Page 1

General Description

The MAX1817 is a compact, high-efficiency, dual-output step-up converter for portable devices that provides both the main logic supply and the LCD bias. The

device operates from an input voltage of +1.5V to

+5.5V, allowing the use of 2- or 3-cell alkaline batteries,

or 1-cell lithium-ion (Li+) batteries.

The MAX1817’s main regulator supplies 125mA at

either a preset 3.3V or an adjustable 2.5V to 5.5V output voltage with up to 88% efficiency. A 0.1µA shutdown state also minimizes battery drain. The

MAX1817’s secondary step-up converter provides the

LCD bias voltage and is adjustable up to +28V.

Other features include a fast switching frequency to

reduce the size of external components and a low quiescent current to maximize battery life. Both outputs can

be independently shut down for improved flexibility.

The MAX1817 is supplied in a compact 10-pin µMAX

package. The MAX1817 evaluation kit (MAX1817EVKIT)

is available to speed up design.

________________________Applications

Organizers/Translators

PDAs

MP3 Players

GPS Receivers

Features

♦ Dual Step-Up Converter in a Tiny 10-Pin µMAX

Package

♦ Main Output

Up to 125mA Load Current

Fixed 3.3V or Adjustable 2.5V to 5.5V

Up to 88% Efficiency

Internal Switch

♦ LCD Output

Up to 28V for LCD Bias

Internal Switch

♦ Input Voltage Range +1.5V to +5.5V

♦ Minimal External Components Required

♦ 0.1µA Logic-Controlled Shutdown

♦ Low 15µA Quiescent Supply Current

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

________________________________________________________________ Maxim Integrated Products 1

Pin Configuration

MAX1817

LX

ONLCD

ON

FB

OUT

FBLCDLCD ON/OFF

+1.5V

TO +5.5V

MAIN ON/OFF MAIN

LCD

AGND GND

LXLCD

Typical Operating Circuit

19-1794 Rev 0; 10/00

Ordering Information

For price, delivery, and to place orders, please contact Maxim Distribution at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

PART

MAX1817EUB -40°C to +85°C 10 µMAX

TEMP. RANGE

PIN-PACKAGE

TOP VIEW

ONLCD

1

FB

2

ON

MAX1817

3

4

5

MAX

µ

10

OUT

9

LX

8

GND

7

LXLCDFBLCD

N.C.AGND

6

Page 2

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

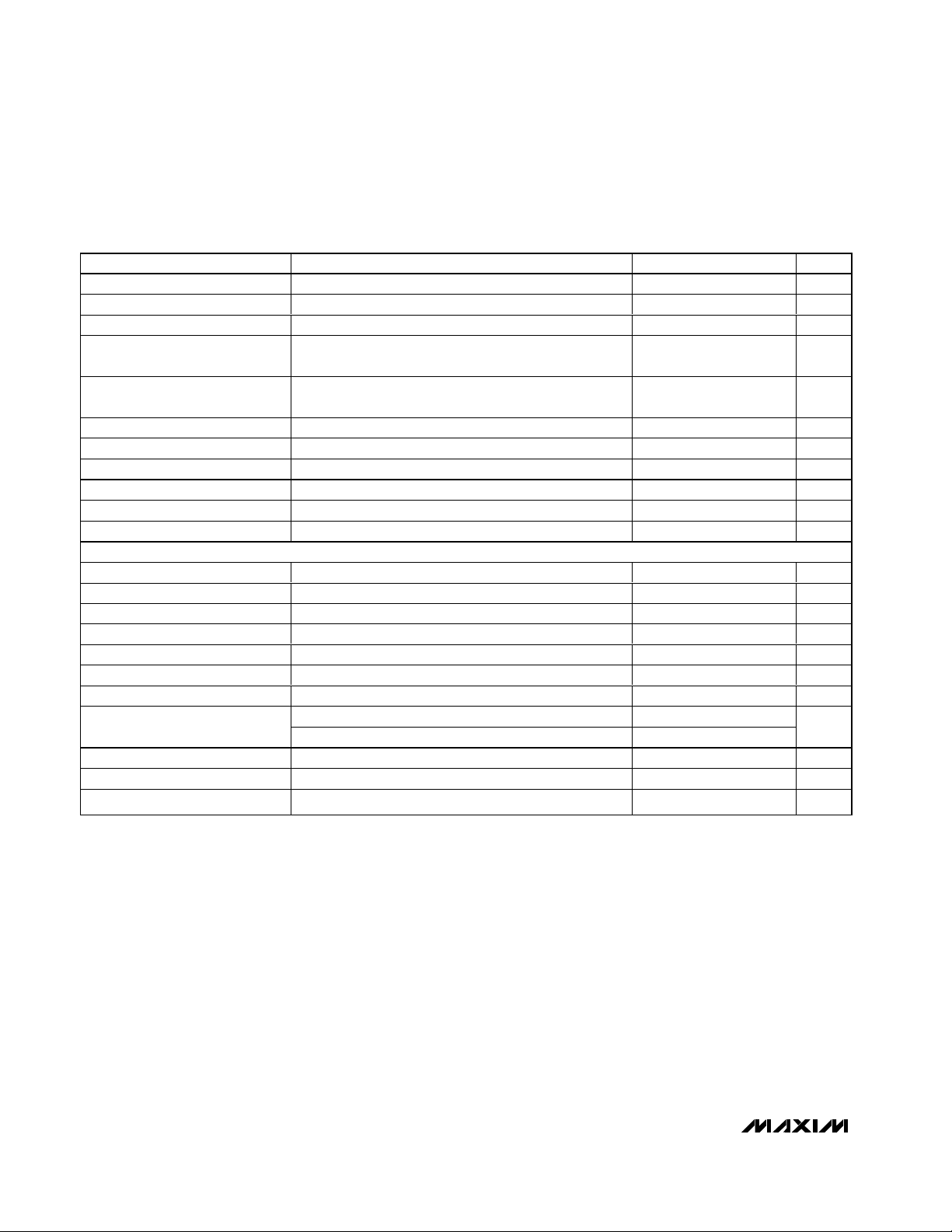

ELECTRICAL CHARACTERISTICS

(VON= V

ONLCD =VOUT

= +3.3V, FB = GND, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

OUT to GND .............................................................-0.3V to +6V

ON, ONLCD, FB, FBLCD, LX to GND ......-0.3V to (V

OUT

+ 0.3V)

LXLCD to GND .......................................................-0.3V to +30V

AGND to GND .......................................................-0.3V to +0.3V

Continuous Power Dissipation (T

A

= +70°C)

10-Pin µMAX (derate 5.6mW/°C above +70°C) ...........444mW

LXLCD, LX Maximum Current ........................................0.5A

RMS

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Dual Mode is a trademark of Maxim Integrated Products.

PARAMETER CONDITIONS MIN TYP MAX UNITS

GENERAL

Input Voltage Range 1.5 5.5 V

Startup Voltage

Quiescent Current from OUT

(Main Only)

Quiescent Current from OUT VFB = V

Shutdown Quiescent Current VON = V

MAIN OUTPUT

OUT Undervoltage Lockout

Fixed-Mode Output Voltage VFB ≤ 45mV 3.14 3.3 3.47 V

Adjustable-Mode FB Regulation

Voltage

FB Input Bias Current VFB = 1.35V 50 nA

FB Dual Mode

Output Voltage Adjustment

Range

Maximum LX On-Time VFB = 0.5V 2.4 5 7.5 µs

Zero Crossing Comparator

Threshold (V

Zero Crossing Comparator

Backup Timer

Line Regulation

Load Regulation

LX On-Resistance V

LX Current Limit 0.5 0.75 1.05 A

TM

LX

R

= 35Ω 1.5

LOAD

= ∞, VFB = 1.35V 1.2 1.55

R

LOAD

VFB = V

V

ONLCD

V

rising, VFB = 1.35V 2.2 2.4

OUT

falling, V

V

OUT

Threshold 45 75 105 mV

- V

)

OUT

= +0.5V 22 45 70 µs

V

FB

I

= 100mA,

OUT

= +2V to +3V

V

IN

V

= +2.5V,

IN

= 10mA to 100mA

I

LOAD

= 3.3V, ILX = 100mA 0.35 0.65 Ω

OUT

= 1.35V,

FBLCD

= 0

= 1.35V 15 30 µA

FBLCD

= 0 0.1 1 µA

ONLCD

= 1.35V 1.95 2.15

FB

510µA

1.20 1.25 1.30 V

2.5 5.5 V

02040mV

1.6 %

1.6 %

V

V

Page 3

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VON= V

ONLCD

= V

OUT

= +3.3V, FB = GND, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

ELECTRICAL CHARACTERISTICS

(VON= V

ONLCD

= V

OUT

= +3.3V, FB = GND, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

LX Leakage Current VON = GND, VLX = 5.5V 0.1 1 µA

ON Input Low Voltage 1.8V < V

ON Input High Voltage 1.8V < V

ON Input Bias Current 1µA

LCD OUTPUT

LXLCD Voltage 28 V

LXLCD On-Resistance V

LXLCD Current Limit 0.28 0.5 0.7 A

LXLCD Leakage Current V

FBLCD Regulation Voltage 1.20 1.25 1.30 V

FBLCD Input Bias Current V

LCD Line Regulation I

LCD Load Regulation I

Maximum LXLCD On-Time 4 9 14 µs

Minimum LXLCD Off-Time

ONLCD Input Low Voltage 2.5V < V

ONLCD Input High Voltage 2.5V < V

ONLCD Input Bias Current 1µA

PARAMETER CONDITIONS MIN TYP MAX UNITS

< 5.5V, VFB = 0.5V 400 mV

OUT

< 5.5V, VFB = 0.5V 1.6 V

OUT

= 3.3V, I

OUT

= 28V, V

LXLCD

= 1.35V 50 nA

FBLCD

= 5mA, VIN = +2V to +3V 0.1 %

LOAD

= 1mA to 5mA, VIN = +2.5V 0.5 %

LOAD

V

≥ 1.2V 0.5 1 1.5

FBLCD

V

≤ 0.7V 2.4 5 7.5

FBLCD

OUT

OUT

= 100mA 1.1 2.0 Ω

LXLCD

= 0 0.1 1 µA

ONLCD

< 5.5V 400 mV

< 5.5V 1.6 V

µs

GENERAL

Input Voltage Range 1.5 5.5 V

Startup Voltage R

Quiescent Current from OUT

(Main Only)

Quiescent Current from OUT VFB = V

Shutdown Quiescent Current VON = V

MAIN OUTPUT

OUT Undervoltage Lockout

Fixed-Mode Output Voltage VFB ≤ 45mV 3.14 3.47 V

Adjustable-Mode FB Regulation

Voltage

FB Input Bias Current VFB = 1.35V 50 nA

PARAMETER CONDITIONS MIN MAX UNITS

= ∞, VFB = 1.35V 1.7 V

LOAD

V

= V

FB

V

rising, VFB = 1.35V 2.4

OUT

falling, VFB = 1.35V 1.95

V

OUT

= 1.35V, V

FBLCD

= 1.35V 30 µA

FBLCD

= 0 1 µA

ONLCD

= 0 10 µA

ONLCD

1.20 1.30 V

V

Page 4

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VON= V

ONLCD

= V

OUT

= +3.3V, FB = GND, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

Note 1: Specifications to -40°C are guaranteed by design and not production tested.

FB Dual Mode Threshold 45 105 mV

Outp ut V ol tag e Ad j ustm ent Rang e 2.5 5.5 V

Maximum LX On-Time VFB = 0.5V 2.4 7.5 µs

Zero Crossing Comparator

Threshold (V

Zero Crossing Comparator

Backup Timer

LX On-Resistance V

LX Current Limit 0.42 1.05 A

LX Leakage Current VON = GND, VLX = 5.5V 1 µA

ON Input Low Voltage 1.8V < V

ON Input High Voltage 1.8V < V

ON Input Bias Current 1µA

LCD OUTPUT

LXLCD Voltage 28 V

LXLCD On-Resistance V

LXLCD Current Limit 0.25 0.7 A

LXLCD Leakage Current V

FBLCD Regulation Voltage 1.20 1.30 V

FBLCD Input Bias Current V

Maximum LXLCD On-Time 4 14 µs

Minimum LXLCD Off-Time

ONLCD Input Low Voltage 2.5V < V

ONLCD Input High Voltage 2.5V < V

ONLCD Input Bias Current 1µA

PARAMETER CONDITIONS MIN MAX UNITS

LX

- V

)

OUT

V

= 0.5V 22 70 µs

FB

= 3.3V, ILX = 100mA 0.65 Ω

OUT

< 5.5V, VFB = 0.5V 400 mV

OUT

< 5.5V, VFB = 0.5V 1.6 V

OUT

= 3.3V, I

OUT

= 28V, V

LXLCD

= 1.35V 70 nA

FBLCD

V

≥ 1.2V 0.5 1.5

FBLCD

V

≤ 0.7V 2.2 7.5

FBLCD

OUT

OUT

= 100mA 2 Ω

LXLCD

= 0 1 µA

ONLCD

< 5.5V 400 mV

< 5.5V 1.6 V

040mV

µs

Page 5

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

_______________________________________________________________________________________ 5

Typical Operating Characteristics

(Circuit of Figure 3, TA = +25°C, unless otherwise noted.)

MAIN OUTPUT EFFICIENCY

vs. LOAD CURRENT

MAX1817-01

75

70

65

60

55

50

45

EFFICIENCY (%)

40

35

30

25

0.01 0.1 1 10 100

95

A: VIN = 3.3V,

90

= 5V

V

OUT

85

80

EFFICIENCY (%)

75

70

0.1 10

B: VIN = 2.4V,

= 5V

V

OUT

C: VIN = 2.4V,

= 3.3V

V

OUT

E: VIN = 1.8V,

V

OUT

CIRCUIT OF FIGURE 2

1

LOAD CURRENT (mA)

D: VIN = 1.8V,

V

OUT

= 3.3V

100 1000

= 5V

NO-LOAD SUPPLY CURRENT

vs. INPUT VOLTAGE (LCD OFF)

18

16

14

12

10

8

6

SUPPLY CURRENT (µA)

4

2

0

1.0 2.01.5 2.5 3.0 3.5 4.0

INPUT VOLTAGE (V)

MAIN CONVERTER

SWITCHING WAVEFORM

MAX1817-06

LCD OUTPUT EFFICIENCY

vs. LOAD CURRENT

A: VIN = +2.4V, V

= +2.4V, V

B: V

IN

C: V

= +2.4V, V

IN

= +1.8V, V

D: V

IN

= +1.8V, V

E: V

IN

= +1.8V, V

F: V

IN

LOAD CURRENT (mA)

MAX1817 toc04

C

E

F

= 12V

LCD

= 18V

LCD

= 24V

LCD

= 12V

LCD

= 18V

LCD

= 24V

LCD

V

= 3.3V,

OUT

NO LOAD

STARTUP VOLTAGE vs. LOAD CURRENT

160

A

B

MAX1817-02

D

RESISTIVE LOAD

140

LCD OFF

120

100

80

60

LOAD CURRENT (mA)

40

20

0

1.0 1.21.1 1.3 1.4 1.5 1.6 1.7

STARTUP VOLTAGE (V)

NO-LOAD SUPPLY CURRENT

vs. INPUT VOLTAGE

450

400

350

300

250

200

150

SUPPLY CURRENT (µA)

100

50

0

021 3456

INPUT VOLTAGE (V)

V

OUT

= 18V, NO LOAD

V

LCD

R1 = 1MΩ, R2 = 75k

LCD CONVERTER

SWITCHING WAVEFORM

= 3.3V

MAX1817-07

MAX1817 toc03

MAX1817-05

Ω

A

B

C

0

0

A: ILX, 500mA/div

, 50mV/div, AC-COUPLED

B: V

OUT

, 5V/div

C: V

LX

V

= 2.4V, V

IN

OUT

= 3.3V, I

10µs/div

LOAD,OUT

= 50mA, V

ONLCD

= 0

A

0

B

C

0

A: I

, 500mA/div

LXLCD

, 100mV/div, AC-COUPLED

B: V

LCD

C: V

LXLCD

= 2.4V, V

V

IN

= 18V, I

V

LCD

, 10V/div

OUT

LOAD,LCD

4µs/div

= 3.3V, I

= 5mA

LOAD,OUT

= 0,

Page 6

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 3, TA= +25°C, unless otherwise specified)

400µs/div

MAIN LOAD TRANSIENT RESPONSE

MAX1817-08

A: V

OUT

, 100mV/div, AC-COUPLED

B: I

LOAD, OUT

, 50mA/div

V

IN

= 2.4V, V

OUT

= 3.3V

A

B

0

200µs/div

LCD LOAD TRANSIENT RESPONSE

MAX1817-09

A: V

LCD

, 50mV/div, AC-COUPLED

B: I

LOAD, OUT

, 10mA/div

V

IN

= 2.4V, V

OUT

= 3.3V (NO LOAD), V

LCD

= 18V

A

B

0

400µs/div

MAIN LINE TRANSIENT RESPONSE

MAX1817-10

A: V

OUT,

100mV/div, AC-COUPLED

B: V

IN,

1V/div

V

OUT

= 3.3V, I

LOAD,MAIN

= 20mA, V

ONLCD

= 0

A

B

2.4V

1.8V

200µs/div

LCD LINE TRANSIENT RESPONSE

MAX1817-11

A: V

LCD

, 100mV/div, AC-COUPLED

B: V

IN,

1V/div

V

OUT

= 3.3V (NO LOAD), V

LCD

= 18V, I

LOAD,LCD

= 2mA

A

B

2.4V

1.8V

100µs/div

MAIN OUTPUT TURN-ON/TURN-OFF

RESPONSE

MAX1817-12

A: V

OUT

, 2V/div

B: I

IN,

500mA/div

C: V

ON

, 5V/div

V

IN

= 2.4V, R

LOAD,MAIN

= 165Ω, V

ONLCD

= 0

A

B

0

0

0

C

400µs/div

LCD OUTPUT TURN-ON/TURN-OFF

RESPONSE

MAX1817-13

A: V

LCD

, 10V/div

B: I

IN,

200mA/div

C: V

ONLCD

, 5V/div

V

= 2.4V, V

= 3.3V (NO LOAD), R

= 9kΩ

A

B

0

0

0

C

Page 7

________________Detailed Description

The MAX1817 dual step-up converter is designed to

supply the main power and LCD bias for low-power,

hand-held devices. The MAX1817’s main step-up converter includes a 0.35Ω N-channel power MOSFET

switch and provides a fixed 3.3V or adjustable 2.5V to

5.5V output at up to 125mA from an input as low as

1.5V. The MAX1817’s LCD bias step-up converter

includes a high-voltage 1.1Ω power MOSFET switch to

support as much as 5mA at 28V (Figure 1). During

startup, the MAX1817 extends the LCD MOSFET switch

minimum off-time, limiting surge current. Both converters require an inductor and external rectifier.

The MAX1817 runs in bootstrap mode, powering the IC

from the main step-up converter’s output. Independent

logic-controlled shutdown for the main and LCD stepup converters reduces quiescent current to 0.1µA.

Main Step-Up Converter

The MAX1817 main step-up converter runs from a

+1.5V to +5.5V input voltage and produces a fixed 3.3V

or adjustable 2.5V to 5.5V output voltage as well as

biasing the internal control circuitry. The MAX1817

switches only as often as is required to supply sufficient

power to the load. This allows the converter to operate

at lower frequencies at light loads, improving efficiency.

The control scheme maintains regulation when the error

amplifier senses the output voltage is below the feedback threshold, turning on the internal N-channel MOSFET and initiating an on-time. The on-time is terminated

when the 0.75A current limit is reached or when the

maximum on-time is reached. The N-channel MOSFET

remains off until the inductor current drops to 0, forcing

discontinuous inductor current. At the end of a cycle,

the error comparator waits for the voltage at FB to drop

below the regulation threshold, at which time another

cycle is initiated.

The main step-up converter uses a startup oscillator to

allow it to start from an input voltage as low as +1.2V.

This is necessary since the control circuitry is powered

from the step-up converter output (OUT). When the

voltage at OUT is below the OUT undervoltage lockout,

a fixed 50% duty cycle drives the internal N-channel

MOSFET, forcing the main output voltage to rise. Once

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

_______________________________________________________________________________________ 7

Pin Description

PIN NAME FUNCTION

Main Output Feedback Input. Connect FB to GND for fixed 3.3V main output. For other output

1FB

2ON

3 ONLCD

4 FBLCD

5 AGND Analog Ground. Connect AGND to GND as close to the IC as possible.

6 N.C. No Connection. Not internally connected.

7 LXLCD

8 GND Power Ground. Connect GND to AGND as close to the IC as possible.

9LX

10 OUT

voltages, use a resistive voltage-divider to set the output voltage. The feedback regulation voltage

is 1.25V at FB.

Main Step-Up Converter On/Off Control. Connect ON to OUT for automatic startup. Connect ON to

GND to put the IC into shutdown mode.

LCD Output On/Off Control. Connect ONLCD to OUT to enable the LCD output. Connect ONLCD

to GND to disable the LCD output. The main output must be ≥2.4V to enable the LCD output.

LCD Output Feedback Input. Use a resistive voltage-divider from the LCD output to FBLCD to set

the voltage. The feedback regulation voltage is 1.25V at FBLCD.

LCD Output Switching Node. Drain of the internal N-channel MOSFET that drives the LCD output.

Connect an external inductor and rectifier to LXLCD.

Main Output Switching Node. Drain of the internal N-channel MOSFET that drives the main output.

Connect an external inductor and rectifier to LX.

Main Step-Up Converter Output. OUT is used to measure the output voltage in fixed mode (FB =

GND) and is the internal bias supply input to the IC. When shut down (ON = ONLCD = GND), OUT

is high impedance, drawing 1µA (max).

Page 8

MAX1817

the output voltage rises above the undervoltage threshold, the control circuitry is enabled, allowing proper

regulation of the output voltage.

LCD Step-Up Converter

The MAX1817’s LCD step-up converter generates an

LCD bias voltage up to 28V by use of a 500mA, 1.1Ω

internal N-channel switching MOSFET (Figure 1). The

LCD step-up converter control circuitry is powered from

the main step-up converter output (OUT), so the voltage

at OUT must be above the OUT undervoltage lockout

voltage for the LCD step-up converter to operate.

During startup, the MAX1817 extends the minimum offtime to 5µs for V

FBLCD

voltages <0.9V, limiting initial

surge current. The LCD step-up converter features an

independent shutdown control, ONLCD.

The LCD step-up converter features a minimum-offtime, current-limited control scheme. A pair of oneshots that set a minimum off-time and a maximum ontime governs the duty cycle. The switching frequency

can be up to 500kHz and depends upon the load, and

input and output voltages.

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

8 _______________________________________________________________________________________

Figure 1. MAX1817 Simplified Functional Diagram

V

IN

FB

ON

ON

ON

OFF

ONLCD

OFF

75mV

SHUTDOWN

LOGIC

MAIN

SHUTDOWN

LOGIC

LCD

MAX1817

DUAL-MODE FEEDBACK

UNDERVOLTAGE

LOCKOUT

1.25V

1.25V

AGND

AGND

ERROR

COMPARATOR

MAIN

AGND

STARTUP

BIAS

LCD

ERROR

COMPARATOR

LCD

GND

ZEROCROSSING

DETECTOR

CONTROL

LOGIC

MAIN

CURRENT

LIMIT

MAIN

CONTROL

LOGIC

LCD

CURRENT

LIMIT

LCD

GND

GND

OUT

LXLCD

FBLCD

LX

MAIN

LCD

Page 9

Low-Voltage Startup

The MAX1817’s internal circuitry is powered from OUT.

The main step-up converter has a low-voltage startup

circuit to control main DC-DC converter operation until

V

OUT

exceeds the 2.2V (typ) undervoltage lockout

threshold. The minimum startup voltage is a function of

load current (see Typical Operating Characteristics).

The MAX1817 main converter typically starts up into a

35Ω load with input voltages down to +1.5V, allowing

startup with two alkaline cells even in deep discharge.

Shutdown: ON and ONLCD

The MAX1817 features independent shutdown control

of the main and LCD step-up converters. With both

converters shut down, supply current is reduced to

0.1µA. A logic low at ON shuts down the main step-up

converter, and LX enters a high-impedance state.

However, the main output remains connected to the

input through the inductor and output rectifier, holding

V

OUT

to one diode drop below the input voltage when

the main converter is shut down. If the input voltage is

sufficiently high to drive V

OUT

above the undervoltage

lockout voltage, the LCD step-up converter operates.

A logic low at ONLCD shuts down the LCD step-up

converter, and LXLCD enters a high-impedance state.

The LCD output remains connected to the input

through the inductor and output rectifier, holding it to

one diode drop below the input.

___________________Design Procedure

Setting the Main Output Voltage

The main step-up converter feedback input (FB) features Dual Mode operation. With FB grounded, the

main output voltage is preset to 3.3V. It can also be

adjusted from 2.5V to 5.5V with external resistors R3

and R4 as shown in Figure 2. To set the output voltage

externally, select resistor R4 from 10kΩ to 100kΩ.

Calculate R3 using:

R3 = R4 [(V

OUT

/ VFB) – 1]

where V

FB

= 1.25V, and V

OUT

can range from 2.5V to

5.5V.

Setting the LCD Output Voltage

Set the LCD output voltage with two external resistors

R1 and R2 as shown in Figure 3. Since the input leakage current at FBLCD has a maximum of 50nA, large

resistors can be used without significant accuracy loss.

Begin by selecting R2 in the 10kΩ to 100kΩ range, and

calculate R1 using the following equation:

R1 = R2 [(V

LCD

/ V

FBLCD

) – 1]

where V

FBLCD

= 1.25V, and V

LCD

can range from V

IN

to 28V.

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

_______________________________________________________________________________________ 9

Figure 2. Setting Main Output Voltage Using External Resistors Figure 3. Typical Application Circuit

OFF

OFF

LCD

MAIN

ON

ON

C1

10µF

L2

10µH

LX

ONLCD

MAX1817

ON

AGND GND

L1

10µH

LXLCD

FBLCD

OUT

V

IN

D1

D2

4.7pF

C4

R3

300k

FB

R4

100k

C3

22µF

R1

1M

R2 75k

MAIN 5V

C2

1µF

LCD

18V

OFF

OFF

MAIN

V

IN

LCD

C1

10µF

ON

ONLCD

ON

ON

AGND GND

L2

10µH

LX

MAX1817

L1

10µH

D2

LXLCD

FBLCD

OUT

FB

D1

LCD 18V

C2

4.7pF

C4

C3

22µF

R1

1M

R2 75k

MAIN 3.3V

1µF

Page 10

MAX1817

Using a Charge Pump to Make Negative

LCD Output Voltage

The MAX1817 can generate a negative LCD output by

adding a diode-capacitor charge-pump circuit (D3, D4,

and C6) to the LXLCD pin as shown in Figure 4. FBLCD

is driven through a resistive voltage-divider from the

positive output, which is not loaded, allowing a very

small capacitor value at C2. For best stability and lowest ripple, the time constant of the R1 + R2 series combination and C2 should be near that of C5 and the

effective load resistance. Output load regulation of the

negative output degrades compared to the standard

positive output circuit and may rise at very light loads. If

this is not acceptable, reduce the resistance of R1 and

R2, while maintaining their ratio, to effectively preload

the output with a few hundred µA. This is why the R1

and R2 values shown in Figure 4 are lower than typical

values for a positive-output design. When loaded, the

magnitude of the negative output voltage is slightly

lower (closer to ground by approximately a diode forward voltage) than the voltage on C2.

Applications Information

Inductor Selection

The MAX1817’s high switching frequency allows the

use of small surface-mount inductors. The 10µH values

shown in Figure 3 are recommended for most applications, although values between 4.7µH and 47µH are

suitable. Smaller inductance values typically offer a

smaller physical size for a given series resistance,

allowing the smallest overall circuit dimensions. Larger

inductance values exhibit higher output current capability, but larger physical dimensions.

Circuits using larger inductance values may start up at

lower input voltages and exhibit less ripple, but they

may provide reduced output power. This occurs when

the inductance is sufficiently large to prevent the maximum current limit from being reached before the maximum on-time expires. The inductor’s saturation current

rating should be greater than the peak switching current. However, it is generally acceptable to bias most

inductors into saturation by as much as 20%, although

this may slightly reduce efficiency.

For best efficiency, select inductors with resistance no

greater than the internal N-channel FET resistance in

each step-up converter.

For maximum output current, choose L such that:

L < [(V

IN

✕

tON) / I

PEAK

]

where tONis the maximum switch on-time (5µs for main

step-up converter) or 9µs for LCD step-up converter)

and I

PEAK

is the switch peak current limit (0.75A for the

main step-up converter, or 0.5A for the LCD step-up

converter). With this inductor value, the maximum output

current the main converter is able to deliver is given by:

I

OUT(MAX)

= 0.5 ✕I

PEAK

/ (1 + tON/ t

OFF

)

where tON/ t

OFF

= (V

OUT

+ VD- VIN) / (VIN- VON), V

IN

and V

OUT

are the input and output voltages, VDis the

Schottky diode drop (0.3V typ), and VON= I

PEAK

✕

RON, where RONis the switch on-resistance.

For V

IN

= 1.5V and V

OUT

= 3.3V, with a minimum I

PEAK

value of 0.5A, and V

ON(MAX)

given by (0.5) ✕ (0.65) =

0.325V, the available output current that the converter

can provide is at least 90mA.

For larger inductor values, I

PEAK

is determined by:

I

PEAK

= [(V

IN

✕

tON) / L]

External Rectifiers

The high maximum switching frequency of the

MAX1817 requires a high-speed rectifier. Schottky

diodes such as the Motorola MBR0530 or the Nihon

EP05Q03L are recommended. To maintain high efficiency, the average current rating of the Schottky diode

should be greater than the peak switching current. A

junction diode such as the Central Semiconductor

CMPD4448 can be used for the LCD output with little

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

10 ______________________________________________________________________________________

Figure 4. Negative Voltage for LCD Bias

C6

R3

L1,10µH

V

IN

C1

10µF

LX

L2

10µH

LXLCD

MAX1817

ONLCD

FBLCD

ON

AGND GND

OUT

FB

D2

0.1µF

1

D1**

C3

22µF

MAIN

C4

10pF

16.5k

R1

240k

*D3, D4 = CENTRAL SEMICONDUCTOR

CMPD7000 DUAL

**D1 = CENTRAL SEMICONDUCTOR

CMSD4448 (1N4148)

D4*

D3*

-19V

V

C5

1µF

LCD

C2

0.1µF

R2

Page 11

loss in efficiency. Choose a reverse breakdown voltage

greater than the output voltage.

Input Bypass Capacitor

The input supplies high currents to the inductors and

requires local bulk bypassing close to the inductors. A

low equivalent series resistance (ESR) input capacitor

connected in parallel with the battery will reduce peak

battery currents and input-reflected noise. Battery

bypassing is especially helpful at low input voltages

and with high-impedance batteries (such as alkaline

types). Benefits include improved efficiency and lower

useful end-of-life voltage for the battery. A single 10µF

low-ESR surface-mount capacitor is sufficient for most

applications.

Output Bypass Capacitors

For most applications, use a small surface-mount 22µF

or greater ceramic capacitor on the main converter output, and a 1µF or greater ceramic capacitor on the LCD

output. For small ceramic capacitors, the output ripple

voltage is dominated by the capacitance value. If tantalum or electrolytic capacitors are used, the ESR of the

capacitors dominates the output ripple voltage.

Decreasing the ESR reduces the output ripple voltage

and the peak-to-peak transient voltage.

LCD Compensation

The MAX1817’s LCD step-up converter feedback

requires a small 4.7pF feed-forward capacitor for the

typical application circuit. Circuits with adjustable V

OUT

(main converter) from 2.5V to 5.5V may require a larger

value LCD feed-forward capacitor to prevent multipulsing of the LCD converter. Larger feed-forward capacitors slightly degrade load regulation, so choose the

smallest value capacitor that provides stability.

Layout Considerations

The MAX1817’s high-frequency operation makes PC

board layout important for optimal performance. Use

separate analog and power ground planes. Connect

the two planes together at a single point as close as

possible to the IC. Use surface-mount components

where possible. If leaded components are used, minimize lead lengths to reduce stray capacitance and

keep the components close to the IC to minimize trace

resistance. Where an external voltage-divider is used to

set output voltage, the traces from FB or FBLCD to the

feedback resistors should be extremely short (less than

0.2in or 5mm) to minimize coupling from LX and

LXLCD. Refer to the MAX1817 evaluation kit for a full

PC board example.

____________________Chip Information

TRANSISTOR COUNT: 2785

PROCESS: BiCMOS

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

______________________________________________________________________________________ 11

Page 12

MAX1817

Compact, High-Efficiency, Dual-Output

Step-Up DC-DC Converter

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

10LUMAX.EPS

Loading...

Loading...