Page 1

General Description

The MAX1606 is a step-up DC-DC converter that contains a 0.5A internal power switch and a 0.5A output

isolation switch in an 8-pin µMAX package. The IC

operates from a 2.4V to 5.5V supply voltage but can

boost battery voltages as low as 0.8V up to 28V.

The MAX1606 uses a unique control scheme that provides high efficiency over a wide range of load conditions. An internal 0.5A MOSFET reduces external

component count, and a high switching frequency (up

to 500kHz) allows for tiny surface-mount components.

The current limit can be set to 500mA, 250mA, or

125mA, allowing the user to reduce the output ripple

and component size in low-current applications.

Additional features include a low quiescent supply current and a true shutdown mode that saves power by

disconnecting the output from the input. The MAX1606

is ideal for small LCD panels with low current requirements but can also be used in other applications. A

MAX1606 evaluation kit is available to help speed up

design time.

________________________Applications

LCD Bias Generators

Cellular or Cordless Phones

Palmtop Computers

Personal Digital Assistants (PDAs)

Organizers

Handy Terminals

Features

♦ Adjustable Output Voltage up to 28V

♦ 20mA at 20V from a Single Li+ Battery

♦ True Shutdown (Output Disconnected from Input)

♦ Output Short-Circuit Protection

♦ 88% Efficiency

♦ Up to 500kHz Switching Frequency

♦ Selectable Inductor Current Limit

(125mA, 250mA, or 500mA)

♦ 0.1µA Shutdown Current

♦ 8-Pin µMAX Package

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

________________________________________________________________ Maxim Integrated Products 1

Pin Configuration

V

IN

= 0.8V TO 5.5V

V

CC

= 2.4V TO 5.5V

V

OUT

= V

IN

TO 28V

ON

OFF

SHDN

V

CC

LIM

SW

BATT

GND

LX

FB

MAX1606

Typical Operating Circuit

19-1744; Rev 0; 7/00

For free samples and the latest literature, visit www.maxim-ic.com or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

Ordering Information

PART TEMP. RANGE PIN-PACKAGE

MAX1606EUA -40°C to +85°C8 µMAX

TOP VIEW

BATT

1

FB

2

3

V

CC

4

8

SW

7

MAX1606

µMAX

SHDN

6

LIM

5

LXGND

Page 2

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

2 _______________________________________________________________________________________

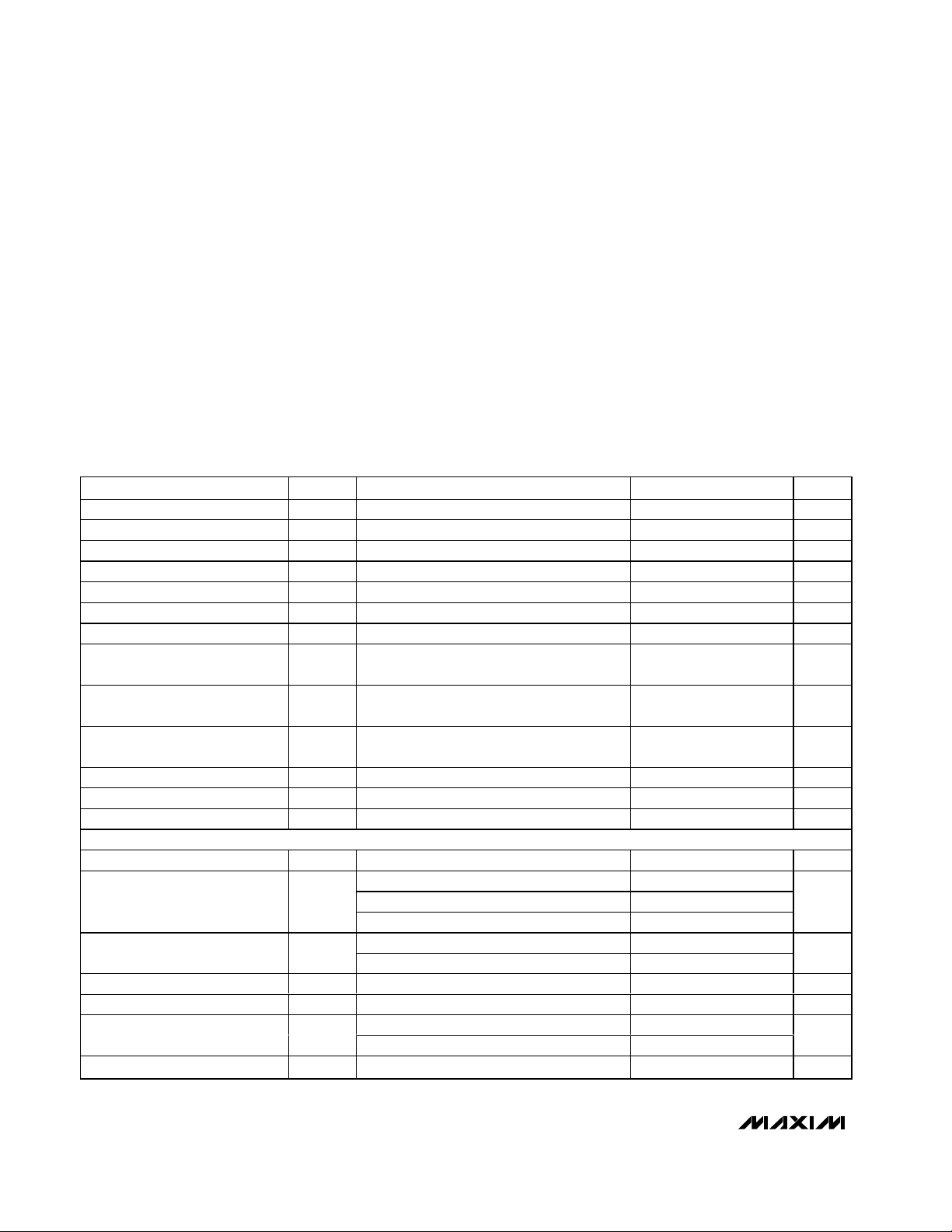

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= 3.3V, VCC= BATT = SHDN, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCC, FB, BATT, SW to GND .....................................-0.3V to +6V

BATT to SW ..............................................................-0.3V to +6V

SHDN, LIM to GND.....................................-0.3V to (V

CC

+ 0.3V)

LX to GND ..............................................................-0.3V to +30V

Current into LX or BATT..............................................600mA

RMS

Current out of SW .......................................................600mA

RMS

Output Short-Circuit Duration ........................................Indefinite

Continuous Power Dissipation (T

A

= +70°C)

8-Pin µMAX (derate 4.1mW/°C above +70°C).............330mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

)

µ

VCC Supply Voltage V

BATT Input Voltage Range V

VCC Undervoltage Lockout V

VCC Quiescent Supply Current I

VCC Shutdown Supply Current SHDN = GND 0.1 1 µA

BATT Input Supply Current I

BATT Shutdown Supply Current SHDN = GND 0.1 1 µA

VCC Line Regulation ∆V

BATT Line Regulation ∆V

Load Regulation ∆V

Efficiency L1 = 100µH, V

Feedback Set Point V

Feedback Input Bias Current I

INDUCTOR CONNECTIONS (LX, SW)

LX Voltage Range V

LX On-Resistance R

LX Leakage Current VLX = 28V 2 µA

Maximum LX On-Time t

Minimum LX Off-Time t

SW Leakage Current SW = GND, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

BATT

UVLO

CC

BATT

LNR

LNR

LDR

FB

FB

LX(MAX

(Note 1) 2.4 5.5 V

(Note 1) 0.8 5.5 V

VCC falling, 30mV typical hysteresis 2.0 2.2 2.37 V

VFB = 1.3V 160 320 µA

VFB = 1.3V 20 40 µA

V

= 18V, I

OUT

= V

V

CC

LIM

V

= 18V, I

OUT

= V

V

CC

LIM

V

= 18V, VCC = V

OUT

I

= 0mA to 20mA

LOAD

= 1mA, V

LOAD

= 2.4V to 5.5V

= 1mA,

LOAD

= 3.3V, V

BATT

BATT

BATT

= 3.6V, I

= 3.6V,

BATT

= 0.8V to 5.5V

= V

= 3.3V,

LIM

= 10mA 88 %

LOAD

0.1 %/V

0.05 %/V

0.05 %/mA

1.225 1.25 1.275 V

VFB = 1.3V 5 100 nA

LX

LIM = V

CC

0.40 0.50 0.56

LIM = floating 0.20 0.25 0.285LX Switch Current Limit I

28 V

LIM = GND 0.10 0.125 0.15

LX

ON

OFF

VCC = 5V, I

VCC = 3.3V, ILX = 100mA 1 2

VFB > 1.1V 0.8 1.0 1.2

VFB < 0.8V (soft-start) 3.9 5.0 6.0

= 100mA 0.8

LX

10 13 16 µs

= 5.5V 1

BATT

A

Ω

µs

A

Page 3

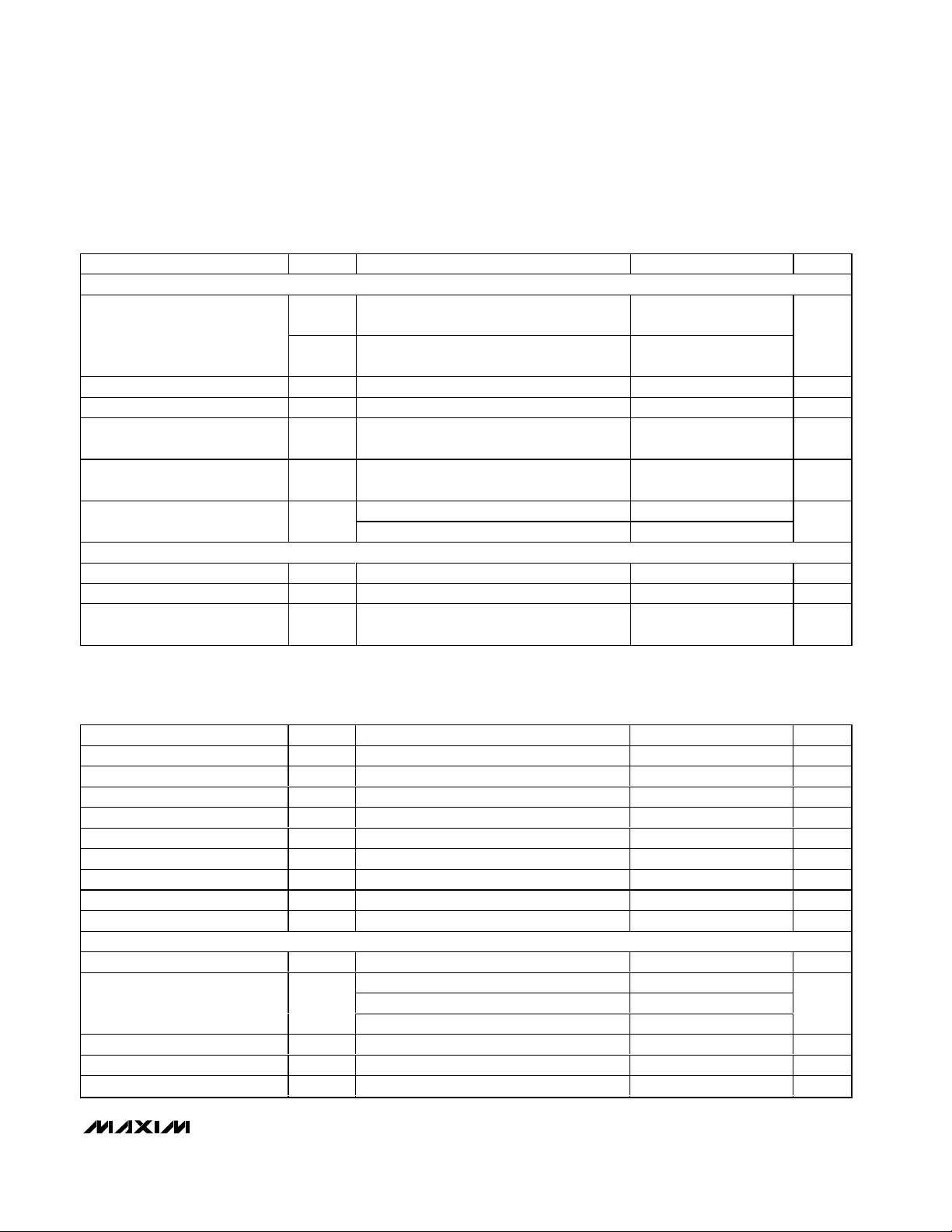

)

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS

(VCC= 3.3V, VCC= BATT = SHDN, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 3.3V, VCC= BATT = SHDN, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

)

CONTROL INPUTS (SHDN, LIM)

SHDN Input Threshold

SHDN Input Bias Current I

LIM Input Low Level 2.4V ≤ VCC ≤ 5.5V 0.4 V

LIM Input Float Level

LIM Input High Level 2.4V ≤ VCC ≤ 5.5V

LIM Input Bias Current I

PMOS ISOLATION SWITCH (BATT to SW)

PMOS Current Limit V

PMOS On-Resistance R

Soft-Start Time t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

SHDN

LIM

DS(ON

SS

2.4V ≤ VCC ≤ 5.5V

2.4V ≤ VCC ≤ 5.5V

VCC = 5.5V, V

2.4V ≤ V

I

LIM

SHDN = VCC, LIM = GND or V

SHDN = GND 0.1 1

C C

VCC = 2.5V, V

VCC = 2.5V, V

R

SW

≤ 5.5V,

CC

= ±0.5µA

= 2.5V, V

= 50Ω to GND

= 0 to 5.5V -1 1 µA

SHDN

CC

= 1.5V 0.65 0.85 1.5 A

BATT

= 1.5V, ISW = 100mA 0.25 0.4 Ω

BATT

= 1.5V,

BATT

0.8 ×

V

CC

( V

/ 2)

C C

- 0.25V

V

CC

- 0.4V

-2 2

0.3 ms

0.2 ×

V

CC

( V

/ 2)

C C

+ 0.25V

V

V

V

µA

VCC Supply Voltage V

BATT Input Voltage Range V

VCC Undervoltage Lockout V

VCC Quiescent Supply Current I

VCC Shutdown Supply Current SHDN = GND 1 µA

BATT Input Supply Current I

BATT Shutdown Supply Current SHDN = GND 1 µA

Feedback Set Point V

Feedback Input Bias Current I

INDUCTOR CONNECTIONS (LX, SW)

LX Voltage Range V

LX Switch Current Limit I

LX On-Resistance R

LX Leakage Current VLX = 28V 2 µA

Maximum LX On-Time t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

BATT

UVLO

CC

BATT

FB

FB

LX

LX(MAX

ON

(Note 1) 2.4 5.5 V

(Note 1) 0.8 5.5 V

VCC falling, 30mV typical hysteresis 2.0 2.37 V

VFB = 1.3V 360 µA

VFB = 1.3V 40 µA

1.215 1.285 V

VFB = 1.3V 100 nA

LIM = V

CC

LIM = floating 0.18 0.30

LIM = GND 0.08 0.17

VCC = 3.3V, ILX = 100mA 2 Ω

LX

0.35 0.58

917µs

28 V

A

Page 4

)

Typical Operating Characteristics

(VCC= 3.3V, V

BATT

= 3.6V, L1 = 10µH, SHDN = LIM = VCC, V

OUT(NOM)

= 18V (Figure 3), TA= +25°C, unless otherwise noted.)

Note 1: The MAX1606 requires a supply voltage between +2.4V and +5.5V; however, the input voltage (V

BATT

) used to power the

inductor can vary from +0.8V to 5.5V.

Note 2: Specifications to -40°C are guaranteed by design and not production tested.

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 3.3V, VCC= BATT = SHDN, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

Minimum LX Off-Time t

SW Leakage Current SW = GND, V

CONTROL INPUTS (SHDN, LIM)

SHDN Input Threshold

SHDN Input Bias Current I

LIM Input Low Level 2.4V ≤ VCC ≤ 5.5V 0.4 V

LIM Input Float Level

LIM Input High Level 2.4V ≤ VCC ≤ 5.5V

LIM Input Bias Current I

PMOS ISOLATION SWITCH (BATT to SW)

PMOS Current Limit VCC = 2.5V, V

PMOS On-Resistance R

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

OFF

V

V

SHDN

VFB > 1.1V 0.75 1.25

VFB < 0.8V (soft-start) 3.8 6.0

= 5.5V

BATT

IH

IL

2.4V ≤ VCC ≤ 5.5V

2.4V ≤ VCC ≤ 5.5V

VCC = 5.5V, V

2.4V ≤ V

I

= ±0.5µA

LIM

CC

SHDN

≤ 5.5V,

= 0 to 5.5V -1 1 µA

0.8 ×

V

CC

( V

C C

- 0.25V

V

CC

/ 2)

0.2 ×

( V

+ 0.25V

- 0.4V

LIM

DS(ON

SHDN = VCC, LIM = GND or V

CC

SHDN = GND 1

= 1.5V 0.65 1.5 A

BATT

VCC = 2.5V, V

= 1.5V, ISW = 100mA 0.4 Ω

BATT

-2 2

V

C C

1

CC

/ 2)

µs

µA

V

V

V

µA

OUTPUT VOLTAGE vs. SUPPLY VOLTAGE

18.2

18.1

18.0

17.9

17.8

OUTPUT VOLTAGE (V)

17.7

17.6

2.0 3.5 4.02.5 3.0 4.5 5.0 5.5

18.2

MAX1606 toc01

I

OUT

I

OUT

VCC (V)

= 5mA

= 1mA

18.1

18.0

17.9

17.8

OUTPUT VOLTAGE (V)

17.7

17.6

OUTPUT VOLTAGE vs. BATTERY VOLTAGE

I

= 5mA

OUT

I

= 1mA

OUT

0231 456

V

(V)

BATT

18.2

18.1

MAX1606 toc02

18.0

17.9

17.8

OUTPUT VOLTAGE (V)

17.7

17.6

OUTPUT VOLTAGE vs. LOAD CURRENT

LIM = GND

LIM = OPEN

0105 152025

LOAD CURRENT (mA)

LIM = V

CC

MAX1606 toc03

Page 5

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(VCC= 3.3V, V

BATT

= 3.6V, L1 = 10µH, SHDN = LIM = VCC, V

OUT(NOM)

= 18V (Figure 3), TA= +25°C, unless otherwise noted.)

EFFICIENCY vs. SUPPLY VOLTAGE

100

I

= 5mA

90

80

70

EFFICIENCY (%)

60

50

40

2.0 3.5 4.02.5 3.0 4.5 5.0 5.5

OUT

I

= 1mA

OUT

L1 = 10µH, LIM = V

L1 = 100µH, LIM = OPEN

VCC (V)

EFFICIENCY vs. LOAD CURRENT

(L1 = 47µH)

100

90

80

70

EFFICIENCY (%)

60

50

LIM = OPEN

LIM = GND

CC

LIM = V

EFFICIENCY vs. BATTERY VOLTAGE

100

90

MAX1606 toc04

80

70

60

50

EFFICIENCY (%)

40

30

20

021 3456

EFFICIENCY vs. LOAD CURRENT

(L1 = 100µH)

100

90

MAX1607 toc07

CC

80

70

EFFICIENCY (%)

60

50

LIM = OPEN

LIM = GND

EFFICIENCY vs. LOAD CURRENT

(L1 = 10µH)

MAX1606 toc05

100

90

80

70

EFFICIENCY (%)

60

50

40

0105 152025

LIM = OPEN

LIM = GND

LOAD CURRENT (mA)

I

= 5mA

OUT

I

= 1mA

OUT

L1 = 10µH, LIM = V

L1 = 100µH, LIM = OPEN

V

(V)

BATT

CC

PEAK INDUCTOR CURRENT LIMIT

vs. SUPPLY VOLTAGE

600

V

= 3.6V

BATT

500

MAX1607 toc08

400

LIM = V

CC

300

200

CURRENT LIMIT (mA)

100

LIM = V

LIM = V

CC

LIM = OPEN

LIM = GND

MAX1606 toc06

CC

MAX1606 toc09

40

010155202530

LOAD CURRENT (mA)

PEAK INDUCTOR CURRENT LIMIT

vs. BATTERY VOLTAGE

600

VCC = 3.3V

500

400

300

200

CURRENT LIMIT (mA)

100

0

0.5 2.51.5 3.5 4.5 5.5

V

BATT

(V)

LIM = V

LIM = OPEN

LIM = GND

CC

MAX1606 toc10

40

010155202530

LOAD CURRENT (mA)

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

180

160

140

120

100

(mA)

CC

I

80

60

40

20

0

021345

VCC (V)

MAX1606 toc11

0

2.0 3.5 4.02.5 3.0 4.5 5.0 5.5

VCC (V)

SUPPLY CURRENT

vs. LOAD CURRENT

4.0

3.5

3.0

2.5

(mA)

2.0

CC

I

1.5

1.0

0.5

0

0 5 10 15 20 25

LIM = GND

(125mA)

LIM = OPEN

(250mA)

LOAD CURRENT (mA)

LIM = V

(500mA)

MAX1606 toc12

CC

Page 6

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

6 _______________________________________________________________________________________

Pin Description

Typical Operating Characteristics (continued)

(VCC= 3.3V, V

BATT

= 3.6V, L1 = 10µH, SHDN = LIM = VCC, V

OUT(NOM)

= 18V (Figure 3), TA= +25°C, unless otherwise noted.)

0

17.9V

500mA

18.1V

18V

0

10mA

40µs/div

LOAD TRANSIENT

MAX1606 toc14

A: I

OUT

= 1mA TO 10mA, 10mA/div

B: V

OUT

= 18V, 100mV/div

C: I

L1

, 500mA/div

A

B

C

6V

4V

2V

18.1V

18V

17.9V

LINE TRANSIENT

MAX1606 toc13

A

B

500mA

20V

10V

SHUTDOWN WAVEFORM

4V

2V

0

0

0

MAX1606 toc15

A

B

C

400µs/div

= 1.8kΩ

OUT

A: V

= VCC = 2.4V TO 5.5V, 2V/div

BATT

= 18V, R

B: V

OUT

OUT

100µs/div

= 3.6kΩ, 100mV/div

A: V

B: V

C: I

L1

, 2V/div

SHDN

, 10V/div, R

OUT

, 500mA/div

PIN NAME FUNCTION

Inductor Supply Voltage, 0.8V to 5.5V. Internally connected to the source of a P-channel

1 BATT

2FB

3VCCIC Supply Voltage, 2.4V to 5.5V. Bypass VCC to GND with a 1µF or greater capacitor.

4 GND Ground

5LX

6 LIM

7 SHDN

8SW

MOSFET used to isolate the output from the input during shutdown. Bypass with a 10µF or

greater capacitor.

Feedback Input. Connect to a resistive divider network between the output and GND to set the

output voltage between V

and 28V. The feedback threshold is 1.25V.

BATT

Inductor Switching Connection. Internally connected to the drain of a 28V N-channel MOSFET.

LX is high impedance in shutdown.

Inductor Current-Limit Selection. Connect LIM to V

for 500mA, leave LIM floating for 250mA,

CC

or connect LIM to GND for 125mA.

Active-Low Shutdown Input. A logic low shuts down the device and reduces the supply current

to 0.1µA. When shutdown, the MAX1606 isolates the output from the input by turning off the Pchannel MOSFET between BATT and SW. Connect SHDN to V

for normal operation.

CC

Isolation Switch Output, Inductor Connection. Internally connected to the drain of a P-channel

MOSFET used to isolate the output from the input during shutdown.

Page 7

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

_______________________________________________________________________________________ 7

Detailed Description

The MAX1606 step-up DC-DC converter operates from a

2.4V to 5.5V supply and converts voltages as low as

0.8V up to 28V. The device includes an internal switching MOSFET with a 0.8Ω on-resistance and selectable

current limit (Figure 1) and consumes 160µA of supply

current. During startup, the MAX1606 extends the minimum off-time, limiting initial battery surge current. The

MAX1606 uses a P-channel MOSFET to isolate the output from the input during true shutdown mode. This isolation switch also includes short-circuit current limiting,

which protects the inductor and diode during a short-circuit fault.

Control Scheme

The MAX1606 features a minimum off-time, current-limited control scheme. The duty cycle is governed by a pair

of one-shots that set a minimum off-time and a maximum

on-time. The switching frequency can be up to 500kHz

and depends upon the load and input voltage. The peak

current limit of the internal N-channel MOSFET is pin

selectable and may be set at 125mA, 250mA, or 500mA

(Figure 2).

Figure 1. Functional Diagram

Figure 2. Setting the Peak Inductor Current Limit

VIN = 0.8V TO 5.5V BATT

SW

C2

= 2.4V TO 5.5V

V

CC

C1

ON

OFF

V

CC

(2.4V TO 5.5V)

V

CC

V

CC

LIM

SHDN

SHUTDOWN

LOGIC

V

CC

(2.4V TO 5.5V)

LOGIC

CONTROL

ERROR

AMPLIFIER

V

CC

MAX1606

CURRENT

LIMIT

1.25V

L1

10µH

LX

N

I

LIM

FB

V

CC

(2.4V TO 5.5V)

D1

C

FF

V

CC

V

= V

TO 28V

OUT

IN

C

OUT

R1

R2

MAX1606 MAX1606 MAX1606

LIM

GND

I

= 500mA I

PEAK

NO CONNECTION

LIM

GND

= 250mA I

PEAK

LIM

GND

PEAK

= 125mA

Page 8

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

8 _______________________________________________________________________________________

Setting the Output Voltage (FB)

Adjust the output voltage by connecting a voltagedivider from the output (V

OUT

) to FB (Figure 3). Select

R2 between 10kΩ and 200kΩ. Calculate R1 with the following equation:

R1 = R2 [(V

OUT

/ VFB) – 1]

where VFB= 1.25V and V

OUT

may range from V

BATT

to

28V. The input bias current of FB has a maximum value

of 100nA, which allows large-value resistors to be used.

For less than 1% error, the current through R2 should

be greater than 100 times the feedback input bias current (IFB).

Current-Limit Select Pin (LIM)

The MAX1606 allows a selectable inductor current limit

of 125mA, 250mA, or 500mA (Figure 2). This allows

flexibility in designing for higher current applications or

for smaller, compact designs. The lower current limit

allows the use of a physically smaller inductor in spacesensitive, low-power applications. Connect LIM to V

CC

for 500mA, leave floating for 250mA, or connect to

GND for 125mA.

Shutdown (

SHDN

)

Pull SHDN low to enter shutdown. During shutdown the

supply current drops to 0.1µA, the output is disconnected from the input, and LX enters a high-impedance

state. The capacitance and load at the output determine the rate at which V

OUT

decays. SHDN can be

pulled as high as 6V, regardless of the input and output

voltages.

With the typical step-up converter circuit, the output

remains connected to the input through the inductor and

output rectifier, holding the output voltage to one diode

drop below V

IN

when the converter is shutdown and

allowing the output to draw power from the input. The

MAX1606 features true shutdown, which uses an internal

P-channel MOSFET to disconnect the output from the

input when the MAX1606 is shutdown. This eliminates

power drawn from the input during shutdown.

Separate/Same Power for V

BATT

and V

CC

Separate voltage sources can supply the inductor

(V

BATT

) and the IC (VCC). Since the chip bias is provided by a logic supply (2.4V to 5.5V), this allows the output power to be sourced directly from low-voltage

batteries (0.8V to 5.5V). Conversely, V

BATT

and V

CC

can also be supplied from one supply if it remains within VCC’s operating limits (2.4V to 5.5V).

Design Procedure

Inductor Selection

Smaller inductance values typically offer smaller physical size for a given series resistance or saturation current. Circuits using larger inductance values may start

up at lower input voltages and exhibit less ripple, but

also provide reduced output power. This occurs when

the inductance is sufficiently large to prevent the maximum current limit from being reached before the maximum on-time expires. The inductor’s saturation current

rating should be greater than the peak switching current. However, it is generally acceptable to bias the

inductor into saturation by as much as 20%, although

this will slightly reduce efficiency.

Picking the Current Limit

The peak LX current limit (I

LX(MAX)

) required for the

application may be calculated from the following equation:

where t

OFF(MIN)

= 0.8µs, and V

BATT(MIN)

is the minimum voltage used to supply the inductor. The set current limit must be greater than this calculated value.

Select the appropriate current limit by connecting LIM

to VCC, GND, or leaving it unconnected (see Current-

Limit Select Pin and Figure 2).

Diode Selection

The high switching frequency of 500kHz requires a highspeed rectifier. Schottky diodes, such as the Motorola

MBRS0530 or the Nihon EP05Q03L, are recommended.

To maintain high efficiency, the average current rating of

the Schottky diode should be greater than the peak

Figure 3. Typical Application Circuit

L1

10µH

V

= 0.8V TO 5.5V

BATT

C2

10µF

= 2.4V TO 5.5V

V

CC

C1

1µF

ON

OFF

SW

BATT

V

CC

LIM

SHDN

MAX1606

GND

D1

LX

C

FF

10pF

FB

1MΩ

75k

V

OUT

R1

R2

= 18V

C

OUT

1µF

I

LX MAX

()

VI

×

OUT OUT MAX

≥

V

BATT MIN

()

()

VV t

OUT BATT MIN OFF MIN

()

+

−

×

() ()

L

×2

Page 9

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

_______________________________________________________________________________________ 9

switching current. Choose a reverse breakdown voltage

greater than the output voltage.

Capacitors

For most applications, use a small 1µF ceramic surface-mount output capacitor. For small ceramic capacitors, the output ripple voltage is dominated by the

capacitance value. If tantalum or electrolytic capacitors

are used, the higher ESR increases the output ripple

voltage. Decreasing the ESR reduces the output ripple

voltage and the peak-to-peak transient voltage.

Surface-mount capacitors are generally preferred

because they lack the inductance and resistance of

their through-hole equivalents.

Two inputs, VCCand V

BATT

, require bypass capacitors.

Bypass VCCwith a 1µF ceramic capacitor as close to

the IC as possible. The BATT input supplies high currents to the inductor and requires local bulk bypassing

close to the inductor. A 10µF low-ESR surface-mount

capacitor is sufficient for most applications.

A feed-forward capacitor connected from the output to

FB improves stability over a wide range of battery voltages. A 10pF capacitor is sufficient for most applications. Larger values (up to 47pF) may be needed with

lower current-limit settings (LIM = GND or open) and

low input voltages, or with nonoptimum PC board layouts. Note that increasing CFFmay slightly affect load

regulation.

PC Board Layout and Grounding

Careful printed circuit layout is important for minimizing

ground bounce and noise. Keep the MAX1606’s

ground pin and the ground leads of the input and output capacitors less than 0.2in (5mm) apart. In addition,

keep all connections to FB and LX as short as possible.

In particular, external feedback resistors should be as

close to FB as possible. To minimize output voltage ripple, and to maximize output power and efficiency, use a

ground plane and solder GND directly to the ground

plane. Refer to the MAX1606EVKIT evaluation kit for a

layout example.

Applications Information

Negative Voltage for LCD Bias

The MAX1606 can also generate a negative output by

adding a diode-capacitor charge-pump circuit (D1, D2,

and C3) to the LX pin as shown in Figure 4. Feedback

is still connected to the positive output, which is not

loaded, allowing a very small capacitor value at C4. For

best stability and lowest ripple, the time constant of the

R1-R2 series combination and C4 should be near or

less than that of C2 and the effective load resistance.

Output load regulation of the negative output is somewhat looser than with the standard positive output circuit, and may rise at very light loads due to coupling

through the capacitance of D2. If this is objectionable,

reduce the resistance of R1 and R2, while maintaining

their ratio, to effectively preload the output with a few

hundred microamps. This is why the R1-R2 values

shown in Figure 4 are about four-times lower than typical values used for a positive-output design. When

loaded, the negative output voltage will be slightly

lower (closer to ground by approximately a diode forward voltage) than the inverse of the voltage on C4.

Figure 4. Negative Voltage for LCD Bias

Chip Information

TRANSISTOR COUNT: 3883

= 0.8V TO 5.5V

V

IN

C5

10µF

V

= 2.4V TO 5.5V

CC

C6

1µF

ON

OFF

SW

BATT

V

CC

LIM

SHDN

L1

10µH

MAX1606

D1, D2 = CENTRAL SEMICONDUCTOR

CMPD7000 (DUAL)

D3 = CENTRAL SEMICONDUCTOR

CMSD4448 (1N4148)

1Ω

D1

R3

D3

C1

0.1µF

LX

FB

GND

C4

0.01µF

C2

1µF

R1

240k

V

NEG

R2

16.5k

= -19V

C1

1nF

D2

Page 10

MAX1606

28V Internal Switch LCD Bias Supply

with True Shutdown

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

10 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2000 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

Loading...

Loading...