Page 1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

________________General Description

The MAX1664 integrates power-supply and backplane

drive circuitry for active-matrix thin-film-transistor (TFT) liquid crystal displays. Included are a single-output, pulsewidth-modulation boost converter (0.25Ω switch), a

dual-output (positive and negative) gate-driver supply

using one inductor, an LCD backplane driver, and a simple phase-locked loop to synchronize all three outputs.

High switching frequency (1MHz nominal) and phaselocked operation allow the use of small, minimumheight external components while maintaining low

output noise. A +2.8V to +5.5V input voltage range

allows operation with any logic supply. Output voltages

are adjustable to +5.5V (DC-DC 1) and to +28V and

-10V (DC-DC 2). The negative output voltage can be

adjusted to -20V with additional components. Also

included are a logic-level shutdown and a “Ready” output (RDY) that signals when all three outputs are in regulation.

The boost-converter operating frequency can be set at

16, 24, or 32 times the backplane clock. This flexibility

allows a high DC-DC converter frequency to be used

with LCD backplane clock rates ranging from 20kHz to

72kHz. The MAX1664 is supplied in a 1.1mm-high

TSSOP package.

________________________Applications

LCD Modules

LCD Panels

____________________________Features

♦ Integrates All Active Circuitry for Three DC-DC

Converters

♦ Ultra-Small External Components

(ceramic capacitors, 2µH to 5µH inductors)

♦ DC-DC Converters Phase-Locked to Backplane

Frequency for Lowest Noise

♦ Low Operating Voltage (down to +2.8V)

♦ Adjustable Output Voltage from V

IN

to +5.5V

♦ Load Currents Up to 500mA

♦ Adjustable TFT Gate Driver Output:

Positive, V

IN

to +28V

Negative, 0 to -10V (-20V with added

components)

♦ Includes 0.35Ω Backplane Driver

♦ 1µA Shutdown Current

♦ Power-Ready Output Signal

MAX1664

________________________________________________________________

Maxim Integrated Products

1

REF

FB2-

IN INP

LX2P

LX2N

FB2+

PGND2

PLLC

GND

FPLL

RDY

REF

SHDN

ON

OFF

5.5V

-10V

28V

BPV

SS

BACKPLANE

DRIVER

V

SUPPLY

2.8V TO 5.5V

BPDRV

BPV

DD

PGND1

FB1

LX1

BPCLK

MAX1664

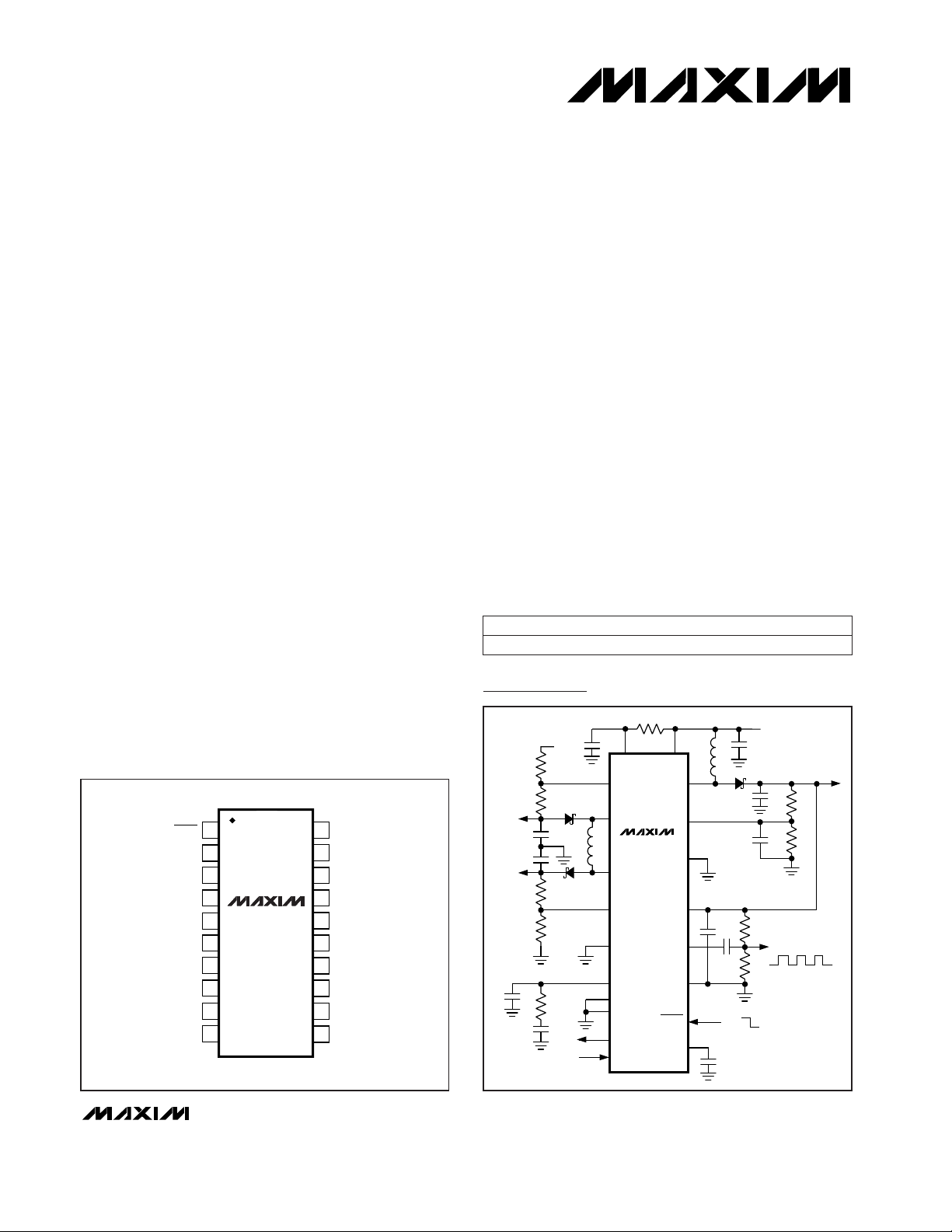

Typical Operating Circuit

___________________Pin Configuration

19-1356; Rev 0; 4/98

PART

MAX1664CUP 0°C to +70°C

TEMP. RANGE PIN-PACKAGE

20 TSSOP

_______________Ordering Information

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

FPLL

LX1

PGND1

PGND2REF

FB1

RDY

SHDN

TOP VIEW

LX2N

LX2P

INP

BPCLKFB2+

FB2-

IN

GND

12

11

9

10

BPV

DD

BPDRVBPV

SS

PLLC

MAX1664

TSSOP

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

Page 2

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

2 _______________________________________________________________________________________

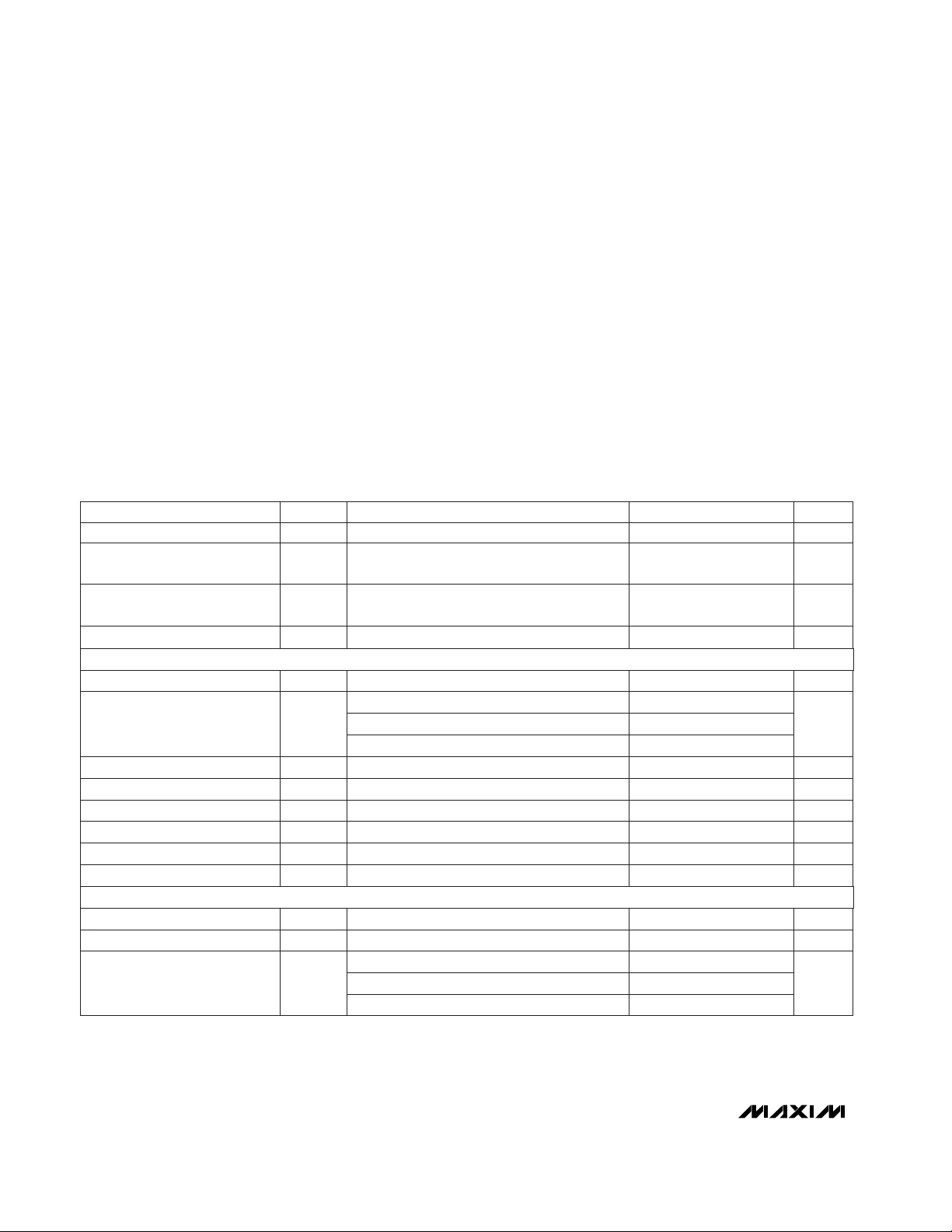

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= V

INP

= 3.3V, SHDN = IN, V

BPVDD

= 4V, V

BPVSS

= -1V, PGND1 = PGND2 = FPLL = GND, f

BPCLK

= 30kHz, TA= 0°C to +70°C,

unless otherwise noted. Typical values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

RDY, IN, BPVDDto GND...........................................-0.3V to +6V

FB2-, PGND1, PGND2 to GND ..........................................±0.3V

LX1 to PGND1..........................................................-0.3V to +6V

BPV

SS

to GND.......................................................-3.3V to +0.3V

BPVDD to BPV

SS

......................................................-0.3V to +6V

BPDRV to BPV

SS

..................................-0.3V to (V

BPVDD

+ 0.3V)

LX2P to INP ............................................................-15V to +0.3V

LX2N to PGND2......................................................-0.3V to +30V

SHDN, INP, FB1, FB2+, REF, PLLC,

BPCLK, FPLL to GND................................-0.3V to (V

IN

+0.3V)

RDY Sink Current................................................................20mA

LX2P, LX2N Peak Switch Currents.................................±750mA

Continuous Power Dissipation (TA= +70°C)

20-Pin TSSOP (derate 7mW/°C above+70°C) ..............559mW

Operating Temperature Range...............................0°C to +70°C

Junction Temperature......................................................+150°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

FPLL = IN

FPLL = REF

FPLL = GND

Rising edge, 2% hysteresis

V

LX1

= 6V

FPLL = REF

FPLL = GND

V

FB1

= 1.3V

V

FB1+

= V

FB2+

= 1.3V, V

FB2-

= -0.1V;

IIN+ I

INP

SHDN = GND, VIN= 5.5V; IIN+ I

INP

FPLL = IN

CONDITIONS

8 x f

BPCLK

12 x f

BPCLK

Hz

16 x f

BPCLK

f

OP2(MAX)

Maximum Operating Frequency

V-10 0V

OUT2-

Negative Output Voltage Range

VV

IN

28V

OUT2+

Positive Output Voltage Range

V1.091 1.125 1.159V

TH_RDY

Power-Ready Trip Level

A1.2 1.5 1.8I

LIM(LX1)

LX1 Peak Current Limit

µA0.1 10I

LKG(LX1)

LX1 Leakage Current

Ω0.25 0.5R

ON(LX1)

LX1 On Resistance

nA100I

FB1

FB1 Input Bias Current

16 x f

BPCLK

Operating Frequency

V2.5 2.8V

UVLO

V2.8 5.5V

IN

Input Supply Range

Undervoltage Lockout

Threshold

24 x f

BPCLK

Hz

32 x f

BPCLK

f

OP1

VV

IN

5.5V

OUT1

Output Voltage Range

mA0.5 2I

Q

Quiescent Current

µA0.01 10I

SD

Shutdown Current

UNITSMIN TYP MAXSYMBOLPARAMETER

0 < I

LX1

< 1.2A V1.2125 1.2500 1.275V

FB1

FB1 Regulation Voltage

DC-DC 1 (PWM MAIN OUTPUT)

DC-DC 2 (PFM)

Page 3

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

INP

= 3.3V, SHDN = IN, V

BPVDD

= 4V, V

BPVSS

= -1V, PGND1 = PGND2 = FPLL = GND, f

BPCLK

= 30kHz, TA= 0°C to +70°C,

unless otherwise noted. Typical values are at T

A

= +25°C.)

V

BPCLK

= 0 or 3.3V

SHDN = GND

Source and sink

Rising edge, 40mV hysteresis

SHDN = GND

Falling edge, 40mV hysteresis

V

LX2N

= 28V, V

LX2P

= -10V

V

FB2+

= 1.3V, V

FB2-

= -0.1V

CONDITIONS

µA0.01 1I

IN(BPCLK)

BPCLK Input Current

V0.7 x V

IN

V

IH(BPCLK)

BPCLK Input High Voltage

V0.3 x V

IN

V

IL(BPCLK)

BPCLK Input Low Voltage

µA80 200I

IN(BPVDD)

BPVDDSupply Current

µA-10 10I

LKG(BPDRV)

BPDRV Leakage Current

Ω0.35 0.7R

ON(BPDRV)

BPDRV On-Resistance

µA0.1 10I

SHDN(BP)

BPVDDShutdown Current

V2.5 5.5V

VDD to VSS

BPVDDto BPVSSVoltage

Range

V-3 0V

BPVSS

BPVSSSupply Range

V2.5 5.5V

BPVDD

BPVDDSupply Range

mV-15 0 15V

FB2-

V1.225 1.25 1.275V

FB2+

FB2+ Regulation Voltage

FB2- Regulation Voltage

V1.091 1.125 1.159V

TH(RDY)

FB2+ Power-Ready Trip Level

mV85 120 165V

TH(RDY)

FB2- Power-Ready Trip Level

µA0.05 10

I

LKG(LX2N)

,

I

LKG(LX2P)

LX2N, LX2P Leakage Current

nA-100 100

I

FB2+

,

I

FB2-

FB2+, FB2- Input Bias Current

Ω0.9 1.7

R

ON(LX2N)

,

R

ON(LX2P)

LX2N, LX2P On-Resistance

UNITSMIN TYP MAXSYMBOLPARAMETER

C

PLLC

= 22nF

R

PLLC

= 100kΩ

C

SHUNT

= 2.2nF

PLLC = REF, BPCLK = GND

40 72

BPCLK Input Frequency

Range

27 48 kHz

20 36

f

BPCLK

MHz1.63 1.92 2.20f

C

VCO Center Frequency

(Note 1)

-2µA < I

REF

< 50µA

V0.90 1.05 1.20V

REF(UVLO)

Undervoltage Lockout

V1.225 1.250 1.275V

REF

Reference Voltage

(0.10 x VIN) typical hysteresis V0.3 x V

IN

V

IL(SHDN)

SHDN Input Low Voltage

FPLL = GND or IN µA0.01 1I

IN(FPLL)

FPLL Input Current

µA0.01 1I

IN(SHDN)

SHDN Input Current

V0.7 x V

IN

V

IH(SHDN)

SHDN Input High Voltage

I

SINK

= 2mA V0.05 0.4V

OL(RDY)

RDY Output Low Voltage

V

RDY

= 5.5V µA0.01 1I

LKG(RDYOH)

RDY Output High Leakage

FPLL = GND

FPLL = REF

FPLL = IN

Note 1: DC-DC 1 operates at one-half of the VCOfrequency (fC / 2).

BACKPLANE DRIVER

PLL

LOGIC SIGNALS

Page 4

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

4 _______________________________________________________________________________________

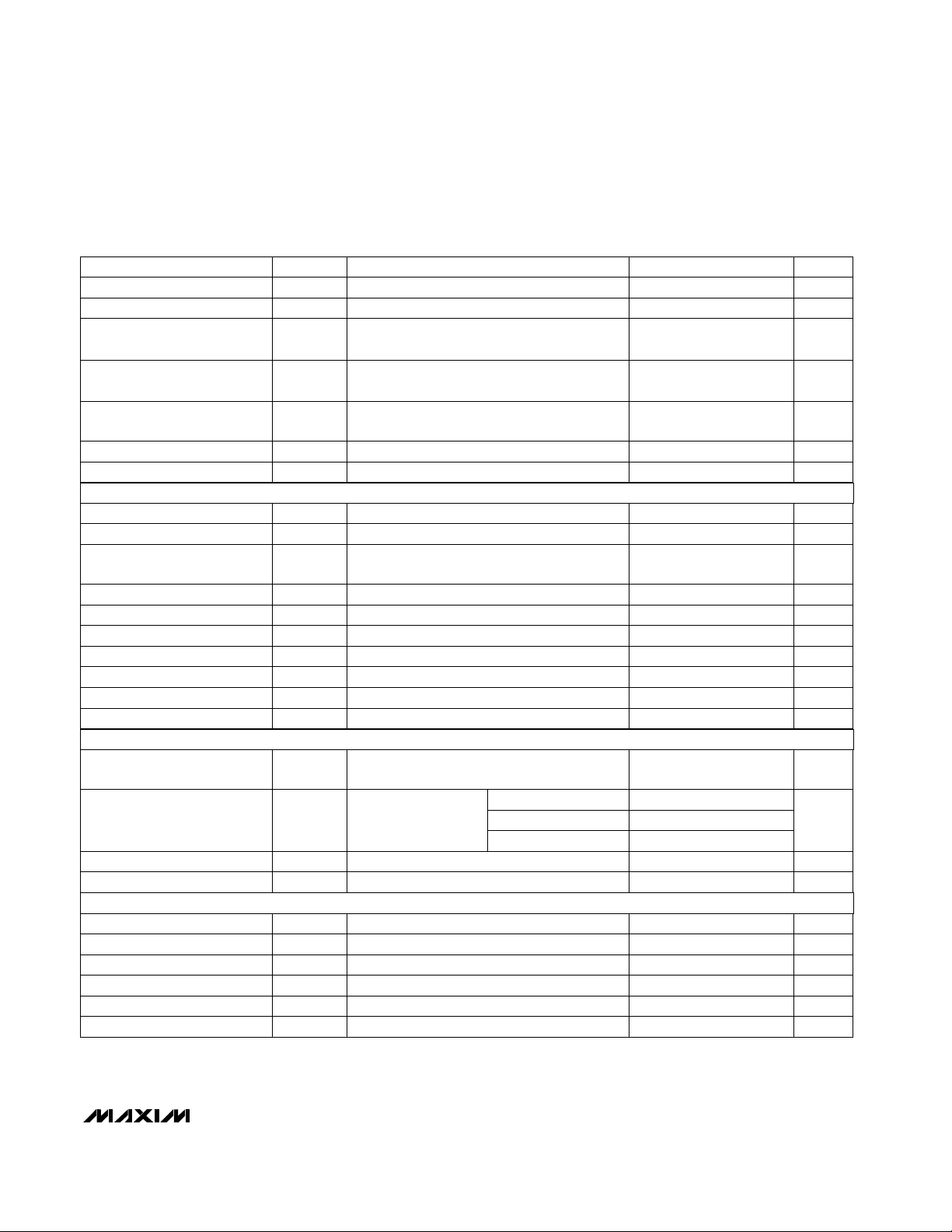

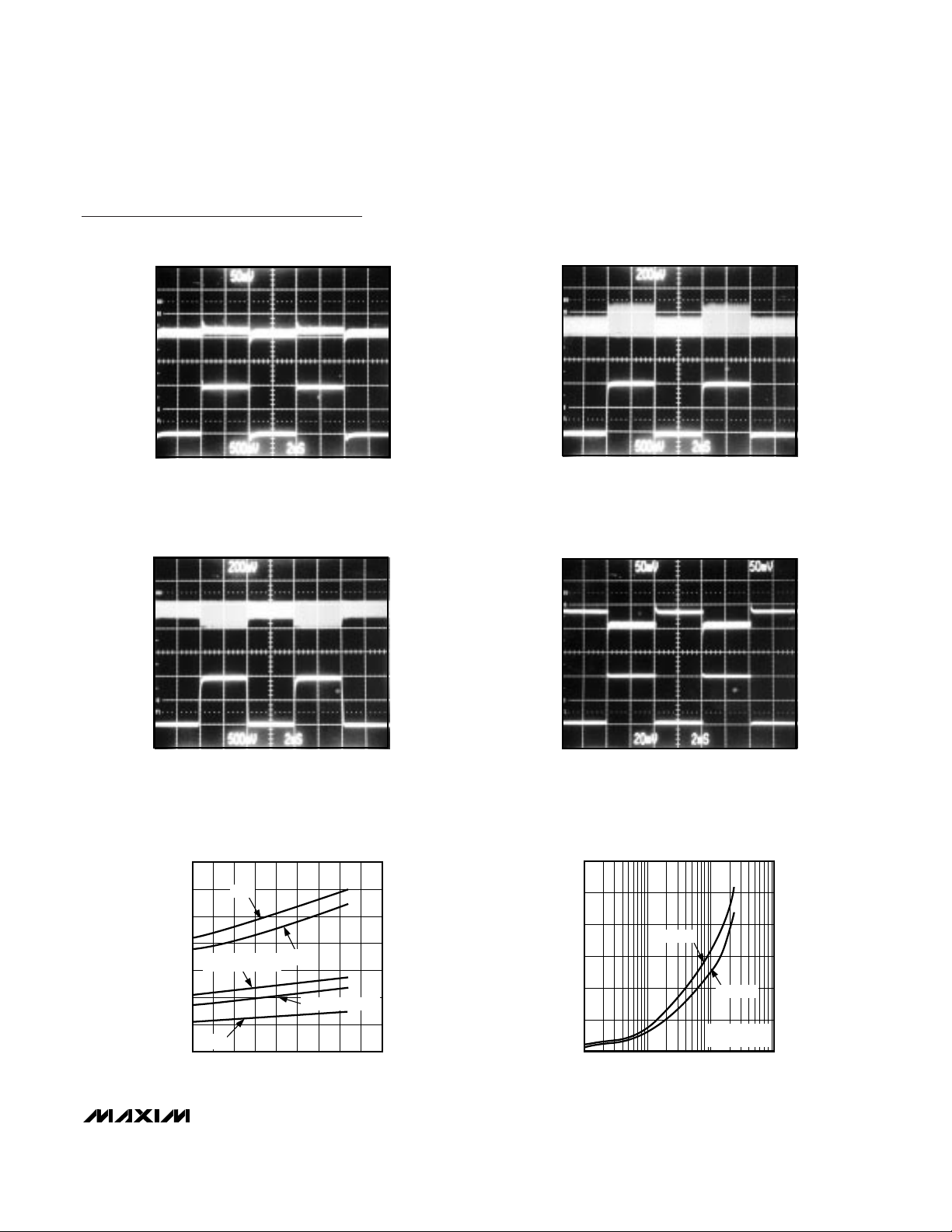

__________________________________________Typical Operating Characteristics

(f

BPCLK

= 22.5kHz, FPLL = GND, L1 = 3.3µH, L2 = 4.7µH, TA= +25°C, unless otherwise noted.)

100

0

1 10 100 1000

DC-DC 1 EFFICIENCY vs. LOAD CURRENT

(V

OUT1

= +5V)

20

MAX1664 TOC01

LOAD CURRENT (mA)

EFFICIENCY (%)

40

60

80

90

10

30

50

70

VIN = 3V

VIN = 4.5V

100

0

1 10 100

DC-DC 2 EFFICIENCY vs. LOAD CURRENT

(V

OUT2-

= -5V)

20

10

MAX1664 TOC02

LOAD CURRENT (mA)

EFFICIENCY (%)

40

30

60

70

50

80

90

V

OUT2+

UNLOADED

VIN = 5V

VIN = 3.3V

100

0

1 10 100

DC-DC 2 EFFICIENCY vs. LOAD CURRENT

(V

OUT2+

= +15V)

20

10

MAX1664 TOC03

LOAD CURRENT (mA)

EFFICIENCY (%)

40

30

60

70

50

80

90

V

OUT2-

UNLOADED

VIN = 5V

VIN = 3.3V

10mV/div

V

OUT1

RIPPLE

MAX1664 TOC04

I

OUT1

= 250mA, L = 3.3µH

500ns/div

V

OUT2

100mV/

div

V

OUT2+

RIPPLE

MAX1664 TOC05

2µs/div

V

OUT2+

= 15V, VIN = 3.3V, I

LOAD

= 9mA,

C

OUT2

= 0.22µF, AC COUPLED

V

OUT2-

50mV/

div

V

OUT2-

RIPPLE

MAX1664 TOC06

5µs/div

V

OUT2-

= -5V, VIN = 3.3V, I

LOAD

= 5mA,

C

OUT2-

= 0.47µF, AC COUPLED

Page 5

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

_______________________________________________________________________________________

5

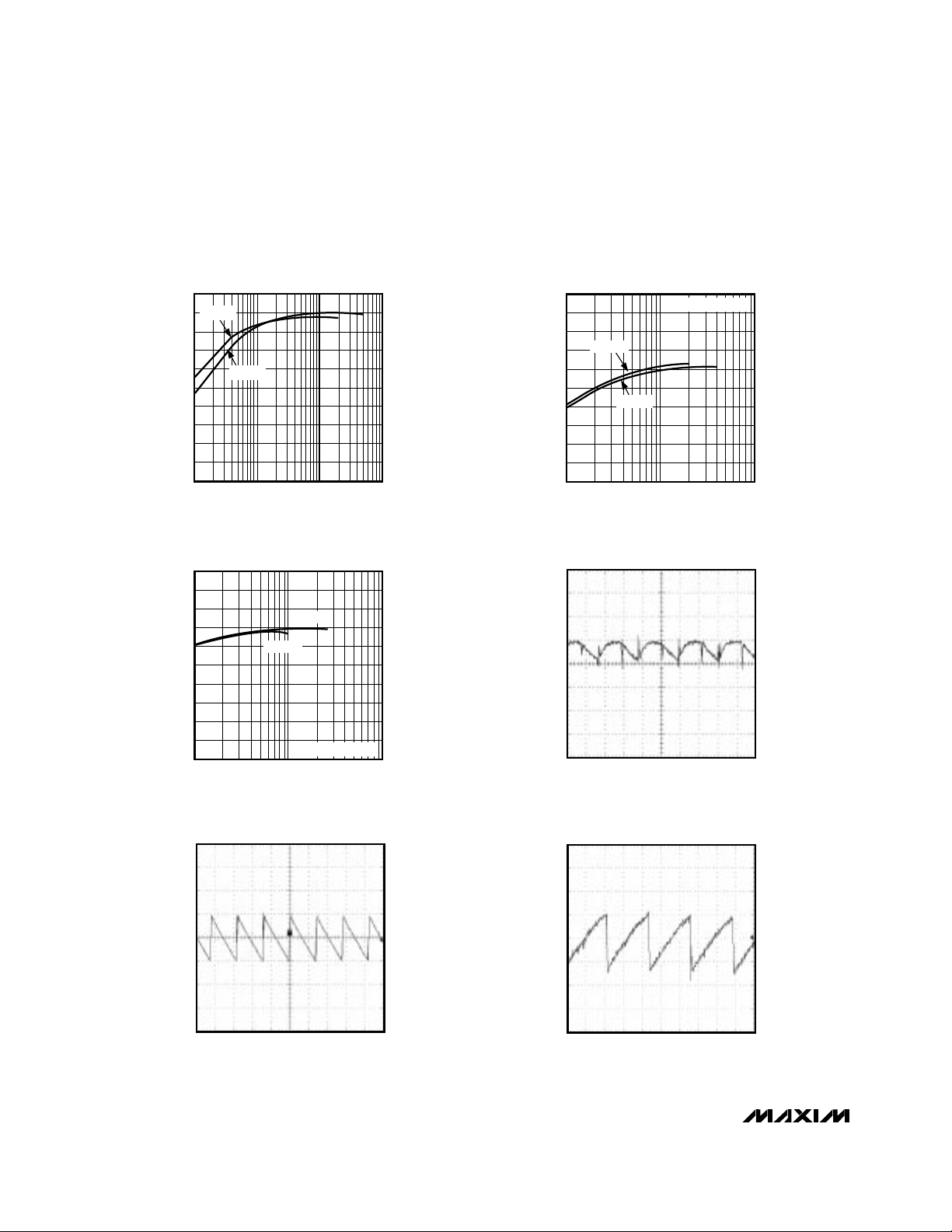

Typical Operating Characteristics (continued)

(f

BPCLK

= 22.5kHz, FPLL = GND, L1 = 3.3µH, L2 = 4.7µH, TA= +25°C, unless otherwise noted.)

V

OUT2-

= -5V, I

LOAD

= 5mA, C

OUT2-

= 0.47µF

A: V

OUT2-

, 200mV/div, AC COUPLED

B: V

IN

, 3V to 4V

V

OUT2-

LINE-TRANSIENT RESPONSE

A

B

MAX1664 TOC09

200mV/

div

500mV/

div

2ms/div

V

OUT1

= 5V, VIN = 3.3V, C

OUT1

= 20µF

A: V

OUT1

, 50mV/div, AC COUPLED

B: I

OUT1

, 25mA TO 225mA, 100mA/div

V

OUT1

LOAD-TRANSIENT RESPONSE

A

B

MAX1664 TOC10

50mV/

div

100mA/

div

2ms/div

0

400

200

800

600

1200

1000

1400

0 20 3010 40 50 60 70 80 90

INTERNAL FET ON-RESISTANCE

vs. TEMPERATURE

MAX1664 TOC 11

TEMPERATURE (°C)

INTERNAL FET ON-RESISTANCE (mΩ)

LX2N

LX2P

BPDRV N-CHANNEL

LX1

BPDRV P-CHANNEL

300

0

0.001 0.01 0.1 1

BPDRV RISE AND FALL TIME

vs. LOAD CAPACITANCE

MAX1664 TOC12

LOAD CAPACITANCE (µF)

RISE/FALL TIME (ns)

100

200

250

50

150

C

LOAD

FROM

BPDRV TO GND

RISE TIME

FALL TIME

V

OUT1

= 5V, I

LOAD

= 250mA, C

OUT1

= 20µF

A: V

OUT1

, 50mV/div, AC COUPLED

B: V

IN

, 3V to 4V

V

OUT1

LINE-TRANSIENT RESPONSE

A 50mV/

div

500mV/

div

2ms/div

B

MAX1664 TOC07

V

OUT2+

= 15V, I

LOAD

= 5mA, C

OUT2+

= 0.22µF

A: V

OUT2+

, 200mV/div, AC COUPLED

B: V

IN

, 3V to 4V

V

OUT2+

LINE-TRANSIENT RESPONSE

A

B

MAX1664 TOC08

200mV/

div

500mV/

div

2ms/div

Page 6

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(f

BPCLK

= 22.5kHz, FPLL = GND, L1 = 3.3µH, L2 = 4.7µH, TA= +25°C, unless otherwise noted.)

VIN = 3.3V; V

OUT2+

= 15V/8mA, V

OUT2-

= -5V/10mA

NOTE: LX2N, LX2P PULSES ARE SYNCHED TO DC-DC 1

DC-DC 2 SWITCHING WAVEFORMS

DISCONTINUOUS CONDUCTION

VLX2N

V

LX2P

I

L2

5V/div

500mA/

div

1µs/div

5V/div

C

LOAD

= 10,000pF

BPCLK TO BPDRV FALLING DELAY

BPCLK

BPDRV

2V/div

5V/div

100ns/div

MAX1664 TOC14

5V/div

2V/div

BPDRV

BPCLK

100ns/div

BPCLK TO BPDRV RISING DELAY

MAX1664 TOC14(a))

C

LOAD

= 10,000pF

0

0.4

0.2

1.0

0.8

0.6

1.6

1.4

1.2

1.8

0 21 3 4 5 6

NO-LOAD SUPPLY CURRENT

vs. INPUT VOLTAGE

MAX1664 TOC15

INPUT VOLTAGE (V)

NO-LOAD SUPPLY CURRENT (mA)

INCLUDES ALL

EXTERNAL COMPONENT

CURRENTS

5V/div

2V/div

5V/div

5V/div

10V/div

5V/div

SHDN

V

REF

V

OUT2-

V

OUT2+

RDY

V

OUT1

500µs/div

OUT-OF-SHUTDOWN SEQUENCE

MAX1664 TOC16(a)

5V/div

500mA/div

V

LX1

I

LI

I

OUT1

= 300mA, L1 = 3.3µH

500ns/div

DC-DC 1 SWITCHING WAVEFORMS

MAX1664 TOC17(a)

Page 7

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

_______________________________________________________________________________________ 7

PLL Compensation. Connect compensation network as in Figure 4.PLLC9

Backplane Driver Negative Supply. Typically connected to PGND1. May be connected to a separate supply.BPV

SS

10

Backplane Driver OutputBPDRV11

Backplane Driver Positive Supply. Typically connected to V

OUT1

of DC-DC 1. May be connected to a

separate supply.

BPV

DD

12

Backplane Driver Clock Input. See Table 1 for input frequency ranges.BPCLK13

Analog Ground. Connect to PGND1 and PGND2. See

Supply Connections and Layout

section.GND5

Supply Input to the IC. The input voltage range is +2.8V to +5.5V.IN6

Regulator Feedback Input for Negative Output, DC-DC 2. Regulates to 0V nominal.FB2- 7

Regulator Feedback Input for Positive Output, DC-DC 2. Regulates to 1.25V nominal.FB2+8

Internal Reference Output. Connect a 0.22µF capacitor from this pin to GND. REF can source up to 50µA.REF4

Regulator Feedback Input, DC-DC 1. Regulates to 1.25V nominal.FB13

PIN

Ready Indicator Output, DC-DC 1 and DC-DC 2. Open-drain N-channel output becomes high impedance

when all three outputs are within 10% of regulation.

RDY2

Shutdown Input. Drive low to enter shutdown mode. Drive high or connect to IN for normal operation. All IC

sections are off when SHDN is low.

SHDN

1

FUNCTIONNAME

Power Ground 1. Connect to PGND2. Source of internal LX1 N-channel MOSFET.PGND118

Drain of Internal LX1 N-Channel MOSFETLX119

Sets the BPCLK input frequency range for PLL synchronization. Connect to GND, REF, or IN. See Table 1.FPLL20

DC-DC 2 Power Input. Source of Internal LX2P P-channel MOSFET.INP14

Drain of Internal LX2P P-Channel MOSFETLX2P15

Drain of Internal LX2N N-Channel MOSFETLX2N16

Power Ground 2. Connect to PGND1. Source of internal LX2N N-channel MOSFET.PGND217

______________________________________________________________Pin Description

Page 8

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

8 _______________________________________________________________________________________

_______________Detailed Description

The MAX1664 combines power supply and backplane

drive circuitry for active matrix thin-film-transistor (TFT)

liquid crystal displays (LCD) into one IC. Included are a

pulse-width-modulation (PWM) boost converter, a dualoutput (positive and negative) converter using one

inductor, an LCD backplane driver, and a phaselocked loop (PLL) to synchronize all three outputs to the

backplane clock.

A high switching frequency (1MHz nominal) and phaselocked operation allow the use of small, minimumheight external components while maintaining low

output noise. Output voltages are adjustable to +5.5V

(DC-DC 1) and to +28V and -10V (DC-DC 2). The negative output voltage can be set to as low as -20V with

additional components.

The frequency ratio between the DC-DC 1 converter

and the backplane clock can be set to 16, 24, or 32.

This flexibility allows high DC-DC converter frequencies

to be used with LCD backplane clock rates ranging

from 20kHz to 72kHz.

Start-Up

At start-up, both converters remain disabled until V

REF

reaches 90% of its nominal value. V

OUT1

is activated

first. Once V

OUT1

is regulated, V

OUT2-

is enabled.

V

OUT2+

is held at 0 until V

OUT2-

is within 90% of its regulation target. All three outputs power up in a similar

order when power is applied or when coming out of

shutdown. See the Out-of-Shutdown Sequence photo in

the

Typical Operating Characteristics

section.

DC-DC 1 Boost Converter

DC-DC 1 uses a current-mode boost PWM architecture

to produce a positive regulated voltage, adjustable

from 3V to 5.5V (but not less than VIN). This converter

uses an internal N-channel MOSFET with a maximum

on-resistance of 0.5Ω. Cycle-by-cycle peak current limiting protects the switch under fault conditions. Upon

start-up, DC-DC 1 is the first converter to be enabled.

BACKPLANE

DRIVER

BPV

SS

BPDRV

BPV

DD

PGND1

FB1

LX1

V

SUPPLY

2.8V TO 5.5V

V

OUT1

5.5V

SHDN

REF

1.25V

REF

PHASE

DET

VCO

÷4 ÷2

÷N

FPLL

BPCLK

PLLC

PGND2

FB2+

LX2N

DC-DC 2 DC-DC 1

LX2P

INP IN

FB2-

REF

V

OUT2-

-10V

V

OUT2+

28V

IN

REF

GND

GNDRDY

MAX1664

Figure 1. Functional Diagram

Page 9

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

_______________________________________________________________________________________ 9

Fixed-frequency, current-mode operation ensures that

the switching noise exists only at the operating frequency and its harmonics. The switching frequency is phase

locked to the backplane clock input. Table 1 illustrates

the possible switching-frequency options.

DC-DC 2 Dual Outputs

DC-DC 2 uses a synchronized, fixed on-time PFM

architecture to provide the positive and negative output

voltages that allow the driver ICs to turn the TFT gates

on and off. When pulses occur, they are synchronized

to DC-DC 1, thereby minimizing converter interactions

and subharmonic interference.

The DC-DC 2 inductor current is always discontinuous,

enabling the dual outputs to be regulated independently. This allows one output to be at 100% load while the

other is at no load.

DC-DC 2 Operation

In normal operation, DC-DC 2 alternates between

charging the negative and positive outputs (Figure 1).

During the first half-cycle of the PFM clock period, both

the N-channel and P-channel MOSFETs turn on, applying the input supply across inductor L2. This causes

the inductor current to ramp up at a rate proportional to

V

INP

. During the second half-cycle, the P-channel

MOSFET turns off and the inductor transfers its energy

into the negative output filter capacitor.

Assuming that the energy transfer is completed during

this second half-cycle and the inductor current ramps

down to zero, the process is repeated for the positive

output during the next clock cycle. During the first half

of the second clock cycle, both the N-channel and Pchannel MOSFETs turn on again. The current in the

inductor again rises at the same rate. During the second half of the second clock cycle, the N-channel

MOSFET is turned off and this time the inductor energy

transfers to the positive output filter capacitor.

During conditions of heavy loads, DC-DC 2 will continue to operate in this manner, alternately delivering

pulses to the negative and positive outputs. For lighter

loads, the controller may skip one or more cycles of

either polarity, thereby keeping the outputs in regulation. See Table 1 for the relationship between the maximum DC-DC 2 pulse frequency and the backplane

clock frequency.

Outputs with Low Step-Up or Inversion Ratios

For DC-DC 2 output voltage setpoints, which require

minimum step-up or inversion ratios (for example,

V

OUT+

< 6V or V

OUT-

> -3V, when V

INP

= 5V), more

than one half-cycle may be required to transfer the

inductor energy to the appropriate output filter capacitor. In such cases, subsequent conversion cycles are

delayed, as necessary, by one or more PFM clock

cycles to preserve discontinuous mode operation.

Backplane Driver

The MAX1664 provides a low-impedance backplane driver, as shown in Figure 1, that level-translates the BPCLK

signal from a logic level to BPVDD/BPVSSlevels. The

backplane driver consists of an N-channel/P-channel

complementary pair of high-current MOSFETs. These

devices drive BPDRV to either BPVDDor BPV

SS

when

BPCLK goes either high or low, respectively. The switches have a maximum on-resistance of 0.7Ω with a typical

propagation delay of 50ns. Power for the backplane driver can be taken from the output of DC-DC 1, V

OUT1

, as

shown in the

Typical Operating Circuit

.

Phase-Locked Loop

The MAX1664 contains an on-board PLL to synchronize

the PWM and PFM converter clocks to the backplane

clock (Figure 2). This will minimize noise and interference. The PLL is a frequency-multiplying type, generating a nominal 1MHz clock signal for DC-DC 1 and a

nominal 500kHz clock for DC-DC 2. Three input frequency ranges, spanning 20kHz to 72kHz, permit synchronization over a broad range of backplane clock

input frequencies while maintaining optimal conversion

frequencies (Table 1).

FPLL

f

BPCLK

(kHz)

f

DC-DC 1

(kHz)

f

DC-DC 2 MAX

(kHz)

f

DC-DC 1

:

f

BPCLK

f

DC-DC 2 MAX

:

f

BPCLK

N*

IN 40 to 72 640 to 1152 320 to 576 16:1 8:1 32

REF 27 to 48 640 to 1152 320 to 576 24:1 12:1 48

GND 20 to 36 640 to 1152 320 to 576 32:1 16:1 64

Table 1. Switching Frequency Options

*

See Figure 2

Page 10

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

10 ______________________________________________________________________________________

The heart of the PLL is the VCO, which is trimmed to a

nominal frequency of 1.92MHz for a control voltage (at

the PLLC pin) of 1.250V. This high-frequency internal

clock is divided digitally with a division ratio selected

by pin-strapping FPLL to GND, REF, or IN. This divided

clock is compared to the backplane clock by an internal phase comparator (rising-edge triggered). The

phase detector in turn adjusts the VCO control voltage

until the two frequencies (and phases) match. This

feedback loop is compensated at the PLLC pin.

In some applications, the backplane clock may be halted for several cycles between screen scans or may not

be immediately applied on power-up. The PLL contains

a proprietary phase-detector architecture that minimizes frequency error during clock dropouts of more

than two cycles and re-establishes lock immediately

when the clock resumes.

Ready Indicator (RDY)

The RDY pin has an open-drain output and indicates

when all three outputs are in regulation. The open-drain

output becomes high impedance when all three converter outputs are within 10% of their regulation setpoints.

Design Procedure and

______________Component Selection

Output Voltage Selection

The three output voltages as well as the DC bias for the

backplane clock are adjustable on the MAX1664, as

shown in Figure 3. Set each output using two standard

1% resistors to form a voltage divider between the

selected output and its respective feedback pin. Use

the following equations to calculate the resistances.

DC-DC 1 Output

For V

OUT1

= 5V, typical values are R2 = 100kΩ and R1

= 301kΩ. To set V

OUT1

to another voltage, choose R2 =

100kΩ and C

FB1

= 50pF, and calculate R1 as follows:

DC-DC 2 Positive Output

For V

OUT2+

= 15V, typical values are R8 = 49.9kΩ and

R7 = 549kΩ. To set V

OUT2+

to another voltage, choose

R8 = 49.9kΩ and calculate R7 as follows:

DC-DC 2 Negative Output

For the negative output voltage, the FB2- threshold voltage is 0. For V

OUT2-

= -5V, typical values are R5 =

49.9kΩ and R6 = 200kΩ. To set V

OUT2+

to another volt-

age, choose R5 = 49.9kΩ and calculate R6 as follows:

DC Bias for the Backplane Driver

For V

DCBIAS

= V

BPVDD

/2, typical values are R3 = R4 =

100kΩ. To set the DC bias to a different value, choose

R4 and calculate R3 as follows:

R3 R4

V - V

V - V

- 1

BPVDD BPVSS

DCBIAS BPVSS

=

R6 R5

V

V

OUT2-

REF

=

R7 R8

V

V

- 1

OUT2

FB2

=

+

+

R1 R2

V

V

- 1

OUT1

FB1

=

PHASE

DETECTOR

VCO

÷4

÷2

PLLC

÷N*

IN

REF

BPCLK

*SEE TABLE 1 FOR

SELECTED VALUES OF N.

DC-DC 1

R

PLLC

C

PLLC

C

SHUNT

DC-DC 2

GND

Figure 2. Internal PLL Operation within the MAX1664

BPV

DD

C

FB1

R2

R1

FB2+

FB2-

BPDRV

FB1

R5

R6

V

OUT2-

R7

R8

REF

BPV

SS

C

C

V

OUT1

V

OUT2+

R3

DC

BIAS

R4

MAX1664

Figure 3. Output Voltage Selection

Page 11

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

______________________________________________________________________________________ 11

Inductor Selection

The optimum inductor value for L1 is 3.3µH, as shown

in Figure 4. Inductors with less than 300mΩ DC series

resistance are recommended to achieve the highest

efficiency. Using a larger value for L1 (e.g., 4.7µH)

increases the output current capability of DC-DC 1 (by

reducing the peak ripple current) at the expense of size

and the additional output filter capacitance needed for

loop stability.

For DC-DC 2, at large input voltages (i.e., 5V) and low

switching frequencies (i.e., ≤400kHz), the value of L2

should be increased (e.g., 6.8µH or 10µH) to limit the

peak current. In some cases it may be necessary to

reduce the value of L2 to increase the output current

capability of DC-DC 2 (Table 2). The relationship between

input voltage, output voltage, switching frequency, inductor value, and maximum load current for DC-DC 2 is complex and nonlinear. This relationship is summarized in

Table 2. The L2 equation is as follows:

where:

Internal MOSFET on-resistance:

R

ON(LX2P)

= R

ON(LX2N)

= 0.9Ω typical

External inductor DC resistance:

R

L2

= 0.3Ω typical

Inductor peak current:

I

PEAK

= 700mA (750mA absolute maximum)

Due to the MAX1664’s high switching frequency, inductors with a high-frequency core material such as ferrite

are recommended. Powdered iron compounds are not

recommended due to their higher core losses. Typical

small-size, low-profile inductors include the ILS-3825

(Dale Electronics-Vishay) and the CLQ61B (Sumida).

These inductors are primarily used for DC-DC

converters with low height requirements. See Table 3

for more information on manufacturers who provide

low-profile inductors.

L2

V - R R R

(I )

2

I x 2 f

INP ON(LX2P) ON(LX2N) L2

PEAK

PEAK DC-DC 1

>

+ +

[ ]

( )

REF

FB2-

IN INP

LX2P

LX2N

FB2+

R8

49.9k

R7

549k

R6

200k

R5

49.9k

D3

D2

L2

4.7µH

PGND2

PLLC

GND

FPLL

RDY

REF

SHDN

ON

OFF

V

OUT1

5.5V

2.2µF

3 x 10µF

0.22µF

22nF

100k

2.2nF

0.22µF

0.47µF

50pF

2 x 10µF

10µF

10µF2.2µF

33Ω

0.47µF

3.3µH

R1

301k

R2

100k

R3

100k

R4

100k

V

OUT2-

-5V

V

OUT2+

15V

BPV

SS

BACKPLANE

DRIVER

V

SUPPLY

2.8V TO 5.5V

BPDRV

BPV

DD

PGND1

FB1

LX1

BPCLK

MAX1664

Figure 4. Detailed Typical Operating Circuit

Page 12

MAX1664

12 ______________________________________________________________________________________

Diode Selection

The MAX1664’s high switching frequency requires fast

diodes. Schottky diodes such as the MBR0520L and

MBR0540L (Motorola) are recommended because they

have the necessary power ratings in a low-height SOD123 package. Also recommended is the MBRM5817

which is 1.1mm high. Use a Schottky diode with a forward current rating greater than:

For the positive output of DC-DC 2, use a Schottky

diode with a voltage rating that exceeds V

OUT2+

. For

the negative output, use a Schottky diode with a rating

that exceeds V

IN

+ V

OUT2-

. See Table 3 for more

information on Schottky diode manufacturers.

Filter Capacitor Selection

An output filter capacitor’s ESR and size can greatly

influence a switching converter’s output ripple, as

shown in the following equation.

V I x R I

t

C

DC-DC 1 t

1

f

V V - V

V V

DC-DC 2 t

1

2 f

RIPPLE(PK PK) PEAK ESR OUT

ON

OUT

ON

DC-DC 1

OUT1 F IN

OUT1 F

ON

DC-DC 1

−

≅ +

=

+

+

=

.

I

I V

V

F

OUT OUT

IN

>

0 9

Table 2. Typical DC-DC 2 Operation

*

Note: Absolute maximum peak current at LX2P and LX2N is 750mA.

Active Matrix Liquid Crystal Display

(AMLCD) Supply

INDUCTOR PEAK

CURRENT*

(mA)

f

DC-DC 2(MAX)

(kHz)

I

OUT2-(MAX)

(mA)

I

OUT2+(MAX)

(mA)

L2

(µH)

f

BPCLK

(kHz)

V

IN

(V)

V

OUT2-

(V)

V

OUT2+

(V)

50048015104.730.05.0-10+20

55040018104.725.05.0-10+20

64036020114.722.55.0-10+20

67948017102.730.04.5-10+20

4504801284.730.04.5-10+20

5004001484.725.04.5-10+20

5803601694.722.54.5-10+20

496480844.730.03.3-10+20

340480544.730.03.3-10+20

5834001062.725.03.3-10+20

370400744.725.03.3-10+20

6433601262.722.53.3-10+20

425360844.722.53.3-10+20

451480632.730.03.0-10+20

300480434.730.03.0-10+20

530400842.725.03.0-10+20

340400524.725.03.0-10+20

5853601052.722.53.0-10+20

385360634.722.53.0-10+20

60036043204.722.55.0-5+15

55036035154.722.54.5-5+15

64336027102.722.53.3-5+15

4253601974.722.53.3-5+15

5853602382.722.53.0-5+15

3753601564.722.53.0-5+15

Page 13

Ceramic capacitors are recommended because they

have low ESR and the lowest profile. Typical ceramic

capacitors are the C3225X5R series from TDK and

JMK325 series from Taiyo Yuden. See Table 3 for more

information on the manufacturers who provide surfacemount ceramic capacitors.

PLL Compensation

In most applications, the recommended compensation

component values shown in Figure 4 will give optimal

system performance. If no backplane clock is used,

connect PLLC to REF.

_____________Applications Information

Increasing V

OUT

Above 5.5V

For V

OUT1

output voltages above 5.5V, connect the

supplemental charge pump circuit shown in Figure 5.

The connection shown supplies a 10V 150mA output,

but other voltages from 2 x VINto 10V can be set by

selecting the appropriate values for R1 and R2 (see

DC-DC 1 Output

section). C2–C4 are shown as parallel

combinations of 3.3µF ceramic capacitors so that a

1.1mm height restriction can be met. If height is not

restricted, then larger values can be used instead of

parallel capacitor combinations.

3.3V to -20V Charge-Pump Configuration

For applications requiring negative voltages down to

-20V, an inverting charge-pump block can be added to

the V

OUT2-

output (Figure 6). Typical values for CFand

C

OUT

are 0.47µF to 1µF and 4.7µF to 10µF, respective-

ly. As a general rule, C

OUT

should be ten times greater

than CF. This circuit operates as follows:

1) During the first PFM cycle, the voltage at V1 is

charged by inductor L2 to some fraction of its final

steady-state voltage, in the normal manner described

in the

Detailed Description

.

2) During the first half of subsequent PFM cycles, pin

LX2P is pulled to V

INP

, and capacitor CFis charged

to (V

INP

+V1 - VD), where VDis a diode forward

voltage.

3) During subsequent second half-cycles when LX2P

flies negatively below V1, capacitor CFtransfers

some of its energy to output capacitor C

OUT

, which

then is charged to a negative voltage of approximately (V

INP

+ 2 x V1 - 2x VD).

4) This process continues until V

OUT

reaches the

desired voltage, as determined by the ratio of the

FB2- feedback resistors.

5) During steady-state (in-regulation) operation, the

magnitude of the voltage at LX2P is equal to

(V

OUT

/ 2 - V

INP

/ 2 + VD), which must be limited to

less than 10V.

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

______________________________________________________________________________________ 13

MANUFACTURER PHONE FAX

Dale Inductors (605) 668-4131 (605) 665-1627

Sumida USA (847) 956-0666 (847) 956-0702

Central Semiconductor (516) 435-1110 (516) 435-1824

International Rectifier (310) 322-3331 (310) 322-3232

TDK (847) 390-4373 (847) 390-4428

Vishay/Vitramon (203) 268-6261 (203) 452-5670

Table 3. Component Manufacturers

MAX1664

LX1

C3

3.3µF (x6)

C4

3.3µF (x2)

R2

13k

D1, D2, D3— MBRM5817

C1, C2, C3—ALL CERAMIC TYPES

R1

91k

C2

3.3µF (x2)

50pF

D2

33Ω

IN INP

D3

D1

V

1

10V

150mA

V

SUPPLY

2.8V TO 3.6V

PGND1

FB1

C1

3.3µF (x2)

3.3µH

0.47µF

Figure 5. Charge Pump Configuration to Increase V

OUT1

Above 5.5V.

Motorola (602) 303-5454 (602) 994-6430

Marcon/United

Chemicon

(847) 696-2000 (847) 696-9278

Taiyo Yuden (408) 573-4150 (408) 573-4159

INDUCTORS

DIODES

CERAMIC CAPACITORS

Page 14

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

14 ______________________________________________________________________________________

Figure 7a. MAX1664 Component Placement Guide Figure 7b. MAX1664 PC Board Layout—Component Side

1.0"

1.0"

Supply Connections and Layout

The MAX1664 performs both precision analog and

high-power switching functions. Carefully plan supply

connections, bypassing, and layout. Bypass IN and INP

with a 33Ω isolation resistor (R9, Figure 4) between

them. In addition, sufficient low-ESR bypassing must be

provided on the INP bus to ensure stability of DC-DC 1.

A solid ground plane under the power components,

with a separate ground plane under the analog nodes,

is highly recommended. These ground planes should

be connected at a single, quiet point. Analog reference

and feedback signals should be referred to and routed

over the analog ground plane. Figure 7 shows a typical

layout using separate ground planes.

REF

R5

R6

R7

R8

FB2-

LX2P

L2

LX2N

FB2+

D3

D2

D5

D4

C

F

V1

PGND2

0.47µF

0.22µF

C

OUT

4.7µF

V

OUT2-

-20V

V

OUT2+

28V

MAX1664

Figure 6. V

OUT2

- Voltage-Doubler Charge Pump

Page 15

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

______________________________________________________________________________________ 15

Figure 7c. MAX1664 PC Board Layout—Solder Side

TRANSISTOR COUNT: 838

___________________Chip Information

1.0"

Page 16

MAX1664

Active-Matrix Liquid Crystal Display

(AMLCD) Supply

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1998 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

________________________________________________________Package Information

TSSOP.EPS

Loading...

Loading...