Page 1

General Description

The MAX15020 high-voltage step-down DC-DC converter operates over an input voltage range of 7.5V to

40V. The device integrates a 0.2Ω high-side switch and

is capable of delivering 2A load current with excellent

load and line regulation. The output is dynamically

adjustable from 0.5V to 36V through the use of an external reference input (REFIN). The MAX15020 consumes

only 6µA in shutdown mode.

The device utilizes feed-forward voltage-mode architecture for good noise immunity in the high-voltage switching environment and offers external compensation for

maximum flexibility. The switching frequency is selectable to 300kHz or 500kHz and can be synchronized to

an external clock signal of 100kHz to 500kHz by using

the SYNC input. The IC features a maximum duty cycle

of 95% (typ) at 300kHz.

The device includes configurable undervoltage lockout

(UVLO) and soft-start. Protection features include

cycle-by-cycle current limit, hiccup-mode for output

short-circuit protection, and thermal shutdown. The

MAX15020 is available in a 20-pin TQFN 5mm x 5mm

package and is rated for operation over the

-40°C to +125°C temperature range.

Applications

Printer Head Driver Power Supply

Automotive Power Supply

Industrial Power Supply

Step-Down Power Supply

Features

o Wide 7.5V to 40V Input Voltage Range

o 2A Output Current, Up to 96% Efficiency

o Dynamic Programmable Output Voltage (0.5V to

36V)

o Maximum Duty Cycle of 95% (typ) at 300kHz

o 100kHz to 500kHz Synchronizable SYNC

Frequency Range

o Configurable UVLO and Soft-Start

o Low-Noise, Voltage-Mode Step-Down Converter

o Programmable Output-Voltage Slew Rate

o Lossless Constant Current Limit with Fixed

Timeout to Hiccup Mode

o Extremely Low-Power Consumption (< 6µA typ) in

Shutdown Mode

o 20-Pin (5mm x 5mm) Thin QFN Package

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

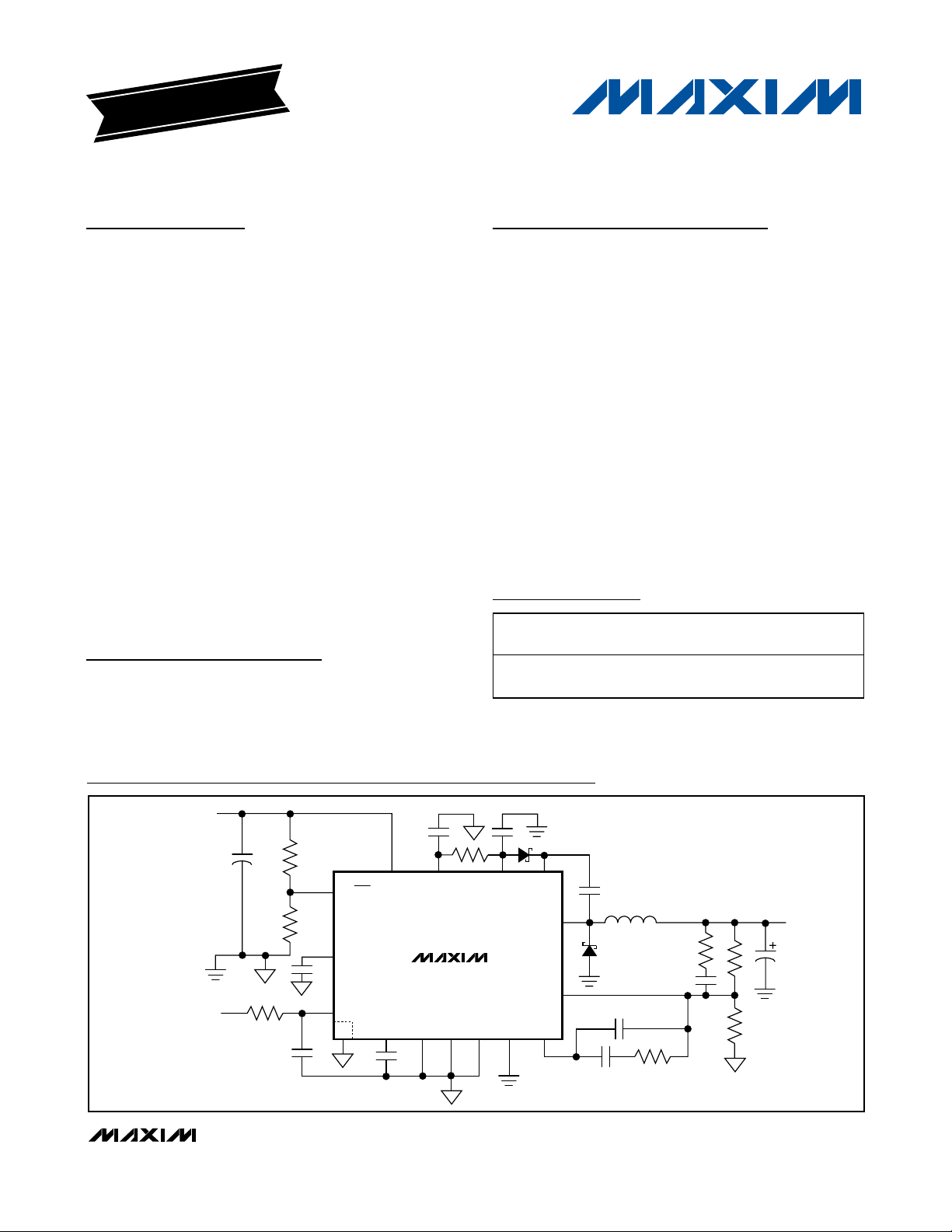

MAX15020

ON/OFF

IN

DVREG

V

OUT

(0.5V TO 36V)

LX

REFOUT

REFIN

EP

SS

PWM

INPUT

V

IN

(7.5V TO 40V)

BST

FB

COMP

SYNC GND FSEL

PGND

REG

Typical Operating Circuit

19-0811; Rev 0; 4/07

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead-free package.

*

EP = Exposed pad.

PART

TEMP RANGE

PINPACKAGE

PKG

CODE

MAX15020ATP+

T2055-5

Pin Configuration appears at end of data sheet.

EVALUATION KIT

AVAILABLE

-40°C to +125°C

20 TQFN-EP*

(5mm x 5mm)

Page 2

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

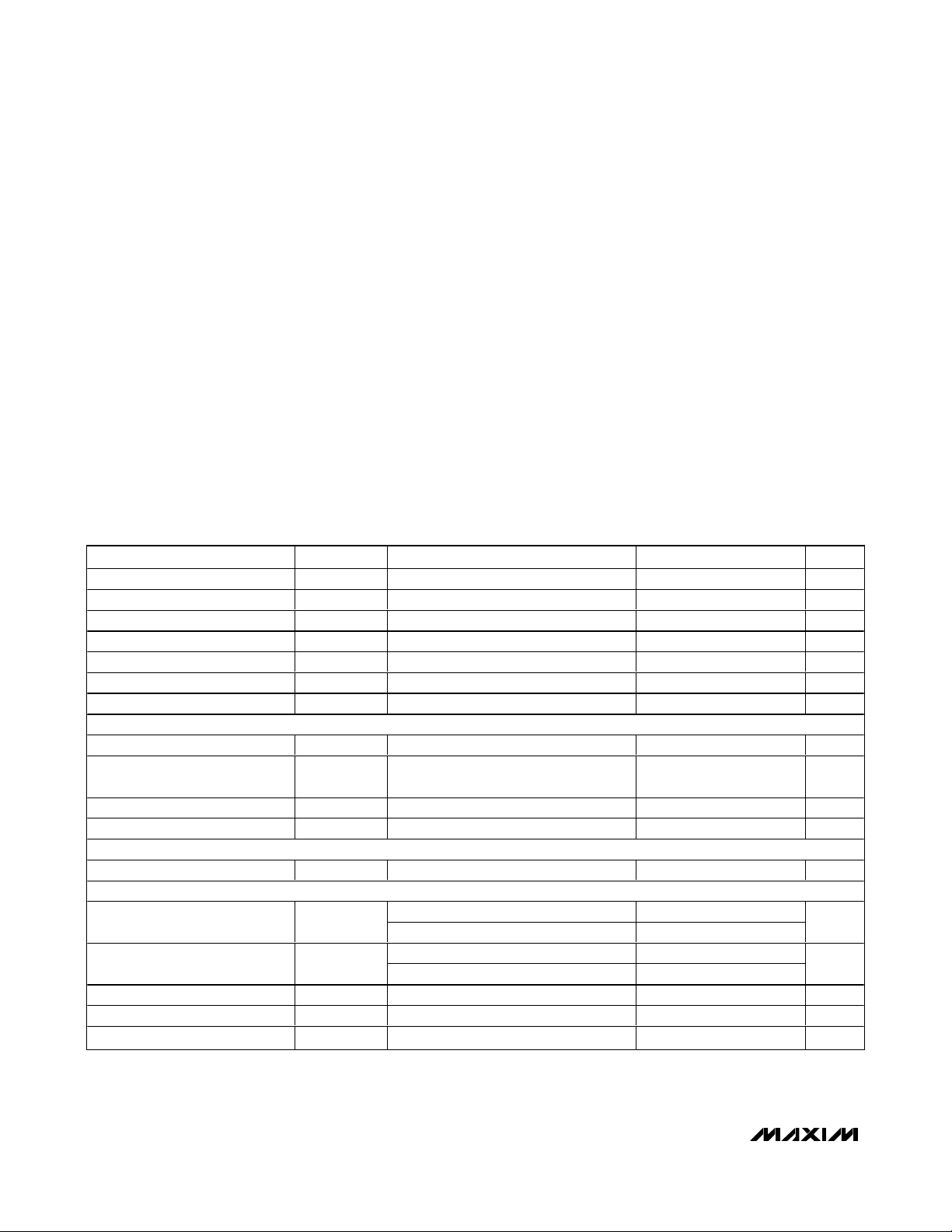

ELECTRICAL CHARACTERISTICS

(VIN= 36V, V

REG

= V

DVREG

, V

PGND

= V

GND

= VEP= 0V, V

SYNC

= 0V, C

REFOUT

= 0.1µF, TA= TJ= -40°C to +125°C, FSEL = REG,

unless otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, ON/OFF to GND........…....................................-0.3V to +45V

LX to GND................................................-0.715V to (V

IN

+ 0.3V)

BST to GND ..................................................-0.3V to (V

IN

+ 12V)

BST to LX................................................................-0.3V to +12V

PGND, EP to GND .................................................-0.3V to +0.3V

REG, DVREG, SYNC to GND .................................-0.3V to +12V

FB, COMP, FSEL, REFIN, REFOUT,

SS to GND .............................................-0.3V to (V

REG

+ 0.3V)

Continuous Current through Internal Power MOSFET

T

J

= +125°C..........................................................................4A

T

J

= +150°C.......................................................................2.7A

Continuous Power Dissipation (T

A

= +70°C)

20-Pin Thin QFN, single-layer board (5mm x 5mm)

(derate 21.3mW/°C above +70°C)...........................1702.1mW

20-Pin Thin QFN, multilayer board (5mm x 5mm)

(derate 34.5mW/°C above +70°C)...........................2758.6mW

Maximum Junction Temperature .....................................+150°C

Storage Temperature Range ............................-60°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

Input Voltage Range V

UVLO Rising Threshold UVLO

UVLO Falling Threshold UVLO

UVLO Hysteresis UVLO

Quiescent Supply Current VIN = 40V, VFB = 1.3V 1.6 2.8 mA

Switching Supply Current VIN = 40V, VFB = 0V 14.5 mA

Shutdown Current I

ON/OFF CONTROL

Input-Voltage Threshold V

Input-Voltage Threshold

Hysteresis

Input Bias Current V

Shutdown Threshold Voltage V

INTERNAL VOLTAGE REGULATOR (REG)

Output Voltage I

OSCILLATOR

Frequency f

Maximum Duty Cycle D

SYNC/FSEL High-Level Voltage 2 V

SYNC/FSEL Low-Level Voltage 0.8 V

SYNC Frequency Range f

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN

RISING

FALLING

HYST

SHDN

ON/OFF

SD

SW

MAX

SYNC

V

V

V

V

V

V

V

= 0.2V, VIN = 40V 6 15 µA

ON/OFF

rising 1.200 1.225 1.270 V

ON/OFF

= 0V to V

ON/OFF

= 0 to 20mA 7.1 8.3 V

REG

= 0V 450 550

FSEL

= V

FSEL

FSEL

FSEL

FSEL

REG

= 0V 85

= V

REG

= V

REG

IN

7.5 40.0 V

6.80 7.20 7.45 V

6.0 6.5 7.0 V

0.7 V

120 mV

-250 +250 nA

0.2 V

270 330

90

100 550 kHz

kHz

%

Page 3

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

_______________________________________________________________________________________ 3

Note 1: Limits are 100% production tested at TA = TJ = +25°C. Limits at -40°C and +125°C are guaranteed by design.

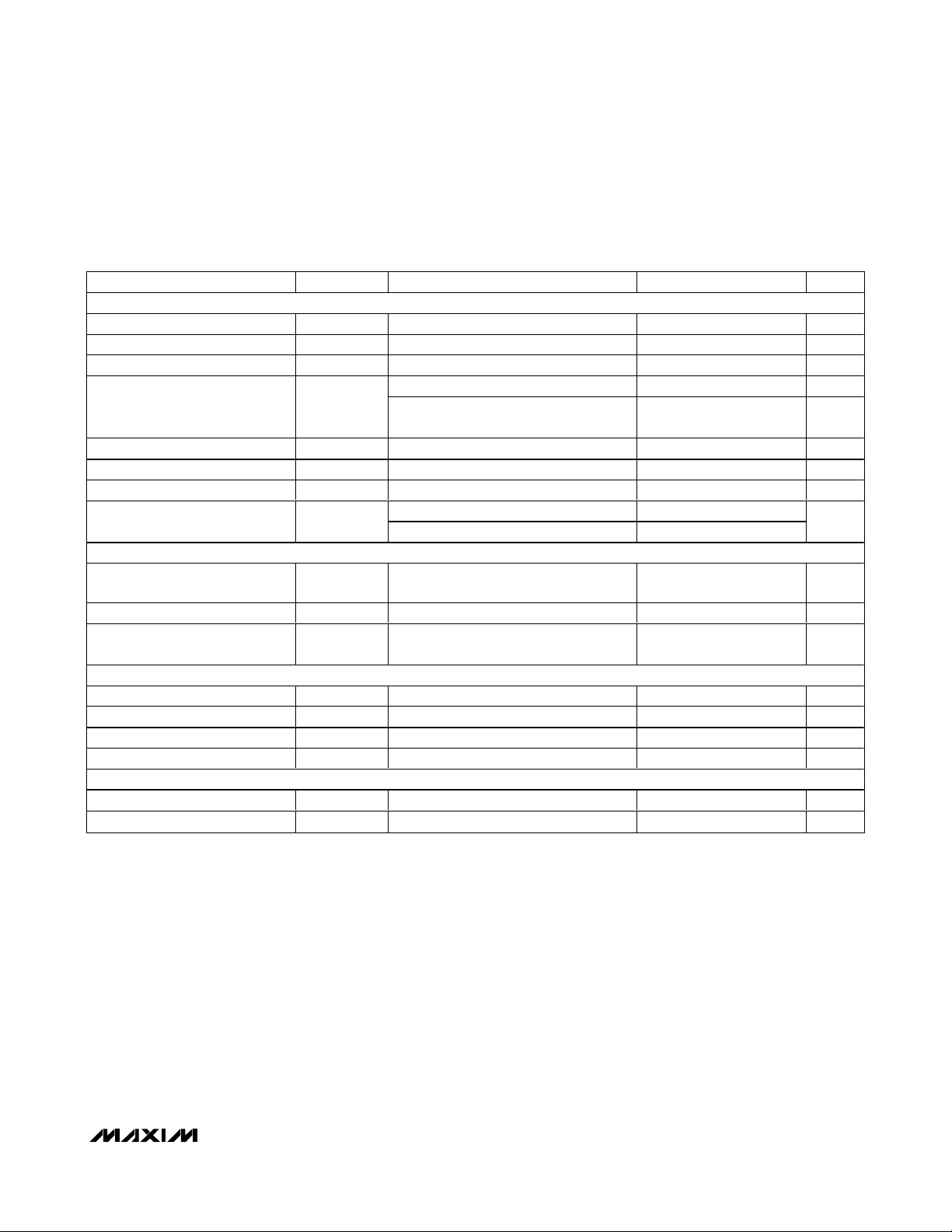

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 36V, V

REG

= V

DVREG

, V

PGND

= V

GND

= VEP= 0V, V

SYNC

= 0V, C

REFOUT

= 0.1µF, TA= TJ= -40°C to +125°C, FSEL = REG,

unless otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

SOFT-START/REFIN/REFOUT/FB

Soft-Start Current I

REFOUT Output Voltage 0.97 0.98 1.01 V

REFIN Input Range 0 3.6 V

FB Accuracy

FB Input Current VSS = 0.2V, VFB = 0V -250 +250 nA

Open-Loop Gain 80 dB

Unity-Gain Bandwidth 1.8 MHz

PWM Modulator Gain (VIN /

V

)

RAMP

CURRENT-LIMIT COMPARATOR

Cycle-by-Cycle Switch Current

Limit

Number of ILIM Events to Hiccup 4

Hiccup Timeout 512

POWER SWITCH

Switch On-Resistance V

BST Leakage Current V

Switch Leakage Current VIN = 40V, VLX = V

Switch Gate Charge V

THERMAL SHUTDOWN

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis 20 °C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SS

I

ILIM

SHDN

REFIN = REFOUT 0.97 0.98 1.01 V

FB = COMP, V

f

= 100kHz, VIN = 7.5V 9.4

SYNC

f

= 500kHz, VIN = 40V 8.9

SYNC

- VLX = 6V 0.18 0.35 Ω

BST

= VLX = VIN = 40V 10 µA

BST

- VLX = 6V 10 nC

BST

= 0.2V to 3.6V

REFIN

BST

81526µA

V

REFIN

- 5mV

= 0V 10 µA

V

REFIN

2.5 3.5 4.5 A

+160 °C

V

REFIN

+ 5mV

mV

V/V

—

Clock

periods

Page 4

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

4 _______________________________________________________________________________________

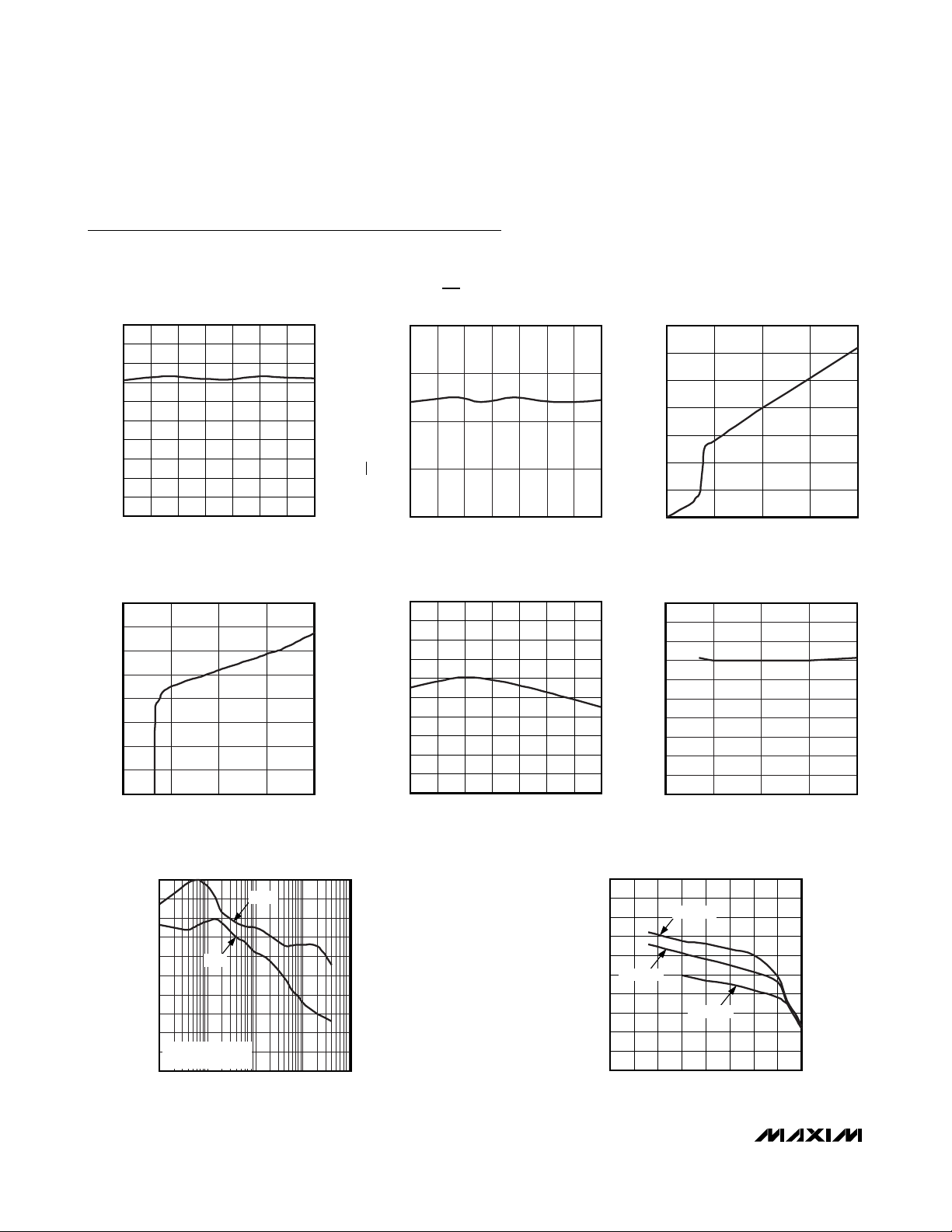

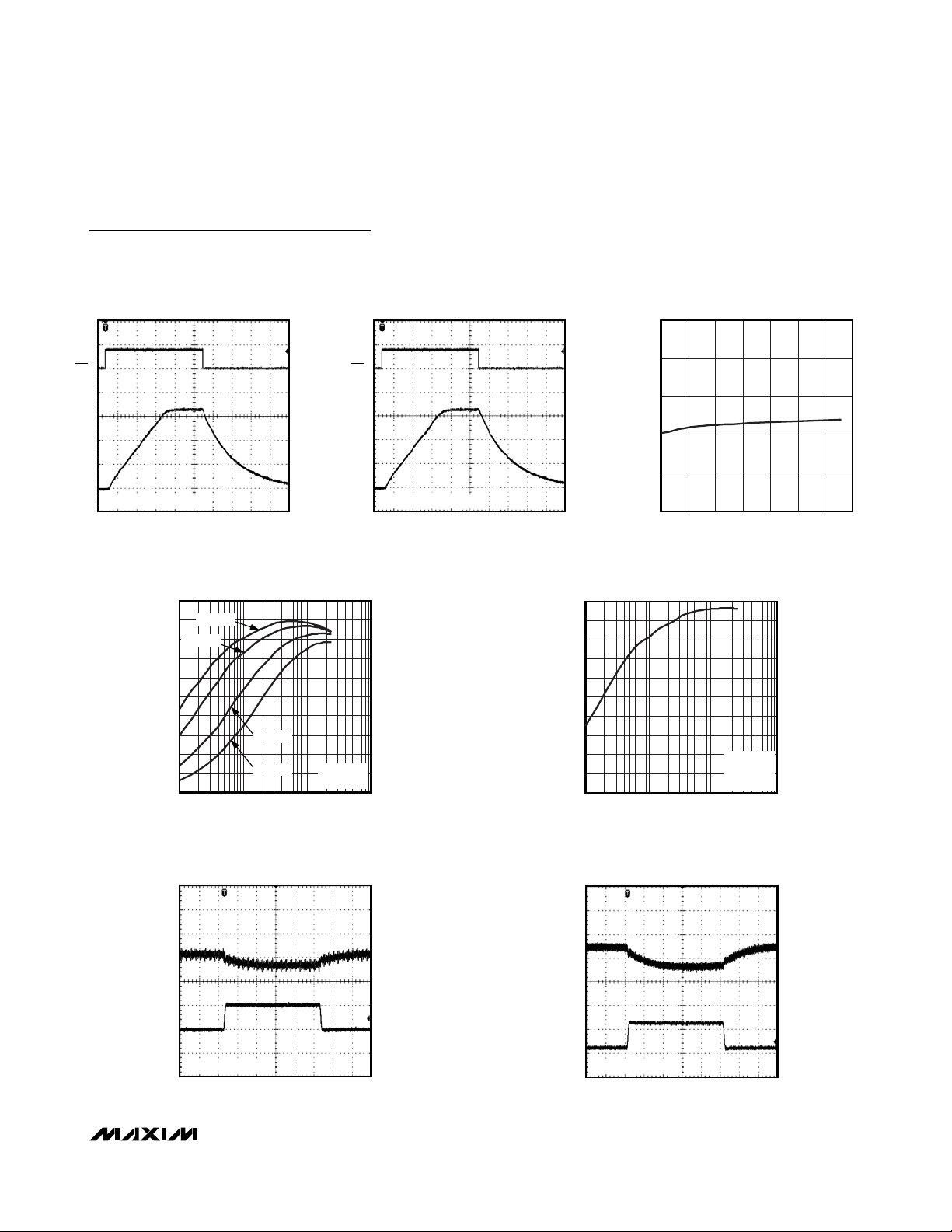

Typical Operating Characteristics

(VIN= 36V, Circuit of Figure 2, TA= +25°C, unless otherwise noted.)

UNDERVOLTAGE LOCKOUT HYSTERESIS

vs. TEMPERATURE

MAX15020 toc01

TEMPERATURE (°C)

UNDERVOLTAGE LOCKOUT HYSTERESIS

1108535 6010-15

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0

-40 135

ON/OFF THRESHOLD HYSTERESIS

vs. TEMPERATURE

MAX15020 toc02

TEMPERATURE (°C)

ON/OFF THRESHOLD HYSTERESIS (V)

1108535 6010-15

0.05

0.10

0.15

0.20

0

-40 135

SHUTDOWN SUPPLY CURRENT

vs. INPUT VOLTAGE

MAX15020 toc03

INPUT VOLTAGE (V)

SUPPLY CURRENT (µA)

302010

1

2

3

4

5

6

7

0

040

NO-LOAD SUPPLY CURRENT

vs. INPUT VOLTAGE

MAX15020 toc04

INPUT VOLTAGE (V)

SUPPLY CURRENT (mA)

302010

2

4

8

6

10

12

14

16

0

040

OPERATING FREQUENCY

vs. TEMPERATURE

MAX15020 toc05

TEMPERATURE (°C)

OPERATING FREQUENCY (kHz)

1108535 6010-15

290

292

294

296

298

300

302

304

306

308

288

-40 135

MAXIMUM DUTY CYCLE

vs. INPUT VOLTAGE

MAX15020 toc06

INPUT VOLTAGE (V)

DUTY CYCLE (%)

302010

86

88

82

84

90

92

94

96

98

100

80

040

LOOP GAIN/PHASE

vs. FREQUENCY

MAX15020 toc07

FREQUENCY (kHz)

GAIN (dB)

PHASE (DEGREES)

100101

-40

-30

-20

-10

0

10

20

30

40

50

-50

-144

-108

-72

-36

0

36

72

108

144

180

-180

0.1 1000

PHASE

VIN = 37V, V

OUT

= 15V,

I

OUT

= 2.02A

GAIN

MAXIMUM LOAD CURRENT

vs. INPUT VOLTAGE

MAX15020 toc08

INPUT VOLTAGE (V)

LOAD CURRENT (A)

353020 2510 155

2.6

2.7

2.8

2.9

3.0

3.1

3.2

3.3

3.4

3.5

2.5

040

TA = -45°C

TA = +25°C

TA = +85°C

Page 5

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

_______________________________________________________________________________________

5

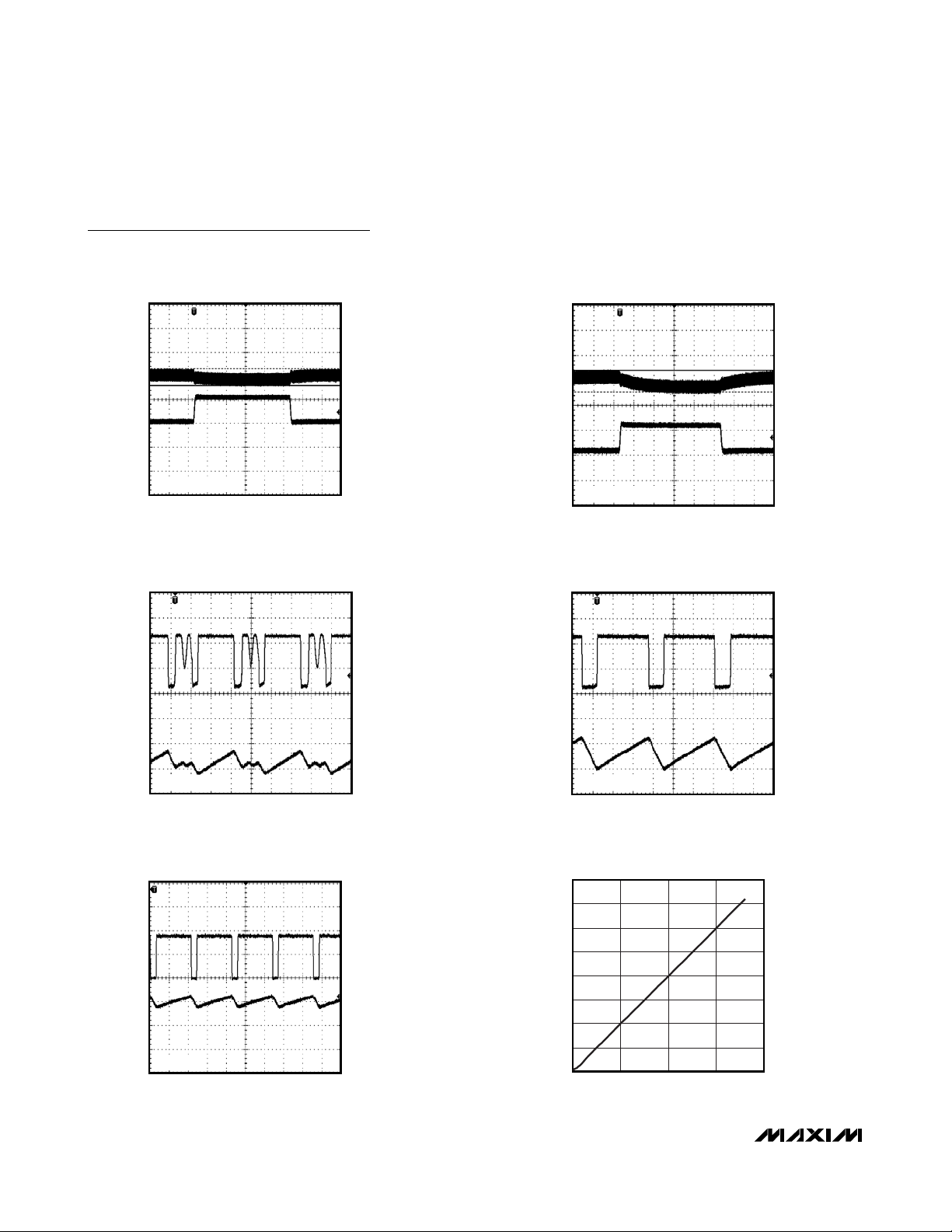

Typical Operating Characteristics (continued)

(VIN= 36V, Circuit of Figure 2, TA= +25°C, unless otherwise noted.)

LOAD TRANSIENT

MAX15020 toc14

200µs/div

50mV/div

AC-COUPLED

2A

1A

I

OUT

V

OUT

VIN = 12V, V

OUT

= 3.3V

LOAD TRANSIENT

MAX15020 toc15

200µs/div

50mV/div

AC-COUPLED

1.2A

0.2A

V

OUT

I

OUT

VIN = 12V, V

OUT

= 3.3V

TURN-ON/TURN-OFF WAVEFORM

V

OUT

VIN = 40V, R

MAX15020 toc12

V

ON/OFF

TURN-ON/TURN-OFF WAVEFORM

V

OUT

VIN = 12V, R

= 27Ω

LOAD

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

MAX15020 toc09

5V/div

V

ON/OFF

0V

1V/div

0V

10ms/div

EFFICIENCY vs. LOAD CURRENT

VIN = 7.5V

VIN = 12V

VIN = 24V

VIN = 40V

0.01 10

OUTPUT CURRENT (A)

fS = 500kHz

V

10.1

OUT

= 3.3V

LOAD

= 27Ω

10ms/div

MAX15020 toc10

REFOUT VOLTAGE vs. TEMPERATURE

1.05

5V/div

0V

1V/div

0V

1.03

1.01

0.99

REFOUT VOLTAGE (V)

0.97

0.95

-40 135

TEMPERATURE (°C)

EFFICIENCY vs. LOAD CURRENT

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.01 10

OUTPUT CURRENT (A)

10.1

fS = 500kHz

= 40V

V

IN

= 30V

V

OUT

MAX15020 toc11

11085603510-15

MAX15020 toc13

Page 6

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VIN= 36V, Circuit of Figure 2, TA= +25°C, unless otherwise noted.)

HEAVY-LOAD

SWITCHING WAVEFORMS

MAX15020 toc20

1µs/div

20V/div

0V

1A/div

0A

I

LX

V

LX

I

LOAD

= 2A

FEEDBACK VOLTAGE

vs. REFIN INPUT VOLTAGE

MAX15020 toc21

REFIN INPUT VOLTAGE (V)

FEEDBACK VOLTAGE (V)

321

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0

04

LOAD TRANSIENT

V

OUT

I

OUT

VIN = 40V, V

LIGHT-LOAD SWITCHING WAVEFORMS

V

LX

OUT

= 30V

200µs/div

MAX15020 toc16

MAX15020 toc18

50mV/div

AC-COUPLED

2A

1A

20V/div

0V

LOAD TRANSIENT

V

OUT

I

OUT

VIN = 40V, V

OUT

= 30V

200µs/div

SWITCHING WAVEFORMS

V

LX

MAX15020 toc17

50mV/div

AC-COUPLED

1.1A

0.25A

MAX15020 toc19

20V/div

0V

I

LX

I

= 40mA

LOAD

1µs/div

1A/div

0A

I

LX

I

= 500mA

LOAD

1µs/div

1A/div

0A

Page 7

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

_______________________________________________________________________________________

7

Typical Operating Characteristics (continued)

(VIN= 36V, Circuit of Figure 2, TA= +25°C, unless otherwise noted.)

SOFT-START VOLTAGE RISE

vs. REFIN VOLTAGE RISE

MAX15020 toc22

V

REFIN

dv/dt (V/ms)

V

SS

dv/dt (V/ms)

0.1 1

0.1

1

10

0.01

0.01 10

CSS = 0.1µF

CSS = 0.01µF

VSS AND V

OUT

RESPONSE TO REFIN PWM

MAX15020 toc23

2ms/div

1V

0.5V

0V

0V

20V/div

1V/div

1V/div

0V

V

PWM

V

REFIN

V

SS

V

OUT

D = 70% TO 100%

10kΩ and 0.1µF RC ON REFIN

MODULATOR GAIN

vs. INPUT VOLTAGE

MAX15020 toc24

INPUT VOLTAGE (V)

MODULATOR GAIN (V/V)

353025201510

8.5

9.0

9.5

10.0

10.5

11.0

8.0

540

SOFT-START CHARGE CURRENT

vs. TEMPERATURE

MAX15020 toc25

TEMPERATURE (°C)

SOFT-START CHARGE CURRENT (µA)

1108535 6010-15

14.6

14.7

14.8

14.9

15.0

15.1

15.2

15.3

15.4

15.5

14.5

-40 135

Page 8

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

8 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 COMP Voltage-Error-Amplifier Output. Connect COMP to the necessary compensation feedback network.

2FB

3 ON/OFF

Feedback Regulation Point. Connect to the center tap of an external resistor-divider connected between

the output and GND to set the output voltage. The FB voltage regulates to the voltage applied to REFIN.

ON/OFF Control. The ON/OFF rising threshold is set to approximately 1.225V. Connect to the center tap of

a resistive divider connected between IN and GND to set the turn-on (rising) threshold. Connect ON/OFF to

GND to shut down the IC. Connect ON/OFF to IN for always-on operation given that V

UVLO threshold. ON/OFF can be used for power-supply sequencing.

has risen above the

IN

4 REFOUT

5 SS Soft-Start. Connect a 0.01µF or greater ceramic capacitor from SS to GND. See the Soft-Start (SS) section.

6 REFIN

7 FSEL

8 SYNC

9 DVREG

10 PGND

11 N.C. No Connection. Leave unconnected or connect to GND

12 BST

13, 14, 15 LX Source Connection of Internal High-Side Switch. Connect the inductor and rectifier diode’s cathode to LX.

16, 17, 18 IN Supply Input Connection. Connect to an external voltage source from 7.5V to 40V.

19 REG

20 GND

—EP

0.98V Reference Voltage Output. Bypass REFOUT to GND with a 0.1µF ceramic capacitor. REFOUT is to

be used only with REFIN. It is not to be used to power any other external circuitry.

External Reference Input. Connect to an external reference. V

Connect REFIN to REFOUT to use the internal 1V reference. See the Reference Input and Output (REFIN,

REOUT) section.

Internal Switching Frequency Selection Input. Connect FSEL to REG to select f

to GND to select f

Oscillator Synchronization Input. SYNC can be driven by an external 100kHz to 500kHz clock to

synchronize the MAX15020’s switching frequency. Connect SYNC to GND to disable the synchronization

function. When using SYNC, connect FSEL to REG.

Power Supply for Internal Digital Circuitry. Connect a 10Ω resistor from REG to DVREG. Connect DVREG to

the anode of the boost diode, D2 in Figure 2. Bypass DVREG to GND with at least a 1µF ceramic capacitor.

Power-Ground Connection. Connect the input filter capacitor’s negative terminal, the anode of the

freewheeling diode, and the output filter capacitor’s return to PGND. Connect externally to GND at a single

point near the input bypass capacitor’s return terminal.

High-Side Gate Driver Supply. Connect BST to the cathode of the boost diode and to the positive terminal

of the boost capacitor.

8V Internal Regulator Output. Bypass to GND with at least a 1µF ceramic capacitor. Do not use REG to

power external circuitry.

Ground Connection. Solder the exposed pad to a large GND plane. Connect GND and PGND together at

one point near the input bypass capacitor return terminal.

Exposed Pad. Connect EP to GND. Connecting EP does not remove the requirement for proper ground

connections to the appropriate pins. See the PCB Layout and Routing section.

= 500kHz. When an external clock is connected to SYNC connect FSEL to REG.

SW

regulates to the voltage applied to REFIN.

FB

= 300kHz. Connect FSEL

SW

Page 9

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

_______________________________________________________________________________________ 9

Figure 1. Functional Diagram

ON/OFF

REG

REFOUT

REFIN

COMP

SYNC

IN

LDO

REF

EN

REF

THERMAL

SSA

IN

RAMP

REF

ICSS

SS

E/A

FB

EN

OSC

VPOK

SHDN

REF

OK

ENABLE

SWITCHING

REGOK

OVERLOAD

MANAGEMENT

LOGIC

CPWM

ILIM

CLK

MAX15020

IN

HIGH-SIDE

CURRENT

SENSE

REF_ILIM

BST

LX

DVREG

PGND

FSEL

CLK

GND

Page 10

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

10 ______________________________________________________________________________________

Figure 2. Typical Application Circuit

Detailed Description

The MAX15020 voltage-mode step-down converter

contains an internal 0.2Ω power MOSFET switch. The

MAX15020 input voltage range is 7.5V to 40V. The

internal low R

DS(ON)

switch allows for up to 2A of output current. The external compensation, voltage feedforward, and automatically adjustable maximum ramp

amplitude simplify the loop compensation design allowing for a variety of L and C filter components. In shutdown, the supply current is typically 6µA. The output

voltage is dynamically adjustable from 0.5V to 36V.

Additional features include an externally programmable

UVLO through the ON/OFF pin, a programmable soft-

start, cycle-by-cycle current limit, hiccup-mode output

short-circuit protection, and thermal shutdown.

Internal Linear Regulator (REG)

REG is the output terminal of the 8V LDO powered from

IN and provides power to the IC. Connect REG externally to DVREG to provide power for the internal digital

circuitry. Place a 1µF ceramic bypass capacitor, C2,

next to the IC from REG to GND. During normal opera-

tion, REG is intended for powering up only the internal

circuitry and should not be used to supply power to the

external loads.

UVLO/ON/

OFF

Threshold

The MAX15020 provides a fixed 7V UVLO function

which monitors the input voltage (V

IN

). The device is

held off until VINrises above the UVLO threshold.

ON/OFF provides additional turn-on/turn-off control.

Program the ON/OFF threshold by connecting a resistive divider from IN to ON/OFF to GND. The device

turns on when V

ON/OFF

rises above the ON/OFF thresh-

old (1.225V), given that VINhas risen above the UVLO

threshold.

Driving ON/OFF to ground places the IC in shutdown.

When in shutdown the internal power MOSFET turns

off, all internal circuitry shuts down, and the quiescent

supply current reduces to 6µA (typ.). Connect an RC

network from ON/OFF to GND to set a turn-on delay

that can be used to sequence the output voltages of

multiple devices.

V

IN

7.5V TO 40V

C3

0.1µF

C1

560µF

PWM

INPUT

R1

97.5kΩ

R2

4.02kΩ

R3

10kΩ

0Ω

C10

1µF

C9

0.1µF

R5

10Ω

C2

1µF

0.22µF

ON/OFF

DVREG

REG

REFIN

C8

IN

SS

REFOUT

C5

0.1µF

D2

MAX15020

SYNC GND FSEL

BST

PGND

COMP

C4

1µF

L1

D1

C13

330pF

22µH

R6

10kΩ

C11

0.027µF

R9

15.8kΩ

LX

FB

EP

C12

0.1µF

R7

10kΩ

0.1µF

R8

340Ω

V

OUT

C7

C6

560µF

Page 11

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

______________________________________________________________________________________ 11

Soft-Start (SS)

At startup, after VINis applied and the UVLO threshold

is reached, a 15µA (typ) current is sourced into the

capacitor (C

SS

) connected from SS to GND forcing the

VSSvoltage to ramp up slowly. If V

REFIN

is set to a DC

voltage or has risen faster than the CSScharge rate,

then V

SS

will stop rising once it reaches V

REFIN

. If

V

REFIN

rises at a slower rate, VSSwill follow the V

REFIN

voltage rise rate. V

OUT

rises at the same rate as V

SS

since VFBfollows VSS.

Set the soft-start time (tSS) using following equation:

where t

SS

is in seconds and CSSis in Farads.

Reference Input and

Output (REFIN, REFOUT)

The MAX15020 features a reference input for the internal error amplifier. The IC regulates FB to the SS voltage

which is driven by the DC voltage applied to REFIN.

Connect REFIN to REFOUT to use the internal 0.98V reference. Connect REFIN to a variable DC voltage source

to dynamically control the output voltage. Alternatively,

REFIN can also be driven by a duty-cycle control PWM

source through a lowpass RC filter (Figure 2).

Internal Digital Power Supply (DVREG)

DVREG is the supply input for the internal digital power

supply. The power for DVREG is derived from the output of the internal regulator (REG). Connect a 10Ω

resistor from REG to DVREG. Bypass DVREG to GND

with at least a 1µF ceramic capacitor.

Error Amplifier

The output of the internal error amplifier (COMP) is

available for frequency compensation (see the

Compensation Design

section). The inverting input is

FB, the noninverting input is SS, and the output is

COMP. The error amplifier has an 80dB open-loop gain

and a 1.8MHz GBW product. When an external clock is

used, connect FSEL to REG.

Oscillator/Synchronization Input (SYNC)

With SYNC connected to GND, the IC uses the internal

oscillator and switches at a fixed frequency of 300kHz or

500kHz based upon the selection of FSEL. For external

synchronization, drive SYNC with an external clock from

100kHz to 500kHz and connect FSEL to REG. When driven with an external clock, the device synchronizes to

the rising edge of SYNC.

PWM Comparator/Voltage Feed-Forward

An internal ramp generator is compared against the

output of the error amplifier to generate the PWM signal. The maximum amplitude of the ramp (V

RAMP

) automatically adjusts to compensate for input voltage and

oscillator frequency changes. This causes the V

IN

/

V

RAMP

to be a constant 9V/V across the input voltage

range of 7.5V to 40V and the SYNC frequency range of

100kHz to 500kHz. This simplifies loop compensation

design by allowing large input voltage ranges and

large frequency range selection.

Output Short-Circuit

Protection (Hiccup Mode)

The MAX15020 protects against an output short circuit

by utilizing hiccup-mode protection. In hiccup mode, a

series of sequential cycle-by-cycle current-limit events

cause the part to shut down and restart with a soft-start

sequence. This allows the device to operate with a continuous output short circuit.

During normal operation, the switch current is measured

cycle-by-cycle. When the current limit is exceeded, the

internal power MOSFET turns off until the next on-cycle

and the hiccup counter increments. If the counter

counts four consecutive overcurrent limit events, the

device discharges the soft-start capacitor and shuts

down for 512 clock periods before restarting with a softstart sequence. Each time the power MOSFET turns on

and the device does not exceed the current limit, the

counter is reset.

Thermal-Overload Protection

The MAX15020 features an integrated thermal-overload protection. Thermal-overload protection limits the

total power dissipation in the device and protects it in

the event of an extended thermal fault condition. When

the die temperature exceeds +160°C, an internal thermal sensor shuts down the part, turning off the power

MOSFET and allowing the IC to cool. After the temperature falls by 20°C, the part restarts beginning with the

soft-start sequence.

VC

t

=

SS

×

REFIN SS

A

15µ

Page 12

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

12 ______________________________________________________________________________________

Applications Information

Setting the ON/

OFF

Threshold

When the voltage at ON/OFF rises above 1.225V, the

MAX15020 turns on. Connect a resistive divider from IN

to ON/OFF to GND to set the turn-on voltage (see

Figure 2). First select the ON/OFF to the GND resistor

(R2), then calculate the resistor from IN to ON/OFF (R1)

using the following equation:

where V

IN

is the input voltage at which the converter

turns on, V

ON/OFF

= 1.225V and R2 is chosen to be

less than 600kΩ.

If ON/OFF is connected to IN directly, the UVLO feature

monitors the supply voltage at IN and allows operation

to start when VINrises above 7.2V.

Setting the Output Voltage

Connect a resistor-divider from OUT to FB to GND to

set the output voltage (see Figure 2). First calculate the

resistor (R7) from OUT to FB using the guidelines in the

Compensation Design

section. Once R7 is known, cal-

culate R8 using the following equation:

where V

FB

= REFIN and REFIN = 0 to 3.6V.

Setting the Output-Voltage Slew Rate

The output-voltage rising slew rate tracks the VSSslew

rate, given that the control loop is relatively fast compared with the VSSslew rate. The maximum V

SS

upswing slew rate is controlled by the soft-start current

charging the capacitor connected from SS to GND

according to the formula below:

when driving VSSwith a slow-rising voltage source at

REFIN, V

OUT

will slowly rise according to the V

REFIN

slew rate.

The output-voltage falling slew rate is limited to the discharge rate of C

SS

assuming there is enough load current to discharge the output capacitor at this rate. The

C

SS

discharge current is 15µA. If there is no load, then

the output voltage falls at a slower rate based upon

leakage and additional current drain from C

OUT

.

Inductor Selection

Three key inductor parameters must be specified for

operation with the MAX15020: inductance value (L),

peak inductor current (I

PEAK

), and inductor saturation

current (I

SAT

). The minimum required inductance is a

function of operating frequency, input-to-output voltage

differential, and the peak-to-peak inductor current

(∆I

L

). Higher ∆ILallows for a lower inductor value while

a lower ∆I

L

requires a higher inductor value. A lower

inductor value minimizes size and cost and improves

large-signal and transient response, but reduces efficiency due to higher peak currents and higher peak-topeak output voltage ripple for the same output

capacitor. Higher inductance increases efficiency by

reducing the ripple current. Resistive losses due to

extra wire turns can exceed the benefit gained from

lower ripple current levels especially when the inductance is increased without also allowing for larger

inductor dimensions. A good compromise is to choose

∆I

P-P

equal to 40% of the full load current.

Calculate the inductor using the following equation:

VINand V

OUT

are typical values so that efficiency is

optimum for typical conditions. The switching frequency (fSW) is fixed at 300kHz or 500kHz and can vary

between 100kHz and 500kHz when synchronized to an

external clock (see the

Oscillator/Synchronization Input

(SYNC)

section). The peak-to-peak inductor current,

which reflects the peak-to-peak output ripple, is worst

at the maximum input voltage. See the

Output

Capacitor Selection

section to verify that the worst-case

output ripple is acceptable. The inductor saturating

current (I

SAT

) is also important to avoid runaway current during continuous output short circuit. Select an

inductor with an I

SAT

specification higher than the max-

imum peak current limit of 4.5A.

⎣

⎦

RR

12 1=×

⎡

⎢

V

⎢

ON OFF

R

8

R

=

⎡

V

OUT

⎢

V

FB

⎣

V

IN

/

⎤

−

⎥

⎥

7

⎤

1

−

⎥

⎦

VV V

IN OUT OUT

L

=

−()

Vf I

IN SW L

×

××

∆

dV

OUT SS SS

dt

RRRdV

+

78

=

8

RRRI

+

×=

dt

78

8

C

SS

Page 13

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

______________________________________________________________________________________ 13

Input Capacitor Selection

The discontinuous input current of the buck converter

causes large input ripple currents and therefore the

input capacitor must be carefully chosen to keep the

input-voltage ripple within design requirements. The

input-voltage ripple is comprised of ∆V

Q

(caused by the

capacitor discharge) and ∆V

ESR

(caused by the ESR

(equivalent series resistance) of the input capacitor).

The total voltage ripple is the sum of ∆V

Q

and ∆V

ESR

.

Calculate the input capacitance and ESR required for a

specified ripple using the following equations:

where:

I

OUT_MAX

is the maximum output current, D is the duty

cycle, and fSWis the switching frequency.

The MAX15020 includes internal and external UVLO

hysteresis and soft-start to avoid possible unintentional

chattering during turn-on. However, use a bulk capacitor if the input source impedance is high. Use enough

input capacitance at lower input voltages to avoid possible undershoot below the UVLO threshold during

transient loading.

Output Capacitor Selection

The allowable output-voltage ripple and the maximum

deviation of the output voltage during load steps determine the output capacitance and its ESR. The output

ripple is mainly composed of ∆VQ(caused by the

capacitor discharge) and ∆V

ESR

(caused by the voltage drop across the ESR of the output capacitor). The

equations for calculating the peak-to-peak output voltage ripple are:

Normally, a good approximation of the output-voltage

ripple is ∆V

RIPPLE

≈ ∆V

ESR

+ ∆VQ. If using ceramic

capacitors, assume the contribution to the output-voltage ripple from ESR and the capacitor discharge to be

equal to 20% and 80%, respectively. ∆I

L

is the peak-to-

peak inductor current (see the

Input Capacitor

Selection

section) and fSWis the converter’s switching

frequency.

The allowable deviation of the output voltage during

fast load transients also determines the output capacitance, its ESR, and its equivalent series inductance

(ESL). The output capacitor supplies the load current

during a load step until the controller responds with a

greater duty cycle. The response time (t

RESPONSE

)

depends on the closed-loop bandwidth of the converter

(see the

Compensation Design

section). The resistive

drop across the output capacitor’s ESR, the drop

across the capacitor’s ESL (∆V

ESL

), and the capacitor

discharge cause a voltage droop during the load step.

Use a combination of low-ESR tantalum/aluminum electrolytic and ceramic capacitors for better transient load

and voltage ripple performance. Surface-mount capacitors and capacitors in parallel help reduce the ESL.

Keep the maximum output-voltage deviations below the

tolerable limits of the electronics powered. Use the following equations to calculate the required ESR, ESL,

and capacitance value during a load step:

where I

STEP

is the load step, t

STEP

is the rise time of the

load step, and t

RESPONSE

is the response time of the

controller.

∆

V

ESR

=

⎛

I

⎜

OUT MAX

⎝

IDD

OUT MAX

C

=

IN

ESR

_

_

∆

Vf

×

QSW

∆

+

2

()

1

×

I

⎞

L

⎟

⎠

−

−()

VV V

∆I

D

IN OUT OUT

=

L

=

Vf L

IN SW

V

OUT

V

IN

×

××

∆

I

∆

V

=

Q

16

=×

∆∆

V ESR I

ESR L

L

××

Cf

OUT SW

V

ESR

=

I

STEP

It

STEP RESPONSE

=

OUT

∆

Vt

ESL STEP

=

×

∆

V

Q

×

I

STEP

ESR

C

ESL

Page 14

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

14 ______________________________________________________________________________________

Compensation Design

The MAX15020 uses a voltage-mode control scheme

that regulates the output voltage by comparing the

error-amplifier output (COMP) with an internal ramp to

produce the required duty cycle. The output lowpass

LC filter creates a double pole at the resonant frequency, which has a gain drop of -40dB/decade. The error

amplifier must compensate for this gain drop and

phase shift to achieve a stable closed-loop system.

The basic regulator loop consists of a power modulator,

an output feedback divider, and a voltage error amplifier. The power modulator has a DC gain set by V

IN

/

V

RAMP

, with a double pole and a single zero set by the

output inductance (L), the output capacitance (C

OUT

)

(C6 in the Figure 2) and its ESR. The power modulator

incorporates a voltage feed-forward feature, which automatically adjusts for variations in the input voltage

resulting in a DC gain of 9. The following equations

define the power modulator:

The switching frequency is internally set at 300kHz or

500kHz, or can vary from 100kHz to 500kHz when driven

with an external SYNC signal. The crossover frequency

(fC), which is the frequency when the closed-loop gain is

equal to unity, should be set as f

SW

/ 2π or lower.

The error amplifier must provide a gain and phase

bump to compensate for the rapid gain and phase loss

from the LC double pole. This is accomplished by utilizing a Type 3 compensator that introduces two zeros

and three poles into the control loop. The error amplifier

has a low-frequency pole (fP1) near the origin.

In reference to Figures 3 and 4, the two zeros are at:

And the higher frequency poles are at:

Compensation when fC< f

ESR

Figure 3 shows the error-amplifier feedback as well as

its gain response for circuits that use low-ESR output

capacitors (ceramic). In this case f

ZESR

occurs after fC.

f

Z1

is set to 0.8 x f

LC(MOD)

and fZ2is set to fLCto compensate for the gain and phase loss due to the double

pole. Choose the inductor (L) and output capacitor

(C

OUT

) as described in the

Inductor Selection

and

Output Capacitor Selection

sections.

Choose a value for the feedback resistor R6 in Figure 3

(values between 1kΩ and 10kΩ are adequate).

C12 is then calculated as:

fCoccurs between fZ2and fP2. The error-amplifier gain

(GEA) at fCis due primarily to C11 and R9.

Therefore, GEA(fC) = 2π x fCx C11 x R9 and the modulator gain at fCis:

Since G

EA(fC)

x G

MOD(fC)

= 1, C11 is calculated by:

fP2is set at 1/2 the switching frequency (fSW). R6 is

then calculated by:

Since R7 >> R6, R7 + R6 can be approximated as R7.

R7 is then calculated as:

fP3is set at 5 x fC. Therefore, C13 is calculated as:

V

IN

G

MOD DC

=

f

LC

f

ESR

==

()

V

RAMP

1

×

2

LC

=

2ππ

1

××

C ESR

OUT

f

=

ZZ12

=

f

PP23

2611

1

RC

2912

××

1

××

π

RC

and f

and f

=

9

=

26711

1

RR C

×+×ππ

()

1

12 13

CC

29

π

⎛

××

R

⎜

⎝

12 13

CC

C

12

=

208 9

×××π .

1

fR

LC

G

MOD DC

()

LC f

OUT C

2

MOD DC

()

2

G

MOD fC

()

C

11

2

()=×× ×2

π

fLC

×× ××π

C OUT

=

RG

9

R

6

=

21105

1

Cf

×××π .

SW

R

7

=

1

fC

211

××π

LC

C

C

13

=

2129 1

×

⎞

⎟

⎠

+

12

×××

CRf

P

3

−π

Page 15

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

______________________________________________________________________________________ 15

Compensation when fC> f

ZESR

For larger ESR capacitors such as tantalum and aluminum electrolytics, f

ZESR

can occur before fC. If f

ZESR

< fC, then fCoccurs between fP2and fP3. fZ1and f

Z2

remain the same as before, however, fP2is now set

equal to f

ZESR

. The output capacitor’s ESR zero frequency is higher than fLCbut lower than the closedloop crossover frequency. The equations that define

the error amplifier’s poles and zeros (fZ1, fZ2, fP1, fP2,

and fP3) are the same as before. However, fP2is now

lower than the closed-loop crossover frequency. Figure

4 shows the error-amplifier feedback as well as its gain

response for circuits that use higher-ESR output capacitors (tantalum or aluminum electrolytic).

Pick a value for the feedback resistor R9 in Figure 4

(values between 1kΩ and 10kΩ are adequate).

C12 is then calculated as:

The error-amplifier gain between fP2and fP3is approximately equal to R9 / R6 (given that R6 << R7). R6 can

then be calculated as:

C11 is then calculated as:

Since R7 >> R6, R7 + R6 can be approximated as R7.

R7 is then calculated as:

f

P3

is set at 5 x fC. Therefore, C13 is calculated as:

Based on the calculations above, the following compensation values are recommended when the switching frequency of DC-DC converter ranges from 100kHz

to 500kHz. (Note: The compensation parameters in

Figure 2 are strongly recommended if the switching

frequency is from 300kHz to 500kHz.)

Figure 3. Error-Amplifier Compensation Circuit (Closed-Loop

and Error-Amplifier Gain Plot) for Ceramic Capacitors

Figure 4. Error-Amplifier Compensation Circuit (Closed-Loop

and Error-Amplifier Gain Plot) for Higher ESR Output Capacitors

C13

R9

C12

FB

ERROR

AMPLIFIER

SS

f

f

P3

P2

COMP

ERRORAMPLIFIER

GAIN

FREQUENCY (Hz)

GAIN

(dB)

C11

R6

V

OUT

R7

R8

CLOSED-LOOP

GAIN

f

Z1

f

Z2fC

C13

R9

C12

FB

ERROR

AMPLIFIER

SS

f

C

f

P2

f

P3

COMP

ERRORAMPLIFIER

GAIN

FREQUENCY (Hz)

GAIN

(dB)

C11

R6

V

OUT

R7

R8

CLOSED-LOOP

GAIN

f

f

Z1

Z2

C

12

=

208 9

×××π .

1

fR

LC

2

LC

2

f

C

×

R

R

6

=

C

116=

Rf

910

××

C ESR

OUT

R

7

=

C

13

=

2129 1

1

fC

211

××π

LC

C

12

×××

CRf

−π

P

3

Page 16

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

16 ______________________________________________________________________________________

Power Dissipation

The MAX15020 is available in a thermally enhanced

package and can dissipate up to 2.7W at T

A

= +70°C.

When the die temperature reaches +160°C, the part

shuts down and is allowed to cool. After the parts cool

by 20°C, the device restarts with a soft-start.

The power dissipated in the device is the sum of the

power dissipated from supply current (PQ), transition

losses due to switching the internal power MOSFET

(P

SW

), and the power dissipated due to the RMS cur-

rent through the internal power MOSFET (P

MOSFET

).

The total power dissipated in the package must be limited such that the junction temperature does not

exceed its absolute maximum rating of +150°C at maximum ambient temperature. Calculate the power lost in

the MAX15020 using the following equations:

The power loss through the switch:

RONis the on-resistance of the internal power MOSFET

(see the

Electrical Characteristics

table).

The power loss due to switching the internal MOSFET:

where tRand tFare the rise and fall times of the internal

power MOSFET measured at LX.

The power loss due to the switching supply current

(I

SW

):

PQ= VINx I

SW

The total power dissipated in the device is:

P

TOTAL

= P

MOSFET

+ PSW+ P

Q

PCB Layout and Routing

Use the following guidelines to layout the switching

voltage regulator:

1) Place the IN and DVREG bypass capacitors close

to the MAX15020 PGND pin. Place the REG

bypass capacitor close to the GND pin.

2) Minimize the area and length of the high-current

loops from the input capacitor, switching MOSFET,

inductor, and output capacitor back to the input

capacitor negative terminal.

3) Keep short the current loop formed by the switching MOSFET, Schottky diode, and input capacitor.

4) Keep GND and PGND isolated and connect them

at one single point close to the negative terminal

of the input filter capacitor.

5) Place the bank of output capacitors close to the

load.

6) Distribute the power components evenly across

the board for proper heat dissipation.

7) Provide enough copper area at and around the

MAX15020 and the inductor to aid in thermal dissipation.

8) Use 2oz copper to keep the trace inductance and

resistance to a minimum. Thin copper PCBs can

compromise efficiency since high currents are

involved in the application. Also, thicker copper

conducts heat more effectively, thereby reducing

thermal impedance.

9) Place enough vias in the pad for the EP of the

MAX15020 so that the heat generated inside can

be effectively dissipated by PCB copper.

PI R

MOSFET RMS MOSFET ON

IIIII

RMS MOSFET

_

P

SW

=×

_

2

=+×

[]

II

PK OUT

II

PK OUT

VI tt f

IN OUT R F SW

=

()

PK

+

=+

+

=

−

××××()

2

PK PK PK

+

∆

I

L

2

∆

I

L

−

2

4

+

−−

D

×

3

Page 17

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

______________________________________________________________________________________ 17

Pin Configuration

Chip Information

PROCESS: BiCMOS

TOP VIEW

REG

GND

LX

LX

LX

15 14 12 11

IN

16

IN

17

18

19

20

MAX15020

+

12IN45

FB

COMP

THIN QFN

(5mm x 5mm)

13

3

ON/OFF

BST

REFOUT

N.C.

SS

PGND

10

DVREG

9

8

SYNC

FSEL

7

REFIN

6

Page 18

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

18 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

PACKAGE OUTLINE,

16, 20, 28, 32, 40L THIN QFN, 5x5x0.8mm

21-0140

QFN THIN.EPS

1

K

2

Page 19

MAX15020

2A, 40V Step-Down DC-DC Converter with

Dynamic Output-Voltage Programming

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

19

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

PACKAGE OUTLINE,

16, 20, 28, 32, 40L THIN QFN, 5x5x0.8mm

21-0140

2

K

2

Loading...

Loading...