Page 1

General Description

The MAX16834 is a current-mode high-brightness LED

(HB LED) driver for boost, buck-boost, SEPIC, and highside buck topologies. In addition to driving an n-channel

power MOSFET switch controlled by the switching controller, it also drives an n-channel PWM dimming switch to

achieve LED PWM dimming. The MAX16834 integrates

all the building blocks necessary to implement a fixed-frequency HB LED driver with wide-range dimming control.

The MAX16834 features constant-frequency peak current-mode control with programmable slope compensation to control the duty cycle of the PWM controller.

A dimming driver designed to drive an external n-channel MOSFET in series with the LED string provides

wide-range dimming control up to 20kHz. In addition to

PWM dimming, the MAX16834 provides analog dimming using a DC input at REFI. The programmable

switching frequency (100kHz to 1MHz) allows design

optimization for efficiency and board space reduction.

A single resistor from RT/SYNC to ground sets the

switching frequency from 100kHz to 1MHz while an

external clock signal at RT/SYNC disables the internal

oscillator and allows the MAX16834 to synchronize to

an external clock. The MAX16834’s integrated highside current-sense amplifier eliminates the need for a

separate high-side LED current-sense amplifier in

buck-boost applications.

The MAX16834 operates over a wide supply range of

4.75V to 28V and includes a 3A sink/source gate driver

for driving a power MOSFET in high-power LED driver

applications. The MAX16834 is also suitable for DC-DC

converter applications such as boost or buck-boost.

Additional features include external enable/disable

input, an on-chip oscillator, fault indicator output (FLT)

for LED open/short or overtemperature conditions, and

an overvoltage protection sense input (OVP+) for true

overvoltage protection.

The MAX16834 is available in a thermally enhanced

4mm x 4mm, 20-pin TQFN-EP package and is specified

over the automotive -40°C to +125°C temperature range.

Applications

Single-String LED LCD Backlighting

Automotive Rear and Front Lighting

Projection System RGB LED Light Sources

Architectural and Decorative Lighting (MR16, M111)

Spot and Ambient Lights

DC-DC Boost/Buck-Boost Converters

Features

o Wide Input Operating Voltage Range (4.75V to

28V)

o 3000:1 PWM Dimming

o Analog Dimming

o Integrated PWM Dimming MOSFET Driver

o Integrated High-Side Current-Sense Amplifier for

LED Current Sense in Buck-Boost Converter

o 100kHz to 1MHz Programmable High-Frequency

Operation

o External Clock Synchronization Input

o Programmable UVLO

o Internal 7V Low-Dropout Regulator

o Fault Output (FLT) for Overvoltage, Overcurrent,

and Thermal Warning Faults

o Programmable True Differential Overvoltage

Protection

o 20-Pin TQFN-EP Package

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

________________________________________________________________

Maxim Integrated Products

1

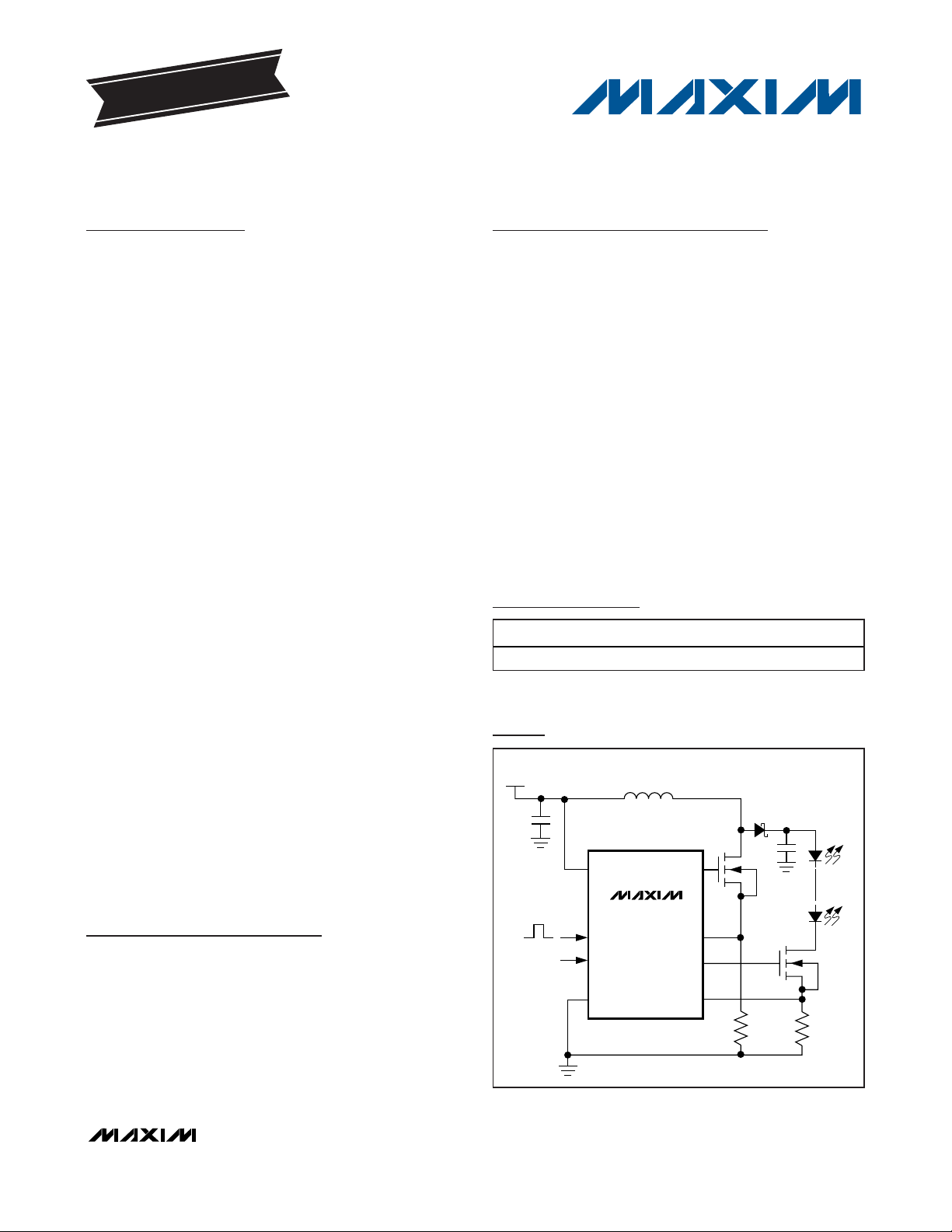

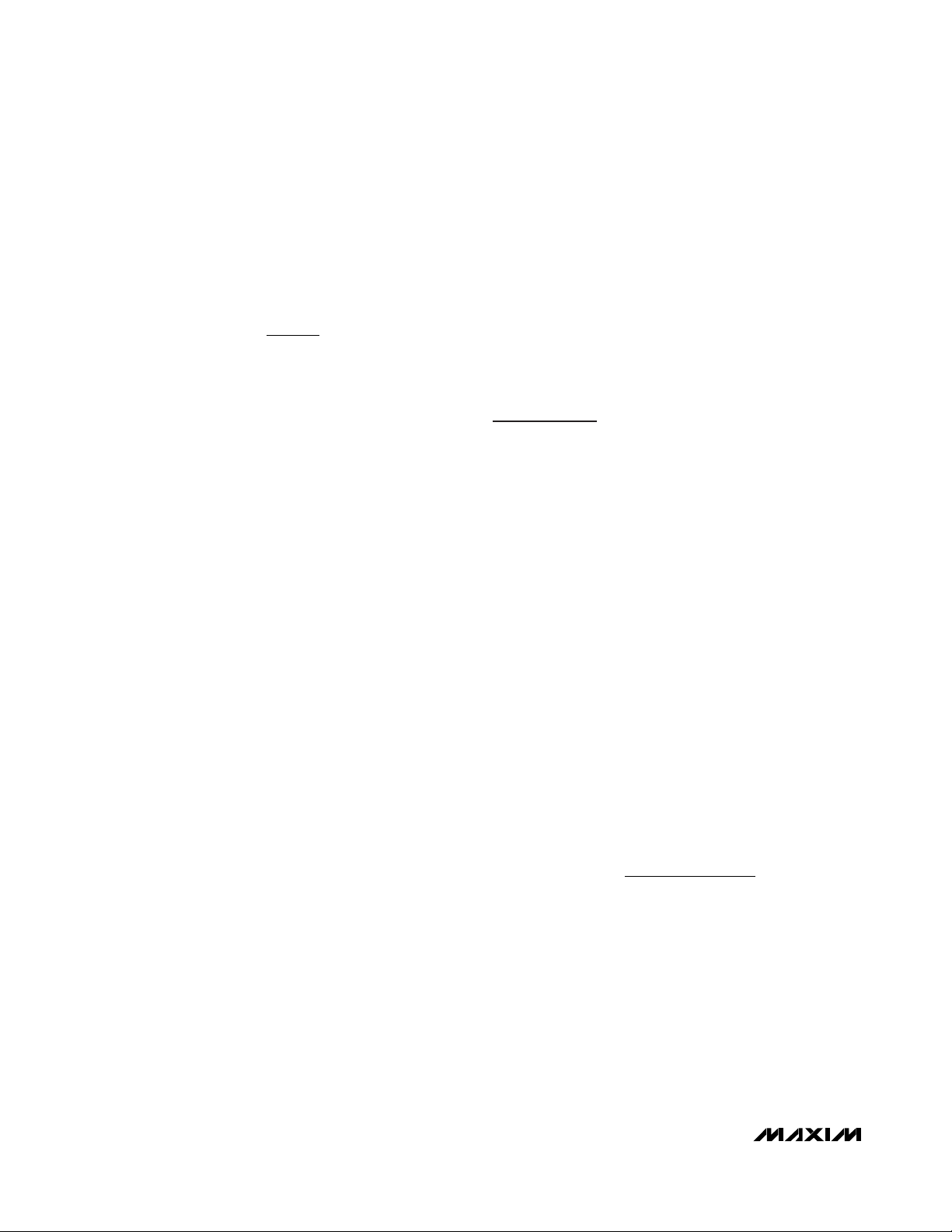

Simplified Application Circuit

Ordering Information

19-4235; Rev 0; 8/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

+

Denotes a lead-free/RoHS-compliant package.

*

EP = Exposed pad.

PART TEMP RANGE

PIN-PACKAGE

MAX16834ATP+

-40°C to +125°C 20 TQFN-EP*

Pin Configuration appears at end of data sheet.

IN

MAX16834

PWMDIM

REFI

PGND

BOOST LED DRIVER

NDRV

CS

DIMOUT

SENSE+

LED+

LEDs

LED-

V

OFF

IN

ANALOG

ON

DIM

Page 2

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

2 _______________________________________________________________________________________

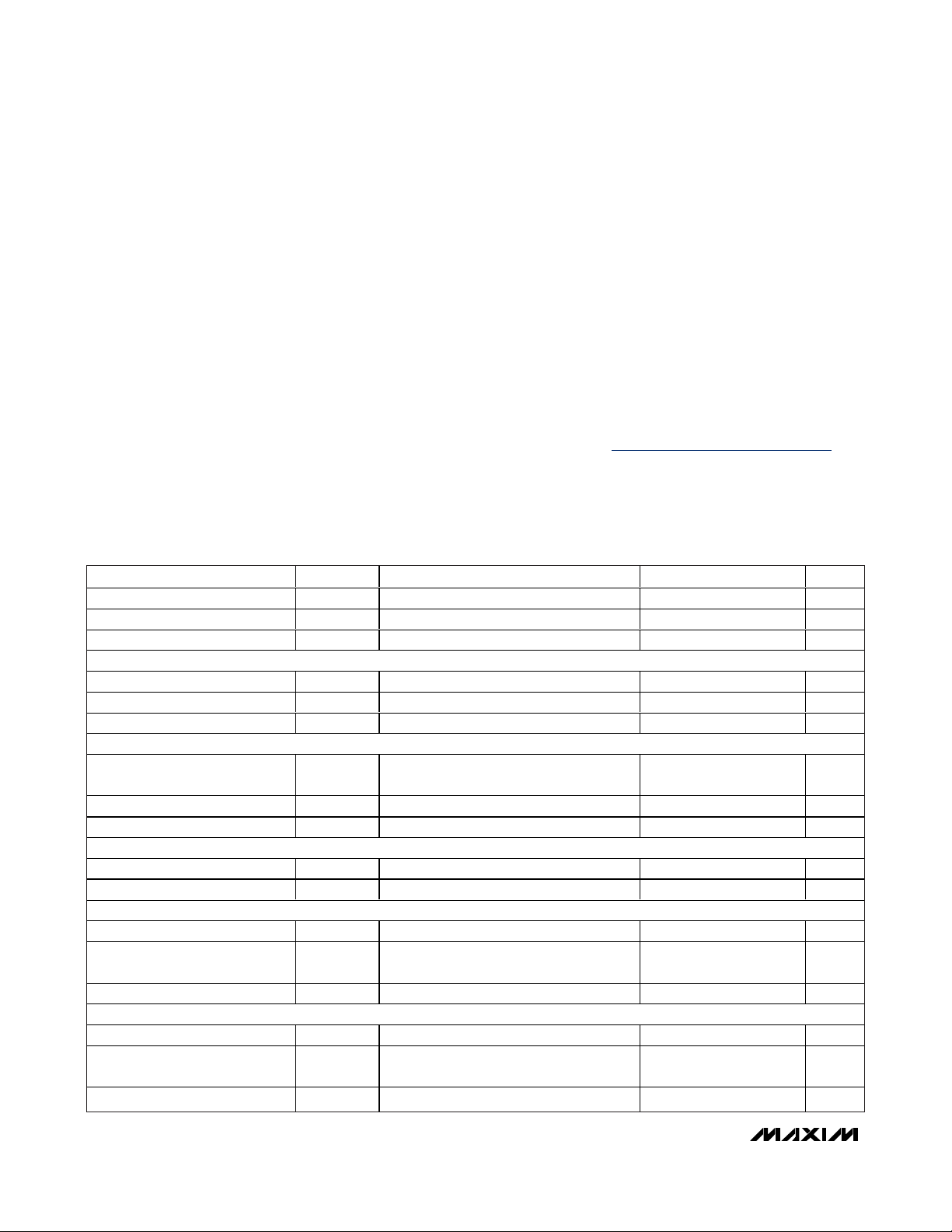

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= VHV= 12V, V

UVEN

= 5V, VLV= V

PWMDIM

= SGND, C

VCC

= 4.7µF, C

LCV

= 100nF, C

REF

= 100nF, R

SENSE+

= 0.1Ω,

R

RT

= 10kΩ, TA= TJ= -40°C to +125°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial

.

IN, HV, LV to SGND................................................-0.3V to +30V

OVP+, SENSE+, DIMOUT, CLV to SGND ..............-0.3V to +30V

SENSE+ to LV........................................................-0.3V to +0.3V

HV, IN to LV ............................................................-0.3V to +30V

OVP+, CLV, DIMOUT to LV ......................................-0.3V to +6V

PGND to SGND .....................................................-0.3V to +0.3V

V

CC

to SGND..........................................................-0.3V to +12V

NDRV to PGND...........................................-0.3V to (V

CC

+ 0.3V)

All Other Pins to SGND.............................................-0.3V to +6V

NDRV Continuous Current................................................±50mA

DIMOUT Continuous Current..............................................±2mA

V

CC

Short-Circuit Current to SGND Duration ...........................1s

Continuous Power Dissipation (T

A

= +70°C)

20-Pin TQFN 4mm x 4mm

(derate 25.6mW/°C* above +70°C) ............................2051mW

Junction-to-Ambient Thermal Resistance (

θ

JA

) (Note 1).....39°C/W

Junction-to-Case Thermal Resistance (

θ

JC

) (Note 1) ........6°C/W

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

*

As per JEDEC51 standard (multilayer board).

Input Voltage Range V

Quiescent Supply Current I

Shutdown Supply Current I

INTERNAL LINEAR REGULATOR (VCC)

Output Voltage V

Dropout Voltage V

Short-Circuit Current VCC = 0V, VIN = 12V 80 300 mA

LINEAR REGULATOR (CLV)

Output Voltage (V

Dropout Voltage V

Short-Circuit Current V

REFERENCE VOLTAGE (REF)

Output Voltage V

REF Short-Circuit Current V

UNDERVOLTAGE LOCKOUT/ENABLE INPUT (UVEN)

UVEN On Threshold Voltage V

UVEN Threshold Voltage

Hysteresis

Input Leakage Current I

PWMDIM

PWMDIM On Threshold Voltage V

PWMDIM Threshold Voltage

Hysteresis

Input Leakage Current V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN

Q

SHDN

CC

OD

CLV - VLV

DO

REF

UVEN_THUP

LEAK

PWMDIM

Excluding I

V

UVEN

0 ≤ ICC ≤ 50mA, 9.5V ≤ VIN ≤ 28V 6.3 7 7.7 V

ICC = 35mA (Note 2) 0.65 1.8 V

0 ≤ I

CLV

)

6V ≤ V

I

= 2mA, 0 ≤ VLV ≤ 23.3V (Note 3) 0.5 V

CLV

= 12V, VIN = 12V, VHV = 24V 2.2 10 mA

CLV

0 ≤ I

REF

= 0 30 mA

REF

V

UVEN

PWMDIM

LED

= 0 30 60 µA

≤ 2mA, 6V ≤ VHV ≤ 28V,

≤ 22V

(HV-LV)

≤ 1mA, 4.75V ≤ VIN ≤ 28V 3.625 3.70 3.775 V

= 0 I1I µA

= 0 I1I µA

4.75 28 V

4.7 5 5.3 V

1.395 1.435 1.475 V

200 mV

1.395 1.435 1.475 V

200 mV

610mA

Page 3

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

_______________________________________________________________________________________ 3

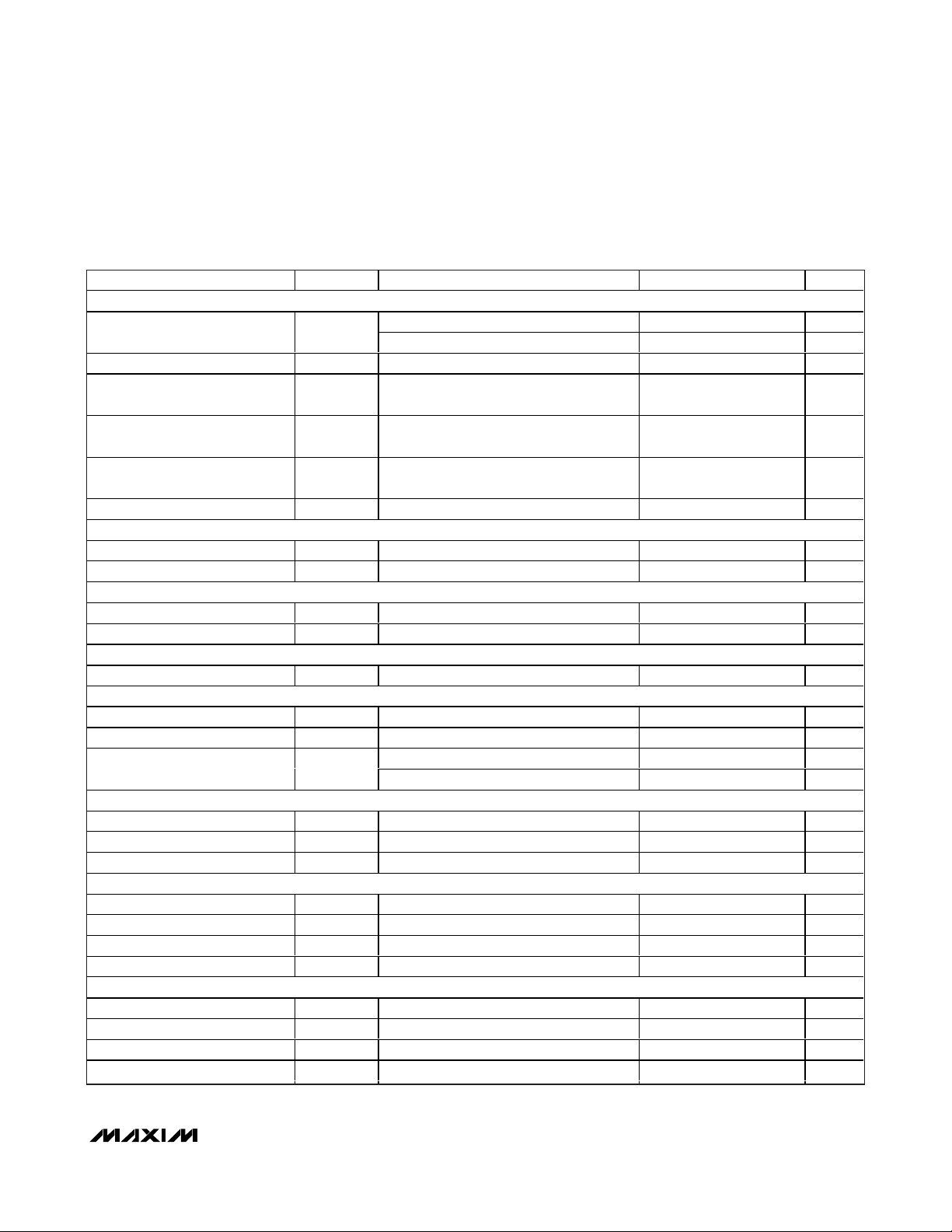

ELECTRICAL CHARACTERISTICS (continued)

(VIN= VHV= 12V, V

UVEN

= 5V, VLV= V

PWMDIM

= SGND, C

VCC

= 4.7µF, C

LCV

= 100nF, C

REF

= 100nF, R

SENSE+

= 0.1Ω,

R

RT

= 10kΩ, TA= TJ= -40°C to +125°C, unless otherwise noted. Typical values are at TA= +25°C.)

OSCILLATOR

Oscillator Frequency f

Oscillator Frequency Range (Note 4) 100 1000 kHz

External Sync Input Clock High

Threshold

External Sync Input Clock Low

Threshold

External Sync Input High Pulse

Width

Maximum External Sync Period 50 µs

SLOPE COMPENSATION (SC)

SC Pullup Current I

SC Discharge Resistance R

REFI

REFI Input Bias Current V

REFI Input Common-Mode Range (Note 4) 0 2 V

SENSE+

SENSE+ Input Bias Current (V

HIGH-SIDE LED CURRENT-SENSE AMPLIFIER (V

Input Offset Voltage VLV > 5V, (V

Voltage Gain A

3dB Bandwidth

LOW-SIDE LED CURRENT-SENSE AMPLIFIER

Input Offset Voltage VLV < 1V, (V

Voltage Gain A

3dB Bandwidth 600 kHz

CURRENT ERROR AMPLIFIER (TRANSCONDUCTANCE AMPLIFIER)

Transconductance g

Open-Loop DC Gain A

Input Offset Voltage -10 0 +10 mV

COMP Voltage Range V

PWM COMPARATOR

Input Offset Voltage 0.6 0.65 0.70 V

Propagation Delay t

Minimum On-Time t

Duty Cycle (Note 4) 90 99.5 %

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

OSC

SCPU

SCD

V

V

m

V

COMP

PD

ON(MIN)

R

RT/SYNC

R

RT/SYNC

(Note 4) 2 V

(Note 4) 0.4 V

(Note 4) 200 ns

VSC = 100mV 80 100 120 µA

VSC = 100mV 8 Ω

REFI

VLV > 5V, (V

(V

(V

VLV < 1V, (V

V

COMP

(Note 4) 0.4 2.5 V

50mV overdrive 40 ns

On-time includes blanking time 100 ns

= 5kΩ 0.9 1 1.1 MHz

= 25kΩ 180 200 220 kHz

= 1V I1I µA

- VLV) = 100mV 250 µA

SENSE+

- VLV)

SENSE+

- VLV) = 0.1V, no load 1.8 MHz

SENSE+

- VLV) = 0.02V, no load 600 kHz

SENSE+

= 2V, V

- VLV) = 5mV -2.4 0 +2.4 mV

SENSE+

- VLV) = 0.2V 9.7 9.9 10.1 V/V

SENSE+

- VLV) = 0V -2 0 +2 mV

SENSE+

- VLV) = 0.2V 9.7 9.9 10.1 V/V

SENSE+

= 5V 400 500 600 µS

PWMDIM

60 dB

Page 4

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

4 _______________________________________________________________________________________

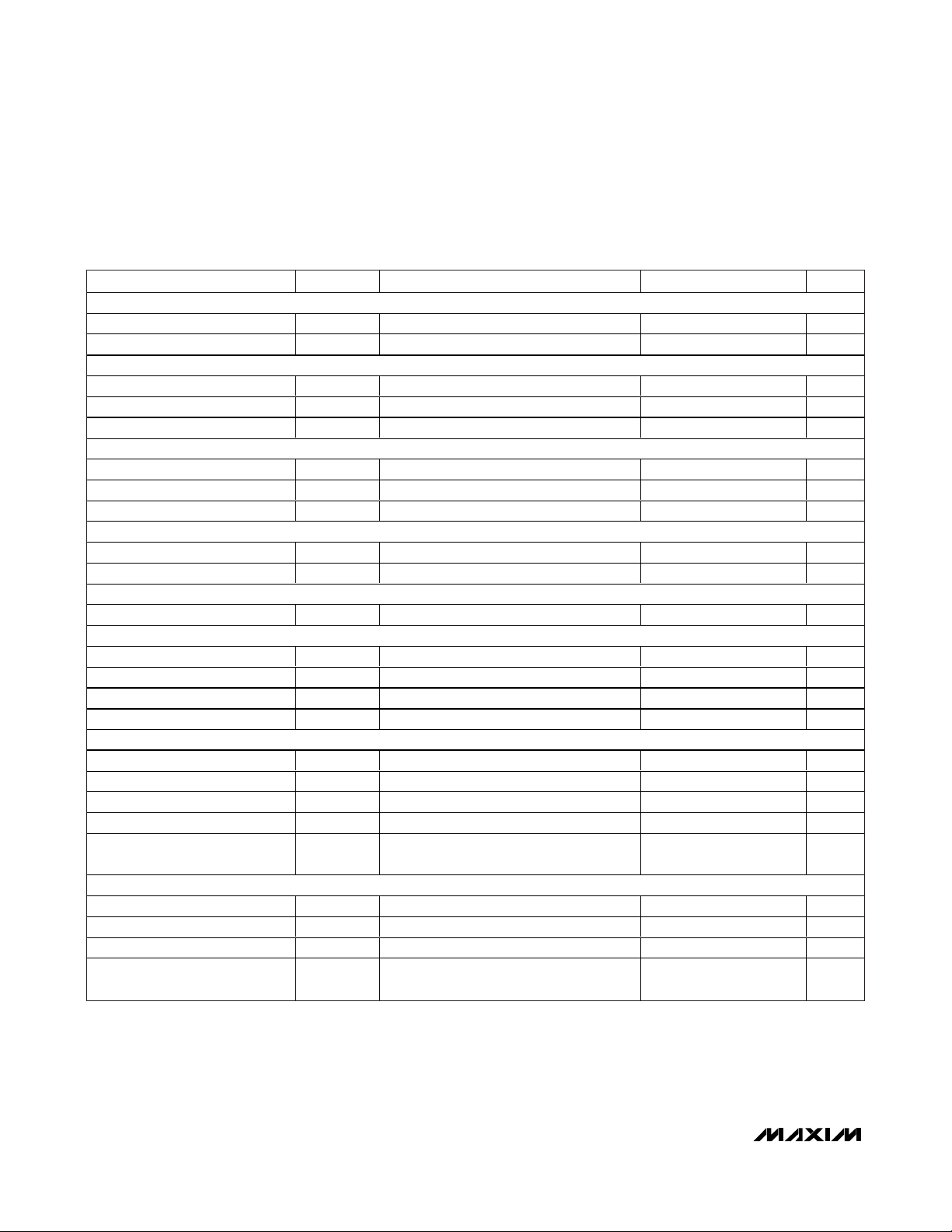

ELECTRICAL CHARACTERISTICS (continued)

(VIN= VHV= 12V, V

UVEN

= 5V, VLV= V

PWMDIM

= SGND, C

VCC

= 4.7µF, C

LCV

= 100nF, C

REF

= 100nF, R

SENSE+

= 0.1Ω,

R

RT

= 10kΩ, TA= TJ= -40°C to +125°C, unless otherwise noted. Typical values are at TA= +25°C.)

Note 2: Dropout voltage is defined as VIN- VCC, when VCCis 100mV below the value of VCCfor VIN= 9.5V.

Note 3: Dropout is defined as V

HV

- V

CLV

, when V

CLV

is 100mV below the value of V

CLV

for VHV= 8V.

Note 4: Not production tested. Guaranteed by design.

CURRENT PEAK LIMIT COMPARATOR

Trip Threshold Voltage 0.25 0.3 0.35 V

Propagation Delay 50mV overdrive with respect to NDRV 40 ns

OVERVOLTAGE PROTECTION INPUT (OVP+)

OVP+ On Threshold Voltage V

OVP+ Hysteresis 200 mV

OVP+ Input Leakage Current (V

HIGH-SIDE LED SHORT COMPARATOR

Off Threshold V

On Threshold V

Error Reject Blankout f

LOW-SIDE LED SHORT COMPARATOR

Off Threshold 0.27 0.30 0.33 V

Error Reject Blankout 5µs

HICCUP TIMER

Hiccup Time f

GATE-DRIVER OUTPUT (NDRV)

NDRV Peak Pullup Current VCC = 7V 3 A

NDRV Peak Pulldown Current VCC = 7V 3 A

p-Channel MOSFET R

n-Channel MOSFET R

DIMOUT

DIMOUT Peak Pullup Current (V

DIMOUT Peak Pulldown Current (V

p-Channel MOSFET R

n-Channel MOSFET R

PWMDIM to DIMOUT

Propagation Delay

FAULT FLAG (FLT)

FLT Pulldown Current V

FLT Leakage Current V

Thermal Warning On Threshold +140 °C

Thermal Warning Threshold

Hysteresis

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DSON

DSON

DSON

DSON

OVP_ON

- VLV) = 1.235V -1 +1 µA

OVP

- V

CLV

LV

- V

CLV

LV

= 500kHz 256 µs

OSC

= 500kHz 8.2 ms

OSC

(VCC - V

V

(V

(V

NDRV

= 0.1V 0.9 1.7 Ω

NDRV

- VLV) = 5V 25 50 mA

CLV

- VLV) = 5V 25 50 mA

CLV

- V

CLV

DIMOUT

- VLV) = 0.1V 25 Ω

DIMOUT

= 0.2V 2 5 10 mA

FLT

= 1.0V I1I µA

FLT

) = 0.1V 1.2 1.9 Ω

) = 0.1V 31 Ω

1.375 1.435 1.495 V

4.0 4.3 4.6 V

4.1 4.4 4.7 V

200 ns

20 °C

Page 5

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

_______________________________________________________________________________________ 5

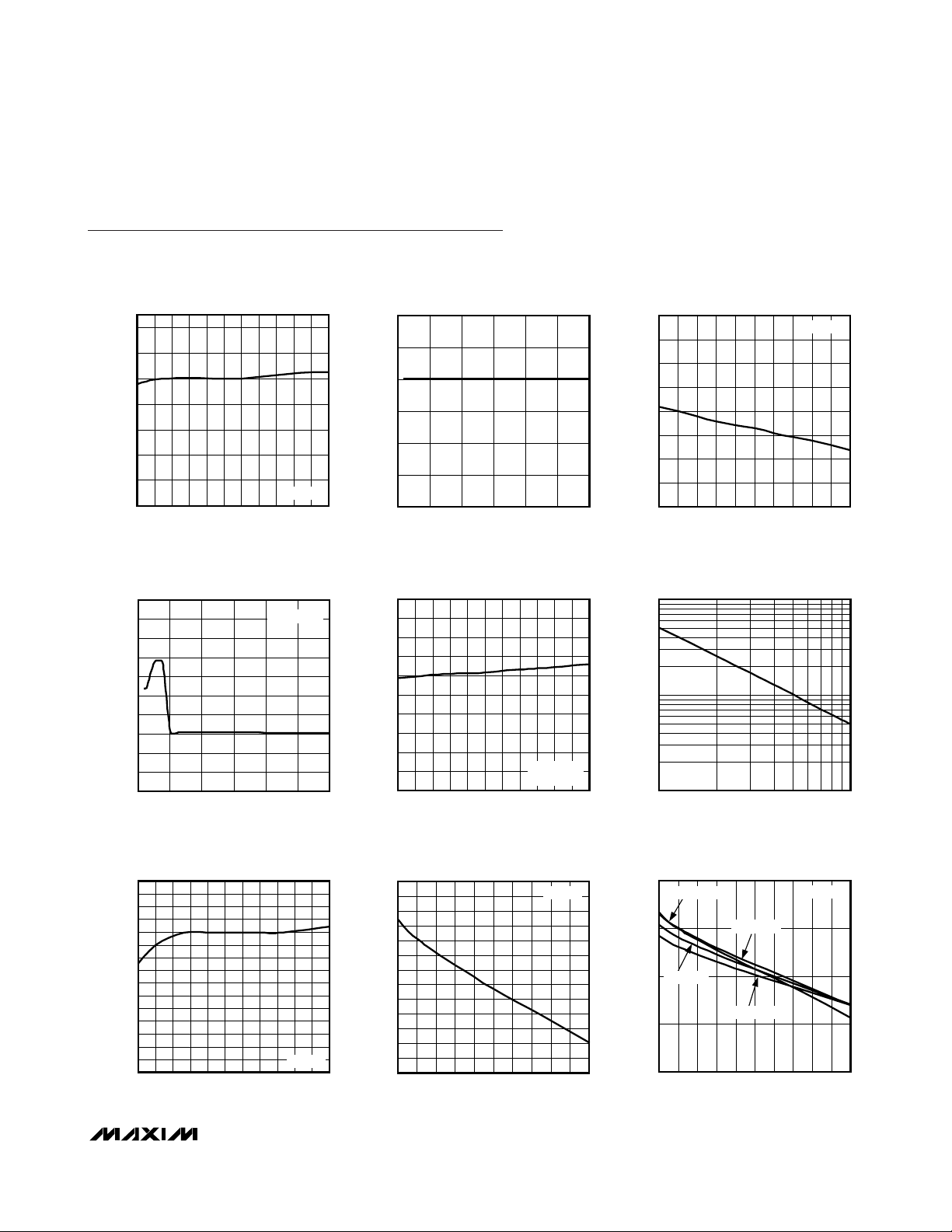

V

(V)

Typical Operating Characteristics

(VIN= VHV= 12V, V

UVEN

= 5V, VLV= V

PWMDIM

= SGND, C

VCC

= 4.7µF, C

LCV

= 100nF, C

REF

= 100nF, R

SENSE+

= 0.1Ω,

R

RT

= 10kΩ, TA= +25°C, unless otherwise noted.)

V

vs. TEMPERATURE

REF

3.74

3.72

3.70

(V)

3.68

REF

V

3.66

3.64

3.62

3.60

-40 125

TEMPERATURE (°C)

VIN = 12V

11095-25 -10 5 35 50 6520 80

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

20

18

16

14

12

10

8

6

SUPPLY CURRENT (mA)

4

2

0

428

SUPPLY VOLTAGE (V)

PWMDIM = 0

242016128

3.80

3.75

MAX16834 toc01

3.70

(V)

3.65

REF

V

3.60

3.55

3.50

10

9

MAX16834 toc04

8

7

6

5

4

3

SUPPLY CURRENT (mA)

2

1

0

V

REF

428

vs. TEMPERATURE

-40 125

vs. SUPPLY VOLTAGE

SUPPLY VOLTAGE (V)

SUPPLY CURRENT

VIN = 12V

PWMDIM = 0

TEMPERATURE (°C)

242016128

1109565 80-10 5 20 35 50-25

3.7020

3.7015

MAX16834 toc02

3.7010

3.7005

3.7000

REF

3.6995

3.6990

3.6985

3.6980

100

MAX16834 toc05

10

RT (kΩ)

1

V

vs. I

REF

010

I

(mA)

REF

RT vs. SWITCHING FREQUENCY

VIN = 12V

SWITCHING FREQUENCY (kHz)

REF

VIN = 12V

MAX16834 toc03

981 2 3 5 64 7

MAX16834 toc06

1000100

SWITCHING FREQUENCY

605

604

603

602

601

600

599

598

597

596

595

594

SWITCHING FREQUENCY (kHz)

593

592

591

590

-40 125

TEMPERATURE (°C)

VIN = 12V

1109565 80-10 5 20 35 50-25

MAX16834 toc07

7.16

7.14

7.12

7.10

7.08

7.06

(V)

7.04

CC

7.02

V

7.00

6.98

6.96

6.94

6.92

6.90

0100

vs. TEMPERATURE

VCC vs. I

ICC (mA)

CC

VIN = 12V

908060 7020 30 40 5010

MAX16834 toc08

7.2

TA = +125°C

7.1

(V)

7.0

TA = +25°C

CC

V

6.9

6.8

0100

VCC vs. I

TA = +100°C

TA = -40°C

ICC (mA)

CC

VIN = 12V

MAX16834 toc09

908070605040302010

Page 6

Pin Description

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

6 _______________________________________________________________________________________

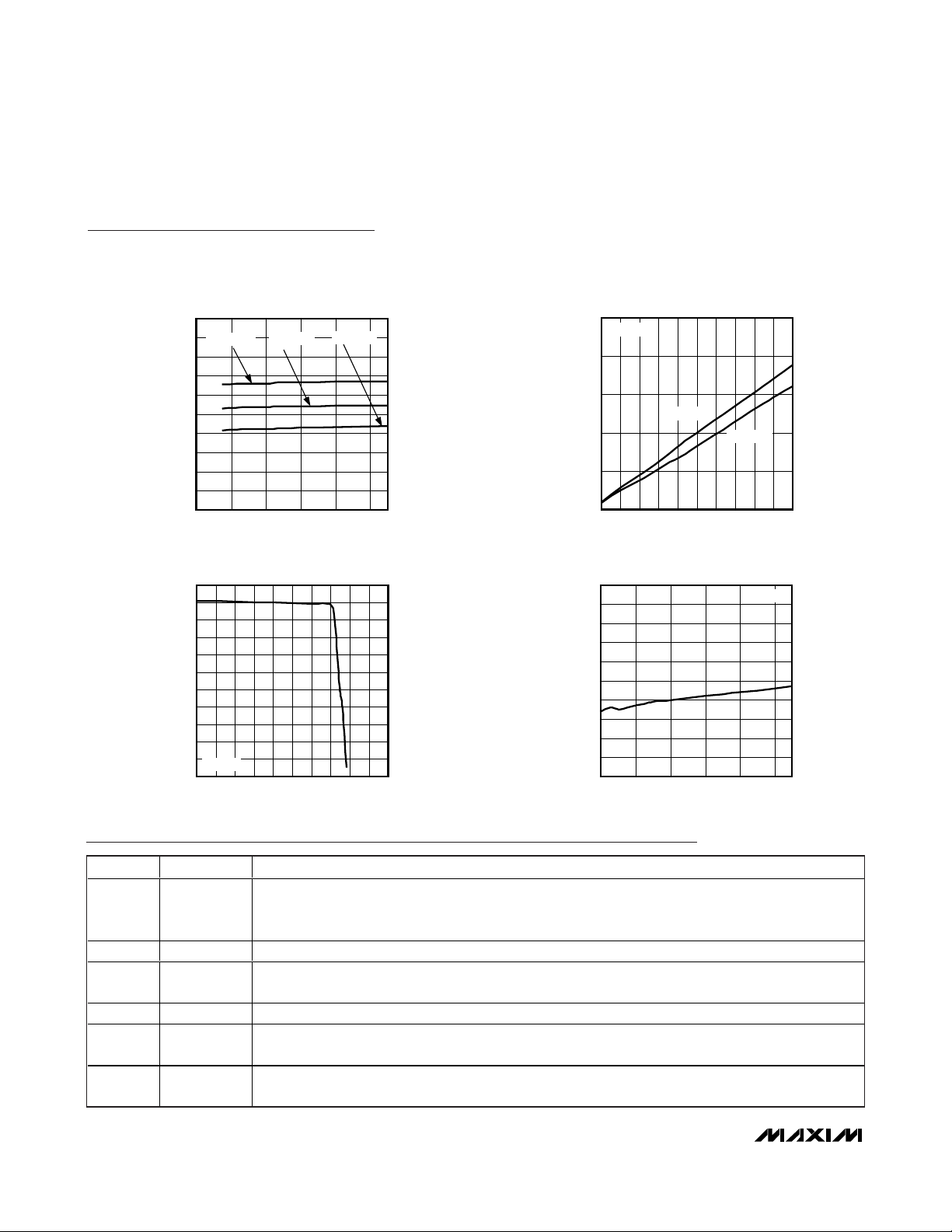

Typical Operating Characteristics (continued)

(VIN= VHV= 12V, V

UVEN

= 5V, VLV= V

PWMDIM

= SGND, C

VCC

= 4.7µF, C

LCV

= 100nF, C

REF

= 100nF, R

SENSE+

= 0.1Ω,

R

RT

= 10kΩ, TA= +25°C, unless otherwise noted.)

VCC vs. V

IN

MAX16834 toc10

VIN (V)

V

CC

(V)

26

22

1814

10

7.02

7.04

7.06

7.08

7.10

7.12

7.14

7.16

7.18

7.20

7.00

6

TA = +125°C

TA = +25°C

TA = -40°C

NDRV RISE/FALL TIME

vs. CAPACITANCE

MAX16834 toc11

CAPACITANCE (nF)

NDRV RISE TIME (ns)

987654321

10

20

30

40

50

0

010

VIN = 12V

RISE TIME

FALL TIME

V

CLV

vs. V

HV

MAX16834 toc13

VHV (V)

V

CLV

(V)

26

22

18

14

10

5.01

5.02

5.03

5.04

5.05

5.06

5.07

5.08

5.09

5.10

5.00

6

VIN = 12V

V

CLV

vs. I

CLV

MAX16834 toc12

I

CLV

(mA)

V

CLV

(V)

4.54.03.0 3.51.0 1.5 2.0 2.50.5

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

5.50

0

05.0

VIN = 12V

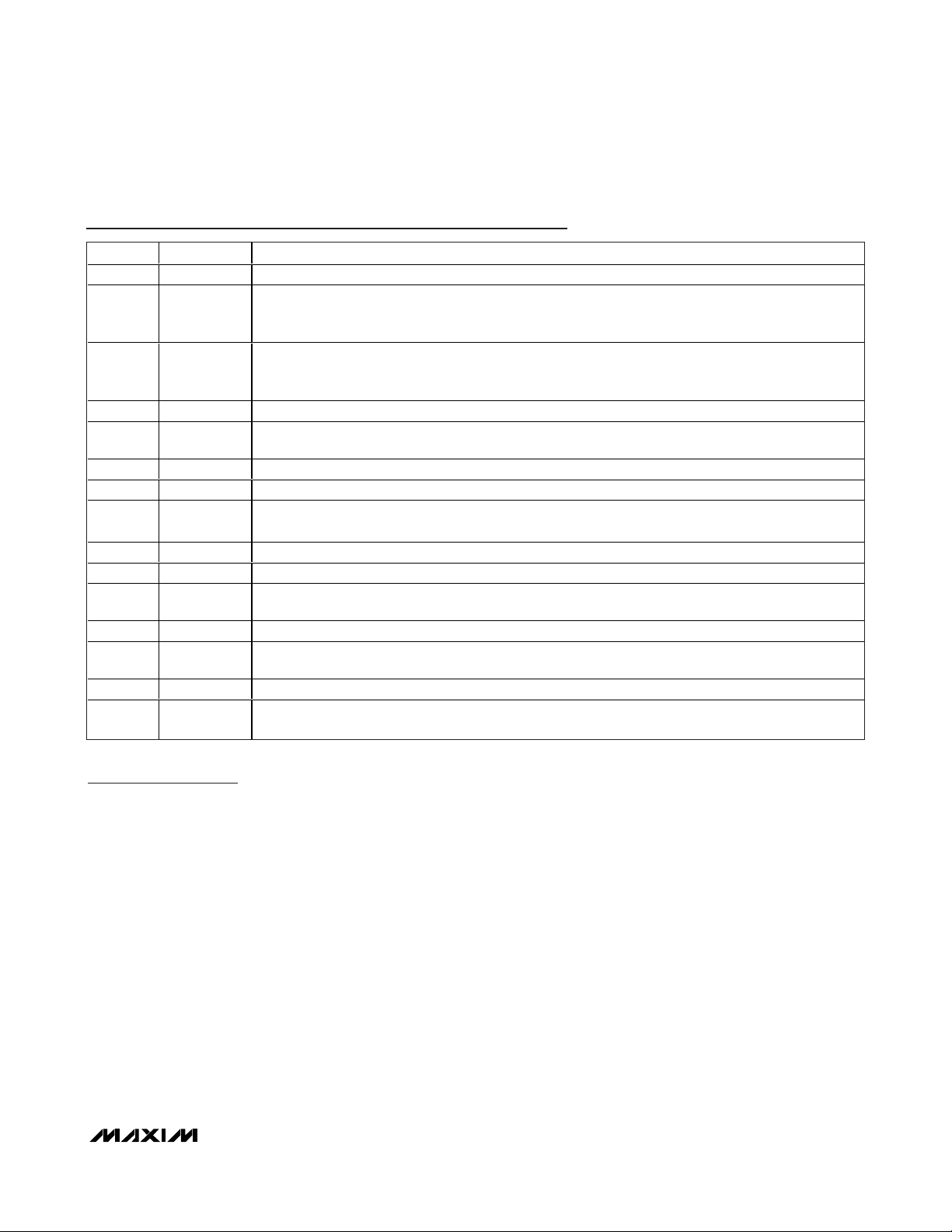

PIN NAME FUNCTION

LED-String Overvoltage Protection Input. Connect a resistive voltage-divider between the positive

1 OVP+

2 SGND Signal Ground

3 COMP

4 REF 3.7V Reference Output Voltage. Bypass REF to SGND with a 0.1µF to 0.22µF ceramic capacitor.

5 REFI

6SC

output, OVP+, and LV to set the overvoltage threshold. OVP+ has a 1.435V threshold voltage with a

200mV hysteresis.

Error-Amplifier Output. Connect an RC network from COMP to SGND for stable operation. See the

Feedback Compensation section.

Current Reference Input. V

provides a reference voltage for the current-sense amplifier to set the

REFI

LED current.

Current-Mode Slope Compensation Setting. Connect to an appropriate external capacitor from SC to

SGND to generate a ramp signal for stable operation.

Page 7

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

_______________________________________________________________________________________ 7

Pin Description (continued)

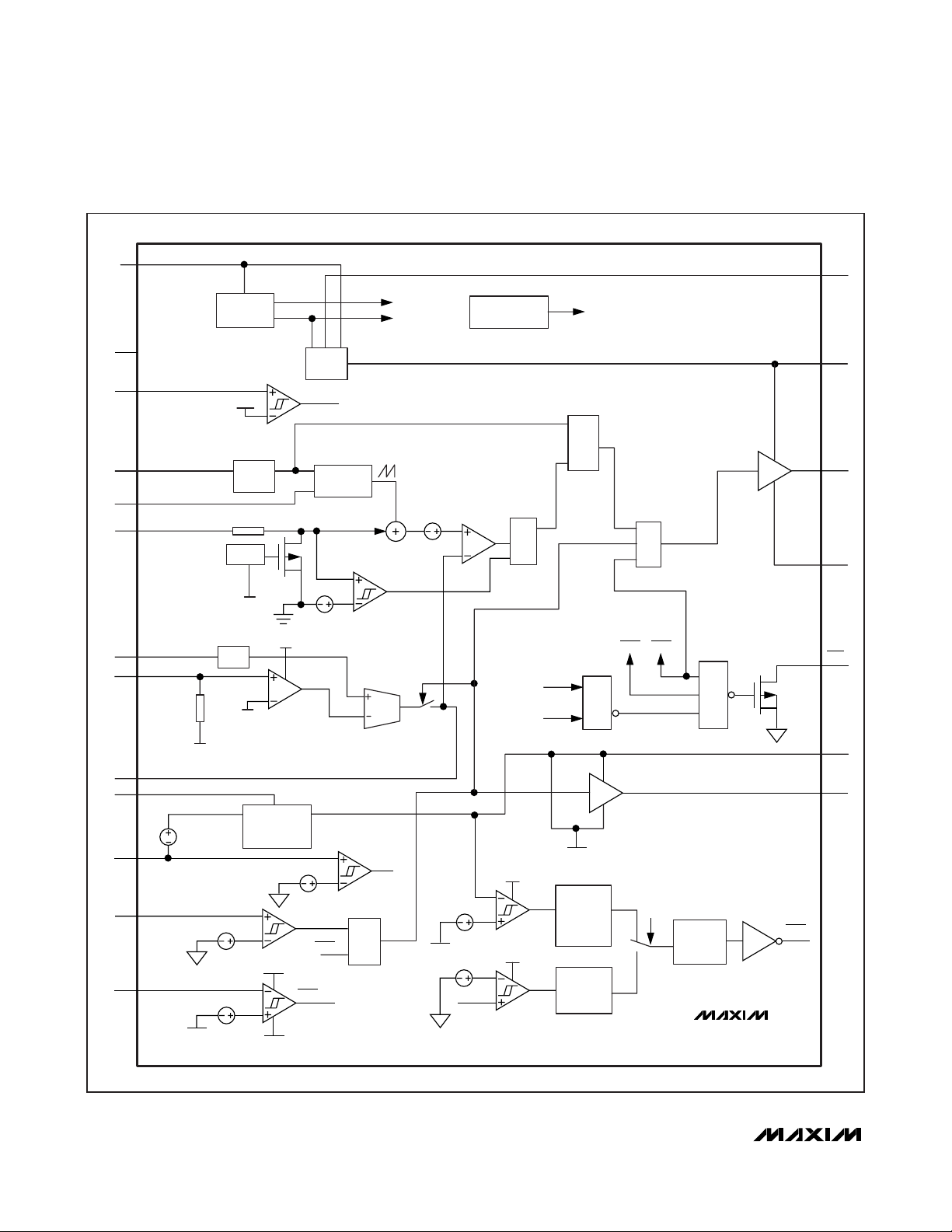

Detailed Description

The MAX16834 is a current-mode, high-brightness LED

(HB LED) driver designed to control a single-string LED

current regulator with two external n-channel MOSFETs.

The MAX16834 integrates all the building blocks necessary to implement a fixed-frequency HB LED driver

with wide-range dimming control. The MAX16834

allows implementation of different converter topologies

such as SEPIC, boost, buck-boost, or high-side buck

current regulator.

The MAX16834 features a constant-frequency, peak-current-mode control with programmable slope compensation to control the duty cycle of the PWM controller. A

dimming driver offers a wide-range dimming control for

the external n-channel MOSFET in series with the LED

string. In addition to PWM dimming, the MAX16834

allows for analog dimming of LED current.

The MAX16834 switching frequency (100kHz to 1MHz)

is adjustable using a single resistor from RT/SYNC. The

MAX16834 disables the internal oscillator and synchronizes if an external clock is applied to RT/SYNC. The

switching MOSFET driver sinks and sources up to 3A,

making it suitable for high-power MOSFETs driving in

HB LED applications, and the dimming control allows

for wide PWM dimming at frequencies up to 20kHz.

The MAX16834 is suitable for boost and buck-boost

LED drivers (Figures 2 and 3).

The MAX16834 operates over a wide 4.75V to 28V supply range. Additional features include external

enable/disable input, an on-chip oscillator, fault indicator output (FLT) for LED open/short or overtemperature

conditions, and an overvoltage protection circuit for

true differential overvoltage protection (Figure 1).

The MAX16834 is also suitable for DC-DC converter

applications such as boost or buck-boost (Figures 6

and 7). Other applications include boost LED drivers

with automotive load dump protection (Figure 4) and

high-side buck LED drivers (Figure 5).

PIN NAME FUNCTION

7 FLT Active-Low, Open-Drain Fault Indicator Output. See the Fault Indicator (

Resistor-Programmable Switching Frequency Setting/Sync Control Input. Connect a resistor from

8 RT/SYNC

9 UVEN

10 PWMDIM PWM Dimming Input. Connect to an external PWM signal for dimming operation.

11 CS

12 PGND Power Ground

13 NDRV External n-Channel Gate-Driver Output

14 V

15 IN Positive Power-Supply Input. Bypass to PGND with at least a 0.1µF ceramic capacitor.

16 HV High-Side Positive Supply Input Referred to LV. HV provides power to high-side linear regulator CLV.

17 CLV

18 DIMOUT External Dimming MOSFET Gate Driver. DIMOUT is capable of sinking/sourcing 50mA.

19 LV

20 SENSE+ LED Current-Sense Positive Input

—EP

CC

RT/SYNC to SGND to set the switching frequency. Drive RT/SYNC to synchronize the switching

frequency with an external clock.

Undervoltage-Lockout (UVLO) Threshold/Enable Input. UVEN is a dual-function adjustable UVLO

threshold input with an enable feature. Connect UVEN to VIN through a resistive voltage-divider to

program the UVLO threshold. Observe the absolute maximum value for this pin.

Current-Sense Amplifier Positive Input. Connect a resistor from CS to PGND to set the inductor peak

current limit.

7V Low-Dropout Voltage Regulator. Bypass to PGND with at least a 1µF low-ESR ceramic capacitor.

provides power to the n-channel gate driver (NDRV).

V

CC

5V High-Side Regulator Output. CLV provides power to the dimming MOSFET driver. Connect a 0.1µF

to 1µF ceramic capacitor from CLV to LV for stable operation.

High-Side Reference Voltage Input. Connect to SGND for boost configuration. Connect to IN for buckboost configuration.

Exposed Pad. Connect EP to a large-area contiguous copper ground plane for effective power

dissipation. Do not use as the main IC ground connection. EP must be connected to SGND.

FLT

) section.

Page 8

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

8 _______________________________________________________________________________________

Figure 1. Internal Block Diagram

IN

SGND

UVEN

RT/SYNC

SC

CS

REFI

SENSE+

1kΩ

V

LV

COMP

HV

V

LV

PWMDIM

OVP+

BG

V

REFERENCE

V

BG

OSC

5kΩ

BLANK

NDRVB

LPF

V

LV

HIGH-SIDE

REGULATOR

BG

V

AV = 9.9

5V

V

HV

REF

V

FLTA

7V

LDO

UVLO

RAMP

GENERATOR

CURRENT-LIMIT

COMPARATOR

0.3V

LED CURRENTSENSE AMPLIFIERS

LV REFERENCE

SWITCH

BG

FLTB

ERROR

AMPLIFIER

g

REFHI

AND

TO

INTERNAL

CIRCUITRY

m

0.6V

V

LV

TEMPERATURE

PWM

COMP

4.3V

0.3V

SENSE+

SENSE

V

OR

PWMDIM

V

IN

REF

OT

OT

S

Q

R

AND

V

LV

128 TOSC

ERROR

REJECT

DELAY

5µs ERROR

REJECT

DELAY

AND

REFHI

FLTAFLTB

NDRVB

4096 TOSC

HICCUP

TIMER

AND

FLTB

REF

V

CC

NDRV

PGND

FLT

CLV

DIMOUT

V

BG

V

LV

V

LV

MAX16834

Page 9

MAX16834

Undervoltage Lockout/Enable

The MAX16834 features an adjustable UVLO using the

enable input (UVEN). Connect UVEN to VINthrough a

resistive divider to set the UVLO threshold. The

MAX16834 is enabled when the V

UVEN

exceeds the

1.435V (typ) threshold. See the

Setting the UVLO

Threshold

section for more information.

UVEN also functions as an enable/disable input to the

device. Drive UVEN low to disable the output and high

to enable the output.

Reference Voltage (REF)

The MAX16834 features a 3.7V reference output, REF.

REF provides power to most of the internal circuit blocks

except for the output drivers and is capable of sourcing

1mA to external circuits. Connect a 0.1µF to 0.22µF

ceramic capacitor from REF to SGND. Connect REF to

REFI through a resistive divider to set the LED current.

Reference Input (REFI)

The output current is proportional to the voltage at

REFI. Applying an external DC voltage at REFI or using

a potentiometer from REF to SGND allows analog dimming of the output current.

High-Side Reference Voltage Input (LV)

LV is a reference input. Connect LV to SGND for boost

and SEPIC topologies. Connect LV to IN for buck-boost

and high-side buck topologies.

Dimming Driver Regulator

Input Voltage (HV)

The voltage at HV provides the input voltage for the

dimming driver regulator. For boost or SEPIC topology,

connect HV either to IN or to VCC. For buck-boost, connect HV to a voltage higher than IN. The voltage at HV

must not exceed 28V with respect to PGND. For the

high-side buck, connect HV to IN.

Dimming MOSFET Driver (DIMOUT)

The MAX16834 requires an external n-channel MOSFET

for PWM dimming. Connect the gate of the MOSFET to

the output of the dimming driver, DIMOUT, for normal

operation. The dimming driver is capable of sinking or

sourcing up to 50mA of current.

n-Channel MOSFET Switch Driver (NDRV)

The MAX16834 drives an external n-channel switching

MOSFET. NDRV swings between VCCand PGND.

NDRV is capable of sinking/sourcing 3A of peak current,

allowing the MAX16834 to switch MOSFETs in highpower applications. The average current demanded

from the supply to drive the external MOSFET depends

on the total gate charge (QG) and the operating

frequency of the converter, fSW. Use the following equation to calculate the driver supply current I

NDRV

required for the switching MOSFET:

I

NDRV

= QGx f

SW

Pulse Dimming Inputs (PWMDIM)

The MAX16834 offers a dimming input (PWMDIM) for

pulse-width modulating the output current. PWM dimming can be achieved by driving PWMDIM with a pulsating voltage source. When the voltage at PWMDIM is

greater than 1.435V, the PWM dimming MOSFET turns

on and when the voltage on PWMDIM is below 1.235V,

the PWM dimming MOSFET turns off.

High-Side Linear Regulator (V

CLV

)

The MAX16834’s 5V high-side regulator (CLV) powers

up the dimming MOSFET driver. V

CLV

is measured with

respect to LV and sources up to 2mA of current.

Bypass CLV to LV with a 0.1µF to 1µF low-ESR ceramic

capacitor. The maximum voltage on CLV with respect

to PGND must not exceed 28V. This limits the input voltage for buck-boost topology.

Low-Side Linear Regulator (VCC)

The MAX16834’s 7V low-side linear regulator (VCC) powers up the switching MOSFET driver with sourcing capability of up to 50mA. Use at least a 1µF low-ESR ceramic

capacitor from VCCto PGND for stable operation.

LED Current-Sense Input (SENSE+)

The differential voltage from SENSE+ to LV is fed to an

internal current-sense amplifier. This amplified signal is

then connected to the negative input of the transconductance error amplifier. The voltage gain factor of this

amplifier is 9.9 (typ).

Internal Transconductance Error Amplifier

The MAX16834 has a built-in transconductance amplifier used to amplify the error signal inside the feedback

loop. The amplified current-sense signal is connected

to the negative input of the gmamplifier with the current

reference connected to REFI. The output of the op amp

is controlled by the input at PWMDIM. When the signal

at PWMDIM is high, the output of the op amp connects

to COMP; when the signal at PWMDIM is low, the output of the op amp disconnects from COMP to preserve

the charge on the compensation capacitor. When the

voltage at PWMDIM goes high, the voltage on the compensation capacitor forces the converter into a steady

state. COMP is connected to the negative input of the

PWM comparator with CMOS inputs, which draw very

little current from the compensation capacitor at COMP

and thus prevent discharge of the compensation

capacitor when the PWMDIM input is low.

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

_______________________________________________________________________________________ 9

Page 10

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

10 ______________________________________________________________________________________

Internal Oscillator

The internal oscillator of the MAX16834 is programmable from 100kHz to 1MHz using a single resistor at

RT/SYNC. Use the following formula to calculate the

switching frequency:

where RT is the resistor from RT/SYNC to SGND.

The MAX16834 synchronizes to an external clock signal

at RT/SYNC. The application of an external clock disables the internal oscillator allowing the MAX16834 to

use the external clock for switching operation. The

internal oscillator is enabled if the external clock is

absent for more than 50µs. The synchronizing pulse

minimum width for proper synchronization is 200ns.

Switching MOSFET

Current-Sense Input (CS)

CS is part of the current-mode control loop. The switching control uses the voltage on CS, set by R

CS

, to terminate the on pulse width of the switching cycle, thus

achieving peak current-mode control. Internal leadingedge blanking is provided to prevent premature turn-off

of the switching MOSFET in each switching cycle.

Slope Compensation (SC)

The MAX16834 uses an internal-ramp generator for

slope compensation. The ramp signal also resets at the

beginning of each cycle and slews at the rate programmed by the external capacitor connected at SC.

The current source charging the capacitor is 100µA.

Overvoltage Protection (OVP+)

OVP+ sets the overvoltage threshold limit across the

LEDs. Use a resistive divider between output OVP+

and LV to set the overvoltage threshold limit. An internal

overvoltage protection comparator senses the differential voltage across OVP+ and LV. If the differential voltage is greater than 1.435V, NDRV is disabled and FLT

asserts. When the differential voltage drops by 200mV,

NDRV is enabled and FLT deasserts. The PWM dim-

ming MOSFET is still controlled by the PWMDIM input.

Fault Indicator (

FLT

)

The MAX16834 features an active-low, open-drain fault

indicator (FLT). FLT asserts when one of the following

occurs:

1) Overvoltage across the LED string

2) Short-circuit condition across the LED string, or

3) Overtemperature condition

When the output voltage drops below the overvoltage

set point minus the hysteresis, FLT deasserts. Similarly

during the short-circuit period, the fault signal

deasserts when the dimming MOSFET is on, which

happens every hiccup cycle during short circuit. During

overtemperature fault, the FLT signal is the inverse of

the PWM input.

Applications Information

Setting the UVLO Threshold

The UVLO threshold is set by resistors R1 and R2 (see

Figure 2). The MAX16834 turns on when the voltage

across R2 exceeds 1.435V, the UVLO threshold. Use

the following equation to set the desired UVLO threshold:

In a typical application, use a 10kΩ resistor for R2 and

then calculate R1 based on the desired UVLO threshold.

Setting the Overvoltage Threshold

The overvoltage threshold is set by resistors R4 and R9

(see Figure 2). The overvoltage circuit in the MAX16834

is activated when the voltage on OVP+ with respect to

LV exceeds 1.435V. Use the following equation to set

the desired overvoltage threshold:

Programming the LED Current

The LED current is programmed using the voltage on

REFI and the LED current-sense resistor R10 (see

Figure 2). The current is given by:

where V

REF

is 3.7V and the resistors R5, R6, and R10

are in ohms. The regulation voltage on the LED currentsense resistor must not exceed 0.3V to prevent activation of the LED short-circuit protection circuit.

5000k

f (kHz)

OSC

=×

RT(k )

Ω

Ω

(kHz )

VVRRR

=+1 435 1 2 2.( )/

UVEN

VVRRR

=+1 435 4 9 9.( )/

OV

VR

×

I

=

LED

REF

RRR

×+×

10 6 5 9 9().

5

A

()

Page 11

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

______________________________________________________________________________________ 11

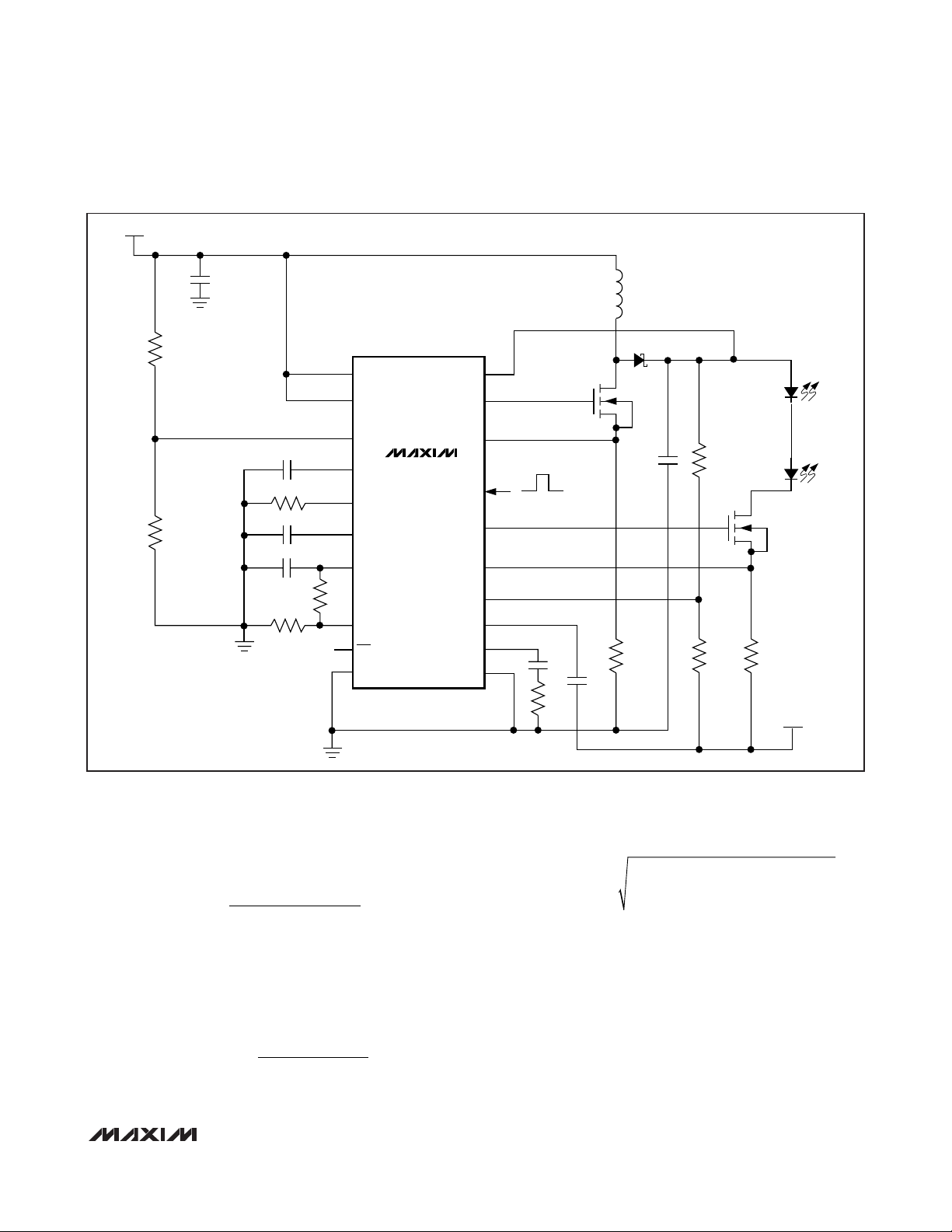

Boost Configuration

In the boost converter (Figure 2), the average inductor

current varies with the line voltage. The maximum average current occurs at the lowest line voltage. For the

boost converter, the average inductor current is equal

to the input current.

Calculate maximum duty cycle using the below equation.

where V

LED

is the forward voltage of the LED string in

volts, VDis the forward drop of the rectifier diode D1 in

volts (approximately 0.6V), V

INMIN

is the minimum input

supply voltage in volts, and V

FET

is the average drain to

source voltage of the MOSFET Q1 in volts when it is on.

Use an approximate value of 0.2V initially to calculate

D

MAX

. A more accurate value of the maximum duty

cycle can be calculated once the power MOSFET is

selected based on the maximum inductor current.

Use the following equations to calculate the maximum

average inductor current IL

AVG

, peak-to-peak inductor

current ripple ∆IL, and the peak inductor current ILPin

amperes:

Figure 2. Boost LED Driver

V

IN

C1

L1

R1

LV

IN

UVEN

C2

R3

C5

R2

C4

R5

HV

MAX16834

SC

RT/SYNC

V

CC

REF

R6

REFI

SGND

FLT

NDRV

CS

PWMDIM

DIMOUT

SENSE+

OVP+

CLV

COMP

PGND

Q1

ON

OFF

C7

R7

D1

C3

R4

Q2

R8

C6

R9

LED+

LEDs

LED-

R10

VVV

+−

LED D

=

VVV

+−

LEDDFET

D

MAX

INMIN

I

IL

AVG

LED

=

D

−1

MAX

Page 12

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

12 ______________________________________________________________________________________

Allowing the peak-to-peak inductor ripple (∆IL) to be

±30% of the average inductor current:

and

The inductance value (L) of the inductor L1 in henries

(H) is calculated as:

where fSWis the switching frequency in hertz, V

INMIN

and V

FET

are in volts, and ∆IL is in amperes.

Choose an inductor that has a minimum inductance

greater than the calculated value. The current rating of

the inductor should be higher than ILPat the operating

temperature.

Buck-Boost Configuration

In the buck-boost LED driver (Figure 3), the average

inductor current is equal to the input current plus the

LED current.

Calculate maximum duty cycle using the below equation:

where V

LED

is the forward voltage of the LED string in

volts, VDis the forward drop of the rectifier diode D1

(approximately 0.6V) in volts, V

INMIN

is the minimum

input supply voltage in volts, and V

FET

is the average

drain to source voltage of the MOSFET Q1 in volts when

it is on. Use an approximate value of 0.2V initially to calculate D

MAX

. A more accurate value of maximum duty

cycle can be calculated once the power MOSFET is

selected based on the maximum inductor current.

Use the below equations to calculate the maximum

average inductor current IL

AVG

, peak-to-peak inductor

current ripple ∆IL, and the peak inductor current ILPin

amperes:

Allowing the peak-to-peak inductor ripple ∆I

L

to be

±30% of the average inductor current:

The inductance value (L) of the inductor L1 in henries is

calculated as:

where f

SW

is the switching frequency in hertz, V

INMIN

and V

FET

are in volts, and ∆IL is in amperes. Choose an

inductor that has a minimum inductance greater than

the calculated value.

Peak Current-Sense Resistor (R8)

The value of the switch current-sense resistor R8 for the

boost and buck-boost configurations is calculated as

follows:

where 0.25V is the minimum peak current-sense threshold, ILPis the peak inductor current in amperes, and

the factor 1.25 provides a 25% margin to account for

tolerances. The worst cycle-by-cycle current limiter triggers at 350mV (max). The I

SAT

of the inductor should

be higher than 0.35V/R8.

Output Capacitor

The function of the output capacitor is to reduce the

output ripple to acceptable levels. The ESR, ESL, and

the bulk capacitance of the output capacitor contribute

to the output ripple. In most applications, the output

ESR and ESL effects can be dramatically reduced by

using low-ESR ceramic capacitors. To reduce the ESL

and ESR effects, connect multiple ceramic capacitors

in parallel to achieve the required bulk capacitance. To

minimize audible noise generated by the ceramic

capacitors during PWM dimming, it may be necessary

to minimize the number of ceramic capacitors on the

output. In these cases an additional electrolytic or tantalum capacitor provides most of the bulk capacitance.

Boost and buck-boost configurations: The calculation of the output capacitance is the same for both

boost and buck-boost configurations. The output ripple

is caused by the ESR and the bulk capacitance of the

output capacitor if the ESL effect is considered negligible. For simplicity, assume that the contributions from

∆∆IIL

∆IIL

=××03 2.

LAVG

=××

LAVG

IL IL

=+

PAVG

03 2

.

I

L

2

IL IL

=+

PAVG

I

∆

L

2

VVD

()

L

=

−×

INMIN FET MAX

fI

×

∆

SW L

VV

+

D

=

MAX

VVV V

LED D INMIN FET

IL

AVG

LED D

++ −

I

LED

=

D

−1

MAX

VVD

()

L

=

−×

INMIN FET MAX

fI

×

∆

SW L

025

R

8

.

=

IL

(.)

P

×

125

Ω

Page 13

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

______________________________________________________________________________________ 13

ESR and the bulk capacitance are equal, allowing 50%

of the ripple for the bulk capacitance. The capacitance

is given by:

where I

LED

is in amperes, C

OUT

is in farads, fSWis in

hertz, and ∆V

OUTRIPPLE

is in volts. The remaining 50%

of allowable ripple is for the ESR of the output capacitor. Based on this, the ESR of the output capacitor is

given by:

where IL

P

is the peak inductor current in amperes.

Use the below equation to calculate the RMS current

rating of the output capacitor:

Input Capacitor

The input filter capacitor bypasses the ripple current

drawn by the converter and reduces the amplitude of

high-frequency current conducted to the input supply.

The ESR, ESL, and the bulk capacitance of the input

capacitor contribute to the input ripple. Use a low-ESR

input capacitor that can handle the maximum input

RMS ripple current from the converter.

For the boost configuration, the input current is the

same as the inductor current. For buck-boost

Figure 3. Buck-Boost LED Driver (V

LED+

< 28V)

V

IN

C1

R1

LV

IN

C2

R3

C5

R2

C4

R5

UVEN

SC

MAX16834

RT/SYNC

V

CC

REF

R6

REFI

FLT

SGND

NDRV

PWMDIM

DIMOUT

SENSE+

OVP+

CLV

COMP

PGND

HV

Q1

CS

ON

OFF

C7

R7

L1

D1

C3

R8

C6

R4

Q2

R9

R10

LED+

LED-

V

LEDs

IN

ID

××

2

LED MAX

≥

Vf

∆

OUTRIPPLE SW

×

C

OUT

V

∆Ω()

<

OUTRIPPLE

IL

×

()2

P

ESR

COUT

(IL (1 D )) D

I

COUT(RMS)

=

AVG MAX

IL

+-(

VVG

A

××

××DD

MAX MAX

2

MAX

2

)( )

1-

Page 14

MAX16834

configuration, the input current is the inductor current

minus the LED current. But for both configurations, the

ripple current that the input filter capacitor has to supply is the same as the inductor ripple current with the

condition that the output filter capacitor should be connected to ground for buck-boost configuration. This

reduces the size of the input capacitor, as the inductor

current is continuous with maximum ±30% ripple.

Neglecting the effect of LED current ripple, the calculation of the input capacitor for boost as well as buckboost configurations is the same.

Neglecting the effect of the ESL, the ESR, and the bulk

capacitance at the input contributes to the input voltage

ripple. For simplicity, assume that the contribution from

the ESR and the bulk capacitance is equal. This allows

50% of the ripple for the bulk capacitance. The capacitance is given by:

where ∆ILis in amperes, CINis in farads, fSWis in hertz,

and ∆VINis in volts. The remaining 50% of allowable

ripple is for the ESR of the output capacitor. Based on

this, the ESR of the input capacitor is given by:

where ∆IL is in amperes, ESR

CIN

is in ohms, and ∆V

IN

is in volts.

Use the below equation to calculate the RMS current

rating of the input capacitor:

Slope Compensation

Slope compensation should be added to converters

with peak current-mode control operating in continuous

conduction mode with more than 50% duty cycle to

avoid current loop instability and subharmonic oscillations. The minimum amount of slope added to the peak

inductor current to stabilize the current control loop is

half of the falling slope of the inductor.

In the MAX16834, the slope compensating ramp is

added to the current-sense signal before it is fed to the

PWM comparator. Connect a capacitor (C2 in the application circuit) from SC to ground for slope compensation. This capacitor is charged with a 100µA current

source and discharged at the beginning of each switching cycle to generate the slope compensation ramp.

The value of the slope compensation capacitor C2 is

calculated as shown below:

Boost configuration:

where C2 is in farads, L is the inductance of the inductor L1 in henries, 100µA is the pullup current from SC,

V

LED

and V

INMIN

are in volts, and R8 is the switch cur-

rent-sense resistor in ohms.

Buck-boost configuration:

where C2 is in farads, L is the inductance of the inductor L1 in henries, 100µA is the pullup current from SC,

V

LED

is in volts, and R8 is the switch current-sense

resistor in ohms.

Selection of Power Semiconductors

Switching MOSFET

The switching MOSFET (Q1) should have a voltage rating sufficient to withstand the maximum output voltage

together with the diode drop of the rectifier diode D1

and any possible overshoot due to ringing caused by

parasitic inductances and capacitances. Use a

MOSFET with a drain-to-source voltage rating higher

than that calculated by the following equations:

Boost configuration:

where VDSis the drain-to-source voltage in volts and

VDis the forward drop of the rectifier diode D1. The factor of 1.2 provides a 20% safety margin.

Buck-boost configuration:

where VDSis the drain-to-source voltage in volts and

VDis the forward drop of the rectifier diode D1. The factor of 1.2 provides a 20% safety margin.

The continuous drain current rating of the selected

MOSFET, when the case temperature is at +70°C,

should be greater than the value calculated by the fol-

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

14 ______________________________________________________________________________________

I

∆

C

≥

IN

ESR

CIN

I

CIN(RMS)

L

Vf

××

∆4

IN SW

V

∆

IN

<

I

×

∆ 2

L

∆I

L

=

3

2

-

L

×× ×

C2

C2

3 100 10

=

(V - V ) R8

LED INMIN

L

×× ×

3 100 10

=

(V ) R8

××

LED

6

××

2

-

6

2

VVV

=+

()

DS LED D

×12.

VVV V

=+ +

()

DS LED INMAX D

×12.

Page 15

lowing equation. The MOSFET must be mounted on a

board as per manufacturer specifications to dissipate

the heat.

The RMS current rating of the switching MOSFET Q1 is

calculated as follows for boost and buck-boost configurations:

where ID

RMS

is the MOSFET Q1’s drain RMS current in

amperes.

The MOSFET Q1 will dissipate power due to both

switching losses as well as conduction losses. The conduction losses in the MOSFET is calculated as follows:

where R

DSON

is the on-resistance of Q1 in ohms with

an assumed junction temperature of +100°C, P

COND

is

in watts, and IL

AVG

is in amperes.

Use the following equations to calculate the switching

losses in the MOSFET:

Boost configuration:

Buck-boost configuration:

where IGONand IG

OFF

are the gate currents of the

MOSFET Q1 in amperes when it is turned on and

turned off, respectively, V

LED

and V

INMAX

are in volts,

IL

AVG

is in amperes, fSWis in hertz, and CGDis the

gate-to-drain MOSFET capacitance in farads.

Choose a MOSFET that has a higher power rating than

that calculated by the following equation when the

MOSFET case temperature is at +70°C:

Rectifier Diode

Use a Schottky diode as the rectifier (D1) for fast

switching and to reduce power dissipation. The selected Schottky diode must have a voltage rating 20%

above the maximum converter output voltage. The maximum converter output voltage is V

LED

in boost configu-

ration and V

LED

+ V

INMAX

in buck-boost configuration.

The current rating of the diode should be greater than

I

D

in the following equation:

Dimming MOSFET

Select a dimming MOSFET (Q2) with continuous current

rating at +70°C, higher than the LED current by 30%.

The drain-to-source voltage rating of the dimming

MOSFET must be higher than V

LED

by 20%.

Feedback Compensation

The LED current control loop comprising of the switching converter, the LED current amplifier, and the error

amplifier should be compensated for stable control of

the LED current. The switching converter small-signal

transfer function has a right half-plane (RHP) zero for

both boost and buck-boost configurations as the inductor current is in continuous conduction mode. The RHP

zero adds a 20dB/decade gain together with a 90°

phase lag, which is difficult to compensate. The easiest

way to avoid this zero is to roll off the loop gain to 0dB

at a frequency less than one-fifth of the RHP zero frequency with a -20dB/decade slope.

The worst-case RHP zero frequency (f

ZRHP

) is calculat-

ed as follows:

Boost configuration:

Buck-boost configuration:

where f

ZRHP

is in hertz, V

LED

is in volts, L is the induc-

tance value of L1 in henries (H), and I

LED

is in amperes.

The switching converter small-signal transfer function

also has an output pole for both boost and buck-boost

configurations. The effective output impedance that

determines the output pole frequency together with the

output filter capacitance is calculated as:

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

______________________________________________________________________________________ 15

ID IL D

⎛

=

()

⎜

RMS AVG MAX

⎝

×

⎞

×213.

⎟

⎠

2

××

PILDR

=

COND AVG MAX DSON

()

⎛

IL V C f

P

SW

AVG LED GD SW

=

⎜

⎝

⎛

11

×+

⎜

IG IG

⎝

ON OF

⎛

IL V V C f

×+ ××

()

P

SW

AVG LED INMAX GD SW

=

⎜

⎝

⎛

1

×

⎜

GGIG

I

⎝

ON OFF

1

+

2

×××

2

⎞

⎟

⎠

⎞

⎟

⎠

FF

2

2

⎞

⎟

⎠

⎞

⎟

⎠

PWP WPW

() () ()=+

TOT COND SW

IIL D

=× ×().115-

DAVG MAX

f

ZRHP

V

=

()12-

LED

××

2LI

π

MAX

LED

D

×

D

×

f

=

ZRHP

2LI

V

π

()12-

LED

×× ×

MAX

LED

D

MAX

Page 16

MAX16834

Boost configuration:

Buck-boost configuration:

where R

LED

is the dynamic impedance (rate of change

of voltage with current) of the LED string at the operating current, R10 is the LED current-sense resistor in

ohms, V

LED

is in volts, and I

LED

is in amperes.

The output pole frequency for both boost and buckboost configurations is calculated as follows:

where f

P2

is in hertz, C

OUT

is the output filter capaci-

tance in farads, R

OUT

is the effective output impedance

in ohms calculated above.

Compensation components R7 and C7 perform two

functions. C7 introduces a low-frequency pole that

introduces a -20dB/decade slope into the loop gain. R7

flattens the gain of the error amplifier for frequencies

above the zero formed by R7 and C7. For compensation, this zero is placed at the output pole frequency f

P2

such that it provides a -20dB/decade slope for frequencies above f

P2

for the complete loop gain.

The value of R7 needed to fix the total loop gain at f

P2

such that the total loop gain crosses 0dB at

-20dB/decade at one-fifth of the RHP zero can be calculated as follows:

where R7 is the compensation resistor in ohms, f

ZRHP

and fP2are in hertz, R8 is the switch current-sense

resistor in ohms, R10 is the LED current-sense resistor

in ohms, factor 9.9 is the gain of the LED current amplifier, and GM

COMP

is the transconductance of the error

amplifier in Siemens.

The value of C7 can be calculated as:

where C7 is in farads, f

P2

is in hertz, and R7 is in ohms.

To minimize switching frequency noise, an additional

capacitor can be added in parallel with the series combination of R7 and C7. The pole from this capacitor and

R7 must be a decade higher than the loop crossover

frequency.

Short-Circuit Protection

Boost Configuration

In the boost configuration (Figure 2), if the LED string is

shorted then the excess current flowing in the LED current-sense resistor will cause NDRV to stop switching.

The input voltage will appear on the output capacitor,

and this causes very high peak currents to flow in the

LED current-sense resistor R10 because the dimming

MOSFET (Q2) is on. Once the voltage across the LED

current-sense resistor exceeds 300mV for more than

5µs, then the dimming MOSFET Q2 turns off and stays

off for 4096 switching clock cycles. At the same time,

NDRV is also off. The MAX16834 goes into the hiccup

mode and recovers from hiccup once the short has

been removed. The power dissipation in the dimming

MOSFET (Q2) is minimized during a short across the

LED string. During the same period, FLT only goes high

when the dimming MOSFET is on.

Buck-Boost Configuration

In the case of the buck-boost configuration (Figure 3),

once an LED string short occurs then the behavior is

different. A short across the LED string causes a high

current spike due to the external capacitors at the output. The regulation loop will cause NDRV to stop

switching. This causes the voltage on HV to drop if its

voltage is derived from LED+. The voltage on CLV will

drop, and this drop is detected after 128 clock cycles.

The dimming MOSFET and the switching MOSFET will

stop switching. It stays off for 4096 clock cycles, and

the cycle repeats itself. The short across the LED string

will cause the MAX16834 to go into a hiccup mode. At

the same time the FLT signal asserts itself for 4096

clock cycles every hiccup cycle. In the case where the

HV voltage is derived from a source different than

LED+, then the LED current will stay in regulation even

during a short across the LED string. In this case, FLT

does not assert itself during the short.

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

16 ______________________________________________________________________________________

R

OUT

()

=

RRIV

()

LED LED LED

10

LED LED

+×+

10

RRV

+×

R

=

OUT

RRID V

()

LED LED MAX

()

LED LED

+×× +

10

10

LLED

RRV

+×

1

××2π

CR

OUT OUT

=

f

P

2

fR

R

7

=

fDR GM

51 1099

××− × ××().

2

PMAX COMP

ZRHP

8

×

C

7

=

1

Rf

××2π

7

P

2

Page 17

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

______________________________________________________________________________________ 17

Figure 4. Boost LED Driver with Automotive Load Dump Protection

V

IN

C1

L1

R1

D2

24V

R2

Q3

C8

C2

R3

C5

C4

R5

LV

IN

UVEN

HV

MAX16834

SC

RT/SYNC

V

CC

REF

R6

REFI

SGND

FLT

NDRV

CS

PWMDIM

DIMOUT

SENSE+

OVP+

CLV

COMP

PGND

Q1

ON

OFF

C7

R7

D1

C3

R4

Q2

R8

C6

R9

R10

LED+

LEDs

LED-

Page 18

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

18 ______________________________________________________________________________________

Figure 5. High-Side Buck LED Driver

V

IN

LED+

C1

R1

R2

D1

LV

IN

UVEN

C2

SC

R3

C5

C4

R6

R5

RT/SYNC

V

CC

REF

REFI

FLT

SGND

MAX16834

NDRV

CS

PWMDIM

DIMOUT

SENSE+

OVP+

CLV

COMP

PGND

HV

Q1

ON

OFF

C7

C6

R7

V

LV

C3

L1

V

LV

R4

Q2

R8

R9

R10

LED-

V

LEDs

LV

Page 19

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

______________________________________________________________________________________ 19

Figure 6. Boost DC-DC Converter

V

IN

C1

L1

V

R1

LV

FLT

D1

OUT

C2

R3

C5

R2

C4

R5

IN

UVEN

HV

MAX16834

SC

RT/SYNC

V

CC

REF

R6

REFI

SGND

NDRV

CS

PWMDIM

DIMOUT

SENSE+

OVP+

CLV

COMP

PGND

V

REF

Q1

C3 R4

R10

C6

R8

R7

OPTIONAL

R9

Page 20

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

20 ______________________________________________________________________________________

Figure 7. Buck-Boost DC-DC Converter

V

IN

C1

L1

R1

R2

LV

IN

C2

R3

C5

C4

R5

UVEN

SC

MAX16834

RT/SYNC

V

CC

REF

R6

REFI

FLT

SGND

HV

NDRV

CS

PWMDIM

DIMOUT

SENSE+

OVP+

CLV

COMP

PGND

Q1

V

REF

N.C.

C6

R7

D1

C3 R4

R9

R8

R11

R10

V

OUT

V

IN

Page 21

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

______________________________________________________________________________________ 21

Layout Recommendations

Typically, there are two sources of noise emission in a

switching power supply: high di/dt loops and high dv/dt

surfaces. For example, traces that carry the drain current often form high di/dt loops. Similarly, the heatsink

of the MOSFET connected to the device drain presents

a dv/dt source; therefore, minimize the surface area of

the heatsink as much as is compatible with the MOSFET power dissipation or shield it. Keep all PCB traces

carrying switching currents as short as possible to minimize current loops. Use ground planes for best results.

Careful PCB layout is critical to achieve low switching

losses and clean, stable operation. Use a multilayer

board whenever possible for better noise immunity and

power dissipation. Follow these guidelines for good

PCB layout:

1) Use a large contiguous copper plane under the

MAX16834 package. Ensure that all heat-dissipating components have adequate cooling.

2) Isolate the power components and high-current

path from the sensitive analog circuitry.

3) Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable, jitter-free operation. Keep switching loops short

such that:

a) The anode of D1 must be connected very close

to the drain of the MOSFET Q1.

b) The cathode of D1 must be connected very

close to C

OUT

.

c) C

OUT

and the current-sense resistor R8 must

be connected directly to the ground plane.

4) Connect PGND and SGND to a star-point configuration.

5) Keep the power traces and load connections short.

This practice is essential for high efficiency. Use

thick copper PCBs (2oz vs. 1oz) to enhance fullload efficiency.

6) Route high-speed switching nodes away from the

sensitive analog areas. Use an internal PCB layer

for the PGND and SGND plane as an EMI shield to

keep radiated noise away from the device, feedback dividers, and analog bypass capacitors.

7) To prevent discharge of the compensation capacitors during the off-time of the dimming cycle,

ensure that the PCB area close to these components has extremely low leakage. Discharge of

these capacitors due to leakage results in reduced

performance of the dimming circuitry.

Page 22

MAX16834

High-Power LED Driver with Integrated High-Side LED

Current Sense and PWM Dimming MOSFET Driver

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

22

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

22

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

20-TQFN-EP T2044-3

21-0139

MAX16834

TQFN

TOP VIEW

19

20

18

17

7

6

8

SGND

REF

REFI

9

OVP+

V

CC

PGND

CS

IN

1+2

DIMOUT

45

15 14 12 11

LV

SENSE+

UVEN

RT/SYNC

FLT

SC

COMP

NDRV

3

13

CLV

16

*EP

*EP = EXPOSED PAD.

10

PWMDIM

HV

Pin Configuration

Chip Information

PROCESS: BiCMOS–DMOS

Loading...

Loading...