Page 1

General Description

The MAX15031 consists of a constant-frequency pulsewidth modulating (PWM) step-up DC-DC converter with

an internal switch and a high-side current monitor with

high-speed adjustable current limiting. This device can

generate output voltages up to 76V and provides current

monitoring up to 4mA (up to 300mW). The MAX15031

can be used for a wide variety of applications such as

avalanche photodiode biasing, PIN biasing, or varactor

biasing, and LCD displays. The MAX15031 operates

from 2.7V to 11V.

The constant-frequency (400kHz), current-mode PWM

architecture provides low-noise output voltage that is

easy to filter. A high-voltage, internal power switch

allows this device to boost output voltages up to 76V.

Internal soft-start circuitry limits the input current when

the boost converter starts. The MAX15031 features a

shutdown mode to save power.

The MAX15031 includes a current monitor with more

than three decades of dynamic range and monitors current ranging from 500nA to 2mA with high accuracy.

Resistor-adjustable current limiting protects the APD

from optical power transients. A clamp diode protects

the monitor’s output from overvoltage conditions. Other

protection features include cycle-by-cycle current limiting of the boost converter switch, undervoltage lockout,

and thermal shutdown if the die temperature reaches

+160°C.

The MAX15031 is available in a thermally enhanced

4mm x 4mm, 16-pin TQFN package and operates over

the -40°C to +125°C automotive temperature range.

Applications

Avalanche Photodiode Biasing and Monitoring

PIN Diode Bias Supplies

Low-Noise Varactor Diode Bias Supplies

FBON Modules

GPON Modules

LCD Displays

Features

o Input Voltage Range

+2.7V to +5.5V (Using Internal Charge Pump) or

+5.5V to +11V

o Wide Output-Voltage Range from (VIN+ 1V) to 76V

o Internal 1Ω (typ) 80V Switch

o 300mW Boost Converter Output Power

o Accurate ±10% (500nA to 1mA) and ±3.5% (1mA

to 4mA) High-Side Current Monitor

o Resistor-Adjustable Ultra-Fast APD Current Limit

(1µs Response Time)

o Open-Drain Current-Limit Indicator Flag

o 400kHz Fixed Switching Frequency

o Constant PWM Frequency Provides Easy Filtering

in Low-Noise Applications

o Internal Soft-Start

o 2µA (max) Shutdown Current

o -40°C to +125°C Temperature Range

o Small Thermally Enhanced, 4mm x 4mm, 16-Pin

TQFN Package

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

________________________________________________________________

Maxim Integrated Products

1

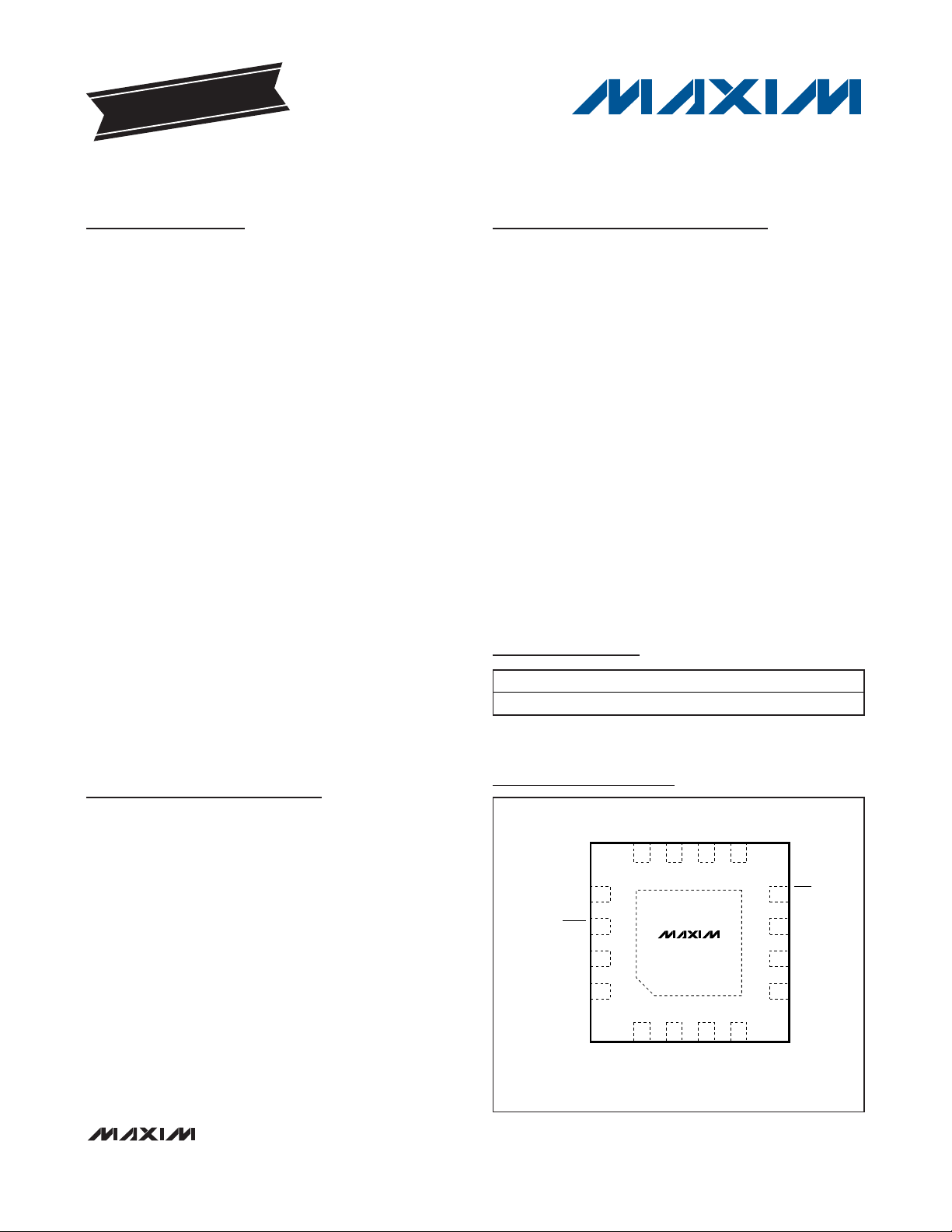

Pin Configuration

Ordering Information

19-4299; Rev 1; 3/09

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE

PIN-PACKAGE

MAX15031ATE+

-40°C to +125°C 16 TQFN-EP*

+

Denotes a lead(Pb)-free/RoHS-compliant package.

*

EP = Exposed pad.

Typical Operating Circuits appear at end of data sheet.

TOP VIEW

BIAS

13

14

SHDN

PGND

15

16

LX

*EXPOSED PAD

APD

12 11 9

+

12

PWR

(4mm

CLAMP

MAX15031

CP

THIN QFN

× 4mm)

10

3

CN MOUT

*EP

4

RLIM

IN

ILIM

8

7

CNTRL

FB

6

SGND

5

Page 2

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

2 _______________________________________________________________________________________

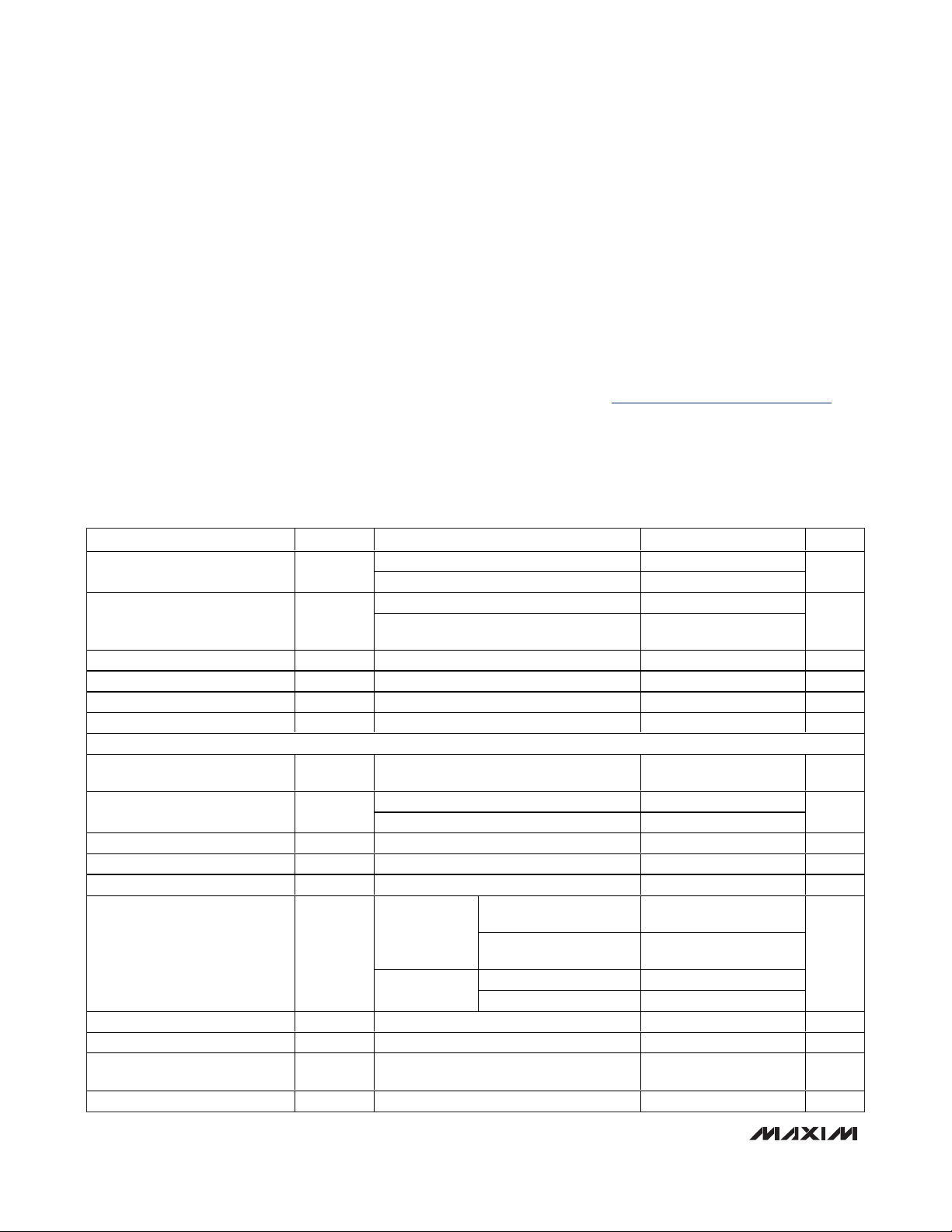

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= V

PWR

= 3.3V. V

SHDN

= 3.3V. CIN= C

PWR

= 10µF. CCP= 10nF, V

CNTRL

= VIN. V

RLIM

= 0. V

PGND

= V

SGND

= 0. V

BIAS

= 40V.

APD = unconnected. CLAMP = unconnected. ILIM = unconnected, MOUT = unconnected. T

A

= TJ= -40°C to +125°C, unless other-

wise noted. Typical values are at T

A

= +25°C.) (Note 2)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial

.

PWR, IN to SGND ...................................................-0.3V to +12V

LX to PGND ............................................................-0.3V to +80V

BIAS, APD to SGND ...............................................-0.3V to +80V

SHDN to SGND............................................-0.3V to (V

IN

+ 0.3V)

CLAMP to SGND......................................-0.3V to (V

BIAS

+ 0.3V)

FB, ILIM, RLIM, CP, CN, CNTRL to SGND .............-0.3V to +12V

PGND to SGND .....................................................-0.3V to +0.3V

MOUT to SGND ....................................-0.3V to (V

CLAMP

+ 0.3V)

Continuous Power Dissipation

16-Pin TQFN (derate 25mW/°C above +70°C) ............2000mW

Thermal Resistance (Note 1)

θ

JA

....................................................................................40°C/W

θ

JC

......................................................................................6°C/W

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Supply Voltage Range VIN, V

Supply Current I

Undervoltage Lockout Threshold V

Undervoltage Lockout Hysteresis V

Shutdown Current I

Shutdown Input Bias Current I

BOOST CONVERTER

Output-Voltage Adjustment

Range

Switching Frequency f

Maximum Duty Cycle D

FB Set-Point Voltage V

FB Input Bias Current I

Internal Switch On-Resistance R

Peak Switch Current Limit I

LX Leakage Current VLX = 36V 1 µA

Line Regulation

Load Regulation 0 ≤ I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

PWR

CP connected to IN, CCP = open 5.5 11

VFB = 1.4V, no switching 1 2

SUPPLY

UVLO

UVLO_HYS

IN_SHDN

BIAS_SHDNVBIAS

SW

CLK

FB

FB

VIN = 11V, VFB = 1.4V (no switching),

C

= open, CP = IN

CP

VIN rising 2.375 2.5 2.675 V

SHDN pulled low 2 µA

= 3.3V, V

VIN = V

PWR

2.9V ≤ V

2.9V ≤ V

PWR

PWR

ILX = 100mA

ON

ILX = 100mA,

= V

V

CP

IN V

LIM_LX

2.9V ≤ V

I

LOAD

PWR

= 4.5mA

≤ 4.5mA 1 %

LOAD

2.7 5.5

1.2 3

100 mV

= 0 30 µA

SHDN

VIN +

1V

76 V

= 5V 360 400 440

≤ 11V, V

≤ 11V, VIN = V

= V

IN

PWR

PWR

352 400 448

86 90 94 %

1.2201 1.245 1.2699 V

100 nA

V

= VIN = 2.9V,

PWR

V

= 5.5V

CP

= VIN = 5.5V,

V

PWR

= 10V

V

CP

V

= VIN = VCP = 5.5V 1 2

PWR

= VIN = VCP = 11V 1 2

PWR

12

12

0.8 1.2 1.6 A

≤ 11V, V

PWR

= VIN,

0.2 %

V

mA

kHz

Ω

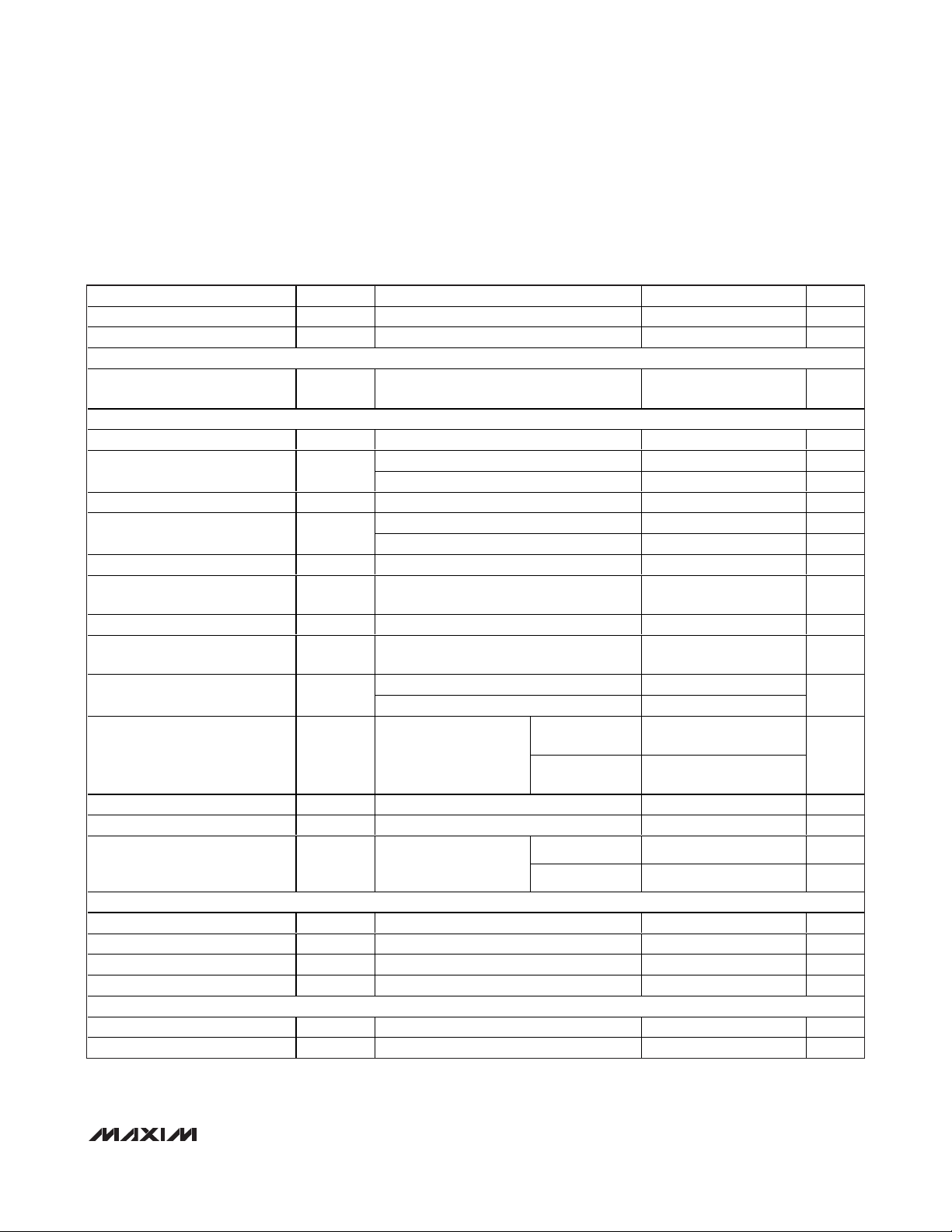

Page 3

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

_______________________________________________________________________________________ 3

Note 2: All minimum/maximum parameters are tested at TA= +125°C. Limits over temperature are guaranteed by design.

Note 3: Guaranteed by design and not production tested.

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

PWR

= 3.3V. V

SHDN

= 3.3V. CIN= C

PWR

= 10µF. CCP= 10nF, V

CNTRL

= VIN. V

RLIM

= 0. V

PGND

= V

SGND

= 0. V

BIAS

= 40V.

APD = unconnected. CLAMP = unconnected. ILIM = unconnected, MOUT = unconnected. T

A

= TJ= -40°C to +125°C, unless other-

wise noted. Typical values are at T

A

= +25°C.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Soft-Start Duration 8ms

Soft-Start Steps (0.25 x I

LIM_LX

) to I

LIM_LX

32 Steps

CONTROL INPUT (CNTRL)

Maximum Control Input Voltage

Range

FB set point is regulated to V

CNTRL

1.25 V

CURRENT MONITOR

Bias Voltage Range V

Bias Quiescent Current I

Voltage Drop V

Dynamic Output Resistance at

MOUT

BIAS

BIAS

DROPIAPD

R

MOUT

I

= 500nA 100 µA

APD

I

= 2mA 3.2 mA

APD

= 2mA, V

I

= 500nA 1 GΩ

APD

I

= 2.5mA 890 MΩ

APD

DROP

= V

BIAS

- V

APD

10 76 V

1V

MOUT Output Leakage APD is unconnected 1 nA

V

-

Output Clamp Voltage

Output Clamp Leakage Current V

Output-Voltage Range V

Current Gain I

Power-Supply Rejection Ratio PSRR

APD Input Current Limit I

Current-Limit Adjustment Range 12.45kΩ ≥ R

Power-Up Settling Time t

MOUT

V

CLAMP

MOUT

MOUT/IAPD

Forward diode current = 1mA 0.5 0.73 0.95 V

10V ≤ V

is unconnected

I

APD

I

APD

(∆I

V

LIM_APDVAPD

I

MOUT

0.1%, 10nF connected

S

from APD to ground

BIAS

= V

BIAS

= 76V 1 nA

CLAMP

≤ 76V, 0 ≤ I

≤ 1mA, CLAMP

APD

V

BIAS

-

1V

= 500nA 0.095 0.1 0.11

= 2mA 0.965 0.1 0.1035

I

= 500nA

MOUT/IMOUT

= 10V to 76V

BIAS

= 35V, R

settles to within

APD

BIAS

,

(Note 3)

= 5µA to

I

APD

)/∆V

1mA

= 3.3kΩ 3.15 3.75 4.35 mA

LIM

≥ 2.5kΩ 15mA

LIM

I

= 500nA 7.5 ms

APD

I

= 2.5mA 90 µs

APD

-1000 +300 +1500

-250 +24 +250

V

ppm/V

LOGIC INPUTS/OUTPUTS

SHDN Input-Voltage Low V

SHDN Input-Voltage High V

ILIM Output-Voltage Low V

ILIM Output Leakage Current I

OL

OH

IL

IH

I

= 2mA 0.3 V

LIM

V

= 11V 1 µA

ILIM

2.4 V

0.8 V

THERMAL PROTECTION

Thermal Shutdown Temperature rising +160 °C

Thermal Shutdown Hysteresis 10 °C

Page 4

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

4 _______________________________________________________________________________________

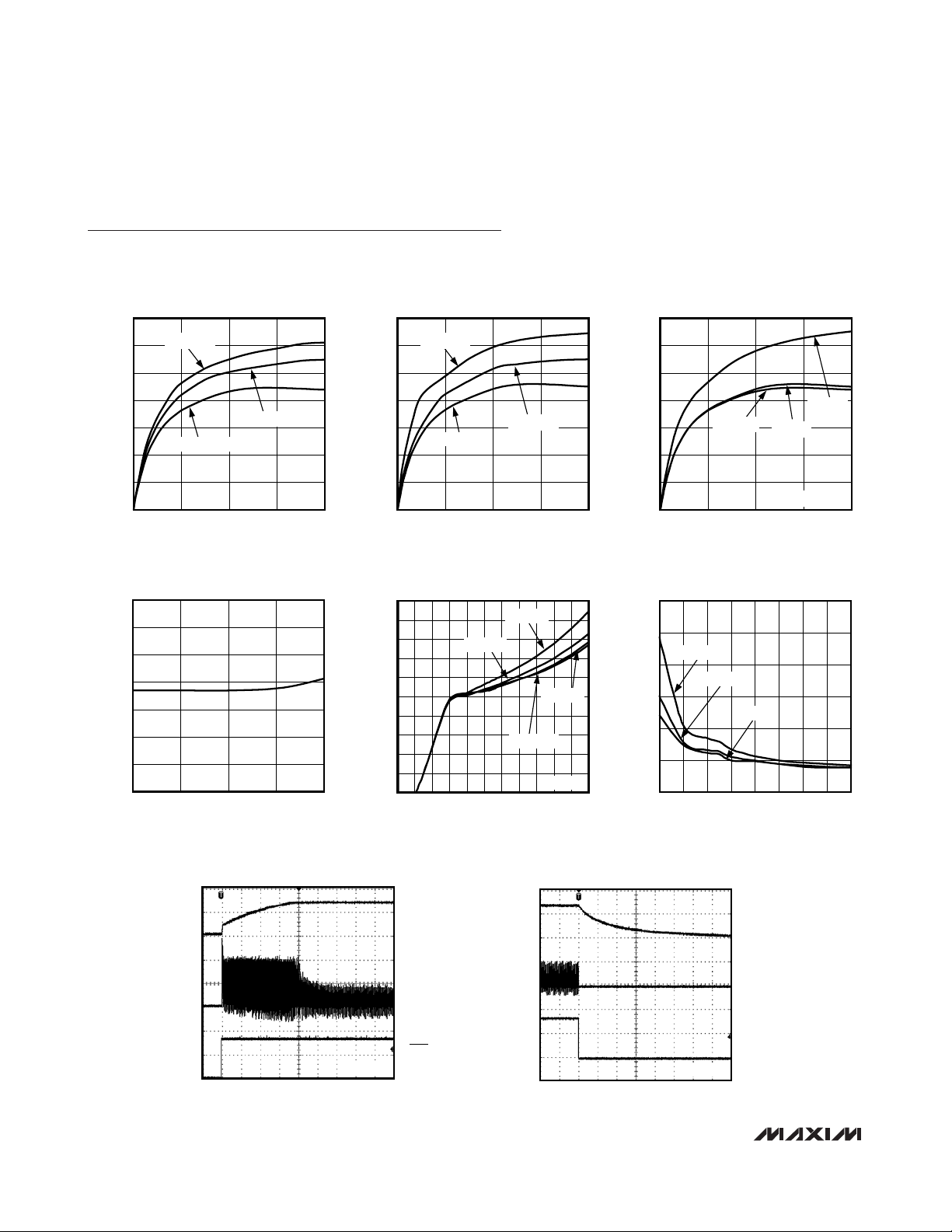

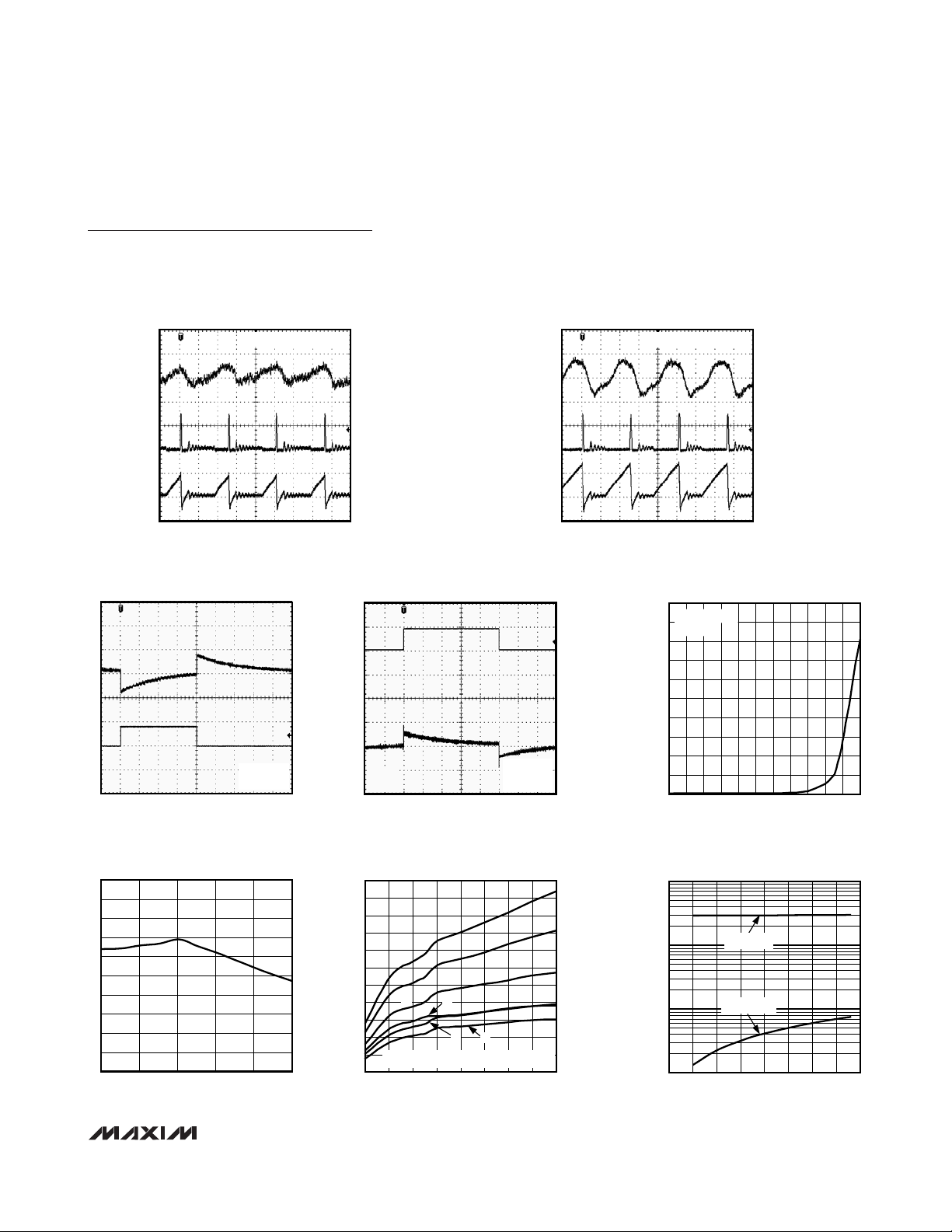

Typical Operating Characteristics

(V

PWR

= VIN= 3.3V, V

OUT

= 70V, circuit of Figure 3 (Figure 4 for VIN> 5.5V), unless otherwise noted.)

EFFICIENCY vs. LOAD CURRENT

MAX15031 toc01

LOAD CURRENT (mA)

EFFICIENCY (%)

321

10

20

30

40

50

60

70

0

04

V

OUT

= 30V

V

OUT

= 55V

V

OUT

= 70V

V

IN

= 3.3V

EFFICIENCY vs. LOAD CURRENT

MAX15031 toc02

LOAD CURRENT (mA)

EFFICIENCY (%)

321

10

20

30

40

50

60

70

0

04

V

OUT

= 30V

V

OUT

= 55V

V

OUT

= 70V

V

IN

= 5V

EFFICIENCY vs. LOAD CURRENT

MAX15031 toc03

LOAD CURRENT (mA)

EFFICIENCY (%)

321

10

20

30

40

50

60

70

0

04

VIN = 3.3V

VIN = 5V

VIN = 8V

V

OUT

= 70V

MINIMUM STARTUP VOLTAGE

vs. LOAD CURRENT

MAX15031 toc04

LOAD CURRENT (mA)

MINIMUM STARTUP VOLTAGE (V)

321

2.49

2.50

2.51

2.52

2.53

2.54

2.55

2.48

04

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX15031 toc05

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (mA)

1097 82 3 4 5 61

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0

011

VFB = 1.4V

TA = +125°C

TA = +85°C

TA = -40°C

TA = +25°C

NO-LOAD SUPPLY CURRENT

vs. SUPPLY VOLTAGE

XMAX15031 toc06

SUPPLY VOLTAGE (V)

NO-LOAD SUPPLY CURRENT (mA)

10987654

10

20

30

40

50

60

0

311

TA = +85°C

TA = -40°C

TA = +25°C

EXITING SHUTDOWN

MAX15031 toc07

1ms/div

V

OUT

50V/div

I

L

500mA/div

V

SHDN

2V/div

3V

0V

0mA

I

OUT

= 1mA

ENTERING SHUTDOWN

MAX15031 toc08

4ms/div

OUTPUT VOLTAGE

50V/div

INDUCTOR CURRENT

500mA/div

SHUTDOWN VOLTAGE

2V/div

3V

70V

0V

0mA

I

LOAD

= 1mA

Page 5

LIGHT-LOAD SWITCHING

WAVEFORM WITH RC FILTER

MAX15031 toc09

1µs/div

V

BIAS

AC-COUPLED

V

LX

50V/div

I

L

500mA/div

1mV/div

0mA

0V

I

OUT

= 0.1mA, V

BIAS

= 70V

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

_______________________________________________________________________________________ 5

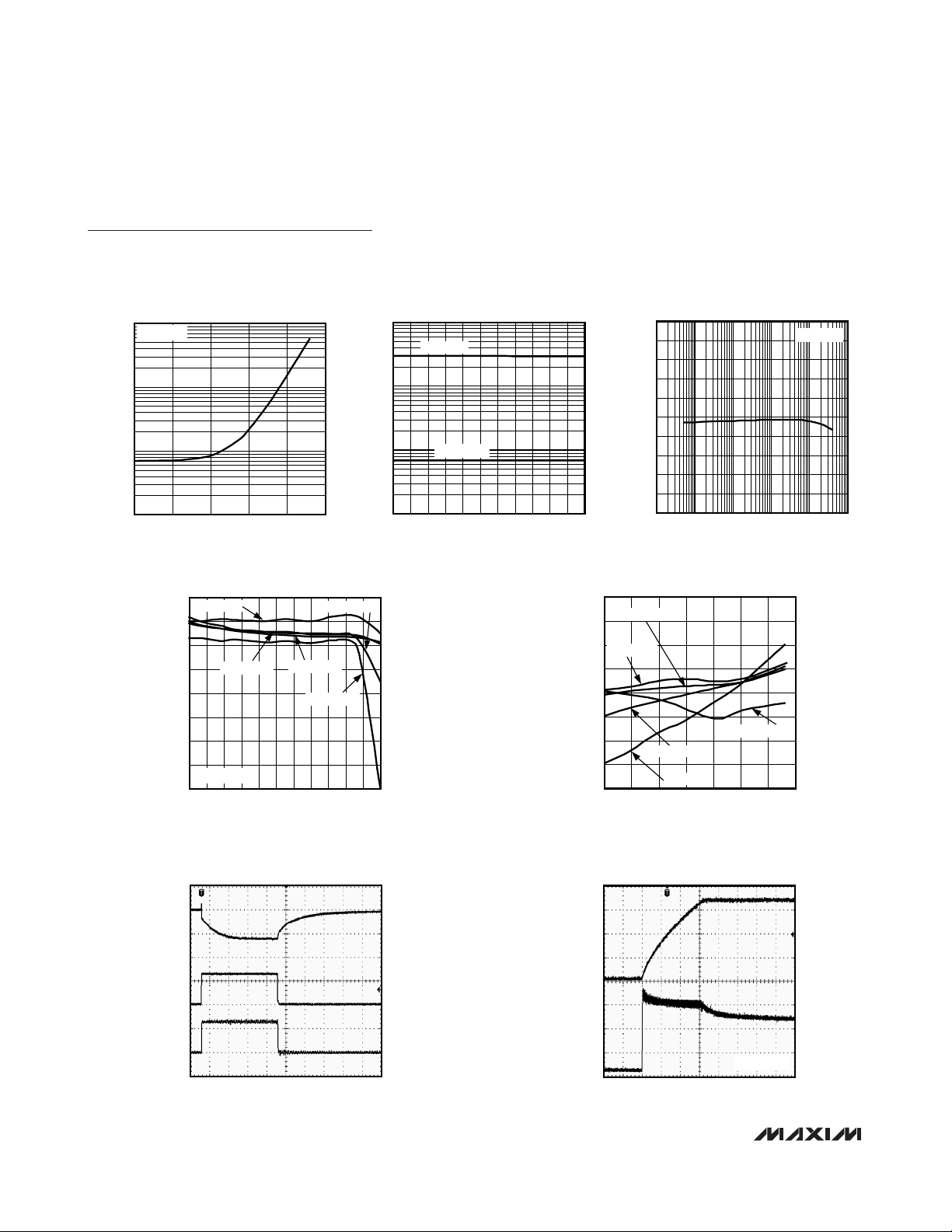

Typical Operating Characteristics (continued)

(V

PWR

= VIN= 3.3V, V

OUT

= 70V, circuit of Figure 3 (Figure 4 for VIN> 5.5V), unless otherwise noted.)

MAXIMUM LOAD CURRENT

vs. INPUT VOLTAGE

MAX15031 toc15

INPUT VOLTAGE (V)

MAXIMUM LOAD CURRENT (mA)

1097 85 64

10

20

30

40

50

60

70

80

90

100

110

0

311

A

B

C

A: V

OUT

= 30V, B: V

OUT

= 35V, C: V

OUT

= 45V,

D: V

OUT

= 55V, E: V

OUT

= 60V, F: V

OUT

= 72V

D

E

F

LOAD REGULATION

MAX15031 toc14

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

4321

68.2

68.4

68.6

68.8

69.0

69.2

69.4

69.6

69.8

70.0

68.0

05

BIAS CURRENT

vs. BIAS VOLTAGE

MAX15031 toc16

BIAS VOLTAGE (V)

BIAS CURRENT (mA)

70605040302010

0.1

1

10

0.01

080

I

APD

= 2mA

I

APD

= 500nA

LOAD-TRANSIENT RESPONSE

100ms/div

HEAVY-LOAD SWITCHING

WAVEFORM WITH RC FILTER

MAX15031 toc11

V

OUT

= 3.3V

V

IN

= 70V

V

OUT

AC-COUPLED

200mV/div

I

LOAD

5mA/div

0mA

LINE-TRANSIENT RESPONSE

100ms/div

MAX15031 toc12

V

OUT

I

OUT

t

RISE

= 70V

= 1mA

= 50µs

V

IN

2V/div

3.3V

V

OUT

AC-COUPLED

100mV/div

MAX15031 toc10

I

OUT

1µs/div

= 4mA, V

BIAS

= 70V

V

BIAS

AC-COUPLED

1mV/div

V

LX

50V/div

0V

I

L

500mA/div

0mA

LX LEAKAGE CURRENT

vs. TEMPERATURE

200

CURRENT INTO

180

LX PIN

160

140

120

100

80

60

LX LEAKAGE CURRENT (nA)

40

20

0

-40 125

TEMPERATURE (°C)

MAX15031 toc13

1109565 80-10 5 20 35 50-25

Page 6

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

PWR

= VIN= 3.3V, V

OUT

= 70V, circuit of Figure 3 (Figure 4 for VIN> 5.5V), unless otherwise noted.)

BIAS CURRENT

vs. APD CURRENT

MAX15031 toc17

APD CURRENT (mA)

BIAS CURRENT (mA)

10.10.010.001

0.1

1

10

0.01

0.0001 10

V

BIAS

= 70V

BIAS CURRENT

vs. TEMPERATURE

MAX15031 toc18

TEMPERATURE (°C)

BIAS CURRENT (mA)

1109580655035205-10-25

0.1

1

10

0.01

-40 125

I

APD

= 2mA

I

APD

= 500nA

GAIN ERROR

vs. APD CURRENT

MAX15031 toc19

I

APD

(µA)

GAIN ERROR (%)

1000100101

-4

-3

-2

-1

0

1

2

3

4

5

-5

0.1 10,000

V

BIAS

= 70V

GAIN ERROR

vs. TEMPERATURE

MAX15031 toc20

TEMPERATURE (°C)

GAIN ERROR (%)

11095-25 -10 5 35 50 6520 80

-2.5

-2.0

-1.5

-1.0

-0.5

0

0.5

1.0

-3.0

-40 125

V

BIAS

= 70V

I

APD

= 500nA

I

APD

= 50µA

I

APD

= 5µA

I

APD

= 2mA

I

APD

= 500µA

GAIN ERROR

vs. BIAS VOLTAGE

MAX15031 toc21

BIAS VOLTAGE (V)

GAIN ERROR (%)

706020 30 40 50

-0.60

-0.40

-0.20

0

0.20

0.40

0.60

0.80

-0.80

10 80

I

APD

= 500nA

I

APD

= 50µA

I

APD

= 5µA

I

APD

= 2mA

I

APD

= 500µA

APD TRANSIENT RESPONSE

MAX15031 toc22

20µs/div

V

APD

AC-COUPLED

70V

2V/div

I

APD

2.5mA/div

I

MOUT

0.25mA/div

0mA

0mA

STARTUP DELAY

MAX15031 toc23

200µs/div

V

BIAS

20V/div

I

MOUT

20nA/div

3V

0nA

I

APD

= 500nA

Page 7

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(V

PWR

= VIN= 3.3V, V

OUT

= 70V, circuit of Figure 3 (Figure 4 for VIN> 5.5V), unless otherwise noted.)

VOLTAGE DROP

vs. APD CURRENT

MAX15031 toc28

I

APD

(µA)

V

BIAS

- V

APD

(V)

1000100101

0.20

0.40

0.60

0.80

1.00

1.20

1.40

0

0.1 10,000

TA = +25°C

TA = -40°C

TA = +125°C

TA = +85°C

SWITCHING FREQUENCY

vs. TEMPERATURE

MAX15031 toc29

TEMPERATURE (°C)

SWITCHING FREQUENCY (kHz)

1109565 80-10 5 20 35 50-25

320

340

360

380

400

420

440

460

480

500

300

-40 125

STARTUP DELAY

100µs/div

STARTUP DELAY

MAX15031 toc24

I

APD

MAX15031 toc26

= 2mA

V

APD

20V/div

3V

I

MOUT

50µA/div

0nA

V

BIAS

2V/div

SHORT-CIRCUIT RESPONSE

STARTUP DELAY

100µs/div

I

V

APD

BIAS

MAX15031 toc25

= 500nA

= 5V

MAX15031 toc27

V

APD

2V/div

0V

I

MOUT

20nA/div

0nA

I

LIM

2V/div

0V

40µs/div

I

V

APD

BIAS

= 2mA

= 5V

0V

I

MOUT

50µA/div

0nA

40ms/div

V

BIAS

T

A

R

LIM

= 70V

= +85°C

= 2kΩ

I

BIAS

2mA/div

0mA

Page 8

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

PWR

= VIN= 3.3V, V

OUT

= 70V, circuit of Figure 3 (Figure 4 for VIN> 5.5V), unless otherwise noted.)

SWITCHING FREQUENCY

vs. INPUT VOLTAGE

500

480

460

440

420

400

380

360

SWITCHING FREQUENCY (kHz)

340

320

300

212

INPUT VOLTAGE (V)

FB SET-POINT VARIATION

vs. TEMPERATURE

1.277

VIN = 2.9V

1.257

1.247

1.237

1.227

VIN = 5.5V

VIN = 2.9V

VIN = 5.5V

10864

FB RISING

FB FALLING

MAX15031 toc30

MAX15031 toc32

SWITCHING FREQUENCY AND

DUTY CYCLE vs. LOAD CURRENT

420

415

410

405

400

395

390

SWITCHING FREQUENCY (kHz)

385

380

04

SWITCHING FREQUENCY

LOAD CURRENT (mA)

APD OUTPUT RIPPLE VOLTAGE

MAX15031 toc31

DUTY CYCLE

MEASURED AT CN

321

MAX15031 toc33

60

50

40

DUTY CYCLE

30

20

10

0

V

APD

AC-COUPLED, 55V

200µV/div

1.217

FB SET-POINT VOLTAGE VARIATION (V)

1.207

-40 125

TEMPERATURE (°C)

APD OUTPUT RIPPLE VOLTAGE

0.1µF CAPACITOR CONNECTED

FROM APD TO GND.

2µs/div

1109580655035205-10-25

MAX15031 toc34

V

APD

AC-COUPLED, 55V

100µV/div

2µs/div

APD OUTPUT RIPPLE VOLTAGE

0.1µF CAPACITOR CONNECTED

FROM APD TO GND.

2µs/div

MAX15031 toc35

V

APD

AC-COUPLED, 70V

500µV/div

Page 9

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

_______________________________________________________________________________________ 9

Pin Description

PIN NAME FUNCTION

1 PWR

2CP

3CN

4IN

5 SGND

6FB

7 CNTRL

8 ILIM Open-Drain Current-Limit Indicator. ILIM asserts low when the APD current limit has been exceeded.

9 RLIM

10 MOUT Current-Monitor Output. MOUT sources a current 1/10th of I

11 CLAMP Clamp Voltage Input. CLAMP is the external potential used for voltage clamping of MOUT.

12 APD Reference Current Output. APD provides the source current to the cathode of the photodiode.

13 BIAS

14 SHDN

15 PGND

16 LX

—EP

Boost Converter Input Voltage. PWR powers the switch driver and charge pump. Bypass PWR to PGND with a

ceramic capacitor of 1µF minimum value.

Positive Terminal of the Charge-Pump Flying Capacitor for 2.7V to 5.5V Supply Voltage Operation. Connect

CP to IN when the input voltage is in the 5.5V to 11V range.

Negative Terminal of the Charge-Pump Flying Capacitor for 2.7V to 5.5V Supply Voltage Operation. Leave CN

unconnected when the input voltage is in the 5.5V to 11V range.

Input Supply Voltage. IN powers all blocks of the MAX15031 except the switch driver and charge pump.

Bypass IN to PGND with a ceramic capacitor of 1µF minimum value.

Signal Ground. Connect directly to the local ground plane. Connect SGND to PGND at a single point, typically

near the return terminal of the output capacitor.

Feedback Regulation Input. Connect FB to the center tap of a resistive voltage-divider from the output (V

to SGND to set the output voltage. The FB voltage regulates to 1.245V (typ) when V

and to V

Control Input for Boost Converter Output-Voltage Programmability. Allows the feedback set-point voltage to be

set externally by CNTRL when CNTRL is less than 1.245V. Pull CNTRL above 1.5V (typ) to use the internal

1.245V (typ) feedback set-point voltage.

Current-Limit Resistor Connection. Connect a resistor from RLIM to SGND to program the APD current-limit

threshold.

Bias Voltage Input. Connect BIAS to the boost converter output (V

filter for ripple attenuation. BIAS provides the voltage bias for the current monitor and is the current source for

APD.

Active-Low Shutdown Control Input. Apply a logic-low voltage to SHDN to shut down the device and reduce

the supply current to 2µA (max). Connect SHDN to IN for normal operation. Ensure that V

than the input voltage, V

Power Ground. Connect the negative terminals of the input and output capacitors to PGND. Connect PGND

externally to SGND at a single point, typically at the return terminal of the output capacitor.

Drain of Internal 80V n-Channel DMOS. Connect inductor and diode to LX. Minimize the trace area at LX to

reduce switching noise emission.

Exposed Pad. Connect EP to a large contiguous copper plane at SGND potential to improve thermal

dissipation. Do not use as the main SGND connection.

voltage when V

CNTRL

.

IN

is below 1.245V (typ).

CNTRL

APD

.

) either directly or through a lowpass

OUT

is above 1.5V (typ)

CNTRL

is not greater

SHDN

OUT

)

Page 10

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

10 ______________________________________________________________________________________

Functional Diagram

Detailed Description

The MAX15031 constant-frequency, current-mode, PWM

boost converter is intended for low-voltage systems that

require a locally generated high voltage. This device can

generate a low-noise, high output voltage required for

PIN and varactor diode biasing and LCD displays. The

MAX15031 operates either from +2.7V to +5.5V or from

+5.5V to +11V. For 2.7V to 5.5V operation, an internal

charge pump with an external 10nF ceramic capacitor is

used. For 5.5V to 11V operation, connect CP to IN and

leave CN unconnected.

The MAX15031 operates in discontinuous mode in

order to reduce the switching noise caused by reversevoltage recovery charge of the rectifier diode. Other

continuous mode boost converters generate large voltage spikes at the output when the LX switch turns on

because there is a conduction path between the output, diode, and switch to ground during the time needed for the diode to turn off and reverse its bias voltage.

To reduce the output noise even further, the LX switch

turns off by taking 10ns typically to transition from ON

to OFF. As a consequence, the positive slew rate of the

LX node is reduced and the current from the inductor

does not “force” the output voltage as hard as would

be the case if the LX switch were to turn off faster.

The constant-frequency (400kHz) PWM architecture

generates an output voltage ripple that is easy to filter.

An 80V vertical DMOS device used as the internal

power switch is ideal for boost converters with output

voltages up to 76V. The MAX15031 can also be used in

other topologies where the PWM switch is grounded,

like SEPIC and flyback converters.

PWR

OUTPUT ERROR AND CURRENT

FB

CNTRL

SGND

V

REF

V

REF

MUX

REFERENCE

COMPARATOR

COMPARATOR

-A

+A

-C

+C

SOFTSTART

PEAK CURRENT-LIMIT

COMPARATOR

SWITCH

CONTROL

LOGIC

80V

DMOS

CURRENT

LX

PGND

SWITCH

SENSE

CN

CP

IN

CHARGE

PUMP

(DOUBLER)

UVLO

THERMAL

SHUTDOWN

MAX15031

BIAS AND

REFERENCE

CLK

OSCILLATOR

400kHz

SHDN BIAS

1x

V

REF

CURRENT

MONITOR

10x

CURRENT-

LIMIT

ADJUSTMENT

CURRENT

LIMIT

CLAMP

MOUT

RLIM

APD

ILIM

Page 11

MAX15031

The MAX15031 includes a versatile current monitor

intended for monitoring the APD, PIN, or varactor diode

DC current in fiber and other applications. The

MAX15031 features more than three decades of

dynamic current ranging from 500nA to 4mA and provides an output current accurately proportional to the

APD current at MOUT.

The MAX15031 also features a shutdown logic input to

disable the device and reduce its standby current to

2µA (max).

Fixed-Frequency PWM Controller

The heart of the MAX15031 current-mode PWM controller is a BiCMOS multiple-input comparator that

simultaneously processes the output-error signal and

switch current signal. The main PWM comparator uses

direct summing, lacking a traditional error amplifier and

its associated phase shift. The direct summing configuration approaches ideal cycle-by-cycle control over the

output voltage since there is no conventional error

amplifier in the feedback path.

The device operates in PWM mode using a fixed-frequency, current-mode operation. The current-mode frequency loop regulates the peak inductor current as a

function of the output error signal.

The current-mode PWM controller is intended for DCM

(discontinuous conduction mode) operation. No internal

slope compensation is added to the current signal.

Charge Pump

At low supply voltages (2.7V to 5.5V), internal chargepump circuitry and an external 10nF ceramic capacitor

connected between CP and CN double the available internal supply voltage to drive the internal switch efficiently.

In the 5.5V to 11V supply voltage range, the charge

pump is not required. In this configuration, disable the

charge pump by connecting CP to IN and leaving CN

unconnected.

Monitor Current Limit (RLIM)

The current limit of the current monitor is programmable

from 1mA to 5mA. Connect a resistor from RLIM to

ground to program the current-limit threshold up to 5mA.

The current monitor mirrors the current out of APD with

a 1:10 ratio, and the MOUT current can be converted to

a voltage signal by connecting a resistor from MOUT to

SGND.

The APD current-monitor range is from 500nA to 4mA,

and the MOUT current-mirror output accuracy is ±10%

from 500nA to 1mA of APD current and ±3.5% from

1mA to 4mA of APD current.

Clamping the Monitor

Output Voltage (CLAMP)

CLAMP provides a means for diode clamping the voltage at MOUT; thus V

MOUT

is limited to (V

CLAMP

+

0.6V). CLAMP can be connected to either an external

supply or BIAS. CLAMP can be left unconnected if voltage clamping is not required.

Adjusting the Boost Converter

Output Voltage (FB/CNTRL)

The boost converter output voltage can be set by connecting FB to a resistor-divider from V

OUT

to ground.

The set-point feedback reference is the 1.245 (typ)

internal reference voltage when V

CNTRL

> 1.5V and is

equal to the CNTRL voltage when V

CNTRL

< 1.25V.

To change the converter output on the fly, apply a voltage lower than 1.25V (typ) to the CNTRL input and

adjust the CNTRL voltage, which is the reference input

of the error amplifier when V

CNTRL

< 1.25V (see the

Functional Diagram

). This feature can be used to adjust

the APD voltage based on the APD mirror current,

which compensates for the APD avalanche gain variation with temperature and manufacturing process. As

shown in Figure 4, the voltage signal proportional to the

MOUT current is connected to the ADC (analog to digital) input of the APD module, which then controls the

reference voltage of the boost converter error amplifier

through a DAC (digital to analog) block connected to

the CNTRL input. The BIAS voltage and, therefore, the

APD current, are controlled based on the MOUT mirror

current, forming a negative feedback loop.

Shutdown (

SHDN

)

The MAX15031 features an active-low shutdown input

(SHDN). Pull SHDN low to enter shutdown. During shut-

down, the supply current drops to 2µA (30µA from

BIAS) (max). However, the output remains connected to

the input through the inductor and the output diode,

holding the output voltage to one diode drop below

PWR when the MAX15031 shuts down. Connect SHDN

to IN for always-on operation.

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

______________________________________________________________________________________ 11

Page 12

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

12 ______________________________________________________________________________________

Design Procedure

Setting the Output Voltage

Set the MAX15031 output voltage by connecting a resistive divider from the output to FB to SGND (Figure 1).

Select R1(FB to SGND resistor) between 200kΩ and

400kΩ. Calculate R2(V

OUT

to FB resistor) using the fol-

lowing equation:

where V

OUT

can range from (VIN+ 1V) to 76V and V

REF

= 1.245V or V

CNTRL

depending on the V

CNTRL

value.

For V

CNTRL

> 1.5V, the internal 1.245V (typ) reference

voltage is used as the feedback set point (V

REF

=

1.245V) and for V

CNTRL

< 1.25V, V

REF

= V

CNTRL

.

Determining Peak Inductor Current

If the boost converter remains in the discontinuous

mode of operation, then the approximate peak inductor

current, I

LPEAK

(in amperes), is represented by the for-

mula below:

where TSis the switching period in microseconds,

V

OUT

is the output voltage in volts, V

IN_MIN

is the mini-

mum input voltage in volts, I

OUT_MAX

is the maximum

output current in amperes, L is the inductor value in

microhenrys, and η is the efficiency of the boost converter (see the

Typical Operating Characteristics

).

Determining the Inductor Value

Three key inductor parameters must be specified for

operation with the MAX15031: inductance value (L),

inductor saturation current (I

SAT

), and DC resistance

(DCR). In general, the inductor should have a saturation

current rating greater than the maximum switch peak

current-limit value (I

LIM-LX

= 1.6A). Choose an inductor

with a low-DCR resistance for reasonable efficiency.

Use the following formula to calculate the lower bound

of the inductor value at different output voltages and

output currents. This is the minimum inductance value

for discontinuous mode operation for supplying full

300mW of output power.

where V

IN_MIN

, V

OUT

(both in volts), and I

OUT

(in

amperes) are typical values (so that efficiency is optimum for typical conditions), TS(in microseconds) is the

period, η is the efficiency, and I

LIM_LX

is the peak

switch current in amperes (see the

Electrical

Characteristics

table).

Calculate the optimum value of L (L

OPTIMUM

) to ensure

the full output power without reaching the boundary

between continuous conduction mode (CCM) and DCM

using the following formula:

For a design in which VIN= 3.3V, V

OUT

= 70V, I

OUT

=

3mA, η = 45%, I

LIM-LX

= 1.3A, and TS= 2.5µs: L

MIN

=

1.3µH and L

MAX

= 23µH.

For a worse-case scenario in which VIN= 2.9V, V

OUT

=

70V, I

OUT

= 4mA, η = 43%, I

LIM-LX

= 1.3A, and TS=

2.5µs: L

MIN

= 1.8µH and L

MAX

= 15µH.

The choice of 4.7µH is reasonable given the worst-case

scenario above. In general, the higher the inductance,

the lower the switching noise. Load regulation is also

better with higher inductance.

Figure 1. Adjustable Output Voltage

V

OUT

R

2

FB

MAX15031

R

1

RR

21

⎡

⎛

V

=

OUT

⎢

⎜

V

⎝

REF

⎣

⎤

⎞

1

−

⎥

⎟

⎠

⎦

2T I (V V )

×× ×

S OUT OUT IN_MIN

L[H]

µη=

MIN

−

2

I

×

LIM-LX

L[H]

OPTIMUM

where L [ H]

MAX

µη=

2

V(VV)T

IN_MIN

L

MAX

µµ=

−

OUT IN_MIN S

×××IV

2

OUT

I

LPEAK

×× ×

=

S OUT IN_MIN OUT_MAX

−

L

×

η

2T (V V )I

[]

.H225

××

2

OUT

Page 13

MAX15031

Diode Selection

The MAX15031’s high switching frequency demands a

high-speed rectifier. Schottky diodes are recommended for most applications because of their fast recovery

time and low forward-voltage drop. Ensure that the

diode’s peak current rating is greater than the peak

inductor current. Also the diode reverse-breakdown

voltage must be greater than V

OUT

. The output voltage

of the boost converter.

Output Filter Capacitor Selection

For most applications, use a small output capacitor of

0.1µF or greater. To achieve low output ripple, a capacitor with low ESR, low ESL, and high capacitance value

should be selected. If tantalum or electrolytic capacitors

are used to achieve high capacitance values, always

add a smaller ceramic capacitor in parallel to bypass

the high-frequency components of the diode current.

The higher ESR and ESL of electrolytic capacitors

increase the output ripple and peak-to-peak transient

voltage. Assuming the contribution from the ESR and

capacitor discharge equals 50% (proportions may vary),

calculate the output capacitance and ESR required for a

specified ripple using the following equations:

For very low output ripple applications, the output of the

boost converter can be followed by an RC filter to further

reduce the ripple. Figure 2 shows a 100Ω (RF), 0.1µF

(CF) filter used to reduce the switching output ripple to

1mV

P-P

with a 0.1mA load or 2mV

P-P

with a 4mA load.

The output-voltage regulation resistor-divider must remain

connected to the diode and output capacitor node.

Use X7R ceramic capacitors for more stability over the full

temperature range. Use an X5R capacitor for -40°C to

+85°C applications.

Input Capacitor Selection

Bypass PWR to PGND with a 1µF (min) ceramic capacitor and bypass IN to PGND with a 1µF (min) ceramic

capacitor. Depending on the supply source impedance, higher values may be needed. Make sure that the

input capacitors are close enough to the IC to provide

adequate decoupling at IN and PWR as well. If the layout cannot achieve this, add another 0.1µF ceramic

capacitor between IN and PGND (or PWR and PGND)

in the immediate vicinity of the IC. Bulk aluminum electrolytic capacitors may be needed to avoid chattering

at low input voltage. In case of aluminum electrolytic

capacitors, calculate the capacitor value and ESR of

the input capacitor using the following equations:

OOU

Figure 2. Typical Operating Circuit with RC Filter

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

______________________________________________________________________________________ 13

OUT

Ω

⎡

IxL

LPEAK OPTIM

T

⎢

S

⎢

⎣

0.5 x

∆V

=ESR m

I

(V V )−

OUT IN_MIN

OUT

T

I

C

[]µFV=−

OUT

0.5 x

OUT

∆

[]

UUM

⎤

⎥

⎥

⎦

VxI

C

[]µηFV=

IN

OUT OUT

xV x0.5x

IN_MIN IN

[]

⎡

TT

⎢

∆

⎢

⎣

0.5 xΩ∆ x η

VxV

=ESR m

VxI

OUT

IxL xV

LPEAK OPTIMUM OUT

−

S

V(VV

IN_MIN OUT I

IN IN_M

OUT

−

NN_MIN

IIN

)

⎤

⎥

⎥

⎦

VIN = 2.7V TO 5.5V V

C

PWR

C

CP

PWR

CNTRL

SHDN

CP

CN

PGND

IN

MAX15031

SGND

L1

C

IN

BIAS

R

F

LX

FB

D1

R

2

R

1

100Ω

C

OUT1

C

F

0.1µF

OUT

Page 14

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

14 ______________________________________________________________________________________

Determining Monitor Current Limit

Calculate the value of the monitor current-limit resistor,

R

LIM

, for a given APD current limit, I

LIMIT

, using the fol-

lowing equation:

The R

LIM

resistor, R

LIM

, ranges from 12.45kΩ to 2.5Ω

for APD currents from 1mA to 5mA.

Applications Information

Using APD or PIN Photodiodes

in Fiber Applications

When using the MAX15031 to monitor APD or PIN photodiode currents in fiber applications, several issues

must be addressed. In applications where the photodiode must be fully depleted, keep track of voltages budgeted for each component with respect to the available

supply voltage(s). The current monitors require as

much as 1.1V between BIAS and APD, which must be

considered part of the overall voltage budget.

Additional voltage margin can be created if a negative

supply is used in place of a ground connection, as long

as the overall voltage drop experienced by the

MAX15031 is less than or equal to 76V. For this type of

application, the MAX15031 is suggested so the output

can be referenced to “true” ground and not the negative

supply. The MAX15031’s output current can be referenced as desired with either a resistor to ground or a

transimpedance amplifier. Take care to ensure that output voltage excursions do not interfere with the required

margin between BIAS and MOUT. In many fiber applications, MOUT is connected directly to an ADC that operates from a supply voltage that is less than the voltage

at BIAS. Connecting the MAX15031’s clamping diode

output, CLAMP, to the ADC power supply helps avoid

damage to the ADC. Without this protection, voltages

can develop at MOUT that might destroy the ADC. This

protection is less critical when MOUT is connected

directly to subsequent transimpedance amplifiers (linear

or logarithmic) that have low-impedance, near-groundreferenced inputs. If a transimpedance amplfier is used

on the low side of the photodiode, its voltage drop must

also be considered. Leakage from the clamping diode

is most often insignificant over nominal operating conditions, but grows with temperature.

To maintain low levels of wideband noise, lowpass filtering the output signal is suggested in applications where

only DC measurements are required. Connect the filter

capacitor at MOUT. Determining the required filtering

components is straightforward, as the MAX15031

exhibits a very high output impedance of 890MΩ.

In some applications where pilot tones are used to identify specific fiber channels, higher bandwidths are desired

at MOUT to detect these tones. Consider the minimum

and maximum currents to be detected, then consult the

frequency response and noise typical operating curves.

If the minimum current is too small, insufficient bandwidth

could result, while too high a current could result in

excessive noise across the desired bandwidth.

Layout Considerations

Careful PCB layout is critical to achieve low switching

losses and clean and stable operation. Protect sensitive

analog grounds by using a star ground configuration.

Connect SGND and PGND together close to the device

at the return terminal of the output bypass capacitor.

Do not connect them together anywhere else. Keep all

PCB traces as short as possible to reduce stray capacitance, trace resistance, and radiated noise. Ensure that

the feedback connection to FB is short and direct.

Route high-speed switching nodes away from the sensitive analog areas. Use an internal PCB layer for SGND

as an EMI shield to keep radiated noise away from the

device, feedback dividers, and analog bypass capacitors. Refer to the MAX15031 evaluation kit data sheet

for a layout example.

R10

=×

LIM

1.245V

I (mA)

LIMIT

Page 15

MAX15031

MAX15031

CNTRL

CP

CN

IN

PGND

FB

BIAS

SHDN

MOUTAPDSGNDRLIM

PWR

LX

GPIO

ILIM

GPIO

CLAMP

V

DD

µC

V

DD

APD

C

IN

1µF

C

CP

10nF

R

MOUT

10kΩ

C

OUT

0.1µF

C

MOUT

(OPTIONAL)

R

1

6.34kΩ

R

LIM

2.87kΩ

R

2

348kΩ

V

IN

C

PWR

1µF

L1

4.7µH

D1

V

OUT

(70V MAX)

DAC

ADC

R

F

100Ω

R

ADJ

C

F

0.1µF

Typical Operating Circuits

Figure 3. Typical Operating Circuit for VIN= 2.7V to 5.5V

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

______________________________________________________________________________________ 15

Page 16

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

16 ______________________________________________________________________________________

Typical Operating Circuits (continued)

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

16 TQFN T1644-4

21-0139

Chip Information

PROCESS: BiCMOS

Figure 4. Typical Operating Circuit for VIN= 5.5V to 11V

L1

= 5.5V TO 11V

V

IN

4.7µH

D1

V

OUT

(70V MAX)

C

IN

1µF

R

2.87kΩ

LIM

PWR

CNTRL

IN

CP

CN

C

1µF

MAX15031

PWR

APD

LX

PGND

BIAS

SHDN

ILIM

CLAMP

MOUTAPDSGNDRLIM

R

FB

MOUT

10kΩ

V

DD

C

OUT

0.1µF

C

MOUT

(OPTIONAL)

R

F

100Ω

C

F

0.1µF

GPIO

GPIO

V

DD

ADC

R

2

348kΩ

R

1

634kΩ

µC

DAC

Page 17

MAX15031

80V, 300mW Boost Converter and Current

Monitor for APD Bias Applications

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

17

© 2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

0 10/08 Initial release —

1 3/09 Updated Electrical Characteristics and added new Note 3. 3

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Loading...

Loading...