Page 1

General Description

The MAX1464 is a highly integrated, low-power, lownoise multichannel sensor signal processor optimized

for industrial, automotive, and process-control applications such as pressure sensing and compensation,

RTD and thermocouple linearization, weight sensing

and classification, and remote process monitoring with

limit indication.

The MAX1464 accepts sensors with either single-ended

or differential outputs. The MAX1464 accommodates

sensor output sensitivities from 1mV/V to 1V/V. The

MAX1464 provides amplification, calibration, signal linearization, and temperature compensation that enable

an overall performance approaching the inherent

repeatability of the sensor without requiring any external trim components.

Two 16-bit voltage-output DACs and two 12-bit PWMs

can be used to indicate each of the temperature-compensated sensor signals independently, as a sum or

difference signal, or user-defined relationship between

each signal and temperature. Uncommitted op amps

are available to buffer the DAC outputs, drive heavier

external loads, or provide additional gain and filtering.

The MAX1464 incorporates a 16-bit CPU, user-programmable 4kB of FLASH program memory, 128 bytes

of FLASH user information, one 16-bit ADC, two 16-bit

DACs, two 12-bit PWM digital outputs, four rail-to-rail

op amps, one SPI™-compatible interface, two GPIOs,

and one on-chip temperature sensor.

The MAX1464 operates from a single 5.0V (typ) supply

and is packaged for automotive, industrial, and commercial temperature ranges in a 28-pin SSOP package.

Applications

Pressure Sensor Signal Conditioning

Weight Measurement Systems

Thermocouple and RTD Linearization

Transducers and Transmitters

Process Indicators

Calibrators and Controllers

GMR and MR Magnetic Direction Sensors

Features

♦ Programmable Amplification, Calibration,

Linearization, and Temperature Compensation

♦ Two Differential or Four Single-Ended ADC Input

Channels

♦ Accommodates Sensor Output Sensitivities from

1mV/V to 1V/V

♦ Two DAC/PWM Output Signal Channels

♦ Supports 4–20mA Current Loop Applications

♦ 4kB of FLASH Memory for Code and Coefficients

♦ 128 Bytes of FLASH Memory for User Information

♦ Integrated Temperature Sensing

♦ Flexible Dual Op-Amp Block

♦ Programmable Sensor Input Gain and Offset

♦ Programmable Sensor Sampling Rate and

Resolution

♦ No External Trim Components Required

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

________________________________________________________________ Maxim Integrated Products 1

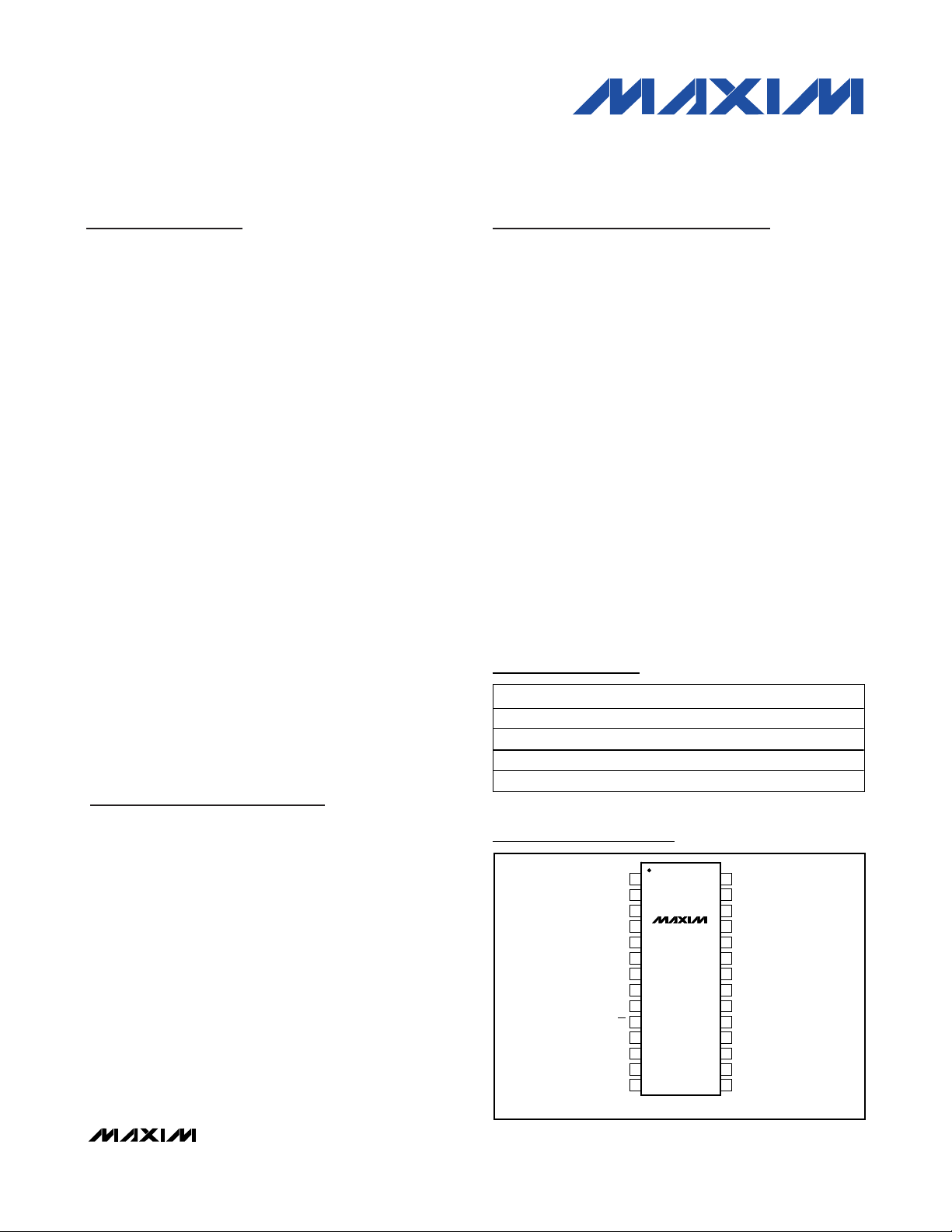

Ordering Information

19-3579; Rev 0; 2/05

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

*Dice are tested at TA= +25°C, DC parameters only.

Functional Diagram and Detailed Block Diagram appear at

end of data sheet.

SPI is a trademark of Motorola, Inc.

Pin Configuration

PART TEMP RANGE PIN-PACKAGE

MAX1464CAI 0°C to +70°C 28 SSOP

MAX1464C/W* 0°C to +70°C Die

MAX1464EAI -40°C to +85°C 28 SSOP

MAX1464AAI -40°C to +125°C 28 SSOP

TOP VIEW

OUT1SM

AMP1M

AMP1P

OUT1LG

CKSEL

CKIO

SCLK

1

2

3

4

MAX1464

5

N.C.

6

V

DD

7

N.C.

8

9

10

CS

11

DO

12

DI

13

14

V

SS

SSOP

28

27

26

25

24

23

22

21

20

19

18

17

16

15

OUT2SM

AMP2M

AMP2P

OUT2LG

V

REF

INP1

INM1

INP2

INM2

V

SS

V

SSF

GPIO2

GPIO1

V

DDF

Page 2

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

2 _______________________________________________________________________________________

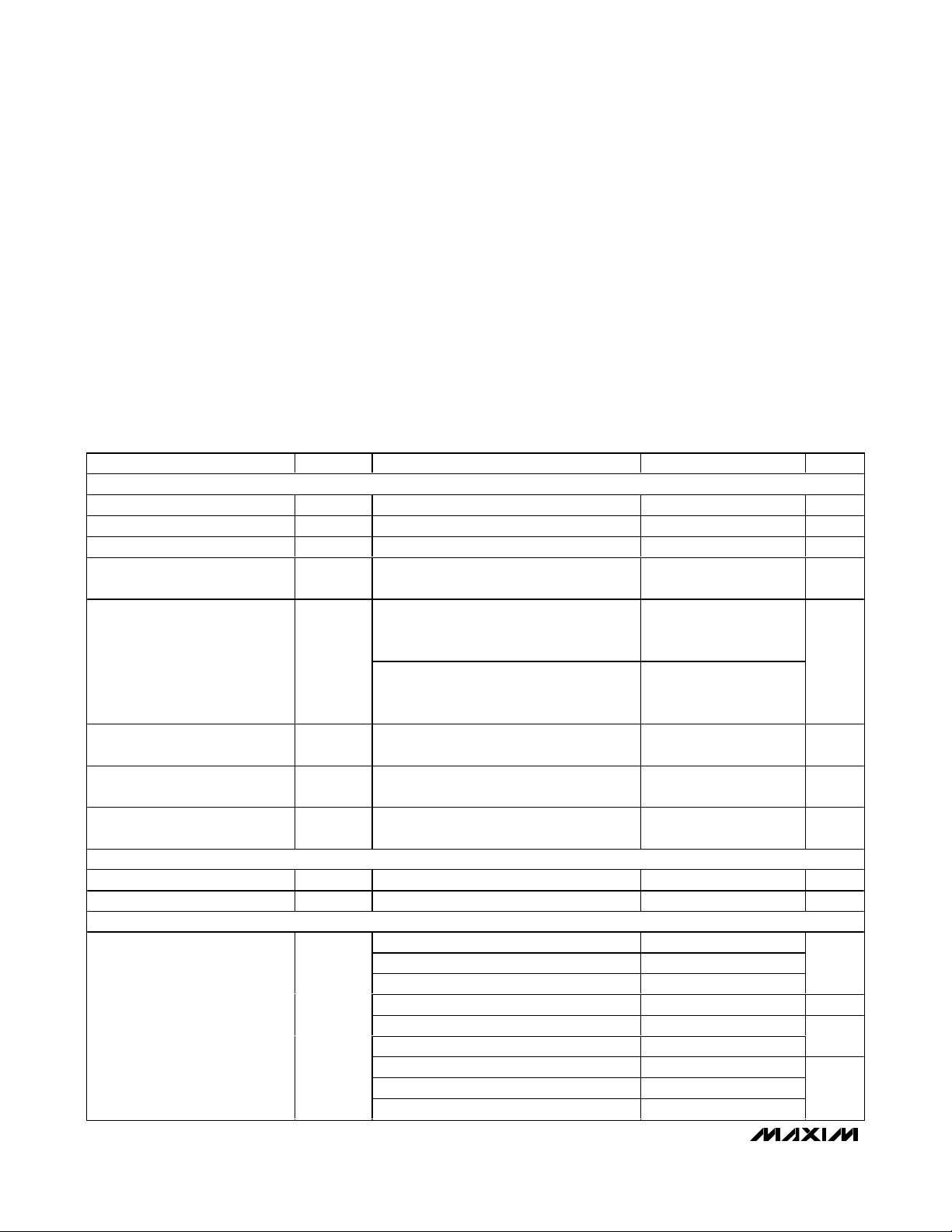

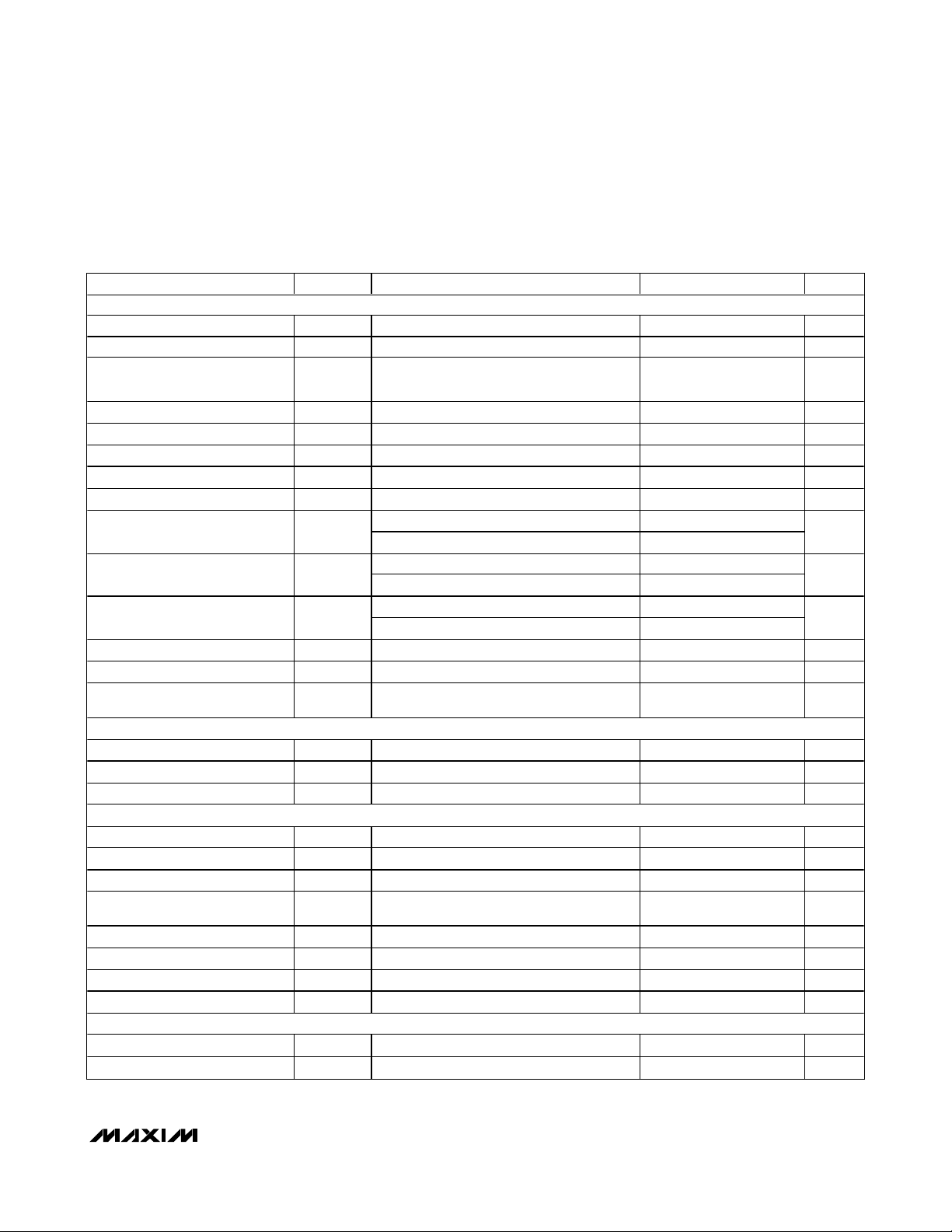

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

DDF

= VDD= 4.5V to 5.5V, V

SSF

= VSS= 0V, f

CLK

= 4.0MHz, TA= T

MIN

to T

MAX

. Typical values are at V

DDF

= VDD= 5.0V, V

SSF

= VSS= 0V,

T

A

= +25°C, unless otherwise noted.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto VSS.............................................................-0.3V to +6.0V

V

DDF

to VSS...........................................................-0.3V to +6.0V

V

SSF

to VSS............................................................-0.3V to +0.3V

All Other Pins to V

SS

...................................-0.3V to (VDD+ 0.3V)

Continuous Power Dissipation (T

A

= +70°C)

28-Pin SSOP (derate 9.1mW/°C above +70°C) ..........727mW

Operating Temperature Ranges

MAX1464CAI .....................................................0°C to +70°C

MAX1464C/W.....................................................0°C to +70°C

MAX1464EAI...................................................-40°C to +85°C

MAX1464AAI ................................................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................ +300°C

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

SUPPLY

Supply Voltage V

DD

VSS = V

SSF

= 0V 4.5 5.0 5.5 V

FLASH Supply Voltage V

DDF

VSS = V

SSF

= 0V 4.5 5.0 5.5 V

Base Operating Current I

BO

CPU stopped (Note 2)

µA

CPU Current I

CPU

All modules off, CPU = on, additive to IBO,

I

CPU

= IDD + I

DDF

(Note 3)

µA

All modules off, ADC = on, ADC clk =

1MHz, additive to I

BO

; the CPU and ADC

are not on at the same time

ADC Current (Note 3) I

ADC

All modules off, ADC = on, ADC clk = 7kHz,

additive to I

BO

; the CPU and ADC are not

on at the same time

µA

DAC Current I

DACn

All modules off, DAC = on, additive to I

BO

(n = 1 or 2) (Note 4)

µA

Large Op-Amp Current I

OPLGn

All modules off, CPU stopped, large op

amp = on (n = 1 or 2)

µA

Small Op-Amp Current I

OPSMn

All modules off, CPU stopped, small op

amp = on (n = 1 or 2)

µA

POWER-ON RESET

V

DDF

POR Threshold VDD > V

DDF

3.6 4.0 4.3 V

V

DDF

POR Hysteresis

V

ANALOG INPUT

PGA[4:0] = 00000, CLK[2:0] = 000

PGA[4:0] = 01010, CLK[2:0] = 000 55

PGA[4:0] = 11111, CLK[2:0] = 000 36

kΩ

PGA[4:0] = 00000, CLK[2:0] = 011 3.4 MΩ

PGA[4:0] = 01010, CLK[2:0] = 011

PGA[4:0] = 11111, CLK[2:0] = 011

kΩ

PGA[4:0] = 00000, CLK[2:0] = 110 27

PGA[4:0] = 01010, CLK[2:0] = 110 3.5

Differential Input Impedance

(INP1 to INM1 and

INP2 to INM2)

R

DIN

PGA[4:0] = 11111, CLK[2:0] = 110 2.3

MΩ

575 720 890

540 840 1240

690 1040 1394

-0.85

430

440

288

465 765 1060

425 550 730

430 673 1020

110 190 265

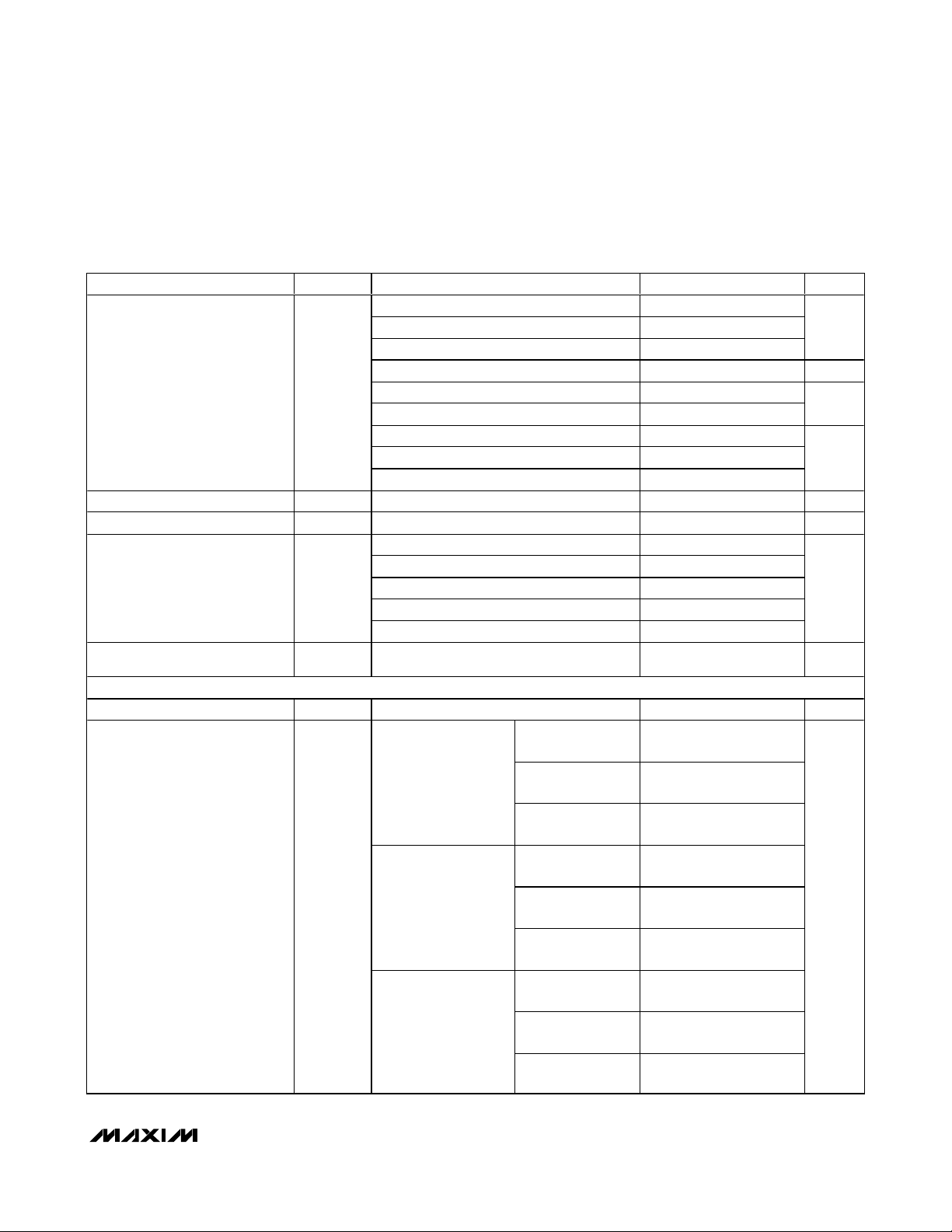

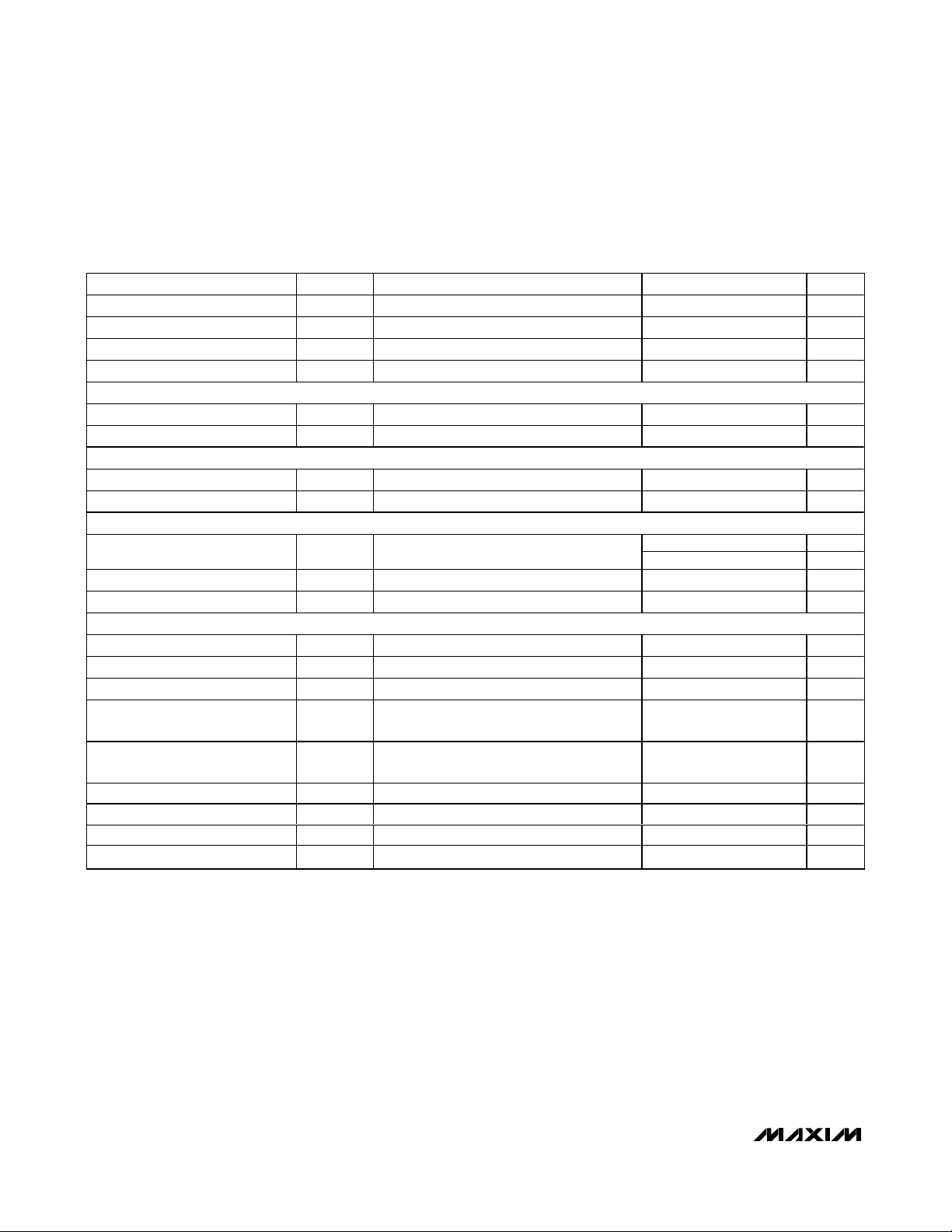

Page 3

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(V

DDF

= VDD= 4.5V to 5.5V, V

SSF

= VSS= 0V, f

CLK

= 4.0MHz, TA= T

MIN

to T

MAX

. Typical values are at V

DDF

= VDD= 5.0V, V

SSF

= VSS= 0V,

T

A

= +25°C, unless otherwise noted.) (Note 1)

Single-Sided Input Impedance

(INP1 to V

INP2 to V

Common-Mode Rejection Ratio CMRR Common-mode voltage VCM = V

Differential Signal-Gain Range Selectable in 17 steps (Note 5) 0.99 to 244 V/V

Differential Signal Gain A

Gain-Error Temperature

Coefficient

COARSE-OFFSET DAC

Resolution 3-bit plus sign 4 Bits

Effective Offset Adjustment at the

ADC Input

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

, INM1 to VSS,

SS

, INM2 to VSS)

SS

R

VDIFF

GETC

OA

SIN

ADC

ADC

PGA[4:0] = 00000, CLK[2:0] = 000 430

PGA[4:0] = 01010, CLK[2:0] = 000 55

PGA[4:0] = 11111, CLK[2:0] = 000 36

PGA[4:0] = 00000, CLK[2:0] = 011 3.4 MΩ

PGA[4:0] = 01010, CLK[2:0] = 011 440

PGA[4:0] = 11111, CLK[2:0] = 011 288

PGA[4:0] = 00000, CLK[2:0] = 110 27

PGA[4:0] = 01010, CLK[2:0] = 110 3.5

PGA[4:0] = 11111, CLK[2:0] = 110 2.3

PGA[4:0] = 00000 0.95 0.99 1.05

PGA[4:0] = 00001 7.3 7.7

PGA[4:0] = 01010 71 77 82

PGA[4:0] = 10100 137 153 168

PGA[4:0] = 11110 203 244 283

PGA[4:0] = 00000 -8 ppm/°C

REF = VDD,

CO[3:0] = 0111

REF = VDD,

CO[3:0] = 0011

REF = VDD,

CO[3:0] = 0000

to V

SS

PGA[4:0] =

00000 to 01000

PGA[4:0] =

01010 to 10000

PGA[4:0] =

10100 to 11110

PGA[4:0] =

00000 to 01000

PGA[4:0] =

01010 to 10000

PGA[4:0] =

10100 to 11110

PGA[4:0] =

00000 to 01000

PGA[4:0] =

01010 to 10000

PGA[4:0] =

10100 to 11110

DD

0.008 %FS

137 147 157

273 291 308

525 578 630

57 64 69

113 126 136

228 251 276

-3 -1 +1

-7 -2.4 +2

-11 -4 +3

8.2

kΩ

kΩ

MΩ

V/V

% of

ADC

Ref

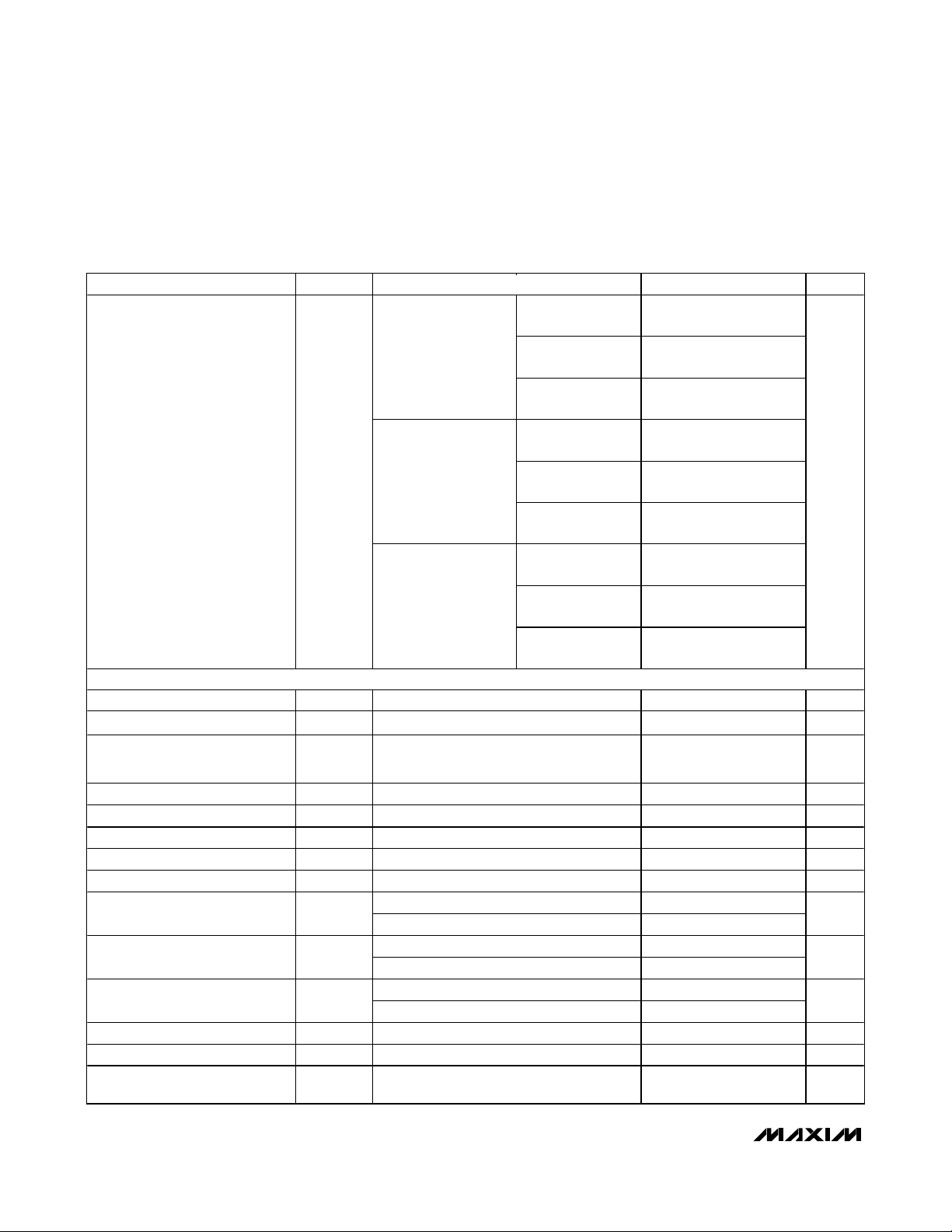

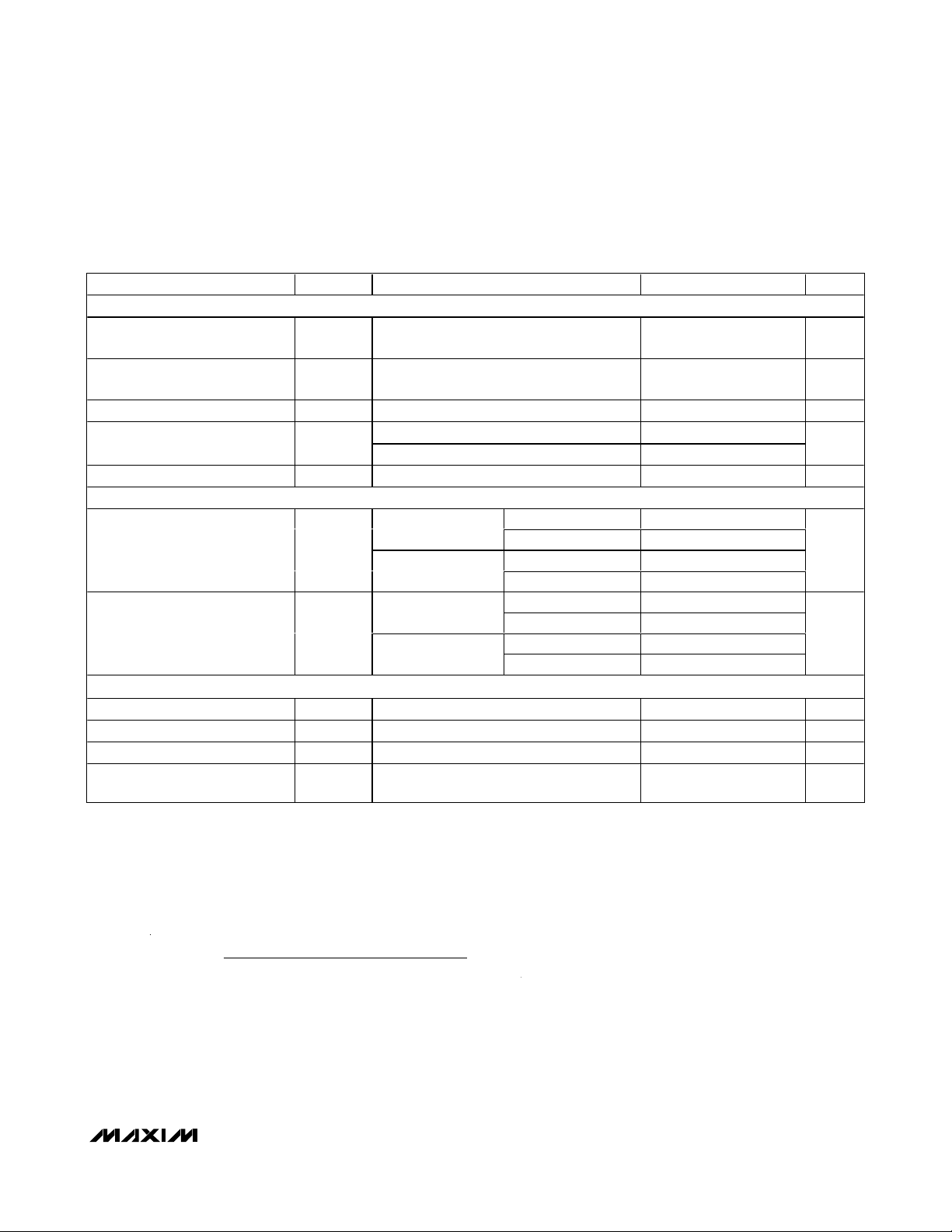

Page 4

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

DDF

= VDD= 4.5V to 5.5V, V

SSF

= VSS= 0V, f

CLK

= 4.0MHz, TA= T

MIN

to T

MAX

. Typical values are at V

DDF

= VDD= 5.0V, V

SSF

= VSS= 0V,

T

A

= +25°C, unless otherwise noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Effective Offset Adjustment at the

ADC Input

SMALL OP AMP

Input Offset Voltage VOS_

Input Bias Current IB_

DC Gain A

Gain Bandwidth Product GBW_

Slew Rate SR_

Common-Mode Input Range CMR_

Common-Mode Rejection Ratio CMRR_SMV

Power-Supply Rejection Ratio PSRR_

Input-Referred Noise Voltage VN_

Output High Voltage VOH_

Output Low Voltage VOL_

Output Source Current I

Output Sink Current I

Maximum Output Load

Capacitance

REF = VDD,

CO[3:0] = 1000

OA

ADC

REF = VDD,

CO[3:0] = 1011

REF = VDD,

CO[3:0] = 1111

SM

SM

VOL_SM

OUTnSM = 0.5V to 4.5V (n = 1 or 2),

R

LOAD

SMAVOL_SM

A

SM

VOL_SM

SM

CM_OPAMP

At DC 70 dB

SM

0.1Hz to 1kHz 8.5

SM

0.1Hz to 1MHz 100

R

SM

SM

SRC_SMVOUTnSM

SNK_SMVOUTnSM

C

_

L

SM

LOAD

R

LOAD

R

LOAD

R

LOAD

R

LOAD

PGA[4:0] =

00000 to 01000

PGA[4:0] =

01010 to 10000

PGA[4:0] =

10100 to 11110

PGA[4:0] =

00000 to 01000

PGA[4:0] =

01010 to 10000

PGA[4:0] =

10100 to 11110

PGA[4:0] =

00000 to 01000

PGA[4:0] =

01010 to 10000

PGA[4:0] =

10100 to 11110

= ∞

= +1V/V 2.7 MHz

= +1V/V 2.2 V/µs

= VSS to V

DD

= ∞ VDD - 0.1

= 4.7kΩ to V

SS

= ∞ 0.1

= 4.7kΩ to V

= V

= V

OH_SM

OL_SM

DD

, R

, R

LOAD

= 4.7kΩ to V

LOAD

= 4.7kΩ to V

= ∞, phase margin > 55° 120 pF

-15 -10 -4

-29 -19 -10

-56 -38 -20

-79 -73 -66

-155 -145 -135

-317 -287 -257

-162 -156 -150

-327 -309 -293

-675 -614 -555

0 ±15 mV

±1 nA

100 dB

VSS + 0.02 VDD - 0.02 V

70 dB

VDD - 0.15

SS

DD

-1.04 mA

% of

ADC

Ref

µV

RMS

V

0.15

V

1.04 mA

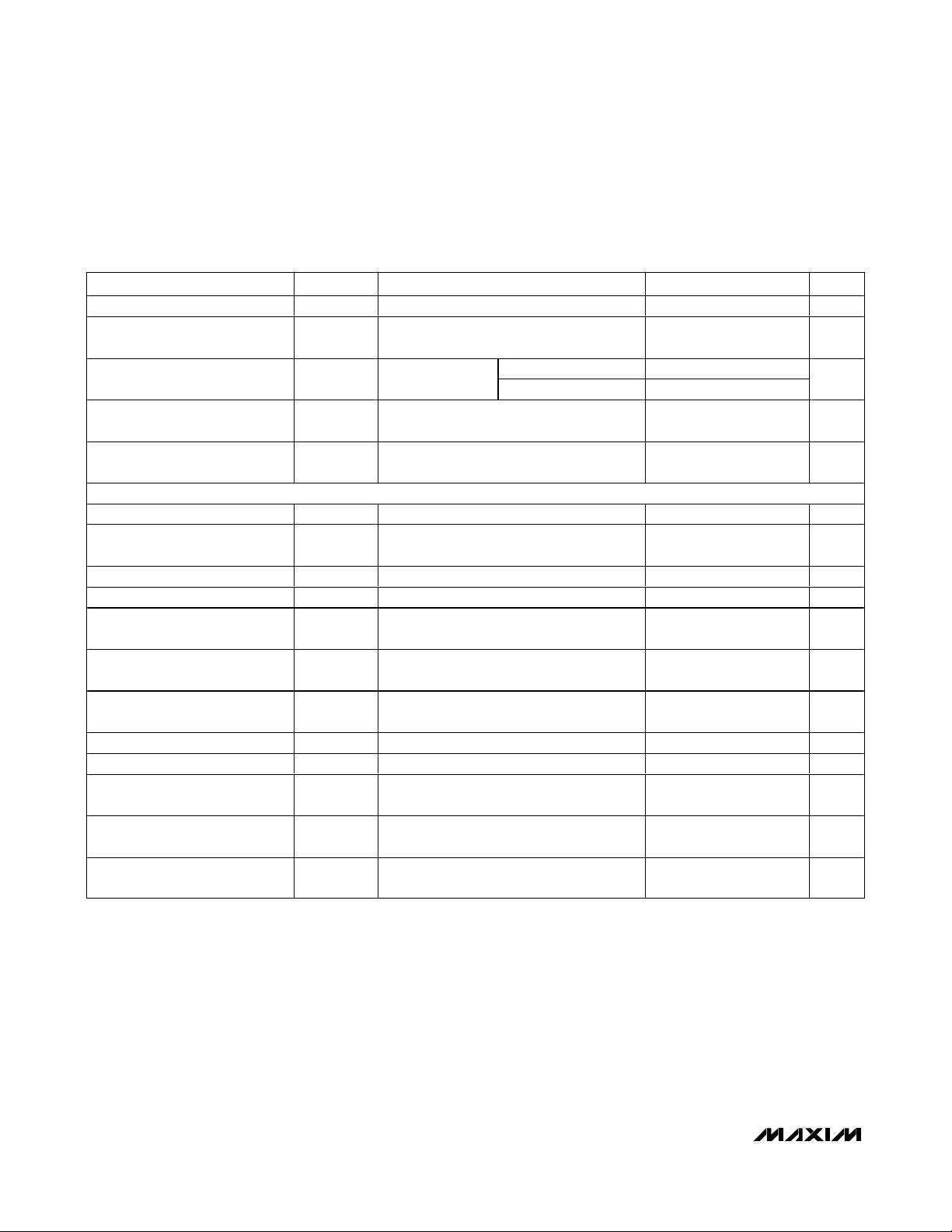

Page 5

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(V

DDF

= VDD= 4.5V to 5.5V, V

SSF

= VSS= 0V, f

CLK

= 4.0MHz, TA= T

MIN

to T

MAX

. Typical values are at V

DDF

= VDD= 5.0V, V

SSF

= VSS= 0V,

T

A

= +25°C, unless otherwise noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LARGE OP AMP

Input Offset Voltage

Input Bias Current IB_

DC Gain A

Gain Bandwidth Product GBW_

Slew Rate SR_

Common-Mode Input Range CMR_

Common-Mode Rejection Ratio CMRR_LGV

Power-Supply Rejection Ratio PSRR_

Input-Referred Noise Voltage VN_

Output-Voltage High VOH_

Output-Voltage Low VOL_

Output Source Current I

Output Sink Current I

Maximum Output Load

Capacitance

OP-AMP SWITCH

Analog Signal Range V

On-Resistance R

Off-Isolation V

DIGITAL-TO-ANALOG CONVERTER

Resolution RES

Integral Nonlinearity INL

Differential Nonlinearity DNL

Offset Error V

Bit Weight BW

Power-Supply Rejection PSR

Output Noise ON

Output Settling Time ST

PULSE-WIDTH MODULATOR

Resolution RES

Period P

V

OS_LG

LG

VOL_LG

OUTnLG = 0.5V to 4.5V (n = 1 or 2),

R

LOAD

LGAVOL_LG

A

LG

VOL_LG

LG

CM OPAMP

At DC 70 dB

LG

0.1Hz to 1kHz 19

LG

0.1Hz to 1MHz 160

R

LOAD

LG

R

LOAD

R

LOAD

LG

R

LOAD

SRC_LGVOUTnLG

SNK_LGVOUTnLG

C

_

L

SW

ON

ISO

DAC OS

DAC

PWMfCLK

R

LG

DAC

DAC

DAC

LOAD

DAC ref = VDD, DAC data = 0000h

DAC ref = 5VDC 91.55 µV/LSB

DAC

At DC, DAC ref = V

DAC

DAC buffer is the small op amp ±3 LSB

DAC

To 0.1% of final value 250 µs

(Note 6) 12 Bits

PWM

= 4.0MHz 8.192 ms

= ∞

= +1V/V 4.0 MHz

= +1V/V 3.2 V/µs

= VSS to V

= ∞ VDD - 0.1

= 1kΩ to V

= ∞ 0.03

= 1kΩ to V

= V

OH_LG

= V

OL_LG

= ∞, phase margin > 55° 200 pF

SS

DD

DD

, R

= 1kΩ to V

LOAD

, R

REF

LOAD

= 1kΩ to V

VSS + 0.02 V

VDD - 0.125

SS

DD

V

V

SS

/ 2

DD

- 0.06

0±6mV

±225 nA

100 dB

- 0.02 V

DD

70 dB

µV

RMS

V

0.13

V

-4.9 mA

4.9 mA

V

DD

V

5kΩ

80 dB

16 Bits

3 Bits

±1 Bits

V

/ 2

DD

+ 0.06

V

0.02 %FS

Page 6

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

DDF

= VDD= 4.5V to 5.5V, V

SSF

= VSS= 0V, f

CLK

= 4.0MHz, TA= T

MIN

to T

MAX

. Typical values are at V

DDF

= VDD= 5.0V, V

SSF

= VSS= 0V,

T

A

= +25°C, unless otherwise noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Bit Weight BW

Offset Error V

Gain Error GE

Output Jitter OJ

EXTERNAL REFERENCE INPUT

Reference Input Voltage Range V

Reference Input Resistance R

INTERNAL VOLTAGE REFERENCE

Internal Voltage Reference V

Temperature Coefficient TC

TEMPERATURE SENSOR

Sensitivity Sens

Nonlinearity Error INL

Hysteresis Hist

ANALOG-TO-DIGITAL CONVERTER

Resolution RES

Integral Nonlinearity INL

Differential Nonlinearity DNL

ADC Offset Error V

Channel-to-Channel Offset Error

Matching

ADC Offset-Supply Rejection OSR

ADC Gain-Supply Rejection GSR

Offset Temperature Coefficient TA = -40°C to +125°C 0.03 %FS

Ratiometricity PGA[4:0] = 00000 to 01000 0.02 %FS

PWM_OS

REF

REF

ADC_OS

∆V

ADC_OS

PWM

PWM

PWM

IR

IR

TS

TS

TS

ADC

ADC

ADC

ADC

ADC

PWM data = 0000h ±1 µs

(Note 7) ±0.025 %

V

= 2.5V, ADC = ON, DACs = ON 100 kΩ

REF

(Note 8) 4.5 4.92 5.35 V

PGA[4:0] = 00001, CO[3:0] = 0110

PGA[4:0] = 00000 (0.99),

CO[3:0] = 0000 (Note 9)

At DC, ADC ref = V

At DC, ADC ref = V

= 5V 0.3 %FS

REF

= 5V 0.005 %FS

REF

2 µs/LSB

1/4 LSB

2.25 2.5 2.75 V

±110 ppm/°C

+2 mV/°C

+95 LSB/°C

±0.5 %FS

±0.1 %FS

16 Bits

2 Bits

±1 LSB

4 %FS

±1 LSB

Page 7

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(V

DDF

= VDD= 4.5V to 5.5V, V

SSF

= VSS= 0V, f

CLK

= 4.0MHz, TA= T

MIN

to T

MAX

. Typical values are at V

DDF

= VDD= 5.0V, V

SSF

= VSS= 0V,

T

A

= +25°C, unless otherwise noted.) (Note 1)

Note 1: Current into a pin is defined as positive. Current out of a pin is defined as negative. All voltages are referenced to V

SS

.

Note 2: All modules are off, except internal reference, oscillator, and power-on reset (POR) and CKSEL bit is set to zero.

Note 3: The CPU and ADC are not on at the same time. The ADC and CPU currents are not additive.

Note 4: I

DACn

does not include output buffer currents (I

OPLGn

or I

OPSMn

).

Note 5: For gains above 240, an additional digital gain can be provided by the CPU.

Note 6: The PWM input data is the 12-bit left-justified data in the 16-bit input field.

Note 7: PWM gain error measured as:

Note 8: The internal reference voltage has a nominal value of 5V (4

✕ V

BG

) even when VDDis greater or less than 5VDC.

Note 9: Input-referred offset error is the ADC offset error divided by the PGA gain.

Note 10: When the CKIO is configured in output mode to observe the internal oscillator signal, the total current is above the

specified limits.

Note 11: f

CLK

must be within 5% of 4MHz.

Note 12: Allow a minimum elapsed time of 4.2ms when executing a FLASH erase command, before sending any other command.

Allow a minimum elapsed time of 80µs between FLASH write commands.

Note 13: FLASH programming current is guaranteed by design.

GE

PWM F Xh PWM Xh

PWM

OUT OUT

=

()−()

×

00 100

3584

100%

DIGITAL INPUTS (GPIO1, GPIO2, SCLK, DI, CKSEL, CKIO, CS)

Input High Threshold Voltage V

Input Low Threshold Voltage V

Input Hysteresis V

Input Leakage Current I

Input Capacitance C

DIGITAL OUTPUTS (GPIO1, GPIO2, DO, CKIO)

Output-Voltage High V

Output-Voltage Low V

FLASH MEMORY

Maximum Erase Cycles (Notes 11, 12) 10k Cycles

Minimum Erase Time t

Minimum Write Time t

FLASH Programming Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IH

IL

IHYS

IN

IN

OH

OL

ERASE

WRITE

DDFP

CKSEL, CS = V

GPIO1, GPIO2, SCLK, DI, CKIO = V

R

= ∞

LOAD

R

= 2kΩ to V

LOAD

R

= ∞

LOAD

R

= 2kΩ to V

LOAD

(Notes 11, 12) 4.2 ms

(Notes 11, 12) 80 µs

Writing to the FLASH or erasing the FLASH

(Note 13)

SS

SS

DD

DD

GPIO1, GPIO2, DO VDD - 0.1

CKIO (Note 10) 4.9

GPIO1, GPIO2, DO VDD - 0.15

CKIO (Note 10) 4.6

GPIO1, GPIO2, DO 0.05

CKIO (Note 10) 0.1

GPIO1, GPIO2, DO 0.2

CKIO (Note 10) 0.4

0.8 x

V

DD

0.2 x

0.2 V

38 -90

38 +90

5pF

30 mA

V

DD

V

V

µA

V

V

Page 8

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

8 _______________________________________________________________________________________

TIMING CHARACTERISTICS

(V

DDF

= VDD= 4.5V to 5.5V, V

SSF

= VSS= 0V, f

CLK

= 4.0MHz, TA= T

MIN

to T

MAX

. Typical values are at V

DDF

= VDD= 5.0V, V

SSF

= VSS= 0V,

T

A

= +25°C, unless otherwise noted.) (Note 1)

PARAMETER

CONDITIONS

UNITS

Programming Temperature T

PROG

°C

Internal Oscillator Clock

Frequency

f

ICLK

OSC[4:0] = 00000 3.3

5.3

MHz

Min 0.2

External Clock Frequency f

ECLK

V

CKSEL

= 0

Max 5

MHz

External Master Clock Input Low

Time

t

ECLK

= 1 / f

ECLK

40 60

%

t

ECLK

External Master Clock Input High

Time

t

ECLK

= 1 / f

ECLK

40 60

%

t

ECLK

SERIAL INTERFACE (Figure 1)

SCLK Setup to Falling Edge CS t

SC

30 ns

CS Falling Edge to SCLK Rising

Edge Setup Time

t

CSS

30 ns

CS Idle Time t

CSI

f

CLK

= 4MHz 1.5 µs

CS Period t

CS

f

CLK

= 4MHz 4 µs

SCLK Falling Edge to Data Valid

Delay

t

DO

C

LOAD

= 200pF 80 ns

Data Valid to SCLK Rising Edge

Setup Time

t

DS

30 ns

Data Valid to SCLK Rising Edge

Hold Time

t

DH

30 ns

SCLK High Pulse Width t

CH

ns

SCLK Low Pulse Width t

CL

ns

CS Rising Edge to SCLK Rising

Edge Hold Time

t

CSH

30 ns

CS Falling Edge to Output

Enable

t

DV

C

LOAD

= 200pF 25 ns

CS Rising Edge to Output

Disable

t

TR

C

LOAD

= 200pF 25 ns

SYMBOL

f

ECLKIN_LO

f

ECLKIN_HI

MIN TYP MAX

125

4.15

100

100

Page 9

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

_______________________________________________________________________________________ 9

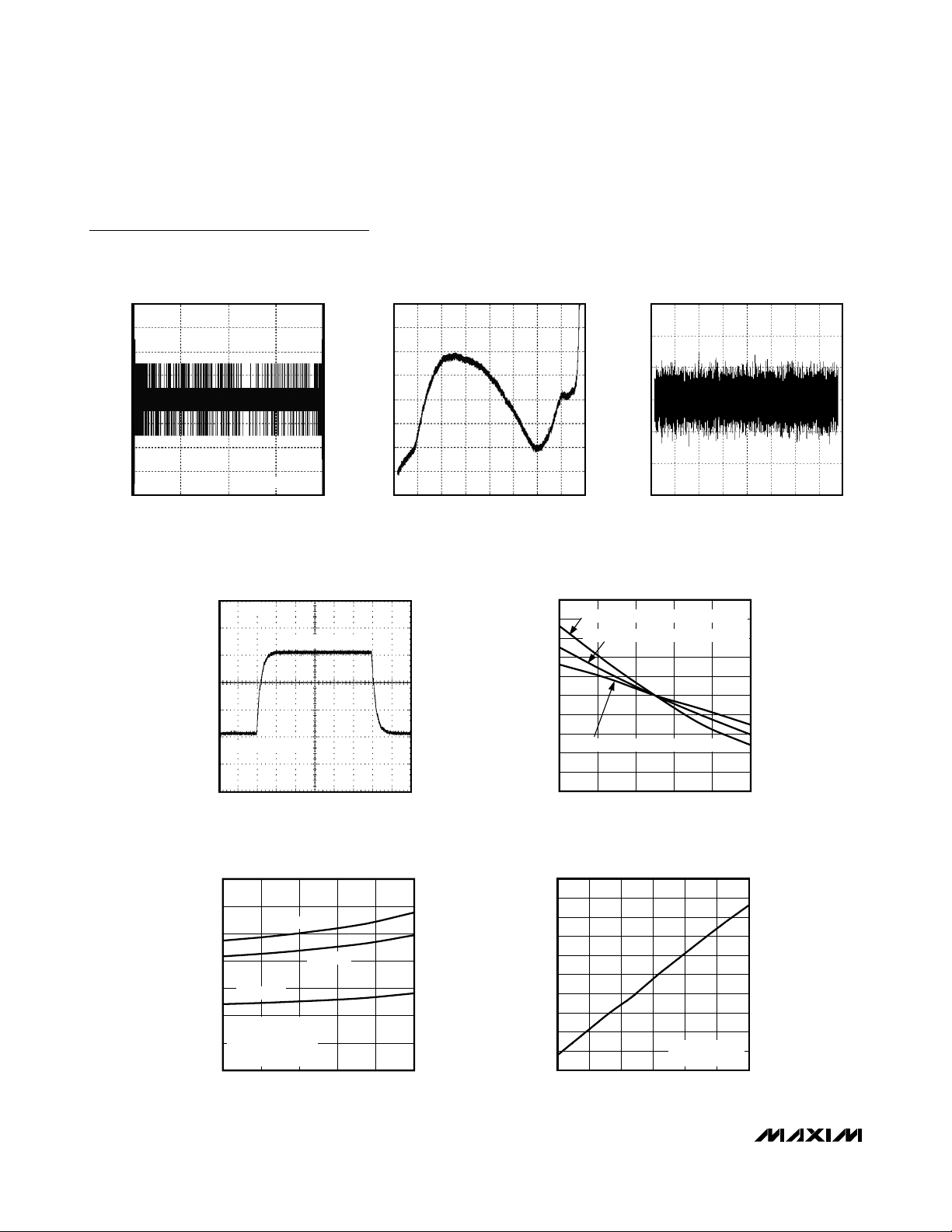

Typical Operating Characteristics

(VDD= 5.0V, TA= +25°C, unless otherwise noted.)

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX1464 toc01

SUPPLY VOLTAGE, VDD (V)

SUPPLY CURRENT, I

DD

(mA)

5.35.14.7 4.9

2.30

2.35

2.40

2.45

2.50

2.55

2.60

2.65

2.25

4.5 5.5

CPU ON 2% OF TIME

ADC ON 98% OF TIME

ADC

CLK

= 1MHz

DAC1 ON

SMALL OP AMP ON

TA = +125°C

TA = +25°C

TA = -40°C

SUPPLY CURRENT

vs. INTERNAL CLOCK FREQUENCY

MAX1464 toc02

INTERNAL CLOCK FREQUENCY (MHz)

SUPPLY CURRENT, I

DD

(mA)

4.54.03.5

2.25

2.30

2.35

2.40

2.45

2.50

2.55

2.60

2.65

2.70

2.20

3.0 5.0

CPU ON 2% OF TIME

ADC ON 98% OF TIME

ADC

CLK

= 1MHz

DAC1 ON

SMALL OP AMP ON

MODULE CURRENT

vs. TEMPERATURE

MAX1464 toc03

TEMPERATURE (°C)

MODULE CURRENT (mA)

98704315-13

0.7

0.9

1.1

1.3

1.5

1.7

1.9

2.1

2.3

2.5

0.5

-40 125

DAC + LARGE OP AMP

DAC + SMALL OP AMP

ADC

BASE

BASE OPERATING CURRENT

vs. SUPPLY VOLTAGE

MAX1464 toc04

SUPPLY VOLTAGE, VDD (V)

BASE OPERATING CURRENT, I

BO

(mA)

5.35.14.7 4.9

0.67

0.69

0.71

0.73

0.75

0.77

0.79

0.81

0.65

4.5 5.5

TA = +125°C

TA = +25°C

TA = -40°C

ADC RATIOMETRICITY ERROR

vs. SUPPLY VOLTAGE

MAX1464 toc05

SUPPLY VOLTAGE, VDD (V)

ADC RATIOMETRICITY ERROR (%FS)

5.35.14.7 4.9

-0.03

-0.02

-0.01

0

0.01

0.02

0.03

0.04

-0.04

4.5 5.5

ADC INPUT = 0.75 x V

DD

ADC INPUT = 0.5 x V

DD

ADC INPUT = 0

ADC INPUT = -0.75 x V

DD

ADC INPUT = -0.5 x V

DD

ADC

REF

= V

DD

PGA[4:0] = 00000

ADC INL

MAX1464 toc06

1.00.5-0.5 0-1.0

INPUT VOLTAGE NORMALIZED TO FULL SCALE

ADC NONLINEARITY ERROR (%FS)

-0.004

-0.002

0

0.002

0.004

0.006

-0.006

PGA[4:0] = 01000

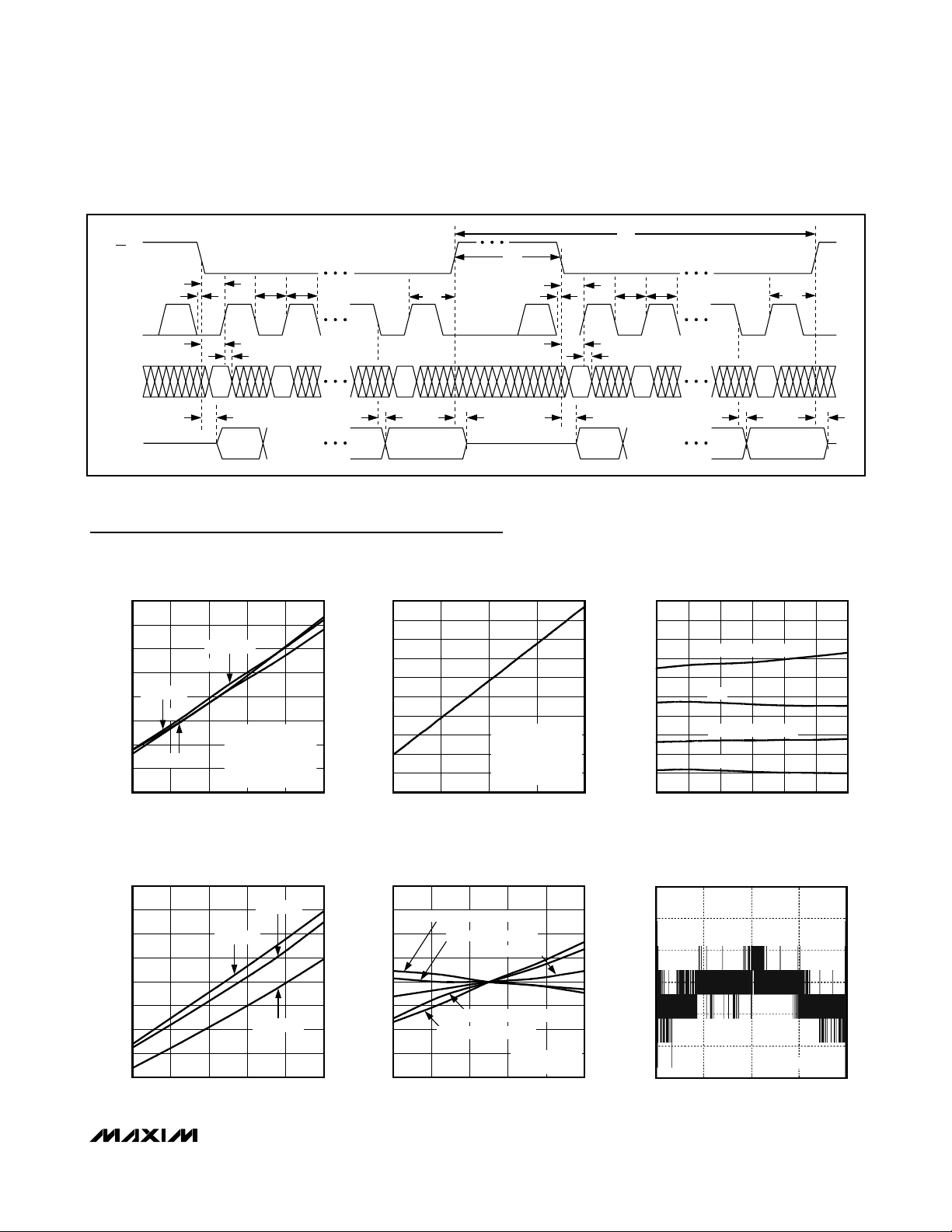

Figure 1. Serial Interface Timing Diagram

CS

t

SCLK

DI

DO

CSS

t

SC

t

DS

t

DV

t

DH

tCLt

CH

t

DO

t

CS

t

CSI

t

CSS

t

CSH

t

TR

t

SC

t

DS

t

DV

t

DH

tCLt

CH

t

DO

t

CSH

t

TR

Page 10

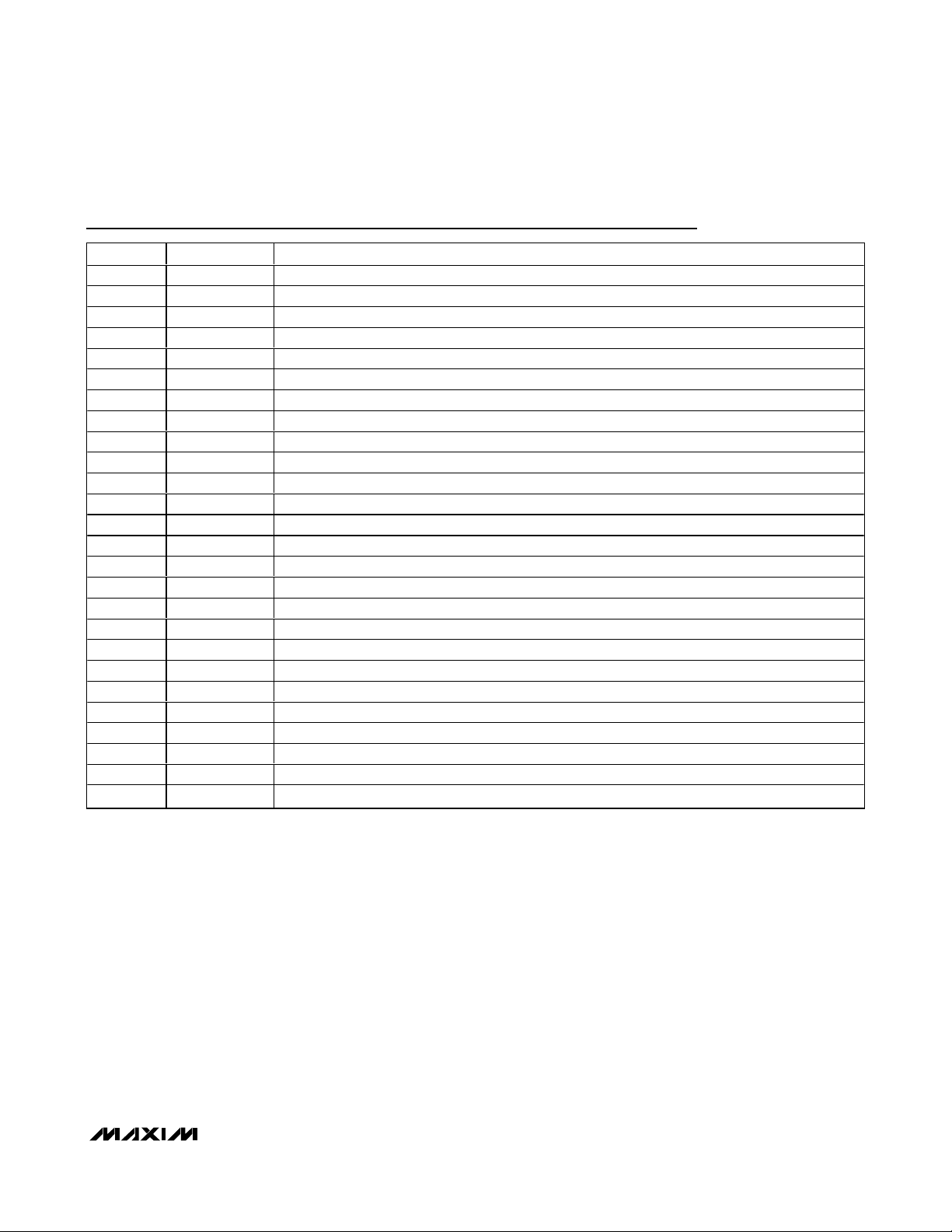

TEMPERATURE SENSOR OUTPUT

vs. TEMPERATURE

MAX1464 toc13

TEMPERATURE (°C)

TEMPERATURE SENSOR OUTPUT (ADC CODE)

97.5 125.070.042.515.0-12.5

0

-2000

4000

2000

8000

12,000

10,000

14,000

6000

16,000

-4000

-40.0

PGA[4:0] = [00001]

CO[3:0] = 0110

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VDD= 5.0V, TA= +25°C, unless otherwise noted.)

INTERNAL OSCILLATOR FREQUENCY

vs. SUPPLY VOLTAGE

MAX1464 toc12

SUPPLY VOLTAGE, VDD (V)

INTERNAL OSCILLATOR FREQUENCY (MHz)

5.35.14.94.7

3.85

3.90

3.95

4.00

4.05

4.10

4.15

3.80

4.5 5.5

TA = -40°C

TA = +125°C

T

A

= +25°C

OSCILLATOR

FREQUENCY TRIMMED

TO 4MHz AT +25°C,

V

DD

= 5V

4

3

2

1

0

-1

ADC DNL ERROR (LSB)

-2

-3

-4

-1.0 1.0

INPUT VOLTAGE NORMALIZED TO FULL SCALE

1V/div

ADC DNL

PGA[4:0] = 01000

0.50-0.5

DAC DYNAMIC RESPONSE

5

4

3

2

1

DAC CODE = C000h

0

MAX1464 toc07

DAC CODE = 4000h

200µs/div

0.04

DAC INL

0.03

0.02

0.01

0

-0.01

-0.02

DAC NONLINEARITY ERROR (%FS)

-0.03

-0.04

-0.8 0.8

INPUT NORMALIZED TO FULL SCALE

MAX1464 toc10

ERROR (%FS)

3

2

MAX1464 toc08

1

0

-1

DAC DNL ERROR (LSB)

-2

0.60.4-0.6 -0.4 -0.2 0 0.2

-3

-0.8 0.8

INPUT VOLTAGE NORMALIZED TO FULL SCALE

DAC RATIOMETRICITY ERROR

vs. SUPPLY VOLTAGE

0.05

0.04

0.03

0.02

0.01

-0.01

-0.02

-0.03

-0.04

-0.05

DAC INPUT = 5555CH (4.5V AT VDD = 5V)

DAC INPUT = 0000CH (2.5V AT VDD = 5V)

0

DAC INPUT = AAABCH (0.5V AT VDD = 5V)

4.5 5.5

SUPPLY VOLTAGE, VDD (V)

DAC DNL

MAX1464 toc09

0.60.40.20-0.2-0.4-0.6

MAX1464 toc11

5.35.14.94.7

Page 11

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

______________________________________________________________________________________ 11

Pin Description

PIN NAME FUNCTION

1 OUT1SM Small Op Amp 1 Output

2 AMP1M Op Amp 1 Negative Input

3 AMP1P Op Amp 1 Positive Input

4 OUT1LG Large Op Amp 1 Output

5, 7 N.C. No Connection

6VDDPositive Supply Voltage Input. Bypass VDD to VSS with a 0.1µF ceramic capacitor.

8 CKSEL Clock-Select Digital Input

9 CKIO Clock Digital Input/Output

10 CS SPI Chip-Select Digital Input. Active low.

11 DO SPI Data Output

12 DI SPI Data Input

13 SCLK SPI Interface Clock

14, 19 V

15 V

16 GPIO1 General-Purpose Digital Input/Output 1

17 GPIO2 General-Purpose Digital Input/Output 2

18 V

20 INM2 Negative Input for ADC Channel 2

21 INP2 Positive Input for ADC Channel 2

22 INM1 Negative Input for ADC Channel 1

23 INP1 Positive Input for ADC Channel 1

24 V

25 OUT2LG Large Op Amp 2 Output

26 AMP2P Op Amp 2 Positive Input

27 AMP2M Op Amp 2 Negative Input

28 OUT2SM Small Op Amp 2 Output

SS

DDF

SSF

REF

Negative Power-Supply Input

Positive Supply Voltage for FLASH Memory. Bypass V

Negative Power-Supply Input for FLASH Memory

External Reference Voltage Input for ADC and DACs

to VSS with a 0.1µF ceramic capacitor.

DDF

Page 12

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

12 ______________________________________________________________________________________

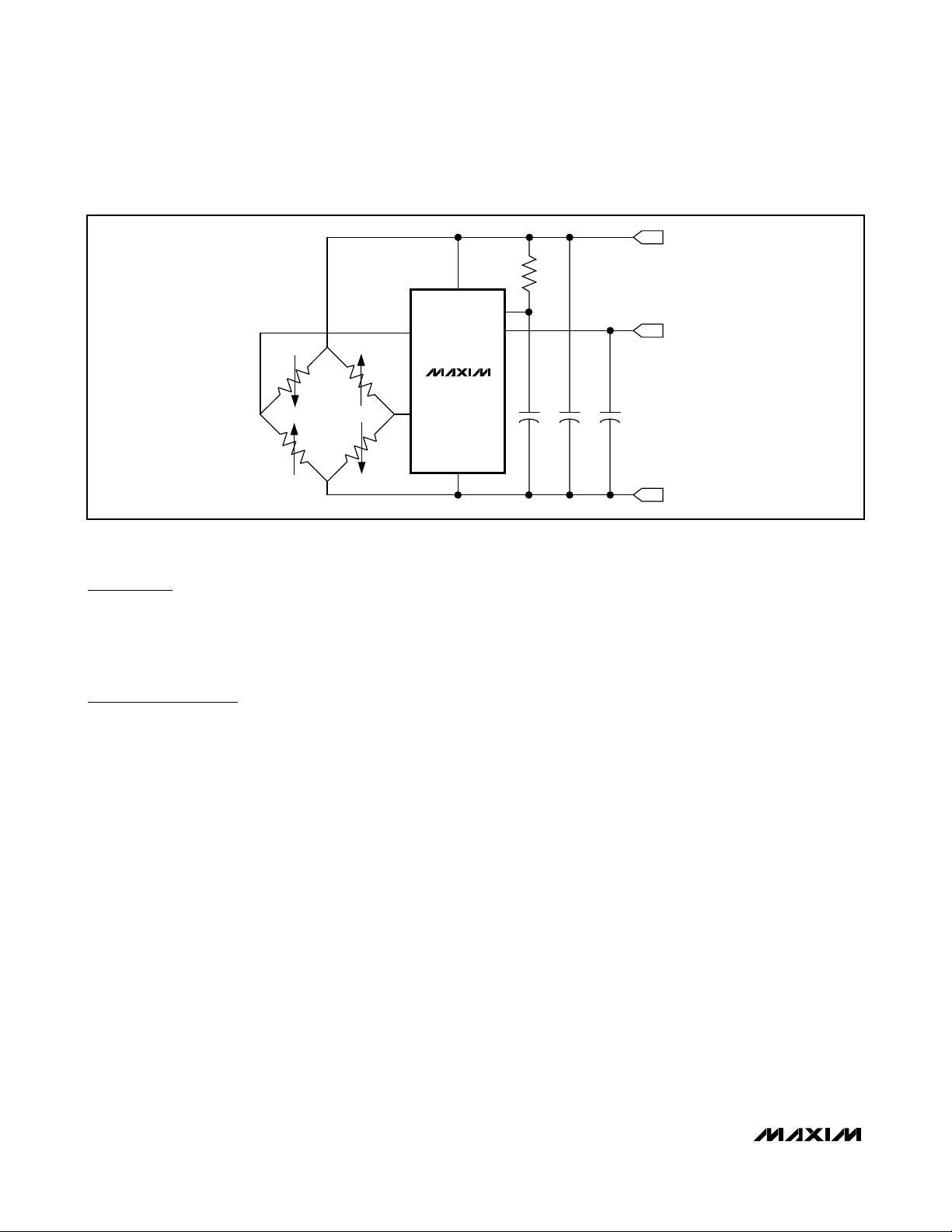

Typical Application Circuit

Analog ratiometric output configuration (Figure 2) provides an output that is proportional to the power-supply

voltage. Ratiometricity is an important consideration for

automotive, battery-operated instruments, and some

industrial applications.

Detailed Description

The MAX1464 is a highly integrated, low-power, lownoise multichannel sensor signal processor optimized

for industrial, automotive, and process-control applications, such as pressure sensing and compensation,

RTD and thermocouple linearization, weight sensing

and classification, and remote process monitoring with

limit indication.

The MAX1464 incorporates a 16-bit CPU, user-programmable 4kB of FLASH memory, 128 bytes of FLASH user

information, 16-bit ADC, two 16-bit DACs, two 12-bit

PWM digital outputs, four rail-to-rail op amps, SPI interface, two GPIOs, and one on-chip temperature sensor.

Each sensor signal can be amplified, compensated for

temperature, linearized, and the offset and full scale

can be adjusted to the desired value. The MAX1464

can provide outputs as analog voltage (DAC) or digital

(PWM, GPIOs), or simple on/off alarm indication

(GPIOs). The uncommitted op amps can be used to

implement 4–20mA current loops or for additional gain

and filtering. Each DAC output is routed to either a

small or large op amp. Large op amps are capable of

driving heavier external loads. The unused circuit functions can be turned off to save power.

All sensor linearization and on-chip temperature compensation is done by a user-defined algorithm stored in

FLASH memory. The user-defined algorithm is programmed over the serial interface and stored in 4kB of

integrated FLASH memory.

The MAX1464 uses an internal 4MHz oscillator or an

externally supplied 4MHz clock. CPU code execution

and ADC operation is fully synchronized to minimize

the noise interference of a CPU-based sensor processor system. The CPU sequentially executes instructions

stored in FLASH memory.

Sensor Input

The MAX1464 provides two differential signal inputs,

INP1-INM1 and INP2-INM2. These inputs can also be

configured as four single-ended signals. Each input

can have a common-mode range from VDDto VSSand

a 0.99V/V to 244V/V programmable-gain range. The differential input signals are summed with the output of

the coarse offset DAC (CO DAC) for offset correction

prior to being amplified by the programmable-gain

amplifier (PGA). The resulting signal is applied to the

differential input of the ADC for conversion.

The CPU can be programmed to measure one or two

differential inputs plus the internal temperature sensor

defined in user-supplied algorithm. For example, the

differential inputs can be measured many times while

the temperature can be measured less frequently.

Figure 2. Basic Bridge Sensor Ratiometric Output Configuration

22Ω

V

DD

V

DDF

INPn

OUTnSM OUT

5VDC

SENSOR

INMn

MAX1464

V

SS

0.1µF

0.1µF 100pF

GND

Page 13

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

______________________________________________________________________________________ 13

On-Chip Temperature Sensing

The on-chip temperature sensor changes +2mV/°C over

the operating range. The ADC converts the temperature

sensor in a similar manner as the sensor inputs. During

an ADC conversion of the temperature sensor, the ADC

automatically uses four times the internal 1.25V reference

as the ADC full-scale reference (5V). The temperature

data format is 15-bit plus sign in two’s-complement format. Gain offset compensation can be programmed to

utilize the full-scale range of the ADC. Offset compensation by the CO DAC is provided so that the nominal temperature measurement can be centered at the ADC

output value. Use the CPU to provide additional digital

gain and offset correction.

Output Format

There are two output modules in the MAX1464—DOP1

(DAC Op Amp PWM 1) and DOP2 (DAC Op Amp PWM

2). Each of the DOP modules contains a 16-bit DAC, a

12-bit digital PWM converter, a small op amp, and a

large op amp with high-output-drive capability. Each

module can be configured in several different modes to

suit a wide range of output signal requirements. Either

the DAC or the PWM can be selected as the primary

output signal. The DAC output signal must be routed to

one of the two op amps before being made available to

a device pin. See the DAC, Op Amp, PWM Modules

(DPOn) section for details. Additional digital outputs are

available on the GPIOs.

Initialization

A user-defined initialization routine is required to configure the oscillator frequency and various analog modules,

e.g., PGA gain, ADC resolution, ADC clock settings, etc.

After the initialization routine, the CPU can start execution

of the main program.

Power-On Reset (POR)

The MAX1464 contains a POR circuit to disable CPU

execution until adequate VDDand V

DDF

voltage are

available for operation. Once the power-on state has

been reached, the MAX1464 is kept under reset condition for 250µs before the CPU starts execution. Below

the POR threshold, all internal CPU registers are set to

their POR default state. Power-on control bits for internal

modules are reset to the OFF condition.

CPU Architecture

The CPU provides a wide range of functionality to be

incorporated in an embedded system. The CPU can

compensate nonlinear and temperature-dependent sensors, check for over/underlimit conditions, output sensor

or temperature data as an analog signal or pulse-widthmodulated digital signal, and execute control strategies.

The CPU can perform a limited amount of signal processing (filtering). A timer is included so that uniform

sampling (equally spaced ADC conversions) of the

input sensors can be performed.

The CPU registers and ports are implemented in volatile,

static memory. There are several registers contained in

various peripheral modules that provide module configuration settings, control functions, and data. These module

registers are accessible through an indirect addressing

scheme as described in detail in the CPU Registers,

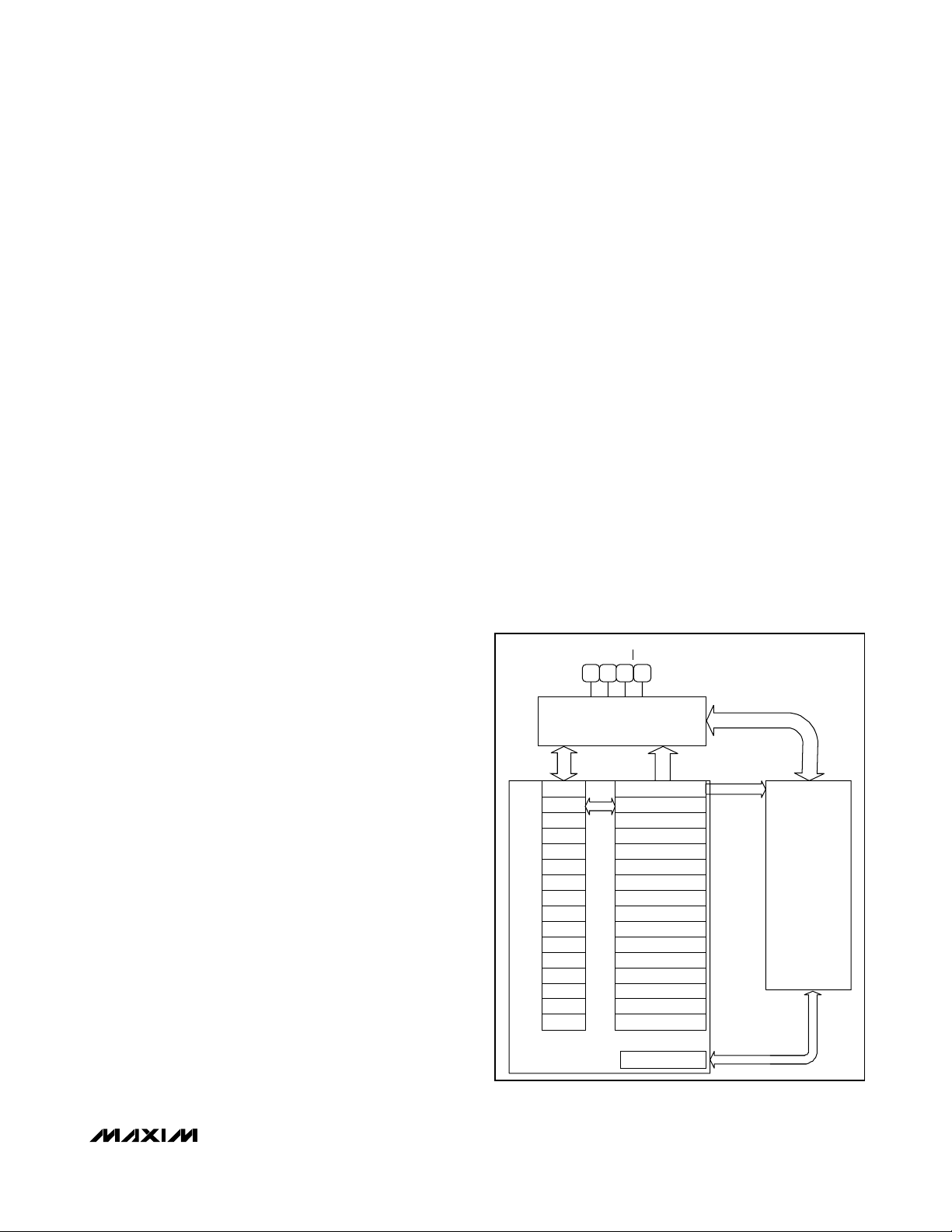

CPU Ports, and Modules sections. Figure 3 shows the

CPU architecture.

CPU Registers

The MAX1464 incorporates a CPU with 16 internal registers. All the CPU registers have a 16-bit data word width.

Five of the 16 registers have predefined functional operations that are dependent on the instruction being executed. The remaining registers are general purpose.

The CPU registers are embedded in the CPU itself and

are not all directly accessible by the serial interface. The

accumulator register (A), the pointer register (P), and the

instruction (FLASH data) can be read through the serial

interface when the CPU is halted. This enables a single-

Figure 3. CPU Architecture

SCLKDIDO

SERIAL INTERFACE

P0

P1

P2

P1

CPU

P3

P4

P5

P6

P7

P8

PA

PB

PC

PD

PE

PF

CPU PORTS

CS

R0 POINTER (P)

R1 ACCUMULATOR (A)

R2

R3 MULTIPLICAND (N)

R4 MULTIPLIER (M)

R5 INDEX (I)

R6

R7

R8

R9

RA

RB

RC

RD

RE

RF

CPU REGISTERS

INSTRUCTION

ADDRESS

FLASH DATA

FLASH MEMORY

(4kB)

Page 14

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

14 ______________________________________________________________________________________

step mode of code execution to ease code writing and

debugging. A special program instruction sequence is

required to observe the other CPU registers. Table 1 lists

the CPU registers.

CPU Ports

The MAX1464 incorporates 16 CPU ports that are directly

accessible by the serial interface. All the CPU ports have

a 16-bit data word width. The contents of the ports can

be read and written by transferring data to and from the

accumulator register (A) using the RDX and WRX instructions. No other CPU instructions act on the CPU ports.

Three CPU ports PD, PE, and PF have uniquely defined

operation for reading and writing data to and from the

peripheral modules. All CPU ports are static and volatile.

Table 2 lists the CPU ports.

Modules

The MAX1464 modules are the functional blocks used

to process analog and digital signals to and from the

CPU. Each module is addressed through CPU ports PD,

PE, and PF, as described in the CPU Ports section. All

modules use static, volatile registers for data retention.

There are three types of module registers: configuration,

data, and control. They are used to put a module into a

particular mode of operation. Configuration registers

hold configuration bits that control static settings such

as PGA gain, coarse offset, etc. Data registers hold

input data such as DAC and PWM input words or output

data such as the result of an ADC conversion. Control

registers are used to initiate a process (such as an ADC

conversion or a timer) or to turn modules on and off

(such as op amps, DAC outputs, PWM outputs, etc.)

Table 3 lists the module registers.

ADC Module

The ADC module (Figure 4) contains a 9-bit to 16-bit

sigma-delta converter with multiplexed differential and

single-ended signal inputs, a CO DAC, four reference

voltage inputs, two differential or four single-ended

external inputs, and 15 single-ended internal voltages

for measurement. The ADC output data is 16-bit two’scomplement format. The conversion channel, modes,

and reference sources are all set in ADC configuration

registers. The conversion time is a function of the selected resolution and ADC clock frequency. The CPU can

be programmed to convert any of the inputs and the

internal temperature sensor in any desired sequence.

For example, the differential inputs may be converted

many times and conversions of temperature performed

less frequently. See Table 4.

The ADC reference can be selected as VDDfor conversions ratiometric to the power supply, 2 x V

REF

input for

conversions relative to an external voltage, and VBGx 4,

which is an internally generated bandgap reference

voltage. Note that because V

REF

external = 2.5V and

V

BG

= 1.25V, the ADC’s reference voltage is always

close to 5.0V. The ADC voltage reference is also used

by the CO DAC to maintain a signal conversion that is

completely ratiometric to the selected reference source.

The four analog inputs (INP1, INM1, INP2, INM2) and

several internal circuit nodes can be multiplexed to the

ADC for a single-ended conversion relative to V

SS

. The

selection of which circuit node is multiplexed to the ADC

is controlled by the ADC_Control register. The ADC can

measure each of the op-amp output nodes with gain for

converting user-defined circuits or incorporating system

diagnostic test functions. The DAC outputs can be converted by the ADC with either op amp arranged as

unity-gain buffers on the DAC outputs. The internal

power nodes, VDDand VSS, and the bandgap reference,

V

BG

can be multiplexed to the ADC for conversion as

well. These measurement modes are defined and initiated in the ADC_Control register. See Tables 5 and 7 for

the single-ended configuration.

ADC Registers

The ADC module has 10 registers for configuration,

control, and data output. There are three conversion

channels in the ADC; channel 1, channel 2, and temperature. Channels 1 and 2 are associated with the differential signal input pairs INP1-INM1 and INP2-INM2,

respectively. The temperature channel is associated

with the integrated temperature sensor. Each channel

has two configuration registers (ADC_Config_nA and

ADC_Config_nB where n = 1, 2, or T) for setting conversion resolution, reference input, coarse offsets, etc.

The data output from a conversion of channel 1, 2, or T

is stored in the respective data output register

ADC_Data_n where n = 1, 2, or T. Each of the channels

can be used to convert single-ended inputs as listed in

Table 7. The ADC_Control register controls which channel is to be converted and what single-ended input, if

any, is to be directed to that channel. See Tables 8

through 13.

Conversion Start

To initiate an ADC conversion, a word is written to the

ADC_Control register with either CNVT1, CNVT2, or

CNVTT bit set to a 1 (Table 6). When an ADC conversion is initiated, the CPU is halted and all CPU and

FLASH activities cease. All CNVT1, CNVT2, and CNVTT

bits are cleared after the ADC conversion is completed.

Upon completion of the conversion, the ADC result is

latched into the respective ADC_Data_n register. In

addition, the convert bits in control register 0 are all

reset to zero. The CPU clock is then enabled and program execution continues

Page 15

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

______________________________________________________________________________________ 15

Single-ended inputs can be converted by either channel

1 or 2 by initiating a conversion on the appropriate channel with the SE[3:0] bits set to the desired single-ended

input (Table 7). Several of the single-ended signals are

converted with a fixed gain. The reduced gain of 0.7V/V

allows signals at or near the supply rails to be converted

without concern of saturation. Other single-ended signals

can be converted with the full selectable PGA gain range.

Programmable-Gain Amplifier

The gain of the differential inputs and several

single-ended inputs can be set to values between

0.99V/V to 244V/V as shown in Table 14. The PGA bits

are set in ADC_Config_nA where n = 1, 2, or T. The gain

setting must be selected prior to initiating a conversion.

ADC Conversion Time and Resolution

The ADC conversion time is a function of the selected

resolution, ADC clock (f

ADC

), and system clock frequen-

cy (f

CLK

). The resolution can be selected from 9 bits to 16

bits in the ADC_Config_nA (where n = 1, 2, or T) register

by bits RESn[2:0]. The lower resolution settings (9 bit)

convert faster than the higher resolution settings (16 bit).

The ADC clock f

ADC

is derived from the primary system

clock f

CLK

by a prescalar divisor. The divisor can be set

from 4 to 512, producing a range of f

ADC

from 1MHz

down to 7.8125kHz when f

CLK

is operating at 4.0MHz.

Other values of f

CLK

produce other scaled values of

f

ADC

. See Tables 15 and 16.

Systems operating with very low power consumption

benefit from the reduced f

ADC

clock rate. Slower clock

speeds require less operating current. Systems operating from a larger power consumption budget can use

the highest f

ADC

clock rate to improve speed perfor-

mance over power performance.

The ADC conversion times for various resolution and

clock-rate settings are summarized in Table 17. The

conversion time is calculated by the formula:

t

CONVERT

= (no. of f

ADC

clocks per conversion) /

f

ADC

Figure 4. ADC Module

INP1

INM1

INP2

INM2

TEMPERATURE

SENSOR

V

DD

2 x V

REF

4 x V

BG

REF

CO

DAC

M

U

X

V

SS

NO. SINGLE-ENDED

1

V

BG

2

OUTnSM

3

OUTnLG

4

V

DD

V

5

SS

DACnOUT VIA OUTnSM

6

7

DACnOUT VIA OUTnLG

INPn

8

9

INMn

PGA

ADC

VBG

00h ADC_Control

01h ADC_Data_1

02h ADC_Config_1A

03h

ADC_Config_1B

04h ADC_Data_2

05h ADC_Config_2A

06h ADC_Config_2B

07h ADC_Data_T

08h ADC_Config_TA

09h ADC_Config_TB

Page 16

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

16 ______________________________________________________________________________________

Coarse-Input Offset Adjustment

Differential input signals that have an offset can be partially nulled by the input coarse-offset (CO) DAC. An offset voltage is added to the input signal prior to gaining

the signal. This allows a maximum gain to be applied to

the differential input signal without saturating the conversion channel. The CO signal added to the differential signal is a percentage of the full-scale ADC reference

voltage as referred to the ADC inputs. Low PGA gain settings add smaller amounts of coarse offset to the differential input. Large PGA gain settings enable correspondingly larger amounts of coarse offset to be

added to the input signal. The CO DAC also applies to

the temperature channel enabling offset compensation

of the temperature signal. See Table 18.

Bias Current Settings

The analog circuitry within the ADC module operates

from a current bias setting that is programmable. The

programmable levels of operation are fractions of the

full bias current. The operating power consumption of

the ADC can be reduced at the penalty of increased

conversion times that may be desirable in very-lowpower applications. It is recommended operating the

ADC at full bias when possible. The amount of bias as

a fraction of full bias is shown in Table 19. The setting is

controlled by the BIASn[2:0] bits in the ADC_config_nb

registers where n = 1, 2, or T.

Reference Input Voltage Select

The ADC can use one of three different reference voltage inputs depending on the conversion channel and

REFn setting as shown in Table 20. The differential

inputs can be converted ratiometrically to the supply

voltage (V

DD

), converted ratiometrically to an externally

supplied voltage at V

REF

, or converted nonratiometrically using a fixed voltage source derived from the

internal bandgap voltage source. The temperature

channel is always converted using the internal bandgapderived voltage source and therefore is not selectable.

Output Sample Rate

Generally, the sensor and temperature data are converted and calculated by an algorithm in the execution loop.

The output sample rate of the data depends on the conversion time, the CPU algorithm loop time, and the time to

store the result in the DOPn_DATA register. To achieve

uniform sampling, the instruction code must be written to

provide a consistent algorithm loop time, including

branch instruction variations. This total loop time interval

should be repeatable for a uniform output rate.

The MAX1464 has a built-in timer that can be used to

ensure that the sampling interval is uniform. The timeout

value can be set so the CPU computations and the read-

ing of the serial interface, if required, can be completed

before timeout. The GPIO pins can be utilized to interrupt

an external master microcontroller when the ADC conversion is done and/or when the CPU computations are

done so the serial interface can be read quickly.

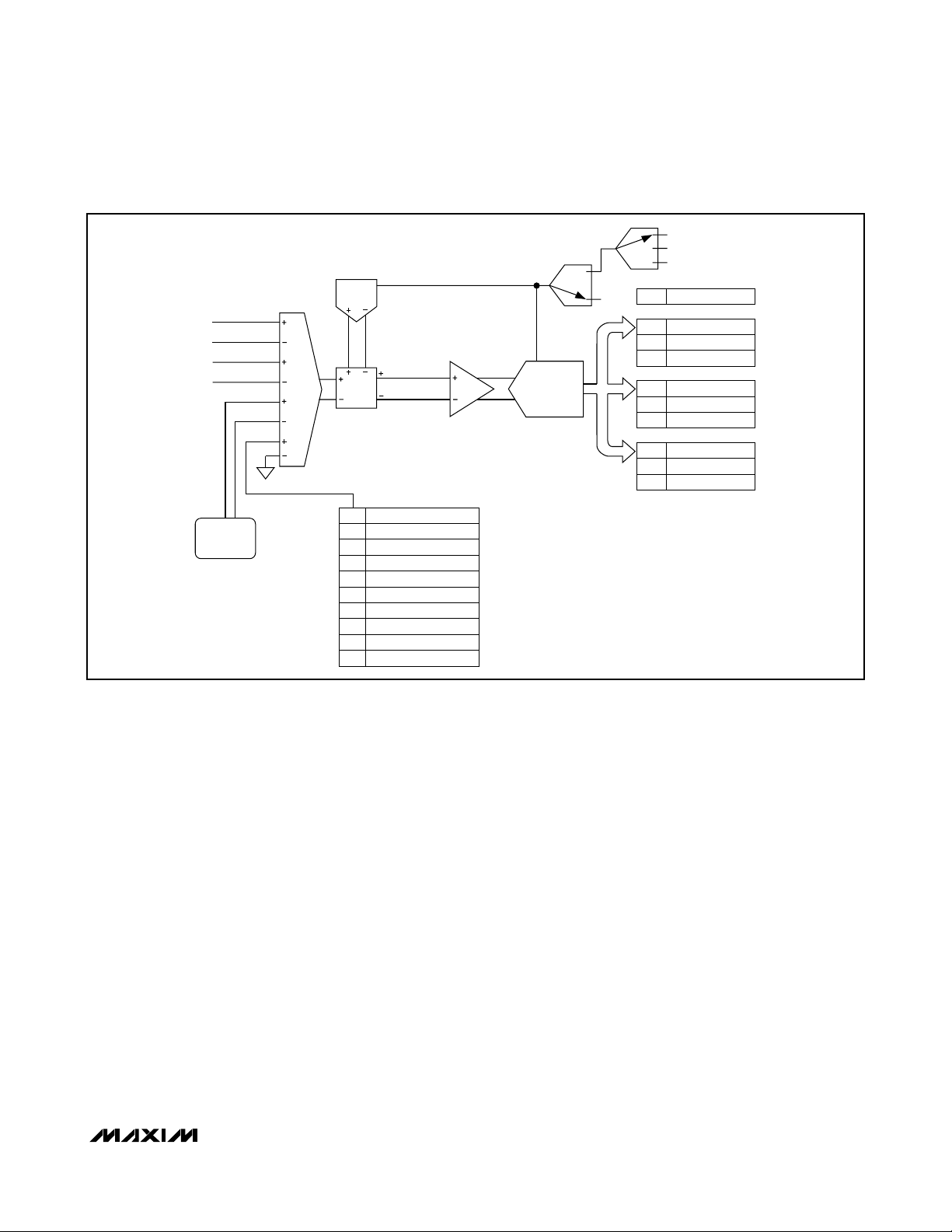

DAC, Op Amp, PWM Modules (DOPn)

There are two output modules in the MAX1464—DOP1

and DOP2 (Figure 5). Each of the DOP modules contains a 16-bit DAC, a 12-bit digital PWM converter, a

small op amp, and a large op amp with high-outputdrive capability. Switches in the DOP module enable a

range of interconnectivity among the converters, op

amps, and the external pins. Either the DAC or the

PWM can be selected as the primary output signal. The

DAC output signal is routed to one of the op amps and

made available to a device pin. The signal-switching

arrangement also allows the unused op amp to be configured as an uncommitted device with all connections

available to external pins.

The DAC and op amps have a power-control bit in the

power module. When power is disabled, all circuits in

the DAC and the op amp are disabled with inputs and

outputs in a tri-state condition. The proper bits in the

power module must be enabled for operation of the

DAC and op amps.

The DAC input is a 16-bit two’s-complement value. An

input value of 0000h produces an output voltage of one

half the DAC reference voltage. The DAC output voltage

increases for positive two’s-complement numbers, and

decreases for negative two’s-complement numbers.

The PWM input is a 12-bit two’s complement value. It

shares the same input register (DOPn_Data) as the

DAC, using the 12 MSBs of the 16-bit register. An input

value of 000Xh produces a 50% duty cycle waveform at

the output. The PWM output duty cycle increases for

positive two’s-complement numbers, and decreases for

negative two’s-complement numbers.

DOP_n Configuration Options

Each of the DOP modules can be configured in several

different modes to suit a wide range of output signal

requirements. The Functional Diagram shows the various

switch settings of the configuration and control registers.

In situations where configuration settings create a conflict in switch activation, a priority is applied to the switch

logic to prevent the conflict.

The DAC and/or the PWM can be selected as the output signal source. The DAC output signal is routed to

one of the op amps and made available to a device

pin. Selecting the large op amp as the DAC output driver device enables a robust current drive capability for

driving signals into low-impedance loads or across

Page 17

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

______________________________________________________________________________________ 17

long lengths of wire. The unity-gain buffer configuration

is automatically selected, and it provides the DAC output signal directly to the device pin OUTnLG. With the

large op amp selected, the small op amp can be used

as an independent device for external circuit applications when the PWM is disabled. Alternatively, the PWM

can also be enabled to drive the OUTnSM device pin,

in which case the small op amp is OFF.

Selecting the small op amp as the DAC output driver

device is useful for routing the output signal to other circuits in an embedded control system with high-impedance load connections. The unity-gain buffer configuration

is automatically selected, and it provides the DAC output

signal directly to the device pin OUTnSM. With the small

op amp selected, the large op amp can be used as an

independent device for external circuit applications when

the PWM is disabled. Alternatively, the PWM can also be

enabled to drive the OUTnLG device pin, in which case

the large op amp is OFF.

The DAC has two reference voltage sources available by

selection, VDDand V

REF

input. When the external refer-

ence is selected (V

REF

), the actual DAC reference is 2 x

V

REF

. See V

REF

to 2.5V for nominal operation. The output

of the DAC is a voltage proportional to the reference voltage selected, where the proportionality scaling (DAC

input) is set in the data input register DOPn_Data.

The DOP module also provides a 12-bit digital PWM

output. At a nominal 4MHz frequency, the frequency of

the PWM is 122Hz (PWM period = 8.192ms). The DAC

and the PWM share the same input register,

DOPn_Data, where the PWM uses the 12 MSBs, in

two’s-complement format. An input of 000Xh (4 LSBs

are ignored) outputs a 50% duty cycle waveform at the

selected output pin (either OUTnSM or OUTnLG). The

PWM bit weight is 2µs, at a nominal frequency of 4MHz.

The minimum duty cycle is obtained when the input is

800Xh (duty cycle is 0 / 4096 = 0), and the maximum

duty cycle at 7FFXh (duty cycle is 4095 / 4096 =

99.98%). A new PWM input word is only effective at the

end of a current PWM cycle, therefore preventing PWM

glitches on the output.

Either the small or the large op amp in the DOP module

can also be selected as an uncommitted op amp in the

MAX1464. The op amps can be configured as a unitygain buffer, where the output is internally connected to the

negative terminal of the op amp, or a stand-alone op amp,

where both AMPnM and AMPnP can be externally connected for various analog functions. In the case of a buffer,

the device pin AMPnM is in high-impedance mode, as the

feedback loop around the op amp is connected internally.

OUTnSM

Figure 5. DOP1 and DOP2 Modules

AMPnM

SW10

V

DD

SW0

SM

SW1

SW2

SW3

REF

DAC

SW4

2 x V

REF

10h OR 13h DOPn_Data

11h OR 14h DOPn_Control

12h OR 15h DOPn_Config

AMPnP

OUTnLG

SW11

SW5

SW6

LG

SW7

30h OpAmp_Config

SW8

PWM

SW9

Page 18

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

18 ______________________________________________________________________________________

Every function of the DOP module can be selected individually (DAC, PWM, or op amp), or two out of the three functions of the DOP module can be selected at the same time

(PWM and op amp, or DAC and PWM, or DAC and op

amp), as there are only two output pins for the module,

OUTnSM and OUTnLG. The various configuration options

for the DOP are shown in Table 21. The PWRDAC and

PWROP bits are in the power-on control register (address

= 31h), and the remaining bits are in the DOP registers.

See Tables 21 through 27.

Timer Module

The timer module (Figure 6) comprises a 12-bit counter, a

4-bit prescalar, and control and configuration registers.

When the timer is enabled and initiated, the system master

clock, MCLK, is prescaled by the divisor set by PS[3:0] in

the TMR_Config register and the result applied to the 12bit upcounter. When the counter value matches the timeout value TO[11:0] in register TMR_Config, bit TMDN is set

to 1. The CPU can poll the timer done bit TMDN to check

its status.

The timer module provides a feature that enables the CPU

to be put into a low-power halt mode for the duration of the

timer interval. Setting the ENAHALT bit in the TMR_Control

register while starting the timer (setting the timer enable bit

TMEN to 1), or while the timer is already enabled and

counting halts the CPU at the present instruction until the

TMDN bit becomes set by the counter. The CPU commences execution with the next instruction. All CPU registers and ports are fully static and retain all data during the

elapsed time interval.

The time interval between TMEN being set to 1, and

TMDN being set to 1 can be computed as follows:

Time Interval = (2 / f

OSC

) x {(prescale value N)

x (timeout value TO[11:0]) + 1.5}

The maximum time interval given f

OSC

= 4MHz clock is

786ms.

Power Control

The power to various subcircuits in the MAX1464 can be

turned on and off by CPU control and by the serial interface. Unused subcircuits and modules can be turned off

to reduce power consumption. The default state after

power-on is all subcircuits and modules powered off.

This enables low-power embedded systems to turn on

only the needed modules after exiting a low-power CPU

halt timer interval. Modules can be turned on and off as

needed; however, care must be exercised to allow for

module initialization and settling prior to use.

Oscillator Control

The MAX1464 has a fully integrated oscillator with a

nominal 4MHz frequency. An external clock source can

be used when the clock-select pin CKSEL = 0, operating

all internal timing functions. CKIO can also be configured

as an output source of the internal oscillator clock.

GPIO Module

The MAX1464 contains two general-purpose digital

input/output (GPIO) modules, GPIO1 and GPIO2, which

can be written and read by CPU control and by the serial interface. These two I/O pins operate independently

of each other. They can be configured as inputs, outputs, or one input and one output. When configured as

an input, there are two modes of sensing digital inputs;

as a voltage or logic level, or as an edge detector. In

edge-detector mode, either a rising or falling edge can

be selected for detection. A bit is set in the GPIO control register upon detection of the selected edge.

The GPIO pins have nominal 100kΩ pulldown resistors

to V

SS

as in Figure 6. Pulldown resistors provide a low

logic level when the pin is unconnected. The GPIO may

also serve as an input pin and its state is read from the

GPIO control register (Tables 28 and 29). When using

the GPIO pin as a general-purpose output, its output

state is defined by writing to the GPIO control register.

The GPIOn pins can be configured as an alert output

that goes low or high whenever a fault condition happens, e.g., remote sensor line disconnection, overflow

conditions in the CPU program execution, etc.

All input and output control for the GPIO1 and GPIO2

pins are contained in GPIO1_Control (address = 40h)

and GPIO2_Control (address = 41h), respectively.

Figure 7 shows the GPIO1 and GPIO2 modules.

Serial Interface Timing and Operation

The MAX1464 serial interface is a high-speed asynchronous data input and output communication port,

providing access to internal registers for calibration of

embedded control sensor systems. All the FLASH

memory is read and write accessible by the serial inter-

Figure 6. Timer Module

20hTMR_Control

21hTMR_Config

12-BIT COUNTER

TIMEOUT VALUE

PRESCALER

MCLK

Page 19

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

______________________________________________________________________________________ 19

face for programming of instruction code and calibration coefficients. The MAX1464 serial interface can

operate in 4-wire SPI-compatible mode or in a 3-wire

mode (default on power-up). In 3-wire mode, the DI and

DO lines can be connected together, forming a bidirectional data line. The serial interface lines consist of

chip-select (CS), serial clock (SCLK), data in (DI), and

data out (DO).

The MAX1464 serial interface is selected by asserting

CS low. The serial input clock, SCLK, is gated internally

to begin sequencing the DI input data and outputting

the output data onto DO. When CS rises, the data that

was clocked into DI is loaded into an internal register

set (IRS[7:0]). The MAX1464 chip-select line CS cannot

be connected low continuously for normal operation.

The serial interface can be used both during sensor

calibration, as well as during normal operation. Each

byte of data written into the MAX1464 serial port contains a 4-bit addresses nibble (IRSA [3:0]) and a 4-bit

data nibble (IRSD [3:0]). The IRS register holds both

the IRSD and IRSA nibbles as follows:

IRS [7:0] = IRSD [3:0], IRSA [3:0]

Four bytes of IRS information must be written into the

serial interface to transfer 16 bits of data through IRSD

into a MAX1464 internal register. All serial data written

into the MAX1464 is transferred through the IRS register.

The DI is read in with the LSB of the IRSA nibble first

and the MSB of the IRSD nibble last. Figure 8 shows

serial interface data input.

The IRSA bits are decoded to determine which register

the IRSD bits should be latched into. The IRSA bits

can address the DHR, the PFAR, the CR, and the IMR.

All serial data read from the serial interface is sourced

from the 16-bit DHR. Any data to be read by the serial

interface must first be placed into the internal DHR register

before being accessible for reading by the serial interface.

The entire 16-bit content of the DHR register is read out

through the DO pin by applying 16 successive clock

pulses to SCLK while CS remains low. DHR is clocked

out MSB bit first. Figure 9 shows the 4-wire mode data

read from the DHR register

In 4-wire mode, data is transferred into DI during the

clocking of data out of DO. Therefore, the last 8 bits

clocked into the DI pin during this data transfer are

latched into the IRS register and decoded when CS

returns high.

When the MAX1464 serial interface is configured in 3wire mode, the 16-bit DHR data is read out immediately

following the command for 3-wire mode enable. Figure

10 shows the 3-wire enable command (IRS[7:0] = 19h)

clocked into DI with a subsequent 16-bit read of DHR

on DO. DO remains in high impedance (tri-state) until

the 3-wire enable command is received. Then DO goes

into low-impedance drive mode during the next low

cycle of CS. As SCLK is clocked 16 times, the data in

DHR is clocked out at DO. The 3-wire enable command

is the command that sets the MAX1464 ready for output

on DO on the next low cycle of CS. Following the DHR

output on the low cycle of CS, the DO line returns to

high-impedance state until the next 3-wire enable command is received. The MAX1464 can receive an indefinite number of inputs to DI without the need for a 3-wire

enable command to be received.

When the IRSD[3:0] nibble is written to the command

register (CR), i.e., when IRSA[3:0] = 1000, the nibble is

decoded and a command operation is initiated. The

command register decoding is shown in Table 39.

When the IRSD[3:0] nibble is written to the IMR, i.e.,

when IRSA[3:0] = 1000, the nibble is decoded and a

command operation is initiated. The IMR decoding is

shown in Table 40.

Note that after power is applied and the POR function

completes, the serial interface default is the 3-wire mode

for receiving data on DI only. The DO line is a highimpedance output until the MAX1464 receives either the

4-wire or 3-wire mode command in the IMR. In the case

of a 3-wire mode command, DO switches from a highimpedance state to a driving state only for the next cycle

of CS, returning to high impedance afterwards.

All commands, with the exception of programming or

erasing the FLASH memory, are completed within eight

internal master clock cycles of CS returning from low to

high. This is 4µs for a 4MHz oscillator frequency or

external clock input (1 internal master clock = 2 external/internal oscillator periods). FLASH memory programming and erasing require additional time of 80µs

and 4.2ms, respectively.

Figure 7. GPIO1 and GPIO2 Modules

40h OR 41hGPIOn_Control

EDGE OR LEVEL DETECT

GPIOn

100kΩ

TRI-STATE

BUFFER

V

SS

Page 20

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

20 ______________________________________________________________________________________

FLASH Memory

There are 4096 bytes of programmable/erasable FLASH

memory for CPU program instructions and coefficients

storage. In addition, there are 128 bytes of FLASH memory accessible only by the serial interface for storage of

user information data.

These two FLASH memory locations are separated as

partitions. The program/coefficient memory is FLASH

partition 0 and the information memory is FLASH partition 1. Each partition is accessible by the serial interface for reading, erasing, and writing data. Program/

coefficient memory partition 0 is accessible by the CPU

as read only, and partition 1 is not accessible by the

CPU. The CPU cannot erase or write data to either of

the FLASH memory partitions.

FLASH partition 0 is selected during the POR cycle.

FLASH partition 1 is selected by sending the halt CPU

command (IRS[7:0] = 78h) and changing the partition

selected by sending the change partition command

(IRS[7:0] = F8h). A following halt command (IRS[7:0] =

78h) resets the selected partition to partition 0.

Modifying the FLASH Contents

The MAX1464 FLASH memory contents must be erased

(contents = FFh) before the desired contents can be written. There is no individual byte-erase command, but

either a total-erase command (IRS[7:0] = E8h) where all

the selected partition is erased (4kB for partition 0 or 128

bytes for partition 1) or a page-erase command (IRS[7:0]

= D8h), where only 64 bytes are erased, and the page is

selected by PFAR[11:6]. There are 64 pages in FLASH

partition 0, and only 2 pages in FLASH partition 1.

The programming of the MAX1464 FLASH memory

must use the following procedure (all the commands

are to be sent through the serial interface, and are

hexadecimal values of IRS[7:0]):

Figure 8. Serial Interface Data Input

Figure 9. 4-Wire Mode Data Read from DHR Register

Figure 10. 3-Wire Mode Data Read from DHR Register

CS

SCLK

DI

CS

SCLK

IRS1

DI

DO

IRS0

IRSA1

IRSA0

DHR15 DHR14 DHR13 DHR12 DHR11 DHR10 DHR9 DHR8 DHR7 DHR6 DHR5 DHR4 DHR3 DHR2 DHR1 DHR0

IRS2

IRSA2

IRS0

IRSA0

IRS3

IRSA3

IRS1

IRSA1

IRS4

IRSD0

CS

SCLK

DI

1

IRSA00IRSA10IRSA21IRSA31IRSD00IRSD10IRSD20IRSD3

DO

IRS5

IRSD1

IRS2

IRSA2

IRS3

IRSA3

IRS6

IRS7

IRSD2

IRSD3

DHR15 DHR14 DHR13 DHR12 DHR11 DHR10 DHR9 DHR8 DHR7 DHR6 DHR5 DHR4 DHR3 DHR2 DHR1 DHR0

IRS0

IRSA0

IRS4

IRSD0

IRS1

IRSA1

IRS5

IRSD1

IRS2

IRSA2

IRS3

IRSA3

IRS6

IRSD2

IRS4

IRSD0

IRS7

IRSD3

IRS5

IRSD1

IRS6

IRSD2

IRS7

IRSD3

Page 21

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

______________________________________________________________________________________ 21

1) Halt the CPU:

78

2) If partition 1 is to be modified, enter the following

command:

F8

Otherwise, partition 0 is selected.

3) Turn off all analog modes:

03 02 01 00 (write 0000h to DHR[15:0])

D4 (write Dh to PFAR[3:0])

08 (write DHR, 1000h to CPU port

pointed by PFAR[3:0], port D)

03 02 31 10 (write 0031h to DHR[15:0])

E4 (write Eh to PFAR[3:0])

08 (write DHR, 0031h to CPU port

pointed by PFAR[3:0], port E)

83 02 01 00 (write 8000h to DHR[15:0])

F4 (write Fh to PFAR[3:0])

08 (write DHR, 8000h to CPU port

pointed by PFAR[3:0], port F)

At this point, all the MAX1464 analog modules are off.

4) For erasing the whole partition, send the following

command:

E8

Otherwise, if only a page erase is required, first write

PFAR[11:6] with the page address, as:

07 X6 X5 04 (write 0XX0h to PFAR[15:0])

Note that the 2 lower bits of PFAR[7:4] should be

zero, and only the upper 2 bits of that nibble should

be set to the desired value. Then, after writing the

page address, send the page-erase command:

D8

5) Wait at least 4.2ms before sending any other

command to allow the necessary time for the

erase operation to complete.

6) Write the address of the FLASH byte to be written

to PFAR[15:0]:

07 X6 X5 X4 (write 0XXXh to PFAR[15:0])

7) Write the contents of the byte to DHR[7:0]:

X1 X0 (write XXh to DHR[7:0], high nibble

at DHR[7:4])

8) Send the command to execute the FLASH write:

18

9) Repeat steps 6, 7, and 8 for all the bytes to be

written. It is not necessary to send the whole

address and data for every byte that is written. Only

the nibbles that are modified in the PFAR and in the

DHR from previous values must be changed. The

time interval between successive write commands

(18h) must be at least 80µs.

10) If partition 1 was selected in step 2, and the user

wants to switch back to partition 0, send the follow

ing command:

78

At this point, partition 0 is selected. The user may

want to go back to step 4 to program partition 0, or

just continue on.

Reading the FLASH Contents

The procedure to read the FLASH contents is no different

from reading any other information from the MAX1464.

The FLASH contents must be copied to the DHR and

read through the serial interface:

1) If the CPU is not halted, halt the CPU:

78

2) If partition 1 is to be read, enter the following

command:

F8

Otherwise, partition 0 is selected.

3) Write the address of the flash byte to be read to

PFAR[15:0]:

07 X6 X5 X4 (write 0XXXh to PFAR[15:0])

4) Copy the contents of FLASH addressed by PFAR to

DHR:

38

5) If the interface is configured in 3-wire mode, send

19

to enable DO on the next CS cycle. Then tri-

state the DI driver, and send 16 SCLK pulses on

the following CS cycle, and DO outputs DHR[15:0].

The FLASH data is present at DHR[7:0]. See Figure

10 for details.

If the interface is configured in 4-wire mode, there

is no need to enable the DO line, as it has already

been enabled by a previous IRS command 09h.

Send the 16 SCLK pulses and retrieve the data on

the DO line.

6) Repeat steps 3, 4, and 5 for every byte to be read.

Only the nibbles that are modified in the PFAR register are required to be sent.

Page 22

MAX1464

Low-Power, Low-Noise Multichannel

Sensor Signal Processor

22 ______________________________________________________________________________________

Program and Coefficient Memory

The program and coefficient memory, FLASH partition 0,

is addressed by the CPU and by the serial interface

sequentially from 0000h (0 dec) to 0FFFh (4095 dec).

Program execution by the CPU always begins at address

0000h and proceeds toward 0FFFh in 1-byte increments.

Although both the CPU and the serial interface can

address a 16-bit field, the FLASH size only uses 12

bits. Therefore, the leading 4 MSBs of the address field

are ignored. It is advisable to have all leading bits of

the 16-bit address in PFAR[15:0] set to zero.

The FLASH memory in partition 0 can be erased in individual 64-byte pages using the page-erase command,

or erased in bulk using the all-erase command. The

information data memory (partition 1) is unaffected by

any operation performed on partition 0.

Information Data Memory

The information data memory, FLASH partition 1, is

addressed by bytes sequentially from 00h (0 dec) to 7Fh

(127 dec). The addressed byte should have all leading

bits of the 16-bit address in PFAR[15:0] set to zero.

The FLASH memory in partition 1 has only two 64-byte

pages that can be erased separately using the pageerase command, or erased together using the all-erase

command. Data in partition 0 is not affected by any

operation performed on partition 1.

MAX1464 CPU Instruction Set

The MAX1464 CPU has 16 instructions used to perform

all calculations for sensor compensation, linearization,

and signal output functions. Each instruction comprises

a 4-bit op code and a 4-bit CPU register address. The

op code describes what operation to perform; the register address describes what register, or registers, to

perform the operation on.

Instruction Format

All instructions are single-byte instructions with the

exception of load data from instruction memory. LDX

fetches the 2 following bytes of instruction memory and

loads them into a register. This is how calibration and

compensation coefficients are stored within the

MAX1464. Any number of coefficients can be stored in

instruction memory. The instruction code format is as

follows:

Instruction Set Details

LDX Load Register X

Op-code: 0000 XXXX

BINARY

0Xh

Operation:

X-register ← [PC+1] : [PC+2]

PC-register ← PC + 3 (point to next instruction)

CPU Cycles required:

3 cycles

Instruction:

Loads the next 2 bytes of program memory into CPU

register X. Register X can be any of the 16 CPU registers. Program counter (PC) is incremented twice during

the fetches of the next 2 bytes and incremented a third

time to point to the next instruction in program memory.

Two’s-complement data format is preserved.

No branching occurs.

No other registers are affected.

CLX Clear Register X

Op-code: 0001 XXXX

BINARY

1Xh

Operation: