Page 1

General Description

The MAX15008 features a 300mA LDO regulator, a voltage tracker, and an overvoltage protection (OVP) controller to protect downstream circuits from high-voltage

load dump. The MAX15010 includes only the 300mA

LDO voltage regulator and voltage tracker. Both devices

operate over a wide 5V to 40V supply voltage range and

are able to withstand load-dump transients up to 45V. The

MAX15008/MAX15010 feature short-circuit and thermalshutdown protection. These devices offer highly integrated power-management solutions for automotive

applications such as instrument clusters, climate control,

and a variety of automotive power-supply circuits.

The 300mA LDO regulator consumes less than 67µA quiescent current at light loads and is well suited to power

always-on circuits during “key off” conditions. The LDO

features independent enable and hold inputs as well as a

microprocessor (µP) reset output with an adjustable reset

timeout period.

The voltage tracker accurately (±3mV) tracks a voltage

applied to its input from either the LDO output or an external source. It can supply up to 50mA of current to a

remote sensor, allowing for precise ratiometric tracking in

automotive applications. A separate enable input turns

the tracker on or off, reducing supply current when the

tracker is unused. The voltage tracker also features protection against battery reversal, an output short circuit to

the battery, or an output-voltage excursion below ground

potential to as much as -5V.

The MAX15008 OVP controller operates with an external

enhancement mode n-channel MOSFET. While the monitored voltage remains below the adjustable threshold, the

MOSFET stays on. When the monitored voltage exceeds

the OVP threshold, the OVP controller quickly turns off the

external MOSFET. The OVP controller is configurable as a

load-disconnect switch or a voltage limiter.

The MAX15008/MAX15010 are available in a thermally

enhanced, 32-pin (5mm x 5mm) TQFN package and are

fully specified over the -40°C to +125°C automotive operating temperature range.

Applications

Instrument Clusters

Climate Control

AM/FM Radio Power Supply

Multimedia Power Supply

Telematics Power Supply

Features

o 300mA LDO Regulator, Voltage Tracker, and OVP

Controller (MAX15008)

o 300mA LDO Regulator and Voltage Tracker

(MAX15010)

o 50mA Voltage Tracker with ±3mV Tracking Accuracy

o 5V to 40V Wide Operating Supply Voltage Range

o 45V Load Dump Protection

o 67µA Quiescent Current LDO Regulator

o OVP Controller Disconnects or Limits Output from

Battery Overvoltage Conditions (MAX15008)

o LDO Regulator with Enable, Hold, and Reset

Features

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

________________________________________________________________

Maxim Integrated Products

1

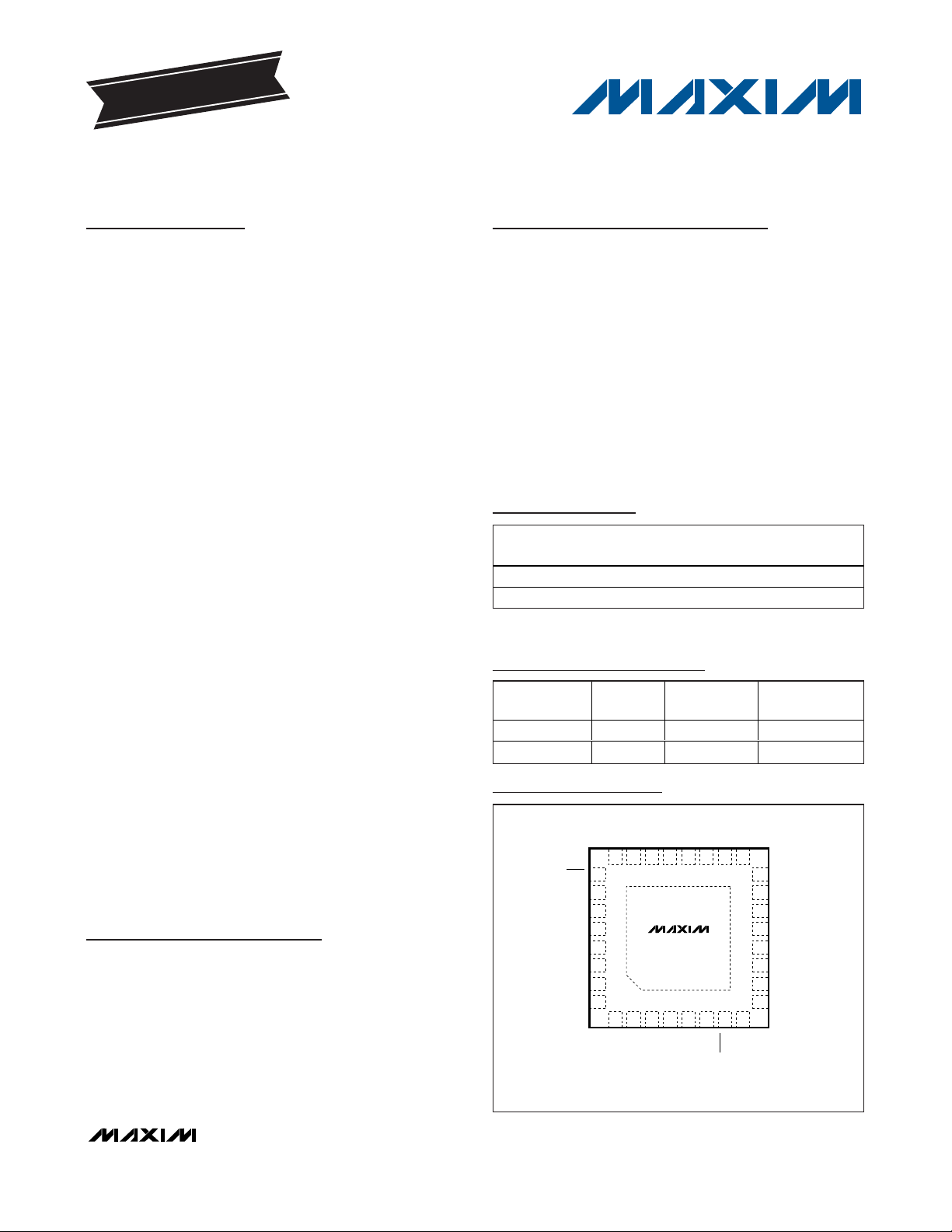

Pin Configurations

19-0996; Rev 1; 2/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Typical Operating Circuits appear at end of data sheet.

Pin Configurations continued at end of data sheet.

Ordering Information

+

Denotes a lead-free package.

*

EP = Exposed pad.

PART LDO

TRACKER

OVP

CONTROLLER

MAX15008 √√ √

MAX15010 √√ —

Selector Guide

EVALUATION KIT

AVAILABLE

PART

TEMP RANGE

PINPACKAGE

PKG

CODE

MAX15008ATJ+

T3255-4

MAX15010ATJ+

T3255-4

-40°C to +125°C 32 TQFN-EP*

-40°C to +125°C 32 TQFN-EP*

TOP VIEW

N.C.

OUT_LDO

IN

OUT_LDO

21

MAX15008

4567

3

ADJ

SGND

OUT_TRK

TQFN

(5mm x 5mm)

IN

*EP

PGND

EN_PROT

EN_TRK

17

8

N.C.

RESET

16

15

14

13

12

11

10

9

EN_LDO

FB_LDO

REF

SOURCE

GATE

N.C.

FB_PROT

CT

HOLD

N.C.

N.C.

N.C.

FB_TRK

TRACK

N.C.

N.C.

*EP = EXPOSED PAD

N.C.

2324 22 20 19 18

25

26

27

28

29

30

31

+

32

12

N.C.

N.C.

Page 2

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

2 _______________________________________________________________________________________

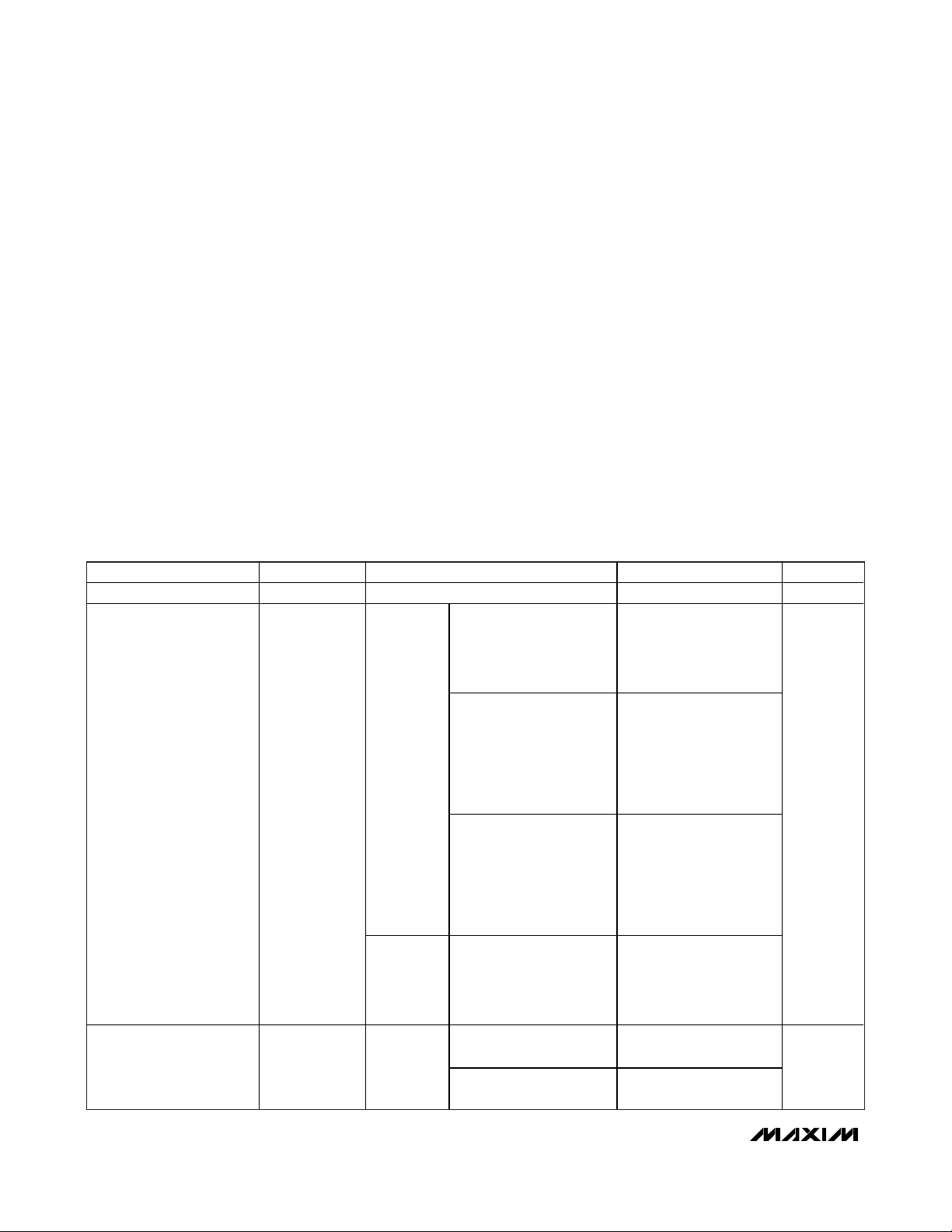

ABSOLUTE MAXIMUM RATINGS

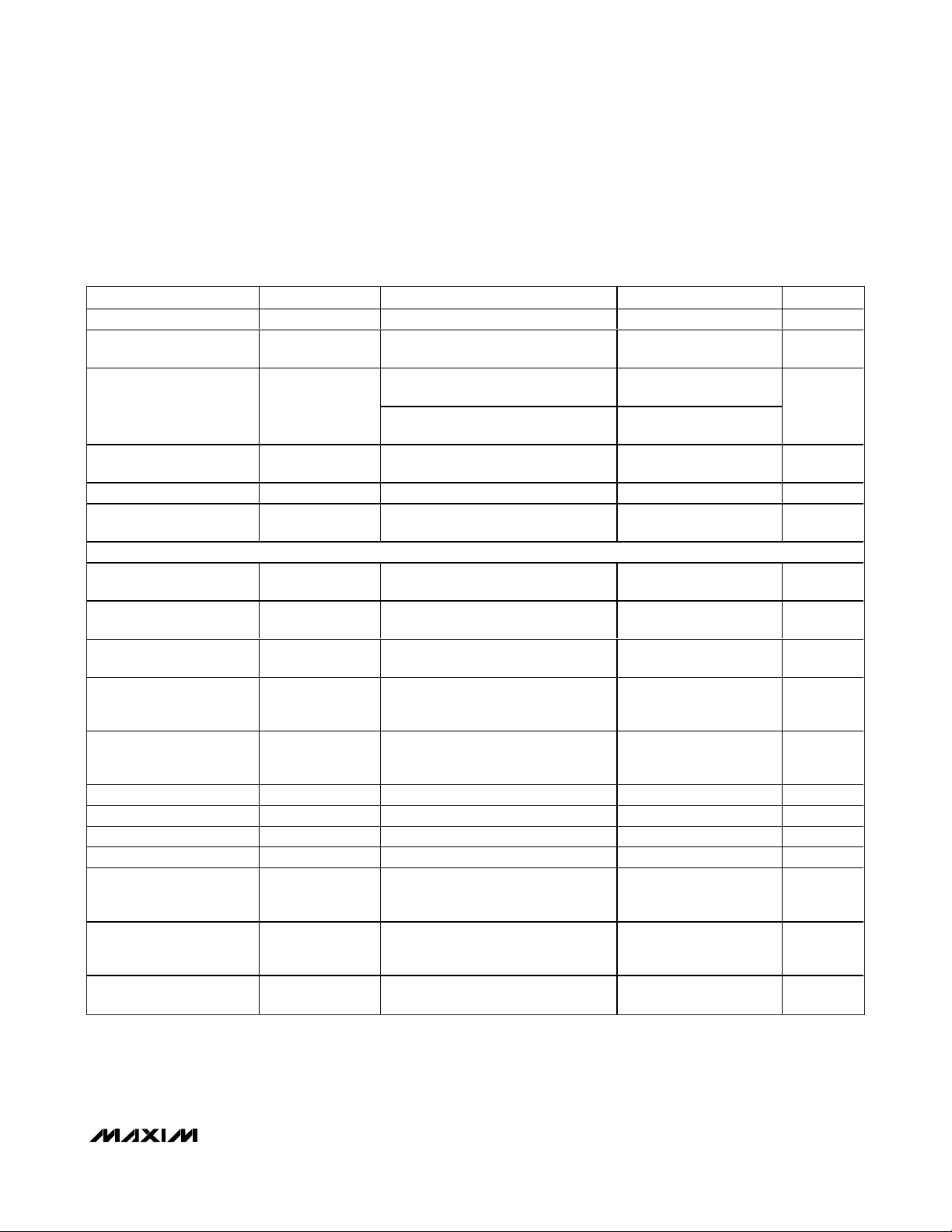

ELECTRICAL CHARACTERISTICS

(VIN= V

TRACK

= +14V, V

SGND

= V

PGND

= 0V, C

GATE

= 6000pF, CIN= 10µF (ESR ≤ 1.5Ω), C

OUT_LDO

= 22µF (ceramic), C

TRACK

=

3.3µF (ceramic) (ESR ≤ 1.5Ω), C

OUT_TRK

= 10µF (ESR ≤ 1.5Ω), C

REF

= 1000pF, V

OUT_LDO

= 5V, TA= TJ= -40°C to +125°C, unless

otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(All pins referenced to SGND, unless otherwise noted.)

IN, GATE.................................................................-0.3V to +45V

TRACK.....................................................................-20V to +45V

EN_LDO, EN_PROT, EN_TRK .....................-0.3V to (V

IN

+ 0.3V)

SOURCE ......................................................-0.3V to (V

IN

+ 0.3V)

TRACK to OUT_TRK................................................-40V to +40V

OUT_TRK, FB_TRK, ADJ...........................................-5V to +45V

OUT_LDO, FB_LDO, FB_PROT, RESET.................-0.3V to +12V

GATE to SOURCE ..................................................-0.3V to +12V

HOLD................................................-0.3V to (V

OUT_LDO

+ 0.3V)

REF to SGND............................................................-0.3V to +6V

CT to SGND............................................................-0.3V to +12V

SGND to PGND .....................................................-0.3V to +0.3V

IN, OUT_LDO Current .......................................................700mA

TRACK, OUT_TRK Current ...............................................350mA

Current Sink/Source (all remaining pins) ............................50mA

Continuous Power Dissipation (T

A

= +70°C)

32-Pin TQFN (derate 34.5mW/°C above +70°C).............2.7W*

Thermal Resistance

θ

JA

..............................................................................29.0°C/W

θ

JC

................................................................................1.7°C/W

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

*

As per JEDEC51 Standard, Multilayer Board (PCB).

Supply Voltage Range V

Supply Current I

Shutdown Supply Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SHDN

IN

MAX15008

IN

MAX15010

E N _LD O =

E N _P ROT =

EN_TRK = 0V,

measured

from SGND

EN_LDO = IN, EN_TRK =

EN_PROT = 0V, I

= 0µA, LDO on, tracker

off, protector off,

measured from SGND

EN_LDO = EN_TRK = IN,

EN_PROT = 0V, LDO on,

I

OUT_LDO

on, I

protector off, V

V

OUT_TRK

measured from SGND

EN_LDO = EN_TRK =

EN_PROT = IN, LDO on,

I

OUT_LDO

on, I

protector on, V

V

OUT_TRK; VADJ

measured from SGND

EN_LDO = EN_TRK = IN,

LDO on, I

100µA, tracker on,

I

OUT_TRK

measured from SGND

TA = -40°C to +85°C 16 30

T

A

= 100µA, tracker

OUT_TRK

, V

= 100µA, tracker

OUT_TRK

OUT_LDO

= 0µA,

= -40°C to +125°C 40

OUT_LDO

= 0µA,

FB_TRK

= V

ADJ

= 0µA,

FB_TRK

= V

=

REF,

=

REF,

=

540V

67 85

120 180

190 280

115 160

µA

µA

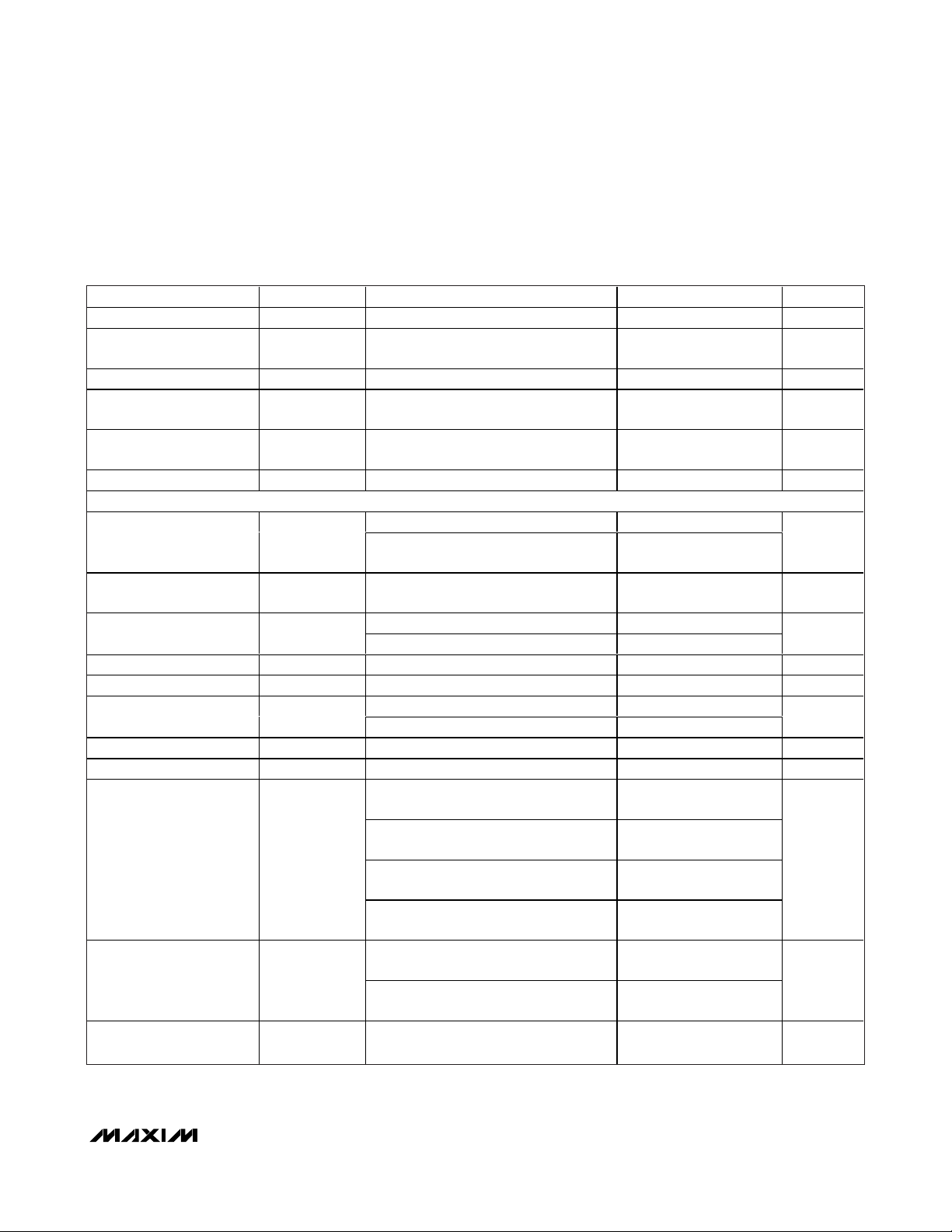

Page 3

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

TRACK

= +14V, V

SGND

= V

PGND

= 0V, C

GATE

= 6000pF, CIN= 10µF (ESR ≤ 1.5Ω), C

OUT_LDO

= 22µF (ceramic), C

TRACK

=

3.3µF (ceramic) (ESR ≤ 1.5Ω), C

OUT_TRK

= 10µF (ESR ≤ 1.5Ω), C

REF

= 1000pF, V

OUT_LDO

= 5V, TA= TJ= -40°C to +125°C, unless

otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

Dual Mode is a trademark of Maxim Integrated Products, Inc.

IN Undervoltage Lockout V

IN Undervoltage Lockout

Hysteresis

Internal Voltage Reference REF I

Internal Voltage Reference

Maximum Current

Thermal-Shutdown

Temperature

Thermal Hysteresis T

LDO

Output Voltage V

FB_LDO Set-Point Voltage V

Dual Mode™ FB_LDO

Threshold

FB_LDO Input Current I

LDO Output Voltage Range V

LDO Dropout Voltage

(Note 3)

LDO Output Current I

LDO Output Current Limit I

OUT_LDO Line Regulation

OUT_LDO Load Regulation

OUT_LDO Power-Supply

Rejection Ratio

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

UVLO_HYST

T

OUT_LDO

UVLO

I

REF

SHDN

HYST

VIN falling, GATE disabled 4.10 4.27 4.45 V

= 0µA 1.21 1.235 1.26 V

REF

ΔV

REF

I

= 1mA, FB_LDO = SGND 4.92 5 5.09

LOAD

I

LOAD

= ±200mV -6 +6 µA

= 300mA, VIN = 8V,

FB_LDO = SGND

FB_LDO

V

FB_LDO_TH

FB_LDO

LDO_ADJ

V

DO

OUT_LDO

LIM_LDO

ΔV

OUT

ΔV

IN

With respect to SGND, I

V

OU T _L D O

= 5V ( ad j ustab l e outp ut op ti on)

FB_LDO rising 0.125

FB_LDO falling 0.064

V

= 1V -100 +100 nA

FB_LDO

Adjustable output option (Note 2) 1.8 11.0 V

I

= 300mA 775 1500

LOAD

I

= 200mA 520 1000

LOAD

(Note 4) 300 mA

OUT_LDO = GND, VIN = 6V 330 500 700 mA

6V ≤ VIN ≤ 40V, I

V

6V ≤ VIN ≤ 40V, I

V

/

6V ≤ VIN ≤ 40V, I

OUT_LDO

OUT_LDO

LOAD

= 5V

LOAD

= 3.3V

LOAD

FB_LDO = SGND, V

6V ≤ VIN ≤ 40V, I

V

OUT_LDO

LOAD

= 3.3V

1mA to 300mA, VIN = 8V,

ΔV

ΔI

PSRR

OUT

OUT

FB_LDO = SGND, V

/

1mA to 300mA, VIN = 6.3V,

V

OUT_LDO

I

LOAD

C

OUT_LDO

= 3.3V

= 10mA, f = 100Hz, 500mV

= 22µF, V

= 1mA,

LOAD

= 1mA,

= 1mA,

= 20mA,

OUT_LDO

= 5V

= 20mA,

OUT_LDO

OUT_LDO

= 5V

= 5V

,

P-P

260 mV

+160 °C

20 °C

4.80 5 5.11

V

1.21 1.235 1.26 V

V

mV

0.03 0.2

0.03 0.1

mV/V

0.27 1

0.27 0.5

0.054 0.15

mV/mA

0.038 0.1

60 dB

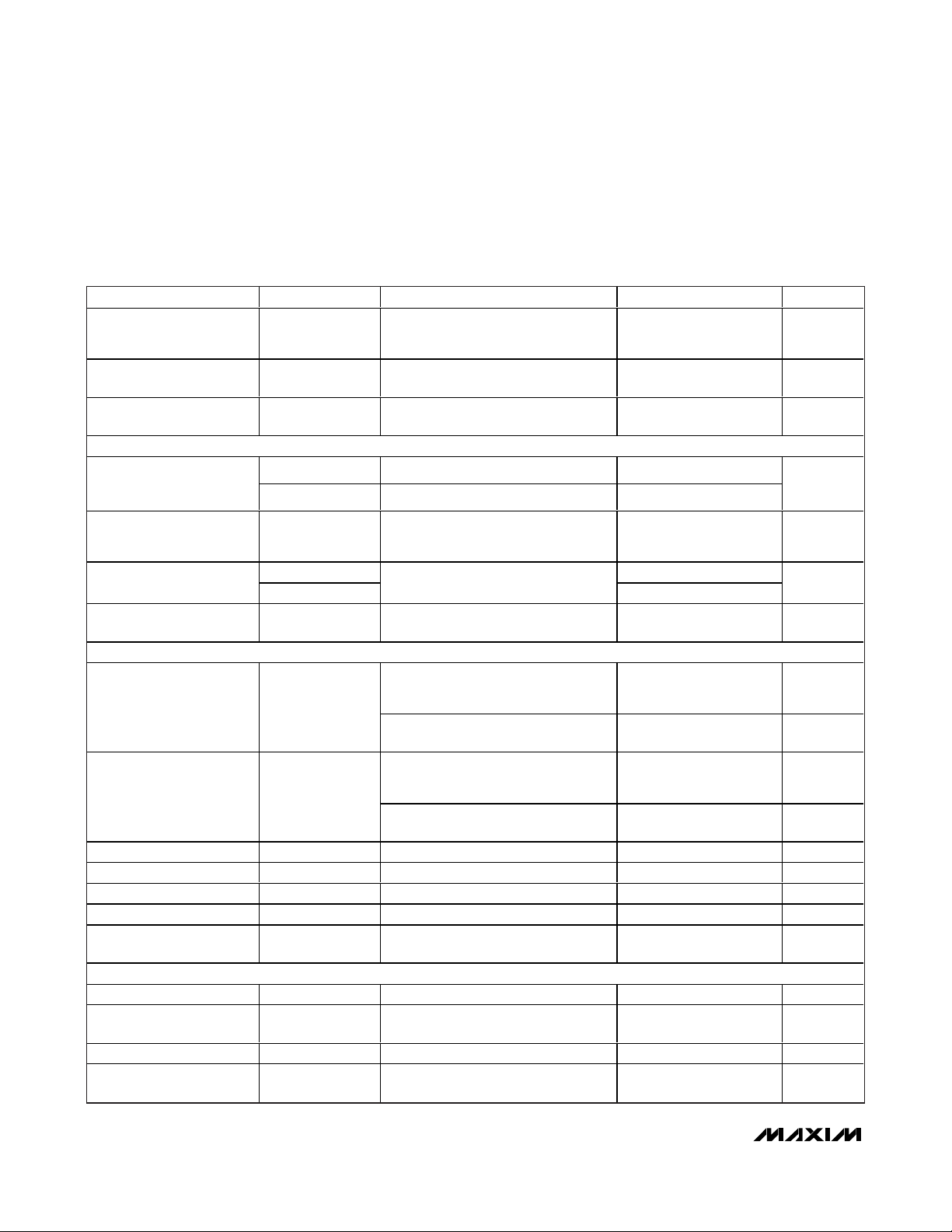

Page 4

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

TRACK

= +14V, V

SGND

= V

PGND

= 0V, C

GATE

= 6000pF, CIN= 10µF (ESR ≤ 1.5Ω), C

OUT_LDO

= 22µF (ceramic), C

TRACK

=

3.3µF (ceramic) (ESR ≤ 1.5Ω), C

OUT_TRK

= 10µF (ESR ≤ 1.5Ω), C

REF

= 1000pF, V

OUT_LDO

= 5V, TA= TJ= -40°C to +125°C, unless

otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

OUT_LDO Startup Delay

Time

OUT_LDO Overvoltage

Protection Threshold

OUT_LDO Overvoltage

Protection Sink Current

ENABLE/HOLD INPUTS

EN_LDO, EN_PROT,

EN_TRK Input Threshold

Voltage

EN_LDO, EN_PROT,

EN_TRK Input Pulldown

Current

HOLD Input Threshold

Voltage

HOLD Input Pullup I

RESET

RESET Voltage Threshold

High

RESET Voltage Threshold

Low

V

OUT_LDO

CT Ramp Current I

CT Ramp Threshold V

RESET Output-Voltage Low V

RESET Open-Drain

Leakage Current

LOAD DUMP PROTECTOR (MAX15008 only)

FB_P ROT Thr eshol d V ol tag eV

FB_PROT Threshold

Hysteresis

FB_PROT Input Current I

Startup Response Time t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

t

STARTUP_DELAY

I

OUT_LDO

to 10% of V

= 0mA, from EN_LDO rising

OUT_LDO

(nominal),

30 µs

FB_LDO = SGND

V

OV_TH

I

OV

V

IH

V

IL

I

EN_PD

V

IH

V

IL

HOLD_PU

1mA sink from OUT_LDO 105 110 %V

V

OUT_LDO

= V

(nominal) x 1.15 8 19 mA

OUT

2

0.7

EN_ is internally pulled low to SGND 1 µA

1.4

0.4

HOLD is internally pulled high to

OUT_LDO

0.6 µA

RESET goes HIGH when rising

90.0 92.5 95.0 %V

90.0 92.5 95.0 %V

V

RESET_H

V

OUT_LDO

crosses this threshold,

FB_LDO = SGND

RESET goes HIGH when rising

V

OUT_LDO

crosses this threshold

RESET goes LOW when falling

88 90 92 %V

88 90 92 %V

4%V

20 µs

to RESET Delay t

V

R ES ET _L

RESET_FALL

CT

CT_TH

OL

I

LEAK_RESET

TH_PROT

V

HYST

FB_PROT

START

V

OUT_LDO

crosses this threshold,

FB_LDO = SGND

RESET goes LOW when falling

V

OUT_LDO

V

OUT_LDO

crosses this threshold

falling, 0.1V/µs 19 µs

VCT = 0V 1.50 2.0 2.35 µA

VCT rising 1.19 1.235 1.27 V

I

= 1mA, output asserted 0.1 V

SINK

Output not asserted 150 nA

FB_PROT rising 1.20 1.235 1.27 V

V

FB_PROT

= 1.4V -100 +100 nA

EN_PROT rising, EN_LDO = IN, to

= 0.5V

V

GATE

OUT_LDO

V

V

OUT_LDO

FB_LDO

OUT_LDO

FB_LDO

TH_PROT

Page 5

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

TRACK

= +14V, V

SGND

= V

PGND

= 0V, C

GATE

= 6000pF, CIN= 10µF (ESR ≤ 1.5Ω), C

OUT_LDO

= 22µF (ceramic), C

TRACK

=

3.3µF (ceramic) (ESR ≤ 1.5Ω), C

OUT_TRK

= 10µF (ESR ≤ 1.5Ω), C

REF

= 1000pF, V

OUT_LDO

= 5V, TA= TJ= -40°C to +125°C, unless

otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

Note 1: Limits to -40°C are guaranteed by design.

Note 2: 1.8V is the minimum limit for proper HOLD functionality.

Note 3: Dropout is defined as V

IN

- V

OUT_LDO

when V

OUT_LDO

is 98% of the value of V

OUT_LDO

for VIN= V

OUT_LDO

+ 1.5V.

Note 4: Maximum output current may be limited by the power dissipation of the package.

GATE Rise Time t

FB_PROT to GATE Turn-Off

Propagation Delay

GATE Output High Voltage V

GATE Output Pulldown

Current

GATE C har g e- P um p C ur r ent I

GATE-to-SOURCE Clamp

Voltage

TRACKER

Tracker Supply Voltage

Range

ADJ, FB_TRK Input Voltage V

Tracker Output CommonMode Range

Tracking Accuracy Over

Line

Tracking Accuracy Over

Load

ADJ, FB_TRK Input Current I

Dropout Voltage V

Tracker Output Current I

Output Current Limit I

Current Consumption I

OUT_TRK Power-Supply

Rejection Ratio

OUT_TRK Reverse Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

GATE

t

OV

GATE

I

GATEPD

GATE

V

CLMP

V

TRACK

ADJ, VFB_TRK

V

CM

ΔV

Q_LINE

ΔV

Q_LOAD

FB_TRK, IADJ

DO

OUT_TRK

OUT_TRK_LIM

Q

GATE rising to +8V, V

FB_P ROT step fr om V

to V

TH_PROT

V

SOURCE

R

GATE

V

SOURCE

R

GATE

V

GATE

+ 250mV

= VIN = 5.5V,

to IN = 1MΩ

= VIN; VIN ≥ 14V,

to IN = 1MΩ

= 5V, V

EN_PROT

GATE = SGND 45 µA

I

OUT_LDO

V

OUT_TRK

ΔV

V

TRACK

50mA, V

ΔV

V

FB_TRK

V

OUT_TRK

V

ADJ

V

OUT_TRK

IQ = I

50mA, V

= 20mA, V

= 5V, V

Q

= V

FB_TRK

- V

= 6V, 0.1mA ≤ I

= V

ADJ

FB_TRK

= V

ADJ

- V

Q

= V

= 5V, I

= V

OUT_TRK

= 0V 85 100 115 mA

- I

TRACK

ADJ

OUT_TRK

= V

= EN_PROT = SGND, EN_TRK = IN

PSRR

OUT_TRK_REVERSE

I

OUT_LDO

500mV

V

ADJ

V

TRACK

40V, V

= 10mA, f = 100Hz,

, V

OUT_TRK

P-P

= 5V

= 14V, V

= 5V

ADJ

SOURCE

T H _ P R OT

= 0V 1 ms

- 250m V

IN +

3.2

IN +

7.0

0.6 µs

IN +

3.5

IN +

8.1

IN +

3.8

IN +

9.5

= 0V 63 100 mA

12 16 18 V

540V

TRACK

- 0.5

TRACK

- 0.5

FB_TRK

TRACK

ADJ

OUT_TRK

ADJ

=

= 6V to 28V,

OUT_TRK

≤

= 5V,

1.1

1.1

-3 +3 mV

-3 +3 mV

= 5V 0.03 0.2 µA

OUT_TRK

= 50mA 0.28 0.5 V

= 5V 50 mA

FB_TRK

= V

OUT_TRK

, I

OUT_TRK

= 5V, EN_LDO

FB_TRK

= V

=

,

FB_TRK

2.7 6 mA

60 dB

=

10 µA

V

V

V

Page 6

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

6 _______________________________________________________________________________________

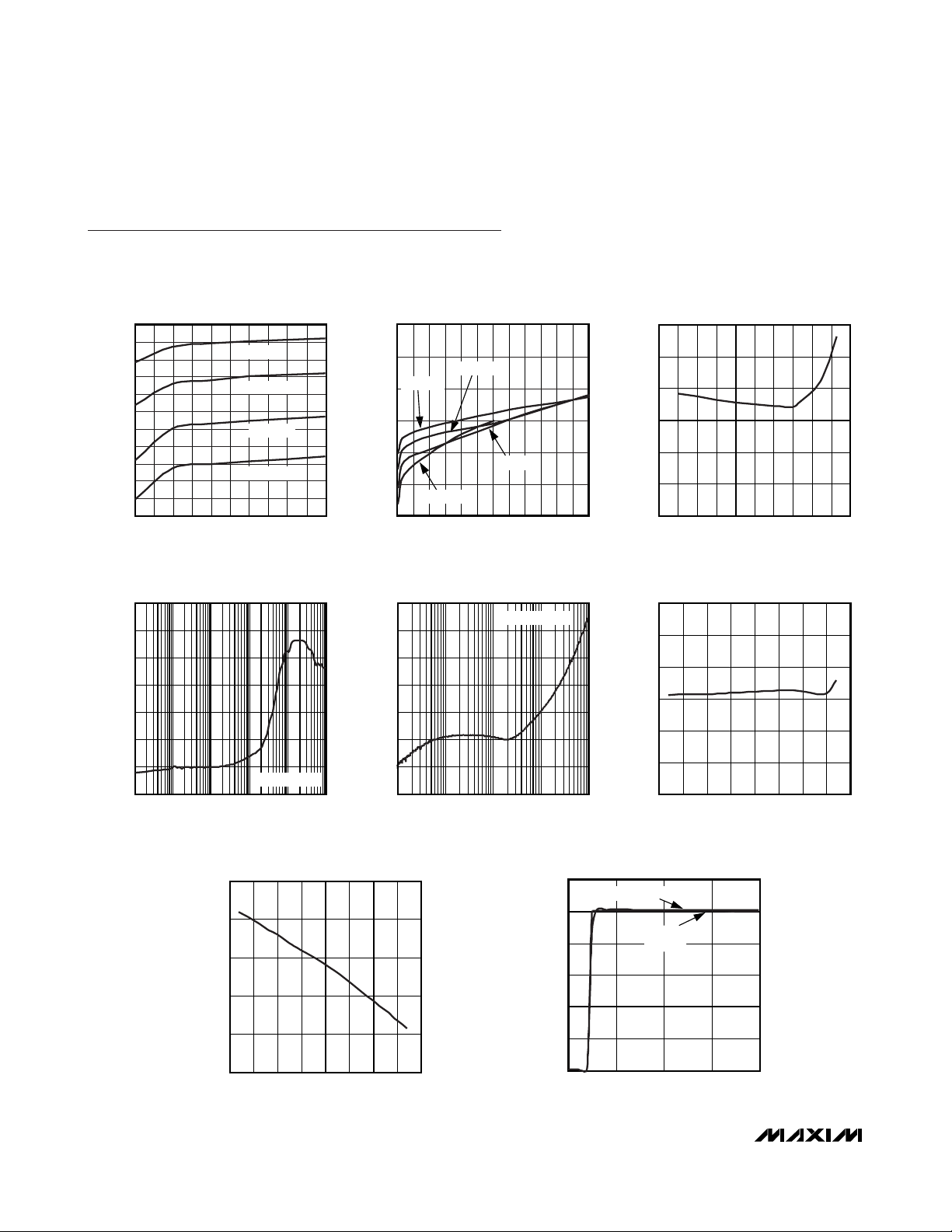

Typical Operating Characteristics

(VIN= V

EN_

= +14V, CIN= 10µF, C

OUT_LDO

= 22µF, C

TRACK

= C

OUT_TRK

= 10µF, V

OUT_LDO

= 5V, FB_LDO = SGND, TA= +25°C,

unless otherwise specified.)

LDO GROUND CURRENT

vs. LOAD CURRENT

MAX15008 toc01

LOAD CURRENT (mA)

0 0.3 0.6 0.90.1 0.4 0.70.2 0.5 0.8 1.0

74

70

72

68

66

64

62

60

58

56

54

52

GROUND CURRENT (μA)

TA = -40°C

TA = +25°C

TA = +85°C

TA = +125°C

LDO GROUND CURRENT

vs. LOAD CURRENT

MAX15008 toc02

LOAD CURRENT (mA)

0 75 150 22525 100 17550 125 200 250 275 300

100

90

110

80

70

60

50

GROUND CURRENT (μA)

TA = +25°C

TA = -40°C

TA = +85°C

TA = +125°C

SHUTDOWN SUPPLY CURRENT

vs. TEMPERATURE

MAX15008 toc03

TEMPERATURE (°C)

20 40-40 100-60 12080060-20 140

25

20

30

15

10

5

0

I

SHDN

(μA)

LDO POWER-SUPPLY REJECTION RATIO

MAX15008 toc04

FREQUENCY (Hz)

0.01 1010.1 100 1000

0

-10

-20

-30

-40

-50

-60

-70

PSRR (dB)

I

OUT_LDO

= 10mA

TRACKER POWER-SUPPLY REJECTION RATIO

MAX15008 toc05

FREQUENCY (kHz)

0.1 101 100 1000

0

-10

-20

-30

-40

-50

-60

-70

TRACKER PSRR (dB)

I

OUT_LDO

= 10mA

VIN UVLO HYSTERESIS

vs. TEMPERATURE

MAX15008 toc06

TEMPERATURE (°C)

-50 7525-25 125500 100 150

400

350

300

250

200

150

100

UVLO HYSTERESIS (mV)

REF VOLTAGE

vs. TEMPERATURE

MAX15008 toc07

TEMPERATURE (°C)

-50 7525-25 125500 100 150

1.245

1.240

1.235

1.230

1.225

1.220

V

REF

(V)

LDO OUTPUT VOLTAGE

vs. INPUT VOLTAGE

MAX15008 toc08

VIN (V)

02010 30 40

6

5

4

3

2

1

0

V

OUT_LDO

(V)

I

OUT_LDO

= 10mA

I

OUT_LDO

= 300mA

(PULSED)

Page 7

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

_______________________________________________________________________________________

7

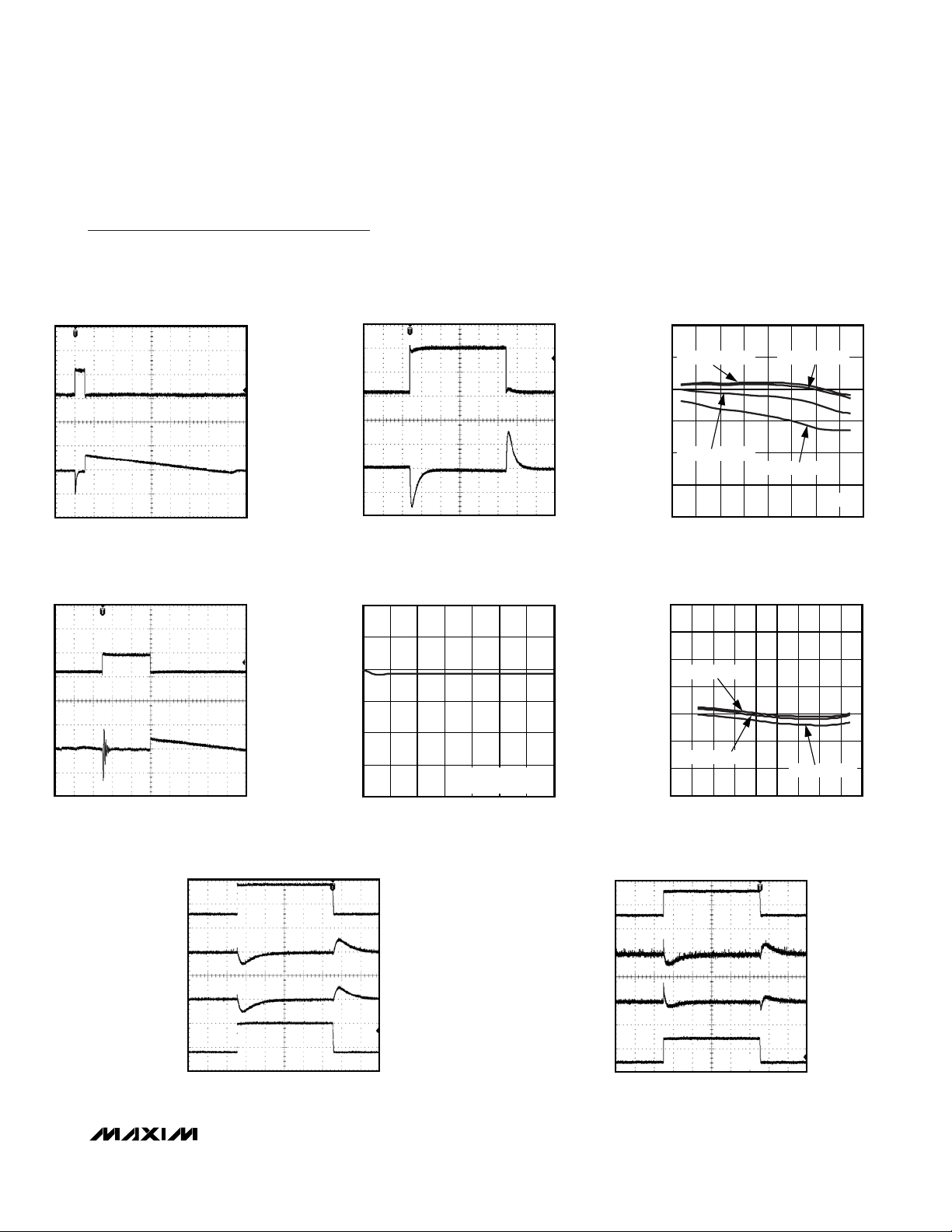

Typical Operating Characteristics (continued)

(VIN= V

EN_

= +14V, CIN= 10µF, C

OUT_LDO

= 22µF, C

TRACK

= C

OUT_TRK

= 10µF, V

OUT_LDO

= 5V, FB_LDO = SGND, TA= +25°C,

unless otherwise specified.)

LDO LOAD-TRANSIENT RESPONSE

2ms/div

TRACKER LOAD-TRANSIENT RESPONSE

400μs/div

MAX15008 toc09

MAX15008 toc12

I

OUT_LDO

100mA/div

0A

V

OUT_LDO

5V, AC-COUPLED

20mV/div

I

OUT_TRK

50mA/div

0A

V

OUT_TRK

5V, AC-COUPLED

20mV/div

LDO LOAD-TRANSIENT RESPONSE

0

-0.5

-1.0

(mV)

-1.5

OUT_TRK

- V

ADJ

-2.0

V

-2.5

-3.0

400μs/div

TRACKER ACCURACY

vs. LOAD CURRENT

ADJ = OUT_LDO

FB_TRK = OUT_TRK

I

(mA)

OUT_TRK

MAX15008 toc10

50100204030 60 70

I

OUT_LDO

100mA/div

0A

V

OUT_LDO

5V, AC-COUPLED

100mV/div

MAX15008 toc13

LDO OUTPUT VOLTAGE

vs. TEMPERATURE

5.10

I

OUT_LDO

I

OUT_LDO

= 100μA I

= 100mA

I

OUT_LDO

TEMPERATURE (°C)

OUT_LDO

5.05

5.00

(V)

4.95

OUT_LDO

V

4.90

4.85

4.80

-50 7525-25 125500 100 150

TRACKER ACCURACY (V

vs. TEMPERATURE

3

2

1

I

= 100μA

OUT_TRK

0

-1

-2

TRACKER ACCURACY (mV)

I

= 1mA

OUT_TRK

-3

-4

0 125-75 100755025-25-50 150

TEMPERATURE (°C)

= 300mA

FB_TRK

I

OUT_TRK

= 10mA

VIN = 8V

= V

= 70mA

MAX15008 toc11

)

ADJ

MAX15008 toc14

V

20V/div

V

OUT_LDO

3.3V, AC-COUPLED

50mV/div

V

OUT_TRK

3.3V, AC-COUPLED

50mV/div

V

OUT_PROT

20V/div

LINE-TRANSIENT RESPONSE

IN

40ms/div

MAX15008 toc15

V

10V/div

0V

0V

V

OUT_LDO

3.3V, AC-COUPLED

20mV/div

V

OUT_TRK

3.3V, AC-COUPLED

20mV/div

V

OUT_PROT

10V/div

LINE-TRANSIENT RESPONSE

IN

MAX15008 toc16

40ms/div

0V

0V

Page 8

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

8 _______________________________________________________________________________________

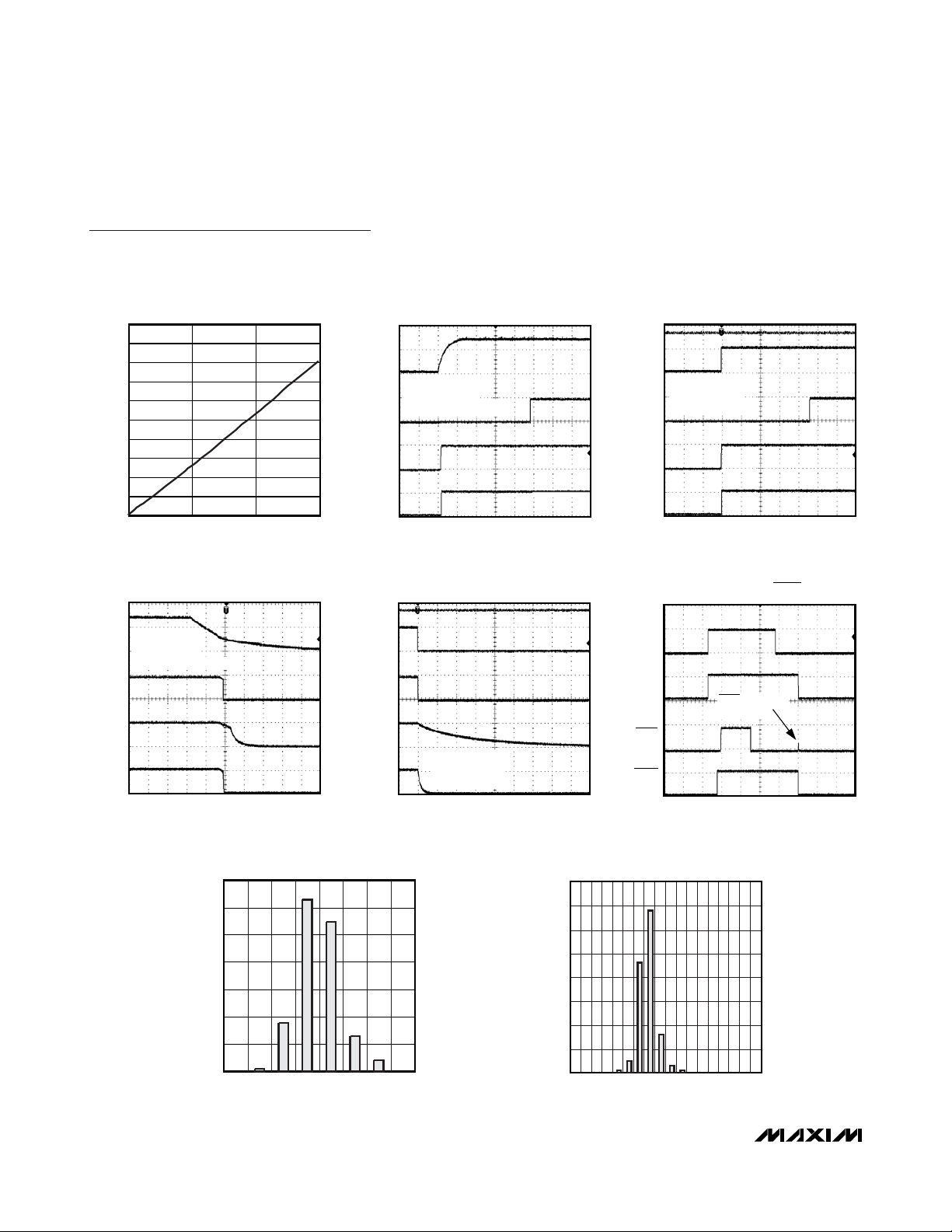

Typical Operating Characteristics (continued)

(VIN= V

EN_

= +14V, CIN= 10µF, C

OUT_LDO

= 22µF, C

TRACK

= C

OUT_TRK

= 10µF, V

OUT_LDO

= 5V, FB_LDO = SGND, TA= +25°C,

unless otherwise specified.)

1000

900

800

700

600

500

400

300

LDO DROPOUT VOLTAGE (mV)

200

100

LDO DROPOUT VOLTAGE

vs. LOAD CURRENT

0

0 200100 300

I

(mA)

OUT_LDO

MAX15008 toc17

V

V

V

10V/div

V

RESET

5V/div

OUT_LDO

5V/div

OUT_TRK

5V/div

IN

STARTUP RESPONSE THROUGH V

I

= 100mA

OUT_LDO

= 100mA

I

OUT_TRK

EN_LDO = EN_TRK = IN

20ms/div

IN

MAX15008 toc18

STARTUP RESPONSE THROUGH EN

V

IN

20V/div

V

EN_LDO

5V/div

0V

0V

V

0V

V

0V

V

RESET

5V/div

OUT_LDO

5V/div

OUT_TRK

5V/div

I

OUT_LDO

I

OUT_TRK

V

EN_TRK

= 100mA

= 100mA

= V

EN_LDO

20ms/div

MAX15008 toc19

0V

0V

0V

0V

0V

V

V

SHUTDOWN RESPONSE THROUGH V

V

IN

10V/div

I

= 100mA

OUT_LDO

= 70mA

I

OUT_TRK

= V

V

EN_TRK

V

RESET

5V/div

OUT_LDO

5V/div

OUT_TRK

5V/div

EN_LDO

= V

IN

20ms/div

MAX15008 toc20

IN

V

0V

0V

V

OUT_LDO

0V

V

OUT_TRK

0V

SHUTDOWN RESPONSE THROUGH EN

V

IN

20V/div

EN_LDO

5V/div

V

RESET

5V/div

5V/div

5V/div

GROUND CURRENT DISTRIBUTION

HISTOGRAM (T

70

60

50

40

30

NUMBER OF PARTS

20

10

0

696765

GROUND CURRENT (μA)

= -40°C)

A

7371

75

77 79

EN_LDO = EN_TRK

= 100mA

I

OUT_LDO

= 70mA

I

OUT_TRK

400μs/div

MAX15008 toc23

MAX15008 toc21

0V

V

EN_LDO

5V/div

0V

V

OUT_LDO

5V/div

0V

HOLD

0V

5V/div

RESET

5V/div

0V

GROUND CURRENT DISTRIBUTION

HISTOGRAM (T

80

70

60

50

40

30

NUMBER OF PARTS

20

10

0

49

53

45

47

59 63 67 71 75

51 55

GROUND CURRENT (μA)

LDO, EN_LDO, AND HOLD TIMING

HOLD PULLED UP

TO OUT_LDO

200ms/div

= +125°C)

A

MAX15008 toc24

73 77

6557

69

61

79

MAX15008 toc22

0V

0V

0V

0V

Page 9

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

_______________________________________________________________________________________

9

Typical Operating Characteristics (continued)

(VIN= V

EN_

= +14V, CIN= 10µF, C

OUT_LDO

= 22µF, C

TRACK

= C

OUT_TRK

= 10µF, V

OUT_LDO

= 5V, FB_LDO = SGND, TA= +25°C,

unless otherwise specified.)

PROTECTOR GATE VOLTAGE

vs. INPUT VOLTAGE (MAX15008 ONLY)

50

45

40

V

35

GATE

30

25

20

GATE VOLTAGE (V)

15

10

5

0

20 2515 30 4010 3550

VIN (V)

OVERVOLTAGE LIMIT FAULT

(MAX15008 ONLY)

V

IN

20V/div

V

GATE

20V/div

I

= 1A

OUT_PROT

OV THRESHOLD = 35V

V

OUT_PROT

20V/div

40ms/div

V

IN

MAX15008 toc28

V

IN

10V/div

MAX15008 toc25

V

GATE

10V/div

V

OUT_PROT

10V/div

7

6

0V

0V

0V

5

4

3

2

RESET TIMEOUT DELAY (ms)

1

0

PROTECTOR STARTUP RESPONSE

(MAX15008 ONLY)

10ms/div

I

OUT_PROT

MAX15008 toc26

RESET TIMEOUT DELAY

vs. C

RESET

8621040

C

(nF)

RESET

= 1A

OVERVOLTAGE SWITCH FAULT

(MAX15008 ONLY)

V

10V/div

20V/div

V

OUT_PROT

20V/div

V

GATE

IN

I

OUT_PROT

= 25V

V

OV

= 1A

400μs/div

0V

0V

0V

RESET TIMEOUT DELAY

vs. TEMPERATURE

2.0

1.8

1.6

MAX15008 toc29

RESET TIMEOUT DELAY (ms)

C

= 2.2nF

RESET

1.4

1.2

1.0

0.8

0.6

0.4

C

= 220pF

RESET

0.2

0

-25 250 100 12550 15075-50

TEMPERATURE (°C)

MAX15008 toc27

0V

0V

0V

MAX15008 toc30

Page 10

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

10 ______________________________________________________________________________________

Pin Description

PIN

MAX15008 MAX15010

1, 2, 8, 11,

23, 24, 26,

27, 28, 31,

32

3 3 OUT_TRK

4 4 ADJ

5 5 SGND Signal Ground

6 6 PGND

1, 2, 8,

10–13, 18,

23, 24, 26,

27, 28, 31,

32

NAME FUNCTION

N.C. No Connection. Not internally connected.

Tracker Output. Bypass OUT_TRK to SGND with a 10µF (min) capacitor with low ESR

(≤ 1.5Ω).

Tracker Amplifier Input. Connect ADJ to OUT_LDO or to an external source to track.

Alternatively, connect ADJ to REF to provide the reference voltage to the tracker.

Ground. PGND is also the return path for the overvoltage protector pulldown current for

the MAX15008. In this case, connect PGND to SGND at the negative terminal of the

bypass capacitor connected to the source of the external MOSFET. For the MAX15010,

connect PGND to SGND together to the local ground plane.

77RESET

99CT

10 — FB_PROT

12 — GATE

13 — SOURCE

14 14 REF 1.235V Voltage Reference Output. Bypass REF to SGND with a 1nF or larger capacitor.

Active-Low Open-Drain Reset Output. RESET is low while OUT_LDO is below the reset

threshold. Once OUT_LDO has exceeded the reset threshold, RESET remains low for

the duration of the reset timeout period before going high.

Reset Timeout Adjust Input. Connect a capacitor (C

the reset timeout period. See the Setting the

Overvoltage Threshold Adjustment Input. Connect FB_PROT to an external resistive

voltage-divider network to adjust the desired overvoltage threshold. Use FB_PROT to

monitor a system input or output voltage. See the Setting the Overvoltage Threshold

(MAX15008 Only) section.

P r otector Gate D r i ve O utp ut. C onnect GATE to the g ate of an exter nal n- channel M OS FE T.

G ATE i s the outp ut of a char g e p um p w i th a 45µA p ul l up cur r ent to 7.1V ( typ ) ab ove IN

d ur i ng nor m al op er ati on. GATE i s q ui ckl y tur ned off thr oug h a 63m A i nter nal p ul l d ow n

d ur i ng an over vol tag e cond i ti on. G ATE then r em ai ns l ow unti l FB_P RO T has d ecr eased

96% b el ow the thr

Output-Voltage Sense Input. Connect SOURCE to the source of the external n-channel

MOSFET.

) from CT to ground to adjust

RESET

RESET

Timeout Period section.

eshol d . GATE p ul l s l ow w hen E N _P RO T i s l ow .

Page 11

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

______________________________________________________________________________________ 11

Pin Description (continued)

PIN

MAX15008 MAX15010

15 15 FB_LDO

16 16 EN_LDO

17 17 EN_TRK

18 — EN_PROT

19, 20 19, 20 IN Regulator Input. Bypass IN to SGND with a 10µF capacitor (ESR ≤ 1.5Ω).

21, 22 21, 22 OUT_LDO

25 25 HOLD

NAME FUNCTION

LDO Voltage Feedback Input. Connect FB_LDO to SGND to select the preset +5V

output voltage. Connect FB_LDO to an external resistive voltage-divider for adjustable

output operation. See the Setting the Output Voltage section.

Active-High LDO Enable Input. Connect EN_LDO to IN or to a logic-high voltage to turn

on the regulator. To place the LDO in shutdown, pull EN_LDO low or leave unconnected

and leave HOLD unconnected. EN_LDO is internally pulled to SGND through a 1µA

current sink. See the Control Logic section.

Active-High Tracker Enable Input. Connect EN_TRK to IN or to a logic-high voltage to

turn on the tracker. Pull EN_TRK low or leave unconnected to place tracker in

shutdown. EN_TRK is internally pulled to SGND through a 1µA current sink.

Protector Enable Input. Drive EN_PROT low to force GATE low and turn off the external

n-channel MOSFET. EN_PROT is internally pulled to SGND by a 1µA sink. Connect

EN_PROT to IN for normal operation.

LDO Regulator Output. Bypass OUT_LDO to SGND with a low-ESR capacitor with a

minimum value of 22µF. Fixed +5V or adjustable output (+1.8V to +11V). See the

Setting the Output Voltage section.

Active-Low Hold Input. If EN_LDO is high when HOLD is forced low, the regulator

latches the state of the EN_LDO input and allows the regulator to remain turned on

when EN_LDO is subsequently pulled low. To shut down the regulator, release HOLD

after EN_LDO is pulled low. If HOLD functionality is unused, connect HOLD to

OUT_LDO or leave unconnected. HOLD is internally pulled up to OUT_LDO through a

0.6µA current source. See the Control Logic section.

29 29 FB_TRK

30 30 TRACK Tracker Input. Bypass TRACK to the SGND with a 3.3µF ceramic capacitor.

EP EP EP

Tracker Amplifier Feedback. Connect FB_TRK directly to OUT_TRK or through an

external resistive voltage-divider.

Exposed Pad. Connect EP to SGND plane. EP also functions as a heatsink to maximize

thermal dissipation. Do not use as the main ground connection.

Page 12

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

12 ______________________________________________________________________________________

Functional Diagram

IN

V

ENABLE LDO

HOLD

-20V TO +40V

5V TO 40V

IN

IN

EN_LDO

HOLD

REF

TRACK

CONTROL

LOGIC

BIAS AND VOLTAGE

REFERENCE

V

REF

0.92 x V

REF

REVERSE-BATTERY

ADJ

PROTECTION

LDO

2μA

V

REF

1.235V

V

TRACKER

REF

5V LDO

OUT_LDO

M

U

X

FB_LDO

0.125V

CT

RESET

OUT_TRK

OUTPUT

RESET

OUTPUT

TRACKER

OUTPUT

ENABLE

TRACKER

ENABLE

PROTECTOR

EN_TRK

EN_PROT

IN

GATE UVLO

4.75V

V

REF

OVERVOLTAGE PROTECTOR

(MAX15008 ONLY)

EP SGND PGND

FB_TRK

GATE

SOURCE

FB_PROT

V

IN

PROTECTOR

OUTPUT

Page 13

Detailed Description

The MAX15008/MAX15010 integrate a 300mA LDO

voltage regulator, a voltage tracker, and an OVP controller. These devices operate over a wide 5V to 40V

supply voltage range and are able to withstand loaddump transients up to 45V.

The MAX15008/MAX15010 feature a 300mA LDO regulator that consumes less than 70µA of current under

light-load conditions and feature a fixed 5V or an

adjustable output voltage (1.8V to 11V). Connect

FB_LDO to ground to select a fixed 5V output voltage

or select the LDO output voltage by connecting an

external resistive voltage-divider at FB_LDO. The regulator sources at least 300mA of current and includes a

current limit of 330mA (min). Enable the LDO by pulling

EN_LDO high.

The tracker can be powered from the LDO input supply voltage or an independent voltage source. It is

designed to supply power to a remote sensor and is

able to handle the severe conditions in automotive

applications. Set the tracker output voltage by connecting a resistive voltage-divider to OUT_TRK and

connecting ADJ to the tracking source. The tracker

feedback, FB_TRK, and a separate tracker reference

voltage input, ADJ, offer the flexibility of setting the

tracker output to be lower, equal to, or higher than the

main (LDO) output. Pull EN_TRK to SGND to turn the

tracker off and keep the device in always-on, lowquiescent-current operation.

The OVP controller (MAX15008 only) relies on an external MOSFET with adequate voltage rating (V

DSS

) to

protect downstream circuitry from overvoltage transients. The OVP controller drives the gate of the external n-channel MOSFET, and is configurable to operate

as an overvoltage protection switch or as a closed-loop

voltage limiter.

GATE Voltage (MAX15008 Only)

The MAX15008 uses a high-efficiency charge pump to

generate the GATE voltage for the external n-channel

MOSFET. Once the input voltage, VIN, exceeds the

undervoltage lockout (UVLO) threshold, the internal

charge pump fully enhances the external n-channel

MOSFET. An overvoltage condition occurs when the

voltage at FB_PROT goes above the threshold voltage,

V

TH_PROT

. After V

TH_PROT

is exceeded, GATE is quickly pulled to PGND with a 63mA pulldown current. The

MAX15008 includes an internal clamp from GATE to

SOURCE that ensures that the voltage at GATE never

exceeds one diode drop below SOURCE during gate

discharge. The voltage clamp also prevents the GATEto-SOURCE voltage from exceeding the absolute maximum rating for the V

GS

of the external MOSFET in case

the source terminal is accidentally shorted to 0V.

Overvoltage Monitoring (MAX15008 Only)

The OVP controller monitors the voltage at FB_PROT

and controls an external n-channel MOSFET, isolating,

or limiting the load during an overvoltage condition.

Operation in OVP switch mode or limiter mode

depends on the connection between FB_PROT and the

external MOSFET.

Overvoltage Switch Mode

When operating in OVP switch mode, the FB_PROT

divider is connected to the drain of the external

MOSFET. The feedback path consists of the voltagedivider tapped at FB_PROT, FB_PROT’s internal

comparator, the internal gate charge pump/gate

pulldown, and the external n-channel MOSFET (Figure

1). When the programmed overvoltage threshold is

exceeded, the internal comparator quickly pulls GATE

to ground and turns off the external MOSFET,

disconnecting the power source from the load. In this

configuration, the voltage at the source of the

MOSFET is not monitored. When the voltage at

FB_PROT decreases below the overvoltage threshold,

the MAX15008 raises the voltage at GATE, reconnecting

the load to the power source.

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

______________________________________________________________________________________ 13

Figure 1. Overvoltage Switch Configuration (MAX15008)

V

IN

IN

FB_PROT

MAX15008

SGND

GATE

PROTECTOR

OUTPUT

SOURCE

Page 14

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

14 ______________________________________________________________________________________

Overvoltage-Limiter Mode

When operating in overvoltage-limiter mode, the feedback path consists of SOURCE, FB_PROT’s internal

comparator, the internal gate charge pump/gate pulldown, and the external n-channel MOSFET (Figure 2).

This configuration results in the external MOSFET operating as a hysteretic voltage regulator.

During normal operation, GATE is enhanced 8.1V

above VIN. The external MOSFET source voltage is

monitored through a resistive voltage-divider between

SOURCE and FB_PROT. When V

SOURCE

exceeds the

adjustable overvoltage threshold, an internal pulldown

switch discharges the gate voltage and quickly turns

the MOSFET off. Consequently, the source voltage

begins to fall. The V

SOURCE

fall time is dependent on

the MOSFET’s gate charge, the internal charge-pump

current, the output load, and any load capacitance at

SOURCE. When the voltage at FB_PROT is below the

overvoltage threshold by an amount equal to the hysteresis, the charge pump restarts and turns the

MOSFET back on. In this way, the OVP controller

attempts to regulate V

SOURCE

around the overvoltage

threshold. SOURCE remains high during overvoltage

transients and the MOSFET continues to conduct during an overvoltage event. The hysteresis of the

FB_PROT comparator and the gate turn-on delay force

the external MOSFET to operate in a switched on/off

sequence during an overvoltage event.

Exercise caution when operating the MAX15008 in

voltage-limiting mode for long durations. Care must be

taken against prolonged or repeated exposure to

overvoltage events while delivering large amounts of

load current as the power dissipation in the external

MOSFET may be high under these conditions. To prevent damage to the MOSFET, implement proper

heatsinking. The capacitor connected between

SOURCE and ground can also be damaged if the ripple current rating for the capacitor is exceeded.

As the transient voltage decreases, the voltage at

SOURCE falls. For fast-rising transients and very large

MOSFETs, connect an additional capacitor from GATE

to PGND. This capacitor acts as a voltage-divider work-

ing against the MOSFET’s drain-to-gate capacitance. If

using a very low gate charge MOSFET, additional

capacitance from GATE to ground might be required to

reduce the switching frequency.

Control Logic

The MAX15008/MAX15010 LDO features two logic

inputs, EN_LDO and HOLD, making these devices suitable for automotive applications. For example, when

the ignition key signal drives EN_LDO high, the regulator turns on and remains on even if EN_LDO goes low,

as long as HOLD is forced low and stays low after initial

regulator power-up. In this state, releasing HOLD turns

the regulator output (OUT_LDO) off. This feature makes

it possible to implement a self-holding circuit without

external components. Forcing EN_LDO low and HOLD

high (or unconnected) places the regulator into shutdown mode reducing the supply current to less than

16µA. Table 1 shows the state of OUT_LDO with

respect to EN_LDO and HOLD. Leave HOLD uncon-

nected or connect directly to OUT_LDO to allow the

EN_LDO input to act as a standard on/off logic input for

the regulator.

Figure 2. Overvoltage Limiter (MAX15008)

V

IN

IN

MAX15008

SGND

GATE

PROTECTOR

SOURCE

FB_PROT

OUTPUT

Page 15

Applications Information

Load Dump

Most automotive applications run off a multicell 12V

lead-acid battery with a nominal voltage that swings

between 9V and 16V, depending on load current,

charging status, temperature, and battery age, etc. The

battery voltage is distributed throughout the automobile

and is locally regulated down to voltages required by

the different system modules. Load dump occurs when

the alternator is charging the battery and the battery

becomes disconnected. Power in the alternator (behaving now essentially as an inductor) flows into the distributed power system and elevates the voltage seen at

each module. The voltage spikes have rise times typically greater than 5ms and decay within several hundred milliseconds but can extend out to 1s or more

depending on the characteristics of the charging system. These transients are capable of destroying semiconductors on the first fault event.

The MAX15008/MAX15010 feature load-dump transient

protection up to +45V.

Setting the Output Voltage

The MAX15008/MAX15010 feature dual-mode operation: these devices operate in either a preset voltage

mode or an adjustable mode. In preset voltage mode,

internal feedback resistors set the linear regulator out-

put voltage (V

OUT_LDO

) to 5V. To select the preset 5V

output voltage, connect FB_LDO to SGND.

To select an adjustable output voltage between 1.8V

and 11V, use two external resistors connected as a

voltage-divider to FB_LDO (Figure 3). Set the output

voltage using the following equation:

V

OUT_LDO

= V

FB_LDO

x (R1 + R2) / R

2

where V

FB_LDO

= 1.235V and R2≤ 50kΩ.

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

______________________________________________________________________________________ 15

Figure 3. Setting the LDO Output Voltage

Table 1. EN_LDO/

HHOOLLDD

Truth Table/State Table

OPERATION STATE EN_LDO HOLD OUT_LDO COMMENT

Initial State Low Don’t care OFF

Turn-On State High Don’t care ON

Hold Setup State High Low ON

Hold State Low Low ON

Off State Low

EN_LDO is pulled to SGND through an internal pulldown. HOLD

is unconnected and is internally pulled up to OUT_LDO. The

regulator is disabled.

EN_LDO is externally driven high turning regulator on. HOLD is

pulled up to OUT_LDO.

HOLD is externally pulled low while EN_LDO remains high

(latches EN_LDO state).

EN_LDO is driven low or left unconnected. HOLD remains

externally pulled low keeping the regulator on.

High or

unconnected

OFF

HOLD is driven high or left unconnected while EN_LDO is low.

The regulator is turned off and EN_LDO/HOLD logic returns to the

initial state.

V

IN

IN

MAX15008

MAX15010

OUT_LDO

FB_LDO

SGND

R1

R2

Page 16

MAX15008/MAX15010

Setting the

RESET

Timeout Period

The reset timeout period is adjustable to accommodate

a variety of applications. Set the reset timeout period by

connecting a capacitor, C

RESET

, between CT and

SGND. Use the following formula to select the reset

timeout period, t

RESET

:

t

RESET

= C

RESET

x V

CT_TH

/ I

CT

where t

RESET

is in seconds and C

RESET

is in µF.

V

CT_TH

is the CT ramp threshold in volts and ICTis the

CT ramp current in µA, as described in the

Electrical

Characteristics

table.

Leave CT open to select an internally fixed timeout period of 10µs. To maintain reset timeout accuracy, use a

low-leakage (< 10nA) type capacitor.

Tracker Input/Feedback Adjustment

The tracker can be powered from the LDO input supply

voltage or an independent voltage source. It is

designed to supply power to a remote sensor and its

supply input, TRACK, is able to handle the severe conditions in automotive applications such as battery

reversal and load-dump transients up to 45V.

The tracker feedback, FB_TRK, and a separate tracker

reference voltage input, ADJ, offer the flexibility of set-

ting the tracker output to be lower, equal to, or higher

than the main (LDO) output. Other external voltages

can also be tracked.

Connect ADJ to OUT_LDO and FB_TRK to OUT_TRK to

track the LDO output voltage directly (Figure 4a). To

track a voltage higher than V

OUT_LDO

, directly connect

ADJ to OUT_LDO and connect FB_TRK to OUT_TRK

through a resistive voltage-divider (Figure 4b). To track

a voltage lower than the LDO regulator output,

V

OUT_LDO

, directly connect FB_TRK to OUT_TRK and

connect ADJ to OUT_LDO through a resistive voltagedivider (Figure 4c). To track an external voltage VXwith

a generic attenuation/amplification ratio, connect resistive voltage-dividers between ADJ and the voltage input

or output to be tracked (VX), and between OUT_TRK

and FB_TRK (Figure 4d). Pay attention to the resistive

loading of the voltage VXdue to the divider R5, R6.

To track the internal REF voltage (1.235V), directly connect

ADJ to REF. The voltage at FB_TRK or ADJ should be

greater than or equal to 1.1V and less than V

TRACK

- 0.5V.

Resistors should have a tolerance of 1% or better. Their

values should be low enough to ensure that the divider

current is at least 100x the maximum input bias current

at pins FB_TRK and ADJ (I

FB_TRK_ADJ

, max = 0.2µA).

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

16 ______________________________________________________________________________________

Figure 4. Tracker Input and Feedback Adjustment

V

IN

V

IN

IN

TRACK

TO TRACK V

V

OUT_TRK

IN

TRACK

TO TRACK A VOLTAGE LOWER THAN V

V

OUT_TRK

= V

R5 + R6 < V

MAX15008

MAX15010

OUT_LDO

= V

OUT_LDO

(a)

MAX15008

MAX15010

x R6 / (R5 + R6),

OUT_LDO

OUT_LDO

(c)

OUT_LDO

OUT_TRK

FB_TRK

:

OUT_LDO

OUT_TRK

FB_TRK

/ 20μA

ADJ

ADJ

OUT_LDO

:

LDO

OUTPUT

TRACKER

OUTPUT

LDO

OUTPUT

R5

R6

TRACKER

OUTPUT

V

IN

V

IN

IN

MAX15008

MAX15010

TRACK

TO TRACK A VOLTAGE HIGHER THAN

V

OUT_TRK

TO TRACK A GENERIC VOLTAGE V

= VX x (R6 / (R5 + R6)) x ((R3 + R4) / R4),

V

OUT_TRK

R5 + R6 < V

V

OUT_LDO

= V

OUT_LDO

R3 + R4 < V

OUT_TRK

(b)

IN

MAX15008

MAX15010

TRACK

/ 20μA, R3 + R4 < V

X

(d)

OUT_LDO

ADJ

OUT_TRK

FB_TRK

:

x (R3 + R4) / R4,

/ 20μA

ADJ

OUT_TRK

FB_TRK

OUT_TRK

R3

R4

R6

R3

R4

:

X

/ 20μA

LDO

OUTPUT

TRACKER

OUTPUT

R5

V

X

TRACKER

OUTPUT

Page 17

Setting the Overvoltage Threshold

(MAX15008 Only)

The MAX15008 provides an accurate means to set the

overvoltage threshold for the OVP controller using

FB_PROT. Use a resistive voltage-divider to set the

desired overvoltage threshold (Figure 5). FB_PROT has

a rising 1.235V threshold with a 4% falling hysteresis.

Begin by selecting the total end-to-end resistance,

R

TOTAL

= R5+ R6. Choose R

TOTAL

to yield a total cur-

rent equivalent to a minimum of 100 x I

FB_PROT

(FB_PROT’s input maximum bias current) at the

desired overvoltage threshold. See the

Electrical

Characteristics

table.

For example:

With an overvoltage threshold (VOV) set to 20V,

R

TOTAL

< 20V / (100 x I

FB_PROT

), where I

FB_PROT

is

FB_PROT’s maximum 100nA bias current:

R

TOTAL

< 2MΩ

Use the following formula to calculate R6:

R6= V

TH_PROT

x R

TOTAL

/ V

OV

where V

TH_PROT

is the 1.235V FB_PROT rising threshold and VOVis the desired overvoltage threshold. R6=

124kΩ:

R

TOTAL

= R5+ R

6

where R5= 1.88MΩ. Use a standard 1.87MΩ resistor.

A lower value for total resistance dissipates more

power, but provides better accuracy and robustness

against external disturbances.

Input Transients Clamping

When the external MOSFET is turned off during an

overvoltage event, stray inductance in the power path

may cause additional input-voltage spikes that exceed

the V

DSS

rating of the external MOSFET or the absolute

maximum rating for the MAX15008 (IN, TRACK).

Minimize stray inductance in the power path using wide

traces and minimize the loop area included by the

power traces and the return ground path.

For further protection, add a zener diode or transient

voltage suppressor (TVS) rated below the absolute

maximum rating limits (Figure 6).

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

______________________________________________________________________________________ 17

Figure 5. Setting the Overvoltage Threshold (MAX15008)

Figure 6. Protecting the MAX15008 Input from High-Voltage

Transients

V

IN

IN

TVS

MAX15008

GATE

SOURCE

SGND

LOAD

V

IN

R5

R6

IN

MAX15008

FB_PROT

SGND

GATE

SOURCE

PROTECTOR

OUTPUT

V

IN

IN

MAX15008

SGND

GATE

SOURCE

FB_PROT

PROTECTOR

OUTPUT

R5

R6

Page 18

MAX15008/MAX15010

External MOSFET Selection

Select the external MOSFET with adequate voltage

rating, V

DSS

, to withstand the maximum expected loaddump input voltage. The on-resistance of the MOSFET,

R

DS(ON)

, should be low enough to maintain a minimal

voltage drop at full load, limiting the power dissipation

of the MOSFET.

During regular operation, the power dissipated by the

MOSFET is:

P

NORMAL

= I

LOAD

2

x R

DS(ON)

Normally, this power loss is small and is safely handled

by the MOSFET. However, when operating the

MAX15008 in overvoltage-limiter mode under prolonged or frequent overvoltage events, select an external MOSFET with an appropriate power rating.

During an overvoltage event, the power dissipation in

the external MOSFET is proportional to both load current and to the drain-source voltage, resulting in high

power dissipated in the MOSFET (Figure 7). The power

dissipated across the MOSFET is:

P

OV_LIMITER

= VQ1x I

LOAD

where VQ1is the voltage across the MOSFET’s drain

and source during overvoltage-limiter operation, and

I

LOAD

is the load current.

Overvoltage-Limiter Mode

Switching Frequency

When the MAX15008 is configured in overvoltagelimiter mode, the external n-channel MOSFET is subse-

quently switched on and off during an overvoltage

event. The output voltage at SOURCE resembles a

periodic sawtooth waveform. Calculate the period of

the waveform, t

OVP

, by summing three time intervals

(Figure 8):

t

OVP

= t1+ t2+ t

3

where t1is the V

SOURCE

output discharge time, t2 is the

GATE delay time, and t

3

is the V

SOURCE

output charge time.

During an overvoltage event, the power dissipated

inside the MAX15008 is due to the gate pulldown current, I

GATEPD

. This amount of power dissipation is

worse when I

SOURCE

= 0 (C

SOURCE

is discharged only

by the internal current sink).

The worst-case internal power dissipation contribution

in overvoltage-limiter mode, P

OVP

, in watts can be

approximated using the following equation:

where VOVis the overvoltage threshold voltage in volts

and I

GATEPD

is the 63mA (typ) GATE pulldown current.

Output Discharge Time (t1)

When the voltage at SOURCE exceeds the adjusted

overvoltage threshold, GATE’s internal pulldown is

enabled until V

SOURCE

drops by 4%. The internal cur-

rent sink, I

GATEPD

, and the external load current,

I

LOAD

, discharge the external capacitance from

SOURCE to ground.

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

18 ______________________________________________________________________________________

Figure 8. MAX15008 Timing Diagram

Figure 7. Power Dissipated Across MOSFETs During an

Overvoltage Fault (Overvoltage Limiter Mode)

V

MAX

GATE

+ VQ1 -

I

LOAD

V

SOURCE

V

SOURCE

IN

PV I

=×× ×0981.

OVP OV GATEPD

t

OVP

t

V

OV

TVS

MAX15008

FB_PROT

SGND

SOURCE

LOAD

GATE

SOURCE

t

1

t

OVP

t

2

t

3

Page 19

Calculate the discharge time, t1, using the following

equation:

where t1is in ms, VOVis the adjusted overvoltage

threshold in volts, I

LOAD

is the external load current in

mA, and I

GATEPD

is the 63mA (typ) internal pulldown

current of GATE. C

SOURCE

is the value of the capacitor

connected between the source of the MOSFET and

PGND in µF.

GATE Delay Time (t2)

When SOURCE falls 4% below the overvoltage threshold

voltage, the internal current sink is disabled and the

internal charge pump begins recharging the external

GATE voltage. Due to the external load, the SOURCE

voltage continues to drop until the gate of the MOSFET is

recharged. The time needed to recharge GATE and reenhance the external MOSFET is approximately:

where t2is in µs, C

iss

is the input capacitance of the

MOSFET in pF, and V

GS(TH)

is the gate-to-source threshold voltage of the MOSFET in volts. VFis the 0.7V (typ)

internal clamp diode forward voltage of the MOSFET in

volts, and I

GATE

is the charge-pump current 45µA (typ).

Any external capacitance between GATE and PGND will

add up to C

iss

.

During t2, the SOURCE capacitance, C

SOURCE

, loses

charge through the output load. The voltage across

C

SOURCE

decreases by ΔV2 until the MOSFET reaches

its V

GS(TH)

threshold. Approximate ΔV2using the fol-

lowing formula:

SOURCE Output Charge Time (t3)

Once the GATE voltage exceeds the gate-to-source threshold, V

GS(TH)

, of the external MOSFET, the MOSFET turns

on and the charge through the internal charge pump with

respect to the drain potential, QG, determines the slope of

the output-voltage rise. The time required for the SOURCE

voltage to rise again to the overvoltage threshold is:

where ΔV

SOURCE

= (VOVx 0.04) + ΔV2 in volts, and

C

rss

is the MOSFET’s reverse transfer capacitance in

pF. Any external capacitance between GATE and

PGND adds up to C

rss

.

Power Dissipation/Junction Temperature

During normal operation, the MAX15008/MAX15010

has two main sources of internal power dissipation: the

LDO and the voltage tracker.

Calculate the power dissipation due to the LDO as:

P

LDO

= (VIN- V

OUT_LDO

) x I

OUT_LDO

where VINis the LDO input supply voltage in volts,

V

OUT_LDO

is the output voltage of the LDO in volts, and

I

OUT_LDO

is the LDO total load current in mA.

Calculate power dissipation due to the tracker as:

P

TRK

= (V

TRACK

- V

OUT_TRK

) x I

OUT_TRK

where V

TRACK

is the tracker input supply voltage in

volts, V

OUT_TRK

is the output voltage of the tracker in

volts, and I

OUT_TRK

is the tracker load current in mA.

The total power dissipation P

DISS

in mW as:

P

DISS

= P

LDO

+ P

TRK

For prolonged exposure to overvoltage events, use the

VINand V

TRACK

voltages expected during overvoltage

conditions. Under these circumstances the corresponding internal power dissipation contribution, P

OVP

,

calculated in the

Overvoltage-Limiter Mode Switching

Frequency

section should also be included in the total

power dissipation, P

DISS

.

For a given ambient temperature, TA, calculate the

junction temperature, TJ, as follows:

TJ= TA+ P

DISS

x θ

JA

where TJand TAare in °C and θJAis the junction-toambient thermal resistance in °C/W as listed in the

Absolute Maximum Ratings

section.

The junction temperature should never exceed +150°C

during normal operation.

Thermal Protection

When the junction temperature exceeds TJ= +160°C,

the MAX15008/MAX15010 shut down to allow the

device to cool. When the junction temperature drops to

+140°C, the thermal sensor turns all enabled blocks

on again, resulting in a cycled output during continuous thermal-overload conditions. Thermal protection

protects the MAX15008/MAX15010 from excessive

power dissipation. For continuous operation, do not

exceed the absolute maximum junction temperature

rating of +150°C.

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

______________________________________________________________________________________ 19

0.04 V

×

tC

=×

1 SOURCE

II

LOAD GATEPD

OV

+

tC

2

=×

VV

iss

+

()

GS TH F

I

GATE

It

×

ΔV

LOAD

=

2

C

2

SOURCE

CV

×Δ

rss SOURCE

t

=

3

I

GATE

Page 20

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

20 ______________________________________________________________________________________

Typical Operating Circuits

GATE

5V TO 40V INPUT

C

IN

C

TRACK

SOURCE FB_PROT

IN

TRACK

MAX15008

EN_LDOLDO ON/OFF

EN_PROTPROTECTOR ON/OFF

5V TO 40V INPUT

C

IN

C

TRACK

EN_TRKTRACKER ON/OFF

HOLDHOLD

CT REF SGND

C

RESET

IN

TRACK

C

REF

MAX15010

EN_LDOLDO ON/OFF

EN_TRKTRACKER ON/OFF

HOLDHOLD

REF

C

REF

CT PGND SGND

C

RESET

PGND

OUT_TRK

FB_TRK

ADJ

OUT_LDO

FB_LDO

RESET

FB_TRK

OUT_TRK

ADJ

OUT_LDO

FB_LDO

RESET

C

SOURCE

C

OUT_TRK

DC-DC

MAX5073

R

PU

R

PU

TRACKER OUTPUT

C

OUT_LDO

C

OUT_TRK

C

OUT_LDO

300mA

TRACKER OUTPUT

5V

300mA

5V

V

RESET/EN

I/O

CC

50mA

V

CC

RESET/EN

I/O

μC

μC

V

V

OUT1

OUT2

Page 21

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

______________________________________________________________________________________ 21

Chip Information

PROCESS: BiCMOS

MAX15010

TQFN

(5mm x 5mm)

+

TOP VIEW

29

30

28

27

12

11

13

N.C.

ADJ

SGND

PGND

RESET

14

N.C.

N.C.

OUT_LDO

IN

N.C.

IN

N.C.

12

N.C.

4567

2324 22 20 19 18

FB_TRK

TRACK

REF

N.C.

N.C.

N.C.

OUT_TRK

OUT_LDO

3

21

31

10

N.C.

N.C.

32

9

N.C.

CT

N.C.

26

15

FB_LDO

*EP

*EP = EXPOSED PAD

N.C.

25

16

EN_LDO

N.C.

EN_TRK

8

17

HOLD

Pin Configurations (continued)

Page 22

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

22 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QFN THIN.EPS

Page 23

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

______________________________________________________________________________________ 23

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Page 24

MAX15008/MAX15010

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

0 9/07 Initial release —

1 1/08

REVISION

DATE

Removed future product asterisks, updated Electrical Characteristics table and

Typical Operating Characteristics section.

DESCRIPTION

PAGES

CHANGED

1, 2, 6, 8

Loading...

Loading...