Page 1

19-4503; Rev 0; 4/09

3-Channel, Low-Leakage ESD Protector

General Description

The MAX14541E low-capacitance Q15kV ESD-protection

diode array is designed to protect sensitive electronics

attached to communication lines. Each channel consists

of a pair of diodes that steer ESD current pulses to VCC

or GND.

The MAX14541E protects against ESD pulses up to

Q15kV Human Body Model (HBM) and Q15kV Air-Gap

Discharge, as specified in IEC 61000-4-2. The device

has a 6pF (typ) on-capacitance per channel, making

them ideal for use on high-speed data I/O interfaces.

The MAX14541E is a triple I/O protector designed for

biometric connectors, portable connectors, and SVGA

video connections with ultra-low leakage current.

The device is available in a 5-pin SC70 package and is

specified over the -40NC to +125NC automotive operating

temperature range.

Applications

Glucose Meters

MP3 Players

Digital Cameras

Handheld Equipment

Features

S High-Speed Data Line ESD Protection

±15kV Human Body Model

±15kV IEC 61000-4-2 Air-Gap Discharge

±8kV IEC 61000-4-2 Contact Discharge

S 6pF (typ) Low Input Capacitance

S 1nA (max) Low-Leakage Current

S +0.9V to +16V Supply Voltage Range

S 5-Pin SC70 (2.0mm x 2.2mm) Package

Ordering Information

PART

MAX14541EAXK+T -40NC to +125NC 5 SC70 ATY

+Denotes a lead(Pb)-free/RoHS-compliant package.

T = Tape and reel.

TEMP

RANGE

PIN-

PACKAGE

TOP

MARK

MAX14541E

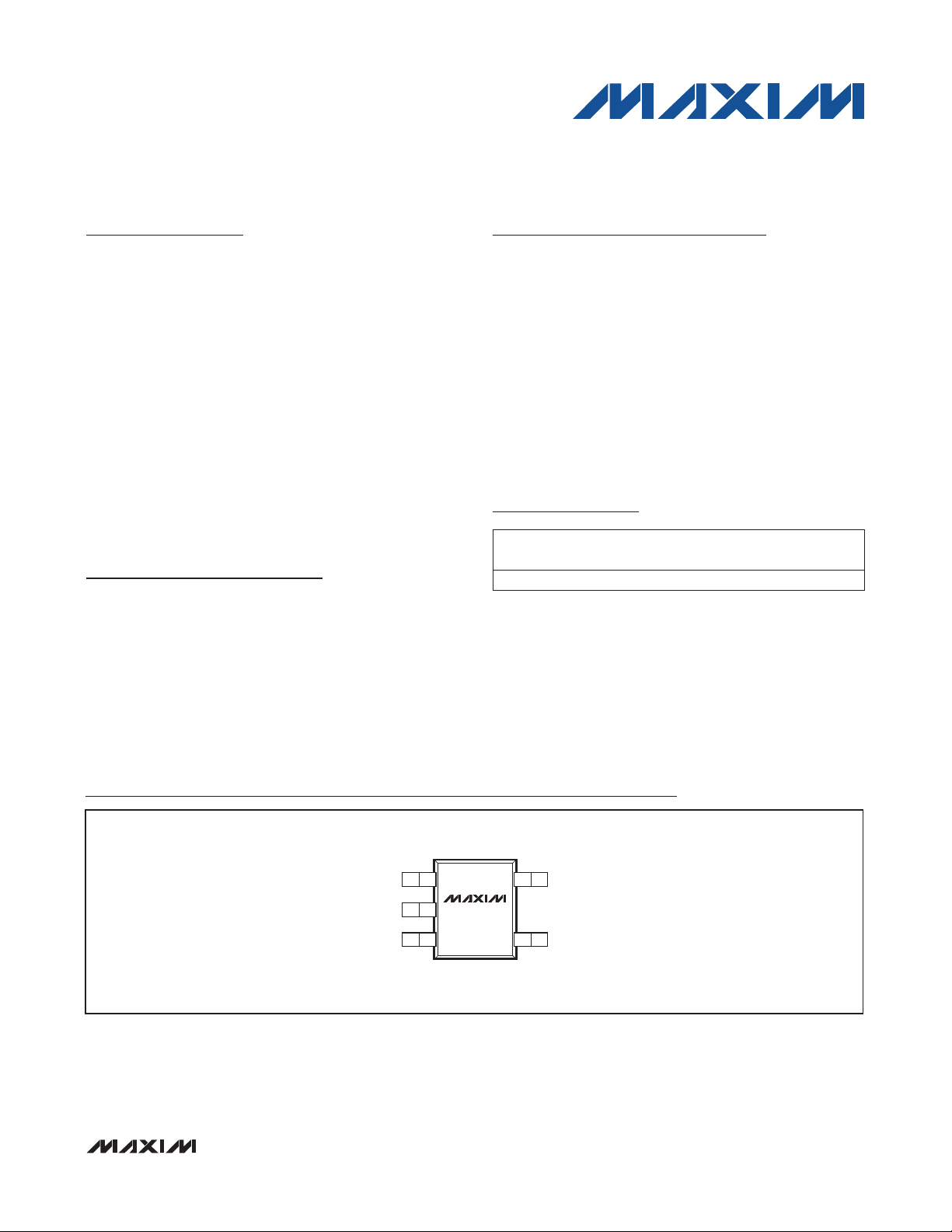

Pin Configuration

TOP VIEW

1

2

3

+

MAX14541E

SC70

5

I/O-3

4

I/O-2

V

CC

GND

I/O-1

_______________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

3-Channel, Low-Leakage ESD Protector

ABSOLUTE MAXIMUM RATINGS

(Voltages referenced to GND.)

VCC to GND ...........................................................-0.3V to +18V

I/O-1, I/O-2, I/O-3 to GND ........................ -0.3V to (VCC + 0.3V)

Continuous Power Dissipation (TA = +70NC)

5-Pin SC70 (derate 3.1mW/NC above +70NC) .........246.9mW

Thermal Resistance (Note 1)

BJA .............................................................................324NC/W

BJC ............................................................................115NC/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

MAX14541E

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may

affect device reliability.

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

ELECTRICAL CHARACTERISTICS

(VCC = +5V, TA = T

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage V

Supply Current I

Diode Forward Voltage V

Channel Clamp Voltage

(Note 3)

Channel Leakage Current

(Note 4)

I/O Capacitance Bias of VCC/2, f = 1MHz (Note 4) 6 7 pF

ESD PROTECTION

Human Body Model ±15 kV

IEC 61000-4-2 Air-Gap

Discharge

IEC 61000-4-2 Contact

Discharge

Note 2: Parameters are 100% production tested at TA = +25°C. Specifications over temperature guaranteed by design only.

Note 3: Idealized clamp voltages. See the Applications Information section for more information.

Note 4: Guaranteed by design, not production tested.

MIN

to T

, unless otherwise noted. Typical values are at TA = +25NC.) (Note 2)

MAX

CC

CC

IF = 10mA, TA = +25°C 0.65 0.95 V

F

TA = +25°C, ±15kV

Human Body Model,

IF = 10A

TA = +25°C, ±8kV

Contact Discharge

V

(IEC 61000-4-2),

C

IF = 24A

TA = +25°C, ±15kV

Air-Gap Discharge

(IEC 61000-4-2),

IF = 45A

TA = -40°C to +50°C -1 +1 nA

TA = -40°C to +125°C -1 +1 µA

Operating Temperature Range ........................ -40NC to +125NC

Storage Temperature Range ............................ -65NC to +150NC

Junction Temperature .....................................................+150NC

Lead Temperature (soldering, 10s) ................................+300NC

0.9 16 V

1 100 nA

Positive transients

Negative transients -25

Positive transients

Negative transients -60

Positive transients

Negative transients -100 V

±15 kV

VCC +

25

VCC +

60

VCC +

100

±8 kV

V

V

V

2 ______________________________________________________________________________________

Page 3

3-Channel, Low-Leakage ESD Protector

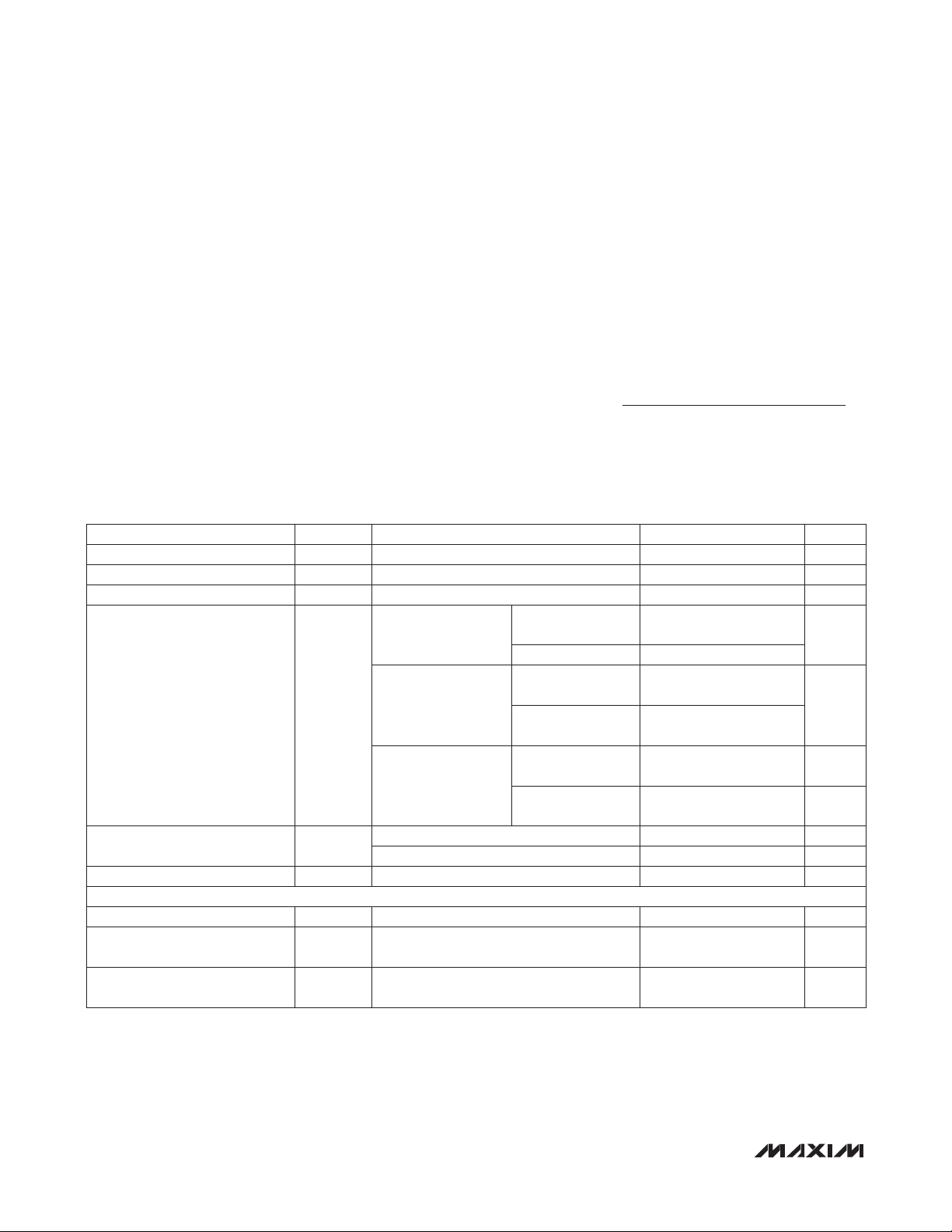

SUPPLY CURRENT

CLAMP VOLTAGE

I/O LEAKAGE CURRENT

INPUT CAPACITANCE

INPUT CAPACITANCE

Typical Operating Characteristics

(VCC = +5V, TA = +25NC, unless otherwise noted.)

MAX14541E

100

10

1

0.1

SUPPLY CURRENT (nA)

0.01

0.001

-40

VCC = 12V

VCC = 3.3V

INPUT CAPACITANCE (pF)

vs. TEMPERATURE

TEMPERATURE (oC)

vs. INPUT VOLTAGE

10

8

6

VCC = 5V

4

2

VCC = 5V

80 955 655020-25 35-10 125110

VCC = 3.3V

MAX14541E toc01

1.1

vs. DC CURRENT

1.0

0.9

CLAMP VOLTAGE (V)

0.8

0.7

10 90

I/O TO V

MAX14541E toc04

CC

I/O TO GND

7050 11030 130 150

DC CURRENT (mA)

10

MAX14541E toc02

0.1

I/O LEAKAGE CURRENT (nA)

0.01

0.001

vs. INPUT VOLTAGE

10

VCC = 12V

8

6

4

INPUT CAPACITANCE (pF)

2

vs. TEMPERATURE

1

VCC = 12V

VCC = 5V

-40

TEMPERATURE (oC)

VCC = 3.3V

80 955 655020-25 35-10 125110

MAX14541E toc05

MAX14541E toc03

0

0

21 43 5

INPUT VOLTAGE (V)

0

0

INPUT VOLTAGE (V)

8 1062 4 12

_______________________________________________________________________________________ 3

Page 4

3-Channel, Low-Leakage ESD Protector

_______________________________________________________________Pin Description

PIN NAME FUNCTION

1 V

2 GND Ground. Connect GND with a low-impedance connection to the ground plane.

3 I/O-1 ESD-Protected Channel

4 I/O-2 ESD-Protected Channel

5 I/O-3 ESD-Protected Channel

CC

Power-Supply Input. Bypass VCC to GND with a 0.1FF ceramic capacitor as close as possible to

the device.

MAX14541E

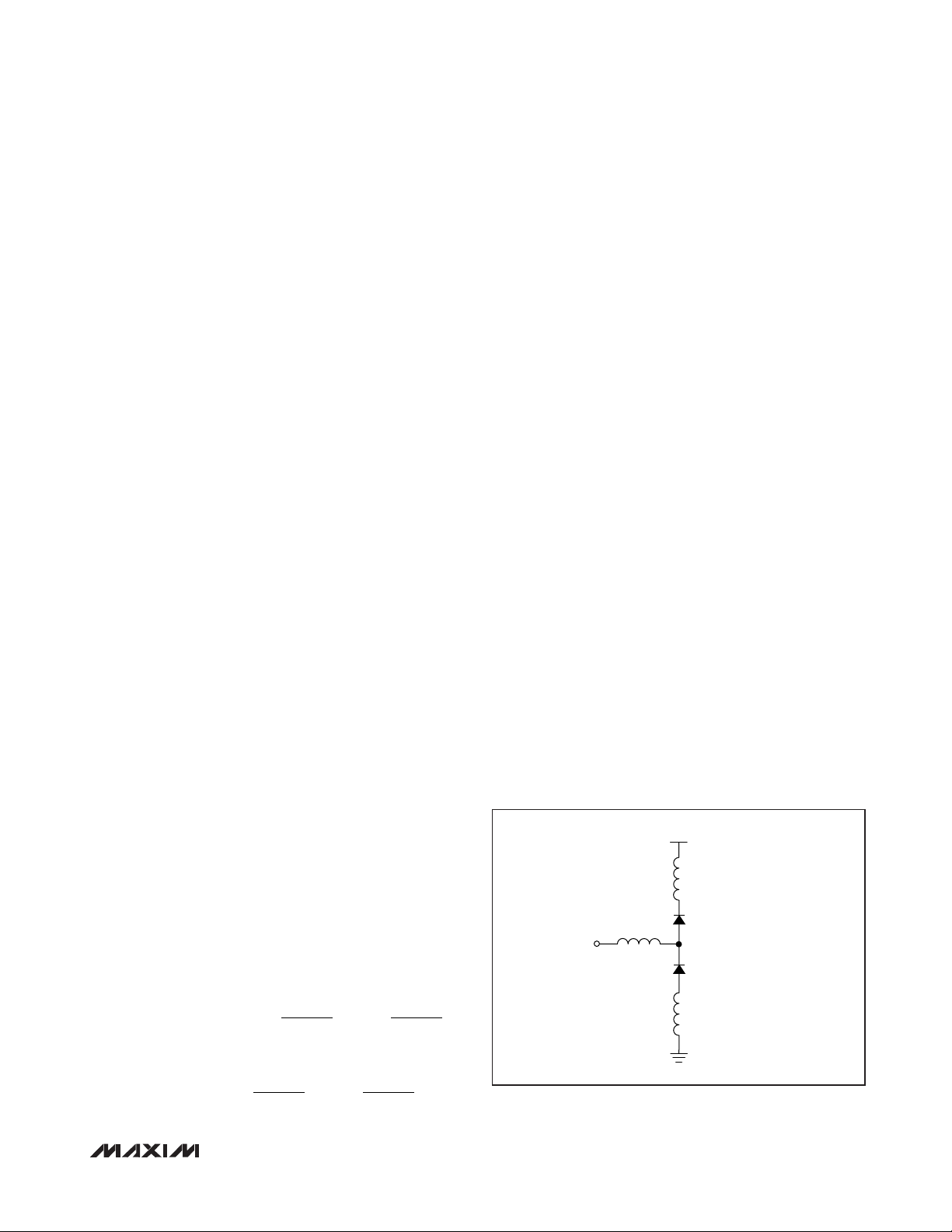

__________________________________________________________Functional Diagram

MAX14541E

V

CC

I/O-1 I/O-2

I/O-3

GND

4 ______________________________________________________________________________________

Page 5

3-Channel, Low-Leakage ESD Protector

( )

________________Detailed Description

The MAX14541E low-leakage, low-capacitance, Q15kV

ESD-protection diode arrays are suitable for high-speed

and general-signal ESD protection. Low input capacitance makes this device ideal for ESD protection of

high-speed signals. Each channel consists of a pair of

diodes that steer ESD current pulses to VCC or GND. The

MAX14541E is a 3-channel device (see the Functional

Diagram).

The MAX14541E is designed to work in conjunction with

a device’s intrinsic ESD protection. The MAX14541E

limits the excursion of the ESD event to below Q25V

peak voltage when subjected to the Human Body Model

waveform. When subjected to the IEC 61000-4-2 Contact

Discharge waveform, the peak voltage is limited to

Q60V. The peak voltage is limited to Q100V when subjected to Air-Gap Discharge. The device protected by

the MAX14541E must be able to withstand these peak

voltages, plus any additional voltage generated by the

parasitic of the board.

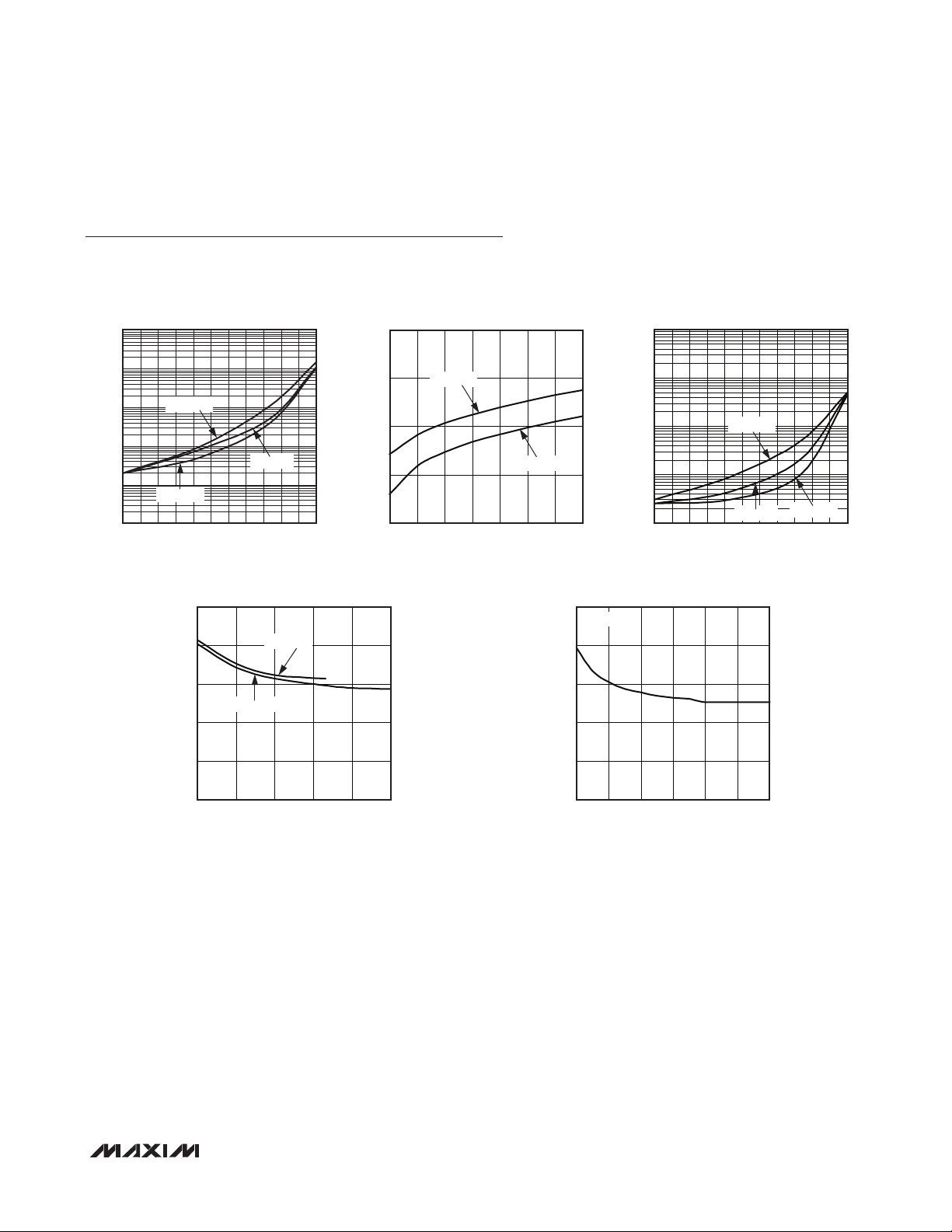

___________Applications Information

Design Considerations

Maximum protection against ESD damage results from

proper board layout (see the Layout Recommendations

section). A good layout reduces the parasitic series

inductance on the ground line, supply line, and protected signal lines. The MAX14541E ESD diodes clamp the

voltage on the protected lines during an ESD event and

shunt the current to GND or VCC. In an ideal circuit, the

clamping voltage (VC) is defined as the forward voltage

drop (VF) of the protection diode, plus any supply voltage present on the cathode.

For positive ESD pulses:

VC = VCC + V

For negative ESD pulses:

VC = -V

The effect of the parasitic series inductance on the lines

must also be considered (Figure 1).

For positive ESD pulses:

F

F

where I

is the ESD current pulse.

ESD

During an ESD event, the current pulse rises from zero

to peak value in nanoseconds (Figure 2). For example,

in a +15kV IEC 61000-4-7 Air-Gap Discharge ESD event,

the pulse current rises to approximately 45A in 1ns

(di/dt = 45 x 109). An inductance of only 10nH adds an

additional 450V to the clamp voltage, and represents

approximately 0.5in of board trace. Regardless of the

device’s specified diode clamp voltage, a poor layout

with parasitic inductance significantly increases the

effective clamp voltage at the protected signal line.

Minimize the effects of parasitic inductance by placing

the MAX14541E as close as possible to the connector

(or ESD contact point).

A low-ESR 0.1FF capacitor is required between VCC and

GND to get the maximum ESD protection possible. This

bypass capacitor absorbs the charge transferred by a

positive ESD event. Ideally, the supply rail (VCC) would

absorb the charge caused by a positive ESD strike

without changing its regulated value. All power supplies

have an effective output impedance on their positive

rails. If a power supply’s effective output impedance is

1I, then by using V = I x R, the clamping voltage of VC

increases by the equation VC = I

ESD

x R

. A +8kV IEC

OUT

61000-4-2 ESD event generates a current spike of 24A.

The clamping voltage increases by V

= 24A x 1I, or

C

VC = 24V. Again, a poor layout without proper bypassing

increases the clamping voltage. A ceramic chip capacitor mounted as close as possible to the MAX14541E

VCC pin is the best choice for this application. A bypass

capacitor should also be placed as close as possible to

the protected device.

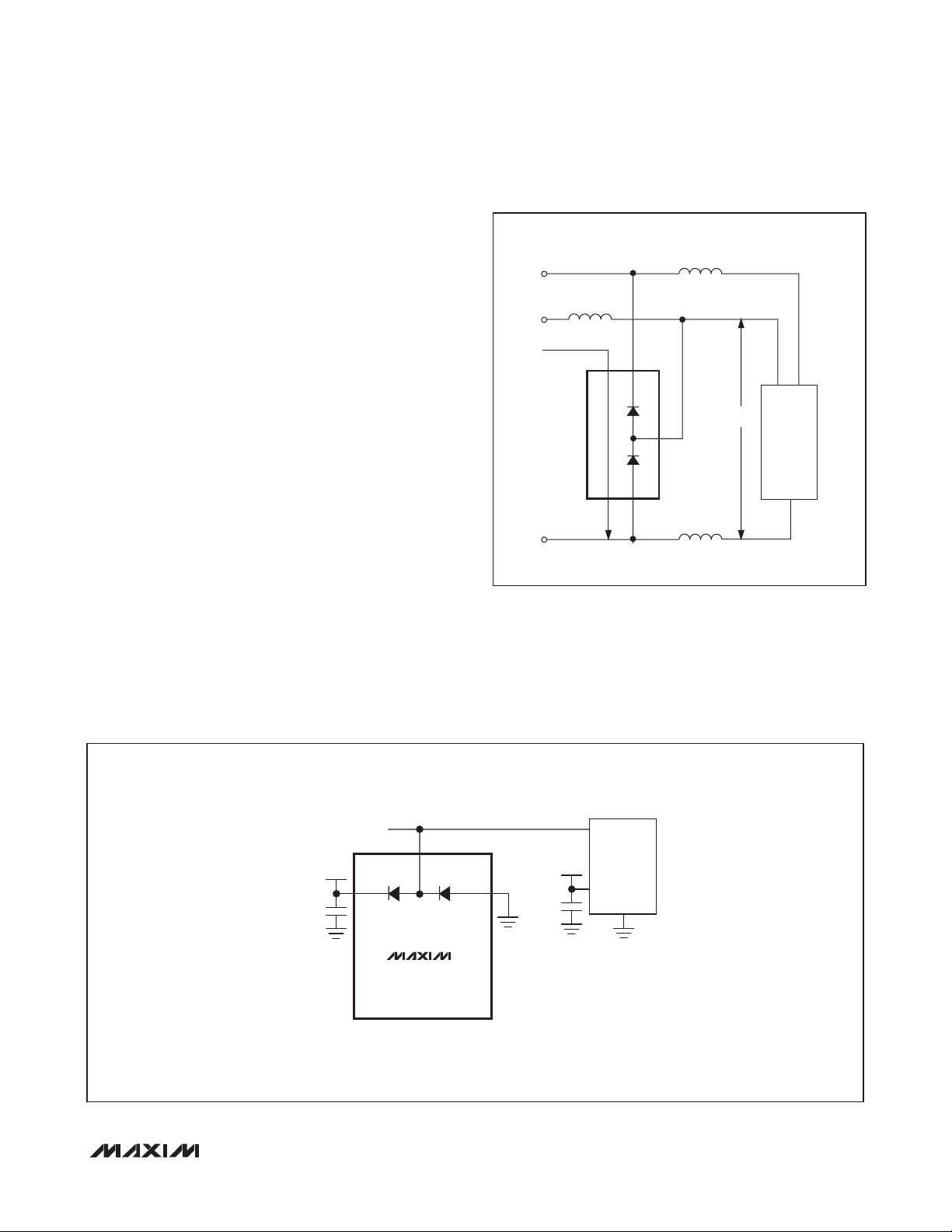

POSITIVE SUPPLY RAIL

L2

D1

I/O_

D2

PROTECTED

LINE

L1

MAX14541E

d I

V V V L1 L2

= + + × + ×

C CC F(D1)

ESD

dt dt

For negative ESD pulses:

V V L1 L3

= − + × + ×

C F(D2)

_______________________________________________________________________________________ 5

d(I ) d(I )

ESD ESD

dt dt

d(I )

ESD

L3

GROUND RAIL

Figure 1. Parasitic Series Inductance

Page 6

3-Channel, Low-Leakage ESD Protector

standard is generally lower than that measured using the

I

100%

90%

PEAK

I

MAX14541E

tR = 0.7ns to 1ns

10%

30ns

t

60ns

Human Body Model. Figure 2 shows the current waveform for the Q8kV IEC 61000-4-2 Level 4, ESD Contact

Discharge test. The Air-Gap Discharge test involves

approaching the device with a charged probe. The

Contact Discharge method connects the probe to the

device before the probe is energized.

R

C

1MI

CHARGE-CURRENT-

LIMIT RESISTOR

R

D

1.5kI

DISCHARGE

RESISTANCE

Figure 2. IEC 61000-4-2 ESD Generator Current Waveform

ESD Protection

ESD protection can be tested in various ways. The

MAX14541E are characterized for protection to the following limits:

U Q15kV using the Human Body Model

U Q8kV using the Contact Discharge Method specified

in IEC 61000-4-2

U Q15kV using the IEC 61000-4-2 Air-Gap Discharge

Method

________________ESD Test Conditions

ESD performance depends on a number of conditions.

Contact Maxim for a reliability report that documents test

setup, methodology, and results.

Human Body Model

Figure 3 shows the Human Body Model, and Figure

4 shows the current waveform it generates when discharged into a low impedance. This model consists of a

100pF capacitor charged to the ESD voltage of interest

which is then discharged into the device through a 1.5kI

resistor.

IEC 61000-4-2

The IEC 61000-4-2 standard covers ESD testing and

performance of finished equipment. The MAX14541E

helps users design equipment that meets Level 4 of

IEC 61000-4-2. The main difference between tests done

using the Human Body Model and IEC 61000-4-2 Model

is higher peak current in IEC 61000-4-2. Because series

resistance is lower in the IEC 61000-4-2 ESD test model

(Figure 5), the ESD-withstand voltage measured to this

HIGH-

VOLTAGE

DC

SOURCE

100pF

STORAGE

C

s

CAPACITOR

Figure 3. Human Body ESD Test Model

PEAK-TO-PEAK RINGING

I

r

(NOT DRAWN TO SCALE)

AMPERES

IP 100%

90%

36.8%

10%

0

0

t

RL

TIME

t

DL

CURRENT WAVEFORM

Figure 4. Human Body Model Current Waveform

HIGH-

VOLTAGE

DC

SOURCE

R

C

50I to 100I

CHARGE-CURRENT-

LIMIT RESISTOR

C

s

150pF

R

D

330I

DISCHARGE

RESISTANCE

STORAGE

CAPACITOR

Figure 5. IEC 61000-4-2 ESD Test Model

DEVICE

UNDER

TEST

DEVICE

UNDER

TEST

6 ______________________________________________________________________________________

Page 7

3-Channel, Low-Leakage ESD Protector

__________Layout Recommendations

Proper circuit-board layout is critical to suppress ESDinduced line transients (see Figure 6). The MAX14541E

clamps to 100V; however, with improper layout, the

voltage spike at the device can be much higher. A lead

inductance of 10nH with a 45A current spike results in an

additional 450V spike on the protected line. It is essential

that the layout of the PCB follows these guidelines:

1) Minimize trace length between the connector or input

terminal, I/O_, and the protected signal line.

2) Use separate planes for power and ground to reduce

parasitic inductance and to reduce the impedance to

the power rails for shunted ESD current.

3) Ensure short low-inductance ESD transient return

paths to GND and VCC.

4) Minimize conductive power and ground loops.

5) Do not place critical signals near the edge of the

PCB.

6) Bypass VCC to GND with a low-ESR ceramic capacitor as close as possible to VCC.

7) Bypass the supply of the protected device to GND

with a low-ESR ceramic capacitor as close as possible to the supply pin.

V

CC

L1

PROTECTED LINE

NEGATIVE ESD

CURRENT

PULSE

PATH TO

GROUND

GND

D1

I/O_

D2

Figure 6. Layout Considerations

MAX14541E

L2

V

C

PROTECTED

CIRCUIT

L3

___________________________________________________Typical Application Circuit

0.1µF

V

I/0

CC

PROTECTED

CIRCUIT

I/0 LINE

I/0_

V

CC

0.1µF

MAX14541E

_______________________________________________________________________________________ 7

Page 8

3-Channel, Low-Leakage ESD Protector

__________________________Chip Information

PROCESS: BiCMOS

MAX14541E

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

5 SC70 X5+1

21-0076

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

8 Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

©

2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...