Page 1

General Description

The MAX1566/MAX1567 provide a complete powersupply solution for digital cameras. They improve performance, component count, and size compared to conventional multichannel controllers in 2-cell AA,

1-cell lithium-ion (Li+), and dual-battery designs. On-chip

MOSFETs provide up to 95% efficiency for critical power

supplies, while additional channels operate with external

FETs for optimum design flexibility. This optimizes overall

efficiency and cost, while also reducing board space.

The MAX1566/MAX1567 include six high-efficiency DCto-DC conversion channels:

• Step-up DC-to-DC converter with on-chip power FETs

• Main DC-to-DC converter with on-chip FETs, configurable to step either up or down

• Step-down core DC-to-DC converter with on-chip

FETs

• DC-to-DC controller for white LEDs or other output

• Extra DC-to-DC controller (typically for LCD); two

extra controllers on the MAX1566

• Transformerless inverting DC-to-DC controller (typically for negative CCD bias) on the MAX1567

All DC-to-DC channels operate at one fixed frequency

settable from 100kHz to 1MHz to optimize size, cost, and

efficiency. Other features include soft-start, power-OK

outputs, and overload protection. The MAX1566/

MAX1567 are available in space-saving 40-pin thin QFN

packages. An evaluation kit is available to expedite

designs.

Applications

Digital Cameras

PDAs

Features

♦ 95% Efficient Step-Up DC-to-DC Converter

♦ 0.7V Minimum Input Voltage

♦ Main DC-to-DC Configurable as Either Step-Up or

Step-Down

♦ Combine Step-Up and Step-Down for 90%

Efficient Boost-Buck

♦ 95% Efficient Step-Down for DSP Core

♦ Regulate LED Current for Four, Six, or More LEDs

♦ Open LED Overvoltage Protection

♦ Transformerless Inverting Controller (MAX1567)

♦ Three Extra PWM Controllers (Two on the

MAX1567)

♦ Up to 1MHz Operating Frequency

♦ 1µA Shutdown Mode

♦ Soft-Start and Overload Protection

♦ Compact 40-Pin 6mm x 6mm Thin QFN Package

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

________________________________________________________________ Maxim Integrated Products 1

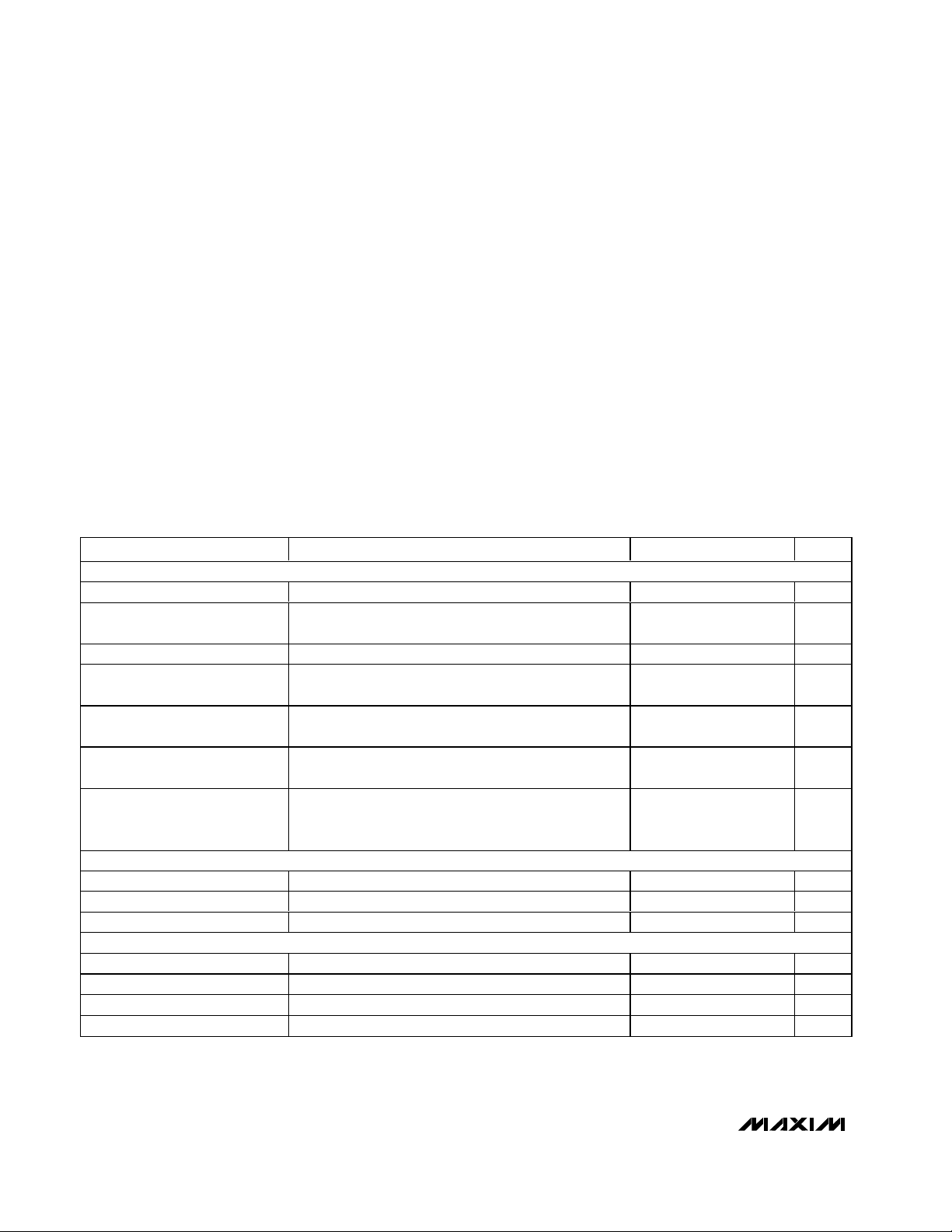

Pin Configuration

Ordering Information

19-2882; Rev 0; 5/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

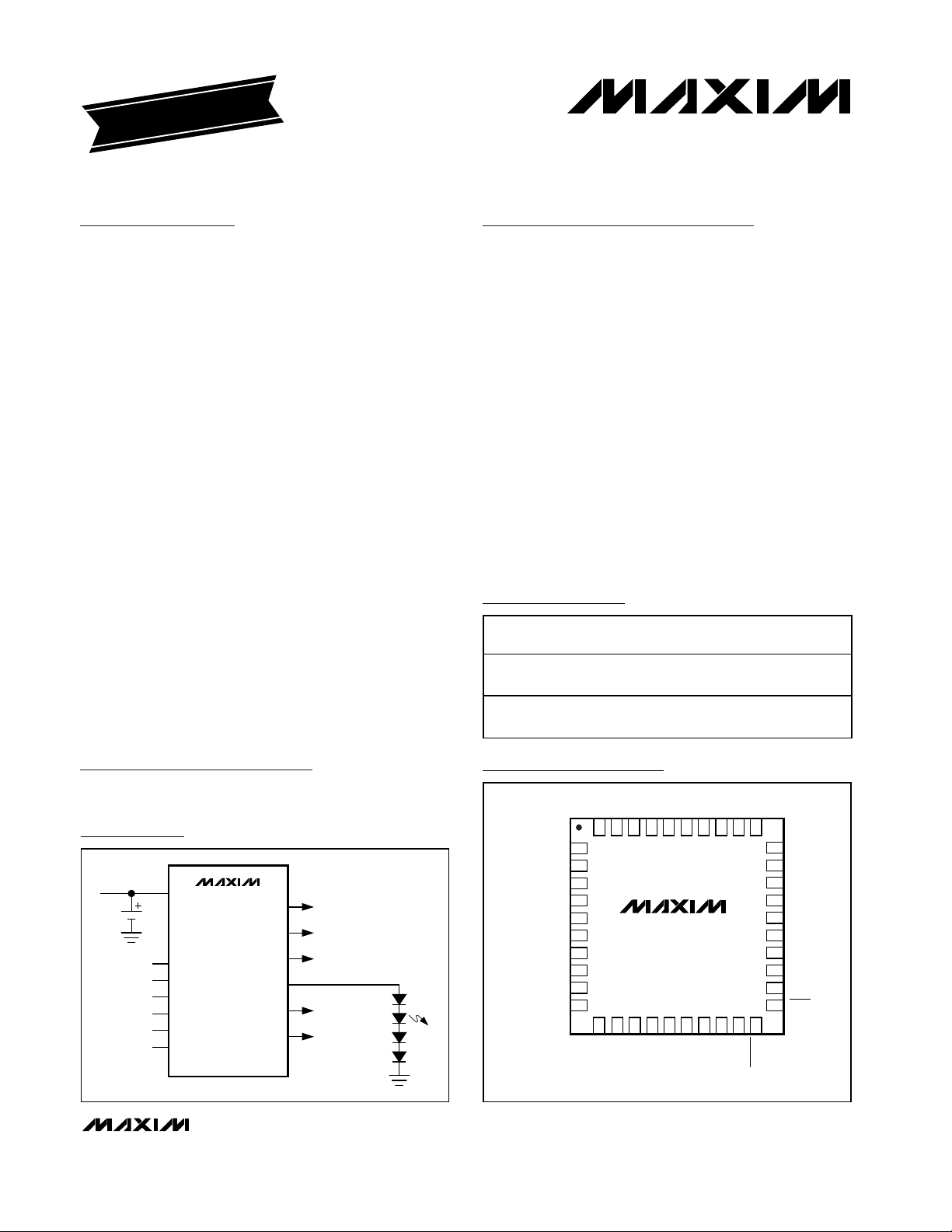

Typical Operating Circuit

PART TEMP RANGE PIN-PACKAGE

MAX1566ETL -40°C to +85°C

MAX1567ETL -40°C to +85°C

40 Thin QFN

6mm x 6mm

40 Thin QFN

6mm x 6mm

AUX2

FUNCTION

Step-up

controller

Inverting

controller

Li+ OR 2AA

BATTERY INPUT

ONSU

ONM

ONSD

ON3(LED)

ON1

ON2

MAX1567

STEP-UP

MAIN DC-TO-DC

STEP-DN

AUX3

AUX1

AUX2

SYSTEM 5V

3.3V LOGIC

1.8V CORE

CCD/LCD + 15V

CCD - 7.5V

LEDS

TOP VIEW

FB3H

CC1

FB1

ON1

PGSD

LXSD

PVSD

ONSD

FBSD

CCSD

ON3

40 36373839

1

2

3

4

5

6

7

8

9

10

11

12

SUSD

FB3L

CC3

PV

DL1

DL3

DL2

GND

INDL2

3435

33

MAX1566/MAX1567

18

CCM

15

14

13

REF

FBM

ONM

CCSU

FBSU

19 2016 17

ONSU

SCF

FB2

3132

30

29

28

27

26

25

24

23

22

21

AUX1OK

6mm x 6mm

THIN QFN

CC2

ON2

PVM

LXM

PGM

PVSU

LXSU

PGSU

OSC

SDOK

Page 2

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

PV, PVSU, SDOK, AUX1OK, SCF, ON_, FB_,

SUSD to GND ....................................................... -0.3V to +6V

PG_ to GND...........................................................-0.3V to +0.3V

DL1, DL3, INDL2, PVM, PVSD to GND …-0.3V to (PVSU + 0.3V)

DL2 to GND ............................................-0.3V to (INDL2 + 0.3V)

LXSU Current (Note 1) ..........................................................3.6A

LXM Current (Note 1) ............................................................3.6A

LXSD Current (Note 1) ........................................................2.25A

REF, OSC, CC_ to GND...........................-0.3V to (PVSU + 0.3V)

Continuous Power Dissipation (T

A

= +70°C)

40-Pin Thin QFN (derate 26.3mW/°C above +70°C) .2105mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

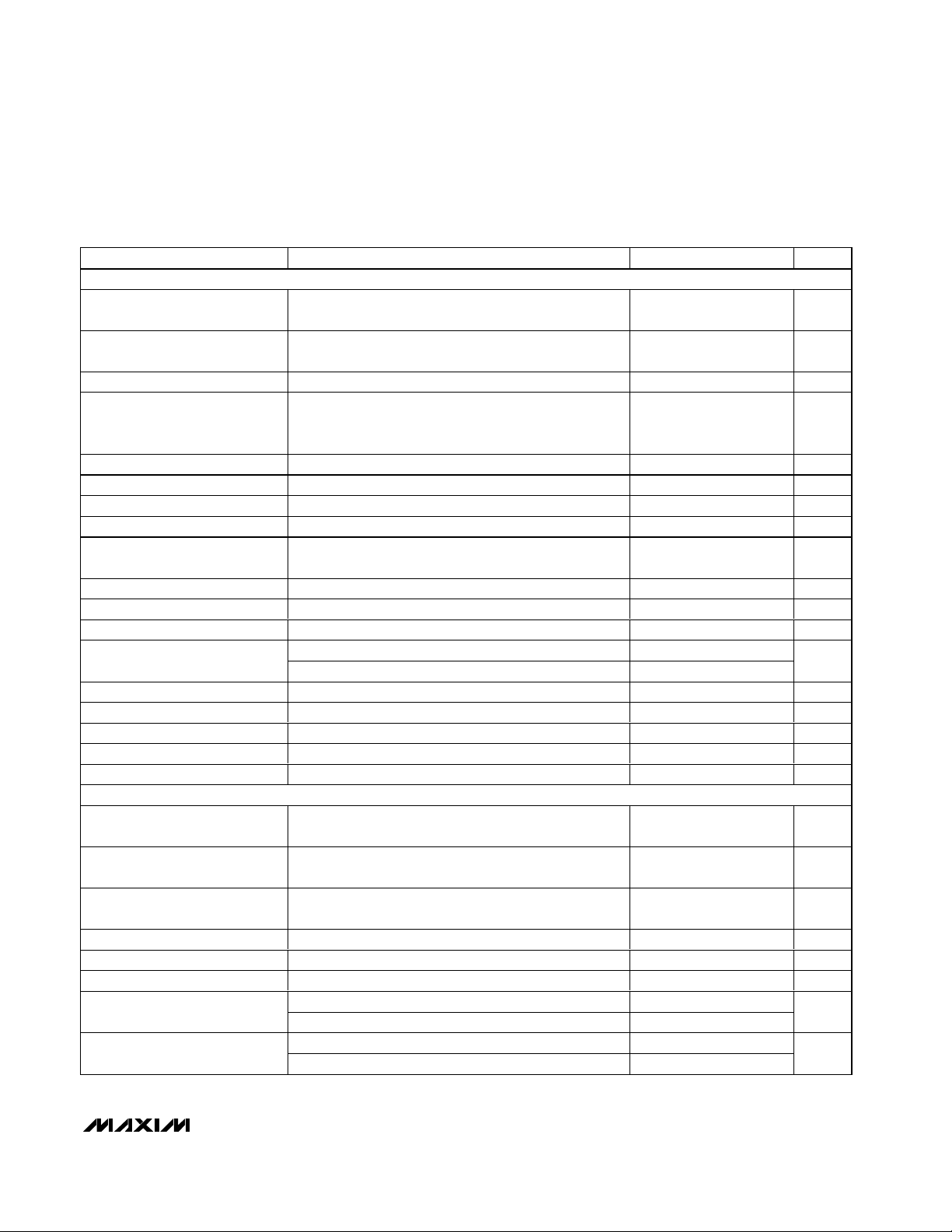

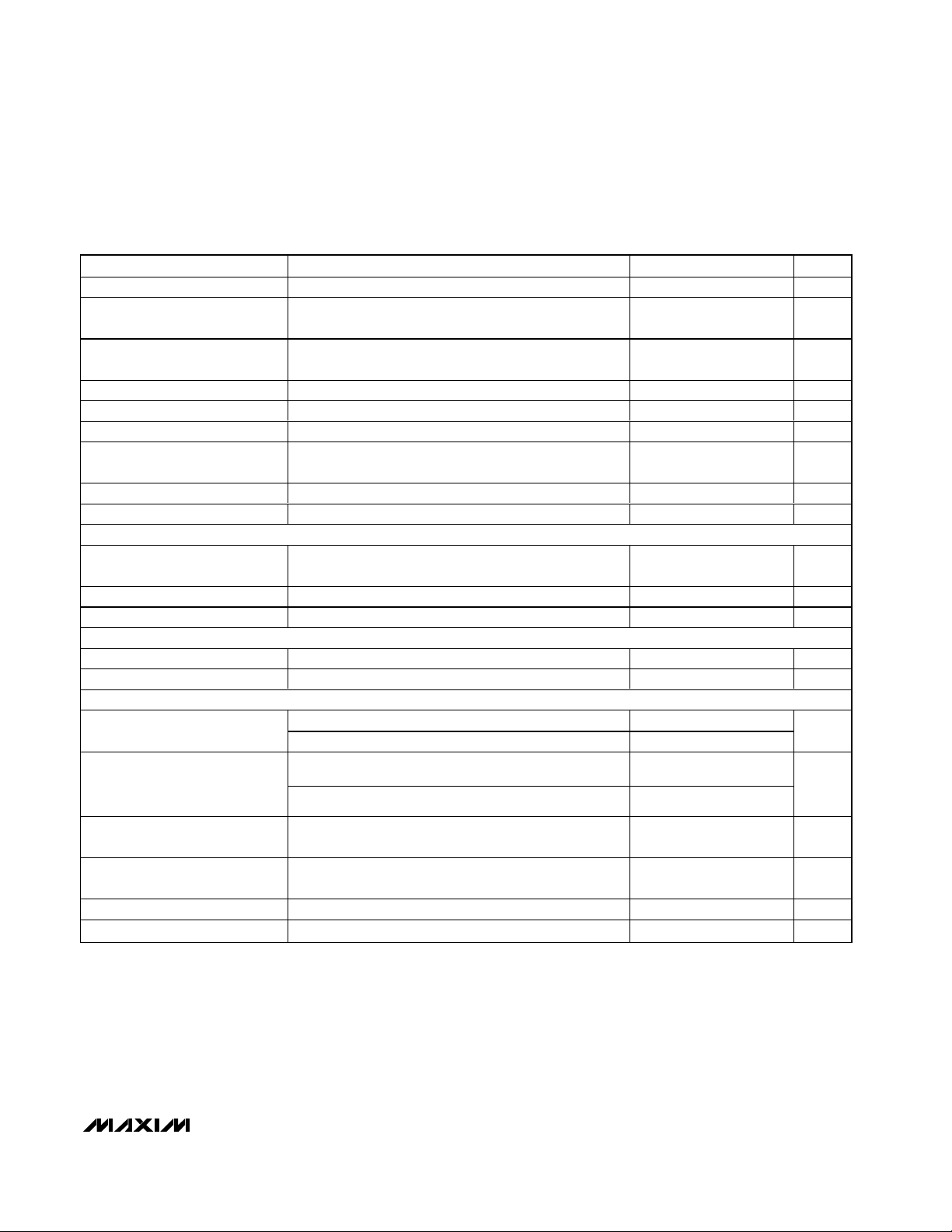

ELECTRICAL CHARACTERISTICS

(V

PVSU

= VPV= V

PVM

= V

PVSD

= V

INDL2

= 3.6V, TA= 0°C to +85°C, unless otherwise noted.)

Note 1: LXSU has internal clamp diodes to PVSU and PGSU, LXM has internal clamp diodes to PVM and PGM, and LXSD has inter-

nal clamp diodes to PVSD and PGSD. Applications that forward bias these diodes should take care not to exceed the

devices’ power dissipation limits.

PARAMETER CONDITIONS MIN TYP MAX UNITS

GENERAL

Input Voltage Range (Note 2) 0.7 5.5 V

Step-Up Minimum Startup

Voltage (Note 2)

I

< 1mA, TA = +25°C; startup voltage tempco is

LOAD

-2300ppm/°C (typ) (Note 3)

Shutdown Supply Current into PV PV = 3.6V 0.1 10 µA

Supply Current into PV with Step-

Up Enabled

Supply Current into PV with Step-

Up and Step-Down Enabled

Supply Current into PV with Step-

Up and Main Enabled

Total Supply Current from PV and

PVSU with Step-Up and One

AUX Enabled

ONSU = 3.6V, FBSU = 1.5V

(does not include switching losses)

ONSU = ONSD = 3.6V, FBSU = 1.5V, FBSD = 1.5V

(does not include switching losses)

ONSU = ONM = 3.6V, FBSU = 1.5V, FBSD = 1.5V

(does not include switching losses)

ONSU = ON1 = 3.6V, FBSU = 1.5V, FB2 = 1.5V

(does not include switching losses)

REFERENCE

Reference Output Voltage I

Reference Load Regulation 10µA < I

= 20µA 1.23 1.25 1.27 V

REF

< 200µA 4.5 10 mV

REF

Reference Line Regulation 2.7 < PVSU < 5.5V 1.3 5 mV

OSCILLATOR

OSC Discharge Trip Level Rising edge 1.225 1.25 1.275 V

OSC Discharge Resistance OSC = 1.5V, I

= 3mA 52 80 Ω

OSC

OSC Discharge Pulse Width 150 ns

OSC Frequency R

= 47kΩ, C

OSC

= 100pF 500 kHz

OSC

0.9 1.1 V

300 450 µA

450 700 µA

450 700 µA

400 650 µA

Page 3

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

_______________________________________________________________________________________ 3

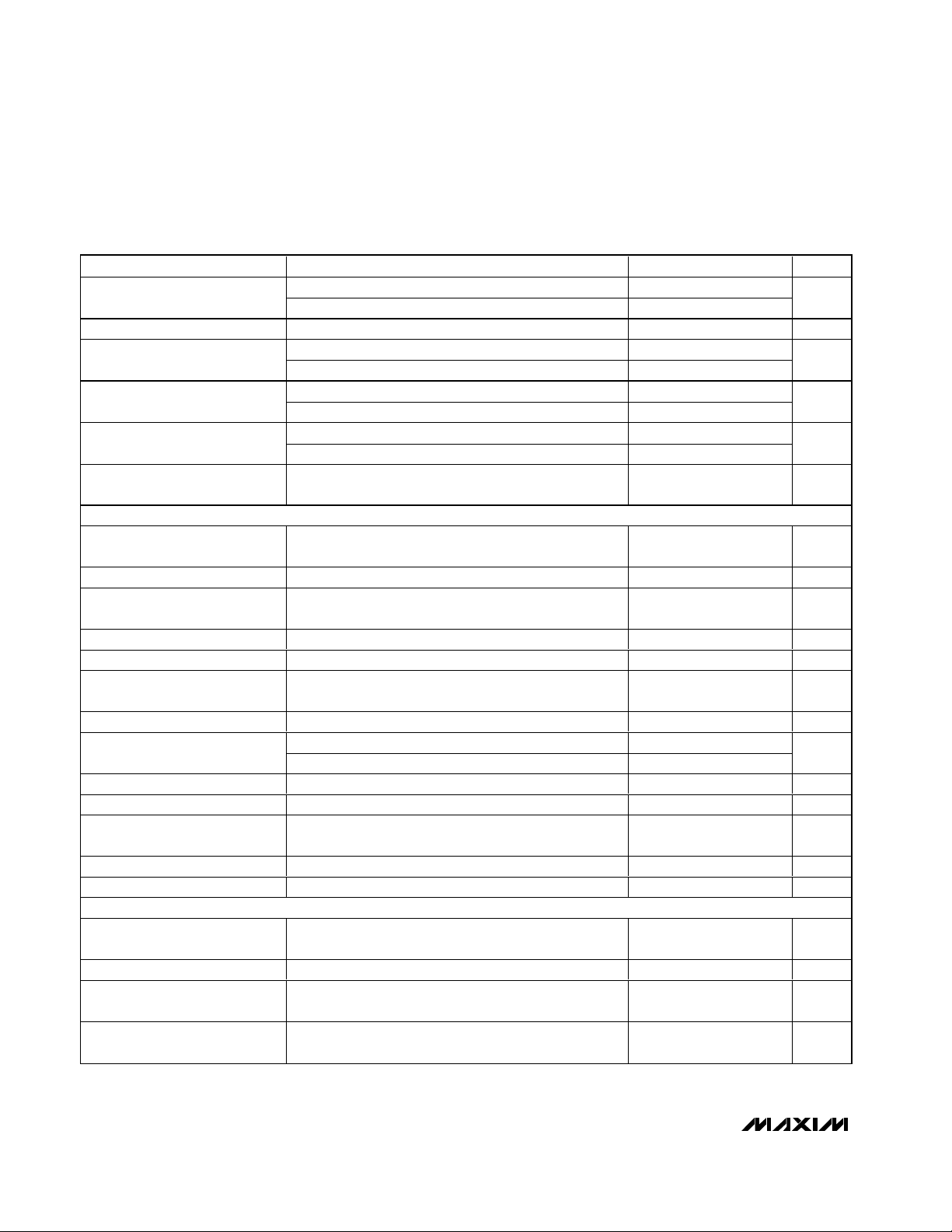

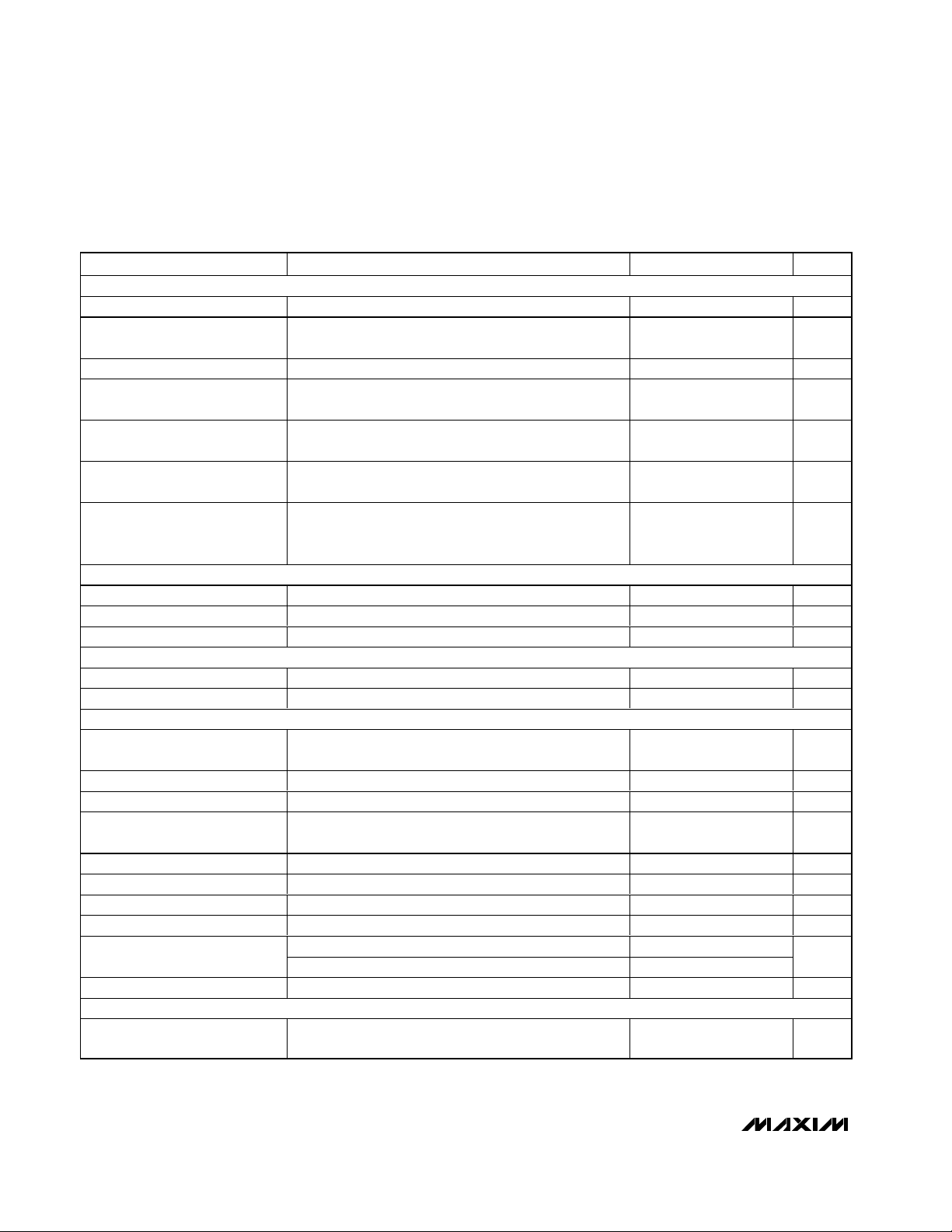

ELECTRICAL CHARACTERISTICS (continued)

(V

PVSU

= VPV= V

PVM

= V

PVSD

= V

INDL2

= 3.6V, TA= 0°C to +85°C, unless otherwise noted.)

Idle Mode is a trademark of Maxim Integrated Products, Inc.

PARAMETER CONDITIONS MIN TYP MAX UNITS

STEP-UP DC-TO-DC

Step-Up Startup-to-Normal

Operating Threshold

Step-Up Startup-to-Normal

Operating Threshold Hysteresis

Rising edge or falling edge (Note 4) 2.30 2.5 2.65 V

80 mV

Step-Up Voltage Adjust Range 3.0 5.5 V

Start Delay of ONSD, ONM,

ON1, ON2, and ON3 after

SU in Regulation

1024

OSC

cycles

FBSU Regulation Voltage 1.231 1.25 1.269 V

FBS U to C C S U Tr anscond uctance FBSU = CCSU 80 135 185 µS

FBSU Input Leakage Current FBSU = 1.25V -100 0.01 +100 nA

Idle Mode

Current-Sense Amplifier

Transresistance

TM

Trip Level 150 mA

0.275 V/A

Step-Up Maximum Duty Cycle FBSU = 1V 80 85 90 %

PVSU Leakage Current V

LXSU Leakage Current V

Switch On-Resistance

= 0V, PVSU = 3.6V 0.1 5 µA

LX

LX

= V

OUT

= 3.6V

0.1 5 µA

N channel 95 150

P channel 150 250

mΩ

N-Channel Current Limit 1.8 2.1 2.4 A

P-Channel Turn-Off Current 20 mA

Startup Current Limit PVSU = 1.8V (Note 5) 450 mA

Startup t

OFF

PVSU = 1.8V 700 ns

Startup Frequency PVSU = 1.8V 200 kHz

MAIN DC-TO-DC CONVERTER

Main Step-Up Voltage

Adjust Range

Main Step-Down Voltage

Adjust Range

PVM Undervoltage Lockout in

Step-Down Mode

SUSD = PVSU 3 5.5 V

SUSD = GND, PVM must be greater than output (Note 6) 2.45 5.00 V

SUSD = GND (Note 6) 2.45 2.5 2.55 V

Regulation Voltage 1.231 1.25 1.269 V

FBM to CCM Transconductance FBM = CCM 80 135 185 µS

FBM Input Leakage Current FBM = 1.25V -100 0.01 +100 nA

Idle Mode Trip Level

Current-Sense Amplifier

Transresistance

Step-up mode (SUSD = PVSU) 150

Step-down mode (SUSD = GND) 100

Step-up mode (SUSD = PVSU) 0.25

Step-down mode (SUSD = GND) 0.5

mA

V/A

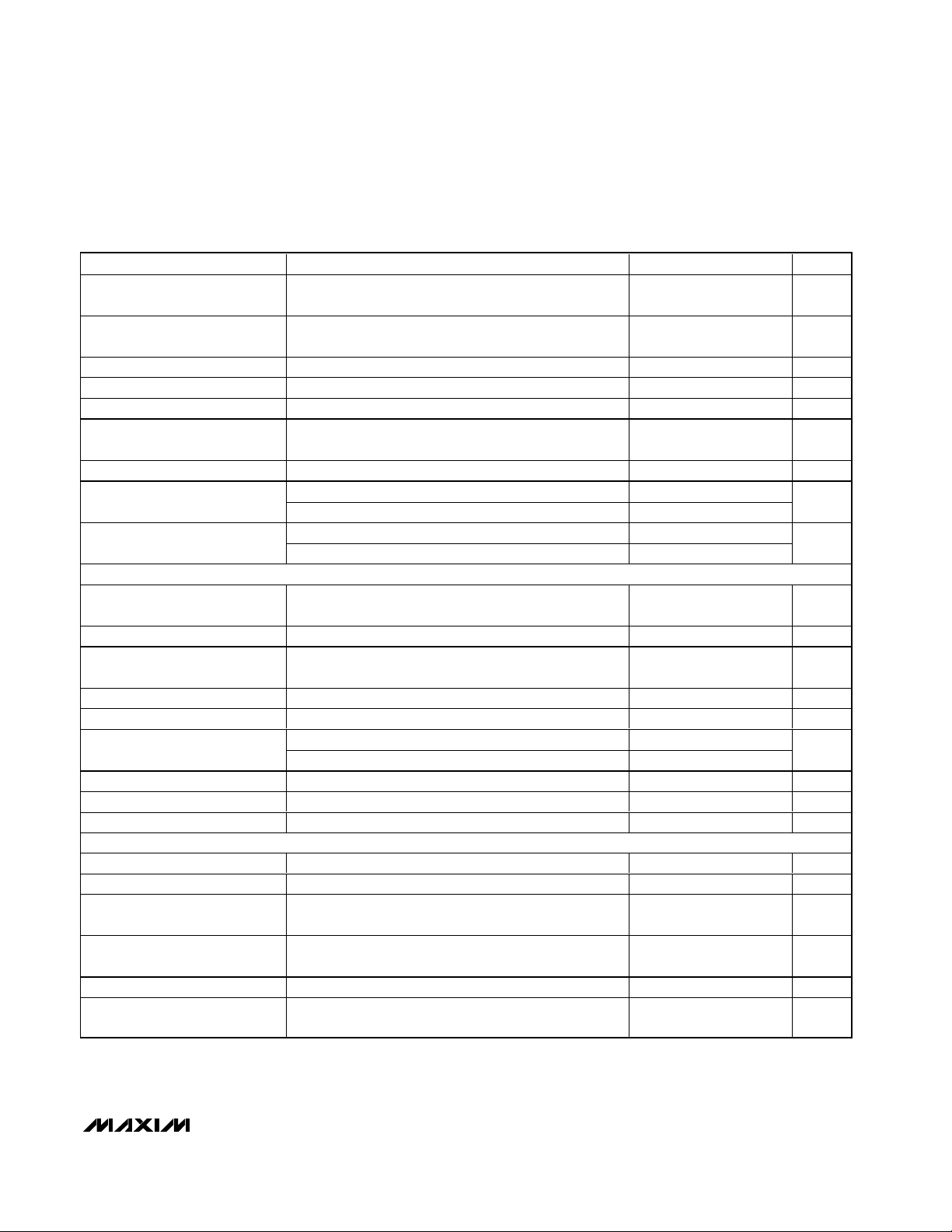

Page 4

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

PVSU

= VPV= V

PVM

= V

PVSD

= V

INDL2

= 3.6V, TA= 0°C to +85°C, unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Maximum Duty Cycle (Note 6)

LXM Leakage Current V

Switch On-Resistance

Main Switch Current Limit

Synchronous Rectifier

Turn-Off Current

Soft-Start Interval 4096

STEP-DOWN DC-TO-DC CONVERTER

Step-Down Output-Voltage Adjust

Range

FBSD Regulation Voltage 1.231 1.25 1.269 V

FBSD to CCSD

Transconductance

FBSD Input Leakage Current FBSD = 1.25V -100 0.1 +100 nA

Idle Mode Trip Level 100 mA

Current-Sense Amplifier

Transresistance

LXSD Leakage Current V

Switch On-Resistance

P-Channel Current Limit 0.65 0.77 0.90 A

N-Channel Turn-Off Current 20 mA

Soft-Start Interval 2048

SDOK Output Low Voltage 0.1mA into SDOK 0.01 0.1 V

SDOK Leakage Current ONSU = GND 0.01 1 µA

AUX1, 2, 3 DC-TO-DC CONTROLLERS

INDL2 Undervoltage

Lockout

Maximum Duty Cycle FB_ = 1V 80 85 90 %

FB1, FB2 (MAX1566), FB3H

Regulation Voltage

FB2 (MAX1567) Inverter

Regulation Voltage

Step-up mode (SUSD = PVSU) 80 85 90

Step-down mode (SUSD = GND) 95

= 0 to 3.6V, PVSU = 3.6V 0.1 5 µA

LXM

N channel 95 150

P channel 150 250

Step-up mode (SUSD = PVSU) 1.8 2.1 2.4

Step-down mode (SUSD = GND) 0.70 0.8 0.95

Step-up mode (SUSD = PVSU) 20

Step-down mode (SUSD = GND) 20

PVSD must be greater than output (Note 7) 1.25 5.00 V

FBSD = CCSD 80 135 185 µS

0.5 V/A

= 0 to 3.6V, PVSU = 3.6V 0.1 5 µA

LXSD

N channel 95 150

P channel 150 250

2.45 2.5 2.55 V

1.231 1.25 1.269 V

-0.01 0 +0.01 V

cycles

cycles

%

mΩ

A

mA

OSC

mΩ

OSC

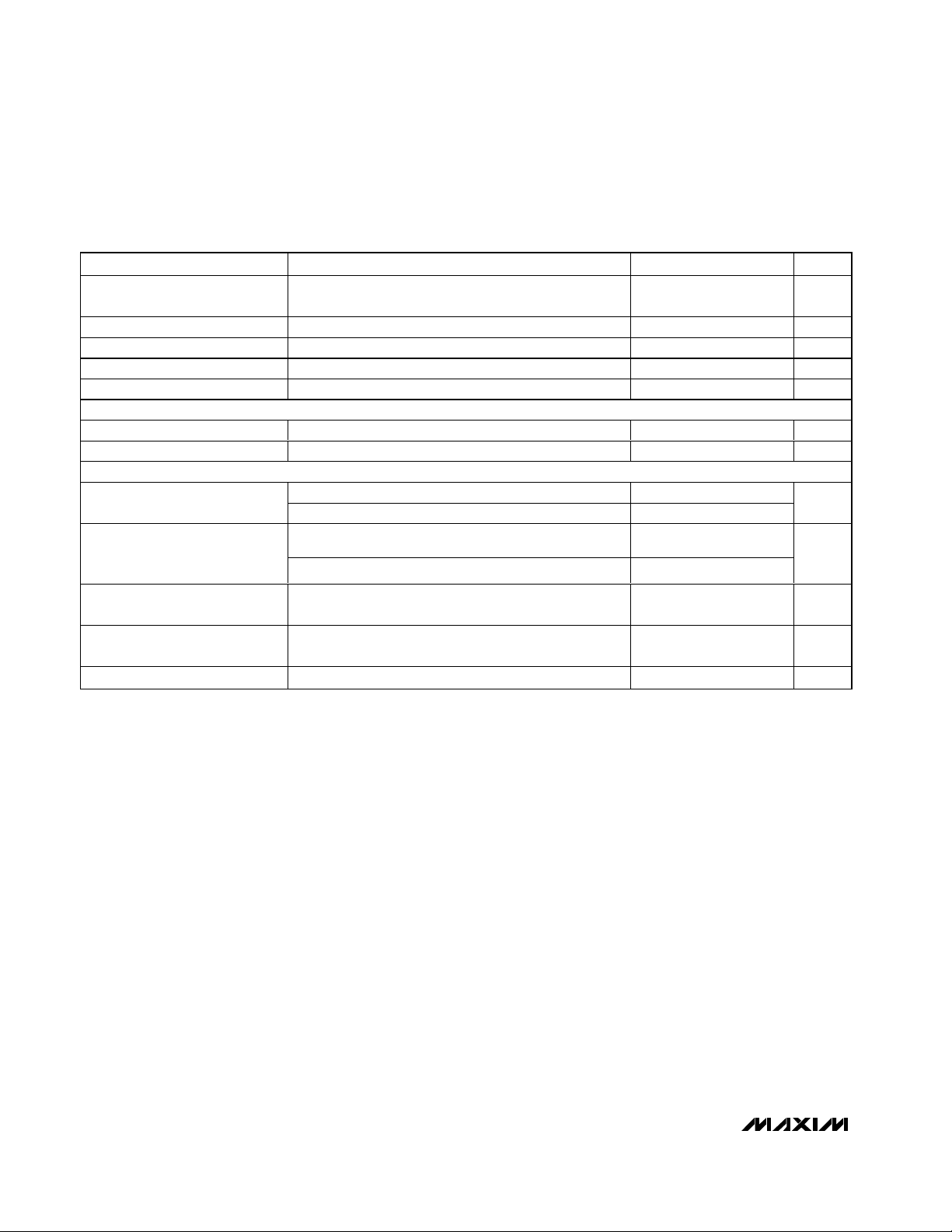

Page 5

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(V

PVSU

= VPV= V

PVM

= V

PVSD

= V

INDL2

= 3.6V, TA= 0°C to +85°C, unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

FB3L Regulation Voltage 0.19 0.2 0.21 V

AUX1, AUX2 FB to CC

Transconductance

AUX3 FBL or FBH to CC

Transconductance

80 135 185 µS

50 100 150 µS

FB_ Input Leakage Current -100 0.1 +100 nA

DL_ Driver Resistance Output high or low 2.5 7 Ω

DL_ Drive Current Sourcing or sinking 0.5 A

OSC

Soft-Start Interval 4096

cycles

AUX1OK Output Low Voltage 0.1mA into AUX1OK 0.01 0.1 V

AUX1OK Leakage Current ONSU = GND 0.01 1 µA

OVERLOAD PROTECTION

OSC

Overload Protection Fault Delay 100,000

cycles

SCF Leakage Current ONSU = PVSU, FBSU = 1.5V 0.1 1 µA

SCF Output Low Voltage 0.1mA into SCF 0.01 0.1 V

THERMAL-LIMIT PROTECTION

Thermal Shutdown 160 °C

Thermal Hysteresis 20 °C

LOGIC INPUTS (ON_, SUSD)

ONSU Input Low Level

ONSU Input High Level

1.1V < PVSU < 1.8V 0.2

1.8V < PVSU < 5.5V 0.4

1.1V < PVSU < 1.8V

(PVSU

- 0.2)

V

V

1.8V < PVSU < 5.5V 1.6

ONM, ONSD, ON1, ON2, ON3,

SUSD Input Low Level

ONM, ONSD, ON1, ON2, ON3,

SUSD Input High Level

2.7V < PVSU < 5.5V (Note 8) 0.4 V

2.7V < PVSU < 5.5V (Note 8) 1.6 V

SUSD Input Leakage 0.1 1 µA

ON_ Impedance to GND 330 kΩ

Page 6

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(V

PVSU

= VPV= V

PVM

= V

PVSD

= V

INDL2

= 3.6V, TA= -40°C to +85°C, unless otherwise noted.)

PARAMETER CONDITIONS MIN MAX UNITS

GENERAL

Input Voltage Range (Note 2) 0.7 5.5 V

Step-Up Minimum Startup

Voltage (Note 2)

Shutdown Supply Current into PV PV = 3.6V 10 µA

Supply Current into PV with Step-

Up Enabled

Supply Current into PV with Step-

Up and Step-Down Enabled

Supply Current into PV with Step-

Up and Main Enabled

Total Supply Current from PV and

PVSU with Step-Up and One

AUX Enabled

REFERENCE

Reference Output Voltage I

Reference Load Regulation 10µA < I

Reference Line Regulation 2.7V < PVSU < 5.5V 5 mV

OSCILLATOR

OSC Discharge Trip Level Rising edge 1.225 1.275 V

OSC Discharge Resistance OSC = 1.5V, I

STEP-UP DC-TO-DC CONVERTER

Step-Up Startup-to-Normal

Operating Threshold

Step-Up Voltage Adjust Range 3.0 5.5 V

FBSU Regulation Voltage 1.231 1.269 V

FBSU to CCSU

Transconductance

FBSU Input Leakage Current FBSU = 1.25V -100 +100 nA

Step-Up Maximum Duty Cycle FBSU = 1V 80 90 %

PVSU Leakage Current V

LXSU Leakage Current V

Switch On-Resistance

N-Channel Current Limit 1.8 2.4 A

MAIN DC-TO-DC CONVERTER

Main Step-Up Voltage

Adjust Range

I

< 1mA, TA = +25°C; startup voltage tempco is

LOAD

-2300ppm/°C (typ) (Note 3)

ONSU = 3.6V, FBSU = 1.5V

(does not include switching losses)

ONSU = ONSD = 3.6V, FBSU = 1.5V, FBSD = 1.5V

(does not include switching losses)

ONSU = ONM = 3.6V, FBSU = 1.5V, FBSD = 1.5V

(does not include switching losses)

ONSU = ON1 = 3.6V, FBSU = 1.5V, FB2 = 1.5V

(does not include switching losses)

= 20µA 1.23 1.27 V

REF

< 200µA 10 mV

REF

= 3mA 80 Ω

OSC

1.1 V

400 µA

600 µA

600 µA

550 µA

Rising edge or falling edge (Note 4) 2.30 2.65 V

FBSU = CCSU 80 185 µS

= 0V, PVSU = 3.6V 5 µA

LX

= V

LX

= 3.6V 5 µA

OUT

N channel 150

P channel 250

SUSD = PVSU 3.0 5.5 V

mΩ

Page 7

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(V

PVSU

= VPV= V

PVM

= V

PVSD

= V

INDL2

= 3.6V, TA= -40°C to +85°C, unless otherwise noted.)

PARAMETER CONDITIONS MIN MAX UNITS

Main Step-Down Voltage

Adjust Range

PVM Undervoltage Lockout in

Step-Down Mode

SUSD = GND, PVM must be greater than output (Note 6) 2.45 5.00 V

SUSD = GND (Note 6) 2.45 2.55 V

Regulation Voltage 1.225 1.275 V

FBM to CCM Transconductance FBM = CCM 80 185 µS

FBM Input Leakage Current FBM = 1.25V -100 +100 nA

Maximum Duty Cycle

LXM Leakage Current V

Switch On-Resistance

Main Switch Current Limit

Step-up mode (SUSD = PVSU),

step-down mode (SUSD = GND) (Note 6)

= 0 to 3.6V, PVSU = 3.6V 5 µA

LXM

80 90 %

N channel 150

P channel 250

Step-up mode (SUSD = PVSU) 1.8 2.4

Step-down mode (SUSD = GND) 0.70 0.95

mΩ

A

STEP-DOWN DC-TO-DC CONVERTER

Step-Down Output Voltage

Adjust Range

PVSD must be greater than output (Note 7) 1.25 5.00 V

FBSD Regulation Voltage 1.225 1.275 V

FBSD to CCSD

Transconductance

FBSD = CCSD 80 185 µS

FBSD Input Leakage Current FBSD = 1.25V -100 +100 nA

LXSD Leakage Current V

Switch On-Resistance

= 0 to 3.6V, PVSU = 3.6V 5 µA

LXSD

N channel 150

P channel 250

mΩ

P-Channel Current Limit 0.65 0.90 A

SDOK Output Low Voltage 0.1mA into SDOK 0.1 V

SDOK Leakage Current ONSU = GND 1 µA

AUX1, 2, 3 DC-TO-DC CONTROLLERS

INDL2 Undervoltage Lockout 2.45 2.55 V

Maximum Duty Cycle FB_ = 1V 80 90 %

FB1, FB2 (MAX1566), FB3H

Regulation Voltage

FB2 (MAX1567) Inverter

Regulation Voltage

1.225 1.275 V

-0.01 +0.01 V

FB3L Regulation Voltage 0.19 0.21 V

AUX1, AUX2 FB to CC

Transconductance

80 185 µS

Page 8

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

8 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

PVSU

= VPV= V

PVM

= V

PVSD

= V

INDL2

= 3.6V, TA= -40°C to +85°C, unless otherwise noted.)

Note 2: The MAX1566/MAX1567 are powered from the step-up output (PVSU). An internal low-voltage startup oscillator drives the

step-up starting at approximately 0.9V until PVSU reaches approximately 2.5V. When PVSU reaches 2.5V, the main control

circuitry takes over. Once the step-up is up and running, it can maintain operation with very low input voltages; however,

output current is limited.

Note 3: Since the device is powered from PVSU, a Schottky rectifier, connected from the battery to PVSU, is required for low-voltage

startup.

Note 4: The step-up regulator is in startup mode until this voltage is reached. Do not apply full load current during startup. A power-

OK output can be used with an external PFET to gate the load until the step-up is in regulation. See the

AUX1OK, SDOK

,

and SCF Connections section.

Note 5: The step-up current limit in startup refers to the LXSU switch current limit, not the output current limit.

Note 6: If the main converter is configured as a step-up (SUSD = PVSU), the P-channel synchronous rectifier is disabled until the

2.5V normal operation threshold has been exceeded. If the main converter is configured as a step-down (SUSD = GND), all

step-down operation is locked out until the normal operation threshold has been exceeded. When the main is configured as

a step-down, operation in dropout (100% duty cycle) can only be maintained for 100,000 OSC cycles before the output is

considered faulted, triggering global shutdown.

Note 7: Operation in dropout (100% duty cycle) can only be maintained for 100,000 OSC cycles before the output is considered

faulted, triggering global shutdown.

Note 8: ONM, ONSD, ON1, ON2, and ON3 are disabled until 1024 OSC cycles after PVSU reaches 2.7V.

PARAMETER CONDITIONS MIN MAX UNITS

AUX3 FBL or FBH to CC

Transconductance

FB_ Input Leakage Current -100 +100 nA

DL_ Driver Resistance Output high or low 7 Ω

AUX1OK Output Low 0.1mA into AUX1OK 0.1 V

AUX1OK Leakage Current ONSU = GND 1 µA

OVERLOAD PROTECTION

SCF Leakage Current ONSU = PVSU, FBSU = 1.5V 1 µA

SCF Output Low Voltage 0.1mA into SCF 0.1 V

LOGIC INPUTS (ON_, SUSD)

ONSU Input Low Level

ONSU Input High Level

ONM, ONSD, ON1, ON2, ON3,

SUSD Input Low Level

ONM, ONSD, ON1, ON2, ON3,

SUSD Input High Level

SUSD Input Leakage 1 µA

35 150 µS

1.1V < PVSU < 1.8V 0.2

1.8V < PVSU < 5.5V 0.4

1.1V < PVSU < 1.8V

(PVSU

- 0.2)

1.8V < PVSU < 5.5V 1.6

2.7V < PVSU < 5.5V (Note 8) 0.4 V

2.7V < PVSU < 5.5V (Note 8) 1.6 V

v

V

Page 9

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

_______________________________________________________________________________________ 9

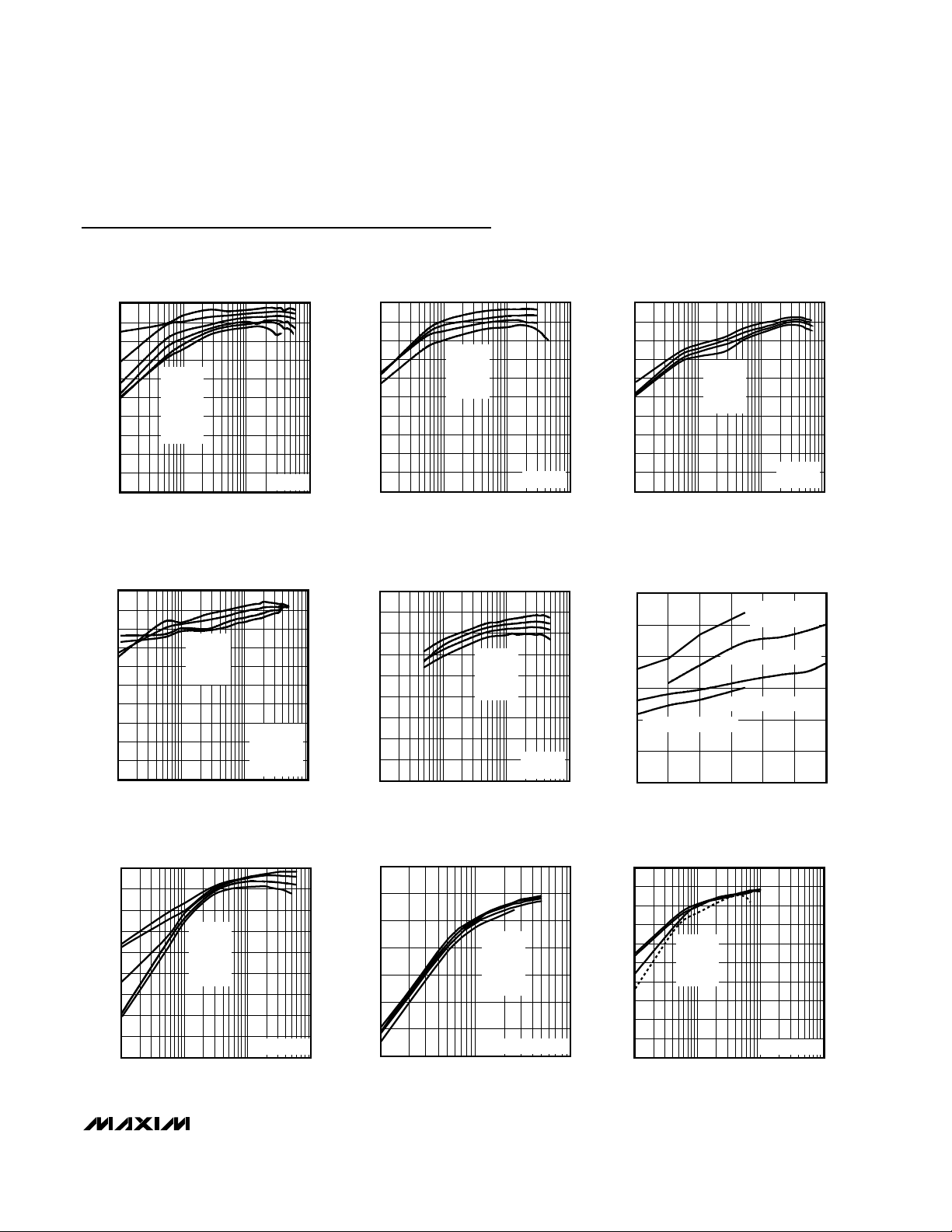

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

STEP-UP EFFICIENCY vs. LOAD CURRENT

100

90

80

70

60

50

40

EFFICIENCY (%)

30

VIN = 4.5V

= 3.8V

V

IN

= 3.2V

V

IN

= 2.5V

V

IN

= 2.0V

V

IN

= 1.5V

V

IN

20

10

0

1100010010

VSU = 5V

LOAD CURRENT (mA)

STEP-DOWN EFFICIENCY

vs. LOAD CURRENT

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 100010010

VIN = 2.5V

= 3.0V

V

IN

= 3.8V

V

IN

= 4.5V

V

IN

LOAD CURRENT (mA)

SD = 1.8V

SD INPUT

CONNECTED

TO BATT

MAX1566/67 toc01

MAX1566/67 toc04

EFFICIENCY (%)

MAIN (STEP-UP) EFFICIENCY

vs. LOAD CURRENT

100

90

80

70

60

50

40

EFFICIENCY (%)

30

VIN = 3.2V

= 2.5V

V

IN

= 2.0V

V

IN

= 1.5V

V

IN

20

10

0

1 100010010

OUTPUT CURRENT (mA)

BOOST-BUCK EFFICIENCY (SU + SD)

vs. LOAD CURRENT

100

90

80

70

60

50

40

30

20

10

1100010010

LOAD CURRENT (mA)

BOOST-BUCK EFFICIENCY

VIN = 4.5V

= 3.8V

V

IN

= 3.2V

V

IN

= 2.5V

V

IN

VM = 3.3V

= 5V

V

0

1 100010010

SU

OUTPUT CURRENT (mA)

EFFICIENCY vs. INPUT VOLTAGE

VM = 3.3V

= 200mA

I

SU = 5V, I

AUX2 = 8V, I

OUTVM

OUTSU

OUT2

= 500mA

= 100mA

95

90

85

80

SU + SD, I

OUT3

= 350mA

75

70

1.5 2.5 3.5 4.5

INPUT VOLTAGE (V)

VIN = 3.2V

= 2.5V

V

IN

= 2.0V

V

IN

= 1.5V

V

IN

VM = 3.3V

VSU = 3.3V

SD = 1.8V

(SU + MAIN AS STEP-DOWN) vs. LOAD CURRENT

100

90

80

MAX1566/67 toc02

70

60

50

40

EFFICIENCY (%)

30

20

10

100

MAX1566/67 toc05

EFFICIENCY (%)

MAX1566/67 toc03

MAX1566/67 toc06

AUX EFFICIENCY vs. LOAD CURRENT

90

80

70

60

50

40

EFFICIENCY (%)

30

VIN = 4.5V

= 3.8V

V

IN

= 3.0V

V

IN

= 2.0V

V

IN

= 1.5V

V

IN

20

10

0

1 100010010

LOAD CURRENT (mA)

V

OUT_AUX

= 5V

MAX1566/67 toc07

AUX EFFICIENCY vs. LOAD CURRENT

100

90

80

70

60

EFFICIENCY (%)

50

VIN = 4.5V

= 3.8V

V

IN

= 3.0V

V

IN

= 2.0V

V

IN

= 1.5V

V

IN

40

V

30

110100

OUT_AUX

LOAD CURRENT (mA)

MAX1566/67 toc08

EFFICIENCY (%)

= 15V

100

90

80

70

60

50

40

30

20

10

0

1 100010010

MAX1567 AUX2 EFFICIENCY

vs. LOAD CURRENT

VIN = 2.5V

= 3.0V

V

IN

= 3.8V

V

IN

= 4.5V

V

IN

V

= -7.5V

AUX2

LOAD CURRENT (mA)

MAX1566/67 toc09

Page 10

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

10 ______________________________________________________________________________________

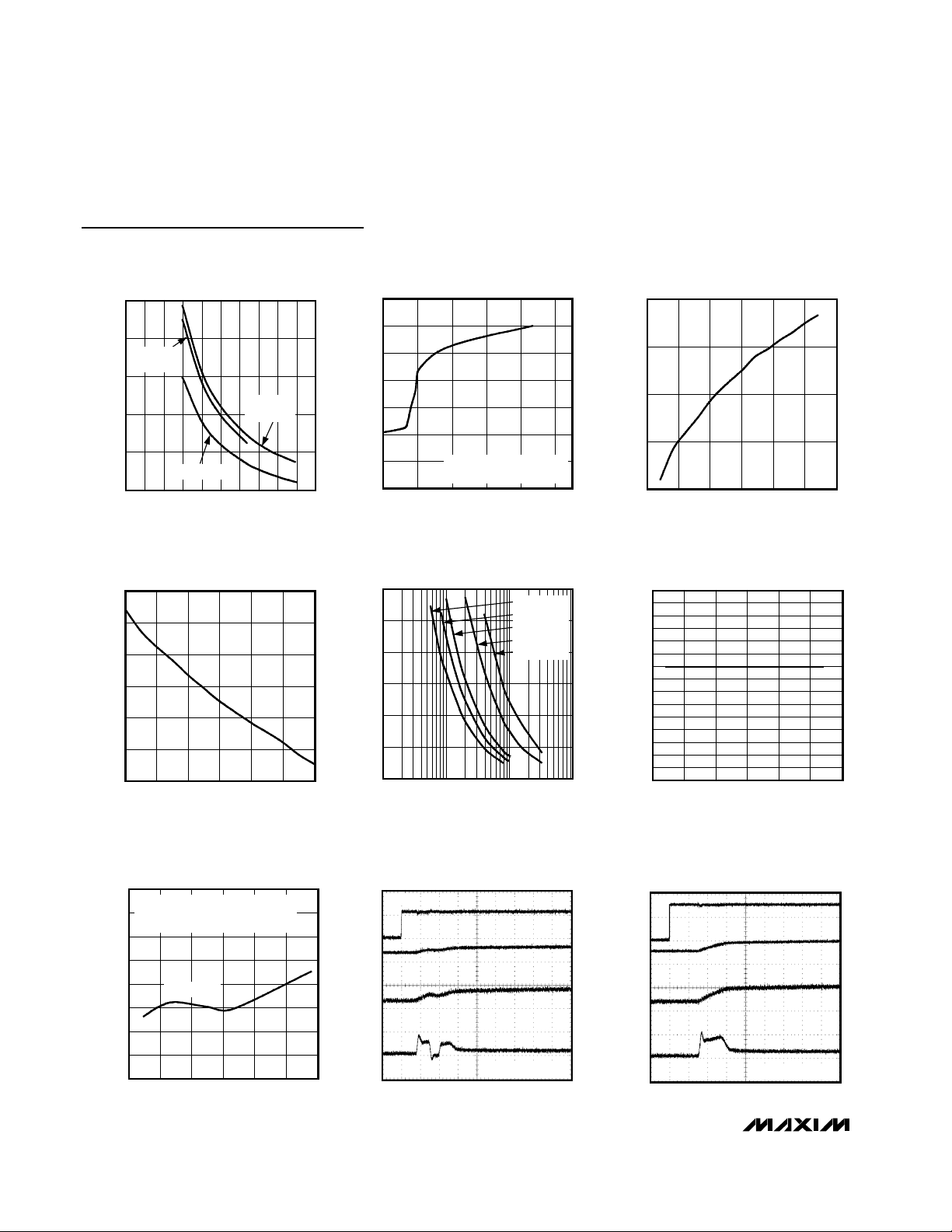

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

0.5

1.0

1.5

2.0

2.5

3.0

021345

NO-LOAD INPUT CURRENT

vs. INPUT VOLTAGE (SWITCHING)

MAX1566/67 toc10

INPUT VOLTAGE (V)

INPUT CURRENT (mA)

VSU = 5.0V ONLY

VSU = 5.0V

+ V

SD

= 1.8V

VSU = 5.0V

+ V

M

= 3.3V

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

0600200 400 800 1000

MINIMUM STARTUP VOLTAGE

vs. LOAD CURRENT (OUTSU)

MAX1566/67 toc11

LOAD CURRENT (mA)

MINIMUM STARTUP VOLTAGE (V)

WITH NO SCHOTTKY RECTIFER

FROM BATT TO PVSU

1.251

1.248

1.246

1.243

-50 25-25 0 50 75 100

REFERENCE VOLTAGE vs. TEMPERATURE

MAX1566/67 toc12

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

1.254

1.250

1.249

1.248

1.247

1.246

1.245

1.244

0 100 200 30050 150 250

REFERENCE VOLTAGE

vs. REFERENCE LOAD CURRENT

MAX1566/67 toc13

REFERENCE LOAD CURRENT (µA)

REFERENCE VOLTAGE (V)

0

1100010010

OSCILLATOR FREQUENCY vs. R

OSC

400

800

600

200

1000

MAX1566/7 toc14

R

OSC

(kΩ)

OSCILLATOR FREQUENCY (kHz)

C

OSC

= 470pF

C

OSC

= 330pF

C

OSC

= 220pF

C

OSC

= 100pF

C

OSC

= 47pF

315

314

313

312

311

310

309

308

307

306

305

304

303

302

301

300

-50 25-25 0 50 75 100

SWITCHING FREQUENCY vs. TEMPERATURE

MAX1566/67 toc15

TEMPERATURE (°C)

SWITCHING FREQUENCY (kHz)

88

87

86

85

84

83

82

81

80

0600200 400 800 1000 1200

AUX_ MAXIMUM DUTY CYCLE

vs. FREQUENCY

MAX1566/67 toc16

FREQUENCY (kHz)

MAXIMUM DUTY CYCLE (%)

WHEN THIS DUTY CYCLE IS

EXCEEDED FOR 100,000 CLOCK CYCLES,

THE MAX1566/MAX1567 SHUT DOWN

C

OSC

= 100pF

STEP-UP STARTUP WAVEFORMS

MAX1566/67 toc17

100µs/div

I

IN

1A/div

ONSU

2V/div

V

SU

= 3.3V

5V/div

I

OUT_SU

100mA/div

VIN = 2V, VSU = 3.3V

0V

0V

0A

0A

STEP-UP STARTUP WAVEFORMS

MAX1566/67 toc18

100µs/div

I

IN

1A/div

ONSU

2V/div

V

SU

= 5V

5V/div

I

OUT_SU

100mA/div

VIN = 3.0V, VSU = 5V

0V

0V

0A

0A

Page 11

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 11

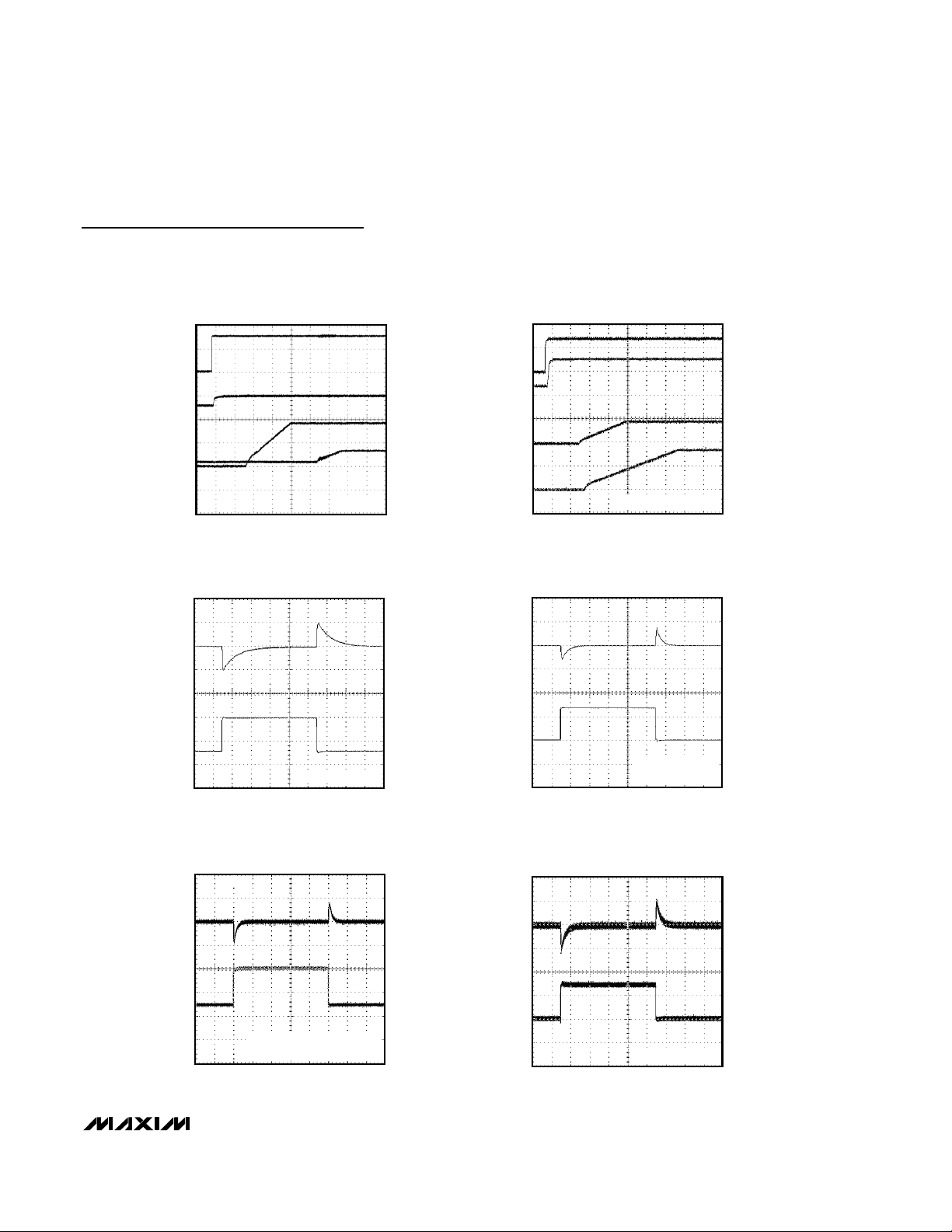

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

MAIN (STEP-UP MODE) AND STEP-DOWN

STARTUP WAVEFORMS

0V

0V

0V

0V

2ms/div

STEP-UP LOAD TRANSIENT RESPONSE

0V

MAX1566/67 toc19

VIN = 3.0V

MAX1566/67 toc21

=

ONSU

=

ONSD

ONM

2V/div

V

SU

5V/div

V

SD

1V/div

VM (MAIN

AS BOOST)

2V/div

V

SU

AC-COUPLED

100mV/div

MAIN (STEP-DOWN MODE) AND STEP-DOWN

0V

0V

0V

0V

0V

STARTUP WAVEFORMS

(MAIN AS STEP-DOWN)

2ms/div

MAX1566/67 toc20

MAIN (STEP-UP MODE)

LOAD TRANSIENT RESPONSE

MAX1566/67 toc22

ONSU

=

ONM =

ONSD

2V/div

V

SU

2V/div

V

SD

2V/div

V

M

2V/div

V

M

AC-COUPLED

100mV/div

I

0A

VIN = 3.0V, VSU = 5V

1ms/div

SU

200mA/div

0A

(MAIN AS STEP-UP)

= 3.0V, VM = 3.3V

V

IN

1ms/div

I

M

100mA/div

MAIN (STEP-DOWN MODE)

LOAD TRANSIENT RESPONSE

0V

0A

(MAIN AS STEP-DOWN FROM SU)

= 3.0V, VM = 3.3V

V

IN

1ms/div

MAX1566/67 toc23

V

M

AC-COUPLED

200mV/div

I

M

200mA/div

STEP-DOWN TRANSIENT RESPONSE

0V

0A

VIN = 3.0V, VSD = 1.8V

1ms/div

MAX1566/67 toc24

V

SD

AC-COUPLED

20mV/div

ISD

100mA/div

Page 12

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

12 ______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

AUX3 Controller Voltage Feedback Input. Connect a resistive voltage-divider from the step-up

1 FB3H

converter output to FBH to set the output voltage. The feedback threshold is 1.25V. This pin is high

impedance in shutdown. FB3H can provide conventional voltage feedback (with FB3L grounded) or

open-LED protection in white LED drive circuits.

AUX1 Controller Compensation Node. Connect a series resistor-capacitor from this pin to GND to

2 CC1

3 FB1

4 ON1

compensate the converter control loop. This pin is actively driven to GND in shutdown, overload, and

thermal limit. See the AUX Compensation section.

AUX1 Controller Feedback Input. The feedback threshold is 1.25V. This pin is high impedance in

shutdown.

AUX1 Controller On/Off Input. Logic high = on; however, turn-on is locked out until 1024 OSC cycles

after the step-up has reached regulation. This pin has an internal 330kΩ pulldown resistance to GND.

5 PGSD Power Ground. Connect all PG_ pins to GND with short wide traces as close to the IC as possible.

6 LXSD

7 PVSD

Step-Down Converter Switching Node. Connect to the inductor of the step-down converter. LXSD is

high impedance in shutdown.

Step-Down Converter Input. Bypass to GND with a 1µF ceramic capacitor. The step-down efficiency

is measured from this input.

Step-Down Converter On/Off Control Input. Logic high = on; however, turn-on is locked out until 1024

8 ONSD

9 FBSD

OSC cycles after the step-up has reached regulation. This pin has an internal 330kΩ pulldown

resistance to GND.

Step-Down Converter Feedback Input. The feedback threshold is 1.25V. This pin is high impedance

in shutdown.

Step-Down Converter Compensation Node. Connect a series resistor-capacitor from this pin to GND

10 CCSD

for compensating the converter control loop. This pin is actively driven to GND in shutdown, overload,

and thermal limit. See the Step-Down Compensation section.

Configures the Main Converter as a Step-Up or a Step-Down. This function must be hardwired. On-

11 SUSD

the-fly changes are not allowed. With SUSD connected to PV, the main is configured as a step-up

and PVM is the converter output. With SUSD connected to GND, the main is configured as a stepdown and PVM is the power input.

Main Converter Compensation Node. Connect a series resistor-capacitor from this pin to GND for

12 CCM

13 FBM

compensating the converter control loop. This pin is actively driven to GND in shutdown, overload,

and thermal limit. See the Step-Up Compensation section when the main is used in step-up mode

and the Step-Down Compensation section when the main is used in step-down mode.

Main Converter Feedback Input. The feedback threshold is 1.25V. This pin is high impedance in

shutdown. The main output voltage must not be set higher than the step-up output.

On/Off Control for the Main DC-to-DC Converter. Logic high = on; however, turn-on is locked out until

14 ONM

15 REF

1024 OSC cycles after the step-up has reached regulation. This pin has an internal 330kΩ pulldown

resistance to GND. SUSD pin configures the main converter as a step-up or step-down.

Reference Output. Bypass REF to GND with a 0.1µF or greater capacitor. The maximum-allowed REF

load is 200µA. REF is actively pulled to GND when the step-up is shut down (all converters turn off).

Page 13

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 13

Pin Description (continued)

PIN NAME FUNCTION

Step-Up Converter Compensation Node. Connect a series resistor-capacitor from this pin to GND for

16 CCSU

17 FBSU

18 ONSU

19 SCF

20 AUX1OK

21 SDOK

22 OSC

23 PGSU Power Ground. Connect all PG_ pins to GND with short wide traces as close to the IC as possible.

24 LXSU

25 PVSU

26 PGM Power Ground. Connect all PG_ pins to GND with short wide traces as close to the IC as possible.

27 LXM

28 PVM

29 ON2

30 CC2

compensating the converter control loop. This pin is actively driven to GND in shutdown, overload,

and thermal limit. See the Step-Up Compensation section.

Step-Up Converter Feedback Input. The feedback threshold is 1.25V. This pin is high impedance in

shutdown.

Step-Up Converter On/Off Control. Logic high = on. All other ON_ pins are locked out until 1024 OSC

cycles after the step-up DC-to-DC converter output has reached its final value. This pin has an

internal 330kΩ pulldown resistance to GND.

Open-Drain, Active-Low, Short-Circuit Flag Output. SCF goes open when overload protection occurs

and during startup. SCF can drive high-side PFET switches connected to one or more outputs to

completely disconnect the load when the channel turns off in response to a logic command or an

overload. See the Status Outputs (

SDOK, AUX1OK

, SCF) section.

Open-Drain, Active-Low, Power-OK Signal for AUX1 Controller. AUX1OK goes low when the AUX1

controller has successfully completed soft-start. AUX1OK goes high impedance in shutdown,

overload, and thermal limit.

Open-Drain, Active-Low, Power-OK Signal for Step-Down Converter. SDOK goes low when the step-

down has successfully completed soft-start. SDOK goes high impedance in shutdown, overload, and

thermal limit.

Oscillator Control. Connect a timing capacitor from OSC to GND and a timing resistor from OSC to

PVSU (or other DC voltage) to set the oscillator frequency between 100kHz and 1MHz. See the

Setting the Switching Frequency section. This pin is high impedance in shutdown.

Step-Up Converter Switching Node. Connect to the inductor of the step-up converter. LXSU is high

impedance in shutdown.

Power Output of the Step-Up DC-to-DC Converter. PVSU can also power other converter channels.

Connect PVSU and PV together.

Main Converter Switching Node. Connect to the inductor of the main converter (can be configured as

a step-up or step-down by SUSD). LXM is high impedance in shutdown.

When SUSD = PVSU, the main converter is configured as a step-up and PVM is the main output.

When SUSD = GND, the main is configured as a step-down and PVM is the power input.

AUX2 Controller On/Off Input. Logic high = on; however, turn-on is locked out until 1024 OSC cycles

after the step-up has reached regulation. This pin has an internal 330kΩ pulldown resistance to GND.

AUX2 Controller Compensation Node. Connect a series resistor-capacitor from this pin to GND to

compensate the converter control loop. This pin is actively driven to GND in shutdown, overload, and

thermal limit. See the AUX Compensation section.

Page 14

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

14 ______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

AUX2 Controller

31 FB2

Feedback Input. This

pin is high impedance

in shutdown.

Voltage Input for AUX2

32 INDL2

Gate Driver. The voltage

at INDL2 sets the high

gate-drive voltage.

33 GND Analog Ground. Connect to all PG_ pins as close to the IC as possible.

AUX2 Controller Gate-

34 DL2

Drive Output. DL2

drives between INDL2

and GND.

AUX3 Controller Gate-Drive Output. Connect to the gate of an N-channel MOSFET. DL3 drives

35 DL3

between GND and PVSU and supplies up to 500mA. This pin is actively driven to GND in shutdown,

overload, and thermal limit.

AUX1 Controller Gate-Drive Output. Connect to the gate of an N-channel MOSFET. DL1 drives

36 DL1

between GND and PVSU and supplies up to 500mA. This pin is actively driven to GND in shutdown,

overload, and thermal limit.

37 PV IC Power Input. Connect PVSU and PV together.

AUX3 Controller Compensation Node. Connect a series resistor-capacitor from this pin to GND for

38 CC3

compensating the converter control loop. This pin is actively driven to GND in shutdown, overload,

and thermal limit. See the AUX Compensation section.

MAX1566 (AUX2 is configured as a boost): FB2 feedback threshold is

1.25V.

MAX1567 (AUX2 is configured as an inverter): FB2 feedback threshold is

0V.

MAX1566 (AUX2 is configured as a boost): connect INDL2 to PVSU for

optimum N-channel gate drive.

MAX1567 (AUX2 is configured as an inverter): connect INDL2 to the

external P-channel MOSFET source to ensure the P channel is completely

off when DL2 swings high.

The MAX1566 configures DL2 to drive an N-channel FET in a boost

configuration. DL2 is driven low in shutdown, overload, and thermal limit.

The MAX1567 configures DL2 to drive a PFET in an inverter configuration.

DL2 is driven high in shutdown, overload, and thermal limit.

AUX3 Controller Current-Feedback Input. Connect a resistor from FB3L to GND to set LED current in

39 FB3L

40 ON3

LED boost-drive circuits. The feedback threshold is 0.2V. Connect this pin to GND if using only the

FB3H feedback. This pin is high impedance in shutdown.

AUX3 Controller On/Off Input. Logic high = on; however, turn-on is locked out until 1024 OSC cycles

after the step-up has reached regulation. This pin has an internal 330kΩ pulldown resistance to GND.

Exposed Metal Pad. This pad is connected to ground. Note this internal connection is a soft-connect,

meaning there is no internal metal or bond wire physically connecting the exposed pad to the GND

Pad EP

pin. The connection is through the silicon substrate of the die and then through a conductive epoxy.

Connecting the exposed pad to ground does not remove the requirement for a good ground

connection to the appropriate pins.

Page 15

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 15

Detailed Description

The MAX1566/MAX1567 include the following blocks to

build a multiple-output digital camera power-supply

system. Both devices can accept inputs from a variety

of sources including 1-cell Li+ batteries, 2-cell alkaline

or NiMH batteries, and even systems designed to

accept both battery types. The MAX1566/

MAX1567 include six DC-to-DC converter channels to

generate all required voltages:

• Step-up DC-to-DC converter (_SU pins) with on-chip

power FETS

• Main DC-to-DC converter (_M pins) with on-chip

power FETS that can be configured as either a stepup or step-down DC-to-DC converter

• Step-down core DC-to-DC converter with on-chip

MOSFETs (_SD pins)

• AUX1 DC-to-DC controller for boost and flyback

converters

• AUX2 DC-to-DC controller for boost and flyback

converters (MAX1566)

• AUX2 DC-to-DC controller for inverting DC-to-DC

converters (MAX1567)

• AUX3 DC-to-DC controller for white LED as well as

conventional boost applications; includes open LED

overvoltage protection

Step-Up DC-to-DC Converter

The step-up DC-to-DC switching converter typically is

used to generate a 5V output voltage from a 1.5V to

4.5V battery input, but any voltage from VINto 5V can

be set. An internal NFET switch and external synchronous rectifier allow conversion efficiencies as high as

95%. Under moderate to heavy loading, the converter

operates in a low-noise PWM mode with constant

frequency and modulated pulse width. Switching

harmonics generated by fixed-frequency operation are

consistent and easily filtered. Efficiency is enhanced

under light (<75mA typ) loading by an Idle Mode that

switches the step-up only as needed to service the

load. In this mode, the maximum inductor current is

150mA for each pulse.

Main DC-to-DC Converter (Step-Up or

Step-Down)

The main converter can be configured as a step-up

(Figure 2) or a step-down converter (Figure 1) with the

SUSD pin. The main DC-to-DC converter is typically

used to generate 3.3V, but any voltage from 2.7V to 5V

can be set; however, the main output must not be set

higher than the step-up output (PVSU).

An internal MOSFET switch and synchronous rectifier

allow conversion efficiencies as high as 95%. Under

moderate to heavy loading, the converter operates in a

low-noise PWM mode with constant frequency and

modulated pulse width. Switching harmonics generated

by fixed-frequency operation are consistent and easily

filtered. Efficiency is enhanced under light loading

(<150mA typical for step-up mode, <100mA typical for

step-down mode) by assuming an Idle Mode during

which the converter switches only as needed to service

the load.

Step-down operation can be direct from a Li+ cell if the

minimum input voltage exceeds the desired output by

approximately 200mV. Note that if the main DC-to-DC,

operating as a step-down, operates in dropout, the

overload protection circuit senses an out-of-regulation

condition and turns off all channels.

Li+ to 3.3V Boost-Buck Operation

When generating 3.3V from an Li+ cell, boost-buck

operation may be needed so a regulated output can be

maintained for input voltages above and below 3.3V. In

that case, it may be best to configure the main converter as a step-down (SUSD = GND) and to connect its

input, PVM, to the step-up output (PVSU), set to a voltage at or above 4.2V (Figures 1 and 3). The compound

efficiency with this connection is typically up to 90%.

This connection is also suitable for designs that must

operate from both 1-cell Li+ and 2 AA cells.

Note that the step-up output supplies both the step-up

load and the main step-down input current when the

main is powered from the step-up. The main input current reduces the available step-up output current for

other loads.

2 AA to 3.3V Operation

In designs that operate only from 2 AA cells, the main

DC-to-DC can be configured as a boost converter (SUSD

= PVM) to maximize the 3.3V efficiency (Figure 2).

Page 16

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

16 ______________________________________________________________________________________

Figure 1. Typical 1-Cell Li+ Powered System (3.3V logic is stepped down from +5V, and 1.8V core is stepped down directly from the

battery. Alternate connections are shown in the following figures.)

V

BATT

1 Li+

2.8V TO

4.2V

L1

V

C8

R1

1MΩ

R2

90.9kΩ

SU

R9

1.4µH

D1

0.1µF

R4

47kΩ

C3

100pF

R10

C9

C1

1µF

D2–D5

LEDS

R3

R5

C4

10Ω

R6

R7

C5

R8

C6

C7

C15

10µF

MAX1567

AUX1

PWM

DL3

FB3H

FB3L

REF

OSC

ONSU

ONM

ONSD

ON3 (LED)

ON1

ON2

SUSD

CCSU

CCSD

CCM

CC3

CC1

CC2

GND

OUTSU

AUX3

PWM

CURRENT-

MODE

STEP-UP

PWM

PWR ON

OR FAULT

CURRENT-

MODE UP

OR DOWN

CURRENT-

SDOK

PWM

MODE

STEP-

DOWN

PWM

AUX2

INVERTING

PWM

OK

N1

C2

OUTSU

AUX1OK

PGSD

DL1

FB1

INDL2

DL2

FB2

PVSU

LXSU

PGSU

FBSU

SCF

PVM

LXM

PGM

FBM

PVSD

LXSD

FBSD

C16

10µF

PV

1.2µH

N2

5.6µH

L2

D8

L5

10µH

150kΩ

L6

R17

40.2kΩ

L4

10µH

R19

D6

P1

D7

R13

549kΩ

C11

10µF

90.9kΩ

C13

10µF

C18

1µF

22µH

TO

V

BATT

R18

R20

90.9kΩ

L3

TO

BATT

TO V

90.9kΩ

R14

C12

22µF

R11

1MΩ

BATT

C17

1µF

R15

274kΩ

R16

90.9kΩ

C14

22µF

TO REF

V

M

+3.3V

200mA

V

+1.8V

350mA

15V

20mA

C10

47µF

SD

R12

90.9kΩ

-7.5V

40mA

V

SU

+5V

500mA

Page 17

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 17

Figure 2. Typical 2-Cell AA-Powered System (3.3V is boosted from the battery and 1.8V is stepped down from VM(3.3V).)

V

BATT

2 AA

1.5V TO

3.4V

C15

10µF

MAX1567

AUX3

PWM

CURRENT-

MODE

STEP-UP

PWM

PWR ON

OR FAULT

CURRENT-

MODE UP

OR DOWN

PWM

CURRENT-

MODE

STEP-

DOWN

PWM

SDOK

AUX1

PWM

AUX2

INVERTING

PWM

OK

L1

V

SU

R9

C8

D1

R1

1MΩ

R2

90.9kΩ

47kΩ

R4

100pF

TO V

C3

R10

C9

1.4µH

0.1µF

SU

N1

C2

OUTSU

DL3

FB3H

FB3L

REF

OSC

ONSU

ONM

ONSD

ON3 (LED)

ON1

ON2

SUSD

CCSU

CCSD

CCM

CC3

CC1

CC2

GND

C1

1µF

D2–D5

LEDS

R3

10Ω

R5

R6

C4

R7

C5

R8

C6

C7

OUTSU

AUX1OK

PGSD

DL1

FB1

INDL2

DL2

FB2

PVSU

LXSU

PGSU

FBSU

SCF

PVM

LXM

PGM

FBM

PVSD

LXSD

FBSD

10µF

PV

C16

N2

D8

L5

3.3µH

L6

10µH

4.7µH

R19

40.2kΩ

L2

1.2µH

L4

D6

P1

D7

R13

549kΩ

C11

10µF

C12

10µF

C13

10µF

C18

1µF

22µH

TO

V

BATT

V

TO

V

R20

90.9kΩ

L3

TO

BATT

M

TO V

90.9kΩ

SU

C17

1µF

R14

R15

274kΩ

R16

90.9kΩ

C14

47µF

R11

1MΩ

90.9kΩ

TO REF

R17

150kΩ

R18

V

+1.8V

250mA

15V

20mA

C10

47µF

SD

R12

90.9kΩ

-7.5V

40mA

C21

47µF

V

SU

+5V

350mA

V

+3.3V

500mA

M

Page 18

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

18 ______________________________________________________________________________________

Figure 3. Li+ or Multibattery Input (This power supply accepts inputs from 1.5V to 4.2V, so it can operate from either 2 AA cells or 1

Li+ cell. The 3.3V logic supply and the 1.8V core supply are both stepped down from 5V for true boost-buck operation.)

V

BATT

2 AA OR Li+

1.5V TO

4.2V

L1

V

C8

D1

R1

1MΩ

R2

90.9kΩ

SU

R9

R4

47kΩ

100pF

C3

R10

C9

1.4µH

0.1µF

N1

C2

C1

1µF

D2–D5

LEDS

R5

C4

R3

10Ω

R6

R7

C5

R8

C6

C7

C15

10µF

MAX1567

DL3

FB3H

FB3L

REF

OSC

ONSU

ONM

ONSD

ON3 (LED)

ON1

ON2

SUSD

CCSU

CCSD

CCM

CC3

CC1

CC2

GND

OUTSU

AUX3

PWM

CURRENT-

MODE

STEP-UP

PWM

PWR ON

OR FAULT

CURRENTMODE UP

OR DOWN

PWM

CURRENT-

MODE

STEPDOWN

SDOK

PWM

AUX1

PWM

AUX2

INVERTING

PWM

OK

OUTSU

AUX1OK

PGSD

DL1

FB1

INDL2

DL2

FB2

PVSU

LXSU

PGSU

FBSU

SCF

PVM

LXM

PGM

FBM

PVSD

LXSD

FBSD

10µF

PV

C16

N2

D8

L5

10µH

150kΩ

L6

10µH

4.7µH

R17

R19

40.2kΩ

L2

1.2µH

L4

D6

P1

D7

R13

549kΩ

C11

10µF

90.9kΩ

C13

10µF

22µH

TO

V

BATT

R18

R20

90.9kΩ

C18

1µF

L3

TO

BATT

TO V

SU

C17

1µF

R14

90.9kΩ

R15

274kΩ

R16

90.9kΩ

C12

22µF

C14

22µF

R11

1MΩ

TO REF

V

M

+3.3V

200mA

V

+1.8V

200mA

15V

20mA

C10

47µF

SD

R12

90.9kΩ

-7.5V

40mA

V

SU

+5V

100mA

Page 19

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 19

Figure 4. MAX1566 Functional Diagram

V

SU

2.35V

ONSU

V

REF

1V

ONSU

SOFT-START TIMER

CLOCK-CYCLE

FAULT TIMER

OSC

CCSU

FBSU

STEP-UP

DONE

(SUSSD)

CCSD

FBSD

ONSD

CC_

FB_

ON_

INTERNAL

POWER-

REFOK

100,000-

SUSSD

SUSSD

OK

SOFT-START

GENERATOR

SOFT-START

GENERATOR

FLTALL

SOFT-START

GENERATOR

FLTALL

REF

RAMP

RAMP

RAMP

DIE OVER

TEMP

ONE-SHOT

300ns

FAULT

TO

V

TO

V

TO

V

NORMAL

MODE

IN

CLK

REF

REF

REF

FLTALL

STARTUP

OSCILLATOR

FAULT

CURRENT-

MODE

DC-TO-DC

STEP-UP

FAULT

CURRENT-

MODE

DC-TO-DC

STEP-DOWN

FAULT

1 OF 3

VOLTAGE-MODE

DC-TO-DC

CONTROLLERS

AUX_

DL_

TO INTERNAL

POWER

1.25V

REFERENCE

FLTALL

FLTALL

SUSSD

TO V

PV

PVSU

LXSU

PGSU

ONSU

PVSD

LXSD

PGND

SDOK

CLK

MAX1566

REF

GND

REF

FAULT

CURRENT-

MODE

DC-TO-DC

STEP-DOWN

OR

STEP-UP

SOFT-START

RAMP

GENERATOR

SUSD

PVM

LXM

PGM

FBM

ONM

AUX1OK

Page 20

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

20 ______________________________________________________________________________________

Core Step-Down DC-to-DC Converter

The step-down DC-to-DC is optimized for generating low

output voltages (down to 1.25V) at high efficiency. The

step-down runs from the voltage at PVSD. This pin can

be connected directly to the battery if sufficient headroom exists to avoid dropout; otherwise, PVSD can be

powered from the output of another converter. The stepdown can also operate with the step-up, or the main converter in step-up mode, for boost-buck operation.

Under moderate to heavy loading, the converter operates in a low-noise PWM mode with constant frequency

and modulated pulse width. Efficiency is enhanced

under light (<75mA typ) loading by assuming an Idle

Mode during which the step-down switches only as

needed to service the load. In this mode, the maximum

inductor current is 100mA for each pulse. The stepdown DC-to-DC is inactive until the step-up DC-to-DC

is in regulation.

The step-down also features an open-drain SDOK out-

put that goes low when the step-down output is in regulation. SDOK can be used to drive an external MOSFET

switch that gates 3.3V power to the processor after the

core voltage is in regulation. This connection is shown

in Figure 15.

AUX1, AUX2, and AUX3 DC-to-DC

Controllers

The three auxiliary controllers operate as fixed-frequency voltage-mode PWM controllers. They do not have

internal MOSFETs, so output power is determined by

external components. The controllers regulate output

voltage by modulating the pulse width of the DL_ drive

signal to an external MOSFET switch.

On the MAX1566, AUX1 and AUX2 are boost/flyback

PWM controllers. On the MAX1567, AUX1 is a boost/flyback PWM controller, but AUX2 is an inverting PWM

controller. On both devices, AUX3 is a boost/flyback

controller that can be connected to regulate output voltage and/or current (for white-LED drive).

Figure 5 shows a functional diagram of an AUX boost

controller channel. A sawtooth oscillator signal at OSC

governs timing. At the start of each cycle, DL_ goes high,

turning on the external NFET switch. The switch then

turns off when the internally level-shifted sawtooth rises

above CC_ or when the maximum duty cycle is exceeded. The switch remains off until the start of the next cycle.

A transconductance error amplifier forms an integrator at

CC_ to maintain high DC loop gain and accuracy.

The auxiliary controllers do not start until 1024 OSC

cycles after the step-up DC-to-DC output is in regulation. If the auxiliary controller remains faulted for

100,000 OSC cycles (200ms at 500kHz), then all

MAX1566/MAX1567 channels latch off.

Maximum Duty Cycle

The AUX PWM controllers have a guaranteed maximum

duty cycle of 80%: all controllers can achieve at least

80% and typically reach 85%. In boost designs that

employ continuous current, the maximum duty cycle

limits the boost ratio so:

1 - VIN/ V

OUT

< 80%

With discontinuous inductor current, no such limit exists

for the input/output ratio since the inductor has time to

fully discharge before the next cycle begins.

AUX1

AUX1 can be used for conventional DC-to-DC boost

and flyback designs (Figures 8 and 9). Its output (DL1)

is designed to drive an N-channel MOSFET. Its feedback (FB1) threshold is 1.25V.

AUX2

In the MAX1566, AUX2 is identical to AUX1. In the

MAX1567, AUX2 is an inverting controller that generates a regulated negative output voltage, typically for

CCD and LCD bias. This is useful in height-limited

designs where transformers may not be desired.

The AUX2 MOSFET driver (DL2) in the MAX1567 is

designed to drive P-channel MOSFETs. INDL2 biases

the driver so V

INDL2

is the high output level of DL2.

INDL2 should be connected to the P-channel MOSFET

source to ensure the MOSFET turns completely off when

DL2 is high. See Figure 10 for a typical inverter circuit.

AUX3 DC-to-DC Controller, LED Driver

The AUX3 step-up DC-to-DC controller has two feedback inputs, FB3L and FB3H, with feedback thresholds

of 0.2V (FB3L) and 1.25V (FB3H). If used as a conventional voltage-output step-up, FB3L is grounded and

FB3H is used as the feedback input. In that case, AUX3

behaves exactly like AUX1.

If AUX3 is used as a switch-mode boost current source

for white LEDs, FB3L provides current-sensing feedback, while FB3H provides (optional) open-LED overvoltage protection (Figure 7).

Page 21

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 21

FB2

Figure 5. AUX Controller Functional Diagram

CC2

REF

OSC

R

0.85 REF

REFI

LEVEL SHIFT

SOFT-START

Q

S

MAX1567

AUX2 INVERTER

CLK

DL_

FB

CC

REF

OSC

IN 1024 CLOCK CYCLES, SOFT-START

RAMPS UP REFI FROM 0V TO V

MAX1566/MAX1567 AUX_ BOOST

CONTROLLERS AND RAMPS DOWN

REFI FROM V

MAX1567 AUX2 INVERTER.

REF

0.85 REF

TO 0V IN

REFI

LEVEL SHIFT

SOFT-START

FAULT PROTECTION

MAX1566/MAX1567

ENABLE

R

Q

S

DL_

AUX_ BOOST

CLK

FAULT PROTECTION

IN

REF

ENABLE

Page 22

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

22 ______________________________________________________________________________________

Master-Slave Configurations

The MAX1566/MAX1567 support MAX1801 slave PWM

controllers that obtain input power, a voltage reference,

and an oscillator signal directly from the MAX1566/

MAX1567 master. The master-slave configuration allows

channels to be easily added and minimizes system cost

by eliminating redundant circuitry. The slaves also control the harmonic content of noise because their operating frequency is synchronized to that of the MAX1566/

MAX1567 master converter. A MAX1801 connection to

the MAX1566/MAX1567 is shown in Figure 14.

Status Outputs (

SDOK, AUX1OK

, SCF)

The MAX1566/MAX1567 include three versatile status

outputs that can provide information to the system. All

are open-drain outputs and can directly drive MOSFET

switches to facilitate sequencing, disconnect loads

during overloads, or perform other hardware-based

functions.

Figure 6. Oscillator Functional Diagram

Figure 7. LED drive with open LED overvoltage protection is

provided by the additional feedback input to AUX3, FB3H.

Figure 8. +15V LCD Bias with Basic Boost Topology

Figure 9. +15V and -7.5V CCD Bias with Transformer

V

SU

R

OSC

OSC

V

C

OSC

TO

V

BATT

(1.25V)

REF

150ns

ONE-SHOT

MAX1566

MAX1567

MAX1566

MAX1567

(PARTIAL)

PVSU

DL3

D2–D5

LEDS

R1

R2

FB3H

(1.25V)

FB3L

(0.2V)

AUX3

PWM

MAX1566

MAX1567

(PARTIAL)

AUX

PWM

NOTE: THIS CIRCUIT CAN OPERATE WITH AUX1, AUX2,

OR AUX3 ON THE MAX1566, AND WITH AUX1 OR AUX3 ON

THE MAX1567. TO USE AUX3, FB3L = GND, AND

FB3H IS USED FOR FEEDBACK.

MAX1566

MAX1567

(PARTIAL)

AUX

PWM

PVSU

PVSU

DL_

FB_

TO

V

BATT

+15V

50mA

D6

Q1

DL_

FB_

TO

V

BATT

Q1

D2

LCD

+15V

50mA

CCD+

-7.5V

30mA

CCD-

NOTE: THIS CIRCUIT CAN OPERATE WITH AUX1, AUX2,

R3

NOTE: IF OPEN LED PROTECTION IS NOT

REQUIRED, REMOVE R2 AND R3 AND GROUND FB3H.

OR AUX3 ON THE MAX1566, AND WITH AUX1 OR AUX3 ON

THE MAX1567. TO USE AUX3, FB3L = GND, AND

FB3H IS USED FOR FEEDBACK.

Page 23

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 23

SDOK pulls low when the step-down has successfully

completed soft-start. SDOK goes high impedance in

shutdown, overload, and thermal limit. A typical use for

SDOK is to drive a P-channel MOSFET that connects

3.3V power to the CPU I/O after the CPU core is powered up (Figure 15), thus providing safe sequencing in

hardware without system intervention.

AAUUXX11OOKK

pulls low when the AUX1 controller has suc-

cessfully completed soft-start. AUX1OK goes high

impedance in shutdown, overload, and thermal limit. A

typical use for AUX1OK is to drive a P-channel MOSFET

that connects 5V power to the CCD after the 15V CCD

bias (generated by AUX1) is powered up (Figure 16).

SCF goes high (high impedance, open drain) when

overload protection occurs. Under normal operation,

SCF pulls low. SCF can drive a high-side P-channel

MOSFET switch that can disconnect a load during

power-up or when a channel turns off in response to a

logic command or an overload. Several connections

are possible for SCF. One is shown in Figure 17 where

SCF provides load disconnect for the step-up on fault

and power-up.

Figure 10. Regulated -7.5V Negative CCD (Bias is provided by

conventional inverter (works only with the MAX1567).)

Figure 11. ±15V Output Using an AUX-Driven Boost with

Charge-Pump Inversion

Figure 12. +15V and -7.5V CCD Bias Without Transformer

Using Boost with a Diode-Capacitor Charge Pump (A positiveoutput linear regulator (MAX1616) can be used to regulate the

negative output of the charge pump.)

MAX1567

(PARTIAL)

INDL2

DL2

AUX2

INVERTING

PWM

FB2

REF

L1

TO V

BATT

AUX_

PWM

PVSU

10µH

1µF

FB_

DL_

MAX1566

MAX1567

(PARTIAL)

TO V

BATT

-7.5V

100mA

R

TOP

R

REF

D2

C2

1µF

1µF

C1

D1

Q1

R1

1MΩ

90.9kΩ

D3

V

OUT+

+15V

20mA

R2

V

OUT-

-15V

C3

10mA

1µF

TO V

BATT

AUX_

PWM

FB_

PVSU

DL_

MAX1566/MAX1567

(PARTIAL)

SHDNIN

GND

OUT

+1.25V

FB_

MAX1616

NOTE: THIS CIRCUIT CAN OPERATE WITH AUX1, AUX2, OR AUX3 ON THE MAX1566,

AND WITH AUX1 OR AUX3 ON THE MAX1567. TO USE AUX3, FB3L = GND,

AND FB3H IS USED FOR FEEDBACK.

+15V

20mA

-7.5V

20mA

Page 24

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

24 ______________________________________________________________________________________

Figure 15. Using

SDOK

to Drive External PFET that Gates 3.3V Power to CPU After 1.8V Core Voltage Is in Regulation

Figure 14. Adding a PWM Channel with an External MAX1801

Slave Controller

Figure 13. SEPIC Converter Additional Boost-Buck Channel

INPUT

1-CELL

Li+

V

SU

L2

PV PVSU

PART OF

MAX1566

MAX1567

(PARTIAL)

DL_

FB_

L1

C2

Q1

D1

MAX1566

MAX1567

(PARTIAL)

CURRENT-

SUSD

MODE UP

OR DOWN

PWM

OUTPUT

3.3V

R1

R2

PVM

LXM

TO BATT

V

OUT

DL

MAX1801

FB

COMP

GND

IN

OSC

REF

DCON

PVSU

OSC

REF

MAX1566

MAX1567

(PARTIAL)

L3

V

M

+3.3V

3.3V

TO

CPU

PGM

FBM

SDOK

PVSD

CURRENT-

MODE

STEPDOWN

PWM

LXSD

FBSD

PGSD

TO

V

BATT

L4

V

SD

+1.8V

350mA

Page 25

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 25

Soft-Start

The MAX1566/MAX1567 channels feature a soft-start

function that limits inrush current and prevents excessive battery loading at startup by ramping the output

voltage of each channel up to the regulation voltage.

This is accomplished by ramping the internal reference

inputs to each channel error amplifier from 0V to the

1.25V reference voltage over a period of 4096 oscillator

cycles (16ms at 500kHz) when initial power is applied

or when a channel is enabled.

The step-down soft-start ramp takes half the time (2048

clock cycles) of the other channel ramps. This allows

the step-down and main outputs to track each other

and rise at nearly the same dV/dt rate on power-up.

Once the step-down output reaches its regulation point

(1.5V or 1.8V typ), the main output (3.3V typ) continues

to rise at the same ramp rate. See the Typical

Operating Characteristics Main and Step-Down Startup

Waveforms graphs.

Soft-start is not included in the step-up converter to

avoid limiting startup capability with loading.

Fault Protection

The MAX1566/MAX1567 have robust fault and overload

protection. After power-up, the device is set to detect

an out-of-regulation state that could be caused by an

overload or short. If any DC-to-DC converter channel

(step-up, main, step-down, or any of the auxiliary controllers) remains faulted for 100,000 clock cycles

(200ms at 500kHz), then all outputs latch off until the

step-up DC-to-DC converter is reinitialized by the

ONSU pin or by cycling the input power. The faultdetection circuitry for any channel is disabled during its

initial turn-on soft-start sequence.

An exception to the standard fault behavior is that there

is no 100,000 clock cycle delay in entering the fault

state if the step-up output (PVSU) is dragged below its

2.5V UVLO threshold or is shorted. In this case, the

Figure 16.

AUX1OK

Drives an External PFET that Gates 5V Supply to the CCD After the +15V CCD Bias Supply Is Up

MAX1566

MAX1567

(PARTIAL)

AUX1

PWM

CURRENT-

MODE

STEP-UP

PWM

PVSU

TO

V

BATT

AUX1OK

PVSU

LXSU

PGSU

FBSU

DL1

FB1

PV

15V

D6

TO

V

BATT

L2

100mA

GATED +5V

TO CCD

V

SU

+5V

Page 26

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

26 ______________________________________________________________________________________

step-up UVLO immediately triggers and shuts down all

channels. The step-up then continues to attempt starting. If the step-up output short remains, these attempts

cannot succeed since PVSU remains near ground.

If a soft-short or overload remains on PVSU, the startup

oscillator switches the internal N-channel MOSFET, but

fault is retriggered if regulation is not achieved by the

end of the soft-start interval. If PVSU is dragged below

the input, the overload is supplied by the body diode of

the internal synchronous rectifier, or by a Schottky

diode connected from the battery to PVSU. If desired,

this overload current can be interrupted by a P-channel

MOSFET controlled by SCF, as shown in Figure 17.

Reference

The MAX1566/MAX1567 has a precise 1.250V reference. Connect a 0.1µF ceramic bypass capacitor from

REF to GND within 0.2in (5mm) of the REF pin. REF can

source up to 200µA and is enabled whenever ONSU is

high and PVSU is above 2.5V. The auxiliary controllers

and MAX1801 slave controllers (if connected) each sink

up to 30µA REF current during startup. In addition, the

feedback network for the AUX2 inverter (MAX1567) also

draws current from REF. If the 200µA REF load limit

must be exceeded, buffer REF with an external op amp.

Oscillator

All DC-to-DC converter channels employ fixed-frequency

PWM operation. The operating frequency is set by an RC

network at the OSC pin. The range of usable settings is

100kHz to 1MHz. When MAX1801 slave controllers are

added, they operate at the frequency set by OSC.

The oscillator uses a comparator, a 150ns one-shot, and

an internal NFET switch in conjunction with an external

timing resistor and capacitor (Figure 6). When the switch

is open, the capacitor voltage exponentially approaches

the step-up output voltage from zero with a time constant

given by the product of R

OSC

and C

OSC

. The comparator output switches high when the capacitor voltage

reaches V

REF

(1.25V). In turn, the one-shot activates the

internal MOSFET switch to discharge the capacitor for

150ns, and the cycle repeats. The oscillation frequency

changes as the main output voltage ramps upward following startup. The oscillation frequency is then constant

once the main output is in regulation.

Low-Voltage Startup Oscillator

The MAX1566/MAX1567 internal control and referencevoltage circuitry receive power from PVSU and do not

function when PVSU is less than 2.5V. To ensure lowvoltage startup, the step-up employs a low-voltage

startup oscillator that activates at 0.9V if a Schottky rectifier is connected from V

BATT

to PVSU (1.1V with no

Schottky rectifier). The startup oscillator drives the internal N-channel MOSFET at LXSU until PVSU reaches

2.5V, at which point voltage control is passed to the

current-mode PWM circuitry.

Once in regulation, the MAX1566/MAX1567 operate

with inputs as low as 0.7V since internal power for the

IC is supplied by PVSU. At low input voltages, the step-

Figure 17. SCF Drives PFET Load Switch on 5V to Disconnect

Load on Fault and Allow Full-Load Startup

Figure 18. Setting PVSD for Outputs Below 1.25V

CURRENT-MODE

PWR ON

OR FAULT

V

SU

3.3V

MAX1566

MAX1567

(PARTIAL)

STEP-UP

PWM

OK

PVSU

PV

CURRENT-MODE

STEP-DOWN

FBSD

R3

100kΩ

PV

PVSU

LXSU

PGSU

FBSD

SCF

MAX1566

MAX1567

(PARTIAL)

V

FBSD

1.25V

R2

100kΩ

R1

56kΩ

V

SU

V

0.8V

+5V

SD

TO

V

BATT

L2

PVSD

10µF

LXSD

PGSD

4.7µH

22µF

Page 27

MAX1566/MAX1567

Six-Channel, High-Efficiency, Digital

Camera Power Supplies

______________________________________________________________________________________ 27

up may have difficulty starting into heavy loads (see the

Minimum Startup Voltage vs. Load Current (OUTSU)

graph in the Typical Operating Characteristics); however,

this can be remedied by connecting an external Pchannel load switch driven by SCF so the load is not

connected until the PVSU is in regulation (Figure 17).

Shutdown

The step-up converter is activated with a high input at

ONSU. The main converter (step-up or step-down) is activated by a high input on ONM. The step-down and auxiliary DC-to-DC converters 1, 2, and 3 activate with high

inputs at ONSD, ON1, ON2, and ON3, respectively. The

step-down, main, and AUX_ converters cannot be activated until PVSU is in regulation. For automatic startup, connect ON_ to PVSU or a logic level greater than 1.6V.

Design Procedure

Setting the Switching Frequency

Choose a switching frequency to optimize external

component size or circuit efficiency for the particular

application. Typically, switching frequencies between

400kHz and 500kHz offer a good balance between

component size and circuit efficiency—higher frequencies generally allow smaller components, and lower frequencies give better conversion efficiency. The

switching frequency is set with an external timing resistor (R

OSC

) and capacitor (C

OSC

). At the beginning of a

cycle, the timing capacitor charges through the resistor

until it reaches V

REF

. The charge time, t1, is as follows:

t1= -R

OSC

x C

OSC

x In(1 - 1.25 / V

PVSU

)

The capacitor voltage then decays to zero over time, t

2

= 150ns. The oscillator frequency is as follows:

f

OSC

= 1 / (t1+ t2)

f

OSC

can be set from 100kHz to 1MHz. Choose C

OSC

between 22pF and 470pF. Determine R

OSC

:

R

OSC

= (150ns - 1 / f

OSC

) / (C

OSC

ln[1 - 1.25 / V

PVSU

])

See the Typical Operating Characteristics for f

OSC

vs.

R

OSC

using different values of C

OSC

.

Setting Output Voltages

All MAX1566/MAX1567 output voltages are resistor set.

The FB_ threshold is 1.25V for all channels except for

FB3L (0.2V) on both devices and FB2 (inverter) on the

MAX1567. When setting the voltage for any channel

except the MAX1567 AUX2, connect a resistive voltage-divider from the channel output to the corresponding FB_ input and then to GND. The FB_ input bias

current is less than 100nA, so choose the bottom-side

(FB_-to-GND) resistor to be 100kΩ or less. Then calculate the top-side (output-to-FB_) resistor:

R

TOP

= R

BOTTOM

[(V

OUT

/ 1.25) - 1]

When using AUX3 to drive white LEDs (Figure 7), select

the LED current-setting resistor (R3, Figure 7) using the

following formula:

R3 = 0.2V / I

LED

The FB2 threshold on the MAX1567 is 0V. To set the

AUX2 negative output voltage, connect a resistive voltage-divider from the negative output to the FB2 input,

and then to REF. The FB2 input bias current is less than

100nA, so choose the REF-side (FB2-to-REF) resistor

(R

REF

) to be 100kΩ or less. Then calculate the top-side

(output-to-FB2) resistor:

R

TOP

= R

REF

(-V

OUT(AUX2)

/ 1.25)

General Filter Capacitor Selection

The input capacitor in a DC-to-DC converter reduces

current peaks drawn from the battery or other input