Page 1

General Description

The MAX17062 is a high-performance step-up DC-DC

converter that provides a regulated supply voltage for

active-matrix thin-film transistor (TFT) liquid-crystal displays (LCDs). The MAX17062 incorporates currentmode, fixed-frequency, pulse-width modulation (PWM)

circuitry with a built-in n-channel power MOSFET to

achieve high efficiency and fast-transient response.

Users can select 640kHz or 1.2MHz operation using a

logic input pin (FREQ). The high switching frequencies

allow the use of ultra-small inductors and low-ESR

ceramic capacitors. The current-mode architecture provides fast transient response to pulsed loads. A compensation pin (COMP) gives users flexibility in adjusting

loop dynamics. The 22V internal MOSFET can generate

output voltages up to 20V from an input voltage

between 2.6V and 5.5V. Soft-start slowly ramps the input

current and is programmed with an external capacitor.

The MAX17062 is available in a 10-pin TDFN package.

Applications

Notebook Computer Displays

LCD Monitor Panels

LCD TV Panels

Features

o 90% Efficiency

o Adjustable Output from V

IN

to 20V

o 2.6V to 5.5V Input Supply Range

o Input Supply Undervoltage Lockout

o Pin-Programmable 640kHz/1.2MHz Switching

Frequency

o Programmable Soft-Start

o Improved EMI

o FB Regulation Voltage Tolerance < 1%

o Small 10-Pin TDFN Package

o Thermal-Overload Protection

MAX17062

TFT-LCD Step-Up DC-DC Converter

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

19-1042; Rev 0; 10/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

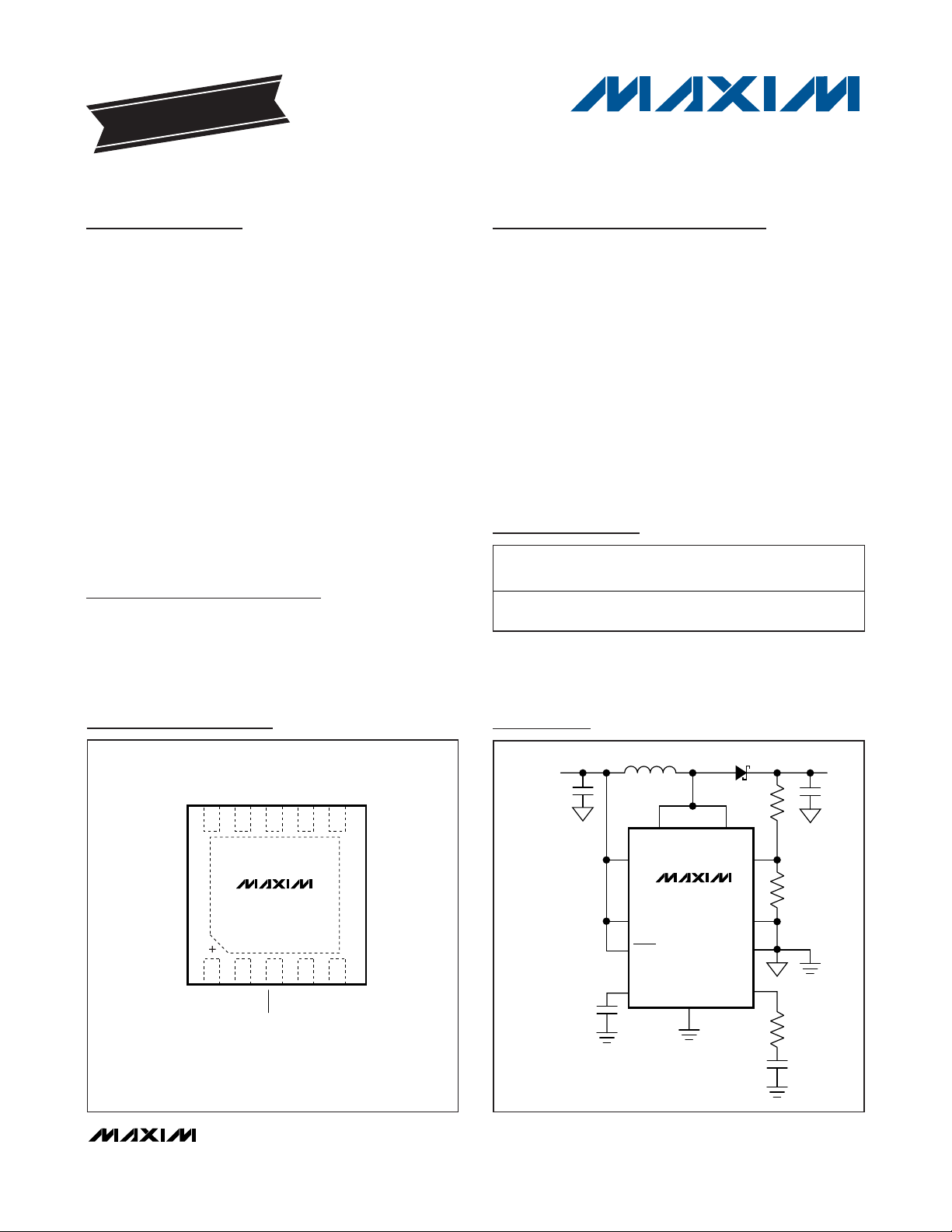

Pin Configuration

LX LX

FB

PGND

PGND

AGND

FREQ

IN

COMP

SS

EP

1

4

5

2

3

9

8

67

10

V

OUT

V

IN

2.6V TO 5.5V

SHDN

MAX17062

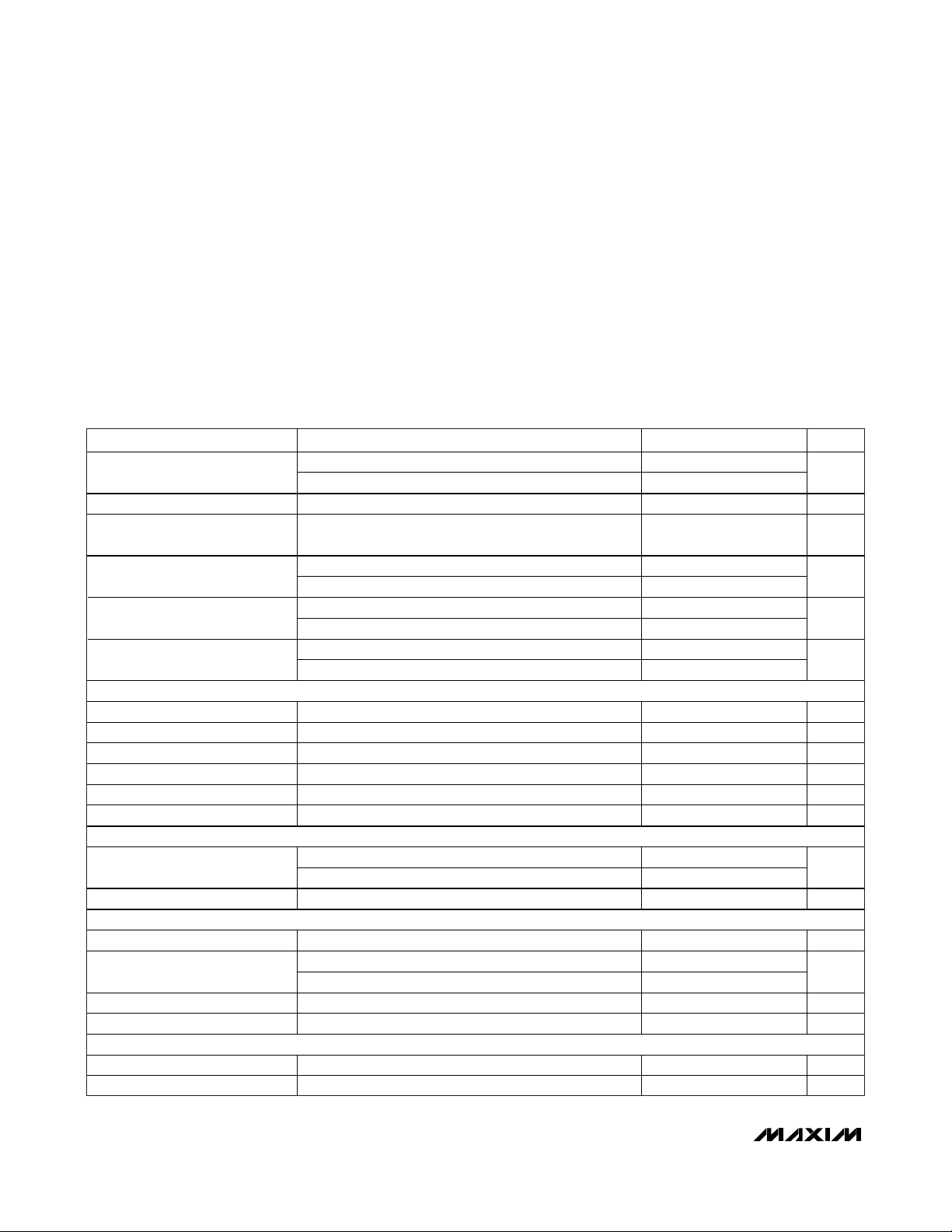

Minimal Operating Circuit

+

Denotes a lead-free package.

*

EP = Exposed pad.

T = Tape and reel.

PART TEMP RANGE

MAX17062ETB+T -40°C to +85°C

PINPACKAGE

10 TDFN-EP*

(3mm x 3mm)

PKG

CODE

T1033-2

SS

TOP VIEW

*EP = EXPOSED PAD.

FREQ

10 9 8 7 6

MAX17062

12345

FB

COMP

TDFN

(3mm x 3mm)

LX

*EP

PGND

LX

PGND

IN

SHDN

Page 2

MAX17062

TFT-LCD Step-Up DC-DC Converter

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= V

SHDN

= 3V, FREQ = 3V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

LX to AGND ............................................................-0.3V to +22V

IN, SHDN, FREQ, FB to AGND..............................-0.3V to +7.5V

COMP, SS to AGND ....................................-0.3V to (V

IN

+ 0.3V)

PGND to AGND .....................................................-0.3V to +0.3V

LX Switch Maximum Continuous RMS Current .....................3.2A

Continuous Power Dissipation (T

A

= +70°C)

10-Pin TDFN (derate 24.4mW/°C above +70°C)..........1951mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +160°C

Lead Temperature (soldering, 10s) .................................+300°C

Input Voltage Range

Output Voltage Range 20 V

IN Undervoltage-Lockout

Threshold

IN Quie scent Current

IN Shutdown Current

Thermal Shutdown

ERROR AMPLIFIER

FB Regulation Voltage Level to produce V

FB Input Bia s Current VFB = 1.24V 75 150 225 nA

FB L ine Regulation Level to produce V

Transconductance 110 250 450 μS

Voltage Gain 2400 V/V

Shutdown FB Input Voltage SHDN = AGND 0.05 0.10 0.15 V

OSCILLATOR

Frequency

Max imum Duty C yc le 88 91 94 %

n-CHANNEL MOSFET

Current Lim it VFB = 1V, 75% duty cycle, IN = 5V 3.9 4.6 5.3 A

On-Resistance

Leakage Current VLX = 20V 11 20 μA

Current-Sense Tran sresi stance IN = 5V 0.09 0.15 0.25 V/A

SOFT-START

Reset Switch Re sistance 100

Charge Current VSS = 1.2V 2 4 6 μA

PARAMETER CONDITIONS MIN TYP MA X UNITS

V

< 18V 2.6 5.5

OUT

18V < V

V

VFB = 1.3V, not switching 0.3 0.6

V

SHDN = AGND, TA = +25°C 0.01 10.0

SHDN = AGND, T

Temperature ris ing 160

Hysteresis 20

FREQ = AGND 500 640 780

FREQ = IN 1000 1200 1400

IN = 5V 100 170

IN = 3V 125 210

OUT

rising, typical hysteresis i s 50mV 2.30 2.45 2.57 V

IN

= 1.0V, switching 1.5 2.5

FB

< 20V 4.0 5.5

= +85°C 0.01

A

COMP

COMP

= 1.24V 1.23 1.24 1.25 V

= 1.24V, VIN = 2.6V to 5.5V 0.01 0.15 %/V

V

mA

μA

°C

kHz

m

Page 3

MAX17062

TFT-LCD Step-Up DC-DC Converter

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

SHDN

= 3V, FREQ = 3V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.) (Note 1)

ELECTRICAL CHARACTERISTICS

(VIN= V

SHDN

= 3V, FREQ = 3V, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

CONTROL I NPU TS

SHDN, FREQ Input Low Voltage VIN = 2.6V to 5.5V

SHDN, FREQ Input High Voltage VIN = 2.6V to 5.5V

SHDN, FREQ Input Hysteresis VIN = 2.6V to 5.5V

FREQ Pulldown Current 3 6 9 μA

SHDN Input Current

PARAMETER CONDITIONS MIN TYP MA X UNITS

0.3

V

IN

0.7

V

IN

SHDN = AGND, TA = +25°C -1 +1

SHDN = AGND, T

= +85°C 0

A

V

0.1

V

IN

V

V

μA

Input Voltage Range

Output Voltage Range 20 V

IN Undervoltage-Lockout

Threshold

IN Quie scent Current

ERROR AMPLIFIER

FB Regulation Voltage Level to produce V

FB Input Bia s Current VFB = 1.24V 225 nA

FB L ine Regulation Level to produce V

Transconductance 110 450 μS

Shutdown FB Input Voltage SHDN = AGND 0.05 0.15 V

OSCILLATOR

Frequency

Maximum Duty Cycle 87 95 %

n-CHANNEL MOSFET

Current Lim it VFB = 1V, 75% duty c ycle, IN = 5V 3.9 5.3 A

On-Resistance

Current-Sense Tran sresi stance IN = 5V 0.09 0.25 V/A

SOFT-START

Reset Switch Re sistance 100

Charge Current VSS = 1.2V 2 6 μA

PARAMETER CONDITIONS MIN TY P MAX UNITS

V

< 18V 2.6 5.5

OUT

18V < V

V

rising, typical hysteresis i s 50mV 2.30 2.57 V

IN

VFB = 1.3V, not switching 0.6

= 1.0V, switching 2.5

V

FB

FREQ = AGND 450 830

FREQ = IN 950 1500

IN = 5V 170

IN = 3V 210

< 20V 4.0 5.5

OUT

= 1.24V 1.227 1.253 V

COMP

= 1.24V, VIN = 2.6V to 5.5V 0.15 %/V

COMP

V

mA

kHz

m

Page 4

MAX17062

TFT-LCD Step-Up DC-DC Converter

4 _______________________________________________________________________________________

Note 1: Limits are 100% tested at TA= +25°C. Maximum and minimum limits over temperature are guaranteed by design.

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

SHDN

= 3V, FREQ = 3V, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

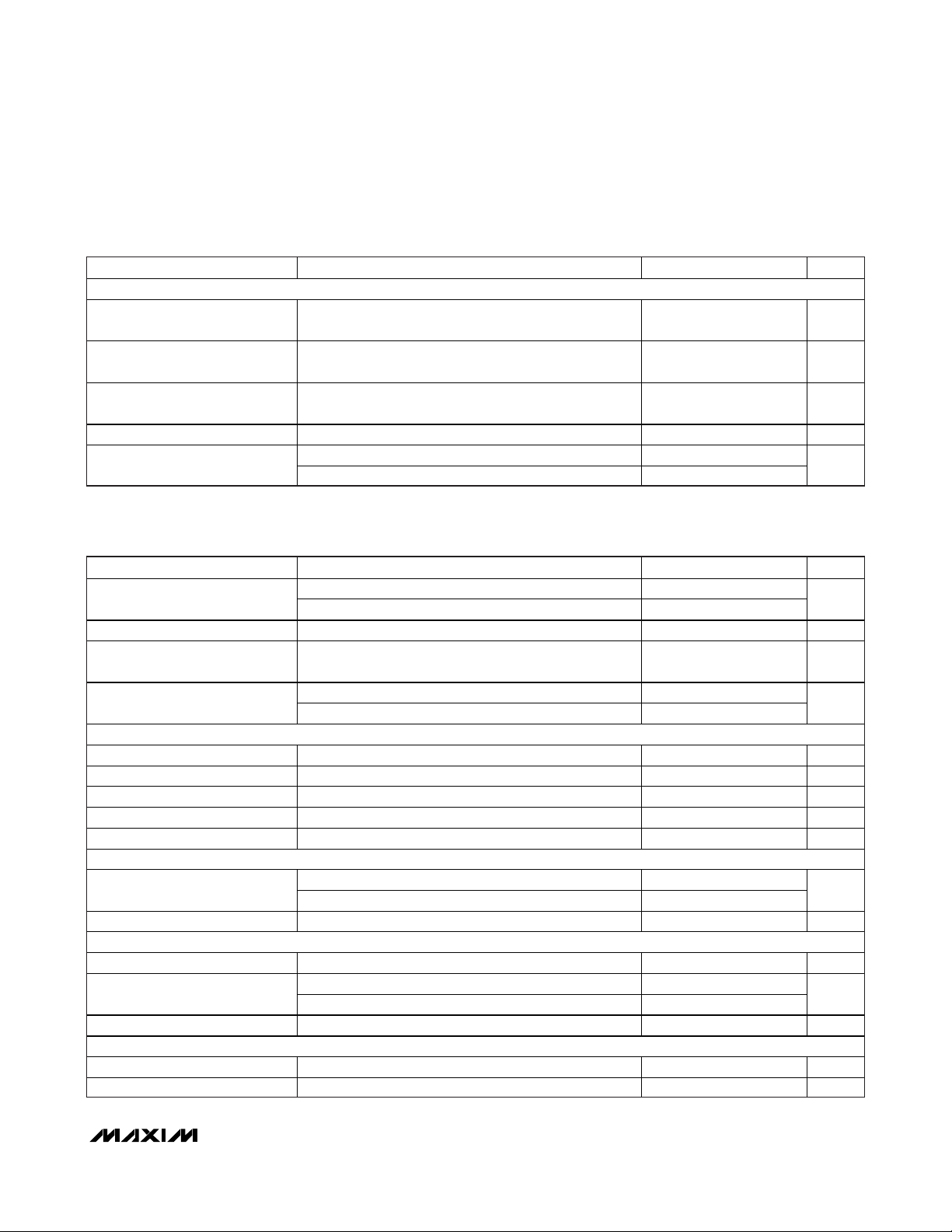

Typical Operating Characteristics

(Circuit of Figure 1. VIN= 5V, V

MAIN

= 15V, TA= +25°C, unless otherwise noted.)

CONTROL I NPU TS

SHDN, FREQ Input Low Voltage VIN = 2.6V to 5.5V

SHDN, FREQ Input High Voltage VIN = 2.6V to 5.5V

PARAMETER CONDITIONS MIN TY P MAX UNITS

0.7

V

IN

V

0.3

V

IN

V

EFFICIENCY vs. LOAD CURRENT

= 5V, V

(V

f

= 640kHz

OSC

L = 4.7μH

IN

LOAD CURRENT (mA)

100

90

80

70

EFFICIENCY (%)

60

50

1 1000

= 15V)

OUT

f

= 1.2MHz

OSC

L = 2.7μH

10010

1400

1300

1200

1100

1000

900

800

SWITCHING FREQUENCY (kHz)

700

600

500

2.5 5.5

100

MAX17062 toc01

90

80

70

EFFICIENCY (%)

60

50

1 1000

SWITCHING FREQUENCY

vs. INPUT VOLTAGE

FREQ = IN

FREQ = GND

INPUT VOLTAGE (V)

EFFICIENCY vs. LOAD CURRENT

(V

IN

f

= 640kHz

OSC

L = 4.7μH

LOAD CURRENT (mA)

5.04.54.03.53.0

= 3.3V, V

MAX17062 toc04

= 9V)

OUT

f

= 1.2MHz

OSC

L = 2.7μH

10010

SUPPLY CURRENT (mA)

LOAD REGULATION

(V

1.0

MAX17062 toc02

0.5

0

LOAD REGULATION (%)

-0.5

-1.0

1 1000

OUT

LOAD CURRENT (mA)

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

2.5 5.5

SWITCHING

NONSWITCHING

SUPPLY VOLTAGE (V)

= 15V)

5.04.54.03.53.0

VIN = 5.0V

VIN = 3.3V

10010

MAX17062 toc05

MAX17062 toc03

Page 5

MAX17062

TFT-LCD Step-Up DC-DC Converter

_______________________________________________________________________________________

5

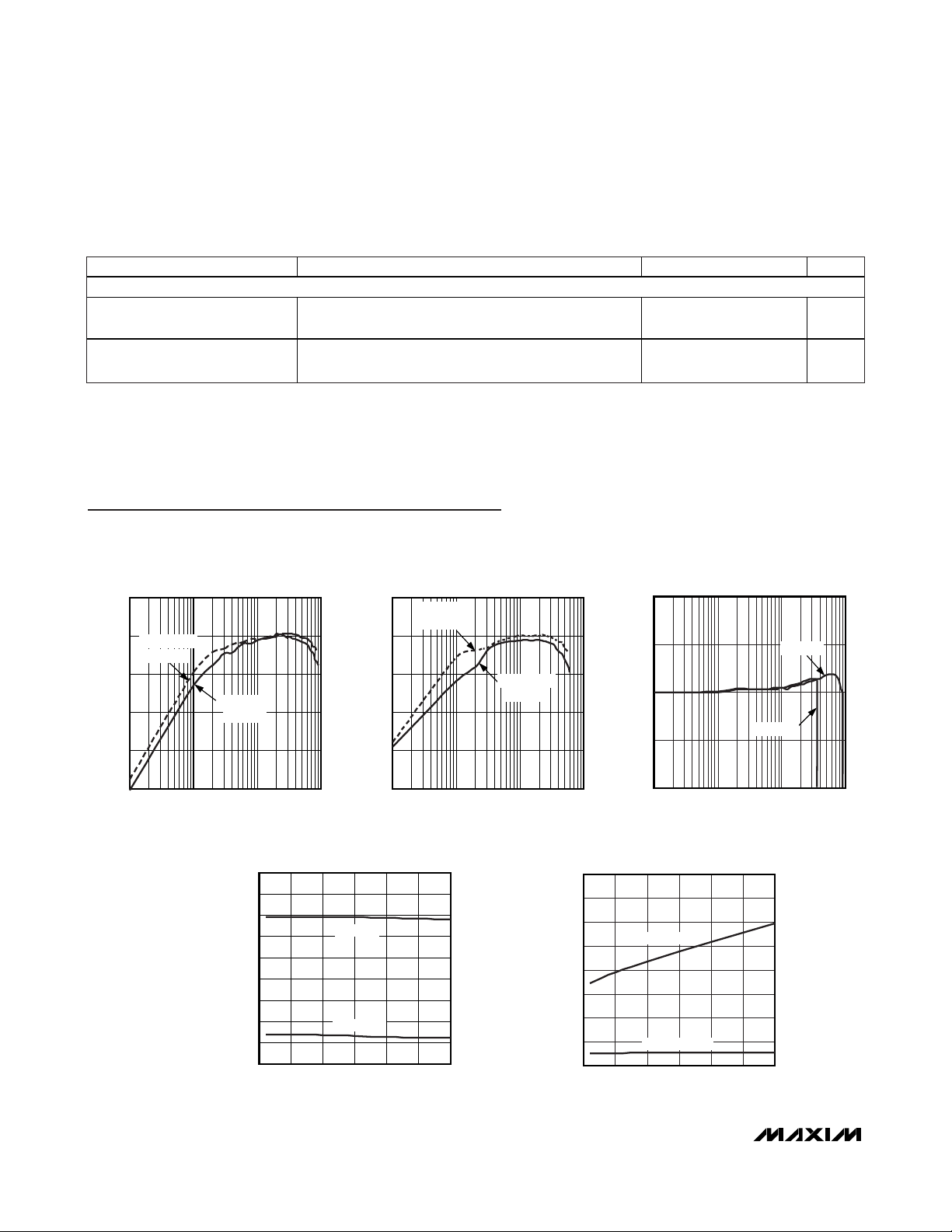

Typical Operating Characteristics (continued)

(Circuit of Figure 1. VIN= 5V, V

MAIN

= 15V, TA= +25°C, unless otherwise noted.)

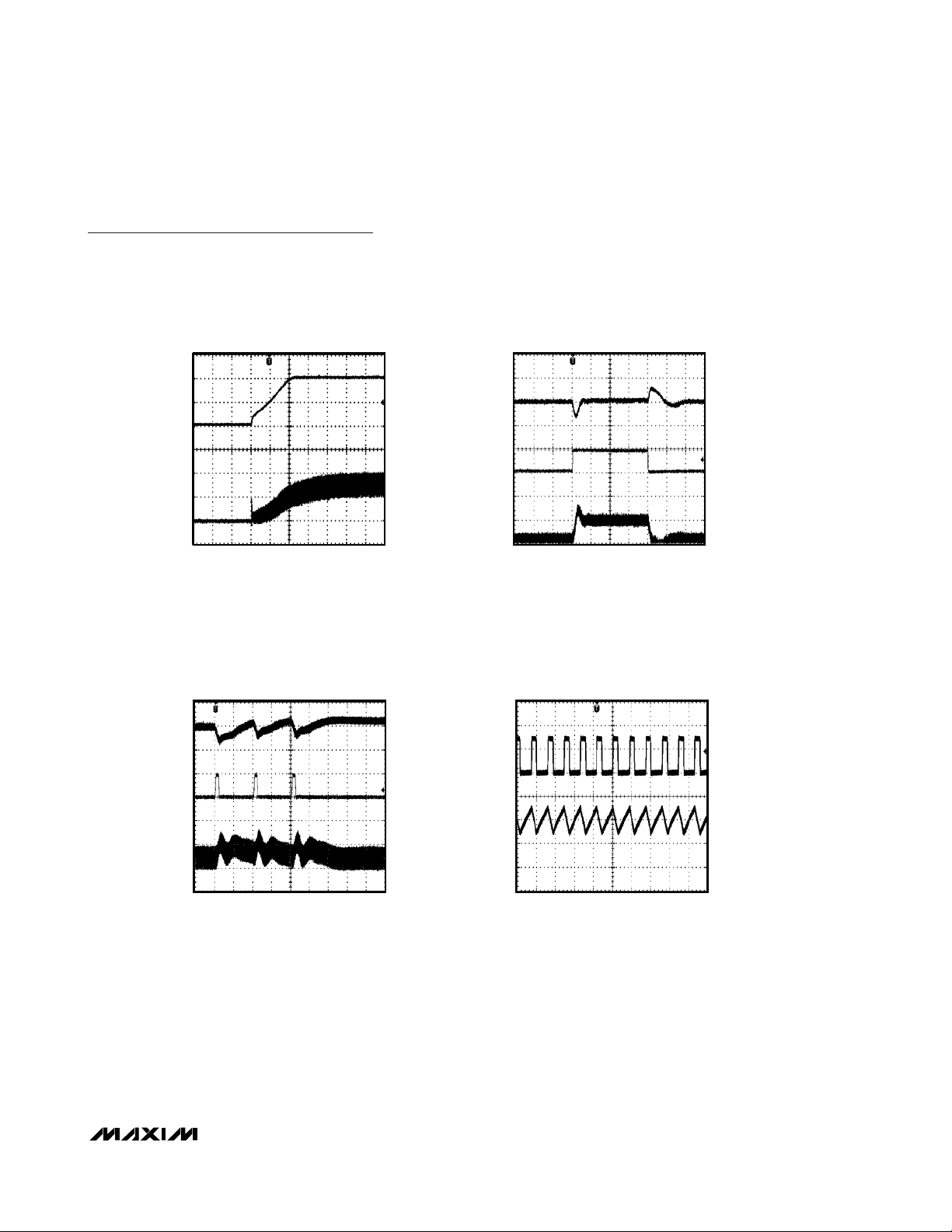

SOFT-START

= 30Ω)

(R

LOAD

2ms/div

MAX17062 toc06

PULSED LOAD-TRANSIENT RESPONSE

= 100mA TO 1.1A)

(I

LOAD

MAX17062 toc08

V

OUT

5V/div

OV

INDUCTOR

CURRENT

1A/div

OA

15V

V

OUT

200mV/div

AC-COUPLED

I

OUT

1A/div

0.1A

INDUCTOR

CURRENT

1A/div

0A

LOAD-TRANSIENT RESPONSE

= 50mA TO 550mA)

(I

LOAD

L = 2.7μH

R

COMP

C

COMP1

= 47k

= 560pF

100μs/div

Ω

SWITCHING WAVEFORMS

= 600mA)

(I

LOAD

MAX17062 toc07

MAX17062 toc09

15V

V

OUT

500mV/div

AC-COUPLED

0V

I

OUT

500mA/div

50mA

INDUCTOR

CURRENT

2A/div

0A

LX

10V/div

0V

INDUCTOR

CURRENT

1A/div

0A

L = 2.7μH

R

COMP

C

COMP1

= 47kΩ

= 560pF

10μs/div

1μs/div

Page 6

MAX17062

TFT-LCD Step-Up DC-DC Converter

6 _______________________________________________________________________________________

Pin Description

Figure 1. Typical Operating Circuit

PIN NAME FUNCTION

1 COMP

2 FB

3 SHDN Shutdown Control Input. Drive SHDN low to turn off the MAX17062.

4, 5 PGND Power Ground. Connect pin s 4 and 5 directly together.

6, 7 LX

8 IN Supply Pin. Bypass IN with a minimum 1μF ceramic capac itor directly to AGND.

9 FREQ

10 SS

EP AGND Exposed Pad. Connect to AGND.

Compensation Pin for Error Amplifier. Connect a ser ie s RC from COMP to ground. See the Loop

Compensation section for component selection guidelines.

Feedback Pin. The FB regulation voltage is 1.24V nominal. Connect an external resistive voltage-divider

between the step-up regulator’s output (V

) and AGND, with the center tap connected to FB. Place the

OUT

div ider close to the IC and minimize the trace area to reduce noise coupling. Set V

Output Voltage Select ion section.

Switch Pin. LX is the drain of the internal MOSFET. Connect the inductor/rectifier diode junction to LX and

min im ize the trace area for lower EMI. Connect pin s 6 and 7 together.

Frequency-Select Input. When FREQ is low, the oscillator frequency is set to 640kHz. When FREQ is high,

the frequency is 1.2MHz. This input has a 6μA pulldown current.

Soft-Start Control Pin. Connect a soft-start capacitor (C

) to this pin. Leave open for no soft-start. The soft-

SS

start capacitor is charged with a constant current of 4μA. Full current lim it is reached when the voltage of

SS pin is charged to 1.5V, which is the current-lim it time, t = 2.4 10

discharged to ground when SHDN is low. When SHDN goes high, the soft-start capacitor is charged to 0.4V,

after which soft-start begins.

according to the

OUT

5

CSS. The soft- start capacitor is

V

IN

4.5V TO 5.5V

C1

4.7μF

10V

4.7μF

10V

L1

2.7μH

C2

1μF

R1

10Ω

8

C3

IN

MAX17062

3

SHDN

9

FREQ

10

SS

C4

33nF

COMP

1

R2

47kΩ

C5

560pF

PGND

PGND

AGND

C6

OPEN

6

LX

7

LX

5

4

2

FB

EP

D1

C7

10μF

25V

R4

221kΩ

R3

20kΩ

V

OUT

+15V/600mA

C8

10μF

25V

Page 7

Detailed Description

The MAX17062 is a highly efficient power supply that

employs a current-mode, fixed-frequency, PWM architecture for fast-transient response and low-noise operation. The device regulates the output voltage through a

combination of an error amplifier, two comparators, and

several signal generators (Figure 2). The error amplifier

compares the signal at FB to 1.24V and varies the

COMP output. The voltage at COMP determines the

current trip point each time the internal MOSFET turns

on. As the load changes, the error amplifier sources or

sinks current to the COMP output to command the

inductor peak current necessary to service the load. To

maintain stability at high duty cycles, a slope-compensation signal is summed with the current-sense signal.

At light loads, this architecture allows the MAX17062 to

“skip” cycles to prevent overcharging the output voltage.

In this region of operation, the inductor ramps up to a

peak value of approximately 50mA, discharges to the

output, and waits until another pulse is needed again.

Output Current Capability

The output current capability of the MAX17062 is a

function of current limit, input voltage, operating frequency, and inductor value. Because of the slope compensation used to stabilize the feedback loop, the

inductor current limit depends on the duty cycle. The

current limit is determined by the following equation:

I

LIM

= (1.26 - 0.35 x D) x I

LIM_EC

where I

LIM_EC

is the current limit specified at 75% duty

cycle (see the

Electrical Characteristics

table) and D is

the duty cycle.

The output current capability depends on the currentlimit value and is governed by the following equation:

where I

LIM

is the current limit calculated above, η is the

regulator efficiency (85% nominal), and D is the duty

cycle. The duty cycle when operating at the current

limit is:

where V

DIODE

is the rectifier diode forward voltage and

RONis the on-resistance of the internal MOSFET.

MAX17062

TFT-LCD Step-Up DC-DC Converter

_______________________________________________________________________________________ 7

Figure 2. MAX17062 Functional Diagram

SHDN

BIAS

COMP

ERROR

AMPLIFIER

FB

∞

1.24V

SLOPE

FREQ

OSCILLATOR

6μA

COMPEN-

SATION

Σ

SKIP

COMPARATOR

ERROR

COMPARATOR

CLOCK

SKIP

CONTROL

AND DRIVER

LOGIC

CURRENT

SENSE

4μA

SOFTSTART

N

MAX17062

IN

SS

LX

PGND

II

OUT MAX LIM

()

⎢

⎢

⎣

⎡

.

05

DV

××

fLVV

×

OSC

⎤

IN

=−

××

⎥

⎥

⎦

VVV

−+

OUT IN DIODE

VIRV

−× +

OUT LIM ON DIODE

D

=

IN

OUT

η

Page 8

MAX17062

Soft-Start

The MAX17062 can be programmed for soft-start upon

power-up with an external capacitor. When the shutdown

pin is taken high, the soft-start capacitor (CSS) is immediately charged to 0.4V. Then the capacitor is charged at a

constant current of 4μA (typ). During this time, the SS

voltage directly controls the peak inductor current, allowing 0A at VSS= 0.4V to the full current limit at VSS= 1.5V.

The maximum load current is available after the soft-start

is completed. When the SHDN pin is taken low, the softstart capacitor is discharged to ground.

Frequency Selection

The MAX17062’s frequency can be user selected to

operate at either 640kHz or 1.2MHz. Connect FREQ to

AGND for 640kHz operation. For a 1.2MHz switching

frequency, connect FREQ to IN. This allows the use of

small, minimum-height external components while

maintaining low output noise. FREQ has an internal

pulldown, allowing the user the option of leaving FREQ

unconnected for 640kHz operation.

Shutdown

The MAX17062 shuts down to reduce the supply current to 0.01μA when SHDN is low. In this mode, the

internal reference, error amplifier, comparators, and

biasing circuitry turn off, and the n-channel MOSFET is

turned off. The step-up regulator’s output is connected

to IN by the external inductor and rectifier diode.

Thermal-Overload Protection

Thermal-overload protection prevents excessive power

dissipation from overheating the MAX17062. When the

junction temperature exceeds TJ= +160°C, a thermal

sensor immediately activates the fault protection, which

shuts down the MAX17062, allowing the device to cool

down. Once the device cools down by approximately

20°C, the MAX17062 starts up automatically.

Applications Information

Step-up regulators using the MAX17062 can be

designed by performing simple calculations for a first

iteration. All designs should be prototyped and tested

prior to production. Table 1 provides a list of power components for the typical applications circuit (Figure 1).

Table 2 lists component suppliers.

External-component-value choice is primarily dictated

by the output voltage and the maximum load current,

as well as maximum and minimum input voltages.

Begin by selecting an inductor value. Once L is known,

choose the diode and capacitors.

Inductor Selection

The minimum inductance value, peak current rating, and

series resistance are factors to consider when selecting

the inductor. These factors influence the converter’s efficiency, maximum output load capability, transientresponse time, and output-voltage ripple. Physical size

and cost are also important factors to be considered.

The maximum output current, input voltage, output voltage, and switching frequency determine the inductor

value. Very high inductance values minimize the current ripple and therefore reduce the peak current,

which decreases core losses in the inductor and I2R

losses in the entire power path. However, large inductor values also require more energy storage and more

turns of wire, which increase physical size and can

increase I2R losses in the inductor. Low inductance values decrease the physical size but increase the current

ripple and peak current. Finding the best inductor

involves choosing the best compromise between circuit

efficiency, inductor size, and cost.

The equations used here include a constant LIR, which

is the ratio of the inductor peak-to-peak ripple current

to the average DC inductor current at the full load current. The best trade-off between inductor size and circuit efficiency for step-up regulators generally has an

LIR between 0.3 and 0.5. However, depending on the

TFT-LCD Step-Up DC-DC Converter

8 _______________________________________________________________________________________

Table 1. Component List

Table 2. Component Suppliers

DESIGNATION DESCRIPTION

4.7μF ±10%, 10V X5R ceramic capacitors

C1, C2

C7, C8

D1

L1

(0603)

TDK C1608X5RIA475K

10μF±10%, 25V X5R ceramic capacitors

(1210)

TDK C3225X5RIE106K

3A, 30V Schottky diode (M-Flat)

Toshiba CMS03

2.7μH ±20% power inductor

TOKO FDV0630-2R7M

SUPPLIER PHONE FAX WEBSITE

TDK 847-803-6100 847-390-4405 www.component.tdk.com

TOKO 847-297-0070 847-699-7864 www.tokoam.com

Toshiba 949-455-2000 949-859-3963 www.toshiba.com/taec

Page 9

AC characteristics of the inductor core material and the

ratio of inductor resistance to other power-path resistances, the best LIR can shift up or down. If the inductor resistance is relatively high, more ripple can be

accepted to reduce the number of turns required and

increase the wire diameter. If the inductor resistance is

relatively low, increasing inductance to lower the peak

current can decrease losses throughout the power

path. If extremely thin high-resistance inductors are

used, as is common for LCD panel applications, the

best LIR can increase to between 0.5 and 1.0.

Once a physical inductor is chosen, higher and lower

values of the inductor should be evaluated for efficiency improvements in typical operating regions.

Calculate the approximate inductor value using the typical input voltage (VIN), the maximum output current

(I

MAIN(MAX)

), the expected efficiency (η

TYP

) taken from

an appropriate curve in the

Typical Operating

Characteristics

, and an estimate of LIR based on the

above discussion:

Choose an available inductor value from an appropriate

inductor family. Calculate the maximum DC input current at the minimum input voltage V

IN(MIN)

using con-

servation of energy and the expected efficiency at that

operating point (η

MIN

) taken from an appropriate curve

in the

Typical Operating Characteristics

:

Calculate the ripple current at that operating point and

the peak current required for the inductor:

The inductor’s saturation current rating and the

MAX17062’s LX current limit (I

LIM

) should exceed

I

PEAK

, and the inductor’s DC current rating should

exceed I

IN(DC,MAX)

. For good efficiency, choose an

inductor with less than 0.1Ω series resistance.

Considering the typical operating circuit (Figure 1), the

maximum load current (I

MAIN(MAX)

) is 600mA with a

15V output and a typical input voltage of 5V. Choosing

an LIR of 0.5 and estimating efficiency of 85% at this

operating point:

Using the circuit’s minimum input voltage (4.5V) and

estimating efficiency of 85% at that operating point:

The ripple current and the peak current are:

Output Capacitor Selection

The total output-voltage ripple has two components: the

capacitive ripple caused by the charging and discharging of the output capacitance, and the ohmic ripple due

to the capacitor’s equivalent series resistance (ESR):

and:

where I

PEAK

is the peak inductor current (see the

Inductor Selection

section). For ceramic capacitors,

the output-voltage ripple is typically dominated by

V

RIPPLE(C)

. The voltage rating and temperature charac-

teristics of the output capacitor must also be considered.

VV V

V

RI PPLE RIPPLE C R IPPLE ESR

RI PPLE

() ( )

(

=+

CC

MAIN

OUT

MAIN IN

MAIN OSC

I

C

VV

Vf

V

)

≈

−

⎛

⎝

⎜

⎞

⎠

⎟

RR IPPLE ESR PEAK ESR COUT

IR

() ( )

≈

MAX17062

TFT-LCD Step-Up DC-DC Converter

_______________________________________________________________________________________ 9

2

L

⎛

V

=

⎜

V

⎝

MAIN

IN

⎛

⎞

⎜

⎟

⎜

I f LIR

⎠

MAIN MAX OSC

⎝

VV

−

MAIN IN

×

()

⎞

⎟

⎟

⎠

⎛

⎞

η

TYP

⎜

⎟

⎝

⎠

I

IN DC MAX

(, )

IV

MAIN MAX MAIN

=

V

IN MIN MIN

×

()

×η

()

I

RIPPLE

VVV

IN MIN MAIN IN MIN

=

( )

×−

() ()

LV f

××

MAIN OSC

2

V

5

⎛

L

⎞

=

⎜

⎟

⎝

⎠

V

15

VV

15 5

⎛

⎜

⎝

AMHz..

×

06 12

−

.

085

⎞

⎛

⎞

.

27

.

050

≈μH

⎟

⎠

⎟

⎜

⎠

⎝

AV

.

×

I

IN DC MAX(, )

06 15

V

. .

45 085

≈

235

A

.=

×

VV V

. ( .)

×−

I

RIPPLE

IA

PEAK

45 15 45

=

H V MHz

. .

μ× ×

27 15 12

A

.

.

=+ ≈

235

097

2

.

.

284

≈

097

A

A

II

PEAK IN DC MAX

I

=+

(, )

RIPPLE

2

Page 10

MAX17062

Input Capacitor Selection

The input capacitor (CIN) reduces the current peaks

drawn from the input supply and reduces noise injection

into the IC. Two 4.7μF ceramic capacitors are used in

the

Typical Operating Circuit

(Figure 1) because of the

high source impedance seen in typical lab setups.

Actual applications usually have much lower source

impedance since the step-up regulator often runs

directly from the output of another regulated supply.

Typically, CINcan be reduced below the values used in

the typical operating circuit. Ensure a low-noise supply

at IN by using adequate C

IN

. Alternatively, greater voltage variation can be tolerated on CINif IN is decoupled

from CINusing an RC lowpass filter (see R1 and C3 in

Figure 1).

Rectifier Diode Selection

The MAX17062’s high switching frequency demands a

high-speed rectifier. Schottky diodes are recommended for most applications because of their fast recovery

time and low forward voltage. The diode should be

rated to handle the output voltage and the peak switch

current. Make sure that the diode’s peak current rating

is at least I

PEAK

calculated in the

Inductor Selection

section and that its breakdown voltage exceeds the

output voltage.

Output Voltage Selection

The MAX17062 operates with an adjustable output from

VINto 20V. Connect a resistive voltage-divider from the

output (V

MAIN

) to AGND with the center tap connected

to FB (see Figure 1). Select R2 in the 10kΩ to 50kΩ

range. Calculate R1 with the following equation:

where VFB, the step-up regulator’s feedback set point,

is 1.24V (typ). Place R1 and R2 close to the IC.

Loop Compensation

The voltage feedback loop needs proper compensation

to prevent excessive output ripple and poor efficiency

caused by instability. This is done by connecting a

resistor (R

COMP

) and capacitor (C

COMP

) in series from

COMP to AGND, and another capacitor (C

COMP2

) from

COMP to AGND. R

COMP

is chosen to set the high-

frequency integrator gain for fast transient response,

while C

COMP

is chosen to set the integrator zero to

maintain loop stability. The second capacitor, C

COMP2

,

is chosen to cancel the zero introduced by outputcapacitance ESR. For optimal performance, choose the

components using the following equations:

For the ceramic output capacitor, where ESR is small,

C

COMP2

is optional. The best gauge of correct loop

compensation is by inspecting the transient response

of the MAX17062. Adjust R

COMP

and C

COMP

as neces-

sary to obtain optimal transient performance.

Soft-Start Capacitor

The soft-start capacitor should be large enough that it

does not reach final value before the output has

reached regulation. Calculate CSSto be:

where C

OUT

is the total output capacitance including

any bypass capacitor on the output bus, V

OUT

is the

maximum output voltage, I

INRUSH

is the peak inrush

current allowed, I

OUT

is the maximum output current

during power-up, and VINis the minimum input voltage.

The load must wait for the soft-start cycle to finish

before drawing a significant amount of load current.

The duration after which the load can begin to draw

maximum load current is:

t

MAX

= 2.4 x 105x C

SS

TFT-LCD Step-Up DC-DC Converter

10 ______________________________________________________________________________________

⎛

V

RR

12 1 =× −

⎜

⎝

MAIN

V

FB

⎞

⎟

⎠

C

COMP

R

COMP

C

COMP

2

315

≈

≈

.

0 0036

≈

VV C

×× ×

IN OUT OUT

LI

×

VC

OUT OUT

10

IR

××

MAIN MAX COMP

RLI

×××

ESR MAIN MAX

VV

()

MAIN MAX

×

()

×

IN OUT

()

−

CC

>× × ×

21 10

SS OUT

⎛

VVV

OUT IN OUT

VI I V

×−×

IN INRUSH OUT OUT

⎜

⎜

⎜

⎝

6

2

−×

⎞

⎟

⎟

⎟

⎠

Page 11

Multiple-Output Power Supply for TFT-LCD

Figure 3 shows a power supply for active-matrix TFTLCD flat-panel displays. Output-voltage transient performance is a function of the load characteristic. Add or

remove output capacitance (and recalculate compensation-network component values) as necessary to meet

the required transient performance. Regulation performance for secondary outputs (VGON and VGOFF)

depends on the load characteristics of all three outputs.

PCB Layout and Grounding

Careful PCB layout is important for proper operation. Use

the following guidelines for good PCB layout:

1) Minimize the area of high-current loops by placing

the inductor, rectifier diode, and output capacitors

near the input capacitors and near the LX and

PGND pins. The high-current output loop goes from

the positive terminal of the input capacitor to the

inductor, to the IC’s LX pin, out of PGND, and to the

input capacitor’s negative terminal. The high-current output loop is from LX switch node to the rectifier diode (D1) to the output capacitors, and

reconnecting negative terminals of output capacitors to PGND of the IC. This loop has very high

di/dt, and it is critical to minimize the area of this

loop. Connect these loop components with short,

wide connections. Avoid using vias in the high-current paths. If vias are unavoidable, use many vias in

parallel to reduce resistance and inductance.

2) Create a power ground island (PGND) consisting of

the input and output capacitor grounds and PGND

pins. Connect all these together with short, wide

traces or a small ground plane. Maximizing the

width of the power ground traces improves efficiency and reduces output voltage ripple and noise

spikes. Create an analog ground plane (AGND)

consisting of the feedback-divider ground connection, the COMP and SS capacitor ground connections, and the device’s exposed backside pad.

Connect the AGND and PGND islands by connecting the PGND pins directly to the exposed backside

pad. Make no other connections between these

separate ground planes.

MAX17062

TFT-LCD Step-Up DC-DC Converter

______________________________________________________________________________________ 11

Figure 3. Multiple-Output TFT-LCD Power Supply

V

4.5V TO 5.5V

D2 D3

VGOFF

-15V

C11

0.22μF

IN

4.7μF

10V

C2

R5

10Ω

C3

1μF

R1

100kΩ

10

C4

33nF

C1

4.7μF

10V

1

2

L1

2.7μH

8

IN

U1

MAX17062

3

SHDN

9

FREQ

SS

COMP

1

R2

47kΩ

C5

560pF

C12

0.1μF

33

LX

LX

PGND

PGND

FB

AGND

C14

0.1μF

D1

6

7

5

4

2

EP

C6

OPEN

C7

10μF

25V

R4

221kΩ

R3

20kΩ

2

C15

0.22μF

1

C8

10μF

25V

VGON

+29V

V

OUT

+15V/600mA

Page 12

MAX17062

3) Place the feedback voltage-divider-resistors as

close to the FB pin as possible. The divider’s center

trace should be kept short. Placing the resistors far

away causes the FB trace to become an antenna

that can pick up switching noise. Avoid running the

feedback trace near LX.

4) Place the IN pin bypass capacitor as close to the

device as possible. The ground connection of the

IN bypass capacitor should be connected directly

to AGND pins with a wide trace.

5) Minimize the length and maximize the width of the

traces between the output capacitors and the load

for best transient responses.

6) Minimize the size of the LX node while keeping it

wide and short. Keep the LX node away from the

feedback node and analog ground. Use DC traces

as a shield if necessary.

Refer to the MAX17062 Evaluation Kit for an example of

proper board layout.

Chip Information

TRANSISTOR COUNT: 3612

PROCESS: BiCMOS

TFT-LCD Step-Up DC-DC Converter

12 ______________________________________________________________________________________

Page 13

MAX17062

TFT-LCD Step-Up DC-DC Converter

______________________________________________________________________________________ 13

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

6, 8, &10L, DFN THIN.EPS

Page 14

MAX17062

TFT-LCD Step-Up DC-DC Converter

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

COMMON DIMENSIONS

SYMBOL MIN. MAX.

A 0.70 0.80

D 2.90 3.10

E 2.90 3.10

0.00 0.05

A1

L 0.20 0.40

0.25 MIN.k

A2 0.20 REF.

PACKAGE VARIATIONS

PKG. CODE N D2 E2 e JEDEC SPEC b

T633-2 6 1.50±0.10 2.30±0.10 0.95 BSC MO229 / WEEA 0.40±0.05 1.90 REF

T833-2 8 1.50±0.10 2.30±0.10 0.65 BSC MO229 / WEEC 0.30±0.05 1.95 REF

T833-3 8 1.50±0.10 2.30±0.10 0.65 BSC MO229 / WEEC 0.30±0.05 1.95 REF

1.50±0.10 MO229 / WEED-3

2.30±0.10 MO229 / WEED-3 2.00 REF0.25±0.050.50 BSC1.50±0.1010T1033-2

0.40 BSC - - - - 0.20±0.05 2.40 REFT1433-2 14 2.30±0.101.70±0.10

[(N/2)-1] x e

2.00 REF0.25±0.050.50 BSC2.30±0.1010T1033-1

2.40 REF0.20±0.05- - - - 0.40 BSC1.70±0.10 2.30±0.1014T1433-1

Loading...

Loading...