Page 1

19-4719; Rev 0; 7/09

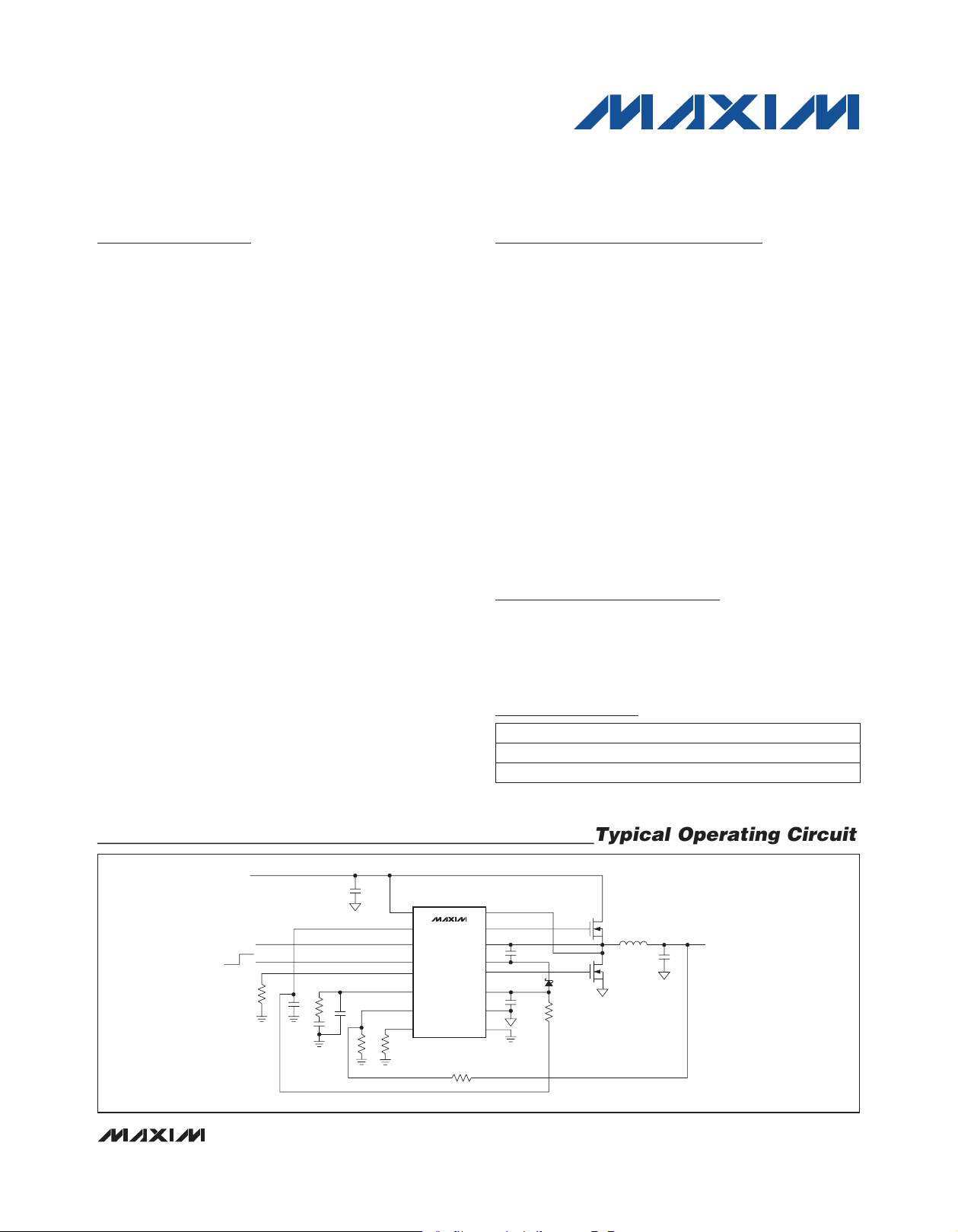

Typical Operating Circuit

40V, High-Performance, Synchronous

General Description

The MAX15046 synchronous step-down controller operates from a 4.5V to 40V input voltage range and generates an adjustable output voltage from 85% of the input

voltage down to 0.6V, supporting loads up to 25A. The

device allows monotonic startup into a prebiased bus

without discharging the output and features adaptive

internal digital soft-start.

The MAX15046 offers the ability to adjust the switching

frequency from 100kHz to 1MHz with an external resistor. The MAX15046’s adaptive synchronous rectification eliminates the need for an external freewheeling

Schottky diode. The device also utilizes the external

low-side MOSFET’s on-resistance as a current-sense

element, eliminating the need for a current-sense resistor. This protects the DC-DC components from damage

during output overloaded conditions or output shortcircuit faults without requiring a current-sense resistor.

Hiccup-mode current limit reduces power dissipation

during short-circuit conditions. The MAX15046 includes

a power-good output and an enable input with precise

turn-on/turn-off threshold, which can be used for input

supply monitoring and for power sequencing.

Additional protection features include sink-mode current

limit, and thermal shutdown. Sink-mode current limit prevents reverse inductor current from reaching dangerous

levels when the device is sinking current from the output.

Buck Controller

Features

S Input Voltage Ranges from 4.5V to 40V or 5V

Q10%

S Adjustable Outputs from 0.85 x V

S Adjustable Switching Frequency (100kHz to 1MHz)

with Q10% (1MHz) Accuracy

S Adaptive Internal Digital Soft-Start

S Up to 25A Output Capability

S Cycle-by-Cycle Valley-Mode Current Limit with

Adjustable, Temperature-Compensated Threshold

(30mV to 300mV)

S Monotonic Startup into Prebiased Output

S Q1% Accurate Voltage Reference

S 3A-Peak Gate Drivers

S Hiccup-Mode Short-Circuit Protection (Patent-

Pending Architecture)

S Overtemperature Shutdown

S Power-Good (PGOOD) Output and Enable Input

(EN) with Q5% Accurate Threshold

S Thermally Enhanced 16-Pin QSOP Package

Applications

Industrial Power Supplies (PLC, Industrial

Computers, Fieldbus Components, Fieldbus

Couplers)

Telecom Power Supplies

Base Stations

Ordering Information

Down to 0.6V

IN

MAX15046

The MAX15046 is available in a 16-pin QSOP or 16-pin

QSOP-EP package and operates over the -40NC to +125NC

temperature range.

Pin Configurations appear at end of data sheet.

4.5V TO 40V

V

IN

ON

OFF

R4

C1

IN

MAX15046

V

CC

PGOOD

EN

LIM

C5

R3

C6

C7

R1

COMP

FB

RT

R3

+

*EP = Exposed pad.

CSP

DH

LX

BST

DL

DRV

PGND

GND

R2

PART TEMP RANGE PIN-PACKAGE

MAX15046AAEE+ -40°C to +125°C 16 QSOP

MAX15046BAEE+ -40°C to +125°C 16 QSOP-EP*

Denotes a lead(Pb)-free/RoHS-compliant package.

Q1

C3

0.6V TO 0.85V x V

V

OUT

IN

L1

C2

D1

C4

R5

Q2

_______________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

40V, High-Performance, Synchronous

Buck Controller

ABSOLUTE MAXIMUM RATINGS

IN to GND ..............................................................-0.3V to +45V

VCC to GND ..................... -0.3V to lower of (VIN + 0.6V) and 6V

EN, DRV to GND ..................................................... -0.3V to +6V

PGOOD to GND ....................................................-0.3V to +45V

PGND to GND ......................................................-0.3V to +0.3V

DL to PGND .............................................-0.3V to (V

BST to PGND .......................................................-0.3V to +50V

LX and CSP to PGND ...............................................-1V to +45V

LX and CSP to PGND ............................-2V (50ns max) to +45V

MAX15046

BST to LX .................................................................-0.3V to +6V

CSP to LX .............................................................-0.3V to +0.3V

DH to LX .................................................. -0.3V to (V

All Other Pins to GND .............................. -0.3V to (VCC + 0.3V)

VCC Short Circuit to GND ..........................................Continuous

PGOOD Maximum Sink Current .........................................20mA

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-lay-

er board. For detailed information on package thermal considerations, refer to http://www.maxim-ic.com/thermal-tutorial.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may

affect device reliability.

DRV

BST

+ 0.3V)

+ 0.3V)

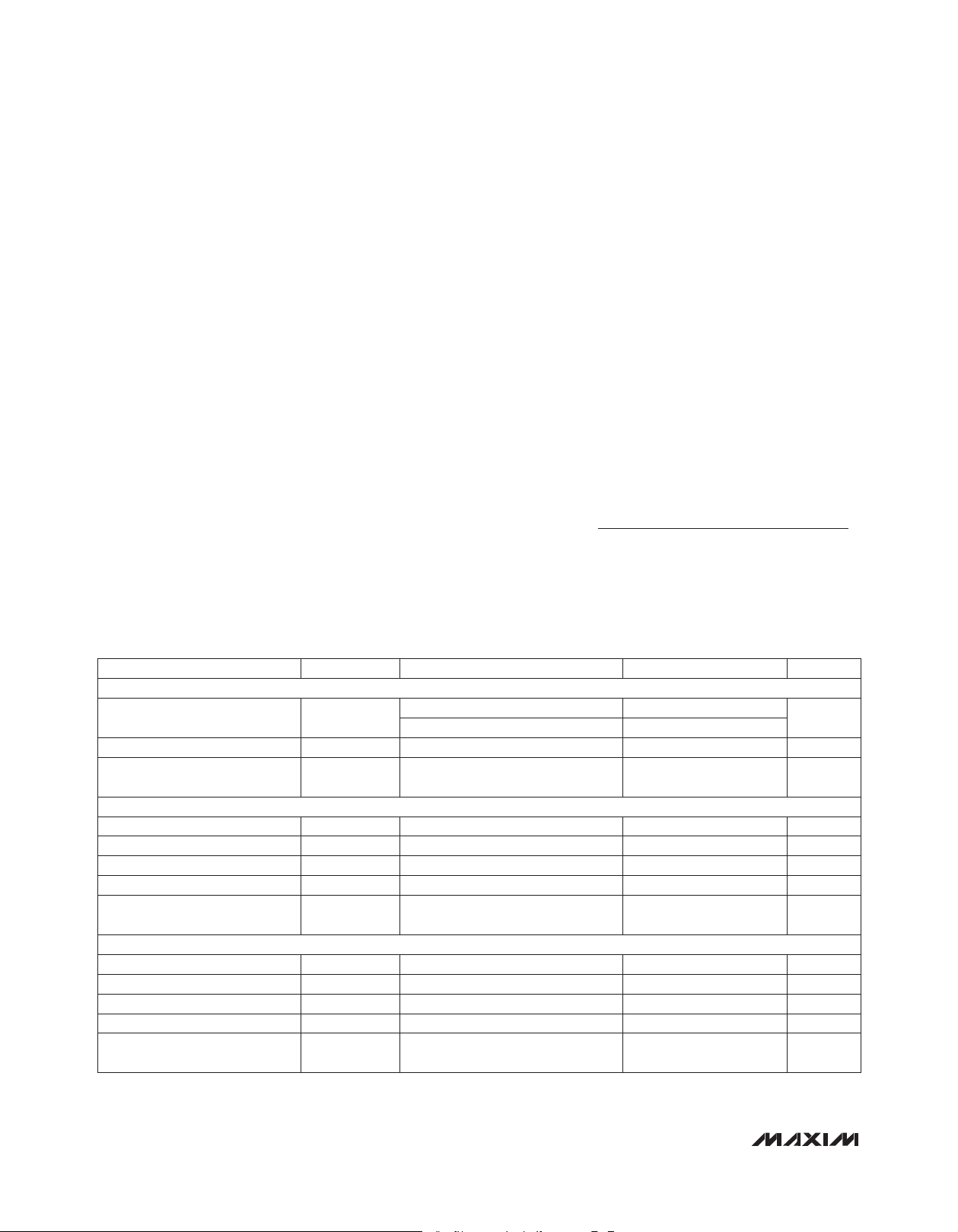

ELECTRICAL CHARACTERISTICS

(VIN = 24V, VEN = 5V, V

noted. Typical values are at TA = +25NC.) (Note 2)

GND

= V

= 0V, CIN = 1FF, C

PGND

VCC

Continuous Power Dissipation (TA = +70NC):

16-Pin QSOP (derate 9.6mW/NC above +70NC) .......771.5mW

16-Pin QSOP-EP (derate 22.7mW/NC above +70NC) 1818.2mW

Junction-to-Case Thermal Resistance (θJC) (Note 1)

16-Pin QSOP ................................................................37NC/W

16-Pin QSOP-EP ............................................................6NC/W

Junction-to-Ambient Thermal Resistance (θJA) (Note 1)

16-Pin QSOP ...........................................................103.7NC/W

16-Pin QSOP-EP ..........................................................44NC/W

Operating Temperature Range ........................ -40NC to +125NC

Junction Temperature .....................................................+150NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (soldering, 10s) ................................+300NC

= 4.7FF, RRT = 49.9kI, TA = TJ = -40NC to +125NC, unless otherwise

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SYSTEM SPECIFICATIONS

Input-Voltage Range V

Quiescent Supply Current I

Shutdown Supply Current I

VCC REGULATOR

Output Voltage V

VCC Regulator Dropout VIN = 4.5V, I

VCC Short-Circuit Output Current VIN = 5V 30 55 90 mA

VCC Undervoltage Lockout V

VCC Undervoltage Lockout

Hysteresis

ERROR AMPLIFIER (FB, COMP)

FB Input-Voltage Set Point V

FB Input Bias Current I

FB to COMP Transconductance g

Open-Loop Gain 80 dB

Unity-Gain Bandwidth

IN

IN_Q

IN_SBY

VCC

CCUVLO

FB

FB

M

VIN = VCC = V

VIN = 24V, VFB = 0.9V, no switching 2 3 mA

VIN = 24V, VEN = 0V, I

PGOOD = unconnected

6V ≤ VIN ≤ 40V, I

V

rising 3.8 4 4.2 V

VCC

VFB = 0.6V -250 +250 nA

I

= Q20FA

COMP

Capacitor from COMP to GND =

47pF

DRV

= 0,

VCC

= 6mA 5 5.25 5.5 V

LOAD

= 25mA 0.18 0.45 V

LOAD

4.5 40

4.5 5.5

0.35 0.55 mA

400 mV

584 590 596 mV

600 1200 1800

5 MHz

V

FS

2 ______________________________________________________________________________________

Page 3

40V, High-Performance, Synchronous

Buck Controller

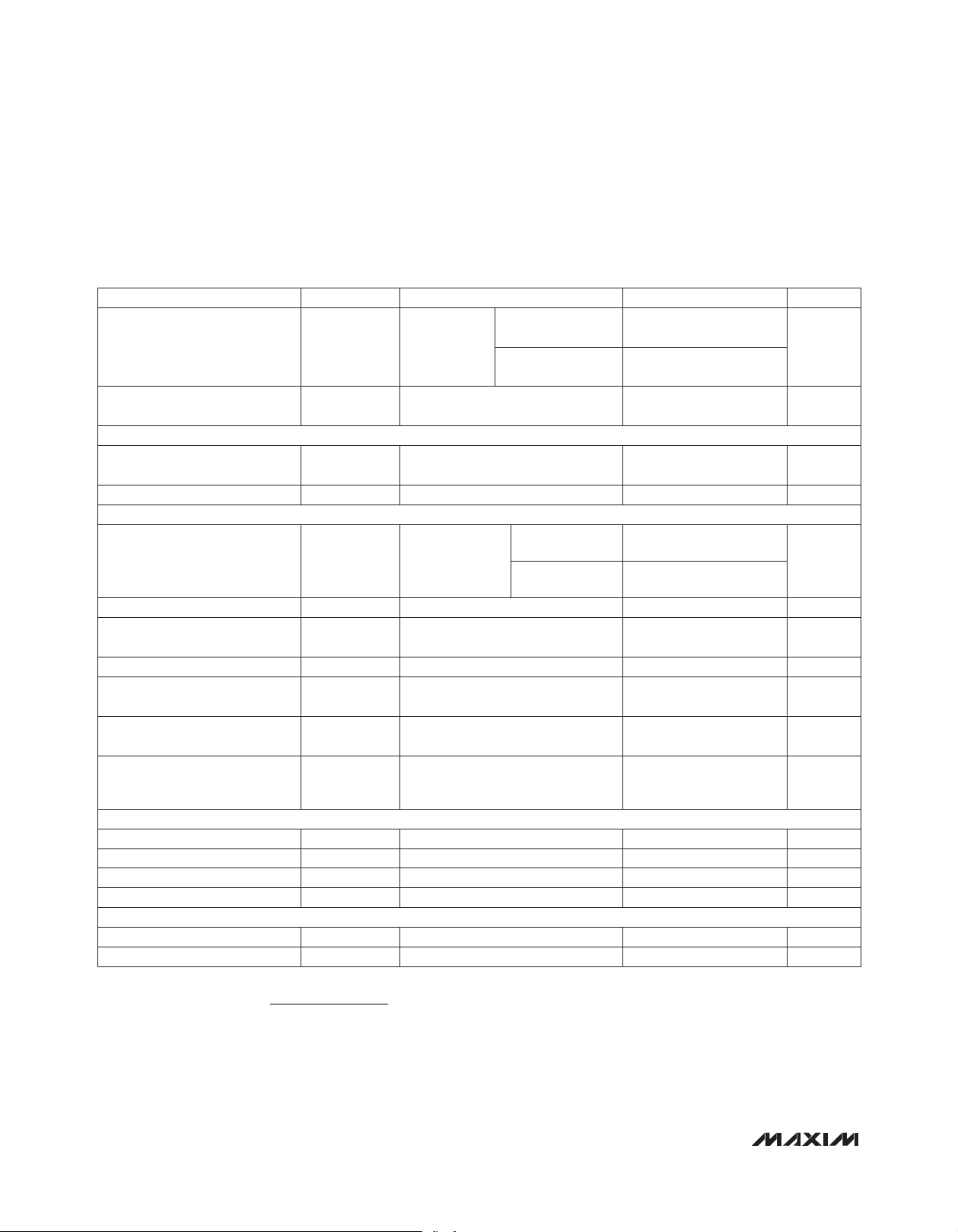

ELECTRICAL CHARACTERISTICS (continued)

(VIN = 24V, VEN = 5V, V

noted. Typical values are at TA = +25NC.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

COMP-RAMP

COMP Source/Sink Current I

ENABLE (EN)

EN Input High V

EN Input Low V

EN Input Leakage Current I

OSCILLATOR

Switching Frequency (100kHz) f

Switching Frequency (300kHz) f

Switching Frequency (1MHz) f

Switching Frequency Adjustment

Range

RT Voltage V

PWM MODULATOR

PWM Ramp Peak-to-Peak

Amplitude

PWM Ramp Valley V

Minimum Controllable On-Time 70 125 ns

Maximum Duty Cycle

Minimum Low-Side On-Time

OUTPUT DRIVERS/DRIVERS SUPPLY (V

Undervoltage Lockout V

DRV Undervoltage Lockout

Hysteresis

DH On-Resistance

DL On-Resistance

DH Peak Current C

Minimum Voltage 200 mV

GND

= V

= 0V, CIN = 1FF, C

PGND

COMP

EN_H

EN_L

EN

SW

SW

SW

RT

V

RAMP

VALLEY

DRV

DRV_UVLOVDRV

= 4.7FF, RRT = 49.9kI, TA = TJ = -40NC to +125NC, unless otherwise

VCC

V

= 1.4V 50 80 110

COMP

VEN rising 1.14 1.20 1.26 V

VEN falling 1.05 V

VEN = 5.5V -1 +1

RRT = 150kI

RRT = 49.9kI

RRT = 14.3kI

(Note 3) 100 1000 kHz

RRT = 49.9kI

fSW = 300kHz (RRT = 49.9kI)

fSW = 1MHz (RRT = 49.9kI)

)

rising 4.0 4.2 4.4 V

Low, sinking 100mA,

V

- VLX = 5V

BST

High, sourcing 100mA,

V

- VLX = 5V

BST

Low, sinking 100mA,

V

= VCC = 5.25V

DRV

High, sourcing 100mA,

V

= VCC = 5.25V

DRV

Sinking,

V

- VLX = 5V

LOAD

= 10nF

BST

Sourcing,

V

- VLX = 5V

BST

80 100 120 kHz

270 300 330 kHz

0.9 1 1.1 MHz

1.15 1.2 1.25 V

1.5 V

1.5 V

85 87.5 %

110 ns

400 mV

1 3

1.5 4

1 3

1.5 4

3

2

MAX15046

FA

FA

I

A

_______________________________________________________________________________________ 3

Page 4

40V, High-Performance Synchronous

Buck Controller

ELECTRICAL CHARACTERISTICS (continued)

(VIN = 24V, VEN = 5V, V

noted. Typical values are at TA = +25NC.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DL Peak Current C

MAX15046

DH, DL Break-Before-Make Time

(Dead Time)

SOFT-START

Soft-Start Duration 2048

Reference Voltage Steps 64 Steps

CURRENT LIMIT/HICCUP

Cycle-by-Cycle Valley CurrentLimit Threshold Adjustment

Range

GND

= V

= 0V, CIN = 1FF, C

PGND

= 4.7FF, RRT = 49.9kI, TA = TJ = -40NC to +125NC, unless otherwise

VCC

= 10nF

LOAD

V

- V

CSP

PGND

valley limit =

V

/10

LIM

Sinking, V

= 5.25V

Sourcing, V

VCC = 5.25V

V

LIM

,

V

LIM

= VCC

DRV

=

DRV

= 0.3V 30

= 3V 300

3

2

10 ns

Switching

A

Cycles

mV

LIM Reference Current I

LIM Reference Current

Temperature Coefficient

CSP Input Bias Current V

Number of Consecutive CurrentLimit Events to Hiccup

Hiccup Timeout 4096

Peak Low-Side Sink Current-Limit

Threshold

POWER-GOOD (PGOOD)

PGOOD Threshold VFB rising 90 94 97.5 %V

PGOOD Threshold Hysteresis VFB falling 2.65 %V

PGOOD Output Low Voltage V

PGOOD Output Leakage Current I

THERMAL SHUTDOWN

Thermal Shutdown Threshold Temperature rising +150

Thermal Shutdown Hysteresis 20

Note 2: All devices are 100% tested at room temperature and guaranteed by design over the specified temperature range.

Note 3: Select RRT as:

R

=

RT

f (1 x 10 )(f )

+

SW SW

LIM

PGOOD_LIPGOOD

LEAK_PGOODVPGOOD

×

-7 2

9

17.3 10

V

= 0.3V to 3V, TA = +25NC

LIM

= 40V -1 +1

CSP

7 Events

V

- V

CSP

R

= 30kI, V

ILIM

TA = +25NC

, where fSW is in Hertz.

, sink limit = V

PGND

= 1.5V,

LIM

= 2mA, VEN = 0V 0.4 V

= 40V, VEN = 5V, VFB = 1V -1 +1

LIM

/20,

45 50 55

2300

75 mV

ppm/NC

Switching

Cycles

FA

FA

FB

FB

FA

NC

NC

4 ______________________________________________________________________________________

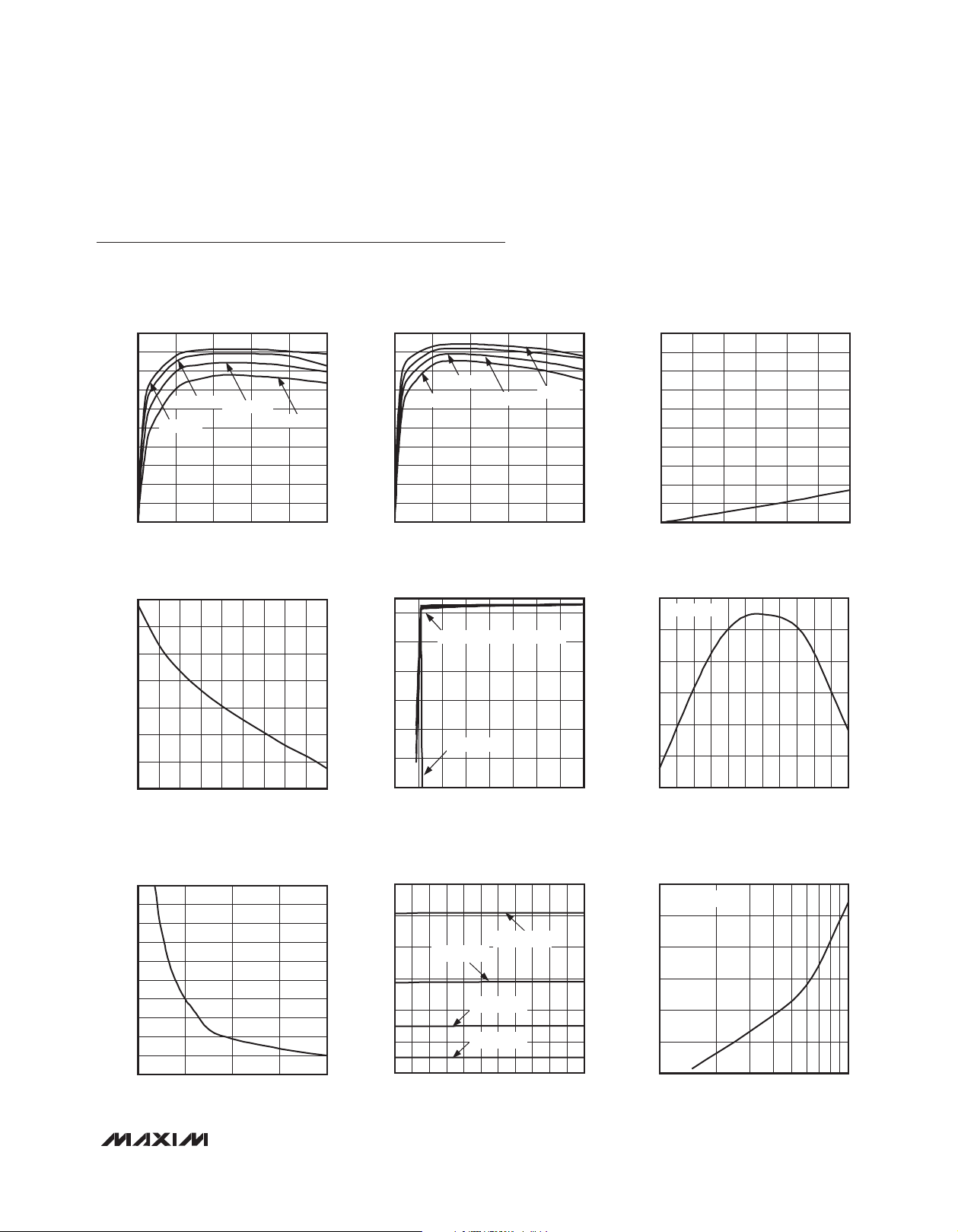

Page 5

40V, High-Performance Synchronous

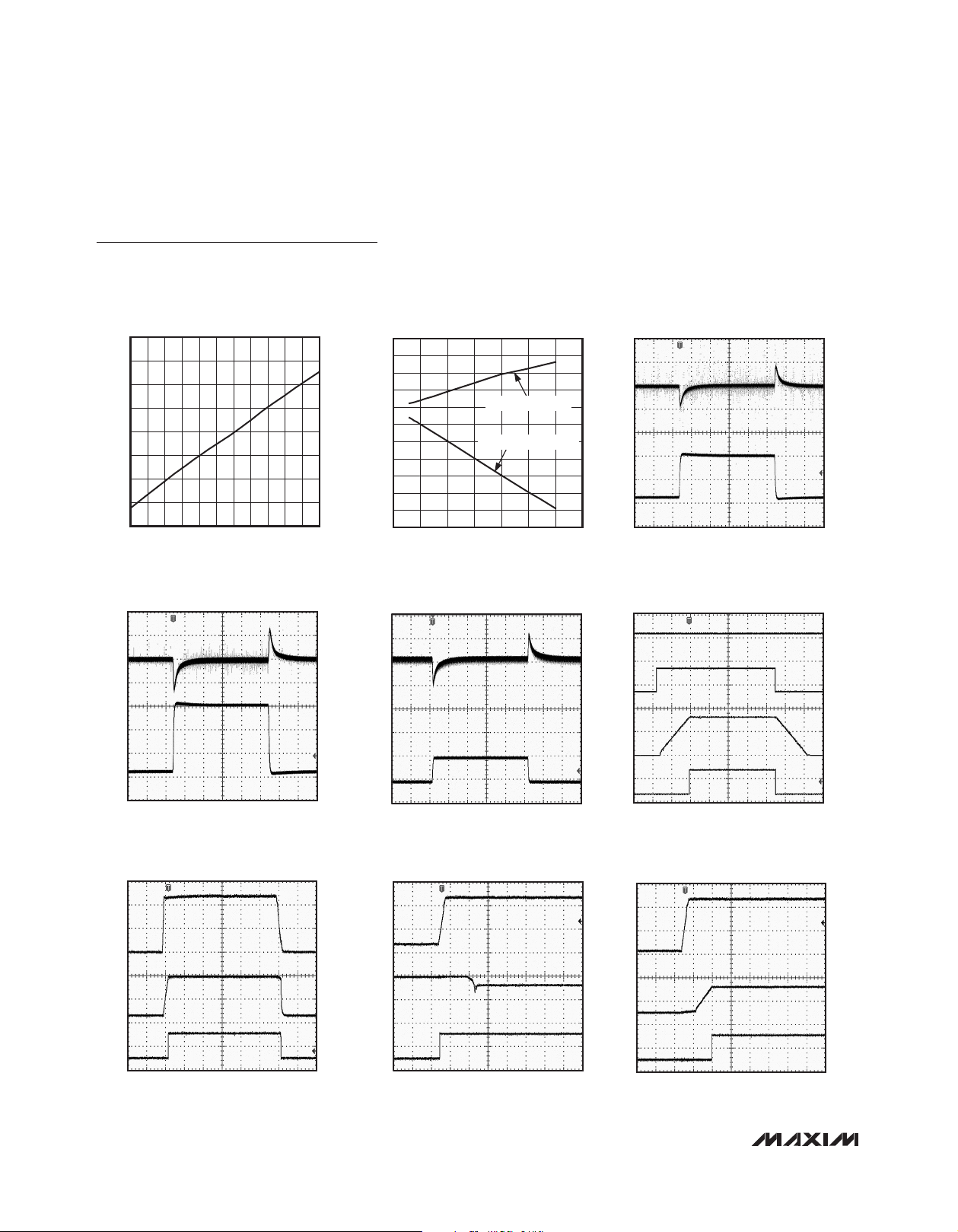

EFFICIENCY vs. LOAD CURRENT

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

EFFICIENCY (%)

V

(V)

FREQUENCY (kHz)

FREQUENCY (kHz)

Buck Controller

Typical Operating Characteristics

(VIN = 24V, TA = +25NC, unless otherwise noted.)

MAX15046

(VIN = 24V)

100

90

80

70

60

50

40

30

20

10

0

V

= 3.3V

OUT

V

= 1.8V

OUT

V

= 5V

OUT

0 15

LOAD CURRENT (A)

VCC vs. LOAD CURRENT

5.256

5.254

5.252

5.250

(V)

CC

V

5.248

5.246

5.244

5.242

LOAD CURRENT (mA)

(VIN = 12V)

100

90

MAX15046 toc01

80

70

V

= 1.2V

OUT

12963

60

50

40

30

20

10

0

0 15

V

= 1.2V

OUT

V

= 1.8V

OUT

V

OUT

LOAD CURRENT (A)

= 3.3V

V

= 5V

OUT

12963

0.50

0.45

MAX15046 toc02

0.40

0.35

0.30

0.25

0.20

0.15

% OUTPUT FROM NORMAL

0.10

0.05

0

VCC LINE REGULATION

MAX15046 toc05

(V)

V

CC

5.266

5.265

5.264

5.263

5.262

5.261

5.260

4035302520151050 45

MAX15046 toc04

5.2

I

= 5mA, 10mA, 20mA, 30mA

5.0

4.8

CC

4.6

4.4

4.2

4.0

0 40

VCC

I

VCC

= 40mA

VIN (V)

3530252015105

V

vs. LOAD CURRENT

OUT

0 12

LOAD CURRENT (A)

108642

VCC vs. TEMPERATURE

I

= 5mA

LOAD

-40 125

TEMPERATURE (NC)

1109580655035205-10-25

MAX15046 toc03

MAX15046 toc06

SWITCHING FREQUENCY

vs. R

1000

900

800

700

600

500

400

300

200

100

0

0 160

RT

RRT (kI)

_______________________________________________________________________________________ 5

SWITCHING FREQUENCY

vs. TEMPERATURE

1200

1000

MAX15046 toc07

800

600

400

200

0

1208040

-40 125

RT = 25.5kI

TEMPERATURE (NC)

RT = 14.3kI

RT = 49.9kI

RT = 150kI

MAX15046 toc08

1109580655035205-10-25

2.8

CDH = CDL = 0

2.7

2.6

(mA)

2.5

IN

I

2.4

2.3

2.2

100 1000

IIN vs.

SWITCHING FREQUENCY

MAX15046 toc09

FREQUENCY (kHz)

Page 6

40V, High-Performance, Synchronous

Buck Controller

Typical Operating Characteristics (continued)

(VIN = 24V, TA = +25NC, unless otherwise noted.)

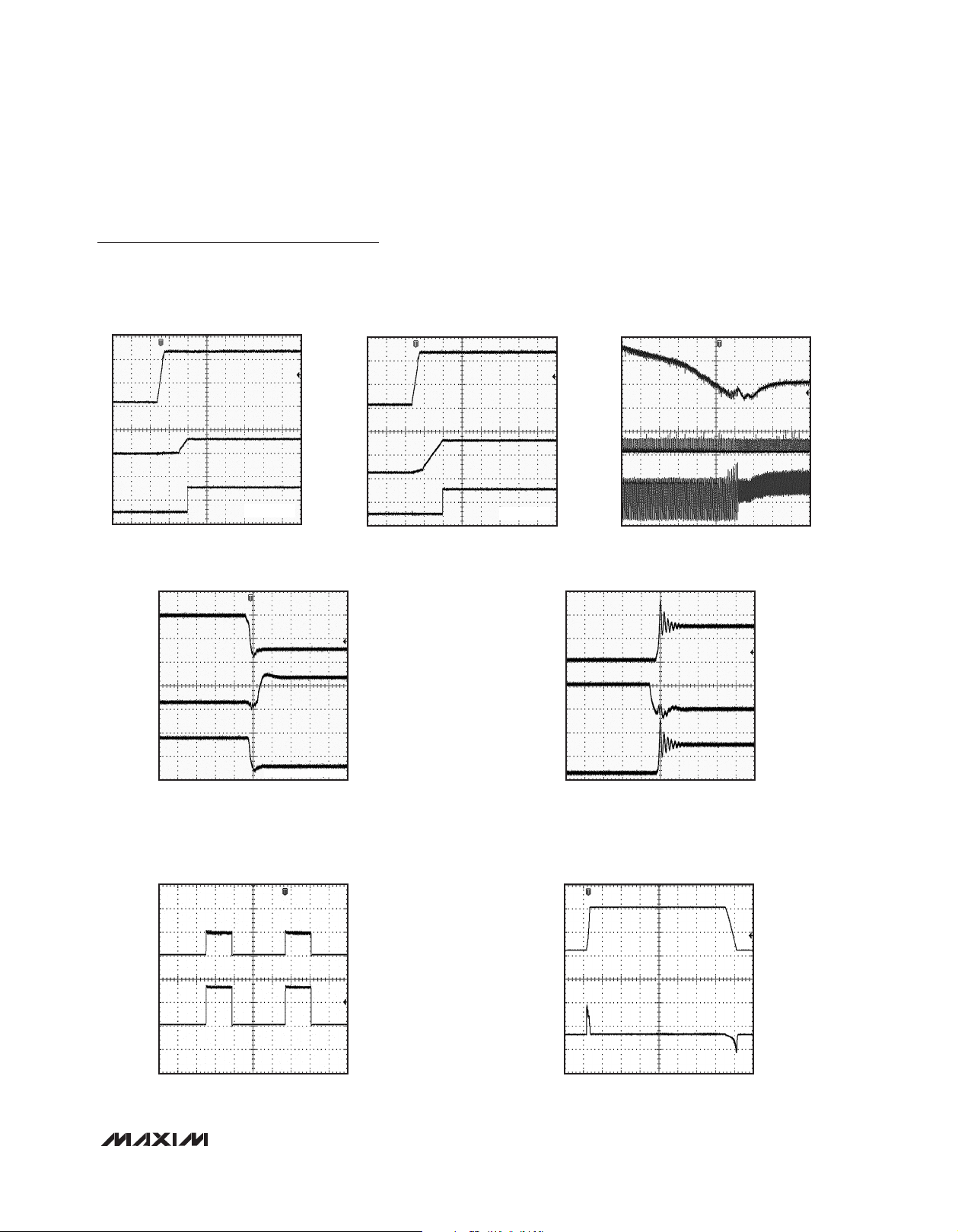

LIM REFERENCE CURRENT

vs. TEMPERATURE

80

75

70

MAX15046

65

60

CURRENT (FA)

55

50

45

40

-40 125

TEMPERATURE (NC)

LOAD TRANSIENT ON OUT (1A TO 15A)

200Fs/div

11095-25 -10 5 35 50 6520 80

MAX15046 toc12b

SINK AND SOURCE CURRENT LIMIT

THRESHOLDS vs. RESISTANCE (R

0.20

0.15

0.10

MAX15046 toc10

0.05

0

-0.05

-0.10

-0.15

-0.20

CURRENT-LIMIT THRESHOLD (V)

-0.25

-0.30

-0.35

0 70

LOAD TRANSIENT ON OUT (1A TO 6A)

V

OUT

200mV/div

I

OUT

5A/div

SINK CURRENT LIMIT

SOURCE CURRENT LIMIT

RESISTANCE (kI)

200Fs/div

ILIM

605030 402010

MAX15046 toc12c

)

MAX15046 toc11

V

OUT

100mV/div

I

OUT

5A/div

LOAD TRANSIENT ON OUT (1A TO 10A)

200Fs/div

MAX15046 toc12a

STARTUP DISABLE FROM EN

= 3.3I)

(R

LOAD

4ms/div

MAX15046 toc13

V

OUT

200mV/div

I

OUT

5A/div

IN

20V/div

EN

5V/div

V

OUT

2V/div

PGOOD

5V/div

STARTUP AND DISABLE FROM IN

= 3.3kI)

(R

LOAD

20ms/div

MAX15046 toc14

IN

10V/div

V

OUT

2V/div

PGOOD

5V/div

STARTUP WITH PREBIASED

OUTPUT (4.0V)

4ms/div

MAX15046 toc15a

24V

IN

10V/div

4V

V

OUT

2V/div

PGOOD

5V/div

STARTUP WITH PREBIASED

OUTPUT (1.0V)

4ms/div

6 ______________________________________________________________________________________

MAX15046 toc15b

24V

IN

10V/div

1V

V

OUT

2V/div

PGOOD

5V/div

Page 7

40V, High-Performance, Synchronous

STARTUP WITH PREBIASED

Buck Controller

Typical Operating Characteristics (continued)

(VIN = 24V, TA = +25NC, unless otherwise noted.)

MAX15046

OUTPUT (2V)

4ms/div

MAX15046 toc15c

V

OUT

= 3.3V

DH_ AND DL_ DISOVERLAP

40ns/div

24V

IN

10V/div

2V

V

OUT

2V/div

PGOOD

5V/div

MAX15046 toc17a

STARTUP WITH PREBIASED

OUTPUT (0.5V)

V

DH

20V/div

V

DL

5V/div

V

LX

20V/div

4ms/div

MAX15046 toc15d

V

OUT

= 3.3V

SINK CURRENT-LIMIT WAVEFORMS

24V

V

IN

10V/div

0.5V

V

OUT

2V/div

PGOOD

5V/div

DH_ AND DL_ DISOVERLAP

40ns/div

(5V PREBIASED)

200Fs/div

MAX15046 toc17b

MAX15046 toc16

V

DH

20V/div

V

DL

5V/div

V

LX

20V/div

V

OUT

500mV/div

V

LX

50V/div

I

LX

5A/div

OUTPUT SHORT-CIRCUIT BEHAVIOUR

OUTPUT VOLTAGE AND CURRENT

10ms/div

MAX15046 toc18

V

OUT

200mV/div

I

OUT

10A/div

LINE-TRANSIENT RESPONSE

10ms/div

MAX15046 toc19

24V

V

IN

200mV/div

5V

V

OUT

(AC-COUPLED)

200mV/div

_______________________________________________________________________________________ 7

MONITOR

Page 8

40V, High-Performance, Synchronous

Buck Controller

Pin Description

PIN NAME FUNCTION

1 IN

2 V

MAX15046

3 PGOOD

4 EN

5 LIM

6 COMP Error-Amplifier Output. Connect compensation network from COMP to FB or from COMP to GND.

7 FB

8 RT

9 GND Analog Ground. Connect PGND and AGND together at a single point.

10 PGND Power Ground. Use PGND as a return path for the low-side MOSFET gate driver.

11 DRV

12 DL Low-Side External MOSFET Gate-Driver Output. DL swings from DRV to PGND.

13 BST

14 LX

15 DH High-Side External MOSFET Gate-Driver Output. DH swings from BST to LX.

16 CSP Current-Sense Positive Input. Connect to the drain of low-side MOSFET with Kelvin connection.

— EP

CC

Regulator Input. Connect to the input rail of the buck converter. Bypass IN to PGND with a 100nF

minimum ceramic capacitor. When operating in the 5V Q10% range, connect IN to VCC.

5.25V Linear Regulator Output. Bypass VCC to PGND with a ceramic capacitor of at least 4.7FF

when VCC supplies MOSFET gate-driver current at DRV or 2.2FF when VCC is not used to power

DRV.

Open-Drain Power-Good Output. Pull up PGOOD to an external power supply or output with an

external resistor.

Active-High Enable Input. Pull EN to GND to disable the buck converter output. Connect to VCC

for always-on operation. EN can be used for power sequencing and as a UVLO adjustment input.

Current-Limit Input. Connect a resistor from LIM to GND to program the current-limit threshold from

30mV (R

Feedback Input (Inverting Input of Error Amplifier). Connect FB to a resistive divider between the

buck converter output and GND to adjust the output voltage from 0.6V up to 0.85 x IN.

Oscillator-Timing Resistor Input. Connect a resistor from RT to GND to set the oscillator frequency

from 100kHz to 1MHz.

Gate-Driver Supply Voltage. DRV is internally connected to the low-side driver supply. Bypass DRV to

PGND with a 2.2FF minimum ceramic capacitor (see the Typical Application Circuits).

Boost Flying Capacitor Connection. Internally connected to the high-side driver supply. Connect a

ceramic capacitor of at least 100nF between BST and LX and a diode between BST and DRV for

the high-side MOSFET gate-driver supply.

Inductor Connection. Also serves as a return terminal for the high-side MOSFET driver current.

Connect LX to the switching side of the inductor.

Exposed Pad. EP is internally connected to ground. Connect EP to a large copper ground plane to

maximize thermal performance.

= 6kI) to 300mV (R

LIM

= 60kI).

LIM

8 ______________________________________________________________________________________

Page 9

40V, High-Performance, Synchronous

Buck Controller

Functional Diagram

MAX15046

VREF

RT

ENABLE

EN

VREF

V_BGAP

VIN_OK

V_BGAP

V

CC

BGAP_OK

BGAP_OK

V_DRV

VIN_OK

LIM

IN

COMPARATOR

BGAP_OK

BANDGAP

OK

GENERATOR

INTERNAL

VOLTAGE

REGULATOR

V

CC

UVLO

DRV

UVLO

THERMAL

SHUTDOWN

AND ILIM

CURRENT

GENERATOR

IN

UVLO

MAX15046

EN_INT

BGAP_OK

VL_OK

VDRV_OK

SHUTDOWN

VIN_OK

OSCILLATOR

V

REF

V

BGAP

OSC ENABLE

DC-DC

OSCILLATOR

ENABLE

LOGIC

VIN_OK

I

BIAS

= 0.6V

= 1.24V

CK

AND

MAIN

BIAS

CURRENT

GENERATOR

BANDGAP

REFERENCE

HICCUP

VREF

CK

ENABLE

VREF

CK

DH_DL_ENABLE

HICCUP TIMEOUT

CURRENT-LIMIT

RAMP GENERATOR

CK

SINK

CURRENT-LIMIT

COMPARATOR

VALLEY

COMPARATOR

SOFT-START/STOP

AND

HICCUP

LOGIC

PWM

CONTROL

LOGIC

HICCUP TIMEOUT

RAMP

LIM/20

LIM/10

FB

DAC_VREF

DH_DL_ENABLE

HICCUP

VREF

G

M

PWM

COMPARATOR

PWM

HIGH-

SIDE

DRIVER

LOW-

SIDE

DRIVER

ENABLE

PGOOD

COMPARATOR

COMP

BST

DH

LX

CSP

DRV

DL

PGND

FB

PGOOD

GND

_______________________________________________________________________________________ 9

Page 10

40V, High-Performance, Synchronous

Buck Controller

Detailed Description

The MAX15046 synchronous step-down controller operates from a 4.5V to 40V input-voltage range and generates an adjustable output voltage from 85% of the inputvoltage down to 0.6V while supporting loads up to 25A.

As long as the device supply voltage is within 5.0V to

5.5V, the input power bus (VIN) can be as low as 3.3V.

The MAX15046 offers adjustable switching frequency

from 100kHz to 1MHz with an external resistor. The

MAX15046

adjustable switching frequency provides design flexibility in selecting passive components. The MAX15046

adopts an adaptive synchronous rectification to eliminate external freewheeling Schottky diodes and improve

efficiency. The device utilizes the on-resistance of the

external low-side MOSFET as a current-sense element.

The current-limit threshold voltage is resistor-adjustable

from 30mV to 300mV and is temperature-compensated,

so that the effects of the MOSFET R

over temperature are reduced. This current-sensing

scheme protects the external components from damage

during output overloaded conditions or output shortcircuit faults without requiring a current-sense resistor.

Hiccup-mode current limit reduces power dissipation

during short-circuit conditions. The MAX15046 includes

a power-good output and an enable input with precise

turn-on/-off threshold to be used for monitoring and for

power sequencing.

The MAX15046 features internal digital soft-start that

allows prebias startup without discharging the output. The

digital soft-start function employs sink current limiting to

prevent the regulator from sinking excessive current when

the prebias voltage exceeds the programmed steadystate regulation level. The digital soft-start feature prevents

the synchronous rectifier MOSFET and the body diode of

the high-side MOSFET from experiencing dangerous levels of current while the regulator is sinking current from the

output. The MAX15046 shuts down at a +150NC junction

temperature to prevent damage to the device.

DS(ON)

DC-DC PWM Controller

The MAX15046 step-down controller uses a PWM voltage-mode control scheme (see the Functional Diagram).

Control-loop compensation is external for providing maximum flexibility in choosing the operating frequency and

output LC filter components. An internal transconductance error amplifier produces an integrated error voltage at COMP that helps to provide higher DC accuracy.

The voltage at COMP sets the duty cycle using a PWM

variation

comparator and a ramp generator. On the rising edge

of an internal clock, the high-side n-channel MOSFET

turns on and remains on until either the appropriate duty

cycle or the maximum duty cycle is reached. During

the on-time of the high-side MOSFET, the inductor current ramps up. During the second-half of the switching

cycle, the high-side MOSFET turns off and the low-side

n-channel MOSFET turns on. The inductor releases the

stored energy as the inductor current ramps down, providing current to the output. Under overload conditions,

when the inductor current exceeds the selected valley

current-limit threshold (see the Current-Limit Circuit (LIM)

section), the high-side MOSFET does not turn on at the

subsequent clock rising edge and the low-side MOSFET

remains on to let the inductor current ramp down.

Internal 5.25V Linear Regulator

An internal linear regulator (VCC) provides a 5.25V nominal supply to power the internal functions and to drive the

low-side MOSFET. Connect IN and V

using an external 5V Q10% power supply. The maximum

regulator input voltage (VIN) is 40V. Bypass IN to GND

with a 1FF ceramic capacitor. Bypass the output of the

linear regulator (VCC) with a 4.7FF ceramic capacitor to

GND. The VCC dropout voltage is typically 180mV. When

VIN is higher than 5.5V, V

MAX15046 also employs an undervoltage lockout circuit

that disables the internal linear regulator when V

falls below 3.6V (typical). The 400mV UVLO hysteresis

prevents chattering on power-up/power-down.

is typically 5.25V. The

VCC

together when

CC

VCC

MOSFET Gate Drivers (DH, DL)

DH and DL are optimized for driving large-size n-channel

power MOSFETs. Under normal operating conditions and

after startup, the DL low-side drive waveform is always

the complement of the DH high-side drive waveform,

with controlled dead time to prevent crossconduction or

“shoot-through.” An adaptive dead-time circuit monitors

the DH and DL outputs and prevents the opposite-side

MOSFET from turning on until the MOSFET is fully off.

Thus, the circuit allows the high-side driver to turn on

only when the DL gate driver has turned off preventing

the low side (DL) from turning on until the DH gate driver

has turned off.

The adaptive driver dead time allows operation without

shoot-through with a wide range of MOSFETs, minimizing delays and maintaining efficiency. There must be a

low-resistance, low-inductance path from DL and DH to

the MOSFET gates for the adaptive dead-time circuits

10 _____________________________________________________________________________________

Page 11

40V, High-Performance, Synchronous

to function properly. The stray impedance in the gate

discharge path can cause the sense circuitry to interpret

the MOSFET gate as “off” while the VGS of the MOSFET

is still high. To minimize stray impedance, use very short,

wide traces.

Synchronous rectification reduces conduction losses in

the rectifier by replacing the normal low-side Schottky

catch diode with a low-resistance MOSFET switch. The

MAX15046 features a robust internal pulldown transistor

with a typical 1I R

resistance prevents DL from being pulled up during the

fast rise time of the LX node, due to capacitive coupling

from the drain to the gate of the low-side synchronous

rectifier MOSFET.

High-Side Gate-Drive Supply (BST)

An external Schottky diode between BST and DH is

required to boost the gate voltage above LX providing

the necessary gate-to-source voltage to turn on the highside MOSFET. The boost capacitor connected between

BST and LX holds up the voltage across the floating gate

driver during the high-side MOSFET on-time.

to drive DL low. This low on-

DS(ON)

Buck Controller

The charge lost in the boost capacitor for delivering the

gate charge is replenished when the high-side MOSFET

turns off and the LX node goes to ground. When LX is

low, the external diode between V

es the boost capacitor. See the Boost Capacitor and

Diode Selection section in the Applications Information

to choose the right boost capacitor and diode.

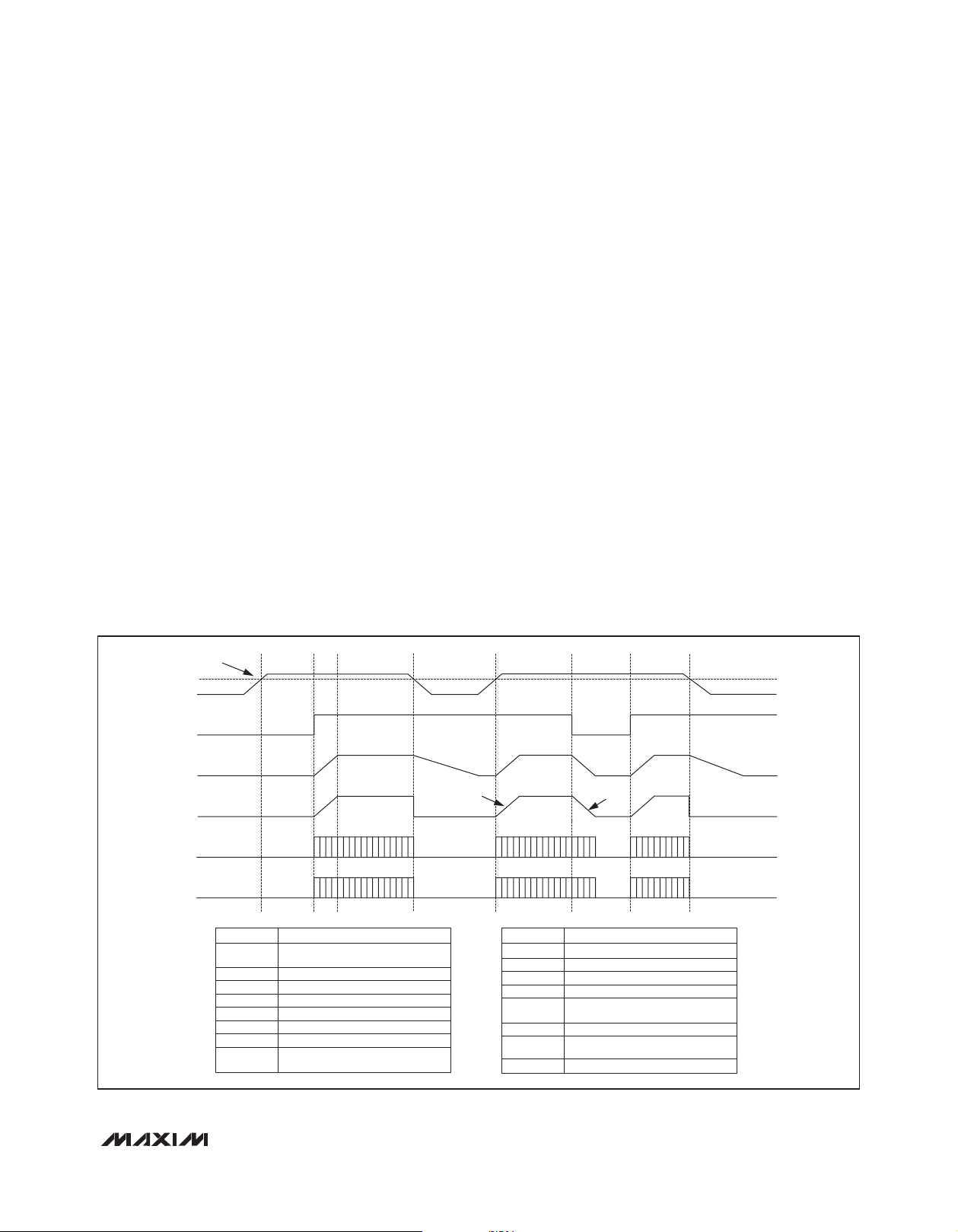

Enable Input (EN), Soft-Start, and Soft-Stop

Drive EN high to turn on the MAX15046. A soft-start

sequence starts to increase (step-wise) the reference

voltage of the error amplifier. The duration of the softstart ramp is 2048 switching cycles and the resolution is

1/64th of the steady-state regulation voltage allowing a

smooth increase of the output voltage. A logic-low on EN

initiates a soft-stop sequence by stepping down the reference voltage of the error amplifier. After the soft-stop

sequence is completed, the MOSFET drivers are both

turned off. See Figure 1.

Connect EN to VCC for always-on operation. Owing to

the accurate turn-on/-off thresholds, EN can be used

as a UVLO adjustment input, and for power sequencing

together with the PGOOD outputs.

and BST recharg-

DRV

MAX15046

UVLO

V

V

OUT

DAC_VREF

B

CC

EN

DH

DL

SYMBOL DEFINITION

DAC_VREF

Undervoltage threshold value is provided in

UVLO

the Electrical Characteristics table.

V

Internal 5.25V linear regulator output.

CC

Active-high enable input.

EN

V

Regulator output voltage.

OUT

Regulator internal soft-start and soft-stop signal.

Regulator high-side gate-driver output.

DH

Regulator low-side gate-driver output.

DL

V

rising while below the UVLO threshold.

A

CC

EN is low.

C D

E

2048 CLOCK

CYCLES

F

SYMBOL DEFINITION

B

C

D

E

F

G

H

I

G

2048 CLOCK

CYCLES

VCC is higher than the UVLO threshold. EN is low.

EN is pulled high. DH and DL start switching.

Normal operation.

V

drops below UVLO.

CC

V

goes above the UVLO threshold. DH and DL

CC

start switching. Normal operation.

EN is pulled low. V

EN is pulled high. DH and DL start switching.

Normal operation.

V

drops below UVLO.

CC

H IA

enters soft-stop.

OUT

Figure 1. Power On-Off Sequencing

______________________________________________________________________________________ 11

Page 12

40V, High-Performance, Synchronous

Buck Controller

When the valley current limit is reached during soft-start,

the MAX15046 regulates to the output impedance times

the limited inductor current and turns off after 4096 clock

cycles. When starting up into a large capacitive load (for

example), the inrush current will not exceed the currentlimit value. If the soft-start is not completed before 4096

clock cycles, the device turns off. The device remains

off for 8192 clock cycles before trying to soft-start again.

This implementation allows the soft-start time to be

automatically adapted to the time necessary to keep the

MAX15046

inductor current below the limit while charging the output

capacitor.

Power-Good Output (PGOOD)

The MAX15046 includes a power-good comparator to

monitor the output voltage and detect the power-good

threshold, fixed at 93% of the nominal FB voltage. The

open-drain PGOOD output requires an external pullup

resistor. PGOOD sinks up to 2mA of current while low.

PGOOD goes high (high-Z) when the regulator output

increases above 93% of the designed nominal regulated

voltage. PGOOD goes low when the regulator output voltage drops to below 90% of the nominal regulated voltage.

PGOOD asserts low during the hiccup timeout period.

Startup into a Prebiased Output

When the MAX15046 starts into a prebiased output, DH

and DL are off so that the converter does not sink current

from the output. DH and DL do not start switching until

the PWM comparator commands the first PWM pulse.

The first PWM pulse occurs when the ramping reference

voltage increases above the FB voltage.

When the output voltage is biased above the output set

point, the controller tries to pull the output down to the

set point once the internal soft-start is complete. This

pulldown is controlled by the sink current limit, which is

slowly increased to its normal value to minimize output

undershoot.

Current-Limit Circuit (LIM)

The current-limit circuit employs a ‘valley’ and sink

current-sensing algorithm that uses the on-resistance

of the low-side MOSFET as a current-sensing element,

to eliminate costly sense resistors. The current-limit

circuit is also temperature compensated to track the

on-resistance variation of the MOSFET overtemperature.

The current limit is adjustable with an external resistor at

LIM and accommodates MOSFETs with a wide range of

on-resistance characteristics (see the Setting the Valley

Current Limit section). The adjustment range is from 0.3V

to 3V for the valley current limit, corresponding to resistor

values of 6kI to 60kI. The valley current-limit threshold

across the low-side MOSFET is precisely 1/10th of the

voltage at LIM, while the sink current-limit threshold is

1/20th of the voltage at LIM.

Valley current limit acts when the inductor current flows

towards the load, and CSP is more negative than PGND

during the low-side MOSFET on-time. If the magnitude of

the current-sense signal exceeds the valley current-limit

threshold at the end of the low-side MOSFET on-time, the

MAX15046 does not initiate a new PWM cycle and lets

the inductor current decay in the next cycle. The controller also ‘rolls back’ the internal reference voltage so that

the controller finds a regulation point determined by the

current-limit value and the resistance of the short. In this

manner, the controller acts as a constant current source.

This method greatly reduces inductor ripple current

during the short event, which reduces inductor sizing

restrictions and reduces the possibility for audible noise.

After 4096 clock cycles, the device goes into hiccup

mode. Once the short is removed, the internal reference

voltage soft-starts back up to the normal reference voltage and regulation continues.

Sink current limit is implemented by monitoring the voltage drop across the low-side MOSFET when CSP is

more positive than PGND. When the voltage drop across

the low-side MOSFET exceeds 1/20th of the voltage at

LIM at any time during the low-side MOSFET on-time, the

low-side MOSFET turns off and the inductor current flows

from the output through the body diode of the high-side

MOSFET. When the sink current limit activates, the DH/

DL switching sequence is no longer complementary and

both MOSFETs are turned off.

Carefully observe the PCB layout guidelines to ensure

that noise and DC errors do not corrupt the currentsense signals at CSP and PGND. Mount the MAX15046

close to the low-side MOSFET with short, direct traces

making a Kelvin-sense connection so that trace resistance does not add to R

of the low-side MOSFET.

DS(ON)

Hiccup Mode Overcurrent Protection

Hiccup mode overcurrent protection reduces power

dissipation during prolonged short-circuit or severe

overload conditions. An internal 3-bit counter counts up

on each switching cycle when the valley current-limit

threshold is reached. The counter counts down on each

switching cycle when the threshold is not reached, and

stops at zero (000). When the current-limit condition

persists and the counter reaches 111 (= 7 events), the

12 _____________________________________________________________________________________

Page 13

40V, High-Performance, Synchronous

MAX15046 stops both DL and DH drivers and waits for

4096 switching cycles (hiccup timeout delay) before

attempting a new soft-start sequence. The hiccup-mode

protection remains active during the soft-start time.

Undervoltage Lockout

The MAX15046 provides an internal undervoltage lockout (UVLO) circuit to monitor the voltage on VCC. The

UVLO circuit prevents the MAX15046 from operating

when VCC is lower than VUVLO. The UVLO threshold is

4V, with 400mV hysteresis to prevent chattering on the

rising/falling edge of the supply voltage. DL and DH stay

low to inhibit switching when the device is in undervoltage lockout.

Thermal-Overload Protection

Thermal-overload protection limits total power dissipation in the MAX15046. When the junction temperature of

the device exceeds +150NC, an on-chip thermal sensor

shuts down the device, forcing DL and DH low, which

allows the device to cool. The thermal sensor turns the

device on again after the junction temperature cools by

20NC. The regulator shuts down and soft-start resets

during thermal shutdown. Power dissipation in the LDO

regulator and excessive driving losses at DH/DL trigger

thermal-overload protection. Carefully evaluate the total

power dissipation (see the Power Dissipation section) to

avoid unwanted triggering of the thermal-overload protection in normal operation.

Applications Information

Buck Controller

The maximum voltage conversion ratio is limited by the

maximum duty cycle (D

V D V (1-D ) V

OUT max DROP2 max DROP1

<

D -

V V

IN IN

where V

max

is the sum of the parasitic voltage drops

DROP1

in the inductor discharge path, including synchronous

rectifier, inductor, and PCB resistance. V

sum of the resistance in the charging path, including

high-side switch, inductor, and PCB resistance. In practice, provide adequate margin to the above conditions

for good load-transient response.

Set the MAX15046 output voltage by connecting a resistive divider from the output to FB to GND (Figure 2).

Select R2 from between 4kI and 16kI. Calculate R1

with the following equation:

R R -1

1 2

where VFB = 0.59V (see the Electrical Characteristics

table) and V

can range from 0.6V to (0.85 O VIN).

OUT

Resistor R1 also plays a role in the design of the Type

III compensation network. Review the values of R1 and

R2 when using a Type III compensation network (see the

Type III Compensation Network (Figure 4) section).

):

max

× + ×

is the

DROP2

Setting the Output Voltage

V

=

OUT

V

FB

MAX15046

Effective Input-Voltage Range

The MAX15046 operates from 4.5V to 40V input supplies

and regulates output down to 0.6V. The minimum voltage

conversion ratio (V

OUT/VIN

) is limited by the minimum

controllable on-time. For proper fixed-frequency PWM

operation, the voltage conversion ratio must obey the

following condition:

V

OUT

t f

> ×

IN

ON(MIN) SW

is the switching fre-

SW

where t

ON(MIN)

V

is 125ns and f

quency in Hertz. Pulse skipping occurs to decrease the

effective duty cycle when the desired voltage conversion

does not meet the above condition. Decrease the switching frequency or lower the input voltage VIN to avoid

pulse skipping.

______________________________________________________________________________________ 13

FB

MAX15046

Figure 2. Adjustable Output Voltage

OUT

R

1

R

2

Page 14

40V, High-Performance, Synchronous

Buck Controller

Setting the Switching Frequency

An external resistor connecting RT to GND sets the

switching frequency (fSW). The relationship between fSW

and RRT is:

R

=

RT

17.3 10

f (1x10 ) x (f )

+

SW SW

where fSW is in kHz and R

300kHz switching frequency is set with R

Higher frequencies allow designs with lower inductor

MAX15046

9

×

-7 2

is in kI. For example, a

RT

= 49.9kI.

RT

values and less output capacitance. Peak currents and

I2R losses are lower at higher switching frequencies, but

core losses, gate-charge currents, and switching losses

increase.

Inductor Selection

Three key inductor parameters must be specified for

operation with the MAX15046: inductance value (L),

inductor saturation current (I

), and DC resistance

SAT

(RDC). To determine the inductance, select the ratio of

inductor peak-to-peak AC current to DC average current (LIR) first. For LIR values that are too high, the RMS

currents are high, and therefore I2R losses are high.

Use high-valued inductors to achieve low LIR values.

Typically, inductor resistance is proportional to inductance for a given package type, which again makes I2R

losses high for very low LIR values. A good compromise

between size and loss is a 30% peak-to-peak ripple current to average-current ratio (LIR = 0.3). The switching

frequency, input voltage, output voltage, and selected

LIR determine the inductor value as follows:

V (V - V )

OUT IN OUT

L

=

V f I LIR

× × ×

IN SW OUT

saturation current rating (I

) must be high enough to

SAT

ensure that saturation cannot occur below the maximum

current-limit value (I

CL(MAX)

), given the tolerance of the

on-resistance of the low-side MOSFET and of the LIM

reference current (I

select an inductor with a saturation current (I

where I

CL(TYP)

is the typical current-limit set point. The

factor 1.35 includes R

). Combining these conditions,

LIM

≥ ×

I 1.35 I

SAT CL(TYP)

DS(ON)

variation of 25% and 10%

SAT

) of:

for the LIM reference current error. A variety of inductors

from different manufacturers are available to meet this

requirement (for example, Vishay IHLP-4040DZ-1-5 and

other inductors from the same series).

Setting the Valley Current Limit

The minimum current-limit threshold must be high enough

to support the maximum expected load current with the

worst-case low-side MOSFET on-resistance value as the

R

of the low-side MOSFET is used as the current-

DS(ON)

sense element. The inductor’s valley current occurs at

I

LOAD(MAX)

minus one half of the ripple current. The

minimum value of the current-limit threshold voltage

(V

) must be higher than the voltage on the low-side

ITH

MOSFET during the ripple-current valley,

LIR

> × ×

V R I 1

ITH DS(ON,MAX) LOAD(MAX)

where R

DS(ON,MAX)

in I is the maximum on-resistance

−

2

of the low-side MOSFET at maximum load current

I

LOAD(MAX)

and is calculated from the following equation:

R R [1 TC (T - T )]= × + ×

where VIN, V

OUT

, and I

are typical values. The

OUT

DS(ON,MAX) DS(ON) MOSFET MAX AMB

switching frequency is set by RT (see Setting the

Switching Frequency section). The exact inductor value

is not critical and can be adjusted to make trade-offs

among size, cost, and efficiency. Lower inductor values minimize size and cost, but also improve transient

response and reduce efficiency due to higher peak currents. On the other hand, higher inductance increases

efficiency by reducing the RMS current.

where R

(in I is the on-resistance of the low-

DS(ON)

side MOSFET at ambient temperature T

Celsius), TC

MOSFET

is the temperature coefficient of

the low-side MOSFET in ppm/NC, and T

Celsius) is the temperature at maximum load current

I

LOAD(MAX)

. Obtain the R

DS(ON)

and TC

MOSFET data sheet.

Find a low-loss inductor with the lowest possible DC

resistance that fits in the allotted dimensions. The

14 _____________________________________________________________________________________

(in degrees

AMB

(in degrees

MAX

MOSFET

from the

Page 15

40V, High-Performance, Synchronous

Connect an external resistor (R

to adjust the current-limit threshold, which is temperature-compensated with a temperature coefficient of

-2300ppm/NC. The relationship between the current-limit

threshold (V

R

LIM

where R

) and R

ITH

=

50 10 1 2300 (T - T

× × + ×

is in I, V

LIM

is:

LIM

10 V

6

−

is in V, T

ITH

NC.

An R

resistance range of 6kI to 60kI corresponds

LIM

to a current-limit threshold of 30mV to 300mV. Use 1%

tolerance resistors when adjusting the current limit to

minimize error in the current-limit threshold.

The input filter capacitor reduces peak current drawn

from the power source and reduces noise and voltage

ripple on the input caused by the switching circuitry. The

input capacitor must meet the ripple current requirement

(I

) imposed by the switching currents as defined by

RMS

the following equation:

I IV=

RMS LOAD(MAX)

I

attains a maximum value when the input volt-

RMS

age equals twice the output voltage (VIN = 2V

so I

RMS(MAX)

= I

LOAD(MAX)/2

nontantalum capacitors (ceramic, aluminum, polymer, or

OS-CON) are preferred at the inputs due to the robustness of nontantalum capacitors to accommodate high

inrush currents of systems being powered from very low

impedance sources. Additionally, two (or more) smallervalue low-ESR capacitors should be connected in parallel to reduce high-frequency noise.

The key selection parameters for the output capacitor

are capacitance value, ESR, and voltage rating. These

parameters affect the overall stability, output ripple voltage, and transient response. The output ripple has two

components: variations in the charge stored in the output

capacitor, and the voltage drop across the capacitor’s

ESR caused by the current flowing into and out of the

capacitor:

DV

RIPPLE

= DV

) from LIM to GND

LIM

×

ITH

MAX AMB)

MAX

and T

AMB

are in

Input Capacitor

V (V - V )

OUT IN OUT

IN

. For most applications,

Output Capacitor

+ DV

ESR

Q

OUT

),

Buck Controller

The output-voltage ripple as a consequence of the ESR

and the output capacitance is:

V I ESR

∆ = ×

ESR P-P

I

V

∆ =

Q

I

= ×

P-P

where I

is the peak-to-peak inductor current ripple

P-P

(see the Inductor Selection section). Use these equations for initial capacitor selection. Decide on the final

values by testing a prototype or an evaluation circuit.

Check the output capacitor against load-transient

response requirements. The allowable deviation of the

output voltage during fast load transients determines

the capacitor output capacitance, ESR, and equivalent

series inductance (ESL). The output capacitor supplies

the load current during a load step until the controller

responds with a higher duty cycle. The response time

(t

RESPONSE

) depends on the closed-loop bandwidth of

the converter (see the Compensation Design section).

The resistive drop across the ESR of the output capacitor, the voltage drop across the ESL (DV

capacitor, and the capacitor discharge, cause a voltage

droop during the load step.

Use a combination of low-ESR tantalum/aluminum electrolytic and ceramic capacitors for improved transient

load and voltage ripple performance. Nonleaded capacitors and capacitors in parallel help reduce the ESL.

Keep the maximum output-voltage deviation below the

tolerable limits of the load. Use the following equations to

calculate the required ESR, ESL, and capacitance value

during a load step:

=

ESR

C

OUT

=

ESL

t

RESPONSE

where I

load step, t

is the load step, t

STEP

RESPONSE

ler, and fO is the closed-loop crossover frequency.

P-P

8 C f

× ×

OUT SW

V - V V

IN OUT OUT

f L V

×

SW IN

∆

V

ESR

I

STEP

I t

STEP RESPONSE

=

∆ ×

V t

ESL STEP

I

STEP

≅

×

∆

V

Q

1

×

3 f

O

is the rise time of the

STEP

ESL

) of the

is the response time of the control-

MAX15046

______________________________________________________________________________________ 15

Page 16

40V, High-Performance, Synchronous

Buck Controller

Compensation Design

The MAX15046 provides an internal transconductance

amplifier with the inverting input and the output available

for external frequency compensation. The flexibility of

external compensation offers wide selection of output

filtering components, especially the output capacitor.

Use high-ESR aluminum electrolytic capacitors for costsensitive applications. Use low-ESR tantalum or ceramic

capacitors at the output for size-sensitive applications.

MAX15046

The high switching frequency of the MAX15046 allows

the use of ceramic capacitors at the output. Choose all

passive power components to meet the output ripple,

component size, and component cost requirements.

Choose the compensation components for the error

amplifier to achieve the desired closed-loop bandwidth

and phase margin.

To choose the appropriate compensation network type,

the power-supply poles and zeros, the zero-crossover

frequency, and the type of the output capacitor must be

determined first.

In a buck converter, the LC filter in the output stage introduces a pair of complex poles at the following frequency:

OUT OUT

π × ×

f

SW

f

≤

O

10

1

1

OUT

=

f

PO

π × ×

2 L C

The output capacitor introduces a zero at:

=

f

ZO

2 ESR C

where ESR is the equivalent series resistance of the

output capacitor.

The loop-gain crossover frequency (fO), where the loop

gain equals 1 (0dB) should be set below 1/10th of the

switching frequency:

Choosing a lower crossover frequency reduces the

effects of noise pickup into the feedback loop, such as

jittery duty cycle.

To maintain a stable system, two stability criteria must

be met:

1) The phase shift at the crossover frequency, fO, must

be less than 180N. In other words, the phase margin

of the loop must be greater than zero.

2) The gain at the frequency where the phase shift is

-180N (gain margin) must be less than 1.

Maintain a phase margin of around 60N to achieve a robust

loop stability and well-behaved transient response.

When using an electrolytic or large-ESR tantalum output

capacitor, the capacitor ESR zero fZO typically occurs

between the LC poles and the crossover frequency fO

(fPO < fZO < fO). Choose the Type II (PI-Proportional,

Integral) compensation network.

When using a ceramic or low-ESR tantalum output

capacitor, the capacitor ESR zero typically occurs above

the desired crossover frequency fO, that is fPO < f

fZO. Choose the Type III (PID- Proportional, Integral, and

Derivative) compensation network.

<

O

Type II Compensation Network

(Figure 3)

If fZO is lower than fO and close to fPO, the phase lead of

the capacitor ESR zero almost cancels the phase loss of

one of the complex poles of the LC filter around the crossover frequency. Use a Type II compensation network with

a midband zero and a high-frequency pole to stabilize

the loop. In Figure 3, RF and CF introduce a midband

zero (fZ1). RF and CCF in the Type II compensation network provide a high-frequency pole (fP1), which mitigates

the effects of the output high-frequency ripple.

Use the following steps to calculate the component

values for Type II compensation network as shown in

Figure 3:

1) Calculate the gain of the modulator (GAIN

comprised of the regulator’s pulse-width modulator,

LC filter, feedback divider, and associated circuitry

at crossover frequency:

V V

IN FB

GAIN

where VIN is the input voltage of the regulator, V

is the amplitude of the ramp in the pulse-width modulator, VFB is the FB input voltage set point (0.6V typically,

see the Electrical Characteristics table), and V

desired output voltage.

The gain of the error amplifier (GAINEA) in midband

frequencies is:

where gM is the transconductance of the error amplifier.

= × ×

MOD

V 2 f L V

RAMP O OUT OUT

GAINEA = gM x R

ESR

π × ×

( )

F

OUT

MOD

RAMP

is the

),

16 _____________________________________________________________________________________

Page 17

40V, High-Performance, Synchronous

I 1 I

1

1

The total loop gain, which is the product of the modulator

gain and the error-amplifier gain at fO, is:

1) GAIN GAIN 1

So :

V V

IN FB

V (2 f L ) V

OSC O OUT OUT

Solving for R :

R

=

F

× =

MOD EA

× × × × =

V 2 f L V

OSC O OUT OUT

ESR

π × ×

F

× π × × ×

( )

V V g ESR

× × ×

FB IN M

g R 1

M F

Buck Controller

Type III Compensation Network

(See Figure 4)

When using a low-ESR tantalum or ceramic type, the

ESR-induced zero frequency is usually above the targeted zero crossover frequency (fO). Use Type III compensation. Type III compensation provides two zeros

and three poles at the following frequencies:

=

f

Z1

π × ×

2 R C

F F

=

f

Z2

2 C (R R )

1

π × × +

MAX15046

2) Set a midband zero (fZ1) at 0.75 x fPO (to cancel one

of the LC poles):

= = ×

f 0.75 f

Z1 PO

1

π × ×

2 R C

F F

Solving for CF:

=

C

F

π × × ×

2 R f 0.75

1

F PO

3) Place a high-frequency pole at fP1 = 0.5 x fSW (to

attenuate the ripple at the switching frequency fSW)

and calculate CCF using the following equation:

=

C

CF

π × ×

V

OUT

R

1

R

2

V

REF

1

R f -

F SW

g

M

R

C

1

C

F

COMP

F

C

F

CF

Two midband zeros (fZ1 and fZ2) cancel the pair of complex poles introduced by the LC filter:

f

= 0

P1

fP1 introduces a pole at zero frequency (integrator) for

nulling DC output-voltage errors:

1

=

f

P2

π × ×

2 R C

I I

Depending on the location of the ESR zero (fZO), use fP2

to cancel fZO, or to provide additional attenuation of the

high-frequency output ripple:

=

f

P3

π × ×

2 R

F

×

C C

F CF

+

C C

F CF

fP3 attenuates the high-frequency output ripple.

Place the zeros and poles such that the phase margin

peaks around fO.

Ensure that RF >> 2/gM and the parallel resistance of

R1, R2, and RI is greater than 1/gM. Otherwise, a 180N

phase shift is introduced to the response making the

loop unstable.

Use the following compensation procedures:

1) With RF >> 10kI, place the first zero (fZ1) at 0.8 x

fPO:

= = ×

f 0.8 f

Z1 PO

1

π × ×

2 R C

F F

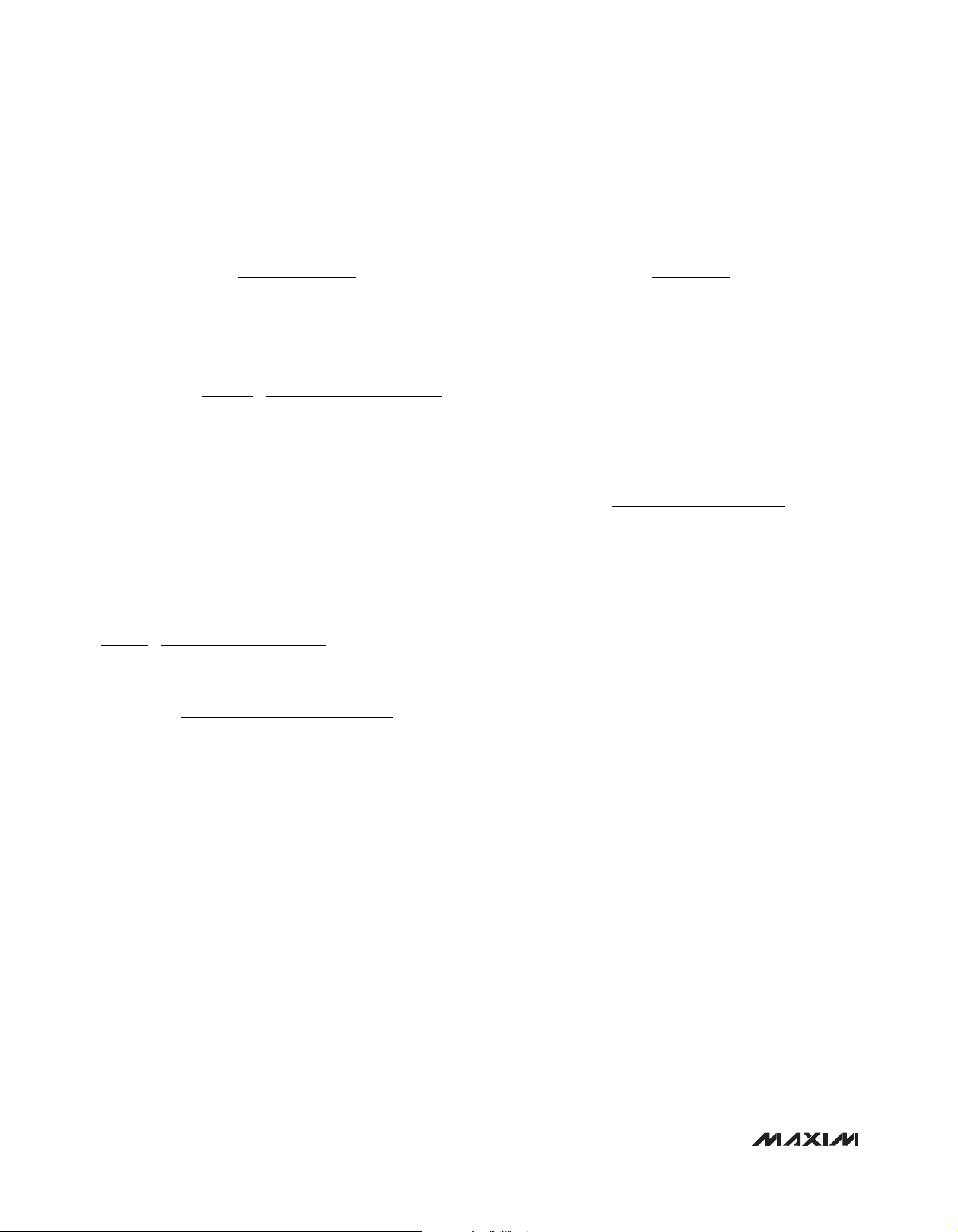

Figure 3. Type II Compensation Network

______________________________________________________________________________________ 17

Page 18

40V, High-Performance, Synchronous

Buck Controller

So:

Once fP2 is known, calculate RI:

MAX15046

=

C

F

π × × ×

2 R 0.8 f

2) The gain of the modulator (GAIN

the pulse-width modulator, LC filter, feedback divider,

and associated circuitry at crossover frequency is:

MAX15046

GAIN

MOD

The gain of the error amplifier (GAINEA) in midband

frequencies is:

The total loop gain as the product of the modulator gain

and the error amplifier gain at fO is 1.

So :

V

IN

V

Solving for C :

3) Use the second pole (fP2) to cancel f

< fZO < f

does not flatten out soon after the 0dB crossover, and

maintains -20dB/decade slope up to 1/2 of the switching

frequency. This is likely to occur if the output capacitor

is low-ESR tantalum. Set fP2 = fZO.

When using a ceramic capacitor, the capacitor ESR

zero (fZO) is likely to be located even above one half

of the switching frequency, fPO < fO < f

this case, place the frequency of the second pole (fP2)

high enough in order not to significantly erode the phase

margin at the crossover frequency. For example, set fP2

at 5 x fO so that the contribution to phase loss at the

crossover frequency fO is only about 11N:

× × π × × × =

RAMP

(2 f ) C L

C

=

I

SW/2

V

IN

= ×

V

RAMP

GAIN 2 f C R

EA O I F

GAIN GAIN 1

MOD EA

1

2

π × × ×

O OUT OUT

I

V 2 f L C

× π × × ×

RAMP O OUT OUT

. The frequency response of the loop gain

( )

fP2 = 5 x f

1

F PO

), comprised of

MOD

1

2

π × × ×

(2 f ) L C

O OUT OUT

= π × × ×

× =

2 f C R 1

V R

×

IN F

ZO

SW/2

O

O I F

when fPO < f

< fZO. In

1

=

R

I

π × ×

2 f C

P2 I

4) Place the second zero (fZ2) at 0.2 x fO or at fPO,

whichever is lower and calculate R1 using the following

equation:

R - R

1 I

5) Place the third pole (fP3) at one half the switching

frequency and calculate CCF:

C

=

CF

2 0.5 f R C - 1

π × × × ×

( )

6) Calculate R2 as:

R R

= ×

2 1

1

=

2 f C

π × ×

Z2 I

V

FB

V V

OUT FB

C

F

SW F F

−

MOSFET Selection

The MAX15046 step-down controller drives two external logic-level n-channel MOSFETs. The key selection

parameters to choose these MOSFETs include:

U On-resistance (R

U Maximum Drain-to-Source Voltage (V

O

U Minimum Threshold Voltage (V

U Total Gate Charge (QG)

U Reverse Transfer Capacitance (C

U Power Dissipation

The two n-channel MOSFETs must be a logic-level

type with guaranteed on-resistance specifications at

VGS = 4.5V. For maximum efficiency, choose a highside MOSFET that has conduction losses equal to the

switching losses at the typical input voltage. Ensure that

the conduction losses at minimum input voltage do not

exceed the MOSFET package thermal limits, or violate

the overall thermal budget. Also ensure that the conduction losses plus switching losses at the maximum input

voltage do not exceed package ratings or violate the

DS(ON)

)

DS(MAX)

TH(MIN)

)

RSS

)

18 _____________________________________________________________________________________

Page 19

40V, High-Performance, Synchronous

R

F

g

G_TOTAL

Q

=

∆

V

C

CF

C

F

M

x f

G

BST

= 100mV to 300mV)

BST

COMP

SW

V

OUT

R

R

I

1

C

I

R

2

Figure 4. Type III Compensation Network

V

REF

overall thermal budget. Ensure that the DL gate driver

can drive the low-side MOSFET. In particular, check

that the dv/dt caused by the high-side MOSFET turning

on does not pull up the low-side MOSFET gate through

the drain-to-gate capacitance of the low-side MOSFET,

which is the most frequent cause of crossconduction

problems.

Check power dissipation when using the internal linear

regulator to power the gate drivers. Select MOSFETs

with low gate charge so that VCC can power both drivers

without overheating the device:

P

= VCC x Q

DRIVE

where Q

G_TOTAL

is the sum of the gate charges of the

two external MOSFETs.

Boost Capacitor and Diode Selection

The MAX15046 uses a bootstrap circuit to generate

the necessary gate-to-source voltage to turn on the

high-side MOSFET. The selected n-channel high-side

MOSFET determines the appropriate boost capacitance

value (C

in the Typical Application Circuits) accord-

BST

ing to the following equation:

C

BST

where QG is the total gate charge of the high-side

MOSFET and DV

is the voltage variation allowed

BST

on the high-side MOSFET driver after turn-on. Choose

DV

such that the available gate-drive voltage is not

BST

significantly degraded (e.g. DV

when determining C

BST

.

Buck Controller

Use a low-ESR ceramic capacitor as the boost capacitor

with a minimum value of 100nF.

A small-signal diode can be used for the bootstrap circuit and must have a minimum voltage rating of VIN +

3V to withstand the maximum BST voltage. The average

forward current of the diode should meet the following

requirement:

IF > Q

where Q

is the gate charges of the low-side MOSFET.

GATE

The maximum power dissipation of the device depends

on the thermal resistance from the die to the ambient

environment and the ambient temperature. The thermal

resistance depends on the device package, PCB copper

area, other thermal mass, and airflow.

The power dissipated into the package (PT) depends

on the supply configuration (see the Typical Application

Circuits). Use the following equation to calculate power

dissipation:

PT = VIN x [Q

where IQ is the quiescent supply current at the switching

frequency. See the IIN vs. Switching Frequency graph in

the Typical Operating Characteristics for the IQ.

Use the following equation to estimate the temperature

rise of the die:

TJ = TA + (PT x BJA)

where BJA is the junction-to-ambient thermal impedance

of the package, PT is power dissipated in the device,

and TA is the ambient temperature. The B

for the 16-pin QSOP and 53NC/W for the 16-pin QSOPEP package on multilayer boards, with the conditions

specified by the respective JEDEC standards (JESD51-5,

JESD51-7). An accurate estimation of the junction temperature requires a direct measurement of the case

temperature (TC) when actual operating conditions

significantly deviate from those described in the JEDEC

standards. The junction temperature is then:

TJ = TC + (PT x BJC)

Use 37NC/W as BJC thermal impedance for the 16-pin

QSOP package and 6NC/W for the 16-pin QSOP-EP

package. The case-to-ambient thermal impedance (BCA)

is dependent on how well the heat is transferred from the

PCB to the ambient. Use large copper areas to keep the

PCB temperature low.

x f

GATE

G_TOTAL

SW

Power Dissipation

x fSW + IQ]

is 103.7NC/W

JA

MAX15046

______________________________________________________________________________________ 19

Page 20

40V, High-Performance, Synchronous

Buck Controller

PCB Layout Guidelines

Careful PCB layout is critical to achieve clean and stable

operation. The switching power stage requires particular

attention. Follow these guidelines for good PCB layout:

1) Place decoupling capacitors as close as possible to

the IC. Connect the power ground plane (connected

to PGND) and signal ground plane (connected to

GND) at one point near the device.

2) Connect input and output capacitors to the power

MAX15046

ground plane; connect all other capacitors to the signal ground plane.

3) Keep the high-current paths as short and wide as

possible. Keep the path of switching current (C2 to

IN and C2 to PGND) short. Avoid vias in the switching

paths.

4) Connect CSP to the drain of the low-side FET using a

Kelvin connection for accurate current-limit sensing.

5) Ensure all feedback connections are short and direct.

Place the feedback resistors as close as possible to the

IC.

6) Route high-speed switching nodes (BST, LX, DH, and

DL) away from sensitive analog areas (RT, FB, COMP,

and LIM).

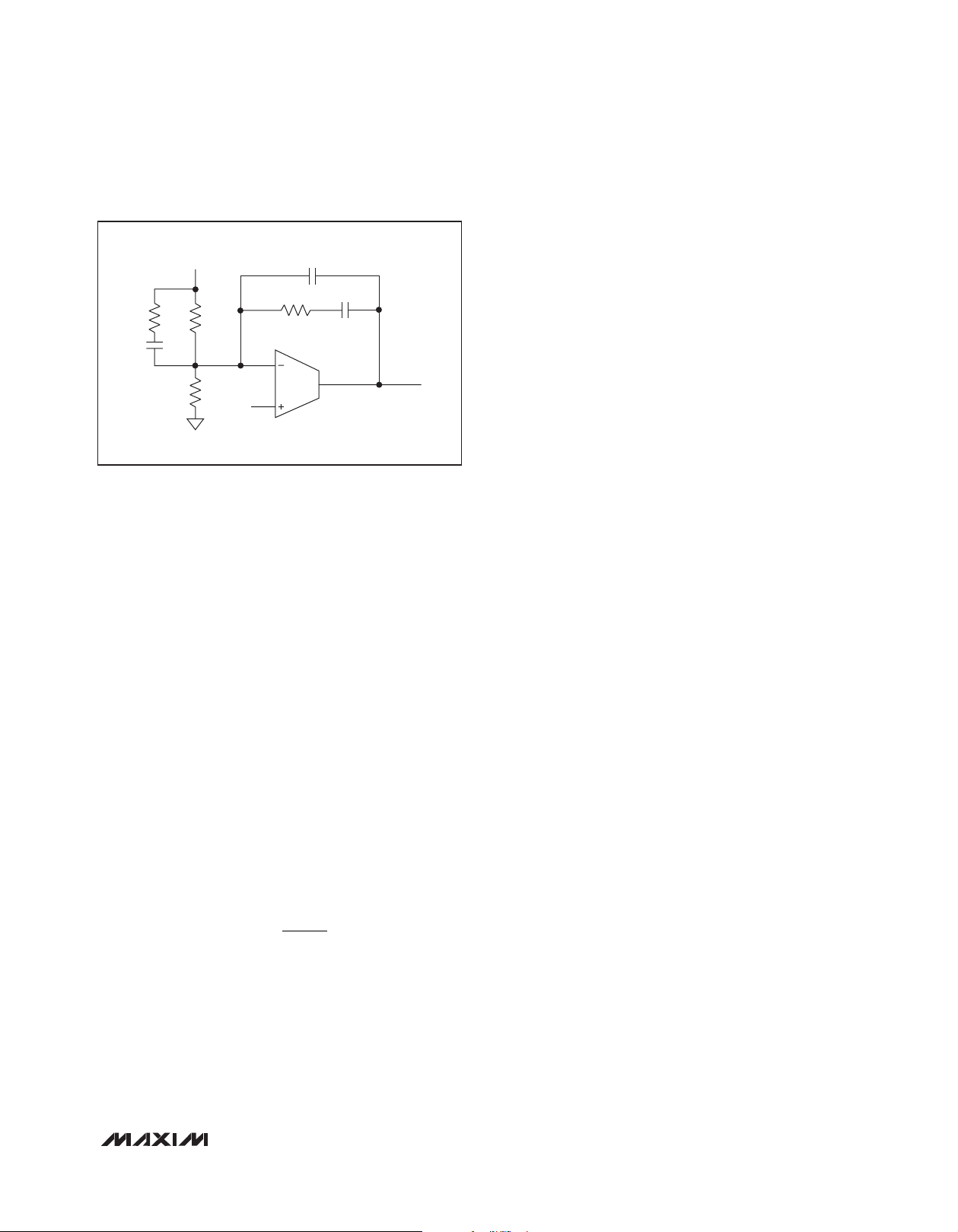

24V Supply, 3.3V Output Operation

Typical Application Circuit 1 in the Typical Application

Circuits section shows an application circuit that oper-

ates out of 24V and outputs up to 10A at 3.3V. R5 sets

the switching frequency to 350kHz.

Single 4.5V to 5.5V Supply Operation

Typical Application Circuit 2 in the Typical Application

Circuits section shows an application circuit for a single

+4.5V to +5.5V power-supply operation.

Auxiliary 5V Supply Operation

Typical Application Circuit 3 in the Typical Application

Circuits section shows an application circuit for a +24V

supply to drive the external MOSFETs and an auxiliary

+5V supply to power the device

20 _____________________________________________________________________________________

Page 21

40V, High-Performance, Synchronous

Buck Controller

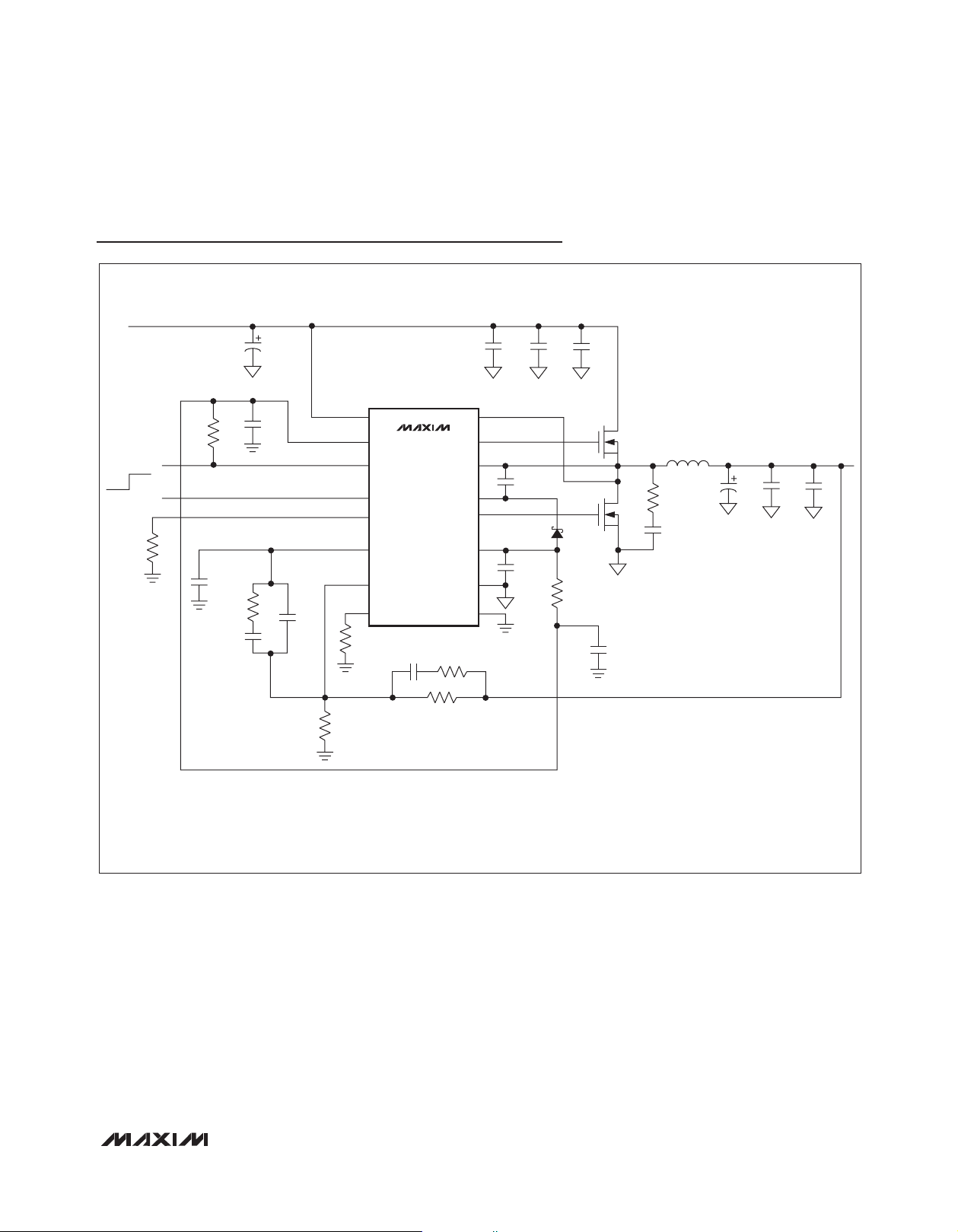

Typical Application Circuits

TYPICAL APPLICATION CIRCUIT 1

V

IN

+24V

330FF

C1

10FF

C2

10FF

C3

C4

0.1FF

MAX15046

ON

OFF

R9

32.4kI

Q1: VISHAY SILICONIX Si7850DP

Q2: VISHAY SILICONIX Si7460DP

D1: DIODES INC. ZHCS506

L1: COILCRAFT MSS1278-142ML

C1: PANASONIC EEVFK1H331Q

C8: SANYO 6CE470EX

C13

68pF

R7

51kI

22.6kI

C14

1500pF

10.7kI

R4

45.3kI

R3

CSP

DRV

PGND

GND

BST

Q1

R1

1kI

C7

2700pF

L1

1.4mH

470FF

C8

C9

22FF

22FF

DH

LX

DL

C5

0.47FF

C6

2.2FF

D1

R2

2.2I

C11

4.7FF

Q2

C10

V

+3.3V

OUT

R6

10kI

R5

32.4kI

IN

V

CC

PGOOD

EN

LIM

COMP

FB

RT

MAX15046

C12

1200pF

C16

1FF

R8

C15

15pF

______________________________________________________________________________________ 21

Page 22

40V, High-Performance, Synchronous

Buck Controller

Typical Application Circuits (continued)

TYPICAL APPLICATION CIRCUIT 2

V

IN

+4.5V TO +5.5V

C1

C2

MAX15046

PGOOD

ENABLE

R4

C7

V

AUX

+4.5V TO +5.5V

C1

PGOOD

ENABLE

R4

C7

IN

MAX15046

V

CC

PGOOD

EN

LIM

COMP

R3

C8

C9

R1

FB

RT

R3

CSP

DH

LX

C3

BST

DL

D1

DRV

C6

PGND

GND

R2

Q1

L1

Q2

C4

V

OUT

C5

TYPICAL APPLICATION CIRCUIT 3

V

IN

+24V

C2

IN

MAX15046

V

CC

PGOOD

EN

LIM

COMP

R3

C8

C9

R1

FB

RT

R3

CSP

BST

DRV

PGND

GND

Q1

DH

LX

C3

DL

D1

C6

L1

Q2

C4

V

OUT

C5

R2

22 _____________________________________________________________________________________

Page 23

40V, High-Performance, Synchronous

Buck Controller

Pin Configurations

MAX15046

TOP VIEW

+

V

PGOOD

LIM

COMP

IN

1

2

CC

3

MAX15046A

4

EN

5

6

7

FB

RT

8

16

CSP

15

DH

14

LX

13

BST

12

DL

DRV

11

10

PGND

9

GND

QSOP

Chip Information

PROCESS: BiCMOS

+

V

PGOOD

LIM

COMP

IN

1

2

CC

3

4

EN

MAX15046B

5

6

EXPOSED

7

FB

RT

8

PAD

16

CSP

15

DH

14

LX

13

BST

12

DL

DRV

11

10

PGND

9

GND

QSOP-EP

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

16 QSOP E16+4

16 QSOP-EP E16E+9

21-0055

21-0112

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 23

©

2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...