Page 1

19-6008; Rev 0; 9/11

MAX17047

ModelGauge m3 Fuel Gauge

General Description

The MAX17047 incorporates the Maxim ModelGauge™

m3 algorithm that combines the excellent short-term

accuracy and linearity of a coulomb counter with the

excellent long-term stability of a voltage-based fuel gauge,

along with temperature compensation to provide industryleading fuel-gauge accuracy. ModelGauge m3 cancels

offset accumulation error in the coulomb counter, while

providing better short-term accuracy than any purely

voltage-based fuel gauge. Additionally, the ModelGauge

m3 algorithm does not suffer from abrupt corrections that

normally occur in coulomb-counter algorithms, since tiny

continual corrections are distributed over time.

The device automatically compensates for aging, temperature, and discharge rate and provides accurate

state of charge (SOC) in mAh or % over a wide range of

operating conditions. The device provides two methods

for reporting the age of the battery: reduction in capacity

and cycle odometer.

The device provides precision measurements of current,

voltage, and temperature. Temperature of the battery

pack is measured using an external thermistor supported

by ratiometric measurements on an auxiliary input. A

2-wire (I2C) interface provides access to data and control

registers. The IC is available in a lead(Pb)-free, 3mm x

3mm, 10-pin TDFN package.

Applications

2.5G/3G/4G Wireless

Handsets

Smartphones/PDAs

Tablets and Handheld

Computers

Portable Game Players

e-Readers

Digital Still and Video

Cameras

Portable Medical Equipment

Features

S Accurate Battery-Capacity Estimation

Temperature, Age, and Rate Compensated

Does Not Require Empty, Full, or Idle States to

Maintain Accuracy

S Precision Measurement System

No Calibration Required

S ModelGauge m3 Algorithm

Long-Term Influence by Voltage Fuel Gauge

Cancels Coulomb-Counter Drift

Short-Term Influence by Coulomb Counter

Provides Excellent Linearity

Adapts to Cell Characteristics

S External Temperature-Measurement Network

Actively Switched Thermistor Resistive Divider

Reduces Current Consumption

S Low Quiescent Current

25µA Active, < 0.5µA Shutdown

S Alert Indicator for SOC, Voltage, Temperature, and

Battery Removal/Insertion Events

S AtRate Estimation of Remaining Capacity

S 2-Wire (I2C) Interface

S Tiny, Lead(Pb)-Free, 3mm x 3mm, 10-Pin TDFN

Package

Ordering Information appears at end of data sheet.

For related parts and recommended products to use with this part,

refer to: www.maxim-ic.com/MAX17047.related

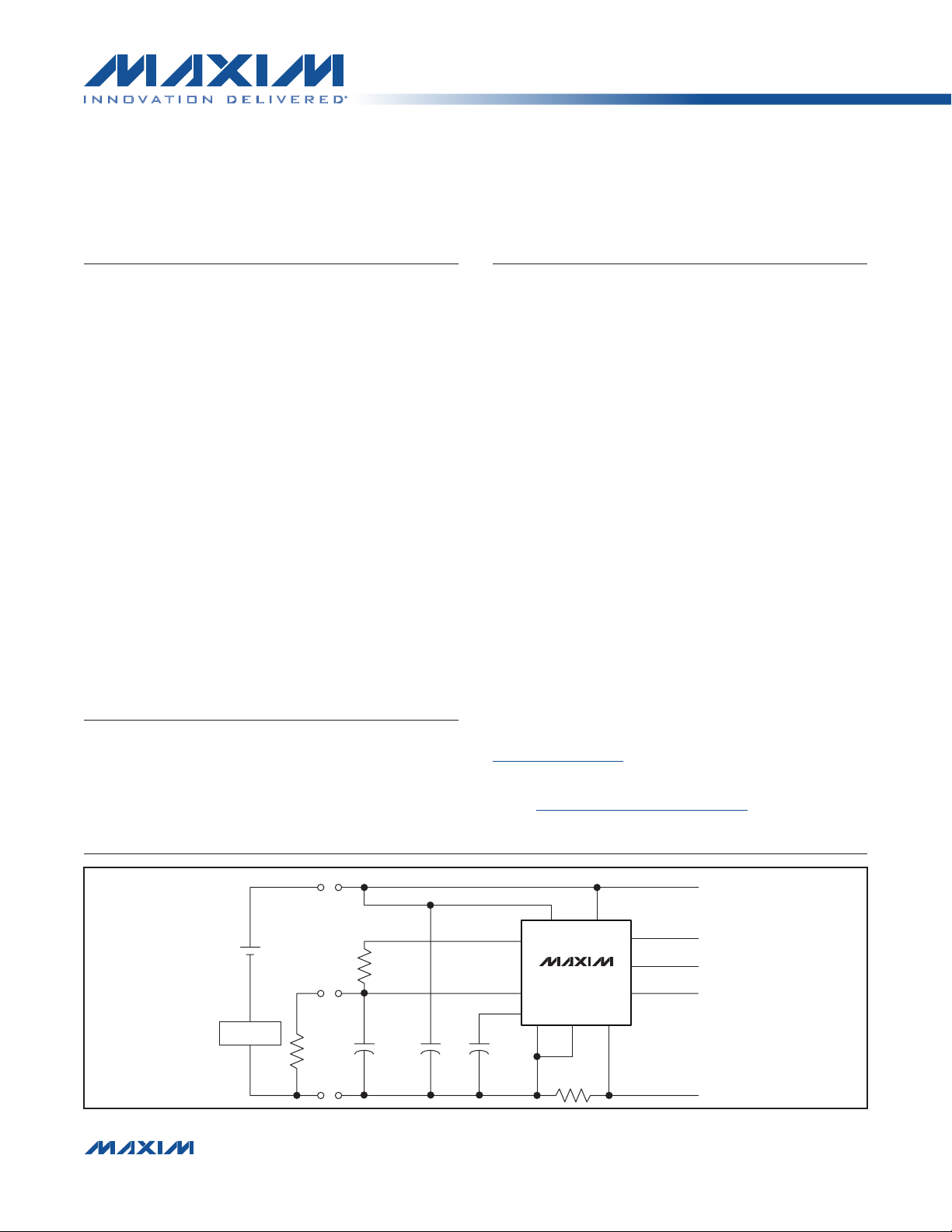

Simplified Operating Circuit

BATTERY PACK

PK+

OPTIONAL

10kI

T

PROTECTION

ModelGauge is a trademark of Maxim Integrated Products, Inc.

����������������������������������������������������������������� Maxim Integrated Products 1

OPTIONAL

10kI

NTC

THERMISTOR

PK-

OPTIONAL

10nF

V

BATTVTT

THRM

AIN SCL

REG

0.1µF0.1µF

MAX17047

CSP

10mI

RSNS

SYSTEM

ALRT

SDA

CSNEP

HOST

µP

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX17047

ModelGauge m3 Fuel Gauge

ABSOLUTE MAXIMUM RATINGS

V

, SDA, SCL, ALRT to CSP .............................-0.3V to +6V

BATT

REG to CSP ..........................................................-0.3V to +2.2V

VTT to CSP ............................................................... -0.3V to +6V

THRM, AIN to CSP .....................................-0.3V to (VTT + 0.3V)

CSN to CSP ................................................................-2V to +2V

Continuous Sink Current (VTT) ...........................................20mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

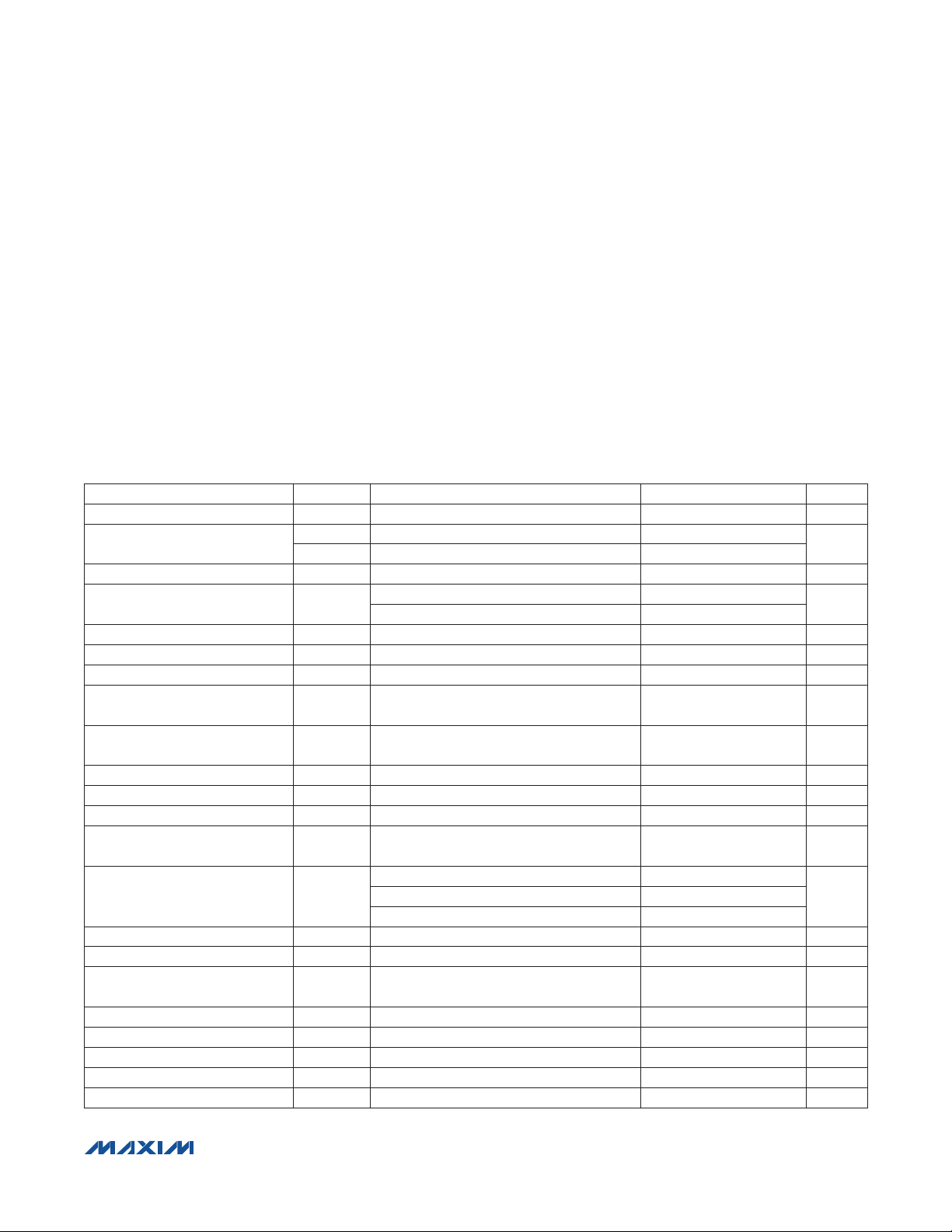

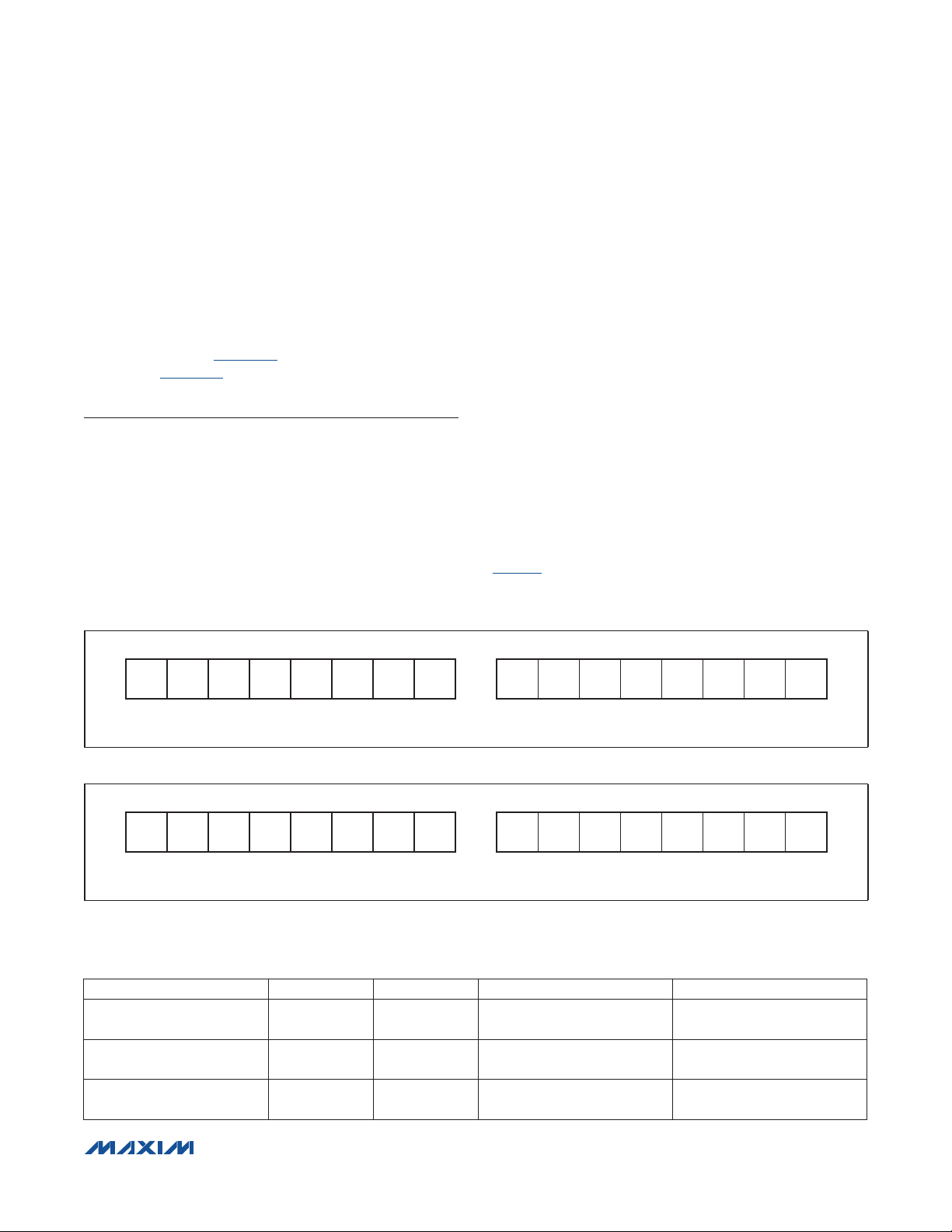

ELECTRICAL CHARACTERISTICS

(V

= 2.5V to 4.5V, TA = -20NC to +70NC, unless otherwise noted. Typical values are at TA = +25NC.) (Note 1)

BATT

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage V

Supply Current

REG Regulation Voltage V

Measurement Error, V

Measurement Resolution, V

V

Measurement Range V

BATT

BATT

BATT

BATT

I

DD0

I

DD1

V

GERR

V

REG

LSb

FS

Input Resistance CSN, AIN 15

Ratiometric Measurement

Accuracy, AIN

Ratiometric Measurement

Resolution, AIN

Current Register Resolution I

Current Full-Scale Magnitude I

Current Offset Error I

Current Gain Error I

Time-Base Accuracy t

T

GERR

T

LSb

OERR

GERR

ERR

LSb

FS

THRM Output Drive I

THRM Precharge Time t

SDA, SCL, ALRT

Input Logic High

PRE

V

IH

SDA, SCL, ALRT Input Logic Low V

SDA, ALRT Output Logic Low V

SDA, ALRT Pulldown Current I

OL

PD

ALRT Leakage 1

THRM Operating Range 2.5 V

(Note 2) 2.5 4.5 V

Shutdown mode, TA P +50NC

Active mode, average current 25 42

TA = +25NC

V

= 3.6V at TA = +25NC

DD

TA = 0NC to +50NC

TA = -20NC to +70NC

= 0.5mA V

OUT

0.5 V

IL

IOL = 4mA 0.4 V

Active mode, V

Continuous Sink Current (SCL, SDA, ALRT) ......................20mA

Operating Temperature Range .......................... -40NC to +85NC

Storage Temperature Range ............................ -55NC to +125NC

Lead Temperature (soldering 10s) .................................+300NC

Soldering Temperature (reflow) ......................................+260NC

0.5 2

1.5 1.9 V

-7.5 +7.5

-20 +20

0.625 mV

2.5 4.98 V

-0.5 +0.5 %

0.0244

1.5625

Q51.2

Q1.5 FV

-1 +1

-1 +1

-2.5 +2.5

-3.5 +3.5

- 0.1 V

TT

8.48 ms

1.5 V

SDA

= 0.4V, V

= 0.4V 0.05 0.2 0.4

ALRT

TT

FA

mV

MI

% Full

Scale

FV

mV

% of

Reading

%

FA

FA

V

����������������������������������������������������������������� Maxim Integrated Products 2

Page 3

MAX17047

ModelGauge m3 Fuel Gauge

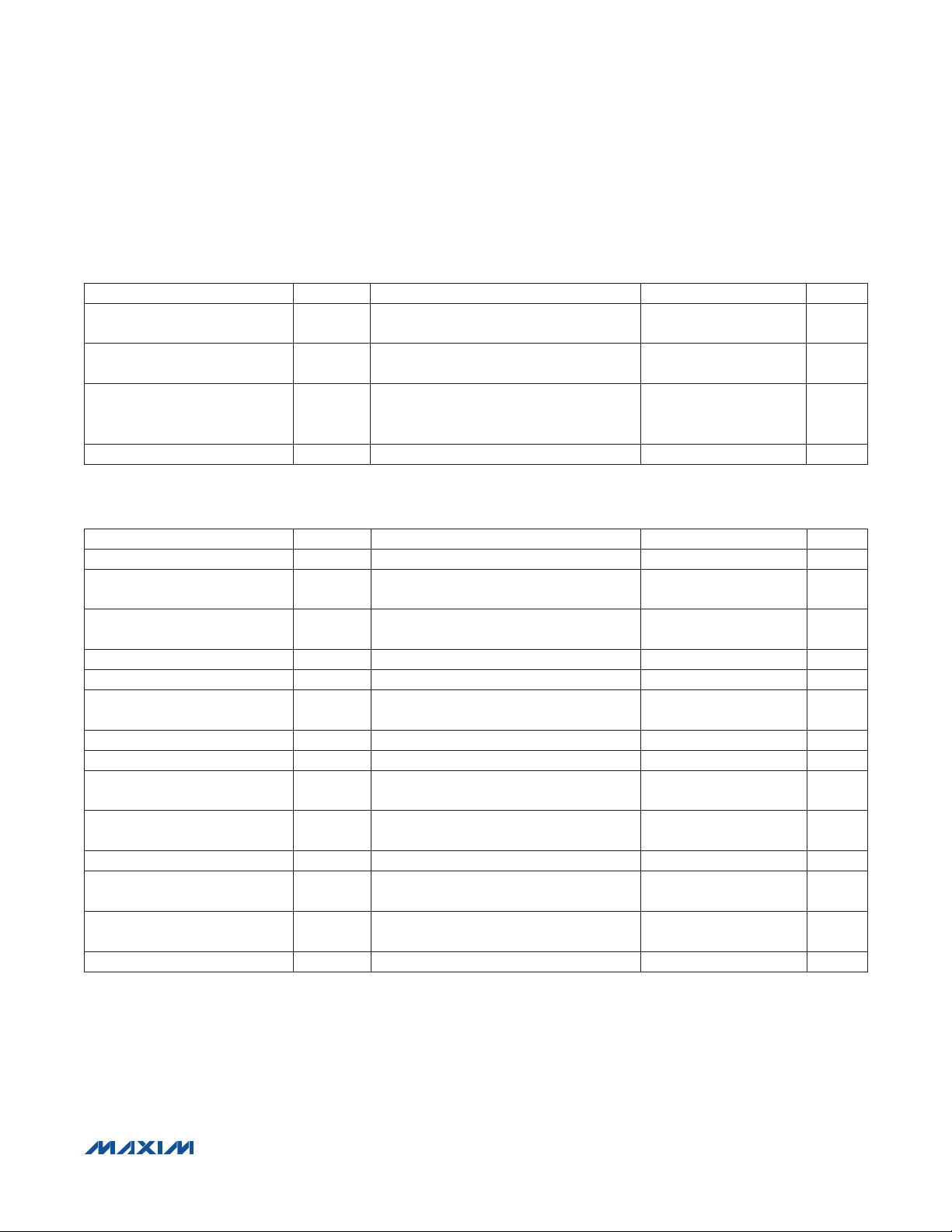

ELECTRICAL CHARACTERISTICS (continued)

(V

= 2.5V to 4.5V, TA = -20NC to +70NC, unless otherwise noted. Typical values are at TA = +25NC.) (Note 1)

BATT

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Battery-Removal Detection

Threshold—V

AIN

Rising

Battery-Removal Detection

Threshold—V

AIN

Falling

Battery-Removal Detection

Comparator Delay

External AIN Capacitance

ELECTRICAL CHARACTERISTICS (2-WIRE INTERFACE)

(2.5V P V

SCL Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated)

START Condition

Low Period of SCL Clock t

High Period of SCL Clock t

Setup Time for a Repeated

START Condition

Data Hold Time t

Data Setup Time t

Rise Time of Both SDA and SCL

Signals

Fall Time of Both SDA and SCL

Signals

Setup Time for STOP Condition t

Spike Pulse Widths

Suppressed by Input Filter

Capacitive Load for Each Bus

Line

SCL, SDA Input Capacitance C

Note 1: Specifications are 100% tested at TA = +25°C. Limits over the operating range are guaranteed by design and

Note 2: All voltages are referenced to CSP.

Note 3: Timing must be fast enough to prevent the device from entering shutdown mode due to bus low for a period > 45s minimum.

Note 4: f

Note 5: The maximum t

Note 6: This device internally provides a hold time of at least 100ns for the SDA signal (referred to the minimum VIH of the SCL

Note 7: Filters on SDA and SCL suppress noise spikes at the input buffers and delay the sampling instant.

Note 8: CB—total capacitance of one bus line in pF.

P 4.5V, TA = -20NC to +70NC.) (Note 1)

BATT

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

characterization.

must meet the minimum clock low time plus the rise/fall times.

SCL

HD:DAT

signal) to bridge the undefined region of the falling edge of SCL.

V

DETR

V

t

TOFF

DETF

V

- V

THRM

V

THRM

V

AIN

AIN

- V

AIN

step from 70% to 100% of V

ALRT falling; Alrtp = logic 0;

THRM

to

EnAIN = logic 1; FTHRM = logic 1

R

= 10kI NTC

THM

SCL

t

BUF

t

HD:STA

LOW

HIGH

t

SU:STA

HD:DAT

SU:DAT

t

R

t

SU:STO

t

SP

C

BIN

(Note 3) 0 400 kHz

(Note 4) 0.6

(Notes 5, 6) 0 0.9

(Note 5) 100 ns

F

(Note 7) 0 50 ns

(Note 8) 400 pF

B

has only to be met if the device does not stretch the low period (t

40 125 200 mV

70 150 230 mV

100

100 nF

1.3

1.3

0.6

0.6

20 +

0.1C

20 +

0.1C

B

B

300 ns

300 ns

0.6

60 pF

) of the SCL signal.

LOW

Fs

Fs

Fs

Fs

Fs

Fs

Fs

Fs

����������������������������������������������������������������� Maxim Integrated Products 3

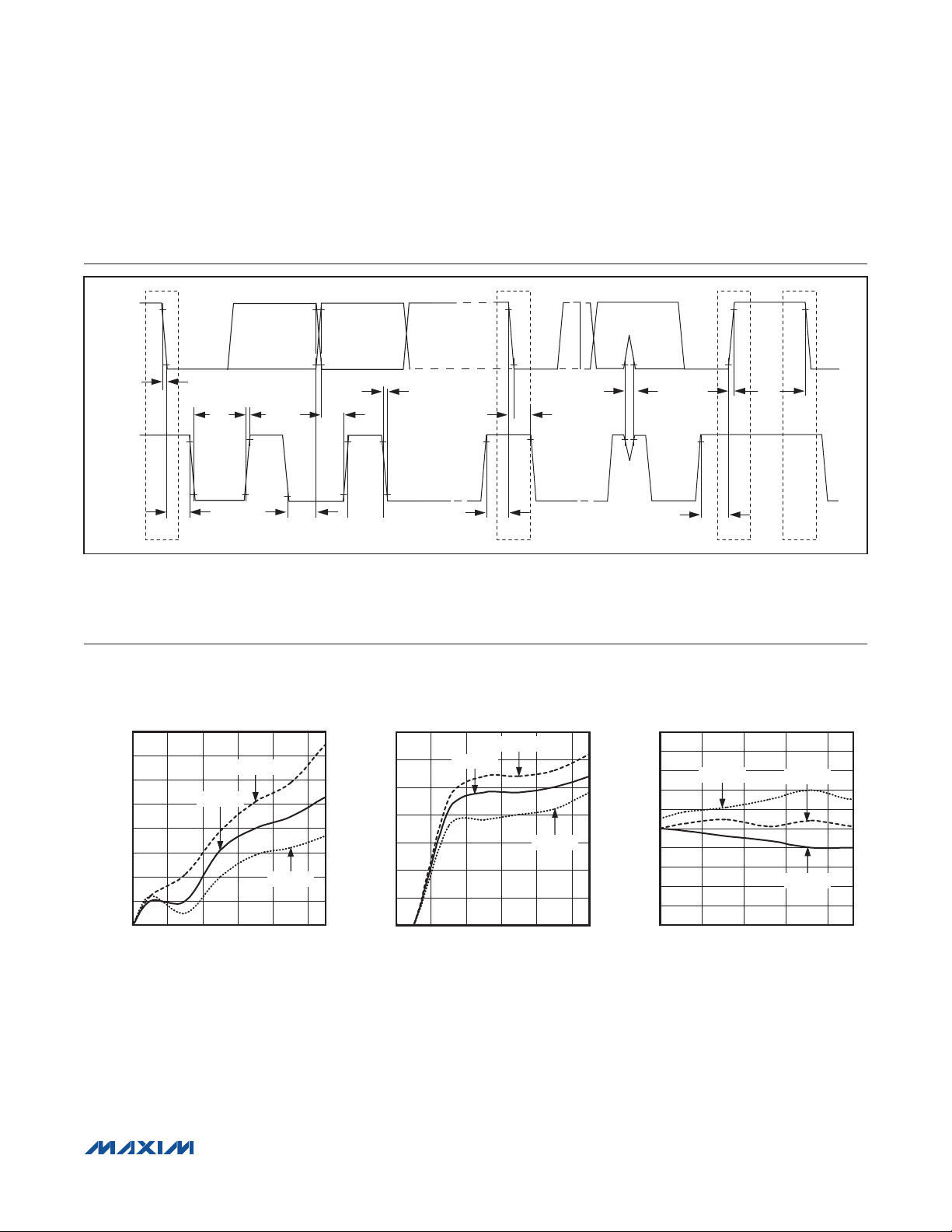

Page 4

SDA

SCL

MAX17047

ModelGauge m3 Fuel Gauge

I2C Bus Timing Diagram

t

F

t

t

LOW

t

R

SU:DAT

t

F

t

HD:STA

t

SPtR

t

BUF

t

HD:STA

S Sr

Figure 1. I2C Bus Timing Diagram

(T

= +25°C, unless otherwise noted.)

A

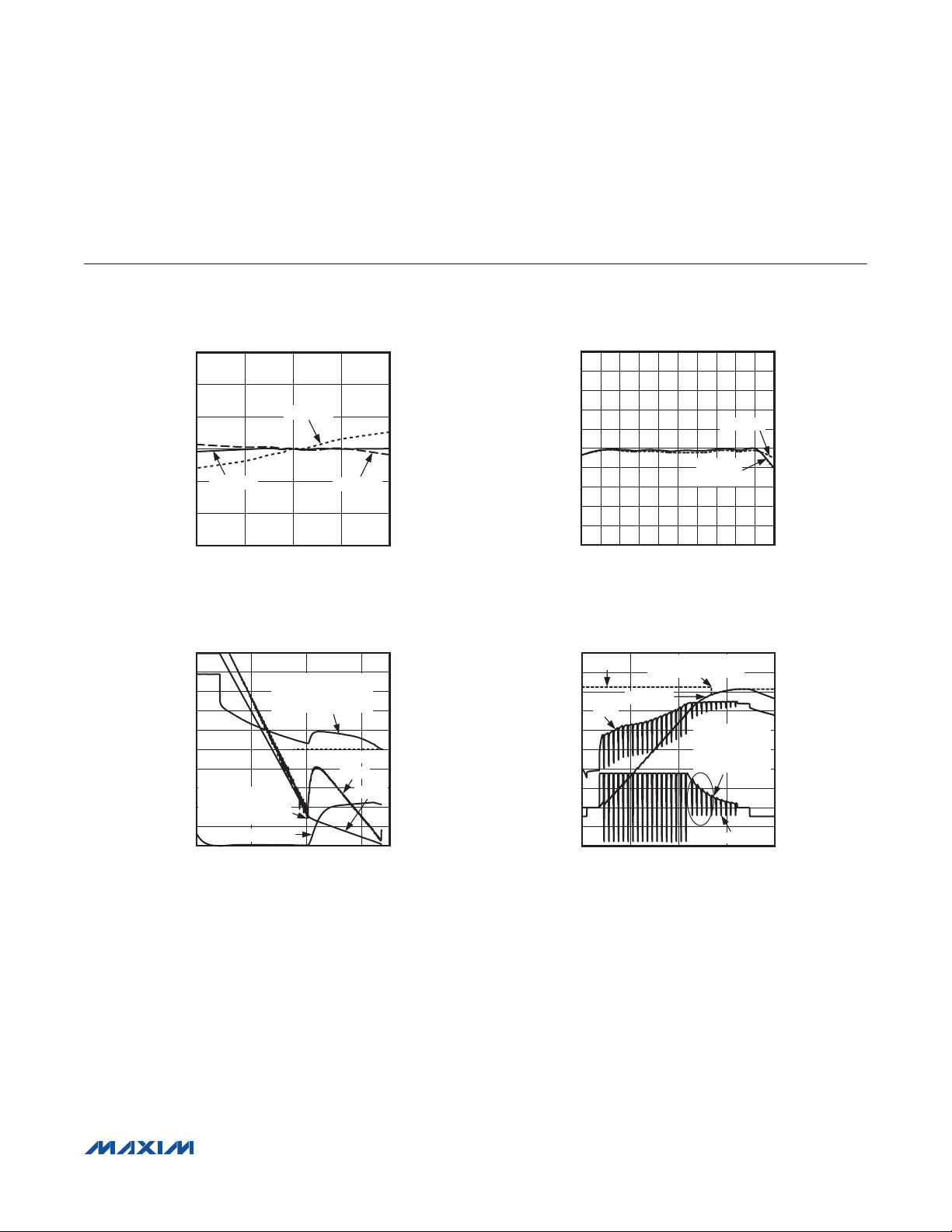

SHUTDOWN CURRENT

vs. SUPPLY VOLTAGE

0.8

0.7

0.6

0.5

0.4

0.3

SHUTDOWN CURRENT (µA)

0.2

0.1

0

0

T

= +25°C

A

T

= +70°C

A

TA = -20°C

V

(V)

BATT

t

HD:DAT

t

SU:STA

t

SU:STO

P

S

Typical Operating Characteristics

ACTIVE CURRENT vs. SUPPLY VOLTAGE

35

30

MAX17047 toc01

25

20

15

ACTIVE CURRENT (µA)

10

5

541 2 3

0

0

= +25°C

T

A

T

= +70°C

A

MAX17047 toc02

TA = -20°C

54321

V

(V)

BATT

vs. TEMPERATURE AND SUPPLY VOLTAGE

10

8

6

4

2

0

-2

-4

VOLTAGE ADC ERROR (mV)

-6

-8

-10

2.2

VOLTAGE ADC ERROR

TA = -20°C

V

BATT

(V)

T

A

T

A

= +70°C

= +25°C

MAX17047 toc03

4.23.73.22.7

����������������������������������������������������������������� Maxim Integrated Products 4

Page 5

(T

= +25°C, unless otherwise noted.)

A

MAX17047

ModelGauge m3 Fuel Gauge

Typical Operating Characteristics (continued)

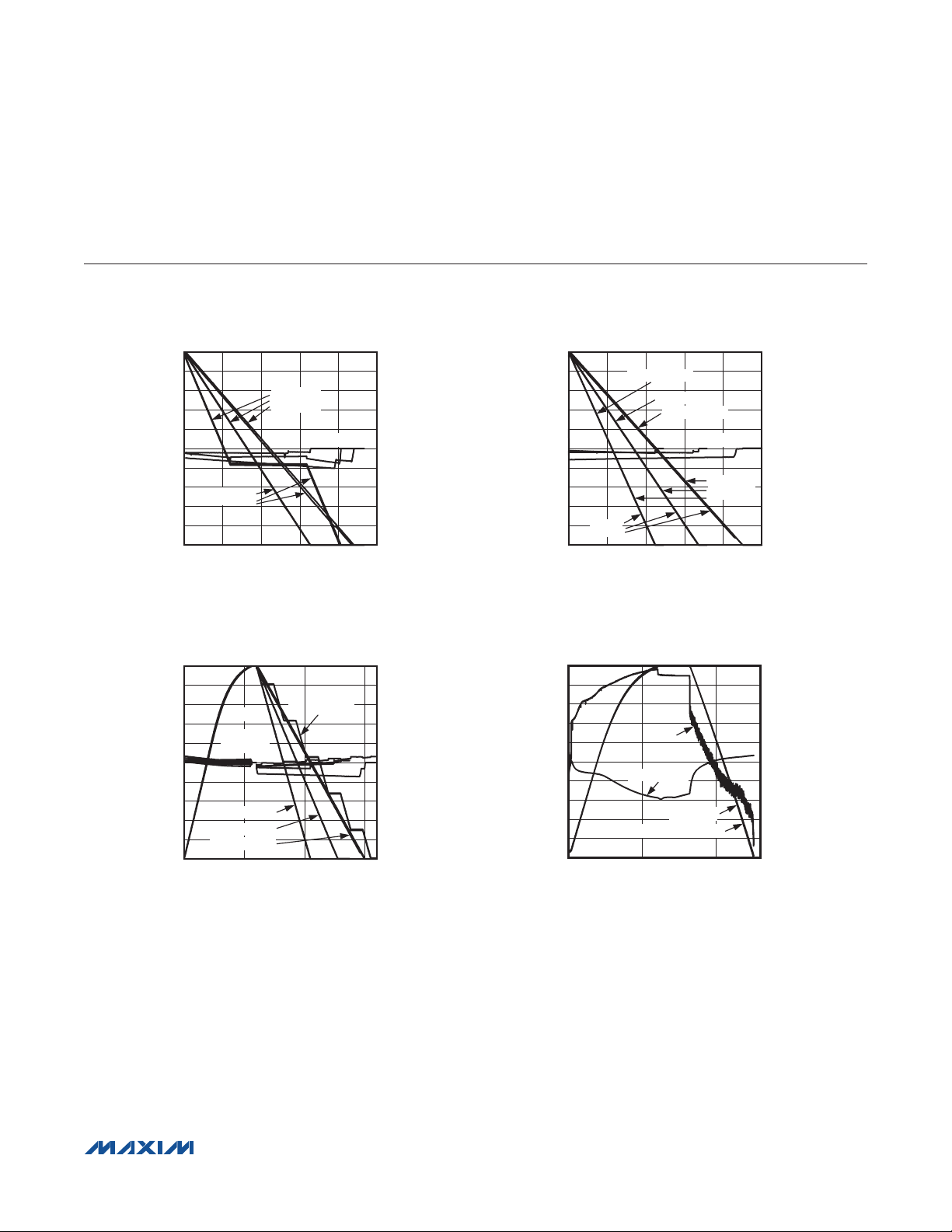

CURRENT ADC ERROR

vs. TEMPERATURE

15

10

5

0

-5

CURRENT ADC ERROR (mA)

TA = +25°C

-10

-15

-2 2

TA = -20°C

CURRENT FORCED (A)

RESPONSE TO TEMPERATURE TRANSIENT

AT CONSTANT-CURRENT LOAD

100

90

80

70

60

50

40

30

FUEL GAUGE CHANGES

SOC (%), TEMPERATURE (°C)

TRAJECTORY AFTER

20

TEMPERATURE CHANGE

10

0

TEMPERATURE

0 3

V

RISES WITH

CELL

TEMPERATURE DURING

CONSTANT LOAD

EMPTY VOLTAGE

21

TIME (Hr)

TA = +70°C

10-1

MAX17047 toc06

SOC

AV

SOC

REP

MAX17047 toc04

4.4

4.2

4.0

3.8

3.6

3.4

3.2

3.0

2.8

2.6

2.4

(V)

CELL

V

AUXILIARY INPUT ADC ERROR

vs. TEMPERATURE

1.00

0.80

0.60

0.40

0.20

0

-0.20

-0.40

-0.60

AUXILIARY INPUT ADC ERROR (%)

-0.80

-1.00

AIN RATIO TO VTT (%)

TA = -20°C

T

END-OF-CHARGE DETECTION

8000

FullCAP

7000

6000

V

5000

4000

3000

2000

1000

CAPACITY (mAh); CURRENT (mA)

-1000

-2000

CELL

0

0 8

VALID END-OF-CHARGE

DETECTION EVENT

RemCap

REP

TIME (Hr)

TA = +70°C

= +25°C

A

MAX17047 toc07

NEAR-FULL

FALSE CHARGE

TERMINATION

EVENTS

CURRENT

642

908060 7020 30 40 50100 100

MAX17047 toc05

4.7

4.5

4.3

4.1

3.9

3.7

3.5

3.3

3.1

2.9

2.7

(V)

CELL

V

����������������������������������������������������������������� Maxim Integrated Products 5

Page 6

(TA = +25°C, unless otherwise noted.)

MAX17047

ModelGauge m3 Fuel Gauge

Typical Operating Characteristics (continued)

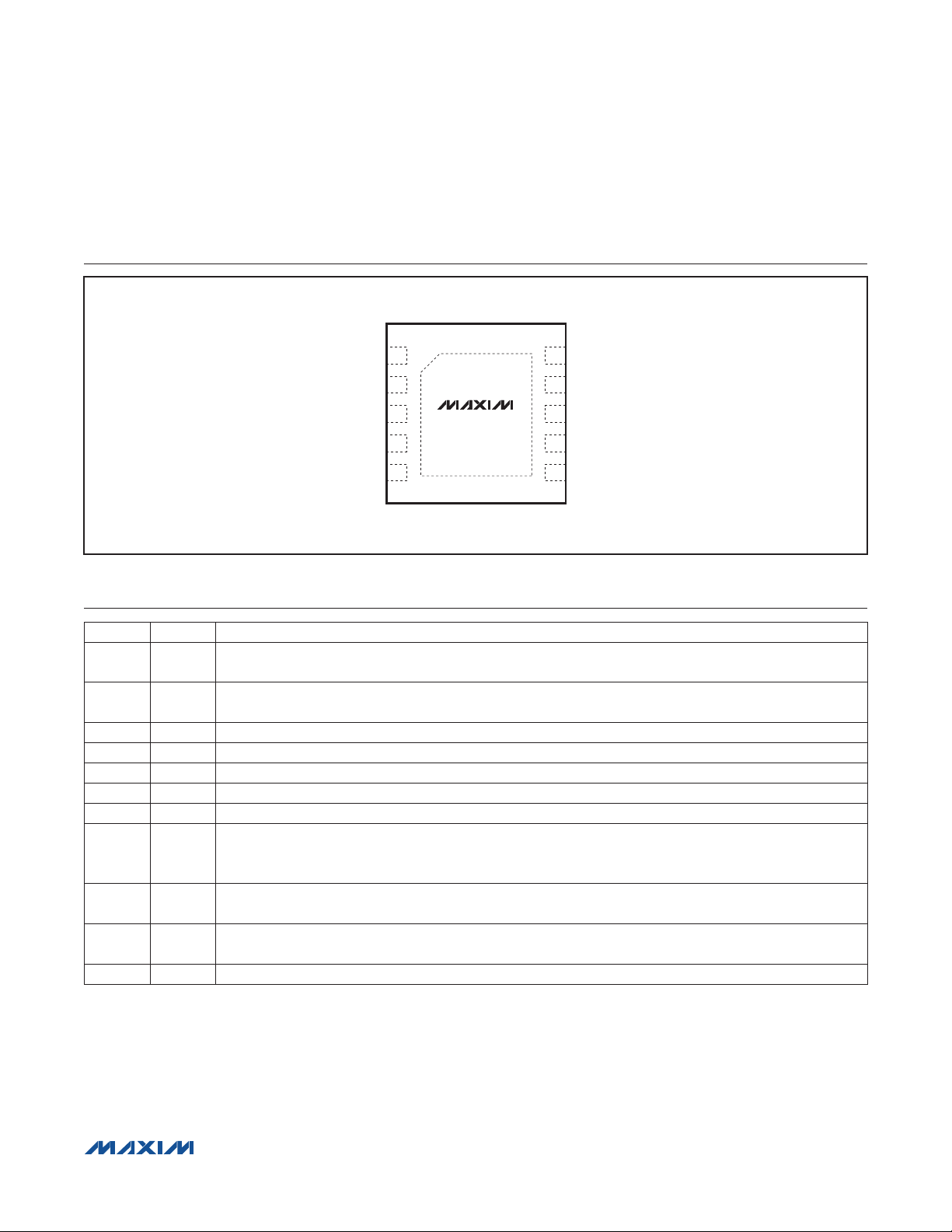

100

90

80

70

60

50

40

30

20

10

STATE OF CHARGE (%) OR TEMPERATURE (°C)

0

SOC

0 10

REFERENCE

SOC

ERROR

REP

TIME (Hr)

CHARGE AND DISCHARGE AT +20°C

100

90

COLD DISCHARGE (0°C)

80

70

60

50

40

STATE OF CHARGE (%)

30

20

10

0

0 15

SOC

REFERENCE

SOC

C/4 DISCHARGE

C/7 DISCHARGE

C/9 DISCHARGE

REP

C/2 DISCHARGE

ERROR

105

TIME (Hr)

MAX17047 toc08

8642

MAX17047 toc10

10

8

6

4

2

0

-2

-4

-6

-8

-10

10

8

6

4

2

0

-2

-4

-6

-8

-10

ERROR (%)

ERROR (%)

100

90

80

70

60

50

40

STATE OF CHARGE (%)

30

20

10

0

0 10

SOC

C/4 DISCHARGE

C/4 DISCHARGE

C/4 DISCHARGE

ERROR

REP

TIME (Hr)

CHARGE AND DISCHARGE IN

ACTUAL SYSTEM

100

90

80

DISCHARGE AT +40°C

70

60

50

40

30

20

10

STATE OF CHARGE (%) OR TEMPERATURE (°C)

0

0

V

CELL

TEMPERATURE

SOC

REFERENCE SOC

TIME (Hr)

REP

(%)

MAX17047 toc09

REFERENCE

SOC

8642

MAX17047 toc11

(%)

105

10

8

6

4

2

0

-2

-4

-6

-8

-10

4.2

4.1

4.0

3.9

3.8

3.7

3.6

3.5

3.4

3.3

3.2

ERROR (%)

(V)

CELL

V

����������������������������������������������������������������� Maxim Integrated Products 6

Page 7

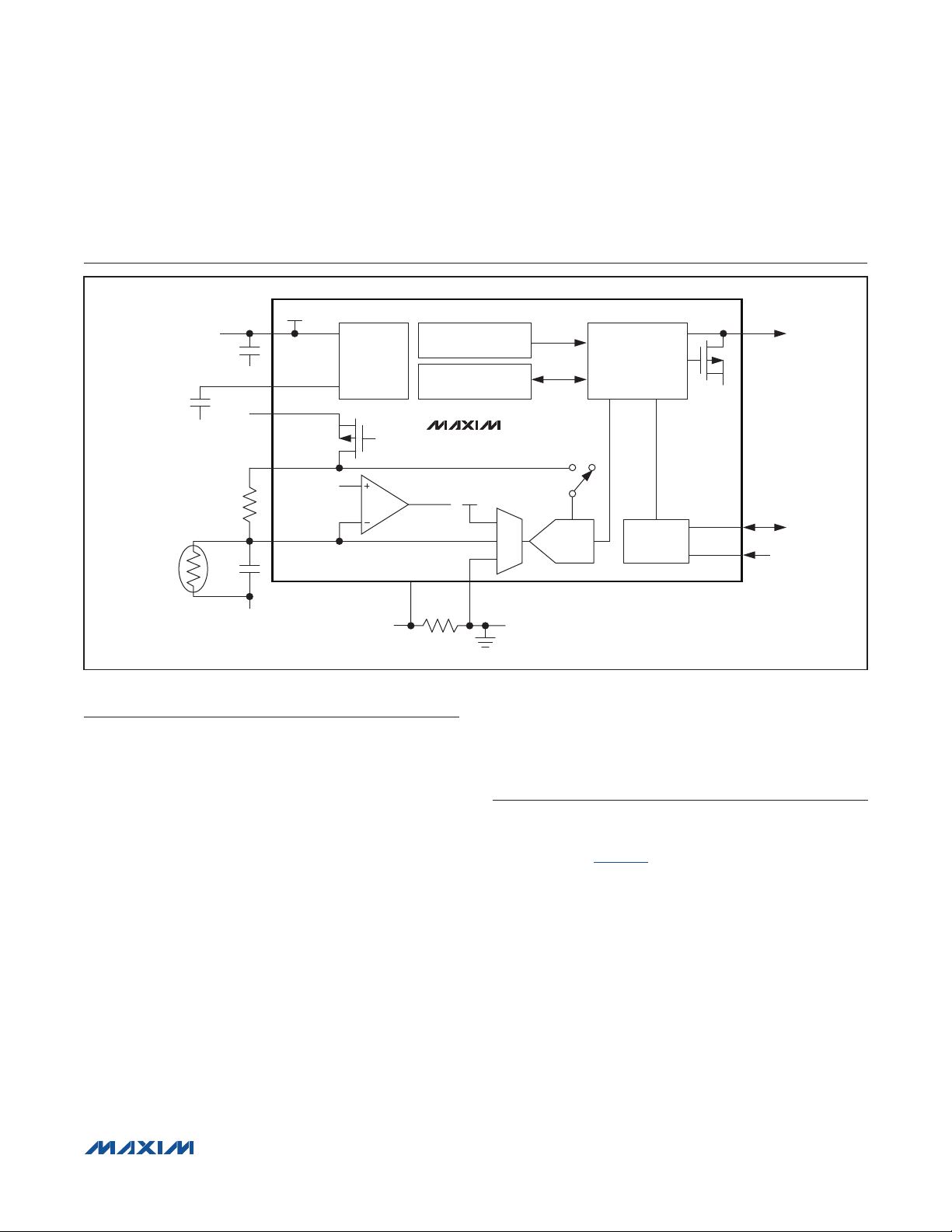

TOP VIEW

MAX17047

ModelGauge m3 Fuel Gauge

Pin Configuration

V

SCL

SDA

+

1

TT

2 9

3

4

5 6

MAX17047

TDFN

V

10

BATT

THRMAIN

ALRT

8

REG

7

EP

CSPCSN

PIN NAME FUNCTION

1 V

2 AIN

Supply Input for Thermistor Bias Switch. Connect to supply for ratiometric AIN pin-voltage measurements.

TT

In most applications, connect VTT to V

BATT

.

Auxiliary Voltage Input. Auxiliary voltage input from external thermal-measurement network. AIN also

provides battery insertion/removal detection. Connect to V

, if not used.

BATT

3 SCL Serial Clock Input. 2-wire clock line. Input only.

4 SDA Serial Data Input/Out. 2-wire data line. Open-drain output driver.

5 CSN Sense Resistor Connection. System ground connection and sense resistor input.

6 CSP Chip Ground and Sense Resistor Input

7 REG

Voltage Regulator Bypass. Connect a 0.1FF capacitor from REG to CSP.

Alert Indication. An open-drain n-channel output used to indicate specified condition thresholds have been

8 ALRT

met. A 200kI pullup resistor to power rail is required for use as an output. Alternatively, ALRT can operate

as a shutdown input with the output function disabled.

9 THRM

10 V

BATT

Thermistor Bias Connection. Supply for thermistor resistor-divider. Connect to the high side of the

thermistor/resistor-divider. THRM connects internally to VTT during temperature measurement.

Power-Supply and Battery Voltage-Sense Input. Kelvin connect to positive terminal of battery pack. Bypass

with a 0.1FF capacitor to CSP.

— EP Exposed Pad. Connect to CSP.

Pin Description

����������������������������������������������������������������� Maxim Integrated Products 7

Page 8

0.1µF

PK-

PK+

0.1µF

10nF

PK+

PK-

PK-

V

BATT

REG

V

TT

THRM

V

THRM

- V

DETR/VDETF

AIN

MAX17047

ModelGauge m3 Fuel Gauge

Block Diagram

IN

2V LDO

OUT

P

PK- SYSTEM GROUND

32kHz OSCILLATOR

OCV CALCULATION

MAX17047

BATTERY

REMOVAL

DETECT

CSP CSN

10mI

RSNS

V

BATT

MUX

REF ADC

12-BIT ADC

ModelGauge m3

ALGORITHM

REF

2

I

C

INTERFACE

ALRT

CSP

SDA

SCL

Detailed Description

The MAX17047 incorporates the Maxim ModelGauge m3

algorithm that combines the excellent short-term accuracy and linearity of a coulomb counter with the excellent

long-term stability of a voltage-based fuel gauge, along

with temperature compensation to provide industryleading fuel-gauge accuracy. ModelGauge m3 cancels

offset accumulation error in the coulomb counter, while

providing better short-term accuracy than any purely

voltage-based fuel gauge. Additionally, the ModelGauge

m3 algorithm does not suffer from abrupt corrections that

normally occur in coulomb-counter algorithms, since tiny

continual corrections are distributed over time.

The device automatically compensates for aging, temperature, and discharge rate and provides accurate SOC

in mAh or % over a wide range of operating conditions.

The device provides two methods for reporting the age

of the battery: reduction in capacity and cycle odometer.

The device provides precision measurements of current,

voltage, and temperature. Temperature of the battery

pack is measured using an external thermistor supported

����������������������������������������������������������������� Maxim Integrated Products 8

by ratiometric measurements on an auxiliary input. A

2-wire (I2C) interface provides access to data and control

registers. The device is available in a 3mm x 3mm, 10-pin

TDFN package.

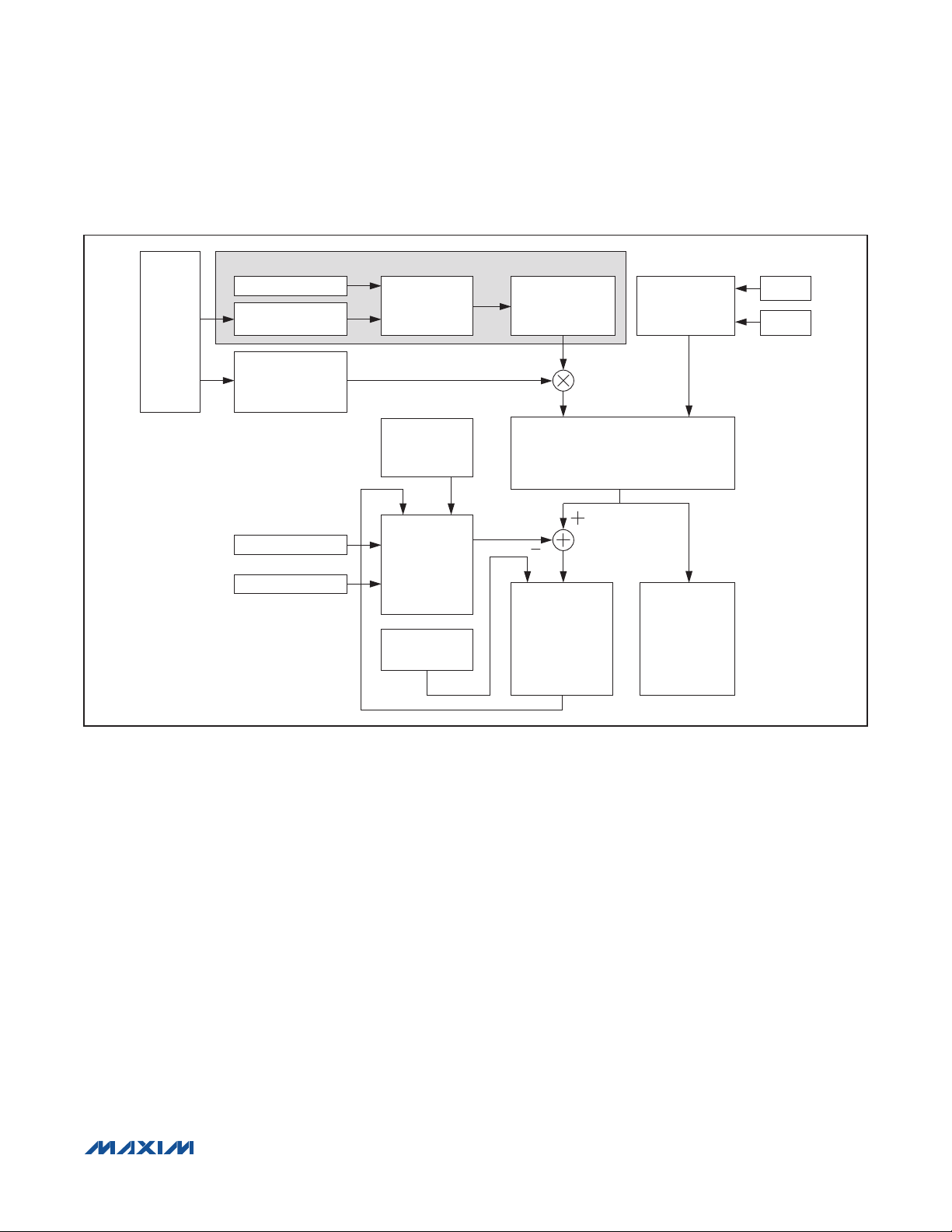

ModelGauge m3 Algorithm

The ModelGauge m3 algorithm combines a high-accuracy coulomb counter with a voltage fuel gauge (VFG) as

represented in Figure 2.

Classical coulomb-counter-based fuel gauges have

excellent linearity and short-term performance. However,

they suffer from drift due to the accumulation of the offset

error in the current-sense measurement. Although the

offset error is often very small, it cannot be eliminated,

causes the reported capacity error to increase over

time, and requires periodic corrections. Corrections are

usually performed at full or empty. Some other systems

also use the relaxed battery voltage to perform corrections. These systems determine the SOC based on the

battery voltage after a long time of no current flow. Both

have the same limitation: if the correction condition is not

observed over time in the actual application, the error in

Page 9

RELAXED

CELL

DETECTION

VOLTAGE

OCV TEMPERATURE-

COMPENSATION LEARN

CAPACITY LEARN

mAh PER %

ModelGauge m3 Fuel Gauge

VOLTAGE FUEL GUAGE

OCV CALCULATION

OCV OUTPUT

EMPTY

DETECTION

OCV TABLE LOOKUP

% REMAINING OUTPUT

MIXING ALGORITHM

mAh OUTPUT

RemCap

MIX

SOC

MIX

MAX17047

COULOMB COUNTER

mAh OUTPUT

CURRENT

TIME

CURRENT

TEMPERATURE

APPLICATION

EMPTY

COMPENSATION

END-OF-CHARGE

DETECTION

Figure 2. ModelGauge m3 Overview

the system is boundless. The performance of classic

coulomb counters is dominated by the accuracy of such

corrections.

Classical voltage-measurement-based SOC estimation

has poor accuracy due to inadequate cell modeling, but

does not accumulate offset error over time.

The device includes an advanced VFG, which estimates

open-circuit voltage (OCV), even during current flow, and

simulates the nonlinear internal dynamics of a lithium-ion

(Li+) battery to determine the SOC with improved accuracy. The model considers the time effects of a battery

caused by the chemical reactions and impedance in the

battery to determine SOC based on table lookup. This

SOC estimation does not accumulate offset error over

time.

The ModelGauge m3 algorithm combines a high-accuracy coulomb counter with a VFG. The complementary

APPLICATION

OUTPUTS:

SOC

REP

RemCap

REP

SOC

AV

RemCap

AV

TTE

FullCAP

CELL CHEMISTRY

OUTPUTS:

OCV

CYCLES

R

CELL

FullCAPNom

AGE

combined result eliminates the weaknesses of both the

coulomb counter and the VFG, while providing the

strengths of both. A mixing algorithm combines the VFG

capacity with the coulomb counter and weighs each

result so that both are used optimally to determine the

battery state. In this way, the VFG capacity result is used

to continuously make small adjustments to the battery

state, canceling the coulomb-counter drift.

The ModelGauge m3 algorithm uses this battery state

information and accounts for temperature, battery current, age, and application parameters to determine the

remaining capacity available to the system.

The ModelGauge m3 algorithm continually adapts to the

cell and application through independent learning routines. As the cell ages, its change in capacity is monitored

and updated and the VFG dynamics adapt based on cellvoltage behavior in the application.

����������������������������������������������������������������� Maxim Integrated Products 9

Page 10

MAX17047

ModelGauge m3 Fuel Gauge

OCV Estimation and Coulomb-Count Mixing

The core of the ModelGauge m3 algorithm is a mixing

algorithm that combines the OCV state estimation with

the coulomb counter. After power-on reset of the IC,

coulomb-count accuracy is unknown. The OCV state

estimation is weighted heavily compared to the coulombcount output. As the cell progresses through cycles in

the application, coulomb-counter accuracy improves

and the mixing algorithm alters the weighting so that the

coulomb-counter result is dominant. From this point forward, the IC switches to servo mixing. Servo mixing provides a fixed magnitude error correction to the coulomb

count, up or down, based on the direction of error from

the OCV estimation. This allows differences between

the coulomb count and OCV estimation to be corrected

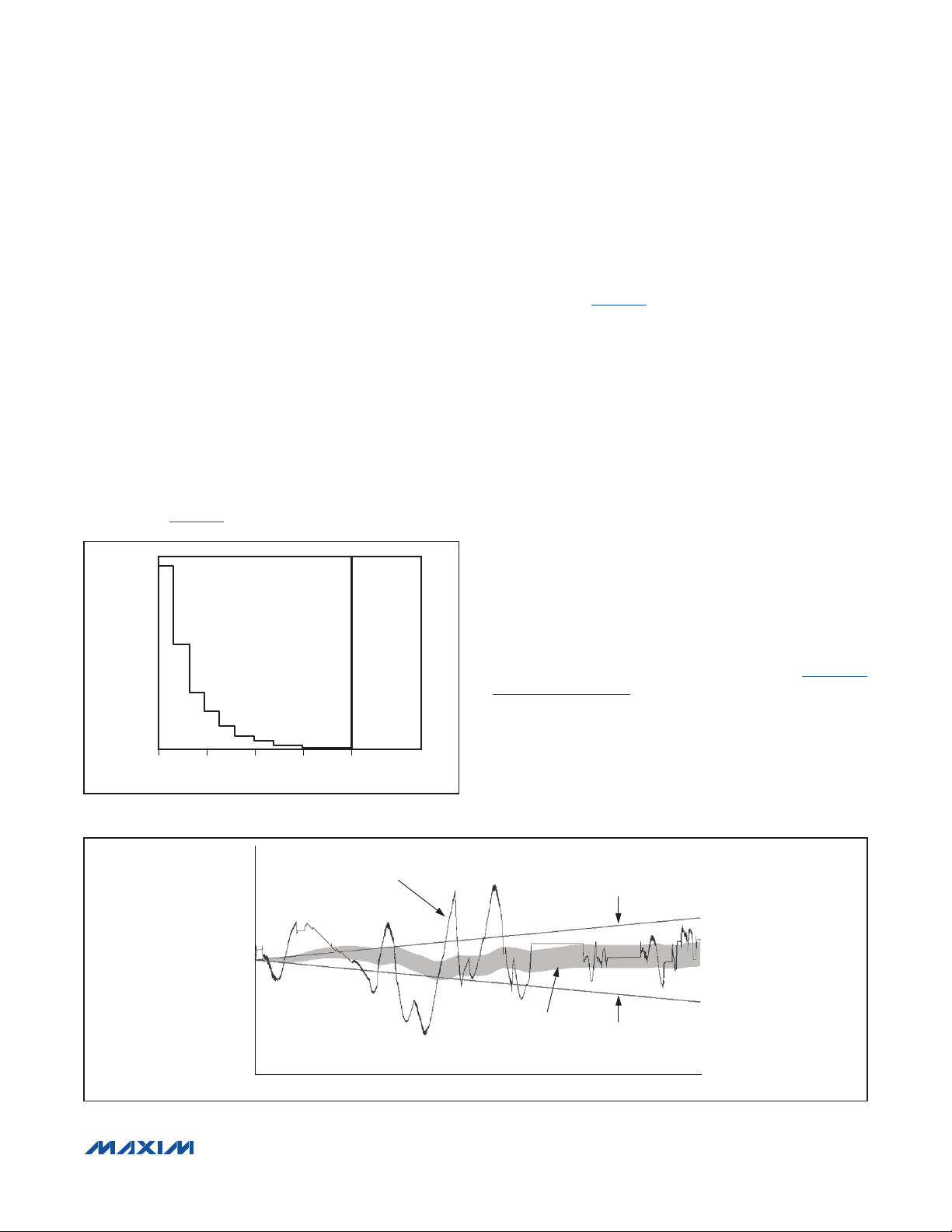

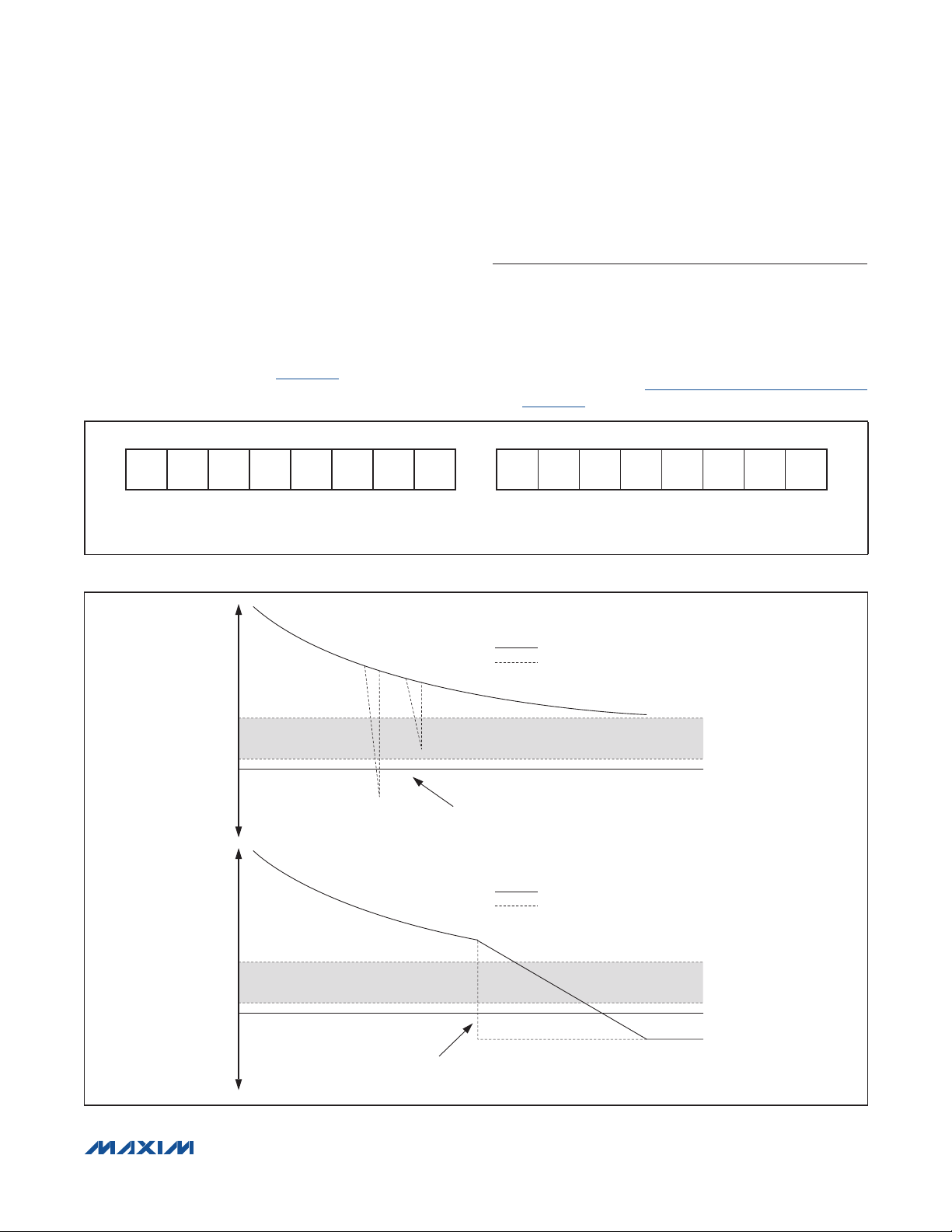

quickly. See Figure 3.

100%

COULOMB-COUNT INFLUENCE SERVO MIXING

MIXING RATIO

OCV AND COULOMB-COUNT

OCV

INFLUENCE

0%

CELL CYCLES

Figure 3. ModelGauge m3 OCV and Coulomb-Count Mixing

1.501.000.500

2.00

The resulting output from the mixing algorithm does

not suffer drift from current measurement offset error

and is more stable than a stand-alone OCV estimation

algorithm; see Figure 4. Initial accuracy depends on the

relaxation state of the cell. The highest initial accuracy is

achieved with a fully relaxed cell.

Fuel-Gauge Empty Compensation

As the temperature and discharge rate of an application changes, the amount of charge available to the

applica tion also changes. The ModelGauge m3 algorithm dis tinguishes between remaining capacity of the

cell (RemCap

) and remaining capacity of the appli-

MIX

cation (RemCapAV) and reports both results to the user.

Fuel-Gauge Learning

The device periodically makes internal adjustments

to cell characterization and application information to

remove initial error and maintain accuracy as the cell

ages. These adjustments always occur as small undercorrections to prevent instability of the system and

prevent any noticeable jumps in the fuel-gauge outputs.

Learning occurs automatically without any input from the

host. To maintain learned accuracy through power loss,

the host must periodically save learned information and

then restore after power is returned. See the Power-Up

and Power-On Reset section for details:

• Application Capacity (FullCAP). This is the total

capacity available to the application at full. Through the

user-defined registers, ICHGTerm and FullSOCThr,

the device detects end-of-charge conditions as the

cell is cycled. These points allow the device to learn

the capacity of the cell based on the charge termination experienced during operation.

TYPICAL OCV ESTIMATION

ERROR AS CELL IS CYCLED

STATE-OF-CHARGE ERROR

TIME

Figure 4. ModelGauge m3 Algorithm Mixing Conceptual Illustration

���������������������������������������������������������������� Maxim Integrated Products 10

MAXIMUM COULOMB-COUNTER ERROR

(SHADED AREA)

ModelGauge m3

OCV + COULOMB-COUNT MIXING

MAXIMUM ERROR RANGE

Page 11

MAX17047

ModelGauge m3 Fuel Gauge

• Cell Capacity (FullCapNom). This is the total cell

capacity at full, according to the VFG. This includes

some capacity that is not available to the application

at high loads and/or low temperature. The device

periodically compares percent change based on OCV

measurement vs. coulomb-count change as the cell

charges and discharges. This information allows the

device to maintain an accurate estimation of the cell’s

capacity in mAh as the cell ages.

• Voltage Fuel-Gauge Adaptation. The device

observes the battery’s relaxation response and

adjusts the dynamics of the VFG. This adaptation

adjusts the RCOMP0 register during qualified cell

relaxation events.

• Empty Compensation. The device updates inter-

nal data whenever cell empty is detected (V

V�empty) to account for cell age or other cell deviations from the characterization information.

CELL

<

Determining Fuel-Gauge Accuracy

To determine the true accuracy of a fuel gauge, as experienced by end users, the battery should be exercised

in a dynamic manner. The end-user accuracy cannot be

understood with only simple cycles.

To challenge a correction-based fuel gauge, such as

coulomb counters, test the battery with partial loading

sessions. For example, a typical user may operate the

device for 10min and then stop using for an hour or more.

A robust test method includes these kinds of sessions

many times at various loads, temperatures, and duration.

Refer to Application Note 4799: Cell Characterization

Procedure for a ModelGauge m3 Fuel Gauge.

Initial Accuracy

The device uses the first voltage reading after power-up

or after cell insertion to determine the starting output of

the fuel gauge. It is assumed that the cell is fully relaxed

prior to this reading; however, this is not always the

case. If the cell was recently charged or discharged, the

voltage measured by the device may not represent the

true state of charge of the cell, resulting in initial error in

the fuel gauge outputs. In most cases, this error is minor

and is quickly removed by the fuel gauge algorithm during normal operation.

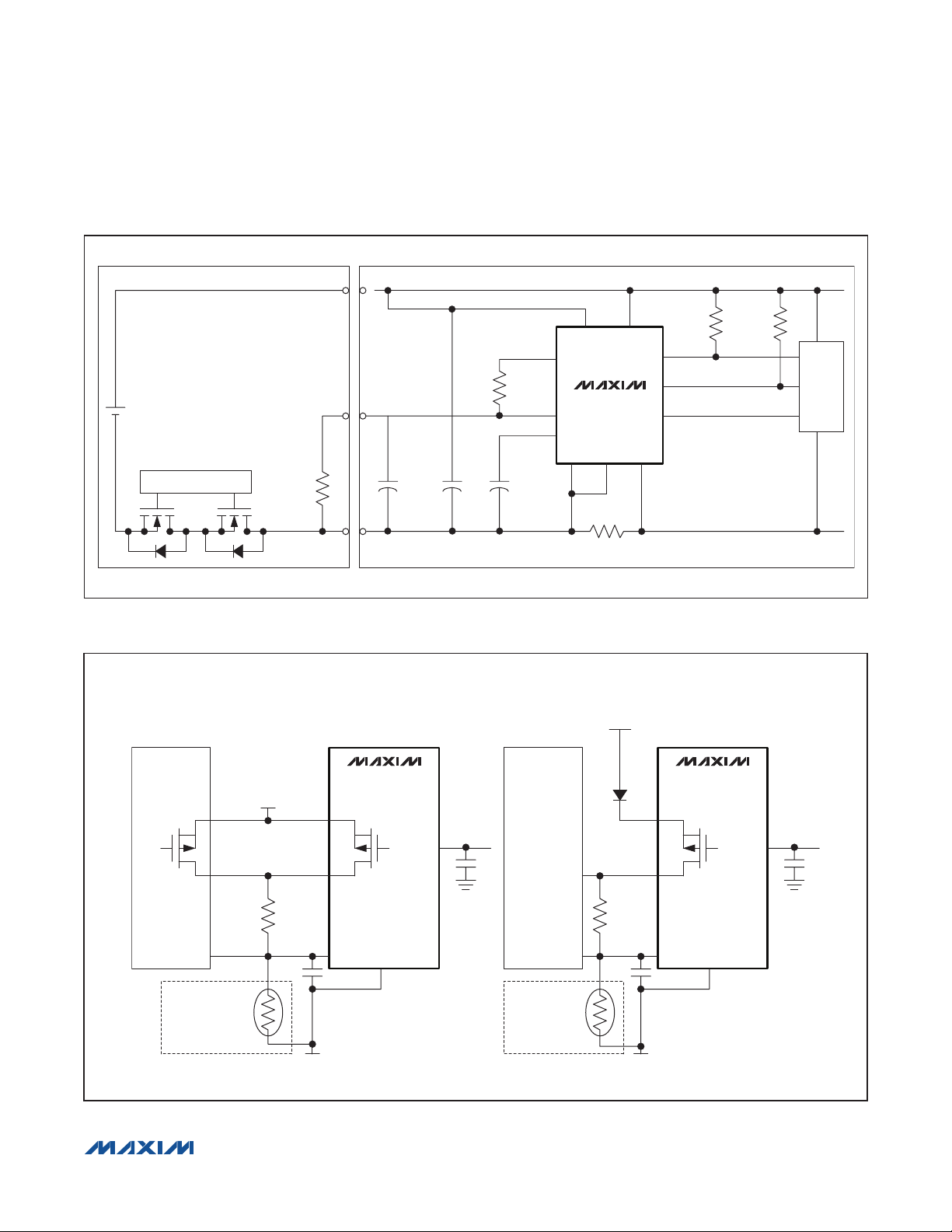

Typical Operating Circuit

The device is designed to mount outside the cell pack

that it monitors. Voltage of the battery pack is measured

directly at the pack terminals by the V

connections. Current is measured by an external sense

resistor placed between the CSP and CSN pins. An

external resistor-divider network allows the device to

measure temperature of the cell pack by monitoring the

AIN pin. The THRM pin provides a strong pullup for the

resistor-divider that is internally disabled when temperature is not being measured.

Communication to the host occurs over a standard I2C

interface. SCL is an input from the host, and SDA is an

open-drain I/O pin that requires an external pullup. The

ALRT pin is an output that can be used as an external

interrupt to the host processor if certain application conditions are detected. ALRT can also function as an input,

allowing the host to shut down the device. This pin is

also open drain and requires an external pullup resistor.

Figure 5 is the typical operating circuit.

The device can share the cell thermistor circuit with the

system charger. In this circuit, there is a single thermistor inside the cell pack and a single bias resistor external to the cell pack. The device shares the same external bias as the charger circuit and measurement point

on the thermistor. In this configuration, each device

can measure temperature individually or simultaneously

without interference. Alternatively, if the bias voltage in

the charger circuit is not available to the device, a separate bias voltage on the VTT pin can be used. For proper

operation, the separate bias voltage must be larger than

the minimum operating voltage of the device, but no

larger than one diode drop above the charger circuit

bias voltage. See Figure 6.

BATT

and CSP

���������������������������������������������������������������� Maxim Integrated Products 11

Page 12

MAX17047

ModelGauge m3 Fuel Gauge

BATTERY PACK

THERMISTOR

MEASUREMENT OPTIONAL

OPTIONAL

PROTECTION IC

THERMISTOR

Figure 5. Typical Operating Circuit

10kI

NTC

PK+

T

PK-

OPTIONAL

10nF

V

BATTVTT

THRM

OPTIONAL

10kI

REG

0.1µF0.1µF

MAX17047

AIN SCL

CSP

10mI

RSNS

BIAS

V

< V

2.8V < V

BIAS

INTERNAL

SYSTEM

OPTIONAL

ALRT

SDA

CSNEP

+ 0.6V

200kI

OPTIONAL

5kI

HOST

µP

CHARGER WITH

V

+ THRM

TT

AVAILABLE

THERMISTOR

CELL PACK

V

BIAS

VOLTAGE BASED

P P

ON EXISTING

CHARGER REQUIREMENTS

INSIDE

V

THRM

AIN

MAX17047 + CHARGER

PK- PK-

MAX17047

TT

CSP

WITH EXTERNAL BIAS

V

SYSTEM

V

BATT

CHARGER WITH

INTERNAL

OFF DURING

DISCHARGE

THERMISTOR

CELL PACK

Figure 6. Operating Circuits that Share Pack Thermistor with System Charger

���������������������������������������������������������������� Maxim Integrated Products 12

BIAS

V

INTERNAL

ON DURING

CHARGE

INSIDE

MAX17047

V

TT

P

THRM

AIN

CSP

MAX17047 + CHARGER

WITH INTERNAL BIAS

V

SYSTEM

V

BATT

Page 13

MAX17047

ModelGauge m3 Fuel Gauge

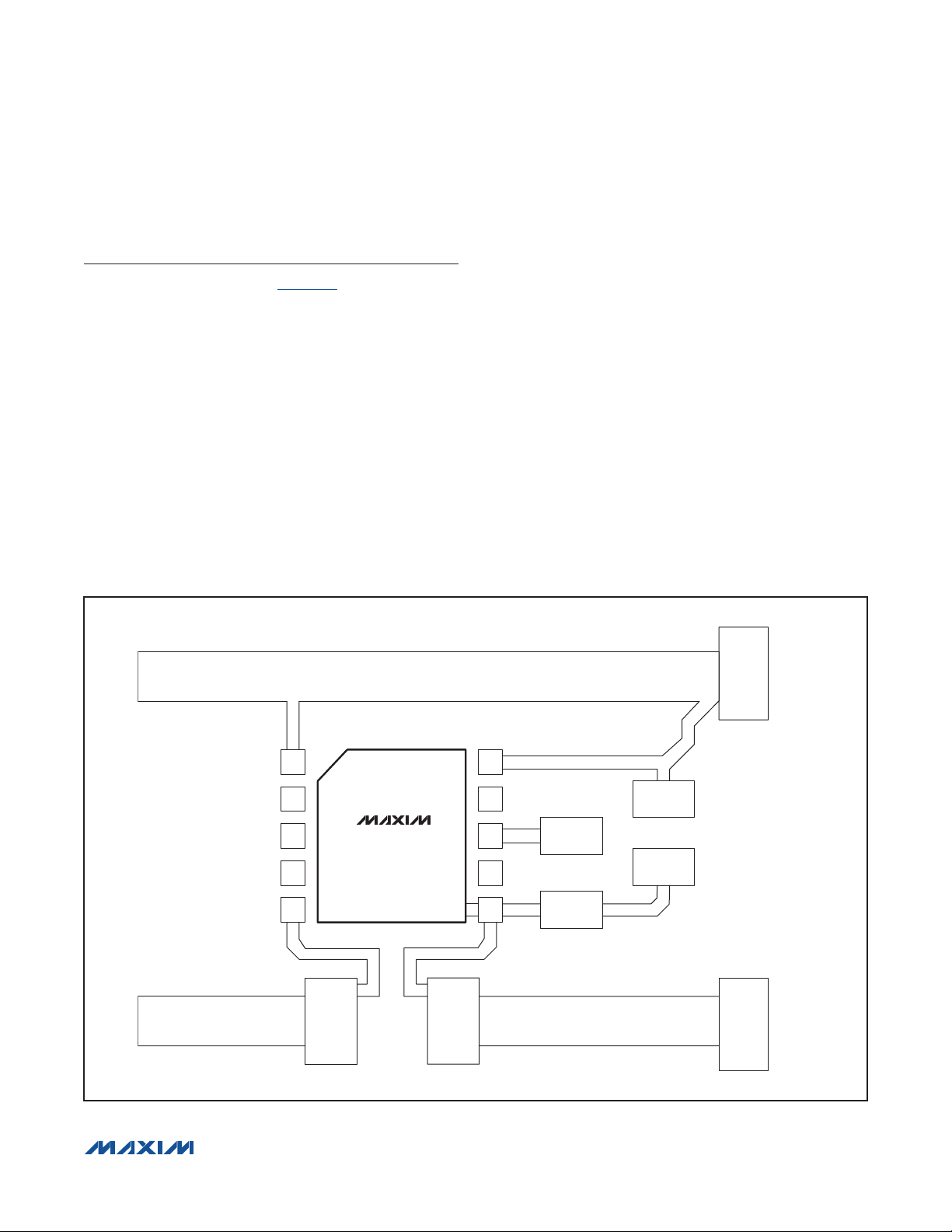

Recommended Layout

Proper circuit layout (see Figure 7) is essential for

measurement accuracy when using the MAX17047

ModelGauge m3 IC. The recommended layout guidelines are as follows:

1) Mount R

device shares both voltage and current measurements on the CSP pin. Therefore, it is important to limit

the amount of trace resistance between the currentsensing resistor and PACK-.

2) V

BATT

PACK+. The device shares the V

voltage measurement and IC power. Limiting the

voltage loss through this trace is important to voltagemeasurement accuracy. PCB resistance that cannot

be removed can be compensated for during characterization of the application cell.

POSITIVE POWER BUS

as close as possible to PACK-. The

SNS

trace should make a Kelvin connection to

pin for both

BATT

3) CSN and CSP traces should make Kelvin connections

to R

. The device measures current differentially

SNS

through the CSN and CSP pins. Any shared highcurrent paths on these traces will affect currentmeasurement gain accuracy. PCB resistance that

cannot be removed can be compensated for during

characterization of the application cell.

4) V

capacitor trace loop area should be minimized.

BATT

The device shares the V

pin for both voltage mea-

BATT

surement and IC power. Limiting noise at the V

BATT

pin is important to current-measurement accuracy.

5) REG capacitor trace loop area should be minimized.

The helps filter any noise from the internal regulated

supply.

6) There are no limitations on any other IC connection.

Connections to THRM, ALRT, SDA, SCL, VTT, and

AIN, as well as any external components mounted to

these pins, have no special layout requirements.

PACK +

CONTACT

NEGATIVE POWER BUS

Figure 7. Proper Board Layout

���������������������������������������������������������������� Maxim Integrated Products 13

V

AIN

SCL

SDA

CSN

V

BATT

TT

THRM

MAX17047

EP

R

SNS

REG

ALRT

CSP

C

REG

C

VBATT

PACK CONTACT

Page 14

MAX17047

ModelGauge m3 Fuel Gauge

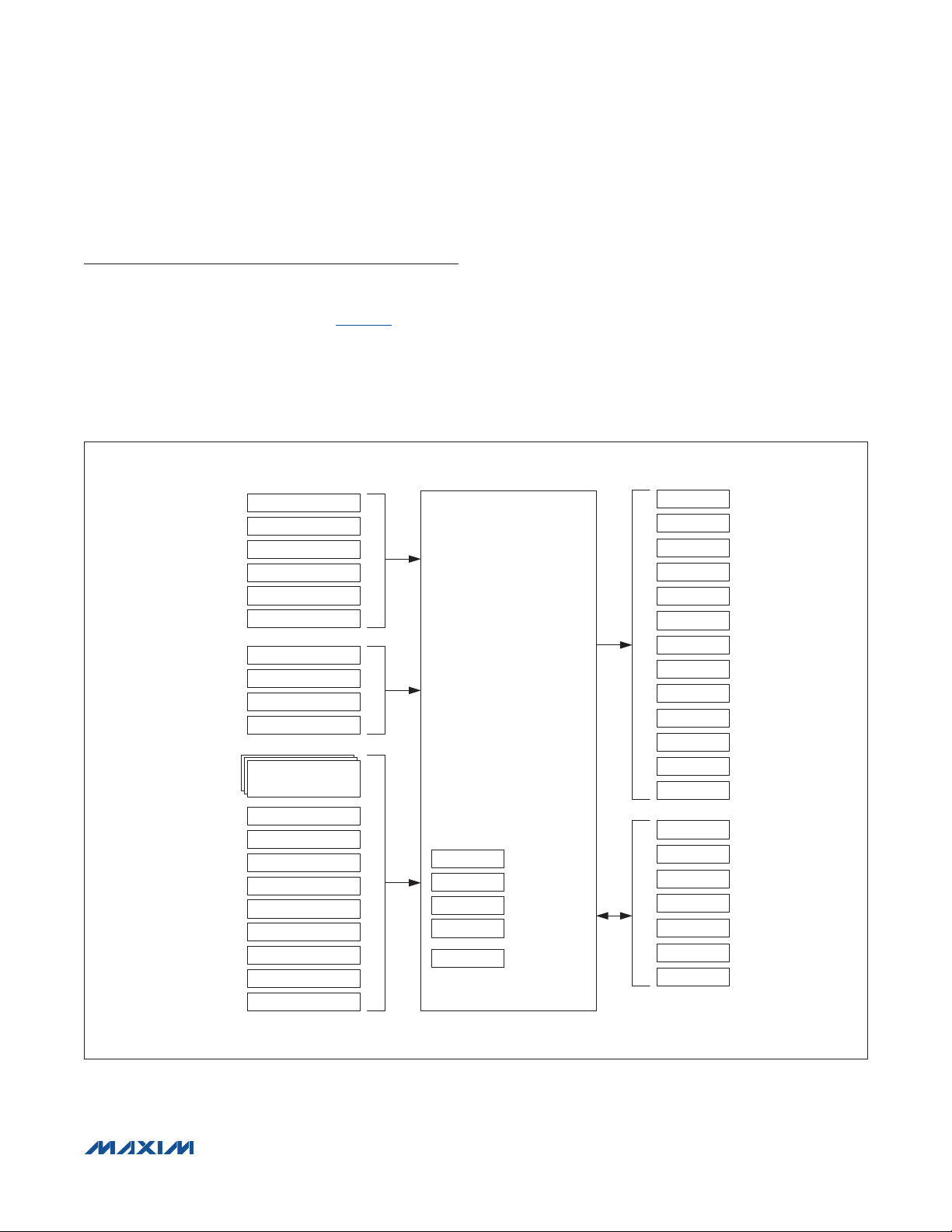

ModelGauge m3 Registers

To calculate accurate results, ModelGauge m3 requires

information about the cell, the application, and real-time

information measured by the device. Figure 8 shows all

inputs and outputs to the algorithm grouped by category.

Analog input registers are the real-time measurements

of voltage, temperature, and current performed by the

device. Application-specific registers are programmed

by the customer to reflect the operation of the applica-

V

CELL

CURRENT

ANALOG

INPUTS

APPLICATION

SPECIFIC

CELL

CHARACTERIZATION

INFORMATION

TEMPERATURE

AverageV

CELL

AverageCurrent

AverageTemperature

DesignCap

ICHGTerm

FullSOCThr

V_empty

CHARACTERIZATION

TABLE

QResidual Table

FCTC

RCOMP0

TempCo

TempNom

TempLim

V_empty

FullCapNom

Iavg_empty

LearnCFG

FilterCFG

RelaxCFG

MiscCFG

tion. The Cell Characterization Information registers

hold characterization data that models the behavior of

the cell over the operating range of the application. The

Algorithm Configuration registers allow the host to adjust

performance of the device for their application. The Save

and Restore registers allow an application to maintain

accuracy of the algorithm after the device has been

power cycled. The following sections describe each

register in detail.

SOC

MIX

RemCap

MIX

SOC

REP

RemCap

REP

SOC

AV

RemCap

AV

ModelGauge

ALGORITHM

OUTPUTS

SAVE AND

RESTORE

INFORMATION

ModelGauge ALGORITHM

ALGORITHM

CONFIGURATION

AtRate

TTE

AGE

CYCLES

OCV

FullCAP

FullCapNom

FSTAT

FullCAP

CYCLES

QResidual Table

RCOMP0

TempCo

dQacc

dPacc

Figure 8. ModelGauge m3 Register Map

���������������������������������������������������������������� Maxim Integrated Products 14

Page 15

MAX17047

ModelGauge m3 Fuel Gauge

ModelGauge Algorithm

Output Registers

The following registers hold the output results from the

ModelGauge m3 algorithm.

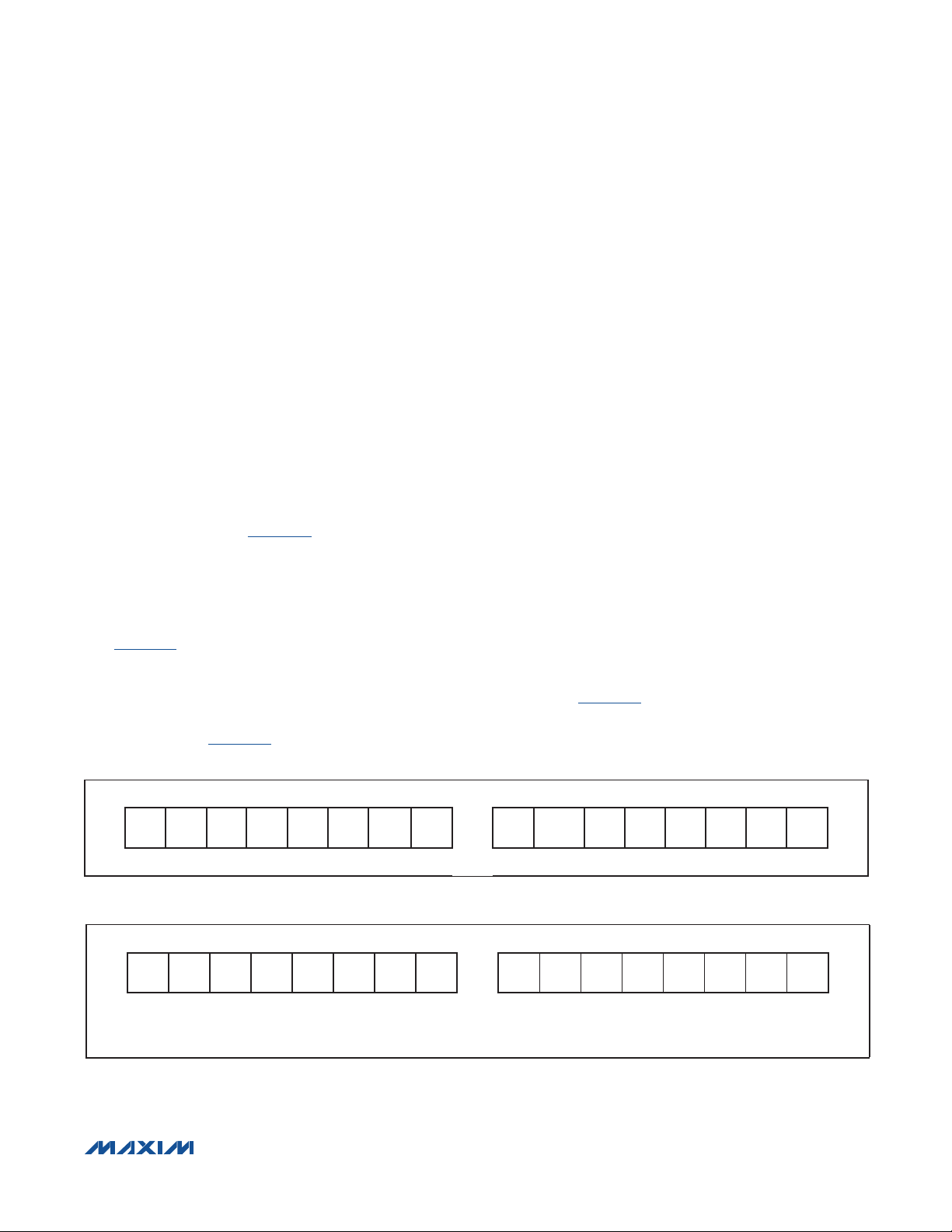

SOC

The SOC

register holds the calculated present state

MIX

of charge of the cell before any empty compensation

adjustments are performed. The register value is stored

as a percentage with a resolution of 0.0039% per LSb.

If an 8-bit state-of-charge value is desired, the host can

discard the lower byte and use only the upper byte of

the register with a resolution of 1.0%. Figure 9 shows the

SOC

Figure 9. SOC

register format.

MIX

MSB—ADDRESS 0Dh LSB—ADDRESS 0Dh

7

6

5

2

2

2

MSb LSb MSb LSb

Register Format (Output)

MIX

4

2

Register (0Dh)

MIX

3

2

2

2

2

1

0

2

The RemCap

RemCap

register holds the calculated remain-

MIX

Register (0Fh)

MIX

ing capacity of the cell before any empty compensation

adjustments are performed. The value is stored in terms

of FVh and must be divided by the application senseresistor value to determine remaining capacity in mAh.

Figure 10 shows the RemCap

SOC

is a filtered version of the SOCAV register that

REP

register format.

MIX

SOC

REP

Register (06h)

prevents large jumps in the reported value caused by

changes in the application such as abrupt changes in

load current. The register value is stored as a percentage with a resolution of 0.0039% per LSb. If an 8-bit SOC

value is desired, the host can discard the lower byte and

use only the upper byte of the register with a resolution

of 1.0%. Figure 11 shows the SOC

-1

2

-8

2

20 UNITS: 1.0%

-22-32-4

2

UNITS: 0.0039%

-52-6

2

register format.

REP

-72-8

2

MSB—ADDRESS 0Fh LSB—ADDRESS 0Fh

15214213212211210

2

MSb LSb MSb LSb

Figure 10. RemCap

7

2

MSb LSb MSb LSb

Figure 11. SOC

Register Format (Output)

MIX

MSB—ADDRESS 06h LSB—ADDRESS 06h

6

5

4

2

2

2

Register Format (Output)

REP

���������������������������������������������������������������� Maxim Integrated Products 15

3

2

2

9

2

2

2

8

2

1

0

2

7

6

2

2

20 UNITS: 5.0FVh/R

(0.5mAh WHEN R

-1

2

2

-8

2

UNITS: 0.0039%

20 UNITS: 1.0%

5

2

-22-32-42-5

SENSE

SENSE

4

2

2

= 0.010I)

3

2

1

2

2

-6

2

2

2

-72-8

0

Page 16

MAX17047

ModelGauge m3 Fuel Gauge

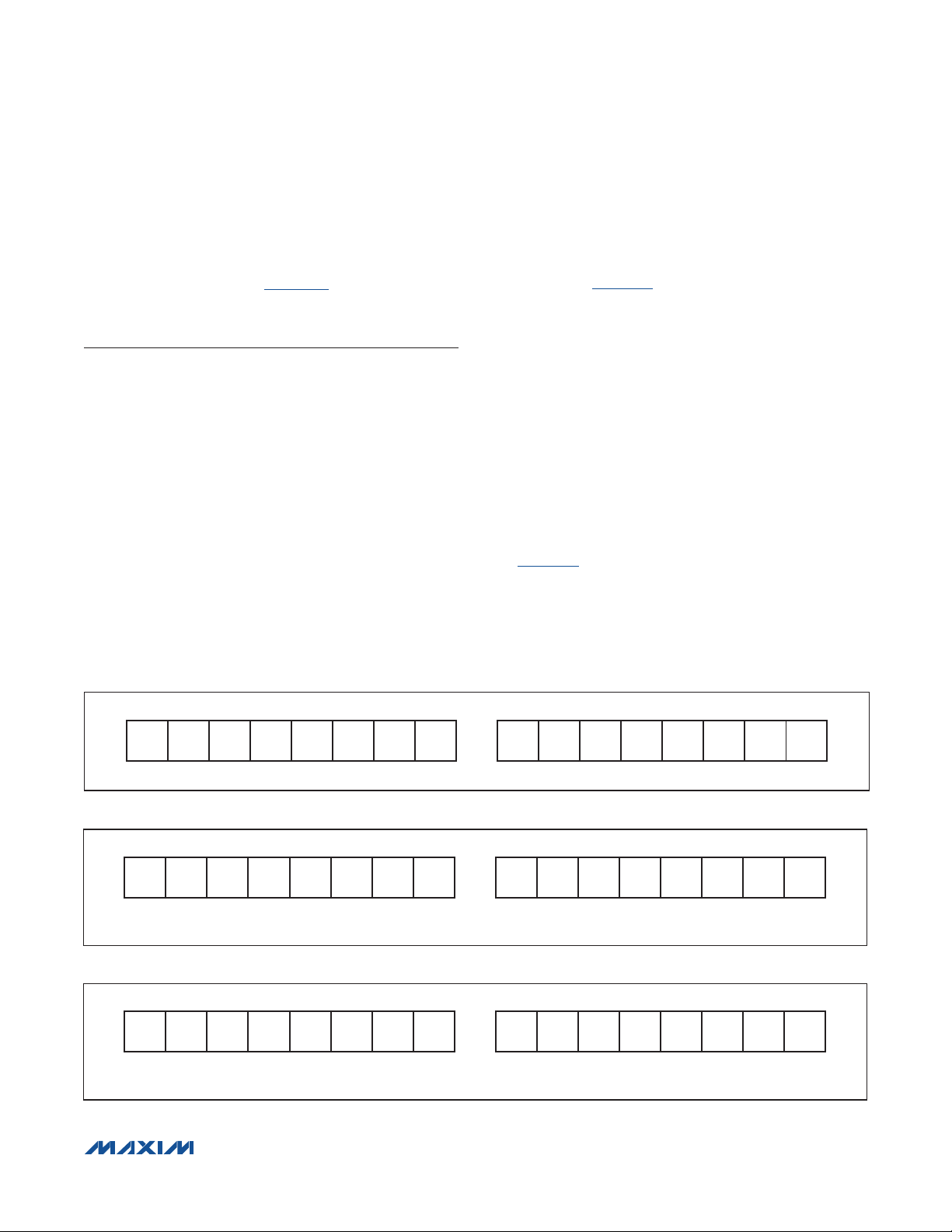

RemCap

RemCap

is a filtered version of the RemCapAV register

REP

Register (05h)

REP

that prevents large jumps in the reported value caused by

changes in the application such as abrupt changes in load

current. The value is stored in terms of FVh and must be

divided by the application sense-resistor value to determine

remaining capacity in mAh. During application idle periods

where the AverageCurrent Register value is less than Q6

LSbs, RemCap

rent during this period is still accumulated into RemCap

and is slowly reflected in RemCap

charging occurs. Figure 12 shows the RemCap

does not change. The measured cur-

REP

once cell loading or

REP

REP

MIX

register

format.

SOCAV Register (0Eh)

The SOCAV register holds the calculated present state

of charge of the cell based on all inputs from the

ModelGauge m3 algorithm including empty compensation. The register value is stored as a percentage with a

MSB—ADDRESS 05h LSB—ADDRESS 05h

15214213212211210

2

MSb LSb MSb LSb

Figure 12. RemCap

Register Format (Output)

REP

9

2

8

2

resolution of 0.0039% per LSb. If an 8-bit state-of-charge

value is desired, the host can discard the lower byte and

use only the upper byte of the register with a resolution of

1.0%. The SOCAV register value is an unfiltered calcula-

tion. Jumps in the value can be caused by changes in

the application such as abrupt changes in load current.

Figure 13 shows the SOCAV register format.

RemCapAV Register (1Fh)

The RemCapAV register holds the calculated remaining capacity of the cell based on all inputs from the

ModelGauge m3 algorithm including empty compensation. The value is stored in terms of FVh and must

be divided by the application sense-resistor value to

determine the remaining capacity in mAh. The register

value is an unfiltered calculation. Jumps in the value can

be caused by changes in the application such as abrupt

changes in load current. Figure 14 shows the RemCapAV

register format.

7

6

5

4

3

2

1

2

2

2

20 UNITS: 5.0FVh/R

(0.5mAh WHEN R

SENSE

SENSE

2

2

= 0.010I)

2

2

0

2

MSB—ADDRESS 0Eh LSB—ADDRESS 0Eh

7

6

5

4

3

2

1

2

2

2

2

2

2

2

MSb LSb MSb LSb

Figure 13. SOCAV Register Format (Output)

MSB—ADDRESS 1Fh LSB—ADDRESS 1Fh

15214213212211210

2

MSb LSb MSb LSb

Figure 14. RemCapAV Register Format (Output)

���������������������������������������������������������������� Maxim Integrated Products 16

2

0

2

9

8

2

-1

2

-8

2

20 UNITS: 1.0%

2

20 UNITS: 5.0FVh/R

(0.5mAh WHEN R

-22-32-42-5

2

UNITS: 0.0039%

7

6

2

2

5

SENSE

SENSE

4

2

2

= 0.010I)

3

-6

2

2

-72-8

2

2

1

2

0

2

Page 17

MAX17047

ModelGauge m3 Fuel Gauge

SOCVF Register (FFh)

The SOCVF register holds the calculated present SOC of

the battery according to the voltage fuel gauge. The register value is stored as a percentage with a resolution of

0.0039% per LSb. If an 8-bit SOC value is desired, the host

can discard the lower byte and use only the upper byte of

Alternatively, the TTE register can be used to estimate time

to empty for any given current load. Whenever the AtRate

register is programmed to a negative number, representing

a discharge current, the TTE register displays the estimated

time to empty for the application based on the AtRate regis-

ter value. Figure 16 shows the TTE register format.

the register with a resolution of 1.0%. Figure 15 shows the

SOCVF register format.

TTE Register (11h)

The TTE register holds the estimated time to empty for

the application under present conditions. The TTE value

is determined by dividing the RemCapAV register by the

AverageCurrent register. The result is stored in the TTE

register with a resolution of 5.625s per LSb.

The Age register contains a calculated percentage value

of the application’s present cell capacity compared to its

expected capacity. The result can be used by the host to

gauge the cell’s health as compared to a new cell of the

same type. The result is displayed as a percentage value

from 0 to 256% with a 0.0039% LSb. Figure 17 shows the

Age register format. The equation for the register output is:

Age Register = 100% O (FullCAP Register/

DesignCap Register)

MSB—ADDRESS FFh LSB—ADDRESS FFh

7

6

5

4

3

2

1

2

2

2

2

2

2

2

MSb LSb MSb LSb

Figure 15. SOCVF Register Format (Output)

0

2

-1

2

-8

2

20 UNITS: 1.0%

-22-32-42-5

2

UNITS: 0.0039%

Age Register (07h)

-6

2

-72-8

2

MSB—ADDRESS 11h LSB—ADDRESS 11h

10

9

8

7

6

5

4

2

2

2

2

2

2

2

MSb LSb MSb LSb

Figure 16. TTE Register Format (Output)

MSB—ADDRESS 07h LSB—ADDRESS 07h

7

6

5

4

3

2

2

2

2

2

MSb LSb MSb LSb

Figure 17. Age Register Format (Output)

���������������������������������������������������������������� Maxim Integrated Products 17

2

2

2

3

2

1

0

2

2

2

20 UNITS: 3.0min

2

20 UNITS: 1.0%

-8

2

1

2

-1

-22-32-42-5

2

UNITS: 0.0039%

0

-12-2

2

2

-3

2

2

-42-5

2

-6

-72-8

2

Page 18

MAX17047

ModelGauge m3 Fuel Gauge

Cycles Register (17h)

The Cycles register accumulates total percent change in

the cell during both charging and discharging. The result

is stored as a total count of full charge/discharge cycles.

For example, a full charge/discharge cycle results in

the Cycles register incrementing by 100%. The Cycles

register has a full range of 0 to 65535% with a 1% LSb.

This register is reset to 0% at power-up. To maintain the

lifetime cycle count of the cell, this register must be periodically saved by the host and rewritten to the device at

power-up. See the Save and Restore Registers section

for details. See Figure 18 for the Cycles register format.

VFOCV Register (FBh)

The VFOCV register contains the raw open-circuit volt-

in other internal calculations and can be read for debug

purposes. The result is a 12-bit value ranging from 2.5V

to 5.119V where 1 LSb is 1.25mV. The bottom 4 bits of

this register are don’t care bits. See Figure 19 for the

VFOCV register format.

FullCAP Register (10h)

This register holds the ModelGauge m3 algorithm calcu-

lated full capacity of the cell under best-case conditions

(light load, hot). A new full-capacity value is calculated

after the end of every charge cycle in the application. The

value is stored in terms of FVh and must be divided by

the application sense-resistor value to determine capac-

ity in mAh. Figure 20 is the FullCAP register format. See

the End-of-Charge Detection section.

age output of the voltage fuel gauge. This value is used

MSB—ADDRESS 17h LSB—ADDRESS 17h

15214213212211210

2

MSb LSb MSb LSb

Figure 18. Cycles Register Format (Output)

9

2

8

2

7

2

20 UNITS: 1.0%

6

2

5

4

2

2

3

2

2

1

2

2

0

2

MSB—ADDRESS FBh LSB—ADDRESS FBh

11210

2

MSb LSb MSb LSb

Figure 19. VFOCV Register Format (Output)

15214213212211210

2

MSb LSb MSb LSb

Figure 20. FullCAP Register Format (Output)

9

8

7

6

5

2

2

2

2

2

MSB—ADDRESS 10h LSB—ADDRESS 10h

2

���������������������������������������������������������������� Maxim Integrated Products 18

4

2

9

8

2

3

2

2

2

20 UNITS: 1.25mV

X = DON’T CARE

7

2

2

20 UNITS: 5.0FVh/R

(0.5mAh WHEN R

1

2

6

5

2

SENSE

SENSE

0

2

X X X X

4

2

3

2

= 0.010I)

2

1

2

2

0

2

Page 19

MAX17047

ModelGauge m3 Fuel Gauge

FullCapNom Register (23h)

Application-Specific Registers

This register holds the calculated full capacity of the cell,

not including temperature and charger tolerance. New

full capacity values are calculated periodically by the IC

during operation. The value is stored in terms of FVh and

must be divided by the application sense resistor value

to determine capacity in mAh. This register is used to

calculate the outputs of the ModelGauge m3 algorithm

and is available to the user only for debug. Figure 21 is

the FullCapNom register format.

QH Register (4Dh)

The QH register displays the raw coulomb count generated by the device. This register is used internally as an

input to the mixing algorithm. Monitoring changes in QH

over time can be useful for debugging device operation.

The QH register is set to 0000h at power-up. The QH reg-

The following registers define the behavior of the applica-

tion. They must be programmed by the user before the

ModelGauge m3 algorithm is accurate. Any changes to

these register values require recharacterization of the cell.

DesignCap Register (18h)

The DesignCap register holds the expected capacity of

the cell. This value is used to determine age and health

of the cell by comparing against the calculated pres-

ent capacity stored in the FullCAP register. DesignCap

has an LSb equal to 5.0FVh and a full range of 0 to

327.68mVh. The user should multiply the mAh capac-

ity of the cell by the sense resistor value to determine

the FVh value to store in the DesignCap register. The

DesignCap register format is shown in Figure 23.

ister format is shown in Figure 22.

MSB—ADDRESS 23h LSB—ADDRESS 23h

15214213212211210

2

MSb LSb MSb LSb

Figure 21. FullCapNom Register Format (Output)

9

2

8

2

7

6

2

2

20 UNITS: 5.0FVh/R

(0.5mAh WHEN R

5

2

SENSE

SENSE

4

2

2

= 0.010I)

3

2

1

2

2

0

2

MSB—Address 4Dh LSB—ADDRESS 4Dh

15214213212211210

2

MSb LSb MSb LSb

Figure 22. QH Register Format (Output)

MSB—ADDRESS 18h LSB—ADDRESS 18h

15214213212211210

2

MSb LSb MSb LSb

Figure 23. DesignCap Register Format (Input)

���������������������������������������������������������������� Maxim Integrated Products 19

9

2

2

8

2

9

8

2

7

6

2

2

20 UNITS: 5.0FVh/R

(0.5mAh WHEN R

7

2

2

20 UNITS: 5.0FVh/R

(0.5mAh WHEN R

5

2

6

5

2

SENSE

SENSE

SENSE

SENSE

4

2

2

= 0.010I)

4

2

2

= 0.010I)

3

3

2

1

2

2

2

2

2

0

2

1

0

2

Page 20

MAX17047

ModelGauge m3 Fuel Gauge

FullSOCThr Register (13h)

End-of-Charge Detection

The FullSOCThr register gates detection of end-ofcharge. SOCVF must be larger than the FullSOCThr

value before ICHGTerm is compared to the Average

Current register value. The recommended FullSOCThr

register setting for most applications is 95%. See the

ICHGTerm register description for details. The FullSOCThr

register is 70% at power-up. Figure 24 is the FullSOCThr

register format.

MSB—ADDRESS 13h LSB—ADDRESS 13h

7

6

5

4

3

2

1

2

2

2

2

2

2

2

MSb LSb MSb LSb

Figure 24. FullSOCThr Register Format (Input)

0

2

The device detects the end of a charge cycle when

the application current falls into the band set by the

ICHGTerm register value. By monitoring both the current

and average current registers, the device can reject false

end-of-charge events such as application load spikes

or early charge-source removal. See the End-of-Charge

Detection graph in the Typical Operating Characteristics

and Figure 25.

-1

2

-8

2

20 UNITS: 1%

-22-32-42-5

2

UNITS: 0.0039%

Figure 25

AVERAGE CURRENT

CHARGING

CURRENT

-6

2

-72-8

2

0mA

DISCHARGING

CHARGING

0mA

DISCHARGING

Figure 25. False End-of-Charge Events

���������������������������������������������������������������� Maxim Integrated Products 20

HIGH-CURRENT LOAD SPIKES DO NOT GENERATE END-OF-CHARGE

DETECTION BECAUSE CURRENT AND AVERAGE CURRENT READINGS

DO NOT FALL INTO THE DETECTION AREA AT THE SAME TIME.

AVERAGE CURRENT

CURRENT

EARLY CHARGER REMOVAL DOES NOT GENERATE END-OF-CHARGE

DETECTION BECAUSE CURRENT AND AVERAGE CURRENT READINGS

DO NOT FALL INTO THE DETECTION AREA AT THE SAME TIME.

1.25 x ICHGTerm

0.125 x ICHGTerm

1.25 x ICHGTerm

0.125 x ICHGTerm

Page 21

MAX17047

ModelGauge m3 Fuel Gauge

When a proper end-of-charge event is detected, the

device learns a new FullCAP register value based on

the RemCap

output. If the old FullCAP value was too

REP

high, it is adjusted downward after the last valid end-

CHARGING

0mA

DISCHARGING

of-charge detection. If the old FullCAP was too low, it is

adjusted upward to match RemCap

. This prevents

REP

the calculated state of charge from ever reporting a value

greater than 100%. See Figure 26.

AVERAGE CURRENT

CURRENT

1.25 x ICHGTerm

0.125 x ICHGTerm

CORRECT

END-OF-CHARGE

DETECTION AREA

CASE 1: OLD FullCAP TOO HIGH

CASE 2: OLD FullCAP TOO LOW

RemCap

Figure 26. FullCAP Learning at End of Charge

���������������������������������������������������������������� Maxim Integrated Products 21

NEW FullCAP

REP

Page 22

MAX17047

ModelGauge m3 Fuel Gauge

ICHGTerm Register (1Eh)

The ICHGTerm register allows the device to detect when

a charge cycle of the cell has completed. The host

should set the ICHGTerm register value equal to the

exact charge termination current used in the application.

The device detects end of charge if all the following conditions are met:

• SOCVF > FullSOCThr

• ANDICHGTermx0.125<Current<ICHGTermx1.25

• AND ICHGTerm x 0.125 < Average Current <

ICHGTerm x 1.25

Values are stored in FV. Multiply the termination current

The V_empty register sets thresholds related to empty

detection during operation. Figure 28 is the V_empty

register format.

VE8:VE0—Empty Voltage. Sets the voltage level for

detecting empty. A 10mV resolution gives a 0 to 5.11V

range. This value is written to 3.12V at power-up.

VR6:VR0—Recovery Voltage. Sets the voltage level for

clearing empty detection. Once the cell voltage rises

above this point, empty voltage detection is reenabled.

A 40mV resolution gives a 0 to 5.08V range. This value is

written to 3.68V at power-up.

V_empty Register (3Ah)

by the sense resistor to determine the desired register

value. This register has the same range and resolution

as the Current register. Figure 27 shows the ICHGTerm

register format. ICHGTerm defaults to 150mA (03C0h) at

power-up.

MSB—ADDRESS 1Eh LSB—ADDRESS 1Eh

14213212211210

S 2

MSb LSb MSb LSb

Figure 27. ICHGTerm Register Format (Input)

9

2

8

2

7

6

2

2

UNITS: 1.5625FV/R

5

2

2

SENSE

4

3

2

2

1

2

2

0

2

MSB—ADDRESS 3Ah LSB—ADDRESS 3Ah

VE8VE8VE6VE5VE4VE3VE2VE

MSb LSb MSb LSb

Figure 28. V_empty Register Format (Input)

���������������������������������������������������������������� Maxim Integrated Products 22

1

VE0VR6VR5VR4VR3VR2VR1VR

VR0 UNITS: 40mV

VE0 UNITS: 10mV

0

Page 23

MAX17047

ModelGauge m3 Fuel Gauge

Cell Characterization

Information Registers

Proper cell characterization is required to achieve accuracy. The following registers (Table 1) hold information

that must be generated through a cell-characterization

procedure. Maxim provides a cell-characterization service. Contact the factory for details.

Algorithm Configuration Registers

The following registers allow operation of the ModelGauge

m3 algorithm to be adjusted for the application. It is recommended that the default values for these registers be used.

FilterCFG Register (29h)

The FilterCFG register sets the averaging time period for

all A/D readings, for mixing OCV results and coulombcount results. It is recommended that these values are

not changed unless absolutely required by the application. Figure 29 shows the FilterCFG register format:

CURR3:CURR0—Sets the time constant for the

AverageCurrent register. The default POR value of 4h gives

a time constant of 11.25. The equation setting the period is:

AverageCurrent time constant = 175.8ms O 2

VOLT2:VOLT0—Sets the time constant for the

AverageV

register. The default POR value of 2h gives

CELL

a time constant of 45.0s. The equation setting the period is:

AverageV

time constant = 175.8ms O 2

CELL

(2+CURR)

(6+VOLT)

MIX3:MIX0—Sets the time constant for the mixing algorithm. The default POR value of Dh gives a time constant

of 12.8 hours. The equation setting the period is:

Mixing Period = 175.8ms O 2

(5+MIX)

TEMP2:TEMP0—Sets the time constant for the

AverageTemperature register. The default POR value of

1h gives a time constant of 12min. The equation setting

the period is:

AvergeTemperature time constant = 175.8ms x 2

(8 + TEMP)

X—Reserved. Do not modify.

Table 1. Cell Characterization Information

Registers

REGISTER ADDRESS

Characterization Table (48 words) 80h to AFh

FullCap 10h

DesignCap 18h

ICHGTerm 1Eh

FullCapNom 23h

RCOMP0 38h

lavg_empty 36h

TempCo 39h

QResidual 00 12h

QResidual 10 22h

QResidual 20 32h

QResidual 30 42h

MSB—ADDRESS 29h LSB—ADDRESS 29h

X X

MSb LSb MSb LSb

Figure 29. FilterCFG Register Format (Input)

TEMP 2TEMP 1TEMP

���������������������������������������������������������������� Maxim Integrated Products 23

MIX3 MIX2 MIX1 MIX0 VOLT2 VOLT1 VOLT0

0

CURR 3CURR 2CURR 1CURR

0

Page 24

MAX17047

ModelGauge m3 Fuel Gauge

RelaxCFG Register (2Ah)

The RelaxCFG register defines how the device detects

if the cell is in a relaxed state. See Figure 31. For a cell

to be considered relaxed, current flow through the cell

must be kept at a minimum while the change in the cell’s

voltage over time, dV/dt, shows little or no change. If

AverageCurrent remains below the Load threshold while

V

changes less than the dV threshold over two

CELL

consecutive periods of dt, the cell is considered relaxed.

Figure 30 shows the RelaxCFG register format:

Load6:Load0—Sets the threshold, which the

AverageCurrent register is compared against. The

AverageCurrent register must remain below this threshold value for the cell to be considered unloaded. Load is

an unsigned 7-bit value where 1 LSb = 50FV. The default

value is 800FV.

dV4:dV0—Sets the threshold, which V

against. If the cell’s voltage changes by less than dV over

two consecutive periods set by dt, the cell is considered

relaxed; dV has a range of 0 to 40mV where 1 LSb =

1.25mV. The default value is 1.75mV.

dt3:dt0—Sets the time period over which change in

V

is compared against dV. If the cell’s voltage

CELL

changes by less than dV over two consecutive periods

set by dt, the cell is considered relaxed. The default

value is 6 minutes. The comparison period is calculated

as:

Relaxation Period = 2dt O 0.1758s

MSB—ADDRESS 2Ah LSB—ADDRESS 2Ah

Load6Load5Load4Load3Load2Load1Load0dV4 dV3 dV2 dV1 dV0 dt3 dt2 dt1 dt0

MSb LSb MSb LSb

LOAD0 UNITS: 50FV/R

(5.0mAh WHEN R

SENSE

SENSE

= 0.010I)

Figure 30. RelaxCFG Register Format (Input)

is compared

CELL

0

AVERAGE

CURRENT

DISCHARGING

CELL

VOLTAGE

dV2

dt1 dt2 dt3 dt4 dt5 dt6

CELL UNLOADED

(RELAXATION BEGINS)

Figure 31. Cell Relaxation Detection

���������������������������������������������������������������� Maxim Integrated Products 24

dV3

dV4

dV5

RELAXATION LOAD THRESHOLD

dV6

FIRST

READING

BELOW

dv/dt

THRESHOLD

SECOND

READING

BELOW

dV/dt

THRESHOLD

CELL IS RELAXED

RelDt BIT SET

CELL CAPACITY IS

LEARNED

48 TO 96

MINUTES

LONG RELAXATION

RelDt2 BIT SET

Page 25

MAX17047

ModelGauge m3 Fuel Gauge

LearnCFG Register (28h)

The LearnCFG register controls all functions relating

to adaptation during operation. The LearnCFG register

default values should not be changed unless specifically

required by the application. Figure 32 is the LearnCFG

register format:

0—Bit must be written 0. Do not write 1.

1—Bit must be written 1. Do not write 0.

Filt Empty—Empty Detect Filter. This bit selects whether

empty is detected by a filtered or unfiltered voltage reading. Setting this bit to 1 causes the empty detection algorithm to use the AverageV

0 forces the empty detection algorithm to use the V

register. Setting this bit to

CELL

CELL

register. This bit is written to 0 at power-up.

LS2:LS0—Learn Stage. See Figure 3 The Learn Stage

value controls the influence of the VFG on the mixing

algorithm. At power-up, Learn Stage defaults to 0h, making the voltage fuel gauge dominate. Learn Stage then

advances to 7h over the course of two full cell cycles to

make the coulomb counter dominate. Host software can

write the Learn Stage value to 7h to advance to the final

stage at any time. Writing any value between 1h and

6h is ignored. Learn Stage reflects the D5, D6, and D7

bits of the Cycles register. Update the Cycles register

to advance to an intermediate state. For example, set

Cycles = 160% to advance to Learn Stage 5.

MiscCFG Register (2Bh)

The MiscCFG control register enables various other

functions of the device. The MiscCFG register default

values should not be changed unless specifically

required by the application. Figure 33 is the MiscCFG

register format:

0—Bit must be written 0. Do not write 1.

1—Bit must be written 1. Do not write 0.

X—Don’t Care. Bit may read 0 or 1.

SACFG1:SACFG0—SOC Alert Config. SOC Alerts can

be generated by monitoring any of the SOC registers as

follows. SACFG defaults to 00 at power-up:

0 0 SOC Alerts are generated based on the SOC

register.

0 1 SOC Alerts are generated based on the SOC

register.

1 0 SOC Alerts are generated based on the SOC

register.

1 1 SOC Alerts are generated based on the SOCVF

register.

REP

AV

MIX

MSB—ADDRESS LSB—ADDRESS

0 0 1 0 0 1 1 0 0 LS2LS1LS

MSb LSb MSb LSb

Figure 32. LearnCFG Register Format (Input/Output)

MSB—ADDRESS 2Bh LSB—ADDRESS 2Bh

0 0 X X enBi1 0 MR4MR

MSb LSb MSb LSb

Figure 33. MiscCFG Register Format (Input)

���������������������������������������������������������������� Maxim Integrated Products 25

3

MR2MR1MR01 0 0

MR0 UNITS: 6.25µV

0

Filt

1

Empty

1 1

SACFG 1SACFG

0

Page 26

MAX17047

ModelGauge m3 Fuel Gauge

MR4:MR0—Mixing Rate. This value sets the strength of

the servo mixing rate after the final mixing state has been

reached (> 2.08 complete cycles). The units are MR0 =

6.25FV, giving a range up to 19.375mA with a standard

0.010I sense resistor. Setting this value to 00000b

disables servo mixing and the IC continues with timeconstant mixing indefinitely. The default setting is 25FV

or 2.5mA with a standard sense resistor.

enBi1—Enable reset on battery-insertion detection. Set

this bit to 1 to force a reset of the fuel gauge whenever a

battery insertion is detected based on AIN pin monitoring.

This bit is written to 1 at power-up.

FSTAT Register (3Dh)

The FSTAT register is a read-only register that monitors

the status of the ModelGauge algorithm. Do not write

to this register location. Figure 34 is the FSTAT register

format:

RelDt—Relaxed cell detection. This bit is set to a 1 whenever the ModelGauge m3 algorithm detects that the cell

is in a fully relaxed state. This bit is cleared to 0 whenever

a current greater than the Load threshold is detected.

See Figure 31.

RelDt2—Long Relaxation. This bit is set to a 1 whenever

the ModelGauge m3 algorithm detects that the cell has

been relaxed for a period of 48 to 96 minutes or longer.

This bit is cleared to 0 whenever the cell is no longer in a

relaxed state. See Figure 31.

DNR—Data Not Ready. This bit is set to 1 at cell insertion and remains set until the output registers have been

updated. Afterwards, the IC clears this bit indicating the

fuel gauge calculations are now up to date. This takes

between 445ms and 1.845s depending on whether the

IC was in a powered state prior to the cell-insertion event.

EDet—Empty Detection. This bit is set to 1 when the IC

detects that the cell empty point has been reached. This

bit is reset to 0 when the cell voltage rises above the

recovery threshold. See the V_empty register for details.

X—Don’t Care. This bit is undefined and can be logic

0 or 1.

AtRate Register (04h)

The AtRate register allows host software to estimate

remaining capacity, SOC, and time to empty for a theoretical load current. Whenever the AtRate register is programmed to 0 or a positive value, the device uses A/D

measurements for determining the SOCAV, RemCapAV,

and TTE register values. Whenever the AtRate register is

programmed to a negative value indicating a hypothetical discharge current, the SOCAV, RemCapAV, and TTE

registers calculate their values for the AtRate register

theoretical current instead. The AtRate register holds a

two’s-complement 16-bit value. Do not write 8000h to

this register. Figure 35 shows the AtRate register format.

MSB—ADDRESS 3Dh LSB—ADDRESS 3Dh

X X X X X X RelDt EDet X RelDt2 X X X X X DNR

MSb LSb MSb LSb

Figure 34. FSTAT Register Format (Output)

MSB—ADDRESS 04h LSB—ADDRESS 04h

14213212211210

S 2

MSb LSb MSb LSb

Figure 35. AtRate Register Format (Input)

���������������������������������������������������������������� Maxim Integrated Products 26

9

2

8

2

7

6

2

2

20 UNITS: 1.5625FV/R

X = DON’T CARE

5

2

4

2

SENSE

3

2

2

1

2

2

0

2

Page 27

MAX17047

ModelGauge m3 Fuel Gauge

Power-Up and Power-On Reset

Any power-on reset (POR) of the device resets all

memory locations to their default POR value. This

removes any custom cell characterization and application data, affects ALRT interrupt and shutdown mode settings, and resets all learned adjustments made by the fuel

gauge. To maintain accuracy of the fuel gauge and reset

operation settings of the device, the host must reload

all application memory data and restore all learned fuelgauge information. Note that the device may take up to

445ms to completely reset operation after a POR event

occurs. See Figure 36. Saved data should not be restored

until after this period is over. The following procedure is

recommended:

1) Read Status register. If POR = 0, exit.

2) Wait 600ms for POR operation to fully complete.

3) Restore all application register values.

4) Restore fuel gauge learned-value information (see the

Save and Restore Registers section).

5) Clear POR bit.

Save and Restore Registers

The device is designed to operate outside the battery

pack and can therefore be exposed to power loss when

in the application. To prevent the loss of learned information during power cycles, a save-and-restore procedure

can be used to maintain register values in nonvolatile

memory external to the device. The registers (Table 2)

must be stored externally and then rewritten to the device

after power-up to maintain a learned state of operation.

Table 2. Save and Restore Registers

REGISTER ADDRESS

FullCap 10h

Cycles 17h

RCOMP0 38h

TempCo 39h

QResidual 00 12h

QResidual 10 22h

QResidual 20 32h

QResidual 30 42h

dQacc 45h

dPacc 46h

V

BATT

AIN

A/ D

READINGS

OUTPUT

REGISTERS

CELL

INSERTION

Figure 36. Power-Up Operation

���������������������������������������������������������������� Maxim Integrated Products 27

V

BATT

270ms

> V

DDMIN

A/D

MEASUREMENTS

COMPLETE

1.4s UNTIL NEXT TEMPERATURE READING

175ms

SOC VALUES

UPDATED

Page 28

MAX17047

ModelGauge m3 Fuel Gauge

Note that some registers are application outputs, some

registers are for internal calculations, and some are

characterization setup registers. Registers that are not

internal are described in their own sections. These values

should be stored by the application at periodic intervals.

Some recommended back-up events are:

• End-of-charge

• End-of-discharge

• Priortoapplicationenteringshutdownstate

The host is responsible for loading the default characterization data at first power-up of the device, and restoring

the default characterization data plus learned information

on subsequent power-up events.

Battery Removal and Insertion

The device detects when a cell has been removed or

inserted into the application. This allows the device to

adjust to the new cell to maintain accuracy. The removaldetection feature also allows the device to quickly warn the

host processor through interrupt of impending power loss

if enabled.

Detection occurs by monitoring the AIN pin voltage compared to the THRM pin. Whenever a cell is present, the

external resistor-divider network sets the voltage of AIN.

When the cell is removed, the remaining external resistor

pulls AIN to the THRM pin voltage level. Whenever V

< V

present in the application. If V

device determines that no cell is present at that time.

THRM

- V

, the device determines that a cell is

DETF

AIN

> V

THRM

- V

Cell Insertion (IC Already Powered)

The device is ready to detect a cell insertion if either the

ETHRM or FTHRM bits of the CONFIG register are set

to enable the THRM pin output. See Figure 37. When a

cell insertion is detected, the fuel gauge is reset and all

fuel-gauge outputs are updated to reflect the SOC of the

newly inserted cell. This process can take up to 1.845s

(FTHRM = 0) or 620ms (FTHRM = 1) from time of insertion. Note that the device uses the cell voltage as a starting point for the fuel gauge. If the cell voltage is not fully

relaxed at time of insertion, the fuel gauge begins with

DETR

AIN

, the

some initial error. See the Fuel-Gauge Learning section

for details. The host can disable this feature by clearing

the enBi1 bit in the MiscCFG register.

The device can also be configured to alert the host when

cell insertion occurs. When Bei = 1 in the CONFIG register, the device generates an interrupt on the ALRT pin

at the start of the first temperature conversion after insertion. This could take up to 1.4s to occur. This feature is

useful if the application uses more than one cell type and

the IC must be reconfigured at each insertion.

Cell Removal

The device detects a cell removal if either the ETHRM or

FTHRM bits of the CONFIG register are set to enable the

THRM pin output. Cell removal does not affect IC operation. The device continues to update fuel-gauge outputs.

The host should monitor the Br and Bst bits of the Status

register to determine if the fuel-gauge outputs are valid.

The device can also be configured to alert the host when

cell removal occurs. When Ber = 1 in the CONFIG register, the device generates an interrupt on the ALRT pin

at the start of the first temperature conversion after insertion. This could take up to 1.4s to occur. This feature is

useful if the application uses more than one cell type and

the IC must be reconfigured at each insertion.

Fast Detection of Cell Removal

The device can be configured to quickly alert the host of

impending power loss on cell removal. This fast response

allows the system to quickly and gracefully hibernate to

prevent power loss during battery swap. When Ber = 1 and

FTHRM = 1 in the CONFIG register, an interrupt on the

ALRT pin is generated within 100Fs after V

greater than V

is recommended that all other IC interrupts are disabled

to prevent the host from spending time determining the

cause of the interrupt. Fast detection of cell removal has

no affect on fuel-gauge operation, but leaving the external resistor-divider active increases current consumption

of the application. See Figure 38.

THRM

- V

. If fast detection is used, it

DETR

AIN

becomes

���������������������������������������������������������������� Maxim Integrated Products 28

Page 29

V

BATT

AIN

A/ D

READINGS

OUTPUT

REGISTERS

MAX17047

ModelGauge m3 Fuel Gauge

CELL INSERTION FROM POWERED STATE (FTHRM = 0)

UP TO 1.4s

270ms

175ms

CELL INSERTION FROM POWERED STATE (FTHRM = 1)

V

BATT

AIN

A/ D

READINGS

OUTPUT

REGISTERS

Figure 37. Operation After Cell Insertion

Figure 38

CELL

INSERTION

V

BATT

CELL

INSERTION

CELL

INSERTION

DETECTED

UP TO

175ms

CELL

INSERTION

DETECTED

CELL REMOVAL

(Ber = 1, FTHRM = 1)

MEASUREMENTS

COMPLETE

270ms

MEASUREMENTS

COMPLETE

A/D

A/D

SOC VALUES

UPDATED

175ms

SOC VALUES

UPDATED

Figure 38. Fast Detection of Cell Removal