Page 1

________________General Description

The MAX1639 is an ultra-high-performance, step-down

DC-DC controller for CPU power in high-end computer

systems. Designed for demanding applications in which

output voltage precision and good transient response are

critical for proper operation, it delivers over 35A from 1.1V

to 4.5V with ±1% total accuracy from a +5V ±10% supply.

Excellent dynamic response corrects output transients

caused by the latest dynamically clocked CPUs. This

controller achieves over 90% efficiency by using synchronous rectification. Flying-capacitor bootstrap circuitry

drives inexpensive, external N-channel MOSFETs.

The switching frequency is pin-selectable for 300kHz,

600kHz, or 1MHz. High switching frequencies allow the

use of a small surface-mount inductor and decrease output filter capacitor requirements, reducing board area

and system cost.

Output overvoltage protection is enforced by a crowbar

circuit that turns on the low-side MOSFET with 100%

duty factor when the output is 200mV above the normal

regulation point. Other features include internal digital

soft-start, a power-good output, and a 3.5V ±1% reference output. The MAX1639 is available in a 16-pin

narrow SOIC package.

________________________Applications

Local DC-DC Converters for CPUs

Workstations

Desktop Computers

LAN Servers

GTL Bus Termination

____________________________Features

♦ Better than ±1% Output Accuracy Over

Line and Load

♦ Greater than 90% Efficiency Using N-Channel

MOSFETs

♦ Pin-Selected High Switching Frequency:

300kHz, 600kHz, or 1MHz

♦ Over 35A Output Current

♦ Resistor-Divider Adjustable Output from

1.1V to 4.5V

♦ Current-Mode Control for Fast Transient

Response and Cycle-by-Cycle Current-Limit

Protection

♦ Short-Circuit Protection with Foldback Current

Limiting

♦ Crowbar Overvoltage Protection

♦ Power-Good (PWROK) Output

♦ Digital Soft-Start

♦ High-Current (2A) Drive Outputs

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

________________________________________________________________

Maxim Integrated Products

1

19-1337; Rev 0; 2/98

PART

MAX1639ESE -40°C to +85°C

TEMP. RANGE PIN-PACKAGE

16 Narrow SO

_______________Ordering Information

__________

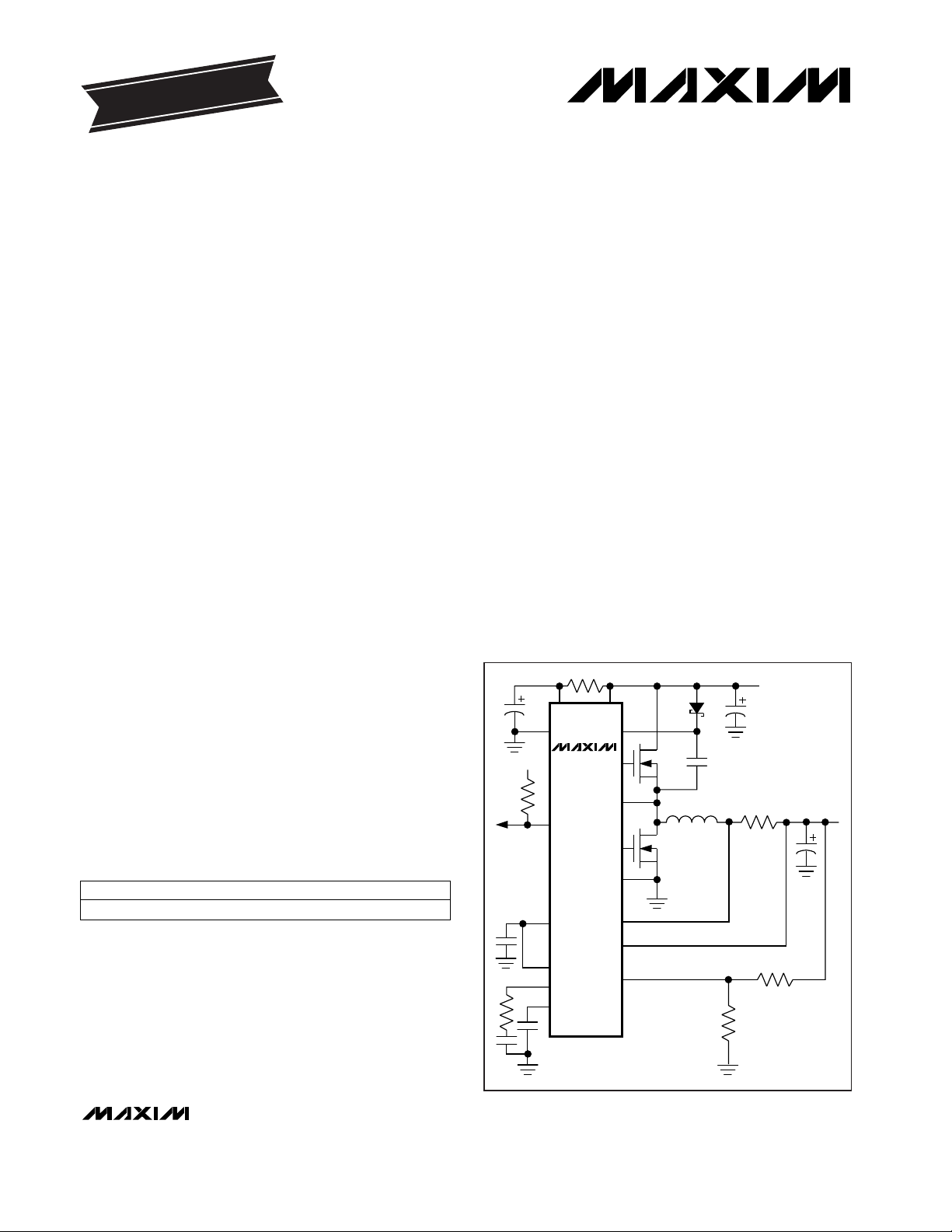

Typical Operating Circuit

Pin Configuration appears at end of data sheet.

V

CC

AGND

REF

FREQ

CC1

CC2

DL

PWROK

LX

BST

DH

PGND

TO V

DD

CSH

OUTPUT

1.1V TO 4.5V

INPUT

+5V

V

DD

CSL

FB

MAX1639

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

EVALUATION KIT

AVAILABLE

Page 2

FREQ Input Voltage

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDD= VCC= +5V, PGND = AGND = 0V, FREQ = REF, TA= 0°C to +85°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDD, VCC, PWROK to AGND....................................-0.3V to +6V

PGND to AGND ..................................................................±0.3V

CSH, CSL to AGND....................................-0.3V to (VCC+ 0.3V)

DL to PGND................................................-0.3V to (VDD+ 0.3V)

REF, CC1, CC2, FREQ, FB to AGND .........-0.3V to (V

CC

+ 0.3V)

BST to PGND..........................................................-0.3V to +12V

BST to LX..................................................................-0.3V to +6V

DH to LX.............................................(LX - 0.3V) to (BST + 0.3V)

Continuous Power Dissipation (TA= +70°C)

16-Pin Narrow SO (derate 8.70mW/°C above +70°C) ....696mW

SO θJC...........................................................................65°C/W

Operating Temperature Range

MAX1639ESE....................................................-40°C to +85°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

FREQ = AGND

FREQ = REF

VCC= V

DD

FREQ = V

CC

PWROK = 5.5V

Includes line and load

regulation errors

I

SINK

= 2mA, VCC= 4.5V

Falling FB, 1% hysteresis with respect to V

REF

Rising FB, 1% hysteresis with respect to V

REF

0µA < I

REF

< 100µA

No load

VCC= VDD= 5.5V, FB forced 60mV above

regulation point, operating or standby mode

VCCrising edge, 1% hysteresis

V

REF

= 0V

Rising edge, 1% hysteresis

CONDITIONS

kHz

255 300 345

Switching Frequency 540 600 660

850 1000 1150

µA1PWROK Output Current High

V0.4PWROK Output Voltage Low

%

6.5 8 9.5

PWROK Trip Level

-7.5 -6 -4.5

mA0.5 4.0Reference Short-Circuit Current

V2.7 3.0Reference Undervoltage Lockout

V4.5 5.5Input Voltage Range

V

1.083 1.117

1.089 1.111

FB Voltage

mV10Reference Load Regulation

V3.465 3.5 3.535Reference Voltage

mA0.1VDDSupply Current (IDD)

V4.0 4.2Input Undervoltage Lockout

UNITSMIN TYP MAXPARAMETER

TA= +25°C to +85°C

TA= 0°C to +85°C

2.5

5

CSH - CSL = 0mV to 80mV %1AC Load Regulation

CSH - CSL = 0mV to 80mV %0.1DC Load Regulation

FB overdrive = 60mV

FB overdrive = 0V

Operating

mode

mA

3.6 10

VCC= V

DD

= 5.5V

V

REF

= 0V

Shutdown

mode

VCCSupply Current (ICC)

VCC(high)

GND (low)

FREQ = V

CC

%

VCC- 0.1

Maximum Duty Cycle

0.2

85 90

FREQ Input Voltage V

REF (mid) 3.3 3.7

Page 3

ELECTRICAL CHARACTERISTICS (continued)

(VDD= V

CC

= +5V, PGND = AGND = 0V, FREQ = REF, TA= 0°C to +85°C, unless otherwise noted.)

MAX1639

_______________________________________________________________________________________

3

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

15 38 70

mV

FB = 0V (foldback)

Current-Limit Trip Voltage

DL On-Resistance Ω

50 µABST = 12V, LX = 7V, REF = GNDBST Leakage Current

1536 1 / f

OSC

To full current limitSoft-Start Time

85 100 115FB = 1.1V

FB Input Current

CC2 Clamp Voltage

PARAMETER MIN TYP MAX UNITS

FREQ Input Current 4 µA

±0.1 µA

2.4 3.0

V

4 V

CC

CC2 Source/Sink Current 100 µA

0.7 2DH On-Resistance

Maximum

0.7 2

Ω

DH, DL Source/Sink Current 2 A

DH, DL Dead Time 0 30 ns

CONDITIONS

Minimum

30mV overdrive

BST - LX = 4.5V

VDD= 4.5V

DH = DL = 2.5V

ELECTRICAL CHARACTERISTICS

(VDD= VCC= +5V, PGND = AGND = 0V, FREQ = REF, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

Note 1: Specifications from 0°C to -40°C are guaranteed by design, not production tested.

FREQ = REF

FREQ = V

CC

BST - LX = 4.5V

FREQ = V

CC

Falling FB, 1% hysteresis with respect to V

REF

Rising FB, 1% hysteresis with respect to V

REF

FREQ = AGND

VDD= 4.5V

Ω2

%84

DL On-Resistance

VCCrising edge, 1% hysteresis

Ω

VCC= V

DD

2

CONDITIONS

510 690

Maximum Duty Cycle

800 1200

DH On-Resistance

Switching Frequency

FB = 1.1VCurrent-Limit Trip Voltage mV70 130

6 10

kHz

240 360

%

-8 -4

PWROK Trip Level

V3.9 4.3Input Undervoltage Range

V4.5 5.5Input Voltage Range

UNITSMIN TYP MAXPARAMETER

CC2 Transconductance

CC1 Output Resistance 10 kΩ

1 mmho

CSH, CSL Input Current 50 µACSH = CSL = 1.1V

VCC= VDD=

5.5V

mA

12

VDDSupply Current

3

Includes line and load regulation errors

No load

V1.072 1.128FB Voltage

V3.448 3.553Reference Voltage

VCC= VDD= 5.5V, FB forced 60mV above

regulation point, operating or shutdown mode

mA0.2VDDSupply Current

Operating mode FB overdrive = 60mV

VREF = 0VShutdown mode

Page 4

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

4 _______________________________________________________________________________________

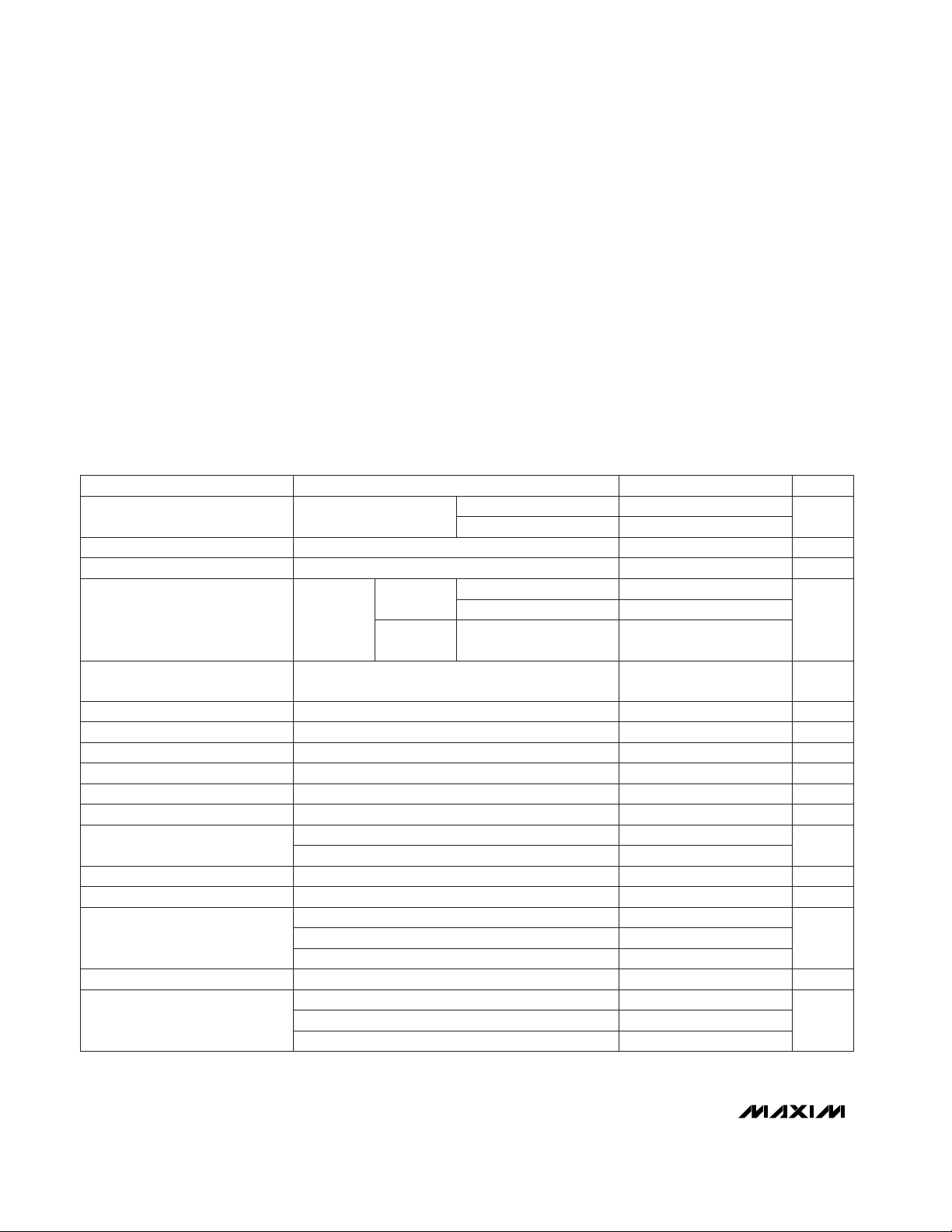

FOLDBACK CURRENT LIMIT

(V

OUT

= 2.5V, NOMINAL)

MAX1639-02

A: V

OUT

= 0.5V/div

B: INDUCTOR CURRENT, 5A/div

A

B

10µs/div

START-UP WAVEFORMS

MAX1639-03

A: INDUCTOR CURRENT, 2A/div

B: V

OUT

= 1V/div

A

B

400µs/div

1µs/div

SWITCHING WAVEFORMS

C

0

MAX1639-04

VIN = 5V, V

OUT

= 2.5V, LOAD = 0A

A: V

OUT

, 20mV/div

B: INDUCTOR CURRENT, 2A/div

C: LX, 5V/div

B

A

LOAD-TRANSIENT RESPONSE

(V

OUT

= 2.5V)

MAX1639-01

VIN = 5V, V

OUT

= 2.5V, LOAD = 8A

A: V

OUT

, 100mV/div, AC COUPLED

B: INDUCTOR CURRENT, 5A/div

A

B

10µs/div

__________________________________________Typical Operating Characteristics

(TA = +25°C, using the MAX1639 evaluation kit, unless otherwise noted.)

100

50

0.1 10

EFFICIENCY vs. OUTPUT CURRENT

60

90

80

70

MAX1639-05

OUTPUT CURRENT (A)

EFFICIENCY (%)

1

3.5V

1.8V

2.5V

50

55

0

MAXIMUM DUTY CYCLE vs.

SWITCHING FREQUENCY

65

60

70

MAX1639-06

SWITCHING FREQUENCY (kHz)

MAXIMUM DUTY CYCLE (%)

85

95

90

75

80

200 800 1000 1200

100

600400

Page 5

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

_______________________________________________________________________________________ 5

______________________________________________________________Pin Description

7 Analog GroundAGND

6

Reference Output, 3.5V. Bypass REF to AGND with 0.1µF (min). Sources up to 100µA for external

loads. Force REF below 2V to turn off the controller.

REF

5 Analog Supply Input, 5V. Use an RC filter network, as shown in Figure 1. V

CC

4 Current-Sense Amplifier’s Noninverting InputCSH

3

Current-Sense Amplifier’s Inverting Input. Place the current-sense resistor very close to the controller IC,

and use a Kelvin connection.

CSL

2

Open-Drain Logic Output. PWROK is high when the voltage on FB is within +8% and -6% of its setpoint.

PWROK

8 Voltage-Feedback Input. The voltage at this input is regulated to 1.100V.FB

9

Fast-Loop Compensation Capacitor Input. Connect a ceramic capacitor and resistor in series from

CC1 to AGND. See the section

Compensating the Feedback Loop

.

CC1

FUNCTIONNAME

1

Boost-Capacitor Bypass for High-Side MOSFET Gate Drive. Connect a 0.1µF capacitor and low-leakage Schottky diode as a bootstrapped charge-pump circuit to derive a 5V gate drive from VDDfor DH.

BST

10

Slow-Loop Compensation Capacitor Input. Connect a ceramic capacitor from CC2 to AGND. See the

section

Compensating the Feedback Loop.

CC2

11

Frequency-Select Input. FREQ = VCC: 1MHz

FREQ = REF: 600kHz

FREQ = AGND: 300kHz

FREQ

12

Power Input for MOSFET Drivers, 5V. Bypass VDDto PGND within 0.2 in. (5mm) of the VDDpin using a

0.1µF capacitor and 4.7µF capacitor connected in parallel.

V

DD

13

Low-Side Synchronous Rectifier Gate-Drive Output. DL swings between PGND and VDD. See the

section

BST High-Side Gate-Driver Supply and MOSFET Drivers

.

DL

14 PGND Power Ground

15 LX Switching Node. Connect LX to the high-side MOSFET source and inductor.

16 DH

High-Side Main MOSFET Switch Gate-Drive Output. DH is a floating driver output that swings from LX

to BST, riding on the LX switching-node voltage. See the section

BST High-Side Gate-Driver Supply

and MOSFET Drivers

.

PIN

Page 6

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

6 _______________________________________________________________________________________

N1

N2

D1

(OPTIONAL)

R3

(OPTIONAL)

R4

(OPTIONAL)

V

CC

V

DD

PWROK

BST

DH

LX

DL

PGND

CSH

FB

AGND

R8

C8

R7

CC1

CC2

CC1

1000pF

CC2

0.056µF

REF

C4, 1.0µF

CERAMIC

RC1

1k

TO

AGND

R6

100k

C5

0.1µF

C6

10µF

R5

10Ω

TO V

DD

FREQ

C7

0.1µF

D2

CMPSH-3

C3

0.1µF

L1

R1

V

IN

= 4.5V

TO 5.5V

C1

C2

MAX1639

V

OUT

= 1.1V

TO 4.5V

CSL

Figure 1. Standard Application Circuit

_______Standard Application Circuits

The predesigned MAX1639 circuit shown in Figure 1

meets a wide range of applications with output currents

up to 35A. Use Table 1 to select components appropriate for the desired output current range, and adapt the

evaluation kit PC board layout as necessary. This circuit represents a good set of trade-offs between cost,

size, and efficiency while staying within the worst-case

specification limits for stress-related parameters, such

as capacitor ripple current.

The MAX1639 circuit was designed for the specified frequencies. Do not change the switching frequency with-

out first recalculating component values—particularly

the inductance, output filter capacitance, and RC1

resistance values.

___________________Detailed Description

The MAX1639 is a BiCMOS power-supply controller

designed for use in switch-mode, step-down (buck)

topology DC-DC converters. Synchronous rectification

provides high efficiency. It is intended to provide the

high precision, low noise, excellent transient response,

and high efficiency required in today’s most demanding applications.

Page 7

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

_______________________________________________________________________________________ 7

Table 1. Component List for Standard Applications

(x5) 560µF, Sanyo OS-CON 4SP560M

Central Semiconductor CMPSH-3

0.3µH, 25A, 0.9mΩ

Panasonic ETQPAF0R3E

(x2) 7mΩ, Dale WSL-2512-R007-J

(x3) 330µF, Sanyo OS-CON 6SA330M

LOAD REQUIREMENT

Schottky diode, Motorola MBRD640

(x2) 0.010Ω, 30V, D2PAK, Fairchild FDB7030L

(x2) 0.014Ω, 30V, SO8, Fairchild FDS6680

(x2) 0.010Ω, 30V, D2PAK, Fairchild FDB7030L

(x2) 0.014Ω, 30V, SO8, Fairchild FDS6680

1.8V, 20A

C2

(x2) 560µF, Sanyo OS-CON 4SP560M

Central Semiconductor CMPSH-3

1.0µH, 9.3A, SMD

Coiltronics UP2B-1R0

1.0µH, 10A, SMD

Coilcraft D03316P-102HC

9mΩ Dale,

WSL-2512-R009-J

330µF, Sanyo OS-CON 6SA330M

D1 (optional) Schottky diode, Nihon NSQ03A02

0.014Ω, 30V, SO8

Fairchild FDS6680

0.018Ω, 30V, SO8

International Rectifier IRF7413

N1

0.014Ω, 30V, SO8

Fairchild FDS6680

0.018Ω, 30V, SO8

International Rectifier IRF7413

D2

N2

2.5V, 8A

L1

R1

COMPONENT

C1

Note: Parts used in evaluation board are shown in bold.

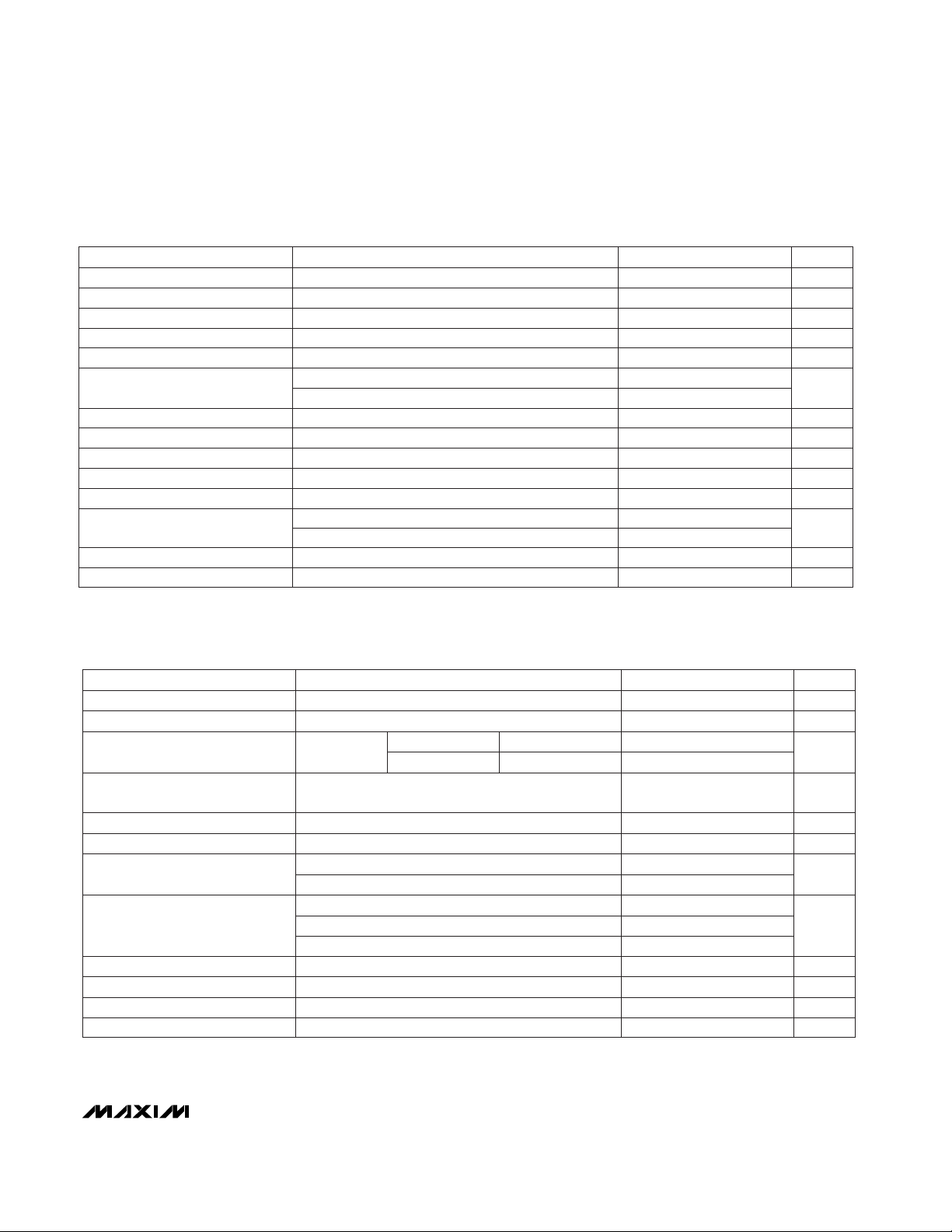

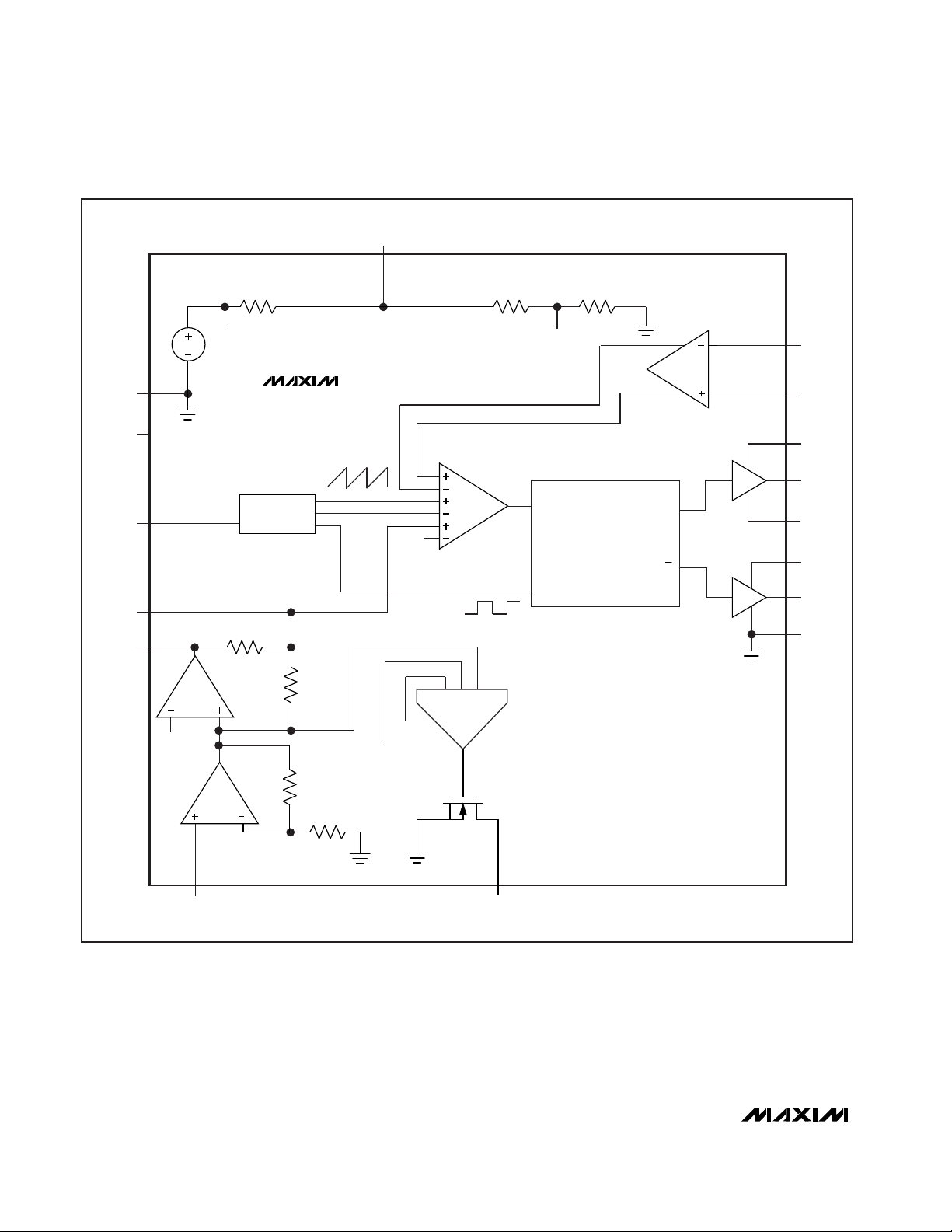

PWM Controller Block and Integrator

The heart of the current-mode PWM controller is a

multi-input, open-loop comparator that sums three signals (Figure 2): the buffered feedback signal, the current-sense signal, and the slope-compensation ramp.

This direct-summing configuration approaches ideal

cycle-by-cycle control over the output voltage. The output voltage error signal is generated by an error amplifier that compares the amplified feedback voltage to an

internal reference.

Each pulse from the oscillator sets the main PWM latch

that turns on the high-side switch for a period determined by the duty factor (approximately V

OUT

/ VIN). The

current-mode feedback system regulates the peak

inductor current as a function of the output voltage error

signal. Since average inductor current is nearly the same

as peak current (assuming the inductor value is set relatively high to minimize ripple current), the circuit acts as

a switch-mode transconductance amplifier. It pushes the

second output LC filter pole, normally found in a dutyfactor-controlled (voltage-mode) PWM, to a higher frequency. To preserve inner-loop stability and eliminate

regenerative inductor current staircasing, a slopecompensation ramp is summed into the main PWM comparator. Under fault conditions where the inductor current exceeds the maximum current-limit threshold, the

high-side latch resets, and the high-side switch turns off.

Internal Reference

The internal 3.5V reference (REF) is accurate to ±1%

from 0°C to +85°C, making REF useful as a system reference. Bypass REF to AGND with a 0.1µF (min)

ceramic capacitor. A larger value (such as 2.2µF) is

recommended for high-current applications. Load regulation is 10mV for loads up to 100µA. Reference

undervoltage lockout is between 2.7V and 3V. Shortcircuit current is less than 4mA.

Synchronous-Rectifier Driver

Synchronous rectification reduces conduction losses in

the rectifier by shunting the normal Schottky diode or

MOSFET body diode with a low-on-resistance MOSFET

switch. The synchronous rectifier also ensures proper

start-up by precharging the boost-charge pump used

for the high-side switch gate-drive circuit. Thus, if you

must omit the synchronous power MOSFET for cost or

other reasons, replace it with a small-signal MOSFET,

such as a 2N7002.

The DL drive waveform is simply the complement of the

DH high-side drive waveform (with typical controlled

dead time of 30ns to prevent cross-conduction or

shoot-through). The DL output’s on-resistance is 0.7Ω

(typ) and 2Ω (max).

10.0kΩ, 1%

10.0kΩ, 1%

R7

6.19kΩ, 1%

12.7kΩ, 1%

R8

Page 8

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

8 _______________________________________________________________________________________

+

-

REF

REF2

REF

FB PWROK

CC2

CC1

REF1

24R

11R

N

10k

40k

WINDOW

CONTROL AND

DRIVE LOGIC

OSCILLATOR

SLOPE

COMPENSATION

AGND

V

CC

FREQ

REF1

REF

REF2

CSL

CSH

BST

DH

LX

V

DD

DL

RESET

Q

Q

SET

PGND

MAX1639

gm

Figure 2. Simplified Block Diagram

Page 9

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

_______________________________________________________________________________________ 9

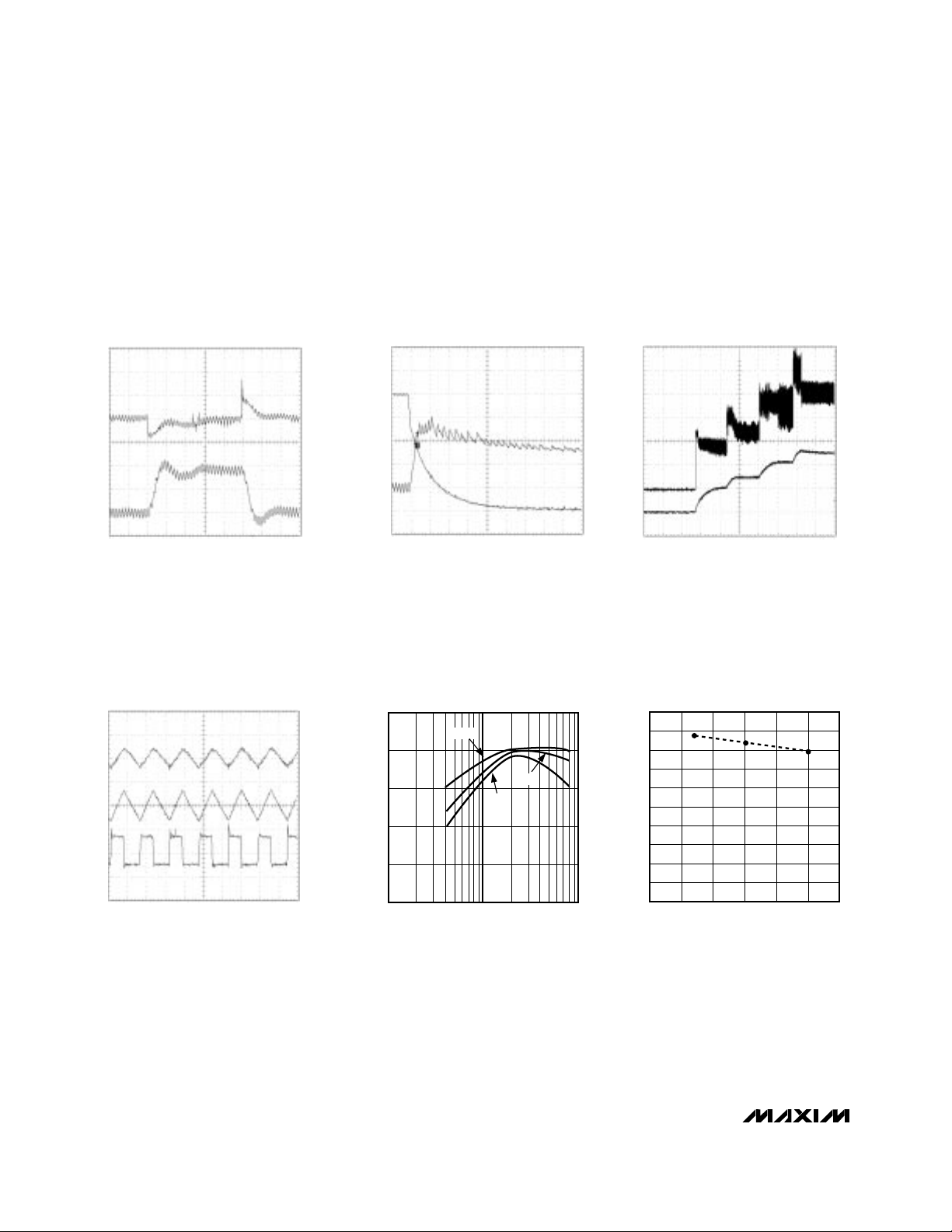

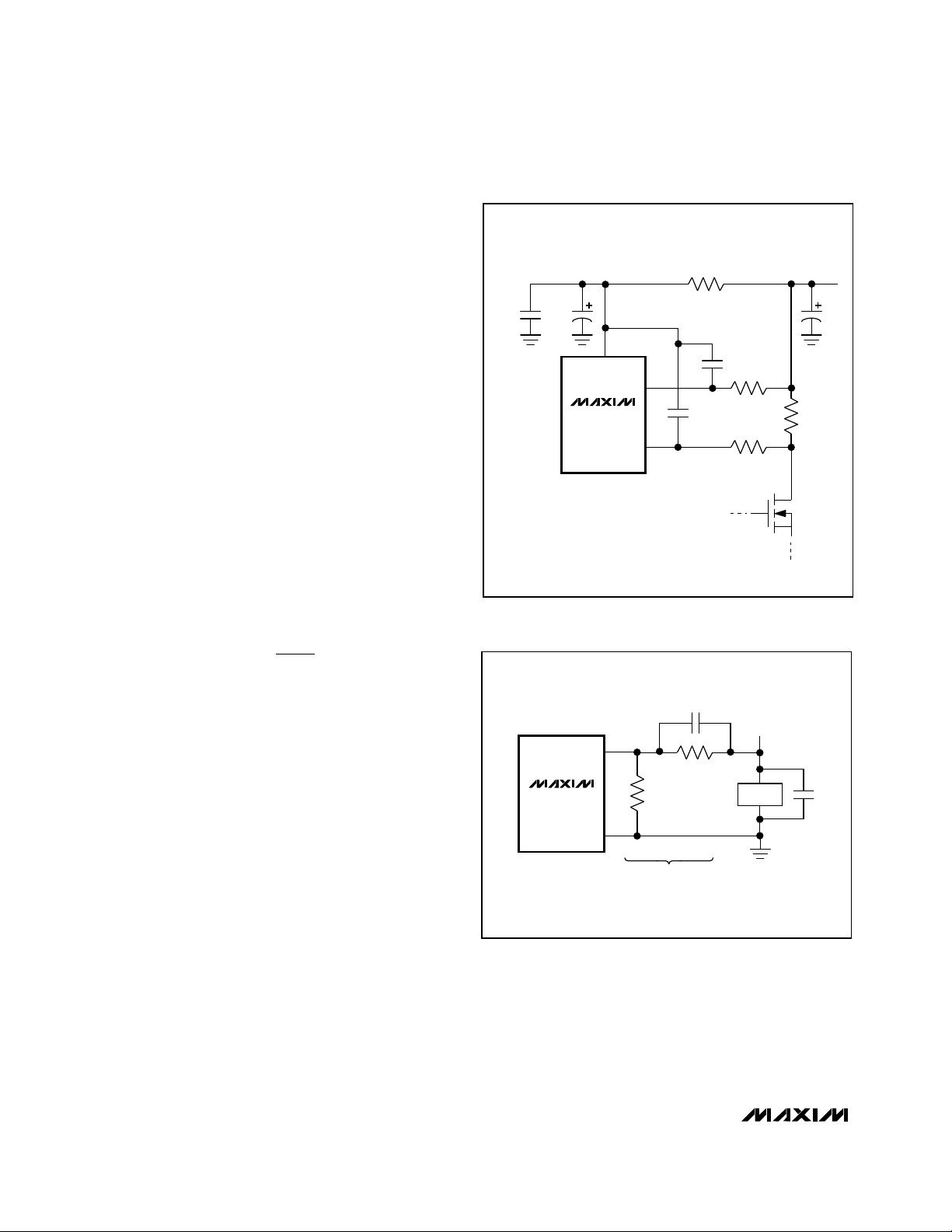

BST High-Side Gate-Driver Supply

and MOSFET Drivers

Gate-drive voltage for the high-side N-channel switch

is generated using a flying-capacitor boost circuit

(Figure 3). The capacitor is alternately charged from

the +5V supply and placed in parallel with the highside MOSFET’s gate and source terminals.

Gate-drive resistors (R3 and R4) can often be useful to

reduce jitter in the switching waveforms by slowing

down the fast-slewing LX node and reducing ground

bounce at the controller IC. However, switching loss

may increase. Low-value resistors from around 1Ω to

5Ω are sufficient for many applications.

Current Sense

and Overload Current Limiting

The current-sense circuit resets the main PWM latch

and turns off the high-side MOSFET switch whenever

the voltage difference between CSH and CSL from current through the sense resistor (R1) exceeds the peak

current limit (100mV typical).

Current-mode control provides cycle-by-cycle currentlimit capability for maximum overload protection.

During normal operation, the peak current limit set by

the current-sense resistor determines the maximum

output current. When the output is shorted, the peak

current may be higher than the set current limit due to

delays in the current-sense comparator. Thus, foldback

current limiting is employed where the set current-limit

point is reduced from 100mV to 38mV as the output

(feedback) voltage falls (Figure 4). When the shortcircuit condition is removed, the feedback voltage will

rise and the current-limit voltage will revert to 100mV.

The foldback current-limit circuit is designed to ensure

startup into a resistive load.

High-Side Current Sensing

The common-mode input range of the current-sense

inputs (CSH and CSL) extends to VCC, so it is possible

to configure the circuit with the current-sense resistor

on the input side rather than on the load side (Figure 5).

This configuration improves efficiency by reducing the

power dissipation in the sense resistor according to the

duty ratio.

In the high-side configuration, if the output is shorted

directly to GND through a low-resistance path, the

current-sense comparator may be unable to enforce a

current limit. Under such conditions, circuit parasitics

such as MOSFET R

DS(ON)

typically limit the shortcircuit current to a value around the peak-currentlimit setting.

Attach a lowpass-filter network between the currentsense pins and resistor to reduce high-frequency

common-mode noise. The filter should be designed

with a time constant of around one-fifth of the on-time

(130ns at 600kHz, for example). Resistors in the 20Ω to

100Ω range are recommended for R9 and R10.

Connect the filter capacitors C9 and C10 from V

CC

to

CSH and CSL, respectively.

Values of 39Ω and 3.3nF are suitable for many

designs. Place the current-sense filter network close to

the IC, within 0.1 in (2.5mm) of the CSH and CSL pins.

C3

C1

L1

D2

V

IN

= 5V

V

DD

N1

R4

DH

LEVEL

TRANSLATOR

CONTROL AND

DRIVE LOGIC

N2

R3

PGND

R3 AND R4

ARE OPTIONAL

LX

DL

BST

MAX1639

Figure 3. Boost Supply for Gate Drivers

0

20

10

50

40

30

60

70

100

90

80

20 30100 40 50 60 70 80 90 100

V

FB

(%)

I

LIM

(%)

Figure 4. Foldback Current Limit

Page 10

Overvoltage Protection

When the output exceeds the set voltage, the synchronous rectifier output (DL) is driven high (and DH is driven low). This causes the inductor to quickly dissipate

any stored energy and force the fault current to flow to

ground. Current is limited by the source impedance

and parasitic resistance of the current path, so a fuse is

required in series with the +5V input to protect against

low-impedance faults, such as a shorted high-side

MOSFET. Otherwise, the low-side MOSFET will eventually fail. DL will go low if the input voltage drops below

the undervoltage lockout point.

Internal Soft-Start

Soft-start allows a gradual increase of the internal current limit at start-up to reduce input surge currents. An

internal DAC raises the current-limit threshold from 0V

to 100mV in four steps (25mV, 50mV, 75mV, and

100mV) over the span of 1536 oscillator cycles.

__________________Design Procedure

Setting the Output Voltage

Set the output voltage by connecting R7 and R8 (Figure 6)

to the FB pin from the output to AGND. R7 is given by the

following equation:

where VFB= 1.1V. Since the input bias current at FB

has a maximum value of ±0.1µA, values up to 10kΩ

can be used for R8 with no significant accuracy loss.

Values under 1kΩ are recommended to improve noise

immunity. Place R7 and R8 very close to the MAX1639,

within 0.2in (5mm) of the FB pin.

Feed-Forward Compensation

An optional compensation capacitor (C8), typically

220pF, may be needed across the upper feedback

resistor to counter the effects of stray capacitance on the

FB pin, and to help ensure stable operation when highvalue feedback resistors are used (Figure 6). Empirically

adjust the feed-forward capacitor as needed.

Specifying the Inductor

Three key inductor parameters must be specified:

inductance value (L), peak current (I

PEAK

), and DC

resistance (RDC). The following equation includes a

constant LIR, which is the ratio of inductor peak-topeak AC current to DC load current. Typically LIR can

be between 0.1 to 0.5. A higher LIR value allows for

smaller inductors and better transient response, but

results in higher losses and output ripple. A good compromise between size and loss is a 30% ripple current

to load current ratio (LIR = 0.30), which corresponds to

a peak inductor current 1.15 times higher than the DC

load current.

R R x

V

V

OUT

FB

7 8 1 = −

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

10 ______________________________________________________________________________________

C10

4.7nF

R1

C9

4.7nF

R9

39Ω

R5

10Ω

R10

39Ω

CSH

V

CC

CSL

MAX1639

N1

C5

0.1µFC610µF

C1

V

IN

Figure 5. High-Side Current Sense

R8

PLACE VERY CLOSE

TO MAX1639

R7

FB

AGND

V

OUT

C8 (OPTIONAL)

LOAD

MAX1639

Figure 6. Output Selection

Page 11

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

______________________________________________________________________________________ 11

where f is the switching frequency, between 300kHz

and 1MHz; I

OUT

is the maximum DC load current; and

LIR is the ratio of AC to DC inductor current (typically

0.3). The exact inductor value is not critical and can be

adjusted to make trade-offs among size, transient

response, cost, and efficiency. Although lower inductor

values minimize size and cost, they also reduce efficiency due to higher peak currents. In general, higher

inductor values increase efficiency, but at some point

resistive losses due to extra turns of wire exceed the

benefit gained from lower AC current levels. Loadtransient response can be adversely affected by

high inductor values, especially at low (VIN- V

OUT

)

differentials.

The peak inductor current at full load is 1.15 x I

OUT

if

the previous equation is used; otherwise, the peak current can be calculated using the following equation:

The inductor’s DC resistance is a key parameter for efficient performance, and should be less than the currentsense resistor value.

Calculating the Current-Sense

Resistor Value

Calculate the current-sense resistor value according to

the worst-case minimum current-limit threshold voltage

(from the

Electrical Characteristics

) and the peak

inductor current required to service the maximum load.

Use I

PEAK

from the equation in the section

Specifying

the Inductor

.

The high inductance of standard wire-wound resistors

can degrade performance. Low-inductance resistors,

such as surface-mount power metal-strip resistors, are

preferred. The current-sense resistor’s power rating

should be higher than the following:

In high-current applications, connect several resistors

in parallel as necessary to obtain the desired resistance and power rating.

Selecting the Output Filter Capacitor

Output filter capacitor values are generally determined

by effective series resistance (ESR) and voltage-rating

requirements, rather than by the actual capacitance

value required for loop stability. Due to the high switching currents and demanding regulation requirements in

a typical MAX1639 application, use only specialized

low-ESR capacitors intended for switchingregulator applications, such as AVX TPS, Kemet T510,

Sprague 595D, Sanyo OS-CON, or Sanyo GX series. Do

not use standard aluminum-electrolytic capacitors,

which can cause high output ripple and instability due

to high ESR. The output voltage ripple is usually dominated by the filter capacitor’s ESR, and can be approximated as I

RIPPLE

x R

ESR

. To ensure stability, the

capacitor must meet

both

minimum capacitance and

maximum ESR values as given in the following equations:

Compensating the Feedback Loop

The feedback loop needs proper compensation to prevent excessive output ripple and poor efficiency

caused by instability. Compensation cancels unwanted

poles and zeros in the DC-DC converter’s transfer function that are due to the power-switching and filter elements with corresponding zeros and poles in the

feedback network. These compensation zeros and

poles are set by the compensation components CC1,

CC2, and RC1. The objective of compensation is to

ensure stability by ensuring that the DC-DC converter’s

phase shift is less than 180° by a safe margin, at the

frequency where the loop gain falls below unity.

Canceling the Sampling Pole

and Output Filter ESR Zero

Compensate the fast-voltage feedback loop by connecting a resistor and a capacitor in series from the

CC1 pin to AGND. The pole from CC1 can be set to

cancel the zero from the filter-capacitor ESR. Thus the

capacitor at CC1 should be as follows:

C

V

V

V

V x R x f

R R

OUT

REF

OUT

IN MIN

OUT SENSE OSC

ESR SENSE

( )

>

+

<

1

I x R

OUT MAX SENSE( )

2

R

mV

I

SENSE

PEAK

=

85

I I

V V V

f x L x V

PEAK OUT

OUT INMAX OUT

OSC IN MAX

( )

( )

= +

−

( )

2

L

V V V

V x f x I x LIR

OUT INMAX OUT

IN MAX OSC OUT

( )

( )

=

−

( )

Page 12

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

12 ______________________________________________________________________________________

Resistor RC1 sets a zero that can be used to compensate for the sampling pole generated by the switching

frequency. Set RC1 to the following:

The CC1 pin’s output resistance is 10kΩ.

Setting the Dominant Pole

and Canceling the Load and Output Filter Pole

Compensate the slow-voltage feedback loop by adding

a ceramic capacitor from the CC2 pin to AGND. This is

an integrator loop used to cancel out the DC loadregulation error. Selection of capacitor CC2 sets the

dominant pole and a compensation zero. The zero is typically used to cancel the unwanted pole generated by the

load and output filter capacitor at the maximum load current. Select CC2 to place the zero close to or slightly

lower than the frequency of the unwanted pole, as follows:

The transconductance of the integrator amplifier at CC2

is 1mmho. The voltage swing at CC2 is internally

clamped around 2.4V to 3V minimum and 4V to V

CC

maximum to improve transient response times. CC2

can source and sink up to 100µA.

Choosing the MOSFET Switches

The two high-current N-channel MOSFETs must be

logic-level types with guaranteed on-resistance specifications at VGS= 4.5V. Lower gate-threshold specs are

better (i.e., 2V max rather than 3V max). Gate charge

should be less than 200nC to minimize switching losses

and reduce power dissipation.

I2R losses are the greatest heat contributor to MOSFET

power dissipation and are distributed between the

high- and low-side MOSFETs according to duty factor,

as follows:

Gate-charge losses are dissipated in the IC, and do not

heat the MOSFETs. Ensure that both MOSFETs are at a

safe junction temperature by calculating the temperature

rise according to package thermal-resistance specifications. The high-side MOSFET’s worst-case dissipation

occurs at the maximum output voltage and minimum

input voltage. For the low-side MOSFET, the worst case

is at the maximum input voltage when the output is shortcircuited (consider the duty factor to be 100%).

Calculating IC Power Dissipation

Power dissipation in the IC is dominated by average

gate-charge current into both MOSFETs. Average current is approximately:

IDD= (QG1+ QG2) x f

OSC

where IDDis the drive current, QGis the total gate

charge for each MOSFET, and f

OSC

is the switching

frequency.

Power dissipation of the IC is:

PD= ICCx VCC+ IDDx V

DD

where ICCis the quiescent supply current of the IC.

Junction temperature for the IC is primarily a function of

the PC board layout, since most of the heat is removed

through the traces connected to the pins and the

ground and power planes. A 16-pin narrow SO on a

typical four-layer board with ground and power planes

show equivalent junction-to-ambient thermal

impedance of (θJA) about 80°C/W. Junction temperature of the die is approximately:

TJ= PDx θJA+ T

A

where TAis the ambient temperature.

Selecting the Rectifier Diode

The rectifier diode D1 is a clamp that catches the negative inductor swing during the 30ns typical dead time

between turning off the high-side MOSFET and turning

on the low-side MOSFET synchronous rectifier. D1 must

be a Schottky diode, to prevent the MOSFET body

diode from conducting. It is acceptable to omit D1 and

let the body diode clamp the negative inductor swing,

but efficiency will drop about 1%. Use a 1N5819 diode

for loads up to 3A, or a 1N5822 for loads up to 10A.

Adding the BST Supply Diode

and Capacitor

A signal diode, such as a 1N4148, works well for D2 in

most applications, although a low-leakage Schottky

diode provides slightly improved efficiency. Do not use

P low side I x R x

V

V

D LOAD DS ON

OUT

IN

( )

( )

= −

2

1

P high side I x R x

V

V

D LOAD DS ON

OUT

IN

( )

( )

=

2

CC

mmho x C

x

V

I

OUT OUT

OUT MAX

2

1

4

( )

=

RC

V

V

f x CC

OUT

IN

OSC

1

1

2 1

=

+

CC

C x R

k

OUT ESR

110

=Ω

Page 13

MAX1639

High-Speed Step-Down Controller with

Synchronous Rectification for CPU Power

______________________________________________________________________________________ 13

large power diodes, such as the 1N4001 or 1N5817.

Exercise caution in the selection of Schottky diodes,

since some types exhibit high reverse leakage at high

operating temperatures. Bypass BST to LX using a

0.1µF capacitor.

Selecting the Input Capacitors

Place a 0.1µF ceramic capacitor and 10µF capacitor

between VCCand AGND, as well as between VDDand

PGND, within 0.2 in. (5mm) of the VCCand VDDpins.

Select low-ESR input filter capacitors with a ripplecurrent rating exceeding the RMS input ripple current,

connecting several capacitors in parallel if necessary.

RMS input ripple current is determined by the input

voltage and load current, with the worst-possible case

occurring at VIN= 2 x V

OUT

:

__________Applications Information

Efficiency Considerations

Refer to the MAX796–MAX799 data sheet for information on calculating losses and improving efficiency.

PC Board Layout Considerations

Good PC board layout and routing are

required

in highcurrent, high-frequency switching power supplies to

achieve good regulation, high efficiency, and stability.

The PC board layout artist must be provided with explicit

instructions concerning the placement of power-switching components and high-current routing. It is strongly

recommended that the evaluation kit PC board layouts

be followed as closely as possible. Contact Maxim’s

Applications Department concerning the availability of

PC board examples for higher-current circuits.

In most applications, the circuit is on a multilayer

board, and full use of the four or more copper layers is

recommended. Use the top layer for high-current

power and ground connections. Leave the extra copper on the board as a pseudo-ground plane. Use the

bottom layer for quiet connections (REF, FB, AGND),

and the inner layers for an uninterrupted ground plane.

A ground plane and pseudo-ground plane are essential

for reducing ground bounce and switching noise.

Place the high-power components (C1, R1, N1, D1, N2,

L1, and C2 in Figure 1) as close together as possible.

Minimize ground-trace lengths in high-current paths.

The surface-mount power components should be

butted up to one another with their ground terminals

almost touching. Connect their ground terminals using

a wide, filled zone of top-layer copper (the pseudoground plane), rather than through the internal ground

plane. At the output terminal, use vias to connect the

top-layer pseudo-ground plane to the normal innerlayer ground plane at the output filter capacitor ground

terminals. This minimizes interference from IR drops

and ground noise, and ensures that the IC’s AGND is

sensing at the supply’s output terminals.

Minimize high-current path trace lengths. Use very

short and wide traces. From C1 to N1: 0.4 in. (10mm)

max length; D1 anode to N2: 0.2 in. (5mm) max length;

LX node (N1 source, N2 drain, D1 cathode, inductor

L1): 0.6 in. (15mm) max length.

I I

V V V

V

I I when V V

RMS LOAD MAX

OUT IN OUT

IN

RMS OUT IN OUT

( )

/

( )

=

−

= =2 2

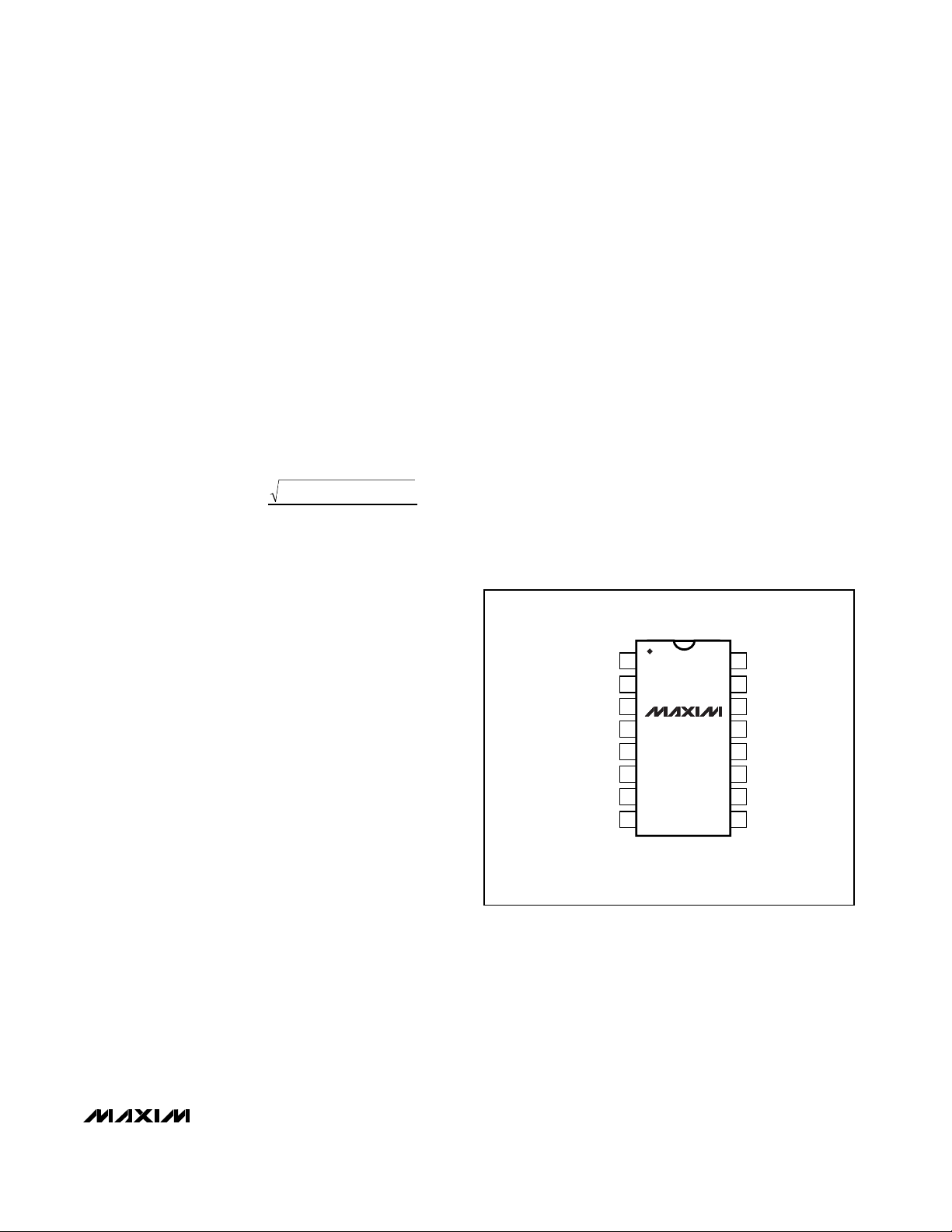

___________________Pin Configuration

___________________Chip Information

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

BST DH

LX

PGND

DL

V

DD

FREQ

CC2

CC1

TOP VIEW

MAX1639

16 SOIC

PWROK

CSL

REF

CSH

V

CC

AGND

FB

TRANSISTOR COUNT: 3135

SUBSTRATE CONNECTED TO AGND

Loading...

Loading...