Page 1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

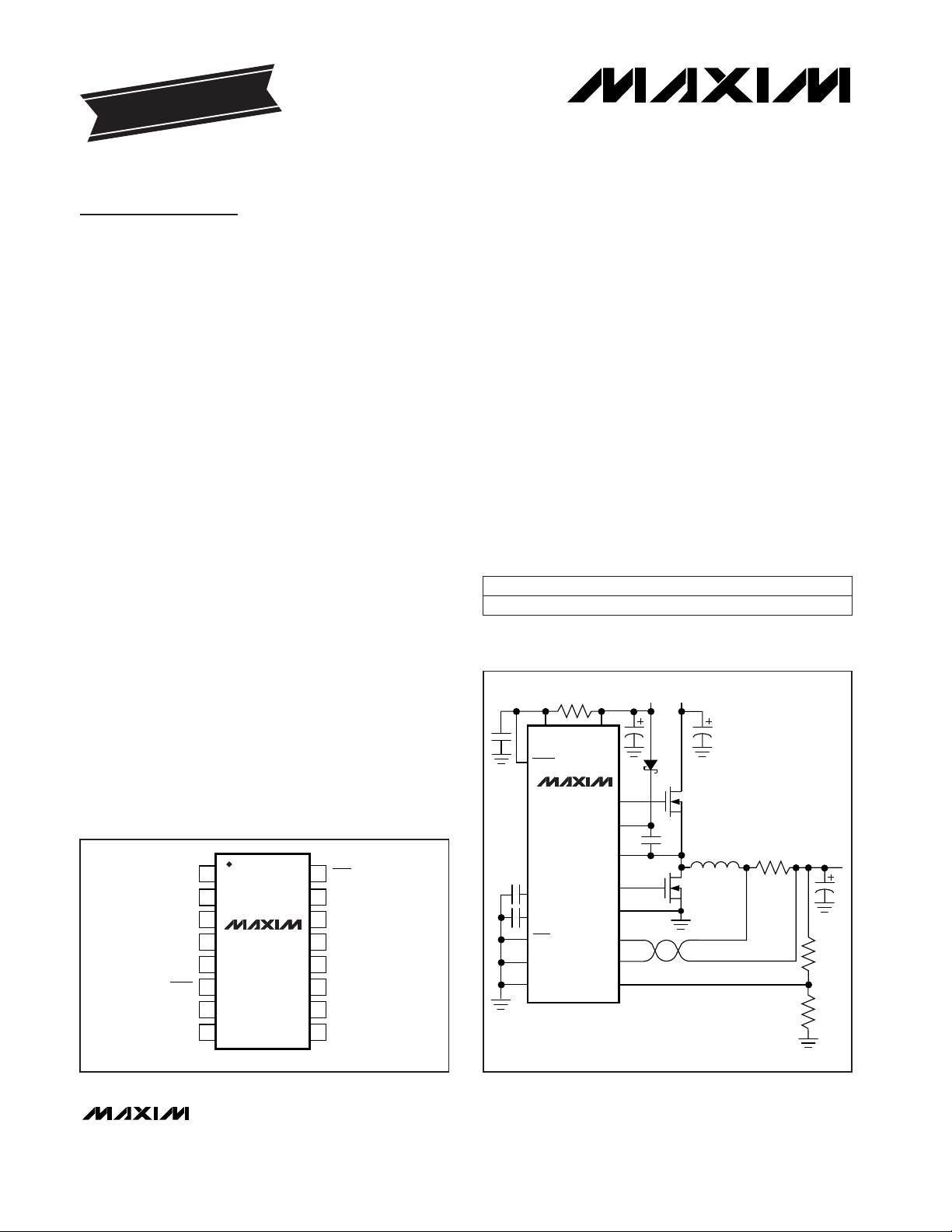

General Description

The MAX1637 synchronous, buck, switch-mode powersupply controller generates the CPU supply voltage in

battery-powered systems. The MAX1637 is a strippeddown version of the MAX1636 in a smaller 16-pin QSOP

package. The MAX1637 is intended to be powered separately from the battery by an external bias supply (typically the +5V system supply) in applications where the

battery exceeds 5.5V. The MAX1637 achieves excellent

DC and AC output voltage accuracy. This device can

operate from a low input voltage (3.15V) and delivers the

excellent load-transient response needed by upcoming

generations of dynamic-clock CPUs.

Using synchronous rectification, the MAX1637 achieves

up to 95% efficiency. Efficiency is greater than 80%

over a 1000:1 load-current range, which extends battery life in system-suspend or standby mode. Excellent

dynamic response corrects output load transients

caused by the latest dynamic-clock CPUs within five

300kHz clock cycles. Powerful 1A on-board gate driversensure fast external N-channel MOSFET switching.

The MAX1637 features a logic-controlled and synchronizable, fixed-frequency, pulse-width-modulation

(PWM) operating mode. This reduces noise and RF

interference in sensitive mobile-communications and

pen-entry applications. Asserting the SKIP pin enables

fixed-frequency mode, for lowest noise under all load

conditions. For a stand-alone device that includes a

+5V VL linear regulator and low-dropout capabilities,

refer to the MAX1636 data sheet.

________________________Applications

Notebook Computers Subnotebook Computers

Handy-Terminals, PDAs

____________________________Features

♦ ±2% DC Accuracy

♦ 0.1% (typ) DC Load Regulation

♦ Adjustable Switching Frequency to 350kHz

♦ Idle Mode™ Pulse-Skipping Operation

♦ 1.10V to 5.5V Adjustable Output Voltage

♦ 3.15V Minimum IC Supply Voltage (at V

CC

pin)

♦ Internal Digital Soft-Start

♦ 1.1V ±2% Reference Output

♦ 1µA Total Shutdown Current

♦ Output Overvoltage Crowbar Protection

♦ Output Undervoltage Shutdown (foldback)

♦ Tiny 16-Pin QSOP Package

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

________________________________________________________________

Maxim Integrated Products

1

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

CSH SKIP

LX

DH

BST

PGND

DL

V

GG

V

CC

TOP VIEW

MAX1637

QSOP

CSL

FB

SHDN

CC

REF

SYNC

GND

__________________Pin Configuration

__________Typical Operating Circuit

19-1321; Rev 1; 2/98

PART

MAX1637EEE -40°C to +85°C

TEMP. RANGE PIN-PACKAGE

16 QSOP

EVALUATION KIT

AVAILABLE

______________Ordering Information

Idle Mode is a trademark of Maxim Integrated Products.

MAX1637

SHDN

GND

V

BATT

V

BIAS

DL

PGND

LX

DH

V

CC

V

GG

BST

CSH

CSL

FB

SKIP

SYNC

REF

CC

OUTPUT

Page 2

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

2 _______________________________________________________________________________________

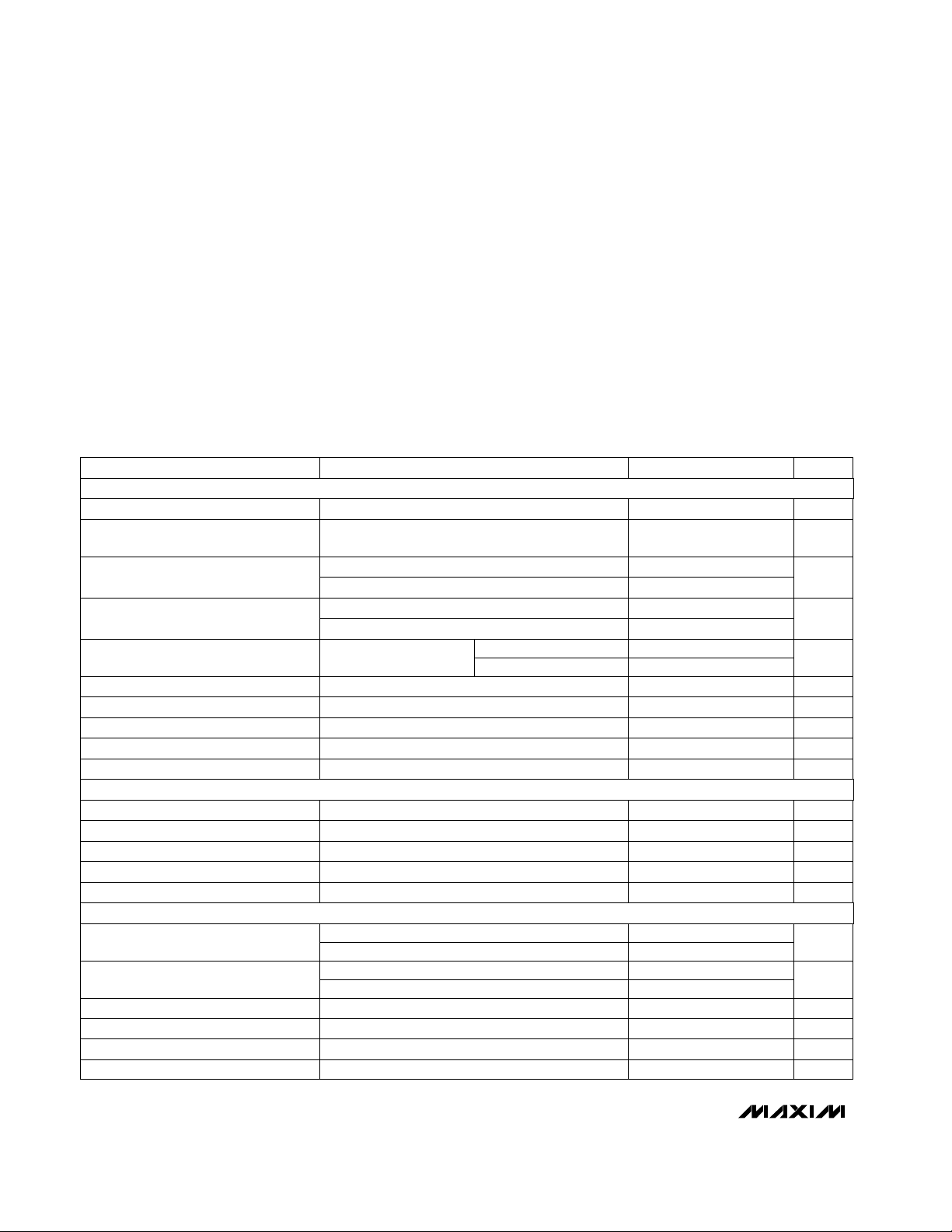

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VCC= VGG= 5V, SYNC = VCC, I

REF

= 0mA, TA= 0°C to +85°C, unless otherwise noted. Typical values are at

T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

GND to PGND .............................................................+2V to -2V

LX, BST to GND......................................................-0.3V to +36V

BST, DH to LX...........................................................-0.3V to +6V

V

CC

, VGG, CSL, CSH, SHDN to GND.......................-0.3V to +6V

DL to GND..................................................-0.3V to (V

GG

+ 0.3V)

REF, SKIP, SYNC, CC to GND ...................-0.3V to (V

CC

+ 0.3V)

REF Output Current.............................................................20mA

REF Short-Circuit to GND..............................................Indefinite

Operating Temperature Range ...........................-40°C to +85°C

Continuous Power Dissipation (T

A

= +70°C)

QSOP (derate 8.3mW/°C above +70°C)......................667mW

Storage Temperature Range.............................-65°C to +160°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10sec).............................+300°C

SYNC = GND

SYNC = V

CC

FB tied to V

OUT

, 0mV < (CSH - CSL) < 80mV,

includes line and load regulation

VCC= 3.15V to 5.5V

REF load = 0µA to 50µA

VCC, V

GG

REF load = 0µA

Rising edge, hysteresis = 15mV

Rising edge, hysteresis = 15mV

SHDN = GND, VCC= V

GG

CSH - CSL = 0mV to CSH - CSL = 100mV

CSH - CSL

VCC= 5V

VCC= 3.3V

SHDN to full current limit, four levels

VFB= V

REF

CONDITIONS

170 200 230

Oscillator Frequency kHz

270 300 330

mV3REF Line Regulation

mV10REF Load Regulation

V1.080 1.100 1.120REF Output Voltage

V2.80 3.05VGGUndervoltage Lockout Threshold

V2.80 3.05VCCUndervoltage Lockout Threshold

%2AC Load Regulation

mV20 30 40Idle-Mode Switchover Threshold

clocks512Soft-Start Ramp Time

nA-50 50FB Input Current

V3.15 5.5Input Voltage Range

µA0.5 3Shutdown Supply Current

V1.080 1.100 1.120Output Voltage

V

REF

5.5

Output Adjustment Range V

V

REF

3.6

UNITSMIN TYP MAXPARAMETER

CSH > CSL

CSH < CSL

80 100 120

Current-Limit Threshold mV

-145 -100 -55

Output not switching

1.5 2.5

Power Consumption mW

1 1.75

SYNC = GND

SYNC = V

CC

ns200SYNC Input Pulse Width High

%

93 96

89 92

Maximum Duty Factor

(Note 1)

kHz240 340SYNC Input Frequency Range

ns200SYNC Input Rise/Fall Time

ns200SYNC Input Pulse Width Low

VCC= VGG= 5V

VCC= VGG= 3.3V

SMPS CONTROLLER

INTERNAL REFERENCE

OSCILLATOR

Page 3

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

_______________________________________________________________________________________ 3

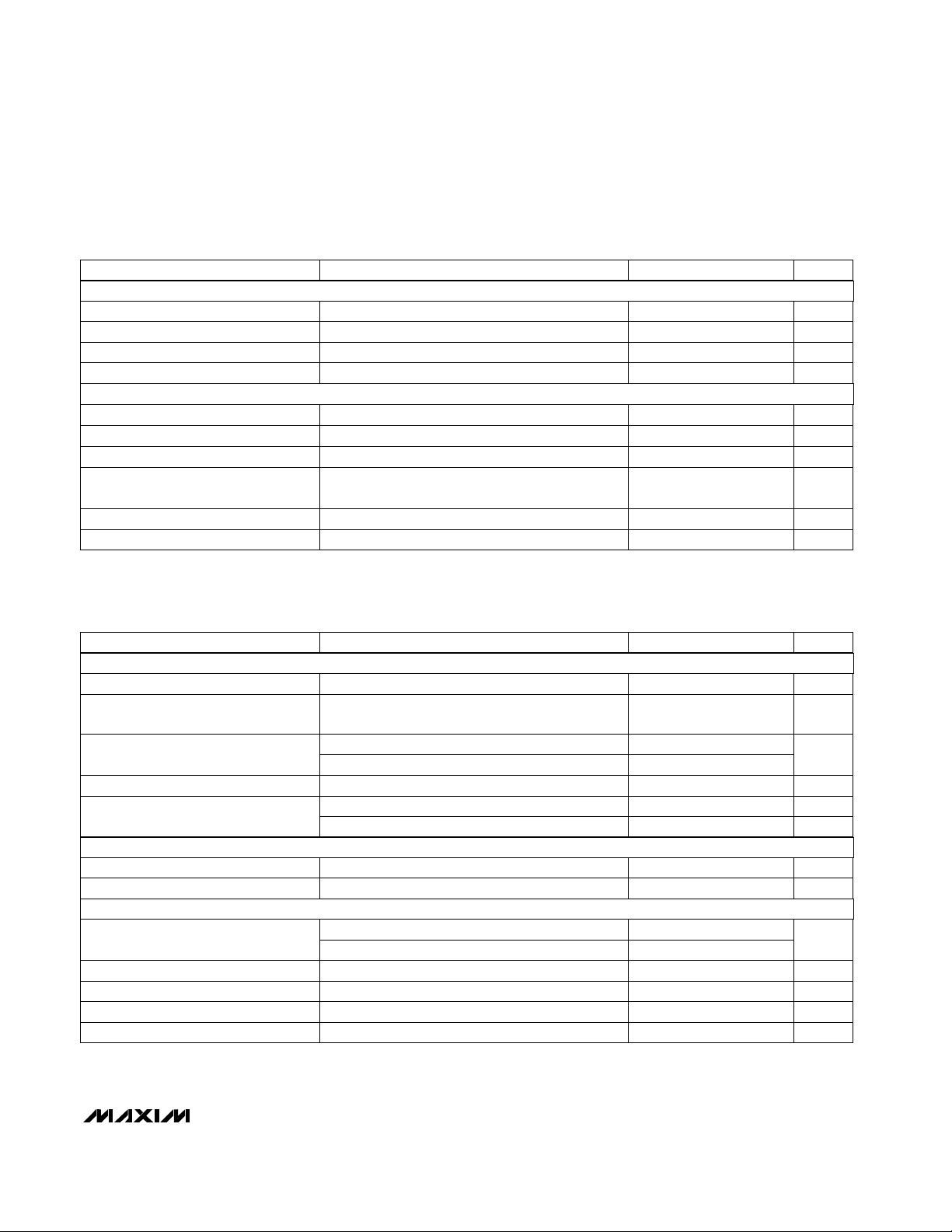

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VCC= VGG= 5V, SYNC = VCC, I

REF

= 0mA, TA= 0°C to +85°C, unless otherwise noted. Typical values are at

T

A

= +25°C.)

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VCC= VGG= 5V, SYNC = VCC, I

REF

= 0mA, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

High or low, DH or DL

DH or DL forced to 2V

CSH = CSL = 5V, VCC= VGG= GND,

either CSH or CSL input

FB to DL delay, 22mV overdrive, C

GATE

= 2000pF

FB, with respect to regulation point

From shutdown or power-on-reset state

Pin at GND or V

CC

SHDN, SKIP, SYNC

% of nominal output

SHDN, SKIP, SYNC

CONDITIONS

Ω7Gate Driver On-Resistance

A1Gate Driver Sink/Source Current

µA10Current-Sense Input Leakage Current

µA-1 1Logic Input Bias Current

V0.8Logic Input Voltage Low

V2.4Logic Input Voltage High

µs1.25Overvoltage Fault Propagation Delay

%4 7 10Overvoltage Trip Threshold

clocks6144Output Undervoltage Lockout Delay

%60 70 80Output Undervoltage Lockout Threshold

UNITSMIN TYP MAXPARAMETER

FB tied to V

OUT

, 0mV < (CSH - CSL) < 80mV,

includes line and load regulation

SYNC = GND

VCC, V

GG

SYNC = V

CC

Rising edge, hysteresis = 15mV

Rising edge, hysteresis = 15mV

VCC= 3.3V

VCC= VGG= 3.3V, output not switching

VCC= 5V

VCC= VGG= 5V, output not switching

CSH > CSL

CONDITIONS

kHz240 340SYNC Input Frequency Range

ns200SYNC Input Rise/Fall Time

ns200SYNC Input Pulse Width Low

ns200SYNC Input Pulse Width High

kHz

170 230

Oscillator Frequency

262 338

V2.80 3.05VGGUndervoltage Lockout Threshold

V2.80 3.05VCCUndervoltage Lockout Threshold

mW1.75

Power Consumption

mW2.5

mV70 130Current-Limit Threshold

V1.080 1.120Output Voltage

V3.15 5.5Input Voltage Range

V

REF

3.6

Output Adjustment Range V

V

REF

5.5

UNITSMIN TYP MAXPARAMETER

OVERVOLTAGE PROTECTION

INPUTS AND OUTPUTS

SMPS CONTROLLER

INTERNAL REFERENCE

OSCILLATOR

Page 4

0

10

5

15

20

0 3 41 2 5 6 87 9

SUPPLY CURRENT

vs. LOAD CURRENT

MAX1637-07

LOAD CURRENT (A)

V

CC

+ V

GG

SUPPLY CURRENT (mA)

SYNC = HIGH

SYNC = LOW

SKIP = LOW

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VCC= VGG= 5V, SYNC = VCC, I

REF

= 0mA, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

SHDN, SKIP, SYNC

SHDN, SKIP, SYNC

% of nominal output

FB, with respect to regulation point

CONDITIONS

V0.8Logic Input Voltage Low

V2.4Logic Input Voltage High

%60 80Output Undervoltage Lockout Threshold

%4.0 10Overvoltage Trip Threshold

UNITSMIN TYP MAXPARAMETER

Note 1: Guaranteed by design, not production tested.

Note 2: Specifications from -40°C to 0°C are guaranteed by design and not production tested.

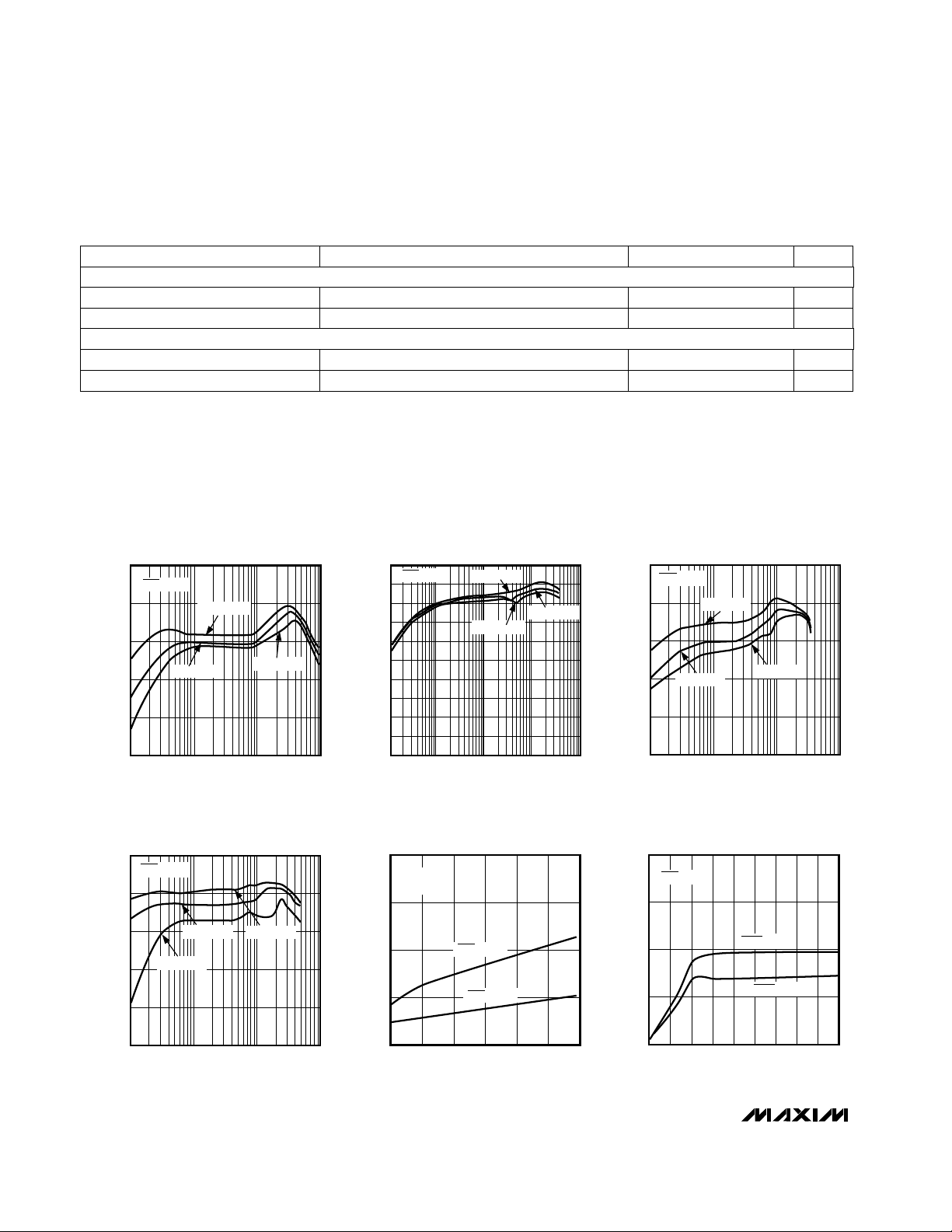

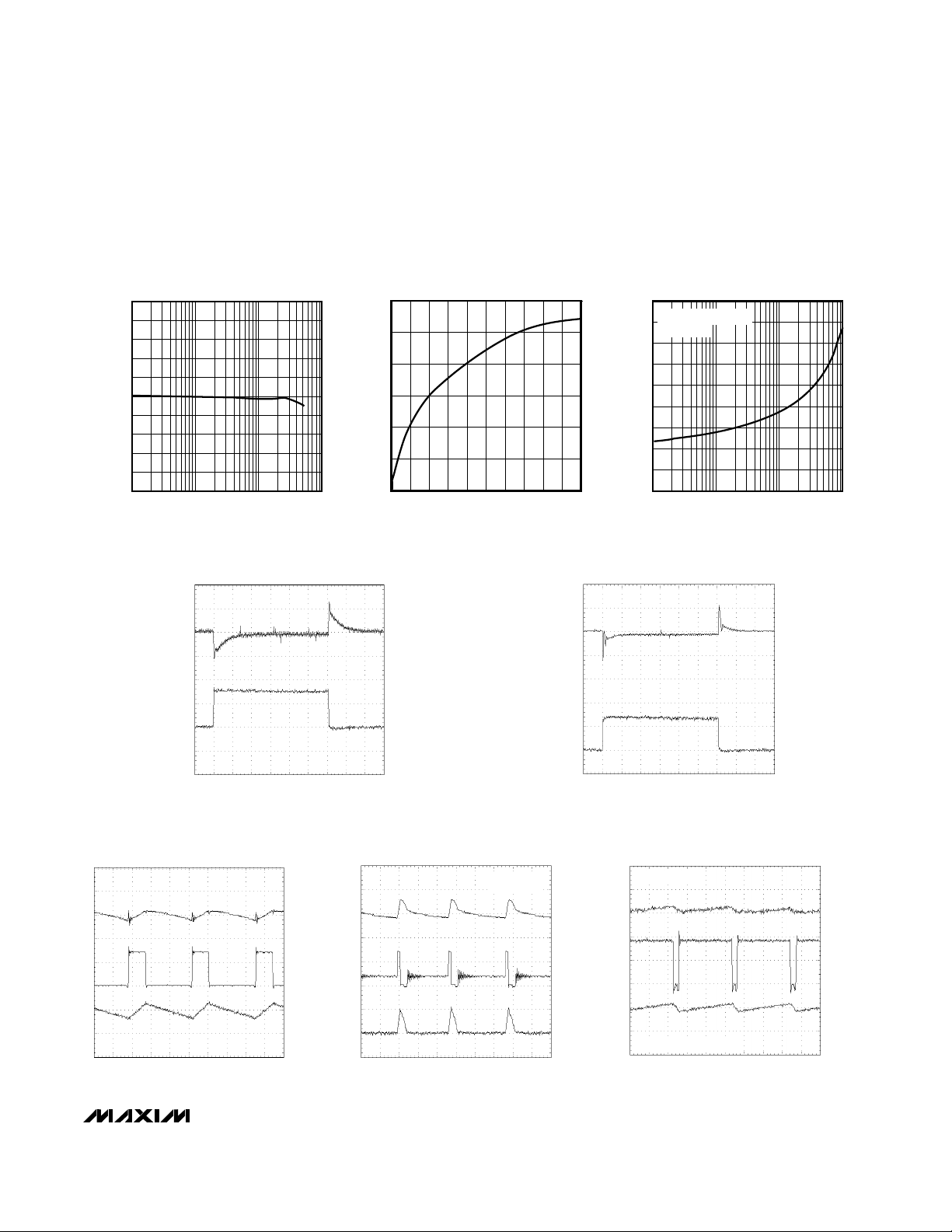

__________________________________________Typical Operating Characteristics

(V

OUT

= 3.3V, TA = +25°C, unless otherwise noted.)

100

50

0.01 1010.1

EFFICIENCY vs. LOAD CURRENT

(1.7V/7A CIRCUIT)

70

60

90

80

MAX1637-01

LOAD CURRENT (A)

EFFICIENCY (%)

SKIP = LOW

V

BATT

= 7V

V

BATT

= 15V

V

BATT

= 22V

100

0

0.001 1010.01 0.1

EFFICIENCY vs. LOAD CURRENT

(2.5V/3A CIRCUIT)

40

30

20

10

80

70

90

60

50

MAX1637-02

LOAD CURRENT (A)

EFFICIENCY (%)

V

BATT

= 15V

SKIP = LOW

V

BATT

= 7V

V

BATT

= 22V

100

50

0.01 1010.1

EFFICIENCY vs. LOAD CURRENT

(2.5V/2A CIRCUIT)

70

60

90

80

MAX1637-03

LOAD CURRENT (A)

EFFICIENCY (%)

V

BATT

= 7V

SKIP = LOW

V

BATT

= 15V

V

BATT

= 22V

100

50

0.01 1010.1

EFFICIENCY vs. LOAD CURRENT

(3.3V/3A CIRCUIT)

70

60

90

80

MAX1637-04

LOAD CURRENT (A)

EFFICIENCY (%)

V

BATT

= 5V

V

BATT

= 30V

V

BATT

= 15V

SKIP = LOW

0

10

5

15

20

3.0 4.03.5 4.5 5.0

5.5

6.0

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX1637-06

SUPPLY VOLTAGE (V)

V

CC

+ V

GG

SUPPLY CURRENT (mA)

I

LOAD

= 1A

V

OUT

= 3.3V

SKIP = HIGH

SKIP = LOW

OVERVOLTAGE PROTECTION

INPUTS AND OUTPUTS

Page 5

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

_______________________________________________________________________________________

5

10

-10

0.01 1010.1

LOAD REGULATION

vs. LOAD CURRENT

-2

-6

-8

6

8

4

0

-4

2

MAX1637-08

LOAD CURRENT (A)

LOAD REGULATION ∆V

OUT

(mV)

0

0.3

0.2

0.1

0.4

0.5

0.6

0 403010 20 50 60 70 80 90 100

REF LOAD-REGULATION ERROR

vs. REF LOAD CURRENT

MAX1637-09

REF LOAD CURRENT (µA)

REF LOAD REGULATION ∆V (mV)

900

0

0.01 1010.1

DROPOUT VOLTAGE

vs. LOAD CURRENT

300

200

100

700

800

600

400

500

MAX1637-10

LOAD CURRENT (A)

DROPOUT VOLTAGE (mV)

V

OUT

FORCED TO 3.27V

SYNC = V

CC

V

OUT

20mV/div

V

LX

INDUCTOR

CURRENT

1A

0V

5V

0A

SWITCHING WAVEFORMS

(PWM MODE)

MAX1637-13

1µs/div

V

OUT

50mV/div

LOAD

CURRENT

0A

2A

4A

LOAD-TRANSIENT RESPONSE

(3.3V/3A, PWM MODE)

MAX1637 TOC11

100µs/div

V

OUT

50mV/div

5A LOAD CURRENT

0A

10A

LOAD-TRANSIENT RESPONSE

(1.8V, PWM MODE)

MAX1637 TOC12

100µs/div

V

OUT

50mV/div

V

LX

INDUCTOR

CURRENT

1A

0V

5V

0A

SWITCHING WAVEFORMS

(PFM MODE)

MAX1637-14

20µs/div

V

OUT

= 1.7V

1µs/div

SWITCHING WAVEFORMS

DROPOUT OPERATION

MAX1637-15

V

OUT

10mV/div

V

LX

2V/div

INDUCTOR

CURRENT

1A

0A

V

OUT

FORCED TO 3.27V

SYNC = V

CC

____________________________________Typical Operating Characteristics (continued)

(V

OUT

= 3.3V, TA = +25°C, unless otherwise noted.)

Page 6

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

6 _______________________________________________________________________________________

____________________________________Typical Operating Characteristics (continued)

(V

OUT

= 3.3V, TA = +25°C, unless otherwise noted.)

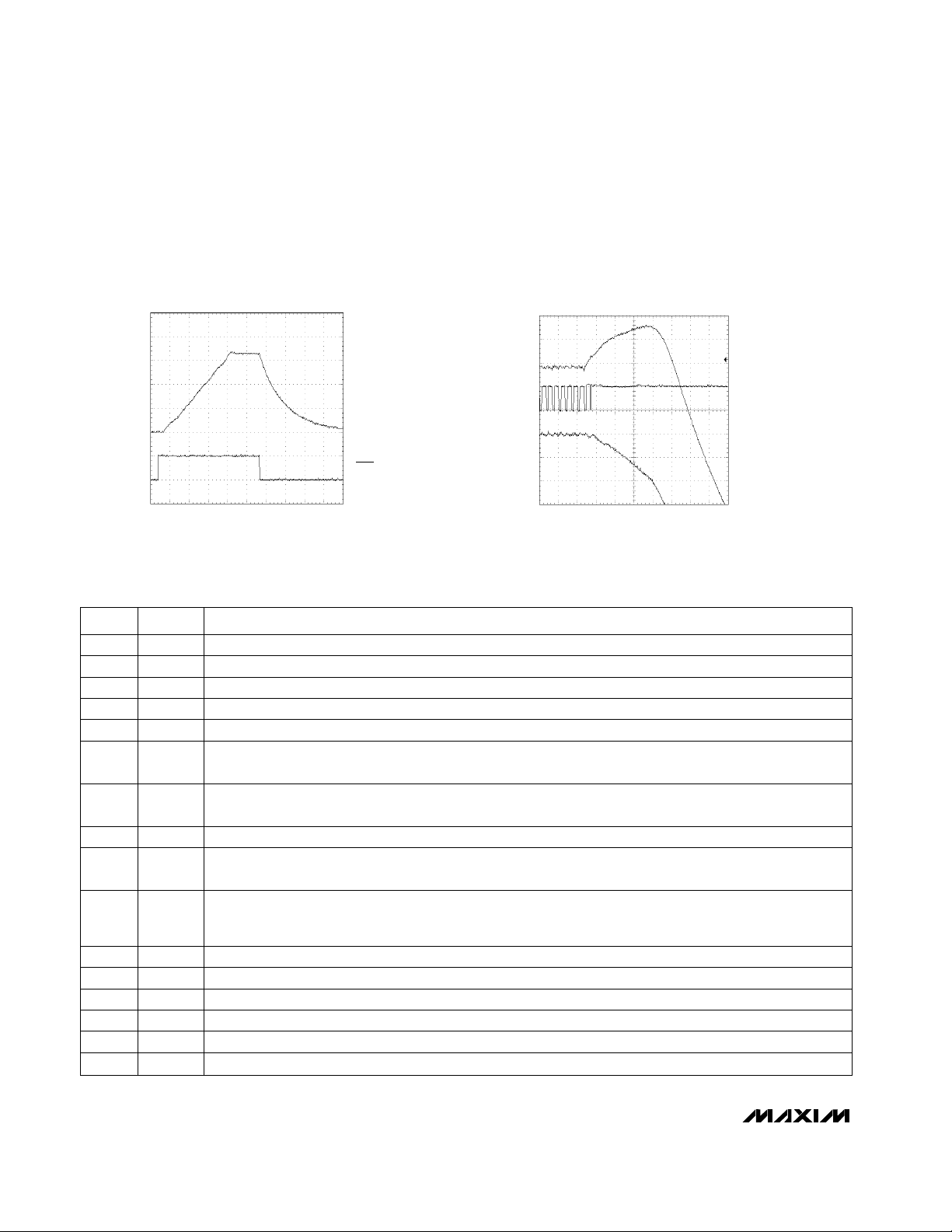

500µs/div

TIME EXITING SHUTDOWN

(V

OUT

= 3.3V, I

LOAD

= 7A)

MAX1637-16

V

OUT

1V/div

V

SHDN

5V/div

V

OUT

100mV/div

V

DL

INDUCTOR

CURRENT

-5A

0A

0V

5V

-10A

OVERVOLTAGE-PROTECTION WAVEFORMS

(V

IN

SHORTED TO V

OUT

THROUGH A 0.5Ω RESISTOR)

MAX1637-17

10µs/div

______________________________________________________________Pin Description

PIN

High-Side Current-Sense InputCSH1

FUNCTIONNAME

Low-Side Current-Sense InputCSL2

Compensation Pin. Connect a small capacitor to GND to set the integration time constant.CC4

Feedback Input. Connect to center of resistor divider.FB3

Shutdown Control Input. Turns off entire IC. When low, reduces supply current below 0.5µA (typ). Drive with

logic input or connect to RC network between GND and VCCfor automatic start-up.

SHDN

6

Analog GroundGND8

Oscillator Frequency Select and Synchronization Input. Tie to VCCfor 300kHz operation; tie to GND for

200kHz operation.

SYNC7

1.100V Reference Output. Capable of sourcing 50µA for external loads. Bypass with 0.22µF minimum.REF5

Gate-Drive and Boost-Circuit Power Supply. Can be driven from a supply other than VCC. If the same supply

is used by both VCCand VGG, isolate VCCfrom VGGwith a 20Ω resistor. Bypass to PGND with a 4.7µF

capacitor. VGGcurrent = (QG1+ QG2) x f, where QGis the MOSFET gate charge at VGS= VGG.

V

GG

10

Power GroundPGND12

Low-Side Gate-Driver OutputDL11

High-Side Gate-Driver OutputDH14

Low-Noise Mode Control. Forces fixed-frequency PWM operation when high.

SKIP

16

Inductor ConnectionLX15

Boost Capacitor ConnectionBST13

Main Analog Supply-Voltage Input to the Chip. VCCpowers the PWM controller, logic, and reference. Input

range is 3.15V to 5.5V. Bypass to GND with a 0.1µF capacitor close to the pin.

V

CC

9

Page 7

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

_______________________________________________________________________________________ 7

MAX1637

0.1µF

V

BIAS

+5V

NOMINAL

0.1µF

1µF

470pF

C1

Q1

CMPSH-3

Q2

C2

L1

*

R1

R2

R3

OUTPUT

4.7µF

*SEE

RECTIFIER CLAMP DIODE

SECTION

**OPTIONAL RC NETWORK FOR POWER-ON-RESET

DL

PGND

LX

DH

BST

V

GG

V

CC

V

BATT

CSH

CSL

FB

1M

**

ON/OFF

CC

GND

SHDN

REF

SYNC

20Ω

SKIP

0.01µF**

Figure 1. Standard Application Circuit

______Standard Application Circuit

The basic MAX1637 buck converter (Figure 1) is easily

adapted to meet a wide range of applications where a

5V or lower supply is available. The components listed

in Table 1 represent a good set of trade-offs among

cost, size, and efficiency, while staying within the worstcase specification limits for stress-related parameters

such as capacitor ripple current. Do not change the circuit’s switching frequency without first recalculating

component values (particularly inductance value at

maximum battery voltage).

The power Schottky diode across the synchronous rectifier is optional because the MOSFETs chosen incorporate a high-speed silicon diode. However, installing the

Schottky will generally improve efficiency by about 1%.

If used, the Schottky diode DC current must be rated to

at least one-third of the maximum load current.

_______________Detailed Description

The MAX1637 is a BiCMOS, switch-mode power-supply

(SMPS) controller designed primarily for buck-topology

regulators in battery-powered applications where high

efficiency and low quiescent supply current are critical.

Light-load efficiency is enhanced by automatic idlemode operation—a variable-frequency, pulse-skipping

mode that reduces transition and gate-charge losses.

The step-down, power-switching circuit consists of two

N-channel MOSFETs, a rectifier, and an LC output filter.

Output voltage for this device is the average AC voltage at the switching node, which is regulated by

changing the duty cycle of the MOSFET switches. The

gate-drive signal to the high-side N-channel MOSFET,

which must exceed the battery voltage, is provided by

a flying-capacitor boost circuit that uses a 100nF

capacitor between BST and LX. Figure 2 shows the

major circuit blocks.

Page 8

LOAD CURRENT

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

8 _______________________________________________________________________________________

Table 1. Component Selection for Standard Applications

Table 2. Component Suppliers

2.5VOutput Voltage Range

300kHzFrequency

Chipset SupplyApplication

1/2 Si4902DY or

1/2 MMDF3NO3HD

Q1 High-Side

MOSFET

7V to 22VInput Voltage Range

(619) 661-6835(81) 7-2070-1174Sanyo

Tokin (408) 432-8020

(847) 390-4373

(1) 408-434-0375

(1) 847-390-4428TDK

Sprague

(847) 956-0666(81) 3-3607-5144Sumida

(603) 224-1961

(714) 373-7939

(408) 988-8000

(1) 714-373-7183Panasonic

(1) 603-224-1430

(1) 408-970-3950Siliconix

(602) 303-5454(1) 602-994-6430Motorola

(847) 696-2000

COMPANY

Matsuo (714) 969-2491(1) 714-960-6492

USA PHONE

FACTORY FAX

(COUNTRY CODE)

(1) 847-696-9278

Marcon/United

Chemi-Con

COMPANY

Central

Semiconductor

Fairchild (408) 721-2181(1) 408-721-1635

(512) 992-7900(1) 512-992-3377IRC

Dale

(310) 322-3331(1) 310-322-3332

International

Rectifier (IR)

(605) 668-4131

(847) 639-6400

(561) 241-7876

(1) 847-639-1469Coilcraft

(1) 605-665-1627

(1) 561-241-9339Coiltronics

USA PHONE

(516) 435-1110

(803) 946-0690

FACTORY FAX

(COUNTRY CODE)

(1) 516-435-1824

(1) 803-626-3123AVX

2.5V

300kHz

Chipset Supply

International Rectifier

IRF7403 or

Siliconix Si4412

7V to 22V

3.3V1.7V

300kHz300kHz

General PurposeCPU Core

International Rectifier

IRF7403 or

Siliconix Si4412

Fairchild FDS9412 or

International Rectifier

IRF7403

4.75V to 30V7V to 22V

10µF, 25V ceramic

Tokin C34Y5U1E106Z

or Marcon/United

Chemicon

THCR40E1E106ZT

10µF, 25V ceramic

Tokin C34Y5U1E106Z

or Marcon/United

Chemicon

THCR40E1E106ZT

C1 Input Capacitor

0.020Ω, 1% (2010)

Dale WSL-2010-R020F

0.033Ω, 1% (2010)

Dale WSL-2010-R033F

R1 Resistor

470µF, 6.3V tantalum

Kemet

T510X477(1)006AS or

470µF, 4V tantalum

Sprague

594D477X0004R2T

220µF, 6.3V tantalum

Sprague

595D227X96R3C2

C2 Output Capacitor

10µH

Sumida CDRH125-100

10µH

Coilcraft

DO3316P-103 or

Coiltronics UP2-100

L1 Inductor

International Rectifier

IRF7413 or

Siliconix Si4410DY

1/2 Si4902DY or

1/2 MMDF3NO3HD

Q2 Low-Side MOSFET

10µF, 30V

Sanyo OS-CON

4 x 10µF, 25V ceramic

Tokin C34Y5U1E106Z

or Marcon/United

Chemicon

THCR40E1E106ZT

0.020Ω, 1% (2010)

Dale WSL-2010-R020F

0.010Ω, 1% (2512)

Dale WSL-2512-R010F

470µF, 6.3V tantalum

Kemet

T510X477(1)006AS or

470µF, 4V tantalum

Sprague

594D477X0004R2T

3 x 470µF, 6.3V tantalum

Kemet

T510X477(1)006AS or

470µF, 4V tantalum

Sprague

594D477X0004R2T

10µH Sumida

CDRH125-100

2.2µH

Panasonic P1F2R0HL or

Coiltronics UP4-2R2 or

Coilcraft

DO5022P-222HC

International Rectifier

IRF7413 or

Siliconix Si4410DY

Fairchild FDS6680 or

Siliconix Si4420DY

COMPONENT

3A (EV KIT)2A 3A7A (EV KIT)

LOAD CURRENT

Page 9

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

_______________________________________________________________________________________ 9

The pulse-width-modulation (PWM) controller consists

of a multi-input PWM comparator, high-side and lowside gate drivers, and logic. It uses a 200kHz/300kHz

synchronizable oscillator. The MAX1637 contains faultprotection circuits that monitor the PWM output for

undervoltage and overvoltage. It includes a 1.100V pre-

cision reference. The circuit blocks are powered from

an internal IC power rail that receives power from VCC.

VGGprovides direct power to the synchronous-switch

gate driver, but provides indirect power to the highside-switch gate driver via an external diode-capacitor

boost circuit.

REF

IC

POWER

200kHz

TO

300kHz

OSC

PWM

LOGIC

3.15V TO 5.5V

V

BATT

V

OUT

REF

SHDN

SYNC

V

CC

DL

PGND

LX

DH

BST

V

GG

SKIP

CSH

CSL

FB

CC

REF

GND

V

REF

+7%

V

REF

-30%

+

60kHz

LP FILTER

SHUTDOWN

CONTROL

1.1V

REF.

ERROR

INTEGRATOR

+

-

+

-

+

-

+

-

+

MAX1637

gm

OVERVOLTAGE

FAULT

UNDERVOLTAGE

FAULT

OFF

SLOPE

COMPENSATION

V

BIAS

Figure 2. Functional Diagram

Page 10

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

10 ______________________________________________________________________________________

PWM Controller Block

The heart of the current-mode PWM controller is a

multi-input, open-loop comparator that sums four signals: the output voltage error signal with respect to

the reference voltage, the current-sense signal, the

integrated voltage-feedback signal, and the slope-

compensation ramp (Figure 3). The PWM controller is

a direct-summing type, lacking a traditional error

amplifier and the phase shift associated with it. This

direct-summing configuration approaches ideal

cycle-by-cycle control over the output voltage.

SHOOTTHROUGH

CONTROL

R

Q

30mV

R Q

LEVEL

SHIFT

1X

gm

2X

OSC

LEVEL

SHIFT

REF

CURRENT

LIMIT

SYNCHRONOUS

RECTIFIER CONTROL

SHDN

CK

-100mV

CSH

CSL

CC

REF

FB

BST

DH

LX

V

GG

DL

PGND

S

S

SLOPE

COMPENSATION

SKIP

COUNTER

DAC

SOFT-START

Figure 3. PWM Controller Functional Diagram

Page 11

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

______________________________________________________________________________________ 11

Idle Mode

When SKIP is low, idle-mode circuitry automatically

optimizes efficiency throughout the load-current range.

Idle mode dramatically improves light-load efficiency

by reducing the effective frequency, subsequently

reducing switching losses. It forces the peak inductor

current to ramp to 30% of the full current limit, delivering extra energy to the output and allowing subsequent

cycles to be skipped. Idle mode transitions seamlessly

to fixed-frequency PWM operation as load current

increases (Table 3).

Fixed-Frequency Mode

When SKIP is high, the controller always operates in

fixed-frequency PWM mode for lowest noise. Each pulse

from the oscillator sets the main PWM latch that turns on

the high-side switch for a period determined by the duty

factor (approximately V

OUT

/ VIN). As the high-side switch

turns off, the synchronous rectifier latch is set; 60ns later,

the low-side switch turns on. The low-side switch stays on

until the beginning of the next clock cycle.

In PWM mode, the controller operates as a fixed-frequency, current-mode controller in which the duty factor is set by the input/output voltage ratio. PWM mode

(SKIP = high) forces two changes on the PWM con-

troller. First, it disables the minimum-current comparator, ensuring fixed-frequency operation. Second, it

changes the detection threshold for reverse-current

limit from 0mV to -100mV, allowing the inductor current

to reverse at light loads. This results in fixed-frequency

operation and continuous inductor-current flow. PWM

mode eliminates discontinuous-mode inductor ringing

and improves cross-regulation of transformer-coupled,

multiple-output supplies.

The current-mode feedback system regulates the peak

inductor-current value as a function of the output voltage error signal. In continuous-conduction mode, the

average inductor current is nearly the same as the

peak current, so the circuit acts as a switch-mode

transconductance amplifier. This pushes the second

output LC filter pole, normally found in a duty-factorcontrolled (voltage-mode) PWM, to a higher frequency.

To preserve inner-loop stability and eliminate regenerative inductor-current “staircasing,” a slope-compensation ramp is summed into the main PWM comparator to

make the apparent duty factor less than 50%.

The relative gains of the voltage-sense and currentsense inputs are weighted by the values of the current

sources that bias four differential input stages in the

main PWM comparator (Figure 4). The voltage sense

into the PWM has been conditioned by an integrated

component of the feedback voltage, yielding excellent

DC output voltage accuracy. See the

Output Voltage

Accuracy

section for details.

Constant frequency PWM,

continuous inductor current

HeavyLow

Constant frequency PWM,

continuous inductor current

HeavyHigh

Constant frequency PWM,

continuous inductor current

LightHigh

SKIP

Pulse-skipping, discontinuous inductor current

LightLow

DESCRIPTION

LOAD

CURRENT

Table 3. SKIP PWM Table

PWM

PWM

PWM

Idle

MODE

Figure 4. Main PWM Comparator Functional Diagram

V

CC

CC

I1

REF

CSH

CSL

FB

I2

SLOPE COMPENSATION

R1

I3 I4

R2

UNCOMPENSATED

HIGH-SPEED

LEVEL TRANSLATOR

AND BUFFER

V

BIAS

TO PWM

LOGIC

OUTPUT DRIVER

Page 12

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

12 ______________________________________________________________________________________

REF, VCC, and VGGSupplies

The 1.100V reference (REF) is accurate to ±2% over

temperature, making REF useful as a precision system

reference. Bypass REF to GND with a 0.22µF (min)

capacitor. REF can supply up to 50µA for external

loads. Loading REF reduces the main output voltage

slightly because of the reference load-regulation error.

The MAX1637 has two independent supply pins, V

CC

and VGG. VCCpowers the sensitive analog circuitry of

the SMPS, while VGGpowers the high-current MOSFET

drivers. No protection diodes or sequencing requirements exist between the two supplies. Isolate VGGfrom

VCCwith a 20Ω resistor if they are powered from the

same supply. Bypass VCCto GND with a 0.1µF capacitor located directly adjacent to the pin. Use only smallsignal diodes for the boost circuit (10mA to 100mA

Schottky or 1N4148 diodes are preferred), and bypass

VGGto PGND with a 4.7µF capacitor directly at the

package pins. The VCCand VGGinput range is 3.15V

to 5.5V.

High-Side Boost Gate Drive (BST)

Gate-drive voltage for the high-side N-channel switch is

generated by a flying-capacitor boost circuit (Figure 2).

The capacitor between BST and LX is alternately

charged from the VGGsupply and placed parallel to

the high-side MOSFET’s gate-source terminals.

On start-up, the synchronous rectifier (low-side

MOSFET) forces LX to 0V and charges the boost

capacitor to VGG. On the second half-cycle, the SMPS

turns on the high-side MOSFET by closing an internal

switch between BST and DH. This provides the necessary enhancement voltage to turn on the high-side

switch, an action that boosts the gate-drive signal

above the battery voltage.

Ringing at the high-side MOSFET gate (DH) in discontinuous-conduction mode (light loads) is a natural operating condition. It is caused by residual energy in the

tank circuit, formed by the inductor and stray capacitance at the switching node, LX. The gate-drive negative rail is referred to LX, so any ringing there is directly

coupled to the gate-drive output.

Synchronous-Rectifier Driver (DL)

Synchronous rectification reduces conduction losses in

the rectifier by shunting the normal Schottky catch

diode with a low-resistance MOSFET switch. Also, the

synchronous rectifier ensures proper start-up of the

boost gate-driver circuit. If the synchronous power

MOSFET is omitted for cost or other reasons, replace it

with a small-signal MOSFET, such as a 2N7002.

If the circuit is operating in continuous-conduction

mode, the DL drive waveform is simply the complement

of the DH high-side-drive waveform (with controlled

dead time to prevent cross-conduction or “shootthrough”). In discontinuous (light-load) mode, the synchronous switch is turned off as the inductor current

falls through zero.

Shutdown Mode and Power-On Reset

SHDN is a logic input with a threshold of about 1.5V

that, when held low, places the IC in its 0.5µA shutdown mode. The MAX1637 has no power-on-reset circuitry, and the state of the device is not known on initial

power-up. In applications that use logic to drive SHDN,

it may be necessary to toggle SHDN to initialize the

part once VCCis stable. In applications that require

automatic start-up, drive SHDN through an external RC

network (Figure 5). The network will hold SHDN low

until VCCstabilizes. Typical values for R and C are 1MΩ

and 0.01µF. For slow-rising VCC, use a larger capacitor.

When cycling VCC, VCCmust stay low long enough to

discharge the 0.01µF capacitor, otherwise the circuit

may not start. A diode may be added in parallel with

the resistor to speed up the discharge.

Current-Limiting and Current-

Sense Inputs (CSH and CSL)

The current-limit circuit resets the main PWM latch and

turns off the high-side MOSFET switch whenever the

voltage difference between CSH and CSL exceeds

100mV. This limiting is effective for both current flow

directions, putting the threshold limit at ±100mV. The

tolerance on the positive current limit is ±20%, so the

external low-value sense resistor (R1) must be sized for

80mV / I

PEAK

, where I

PEAK

is the peak inductor current

required to support the full load current. Components

must be designed to withstand continuous current

stresses of 120mV / R1.

MAX1637

SHDN

R = 1MΩ

C = 0.01µF

V

IN

V

GG

C

R

V

CC

Figure 5. Power-On Reset RC Network for Automatic Start-Up

Page 13

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

______________________________________________________________________________________ 13

For prototyping or for very high-current applications, it

may be useful to wire the current-sense inputs with a

twisted pair rather than PC traces (two pieces of

wrapped wire twisted together are sufficient). This

reduces the noise picked up at CSH and CSL, which can

cause unstable switching and reduced output current.

Oscillator Frequency

and Synchronization (SYNC)

The SYNC input controls the oscillator frequency as follows: low selects 200kHz, high selects 300kHz. SYNC

can also be used to synchronize with an external 5V

CMOS or TTL clock generator. It has a guaranteed

240kHz to 340kHz capture range. A high-to-low transition on SYNC initiates a new cycle.

Operation at 300kHz optimizes the application circuit

for component size and cost. Operation at 200kHz

increases efficiency, reduces dropout, and improves

load-transient response at low input-output voltage differences (see the

Low-Voltage Operation

section).

Output Voltage Accuracy (CC)

Output voltage error is guaranteed to be within ±2%

over all conditions of line, load, and temperature. The

MAX1637’s DC load regulation is typically better than

0.1%, due to its integrator amplifier. The device optimizes transient response by providing a feedback signal with a direct path from the output to the main

summing PWM comparator. The integrated feedback

signal from the CC transconductance amplifier is also

summed into the PWM comparator, with the gain

weighted so that the signal has only enough gain to

correct the DC inaccuracies. The integrator’s response

time is determined by the time constant set by the

capacitor placed on the CC pin. The time constant

should neither be so fast that the integrator responds to

the normal V

OUT

ripple, nor too slow to negate the integrator’s effect. A 470pF to 1500pF CC capacitor is sufficient for 200kHz to 300kHz frequencies.

Figure 6 shows the output voltage response to a 0A to

3A load transient with and without the integrator. With

the integrator, the output voltage returns to within 0.1%

of its no-load value with only a small AC excursion.

Without the integrator, load regulation is degraded

(Figure 6b). Asymmetrical clamping at the integrator

output prevents worsening of load transients during

pulse-skipping mode.

Output Undervoltage Lockout

The output undervoltage-lockout circuit protects

against heavy overloads and short-circuits at the main

SMPS output. This scheme employs a timer rather than

a foldback current limit. The SMPS has an undervoltage-protection circuit, which is activated 6144 clock

cycles after the SMPS is enabled. If the SMPS output is

under 70% of the nominal value, it is latched off and

does not restart until SHDN is toggled. Applications

that use the recommended RC power-on-reset circuit

will also clear the fault condition when VCCfalls below

0.5V (typical). Note that undervoltage protection can

0

2

4

-50

50

I

OUT

(A)

V

OUT

(mV)

(100µs/div)

CC = 470pF

V

OUT

= 3.3V

INTEGRATOR

ACTIVE

Figure 6a. Load-Transient Response with Integrator Active

0

2

4

-50

50

I

OUT

(A)

V

OUT

(mV)

(100µs/div)

CC = REF

V

OUT

= 3.3V

INTEGRATOR

DEACTIVATED

Figure 6b. Load-Transient Response with Integrator

Deactivated

Page 14

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

14 ______________________________________________________________________________________

make prototype troubleshooting difficult since only

20ms or 30ms elapse before the SMPS is latched off.

The overvoltage crowbar protection is disabled in output undervoltage mode.

Output Overvoltage Protection

The overvoltage crowbar-protection circuit is intended

to blow a fuse in series with the battery if the main

SMPS output rises significantly higher than its standard

level (Table 4). In normal operation, the output is compared to the internal precision reference voltage. If the

output goes 7% above nominal, the synchronous-rectifier MOSFET turns on 100% (the high-side MOSFET is

simultaneously forced off) in order to draw massive

amounts of battery current to blow the fuse. This safety

feature does not protect the system against a failure of

the controller IC itself, but is intended primarily to guard

against a short across the high-side MOSFET. A crowbar event is latched and can only be reset by a rising

edge on SHDN (or by removal of the VCCsupply voltage). The overvoltage-detection decision is made relative to the regulation point.

Internal Digital Soft-Start Circuit

Soft-start allows a gradual increase of the internal current-limit level at start-up to reduce input surge currents. The SMPS contains an internal digital soft-start

circuit controlled by a counter, a digital-to-analog converter (DAC), and a current-limit comparator. In shutdown, the soft-start counter is reset to zero. When the

SMPS is enabled, its counter starts counting oscillator

pulses, and the DAC begins incrementing the comparison voltage applied to the current-limit comparator. The

DAC output increases from 0mV to 100mV in five equal

steps as the count increases to 512 clocks. As a result,

the main output capacitor charges up relatively slowly.

The exact time of the output rise depends on output

capacitance and load current, but it is typically 1ms

with a 300kHz oscillator.

Setting the Output Voltage

The output voltage is set via a resistor divider connected to FB (Figure 1). Calculate the output voltage with

the following formula:

V

OUT

= V

REF

(1 + R2 / R3)

where V

REF

= 1.1V nominal.

Recommended normal values for R3 range from 5kΩ to

100kΩ. To achieve a 1.1V nominal output, connect FB

directly to CSL. Remote output voltage sensing is possible by using the top of the external resistor divider as

the remote sense point.

__________________Design Procedure

The standard application circuit (Figure 1) contains a

ready-to-use solution for common application needs.

Use the following design procedure to optimize the

basic schematic for different voltage or current requirements. But before beginning a design, firmly establish

the following:

• Maximum input (battery) voltage, V

IN(MAX)

. This

value should include the worst-case conditions, such

as no-load operation when a battery charger or AC

adapter is connected but no battery is installed.

V

IN(MAX)

must not exceed 30V.

• Minimum input (battery) voltage, V

IN(MIN)

. This value

should be taken at full load under the lowest battery

conditions. If the minimum input-output difference is

less than 1.5V, the filter capacitance required to

maintain good AC load regulation increases (see

Low-Voltage Operation

section).

Table 4. Operating Modes

All circuit blocks offLowShutdown

REF = off, DL = lowHigh

Output

Undervoltage

Lockout

REF = off, DL = highHigh

Overvoltage

(Crowbar)

—

V

OUT

below 70% of

nominal after 20ms to

30ms timeout expires

V

OUT

greater than 7%

above regulation point

V

OUT

in regulation

CONDITIONSMODE

All circuit blocks activeHighRun

STATUS

SHDN

Lowest current consumption

Rising edge on SHDN exits

UVLO

Rising edge on SHDN exits

crowbar

Normal operation

NOTES

Page 15

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

______________________________________________________________________________________ 15

Inductor Value

The exact inductor value is not critical and can be

freely adjusted to allow trade-offs among size, cost,

and efficiency. Lower inductor values minimize size

and cost, but reduce efficiency due to higher peakcurrent levels. The smallest inductor value is obtained

by lowering the inductance until the circuit operates at

the border between continuous and discontinuous

mode. Further reducing the inductor value below this

crossover point results in discontinuous-conduction

operation, even at full load. This helps lower output filter

capacitance requirements, but efficiency suffers under

these conditions, due to high I2R losses. On the other

hand, higher inductor values produce greater efficiency, but also result in resistive losses due to extra wire

turns—a consequence that eventually overshadows the

benefits gained from lower peak current levels. High

inductor values can also affect load-transient response

(see the V

SAG

equation in the

Low-Voltage Operation

section). The equations in this section are for continuous-conduction operation.

Three key inductor parameters must be specified:

inductance value (L), peak current (I

PEAK

), and DC

resistance (RDC). The following equation includes a

constant, LIR, which is the ratio of inductor peak-topeak AC current to DC load current. A higher LIR value

allows lower inductance, but results in higher losses

and ripple. A good compromise is a 30% ripple-current

to load-current ratio (LIR = 0.3), which corresponds to a

peak inductor current 1.15 times higher than the DC

load current.

L = V

OUT(VIN(MAX)

- V

OUT

) / (V

IN(MIN)

x ƒ x I

OUT

x

LIR)

where ƒ = switching frequency (normally 200kHz or

300kHz), and I

OUT

= maximum DC load current.

The peak current can be calculated as follows:

I

PEAK

= I

LOAD

+ [V

OUT(VIN(MAX)

- V

OUT

) / (2 x ƒ x L

x V

IN(MAX)

)]

The inductor’s DC resistance should be low enough

that RDCx I

PEAK

< 100mV, as it is a key parameter for

efficiency performance. If a standard, off-the-shelf

inductor is not available, choose a core with an LI2rating greater than L x IPEAK2and wind it with the largest

diameter wire that fits the winding area. For 300kHz

applications, ferrite-core material is strongly preferred;

for 200kHz applications, Kool-Mu®(aluminum alloy) or

even powdered iron is acceptable. If light-load efficiency is unimportant (in desktop PC applications, for

example), then low-permeability iron-powder cores can

be acceptable, even at 300kHz. For high-current applications, shielded-core geometries (such as toroidal or

pot core) help keep noise, EMI, and switchingwaveform jitter low.

Current-Sense Resistor Value

The current-sense resistor value is calculated according to the worst-case, low-current limit threshold voltage (from the

Electrical Characteristics

) and the peak

inductor current:

R

SENSE

= 80mV / I

PEAK

Use I

PEAK

from the second equation in the

Inductor

Value

section. Use the calculated value of R

SENSE

to

size the MOSFET switches and specify inductor saturation-current ratings according to the worst-case highcurrent-limit threshold voltage:

I

PEAK

= 120mV / R

SENSE

Low-inductance resistors, such as surface-mount metal

film, are recommended.

Input Capacitor Value

Connect low-ESR bulk capacitors directly to the drain

on the high-side MOSFET. The bulk input filter capacitor is usually selected according to input ripple current

requirements and voltage rating, rather than capacitor

value. Electrolytic capacitors with low enough equivalent series resistance (ESR) to meet the ripple-current

requirement invariably have sufficient capacitance values. Aluminum electrolytic capacitors, such as Sanyo

OS-CON or Nichicon PL, are superior to tantalum

types, which risk power-up surge-current failure, especially when connecting to robust AC adapters or lowimpedance batteries. RMS input ripple current (I

RMS

) is

determined by the input voltage and load current, with

the worst case occurring at VIN= 2 x V

OUT

. Therefore,

when VINis 2 x V

OUT

:

I

RMS

= I

LOAD

/ 2

VCCand VGGshould be isolated from each other with a

20Ω resistor and bypassed to ground independently.

Place a 0.1µF capacitor between VCCand GND, as

close to the supply pin as possible. A 4.7µF capacitor

is recommended between VGGand PGND.

Output Filter Capacitor Value

The output filter capacitor values are generally determined by the ESR and voltage-rating requirements,

rather than by actual capacitance requirements for loop

stability. In other words, the low-ESR electrolytic capacitor that meets the ESR requirement usually has more

output capacitance than is required for AC stability.

Kool-Mu is a trademark of Magnetics, Inc.

Page 16

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

16 ______________________________________________________________________________________

Use only specialized low-ESR capacitors intended for

switching-regulator applications, such as AVX TPS,

Sprague 595D, Sanyo OS-CON, or Nichicon PL series.

To ensure stability, the capacitor must meet both minimum capacitance and maximum ESR values as given

in the following equations:

COUT > V

REF

(1 + V

OUT

/ V

IN(MIN)

) / V

OUT

x R

SENSE

x ƒ

R

ESR

< R

SENSE

x V

OUT

/ V

REF

where R

ESR

can be multiplied by 1.5, as discussed

below.

These equations are worst case, with 45 degrees of

phase margin to ensure jitter-free, fixed-frequency

operation, and provide a nicely damped output

response for zero to full-load step changes. Some costconscious designers may wish to bend these rules with

less-expensive capacitors, particularly if the load lacks

large step changes. This practice is tolerable if some

bench testing over temperature is done to verify

acceptable noise and transient response.

No well-defined boundary exists between stable and

unstable operation. As phase margin is reduced, the first

symptom is timing jitter, which shows up as blurred edges

in the switching waveforms where the scope does not quite

sync up. Technically speaking, this jitter (usually harmless)

is unstable operation since the duty factor varies slightly.

As capacitors with higher ESRs are used, the jitter

becomes more pronounced, and the load-transient output

voltage waveform starts looking ragged at the edges.

Eventually, the load-transient waveform has enough ringing

on it that the peak noise levels exceed the allowable output

voltage tolerance. Note that even with zero phase margin

and gross instability, the output voltage seldom declines

beyond I

PEAK

x R

ESR

(under constant loads).

Designers of RF communicators or other noise-sensitive analog equipment should be conservative and stay

within the guidelines. Designers of notebook computers

and similar commercial-temperature-range digital systems can multiply the R

ESR

value by a factor of 1.5

without affecting stability or transient response.

The output voltage ripple, which is usually dominated by

the filter capacitor’s ESR, can be approximated as

I

RIPPLE

x R

ESR

. There is also a capacitive term, so the

full equation for ripple in continuous-conduction mode is

V

RIPPLE(p-p)

= I

RIPPLE

x [R

ESR

+ 1 / (2πƒ x C

OUT

)]. In

idle mode, the inductor current becomes discontinuous,

with high peaks and widely spaced pulses, so the noise

can actually be higher at light load (compared to full

load). In idle mode, calculate the output ripple as follows:

V

RIPPLE(p-p)

= (0.02 x R

ESR

/ R

SENSE

) + [0.0003 x L x

(1 / V

OUT

+ 1 / (VIN- V

OUT

)) / R

SENSE

2

x CF]

Selecting Other Components

MOSFET Switches

The high-current N-channel MOSFETs must be logiclevel types with guaranteed on-resistance specifications

at VGS= 4.5V. Lower gate-threshold specifications are

better (i.e., 2V max rather than 3V max). Drain-source

breakdown voltage ratings must at least equal the maximum input voltage, preferably with a 20% margin. The

best MOSFETs have the lowest on-resistance per

nanocoulomb of gate charge. Multiplying R

DS(ON)

by

Qg provides a good figure of merit for comparing various MOSFETs. Newer MOSFET process technologies

with dense cell structures generally perform best. The

internal gate drivers tolerate >100nC total gate charge,

but 70nC is a more practical upper limit to maintain best

switching times.

In high-current applications, MOSFET package power

dissipation often becomes a dominant design factor.

I2R power losses are the greatest heat contributor for

both high-side and low-side MOSFETs. I2R losses are

distributed between Q1 and Q2 according to duty factor, as shown in the following equations. Generally,

switching losses affect only the upper MOSFET since

the Schottky rectifier usually clamps the switching node

before the synchronous rectifier turns on. Gate-charge

losses are dissipated by the driver and do not heat the

MOSFET. Calculate the temperature rise according to

package thermal-resistance specifications to ensure

that both MOSFETs are within their maximum junction

temperature at high ambient temperature. The worstcase dissipation for the high-side MOSFET occurs at

both extremes of input voltage, and the worst-case dissipation for the low-side MOSFET occurs at maximum

input voltage.

Duty = (V

OUT

+ VQ2) / (VIN- VQ1)

P

D (UPPER FET)

= I

LOAD

2

x R

DS(ON)

x duty + VINx

I

LOAD

x ƒ x [(VINx C

RSS

) / I

GATE

+ 20ns]

P

D (LOWER FET)

= I

LOAD

2

x R

DS(ON)

x (1 - duty)

where VQ= the on-state voltage drop (I

LOAD

x

R

DS(ON)

), C

RSS

= the MOSFET reverse transfer capaci-

tance, I

GATE

= the DH driver peak output current capability (1A typ), and the DH driver inherent rise/fall time is

20ns. The MAX1637’s output undervoltage shutdown

function protects the synchronous rectifier under output

short-circuit conditions. To reduce EMI, add a 0.1µF

ceramic capacitor from the high-side switch drain to

the low-side switch source.

Page 17

Rectifier Clamp Diode

The rectifier is a clamp across the low-side MOSFET

that catches the negative inductor swing during the

60ns dead time between turning one MOSFET off and

turning each low-side MOSFET on. The latest generations of MOSFETs incorporate a high-speed silicon

body diode, which serves as an adequate clamp diode

if efficiency is not of primary importance. A Schottky

diode can be placed in parallel with the body diode to

reduce the forward voltage drop, typically improving

efficiency 1% to 2%. Use a diode with a DC current rating equal to one-third of the load current; for example,

use an MBR0530 (500mA-rated) type for loads up to

1.5A, a 1N5819 type for loads up to 3A, or a 1N5822

type for loads up to 10A. The rectifier’s rated reversebreakdown voltage must be at least equal to the maximum input voltage, preferably with a 20% margin.

Boost-Supply Diode D2

A signal diode such as a 1N4148 works well in most

applications. Do not use large power diodes, such as

1N5817 or 1N4001.

Low-Voltage Operation

Low input voltages and low input-output differential voltages each require extra care in their design. Low

VIN-V

OUT

differentials can cause the output voltage to

sag when the load current changes abruptly. The sag’s

amplitude is a function of inductor value and maximum

duty factor (D

MAX

, an

Electrical Characteristics

parameter, 93% guaranteed over temperature at f = 200kHz) as

follows:

V

SAG

= [(I

STEP

)2x L] / [2CFx (V

IN(MIN)

x D

MAX

-

V

OUT

)]

Table 5 is a low-voltage troubleshooting guide. The

cure for low-voltage sag is to increase the output

capacitor’s value. For example, at VIN= 5.5V, V

OUT

=

5V, L = 10µH, ƒ = 200kHz, and I

STEP

= 3A, a total

capacitance of 660µF keeps the sag below 200mV.

Note that only the capacitance requirement increases;

the ESR requirements do not change. Therefore, the

added capacitance can be supplied by a low-cost bulk

capacitor in parallel with the normal low-ESR capacitor.

__________Applications Information

Heavy-Load Efficiency Considerations

The major efficiency-loss mechanisms under loads are

as follows, in the usual order of importance:

• P(I2R) = I2R losses

• P(tran) = transition losses

• P(gate) = gate-charge losses

• P(diode) = diode-conduction losses

• P(cap) = capacitor ESR losses

• P(IC) = losses due to the IC’s operating supply current

Inductor core losses are fairly low at heavy loads

because the inductor’s AC current component is small.

Therefore, these losses are not considered in this

analysis. Ferrite cores are preferred, especially at

300kHz, but powdered cores, such as Kool-Mu, can

also work well.

Efficiency = P

OUT

/ PINx 100%

= P

OUT

/ (P

OUT

+ P

TOTAL

) x 100%

P

TOTAL

= P(I2R) + P(tran) + P(gate) + P(diode) +

P(cap) + P(IC)

P = (I2R) = I

LOAD

2

x (RDC+ R

DS(ON)+RSENSE

)

where RDCis the DC resistance of the coil, R

DS(ON)

is

the MOSFET on-resistance, and R

SENSE

is the current-

sense resistor value. The R

DS(ON)

term assumes identical MOSFETs for the high-side and low-side switches

because they time-share the inductor current. If the

MOSFETs are not identical, their losses can be estimated by averaging the losses according to duty factor.

PD(tran) = transition loss = VINx I

LOAD

x ƒ x

[(VINC

RSS

/ I

GATE

) + 20ns]

where C

RSS

is the reverse transfer capacitance of the

high-side MOSFET (a data sheet parameter), I

GATE

is

the DH gate-driver peak output current (1.5A typ), and

the rise/fall time of the DH driver is typically 20ns.

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

______________________________________________________________________________________ 17

Table 5. Low-Voltage Troubleshooting Guide

Low VIN-V

OUT

differential,

under 1V

Low VIN-V

OUT

differential,

under 1.5V

Dropout voltage is

too high

Sag or droop in V

OUT

under step-load change

SYMPTOM

Maximum duty-cycle limits

exceeded

Limited inductor-current

slew rate per cycle

ROOT CAUSECONDITION

Reduce operation to 200kHz.

Reduce MOSFET on-resistance

and coil DC resistance.

Increase bulk output capacitance

per formula (see

Low-Voltage

Operation

section). Reduce

inductor value.

SOLUTION

Page 18

MAX1637

P(gate) = Qgx ƒ x V

GG

where Qgis the sum of the gate-charge values for lowside and high-side switches. For matched MOSFETs,

Qgis twice the data-sheet value of an individual

MOSFET. Efficiency can usually be optimized by connecting VGGto the most efficient 5V source, such as

the system +5V supply.

P(diode) = diode conduction losses = I

LOAD

x V

FWD

x tDx ƒ

where tDis the diode conduction time (120ns typ), and

V

FWD

is the diode forward voltage. This power is dissipated in the MOSFET body diode if no external

Schottky diode is used.

P(cap) = input capacitor ESR loss = I

RMS

2

x R

ESR

where I

RMS

is the input ripple current as calculated in

the

Input Capacitor Value

section.

Light-Load Efficiency Considerations

Under light loads, the PWM operates in discontinuous

mode. The inductor current discharges to zero at some

point during the charging cycle. This makes the inductor current’s AC component high compared to the load

current, which increases core losses and I2R losses in

the input-output filter capacitors. For best light-load efficiency, use MOSFETs with moderate gate-charge levels and use ferrite MPP or other low-loss core material.

Avoid powdered-iron cores; even Kool-Mu (aluminum

alloy) is not as desirable as ferrite.

Low-Noise Operation

Noise-sensitive applications such as hi-fidelity multimedia-equipped systems, cellular phones, RF communicating computers, and electromagnetic pen-entry

systems should operate the controller in PWM mode

(SKIP = high). This mode forces a constant switching

frequency, reducing interference due to switching

noise by concentrating the radiated EM fields at a

known frequency outside the system audio or IF bands.

Choose an oscillator frequency for which switchingfrequency harmonics do not overlap a sensitive frequency band. If necessary, synchronize the oscillator

to a tight-tolerance external clock generator.

Powering From a Single

Low-Voltage Supply

The circuit of Figure 7 is powered from a single 3.3V to

5.5V source and delivers 4A at 2.5V. At input voltages

of 3.15V, this circuit typically achieves efficiencies of

90% at 3.5A load currents. When using a single supply

to power both V

BATT

and V

BIAS

, be sure that it does not

exceed the 5.5V rating (6V absolute maximum) for V

GG

and VCC. Also, heavy current surges from the input

may cause transient dips on VCC. To prevent this, the

decoupling capacitor on VCCmay need to be

increased to 2µF or greater. This circuit uses lowthreshold (specified at VGS= 2.7V) IRF7401 MOSFETs

which allow a typical startup of 3.15V at above 4A. Low

input voltages demand the use of larger input capacitors. Sanyo OS-CONs are recommended for their high

capacity and low ESR.

PC Board Layout Considerations

Good PC board layout is required to achieve specified

noise, efficiency, and stable performance. The PC

board layout artist must be given explicit instructions,

preferably a pencil sketch showing the placement of

power-switching components and high-current routing.

See the PC board layout in the MAX1637 evaluation kit

manual for examples. A ground plane is essential for

optimum performance. In most applications, the circuit

will be located on a multi-layer board, and full use of

the four or more copper layers is recommended. Use

the top layer for high-current connections, the bottom

layer for quiet connections (REF, CC, GND), and the

inner layers for an uninterrupted ground plane. Use the

following step-by-step guide:

1) Place the high-power components (C1, C2, Q1, Q2,

D1, L1, and R1) first, with their grounds adjacent.

•

Minimize current-sense resistor trace lengths

and

ensure accurate current sensing with Kelvin connections (Figure 8).

•

Minimize ground trace lengths

in the high-current

paths.

•

Minimize other trace lengths

in the high-current

paths.

— Use >5mm-wide traces.

— CIN to high-side MOSFET drain: 10mm

max length

— Rectifier diode cathode to low side

— MOSFET: 5mm max length

— LX node (MOSFETs, rectifier cathode, induc-

tor): 15mm max length

Ideally, surface-mount power components are butted

up to one another with their ground terminals almost

touching. These high-current grounds are then connected to each other with a wide, filled zone of

top-layer copper so they do not go through vias. The

resulting top-layer subground plane is connected to the

normal inner-layer ground plane at the output ground

terminals, which ensures that the IC’s analog ground is

Miniature, Low-Voltage,

Precision Step-Down Controller

18 ______________________________________________________________________________________

Page 19

sensing at the supply’s output terminals without interference from IR drops and ground noise. Other high-current paths should also be minimized, but focusing

primarily on short ground and current-sense connections eliminates about 90% of all PC board layout problems (see the PC board layouts in the MAX1637

evaluation kit manual for examples).

2) Place the IC and signal components. Keep the main

switching nodes (LX nodes) away from sensitive

analog components (current-sense traces and REF

capacitor). Place the IC and analog components on

the opposite side of the board from the powerswitching node. Important: The IC must be no further than 10mm from the current-sense resistors.

Keep the gate-drive traces (DH, DL, and BST) shorter than 20mm and route them away from CSH, CSL,

and REF. Place ceramic bypass capacitors close to

the IC. The bulk capacitors can be placed further

away.

3) Use a single-point star ground where the input

ground trace, power ground (subground plane), and

normal ground plane meet at the supply's output

ground terminal. Connect both IC ground pins and

all IC bypass capacitors to the normal ground plane.

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

______________________________________________________________________________________ 19

MAX1637

SENSE RESISTOR

HIGH-CURRENT PATH

Figure 8. Kelvin Connections for the Current-Sense Resistors

MAX1637

0.1µF

1µF

IRF7401

CMPSH-3

IRF7401

1µF

470pF

MBRS130

470µF

LOW ESR

TANTALUM

4.7µF

TANTALUM

220µF

OS-CON

V

BIAS

10µH

CDHR125-100

20mΩ

1%

130k

1%

100k

1%

OUTPUT = 2.5V AT 4A

V

CC

20Ω

GND CC

DL

LX

DH

BST

V

GG

CSH

CSL

FB

SHDN

ON/OFF

SKIP

SYNC

REF

PGND

3.15V TO 5.5V

Figure 7. 3.15V to 5.5V Single-Supply Application Circuit

Page 20

MAX1637

Miniature, Low-Voltage,

Precision Step-Down Controller

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1998 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

___________________Chip Information

________________________________________________________Package Information

TRANSISTOR COUNT: 2164

QSOP.EPS

Loading...

Loading...