Page 1

General Description

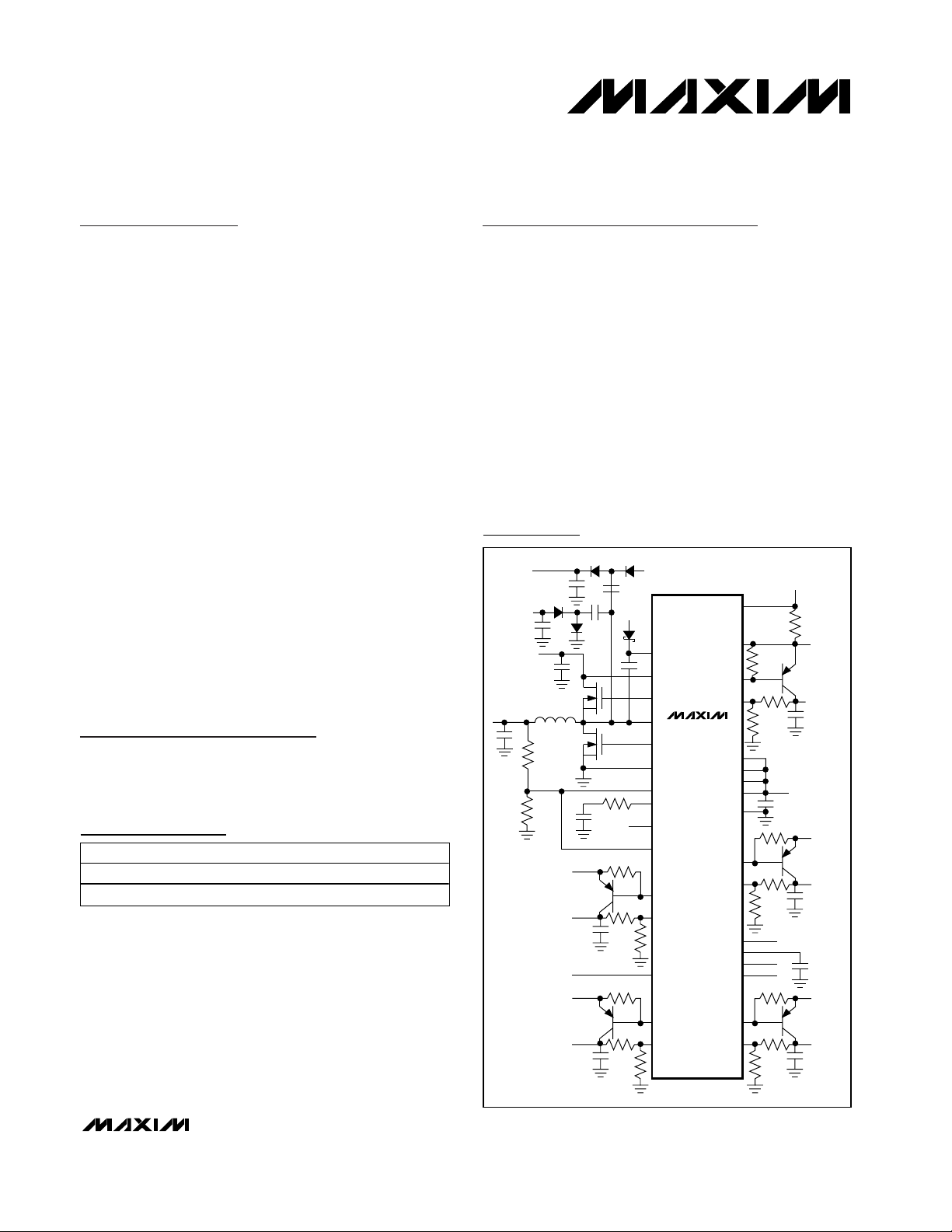

The MAX1530/MAX1531 multiple-output power-supply

controllers generate all the supply rails for thin-film transistor (TFT) liquid-crystal display (LCD) monitors. Both

devices include a high-efficiency, fixed-frequency,

step-down regulator. The low-cost, all N-channel, synchronous topology enables operation with efficiency as

high as 93%. High-frequency operation allows the use

of small inductors and capacitors, resulting in a compact solution. The MAX1530 includes three linear regulator controllers and the MAX1531 includes five linear

regulator controllers for supplying logic and LCD bias

voltages. A programmable startup sequence enables

easy control of the regulators.

The MAX1530/MAX1531 include soft-start functions to

limit inrush current during startup. An internal stepdown converter current-limit function and a versatile

overcurrent shutdown protect the power supplies against

fault conditions. The MAX1530/MAX1531 use a currentmode control architecture, providing fast load transient

response and easy compensation. An internal linear

regulator provides MOSFET gate drive and can be

used to power small external loads.

The MAX1530/MAX1531 can operate from inputs as

high as 28V and are well suited for LCD monitor and TV

applications running directly from AC/DC wall adapters.

Both devices are available in a small (5mm x 5mm),

ultra-thin (0.8mm), 32-pin QFN package and operate

over the -40°C to +85°C temperature range.

Applications

LCD Monitors and TVs

Automotive LCDs

Features

♦ 4.5V to 28V Input Voltage Range

♦ 250kHz/500kHz Current-Mode Step-Down Converter

Small Inductor/Capacitors

No Sense Resistor

♦ Three Positive Linear Regulator Controllers

One Positive and One Negative Additional

Controller (MAX1531)

Small Input and Output Capacitors

♦ Timed Reset Output

♦ Uncommitted Overcurrent Protection (MAX1531)

♦ Soft-Start for All Regulators

♦ Programmable Input Undervoltage Comparator

♦ Programmable Startup Sequencing

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

RESET

V

IN

V

GON

25V

V

GOFF

-9V

V

IN

= 12V

ONL2

V

SOURCE

10V/500mA

V

GAMMA

9.7V

V

N

ONL5

ONL4

ONL3

SEQ

VL

RSTIN

V

OUT

3.3V/1.5A

V

LOGIC

2.5V/500mA

V

OUT

V

L

V

L

V

P

V

N

V

IN

V

IN

V

P

V

L

DRV3

FBL3

FBL1

DRV1

BST

IN

DH

LX

DL

PGND

FB

COMP

FBL2

DRV2

FBL5

DRV5

DRV4

FBL4

CSH

CSL

FREQ

ILIM

VL

EN

AGND

MAX1530

Minimal Operating Circuit

19-2866; Rev 0; 5/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration appears at end of data sheet.

PART TEMP RANGE PIN-PACKAGE

MAX1530ETJ -40°C to +85°C 32 Thin QFN

MAX1531ETJ -40°C to +85°C 32 Thin QFN

Page 2

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

2 _______________________________________________________________________________________

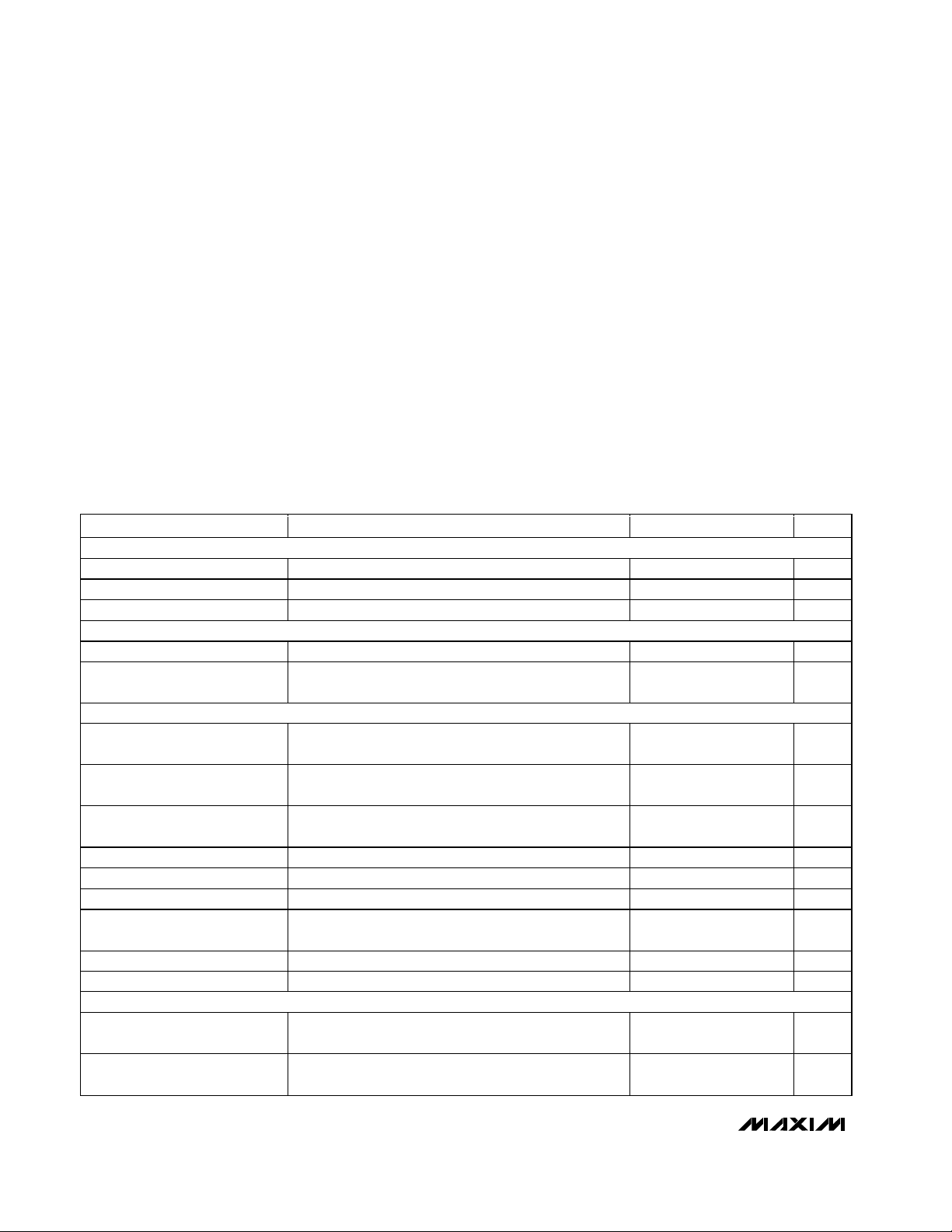

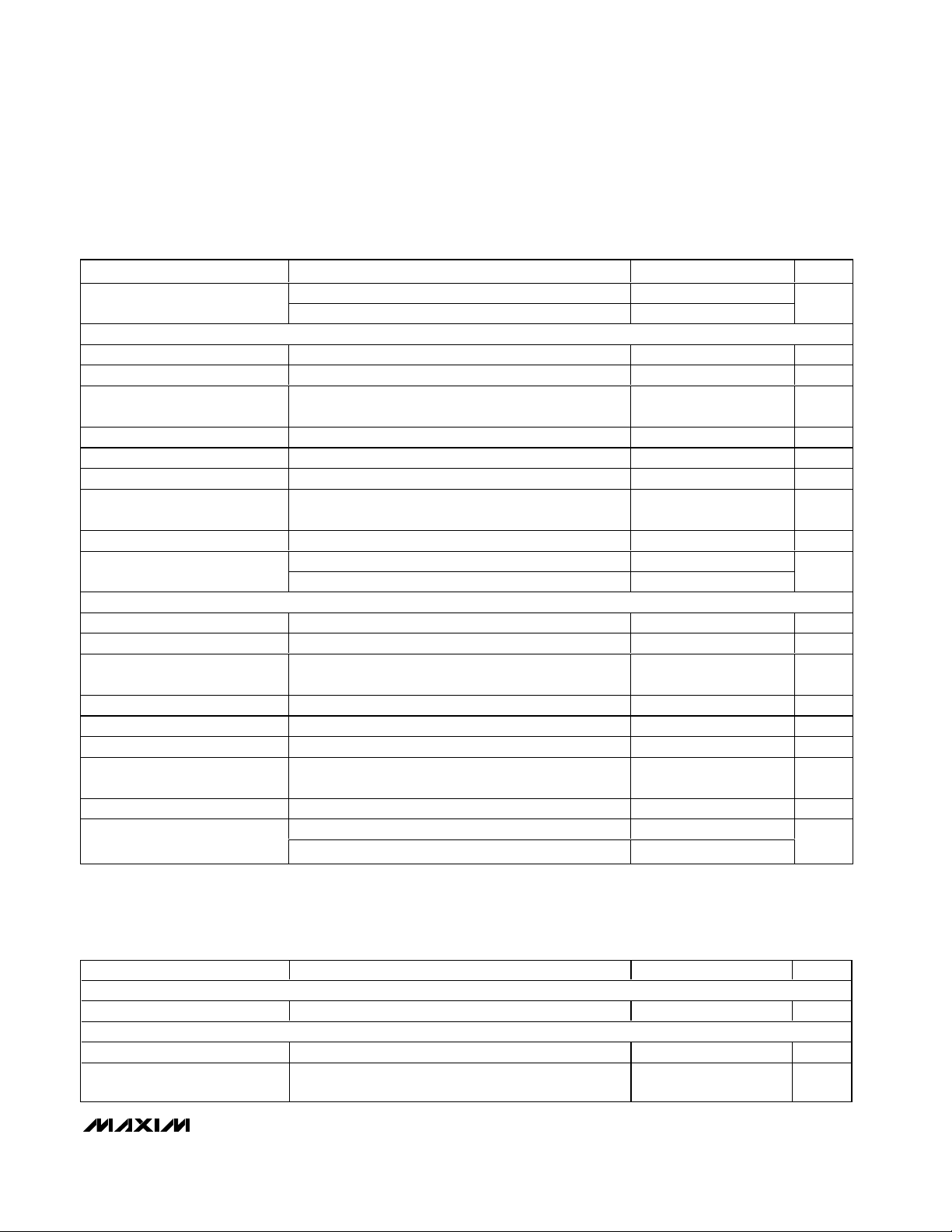

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VIN= 12V, VEN= V

SEQ

= 5V, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, DRV1, DRV2, DRV3, DRV4, CSH,

CSL to AGND .....................................................-0.3V to +30V

DRV5 to VL .............................................................-28V to +0.3V

CSH to CSL ..............................................................-0.3V to +6V

VL to AGND ..............................................................-0.3V to +6V

PGND to AGND...................................................................±0.3V

LX to BST..................................................................-6V to +0.3V

BST to AGND..........................................................-0.3V to +36V

DH to LX .....................................................-0.3V to (BST + 0.3V)

DL to PGND ..................................................-0.3V to (VL + 0.3V)

SEQ, ONL2, ONL3, ONL4, ONL5, COMP,

ILIM to AGND............................................-0.3V to (VL + 0.3V)

RSTIN, RESET, EN, FB, FBL1, FBL2, FBL3, FBL4, FBL5,

FREQ to AGND.....................................................-0.3V to +6V

VL Short Circuit to AGND ...........................................Momentary

Continuous Power Dissipation (T

A

= +70°C)

32-Pin Thin QFN (derate 21.3mW/°C above +70°C) ...1702mW

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

GENERAL

PARAMETER CONDITIONS MIN TYP MAX UNITS

Operating Input Voltage Range (Note 1) 4.5 28.0 V

Quiescent Supply Current V

FB

= V

FBL1

= V

FBL2

= V

IC Disable Supply Current EN = AGND 200 400 µA

VL REGULATOR

VL Output Voltage 5.5V < V

VL Undervoltage Lockout

Threshold

VL rising, 3% hysteresis 3.2 3.5 3.8 V

< 28V, 0 < IVL < 30mA 4.75 5 5.25 V

IN

CONTROL AND SEQUENCE

SEQ, FREQ Input Logic High

Level

SEQ, FREQ Input Logic Low

Level

SEQ, FREQ Input Leakage

Current

2.0 V

0.6 V

-1 +1 µA

ONL_ Input Threshold ONL_ rising, 25mV hysteresis 1.201 1.238 1.275 V

ONL_ Source Current SEQ = EN = VL, V

_ = 0 to 1.24V 1.8 2.0 2.2 µA

ONL

ONL_ Input Leakage Current SEQ = EN = VL, ONL_ = VL -500 +500 nA

ONL_ Input Discharge Clamp

Resistance

SEQ = 0 800 1500 3000 Ω

EN Input Threshold EN rising, 5% hysteresis 1.201 1.238 1.275 V

EN Input Leakage Current -50 +50 nA

FAULT DETECTION

FB, FBL1, FBL2, FBL3, FBL4

Undervoltage Fault Trip Level

FBL5 Undervoltage Fault

Trip Level

FB, FBL1, FBL2, FBL3, FBL4 falling, 25mV hysteresis 1.081 1.114 1.147 V

FBL5 rising, 25mV hysteresis 300 400 500 mV

FBL3

= V

FBL4

= 1.5V, V

= 0 1.7 3.0 mA

FBL5

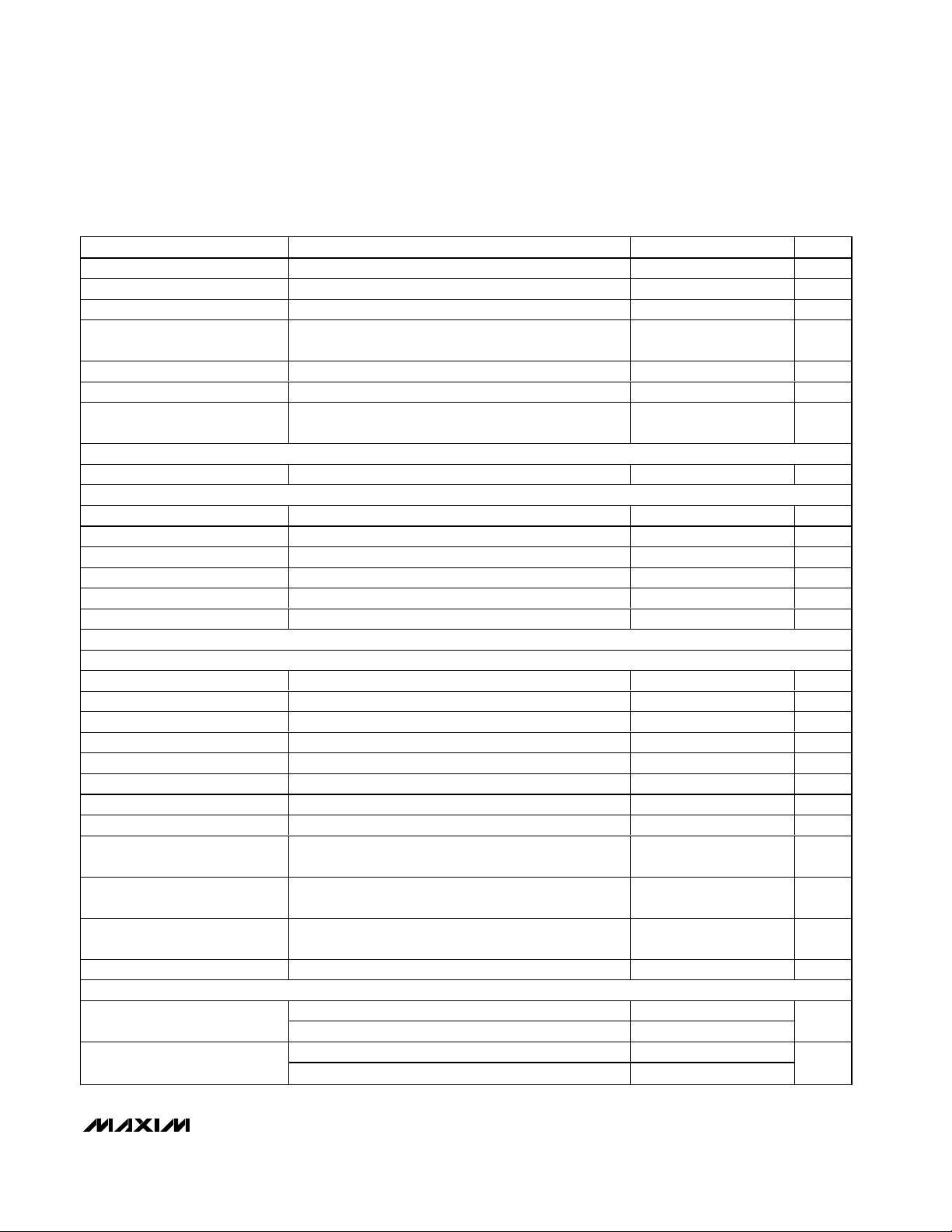

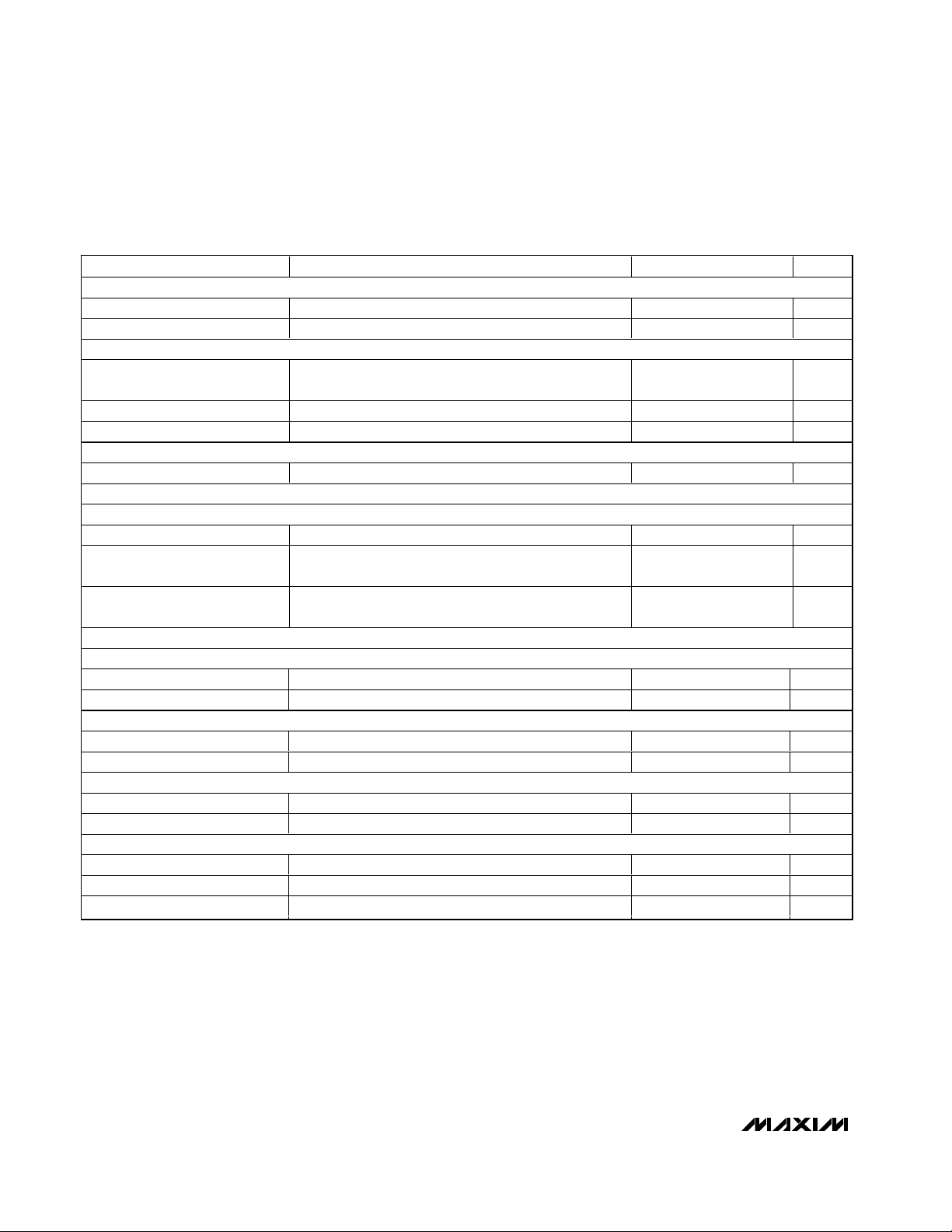

Page 3

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, VEN= V

SEQ

= 5V, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Dual Mode is a trademark of Maxim Integrated Products, Inc.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Comparator Bandwidth For EN, FB, FBL_ 10 kHz

Duration to Trigger Fault Latch For FB, FBL_ 51 64 77 ms

Overcurrent Protection Threshold (V

Overcurrent Sense Common-

Mode Range

CSH Input Current V

CSL Input Current V

Overcurrent Sense Filter RC Time

Constant

- V

) 270 300 330 mV

CSL

, V

CSL

= 2.7V to 28V 100 µA

= V

= 12V -50 +50 nA

CSH

2.7 28.0 V

V

CSH

CSH

CSH

CSL

50 µs

THERMAL PROTECTION

Thermal Shutdown Temperature rising, 15°C hysteresis 160 °C

RESET FUNCTION

RSTIN Reset Trip Level RSTIN falling, 25mV hysteresis 1.081 1.114 1.147 V

RSTIN Input Leakage Current V

= 1.5V -50 +50 nA

RSTIN

Comparator Bandwidth 10 kHz

Reset Timeout Period 102 128 154 ms

RESET Output Low Level I

RESET Output High Leakage V

= -1mA 0.4 V

RESET

= 5V 1 µA

RESET

STEP-DOWN CONTROLLER

ERROR AMPLIFIER

FB Regulation Voltage 1.223 1.238 1.253 V

Transconductance FB to COMP 70 100 140 µS

Voltage Gain FB to COMP 200 V/V

Minimum Duty Cycle 15 %

FB Input Leakage Current V

= 1.5V -50 +50 nA

FB

FB Input Common-Mode Range (Note 2) -0.1 +1.5 V

COMP Output Minimum Voltage V

COMP Output Maximum Voltage V

Current-Sense Amplifier Voltage

Gain

Current-Limit Threshold

(Default Mode)

Current-Limit Threshold

(Adjustable Mode)

= 1.5V 1 V

FB

= 1.175V 3 V

FB

V

IN

- V

LX

2.75 3.5 4.0 V/V

PGND - LX, ILIM = VL 190 250 310 mV

PGND - LX, V

= 1.25V 190 250 310 mV

ILIM

ILIM Inp ut D ual M od e™ Thr eshol d 3.0 3.5 4.00 V

OSCILLATOR

Switching Frequency

Maximum Duty Cycle

FREQ = AGND 200 250 300

FREQ = VL 425 500 575

FREQ = AGND 75 80 88

FREQ = VL 75 80 88

kHz

%

Page 4

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, VEN= V

SEQ

= 5V, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

SOFT-START

Step Size Measured at FB 1.238 / 32 V

Period

FET DRIVERS

DH, DL On-Resistance 3 10 Ω

DH, DL Output Drive Current Sourcing or sinking, V

LX, BST Leakage Current V

POSITIVE LINEAR REGULATOR (LR1)

FBL1 Regulation Voltage V

FBL1 Input Bias Current V

FBL1 Effective Load Regulation

Error (Transconductance)

FBL1 Line Regulation Error I

DRV1 Sink Current V

DRV1 Off-Leakage Current V

FBL1 Input Common-Mode

Range

Soft-Start Step Size Measured at FBL1 1.238 / 32 V

Soft-Start Period

POSITIVE LINEAR REGULATORS (LR2 AND LR3)

FBL_ Regulation Voltage V

FBL_ Input Bias Current V

FBL_ Effective Load Regulation

Error (Transconductance)

FBL_ Line Regulation Error I

DRV_ Sink Current V

DRV_ Off-Leakage Current V

FBL_ Input Common-Mode

Range

Soft-Start Step Size Measured at FBL_ 1.238 / 32 V

FREQ = GND 1024 / f

FREQ = VL 2048 / f

BST

= V

LX

or VDL = V

DH

= V

= 28V 20 µA

IN

/ 2 0.5 A

VL

OSC

OSC

LINEAR REGULATOR CONTROLLERS

= 5V, I

DRV1

= 1.5V -50 +50 nA

FBL1

V

= 5V, I

DRV1

= 100µA, 5.5V < VIN < 28V 5 mV

DRV1

= 1.175V, V

FBL1

= 1.5V, V

FBL1

= 100µA 1.226 1.245 1.264 V

DRV1

= 100µA to 2mA -1.5 -2 %

DRV1

= 5V 3 10 mA

DRV1

= 28V 0.1 10 µA

DRV1

(Note 2) -0.1 +1.5 V

FREQ = GND 1024 / f

FREQ = VL 2048 / f

_ = 5V, I

DRV

_ = 1.5V -50 +50 nA

FBL

V

_ = 5V, I

DRV

_ = 100µA, 5.5V < VIN < 28V 5 mV

DRV

= 1.175V, V

FBL_

_ = 1.5V, V

FBL

_ = 100µA 1.226 1.245 1.264 V

DRV

_ = 50µA to 1mA -1.5 -2 %

DRV

= 5V 2 4 mA

DRV_

_ = 28V 0.1 10 µA

DRV

OSC

OSC

(Note 2) -0.1 +1.5 V

s

s

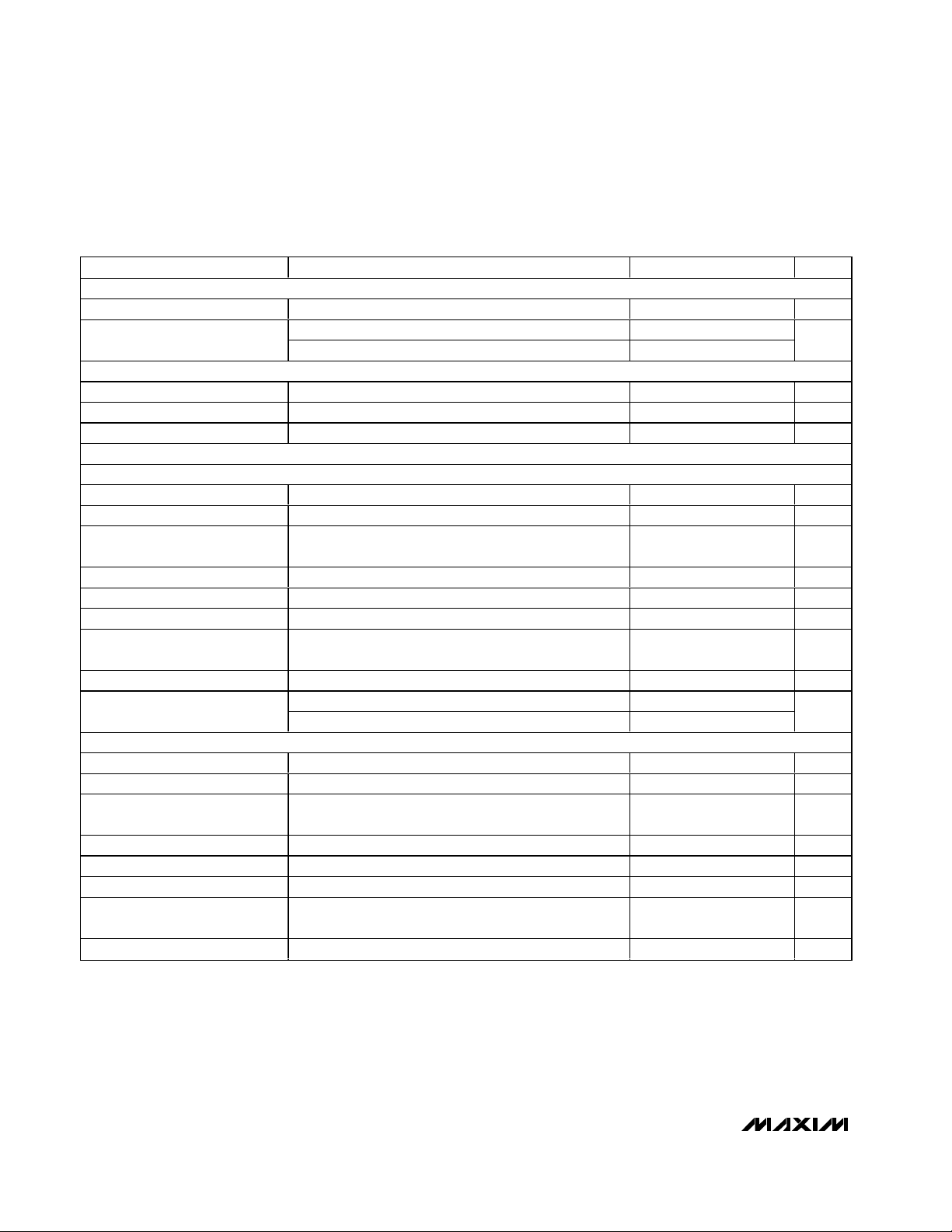

Page 5

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, VEN= V

SEQ

= 5V, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VIN= 12V, VEN= V

SEQ

= 5V, TA = -40°C to +85°C, unless otherwise noted.) (Note 3)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Soft-Start Period

POSITIVE LINEAR REGULATOR (LR4)

FBL4 Regulation Voltage V

FBL4 Input Bias Current V

FBL4 Effective Load Regulation

Error (Transconductance)

FBL4 Line Regulation Error I

DRV4 Sink Current V

DRV4_Off-Leakage Current V

FBL4 Input Common-Mode

Range

Soft-Start Step Size Measured at FBL4 1.238 / 32 V

Soft-Start Period

NEGATIVE LINEAR REGULATOR (LR5)

FBL5 Regulation Voltage V

FBL5 Input Bias Current V

FBL5 Effective Load Regulation

Error (Transconductance)

FBL5 Line Regulation Error I

DRV5 Source Current V

DRV5 Off-Leakage Current V

FBL5 Input Common-Mode

Range

Soft-Start Step Size Measured at FBL5 1.238 / 32 V

Soft-Start Period

FREQ = GND 1024 / f

FREQ = VL 2048 / f

= 5V, I

DRV4

= 1.5V -50 +50 nA

FBL4

V

= 5V, I

DRV4

= 500µA, 5.5V < VIN < 28V 5 mV

DRV4

= 1.175V, V

FBL4

= 1.5V, V

FBL4

= 500µA 1.226 1.245 1.264 V

DRV4

= 500µA to 10mA -1.5 -2 %

DRV4

= 5V 10 28 mA

DRV4

= 28V 0.1 10 µA

DRV4

OSC

OSC

(Note 2) -0.1 +1.5 V

FREQ = GND 1024 / f

FREQ = VL 2048 / f

= -10V, I

DRV5

= 0 -50 +50 nA

FBL5

V

= -10V, I

DRV5

= 100µA, 5.5V < VIN < 28V 5 mV

DRV5

= 200mV, V

FBL5

= 0, V

FBL5

DRV5

= 100µA 100 125 150 mV

DRV5

= 50µA to 1mA -1.5 -2 %

DRV5

= -10V 2 9 mA

DRV5

= -20V 0.1 10 µA

OSC

OSC

(Note 2) -0.1 +1.5 V

FREQ = AGND 1024 / f

FREQ = VL 2048 / f

OSC

OSC

s

s

s

PARAMETER CONDITIONS MIN TYP MAX UNITS

GENERAL

Operating Input Voltage Range (Note 1) 4.5 28.0 V

VL REGULATOR

VL Output Voltage 5.5V < V

VL Undervoltage Lockout

Threshold

VL rising, 3% hysteresis 3.2 3.8 V

< 28V, 0 < IVL < 30mA 4.75 5.25 V

IN

Page 6

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, VEN= V

SEQ

= 5V, TA = -40°C to +85°C, unless otherwise noted.) (Note 3)

Note 1: Operating supply range is guaranteed by VL line regulation test for the range of 5.5V to 28V. Between 4.5V and 5.5V, the V

L

regulator might be in dropout; however, the part continues to operate properly.

Note 2: Guaranteed by design and not production tested.

Note 3: Specifications to -40°C are guaranteed by design and not production tested.

PARAMETER CONDITIONS MIN TYP MAX UNITS

CONTROL AND SEQUENCE

ONL_ Input Threshold ONL_ rising, 25mV hysteresis 1.201 1.275 V

EN Input Threshold EN rising, 5% hysteresis 1.201 1.275 V

FAULT DETECTION

FB, FBL1, FBL2, FBL3, FBL4

Fault Trip Level

FBL5 Fault Trip Level FBL5 rising, 25mV hysteresis 300 500 mV

Overcurrent Protection Threshold (V

RESET FUNCTION

RSTIN Reset Trip Level RSTIN falling, 25mV hysteresis 1.081 1.147 V

ERROR AMPLIFIER

FB Regulation Voltage 1.215 1.260 V

Current-Limit Threshold

(Default Mode)

Current-Limit Threshold

(Adjustable Mode)

POSITIVE LINEAR REGULATOR (LR1)

FBL1 Regulation Voltage V

FBL1 Input Bias Current V

POSITIVE LINEAR REGULATORS (LR2 AND LR3)

FBL_ Regulation Voltage V

FBL_ Input Bias Current V

POSITIVE LINEAR REGULATOR (LR4)

FBL4 Regulation Voltage V

FBL4 Input Bias Current V

NEGATIVE LINEAR REGULATOR (LR5)

FBL5 Regulation Voltage V

FBL5 Input Bias Current V

DRV5 Source Current V

FB, FBL1, FBL2, FBL3, FBL4 falling, 25mV hysteresis 1.081 1.147 V

- V

CSH

) 270 330 mV

CSL

STEP-DOWN CONTROLLER

PGND - LX, ILIM = VL 170 330 mV

PGND - LX, V

= 1.25V 170 330 mV

ILIM

LINEAR REGULATOR CONTROLLERS

= 5V, I

DRV1

= 1.5V

FBL1

_ = 5V, I

DRV

_ = 1.5V -50 +50 nA

FBL

= 5V, I

DRV4

= 1.5V -50 +50 nA

FBL4

= -10V, I

DRV5

= 0 -50 +50 nA

FBL5

= 200mV, V

FBL5

= 100µA 1.220 1.270 V

DRV1

-50 +50 nA

_ = 100µA 1.220 1.270 V

DRV

= 500µA 1.220 1.270 V

DRV4

= 100µA 100 150 mV

DRV5

= -10V 2 mA

DRV5

Page 7

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

_______________________________________________________________________________________ 7

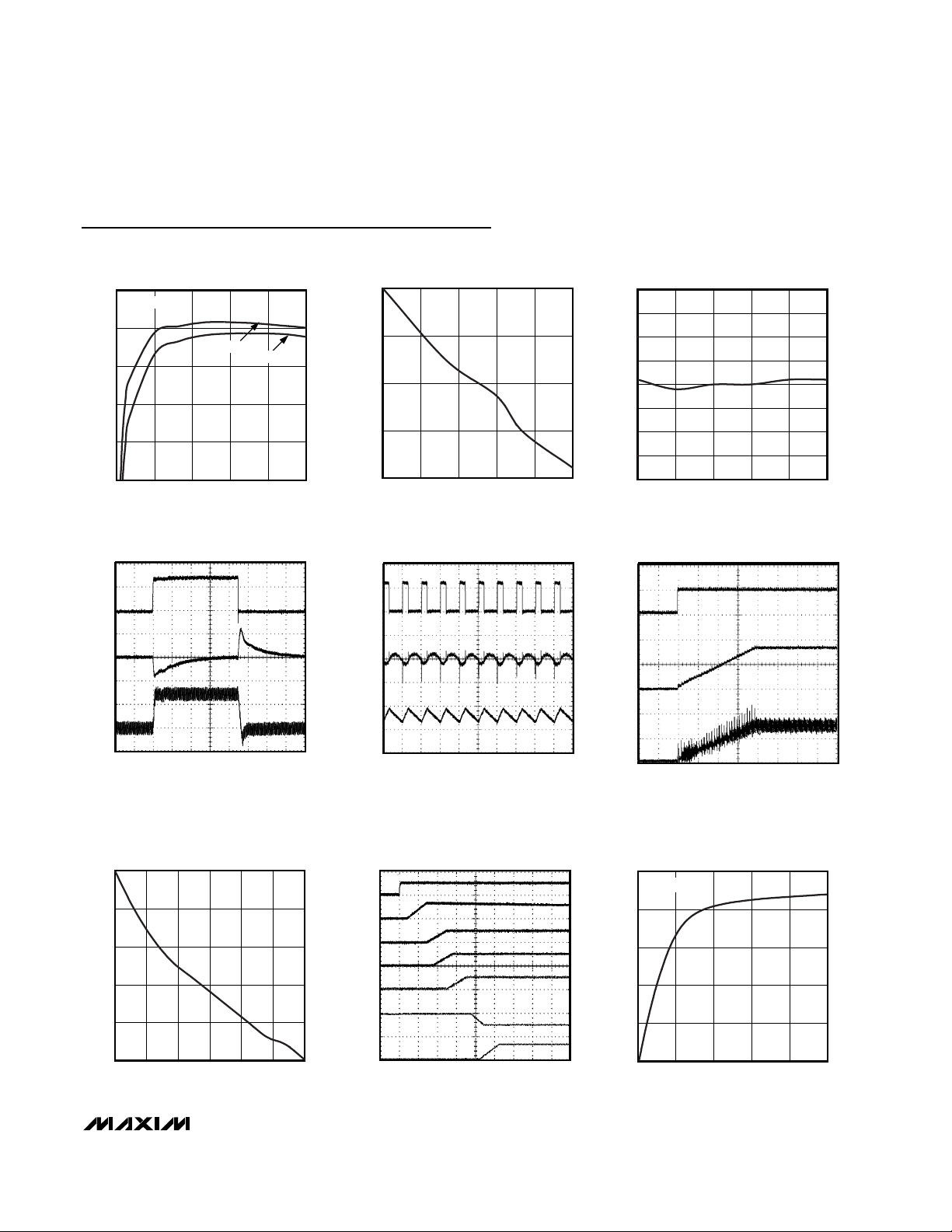

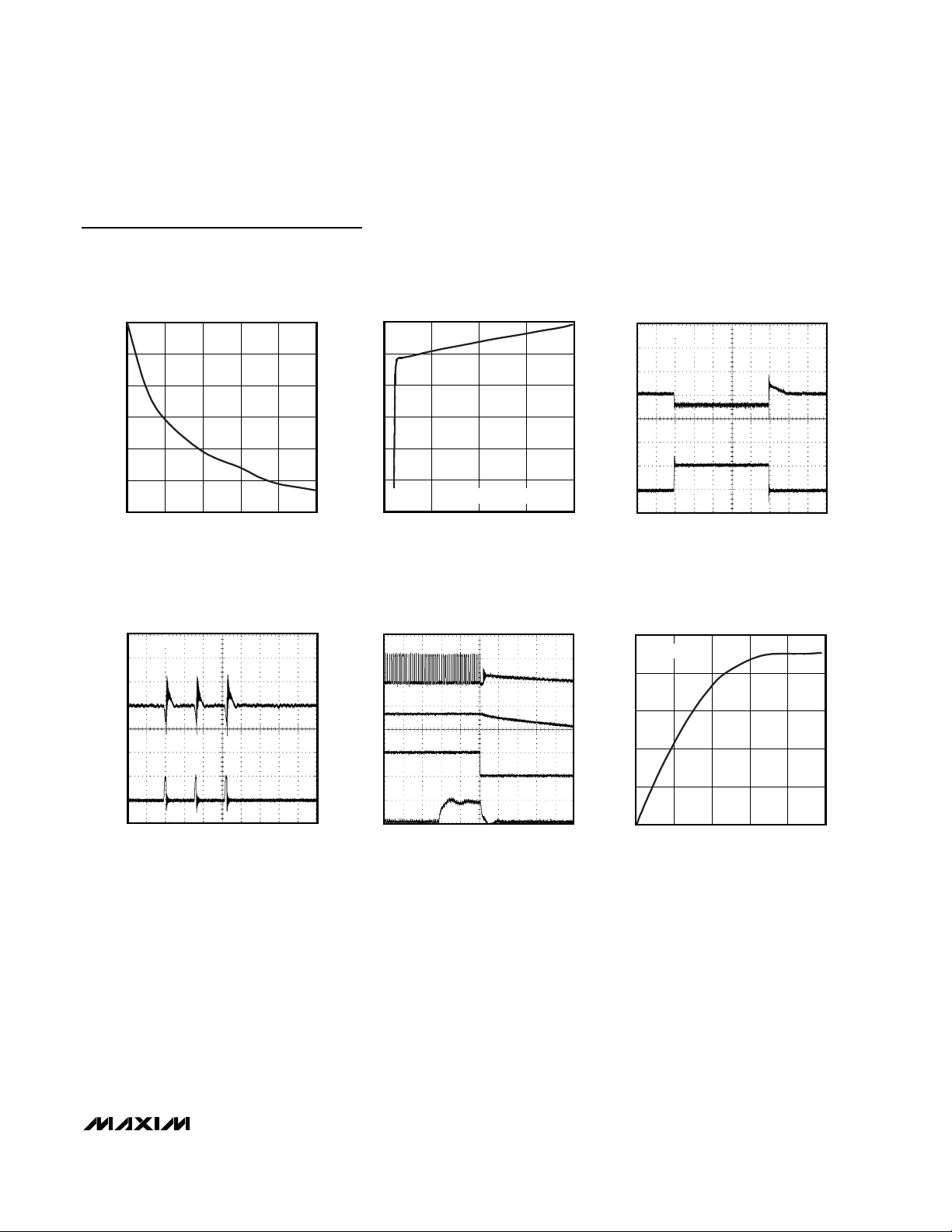

Typical Operating Characteristics

(Circuit of Figure 1; including R5, R6, and D2; TA= +25°C, unless otherwise noted.)

STEP-DOWN EFFICIENCY vs. LOAD CURRENT

MAX1530 toc01

LOAD CURRENT (mA)

EFFICIENCY (%)

1200900600300

60

70

80

90

100

50

0 1500

VIN = 12V

VIN = 20V

fSW = 500kHz

STEP-DOWN LOAD REGULATION

MAX1530 toc02

LOAD CURRENT (mA)

OUTPUT-VOLTAGE ERROR (%)

1200900600300

-0.12

-0.08

-0.04

0

-0.16

0 1500

SWITCHING FREQUENCY vs. LOAD CURRENT

FREQUENCY (kHz)

485

490

495

500

510

505

515

520

480

MAX1530 toc03

LOAD CURRENT (mA)

12009006003000 1500

STEP-DOWN REGULATOR LOAD TRANSIENT

MAX1530 toc04

40µs/div

A: LOAD CURRENT, 1A/div

B: OUTPUT VOLTAGE, 200mV/div, AC-COUPLED

C: INDUCTOR CURRENT, 1A/div

A

0A

B

3.3V

0A

C

STEP-DOWN REGULATOR

SWITCHING WAVEFORM

MAX1530 toc05

2µs/div

A

B

C

A: LX, 10V/div

B: OUTPUT VOLTAGE, 20 mV/div, AC-COUPLED

C: INDUCTOR CURRENT, 1A/div

0V

3.3V

0A

STEP-DOWN REGULATOR

SOFT-START

MAX1530 toc06

1ms/div

A

C

A: EN, 2V/div

B: OUTPUT VOLTAGE, 2V/div

C: INDUCTOR CURRENT, 1A/div

0V

0V

B

0A

VL LOAD REGULATION

MAX1530 toc07

LOAD CURRENT (mA)

VL OUTPUT ERROR (%)

252015105

-0.4

-0.3

-0.2

-0.1

0

-0.5

030

STARTUP SEQUENCE

MAX1530 toc08

4ms/div

A: V

L

, 10V/div

B: V

OUT

, 5V/div

C: V

LOGIC

, 5V/div

D: V

SOURCE

, 20V/div

E: V

GAMMA

, 20V/div

F: V

GOFF

, 20V/div

G: V

GON

, 40V/div

A

B

C

D

E

F

G

LR1 BASE CURRENT

vs. DRV1 VOLTAGE

MAX1530 toc09

DRV1 VOLTAGE (V)

BASE CURRENT (mA)

8642

3

6

9

12

15

0

010

V

FBL1

= 1.175V

Page 8

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

8 _______________________________________________________________________________________

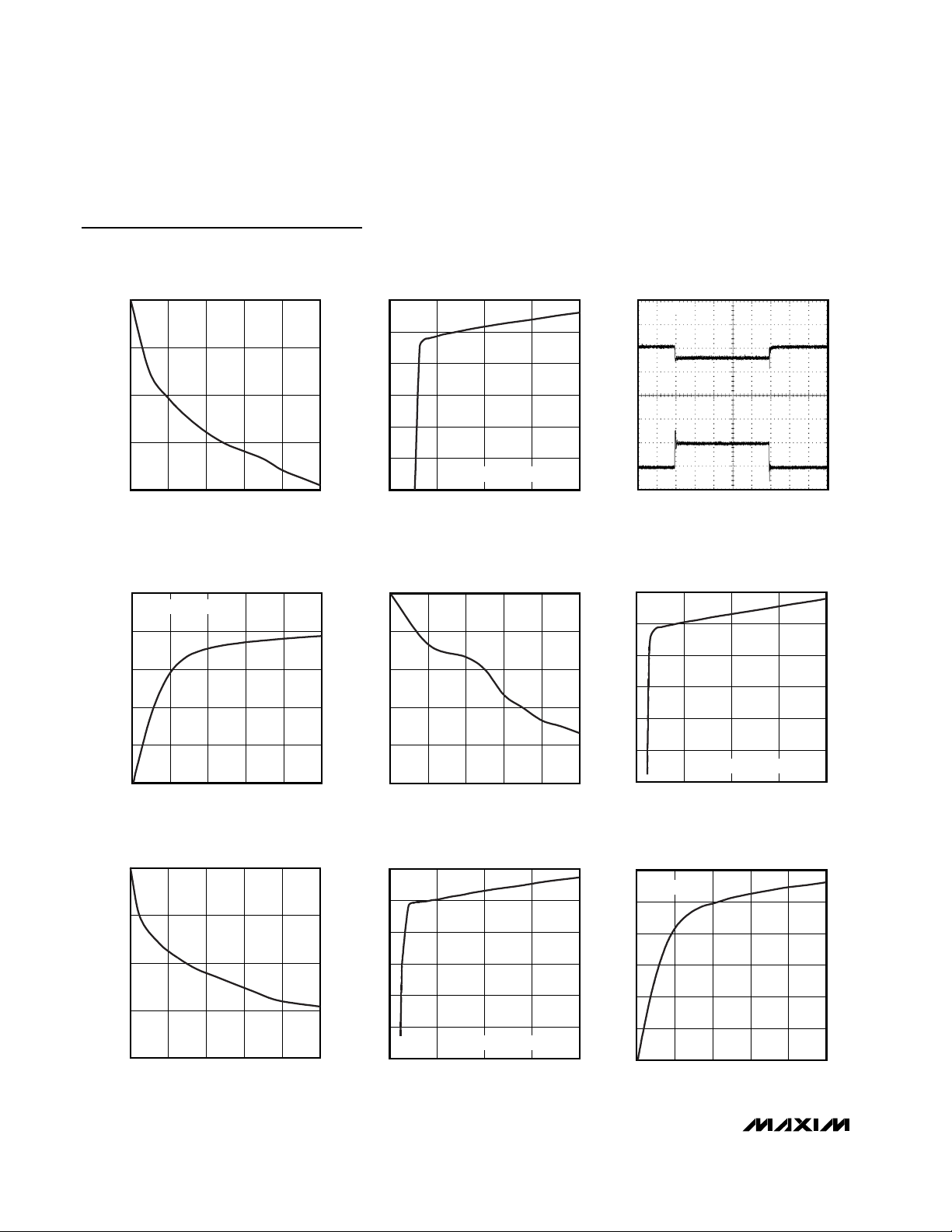

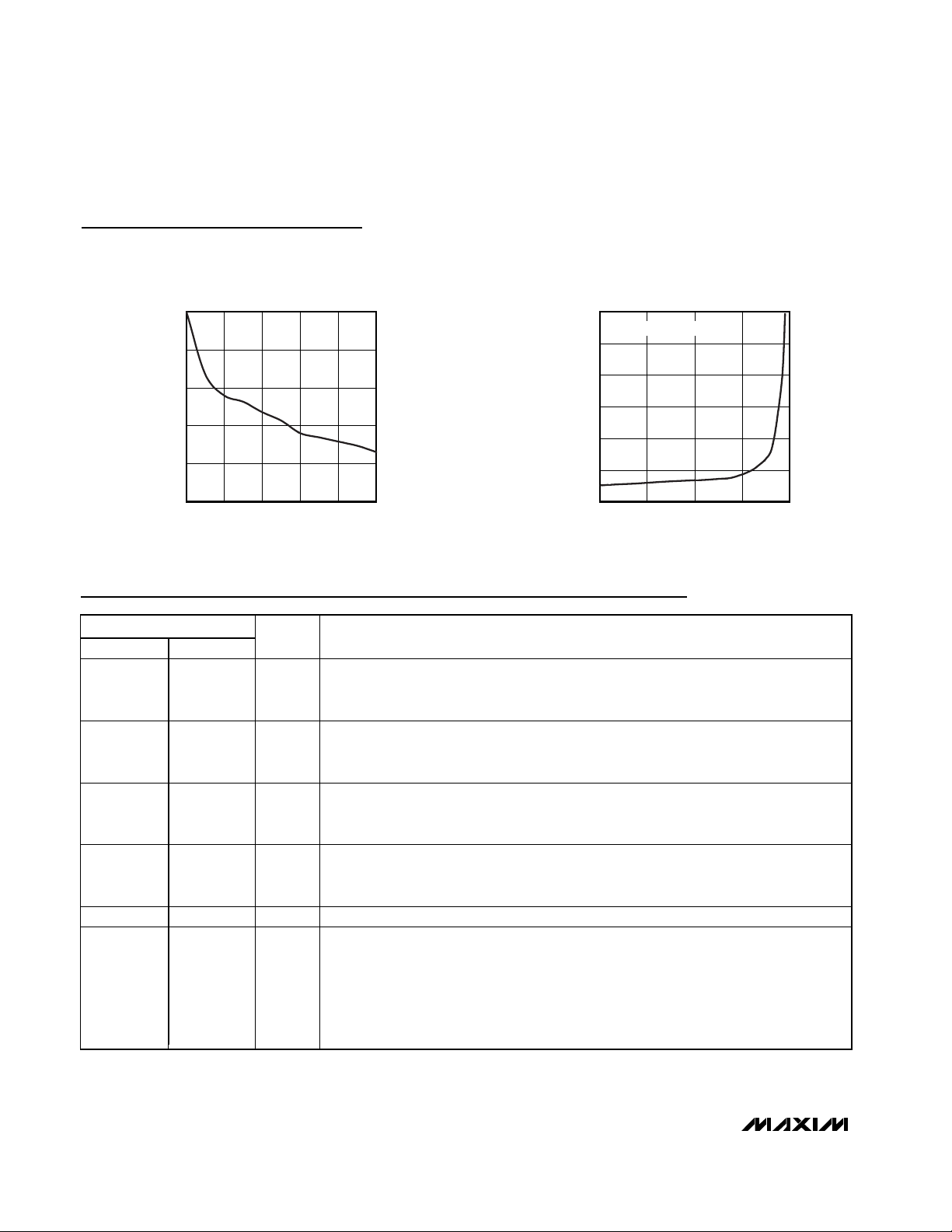

Typical Operating Characteristics (continued)

(Circuit of Figure 1; including R5, R6, and D2; TA= +25°C, unless otherwise noted.)

LR1 NORMALIZED LOAD REGULATION

0

LR1 NORMALIZED LINE REGULATION

0.2

LR1 LOAD TRANSIENT

MAX1530 toc12

-0.5

-1.0

VOLTAGE ERROR (%)

-1.5

-2.0

0 500

LOAD CURRENT (mA)

400300200100

MAX1530 toc10

OUTPUT-VOLTAGE ERROR (%)

LR2/LR3 BASE CURRENT

5

4

3

2

BASE CURRENT (mA)

1

0

vs. DRV2/DRV3 VOLTAGE

V

= V

FBL2

05

= 1.175V

FBL3

DRV2/DRV3 VOLTAGE (V)

MAX1530 toc13

VOLTAGE ERROR (%)

4321

0

-0.2

-0.4

-0.6

-0.8

-1.0

26

200mA LOAD CURRENT

543

INPUT VOLTAGE (V)

LR2 NORMALIZED LOAD REGULATION

0

-0.3

-0.6

-0.9

-1.2

-1.5

050

LOAD CURRENT (mA)

40302010

MAX1530 toc11

A: LR1 OUTPUT VOLTAGE, 100mV/div, AC-COUPLED

B: LR1 LOAD CURRENT, 500mA/div

LR2 NORMALIZED LINE REGULATION

0.2

0

MAX1530 toc14

-0.2

-0.4

-0.6

OUTPUT-VOLTAGE ERROR (%)

-0.8

-1.0

925

INPUT VOLTAGE (V)

A

2.5V

B

0mA

40µs/div

MAX1530 toc15

20mA LOAD CURRENT

211713

LR3 NORMALIZED LOAD REGULATION

0

-0.5

-1.0

VOLTAGE ERROR (%)

-1.5

-2.0

020

LOAD CURRENT (mA)

161284

MAX1530 toc16

LR3 NORMALIZED LINE REGULATION

0.2

0

-0.2

-0.4

-0.6

OUTPUT-VOLTAGE ERROR (%)

-0.8

-1.0

24 40

20mA LOAD CURRENT

INPUT VOLTAGE (V)

vs. DRV VOLTAGE

30

V

= 1.175V

FBL4

25

MAX1530 toc17

20

15

10

BASE CURRENT (mA)

5

363228

0

010

DRV4 VOLTAGE (V)

LR4 BASE CURRENT

MAX1530 toc18

8642

Page 9

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

_______________________________________________________________________________________ 9

Typical Operating Characteristics (continued)

(Circuit of Figure 1; including R5, R6, and D2; TA= +25°C, unless otherwise noted.)

LR4 NORMALIZED LOAD REGULATION

MAX1530 toc19

LOAD CURRENT (mA)

VOLTAGE ERROR (%)

400300200100

-0.5

-0.4

-0.3

-0.2

-0.1

0

-0.6

0 500

LR4 NORMALIZED LINE REGULATION

MAX1530 toc20

INPUT VOLTAGE (V)

OUTPUT-VOLTAGE ERROR (%)

211713

-0.8

-0.6

-0.4

-0.2

0

0.2

-1.0

925

200mA LOAD CURRENT

LR4 LOAD TRANSIENT

MAX1530 toc21

40µs/div

A

B

A: LR4 OUTPUT VOLTAGE, 100mV/div, AC-COUPLED

B: LR4 LOAD CURRENT, 500mA/div

10V

0mA

LR4 PULSED LOAD TRANSIENT

MAX1530 toc22

10µs/div

A

B

A: LR4 OUTPUT VOLTAGE, 100mV/div, AC-COUPLED

B: LR4 LOAD CURRENT, 1A/div

10V

0A

MAX1531

OVERCURRENT PROTECTION (CSH, CSL)

MAX1530 toc23

20µs/div

A: V

LX

, 10V/div

B: V

OUT

, 5V/div

B

C

D

A

C: V

RESET

, 5V/div

D: V

CSH

- V

CSL

, 500mV/div

LR5 BASE CURRENT

vs. DRV5 VOLTAGE

MAX1530 toc24

DRV5 VOLTAGE (V)

BASE CURRENT (mA)

4321

2

4

6

8

10

0

05

V

FBL5

= 0V

Page 10

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1; including R5, R6, and D2; TA= +25°C, unless otherwise noted.)

Pin Description

LR5 NORMALIZED LOAD REGULATION

0

-0.2

-0.4

-0.6

VOLTAGE ERROR (%)

-0.8

-1.0

050

LOAD CURRENT (mA)

40302010

PIN

MAX1530 MAX1531

1 1 DRV2

2 2 FBL2

NAME FUNCTION

Gamma Linear Regulator (LR2) Base Drive. Open drain of an internal N-channel MOSFET.

Connect DRV2 to the base of an external PNP pass transistor to form a positive linear

regulator. (See the Pass Transistor Selection section.)

Gamma Linear Regulator (LR2) Feedback Input. FBL2 regulates at 1.245V nominal.

Connect FBL2 to the center tap of a resistive voltage-divider between the LR2 output and

AGND to set the output voltage. Place the divider close to the FBL2 pin.

MAX1530 toc25

LR5 NORMALIZED LINE REGULATION

1.0

20mA LOAD CURRENT

0.8

0.6

0.4

0.2

OUTPUT-VOLTAGE ERROR (%)

0

-0.2

-25 -9

INPUT VOLTAGE (V)

MAX1530 toc26

-13-17-21

Gate-On Linear Regulator (LR3) Feedback Input. FBL3 regulates at 1.245V nominal.

3 3 FBL3

4 4 DRV3

Connect FBL3 to the center tap of a resistive voltage-divider between the LR3 output and

AGND to set the output voltage. Place the divider close to the FBL3 pin.

Gate-On Linear Regulator (LR3) Base Drive. Open drain of an internal N-channel MOSFET.

Connect DRV3 to the base of an external PNP pass transistor to form a positive linear

regulator. (See the Pass Transistor Selection section.)

5–10, 18, 19 — N. C. No Connection. Not internally connected.

Adjustable Reset Input. RESET asserts low when the monitored voltage is less than the

reset trip threshold. RESET goes to a high-impedance state only after the monitored

voltage remains above the reset trip threshold for the duration of the reset timeout period.

11 11 RSTIN

Connect RSTIN to the center tap of a resistive voltage-divider between the monitored

output voltage and AGND to set the reset trip threshold. The internal RSTIN threshold of

90% of 1.238V allows direct connection of RSTIN to any of the device’s positive feedback

pins.

Page 11

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

______________________________________________________________________________________ 11

Pin Description (continued)

PIN

MAX1530 MAX1531

12 12 RESET

13 13 COMP

14 14 FB

15 15 ILIM

16 16 ONL2

NAME FUNCTION

Open-Drain Reset Output. RESET asserts low when the monitored voltage is less than the

reset trip threshold. RESET goes to a high-impedance state only after the monitored

voltage remains above the reset trip threshold for the duration of the reset timeout period.

RESET also asserts low when VL is less than the VL undervoltage lockout threshold, EN is

low, or the thermal, overcurrent or undervoltage fault latches are set.

Step-Down Regulator Compensation Input. A pole-zero pair must be added to

compensate the control loop by connecting a series resistor and capacitor from COMP to

AGND. (See the Compensation Design section.)

Step-Down Regulator Feedback Input. FB regulates at 1.238V nominal. Connect FB to the

center tap of a resistive voltage-divider between the step-down regulator output and

AGND to set the output voltage. Place the divider close to the FB pin.

Step-Down Regulator Current-Limit Control Input. Connect this dual-mode input to VL to

set the current-limit threshold to its default value of 250mV. The overcurrent comparator

compares the voltage across the low-side N-channel MOSFET with the current-limit

threshold. Connect ILIM to the center tap of a resistive voltage-divider between VL and

AGND to adjust the current-limit threshold to other values. In adjustable mode, the actual

current-limit threshold is 1/5th of the voltage at ILIM over a 0.25V to 3.0V range. The dualmode threshold for switchover to the 250mV default value is approximately 3.5V.

Gamma Linear Regulator (LR2) Enable Input. When EN is above its enable threshold, VL

is above its UVLO threshold, and ONL2 is greater than the internal reference, LR2 is

enabled. Drive ONL2 with a logic signal or, for automatic sequencing, connect a capacitor

from ONL2 to AGND. If SEQ is high, EN is above its threshold, and VL is above its UVLO

threshold, an internal 2µA (typ) current source charges the capacitor. Otherwise, an

internal switch discharges the capacitor. Connecting various capacitors to each ONL_ pin

allows the programming of the startup sequence.

Gate-On Linear Regulator (LR3) Enable Input. When EN is above its enable threshold, VL

is above its UVLO threshold, and ONL3 is greater than the internal reference, LR3 is

enabled. Drive ONL3 with a logic signal or, for automatic sequencing, connect a capacitor

17 17 ONL3

from ONL3 to AGND. If SEQ is high, EN is above its threshold, and VL is above its UVLO

threshold, an internal 2µA (typ) current source charges the capacitor. Otherwise, an

internal switch discharges the capacitor. Connecting various capacitors to each ONL_ pin

allows the programming of the startup sequence.

20 20 PGND Power Ground

Low-Side Gate Driver Output. DL drives the synchronous rectifier of the step-down

21 21 DL

22 22 LX

regulator. DL swings from PGND to VL. DL remains low until VL rises above the UVLO

threshold.

Step-Down Regulator Current-Sense Input. The IC’s current-sense amplifier inputs for

current-mode control connect to IN and LX. Connect IN and LX directly to the high-side Nchannel MOSFET drain and source, respectively. The low-side current-limit comparator

inputs connect to LX and PGND to sense voltage across a low-side N-channel MOSFET.

Page 12

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

12 ______________________________________________________________________________________

Pin Description (continued)

PIN

MAX1530 MAX1531

23 23 DH

24 24 BST

25 25 SEQ

26 26 FREQ

NAME FUNCTION

High-Side Gate Driver Output. DH drives the main switch of the step-down regulator. DH

swings from LX to BST.

Step-Down Regulator Boostrap Capacitor Connection for High-Side Gate Driver. Connect

a 0.1µF ceramic capacitor from BST to LX.

Sequence Control Input for LR2, LR3, LR4, and LR5. Controls the current sources and

switches that charge and discharge the capacitors connected to the ONL_ pins.

Oscillator Frequency Select Input. Connect FREQ to VL for 500kHz operation. Connect

FREQ to AGND for 250kHz operation.

Main Input Voltage (+4.5V to 28V). Bypass IN to AGND with a 1µF ceramic capacitor

27 27 IN

close to the pins. IN powers the VL linear regulator. Connect IN to the drain of the highside MOSFET (for current sense) through a 1Ω resistor.

Internal 5V Linear Regulator Output. Connect a minimum 1µF ceramic capacitor from VL

28 28 VL

to AGND. Place the capacitor close to the pins. VL can supply up to 30mA for gate drive

and external loads. VL remains active when EN is low.

29 29 AGND Analog Ground

Enable Input. This general-purpose on/off control input has an accurate 1.238V (typ) rising

threshold with 5% hysteresis. This allows EN to monitor an input voltage level or other

analog parameter. If EN is less than its threshold, then the main step-down and all linear

30 30 EN

regulators are turned off. VL and the internal reference remain active when EN is low. The

rising edge of EN clears any latched faults except for a thermal fault, which is cleared only

by cycling the input power. An internal filter with a 10µs time constant prevents short

glitches from accidentally clearing the fault latch.

Low-Voltage Logic Linear Regulator (LR1) Feedback Input. FBL1 regulates at 1.245V

31 31 FBL1

32 32 DRV1

— 5 CSH

nominal. Connect FBL1 to the center tap of a resistive voltage-divider between LR1 output

AGND to set the output voltage. Place the divider close to the FBL1 pin. LR1 starts

automatically after the step-down converter soft-start ends.

Low-Voltage Logic Linear Regulator (LR1) Base Drive. Open drain of an internal N-channel

MOSFET. Connect DRV1 to the base of an external PNP pass transistor. (See the Pass

Transistor Selection section.)

Overcurrent Protection Positive Input. CSH is also the supply input for the overcurrent

sense block. CSH and CSL can be used to sense any current in the application circuit and

to shut the device down in an overcurrent condition. This feature is typically used to

protect the main input or the input to one of the linear regulators since they do not have

their own current limits. Insert an appropriate sense resistor in series with the protected

input and connect CSH and CSL to its positive and negative terminals. The controller sets

the fault latch when V

internal lowpass filter prevents large currents of short duration (less than 50µs) or noise

glitches from setting the latch. If the overcurrent protection is not used, connect CSH and

CSL to VL.

CSH

- V

exceeds the 300mV (typ) overcurrent threshold. An

CSL

— 6 CSL Overcurrent Protection Negative Input. See CSH above.

Page 13

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

______________________________________________________________________________________ 13

Pin Description (continued)

PIN

MAX1530 MAX1531

— 7 FBL4

— 8 DRV4

— 9 FBL5

— 10 DRV5

— 18 ONL4

NAME FUNCTION

Source Drive Linear Regulator (LR4) Feedback Input. FBL4 regulates at 1.245V nominal.

Connect FBL4 to the center tap of a resistive voltage-divider between the LR4 output and

AGND to set the output voltage. Place the divider close to the FBL4 pin.

Source Drive Linear Regulator (LR4) Base Drive. Open drain of an internal N-channel

MOSFET. Connect DRV4 to the base of an external PNP pass transistor to form a positive

linear regulator. (See the Pass Transistor Selection section.)

Gate-Off Linear Regulator (LR5) Feedback Input. FBL5 regulates at 125mV nominal.

Connect FBL5 to the center tap of a resistive voltage-divider between the LR5 output and

the internal 5V linear regulator output (VL) to set the output voltage. Place the divider close

to the FBL5 pin.

Gate-Off Linear Regulator (LR5) Base Drive. Open drain of an internal P-channel MOSFET.

Connect DRV5 to the base of an external NPN pass transistor to form a negative linear

voltage regulator. (See the Pass Transistor Selection section.)

Source Drive Linear Regulator (LR4) Enable Input. When EN is above its enable threshold,

VL is above its UVLO threshold, and ONL4 is greater than the internal reference, LR4 is

enabled. Drive ONL4 with a logic signal or, for automatic sequencing, connect a capacitor

from ONL4 to AGND. If SEQ is high, EN is above its threshold, and VL is above its UVLO

threshold, an internal 2µA (typ) current source charges the capacitor. Otherwise, an

internal switch discharges the capacitor. Connecting various capacitors to each ONL_ pin

allows the programming of the startup sequence.

— 19 ONL5

Gate-Off Linear Regulator (LR5) Enable Input. When EN is above its enable threshold, VL

is above its UVLO threshold, and ONL5 is greater than the internal reference, LR5 is

enabled. Drive ONL5 with a logic signal or, for automatic sequencing, connect a capacitor

from ONL5 to AGND. If SEQ is high, EN is above its threshold, and VL is above its UVLO

threshold, an internal 2µA (typ) current source charges the capacitor. Otherwise, an

internal switch discharges the capacitor. Connecting various capacitors to each ONL_ pin

allows the programming of the startup sequence.

Page 14

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

14 ______________________________________________________________________________________

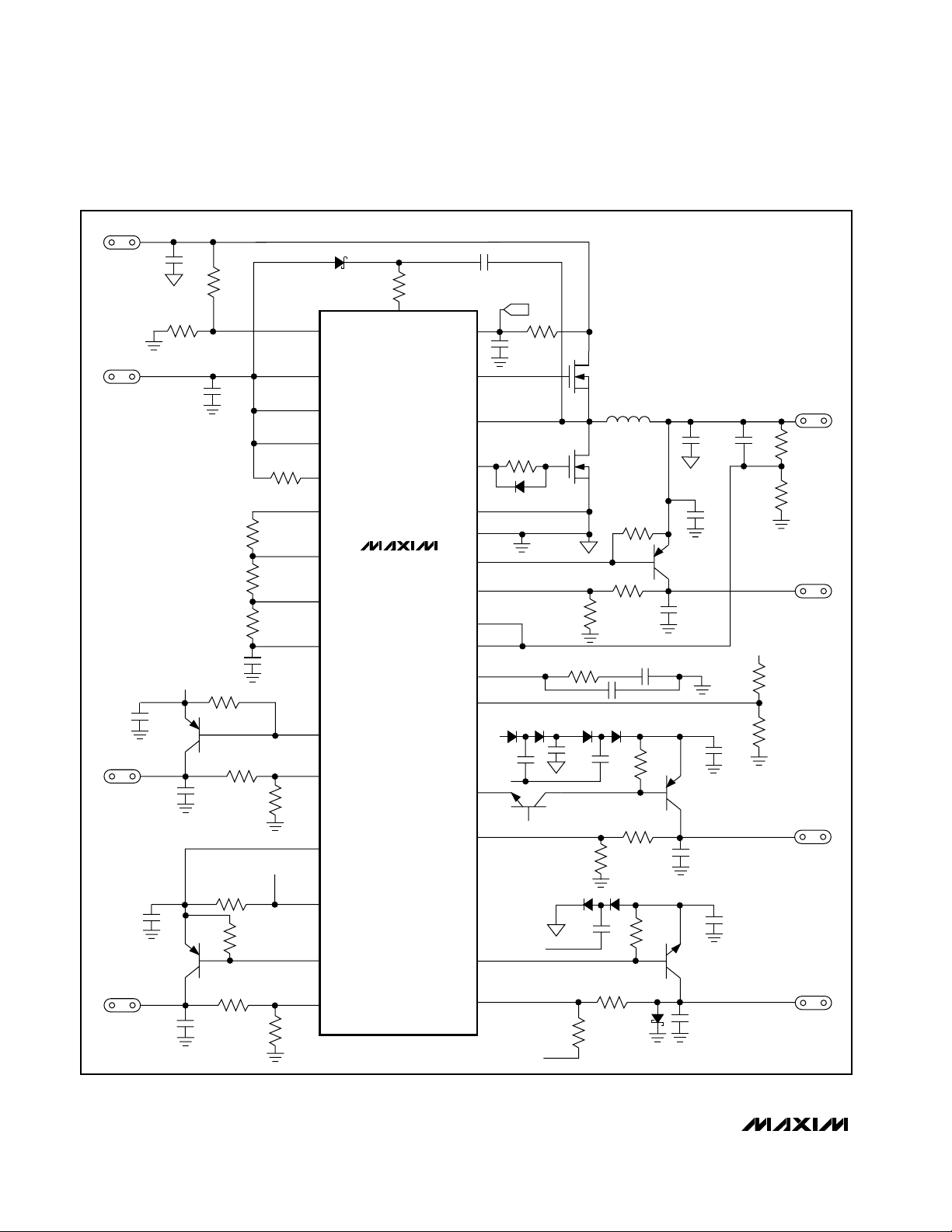

Figure 1. MAX1531 Standard Application Circuit

= 12V

V

IN

C3

4.7µF

25V

20.0kΩ

V

L

5V/30mA

C20

0.1µF

V

GAMMA

9.7V/50mA

2.2µF

V

SOURCE

10V/500mA

C21

C13

4.7µF

16V

Q2

Q4

R3

124kΩ

1%

R4

1%

C4

1µF

R7

100kΩ

R14

121kΩ

1%

R15

68.1kΩ

1%

R16

43.2kΩ

1%

C11

0.1µF

R17

V

IN

6.8kΩ

R18

68.1kΩ

1%

C12

0.47µF

R20

0.5Ω

1%

75kΩ

R22

1%

R21

1.5kΩ

R19

10kΩ

1%

V

IN

R23

10.7kΩ

1%

D1

R5*

10Ω

24

30

EN IN

28

VL

26

FREQ

25

SEQ

12

RESET

16

ONL2

17

ONL3

18

ONL4

19

ONL5

1

DRV2

2

FBL2

6

CSL

5

CSH

8

DRV4

7

BST

MAX1531

PGND

AGND

DRV1

FBL1

RSTIN

COMP

ILIM

DRV3

FBL3

DRV5

FBL5FBL4

C5

0.1µF

IN

R12

IN

0.1µF

Q6

C14

LX

C1

1µF

10Ω

D2*

R6*

1Ω

N1-A

L1

10µH

C7

22µF

N1-B

R8

6.8kΩ

R26

1%

D4

C6

0.1µF

D5

R28

90.9kΩ

1%

*OPTIONAL

R9

10kΩ

1%

C10

470pF

C2, OPEN

R25

200kΩ

1%

D6

R24

6.8kΩ

R27

6.8kΩ

R10

10kΩ

1%

R11

100kΩ

D3

C8

0.1µF

IN

10.5kΩ

C17

0.1µF

LX

R29

48.7kΩ

1%

VL

6.3V

C22

2.2µF

Q1

C9

10µF

6.3V

C15

0.1µF

Q3

C16

0.47µF

C18

0.1µF

Q5

C19

0.47µF

27

23

DH

22

LX

21

DL

20

29

32

31

11

14

FB

13

15

V

4

3

10

9

C23

150pF

VL

R12

300kΩ

R13

150kΩ

V

OUT

3.3V/1.5A

R1

17.8kΩ

1%

R2

10.7kΩ

1%

V

LOGIC

2.5V/500mA

V

GON

25V/20mA

V

GOFF

-9V/50mA

Page 15

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

______________________________________________________________________________________ 15

Figure 2. MAX1530 Standard Application Circuit

V

= 12V

IN

C3

V

L

5V/30mA

C20

0.1µF

V

GAMMA

9.7V/50mA

4.7µF

25V

R4

20.0kΩ

1%

V

Q2

R3

124kΩ

1%

C4

1µF

R7

100kΩ

R14

121kΩ

1%

C11

0.1µF

R17

IN

6.8kΩ

R18

68.1kΩ

1%

C12

0.47µF

R19

10kΩ

1%

D1

R5*

10Ω

24

30

EN IN

28

VL

26

FREQ

25

SEQ

12

RESET

16

ONL2

17

ONL3

5

N.C.

6

N.C.

7

N.C.

8

N.C.

1

DRV2

2

FBL2

9

N.C.

10

N.C.

BST

MAX1530

PGND

AGND

DRV1

FBL1

RSTIN

COMP

ILIM

DRV3

FBL3

N.C.

N.C.

C5

0.1µF

IN

R12

C1

1µF

R6*

10Ω

D2*

1Ω

N1-A

L1

10µH

C7

C23

22µF

150pF

6.3V

C22

2.2µF

Q1

C9

10µF

6.3V

VL

R12

300kΩ

R13

C21

2.2µF

Q4

C13

4.7µF

150kΩ

R11

100kΩ

R23

10.7kΩ

N1-B

R8

6.8kΩ

R10

R9

10kΩ

10kΩ

1%

1%

C10

470pF

C2, OPEN

V

IN

R24

6.8kΩ

R22

75kΩ

1%

1%

27

23

DH

22

LX

21

DL

20

29

32

31

11

14

FB

13

15

4

3

19

18

3.3V/1.5A

R1

17.8kΩ

1%

R2

10.7kΩ

1%

2.5V/500mA

V

10V/500mA

V

OUT

V

LOGIC

SOURCE

*OPTIONAL

Page 16

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

16 ______________________________________________________________________________________

Standard Application Circuit

The standard application circuit (Figure 1) of the

MAX1531 is a complete power-supply system for TFT

LCD monitors. The circuit generates a 3.3V/1.5A main

output, a 2.5V/500mA output for the timing controller

and digital sections of source/gate drive ICs, a

10V/500mA source drive supply voltage, a 9.7V/50mA

gamma reference, a 25V/20mA gate-on voltage, and a

-10V/50mA gate-off voltage. The input voltage is 12V

±10%. Table 1 lists the selected components and Table

2 lists the component suppliers. The standard application circuit (Figure 2) of the MAX1530 is similar to the

MAX1531 application circuit except that gate-on and

gate-off voltages are eliminated.

Detailed Description

The MAX1530/MAX1531 power-supply controllers provide logic and bias power for LCD monitors. Figure 3

shows the IC functional diagram. The main step-down

controller employs a current-mode PWM control method

to ease compensation requirements and provide excellent load- and line-transient response. The use of synchronous rectification yields excellent efficiency.

The MAX1530 includes three analog gain blocks to

control three auxiliary positive linear regulators, and the

MAX1531 includes five analog gain blocks to control

four positive and one negative linear regulators. Use

the positive gain blocks to generate low-voltage rails

directly from the input voltage or the main step-down

converter output, or higher voltages using charge

Table 1. Selected Component List

Table 2. Component Suppliers

*For MAX1531 only.

DESIGNATION DESCRIPTION

C3

C7

C9

C12, C19*

C13

C21, C22

D1, D6*

D2

SUPPLIER PHONE FAX WEBSITE

Central Semi 516-435-1110 516-435-1824 www.centralsemi.com

Fairchild 888-522-5372 972-910-8036 www.fairchildsemi.com

Sumida 847-956-0666 847-956-0702 www.sumida.com

TDK 847-803-6100 847-390-4405 www.components.tdk.com

4.7µF, 25V X7R ceramic capacitor (1210)

TDK C3225X7R1E475K

22µF, 6.3V X7R ceramic capacitor

TDK C3216X7R0J226M

10µF, 6.3V X5R ceramic capacitor

TDK C2012X5R0J106M

0.47µF, 16V X7R ceramic capacitors (0805)

TDK C2012X7R1C474K

4.7µF, 16V X7R ceramic capacitor

TDK C3216X7R1C475K

2.2µF, 25V X7R ceramic capacitors (1206)

TDK C3216X7R1C475M

100mA, 30V Schottky diodes (SOD523)

Central Semiconductor CMOSH-3

100mA, 75V, small-signal switching diode,

SOT23 Fairchild Semiconductor MMBD4148

DESIGNATION DESCRIPTION

D3*, D4*, D5*

L1

N1

Q1, Q4

Q2, Q3*

Q5*, Q6*

200mA, 25V dual Schottky diodes (SOT23)

Fairchild BAT54S

10µH, 2.3A (DC) inductor

Sumida CDR7D28MN-100

2.5A, 30V dual N-channel MOSFET (6-pin

Super SOT)

Fairchild FDC6561AN

3A, 60V l ow - satur ati on P N P b i p ol ar tr ansi stor s

( S O T- 223)

Fai r chi l d N Z T660A

200mA, 40V PNP bipolar transistors (SOT23)

Fairchild MMBT3906

200m A, 40V N P N b i p ol ar tr ansi st or s ( S OT23)

Fai r chi l d M M BT3904

Page 17

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

______________________________________________________________________________________ 17

Figure 3. IC Functional Diagram

FREQ

EN

RSTIN

RESET

GND

COMP

FB

ILIM

ONL2

ONL3

ONL4

ONL5

SEQ

DRV1

V

REF

FBL1

CSH

CSL

DRV2 DRV5

300mV

VLOK

TIMER

COMP

FB

ILIM

PGND

SEQUENCE

SOFTSTART

LR1

0.9VREF

OSC REF

SLOPECLOCK

STEP-DOWN

CONTROLLER

SS DONE FLTMDC-DC EN

ON2

ON3

ON4

ON5

SEQ

EN

FLT1

FLTCS

IN

FAULT

LOGIC

DH

LX

DL

FLTM

FLT3

LDO3EN

LDO4EN

FLT4

V

REF

HIGH-SIDE

DRIVER

LOW-SIDE

DRIVER

THERMAL

VL

VL

MAX1531

SOFTSTART

LR3

0.9VREF

SOFT-

START

LR4

0.9VREF

IN

VL

BST

DH

LX

DL

PGND

DRV3

V

REF

FBL3

DRV4

V

REF

FBL4

V

REF

FBL2 FBL5

SOFTSTART

LR2

0.9VREF

LDO2EN LDO5EN

FLT5FLT2

VLOKEN

SOFT-

START

400mV

LR5

V

REF

Page 18

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

18 ______________________________________________________________________________________

pumps attached to the switching node or extra windings coupled to the step-down converter inductor. The

negative gain block (MAX1531) can be used in conjunction with a charge pump or coupled winding to

generate the LCD gate-off voltage or other negative

supplies.

Step-Down Controller

The MAX1530/MAX1531 include step-down controllers

that use a fixed-frequency current-mode PWM control

scheme (Figure 4). An internal transconductance

amplifier establishes an integrated error voltage at the

COMP pin. The heart of the current-mode PWM controller is an open-loop comparator that compares an

integrated voltage-feedback signal with an amplified

current-sense signal plus a slope-compensation ramp.

At each rising edge of the internal clock, the high-side

MOSFET turns on until the PWM comparator trips or the

maximum duty cycle is reached. During this on-time,

current ramps up through the inductor, sourcing current to the output and storing energy in a magnetic

field. The current-mode feedback system regulates the

peak inductor current as a function of the output voltage error signal. Since the average inductor current is

nearly the same as the peak inductor current (assuming that the inductor value is relatively high to minimize

ripple current), the circuit acts as a switch-mode

transconductance amplifier. That pushes the output LC

filter pole, normally found in a voltage-mode PWM, to a

higher frequency. To preserve loop stability, the slopecompensation ramp is summed into the main PWM

comparator.

During the second half of the cycle, the high-side MOSFET turns off and the low-side N-channel MOSFET turns

on. Now the inductor releases the stored energy as its

current ramps down, providing current to the output.

The output capacitor stores charge when the inductor

current exceeds the load current and discharges when

the inductor current is lower, smoothing the voltage

across the load. Under overload conditions, when the

inductor current exceeds the selected current limit (see

Current Limit Circuit), the high-side MOSFET is not

turned on at the rising edge of the clock and the lowside MOSFET remains on to let the inductor current

ramp down.

Under light-load conditions, the MAX1530/MAX1531

maintain a constant switching frequency to minimize

cross-regulation errors in applications that use a transformer. The low-side gate-drive waveform is the complement of the high-side gate-drive waveform, which

causes the inductor current to reverse under light loads.

Current-Sense Amplifier

The MAX1530/MAX1531s’ current-sense circuit amplifies the current-sense voltage generated by the highside MOSFET’s on-resistance. This amplified

current-sense signal and the internal slope compensation signal are summed together and fed into the PWM

comparator’s inverting input. Place the high-side MOSFET near the controller, and connect IN and LX to the

MOSFET using Kelvin-sense connections to guarantee

current-sense accuracy and improve stability.

Current-Limit Circuit

The MAX1530/MAX1531 include two current-limit circuits that use the two MOSFETs’ on-resistances as current-sensing elements (Figure 4). The high-side

MOSFET’s voltage is used with a fixed 400mV (typ) current-limit threshold during the high-side on-times. The

low-side MOSFET’s voltage is used with an adjustable

current-limit threshold during the low-side on-times.

Using both circuits together ensures that the current is

always measured and controlled.

The high-side MOSFET current limit employs a peak

current limit. If the voltage across the high-side MOSFET, measured from IN to LX, exceeds the 400mV

threshold during an on-time, the high-side MOSFET

turns off and the low-side MOSFET turns on.

The low-side MOSFET current-limit circuit employs a

“valley” current limit. If the voltage across the low-side

MOSFET, measured from LX to PGND, exceeds the

low-side threshold at the end of a low-side on-time, the

low-side MOSFET remains on and the high-side MOSFET stays off for the entire next cycle.

Figure 4. Step-Down Controller Block Diagram

CURRENT

SLOPE

SS DONE

DC-DC EN

V

REF

COMP

CLOCK

ILIM

SOFTSTART

FB

GM

0.9VREF

∑

CURRENT

SENSE

AND

CURRENT

LIMIT

PWM COMP

LIMIT

FAULT COMPARATOR

RSQ

Q

IN

DH

DL

LX

PGND

FLTM

Page 19

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

______________________________________________________________________________________ 19

The ILIM pin is a dual-mode input. When ILIM is connected to VL, a default low-side current limit of 250mV

(typ) is used. If ILIM is connected to a voltage between

250mV and 3V, the low-side current limit is typically

1/5th the ILIM voltage.

The MAX1530/MAX1531s’ current limits are comparatively inaccurate, since the maximum load current is a

function of the MOSFETs’ on-resistances and the inductor value, as well as the accuracy of the two thresholds.

However, using MOSFET current sensing reduces both

cost and circuit size and increases efficiency, since

sense resistors are not needed.

MOSFET Gate Drivers (DH, DL)

The DH and DL drivers are optimized for driving moderate-size high-side and low-side MOSFETs. Adaptive

dead-time circuits monitor the DL and DH drivers and

prevent either FET from turning on until the other is fully

off. This algorithm allows operation without shootthrough with a wide range of MOSFETs, minimizing

delays and maintaining efficiency. When the gates are

turning off, there must be low-resistance, low-inductance paths from the gate drivers to the MOSFET gates

for the adaptive dead-time circuit to work properly.

Otherwise, the sense circuitry in the MAX1530/

MAX1531 interpret the MOSFET gate as "off" while gate

charge actually remains. Use short, wide traces measuring less than 50 squares (at least 20 mil wide if the

MOSFET is 1in from the device).

It is advantageous to slow down the turn-on of both

gate drivers if there is noise coupling between the

switching regulator and the linear regulators. The noise

coupling can result in excessive switching ripple on the

linear regulator outputs. Slowing down the turn-on of

the gate drivers proves to be an effective way of reducing the output ripple. Take care to ensure that the turnoff times are not affected at the same time. As

explained above, slowing down the turn-off times may

result in shoot-through problems. In Figure 1, a 10Ω

resistor (R5) is inserted in series with the BST pin to

slow down the turn-on of the high-side MOSFET (N1-B)

without affecting the turn-off. A 10Ω resistor (R6) is also

inserted between DL and the gate of the low-side MOSFET (N1-A) to slow its turn-on. Because the gate resistor would slow down the turn-off time, connect a

switching diode (D2) (such as 1N4148) in parallel with

the gate resistor as shown in Figure 1 to prevent potential shoot-through.

High-Side Gate-Drive Supply (BST)

A flying-capacitor bootstrap circuit generates gatedrive voltage for the high-side N-channel switch (Figure

1). The capacitor C5 between BST and LX is alternately

charged from the VL supply and placed parallel to the

high-side MOSFET’s gate-source terminals.

On startup, the synchronous rectifier (low-side MOSFET) forces LX to ground and charges the boost

capacitor from VL through diode D1. On the second

half-cycle, the switch-mode power supply turns on the

high-side MOSFET by closing an internal switch

between BST and DH. This provides the necessary

gate-to-source voltage to turn on the high-side switch,

an action that boosts the 5V gate-drive signal above

the input voltage.

Oscillator Frequency Selection (FREQ)

The FREQ pin can be used to select the switching frequency of the step-down regulator. Connect FREQ to

VL for 500kHz operation. Connect FREQ to AGND for

250kHz operation. The 500kHz operation minimizes the

size of the inductor and capacitors. The 250kHz operation improves efficiency by 2% to 3%.

Linear Regulator Controllers

The MAX1530/MAX1531 include three positive linear

regulator controllers, LR1, LR2, and LR3. These linear

regulator controllers can be used with external pass

transistors to regulate supplies for TFT LCDs. The

MAX1531 includes an additional positive linear regulator controller (LR4) and a negative linear regulator controller (LR5).

Low-Voltage Logic Regulator Controller (LR1)

LR1 is an analog gain block with an open-drain Nchannel output. It drives an external PNP pass transistor with a 6.8kΩ base-to-emitter resistor. Its guaranteed

base drive sink current is at least 3mA. The regulator

including transistor Q1 in Figure 1 uses a 10µF output

capacitor and is designed to deliver 500mA at 2.5V.

LR1 is typically used to generate low-voltage logic supplies for the timing controller and the digital sections of

the TFT LCD source/gate driver ICs.

LR1 is enabled when the soft-start of the main stepdown regulator is complete. (See the Startup Sequence

(ONL_,SEQ) section.) Each time it is enabled, the controller goes through a soft-start routine that ramps up its

internal reference DAC. (See the Soft-Start section.)

Gamma Regulator Controller (LR2)

LR2 is an analog gain block with an open-drain Nchannel output. It drives an external PNP pass transistor with a 6.8kΩ base-to-emitter resistor. Its guaranteed

base drive sink current is at least 2mA. The regulator

including transistor Q2 in Figure 1 uses a 0.47µF output

capacitor and is designed to deliver 50mA at 9.7V.

Page 20

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

20 ______________________________________________________________________________________

LR2 is typically used to generate the TFT LCD gamma

reference voltage, which is usually 0.3V below the

source drive supply voltage.

LR2 is enabled when the step-down regulator is

enabled and the voltage on ONL2 exceeds ONL2 input

threshold (1.238V typ). (See the Startup Sequence

(ONL_,SEQ) section.) Each time it is enabled, the controller goes through a soft-start routine that ramps up its

internal reference DAC. (See the Soft-Start section).

Linear Regulator Controller (LR3)

LR3 is an analog gain block with an open-drain Nchannel output. It drives an external PNP pass transistor with a 6.8kΩ base-to-emitter resistor. Its guaranteed

base drive sink current is at least 2mA. The regulator,

including Q3 in Figure 1, uses a 0.47µF output capacitor and is designed to deliver 20mA at 25V. The regulator including Q3 in Figure 2 uses a 4.7µF output

capacitor and is designed to deliver 500mA at 10V.

For the MAX1531 (Figure 1), LR3 is typically used to generate the TFT LCD gate driver’s gate-on voltage. A sufficient input voltage can be produced using a

charge-pump circuit as shown in Figure 1. Note that the

voltage rating of the DRV3 output is 28V. If higher voltages are present, an external cascode NPN transistor

(Q6) should be used with the emitter connected to

DRV3, the base to VIN(which is the connection point of

C1 and R12 in Figure 1), and the collector to the base of

the PNP pass transistor (Figure 1). For the MAX1530

(Figure 2), LR3 is typically used to generate the TFT LCD

source drive supply voltage. The input for this regulator

can come directly from the input supply, be produced

from an external step-up regulator, or from an extra winding coupled to the main step-down regulator inductor.

LR3 is enabled when the step-down regulator is

enabled and the voltage on ONL3 exceeds the ONL3

input threshold (1.238V typ). (See the Startup Sequence

(ONL_,SEQ) section.) Each time it is enabled, the controller goes through a soft-start routine that ramps up its

internal reference DAC. (See the Soft-Start section.)

Source Drive Regulator Controller (LR4)

(MAX1531 Only)

LR4 is an analog gain block with an open-drain Nchannel output. It drives an external PNP pass transistor with a 1.5kΩ base-to-emitter resistor. Its guaranteed

base drive sink current is at least 10mA. The regulator

including Q4 in Figure 1 uses a 4.7µF output capacitor

and is designed to deliver 500mA at 10V. The regulator’s fast transient response allows it to handle brief

peak currents up to 2A.

LR4 is typically used to generate the TFT LCD source

drive supply voltage. The input for this regulator can

come directly from the input supply, be produced from

an external step-up regulator, or from an extra winding

coupled to the main step-down regulator inductor.

LR4 is enabled when the step-down regulator is

enabled and the voltage on ONL4 exceeds the ONL4

input threshold (1.238V typ). (See the Startup

Sequence (ONL_,SEQ) section.) Each time it is

enabled, the regulator goes through a soft-start routine

that ramps up its internal reference DAC from 0V to

1.238V (typ). (See the Soft-Start section.)

The standard application circuit in Figure 1 powers the

LR4 regulator directly from the input supply and uses

the MAX1531’s general-purpose overcurrent protection

function to protect the input supply from excessive load

currents. (See the Overcurrent Protection section.)

Gate-Off Regulator Controller (LR5) (MAX1531 Only)

LR5 is an analog gain block with an open-drain P-channel output. It drives an external NPN pass transistor

with a 6.8kΩ base-to-emitter resistor. Its guaranteed

base drive sink current is at least 2mA. The regulator

including Q5 in Figure 1 uses a 0.47µF output capacitor

and is designed to deliver 10mA at -10V.

LR5 is typically used to generate the TFT LCD gate driver’s gate-off voltage. A negative input voltage can be

produced using a charge-pump circuit as shown in

Figure 1. Use as many stages as necessary to obtain

the required output voltage.

LR5 is enabled when the step-down regulator is

enabled and the voltage on ONL5 exceeds the ONL5

input threshold (1.238V typ). (See the Startup

Sequence (ONL_,SEQ) section.) Each time it is

enabled, the regulator goes through a soft-start routine

that ramps down its internal reference DAC from VL to

125mV (typ). (See the Soft-Start section.)

Internal 5V Linear Regulator (VL)

All MAX1530/MAX1531 functions, except the thermal

sensor, are internally powered from the on-chip, lowdropout 5V regulator. The maximum regulator input

voltage (VIN) is 28V. Bypass the regulator’s output (VL)

with at least a 1µF ceramic capacitor to AGND. The

VIN-to-VL dropout voltage is typically 200mV, so when

V

IN

is less than 5.2V, VL is typically VIN- 200mV. The

internal linear regulator can source up to 30mA to supply the device, power the low-side gate driver, charge

the external boost capacitor, and supply small external

loads. When driving particularly large MOSFETs, little or

no regulator current may be available for external

Page 21

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

______________________________________________________________________________________ 21

loads. For example, when switched at 500kHz, large

MOSFETs with a total of 40nC total gate charge would

require 40nC × 500kHz, which is approximately 20mA.

On/Off Control (EN)

The EN pin has an accurate 1.238V (typ) rising threshold with 5% hysteresis. The accurate threshold allows it

to be used to monitor the input voltage or other analog

signals of interest. If VENvoltage is less than its threshold, then the step-down regulator and all linear regulators are turned off. VL and the internal reference remain

active when EN is low to allow an accurate EN threshold. A rising edge on the pin clears any latched faults

except for a thermal fault, which is cleared only by

cycling the input power.

Undervoltage Lockout

If VL drops below 3.4V (typ), the MAX1530/MAX1531

assume that the supply voltage is too low to make valid

decisions. Therefore, the undervoltage lockout (UVLO)

circuitry turns off all the internal bias supplies. Switching

is inhibited, and the DL and DH gate drivers are forced

low. After VL rises above 3.5V (typ), the fault and thermal

shutdown latches are cleared and startup begins if EN is

above its threshold.

Startup Sequence (ONL_, SEQ)

The MAX1530/MAX1531 are not enabled unless all four

of the following conditions are met: 1) VL exceeds the

UVLO threshold, 2) EN is above 1.238V, 3) the fault

latch is not set, and 4) the thermal shutdown latch is not

set. After all four conditions are met, the step-down controller starts switching and enables soft-start (Figure 5).

After the step-down regulator soft-start is done, the lowvoltage logic linear regulator controller (LR1) soft-starts.

The remaining linear regulator controllers and the

sequence block that can be used to control them are

enabled at the same time as the step-down regulator.

The SEQ logic input is used in combination with the

ONL_ pins to control the startup sequence. When SEQ

is high and the sequence block is enabled, each ONL_

pin sources 2µA (typ). When the voltage on an ONL_

pin reaches 1.238V (typ), its respective linear regulator

controller (LR_) is enabled. When SEQ is low or the

sequence block is not enabled, each ONL_ pin is connected to ground through a 1.5kΩ internal MOSFET.

The sequence block allows the user to program the

startup of LR2 to LR5 in any desired sequence. If no

capacitor is placed on an ONL_ pin, its LR_ controller

starts immediately after the sequence block is enabled

and SEQ goes high. Placing a 1.5nF capacitor on an

ONL_ pin provides about 1ms delay for the respective

LR_ controller. Placing different size capacitors on

each ONL_ pin allows any arbitrary startup sequence.

An arbitrary startup sequence can also be created with

a single capacitor (Figure 6). Capacitor C1, together

with the 8µA current (2µA per ONL_ pin), is chosen to

provide the desired delay for the controller that starts

last (ONLd). Using 0.1µF for C1 provides about 16ms

Figure 6. Single-Capacitor Sequence Configuration

Figure 5. Startup Conditions

EN > 1.24V

AND

STEP-DOWN

REGULATOR

STARTUP

STEP-DOWN

SOFT-START

LR1

STARTUP

DONE

VL > 3.5V

LR2

STARTUP

SEQUENCE

BLOCK

ENABLED

ONL3 > 1.24V

LR3

STARTUP

SEQ = HIGH

LR4

STARTUP

ONL_

CURRENT

SOURCES ON

ONL5 > 1.24VONL2 > 1.24V ONL4 > 1.24V

LR5

STARTUP

SEQ

1.238V

LRa

LRb

LRc

LRd

ONLa ONLb ONLc ONLd

R3

150kΩ

5V

ONL_

0V

OFF

OFF

OFF

OFF

16ms

R2

75kΩ

ONLa ONLb ONLc ONLd

R1

51kΩ

ON

ON

ON

ON

C1

0.1µF

OFF

OFF

OFF

OFF

Page 22

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

22 ______________________________________________________________________________________

total delay. Because of the 6µA current flowing through

R1 (51kΩ), the voltage on ONLc is 0.31V greater than

the voltage on ONLd and it crosses the 1.238V threshold and enables its LR_ controller about 4ms before

ONLd’s controller. Similarly, the 4µA current through R2

(75kΩ) and the 2µA current through R3 (150kΩ) cause

their LR_ controllers to each start about 4ms before the

next one. Any desired sequence and delay can be programmed by calculating the charge rate of C1 and voltage drops across R1 through R3.

Soft-Start

The soft-start function controls the slew rate of the output voltages and reduces inrush currents during startup. Each regulator (step-down, LR1 to LR5) goes

through a soft-start routine after it is enabled. During

soft-start, the reference voltage for each positive regulator gradually ramps up from 0V to the internal reference in 32 steps. The reference voltage of the negative

regulator ramps down from VL to 125mV in 32 steps.

The total soft-start period for each regulator is 1024

clock cycles for 250kHz switching frequency and 2048

clock cycles for 500kHz switching frequency.

Reset

The MAX1530/MAX1531 include an open-drain timed

microprocessor supervisor function to ensure proper

startup of digital circuits. The RESET output asserts low

whenever RSTIN is less than the RSTIN trip threshold.

RESET also asserts low when VL is less than the VL

UVLO threshold, EN is low, or the thermal, undervoltage or overcurrent fault latches are set. RESET enters

the high-impedance state only after RSTIN remains

above the trip threshold for the duration of the reset

timeout period. The state of RESET has no effect on

other portions of the IC.

The RSTIN threshold (1.114V typ) is designed to allow

RSTIN to directly connect to any of the MAX1530/

MAX1531s’ feedback input pins, eliminating the need

for an additional resistive divider. Typically, RSTIN is

connected to FB or FBL1 to monitor the supply voltage

for digital logic ICs, but it can be used to monitor any

desired output voltage or it can even be used as a general-purpose comparator.

Fault Protection

Undervoltage Protection

After its soft-start is done, if the output of the main stepdown regulator or any of the linear-regulator outputs

(LR1 to LR5) are below 90% of their normal regulation

point, the MAX1530/MAX1531 activate an internal fault

timer. If the fault condition remains continuously for the

entire fault timer duration, the MAX1530/MAX1531 set

the fault latch, shutting down all the regulator outputs.

Undervoltage faults do not turn off VL. Once the fault

condition is removed, cycling the input voltage or

applying a rising edge on SEQ or EN clears the fault

latch and reactivates the device.

Thermal Protection

The thermal protection limits total power dissipation in

the MAX1530/MAX1531. If the junction temperature

exceeds +160°C, a thermal sensor immediately sets the

thermal fault latch, shutting off all the IC’s outputs

including VL, allowing the device to cool down. The only

way to clear the thermal fault latch is to cycle the input

voltage after the device cools down by at least 15°C.

Overcurrent Protection Block (CSH, CSL)

(MAX1531 Only)

The MAX1531 includes an uncommitted overcurrent

protection block that can be used to measure any input

or output current, using a current-sense resistor or

other sense element. If the measured current exceeds

the overcurrent protection threshold (300mV typ), the

MAX1531 immediately sets the undervoltage fault latch,

shutting down all the regulator outputs. Overcurrent

faults do not turn off VL. An internal lowpass filter prevents large current transients of short duration (less

than 50µs) from setting the latch. Once the overcurrent

condition is removed, cycling the input voltage clears

the fault latch and reactivates the device. A rising edge

on SEQ or EN also clears the fault latch.

In Figure 1’s circuit, the overcurrent protection is used

with the LR4 source driver regulator since that regulator

is powered directly from the input supply and has no

current limit of its own. The current-sense resistor is

placed in series with the input supply, before the linear

regulator’s external PNP pass transistor. CSH and CSL

are connected to the positive and negative sides of the

sense resistor.

Design Procedures

Main Step-Down Regulator

Inductor Selection

Three key inductor parameters must be specified:

inductance value (L), peak current (I

PEAK

), and DC

resistance (R

DC

). The following equation includes a

constant, LIR, which is the ratio of peak-to-peak inductor ripple current to DC load current. A higher LIR value

allows smaller inductance, but results in higher losses

and higher ripple. A good compromise between size

and losses is typically found at a 30% ripple current to

Page 23

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

______________________________________________________________________________________ 23

load current ratio (LIR = 0.3), which corresponds to a

peak inductor current 1.15 times the DC load current:

where I

LOAD(MAX)

is the maximum DC load current,

and the switching frequency fSWis 500kHz when FREQ

is tied to VL, and 250kHz when FREQ is tied to AGND.

The exact inductor value is not critical and can be

adjusted to make trade-offs among size, cost, and efficiency. Lower inductor values minimize size and cost,

but they also increase the output ripple and reduce the

efficiency due to higher peak currents. On the other

hand, higher inductor values increase efficiency, but at

some point increased resistive losses due to extra turns

of wire will exceed the benefit gained from lower AC

current levels.

The inductor’s saturation current must exceed the peak

inductor current. The peak current can be calculated by:

The inductor’s DC resistance should be low for good

efficiency. Find a low-loss inductor having the lowest

possible DC resistance that fits in the allotted dimensions. Ferrite cores are often the best choice, though

powdered iron is inexpensive and can work well at

250kHz. Shielded-core geometries help keep noise,

EMI, and switching waveform jitter low.

MOSFET Selection and Current-Limit Setting

The MAX1530/MAX1531s’ step-down controller drives

two external logic-level N-channel MOSFETs. Since the

R

DS(ON)

of each MOSFET is used as a sense resistor to

provide current-sense signals to the PWM, their

R

DS(ON)

values are important considerations in component selection.

The R

DS(ON)

of the high-side MOSFET (N1) provides an

inductor current-sense signal for current-mode operation and also provides a crude maximum current limit

during the high-side on-time that prevents runaway currents if the inductor saturates. The MOSFET voltage is

measured across the high-side MOSFET from V

IN

to LX

and is limited to 400mV (typ). To ensure the desired

output current with sufficient margin, choose a MOSFET

with R

DS(ON)

low enough that the peak current does

not generate more than 340mV across the MOSFET,

even when the MOSFET is hot. If the MOSFET’s

R

DS(ON)

is not specified at a suitable temperature, use

the maximum room temperature specification and add

0.5% per °C for the R

DS(ON)

increase with temperature:

To ensure stable operation of the current-mode PWM,

the minimum current-sense ripple signal should exceed

12mV. Since this value depends on the minimum

R

DS(ON)

of the high-side MOSFET, which is not typically a specified parameter, a good rule of thumb is to

choose the typical room temperature R

DS(ON)

about 2

times the amount needed for this:

For example, Figure 1’s circuit is designed for 1.5A and

uses a dual MOSFET (N1) for both the high-side and

low-side MOSFETs. Its maximum R

DS(ON)

at room tem-

perature is 145mΩ and an estimate of its maximum

R

DS(ON)

at our chosen maximum temperature of +85°C

is 188mΩ. Since the inductor ripple current is 0.5A, the

peak current through the MOSFET is 1.75A. So the maximum peak current-sense signal is 330mV, which is less

than 340mV. Using the typical R

DS(ON)

of 113mΩ and

the ripple current of 0.5A, the current ripple signal for the

PWM is 56mV, much greater than the required 24mV.

The R

DS(ON)

of the low-side MOSFET (also N1) provides current-limit information during the low-side ontime that inhibits a high-side on-time if the MOSFET

voltage is too high. The voltage is measured across the

low-side MOSFET from PGND to LX and the threshold

is set by ILIM. To use the preset 250mV (typ) threshold,

connect ILIM to VL and choose a MOSFET with

R

DS(ON)

low enough that the “valley” current does not

generate more than 190mV across the MOSFET, even

when the MOSFET is hot. If the MOSFET’s R

DS(ON)

is

not specified at a suitable temperature, use the maximum room temperature specification and add 0.5% per

°C for the R

DS(ON)

increase with temperature:

If the MOSFET’s R

DS(ON)

is lower than necessary, there

is no need to adjust the current-limit threshold using

ILIM. If the MOSFET’s R

DS(ON)

is too high, adjust the

current-limit threshold using a resistive-divider between

VVV

×−

()

OUT IN OUT

=

V f I LIR

×× ×

IN SW LOAD MAX

()

L

I

RIPPLE

II

PEAK LOAD MAX

VVV

×−

()

OUT IN OUT

=

fLV

××

SW IN

I

=+

()

RIPPLE

2

IR mV

×<

PEAK DS ON HOT

()_

340

IR mV

RIPPLE DS ON TYP

×>

()_

24

IR mV

VALLEY DS ON HOT

III

VALLEY OUT RIPPLE

=−

×<

()_

/

190

2

Page 24

MAX1530/MAX1531

Multiple-Output Power-Supply Controllers for

LCD Monitors

24 ______________________________________________________________________________________

VL and AGND at ILIM. The threshold is approximately

1/5th the voltage on ILIM over a range of 0.25V to 3V:

K is the accuracy of the current-limit threshold, which is

20% when the threshold is 250mV.

For example, Figure 1’s N1 MOSFET has a maximum

R

DS(ON)