Page 1

General Description

The MAX1813 step-down controller is intended for core

CPU DC-DC converters in notebook computers. The

controller features a dynamically adjustable output (5bit DAC), ultra-fast transient response, high DC accuracy, and high efficiency necessary for leading-edge

CPU core power supplies. Maxim’s proprietary QuickPWM™ quick-response, constant-on-time PWM control

scheme handles wide input/output voltage ratios with

ease and provides 100ns “instant-on” response to load

transients while maintaining a relatively constant switching frequency.

The MAX1813 is designed specifically for CPU core

applications requiring a voltage-positioned supply. The

voltage-positioning input (VPCS), combined with a

high-DC-accuracy control loop, is used to implement a

power supply that modifies its output set point in

response to the load current. This arrangement

decreases full-load power dissipation and reduces the

required number of output capacitors.

The output voltage can be dynamically adjusted

through the 5-bit digital-to-analog converter (DAC)

inputs over a 0.600V to 2V range. The MAX1813

includes an internal multiplexer that selects between

three different DAC code settings. The first two inputs

are controlled by five digital input pins (D0–D4). The

third input is used for the suspend mode and controlled

by two 4-level input pins (S0, S1). Output voltage transitions are accomplished with a proprietary precision

slew-rate control that minimizes surge currents to and

from the battery while guaranteeing “just-in-time” arrival

at the new DAC setting.

The MAX1813’s 28V input range enables single-stage

buck conversion from high-voltage batteries for the

maximum possible efficiency. Alternatively, the controller’s high-frequency capability combined with twostage conversion (stepping down the +5V system

supply instead of the battery) allows the smallest possible physical size.

The MAX1813 is available in a 28-pin QSOP package.

Applications

Notebook Computers

(Intel IMVP–II™/Coppermine™)

Docking Stations

CPU Core Supply

Single-Stage (BATT to V

CORE

) Converters

Two-Stage (+5V to V

CORE

) Converters

Features

♦ High-Efficiency Voltage Positioning

♦ Quick-PWM Architecture

♦ ±1% V

OUT

Accuracy Over Line

♦ Adjustable Output Slew Rate

♦ 0.600V to 2V Adjustable Output Range (5-Bit DAC)

♦ 2V to 28V Battery Input Range

♦ 200/300/600/1000kHz Switching Frequency

♦ Output Undervoltage and Overvoltage Protection

♦ Drives Large Synchronous-Rectifier MOSFETs

♦ ±20% Accurate Current-Limit

♦ 10µA Shutdown Supply Current

♦ 2V ±1% Reference Output

♦ Power-Good (PGOOD) Indicator

♦ Small 28-Pin QSOP Package

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-2010; Rev 0; 4/01

For price, delivery, and to place orders, please contact Maxim Distribution at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Quick-PWM is a trademark of Maxim Integrated Products, Inc.

Coppermine and IMVP-

ΙΙ

are trademarks of Intel Corp.

Typical Operating Circuit appears at end of data sheet.

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DH

LX

BST

D0

D1

D2

PGND

D3

D4

CODE

ZMODE

SUS

V

DD

DL

GND

PGOOD

ILIM

REF

TON

V

CC

S1

S0

CC

FB

TIME

SKP/SDN

VPCS

V+

QSOP

TOP VIEW

MAX1813

Pin Configuration

PART TEMP. RANGE PIN-PACKAGE

MAX1813EEI -40°C to +85°C 28 QSOP

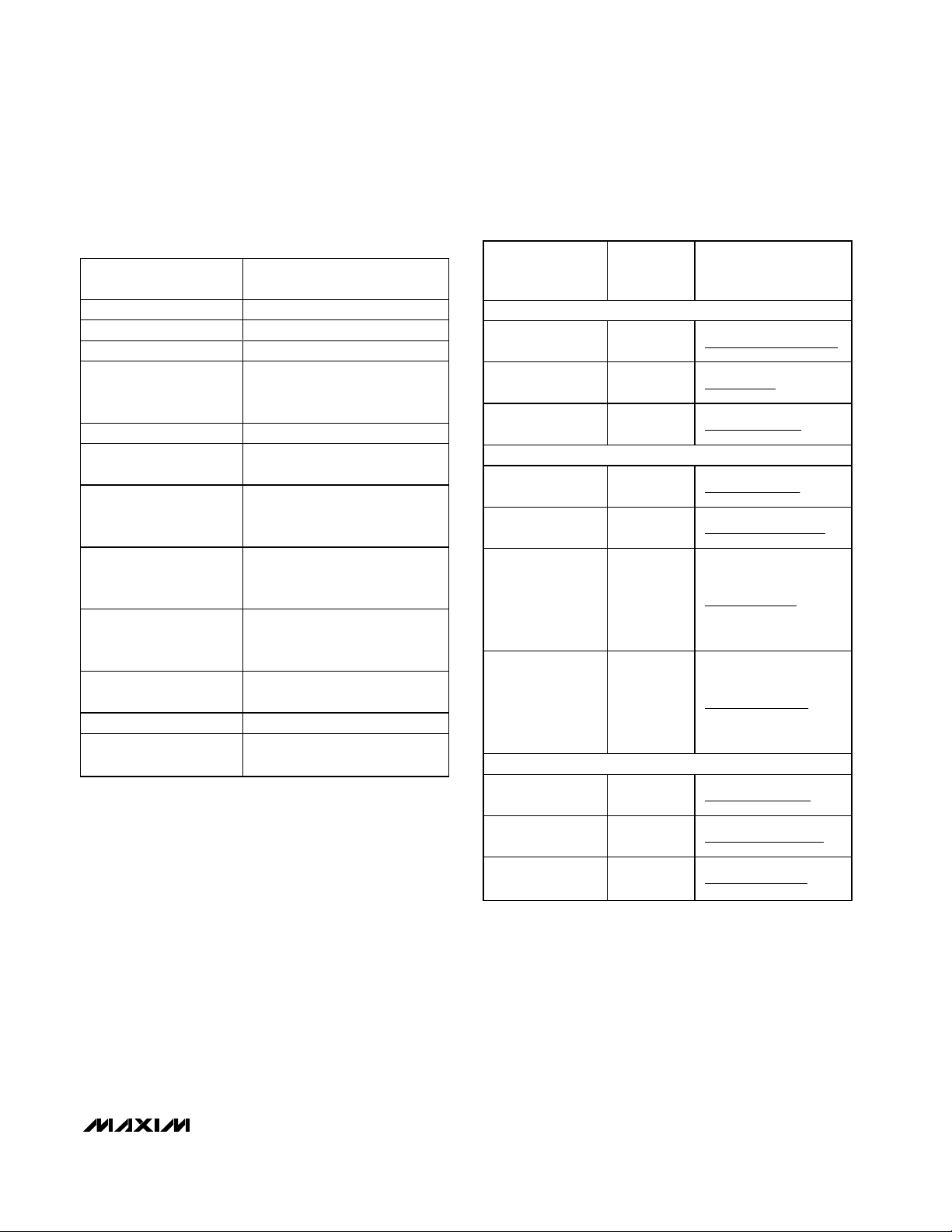

Page 2

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V+ = +15V, VCC= VDD= 5V, VPCS = ZMODE = GND = PGND, SKP/SDN = CODE = VCC, V

OUT

set to 1.5V,

T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: SKP/SDN may be forced to 12V, temporarily exceeding the absolute maximum rating, for the purpose of debugging proto-

type breadboards, using the no-fault test mode.

V+ to GND ..............................................................-0.3V to +30V

V

CC

, VDDto GND .....................................................-0.3V to +6V

PGND to GND.....................................................................±0.3V

D0–D4, CODE, ZMODE, SUS, PGOOD to GND ......-0.3V to +6V

SKP/SDN to GND (Note 1) .....................................-0.3V to +16V

ILIM, FB, CC, REF,

TON, TIME, S0, S1 to GND......................-0.3V to (V

CC

+ 0.3V)

VPCS to GND ............................................................-2V to +30V

DL to PGND................................................-0.3V to (VDD+ 0.3V)

BST to PGND..........................................................-0.3V to +36V

DH to LX....................................................-0.3V to (V

BST

+ 0.3V)

LX to BST..................................................................-6V to +0.3V

REF Short Circuit to GND ...........................................Continuous

Continuous Power Dissipation (TA= +70°C)

28-Pin QSOP (derate 10.8mW/°C above +70°C)..........860mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

)

PWM CONTROLLER

Input Voltage Range

DC Output Voltage Accuracy

(Notes 2, 3)

VPCS Input Bias Current I

VPCS Transconductance G

VPCS Linear Input Range ±100 mV

FB Input Resistance R

TIME Frequency Accuracy

ILIM Input Leakage Current I

On-Time (Note 4) t

Minimum Off-Time (Note 4) t

BIAS AND REFERENCE

Quiescent Supply Current (VCC)I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Battery voltage, V+ 2 28

V

VPS

m

FB

ILIM

ON

OFF(MIN

CC

, V

CC

DD

V+ = 4.5V to 28V, VPCS = GND, DAC

codes from 0.925V to 2.0V

V+ = 4.5V to 28V, VPCS = GND, DAC

codes from 0.700V to 0.900V

V+ = 4.5V to 28V, VPCS = GND, DAC

codes from 0.600V to 0.675V

V

= 0 or 28V -1 +1 µA

VPCS

V

= 0 to -100mV 18 20 22 µS

VPCS

38kHz nominal, R

150kHz nominal, R

380kHz nominal, R

V

= 0 or 5.0V 0.01 100 nA

ILIM

V+ = 5.0V, VFB = 1.2V TON = GND 250 270 290

V+ = 12V, VFB = 1.2V

TON = REF, open, or V

TON = GND 300 375

Measured at VCC, FB forced above the

regulation point

= 470kΩ -12 +12

TIME

= 120kΩ -8 +8

TIME

= 47kΩ -12 +12

TIME

TON = REF 165 190 215

TON = open 320 355 390

TON = V

CC

CC

4.5 5.5

-1 +1

-1.5 +1.5

-1.83 +1.83

115 180 265 kΩ

465 515 563

400 500

1.4 2.5 mA

V

%

%

ns

ns

Page 3

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V+ = +15V, VCC= VDD= 5V, VPCS = ZMODE = GND = PGND, SKP/SDN = CODE = VCC, V

OUT

set to 1.5V,

T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Quiescent Supply Current (VDD)I

Quiescent Supply Current (V+) I+ Measured at V+ 25 40 µA

Shutdown Supply Current (VCC) SKP/SDN = GND 2 5 µA

Shutdown Supply Current (VDD) SKP/ SDN = GND <1 5 µA

Shutdown Supply Current (V+) SKP/SDN = GND, VCC = VDD = 0 or 5V <1 5 µA

Reference Voltage V

REF Fault Lockout Voltage Falling edge, 1% hysteresis 1.5 1.6 1.7 V

FAULT PROTECTION

Output Overvoltage Fault Preset

Threshold

Output Overvoltage Fault

Propagation Delay

Output Undervoltage Fault

Threshold

Output Undervoltage Fault

Propagation Delay

Output Undervoltage FaultBlanking Time

Current-Limit Threshold (Positive,

Default)

Current-Limit Threshold

(Positive, Adjustable)

Negative Current-Limit Threshold

Zero-Crossing Current-Limit

Threshold

Thermal Shutdown Threshold Rising temperature, hysteresis = 15°C 160 °C

VCC Undervoltage Lockout

Threshold

PGOOD Lower Trip Threshold

PGOOD Upper Trip Threshold

PGOOD Propagation Delay

PGOOD Output Low Voltage I

PGOOD Leakage Current High state, forced to 5.5V 1 µA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

t

V

V

DD

REF

OVP

OVP

ITH

ITH

Measured at VDD, FB forced above the

regulation point

VCC = 4.5V to 5.5V, -40µA ≤ I

Measured at FB

FB forced to 2% above trip threshold 1.5 µs

With respect to unloaded output voltage 60 70 80 %

FB forced to 2% below trip threshold 10 µs

From SKP/SDN signal going high, clock

speed set by R

V

- V

GND

V

- V

GND

V

- V

GND

V

CC

- V

V

GND

Rising edge, hysteresis = 20mV, switching

disabled below this level

Measured at FB with respect to unloaded

output voltage, falling edge

Measured at FB with respect to unloaded

output voltage, rising edge

Falling edge, FB forced 2% below or

above PGOOD trip threshold

= 1mA 0.4 V

SINK

TIME

, ILIM = V

VPCS

VPCS

, with respect to V

VPCS

VPCS

CC

≤ +40µA 1.98 2 2.02 V

REF

CODE = GND 2.20 2.25 2.30

CODE = V

CC

V

= 0.5V 40 50 60

ILIM

V

= 2V (REF) 143 200 265

ILIM

, ILIM =

ITH

1.95 2.00 2.05

40 50 60 mV

-72 -56 -40 mV

4.05 4.45 V

-15 -12.5 -10.5 %

81012%

<1 5 µA

256 clks

5mV

1.5 µs

V

mV

Page 4

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V+ = +15V, VCC= VDD= 5V, VPCS = ZMODE = GND = PGND, SKP/SDN = CODE = VCC, V

OUT

set to 1.5V,

T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

)

GATE DRIVERS

DH Gate Driver On-Resistance R

DL Gate Driver On-Resistance R

DH Gate Driver Source/Sink

Current

DL Gate Driver Sink Current I

DL Gate Driver Source Current I

Dead Time

LOGIC AND I/O

Logic Input High Voltage V

Logic Input Low Voltage V

DAC Z-Mode Programming

Resistor, Low

DAC Z-Mode Programming

Resistor, High

D0−D4, CODE Pull Up/Down

Logic Input Current

4-Level Logic Input High (VCC) TON (200kHz operation), S0, S1

4-Level Logic Input UpperMiddle (Float)

4-Level Logic Input LowerMiddle (REF)

4-Level Logic Low (GND) TON (1000kHz operation), S0, S1 0.5 V

SKP/SDN High Input Level

(Skip Mode)

SKP/SDN Float Input Level

(Forced-PWM Mode)

SKP/SDN Low Input Level

(Shutdown Mode)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ON (D H ) VBST

ON(DL

I

DH

DL

DL

IH

IL

- VLX forced to 5V 1.2 3.5 Ω

High state (pull up) 1.3 3.5

Low state (pull down) 0.4 1.0

DH forced to 2.5V, V

DL forced to 5V 4.0 A

DL forced to 2.5V 1.3 A

DL rising 35

DH rising 26

D0−D4, CODE, SUS, ZMODE; VCC = 4.5V

to 5.5V

D0−D4, CODE, SUS, ZMODE; VCC = 4.5V

to 5.5V

D0−D4, 0 to 0.4V or 2.6V to 5.5V applied to

the resistor, ZMODE = CODE = GND or

ZMODE = CODE = V

D0−D4, 0 to 0.4V or 2.6V to 5.5V applied to

the resistor, ZMODE = CODE = GND or

ZMODE = CODE = V

Entering impedance

mode

D0−D4, CODE = V

SUS, ZMODE = GND or V

TON (300kHz operation), S0, S1 2.8 3.85 V

TON (600kHz operation), S0, S1 1.65 2.35 V

- VLX forced to 5V 2.0 A

BST

2.4 V

CC

95 kΩ

CC

Pull up 40

Pull down 8

CC

CC

-1 +1

-1 +1

V

-

CC

0.4

2.8 6.0 V

1.4 2.2 V

Ω

ns

0.8 V

1.05 kΩ

kΩ

µA

0.5 V

V

Page 5

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V+ = +15V, VCC= VDD= 5V, VPCS = ZMODE = GND = PGND, SKP/SDN = CODE = VCC, V

OUT

set to 1.5V,

T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V+ = +15V, VCC= VDD= 5V, VPCS = ZMODE = GND = PGND, SKP/SDN = CODE = VCC, V

OUT

set to 1.5V,

T

A

= -40°C to +85°C, unless otherwise noted.) (Note 5)

SKP/SDN NO FAULT Input Level 12 15 V

SKP/SDN, 4-Level Logic Input

Current

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SKP/SDN, TON, S0, S1 = GND or V

CC

-3 3 µA

PWM CONTROLLER

Input Voltage Range

DC Output Voltage Accuracy

(Notes 2, 3)

VPCS Input Bias Current I

VPCS Transconductance G

FB Input Resistance R

ILIM Input Leakage Current I

On-Time (Note 4) t

Minimum Off-Time (Note 4) t

BIAS AND REFERENCE

Quiescent Supply Current (VCC)I

Quiescent Supply Current (VDD)I

Quiescent Supply Current (V+) I+ Measured at V+ 40 µA

Shutdown Supply Current (VCC) SKP/SDN = GND 5 µA

Shutdown Supply Current (VDD) SKP/SDN = GND 5 µA

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

Battery voltage, V+ 2 28

VPS

m

FB

ILIM

ON

OFF(M IN)

CC

DD

, V

V

CC

DD

V+ = 4.5V to 28V, VPCS = GND, DAC

codes from 0.925V to 2.0V

V+ = 4.5V to 28V, VPCS = GND, DAC

codes from 0.700V to 0.900V

V+ = 4.5V to 28V, VPCS = GND, DAC

codes from 0.600V to 0.675V

V

= 0 or 28V -1 +1 µA

VPCS

V

= 0 to -40mV 18 22

VPS

V

= 0 to -100mV 16.5 22

VPS

380kHz nominal, R

150kHz nominal, R

38kHz nominal, R

V

= 0 or 5.0V 100 nA

ILIM

V+ = 5.0V, VFB = 1.2V TON = GND 250 290

V+ = 12V, VFB = 1.2V

TON = REF, open, or V

TON = GND 375

Measured at VCC, FB forced above the

regulation point

Measured at VDD, FB forced above the

regulation point

= 47kΩ -12 +12

TIME

= 120kΩ -8 +8TIME Frequency Accuracy

TIME

= 470kΩ -12 +12

TIME

TON = REF 165 215

TON = open 320 390

TON = V

CC

CC

4.5 5.5

-1 +1

-1.5 +1.5

-1.83 +1.83

115 265 kΩ

465 563

500

2.5 mA

5 µA

V

%

µS

%

ns

ns

Page 6

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V+ = +15V, VCC= VDD= 5V, VPCS = ZMODE = GND = PGND, SKP/SDN = CODE = VCC, V

OUT

set to 1.5V,

T

A

= -40°C to +85°C, unless otherwise noted.) (Note 5)

)

Shutdown Supply Current (V+) SKP/SDN = GND, VCC = VDD = 0 or 5V 5 µA

Reference Voltage V

REF Fault Lockout Voltage Falling edge, 1% hysteresis 1.5 1.7 V

FAULT PROTECTION

Output Overvoltage Fault Preset

Threshold

Output Undervoltage Fault

Threshhold

Current-Limit Threshold

(Positive, Default)

Current-Limit Threshold

(Positive, Adjustable)

Negative Current-Limit Threshold

VCC Undervoltage Lockout

Threshold

PGOOD Lower Trip Threshold

PGOOD Upper Trip Threshold

PGOOD Output Low Voltage I

PGOOD Leakage Current High state, forced to 5.5V 1 µA

GATE DRIVERS

DH Gate Driver On-Resistance R

DL Gate Driver On-Resistance R

LOGIC AND I/O

Logic Input High Voltage V

Logic Input Low Voltage V

DAC Z-Mode Programming

Resistor, Low

DAC Z-Mode Programming

Resistor, High

Logic Input Current

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

REF

V

OVP

V

ITH

V

ITH

ON ( D H ) VBST

ON(DL

IH

VCC = 4.5V to 5.5V, -40µA ≤ I

Measured at FB

With respect to unloaded output voltage 60 80 %

V

GND

V

GND

V

GND

ILIM = V

Rising edge, hysteresis = 20mV, switching

disabled below this level

Measured at FB with respect to unloaded

output voltage, falling edge

Measured at FB with respect to unloaded

output voltage, rising edge

SINK

High state (pull up) 3.5

Low state (pull down) 1.0

D0−D4, CODE, SUS, ZMODE; VCC = 4.5V

to 5.5V

D0−D4, CODE, SUS, ZMODE; VCC = 4.5V

IL

to 5.5V

D0−D4, 0 to 0.4V or 2.6V to 5.5V applied to

the resistor, ZMODE = CODE = GND or

ZMODE = CODE = V

D0−D4, 0 to 0.4V or 2.6V to 5.5V applied to

the resistor, ZMODE = CODE = GND or

ZMODE = CODE = V

D0−D4, CODE = V

SUS, ZMODE = GND or V

CODE = GND 2.20 2.30

CODE = V

- V

- V

- V

= 1mA 0.4 V

- VLX forced to 5V 3.5 Ω

, ILIM = V

VPCS

VPCS

, with respect to V

VPCS

CC

CC

CC

CC

CC

≤ +40µA 1.98 2.02 V

REF

CC

V

= 0.5V 40 60

ILIM

V

= 2V (REF) 143 265

ILIM

,

ITH

CC

1.95 2.05

40 60 mV

-75 -35 mV

4.05 4.45 V

-15 -10.5 %

812%

2.4 V

95 kΩ

-1 +1

-1 +1

V

mV

Ω

0.8 V

1.05 kΩ

µA

Page 7

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

_______________________________________________________________________________________ 7

Note 2: Output voltage accuracy specifications apply to DAC voltages from 0.6V to 2.0V.

Note 3: When the inductor is in continuous conduction, the output voltage will have a DC regulation level higher than the error-com-

parator threshold by 50% of the ripple. In discontinuous conduction (SKP/SDN = V

CC

, light load), the output voltage will

have a DC regulation level higher than the trip level by approximately 1.5% due to slope compensation.

Note 4: On-time and off-time specifications are measured from 50% to 50% at the DH pin, with LX forced to 0, BST forced to 5V,

and a 500pF capacitor from DH to LX to simulate external MOSFET gate capacitance. Actual in-circuit times may be different due to MOSFET switching speeds.

Note 5: Specifications to -40°C are guaranteed by design, not production tested.

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V+ = +15V, VCC= VDD= 5V, VPCS = ZMODE = GND = PGND, SKP/SDN = CODE = VCC, V

OUT

set to 1.5V,

T

A

= -40°C to +85°C, unless otherwise noted.) (Note 5)

4-Level Logic Input High (VCC) TON (200kHz operation), S0, S1

4-Level Logic Input UpperMiddle (Float)

4-Level Logic Input LowerMiddle (REF)

4-Level Logic Low (GND) TON (1000kHz operation), S0, S1 0.5 V

SKP/SDN High Input Level

(Skip Mode)

SKP/SDN Float Input Level

(Forced-PWM Mode)

SKP/SDN Low Input Level

(Shutdown Mode)

SKP/SDN NO FAULT Input Level 12 15 V

SKP/SDN, 4-Level Logic Input

Current

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

V

-

CC

0.4

TON (300kHz operation), S0, S1 2.8 3.85 V

TON (600kHz operation), S0, S1 1.65 2.35 V

2.8 6.0 V

1.4 2.2 V

SKP/SDN, TON, S0, S1 = GND or V

CC

-3 +3 µA

0.5 V

V

Page 8

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

8 _______________________________________________________________________________________

Typical Operating Characteristics

(Circuit from Figure 1, components from Table 2, TA= +25°C, unless otherwise noted.)

100

50

0.01 0.1 1 10 100

EFFICIENCY vs. LOAD CURRENT

(V

OUT

= 1.4V)

60

MAX1813 toc01

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

A1

B1

C1

D1

C2

D2

B2

A2

100

50

0.01 0.1 1 10 100

EFFICIENCY vs. LOAD CURRENT

(V

OUT

= 1.1V)

60

MAX1813 toc02

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

A1

B1

C1

D1

C2

D2

B2

A2

100

50

0.01 0.1 1 10 100

EFFECTIVE EFFICIENCY vs. LOAD CURRENT

(V

OUT

= 1.4V)

60

MAX1813 toc03

LOAD CURRENT (A)

EFFECTIVE EFFICIENCY (%)

70

80

90

A1

B1

C1

D1

C2

D2

B2

A2

100

50

0.01 0.1 1 10 100

EFFECTIVE EFFICIENCY vs. LOAD CURRENT

(V

OUT

= 1.1V)

60

MAX1813 toc04

LOAD CURRENT (A)

EFFECTIVE EFFICIENCY (%)

70

80

90

A1

B1

C1

D1

C2

D2

B2

A2

1.28

1.30

1.32

1.34

1.36

1.38

1.40

1.42

1.44

0105 15202530

OUTPUT VOLTAGE vs. LOAD CURRENT

(V

OUT

= 1.4V)

MAX1813 toc05

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

V

BATT

= 24V

V

BATT

= 7V

PWM MODE

SKIP MODE

0105 15202530

OUTPUT VOLTAGE vs. LOAD CURRENT

(V

OUT

= 1.1V)

MAX1813 toc06

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

1.00

1.04

1.02

1.08

1.06

1.12

1.10

1.14

V

BATT

= 24V

V

BATT

= 7V

PWM MODE

SKIP MODE

0

50

100

150

200

250

300

350

400

0105 15202530

SWITCHING FREQUENCY

vs. LOAD CURRENT

MAX1813 toc07

LOAD CURRENT (A)

SWITCHING FREQUENCY (kHz)

PWM MODE

SKIP MODE

V

OUT

= 1.4V

V

BATT

= 7V

275

285

295

305

315

325

084 12162024

SWITCHING FREQUENCY

vs. BATTERY INPUT VOLTAGE

MAX1813 toc08

BATTERY INPUT VOLTAGE (V)

SWITCHING FREQUENCY (kHz)

I

OUT

= 10A

V

OUT

= 1.4V

V

OUT

= 1.1V

EFFICIENCY CURVE LEGEND

SKIP MODE (SKIP = GND)

A1: V+ = 4.5V

B1: V+ = 7V

C1: V+ = 15V

D1: V+ = 24V

PWM MODE (SKIP = V

CC

)

A2: V+ = 4.5V

B2: V+ = 7V

C2: V+ = 15V

D2: V+ = 24V

Page 9

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

_______________________________________________________________________________________ 9

Typical Operating Characteristics (continued)

(Circuit from Figure 1, components from Table 2, TA= +25°C, unless otherwise noted.)

340

320

300

280

260

SWITCHING FREQUENCY (kHz)

240

220

2.0

1.5

1.0

0.5

0

DEVIATION (mV)

-0.5

VPCS

V

-1.0

-1.5

-2.0

SWITCHING FREQUENCY

vs. TEMPERATURE

I

= 20A

OUT

I

= 10A

OUT

I

= 5A

OUT

I

= 1A

OUT

-40 10-15 35 60 85

TEMPERATURE (°C)

CURRENT-LIMIT DEVIATION

vs. TEMPERATURE

V

= 2V

ILIM

V

= 0.5V

ILIM

-40 -15 10 35 60 85

TEMPERATURE (°C)

MAX1813 toc09

MAX1813 toc11

ON TIME

vs. TEMPERATURE

420

I

= 20A

OUT

= 1A

I

OUT

I

OUT

400

380

360

340

ON TIME (ns)

320

300

I

280

260

-40 -15 10 35 60 85

OUT

TEMPERATURE (°C)

NO-LOAD SUPPLY CURRENT

vs. BATTERY INPUT VOLTAGE (SKIP MODE)

1.2

ICC + I

I

DD

BATT

1.0

0.8

V

= 1.4V

OUT

SKP/SDN = V

0.6

CODE = ZMODE = GND

0.4

SUPPLY CURRENT (mA)

0.2

0

08124 162024

CC

BATTERY INPUT VOLTAGE (V)

MAX1813 toc10

= 5A

= 10A

MAX1813 toc12

NO-LOAD SUPPLY CURRENT

vs. BATTERY INPUT VOLTAGE (PWM MODE)

40

ICC + I

I

DD

BATT

35

30

25

20

15

SUPPLY CURRENT (mA)

10

V

= 1.4V

OUT

SKP/SDN = FLOAT

5

CODE = ZMODE = GND

0

084 12162024

BATTERY INPUT VOLTAGE (V)

MAX1813 toc13

TRANSITION FREQUENCY vs. R

1000

(kHz)

100

SLEW

f

TA = -40°C, 25°C, 85°C

10

10 100 1000

R

(kΩ)

TIME

TIME

MAX1813 toc14

Page 10

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit from Figure 1, components from Table 2, TA= +25°C, unless otherwise noted.)

20µs/div

LOAD TRANSIENT

(PWM MODE)

20A

0

A

B

MAX1813 toc15

1.41V

1.31V

10A

1.36V

A. I

OUT

= 0.3A TO 22A, 10A/div

B. V

OUT

= 1.4V, 50mV/div

SKP/SDN = FLOAT

20

µs/div

LOAD TRANSIENT

(SKIP MODE)

20A

0

A

B

MAX1813 toc16

1.41V

1.31V

10A

1.36V

A. I

OUT

= 0.3A TO 22A, 10A/div

B. V

OUT

= 1.4V, 50mV/div

SKP/SDN = V

CC

20µs/div

LOAD TRANSIENT

(VOLTAGE POSITIONING DISABLED)

20A

0

A

B

MAX1813 toc17

1.46V

1.36V

10A

1.41V

A. I

OUT

= 0.3A to 22A, 10A/div

B. V

OUT

= 1.4V, 50mV/div

SKP/SDN = FLOAT

40A

20A

0

1.4V

0

100mV

-100mV

A. I

B. V

C. VPCS, 200mV/div

ILIM = V

OUTPUT OVERLOAD WAVEFORM

= 0 TO 40A, (0 to 35mΩ), 20A/div

OUT

= 1.4V, 1V/div

OUT

CC

40µs/div

MAX1813 toc18

DYNAMIC TRANSITION

(ZMODE TRANSITION)

5V

A

B

C

0

5V

10A

0

-10A

1.3V

1.2V

1.1V

A. V

= 0 TO 5V, 5V/div

ZMODE

B. PGOOD, 5V/div

C. INDUCTOR CURRENT, 10A/div

= 1.3V TO 1.15V, I

D. V

OUT

CODE = V

CC

40

µs/div

OUT

MAX1813 toc19

= 1A, 100mV/div

15A

-5A

-15A

1.3V

0.85V

5V

0

5V

5A

A

B

C

D

DYNAMIC TRANSITION

(SUS TRANSITION)

40

A. V

= 0 TO 5V, 5V/div

SUS

B. PGOOD, 5V/div

C. INDUCTOR CURRENT, 10A/div

= 1.3V TO 0.85V, I

D. V

OUT

CODE = V

CC

µs/div

= 1A, 500mV/div

OUT

MAX1813 toc20

A

B

C

D

Page 11

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________ 11

Typical Operating Characteristics (continued)

(Circuit from Figure 1, components from Table 2, TA= +25°C, unless otherwise noted.)

1.6V

1.4V

20A

STARTUP WAVEFORM

(HEAVY LOAD)

0

5V

0

0

0

MAX1813 toc21

A

B

C

D

1.6V

0

5V

0

1.4V

0

10A

0

STARTUP WAVEFORM

(NO LOAD, PWM MODE)

MAX1813 toc22

A

B

C

D

= 0 TO 1.6V, 2V/div

A. V

SKP/SDN

B. PGOOD, 5V/div

= 1.4V, R

C. V

OUT

D. INDUCTOR CURRENT, 20A/div

STARTUP WAVEFORM

(NO LOAD, SKIP MODE)

5V

0

5V

0

1.4V

0

10A

0

= 0 TO 5V

A. V

SKP/SDN

B. PGOOD, 5V/div

= 1.4V, NO LOAD, 1V/div

C. V

OUT

D. INDUCTOR CURRENT, 10A/div

200µs/div

= 63mΩ, 1V/div

OUT

200

µs/div

MAX1813 toc23

200

µs/div

= 0 TO 1.6V, 2V/div

A. V

SKP/SDN

B. PGOOD, 5V/div

= 1.4V, NO LOAD, 1V/div

C. V

OUT

D. INDUCTOR CURRENT, 10A/div

SHUTDOWN WAVEFORM

A

B

C

D

1.6V

0

5V

0

1.4V

20A

0

= 0 TO 1.6V, 2V/div

A. V

SKP/SDN

B. PGOOD, 5V/div

= 1.4V, R

C. V

OUT

D. INDUCTOR CURRENT, 20A/div

40

µs/div

= 63mΩ, 1V/div

OUT

MAX1813 toc24

A

B

C

D

Page 12

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

12 ______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1V+

2 VPCS

3 SKP/SDN

4 TIME

5 FB Feed b ack Inp ut. C onnect FB to the j uncti on of the exter nal i nd uctor and outp ut cap aci tor ( Fi g ur e 1) .

6CC

7, 8 S0, S1

9V

10 TON

CC

Battery Voltage Sense Connection. Connect V+ to the input power source. V+ is used only for PWM

one-shot timing. DH on-time is inversely proportional to the input voltage over a 2V to 28V range.

Current-Sense Input. Connect a current-sense resistor (R

voltage on VPCS controls both the voltage-positioning and current-limit circuits. The slope of the

voltage-positioned output is controlled with the current-sense resistor and the gain resistor connected

between CC and REF. See Setting Voltage Positioning. The current-limit threshold is set by ILIM. If the

current-sense signal (inductor current × R

will not initiate a new cycle. VPCS can also be connected to LX to reduce component count, but CC

must be connected to REF to disable the voltage positioning.

Combined Shutdown and Skip-Mode Control. Drive SKP/SDN to GND for shutdown, leave SKP/SDN

open for low-noise forced-PWM mode, or drive to V

Shutdown mode: SKP/SDN = GND

Low-noise forced-PWM mode: SKP/SDN = open

Normal pulse-skipping operation: SKP/SDN = V

Low-noise forced PWM mode causes inductor current recirculation at light loads and suppresses

pulse-skipping operation. Forcing SKP/SDN with 12V to 15V clears the fault latch and disables

undervoltage protection, overvoltage protection, and thermal shutdown with otherwise normal pulseskipping operation. Exiting shutdown clears the fault latch.

Do not connect SKP/SDN to voltages over 15V.

Slew-Rate Adjustment Pin. Connect a resistor from TIME to GND to set the internal slew-rate clock. A

470kΩ to 47kΩ resistor sets the clock from 38kHz to 380kHz, respectively:

= 150kHz x 120kΩ / R

f

SLEW

Compensation Capacitor and Voltage-Positioning Gain Adjustment. Connect a 47pF to 1000pF (47pF

typ) capacitor from CC to GND to adjust the loop’s response time. Connect a resistor (R

CC to REF to set the gain of the voltage positioning amplifier.

VV

OUT OUT PROG

where the voltage-positioning amplifer’s transconductance (G

Suspend-Mode Voltage Select Inputs. S0 and S1 are 4-level logic inputs that select the suspendmode VID code for for the suspend-mode multiplexer inputs. If SUS is high, the suspend-mode VID

code is delivered to the DAC. See Suspend-Mode Internal Mux.

Analog Supply Voltage Input for PWM Core. Connect VCC to the system supply voltage (4.5V to 5.5V)

through a series 20Ω resistor. Bypass to GND with a 0.22µF or greater capacitor as close to the

MAX1813 as possible.

On-Time Selection-Control Input. This is a 4-level input used to determine DH on-time. Connect to

GND, REF, or V

1000kHz, REF = 600kHz, floating = 300kHz, and V

, or leave TON unconnected to set the following switching frequencies: GND =

CC

.

TIME

=+

()

) exceeds the current-limit threshold, the MAX1813

SENSE

for normal pulse-skipping operation:

CC

CC

GR V

m AVPS VPCS

1

= 200kHz.

CC

) between VPCS and PGND. The

SENSE

V

REF

m

) is typically 20µS.

AVPS

) from

Page 13

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________ 13

Pin Description (continued)

PIN NAME FUNCTION

+2.0V Reference Voltage Output. Bypass to GND with a 0.22µF or greater capacitor. The reference

11 REF

12 ILIM

13 PGOOD

14 GND Analog Ground

15 PGND Power Ground. PGND is one of the inputs to the current-limit comparator.

16 DL

17 V

18 SUS

19 ZMODE

20 CODE

21−25 D4−D0

26 BST

27 LX

28 DH High-Side Gate Driver Output. DH swings from LX to BST.

DD

can sink and source ±40µA (min) for external loads. Loading REF degrades FB accuracy according to

the REF load regulation error.

Current-Limit Adjustment. The PGND - VPCS current-limit threshold defaults to 50mV if ILIM is tied to

V

. In adjustable mode, the current-limit threshold voltage is 1/10th the voltage seen at ILIM over a

CC

500mV to 2.0V range. The logic threshold for switchover to the 50mV default value is approximately

V

- 1V. Connect ILIM to REF for a fixed 200mV threshold.

CC

Open-Drain Power-Good Output. PGOOD is normally high when the output is in regulation. If V

within a +10%/-12.5% window of the DAC setting, PGOOD is asserted low. During DAC code

transitions, PGOOD is forced high until 1 clock period after the slew-rate controller finishes the

transition. PGOOD is low in shutdown, undervoltage lockout, and during soft-start. Any fault condition

forces PGOOD low, and it remains low until the fault is cleared.

Low-Side Gate-Driver Output. DL swings from GND to V

at the end of the shutdown sequence.

Supply Input for the DL Gate Drive. Connect to the system supply voltage (4.5V to 5.5V). Bypass to

PGND with a 1µF or greater capacitor.

Suspend-Mode Control Input. When SUS is high, the suspend-mode VID code, as programmed by S0

and S1, is delivered to the DAC. SUS overrides ZMODE. Connect SUS to GND if the suspend-mode

multiplexer is not used. See Table 6.

Performance-Mode Mux Contol Input. If SUS is low, ZMODE selects between two different VID codes.

If ZMODE = GND with CODE = V

logic-level voltages on D0−D4. When initially entering impedance mode, the VID code is determined

by the impedance at D0−D4. See Tables 5 and 7.

Code Select Input. CODE acts like another VID code input to select between the Intel Mobile Voltage

Position II (IMVP-II™) or Coppermine™ VID codes. CODE also determines the polarity of the ZMODE

input. See Tables 5 and 7.

VID Code Inputs. D0 is the LSB and D4 is the MSB of the internal 5-bit DAC (see Tables 5 and 7). If

ZMODE = GND with CODE = V

digital inputs, and the VID code is set by the logic-level voltages on D0−D4. When initially entering

impedance mode, the VID code is determined by the impedance at D0−D4 as follows:

Logic Low = source impedance is ≤1kΩ ±5%

Logic High = source impedance is ≥100kΩ ±5%.

Boost Flying-Capacitor Connection. Connect to an external capacitor and diode according to the

standard high-power application circuit (Figure 1). An optional resistor in series with BST allows DH

pullup current to be adjusted.

External Inductor Connection. Connect LX to the switched side of the inductor. LX serves as the lower

supply rail for the DH high-side gate driver. LX does not connect to the current-limit comparator.

, or ZMODE = VCC with CODE = GND, the VID code is set by the

CC

, or ZMODE = VCC with CODE = GND, D0−D4 are high-impedance

CC

. DL is forced high when a fault occurs, and

DD

FB

is not

Page 14

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

14 ______________________________________________________________________________________

Detailed Description

The MAX1813 buck controller is targeted for low-voltage, high-current CPU core power supplies for notebook computers, which typically exhibit 0 to 22A (or

greater) load steps. The proprietary Quick-PWM pulsewidth modulator in the converter is specifically

designed for handling fast load steps while maintaining

a relatively constant operating frequency and inductor

operating point over a wide range of input voltages.

The Quick-PWM architecture circumvents the poor

load-transient timing problems of fixed-frequency current-mode PWMs while also avoiding the problems

caused by widely varying switching frequencies in conventional constant on-time and constant off-time PFM

schemes.

+5V Bias Supply (VCCand VDD)

The MAX1813 requires an external +5V bias supply in

addition to the battery. Typically, this +5V bias supply

is the notebook’s 95% efficient +5V system supply.

Keeping the bias supply external to the IC improves

efficiency and eliminates the cost associated with the

+5V linear regulator that would otherwise be needed to

supply the PWM circuit and gate drivers. If stand-alone

capability is needed, the +5V supply can be generated

with an external linear regulator.

The +5V bias supply powers V

CC

(PWM controller) and

VDD(gate-drive power). The maximum current is:

I

BIAS

= ICC+ ƒSW(QG1+ QG2) = 15mA to 45mA (typ)

where I

CC

is 1.4mA (typ), ƒSWis the switching frequen-

cy, and Q

G1

and QG2are the MOSFET total gate-

charge specification limits at VGS= 5V.

The battery input (V+) and +5V bias inputs (VCCand

VDD) can be connected together if the input source is a

fixed 4.5V to 5.5V supply. If the +5V bias supply is

powered up prior to the battery supply, the enable signal (SKP/SDN) must be delayed until the battery voltage is present in order to ensure startup.

Free-Running, Constant-On-Time PWM

Controller with Input Feed-Forward

The Quick-PWM control architecture is a constant-ontime, current-mode type with voltage feed-forward

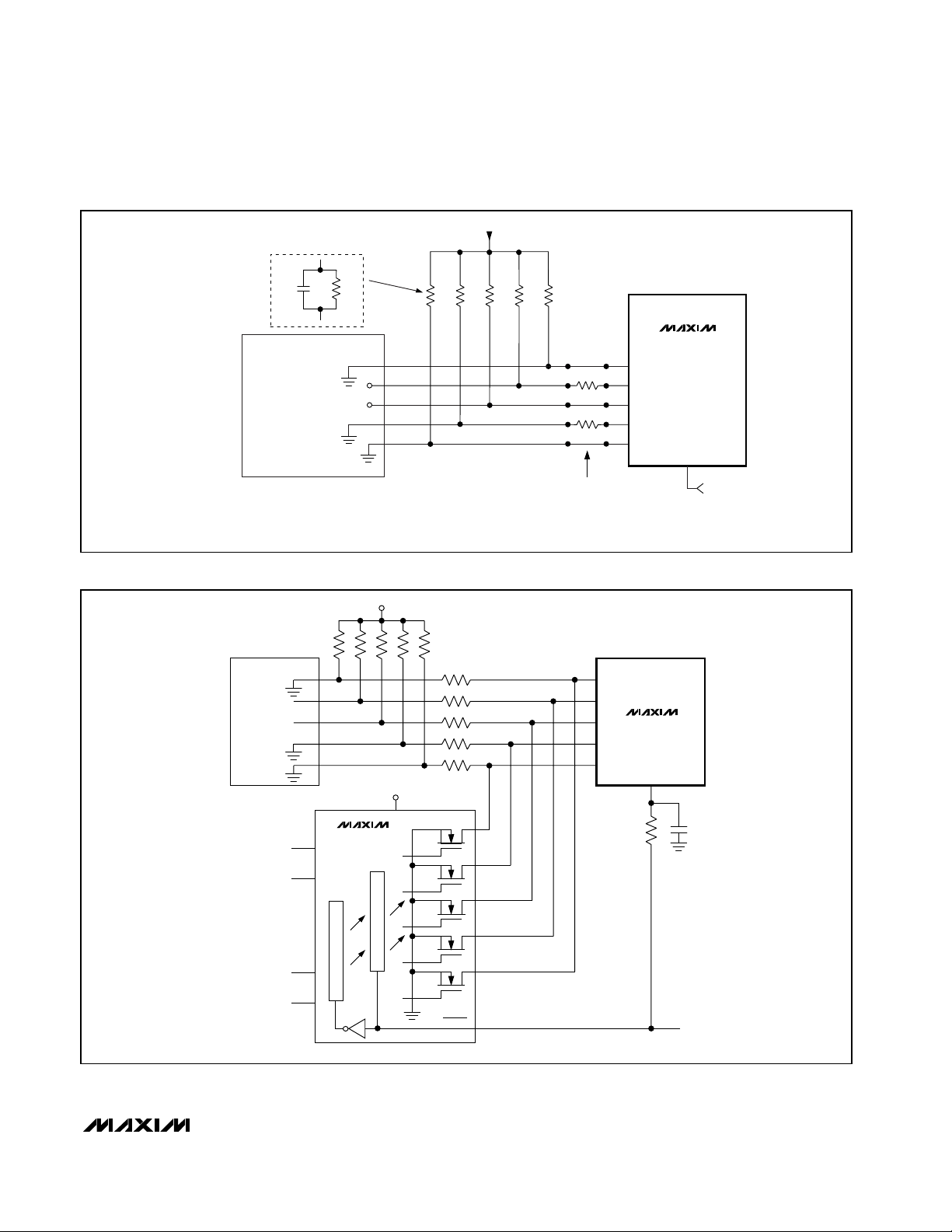

Figure 1. Standard High-Power Application Circuit

POWER-GOOD

+5V INPUT

BIAS SUPPLY

INDICATOR

SUSPEND

MODE

TO V

1µF

R

GATE

100kΩ

C

47pF

0.22µF

CC

C1

COMP

C

REF

R

120kΩ

R

AVPS

150kΩ

OPEN

OPEN

TIME

V

CC

ILIM

PGOOD

TIME

CC

REF

SUS

S0

S1

CODE

D0

D1

D2

D3

D4

R1

20Ω

MAX1813

SKP/SDN

V

DD

BST

VPCS

PGND

GND

ZMODE

TON

V+

DH

LX

DL

FB

BATTERY (V

C2

7V TO 24V

1µF

D1

C

BST

0.1µF

R

VPCS

100Ω

C

VPCS

1nF

R

C

1nF

OPEN (300kHz)

OPEN (FORCED-PWM)

FB

FB

100Ω

Q

Q

H

L

R

C

IN

SENSE

)

BATT

L1

0.68µH

D2

NOTE: SEE TABLE 1 FOR COMPLETE

LIST OF COMPONENT VALUES

1.4V OUTPUT

UP TO 22A

C

OUT

Page 15

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________ 15

(Figure 2). This architecture relies on the output ripple

voltage to provide the PWM ramp signal. Thus, the output filter capacitor’s equivalent series resistance (ESR)

acts as a feedback resistor. The control algorithm is

simple: the high-side switch on-time is determined solely by a one-shot whose period is inversely proportional

to input voltage and directly proportional to output voltage (see On-Time One-Shot). Another one-shot sets a

minimum off-time (400ns typ). The on-time one-shot is

triggered if the error comparator is low, the low-side

switch current is below the current-limit threshold, and

the minimum off-time one-shot has timed out.

On-Time One-Shot (TON)

The heart of the PWM core is the one-shot that sets the

high-side switch on-time. This fast, low-jitter, adjustable

one-shot includes circuitry that varies the on-time in

response to the input and output voltages. The high-

side switch on-time is inversely proportional to V+ and

directly proportional to the output voltage as set by the

DAC code. This algorithm results in a nearly constant

switching frequency despite the lack of a fixed-frequency clock generator. The benefits of a constant switching frequency are twofold: first, the frequency can be

selected to avoid noise-sensitive regions such as the

455kHz IF band; second, the inductor ripple-current

operating point remains relatively constant, resulting in

Table 1. Component Selection for

Standard Applications

Table 2. Component Suppliers

COMPONENT

Output Voltage 0.6V to 1.75V

Input Voltage Range 7V to 24V

Maximum Load Current 22A

0.68µH

Inductor

Frequency 300kHz (TON = float)

High-Side MOSFET

Low-Side MOSFET

Input Capacitor

Output Capacitor

Current-Sense Resistor

ILIM Level VCC (Default)

Voltage-Positioning Gain

Resistor

Sumida CDEP134H-0R6 or

Panasonic ETQP6F0R6BFA

International Rectifier

(2) IRF7811A

Fairchild (3) FDS7764A or

International Rectifier

(3) IRF7822A

(6) 10µF, 25V

Taiyo Yuden TMK432BJ106 or

TDK C4532X5R1E106M

(6) 220µF

Panasonic

EEFUE0E221R

1.5mΩ Dale WSL 2512, plus

0.5mΩ copper PC board trace

150kΩ

CIRCUIT 1

(FIGURE 1)

M A NUF ACT URER

MOSFETs

Fairchild

Semiconductor

International

Rectifier

Siliconix

Capacitors

Kemet

Panasonic

Sanyo

Taiyo Yuden

Inductors

Coilcraft

Coiltronics

Sumida

PH ONE

[ C OUN TRY

CO DE]

[1] 888-

522-5372

[1] 310-

322-3331

[1] 203-

268-6261

[1] 408-

986-0424

[1] 847-

468-5624

[ 65] 281-

3226

( S i ng ap or e)

[ 1] 408-

749- 9714

[03] 3667-

3408

(Japan)

[1] 408-

573-4150

[1] 800-

322-2645

[1] 561-

752-5000

[1] 408-

982-9660

WEBSITE

www.fairchildsemi.com

www.irf.com

www.vishay.com

www.kemet.com

www.panasonic.com

www.secc.co.jp

www.t-yuden.com

www.coilcraft.com

www.coiltronics.com

www.sumida.com

Page 16

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

16 ______________________________________________________________________________________

Figure 2. Functional Diagram

V

BATT

5V TO 24V

5V BIAS

SUPPLY

TON

GND

CHIP

SUPPLY

V

CC

5V

BIAS

V+

TON

COMPUTE

FROM

DAC

Q

TOFF

ONE-SHOT

TRIG

REF

MAX1813

ILIM

BST

DH

9R

R

LX

REF

2V

REF

CC

VPCS

Gm

SKP/SDN

REF

-12%

PGOOD

TRIG

TON

ONE-SHOT

REF

+10%

SET

Q

S

Q

5-BIT

R-2R

DAC

R

Q

CLR

2V

REF

OVP/UVP

DETECT

ZERO

CROSSING

SET

Q

S

R

Q

CLR

DECODER

(SEE FIGURE 6)

SLEW-RATE CONTROLLER

D0CODEZMODE D1 D2 D3 D4

AND

SOFT-START

OSC

VPCS

V

DD

DL

PGND

FB

SUS

S0

S1

TIME

V

OUT

Page 17

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________ 17

easy design methodology and predictable output voltage ripple.

where K is set by the TON pin-strap connection, and

75mV is an approximation to accommodate for the

expected drop across the low-side MOSFET switch and

current-sense resistor (Table 3).

The on-time one-shot has good accuracy at the operating points specified in the Electrical Characteristics

table. On-times at operating points far removed from

the conditions specified can vary over a wide range.

For example, the 1000kHz setting will typically run

about 10% slower with inputs much greater than +5V,

due to the very short on-times required.

Although the on-time is set by TON, the input voltage,

and the output voltage, other factors also contribute to

the overall switching frequency. The on-time guaranteed in the Electrical Characteristics table is influenced

by switching delays in the external high-side MOSFET.

Resistive losses—including the inductor, both

MOSFETs, output capacitor ESR, and PC board copper

losses in the output and ground—tend to raise the

switching frequency at higher output currents. Switch

dead-time can increase the effective on-time, reducing

the switching frequency. This effect occurs only in

PWM mode (SKP/SDN = float) when the inductor current reverses at light or negative load currents. With

reversed inductor current, the inductor’s EMF causes

LX to go high earlier than normal, extending the on-time

by a period equal to the DH-rising dead-time (26ns

typ).

When the controller operates in continuous

mode, the dead-time is no longer a factor, and the

actual switching frequency is:

where V

DROP1

is the sum of the parasitic voltage drops

in the inductor discharge path, including synchronous

rectifier, inductor, and PC board resistances; V

DROP2

is

the sum of the resistances in the charging path, including high-side switch, inductor, and PC board resistances; and tONis the on-time calculated by the

MAX1813.

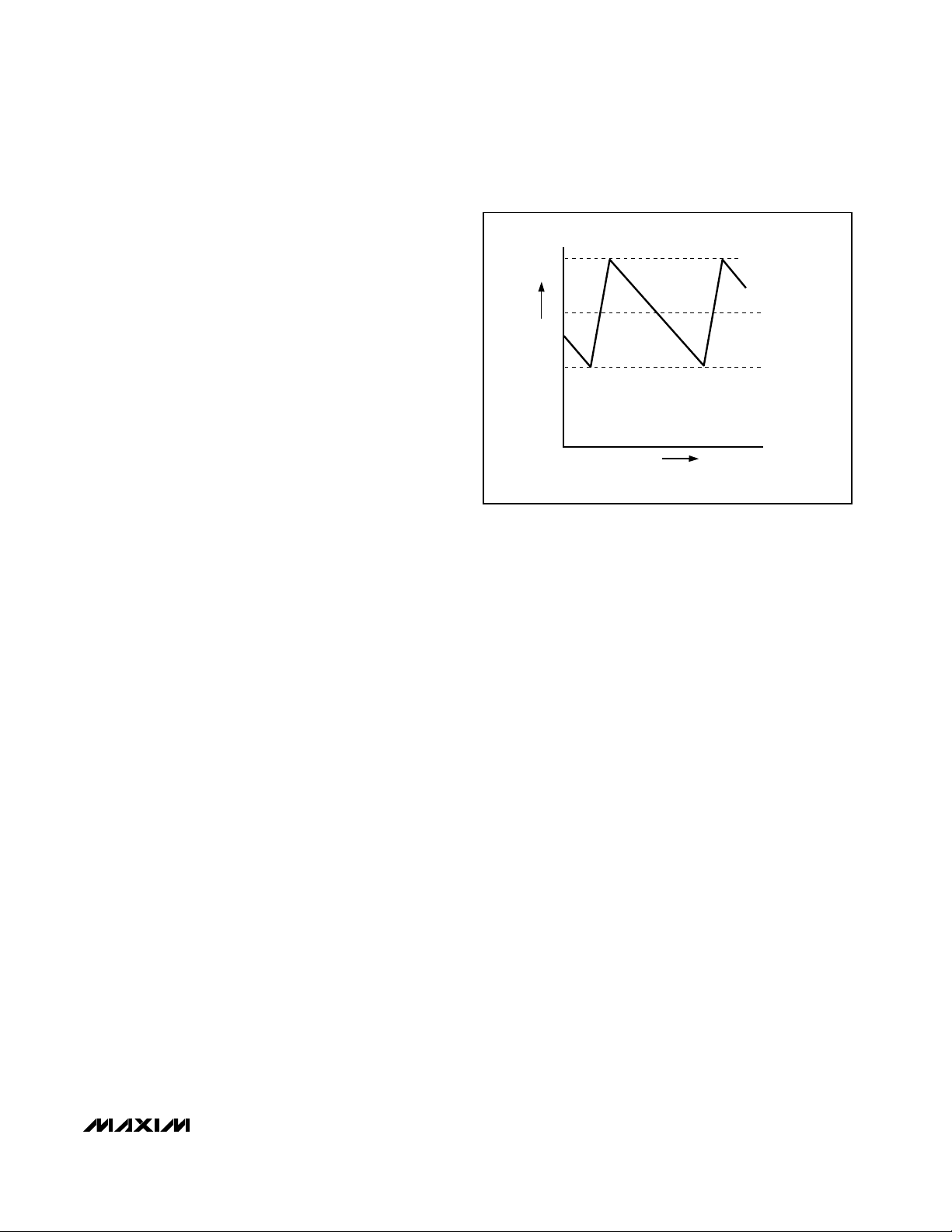

Automatic Pulse-Skipping Switchover

In skip mode (SKP/SDN = high, Table 4), an inherent

automatic switchover to PFM takes place at light

loads (Figure 3). This switchover is controlled by a

comparator that truncates the low-side switch on-time

at the inductor current’s zero crossing. This mechanism

causes the threshold between pulse-skipping PFM and

nonskipping PWM operation to coincide with the

boundary between continuous and discontinuous

inductor-current operation. For a 7V to 24V input voltage range, this threshold is relatively constant, with

ƒ=

+

+−

SW

OUT DROP1

ON IN DROP1 DROP2

(V V )

t(V V V )

t

K(V 75mV)

V

ON

OUT

IN

=

+

Table 3. Approximate K-Factor Errors

Figure 3. Pulse-Skipping/Discontinuous Crossover Point

∆i

∆t

INDUCTOR CURRENT

- V

V

BATT

=

ON-TIME0 TIME

OUT

L

I

PEAK

I

LOAD

= I

/2

PEAK

TON SETTING

(kHz)

200 4.9 ±9 1.8

300 3.3 ±10 2.0

600 1.8 ±13 2.9

1000 1.05 ±13 3.5

K-FACTOR

(µs)

APPROXIMATE

K-FACTOR ERROR

(%)

MINIMUM RECOMMENDED V

AT V

OUT

= 1.4V (V)

BATT

Page 18

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

18 ______________________________________________________________________________________

only a minor dependence on the input voltage:

where K is the on-time scale factor (Table 3). The loadcurrent level at which PFM/PWM crossover occurs

(I

LOAD(SKIP)

) is equal to 1/2 the peak-to-peak ripple

current, which is a function of the inductor value (Figure

3). For example, in the standard application circuit with

K = 3.3µs (300kHz), VIN= 12V, V

OUT

= 1.4V, and L =

0.68µH, switchover to pulse-skipping operation occurs

at I

LOAD

= 3.0A or about 1/4 full load. The crossover

point occurs at an even lower value if a swinging (softsaturation) inductor is used.

The switching waveforms may appear noisy and asynchronous when light loading causes pulse-skipping

operation; this is a normal operating condition that

improves light-load efficiency. Trade-offs in PFM noise

vs. light-load efficiency are made by varying the inductor value. Generally, low inductor values produce a

broader efficiency vs. load curve, while higher values

result in higher full-load efficiency (assuming that the

coil resistance remains fixed) and less output voltage

ripple. Penalties for using higher inductor values

include larger physical size and degraded load-transient response (especially at low input voltage levels).

Forced-PWM Mode

The low-noise, forced-PWM mode (SKP/SDN left floating, Table 4) disables the zero-crossing comparator

that controls the low-side switch on-time. The resulting

low-side gate-drive waveform is forced to be the complement of the high-side gate-drive waveform. This, in

turn, causes the inductor current to reverse at light

loads because the PWM loop strives to maintain a duty

ratio of V

OUT/VIN

. The benefit of forced-PWM mode is

to keep the switching frequency nearly constant, but it

results in higher no-load supply current that can be

15mA to 45mA, depending on the external MOSFETs

and switching frequency.

The MAX1813 uses forced-PWM mode during all transitions, while the slew-rate controller is active. During

downward output voltage transitions, forced-PWM

allows the MAX1813 to sink current, thereby rapidly

pulling down the output voltage. When a transition uses

high negative inductor current, due to voltage positioning, the output voltage may not settle to its intended

final value until after the slew-rate controller terminates.

For this reason, most applications should use PWM

mode exclusively, although skip mode is beneficial in

the low-power suspend state (see Shutdown and Mode

Control).

Shutdown and Mode Control (SKP/SDN)

When SKP/SDN is driven low, the MAX1813 enters the

low-current shutdown mode (Table 4). Shutdown forces

PGOOD low immediately and ramps down the output

voltage in 25mV increments at the clock rate set by

R

TIME

. Once the output voltage ramps down, the

MAX1813 pulls DH low, forces DL high, and shuts

down the reference, so the total supply current (ICC+

I

DD

+ I+) drops to 4µA (typ).

When SKP/SDN is left floating or driven high, the

MAX1813 begins the startup sequence. First, the reference powers up. After the reference exceeds its 1.6V

undervoltage lockout threshold, the DAC determines

the target output voltage and starts ramping up the output voltage. The slew-rate controller increases the out-

IK

V

2L

VV

V

LOAD(SKIP)

OUT IN OUT

IN

≈

−

Table 4. Operating Mode Truth Table

SKP/SDN DL MODE COMMENTS

GND High Shutdown Micropower shutdown state (ICC = 2µA typ).

V

CC

Float Switching Forced PWM

Switching

Normal

Operation

Automatic switchover from PWM mode to pulse-skipping PFM mode at

light loads. Prevents inductor current from recirculating into the input.

Low-noise forced-PWM mode causes inductor current to reverse at

light loads and suppresses pulse-skipping operation.

12V Switching

VCC or Float High FAULT

NO-FAULT Test

Mode

Test mode with overvoltage, undervoltage, and thermal shutdown

faults disabled. Otherwise, the converter operates as if SKP/SDN =

.

V

CC

The fault latch set by the overvoltage protection, output undervoltage

protection, or thermal shutdown. The MAX1813 will remain in FAULT

mode until V

power is cycled or SKP/SDN is forced low.

CC

Page 19

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________ 19

put voltage in 25mV increments at the clock rate set by

R

TIME

until the MAX1813 reaches the selected output

voltage. The MAX1813 does not feature traditional variable current-limit soft-start, so full output current is

immediately available. Once the slew-rate controller terminates, output undervoltage fault blanking period

ends, and the output voltage is in regulation, PGOOD

goes high.

Leave SKP/SDN floating for forced-PWM operation, or

connect SKP/SDN to VCCfor normal operation. During

all transitions, the MAX1813 uses PWM mode while the

slew-rate controller is active. Exiting shutdown clears

the fault latch.

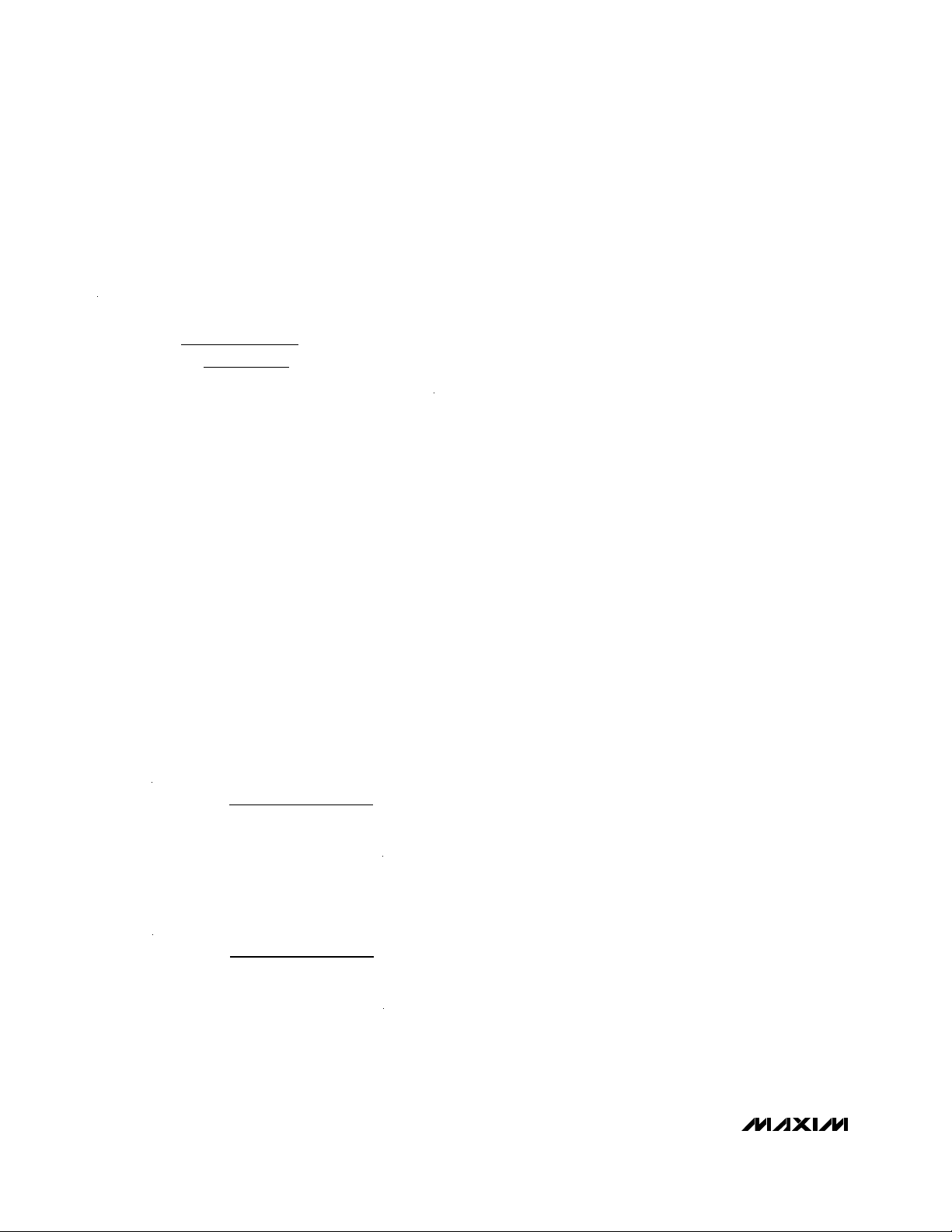

Current-Limit Circuit (ILIM)

The current-limit circuit employs a unique “valley” current-sensing algorithm. If the current-sense signal is

above the current-limit threshold, the MAX1813 will not

initiate a new cycle (Figure 4). The actual peak current

is greater than the current-limit threshold by an amount

equal to the inductor ripple current. Therefore the exact

current-limit characteristic and maximum load capability are a function of the current-limit threshold, inductor

value, and input voltage. The reward for this uncertainty

is robust, loss-less over-current sensing. When combined with the undervoltage protection circuit, this current-limit method is effective in almost every

circumstance.

There is also a negative current limit that prevents

excessive reverse inductor currents when V

OUT

is sinking current. The negative current-limit threshold is set to

approximately 120% of the positive current limit and

therefore tracks the positive current limit when ILIM is

adjusted.

The MAX1813 measures the current by sensing the

voltage between VPCS and PGND. Connect an external

sense resistor between the source of the low-side Nchannel MOSFET and PGND. The signal provided by

this current-sense resistor is also used for voltage positioning (see Setting Voltage Positioning). Reducing the

sense voltage increases the relative measurement

error. However, the configuration eliminates the uncertainty of using the low-side MOSFET on-resistance to

measure the current, so the resulting current-limit tolerance is tighter when sensing with a 1% sense resistor.

The voltage at ILIM sets the current-limit threshold. For

voltages from 500mV to 2V, the current-limit threshold

voltage is precisely 0.1 x V

ILIM

. Set this voltage with a

resistive divider between REF and GND. The currentlimit threshold defaults to 50mV when ILIM is tied to

VCC. The logic threshold for switchover to this 50mV

default value is approximately VCC- 1V.

Carefully observe the PC board layout guidelines to

ensure that noise and DC errors don’t corrupt the current-sense signals seen by VPCS and GND. The IC

must be mounted close to the current-sense resistor

with short, direct traces making a Kelvin sense connection (see PC Board Layout Guidelines).

MOSFET Gate Drivers (DH and DL)

The DH and DL drivers are optimized for driving moderate-sized, high-side and larger, low-side power

MOSFETs. This is consistent with the low duty factor

seen in the notebook CPU environment, where a large

V

IN

- V

OUT

differential exists. An adaptive dead-time

circuit monitors the DL output and prevents the highside FET from turning on until DL is fully off. There must

be a low-resistance, low-inductance path from the DL

driver to the MOSFET gate for the adaptive dead-time

circuit to work properly. Otherwise, the sense circuitry

in the MAX1813 will interpret the MOSFET gate as “off”

while there is actually charge still left on the gate. Use

very short, wide traces (50 to 100 mils wide if the MOSFET is 1 inch from the device). The dead time at the

other edge (DH turning off) is determined by a fixed

35ns internal delay.

The internal pulldown transistor that drives DL low is

robust, with a 0.4Ω (typ) on-resistance. This helps prevent DL from being pulled up during the fast rise-time

of the LX node, due to capacitive coupling from the

drain to the gate of the low-side synchronous-rectifier

MOSFET. However, for high-current applications, some

combinations of high- and low-side FETs may cause

excessive gate-drain coupling, leading to poor

Figure 4. “Valley” Current-Limit Threshold Point

I

PEAK

I

LOAD

I

LIMIT

INDUCTOR CURRENT

0 TIME

Page 20

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

20 ______________________________________________________________________________________

efficiency, EMI, and shoot-through currents. This is

often remedied by adding a resistor less than 5Ω in

series with BST, which increases the turn-on time of the

high-side FET without degrading the turn-off time

(Figure 5).

DAC Converter (D0-D4)

The digital-to-analog converter (DAC) programs the

output voltage. It receives a preset digital code from

the CPU pins, digital logic, general-purpose I/O, or an

external multiplexer. Do not leave D0–D4 floating; use

1MΩ or less pullups if the inputs may float.

The state of DO–D4 can be changed while the switchmode power supply is active, initiating a transition to a

new output voltage level. During this interval, the slewrate controller is active, so the MAX1813 uses forcedPWM mode. If this mode of DAC control is used,

connect ZMODE low. Change D0–D4 together, avoiding greater than 1µs skew between bits. Otherwise,

incorrect DAC readings may cause a partial transition

to the wrong voltage level, lengthening the overall transition time. The available DAC codes and resulting output voltages (Table 5) are compatible with the

Coppermine™ and Intel’s Mobile Voltage Positioning II

(IMVP-II™) specifications.

VID Code Options (CODE)

The MAX1813 contains two separate sets of VID codes.

The CODE pin selects between the two output voltage

tables (Table 5). Drive CODE low to select the older

0.925V to 2.000V DAC codes, which are compatible

with the Coppermine specifications. Drive CODE high

to select the new 0.600V to 1.750V DAC codes, which

are compatible with the IMVP-II specifications. CODE

also determines the polarity of ZMODE (Table 7).

Suspend-Mode Operation (S0, S1)

When the CPU clock stops, the processor enters suspend mode and requires a lower supply voltage to minimize power consumption. The MAX1813 includes

suspend-mode output voltages that are selected using

two 4-level input pins (S0 and S1, Table 6). When the

CPU clock stops, drive SUS high to transition to the

suspend-mode output voltage. During the transition,

the MAX1813 asserts forced-PWM mode to sink current

and pull down the output voltage until PGOOD goes

high.

When SUS is driven high, suspend mode overrides the

5-bit DAC setting. When SUS is low, the MAX1813

determines the output voltage from the 5-bit DAC

(D0–D4), CODE, and ZMODE settings.

Internal Multiplexers (ZMODE, SUS)

The MAX1813 has a unique internal multiplexer that

can select one of three different VID code settings for

different processor states. Depending on the logic level

at SUS, the suspend (SUS) mode multiplexer selects

the VID code settings from either the D0-D4 input

decoder or the S0/S1 input decoder. The ZMODE multiplexer selects one of the two D0-D4 input modes, setting the VID code based on either the voltage on D0-D4

(logic mode) or the impedance decoder output (impedance mode) (Figure 6).

When SUS is high, the suspend-mode multiplexer

selects the VID code from the S0/S1 input decoder. The

decoder outputs are determined by inputs S0 and S1

(Table 6). When SUS is low, the suspend-mode multiplexer selects the D0-D4 input decoder output.

In logic mode (Table 7), the logic-level voltages on D0D4 set the DAC settings. In this mode, the inputs are

continuously active and can be dynamically changed

by external logic. The logic-mode VID code setting is

typically used for the battery-mode state, and the

source of this code is sometimes the VID pins of the

CPU with suitable pullup resistors.

Impedance mode (Table 7) is programmed by external

resistors in series with D0–D4, using a unique scheme

that allows two sets of data bits using only one set of

pins. When the MAX1813 initially enters impedance

mode, the resistances at D0–D4 are sampled by the

impedance decoder to see if there is a large resistance

in series with the pin. If the voltage level on a DAC input

pin is a logic low, an internal switch connects that pin to

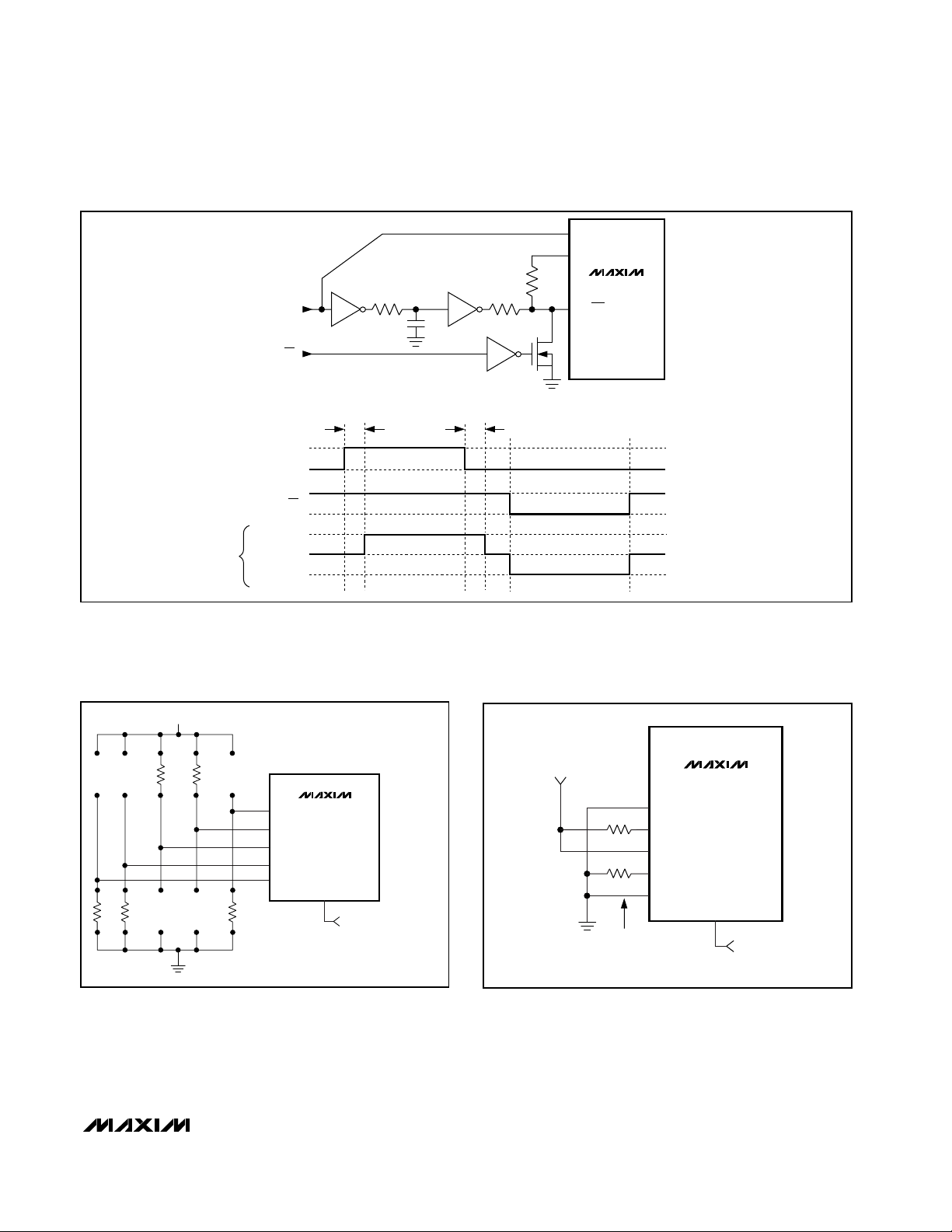

Figure 5. Reducing the Switching-Node Rise Time

+5V

5Ω TYP

BST

DH

MAX1813

LX

V

BATT

Page 21

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________ 21

Table 5. Output Voltage vs. DAC Codes

*In the NO CPU State, DH and DL are held low and the slew-rate controller is set for 0.425V.

D4 D3 D2 D1 D0

0 0 0 0 0 2.000 1.750

0 0 0 0 1 1.950 1.700

0 0 0 1 0 1.900 1.650

0 0 0 1 1 1.850 1.600

0 0 1 0 0 1.800 1.550

0 0 1 0 1 1.750 1.500

0 0 1 1 0 1.700 1.450

0 0 1 1 1 1.650 1.400

0 1 0 0 0 1.600 1.350

0 1 0 0 1 1.550 1.300

0 1 0 1 0 1.500 1.250

0 1 0 1 1 1.450 1.200

0 1 1 0 0 1.400 1.150

0 1 1 0 1 1.350 1.100

0 1 1 1 0 1.300 1.050

0 1 1 1 1 NO CPU* 1.000

1 0 0 0 0 1.275 0.975

1 0 0 0 1 1.250 0.950

1 0 0 1 0 1.225 0.925

1 0 0 1 1 1.200 0.900

1 0 1 0 0 1.175 0.875

1 0 1 0 1 1.150 0.850

1 0 1 1 0 1.125 0.825

1 0 1 1 1 1.100 0.800

1 1 0 0 0 1.075 0.775

1 1 0 0 1 1.050 0.750

1 1 0 1 0 1.025 0.725

1 1 0 1 1 1.000 0.700

1 1 1 0 0 0.975 0.675

1 1 1 0 1 0.950 0.650

1 1 1 1 0 0.925 0.625

1 1 1 1 1 NO CPU* 0.600

OUTPUT VOLTAGE (V)

CODE = 0 CODE = 1

Page 22

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

22 ______________________________________________________________________________________

an internal 40kΩ pullup for about 4µs to see if the pin

voltage can be forced high (Figure 7). If the pin voltage

cannot be pulled to a logic high, the pin is considered

low impedance, and its impedance-mode logic state is

low. If the pin can be pulled to a logic high, the impedance is considered high and so is the impedancemode logic state. Similarly, if the voltage level on the

pin is a logic high, an internal switch connects the pin

to an internal 8kΩ pulldown to see if the pin voltage can

be forced low. If so, the pin is high impedance, and its

impedance-mode logic state is high. In either sampling

condition, if the pin’s logic level does not change, the

pin is determined to be low impedance, and the impedance-mode logic state is low.

A high pin impedance (logic high) is 100kΩ or greater,

and a low impedance (logic low) is 1kΩ or less. The

guaranteed levels for these impedances are 95kΩ and

1.05kΩ to allow the use of standard 100kΩ and 1kΩ resistors with 5% tolerance.

Output Voltage Transition Timing (TIME)

The MAX1813 is designed to perform output voltage

transitions in a controlled manner, automatically minimizing input surge currents. This feature allows the circuit designer to achieve nearly ideal transitions,

guaranteeing just-in-time arrival at the new output voltage level with the lowest possible peak currents for a

given output capacitance. This makes the IC very suitable for IMVP-II CPUs and other CPUs that operate in

two or more modes with different core voltage levels.

The IMVP-II CPUs operate at multiple clock frequencies

and require multiple core voltages. When transitioning

*Float = no connection

Figure 6. Internal Multiplexers Block Diagram

Table 6. Suspend-Mode Output Voltages

Table 7. ZMODE Polarity Table

ZMODE

D0

D1

D2

D3

D4

IMPEDANCE

DECODER

IN OUT

(FIGURE 7)

MUX

01 OR 10

OUT

00 OR 11

SEL0 SEL1

D0-D4

DECODER

CODE

OUT

SUS MUX

0

OUT

DAC

ZMODE

CODE

SUS

S0

S1

MAX1813

S0/S1

DECODER

1

OUT

IN

SUS

S1 S0 OUTPUT VOLTAGE (V)

GND GND 0.975

GND REF 0.950

GND Float* 0.925

GND V

CC

0.900

REF GND 0.875

REF REF 0.850

REF Float* 0.825

REF V

CC

0.800

Float* GND 0.775

Float* REF 0.750

Float* Float* 0.725

Float* V

V

CC

V

CC

V

CC

V

CC

CC

GND 0.675

REF 0.650

Float* 0.625

V

CC

0.700

0.600

CODE ZMODE

0 0 Impedance Mode

0 1 Logic Mode

1 0 Logic Mode

1 1 Impedance Mode

Page 23

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________ 23

from one clock frequency to another, the CPU first goes

into a low-power state, then the output voltage and

clock frequency are changed. The change must be

accomplished in 100µs or the system may halt.

At the beginning of an output voltage transition, the

MAX1813 forces the PGOOD output high. PGOOD

remains masked high until the slew-rate controller has

set the internal DAC to the final value and one additional slew-rate clock period has passed.

The output voltage transition is performed in 25mV

increments, preceded by a 4µs delay and followed by

one additional clock period after which PGOOD will

remain high if the output voltage is in regulation. The

total time for a transition depends on R

TIME

, the voltage

difference, and the accuracy of the MAX1813’s slewrate clock. The greater the output capacitance, the

higher the surge current required for the transition. The

MAX1813 will automatically control the current to the

minimum level required to complete the transition in the

calculated time, as long as the surge current is less

than the current limit set by ILIM. The transition time is

given by:

where ƒ

SLEW

= 150kHz x 120kΩ/R

TIME

, V

OLD

is the

original output voltage, and V

NEW

is the new output

voltage. See TIME Frequency Accuracy in Electrical

Characteristics for ƒ

SLEW

accuracy.

The practical range of R

TIME

is 47kΩ to 470kΩ, corre-

sponding to 2.6µs to 26µs per 25mV step. Although the

DAC takes discrete 25mV steps, the output filter makes

the transitions relatively smooth. The average inductor

current required to make an output voltage transition is:

Power-On Reset and Undervoltage

Lockout

VCCundervoltage lockout (UVLO) circuitry inhibits

switching, forces PGOOD low, and forces the DL gate

driver high. If the VCCvoltage drops below 4.2V, it is

assumed that there is not enough supply voltage to

make valid decisions. To protect the output from overvoltage faults, DL is forced high in this mode; this will

force the output to ground. This results in large negative inductor current and possibly small negative output

voltages. If V

CC

is likely to drop in this fashion, the output can be clamped with a Schottky diode to PGND to

reduce the negative excursion.

Power-on reset (POR) occurs when V

CC

rises above

approximately 2V. This resets the fault latch and prepares the PWM for operation. When V

CC

rises above

4.2V, the DAC inputs are sampled, and the output voltage begins to slew to the DAC setting. To ensure correct startup, V+ should be present before VCC. If the

converter attempts to bring the output into regulation

without V+ present, the fault latch will trip. For automatic startup, the battery voltage (V+) should be present

before VCC. The SKP/SDN pin can be forced low or

V

CC

power cycled to reset the fault latch.

Power-Good Output (PGOOD)

PGOOD is the open-drain output of a window comparator. This power-good output remains high impedance

as long as the output voltage is within +10%/-12.5% of

the regulation voltage. When the output voltage is

greater than 10% or less than the -12.5% window limits,

the internal MOSFET is activated and pulls the output

low. While the slew-rate controller is active (except during startup and shutdown), the MAX1813 forces

PGOOD high. PGOOD is low in shutdown, input undervoltage lockout, and during startup. Any fault condition

forces PGOOD low until the fault is cleared. For logiclevel output voltages, connect an external pullup resistor between PGOOD and V

CC

(or VDD). A 100kΩ

resistor works well in most applications.

I C 25mV

L OUT SLEW

≅×׃

t 4s +

1

1+

V-V

25mV

TRAN

SLEW

OLD NEW

≤µ

ƒ

Figure 7. Internal Mux Impedance-Mode Data Test and Latch

+5V

V

CC

GND

MAX1813

B-DATA

LATCH

3.0V TO 5.5V

26kΩ

26kΩ 26kΩ 26kΩ 26kΩ

D4

100kΩ

D3

100kΩ

D2

D1

D0

8kΩ

8kΩ 8kΩ 8kΩ 8kΩ

Page 24

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

24 ______________________________________________________________________________________

Output Overvoltage Protection

The overvoltage protection circuit is designed to protect the CPU against a shorted high-side MOSFET by

drawing high current and activating the battery’s protection circuit. The output voltage is continuously monitored for overvoltage. If the output exceeds the

overvoltage threshold, the fault protection is triggered

and the circuit shuts down. The DL low-side gate-driver

output latches high, which turns on the synchronousrectifier MOSFET with 100% duty and, in turn, rapidly

discharges the output filter capacitor, forcing the output

to ground. If the condition that caused the overvoltage

(such as a shorted high-side MOSFET) persists, the

battery’s protection circuit will engage. The MAX1813 is

latched off and won’t restart until SKP/SDN is toggled

or VCCpower is cycled.

Overvoltage protection can be defeated using the nofault test mode (see No-Fault Test Mode).

Output Undervoltage Protection

The output undervoltage protection (UVP) function is

similar to foldback current limiting but employs a timer

rather than a variable current limit. If the MAX1813 output voltage is under 70% of the nominal value, the

PWM is latched off and won’t restart until SKP/SDN is

toggled or VCCpower is cycled. To allow startup, UVP

is ignored during the undervoltage fault-blanking time

(the first 256 cycles of the slew rate after startup).

UVP can be defeated using the no-fault test mode (see

No-Fault Test Mode).

Thermal Fault Protection

The MAX1813 features a thermal fault protection circuit.

When the temperature rises above +160°C, the DL lowside gate-driver output latches high until SKP/SDN is

toggled or VCCpower is cycled. The threshold has

+15°C of thermal hysteresis, which prevents the regulator from restarting until the die cools off.

Thermal shutdown can be defeated using the no-fault

test mode (see No-Fault Test Mode).

No-Fault Test Mode

The over/undervoltage protection features can complicate the process of debugging prototype breadboards

since there are at most a few milliseconds in which to

determine what went wrong. Therefore, a test mode is

provided to disable the overvoltage protection, undervoltage protection, and thermal shutdown features, and

clear the fault latch if it has been set. In “no-fault” test

mode, the regulator operates as if SKP/SDN were high

(SKIP mode). Forcing 12V to 15V on SKP/SDN activates

no-fault test mode.

Design Procedure

Firmly establish the input voltage range and maximum

load current before choosing a switching frequency

and inductor operating point (ripple-current ratio). The

primary design trade-off lies in choosing a good switching frequency and inductor operating point, and the following four factors dictate the rest of the design:

Input voltage range: The maximum value (V

IN(MAX)

)