Page 1

General Description

The MAX15050/MAX15051 high-efficiency switching regulators deliver up to 4A load current at output voltages

from 0.6V to (0.9 x V

IN

). The devices operate from 2.9V

to 5.5V, making them ideal for on-board point-of-load

and postregulation applications. Total output-voltage

accuracy is within ±1% over load, line, and temperature.

The MAX15050/MAX15051 feature 1MHz fixed-frequency PWM operation. The MAX15050 features pulse-skip

mode to improve light-load efficiency. The MAX15050

soft-starts in a monotonic mode and then operates in

the forced PWM mode or pulse-skip mode depending

on the output load current condition. The MAX15051

soft-starts in the monotonic mode and operates in the

forced PWM mode. The high operating frequency

allows for small-size external components.

The low-resistance on-chip nMOS switches ensure high

efficiency at heavy loads while minimizing critical parasitic

inductances, making the layout a much simpler task with

respect to discrete solutions. Following a simple layout

and footprint ensures first-pass success in new designs.

The MAX15050/MAX15051 incorporate a high-bandwidth

(> 26MHz) voltage-error amplifier. The voltage-mode control

architecture and the voltage-error amplifier permit a type III

compensation scheme to achieve maximum loop bandwidth, up to 200kHz. High loop bandwidth provides fast

transient response, resulting in less required output capacitance and allowing for all-ceramic capacitor designs.

The MAX15050/MAX15051 feature an output overload

hiccup protection and peak current limit on both highside and low-side MOSFETs. These features provide for

ultra-safe operation in the cases of short-circuit conditions, severe overloads, or in converters with bulk electrolytic capacitors.

The MAX15050/MAX15051 feature an adjustable output voltage. The output voltage is adjustable by using two external

resistors at the feedback or by applying an external reference

voltage to the REFIN/SS input. The MAX15050/MAX15051

offer programmable soft-start time using one capacitor to

reduce input inrush current. A built-in thermal shutdown protection assures safe operation under all conditions. The

MAX15050/MAX15051 are available in a 2mm x 2mm,

16-bump (4 x 4 array), 0.5mm pitch WLP package.

Applications

Features

o Internal 18mΩ R

DS(ON)

MOSFETs

o Pulse-Skip Mode for High-Efficiency Light Load

(MAX15050)

o Continuous 4A Output Current

o ±1% Output-Voltage Accuracy Over Load, Line,

and Temperature

o Operates from 2.9V to 5.5V Supply

o Adjustable Output from 0.6V to (0.9 x V

IN

)

o Adjustable Soft-Start Reduces Inrush Supply Current

o Factory-Trimmed 1MHz Switching Frequency

o Compatible with Ceramic, Polymer, and

Electrolytic Output Capacitors

o Safe Startup Into Prebias Output

o Enable Input/Power-Good Output

o Fully Protected Against Overcurrent and

Overtemperature

o Overload Hiccup Protection

o Sink/Source Current for DDR Applications

o 2mm x 2mm, 16-Bump (4 x 4 Array), 0.5mm Pitch

WLP Package

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

19-4915; Rev 2; 3/10

EVALUATION KIT

AVAILABLE

+

Denotes a lead(Pb)-free/RoHS-compliant package.

Pin Configuration appears at end of data sheet.

OUTPUT

INPUT

2.9V TO 5.5V

BST

LX

IN

EN

V

DD

GND

FB

V

DD

COMP

PWRGD

REFIN/SS

GND

MAX15050

MAX15051

Typical Operating Circuit

Server Power Supplies

Point-of-Load

ASIC/CPU/DSP Core

and I/O Voltages

DDR Power Supplies

Base-Station Power

Supplies

Telecom and

Networking Power

Supplies

RAID Control Power

Supplies

Portable Applications

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

PART TEMP RANGE

M A X1 5 0 5 0 E WE + - 40°C to + 85°C 16 WLP Yes

M A X1 5 0 5 1 E WE + - 40°C to + 85°C 16 WLP No

PINPACKAGE

SKIP

MODE

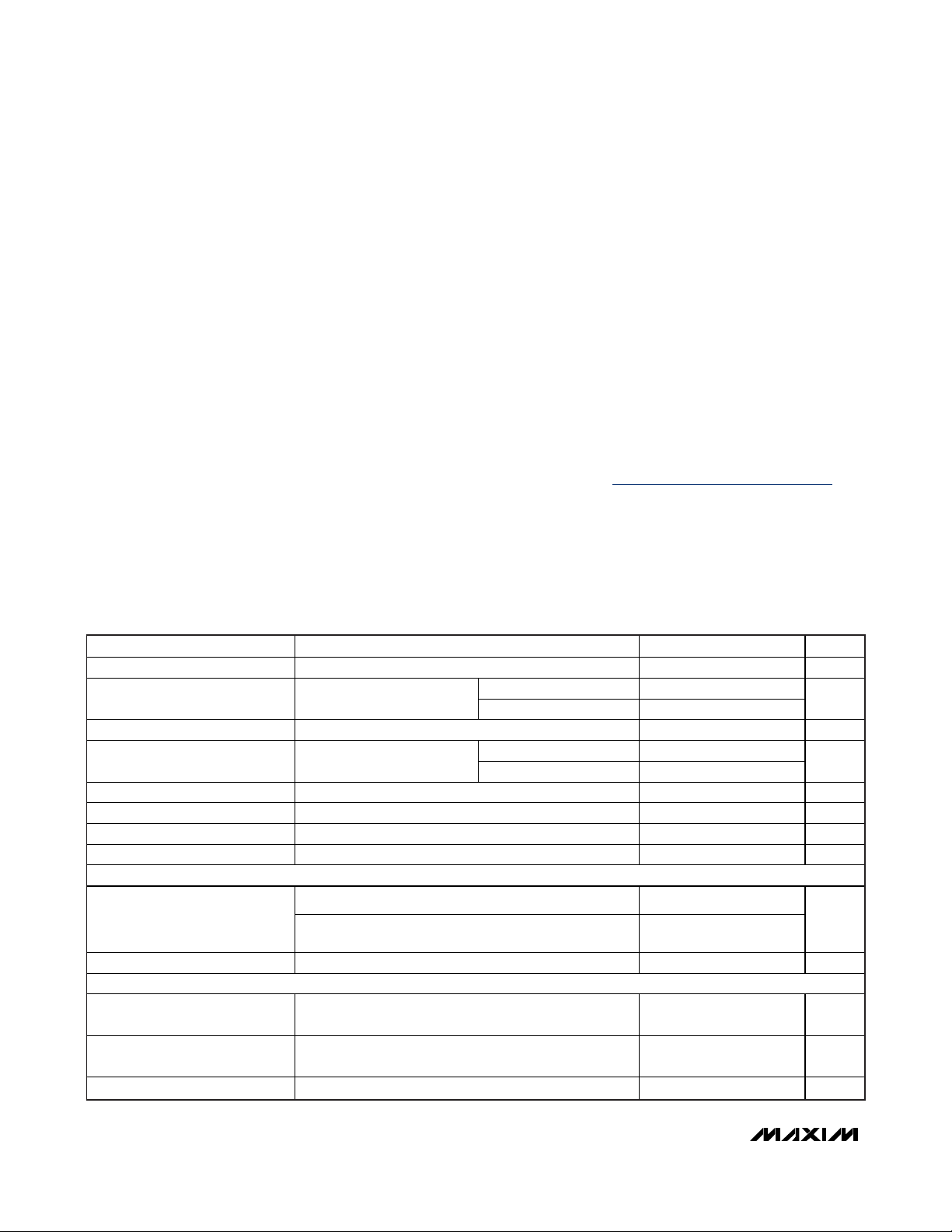

Page 2

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= VEN= 5V, C

VDD

= 2.2µF, TA= -40°C to +85°C, typical values are at TA= +25°C, unless otherwise noted.) (Note 4)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, PWRGD to GND..................................................-0.3V to +6V

V

DD

to GND..................-0.3V to the lower of +4V or (VIN+ 0.3V)

COMP, FB, REFIN/SS to GND....................-0.3V to (V

DD

+ 0.3V)

EN to GND................................................................-0.3V to +6V

BST to LX..................................................................-0.3V to +6V

BST to GND ............................................................-0.3V to +12V

LX to GND ....................-0.3V to the lower of +6V or (V

IN

+ 0.3V)

LX to GND (Note 1) ..-1V to the lower of +6V or (V

IN

+ 1V) for 50ns

I

LX(RMS)

....................................................................................6A

V

DD

Output Short-Circuit Duration .............................Continuous

Converter Output Short-Circuit Duration ....................Continuous

Continuous Power Dissipation (T

A

= +70°C)

16-Bump (4 x 4 Array), 0.5mm Pitch WLP

(derate 20.4mW/°C above +70°C)..............................1000mW

Thermal Resistance (Note 2)

θ

JA

.................................................................................49°C/W

θ

JC

...................................................................................9°C/W

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Operating Junction Temperature

at Maximum Current (Note 3)........................................+105°C

Storage Temperature Range .............................-65°C to +150°C

Soldering Temperature (soldering, 10s) ..........................+260°C

Note 1: LX has internal clamp diodes to GND and IN. Applications that forward bias these diodes should take care not to exceed

the IC’s power dissipation limit of the device.

Note 2: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial

.

Note 3: Operating the junction temperature above +105°C will degrade the life of the device.

PARAMETER CONDITIONS MIN TYP MAX UNITS

IN Voltage Range 2.9 5.5 V

IN Supply Current No load, no switching

Total Shutdown Current from IN VIN = V

VDD Undervoltage Lockout

Threshold

VDD Undervoltage Deglitching 10 µs

VDD Output Voltage I

VDD Dropout VIN = 2.9V, I

VDD Current Limit VDD = 0V 20 37 mA

BST

BST Supply Current

IN to BST On-Resistance VIN = 3.3V, IIN = 0.16A 4

PWM COMPARATOR

PWM Comparator Propagation

Delay

PWM Peak-to-Peak Ramp

Ampl itude

PWM Valley Amplitude 0.76 V

VIN = 3.3V 4.8 8

= 5V 5.3 8.5

V

IN

- VLX = 5V, VEN = 0V 10 20 µA

BST

LX starts/stops switching,

no load

= 0 to 10mA 3.1 3.3 3.5 V

VDD

= 10mA 0.09 V

VDD

MAX15050, V

MAX15051, V

no switching

10mV overdrive 20 ns

1 V

BST

IN

= 5V, V

= V

LX

= 3.3V, V

VDD ris ing 2.6 2.8

falling 2.35 2.55

V

DD

= 0V, no switching 10

LX

= 6.6V,

BST

250

mA

V

µA

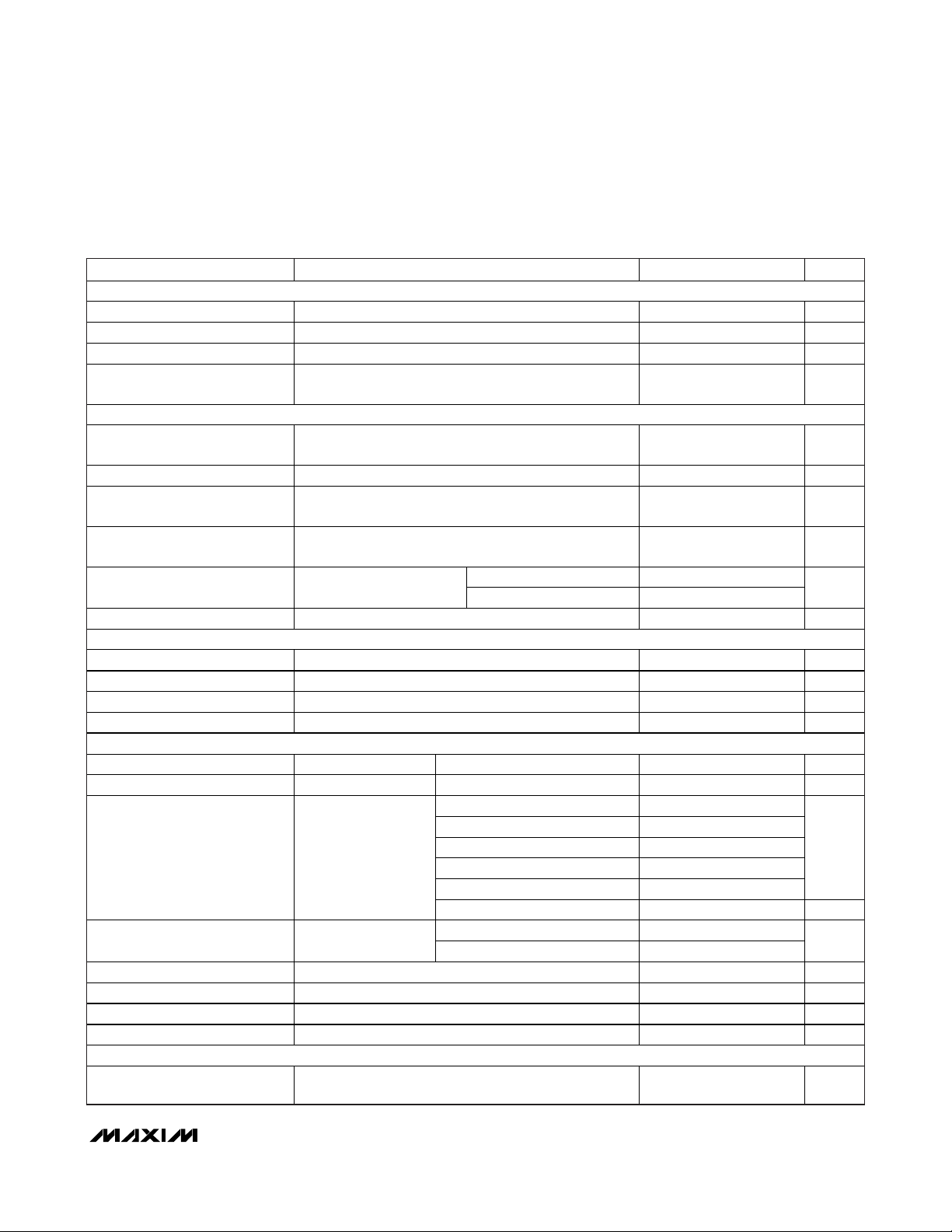

Page 3

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= VEN= 5V, C

VDD

= 2.2µF, TA= -40°C to +85°C, typical values are at TA= +25°C, unless otherwise noted.) (Note 4)

PARAMETER CONDITIONS MIN TYP MAX UNITS

COMP

COMP Clamp Voltage High V

COMP Clamp Voltage Low V

COMP Slew Rate V

COMP Shutdown Res istance

ERROR AMPLIFIER

FB Regulation Accuracy Using

External Resistors

Open-Loop Voltage Gain 115 dB

Error-Amplifier Unity-Gain

Bandwidth

Error-Amplifier Common-Mode

Input Range

Error-Amplifier Maximum Output

Current

FB Input Bias Current VFB = 0.7V 70 nA

REFIN/SS

REFIN/SS Common-Mode Range V

REFIN/SS Charging Current V

REFIN/SS Offset Voltage V

REFIN/SS Pulldown Resistance VIN= V

LX (ALL BUMPS COMBINED)

LX On-Resistance, High Side ILX = -500mA VIN = V

LX On-Resistance, Low Side ILX = 500mA VIN = 3.3V 18 50 m

LX Current-Limit Thresholds VIN= 3.3V

LX Leakage Current V

LX Switching Frequenc y VIN= 3.3V 0.9 1 1.1 MHz

LX Maximum Duty Cycle VIN= 3.3V 90 96 %

LX Minimum On-Time VIN= 3.3V 80 ns

RMS LX Output Current 4 A

ENABLE

EN Input Logic-Low Threshold

(Falling)

= 2.9V to 5V, V

DD

= 2.9V to 5V, V

DD

= 0.7V to 0.5V, V

FB

From COMP to GND, V

= V

V

EN

REFIN/SS

0.594 0.6 0.606 V

26 MHz

= 2.9V to 3.5V 0 VDD - 2 V

V

DD

V

= 1V, no sw itching,

COMP

V

REFIN/SS

DD

REFIN/SS

REFIN/SS

EN

0.7 V

= 0.6V

= 2.9V to 3.5V 0 V

= 0.45V 6 8 10 µA

= 0.9V, FB shorted to COMP -4.5 +4.5 mV

= 3.3V, V

DD

= 0V

= 0.5V, V

FB

FB

= 0V

REFIN/SS

= 0.7V, V

REFIN/SS

IN

REFIN/SS

REFIN/SS

= 0.6V 1.4 V/µs

= 3.3V, V

V

FB

V

FB

= 0.1V 300

BST

High-side sourcing 5.4 8

Low-side sourcing 7

Low-side sink ing 7

Zero-crossing current threshold 0.2

Skip h igh-side sourcing 0.58

Sink current-limit DAC steps 4 Steps

V

= 0V -10

LX

= 5V 10

V

LX

= 0.6V 2 V

= 0.6V 0.68 V

= 100mV,

COMP

= 0.7V, sink 1

= 0.5V, source -1

- V

= 3.3V 24 54 m

LX

6

- 2 V

DD

mA

A

µA

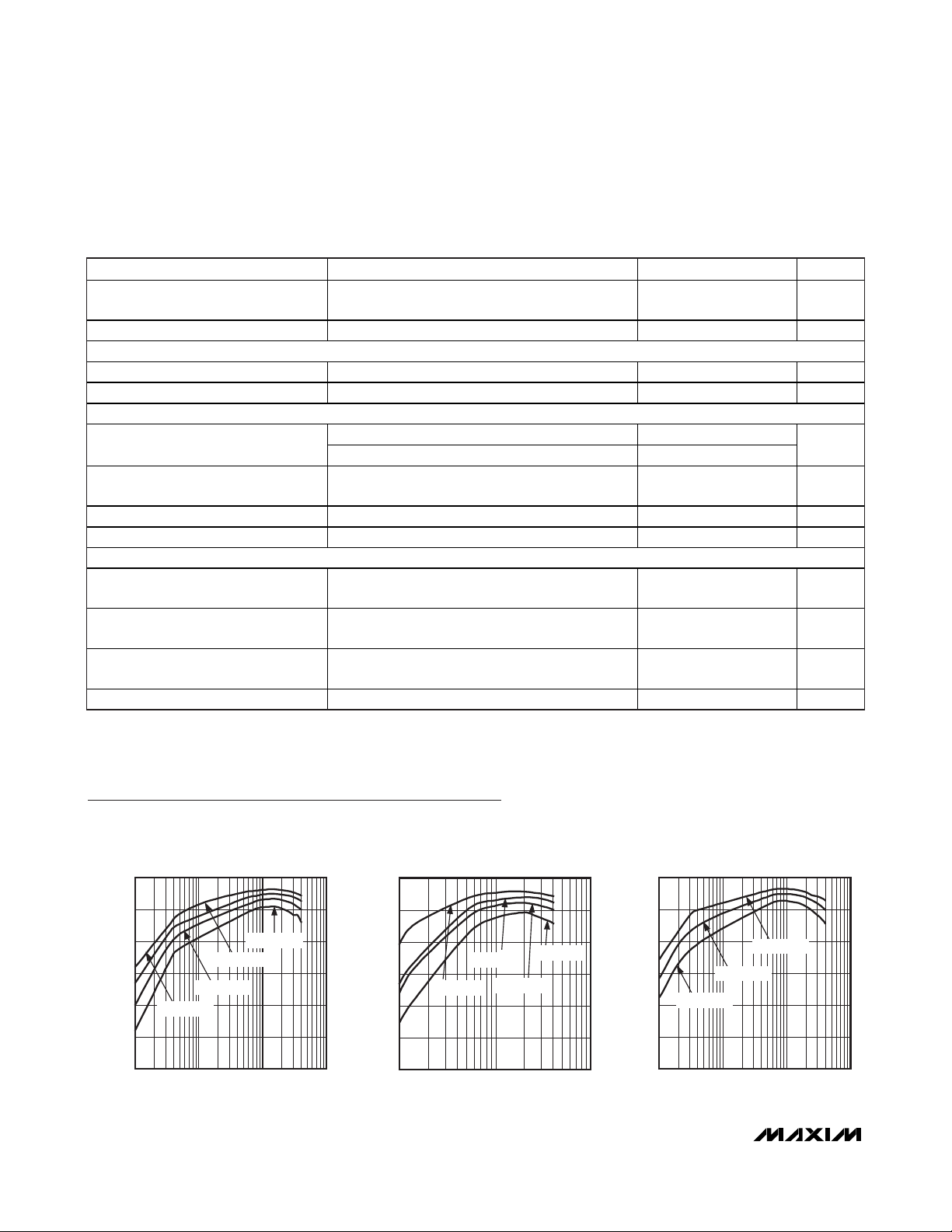

Page 4

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

4 _______________________________________________________________________________________

Note 4: Specifications are 100% production tested at TA = +25°C. Limits over the operating temperature range are guaranteed by

design and characterization.

ELECTRICAL CHARACTERISTICS (continued)

(VIN= VEN= 5V, C

VDD

= 2.2µF, TA= -40°C to +85°C, typical values are at TA= +25°C, unless otherwise noted.) (Note 4)

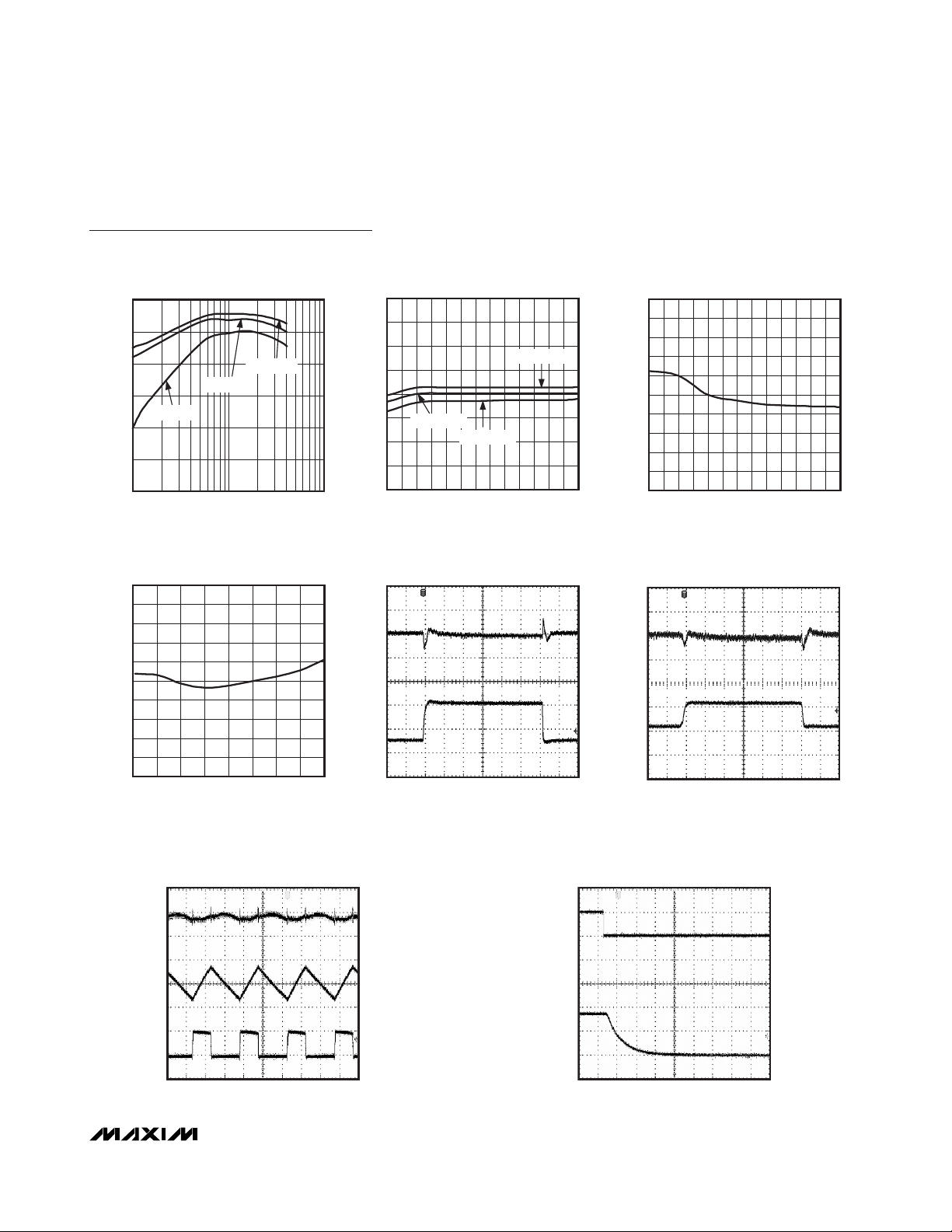

Typical Operating Characteristics

(VIN= 5V, output voltage = 1.8V, I

LOAD

= 4A, and TA = +25°C, circuit of Figure 1, unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

EN Input Logic-High Threshold

(Rising)

EN Input Current VEN = 0 or 5V 0.01 1 µA

THERMAL SHUTDOWN

Thermal-Shutdown Threshold +165 °C

Thermal-Shutdown Hysteresis 20 °C

POWER-GOOD (PWRGD)

Power-Good Threshold Voltage

Power-Good Edge Deglitch VFB falling or rising 48

PWRGD Output-Voltage Low I

PWRGD Leakage Current V

OVERCURRENT LIMIT (HICCUP MODE)

Current-Limit Startup Blan king 112

Autoretr y Restart Time 896

FB Hiccup Threshold VFB falling 70

Hiccup Threshold B lank ing Time VFB falling 36 µs

1.5 V

VFB falling, V

rising, V

V

FB

= 4mA 0.03 0.15 V

PWRGD

= 5V, V

PWRGD

REFIN/SS

REFIN/SS

= 0.6V 87 90 93

= 0.6V 92.5

= 0.9V, V

FB

REFIN/SS

= 0.6V 0.1 1 µA

% of

V

REFIN/SS

Clock

cycles

Clock

cycles

Clock

cycles

% of

V

REFIN/SS

EFFICIENCY vs. LOAD CURRENT

(V

= 5V) (MAX15050)

100

90

80

70

EFFICIENCY (%)

60

50

40

0.01 10

IN

V

= 2.5V

OUT

V

= 3.3V

OUT

V

= 1.8V

OUT

LOAD CURRENT (A)

V

OUT

10.1

EFFICIENCY vs. LOAD CURRENT

VIN = 5V (MAX15051)

100

MAX15050 toc01

= 1.2V

90

80

V

= 2.5V

70

EFFICIENCY (%)

60

50

40

0.1 1 10

V

= 3.3V

OUT

LOAD CURRENT (A)

OUT

V

= 1.8V

OUT

MAX15050 toc01b

V

= 1.2V

OUT

EFFICIENCY vs. LOAD CURRENT

(V

= 3.3V) (MAX15050)

V

OUT

IN

V

OUT

= 1.2V

LOAD CURRENT (A)

= 1.8V

V

= 2.5V

OUT

10.1

100

90

80

70

EFFICIENCY (%)

60

50

40

0.01 10

MAX15050 toc02

Page 5

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

_______________________________________________________________________________________

5

Typical Operating Characteristics (continued)

(VIN= 5V, output voltage = 1.8V, I

LOAD

= 4A, and TA = +25°C, circuit of Figure 1, unless otherwise noted.)

EFFICIENCY vs. LOAD CURRENT

= 3.3V (MAX15051)

V

V

= 1.2V

OUT

IN

V

= 1.8V

OUT

LOAD CURRENT (A)

V

= 2.5V

OUT

100

90

80

70

EFFICIENCY (%)

60

50

40

0.1 1 10

LOAD REGULATION

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

% OUTPUT FROM NORMAL

-0.6

-0.8

-1.0

LOAD CURRENT (A)

FREQUENCY vs. INPUT VOLTAGE

1.20

1.15

MAX15050 toc02b

1.10

1.05

1.00

0.95

FREQUENCY (MHz)

0.90

0.85

0.80

TA = +25NC

TA = -40NC

2.9 5.5

INPUT VOLTAGE (V)

LOAD-TRANSIENT RESPONSE

MAX15050 toc05

3.0 3.52.52.01.51.00.504.0

40µs/div

TA = +85NC

MAX15050 toc06

5.35.13.1 3.3 3.5 3.9 4.1 4.3 4.5 4.73.7 4.9

MAX15050 toc03

V

OUT

AC-COUPLED

200mV/div

4A

I

OUT

2A/div

1A

LINE REGULATION

(I

= 4A)

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

% OUTPUT FROM NORMAL

-0.6

-0.8

-1.0

2.9 5.5

LOAD

INPUT VOLTAGE (V)

LOAD-TRANSIENT RESPONSE

40µs/div

5.35.14.7 4.93.5 3.7 3.9 4.1 4.3 4.53.1 3.3

MAX15050 toc07

MAX15050 toc04

V

OUT

AC-COUPLED

100mV/div

4A

I

OUT

2A/div

2A

SWITCHING WAVEFORMS

400ns/div

MAX15050 toc08

V

OUT

AC-COUPLED

50mV/div

I

LX

1A/div

V

LX

2V/div

0V

SHUTDOWN WAVEFORM

10µs/div

MAX15050 toc09

V

EN

5V/div

V

OUT

1V/div

Page 6

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VIN= 5V, output voltage = 1.8V, I

LOAD

= 4A, and TA = +25°C, circuit of Figure 1, unless otherwise noted.)

SOFT-START WAVEFORM

400µs/div

MAX15050 toc10

V

EN

5V/div

V

OUT

1V/div

12

10

8

6

4

INPUT SHUTDOWN CURRENT (µA)

2

0

-40

RMS INPUT CURRENT DURING SHORT

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

RMS INPUT CURRENT (A)

0.10

0.05

CIRCUIT vs. INPUT VOLTAGE

V

= 0V

OUT

0

2.9 5.5

INPUT VOLTAGE (V)

MAX15050 toc13

5.35.14.7 4.93.5 3.7 3.9 4.1 4.3 4.53.1 3.3

FEEDBACK VOLTAGE vs. TEMPERATURE

0.606

0.604

0.602

0.600

0.598

FEEDBACK VOLTAGE (V)

0.596

0.594

-40 85

INPUT SHUTDOWN CURRENT

vs. INPUT VOLTAGE

VIN = 3.3V

VIN = 5V

INPUT VOLTAGE (V)

TEMPERATURE (°C)

HICCUP CURRENT LIMIT

MAX15050 toc11

8065-25 -10 5 3520 50

400µs/div

SOFT-START WITH REFIN/SS

MAX15050 toc14

603510-15

400µs/div

MAX15050 toc12

MAX15050 toc15

V

OUT

1V/div

I

OUT

5A/div

I

IN

2A/div

I

IN

1A/div

V

REFIN/SS

500mV/div

V

OUT

1V/div

V

PWRGD

2V/div

STARTING INTO PREBIASED

OUTPUT WITH 2A LOAD

0V

0V

0A

0V

400µs/div

MAX15050 toc16

V

EN

2V/div

V

OUT

1V/div

I

OUT

2A/div

V

PWRGD

5V/div

STARTING INTO PREBIASED

OUTPUT WITH NO LOAD

0V

0V

0V

400µs/div

MAX15050 toc17

V

EN

2V/div

V

OUT

1V/div

V

PWRGD

2V/div

Page 7

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(VIN= 5V, output voltage = 1.8V, I

LOAD

= 4A, and TA = +25°C, circuit of Figure 1, unless otherwise noted.)

Pin Description

CASE TEMPERATURE

vs. AMBIENT TEMPERATURE

100

I

= 4A

LOAD

80

60

40

20

0

CASE TEMPERATURE (°C)

-20

-40

-40 85

AMBIENT TEMPERATURE (°C)

TRANSITION FROM SKIP MODE

TO FORCED PWM

MAX15050 toc18

603510-15

10ms/div

MAX15050 toc19

I

OUT

2A/div

V

LX

5V/div

V

OUT

500mV/div

TRANSITION FROM FORCED PWM

TO SKIP MODE

10ms/div

BUMP NAME FUNCTION

A1, A2 GND

A3, A4 IN

B1, B2,

B3

LX

B4 V

C1 BST

C2, C3 I.C. Internally Connected. Leave unconnected or connect to ground.

C4 EN Enable Input. Connect EN to GND to disable the device. Connect EN to IN to enable the device.

D1 PWRGD

D2 FB

D3 COMP

Analog/Power Ground. Connect GND to the PCB ground plane at one point near the input bypass

capacitor return terminal as close as possible to the device.

Power-Supply Input. Input supply range is from 2.9V to 5.5V. Bypass IN to GND with a 22µF ceramic

capacitor in parallel to a 0.1µF ceramic capacitor as close as possible to the device.

Inductor Connection. All LX bumps are internally connected together. Connect all LX bumps to the

switched side of the inductor. LX is high impedance when the device is in shutdown mode.

3.3V LDO Output. VDD powers the internal analog core. Connect a low-ESR, ceramic capacitor with a

DD

minimum value of 2.2µF from V

to GND.

DD

High-Side MOSFET Driver Supply. Connect BST to LX with a 0.1µF capacitor.

Power-Good Output. PWRGD is an open-drain output that goes high impedance when V

of V

REFIN/SS

V

REFIN/SS

mode, V

and V

or V

DD

REFIN/SS

REFIN/SS

is below the internal UVLO threshold, or the device is in thermal shutdown.

is above 0.54V. PWRGD is internally pulled low when VFB falls below 90% of

is below 0.54V. PWRGD is internally pulled low when the device is in shutdown

Feedback Input. Connect FB to the center tap of an external resistor-divider from the output to GND to set

the output voltage from 0.6V to 90% of V

.

IN

Voltage-Error Amplifier Output. Connect the necessary compensation network from COMP to FB and the

converter output (see the Compensation Design section). COMP is internally pulled to GND when the

device is in shutdown mode.

MAX15050 toc20

exceeds 92.5%

FB

I

OUT

2A/div

V

LX

5V/div

V

OUT

500mV/div

D4 REFIN/SS

External Reference Input/Soft-Start Timing Capacitor Connection. Connect REFIN/SS to a system voltage to

force FB to regulate to REFIN/SS voltage. REFIN/SS is internally pulled to GND when the device is in

shutdown and thermal shutdown mode. If no external reference is applied, the internal 0.6V reference is

automatically selected. REFIN/SS is also used to perform soft-start. Connect a minimum of 1nF capacitor

from REFIN/SS to GND to set the startup time (see the Soft-Start and Reference Input (REFIN/SS) section).

Page 8

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

8 _______________________________________________________________________________________

Block Diagram

V

DD

MAX15050

EN

SHUTDOWN

CONTROL

UVLO

CIRCUITRY

3.3V (LDO)

CURRENT-LIMIT

COMPARATOR

MAX15051

BIAS

GENERATOR

VOLTAGE

REFIN/SS

FB

REFERENCE

SOFT-START

THERMAL

SHUTDOWN

ERROR

AMPLIFIER

PWM

COMPARATOR

V

RAMP

SHDN

1V

P-P

CONTROL

LOGIC

CURRENT-LIMIT

COMPARATOR

OSCILLATOR

LX

ILIM THRESHOLD

BST SWITCH

IN

BST

IN

LX

GND

ILIM

THRESHOLD

COMP

SHDN

COMP CLAMPS

FB

0.9 x V

REFIN/SS

PWRGD

GND

Page 9

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

_______________________________________________________________________________________ 9

Figure 1. All-Ceramic Capacitor Design with V

OUT

= 1.8V

Detailed Description

The MAX15050/MAX15051 high-efficiency, voltagemode switching regulators can deliver up to 4A of output current. The MAX15050/MAX15051 provide output

voltages from 0.6V to (0.9 x V

IN

) from 2.9V to 5.5V input

supplies, making them ideal for on-board point-of-load

applications. The output-voltage accuracy is better than

±1% over load, line, and temperature.

The MAX15050/MAX15051 feature a 1MHz fixed switching frequency, allowing the user to achieve all-ceramic

capacitor designs and fast transient responses. The high

operating frequency minimizes the size of external components. The MAX15050/MAX15051 are available in a

2mm x 2mm, 16-bump (4 x 4 array), 0.5mm pitch WLP

package. The REFIN/SS function makes the

MAX15050/MAX15051 ideal solutions for DDR and tracking power supplies. Using internal low-R

DS(ON)

(24mΩ

and 18mΩ) n-channel MOSFETs for the high- and lowside switches, respectively, maintains high efficiency at

both heavy-load and high-switching frequencies.

The MAX15050/MAX15051 employ voltage-mode control architecture with a high-bandwidth (> 26MHz) error

amplifier. The op-amp voltage-error amplifier works with

type III compensation to fully utilize the bandwidth of

the high-frequency switching to obtain fast transient

response. Adjustable soft-start time provides flexibilities

to minimize input startup inrush current. An open-drain,

power-good (PWRGD) output goes high impedance

when V

FB

exceeds 92.5% of V

REFIN/SS

and V

REFIN/SS

is above 0.54V. PWRGD goes low when VFBfalls below

90% of V

REFIN/SS

or V

REFIN/SS

is below 0.54V.

Controller Function

The controller logic block is the central processor that

determines the duty cycle of the high-side MOSFET

under different line, load, and temperature conditions.

Under normal operation, where the current-limit and

temperature protection are not triggered, the controller

logic block takes the output from the PWM comparator

and generates the driver signals for both high-side and

low-side MOSFETs. The control logic block controls the

break-before-make logic and the timing for charging

the bootstrap capacitors. The error signal from the voltage-error amplifier is compared with the ramp signal

generated by the oscillator at the PWM comparator to

produce the required PWM signal. The high-side switch

turns on at the beginning of the oscillator cycle and

Typical Application Circuit

INPUT

2.9V TO 5.5V

22µF

IN

IN

V

ON

EN

REFIN/SS

U1

MAX15050

MAX15051

DD

GND

0.1µF

2.2µF

C3

C5

OFF

C8

0.033µF

C1

BST

BST

GND

COMP

PWRGD

C15

1000pF

OPTIONAL

C2

47µF

OUTPUT

1.8V/4A

C4

0.01µF

R3

8.06kΩ

1%

R7

4.02kΩ

1%

C9

0.1µF

LX

LX

LX

FB

0.82µH

C11

1500pF

L1

C12

56pF

R4

5.62kΩ

R10

2.2Ω

R5

20kΩ

C10

1000pF

71.5Ω

R6

V

DD

Page 10

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

10 ______________________________________________________________________________________

turns off when the ramp voltage exceeds the V

COMP

signal or the current-limit threshold is exceeded. The

low-side switch then turns on for the remainder of the

oscillator cycle.

Skip Mode (MAX15050)

The MAX15050 features a skip function. In skip mode,

the MAX15050 switches only as necessary to maintain

the output at light loads (not capable of sinking current

from the output). This maximizes light-load efficiency

and reduces the input quiescent current.

In skip mode, the low-side switch is turned off when the

inductor current decreases to 0.2A (typ) to ensure no

reverse current flowing from the output capacitor.

The high-side switch minimum on-time is controlled to

guarantee that 0.9A current is reached to avoid high

frequency bursts at no-load conditions, which prevents

a rapid increase of the supply current caused by additional switching losses. Under heavy load, the device

operates as a PWM converter.

Current Limit

The internal, high-side MOSFET has a typical 8A peak

current-limit threshold. When current flowing out of LX

exceeds this limit, the high-side MOSFET turns off and

the low-side MOSFET turns on. The low-side MOSFET

remains on until the inductor current falls below the lowside current limit. This lowers the duty cycle and causes the output voltage to droop until the current limit is

no longer exceeded. The MAX15050/MAX15051 use a

hiccup mode to prevent overheating during short-circuit output conditions.

During current limit, if VFBdrops below 70% of

V

REFIN/SS

and stays below this level for typically 36µs

or more, the device enters hiccup mode. The high-side

MOSFET and the low-side MOSFET turn off and both

COMP and REFIN/SS are internally pulled low. The

device remains in this state for 896 clock cycles and

then attempts to restart for 112 clock cycles. If the faultcausing current limit has cleared, the device resumes

normal operation. Otherwise, the device reenters hiccup mode.

Soft-Start and Reference Input (REFIN/SS)

The MAX15050/MAX15051 utilize an adjustable softstart function to limit inrush current during startup. An

8µA (typ) current source charges an external capacitor

connected to REFIN/SS. The soft-start time is adjusted

by the value of the external capacitor from REFIN/SS to

GND. The required capacitance value is determined as:

where tSSis the required soft-start time in seconds.

Connect a minimum 1nF capacitor between REFIN/SS

and GND. REFIN/SS is also an external reference input

(REFIN/SS). The device regulates FB to the voltage

applied to REFIN/SS. The internal soft-start is not available when using an external reference. Figure 2 shows

a method of soft-start when using an external reference. If an external reference is not applied, the device

uses the internal 0.6V reference.

Undervoltage Lockout (UVLO)

The UVLO circuitry inhibits switching when VDDis

below 2.55V (typ). Once VDDrises above 2.6V (typ),

UVLO clears and the soft-start function activates. A

50mV hysteresis is built-in for glitch immunity.

BST

The gate-drive voltage for the high-side, n-channel

switch is generated by a flying-capacitor boost circuit.

The capacitor between BST and LX is charged from the

VINsupply while the low-side MOSFET is on. When the

low-side MOSFET is switched off, the voltage of the

capacitor is stacked above LX to provide the necessary

turn-on voltage for the high-side internal MOSFET.

Power-Good Output (PWRGD)

PWRGD is an open-drain output that goes high

impedance when VFBis above 92.5% x V

REFIN/SS

and

V

REFIN/SS

is above 0.54V. PWRGD pulls low when V

FB

is below 90% of V

REFIN/SS

for at least 48 clock cycles

or V

REFIN/SS

is below 0.54V. PWRGD is low during

shutdown.

Figure 2. Typical Soft-Start Implementation with External

Reference

At

×806µ

C

=

SS

V

.

REFIN/SS

C

R1

R2

MAX15050

MAX15051

Page 11

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

______________________________________________________________________________________ 11

Setting the Output Voltage

The MAX15050/MAX15051 output voltage is adjustable

from 0.6V to 90% of VINby connecting FB to the center

tap of a resistor-divider between the output and GND

(Figure 3). To determine the values of the resistordivider, first select the value of R3 between 2kΩ and

10kΩ. Then use the following equation to calculate R4:

R4 = (V

FB

x R3)/(V

OUT

- VFB)

where V

FB

is equal to the reference voltage at

REFIN/SS and V

OUT

is the output voltage. For V

OUT

=

V

FB

, remove R4. If no external reference is applied at

REFIN/SS, the internal reference is automatically selected and V

FB

becomes 0.6V.

Shutdown Mode

Drive EN to GND to shut down the device and reduce

quiescent current to less than 10µA. During shutdown,

LX is high impedance. Drive EN high to enable the

MAX15050/MAX15051.

Thermal Protection

Thermal-overload protection limits total power dissipation in the device. When the junction temperature

exceeds TJ= +165°C, a thermal sensor forces the

device into shutdown, allowing the die to cool. The thermal sensor turns the device on again after the junction

temperature cools by 20°C, causing a pulsed output

during continuous overload conditions. The soft-start

sequence begins after recovery from a thermal-shutdown condition.

Applications Information

IN and VDDDecoupling

To decrease the noise effects due to the high switching

frequency and maximize the output accuracy of

the MAX15050/MAX15051, decouple VINwith a 22µF

capacitor in parallel with a 0.1µF capacitor from VINto

GND. Also decouple VDDwith a 2.2µF capacitor from V

DD

to GND. Place these capacitors as close as possible to

the device.

Inductor Selection

Choose an inductor with the following equation:

where LIR is the ratio of the inductor ripple current to

full load current at the minimum duty cycle and fSis the

switching frequency (1MHz). Choose LIR between 20%

to 40% for best performance and stability.

Use an inductor with the lowest possible DC resistance

that fits in the allotted dimensions. Powdered iron or fer-

rite core types are often the best choice for performance. With any core material, the core must be large

enough not to saturate at the current limit of the

MAX15050/MAX15051.

Output-Capacitor Selection

The key selection parameters for the output capacitor

are capacitance, ESR, ESL, and voltage-rating requirements. These affect the overall stability, output ripple

voltage, and transient response of the DC-DC converter. The output ripple occurs due to variations in the

charge stored in the output capacitor, the voltage drop

due to the capacitor’s ESR, and the voltage drop due to

the capacitor’s ESL. Estimate the output-voltage ripple

due to the output capacitance, ESR, and ESL as follows:

where the output ripple due to output capacitance,

ESR, and ESL is:

whichever is higher.

Figure 3. Setting the Output Voltage with a Resistor VoltageDivider

VVV

×−

()

L

OUT IN OUT

=

f V LIR I

×××

S IN OUT MAX

()

LX

MAX15050

MAX15051

FB

R3

R4

VV

RIPPLE RIPPLE C

VV

RIPPLE ESR RIPPLE ESL

V

RIPPLE C

VIx

RIPPLE ESR P P()=−

and V

RIPPLE ESL

V

RIPPLE ESL

=+

() ()

=

()

xC xf

8

+

I

−

PP

OUT S

()

EESR

I

−

PP

=

()

()

=

t

ON

I

−

PP

t

OFF

xx ESL or

x ESL

Page 12

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

The peak-to-peak inductor current (I

P-P

) is:

Use these equations for initial output-capacitor selection. Determine final values by testing a prototype or an

evaluation circuit. A smaller ripple current results in less

output-voltage ripple. Since the inductor ripple current

is a factor of the inductor value, the output-voltage ripple decreases with larger inductance. Use ceramic

capacitors for low ESR and low ESL at the switching

frequency of the converter. The ripple voltage due to

ESL is negligible when using ceramic capacitors.

Load-transient response depends on the selected output capacitance. During a load transient, the output

instantly changes by ESR x ∆I

LOAD

. Before the controller can respond, the output deviates further,

depending on the inductor and output capacitor values. After a short time, the controller responds by regulating the output voltage back to its predetermined

value. The controller response time depends on the

closed-loop bandwidth. A higher bandwidth yields a

faster response time, preventing the output from deviating further from its regulating value. See the

Compen-

sation Design

section for more details. The minimum

recommended output capacitance for the MAX15051

and MAX15051 is 47µF and 22µF, respectively.

Input-Capacitor Selection

When transitioning from skip mode to PWM mode

(MAX15050) with a large current load step, additional output capacitance can be used to help minimize the loadtransient response. The input capacitor reduces the

current peaks drawn from the input power supply and

reduces switching noise in the device. The total input

capacitance must be equal to or greater than the value

given by the following equation to keep the input ripple

voltage within the specification and minimize the high-frequency ripple current being fed back to the input source:

where V

IN-RIPPLE

is the maximum-allowed input ripple

voltage across the input capacitors and is recommended to be less than 2% of the minimum input voltage, D

is the duty cycle (V

OUT/VIN

), TSis the switching period

(1/fS) = 1µs, and I

OUT

is the output load.

The impedance of the input capacitor at the switching frequency should be less than that of the input source so

high-frequency switching currents do not pass through

the input source, but are instead shunted through the

input capacitor. The input capacitor must meet the ripple

current requirement imposed by the switching currents.

The RMS input ripple current is given by:

where I

RIPPLE

is the input RMS ripple current.

Compensation Design

The power transfer function consists of one double pole

and one zero. The double pole is introduced by the

inductor, L, and the output capacitor, CO. The ESR of the

output capacitor determines the zero. The double pole

and zero frequencies are given as follows:

where RLis equal to the sum of the output inductor’s DC

resistance (DCR) and the internal switch resistance,

R

DS(ON)

. A typical value for R

DS(ON)

is 25mΩ. ROis the

output load resistance, which is equal to the rated output

voltage divided by the rated output current. ESR is the

total equivalent series resistance of the output capacitor. If

there is more than one output capacitor of the same type

in parallel, the value of the ESR in the above equation is

equal to that of the ESR of a single output capacitor divided by the total number of output capacitors.

The MAX15050/MAX15051 high switching frequency

allows the use of ceramic output capacitors. Since the ESR

of ceramic capacitors is typically very low, the frequency of

the associated transfer function zero is higher than the

unity-gain crossover frequency, fC, and the zero cannot be

used to compensate for the double pole created by the

output inductor and capacitor. The double pole produces

a gain drop of 40dB/decade and a phase shift of 180°. The

compensation network must compensate for this gain drop

and phase shift to achieve a stable high-bandwidth closedloop system. Therefore, use type III compensation as

shown in Figure 4 and Figure 5. Type III compensation

possesses three poles and two zeros with the first pole,

f

P1_EA

, located at zero frequency (DC). Locations of other

poles and zeros of the type III compensation are given by:

12 ______________________________________________________________________________________

I

PP

−

VV

−

IN OUTSOUT

=

fL

×

V

x

V

IN

C

IN MIN

_

DxT xI

=

SOUT

V

IN RIPPLE

−

VVV

×−()

OUT IN OUT

V

IN

II

RIPPLE LOAD

=×

O

1

1

xR xC

π

xR xC

π

1

+

⎛

R ESR

O

⎜

⎝

+

RR

OL

O

1

⎞

⎟

⎠

==

ff

PLC P LC

12

__

π

2

xLxC x

f

Z ESR

_

=

2π

x ESR x C

f

f

ZEA1

ZEA2

=

_

211

=

_

233

Page 13

MAX15050/MAX15051

The above equations are based on the assumptions that

C1 >> C2, and R3 >> R2, which are true in most applications. Placements of these poles and zeros are determined by the frequencies of the double pole and ESR

zero of the power transfer function. It is also a function

of the desired closed-loop bandwidth. The following

section outlines the step-by-step design procedure to

calculate the required compensation components for

the MAX15050/MAX15051.

The output voltage is determined by:

where VFBis the feedback voltage equal to V

REFIN/SS

or 0.6V depending whether or not an external reference

voltage is applied to REFIN/SS.

For V

OUT

= VFB, R4 is not needed.

The zero-cross frequency of the closed-loop, fC, should

be between 10% and 20% of the switching frequency,

fS (1MHz). A higher zero-cross frequency results in

faster transient response. Once fCis chosen, C1 is calculated from the following equation:

where V

P-P

= 1V

P-P

(typ).

Due to the underdamped nature of the output LC double

pole, set the two zero frequencies of the type III compensation less than the LC double-pole frequency to provide

adequate phase boost. Set the two zero frequencies to

80% of the LC double-pole frequency. Hence:

Setting the second compensation pole, f

P2_EA

, at

f

Z_ESR

yields:

Set the third compensation pole at 1/2 of the switching

frequency (500kHz) to gain phase margin. Calculate

C2 as follows:

The above equations provide accurate compensation

when the zero-cross frequency is significantly higher

than the double-pole frequency. When the zero-cross

frequency is near the double-pole frequency, the actual

zero-cross frequency is higher than the calculated frequency. In this case, lowering the value of R1 reduces

the zero-cross frequency. Also, set the third pole of the

type III compensation close to the switching frequency

(1MHz) if the zero-cross frequency is above 200kHz to

boost the phase margin. The recommended range for

R3 is 2kΩ to 10kΩ. Note that the loop compensation

remains unchanged if only R4’s resistance is altered to

set different outputs.

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

______________________________________________________________________________________ 13

Figure 4. Type III Compensation Network

Figure 5. Type III Compensation Illustration

f

PEA

2_

f

PEA3

_

=

=

1

xR xC

π

223

1

x

π

RRxC12

2

VR

×

R

43=

FB

VV

()

−

OUT FB

C

1

=

xxRx

231

.

1 5625

⎛

⎞

V

IN

⎜

⎟

V

⎝

⎠

−

PP

R

L

+×

()π

R

O

f

C

L x C x R ESR

x

OO

RR

L x C x R ESR

x

OO

RR

C

R

1

3

=

1

=

08 1

1

xR

08 3

xC

C x ESR

O

R

23=

C

+

()

+.

LO

+

()

+.

LO

C

2

=

xR x f

π

1

1

S

L

LX

C

OUT

MAX15050

MAX15051

FB

C1

COMP

R1

C2

V

OUT

R3

R4

R2

C3

GAIN (dB)

COMPENSATION

TRANSFER

FUNCTION

POWER-STAGE

TRANSFER

FUNCTION

FIRST AND SECOND ZEROS

FREQUENCY (Hz)

DOUBLE POLE

OPEN-LOOP

GAIN

THIRD

POLE

SECOND

POLE

Page 14

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

14 ______________________________________________________________________________________

Soft-Starting Into a Prebiased Output

The MAX15050/MAX15051 can soft-start into a prebiased output without discharging the output capacitor.

In safe prebiased startup, both low-side and high-side

switches remain off to avoid discharging the prebiased

output. PWM operation starts when the voltage on

REFIN/SS crosses the voltage on FB. The PWM activity

starts with the low-side switch turning on first to build

the bootstrap capacitor charge. Power-good (PWRGD)

asserts 48 clock cycles after FB crosses 92.5% of the

final regulation set point. After 4096 clock cycles, the

MAX15050 switches from prebiased safe-startup mode

to either a skip mode or a forced PWM mode depending on whether the inductor current reaches zero. The

MAX15051 switches from the prebiased safe-startup

mode to forced PWM mode regardless of inductor current level.

The MAX15051 also can start into a prebiased voltage

higher than the nominal set point without abruptly discharging the output. This is achieved by using the sink

current control of the low-side MOSFET, which has four

internally set sinking current-limit thresholds. An internal

4-bit DAC steps through these thresholds, starting from

the lowest current limit to the highest, in 128 clock

cycles on every power-up.

PCB Layout Considerations and

Thermal Performance

Careful PCB layout is critical to achieve clean and stable operation. It is highly recommended to duplicate

the MAX15050/MAX15051 evaluation kit layout for optimum performance. If deviation is necessary, follow

these guidelines for good PCB layout:

1) Place capacitors on IN, V

DD

, and REFIN/SS as

close as possible to the device and the corresponding bump using direct traces.

2) Keep the high-current paths as short and wide as

possible. Keep the path of switching current short

and minimize the loop area formed by LX, the output capacitors, and the input capacitors.

3) Connect IN, LX, and GND separately to a large

copper area to help cool the device to further

improve efficiency and long-term reliability.

4) Ensure all feedback connections are short. Place

the feedback resistors and compensation components as close to the device as possible.

5) Route high-speed switching nodes, such as LX and

BST, away from sensitive analog areas (FB, COMP).

Chip Information

PROCESS: BiCMOS

WLP

GND IN

IN

GND

A1 A2 A3 A4

B1 B2 B3 B4

C1 C2 C3

C4

D1 D2 D3

D4

LX LX

V

DD

LX

I.C. I.C.

EN

BST

PWRGD FB COMP REFIN/SS

TOP VIEW

(BUMPS ON BOTTOM)

MAX15050/MAX15051

Pin Configuration

Package Information

For the latest package outline information and land patterns,

go to www.maxim-ic.com/packages

. Note that a “+”, “#”, or

“-” in the package code indicates RoHS status only. Package

drawings may show a different suffix character, but the drawing

pertains to the package regardless of RoHS status.

PACKAGE

TYPE

PACKAGE

CODE

OUTLINE NO.

LAND

PATTERN NO.

16 WLP W162C2+1

21-0200

—

Page 15

MAX15050/MAX15051

High-Efficiency, 4A, 1MHz, Step-Down Regulators

with Integrated Switches in 2mm x 2mm Package

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

15

© 2010 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

0 8/09 Initial release. —

1

2

REVISION

DATE

10/09

3/10

DESCRIPTION

Remove future product asterisk for MAX15051, update Electrical Characteris tics

table and Typical Operating Characteristics.

Revised Absolute Maximum Ratings and Electrical Characteristics table global

and note.

PAGES

CHANGED

1, 2, 4, 5, 6, 12,

14

2, 3, 4

Loading...

Loading...