Page 1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

General Description

The MAX1669 fan controller includes a precise digital

thermometer that reports the temperature of a remote

sensor. The remote sensor is a diode-connected transistor—typically a low-cost, easily mounted 2N3906 PNP

type—replacing conventional thermistors or thermocouples. Remote accuracy is ±3°C for transistors from multiple manufacturers, with no calibration needed. The

MAX1669 has an independent fan controller with a lowcurrent logic output requiring external power components to interface to a DC brushless fan. The fan

controller has two modes of operation: a low-frequency

(20Hz to 160Hz) PWM mode intended for driving the fan

motor, or a high-impedance DAC output that generates

a variable DC control voltage. In PWM mode, the FAN

frequency can be synchronized to an external clock.

Other key features include general-purpose inputs/outputs (GPIOs) for fan presence detection and a thermostat output intended as a fan override signal in case the

host system loses the ability to communicate. The internal ADC has a wide input voltage range and gives

overrange readings when too large an input voltage is

applied. Other error-checking includes temperature

out-of-range indication and diode open/short faults.

The MAX1669 is available in a space-saving 16-pin

QSOP package that allows it to fit adjacent to the

SLOT1 connector.

Applications

Pentium®CPU Cooling

Desktop Computers

Notebook Computers

Servers

Workstations

Features

♦ Measures Remote CPU Temperature

♦ No Calibration Required

♦ 20Hz to 160Hz PWM Output for Fan

♦ PWM Frequency Sync Input (260kHz)

♦ Flexible Fan Interface: Linear or PWM

♦ SMBus 2-Wire Serial Interface

♦ Programmable Under/Overtemperature Alarms

♦ ALERT Latched Interrupt Output

♦ OVERT Thermostat Output

♦ Two GPIO Pins

♦ Write-Once Configuration Protection

♦ Supports SMBus Alert Response

♦ ±3°C Temperature Accuracy (-40°C to +125°C,

remote)

♦ 3µA Standby Supply Current

♦ +3V to +5.5V Supply Range

♦ Small 16-Pin QSOP Package

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

________________________________________________________________ Maxim Integrated Products 1

19-1574; Rev 0; 1/00

PART

MAX1669EEE

-40°C to +85°C

TEMP. RANGE PIN-PACKAGE

16 QSOP

Pentium is a registered trademark of Intel Corp.

Pin Configuration

Ordering Information

Typical Operating Circuit appears at end of data sheet.

TOP VIEW

1

I/O1 OVERT

I/O2

2

ADD0

3

MAX1669

4

ADD1

ADD2

5

AGND

6

DXN

7

DXP

8

16

15

14

13

12

11

10

9

ALERT

SMBDATA

SMBCLK

PGND

FAN

SYNC

V

CC

QSOP

Page 2

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

2 _______________________________________________________________________________________

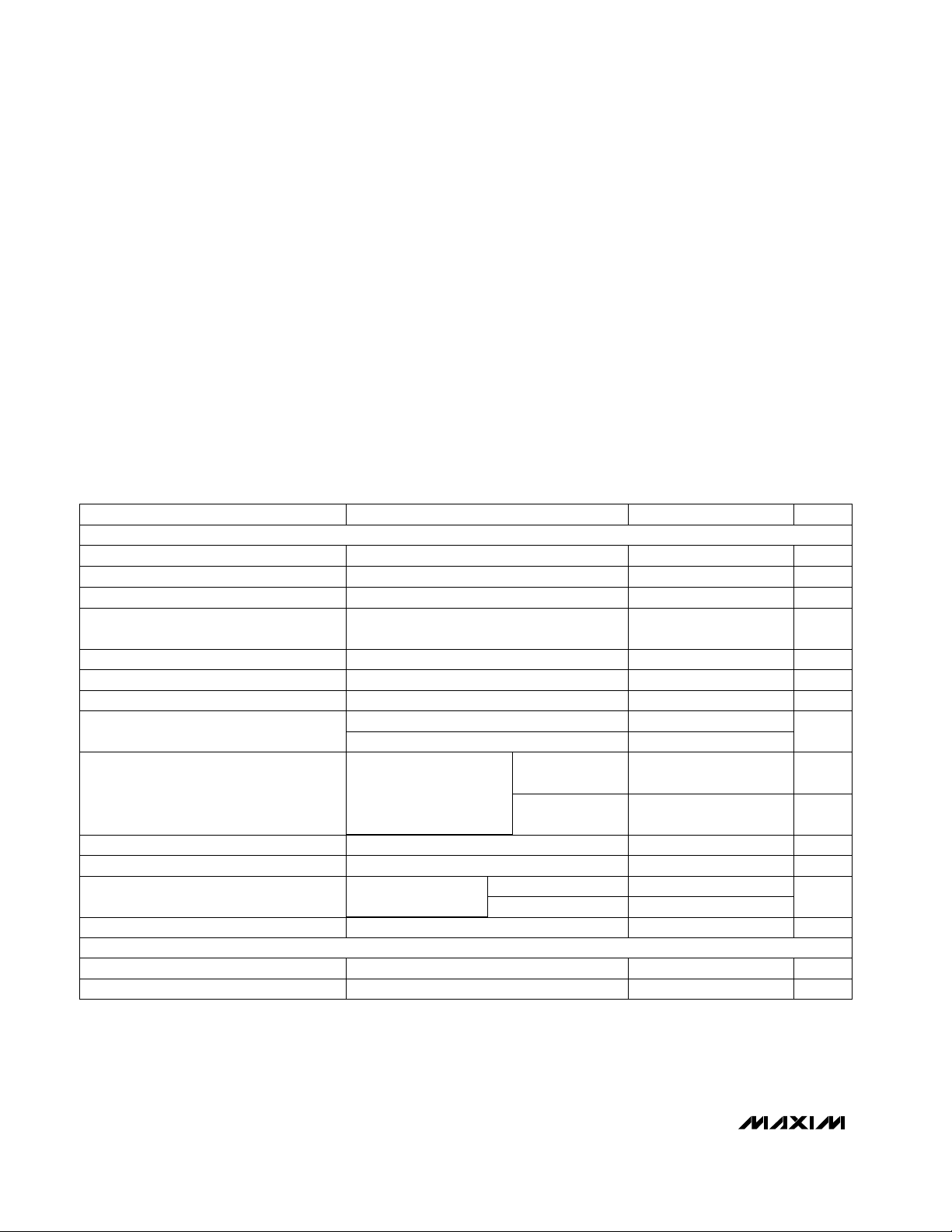

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= +3.3V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCCto AGND...........................................................-0.3V to +6V

DXP, ADD_ to AGND.................................-0.3V to (V

CC

+ 0.3V)

DXN to AGND.......................................................-0.3V to +0.8V

SMBCLK, SMBDATA, ALERT, SYNC,

I/O1, I/O2, OVERT, FAN to AGND ......................-0.3V to +6V

FAN to PGND ............................................-0.3V to (V

CC

+ 0.3V)

PGND to AGND ....................................................-0.3V to +0.3V

PWM Current....................................................-50mA to +50mA

SMBDATA Current .............................................-1mA to +50mA

I/O1, I/O2 Current...............................................-1mA to +25mA

DXN Current ......................................................................±1mA

ESD Protection (all pins, Human Body Model) .................2000V

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.30mW/°C above +70°C).......667mW

Operating Temperature Range (extended)......-55°C to +125°C

Junction Temperature.....................................................+150°C

Storage Temperature Range ............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

FAN output set to

DAC mode

FAN output set to

150Hz mode

TR= 0°C to +100°C, diode ideality factor = 1.013

High level

PWM mode, V

FAN

forced to 0.4V

PWM mode, V

FAN

forced to 2.9V

Monotonicity guaranteed

V

DXP

forced to V

DXN

+ 0.65V

SMBus static

Autoconvert mode

From stop bit to conversion complete

VCC, falling edge

VCCinput, disables A/D conversion,

rising edge

Autoconvert mode,

average measured over 1s

CONDITIONS

mA

-10

FAN Output Sink Current

mA

10

FAN Output Source Current

V

0.7

DXN Source Voltage

80 100 120

µARemote-Diode Source Current

Hz

1.6 2 2.4

Conversion Rate

ms

47 62 78

Conversion Time

µA

360

µA

75 150

Average Operating Supply Current

°CTemperature Error, Remote Diode (Note 2)

Bits

8

Resolution (Note 1)

310

µAStandby Supply Current

mV

50

POR Threshold Hysteresis

V

1 1.9 2.5

Power-On Reset Threshold

-3 3

V

3 5.5

Supply Voltage Range

V

2.6 2.8 2.95

Undervoltage Lockout Threshold

mV

50

Undervoltage Lockout Hysteresis

UNITSMIN TYP MAXPARAMETER

SMBCLK at 10kHz

3

Low level

81012

ADC AND POWER SUPPLY

FAN OUTPUT

Page 3

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

_______________________________________________________________________________________ 3

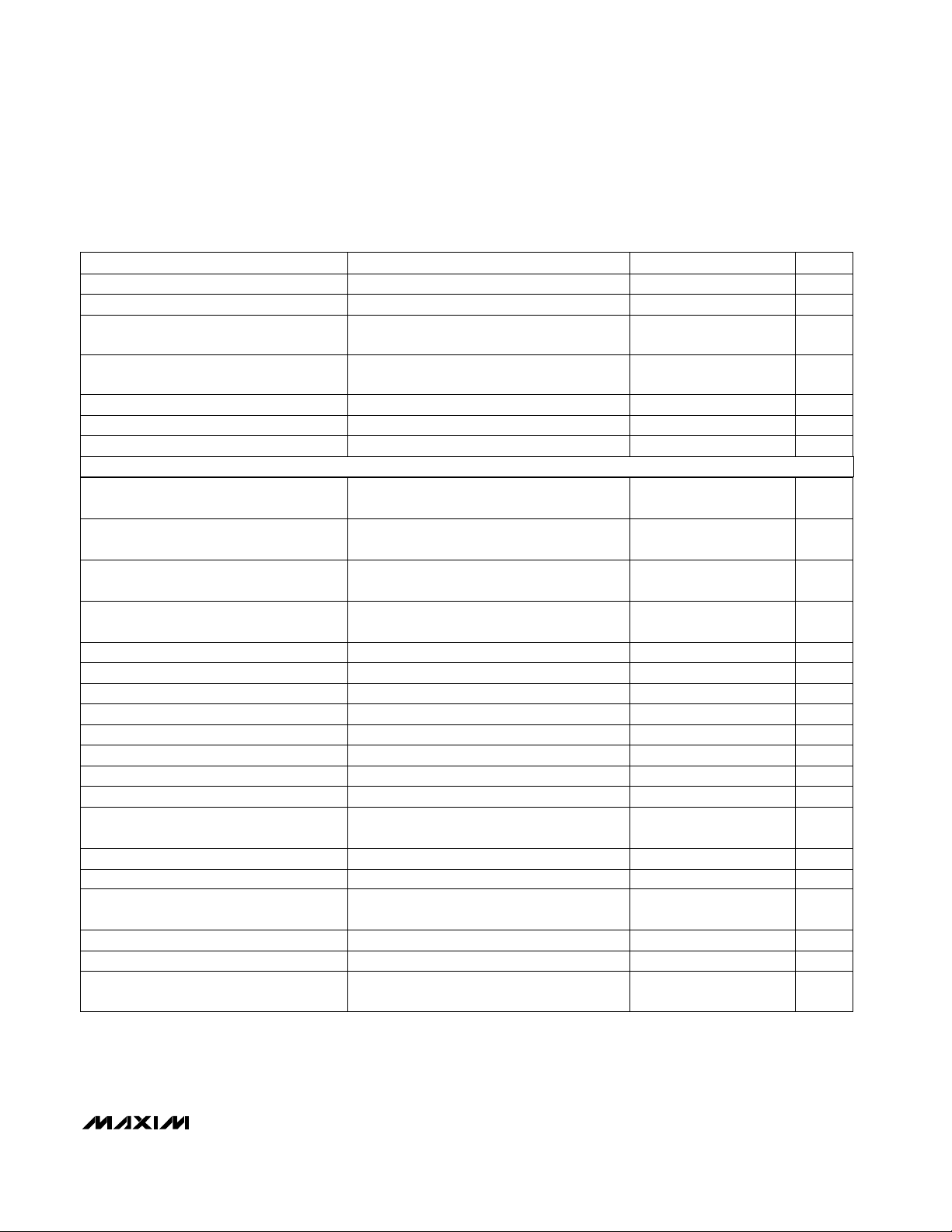

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +3.3V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Logic Input High Voltage

PARAMETER MIN TYP MAX UNITS

FAN PWM Frequency Error

-20 +20

%

FAN Total Unadjusted Error

-4 4

%FS

FAN Output Voltage High

2.96 3.06

V

CONDITIONS

PWM mode, any setting

DAC mode, any setting, RL= 10kΩ to GND

DAC mode, FAN duty factor = 1111b,

I

OUT

= 5mA

SYNC Input Low Period

500

ns

SYNC Input High Period

500

ns

SYNC Capture Range

140 260 400

kHz

2.1

V

Logic Input Low Voltage

0.8

V

SMBDATA, ALERT, OVERT, I/O1, I/O2

Output Low Sink Current

6

mA

FAN Output Voltage Low

0.05 0.2

V

ALERT, OVERT, I/O1, I/O2 Output

High Leakage Current

1

µA

Logic Input Current

-1 1

µA

SMBus Input Capacitance

5

pF

SMBus Clock Frequency

DC 100

kHz

SMBCLK Clock Low Time (t

LOW

)

4.7

µs

SMBCLK Clock High Time (t

HIGH

)

4

µs

SMBus Rise Time

1

µs

SMBus Fall Time

300

ns

SMBus Start Condition Setup Time

4.7

µs

SMBus Repeated Start Condition Setup

Time (t

SU:STA

)

500

ns

SMBus Start Condition Hold Time (t

HD:STA

)

4

µs

SMBus Stop Condition Setup Time (t

SU:STO

)

4

µs

SMBus Data Valid to SMBCLK

Rising-Edge Time (t

SU:DAT

)

250

ns

Pin forced to 5.5V

Logic inputs forced to VCCor GND

ADD_, I/O1, I/O2, SYNC, SMBCLK, SMBDATA;

VCC= 3V to 5.5V

ADD_, I/O1, I/O2, SYNC, SMBCLK, SMBDATA;

VCC= 3V to 5.5V

SMBCLK, SMBDATA

(Note 3)

Pin forced to 0.4V

10% to 10% points

90% to 90% points

SMBCLK, SMBDATA, 10% to 90% points

SMBCLK, SMBDATA, 90% to 10% points

90% to 90% points

DAC mode, FAN duty factor = 0000b,

I

OUT

= -5mA

10% of SMBDATA to 90% of SMBCLK

90% of SMBCLK to 10% of SMBDATA

10% or 90% of SMBDATA to 10% of SMBCLK

SMBus Data-Hold Time (t

HD:DAT

)

0

µs

SMBus Bus-Free Time (t

BUF

)

4.7

µs

SMBCLK Falling Edge to SMBus

Data-Valid Time

1

µs

(Note 4)

Between start/stop conditions

Master clocking-in data

SMBus INTERFACE (Figures 7, 8)

Page 4

Note 1: Guaranteed but not 100% tested.

Note 2: T

R

is the junction temperature of the remote diode. The temperature error specification is optimized to and guaranteed for a

diode-connected 2N3906 transistor with ideality factor = 1.013. Variations in the ideality factor “m” of the actual transistor

used will increase the temperature error by *. See the Temperature Error vs. Remote Diode Temperature graph in the

Typical Operating Characteristics for typical temperature errors using several random 2N3906s. See Remote Diode

Selection for remote diode forward-voltage requirements.

Note 3: The SMBus logic block is a static design that works with clock frequencies down to DC. While slow operation is possible, it

violates the 10kHz minimum clock frequency and SMBus specifications, and may monopolize the bus.

Note 4: Note that a transition must internally provide at least a hold time in order to bridge the undefined region (300ns max) of

SMBCLK’s falling edge.

Note 5: Specifications to -40°C are guaranteed by design and not production tested.

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

4 _______________________________________________________________________________________

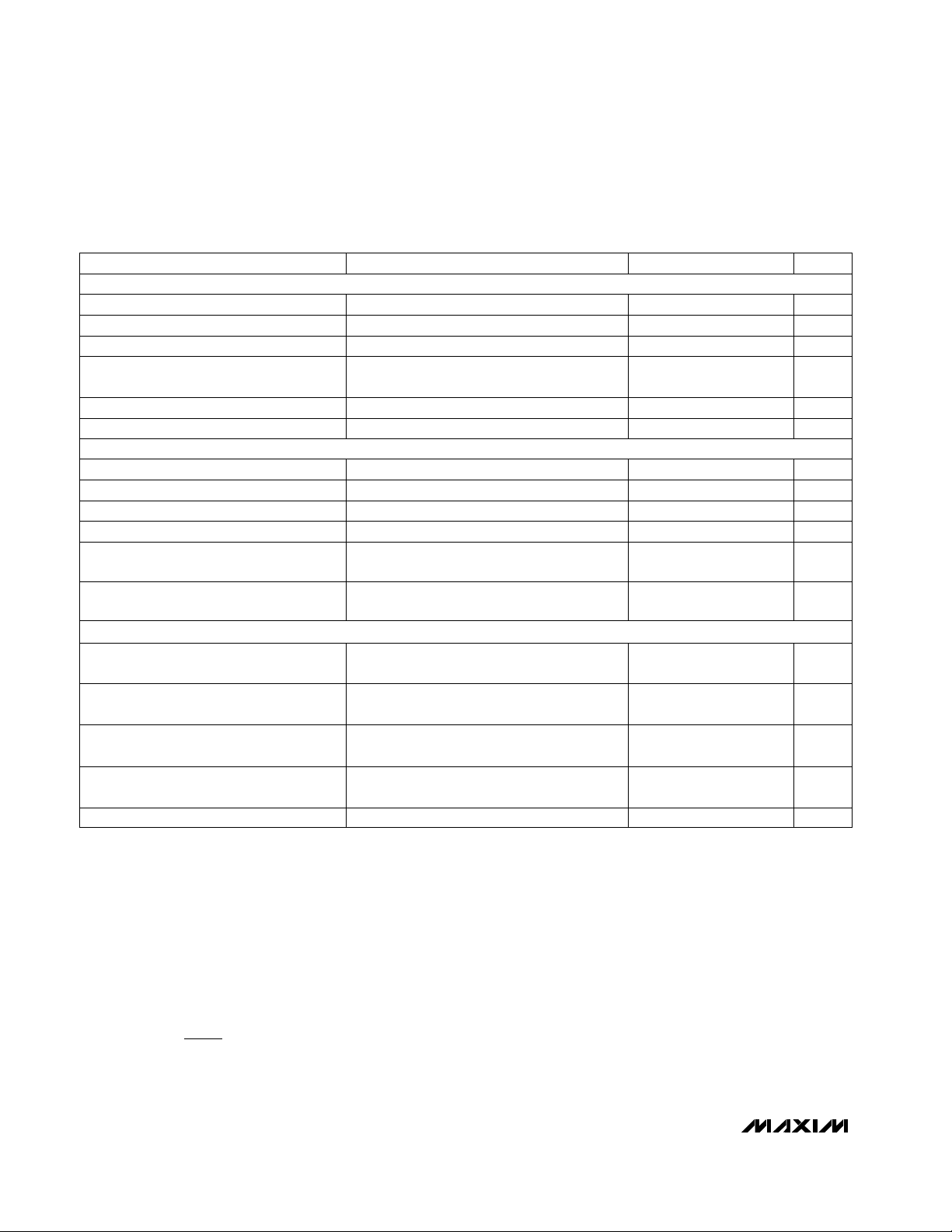

ELECTRICAL CHARACTERISTICS

(VCC= +3.3V, TA= -40°C to +85°C, unless otherwise noted.) (Note 5)

Pin forced to 0.4V

ADD_, I/O1, I/O2, SYNC, SMBCLK, SMBDATA;

VCC= 3V to 5.5V

ADD_, I/O1, I/O2, SYNC, SMBCLK, SMBDATA;

V

CC

= 3V to 5.5V

Logic inputs forced to VCCor GND

Pin forced to 5.5V

µA

-1 1

Logic Input Current

µA

1

ALERT, OVERT, I/O1, I/O2 Output

High Leakage Current

V

0.2

FAN Output Voltage Low

mA

6

SMBDATA, ALERT, OVERT, I/O1, I/O2

Output Low Sink Current

V

0.8

Logic Input Low Voltage

V

2.1

Logic Input High Voltage

DAC mode, FAN duty factor = 1111b,

I

OUT

= 5mA

DAC mode, any setting, RL= 10kΩ to GND

PWM mode, any setting

PWM mode, V

FAN

forced to 0.4V

PWM mode, V

FAN

forced to 2.9V

Monotonicity guaranteed

Autoconvert mode

From stop bit to conversion complete

TR= -55°C to +125°C, diode ideality factor = 1.013

Autoconvert mode, average measured over

1sec, FAN output set to 150Hz mode

CONDITIONS

V

2.94

FAN Output Voltage High

%FS

-5 5

FAN Total Unadjusted Error

%

-25 +25

FAN PWM Frequency Error

mA

-10

FAN Output Sink Current

mA

10

FAN Output Source Current

Hz

1.6 2.4

Conversion Rate

ms

47

Conversion Time

µA

100

Average Operating Supply Current

Bits

8

Temperature Resolution (Note 1)

°C

-5 5

Temperature Error, Remote Diode (Note 2)

UNITSMIN MAXPARAMETER

DAC mode, FAN duty factor = 0000b,

I

OUT

= -5mA

V

3 5.5

Supply Voltage Range

ADC AND POWER SUPPLY

FAN OUTPUT

SMBus INTERFACE

1 013

*

.

=−

m

1 273 15

. ∆T

()

kT C

+

°

()

R

Page 5

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

_______________________________________________________________________________________ 5

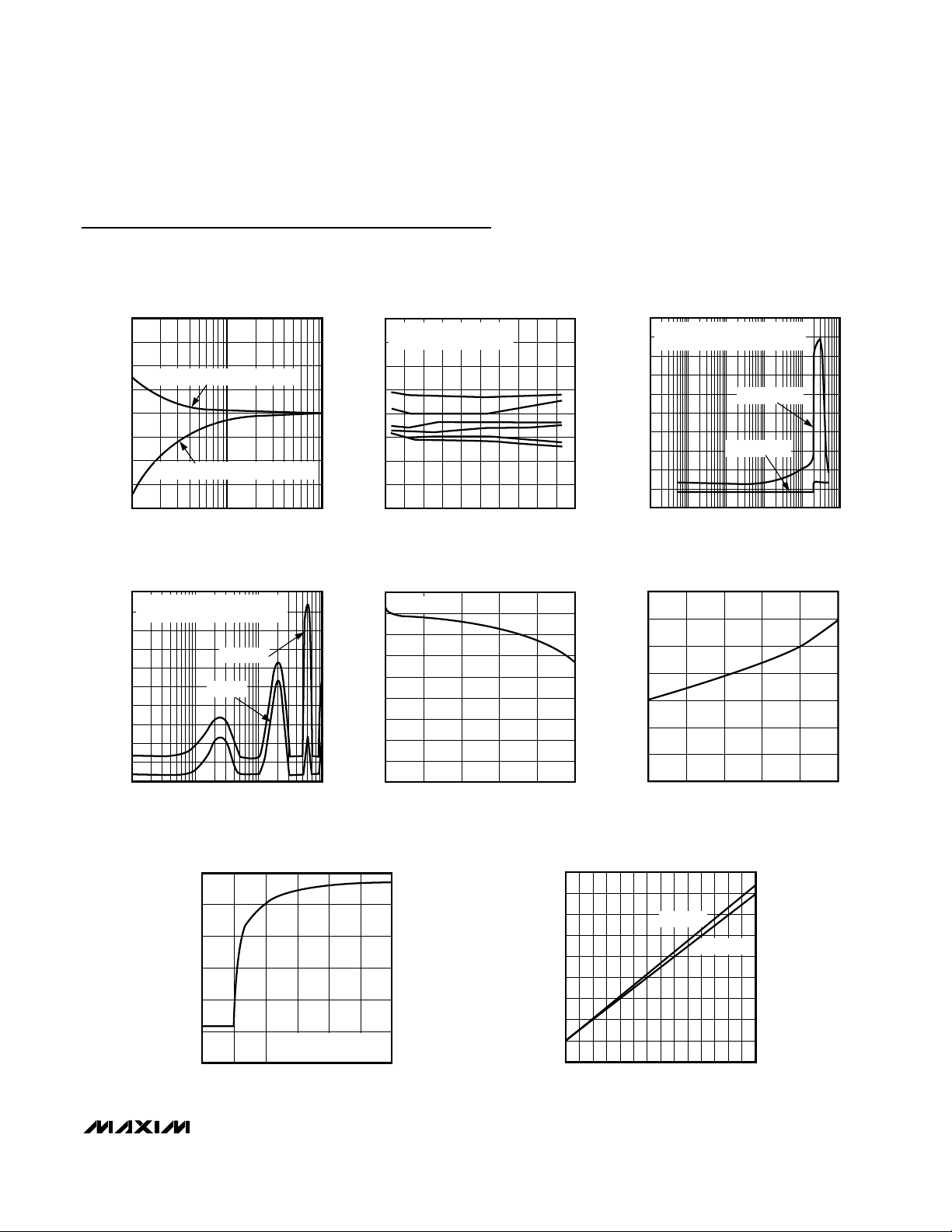

Typical Operating Characteristics

(Temperature error = measured - actual, TA= +25°C, unless otherwise noted.)

TEMPERATURE ERROR

vs. LEAKAGE RESISTANCE

40

30

20

10

-10

-20

TEMPERATURE ERROR (°C)

-30

-40

PATH = DXP TO GND; CONFIG = 02h

0

PATH = DXP TO V

1 10 100

LEAKAGE RESISTANCE (MΩ)

(5V); CONFIG = 02h

CC

TEMPERATURE ERROR vs.

COMMON-MODE NOISE FREQUENCY

8

VIN = 50mVp-p AC-COUPLED TO DXN

7

C = DXN - DXP CAPACITANCE

6

5

4

3

2

1

TEMPERATURE ERROR (°C)

0

-1

-2

1M 1G100M10M

C = 2200pF

C = 27nF

FREQUENCY (Hz)

MAX1669-01

MAX1669-04

2.0

1.5

1.0

0.5

0

-0.5

TEMPERATURE ERROR (°C)

-1.0

-1.5

-2.0

2

0

-2

-4

-6

-8

-10

TEMPERATURE ERROR (°C)

-12

-14

-16

TEMPERATURE ERROR

vs. REMOTE DIODE TEMPERATURE

RANDOM 2N3906s FROM

DIFFERENT MANUFACTURERS

-60 20-20 60 100-40 400 80 120 140

TEMPERATURE (°C)

TEMPERATURE ERROR

vs. DXP - DXN CAPACITANCE

V

= 5V

CC

02010 30 40 50

DXP-DXN CAPACITANCE (nF)

MAX1669-02

MAX1669-05

TEMPERATURE ERROR vs.

POWER-SUPPLY NOISE FREQUENCY

18

VIN = SQUARE WAVE APPLIED TO

16

14

12

10

TEMPERATURE ERROR (°C)

-2

WITH NO 0.1µF VCC CAPACITOR

V

CC

VIN = 250mVp-p

8

6

4

2

0

1K 10K 100K 1M 10M 100M

VIN = 100mVp-p

PSNF (Hz)

STANDBY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

7

6

5

4

3

2

STANDBY SUPPLY CURRENT (µA)

1

0

3.0 4.03.5 4.5 5.0 5.5

SUPPLY VOLTAGE (V)

MAX1669-03

MAX1669-06

RESPONSE TO THERMAL SHOCK

120

100

80

60

TEMPERATURE (°C)

40

20

0

-2 2 406810

CMPT3906 IMMERSED IN

+115°C FLUORINERT BATH

TIME (sec)

MAX1669-07

PWM FREQUENCY vs. CODE (F3F2F1F0)

180

160

140

120

100

80

60

PWM FREQUENCY (Hz)

40

20

0

042 5 7 8 10 123169111314

V

= +5V

CC

CODE (F3F2F1F0)

V

CC

= +3.3V

MAX1669-08

Page 6

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

6 _______________________________________________________________________________________

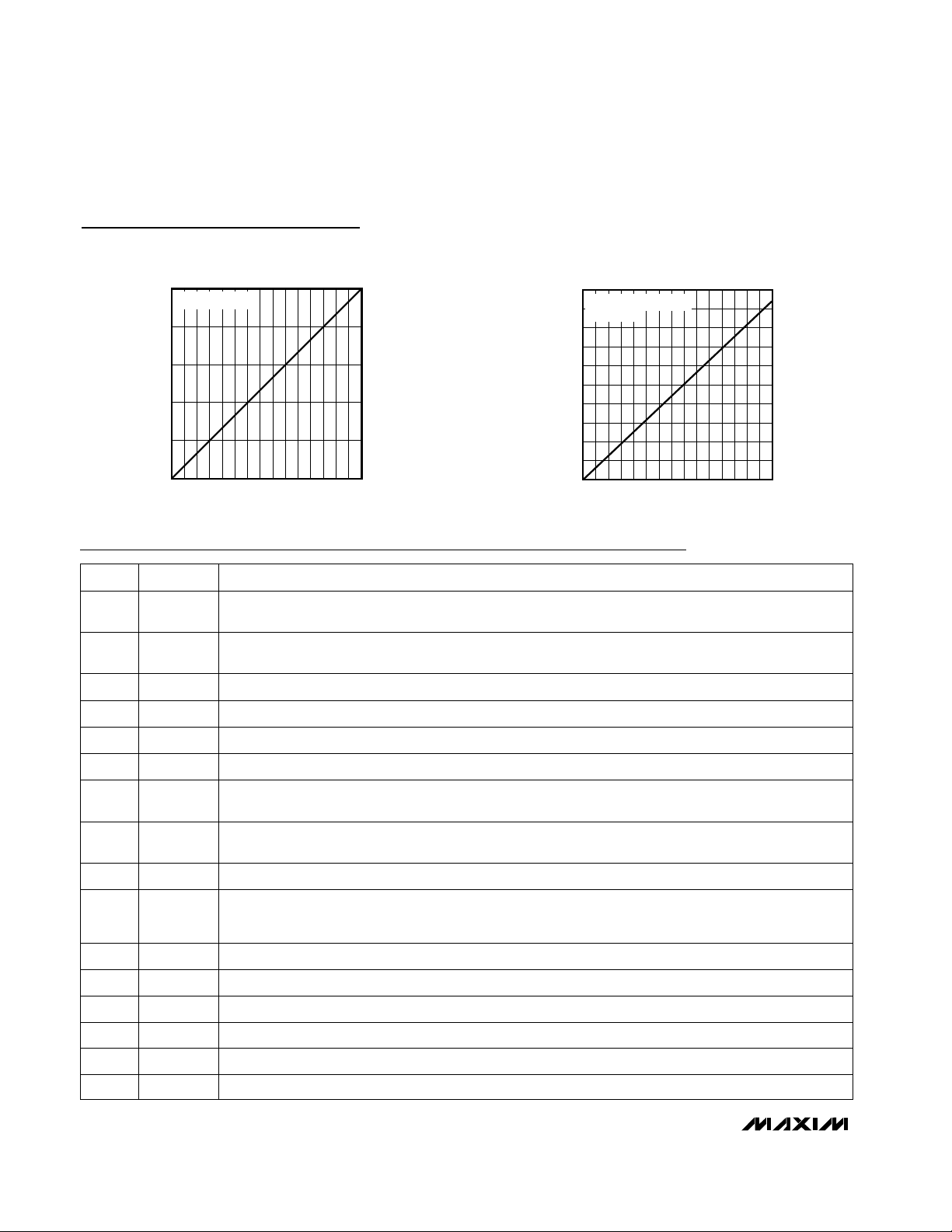

Typical Operating Characteristics (continued)

(Temperature error = measured - actual, TA= +25°C, unless otherwise noted.)

Pin Description

NAME FUNCTION

1

I/O1

General-Purpose Open-Drain Logic Input/Output 1. I/O1 is intended for driving LEDs, driving power-plane

switching MOSFETs, or detecting fan presence or chassis intrusion.

2 I/O2

General-Purpose Open-Drain Logic Input/Output 2. I/O2 is intended for driving LEDs, driving power-plane

switching MOSFETs, or detecting fan presence or chassis intrusion.

PIN

3 ADD0 SMBus Address Select Pin 0. See Table 11.

4 ADD1 SMBus Address Select Pin 1. See Table 11.

8 DXP

Combined Current Source and ADC Positive Input from Remote Diode. Place a 2200pF capacitor

between DXP and DXN for noise filtering.

7 DXN

Combined Current Sink and ADC Negative Input from Remote Diode. DXN is normally biased to a diode

voltage above ground.

6 AGND Analog Ground

5 ADD2 SMBus Address Select Pin 2. See Table 11.

13 SMBCLK SMBus Serial-Clock Input

12 PGND Power Ground

11 FAN

Fan-Control Logic Output. Swings from PGND to VCCin PWM mode, or PGND to 0.94 · VCCin DAC mode.

10 SYNC

Oscillator Synchronization Input. Connect to AGND to use internal clock. Capture range is 140kHz to

400kHz. The synchronization signal is internally applied to the FAN PWM clock. See Table 5 for synchronized frequencies.

9 V

CC

Supply Voltage Input, +3V to +5.5V. Bypass to AGND with a 0.1µF capacitor.

16

OVERT

Active-Low, Open-Drain Thermostat Output. Activated by T

CRIT

threshold

15

ALERT

Active-Low, Open-Drain SMBus Alert (interrupt) Output

14 SMBDATA Open-Drain SMBus Serial-Data Input/Output

PWM DUTY FACTOR vs. CODE (D3D2D1D0)

100

V

= +3.3V OR +5V

CC

80

60

40

DUTY FACTOR (%)

20

0

042 5 7 8 10 1231 6 9 11 131415

CODE (D3D2D1D0)

MAX1669-09

DAC OUTPUT vs. CODE (D3D2D1D0)

5.0

I

= +10mA TO -10mA

LOAD

4.5

= +5V

V

CC

4.0

3.5

3.0

2.5

2.0

DAC OUTPUT (V)

1.5

1.0

0.5

0

042 5 7 8 10 1231691114

CODE (D3D2D1D0)

13

MAX1669-10

15

Page 7

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

_______________________________________________________________________________________ 7

_______________Detailed Description

The MAX1669 temperature sensor is designed to work

with an external microcontroller (µC) or other intelligent

devices in computer fan-control applications. The µC is

typically a power-management or keyboard controller,

generating SMBus serial commands by “bit-banging’’

general-purpose input/output (GPIO) pins or through a

dedicated SMBus interface block.

Essentially an 8-bit serial analog-to-digital converter

(ADC) with a sophisticated front end, the temperature

measurement channel contains a switched-current

source, a multiplexer, and an integrating ADC.

Temperature data from the ADC is loaded into a data

register, where it is automatically compared with data

previously stored in over/undertemperature alarm registers and the critical register (Figure 1).

Figure 1. MAX1669 Temperature Sensor Functional Diagram

DXP

DXN

GND

V

CC

ADD0

ADD1

ADD2

SMBDATA

SMBCLK

ALERT

MUX

8

8

COMMAND-BYTE

(INDEX) REGISTER

REMOTE-TEMPERATURE

DATA REGISTER

HIGH-TEMPERATURE

THRESHOLD

LOW-TEMPERATURE

THRESHOLD

8

DIGITAL COMPARATOR

ADC

CONTROL

LOGIC

CONFIGURATION

BYTE REGISTER

STATUS BYTE REGISTER

ALERT RESPONSE

ADDRESS REGISTER

R

SQ

ADDRESS

DECODER

SMB

READ WRITE

88

MAX1669

CONTROL

LOGIC

TEMPERATURE SENSOR

I/O1

I/O2

GENERAL-PURPOSE

I/O CONTROLLER

TEMPERATURE

T

CRIT

-5°C

OVERT

R

S

Q

CONTROL

LOGIC

Page 8

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

8 _______________________________________________________________________________________

The PWM or DAC fan control circuitry is completely

independent from the temperature measurement, and

software closes the temperature-control feedback loop

(Figure 2).

ADC and Multiplexer

The ADC is an averaging type that integrates over a

62ms period (typ), with excellent noise rejection. The

multiplexer automatically steers bias currents through

the remote diode, measures the forward voltage, and

calculates the temperature.

The DXN input is biased at 0.7V above ground by an

internal diode to set up the analog-to-digital (A/D)

inputs for a differential measurement. The worst-case

DXP-DXN differential input voltage range is 0.21V to

0.95V. Diode voltages that are outside the ADC input

range cause overrange indications rather than nonmonotonic readings. Overrange readings will return

+127°C. Excess resistance in series with the remote

diode causes approximately +1/2°C error/Ω. Likewise,

200µV of offset voltage forced on DXP-DXN causes

approximately +1°C error.

A/D Conversion Sequence

When the device is taken out of standby mode, the

result of the measurement is available one conversion

time later (78ms max). If the ADC is busy, the results of

the previous conversion are always available. Toggling

the standby mode on and off is a good way to initiate a

new conversion since this action resets the rate timer.

Low-Power Standby Mode

Supply-current drain during the 62ms conversion period is 500µA. Between conversions, the instantaneous

supply current is 18µA. In standby mode, supply current drops to 3µA and the fan output is disabled.

SMBus Digital Interface

From a software perspective, the MAX1669 appears as

a set of byte-wide registers that contain temperature

data, alarm threshold values, or control bits. A standard

SMBus 2-wire serial interface is used to read temperature data and write control bits and alarm threshold

data.

The MAX1669 employs four standard SMBus protocols:

write byte, read byte, send byte, and receive byte

(Figure 3). The two shorter protocols (receive and

send) allow quicker transfers, provided that the correct

data register was previously selected by a write or read

byte instruction. Use caution with the shorter protocols

in multimaster systems since a second master could

overwrite the command byte without informing the first

master.

The temperature data format is 7 bits plus sign in two’s

complement form for each channel, with the LSB representing +1°C (Table 1), MSB transmitted first.

Measurements are offset by +1/2°C to minimize internal

rounding errors; for example, +99.5°C to +100.4°C is

reported as +100°C.

Alarm Threshold Registers

Three registers store alarm threshold data, with hightemperature (T

HIGH

) and low-temperature (T

LOW

) reg-

isters that activate the ALERT output, and a critical

overtemperature register (T

CRIT

) that activates the

OVERT output. If a measured temperature equals or

exceeds the T

HIGH

or T

LOW

threshold value, an ALERT

interrupt is asserted. Do not set the T

CRIT

register to

values outside of the temperatures in Table 1.

The power-on-reset (POR) state of the T

HIGH

register is

full scale (0111 1111b or +127°C). The POR state of the

T

LOW

register is 1100 1001b or -55°C. The POR state of

the T

CRIT

register is 0110 0100b or +100°C.

OVERT

Thermostat Output

The OVERT output is a self-clearing interrupt output

that is activated when the temperature equals or

exceeds T

CRIT

. OVERT normally goes low when active,

but this polarity can be changed through the configuration register. The latch is cleared when the temperature

reading is equal to or less than T

CRIT

minus 5°C, which

provides for 5°C of hysteresis.

The ALERT and OVERT comparisons are made after

each conversion, and at the end of a write command to

their respective temperature limit registers. For example, if the limit is changed while the device is in standby

Figure 2. MAX1669 Fan-Control Functional Diagram

FREQ

REGISTER

DUTY

REGISTER

(0XF0)

UPPER NIBBLE

4

CONTROLLER

AND

PWM

DAC

MUX

FANON

OVERT

MAX1669

DRIVER

CONTROL

LOGIC

FAN

Page 9

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

_______________________________________________________________________________________ 9

mode, the ALERT and OVERT outputs respond correct-

ly according to the last valid A/D result.

Note that the ALERT output does not respond to T

CRIT

(OVERT) comparisons.

The OVERT latch can implement an override control to

the FAN output, which forces the fan to V

CC

whenever

the T

CRIT

threshold is crossed. This override switch is

the backup fan control loop, and is enabled through the

FAN ON bit in the configuration register (bit 2). Note

that changing the duty to 100% in this way doesn’t

affect the contents of the DUTY register, and the FAN

output reverts to the preprogrammed duty factor (or

DAC voltage) when the OVERT latch is reset.

Diode Fault Alarm

A continuity fault detector at DXP detects whether the

remote diode has an open-circuit condition, short-circuit to GND, or short-circuit DXP-to-DXN condition. At

the beginning of each conversion, the diode fault is

checked and the status byte updated. This fault detector is a simple voltage detector; DXP rising above VCC1V or falling below DXN + 40mV constitutes a fault condition. Also, if the ADC has an extremely low differential

input voltage, the diode is assumed to be shorted and

a fault occurs. Note that the diode fault isn’t checked

until a conversion is initiated, so immediately after

power-on reset the status byte indicates no fault is present even if the diode path is broken. Any diode fault

will return a +127°C fault reading and cause ALERT to

go low.

Write Byte Format

Read Byte Format

7-bit slave address:

equivalent to chip-select line

Command byte: selects which

register you are writing to

Data byte: data goes into the register

set by the command byte (to set

thresholds, configuration masks, and

sampling rate)

Slave address:

equivalent to chip-select

line

Command byte: selects

which register you are

reading from

Slave address: repeated

due to change in dataflow direction

Data byte: reads from

the register set by the

command byte

S = Start condition Shaded = Slave transmission

P = Stop condition

A

= Not acknowledged

Figure 3. SMBus Protocols

S

1

WR1ACK1COMMAND

8 bits

ACK

1

S1ADDRESS

7 bits

RD1ACK1DATA

8 bits

A

1

P

1

1

S ADDRESS

7 bits 1

WR ACK

1 8 bits

COMMAND ACK

1 8 bits

DATA ACK

1 1

P

TEMP (°C)

ROUNDED

TEMP (°C)

+0.25 +0

+0.50 +1

+25.25 +25

+126.00 +126

+0.00 +0

-0.25 +0

-0.50 +0

-0.75 -1

+127.00

+130.00 +127

+127

+126.50 +127

-1.00 -1

-25.00 -25

-25.50 -26

-54.75 -55

-55.00 -55

-65.00 -65

-70.00 -65

DIGITAL OUTPUT

DATA BITS

SIGN MSBs LSBs

1 111 1111

0 000 0000

1 110 0111

0 000 0001

0 001 1001

0 111 1110

0 000 0000

0 000 0000

1 110 0110

1 100 1001

0 000 0000

1 111 1111

1 100 1001

1 011 1111

1 011 1111

0 111 1111

0 111 1111

0 111 1111

Table 1. Data Format (Two’s Complement)

ADDRESS

7 bits

Page 10

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

10 ______________________________________________________________________________________

ALERT

Interrupts

The ALERT interrupt output signal is latched and can

only be cleared by reading the Alert Response

address. Interrupts are generated in response to T

HIGH

and T

LOW

comparisons, when there is a fault with the

remote diode, or when a high-to-low or low-to-high transition at I/O1 or I/O2 is detected.

The interrupt does not halt automatic conversions; new

temperature data continues to be available over the

SMBus interface after ALERT is asserted. The interrupt

output is open-drain so that devices can share a common interrupt line. The interface responds to the SMBus

Alert Response address, an interrupt pointer returnaddress feature (see the Alert Response Address section).

The ALERT interrupt latch is set when the temperature

exceeds an ALARM threshold. ALERT will not be set

again until the threshold is reprogrammed. This prevents the ALERT latch from being set again during the

interval between reading the Alert Response address

and updating the offending alarm threshold. Note that

this behavior is identical to the MAX1618 but is slightly

different from the MAX1617, which continues to interrupt until the temperature no longer exceeds the alarm

threshold. Note also that if some new alarm condition

occurs, such as crossing the other alarm threshold or

having a GPIO transition, a new interrupt is generated.

ALERT Response Address

The SMBus Alert Response interrupt pointer provides

quick fault identification for simple slave devices that

lack the complex, expensive logic needed to be a bus

master. Upon receiving an ALERT interrupt signal, the

host master can broadcast a receive byte transmission

to the Alert Response slave address (0001100b). Then

any slave device that generated an interrupt attempts

to identify itself by putting its own address on the bus

(Table 2).

The Alert Response can activate several different slave

devices simultaneously, similar to the I2C General Call.

If more than one slave attempts to respond, bus arbitration rules apply, and the device with the lower address

code wins. The losing device does not generate an

acknowledge and continues to hold the ALERT line low

until serviced. Successful reading of the alert response

address clears the interrupt latch.

Command Byte Functions

The 8-bit command byte register (Table 3) is the master

index that points to the MAX1669’s other registers. The

register’s POR state is 00000001b, so a receive byte

transmission (a protocol that lacks the command byte)

that occurs immediately after POR returns the current

remote temperature data.

One-Shot Conversion

The one-shot command immediately forces a new conversion cycle to begin. In software standby mode

(STBY bit = 1), a new conversion starts, after which the

device returns to standby mode. If a conversion is in

progress when a one-shot command is received, the

command is ignored. If a one-shot command is

received in autoconvert mode (STBY bit = 0) between

conversions, a new conversion begins, the conversion

rate timer is reset, and the next automatic conversion

takes place after a full period.

Configuration Byte Functions

The configuration byte register (Table 4) is used to

mask (disable) interrupts, set the OVERT output polarity, and put the device in software standby mode. Bit 1

of the configuration byte in Table 4 is for factory use

only and must be set to 1 (value at POR). This register’s

contents can be read back over the serial interface.

FAN PWM Frequency and

Duty Factor Control

The fan speed is controlled by the average voltage

applied to the fan. The average voltage is equal to the

product of the motor power-supply voltage and the

duty factor. The duty factor is equal to zero upon startup and it is software controlled. The FAN output frequency is controlled by the PWM frequency register

unless this register’s code is set to 1111b (Table 5). A

PWM frequency code of 1111b puts the FAN output in

DAC mode. For all other codes, the FAN frequency is in

the 20Hz to 160Hz range as shown in Table 5. For the

possible synchronized frequencies, also see Table 5.

The FAN output duty factor is controlled by the FAN

duty factor register unless the PWM frequency code is

BIT NAME

1 ADD1

2 ADD2

3 ADD3

4 ADD4

0 (LSB) 1

6

7 (MSB) ADD7

ADD6

5 ADD5

FUNCTION

Logic 1

Provide the MAX1669

slave address

Table 2. Read Format for the Alert

Response Address (0001100b)

Page 11

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

______________________________________________________________________________________ 11

REGISTER COMMAND FUNCTION

00h Reserved for future useN/A

RTEMP 01h Read latest temperatureN/A

RSTAT 02h Read status byte (temp flags, I/O_ states)N/A

RCFG 03h Read configuration byte0000 0010b

04h Reserved for future useN/A

05h Reserved for future useN/A

06h Reserved for future useN/A

RHI 07h Read T

HIGH

limit0111 1111b

RLOW 08h Read T

LOW

limit1100 1001b

WCFG 09h Write configuration byteN/A

0Ah Reserved for future useN/A

0Bh Reserved for future useN/A

0Ch Reserved for future useN/A

WHI 0Dh Write T

HIGH

limitN/A

WLOW 0Eh Write T

LOW

limitN/A

OSHT 0Fh

One-shot command. Will execute a single conversion even if the

device is in software standby.

N/A

RCRIT 10h Read T

CRIT

limit0110 0100b

RPROT 11h Read write-once protection byte0000 0000b

RFREQ 12h Read PWM frequency0000 0000b

RDUTY 13h Read FAN duty factor0000 0000b

RGPIO 14h Read GPIO data1100 0000b

15h Reserved for future useN/A

16h Reserved for future useN/A

17h Reserved for future useN/A

WCRIT

POR STATE

18h Write T

CRIT

limitN/A

WPROT 19h Write write-once protection byteN/A

WFREQ 1Ah Write PWM frequencyN/A

WDUTY 1Bh Write FAN duty factorN/A

WGPIO 1Ch Write GPIO dataN/A

RFU 1Dh-FDh Reserved for future useN/A

MFG ID FEh Manufacturing ID code = 4Dh, ASCII code for “M” (for Maxim)

Least Sig Byte

0100 1101b

DEV ID FFh Device ID code, specific to MAX1669

Least Sig Byte

0000 0101b

Table 3. Command Byte Bit Assignments

ID Codes

Page 12

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

12 ______________________________________________________________________________________

set to 1111b. The FAN duty factor can be selected from

0% to 100% in increments of 6.67%.

FAN Output in DAC Mode

If the PWM frequency register is set to code 1111b, the

DAC is multiplexed to the FAN output and the FAN duty

factor register (Table 6) now controls the DAC output

voltage rather than the duty factor. In DAC mode, the

output swing is 0 to 0.94 · V

CC

(out of 4 bits of resolution). To ensure a smooth transition, make sure that the

FAN duty factor code is 0000b prior to setting the PWM

frequency code for DAC mode (1111b). External circuitry must accept an initial FAN DAC voltage of 0.

Must be “1”1

Reserved for future useRFU0

Masks I/O1 ALERT interrupts when high. Set MASK1 = 1 and connect a 10k to 100k

pull-up resistor on I/O1 to configure I/O1 as an output.

MASK14

Masks I/O2 ALERT interrupts when high. Set MASK2 = 1 and connect a 10k to 100k

pull-up resistor on I/O2 to configure I/O2 as an output.

MASK23

Enables FAN duty factor override when high.FAN ON2

OVERT pin polarity control:

0 = active low (low when T

CRIT

is crossed)

1 = active high

POL5

BIT

Standby mode control bit. If high, the device immediately stops converting, forces FAN

low, and enters standby mode. If low, the device continuously autoconverts at a 2Hz rate.

STBY6

Masks T

HIGH

, T

LOW

, and diode fault ALERT interrupts when high. If all three MASK_

bits are set high, ALERT interrupts are totally masked.

MASK0

7

(MSB)

FUNCTIONNAME

1

0

0

0

0

0

0

0

POR STATE

Table 4. Configuration Byte Bit Assignments

Table 5. PWM Frequency Data Byte Bit Assignments (Write Command = 1Ah)

Frequency control bitF04 0

Reserved for future useRFU3–0 0

Frequency control bitF15 0

0

0

POR STATE

Frequency control bit. F3–F0 are decoded as follows:

F3–F0 Frequency (SYNC = GND) Synchronized Frequency (SYNC Clocked)

0000b 20Hz f

SYNC

/13100

0001b 30Hz f

SYNC

/8730

0010b 40Hz f

SYNC

/6550

0011b 50Hz f

SYNC

/5240

0100b 60Hz f

SYNC

/4370

0101b 70Hz f

SYNC

/3740

0110b 80Hz f

SYNC

/3270

0111b 90Hz f

SYNC

/2910

1000b 100Hz f

SYNC

/2620

1001b 110Hz f

SYNC

/2380

1010b 120Hz f

SYNC

/2180

1011b 130Hz f

SYNC

/2020

1100b 140Hz f

SYNC

/1870

1101b 150Hz f

SYNC

/1750

1110b 160Hz f

SYNC

/1640

1111b DAC Mode

Frequency control bit

FUNCTION

F37 (MSB)

F26

NAMEBIT

Page 13

GPIO Data Register

I/O1 and I/O2 are configured through the GPIO data

register and CONFIG byte register (Table 7 and Table 3).

Upon power-up, the GPIOs are set as inputs. To ensure

the I/Os are configured as inputs, set the state of the

DATA1 and DATA2 bits high within the GPIO data register for I/O1 and I/O2, respectively. Figure 4 shows that

by setting the GPIO DATA_ bits high, the open-drain

FET connected to the I/O_ pins goes high impedance.

Next, clear the MASK1 and MASK2 bits low within the

CONFIG byte register to remove the masks on the

ALERT interrupts for I/O1 and I/O2, respectively.

To use I/O1 or I/O2 as an output, first set the MASK1

and MASK2 bits high, respectively. Setting the MASK_

bits high within the CONFIG byte register masks out the

corresponding I/O ALERT interrupts. Since the internal

FETs are open-drain, a pull-up resistor is required from

I/O_ to V

CC

. The DATA1 and DATA2 bits within the

GPIO data register directly control the state of the outputs of I/O1 and I/O2, respectively (Figure 4).

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

______________________________________________________________________________________ 13

BIT NAME NAME

05 D1 FAN duty-factor control bit

03–0 RFU Reserved for future use

0

04

0

D0 FAN duty-factor control bit

6 D2

7 (MSB) D3

FUNCTION

FAN duty-factor control bit

FAN duty-factor control bit. D3–D0 are decoded as follows:

D3–D0 Duty V

OUT

(nominal)

0000b 0% 0V

0001b 6.67% 0.0625

· V

CC

0010b 13.33% 0.125 · V

CC

0011b 20% 0.1875 · V

CC

0100b 26.67% 0.25 · V

CC

0101b 33.33% 0.3125 · V

CC

0110b 40% 0.375 · V

CC

0111b 46.67% 0.4375 · V

CC

1000b 53.33% 0.5 · V

CC

1001b 60% 0.5625 · V

CC

1010b 66.67% 0.625 · V

CC

1011b 73.33% 0.6875 · V

CC

1100b 80% 0.75 · V

CC

1101b 86.67% 0.8125 · V

CC

1110b 93.33% 0.875 · V

CC

1111b 100% 0.9375 · V

CC

Table 6. Fan Duty-Factor Data Byte Bit Assignments (Write Command = 1Bh)

Figure 4. GPIO Logic Diagram

I/O_ PIN

DELAY

MASK_ BITS

ALERT

S

R

GPIO DATA_ BITS

ALERT RESPONSE

Page 14

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

14 ______________________________________________________________________________________

Write-Once Protection

Write-once protection allows the host BIOS code to

configure the MAX1669 and protect against data corruption in the host that might cause spurious writes to

the MAX1669. In particular, write protection allows a

foolproof overtemperature override that forces the fan

on, independent of the host system whether in DAC

mode or PWM mode. The bits in the write-protection

register (Table 8), once set high, cannot be reset low

except by power-on reset.

Having a separate write-protect master register rather

than making the actual registers themselves write once

allows the host to read back and verify each register’s

contents before applying final write protection. Having

individual write-protect control over different registers

allows flexibility in application; for example, the T

CRIT

and configuration register could be protected while

leaving one or both GPIO outputs free to be used as

actuators.

Status Byte Functions

The status byte register (Table 9) indicates which (if

any) temperature thresholds have been exceeded. The

status byte also indicates changes in GPIO states and

transitions and whether there is a fault in the remote

diode DXP-DXN path. After POR, the normal state of all

the flag bits is 0, assuming none of the alarm conditions are present. Bits 2 to 5 of the status byte are

cleared by any successful read of the status byte. Note

that the ALERT interrupt latch is not automatically

cleared when the status flag bit is cleared.

Manufacturer and Device ID Codes

This code identifies the functional capabilities of a particular device. New devices having enhanced or

reduced software or hardware capabilities must be

assigned a new code. The device ID allows the host

system to interrogate the device to determine its capabilities, and use extra features if they’re available. The

device ID code is 2 bytes, for a total of 256X256 possible combinations. The device ID codes are located at

command code 1111 1111b (FFh). If a read-byte operation (as opposed to a read-word) is applied to the

device, it returns the least-significant byte correctly

without the most-significant byte. Table 10 shows the

device ID code for the MAX1669.

Reserved for future useRFU5–0

BIT

For I/O2 configured as an output (MASK2 bit set high and a pull-up resistor on I/O2 ), this

bit corresponds to the GPIO DATA2 block in Figure 4 and controls the output state of I/O2.

To configure I/O2 as an input, set this bit high and clear the MASK2 bit low (Figure 4).

DATA26

For I/O1 configured as an output (MASK1 bit set high and a pull-up resistor on I/O1),

this bit corresponds to the GPIO DATA1 block in Figure 4 and controls the output state

of I/O1. To configure I/O1 as an input, set this bit high and clear the MASK1 bit low

(Figure 4).

DATA1

7

(MSB)

FUNCTIONNAME

0

1

1

POR STATE

Table 7. GPIO Input/Output Data Byte Bit Assignments

Table 8. Write-Once Protection Byte Bit Assignments

Write-protects bit 7 in the GPIO register when high (DATA1).PROT35

BIT

Write-protects certain bits in the configuration register when high:

- STBY standby-mode control (bit 6)

- POL polarity control (bit 5)

- FAN ON control (bit 2)

PROT26

Write-protects the T

CRIT

limit threshold register when high.PROT1

7

(MSB)

FUNCTIONNAME

0

0

0

POR STATE

4 PROT4 0 Write-protects bit 6 in the GPIO register when high (DATA2).

3–0 RFU 0 Reserved for future use

Page 15

Slave Addresses

The MAX1669 appears to the SMBus as one device

having a common address for the temperature sensor

section, GPIO section, and fan-control section. The

device address can be set to one of eight different values by pin-strapping ADD_ pins so that more than one

MAX1669 can reside on the same bus without address

conflicts (Table 11).

The MAX1669 also responds to the SMBus Alert

Response slave address (see the Alert Response

Address section).

POR and UVLO

The MAX1669’s memory is volatile. To prevent ambiguous power-supply conditions from corrupting the data

in memory and causing erratic behavior, a POR voltage

detector monitors VCCand clears the memory if V

CC

falls below 1.85V (typical, see the Electrical Character-

istics table). When power is first applied and VCCrises

above 1.9V (typ), the logic blocks begin operating;

although reads and writes at VCClevels below 3V are

not recommended. A second VCCcomparator, the

ADC UVLO comparator, prevents the ADC from converting until there is sufficient headroom (VCC= 2.8V typ).

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

______________________________________________________________________________________ 15

4 TRAN2*

This bit is set if a low-to-high or high-to-low transition has occurred at I/O2 (regardless of the

state of the mask bits).

3 RHIGH* A high indicates that the high-temperature alarm has activated

This bit is set if a low-to-high or high-to-low transition has occurred at I/O1 (regardless of the

state of the mask bits).

TRAN1*5

BIT

This bit indicates the current state of I/O2 (unlatched).I/O26

This bit indicates the current state of I/O1 (unlatched).I/O1

7

(MSB)

FUNCTIONNAME

1 DIODE A high indicates a remote-diode fault (open-circuit, shorted diode, or DXP short to GND).

0 (LSB) OVERT

When the T

CRIT

threshold is crossed, this bit goes high. The polarity of this bit does not depend

on the POL bit (bit 5 in configuration byte).

A high indicates that the low-temperature alarm has activated.RLOW* 2

Table 9. Status Byte Bit Assignments

*TRAN1 and TRAN2 alarm flags stay high until cleared by POR or until the status byte register is read. RHIGH and RLOW alarm

flags stay high until cleared by POR or the temperature fault is removed and the status byte is read.

0000 00000000 0101

MS BYTE

LSBs MSBs

LS BYTE

LSBs MSBs

MAX1669 ID CODE

Table 10. Device ID Code

Table 11. Slave Address Decoding

(ADD_ Pins)

ADD0

V

CC

GNDGND

GNDGNDGND

ADD1 ADD2 ADDRESS

0011 001b

0011 000b

GND V

CC

GND 0011 010b

GND V

CC

V

CC

0101 001b

V

CC

GND GND 0101 010b

V

CC

GND V

CC

0101 011b

V

CC

V

CC

GND 1001 100b

V

CC

V

CC

V

CC

1001 101b

Page 16

MAX1669

Power-Up Defaults

• Interrupt latch is cleared.

• ADC begins autoconverting at a 2Hz rate.

• Command byte is set to 01h to facilitate quick

remote receive-byte queries.

•T

HIGH

and T

LOW

registers are set to +127°C and

-55°C limits, respectively.

•T

CRIT

register is set to +100°C.

• ALERT and OVERT are reset to high-Z state.

• Device is in low-frequency PWM mode, 20Hz setting.

• PWM output is off (duty factor set to 0%).

• I/O1, I/O2 are high-Z (configured as inputs).

__________Applications Information

Remote Diode Selection

Temperature accuracy depends on having a goodquality, diode-connected, small-signal transistor.

Accuracy has been experimentally verified for all of the

devices listed in Table 12. The MAX1669 can also

directly measure the die temperature of CPUs and

other ICs having on-board temperature-sensing diodes,

such as the Intel Pentium II.

The transistor must be a small-signal type having a relatively high forward voltage; otherwise, the A/D input

voltage range can be violated. The forward voltage

must be greater than 0.25V at 10µA; check to ensure

this is true at the highest expected temperature. The

forward voltage must be <0.95V at 100µA; check to

ensure this is true at the lowest expected temperature.

Do not use large power transistors. Also, ensure that

the base resistance is <100Ω. Tight specifications for

forward-current gain (+50 to +150, for example) indicate that the manufacturer has good process controls

and the devices have consistent VBEcharacteristics.

Series resistance causes +1/2°C error per ohm. When

monitoring the temperature of a remote unit’s internal

diode, ensure that trace series resistance does not

introduce significant error.

ADC Noise Filtering

The ADC is an integrating type with inherently good

noise rejection, especially of low-frequency signals

such as 60Hz/120Hz power-supply hum. Micropower

operation places constraints on high-frequency noise

rejection; therefore, careful PC board layout and proper

external noise filtering is required for high-accuracy

remote measurements in electrically noisy environments.

High-frequency EMI is best filtered at DXP and DXN

with an external 2200pF capacitor. This value can be

increased to about 3300pF (max), including cable

capacitance. Capacitance higher than 3300pF introduces errors due to the rise time of the switched-current source.

Nearly all noise sources tested cause the ADC measurements to be higher than the actual temperature,

typically by +1°C to +10°C, depending on frequency

and amplitude (see Typical Operating Characteristics).

FAN Application Circuits

In PWM mode, the output impedance at FAN is <50Ω,

enabling it to drive an N-channel MOSFET as shown in

the Typical Operating Circuit. Return the source of the

N-channel MOSFET to the system power ground, away

from the ground of the MAX1669. For 3.3V applications,

use low-threshold N-channel MOSFETs (Table 1).

In DAC mode, the FAN output can be linearly controlled

(Figure 5). Upon power-up, the fan is off. The N-channel

MOSFET is biased at the threshold of turning on. As

V

FAN

rises, the fan turns on linearly. To have the fan

turned on at power-up, use the circuit shown in Figure 6.

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

16 ______________________________________________________________________________________

Table 12. Component Manufacturers

Note: Transistors must be diode-connected (base shorted to

collector).

MMBT3906

KST3906

MANUFACTURER MODEL NUMBER

SOT23 BJT

Central Semiconductor (USA)

CMPT3906

Fairchild Semiconductor (USA)

MMBT3906

Rohm Semiconductor (Japan)

SST3906

Samsung (Korea)

MOSFET N-CHANNEL

International Rectifier (USA)

IRF7201

MOSFET P-CHANNEL

International Rectifier (USA)

IRF7205

Motorola (USA)

MMBT3906

Fairchild Semiconductor (USA) FDN359AN

Page 17

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

______________________________________________________________________________________ 17

Figure 5. Linear Fan Control (DAC Mode) with Fan “Off” at Power-Up

Figure 6. Linear Fan Control (DAC Mode) with Fan “On” at Power-Up

+5V

10k10k10k10k

SMBCLK

SMBDATA

ALERT

OVERT

2N3906

2200pF

DXP

MAX1669

DXN

SYNC

ADD0

ADD1

ADD2

AGND PGND

+5V

0.1µF

+12V

V

CC

100k

38k

FAN

I/O1

I/O2

N-CH

IRF7201

38k

SYSTEM POWER

GROUND

10k10k10k10k

V

CC

MAX1669

AGND PGND

2N3906

SMBCLK

SMBDATA

ALERT

OVERT

DXP

2200pF

DXN

SYNC

ADD0

ADD1

ADD2

FAN

I/O1

I/O2

0.1µF

33k

5.1V

ZENER

+12V

22k

P-CH

IRF7205

100k

SYSTEM POWER

GROUND

Page 18

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

18 ______________________________________________________________________________________

Typical Operating Circuit

Figure 7. SMBus Write Timing Diagram

Figure 8. SMBus Read Timing Diagram

AB CDEFG H

t

LOW

SMBCLK

SMBDATA

t

SU:STAtHD:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

AB CDEFG HIJ

t

LOWtHIGH

t

HIGH

t

SU:DAT

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

I

t

SU:STO

I = ACKNOWLEDGE CLOCK PULSE

J = STOP CONDITION

K = NEW START CONDITION

K

J

K

t

BUF

M

L

SMBCLK

SMBDATA

t

t

HD:STA

SU:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

t

SU:DAT

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

I = SLAVE PULLS SMBDATA LINE LOW

t

HD:DAT

J = ACKNOWLEDGE CLOCKED INTO MASTER

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION, DATA EXECUTED BY SLAVE

M = NEW START CONDITION

t

SU:STO

t

BUF

Page 19

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

______________________________________________________________________________________ 19

Chip Information

TRANSISTOR COUNT: 12,924

MAX1669

ADD1

ADD0

SYNC

I/O1

ADD2

V

CC

+12V

AGND PGND

N-CH

FDN 359AN

SYSTEM POWER

GROUND

FAN

DXP

0.1µF

DXN

+3V TO +5.5V

SMBCLK

SMBDATA

ALERT

10k10k10k10k

OVERT

I/O2

2200pF

2N3906

Typical Operating Circuit

Page 20

MAX1669

Fan Controller and Remote Temperature Sensor

with SMBus Serial Interface

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

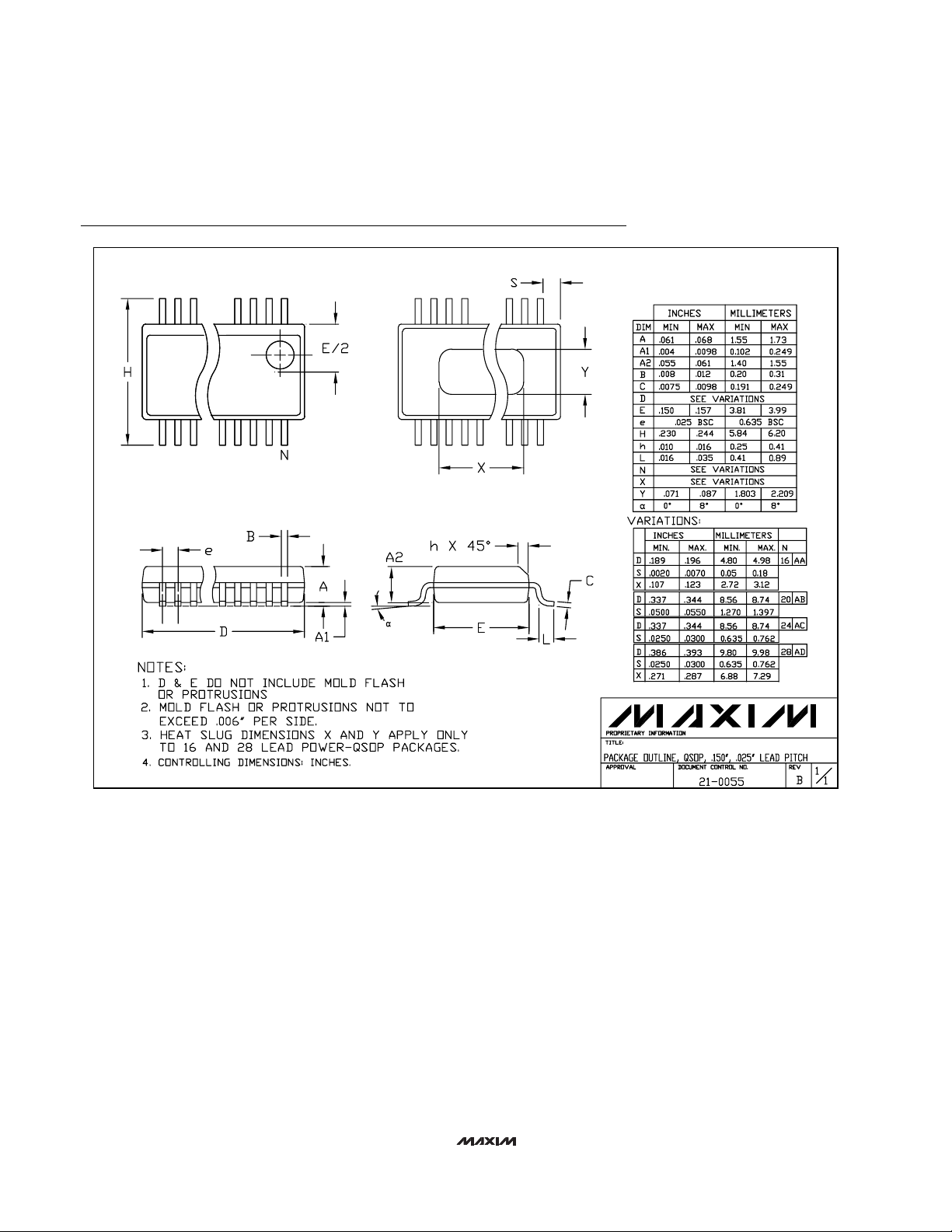

Package Information

QSOP.EPS

Loading...

Loading...