Page 1

19-4717; Rev 0; 7/09

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

General Description

The MAX16065/MAX16066 flash-configurable system

managers monitor and sequence multiple system voltages. The MAX16065/MAX16066 can also accurately

monitor (±2.5%) one current channel using a dedicated

high-side current-sense amplifier. The MAX16065 manages up to twelve system voltages simultaneously, and

the MAX16066 manages up to eight supply voltages.

These devices integrate a selectable differential or single-ended analog-to-digital converter (ADC) and configurable outputs for sequencing power supplies. Device

configuration information, including overvoltage and

undervoltage limits, timing settings, and the sequencing order is stored in nonvolatile flash memory. During a

fault condition, fault flags and channel voltages can be

automatically stored in the nonvolatile flash memory for

later read-back.

The internal 1% accurate 10-bit ADC measures each

input and compares the result to one overvoltage, one

undervoltage, and one early warning limit that can be

configured as either undervoltage or overvoltage. A fault

signal asserts when a monitored voltage falls outside the

set limits. Up to three independent fault output signals

are configurable to assert under various fault conditions.

Because the MAX16065/MAX16066 support a powersupply voltage of up to 14V, they can be powered

directly from the 12V intermediate bus in many systems.

The integrated sequencer provides precise control over

the power-up and power-down order of up to twelve

(MAX16065) or up to eight (MAX16066) power supplies.

Eight outputs (EN_OUT1–EN_OUT8) are configurable

with charge-pump outputs to directly drive external

n-channel MOSFETs.

The MAX16065/MAX16066 include eight/six programmable general-purpose inputs/outputs (GPIO_s). GPIO_s

are flash configurable as dedicated fault outputs, as a

watchdog input or output, or as a manual reset.

The MAX16065/MAX16066 feature nonvolatile fault memory for recording information during system shutdown

events. The fault logger records a failure in the internal

flash and sets a lock bit protecting the stored fault data

from accidental erasure. An SMBus™ or a JTAG serial

interface configures the MAX16065/MAX16066. The

MAX16065 is available in a 48-pin, 7mm x 7mm, TQFN

package, and the MAX16066 is available in a 40-pin,

6mm x 6mm, TQFN package. Both devices are fully

specified from -40NC to +85NC.

SMBus is a trademark of Intel Corp.

Features

S Operate from 2.8V to 14V

S ±2.5% Current-Monitoring Accuracy

S 1% Accurate 10-Bit ADC Monitors 12/8 Voltage

Inputs

S Single-Ended or Differential ADC for System

Voltage/Current Monitoring

S Integrated High-Side Current-Sense Amplifier

S 12/8 Monitored Inputs with Overvoltage/

Undervoltage/Early Warning Limit

S Nonvolatile Fault Event Logger

S Power-Up and Power-Down Sequencing

Capability

S Independent Secondary Sequence Block

S 12/8 Outputs for Sequencing/Power-Good

Indicators

S Two Programmable Fault Outputs and One Reset

Output

S Eight General-Purpose Inputs/Outputs

Configurable as:

Dedicated Fault Outputs

Watchdog Timer Function

Manual Reset

Margin Enable

S SMBus (with Timeout) or JTAG Interface

S Flash Configurable Time Delays and Thresholds

S -40NC to +85NC Operating Temperature Range

Applications

Networking Equipment

Telecom Equipment (Base Stations, Access)

Storage/Raid Systems

Servers

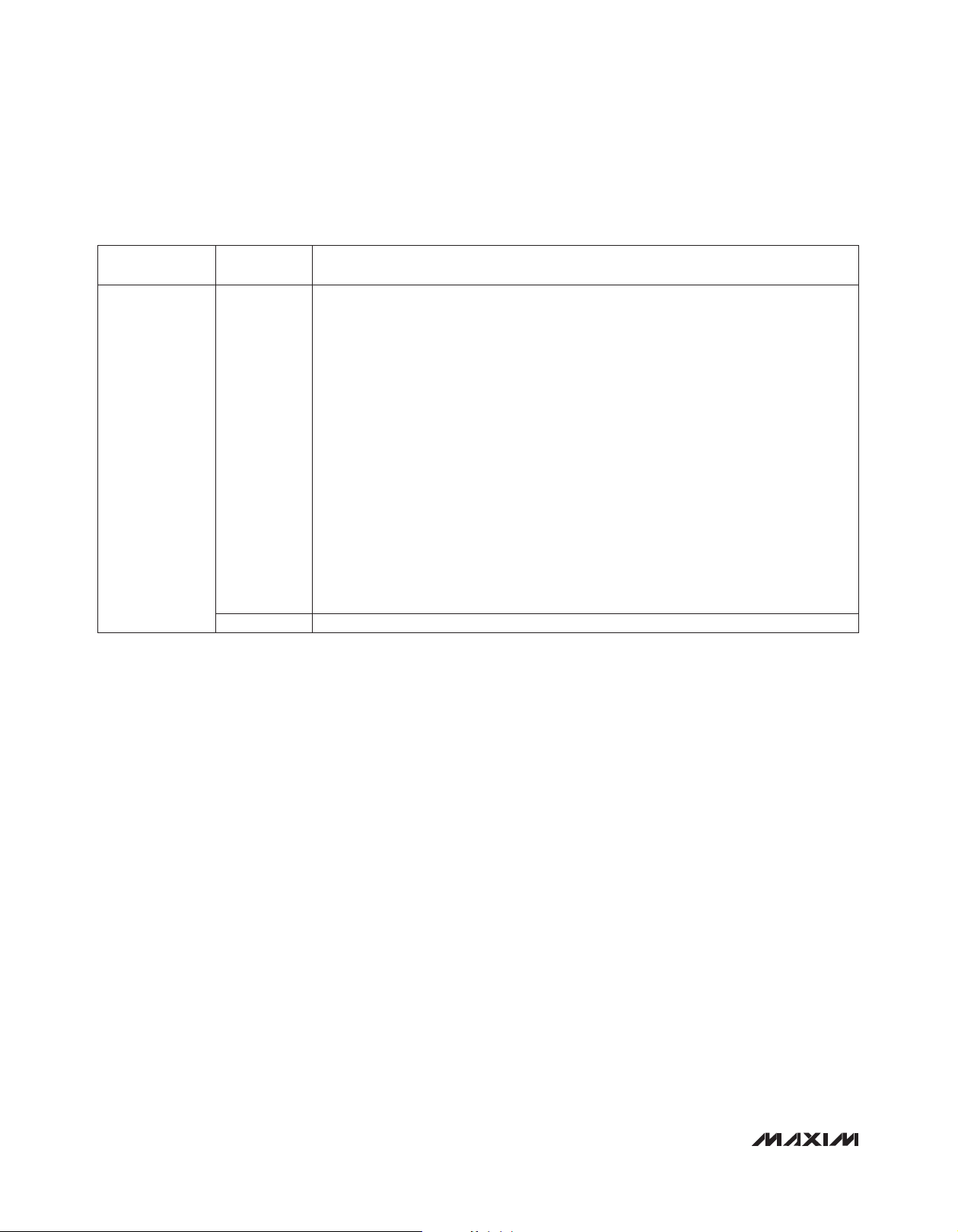

Ordering Information

PART TEMP RANGE PIN-PACKAGE

MAX16065ETM+

MAX16066ETL+

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

Pin Configuration and Typical Operating Circuits appear at

end of data sheet.

-40NC to +85NC

-40NC to +85NC

48 TQFN-EP*

40 TQFN-EP*

MAX16065/MAX16066

_______________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

ABSOLUTE MAXIMUM RATINGS

VCC, CSP, CSM to GND ........................................-0.3V to +15V

CSP to CSM .......................................................... -0.7V to +0.7V

MON_, GPIO_, SCL, SDA, A0, RESET, EN_OUT9–EN_OUT12 to

GND (programmed as open-drain outputs) ........-0.3V to +6V

EN, TCK, TMS, TDI to GND ....................................-0.3V to +4V

DBP, ABP to GND ...-0.3V to the lower of +3V and (VCC + 0.3V)

EN_OUT1–EN_OUT8 to GND (programmed as open-drain

outputs) ............................................................-0.3V to +15V

TDO, EN_OUT_, GPIO_, RESET (programmed as push-pull

outputs)............................................... -0.3V to (V

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may

affect device reliability.

DBP

+ 0.3V)

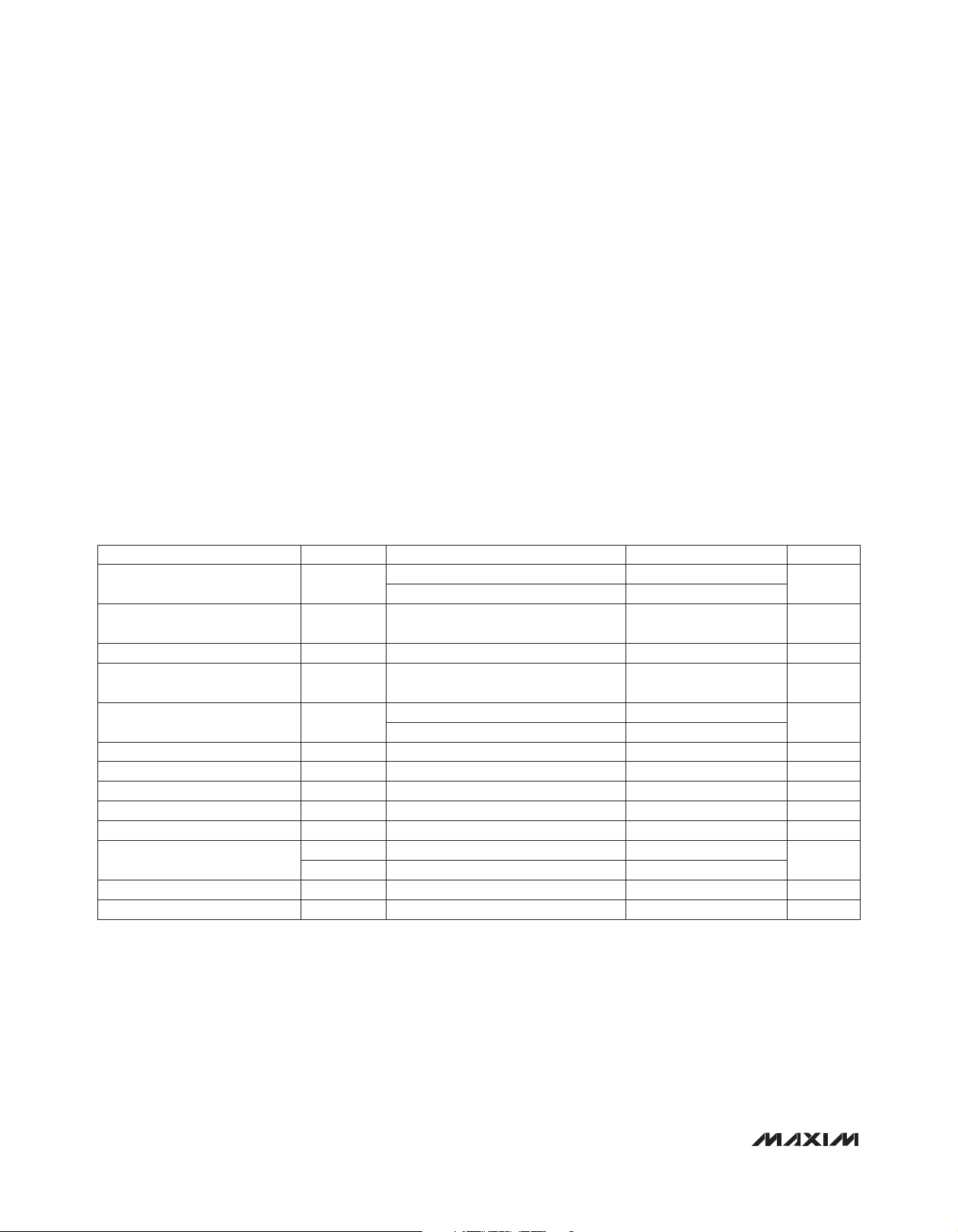

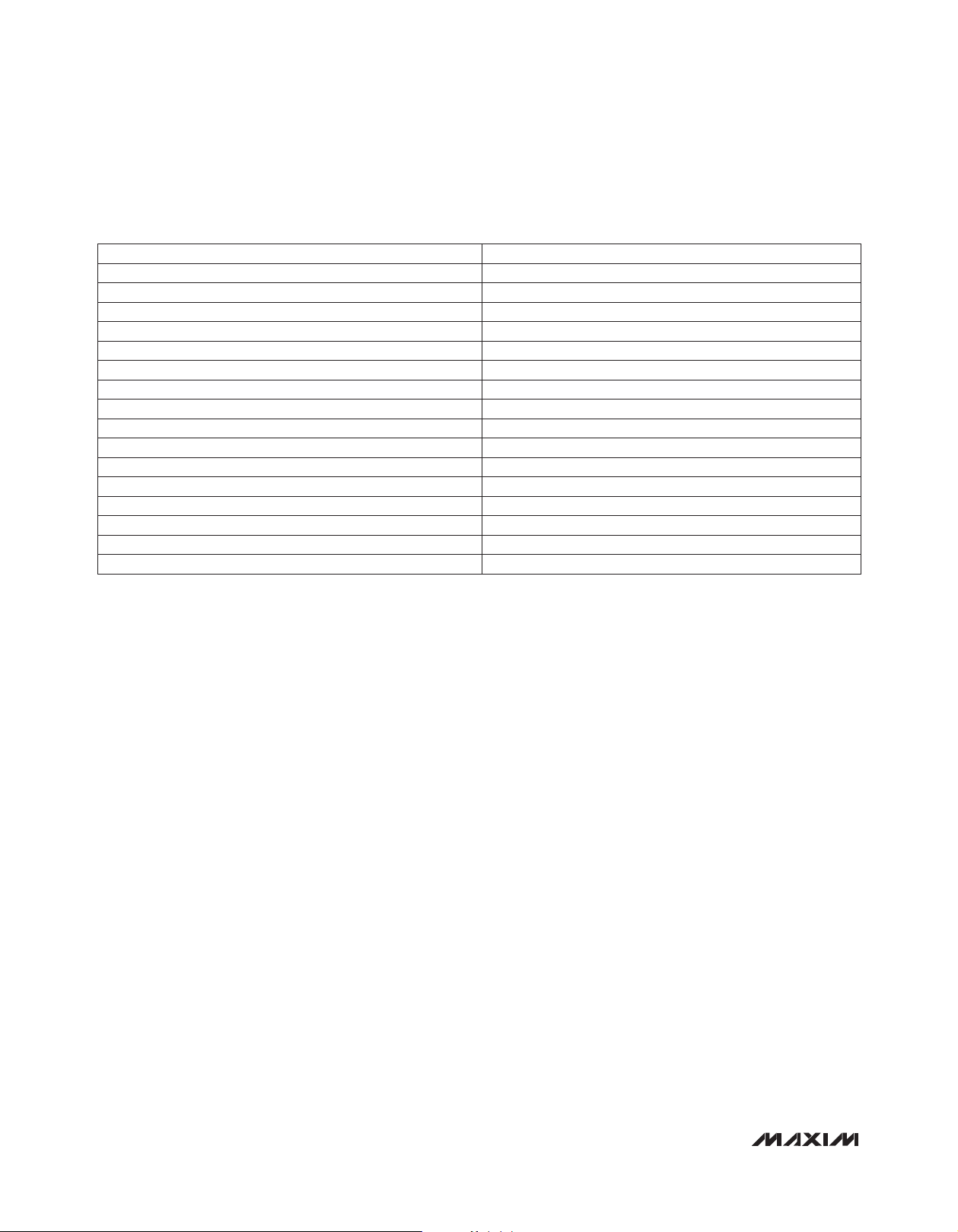

ELECTRICAL CHARACTERISTICS

(VCC = 2.8V to 14V, TA = -40NC to +85NC, unless otherwise specified. Typical values are at ABP = DBP = VCC = 3.3V, TA = +25NC.)

(Note 1)

MAX16065/MAX16066

Operating Voltage Range V

Undervoltage Lockout (Rising) V

Undervoltage Lockout Hysteresis V

Minimum Flash Operating

Voltage

Supply Current I

ABP Regulator Voltage V

DBP Regulator Voltage V

Boot Time t

Flash Writing Time 8-byte word 122 ms

Internal Timing Accuracy (Note 3) -8 +8 %

EN Input Voltage

EN Input Current I

Input Voltage Range 0 5.5 V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

UVLO

UVLO_HYS

V

flash

CC

ABP

DBP

BOOT

V

TH_EN_R

V

TH_EN_F

EN

Reset output asserted low 1.2

(Note 2) 2.8 14

Minimum voltage on VCC to ensure the

device is flash configurable

Minimum voltage on VCC to ensure flash

erase and write operations

No load on output pins 4.5 7

During flash writing cycle 10 14

C

= 1μF, no load, VCC = 5V 2.85 3 3.15 V

ABP

C

= 1μF, no load, VCC = 5V 2.8 3 3.1 V

ABP

VCC > V

EN voltage rising 1.41

EN voltage falling 1.365 1.39 1.415

UVLO

Input/Output Current .........................................................20mA

Continuous Power Dissipation (TA = +70NC)

40-Pin TQFN (derate 26.3mW/NC above +70NC) .......2105mW

48-Pin TQFN (derate 27.8mW/NC above +70NC) .......2222mW

Operating Temperature Range .......................... -40NC to +85NC

Junction Temperature ....................................................+150NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (soldering, 10s) ................................+300NC

V

2.7 V

100 mV

2.7 V

mA

200 350 μs

V

-0.5 +0.5 μA

2 ______________________________________________________________________________________

Page 3

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

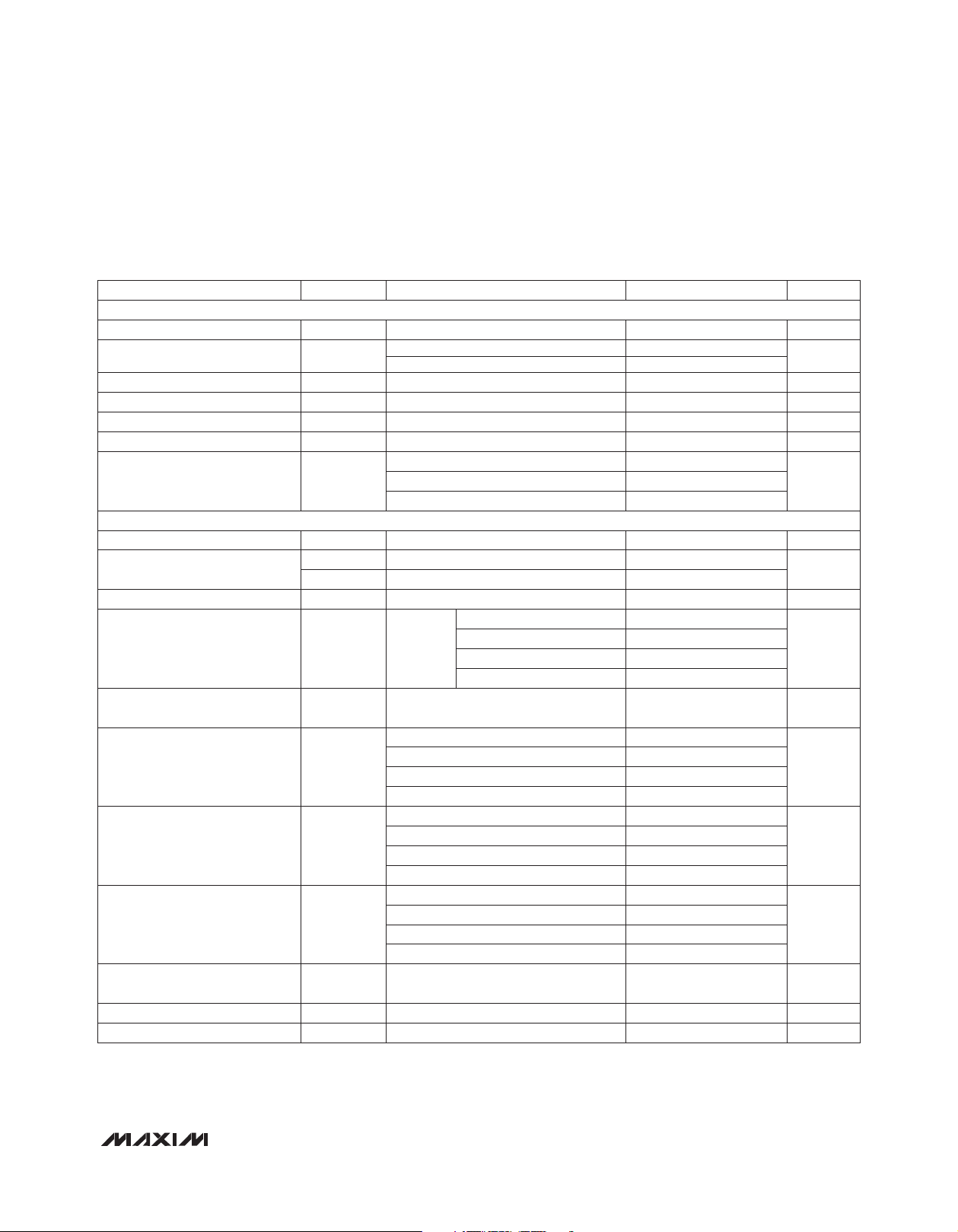

ELECTRICAL CHARACTERISTICS (continued)

(VCC = 2.8V to 14V, TA = -40NC to +85NC, unless otherwise specified. Typical values are at ABP = DBP = VCC = 3.3V, TA = +25NC.)

(Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ADC DC ACCURACY

Resolution 10 Bits

Gain Error ADC

Offset Error ADC

Integral Nonlinearity ADC

Differential Nonlinearity ADC

ADC Total Monitoring Cycle Time t

ADC IN_ Ranges

CURRENT SENSE

CSP Input-Voltage Range V

Input Bias Current

CSP Total Unadjusted Error CSP

Overcurrent Differential

Threshold

V

Fault Threshold

SENSE

Hysteresis

Secondary Overcurrent Threshold

Timeout

V

Ranges

SENSE

ADC Current Measurement

Accuracy

Gain Accuracy

Common-Mode Rejection Ratio CMRR

Power-Supply Rejection Ratio PSRR

CYCLE

I

I

CSM

OVC

OVC

OVC

CSP

CSP

GAIN

TA = +25°C 0.35

TA = -40°C to +85°C 0.70

OFF

INL

DNL

No MON_ fault detected 40 50 μs

1 LSB = 5.43mV 5.56

1 LSB = 1.36mV 1.39

3 14 V

14 25

V

= V

CSP

(Note 4) 2 %FSR

ERR

V

TH

HYS

DEL

SNSVCSP

SNS

CSP

V

CSM

r73h[6:5] = ‘00’ 0

r73h[6:5] = ‘01’ 3 4 5

r73h[6:5] = ‘10’ 12 16 20

r73h[6:5] = ‘11’ 50 64 60

Gain = 6 232

Gain = 12 116

Gain = 24 58

Gain = 48 29

V

SENSE

V

SENSE

V

SENSE

V

SENSE

V

SENSE

gain = 6

CSM

Gain = 48 21.5 25 30.5

Gain = 24 46 51 56

Gain = 12 94 101 108

Gain = 6 190 202 210

= 150mV (gain = 6 only) -2.5

= 50mV, gain = 12 -4

= 25mV, gain = 24

= 10mV, gain = 48

= 20mV to 100mV, V

> 4V 80 dB

CSP

= 5V,

-1.5 +1.5 %

3 5

0.5 % OVC

Q0.2

Q0.2

Q0.5

Q1

80 dB

1 LSB

1 LSB

1 LSB

+2.5

+4

%

V1 LSB = 2.72mV 2.78

μA

mV

TH

ms

mV

%

MAX16065/MAX16066

_______________________________________________________________________________________ 3

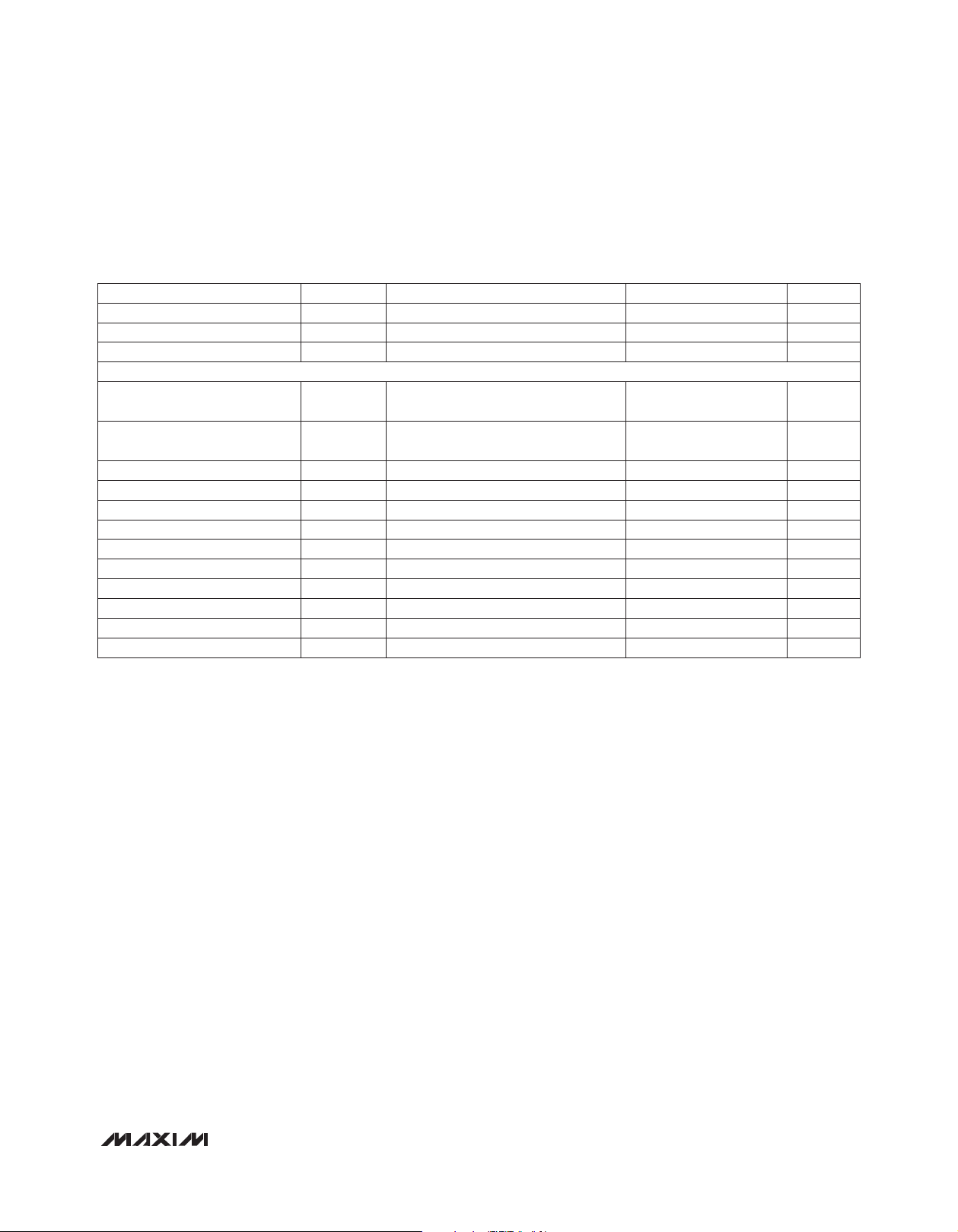

Page 4

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

ELECTRICAL CHARACTERISTICS (continued)

(VCC = 2.8V to 14V, TA = -40NC to +85NC, unless otherwise specified. Typical values are at ABP = DBP = VCC = 3.3V, TA = +25NC.)

(Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

OUTPUTS (EN_OUT_, RESET, GPIO_)

I

= 2mA 0.4

SINK

I

Output-Voltage Low V

Maximum Output Sink Current

Output-Voltage High (Push-Pull) I

Output Leakage (Open Drain)

OUT_ Overdrive (Charge Pump)

(EN_OUT1–EN_OUT8 Only)

OUT_ Pullup Current (Charge

Pump)

MAX16065/MAX16066

SMBus INTERFACE

Logic-Input Low Voltage V

Logic-Input High Voltage V

Input Leakage Current IN = GND or V

Output Sink Current V

Input Capacitance C

SMBus Timeout t

INPUTS (A0, GPIO_)

Input Logic-Low V

Input Logic-High V

WDI Pulse Width t

MR Pulse Width

MR to RESET Delay

MR Glitch Rejection

SMBus TIMING

Serial Clock Frequency f

Bus Free Time Between STOP

and START Condition

START Condition Setup Time t

START Condition Hold Time t

STOP Condition Setup Time t

Clock Low Period t

Clock High Period t

Data Setup Time t

OL

I

CH_UP

IL

IH

OL

IN

TIMEOUT

IL

IH

WDI

t

MR

SCL

t

BUF

SU:STA

HD:STA

SU:STO

LOW

HIGH

SU:DAT

= 10mA, GPIO_ only 0.7

SINK

VCC = 1.2V, I

Total current into EN_OUT_, RESET,

GPIO_, VCC = 3.3V

SOURCE

EN_OUT1–EN_OUT8 = 13.2V 5

I

GATE_

During power up, V

Input voltage falling 0.8 V

Input voltage rising 2.0 V

I

SINK

SCL time low for reset 25 35 ms

= 100μA 2.4 V

= 1μA 10 11 13 V

= 3mA 0.4 V

= 100μA (RESET only)

SINK

= 1V 2.5 4 μA

GATE

CC

-1 +1 μA

5 pF

2.0 V

100 ns

1 μs

0.5 μs

100 ns

1.3 μs

0.6 μs

0.6 μs

0.6 μs

1.3 μs

0.6 μs

100 ns

0.3

30 mA

1

0.8 V

400 kHz

V

μA

4 ______________________________________________________________________________________

Page 5

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

ELECTRICAL CHARACTERISTICS

(VCC = 2.8V to 14V, TA = -40NC to +85NC, unless otherwise specified. Typical values are at ABP = DBP = VCC = 3.3V, TA = +25NC.)

(Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output Fall Time t

Data Hold Time t

Pulse Width of Spike Suppressed t

JTAG INTERFACE

TDI, TMS, TCK Logic-Low Input

Voltage

TDI, TMS, TCK Logic-High Input

Voltage

TDO Logic-Output Low Voltage V

TDO Logic-Output High Voltage V

TDI, TMS Pullup Resistors R

I/O Capacitance C

TCK Clock Period t

TCK High/Low Time t2, t

TCK to TMS, TDI Setup Time t

TCK to TMS, TDI Hold Time t

TCK to TDO Delay t

TCK to TDO High-Z Delay t

OF

HD:DAT

V

V

SP

IL

IH

OL

OH

PU

I/O

1

4

5

6

7

C

= 10pF to 400pF 250 ns

BUS

From 50% SCL falling to SDA change 0.3 0.9 μs

30 ns

Input voltage falling 0.8 V

Input voltage rising 2 V

I

= 3mA 0.4 V

SINK

I

SOURCE

Pullup to DBP 40 50 60 kω

3

= 200μA 2.4 V

5 pF

50 500 ns

15 ns

10 ns

1000 ns

500 ns

500 ns

MAX16065/MAX16066

Note 1: Specifications are guaranteed for the stated global conditions, unless otherwise noted. 100% production tested at TA =

+25NC and TA = +85NC. Specifications at TA = -40NC are guaranteed by design.

Note 2: For V

supply rail.

Note 3: Applies to RESET, fault, autoretry, sequence delays, and watchdog timeout.

Note 4: Total unadjusted error is a combination of gain, offset, and quantization error.

of 3.6V or lower, connect VCC, DBP, and ABP together. For higher supply applications, connect only VCC to the

CC

_______________________________________________________________________________________ 5

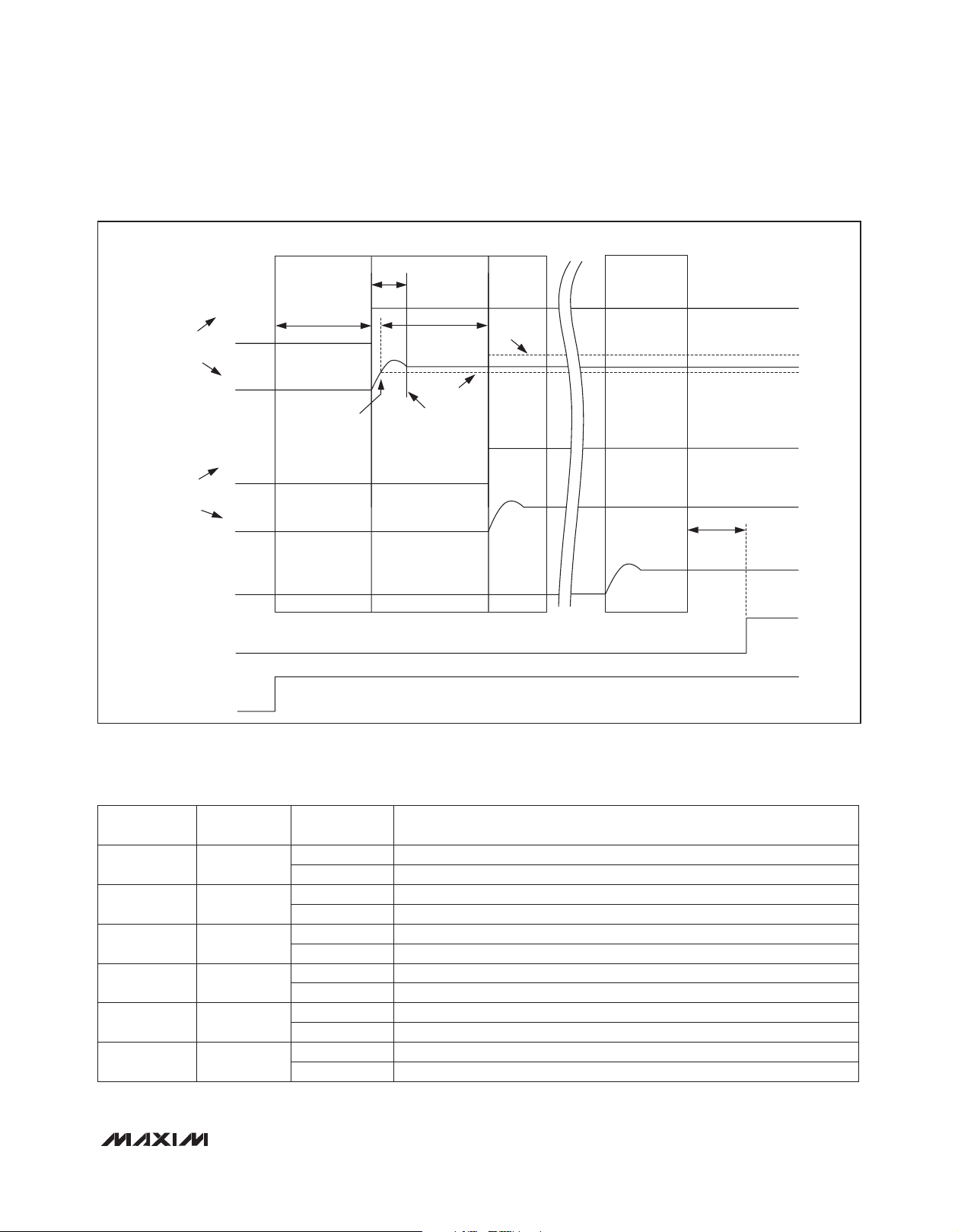

Page 6

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

SDA

t

BUF

SCL

t

HD:STA

t

SU:DAT

t

t

t

LOW

t

HIGH

t

R

HD:DAT

t

F

SU:STA

t

HD:STA

t

SU:STO

START

CONDITION

MAX16065/MAX16066

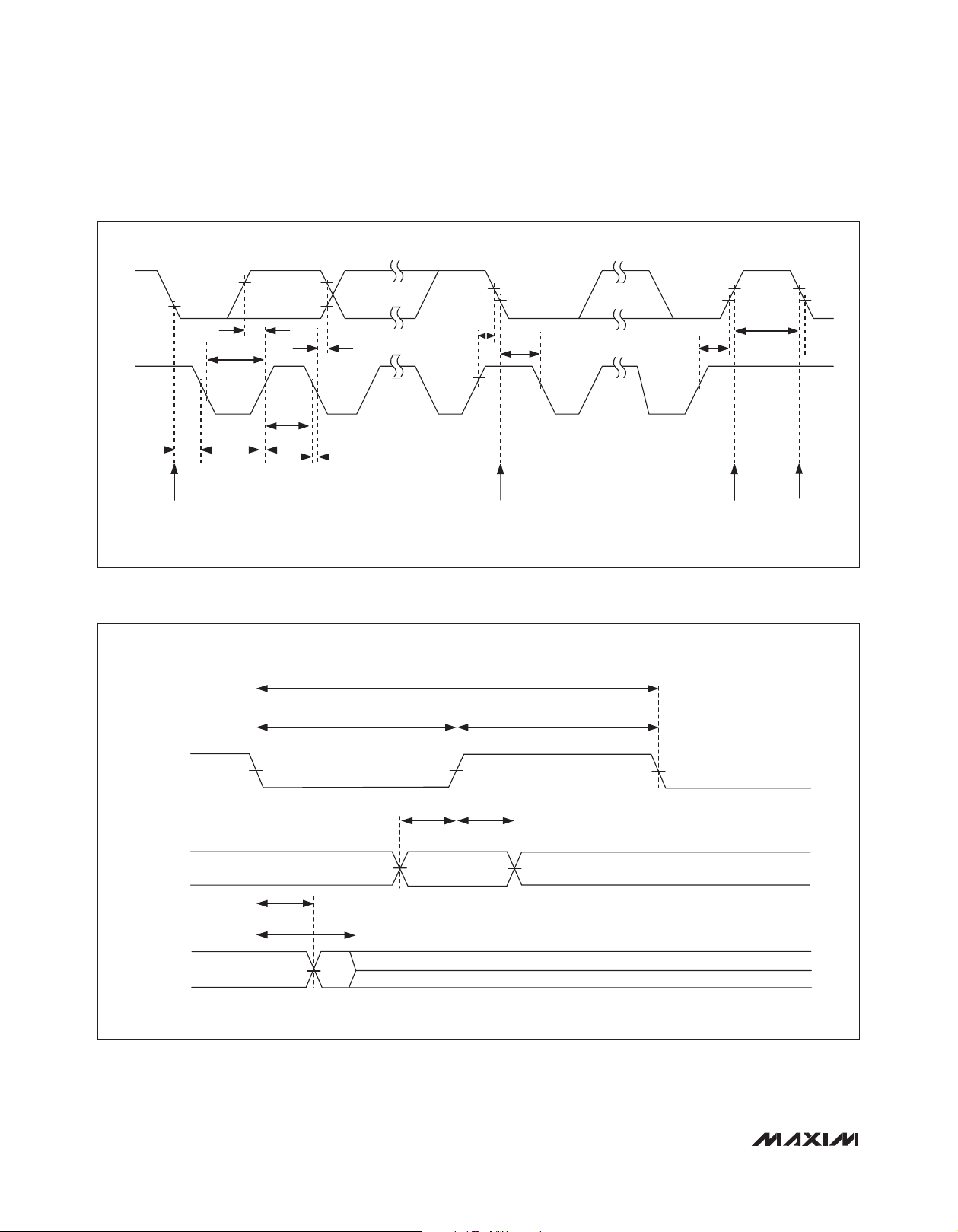

Figure 1. SMBus Timing Diagram

t

2

TCK

TDI, TMS

t

6

t

7

t

4

REPEATED START

CONDITION

t

1

t

5

STOP

CONDITION

t

3

START

CONDITION

TDO

Figure 2. JTAG Timing Diagram

6 ______________________________________________________________________________________

Page 7

12-Channel/8-Channel, Flash-Configurable System

VCC SUPPLY CURRENT

vs. V

CC

SUPPLY VOLTAGE

MAX16065 toc01

VCC (V)

I

CC

(mA)

12108642

1

2

3

4

5

6

0

0 14

TA = +85NC

TA = +25NC

TA = -40NC

FOR LOW-VOLTAGE APPLICATIONS

V

CC

< 3.6V CONNECT ABP AND

DBP TO V

CC

ABP AND DBP

REGULATORS ACTIVE

ABP AND DBP CONNECTED TO V

CC

Managers with Nonvolatile Fault Registers

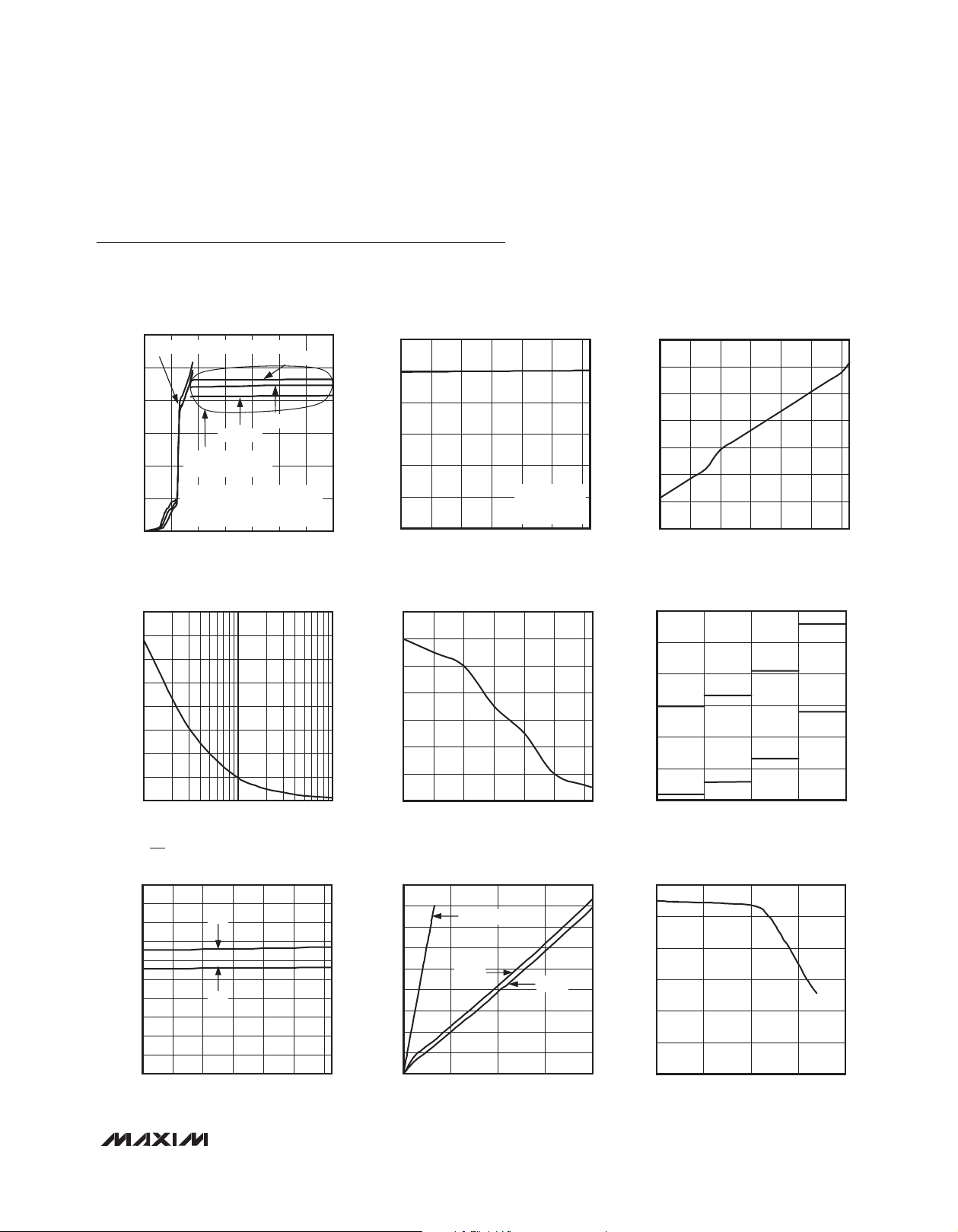

Typical Operating Characteristics

(Typical values are at VCC = 3.3V, T

= +25°C, unless otherwise noted.)

A

MAX16065/MAX16066

TRANSIENT DURATION

vs. THRESHOLD OVERDRIVE (EN)

160

140

120

100

80

60

TRANSIENT DURATION (µs)

40

20

0

1 100

10

EN OVERDRIVE (mV)

NORMALIZED MON_ THRESHOLD

1.2

1.0

0.8

0.6

0.4

NORMALIZED MON_ THRESHOLD

0.2

0

-40 80

NORMALIZED TIMING ACCURACY

0.986

0.984

MAX16065 toc04

0.982

0.980

0.978

0.976

NORMALIZED SLOT DELAY

0.974

0.972

-40

vs. TEMPERATURE

5.6V RANGE,

HALF SCALE,

PUV THRESHOLD

TEMPERATURE (NC)

vs. TEMPERATURE

TEMPERATURE (NC)

NORMALIZED EN THRESHOLD

vs. TEMPERATURE

1.006

1.004

MAX16065 toc02

1.002

1.000

0.998

0.996

NORMALIZED EN THRESHOLD

0.994

6040200-20

0.992

-40

TEMPERATURE (NC)

MAX16065 toc03

806040200-20

MON_ DEGLITCH

vs. TRANSIENT DURATION

120

806040200-20

MAX16065 toc05

TRANSIENT DURATION (µs)

100

80

60

40

20

0

2

4 8 16

DEGLITCH VALUE

MAX16065 toc06

MR TO RESET PROPAGATION DELAY

2.0

1.8

1.6

1.4

1.2

1.0

DELAY (µs)

0.8

0.6

0.4

0.2

0

-40

vs. TEMPERATURE

MAX

MIN

TEMPERATURE (NC)

806020 400-20

MAX16065 toc07

OUTPUT VOLTAGE vs. SINK CURRENT

(OUT = LOW)

0.45

0.40

0.35

0.30

0.25

(V)

OUT

V

0.20

0.15

0.10

0.05

0

0 20

EN_OUT_

GPIO_

I

(mA)

OUT

MAX16065 toc08

RESET

15105

OUTPUT-VOLTAGE HIGH vs. SOURCE

CURRENT (CHARGE-PUMP OUTPUT)

12

10

8

(V)

6

OUT

V

4

2

0

0 4

I

(µA)

OUT

_______________________________________________________________________________________ 7

MAX16065 toc09

321

Page 8

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Typical Operating Characteristics (continued)

(Typical values are at VCC = 3.3V, T

= +25°C, unless otherwise noted.)

A

OUTPUT-VOLTAGE HIGH vs. SOURCE

CURRENT (PUSH-PULL OUTPUT)

3.4

3.3

3.2

3.1

3.0

(V)

2.9

OUT

V

2.8

EN_OUT_

2.7

2.6

2.5

2.4

RESET

0 1500

GPIO_

1000500

I

(µA)

OUT

MAX16065 toc10

INTEGRAL NONLINEARITY vs. CODE

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 1024

MAX16065/MAX16066

NORMALIZED CURRENT-SENSE

ACCURACY vs. TEMPERATURE

1.05

1.03

200mV

1.01

0.99

100mV

0.97

NORMALIZED CURRENT-SENSE OUTPUT

0.95

TEMPERATURE (NC)

25mV

6040200-20-40 80

MAX16065 toc13

ERROR (mV)

-0.2

-0.4

-0.6

-0.8

-1.0

CURRENT-SENSE ACCURACY

1.0

0.8

0.6

0.4

0.2

0

0 30

CODE (LSB)

vs. CSP-CSM VOLTAGE

CSP-CSM VOLTAGE (mV)

DIFFERENTIAL NONLINEARITY vs. CODE

1.0

0.8

MAX16065 toc11

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

896768512 640256 384128

-1.0

0 1024

CODE (LSB)

MAX16065 toc12

896768512 640256 384128

CURRENT-SENSE TRANSIENT DURATION

vs. CSP-CSM OVERDRIVE

1.8

1.6

MAX16065 toc14

1.4

1.2

1.0

0.8

0.6

TRANSIENT DURATION (Fs)

0.4

0.2

252015105

0

0 100

CSP-CSM OVERDRIVE (mV)

80604020

MAX16065 toc15

RESET OUTPUT CURRENT

FET TURN-ON WITH CHARGE PUMP

EN_OUT

I

LOAD

V

LOAD

20ms/div

MAX16065 toc16

SEQUENCING MODE

20ms/div

MAX16065 toc17

18

16

14

12

10

8

6

OUTPUT CURRENT (mA)

4

2

0

vs. SUPPLY VOLTAGE

ABP AND DBP

CONNECTED TO V

ABP AND DBP

REGULATORS ACTIVE

0 14

SUPPLY VOLTAGE (V)

8 ______________________________________________________________________________________

V

CC

RESET

MAX16065 toc18

= 0.3V

12106 842

Page 9

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

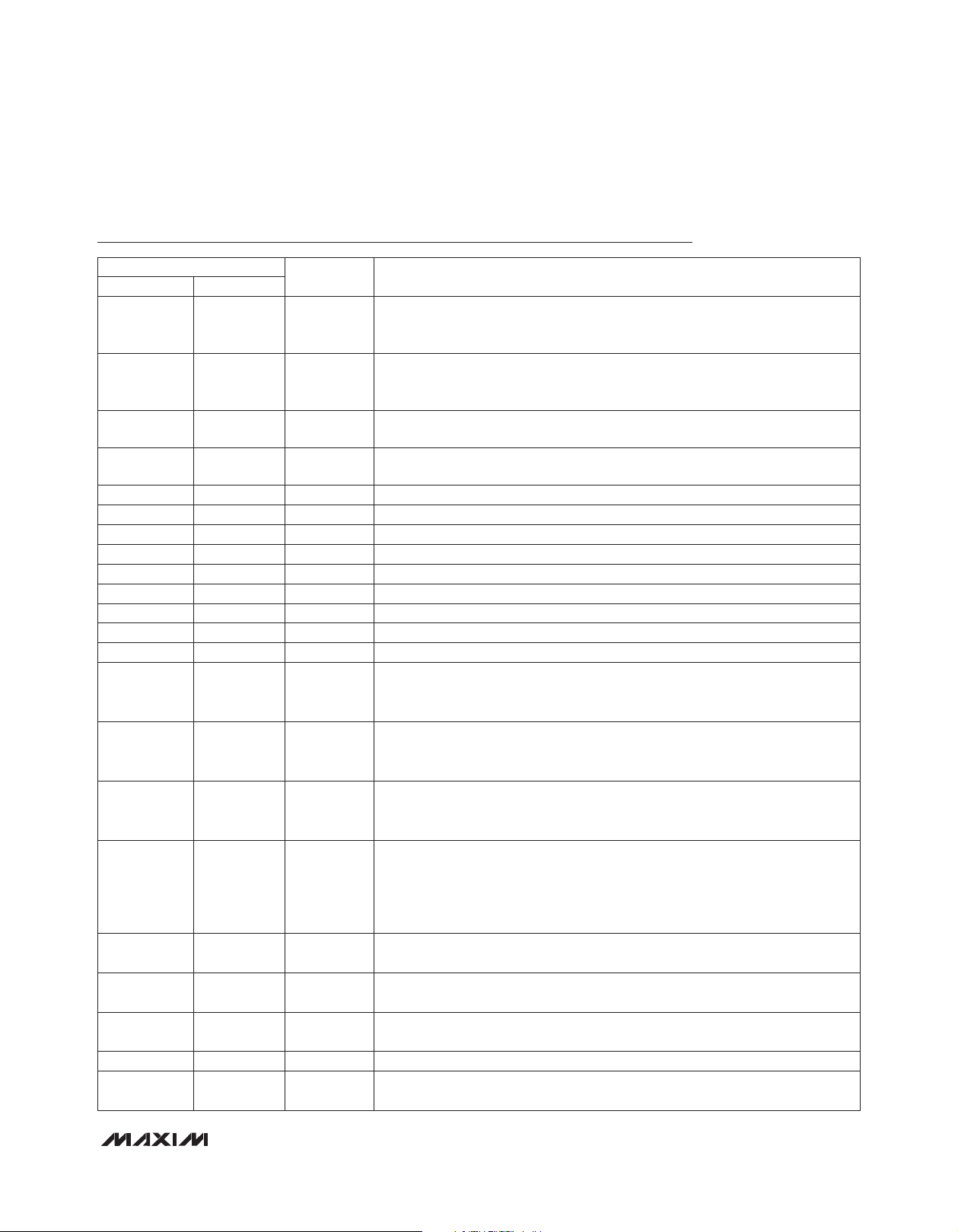

Pin Description

MAX16065/MAX16066

PIN

MAX16065 MAX16066

1–6, 43–46 1–5, 36–40

47, 48 —

7 6 CSP

8 7 CSM

9 8 RESET Configurable Reset Output

10 9 TMS JTAG Test Mode Select

11 10 TDI JTAG Test Data Input

12 11 TCK JTAG Test Clock

13 12 TDO JTAG Test Data Output

14 13 SDA SMBus Serial-Data Open-Drain Input/Output

15 14 A0 Four-State SMBus Address. Address sampled upon POR.

16 15 SCL SMBus Serial-Clock Input

17, 42 16, 35 GND Ground

20–25 17–22

18, 19 —

26–29 —

NAME FUNCTION

MON1–

MON10

MON11,

MON12

GPIO1–

GPIO6

GPIO7,

GPIO8

EN_OUT12–

EN_OUT9

Monitor Voltage Inputs. Set monitor voltage range through configuration

registers. Measured value written to ADC register can be read back through the

SMBus or JTAG interface.

Monitor Voltage Inputs. Set monitor voltage range through configuration

registers. Measured value written to ADC register can be read back through the

SMBus or JTAG interface.

Current-Sense Amplifier Positive Input. Connect CSP to the source side of the

external sense resistor.

Current-Sense Amplifier Negative Input. Connect CSM to the load side of the

external sense resistor.

General-Purpose Input/Outputs. GPIO_s can be configured to act as a TTL input,

a push-pull, open-drain, or high-impedance output or a pulldown circuit during a

fault event.

General-Purpose Input/Outputs. GPIO_s can be configured to act as a TTL input,

a push-pull, open-drain, or high-impedance output or a pulldown circuit during a

fault event or reverse sequencing.

Outputs. Set EN_OUT_ with active-high/active-low logic and with push-pull or

open-drain configuration. EN_OUT_ can be asserted by a combination of IN_

voltages configurable through the flash.

30–37 23–30

38 31 EN

39 32 DBP

40 33 V

41 34 ABP

— — EP

_______________________________________________________________________________________ 9

EN_OUT1–

EN_OUT8

CC

Outputs. Set EN_OUT_ with active-high/active-low logic and with push-pull or

open-drain configuration. EN_OUT_ can be asserted by a combination of IN_

voltages configurable through the flash. EN_OUT1–EN_OUT8 can be configured

with a charge-pump output (+10V above GND) that can drive an external

n-channel MOSFET.

Analog Enable Input. All outputs deassert when VEN is below the enable

threshold.

Digital Bypass. All push-pull outputs are referenced to DBP. Bypass DBP with a

1FF capacitor to GND.

Device Power Supply. Connect VCC to a voltage from 2.8V to 14V. Bypass VCC

with a 10FF capacitor to GND.

Analog Bypass. Bypass ABP with a 1FF ceramic capacitor to GND.

Exposed Pad. Internally connected to GND. Connect to ground, but do not use

as the main ground connection.

Page 10

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

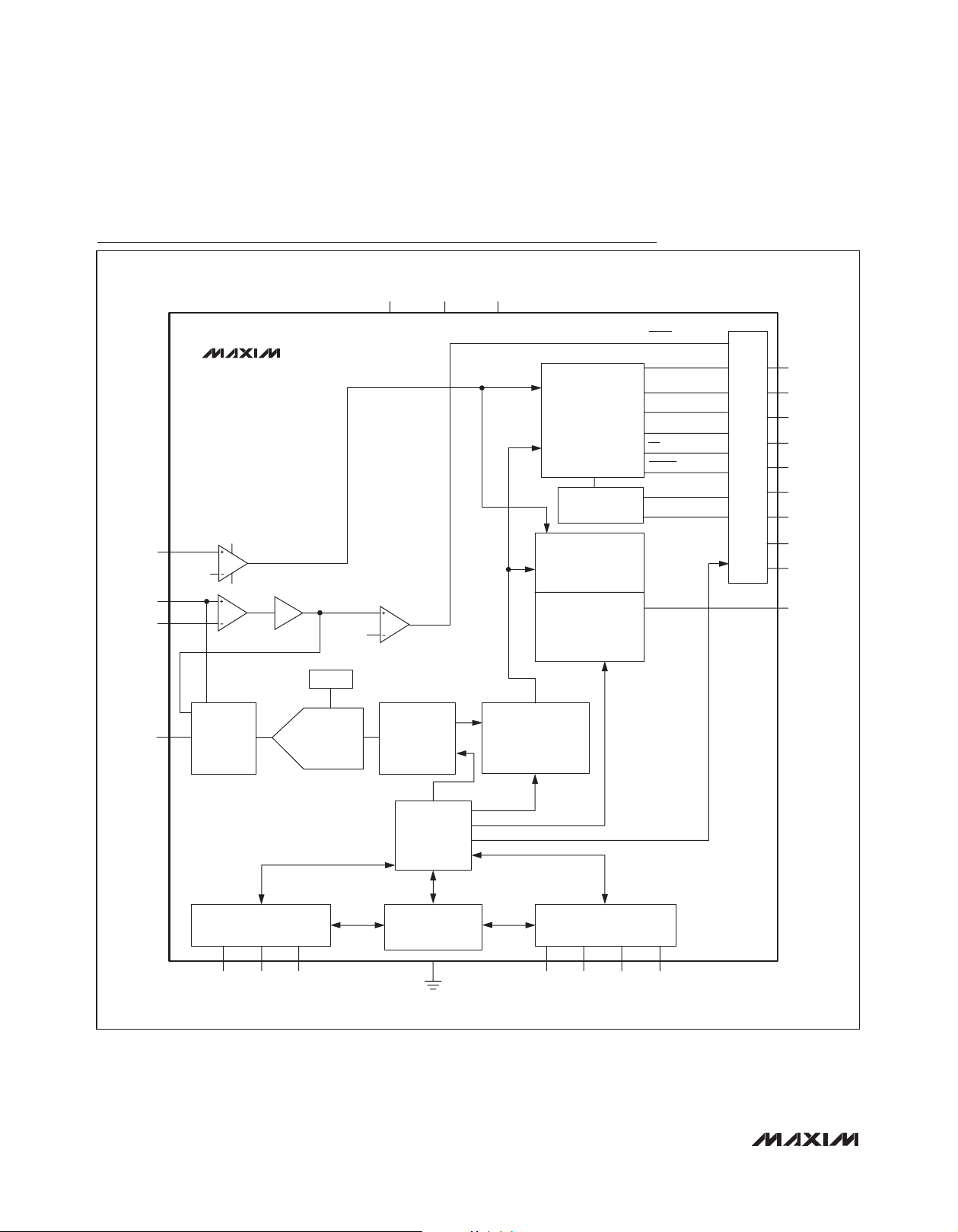

Functional Diagram

V

CC

MAX16065

EN

MAX16065/MAX16066

CSP

CSM

MON1–

MON12

1.4V

VOLTAGE

SCALING

AND

MUX

A

V

V

CSTH

REF

10-BIT ADC

(SAR)

ADC

REGISTERS

ABP DBP

DIGITAL

COMPARATORS

DECODE

LOGIC

WATCHDOG

TIMER

PRIMARY

SEQUENCE

BLOCK

SECONDARY

SEQUENCE

BLOCK

OVERC

RESET

ANYFAULT

FAULT1

FAULT2

MR

MARGIN

WDI

WDO

GPIO1–GPIO8

RESET

G

P

I

O

C

O

N

T

R

O

L

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

GPIO8

EN_OUT1–

EN_OUT12

RAM

REGISTERS

SMBus INTERFACE

AO

SCL SDA

FLASH

MEMORY

GND

TDO TDI TCK TMS

JTAG

INTERFACE

10 _____________________________________________________________________________________

Page 11

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Detailed Description

The MAX16065 manages up to twelve system power

supplies and the MAX16066 can manage up to eight

system power supplies. After boot-up, if EN is high and

the software enable bit is set to ‘1,’ a power-up sequence

begins based on the configuration stored in flash and

the EN_OUT_s are controlled accordingly. When the

power-up sequence is successfully completed, the

monitoring phase begins. An internal multiplexer cycles

through each MON_ input. At each multiplexer stop, the

10-bit ADC converts the monitored analog voltage to a

digital result and stores the result in a register. Each time

a conversion cycle (50Fs, max) completes, internal logic

circuitry compares the conversion results to the overvoltage and undervoltage thresholds stored in memory.

When a result violates a programmed threshold, the

conversion can be configured to generate a fault. GPIO_

can be programmed to assert on combinations of faults.

Additionally, faults can be configured to shut off the system and trigger the nonvolatile fault logger, which writes

all fault information automatically to the flash and writeprotects the data to prevent accidental erasure.

The MAX16065/MAX16066 contain both SMBus and

JTAG serial interfaces for accessing registers and flash.

Use only one interface at any given time. For more information on how to access the internal memory through

these interfaces, see the SMBus-Compatible Interface

and JTAG Serial Interface sections. The memory map

is divided into three pages with access controlled by

special SMBus and JTAG commands.

The factory-default values at POR (power-on reset) for all

RAM registers are ‘0’s. POR occurs when VCC reaches

the undervoltage-lockout threshold (UVLO) of 2.8V (max).

At POR, the device begins a boot-up sequence. During

the boot-up sequence, all monitored inputs are masked

from initiating faults and flash contents are copied to

the respective register locations. During boot-up, the

MAX16065/MAX16066 are not accessible through the

serial interface. The boot-up sequence takes up to

150Fs, after which the device is ready for normal operation. RESET is asserted low up to the boot-up phase and

remains asserted for its programmed timeout period once

sequencing is completed and all monitored channels

are within their respective thresholds. Up to the boot-up

phase, the GPIO_s and EN_OUT_s are high impedance.

Apply 2.8V to 14V to VCC to power the MAX16065/

MAX16066. Bypass VCC to ground with a 10FF capacitor. Two internal voltage regulators, ABP and DBP,

supply power to the analog and digital circuitry within

the device. For operation at 3.6V or lower, disable the

regulators by connecting ABP and DBP to VCC.

ABP is a 3.0V (typ) voltage regulator that powers the internal analog circuitry. Bypass ABP to GND with a 1FF ceramic capacitor installed as close to the device as possible.

DBP is an internal 3.0V (typ) voltage regulator. DBP

powers flash and digital circuitry. All push-pull outputs

refer to DBP. DBP supplies the input voltage to the internal charge pump when the programmable outputs are

configured as charge-pump outputs. Bypass the DBP

output to GND with a 1FF ceramic capacitor installed as

close as possible to the device.

Do not power external circuitry from ABP or DBP.

To sequence a system of power supplies safely, the

output voltage of a power supply must be good before

the next power supply may turn on. Connect EN_OUT_

outputs to the enable input of an external power supply

and connect MON_ inputs to the output of the power

supply for voltage monitoring. More than one MON_ can

be used if the power supply has multiple outputs.

Sequence Order

The MAX16065/MAX16066 provide a system of ordered

slots to sequence multiple power supplies. To determine

the sequence order, assign each EN_OUT_ to a slot

ranging from Slot 1 to Slot 12. EN_OUT_(s) assigned to

Slot 1 are turned on first, followed by outputs assigned

to Slot 2, and so on through Slot 12. Multiple EN_OUT_s

assigned to the same slot turn on at the same time.

Each slot includes a built-in configurable sequence delay

(registers r77h to r7Dh) ranging from 20Fs to 1.6s. During

a reverse sequence, slots are turned off in reverse order

starting from Slot 12. The MAX16065/MAX16066 can be

configured to power-down in simultaneous mode or in

reverse sequence mode as set in r75h[0]. See Tables 5

and 6 for the EN_OUT_ slot assignment bits, and Tables

3 and 4 for the sequence delays.

During power-up or power-down sequencing, the current sequencer state can be found in r21h[4:0].

Power

Sequencing

MAX16065/MAX16066

______________________________________________________________________________________ 11

Page 12

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

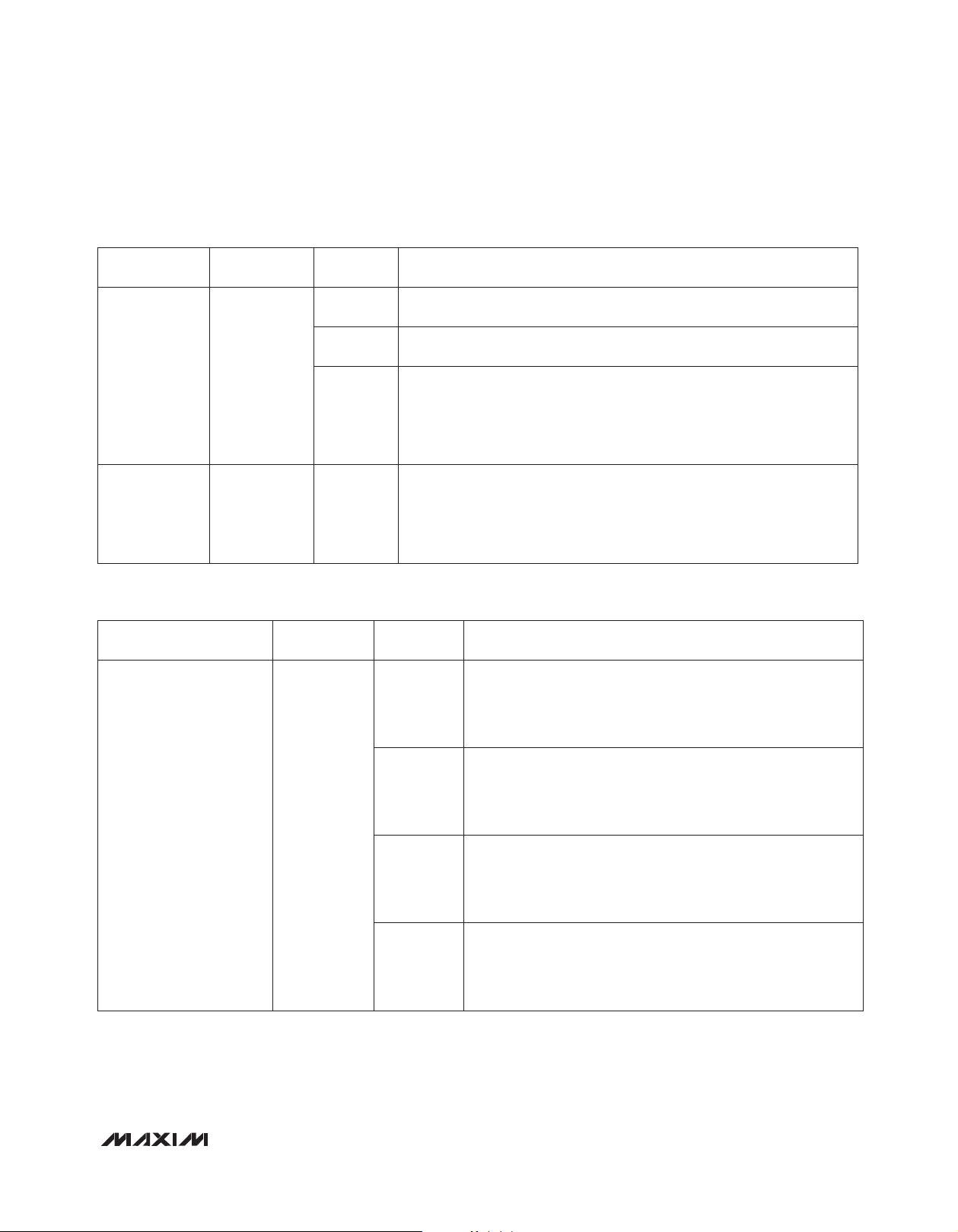

Table 1. Current Sequencer Slot

REGISTER

ADDRESS

21h

MAX16065/MAX16066

BIT RANGE DESCRIPTION

Current Sequencer State:

00000 = Slot 0

00001 = Slot 1

00010 = Slot 2

00011 = Slot 3

00100 = Slot 4

00101 = Slot 5

00110 = Slot 6

00111 = Slot 7

[4:0]

[7:5] Reserved

01000 = Slot 8

01001 = Slot 9

01010 = Slot 10

01011 = Slot 11

01100 = Slot 12

01101 = Secondary sequence monitoring mode

01110 = Primary sequence fault

01111 = Primary sequence monitoring mode

10000 = Secondary sequence fault

10001 to 11111 = Reserved

Multiple Sequencing Groups

The MAX16065/MAX16066 sequencing slots can be

split into two groups: the primary sequence and the secondary sequence. The last slot of the primary sequence

is selected using register bits r7Dh[7:4]. The secondary sequence begins at the slot after the one specified in register bits 7Dh[7:4]. The primary sequence

is controlled by the EN input and the software enable

bit in r73h[0]. Outputs assigned to slots in the primary

sequence turn on, and monitoring begins for inputs

assigned to these slots. RESET deasserts after the primary sequence and timeout period completes.

To initiate secondary sequencing and monitoring, set

the software enable 73h[1] bit to 1. Additionally, if GPIO_

is configured as EN2 then both the software enable 2

and EN2 must be high. Outputs assigned to slots in the

secondary sequence turn on, and monitoring begins for

inputs assigned to these slots. If a GPIO_ is configured

as the RESET2 output, it deasserts after the secondary

sequence and timeout period completes.

If a critical fault occurs in the primary sequence group,

both sequence groups automatically shut down. If a

critical fault occurs in the secondary sequence group,

then just the outputs assigned to slots in the secondary sequence turn off. The failing slot in secondary

sequence is stored in r1Dh.

Multiple sequencing groups can be used to conserve

power by powering down secondary systems when not

in use.

Enable and Enable2

To initiate sequencing/tracking and enable monitoring,

the voltage at EN must be above 1.4V and the software

enable bit in r73h[0] must be set to ‘1.’ To power down

and disable monitoring, either pull EN below 1.35V or

set the Software Enable bit to ‘0.’ See Table 2 for the

software enable bit configurations. Connect EN to ABP

if not used.

If a fault condition occurs during the power-up cycle,

the EN_OUT_ outputs are powered down immediately,

regardless of the state of EN. In the monitoring state,

if EN falls below the threshold, the sequencing state

machine begins the power-down sequence. If EN rises

above the threshold during the power-down sequence,

the sequence state machine continues the power-down

sequence until all the channels are powered off and then

the device immediately begins the power-up sequence.

When in the monitoring state, a register bit, ENRESET,

is set to a ‘1’ when EN falls below the undervoltage

threshold. This register bit latches and must be cleared

through software. This bit indicates if RESET asserted

low due to EN going under the threshold. The POR state

of ENRESET is ‘0’. The bit is only set on a falling edge

12 _____________________________________________________________________________________

Page 13

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

of the EN comparator output or the software enable bit.

If operating in latch-on fault mode, toggle EN or toggle

the Software Enable bit to clear the latch condition and

restart the device once the fault condition has been

removed.

To initiate secondary sequencing and monitoring set the

software enable r73h[1] bit to 1. Additionally, if GPIO_ is

configured as EN2 then both the software enable 2 bit and

EN2 must be high. To power-down and disable monitoring, either drive EN2 low or set the Software Enable2 bit to

‘0.’ See Table 2 for the software enable bit configurations.

When a fault condition occurs during the power-up cycle,

the EN_OUT_ outputs are powered down immediately,

independent of the state of EN2. Drive EN2 low to begin

the secondary power-down sequence. When EN2 is driv-

Table 2. Software Enable Configurations

REGISTER

ADDRESS

73h 273h

FLASH

ADDRESS

BIT RANGE DESCRIPTION

[0] Software enable 1 (primary sequence)

[1] Software enable 2 (secondary sequence)

[2] 1 = Margin mode enabled

Early warning threshold select

[3]

[4]

0 = Early warning is undervoltage

1 = Early warning is overvoltage

Independent watchdog mode enable

1 = Watchdog timer is independent of sequencer

0 = Watchdog timer boots after sequence completes

en high during the power-down sequence, the sequence

state machine continues the power-down sequence until

the secondary channels are powered off and then the

device immediately begins the power-up sequence.

Monitoring Inputs While Sequencing

An enabled MON_ input can be assigned to a slot

ranging from Slot 1 to Slot 12. EN_OUT_s are always

asserted at the beginning of a slot. The supply voltages connected to the MON_ inputs must exceed the

undervoltage threshold before the programmed timeout

period expires otherwise a fault condition will occur. The

undervoltage threshold checking cannot be disabled

during power-up and power-down. See Tables 5 and

6 for the MON_ slot assignment bits. The programmed

MAX16065/MAX16066

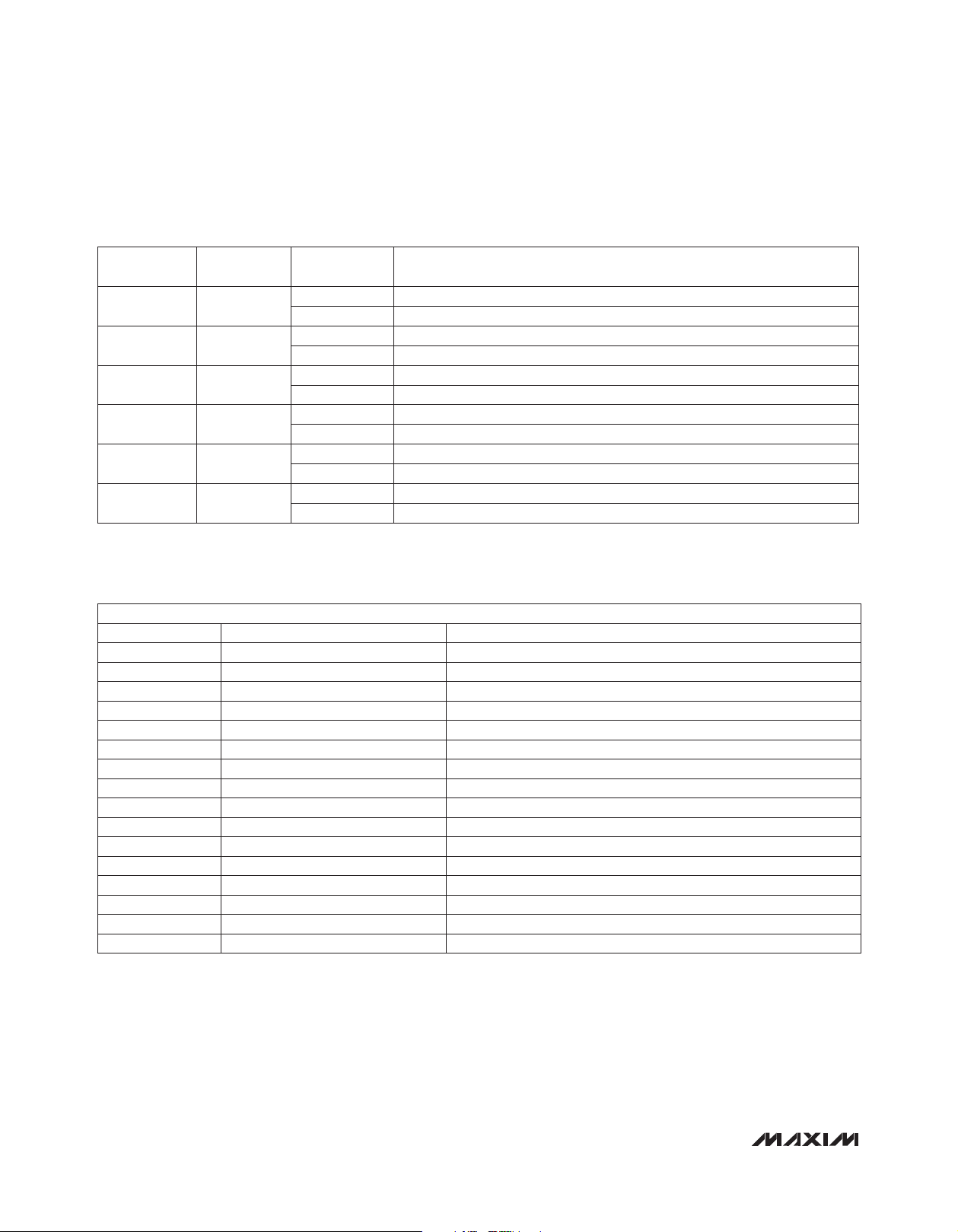

Table 3. Slot Delay Register

REGISTER

ADDRESS

77h 277h

78h 278h

79h 279h

7Ah 27Ah

7Bh 27Bh

7Ch 27Ch

7Dh 27Dh

FLASH

ADDRESS

______________________________________________________________________________________ 13

BIT RANGE DESCRIPTION

[3:0] Sequence Slot 0 Delay

[7:4] Sequence Slot 1 Delay

[3:0] Sequence Slot 2 Delay

[7:4] Sequence Slot 3 Delay

[3:0] Sequence Slot 4 Delay

[7:4] Sequence Slot 5 Delay

[3:0] Sequence Slot 6 Delay

[7:4] Sequence Slot 7 Delay

[3:0] Sequence Slot 8 Delay

[7:4] Sequence Slot 9 Delay

[3:0] Sequence Slot 10 Delay

[7:4] Sequence Slot 11 Delay

[3:0] Sequence Slot 12 Delay

[7:4] Grouped Sequence Split Location, Final Slot of Primary Sequence

Page 14

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 4. Power-Up/Power-Down Slot Delays

CODE VALUE

0000

0001

0010 1ms

0011 2ms

0100 3ms

0101 4ms

0110 6ms

0111 8ms

1000 10ms

1001 12ms

1010 25ms

1011 100ms

1100 200ms

1101 400ms

1110 800ms

MAX16065/MAX16066

1111 1.6s

25Fs

500Fs

sequence delay is then counted before moving to the

next slot.

Slot 0 does not monitor any MON_ input and does not

control any EN_OUT_. Slot 0 waits for the Software

Enable bit r73h[0] to be a logic-high and for the voltage

on EN to rise above 1.4V before initiating the power-up

sequence and counting its own sequence delay.

Any MON_ input that suffers a fault that occurs during

power-up sequencing causes all the EN_OUT_s to turn

off and the sequencer to shut down regardless of the

state of the critical fault enables (see the Faults section

for more information). If a MON_ input is less critical to

system operation, it can be configured as “monitoring

only” (see Table 6) for either the primary or secondary

sequence. Monitoring for MON_ inputs assigned as

“monitoring only” begins after sequencing is complete

for that group, and can trigger a critical fault only if

specifically configured to do so using the critical fault

enables.

Power-Up

On power-up, when EN is high and the Software Enable

bit is 1, the MAX16065/MAX16066 begin sequencing

with Slot 0. After the sequencing delay for Slot 0 expires,

the sequencer advances to Slot 1, and all EN_OUT_s

assigned to the slot assert. All MON_ inputs assigned to

Slot 1 are monitored and when the voltage rises above the

UV fault threshold, the sequence delay counter is started.

When the t

assigned to the slot are above the fault UV threshold,

a fault asserts. EN_OUT_ outputs are disabled and the

MAX16065/MAX16066 return to the power-off state.

When the sequence delay expires, the MAX16065/

MAX16066 proceed to the next slot.

After the voltages on all MON_ inputs assigned to the

last slot exceed the UV fault threshold and the slot delay

expires, the MAX16065/MAX16066 start the reset timeout counter. After the reset timeout, RESET deasserts.

r75h[4:1] sets the t

Power-down starts when EN is pulled low or the Software

Enable bit is set to ‘0.’ Power down EN_OUT_s simultaneously or in reverse-sequence mode by setting the

Reverse Sequence bit (r75h[0]) appropriately.

When the MAX16065/MAX16066 are fully powered up

(including secondary sequence group, if enabled) and

EN or the Software Enable bit is set to ‘0’, the EN_OUT_s

assigned to Slot 12 deassert, the MAX16065/MAX16066

wait for the Slot 12 sequence delay and then proceed to

the previous slot (Slot 11), and so on until the EN_OUT_s

assigned to Slot 1 turn off. When simultaneous powerdown is selected (r75h[0] set to ‘0’), all EN_OUT_s turn

off at the same time.

counter expires before all MON_ inputs

FAULT

delay. See Table 7 for details.

FAULT

Power-Down

Reverse-Sequence Mode

14 _____________________________________________________________________________________

Page 15

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

MAX16065/MAX16066

BOTH ARE

ASSIGNED

TO SLOT 1

BOTH ARE

ASSIGNED

TO SLOT 2

EN_OUT1

MON4

EN_OUT2

MON3

MON5

RESET

SLOT 0

SLOT1-SLOT2

DELAY

UV/OV

MONITORING BEGINS

WHEN MON4

REACHES UV

THRESHOLD

SLOT 1

t

FAULT

SLOT1-SLOT2

MON4 MUST

REACH UV

THRESHOLD BY THIS

TIME

DELAY

UV

OV

SLOT 2

FINAL SLOT

(PRIMARY

SEQUENCE)

RESET

TIMEOUT

EN

Figure 3. Delay and Reset Timing

Table 5. MON_ and EN_OUT_ Assignment Registers

REGISTER

ADDRESS

7Eh 27Eh

7Fh 27Fh

80h 280h

81h 281h

82h 282h

83h 283h

FLASH

ADDRESS

BIT RANGE DESCRIPTION

[3:0] MON1

[7:4] MON2

[3:0] MON3

[7:4] MON4

[3:0] MON5

[7:4] MON6

[3:0] MON7

[7:4] MON8

[3:0] MON9

[7:4] MON10

[3:0] MON11

[7:4] MON12

______________________________________________________________________________________ 15

Page 16

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 5. MON_ and EN_OUT_ Assignment Registers (continued)

REGISTER

ADDRESS

84h 284h

85h 285h

86h 286h

87h 287h

88h 288h

89h 289h

FLASH

ADDRESS

BIT RANGE DESCRIPTION

[3:0] EN_OUT1

[7:4] EN_OUT2

[3:0] EN_OUT3

[7:4] EN_OUT4

[3:0] EN_OUT5

[7:4] EN_OUT6

[3:0] EN_OUT7

[7:4] EN_OUT8

[3:0] EN_OUT9

[7:4] EN_OUT10

[3:0] EN_OUT11

[7:4] EN_OUT12

MAX16065/MAX16066

Table 6. MON_ and EN_OUT_ Slot Assignment Codes

SLOT ASSIGNMENT

CODE MON_ DESCRIPTION

0000 Not assigned

0001 Slot 1

0010 Slot 2

0011 Slot 3

0100 Slot 4

0101 Slot 5

0110 Slot 6

0111 Slot 7

1000 Slot 8

1001 Slot 9

1010 Slot 10

1011 Slot 11

1100 Slot 12

1101 Monitoring only, primary sequence

1110 Monitoring only, secondary sequence

1111 Not assigned

General-purpose input (EN_OUT9–EN_OUT12 only)

General-purpose output (EN_OUT9–EN_OUT12 only)

OUT_ DESCRIPTION

Not assigned

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Slot 8

Slot 9

Slot 10

Slot 11

Slot 12

Not assigned

16 _____________________________________________________________________________________

Page 17

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 7. t

Delay Settings

FAULT

CODE DELAY

0000

0001

0010

0011

0100

0101 1ms

0110 1.5ms

0111 2.5ms

1000 4ms

1001 6ms

1010 10ms

1011 15ms

1100 25ms

1101 40ms

1110 60ms

1111 100ms

120Fs

150Fs

250Fs

380Fs

600Fs

MAX16065/MAX16066

When the secondary sequence group is already powered down and EN or the Software Enable bit is set

to ‘0’, the reverse power-down sequence is similar to

above, but starts from the last slot assigned to the primary sequence r7Dh[7:4]. After the last assigned slot is

powered down the previous slot will power down and so

on until Slot 0 is powered down.

To power down the secondary sequence group, drive

EN2 low or set r75h[1] to ‘0’. The secondary reverse

power-down sequence will start at Slot 12 and end at

the primary sequence monitoring mode state at which

point only the slots assigned to the primary sequence

are active.

Voltage/Current Monitoring

The MAX16065/MAX16066 feature an internal 10-bit

ADC that monitors the MON_ voltage inputs. An internal

multiplexer cycles through each of the enabled inputs,

taking less than 40Fs for a complete monitoring cycle.

Each acquisition takes approximately 3.2Fs. At each

multiplexer stop, the 10-bit ADC converts the analog

input to a digital result and stores the result in a register. ADC conversion results are stored in registers r00h

to r1Ah (see Table 10). Use the SMBus or JTAG serial

interface to read ADC conversion results.

The MAX16065 provides twelve inputs, MON1–MON12,

for voltage monitoring. The MAX16066 provides eight

inputs, MON1–MON8, for voltage monitoring. Each input

voltage range is programmable in registers r43h to r45h

(see Table 9). When MON_ configuration registers are

set to ’11,’ MON_ voltages are not monitored, and the

multiplexer does not stop at these inputs, decreasing

the total cycle time. These inputs cannot be configured

to trigger fault conditions.

The three programmable thresholds for each monitored

voltage include an overvoltage, an undervoltage, and a

secondary warning threshold that can be set in r73h[3]

to be either an undervoltage or overvoltage threshold.

See the Faults section for more information on setting

overvoltage and undervoltage thresholds. All voltage

thresholds are 8 bits wide. The 8 MSBs of the 10-bit ADC

conversion result are compared to these overvoltage

and undervoltage thresholds.

For any undervoltage or overvoltage condition to be

monitored and any faults detected, the MON_ input must

be assigned to a sequence order or set to monitoring

mode as described in the Sequencing section.

Inputs that are not enabled are not converted by the

ADC; they contain the last value acquired before that

channel was disabled.

The ADC conversion result registers are reset to 00h at

boot-up. These registers are not reset when a reboot

command is executed.

Configure the MAX16065/MAX16066 for differential

mode in r46h (Table 9). The possible differential pairs

______________________________________________________________________________________ 17

Page 18

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

are MON1/MON2, MON3/MON4, MON5/MON6, MON7/

MON8, MON9/MON10, MON11/MON12 with the first

input always being at a higher voltage than the second.

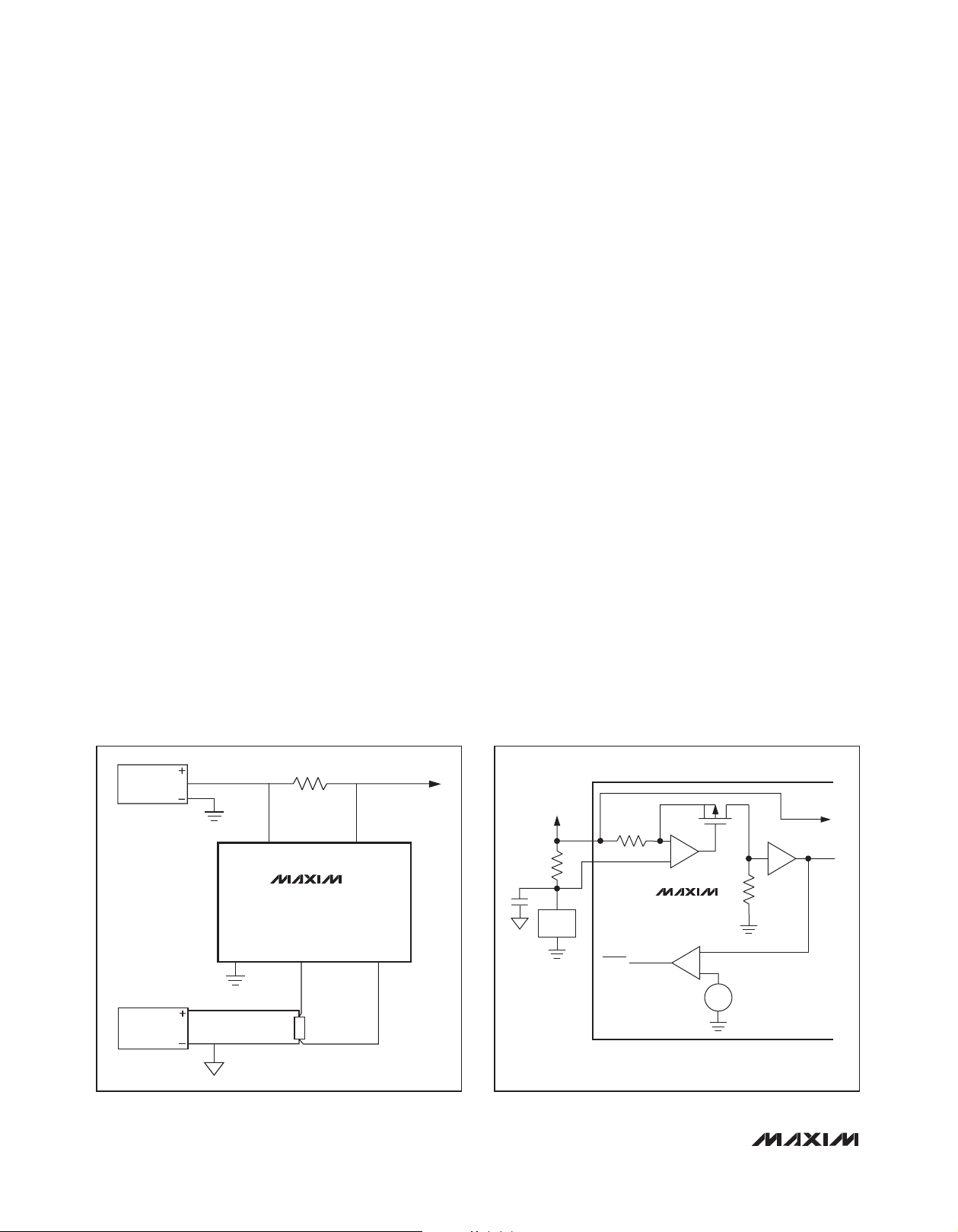

Use differential voltage sensing to eliminate voltage offsets or measure supply current. See Figure 4. In differential mode, the odd-numbered MON_ input measures

the absolute voltage with respect to GND while the result

of the even input is the difference between the odd and

even inputs. See Figure 4 for the typical differential measurement circuit.

Internal Current-Sense Amplifier

The current-sense inputs, CSP/CSM, and a currentsense amplifier facilitate power monitoring (see Figure

5). The voltage on CSP relative to GND is also monitored

by the ADC when the current-sense amplifier is enabled

with r47h[0]. The conversion results are located in registers r19h and r1Ah (see Table 10). There are two selectable voltage ranges for CSP set by r47h[1], see Table

8. Although the voltage can be monitored over SMBus

MAX16065/MAX16066

or JTAG, this voltage has no threshold comparators and

cannot trigger any faults. Regarding the current-sense

amplifier, there are four selectable ranges and the ADC

output for a current-sense conversion is:

X

where X

r18h, V

= (V

ADC

is the 8-bit decimal ADC result in register

ADC

is V

SENSE

CSP

x AV)/1.4V x (28 - 1)

SENSE

- V

and AV is the current-

CSM,

sense voltage gain set by r47h[3:2].

In addition, there are two programmable current-sense

trip thresholds: primary overcurrent and secondary overcurrent. For fast fault detection, the primary overcurrent

threshold is implemented with an analog comparator

connected to the internal OVERC signal. The OVERC

signal can be output on one of the GPIO_s. See the

General-Purpose Inputs/Outputs section for configuring the GPIO_ to output the OVERC signal. The primary

threshold is set by:

ITH = V

where ITH is the current threshold to be set, V

threshold set by r47h[3:2], and R

CSTH/RSENSE

SENSE

is the

CSTH

is the value of

the sense resistor. See Table 8 for a description of r47h.

OVERC depends only on the primary overcurrent threshold. The secondary overcurrent threshold is implemented through ADC conversions and digital comparison set

by r6Ch. The secondary overcurrent threshold includes

programmable time delay options located in r73h[6:5].

Primary and secondary current-sense faults are enabled/

disabled through r47h[0].

General-Purpose Inputs/Outputs

GPIO1–GPIO8 are programmable general-purpose

inputs/outputs. GPIO1–GPIO8 are configurable as a

manual reset input, a watchdog timer input and output,

logic inputs/outputs, fault-dependent outputs. When programmed as outputs, GPIO_s are open drain or pushpull. See Tables 12 and 13 for more detailed information

on configuring GPIO1–GPIO8.

R

ODD

MAX16065

MAX16066

MON

S

ODD

LOAD

MON

EVEN

MON

POWER

SUPPLY

MON

POWER

SUPPLY

Figure 4. Differential Measurement Connections Figure 5. Current-Sense Amplifier

18 _____________________________________________________________________________________

EVEN

I

LOAD

R

SENSE

V

MON

LOAD

CS+

CS-

OVERC

*ADJUSTABLE BY r47h[1:0]

-

+

MAX16065

-

+

+

-

TO ADC MUX

*A

V

*V

CSTH

Page 19

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 8. Overcurrent Primary Threshold and Current-Sense Control

REGISTER

ADDRESS

47h 247h

73h 273h [6:5]

FLASH

ADDRESS

BIT

RANGE

[0]

[1]

[3:2]

DESCRIPTION

1 = Current sense is enabled

0 = Current sense is disabled

1 = CSP full-scale range is 14V

0 = CSP full-scale range is 7V

Overcurrent Primary Threshold and Current-Sense Gain Setting:

00 = 200mV threshold, AV = 6V/V

01 = 100mV threshold, AV = 12V/V

10 = 50mV threshold, AV = 24V/V

11 = 25mV threshold, AV = 48V/V

Overcurrent Secondary Threshold Deglitch:

00 = No delay

01 = 4ms

10 = 15ms

11 = 60ms

MAX16065/MAX16066

Table 9. ADC Configuration Registers

REGISTER ADDRESS

43h 243h

FLASH

ADDRESS

BIT RANGE DESCRIPTION

[1:0]

[3:2]

[5:4]

[7:6]

ADC1 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC2 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC3 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC4 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

______________________________________________________________________________________ 19

Page 20

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 9. ADC Configuration Registers (continued)

REGISTER ADDRESS

44h 244h

MAX16065/MAX16066

45h 245h

FLASH

ADDRESS

BIT RANGE DESCRIPTION

ADC5 Full-Scale Range:

00 = 5.6V

[1:0]

[3:2]

[5:4]

[7:6]

[1:0]

[3:2]

[5:4]

[7:6]

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC6 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC7 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC8 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC9 Full-Scale Range

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC10 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC11 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

ADC12 Full-Scale Range:

00 = 5.6V

01 = 2.8V

10 = 1.4V

11 = Channel not converted

20 _____________________________________________________________________________________

Page 21

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 9. ADC Configuration Registers (continued)

REGISTER ADDRESS

46h 246h

FLASH

ADDRESS

BIT RANGE DESCRIPTION

Differential Conversion ADC1–ADC2:

[0]

[1]

[2]

[3]

[4]

[5]

0 = Disabled

1 = Enabled

Differential Conversion ADC3–ADC4:

0 = Disabled

1 = Enabled

Differential Conversion ADC5–ADC6:

0 = Disabled

1 = Enabled

Differential Conversion ADC7–ADC8:

0 = Disabled

1 = Enabled

Differential Conversion ADC9–ADC10:

0 = Disabled

1 = Enabled

Differential Conversion ADC11–ADC12:

0 = Disabled

1 = Enabled

MAX16065/MAX16066

Table 10. ADC Conversion Results (Read Only)

REGISTER ADDRESS BIT RANGE DESCRIPTION

00h [7:0] ADC1 result (MSB) bits 9–2

01h [7:6] ADC1 result (LSB) bits 1–0

02h [7:0] ADC2 result (MSB) bits 9–2

03h [7:6] ADC2 result (LSB) bits 1–0

04h [7:0] ADC3 result (MSB) bits 9–2

05h [7:6] ADC3 result (LSB) bits 1–0

06h [7:0] ADC4 result (MSB) bits 9–2

07h [7:6] ADC4 result (LSB) bits 1–0

08h [7:0] ADC5 result (MSB) bits 9–2

09h [7:6] ADC5 result (LSB) bits 1–0

0Ah [7:0] ADC6 result (MSB) bits 9–2

0Bh [7:6] ADC6 result (LSB) bits 1–0

0Ch [7:0] ADC7 result (MSB) bits 9–2

0Dh [7:6] ADC7 result (LSB) bits 1–0

0Eh [7:0] ADC8 result (MSB) bits 9–2

0Fh [7:6] ADC8 result (LSB) bits 1–0

10h [7:0] ADC9 result (MSB) bits 9–2

11h [7:6] ADC9 result (LSB) bits 1–0

12h [7:0] ADC10 result (MSB) bits 9–2

13h [7:6] ADC10 result (LSB) bits 1–0

14h [7:0] ADC11 result (MSB) bits 9–2

15h [7:6] ADC11 result (LSB) bits 1–0

16h [7:0] ADC12 result (MSB) bits 9–2

17h [7:6] ADC12 result (LSB) bits 1–0

18h [7:0] Current-sense ADC result

19h [7:0] CSP ADC output (MSB) bits 9–2

1Ah [7:6] CSP ADC output (LSB) bits 1–0

______________________________________________________________________________________ 21

Page 22

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

When GPIO1–GPIO8 are configured as general-purpose inputs/outputs, read values from the GPIO_ ports

through r1Eh and write values to GPIO_s through r3Eh.

Note that r3Eh has a corresponding flash register, which

programs the default state of a general-purpose output.

See Table 11 for more information on reading and writing

to the GPIO_.

Table 11. GPIO_ State Registers

REGISTER

ADDRESS

MAX16065/MAX16066

1Eh —

3Eh 23Eh

FLASH

ADDRESS

BIT RANGE DESCRIPTION

[0] GPIO1 input state

[1] GPIO2 input state

[2] GPIO3 input state

[3] GPIO4 input state

[4] GPIO5 input state

[5] GPIO6 input state

[6] GPIO7 input state

[7] GPIO8 input state

[0] GPIO1 output state

[1] GPIO2 output state

[2] GPIO3 output state

[3] GPIO4 output state

[4] GPIO5 output state

[5] GPIO6 output state

[6] GPIO7 output state

[7] GPIO8 output state

Fault1 and Fault2

GPIO1–GPIO8 are configurable as dedicated fault outputs, Fault1 or Fault2. Fault outputs can assert on one or

more overvoltage, undervoltage, or early warning conditions for selected inputs, as well as the secondary overcurrent comparator. Fault1 and Fault2 dependencies are

set using registers r36h to r3Ah. See Table 14. When

a fault output depends on more than one MON_, the

fault output asserts when one or more MON_ exceeds a

programmed threshold voltage. These fault outputs act

independently of the critical fault system, described in

the Critical Faults section.

Table 12. GPIO_ Configuration Registers

REGISTER

ADDRESS

3Fh 23Fh

40h 240h

22 _____________________________________________________________________________________

FLASH

ADDRESS

BIT RANGE DESCRIPTION

[2:0] GPIO1 configuration

[5:3] GPIO2 configuration

[7:6] GPIO3 configuration (LSB)

[0] GPIO3 configuration (MSB)

[3:1] GPIO4 configuration

[6:4] GPIO5 configuration

[7] GPIO6 configuration (LSB)

Page 23

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 12. GPIO_ Configuration Registers (continued)

REGISTER

ADDRESS

41h 241h

42h 242h

Table 13. GPIO_ Function Configuration Bits

GPIO1 GPIO2 GPIO3 GPIO4 GPIO5 GPIO6 GPIO7 GPIO8

000 Logic input

001 Logic output

010 Fault2 output

011 Fault1 output

100

101

110

111 WDI input — —

ANY_FAULT

output

OVERC

output

MR input

FLASH

ADDRESS

Logic

input

Logic

output

Fault2

output

Fault1

output

RESET2

output

OVERC

output

WDO

output

BIT RANGE DESCRIPTION

[1:0] GPIO6 configuration (MSB)

[4:2] GPIO7 configuration

[7:5] GPIO8 configuration

Output Configuration for GPIO1:

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Logic input Logic input Logic input

Logic output Logic output Logic output

Fault2 output Fault2 output Fault2 output

FAULTPU

output

ANY_FAULT

output

OVERC

output

MR input WDO output MR input

0 = Push-pull

1 = Open drain

Output Configuration for GPIO2:

0 = Push-pull

1 = Open drain

Output Configuration for GPIO3:

0 = Push-pull

1 = Open drain

Output Configuration for GPIO4:

0 = Push-pull

1 = Open drain

Output Configuration for GPIO5:

0 = Push-pull

1 = Open drain

Output Configuration for GPIO6:

0 = Push-pull

1 = Open drain

Output Configuration for GPIO7:

0 = Push-pull

1 = Open drain

Output Configuration for GPIO8:

0 = Push-pull

1 = Open drain

Fault1 output Fault1 output

ANY_FAULT

output

OVERC

output

EXTFAULT

input/output

ANY_FAULT

output

OVERC

output

EN2 input

Logic

input

Logic

output

Fault2

output

Fault1

output

RESET2

output

OVERC

output

WDO

output

MARGIN

input

Logic input Logic input

Logic output

Fault2 output

Fault1 output

ANY_FAULT

output

OVERC

output

MR input WDO output

EN2 input

Logic

output

Fault2

output

FAULTP

output

RESET2

output

OVERC

output

EXTFAULT

input/output

MAX16065/MAX16066

______________________________________________________________________________________ 23

Page 24

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

ANY_FAULT

GPIO1, GPIO3, GPIO4, GPIO5, and GPIO7 are configurable to assert low during any fault condition. This

includes power-up, power-down fault conditions as well

as conditions where Fault1 or Fault2 assert.

Table 14. Fault1 and Fault2 Dependencies

REGISTER

ADDRESS

36h 236h

MAX16065/MAX16066

37h 237h

38h 238h

FLASH

ADDRESS

BIT

RANGE

0 1 = Fault1 depends on MON1

1 1 = Fault1 depends on MON2

2 1 = Fault1 depends on MON3

3 1 = Fault1 depends on MON4

4 1 = Fault1 depends on MON5

5 1 = Fault1 depends on MON6

6 1 = Fault1 depends on MON7

7 1 = Fault1 depends on MON8

0 1 = Fault1 depends on MON9

1 1 = Fault1 depends on MON10

2 1 = Fault1 depends on MON11

3 1 = Fault1 depends on MON12

4

5

6

7

[0] 1 = Fault2 depends on MON1

[1] 1 = Fault2 depends on MON2

[2] 1 = Fault2 depends on MON3

[3] 1 = Fault2 depends on MON4

[4] 1 = Fault2 depends on MON5

[5] 1 = Fault2 depends on MON6

[6] 1 = Fault2 depends on MON7

[7] 1 = Fault2 depends on MON8

1 = Fault1 depends on the overvoltage thresholds of the inputs selected by

r36h and r37h[3:0]

1 = Fault1 depends on the undervoltage thresholds of the inputs selected

by r36h and r37h[3:0]

1 = Fault1 depends on the early warning thresholds of the inputs selected

by r36h and r37h[3:0]

0 = Fault1 is an active-low digital output

1 = Fault1 is an active-high digital output

Second Enable (EN2)

GPIO5 and GPIO7 are configurable as the enable

input for the secondary sequence. See the Multiple

Sequencing Groups section for more details.

DESCRIPTION

24 _____________________________________________________________________________________

Page 25

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 14. Fault1 and Fault2 Dependencies (continued)

MAX16065/MAX16066

REGISTER

ADDRESS

39h 239h

3Ah 23Ah

GPIO1 to GPIO8 are configurable to assert low when

the voltage across CSP and CSM exceed the primary

overcurrent threshold. See the Internal Current-Sense

Amplifier section for more details.

GPIO3 and GPIO8 are configurable to indicate a fault

during power-up or power-down on the secondary

sequence. This output asserts low when a MON_ input

exceeds the overvoltage or undervoltage threshold. The

sequencer will still enter the fault state and turn off all the

EN_OUT_ outputs assigned to the secondary sequence.

GPIO1, GPIO3, GPIO5, and GPIO7 are configurable to

act as an active-low manual reset input, MR. Drive MR

low to assert RESET. RESET remains asserted for the

selected reset timeout period after MR transitions from

low to high. See the RESET2 Output section for more

information on selecting a reset timeout period.

FLASH

ADDRESS

Overcurrent Comparator (OVERC)

Fault-On Power-Up (FAULTPU)

BIT

RANGE

[0] 1 = Fault2 depends on MON9

[1] 1 = Fault2 depends on MON10

[2] 1 = Fault2 depends on MON11

[3] 1 = Fault2 depends on MON12

[4]

[5]

[6]

[7]

[0] 1 = Fault1 depends on secondary overcurrent comparator

[1] 1 = Fault2 depends on secondary overcurrent comparator

[7:2] Reserved

Manual Reset (MR)

1 = Fault2 depends on the overvoltage thresholds of the inputs selected by

r38h and r39h[3:0]

1 = Fault2 depends on the undervoltage thresholds of the inputs selected

by r38h and r39h[3:0]

1 = Fault2 depends on the early warning thresholds of the inputs selected

by r38h and r39h[3:0]

0 = Fault2 is an active-low digital output

1 = Fault2 is an active-high digital output

RESET2 Output

GPIO2, GPIO6, and GPIO8 are configurable to act as

a reset indicator related to the secondary sequence.

RESET2 asserts during power-up/power-down and deasserts following the reset timeout period once the powerup of the secondary sequence is complete. The secondary power-up sequence is completed when any MON_

inputs assigned to Slot 12 exceed the undervoltage

thresholds and Slot 12 sequence delay expires. When

DESCRIPTION

no MON_ inputs are assigned to Slot 12, the power-up

sequence is complete after the slot sequence delay

expires. RESET2 shares configuration bits with RESET

with the exception of polarity (active-high or active-low)

and output type (push-pull or open drain), see Table 23.

During normal monitoring, RESET2 can be configured

to assert when any combination of MON_ inputs violates

configurable combinations of thresholds: undervoltage,

overvoltage, or early warning. Select the combination of

thresholds using r3Bh[1:0], and select the combination

of MON_ inputs using 3Ch[7:1] and 3Dh[4:0]. Note that

MON_ inputs in the secondary sequence configured as

critical faults will always cause RESET2 to assert regardless of these configuration bits.

RESET2 can be configured as push-pull or open drain

using the appropriate GPIO_ configuration bit in r42h

(see Table 12), and is always active-low. Select the

reset timeout for RESET and RESET2 by loading a value

from Table 5 into r3Bh[7:4]. RESET and RESET2 can be

forced to assert by writing a ‘1’ into r3Ch[0]. RESET2

remains asserted for the reset timeout period after a ‘0’

is written into r3Ch[0].

Watchdog Input (WDI) and Output (WDO)

GPIO2, GPIO4, GPIO6, and GPIO8 are configurable as

the watchdog timer output, WDO. GPIO1 is configurable

as WDI. See Table 24 for configuration details. WDO is an

active-low output. See the Watchdog Timer section for more

information about the operation of the watchdog timer.

______________________________________________________________________________________ 25

Page 26

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

External Fault (EXTFAULT)

GPIO4 and GPIO8 are configurable as the external fault

input/output. When configured as push-pull, EXTFAULT

signals that a critical fault has occurred on one or more

monitored voltages or current. When configured as

open-drain, EXTFAULT can be asserted low by an external circuit to trigger a critical fault. This signal can be

used to cascade multiple MAX16065/MAX16066s.

Two configuration bits determine the behavior of the

MAX16065/MAX16066 when EXTFAULT is pulled low

by some other device. Register bit r72h[5], if set to a

‘1’, causes the sequencer state machine to enter the

fault state, deasserting all the outputs, when EXTFAULT

is pulled low. When this happens, the flag bit r1Ch[5]

gets set to indicate the cause of the fault. If register bit

r6Dh[2] is set in addition to r72h[5], EXTFAULT going low

triggers a nonvolatile fault log operation.

Faults

The MAX16065/MAX16066 monitor the input (MON_)

MAX16065/MAX16066

channels and compare the results with an overvoltage

threshold, an undervoltage threshold, and a selectable

overvoltage or undervoltage early warning threshold.

Based on these conditions, the MAX16065/MAX16066

assert various fault outputs and save specific information about the channel conditions and voltages into the

nonvolatile flash. Once a critical fault event occurs, the

failing channel condition, ADC conversions at the time of

the fault, or both can be saved by configuring the event

logger. The event logger records a single failure in the

internal flash and sets a lock bit that protects the stored

fault data from accidental erasure on a subsequent

power-up.

An overvoltage event occurs when the voltage at a monitored input exceeds the overvoltage threshold for that

input. An undervoltage event occurs when the voltage

at a monitored input falls below the undervoltage threshold. Fault thresholds are set in registers r48h to r6Ch as

shown in Table 15. Disabled inputs are not monitored for

fault conditions and are skipped over by the input mul-

tiplexer. Only the upper 8 bits of a conversion result are

compared with the programmed fault thresholds.

The general-purpose inputs/outputs (GPIO1 to GPIO8)

can be configured as ANY_FAULT outputs or dedicated

Fault1 and Fault2 outputs to indicate fault conditions.

These fault outputs are not masked by the critical fault

enable bits shown in Table 18. See the General-Purpose

Inputs/Outputs section for more information on configuring GPIO_s as fault outputs.

Deglitch

Fault conditions are detected at the end of each conversion. When the voltage on an input falls outside a monitored threshold for one acquisition, the input multiplexer

remains on that channel and performs several successive conversions. To trigger a fault, the input must stay

outside the threshold for a certain number of acquisitions

as determined by the deglitch setting in r73h[6:5] and

r74h[6:5] (see Table 16).

Fault Flags

Fault flags indicate the fault status of a particular input.

The fault flag of any monitored input in the device can be

read at any time from registers r1Bh and r1Ch, as shown

in Table 17. Clear a fault flag by writing a ‘1’ to the appropriate bit in the flag register. Unlike the fault signals sent

to the fault outputs, these bits are masked by the critical

fault enable bits (see Table 18). The fault flag is only set

when the matching enable bit in the critical fault enable

register is also set.

If a GPIO_ is configured as an open-drain EXTFAULT

input/output, and EXTFAULT is pulled low by an external

circuit, bit r1Ch[5] is set.

If a fault occurs during the secondary sequence group,

the slot number where the failure occurred is stored

in r1Dh.

The SMBus Alert bit is set if the MAX16065/MAX16066

have asserted the SMBus Alert output. Clear by writing a

‘1’. See the SMBALERT section for more details.

26 _____________________________________________________________________________________

Page 27

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 15. Fault Threshold Registers

MAX16065/MAX16066

REGISTER

ADDRESS

48h 248h [7:0] MON1 secondary threshold

49h 249h [7:0] MON1 overvoltage threshold

4Ah 24Ah [7:0] MON1 undervoltage threshold

4Bh 24Bh [7:0] MON2 secondary threshold

4Ch 24Ch [7:0] MON2 overvoltage threshold

4Dh 24Dh [7:0] MON2 undervoltage threshold

4Eh 24Eh [7:0] MON3 secondary threshold

4Fh 24Fh [7:0] MON3 overvoltage threshold

50h 250h [7:0] MON3 undervoltage threshold

51h 251h [7:0] MON4 secondary threshold

52h 252h [7:0] MON4 overvoltage threshold

53h 253h [7:0] MON4 undervoltage threshold

54h 254h [7:0] MON5 secondary threshold

55h 255h [7:0] MON5 overvoltage threshold

56h 256h [7:0] MON5 undervoltage threshold

57h 257h [7:0] MON6 secondary threshold

58h 258h [7:0] MON6 overvoltage threshold

59h 259h [7:0] MON6 undervoltage threshold

5Ah 25Ah [7:0] MON7 secondary threshold

5Bh 25Bh [7:0] MON7 overvoltage threshold

5Ch 25Ch [7:0] MON7 undervoltage threshold

5Dh 25Dh [7:0] MON8 secondary threshold

5Eh 25Eh [7:0] MON8 overvoltage threshold

5Fh 25Fh [7:0] MON8 undervoltage threshold

60h 260h [7:0] MON9 secondary threshold

61h 261h [7:0] MON9 overvoltage threshold

62h 262h [7:0] MON9 undervoltage threshold

63h 263h [7:0] MON10 secondary threshold

64h 264h [7:0] MON10 overvoltage threshold

65h 265h [7:0] MON10 undervoltage threshold

66h 266h [7:0] MON11 secondary threshold

67h 267h [7:0] MON11 overvoltage threshold

68h 268h [7:0] MON11 undervoltage threshold

69h 269h [7:0] MON12 secondary threshold

6Ah 26Ah [7:0] MON12 overvoltage threshold

6Bh 26Bh [7:0] MON12 undervoltage threshold

6Ch 26Ch [7:0] Secondary overcurrent threshold

FLASH

ADDRESS

BIT RANGE DESCRIPTION

______________________________________________________________________________________ 27

Page 28

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 16. Deglitch Configuration

REGISTER

ADDRESS

73h 273h [6:5]

74h 274h [6:5]

During normal operation, a fault condition can be configured to shut down all the EN_OUT_s and store fault

information in the flash memory by setting the appropri-

MAX16065/MAX16066

ate critical fault enable bits. During power-up and power-down, all sequenced MON_ inputs are considered

critical. Faults during power-up and power-down always

cause the EN_OUT_s to turn off and can store fault information in the flash memory, depending on the contents

of r6Dh[1:0]. Set the appropriate critical fault enable bits

in registers r6Eh to r72h (see Table 18) for a fault condition to trigger a critical fault.

Logged fault information is stored in flash registers r200h

to r20Fh (see Table 19). After fault information is logged,

the flash is locked and must be unlocked to enable a

new fault log to be stored. Write a ‘0’ to r8Ch[1] to unlock

the FAULT flash. Fault information can be configured to

store ADC conversion results and/or fault flags in registers. Select the critical fault configuration in r6Dh[1:0].

FLASH

ADDRESS

BIT RANGE DESCRIPTION

Critical Faults

Overcurrent Comparator Deglitch Time:

00 = No deglitch

01 = 4ms

10 = 15ms

11 = 60ms

Voltage Comparator Deglitch Configuration:

00 = 2 cycles

01 = 4 cycles

10 = 8 cycles

11 = 16 cycles

Set r6Dh[1:0] to ‘11’ to turn off the fault logger. All stored

ADC results are 8 bits wide.

Power-Up/Power-Down Faults

All EN_OUT_s deassert when an overvoltage or undervoltage fault is detected during power-up/power-down

and the MAX16065/MAX16066 return to the poweroff condition. Fault information can be stored to flash

depending on r6D[1:0], see Table 18. GPIO3 and

GPIO8 can be configured as power-up fault outputs

(ANY_FAULT).

Autoretry/Latch Mode

The MAX16065/MAX16066 can be configured for one

of two fault management methods: autoretry or latchon fault. Set r74h[4:3] to ‘00’ to select the latch-on-fault

mode. In this configuration, EN_OUT_s deassert after

a critical fault event. The device does not reinitiate the

power-up sequence until EN is toggled or the Software

Enable bit is toggled. See the Enable section for more

information on setting the software enable bit.

Table 17. Fault Flags

REGISTER

ADDRESS

1Bh

28 _____________________________________________________________________________________

BIT RANGE DESCRIPTION

[0] MON1

[1] MON2

[2] MON3

[3] MON4

[4] MON5

[5] MON6

[6] MON7

[7] MON8

Page 29

12-Channel/8-Channel, Flash-Configurable System

Managers with Nonvolatile Fault Registers

Table 17. Fault Flags (continued)

REGISTER

ADDRESS

1Ch

1Dh

Table 18. Critical Fault Configuration

BIT RANGE DESCRIPTION

[0] MON9

[1] MON10

[2] MON11

[3] MON12

[4] Overcurrent

[5] External fault (EXTFAULT)

[6] SMB alert

[4:0] Slot where failure occurred during secondary sequence

[7:5] Reserved

MAX16065/MAX16066

REGISTER

ADDRESS

6Dh 26Dh

6Eh 26Eh

6Fh 26Fh

FLASH

ADDRESS

BIT

RANGE

Fault Information to Log:

00 = Save failed line flags and ADC values in flash

[1:0]

[2] 1 = Fault log triggered when EXTFAULT is pulled low externally

[7:3] Not used

[0] 1 = Fault log triggered when MON1 is below its undervoltage threshold

[1] 1 = Fault log triggered when MON2 is below its undervoltage threshold

[2] 1 = Fault log triggered when MON3 is below its undervoltage threshold

[3] 1 = Fault log triggered when MON4 is below its undervoltage threshold

[4] 1 = Fault log triggered when MON5 is below its undervoltage threshold

[5] 1 = Fault log triggered when MON6 is below its undervoltage threshold

[6] 1 = Fault log triggered when MON7 is below its undervoltage threshold