Page 1

General Description

The MAX1542/MAX1543 include a high-performance

boost regulator and two high-current operational amplifiers for active matrix, thin-film transistor (TFT), liquidcrystal displays (LCDs). Also included is a logiccontrolled, high-voltage switch with adjustable delay.

The MAX1543 includes an additional high-voltage load

switch and features pin-selectable boost regulator

switching frequency.

The step-up DC-to-DC converter is a high-frequency

640kHz (MAX1543)/1.2MHz (MAX1542/MAX1543) current-mode regulator with a built-in power MOSFET that

allows the use of ultra-small inductors and ceramic

capacitors. It provides fast transient response to pulsed

loads while producing efficiencies over 85%.

The two easy-to-use, high-performance operational

amplifiers can drive the LCD backplane (V

COM

) and/or

the gamma correction divider string. The devices feature high short-circuit current (150mA), fast slew rate

(7.5V/µs), wide bandwidth (12MHz), and Rail-to-Rail

®

inputs and outputs.

The MAX1542/MAX1543 are available in 20-pin thin

QFN packages with a maximum thickness of 0.8mm for

ultra-thin LCD panel design.

Applications

Notebook Computer Displays

LCD Monitor Panels

PDAs

Car Navigation Displays

Features

♦ Ultra-High-Performance Step-Up Regulator

Fast Transient Response to Pulsed Load Using

Current-Mode Control Architecture

High-Accuracy Output Voltage (1.3%)

Built-In 14V, 1.2A, 0.2Ω N-Channel Power

MOSFET with Lossless Current-Sensing

High Efficiency (85%)

8-Step Current-Controlled Digital Soft-Start

♦ Two High-Performance Operational Amplifiers

150mA Output Short-Circuit Current

7.5V/µs Slew Rate

12MHz -3dB Bandwidth

Rail-to-Rail Inputs/Outputs

Unity Gain Stable

♦ Logic-Controlled High-Voltage Switch with

Adjustable Delay

♦ Timer Delay Latch FB Fault Protection

♦ Thermal Protection

♦ 2.6V to 5.5V Input Operating Voltage Range

♦ 3.6mA (Switching), 0.45mA (Not Switching)

Quiescent Current

♦ Ultra-Thin 20-Pin Thin QFN Package

(5mm x 5mm x 0.8mm)

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

________________________________________________________________ Maxim Integrated Products 1

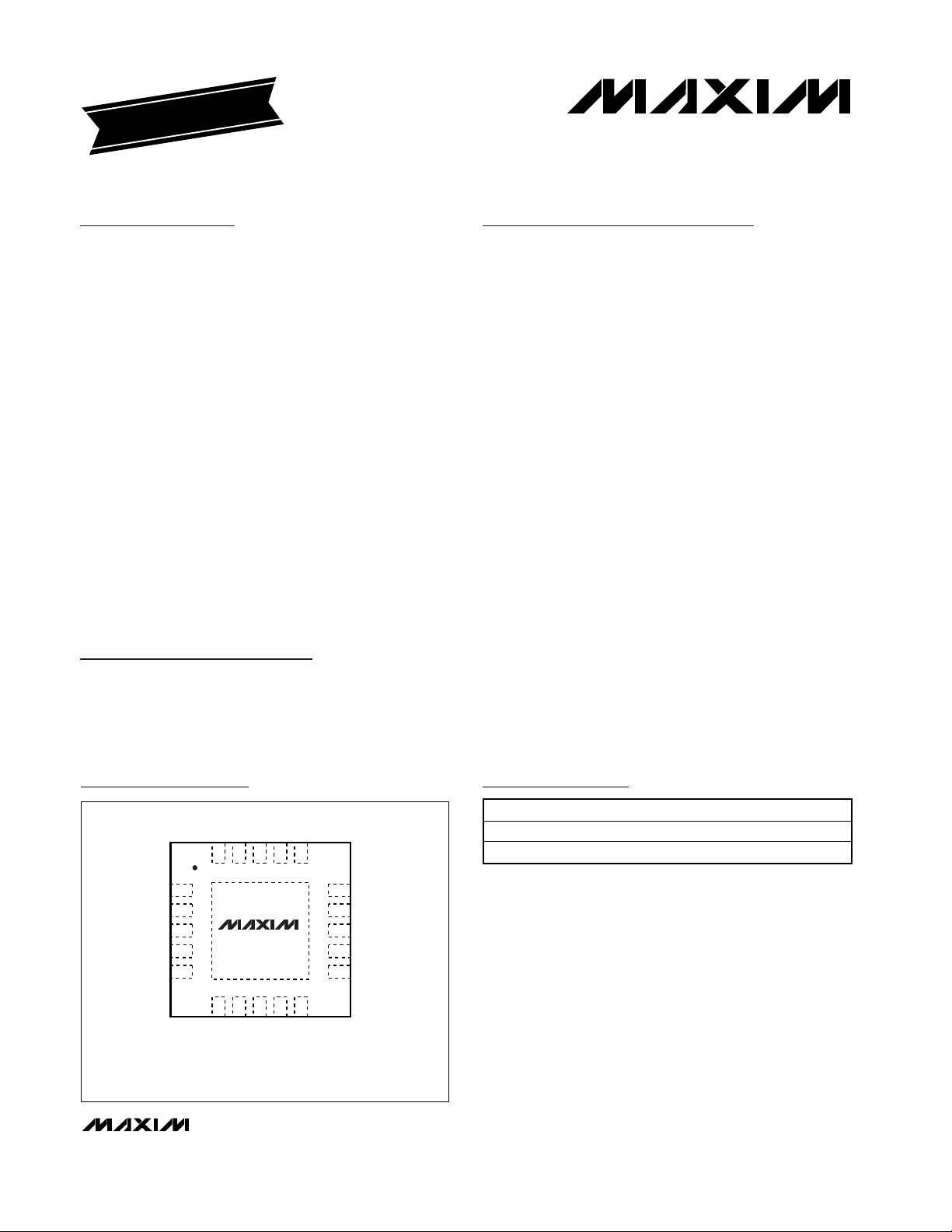

Pin Configurations

Ordering Information

19-2741; Rev 0; 4/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART

PIN-PACKAGE

MAX1542ETP

20 Thin QFN (5mm x 5mm)

MAX1543ETP

20 Thin QFN (5mm x 5mm)

Rail-to-Rail is a registered trademark of Nippon Motorola, Ltd.

Pin Configurations continued at end of data sheet.

TOP VIEW

PGND

AGND

COM

SRC

DRN

20

1

2

I.C.

3

4

5

6

POS1

THIN QFN (5mm x 5mm)

CTL

DEL

COMP

FB

19

18

17

16

15

FREQ

14

IN

13

MAX1543

7

8

OUT1

NEG1

9

OUT2

10

NEG2

LX

12

SUP

POS2

11

TEMP RANGE

-40°C to +85°C

-40°C to +85°C

Page 2

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, CTL, COMP, FB, DEL, FREQ (MAX1543)

to AGND ...............................................................-0.3V to +6V

COMP, FB, DEL to AGND .............................-0.3V to (IN + 0.3V)

PGND to AGND ..................................................................±0.3V

LX to PGND ............................................................-0.3V to +14V

SUP, POS1, NEG1, OUT1, POS2,

NEG2, OUT2 to AGND .......................................-0.3V to +14V

POS1, NEG1, OUT1, POS2, NEG2,

OUT2 to AGND ......................................-0.3V to (SUP + 0.3V)

SRC, COM to AGND...............................................-0.3V to +30V

SRC to COM ...........................................................-0.3V to +30V

SRC to DRN (MAX1543).........................................-0.3V to +30V

COM to AGND ...........................................-0.3V to (SRC + 0.3V)

DRN (MAX1543) to AGND .........................-0.3V to (SRC + 0.3V)

DRN (MAX1543) to COM.........................................-30V to +30V

MAX1542 COM RMS Output Current ...............................+75mA

MAX1543 COM RMS Output Current ...............................±50mA

OUT1, OUT2 Continuous Output Current.........................±75mA

Continuous Power Dissipation (T

A

= +70°C)

20-Pin Thin QFN 5mm x 5mm

(derate 20.8mW/°C above +70°C).............................1667mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature .....................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

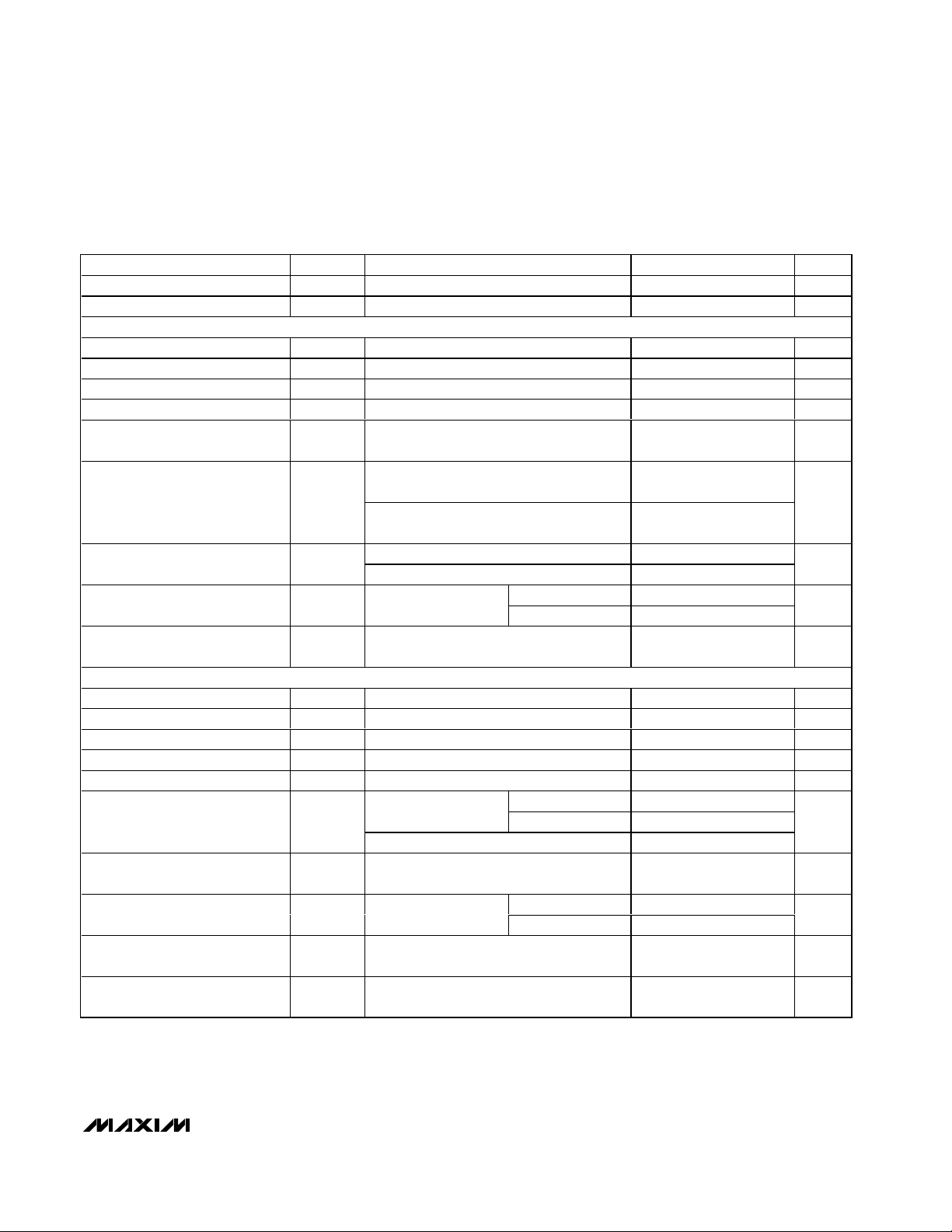

ELECTRICAL CHARACTERISTICS

(VIN= 3V, V

SUP

= 8V, V

SRC

= 28V, FREQ = IN (MAX1543), PGND = AGND = 0, TA= 0°C to +85°C, typical values at TA= +25°C,

unless otherwise noted.)

IN Supply Range V

IN Undervoltage Lockout

Threshold

IN Quiescent Current I

Duration to Trigger Fault

Condition

Thermal Shutdown

MAIN STEP-UP REGULATOR

Output Voltage Range V

Oscillator Maximum Duty Cycle 82 87 92 %

FREQ Input Low Voltage MAX1543, VIN = 2.6V to 5.5V 0.3 x V

FREQ Input High Voltage MAX1543, VIN = 2.6V to 5.5V

FREQ Pulldown Current MAX1543, V

FB Regulation Voltage V

FB Fault Trip Level VFB falling 0.96 1 1.04 V

FB Load Regulation 0 ≤ I

FB Line Regulation VIN = 2.6V to 5.5V -0.08 ±0.15 %/V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN

V

UVLO

MAIN

OSC

VIN rising 2.3 2.5 2.7

VIN falling 2.2 2.35 2.5

VFB = 1.3V, LX not switching 0.45 0.65

IN

VFB = 1.1V, LX switching 3.6 6.5

MAX1542 55

MAX1543

Rising edge 160

Hysteresis 15

MAX1542 1020 1200 1380

MAX1543 FREQ = AGND 512 600 768Operating Frequency f

No load

FB

≤ full load -1 %

MAIN

FREQ = AGND 51

FREQ = IN 55

FREQ = IN 1020 1200 1380

= 1.0V 3.5 5 6.5 µA

FREQ

TA = +85°C 1.224 1.240 1.256

T

= 0°C to +85°C 1.222 1.240 1.258

A

2.6 5.5 V

V

IN

0.7 x

V

IN

13 V

IN

V

mA

ms

°C

kHz

V

V

V

Page 3

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 3V, V

SUP

= 8V, V

SRC

= 28V, FREQ = IN (MAX1543), PGND = AGND = 0, TA= 0°C to +85°C, typical values at TA= +25°C,

unless otherwise noted.)

)

FB Input Bias Current VFB = 1.5V -40 +40 nA

FB Transconductance ∆I

FB Voltage Gain FB to COMP 700 V/V

LX On-Resistance R

LX Leakage Current I

LX Current Limit I

Current-Sense Transresistance 0.30 0.50 0.65 Ω

Soft-Start Step Size I

OPERATIONAL AMPLIFIERS

SUP Supply Range V

SUP Supply Current I

Input Offset Voltage V

Input Bias Current I

Input Common-Mode Voltage

Range

Common-Mode Rejection Ratio CMRR 0 ≤ V

Open-Loop Gain 125 dB

Output Voltage Swing High V

Output Voltage Swing Low V

Short-Circuit Current To V

Output Source-and-Sink Current

Power-Supply Rejection Ratio PSRR

Slew Rate 7.5 V/µs

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= 5µA 75 160 280 µS

COMP

LX(ON

LX

LIM

VLX = 13V 0.01 20 µA

VFB = 1V, duty cycle = 65% 1.2 1.5 1.8 A

210 400 mΩ

MAX1542 14

SS

SUP

SUP

OS

BIAS

V

CM

OH

OL

MAX1543

Buffer configuration, V

VCM = V

/2, TA = +25°C 0 12 mV

SUP

NEG1, NEG2, POS1, POS2 +1 ±50 nA

, V

NEG_

POS_

I

= 100µA

OUT_

I

= 5mA

OUT_

I

= -100µA 2 15

OUT_

I

= -5mA 80 150

OUT_

/2

SUP

Buffer configuration, V

|∆V

< 10mV

OS|

DC, 6V ≤ V

/2

V

SUP

SUP

≤ 13V, V

FREQ = AGND 13Soft-Start Period t

FREQ = IN 14

= 4V, no load 1.3 1.9 mA

POS_

≤ V

SUP

V

V

Source 50 150

Sink 50 140

= 4V,

POS_

, V

POS_

=

NEG_

/ 8 A

LIM

4.5 13.0 V

0V

SUP

50 90 dB

SUP

-15V

SUP

-

2

-

V

SUP

150

SUP

80

-

40 mA

60 100 dB

ms

V

mV

mV

mA

-3dB Bandwidth RL = 10kΩ, CL =10pF, buffer configuration 12 MHz

Gain-Bandwidth Product GBW Buffer configuration 8 MHz

POSITIVE GATE-DRIVER TIMING AND CONTROL SWITCHES

DEL Capacitor Charge Current During startup, V

= 1V 4 5 6 µA

DEL

Page 4

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(VIN= 3V, V

SUP

= 8V, V

SRC

= 28V, FREQ = IN (MAX1543), PGND = AGND = 0, TA= -40°C to +85°C, unless otherwise noted.)

PARAMETER

CONDITIONS

UNITS

DEL Turn-On Threshold

)

V

DEL Discharge Switch OnResistance

During UVLO, V

IN

= 2.2V 20 Ω

CTL Input Low Voltage VIN = 2.6V to 5.5V 0.6 V

CTL Input High Voltage VIN = 2.6V to 5.5V 2 V

CTL Input Leakage Current CTL = AGND or IN -1 +1 µA

CTL-to-SRC Propagation Delay

ns

SRC Input Voltage Range 28 V

MAX1542 70

V

D RN

= 8V , C TL = IN ,

V

D E L

= 1.5V

MAX1543

SRC Input Current I

SRC

V

DRN

= 8V, CTL = AGND, V

DEL

= 1.5V 15 30

µA

DRN Input Current I

DRC

V

DRN

= 8V, CTL = AGND, V

DEL

= 1.5V,

MAX1543

90

µA

MAX1542 5 10

SRC to COM Switch OnResistance

)

V

DEL

= 1.5V,

CTL = IN

MAX1543 15 30

Ω

DRN to COM Switch OnResistance (MAX1543)

)

V

DEL

= 1.5V, CTL = AGND 30 60 Ω

COM to PGND Switch OnResistance (MAX1543)

)

V

DEL

= 1.1V

Ω

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

IN Supply Range V

IN

2.6 5.5 V

VIN rising 2.3 2.7

IN Undervoltage Lockout

Threshold

V

UVLO

VIN falling 2.2 2.5

V

V

FB

= 1.3V, LX not switching

IN Quiescent Current I

IN

V

FB

= 1.1V, LX switching 6.5

mA

MAIN STEP-UP REGULATOR

Output Voltage Range V

MAIN

V

IN

13 V

MAX1542

FREQ = AGND

Operating Frequency f

OSC

MAX1543

FREQ = IN

kHz

FB Regulation Voltage V

FB

No load

V

FB Fault Trip Level VFB falling

V

FB Line Regulation VIN = 2.6V to 5.5V

%/V

FB Transconductance ∆I

COMP

= 5µA 75

µS

LX On-Resistance

)

mΩ

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 3V, V

SUP

= 8V, V

SRC

= 28V, FREQ = IN (MAX1543), PGND = AGND = 0, TA= 0°C to +85°C, typical values at TA= +25°C,

unless otherwise noted.)

SYMBOL

V

TH(DEL

MIN TYP MAX

1.178 1.240 1.302

100

130

100 180

R

SRC(ON

R

DRN(ON

R

COM(ON

R

LX(ON

350 1000 1800

1000 1400

512 768

1000 1400

1.215 1.260

0.96 1.04

150

0.65

0.15

300

400

Page 5

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

_______________________________________________________________________________________ 5

)

)

)

)

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 3V, V

SUP

= 8V, V

SRC

= 28V, FREQ = IN (MAX1543), PGND = AGND = 0, TA= -40°C to +85°C, unless otherwise noted.)

LX Current Limit I

Current-Sense Transresistance 0.30 0.65 Ω

OPERATIONAL AMPLIFIERS

SUP Supply Range V

SUP Supply Current I

Input Offset Voltage V

Input Bias Current I

Input Common-Mode Voltage

Range

Output Voltage Swing High V

Output Voltage Swing Low V

Short-Circuit Current To V

Output Source-and-Sink Current

POSITIVE GATE-DRIVER TIMING AND CONTROL SWITCHES

DEL Capacitor Charge Current During startup, V

DEL Turn-On Threshold V

CTL Input Low Voltage VIN = 2.6V to 5.5V 0.6 V

CTL Input High Voltage VIN = 2.6V to 5.5V 2 V

SRC Input Voltage Range 28 V

SRC Input Current I

DRN Input Current I

SRC to COM Switch OnResistance

DRN to COM Switch OnResistance (MAX1543)

COM to PGND Switch OnResistance (MAX1543)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LIM

SUP

SUP

OS

BIAS

V

CM

OH

TH (DEL

SRC

DRN

R

SRC(ON

R

DRN(ON

R

COM(ON

VFB = 1V, duty cycle = 65% 1.2 1.8 A

4.5 13.0 V

Buffer configuration, V

VCM = V

/2, TA = +25ºC12mV

SUP

= 4V, no load 2.1 mA

POS_

NEG1, NEG2, POS1, POS2 ±50 nA

0V

V

-

I

OUT_

I

OUT_

I

OL

OUT_

I

OUT_

Buffer configuration, V

| ∆V

OS

= 100µA

= 5mA

= -100µA 15

= -5mA 150

SUP

/2

Source 50

Sink 50

= 4V,

POS_

| < 10mV

= 1.0V 4 6 µA

DEL

SUP

15

V

-

SUP

150

40 mA

1.178 1.302 V

V

= 8V, CTL = IN,

DRN

= 1.5V

V

DEL

V

= 8V, CTL = AGND, V

DRN

V

= 8V, CTL = AGND, V

DRN

MAX1542 130

MAX1543 180

= 1.5V 30

DEL

= 1.5V,

DEL

MAX1543

V

= 1.5V, CTL = IN

DEL

V

= 1.5V, CTL = AGND 60 Ω

DEL

V

= 1.1V 350 1800 Ω

DEL

MAX1542 10

MAX1543 30

SUP

150 µA

V

mV

mV

mA

µA

Ω

Page 6

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

6 _______________________________________________________________________________________

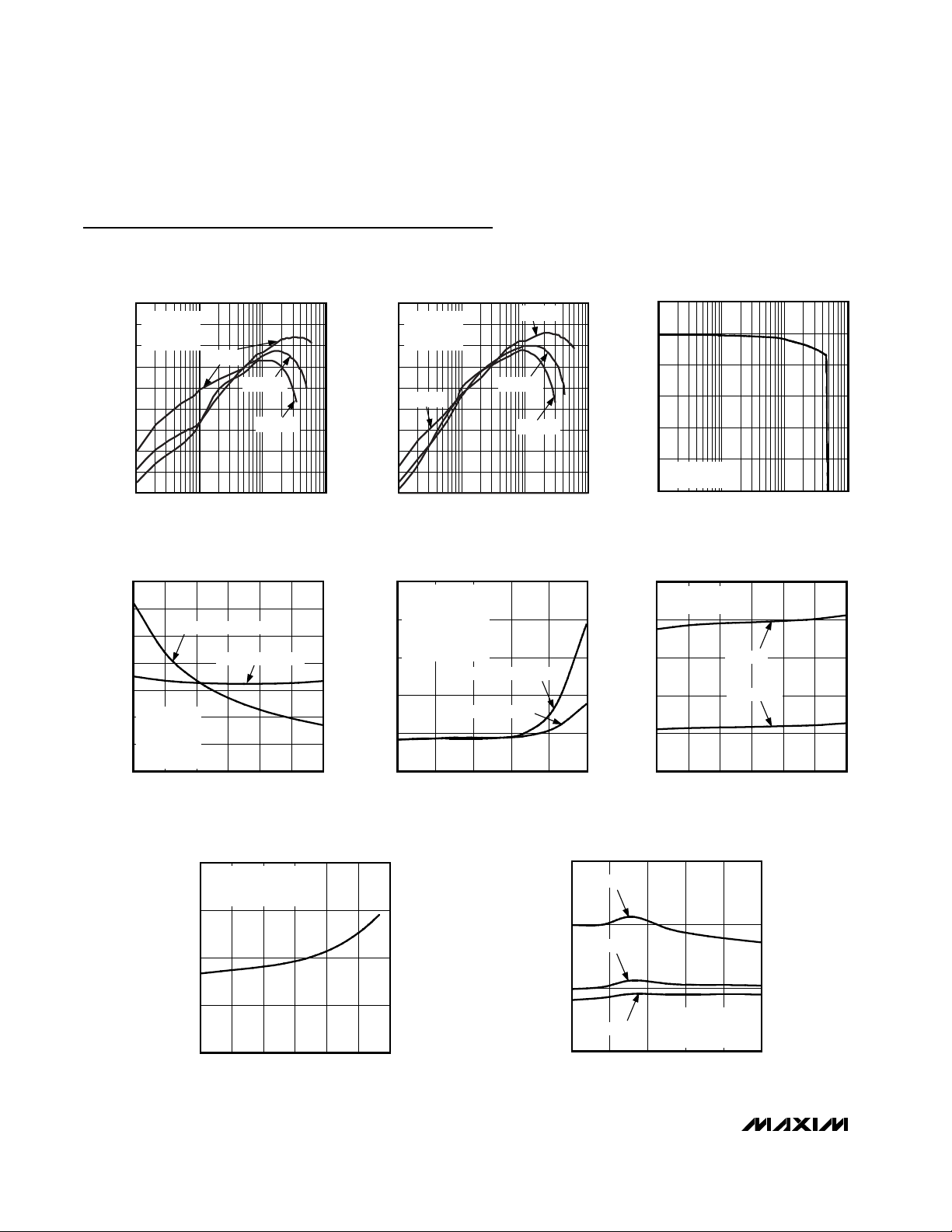

Typical Operating Characteristics

(VIN= 3.3V, V

MAIN

= 8V, f

OSC

= 1.2MHz, TA= +25°C, unless otherwise noted.)

50

1 1000100

STEP-UP REGULATOR EFFICIENCY

vs. LOAD CURRENT (V

MAIN

= 8V)

65

55

85

75

95

70

60

90

80

MAX1542 toc01

LOAD CURRENT (mA)

EFFICIENCY (%)

10

MAX1543

f

OSC

= 1.2MHz

L = 4.7µH

VIN = 3.3V

VIN = 2.7V

VIN = 5V

50

1 100010010

STEP-UP REGULATOR EFFICIENCY

vs. LOAD CURRENT (V

MAIN

= 8V)

65

55

85

75

95

70

60

90

80

MAX1542 toc02

LOAD CURRENT (mA)

EFFICIENCY (%)

MAX1543

f

OSC

= 640kHz

L = 10µH

VIN = 3.3V

VIN = 2.7V

VIN = 5V

VIN = 5V

STEP-UP REGULATOR OUTPUT VOLTAGE

vs. LOAD CURRENT (V

MAIN

= 8V)

MAX1542 toc03

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

10 100

7.6

7.7

7.8

7.9

8.0

8.1

7.5

1 1000

VIN = 3.3V

f

OSC

= 1.2MHz

MAX1542 toc04

VIN (V)

SUPPLY CURRENT (mA)

5.04.54.03.53.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0

2.5 5.5

STEP-UP REGULATOR SUPPLY CURRENT

vs. SUPPLY VOLTAGE

NO LOAD

f

OSC

= 1.2MHz

R

1

= 75kΩ

R

2

= 13.7kΩ

SUP DISCONNECTED

CURRENT INTO INDUCTOR

CURRENT INTO IN PIN

STEP-UP REGULATOR SUPPLY CURRENT

vs. TEMPERATURE

MAX1542 toc05

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

603510-15

0.4

0.8

1.2

1.6

2.0

0

-40 85

NO LOAD

V

IN

= 3.3V

f

OSC

= 1.2MHz

R

1

= 75kΩ

R

2

= 13.7kΩ

SUP DISCONNECTED

CURRENT INTO INDUCTOR

CURRENT INTO IN PIN

MAX1542 toc06

VIN (V)

SWITCHING FREQUENCY (kHz)

5.04.54.03.53.0

600

800

1000

1200

1400

400

2.5 5.5

SWITCHING FREQUENCY

vs. INPUT VOLTAGE

MAX1543

I

MAIN

= 200mA

FREQ = IN

FREQ = AGND

SUP SUPPLY CURRENT

vs. SUP VOLTAGE

MAX1542 toc07

V

SUP

(V)

I

SUP

(mA)

12.010.59.07.56.0

1.00

1.25

1.50

1.75

0.75

4.5 13.5

NO LOAD

BUFFER CONFIGURATION

POS_ = V

SUP

/2

SUP SUPPLY CURRENT

vs. TEMPERATURE

MAX1542 toc08

TEMPERATURE (°C)

I

SUP

(mA)

603510-15

1.2

1.6

2.0

0.8

-40 85

NO LOAD

BUFFER CONFIGURATION

V

POS

= V

SUP

/2

V

SUP

= 13V

V

SUP

= 8V

V

SUP

= 5V

Page 7

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

_______________________________________________________________________________________ 7

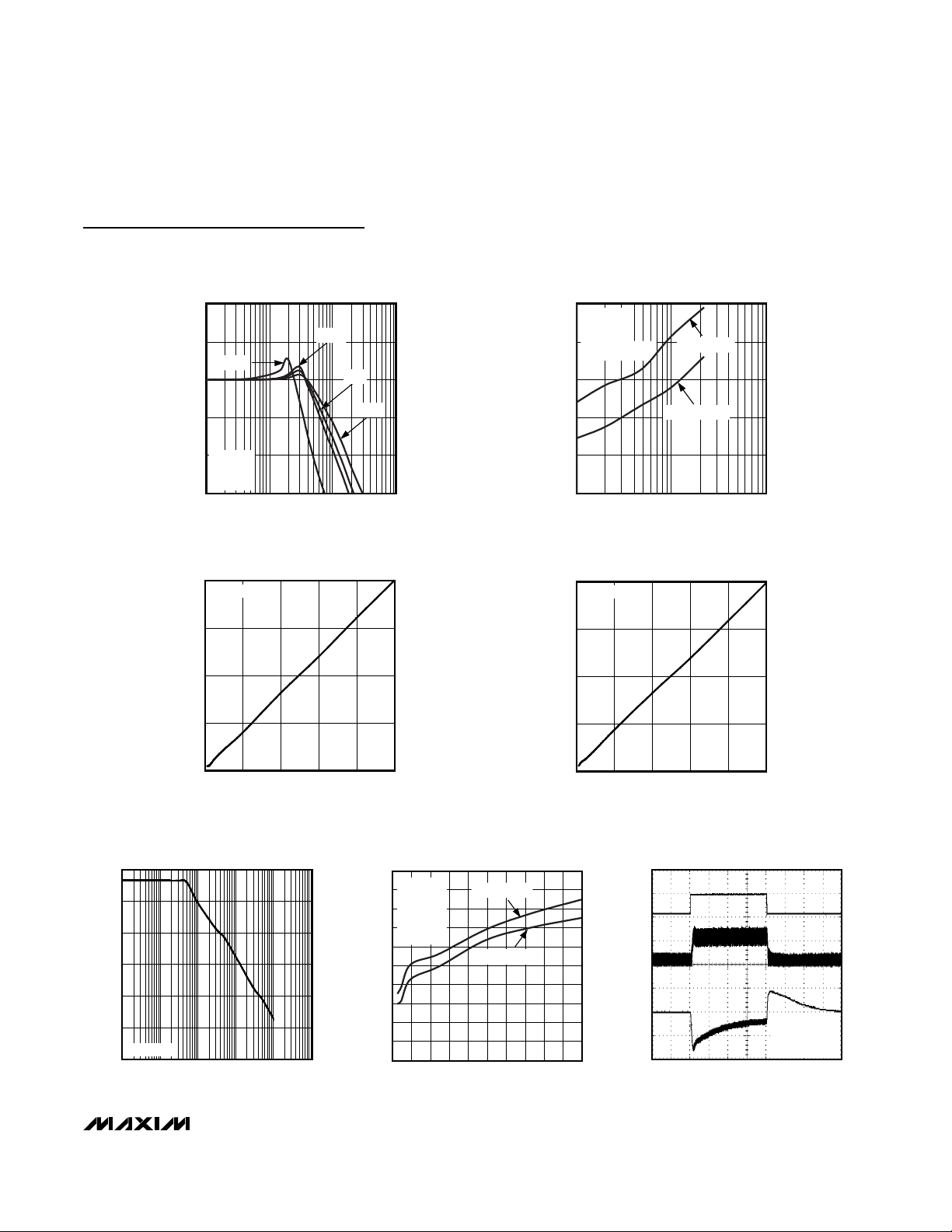

Typical Operating Characteristics (continued)

(VIN= 3.3V, V

MAIN

= 8V, f

OSC

= 1.2MHz, TA= +25°C, unless otherwise noted.)

OPERATIONAL AMPLIFIER

OUTPUT LOW VOLTAGE vs. LOAD

MAX1542 toc12

I

OUT_

(mA)

V

OL

(mV)

8642

40

80

120

160

0

010

V

SUP

= 8V

A

V

= 1

OPERATIONAL AMPLIFIER

OUTPUT HIGH VOLTAGE vs. LOAD

MAX1542 toc11

I

OUT_

(mA)

V

SUP

- V

OUT

(mV)

8642

40

80

120

160

0

010

V

SUP

= 8V

A

V

= 1

POWER-SUPPLY REJECTION RATIO

vs. FREQUENCY

MAX1542 toc13

FREQUENCY (Hz)

PSRR (dB)

1k100101

20

40

60

80

100

120

0

0.1 10k

V

SUP

= 8V

OPERATIONAL AMPLIFIER

SETTLING TIME vs. STEP SIZE

MAX1542 toc14

STEP SIZE (V)

SETTLING TIME (ns)

1.4 1.6 1.81.0 1.20.4 0.6 0.80.2

100

50

200

150

300

250

400

450

350

500

0

0 2.0

V

SUP

= 8V

A

V

= +1

R

L

= 10kΩ

C

L

= 10pF

V

CM

= 4V

RISING EDGE

FALLING EDGE

STEP-UP REGULATOR

LOAD-TRANSIENT RESPONSE

MAX1542 toc15

40µs/div

I

MAIN

200mA/div

I

L

500mA/div

200mA

20mA

V

MAIN

AC-COUPLED

100mV/div

L = 4.7µH

R

COMP

= 120kΩ

C

COMP

= 470pF

OPERATIONAL AMPLIFIER FREQUENCY

RESPONSE FOR VARIOUS C

20

10

1000pF

0

-10

MAGNITUDE (dB)

-20

V

= 8V

SUP

= 1

A

V

= 10kΩ

R

L

-30

100 100k10k1k

FREQUENCY (Hz)

OPERATIONAL AMPLIFIER OVERSHOOT

vs. LOAD CAPACITANCE

V

= 8V

SUP

= 10kΩ

R

L

= 1

A

V

POS_ = 4V ±50mV

1 100 1000

LOAD CAPACITANCE (pF)

RISING EDGE

FALLING EDGE

100pF

56pF

LOAD

15pF

MAX1542 toc09

100

80

60

40

OVERSHOOT (%)

20

0

MAX1542 toc10

Page 8

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

8 _______________________________________________________________________________________

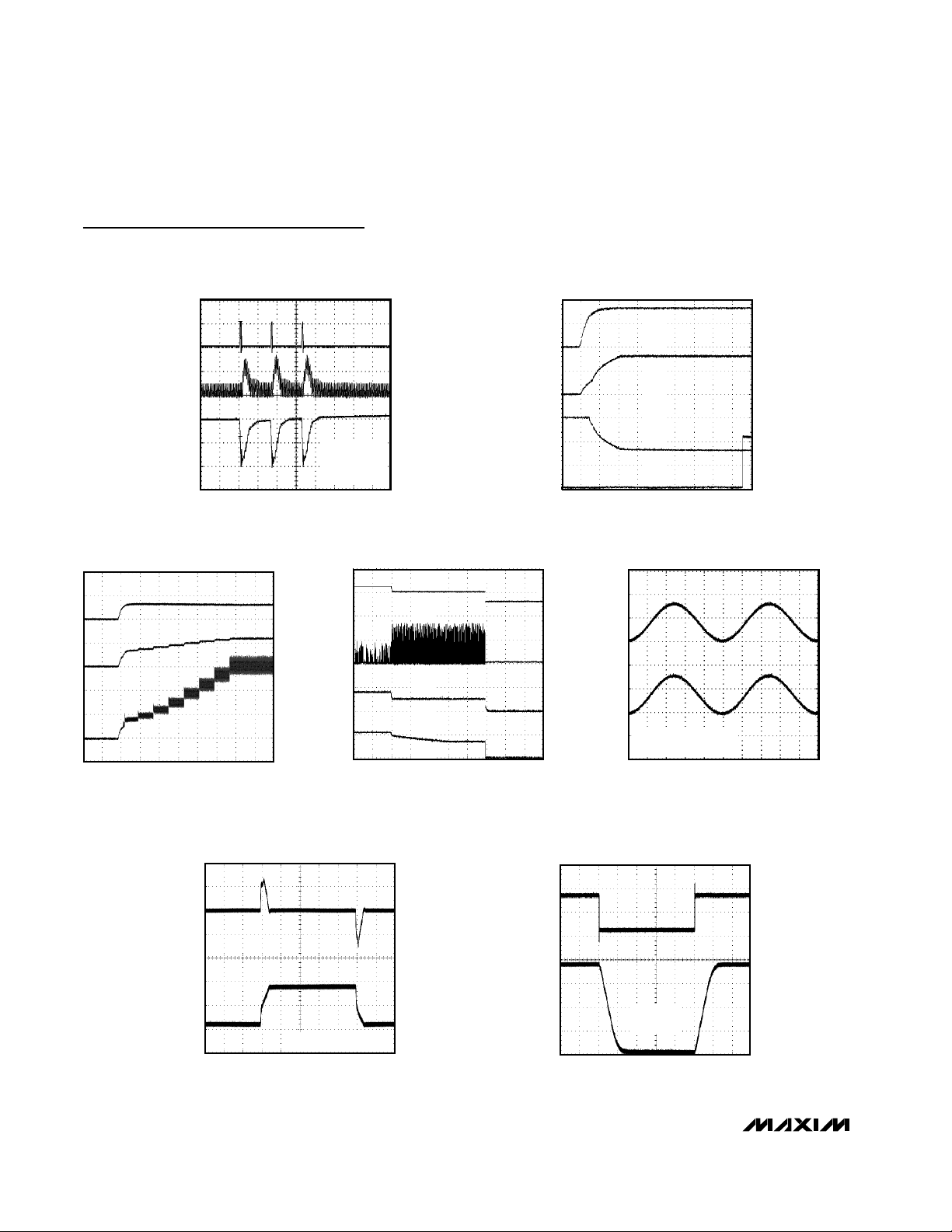

Typical Operating Characteristics (continued)

(VIN= 3.3V, V

MAIN

= 8V, f

OSC

= 1.2MHz, TA= +25°C, unless otherwise noted.)

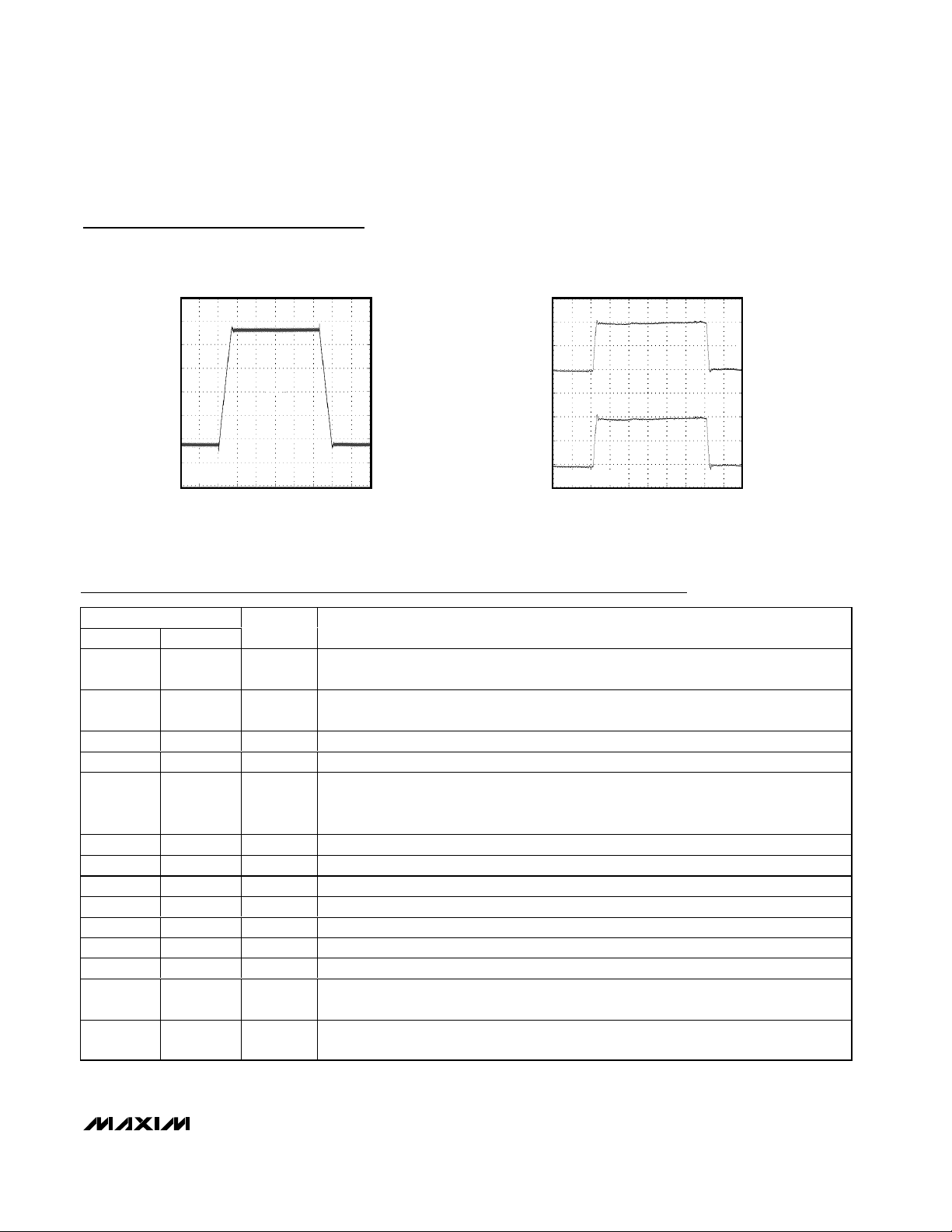

STEP-UP REGULATOR

PULSED LOAD-TRANSIENT RESPONSE

MAX1542 toc16

10µs/div

I

MAIN

1A/div

I

L

500mA/div

V

MAIN

100mV/div

AC-COUPLED

L = 4.7µH

R

COMP

= 120kΩ

C

COMP

= 470pF

STARTUP SEQUENCE

MAX1542 toc17

1ms/div

V

IN

2V/div

V

MAIN

8V/div

V

GOFF

5V/div

V

COM

10V/div

HEAVY-LOAD

SOFT-START WAVEFORMS

MAX1542 toc18

2ms/div

R

LOAD

= 10Ω

V

IN

5V/div

V

MAIN

5V/div

I

L

500mA/div

TIMER DELAY LATCH

RESPONSE TO OVERLOAD

MAX1542 toc19

10ms/div

I

L

2A/div

V

MAIN

5V/div

V

OUT1

5V/div

V

COM

20V/div

OPERATIONAL AMPLIFIER

RAIL-TO-RAIL I/O PERFORMANCE

MAX1542 toc20

100µs/div

V

POS1

5V/div

V

OUT1

5V/div

V

SUP

= 8V

BUFFER CONFIGURATION

OPERATIONAL AMPLIFIER

LOAD-TRANSIENT RESPONSE

MAX1542 toc21

1µs/div

V

OUT1

1V/div

AC-COUPLED

4V

+50

0

-50

I

OUT1

50mA/div

BUFFER CONFIGURATION

OPERATIONAL AMPLIFIER

LARGE-SIGNAL STEP RESPONSE

MAX1542 toc22

1µs/div

V

POS1

500mV/div

AC-COUPLED

4V

V

OUT1

2V/div

V

SUP

= 8V

A

V

= 10

Page 9

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

_______________________________________________________________________________________ 9

Typical Operating Characteristics (continued)

(VIN= 3.3V, V

MAIN

= 8V, f

OSC

= 1.2MHz, TA= +25°C, unless otherwise noted.)

OPERATIONAL AMPLIFIER

SMALL-SIGNAL STEP RESPONSE

MAX1542 toc24

200ns/div

POS_

50mV/div

AC-COUPLED

OUT_

50mV/div

AC-COUPLED

V

SUP

= 8V, AV = 1

CH2 + OVER

6.234%

CH2 - OVER

2.352%

OPERATIONAL AMPLIFIER

LARGE-SIGNAL STEP RESPONSE

MAX1542 toc23

1µs/div

V

OUT_

1V/div

CHI AMPL

4.86V

CHI + OVER

4.970%

AV = 1

Pin Description

MAX1542 MAX1543

1 1 COM

2 2 SRC

3, 15, 20 — N.C. No Connection. Not internally connected.

— 3 I.C. Internal Connection. Make no connection to this pin.

4 4 PGND

5 5 AGND Analog Ground. Connect to power ground (PGND) underneath the IC.

6 6 POS1 Operational Amplifier 1 Noninverting Input

7 7 NEG1 Operational Amplifier 1 Inverting Input

8 8 OUT1 Operational Amplifier 1 Output

9 9 OUT2 Operational Amplifier 2 Output

10 10 NEG2 Operational Amplifier 2 Inverting Input

11 11 POS2 Operational Amplifier 2 Noninverting Input

12 12 SUP

13 13 LX

PIN

NAME FUNCTION

Internal High-Voltage MOSFET Switch Common Terminal. Do not allow the voltage on

COM to exceed V

SRC

.

Switch Input. Source of the internal high-voltage P-channel MOSFET. Bypass SRC to

PGND with a minimum of 0.1µF close to the pins.

Power Ground. PGND is the source of the main boost N-channel power MOSFET. Connect

PGND to the output capacitor ground terminals through a short, wide PC board trace.

Connect to analog ground (AGND) underneath the IC.

Operational Amplifier Power Input. Positive supply rail for the OUT1 and OUT2 amplifiers.

Typically connected to V

MAIN

Power MOSFET N-Channel Drain and Switching Node. Connect the inductor and catch

diode to LX and minimize the trace area for lowest EMI.

. Bypass SUP to AGND with a 0.1µF capacitor.

Page 10

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

10 ______________________________________________________________________________________

Pin Description (continued)

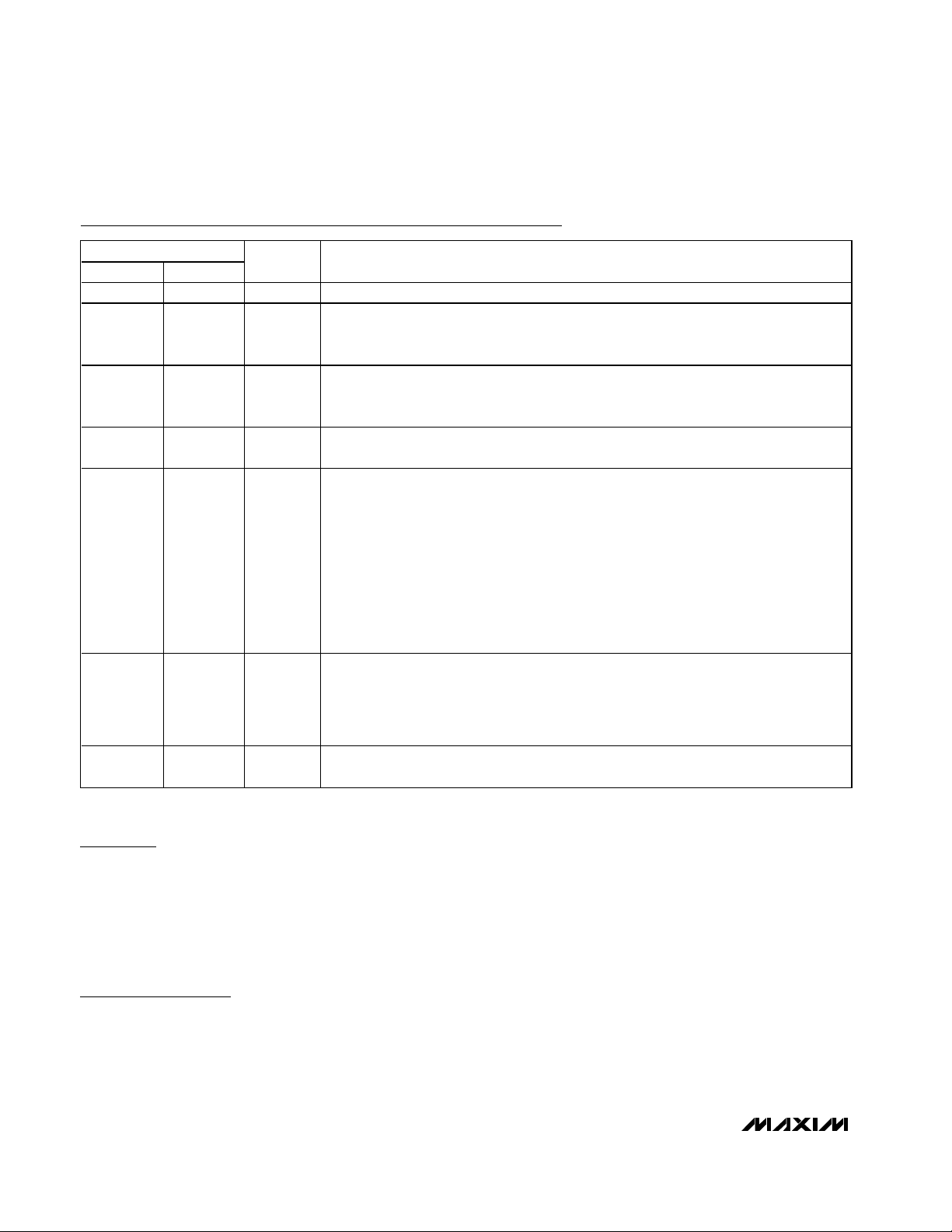

Typical Application Circuits

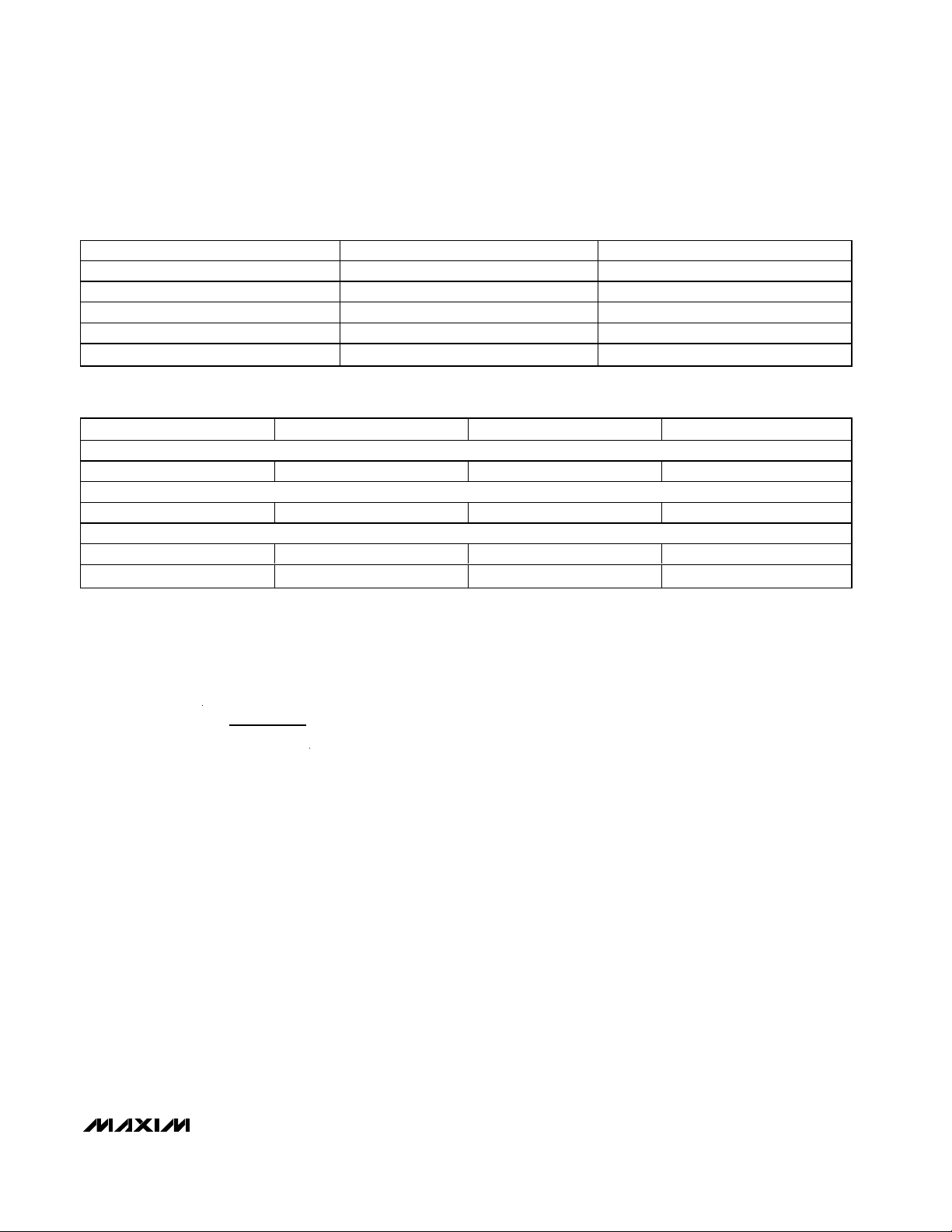

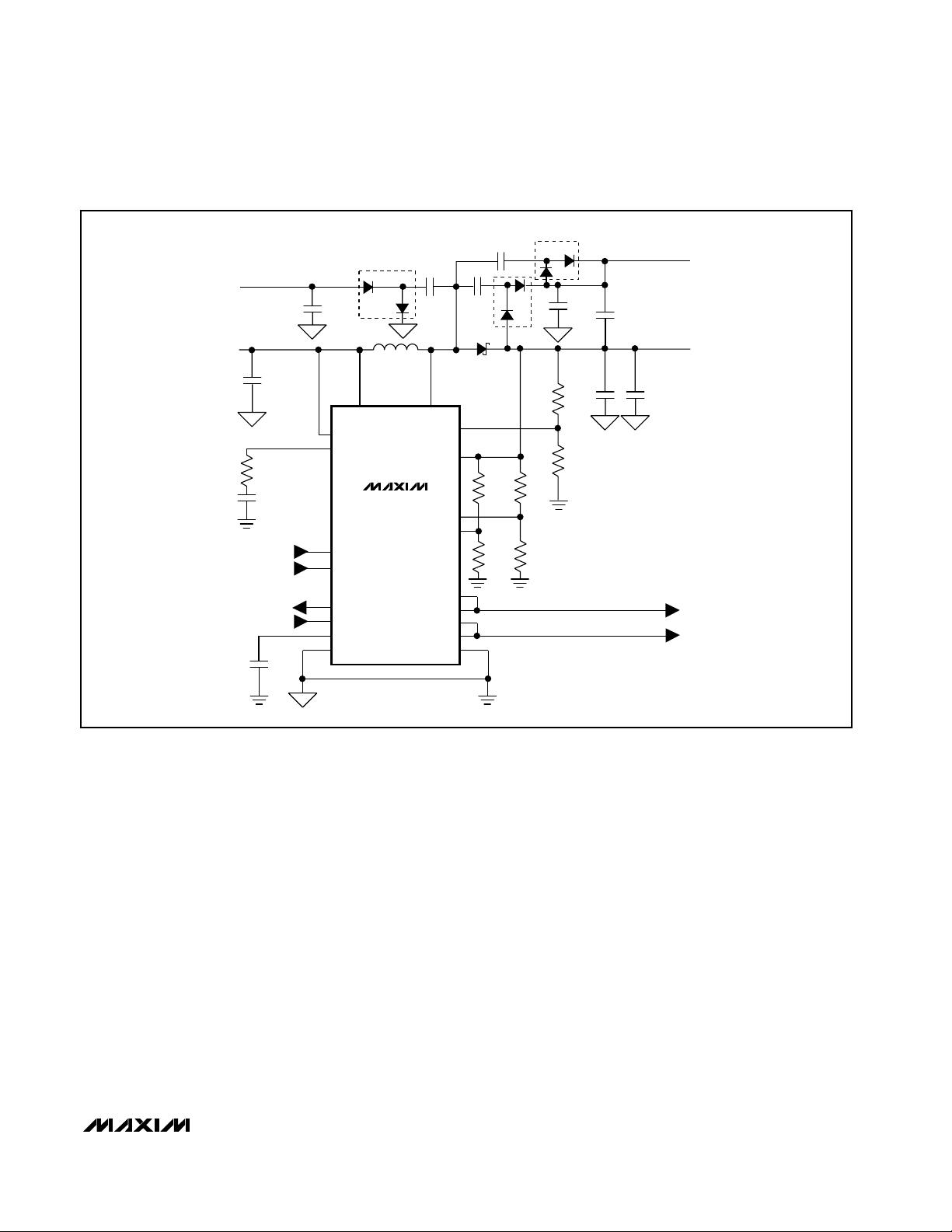

The MAX1542 typical application circuit (Figure 1) and

the MAX1543 typical application circuit (Figure 2) generate an +8V source driver supply and approximately

+22V and -7V gate driver supplies for TFT displays. The

input voltage is from +2.6V to +5.5V. Table 1 lists recommended components and Table 2 lists contact information for component suppliers.

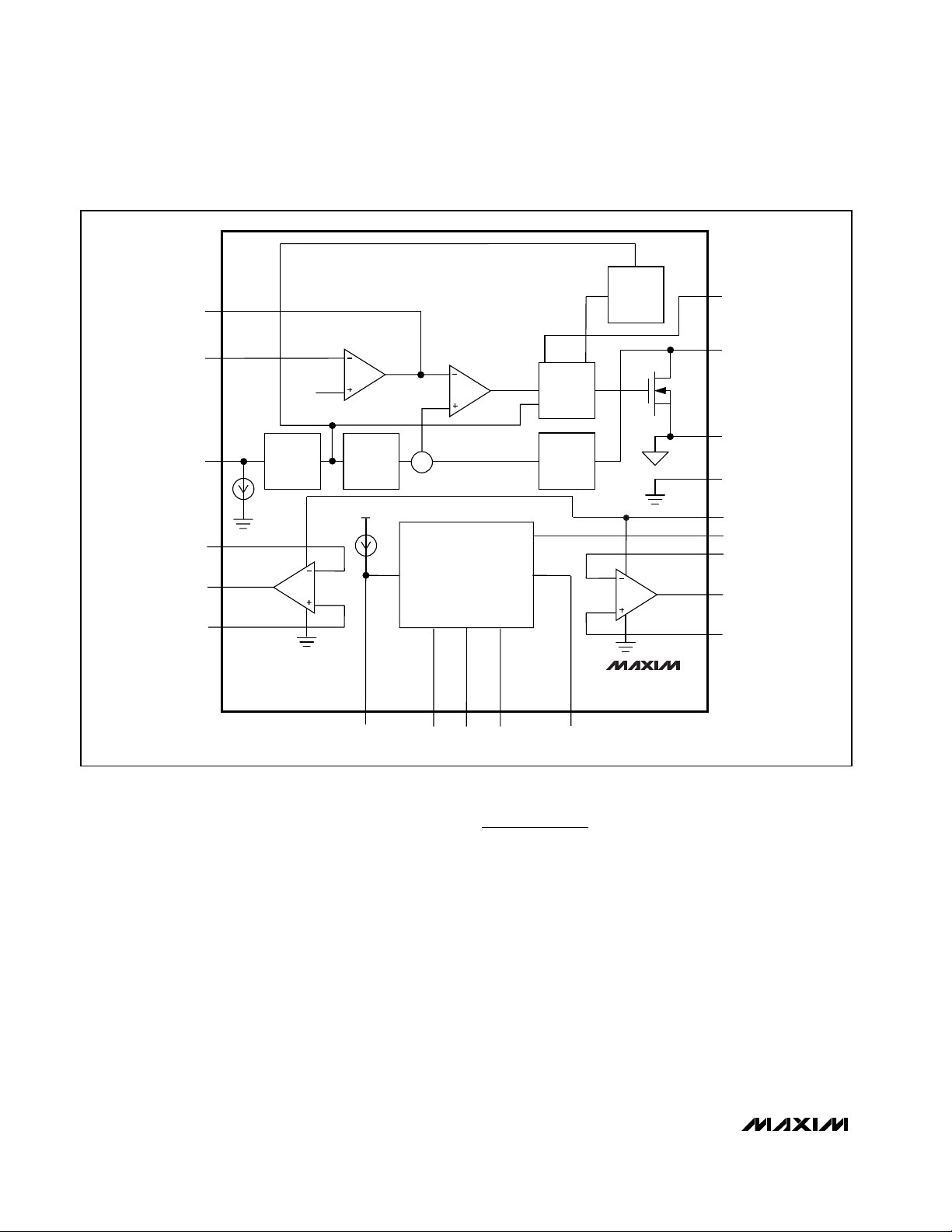

Detailed Description

The MAX1542/MAX1543 include a high-performance

step-up regulator, two high-current operational amplifiers, and startup timing and level-shifting functionality

useful for active matrix TFT LCDs. Figure 3 shows the

MAX1542/MAX1543 functional diagram.

Main Step-Up Converter

The MAX1542/MAX1543 main step-up converter

switches at 1.2MHz or 640kHz (MAX1543 only) (see the

Oscillator Frequency (FREQ) section). The devices

employ a current-mode, fixed-frequency, pulse-width

modulation (PWM) architecture to maximize loop bandwidth providing fast transient response to pulsed loads

found in source drivers for TFT LCD panels. The highswitching frequency also allows the use of low-profile

inductors and capacitors to minimize the thickness of

LCD panel designs. The integrated high-efficiency

MOSFET and the IC’s built-in digital soft-start function

reduce the number of external components required

while controlling inrush current. The output voltage of

the main step-up converter (V

MAIN

) can be set from V

IN

to 13V with an external resistive voltage-divider at FB.

PIN

MAX1542 MAX1543

14 14 IN Supply Voltage. IN can range from 2.6V to 5.5V.

— 15 FREQ

16 16 FB

17 17 COMP

18 18 DEL

19 19 CTL

— 20 DRN

NAME FUNCTION

Oscillator Frequency Select Input. Pull FREQ low or leave it unconnected for 640kHz

operation. Connect FREQ high for 1.2MHz operation. This input has a 5µA pulldown

current.

Step-Up Converter Feedback Input. Regulates to 1.24V (nominal). Connect a resistordivider from the output (V

within 5mm of FB.

Step-Up Regulator Error Amplifier Compensation Point. Connect a series RC from COMP

to AGND. See the Loop Compensation section for component selection guidelines.

High-Voltage Switch Delay Input. Connect a capacitor from DEL to AGND to set the highvoltage switch startup delay. A 5µA current source charges C

For the MAX1542, the high-voltage switch between SRC and COM is disabled until V

exceeds 1.24V. Following the delay period, CTL controls the state of the high-voltage

switch.

For the MAX1543, the switches between SRC, COM, and DRN are disabled and a 1kΩ

pulldown between COM and PGND is enabled until V

delay period, the 1kΩ pulldown is released and CTL controls the state of the high-voltage

switches (see the Delay Control Circuit section).

High-Voltage Switch Control Input. When CTL is high, the high-voltage switch between

COM and SRC is on and the high-voltage switches between COM and DRN (MAX1543)

are off. When CTL is low, the high-voltage switch between COM and SRC is off and the

high-voltage switches between COM and DRN (MAX1543) are on. CTL is inhibited by the

undervoltage lockout and when V

Switch Input. Drain of the internal high-voltage back-to-back P-channel MOSFETs

connected to COM.

) to FB to analog ground (AGND). Place the resistor-divider

MAIN

.

DEL

exceeds 1.24V. Following the

DEL

is less than 1.24V.

DEL

DEL

Page 11

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

______________________________________________________________________________________ 11

The regulator controls the output voltage and the power

delivered to the outputs by modulating the duty cycle

(D) of the power MOSFET in each switching cycle. The

duty cycle of the MOSFET is approximated by:

The device regulates the output voltage through a combination of an error amplifier, two comparators, and

several signal generators (Figure 3). The error amplifier

compares the signal at FB to 1.24V and varies the

COMP output. The voltage at COMP determines the

current trip point each time the internal MOSFET turns

on. As the load varies, the error amplifier sources or

sinks current to the COMP output accordingly to produce the inductor peak current necessary to service

the load. To maintain stability at high duty cycles, a

slope compensation signal is summed with the currentsense signal.

Operational Amplifiers

The MAX1542/MAX1543 include two operational amplifiers that are typically used to drive the LCD backplane

VCOM and/or the gamma correction divider string. The

operational amplifiers feature ±150mA output short-circuit current, 7.5V/µs slew rate, and 12MHz bandwidth.

The rail-to-rail inputs and outputs maximize flexibility.

Short-Circuit Current Limit

The MAX1542/MAX1543 operational amplifiers limit

short-circuit current to ±150mA if the output is directly

shorted to SUP or AGND. In such a condition, the junction temperature of the IC rises until it reaches the thermal shutdown threshold, typically +160°C. Once it

reaches this threshold, the IC shuts down and remains

inactive until IN falls below V

UVLO

.

Driving Pure Capacitive Loads

The operational amplifiers are typically used to drive

the LCD backplane (VCOM) or the gamma correction

divider string. The LCD backplane consists of a distributed series capacitance and resistance, a load easily

driven by the operational amplifiers. However, if the

operational amplifiers are used in an application with a

pure capacitive load, steps must be taken to ensure

stable operation.

As the operational amplifier’s capacitive load increases,

the amplifier bandwidth decreases and gain peaking

increases. A small 5Ω to 50Ω resistance placed between

OUT_ and the capacitive load reduces peaking but

reduces the amplifier gain. An alternative method of

reducing peaking is the use of a snubber circuit. A 150Ω

and 10nF (typ) shunt load, or snubber, does not continuously load the output or reduce amplifier gain.

D

VV

V

MAIN IN

MAIN

≈

−

Table 1. Component List

Table 2. Component Suppliers

DESIGNATION DESCRIPTION PART

C1 10µF ±10%, 6.3V X5R ceramic capacitor TDK C3216X5R0J106K

C8, C9 4.7µF ±10%, 10V X5R ceramic capacitors TDK C3225X5R1A475K

D1 1A, 30V Schottky diode Toshiba CRS02

D2, D3, D4 200mA, 100V dual ultra-fast diodes Fairchild MMBD4148SE

L1 4.7µH, 1.3A inductor Sumida CLS5D11HP-4R7

Inductors

Sumida USA 847-956-0666 847-956-0702 www.sumida.com

Capacitors

TDK 847-803-6100 847-803-6296 www.component.tdk.com

Diodes

Fairchild 888-522-5372 408-822-2104 www.fairchildsemi.com

Toshiba 949-455-2000 949-859-3963 www.toshiba.com/taec/

SUPPLIER PHONE FAX WEBSITE

Page 12

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

12 ______________________________________________________________________________________

Delay Control Circuit

A capacitor from DEL to AGND selects the switch control

block supply startup delay. After the input voltage

exceeds V

UVLO

, a 5µA current source charges C

DEL

.

Once the capacitor voltage exceeds the turn-on threshold (1.24V) COM can be connected to SRC, depending

on the state of CTL. Before startup and when IN is less

than V

UVLO

, DEL is internally connected to AGND to dis-

charge C

DEL

. Select C

DEL

using the following equation:

MAX1542 Control Block Switch

The switch control input (CTL) is not activated until

V

DEL

exceeds the turn-on voltage (1.24V) and the input

voltage (VIN) exceeds V

UVLO

(2.5V). Once activated,

CTL controls the P-channel MOSFET, between COM

and SRC. A high at CTL turns on Q1 between SRC and

COM, and a low at CTL turns Q1 off (Figure 4).

MAX1543 Control Block Switch

The switch control input (CTL) is not activated until the

input voltage (VIN) exceeds V

UVLO

(2.5V) and V

DEL

exceeds the turn-on voltage (1.24V). During UVLO or

when DEL is below the turn-on threshold, COM is

pulled low to PGND through Q3 and a 1kΩ resistance.

Once activated, CTL controls the COM MOSFETs,

switching COM between SRC and DRN. A high at CTL

turns on Q1 and disables Q2. A low at CTL turns on Q2

and turns off Q1 (Figure 4).

Undervoltage Lockout (UVLO)

The UVLO comparator of the MAX1542/MAX1543 compares the input voltage at IN with the UVLO threshold

C DELAY TIME

A

V

DEL

=×()

.5124

µ

Figure 1. MAX1542 Typical Application Circuit

C4

0.1µF

C3

G_OFF

-7V AT 20mA

V

IN

2.6V TO 5.5V

C1

10µF

R8

100kΩ

C11

220pF

0.1µF

C2

COMP

SRC

CTL

COM

DEL

C10

33nF

PGND

L1

4.7µF

MAX1542

0.1µF

D2

LXIN

SUP

POS1

POS2

NEG1

OUT1

NEG2

OUT2

AGND

C5

0.1µF

FB

D1

R5

40kΩ

R6

40kΩ

D3

R1

75kΩ

R3

40kΩ

R4

40kΩ

D4

C6

0.1µF

R2

13.7kΩ

+22V AT 20mA

C7

0.1µF

C8

4.7µF

G_ON

C9

4.7µF

BACKPLANE

V

MAIN

+8V AT 250mA

TO VCOM

Page 13

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

______________________________________________________________________________________ 13

(2.5V rising, 2.35V falling, typ) to ensure that the input

voltage is high enough for reliable operation. The

150mV (typ) hysteresis prevents supply transients from

causing a restart. Once the input voltage exceeds the

UVLO threshold, startup begins. When the input voltage falls below the UVLO threshold, the controller turns

off the N-channel MOSFET, the switch control block

turns off Q1, and the operational amplifier outputs float.

For the MAX1543, the switch control block also turns off

Q2 and turns on Q3 when the input voltage falls below

the UVLO threshold (Figure 4).

Oscillator Frequency (FREQ)

The MAX1542 internal oscillator is preset to 1.2MHz. The

internal oscillator frequency is pin programmable for the

MAX1543. Connect FREQ to ground or leave it unconnected for 640kHz operation and connect it to VINfor

1.2MHz operation. FREQ has a 5µA (typ) pulldown current.

Fault Protection

Once the soft-start routine is complete, if the output of

the main regulator is below the fault detection threshold,

the MAX1542/MAX1543 activate the fault timer. If the

fault condition continuously exists throughout the fault

timer duration, the MAX1542/MAX1543 set the fault

latch, which shuts down the device. After removing the

fault condition, cycle the input voltage (IN) below V

UVLO

to clear the fault latch and reactivate the device.

Digital Soft-Start

The MAX1542/MAX1543 digital soft-start period duration is 14ms (typ). During this time, the MAX1542/

MAX1543 directly limit the peak inductor current, allowing from zero up to the full current-limit value in eight

equal current steps (I

LIM

/8). The maximum load current

is available after output voltage reaches the full regulation threshold (which terminates soft-start), or after the

soft-start timer expires.

Figure 2. MAX1543 Typical Application Circuit

2.6V TO 5.5V

C1

10µF

C11

220pF

G_OFF

-7V AT 20mA

V

IN

R8

100kΩ

C10

33nF

C2

0.1µF

FREQ

COMP

CTL

SRC

COM

DRN

DEL

PGND

D2

L1

4.7µF

MAX1543

C3

0.1µF

LXIN

SUP

POS1

POS2

NEG1

OUT1

NEG2

OUT2

AGND

FB

C4

0.1µF

C5

0.1µF

D1

R5

40kΩ

R6

40kΩR440kΩ

D4

C6

75kΩ

R3

40kΩ

0.1µF

C8

R1

4.7µF

R2

13.7kΩ

D3

G_ON

+22V AT 20mA

C7

0.1µF

+8V AT 250mA

C9

4.7µF

TO VCOM

BACKPLANE

V

MAIN

Page 14

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

14 ______________________________________________________________________________________

Thermal-Overload Protection

Thermal-overload protection prevents excessive power

dissipation from overheating the MAX1542/MAX1543.

When the junction temperature exceeds TJ= +160°C, a

thermal sensor immediately activates the fault protection, which shuts down the device, allowing the IC to

cool. The input voltage must fall (below V

UVLO

) to clear

the fault latch and reactivate the controller.

Thermal-overload protection protects the controller in

the event of fault conditions. For continuous operation,

do not exceed the absolute maximum junction-temperature rating of T

J

= +150°C.

Applications Information

Inductor Selection

The primary considerations in inductor selection are

inductor physical shape, circuit efficiency, and cost.

The factors that determine the inductance value are

input voltage, output voltage, switching frequency, and

maximum output current. Final inductor selection

includes ensuring the chosen inductor meets the application’s peak current and RMS current requirements.

Very high inductance values minimize the current ripple

and therefore reduce the peak current, which decreases core losses in the inductor and I2R losses in the circuit’s entire power path. However, large inductance

Figure 3. Functional Diagram

COMP

FB

1.24V

FREQ*

NEG1

OUT1

POS1

*MAX1543 ONLY.

OSCILLATOR

5µA

ERROR

AMPLIFIER

SLOPE

COMPEN-

SATION

ERROR

COMPARATOR

CLOCK

∑

5µA

DEL CTLSRC COM DRN*

SWITCH

CONTROL

(SEE FIGURE 4)

CONTROL

AND DRIVER

LOGIC

CURRENT

SENSE

SOFTSTART

MAX1542

MAX1543

IN

LX

N

PGND

AGND

SUP

EXT*

NEG2

OUT2

POS2

Page 15

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

______________________________________________________________________________________ 15

values also require more energy storage and more

turns of wire, which increase physical size and can

increase I2R losses in the inductor. Low inductance values decrease the physical size but increase the current

ripple and peak current. Finding the best inductor

involves choosing the best compromise between circuit

efficiency, inductor size, and cost.

The equations used here include a constant, LIR, which

is the ratio of the inductor peak-to-peak ripple current to

the average DC inductor current at the full output current. The best trade-off between inductor size and circuit efficiency for step-up converters generally has an

LIR between 0.3 and 0.5. However, depending on the

AC characteristics of the inductor core material and

ratio of inductor resistance to other power path resistances, the best LIR can shift up or down. If the inductor

resistance is relatively high, more ripple can be accepted to reduce the number of turns required and increase

the wire diameter. If the inductor resistance is relatively

low, increasing inductance to lower the peak current

can decrease losses throughout the power path. If

extremely thin, high-resistance inductors are used, as is

common for LCD panel applications, the best LIR can

increase to between 0.5 and 1.0.

Once a physical inductor is chosen, higher and lower

values of that inductor should be evaluated for efficiency improvements in typical operating regions.

Calculate the approximate inductor value using the typical input voltage (VIN), the maximum output current

(I

MAIN(MAX)

), the expected efficiency (η

TYP

) taken from

an appropriate curve in the Typical Operating

Characteristics, and an estimate for LIR based on the

above paragraphs:

Choose an available inductor value from an appropriate

inductor family. Calculate the maximum DC input current at the minimum input voltage V

IN(MIN)

using con-

servation of energy and the expected efficiency at that

LVx xV V

V x LIR x I x f

IN TYP MAIN IN

MAIN MAIN MAX OSC

( )/

( )

()

≅ −

2

2

η

Figure 4. Switch Control

DEL

CTL

REF

IN

N

5µA

MAX1543 ONLY

2.5V

1kΩ

MAX1542

MAX1543

Q3

N

SRC

Q1

P

COM

P

Q2

P

DRN

Page 16

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

16 ______________________________________________________________________________________

operating point (η

MIN

) taken from an appropriate curve

in the Typical Operating Characteristics:

I

IN(DC,MAX)

= I

MAIN(MAX)

✕ V

MAIN

/ (V

IN(MIN)

✕ η

MIN

)

Calculate the ripple current at that operating point and

the peak current required for the inductor:

I

RIPPLE

= V

IN(MIN)

✕ (V

MAIN-VIN(MIN)

) / (L ✕ f

OSC

✕

V

MAIN

)

I

PEAK

= I

IN(DC,MAX)

+ (I

RIPPLE

) / 2

The inductor’s saturation current rating and the

MAX1542/MAX1543s’ LX current limit (I

LIM

) should

exceed I

PEAK

and the inductor’s DC current rating

should exceed I

IN(DC,MAX)

. For reasonable efficiency,

choose an inductor with less than 0.5Ω series resistance.

Considering the Typical Application Circuits, the maximum load current (I

MAIN(MAX)

) is 200mA with an 8V

output and a typical input voltage of 3.3V.

Choosing an LIR of 0.6 and estimating efficiency of

85% at this operating point:

L = (3.3V)

2

✕

0.85 ✕ (8V - 3.3V) / ((8V)

2

✕

0.6 ✕ 0.2A ✕

1.2MHz) = 4.7µH

Using the circuit’s minimum input voltage (2.7V) and

estimating efficiency of 80% at that operating point,

I

IN(DC,MAX)

= (0.2A ✕ 8V / (2.7V ✕ 0.8)) = 741mA

The ripple current and the peak current are:

I

RIPPLE

= 2.7V ✕ (8V - 2.7V) / (4.7µH ✕ 1.2MHz ✕ 8V)

= 317mA

I

PEAK

= 741mA + (317mA / 2) = 900mA

Output Capacitor Selection

The total output voltage ripple has two components: the

capacitive ripple caused by the charging and discharging of the output capacitance, and the ohmic ripple due to the capacitor’s equivalent series resistance

(ESR):

where I

PEAK

is the peak inductor current (see the

Inductor Selection section). For ceramic capacitors, the

output voltage ripple is typically dominated by V

RIP-

PLE(C)

. The voltage rating and temperature characteris-

tics of the output capacitor must also be considered.

Input Capacitor Selection

The input capacitor (CIN) reduces the current peaks

drawn from the input supply and reduces noise injection into the device. A 10µF ceramic capacitor is used

in the Typical Application Circuits (Figures 1 and 2)

because of the high source impedance seen in typical

lab setups. Actual applications usually have much

lower source impedance since the step-up regulator

often runs directly from the output of another regulated

supply. Typically, CINcan be reduced below the values

used in the Typical Application Circuits. Ensure a lownoise supply at IN by using adequate CIN.

Output Voltage

The MAX1542/MAX1543 operate with an adjustable output from VINto 13V. Connect a resistive voltage-divider

to FB (Typical Application Circuits) from the output

(V

MAIN

) to AGND. Select the resistor values as follows:

where VFB, the step-up converter feedback set point, is

1.24V. Since the input bias current into FB is typically

zero, R2can have a value up to 100kΩ without sacrificing accuracy, although lower values provide better

noise immunity. Connect the resistor-divider as close to

the IC as possible.

Loop Compensation

Choose R

COMP

to set the high-frequency integrator

gain for fast transient response. Choose C

COMP

to set

the integrator zero to maintain loop stability.

For low-ESR output capacitors, use the following equations to obtain stable performance and good transient

response:

To further optimize transient response, vary R

COMP

in

20% steps and C

COMP

in 50% steps while observing

transient response waveforms.

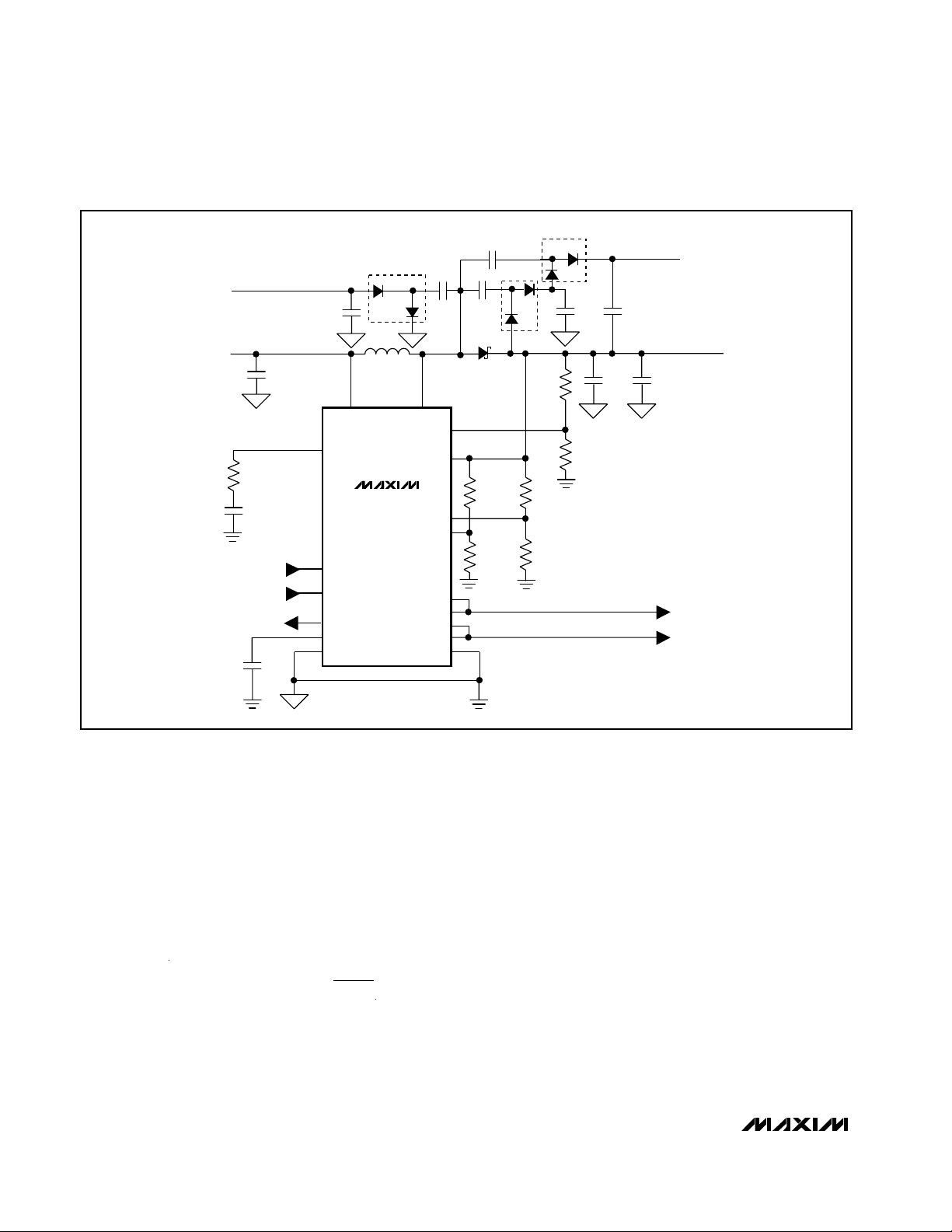

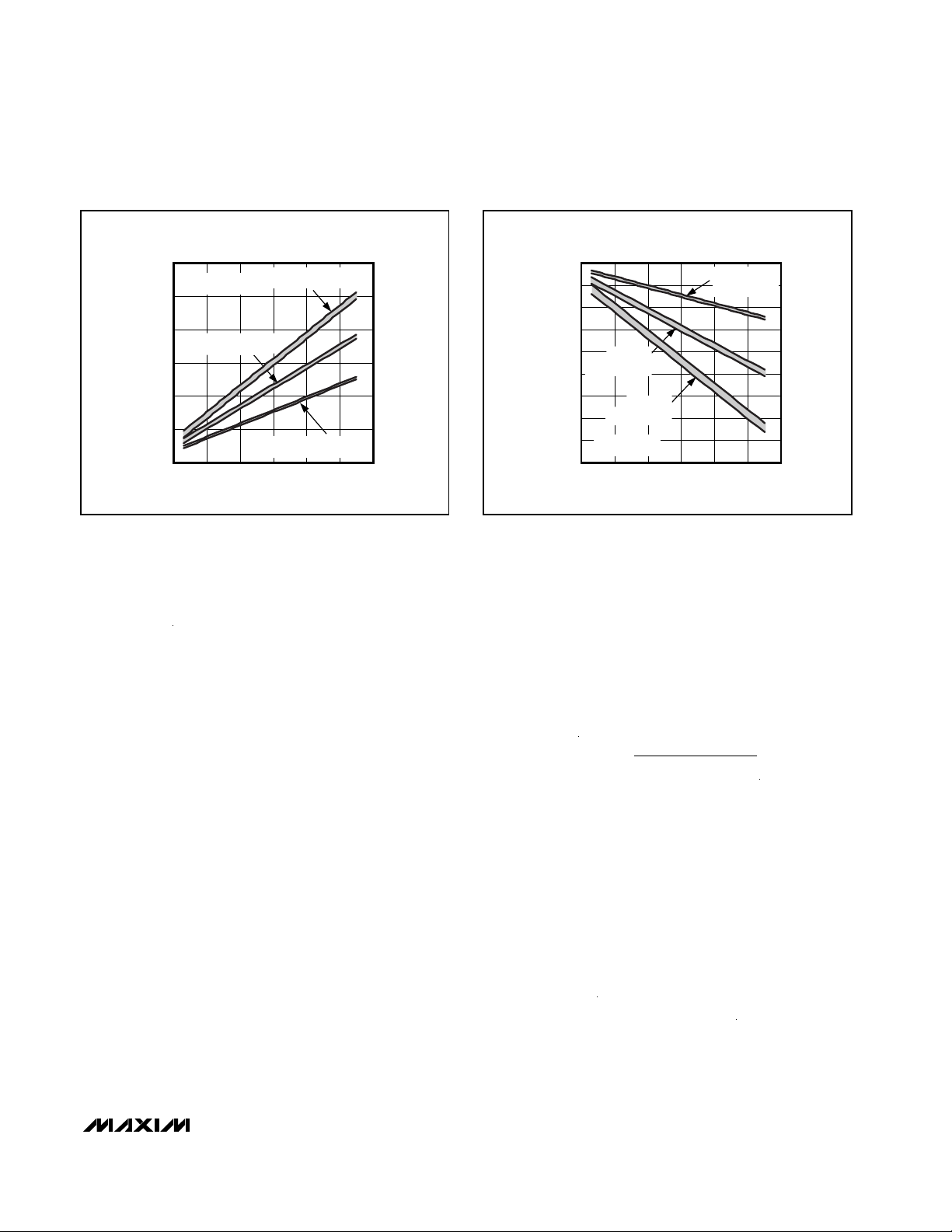

Charge Pumps

Selecting the Number of Charge-Pump Stages

For highest efficiency, always choose the lowest number of charge-pump stages that meet the output

requirements. Figures 5 and 6 show the positive and

R

xV xV xC

LxI

C

VxC

xI xR

COMP

IN OUT OUT

MAIN MAX

COMP

OUT OUT

MAIN MAX COMP

≅

≅

50010

()

()

RR

V

V

MAIN

FB

12

1=−

VV V

V I x R and

V

I

C

VV

V

RIPPLE RIPPLE ESR RIPPLE C

RIPPLE ESR PEAK ESR COUT

RIPPLE C

MAIN

OUT

MAIN IN

MAIN OSC

=+

≅

≅

−

׃

() ()

() ( )

()

,

Page 17

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

______________________________________________________________________________________ 17

negative charge-pump output voltages for a given

V

MAIN

for one-, two-, and three-stage charge pumps,

based on the following equations:

where G_ON is the positive charge-pump output voltage, G_OFF is the negative charge-pump output voltage, n is the number of charge-pump stages, and VDis

the voltage drop across each diode.

VDis the forward voltage drop of the charge-pump

diodes.

Flying Capacitors

Increasing the flying capacitor (C3, C4, and C5) value

increases the output current capability. Increasing the

capacitance indefinitely has a negligible effect on output current capability because the internal switch resistance and the diode impedance limit the source

impedance. A 0.1µF ceramic capacitor works well in

most low-current applications. The flying capacitor’s

voltage rating must exceed the following:

VCX> n ✕ V

MAIN

Where n is the stage number in which the flying capacitor appears, and V

MAIN

is the main output voltage. For

example, the two-stage positive charge pump in the

Typical Application Circuits (Figures 1 and 2) where

V

MAIN

= 8V contains two flying capacitors. The flying

capacitor in the first stage (C5) requires a voltage rat-

ing greater than 8V. The flying capacitor in the second

stage (C4) requires a voltage rating greater than 16V.

Charge-Pump Output Capacitor

Increasing the output capacitance or decreasing the

ESR reduces the output ripple voltage and the peak-topeak transient voltage. With ceramic capacitors, the

output voltage ripple is dominated by the capacitance

value. Use the following equation to approximate the

required capacitor value:

where V

RIPPLE

is the acceptable peak-to-peak output-

voltage ripple.

Charge-Pump Rectifier Diodes

To maximize the available output voltage, use Schottky

diodes with a current rating equal to or greater than two

times the average charge-pump input current. If the

loaded charge-pump output voltage is greater than

required, some or all of the Schottky diodes can be

replaced with low-cost silicon switching diodes with an

equivalent current rating. The charge-pump input current is:

where n is the number of charge-pump stages.

II n

CP IN CP OUT__

=×

C

I

FV

OUT

LOAD

OSC RIPPLE

≥

××2

GON V nV V

G OFF n V V

MAIN MAIN D

MAIN D

_()

_( )

=+ −

=− −

Figure 5. Positive Charge-Pump Output Voltage vs. V

MAIN

Figure 6. Negative Charge-Pump Output Voltage vs. V

MAIN

POSITIVE CHARGE-PUMP

OUTPUT VOLTAGE vs. V

60

= 0.3V TO 1V

V

D

50

40

2-STAGE CHARGE-PUMP

30

G_ON (V)

20

10

0

214

3-STAGE CHARGE-PUMP

1-STAGE CHARGE-PUMP

V

MAIN

MAIN

1210864

(V)

NEGATIVE CHARGE-PUMP

-0

-5

-10

-15

-20

-25

G_OFF (V)

-30

-35

-40

-45

OUTPUT VOLTAGE vs. V

2-STAGE

CHARGE-PUMP

3-STAGE

CHARGE-PUMP

VD = 0.3V TO 1V

214

V

MAIN

MAIN

1-STAGE

CHARGE-PUMP

1210864

(V)

Page 18

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

18 ______________________________________________________________________________________

Power Dissipation

The MAX1542/MAX1543s’ maximum power dissipation

depends on the thermal resistance from the IC die to

the ambient environment and the ambient temperature.

The thermal resistance depends on the IC package, PC

board copper area, other thermal mass, and airflow.

The MAX1542/MAX1543, with their exposed backside

pad soldered to 1in2of PC board copper, can dissipate

about 1.7W into +70°C still air. More PC board copper,

cooler ambient air, and more airflow increase the possible dissipation while less copper or warmer air

decreases the IC’s dissipation capability. The major

components of power dissipation are the power dissipated in the step-up converter and the power dissipated by the operational amplifiers.

Step-Up Converter

The largest portions of power dissipation in the step-up

converter are the internal MOSFET, inductor, and the

output diode. If the step-up converter has 90% efficiency, about 3% to 5% of the power is lost in the internal

MOSFET, about 3% to 4% in the inductor, and about

1% in the output diode. The rest of the 1% to 3% is distributed among the input and output capacitors and the

PC board traces. If the input power is about 3W, the

power lost in the internal MOSFET is about 90mW to

150mW.

Operational Amplifiers

The power dissipated in the operational amplifiers

depends on their output current, the output voltage,

and the supply voltage:

where I

OUT_(SOURCE)

is the output current sourced by

the operational amplifier, and I

OUT_(SINK)

is the output

current that the operational amplifier sinks.

In a typical case where the supply voltage is 8V and

the output voltage is 4V with an output source current

of 30mA, the power dissipated is 120mW.

Layout Procedure

Careful PC board layout and routing are required for

high-frequency switching power supplies to achieve

good regulation, high efficiency, and stability. Use the

following guidelines for good PC board layout:

1) Place the input capacitors close enough to the IC to

provide adequate bypassing (within 1.5cm).

Connect the input capacitors to IN with a wide trace.

Minimize the area of high-current loops by placing

the inductor, output diode, and output capacitors

near the input capacitors and near LX and PGND.

The high-current input loop goes from the positive

terminal of the input capacitor to the inductor, to the

IC’s LX pin, out PGND, and to the input capacitor

negative terminal. The high-current output loop is

from the positive terminal of the input capacitor to

the inductor, to the catch diode (D1), to the positive

terminal of the output capacitors, reconnecting

between the output capacitor and input capacitor

ground terminals. Connect these loop components

together with short, wide connections. Avoid using

vias in the high-current paths. If vias are unavoidable, use many vias in parallel to reduce resistance

and inductance.

2) Create a power ground island (PGND) consisting of

the input and output capacitor grounds, PGND pin,

and the SRC bypass capacitor and other chargepump components. Connect all of these together

with short, wide traces or a small ground plane.

Maximizing the width of the power ground traces

improves efficiency and reduces output voltage ripple and noise spikes.

Create an analog ground island (AGND) consisting

of the AGND pin, FB divider, the operation amplifier

dividers, the COMP and DEL capacitor ground connections, and the device’s exposed backside pad.

Connect the AGND and PGND islands by connecting the PGND pin directly to the exposed backside

pad. Make no other connections between these

separate ground planes.

3) Place the feedback voltage-divider resistors close to

FB. The divider’s center trace should be kept short.

Placing the resistors far away causes their FB traces

to become antennas that can pick up switching

noise. Avoid running the feedback trace near LX or

the switching nodes in the charge pumps.

4) Minimize the length and maximize the width of the

traces between the output capacitors and the load

for best transient response.

5) Minimize the size of the LX node while keeping it

wide and short. Keep the LX node away from the

feedback node (FB) and analog ground. Use DC

traces as shields if necessary.

Refer to the MAX1543 Evaluation Kit for an example of

proper board layout.

PD I V V

PD I V

SOURCE OUT SOURCE SUP OUT

SINK OUT SINK OUT

=×−

=×

_( ) _

_( ) _

()

Page 19

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

______________________________________________________________________________________ 19

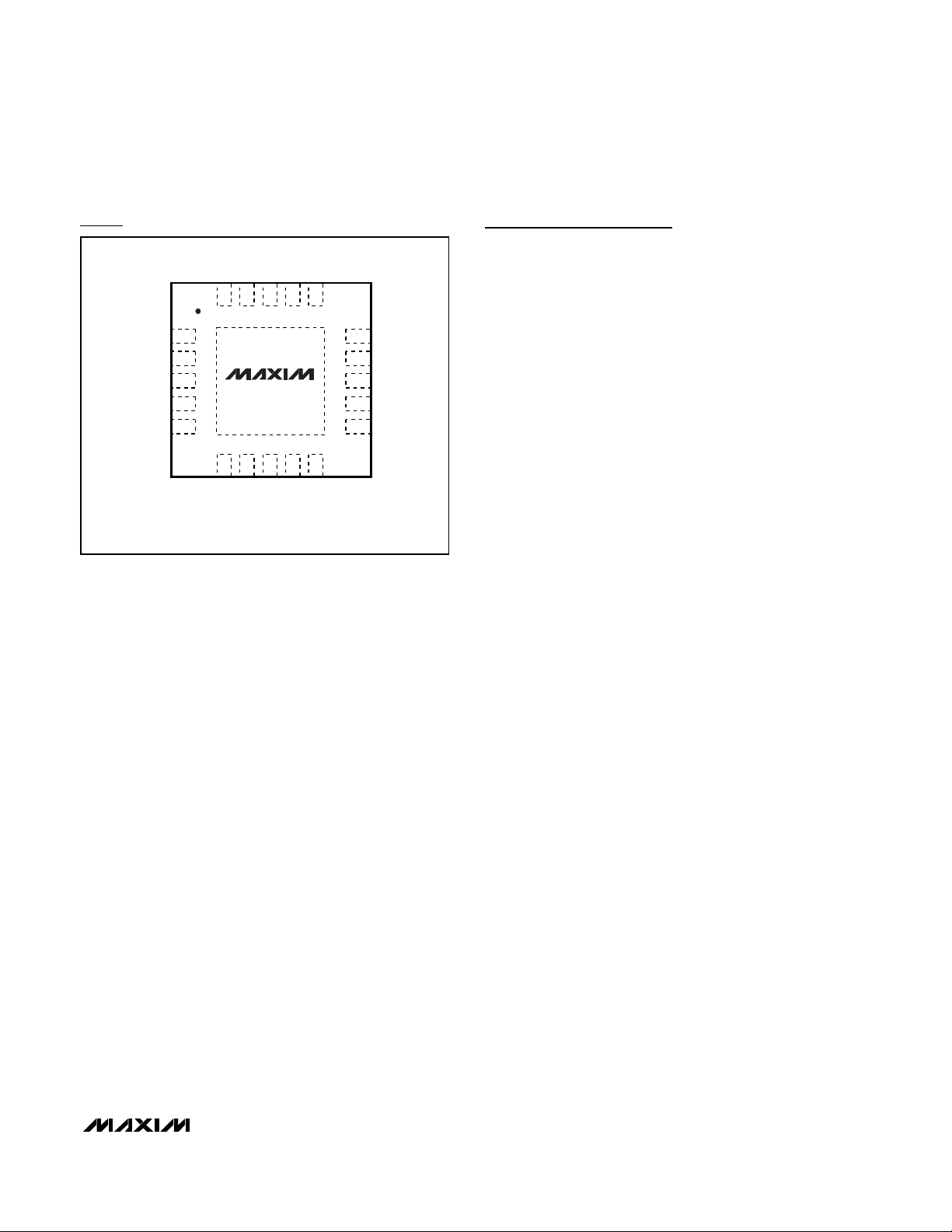

Pin Configurations (continued)

Chip Information

TRANSISTOR COUNT: 2508

PROCESS: BiCMOS

TOP VIEW

N.C.

CTL

DEL

COMP

FB

20

19

18

17

16

COM

SRC

N.C.

PGND

AGND

1

2

3

4

5

6

POS1

MAX1542

7

8

NEG1

OUT1

9

OUT2

THIN QFN

15

14

13

12

11

10

NEG2

N.C.

IN

LX

SUP

POS2

Page 20

MAX1542/MAX1543

TFT LCD DC-to-DC Converter with

Operational Amplifiers

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

D

PIN # 1

I.D.

D/2

C

COMMON DIMENSIONS

A1

0.15 C A

E/2

A3

D2

0.15

C B

E

0.10

C

A

0.08 C

(NE-1) X e

DETAIL A

k

e

(ND-1) X e

L

L

e e

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE

16, 20, 28, 32L, QFN THIN, 5x5x0.8 mm

APPROVAL

C

L

D2/2

b

0.10 M

PIN # 1 I.D.

0.35x45

E2/2

C

k

L

DOCUMENT CONTROL NO.

21-0140

C A B

QFN THIN.EPS

E2

L

CC

L

L

REV.

1

C

2

EXPOSED PAD VARIATIONS

NOTES:

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994.

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JESD 95-1

SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE OPTIONAL, BUT MUST BE LOCATED WITHIN THE

ZONE INDICATED. THE TERMINAL #1 IDENTIFIER MAY BE EITHER A MOLD OR MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.25 mm AND 0.30 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS.

9. DRAWING CONFORMS TO JEDEC MO220.

10. WARPAGE SHALL NOT EXCEED 0.10 mm.

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE

16, 20, 28, 32L, QFN THIN, 5x5x0.8 mm

21-0140

REV.DOCUMENT CONTROL NO.APPROVAL

2

C

2

Loading...

Loading...