Page 1

General Description

The MAX1522/MAX1523/MAX1524 are simple, compact

boost controllers designed for a wide range of DC-DC

conversion topologies, including step-up, SEPIC, and

flyback applications. They are for applications where

extremely low cost and small size are top priorities.

These devices are designed specifically to provide a

simple application circuit and minimize the size and

number of external components, making them ideal for

PDAs, digital cameras, and other low-cost consumer

electronics applications.

These devices use a unique fixed on-time, minimum offtime architecture, which provides excellent efficiency

over a wide-range of input/output voltage combinations

and load currents. The fixed on-time is pin selectable to

either 0.5µs (50% max duty cycle) or 3µs (85% max

duty cycle), permitting optimization of external component size and ease of design for a wide range of output

voltages.

The MAX1522/MAX1523 operate from a +2.5V to +5.5V

input voltage range and are capable of generating a

wide range of outputs. The MAX1524 is intended for

bootstrapped operation, permitting startup with lower

input voltage. All devices have internal soft-start and

short-circuit protection to prevent excessive switching

current during startup and under output fault conditions. The MAX1522/MAX1524 have a latched fault

mode, which shuts down the controller when a shortcircuit event occurs, whereas the MAX1523 reenters

soft-start mode during output fault conditions. The

MAX1522/MAX1523/MAX1524 are available in a spacesaving 6-pin SOT23 package.

________________________Applications

____________________________Features

♦ Simple, Flexible Application Circuit

♦ 2-Cell NiMH or Alkaline Operation (MAX1524)

♦ Low Quiescent Current (25µA typ)

♦ Output Fault Protection and Soft-Start

♦ High Efficiency Over 1000:1 I

OUT

Range

♦ Pin-Selectable Maximum Duty Factor

♦ Micropower Shutdown Mode

♦ Small 6-Pin SOT23 Package

♦ No Current-Sense Resistor

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

________________________________________________________________ Maxim Integrated Products 1

__________Typical Operating Circuit

19-1926; Rev 0; 2/01

For price, delivery, and to place orders, please contact Maxim Distribution at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

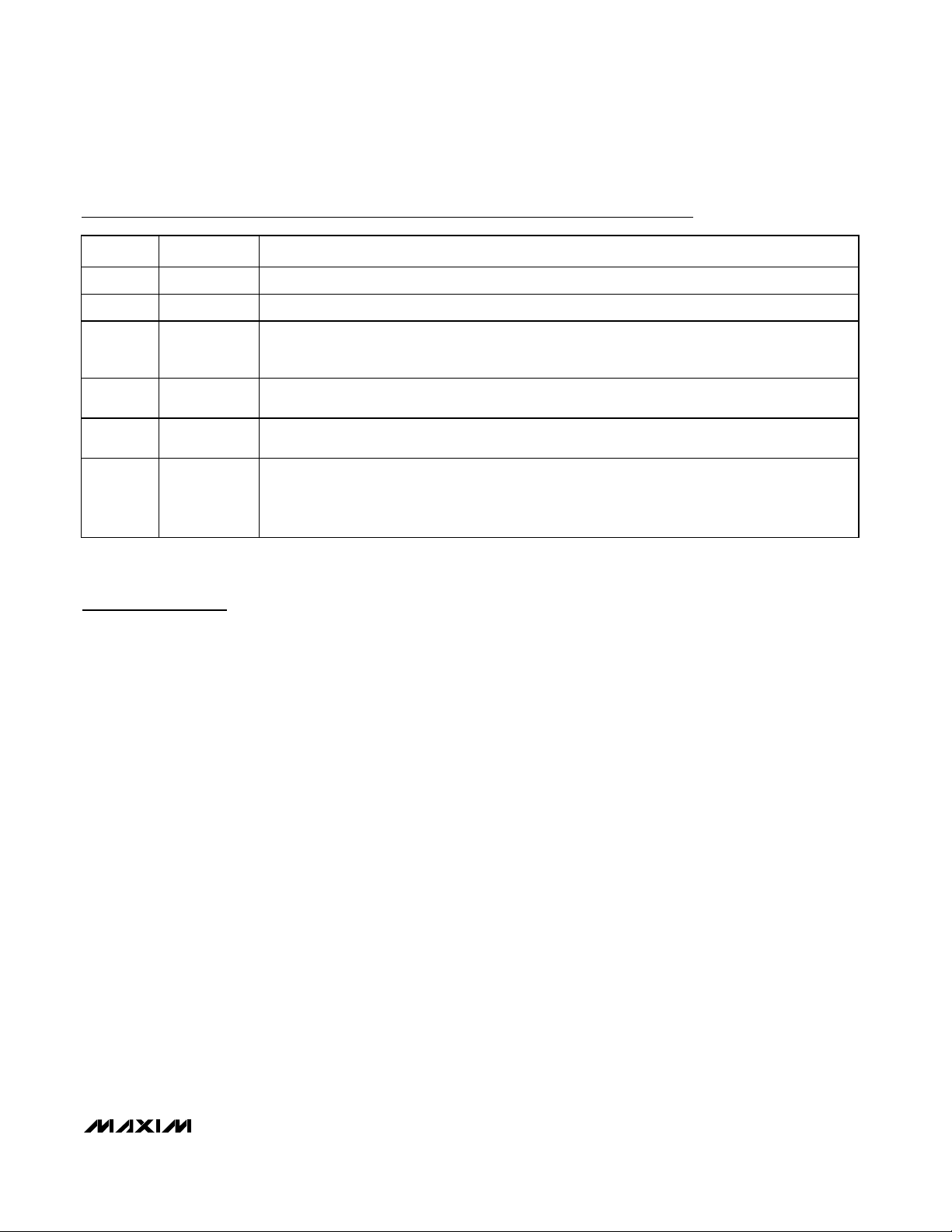

PART

TEMP. RANGE

PINPACKAGE

TOP

MARK

MAX1522EUT-T

6 SOT23-6

AAOX

MAX1523EUT-T

6 SOT23-6

AAOY

MAX1524EUT-T

6 SOT23-6

AAOZ

Ordering Information

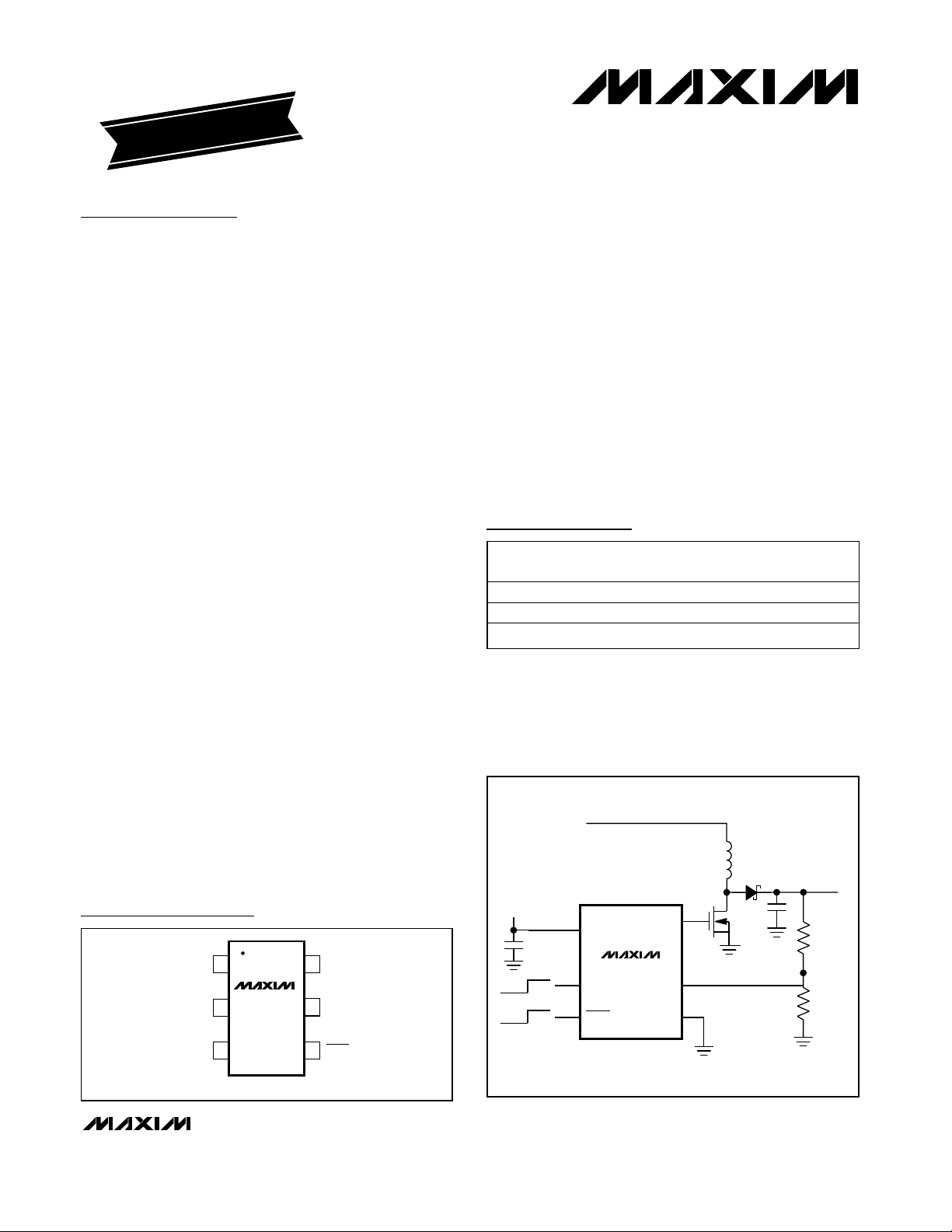

Pin Configurations

FB

SHDNSET

16V

CC

5 EXT

GND

MAX1522

MAX1523

MAX1524

SOT23-6

TOP VIEW

2

34

Low-Cost, High-Current,

or High-Voltage Boost

Conversion

LCD Bias Supplies

Industrial +24V and +28V

Power Supplies

Low-Cost, Multi-Output

Flyback Converters

SEPIC Converters

Low-Cost Battery-

Powered Applications

-40°C to +85°C

-40°C to +85°C

-40°C to +85°C

INPUT

OUTPUT

V

CC

6

V

CC

EXT

5

N

MAX1522

3

MAX1523

4

SET

SHDN

MAX1524

50% 85%

OFF ON

GND

2

FB

1

Page 2

Simple SOT23 Boost Controllers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= SHDN = 3.3V, SET = GND , TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: Actual startup voltage is dependent on the external MOSFET’s V

GS(TH)

.

Note 2: Specification applies after soft-start mode is completed.

V

CC

, FB, SHDN, SET to GND...................................-0.3V to +6V

EXT to GND................................................-0.3V to (V

CC

+ 0.3V)

Continuous Power Dissipation (TA= +70°C)

6-Pin SOT23 (derate 8.7mW/°C above +70°C) ..........696mW

Operating Temperature Range ..........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range.............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

VCC Operating Voltage Range 2.5 5.5 V

MAX1522/MAX1523 2.5

V

CC

Minimum Startup Voltage

f

EXT

> 100kHz, MAX1524 (Note 1), bootstrap required 1.5

V

VCC rising

Undervoltage Lockout

Threshold

V

CC

falling

V

V

CC

Supply Current No load, nonbootstrapped 25 50 µA

V

CC

Shutdown Current SHDN = GND

1µA

SET = GND 0.4 0.5 0.6

Fixed tON Time VFB =1.2V

SET = V

CC

2.4 3.0 3.6

µs

VFB > 0.675V 0.5

Minimum t

OFF

Time

V

FB

< 0.525V 1.0

µs

SET = GND 45 50 55

Maximum Duty Factor

SET = V

CC

80 85 90

%

FB Regulation Threshold

(Note 2)

V

CC

= +2.5V to +5.5V

V

FB Undervoltage Fault

Threshold (Note 2)

FB falling

575 625 mV

FB Input Bias Current VFB = 1.3V 6 50 nA

EXT high 2 4

EXT Resistance I

EXT

= 20mA

EXT low 1.5 3

Ω

Soft-Start Ramp Time 2.2 3.2 4.2 ms

Logic Input High VCC = +2.5V to +5.5V, SET, SHDN 1.6 V

Logic Input Low VCC = +2.5V to +5.5V, SET, SHDN 0.4 V

Logic Input Leakage Current SET, SHDN = VCC or GND -1 +1 µA

MAX1522/MAX1523/MAX1524

2.37 2.47

2.20 2.30

0.001

1.23 1.25 1.27

525

Page 3

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

_______________________________________________________________________________________ 3

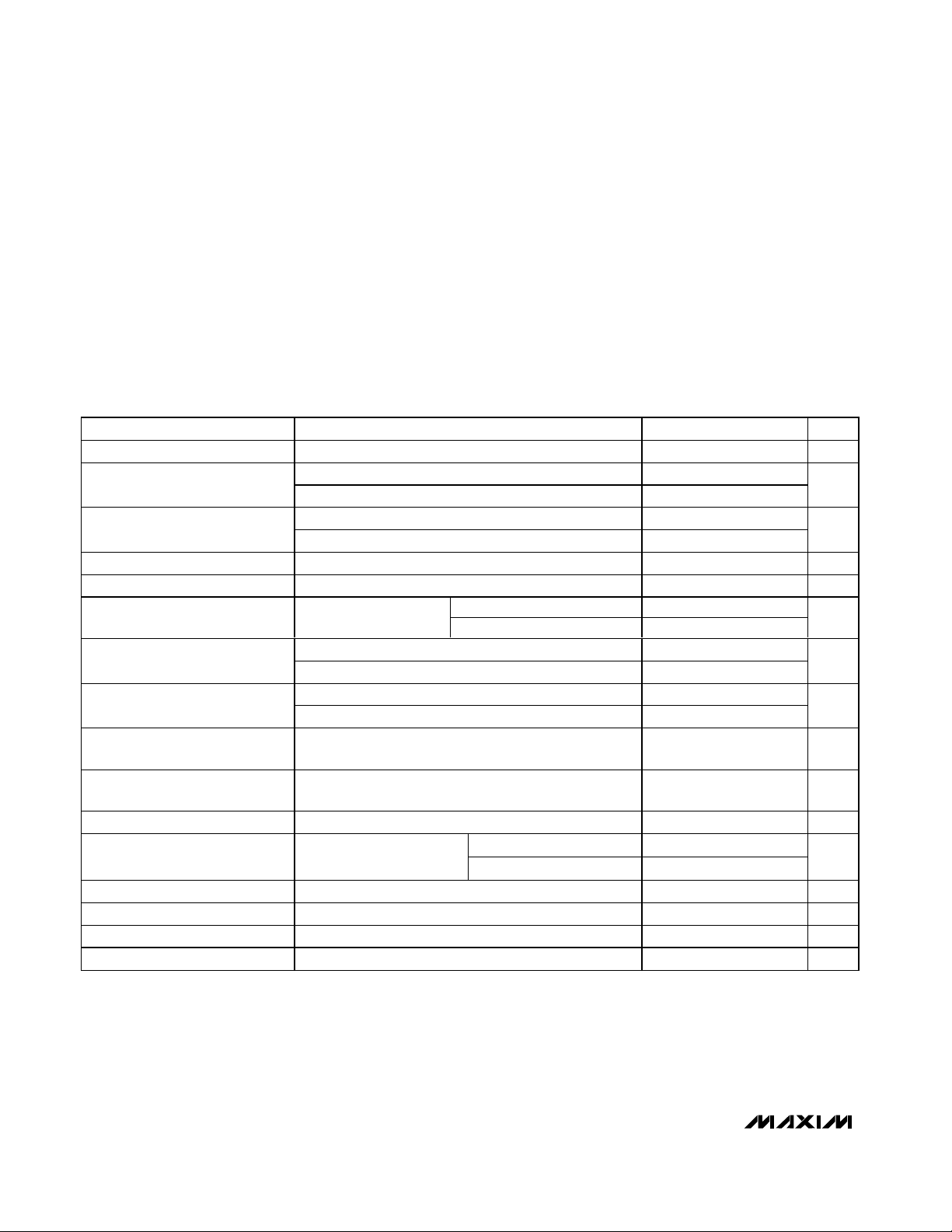

100

50

0.1 1 100 1000

EFFICIENCY vs. LOAD CURRENT

(DESIGN EXAMPLE 1)

70

80

90

MAX1522/3/4 toc01

LOAD CURRENT (mA)

EFFICIENCY (%)

10

60

V

OUT

= +5V

V

IN

= 3.3V

100

50

0.1 1 100 1000

EFFICIENCY vs. LOAD CURRENT

(DESIGN EXAMPLE 2)

70

80

90

MAX1522/3/4 toc02

LOAD CURRENT (mA)

EFFICIENCY (%)

10

60

VIN = +4.2V

VIN = +3.6V

VIN = +2.7V

V

OUT

= +12V

100

50

0.1 1 100 1000

EFFICIENCY vs. LOAD CURRENT

(DESIGN EXAMPLE 3)

70

80

90

MAX1522/3/4 toc03

LOAD CURRENT (mA)

EFFICIENCY (%)

10

60

VIN = +2.4V

VIN = +1.8V

VIN = +3V

MAX1524

V

OUT

= +5V

100

50

0.1 1 100

EFFICIENCY vs. LOAD CURRENT

(DESIGN EXAMPLE 4)

70

80

90

MAX1522/3/4 toc04

LOAD CURRENT (mA)

EFFICIENCY (%)

10

60

VIN = +4.2V

VIN = +2.7V

VIN = +3.6V

V

OUT

= +24V

100

50

0.1 1 100

EFFICIENCY vs. LOAD CURRENT

(DESIGN EXAMPLE 5)

70

80

90

MAX1522/3/4 toc05

LOAD CURRENT (mA)

EFFICIENCY (%)

10

60

VIN = +3.0V

VIN = +2.4V

VIN = +1.8V

MAX1524

V

OUT

= +3.3V

1.75

1.50

1.25

1.00

0.75

05025 75 100

STARTUP INPUT VOLTAGE

vs. OUTPUT CURRENT

MAX1522/3/4 toc06

LOAD CURRENT (mA)

STARTUP VOLTAGE (V)

V

OUT

= +3.3V

BOOTSTRAPPED

RESISTIVE LOADS

10

0.0001

01 3 4

NO-LOAD INPUT CURRENT

vs. INPUT VOLTAGE

0.01

0.1

1

MAX1522/3/4 toc07

INPUT VOLTAGE (V)

INPUT CURRENT (mA)

2

0.001

NONBOOTSTRAPPED

BOOTSTRAPPED

5

400ns/div

SWITCHING WAVEFORM

(CONTINUOUS CONDUCTION)

VIN = +3.3V, V

OUT

= +5V, I

OUT

= 350mA

A : V

OUT

, 200mV/div, AC-COUPLED

B : V

LX

, 5V/div

C : I

L

, 0.5A/div

A

C

B

MAX1522/3/4 toc08

4µs/div

SWITCHING WAVEFORM

(DISCONTINUOUS CONDUCTION)

VIN = +3.3V, V

OUT

= +24V, I

OUT

= 10mA

A : V

OUT

, 200mV/div, AC-COUPLED

B : V

LX

, 10V/div

C : I

L

, 0.5A/div

A

C

B

MAX1522/3/4 toc09

Typical Operating Characteristics

(TA= +25°C, unless otherwise noted.)

Page 4

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

4 _______________________________________________________________________________________

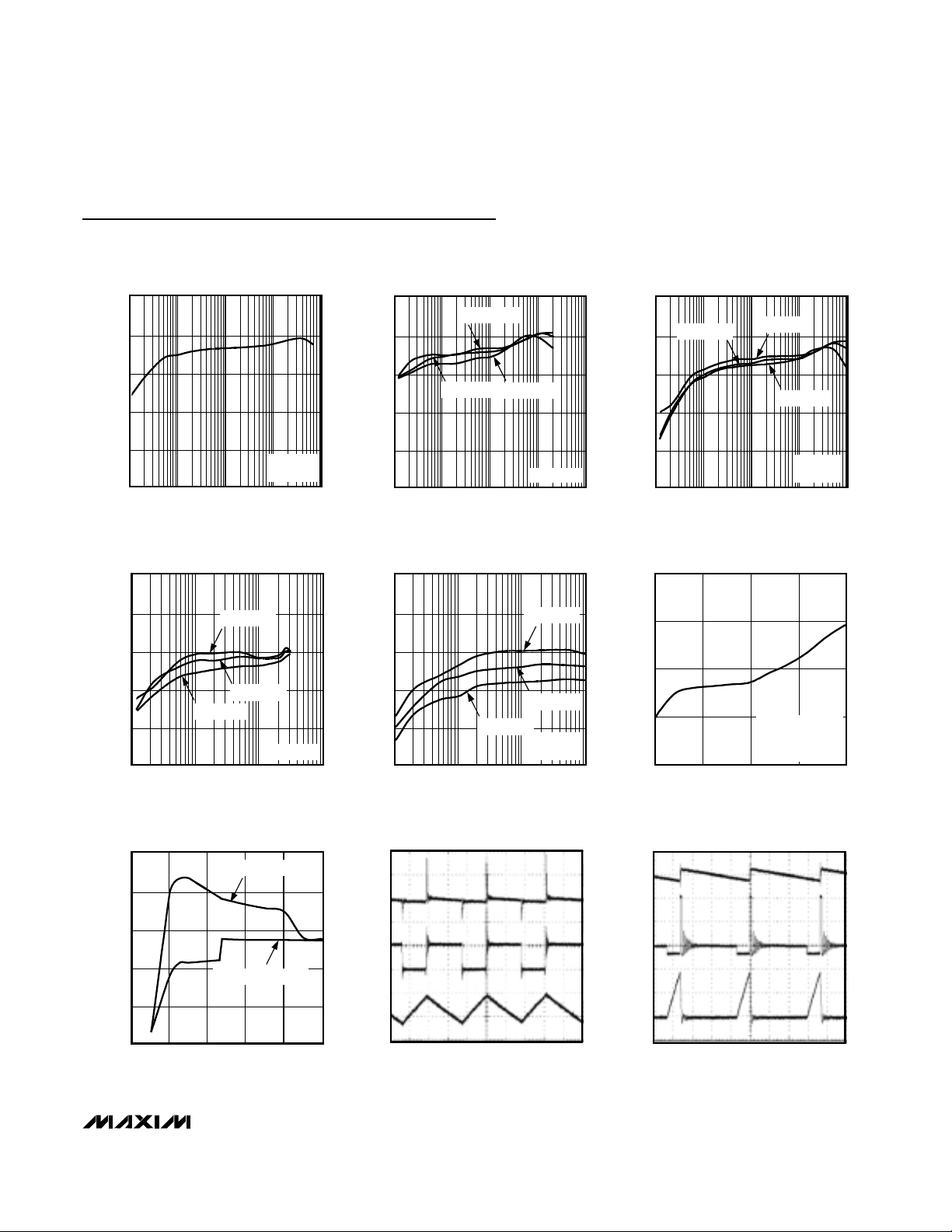

Typical Operating Characteristics (continued)

(TA= +25°C, unless otherwise noted.)

400µs/div

SOFT-START RESPONSE

200Ω RESISTIVE LOAD

A : V

OUT

, 5V/div

B : V

SHDN

, 5V/div

C : I

L

, 1A/div

A

C

B

MAX1522/3/4 toc10

400µs/div

FAULT-DETECTION RESPONSE

A : V

OUT

, 10V/div

B : V

EXT

, 5V/div

C : I

L

, 5A/div

A

C

B

MAX1522/3/4 toc11

MAX1522

40µs/div

LINE-TRANSIENT RESPONSE

VIN = +3.5V TO +4.0V, V

OUT

= +12V, I

OUT

= 60mA

A : V

IN,

500mV/div, AC-COUPLED

B : V

OUT,

10mV/div, AC-COUPLED

A

B

MAX1522/3/4 toc12

100µs/div

LOAD-TRANSIENT RESPONSE

VIN = +3.3V, V

OUT

= +12V, I

OUT

= 30mA TO 120mA

A : I

OUT,

100mA/div

B : V

OUT,

100mV/div, AC-COUPLED

A

B

MAX1522/3/4 toc13

Page 5

Detailed Description

The MAX1522/MAX1523/MAX1524 are simple, compact boost controllers designed for a wide range of

DC-DC conversion topologies including step-up,

SEPIC, and flyback applications. These devices are

designed specifically to provide a simple application

circuit with a minimum of external components and are

ideal for PDAs, digital cameras, and other low-cost

consumer electronics applications.

These devices use a unique fixed on-time, minimum

off-time architecture, which provides excellent efficiency over a wide range of input/output voltage combinations and load currents. The fixed on-time is pin

selectable to either 0.5µs or 3µs, permitting optimization of external component size and ease of design for

a wide range of output voltages.

Control Scheme

The MAX1522/MAX1523/MAX1524 feature a unique

fixed on-time, minimum off-time architecture, which provides excellent efficiency over a wide range of

input/output voltage combinations. The fixed on-time is

pin selectable to either 0.5µs or 3µs for a maximum

duty factor of either 45% or 80%, respectively. An

inductor charging cycle is initiated by driving EXT high,

turning on the external MOSFET. The MOSFET remains

on for the fixed on-time, after which EXT turns off the

MOSFET. EXT stays low for at least the minimum off-

time, and another cycle begins when FB drops below

its 1.25V regulation point.

Bootstrapped vs. Nonbootstrapped

The VCCsupply voltage range of the MAX1522/

MAX1523/MAX1524 is +2.5V to +5.5V. The supply for

V

CC

can come from the input voltage (nonbootstrapped), the output voltage (bootstrapped), or an

independent regulator.

The MAX1522/MAX1523 are usually utilized in a nonbootstrapped configuration, allowing for high or low

output voltage operation. However, when both the input

and output voltages fall within the +2.5V to +5.5V

range, the MAX1522/MAX1523 may be operated in

nonbootstrapped or bootstrapped mode. Bootstrapped

mode provides higher gate-drive voltage to the MOSFET switch, reducing I2R losses in the switch, but will

also increase the VCCsupply current to charge and

discharge the gate. Depending upon the MOSFET

selected, there may be minor variation in efficiency vs.

load vs. input voltage when comparing bootstrapped

and nonbootstrapped configurations.

The MAX1524 is always utilized in bootstrapped configuration for applications where the input voltage range

extends down below 2.5V and the output voltage is

between 2.5V and 5.5V. VCCis connected to the output

(through a 10Ω series resistor) and receives startup

voltage through the DC current path from the input

through the inductor, diode, and 10Ω resistor. The

MAX1524 features a low-voltage startup oscillator that

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

_______________________________________________________________________________________ 5

Pin Description

PIN NAME FUNCTION

1 GND Ground

2 FB Feedback Input. Connect FB to external resistive voltage-divider. FB regulates to 1.25V.

3 SET

On-Time Control. Connect SET to V

CC

to set the fixed 3µs on-time (85% duty cycle). Connect SET to

GND to set the fixed 0.5µs on-time (50% duty cycle). See On-Time SET Input section for more

information.

4 SHDN

Shutdown Control Input. Drive SHDN high for normal operation. Drive SHDN low for low-power

shutdown mode. Driving SHDN low clears the fault latch of the MAX1522 and MAX1524.

5 EXT

External MOSFET Drive. EXT drives the gate of an external NMOS power FET and swings from V

CC

to GND.

6V

CC

Supply Voltage to the IC. Bypass VCC to GND with a 0.1µF capacitor. Connect VCC to a +2.5V to

+5.5V supply, which may come from V

IN

(nonbootstrapped) or V

OUT

(bootstrapped) or from the

output of another regulator. For bootstrapped operation, connect V

CC

to the output through a series

10Ω resistor.

Page 6

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

6 _______________________________________________________________________________________

guarantees startup with input voltages down to 1.5V at

VCC. The startup oscillator has a fixed 25% duty cycle

and will toggle the MOSFET gate and begin boosting

the output voltage. Once the output voltage exceeds

the UVLO threshold, the normal control circuitry is used

and the startup oscillator is disabled. However, N-channel MOSFETs are rarely specified for guaranteed

R

DS(ON)

with VGSbelow 2.5V; therefore, guaranteed

startup down to 1.5V input will be limited by the MOSFET specifications. Nevertheless, the MAX1524 bootstrapped circuit on the MAX1524 EV kit typically starts

up with input voltage below 1V and no load.

The MAX1522/MAX1523 may also be utilized by connecting VCCto the output of an independent voltage

regulator between 2.5V and 5.5V to allow operation with

any combination of low or high input and output voltages. In this case, the independent regulator must supply enough current to satisfy the I

GATE

current as

calculated in the

Power MOSFET Selection section

when considering the maximum switching frequency as

calculated in the CCM or DCM design procedure.

On-Time SET Input

The MAX1522/MAX1523/MAX1524 feature pin-selectable fixed on-time control, allowing their operation to

be optimized for various input/output voltage combinations. Connect SET to V

CC

for the 3µs fixed on-time.

Connect SET to GND for the 0.5µs fixed on-time.

The 3µs on-time setting (SET = V

CC

) permits higher

than 80% guaranteed maximum duty factor, providing

improved efficiency in applications with higher step-up

ratios (such as 3.3V boosting to 12V). This setting is

recommended for higher step-up ratio applications.

The 0.5µs on-time setting (SET = GND) permits higher

frequency operation, minimizing the size of the external

inductor and capacitors. The maximum duty factor is

limited to 45% guaranteed, making this setting suitable

for lower step-up ratios such as 3.3V to 5V converters.

Soft-Start

The MAX1522/MAX1523/MAX1524 have a unique softstart mode that reduces inductor current during startup,

reducing battery, input capacitor, MOSFET, and inductor stresses. The soft-start period is fixed at 3.2ms and

requires no external components.

Fault Detection

Once the soft-start period has expired, if the output

voltage falls to, or is less than, 50% of its regulation

value, a fault is detected. Under this condition, the

MAX1522 disables the regulator until either SHDN is

toggled low or power is removed and reapplied, after

which it attempts to power up again in soft-start. For the

MAX1523, the fault condition is not latched, and softstart is repetitively reinitiated until a valid output voltage

is realized. The MAX1524 has a latched fault detection,

but when bootstrapped, the latch will be cleared when

V

CC

falls below 2.37V.

Shutdown Mode

Drive SHDN to GND to place the MAX1522/MAX1523/

MAX1524 in shutdown mode. In shutdown, the internal

reference and control circuitry turn off, EXT is driven to

GND, the supply current is reduced to less than 1µA,

and the output drops to one diode drop below the input

voltage. Connect SHDN to VCCfor normal operation.

When exiting shutdown mode, the 3.2ms soft-start is

always initiated.

Undervoltage Lockout

The MAX1522/MAX1523 have undervoltage lockout

(UVLO) circuitry, which prevents circuit operation and

MOSFET switching when VCCis less than the UVLO

threshold (2.37V typ). The UVLO comparator has 70mV

of hysteresis to eliminate chatter due to VCCinput

impedance.

Applications Information

Setting the Output Voltage

The output voltage is set by connecting FB to a resistive voltage-divider between the output and GND

(Figures 1 and 2). Select feedback resistor R2 in the

30kΩ to 100kΩ range. R1 is then given by:

where VFB= 1.25V.

Design Procedure

Continuous vs. Discontinuous Conduction

A switching regulator is operating in continuous conduction mode (CCM) when the inductor current is not

allowed to decay to zero. This is accomplished by

selecting an inductor value large enough that the

inductor ripple current becomes less than one half of

the input current. The advantage of this mode is that

peak current is lower, reducing I2R losses and output

ripple.

In general, the best transient performance and most of

the ripple reduction and efficiency increase of CCM are

realized when the inductance is large enough to

reduce the ripple current to 30% of the input current at

maximum load. It is important to note that CCM circuits

operate in discontinuous conduction mode (DCM)

RR

V

V

OUT

FB

12 1=−

Page 7

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

_______________________________________________________________________________________ 7

under light loads. The selection of 30% ripple current

causes this to happen at loads less than approximately

1/6th of maximum load.

There are two common reasons not to run in CCM:

1) High output voltage. In this case, the output-to-

input voltage ratio exceeds the level obtainable

by the MAX1522/MAX1523/MAX1524s’ maximum duty

factor. Calculate the application’s maximum duty cycle

using the equation in the Calculate the Maximum Duty

Cycle section. If this number exceeds 80%, you will

have to design for DCM.

2) Small output current. If the maximum output current

is very small, the inductor required for CCM may be

disproportionally large and expensive. Since I2R losses

are not a concern, it may make sense to use a smaller

inductor and run in DCM. This typically occurs when

the load current times the output-to-input voltage ratio

drops below a few hundred milliamps, although this

also depends on the external components.

Calculate the Maximum Duty Cycle

The maximum duty cycle of the application is given by:

where VDis the forward voltage drop of the Schottky

diode (about 0.5V).

Design Procedure for CCM

On-Time Selection

For CCM to occur, the MAX1522/MAX1523/MAX1524

must be able to exceed the application’s maximum

duty cycle. For applications up to 45% duty cycle, con-

nect SET to GND for 0.5µs on-time to get fast switching

and a smaller inductor. For applications up to 80% duty

cycle, it is necessary to connect SET to VCCfor 3.0µs

on-time. For applications greater than 80% duty cycle,

CCM operation is not guaranteed; see the Design

Procedure for DCM section.

Switching Frequency

A benefit of CCM is that the switching frequency

remains high as the load is reduced, whereas in DCM

the switching frequency varies directly with load. This is

important in applications where switching noise needs

to stay above the audio band. The medium- and heavyload switching frequency in CCM circuits is given by:

Note that f

SWITCHING

is not a function of load and

varies primarily with input voltage. However, when the

load is reduced, a CCM circuit drops into DCM, and

the frequency becomes load dependent:

Calculate the Peak Inductor Current

For CCM, the peak inductor current is given by:

I

VV

V

I

PEAK

OUT D

IN MIN

LOAD MAX

=×

+

×115.

()

()

ƒ≈×

+−

+

×

×

−SWITCHING LIGHT LOAD

ON

OUT D IN

OUT D

LOAD

LOAD MAX

t

VVV

VV

I

I

()

()

.1018

ƒ=×

+−

+

SWITCHING

ON

OUT D IN

OUT D

t

VVV

VV

1

DutyCycle

VVV

VV

MAX

OUT D INMIN

OUT D

()

=

+−

+

×

()

%100

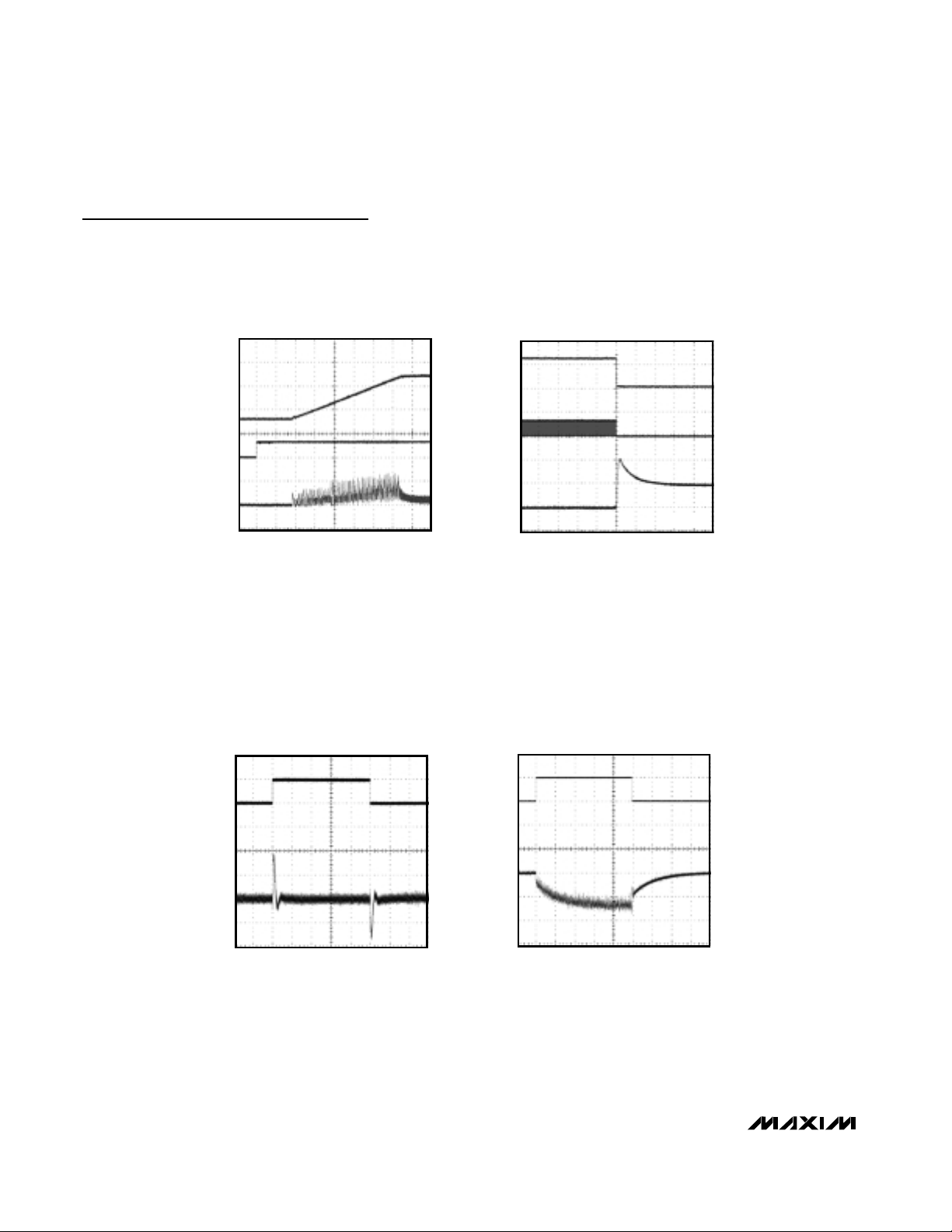

MAX1522

MAX1523

INPUT

2.7V TO 4.2V

C3

0.1µF

OFF ON

6

3

4

5

2

1

V

CC

EXT

SET FB

SHDN GND

C1

10µF

6.3V

L1

33µH

CDR74B-330

D1

MBR0530T3

Q1

FDC633N

R1

130kΩ

1%

OUTPUT

12V

C2

33µF

TPSD336M020R0200

C

FB

220pF

C

FF

220pF

R1

15.0kΩ

1%

Figure 1. MAX1522/MAX1523 Standard Operating Circuit

Page 8

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

8 _______________________________________________________________________________________

Inductor Selection

For CCM, the ideal inductor value is given by:

If L

IDEAL

is not a standard value, choose the next-closest value, either higher or lower. Nominal values within

50% are acceptable. Values lower than ideal will have

slightly higher peak inductor current; values greater

than ideal will have slightly lower peak inductor current.

Due to the MAX1522/MAX1523/MAX1524s’ high switching frequencies, inductors with a ferrite core or equivalent are recommended. Powdered iron cores are not

recommended due to their high losses at frequencies

over 50kHz.

The saturation rating of the selected inductor should

meet or exceed the calculated value for I

PEAK

,

although most coil types can be operated up to 20%

over their saturation rating without difficulty. In addition

to the saturation criteria, the inductor should have as

low a series resistance as possible. The power loss in

the inductor resistance is approximately given by:

Output Capacitor Selection

In CCM, to provide stable operation and to control output sag to less than 0.5%, the output bulk capacitance

should be greater than:

To properly control peak inductor current during the

3.2ms soft-start, the output bulk capacitance should be

less than:

where t

SS

= 3.2ms.

Because the MAX1522/MAX1523/MAX1524 are voltage-mode devices (and therefore do not require an

expensive current-sense resistor), cycle-to-cycle stability is obtained from the output capacitor’s equivalent

series resistance (ESR). Choose an output capacitor

with actual ESR greater than:

Additionally, to control peak inductor current during softstart, the output capacitor’s ESR should be greater

than:

Usually, this prevents the use of ceramic capacitors in

CCM applications. Alternatives include tantalum, electrolytic, and organic types such as Sanyo’s POSCAP.

The output capacitor must also be rated to withstand

the output voltage and the output ripple current, which

is equivalent to I

PEAK

. Since output ripple in boost DC-

DC designs is dominated by capacitor ESR, a capaci-

ESR

V

I

COUT

FB

PEAK

>× ×

−

60 10

3

ESR

L

C

I

V

COUT

OUT

LOAD MAX

IN MIN

>×

()

()

C

It

V

OUT MAX

LOAD MAX SS

OUT

()

()

=

×

C

It

V

OUT MIN

LOAD MAX ON

OUT

()

()

.

=

×

×0 005

P

IVV

V

LR

LOAD OUT D

IN

R

L

≅

×+

×

()

2

L

Vt

I

IDEAL

IN TYP ON TYP

PEAK

=

×

×

() ()

.03

MAX1524

INPUT

3.3V ±10%

C3

0.1µF

OFF ON

6

3

4

5

2

1

V

CC

EXT

SET FB

SHDN GND

C1

10µF

6.3V

L1

33µH

CR43-3R3

D1

CRS01

Q1

FDC633N

R1

100kΩ

1%

OUTPUT

5V

C2

33µF

10TPA33M

C

FF

100pF

R2

33.2kΩ

1%

R3

10Ω

Figure 2. MAX1524 Standard Operating Circuit

Page 9

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

_______________________________________________________________________________________ 9

tance value two or three times larger than C

OUT(MIN)

is

typically needed. Output ripple due to ESR is:

at light and medium loads, and three times as great at

peak load.

Continue the CCM design procedure by going to the

Optional Feed-Forward Capacitor Selection section.

Design Procedure for DCM

On-Time Selection

The MAX1522/MAX1523/MAX1524 may operate in

DCM at any duty cycle as required by the application’s

input and output voltages. However, best performance

is achieved when the maximum duty cycle of the application is similar to the MAX1522/MAX1523/MAX1524s’

maximum duty factor as set using the SET input.

Connect SET to GND for applications with maximum

duty cycles less than 67%. Connect SET to V

CC

for

applications with maximum duty cycles between 67%

and 99%.

Inductor Selection

For DCM, the ideal inductor value is given by:

If L

IDEAL

is not a standard value, choose the next lower

nominal value. The above formula already includes a

factor for ±30% inductor tolerance. Values higher than

ideal may not supply the maximum load when the input

voltage is low, while values much lower than ideal will

have poorer efficiency.

Calculate the Peak Inductor Current

For DCM, the peak inductor current is given by:

The saturation rating of the selected inductor should

meet or exceed the calculated value for I

PEAK

,

although most coil types can be operated up to 20%

over their saturation rating without difficulty. In addition

to the saturation criteria, the inductor should have as

low a series resistance as possible. The power loss in

the inductor resistance is approximately given by:

Due to the MAX1522/MAX1523/MAX1524s’ high switching frequencies, inductors with a ferrite core or equivalent are recommended. Powdered iron cores are not

recommended due to their high losses at frequencies

over 50kHz.

Switching Frequency

In DCM, the switching frequency is proportional to the

load current and is approximately given by:

Note that f

SWITCHING

is a function of load and input

voltage.

Output Capacitor Selection

In DCM, the MAX1522/MAX1523/MAX1524 may use

either a ceramic output capacitor (with very low ESR) or

other capacitors, such as tantalum or organic, with

higher ESR. For less than 2% output ripple, the minimum value for ceramic output capacitors should be

greater than:

To control inductor current during soft-start, the maximum value for any type of output capacitors should be

less than:

where tSS= 3.2ms.

The capacitor should be chosen to provide an output

ripple between 25mV minimum and 2% of V

OUT

maximum. The output ripple due to capacitance ripple and

ESR ripple can be approximated by:

For output ripple close to 2% of V

OUT

, the optional

feed-forward capacitor may not be required. For lower

output ripple, a feed-forward capacitor is necessary for

stability and to control inductor current during soft-start.

V

L

tV

VVVC

t

L

ESR

RIPPLE COUT ESR

ON IN

OUT D IN OUT

ON

COUT

()+

≅×

×

+−

()

×

×

×

1

2

1

22

+

V

IN

C

It

V

OUT MAX

LOAD MAX SS

OUT

()

()

=

×

C

L

tV

VVV V

OUT MIN

ON IN

OUT D IN OUT

()

.

=×

×

+−

()

×

1

2

1

002

22

ƒ≈×

+−

()

×

×

SWITCHING OUT

OUT D IN

ON IN

I

VVV

tV

L07 2

22

.

PII

VV

V

LR PEAK OUT

OUT D

IN

R

L

≅××

+

2

3

I

Vt

L

PEAK

IN MAX ON MAX

=

×

() ()

L

Vt

VVI

IDEAL

IN MIN ON MIN

OUT D LOAD MAX

=

×

×+×

()

()

() ()

()

2

3

V I ESR

RIPPLE ESR PEAK COUT()

.≅× ×03

Page 10

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

10 ______________________________________________________________________________________

Optional Feed-Forward

Capacitor Selection

For proper control of peak inductor current during softstart and for stable switching, the ripple at FB should

be greater than 25mV. Without a feed-forward capacitor connected between the output and FB, the output’s

ripple must be at least 2% of V

OUT

in order to meet this

requirement. Alternatively, if a low-ESR output capacitor

is chosen to obtain small output ripple, then a feed-forward capacitor should be used, and the output ripple

may be as low as 25mV. The approximate value of the

feed-forward capacitor is given by:

Do not use a feed-forward capacitor that is much larger

than this because line-transient performance will

degrade. Do not use a feed-forward capacitor at all if

the output ripple is large enough without it to provide

stable switching because load regulation will degrade.

Optional Feedback Capacitor Selection

When using a feed-forward capacitor, it is possible to

achieve too much ripple at FB. The symptoms of this

include excessive line and load regulation and possibly

high output ripple at light loads in the form of pulse

groupings or “bursts.” Fortunately, this is easy to correct by either choosing a lower-ESR output capacitor or

by adding a feedback capacitor between FB and

ground. This feedback capacitor (CFB), along with the

feed-forward capacitor, form an AC-coupled ripple voltage-divider from the output to FB:

It is relatively simple to determine a good value for C

FB

experimentally. Start with CFB= CFFto cut the FB ripple

in half; then increase or decrease CFBas needed. The

ideal ripple at FB is from 25mV to 40mV, which will provide stable switching, low output ripple at light and

medium loads, and reasonable line and load regulation. Never use a feedback capacitor without also using

a feed-forward capacitor.

Input Capacitor Selection

The input capacitor (CIN) in boost designs reduces the

current peaks drawn from the input supply, increases

efficiency, and reduces noise injection. The source

impedance of the input supply largely determines the

value of CIN. High source impedance requires high

input capacitance, particularly as the input voltage

falls. Since step-up DC-DC converters act as “constantpower” loads to their input supply, input current rises

as input voltage falls. Consequently, in low-input-voltage designs, increasing CINand/or lowering its ESR

can add as many as five percentage points to conversion efficiency. A good starting point is to use the same

capacitance value for CINas for C

OUT

. The input

capacitor must also meet the ripple current requirement

imposed by the switching currents, which is about 30%

of I

PEAK

in CCM designs and 100% of I

PEAK

in DCM

designs.

In addition to the bulk input capacitor, a ceramic 0.1µF

bypass capacitor at VCCis recommended. This capacitor should be located as close to VCCand GND as possible. In bootstrapped configuration, it is recommended

to isolate the bypass capacitor from the output capacitor with a series 10Ω resistor between the output and

V

CC

.

Power MOSFET Selection

The MAX1522/MAX1523/MAX1524 drive a wide variety

of N-channel power MOSFETs (NFETs). Since the output gate drive is limited to VCC, a logic-level NFET is

required. Best performance, especially when VCCis

less than 4.5V, is achieved with low-threshold NFETs

that specify on-resistance with a gate-source voltage

(V

GS

) of 2.7V or less. When selecting an NFET, key

parameters include:

1) Total gate charge (Qg)

2) Reverse transfer capacitance or charge (C

RSS

)

3) On-resistance (R

DS(ON)

)

4) Maximum drain-to-source voltage (V

DS(MAX)

)

5) Minimum threshold voltage (V

TH(MIN)

)

At high switching rates, dynamic characteristics (parameters 1 and 2 above) that predict switching losses

may have more impact on efficiency than R

DS(ON)

,

which predicts I2R losses. Qg includes all capacitances

associated with charging the gate. In addition, this

parameter helps predict the current needed to drive the

gate when switching at high frequency. The continuous

VCCcurrent due to gate drive is:

Use the FET manufacturer’s typical value for Qg (see

manufacturer’s graph of Qg vs. Vgs) in the above

equation since a maximum value (if supplied) is usually

too conservative to be of any use in estimating I

GATE

.

IQg

GATE SWITCHING

=׃

Ripple Ripple

C

CC

FB OUTPUT

FF

FB FF

=

+

×

C

RR

FF

≅× +

−

310

111

2

6

Page 11

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

______________________________________________________________________________________ 11

Diode Selection

The MAX1522/MAX1523/MAX1524s’ high switching fre-

quency demands a high-speed rectifier. Schottky

diodes are recommended for most applications

because of their fast recovery time and low forward

voltage. Ensure that the diode’s current rating is adequate to withstand the diode’s RMS current:

Also, the diode reverse breakdown voltage must

exceed V

OUT

. For high output voltages (50V or above),

Schottky diodes may not be practical because of this

voltage requirement. In these cases, use a high-speed

silicon rectifier with adequate reverse voltage. Another

consideration for high input voltages is reverse leakage

of the diode. This should be considered using the manufacturer’s specification due to its direct influence on

system efficiency.

Layout Considerations

High switching frequencies and large peak currents

make PC board layout a very important part of design.

Good design minimizes excessive EMI on the feedback

paths and voltage gradients in the ground plane, both

of which can result in instability or regulation errors.

Connect the inductor, input filter capacitor, and output

filter capacitor as close together as possible, and keep

their traces short, direct, and wide. Connect their

ground pins at a single common node in a star-ground

configuration. The external voltage-feedback network

should be very close to the FB pin, within 0.2in (5mm).

Keep noisy traces (such as the trace from the junction

of the inductor and MOSFET) away from the voltagefeedback network; also keep them separate, using

grounded copper. The MAX1522/MAX1523/ MAX1524

evaluation kit manual shows an example PC board layout and routing scheme.

Generating Resistance

with PC Board Traces

If the output capacitor’s ESR is too low for proper regulation, it can be increased artificially directly on the PC

board. For example, an additional 50mΩ of ESR added

to the output capacitor provides best regulation. The

resistivity of a 10mil trace using 1oz copper is about

50mΩ per inch. Therefore, a 10mil trace 1in long generates the required resistance.

III

DIODE RMS OUT PEAK()

<×

Page 12

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

12 ______________________________________________________________________________________

PARAMETER EXAMPLE 1 EXAMPLE 2 EXAMPLE 3

V

IN

3.3V ±10% 2.7V to 4.2V 1.8V to 3.0V

V

OUT

5V 12V 5V

I

OUT(MAX)

700mA 200mA 1.0A

R1, R2

274kΩ, 90.9kΩ 866kΩ, 100kΩ 274kΩ, 90.9kΩ

Duty Cycle (max) 45.5% 78.4% 67.3%

t

ON

0.5µs (SET = GND) 3µs (SET = VCC) 3µs (SET = VCC)

f

SWITCHING

691kHz to 909kHz

when I

OUT

> 120mA

221kHz to 261kHz

when I

OUT

> 35mA

152kHz to 224kHz

when I

OUT

> 167mA

I

PEAK

1.48A 1.06A 3.51A

L

IDEAL

3.73µH 33.8µH 6.83µH

L

ACTUAL

Sumida CR43-3R3

3.3µH, 86mΩ, 1.44A

Sumida CDR74B-330

33µH, 180mΩ, 0.97A

Sumida CDRH125-5R8

5.8µH, 17mΩ, 4.4A

P

LR

29mW at I

OUT

= 350mA 22mW at I

OUT

= 100mA 22mW at I

OUT

= 500mA

C

OUT(MIN)

to C

OUT(MAX)

14µF to 448µF 10µF to 53µF 120µF to 640µF

C

OUT

33µF 33µF 150µF

ESR

COUT(MIN)

23mΩ for stability,

51mΩ for soft-start

74mΩ for stability,

70mΩ for soft-start

21mΩ for stability,

21mΩ for soft-start

C

OUT(ACTUAL)

Sanyo POSCAP 10TPA33M

33µF, 10V,

60mΩ, 100mΩ max

AVX TPSD336M020R0200

33µF, 20V,

150mΩ, 200mΩ max

Sanyo POSCAP 6TPB150M

150µF, 6.3V,

40mΩ, 55mΩ max

V

RIPPLE(ESR)

27mVp-p at light loads,

81mVp-p at full load

48mVp-p at light loads,

144mVp-p at full load

42mVp-p at light loads,

126mVp-p at full load

C

FF

100pF 100pF 100pF

C

FB

100pF 330pF 220pF

C

IN

10µF, 6.3V ceramic 10µF, 6.3V ceramic 10µF, 6.3V ceramic

MOSFET Fairchild FDC633N Fairchild FDC633N Vishay Si3446DV

Qg

8nC at Vgs = 3V

12nC at Vgs = 5V

9nC at Vgs = 3.6V 10nC at Vgs = 5V

I

GATE

7.3mA nonbootstrapped,

10.9mA bootstrapped

2.4mA nonbootstrapped 2.2mA bootstrapped

I

DIODE(RMS)

0.96A 0.49A 1.84A

Diode Nihon EP10QY03, 1A Nihon EP10QY03, 1A Nihon EC21QS03L, 2A

Table 1. Design Examples Using CCM

Page 13

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

______________________________________________________________________________________ 13

PARAMETER EXAMPLE 4 EXAMPLE 5

V

IN

2.7V to 4.2V 1.8V to 3.0V

V

OUT

24V 3.3V

I

OUT(MAX)

30mA 100mA

R1, R2 909kΩ, 49.9kΩ 150kΩ, 93.1kΩ

Duty Cycle (max) 89.0% 52.6%

t

ON

3µs

(SET = V

CC

)

0.5µs

(SET = GND)

L

IDEAL

11.9µH 1.14µH

L

ACTUAL

Sumida

CDRH5D28-100

10µH, 65mΩ,

1.3A

Sumida

CDRH4D18-1R0

1µH, 45mΩ,

1.72A

I

PEAK

1.51A 1.80A

P

LR

4.5mW at

I

OUT

= 10mA

5.7mW

I

OUT

= 50mA

f

SWITCHING

208kHz when

I

OUT

= 20mA

737kHz when

I

OUT

= 100mA

C

OUT(MIN)

to

C

OUT(MAX)

0.8µF to 2.7µF 3µF to 97µF

C

OUT(ACTUAL)

Taiyo Yuden

2.2µF, X5R, 35V,

1210

Taiyo Yuden

TMK316BT106ML

10µF, X7R, 6.3V,

1206

ESR

COUT(ACTUAL)

10mΩ 10mΩ

V

RIP P LE ( C OU T+ E S R )

126mVp-p 40mVp-p

C

FF

100pF 220pF

C

FB

220pF 100pF optional

C

IN

10µF, 6.3V 10µF, 6.3V

MOSFET

Fairchild

FDC633N

Vishay Si2302DS

Qg

5nC at Vgs = 3.3V

I

GATE

1.7mA

3.7mA

bootstrapped

I

DIODE(RMS)

0.17A 0.42A

Diode

Nihon

EP10QY03, 1A

Nihon

EP10QY03, 1A

Table 2. Design Examples Using DCM

MANUFACTURER

PHONE WEB

Coilcraft

www.coilcraft.com

Fairchild

www.fairchildsemi.com

International

Rectifier

www.irf.com

Kemet

www.kemet.com

NIC Components

www.niccomp.com

Panasonic

www.panasonic.com

Sumida

www.sumida.com

Taiyo Yuden

www.t-yuden.com

Table 3. Component Manufacturers

Chip Information

TRANSISTOR COUNT: 1302

GMK325BJ225K

8nC at Vgs = 3V

nonbootstrapped

847-639-6400

800-341-0392

310-322-3331

408-986-0424

408-954-8470

847-468-5624

847-956-0666

408-573-4150

Page 14

MAX1522/MAX1523/MAX1524

Simple SOT23 Boost Controllers

Package Information

6LSOT.EPS

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2001 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...