Page 1

General Description

The MAX15022 is a dual-output, pulse-width-modulated

(PWM), step-down DC-DC regulator with dual LDO controllers. The device operates from 2.5V to 5.5V and

each output can be adjusted from 0.6V to the input

supply (V

AVIN

). The MAX15022 delivers up to 4A (regulator 1) and 2A (regulator 2) of output current with two

LDO controllers that can be used to drive two external

PNP transistors to provide two additional outputs. This

device offers the ability to adjust the switching frequency from 500kHz to 4MHz and provides the capability of

optimizing the design in terms of size and performance.

The MAX15022 utilizes a voltage-mode control scheme

with external compensation to provide good noise

immunity and maximum flexibility in selecting inductor

values and capacitor types. The dual switching regulators operate 180° out-of-phase, thereby reducing the

RMS input ripple current and thus the size of the input

bypass capacitor significantly.

The MAX15022 offers the ability to track (coincident or

ratiometric) or sequence during power-up and powerdown operation. When sequencing, it powers up glitchfree into a prebiased output.

Additional features include an internal undervoltage

lockout with hysteresis and a digital soft-start/soft-stop

for glitch-free power-up and power-down. Protection

features include lossless cycle-by-cycle current limit,

hiccup-mode output short-circuit protection, and thermal shutdown.

The MAX15022 is available in a space-saving, 5mm x

5mm, 28-pin TQFN-EP package and is specified for

operation from -40°C to +125°C temperature range.

Applications

RFID Reader Cards

Power-over-Ethernet (PoE) IP Phones

Automotive Multimedia

Multivoltage Supplies

Networking/Telecom

Features

o 2.5V to 5.5V Input-Voltage Range

o Dual-Output Synchronous Buck Regulators

o Integrated Switches for 4A and 2A Output

Currents

o 180° Out-Of-Phase Operation

o Output Voltage Adjustable from 0.6V to V

AVIN

o Two LDO Controllers

o Lossless, Cycle-by-Cycle Current Sensing

o External Compensation for Maximum Flexibility

o Digital Soft-Start and Soft-Stop for Tracking

Applications

o Digital Soft-Start into a Prebiased Load for

Sequencing Applications

o Sequencing or Coincident/Ratiometric Tracking

o Programmable Switching Frequency from 500kHz

to 4MHz

o Thermal Shutdown and Hiccup-Mode Short-

Circuit Protection

o 30µA Shutdown Current

o 100% Maximum Duty Cycle

o Space-Saving (5mm x 5mm) 28-Pin TQFN

Package

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

________________________________________________________________

Maxim Integrated Products

1

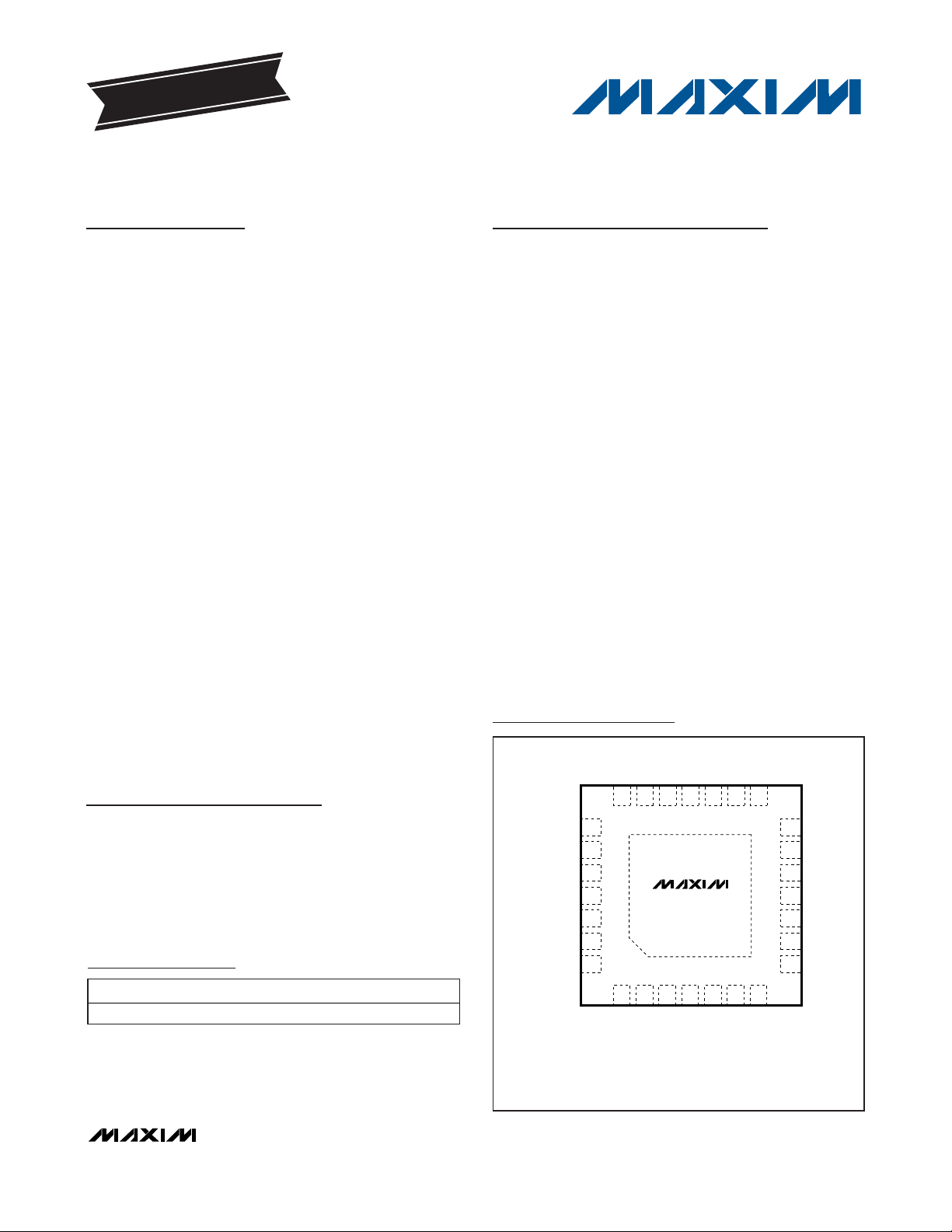

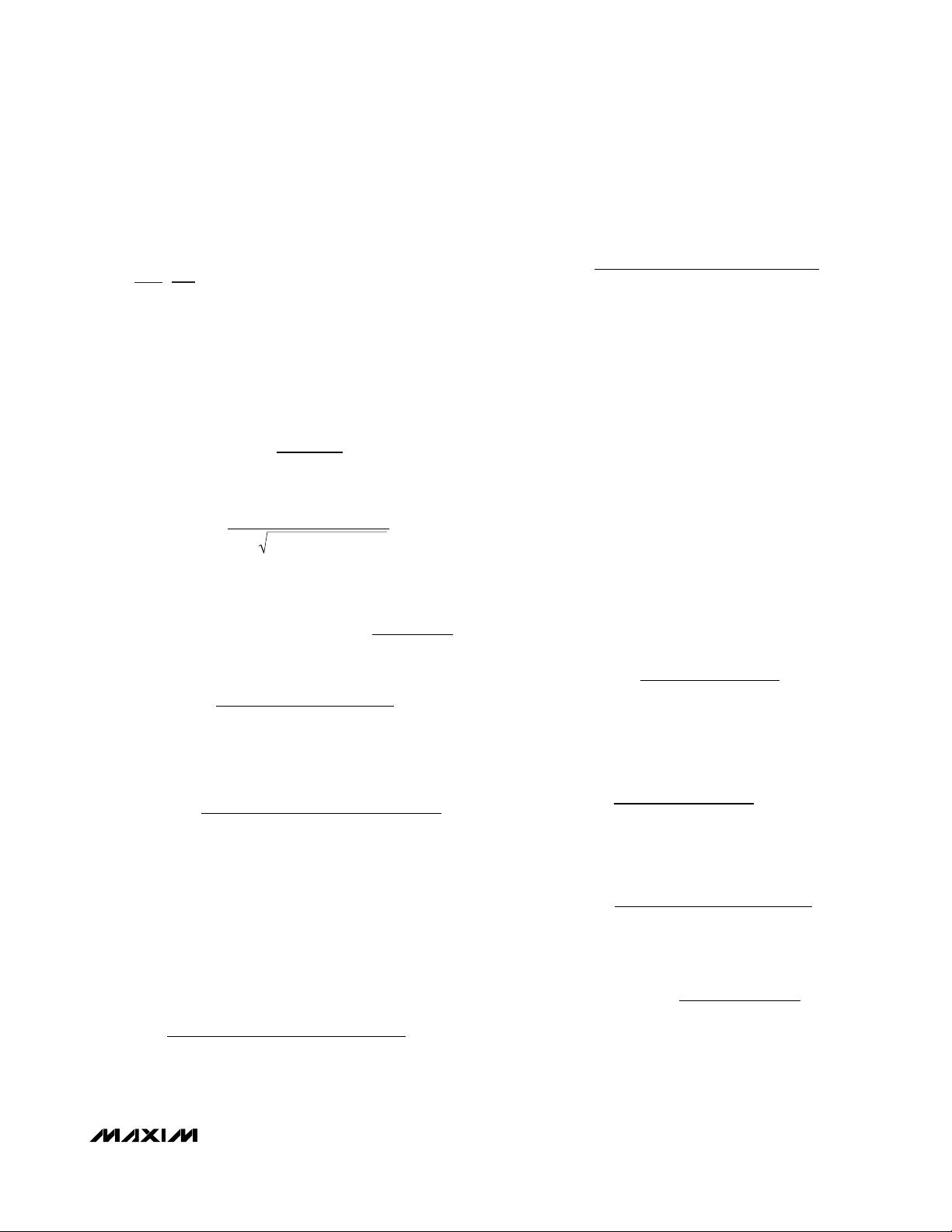

Pin Configuration

Ordering Information

19-4107; Rev 0; 5/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE PIN-PACKAGE

MAX15022ATI+

-40°C to +125°C 28 TQFN-EP*

+

Denotes a lead-free package.

*

EP = Exposed pad.

TOP VIEW

EN4

LX2

PVIN2

18

4

PGND2

DVDD2

EN3

*EP

567

14

FB3

B3

13

12

COMP1

FB1

11

10

EN1

DVDD1

9

8

PGND1

COMP2

FB2

EN2

SGND

AVIN

FB4

2021 19 17 16 15

B4

22

23

24

25

26

27

28

RT

1+2

MAX15022

3

*EP = EXPOSED PAD.

SEL

LX1

PGND1

THIN QFN

(5mm x 5mm)

PVIN1

PVIN1

LX1

PGND1

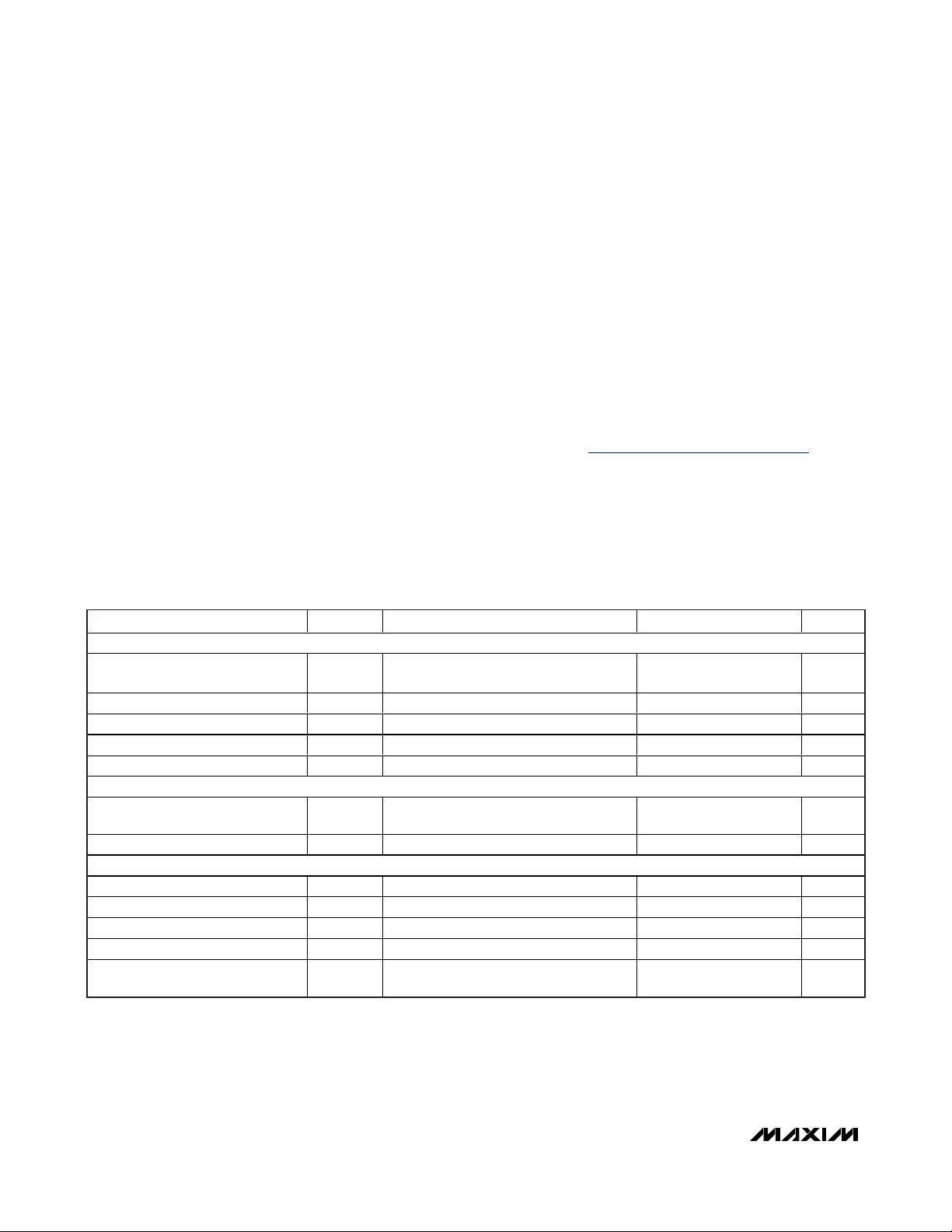

Page 2

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

AVIN

= V

PVIN_

= V

DVDD_

= 3.3V, V

PGND_

= V

SGND

= 0V, RT= 25kΩ, and TA= TJ= -40°C to +125°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 3)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: LX has internal diodes to PGND_ and PVIN_. Applications that forward bias these diodes should take care not to exceed

the IC’s package power dissipation limits.

Note 2: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations see www.maxim-ic.com/thermal-tutorial

.

AVIN, PVIN_, B_, DVDD_, EN_, FB_, RT,

SEL to SGND .........................................................-0.3V to +6V

COMP_ to SGND .....................................-0.3V to (V

AVIN

+ 0.3V)

PGND_ to SGND ...................................................-0.3V to +0.3V

LX Current (Note 1)

Regulator 1...............................................................................6A

Regulator 2...............................................................................3A

Current into Any Pin Other than PVIN_,

LX_ and PGND_.............................................................±50mA

Continuous Power Dissipation (T

A

= +70°C)

28-Pin TQFN (derate 34.5mW/°C above +70°C) .....2758.6mW

Junction-to-Case Thermal Resistance (θ

JC

)(Note 2) .........2°C/W

Junction-to-Ambient Thermal Resistance (θ

JA

)(Note 2) ..29°C/W

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

SYSTEM SPECIFICATIONS

Input-Voltage Range

Undervoltage Lockout Threshold AVIN rising 2.1 2.2 2.3 V

Undervoltage Lockout Hysteresis 0.12 V

Operating Supply Current V

Shutdown Supply Current V

PWM DIGITAL SOFT-START/SOFT-STOP

Soft-Start/Soft-Stop Duration 4096

Reference Voltage Steps 64 Steps

PWM ERROR AMPLIFIERS

FB1, FB2 Input Bias Current -1 +1 μA

FB1, FB2 Voltage Set-Point 0.593 0.599 0.605 V

COMP1, COMP2 Voltage Range I

Error-Amplifier Open-Loop Gain 80 dB

Error-Amplifier Unity-Gain

Bandwidth

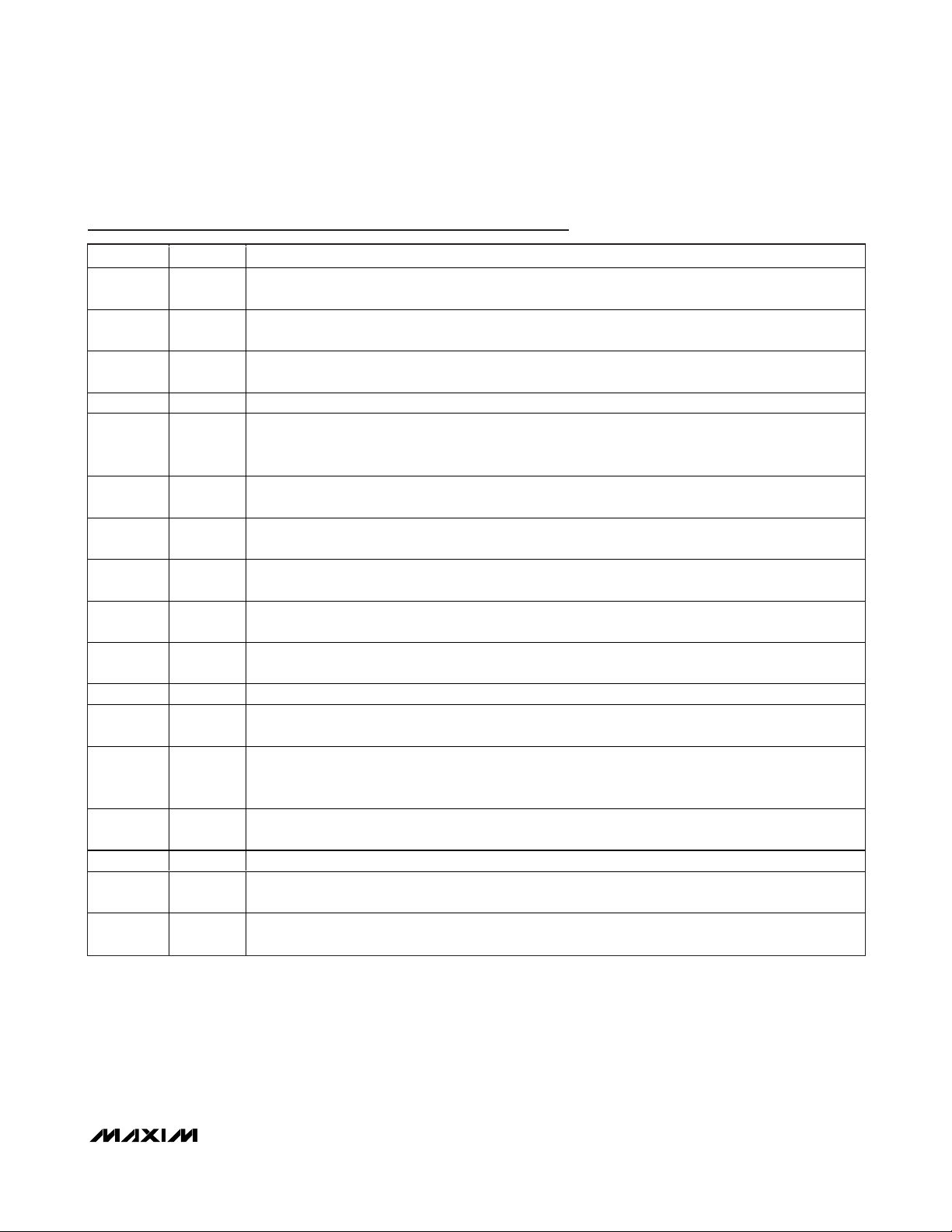

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

= V

AVIN

V

DVDD2

= 1.3V, V

EN_

= 0V 30 65 μA

EN_

_ = -250μA to +250μA 0.3 V

COMP

PVIN1

= V

FB_

= V

PVIN2

= 0.8V 3.5 6 mA

DVDD1

=

2.5 5.5 V

AVIN

12 MHz

- 0.5 V

Clock

Cycles

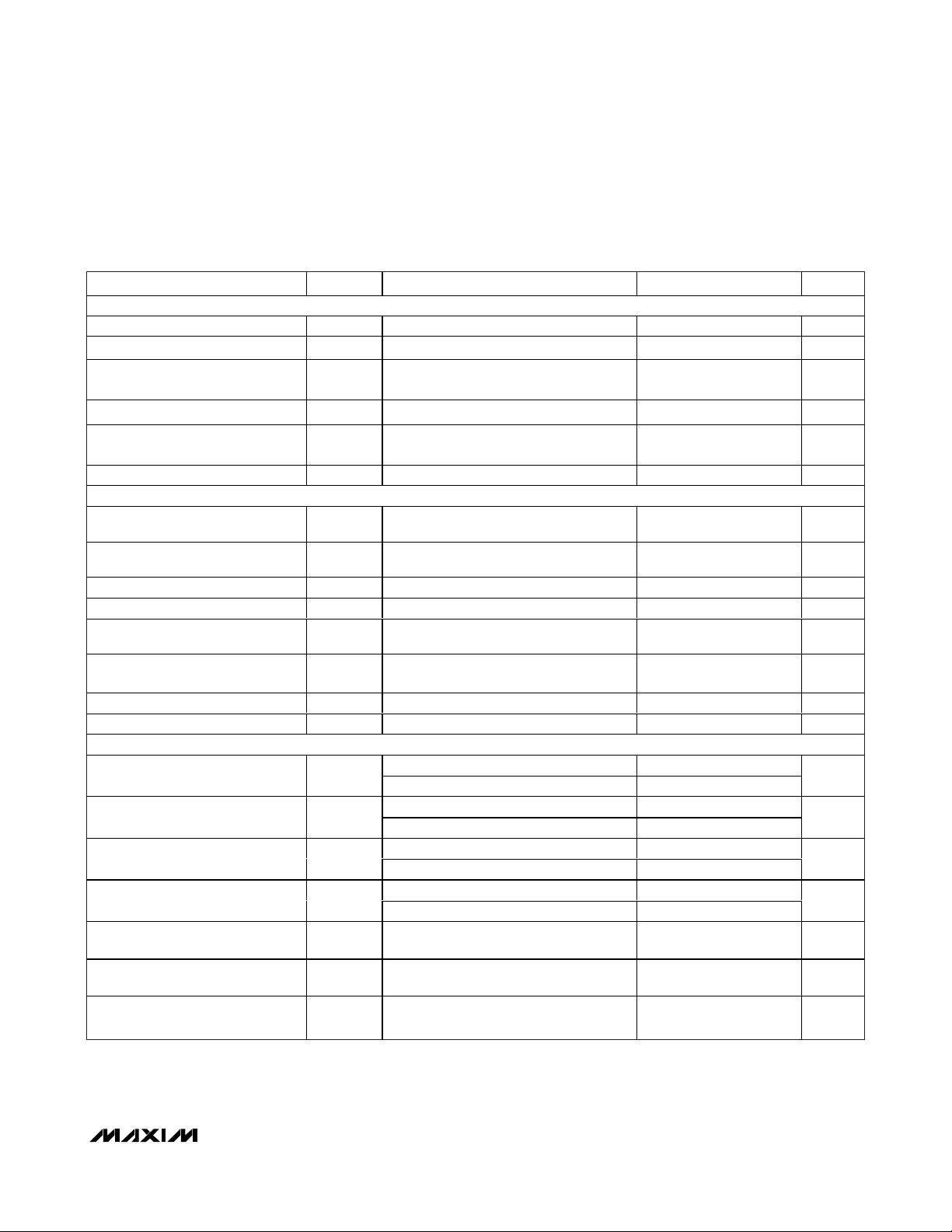

Page 3

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(V

AVIN

= V

PVIN_

= V

DVDD_

= 3.3V, V

PGND_

= V

SGND

= 0V, RT= 25kΩ, and TA= TJ= -40°C to +125°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 3)

LDO CONTROLLERS

FB3, FB4 Input Bias Current -250 +250 nA

FB3, FB4 Voltage Set-point 5mA sink current, VB_ = 0.5V to 5.5V 0.585 0.600 0.615 V

FB3, FB4 to B3, B4

Transconductance

B3, B4 Driver Sink Current V

LDO Soft-Start Duration

LDO Reference Voltage Steps 64 Steps

POWER MOSFETS

Regulator 1 p-Channel MOSFET

R

DSON

Regulator 1 n-Channel MOSFET

R

DSON

Regulator 1 Gate Charge V

Maximum LX1 RMS Current 4A

Regulator 2 p-Channel MOSFET

R

DSON

Regulator 2 n-Channel MOSFET

R

DSON

Regulator 2 Gate Charge V

Maximum LX2 RMS Current 2A

PWM CURRENT LIMIT AND HICCUP MODE

Regulator 1 Peak Current Limit

Regulator 1 Valley Current Limit

Regulator 2 Peak Current Limit

Regulator 2 Valley Current Limit

Number of Cumulative CurrentLimit Events to Hiccup

Number of Consecutive Noncurrent

Limit Cycles to Clear N

Hiccup Timeout N

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CL

2.5mA to 10mA sink current,

V

= 0.5V to 5.5V

B_

FB3, VFB4

V

DVDD1

V

DVDD1

DVDD1

V

DVDD2

V

DVDD2

DVDD2

V

PVIN

V

PVIN

V

PVIN

V

PVIN

V

PVIN

V

PVIN

V

PVIN

V

PVIN

N

CL

N

CLR

HT

= 0V, VB_ = 0.5V to 5.5V 20 mA

= 5V 50 90 mΩ

= 5V 30 50 mΩ

= 5V 8 nC

= 5V 100 180 mΩ

= 5V 60 100 mΩ

= 5V 4 nC

= V

= V

= V

= V

= V

= V

= V

= V

= 3.3V 4.5 4.9 5.3

AVIN

= 2.5V 3.40 3.65 3.95

AVIN

= 3.3V 4.0 5.0 5.65

AVIN

= 2.5V 3.0 3.7 4.25

AVIN

= 3.3V 2.25 2.45 2.65

AVIN

= 2.5V 1.70 1.85 1.98

AVIN

= 3.3V 2.0 2.5 2.83

AVIN

= 2.5V 1.5 1.85 2.13

AVIN

0.56 1.20 2.30 S

512

4

3

8192

Clock

Cycles

Clock

Cycles

Clock

Cycles

Clock

Cycles

A

A

A

A

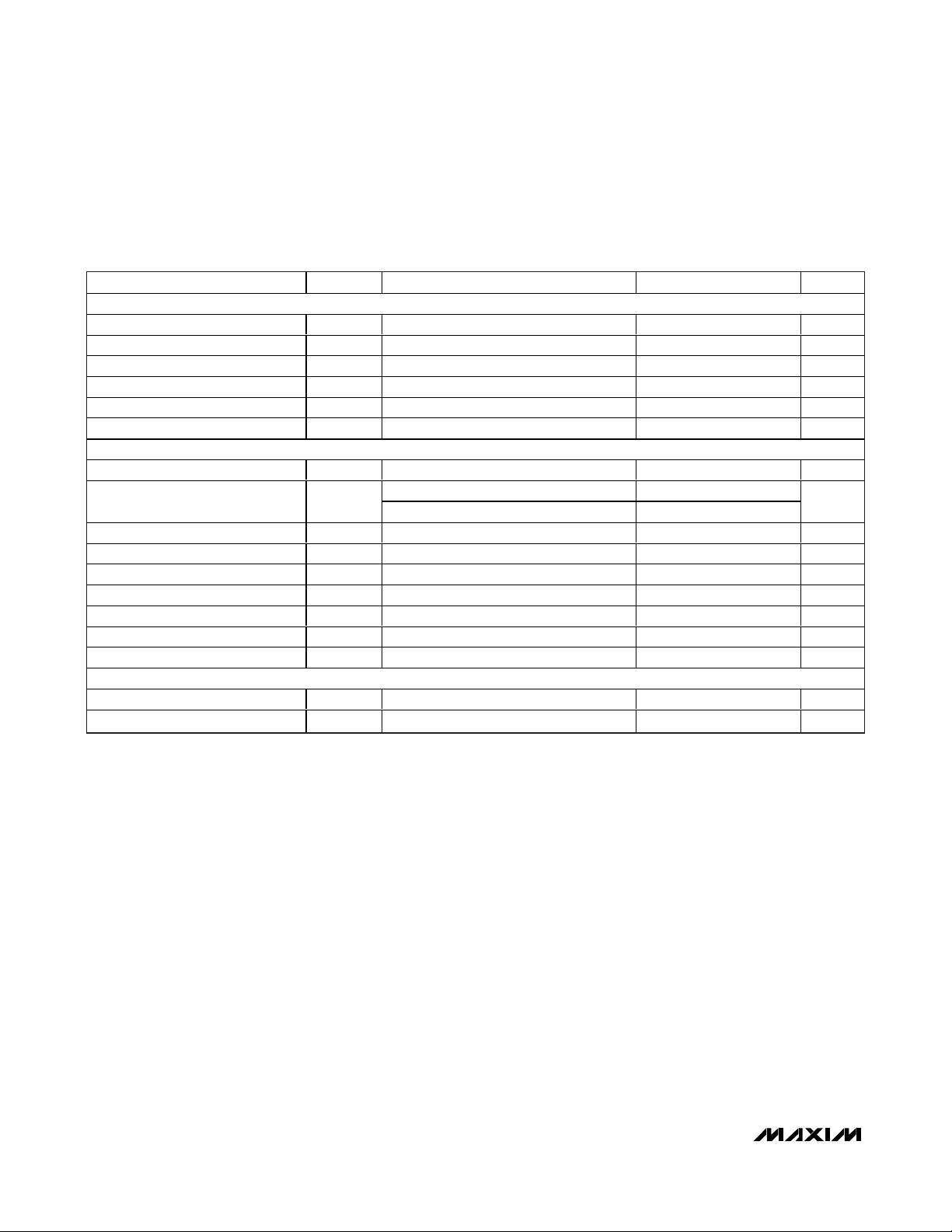

Page 4

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

AVIN

= V

PVIN_

= V

DVDD_

= 3.3V, V

PGND_

= V

SGND

= 0V, RT= 25kΩ, and TA= TJ= -40°C to +125°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 3)

Note 3: Specifications are 100% production tested at TA= +25°C and TA= +125°C. Maximum and minimum specifications over

temperature are guaranteed by design.

Note 4: When operating with V

AVIN

= 2.5V, the maximum operating frequency should be derated to 3MHz.

ENABLE/SEL

EN_ Threshold V

EN_ Hysteresis 0.12 V

EN_ Input Current -2.5 +2.5 μA

SEL High Threshold 0.85 x V

SEL Low Threshold 0.2 x V

SEL Input Bias Current Present only during startup -100 +100 μA

OSCILLATOR

Switching Frequency Range f

Oscillator Accuracy

Phase Shift Between Regulators 180 Degrees

RT Current 0 < VRT < 1.067V 31.30 32.00 32.58 μA

RT Voltage Range V

Minimum Controllable On-Time 60 ns

Minimum Controllable Off-Time 60 ns

PWM Ramp Amplitude V

PWM Ramp Valley 0.3 V

THERMAL SHUTDOWN

Thermal Shutdown Temperature Temperature rising +160 °C

Thermal Shutdown Hysteresis 15 °C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SW

RT

rising 1.207 1.225 1.243 V

EN_

f

= 4MHz x [VRT(V)/1.067(V)] (Note 4) 4000 kHz

SW

fSW ≤ 1500kHz -6 +6

f

> 1500kHz -10 +10

SW

0.130 1.067 V

AVIN

/4 V

AVIN

AVIN

V

V

%

Page 5

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

_______________________________________________________________________________________

5

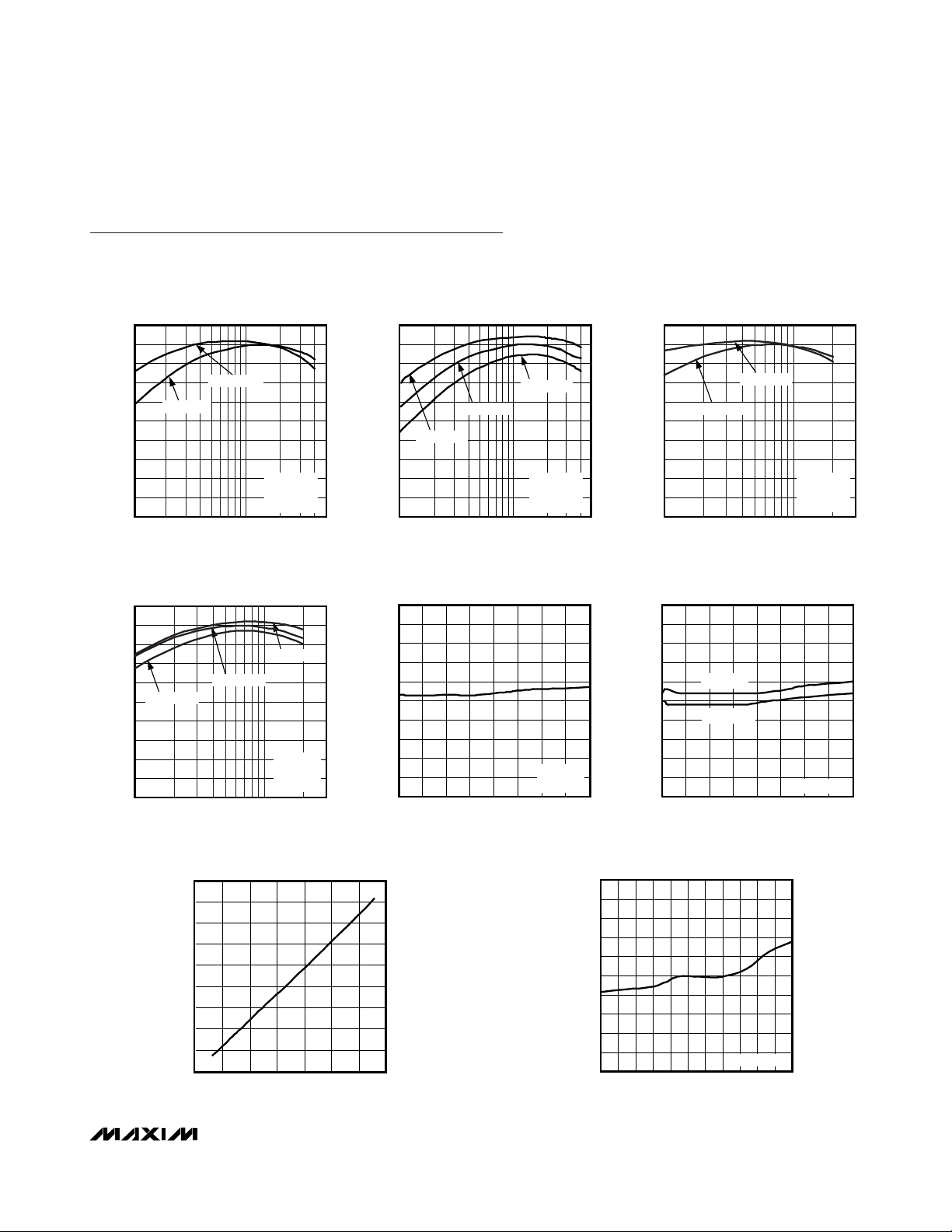

Typical Operating Characteristics

(V

AVIN

= V

DVDD1

= V

DVDD2

= V

PVIN1

= V

PVIN2

= 5V, V

OUT1

= 3.3V, V

OUT2

= 1.5V, V

PGND_

= 0V, RT= 16.5kΩ. TA= +25°C, unless

otherwise noted.)

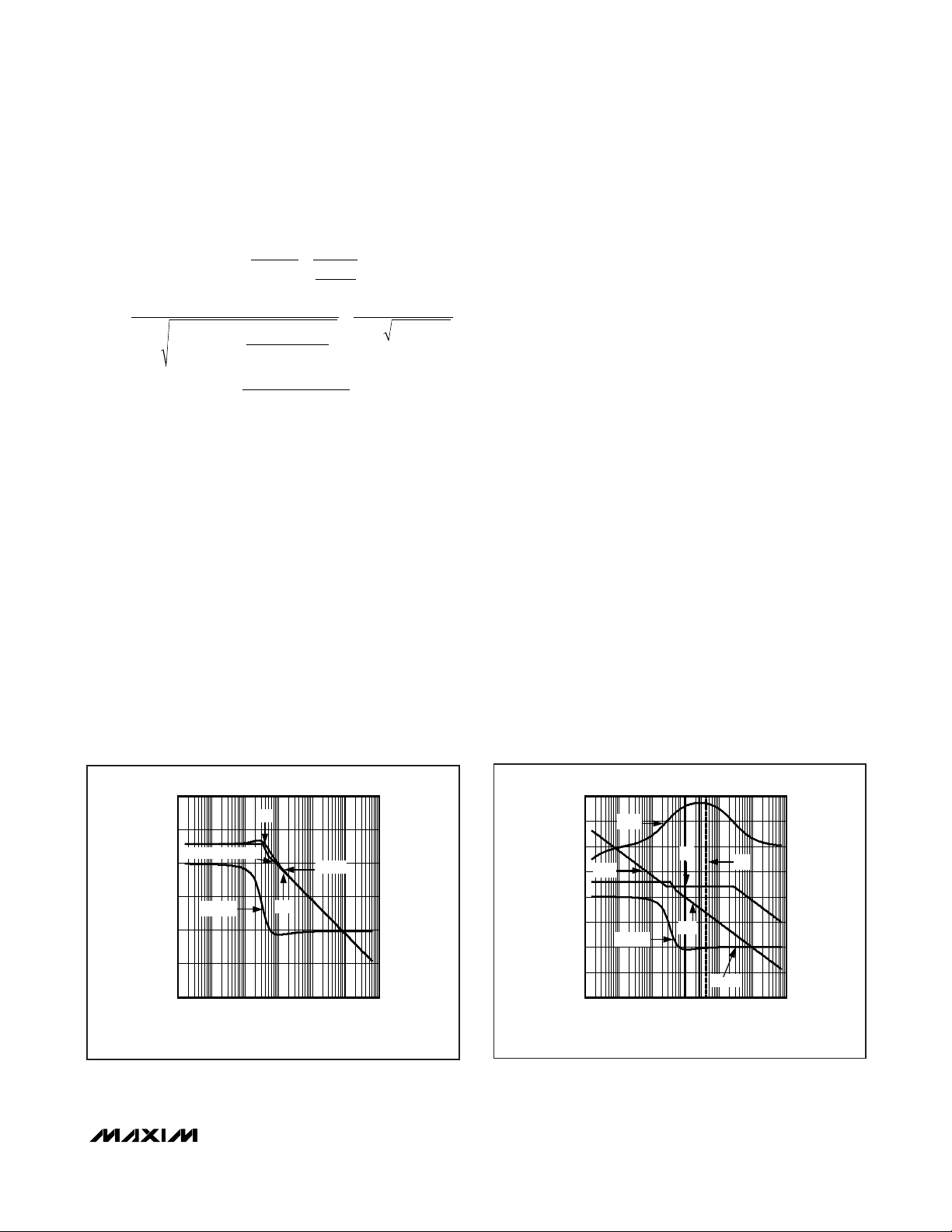

CHANNEL 1 EFFICIENCY

vs. LOAD CURRENT

MAX15022 toc01

LOAD CURRENT (mA)

EFFICIENCY (%)

1000

10

20

30

40

50

60

70

80

90

100

0

100 5000

V

PVIN1

= 3.3V

V

PVIN1

= 5V

V

OUT1

= 1.8V

f

SW

= 2MHz

EN2 = 0V

CHANNEL 1 EFFICIENCY

vs. LOAD CURRENT

MAX15022 toc02

LOAD CURRENT (mA)

EFFICIENCY (%)

1000

10

20

30

40

50

60

70

80

90

100

0

100 5000

V

PVIN1

= 5V

f

SW

= 2MHz

EN2 = 0V

V

OUT1

= 3.3V

V

OUT1

= 1.8V

V

OUT1

= 1.0V

CHANNEL 2 EFFICIENCY

vs. LOAD CURRENT

MAX15022 toc03

LOAD CURRENT (mA)

EFFICIENCY (%)

1000

10

20

30

40

50

60

70

80

90

100

0

100 3000

P

VIN2

= 5V

P

VIN2

= 3.3V

V

OUT2

= 1.5V

f

SW

= 2MHz

EN1 = 0V

CHANNEL 2 EFFICIENCY

vs. LOAD CURRENT

MAX15022 toc04

LOAD CURRENT (mA)

EFFICIENCY (%)

1000

10

20

30

40

50

60

70

80

90

100

0

100 3000

V

OUT2

= 1.0V

V

OUT2

= 1.5V

V

OUT2

= 2.5V

V

PVIN2

= 5V

f

SW

= 2MHz

EN1 = 0V

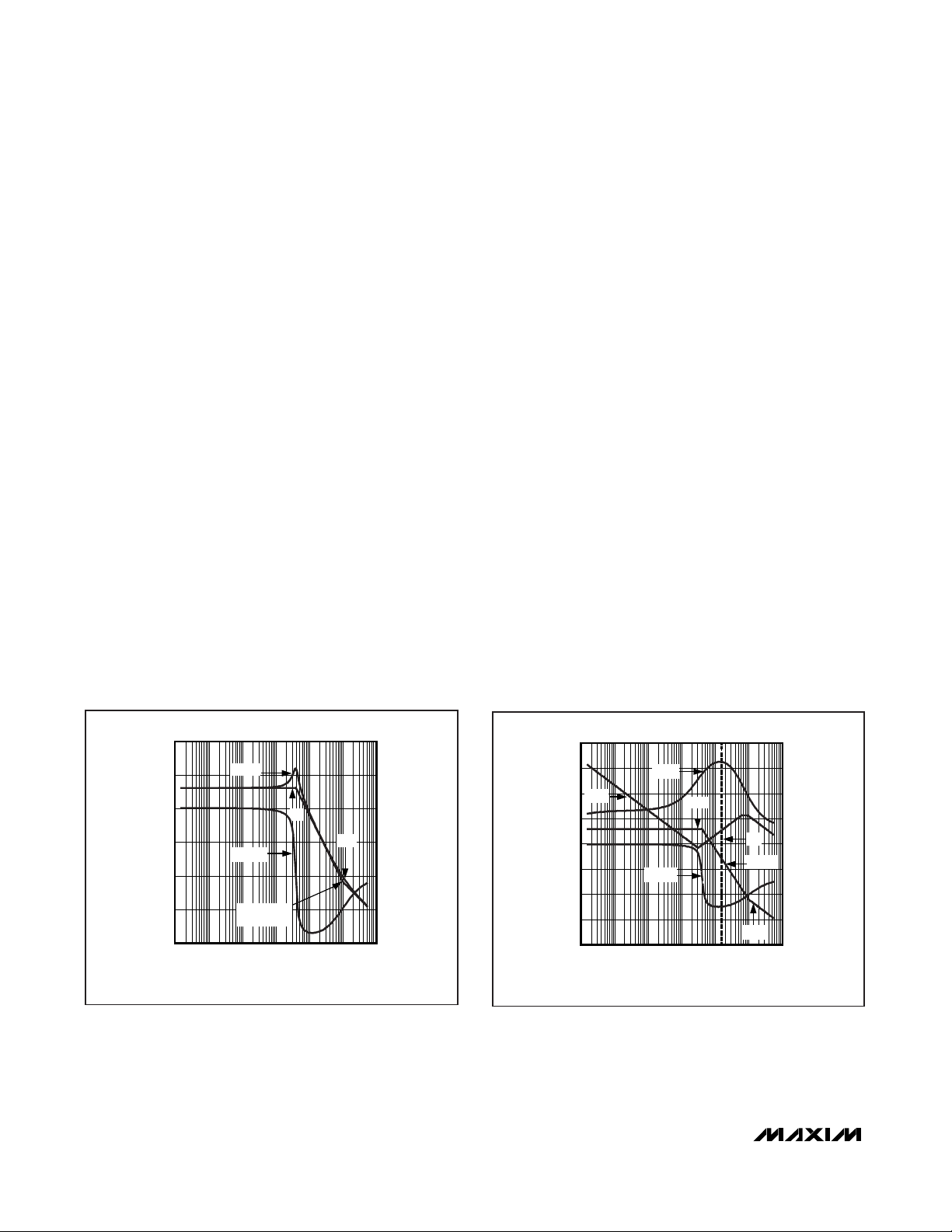

CHANNEL 1

LOAD REGULATION

MAX15022 toc05

LOAD CURRENT (A)

V

OUT1

(V)

3.302

3.304

3.306

3.308

3.310

3.312

3.314

3.316

3.318

3.320

3.300

3.53.02.52.01.51.00.50 4.0

V

PVIN1

= 5V

f

SW

= 2MHz

CHANNEL 2

LOAD REGULATION

MAX15022 toc06

LOAD CURRENT (A)

V

OUT2

(V)

1.251.00

0.75

0.50

0.25

1.5025

1.5030

1.5035

1.5040

1.5045

1.5050

1.5055

1.5060

1.5065

1.5070

1.5020

0

1.50 1.75 2.00

fSW = 2MHz

V

PVIN2

= 5V

V

PVIN2

= 3.3V

SWITCHING FREQUENCY

vs. RT RESISTANCE

MAX15022 toc07

RT RESISTANCE (kΩ)

SWITCHING FREQUENCY (MHz)

35

30

20 2510

15

5

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

0

0

SWITCHING FREQUENCY

vs. TEMPERATURE

MAX15022 toc08

TEMPERATURE (°C)

CHANGE IN SWITCHING FREQUENCY (%)

1109565 80-10 5 20 35 50-25

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

-40 125

fSW = 2MHz

Page 6

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

6 _______________________________________________________________________________________

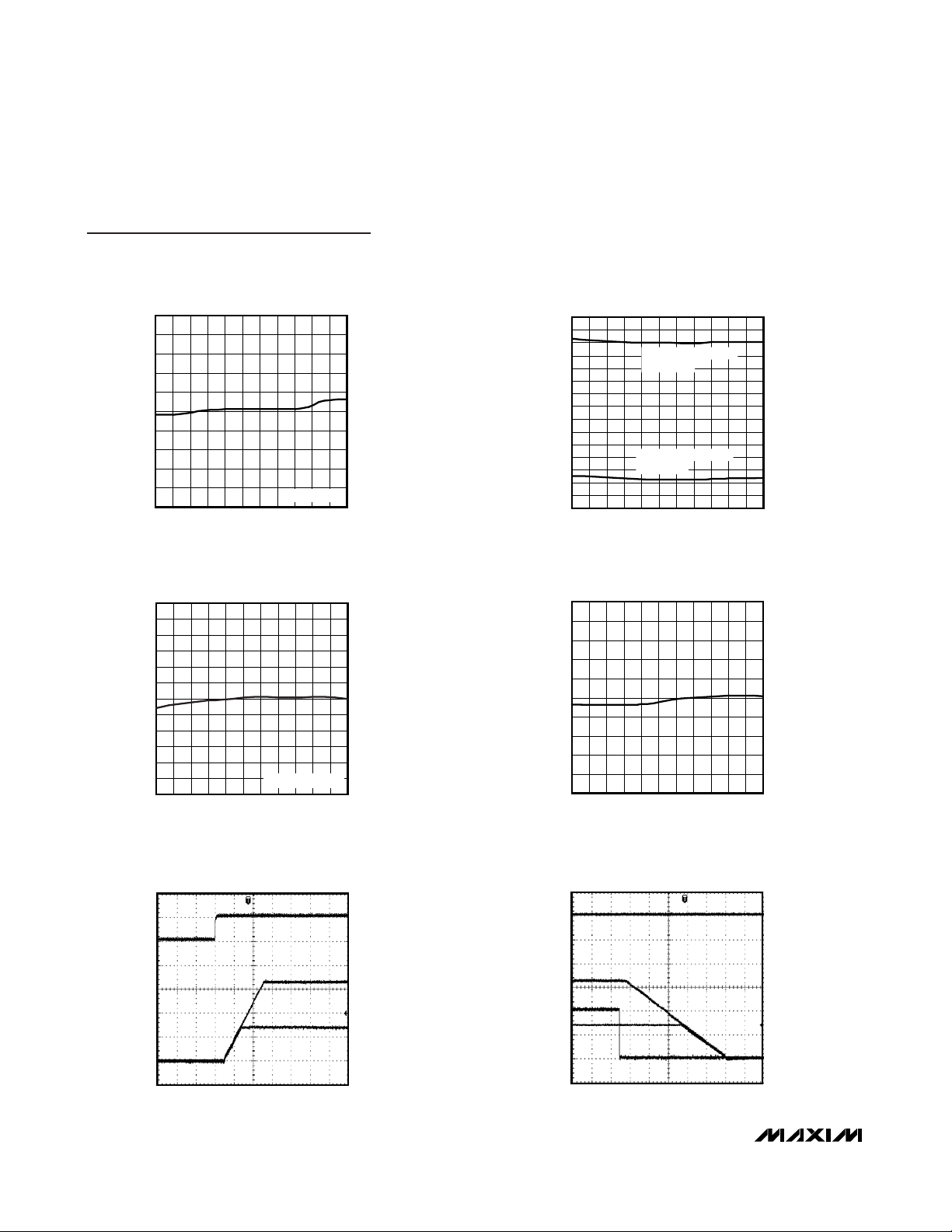

Typical Operating Characteristics (continued)

(V

AVIN

= V

DVDD1

= V

DVDD2

= V

PVIN1

= V

PVIN2

= 5V, V

OUT1

= 3.3V, V

OUT2

= 1.5V, V

PGND_

= 0V, RT= 16.5kΩ. TA= +25°C, unless

otherwise noted.)

EN_ THRESHOLD

vs. TEMPERATURE

MAX15022 toc12

TEMPERATURE (°C)

EN_ THRESHOLD (V)

11095-25 -10 5 35 50 6520 80-40 125

1.215

1.220

1.225

1.230

1.235

1.240

1.245

1.250

1.255

1.260

1.210

5.00

4.75

4.50

4.25

4.00

3.75

3.50

3.25

QUIESCENT CURRENT (mA)

3.00

2.75

2.50

1.030

1.025

1.020

1.015

1.010

1.005

1.000

0.995

0.990

0.985

NORMALIZED UVLO THRESHOLD

0.980

0.975

0.970

QUIESCENT CURRENT

vs. TEMPERATURE

NO SWITCHING

-40 125

TEMPERATURE (°C)

1109565 80-10 5 20 35 50-25

NORMALIZED UNDERVOLTAGE LOCKOUT

THRESHOLD vs. TEMPERATURE

V

(NOM) = 2.2V

UVLO

-40 125

TEMPERATURE (°C)

1109565 80-10 5 20 35 50-25

MAX15022 toc09

MAX15022 toc11

27

26

25

24

23

22

21

20

19

18

17

16

SWITCHING CURRENT (mA)

15

14

13

12

-40 125

SWITCHING CURRENT

vs. TEMPERATURE

REGULATOR 1 ENABLED

V

REGULATOR 2 ENABLED

V

OUT2

TEMPERATURE (°C)

OUT1

= 3.3V

= 1.5V

MAX15022 toc10

1109565 80-10 5 20 35 50-25

COINCIDENT TRACKING SOFT-START

1ms/div

MAX15022 toc13

V

AVIN

5V/div

0V

V

OUT1

1V/div

V

OUT2

1V/div

0V

COINCIDENT TRACKING SOFT-STOP

V

OUT1

EN1

V

OUT2

400μs/div

MAX15022 toc14

V

AVIN

5V/div

0V

1V/div

0V

Page 7

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

_______________________________________________________________________________________

7

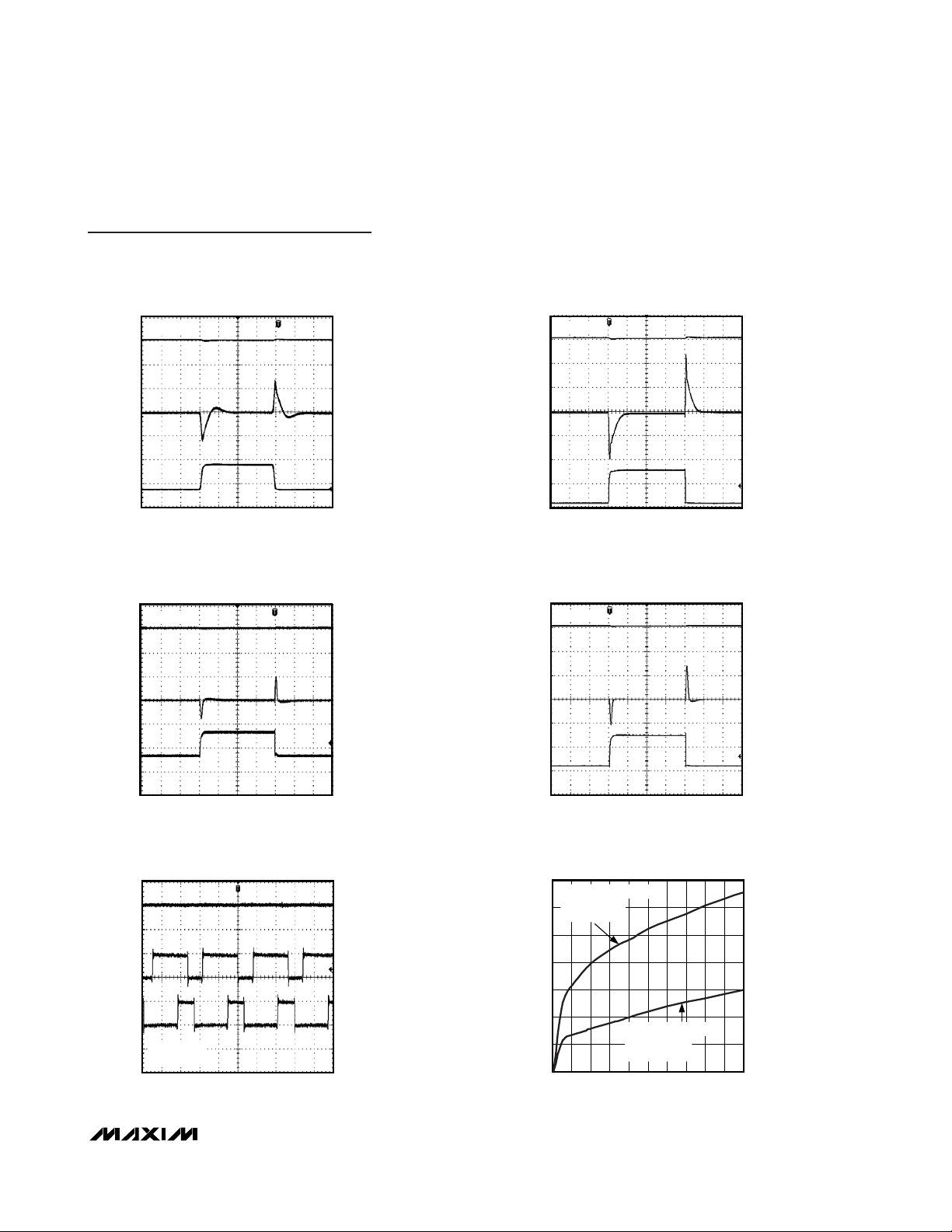

Typical Operating Characteristics (continued)

(V

AVIN

= V

DVDD1

= V

DVDD2

= V

PVIN1

= V

PVIN2

= 5V, V

OUT1

= 3.3V, V

OUT2

= 1.5V, V

PGND_

= 0V, RT= 16.5kΩ. TA= +25°C, unless

otherwise noted.)

CHANNEL 1 LOAD STEP RESPONSE

MAX15022 toc15

V

PVIN1

5V/div

V

OUT1

3.3V, AC-COUPLED

100mV/div

I

OUT1

2A/div

0V

0A

20μs/div

EN2 = 0V

CHANNEL 1 LOAD STEP RESPONSE

MAX15022 toc16

V

PVIN1

5V/div

V

OUT1

3.3V, AC-COUPLED

100mV/div

I

OUT1

2A/div

0V

0A

20μs/div

EN2 = 0V

CHANNEL 2 LOAD STEP RESPONSE

EN1 = 0V

180° OUT-OF-PHASE OPERATION

IOUT1 = 3A

IOUT2 = 1.5A

20μs/div

200ns/div

MAX15022 toc17

MAX15022 toc19

V

PVIN2

5V/div

0V

V

OUT2

1.5V, AC-COUPLED

100mV/div

I

OUT2

1A/div

0A

PVIN1 = PVIN2

5V/div

0V

V

LX1

5V/div

0V

V

LX2

5V/div

0V

CHANNEL 2 LOAD STEP RESPONSE

EN1 = 0V

20μs/div

CHANNEL 3 AND CHANNEL 4 OUTPUT-

VOLTAGE DEVIATION vs. LOAD CURRENT

14

CHANNEL 3, VIN = 3.3V,

= 2.5V

V

OUT3

12

NJT403OP PNP

10

8

6

4

OUTPUT-VOLTAGE DEVIATION (mV)

2

0

0 500

CHANNEL 4, VIN = 2.5V,

= 1.5V

V

OUT4

NJT403OP PNP

LOAD CURRENT (mA)

MAX15022 toc18

450 40035030025020015010050

V

PVIN2

5V/div

0V

V

OUT2

1.5V, AC-COUPLED

100mV/div

I

OUT2

1A/div

0A

MAX15022 toc20

Page 8

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

8 _______________________________________________________________________________________

Pin Description

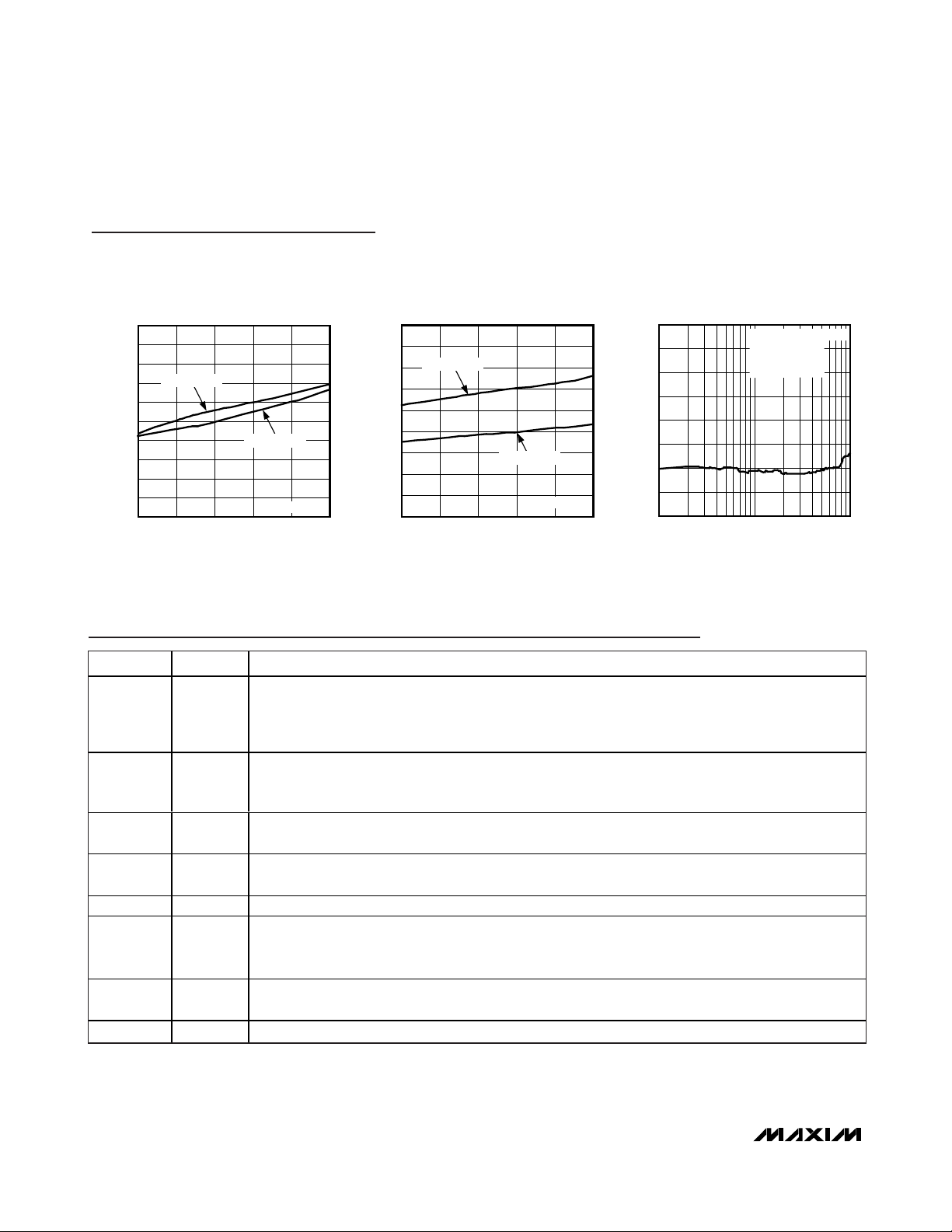

Typical Operating Characteristics (continued)

(V

AVIN

= V

DVDD1

= V

DVDD2

= V

PVIN1

= V

PVIN2

= 5V, V

OUT1

= 3.3V, V

OUT2

= 1.5V, V

PGND_

= 0V, RT= 16.5kΩ. TA= +25°C, unless

otherwise noted.)

2.500

2.495

2.490

2.485

2.480

2.475

2.470

OUTPUT VOLTAGE (V)

2.465

2.460

2.455

2.450

2.90 5.50

CHANNEL 3 OUTPUT VOLTAGE

vs. INPUT VOLTAGE

I

= 10mA

OUT3

I

OUT3

SUPPLY VOLTAGE (V)

= 500mA

V

OUT3

4.984.463.943.42

= 2.5V

MAX15022 toc21

CHANNEL 4 OUTPUT VOLTAGE

vs. INPUT VOLTAGE

1.215

1.210

I

= 500mA

1.205

1.200

1.195

1.190

1.185

OUTPUT VOLTAGE (V)

1.180

1.175

1.170

OUT4

I

OUT4

2.90 5.50

SUPPLY VOLTAGE (V)

= 10mA

V

= 1.5V

OUT4

4.984.463.943.42

-10

MAX15022 toc22

-20

-30

-40

PSRR (dB)

-50

-60

-70

-80

LDO POWER-SUPPLY REJECTION RATIO

0

10 1000

V

= 3.3V, V

IN

= 10mA,

I

OUT3

100mV

APPLIED TO V

100

FREQUENCY (Hz)

P-P

OUT3

SIGNAL

IN

= 2.5V,

MAX15022 toc23

PIN NAME FUNCTION

Track/Sequence Select Input. Connect SEL to SGND to configure the device as a sequencer. Connect

1 SEL

2, 7, 8 PGND1

3, 6 LX1

4, 5 PVIN1

9 DVDD1 Switch Driver Supply for Regulator 1. Connect externally to PVIN1.

10 EN1

11 FB1

12 COMP1 Error-Amplifier Output for Regulator 1. Connect COMP1 to the compensation feedback network.

SEL to AVIN for tracking with output 1 as the master. Leave SEL unconnected for tracking with output 2

as the master. Use the output with the higher voltage as the master and the output with the lower voltage

as the slave.

Power Ground Connection for Regulator 1. Connect the negative terminals of the input and output filter

capacitors to PGND1. Connect PGND1 externally to SGND at a single point, typically at the negative

terminal of the input bypass capacitor.

Inductor Connection for Regulator 1. LX1 is the drain connection of the internal high-side p-channel

MOSFET and the drain connection of the internal synchronous n-channel MOSFET for regulator 1.

Input Supply Voltage for Regulator 1. Connect PVIN1 to an external voltage source from 2.5V to 5.5V.

Bypass PVIN1 to PGND1 with a 1μF (min) ceramic capacitor.

Enable Input for Regulator 1. When configured as a sequencer, EN1 must exceed 1.225V (typ) for the

PWM controller to begin regulating output 1. When configured as a tracker, connect EN1 to the center

tap of a resistive divider from the regulator 2 output.

Feedback Regulation Point for Regulator 1. Connect FB1 to the center tap of a resistive divider from the

regulator 1 output to SGND to set the output voltage. The FB1 voltage regulates to 0.6V (typ).

Page 9

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

_______________________________________________________________________________________ 9

Pin Description (continued)

PIN NAME FUNCTION

13

14

15

16 DVDD2 Switch Driver Supply for Regulator 2. Connect externally to PVIN2.

17 PGND2

18 LX2

19 PVIN2

20 EN4

21 FB4

22 B4

23 COMP2 Error-Amplifier Output for Regulator 2. Connect COMP2 to the compensation feedback network.

24 FB2

25 EN2

B3

FB3

EN3

Transconductance Amplifier Open-Drain Output for LDO Controller 3. Connect B3 to the base of an

external PNP transistor to regulate output 3.

Feedback Regulation Point for LDO Controller 3. Connect to the center tap of a resistive divider from the

output 3 to SGND to set the output voltage. The FB3 voltage regulates to 0.6V (typ).

LDO Enable Input for LDO Controller 3. EN3 must exceed 1.225V (typ) for the LDO controller to begin

regulating output 3.

Power Ground Connection for Regulator 2. Connect the negative terminals of the input and output filter

capacitors to PGND2. Connect PGND2 externally to SGND at a single point, typically at the negative

terminal of the input bypass capacitor.

Inductor Connection for Regulator 2. LX2 is the drain connection of the internal high-side p-channel

MOSFET and the drain connection of the internal synchronous n-channel MOSFET for Regulator 2.

Input Supply Voltage for Regulator 2. Connect to an external voltage source from 2.5V to 5.5V. Bypass

PVIN2 to PGND2 with a 1μF (min) ceramic capacitor.

LDO Enable Input for LDO Controller 4. EN4 must exceed 1.225V (typ) for the LDO controller to begin

regulating output 4.

Feedback Regulation Point for LDO Controller 4. Connect to the center tap of a resistive divider from

output 4 to SGND to set the output voltage. The FB4 voltage regulates to 0.6V (typ).

Transconductance Amplifier Open-Drain Output for LDO Controller 4. Connect B4 to the base of an

external PNP transistor to regulate output 4.

Feedback Regulation Point for Regulator 2. Connect to the center tap of a resistive divider from the

regulator 2 output to SGND to set the output voltage. The FB2 voltage regulates to 0.6V (typ).

Enable Input for Regulator 2. When configured as a sequencer, EN2 must exceed 1.225V (typ) for the

PWM controller to begin regulating output 1. When configured as a tracker, connect EN2 to the center

tap of a resistive divider from the regulator 1 output.

26 SGND

27 AVIN Input Voltage. Bypass AVIN to SGND with a 100nF (min) ceramic capacitor.

28 RT

—EP

Signal Ground. Connect SGND to PGND_ at a single point, typically near the negative terminal of the

input bypass capacitor.

Oscillator Timing Resistor Connection. Connect a 4.2kΩ to 33kΩ resistor from RT to SGND to program

the switching frequency from 500kHz to 4MHz.

Exposed Paddle. Connect EP to a large copper plane at SGND potential to improve thermal dissipation.

Do not use as the main SGND connection.

Page 10

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

10 ______________________________________________________________________________________

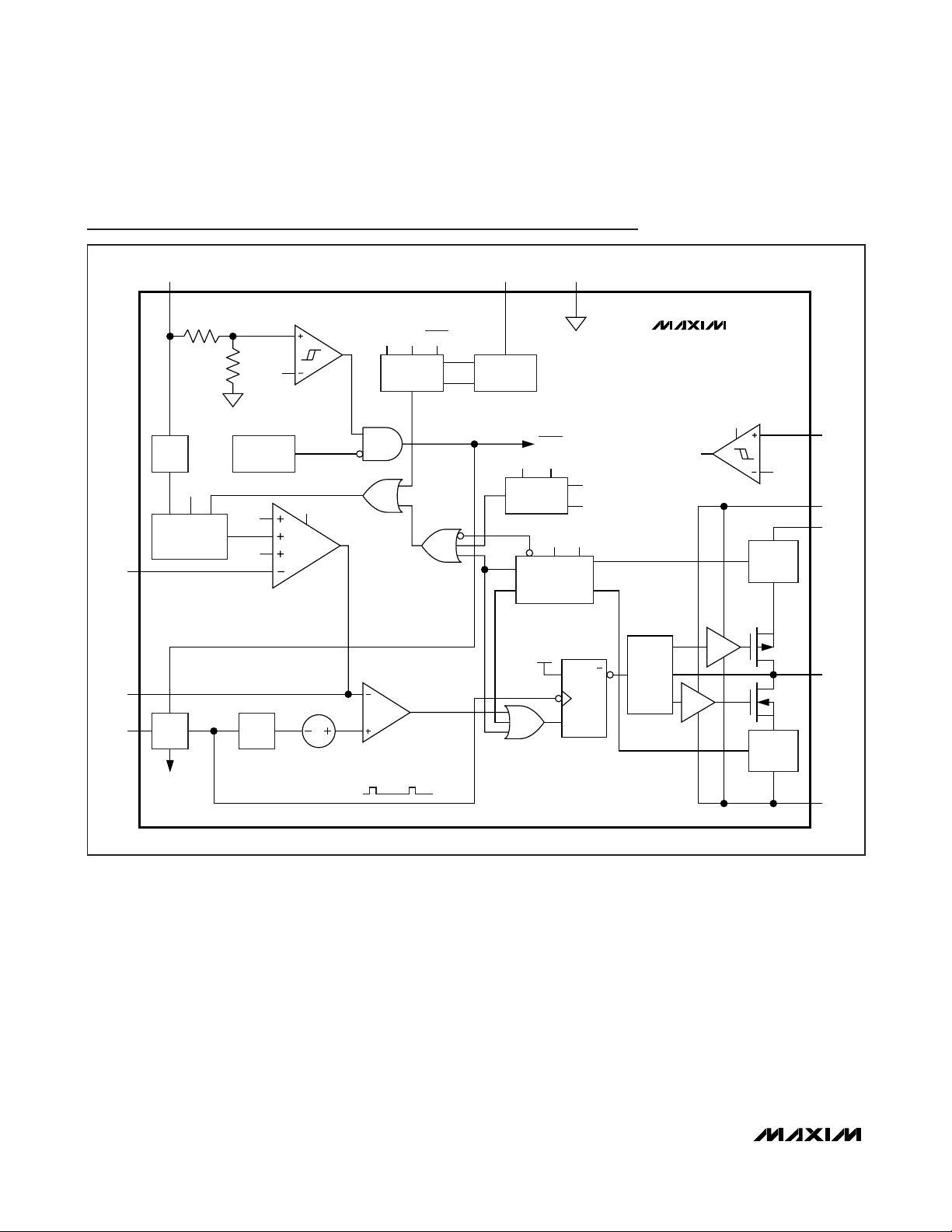

Functional Diagrams

AVIN SEL SGND

ON1 ON2

SHDN

1.225V

1.1V

SEQ1

EN CONFIG SEL DECODE

SEQ2

PWM CONTROLLER 1

FB1

0.6V

REF

CLK1

V

REF

DIGITAL

SOFT-START

AND SOFT-STOP

DOWN1

THERMAL

SHDN

V

REF

V

R1

EN1

SEQ1

E/A

ILIM1

OVL1

SHDN

SEQ1

SEQ2

OVL

CONFIG

CLK1 CLK2

RES

OVERLOAD

MANAGEMENT

OVL1

OVL2

MAX15022

ON1

SEQ1

EN1

1.225V

1.1V

DVDD1

PVIN1

HIGH-SIDE

CURRENT

SENSE

COMP1

AVIN

D

CLK

CPWM

R

CLK1

RT

EN

OSC

CLK2

RAMP

LEVEL

SHIFT

BREAK-

Q

BEFORE-

MAKE

LOW-SIDE

CURRENT

SENSE

LX1

PGND1

Page 11

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

______________________________________________________________________________________ 11

Functional Diagrams (continued)

EN2

FB2

1.225V

1.1V

V

REF

CLK2

DIGITAL

SOFT-START

AND SOFT-STOP

MAX15022

PWM CONTROLLER 2

DUAL LDO CONTROLLERS

SEQ2

ON2

DOWN2

V

REF

V

R2

EN2

SEQ1

E/A

SEQ1

SEQ2

ON1 ON2

EN CONFIG

EN4

EN3

1.225V

SHDN

OVL2

ILIM2

1.1V

1.25V

1.125V

SEQ1 SEQ2

OVL

CONFIG

CLK1 CLK2

RES

OVERLOAD

MANAGEMENT

V

REF

SHDN

V

REF

SHDN

OVL1

OVL2

CLK1

DIGITAL

SOFT-START

CLK2

DIGITAL

SOFT-START

HIGH-SIDE

CURRENT

SENSE

FB3

B3

FB4

B4

DVDD2

PVIN2

COMP2

CLK2

RAMP

LEVEL

SHIFT

CLK

CPWM

AVIN

D

R

BREAK-

Q

BEFORE-

MAKE

LOW-SIDE

CURRENT

SENSE

LX2

PGND2

Page 12

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

12 ______________________________________________________________________________________

Detailed Description

The MAX15022 incorporates dual-output, PWM, stepdown, DC-DC regulators and dual LDO controllers with

tracking and sequencing options. The device operates

over the input-voltage range of 2.5V to 5.5V. Each PWM

regulator provides an adjustable output down to 0.6V

and delivers up to 4A (regulator 1) and 2A (regulator 2)

of load current. The high switching frequency (up to

4MHz) and integrated power switches optimize the

MAX15022 for high-performance and small-size power

management solutions.

Each of the MAX15022 PWM regulator sections utilizes

a voltage-mode control scheme for good noise immunity and offers external compensation allowing for maximum flexibility with a wide selection of inductor values

and capacitor types. The device operates at a fixed

switching frequency that is programmable from 500kHz

to 4MHz with a single resistor. Operating the regulators

with 180° out-of-phase clocking, and at frequencies up

to 4MHz, significantly reduces the RMS input ripple

current. The resulting peak input current reduction (and

increase in the ripple frequency) significantly reduces

the required amount of input bypass capacitance.

The MAX15022 provides coincident tracking, ratiometric tracking, or sequencing to allow tailoring of powerup/power-down sequence depending on the system

requirements. When sequencing, it powers up glitchfree into a prebiased output. The MAX15022 features

two LDO controllers for external PNP pass transistors to

provide two additional outputs.

The MAX15022 includes internal undervoltage lockout

with hysteresis, digital soft-start/soft-stop for glitch-free

power-up and power-down. Protection features include

lossless, cycle-by-cycle current limit, hiccup-mode output short-circuit protection, and thermal shutdown.

Undervoltage Lockout (UVLO)

The supply voltage (V

AVIN

) must exceed the default

UVLO threshold before any operation starts. The UVLO

circuitry keeps the MOSFET drivers, oscillator, and all

the internal circuitry shut down to reduce current consumption. The UVLO rising threshold is 2.2V (typ) with

a 120mV (typ) hysteresis.

Digital Soft-Start/Soft-Stop

The MAX15022 soft-start feature allows the load voltage to ramp up in a controlled manner, eliminating output-voltage overshoot. Soft-start begins after V

AVIN

exceeds the undervoltage lockout threshold and the

enable input is above 1.225V (typ). The soft-start circuitry ramps up the reference voltage, controlling the

rate of rise of the output voltage, and reducing input

surge currents during startup. The soft-start duration is

4096 clock cycles. The output voltage is incremented

through 64 equal steps. The output reaches regulation

when soft-start is completed, regardless of the output

capacitance and load.

For tracking applications, soft-stop commences when the

enable input falls below 1.1V (typ). The soft-stop circuitry

ramps down the reference voltage controlling the outputvoltage rate of fall. The output voltage is decremented

through 64 equal steps in 4096 clock cycles.

Oscillator

Use an external resistor at RT to program the

MAX15022 switching frequency from 500kHz to 4MHz.

Calculate the appropriate resistor value at RT for the

desired output switching frequency (fSW):

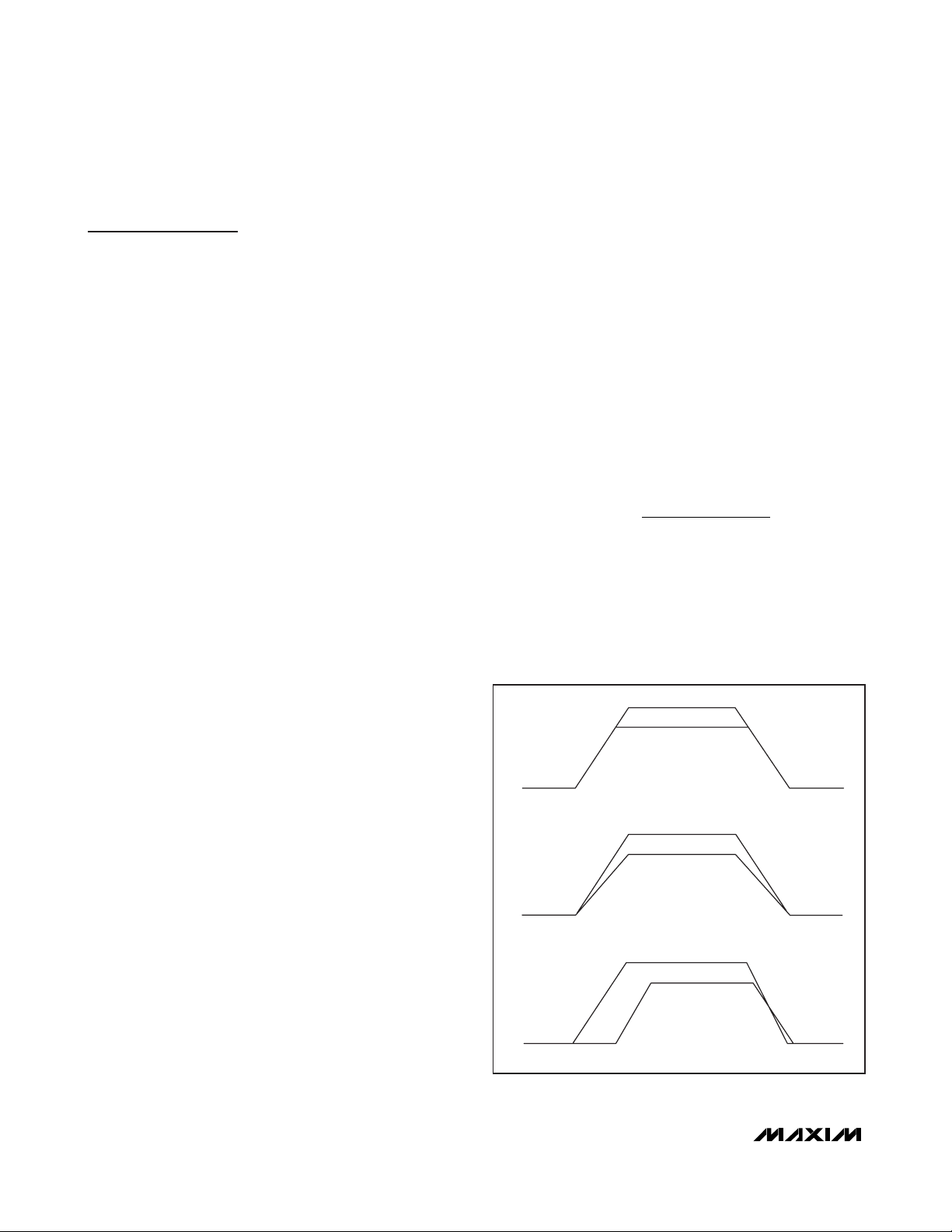

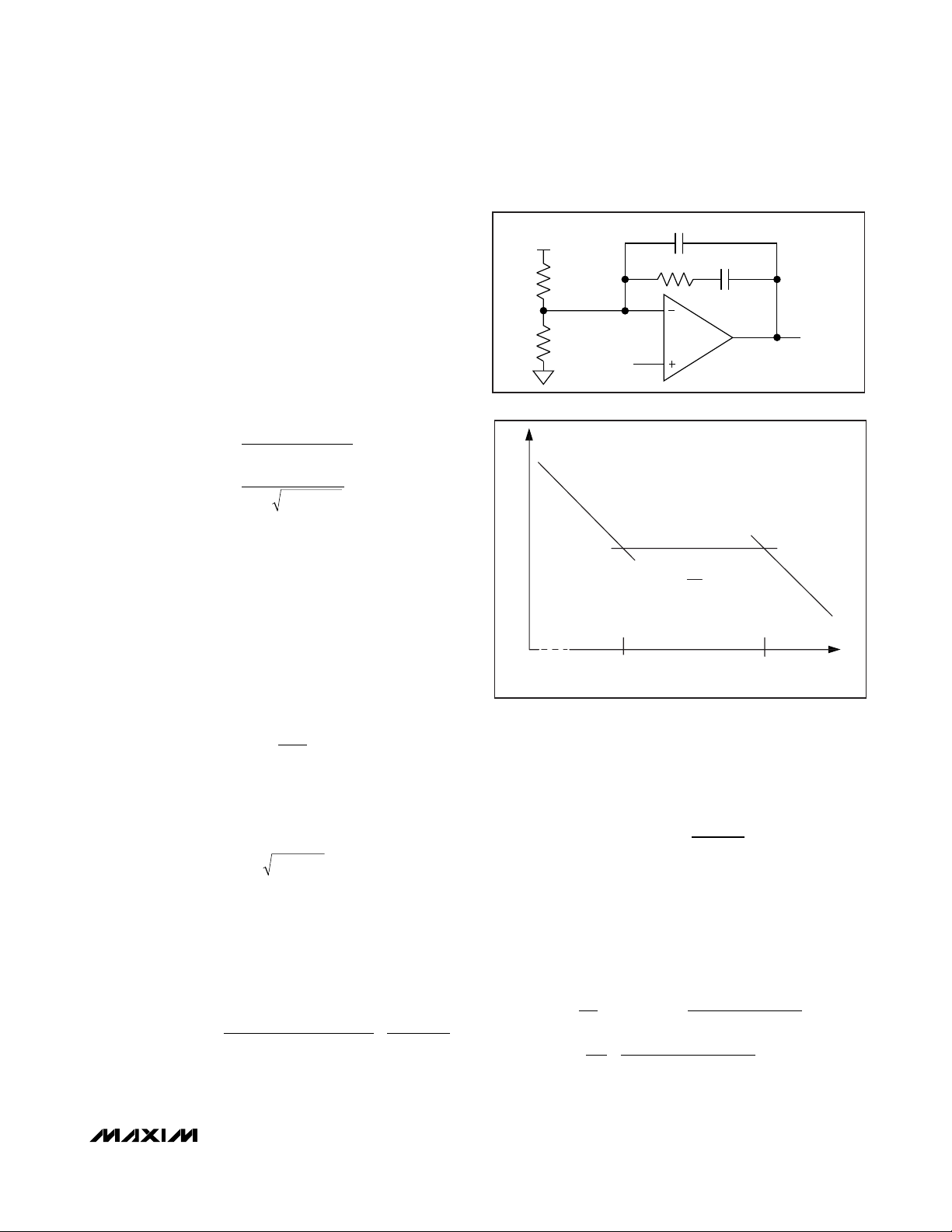

Tracking/Sequencing

The MAX15022 features coincident/ratiometric tracking

and sequencing (see Figure 1). Connect SEL to ground

to configure the device as a sequencer. Connect SEL to

AVIN for tracking with output 1 as the master. Leave SEL

unconnected for tracking with output 2 as the master.

Assign the output with the higher voltage as the master.

Figure 1. Graphical Representation of Coincident Tracking,

Ratiometric Tracking, and Sequencing

067

.

Rk

[]

T

f [kHz] 1 [V]

SW

Ω=

32 μ

A

[]

×

×

4[MHz]

V

OUT1

V

OUT2

SOFT-START

a) COINCIDENT TRACKING OUTPUTS

V

OUT1

V

OUT2

SOFT-START

b) RATIOMETRIC TRACKING OUTPUTS

V

OUT1

V

OUT2

SOFT-START

c) SEQUENCED OUTPUTS

SOFT-STOP

SOFT-STOP

SOFT-STOP

Page 13

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

______________________________________________________________________________________ 13

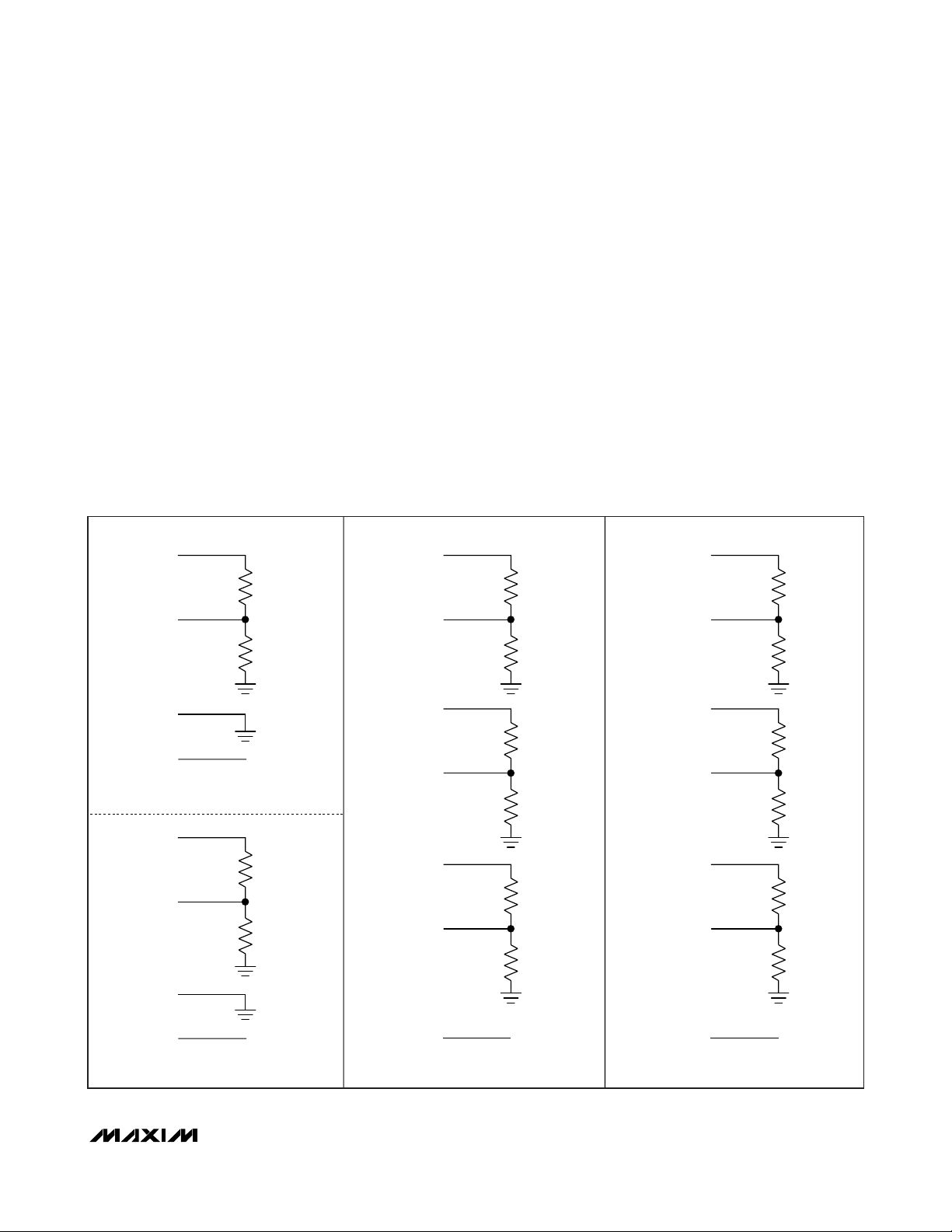

Coincident/Ratiometric Tracking

The enable inputs in conjunction with digital soft-start

and soft-stop provide coincident/ratiometric tracking.

Track an output voltage by connecting a resistive

divider from the output being tracked to its enable

input. For example, for V

OUT2

to coincidentally track

V

OUT1

, connect the same resistive divider used for

FB2, from V

OUT1

to EN2 to SGND (see Figure 2).

Track ratiometrically by connecting EN_ to SGND. This

synchonizes the soft-start and soft-stop of all the regulator references, and hence their respective output voltages will track ratiometrically (see Figure 2).

When the MAX15022 regulators are configured as voltage trackers, output short-circuit fault conditions at

either master or slave output are handled carefully—neither the master nor slave output will remain energized

when the other output is shorted to ground. When the

slave is shorted and enters into hiccup mode, the master will soft-stop. When the master is shorted and the

part enters into hiccup mode, the slave will ratiometrically soft-stop. Coming out of hiccup mode, both outputs

will soft-start coincidently or ratiometrically depending

on their initial configuration. During the thermal shutdown or power-off when the input falls below its UVLO,

the output voltages track down depending on the

respective output capacitance and load.

See Figure 1 for a graphical representation of coincident/ratiometric tracking.

Sequencing

When sequencing, the voltage at the enable inputs

must exceed 1.225V (typ) for each PWM controller to

start (see Figure 1c).

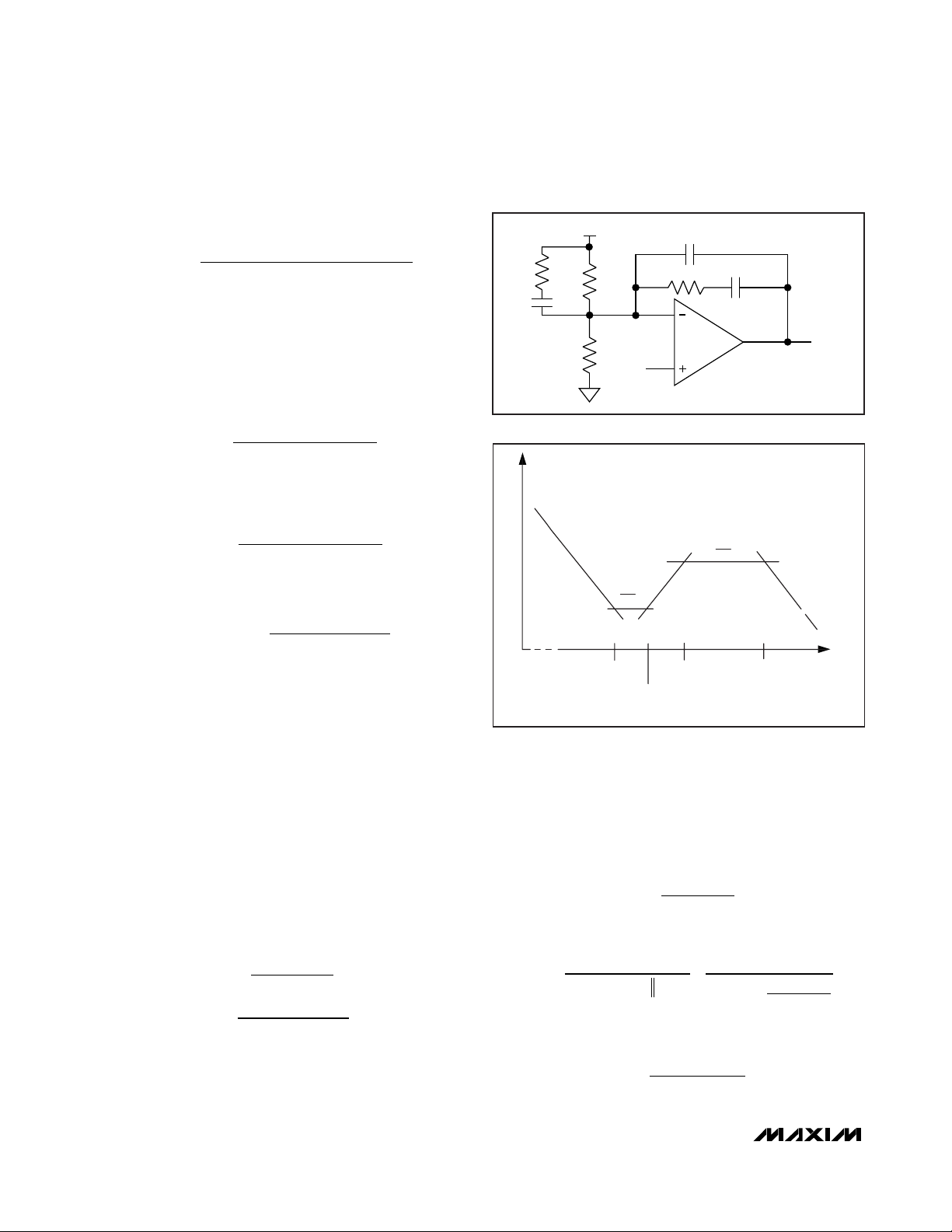

Figure 2. Ratiometric Tracking and Coincident Tracking Configurations

a) b)

RATIOMETRIC TRACKING

V

PVIN1

EN1

COINCIDENT TRACKING

V

PVIN1

EN1

c)

COINCIDENT TRACKING

V

PVIN2

EN2

V

EN2

SEL AVIN

OUTPUT 1 IS THE MASTER AND

OUTPUT 2 IS THE SLAVE.

V

PVIN2

EN2

EN1

SEL UNCONNECTED

OUTPUT 2 IS THE MASTER AND

OUTPUT 1 IS THE SLAVE.

OUT1

EN2

V

OUT2

FB2

SEL

OUTPUT 1 IS THE MASTER AND

OUTPUT 2 IS THE SLAVE.

R

R

R

R

AVIN

V

OUT2

A

EN1

B

V

OUT1

A

FB1

B

SEL

OUTPUT 2 IS THE MASTER AND

OUTPUT 1 IS THE SLAVE.

R

C

R

D

R

C

R

D

UNCONNECTED

Page 14

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

14 ______________________________________________________________________________________

Error Amplifier

The output of the internal voltage-mode error amplifier

(COMP_) is provided for frequency compensation (see

the

Compensation Design Guidelines

section). FB_ is

the inverting input of the error amplifier. The error

amplifier has an 80dB open-loop gain and a 12MHz

gain bandwidth (GBW) product.

Output Short-Circuit

Protection (Hiccup Mode)

The MAX15022 features lossless, high-side peak current limit and low-side, valley current limit. At short duty

cycles, both limits are active. At high duty cycles, only

the high-side peak current limit is active. Either limit

causes the hiccup mode counter (NCL) to increment.

For duty cycles less than 50%, the low-side valley current limit is active. Once the high-side MOSFET turns off,

the voltage across the low-side MOSFET is monitored. If

this voltage does not exceed the current-limit threshold

at the end of the cycle, the high-side MOSFET turns on

normally at the start of the next cycle. If the voltage

exceeds the current-limit threshold just before the

beginning of a new PWM cycle, the controller skips that

cycle. During severe overload or short-circuit conditions, the switching frequency of the device appears to

decrease because the on-time of the low-side MOSFET

extends beyond a clock cycle.

If the current-limit threshold is exceeded for more than

four cumulative clock cycles (NCL), the device shuts

down for 8192 clock cycles (hiccup timeout) and then

restarts with a soft-start sequence. If three consecutive

cycles pass without a current-limit event, the count of

NCLis cleared (see Figure 3). Hiccup mode protects

the device against a continuous output short circuit.

The internal current limit is constant from 5.5V down to

3V and decreases linearly by 50% from 3V to 2V. See

the

Electrical Characteristics

table.

Thermal-Overload Protection

The MAX15022 features an integrated thermal-overload

protection with temperature hysteresis. Thermal-overload protection limits the die temperature of the device

and protects it in the event of an extended thermal fault

condition. When the die temperature exceeds +160°C,

an internal thermal sensor shuts down the device, turning off the internal power MOSFETs and allowing the die

to cool. After the die temperature falls by +15°C (typ),

the device restarts with a soft-start sequence.

Startup into a Prebiased Output

(Sequencing Mode)

In sequencing mode, the regulators start with minimal

glitch into a prebiased output and soft-stop is disabled.

During soft-start, both switches are kept off until the

PWM comparator commands its first PWM pulse. Until

then, the converters do not sink current from the outputs. The first PWM pulse occurs when the ramping reference voltage increases above the FB_ voltage.

LDO Controllers

The MAX15022 provides two additional LDO controllers

to drive external PNP pass transistors. Connect the emitter of each PNP pass transistor to either the input supply

or one of the controller 1 or 2 outputs. Each LDO controller features an independent enable input and digital

soft-start. Connect FB3 and FB4 to the center tap of a

resistive divider from the output of the desired LDO controller to SGND to set the output voltage.

PWM Controllers

Design Procedure

Setting the Switching Frequency

Connect a 4.2kΩ to 33kΩ resistor from RT to SGND to

program the switching frequency (fSW) from 500kHz to

4MHz. Calculate the required resistor value RRTto set

the switching frequency with the following equation:

Higher frequencies allow designs with lower inductor

values and less output capacitance. At higher switching frequencies core losses, gate-charge currents,

and switching losses increase. When operating from

V

AVIN

< 3V, the fSWfrequency should be derated to

3MHz (maximum).

Figure 3. Hiccup-Mode Block Diagram

CURRENT LIMIT

IN

CLR

IN

CLR

R

[]

kAΩ=

RT

COUNT OF 4

N

CL

COUNT OF 3

N

CLR

INITIATE HICCUP

TIMEOUT

f [kHz] 1 [V]

SW

32 4[MHz]

[]

μ

.

××067

N

HT

Page 15

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

______________________________________________________________________________________ 15

Effective Input-Voltage Range

Although the MAX15022’s regulators can operate from

input supplies ranging from 2.5V to 5.5V, the input-voltage range can be effectively limited by the

MAX15022’s duty-cycle limitations for a given output

voltage (V

OUT_

). The maximum input voltage

(V

PVIN_MAX

) can be effectively limited by the control-

lable minimum on-time (t

ON(MIN)

):

where t

ON(MIN)

is 0.06μs (typ).

The minimum input voltage (V

PVIN_MIN

) can be effectively limited by the maximum controllable duty cycle

and is calculated using the following equation:

where V

OUT_

is the regulator output voltage and

t

OFF(MIN)

is the 0.06μs (typ) controllable off-time.

Inductor Selection

Three key inductor parameters must be specified for

operation with the MAX15022: inductance value (L),

peak inductor current (I

PEAK

), and inductor saturation

current (I

SAT

). The minimum required inductance is a

function of operating frequency, input-to-output voltage

differential, and the peak-to-peak inductor current

(ΔI

P-P

). Higher ΔI

P-P

allows for a lower inductor value. A

lower inductance minimizes size and cost and

improves large-signal and transient response.

However, efficiency is reduced due to higher peak currents and higher peak-to-peak output-voltage ripple for

the same output capacitor. A higher inductance

increases efficiency by reducing the ripple current;

however, resistive losses due to extra wire turns can

exceed the benefit gained from lower ripple current levels especially when the inductance is increased without

also allowing for larger inductor dimensions. Choose

the inductor’s peak-to-peak current, ΔI

P-P,

in the range

of 20% to 50% of the full load current; as a rule of

thumb 30% is typical.

Calculate the inductance, L, using the following equation:

where V

PVIN_

is the input supply voltage, V

OUT_

is the

regulator output voltage, and fSWis the switching frequency. Use typical values for V

PVIN_

and V

OUT_

so

that efficiency is optimum for typical conditions. The

switching frequency (fSW) is programmable between

500kHz and 4MHz (see the

Oscillator

section).

The peak-to-peak inductor current (ΔI

P-P

), which

reflects the peak-to-peak output ripple, is largest at the

maximum input voltage. See the

Output-Capacitor

Selection

section to verify that the worst-case output

current ripple is acceptable.

Select an inductor with a saturation current, I

SAT

, higher than the maximum peak current to avoid runaway

current during continuous output short-circuit conditions. Also, confirm that the inductor’s thermal performances and projected temperature rise above ambient

does not exceed its thermal capacity. Many inductor

manufacturers provide bias/load current versus temperature rise performance curves (or similar) to obtain

this information.

Input-Capacitor Selection

The discontinuous input current of the buck converter

causes large input ripple currents and therefore the

input capacitor must be carefully chosen to withstand

the input ripple current and keep the input-voltage ripple within design requirements.

The input-voltage ripple is comprised of ΔVQ(caused

by the capacitor discharge) and ΔV

ESR

(caused by the

ESR of the input capacitor). The total voltage ripple is

the sum of ΔVQand ΔV

ESR

which peaks at the end of

the on-cycle. Calculate the required input capacitance

and ESR for a specified ripple using the following equations:

I

LOAD(MAX)

is the maximum output current, ΔI

P-P

is the

peak-to-peak inductor current, and V

PVIN_

is the input

supply voltage, V

OUT_

is the regulator output voltage,

and fSWis the switching frequency.

V [V]

PVIN_MAX

≤

t [ s] f [MHz]

V [V]

OUT_

ON(MIN) SW

×μ

V [V]

V [V]

PVIN_MIN

≥

1 (t [ s] f [MHz])

−×μ

OFF(MIN) SW

OUT_

V [V] (V [V] V [V])

LH

[]

μ=

OUT_ PVIN_ OUT_

V [V] f [MHz]

PVIN_ SW

×−

××

IA

Δ

PP

−

[]

V [mV]

Δ

ESR

V [V] f [MHz]

Δ

×

QSW

−

××

C

Δ

ESR

[]

m

Ω

=

⎛

I

⎜

LOAD(MAX)

⎝

I [A]

LOAD(MAX)

[]

F

μ

PVIN_

I [A]

−

PP

=

V V [V] V [V]

()

PVIN_ OUT_ OUT_

=

V [V] f [MHz] L

PVIN_ SW

I

Δ

−

PP

+

2

⎛

V [V]

OUT_

×

⎜

V [V]

⎝

PVIN_

×

⎞

[A]

⎟

⎠

⎞

⎟

⎠

[]

H

μ

Page 16

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

16 ______________________________________________________________________________________

Use the following equation to calculate the input ripple

when only one regulator is enabled:

The MAX15022 includes UVLO hysteresis to avoid possible unintentional chattering during turn-on. Use additional

bulk capacitance if the input source impedance is high. If

using a lower input voltage, additional input capacitance

helps to avoid possible undershoot below the undervoltage lockout threshold during transient loading.

Output-Capacitor Selection

The allowed output-voltage ripple and the maximum

deviation of the output voltage during load steps determine the required output capacitance and its ESR. The

output ripple is mainly composed of ΔVQ(caused by

the capacitor discharge) and ΔV

ESR

(caused by the

voltage drop across the equivalent series resistance of

the output capacitor). The equations for calculating the

output capacitance and its ESR are:

where ΔI

P-P

is the peak-to-peak inductor current, and

fSWis the switching frequency.

ΔV

ESR

and ΔVQare not directly additive since they are

out of phase from each other. If using ceramic capacitors, which generally have low ESR, ΔVQ dominates. If

using electrolytic capacitors, ΔV

ESR

dominates.

The allowable deviation of the output voltage during

fast load transients also affects the output capacitance,

its ESR, and its equivalent series inductance (ESL). The

output capacitor supplies the load current during a

load step until the controller responds with an

increased duty cycle. The response time (t

RESPONSE

)

depends on the gain bandwidth of the controller (see

the

Compensation-Design Guidelines

section). The

resistive drop across the output capacitor’s ESR

(ΔV

ESR

), the drop across the capacitor’s ESL (ΔV

ESL

),

and the capacitor discharge (ΔVQ) causes a voltage

droop during the load-step (I

STEP

). Use a combination

of low-ESR tantalum/aluminum electrolyte and ceramic

capacitors for better load transient and voltage ripple

performance. Non-leaded capacitors and capacitors in

parallel help reduce the ESL. Keep the maximum out-

put-voltage deviation below the tolerable limits of the

electronics being powered.

Use the following equations to calculate the required

output capacitance, ESR, and ESL for minimal output

deviation during a load step:

where I

STEP

is the load step, t

STEP

is the rise time of the

load step, and t

RESPONSE

is the response time of the

controller.

Compensation Design Guidelines

The MAX15022 uses a fixed-frequency, voltage-mode

control scheme that regulates the output voltage by

comparing the output voltage against a fixed reference.

The subsequent “error” voltage that appears at the

error-amplifier output (COMP_) is compared against an

internal ramp voltage to generate the required duty

cycle of the PWM. A second order lowpass LC filter

removes the switching harmonics and passes the DC

component of the PWM signal to the output. The LC filter has an attenuation slope of -40dB/decade and introduces 180° of phase shift at frequencies above the LC

resonant frequency. This phase shift in addition to the

inherent 180° of phase shift of the regulator’s negative

feedback system turns the feedback into unstable positive feedback. The error amplifier and its associated

circuitry must be designed to achieve a stable closedloop system.

The basic controller loop consists of a power modulator

(comprised of the regulator’s PWM, associated circuitry,

and LC filter), an output feedback divider, and an error

amplifier. The power modulator has a DC gain set by

V

AVIN/VRAMP

where the ramp voltage (V

RAMP

) is a func-

tion of the V

AVIN

and results in a fixed DC gain of 4V/V,

providing effective feed-forward compensation of inputvoltage supply DC variations. The feed-forward compensation eliminates the dependency of the power modulator’s gain on the input voltage such that the feedback

compensation of the error amplifier requires no modifications for nominal input-voltage changes. The output

filter is effectively modeled as a double-pole and a single zero set by the output inductance (L), the DC resistance of the inductor (DCR), the output capacitance

(C

OUT

), and its equivalent series resistance (ESR).

I [A] I [A]

CIN(RMS) LOAD(MAX)

=×

V [V] V V [V]

OUT_ PVIN_ OUT_

×−

()

V [V]

PVIN_

I [A]

Δ

PP

Δ

QSW

2 V [mV]

×

Δ

I [A]

Δ

PP

CF

[]

μ=

OUT

ESR m

8 V [V] f [MHz]

××

=

Ω

[]

−

ESR

−

V [mV]

Δ

ESR

=

I [A]

STEP

×

V [V]

Δ

Q

ESL STEP

×

I [A]

STEP

C

OUT

ESL

ESR m

[]

Ω

I [A] t

STEP RESPONSE

[]

μ

F

=

V [mV] t

Δ

[]

nH

=

[]

μ

s

[]

s

μ

Page 17

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

______________________________________________________________________________________ 17

Below are equations that define the power modulator:

R

OUT

is the load resistance of the regulator, fLCis the

resonant break frequency of the filter, and f

ESR

is the

ESR zero of the output capacitor. See the

Closed-Loop

Response and Compensation of Voltage-Mode

Regulators

for more information on fLCand f

ESR

.

The switching frequency (fSW) is programmable

between 500kHz and 4MHz. Typically, the crossover

frequency (fCO)—the frequency at which the system’s

closed-loop gain is equal to unity (crosses 0dB)—

should be set at or below one-tenth the switching frequency (fSW/10) for stable closed-loop response.

The MAX15022 provides an internal voltage-mode error

amplifier with its inverting input and its output available to

the user for external frequency compensation. The flexibility of external compensation for each controller offers

a wide selection of output filtering components, especially the output capacitor. For cost-sensitive applications,

use aluminum electrolytic capacitors while for spacesensitive applications, use low-ESR tantalum or multilayer ceramic chip (MLCC) capacitors at the output. The

higher switching frequencies of the MAX15022 allow the

use of MLCC as the primary filter capacitor(s).

First, select the passive and active power components

that meet the application output ripple, component

size, and component cost requirements. Second,

choose the small-signal compensation components to

achieve the desired closed-loop frequency response

and phase margin as outlined below.

Closed-Loop Response and Compensation

of Voltage-Mode Regulators

The power modulator’s LC lowpass filter exhibits a variety of responses, dependent on the value of the L and

C and their parasitics. Higher resistive parasitics

reduce the Q of the circuit, reducing the peak gain and

phase of the system; however, efficiency is also

reduced under these circumstances.

One such response is shown in Figure 4a. In this example, the ESR zero occurs relatively close to the filter’s

resonant break frequency, fLC. As a result, the power

modulator’s uncompensated crossover is approximately one third the desired crossover frequency, fCO. Note

also, the uncompensated rolloff through the 0dB plane

follows a single-pole, -20dB/decade slope and 90° of

phase lag. In this instance, the inherent phase margin

ensures a stable system; however, the gain-bandwidth

product is not optimized.

Figure 4a. Power Modulator Gain and Phase Response with

Lossy Bulk Output Capacitor(s) (Aluminum)

Figure 4b. Power Modulator and Type II Compensator Gain and

Phase Response with Lossy Bulk Output Capacitor(s) (Aluminum)

Gain

MOD(DC)

V

AVIN

===

V

RAMP

V

AVIN

V

AVIN

4V/V

4

1

2LC

××

π

OUT

OUT

f

ESR

1

⎛

R ESR

OUT

⎜

R DCR

⎝

OUT

=

2 ESR C

××

π

≈

⎞

+

⎟

+

⎠

1

OUT

f

=

LC

2LC

×× ×

π

40

20

|G

MOD

0

-20

MAGNITUDE (dB)

-40

-60

-80

10

f

LC

| ASYMPTOTE

< G

MOD

100 1k 10k

FREQUENCY (Hz)

MAX15022 fig04a

|G

MOD

f

ESR

100k

|

1M 10M

90

45

0

-45

PHASE (DEGREES)

-90

-135

-180

|G

MOD

MAX15022 fig04b

f

CO

|

1M 10M

180

135

90

45

0

-45

PHASE (DEGREES)

-90

-135

-180

80

60

40

|GEA|

20

0

-20

MAGNITUDE (dB)

-40

-60

-80

10

<G

EA

f

LC

f

< G

MOD

100 1k 10k 100k

ESR

FREQUENCY (Hz)

Page 18

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

18 ______________________________________________________________________________________

As seen in Figure 4b, a Type II compensator provides for

stable closed-loop operation, leveraging the +20dB/

decade slope of the capacitor’s ESR zero, while extending the closed-loop gain bandwidth of the regulator. The

zero crossover now occurs at approximately three times

the uncompensated crossover frequency, f

CO

.

The Type II compensator’s midfrequency gain (approximately 12dB shown here) is designed to compensate

for the power modulator’s attenuation at the desired

crossover frequency, f

CO

(Gain

E/A

+ Gain

MOD

= 0dB at

fCO). In this example, the power modulator’s inherent

-20dB/decade rolloff above the ESR zero (f

ZERO, ESR

)

is leveraged to extend the active regulation gain bandwidth of the voltage regulator. As shown in Figure 4b,

the net result is a three times increase in the regulator’s

gain bandwidth while providing greater than 75° of

phase margin (the difference between Gain

E/A

and

Gain

MOD

respective phases at crossover, fCO).

Other filter schemes pose their own problems. For

instance, when choosing high-quality filter capacitor(s),

e.g. MLCCs, the inherent ESR zero may occur at a

much higher frequency, as shown in Figure 4c.

As with the previous example, the actual gain and

phase response is overlaid on the power modulator’s

asymptotic gain response. One readily observes the

more dramatic gain and phase transition at or near the

power modulator’s resonant frequency, fLC, versus the

gentler response of the previous example. This is due

to the filter components’ lower parasitic (DCR and ESR)

and corresponding higher frequency of the inherent

ESR zero. In this example, the desired crossover frequency occurs below the ESR zero frequency.

In this example, a compensator with an inherent midfrequency double-zero response is required to mitigate

the effects of the filter’s double-pole phase lag. This is

available with the Type III topology.

As demonstrated in Figure 4d, the Type III’s midfrequency double-zero gain (exhibiting a +20dB/decade

slope, noting the compensator’s pole at the origin) is

designed to compensate for the power modulator’s

double-pole -40dB/decade attenuation at the desired

crossover frequency, fCO(again, Gain

E/A

+ Gain

MOD

=

0dB at fCO) (see Figure 4d).

In the above example, the power modulator’s inherent

(midfrequency) -40dB/decade rolloff is mitigated by the

midfrequency double zero’s +20dB/decade gain to

extend the active regulation gain bandwidth of the voltage regulator. As shown in Figure 4d, the net result is

an approximate doubling in the controller’s gain bandwidth while providing greater than 55° of phase margin

(the difference between Gain

E/A

and Gain

MOD

respec-

tive phases at crossover, fCO).

Design procedures for both Type II and Type III compensators are shown below.

Figure 4c. Power Modulator Gain and Phase Response with

Low-Parasitic Capacitor(s) (MLCCs)

Figure 4d. Power Modulator and Type III Compensator Gain

and Phase Response with Low Parasitic Capacitors (MLCCs)

40

|G

|

20

0

-20

MAGNITUDE (dB)

-40

-60

-80

10

MOD

< G

MOD

|G

|

MOD

ASYMPTOTE

100 1k 10k 100k

FREQUENCY (Hz)

MAX15022 fig04c

f

LC

1M 10M

90

45

0

f

ESR

-45

PHASE (DEGREES)

-90

-135

-180

80

60

40

|GEA|

20

0

-20

MAGNITUDE (dB)

-40

-60

-80

10

< G

EA

f

LC

< G

MOD

100 1k 10k 100k

FREQUENCY (Hz)

MAX15022 fig04d

f

CO

|G

MOD

f

ESR

1M 10M

270

203

135

68

0

|

-68

-135

-203

-270

PHASE (DEGREES)

Page 19

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

______________________________________________________________________________________ 19

Type II: Compensation when fCO> f

ZERO, ESR

When the f

CO

is greater than f

ESR

, a Type II compensation network provides the necessary closed-loop compensated response. The Type II compensation network

provides a midband compensating zero and a high-frequency pole (see Figures 5a and 5b).

RFCF provides the midband zero f

MID,ZERO

, and

RFC

CF

provides the high-frequency pole, f

HIGH,POLE

.

Use the following procedure to calculate the compensation network components.

Calculate the f

ESR

and LC double pole, fLC:

where C

OUT

is the regulator output capacitor and ESR

is the series resistance of C

OUT

. See the

Output-

Capacitor Selection

section for more information on cal-

culating C

OUT

and ESR.

Set the compensator’s leading zero, fZ1, at or below the

filter’s resonant double-pole frequency from:

Set the compensator’s high-frequency pole, f

P1

, at or

below one-half the switching frequency, f

SW

:

To maximize the compensator’s phase lead, set the

desired crossover frequency, fCO, equal to the geometric mean of the compensator’s leading zero, fZ1, and

high-frequency pole, fP1, as follows:

Select the feedback resistor, RF, in the range of 3.3kΩ

to 30kΩ.

Calculate the gain of the modulator (Gain

MOD

)—comprised of the regulator’s PWM, LC filter, feedback divider,

and associated circuitry—at the desired crossover frequency, f

CO

, using the following equation:

where VFBis the 0.6V (typ) FB_ input-voltage set-point,

L is the value of the regulator inductor, ESR is the

series resistance of the output capacitor, and V

OUT_

is

the desired output voltage.

The gain of the error amplifier (Gain

E/A

) in the midband

frequencies is:

The total loop gain is the product of the modulator gain

and the error amplifier gain at f

CO

and should be set

equal to 1 as follows:

Gain

MOD

x Gain

E/A

= 1

So:

Figure 5a. Type II Compensation Network

Figure 5b. Type II Compensation Network Response

f

ESR

f

LC

=

≈

2 ESR C

2LC

1

××

π

1

××

π

OUT

OUT

ff

≤

Z1 LC

f

SW

f

≤

P1

2

fff

=×

CO Z1 P1

Gain 4(V/V)

=×

MOD

ESR [m ]

2 f [kHz] L[ H]

××

πμ

()

CO

Ω

V [V]

FB

×

V [V]

OUT_

C

2ND ASYMPTOTE

-1

)

CF

C

R

F

F

-1

R

F

)

(

R

I

3RD ASYMPTOTE

(ωR

FCCF

2ND POLE

(R

FCCF

V

OUT_

R

1

FB_

R

2

V

REF

GAIN

(dB)

1ST ASYMPTOTE

-1

)

(ωR

1CF

1ST POLE

(AT ORIGIN)

1ST ZERO

(R

FCF

R [k ]

Ω

Gain

E/A

=

R [k ]

F

Ω

1

⎤

⎡

R

F

⎥

10

⎢

R

1

⎦

⎣

R

F

×

R

2 f L x V

π

1

20 log 20 log 0dB

×+× =

⎡

4 ESR x V

⎢

π

××

2 f L x V

10

⎢

⎣

4 ESR x V

×

××

CO OUT_

×

CO OUT_

FB

FB

1

=

COMP_

-1

)

ω (rad/sec)

-1

)

⎤

⎥

⎥

⎦

Page 20

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

20 ______________________________________________________________________________________

Solving for R1:

where VFBis the 0.6V (typ) FB_ input-voltage set-point,

L is the value of the regulator inductor, ESR is the

series resistance of the output capacitor, and V

OUT_

is

the desired output voltage.

1) CFis determined from the compensator’s leading

zero, fZ1, and RFas follows:

2) C

CF

is determined from the compensator’s high-fre-

quency pole, f

P1

, and RFas follows:

3) Calculate R2using the following equation:

where VFB= 0.6V (typ) and V

OUT_

is the output voltage

of the regulator.

Type III: Compensation when f

CO

< f

ESR

As indicated above, the position of the output capacitor’s inherent ESR zero is critical in designing an appropriate compensation network. When low-ESR ceramic

output capacitors (MLCCs) are used, the ESR zero frequency (f

ESR

) is usually much higher than the desired

crossover frequency (fCO). In this case, a Type III compensation network is recommended (see Figure 6a).

As shown in Figure 6b, the Type III compensation network introduces two zeros and three poles into the control loop. The error amplifier has a low-frequency pole

at the origin, two zeros, and two higher frequency poles

at the following frequencies:

Two midband zeros (f

Z1

and fZ2) are designed to compensate for the pair of complex poles introduced by the

LC filter.

f

P1

introduces a pole at zero frequency (integrator) for

nulling DC output-voltage errors.

fP1= at the origin (0Hz)

Depending on the location of the ESR zero (f

ESR

), f

P2

can be used to cancel it, or to provide additional attenuation of the high-frequency output ripple.

fP3attenuates the high-frequency output ripple.

Since CCF<< CFthen:

Figure 6a. Type III Compensation Network

Figure 6b. Type III Compensation Network Response

V

R [k ] 4 ESR[m ] V [V]

ΩΩ

×× ×

R [k ]

Ω

1

FFB

=

2 f [kHz] L[ H] V [V]

×××πμ

CO OUT_

C[F]

μπ=

F

××Ω

2 R [k ] f [kHz]

1

FZ1

R

I

C

I

GAIN

(dB)

OUT_

R

1

FB_

R

2

V

REF

C

CF

C

R

F

F

COMP_

CF]

[μπ=

CF

××Ω

2 R [k ] f [kHz]

1

FP1

V [V]

R[k] R[k]

ΩΩ=×

21

FB

V [V] V [V]

OUT_ FB

−

f

f

Z2

=

Z1

=

2C(RR)

1

××

π

2RC

FF

1

×× +

π

I1I

1ST ASYMPTOTE

-1

)

(ωR

ICF

2ND ASYMPTOTE

1ST POLE

(AT ORIGIN)

(

1ST ZERO

)

(R

FCF

-1

R

F

)

R

1

-1

2ND ZERO

(R

1CI

4TH ASYMPTOTE

3RD ASYMPTOTE

(ωR

FCI

2ND POLE

-1

)

(R

ICI

-1

)

R

F

)

(

R

I

5TH ASYMPTOTE

-1

)

(R

FCCF

-1

)

ICCF

ω (rad/sec)

-1

)

3RD POLE

(R

f

P2

1

=

××π

2RC

II

f

=

P3

π

2R CC

××

1

()

FFCF

=

π

2R

1

CC

××

F

CC

×

FCF

+

FCF

f

=

P3

1

××π

2 R C

FCF

Page 21

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

______________________________________________________________________________________ 21

The locations of the zeros and poles should be such

that the phase margin peaks around fCO.

Set the ratios of fCO-to-fZand fP-to-fCOequal to one another, e.g.,

fCO= f

P = 5 is a good number to get approximately

fZf

CO

60° of phase margin at fCO. Whichever technique, it is

important to place the two zeros at or below the double

pole to avoid the conditional stability issue.

The following procedure is recommended:

1) Select a crossover frequency, fCO, at or below one-

tenth the switching frequency (f

SW

):

2) Calculate the LC double-pole frequency, fLC:

where C

OUT

is the output capacitor of the regulator.

3) Select the feedback resistor, RF, in the range of

3.3kΩ to 30kΩ.

4) Place the compensator’s first zero

at or below the output filter’s double-pole, fLC, as follows:

5) The gain of the modulator (Gain

MOD

)—comprised of

the regulator’s PWM, LC filter, feedback divider, and

associated circuitry—at the crossover frequency is:

The gain of the error amplifier (Gain

E/A

) in midband fre-

quencies is:

The total loop gain is the product of the modulator gain

and the error amplifier gain at f

CO

should be equal to 1,

as follows:

Gain

MOD

x Gain

E/A

= 1

So:

Solving for CI:

6) For those situations where fLC< fCO< f

ESR

< fSW/2,

as with low-ESR tantalum capacitors, the compensator’s second pole (fP2) should be used to cancel

f

ESR

. This provides additional phase margin. On the

system Bode plot, the loop gain maintains its

+20dB/decade slope up to 1/2 of the switching frequency verses flattening out soon after the 0dB

crossover. Then set:

f

P2

= f

ESR

If a ceramic capacitor is used, then the capacitor ESR

zero, f

ESR

, is likely to be located even above 1/2 of the

switching frequency, that is fLC< fCO< fSW/2 < f

ESR

. In

this case, the frequency of the second pole (fP2) should

be placed high enough not to significantly erode the

phase margin at the crossover frequency. For example,

fP2can be set at 5 x fCO, so that its contribution to phase

loss at the crossover frequency f

CO

is only about 11°:

f

P2

= 5 x f

CO

Once fP2is known, calculate RI:

7) Place the second zero (fZ2) at 0.2 x fCOor at fLC,

whichever is lower, and calculate R1using the following equation:

8) Place the third pole (fP3) at 1/2 the switching fre-

quency and calculate C

CF

from:

9) Calculate R

2

as:

where V

FB

= 0.6V (typ).

f [kHz]

f [kHz]

CO

SW

≤

10

1

OUT

f [MHz]

LC

≈

2 L[ H] C F]

××πμ μ[

f

=

Z1

1

××π

2RC

FF

C[F]

μπ=

F

×××Ω

2 R [k ] 0.5 f [kHz]

1

FLC

Gain 4

MOD

=×

(2 f [MHz]) L[ H] C [ F]

×××πμμ

CO

1

2

OUT

Gain 2 f [kHz] C [ F] R [k ]

=× × ×πμΩ

E/A CO I F

2 f [kHz] L[ H] C [ F]

×××

πμμ

()

C pF]

[ =

I

CO OUT

4 R [k ]

×

Ω

F

R[k ]

Ω=

I

××πμ

2 f [kHz] C [ F]

1

P2 I

R[k ]

Ω=

1

2 f [kHz] C [ F]

1

××πμ

Z2 I

C[F]

n =

CF

πΩ

2 0.5 f [MHz] R [k ]

×× ×

()

1

SW F

4

×

(2 f [kHz]) C [ F] L[ H]

×××

πμμ

CO

2 f [kHz] C [ F] R [k ] 1

×× × × =

π pΩ

CO I F

1

2

OUT

R[k] R[k]

21

ΩΩ=×

V [V] V [V]

OUT_ FB

V [V]

FB

−

Page 22

MAX15022

Dual, 4A/2A, 4MHz, Step-Down DC-DC

Regulator with Dual LDO Controllers

22 ______________________________________________________________________________________

LDO Controllers

Design Procedure

PNP Pass Transistors Selection

The pass transistors must meet specifications for current

gain (ß), input capacitance, collector-emitter saturation

voltage, and power dissipation. The transistor’s current

gain limits the guaranteed maximum output current to:

where I

B3/4(MIN)

is the minimum base-drive current and

R

PULL

is the pullup resistor connected between the

transistor’s base and emitter.

In addition, to avoid premature dropout, V

CE-SAT

must

be less than or equal to (V

PVIN_(MIN)

- V

OUT3/4

).

Furthermore, the transistor’s current gain increases the

linear regulator’s DC loop gain (see the

Stability

Requirements

section), so excessive gain destabilizes

the output. Therefore, transistors with high current gain

at the maximum output current, such as Darlington

transistors, are not recommended. The transistor’s

input capacitance and input resistance also create a

second pole, which could be low enough to destabilize

the LDO when the output is heavily loaded.

The transistor’s saturation voltage at the maximum output current determines the minimum input-to-output voltage differential that the linear regulator supports.

Alternately, the package’s power dissipation could limit

the useable maximum input-to-output voltage differential.

The maximum power-dissipation capability of the transistor’s package and mounting must support the actual

power dissipation in the device without exceeding the

maximum junction temperature. The power dissipated

equals the maximum load current multiplied by the

maximum input-to-output voltage differential.

Output 3 and Output 4 Voltage Selection

The MAX15022 positive linear-regulator output voltage

is set with a resistive divider from the desired output

(V

OUT3/4

) to FB3/4 to SGND (see Figures 7 and 8).

First, select the R

2FB3/4

resistance value (below 30kΩ).

Then, solve for R

1FB3/4

:

where V

OUT3/4

can support output voltages as low as

0.6V and V

FB3/4

is 0.6V (typ).

Stability Requirements

The MAX15022’s B3 and B4 outputs are designed to

drive bipolar PNP transistors. These PNP transistors

form linear regulators with positive outputs. An internal

transconductance amplifier drives the external pass

transistors. The transconductance amplifier, pass transistor’s specifications, the base-emitter resistor, and the

output capacitor determine the loop stability.

The total DC loop gain (A

V

) is the product of the gains of

the internal transconductance amplifier, the gain from

base to collector of the pass transistor, and the attenuation of the feedback divider. The transconductance amplifier regulates the output voltage by controlling the pass

transistor’s base current. Its DC gain is approximately:

where gC_is the transconductance of the internal

amplifier and is typically 1.2mA/mV, R

P1/2

is the resistor

across the base and the emitter of the pass transistor in

kΩ, and RINis the input resistance of the pass transistor, and can be calculated by:

The DC gain for the pass transistor (AP), including the

feedback divider, is approximately:

The total DC loop gain for output 3 and output 4 is:

The output capacitance (C

OUT_

) and the load resis-

tance (R

OUT_

) create a dominant pole (f

POLE1

) at:

I [A] I [A]

OUT3/4 B3/4(MIN)

⎛

=

⎜

⎝

−

R

V [V]

BE

PULL

⎞

⎟

[]Ω

⎠

×

β

g

R

[]

IN

Ag

=×

PmPNP

−

R

2FB3/4

RR

1FB3/4 2F

ImA

OUT3/4

=

where g

×

mPNP

−

⎛

RR

×

IN P1/2

×

C_

⎜

RR

+

⎝

IN P1/2

⎛

kx

Ω=

β

⎜

I

⎝

OUT3/4

⎡

R(RR)

OUT3/4 1FB3/4 2FB3/4

⎢

R