Page 1

EVALUATION KIT AVAILABLE

19-6028; Rev 0; 10/11

MAX16841

Controller IC for Dimmable Offline LED Lamps

General Description

The MAX16841 is an LED driver for AC line (100V, 120V,

220V, and 230V AC) input lamps. It features proprietary

control of the input current that allows lamps to dim

smoothly from full to zero light intensity, while providing

active power factor correction (PFC). It is a very flexible

product that can be used in isolated (e.g., flyback) and

nonisolated (e.g., buck) configurations. The conventional

use of an optocoupler in isolated configurations can be

avoided in MAX16841-based designs.

The constant frequency-control technique of the

device allows maximization of the conversion efficiency at both low and high AC line by operating at the

conduction mode that minimizes total conduction and

switching losses.

The device can be configured for universal input (90V to

264V AC) dimmable applications, allowing the design of an

LED lamp that can be operated and dimmed worldwide.

This device can be used without electrolytic capacitors,

thus maximizing the lamp lifetime. In this case, the LED

current is a rectified sinusoid with a frequency that is

twice the AC line frequency.

The device also features thermal shutdown, current limit,

open LED protection, and VCC undervoltage lockout.

The MAX16841 is available in an 8-pin SO package and

operates over the -40NC to +125NC temperature range.

Features

S Smooth Dimming with Leading-Edge (Triac) and

Trailing-Edge Dimmers

S Active Power Factor Correction

S Nonisolated (e.g., Buck) and Isolated

(e.g., Flyback) Topologies

S Universal 90V to 264V AC Input Range

S Constant Frequency-Control Scheme Maximizes

Efficiency at High and Low AC Line Voltage

S Constant Power Control with No Need for

Optocouplers

S Very-Low Quiescent Current

S Output Open and Short Protection

S Thermal Shutdown

S Available in an 8-Pin SO Package

Ordering Information appears at end of data sheet.

Typical Operating Circuits appear at end of data sheet.

For related parts and recommended products to use with this part,

refer to www.maxim-ic.com/MAX16841.related.

Applications

Retrofit LED Lamps with Triac Dimming

Universal Input LED Retrofit Lamps

Industrial and Commercial Lighting

Residential LED Lighting

����������������������������������������������������������������� Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX16841

Controller IC for Dimmable Offline LED Lamps

ABSOLUTE MAXIMUM RATINGS

IN to GND .............................................................. -0.3V to +26V

NDRV, DIMOUT to GND ........................... -0.3V to (VIN + 0.3V)

All Other Pins to GND .............................................-0.3V to +6V

NDRV Continuous Current .............................................. Q10mA

DIMOUT Continuous Current ............................................ Q2mA

Continuous Power Dissipation (TA = +70NC)

8 SO (derate 7mW/NC above +70NC) ..................588.2mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

PACKAGE THERMAL CHARACTERISTICS (Note 1)

8 SO

Junction-to-Ambient Thermal

Resistance (BJA) (based on S8+2) ...........................136NC/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

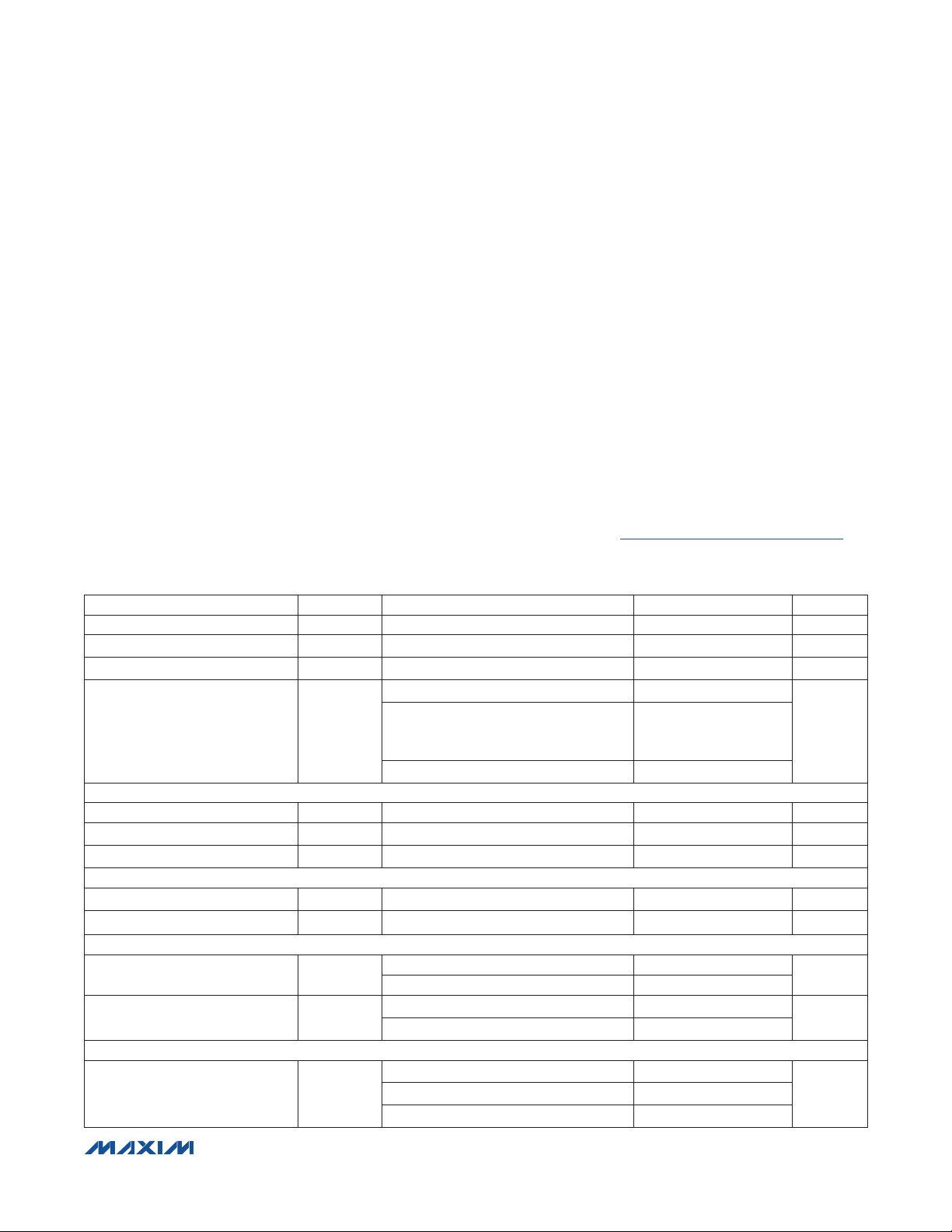

ELECTRICAL CHARACTERISTICS

(VIN = 12V, TA = TJ = -40NC to +125NC, unless otherwise noted. Typical values are at TA = +25NC.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN Operating Range V

IN Undervoltage Threshold UVLOR

IN Overvoltage Threshold OVLOR

IN Input Supply Current I

TH

TH Operating Range 0 4 V

TH Threshold Voltage V

TH Input Supply Current VTH = 0V 0.16 0.3

REFI

REFI Operating Range V

REFI Input Supply Current V

DIMOUT

DIMOUT On-Resistance

TH to DIMOUT Propagation

Delay

INTERNAL OSCILLATOR

Oscillator Frequency

IN

IN

TH

REFI

INVIN

INVIN

rising, V

rising, V

NDRV not switching, VTH = 0V 0.7 1.3 2.6

NDRV switching, 177.5kW/330pF on

NDRV, VTH = 5V, V

VCS = 0V, V

VIN = 8V 1.6

VTH rising, hysteresis = 150mV 1.17 1.215 1.26 V

= 2V 48.5 50 51.5

REFI

DIMOUT = IN

DIMOUT = GND

VTH rising 40 80

VTH falling 40 80

RT = 47.5KI

RT = 177.5kI

RT = 297.5kI

Operating Temperature Range ........................ -40NC to +125NC

Junction Temperature .....................................................+150NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (soldering, 10s) ................................+300NC

Soldering Temperature (reflow) ......................................+260NC

Junction-to-Case Thermal

Resistance (BJC) (based on S8+2) .............................38NC/W

11 20 V

= 1V 9.5 10 10.5 V

HYST

= 1.8V 21 22 23 V

HYST

1.7 2.7 4.2

0.5 3.25 V

20 40

20 40

50

160 180 200

270 300 330

REFI

COMP

= 2.35V

= 2V,

mA

FA

FA

I

ns

kHz

����������������������������������������������������������������� Maxim Integrated Products 2

Page 3

MAX16841

Controller IC for Dimmable Offline LED Lamps

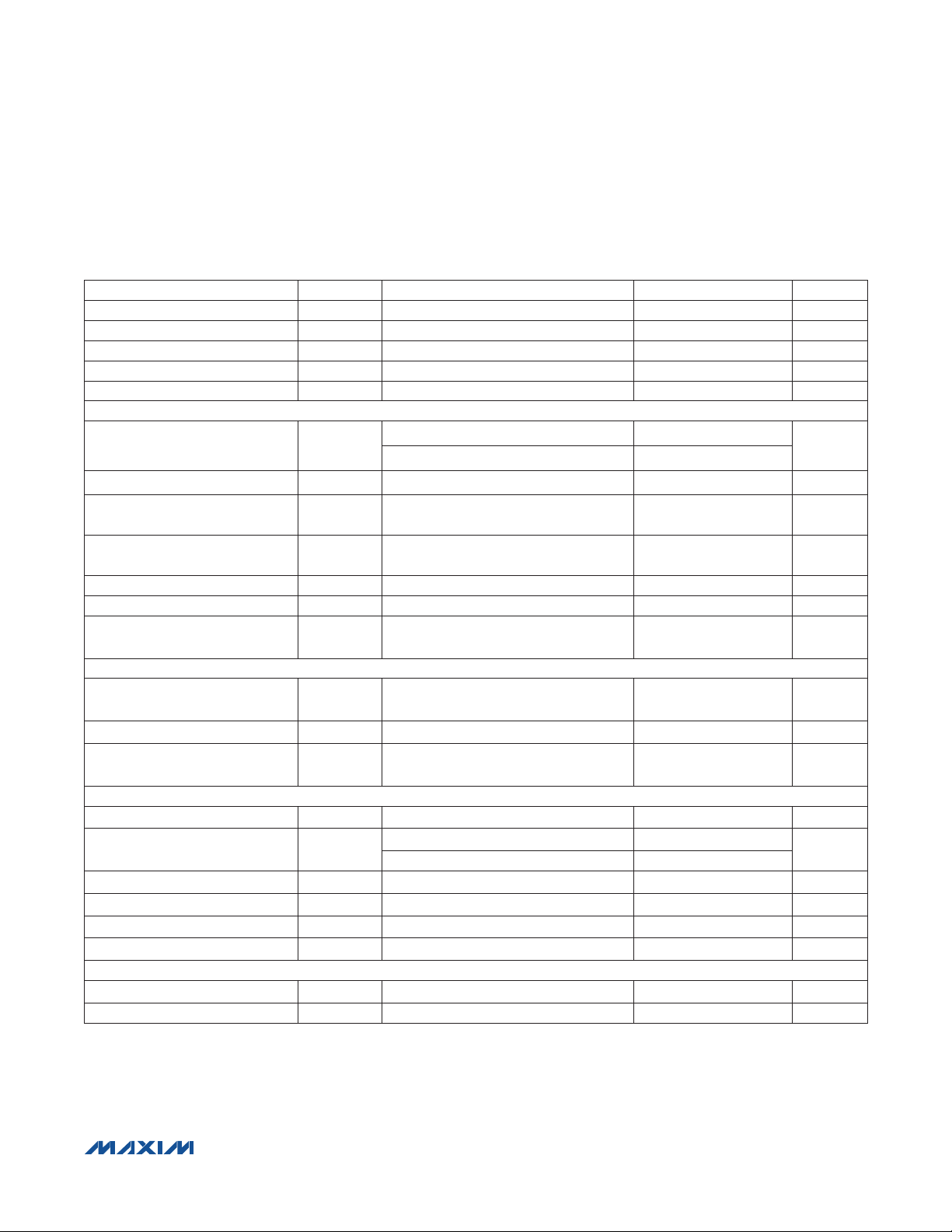

ELECTRICAL CHARACTERISTICS (continued)

(VIN = 12V, TA = TJ = -40NC to +125NC, unless otherwise noted. Typical values are at TA = +25NC.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

RT Resistance Range 47.5 297.5

Oscillator Decode Resolution 6 Bits

Dither Frequency Range 45kHz to 330kHz 1.875 %

Frequency Dither Ramping DAC 7 Bits

Dither Frequency 1.5 kHz

CURRENT SENSE

CS Input Bias Current

CS Voltage at Current Limit V

CS Voltage at Current Limit

Soft-Start

CS Voltage at Hiccup Current

Limit

CS Hiccup Shutdown CS > hiccup 1.2 s

Hiccup Detection Cycles 3 Times

CS Regulation Voltage

TRANSCONDUCTANCE AMPLIFIER

Transconductance G

COMP Sink Current I

COMP Source Current I

NDRV

NDRV Operating Range 0 V

NDRV On-Resistance

NDRV Dead Time Rising or falling 5 Ns

NDRV Rise Time NDRV = 1nF, 10% to 90% 15 ns

NDRV Fall Time NDRV = 1nF, 90% to 10% 15 ns

NDRV Reference Current Startup only 7.5 8 8.5

THERMAL SHUTDOWN

Thermal-Shutdown Threshold TJ rising 164

Thermal Hysteresis 20

Note 2: All parameters are tested at TA = +25NC only. Limits over temperature are guaranteed by design.

CS_LIMIT

m

SINK

SOURCE

VCS = 2V, V

VCS = 2V, V

V

= 2V, V

COMP

VCS = 0.45V

V

= 2.2V, V

COMP

VCS = 0.45V Q0.05V

V

= 2V, V

COMP

V

= 2V, V

COMP

VCS = 0.9V

I

= 50mA to 100mA 2 5.0

NDRV

I

= -50mA to -100mA 1.25 2.5

NDRV

= 4V -1 0 +1

COMP

= 0.7V 60 90 130

COMP

2.1 2.2 2.3 V

2.6 2.7 2.8 V

= 2.35V,

REFI

= 2.35V,

REFI

= 2.35V, VCS = 0V 45 65 85

REFI

= 2.35V,

REFI

448 450 462 V

95 135 175

45 65 85

10 ms

IN

kW

FA

FS

FA

FA

V

I

FA

NC

NC

����������������������������������������������������������������� Maxim Integrated Products 3

Page 4

Controller IC for Dimmable Offline LED Lamps

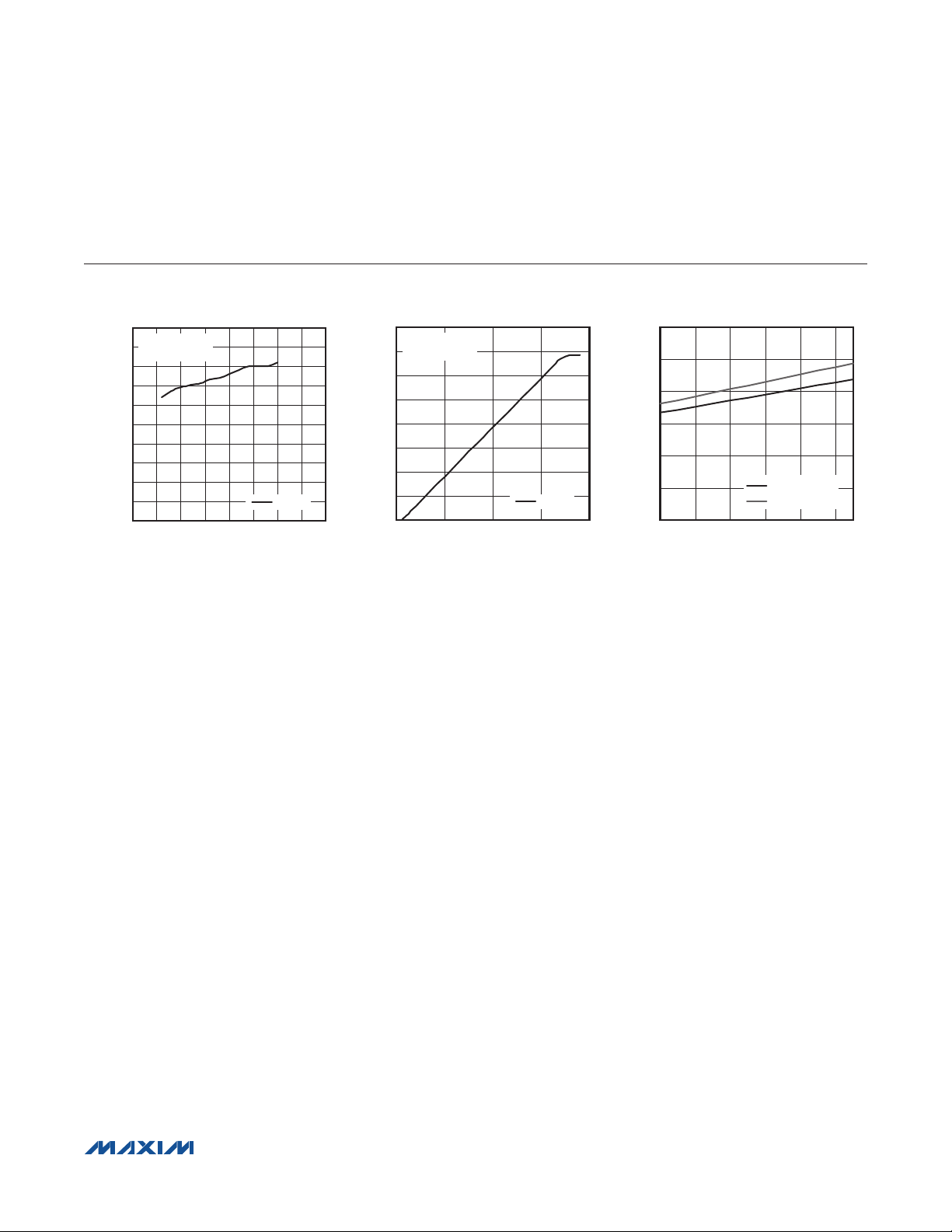

04

(TA = TJ = +25NC, 12 series LED load.)

MAX16841

Typical Operating Characteristics

AVERAGE VCS vs. TEMPERATURE

310

CURRENT-SENSE

309

RESISTOR = 3.3I

308

307

(mV)

306

CS

305

304

AVERAGE V

303

302

301

300

-40 120

TEMPERATURE (°C)

CS (mV)

1008040 600 20-20

MAX16841 toc01

(mV)

CS

V

800

700

600

500

400

300

200

100

CURRENT-SENSE

RESISTOR = 3.3I

0

VCS vs. V

V

REFI

REFI

MAX16841 toc02

QUIESCENT CURRENT

CS (mV)

321

(V)

QUIESCENT CURRENT vs. V

3.0

2.5

2.0

1.5

1.0

0.5

0

9

V

(V)

IN

IQ mA (VTH = 0V)

IQ mA (VTH = 5V)

IN

MAX16841 toc03

1917151311

����������������������������������������������������������������� Maxim Integrated Products 4

Page 5

MAX16841

Controller IC for Dimmable Offline LED Lamps

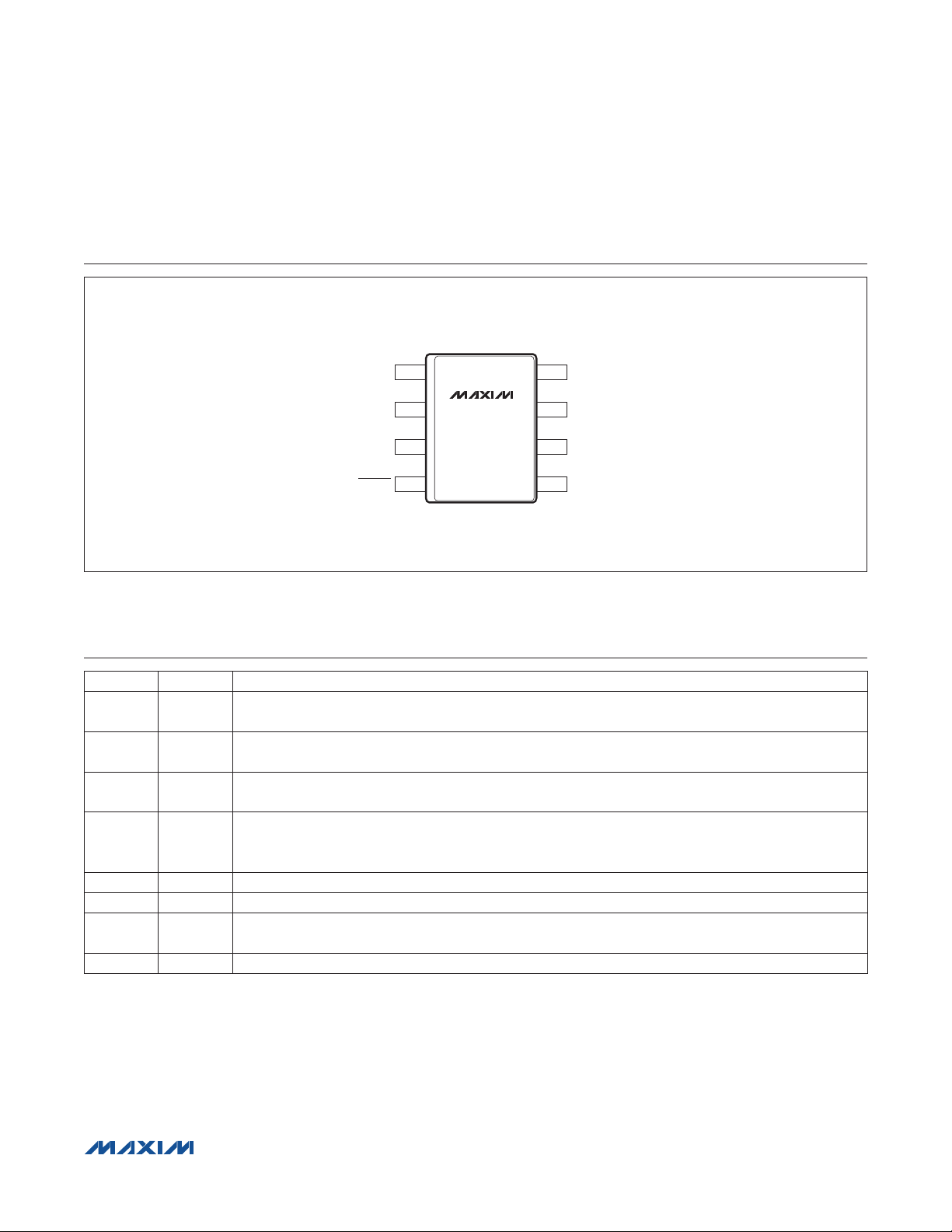

Pin Configuration

TOP VIEW

REFI

COMP

TH

PIN NAME FUNCTION

1 REFI

2 COMP

3 TH

4

5 GND Ground

6 CS Switch Current-Sense Input

7 NDRV

8 IN

DIMOUT

Current Reference Input. The IC sources 50FA current out of this pin. Connect a resistor from REFI to

GND to set the input-current reference.

Compensation Component Connection for the Switching Stage. Connect a suitable RC network to

ground. This is the output of the Gm amplifier.

Sets the Voltage Threshold on the Input at Which Switching Starts. This threshold is set at 1.24V.

Connect a resistor-divider from the bridge rectifier output, TH, and GND.

DIMOUT Drives an External FET to Provide a Resistive Path for the Triac when Input is Low. DIMOUT is

also used to drive an external FET that sets the programmed current to zero when the input voltage is

low.

Gate Drive for the Switching MOSFET. Connect a resistor across NDRV and GND to set the

switching frequency.

Input. Bypass with a 0.1FF or a higher value ceramic capacitor to ground.

+

1

2

3

4

MAX16841

SO

IN

8

NDRV

7

CS

6

GND

5DIMOUT

Pin Description

����������������������������������������������������������������� Maxim Integrated Products 5

Page 6

MAX16841

Controller IC for Dimmable Offline LED Lamps

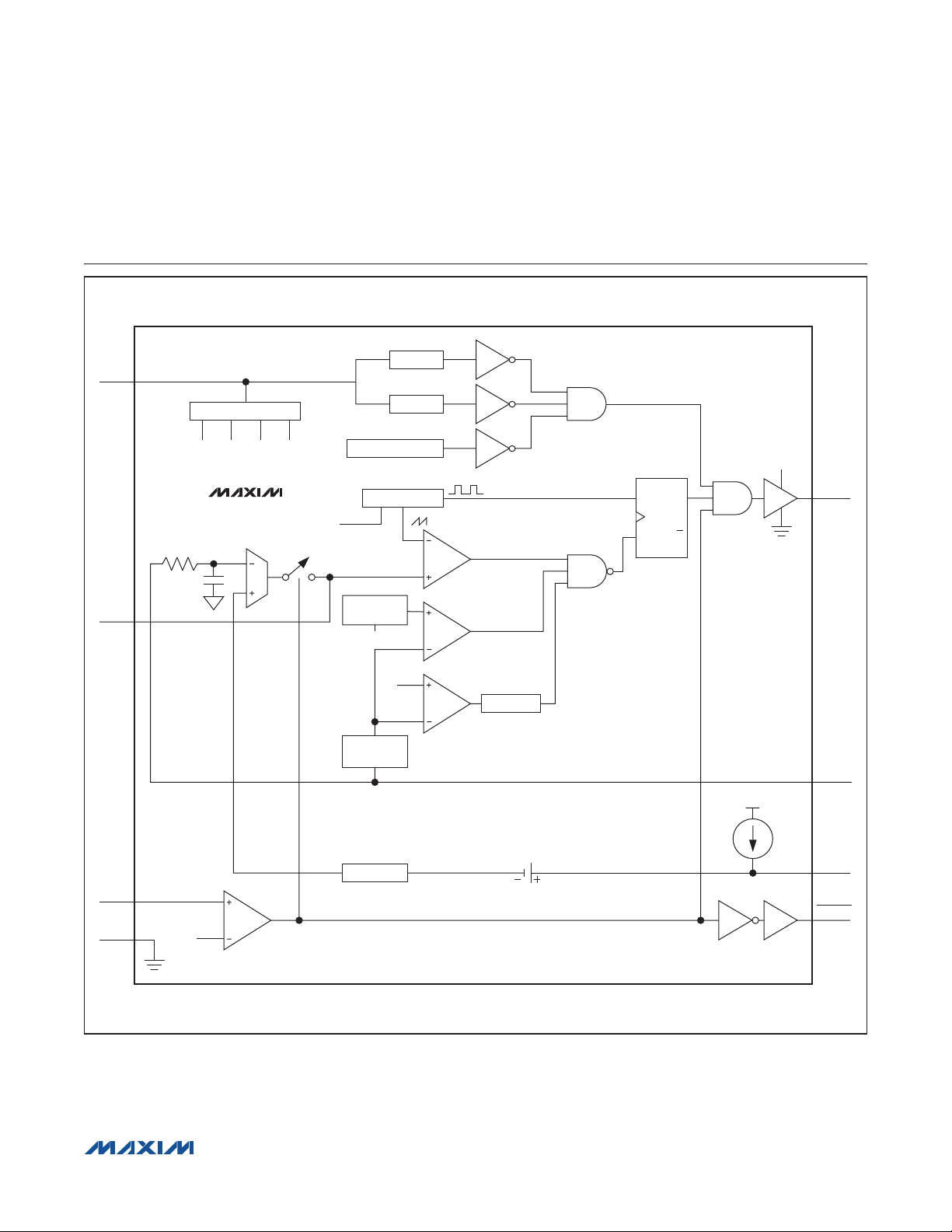

Functional Diagram

COMP

OSCILLATOR

10ms

2.2V

200ns

VIN OV

VIN UVLO

2.7V

2.4V

P-P

CS LIMIT

COMPARATOR

HICCUP

COMPARATOR

1s TIMER

SET

SQ

RQ

CLR

IN

NDRV

GND

CS

V

CC

IN

BIAS

VCC2.2V 2.3V 1.24V

MAX16841

G

m

THERMAL SHUTDOWN

NDRV

SOFT-START

BLANKING

GND

100mV

1/5

TH

1.24V

50µA

REFI

DIMOUT

����������������������������������������������������������������� Maxim Integrated Products 6

Page 7

MAX16841

Controller IC for Dimmable Offline LED Lamps

Detailed Description

The MAX16841 is a fixed-frequency offline LED driver

IC that is compatible with both leading-edge triac dimmers and trailing-edge transistor dimmers. The device

uses a fixed-frequency average current-mode control

scheme to control the switching current in the MOSFET.

In addition, a peak-limit comparator is used to limit the

peak switching current during overload and transient

conditions. The peak-limit comparator has a threshold of

2.2V. For the active PFC, the device uses a proprietary

current-control scheme where the averaged switch current on a cycle-by-cycle basis is set to a programmed

DC value. This maximizes the efficiency of the converter

by operating in continuous-conduction mode (CCM) at

low AC line voltage (100V to 120V) and in discontinuousconduction mode (DCM) at high AC line voltage (220V

to 240V). Switching is initiated when the voltage on the

TH pin exceeds a threshold of 1.24V. In the case of the

buck configuration, the VTH falling threshold should be

set in such a way so that the input voltage exceeds the

maximum forward voltage of the LED string. In the case

of the buck-boost or flyback configuration, this threshold

can be set lower.

The device also uses a proprietary current-sense scheme

to regulate the LED current.

The device switching frequency is adjustable from 50kHz

to 300kHz using a single resistor from NDRV to ground.

The device operates over a wide 11V to 20V supply

voltage. The device’s switching MOSFET gate driver

sources and sinks up to 1A, making it capable of driving

high-voltage MOSFETs in offline LED driver applications for power ranges up to 25W. The device allows for

dimming with leading-edge and trailing-edge dimmers.

Additional features include thermal shutdown and

overvoltage protection.

IN

The device is powered up by the voltage at IN. All the

internal regulators derive power from IN. The operational

voltage is between 11V and 20V.

TH

TH sets the threshold for switching. Switching is initiated once TH crosses 1.24V. The TH comparator has a

150mV hysteresis. In a buck configuration, the VTH falling

threshold should be set in such a way so that the input

voltage is equal to the maximum forward voltage of the

LED string. In a buck-boost configuration, the VTH falling

threshold can be set to a lower level.

DIMOUT

For proper operation with triac dimmers, the load connected to the dimmer should draw at least the startup

current when the dimmer is in the off state. For proper

operation of the timing circuit of the dimmer, there should

always be a close-current path. To ensure this, a bleeder

resistor is connected across IN and GND with the help

of an external FET. DIMOUT drives this external FET on

when VTH goes below the falling threshold. The bleeder

resistor is disconnected when VTH crosses its rising

threshold, resulting in better performance and efficiency.

Internal Oscillator

The internal oscillator of the device is programmable

from 50kHz to 300kHz. Connect a single resistor from

NDRV to GND to set the oscillator frequency. Upon

power-up, an 8FA of current sinks into this resistor. An

internal ramp is then compared against the voltage on

NDRV to determine the oscillator frequency.

Frequency Dithering

The device incorporates a frequency-dithering feature.

This feature helps to reduce EMI.

n-Channel MOSFET Switch Driver (NDRV)

The NDRV driver drives the gate of an external n-channel

switching MOSFET. NDRV switches between IN and

GND. NDRV is capable of sourcing/sinking 1A of peak

current, allowing the device to switch MOSFETs in an

offline LED driver application. The average current drawn

from the supply to drive the external MOSFET depends

on the MOSFET gate charge and switching frequency.

Use the following equation to calculate the MOSFET

driver supply current:

I Qf= ×

NDRV G SW

Switching MOSFET Current Sense (CS)

The switching MOSFET current-sense resistor should be

connected to the CS pin of the device. The device controls the average of the CS signal to a level determined

by the REFI voltage. Internal leading-edge blanking of

200ns (typ) is provided to avoid premature turn-off of

the switching MOSFET in each switching cycle. A peaklimit comparator is used to limit the peak switch current

during overload and transient conditions. The peak-limit

comparator has a threshold of 2.2V (typ).

����������������������������������������������������������������� Maxim Integrated Products 7

Page 8

MAX16841

Controller IC for Dimmable Offline LED Lamps

Input-Current Setting (REFI)

REFI is the external reference for programming the input

current of the LED driver. The input current is proportinal

to the REFI voltage. The IC sources 50FA current out of

this pin and the voltage at the REFI pin can also be set

by connecting a resistor from REFI to GND. Internally, the

REFI signal is downshifted by 100mV and then attenuated by a factor of 5. The attenuated signal is applied to

the positive terminal of the internal error amplifier and this

signal sets the reference for the controller.

Error-Amplifier Output (COMP)

The device includes an internal transconductance

current error amplifier with a typical Gm of 150FS. The

output of the error amplifier is controlled by the TH

comparator output. When the TH comparator is high,

the output of the error amplifier connects to COMP.

When the TH comparator is low, the error amplifier is

disconnected from COMP, preserving the charge on

the compensation capacitor. COMP is connected to the

positive terminal of the PWM comparator.

The device incorporates an average current-mode

control scheme to regulate the input current. The

control loop regulates the average of the CS signal to a

level determined by the REFI voltage. The control loop

consists of the current-sense resistor (RCS) connected

across CS and GND, the transconductance current error

amplifier, an oscillator providing a 2.4V ramp at switching

frequency, the control voltage on the positive input of the

Gm amplifier, and the PWM comparator.

Overvoltage-Protection Input (OVP)

This is the protection feature in a flyback converter during

an open LED condition. The IN pin is connected to the

auxiliary winding of the flyback transformer. During an

open LED condition, the IN voltage increases and NDRV

is disabled once the IN voltage reaches 22.5V (typ).

When the IN voltage drops by 2V, NDRV is enabled.

Short-Circuit Protection

During an output short condition, the inductor current

keeps increasing with input voltage as there is no negative voltage across the inductor during the off period of

the switching cycle. During this condition, the CS voltage

signal peak is at a higher level because the inductor

current is at a higher level than during the normal condition. Once the CS signal exceeds the hiccup threshold

of 2.7V (typ),

Switching is disabled for 1s (typ) if CS exceeds 2.7V (typ)

for three times.

the internal hiccup block gets activated.

Thermal Protection

The device enters into thermal-shutdown mode when

junction temperature exceeds +160NC. During thermal

shutdown, NDRV is disabled. The device recovers from

thermal-shutdown mode once the junction temperature

drops by 20NC.

Applications Information

Figure 1 shows a MAX16841-based, triac-dimmable,

PFC, nonisolated-buck offline LED driver. Components

L1, L2, L3, and C1 provide EMI filtering. During the turnon instant of triac dimming, there would be significant

ringing due to high inrush current to charge the input

capacitor (C9). The ringing could cause the line current

to fall to zero and this would turn off the triac. R3, R22,

and C14 act as a damper and help to limit the inrush

current and ringing. Due to R3, the efficiency of the supply decreases. The damper circuit can be omitted in

nondimming applications. The circuit, consisting of D4,

R5, C2, D3, R6, R4, and Q5, bypasses R3 with Q1 after

1ms of dimming instant, thereby reducing the power

dissipation in R3 and improving efficiency. During the

turn-on instant, capacitor C2 is charged by a constantcurrent source formed by D3, R6, R4, and Q5. Within

1ms time, sufficient voltage develops across C2 to fire

the SCR Q1. Diode D4 provides fast discharge of C2.

Resistors R8, R9, and R10 program the switching threshold. The rising threshold should be set at a voltage higher

than the maximum LED string voltage. When the input

voltage is below the falling threshold, DIMOUT drives

the Q3 FET on, connecting R7 across the diode-bridge

positive and GND. Thus, a close circuit is formed for the

timing circuit of the triac. Diode D2 blocks capacitors C9

and C14 to discharge through R7. This helps to reduce

the inrush current during the triac turn-on instant.

The circuit consisting of R23, R24, D6, and Q2 is a linear

regulator and provides bias to the device.

The buck-converter circuit is formed by C9, LED+, LED-,

C10, L5, Q4, D10, D11, and R20. Capacitor C9 provides

a path for the switching frequency currents. Maximum

value of this capacitor is limited by the input power-factor

requirements. The higher the value of C9, the lower the

input power factor.

Since the input-voltage waveform to the buck converter is

a rectified sinusoid at line frequency, the LED current has

a ripple at double-line frequency. Electrolytic capacitors

C11 and C12 filter this double-line frequency ripple.

����������������������������������������������������������������� Maxim Integrated Products 8

Page 9

MAX16841

Controller IC for Dimmable Offline LED Lamps

Circuit components R11, R12, C15, Q6, Q7, R13, and

R14 are used to control the input current. Q6 and Q7

are matched transistors. The voltage on C15 represents

the average input voltage. The average voltage is then

used to control the current in the current-mirror circuit

formed by R12, R13, R14, Q6, and Q7. The current

flowing into R12 is approximately proportional to the

DB+

L3D1D2

3

AC1

F1

R26

AC2

L1

R1

C1

R2

L2

1

DB-

R3

2

4

Q1

voltage across C15 and is now reflected on the collector

of Q6, and sinks the same amount of current from the

collector of Q7 that flows into R12. Inside the device is

a 50FA current source. The current flowing into R16 sets

the input current, or the average current flowing into R20.

The circuit tries to keep the input power over the line voltage almost constant.

LED+

C9

R22

C14

C2

R5

G

Q2

D4

R34

R23

R24

D6

15V

C8

C13

C10 C11 C12

LED-

D10

L5

DB+

DB+

R11

C15

DB-

R4

R12

Q5

G

R13

REFI

Q7Q6

R14

D3

18V

R6

Figure 1. Nonisolated (Buck) Topology

����������������������������������������������������������������� Maxim Integrated Products 9

R10

DB+

R7

U1

R8

R9

Q3

C16

R16

C4C3

R17

4

3

REFI

1

DIMOUT

MAX16841

TH

REFI

COMP GND

NDRV

IN

8

IN

7

6

CS

52

C5

D12

R21

Q4

R20R18

Page 10

MAX16841

( )

Controller IC for Dimmable Offline LED Lamps

Resistors R16 and R20

The average current in resistor R16 is the average input

current of the buck converter.

If P

is the output power, then the input power is given by:

OUT

P

OUT

P

=

IN

η

P

×π

IN

I

=

IN

2V

×

M

V 2V

= ×

M INrms

I R20 0.1V

×+

IN

R16

=

10µA

V 80%

×

CS

CS

=

IL

P

R

I I 0.5 I

= + ×∆

LP IN Lmax

ILP is the switch peak current. Maximum peak in the

switch current occurs at the peak level of the highest

input voltage.

VCS is 2.2V. Allow 80% margin for tolerances.

Inductor Selection

For optimum efficiency, inductor L5 must be operated in

continuous-conduction mode.

The current in the inductor would be at its maximum level

at peak of the highest input voltage. LED string voltage

is assumed constant. Calculate the duty cycle at peak of

the highest input voltage.

V

D

The percentage peak-to-peak ripple is considered

between 30% and 60% of the inductor current. Assuming

60% peak-to-peak inductor current ripple, the maximum

inductor current is given by:

I

Lmax

The minimum value of the inductor is given by:

2V V D

=

Lmin

LED

=

2V

×

INmax

P

×π

OUT

=

2V

×

LED

× −×

INmax LED

××

0.6 I f

Lmax SW

Figure 2 shows a PFC triac, dimmable, isolated (flyback

topology) offline LED driver.

Here the current through the Q4 MOSFET is controlled.

Current through Q4 is the same as the input current

of the flyback converter. The input-side circuitry is the

same as in the nonisolated buck LED driver that was

previously described. During startup, the device is

powered up from Q2, R10, R11, and D8. Bootstrap from

the bias winding on the transformer turns off the Q2

MOSFET, thus saving power from high-voltage line. Here

the switching threshold programmed by R15, R16, and

R18 can be lower than the LED string voltage.

Output-side electrolytic capacitors C8 and C9 are used

for filtering the double-line frequency current ripple in

LED current.

During an open LED condition, the voltage across the

output capacitors increases and is reflected on the biaswinding side.

Once the bias-winding voltage goes above 22.5V (typ),

NDRV is disabled and the Q4 MOSFET turns off.

Choose the transformer turns ratio based on the voltage

rating of the MOSFET. Use the following expression to

calculate primary-secondary turns ratio:

0.8 V V

×−

N

=

PS

where:

NPS is the primary-secondary turns ratio

V

V

V

Factor 0.8 is taken into account for the voltage spikes,

due to transformer-leakage inductance.

Use the following equation to calculate bias-secondary

turns ratio:

where NAS is the bias-secondary turns ratio and 18V is

the bias voltage for the device.

is the voltage rating of the Q4 MOSFET

DSmax

is the maximum peak input voltage

INmax

LEDmax

is the maximum voltage of the LED string

DSmax INmax

V

NV=

AS

LEDmax

18V

LEDmax

���������������������������������������������������������������� Maxim Integrated Products 10

Page 11

AC1

AC2

MAX16841

Controller IC for Dimmable Offline LED Lamps

DB+

L3D1D6

C5

R7 R10

F1

R24

L1

R1

DB-

C1

R2

L2

R3

Q1

C6

G

C2

R5

Q2

D7

D4

R12

C12

R11

D8

15V

C7

D9

C15

R9

D11

T1

C14

D2

C10

C9

C8

D3

18V

R6

DB-

DB+

R11

C15

R12

REFI

Q6

Q7

Figure 2. Flyback Configuration

R19

R15

R4

Q3

Q5

R16

G

R18

REFI

R21

R17

C3

C4

4

3

1

2

U1

DIMOUT

TH

REFI

COMP

MAX16841

NDRV

GND

8

IN

7

6

CS

5

C13

D12

R14

Q4

R20R23

���������������������������������������������������������������� Maxim Integrated Products 11

Page 12

MAX16841

Controller IC for Dimmable Offline LED Lamps

Choose the transformer’s magnetizing inductance (Lm)

in such a way so that the transformer operates in DCM

above 120V AC input. DCM operation at higher voltages

reduces switching losses in the Q4 MOSFET. Use the following equation to calculate Lm:

2

×

170V D

=

Lm

××

If 2

IN SW

×π

P

IN

=

I

IN

340V

where D is the switching duty cycle at 170V DC and fSW

is the switching frequency.

In DCM conditions, the peak current in Lm can be

calculated with the help of the following equation:

2I V

××

IN INmax

Lm f

×

SW

where V

I

=

P

is the maximum peak input voltage.

INmax

Feedback Compensation

Loop Compensation for

Nonisolated Buck (R17, C3, C4)

The switching converter small-signal transfer function

contains a pole at origin and a zero. The zero location

is inversely related to inductor current and inductance

value. The minimum frequency of the zero location is:

V

f

Zmin

=

LED

2 LI

×π× ×

Lmax

Design the loop compensation in such a way so that the

loop crossover is near f

zero formed by R17 and C4 at f

R17

C4

=

2 f R17

. Place the compensation

Zmin

I R20

Lmax

=

GV

m PP

/5. R20 is given by:

Zmin

×

×

−

5

×π× ×

Zmin

where Gm is the transconductance of the internal error

amplifier and V

P-P

is 2.4V.

Place the compensation pole formed by R17 and

C3 at 5 x f

Zmin

:

C3

=

2 5 f R1 7

×π× × ×

1

Zmin

Loop Compensation

for Flyback Driver (R17, C3, C4)

The switching converter small-signal transfer function is

identical to the buck transfer function. The zero location

is inversely related to primary-magnetizing inductance

and its current. The minimum frequency of the zero

location is:

VN

f

= ×

Zmin

2 Lm I N

LED P

×π× ×

Lmax S

Design the loop compensation in such a way so that the

loop crossover is near f

zero formed by R17 and C4 at f

R17

C4

=

2 f R17

. Place the compensation

Zmin

I R20

Lmmax

=

GV

m PP

/5. R20 is given by:

Zmin

×

×

−

5

×π× ×

Zmin

where Lm is the magnetizing inductance of the flyback

transformer, Gm is the transconductance of the internal

error amplifier, and V

P-P

is 2.4V.

Place the compensation pole formed by R17 and

C3 at 5 x f

Zmin

:

C3

=

2 5 f R1 7

×π× × ×

1

Zmin

���������������������������������������������������������������� Maxim Integrated Products 12

Page 13

MAX16841

Controller IC for Dimmable Offline LED Lamps

Layout Recommendations

Careful PCB layout is critical to achieve low switching

losses, and clean, stable operation. The switchingconverter portion of the circuit has nodes with very fast

voltage changes that could lead to undesirable effects

on the sensitive parts of the circuit.

Follow the guidelines below to reduce noise as much

as possible:

1) Ensure that all heat-dissipating components have

adequate cooling.

2) Isolate the power components and high-current paths

from the sensitive analog circuitry.

3) Have a power ground plane for the switchingconverter power circuit under the power components (input filter capacitor, output filter capacitor,

inductor, MOSFET, rectifier diode, and current-sense

resistor). Connect GND to the power ground plane as

close as possible to GND. Connect all other ground

connections to the power ground plane using vias

close to the terminals

4) There are two loops in the power circuit that carry

high-frequency switching currents. One loop is when

the MOSFET is on (from the input filter capacitor positive terminal, through the output capacitor, inductor,

switching MOSFET, and current-sense resistor, to the

input capacitor negative terminal). The other loop is

when the MOSFET is off (from the output capacitor

negative terminal, through the inductor, the rectifier

diode, and output filter capacitor positive terminal).

Analyze these two loops and make the loop areas as

small as possible. Wherever possible, have a return

path on the power ground plane for the switching

currents on the top-layer copper traces or through

power components. This reduces the loop area considerably and provides a low-inductance path for

the switching currents. Reducing the loop area also

reduces radiation during switching.

���������������������������������������������������������������� Maxim Integrated Products 13

Page 14

MAX16841

Controller IC for Dimmable Offline LED Lamps

Typical Operating Circuits

D2

AC1

AC2

R3

R4

D1

L1

R2

4

Q2

R5

R6

C2

DIMOUT

3

1

2

MAX16841

TH

REFI

COMP GND

C1

NDRV

R1

D7

Q1

D4

D3

8

IN

7

6

CS

5

C4

D5

Q3

R8R7

T1

LED+

C5

LED-

Figure 3. Flyback LED Driver

���������������������������������������������������������������� Maxim Integrated Products 14

Page 15

MAX16841

Controller IC for Dimmable Offline LED Lamps

Typical Operating Circuits (continued)

AC1

AC2

R3

R4

D2

D1

L1

R2

4

Q2

R5

R6

C2

DIMOUT

MAX16841

3

TH

1

REFI

2

COMP GND

C1

NDRV

R1

Q1

D4

8

IN

C4

7

6

CS

5

D3

L2

Q3

R8R7

LED+

C5

LED-

Figure 4. Buck LED Driver

���������������������������������������������������������������� Maxim Integrated Products 15

Page 16

MAX16841

Controller IC for Dimmable Offline LED Lamps

Typical Operating Circuits (continued)

AC1

AC2

R3

R4

D2

D1

L1

R2

4

Q2

R5

R6

C2

DIMOUT

MAX16841

3

TH

1

REFI

2

COMP GND

C1

NDRV

R1

Q1

D4

8

IN

7

6

CS

5

C4

L2

D3

Q3

R8R7

LED-

C5

LED+

Figure 5. Buck-Boost LED Driver

���������������������������������������������������������������� Maxim Integrated Products 16

Page 17

MAX16841

Controller IC for Dimmable Offline LED Lamps

Ordering Information

PART TEMP. RANGE PIN-PACKAGE

MAX16841ASA+

+Denotes a lead(Pb)-free/RoHS-compliant package.

-40NC to +125NC

8 SO

Chip Information

PROCESS: BiCMOS

Package Information

For the latest package outline information and land patterns

(footprints), go to www.maxim-ic.com/packages. Note that a

“+”, “#”, or “-” in the package code indicates RoHS status only.

Package drawings may show a different suffix character, but

the drawing pertains to the package regardless of RoHS status.

PACKAGE

TYPE

8 SO S8+2

PACKAGE

CODE

OUTLINE

NO.

21-0041 90-0096

LAND

PATTERN NO.

���������������������������������������������������������������� Maxim Integrated Products 17

Page 18

MAX16841

Controller IC for Dimmable Offline LED Lamps

Revision History

REVISION

NUMBER

0 10/11 Initial release —

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits) shown in the Electrical

Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 18

©

2011 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...