Page 1

General Description

The MAX1801 step-up slave DC-DC controller is used

with either the MAX1800 (step-up) or the MAX1802 (stepdown) master DC-DC converter to provide a complete

power-supply solution for digital still and digital video

cameras. By using the master converter’s reference voltage and oscillator, the size and the cost of the slave controller are reduced and all converters are guaranteed to

switch at the same frequency.

The MAX1801 drives an external N-channel MOSFET

and can be used in step-up, single-ended primary

inductance converter (SEPIC), and flyback topologies. If

extra supplies are required for a new design, slave controllers can be added to an existing master circuit with

minimal redesign, saving both cost and time. The

MAX1801 features a built-in soft-start, short-circuit protection, and an adjustable duty-cycle limit.

The MAX1801 is available in a space-saving 8-pin

SOT23 package. Separate evaluation kits combining the

MAX1800/MAX1801 (MAX1800EVKIT) and MAX1802/

MAX1801 (MAX1802EVKIT) are available to expedite

designs.

________________________Applications

Features

♦ Provides Simple Expandability for the MAX1800

and MAX1802 Master Converters

♦ Operates in Step-Up, SEPIC, and Flyback

Topologies

♦ 100kHz to 1MHz Adjustable Operating Frequency

♦ Duty-Cycle Limit Adjustable from 40% to 90%

♦ Soft-Start

♦ Short-Circuit Protection

♦ 0.01µA Supply Current in Shutdown Mode

♦ Tiny 8-Pin SOT23 Package

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

________________________________________________________________ Maxim Integrated Products 1

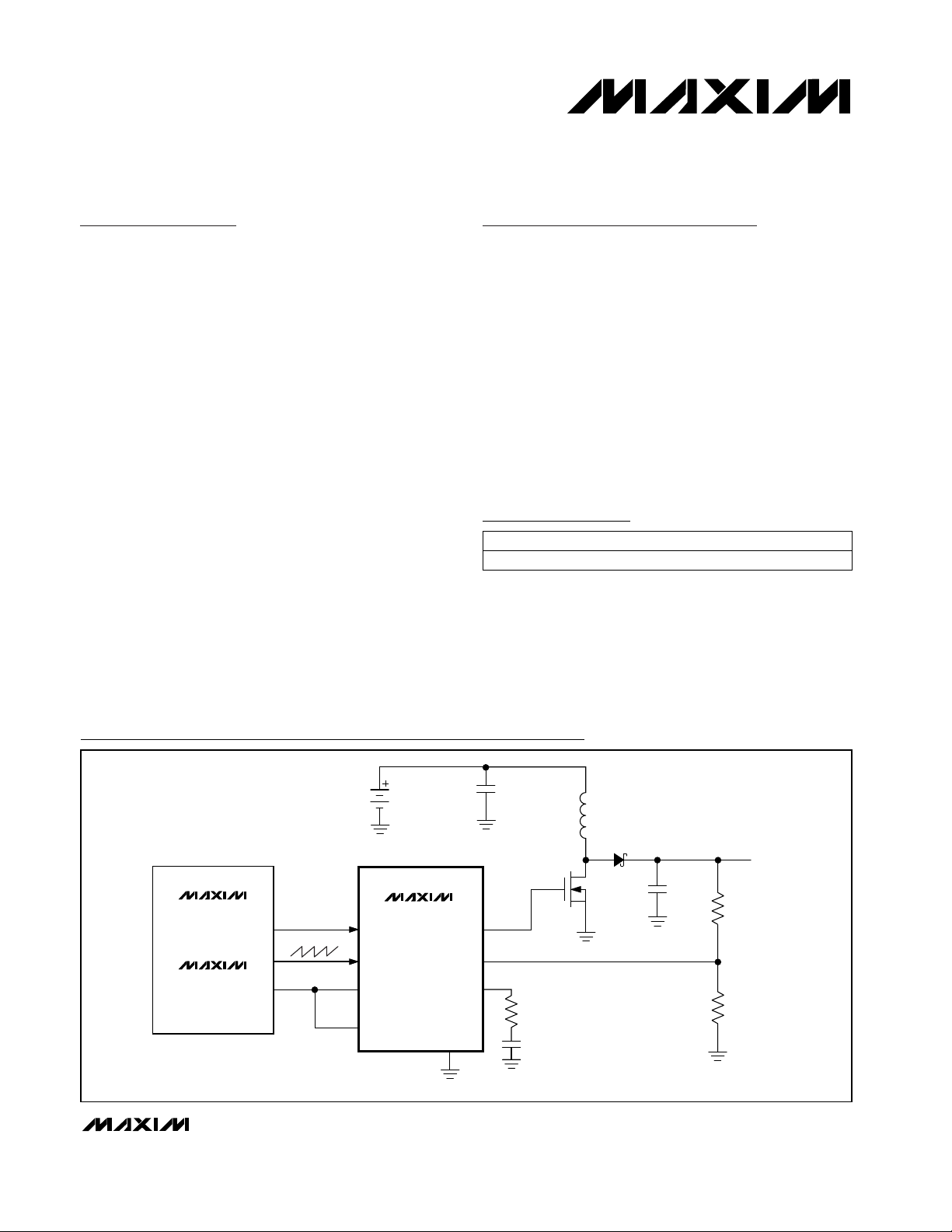

Typical Operating Circuit

19-1741 Rev 0; 10/00

Ordering Information

Pin Configuration appears at end of data sheet.

8 SOT23-8

PIN-PACKAGETEMP. RANGE

-40°C to +85°CMAX1801EKA-T

PART

Digital Still Cameras

Digital Video Cameras

Portable DVD Players

Internet Access Tablets

PDAs

Hand-Held Devices

For price, delivery, and to place orders, please contact Maxim Distribution at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

BATTERY

0.7V TO V

OUT

V

OUT

MAX1800

OR

MAX1802

1.25V

2.2V TO 5.5V

REF

OSC

IN

DCON

MAX1801

DL

FB

COMP

GND

Page 2

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, DCON, REF, OSC, FB to GND.........................-0.3V to +6.0V

DL, COMP to GND.......................................-0.3V to (VIN+ 0.3V)

Continuous Power Dissipation (TA= +70°C)

8-Pin SOT23 (derate 6mW/°C above+70°C)................480mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range. ............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

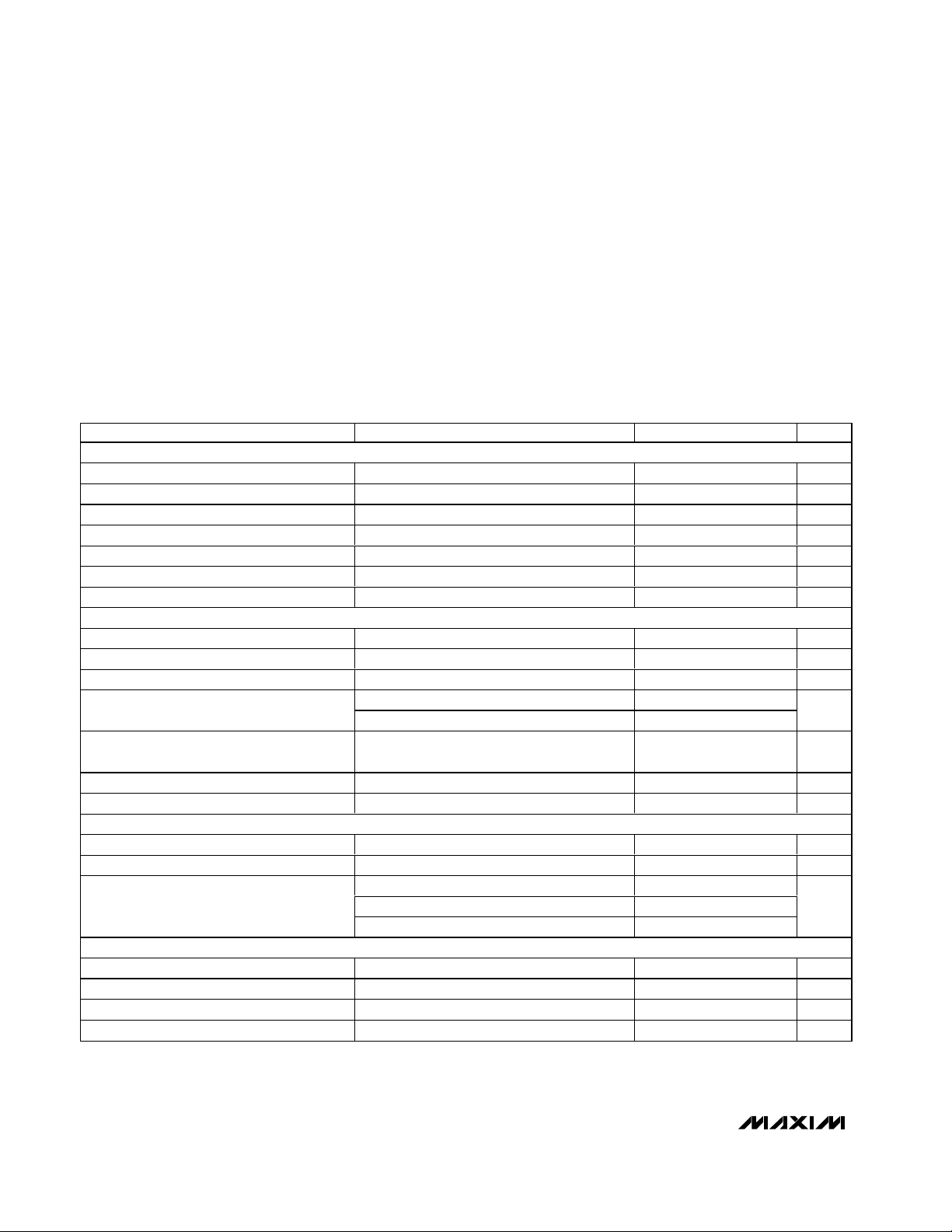

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VIN= +3.3V, V

DCON

= +1.25V, V

REF

= +1.25V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at

T

A

= +25°C.) (Note 1)

GENERAL

VIN Supply Voltage Operating Range 2.7 5.5 V

VIN Undervoltage Lockout Threshold VIN rising 2.2 2.35 2.5 V

REF Input Range 1.19 1.25 1.31 V

REF Undervoltage Lockout Threshold V

Shutdown Supply Current VIN = 5.5V, V

Sleep-Mode Supply Current VIN = 3.3V, V

Quiescent Supply Current V

OSCILLATOR INPUT

OSC Input Leakage Current V

Oscillator Frequency Range 100 1000 kHz

OSC Clock Low Trip Level 0.20 0.25 0.30 V

OSC Clock High Trip Level

Maximum Duty Cycle Adjustment Range

(Note 2)

Maximum Duty Cycle (Note 2) V

Default Maximum Duty Cycle (Note 2) V

INPUTS/OUTPUTS

DCON Input Leakage Current V

DCON Input Sleep-Mode Threshold IIN ≤ 10µA 0.35 0.4 0.45 V

ERROR AMPLIFIER

FB Regulation Voltage 1.238 1.250 1.263 V

FB to COMP Transconductance -5µA < I

FB to COMP Maximum Voltage Gain 2000 V/V

FB Input Leakage Current VFB = 1.35V 30 100 nA

PARAMETER CONDITIONS MIN TYP MAX UNITS

REF

OSC

OSC

V

DCON

f

OSC

DCON

DCON

DCON

V

DCON

V

DCON

V

DCON

rising 0.9 1.0 1.1 V

= 0, V

DCON

= 0, V

DCON

= 0, V

= 1.5V 0.04 1 µA

= 100kHz 40 90 %

= 0 124 300 µA

FB

= 0.625V 0.575 0.625 0.675

= 0.625V, f

= 1.25V, f

= 5.5V 9 100 nA

= 0 0.5 1.1

= V

= V

COMP

OSC

OSC

REF

, during soft-start 13 30

REF

< 5µA 70 100 160 µS

= 0 0.01 1 µA

REF

= 1.25V 5 10 µA

REF

1.00 1.05 1.10

= 100kHz 50 %

= 100kHz 84 %

3.3 10REF Input Current

V

µA

Page 3

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VIN= +3.3V, V

DCON

= +1.25V, V

REF

= +1.25V, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= +3.3V, V

DCON

= +1.25V, V

REF

= +1.25V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at

T

A

= +25°C.) (Note 1)

DRIVER

DL Driver Resistance 2.5 5 Ω

DL Drive Current 0.5 A

SOFT-START

Soft-Start Interval 1024

SHORT-CIRCUIT PROTECTION

Fault Interval 1024

PARAMETER CONDITIONS MIN TYP MAX UNITS

GENERAL

VIN Supply Voltage Operating Range 2.7 5.5 V

VIN Undervoltage Lockout Threshold VIN rising 2.15 2.55 V

REF Input Range 1.19 1.31 V

REF Undervoltage Lockout Threshold V

Shutdown Supply Current VIN = 5.5V, V

Sleep-Mode Supply Current VIN = 3.3V, V

Quiescent Supply Current V

OSCILLATOR INPUT

OSC Input Leakage Current V

Oscillator Frequency Range 100 1000 kHz

OSC Clock Low Trip Level 0.20 0.30 V

OSC Clock High Trip Level

Maximum Duty Cycle Adjustment Range

(Note 2)

INPUTS/OUTPUTS

DCON Input Leakage Current V

DCON Input Sleep-Mode Threshold IIN ≤ 10µA 0.35 0.45 V

PARAMETER CONDITIONS MIN TYP MAX UNITS

V

f

OSC

V

V

V

rising 0.85 1.15 V

REF

= 0, V

DCON

= 0, V

DCON

= 0, V

OSC

= 1.5V 1 µA

OSC

DCON

= 100kHz 40 90 %

DCON

DCON

DCON

DCON

= 0 300 µA

FB

= 0.625V 0.575 0.675

= 5.5V 100 nA

= 0 1.1

= V

REF

= V

, during soft-start 30

REF

= 0 1 µA

REF

= 1.25V 10 µA

REF

1.00 1.10

10REF Input Current

OS C

cycl es

OS C

cycl es

V

µA

Page 4

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= +3.3V, V

DCON

= +1.25V, V

REF

= +1.25V, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

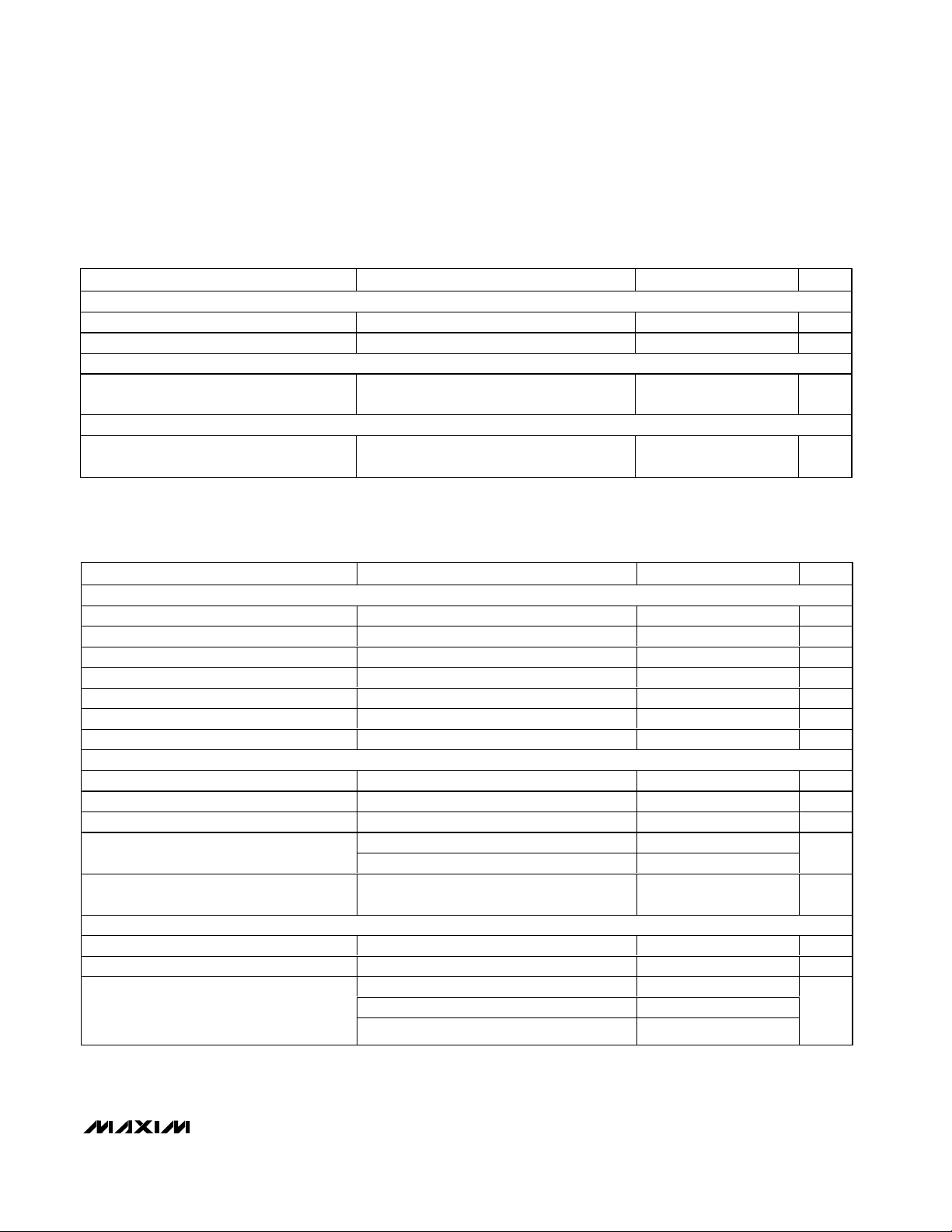

Typical Operating Characteristics

(Circuit of Figure 1, TA = +25°C, unless otherwise noted.)

90

0

1 100010010

EFFICIENCY vs. LOAD CURRENT

30

10

70

50

100

40

20

80

60

MAX1801 toc01

LOAD CURRENT (mA)

EFFICIENCY (%)

V

BATT

= +1.5V

V

OUT

= +12V

V

OUT

= +7V

V

OUT

= +18V

90

0

1 100010010

EFFICIENCY vs. LOAD CURRENT

30

10

70

50

100

40

20

80

60

MAX1801 toc02

LOAD CURRENT (mA)

EFFICIENCY (%)

V

BATT

= +2.4V

V

OUT

= +12V

V

OUT

= +7V

V

OUT

= +18V

90

0

1 100010010

EFFICIENCY vs. LOAD CURRENT

30

10

70

50

100

40

20

80

60

MAX1801 toc03

LOAD CURRENT (mA)

EFFICIENCY (%)

V

BATT

= +3.6V

V

OUT

= +12V

V

OUT

= +18V

V

OUT

= +7V

Note 1: All devices are 100% tested at TA= +25°C. All limits over the temperature range are guaranteed by design.

Note 2: Oscillator signal is generated by the MAX1800 or MAX1802.

PARAMETER CONDITIONS MIN TYP MAX UNITS

ERROR AMPLIFIER

FB Regulation Voltage 1.238 1.263 V

FB to COMP Transconductance -5µA < I

FB Input Leakage Current VFB = 1.35V 100 nA

DRIVER

DL Driver Resistance 5 Ω

< 5µA 70 160 µS

COMP

Page 5

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(Circuit of Figure 1, TA = +25°C, unless otherwise noted.)

MAXIMUM DUTY CYCLE vs. V

100

f

= 500kHz

OSC

80

60

40

MAXIMUM DUTY CYCLE (%)

20

0

0.4 0.60.5 0.7 0.8 0.9 1.0 1.1 1.2

V

(V)

DCON

SLEEP-MODE CURRENT

vs. INPUT VOLTAGE

10

8

6

4

DCON

MAX1801 toc04

MAX1801toc06

DEFAULT MAXIMUM DUTY CYCLE

vs. FREQUENCY

100

80

60

40

20

DEFAULT MAXIMUM DUTY CYCLE (%)

0

0 400200 600 800 1000

FREQUENCY (kHz)

C

OSC

= 470pF

SHUTDOWN CURRENT

vs. REFERENCE VOLTAGE

10

1

0.1

MAX1801 toc05

MAX1801 toc07

SLEEP-MODE CURRENT (µA)

2

0

2.5 3.53.0 4.0 4.5 5.0 5.5

INPUT VOLTAGE (V)

REFERENCE INPUT CURRENT

vs. TEMPERATURE

3.40

3.35

3.30

3.25

REFERENCE CURRENT (µA)

3.20

-40 0-20 20 40 60 80

TEMPERATURE (°C)

MAX1801 toc08

SHUTDOWN CURRENT (µA)

0.01

0.001

0 0.5 1.0 1.5

REFERENCE VOLTAGE (V)

FB TO COMP SMALL-SIGNAL OPEN-LOOP

FREQUENCY RESPONSE

60

50

40

30

20

SMALL-SIGNAL RESPONSE (dB)

10

0

1 100 100010 10,000

FREQUENCY (kHz)

MAX1801 toc09

Page 6

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

6 _______________________________________________________________________________________

Pin Description

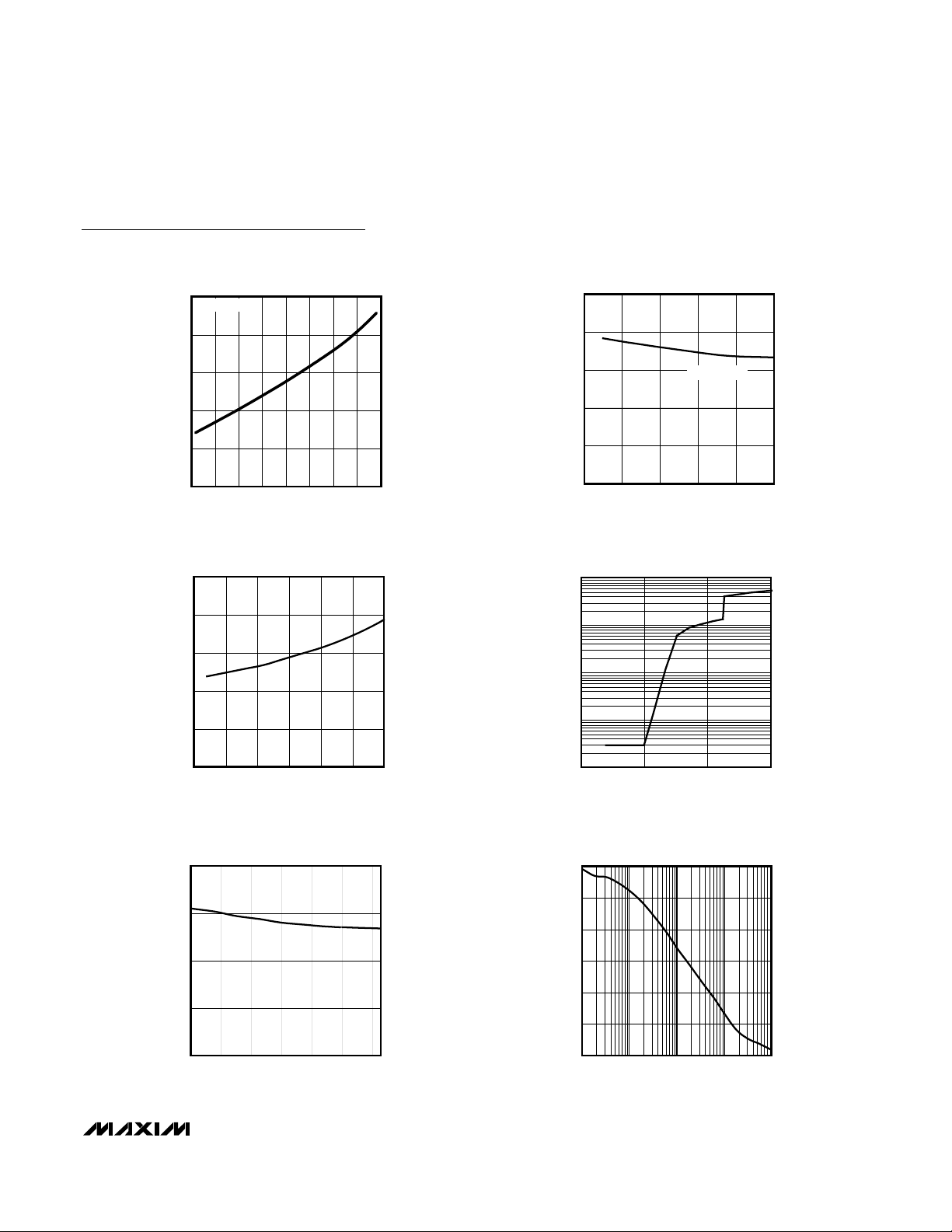

Typical Operating Characteristics (continued)

(Circuit of Figure 1, TA = +25°C, unless otherwise noted.)

OV

OV

OA

PIN NAME FUNCTION

1 OSC

2 GND Ground

3 REF

4 DCON

STARTUP RESPONSE

1ms/div

Oscillator Input. Connect OSC to OSC of the MAX1800 or MAX1802. The oscillator frequency must

be between 100kHz and 1MHz.

1.25V Reference Input. Connect REF to REF of the MAX1800 or MAX1802. REF must be above 1V

for the controller to turn on. Bypass REF to GND with a 0.1µF or greater capacitor.

Maximum Duty-Cycle Control Input. Connect to REF or IN to set the default maximum duty cycle.

Connect a resistive voltage-divider from REF to DCON to set the maximum duty cycle between 40%

and 90%. Pull DCON below 0.35V to turn the controller off.

MAX1801 toc10

V

DCON

5V/div

V

OUT

2V/div

I

IN

0.5A/div

500mA

100mA

LOAD TRANSIENT RESPONSE

OA

VIN = =+2.4V, V

OUT

= +5V, f

400µs/div

MAX1801 toc11

V

OUT

100mV/div

(AC-COUPLED)

I

LOAD

0.2A/div

= 500kHz

OSC

5 COMP

6 FB

7 IN

8 DL

Controller Compensation. Output of transconductance error amplifier. Connect a series resistor and

capacitor to GND to compensate the control loop. See Compensation Design.

Controller Feedback Input. Connect a feedback resistive voltage-divider from the output to FB to

set the output voltage. Regulation voltage is V

IC Supply Bias Input. Bypass IN to GND with a 0.1µF or greater ceramic capacitor. Supply range is

2.7V to 5.5V.

External MOSFET Gate Drive Output. DL swings between IN and GND with typical 500mA drive

current. Connect DL to the gate of the external switching N-channel MOSFET.

REF

(1.25V).

Page 7

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

_______________________________________________________________________________________ 7

MAX1800

Figure 1. Typical Application Circuit

Detailed Description

Master-Slave Configuration

The MAX1801 is a step-up slave DC-DC controller that

obtains its input power, voltage reference, and oscillator signal directly from a MAX1800 or MAX1802 master

DC-DC converter (Figure 1). The master-slave configuration reduces system cost by eliminating redundant

circuitry and controls the harmonic content of noise by

synchronizing converter switching.

Step-Up DC-DC Controller

The MAX1801 controller operates in a low-noise fixedfrequency PWM mode, with output power limited by the

external components. The controller regulates the output voltage by modulating the pulse width of the drive

signal for an external N-channel MOSFET switch. The

user-adjusted switching frequency is constant (100kHz

to 1MHz) and set by the master converter.

Figure 2 shows a block diagram of the MAX1801 PWM

controller. A sawtooth oscillator signal from the master

converter (at OSC) governs the internal timing. At the

beginning of each cycle, DL goes high to turn on the

external MOSFET switch. The MOSFET switch turns off

when the internally level-shifted sawtooth waveform

voltage rises above the voltage at COMP or when the

maximum duty cycle is exceeded. The switch remains

off until the beginning of the next cycle. An internal

transconductance amplifier establishes an integrated

error voltage at COMP, increasing the loop gain for

improved regulation accuracy and compensation control.

Reference

The MAX1801 requires a 1.25V reference voltage that

is obtained from the MAX1800 or the MAX1802. REF

typically sinks 0.5µA in shutdown mode, 3µA in active

mode, and up to 30µA during startup. If multiple

MAX1801 controllers are turned on simultaneously,

ensure that the master voltage reference can provide

sufficient current, or buffer the reference with an appropriate unity-gain amplifier.

OR

MAX1802

C

V

BATT

3.3V

1.25V

R3

R4

IN

OSC

REF

DCON

MAX1801

COMP

GND

IN

10µF

DL

FB

R

C

10k

C

C

1000pF

L

2.2µH

MBRO520L

FDN337N

C

OUT

47µF

V

OUT

R1

R2

Page 8

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

8 _______________________________________________________________________________________

Oscillator

The MAX1801 requires a 0 to 1.25V sawtooth oscillator

signal that is obtained from the MAX1800 or the

MAX1802 (at OSC). The 100kHz to 1MHz oscillator signal sets the converter switching frequency, and it is

used to control pulse-width modulation and maximum

duty cycle.

Maximum Duty Cycle

The MAX1801 uses the master-generated oscillator signal at OSC, the voltage at DCON, and an internal comparator to limit its maximum switching duty cycle (see

Setting the Maximum Duty Cycle). Limiting the duty

cycle can prevent saturation in some magnetic compo-

nents. A low maximum duty cycle can also force the

converter to operate in discontinuous current mode,

simplifying design stability at the cost of a slight reduction in efficiency.

Soft-Start

The MAX1801 features a soft-start function that limits

inrush current and prevents excessive battery loading

at startup by ramping the output voltage to the regulation voltage. This is achieved by increasing the internal

reference to the transconductance amplifier from 0 to

the 1.25V reference voltage over 1024 oscillator cycles

when initial power is applied or when the part is taken

out of shutdown or sleep mode.

Figure 2. PWM Controller Block Diagram

FB

COMP

LEVEL

REFI

REF

SHIFT

SOFT-

START*

R

S

Q

DL

DCON

OSC

*SOFT-START RAMPS REFI FROM 0 TO V

0.4V

1.1V

IN

2.35V

IC

POWER

IN 1024 CLK CYCLES.

REF

CLK

FAULT

PROTECTION

ENABLE

POWER-ON

Page 9

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

_______________________________________________________________________________________ 9

Shutdown

Set V

DCON

less than 0.35V to place the MAX1801 in

sleep mode, which drops the supply current to 5µA. To

reduce the supply current to 10nA, place the MAX1801

in shutdown by setting V

REF

below 0.4V. The MAX1801

enters soft-start when both V

DCON

and V

REF

are at nor-

mal levels.

Short-Circuit Protection

The MAX1801 has a fault protection feature that prevents damage to transformer-coupled or SEPIC circuits

due to an output short circuit. If the output voltage

drops out of regulation, the voltage at COMP is

clamped at 2.7V. If this condition is maintained for 1024

oscillator clock periods at any time following soft-start,

the MAX1801 is disabled to prevent excessive output

current. Restart the controller by cycling the voltage at

DCON or IN to GND and back to a normal state. For a

step-up application, short-circuit current is not limited,

due to the DC current path through the inductor and

output rectifier to the short circuit. If short-circuit protection is required in a step-up configuration, a protection

device such as a fuse must be used to limit short-circuit

current.

Design Procedure

The MAX1801 can operate in a number of DC-DC converter configurations, including step-up, SEPIC, and flyback. The following design discussions are limited to

the step-up configuration shown in Figure 1; SEPIC and

flyback examples are discussed in the Applications

Information section.

Switching Frequency

The MAX1801 switching frequency is set by the

MAX1800 or MAX1802 master converter (refer to the

appropriate data sheet for the design procedure).

Choose a switching frequency to optimize external

component size or efficiency for the particular

MAX1801 application. Typically, switching frequencies

between 400kHz and 500kHz offer a good balance

between component size and efficiency—higher frequencies generally allow smaller components, and

lower frequencies give better conversion efficiency.

Setting the Output Voltages

Set the MAX1801 output voltage by connecting a resistive voltage-divider from the output to FB as shown in

Figure 1. The FB input bias current is less than 100nA,

so choose R2 to be 100kΩ to minimize the effect of

input bias current at FB. Choose R1 according to the

relation:

where V

FB

is 1.25V, the regulation set point for the

MAX1801.

Setting the Maximum Duty Cycle

The master oscillator signal at OSC and the voltage at

DCON are used to generate the internal clock signal

(CLK in Figure 2). The internal clock’s falling edge

occurs when V

OSC

exceeds V

DCON

, the voltage at

DCON set by a resistive voltage-divider. The internal

clock’s rising edge occurs when V

OSC

falls below

0.25V (Figure 3). The maximum duty cycle can be

approximated by the equation:

where f

OSC

and t

FALL

are the oscillator frequency (in

Hz) and the fall time (typically 100ns), respectively.

At 100kHz, the adjustable maximum duty-cycle range is

typically 28% to 92% (see Maximum Duty Cycle vs.

V

DCON

in the Typical Operating Characteristics). The

maximum duty cycle typically defaults to 78% at 100kHz

if V

DCON

is at or above the voltage at V

REF

(1.25V), and

the controller shuts down if V

DCON

is less than 0.4V. If a

resistive voltage-divider is used at DCON, shut down the

MAX1801 by pulling DCON low with an open-drain signal from an external transistor. Drive DCON with appropriate logic levels to turn the MAX1801 on and off if the

default duty-cycle limit is used.

Figure 3. Setting the Maximum Duty Cycle

(V)

V

OSC

1.25

V

DCON

0.25

0

CLK

t

1

t

2

t

2

D

=

MAX

t1 +

t

2

RR

V

11

=−

OUT

2

V

FB

D

MAX OSC FALL

4

R

=

+

34

RR

−

1

ft

()

Page 10

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

10 ______________________________________________________________________________________

Inductor Selection

Select the inductor for either continuous or discontinuous

current. Continuous conduction generally is the most efficient. Use discontinuous current if the step-up ratio

(V

OUT

/ VIN) is greater than 1 / ( 1 – D

MAX

).

Continuous Inductor Current

For most MAX1801 step-up designs, a reasonable

inductor value (L

IDEAL

) can be derived from the following equation, which sets continuous peak-to-peak

inductor current at 1/3 the DC inductor current:

where D, the duty cycle, is given by:

In these equations, VSWis the voltage drop across the

N-channel MOSFET switch, and VDis the forward voltage drop across the rectifier. Given L

IDEAL

, the consis-

tent peak-to-peak inductor current is 0.333 I

OUT

/ (1 – D).

The maximum inductor current is 1.167 I

OUT

/ (1 – D).

Inductance values smaller than L

IDEAL

can be used;

however, the maximum inductor current will rise as L is

reduced, and a larger output capacitance will be

required to maintain output ripple.

The inductor current will become discontinuous if I

OUT

decreases by more than a factor of six from the value

used to determine L

IDEAL

.

Discontinuous Inductor Current

In the discontinuous mode of operation, the MAX1801

controller regulates the output voltage by adjusting the

duty cycle to allow adequate power transfer to the load.

To ensure regulation under worst-case load conditions

(maximum I

OUT

), choose:

The peak inductor current is VIND

MAX

/ (L f

OSC

).

The inductor’s saturation current rating should meet or

exceed the calculated peak inductor current.

Input and Output Filter Capacitors

The input capacitor (CIN) in step-up designs reduces

the current peaks drawn from the battery or input

power source and lessens switching noise in the controller. The impedance of the input capacitor at the

switching frequency should be less than that of the

input source so that high-frequency switching currents

do not pass through the input source.

The output capacitor is required to keep the output voltage ripple small and to ensure stability of the regulation

control loop. The output capacitor must have low

impedance at the switching frequency. Tantalum and

ceramic capacitors are good choices. Tantalum capacitors typically have high capacitance and medium-tolow equivalent series resistance (ESR) so that ESR

dominates the impedance at the switching frequency.

In turn, the output ripple is approximately:

V

RIPPLE

≈ I

L(PEAK)

ESR

where I

L(PEAK)

is the peak inductor current.

Ceramic capacitors typically have lower ESR than tantalum capacitors, but with relatively small capacitance

that dominates the impedance at the switching frequency. In turn, the output ripple is approximately:

V

RIPPLE

≈ I

L(PEAK)ZC

where IL(PEAK) is the peak inductor current, and ZC ≈

1 / (2 p fOSC COUT ).

See the Compensation Design section for a discussion

of the influence of output capacitance and ESR on regulation control loop stability.

The capacitor voltage rating must exceed the maximum

applied capacitor voltage. For most tantalum capacitors, manufacturers suggest derating the capacitor by

applying no more than 70% of the rated voltage to the

capacitor. Ceramic capacitors are typically used up to

the voltage rating of the capacitor. Consult the manufacturer’s specifications for proper capacitor derating.

Bypass Capacitors

If the MAX1801 is placed far from the MAX1800 or

MAX1802 master IC, noise from switching circuits can

affect the MAX1801. Should this be the case, bypass

REF and IN with 0.1µF or greater ceramic capacitors. If

noise is not a problem or if the MAX1801 is placed close

to the master IC, then no extra bypassing is required.

MOSFET Selection

The MAX1801 controller drives an external logic-level

N-channel MOSFET as the circuit switch element. The

key selection parameters are as follows:

• On-resistance (R

DS(ON)

)

• Maximum drain-to-source voltage (V

DS(MAX)

)

• Minimum threshold voltage (V

TH(MIN)

)

• Total gate charge (Qg)

• Reverse transfer capacitance (C

RSS

)

L

IDEAL

VV DD

−−31()()

IN SW

=

If

OUT OSC

V

D

≈−+1

IN

VV

OUT D

VD

OUT MAX

L

≤

If

2

OUT OSC

Page 11

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

______________________________________________________________________________________ 11

Since the external gate drive (DL) swings between IN

and GND, use a MOSFET whose on-resistance is specified at or below VIN. The gate charge, Qg, includes all

capacitance associated with gate charging and helps

to predict the transition time required to drive the MOSFET between on and off states. The power dissipated in

the MOSFET is due to on-resistance and transition losses. The on-resistance loss is:

P1≈ D I

L

2

R

DS(ON)

where D is the duty cycle, ILis the average inductor

current, and R

DS(ON)

is the on-resistance of the MOS-

FET. The transition loss is approximately:

where V

OUT

is the output voltage, ILis the average

inductor current, f

OSC

is the converter switching frequency, and tTis the transition time. The transition time

is approximately Qg/ IG, where Qgis the total gate

charge and IGis the gate drive current (typically 0.5A).

The total power dissipation in the MOSFET is:

P

MOSFET

= P1+ P

2

Diode Selection

For low-output-voltage applications, use a Schottky

diode to rectify the output voltage because of the

diode’s low forward voltage and fast recovery time.

Schottky diodes exhibit significant leakage current at

high reverse voltages and high temperatures. Thus, for

high-voltage, high-temperature applications, use ultrafast junction rectifiers.

Compensation Design

MAX1801 converters use voltage mode to regulate their

output voltages. The following explains how to compensate the control system for optimal performance. The

compensation differs depending on whether the inductor current is continuous or discontinuous.

Discontinuous Inductor Current

For discontinuous inductor current, the PWM converter

has a single pole. The pole frequency and DC gain of

the PWM controller are dependent on the operating

duty cycle, which is:

D = (2 L f

OSC

/ RE)

1/2

where REis the equivalent load resistance, or:

RE= V

IN

2

R

LOAD

/ (V

OUT(VOUT

– VIN))

The frequency of the single pole due to the PWM converter is:

PO= (2 V

OUT

– VIN) / (2 π (V

OUT

– VIN) R

LOADCOUT

)

And the DC gain of the PWM controller is:

AVO= 2 V

OUT(VOUT

– VIN) R

LOAD

/ ((2 V

OUT

– VIN) D)

Note that the pole frequency decreases and the DC

gain increases proportionally as the load resistance

(RLOAD) is increased. Since the crossover frequency

is the product of the pole frequency and the DC gain, it

remains independent of the load.

The gain through the voltage-divider is:

A

VDV

= V

REF

/ V

OUT

And the DC gain of the error amplifier is A

VEA

= 2000V/V.

Thus, the DC loop gain is:

A

VDC

= A

VDVAVEAAVO

The compensation resistor-capacitor pair at COMP cause

a pole and zero at frequencies (in Hz):

PC= GEA/ (4000 π CC) = 1 / (4 x 10

7

π C

C

)

ZC= 1 / (2 π RCCC)

And the ESR of the output filter capacitor causes a zero

in the loop response at the frequency (in Hz):

ZO= 1 / (2π C

OUT

ESR)

The DC gain and the poles and zeros are shown in the

Bode plot of Figure 4.

To achieve a stable circuit with the Bode plot of Figure

4, perform the following procedure:

Figure 4. MAX1801 Discontinuous-Current, Voltage-Mode,

Step-Up Converter Bode Plot

VIft

OUT L OSC T

P

23≈

180°

90°

PHASE

0°

GAIN

(dB)

80

P

A

VDC

60

40

20

O

-20

C

PHASE

ZC = P

O

GAIN

Z

O

FREQUENCY

Page 12

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

12 ______________________________________________________________________________________

1) Choose the compensation resistor RCthat is equivalent to the inverse of the transconductance of the

error amplifier, 1/ RC= GEA= 100µS, or RC= 10kΩ.

This sets the high-frequency voltage gain of the

error amplifier to 0dB.

2) Determine the maximum output pole frequency:

where:

R

LOAD(MIN)

= V

OUT

/ I

OUT(MAX)

3) Place the compensation zero at the same frequency

as the maximum output pole frequency (in Hz):

Solving for C

C

:

Use values of C

C

less than 10nF. If the above calculation determines that the capacitor should be

greater than 10nF, use C

C

= 10nF, skip step 4 , and

proceed to step 5.

4) Determine the crossover frequency (in Hz):

fC= V

REF

/ (π D C

OUT

)

and to maintain at least a 10dB gain margin, make

sure that the crossover frequency is less than or

equal to 1/3 of the ESR zero frequency, or:

3fC≤ Z

O

or:

ESR ≤ D / 6 V

REF

If this is not the case, go to step 5 to reduce the

error amplifier high-frequency gain to decrease the

crossover frequency.

5) The high-frequency gain may be reduced, thus

reducing the crossover frequency, as long as the

zero due to the compensation network remains at or

below the crossover frequency. In this case:

ESR ≤ D / (GEARC6 V

REF

)

and:

f

C

= (GEARC) 2 V

REF

/ (2π DC

OUT

) ≥ 1 / (2π RCCC)

Choose C

OUT

, RC, and CCto simultaneously satisfy

both equations.

Continuous Inductor Current

For continuous inductor current, there are two conditions that change, requiring different compensation.

The response of the control loop includes a right-halfplane zero and a complex pole pair due to the inductor

and output capacitor. For stable operation, the controller loop gain must drop below unity (0dB) at a much

lower frequency than the right-half-plane zero frequency. The zero arising from the ESR of the output capacitor is typically used to compensate the control circuit

by increasing the phase near the crossover frequency,

increasing the phase margin. If a low-value, low-ESR

output capacitor (such as a ceramic capacitor) is used,

the ESR-related zero occurs at too high a frequency

and does not increase the phase margin. In this case,

use a lower value inductor so that it operates with discontinuous current (see the Discontinuous Inductor

Current section).

For continuous inductor current, the gain of the voltage

divider is A

VDV

= V

REF

/ V

OUT

, and the DC gain of the

error amplifier is A

VEA

= 2000. The gain through the

PWM controller in continuous current is:

AVO= (1 / V

REF

) (V

OUT

2

/ VIN)

Thus, the total DC loop gain is:

A

VDC

= 2000 V

OUT

/ V

IN

The complex pole pair due to the inductor and output

capacitor occurs at the frequency (in Hz):

PO= (V

OUT

/ VIN) / (2π (L × C

OUT

)

1/2

)

The pole and zero due to the compensation network at

COMP occur at the frequencies (in Hz):

PC = GEA/ (4000 π CC) = 1 / (4 x 10

7

π C

C

)

ZC= 1 / (2π RCCC)

The frequency (in Hz) of the zero due to the ESR of the

output capacitor is:

ZO= 1 / (2π C

OUT

ESR)

And the right-half-plane zero frequency (in Hz) is:

The Bode plot of the loop gain of this control circuit is

shown in Figure 5.

P

O(MAX)

=

2V - V

V-V C

IN LOAD(MIN)

OUT OUT

OUT

R2π()

IN

Z

C

CC V

12V-V

==

22ππRC R()

CC

=

C OUT OUT

V-V C

OUT IN LOAD(MIN) OUT

R()2

C OUT(MAX) OUT IN

OUT IN

V-V

OUT IN

IV-V

2

Z

RHP

(1- D) R

=

2L

π

LOAD

Page 13

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

______________________________________________________________________________________ 13

To configure the compensation network for a stable

control loop, set the crossover frequency at that of the

zero due to the output capacitor ESR. Use the following

procedure:

1) Determine the frequency of the right-half-plane

zero:

2) Find the DC loop gain:

A

VDC

= 2000 V

OUTVIN

3) Determine the frequency of the complex pole pair

due to the inductor and output capacitor:

f

O

= (V

OUT

/ VIN) / (2π (L C

OUT

)

1/2

)

4) Since response is 2nd order (-40dB per decade)

between the complex pole pair and the ESR zero,

determine the desired amplitude at the complex

pole pair to force the crossover frequency equal to

the ESR zero frequency. Thus:

A(P

O

) = (ZO/ PO)2= L V

IN

2

/ (C

OUT

ESR2V

OUT

2

)

5) Determine the desired compensation pole. Since

the response between the compensation pole and

the complex pole pair is 1st order (-20dB per

decade), the ratio of the frequencies is equal to the

ratio of the amplitudes at those frequencies. Thus:

(P

O

/ PC) = (ADC/ A(PO))

Solving this equation for CC:

CC= V

OUT(COUT

)

3/2

ESR2/ (20MΩ VIN(L)

1/2

)

6) Determine that the compensation resistor, RCfor

the compensation zero frequency, is equal to the

complex pole-pair frequency:

Z

C

= P

O

solving for RC:

R

C

= (VIN/ V

OUT

) ((L C

OUT

)

1/2

/ CC)

Applications Information

Using the MAX1801 with the MAX1800

Step-Up Master DC-DC Converter

The MAX1801 does not generate its own reference or

oscillator. Instead it uses the reference and the oscillator

from a master DC-DC converter such as the MAX1800

step-up master converter. The MAX1800 has circuitry to

generate a 1.25V reference and a 100kHz to 1MHz oscillator signal. The MAX1800 operates from a 1.5V to 5.5V

input voltage, which makes it suitable for applications

with 2- or 3-cell alkaline, NiCd, or NiMH batteries, or 1-cell

lithium primary or lithium-ion (Li+) batteries. Apart from

the reference and the oscillator, the MAX1800 has a single-internal-switch synchronous-rectified step-up DC-DC

converter, three auxiliary step-up DC-DC converter controllers, and a linear regulator controller. For more details,

refer to the MAX1800 data sheet

Using the MAX1801 with the MAX1802

Step-Down Master DC-DC Converter

The MAX1801 does not generate its own reference or

oscillator. Instead, it uses the reference and the oscillator from a master DC-DC converter such as the

MAX1802 step-down master DC-DC converter. The

MAX1802 has circuitry to generate a 1.25V reference

and a 100kHz to 1MHz oscillator signal. The MAX1802

operates from a 2.7V to 11V input voltage, making it

suitable for 4-series alkaline, NiCd, or NiMH cells, or 2series lithium primary or (Li+) batteries. The MAX1802

has a synchronous-rectified step-down DC-DC converter controller, an internal-switch synchronous-rectified

step-down DC-DC converter, and three auxiliary stepup DC-DC converter controllers. For more details, refer

to the MAX1802 data sheet.

Figure 5. MAX1801 Continuous-Current, Voltage-Mode,

Step-Up Converter Bode Plot

PC

A

VDC

PHASE

GAIN

(dB)

O dB

GAIN

PHASE

MARGIN

FREQUENCY

ZC=P

O

GAIN

Z

0

MARGIN

Z

rRHP

180°

90°

PHASE

0°

Z

RHP

=

2

(1- D) R

2L

π

LOAD

Page 14

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

14 ______________________________________________________________________________________

Using the MAX1801 Controller in

SEPIC Configuration

In cases where the battery voltage is above or below

the required output voltage, neither a step-up nor a

step-down converter is suitable; use a step-up/stepdown converter instead. One type of step-up/stepdown converter is the SEPIC shown in Figure 6.

Inductors L1 and L2 can be separate inductors or can

be wound on a single core and coupled as with a transformer. Typically, using a coupled inductor improves

efficiency because some power is transferred through

the coupling so that less power passes through the coupling capacitor, C2. Likewise, C2 should be a low-ESRtype capacitor to improve efficiency. The coupling

capacitor ripple current rating must be greater than the

larger of the input and output currents. The MOSFET

(Q1) drain-source voltage rating and the rectifier (D1)

reverse voltage rating must exceed the sum of the input

and output voltages. Other types of step-up/step-down

circuits are a flyback converter and a step-up converter

followed by a linear regulator.

Using the MAX1801 Controller for a

Multi-Output Flyback Circuit

Some applications require multiple voltages from a single converter that features a flyback transformer.

Figure 7 shows a MAX1801 auxiliary controller in a twooutput flyback configuration. The controller drives an

external MOSFET that switches the transformer primary,

and the two secondaries generate the outputs. Only a

single positive output voltage can be regulated using

the feedback resistive voltage-divider, so the other voltages are set by the turns ratio of the transformer secondaries. The regulation of the other secondary voltages

degrades due to transformer leakage inductance and

winding resistance. Voltage regulation is best when the

load current is limited to a small range. Consult the

transformer manufacturer for the proper design for a

given application.

Using a Charge Pump to Make

Negative Output Voltages

Negative output voltages can be produced without a

transformer using a charge-pump circuit with an auxiliary controller, as shown in Figure 8. When MOSFET Q1

turns off, the voltage at its drain rises to supply current

to V

OUT

+. At the same time, C1 charges to the voltage

at V

OUT

+ through D1. When the MOSFET turns on, C1

discharges through D3, thereby charging C3 to V

OUT

minus the drop across D3, to create roughly the same

voltage as V

OUT

+ at V

OUT

- but with inverted polarity. If

different magnitudes are required for the positive and

negative voltages, a linear regulator can be used at one

of the outputs to achieve the desired voltages, while the

MAX1801 regulates the higher magnitude voltage.

Figure 6. MAX1801 Auxiliary Controller, SEPIC Configuration

Figure 7. MAX1801 Auxiliary Controller, Flyback Configuration

INPUT

1 CELL

Li+

L

MAIN

ON

DCON

MAX1801

COMP

INPUT

MAIN

ON

MAX1801

COMP

R

G

DCON

R

G

EXT

C

C

EXT

C

C

FB

Q

FB

2

OUTPUT

R

R

R

1

R

2

3.3V

1

2

+ OUTPUT

- OUTPUT

D

C

Q

1

2

1

D

3

D

2

1

Page 15

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

______________________________________________________________________________________ 15

Chip Information

TRANSISTOR COUNT: 1130

Pin Configuration

Designing a PC Board

A good PC board layout is important to achieve optimal

performance from the MAX1801. Poor design can cause

excessive conducted and/or radiated noise, both of

which can cause instability and/or regulation errors.

Conductors carrying discontinuous currents should be

kept as short as possible, and conductors carrying

high currents should be made as wide as possible. A

separate low-noise ground plane containing the reference and signal grounds should connect only to the

power-ground plane at one point to minimize the

effects of power-ground currents.

Keep the voltage feedback network very close to the

IC, preferably within 0.2in (5mm) of the FB pin. Nodes

with high dv/dt (switching nodes) should be kept as

small as possible and should be kept away from highimpedance nodes such as FB.

Circuit-board layouts that are susceptible to electrical

noise can require a lowpass RC filter at OSC and

bypassing at REF and IN. If an RC filter is used at OSC,

the pole frequency should be at least 20 times larger

than the oscillator frequency to prevent distortion of the

OSC signal. To ensure minimal loading of the master

oscillator, which would cause an oscillator frequency

shift, choose a filter capacitor smaller than C

OSC

/(100

N), where C

OSC

is the timing capacitor for the master

oscillator and N is the number of MAX1801 slaves connected to the master. Then choose R

FILTER

= 1/(40 π

f

OSCCFILTER

).

If bypass capacitors are required on IN and REF, use

0.1µF ceramic capacitors because of their low impedance at high frequencies. The bypass and filter components should be placed within 5mm (0.2in) of the

MAX1801 pins.

Refer to the MAX1800 evaluation kit (EV kit) or

MAX1802 EV kit data sheets for full PC board examples.

Figure 8. Auxiliary Controller, Charge-Pump Configuration

D

3

V

-

INPUT

C

3

D

MAIN

ON

MAX1801

COMP

DCON

R

G

EXT

C

C

L

FB

C

Q

1

1

1

D

2

C

2

OUT

V

+

OUT

R

1

R

2

TOP VIEW

OSC

1

2

REF

MAX1801

3

4

SOT23-8

87DL

6

5

INGND

FB

COMPDCON

Page 16

MAX1801

Digital Camera Step-Up Slave

DC-DC Controller

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

SOT23, 8L.EPS

Loading...

Loading...