04 2.15 2.28 V

Page 3

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(V

BATT

= 3.6V, SHDN = BATT, SKIP = SYNC = GND, V

REF

= 1.25V (MAX1820 only), TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 2)

CONTROLLER

P-Channel On-Resistance P

N-Channel On-Resistance N

Current-Sense Transresistance R

P-Channel Current-Limit

Threshold

P-Channel Pulse-Skipping

Current Threshold

N-Channel Current-Limit

Threshold

LX Leakage Current I

Maximum Duty Cycle duty

Minimum Duty Cycle duty

SYNC AND OSCILLATOR

SYNC Divide Ratio

(MAX1820X)

SYNC Capture Range

(MAX1820X)

SYNC Leakage Current

Frequency

SYNC Divide Ratio

(MAX1820Y)

SYNC Capture Range

(MAX1820Y)

Internal Oscillator Frequency

(MAX1820Z, MAX1821)

LOGIC INPUTS (SKIP, SHDN)

Logic Input High V

Logic Input Low V

Logic Input Current -1 0.1 1 µA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

RDS

RDS

LX

I

SYNC

f

OSC

ILX = 180mA, V

ILX = 180mA, V

ILX = 180mA, V

ILX = 180mA, V

CS

Duty factor = 100% 0.75 1.2 1.55 A

SKIP = GND 0.04 0.13 0.24 A

SKIP = BATT -1.6 -0.85 -0.45

SKIP = GND 0.02 0.08 0.14

V

BATT

MAX

SKIP = GND 0

MIN

SKIP = BATT, V

S Y N C = si ne w ave, S Y N C i np ut = 200m V

S Y N C = si ne w ave, S Y N C i np ut = 800m V

SYNC = sine wave, AC-coupled,

SYNC input = 500mV

V

SYNC

V

SYNC

MAX1821X)

S Y N C = si ne w ave, S Y N C i np ut = 200m V

S Y N C = si ne w ave, S Y N C i np ut = 800m V

SYNC = sine wave, AC-coupled,

SYNC input = 500mV

SYNC = GND 0.8 1 1.2 MHz

IH

IL

= 3.6V 0.15 0.3

BATT

= 2.6V 0.2

BATT

= 3.6V 0.2 0.35

BATT

= 2.6V 0.3

BATT

0.25 0.50 0.75 V/A

= 5.5V, LX = GND or BATT -1 0.1 1 µA

100 %

= 4.2V

BATT

= 1V (MAX1820Z, MAX1821) -1 +1

= 1V (MAX1820X, MAX1820Y, and

P-P

P-P

P-P

P-P

P-P

P-P

P-P

13 13

13 13

10 13 16 MHz

-5 +5

18 18

18 18

15 19.8 21 MHz

1.6 V

10

0.4 V

Ω

Ω

A

%

Hz/Hz

µA

Hz/Hz

Page 4

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(V

BATT

= 3.6V, SHDN = BATT, SKIP = SYNC = GND, V

REF

= 1.25V (MAX1820 only), TA = -40°C to +85°C, unless otherwise noted.)

(Notes 2, 3)

Input BATT Voltage V

Undervoltage Lockout

Threshold

Quiescent Current I

Quiescent Current in Dropout

Shutdown Supply Current I

ERROR AMPLIFIER

OUT Voltage Accuracy

(MAX1820)

OUT Input Resistance

(MAX1820)

REF Input Current (MAX1820) I

FB Voltage Accuracy

(MAX1821)

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

IN

V

UVLO

Q

SHDN

V

OUT

R

OUT

REF

V

FB

V

BATT

SKIP = GND (MAX1820Z, MAX1821) 300

SKIP = GND (MAX1820X, MAX1820Y, and

MAX1821X)

SKIP = BATT, no switching 2000

SKIP = GND 1000

SKIP = BATT, no switching 1000

SHDN = GND 6 µA

V

REF

SKIP = BATT or GND

V

REF

SKIP = BATT, V

FB = COMP 1.225 1.275 V

rising, 1% hysteresis 2.15 2.55 V

= 1.932 ±0.005V, load = 0 to 600mA,

= 0.227 ±0.005V, load = 0 to 30mA,

≤ 4.2V

BATT

2.6 5.5 V

360

3.33 3.47

0.35 0.45

250 kΩ

1µA

µA

µA

V

FB Input Current (MAX1821) I

Transconductance g

COMP Clamp Low Voltage 0.2 1.0 V

COMP Clamp High Voltage 2.04 2.28 V

CONTROLLER

P-Channel On-Resistance P

N-Channel On-Resistance N

Current-Sense Transresistance R

P-Channel Current-Limit

Threshold

P-Channel Pulse-Skipping

Current Threshold

N-Channel Current-Limit

Threshold

FB

m

RDS

RDS

CS

V

= 1.4V 50 nA

FB

30 85 µS

ILX = 180mA, V

ILX = 180mA, V

Duty factor = 100% 0.75 1.55 A

SKIP = GND 0.04 0.24 A

SKIP = BATT -1.6 -0.45

SKIP = GND 0.01 0.14

= 3.6V 0.3 Ω

BATT

= 3.6V 0.35 Ω

BATT

0.25 0.75 V/A

A

Page 5

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

_______________________________________________________________________________________ 5

Note 2: Limits are 100% production tested at TA= +25°C for UCSP parts. Limits over the entire operating temperature range are

guaranteed by design and characterization but are not production tested.

Note 3: Specifications to -40°C are guaranteed by design and not subject to production test.

ELECTRICAL CHARACTERISTICS (continued)

(V

BATT

= 3.6V, SHDN = BATT, SKIP = SYNC = GND, V

REF

= 1.25V (MAX1820 only), TA = -40°C to +85°C, unless otherwise noted.)

(Notes 2, 3)

40

50

60

70

80

90

100

0 1.00.5 1.5 2.0 2.5 3.0 3.5 4.0

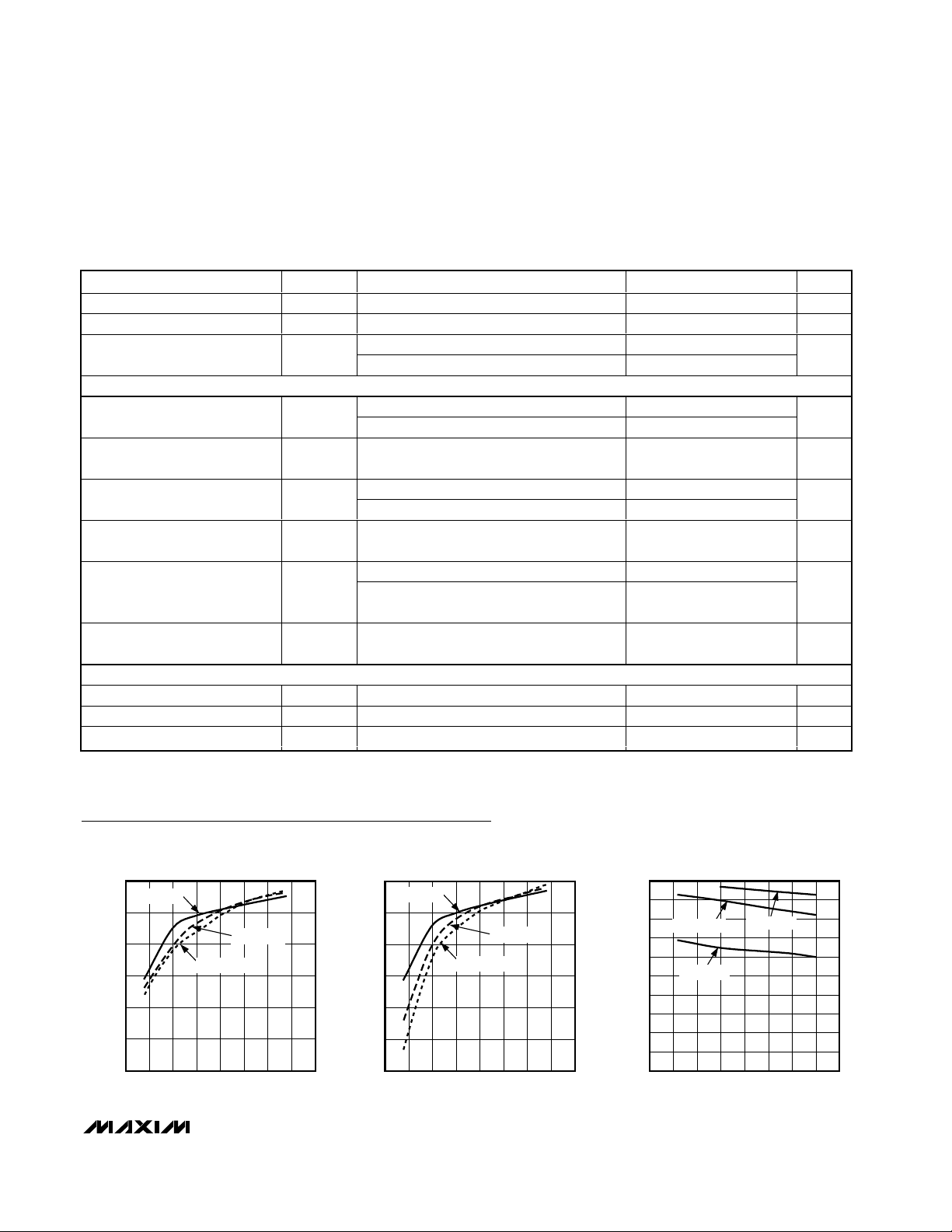

EFFICIENCY vs. OUTPUT VOLTAGE

(NORMAL MODE, V

IN

= 3.6V)

MAX1820/21 toc01

OUTPUT VOLTAGE (V)

EFFICIENCY (%)

R

LOAD

= 10Ω

R

LOAD

= 15Ω

R

LOAD

= 5Ω

40

50

60

70

80

90

100

0 1.00.5 1.5 2.0 2.5 3.0 3.5 4.0

EFFICIENCY vs. OUTPUT VOLTAGE

(PWM MODE, V

IN

= 3.6V)

MAX1820/21 toc02

OUTPUT VOLTAGE (V)

EFFICIENCY (%)

R

LOAD

= 10Ω

R

LOAD

= 15Ω

R

LOAD

= 5Ω

0

20

10

40

30

60

50

70

90

80

100

2.0 3.0 3.52.5 4.0 4.5 5.0 5.5 6.0

MAX1820/21 toc03

VIN (V)

EFFICIENCY (%)

EFFICIENCY vs. INPUT VOLTAGE

NORMAL MODE, R

LOAD

= 10Ω

V

OUT

= 1.8V

V

OUT

= 3.4V

V

OUT

= 0.4V

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

LX Leakage Current I

Maximum Duty Cycle duty

Minimum Duty Cycle duty

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

LX

MAX

V

BATT

SKIP = GND 0

MIN

SKIP = BATT, V

SYNC AND OSCILLATOR

SYNC Divide Ratio

(MAX1820X)

SYNC Capture Range

(MAX1820X)

SYNC Divide Ratio

(MAX1820Y)

SYNC Capture Range

(MAX1820Y)

SYNC Leakage Current I

SYNC

S Y N C = si ne w ave, S Y N C i np ut = 200m V

S Y N C = si ne w ave, S Y N C i np ut = 800m V

SYNC = sine wave, AC-coupled,

SYNC input = 500mV

S Y N C = si ne w ave, S Y N C i np ut = 200m V

S Y N C = si ne w ave, S Y N C i np ut = 800m V

SYNC = sine wave, AC-coupled,

SYNC input = 500mV

V

SYNC

V

SYNC

M AX 1821X )

Internal Oscillator Frequency

(MAX1820Z, MAX1821)

f

OSC

SYNC = GND 0.8 1.2 MHz

LOGIC INPUTS (SKIP, SHDN)

Logic Input High V

Logic Input Low V

IH

IL

Logic Input Current 1µA

= 5.5V, LX = GND or BATT -1 1 µA

100 %

= 4.2V 10

BATT

P-P

P-P

P-P

P-P

P-P

P-P

13 13

13 13

10 16 MHz

18

18

15 21 MHz

= IV ( M AX 1820Z , M AX 1821) -1

= IV ( M AX 1820X , M AX 1820Y , and

18

18

+1

-5 +5

%

Hz/Hz

Hz/Hz

µA

1.6 V

0.4 V

Page 6

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

90

0

1 100010010

MAX1821 EFFICIENCY vs. LOAD CURRENT

(V

OUT

= 3.3V)

30

10

70

50

100

40

20

80

60

MAX1820/21 toc04

LOAD CURRENT (mA)

EFFICIENCY (%)

VIN = 5.0V

VIN = 3.6V

VIN = 5.0V

SKIP = GND (DASHED LINE)

SKIP = BATT (SOLID LINE)

VIN = 3.6V

90

0

1 100010010

MAX1821 EFFICIENCY vs. LOAD CURRENT

(V

OUT

= 2.5V)

30

10

70

50

100

40

20

80

60

MAX1820/21 toc05

LOAD CURRENT (mA)

EFFICIENCY (%)

VIN = 5.0V

VIN = 3.6V

VIN = 3.6V

VIN = 5.0V

SKIP = GND (DASHED LINE)

SKIP = BATT (SOLID LINE)

VIN = 2.7V

VIN = 2.7V

90

0

1 100010010

MAX1821 EFFICIENCY vs. LOAD CURRENT

(V

OUT

= 1.5V)

30

10

70

50

100

40

20

80

60

MAX1820/21 toc06

LOAD CURRENT (mA)

EFFICIENCY (%)

VIN = 5.0V

VIN = 3.6V

SKIP = GND (DASHED LINE)

SKIP = BATT (SOLID LINE)

VIN = 2.7V

0

40

20

80

60

120

100

140

0 200 300100 400 500 600

DROPOUT VOLTAGE vs. LOAD CURRENT

MAX1820/21 toc07

LOAD CURRENT (mA)

DROPOUT VOLTAGE (mV)

V

OUT

= 3.4V

RL = 57mΩ

0

2

1

5

4

3

8

7

6

9

2.0 3.0 3.52.5 4.0 4.5 5.0 5.5

SUPPLY CURRENT vs. SUPPLY VOLTAGE

MAX1820/21 toc08

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (mA)

V

OUT

= 1.5V

SKIP = BATT

20

80

60

40

120

100

200

180

160

140

220

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

SUPPLY CURRENT vs. SUPPLY VOLTAGE

MAX1820/21 toc09

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (µA)

V

OUT

= 1.5V

SKIP = GND

MAX1820/21 toc10

B

C

A

400ns/div

A: V

LX

, 5V/div

B: INDUCTOR CURRENT, 500mA/div

C: V

OUT

(AC-COUPLED), 5mV/div

HEAVY-LOAD SWITCHING WAVEFORMS

(V

IN

= 3.8V, V

OUT

= 3.4V,

I

LOAD

= 600mA, SKIP = BATT)

MAX1820/21 toc11

B

C

A

400ns/div

A: V

LX

, 5V/div

B: INDUCTOR CURRENT, 500mA/div

C: V

OUT

(AC-COUPLED), 5mV/div

MEDIUM-LOAD SWITCHING WAVEFORMS

(V

IN

= 3.8V, V

OUT

= 1.8V,

I

LOAD

= 300mA, SKIP = BATT)

MAX1820/21 toc12

B

C

A

400ns/div

A: V

LX

, 5V/div

B: INDUCTOR CURRENT, 100mA/div

C: V

OUT

(AC-COUPLED), 5mV/div

LIGHT-LOAD PWM SWITCHING WAVEFORMS

(V

IN

= 3.8V, V

OUT

= 0.45V,

I

LOAD

= 30mA, SKIP = BATT)

Page 7

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

LIGHT-LOAD SKIP-SWITCHING WAVEFORMS

= 4.2V, V

(V

IN

LOAD = 30mA, SKIP = GND)

A

B

C

A: V

, 5V/div

LX

B: INDUCTOR CURRENT, 500mA/div

(AC-COUPLED), 20mV/div

C: V

OUT

LOAD TRANSIENT (I

= 1.5V, V

V

OUT

= 1.5V,

OUT

MAX1820/21 toc13

2µs/div

= 20mA TO 420mA,

LOAD

= 3.6V, SKIP = BATT)

IN

MAX1820/21 toc15

EXITING AND ENTERING SHUTDOWN

= 3.6V, V

(V

V

SHDN

5V/div

V

OUT

2V/div

I

BATT

0.5A/div

IN

OUT

2ms/div

LOAD TRANSIENT (I

= 1.5V, VIN = 3.6V, SKIP = GND)

V

OUT

= 3.4V, R

LOAD

LOAD

MAX1820/21 toc14

= 20mA TO 420mA,

MAX1820/21 toc16

= 15Ω)

I

OUT

200mA/div

V

OUT

AC-COUPLED

100mV/div

V

REF

1V/div

V

OUT

1V/div

40µs/div

MAX1820

REF TRANSIENT (V

= 10Ω, VIN = 3.6V, SKIP = BATT)

R

LOAD

= 0.23V TO 1.932V,

REF

20µs/div

C

= 10µF

OUT

MAX1820/21 toc17

I

OUT

200mA/div

V

OUT

AC-COUPLED

100mV/div

200mV/div

V

OUT

AC-COUPLED

20mV/div

40µs/div

LINE TRANSIENT (VIN = 3.6V TO 4.0V,

= 1.5V, I

V

OUT

V

IN

LOAD

40µs/div

= 300mA)

C

OUT

MAX1820/21 toc18

C

OUT

= 10µF

= 10µF

Page 8

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

8 _______________________________________________________________________________________

Pin Description

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

OUTPUT SWITCHING HARMONICS

vs. FREQUENCY

(V

IN

= 3.8V, V

OUT

= 3.4V, I

LOAD

= 600mA)

OUTPUT SWITCHING HARMONICS

= 3.8V, V

(V

IN

vs. FREQUENCY

= 1.8V, I

OUT

LOAD

= 300mA)

1.6

)

1.2

RMS

0.8

HARMONICS (mV

0.4

0

0.1 1 10

FREQUENCY (MHz)

OUTPUT SWITCHING HARMONICS

vs. FREQUENCY

= 4.2V, V

(V

IN

1.6

)

1.2

RMS

0.8

HARMONICS (mV

0.4

0

= 0.4V, I

OUT

LOAD

= 30mA)

MAX1820/21 toc19

MAX1820/21 toc21

1.6

)

1.2

RMS

0.8

HARMONICS (mV

0.4

0

0.1 1 10

FREQUENCY (MHz)

OUTPUT NOISE (VIN = 3.6V,

NOISE (µV/√Hz)

= 1.8V, I

V

OUT

4.0

3.0

2.0

1.0

0

= 300mA)

OUT

MAX1820/21 toc20

MAX1820/21 toc22

MAX1820

UCSP

0.1 1 10

FREQUENCY (MHz)

PIN

MAX1820

µMAX

MAX1821

UCSP

MAX1821

µMAX

0.1 1 10

FREQUENCY (MHz)

NAME FUNCTION

250

100

PWM/Skip-Mode Input. Drive with logic 0 to use PWM at medium

A1 1 A1 1 SKIP

and heavy loads and pulse skipping at light loads. Drive with

logic 1 to force PWM at all loads.

Compensation. Typically, connect an 82kΩ (for MAX1821) or

A2 2 A2 2 COMP

43kΩ (for MAX1820) series resistor and 330pF capacitor from

this pin to GND to stabilize the regulator.

A3 3 ——OUT Output Voltage Sense Input. Connect OUT directly to the output.

Page 9

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

_______________________________________________________________________________________ 9

_______________Detailed Description

The MAX1820/MAX1821 PWM step-down DC-DC converters are optimized for low-voltage, battery-powered

applications where high efficiency and small size are

priorities. The MAX1821 is a general-purpose device

that uses external feedback resistors to set the output

voltage from 1.25V to V

BATT

, and the MAX1820 is

specifically intended to power a linear PA in WCDMA

handsets. An analog control signal dynamically adjusts

the MAX1820’s output voltage from 0.4V to 3.4V with a

settling time <30µs.

The MAX1820/MAX1821 operate at a high 1MHz

switching frequency that reduces external component

size. Each device includes an internal synchronous rectifier that provides for high efficiency and eliminates the

need for an external Schottky diode. The normal operating mode uses constant-frequency PWM switching at

medium and heavy loads, and automatically pulse

skips at light loads to reduce supply current and extend

battery life. An additional forced PWM mode (with

optional external synchronization) switches at a constant frequency, regardless of load, to provide a wellcontrolled spectrum in noise-sensitive applications.

Battery life is maximized by low-dropout operation at

100% duty-cycle and a 0.1µA (typ) logic-controlled

shutdown mode.

PWM Control

The MAX1820/MAX1821 use a slope-compensated,

current-mode PWM controller capable of achieving

100% duty cycle. The current-mode control design is

capable of minimum duty cycles of less than 10%,

ensuring a constant switching frequency with outputs

as low as 0.4V when powered from a single lithium-ion

(Li+) cell. Current-mode feedback provides stable

switching and cycle-by-cycle current limiting for superior load and line response and protection of the internal

MOSFET and synchronous rectifier. The output voltage

is regulated by switching at a constant frequency and

then modulating the power transferred to the load dur-

Pin Description (continued)

PIN

MAX1820

UCSP

——A3 3 FB

A4 4 ——REF

——A4 4 REF

B4 5 B4 5 GND Ground

C4 6 C4 6 PGND Power Ground

C3 7 C3 7 LX

C2 8 C2 8 BATT

C1 9 C1 9 SHDN Active-Low, Shutdown Control Input

B1 10 B1 10 SYNC

MAX1820

µMAX

MAX1821

UCSP

MAX1821

µMAX

NAME FUNCTION

Output Feedback Sense Input. To set the output voltage,

connect FB to the center of an external resistive divider between

the output and GND. FB voltage regulates to 1.25V.

External Reference Input. Connect REF to the output of a D/A

converter for dynamic adjustment of the output voltage. REF-toOUT gain is 1.76.

Internal Reference Bypass. Connect a 0.047µF capacitor from

REF to GND.

Inductor Connection. LX connects to the drains of the internal

power MOSFETs. LX is high impedance in shutdown mode.

Supply Voltage Input. Connect BATT to a 2.6V to 5.5V source.

Bypass BATT to PGND with a low-ESR 10µF capacitor.

Clock Synchronization Input. Drive SYNC with a 13MHz

(MAX1820X, MAX1821X) or 19.8MHz (MAX1820Y) AC-coupled

sine-wave input to synchronize power switching at 1MHz.

MAX1820Z and MAX1821 do not have SYNC capability.

Connect SYNC to GND to use the internally generated,

free-running 1MHz clock. MAX1820Z and MAX1821 SYNC pin

must be connected to GND.

Page 10

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

10 ______________________________________________________________________________________

ing each cycle, using the PWM comparator. The power

transferred to the load is adjusted by changes in the

inductor peak current limit during the first half of each

cycle, based on the output error voltage.

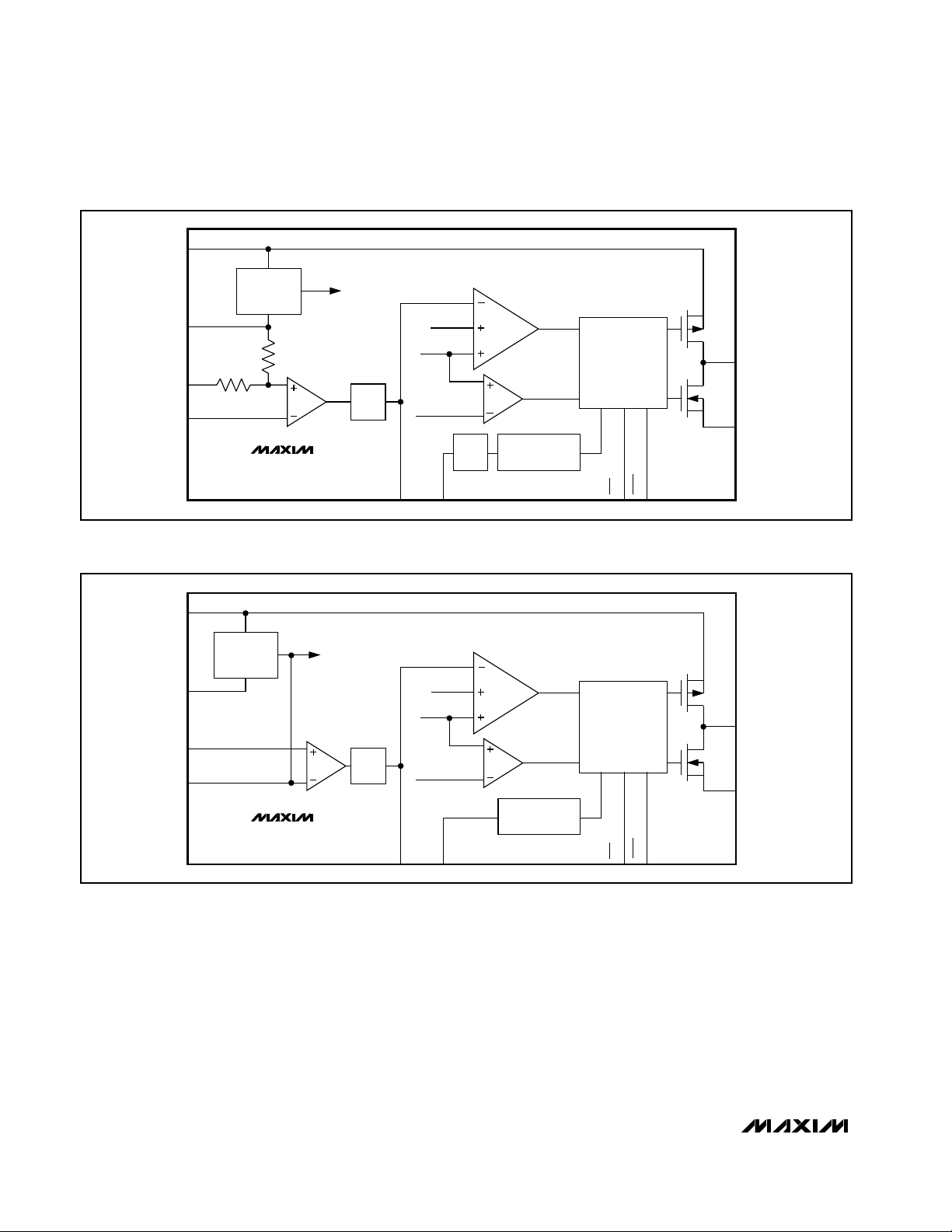

A new cycle begins at each falling edge of the internal

oscillator. The controller turns on the P-channel MOSFET to increase the inductor current, and the slope

compensation block initiates a new reference current

ramp that is summed with the internal P-channel MOSFET current (Figures 1 and 2).

The second half of the cycle begins when the reference

ramp is greater than the error voltage. The P-channel

MOSFET is turned off, the synchronous rectifier is

turned on, and inductor current continues to flow to the

output capacitor. The output capacitor stores charge

when the current is high and releases it when the

inductor current is low, smoothing the voltage across

Figure 1. MAX1820 Simplified Functional Diagram (No SYNC for MAX1820Z)

Figure 2. MAX1821 Simplified Functional Diagram (No SYNC for MAX1821)

BATT

TO

MAX1820

1.25V

IC BIAS

TRANSIMPEDANCE

ERROR AMP

CLAMP

ERROR SIGNAL

SLOPE COMP

CURRENT SENSE

0.45V TO 2.15V

SKIP THRESHOLD

÷13 OR

÷18

PWM

COMPARATOR

SKIP

COMPARATOR

1MHz

OSCILLATOR

GND

OUT

REF

VOLTAGE

REFERENCE

PWM CONTROL

AND

SKIP LOGIC

LX

PGND

SYNC

COMP

BATT

1.25V

TO

IC BIAS

TRANSIMPEDANCE

ERROR AMP

CLAMP

ERROR SIGNAL

SLOPE COMP

CURRENT SENSE

0.45V TO 2.15V

SKIP THRESHOLD

GND

OUT

REF

VOLTAGE

REFERENCE

MAX1821

SYNC

COMP

PWM

COMPARATOR

SKIP

COMPARATOR

1MHz

OSCILLATOR

SKIP

PWM CONTROL

AND

SKIP LOGIC

SKIP

SHDN

LX

PGND

SHDN

Page 11

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

______________________________________________________________________________________ 11

the load. The duty cycle of a buck step-down converter

is ideally a ratio of the output voltage to input voltage in

steady-state condition.

The MAX1820/MAX1821 have internal switch current

limits of 1.2A (typ). If ILXexceeds this maximum, the

high-side FET turns off and the synchronous rectifier

turns on. This lowers the duty cycle and causes the output voltage to droop as long as the load current

remains excessive. There is also a synchronous rectifier

current limit of -0.85A when the device is operating in

forced PWM mode (see the Forced PWM Operation section). If the negative current limit is exceeded, the synchronus rectifier is turned off, and the inductor current

continues to flow through its body diode until the beginning of the next cycle or the inductor current drops to

zero. This means there is a limit on how much current

the device is allowed to shuttle in response to output

power reduction.

Normal Mode Operation

Connecting SKIP to GND enables MAX1820/MAX1821

normal operation (Figure 3). This allows automatic PWM

control at medium and heavy loads and skip mode at

light loads to improve efficiency and reduce quiescent

current to 180µA. Operating in normal mode also allows

the MAX1820/MAX1821 to pulse skip when the peak

inductor current drops below 130mA, corresponding to

a load current of approximately 65mA.

During skip operation, the MAX1820/MAX1821 switch

only as needed to service the load, reducing the

switching frequency and associated losses in the internal switch, the synchronous rectifier, and the external

inductor.

There are three steady-state operating conditions for

the MAX1820/MAX1821 in normal mode. The device

performs in continuous conduction for heavy loads in a

manner identical to forced PWM mode. The inductor

current becomes discontinuous at medium loads,

requiring the synchronous rectifier to be turned off

before the end of a cycle as the inductor current reaches zero. The device enters into skip mode when the

converter output voltage exceeds its regulation limit

before the inductor current reaches its skip threshold level.

During skip mode, a switching cycle initiates when the

output voltage has dropped out of regulation. The Pchannel MOSFET switch turns on and conducts current

to the output-filter capacitor and load until the inductor

current reaches the skip peak current limit. Then the

main switch turns off, and the magnetic field in the

inductor collapses, while current flows through the synchronous rectifier to the output filter capacitor and the

load. The synchronous rectifier is turned off when the

inductor current reaches zero. The MAX1820/ MAX1821

wait until the skip comparator senses a low output voltage again.

Forced PWM Operation

Connect SKIP to BATT for forced PWM operation.

Forced PWM operation is desirable in sensitive RF and

data-acquisition applications to ensure that switching

harmonics do not interfere with sensitive IF and datasampling frequencies. A minimum load is not required

during forced PWM operation since the synchronous

rectifier passes reverse-inductor current as needed to

allow constant-frequency operation with no load.

Figure 3. Standard Operating Circuit

= 2.6V TO 5.5V

V

IN

10µF 0.1µF

0.047µF

* CAN BE OMITTED IF CERAMIC OUTPUT CAPACITOR IS USED.

BATT

SHDN

SYNC

REF

SKIP GND

MAX1821

PGND

COMP

4.7µH

LX

4.7µF

FB

R

C

82kΩ

C1

330pF

C2*

1pF

V

= 1.5V

OUT

R1

6kΩ

R2

30kΩ

Page 12

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

12 ______________________________________________________________________________________

Forced PWM operation uses higher supply current with

no load (3.3mA typ) compared to skip mode.

100% Duty-Cycle Operation

The on-time can exceed one internal oscillator cycle,

which permits operation up to 100% duty cycle. As the

input voltage drops, the duty cycle increases until the

P-channel MOSFET is held on continuously. Dropout

voltage in 100% duty cycle is the output current multiplied by the on-resistance of the internal switch and

inductor, approximately 150mV (I

OUT

= 600mA). Near

dropout, the on-time may exceed one PWM clock

cycle; therefore, small-amplitude subharmonic ripple

may occur.

COMP Clamp

The MAX1820/MAX1821 compensation network has a

0.45V to 2.15V error regulation range. The clamp prevents COMP from rising too high or falling too low to

optimize transient response.

Dropout

Dropout occurs when the input voltage is less than the

desired output voltage plus the IR drops in the circuit

components. The duty cycle is 100% during this condition, and the main switch remains on, continuously

delivering current to the output up to the current limit.

IR drops in the circuit are primarily caused by the onresistance of the main switch and the resistance in the

inductor.

During dropout, the high-side P-channel MOSFET turns

on, and the controller enters a low-current consumption

mode. Every 6µs (6 cycles), the MAX1820/MAX1821

check to see if the device is still in dropout. The device

remains in this mode until the MAX1820/MAX1821 are

no longer in dropout.

Undervoltage Lockout (UVLO)

The MAX1820/MAX1821 do not operate with battery

voltages below the UVLO threshold of 2.35V (typ). The

BATT input remains high impedance until the supply

voltage exceeds the UVLO threshold. This guarantees

the integrity of the output voltage regulation and prevents excessive current during startup and as the battery supply voltage drops during usage.

Synchronous Rectification

An N-channel synchronous rectifier eliminates the need

for an external Schottky diode and improves efficiency.

The synchronous rectifier turns on during the second

half of each cycle (off-time). During this time, the voltage across the inductor is reversed, and the inductor

current falls. In normal mode, the synchronous rectifier

is turned off when either the output falls out of regulation (and another on-time begins) or when the inductor

current approaches zero. In forced PWM mode, the

synchronous rectifier remains active until the beginning

of a new cycle.

SYNC Input and Frequency Control

The MAX1820Z and MAX1821 internal oscillator is set

to a fixed 1MHz switching frequency. The MAX1820Z

and MAX1821 do not have synchronizing capability

and the SYNC pin must be connected to GND. The

MAX1820Y, MAX1820X, and MAX1821X are capable of

synchronizing to external signals. For external synchronization, drive the SYNC pin with a 13MHz (MAX1820X

and MAX1821X) or 19.8MHz (MAX1820Y) AC-coupled

sine wave. SYNC has a perfect 13:1 (MAX1820X and

MAX1821X) or 18:1 (MAX1820Y) clock divider for 1MHz

(MAX1820X and MAX1821X) or 1.1MHz (MAX1820Y)

switching from common system clocks. The input frequency range for SYNC is 10MHz to 16MHz

(MAX1820X, MAX1821X) or 15MHz to 21MHz

(MAX1820Y). Connect SYNC to GND to use the internal

free-running oscillator at 1MHz.

Shutdown Mode

Drive SHDN to GND to place the MAX1820/MAX1821 in

shutdown mode. In shutdown, the reference, control

circuitry, internal switching MOSFET, and the synchronous rectifier turn off, reducing the supply current to

0.1µA, and the output goes high impedance. Connect

SHDN to BATT for normal operation.

Current-Sense Comparators

The MAX1820/MAX1821 use several internal currentsense comparators. In PWM operation, the PWM comparator terminates the cycle-by-cycle on-time (Figures

1 and 2) and provides improved load and line

response. This allows tighter specification of the inductor-saturation current limit to reduce inductor cost. A

second current-sense comparator used across the Pchannel switch controls entry into skip mode. A third

current-sense comparator monitors current through the

internal N-channel MOSFET to prevent excessive

reverse currents and determine when to turn off the

synchronous rectifier. A fourth comparator used at the

P-channel MOSFET detects overcurrent. This protects

the system, external components, and internal

MOSFETs under overload conditions.

Page 13

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

______________________________________________________________________________________ 13

Applications Information

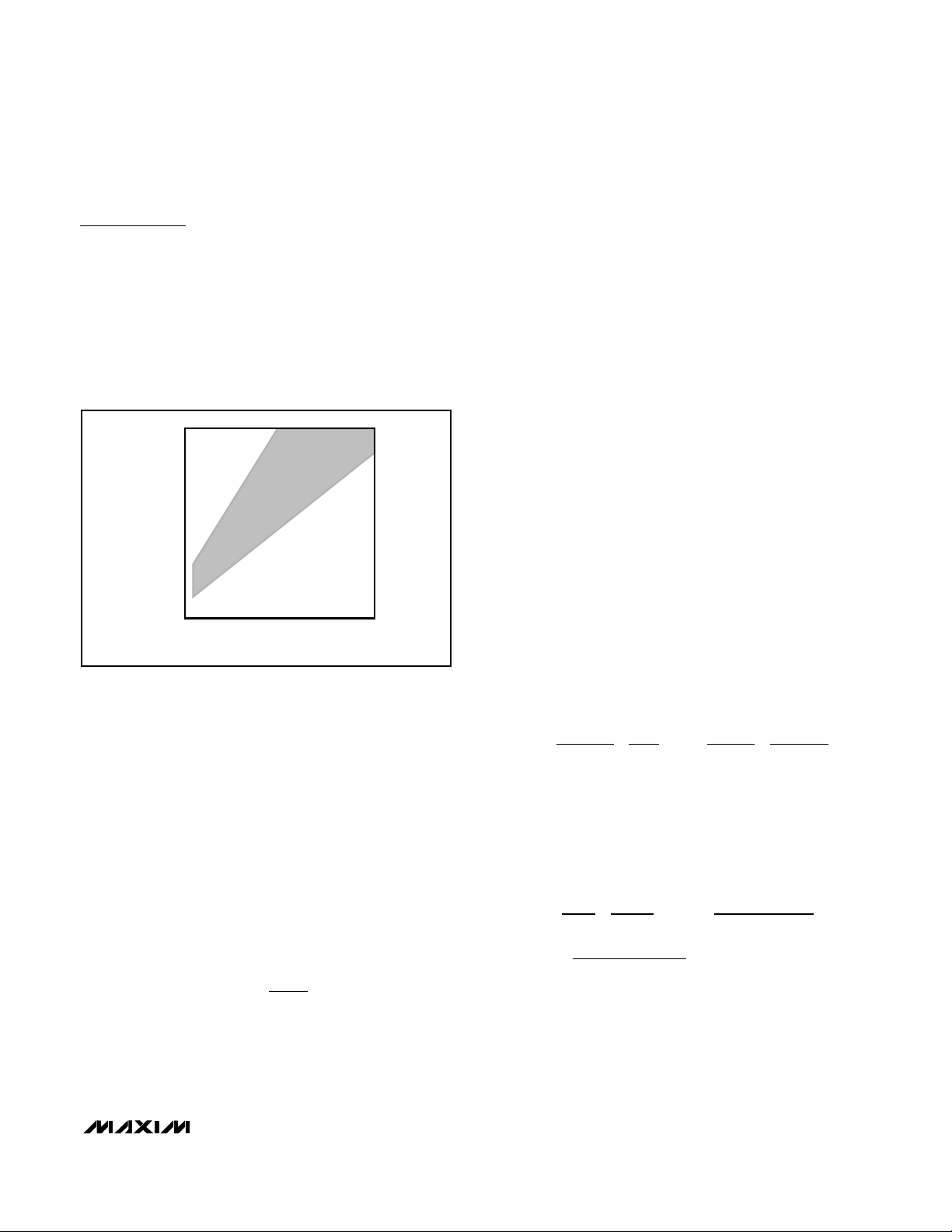

Setting the Output Voltage (MAX1820)

The MAX1820 is optimized for highest system efficiency

when applying power to a linear PA in WCDMA handsets. When transmitting at less than full power, the supply voltage to the PA is reduced (from 3.4V to as low as

0.4V) to greatly reduce battery current. Figure 4 shows

the typical WCDMA PA load profile. The use of a DCDC converter such as the MAX1820 dramatically

reduces battery drain in these applications.

The MAX1820’s output voltage is dynamically

adjustable from 0.4V to V

BATT

by the use of the REF

input. The gain from V

REF

to V

OUT

is internally set to

1.76. V

OUT

can be adjusted during operation by driving

REF with an external DAC. The MAX1820 output

responds to full-scale change in voltage and current in

<30µs.

Setting the Output Voltage (MAX1821)

The MAX1821 is intended for general-purpose stepdown applications where high efficiency is a priority.

Select an output voltage between 1.25V and V

BATT

by

connecting FB to a resistive divider between the output

and GND (Figure 3). Select feedback resistor R2 in the

5kΩ to 30kΩ range. R1 is then given by:

where V

FB

= 1.25V.

Compensation and Stability

The MAX1820/MAX1821 are externally compensated

by placing a resistor and a capacitor (RCand C1) in

series, from COMP to GND (Figure 3). The capacitor

integrates the current from the transimpedance amplifier, averaging output capacitor ripple. This sets the

device speed for transient responses and allows the

use of small ceramic output capacitors because the

phase-shifted capacitor ripple does not disturb the current regulation loop. The resistor sets the proportional

gain of the output error voltage by a factor g

m

✕

RC.

Increasing this resistor also increases the sensitivity of

the control loop to the output capacitor ripple.

This resistor and capacitor set a compensation zero

that defines the system’s transient response. The load

pole is a dynamic pole, shifting the pole frequency with

changes in load. As the load decreases, the pole frequency shifts to the left. System stability requires that

the compensation zero must be placed properly to

ensure adequate phase margin (at least 30° at unity

gain). The following is a design procedure for the compensation network:

1) Select an appropriate converter bandwidth (fC) to

stabilize the system while maximizing transient

response. This bandwidth should not exceed 1/5 of

the switching frequency. Use 100kHz as a reasonable starting point.

2) Calculate the compensation capacitor, C1, based

on this bandwidth:

Resistors R1 and R2 are internal to the MAX1820; use

R1 = 151kΩ and R2 = 199kΩ as nominal values for calculations. These resistors are external to the MAX1821

(see the Setting the Output Voltage section). Using

V

OMAX

= 3.4V, I

OMAX

= 0.6A, gm= 50µs, RCS= 0.75Ω,

C1 is evaluated as:

TION 3

Selecting the nearest standard value of 330pF corresponds to a 103kHz bandwidth, which is still acceptable per the above criteria.

Figure 4. Typical WCDMA PA Load Profile

3.4

3.0

1.0

WCDMA PA SUPPLY VOLTAGE (V)

0.4

30 600

WCDMA PA SUPPLY CURRENT (mA)

R1

=

300

R2 1

V

OUT

V

FB

-

C1

V

O(MAX)

=

I

O(MAX) CS

1

×

g

R

m

R1+R212

R2

××

π f

C

C1

3.4V

=

0.6A10

×

23

..75

Ω

1

××

14 100

50 s

kHz

×

µ

151k +199k

= 341pF

1

99

Ω

k

ΩΩ

Page 14

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

14 ______________________________________________________________________________________

3) Calculate the equivalent load impedance, RL, by:

4) Calculate the compensation resistance (R

C

) value to

cancel out the dominant pole created by the output

load and the output capacitance:

Solving for R

C

gives:

5) Calculate the high-frequency compensation pole to

cancel the zero created by the output capacitor’s

equivalent series resistance (ESR):

Solving for C2 gives:

In this case, C2 can be omitted due to the use of

ceramic capacitors. Larger output capacitors and higher ESR may require the use of capacitor C2.

Inductor Selection

A 4µH to 6µH inductor with a saturation current of at

least 800mA is recommended for most applications.

For best efficiency, the inductor’s DC resistance should

be <200mΩ, and saturation current should be >1A. See

Table 1 for recommended inductors and manufacturers.

For most designs, a reasonable inductor value (L

IDEAL

)

can be derived from the following equation:

where LIR is the inductor current ripple as a percentage.

LIR should be kept between 20% and 40% of the maximum load current for best performance and stability.

The maximum inductor current is:

The inductor current becomes discontinuous if I

OUT

decreases to LIR/2 from the output current value used

to determine L

IDEAL

.

Input Capacitor Selection

The input capacitor reduces the current peaks drawn

from the battery or input power source and reduces

switching noise in the IC. The impedance of the input

capacitor at the switching frequency should be less

than that of the input source so high-frequency switching currents do not pass through the input source.

The input capacitor must meet the ripple-current

requirement (I

RMS

) imposed by the switching currents.

Nontantalum chemistries (ceramic, POSCAP, or OSCON) are preferred due to their resistance to power-up

surge currents:

For optimal circuit reliability, choose a capacitor that

has less than 10°C temperature rise at the peak ripple

current.

Table 1. Suggested Inductors

MANUFACTURER PART NUMBER

Coilcraft DO1606 4.7 120 1.2 5.3 ✕ 5.3 ✕ 2.0

Coilcraft LPT1606-472 4.7 240 (max) 1.2 6.5 ✕ 5.3 ✕ 2.0

Sumida CDRH4D18-4R7 4.7 125 0.84 5 ✕ 5 ✕ 2

Sumida CR43 4.7 108.7 1.15 4.5 ✕ 4.0 ✕ 3.5

Sumida CDRH5D18-4R1 4.1 57 1.95 5.5 ✕ 5.5 ✕ 2.0

×× ×

2

R

=

C

CF

R

×

L OUT

C1

V

OUT(MAX)

R

≈

L

I

OUT(MAX)

1

L OUT C

=

×× ×ππRC RC1

2

3.4V

=

0.6A

4.7

330

µ

pF

1

= 80.8k

INDUCTANCE

(µH)

Ω

ESR (mΩ)

SATURATION

CURRENT (A)

L

IDEAL

=

V(V -V)

OUT BATT OUT

×× ×ƒLIR I

V

BATT OUT(MAX) OSC

LIR

II

L(MAX) OUT(MAX)

=+

1

2

×× ×

2

1

ESR OUT

=

1

×× ×ππRC RC32

2

`

RC

C

×

ESR OUT

Rk

3

4.7 Fµ .

=

80 8

×

.

001

Ω

Ω

.

pF2

055=

=

I

RMS LOAD

V(V -V)

=

I

OUT BATT OUT

V

BATT

DIMENSIONS

(mm)

Page 15

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

______________________________________________________________________________________ 15

Output Capacitor Selection

The output capacitor is required to keep the output voltage ripple small and to ensure regulation control loop

stability. The output capacitor must have low impedance at the switching frequency. Ceramic capacitors

are recommended. The output ripple is approximately:

V

RIPPLE

≈ LIR ✕I

OUT(MAX)

See the Compensation Design section for a discussion

of the influence of output capacitance and ESR on regulation control-loop stability.

The capacitor voltage rating must exceed the maximum

applied capacitor voltage. Consult the manufacturer’s

specifications for proper capacitor derating. Avoid Y5V

and Z5U dielectric types due to their huge voltage and

temperature coefficients of capacitance and ESR.

PC Board Layout and Routing

High switching frequencies and large peak currents

make PC board layout a very important part of design.

Good design minimizes excessive EMI on the feedback

paths and voltage gradients in the ground plane, both

of which can result in instability or regulation errors.

Connect the inductor, input filter capacitor, and output

filter capacitor as close together as possible, and keep

their traces short, direct, and wide. Connect their

ground pins at a single common node in a star-ground

configuration. The external voltage-feedback network

should be very close to the FB pin, within 0.2in (5mm).

Keep noisy traces (from the LX pin, for example) away

from the voltage-feedback network; also, keep them

separate, using grounded copper. Connect GND and

PGND at a single point, as close as possible to the

MAX1820/MAX1821. The MAX1820/MAX1821 evaluation kit manual illustrates an example PC board layout

and routing scheme.

UCSP Package Consideration

For general UCSP package information and PC layout

considerations, refer to the Maxim Application Note

(Wafer-Level Ultra-Chip-Board-Scale Package).

______________________UCSP Reliability

The chip-scale package (UCSP) represents a unique

packaging form factor that may not perform equally to a

packaged product through traditional mechanical reliability tests. UCSP reliability is integrally linked to the

user’s assembly methods, circuit board material, and

usage environment. The user should closely review

these areas when considering use of a UCSP package.

Performance through Operating Life Test and Moisture

Resistance remains uncompromised as it is primarily

determined by the wafer-fabrication process.

Mechanical stress performance is a greater consideration for a UCSP package. UCSPs are attached through

direct solder contact to the user’s PC board, foregoing

the inherent stress relief of a packaged-product lead

frame. Solder joint contact integrity must be considered. Information on Maxim’s qualification plan, test

data, and recommendations are detailed in the UCSP

application note, which can be found on Maxim’s website,

www.maxim-ic.com.

____________________Chip Information

TRANSISTOR COUNT: 2722

Table 2. Capacitor Selection

Table 3. Component Manufacturers

ESR

×+

1

2

׃ ×

()

OSC OUT

C

CAPACITOR

C

BATT

C

OUT

(MAX1820)

C

OUT

(MAX1821)

MANUFACTURER

Coilcraft 847-639-6400 www.coilcraft.com

Kemet 408-986-0424 www.kemet.com

Panasonic 847-468-5624 w w w .p anasoni c.com

Sumida 847-956-0666 www.sumida.com

Taiyo Yuden 408-573-4150 www.t-yuden.com

CAPACITOR

VALUE (µF)

4.7 to 10 <150 Ceramic

2.2 to 4.7 <50 Ceramic

4.7 to 10 <150 Ceramic

USA PHONE

NUMBER

ESR

(mΩ)

CAPACITOR

TYPE

WEBSITE

Page 16

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

16 ______________________________________________________________________________________

Typical Operating Circuits (continued)

1

2

3

4

5

10

9

8

7

6

SYNC

BATT

LXREF

( ) ARE FOR MAX1821 ONLY.

OUT (FB)

COMP

SKIP

MAX1820

MAX1821

µMAX

TOP VIEW

PGNDGND

SHDN

COMP OUT (FB)

SYNC

BATT LX

UCSP

TOP VIEW AFTER ASSEMBLED ON PC BOARD (BUMPS AT THE BOTTOM)

( ) ARE FOR MAX1821 ONLY.

A1 A3A2

B1

C1 C2 C3

A

B

C

1

2

3

GND

PGND

A4

B4

C4

4

REFSKIP

SHDN

Pin Configurations

Ordering Information (continued)

*UCSP reliability is integrally linked to the user’s assembly methods, circuit board material, and environment. Refer to the UCSP

Reliability Notice in the UCSP Reliability section for more information.

✕

4 UCSP AAC

✕

4 UCSP AAV

PART

MAX1821EBC*

MAX1821EUB

MAX1821XEBC*

MAX1821XEUB

SYNC

FREQ (MHz)

No Sync

No Sync

13

13

OUTPUT VOLTAGE TEMP RANGE PIN-PACKAGE UCSP MARK

Programmable -40°C to +85°C3

Programmable -40°C to +85°C 10 µMAX —

Programmable -40°C to +85°C3

Programmable -40°C to +85°C10 µMAX —

INPUT

2.6V TO

5.5V

BATT

SHDN

SYNC

REF

SKIP

LX

PGND

FB

MAX1821

COMP

GND

OUTPUT

1.25V TO 5.5V

Page 17

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

______________________________________________________________________________________ 17

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages.)

12L, USPC.EPS

Page 18

MAX1820/MAX1821

WCDMA Cellular Phone 600mA

Buck Regulators

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

18 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2002 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages.)

10LUMAX EPS

e

10

ÿ 0.50±0.1

0.6±0.1

1

0.6±0.1

TOP VIEW

4X S

H

BOTTOM VIEW

10

DIM

A1

A2 0.030 0.037 0.75 0.95

D1

D2

E1

E2

H

L

L1

1

b

e

S

α

INCHES

MAX

MIN

-A

0.043

0.006

0.002

0.116

0.120

0.114

0.118

0.116

0.120

0.114

0.118

0.187

0.0157

0.007

0.0035

c

0.199

0.0275

0.037 REF

0.0106

0.0197 BSC

0.0078

0.0196 REF

6∞

0∞ 0∞ 6∞

MILLIMETERS

MAX

MIN

-

1.10

0.15

0.05

3.05

2.95

2.89

3.00

2.95

3.05

2.89

3.00

4.75

5.05

0.40

0.70

0.940 REF

0.177

0.270

0.500 BSC

0.090

0.200

0.498 REF

D2

A2

b

D1

A

A1

GAGE PLANE

α

FRONT VIEW

E2

E1

SIDE VIEW

c

L

L1

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE, 10L uMAX/uSOP

REV.DOCUMENT CONTROL NO.APPROVAL

21-0061

1

I

1

Loading...

Loading...