Page 1

General Description

The MAX16064 is a fully integrated 4-channel digital

power-supply controller and monitor IC that can be connected up to four power supplies to provide complete

digital configurability. By interfacing to the power-supply

reference input or feedback node, and the output enable,

the MAX16064 takes control of the power supply to provide tracking, soft-start, sequencing, margining, and

dynamic adjustment of the output voltage.

Power-supply sequencing can be performed

autonomously or controlled over the PMBus™ interface.

Sequencing is controlled during power-down as well as

power-up. Multiple MAX16064s can be combined to

autonomously sequence more supplies. The sequencing

order is stored in an external configuration EEPROM so

sequence order changes can be reprogrammed without

changing the PCB layout.

The MAX16064 features an internal temperature sensor

providing an additional level of system monitoring.

Other features include a reset output and an SMBus™

alert output.

Each channel of the MAX16064 includes an accurate

12-bit analog-to-digital converter (ADC) input and a differential amplifier for accurately monitoring and reporting the voltage at the load without being influenced by any difference in

ground potentials. An integrated 12-bit digital-to-analog converter (DAC) can margin power supplies and dynamically

adjust the output voltage using a closed-loop control system

to provide an output-voltage accuracy of ±0.3%.

The user-programmable registers provide flexible and

accurate control of time events such as delay time and

transition period, monitoring for overvoltage and undervoltage, overtemperature fault and warning handling.

The closed-loop operation is also programmable to make

sure the MAX16064 works with any existing power supply to provide superior regulation accuracy and accurate

margining.

The MAX16064 operates using a PMBus-compliant communication protocol. The device can be programmed

using this protocol or with a free graphic-user interface

(GUI) available from the Maxim website that significantly

reduces development time. Once the configuration is

complete, the results can be saved into an EEPROM or

loaded into the device through PMBus at power-up. This

allows remote configuration of any power supply using

the MAX16064, replacing expensive recalls or field service. The MAX16064 can be programmed with up to 114

distinct addresses to support large systems. The

MAX16064 is offered in a space-saving, 36-pin, lead-free,

6mm x 6mm TQFN package and is fully specified from

-40°C to +85°C.

Features

♦ Accurate Voltage Output Control (AVOC) Controls

Output Voltage with ±0.3% Accuracy

♦ PMBus Interface for Programming, Monitoring,

Sequencing Up and Down, and Margining

♦ Output Voltage and Temperature Monitoring with

Adjustable Monitor Rate

♦ Programmable Soft-Start and Soft-Stop Ramp

Rates

♦ Power-Supply Control using REFIN or FB

Terminals

♦ Master-Slave Clocking Option Provides Accurate

Timing Reference Across Multiple Devices

♦ External EEPROM Interface for Autoboot on

Power-Up

♦ 3.0V to 3.6V Operating Voltage Range

♦ 6mm x 6mm, 36-Pin TQFN Package

Applications

Routers

Servers

Storage Systems

Telecom/Networking

DC-DC Modules and Power Supplies

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

19-4807; Rev 0; 7/09

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

*

EP = Exposed pad.

PART TEMP RANGE

PIN-PACKAGE

MAX16064ETX+ -40°C to +85°C 36 TQFN-EP*

PMBus is a trademark of SMIF, Inc.

SMBus is a trademark of Intel Corp.

Pin Configuration and Typical Operating Circuit appears at

end of data sheet.

Page 2

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

2 _______________________________________________________________________________________

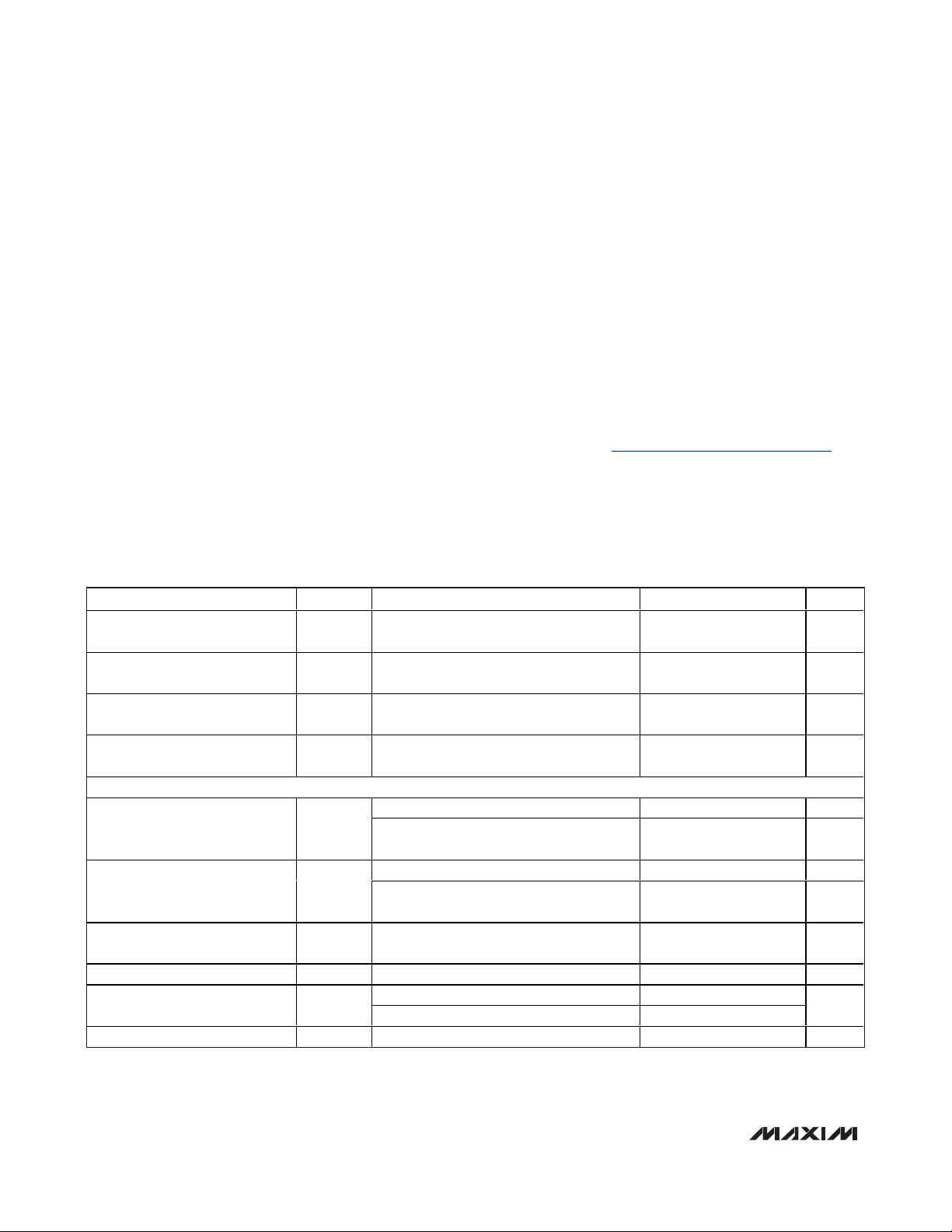

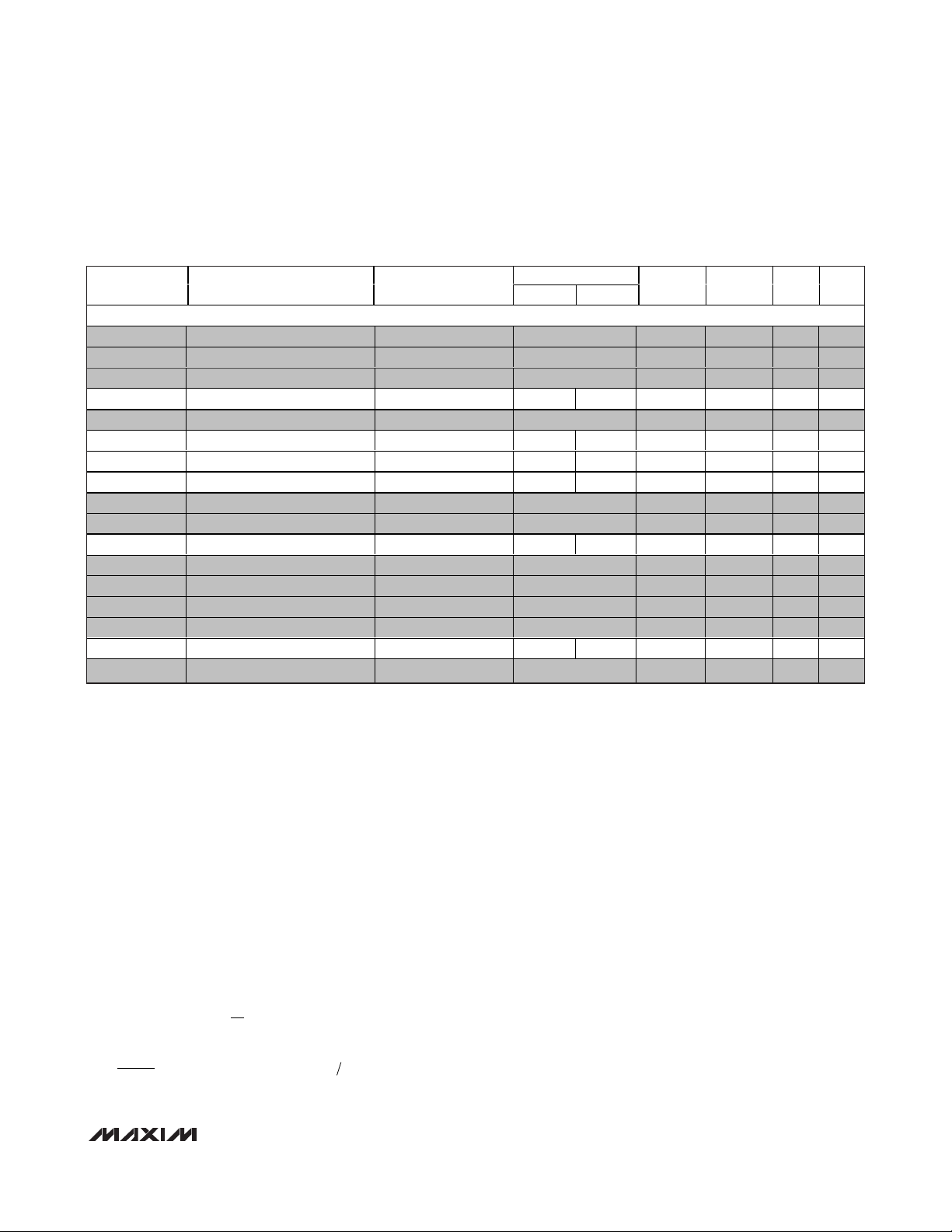

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

AVDD

= V

DVDD

= 3.0V to 3.6V, VEN= 2V, V

RS_+

- V

RS_-

= 2V, V

RS_-

= 0V, TA= TJ= -40°C to +85°C, unless otherwise specified.

Typical values are at V

AVDD

= V

DVDD

= 3.3V, TA= +25°C.) (Note 2)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial

.

AVDD, DVDD to AGND ............................................-0.3V to +4V

AVDD to DVDD......................................................-0.3V to +0.3V

AGND to DGND.....................................................-0.3V to +0.3V

AGND1 to DGND...................................................-0.3V to +0.3V

RS_+, RS_- to AGND................................................-0.3V to +6V

RS_C, A1/SCLE, A2/SDAE,

A3/CONTROL to AGND ......................-0.3V to (AVDD + 0.3V)

RESET, SMBALERT, ENOUT_ to AGND...................-0.3V to +6V

SCL, SDA to DGND ..................................................-0.3V to +4V

DACOUT_, EN, CLKIO, REFO to AGND.....-0.3V to (AVDD + 0.3V)

DACOUT_ Current ..............................................................10mA

SDA Current ........................................................-1mA to +50mA

Input/Output Current (all other pins) ...................................20mA

Continuous Power Dissipation (T

A

= +70°C)

36-Pin 6mm x 6mm TQFN

(derate 35.7mW/°C above +70°C).............................2857mW

Thermal Resistance (Note 1)

θ

JA

................................................................................28°C/W

θ

JC

..................................................................................1°C/W

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

AVDD/DVDD Operating Voltage

Range

AVDD Undervoltage Lockout

(AVDD Rising)

AVDD Undervoltage Lockout

Hysteresis

AVDD and DVDD Total Supply

Current

OUTPUT-VOLTAGE SENSING

Voltage Regulation Accuracy

(2V Range)

Voltage Regulation Accuracy

(5.5V Range)

RS_+, RS_- Differential Mode

Range

RS_- to GND Differential Voltage -250 +250 mV

RS_+ Input Bias Current

RS_- Input Bias Current 2V or 5.5V range, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

UVLO

V

UVLO-HYS

= V

V

RS_+

TA = +25°C, V

T

= -40°C to +85°C, V

A

= 0V

V

RS_-

TA = +25°C, V

T

= -40°C to +85°C, V

A

V

= 0V

RS_-

2V range, V

5.5V range, V

RS_-

= 0V 12 18.5 mA

= 1.0V, V

RS_+

RS_+

= 2.5V, V

RS_+

RS_+

= -0.25V to +2V -20 +20

RS_+

= -0.25V to +5.5V -20 +100

RS_+

= -0.25V to +0.25V -20 0 µA

RS_-

= 0V -4 +4 mV

RS_-

= 1.0V,

= 0V -11 +11 mV

RS_-

= 2.5V,

3.0 3.6 V

2.75 2.8 2.95 V

100 mV

-6 +6 mV

-16.5 +16.5 mV

0 5.5 V

µA

Page 3

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

_______________________________________________________________________________________ 3

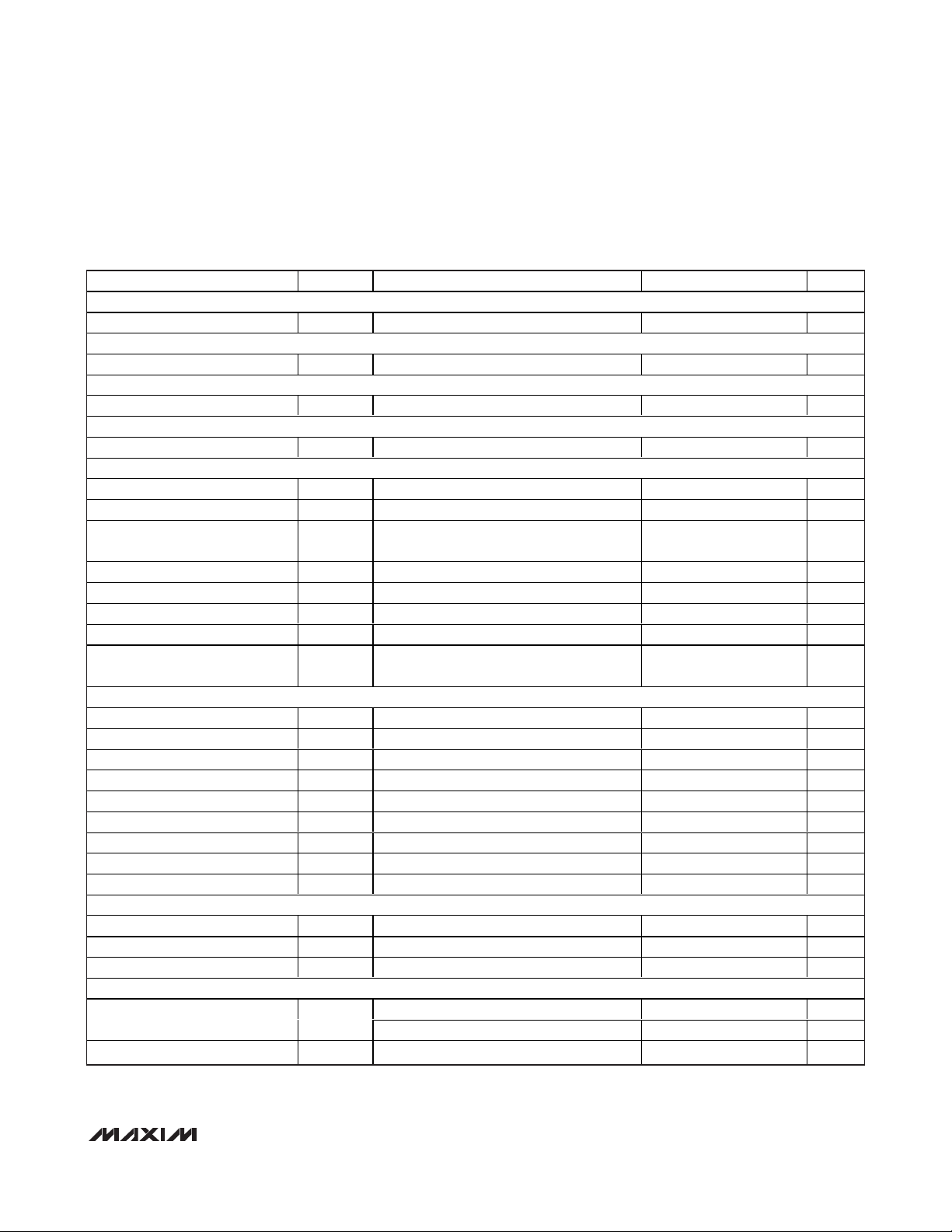

ELECTRICAL CHARACTERISTICS (continued)

(V

AVDD

= V

DVDD

= 3.0V to 3.6V, VEN= 2V, V

RS_+

- V

RS_-

= 2V, V

RS_-

= 0V, TA= TJ= -40°C to +85°C, unless otherwise specified.

Typical values are at V

AVDD

= V

DVDD

= 3.3V, TA= +25°C.) (Note 2)

INTERNAL TEMPERATURE SENSOR

Temperature Sensing Accuracy TA = 0°C to +85°C ±3 °C

INTERNAL OSCILLATOR

Frequency 7.6 8 8.4 MHz

ADC

Resolution 12 Bits

INTERNAL REFERENCE

Reference Voltage V

DAC

Resolution 12 Bits

Differential Nonlinearity DNL -2.5 +2.5 LSB

Maximum Output-Voltage Range No load

Capacitive Load 200 pF

Output-Voltage Slew Rate 0.35 V/µs

DAC Output Resistance 10 Ω

DAC Driving Capability DAC output > 100mV; output error < 25mV -1 +1 mA

DAC Output Leakage Current

CLKIO

Input Logic-Low Voltage 0.8 V

Input Logic-High Voltage 2.1 V

Input Bias Current V

Input Clock Duty Cycle 50 %

Output Low Voltage CLKIO in output mode, I

Output High Leakage V

CLKIO Pullup Voltage 3.6 V

CLKIO Input Frequency Range f

CLKIO Output Frequency 1 MHz

ENABLE INPUT (EN)

EN Falling Threshold Voltage V

EN Rising Threshold Voltage 1.175 1.23 1.281 V

EN Input Leakage Current -0.25 +0.25 µA

OUTPUTS (ENOUT_, RESET, SMBALERT)

Output Low Voltage V

Output Leakage V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

REF

EXT_CLK

EN_TH

OL

TA = +25°C 2.048 V

DAC output switch open,

V

I

V

_ = V

DACOUT

= 3.6V or 0V -1 +1 µA

CLKIO

= 3.6V -1 +1 µA

CLKIO

= 10mA 0.4 V

SINK

= V

AVDD

ENOUT_

DVDD

= 5V, 0V -1 +1 µA

V

REF -

1 LSB

or 0V

REF

= 1.1V, I

= 4mA 0.4 V

SINK

= 100µA 0.4 V

SINK

-250 +250 nA

100 1000 kHz

1.17 1.21 1.23 V

V

Page 4

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

4 _______________________________________________________________________________________

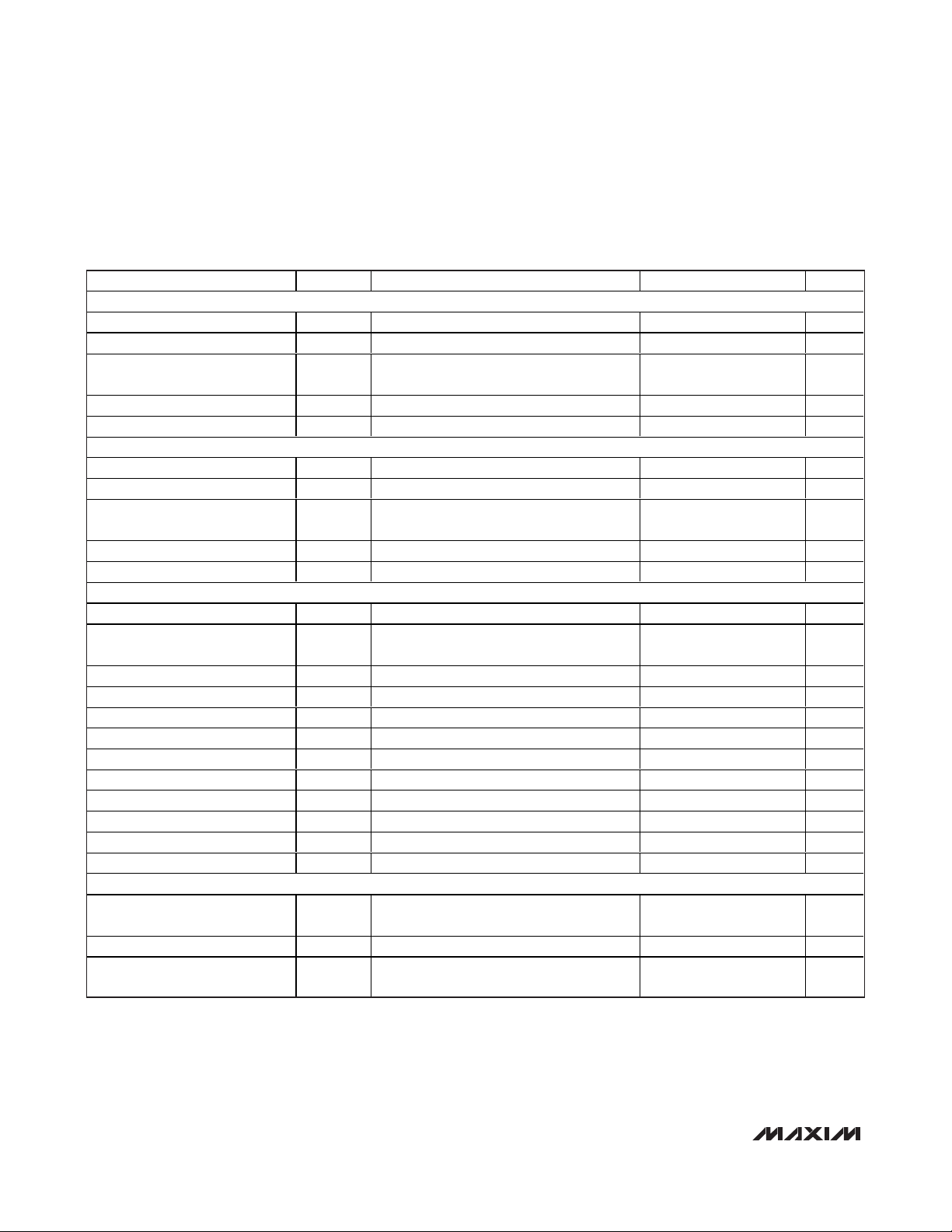

ELECTRICAL CHARACTERISTICS (continued)

(V

AVDD

= V

DVDD

= 3.0V to 3.6V, VEN= 2V, V

RS_+

- V

RS_-

= 2V, V

RS_-

= 0V, TA= TJ= -40°C to +85°C, unless otherwise specified.

Typical values are at V

AVDD

= V

DVDD

= 3.3V, TA= +25°C.) (Note 2)

Note 2: 100% production tested at TA= +25°C. Limits over temperature are guaranteed by design.

Note 3: The MAX16064 supports SCL clock stretching.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ADDRESS PINS (A1/SCLE, A2/SDAE, A3/CONTROL)

Input Logic-Low Voltage 0.3 V

Input Logic-Low Hysteresis 50 mV

V

Input Logic-High Voltage

AVDD

- 0.4

Input Logic-High Hysteresis 50 mV

Input Leakage Current -12 +12 µA

SMBus INTERFACE (SCL, SDA) (Note 3)

SCL, SDA Input Low Voltage V

SCL, SDA Input High Voltage V

SCL, SDA Input Leakage Current

(Per Pin)

Input Capacitance C

SCL, SDA Output Low Voltage V

Input voltage falling 0.8 V

IL

Input voltage rising 2.1 V

IH

Device powered or unpowered, V

IN

OL

to 3.6V, V

I

= 3mA 0.4 V

SINK

SCL

= V

SDA

= 0 or V

AVDD

AVDD

= 0V

-1 +1 µA

10 pF

SMBUS TIMING

Serial-Clock Frequency f

Bus Free Time Between STOP

and START Condition

START Condition Setup Time t

START Condition Hold Time t

STOP Condition Setup Time t

SU:STA

HD:STA

SU:STO

Clock Low Period t

Clock High Period t

Data Setup Time t

SU:DAT

Output Fall Time t

Data Hold Time t

HD:DAT

Pulse Width of Spike Suppressed t

SMBus Timeout t

TIMEOUT

SCL

t

BUF

LOW

HIGH

OF

SP

C

= 10pF to 400pF 300 ns

BUS

From 50% SCL falling to SDA change 300 ns

SMBCLK time low for reset 25 55 ms

10 100 kHz

4.7 µs

4.7 µs

4.0 µs

4.0 µs

4.7 µs

4.0 µs

250 ns

30 ns

OTHER TIMING PARAMETERS

PMBus Command Response

Time

Fault Response Time t

Recovery Time After Device

Reset

t

PMB_RSP

FAULT_RSP

t

RST_WAIT

300 µs

5ms

15 µs

V

Page 5

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

_______________________________________________________________________________________ 5

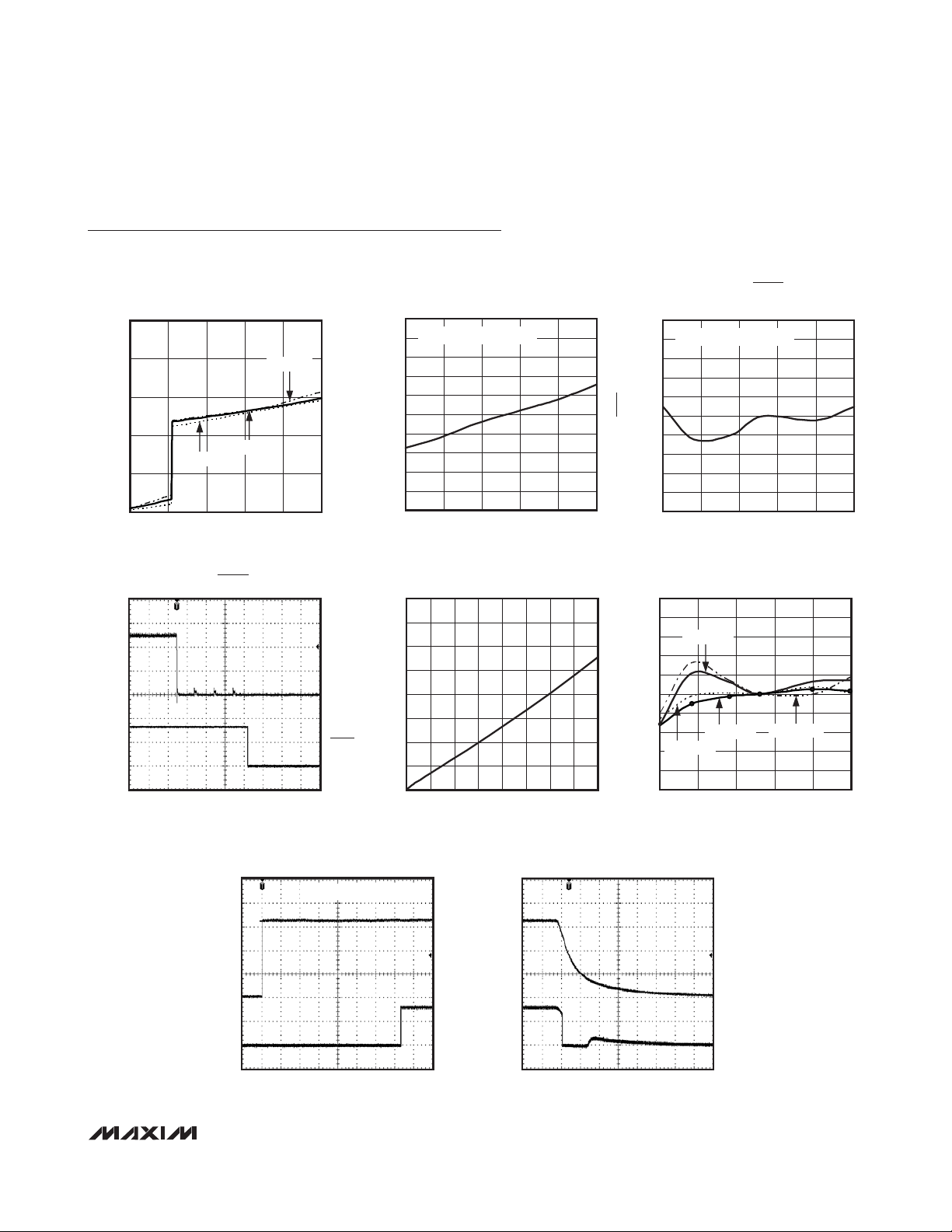

Typical Operating Characteristics

(V

AVDD

= V

DVDD

= 3.3V, TA= +25°C, unless otherwise noted.)

TOTAL SUPPLY CURRENT

vs. SUPPLY VOLTAGE

20

16

12

8

TOTAL SUPPLY CURRENT (mA)

4

0

2.6 3.6

TA = +85

V

AVDD

NC

= V

TA = +25NC

DVDD

UV_FAULT TO RESET RESPONSE

5V

3.3V

1ms/div

(V)

TA = -40NC

3.43.23.02.8

MAX16064 toc04

1.010

1.008

1.006

MAX16064 toc01

1.004

1.002

1.000

0.998

0.996

NORMALIZED EN THRESHOLD

0.994

0.992

0.990

-40 85

0.8

0.7

0.6

V

OUT0

2V/div

RESET

2V/div

0.5

0.4

0.3

0.2

ENOUT_ OUTPUT LOW VOLTAGE (V)

0.1

0

040

NORMALIZED EN THRESHOLD

vs. TEMPERATURE

NORMALIZED AT TA = +25NC

603510-15

TEMPERATURE (NC)

ENOUT_ OUTPUT LOW VOLTAGE

vs. SINK CURRENT

I

(mA)

SINK

NORMALIZED RESET TIMEOUT

1.10

1.08

MAX16064 toc02

1.06

1.04

1.02

1.00

0.98

0.96

NORMALIZED RESET TIMEOUT

0.94

0.92

0.90

0.5

0.4

0.3

MAX16064 toc05

0.2

0.1

-0.1

-0.2

-0.3

-0.4

POWER SUPPLIES OUTPUT ACCURACY (%)

35305 10 15 20 25

-0.5

PERIOD vs. TEMPERATURE

NORMALIZED AT TA = +25NC

-40 85

TEMPERATURE (NC)

603510-15

POWER SUPPLIES OUTPUT ACCURACY

vs. TEMPERATURE

VOUT2 = 1.8V

0

VOUT0 = 5V

VOUT1 = 3.3V

-40 85

TEMPERATURE (NC)

VOUT3 = 1.1V

603510-15

MAX16064 toc03

MAX16064 toc06

ENOUT_WITH AVDD = DVDD RISING

AVDD = DVDD RISING 3.3V/ms

200ms/div

MAX16064 toc07

AVDD = DVDD

1V/div

ENOUT1,2,3,4

2V/div

ENOUT_ WITH AVDD = DVDD FALLING

400Fs/div

MAX16064 toc08

AVDD = DVDD

1V/div

ENOUT1,2,3,4

2V/div

Page 6

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

6 _______________________________________________________________________________________

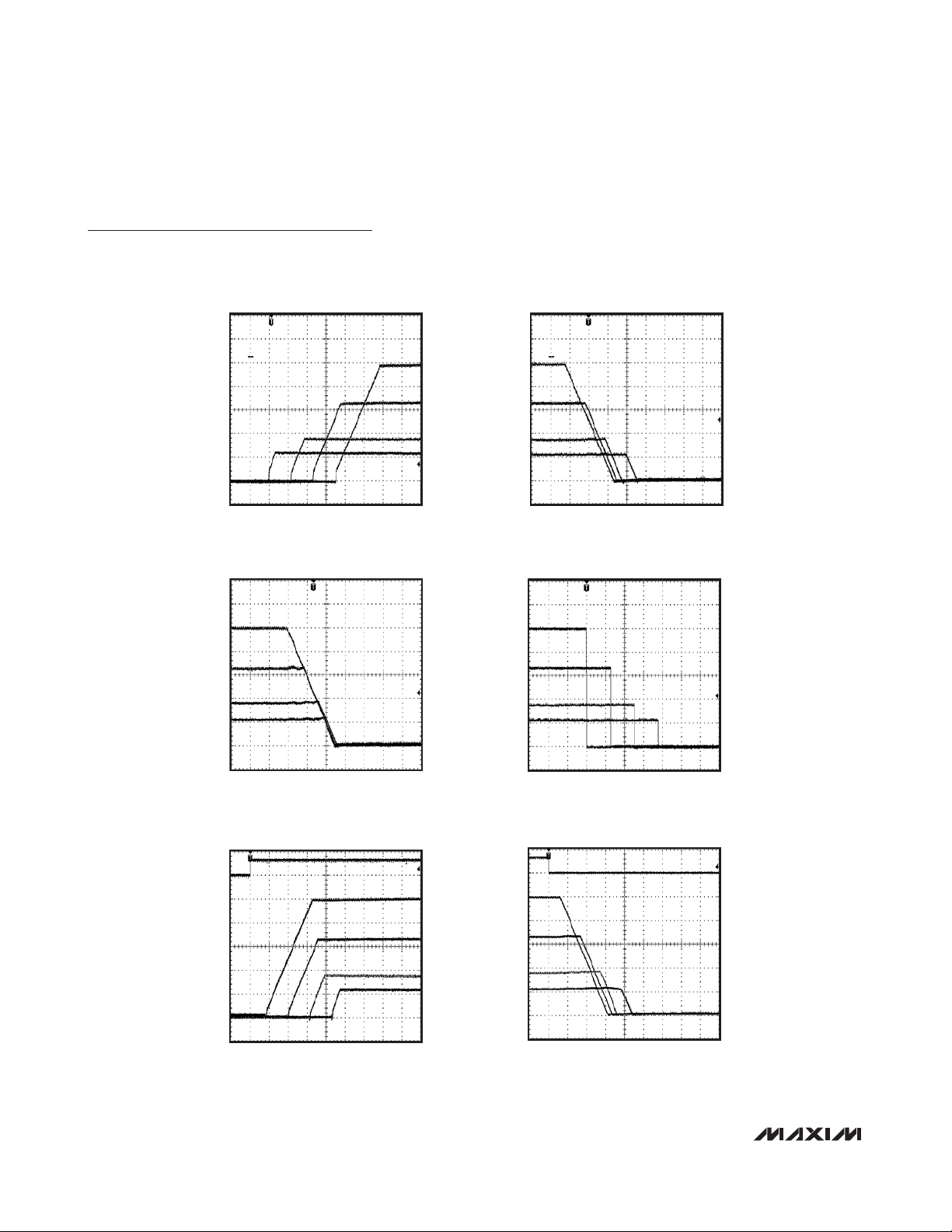

Typical Operating Characteristics (continued)

(V

AVDD

= V

DVDD

= 3.3V, TA= +25°C, unless otherwise noted.)

REFIN MODE SOFT-START

WITH SEQUENCING

2ms/div

REFIN MODE SOFT-STOP

WITH TRACKING

MAX16064 toc09

MAX16064 toc11

VOUT0 = 5V

VOUT1 = 3.3V

VOUT2 = 1.8V

VOUT3 = 1.1V

VOUT0 = 5V

VOUT1 = 3.3V

VOUT2 = 1.8V

VOUT3 = 1.1V

REFIN MODE SOFT-STOP

WITH SEQUENCING

2ms/div

MAX16064 toc10

REFIN MODE OPERATION OFF

WITH SEQUENCING

MAX16064 toc12

VOUT0 = 5V

VOUT1 = 3.3V

VOUT2 = 1.8V

VOUT3 = 1.1V

VOUT0 = 5V

VOUT1 = 3.3V

VOUT2 = 1.8V

VOUT3 = 1.1V

2ms/div

REFIN MODE SOFT-START FROM

A3 WITH SEQUENCING

2ms/div

MAX16064 toc13

REFIN MODE SOFT-STOP FROM

A3/CONTROL

5V/div

VOUT0 = 5V

VOUT1 = 3.3V

VOUT2 = 1.8V

VOUT3 = 1.1V

40ms/div

A3 WITH SEQUENCING

2ms/div

MAX16064 toc14

A3/CONTROL

5V/div

VOUT0 = 5V

VOUT1 = 3.3V

VOUT2 = 1.8V

VOUT3 = 1.1V

Page 7

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

_______________________________________________________________________________________

7

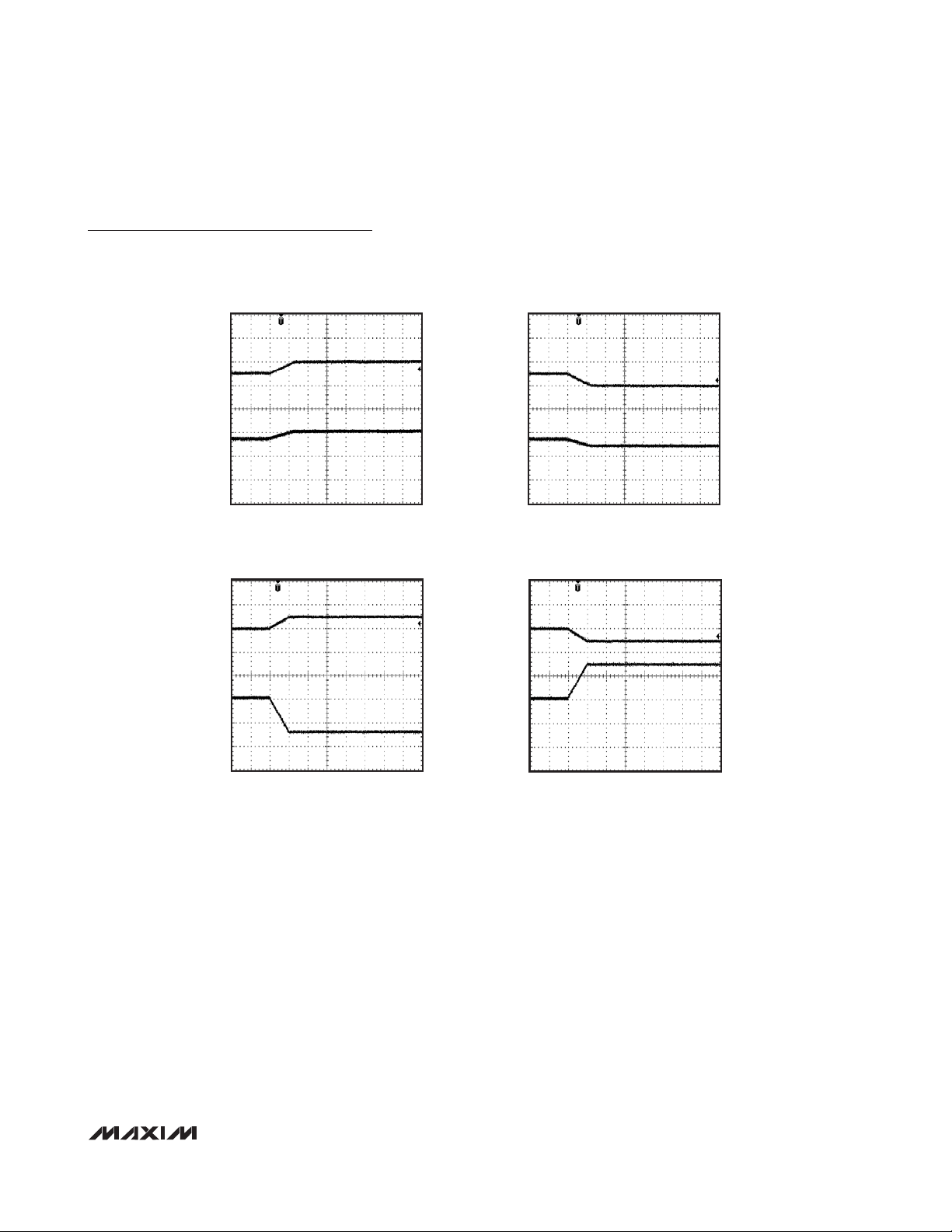

Typical Operating Characteristics (continued)

(V

AVDD

= V

DVDD

= 3.3V, TA= +25°C, unless otherwise noted.)

REFIN MODE MARGINING

500mV HIGH AT 1mV/µs

400Fs/div

FB MODE MARGINING HIGH

FROM 5V TO 5.5V

5V

0.6V

MAX16064 toc15

MAX16064 toc17

5V

VOUT0

1V/div

0.6V

VDACOUT0

200mV/div

VOUT0

1V/div

4.5V

0.54V

0.6V

REFIN MODE MARGINING

500mV LOW AT 1mV/µs

400Fs/div

FB MODE MARGINING LOW

FROM 5V TO 4.5V

5V

MAX16064 toc16

VOUT0

1V/div

VDACOUT0

200mV/div

MAX16064 toc18

VOUT0

1V/div

VDACOUT0

200mV/div

VDACOUT0

200mV/div

400ms/div

400ms/div

Page 8

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

8 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 RS2-

2 RS2+

3 RS3+

4 RS3-

5 RS3C Filter Capacitor for V

6EN

7 DACOUT1

8 AGND Analog Ground. Connect AGND to AGND1 and to DGND externally close to the device.

9 ENOUT0

10 ENOUT1

11 ENOUT2

12 ENOUT3

13 CLKIO

14 A1/SCLE

15 A2/SDAE

Differential Remote-Sense Input 2 Return of the DC-DC Output Voltage. Connect to the return terminal

at the load.

Differential Remote-Sense Input 2 of DC-DC Output Voltage. Connect to the load terminal where the

output must be regulated.

Differential Remote-Sense Input 3 of DC-DC Output Voltage. Connect to the load terminal where the

output must be regulated.

Differential Remote-Sense Input 3 Return of the DC-DC Output Voltage. Connect to the return terminal

at the load.

Amplifier 3. Connect a 1µF capacitor from RS3C to AGND.

SENSE

Enable Input. All ENOUT_ are deasserted when the voltage on EN is below 1.2V (typ). Used to turn

on/off the controlled power supplies in conjunction with the PMBus OPERATION command.

Analog Voltage Output of Internal 12-Bit DAC 1. Connect to TRIM, REFIN, or FB of a DC-DC module

or an LDO to adjust the power-supply output voltage. High impedance in shutdown.

On/Off Signal Output 0. Typically used to turn on/off a power supply. Controlled by the PMBus

OPERATION command or the sequencer. Can be configured as either an active-high or an active-low

open-drain output. See the ENOUT_ Operation section.

On/Off Signal Output 1. Typically used to turn on/off a power supply. Controlled by the PMBus

OPERATION command or the sequencer. Can be configured as either an active-high or an active-low

open-drain output. See the ENOUT_ Operation section.

On/Off Signal Output 2. Typically used to turn on/off a power supply. Controlled by the PMBus

OPERATION command or the sequencer. Can be configured as either an active-high or an active-low

open-drain output. See the ENOUT_ Operation section.

On/Off Signal Output 3. Typically used to turn on/off a power supply. Controlled by the PMBus

OPERATION command or the sequencer. Can be configured as either an active-high or an active-low

open-drain output. See the ENOUT_ Operation section.

Clock Input/Output. User-configurable clock input/output signal. The system controller can provide a

clock input to synchronize the time bases of multiple MAX16064 devices. Alternatively, a MAX16064

can provide a 1MHz output clock to other MAX16064s for synchronization. See the MFR_MODE (D1h)

section. When configured as an output, CLKIO is an open-drain output and a pullup resistor is

required.

Dual-Functioned MAX16064 Slave Address Identifier (LSB) and EEPROM I

MAX16064 Address Assignment and External EEPROM Interface sections.

Dual-Functioned MAX16064 Slave Address Identifier and EEPROM I

MAX16064 Address Assignment and External EEPROM Interface sections.

2

C Clock Output. See the

2

C Data Input/Output. See the

Dual-Functioned MAX16064 Slave Address Identifier (MSB) and Power-Supply On/Off Control Using

16 A3/CONTROL

17 RESET Active-Low, Open-Drain Reset Output

the MFR_MODE Command. See the MAX16064 Address Assignment and A3/CONTROL Operation

sections.

Page 9

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

_______________________________________________________________________________________ 9

Pin Description (continued)

PIN NAME FUNCTION

18 SMBALERT Active-Low, Open-Drain Fault-Detection Interrupt Output

19 SCL SMBus Serial-Clock Input/Output

20 SDA SMBus Serial-Data Input/Output

21 DGND Digital Ground. Connect DGND to AGND and AGND1 externally close to the device.

22 DVDD Digital Power-Supply Input. Connect a 1µF capacitor from DVDD to DGND.

23 RSVD Reserved. Connect to DVDD externally.

24 DACOUT3

25 AGND1 Analog Ground. Connect to AGND and DGND externally close to the device.

26 AVDD Analog Power-Supply Input. Connect a 1µF capacitor from AVDD to AGND.

27 DACOUT2

28 RS1-

29 RS1+

30 RS1C Filter Capacitor for V

31 REFO Reference Output. Connect a 1µF capacitor from REFO to AGND.

32 RS0+

33 RS0C Filter Capacitor for V

34 RS0-

35 DACOUT0

36 RS2C Filter Capacitor for V

—EP

Analog Voltage Output of Internal 12-Bit DAC 3. Connect to TRIM, REFIN, or FB of a DC-DC module

or an LDO to adjust the power-supply output voltage. High impedance in shutdown.

Analog Voltage Output of Internal 12-Bit DAC 2. Connect to TRIM, REFIN, or FB of a DC-DC module

or an LDO to adjust the power-supply output voltage. High impedance in shutdown.

Differential Remote-Sense Input 1 Return of the DC-DC Output Voltage. Connect to the return terminal

at the load.

Differential Remote-Sense Input 1 of DC-DC Output Voltage. Connect to the load terminal where the

output must be regulated.

Amplifier 1. Connect a 1µF capacitor from RS1C to AGND.

SENSE

Differential Remote-Sense Input 0 of DC-DC Output Voltage. Connect to the load terminal where the

output must be regulated.

Amplifier 0. Connect a 1µF capacitor from RS0C to AGND.

SENSE

Differential Remote-Sense Input 0 Return of the DC-DC Output Voltage. Connect to the return terminal

at the load.

Analog Voltage Output of Internal 12-Bit DAC 0. Connect to TRIM, REFIN, or FB of a DC-DC module

or an LDO to adjust the power-supply output voltage. High impedance in shutdown.

Amplifier 2. Connect a 1µF capacitor from RS2C to AGND.

SENSE

Exposed Pad. Internally connected to AGND. Connect EP to the ground plane of the power supplies

for best temperature measurement performance.

Page 10

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

10 ______________________________________________________________________________________

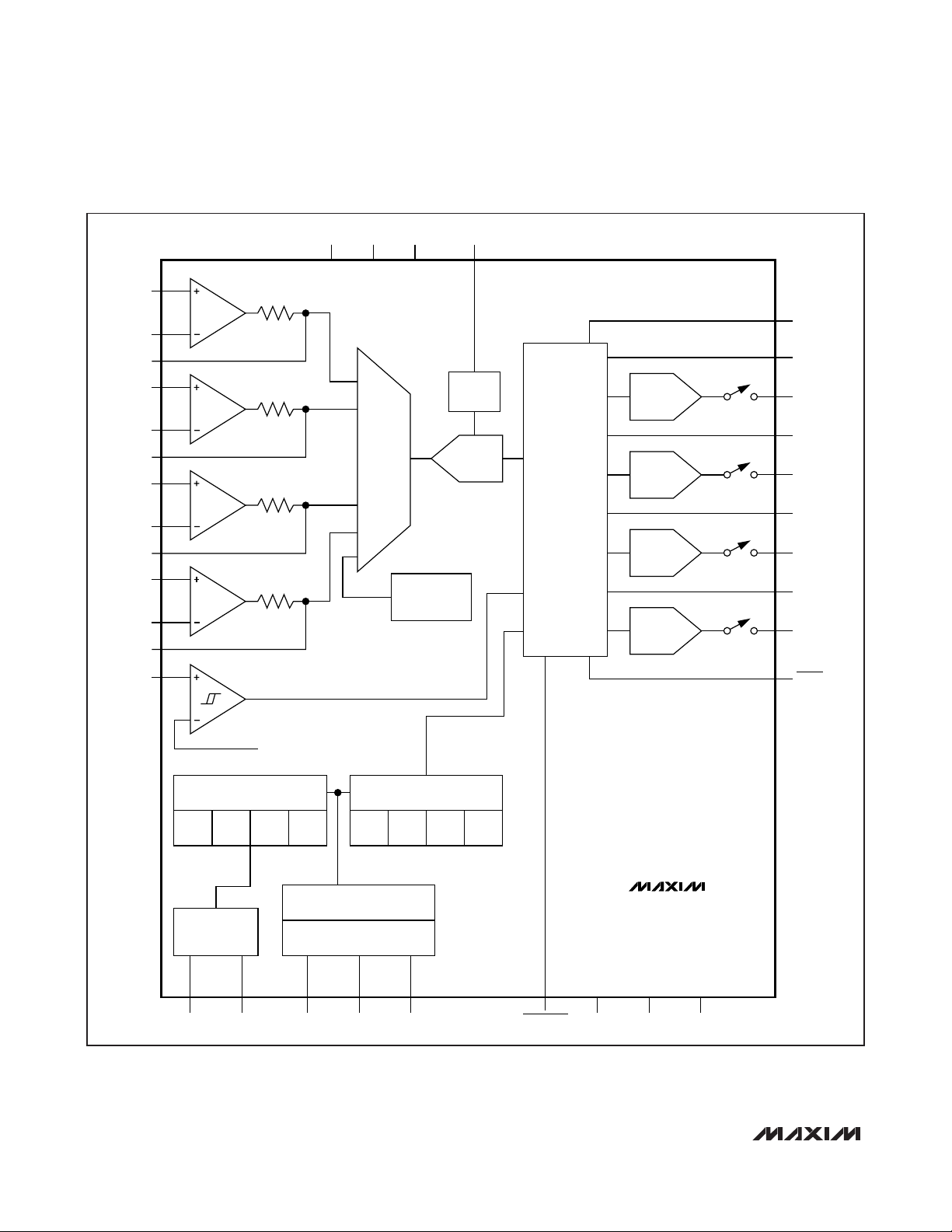

Figure 1. MAX16064 Functional Diagram

RS0+

RS0-

RS0C

RS1+

RS1-

RS1C

RS2+

RS2-

RS2C

RS3+

RS3-

RS3C

EN

VOLTAGE

SCALING

AND

MUX

RSVDDVDDAVDD

INTERNAL

TEMP

SENSOR

REFO

REF

12-BIT ADC

(SAR)

DIGITAL

COMPARATORS

AND

SEQUENCER

12-BIT VOUT

DAC 0

12-BIT VOUT

DAC 1

12-BIT VOUT

DAC 2

12-BIT VOUT

DAC 3

CLK0

ENOUT0

S0

DACOUT0

ENOUT1

S1

DACOUT1

ENOUT2

S2

DACOUT2

ENOUT3

S3

DACOUT3

RESET

1.2V

PMBus DEFAULT MEMORY

(EXTERNAL EEPROM)

PAGE

PAGE1PAGE2PAGE

0

EXTERNAL

EEPROM

INTERFACE

A1/SCLE A2/SDAE A3/CONTROL SCL SDA DGND AGND AGND1SMBALERT

3

I2C SMBus INTERFACE

PAGE

PMBus CONTROL

PMBus

OPERATING MEMORY

PAGE1PAGE2PAGE

0

3

MAX16064

Page 11

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 11

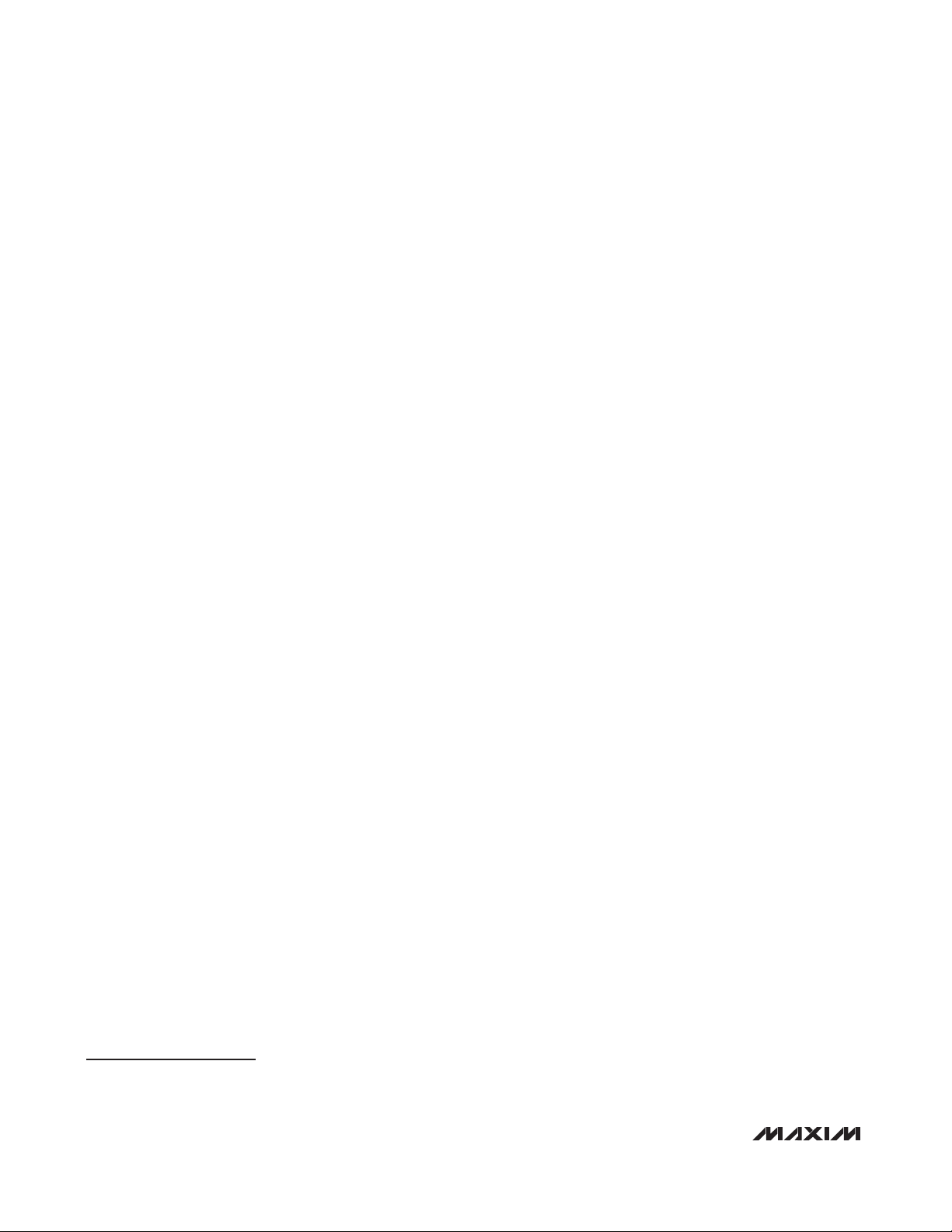

Detailed Description

The MAX16064 adds digital control functionality to four

power supplies. Using a closed-loop control system,

the MAX16064 can continuously adjust the power-supply output voltages to maintain ±0.3% output-voltage

accuracy. The MAX16064 can also be programmed to

sequence, track, and margin each power supply.

A PMBus-compliant interface bus provides access to

configuration parameters of the MAX16064, including

monitoring thresholds, sequence delays, soft-start and

soft-stop slew rates, output-voltage settings, an on-chip

temperature sensor, and more.

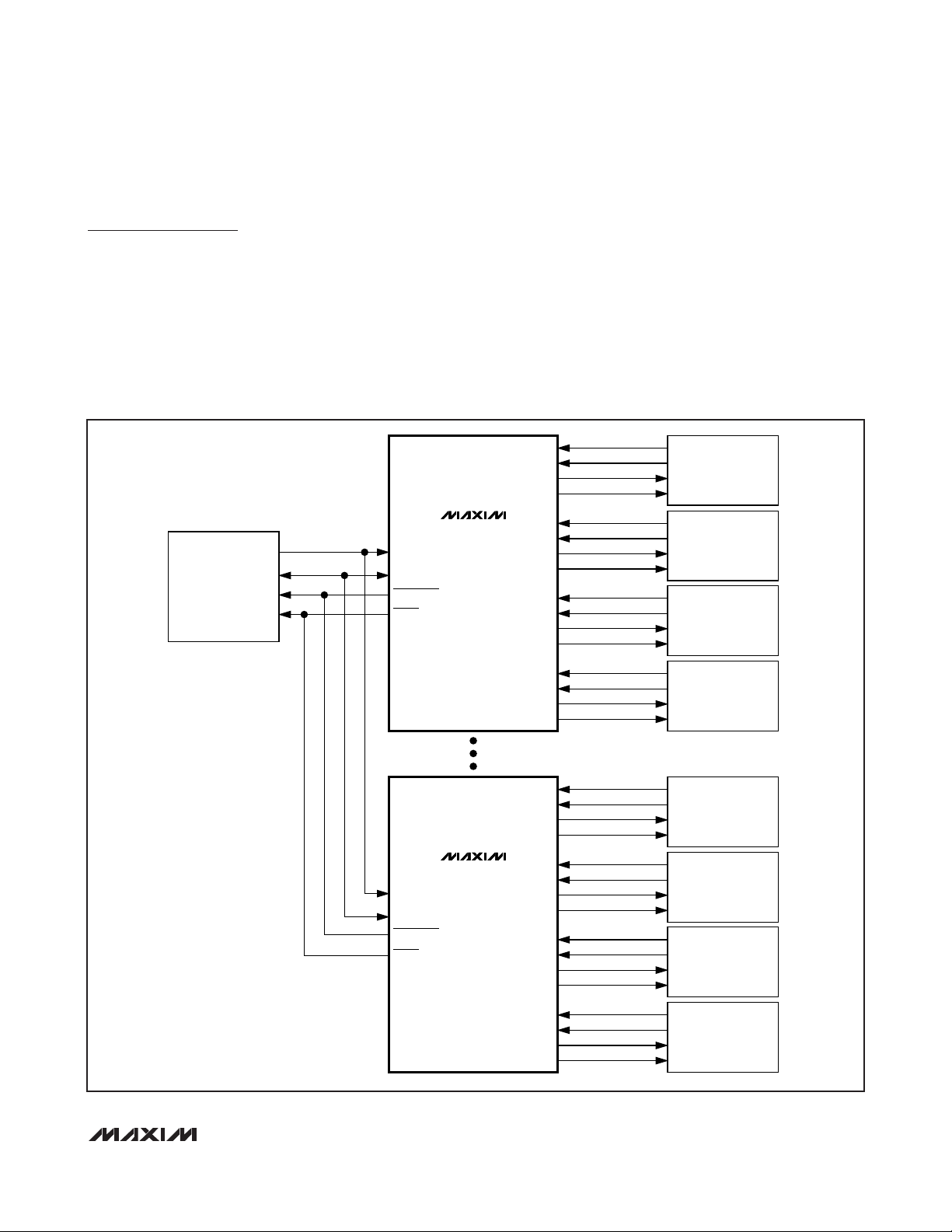

Up to 114 MAX16064s can reside on the same PMBus

bus, each controlling its own power supplies, under

commands from the PMBus system controller, as shown

in Figure 2. The MAX16064s can be placed close to the

power supplies they control so that all sensitive analog

traces are short and less susceptible to noise. The

power supplies can also be placed close to the load

where they provide the best transient response and lowest losses with short power plane runs.

MAX16064

RS0+ VO+

RS0- VO-

DACOUT0 FB

ENOUT0 EN

POWER

SUPPLY

0

RS1+ VO+

RS1- VO-

DACOUT1 FB

ENOUT1 EN

POWER

SUPPLY

1

RS2+ VO+

RS2- VO-

DACOUT2 FB

ENOUT2 EN

POWER

SUPPLY

2

RS3+ VO+

RS3- VO-

DACOUT3 FB

ENOUT3 EN

POWER

SUPPLY

3

SCL

SDA

IRQ

RST

SYSTEM

CONTROLLER

SCL

SDA

SMBALERT

RESET

MAX16064

RS0+ VO+

RS0- VO-

DACOUT0 FB

ENOUT0 EN

POWER

SUPPLY

(N-3)

RS1+ VO+

RS1- VO-

DACOUT1 FB

ENOUT1 EN

POWER

SUPPLY

(N-2)

RS2+ VO+

RS2- VO-

DACOUT2 FB

ENOUT2 EN

POWER

SUPPLY

(N-1)

RS3+ VO+

RS3- VO-

DACOUT3 FB

ENOUT3 EN

POWER

SUPPLY

(N)

SCL

SDA

SMBALERT

RESET

Figure 2. System Application Showing Multiple MAX16064s Controlling Power Supplies

Page 12

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

12 ______________________________________________________________________________________

MAX16064 Operating Modes

Reference Input (REFIN) Mode

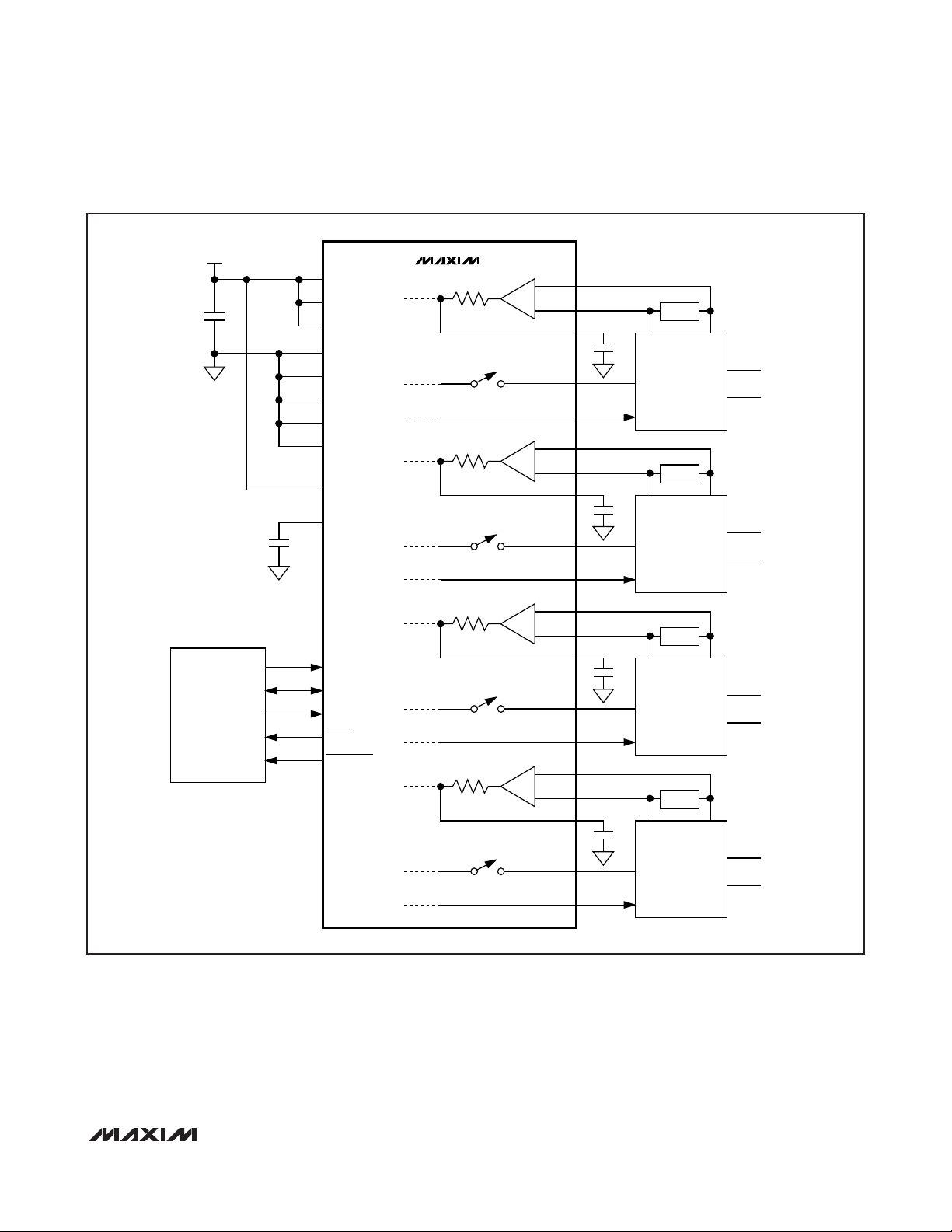

Figure 3 shows how to connect a MAX16064 to the reference voltage input of a typical power supply, allowing

the MAX16064 to fully control the power-supply output

voltage. Connect a DACOUT_ of the MAX16064 to the

REFIN input of the power supply and connect the output-voltage terminals of the power supply to the RS_+

and RS_- sense inputs of the MAX16064. The sensed

voltage on RS_+ and RS_- is filtered by an internal

200Ω resistor and an external capacitor connected to

RS_C, and is digitized by a 12-bit ADC that uses an

accurate internal reference voltage.

Normal operation begins as follows: upon receiving an

OPERATION ON command or a turn-on signal from

A3/CONTROL, the MAX16064 waits the programmed

t

ON_DELAY

time, then switches on the associated

ENOUT_ output and ramps up the power-supply output

voltage to its target VOUT_COMMAND value precisely

in the programmed t

ON_RISE

time. This facilitates easy

implementation of tracking of multiple output rails. On

reaching the target output voltage, the MAX16064 continuously monitors the power-supply output voltage

obtained at the RS_+ and RS_- inputs, and regulates it

to within ±0.3% by incrementing or decrementing the

DACOUT_ output 1 LSB (0.5mV) at a time. The

MAX16064 output-voltage correction rate is controlled

by MFR_MODE.1, VLTO, and DAC_ACT_CNT, as discussed in the

ADC Conversion, Monitoring, and AVOC

Adjustment Rates

section.

Once the requested target power-supply voltage is

reached, it can be margined up or down at a slew rate

programmed by the VOUT_TRANSITION_RATE parameter. To achieve this, the MAX16064 increments or

decrements the DACOUT_ output in a suitable number

of steps that depend on the programmed transition

rate. The number of steps is calculated from the

VOUT_SCALE_LOOP parameter, which must be set to

the ratio of the power-supply output voltage to the

power-supply reference voltage. This ratio is the same

as the voltage-divider ratio implemented on the power

supply from its output voltage node to the inverting

input of its error amplifier. This allows the MAX16064 to

correctly calculate the number of DACOUT steps and

voltage increments/decrements per step and thus

achieve the programmed rise time and transition time.

Since the reference voltage input is provided by the

MAX16064, the REFIN mode provides complete control

of the power supply in terms of soft-start, soft-stop, and

margining transitions.

Upon receiving an OPERATION OFF command or a

turn-off signal from A3/CONTROL, the MAX16064 waits

the programmed t

OFF_DELAY

time, ramps the output

voltage down to zero in the programmed t

OFF_FALL

time, then deasserts the ENOUT_ output. Each of the

four power-supply converters has its own set of delay

parameters, so sequencing is accomplished by loading

different delay times for each power supply.

Feedback (FB) Mode

Some power-supply converters do not provide a reference input. In these applications, the feedback node

can be used instead. Connect a DACOUT_ output of

the MAX16064 to the feedback node (FB) through a

resistor RFBas shown in Figure 5. In steady-state operation, the MAX16064 controls the power-supply voltage

as measured between RS_+ and RS_- to 0.3% accuracy by adjusting DACOUT_ 1 LSB at a time (0.5mV), up

and down as required. This mode of operation is

termed FB mode. Since the MAX16064 does not have

control over the power-supply error-amplifier reference

voltage, this mode relies on the power-supply soft-start

setting to implement the required soft-start time.

Upon receiving an OPERATION ON command or a

turn-on signal from A3/CONTROL, the MAX16064 waits

the programmed t

ON_DELAY

time, turns on the ENOUT_

output, causing the power supply to ramp up its output

voltage to its target value. The soft-start time taken by

the power supply to ramp from zero to its commanded

output voltage should be entered into the MAX16064

with the t

ON_RISE

parameter.

During t

ON_RISE

, the MAX16064 maintains DACOUT_ in

a high-impedance state by keeping the S_ switches

open. This allows the voltage at DACOUT_ to equal that

of the FB node of the power supply. At the end of the

t

ON_RISE

delay time, the internal DAC output voltage is

set to match the external voltage measured on

DACOUT_, and then the DACOUT_ switch S_ is closed.

The voltages on either side of the resistor RFBshould

be equal, or very close to equal. Under these conditions, little or no current flows into the FB node from

DACOUT_ and no perturbations are introduced to the

output voltage. From this point on, the MAX16064

adjusts the voltage at DACOUT_ to provide accurate

output-voltage control. In FB mode, the user must supply t

ON_DELAY

and t

ON_RISE

. If those parameters are

not set (the default values are zero), S_ closes prematurely and causes the supply voltage to overshoot or

undershoot.

Page 13

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 13

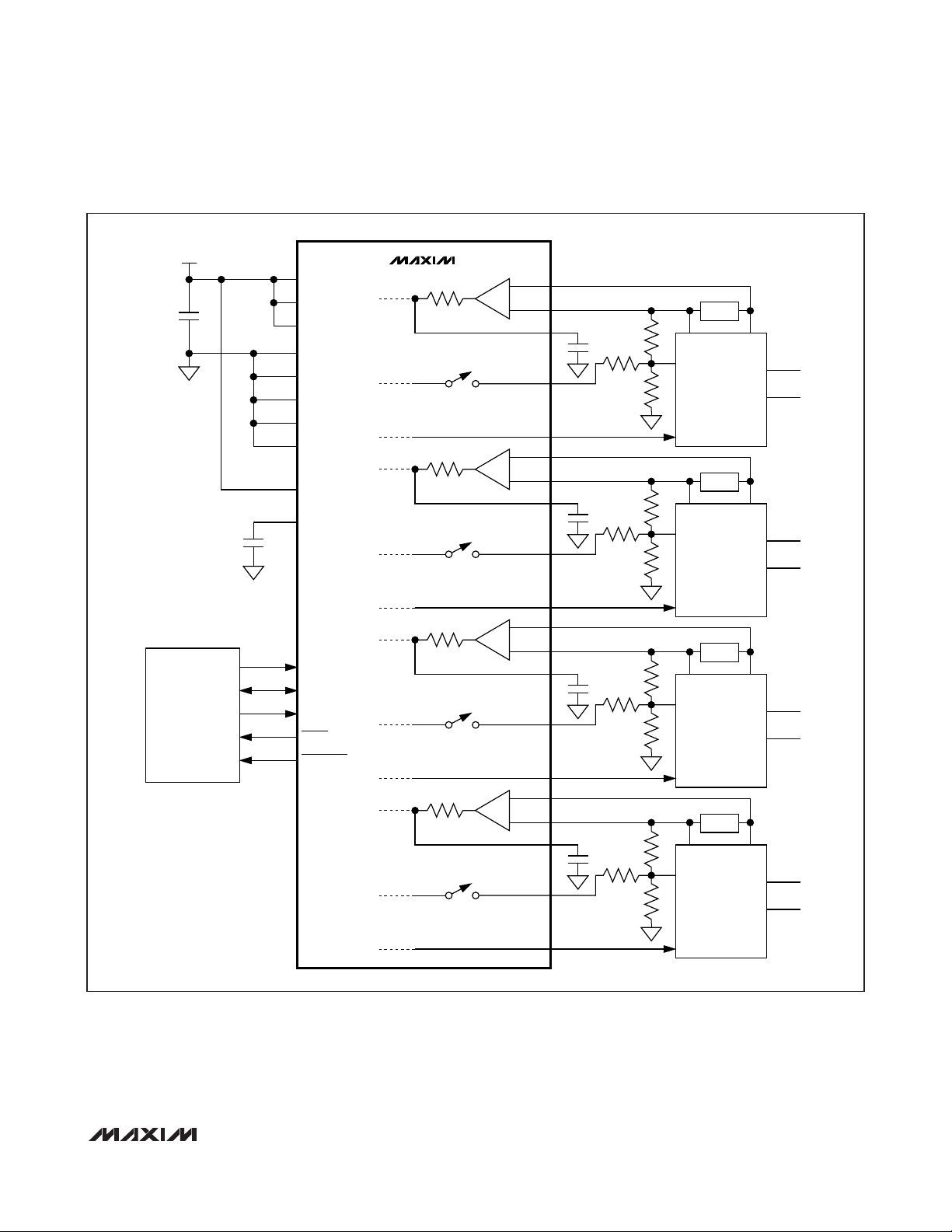

Figure 3. Typical System Application—REFIN Mode

3.3V

1µF

SYSTEM

CONTROLLER

IRQ

1µF

AVDD

DVDD

RSVD

AGND

AGND1

DGND

A1/SCLE

A2/SDAE

A3/CONTROL

REFO

SCL

SDA

EN

RESET

SMBALERT

MAX16064

200Ω

S0

200Ω

S1

200Ω

S2

200Ω

S3

RS0-

RS0+

RS0C

DACOUT0

ENOUT0

RS1-

RS1+

RS1C

DACOUT1

ENOUT1

RS2-

RS2+

RS2C

DACOUT2

ENOUT2

RS3-

RS3+

RS3C

DACOUT3

ENOUT3

LOAD

VO+ VO-

POWER

SUPPLY

REFIN

0

EN

LOAD

VO+ VO-

POWER

SUPPLY

REFIN

1

EN

LOAD

VO+ VO-

POWER

SUPPLY

REFIN

2

EN

LOAD

VO+ VO-

POWER

SUPPLY

REFIN

3

EN

VIN+

VIN-

VIN+

VIN-

VIN+

VIN-

VIN+

VIN-

Page 14

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

14 ______________________________________________________________________________________

After receiving an OPERATION OFF command or a

turn-off signal from A3/CONTROL, the MAX16064 waits

the programmed t

OFF_DELAY

time, deasserts the

ENOUT_ output, and turns off the power supply.

For the FB mode, use the following formula to calculate

the value of RFB:

Where R1is the upper feedback divider resistor, ∆VOis

the required change in output voltage, and ∆V

DAC

is

the DACOUT output-voltage change that the user

allows. The recommended operating range for the

DACOUT_ voltage for power-supply output voltage

adjustment is between 30mV and 2V. Note that ∆V

DAC

is the difference between the steady-state power-supply FB node voltage, VFB, and the voltage limits on

DACOUT_. This is best illustrated with an example as

follows:

Consider an application involving a power supply with

VFB= 0.6V. Let the desired margining be ±10% for a

power-supply output voltage of 1V. For a power supply

with an upper voltage divider resistor R

1

= 10kΩ, RFBis

calculated as follows:

This value of RFBallows the MAX16064 to margin the

power-supply output voltage up by 10%. It is useful to

check the margin low condition by using the formula:

The effective margining range for the 57kΩ resistor

therefore turns out to be between +10% and -24.5%.

Note that the VOUT_TRANSITION_RATE parameter has

no effect on FB mode. The transition time for margining

in the FB mode of operation is a function of the update

rate (f

AVOC

), see the

MFR_DAC_ACT_CNT (E0h)

sec-

tion for the calculation of f

AVOC

. RFBand R1, and is

given by the following formula:

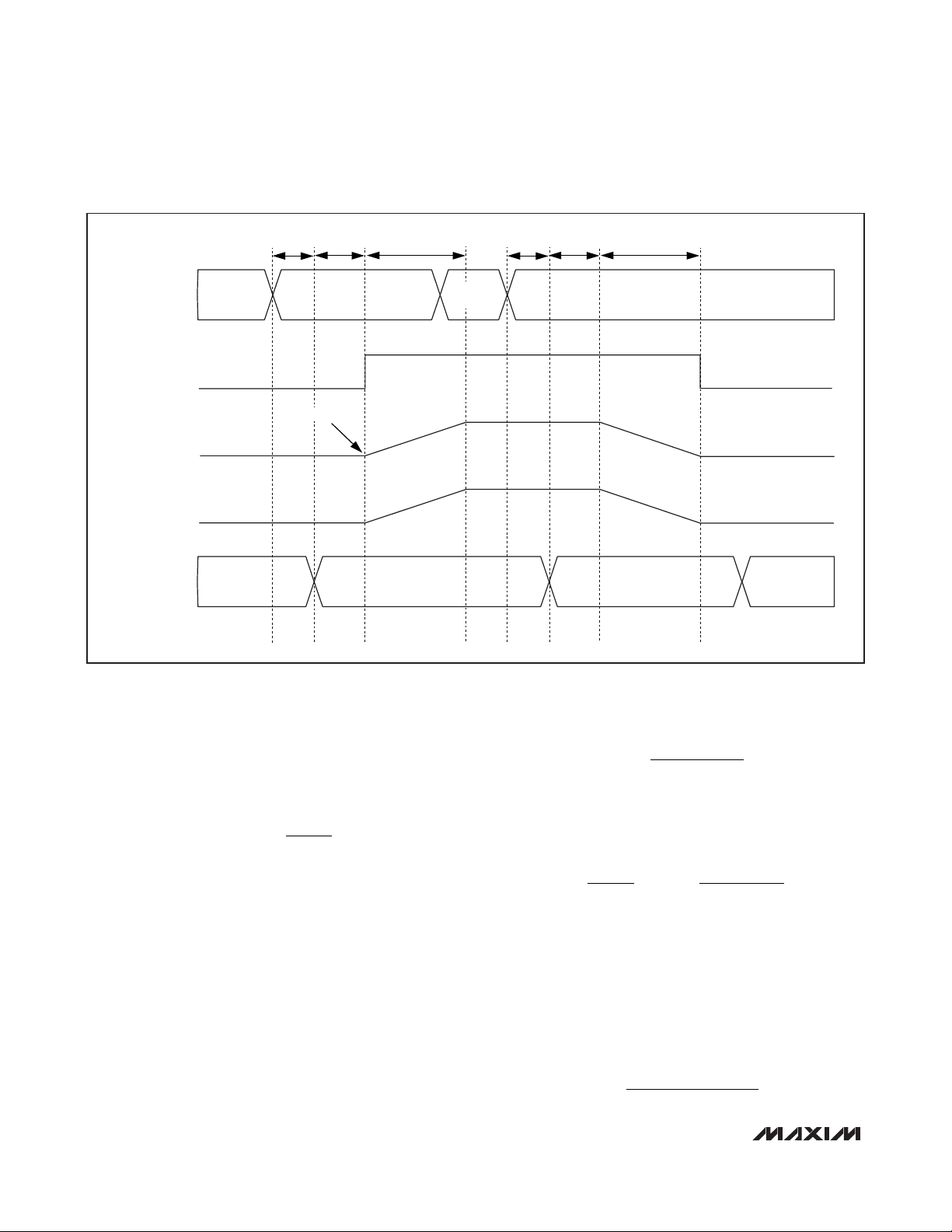

Figure 4. REFIN Mode Timing

t

PMB_RSPtON_DELAY

PMBus

ENOUT_

OPERATION

ON

IDLE IDLE

CLOSE S_

DAC OUTPUT

POWER-SUPPLY

V

OUT

POWER-SUPPLY

OPERATION

RR

=×

FB

V

∆

DAC

1

V

∆

O

t

ON_RISE

TURN-ON

t

PMB_RSPtOFF_DELAY

OPERATION

OFF

t

ON_FALL

TURN-OFF

−

VV

06 003

Rk

=× =

10

FB

(. . )

V

01

.

∆

V

∆

VR

=× = × =

O

DAC

1

R

FB

10

Ω

k

−

VV

20 06

(. . )

Ω

k

57

RxVx

t

FB

⎛

=

⎜

⎝

∆ 2000

FB O

fxR

AVOC

⎞

⎟

⎠

1

k

57ΩΩ

024

.55V

Page 15

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 15

Figure 5. Typical System Application—Feedback Mode

3.3V

1µF

1µF

AVDD

DVDD

RSVD

AGND

AGND1

DGND

A1/SCLE

A2/SDAE

A3/CONTROL

REFO

MAX16064

200Ω

S0

200Ω

S1

RS0-

RS0+

RS0C

DACOUT0

ENOUT0

RS1-

RS1+

RS1C

DACOUT1

LOAD

R1

VO+ VO-

FB

R

FB

R1

R

FB

POWER

SUPPLY

0

EN

LOAD

VO+ VO-

FB

POWER

SUPPLY

1

VIN+

VIN-

VIN+

VIN-

SCL

SDA

SYSTEM

CONTROLLER

IRQ

EN

RESET

SMBALERT

200Ω

S2

200Ω

S3

ENOUT1

RS2-

RS2+

RS2C

DACOUT2

ENOUT2

RS3-

RS3+

RS3C

DACOUT3

ENOUT3

EN

LOAD

R1

VO+ VO-

FB

R

FB

R1

R

FB

POWER

SUPPLY

2

EN

LOAD

VO+ VO-

FB

POWER

SUPPLY

3

EN

VIN+

VIN-

VIN+

VIN-

Page 16

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

16 ______________________________________________________________________________________

Temperature Sensing

To obtain useful temperature readings, place the

MAX16064 in close proximity to the power supplies.

The on-chip temperature sensor on the MAX16064

senses the temperature of the die, which is related to

the exposed pad temperature of the MAX16064 by the

junction-to-case thermal resistance. The exposed pad

of the MAX16064 can connect to the heat dissipating

ground plane of the power supplies, and the power

supplies’ boards can be characterized to obtain the

relationship between the power supplies’ temperature

and temperature as measured by the MAX16064. This

information can be used to set overtemperature fault

settings in the MAX16064.

ADC Conversion, Monitoring,

and AVOC Adjustment Rates

Several timing parameters control the rate at which the

MAX16064 monitors voltages and temperatures and the

rate at which the MAX16064 adjusts the power-supply

output voltages. Each of the four voltage input channels

and the single temperature channel conversions are

performed round-robin fashion. If the input filter is

turned on by setting register MFR_MODE[1] to 0, then

four conversions are performed for each channel

instead of just one. A small programmable delay is

inserted in between each conversion, determined by

the MFR_VLTO register. This establishes the total conversion rate of the voltages and temperature. Smaller

values of MFR_VLTO results in a higher sampling rate,

and larger values of MFR_VLTO allow for more ADC

settling time.

The ADC conversion result registers are compared to

the fault threshold registers at a rate that is independent of the total conversion rate. The value of register

MFR_SAMPLE_RATE determines how frequently this

comparison occurs. Using higher fault comparison

rates increases glitch sensitivity, but slows the

response time of the MAX16064 to PMBus commands.

Using lower fault comparison rates makes the

MAX16064 less sensitive to power-supply output voltage glitches.

PMBus

OPERATION

ON

IDLEIDLE

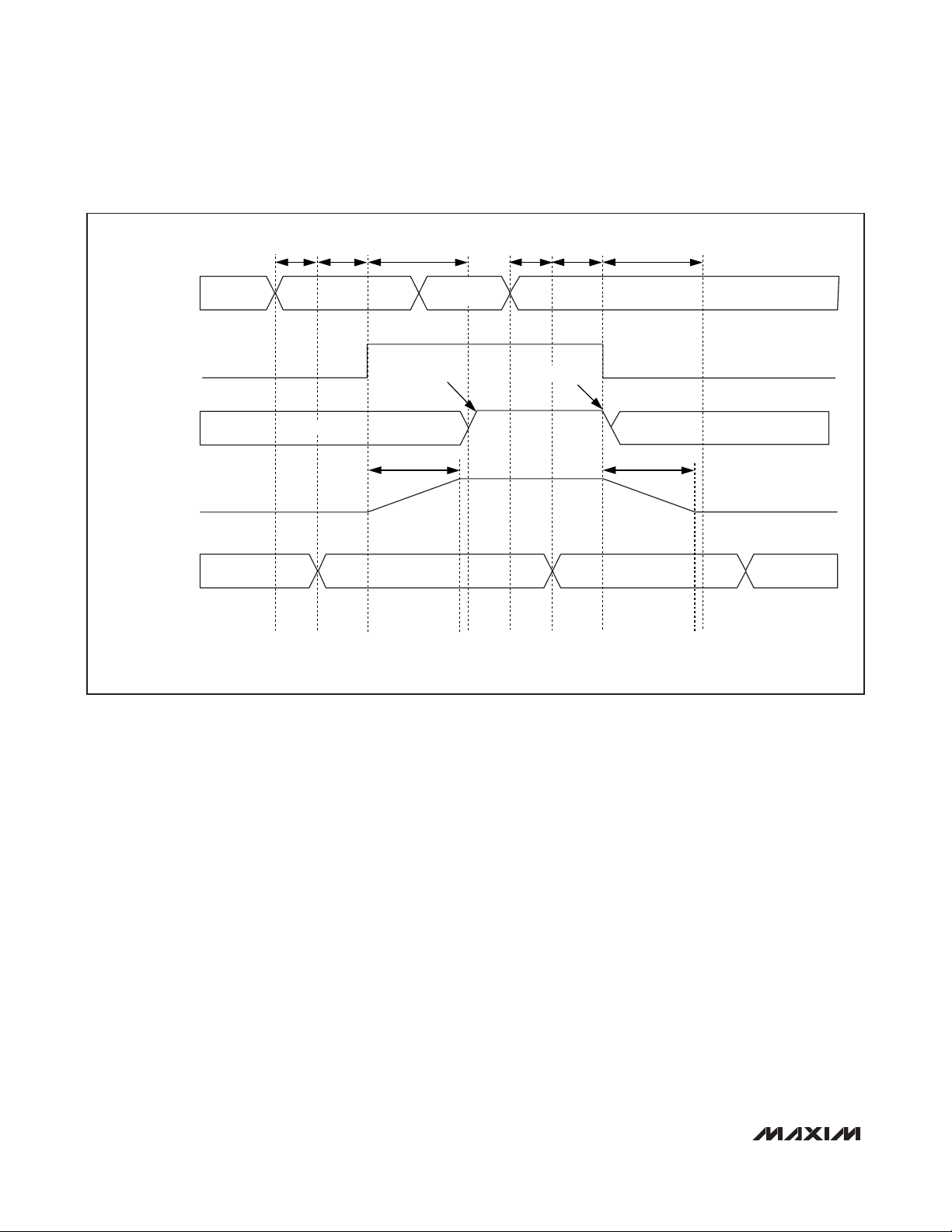

t

PMB_RSPtON_DELAY

t

ON_RISE

t

PS_RISE

t

PS_FALL

t

PMB_RSPtOFF_DELAY

t

OFF_FALL

HIGH-Z

ENOUT_

DAC OUTPUT

POWER-SUPPLY

V

OUT

POWER-SUPPLY

OPERATION

IN FB MODE, t

PS_RISE

AND t

PS_FALL

ARE NOT CONTROLLED BY THE MAX16064 AND ARE DEPENDENT ON POWER-SUPPLY IMPLEMENTATION.

CLOSE S_

TURN-ON

TURN-OFF

OPEN S_

HIGH-Z

OPERATION

OFF

Figure 6. Feedback Mode Timing

Page 17

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 17

Finally, the AVOC system uses a separate control loop

rate that is related to the total ADC conversion rate. The

value of register MFR_DAC_ACT_CNT sets the number

of total ADC conversion cycles (one cycle is a complete

set of ADC conversions for 4 voltages and 1 temperature) that must occur before AVOC changes the DAC

output voltage. Smaller values of MFR_DAC_ACT_CNT

shorten the adjustment time. Larger values of

MFR_DAC_ACT_CNT adjust the output voltage at much

slower rates, reducing possible negative effects on the

power-supply control loop.

External EEPROM Interface

The MAX16064 can communicate with an EEPROM

attached to the A1/SCLE and A2/SDAE. The MAX16064

communicates to the EEPROM with an address byte of

1010 0000 for writing and 1010 0001 for reading. For

the data values of 2 bytes, the most significant byte is

stored in the lower address of the EEPROM, whereas

the least significant byte is stored in the higher address

of the EEPROM.

Upon reset, the MAX16064 tests for the presence of a

configuration EEPROM. It searches for the SIGNATURE

bytes in the attached EEPROM. If the SIGNATURE

bytes are present, it concludes that it has a valid configuration EEPROM and starts reading configuration

information from the attached EEPROM. If the slave

address (MFR_SET_ADDRESS) is a value other than

0x00, this overrides the slave address information previously set by the address A3:A1 pins.

Table 1b shows the contents and addresses of the configuration information expected by the MAX16064. This

information is for reference only. It is recommended to

use a properly configured, working MAX16064 to save

its state to the EEPROM and limit direct modifications to

as few fields as possible (such as the slave address).

Temperature and voltage values are stored in an internal representation, which is not the same as the format

used by the corresponding PMBus commands. For

details on the EEPROM internal representation, see

Conversion Rules (Table 1a).

For example, to store to the EEPROM PAGE 2

VOUT_COMMAND = 3.0V, m = 19995, b = 0, R = -1.

First calculate the PMBUS command value, which is

5998. If the voltage range is 2V, no conversion is

required. Hence write 17h to address 28 and 6Eh to

address 29. If the voltage range is 5.5V, the stored

EEPROM value = 5998/2.75 = 2181. So write 08h to

address 28 and write 85h to address 29.

Note that the conversion is automatically handled by

the MAX16064 when it stores and loads configuration

information.

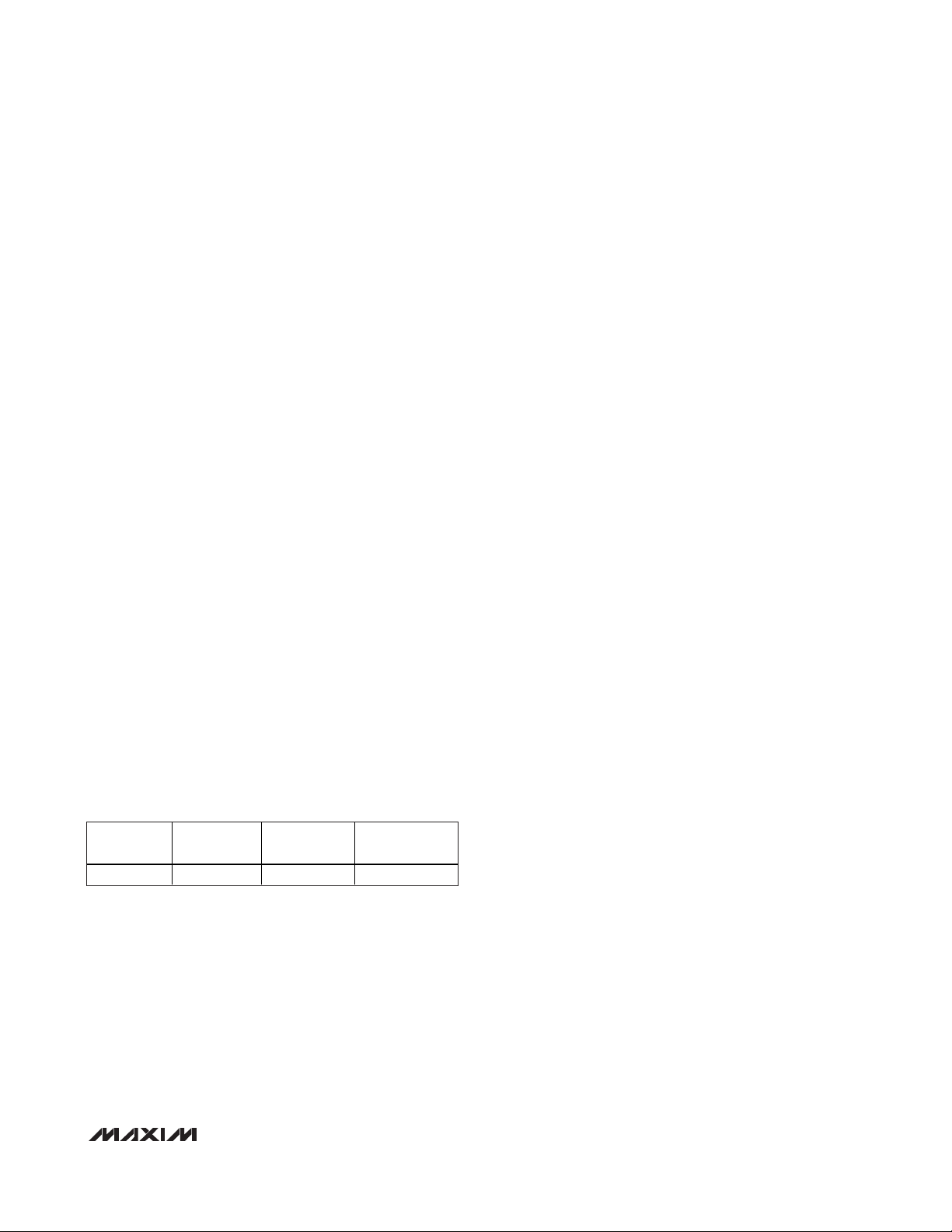

Table 1a. Conversion Rules

READ (INTERNAL TO PMBus) WRITE (PMBus TO INTERNAL)

TEMPERATURE Subtract 3010 (decimal) from the PMBus value Add 3010 (decimal) to the PMBus value

VOLTAGE

No conversion in 2V mode;

multiply by 2.75 in 5.5V mode

No conversion in 2V mode;

divide by 2.75 in 5.5V mode

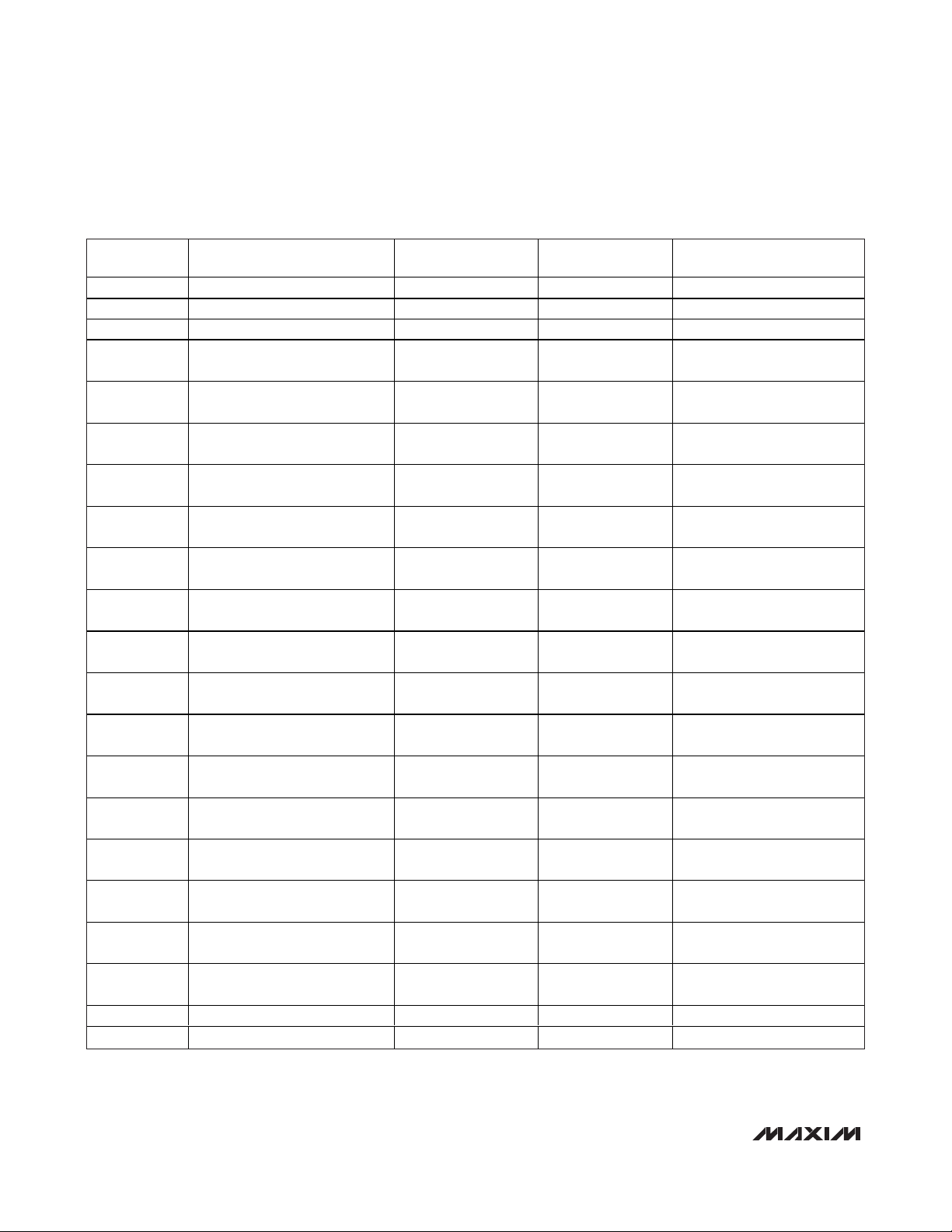

Table 1b. 16-Bit Words Stored in EEPROM

EEPROM

ADDRESS

NAME PAGE

PMBus COMMAND

NOTES

0 MFR_FAULT_REASON — 0E2h —

2 MFR_MODE — 0D1h

Must also match

MFR_TICK_RELOAD

4 TEMPERATURE_PEAK — 0D6h

Internal representation

(temperature)

6 MFR_FAULT_TEMP — 0E4h

Internal representation

(temperature)

8 MFR_VOUT_PEAK 0

10 MFR_VOUT_PEAK 1

12 MFR_VOUT_PEAK 2

14 MFR_VOUT_PEAK 3

0D4h

Internal representation

(voltage)

Page 18

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

18 ______________________________________________________________________________________

Table 1b. 16-Bit Words Stored in EEPROM (continued)

EEPROM

ADDRESS

NAME PAGE

PMBus COMMAND

NOTES

16 MFR_FAULT_VOUT 0

18 MFR_FAULT_VOUT 1

20 MFR_FAULT_VOUT 2

22 MFR_FAULT_VOUT 3

0E3h

Internal representation

(voltage)

24 VOUT_COMMAND 0

26 VOUT_COMMAND 1

28 VOUT_COMMAND 2

30 VOUT_COMMAND 3

21h

Internal representation

(voltage)

32 TON_RISE 0

34 TON_RISE 1

36 TON_RISE 2

38 TON_RISE 3

61h —

40 TON_DELAY 0

42 TON_DELAY 1

44 TON_DELAY 2

46 TON_DELAY 3

60h —

48 VOUT_MARGIN_HIGH 0

50 VOUT_MARGIN_HIGH 1

52 VOUT_MARGIN_HIGH 2

54 VOUT_MARGIN_HIGH 3

25h

Internal representation

(voltage)

56 VOUT_MARGIN_LOW 0

58 VOUT_MARGIN_LOW 1

60 VOUT_MARGIN_LOW 2

62 VOUT_MARGIN_LOW 3

26h

Internal representation

(voltage)

64 TOFF_FALL 0

66 TOFF_FALL 1

68 TOFF_FALL 2

70 TOFF_FALL 3

65h —

72 OT_FAULT_LIMIT — 4Fh

Internal representation

74 MFR_SAMPLE_RATE — 0D3h —

76–87 Reserved (set to 0) — — —

88 MFR_FAULT_RESPONSE 0

90 MFR_FAULT_RESPONSE 1

92 MFR_FAULT_RESPONSE 2

94 MFR_FAULT_RESPONSE 3

0D9h —

96 MFR_FAULT_RETRY 0

98 MFR_FAULT_RETRY 1

100 MFR_FAULT_RETRY 2

102 MFR_FAULT_RETRY 3

0DAh —

Page 19

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 19

Table 1b. 16-Bit Words Stored in EEPROM (continued)

EEPROM

ADDRESS

NAME PAGE

PMBus COMMAND

NOTES

104–115 MFR_DATE — 9Dh —

116 MFR_STATUS_WORD — 0D8h Set to 0

118 WRITE_PROTECT — 10h —

120 ON_OFF_CONFIG 0

122 ON_OFF_CONFIG 1

124 ON_OFF_CONFIG 2

126 ON_OFF_CONFIG 3

02h —

128 VOUT_SCALE_LOOP 0

130 VOUT_SCALE_LOOP 1

132 VOUT_SCALE_LOOP 2

134 VOUT_SCALE_LOOP 3

29h —

136 OT_WARN_LIMIT — 51h

Internal representation

(temperature)

138 Reserved (set to 0) — — —

140 MFR_SET_ADDRESS — 0DBh

Low byte: I

2

C address,

high byte: reserved

142 Reserved (set to 0) — — —

144 TOFF_DELAY 0

146 TOFF_DELAY 1

148 TOFF_DELAY 2

150 TOFF_DELAY 3

64h —

152 VOUT_TRANSITION_RATE 0

154 VOUT_TRANSITION_RATE 1

156 VOUT_TRANSITION_RATE 2

158 VOUT_TRANSITION_RATE 3

27h —

160–175 Reserved (set to 0) 0 — —

176 MFR_MODE_OUTPUT 0

178 MFR_MODE_OUTPUT 1

180 MFR_MODE_OUTPUT 2

182 MFR_MODE_OUTPUT 3

0DEh —

184–199 Reserved (set to 0) — — —

200 MFR_RESET_DELAY — 0DDh —

202 MFR_RESET_OUTPUT — 0E1h —

204 Reserved (set to 0) — — —

206 MFR_TICK_RELOAD — 0D1h —

208 MFR_STATUS_WORD 0

210 MFR_STATUS_WORD 1

212 MFR_STATUS_WORD 2

214 MFR_STATUS_WORD 3

0D8h Set to 0

Page 20

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

20 ______________________________________________________________________________________

Table 1b. 16-Bit Words Stored in EEPROM (continued)

EEPROM

ADDRESS

NAME PAGE

PMBus COMMAND

NOTES

216–237 MFR_LOCATION — 9Ch —

238–255 MFR_SERIAL — 9Eh —

256–297 MFR_USERDATA_00 — 0B0h —

298 VOUT_OV_FAULT_LIMIT 0 40h

Internal representation

(voltage)

300 VOUT_UV_FAULT_LIMIT 0 44h

Internal representation

(voltage)

302 VOUT_OV_WARN_LIMIT 0 42h

Internal representation

(voltage)

304 VOUT_UV_WARN_LIMIT 0 43h

Internal representation

(voltage)

306 VOUT_OV_FAULT_LIMIT 1 40h

Internal representation

(voltage)

308 VOUT_UV_FAULT_LIMIT 1 44h

Internal representation

(voltage)

310 VOUT_OV_WARN_LIMIT 1 42h

Internal representation

(voltage)

312 VOUT_UV_WARN_LIMIT 1 43h

Internal representation

(voltage)

314 VOUT_OV_FAULT_LIMIT 2 40h

Internal representation

(voltage)

316 VOUT_UV_FAULT_LIMIT 2 44h

Internal representation

(voltage)

318 VOUT_OV_WARN_LIMIT 2 42h

Internal representation

(voltage)

320 VOUT_UV_WARN_LIMIT 2 43h

Internal representation

(voltage)

322 VOUT_OV_FAULT_LIMIT 3 40h

Internal representation

(voltage)

324 VOUT_UV_FAULT_LIMIT 3 44h

Internal representation

(voltage)

326 VOUT_OV_WARN_LIMIT 3 42h

Internal representation

(voltage)

328 VOUT_UV_WARN_LIMIT 3 43h

Internal representation

(voltage)

330–509 Unused (set to 0) — — —

510 SIGNATURE (set to 4432h) — N/A —

Page 21

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 21

Figure 7 shows how the MAX16064 interfaces to an

external serial EEPROM using the A1/SCLE and

A2/SDAE in applications where a master controller

does not exist or is not required. Using the GUI, the

user can select each MAX16064 device and configure

all the required output-voltage settings and sequencing/tracking information. Once the configuration is complete, the results can be saved to the external EEPROM

by using the STORE_DEFAULT_ALL command and

configuration restored on the MAX16064 power-on

reset. The EEPROM can also be preprogrammed prior

to board assembly in the manufacturing environment.

A3/CONTROL can be used as a control signal to turn

on/off the power supply in a similar fashion as the

OPERATION command.

Use a serial EEPROM IC with a minimum of 4kb of storage to ensure proper device operation.

MAX16064 Operation

On power-up reset, the MAX16064 goes through an initialization process as shown in Figure 8.

After initialization, the MAX16064 monitors the PMBus and

executes the PMBus commands accordingly. In addition,

if the power supply has been commanded to turn on, the

MAX16064 also monitors the power-supply output voltage

and temperature at the MFR_SAMPLE_RATE. The

PMBus system controller can monitor the power-supply

health by issuing various inquiries and status commands to the MAX16064.

RESET

Output Operation

RESET is an active-low, open-drain output that is low when

the device is powering on. RESET is assigned to one of

the power supplies using the MFR_RESET_OUTPUT

command. When that power-supply output is at the target

voltage, RESET goes high after the reset timeout period

(see Figure 9). The reset timeout period (tRP) is set by the

MFR_RESET_DELAY command.

The MFR_RESET_OUTPUT value defines which powersupply output affects RESET. If MFR_RESET_OUTPUT is

set to 0, 1, 2, or 3, then RESET goes high tRPafter that

output has reached its target value. If MFR_RESET_OUTPUT is any other value, RESET is permanently low.

If the power-supply output selected by

MFR_RESET_OUTPUT is later disabled for any reason

(either due to a fault condition, or an OPERATION OFF

command), then RESET goes low immediately. To

enable faults on any power supply to cause RESET to

go low, set the MFR_MODE_OUTPUT.GLOBALFAULTS

bit to a 1 for all the supplies.

RESET requires an external pullup resistor.

33kΩ33kΩ

V

CC

1µF

1µF

VO+ VO-

1µF

DVDD

AVDD

3.3V

RSVD

EEPROM

24LCXX

SYSTEM

CONTROLLER

DGND

MAX16064

A1/SCLE

A2/SDAE

A3/CONTROL

SCL

SDA

RESET

SMBALERT

POWER

SUPPLY

A1

A2

A3

SCL

SDA

GND

IRQ

AGND

RS_RS_+

RS_C

DACOUT_

REFIN

VIN+

VIN-

REFO

ENOUT_

EN

LOAD

Figure 7. Typical System Application with External EEPROM

Page 22

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

22 ______________________________________________________________________________________

SMBALERT

Output Operation

SMBALERT is an optional interrupt signal defined in

Appendix A of the SMBus specification. The MAX16064

provides an output SMBALERT as this interrupt signal.

SMBALERT is an active-low, open-drain output and it

asserts to signal the PMBus master if any of the voltage

or temperature fault has occurred. Typically,

SMBALERT is connected to all other SMBALERT opendrain signals in the system, creating a wired-OR function with all SMBALERT outputs. When the master is

interrupted by its SMBALERT input, it stops or finishes

the current bus transfer and places an alert response

address (ARA) on the bus. The slave that pulled the

SMBALERT signal low acknowledges the ARA and

places its own address on the bus, identifying itself to

the master as the slave that caused the interrupt.

SMBALERT deasserts when the MAX16064 responds to

the ARA. SMBALERT deasserts when all the fault conditions are removed. SMBALERT is also cleared by the

CLEAR_FAULTS command.

ENOUT_ Operation

When power is applied, all ENOUT_ are held low. Upon

receiving a command to turn on the power supply,

ENOUT_ goes high. The polarity can be changed by

the ENOUT_POL bit of the MFR_MODE_OUTPUT command. Setting the bit to a 1 makes the ENOUT_ active

low. If the bit in the external EEPROM is set to 1, upon

power-up, the ENOUT_ is held low until the bit is copied

from the EEPROM to the on-chip register at which time

the ENOUT_ goes high. Upon receiving a command to

turn on the power supply, ENOUT_ goes low. It takes

1.60ms (typ) to copy the configuration bits from the

EEPROM to the on-chip registers.

EN Operation

The MAX16064 includes an enable input (EN) that controls all ENOUT_ signals in conjunction with the

MFR_MODE command. Unless MFR_MODE.IGNORE_EN

is set, a below-threshold level on EN prevents any

ENOUT_ from turning on. Additionally, if the voltage at

EN falls below the 1.2V (typ) threshold during

OPERATION ON, the MAX16064 follows the fault action

in MFR_FAULT_RESPONSE.EN. Figure 9 shows a typical sequencing with MFR_MODE.IGNORE_EN = 0.

RESET

INITIALIZE

INTERNAL

REGISTERS

SET PMBus

ADDRESS

ACCORDING TO

A3:A1

VALID

EEPROM?

RESTORE

CONFIGURATION

FROM EEPROM

INTERNAL

REFERENCE

STABLE?

ENABLE PMBus

COMMUNICATION

PMBus

COMMAND?

Y

N

Y

Y

N

N

EXECUTE PMBus

COMMAND

ASSERT

SMBALERT

Figure 8. MAX16064 Initialization

Table 2. ENOUT_ Active State

ENOUT_

DEFAULT

STARTUP

STATE

MFR_MODE_OUTPUT.

ENOUT_POL

ENOUT_ ACTIVE

STATE

Low 0 Active high

Low 1 Active low

Page 23

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 23

MAX16064 Address Assignment

The MAX16064 picks a slave address in one of the two

ways described below:

1) Hardwired by A3:A2:A1.

2) Restored from EEPROM at power-on.

Address assignment order is shown in Figure 10.

The MAX16064 reads A3:A2:A1 address pins upon

device reset and determines its address according to

Table 3.

RESET

t

ON0

t

RP

t

OFF0

t

ON1

t

OFF1

t

OFF2

t

OFF3

t

ON2

t

ON3

ENOUT3

ENOUT2

ENOUT1

ENOUT0

EN

NOTE: MFR_RESET_OUTPUT = 3

Figure 9. MAX16064 Typical Sequencing Timing

Table 3. MAX16064 A3:A1 Slave Address Assignment

A3/CONTROL A2/SDAE A1/SCLE ADDRESS (BITS 7–1)

L L L 40h

LLZ 01h*

LZL 02h

LZZ 03h

ZLL 04h

ZLZ 05h

ZZL 06h

ZZZ 07h

L L H 09h

LZH 0Bh

ZLH 0Dh

Page 24

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

24 ______________________________________________________________________________________

The hardwired address pins give 33= 27 address

options. For example, to configure the MAX16064 to

have a slave address of 010 0101 (25h), set A3:A2:A1

= H:L:Z. The MAX16064 also responds to the broadcast address (00h).

If an EEPROM with valid SIGNATURE bytes is attached

to the MAX16064, the MAX16064 tries to restore its

slave address from the EEPROM. This overrides the

address set by the address pins. This gives a total of

128 possible slave addresses. Note that there are 14

reserved addresses that are restricted by the PMBus

specification and may not be used in PMBus systems.

If the address bit 7 from the EEPROM is set to 1, this is

an invalid address and the MAX16064 continues using

the address set by the address pins. When an

EEPROM is attached to A2/SDAE and A1/SCLE, these

pins assume either a logic-high or a logic-low level,

therefore, the resulting number of possible addresses

set by the A3:A2:A1 pins in this scenario is 23= 8.

In addition, for the MAX16064 with an EEPROM

attached, the system controller can change the

MAX16064 slave address by sending the new address

with the MFR_SET_ADDRESS command. However, the

new address is not immediately effective. The new

address must be stored to the EEPROM first using the

STORE_DEFAULT_ALL command. Then, the

MAX16064 power must be cycled to start the address

assignment procedure and recalls the new address

from the EEPROM.

A3/CONTROL Operation

The A3/CONTROL input is utilized in combination with

the A2 and A1 inputs to set the PMBus address when

power is applied to the device. After the PMBus

address detection, the A3/CONTROL input functions as

the PMBus CONTROL input.

The ON_OFF_CONFIG command determines whether

the A3/CONTROL input affects the on/off behavior of the

power supply. When A3/CONTROL is enabled by the

ON_OFF_CONFIG command, a transition of A3/CONTROL from low to high turns the power supply on, as if

the MAX16064 has received an OPERATION ON

command. A transition of A3/CONTROL from high to low

initiates a soft-off to the power supply, as if the

MAX16064 has received an OPERATION OFF command (soft-off, with sequencing). The MAX16064 still

responds to the PMBus OPERATION command while

A3/CONTROL is enabled. To detect the A3/CONTROL

input, the A3/CONTROL signal pulse width has to satisfy the t

A3_LOW

and t

A3_HIGH

requirements to be detect-

ed. See the

ON_OFF_CONFIG (02h)

section and Table

6 for more information.

Table 3. MAX16064 A3:A1 Slave Address Assignment (continued)

A3/CONTROL A2/SDAE A1/SCLE ADDRESS (BITS 7–1)

ZZH 0Fh

L H L 12h

LHZ 13h

ZHL 16h

ZHZ 17h

L H H 1Bh

ZHH 1Fh

H L L 24h

HLZ 25h

HZL 26h

HZZ 27h

HLH 2Dh

HZH 2Fh

H H L 36h

HHZ 37h

H H H 3Fh

*

The shaded addresses are not available if external EEPROM is attached.

Page 25

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 25

Figure 10. MAX16064 Address Assignment

SET SLAVE

POWER ON

POWER OFF

ADDRESS

ACCORDING TO

A3:A1

VALID EEPROM

AND BIT7 STORED

ADDRESS IN EEPROM

IS NOT 1?

N

MFR_SET_ADDR?

N

SAVE TO

EEPROM?

Y

Y

Y

RESTORE SLAVE

ADDRESS FROM

EEPROM

SLAVE ADDRESS

UNCHANGED.

STORE NEW ADDRESS

TEMPORARILY.

SAVE NEW

ADDRESS TO

EEPROM

N

Page 26

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

26 ______________________________________________________________________________________

The dual functionality of A3/CONTROL of the

MAX16064 requires that the system enable signal be

isolated from A3 until the address setting has been

read and latched by the MAX16064. Figure 11 shows

one implementation for the three possible states of the

A3/CONTROL setting. In each case, the system enable

signal (MAX16064_EN) is applied to the input of a

three-state buffer whose output is kept in the highimpedance state by a control input signal (HIZ_EN) for

a time period during which the MAX16064 reads and

latches the A3/CONTROL address setting. After this

period, the control signal HIZ_EN goes low and allows

the system enable signal to be applied to the

MAX16064 A3/CONTROL pin. After a t

A3_LOW

, the

MAX16064_EN signal transitions from low to high and

causes the MAX16064s to commence power-supply

startup operations.

PMBus Digital Interface

From a software perspective, the MAX16064 appears

as a PMBus device capable of executing a subset of

PMBus commands. A PMBus 1.0-compliant device

uses the SMBus version 1.1 for transport protocol and

responds to the SMBus slave address. In this data

sheet, the term SMBus is used to refer to the electrical

characteristics of the PMBus communication using the

SMBus physical layer. The term PMBus is used to refer

to the PMBus command protocol.

The MAX16064 employs five standard SMBus protocols

(Write Word, Read Word, Write Byte, Read Byte, and

Send Byte (see Figures 12–15)) to program output voltage and warning/faults thresholds, read monitored

data, and provide access to all manufacturer-specific

commands.

1µF

A3

A2

A1

REFO

AVDD

REFO

HIZ_EN

MAX16064_EN

HIZ_EN PLACES U1, U2, AND U3 OUTPUTS IN HIGH-IMPEDANCE STATE WHEN ASSERTED.

U1, U2, AND U3 ARE NOT NECESSARY IF AN EEPROM IS ATTACHED TO A1/SCLE

AND A2/SDAE. A1/SCLE, A2/SDAE ARE EITHER PULLED UP OR PULLED DOWN WITH

33kΩ WHEN CONNECTED TO AN EEPROM.

A3/CONTROL

MAX16064_UVLO

t

RST_WAIT

t

A3_LOW

3.3V

33kΩ

MAX16064_EN

HIZ_EN

U1

33kΩ

MAX16064

1µF

A3

A2

A1

REFO

U2

MAX16064

1µF

A3

A2

A1

REFO

U3

MAX16064

Figure 11. Application Diagram with A3/CONTROL as Both Address and On/Off Control Signal

Page 27

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 27

The MAX16064 supports the group command. The

group command is used to send commands to more

than one PMBus device. It is not required that all the

devices receive the same command. However, no

more than one command can be sent to any one

device in one group command packet. The group

command must not be used with commands that

require receiving devices to respond with data, such

as the STATUS_BYTE command. When the

MAX16064 receives a command through this protocol, it immediately begins execution of the

received command after detecting the STOP condition.

The MAX16064 supports the PAGE command and uses

it to select which individual channel to access.

When the data word is transmitted, the lower order byte

is sent first and the higher order byte is sent last. Within

any byte, the most significant bit (MSB) is sent first and

the least significant bit (LSB) is sent last.

The MAX16064 SMBus interface supports Packet Error

Checking (PEC). See the

MFR_MODE (D1h)

section.

ADDR

SLAVE ADDRESS COMMAND BYTE:

SELECTS TO WHICH

COMMAND PARAMETER

TO WRITE

DATA BYTE: DATA FOR THE COMMAND

SET BY THE COMMAND BYTE

WRITE BYTE FORMAT

SW

PA A A

7 BITS

COMMAND

8 BITS

DATA

8 BITS

ADDR

SLAVE ADDRESS COMMAND BYTE:

SELECTS FROM WHICH

COMMAND PARAMETER

TO READ

DATA BYTE: DATA FOR THE COMMAND

SET BY THE COMMAND BYTE

READ BYTE FORMAT

SSRW

PA R AA NA

7 BITS

ADDR

SLAVE ADDRESS:

REPEATED DUE TO

CHANGE IN DATA-FLOW

DIRECTION

7 BITS

COMMAND

8 BITS

DATA

8 BITS

ADDR

SLAVE ADDRESS COMMAND BYTE:

SELECTS TO WHICH

COMMAND PARAMETER

TO WRITE

DATA BYTE: DATA FOR THE COMMAND SET BY THE

COMMAND BYTE

WRITE WORD FORMAT

SW

PA A A

7 BITS

COMMAND

8 BITS

DATA0

8 BITS

ADATA1

8 BITS

ADDR

SLAVE ADDRESS COMMAND BYTE: SEND

COMMAND WITH NO DATA

SEND BYTE FORMAT

SW

S = START CONDITION

SR = REPEATED START CONDITION

P = STOP CONDITION

= SLAVE TRANSMISSION

PA A

7 BITS

COMMAND

8 BITS

ADDR

SLAVE ADDRESS COMMAND BYTE:

SELECTS FROM WHICH

COMMAND PARAMETER

TO READ

DATA BYTE: DATA FOR THE COMMAND SET BY THE

COMMAND BYTE

READ WORD FORMAT

SSRW

PA R AA A

7 BITS

ADDR

SLAVE ADDRESS:

REPEATED DUE TO

CHANGE IN DATA-FLOW

DIRECTION

7 BITS

COMMAND

8 BITS

DATA0

8 BITS

NADATA1

8 BITS

Figure 12. SMBus Protocols

Page 28

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

28 ______________________________________________________________________________________

Figure 13. SMBus Group Command Protocol

SWA A A

SLAVE ADDRESS OF

DEVICE 1

SR W A A

SLAVE ADDRESS OF

DEVICE 2

SR W A A A

SLAVE ADDRESS OF

DEVICE 3

SR W

SLAVE ADDRESS OF

DEVICE n

ADDR1

7 BITS

ADDR2

7 BITS

ADDR3

7 BITS

ADDRn

7 BITS

CMD1

8 BITS

COMMAND BYTE FOR

DEVICE 1

CMD2

8 BITS

COMMAND BYTE FOR

DEVICE 2

CMD3

8 BITS

COMMAND BYTE FOR

DEVICE 3

CMDn

8 BITS

COMMAND BYTE FOR

DEVICE n: NO DATA BYTE

DATA0

8 BITS

DATA BYTES FOR DEVICE 1

8 BITS

DATA BYTES FOR DEVICE 2

DATA0

8 BITS

DATA BYTES FOR DEVICE 3

PA A

ADATA1

8 BITS

ADATA

ADATA1

8 BITS

S = START CONDITION

SR = REPEATED START CONDITION

P = STOP CONDITION

= SLAVE TRANSMISSION

Page 29

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 29

Figure 14. SMBus Protocols with PEC

WRITE BYTE FORMAT

S ADDR W A COMMAND A

7 BITS 8 BITS

SLAVE

ADDRESS

READ BYTE FORMAT

S ADDR W A COMMAND A

7 BITS 8 BITS

SLAVE

ADDRESS

WRITE WORD FORMAT

S ADDR W A COMMAND A

7 BITS 8 BITS

READ WORD FORMAT

S ADDR W A COMMAND A

7 BITS 8 BITS

SLAVE

ADDRESS

COMMAND BYTE:

SELECTS TO WHICH

COMMAND PARAMETER

TO WRITE

COMMAND BYTE:

SELECTS FROM WHICH

COMMAND PARAMETER

TO READ

COMMAND BYTE:

SELECTS TO WHICH

COMMAND PARAMETER

TO WRITE

COMMAND BYTE:

SELECTS FROM WHICH

COMMAND PARAMETER

TO READ

DATA A

8 BITS

DATA BYTE:

DATA FOR

THE COMMAND

SET BY THE

COMMAND BYTE

SR ADDR R A

SLAVE ADDRESS:

REPEATED DUE TO

CHANGE IN DATAFLOW DIRECTION

DATA 0 A D ATA1 A PEC

8 BITS 8 BITS 8 BITS

DATA BYTES: DATA FOR THE

COMMAND SET BY THE

COMMAND BYTE

SR ADDR R A

SLAVE ADDRESS:

REPEATED DUE TO

CHANGE IN DATAFLOW DIRECTION

7 BITS

7 BITS

8 BITS

DATA

8 BITS

DATA BYTES: DATA

FOR THE COMMAND

SET BY THE

COMMAND BYTE

DATA 0 A DATA 1 A PEC

8 BITS

DATA BYTES: DATA FOR THE COMMAND

SET BY THE COMMAND BYTE

PPEC A

NA

A PEC

8 BITS

A P

8 BITS

P

8 BITS

NA

P

SEND BYTE FORMAT

7 BITS 8 BITS 8 BITS

SLAVE

ADDRESS

COMMAND BYTE: SEND

COMMAND WITH NO

DATA

PECS ADDR W A COMMAND A

A P

S = START CONDITION

SR = REPEATED START CONDITION

P = STOP CONDITION

= SLAVE TRANSMISSION

Page 30

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

30 ______________________________________________________________________________________

Figure 15. SMBus Group Command Protocol with PEC

SCL

SDA

A

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SDA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

I = MASTER PULLS SDA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLEAR PULSE

L = STOP CONDITION

M = NEW START CONDITION

BCD

EF

GHIJKLM

t

SU;STA

t

HD;STA

t

SU;DAT

t

HD;DAT

t

SU;STOtBUF

t

LOWtHIGH

Figure 16. SMBus Write Timing Diagram

S ADDR1 W A CMD1 A

7 BITS 8 BITS

SLAVE

ADDRESS OF

DEVICE 1

SR ADDR2 W A CMD2 A

7 BITS 8 BITS

SLAVE

ADDRESS OF

DEVICE 2

SR ADDR3 W A CMD3 A

7 BITS 8 BITS

SLAVE

ADDRESS OF

DEVICE 3

SR ADDRn W A CMDn A

7 BITS 8 BITS

SLAVE

ADDRESS OF

DEVICE n

COMMAND

BYTE FOR

DEVICE 1

COMMAND

BYTE FOR

DEVICE 2

COMMAND

BYTE FOR

DEVICE 3

COMMAND BYTE

FOR DEVICE n: NO

DATA BYTE

DATA BYTES

FOR DEVICE 1

DATA BYTES

FOR DEVICE 2

DATA BYTES

FOR DEVICE 3

DATA 0 A DATA 1 A

8 BITS 8 BITS

DATA 0 A

8 BITS

DATA 0 A DATA 1 A

8 BITS 8 BITS

PECn

8 BITS

DATA 1 A

8 BITS

A P

PEC1

8 BITS

PEC2

8 BITS

PEC3

8 BITS

A

A

A

S = START CONDITION

SR = REPEATED START CONDITION

P = STOP CONDITION

= SLAVE TRANSMISSION

Page 31

MAX16064

±0.3% Accurate, Quad, Power-Supply Controller with

Active-Voltage Output Control and PMBus Interface

______________________________________________________________________________________ 31

Figure 17. SMBus Read Timing Diagram

PMBus Protocol Support

The MAX16064 supports a subset of the commands

defined in the Power System Management Protocol

Specification Part II - Command Language Revision

1.0. For detailed specifications and the complete list of

PMBus commands, refer to Part II of the PMBus specification available at www.PMBus.org. The supported

PMBus commands and the corresponding MAX16064

behavior are described in this document.

All data values are represented in DIRECT format,

unless otherwise stated. Whenever the resolution of the

data is less than the number of bits required, data are

right justified (only the lower bits are significant) and the

higher order bits are zero-padded, unless otherwise

stated. For example, for a 2-byte value where the

MAX16064 only has 12-bit data to return, the

MAX16064 returns data in the lower 12 bits and zeropads the upper 4 bits. Whenever the PMBus specification refers to the PMBus device, it is referring to the

MAX16064 operating in conjunction with a power supply. While the command may call for turning on or off

the PMBus device, the MAX16064 always remains on to

continue communicating with the PMBus master and

the MAX16064 transfers the command to the power

supply accordingly.

Data Format

Voltage data for commanding or reading the output

voltage or related parameters (such as the overvoltage

threshold) are presented in DIRECT format. DIRECT format data is a 2-byte, two’s complement binary value.

DIRECT format data may be used with any command

that sends or reads a parametric value. The DIRECT

format uses an equation and defined coefficients to calculate the desired values. The coefficients used by the

MAX16064 can be found in Table 4.

Interpreting Received DIRECT

Format Values

The host system uses the following equation to convert

the value received from the PMBus device, in this case

the MAX16064, into a reading of volts, degrees Celsius,

or other units as appropriate:

where X is the calculated, real world value in the appropriate units (V, °C, etc.);

m,the slope coefficient, is a 2-byte, two’s complement

integer;

Y is a 2-byte, two’s complement integer received from

the PMBus device;

b, the offset, is a 2-byte, two’s complement integer; and

R, the exponent, is a 1-byte, two’s complement integer.

Sending a DIRECT Format Value

To send a value, the host must use the equation below

to solve for Y:

Y = (mX + b) x 10

R

where:

Y is the 2-byte, two’s complement integer to be sent to

the unit;

m, the slope coefficient, is the 2-byte, two’s complement integer;

X is a real world value, in units such as volts, to be converted for transmission;

b is the offset, is the 2-byte, two’s complement integer;

and

R, the exponent, is the decimal value equivalent to the

1 byte, two’s complement integer.

SCL