Page 1

General Description

The MAX1775 is a dual, step-down DC-DC converter

that generates both the main (+3.3V at over 2A) and

core (+1.8V at up to 1.5A) supplies for a complete

power solution for PDAs, subnotebooks, and other

hand-held devices. The main output is adjustable from

+1.25V to +5.5V. The core output is adjustable from 1V

to 5V. Both switching converters operate at up to

1.25MHz for small external components and use synchronous rectifiers to achieve efficiencies up to 95%.

Operation with up to 100% duty cycle provides the lowest possible dropout voltage to extend useful battery

life.

The MAX1775 accepts inputs from +2.7V up to +28V,

allowing use with many popular battery configurations as

well as AC-DC wall adapters. Digital soft-start reduces

battery current surges at power-up. Both the main and

core converters have separate shutdown inputs. The

MAX1775 comes in a small 16-pin QSOP package.

The MAX1775 evaluation kit is available to help reduce

design time.

________________________Applications

Hand-Held Computers

PDAs

Internet Access Tablets

POS Terminals

Subnotebooks

Features

♦ Dual, High-Efficiency, Synchronous Rectified

Step-Down Converter

♦ Main Power

Adjustable from +1.25V to +5.5V

Over 2A Load Current

Up to 95% Efficiency

♦ Core Power

Adjustable from 1V to 5V

Internal Switches

Up to 1.5A Load Current

Up to 92% Efficiency

♦ 100% (max) Duty Cycle

♦ Up to 1.25MHz Switching Frequency

♦ Input Voltage Range from +2.7V to +28V

♦ 170µA Quiescent Current

♦ 5µA Shutdown Current

♦ Digital Soft-Start

♦ Independent Shutdown Inputs

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

________________________________________________________________ Maxim Integrated Products 1

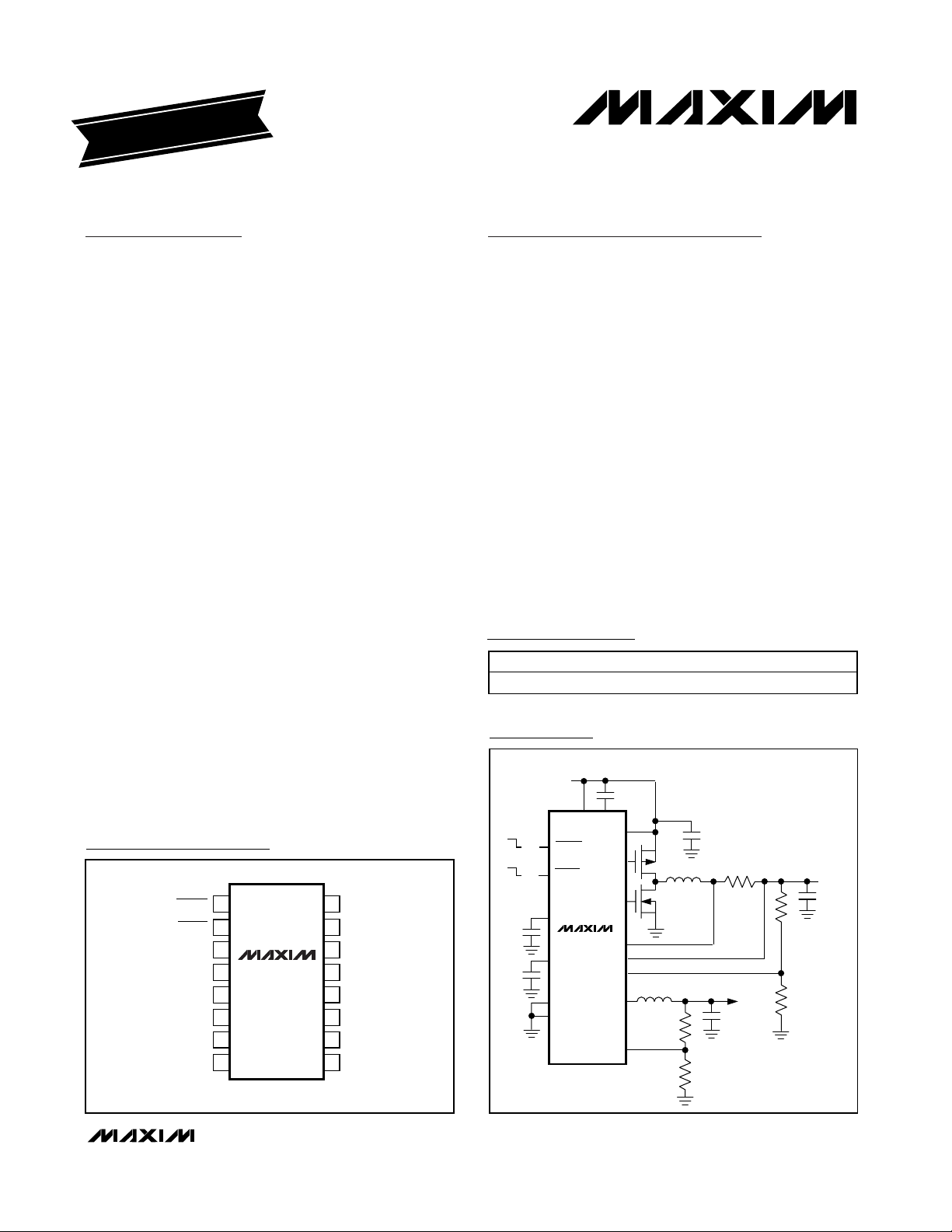

Pin Configuration

19-1811; Rev 1; 8/01

EVA

LUA

TIO

N

KIT

AVA

ILA

B

LE

Ordering Information

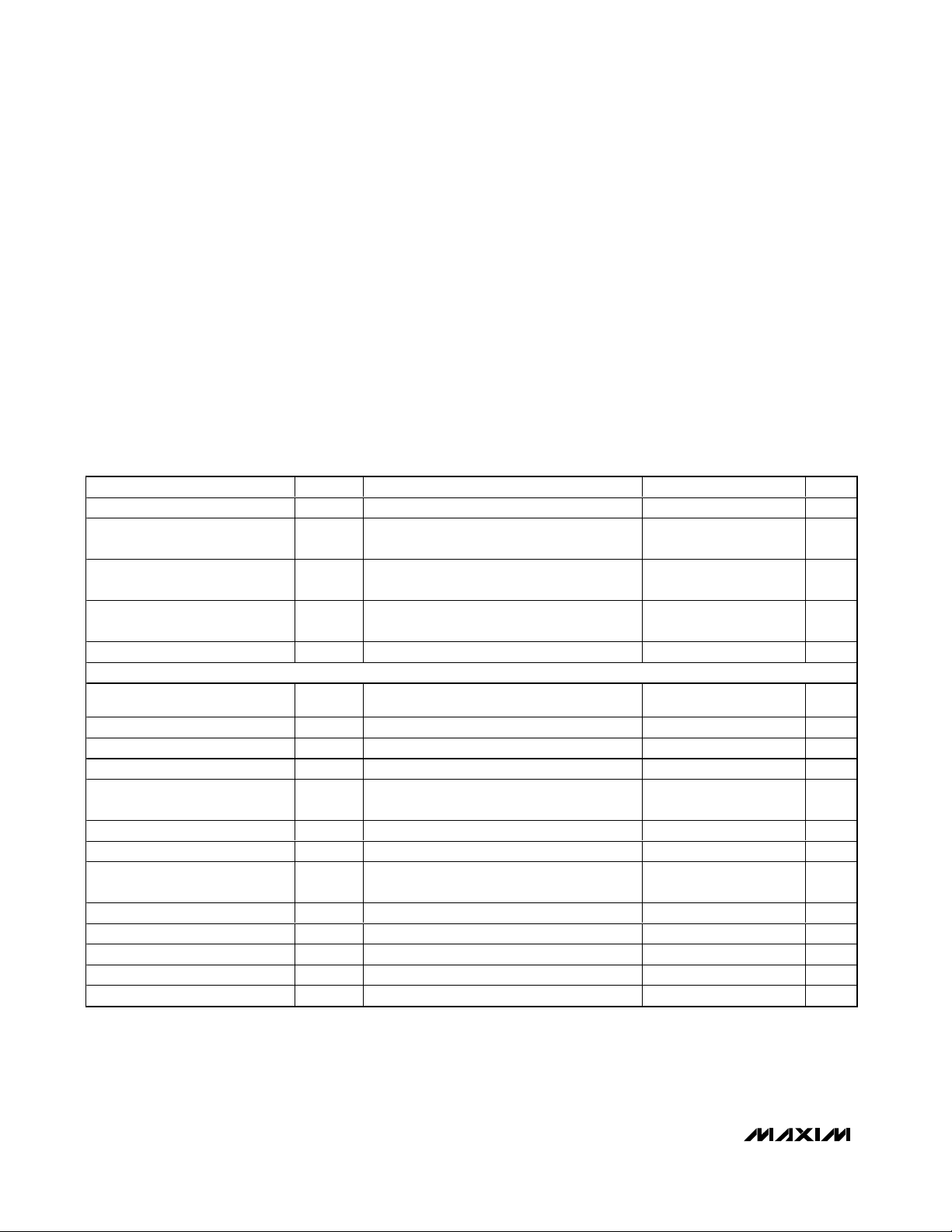

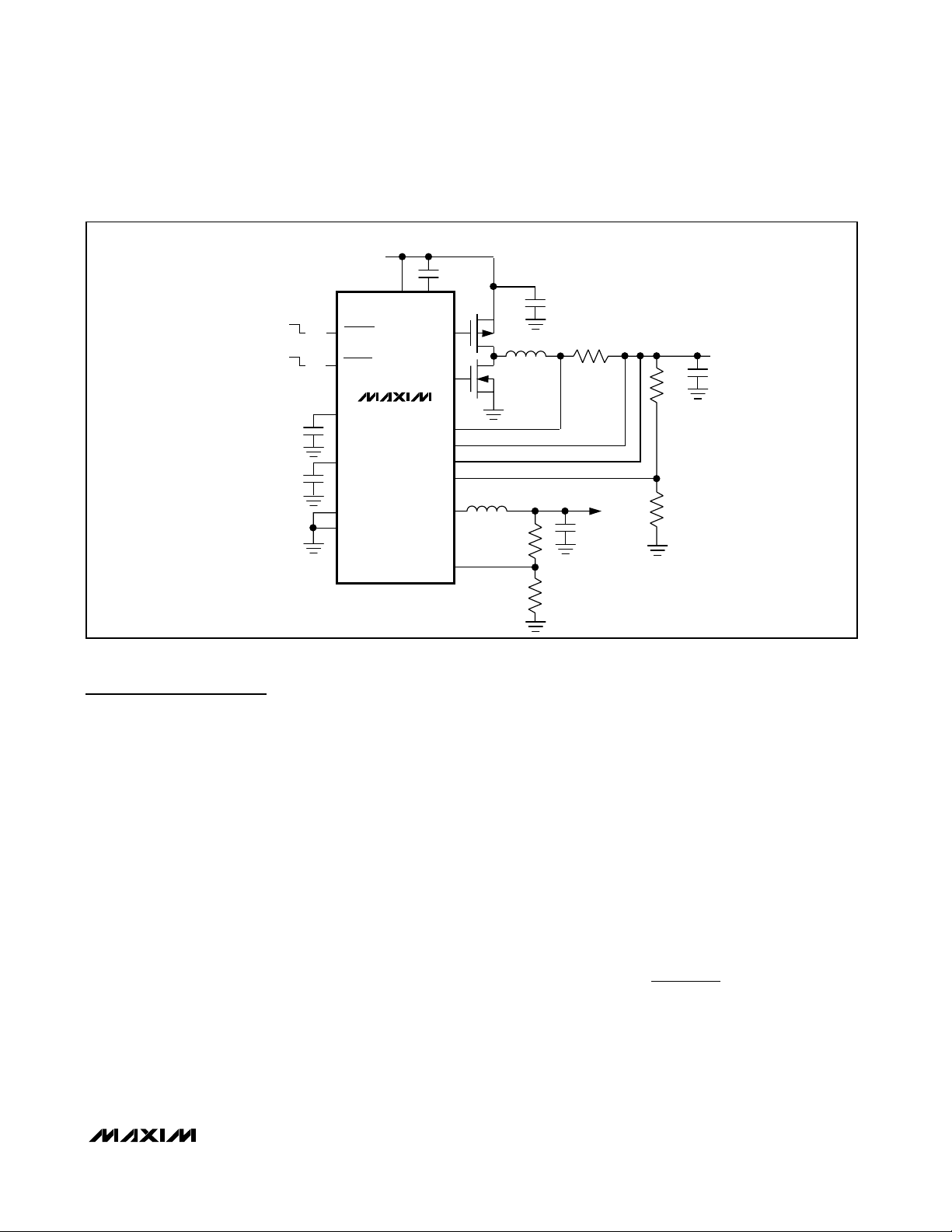

Typical Operating Circuit

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART TEMP. RANGE PIN-PACKAGE

MAX1775EEE -40°C to +85°C 16 QSOP

IN 2.7V TO 5.5V (28V IN CASCADE)

IN

CVH

MAX1775

INC

PDRV

NDRV

CS+

CS-

FBM

LXC

FBC

CORE

1.8V

1.5A

TOP VIEW

ON

OFF

OFF

SHDNM

SHDNC

CVL

REF

PGND

GND

ON

1

SHDNM LXC

2

SHDNC

PGND

3

MAX1775

4

NDRV

CVL

5

IN

6

PDRV

7

CVH

8

16 QSOP

16

15

INC

14

GND

13

FBC

12

CS-

CS+

11

10

FBM

9

REF

MAIN

3.3V

OVER 2A

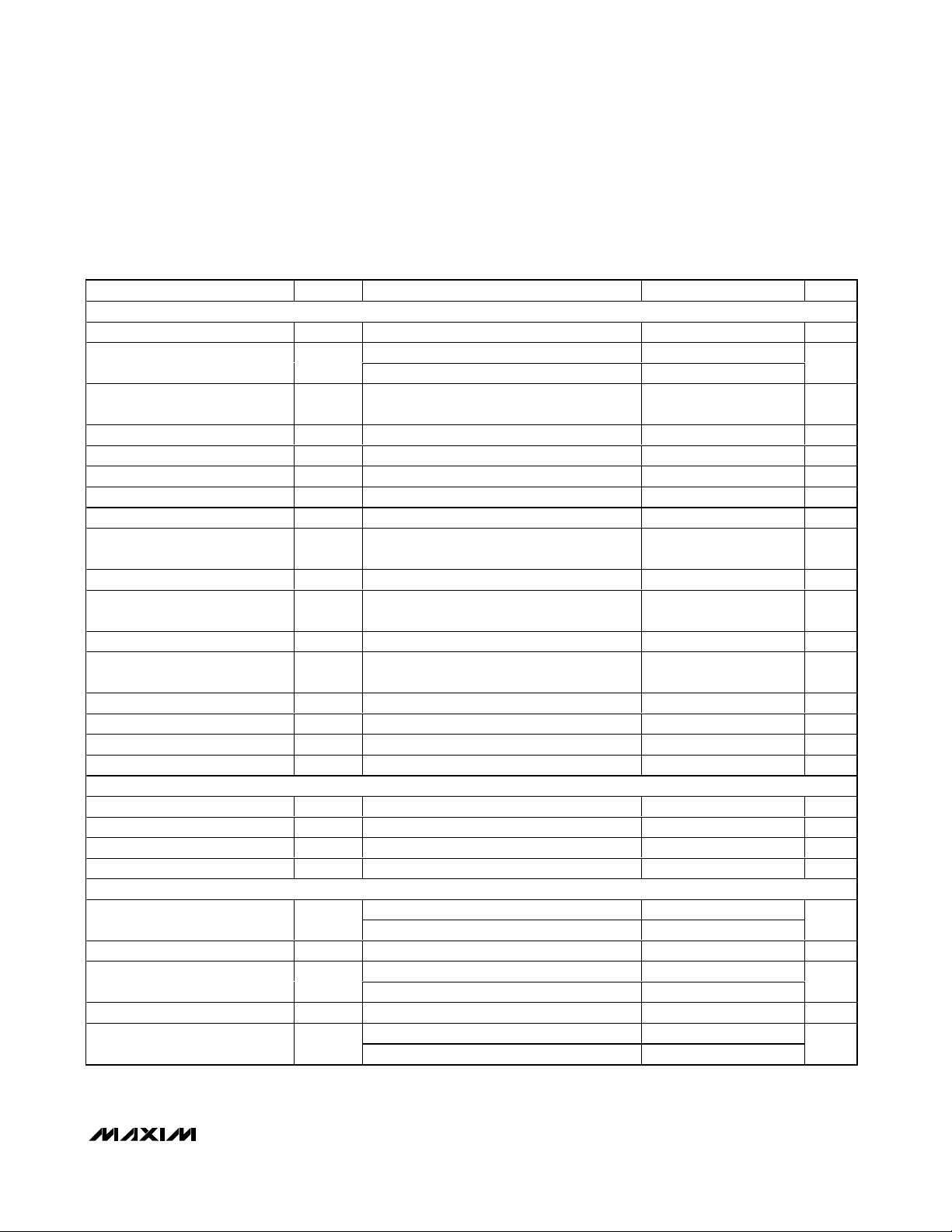

Page 2

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

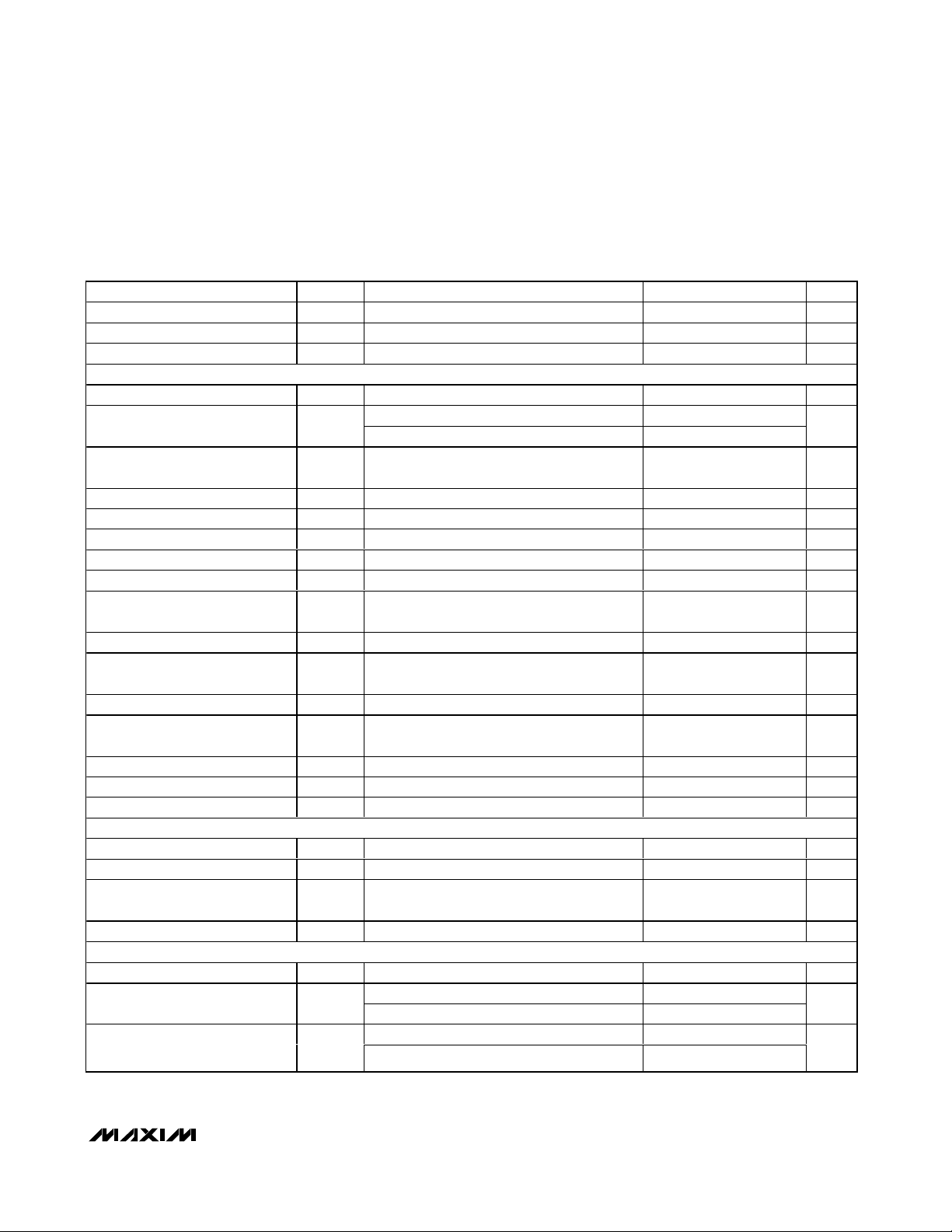

ELECTRICAL CHARACTERISTICS

(VIN= +12V, V

MAIN

= V

INC

= V

CS-

= V

CS+

= +3.3V, V

CORE

= +1.8V, Circuit of Figure 4, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, SHDNM, CVH to GND.......................................-0.3V to +30V

IN to CVH, PDRV ......................................................-0.3V to +6V

PDRV to GND..................................(V

CVH

- 0.3V) to (VIN+ 0.3V)

PGND to GND .......................................................-0.3V to +0.3V

All Other Pins to GND...............................................-0.3V to +6V

Core Output Short Circuit...........................................Continuous

Continuous Power Dissipation

16-Pin QSOP (derate 7.1mW/°C above +70°C)..........571mW

Operating Temperature .......................................-40°C to +85°C

Storage Temperature.........................................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

(

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Voltage V

Input Quiescent Supply Current I

CS- Quiescent Supply Current ICS-

Core Regulator Quiescent

Supply Current

IN Shutdown Supply Current SHDNM = SHDNC = GND 5 30 µA

MAIN REGULATOR

Main Output Voltage Adjust

Range

FBM Regulation Threshold V

FBM Input Current I

Current-Limit Threshold V

Minimum Current-Limit

Threshold

Valley Current Threshold V

Zero Current Threshold V

PDRV, NDRV Gate Drive

Resistance

CS- to CVL Switch Resistance I

PDRV, NDRV Dead Time 50 ns

Maximum Duty Cycle 100 %

Minimum On-Time 200 400 650 ns

Minimum Off-Time 200 400 650 ns

IN

IN

I

INC

FBM

FBM

CLM

V

MIN

VALLEYVCS+

ZERO

V

= +1.5V, V

FBM

V

V

V

V

V

V

V

V

V

V

V

= V

SHDNM

= +1.5V, V

FBM

= V

SHDNM

= +1.5V, V

FBM

= V

SHDNM

C S + - C S - )

FBM

CS+

CS+

CS+

CS-

CVL

= 0 to + 60m V , V

= +1.3V -0.1 0.1 µA

- V

CS-

- V

CS-

- V

CS-

- V

CS-

= +3.3V, I

= 50mA 4.5 8 Ω

2.7 28 V

= +1.5V,

FBC

SHDNC

FBC

SHDNC

FBC

SHDNC

= +3.3V

= +1.5V,

= +3.3V

= +1.5V,

= +3.3V

15 30 µA

110 220 µA

60 120 µA

1.25 5.5 V

= + 2.7V to + 28V 1.21 1.25 1.29 V

IN

60 80 100 mV

61524mV

40 50 60 mV

015mV

= 50mA 2 4.4 Ω

LOAD

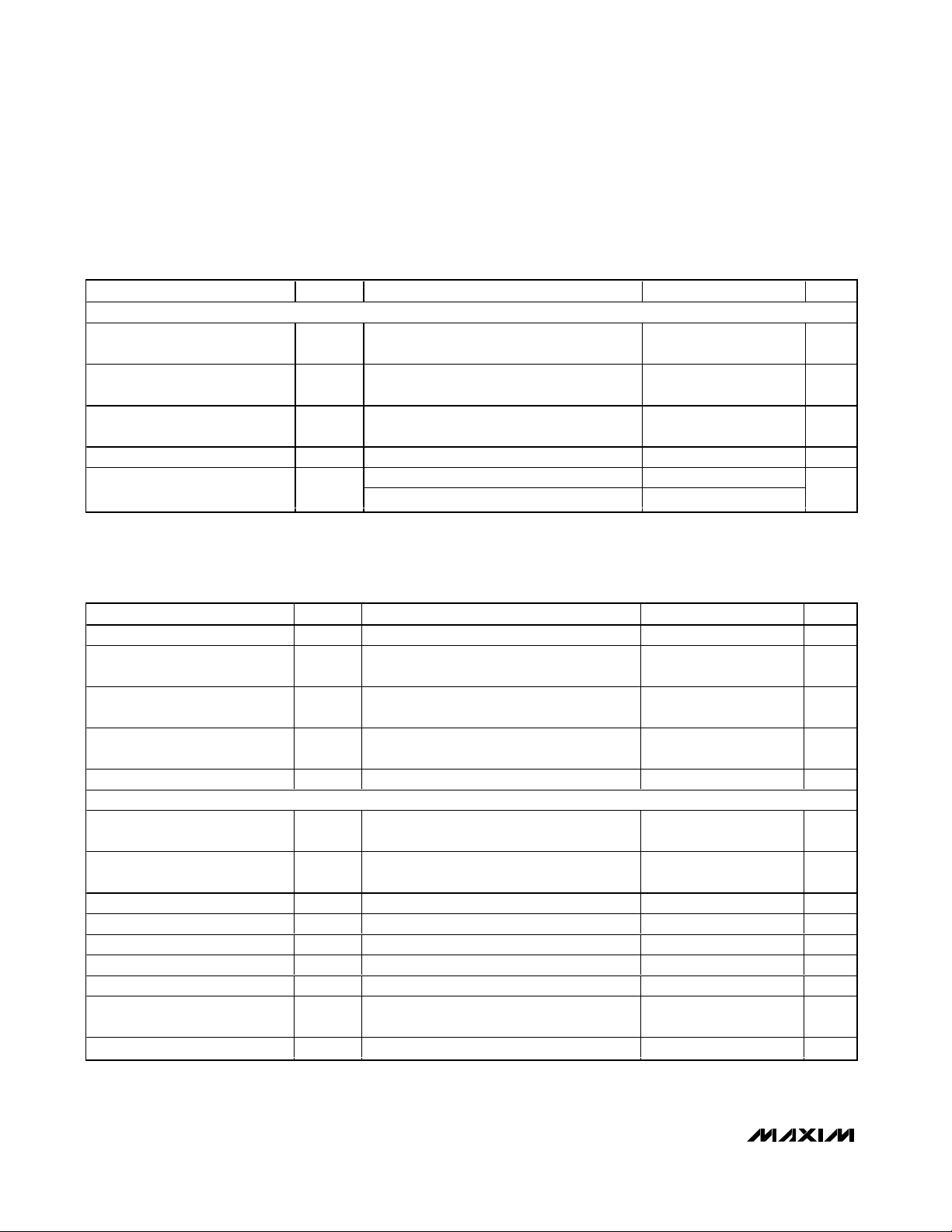

Page 3

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +12V, V

MAIN

= V

INC

= V

CS-

= V

CS+

= +3.3V, V

CORE

= +1.8V, Circuit of Figure 4, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CORE REGULATOR

Input Voltage Range V

INC Undervoltage Lockout

Core Output Voltage Adjust

Range

Maximum Core Load Current (Note 1) 1 1.5 A

FBC Regulation Threshold V

FBC Input Current I

Dropout Voltage (INC to LXC) I

LXC Leakage Current I

LXC P-Channel, N-Channel

On-Resistance

LXC P-Channel Current Limit I

LXC P-Channel Minimum

Current

LXC N-Channel Valley Current 900 1400 2400 mA

LXC N-Channel Zero-Crossing

Current

LXC Dead Time 50 ns

Maximum Duty Cycle 100 %

Minimum On-Time 170 400 670 ns

Minimum Off-Time 170 400 670 ns

REFERENCE

Reference Voltage V

Reference Load Regulation I

Reference Line Regulation VCS- = +2.5V to +5.5V, I

Reference Sink Current I

CVL, CVH REGULATORS

CVL Output Voltage V

CVL Switchover Threshold V

CVH Output Voltage V

CVH Switchover Threshold V

CVL Undervoltage Lockout

INC

FBC

FBC

LXC

CLC

REF

REF

CVL

CVH

IN

2.6 5.5 V

V

rising 2.40 2.47 2.55

INC

falling 2.30 2.37 2.45

V

INC

1.0 5.0 V

V

= +2.5 to +5.5V, I

INC

V

= +1.3V -0.1 0.1 µA

FBC

= 400mA 0.1 0.25 V

OUTC

V

= +5.5V, V

INC

= 0 to +5.5V -10 10 µA

LXC

= 0 to 200mA 0.97 1.0 1.03 V

OUTC

0.25 0.5 Ω

1200 1800 3000 mA

100 200 400 mA

40 110 170 mA

1.23 1.25 1.27 V

= 0 to 50µA 10 mV

REF

= 50µA 5 mV

REF

10 µA

I

= 50mA, V

CVL

I

= 50mA, VCS- = +3.3V 3.2

CVL

rising, hysteresis = 100mV (typ) 2.40 2.47 2.55 V

CS-

VIN = +4V, I

VIN = +12V, I

= +2.7V, VCS- = 0 2.6 2.8 3.1

IN

= 25mA V

CVH

= 50mA V

CVH

IN

IN

- 3.4 V

- 4.3 V

VIN rising, hysteresis = 350mV (typ) 5.5 V

V

rising 2.40 2.47 2.55

CVL

falling 2.30 2.37 2.45

V

CVL

IN

IN

- 2.8

- 3.7

V

V

V

V

Page 4

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +12V, V

MAIN

= V

INC

= V

CS-

= V

CS+

= +3.3V, V

CORE

= +1.8V, Circuit of Figure 4, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.)

ELECTRICAL CHARACTERISTICS

(VIN= +12V, V

MAIN

= V

INC

= V

CS-

= V

CS+

= +3.3V, V

CORE

= +1.8V, Circuit of Figure 4, TA-40°C to +85°C, unless otherwise noted.)

(Note 2)

(

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LOGIC INPUTS

SHDNM, SHDNC Input Low

Voltage

SHDNM, SHDNC Input High

Voltage

SHDNM, SHDNC Input Low

Current

SHDNC Input High Current V

SHDNM Input High Current

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

Input Voltage V

Input Quiescent Supply Current I

CS- Quiescent Supply Current I

Core Regulator Quiescent

Supply Current

IN Shutdown Supply Current SHDNM = SHDNC = GND 30 µA

MAIN REGULATOR

Main Output Voltage Adjust

Range

CS-

I

INC

IN

IN

2.0 V

SHDNM = SHDNC = GND -1 1 µA

= +5.5V 5 µA

SHDNC

V

V

= +5V 2

SHDNM

= +28V 15 30

SHDNM

2.7 28 V

V

FBM

V

SHDNM

V

FBM

V

SHDNM

V

FBM

V

SHDNM

= +1.5V, V

= V

= +1.5V, V

= V

= +1.5V, V

= V

FBC

SHDNC

FBC

SHDNC

FBC

SHDNC

= +1.5V,

= +3.3V

= +1.5V,

= +3.3V

= +1.5V,

= +3.3V

1.25 5.5 V

0.4 V

µA

30 µA

220 µA

120 µA

FBM Regulation Threshold V

FBM Input Current I

FBM

FBM

Current-Limit Threshold V

M i ni m um C ur r ent- Li m i t Thr eshol d V

Valley Current Threshold V

Zero Current Threshold V

PDRV, NDRV Gate Drive

Resistance

CS- to CVL Switch Resistance I

CL

V

C S + - C S - )

V

FBM

V

CS+

CS+

CS+

CS+

V

CS-

CVL

= 0 to + 60m V , V

= + 2.7V to + 28V 1.21 1.29 V

I N

= +1.3V -0.1 0.1 µA

- V

- V

- V

- V

CS-

CS-

CS-

CS-

60 100 mV

624mV

40 60 mV

015mV

= +3.3V 4.4 Ω

= 50mA 8 Ω

Page 5

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +12V, V

MAIN

= V

INC

= V

CS-

= V

CS+

= +3.3V, V

CORE

= +1.8V, Circuit of Figure 4, TA-40°C to +85°C, unless otherwise noted.)

(Note 2)

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

Maximum Duty Cycle 100 %

Minimum On-Time 200 650 ns

Minimum Off-Time 200 650 ns

CORE REGULATOR

Input Voltage Range V

INC Undervoltage Lockout

Core Output Voltage Adjust

Range

Maximum Core Load Current (Note 1) 1 A

FBC Regulation Threshold V

FBC Input Current I

Dropout Voltage (INC to LXC) I

LXC Leakage Current I

LXC P-Channel, N-Channel

On-Resistance

LXC P-Channel Current Limit 1200 3050 mA

LXC P-Channel Minimum

Current

LXC N-Channel Valley Current 880 2450 mA

LXC N-Channel Zero-Crossing

Current

Maximum Duty Cycle 100 %

Minimum On-Time 150 670 ns

Minimum Off-Time 150 670 ns

REFERENCE

Reference Voltage V

Reference Load Regulation I

Reference Line Regulation

Reference Sink Current I

CVL, CVH REGULATORS

CVL Output Voltage V

CVH Output Voltage V

CVL Undervoltage Lockout

INC

FBC

FBC

LXC

REF

REF

CVL

CVH

V

INC

V

INC

V

INC

V

FBC

OUTC

V

INC

REF

V

CS-

I

REF

I

CVL

VIN = +4V, I

VIN = +12V, I

V

CVL

V

CVL

2.6 5.5 V

rising 2.39 2.55

falling 2.29 2.45

1.0 5.0 V

= +2.5V to +5.5V, I

= 0 to 200mA 0.97 1.03 V

OUTC

= +1.3V -0.1 0.1 µA

= 400mA 0.2 V

= +5.5V, V

= 0 to +5.5V -10 10 µA

LXC

0.5 Ω

100 400 mA

35 175 mA

1.22 1.27 V

= 0 to 50µA 10 mV

= +2.5V to +5.5V,

= 50µA

5mV

10 µA

= 50mA, V

= +2.7V, V

IN

= 25mA V

CVH

= 50mA VIN - 3.7

CVH

= 0 2.6 3.1 V

CS-

IN

- 2.8

rising 2.40 2.55

falling 2.30 2.45

V

V

V

Page 6

100

0

1 10 100 1000 10,000

MAIN OUTPUT EFFICIENCY vs. LOAD

20

MAX1775 toc01

LOAD (mA)

EFFICIENCY (%)

40

60

80

70

50

30

10

90

VIN = +12V

VIN = +15V

VIN = +18V

VIN = +5V

VIN = +3.3V

90

0

1 100010010

CORE OUTPUT EFFICIENCY vs. LOAD

30

10

70

50

100

40

20

80

60

MAX1775 toc02

LOAD (mA)

EFFICIENCY (%)

V

INC

= +3.3V

V

INC

= +5V

V

INC

= +2.7V

-2.0

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-40 -15 10 35 60 85

V

REF

ACCURACY vs. TEMPERATURE

MAX1775 toc03

TEMPERATURE (°C)

V

REF

ACCURACY (%)

Typical Operating Characteristics

(Circuit of Figure 1, V

MAIN

= +3.3V, V

CORE

= +1.8V, TA = +25°C, unless otherwise noted.)

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +12V, V

MAIN

= V

INC

= V

CS-

= V

CS+

= +3.3V, V

CORE

= +1.8V, Circuit of Figure 4, TA-40°C to +85°C, unless otherwise noted.)

(Note 2)

Note 1: This parameter is guaranteed based on the LXC P-channel current limit and the LXC N-channel valley current.

Note 2: Specifications to -40°C are guaranteed by design and not production tested.

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

LOGIC INPUTS

SHDNM, SHDNC Input Low

Voltage

SHDNM, SHDNC Input High

Voltage

SHDNM, SHDNC Input Low

Current

SHDNC Input High Current V

SHDNM Input High Current V

2.0 V

SHDNM = SHDNC = GND -1 1 µA

= +5.5V 5 µA

SHDNC

= +28V 30 µA

SHDNM

0.4 V

Page 7

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

_______________________________________________________________________________________ 7

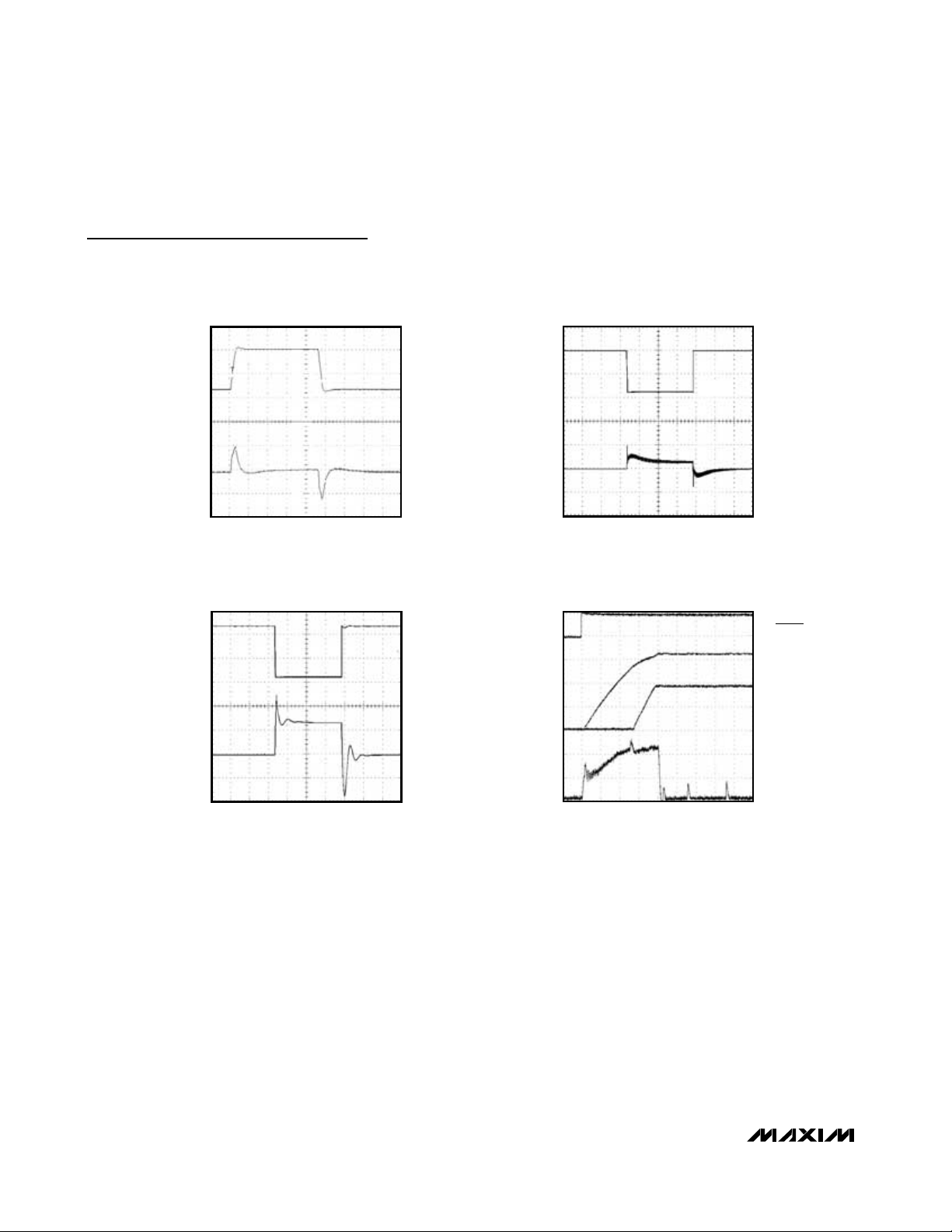

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

MAIN

= +3.3V, V

CORE

= +1.8V, TA = +25°C, unless otherwise noted.)

-0.2

-0.4

-0.6

-0.8

-1.0

-1.2

ACCURACY (%)

REF

-1.4

V

-1.6

-1.8

-2.0

REFERENCE LOAD REGULATION

0

0203010 40 50 60 70 80

MAIN SWITCHING WAVEFORMS,

HEAVY LOAD (1A)

I

(µA)

REF

MAX1775 toc06

MAX1775 toc04

LX

5V/div

MAIN SWITCHING WAVEFORMS,

LIGHT LOAD (100mA)

1µs/div

MAX1775 toc05

CORE SWITCHING WAVEFORMS,

LIGHT LOAD (50mA)

MAX1775 toc07

LX

5V/div

I

LM

500mA/div

V

MAIN

(AC-COUPLED)

20mV/div

LX

5V/div

1000mA

I

LM

500mA/div

1µs/div

CORE SWITCHING WAVEFORMS,

HEAVY LOAD (500mA)

2µs/div

MAX1775 toc08

500mA

0

V

MAIN

(AC-COUPLED)

20mV/div

4V

LXC

2V/div

0

V

CORE

(AC-COUPLED)

20mV/div

500mA

I

LC

250mA/div

0

1µs/div

MAIN LINE-TRANSIENT RESPONSE

(5V TO 12V)

100µs/div

MAX1775 toc09

200mA

I

LC

200mA/div

0

V

CORE

(AC-COUPLED)

20mV/div

12V

V

IN

5V

0

V

MAIN

50mV/div

Page 8

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

MAIN

= +3.3V, V

CORE

= +1.8V, TA = +25°C, unless otherwise noted.)

CORE LINE-TRANSIENT RESPONSE

(3.3V TO 5V)

100µs/div

MAX1775 toc10

MAIN LOAD TRANSIENT (IN DROPOUT

LOAD FROM 50mA TO 500mA)

200µs/div

MAX1775 toc12

5V

V

1V/div

3.3V

V

CORE

50mV/div

400mA

200mA

0

V

MAIN

50mV/div

MAIN LOAD TRANSIENT

(LOAD FROM 100mA to 1A, V

INC

200µs/div

IN

MAX1775 toc11

100mA

= 5V)

1A

I

MAIN

0

V

MAIN

50mV/div

TURN-ON RESPONSE

I

MAIN

(CIRCUIT OF FIGURE 4), NO LOAD

100µs/div

MAX1775 toc13

5V

0

3V

2V

1V

0

400mA

200mA

0mA

SHDNM

V

MAIN

V

CORE

I

IN

Page 9

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

_______________________________________________________________________________________ 9

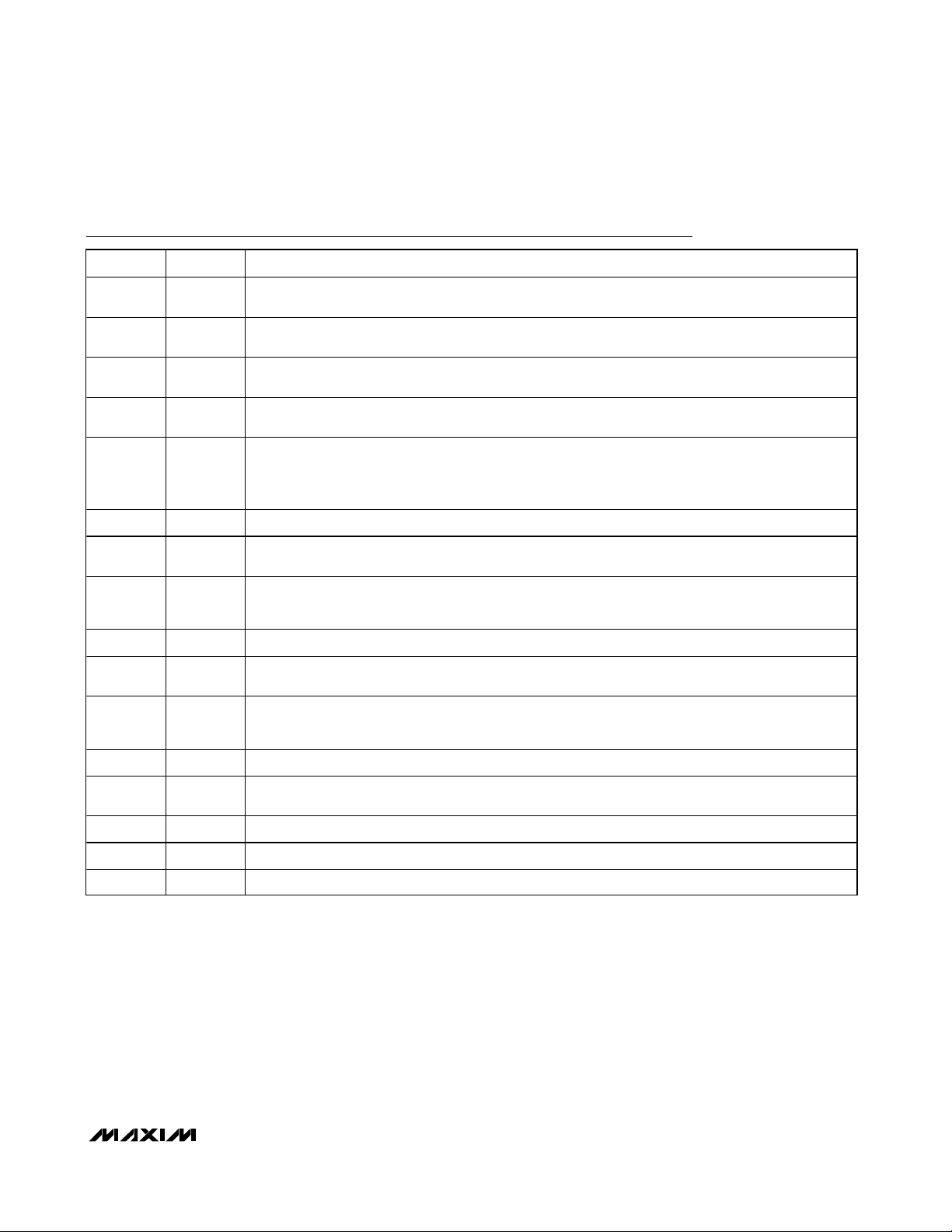

Pin Description

PIN NAME FUNCTION

1 SHDNM

2 SHDNC

3 PGND

4 NDRV

5 CVL

6 IN Power Supply Input

7 PDRV

8 CVH

9 REF Reference Voltage Output. Bypass REF to GND with a 0.22µF or greater capacitor.

10 FBM

11 CS+

12 CS- Main Regulator Low-Side Current-Sense Input. Connect CS- to the main output.

13 FBC

14 GND Analog Ground

Shutdown for Main Regulator. A low voltage on SHDNM shuts off the main output. For normal

operation, connect SHDNM to IN.

Shutdown for Core Regulator. A low voltage on SHDNC shuts off the core output. For normal operation,

connect SHDNC to CVL.

Power Ground. Ground for NDRV and core output synchronous rectifier. Connect all grounds together

close to the IC.

N-Channel Drive Output. Drives the main output synchronous rectifier MOSFET. NDRV swings between

CVL and PGND.

Low-Side Regulator Bypass. CVL is the output of an internal LDO regulator. This is the internal power

supply for the device control circuitry as well as the N-channel driver. Bypass CVL with a 1.0µF or

greater capacitor to GND. When CS- is above the CVL switchover threshold (2.47V), CVL is powered

from the main output.

P-Channel Drive Output. Drives the main output high-side MOSFET switch. PDRV swings between IN

and CVH. The voltage at CVH is regulated at V

High-Side Drive Bypass. CVH is the output of an internal LDO regulator with respect to V

low-side of the P-channel driver output. Bypass with a 1.0µF capacitor or greater to IN. When the input

voltage is less than +5.5V, CVH is switched to PGND.

Main Output Feedback. Connect FBM to a resistive voltage-divider to set main output voltage between

+1.25V to +5.5V.

Main Regulator High-Side Current-Sense Input. Connect the sense resistor between CS+ and CS-.

This voltage is used to set the current limit and to turn off the synchronous rectifier when the inductor

current approaches zero.

Core Output Feedback. Connect FBC to a resistive voltage-divider to set core output between +1.0V to

+5.0V.

- 4.3V unless the input voltage is less than 5.5V.

IN

. This is the

IN

15 INC Core Supply Input

16 LXC Core Converter Switching Node

Page 10

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

10 ______________________________________________________________________________________

Detailed Description

The MAX1775 dual step-down DC-DC converter is

designed to power PDA, palmtop, and subnotebook

computers. Normally, these devices need two separate

power supplies—one for the processor and another

higher voltage supply for the peripheral circuitry. The

MAX1775 provides an adjustable +1.25V to +5.5V main

output designed to power the peripheral circuitry of

PDAs and similar devices. The main output delivers

over 2A output current. The lower voltage core converter has an adjustable +1.0V to +5.0V output, providing

up to 1.5A output current. Both regulators utilize a proprietary regulation scheme, allowing PWM operation at

medium to heavy loads, and automatically switch to

pulse skipping at light loads for improved efficiency.

Figure 1 is the typical application circuit.

Operating Modes for the

Step-Down Converters

When delivering low output currents, the MAX1775

operates in discontinuous conduction mode. Current

through the inductor starts at zero, rises above the minimum current limit, then ramps down to zero during

each cycle (see Typical Operating Characteristics).

The switch waveform may exhibit ringing, which occurs

at the resonant frequency of the inductor and stray

capacitance, due to the residual energy trapped in the

core when the rectifier MOSFET turns off. This does not

degrade the circuit performance.

When delivering medium-to-high output currents, the

MAX1775 operates in PWM continuous-conduction

mode. In this mode, current always flows through the

inductor and never ramps to zero. The control circuit

adjusts the switch duty cycle to maintain regulation

without exceeding the peak switching current set by

the current-sense resistor.

100% Duty Cycle and Dropout

The MAX1775 operates with a duty cycle up to 100%.

This feature extends the input voltage range by turning

the MOSFET on continuously when the supply voltage

approaches the output voltage. This services the load

when conventional switching regulators with less than

100% duty cycle would fail. Dropout voltage is defined

as the difference between the input and output voltages when the input is low enough for the output to

drop out of regulation. Dropout depends on the MOSFET drain-to-source on-resistance, current-sense resistor, and inductor series resistance, and is proportional

to the load current:

Dropout voltage =

I

OUT

✕

[R

DS(ON)

+ R

SENSE

+ R

INDUCTOR

]

Figure 1. Typical Application Circuit (Low Input Voltage)

IN

2.7V TO 5.5V

C1

1µF

8

6

IN

CVH

ON

ON

1µF

0.22µF

15

INC

PDRV

NDRV

CS+

CS-

FBM

LXC

FBC

M1

7

4

M2

11

12

10

L

C

5.4µH

16

13

1

OFF

SHDNM

2

SHDNC

OFF

5

C2

C3

CVL

MAX1775

9

REF

3

PGND

14

GND

R4

R5

L

5µH

C6

10µF

M

R1

33mΩ

C5

22µF

CORE

1.8V

1.5A

MAIN

3.3V

2A

C4

R2

47µF

R3

Page 11

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

______________________________________________________________________________________ 11

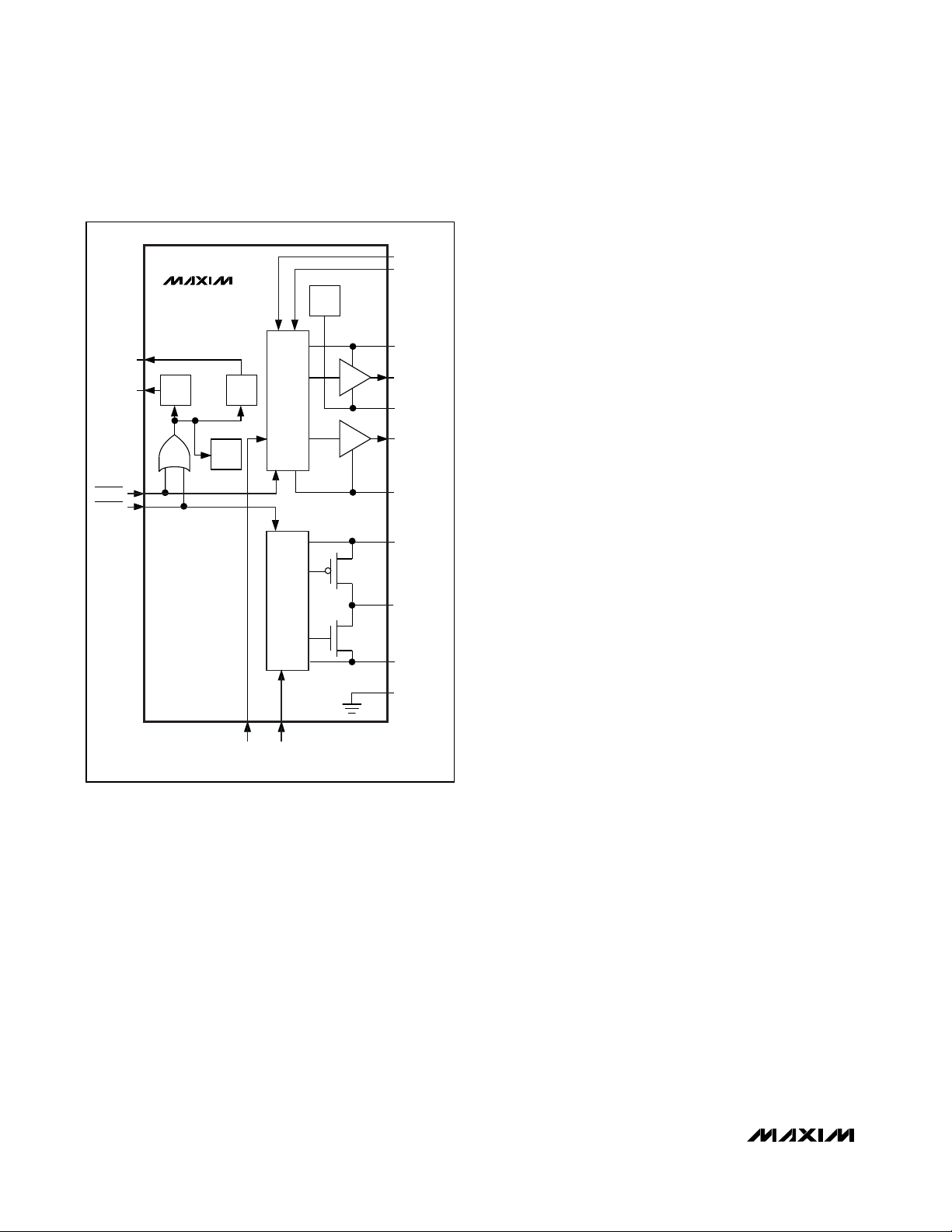

Regulation Control Scheme

The MAX1775 has a unique operating scheme that

allows PWM operation at medium and high current, with

automatic switching to pulse-skipping mode at lower

currents to improve light-load efficiency. Figure 2

shows a simplified block diagram.

Under medium- and heavy-load operation, the inductor

current is continuous and the part operates in PWM

mode. In this mode, the switching frequency is set by

either the minimum on-time or the minimum off-time,

depending on the duty cycle. The duty cycle is approximately the output voltage divided by the input voltage.

If the duty cycle is less than 50%, the minimum on-time

controls the frequency; and the frequency is approximately f ≈ 2.5MHz ✕D, where D is the duty cycle. If the

duty cycle is greater than 50%, the minimum off-time

sets the frequency; and the frequency is approximately

f ≈ 2.5MHz ✕(1 - D).

In both cases, the voltage is regulated by the error

comparator. For low duty cycles (<50%), the P-channel

MOSFET turns on for the minimum on-time, causing

fixed-on-time operation. During the P-channel MOSFET

on-time, the output voltage rises. Once the P-channel

MOSFET turns off, the voltage drops to the regulation

threshold, at which time another cycle is initiated. For

high duty cycles (>50%), the P-channel MOSFET

remains off for the minimum off-time, causing fixed offtime operation. In this case, the P-channel MOSFET

remains on until the output voltage rises to the regulation threshold. Then the P-channel MOSFET turns off for

the minimum off-time, initiating another cycle.

By switching between fixed on-time and fixed off-time

operation, the MAX1775 can operate at high input-output ratios, yet still operate up to 100% duty cycle for

low dropout. Note that when operating in fixed on-time,

the minimum output voltage is regulated; but in fixed

off-time operation, the maximum output voltage is regulated. Thus, as the input voltage drops below approximately twice the output voltage, a decrease in line

regulation can be expected. The drop in voltage is

approximately V

DROP

≈ V

RIPPLE

. At light output loads,

the inductor current is discontinuous, causing the

MAX1775 to operate at lower frequencies, reducing the

MOSFET gate drive and switching losses. In discontinuous mode, under most circumstances, the on-time will

be a fixed minimum of 400ns.

The MAX1775 features four separate current-limit

threshold detectors and a watchdog timer for each of

its step-down converters. In addition to the more common peak current detector and zero crossing detector,

each converter also provides a valley current detector

(I

VALLEY

) and a minimum current detector (I

MIN

). I

VALLEY

is used to force the inductor current to drop to a lower

level after hitting peak current before allowing the Pchannel MOSFET to turn on. This is a safeguard against

inductor current significantly overshooting above the

peak current when the inductor discharges too slowly

when V

OUT

/L is small. I

MIN

is useful in ensuring that a

minimum current is built up in the inductor before turning off the P-channel MOSFET. This helps the inductor

to charge the output near dropout when dI/dt is small

(because (V

IN

- V

OUT

) / L is small) to avoid multiple

Figure 2. Simplified Control System Block Diagram

TOFFMIN

V

MIN

CS+

CS-

V

VALLEY

FB

V

REF

TONMIN

R

PON

QS

PON

V

IN

PSW

V

O

V

CLM

V

ZERO

NON

Q

S

R

NONOVERLAP

PROTECTION

NSW

Page 12

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

12 ______________________________________________________________________________________

pulses and low efficiency. This feature, however, is disabled during dropout and light-load conditions where

the inductor current may take too long to reach the I

MIN

value. A watchdog timer overrides I

MIN

after the Pchannel MOSFET has been on for longer than about

10µs.

Main Step-Down Converter

The main step-down converter features adjustable

+1.25V to +5.5V output, delivering over 2A from a

+2.7V to +28V input (see Setting the Output Voltages).

The use of external MOSFETs and a current-sense

resistor maximizes design flexibility. The MAX1775

offers a synchronous rectifier MOSFET driver that

improves efficiency by eliminating losses through a

diode. The two MOSFET drive outputs, PDRV and

NDRV, control these external MOSFETs. The output

swing of these outputs is limited to reduce power con-

sumption by limiting the amount of injected gate charge

(see Internal Linear Regulators). The main current limit

is sensed through a small sense resistor at the converter output (see Setting the Current Limit). Driving SHDNM

low puts the main converter in a low-power shutdown

mode. The core regulator is still functional when the

main converter is in shutdown.

Core Step-Down Converter

The core step-down converter produces a +1.0V to

+5.0V output from a +2.6V to +5.5V input. The low-voltage input allows the use of internal power MOSFETs, taking advantage of their low R

DS(ON)

, improving efficiency

and reducing board space. Like the main converter, the

core regulator makes use of an N-channel MOSFET synchronous rectifier, improving efficiency and eliminating

the need for an external Schottky diode. Current sensing

is internal to the device, eliminating the need for an

external sense resistor. The maximum and minimum current limits are sensed through the P-channel MOSFET,

while the valley current and zero crossing current are

sensed through the N-channel MOSFET. The core output

voltage is measured at FBC through a resistive voltagedivider. This divider can be adjusted to set the output

voltage level (see Setting the Output Voltages). The core

input can be supplied from the main regulator or an

external supply that does not exceed +5.5V (see High-

Voltage Configuration and Low-Voltage Configuration).

The core converter can be shut down independent of the

main converter by driving SHDNC low. If the main converter output is supplying power to the core and is shut

down, SHDNM controls both outputs. Figure 3 is a simplified block diagram.

Internal Linear Regulators

There are two linear regulators internal to the MAX1775. A

high-voltage linear regulator accepts inputs up to +28V,

reducing it to +2.8V at CVL to provide power to the

MAX1775. Once the voltage at CS- reaches +2.47V, CVL

is switched to CS, allowing it to be driven from the main

converter, improving efficiency. CVL supplies the internal

bias to the IC and power for the NDRV gate driver.

The CVH regulator provides the low-side voltage for the

main regulator’s PDRV output. The voltage at CVH is regulated at 4.3V below VINto limit the voltage swing on

PDRV, reducing gate charge and improving efficiency

(Figure 3).

Reference

The MAX1775 has an accurate internally trimmed

+1.25V reference at REF. REF can source no more than

50µA. Bypass REF to GND with a 0.22µF capacitor.

Figure 3. Simplified Block Diagram

MAX1775

CVL

REF

SHDNM

SHDNC

REF

SOFT-

START

CVL

FBM FBC

CS-

FB

ON

ON

MAIN

BUCK

CORE

BUCK

FB

CS+

CVH

CSCS+

IN

PDRV

CVH

NDRV

PGND

INC

LXC

PGNDC

GND

MAIN

OUT

Page 13

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

______________________________________________________________________________________ 13

Design Procedure

Low-Voltage Configuration

To improve efficiency and conserve board space, the

core regulator operates from low input voltages, taking

advantage of internal low-voltage, low-on-resistance

MOSFETs. When the input voltage remains below 5.5V,

run the core converter directly from the input by connecting INC to IN (Figure 1). This configuration takes

advantage of the core’s low-voltage design and

improves efficiency.

High-Voltage Configuration

For input voltages greater than 5.5V, cascade the main

and core converters by connecting INC to the main output voltage. In this configuration (Figure 4), the core

converter is powered from the main output. Ensure that

the main output can simultaneously supply its load and

the core input current. In this configuration, the main

output voltage must be set above the 2.6V minimum

input voltage of the core converter.

Setting the Output Voltages

The main output voltage may be set from +2.6V and

+5.5V with two external resistors connected as a volt-

age-divider to FBM (Figure 1). Resistor values can be

calculated by the following equation:

R2 = R3 ✕[(V

OUTM

/ V

FBM

) - 1]

where V

FBM

= +1.25V. Choose R3 to be 40kΩ or less.

The core regulator output is adjustable from +1.0V to

+5.0V through two external resistors connected as a

voltage-divider to FBC (Figure 1). Resistor values can

be calculated through the following equation:

R4 = R5

✕

[(V

OUTC

/ V

FBC

) - 1]

where V

FBC

= +1.0V. Choose R5 to be 30kΩ or less.

Setting the Current Limit

The main regulator current limit is set externally through

a small current-sense resistor, R1 (Figure 1). The value

of R1 can be calculated by the following equation:

where V

CLM

= 80mV is the current-sense threshold,

and I

OUT

is the current delivered to the output. The

core converter current limit is set internally and cannot

be modified.

()

Figure 4. High Input Voltage Cascaded Configuration

IN 2.7V TO 28V

ON

ON

0.22µF

1µF

1

OFF

SHDNM

2

SHDNC

OFF

5

CVL

C2

C3

MAX1775

9

REF

3

PGND

14

GND

C1

6

1µF

8

IN

CVH

PDRV

NDRV

CS+

CS-

INC

FBM

LXC

FBC

M1

7

4

M2

11

12

15

10

L

C

5.4µH

16

13

10µH

R4

R5

C6

10µF

R1

33mΩ

L

M

CORE

1.8V

C5

1.5A

22µF

MAIN

3.3V

2A

R2

R3

C4

47µF

R

113 =

V

.

CLM

I

OUT

Page 14

MAX1775

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

14 ______________________________________________________________________________________

Careful layout of the current-sense signal traces is

imperative. Place R1 as close to the MAX1775 as possible. The two traces should have matching length and

width, be as far as possible from noisy switching signals, and be close together to improve noise rejection.

These traces should be used for current-sense signal

routing only and should not carry any load current.

Refer to the MAX1775 Evaluation Kit for layout examples.

Inductor Selection

The essential parameters for inductor selection are

inductance and current rating. The MAX1775 operates

with a wide range of inductance values.

Calculate the inductance value for either core or main,

L

MIN

:

L

MIN

= (VIN- V

OUT

) ✕T

ONMIN

/ I

RIPPLE

where T

ONMIN

is typically 400ns, and I

RIPPLE

is the

continuous conduction ripple current. In continuous

conduction, I

RIPPLE

should be chosen to be 30% of the

maximum load current. With high inductor values, the

MAX1775 begins continuous-conduction operation at a

lower fraction of full load (see Detailed Description).

The inductor’s saturation current must be greater than

the peak switching current to prevent core saturation.

Saturation occurs when the inductor’s magnetic flux

density reaches the maximum level the core can support, and inductance starts to fall. The inductor heating

current rating must be greater than the maximum load

current to prevent overheating. For optimum efficiency,

the inductor series resistance should be less than the

current-sense resistance.

Capacitor Selection

Choose output filter capacitors to service the output ripple current with acceptable voltage ripple. ESR in the

output capacitor is a major contributor to output ripple.

For the main converter, low-ESR capacitors such as

polymer, ceramic, or even tantalum are recommended.

For the core converter, choosing a low-ESR tantalum

capacitor with enough ESR to generate about 1% ripple

voltage across the output is helpful in ensuring stability.

Voltage ripple is the sum of contributions from ESR and

the capacitor value:

V

RIPPLE

≈ V

RIPPLE,ESR

+ V

RIPPLE,C

For tantalum capacitors, the ripple is determined mostly

by the ESR. Voltage ripple due to ESR is:

V

RIPPLE,ESR

≈ R

ESR

✕

I

RIPPLE

For ceramic capacitors, the ripple is mostly due to the

capacitance. The ripple due to the capacitance is

approximately:

V

RIPPLE

,C

≈ L I

RIPPLE

2

/ 2C

OUTVOUT

where V

OUT

is the average output voltage. From this

equation, estimate the output capacitor values for given

voltage ripple as follows:

C

OUT

=

1/2

✕

L I

RIPPLE

2

/ (V

RIPPLE,COUT

✕

V

OUT)

This equation is suitable for initial capacitor selection.

Final values should be set by testing a prototype or evaluation kit. When using tantalum capacitors, use good soldering practices to prevent excessive heat from

damaging the devices and increasing their ESR. Also,

ensure that the tantalum capacitors’ surge-current ratings

exceed the startup inrush and peak switching currents.

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple at IN, caused by the circuit’s switching. Use a

low-ESR capacitor. Two smaller-value low-ESR capacitors can be connected in parallel if necessary. Choose

input capacitors with working voltage ratings higher

than the maximum input voltage. Typically 4µF of input

capacitance for every 1A of load current is sufficient.

More capacitance may improve battery life and noise

immunity.

Place a surface-mount ceramic capacitor at IN very close

to the source of the high-side P-channel MOSFET. This

capacitor bypasses the MAX1775, minimizing the effects

of spikes and ringing on the MAX1775’s operation.

Bypass REF with 0.22µF or greater. Place this capacitor

within 0.2in (5mm) of the IC, next to REF, with a direct

trace to GND.

MOSFET Selection

The MAX1775 drives an external enhancement-mode

P-channel MOSFET and a synchronous-rectifier Nchannel MOSFET. When selecting the MOSFETs,

important parameters to consider are on-resistance

(R

DS(ON)

), maximum drain-to-source voltage

(V

DS(MAX)

), maximum gate-to-source voltage

(V

GS(MAX)

), and minimum threshold voltage (V

TH(MIN)

).

Chip Information

TRANSISTOR COUNT: 3530

PROCESS: BiCMOS

Page 15

Dual-Output Step-Down

DC-DC Converter for PDA/Palmtop Computers

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 15

© 2001 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

MAX1775

QSOP.EPS

Loading...

Loading...