Page 1

19-4964; Rev 0; 9/09

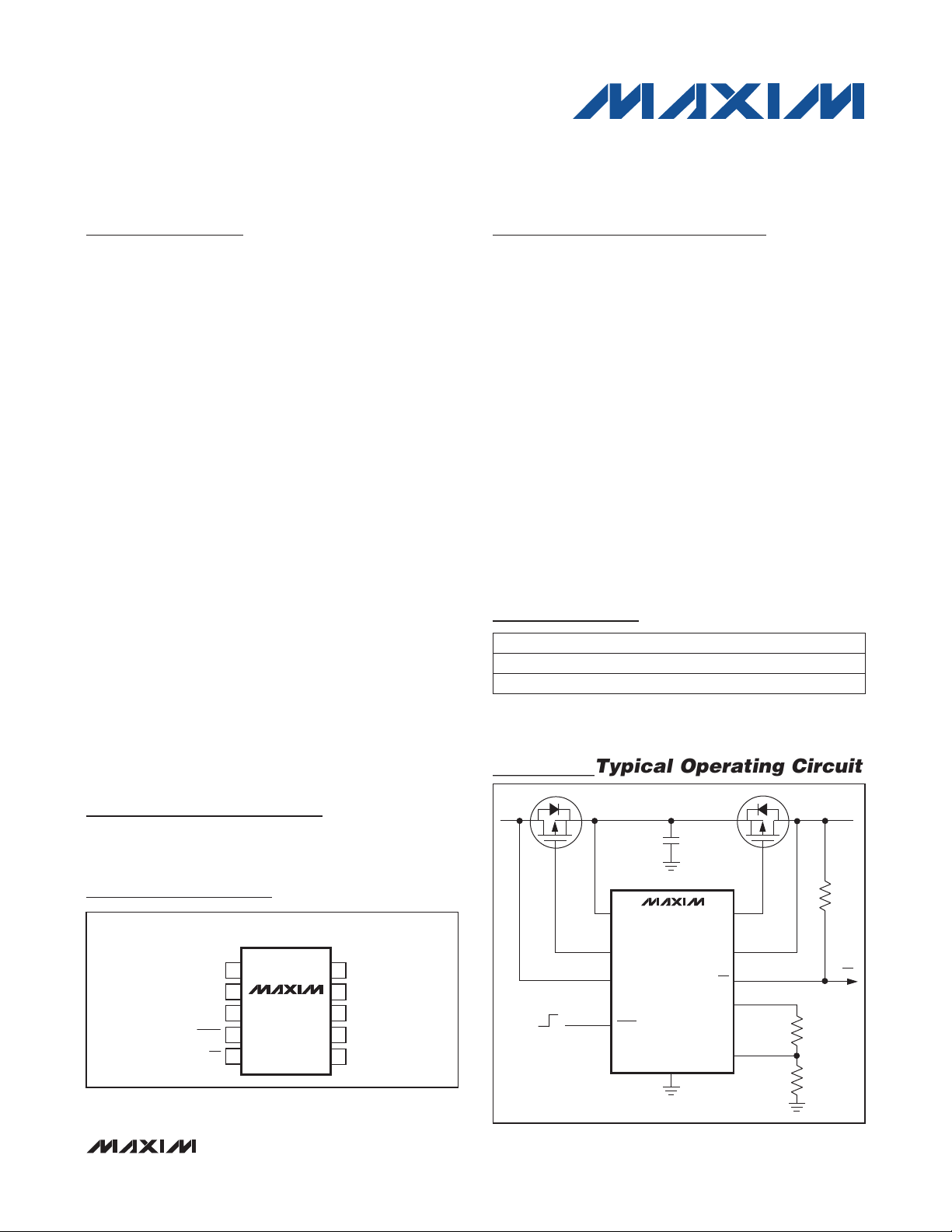

Typical Operating Circuit

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

General Description

The MAX16914/MAX16915 low-quiescent-current overvoltage and reverse-battery protection controllers are

designed for automotive and industrial systems that

must tolerate high-voltage transient and fault conditions.

These conditions include load dumps, voltage dips, and

reversed input voltages. The controllers monitor the input

voltage on the supply line and control two external pFETs

to isolate the load from the fault condition. The external

pFETs are turned on when the input supply exceeds

4.5V and stay on up to the programmed overvoltage

threshold. During high-voltage fault conditions, the controllers regulate the output voltage to the set upper

threshold voltage (MAX16915), or switch to high resistance (MAX16914) for the duration of the overvoltage

transient to prevent damage to the downstream circuitry.

The overvoltage event is indicated through an active-low,

open-drain output, OV.

The reverse-battery pFET behaves as an ideal diode,

minimizing the voltage drop when forward biased. Under

reverse bias conditions, the pFET is turned off, preventing a downstream tank capacitor from being discharged

into the source.

Shutdown control turns off the IC completely, disconnecting the input from the output and disconnecting

TERM from its external resistor-divider to reduce the

quiescent current to a minimum.

Both devices are available in a 10-pin FMAXM package

and operate over the automotive -40NC to +125NC temperature range.

Features

S 4.5V to 19V Input Voltage Operation

S Transient Voltage Protection Up to +44V and -75V

S Adjustable Overvoltage Limit with Resistor-

Divider Shut Off in Shutdown

S Ideal Diode Reverse-Battery Protection

S Low Voltage Drop When Used with Properly Sized

External pFETs

S Back-Charge Prevention

S Overvoltage Indicator

S Shutdown Input

S 29µA Low Operating Current

S 6µA Low Shutdown Current

S Thermal-Overload Protection

S -40NC to +125NC Operating Temperature Range

S Small 10-Pin µMAX Package

S AEC-Q100 Qualified

Ordering Information

PART TEMP RANGE PIN-PACKAGE

MAX16914AUB/V+ -40NC to +125NC 10 FMAX

MAX16915AUB/V+ -40NC to +125NC 10 FMAX

+Denotes a lead(Pb)-free/RoHS-compliant package.

/V denotes an automotive qualified device.

MAX16914/MAX16915

Applications

Automotive

Industrial

Pin Configuration

TOP VIEW

+

1

V

CC

2

GATE1

SENSE IN

µMAX is a registered trademark of Maxim Integrated Products, Inc.

_______________________________________________________________ Maxim Integrated Products 1

3

4

5

MAX16914

MAX16915

10

9

8

7

6

GATE2

SENSE OUT

TERM

SETSHDN

GNDOV

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

V

BATT

OFF

V

CC

MAX16914

MAX16915

GATE1

SENSE IN

ON

SHDN

GND

GATE2

SENSE OUT

OV

TERM

SET

P2P1

V

OUT

OV

R1

R2

Page 2

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

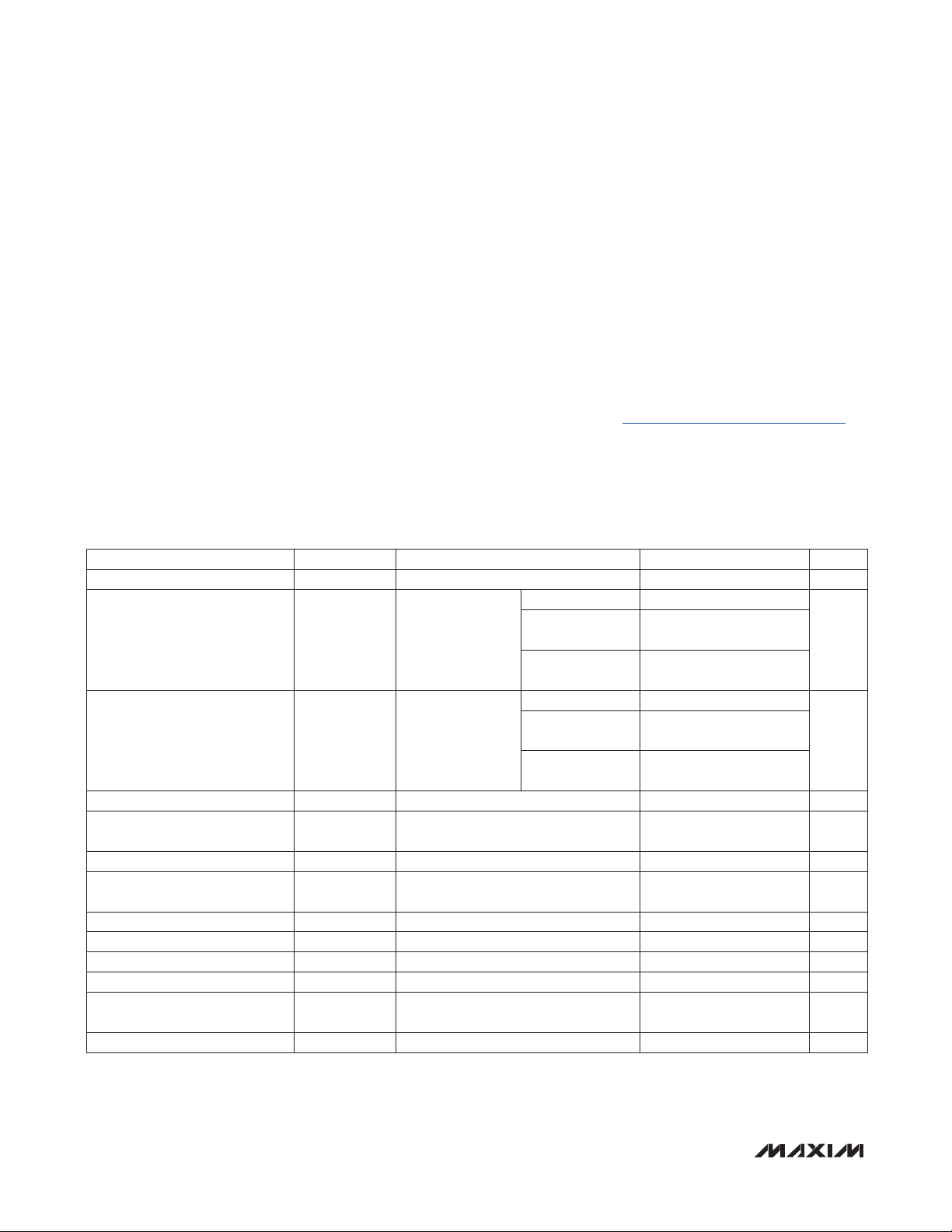

ABSOLUTE MAXIMUM RATINGS

VCC, SENSE OUT, TERM, SHDN, OV to GND for

P 400ms ............................................................. -0.3V to +44V

VCC, SENSE OUT, TERM, SHDN, OV to GND

for P 90s .............................................................-0.3V to +28V

VCC, SENSE OUT, TERM, SHDN, OV to GND .....-0.3V to +20V

SENSE IN to GND for P 2ms ..................................-75V to +44V

SENSE IN to GND for P 90s ..................................-18V to +44V

SENSE IN to GND .................................................-0.3V to +20V

GATE1, GATE2 to VCC ..........................................-16V to +0.3V

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

(VCC = 14V, C

values are at TA = +25NC.) (Note 2)

GATE1

= 32nF, C

= 32nF, SHDN = high, TA = -40NC to +125NC, unless otherwise noted. Typical

GATE2

GATE1, GATE2 to GND ........................... -0.3V to (VCC + 0.3V)

SET to GND .............................................................-0.3V to +8V

Continuous Power Dissipation (TA = +70NC)

10-Pin FMAX (derate 8.8mW/NC above TA = +70NC)

(Note 1) .......................................................................707mW

Operating Temperature Range ........................ -40NC to +125NC

Junction Temperature .....................................................+150NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (soldering, 10s) ................................+300NC

MAX16914/MAX16915

Operating Voltage Range V

Shutdown Supply Current

(I

SENSE IN

I

SHDN

Quiescent Supply Current

(I

SENSE IN

I

SHDN

VCC Undervoltage Lockout V

VCC Undervoltage-Lockout

Hysteresis

SET Threshold Voltage V

SET Threshold Voltage

Hysteresis

SET Input Current I

SHDN Low Threshold V

SHDN High Threshold V

SHDN Pulldown Current I

VCC to GATE Output Low

Voltage

VCC to GATE Clamp Voltage V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

(Note 3) 4.5 19 V

SHDN = low,

V

SENSE OUT

V

TERM

SHDN = high

V

CC

V

SET

V

SET

V

SHDN

VCC = 14V 6.25 7.5 8.5 V

VCC = 42V 14 V

+ I

+ I

+ I

SENSE OUT

)

VCC

+ I

SENSE OUT

)

VCC

+ IOV +

+ IOV +

CC

I

SHDN

I

UVLO

SETTH

V

SETHY

SET

SHDNL

SHDNH

SHDN

V

GVCC1

GVCC2

Q

TA = +25NC 6.0 12

TA = +85NC (Note

= 0V,

= 0V

rising, V

rising -3% +1.20 +3% V

= 1V 0.02 0.2 FA

SET

= 14V, internally pulled to GND 0.5 1.0 FA

3)

TA = +125NC

(Note 3)

TA = +25NC 29 53

TA = +85NC (Note

3)

TA = +125NC

(Note 3)

= 1V , SHDN = high 4.06 4.35 V

1.4 V

6.1 12

6.2 12

30 55

31 57

8 %

4 %

0.4 V

FA

FA

2 ______________________________________________________________________________________

Page 3

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

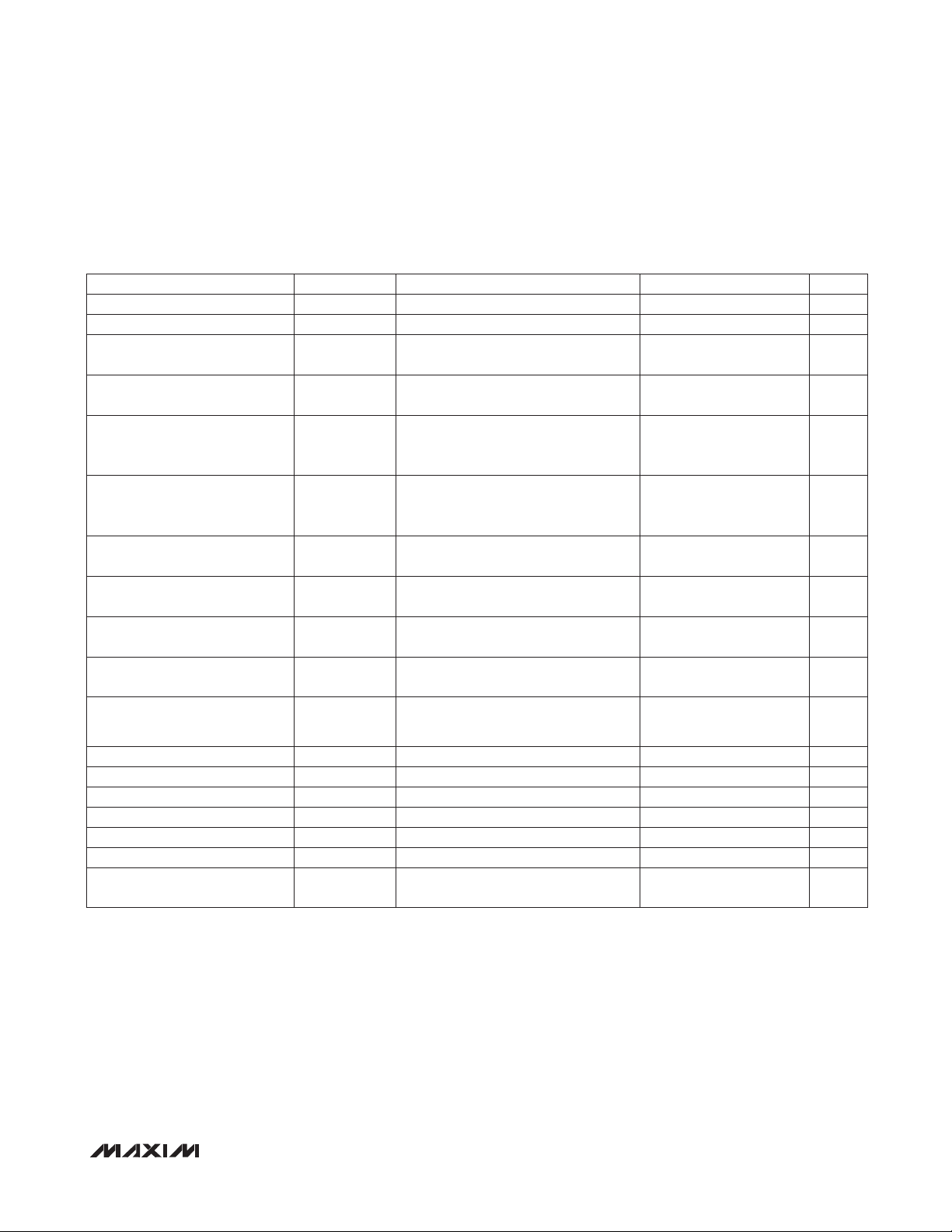

ELECTRICAL CHARACTERISTICS (continued)

(VCC = 14V, C

values are at TA = +25NC.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

TERM On-Resistance R

TERM Output Current I

Back-Charge Voltage Fault

Threshold

Back-Charge Voltage Threshold

Hysteresis

Back-Charge Turn-Off Time

(GATE1)

Back-Charge Recovery Time

(GATE1)

GATE2 Turn-Off Time

GATE2 Turn-On Time

Startup Response Time

(V

Rising)

SHDN

Startup Response Time

(VCC Rising)

Reverse-Battery Voltage Turn-Off

Time/UVLO Turn-Off Time

Thermal-Shutdown Temperature +170 NC

Thermal-Shutdown Hysteresis 20 NC

OV Output Low Voltage V

OV Open-Drain Leakage Current I

SENSE IN Input Current I

SENSE OUT Input Current I

SET to OV Output Low

Propagation Delay

Note 2: All parameters are production tested at TA = +25NC. Limits over the operating temperature range are guaranteed by

design and characterization.

Note 3: Guaranteed by design and characterization.

Note 4: The back-charge voltage, VBC, is defined as the voltage at SENSE OUT minus the voltage at SENSE IN.

Note 5: Defined as the time from when VBC exceeds V

Note 6: Defined as the time from when VBC falls below V

Note 7: Defined as the time from when V

Note 8: Defined as the time from when V

Note 9: The external pFETs can turn on t

Note 10: Defined as the time from when VCC exceeds the undervoltage-lockout threshold (4.3V max) to when V

fall below 1V.

Note 11: Defined as the time from when V

GATE1

= 32nF, C

= 32nF, SHDN = high, TA = -40NC to +125NC, unless otherwise noted. Typical

GATE2

TERM

TERM

V

BCTH

V

BCHY

t

BC

SHDN = high 150 500

SHDN = low, V

V

SENSE OUT

V

SENSE OUT

= 14V (Note 4) 18 25 32 mV

= 14V 50 mV

VCC = 9.5V, V

V

SENSE OUT

stepped from 4.9V to 9.5V

= 0V 1.0 FA

TERM

SENSE IN

= 9V,

6 10 Fs

(Note 5)

t

BCREC

VCC = 9.5V, V

V

SENSE OUT

SENSE IN

stepped from 9.5V to 4.9V

= 9V,

18 30 Fs

(Note 6)

t

START1

t

START2

t

REVERSE

VCC = 9.5V, V

1.5V (Note 7)

VCC = 9.5V, V

1V (Note 8)

VCC = 9.5V, from V

V

falling (Note 9)

GATE_

VCC rising from 2V to 4.5V, SHDN =

high (Note 10)

VCC and V

to 3.25V, V

rising from 1V to

SET

falling from 1.5V to

SET

SHDN

SENSE IN

SENSE OUT

falling from 4.25V

= 4.25V

rising to

3 Fs

20 Fs

100 Fs

0.150 ms

30 Fs

(Note 11)

I

OVBL

OVB

SENSE IN

SENSE OUTVSHDN

t

OVBPD

exceeds V

SET

falls below V

SET

after the IC is powered up and all input conditions are valid.

START

falls below V

CC

= 600FA 0.4 V

SINK

V

= 1.0V 1.0 FA

SET

V

= 0/14V 1 5 FA

SHDN

= 0/14V 2 5 FA

VCC = 9.5V, V

1.5V to V

OV

(25mV typ) to when V

BCTH

BCTH

(1.20V typ) to when V

SETTH

SETTH

SENSE OUT

rising from 1V to

SET

falling

GATE1

- 50mV to when V

GATE1

GATE2

- 5% (1.14V typ) to when V

- 25mV to when V

3 Fs

exceeds VCC - 3.5V.

falls below VCC - 3.5V.

exceeds VCC - 3.5V.

falls below VCC - 3.5V.

GATE2

reaches VCC - 1.75V.

GATE1

GATE1

and V

I

GATE2

MAX16914/MAX16915

_______________________________________________________________________________________ 3

Page 4

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

Typical Operating Characteristics

(VCC = 14V, V

30

25

20

SUPPLY CURRENT (µA)

TERM = OPEN

15

SHDN = HIGH

SET = 0V

NO LOAD

10

4.5 19.0

MAX16914/MAX16915

4.3

4.2

4.1

4.0

3.9

3.8

UVLO TRESHOLD (V)

3.7

3.6

3.5

-40 125

14V

0V

14V

0V

100µF INPUT CAPACITOR, 122µF

OUTPUT CAPACITOR, R

= 14V, MAX16914/MAX16915 Evaluation Kit, TA = +25NC, unless otherwise noted.)

SHDN

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

SUPPLY CURRENT

vs. TEMPERATURE

40

MAX16914

35

MAX16915

MAX16914 toc01

30

MAX16914

MAX16914 toc02

25

MAX16915

20

SUPPLY CURRENT (FA)

TERM = OPEN

SHDN = HIGH

15

SET = 0V, VCC = 14V

NO LOAD

17.012.0 14.59.57.0

SUPPLY VOLTAGE (V)

UVLO THRESHOLD

vs. TEMPERATURE

10

-40 125

TEMPERATURE (NC)

SET THRESHOLD

vs. TEMPERATURE

11085603510-15

1.25

RISING

MAX16914 toc04

RISING

MAX16914 toc05

1.20

1.15

SET THRESHOLD (V)

FALLING

FALLING

1.10

TEMPERATURE (NC)

STARTUP FROM

SHUTDOWN RESPONSE

20µs/div

= 100I

OUT

11085-15 10 35 60

MAX16914 toc07

-40 125

OVERVOLTAGE LIMITER RESPONSE

V

30V

SHDN

2V/div

14V

V

OUT

10V/div

14V

14V

V

GATE1

10V/div

V

GATE2

10V/div

0V

V

= 14V TO 30V

CC

TRIP THRESHOLD = 22V

100µF INPUT CAPACITOR, 22µF

OUTPUT CAPACITOR, R

COV = 10nF

TEMPERATURE (NC)

(MAX16915)

400µs/div

= 100I

OUT

11085603510-15

MAX16914 toc08

V

CC

20V/div

V

OUT

20V/div

V

OV

20V/div

V

GATE2

20V/div

SHUTDOWN SUPPLY CURRENT

vs. SUPPLY VOLTAGE

10

8

6

MAX16914

4

SUPPLY CURRENT (FA)

MAX16915

2

SHDN = LOW

SET = 0V

0

4.5 19.0

SUPPLY VOLTAGE (V)

POWER-UP RESPONSE

22µF INPUT AND OUTPUT CAPACITOR,

R

= 100I, SHDN = HIGH

OUT

40µs/div

OVERVOLTAGE SWITCH-OFF

RESPONSE (MAX16914)

30V

14V

20V

14V

0V

14V

30V

0V

VCC = 14V TO 30V

TRIP THRESHOLD = 22V

100µF INPUT CAPACITOR, 22µF

OUTPUT CAPACITOR, R

1.0µs/div

OUT

= 100I

17.014.512.09.57.0

MAX16914 toc06

MAX16914 toc09

MAX16914 toc03

V

CC

10V/div

V

OUT

10V/div

V

GATE1

10V/div

V

GATE2

10V/div

V

CC

10V/div

V

OUT

10V/div

V

OV

20V/div

V

GATE2

20V/div

4 ______________________________________________________________________________________

Page 5

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

Typical Operating Characteristics (continued)

(VCC = 14V, V

= 14V, MAX16914/MAX16915 Evaluation Kit, TA = +25NC, unless otherwise noted.)

SHDN

MAX16914/MAX16915

BACK-CHARGE RESPONSE

5V

5V

0V

2.2µF INPUT CAPACITOR, 400I

INPUT RESISTOR, 22µF OUTPUT CAPACITOR

1.0µs/div

MAX16914 toc10

V

CC

5V/div

V

OUT

5V/div

V

GATE1

5V/div

VCC - V

GATE_

vs. INPUT VOLTAGE

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

GATE DRIVE VOLTAGE (V)

3.0

1.5

0

4.5 44.0

GATE1

GATE2

SET = GND

SHDN = HIGH

SUPPLY VOLTAGE (V)

6.6

MAX16914 toc11

6.5

6.4

GATE-DRIVE VOLTAGE (V)

6.3

6.2

40.536.027.0 31.513.5 18.0 22.59.0

-40 125

GATE-DRIVE VOLTAGE

vs. TEMPERATURE

GATE1

GATE2

VCC = 14V

SET = GND

SHDN = HIGH

11085603510-15

TEMPERATURE (NC)

Pin Description

PIN NAME FUNCTION

1 V

CC

2 GATE1

3 SENSE IN

4 SHDN

5 OV

6 GND Ground

7 SET

8 TERM

9 SENSE OUT

10 GATE2

Positive Supply Input Voltage. Bypass VCC to GND with a 0.1FF or greater ceramic capacitor.

Gate-Driver Output. Connect GATE1 to the gate of an external p-channel FET pass switch to provide low drain-to-source voltage drop, reverse voltage protection, and back-charge prevention.

Differential Voltage Sense Input (Input Side of IC). Used with SENSE OUT to provide back-charge

prevention when the SENSE IN voltage falls below the SENSE OUT voltage by 25mV.

Active-Low Shutdown/Wake Input. Drive SHDN high to turn on the voltage detectors. GATE2 is

shorted to VCC when SHDN is low. SHDN is internally pulled to GND through a 0.5FA current sink.

Connect SHDN to VCC for always-on operation.

Open-Drain Overvoltage Indicator Output. Connect a pullup resistor from OV to a positive supply

such as VCC. OV is pulled low when the voltage at SET exceeds the internal threshold.

Controller Overvoltage Threshold Programming Input. Connect SET to the center of an external

resistive divider network between TERM and GND to adjust the desired overvoltage switch-off or

limiter threshold.

Voltage-Divider Termination Output. TERM is internally connected to SENSE OUT in the MAX16915

and to VCC in the MAX16914. TERM is high impedance when SHDN is low, forcing the current to

zero in the resistor-divider connected to TERM.

Differential Voltage Sense Input (Output Side Of IC). Used with SENSE IN to provide back-charge

prevention when the SENSE IN voltage falls below the SENSE OUT voltage by 25mV.

Gate-Driver Output. Connect GATE2 to the gate of an external p-channel FET pass switch. GATE2

is driven low during normal operation and quickly regulated or shorted to VCC during an overvoltage condition. GATE2 is shorted to VCC when SHDN is low.

MAX16914 toc12

_______________________________________________________________________________________ 5

Page 6

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

Functional Diagram

V

CC

GATE1

SENSE IN

REG

MAX16914/MAX16915

SHDN

OV

OV1

BANDGAP

BIAS

MAX16914

MAX16915

1.20V

TERM

SWITCH

OV1

TO V

FOR

CC

MAX16914

TO SENSE OUT

FOR MAX16915

GATE2

SENSE OUT

SET

TERM

GND

Detailed Description

The MAX16914/MAX16915 are ultra-small, low-quiescent, high load-current, overvoltage-protection circuits

for automotive or industrial applications. These devices

monitor the input and output voltages and control two

p-channel MOSFETs to protect downstream loads from

reverse-battery, overvoltage, and high-voltage transient

conditions and prevent downstream tank capacitors

from discharging into the source (back-charging).

One MOSFET (P1) eliminates the need for external

diodes, thus minimizing the input voltage drop and

In the MAX16914, the input voltage is monitored (TERM

is internally shorted to VCC—see the Functional Diagram)

making the device an overvoltage switch-off controller.

As the VCC voltage rises, and the programmed overvoltage threshold is tripped, the internal fast comparator

turns off the external p-channel MOSFET (P2), pulling

GATE2 to VCC to disconnect the power source from

the load. When the monitored voltage goes below the

adjusted overvoltage threshold, the MAX16914 enhances GATE2, reconnecting the load to the power source.

Overvoltage Switch-Off Controller

provides back-charge and reverse-battery protection.

The second MOSFET (P2) isolates the load or regulates

the output voltage during an overvoltage condition.

These ICs allow system designers to size the external

p-channel MOSFET to their load current, voltage drop,

and board size.

6 ______________________________________________________________________________________

(MAX16914)

Page 7

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

Overvoltage Limiter

Controller (MAX16915)

In the MAX16915, TERM is internally connected to

SENSE OUT (see the Functional Diagram) allowing the

IC to operate in voltage-limiter mode.

During normal operation, GATE2 is pulled low to fully

enhance the MOSFET. The external MOSFET’s drain

voltage is monitored through a resistor-divider between

TERM, SET, and GND. When the output voltage rises

above the adjusted overvoltage threshold, an internal

comparator pulls GATE2 to VCC turning off P2. When

the monitored voltage goes below the overvoltage

threshold (-4% hysteresis), the p-channel MOSFET (P2)

is turned on again. During a continuous overvoltage

condition, MOSFET (P2) cycles on and off (between the

overvoltage threshold and the hysteresis), generating a

sawtooth waveform with a frequency dependent on the

load capacitance and load current. This process continues to keep the voltage at the output regulated to within

approximately a 4% window. The output voltage is regulated during the overvoltage transients and MOSFET

(P2) continues to conduct during the overvoltage event,

operating in switched-linear mode.

Caution must be exercised when operating the

MAX16915 in voltage-limiting mode for long durations

due to the MOSFET’s power-dissipation consideration

(see the MOSFET Selection section).

The MAX16914/MAX16915 feature an active-low shutdown input (SHDN). Drive SHDN low to switch off FET

(P2), disconnecting the input from the output, thus

placing the IC in low-quiescent-current mode. Reversebattery protection is still maintained.

Reverse-Battery Protection

The MAX16914/MAX16915 feature reverse-battery protection to prevent damage to the downstream circuitry

caused by battery reversal or negative transients. The

reverse-battery protection blocks the flow of current into

the downstream load and allows the circuit designer to

remove series-protection diodes.

Back-Charge Switch-Off

The MAX16914/MAX16915 monitor the input-to-output

differential voltage between SENSE IN and SENSE OUT.

It turns off the external FET (P1) when (V

V

SENSE IN

) > 25mV (see Figure 1) to prevent discharging of a downstream tank capacitor into the battery supply during an input voltage drop, such as a cold-crank

condition or during a superimposed sinusoidal voltage

on top of the supply voltage. It turns on the FET (P1)

again if the back-charge voltage threshold hysteresis of

50mV is satisfied.

Shutdown

SENSE OUT

-

MAX16914/MAX16915

V

- V

= 0V

OUT

BATT

I

OUT

Figure 1. Back-Charge Turn-Off Time

_______________________________________________________________________________________ 7

t

BC

50% (25mV)

= 10µs (max)

50%

V

- V

= 50mV

OUT

BATT

= 9V

V

BATT

Page 8

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

Overvoltage Indicator Output (OV)

The MAX16914/MAX16915 include an active-low,

open-drain overvoltage-indicator output (OV). For the

MAX16914, OV asserts low when VCC exceeds the programmed overvoltage threshold. OV deasserts when the

overvoltage condition is over.

For the MAX16915, OV asserts if V

programmed overvoltage threshold. OV deasserts when

V

drops 4% (typ) below the overvoltage threshold

OUT

level. If the overvoltage condition continues, OV may

toggle with the same frequency as the overvoltage limiter

FET (P2). If the P2 device is turned on for a very short

period (less than t

To obtain a logic-level output, connect a 45kI pullup

resistor from OV to a system voltage less than 44V. A

capacitor connected from OV to GND helps extend the

time that the logic level remains low.

), the OV pin may not toggle.

OVBPD

exceeds the

OUT

Applications Information

MAX16914/MAX16915

Most automotive applications run off a multicell “12V”

lead-acid battery with a nominal voltage that swings

between 9V and 16V (depending on load current, charging status, temperature, battery age, etc.). The battery

voltage is distributed throughout the automobile and is

locally regulated down to voltages required by the different system modules. Load dump occurs when the alternator is charging the battery and the battery becomes

disconnected. The alternator voltage regulator is temporarily driven out of control. Power from the alternator

flows into the distributed power system and elevates the

voltage seen at each module. The voltage spikes have

rise times typically greater than 5ms and decays within

several hundred milliseconds but can extend out to 1s

or more depending on the characteristics of the charging system. These transients are capable of destroying

sensitive electronic equipment on the first “fault event.”

Setting Overvoltage Thresholds

TERM and SET provide an accurate means to set the

overvoltage level for the MAX16914/MAX16915. Use a

resistive divider to set the desired overvoltage condition

(see the Typical Operating Circuit). V

1.20V threshold with a 4% falling hysteresis. Begin by

selecting the total end-to-end resistance:

R

For high accuracy, choose R

rent equivalent to a minimum 100 x I

input bias current at SET.

TOTAL

= R1 + R2

TOTAL

Load Dump

has a rising

SET

to yield a total cur-

SET

where I

SET

is the

For example:

With an overvoltage threshold (VOV) set to 20V, R

< 20V/(100 x I

Use the following formula to calculate R2:

where VTH is the 1.20V SET rising threshold and VOV is

the desired overvoltage threshold.

Then, R2 = 12.0kI.

Use the nearest standard-value resistor lower than the

calculated value. A lower value for total resistance dissipates more power but provides slightly better accuracy.

To determine R1:

Then, R1 = 188kI.

Use the nearest standard-value resistor lower than the

calculated value. A lower value for total resistance dissipates more power but provides slightly better accuracy.

), where I

SET

R

TOTAL

R2 = (VTH x R

R

TOTAL

= 1FA (max).

SET

< 200kI

)/V

TOTAL

= R2 + R1

OV

TOTAL

MOSFET Selection

Output p-Channel MOSFET (P2)

Select the external output MOSFET according to the

application current level. The MOSFET’s on-resistance

(R

minimum voltage drop at full load to limit the MOSFET

power dissipation. Determine the device power rating to

accommodate an overvoltage fault when operating the

MAX16915 in overvoltage-limiting mode. During normal

operation for either IC, the external MOSFET dissipates

little power. The power dissipated in the MOSFET during

normal operation is:

where P

in normal operation, I

and R

MOSFET. Worst-case power dissipation in the output

MOSFET occurs during a prolonged overvoltage event

when operating the MAX16915 in voltage-limiting mode.

The power dissipated across the MOSFET is as follows:

where P

overvoltage-limiting operation, VDS is the voltage across

the MOSFET’s drain and source, and I

current.

) should be chosen low enough to have a

DS(ON)

P

NORM

is the drain-to-source resistance of the

DS(ON)

is the power dissipated in the MOSFET in

OVLO

= I

NORM

is the power dissipated in the MOSFET

LOAD

P

OVLO

2

x R

LOAD

is the output load current,

= VDS x I

DS(ON)

LOAD

LOAD

is the load

8 ______________________________________________________________________________________

Page 9

Ideal Diode, Reverse-Battery, and Overvoltage Protection

Switch/Limiter Controllers with External MOSFETs

Reverse-Polarity Protection MOSFET (P1)

Most battery-powered applications must include reversevoltage protection. Many times this is implemented with

a diode in series with the battery. The disadvantage in

using a diode is the forward-voltage drop of the diode,

which reduces the operating voltage available to downstream circuits (V

The MAX16914/MAX16915 include high-voltage GATE1

drive circuitry allowing users to replace the high-voltage

drop series diode with a low-voltage-drop MOSFET

device (as shown in the Typical Operating Circuit). The

forward-voltage drop is reduced to I

P1. With a suitably chosen MOSFET, the voltage drop

can be reduced to millivolts.

In normal operating mode, internal GATE1 output circuitry enhances P1. The constant enhancement ensures

P1 operates in a low R

junction is not overstressed during high battery-voltage

applications or transients (many MOSFET devices specify

a Q20V VGS absolute maximum). As VCC drops below

10V, GATE1 is limited to GND, reducing P1 VGS to VCC.

In normal operation, the P1 power dissipation is very low:

LOAD

P1 = I

= V

BATTERY

DS(ON)

LOAD

2

- V

DIODE

LOAD

mode, but the gate-source

x R

DS(ON)

x R

).

DS(ON)

of

During reverse-battery conditions, GATE1 is limited to

GND and the P1 gate-source junction is reverse biased.

P1 is turned off and neither the MAX16914/MAX16915

nor the load circuitry is exposed to the reverse-battery

voltage. Care should be taken to place P1 (and its internal drain-to-source diode) in the correct orientation for

proper reverse-battery operation.

Thermal Shutdown

The MAX16914/MAX16915 thermal-shutdown feature

turns off both MOSFETs if the IC junction temperature

exceeds the maximum allowable thermal dissipation.

When the junction temperature exceeds TJ = +170NC,

the thermal sensor signals the shutdown logic, turning off

both GATE1 and GATE2 outputs and allowing the device

to cool. The thermal sensor turns GATE1 and GATE2 on

again after the IC’s junction temperature cools by 20NC.

For continuous operation, do not exceed the absolute

maximum junction-temperature rating of TJ = +150NC.

Chip Information

PROCESS: BiCMOS

MAX16914/MAX16915

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

10 FMAX U10+2

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 9

©

2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

21-0061

Loading...

Loading...