Page 1

General Description

The MAX1363/MAX1364 low-power, 12-bit, 4-channel

analog-to-digital converters (ADCs) feature a digitally

programmable window comparator with an interrupt output for automatic system-monitoring applications. Once

configured, monitor mode automatically asserts an interrupt when any analog input exceeds the programmed

upper or lower thresholds, without interaction to the

host. The MAX1363/MAX1364 respond to the SMBus™

alert, allowing quick identification of the alarming device

on a shared interrupt. A programmable delay between

monitoring intervals lowers power consumption for

reduced monitoring rates.

In addition, the MAX1363/MAX1364 integrate an internal voltage reference, a clock, and a 1.7MHz, highspeed, I2C™-compatible, 2-wire serial interface. The

optimized interface allows a maximum conversion rate

of 94.4ksps in normal mode while reading back the

conversion results. Each of the four analog inputs is

configurable for single-ended or fully differential operation and unipolar or bipolar operation. Two scan modes

utilize on-chip random access memory (RAM) to allow

eight conversions of a selected channel or scanning of

a group of channels to reduce interface overhead.

These devices operate from a single 2.7V to 3.6V

(MAX1363) or 4.5V to 5.5V (MAX1364) supply and

require only 436µA at the maximum sampling rate of

133ksps in monitor mode and 670µA at the maximum

sampling rate of 94.4ksps. AutoShutdown™ powers

down the devices between conversions, reducing supply current to less than 1µA when idle.

The full-scale analog-input range is determined by the

internal reference or by an externally applied reference

voltage ranging from 1V to VDD. The MAX1363 features

a 2.048V internal reference, and the MAX1364 features

a 4.096V internal reference.

The MAX1363/MAX1364 are available in a 10-pin

µMAX®package and are specified over the extended

(-40°C to +85°C) temperature range. For 10-bit applications, refer to the pin-compatible MAX1361/MAX1362

data sheet.

Applications

System Monitoring/Supervision

Servers/Workstations

High-Reliability Power Supplies

Medical Instrumentation

Features

♦ Monitor Mode

Programmable Lower/Upper Trip Threshold

Alarm-Status Register Records Fault Events

SMBus Alert Response

Programmable Sampling Intervals

♦ 12-Bit, I2C-Compatible ADC

±1 LSB INL, ±1 LSB DNL

♦ 4-Channel Single-Ended or 2-Channel Fully

Differential Inputs

♦ Software-Programmable Bipolar/Unipolar

Conversions

♦ Fast Sampling Rate

94.4ksps While Continuously Reading

Conversions

133ksps in Monitor Mode

♦ High-Speed, I

2

C-Compatible Serial Interface

100kHz/400kHz Standard/Fast Mode

Up to 1.7MHz High-Speed Mode

Six Available I2C Slave Addresses

♦ Single Supply

2.7V to 3.6V (MAX1363)

4.5V to 5.5V (MAX1364)

♦ Internal Reference

2.048V (MAX1363)

4.096V (MAX1364)

♦ External Reference: 1V to V

DD

♦ Low Power

436µA in Monitor Mode (133ksps)

670µA at 94.4ksps

6µA at 1ksps

0.5µA in Power-Down Mode

♦ Small Package

10-Pin µMAX

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

________________________________________________________________ Maxim Integrated Products 1

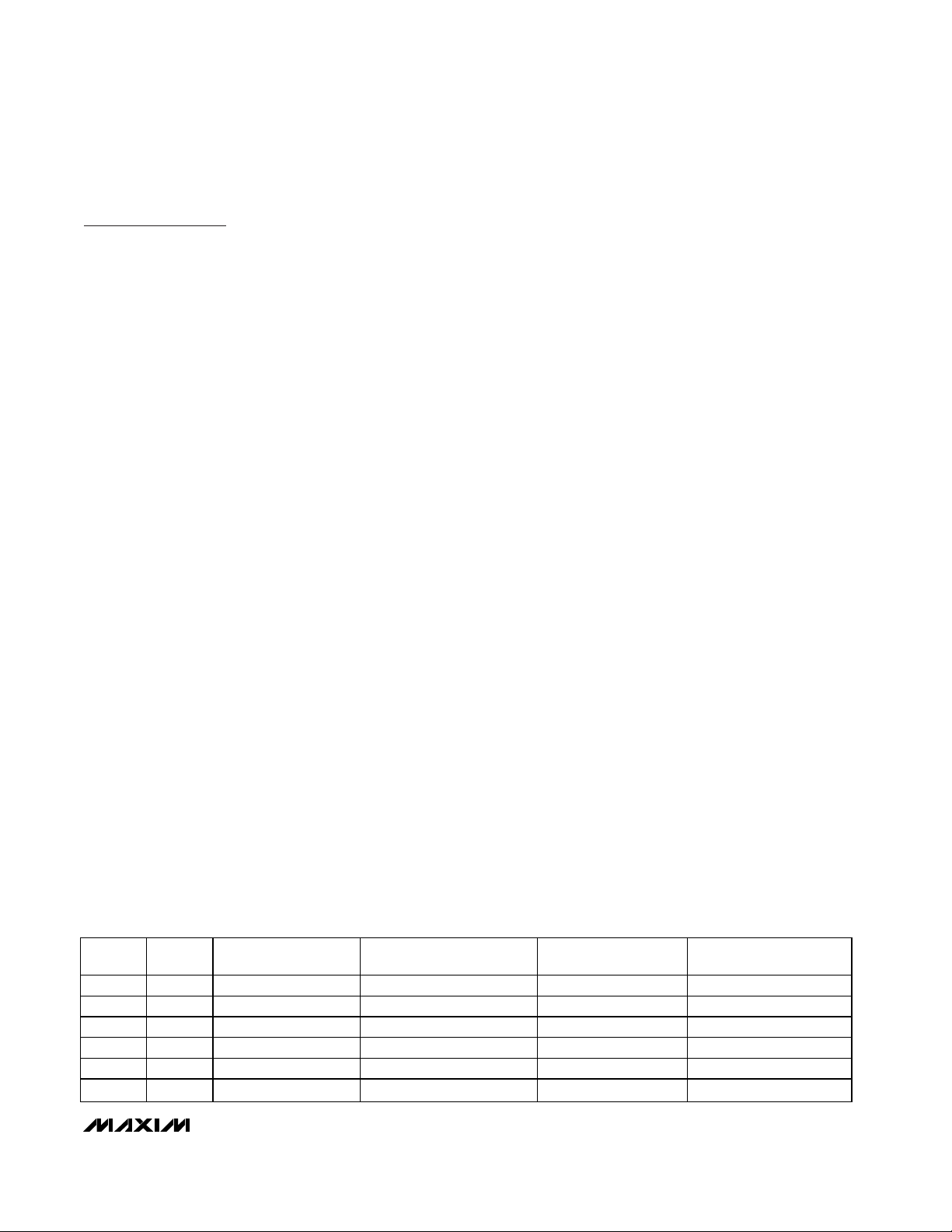

Ordering Information/Selector Guide

19-3338; Rev 0; 7/04

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

SMBus is a trademark of Intel Corporation.

I

2

C is a trademark of Philips Corporation. Purchase of I2C components from Maxim Integrated Products, Inc. or one of its sublicensed Associated Companies, conveys a license under the

Philips I2C Patent Rights to use these components in an I2C system, provided that the system conforms to the I2C Standard

Specification as defined by Philips.

AutoShutdown is a trademark of Maxim Integrated Products, Inc.

µMAX is a registered trademark of Maxim Integrated Products, Inc.

Typical Operating Circuit and Pin Configuration appear at

end of data sheet.

Ordering Information/Selector Guide continued at end of data sheet.

*Future product—contact factory for availability.

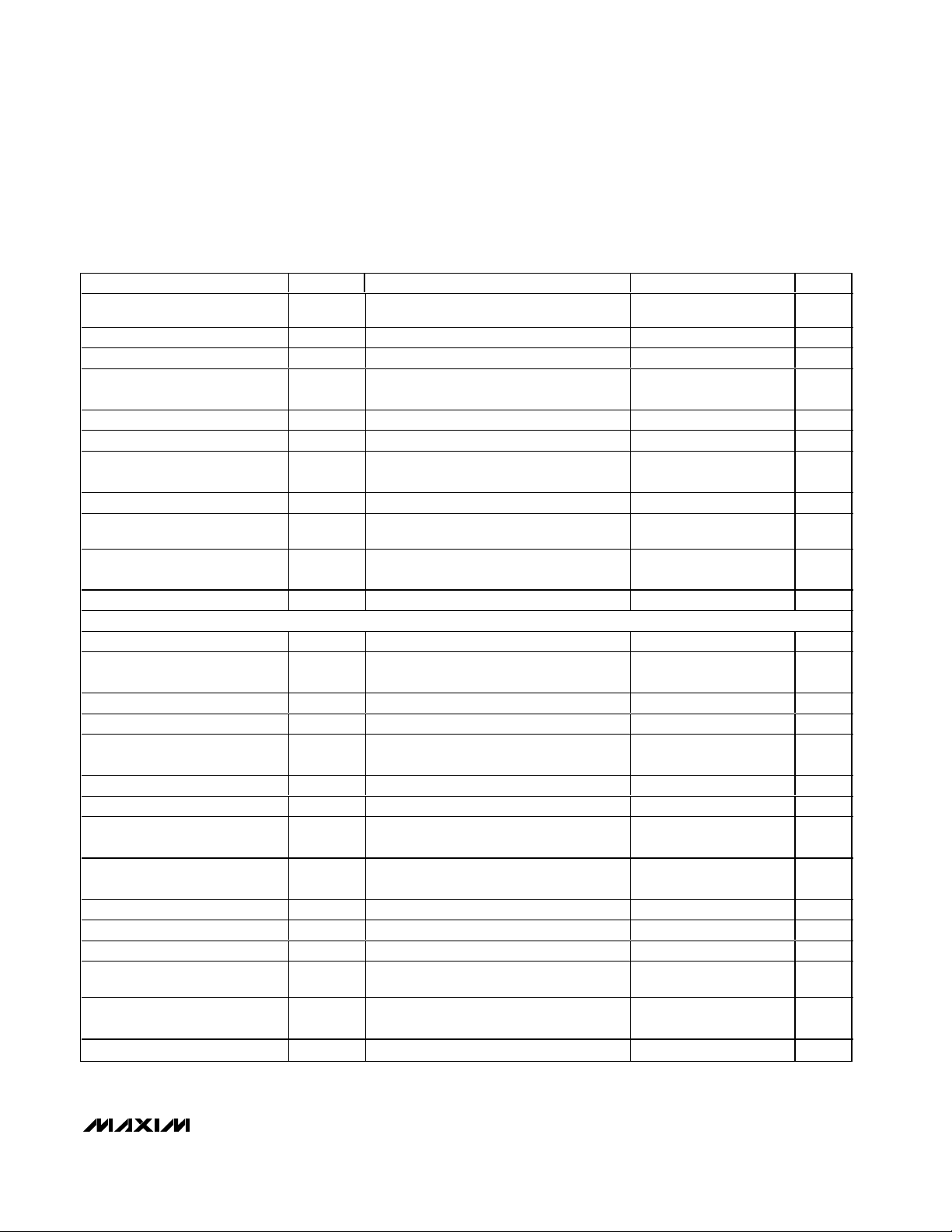

PART TEMP RANGE PIN-PACKAGE I2C SLAVE ADDRESS SUPPLY VOLTAGE (V)

MAX1363EUB -40°C to +85°C 10 µMAX 0110100/0110101 2.7 to 3.6

MAX1363LEUB* -40°C to +85°C 10 µMAX 0110010/0110011 2.7 to 3.6

MAX1363MEUB* -40°C to +85°C 10 µMAX 0110110/0110111 2.7 to 3.6

Page 2

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

2 _______________________________________________________________________________________

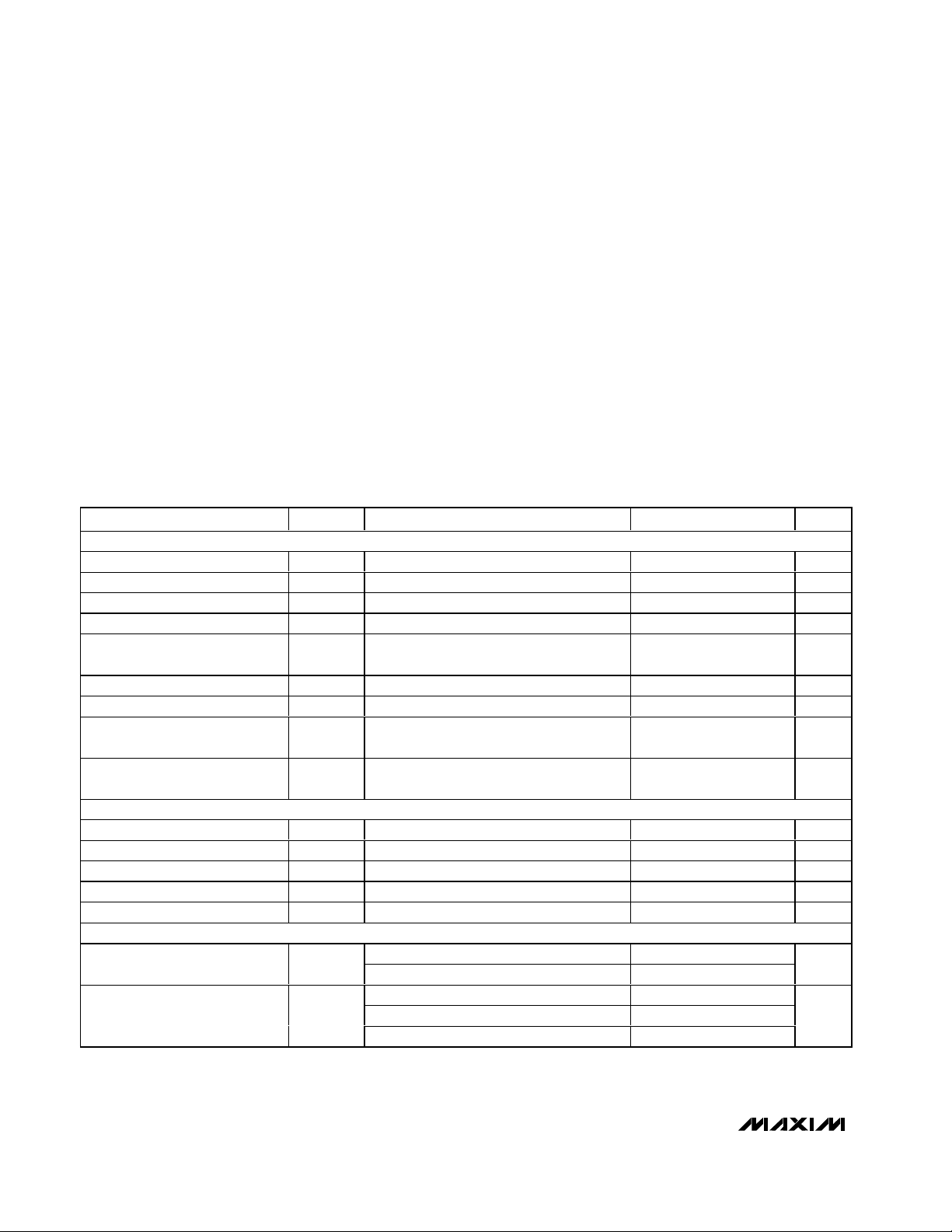

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDD= 2.7V to 3.6V (MAX1363), VDD= 4.5V to 5.5V (MAX1364), V

REF

= 2.048V (MAX1363), V

REF

= 4.096V (MAX1364), C

REF

=

0.1µF, f

SCL

= 1.7MHz, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND..............................................................-0.3V to +6V

AIN0–AIN3, A0, REF to GND......................-0.3V to (V

DD

+ 0.3V)

SDA, SCL, INT to GND.............................................-0.3V to +6V

Maximum Current Into Any Pin.........................................±50mA

Continuous Power Dissipation (T

A

= +70°C)

10-Pin µMAX (derate 5.6mW/°C above +70°C) ........444.4mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

DC ACCURACY (f

Resolution 12 Bits

Relative Accuracy INL (Note 2) ±1 LSB

Differential Nonlinearity DNL No missing codes ±1 LSB

Offset Error ±4 LSB

Offset-Error Temperature

Coefficient

Gain Error (Note 3) ±4 LSB

Gain Temperature Coefficient Relative to FSR 0.3 ppm/°C

Channel-to-Channel Offset

Matching

Channel-to-Channel Gain

Matching

DYNAMIC PERFORMANCE (f

Signal-to-Noise Plus Distortion SINAD 70 dB

Total Harmonic Distortion THD Up to the 5th harmonic -78 dB

Spurious-Free Dynamic Range SFDR 78 dB

Full-Power Bandwidth SINAD > 57dB 3.0 MHz

Full-Linear Bandwidth -3dB point 5.0 MHz

CONVERSION RATE

Conversion Time (Note 4) t

Throughput Rate (Note 5) f

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SAMPLE

= 94.4ksps) (Note 1)

IN(SINE-WAVE)

= 10kHz, V

CONV

SAMPLE

Relative to FSR 0.3 ppm/°C

IN(P-P)

Internal clock 7.5

External clock 10.6

Internal clock, SCAN[1:0] = 01 51

External clock 94.4

Monitor mode, SCAN[1:0] = 10 133

= V

REF

, f

SAMPLE

= 94.4ksps)

±0.1 LSB

±0.1 LSB

µs

ksps

Page 3

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

_______________________________________________________________________________________ 3

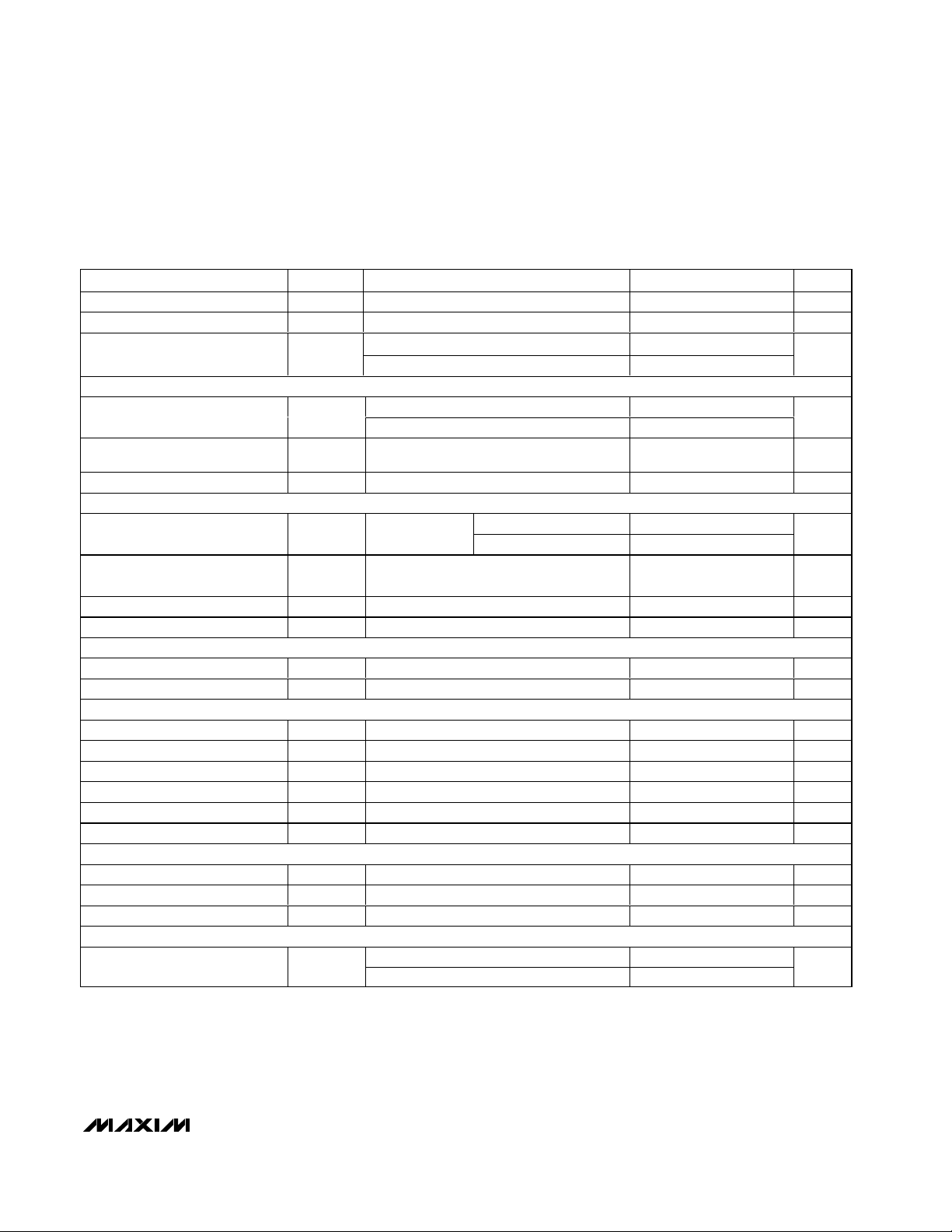

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 2.7V to 3.6V (MAX1363), VDD= 4.5V to 5.5V (MAX1364), V

REF

= 2.048V (MAX1363), V

REF

= 4.096V (MAX1364), C

REF

=

0.1µF, f

SCL

= 1.7MHz, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Track/Hold Acquisition Time 800 ns

Internal Clock Frequency 2.8 MHz

Aperture Delay (Note 6) t

AD

External clock, fast mode 60

External clock, high-speed mode 30

ANALOG INPUT (AIN0–AIN3)

Input Voltage Range, Single

Ended and Differential (Note 7)

Input Multiplexer Leakage

Current

Input Capacitance C

Unipolar 0 V

Bipolar -V

ON/OFF-leakage current, V

IN

INTERNAL REFERENCE (Note 8)

Reference Voltage V

Reference-Voltage Temperature

Coefficient

TCV

REF

TA = +25°C

REF

REF Short-Circuit Current 2mA

REF Source Impedance 1.5 kΩ

EXTERNAL REFERENCE

REF Input Voltage Range V

REF Input Current I

REF

REF

(Note 9) 1 V

f

= 94.4ksps 40 µA

SAMPLE

DIGITAL INPUTS/OUTPUTS (SCL, SDA, A0)

Input High Voltage V

Input Low Voltage V

Input Hysteresis V

Input Current I

Input Capacitance C

Output Low Voltage V

IH

IL

HYST

IN

IN

OL

I

= 3mA 0.4 V

SINK

INT OUTPUT

Output Low Voltage I

= 3mA 0.4 V

SINK

INT Leakage Current No faults detected ±10 µA

Output Capacitance 15 pF

POWER REQUIREMENTS

Supply Voltage V

DD

MAX1363 2.7 3.6

MAX1364 4.5 5.5

= 0 or V

AIN_

DD

/ 2 +V

REF

REF

±0.01 ±1 µA

REF

22 pF

MAX1363 2.027 2.048 2.068

MAX1364 4.055 4.096 4.137

25 ppm/°C

DD

0.7 x V

DD

0.3 x V

0.1 x V

DD

±10 µA

15 pF

/ 2

DD

ns

V

V

V

V

V

V

V

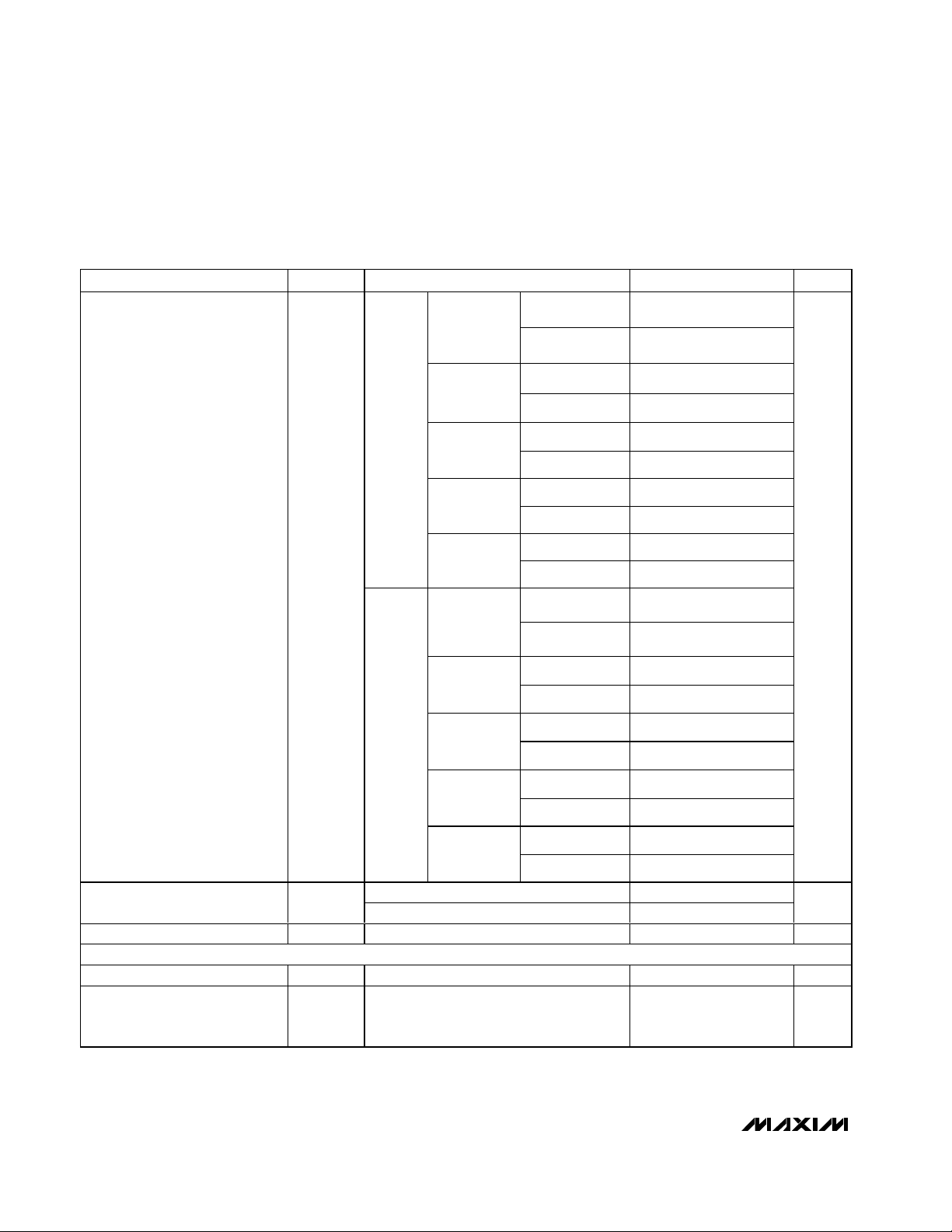

Page 4

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 2.7V to 3.6V (MAX1363), VDD= 4.5V to 5.5V (MAX1364), V

REF

= 2.048V (MAX1363), V

REF

= 4.096V (MAX1364), C

REF

=

0.1µF, f

SCL

= 1.7MHz, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Supply Current I

Shutdown Current

Power-Supply Rejection Ratio PSRR Full-scale input (Note 11) ±0.01 ±0.5 LSB/V

TIMING CHARACTERISTICS FOR FAST MODE (Figures 1a, 2)

Serial Clock Frequency f

Bus Free Time Between a

STOP (P) and a

START (S) Condition

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

f

SAMPLE

133ksps,

monitor mode

(Note 10)

f

SAMPLE

94.4ksps,

external clock

f

SAMPLE

40ksps,

internal clock

f

SAMPLE

10ksps,

internal clock

f

SAMPLE

1ksps,

internal clock

f

SAMPLE

133ksps,

monitor mode

(Note10)

f

SAMPLE

94.4ksps,

external clock

f

SAMPLE

40ksps,

internal clock

f

SAMPLE

10ksps,

internal clock

f

SAMPLE

1ksps, internal

clock

SCL

t

BUF

MAX1363

DD

MAX1364

Internal reference on 333

Internal reference off 0.5 10

=

Internal reference 660 1600

External reference 436 1350

=

Internal reference 900 1150

External reference 670 900

=

Internal reference 530

External reference 230

=

Internal reference 380

External reference 60

=

Internal reference 330

External reference 6

=

Internal reference 660 1600

External reference 436 1350

=

Internal reference 900 1150

External reference 670 900

=

Internal reference 530

External reference 230

=

Internal reference 380

External reference 60

=

Internal reference 330

External reference 6

1.3 µs

400 kHz

µA

µA

Page 5

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 2.7V to 3.6V (MAX1363), VDD= 4.5V to 5.5V (MAX1364), V

REF

= 2.048V (MAX1363), V

REF

= 4.096V (MAX1364), C

REF

=

0.1µF, f

SCL

= 1.7MHz, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Hold Time for START (S)

Condition

Low Period of the SCL Clock t

High Period of the SCL Clock t

Setup Time for a Repeated

START Condition (Sr)

Data Hold Time t

Data Setup Time t

Rise Time of Both SDA and SCL

Signals, Receiving

Fall Time of SDA Transmitting

Setup Time for STOP (P)

Condition

Capacitive Load for Each Bus

Line

t

HD, STA

LOW

HIGH

t

SU, STA

HD, DAT

SU, DAT

t

t

t

SU, STO

C

Measured from 0.3VDD to 0.7V

R

Measured from 0.3VDD to 0.7V

F

B

Pulse Width of Spike Suppressed 50 ns

TIMING CHARACTERISTICS FOR HIGH-SPEED MODE (CB = 400pF, Figures 1a, 2) (Note 12)

Serial Clock Frequency f

Hold Time, Repeated START

Condition (Sr)

t

Low Period of the SCL Clock t

High Period of the SCL Clock t

Setup Time for a Repeated

START Condition (Sr)

t

Data Hold Time t

Data Setup Time t

Rise Time of SCL Signal, Current

Source Enabled

Rise Time of SCL Signal After

Acknowledge Bit

Fall Time of SCL Signal t

Rise Time of SDA Signal t

Fall Time of SDA Signal t

Setup Time for STOP (P)

Condition

t

Capacitive Load for Each Bus

Line

SCLH

HD, STA

LOW

HIGH

SU, STA

HD, DAT

SU, DAT

t

RCL

t

RCL1

FCL

RDA

FDA

SU, STO

C

(Note 13) 1.7 MHz

(Note 13) 320 ns

(Note 14) 0 150 ns

Measured from 0.3VDD to 0.7V

Measured from 0.3VDD to 0.7V

Measured from 0.3VDD to 0.7V

Measured from 0.3VDD to 0.7V

Measured from 0.3VDD to 0.7V

(Notes 13, 14) 400 pF

B

Pulse Width of Spike Suppressed 0 10 ns

DD

DD 0

DD

DD

DD

DD

DD

0.6 µs

1.3 µs

0.6 µs

0.6 µs

0 900 ns

100 ns

0 300 ns

300 ns

0.6 µs

400 pF

160 ns

120 ns

160 ns

10 ns

20 80 ns

20 160 ns

20 80 ns

20 160 ns

20 160 ns

160 ns

Page 6

Typical Operating Characteristics

(VDD= 3.3V (MAX1363), VDD= 5V (MAX1364), f

SCL

= 1.7MHz, external clock, f

SAMPLE

= 94.4ksps, single-ended, unipolar,

T

A

= +25°C, unless otherwise noted.)

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 2.7V to 3.6V (MAX1363), VDD= 4.5V to 5.5V (MAX1364), V

REF

= 2.048V (MAX1363), V

REF

= 4.096V (MAX1364), C

REF

=

0.1µF, f

SCL

= 1.7MHz, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Note 1: Devices configured for unipolar single-ended inputs.

Note 2: Relative accuracy is the deviation of the analog value at any code from its theoretical value after the gain and offset have

been calibrated.

Note 3: Offset nulled.

Note 4: Conversion time is defined as the number of clock cycles needed for conversion multiplied by the clock period.

Conversion time does not include acquisition time. SCL is the conversion clock in the external clock mode.

Note 5: The throughput rate of the I

2

C bus is limited to 94.4ksps. The MAX1363/MAX1364 can perform conversions up to 133ksps

in monitor mode when not reading back results on the I

2

C bus.

Note 6: A filter on the SDA and SCL inputs suppresses noise spikes and delays the sampling instant.

Note 7: The absolute input-voltage range for the analog inputs (AIN0–AIN3) is from GND to V

DD

.

Note 8: When the internal reference is configured to be available at AIN3/REF (SEL[2:1] = 11), decouple AIN3/REF to GND with a

0.01µF capacitor.

Note 9: ADC performance is limited by the converter’s noise floor, typically 300µV

P-P

.

Note 10: Maximum conversion throughput in internal clock mode when the data is not clocked out.

Note 11: For the MAX1363, PSRR is measured as

and for the MAX1364, PSRR is measured as

Note 12: C

B

= total capacitance of one bus line in pF.

Note 13: f

SCLH

must meet the minimum clock low time plus the rise/fall times.

Note 14: A master device must provide a data hold time for SDA (referred to V

IL

of SCL) to bridge the undefined region of SCL’s

falling edge.

(

)

VVVV

(. ) (. )

36 27

FS FS

[]

−

VV

(. . )

36 27

−

N

21

−

×

V

REF

VVVV

(. ) (. )

55 45

FS FS

[]

−

VV

..

55 45

−

×

N

21

−

V

REF

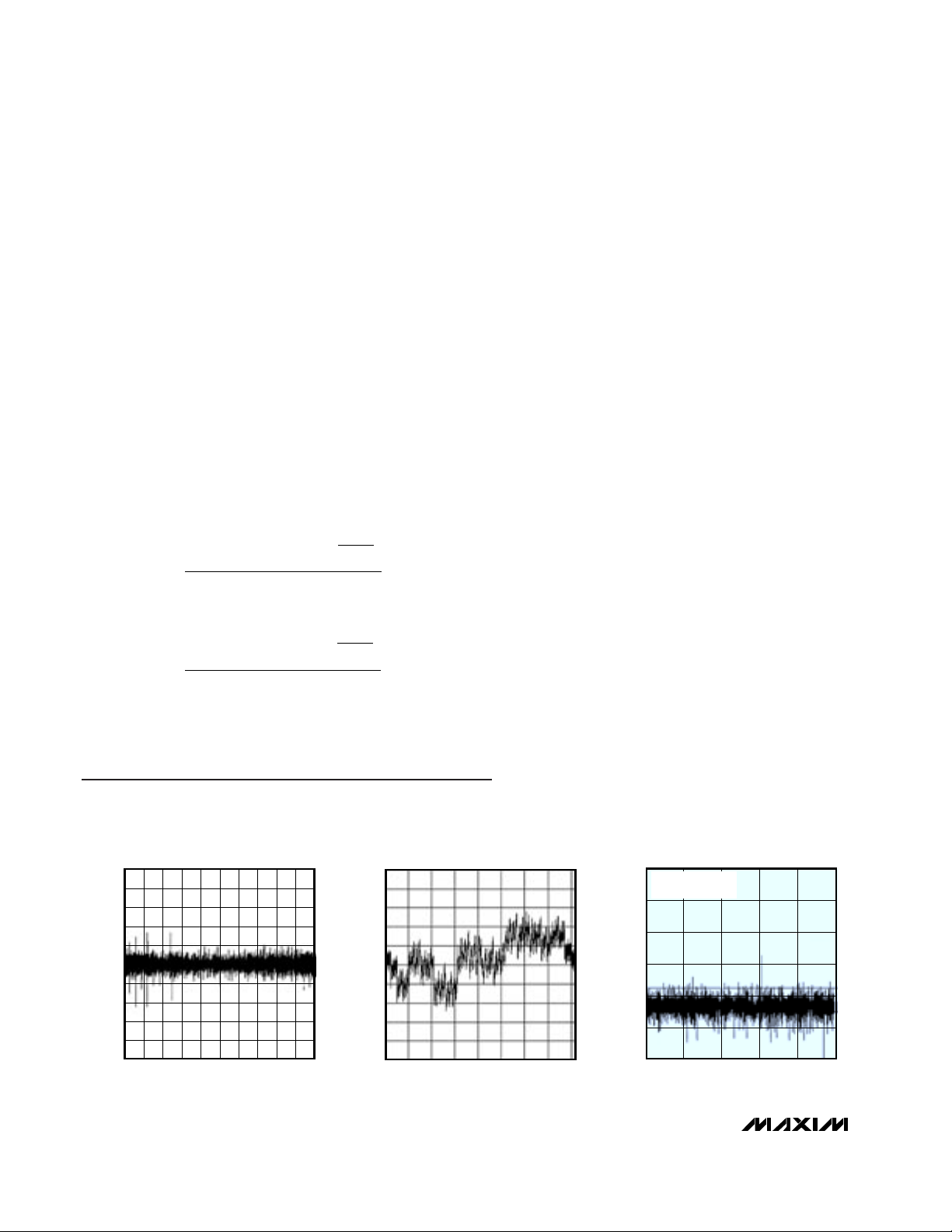

DNL (LSB)

-0.1

-0.2

-0.3

-0.4

-0.5

DIFFERENTIAL NONLINEARITY

vs. DIGITAL CODE

0.5

0.4

0.3

0.2

0.1

0

1000 1500500

0 4000

2000 2500

DIGITAL OUTPUT CODE

3000 3500

MAX1363/64 toc01

1.0

0.8

0.6

0.4

0.2

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

INTEGRAL NONLINEARITY

vs. DIGITAL CODE

0

1000 1500500

0 4000

2000 2500

DIGITAL OUTPUT CODE

3000 3500

MAX1363/64 toc02

FFT PLOT

-60

f

= 94.4ksps

SAMPLE

= 10kHz

f

IN

-80

-100

-120

AMPLITUDE (dBc)

-140

-160

-180

01020304050

FREQUENCY (kHz)

MAX1363/64 toc03

Page 7

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

_______________________________________________________________________________________ 7

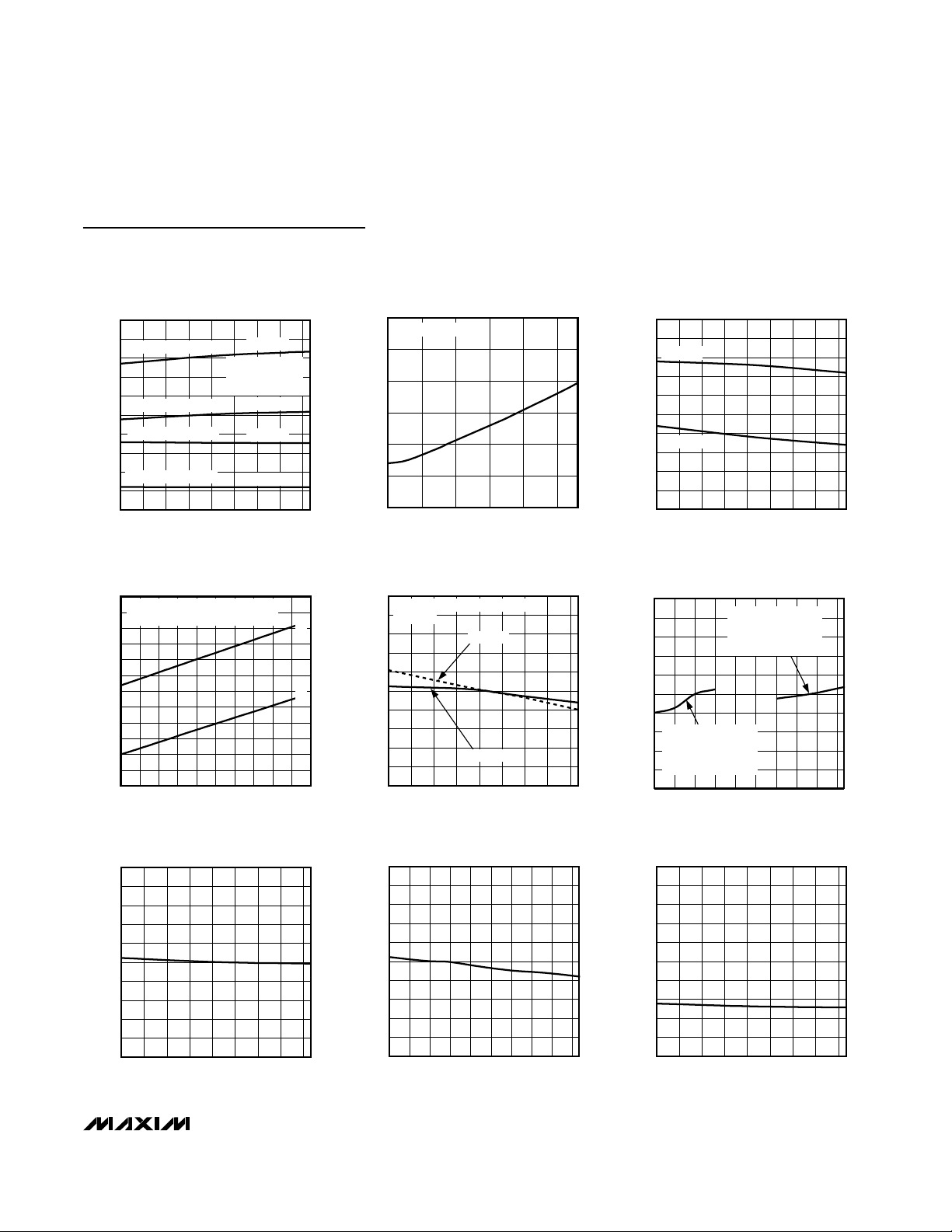

Typical Operating Characteristics (continued)

(VDD= 3.3V (MAX1363), VDD= 5V (MAX1364), f

SCL

= 1.7MHz, external clock, f

SAMPLE

= 94.4ksps, single-ended, unipolar,

T

A

= +25°C, unless otherwise noted.)

0

0.2

0.1

0.4

0.3

0.6

0.5

0.7

0.9

0.8

1.0

-40 -10 5-25 20 35 50 65 80

GAIN ERROR vs. TEMPERATURE

MAX1363/64 toc12

TEMPERATURE (°C)

GAIN ERROR (LSB)

SUPPLY CURRENT vs. TEMPERATURE

800

750

INTERNAL REFERENCE

700

650

600

INTERNAL REFERENCE

550

EXTERNAL REFERENCE

500

450

SUPPLY CURRENT (µA)

400

EXTERNAL REFERENCE

350

300

-40 -10 5-25 20 35 50 65 80

TEMPERATURE (°C)

MAX1364

SETUP BYTE

EXT REF: 10111010

INT REF: 11011010

MAX1363

MAX1364

MAX1363

AVERAGE SUPPLY CURRENT

vs. CONVERSION RATE (EXTERNAL CLOCK)

800

A) INTERNAL REFERENCE ALWAYS ON

750

B) EXTERNAL REFERENCE

700

650

600

(µA)

550

DD

500

450

AVERAGE I

400

350

300

250

200

010 50 70 90

02030406080100

CONVERSION RATE (ksps)

MAX1363/64 toc04

A

MAX1363/64 toc07

B

0.6

0.5

0.4

(µA)

0.3

DD

I

0.2

0.1

1.0010

1.0008

1.0006

1.0004

1.0002

1.0000

NORMALIZED

0.9998

REF

V

0.9996

0.9994

0.9992

0.9990

SHUTDOWN SUPPLY CURRENT

vs. SUPPLY VOLTAGE

SDA = SCL = V

0

2.7 5.2

DD

3.73.2 4.2 4.7

INPUT VOLTAGE (V)

INTERNAL REFERENCE VOLTAGE

vs. TEMPERATURE

NORMALIZED TO REFERENCE VALUE

AT +25°C

MAX1364

MAX1363

-40 -10 5-25 20 35 50 65 80

TEMPERATURE (°C)

MAX1363/64 toc05

1.00010

1.00008

1.00006

MAX1363/64 toc08

1.00004

1.00002

1.00000

NORMALIZED

0.99998

REF

V

0.99996

0.99994

0.99992

0.99990

SHUTDOWN SUPPLY CURRENT

vs. TEMPERATURE

0.50

0.45

MAX1364

0.40

0.35

0.30

0.25

0.20

MAX1363

0.15

SUPPLY CURRENT (µA)

0.10

0.05

0

-40 -10 5-25 20 35 50 65 80

TEMPERATURE (°C)

NORMALIZED REFERENCE VOLTAGE

vs. SUPPLY VOLTAGE

MAX1364

NORMALIZED TO

REFERENCE VALUE AT

= 5V

V

DD

MAX1363

NORMALIZED TO

REFERENCE VALUE AT

= 3.3V

V

DD

2.7 3.3 3.6 3.93.0 4.2 4.5 4.8 5.1 5.4

VDD (V)

MAX1363/64 toc06

MAX1363/64 toc09

OFFSET ERROR vs. TEMPERATURE

0

-0.1

-0.2

-0.3

-0.4

-0.5

-0.6

OFFSET ERROR (LSB)

-0.7

-0.8

-0.9

-1.0

-40 -10 5-25 20 35 50 65 80

TEMPERATURE (°C)

OFFSET ERROR vs. SUPPLY VOLTAGE

0

-0.1

MAX1363/64 toc10

-0.2

-0.3

-0.4

-0.5

-0.6

OFFSET ERROR (LSB)

-0.7

-0.8

-0.9

-1.0

2.7 3.3 3.6 3.93.0 4.2 4.5 4.8 5.1 5.4

VDD (V)

MAX1363/64 toc11

Page 8

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

8 _______________________________________________________________________________________

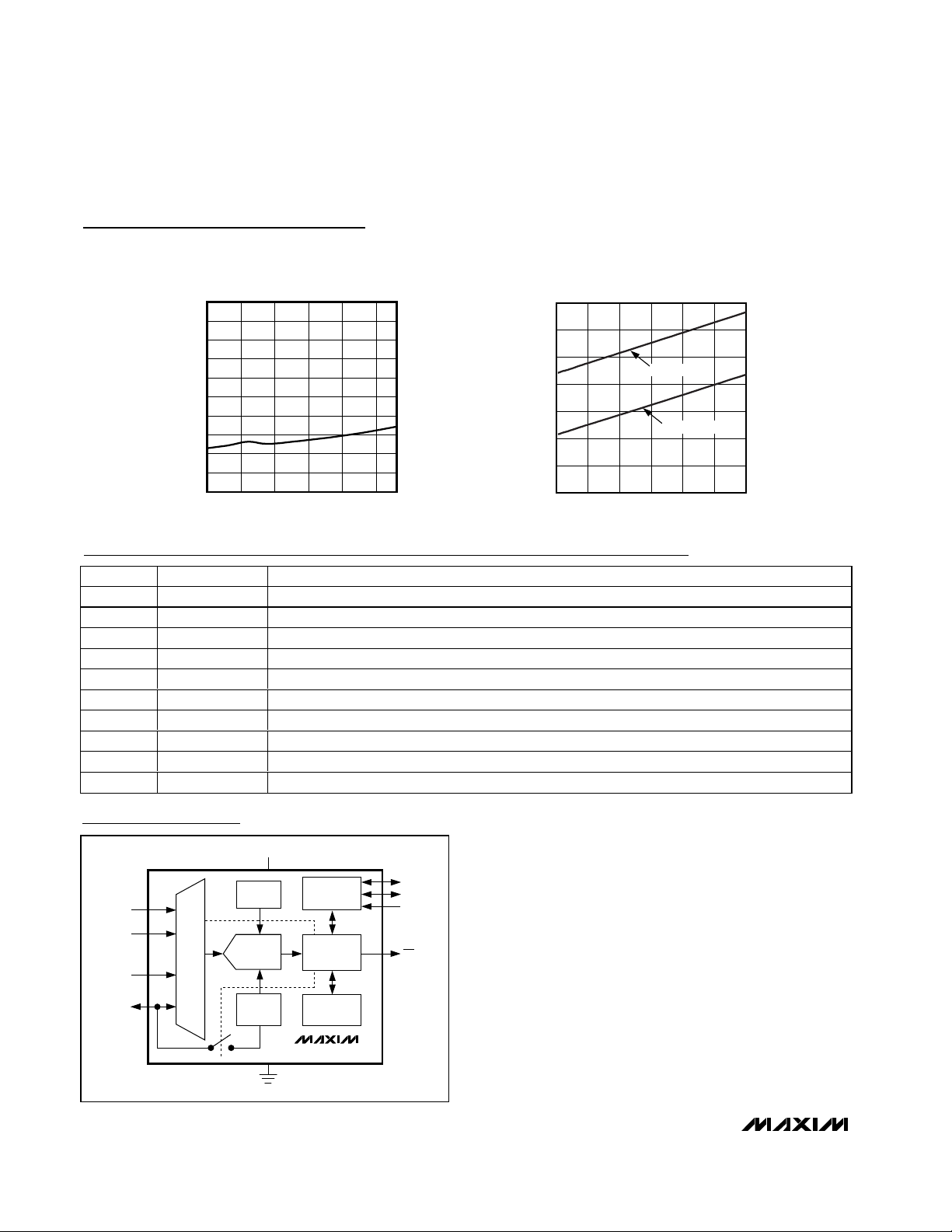

Pin Description

Functional Diagram

Typical Operating Characteristics (continued)

(VDD= 3.3V (MAX1363), VDD= 5V (MAX1364), f

SCL

= 1.7MHz, external clock, f

SAMPLE

= 94.4ksps, single-ended, unipolar,

T

A

= +25°C, unless otherwise noted.)

GAIN ERROR vs. SUPPLY VOLTAGE

1.0

0.9

0.8

0.7

0.6

0.5

0.4

GAIN ERROR (LSB)

0.3

0.2

0.1

0

2.7 3.73.2 4.2 4.7 5.2

VDD (V)

MAX1363/64 toc13

MONITOR-MODE SUPPLY CURRENT

vs. SPEED

700

600

500

400

300

SUPPLY CURRENT (µA)

200

100

0

0 150

INTERNAL REF

EXTERNAL REF

SPEED (ksps)

MAX1363/64 toc14

125100755025

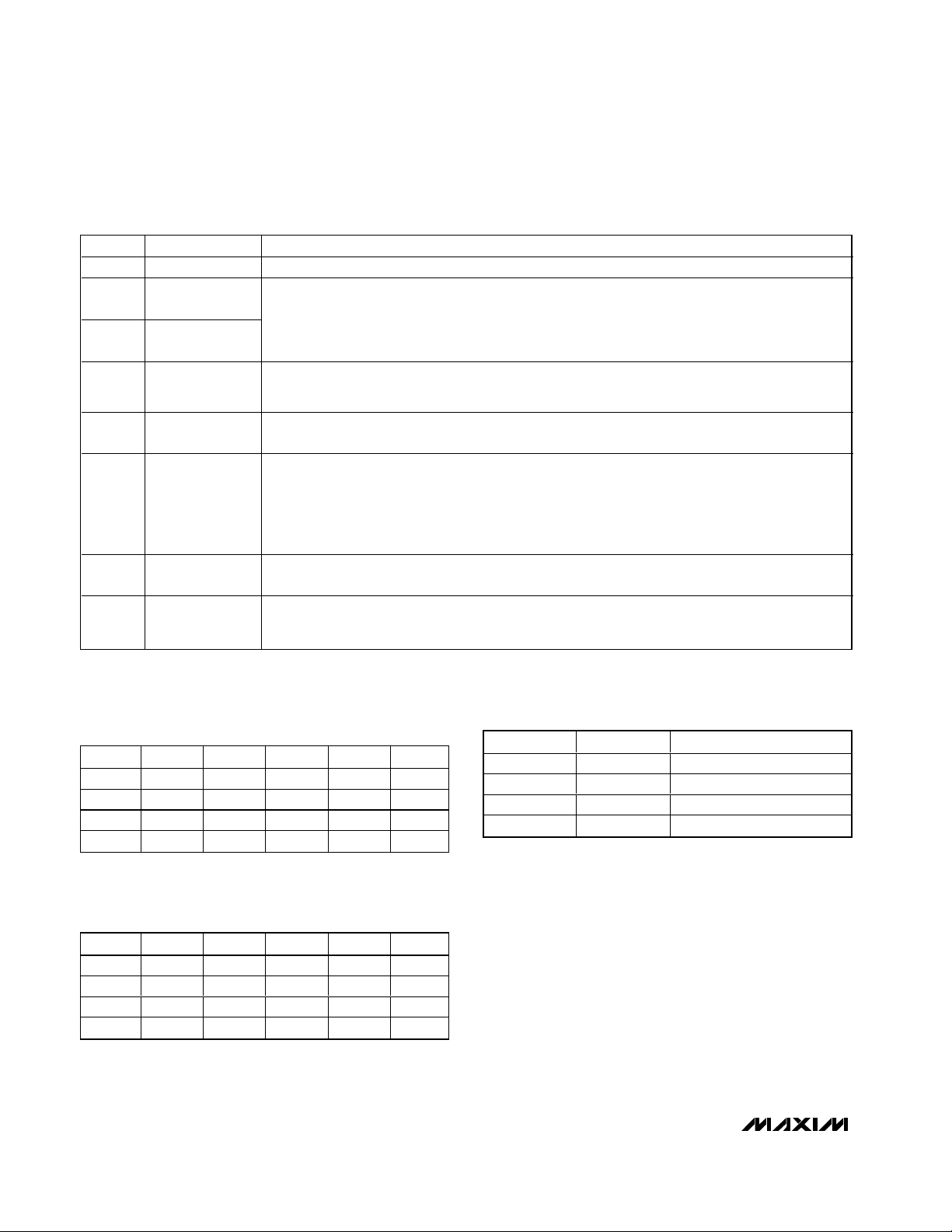

PIN NAME FUNCTION

1 AIN0 Analog Input

2 AIN1 Analog Input

3 AIN2 Analog Input

4 AIN3/V

REF

5A0I

Analog Input or Reference Input or Output. See Table 3.

2

C Address Select Input. Connect to VDD or GND. See Table 1.

6 INT Active-Low, Open-Drain Interrupt Output

7 SCL I2C Clock Input

8 SDA I2C Data Input/Output

9 GND Ground

10 V

DD

Positive Supply Voltage. Bypass V

to GND with a 0.1µF capacitor.

DD

V

DD

SDA

SCL

A0

INT

AIN0

AIN1

AIN2

AIN3/

REF

4:1

MUX

CLK

12-BIT

ADC

INT

REF

GND

I2C

INTERFACE

CONTROL

TRIP

THRESHOLDS

MAX1363/MAX1364

Page 9

Detailed Description

The MAX1363/MAX1364 4-channel ADCs use successive-approximation conversion techniques and fully differential input track/hold (T/H) circuitry to capture and

convert analog signals to a serial 12-bit digital output.

The MAX1363/MAX1364 feature a monitor mode with

programmable trip thresholds and window comparator.

The monitor function asserts an interrupt when any

channel violates the programmed upper or lower

thresholds. SMBus alert response allows the host

microcontroller (µC) to quickly identify which device

caused the interrupt. A programmable delay between

monitoring intervals lowers power consumption at lower

monitor rates.

The MAX1363/MAX1364 integrate an internal voltage

reference and clock. The software configures the analog inputs for unipolar/bipolar and single-ended/fully

differential operation. Integrated first-in/first-out (FIFO)

allows conversion of all channels, or eight conversions

on a selected channel to reduce interface overhead. An

I

2

C-compatible serial interface complies with standard,

fast, and high-speed (1.7MHz) modes.

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

_______________________________________________________________________________________ 9

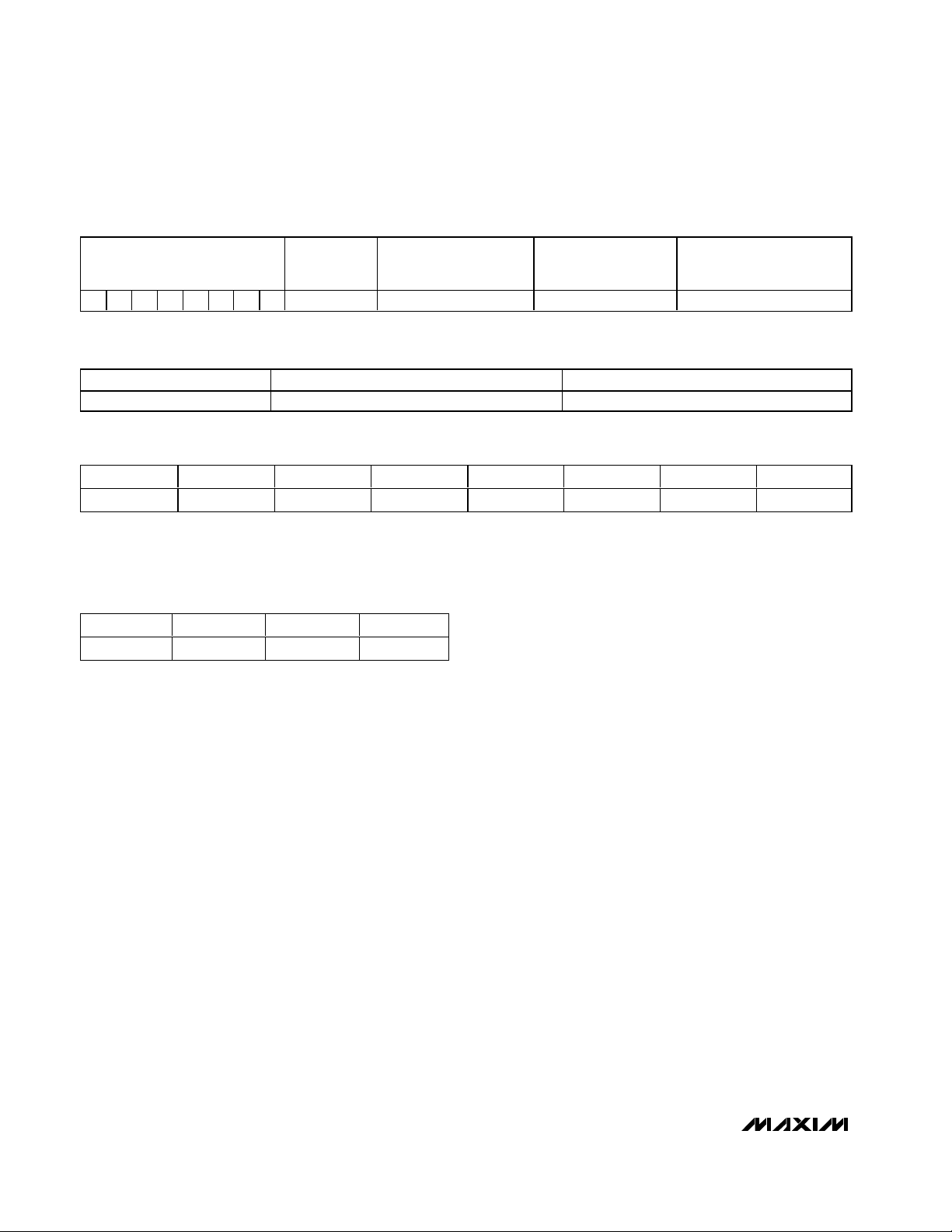

Figure 1a. F/S-Mode 2-Wire Serial-Interface Timing

Figure 2. Load Circuits

Figure 1b. HS-Mode 2-Wire Serial-Interface Timing

SDA

SCL

S

t

SU.STA

t

t

LOW

SU.DAT

t

HIGH

t

R

t

HD.DAT

t

F

SDA

t

t

LOW

SCL

t

HD.STA

Sr Sr

SU.DAT

1 9

t

HIGH

t

RCL

t

t

HD.DAT

FCL

t

SU.STA

t

SU.STA

t

R

t

HD.STA

t

HD.STA

ACK

Sr

ACK

t

SU.STO

9

PS

t

RDA

t

SU.STO

t

RCL1

t

F

t

BUF

t

FDA

P

S

HS-MODE

F/S-MODE

V

DD

I

OL

SDA

V

OUT

400pF

I

OH

Page 10

MAX1363/MAX1364

Power Supply

The MAX1363 (2.7V to 3.6V) and MAX1364 (4.5V to

5.5V) operate from a single supply and consume

670µA (typ) at sampling rates up to 94.4ksps and

436µA in monitor mode at 133ksps. The MAX1363

features a 2.048V internal reference, and the MAX1364

features a 4.096V internal reference. All devices can be

configured for use with an external reference from 1V to

VDD. Bypass VDDto GND using a 0.1µF or greater

ceramic capacitor for best performance.

Analog-Input and Track/Hold

The MAX1363/MAX1364 analog-input architecture contains an analog-input multiplexer (mux), fully differential

T/H, comparator, and a fully differential switched

capacitive digital-to-analog converter (DAC). Figure 3

shows the equivalent input circuit for the MAX1363/

MAX1364.

In single-ended mode, the analog-input mux connects

C

T/H

between the analog input selected by CS[3:0] and

GND (see the Configuration/Setup Bytes (Write Cycle)

section). In differential mode, the analog-input mux

connects C

T/H

to the plus and minus analog inputs

selected by CS[3:0].

During the acquisition interval, the T/H switches are in

the track position, and C

T/H

charges to the analog-input

signal. At the end of the acquisition interval, the T/H

switches move to the hold position, retaining the

charge on C

T/H

as a stable sample of the input signal.

During the conversion, a switched capacitive DAC

adjusts to restore the comparator input voltage to 0V

within the limits of 12-bit resolution. This action requires

12 conversion clock cycles and is equivalent to transferring a charge of 11pF x (VIN+ - VIN-) from C

T/H

to the

binary-weighted capacitive DAC, forming a digital representation of the analog-input signal.

Use a low source impedance to ensure an accurate

sample. A source impedance of up to 1.5kΩ does not

significantly degrade sampling accuracy. For larger

source impedances, connect a 100pF capacitor from

the analog input to GND or buffer the input.

In internal clock mode, the T/H circuitry enters track

mode on the eighth rising clock edge of the address

byte (see the Slave Address section). The T/H circuitry

enters hold mode on the falling clock edge of the

acknowledge bit of the address byte (the ninth clock

pulse). The conversions are then internally clocked, during which time the MAX1363/MAX1364 hold SCL low.

In external clock mode, the T/H circuitry enters track

mode after a valid address on the rising edge of the

clock during the read bit (R/W = 1). Hold mode is

entered on the rising edge of the second clock pulse

during the shifting out of the 1st byte of the result. The

next 12 clock cycles perform the conversions.

The time required for the T/H circuitry to acquire an

input signal is a function of the input sample capacitance. If the analog-input source impedance is high,

the acquisition time constant lengthens and more time

must be allowed between conversions. The acquisition

time (t

ACQ

) is the minimum time needed for the signal

to be acquired. It is calculated by:

t

ACQ

≥ 9 x (R

SOURCE

+ RIN) x C

IN

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

10 ______________________________________________________________________________________

Figure 3. Equivalent Input Circuit

TRACK

TRACK

HOLD

TRACK

HOLD

C

HOLD

C

VDD/2

REF

REF

CAPACITIVE

DAC

CAPACITIVE

DAC

MAX1363

MAX1364

T/H

HOLD

TRACK

HOLD

TRACK

T/H

ANALOG-INPUT MUX

AIN0

AIN1

AIN2

AIN3/REF

GND

Page 11

where R

SOURCE

is the analog-input source impedance,

RIN= 2.5kΩ, and CIN= 22pF. For internal clock mode,

t

ACQ

= 1.5 / f

SCL

, and for external clock mode t

ACQ

=

2 / f

SCL

.

Analog-Input Bandwidth

The MAX1363/MAX1364 feature input-tracking circuitry

with a 5MHz small-signal bandwidth. The 5MHz input

bandwidth makes it possible to digitize high-speed

transient events and measure periodic signals with

bandwidths exceeding the ADC’s sampling rate by

using undersampling techniques. To avoid high-frequency signals from aliasing into the frequency band of

interest, use anti-aliasing filtering.

Analog-Input Range and Protection

Internal protection diodes clamp the analog inputs to V

DD

and GND. These diodes allow the analog inputs to swing

from (GND - 0.3V) to (VDD+ 0.3V) without causing damage to the device. For accurate conversions, the inputs

must remain within 50mV below GND or above V

DD

.

Single-Ended/Differential Input

The SE/DIF of the configuration byte configures the

MAX1363/MAX1364 analog-input circuitry for singleended or differential input. In single-ended mode (SE/DIF

= 1), the digital conversion results are the difference

between the analog input selected by CS[3:0] and GND.

In differential mode (SE/DIF = 0), the digital conversion

results are the difference between the plus and the minus

analog inputs selected by CS[3:0] (see Tables 5 and 6).

Unipolar/Bipolar

Unipolar mode sets the differential input range from 0

to V

REF

. A negative differential analog input in unipolar

mode causes the digital output code to be zero.

Selecting bipolar mode sets the differential input range

to ±V

REF

/ 2. The digital output code is binary in unipolar mode and two’s complement in bipolar mode. (See

the Transfer Functions section.)

In single-ended mode the MAX1363/MAX1364 always

operate in unipolar mode. The analog inputs are internally referenced to GND with a full-scale input range

from 0 to V

REF

(Table 7).

Reference

SEL[2:0] of the setup byte controls the reference and

the AIN3/REF configuration. When AIN3/REF is configured as a reference input or reference output (SEL1 =

1), differential conversions on AIN3/REF appear as if

AIN3/REF is connected to GND. A single-ended conversion in scan mode on AIN3/REF is ignored by an internal

limiter that sets the highest available channel at AIN2.

Internal Reference

The internal reference is 2.048V for the MAX1363 and

4.096V for the MAX1364. SEL1 of the setup byte controls whether AIN3/REF is used for an analog input or a

reference. Decouple AIN3/REF to GND with a 0.1µF

capacitor and a 2kΩ resistor in series with the capacitor. When AIN3/REF is configured as an internal reference output (SEL[1:0] = 11). See the Typical Operating

Circuit. Once powered up, the reference remains on

until reconfigured. Do not use the reference to supply

current for external circuitry.

External Reference

The external reference ranges from 1V to V

DD

. For maximum conversion accuracy, the reference must deliver

40µA and have an impedance of 500Ω or less. For

noisy or high-output-impedance references, insert a

0.1µF bypass capacitor to GND as close to AIN3/REF

as possible.

Clock Modes

The clock mode determines the conversion clock and

the data acquisition and conversion time. The clock

mode also affects the scan mode. The state of the

setup byte’s INT/EXT clock bit determines the clock

mode. At power-up, the MAX1363/MAX1364 default to

internal clock mode (INT/EXT clock = 0).

Internal Clock

See the Configuration/Setup Bytes (Write Cycle) section.

In internal clock mode (CLK = 0), the MAX1363/

MAX1364 use an internal oscillator for the conversion

clock. The MAX1363/MAX1364 begin tracking the analog

input after a valid address on the eighth rising edge of the

clock. On the falling edge of the ninth clock, the analog

signal is acquired and the conversion begins. While converting, the MAX1363/MAX1364 hold SCL low (clock

stretching). After completing the conversion, the results

are stored in internal memory. For scan-mode configurations with multiple conversions (see the Scan Modes section), all conversions happen in succession with each

additional result stored in memory. Once all conversions

are complete, the MAX1363/MAX1364 release SCL,

allowing it to go high. The master can now clock the

results out in the same order as the scan conversion.

The converted results are read back in a FIFO

sequence. If AIN3/REF is configured as a reference

input or output, AIN3/REF is excluded from multichannel scan. If reading continues past the final result

stored in memory, the pointer wraps around and points

to the first result. Only the current conversion results

are read from memory. The MAX1363/MAX1364 must

be addressed with a read command to obtain new conversion results.

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

______________________________________________________________________________________ 11

Page 12

MAX1363/MAX1364

External Clock

See the Configuration/Setup Bytes (Write Cycle) section.

When configured for external clock mode (CLK = 1), the

MAX1363/MAX1364 use SCL as the conversion clock. In

external clock mode, the MAX1363/MAX1364 begin

tracking the analog input on the ninth rising clock edge of

a valid slave address byte. Two SCL clock cycles later,

the analog signal is acquired and the conversion begins.

Unlike internal clock mode, converted data is clocked out

immediately in the format described in the Reading a

Conversion (Read Cycle) section.

The device continuously converts input channels dictated by the scan mode until given a not acknowledge

(NACK). There is no need to readdress the device with

a read command to obtain new conversion results.

The conversion must complete in 1ms or droop on the

T/H capacitor degrades conversion results. Use internal clock mode if the SCL clock period exceeds 60µs.

Use external clock mode for conversion rates from

40ksps to 94.4ksps. Use internal clock mode for conversions under 40ksps. Internal clock mode consumes less

power. Monitor mode always uses internal clock mode.

Applications Section

Power-On Reset

The configuration and setup registers default to a single-ended, unipolar, single-channel conversion on

AIN0 using the internal clock with VDDas the reference

and AIN3/REF configured as an analog input. The

memory contents are unknown at power-up (see the

Software Description section).

I2C-Compatible 2-Wire Serial Interface

The MAX1363/MAX1364 use an I2C-compatible 2-wire

interface consisting of a serial data line (SDA) and serial

clock line (SCL). SDA and SCL facilitate bidirectional

communication between the MAX1363/MAX1364 and

the master at rates up to 1.7MHz. The master (typically

a µC) initiates data transfer on the bus and generates

the SCL signal to permit data transfer. The MAX1363/

MAX1364 behave as I2C slave devices that transfer and

receive data.

SDA and SCL must be pulled high for proper I2C operation. This is typically done with pullup resistors (750Ω

or greater). Series resistors (RS) are optional (see the

Typical Operating Circuit section). The resistors protect

the input architecture of the MAX1363/MAX1364 from

high voltage spikes on the bus lines and minimize

crosstalk and undershoot of the bus signals.

One bit transfers during each SCL clock cycle. A minimum of nine clock cycles is required to transfer a byte

in or out of the MAX1363/MAX1364 (8 bits and an

ACK/NACK). The data on SDA must remain stable during the high period of the SCL clock pulse. Changes in

SDA while SCL is stable and high are considered control signals (see the START and STOP Conditions section). Both SDA and SCL remain high when the bus is

not busy.

START and STOP Conditions

The master initiates a transmission with a START condition (S), which is a high-to-low transition on SDA while

SCL is high. The master terminates a transmission with

a STOP condition (P), which is a low-to-high transition

on SDA while SCL is high (Figure 4). A repeated START

condition (Sr) can be used in place of a STOP condition

to leave the bus active and the mode unchanged (see

the HS I

2

C Mode section).

Acknowledge and Not-Acknowledge Conditions

Data transfers are framed with an acknowledge bit

(ACK) or a not-acknowledge bit (NACK). Both the master and the MAX1363/MAX1364 (slave) generate

acknowledge bits. To generate an acknowledge, the

receiving device must pull SDA low before the rising

edge of the acknowledge-related clock pulse (ninth

pulse) and keep it low during the high period of the

clock pulse (Figure 5).

To generate a not-acknowledge condition, the receiver

allows SDA to be pulled high before the rising edge of

the acknowledge-related clock pulse, and leaves SDA

high during the high period of the clock pulse.

Monitoring the acknowledge bits allows for detection of

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

12 ______________________________________________________________________________________

Figure 4. START and STOP Conditions

Figure 5. Acknowledge Bits

SP

SDA

SCL

S

SDA

SCL

12 89

Sr

NOT ACKNOWLEDGE

ACKNOWLEDGE

Page 13

unsuccessful data transfers. An unsuccessful data transfer happens if a receiving device is busy or if a system

fault has occurred. In the event of an unsuccessful data

transfer, the bus master reattempts communication at a

later time.

Slave Address

The MAX1363/MAX1364 have a 7-bit I2C slave

address. The slave address is selected using A0. The

MAX1363/MAX1364 (EUB, MEUB, and LEUB) have

three base address options, allowing up to six devices

concurrently per I2C bus (see Table 1).

The MAX1363/MAX1364 continuously wait for a START

condition followed by its slave address. When the device

recognizes its slave address, it is ready to accept or

send data depending on the R/W bit (Figure 6).

HS I2C Mode

At power-up, the MAX1363/MAX1364 bus timing is set

for fast mode (F/S mode, up to 400kHz I2C clock), which

limits the conversion rate to approximately 22ksps.

Switch to high-speed mode (HS mode, up to 1.7MHz

I2C clock) to achieve conversion rates up to 94.4ksps.

The MAX1363/MAX1364 convert up to 133ksps in monitor mode, regardless of I2C mode. If conversion results

are unread, I2C bandwidth limitations do not apply (see

the Monitor Mode section).

Select HS mode by addressing all devices on the bus

with the HS-mode master code 0000 1XXX (X = don’t

care). After successfully receiving the HS-mode master

code, the MAX1363/MAX1364 issue a NACK, allowing

SDA to be pulled high for one clock cycle (Figure 7).

After the NACK, the MAX1363/MAX1364 operate in HS

mode. Send a repeated START (Sr) followed by a slave

address to initiate HS-mode communication. If the master generates a STOP condition, the MAX1363/

MAX1364 return to F/S mode. Use a repeated START

condition (Sr) in place of a STOP condition to leave the

bus active and the mode unchanged.

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

______________________________________________________________________________________ 13

Figure 6. MAX1363/MAX1364 Slave Address Byte

Table 1. I2C Slave Selection Table

Figure 7. F/S-Mode to HS-Mode Transfer

SLAVE ADDRESS

011 1000R/W ACK

S

SDA

SCL

A0 STATE SUFFIX ADDRESS

Low EUB 0110100

High EUB 0110101

Low LEUB 0110010

High LEUB 0110011

Low MEUB 0110110

High MEUB 0110111

123456789

000 10XXXNACK

S Sr

SDA

SCL

HS-MODE MASTER CODE

F/S MODE HS MODE

Page 14

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

14 ______________________________________________________________________________________

Figure 8. Example of Writing Setup and Control Bytes

Figure 9. Example of Extended Setup Byte Writing

Table 2. Configuration Byte Format*

*Power-on defaults: 0x01

START

CONDITION

START

ADDRESS

FROM THE MASTER

R/W BIT FROM

THE MASTER

0A AASTOP

CONFIGURATION

BYTE FROM THE MASTER

START

CONDITION

START

CH 0 LT [11:4] BYTE

BIT NAME DESCRIPTION

ADDRESS

FROM THE MASTER

R/W BIT FROM

THE MASTER

0A 1A A

CH 0 LT [3:0];

UT [11:8] BYTE

SETUP BYTE

FROM THE MASTER

7(MSB) CONFIG The configuration byte always starts with 0.

6 SCAN1

5 SCAN0

4 CS3

3 CS2

2 CS1

SCAN1, SCAN0 = [0,0], scans from channel 0 to the upper channel chosen by CS1, CS0.

SCAN1, SCAN0 = [0,1], converts a single channel chosen by CS1, CS0 eight times.

SCAN1, SCAN0 = [1,0] monitor mode monitors from channel 0 to the upper channel chosen by CS1, CS0.

SCAN1, SCAN0 = [1,1], single channel conversion for the channel is chosen by CS0, CS1.

CS3, CS2 = [1,1] enables readback of monitor-mode setup data.

Selects the upper limit of the channel range used for the conversion sequence in scan modes SCAN = [0,0]

and monitor modes SCAN = [1,0].

1 CS0

Selects the conversion channel when SCAN = [0,1] or when SCAN = [1,1].

(Tables 5 and 6)

SETUP

BYTE FROM THE MASTER

ALARM RESET, SCAN

SPEED, BYTE FROM MASTER

CH 1 LT [11:4] BYTECH 0 UT [7:0] BYTEAAAASTOP

1 = single-ended inputs.

0 = differential inputs.

AIN0 and AIN1 form the first differential pair and AIN2 and AIN3 form the second differential pair. (See Tables

4 and 5.)

0 SE/DIF

Selects single-ended or differential conversions. In single-ended mode, input-signal voltages are referenced

to GND. In differential mode, the voltage difference between two channels is measured.

When single-ended mode is used, the MAX1363/MAX1364 perform unipolar conversions regardless of the

UNI/BIP bit in the setup byte.

(Table 7)

Page 15

Software Description

Configuration/Setup Bytes (Write Cycle)

A write cycle begins with the bus master issuing a

START condition followed by 7 address bits and a write

bit (R/W = 0). If the address byte is successfully

received, the MAX1363/MAX1364 (slave) issue an

ACK. The master then writes to the slave. If the most

significant bit (MSB) is 1, the slave recognizes the

received byte as the setup byte (Table 4). If the MSB is

0, the slave recognizes that byte as the configuration

byte (Table 2). Write to the configuration byte before

writing to the setup byte (Figure 8). If enabling RESET

in the setup byte, rewrite the configuration byte after

writing the setup byte, since RESET clears the contents

of the configuration byte back to the power-up state.

When the monitor-setup bit of the setup byte is set to 1,

writing extends up to 13 bytes to clock in monitor-setup

data. Terminate writing monitor-setup data at any time

by issuing a STOP or repeated START condition. If the

slave receives a byte successfully, it issues an ACK

(Figure 9).

Note: When operating in HS mode, a STOP condition

returns the bus into F/S mode (see the HS I

2

C Mode

section).

Automatic Shutdown

AutoShutdown occurs between conversions when the

MAX1363/MAX1364 are idle. When operating in external clock mode, issue a STOP, NACK, or repeated

START condition to place the devices in idle mode and

benefit from automatic shutdown. A STOP condition is

not necessary in internal clock mode for automatic

shutdown because power-down occurs once all contents are written memory. Shutdown reduces supply

current to less than 0.5µA (external reference mode,

typ) and 300µA (internal reference mode, typ).

When idle, the MAX1363/MAX1364 continuously wait

for a START condition followed by their slave address.

Upon reading a valid address byte, the MAX1363/

MAX1364 power up. The internal reference requires

10ms to wake up. Therefore, power up the internal reference 10ms prior to conversion or leave the reference

continuously powered. Wake-up is transparent when

using an external reference or V

DD

as the reference.

Automatic shutdown results in dramatic power savings,

particularly at slow conversion rates with internal clock.

For example, using an external reference at a conversion rate of 10ksps, the average supply current for the

MAX1363 is 60µA (typ) and drops to 6µA (typ) at

1ksps. At 0.1ksps, the average supply current is just

1µA. Table 3 shows AIN3/REF configuration and reference power-down state.

Scan Modes

SCAN1 and SCAN0 of the configuration byte set the

scan-mode configuration. When configuring AIN3/REF

for reference input or output (SEL0 = 1), AIN3/REF is

excluded from a multichannel scan. The scanned

results write to memory in the same order as the conversion. Start a conversion sequence by initiating a

read with the desired scan mode. Read the results from

memory in the order they were converted (see the

Reading a Conversion (Read Cycle) section).

Selecting channel scan mode [0,0] starts converting

from channel 0 up to the channel chosen by CS1, CS0.

Selecting channel scan mode [0,1] converts the channel selected by CS1, CS0 eight times and returns eight

consecutive results.

Selecting monitor mode [1,0] initiates a continuous conversion scan sequence from channel 0 to the channel

selected by CS1, CS0. See the Monitor Mode section

for more details.

Selecting channel scan mode [1,1] performs a single

conversion on the channel selected by CS1, CS0 and

returns the result.

Reading a Conversion (Read Cycle)

Initiate a read cycle to start a conversion sequence and

to obtain conversion results. See the Scan Modes

section for details on the channel-scan sequence. Read

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

______________________________________________________________________________________ 15

Table 3. Reference Voltage and AIN3/REF Format

SEL1 SEL0

00 X V

01 X External reference Reference input Always off

10 0 Internal reference Analog input Always off

10 1 Internal reference Analog input Always on

11 0 Internal reference Reference output Always off

11 1 Internal reference Reference output Always on

INT REF

POWER-DOWN

REFERENCE VOLTAGE AIN3/REF

DD

Analog input Always off

REFERENCE STATE

INTERNAL

Page 16

MAX1363/MAX1364

cycles begin with the bus master issuing a START

condition followed by 7 address bits and a read bit

(R/W = 1). After successfully receiving the address byte,

the MAX1363/MAX1364 (slave) issue an ACK. The master

then reads from the slave. (See Figures 10–13.)

The result is transmitted in 2 bytes. The 1st byte consists of a leading 1 followed by a 2-bit binary channel

address tag, a 12/10 bit flag (1 for the MAX1363/

MAX1364), the first 4 bits of the data result, and the

expected ACK from the master. The 2nd byte contains

D7–D0. To read the next conversion result, issue an

ACK. To stop reading, issue a NACK.

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

16 ______________________________________________________________________________________

Table 4. Setup-Byte Format*

*Power-on defaults: 0x82

Table 5. Channel Selection in SingleEnded Mode (SE/DIF = 1)

Table 6. Channel Selection in Differential

Mode (SE/DIF = 0)

Table 7. SE/DIF and UNI/BIP Table

BIT NAME DESCRIPTION

7 (MSB) Setup Setup byte always starts with 1.

6 REF/AIN SEL1

5 REF/AIN SEL0

4

3 INT/EXT Clock

2 UNI/BIP

INT REF Power

Down

1 Reset

0 Monitor Setup

When [0,0], REF/AIN3 = AIN3, REF = V

When [0,1], REF/AIN3 = REF, apply external reference to REF.

When [1,0], REF/AIN3 = AIN3, REF = internal reference.

When [1,1], REF/AIN3 = REF, REF = internal reference.

(Table 3)

1 = internal reference always powered up.

0 = internal reference always powered down.

(Table 3)

0 = internal clock.

1 = external clock (MAX1363/MAX1364 use the SCL clock for conversions).

0 = unipolar.

1 = bipolar.

Selects unipolar or bipolar conversion mode. In unipolar mode, analog signal in 0 to V

be converted. In differential bipolar mode, input signal can range from -V

single-ended mode is chosen, the SE/DIF bit of configuration byte overrides UNI/BIP, and

conversions are performed in unipolar mode.

1 = no action.

0 = resets INT and configuration register. Setup register and channel trip thresholds are unaffected.

0 = no action.

1 = extends writing up to 13 bytes (104 bits) of alarm reset mask. Scans speed selection and alarm

thresholds. See the Configuring Monitor Mode section.

DD.

REF

/ 2 to +V

REF

REF

range can

/ 2. When

CS1 CS0 CH0 CH1 CH2 CH3

00+

01 +

10 +

11 +

CS1 CS0 CH0 CH1 CH2 CH3

00+01-+

10 +11 -+

SE/DIF UNI/BIP MODE

00Differential inputs, unipolar

01Differential inputs, bipolar

10Single-ended inputs, unipolar

11Single-ended inputs, unipolar

Page 17

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

______________________________________________________________________________________ 17

Table 8. Data Format

Figure 10. Example of Reading the Conversion Result—External Clock Mode

Figure 11. Example of a Single Conversion Using the Internal Clock, SCAN = 1,1

Figure 12. Example of Scan-Mode Conversions Using the Internal Clock, SCAN = 0,0 and 0,1

HIGH CH1 CH0 12/11110000HIGH HIGH

1 0/1 0/1

0 = 10b

1 = 12b

START

CONDITION

START

110/1 0/1 ACK 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

ADDRESS

FROM THE MASTER

DATA

(MSB)

R/W

1 ACK ACK ACK STOP

D8 D7 D6 D5 D4 D3 D2 D1 D0

1, CH ADD, 10b/12b FLAG,

RESULT (4 MSBs)

t

ACQ

t

CONV

R/W

START

ADDRESS

FROM THE MASTER

1 ACK

t

ACQ

MAX1363/MAX1364

KEEPS SCL LOW

6.8µs MAX

t

CONV

1, CH ADD, 10b/12b,

RESULT (4 MSBs)

R/W

START

ADDRESS

FROM THE MASTER

1 ACK

t

ACQ

CONVERSION 1

t

CONV

6.8µs MAX

MAX1363/MAX1364

KEEPS SCL LOW

RESULT (8 LSBs)

ACK

t

ACQ

RESULT (8 LSBs)

CONVERSION 2

t

CONV

ACK/

NACK

ACK STOP

MAX1363/MAX1364

KEEPS SCL LOW

t

ACQ

CONVERSION N

t

CONV

1, CH ADD, 10b/12b,

RESULT (4 MSBs)

1, CH ADD, 10b/12b,

RESULT (4 MSBs)

RESULT N

(8 LSBs)

RESULT 1

(8 LSBs)

ACK

ACKACK

STOPACK

Page 18

MAX1363/MAX1364

When the MAX1363/MAX1364 receive a NACK, they

release SDA allowing the master to generate a STOP or

a repeated START condition.

Monitor Mode

Monitor-Mode Overview

The MAX1363/MAX1364 automatically monitor up to four

input channels. For systems with limited I2C bandwidth,

monitor mode allows the µC to set a window by

programming lower and upper thresholds during initialization, and only intervening if the MAX1363/MAX1364

detect an alarm condition. This allows an interrupt-driven

approach as an alternative to continuously polling the

ADC with the µC. Monitor mode reduces processor overhead and conserves I2C bandwidth.

The following shows an example of events in

monitor mode:

1) Fault condition(s) detected, INT asserted.

2) Host µC services interrupt and sends SMBus alert to

identify the alarming device. The MAX1363/

MAX1364 respond with the I

2

C slave address, pend-

ing arbitration rules. (See the SMBus Alert section.)

3) The MAX1363/MAX1364 release the INT.

4) Host µC reads the alarm-status register, latchedfault register, and current-conversion results to

determine the alarming channel(s) and course

of action.

5) Host µC services alarm(s); adjusts system parameters as needed and/or adjusts lower and upper

thresholds.

6) Host µC resets the alarming channel. See the

Configuring Monitor Mode section.

7) Monitor mode resumes.

8) If there is still an active fault, the device asserts INT

again. See step 1.

Writing SCAN1 and SCAN0 bits = [1,0] in the configuration byte activates monitor mode. The MAX1363/

MAX1364 scan from channels 0 up to the channel

selected by [CS1:CS0] at a rate determined by the

scan delay bits. The MAX1363/MAX1364 compare the

conversion results with the lower and upper thresholds

for each channel. When any conversion exceeds the

threshold, the MAX1363/MAX1364 assert an interrupt

by pulling INT low (if enabled). The MAX1363/

MAX1364 set the corresponding flag bit in the alarmstatus register and write conversion results to the

latched-fault register to record the event causing the

alarm condition.

INT active state is randomly delayed with respect to the

conversion. Depending on the number of channels

scanned and the position in the channel scan sequence,

the maximum possible delay for asserting INT is five

conversion periods (37.5µs typ, Delay = 0,0,0).

Configuring Monitor Mode

To write monitoring setup data, set the monitor-setup bit

(bit 0 in setup byte) to 1 to extend writing up to 104 bits

(13 bytes) of monitoring setup data. The number of bits

written to the MAX1363/MAX1364 depends on whether

the part is in single-ended or differential mode and

whether the upper channel limit is set by [CS1:CS0]

(Table 9).

Terminate writing at any time by using a STOP or

repeated START condition. Previous monitoring setup

data not overwritten remains valid.

A 1 written to the reset alarm CH_ clears the alarm, otherwise no action occurs (Table 10). Deassert INT by

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

18 ______________________________________________________________________________________

Figure 13. Example of Scan-Mode Conversions Using the External Clock, SCAN = 0,0 and 0,1

START

ADDRESS

FROM THE MASTER

1, CH ADD, 10b/12b,

RESULT (4 MSBs)

t

ACQ

1 ACK ACK ACK

ACK ACK

1, CH ADD, 10b/12b

t

ACQ

RESULT N (8 LSBs)

CONVERSION N

RESULT (4 MSBs)

CONVERSION 1

t

ACQ

RESULT (8 LSBs)

t

ACQ

Page 19

clearing all alarms or by initiating an SMBus alert during an alarm condition (see the SMBus Alert section).

The Delay 2, Delay 1, Delay 0 bits set the speed of

monitoring by changing the delay between conversions. Delay 2, 1, 0 = 000 sets the maximum possible

speed; 001 divides the maximum speed by ~2.

Increasing delay values further divides the previous

speed by two.

INT_EN controls the open-drain INT output. Set INT_EN

to 1 to enable the hardware interrupt. Set INT_EN to 0

to disable the hardware interrupt output. The INT output

tri-states when disabled or when there are no alarms.

The master can also poll the alarm status register at

any time to check the alarm status.

Repeat clocking channel threshold data up to the channel programmed by CS1 and CS0 (Table 12). For differential input mode, omit odd channels; the lower and

upper threshold data applies to channel pairs. There is

no need to clock in dummy data for odd (or even)

channels (Table 6).

To disable alarming on a specific channel, set the lower

threshold to 0x800 and the upper threshold to 0x7FF for

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

______________________________________________________________________________________ 19

Table 9. Monitor-Mode Setup Data Format

Table 10. Alarm Reset, Scan Speed Register, and INT_EN Data Format

Table 11. Delay Settings

*When using delay = [0,0,0] in internal reference mode and

AIN3/REF configured as a REF output, the MAX1363/MAX1364

may exhibit a code-dependent gain error due to insufficient

internal reference drive. Gain error caused by this phenomenon

is typically less than 1%FSR (0.1µF C

REF

) and increases with a

larger C

REF

. Avoid this gain error by using an external reference,

V

DD

, as a reference or use an internal reference with AIN3/REF

as an analog input (see Table 4). Alternatively, choose delay bits

other than [0,0,0] to lower the conversion rate.

Table 12. Lower and Upper Threshold Data Format

X = Don’t care.

ACK = Acknowledge.

Alarm reset, scan

speed, INT_EN ,

(8 bits)

RESET

ALARM CH 0

0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

AIN0 thresholds

(24 bits)

RESET

ALARM CH 1

RESET

ALARM CH 2

DELAY 2 DELAY 1 DELAY 0

000 133.0*

001 66.5

010 33.3

011 16.6

100 8.3

101 4.2

110 2.0

111 1.0

CONVERSION RATE

AIN1 thresholds

(skip if differential mode, or

CS1, CS0 < 1) (24 bits)

RESET

ALARM CH 3

MONITOR-MODE

(ksps)

AIN2 thresholds (skip if

CS1, CS0 < 2)

(24 bits)

DELAY 2 DELAY 1 DELAY 0 INT_EN

AIN3 thresholds (skip if differential

mode, or CS1, CS0 < 3)

(24 bits)

BYTE B7 B6 B5 B4 B3 B2 B1 B0 ACKNOWLEDGE

1

2 LT3 LT2 LT1 LT0 (LSB)

3 UT7 UT6 UT5 UT4 UT3 UT2 UT1 UT0 (LSB) ACK

LT11

(MSB)

LT10 LT9 LT8 LT7 LT6 LT5 LT4 ACK

UT11

(MSB)

UT10 UT9 UT8 ACK

Page 20

MAX1363/MAX1364

bipolar mode, or set the lower threshold to 0x000 and

the upper threshold to 0xFFF for unipolar mode.

Readback Mode

Select readback mode by setting CS3, CS2 to [1,1] in

the configuration byte. Begin a read operation to start

reading back monitor-setup data. Clock out delay bit

settings, INT_EN bit, and the lower and upper thresholds programmed for each channel. Readback mode

follows exactly the same format as writing to the monitor-setup data, with the exception of the first 4 alarmreset bits, which are always 1 (Table 13).

Reading in Monitor Mode

Reading in monitor mode reads back the alarm-status

register, latched-fault register, and current-conversion

results as shown in Table 14.

The MAX1363/MAX1364 register pointer loops back to

the beginning of the current-conversion result after

reading the last conversion result. Stop reading at any

time by asserting a STOP condition or NACK.

Note: The MAX1363/MAX1364 do not update the current-conversion results register while reading in monitor

mode. Monitor mode resumes after a STOP condition or

NACK.

Alarm-Status Register and Latched-Fault Register

The latched-fault register records a snapshot of the

alarming channel at the instance that a fault condition is

asserted. An alarm-status bit of 1 (Table 15) indicates a

fault, and the data in the latched-fault register of the

corresponding channel contains the conversion result

that caused the alarm to trip. Resetting alarms does not

clear the latched-fault register, thus the latched-fault

register contains valid data only if an alarm status bit is

high for the given channel.

The current-conversion register contains the most

recent conversion results. If the user attempts to read

past the last result of the current-conversion register,

the MAX1363/MAX1364 wraps back to the beginning of

the current-conversion result.

The latched-fault register and current-conversion register follow the data format in the Reading a Conversion

(Read Cycle) section. Register length depends on the

number of conversions in one monitoring sequence. For

example, when channel pairs 0/1 and channels 2/3 are

monitored differentially, there are only two conversion

results to report. The latched-fault register is 2 x 16 bits

long, after which two current-conversion results follow.

Likewise, if CS0 and CS1 limit the upper bound of the

channel scan range from CH0 to CH2 in single-ended

mode, the latched-fault register clocks out 3 x 16 bits of

data followed by the current-conversion results, also 3 x

16 bits.

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

20 ______________________________________________________________________________________

Table 13. Readback-Mode Format

Table 14. Reading in Monitor-Mode Data Format

Table 15. Alarm-Status Register

0 = Not-alarm condition.

1 = Alarm condition.

Table 16. Latched-Fault and CurrentConversion Register

ALARM RESET/SCAN SPEED

1111D2 D1 D0 INT 24 bits 24 bits 24 bits 24 bits

ALARM-STATUS REGISTER LATCHED-FAULT REGISTER CURRENT-CONVERSION RESULTS

8 bits 16, 32, 48, or 64 bits 16, 32, 48, or 64 bits

CH0 UP CH0 LOW CH1 UP CH1 LOW CH2 UP CH2 LOW CH3 UP CH3 LOW

0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

AIN0

THRESHOLDS

AIN0 AIN1 AIN2 AIN3

16-bit read 16-bit read 16-bit read 16-bit read

AIN1 THRESHOLDS

(SKIP IF DIFFERENTIAL

MODE OR CS1, CS0 < 1)

AIN2 THRESHOLDS

(SKIP IF CS1, CS0 < 2)

AIN3 THRESHOLDS

(SKIP IF DIFFERENTIAL

MODE OR CS1, CS0 < 3)

Page 21

Resetting Alarm

Reset alarms by writing to monitor-setup data. See the

Configuring Monitor Mode section and Table 10.

SMBus Alert

The SMBus-alert feature provides a quick method to

identify alarming devices on a shared interrupt. Upon

receiving an interrupt signal, the host µC can broadcast

a receive byte request to the alert-response slave

address (0001100). Any slave device that generated an

interrupt attempts to identify itself by putting its own

address on the bus. The alert response can activate

several different slave devices simultaneously. If more

than one slave attempts to respond, bus arbitration

rules apply, and the device with the lower address wins

as a consequence of the open-collector bus. The losing

device does not generate an acknowledgement and

continues to hold the alert line low until serviced.

Successful reading of the alert response address deasserts INT.

When the MAX1363/MAX1364 successfully send the

I

2

C address, it can resume and reassert INT right away

(if the fault is still present). To prevent this from happening, monitor mode does not resume until after the host

controller resets the alarm in the alarm status register.

Any alarms not cleared when the device resumes monitor mode reassert INT.

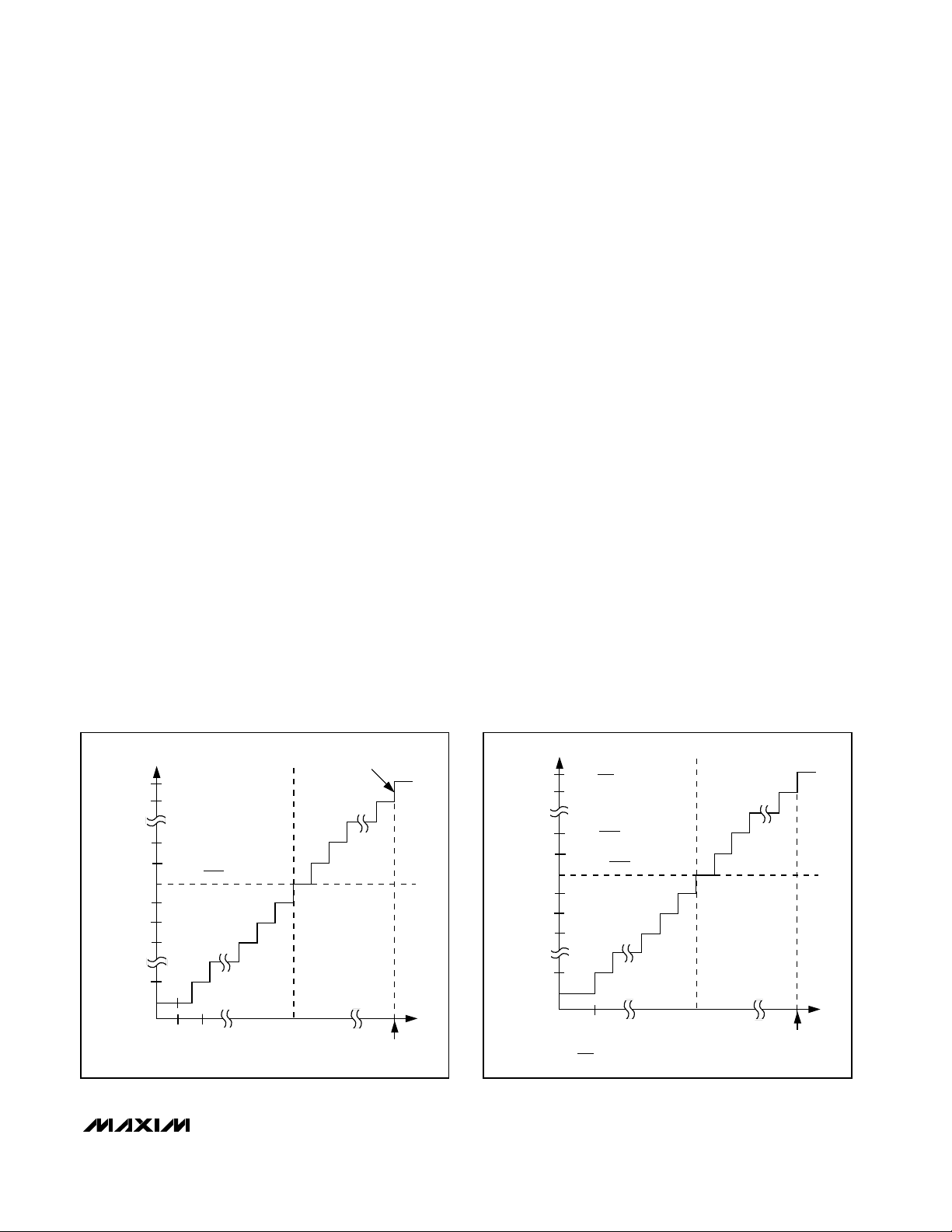

Transfer Functions

Output data coding for the MAX1363/MAX1364 is binary in unipolar mode and two’s complement in bipolar

mode with 1 LSB = V

REF

/ 2N, where N is the number of

bits. Code transitions occur halfway between successive-integer LSB values. Figures 14 and 15 show the

transfer functions for unipolar and bipolar operations,

respectively.

Layout, Grounding, and Bypassing

Only use PC boards. Wire-wrap configurations are not

recommended since the layout should ensure proper

separation of analog and digital traces. Do not run analog and digital lines parallel to each other, and do not

layout digital signal paths underneath the ADC package. Use separate analog and digital PC board ground

sections with only one star point (Figure 16).

High-frequency noise in the power supply (VDD) could

influence the proper operation of the ADC’s fast comparator. Bypass VDDto the star ground with a network

of two parallel capacitors, 0.1µF and 4.7µF, located as

close as possible to the MAX1363/MAX1364 power supply. Minimize capacitor lead length for best supply noise

rejection. For extremely noisy supplies, add an attenuation resistor (5Ω) in series with the power supply.

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

______________________________________________________________________________________ 21

Figure 14. Unipolar Transfer Function

Figure 15. Bipolar Transfer Function

OUTPUT CODE

111...111

111...110

100...010

100...001

100...000

011...111

011...110

011...101

000...001

000...000

FS = REF + GND

ZS = GND

V

REF

1 LSB =

1024

0

1

INPUT VOLTAGE (LSB)(GND)

512

FULL-SCALE

TRANSITION

FS - 0.5 LSB

OUTPUT CODE

V

REF

FS =

011...111

011...110

000...010

000...001

000...000

111...111

111...110

111...101

100...001

100...000

-FS + 0.5 LSB

AIN- ≥

2

2

ZS = AIN-

-V

REF

-FS =

2

1 LSB =

1024

V

REF

+ AIN-

+ AIN-

V

REF

INPUT VOLTAGE (LSB)

AIN-

+FS - 1 LSB

Page 22

MAX1363/MAX1364

Definitions

Integral Nonlinearity

Integral nonlinearity (INL) is the deviation of the values

on an actual transfer function from a straight line. This

straight line can be either a best straight-line fit or a line

drawn between the endpoints of the transfer function,

once offset and gain errors have been nullified. The

MAX1363/MAX1364’s INL is measured using the endpoint method.

Differential Nonlinearity

Differential nonlinearity (DNL) is the difference between

an actual step width and the ideal value of 1 LSB. A

DNL error specification of less than 1 LSB guarantees

no missing codes and a monotonic transfer function.

Aperture Jitter

Aperture jitter (tAJ) is the sample-to-sample variation in

the time between the samples.

Aperture Delay

Aperture delay (tAD) is the time between the falling

edge of the sampling clock and the instant when an

actual sample is taken.

Signal-to-Noise Ratio

For a waveform perfectly reconstructed from digital

samples, the theoretical maximum SNR is the ratio of

the full-scale analog input (RMS value) to the RMS

quantization error (residual error). The ideal, theoretical

minimum analog-to-digital noise is caused by quantization error only and results directly from the ADC’s resolution (N bits):

SNR (MAX)[dB] = 6.02dB x N + 1.76dB

In reality, there are other noise sources besides quantization noise: thermal noise, reference noise, clock jitter,

etc. SNR is computed by taking the ratio of the RMS

signal to the RMS noise, which includes all spectral

components minus the fundamental, the first five harmonics, and the DC offset.

Signal-to-Noise Plus Distortion

Signal-to-noise plus distortion (SINAD) is the ratio of the

fundamental input frequency’s RMS amplitude to RMS

equivalent of all other ADC output signals.

SINAD(dB) = 20 x log (SignalRMS / NoiseRMS)

Effective Number of Bits

Effective number of bits (ENOB) indicates the global

accuracy of an ADC at a specific input frequency and

sampling rate. An ideal ADC’s error consists of quantization noise only. With an input range equal to the

ADC’s full-scale range, calculate the ENOB as follows:

ENOB = (SINAD - 1.76) / 6.02

Total Harmonic Distortion

Total harmonic distortion (THD) is the ratio of the RMS

sum of the input signal’s first five harmonics to the fundamental itself. This is expressed as:

where V

1

is the fundamental amplitude, and V2through

V5are the amplitudes of the 2nd- through 5th-order

harmonics.

Spurious-Free Dynamic Range

Spurious-free dynamic range (SFDR) is the ratio of RMS

amplitude of the fundamental (maximum signal component) to the RMS value of the next largest distortion

component.

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

22 ______________________________________________________________________________________

Figure 16. Power-Supply Grounding Connection

SUPPLIES

GND

DGND3V/5VGND

DIGITAL

CIRCUITRY

R* = 5Ω

*OPTIONAL

= 3V/5V3V OR 5V

V

LOGIC

4.7µF

0.1µF

V

DD

MAX1363

MAX1364

SINAD dB

() log=×

20

Signal

Noise THD

RMS

+

RMS RMS

20

THD

=×

2

VVVV

log

2

2

+++

3

2

4

5

V

1

2

Page 23

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

______________________________________________________________________________________ 23

Ordering Information/Selector Guide (continued)

Pin Configuration

*OPTIONAL

*R

S

*R

S

ANALOG

INPUTS

µC

SDA

SCL

GND

V

DD

SDA

SCL

AIN0

AIN1

AIN2

AIN3/REF

0.1µF

C

REF

0.1µF

2kΩ

R

P

R

P

R

P

3V/5V

3V/5V

3V/5V

MAX1363

MAX1364

4.7µF

INT

INT

Typical Operating Circuit

*Future product—contact factory for availability.

TOP VIEW

1

AIN0

2

AIN1

AIN2

REF

A0 INT

MAX1363

3

MAX1364

4

5

µMAX

10

9

8

7

6

V

DD

GND

SDA

SCLAIN3/V

PART TEMP RANGE PIN-PACKAGE I2C SLAVE ADDRESS SUPPLY VOLTAGE (V)

MAX1364EUB -40°C to +85°C 10 µMAX 0110100/0110101 4.5 to 5.5

MAX1364LEUB* -40°C to +85°C 10 µMAX 0110010/0110011 4.5 to 5.5

MAX1364MEUB* -40°C to +85°C 10 µMAX 0110110/0110111 4.5 to 5.5

Page 24

MAX1363/MAX1364

4-Channel, 12-Bit System Monitors with Programmable

Trip Window and SMBus Alert Response

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2004 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2004 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2004 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

e

10

0 0.50±0.1

0.6±0.1

1

0.6±0.1

A2

TOPVIEW

D2

b

D1

4XS

H

A

A1

FRONTVIEW

GAGEPLANE

α

BOTTOMVIEW

SIDEVIEW

10

1

E2

E1

L

L1

INCHES

DIM

MIN

-A

0.002

A1

A2 0.030 0.037 0.75 0.95

0.116

D1

0.114

D2

0.116

E1

0.114

E2

0.187

H

0.0157

L

L1

0.037REF

0.007

b

e

0.0197BSC

0.0035

c

0.0196REF

S

α

0° 0° 6°

c

PROPRIETARYINFORMATION

TITLE:

MAX

0.043

0.006

0.120

0.118

0.120

0.118

0.199

0.0275

0.0106

0.0078