Page 1

General Description

The MAX16831 is a current-mode, high-brightness LED

(HBLED) driver designed to control two external

n-channel MOSFETs for the single-string LED current

regulation. The MAX16831 integrates all the building

blocks necessary to implement fixed-frequency HBLED

drivers with wide-range dimming control. The

MAX16831 is configurable to operate as a step-down

(buck), step-up (boost), or step-up/-down (buck-boost)

current regulator.

Current-mode control with leading-edge blanking simplifies control-loop design. Internal slope compensation

stabilizes the current loop when operating at duty cycles

above 50%. The MAX16831 operates over a wide input

voltage range and is capable of withstanding automotive load-dump events. Multiple MAX16831s can be

synchronized to each other or to an external clock. The

MAX16831 includes a floating dimming driver for

brightness control with an external n-channel MOSFET

in series with the LED string.

HBLED drivers using the MAX16831 achieve efficiencies of over 90% in automotive applications. The

MAX16831 also includes a 1.4A source and 2.5A sink

gate driver for driving switching MOSFETs in high-power

LED driver applications, such as front light assemblies.

The dimming control allows for wide PWM dimming at

frequencies up to 2kHz. Higher dimming ratios of up to

1000:1 are achievable at lower dimming frequencies.

The MAX16831 is available in a 32-pin thin QFN package

with exposed pad and operates over the -40°C to

+125°C automotive temperature range.

Applications

Automotive Exterior Lighting:

High-Beam/Low-Beam/Signal Lights

Rear Combination Lights (RCL)

Daytime Running Lights (DRL)

Fog Light and Adaptive Front Light Assemblies

Industrial and Architectural Lighting

Emergency Lighting

Projectors with RGB LED Light Sources

Navigation and Marine Indicators

Features

o Wide Input Range: 6V to 76V With Cold-Start

Operation to 5.5V

o Integrated Differential LED Current-Sense

Amplifier

o Floating Dimming Driver Capable of Driving an

n-Channel MOSFET

o 5% LED Current Accuracy

o 200Hz On-Board Ramp Syncs to External PWM

Dimming Signal

o Programmable Switching Frequency (125kHz to

600kHz) and Synchronization

o Output Overvoltage Load Dump, LED Short,

Overtemperature Protection

o Low 107mV LED Current Sense for High

Efficiency

o Enable/Shutdown Input with Shutdown Current

Below 45µA

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

________________________________________________________________

Maxim Integrated Products

1

19-0809; Rev 0; 4/07

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Ordering Information

+

Denotes lead-free package.

*

EP = Exposed pad.

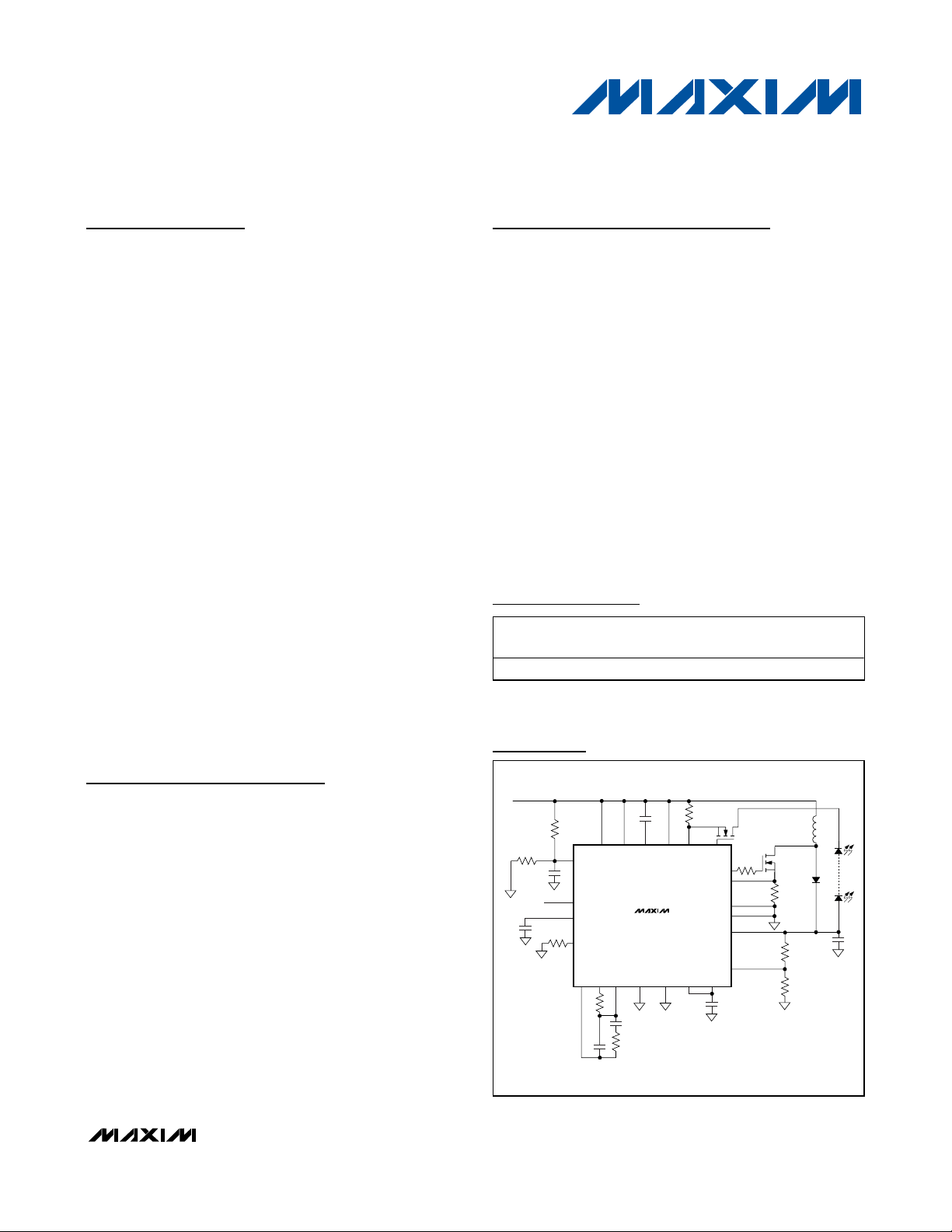

V

IN

DIM

R

CS

C

F

R

T

C

REG1

R

UV2

DRV

DRI

REG1

DIM

CS

V

CC

SNS+

FB

QGND

RTSYNC

CS-

CS+

LO

COMP

REG2

DGT

HI

OV

UVEN

SNS-

AGND

R

SENSE

R2

C2

R

OV1

R

OV2

CLMP

SGND

C

CLMP

C

REG2

R1

C1

R

D

LEDs

BUCK-BOOST CONFIGURATION

R

UV1

C

UVEN

Q

S

MAX16831

Typical Operating Circuits

Pin Configuration appears at end of data sheet.

Typical Operating Circuits continued at end of data sheet.

PART TEMP RANGE

PINPACKAGE

MAX16831ATJ+ -40°C to +125°C 32 TQFN-EP* T3255M-4

PKG

CODE

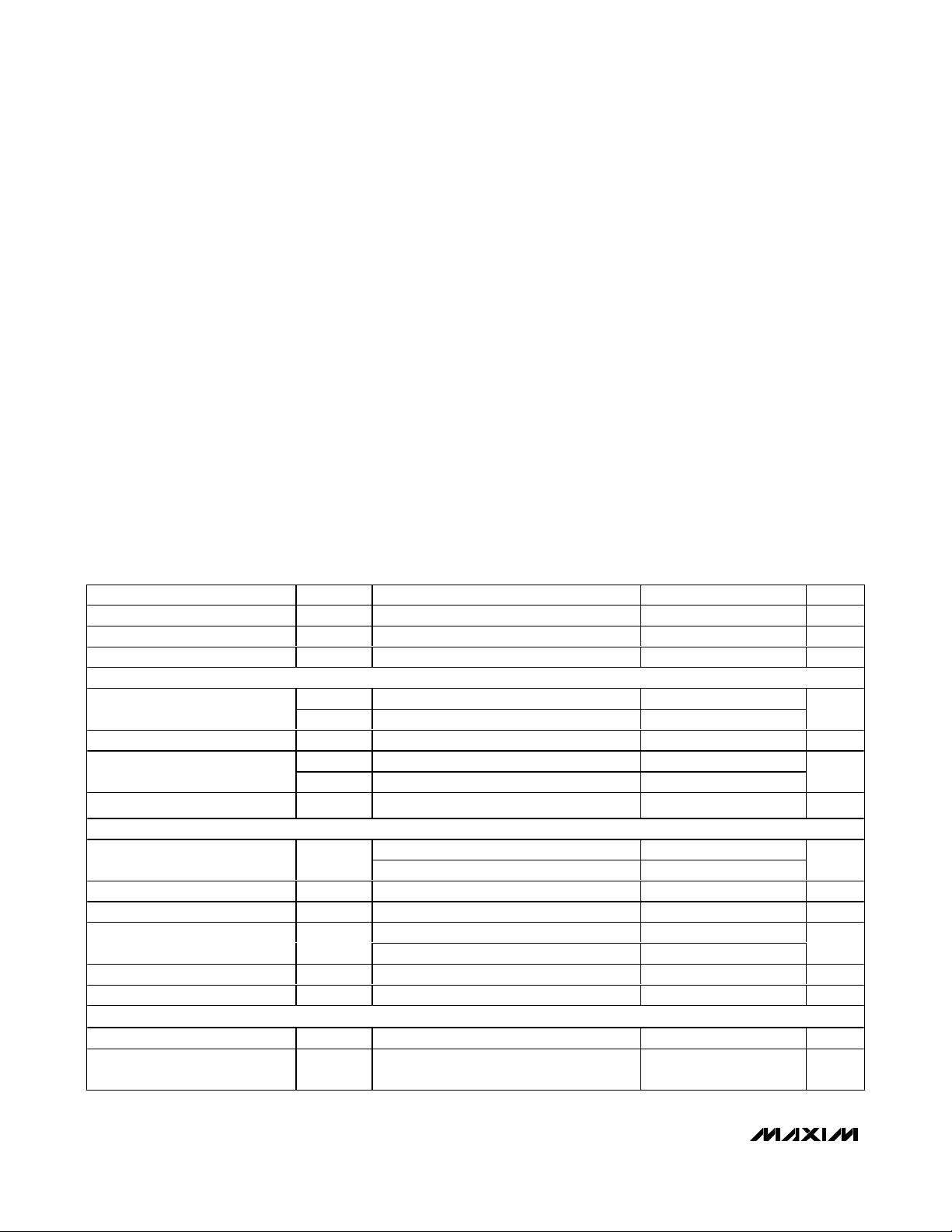

Page 2

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= V

UVEN

= 14V, C

REG1

= 1µF, C

REG2

= 1µF, C

CLMP

= 0.1µF, RT= 25kΩ, TA= TJ = -40°C to +125°C, unless otherwise noted.

Typical specifications are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCC, HI, LO, CLMP to QGND.................................-0.3V to +80V

CS+, CS-, DGT, UVEN to QGND............................-0.3V to +80V

UVEN to QGND ..........................................-0.3V to (V

CC

+ 0.3V)

DRV to SGND .........................................................-0.3V to +18V

DRI, REG2, DIM to AGND ......................................-0.3V to +18V

QGND, SGND to AGND ........................................-0.3V to +0.3V

SNS+ to SNS- ...........................................................-0.3V to +6V

CS, FB, COMP, SNS+, SNS-, OV, REF,

RTSYNC to AGND .................................................-0.3V to +6V

REG1, CLKOUT to AGND ........................................-0.3V to +6V

CS+ to CS- .............................................................-0.3V to +12V

HI to LO ..................................................................-0.3V to +36V

CS+, CS-, DGT, CLMP to LO .................................-0.3V to +12V

CS+, CS-, DGT, CLMP to LO ........................-0.3V to (HI + 0.3V)

HI to CLMP .............................................................-0.3V to +28V

Continuous Power Dissipation* (T

A

= +70°C)

32-Pin TQFN (derate 34.5mW/°C above +70°C) ........2758mW

Thermal Resistance*

θ

JA

.................................................................................29°C/W

θ

JC

................................................................................1.7°C/W

Operating Temperature Range .........................-40°C to +125°C

Maximum Junction Temperature .....................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Reflow Temperature.........................................................+240°C

Lead Temperature (soldering, 10s) .................................+300°C

*As per JEDEC 51 standard, multilayer board (PCB).

Input Voltage Range V

Supply Current I

Shutdown Current I

UVEN

VCC UVLO Threshold

VCC Threshold Hysteresis V

UVEN Threshold

UVEN Input Current I

REGULATORS

REG1 Regulator Output V

REG1 Dropout Voltage I

REG1 Load Regulation ∆V/∆IVCC = 7.5V, 0 ≤ I

REG2 Regulator Output V

REG2 Dropout Voltage I

REG2 Load Regulation ∆V/∆IVCC = 7.5V, 0 ≤ I

HIGH-SIDE REGULATOR (CLMP) (All Voltages Referred to LO) (Note 2)

CLMP UVLO Threshold V

CLMP UVLO Threshold

Hysteresis

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

I

Q

SHDN

V

CC_R

V

CC_F

CC_HYS

V

UVR

V

UVF

UVEN

REG1

REG2

CLMPTHVCLMP

V

CLMPHYS

V

VCC rising 5.5 6.0

VCC falling 5.0 5.5

V

V

V

0 ≤ I

I

7.5V ≤ VCC ≤ 76V, I

VCC = 5.7V, 0 ≤ I

= 0A 2.7 4.5 mA

REG2

≤ 0.8V 25 45 µA

UVEN

rising 1.100 1.244 1.360

UVEN

falling 1.000 1.145 1.260

UVEN

= 0V and V

UVEN

≤ 2mA, 7.5V ≤ VCC ≤ 76V 4.75 5.00 5.25

REG1

= 2mA, VCC = 5.7V 4.00 4.50 5.25

REG1

= 2mA (Note 1) 0.5 1.0 V

REG1

= 20mA (Note 1) 0.5 V

REG2

rising 2.0 2.5 3.0 V

5.5 76.0 V

0.4 V

= 76V, VCC = 77V -0.2 +0.2 µA

UVEN

≤ 2mA 25 Ω

REG1

= 1mA 6.65 7.00 7.35

REG2

≤ 20mA 4.5 5.0

REG2

≤ 20mA 25 Ω

REG2

0.22 V

V

V

V

V

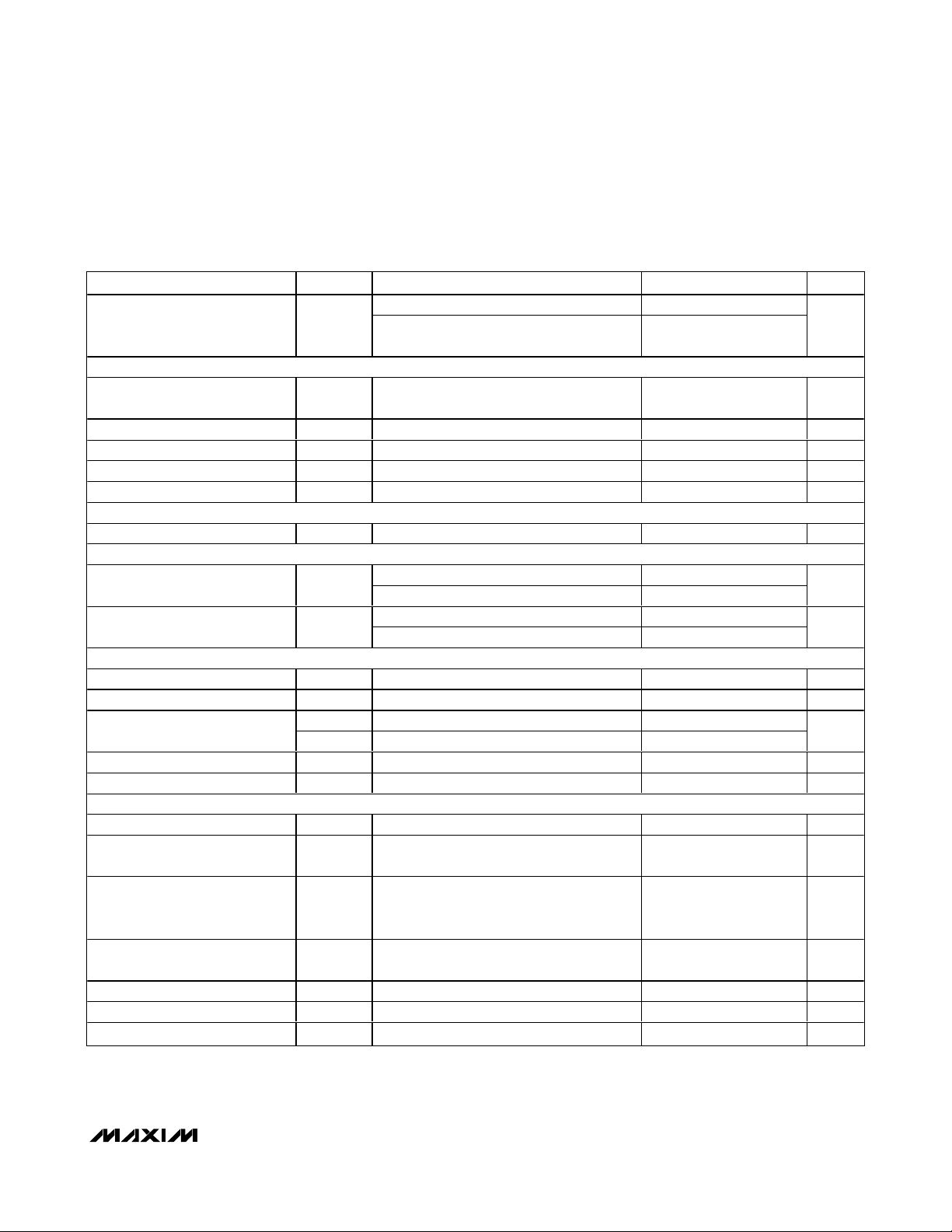

Page 3

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VCC= V

UVEN

= 14V, C

REG1

= 1µF, C

REG2

= 1µF, C

CLMP

= 0.1µF, RT= 25kΩ, TA= TJ = -40°C to +125°C, unless otherwise noted.

Typical specifications are at T

A

= +25°C.)

CLMP Regulator Output Voltage V

CURRENT-SENSE AMPLIFIER (CSA)

Differential Input Voltage Range

Common-Mode Range 0V

CS+ Input Bias Current I

CS- Input Bias Current I

Unity-Gain Bandwidth From (CS+ - CS-) to CS 1.0 MHz

REF OUTPUT BUFFER

REF Output Voltage V

DIM DRIVER

Source Current

Sink Current

GATE DRIVER

DRI UVLO Threshold V

DRI UVLO Threshold Hysteresis V

Driver Output Impedance

Peak Sink Current I

Peak Source Current I

PWM, ILIM, AND HICCUP COMPARATOR

PWM Comparator Offset Voltage V

Peak Current-Limit Comparator

Trip Threshold

Peak Current-Limit Comparator

Propagation Delay (Excluding

Blanking Time)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CLMP

V

-

CS+

V

CS-

CS+

CS-

REF

UVLO_TH

UVLO_HYST

Z

OUT_LVDRI

Z

OUT_HVDRI

SK

SR

8.7V ≤ (V

5.0V ≤ (VHI - VLO) ≤ 8.7V, I

- VLO) ≤ 36V, I

HI

= 1mA 5.5 8.0 10.0

CLMP

(V

- VLO)

CLMP

= 250µA

HI

- 0.7

0 0.3 V

CC

V

- V

CS+

V

CS+

-100µA ≤ I

V

CLMP

V

CLMP

V

CLMP

V

CLMP

= 0.3V -250 +250 µA

CS-

- V

= 0.3V 400 µA

CS-

≤ +100µA 2.85 3.00 3.15 V

REF

- VLO = 4V 5 20

- VLO = 8V 30 67

- VLO = 4V 10 22

- VLO = 8V 40 76

DRI rising 4.0 4.2 4.4 V

0.3 V

= 7.0V, DRV sinking 250mA 2.8 4

= 7.0V, DRV sourcing 250mA 5.0 8

V

= 7.0V 2.5 A

DRI

V

= 7.0V 1.4 A

DRI

COMP

- (V

SNS+

- V

SNS-)

0.7 V

160 200 240 mV

50mV overdrive 40 ns

V

V

mA

mA

Ω

HICCUP Comparator Trip

Threshold

SNS+ Input Bias Current V

SNS- Input Bias Current V

Blanking Time t

BLNK

SNS+

SNS+

= 0V, V

= 0V, V

235 300 385 mV

= 0V -100 -65 µA

SNS-

= 0V -100 -65 µA

SNS-

40 ns

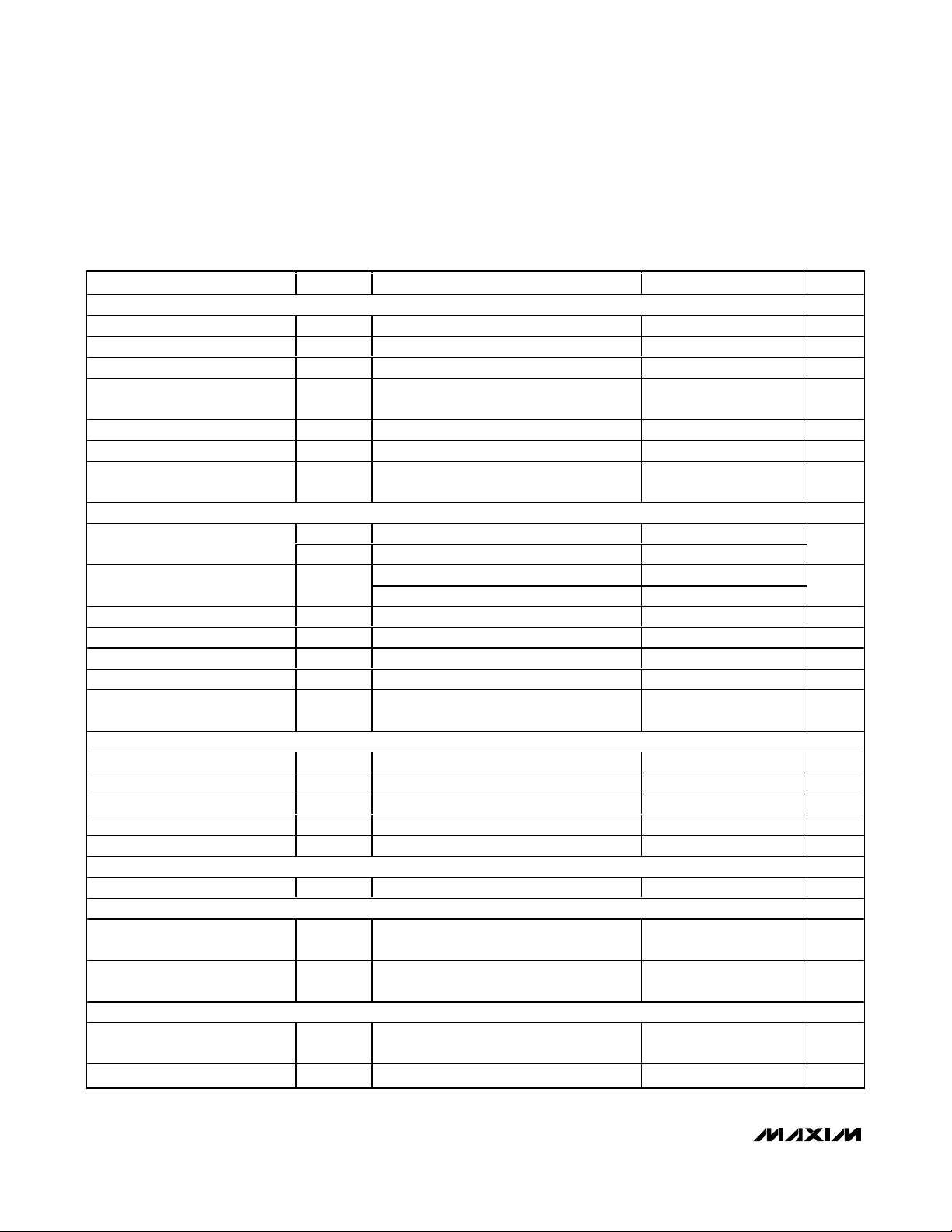

Page 4

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VCC= V

UVEN

= 14V, C

REG1

= 1µF, C

REG2

= 1µF, C

CLMP

= 0.1µF, RT= 25kΩ, TA= TJ = -40°C to +125°C, unless otherwise noted.

Typical specifications are at T

A

= +25°C.)

ERROR AMPLIFIER

FB Input Bias Current -100 +100 nA

EAMP Output Sink Current VFB = 1.735V, V

EAMP Output Source Current VFB = 0.735V, V

EAMP Input Common-Mode

Voltage

EAMP Output Clamp Voltage 1.1 1.7 2.4 V

Voltage Gain A

Unity-Gain Bandwidth GBW

OSCILLATOR, OSC SYNC, CLK, AND CLKOUT

RTSYNC Frequency Range

RTSYNC Oscillator Frequency

RTSYNC High-Level Voltage V

RTSYNC Low-Level Voltage V

CLKOUT High Level I

CLKOUT Low Level I

CLKOUT Maximum Load

Capacitance

DIM SYNC, DIM RAMP, AND DIM PWM GEN

Internal Ramp Frequency f

External Sync Frequency Range f

External Sync Low-Level Voltage V

External Sync High-Level Voltage V

DIM Comparator Offset V

DIGITAL SOFT-START

Soft-Start Duration t

OVERVOLTAGE COMPARATOR, LOAD OVERCURRENT COMPARATOR

OVP Overvoltage Comparator

Threshold

OVP Overvoltage Comparator

Hysteresis

SLOPE COMPENSATION

Slope Compensation Peak

Voltage Per Cycle

Slope Compensation External clock applied to RTSYNC 15 mV/µs

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

f

SWMIN

f

SWMAX

SIHL

SILL

C

CLK_CAPfSW

RAMP

DIM

LTH

HTH

DIMOS

SS

V

OV

V

OV_HYST

= 1V 3 7 mA

COMP

= 1V 2 7 mA

COMP

0 3.0 V

R

= 100kΩ to AGND 80 dB

COMP

R

= 100kΩ to AGND, C

COMP

to AGND

RT = 25kΩ 475 500 525

R

= 100kΩ 106 125 143

T

= 0.8mA 2.8 V

SINK

= 1.6mA 0.4 V

SOURCE

= 500kHz 500 pF

VOV rising 1.20 1.235 1.27 V

Clock generated by R

T

COMP

= 100pF

0.5 MHz

125

500

2.8 V

0.4 V

160 200 240 Hz

80 2000 Hz

0.4 V

3.2 V

170 200 300 mV

4.0 ms

63.5 mV

120 mV

kHz

kHz

Page 5

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VCC= V

UVEN

= 14V, C

REG1

= 1µF, C

REG2

= 1µF, C

CLMP

= 0.1µF, RT= 25kΩ, TA= TJ = -40°C to +125°C, unless otherwise noted.

Typical specifications are at T

A

= +25°C.)

Note 1: Dropout voltage is defined as the input to output differential voltage at which the regulator output voltage drops 100mV below

the nominal output voltage.

Note 2: V

CLMPTH

determines the voltage required to operate the current-sense amplifier. The DIM driver requires 2.5V for (V

CLMP

- VLO)

to drive the external MOSFET. V

HI

is typically one diode drop above V

CLMP

. A large capacitor connected to V

CLMP

slows the

response of the LED current-sense circuitry, resulting in current overshoot. To ensure proper operation, connect a 0.1µF

capacitor from CLMP to LO.

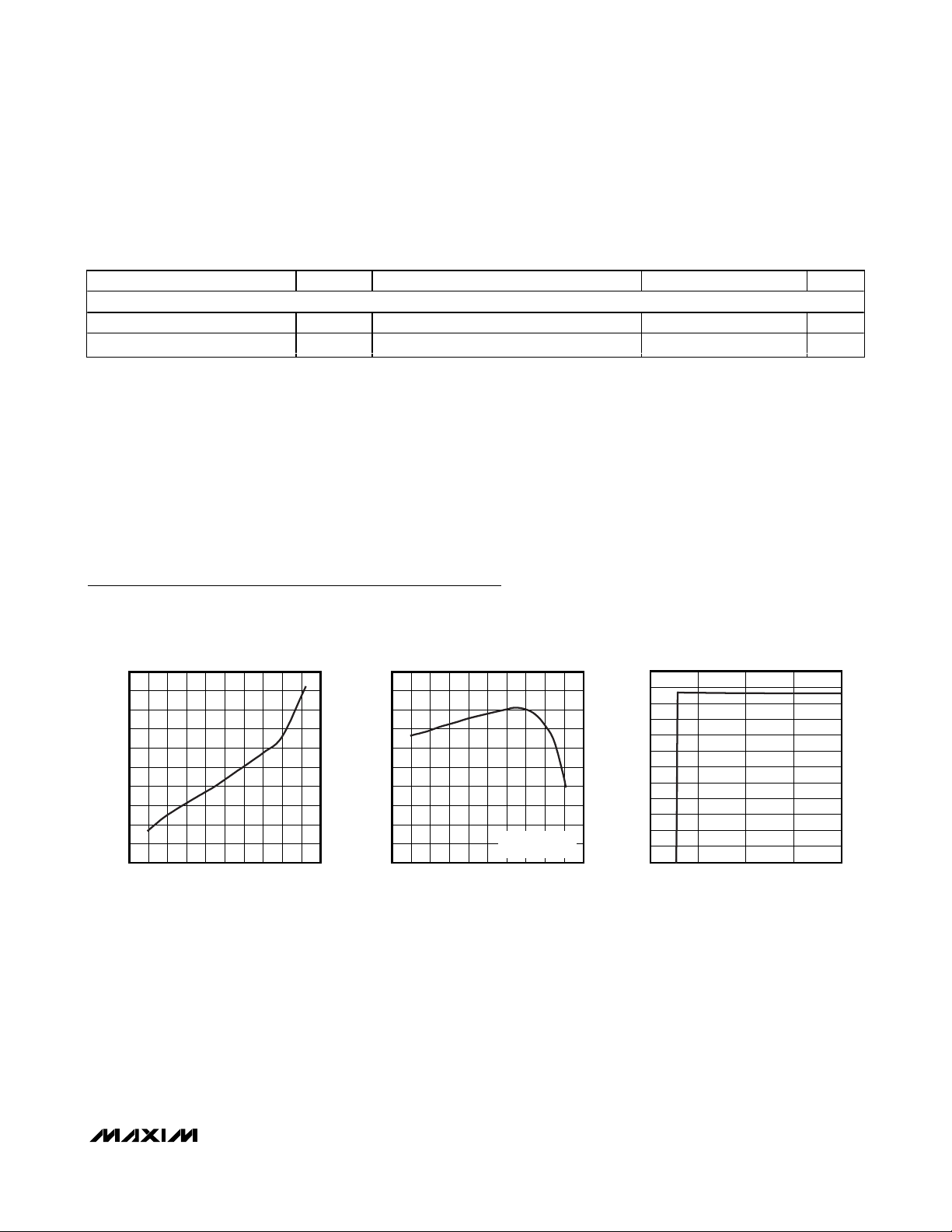

Typical Operating Characteristics

(VCC= V

UVEN

= 14V, C

REG1

= 1µF, C

REG2

= 10µF, C

CLMP

= 0.1µF, RT= 25kΩ, RCS= 0.1Ω, TA= +25°C, unless otherwise noted.)

18

20

19

22

21

24

23

25

27

26

28

-60 -20 0 20-40 40 60 80 120100 140

SHUTDOWN CURRENT

vs. TEMPERATURE

MAX16831 toc01

TEMPERATURE (°C)

SHUTDOWN CURRENT (µA)

2.0

2.2

2.1

2.4

2.3

2.6

2.5

2.7

2.9

2.8

3.0

-60 -20 0 20-40 40 60 80 120100 140

OPERATING CURRENT

vs. TEMPERATURE

MAX16831 toc02

TEMPERATURE (°C)

OPERATING CURRENT (mA)

DGT AND DRV NOT

SWITCHING

40

30

20

10

0

70

60

50

80

90

110

100

120

0 10203040

VOLTAGE ACROSS LED CURRENT-SENSE

RESISTOR vs. SUPPLY VOLTAGE

MAX16831 toc03

SUPPLY VOLTAGE (V)

VOLTAGE ACROSS R

CS

(mV)

THERMAL SHUTDOWN

Thermal Shutdown Temperature T

Hysteresis ∆T

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SHDN

SHDN

Temperature rising +165 °C

20 °C

Page 6

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

6 _______________________________________________________________________________________

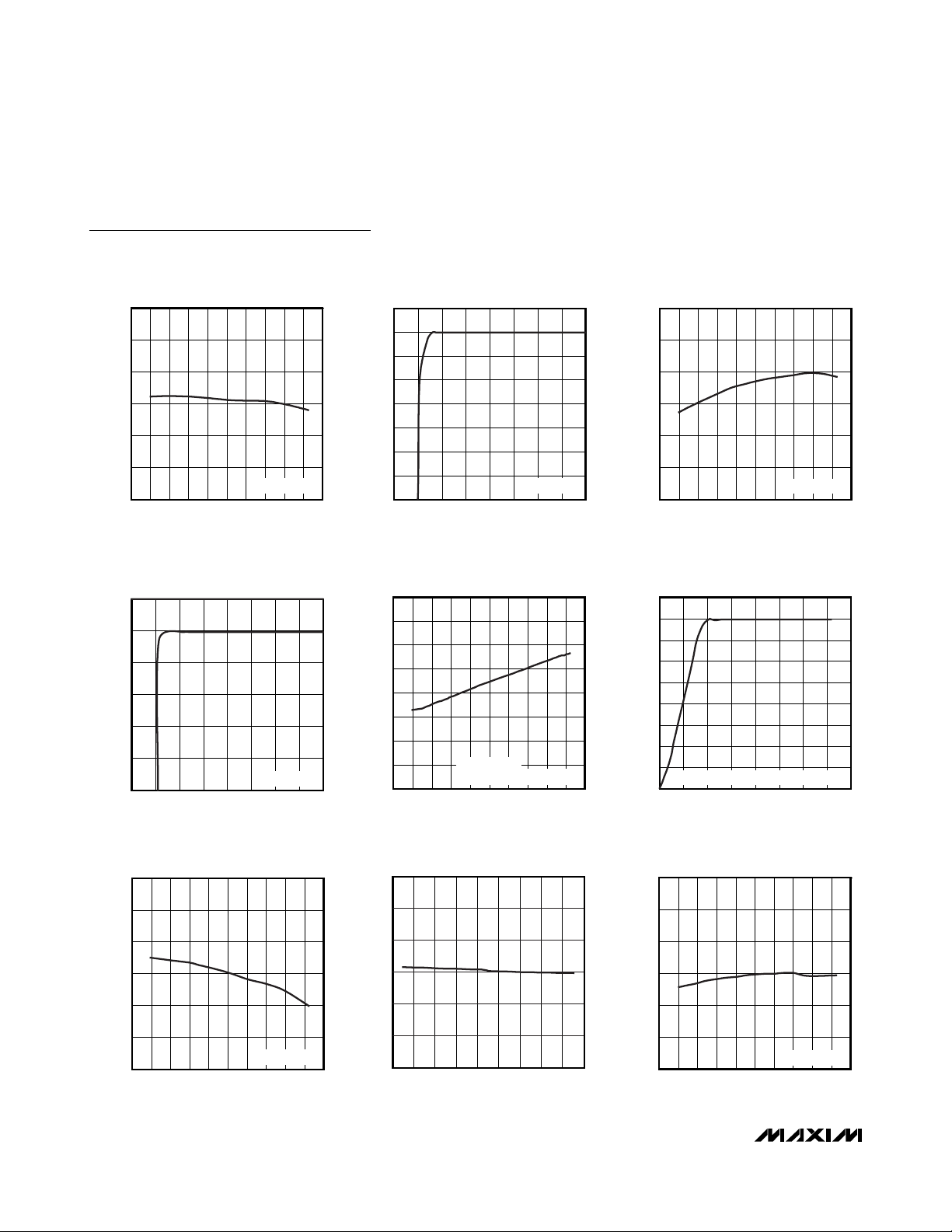

Typical Operating Characteristics (continued)

(VCC= V

UVEN

= 14V, C

REG1

= 1µF, C

REG2

= 10µF, C

CLMP

= 0.1µF, RT= 25kΩ, RCS= 0.1Ω, TA= +25°C, unless otherwise noted.)

6.80

6.95

6.90

6.85

7.00

7.05

7.10

-60 200-40 -20 40 60 80 100 120 140

REG2 OUTPUT VOLTAGE

vs. TEMPERATURE

MAX16831 toc04

TEMPERATURE (°C)

REG2 OUTPUT VOLTAGE (V)

I

REG2

= 20mA

0

2

1

4

3

5

6

7

8

010155 2025303540

REG2 OUTPUT VOLTAGE

vs. SUPPLY VOLTAGE

MAX16831 toc05

SUPPLY VOLTAGE (V)

REG2 OUTPUT VOLTAGE (V)

I

REG2

= 20mA

4.90

4.96

4.94

4.92

4.98

5.00

5.02

-60 200-40 -20 40 60 80 100 120 140

REG1 OUTPUT VOLTAGE

vs. TEMPERATURE

MAX16831 toc06

TEMPERATURE (°C)

REG1 OUTPUT VOLTAGE (V)

I

REG1

= 2mA

0

1

2

3

4

5

6

0105 152025303540

REG1 OUTPUT VOLTAGE

vs. SUPPLY VOLTAGE

MAX16831 toc07

SUPPLY VOLTAGE (V)

REG1 OUTPUT VOLTAGE (V)

I

REG1

= 2mA

7.5

7.7

7.6

7.8

8.1

8.2

8.0

7.9

8.3

-60 -20 0 20 40-40 60 80 100 120 140

CLMP REGULATOR VOLTAGE

vs. TEMPERATURE

MAX16831 toc08

TEMPERATURE (°C)

CLMP VOLTAGE (V)

VHI - VLO = 11V

CLMP VOLTAGE = V

CLMP

- VLO

1

3

2

5

4

6

7

8

9

010155 2025303540

CLMP REGULATOR VOLTAGE

vs. (V

HI

- VLO)

MAX16831 toc09

VHI - VLO (V)

CLMP REGULATOR VOLTAGE (V)

CLMP REGULATOR VOLTAGE = V

CLMP

- V

LO

2.96

2.99

2.98

2.97

3.00

3.01

3.02

-60 200-40 -20 40 60 80 100 120 140

REF OUTPUT VOLTAGE

vs. TEMPERATURE

MAX16831 toc10

TEMPERATURE (°C)

REF OUTPUT VOLTAGE (V)

I

REF

= 100µA

2.96

2.97

2.99

2.98

3.01

3.00

3.02

-225 -125 -75-175 -25 25 75 125 175 225

REF OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX16831 toc11

LOAD CURRENT (µA)

REF OUTPUT VOLTAGE (V)

470

500

490

480

510

520

530

-60 200-40 -20 40 60 80 100 120 140

PWM OSCILLATOR FREQUENCY

vs. TEMPERATURE

MAX16831 toc12

TEMPERATURE (°C)

PWM FREQUENCY (kHz)

RT = 25kΩ

Page 7

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

_______________________________________________________________________________________

7

Typical Operating Characteristics (continued)

(VCC= V

UVEN

= 14V, C

REG1

= 1µF, C

REG2

= 10µF, C

CLMP

= 0.1µF, RT= 25kΩ, RCS= 0.1Ω, TA= +25°C, unless otherwise noted.)

100

200

250

300

350

400

450

500

550

0.005 0.015 0.025 0.035 0.045

PWM OSCILLATOR FREQUENCY

vs. 1/RT CONDUCTANCE

MAX16831 toc13

1/RT (k

Ω

-1

)

PWM FREQUENCY (kHz)

150

2ms/div

200Hz DIMMING OPERATION

10% DIMMING

1A/div

MAX16831 toc14

0A

50% DIMMING

1A/div

0A

90% DIMMING

1A/div

0A

0

30

40

50

60

70

80

90

100

01 2 3

LED CURRENT DUTY CYCLE

vs. DIM VOLTAGE

MAX16831 toc15

DIM VOLTAGE (V)

LED CURRENT DUTY CYCLE (%)

20

10

40ns/div

DRIVER (DRV) RISE TIME

DRV OUTPUT

RISING

MAX16831 toc16

2V/div

0V

5nF CAPACITOR CONNECTED

FROM DRV TO AGND

40ns/div

DRIVER (DRV) FALL TIME

DRV OUTPUT

FALLING

MAX16831 toc17

2V/div

0V

5nF CAPACITOR CONNECTED

FROM DRV TO AGND

40ns/div

DGT RISE TIME

DGT OUTPUT

RISING

14V OFFSET

MAX16831 toc18

2V/div

14V

VHI - VLO = 11V

1nF CAPACITOR CONNECTED

FROM DGT TO AGND

40ns/div

DGT FALL TIME

DGT OUTPUT

FALLING

14V OFFSET

MAX16831 toc19

2V/div

14V

VHI - VLO = 11V

1nF CAPACITOR CONNECTED

FROM DGT TO AGND

Page 8

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

8 _______________________________________________________________________________________8 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1, 24 N.C. No Connection. Not internally connected.

Undervoltage Lockout (UVLO) Threshold/Enable Input. UVEN is a dual-function adjustable UVLO

2 UVEN

threshold input with an enable feature. Connect UVEN to V

program the UVLO threshold. Connect UVEN directly to V

threshold. Apply a voltage greater than 1.244V to UVEN to enable the device.

through a resistive voltage-divider to

CC

to use the 6.0V (max) default UVLO

CC

3 REG1

4 AGND Analog Ground

5 REF

6 DIM

7 RTSYNC

8 CLKOUT

9, 10, 11 I.C. Internally Connected. Must be connected to AGND.

12 COMP

13 CS

14 FB Error-Amplifier Inverting Input

15 OV

16, 17 SGND Switching Ground. SGND is the ground for non-analog and high-current gate driver circuitry.

18 DRV Gate Driver Output. Connect DRV to the gate of an external n-channel MOSFET for switching.

19 DRI

20 SNS+

21 SNS-

5V Regulator Output. REG1 is an internal low-dropout voltage regulator that generates a 5V (V

6V) output voltage and supplies power to internal circuitry. Bypass REG1 to AGND through a 1µF

ceramic capacitor.

Accurate 3V Buffered Reference Output. Connect REF to DIM through a resistive voltage-divider to

apply a DC voltage for analog-controlled dimming functionality. Leave REF unconnected if unused.

Dimming Control Input. Connect DIM to an external PWM signal for PWM dimming. For analogcontrolled dimming, connect DIM to REF through a resistive voltage-divider. The dimming frequency

is 200Hz under these conditions. Connect DIM to AGND to turn off the LEDs.

SYNC Input/Output. The PWM clock is generated by the RTSYNC oscillator. Connect an external

resistor to RTSYNC to select a clock switching frequency from 125kHz to 600kHz or connect RTSYNC

to an external clock to synchronize the MAX16831 with a master clock signal.

Clock Output. CLKOUT buffers the oscillator/clock. Connect CLKOUT to the SYNC input of another

device to operate the MAX16831 in a multichannel configuration. CLKOUT is a logic output.

Error-Amplifier Output. Connect the compensation network from COMP to FB for stable closed-loop

control. Use low-leakage ceramic capacitors in the feedback network.

Current-Sense Amplifier Output. The current-sense amplifier (CSA) senses the differential voltage

across the load sense resistor, R

current. Connect the proper compensation resistor from CS to FB.

Overvoltage Protection Input. Connect OV to HI through a resistive voltage-divider to set the

overvoltage limit for the load. When the voltage at OV exceeds the 1.235V (typ) threshold, an

overvoltage fault is generated and the switching MOSFET turns off. The MOSFET is turned on again

when the voltage at OV drops below 1.17V (typ).

Gate Driver Supply Input. Connect DRI to REG2 to power the primary switching MOSFET driver.

Bypass DRI to AGND through a 10µF ceramic capacitor.

Positive Peak Current-Sense Input. Connect SNS+ to the positive side of the switch current-sense

resistor, R

Negative Peak Current-Sense Input. Connect SNS- to the negative side of the switch current-sense

resistor, R

SENSE

SENSE

.

.

, and generates a voltage, VCS, at CS proportional to the LED

CS

CC

>

Page 9

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

_______________________________________________________________________________________ 9

Detailed Description

The MAX16831 is a current-mode PWM LED driver

used for driving HBLEDs. By using two current regulation loops, 5% output current accuracy is achieved.

One current regulation loop controls the external

switching MOSFET peak current through a sense resistor, R

SENSE

, from SNS+ to SNS-, while the other current

regulation loop controls the average LED string current

through the sense resistor RCSin series with the LEDs.

The wide operating supply range of (6.0V/5.5V

ON/OFF) up to 76V makes the MAX16831 ideal in automotive applications.

The MAX16831 features a programmable undervoltage

lockout (UVEN) that ensures predictable operation during brownout conditions. The input UVEN circuit monitors the supply voltage, VCC, and turns the driver off

when V

CC

drops below the UVLO threshold. Connect

UVEN to V

CC

to use the 5.7V (typ) default UVLO thresh-

old. The MAX16831 includes a cycle-by-cycle current

limit that turns off the gate drive to the external switching MOSFET (Q

S

) during an overcurrent condition. The

MAX16831 features a programmable oscillator that simplifies and optimizes the design of external magnetics.

The MAX16831 includes three internal voltage regulators, REG1, REG2, and CLMP, and a 3V buffered reference output, REF. Connect REG2 to the driver supply,

DRI, to power the switching MOSFET driver.

The MAX16831 is capable of synchronizing with an

external clock or operating in stand-alone mode. A single resistor, R

T

, can be used to adjust the switching frequency from 125kHz to 600kHz for stand-alone

operation. To synchronize the device with an external

clock, apply a clock signal directly to the RTSYNC

input. A buffered clock output, CLKOUT, is available to

configure the MAX16831 in multichannel applications.

_______________________________________________________________________________________ 9

Pin Description (continued)

PIN NAME FUNCTION

22 QGND Analog Ground. Ensure a low-impedance connection between QGND and AGND.

23 DGT

25 LO

26 CS+

27 CS-

28 CLMP

29 HI

30 REG2

31 V

32 I.C. Internally Connected. Must be connected directly to QGND.

—EP

CC

Dimming Gate Driver Output. Connect DGT to the gate of an external n-channel MOSFET for

dimming. DGT is powered by the internal regulator, CLMP, and is referenced to LO.

Low-Voltage Input. LO is the return point for the LED current. When using the MAX16831 in a buckboost configuration, connect LO to V

connect LO to SGND. Connect LO to the junction of the inductor and LED current-sense resistor,

R

, when using a buck configuration.

CS

Noninverting Current-Sense Amplifier Input. Connect CS+ to the positive side of an external sense

resistor, R

Inverting Current-Sense Amplifier Input. Connect CS- to the negative side of an external sense

resistor, R

Internal CLMP Regulator Output. CLMP supplies an 8V (typ) output when V

9V, V

provides the high reference for the dimming driver. V

enable the current-sense amplifier and dimming MOSFET driver. Bypass CLMP to LO with a 0.1µF

ceramic capacitor.

High-Voltage Input. HI is referred to LO. HI supplies power to the current-sense amplifier and

dimming MOSFET gate driver through the CLMP regulator.

Internal Regulator Output. REG2 is an internal voltage regulator that generates a 7V output and

supplies power to internal circuitry. Connect REG2 to DRI to power the switching MOSFET driver

during normal operation. Bypass REG2 to AGND with a 10µF ceramic capacitor.

Supply Voltage Input

Exposed Pad. Connect EP to AGND. EP also functions as a heatsink to maximize thermal dissipation.

Do not use as a ground connection.

, connected in series with the load (LEDs).

CS

, connected in series with the load (LEDs).

CS

is one diode drop below VHI. The CLMP regulator powers the current-sense amplifier and

CLMP

. When using the device in a boost configuration only,

CC

≥ 9V. If VHI is lower than

HI

must be at least 2.5V higher than VLO to

CLMP

Page 10

MAX16831

The MAX16831 features a differential high-side level

shifter to drive an external n-channel MOSFET for dimming. Wide contrast “pulsed” dimming (1000:1) is possible by applying either a low-frequency PWM input

signal or a DC voltage to the dimming input (DIM).

Protection features include peak current limiting,

HICCUP mode current limiting, output overvoltage protection, short-circuit protection, and thermal shutdown.

The HICCUP current-limit circuitry reduces the power

delivered to the load during severe fault conditions.

Nonlatching overvoltage protection limits the voltage on

the external switching MOSFET (Q

S

) under open-circuit

conditions in the LED string. During continuous operation at high input voltages, the power dissipation of the

MAX16831 could exceed the maximum rating and an

internal thermal shutdown circuitry safely turns off the

MAX16831 when the device junction temperature

exceeds +165°C. When the junction temperature drops

below the hysteresis temperature, the MAX16831 automatically re-initiates startup.

Undervoltage Lockout/Enable

The MAX16831 features a dual-purpose adjustable

UVLO input and enable function. Connect UVEN to V

CC

through a resistive voltage-divider to set the undervoltage lockout (UVLO) threshold. The MAX16831 is

enabled when the UVEN exceeds the 1.244V (typ)

threshold. Drive UVEN to ground to disable the output.

Setting the UVLO Threshold

The MAX16831 features a programmable UVLO threshold. Connect UVEN directly to VCCto select the default

6.0V (max) UVLO threshold. Connect UVEN to V

CC

through a resistive voltage-divider to select a UVLO

threshold (Figure 1). Calculate resistor values as follows:

where R

UV1

+ R

UV2

≤ 270kΩ, V

UVEN

is the 1.244V (typ)

threshold voltage, and V

UVLO

is the desired UVLO

threshold in volts at VCC(Figure 1).

The capacitor, C

UVEN

, is required to prevent chattering

at the UVLO threshold due to line impedance drops

during power-up and dimming. If the undervoltage setting is very close to the required minimum operating

voltage, then there can be jumps in the voltage at V

CC

during dimming, which may cause the MAX16831 to

turn on and off when the dimming signal transitions

from low to high. The capacitor, C

UVEN

, should be

large enough to limit the ripple on UVEN to less than

the 100mV (min) UVEN hysteresis so that the device

does not turn off under these circumstances.

Soft-Start

The MAX16831 includes a factory-set 4ms (typ) softstart delay that allows the load current to ramp up in a

controlled manner, minimizing output overshoot. Softstart begins once the device is enabled and V

CC

exceeds the UVLO threshold. Soft-start circuitry slowly

increases the internal soft-start voltage, VSS, resulting

in a controlled rise of the load current. Signals applied

to DIM are ignored until the soft-start duration is complete and a successive delay of 200µs has elapsed.

Internal Regulators

The MAX16831 includes a fixed 5V voltage regulator

REG1, a 7V voltage regulator REG2, and an internal 8V

regulator CLMP. REG1 and REG2 power up when V

CC

exceeds the UVLO threshold. REG1 supplies power to

internal circuitry and remains on during PWM dimming.

It is capable of driving external loads up to 2mA.

REG2 is capable of delivering up to 20mA of current.

Connect REG2 to DRI to generate the supply voltage

for the primary switching MOSFET driver, DRV.

CLMP is powered by HI and supplies power to the current-sense amplifier (CSA). CSA is enabled when

V

CLMP

goes 2.5V above VLOand is disabled when

(V

CLMP

- VLO) falls below 2.28V. The CLMP regulator

also provides power to the dimming MOSFET control

circuitry. CLMP is the output of the CLMP regulator. Do

not use CLMP to power external circuitry. Bypass

CLMP to LO with a 0.1µF ceramic capacitor. A larger

capacitor will result in overshoots of the load current.

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

10 ______________________________________________________________________________________

Figure 1. Setting the UVLO Threshold

⎛

V

RR

=×

UV UV

12

UVEN

⎜

VV

⎝

-

UVLO UVEN

⎞

⎟

⎠

V

IN

R

UV2

UVEN

C

UVEN

R

UV1

V

CC

MAX16831

QGND

Page 11

Reference Voltage Output

The MAX16831 includes a 5% accurate 3V (typ)

buffered reference output, REF. REF is a push-pull output capable of sourcing/sinking 100µA of current and

can drive a maximum load capacitance of 100pF.

Connect REF to DIM through a resistive voltage-divider

to supply an analog signal for dimming. See the

Dimming Input (DIM)

section.

Dimming MOSFET Driver (DDR)

The MAX16831 requires an external n-channel

MOSFET for PWM dimming. Connect the MOSFET to

the output of the DDR dimming driver, DGT, for normal

operation. V

DGT

swings between VLOand V

CLMP

. The

DDR dimming driver is capable of sinking or sourcing

up to 20mA of current. The average current required to

drive the dimming MOSFET (I

DRIVE_DIM

) depends on

the MOSFET’s total gate charge (Q

G_DIM

) and the dim-

ming frequency of the converter, f

DIM

. Use the following equation to calculate the average gate drive current

for the n-channel dimming FET.

I

DRIVE_DIM

= Q

G_DIM

x f

DIM

n-Channel MOSFET Switch Driver (DRV)

The MAX16831 drives an external n-channel MOSFET.

Use an external supply or connect REG2 to DRI to

power the MOSFET driver. The driver output, V

DRV

,

swings between ground and V

DRI

. Ensure that V

DRI

remains below the absolute maximum VGSrating of the

external MOSFET. DRV is capable of sinking 2.5A or

sourcing 1.4A of peak current, allowing the MAX16831

to switch MOSFETs in high-power applications. The

average current sourced to drive the external MOSFET

depends on the total gate charge (QG) and operating

frequency of the converter, fSW. The power dissipation

in the MAX16831 is a function of the average output

drive current (I

DRIVE

). Use the following equations to

calculate the power dissipation in the gate driver section of the MAX16831 due to I

DRIVE

:

I

DRIVE

= QGx f

SW

PD= (I

DRIVE

+ ICC) x V

DRI

where V

DRI

is the supply voltage to the gate driver and

ICCis the operating supply current. I

DRIVE

should not

exceed 20mA.

Dimming Input (DIM)

The dimming input, DIM, functions with either analog or

PWM control signals. Once the internal pulse detector

detects three successive edges of a PWM signal with a

frequency between 80Hz and 2kHz, the MAX16831 synchronizes to the external signal and pulse-width-modulates the LED current at the external DIM input frequency

with the same duty cycle as the DIM input. If an analog

control signal is applied to DIM, the MAX16831 compares the DC input to an internally generated 200Hz

ramp to pulse-width-modulate the LED current (f

DIM

=

200Hz). The output current duty cycle is linearly

adjustable from 0 to 100% (0.2V < V

DIM

< 2.8V).

Use the following formula to calculate the voltage, V

DIM

,

necessary for a given output-current duty cycle, D:

V

DIM

= (D x 2.6) + 0.2V

where V

DIM

is the voltage applied to DIM in volts.

Connect DIM to REF through a resistive voltage-divider

to apply a DC DIM control signal (Figure 2). Use the

required dimming input voltage, V

DIM

, calculated

above and select appropriate resistor values using the

following equation:

R4= R3x V

DIM

/ (V

REF

- V

DIM

)

where V

REF

is the 3V reference output voltage and

30kΩ≤R3+ R4≤ 150kΩ.

For proper operation at startup or after toggling ENABLE,

the controller needs three clock edges or an analog voltage greater than 0.3V on the DIM input.

Oscillator, Clock, and Synchronization

The MAX16831 is capable of stand-alone operation or

synchronizing to an external clock, and driving external

devices in SYNC mode. For stand-alone operation, program the switching frequency by connecting a single

external resistor, RT, between RTSYNC and ground.

Select the switching frequency, fSW, from 125kHz to

600kHz and calculate RTusing the following formula:

where the switching frequency is in kHz and RT is in kΩ.

The MAX16831 is also capable of synchronizing to an

external clock signal ranging from 125kHz to 600kHz.

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

______________________________________________________________________________________ 11

Figure 2. Creating a DIM Input Signal from REF

REF

R

3

R

4

DIM

MAX16831

AGND

kHz

500

R

=×

T

f

SW

25 Ω

k

Page 12

MAX16831

Connect the clock signal to the RTSYNC input. The

MAX16831 synchronizes to the external clock signal

after the detection of five successive clock edges at

RTSYNC.

A buffered clock output, CLKOUT, is capable of driving

the RTSYNC input of an external PWM controller for

multichannel applications. CLKOUT is capable of driving capacitive loads up to 500pF.

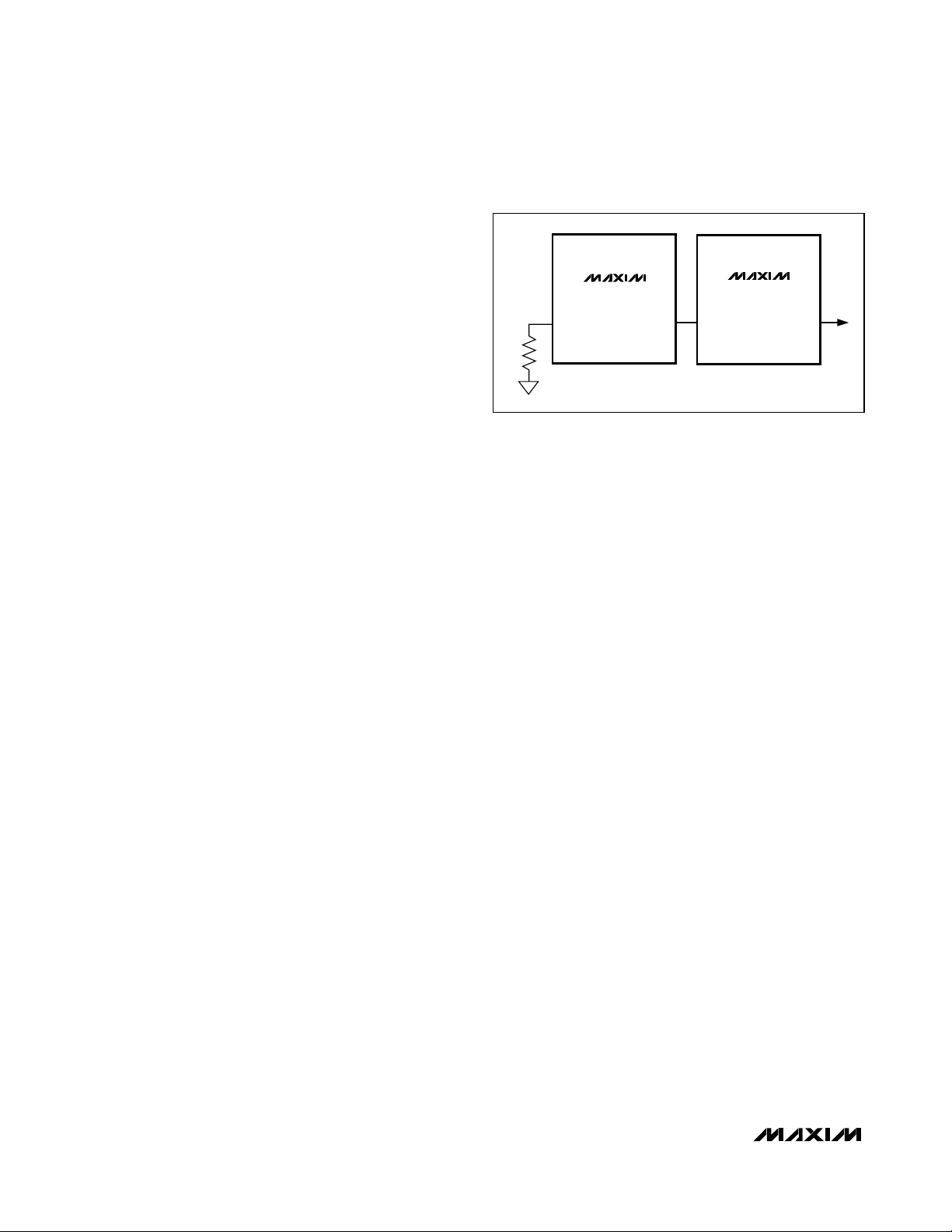

Multichannel Configuration

The MAX16831 is capable of multichannel operation.

Connect CLKOUT to the SYNC input of an external

device to use the MAX16831 as a master clock signal.

Connect an external clock signal to RTSYNC to configure the MAX16831 as a slave. To setup two or more

MAX16831 devices in a daisy-chain/peer-to-peer configuration, drive the RTSYNC input of one MAX16831

with the CLKOUT buffer of another (Figure 3).

ILIM and HICCUP Comparator

R

SENSE

sets the peak current through the inductor for

switching. The differential voltage across R

SENSE

is

compared to the 200mV voltage trip limit of the currentlimit comparator, ILIM. Set the current limit 20% higher

than the peak switch current at the rated output power

and minimum voltage. Use the following equation to

calculate R

SENSE

:

R

SENSE

= V

SENSE

/ (1.2 x I

PEAK

)

where V

SENSE

is the 200mV differential voltage

between SNS+ and SNS- and I

PEAK

is the peak induc-

tor current at full load and minimum input voltage.

When the voltage drop across R

SENSE

exceeds the

ILIM threshold, the MOSFET driver (DRV) terminates

the on-cycle and turns the switch off, reducing the current through the inductor. The FET is turned back on at

the beginning of the next switching cycle.

When the voltage across R

SENSE

exceeds the 300mV

(typ) HICCUP threshold, the HIC comparator terminates

the on-cycle of the device, turning the switching

MOSFET off. Following a startup delay of 4ms (typ), the

MAX16831 re-initiates soft-start. The device will continue to operate in HICCUP mode until the overcurrent

condition is removed.

A built-in 40ns leading-edge blanking circuit of the current-sense signal prevents these comparators from prematurely terminating the on-cycle of the external

switching MOSFET (QS). In some cases, this blanking

time may not be adequate and an additional RC filter

may be required to prevent spurious turn-off.

Load Current Sense

The load-sense resistor, RCS, monitors the current

through the LEDs. The internal floating current-sense

amplifier, CSA, measures the differential voltage across

RCS, and generates a voltage proportional to the LED

current through RCSat CS. This voltage on CS is

referred to AGND. The closed loop regulates the LED

current to a value, I

LED

, given by the following equation:

I

LED

= 0.107V / R

CS

Slope Compensation

The MAX16831 uses an internal ramp generator for

slope compensation. The internal ramp signal is reset

to zero at the beginning of each cycle and has a peakto-peak voltage of 120mV per switching cycle. Use an

external resistor, RT, to set the switching frequency,

fSW, and calculate the slope of the compensating ramp,

m

SLOPE

, using the following equation:

m

SLOPE

= 120 x fSW[mV/s]

where fSWis the switching frequency in Hz. When the

MAX16831 is synchronized to an external clock, the

slope compensation ramp has a slope of 15mV/µs.

Internal Voltage-Error Amplifier (EAMP)

The MAX16831 includes a built-in voltage amplifier,

with tri-state output, which can be used to close the

feedback loop. The buffered output current-sense signal appears at CS, which is connected to the inverting

input, FB, of the error amplifier through resistor R1. The

noninverting input is connected to an internally trimmed

current reference.

The output of the error amplifier is controlled by the signal applied to DIM. When DIM is high, the output of the

amplifier is connected to COMP. The amplifier output is

open when DIM is low. This enables the integrating

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

12 ______________________________________________________________________________________

Figure 3. Master-Slave/Peer-Peer Clock Configuration

MASTER/PEER

MAX16831

RTSYNC

R

T

CLKOUT

SLAVE/PEER

MAX16831

RTSYNC

CLKOUT

Page 13

capacitor to hold the charge when the DIM signal has

turned off the gate drive. When DIM is high again, the

voltage on the compensation capacitors, C1 and C2,

will force the converter into steady-state instantaneously.

PWM Dimming

PWM dimming is achieved by driving DIM with either a

PWM signal or a DC signal. The PWM signal is internally connected to the error amplifier, the dimming

MOSFET gate driver, and the switching MOSFET gate

driver. When the DIM signal is high, the dimming

MOSFET and the switching MOSFET drivers are

enabled and the output of the voltage-error amplifier is

connected to the external compensation network. Also,

the buffered current-sense signal is connected to CS.

Preventing discharge of the compensation capacitor

when the DIM signal is low will allow the control loop to

return the LED current to its original value almost

instantaneously.

When the DIM signal goes low, the output of the error

amplifier is disconnected from the compensation network and the voltage of compensation capacitors, C1

and C2 is preserved. Choose low-leakage capacitors

for C1 and C2. The drivers for the external dimming

and switching MOSFETs are disabled, and the converter stops switching. The inductor energy is now transferred to the output capacitors.

When the DIM signal goes high and the gate drivers are

enabled, the additional voltage on the output capacitor

may cause a current spike on the LED string. A larger

output capacitor will result in a smaller current spike. The

MAX16831 thus achieves fast PWM dimming response.

Fault Protection

The MAX16831 features built-in overvoltage protection,

overcurrent protection, HICCUP mode current-limit protection, and thermal shutdown. Overvoltage protection

is achieved by connecting OV to HI through a resistive

voltage-divider. HICCUP mode limits the power dissipation in the external MOSFETs during severe fault

conditions. Internal thermal shutdown protection safely

turns off the converter when the junction temperature

exceeds +165°C.

Overvoltage Protection

The overvoltage protection (OVP) comparator compares the voltage at OV with a 1.235V (typ) internal reference. When the voltage at OV exceeds the internal

reference, the OVP comparator terminates PWM

switching and no further energy is transferred to the

load. The MAX16831 re-initiates soft-start once the

overvoltage condition is removed. Connect OV to HI

through a resistive voltage-divider to set the overvoltage threshold at the output.

Setting the Overvoltage Threshold

Connect OV to HI or to the high-side of the LEDs

through a resistive voltage-divider to set the overvoltage threshold at the output (Figure 4). The overvoltage

protection (OVP) comparator compares the voltage at

OV with a 1.235V (typ) internal reference. Use the following equation to calculate resistor values:

where VOVis the 1.235V OV threshold. Choose R

OV1

and R

OV2

to be reasonably high-value resistors to prevent discharge of filter capacitors. This will prevent

unnecessary undervoltage and overvoltage conditions

during dimming.

Load-Dump Protection

The MAX16831 features load-dump protection up to

80V. LED drivers using the MAX16831 can sustain single fault load dump events. Repeated load dump events

within very short time intervals can cause damage to the

dimming MOSFET due to excess power dissipation.

Thermal Shutdown

The MAX16831 contains an internal temperature sensor

that turns off all outputs when the die temperature

exceeds +165°C. Outputs are enabled again when the

die temperature drops below +145°C.

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

______________________________________________________________________________________ 13

Figure 4. Setting the Overvoltage Threshold

V

LED+

R

OV1

R

OV2

MAX16831

OV

AGND

VV

⎛

RR

=×

OV OV

12

OV LIM OV

⎜

⎝

-

_

V

OV

⎞

⎟

⎠

Page 14

MAX16831

Applications Information

Inductor Selection

The minimum required inductance is a function of operating frequency, input-to-output voltage differential, and

the peak-to-peak inductor current (∆I

L

). Higher ∆I

L

allows for a lower inductor value while a lower ∆I

L

requires a higher inductor value. A lower inductor value

minimizes size and cost, improves large-signal transient response but reduces efficiency due to higher

peak currents and higher peak-to-peak output ripple

voltage for the same output capacitance. On the other

hand, higher inductance increases efficiency by reducing the ripple current, ∆IL. However, resistive losses

due to extra turns can exceed the benefit gained from

lower ripple current levels, especially when the inductance is increased without also allowing for larger

inductor dimensions. A good compromise is to choose

∆ILequal to 30% of the full load current. The inductor

saturating current is also important to avoid runaway

current during the output overload and continuous

short circuit. Select the I

SAT

to be higher than the maxi-

mum peak current limit.

Buck configuration: In a buck configuration, the average inductor current does not vary with the input. The

worst-case peak current occurs at a high input voltage.

In this case, the inductance L for continuous conduction mode is given by:

where V

INMAX

is the maximum input voltage, fSWis the

switching frequency, and V

OUT

is the output voltage.

Boost configuration: In the boost converter, the average

inductor current varies with line and the maximum average current occurs at low line. For the boost converter,

the average inductor current is equal to the input current. In this case, the inductance L is calculated as:

where V

INMIN

is the minimum input voltage, V

OUT

is the

output voltage, and fSWis the switching frequency.

Buck-boost configuration: In a buck-boost converter,

the average inductor current is equal to the sum of the

input current and the load current. In this case, the

inductance L is:

where V

INMIN

is the minimum input voltage, V

OUT

is the

output voltage, and fSWis the switching frequency.

Output Capacitor

The function of the output capacitor is to reduce the

output ripple to acceptable levels. The ESR, ESL, and

the bulk capacitance of the output capacitor contribute

to the output ripple. In most of the applications, the output ESR and ESL effects can be dramatically reduced

by using low-ESR ceramic capacitors. To reduce the

ESL effects, connect multiple ceramic capacitors in

parallel to achieve the required bulk capacitance.

In a buck configuration, the output capacitance, CF, is

calculated using the following equation:

where ∆V

R

is the maximum allowable output ripple.

In a boost configuration, the output capacitance, CF, is

calculated as:

where I

OUT

is the output current.

In a buck-boost configuration, the output capacitance,

CF, is calculated as:

where V

OUT

is the voltage across the load and I

OUT

is

the output current. Connect the output capacitor(s)

from the output to ground in a buck-boost configuration

(not across the load as for other configurations).

Input Capacitor

An input capacitor connected between UVEN and

ground must be used when configuring the MAX16831

as a buck converter. Use a low-ESR input capacitor

that can handle the maximum input RMS ripple current.

Calculate the maximum allowable RMS ripple using the

following equation:

In most of the cases, an additional electrolytic capacitor should be added to prevent input oscillations due to

line impedances.

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

14 ______________________________________________________________________________________

VV V

×

()-

OUT INMAX OUT

L

=

VfI

××

INMAX SW L

VVV

L

=

×

INMIN OUT INMIN

()-

Vf I

××

OUT SW L

∆

VV

×

L

=

OUT INMIN

VV fI

+××()∆

OUT INMIN SW L

∆

VVV

()-

C

INMAX OUT OUT

≥

F

VLV f

××× ×

∆ 2

R INMAX SW

×

VV I

()-2

C

OUT INMIN OUT

≥

F

VV f

∆

R OUT SW

××

××

VI

××

2

OUT OUT

×+ ×

C

≥

F

VV V f

∆ ()

R OUT INMIN SW

×× -

I VVV

OUT OUT INMIN OUT

I

IN RMS

=

()

()

V

INMIN

2

Page 15

When using the MAX16831 in a boost or buck-boost

configuration, the input RMS current is low and the

input capacitance can be small.

Operating the MAX16831 Without the

Dimming Switch

The MAX16831 can also be used in the absence of the

dimming MOSFET. In this case, the PWM dimming performance is compromised but in applications that do

not require dimming, the MAX16831 can still be used.

A short circuit across the load will cause the MAX16831

to disable the gate drivers and they will remain off until

the input power is recycled.

Switching Power MOSFET Losses

When selecting MOSFETs for switching, consider the

total gate charge, power dissipation, the maximum

drain-to-source voltage, and package thermal impedance. The product of the MOSFET gate charge and

R

DS(ON)

is a figure of merit, with a lower number signifying better performance. Select MOSFETs optimized

for high-frequency switching applications.

MOSFET losses may be broken into three categories:

conduction loss, gate drive loss, and switching loss.

The following simplified power loss equation is true for

all the different configurations.

P

LOSS

= P

CONDUCTION

+ P

GATEDRIVE

+ P

SWITCH

Layout Recommendations

Typically, there are two sources of noise emission in a

switching power supply: high di/dt loops and high dv/dt

surfaces. For example, traces that carry the drain current often form high di/dt loops. Similarly, the heatsink

of the MOSFET connected to the device drain presents

a high dv/dt source; therefore, minimize the surface

area of the heatsink as much as possible. Keep all PCB

traces carrying switching currents as short as possible

to minimize current loops. Use ground planes for best

results.

Careful PCB layout is critical to achieve low switching

losses and clean, stable operation. Use a multilayer

board whenever possible for better noise performance

and power dissipation. Follow these guidelines for

good PCB layout:

• Use a large copper plane under the MAX16831

package. Ensure that all heat-dissipating components have adequate cooling. Connect the exposed

pad of the device to the ground plane.

• Isolate the power components and high-current paths

from sensitive analog circuitry.

• Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable, jitter-free operation. Keep switching loops short.

• Connect AGND, SGND, and QGND to a ground

plane. Ensure a low-impedance connection between

all ground points.

• Keep the power traces and load connections short.

This practice is essential for high efficiency. Use

thick copper PCBs (2oz vs. 1oz) to enhance full-load

efficiency.

• Ensure that the feedback connection to FB is short

and direct.

• Route high-speed switching nodes away from the

sensitive analog areas.

• To prevent discharge of the compensation capacitors, C1 and C2, during the off-time of the dimming

cycle, ensure that the PCB area close to these components has extremely low leakage. Discharge of

these capacitors due to leakage may result in

degraded dimming performance.

Chip Information

PROCESS: BICMOS

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

______________________________________________________________________________________ 15

Pin Configuration

TOP VIEW

N.C.

1

2

UVEN

3

REG1

AGND

4

5

REF

6

DIM

RTSYNC

7

8

CLKOUT

*EP = EXPOSED PAD

CC

V

I.C.

32 31 30 29 28 27 26

+

*EP

9 101112131415

I.C.

REG2

MAX16831

I.C.

I.C.

TQFN

(5mm x 5mm)

HI

COMP

CLMP

CS

CS-

FB

CS+

OV

16

25

LO

SGND

N.C.

24

23

DGT

22

QGND

21

SNS-

20

SNS+

19

DRI

DRV

18

17

SGND

Page 16

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

16 ______________________________________________________________________________________

Functional Diagram

UVEN

QGND

REG1

REF

RTSYNC

CLKOUT

DIM

AGND

V

OV

OV

-

OVP

+

200Hz

-

OSC

200mV

V

BUF

V

CC

UVLO

AND

EN

SHUTDOWN

-

3.0V

+

+

THERMAL

OSC

+

COMP

-

5V

REG1

SLOPE

COMP

POR

EN

OV

MAX16831

CLMP

7V

REG2

OC

SLOPE

+

CMP

-

CONTROL

BLOCK

CLMP

1.3 x V

UGB

SS

ILIM

HIC

+

-

-

+

-

-

HI

200mV

300mV

BLANKING

TIME

40ns

V

V

DDR

CLMP

CLMP

V

LO

CS-

CSA

DRIVER

CS+

10uA

LO

+

V

LO

REG2

R

LS

V

CLMP

DGT

TRI

CS

DRI

DRV

SGND

SNS+

SNS-

EAMP

PWM

SLOPE

-

600mV

+

INTERNAL

TRIM

SS

V

V

OV

SS

X1

COMP

FB

Page 17

MAX16831

V

IN

R

CS

C

F

R

T

C

REG1

R

UV2

DRV

DRI

REG1

CS

V

CC

SNS+

FB

QGND

RTSYNC

CS-

CS+

LO

COMP

REG2

DGT

OV

UVEN

SNS-

AGND

R

SENSE

R2

C2

R

OV1

R

OV2

CLMP

SGND

C

CLMP

C

REG2

R1

C1

R

D

LEDs

BOOST CONFIGURATION

R

UV1

C

UVEN

Q

S

MAX16831

R

3

R

4

HI

REF

DIM

Typical Operating Circuits (continued)

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

______________________________________________________________________________________ 17

Page 18

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

18 ______________________________________________________________________________________

Typical Operating Circuits (continued)

BUCK CONFIGURATION

V

IN

R

C

R

UV2

CLMP

CS

V

HI

R

UV1

C

UVEN

DIM

C

REG1

R

T

CC

UVEN

DIM

REG1

RTSYNC

COMP

CS

FB

AGND

LO

MAX16831

CLMP

SGND

DRI

CS-

CS+

REG2

DGT

QGND

DRV

SNS+

SNS-

R

SENSE

Q

S

LEDs

R

D

OV

C

F

R1

C2

C1

R2

C

REG2

Page 19

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

______________________________________________________________________________________ 19

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QFN THIN.EPS

PACKAGE OUTLINE,

16, 20, 28, 32, 40L THIN QFN, 5x5x0.8mm

21-0140

1

K

2

Page 20

MAX16831

High-Voltage, High-Power LED Driver with

Analog and PWM Dimming Control

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

PACKAGE OUTLINE,

16, 20, 28, 32, 40L THIN QFN, 5x5x0.8mm

21-0140

2

K

2

Loading...

Loading...