Page 1

General Description

The MAX1167/MAX1168 low-power, multichannel, 16bit analog-to-digital converters (ADCs) feature a successive-approximation ADC, integrated +4.096V

reference, a reference buffer, an internal oscillator,

automatic power-down, and a high-speed SPI™/

QSPI™/MICROWIRE™-compatible interface. The

MAX1167/MAX1168 operate with a single +5V analog

supply and feature a separate digital supply, allowing

direct interfacing with +2.7V to +5.5V digital logic.

The MAX1167/MAX1168 consume only 2.9mA (AVDD=

DVDD= +5V) at 200ksps when using an external reference.

AutoShutdown™ reduces the supply current to 145µA at

10ksps and to less than 10µA at reduced sampling rates.

The MAX1167 includes a 4-channel input multiplexer, and

the MAX1168 accepts up to eight analog inputs.

In addition, digital signal processor (DSP)-initiated conversions are simplified with the DSP frame-sync input and

output featured in the MAX1168. The MAX1168 includes

a data-bit transfer input to select between 8-bit-wide or

16-bit-wide data-transfer modes. Both devices feature a

scan mode that converts each channel sequentially or

one channel continuously.

Excellent dynamic performance and low power, combined with ease of use and an integrated reference, make

the MAX1167/MAX1168 ideal for control and data-acquisition operations or for other applications with demanding

power consumption and space requirements. The

MAX1167 is available in a 16-pin QSOP package and the

MAX1168 is available in a 24-pin QSOP package. Both

devices are guaranteed over the commercial (0°C to

+70°C) and extended (-40°C to +85°C) temperature

ranges. Use the MAX1168 evaluation kit to evaluate the

MAX1168.

Applications

Motor Control

Industrial Process Control

Industrial I/O Modules

Data-Acquisition Systems

Thermocouple Measurements

Accelerometer Measurements

Features

♦ 16-Bit Resolution, ±1 LSB DNL (max)

♦ +5V Single-Supply Operation

♦ Adjustable Logic Level (+2.7V to +5.25V)

♦ Input Voltage Range: 0 to V

REF

♦ Internal (+4.096V) or External (+3.8V to AVDD)

Reference

♦ Internal Track/Hold, 4MHz Input Bandwidth

♦ Internal or External Clock

♦ SPI/QSPI/MICROWIRE-Compatible Serial

Interface, MAX1168 Performs DSP-Initiated

Conversions

♦ 8-Bit-Wide or 16-Bit-Wide Data-Transfer Mode

(MAX1168 Only)

♦ 4-Channel (MAX1167) or 8-Channel (MAX1168)

Input Mux

Scan Mode Sequentially Converts Multiple

Channels or One Channel Continuously

♦ Low Power

2.9mA at 200ksps

1.45mA at 100ksps

145µA at 10ksps

0.6µA in Full Power-Down Mode

♦ Small Package Size

16-Pin QSOP (MAX1167)

24-Pin QSOP (MAX1168)

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-2956; Rev 0; 8/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Ordering Information continued at end of data sheet.

SPI/QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

AutoShutdown is a trademark of Maxim Integrated Products, Inc.

Pin Configurations appear at end of data sheet.

*Future product—contact factory for availability.

PART TEMP RANGE

MAX1167ACEE 0°C to +70°C 16 QSOP ±1.2

MAX1167BCEE 0°C to +70°C 16 QSOP ±2

MAX1167CCEE 0°C to +70°C 16 QSOP ±3

MAX1167AEEE* -40°C to +85°C 16 QSOP ±1.2

MAX1167BEEE* -40°C to +85°C 16 QSOP ±2

MAX1167CEEE* -40°C to +85°C 16 QSOP ±3

PINPACKAGE

(LSB)

INL

Page 2

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

AVDDto AGND .........................................................-0.3V to +6V

DV

DD

to DGND.........................................................-0.3V to +6V

DGND to AGND.....................................................-0.3V to +0.3V

AIN_, REF, REFCAP to AGND..................-0.3V to (AV

DD

+ 0.3V)

SCLK, CS, DSEL, DSPR, DIN to DGND ...................-0.3V to +6V

DOUT, DSPX, EOC to DGND...................-0.3V to (DV

DD

+ 0.3V)

Maximum Current into Any Pin............................................50mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C)...........667mW

24-Pin QSOP (derate 9.5mW/°C above +70°C)...........762mW

Operating Temperature Ranges

MAX116_ _ CE_ ..................................................0°C to +70°C

MAX116_ _ EE_ ...............................................-40°C to +85°C

Maximum Junction Temperature .....................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

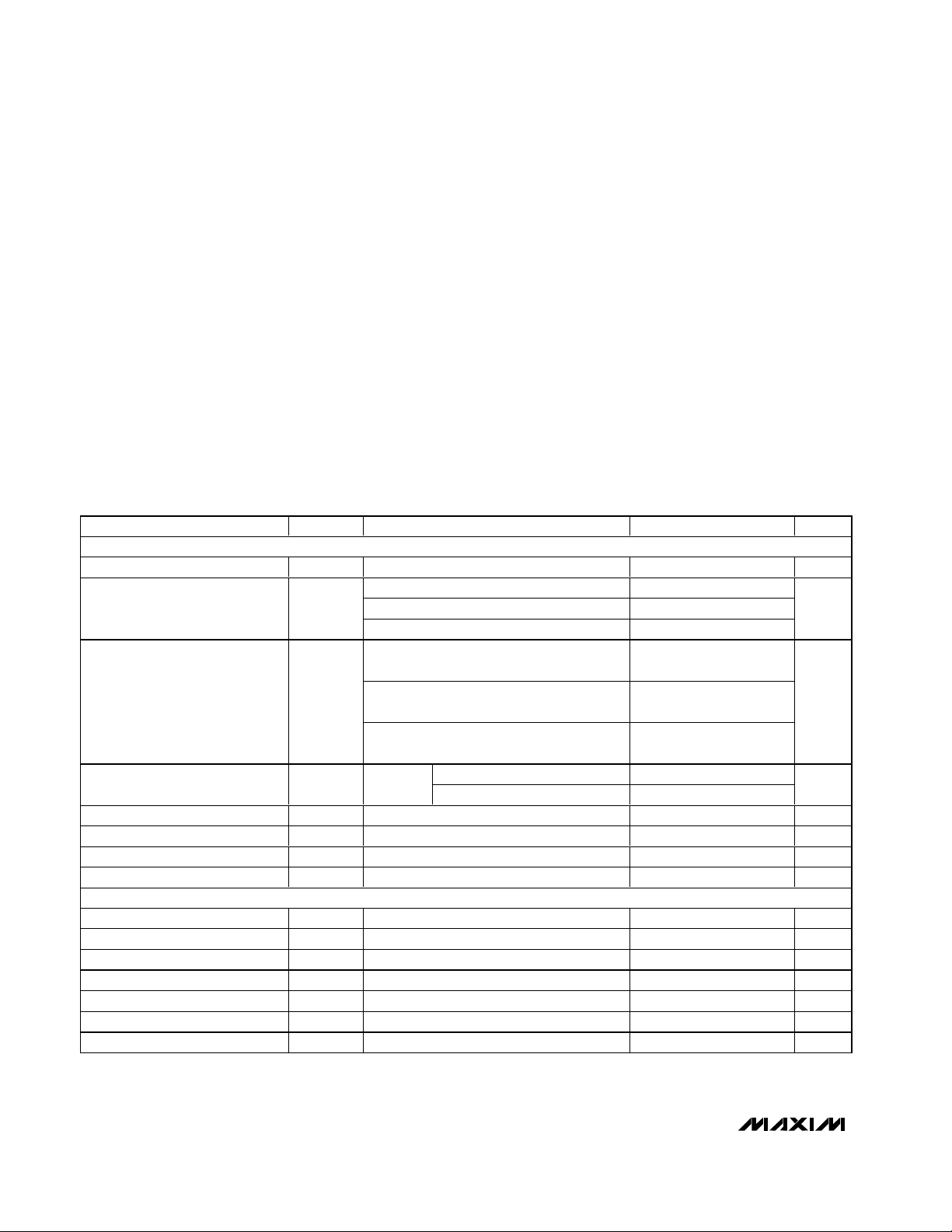

ELECTRICAL CHARACTERISTICS

(AVDD= DVDD= +4.75V to +5.25V, f

SCLK

= 4.8MHz external clock (50% duty cycle), 24 clocks/conversion (200ksps), external V

REF

= +4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

DC ACCURACY (Note 1)

Resolution 16 Bits

Relative Accuracy (Note 2) INL

Differential Nonlinearity DNL

Transition Noise

Offset Error ±0.1 ±10 mV

Gain Error (Note 3) ±0.01 ±0.2 %FSR

Offset Drift 1 ppm/°C

Gain Drift (Note 3) ±1.2 ppm/°C

DYNAMIC SPECIFICATIONS (1kHz sine wave, 4.096V

Signal-to-Noise Plus Distortion SINAD 86 88.5 dB

Signal-to-Noise Ratio SNR 86 88.5 dB

Total Harmonic Distortion THD -100 -90 dB

Spurious-Free Dynamic Range SFDR 92 101 dB

Full-Power Bandwidth -3dB point 4 MHz

Full-Linear Bandwidth SINAD > 85dB 10 kHz

Channel-to-Channel Isolation (Note 4) 96 dB

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

MAX116_A ±1.5 ±2

MAX116_B ±2.0 ±3

MAX116_C ±3.0 ±6

MAX116_A

(16 bit, no missing codes over temperature)

MAX116_B

(16 bit, no missing codes over temperature)

MAX116_C

(15 bit, no missing codes over temperature)

RMS

noise

External reference 0.7

Internal reference 0.8

) (Note 1)

P-P

±1

+1.75

-1.0

±2

LSB

LSB

LSB

RMS

Page 3

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

_______________________________________________________________________________________ 3

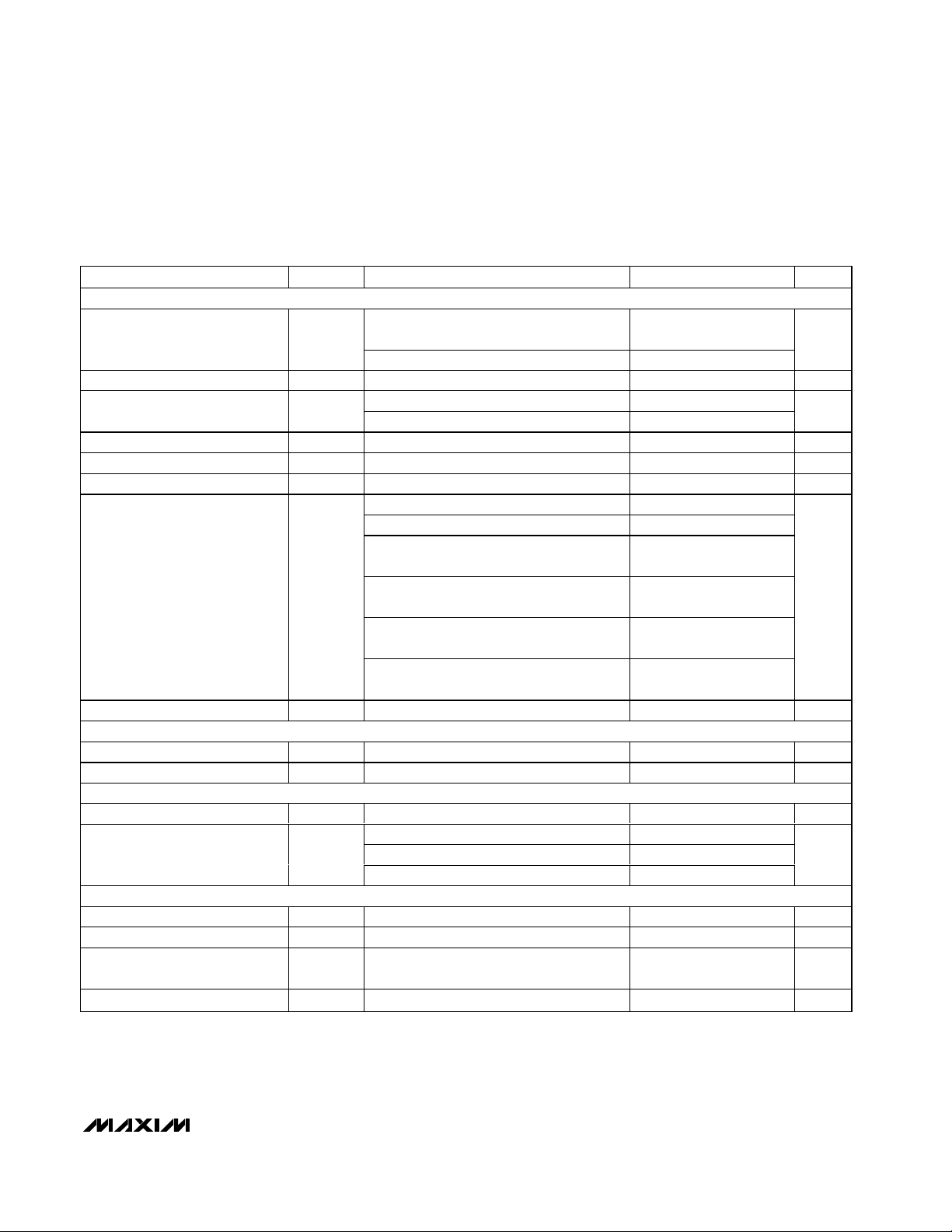

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= +4.75V to +5.25V, f

SCLK

= 4.8MHz external clock (50% duty cycle), 24 clocks/conversion (200ksps), external V

REF

= +4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

CONVERSION RATE

Conversion Time t

Acquisition Time t

Serial Clock Frequency f

Internal Clock Frequency f

Aperture Delay t

Aperture Jitter t

Sample Rate (Note 7) f

Duty Cycle 45 55 %

ANALOG INPUT (AIN_)

Input Range V

Input Capacitance C

EXTERNAL REFERENCE

Input Voltage Range V

Input Current I

INTERNAL REFERENCE

Reference Voltage V

Reference Short-Circuit Current I

Reference Temperature

Coefficient

Reference Wake-Up Time t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Internal clock, no data transfer,

CONV

ACQ

SCLK

INTCLK

AD

AJ

AIN

AIN

REF

REF

REFIN

REFSC

RWAKEVREF

single conversion (Note 5)

External clock 3.75

(Note 6) 729 ns

External clock, data transfer and conversion 0.1 4.8

External clock, data transfer only 9

Internal clock 3.2 4.0 MHz

8-bit-wide data-transfer mode 4.17 200.00

16-bit-wide data-transfer mode 3.125 150.00

Internal clock, single conversion, 8-bit-wide

data-transfer mode

Internal clock, single conversion, 16-bit-

S

wide data-transfer mode

Internal clock, scan mode, 8-bit-wide datatransfer mode (four conversions)

External clock, scan mode, 16-bit-wide

data-transfer mode (four conversions)

_0V

_45pF

3.8 AV

V

_ = 0 110

AIN

SCLK idle 0.1

CS = DVDD, SCLK idle 0.1

4.056 4.096 4.136 V

= 0 5 ms

5.52 7.07

15 ns

<50 ps

89

68

103

82

REF

DD

13 mA

±25 ppm/°C

µs

MHz

ksps

V

V

µA

Page 4

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

4 _______________________________________________________________________________________

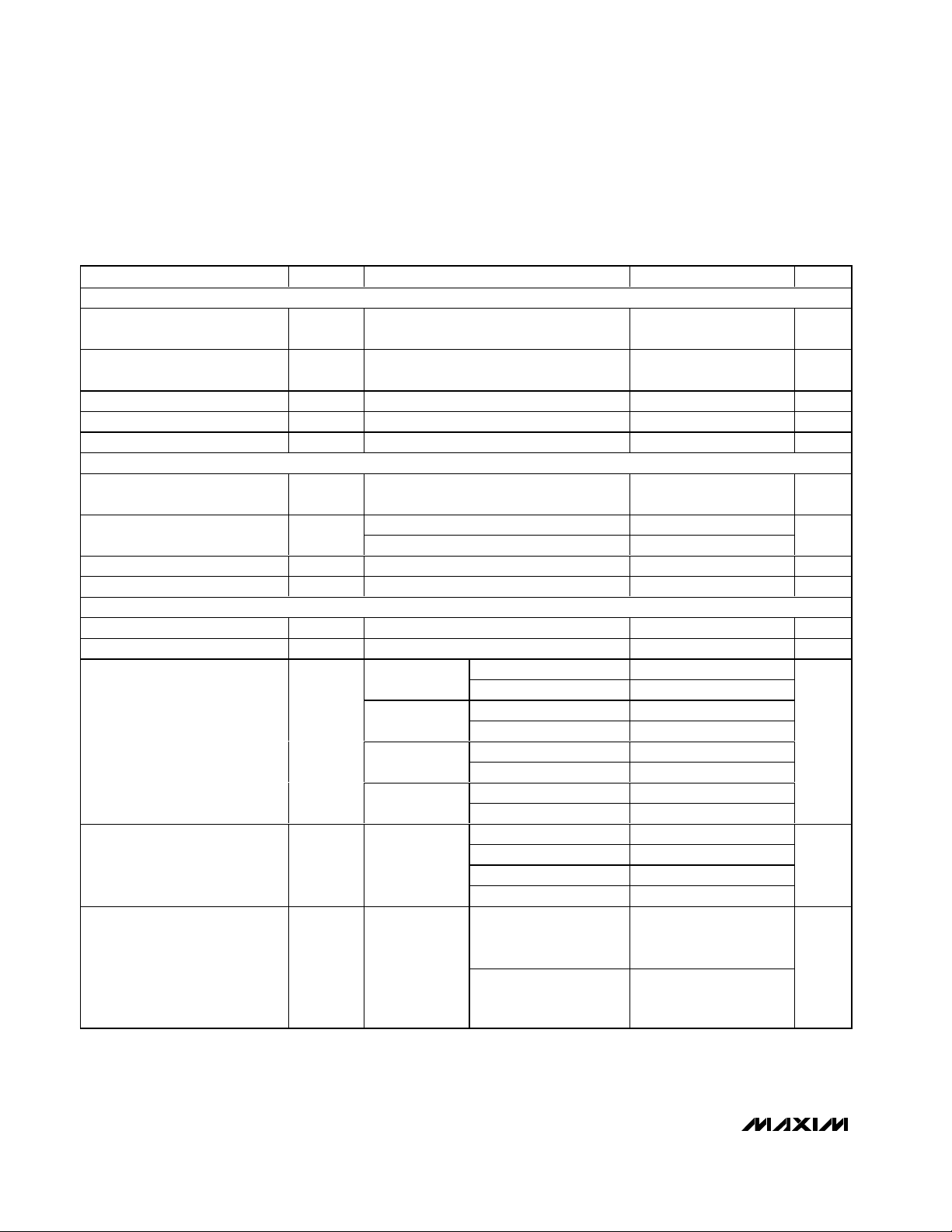

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= +4.75V to +5.25V, f

SCLK

= 4.8MHz external clock (50% duty cycle), 24 clocks/conversion (200ksps), external V

REF

= +4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

DIGITAL INPUTS (SCLK, CS, DSEL, DSPR, DIN) (DVDD = +2.7V to +5.25V)

Input High Voltage V

Input Low Voltage V

Input Leakage Current I

Input Hysteresis V

Input Capacitance C

DIGITAL OUTPUT (DOUT, DSPX, EOC) (DVDD = +2.7V to +5.25V)

Output High Voltage V

Output Low Voltage V

Tri-State Output Leakage Current I

Tri-State Output Capacitance C

POWER SUPPLIES

Analog Supply AV

Digital Supply DV

Analog Supply Current (Note 8) I

Digital Supply Current I

Power-Down Supply Current

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

0.7 ×

DV

DD

0.3 ×

DV

±0.1 ±1 µA

0.2 V

15 pF

DV

-

DD

0.4

±0.1 ±10 µA

15 pF

4.75 5.25 V

2.70 5.25 V

1.01

0.43

HYST

AVDD

DVDD

I

AVDD

I

DVDD

IH

IL

IN

IN

OH

OL

L

OUT

DD

DD

Digital inputs = 0 to DV

+

I

I

I

CS = DV

CS = DV

200ksps

100ksps

10ksps

1ksps

DOUT =

all zeros

CS = DVDD,

SCLK = 0,

DIN = 0,

DSPR = DV

= 0.5mA

SOURCE

= 10mA, DVDD = +4.75V to +5.25V 0.8

SINK

= 1.6mA, DVDD = +2.7V to +5.25V 0.4

SINK

DD

DD

DD

External reference 2.0 2.9

Internal reference 2.9 3.8

External reference 1.0

Internal reference 2.0

External reference 0.1

Internal reference 1.1

External reference 0.01

Internal reference 1.01

200ksps 0.87 1.3

100ksps 0.45

10ksps 0.045

1ksps 0.005

Internal reference and

reference buffer on

between conversions

Internal reference on,

DD

reference buffer off

between conversions

DD

V

V

V

V

mA

mA

mA

Page 5

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= +4.75V to +5.25V, f

SCLK

= 4.8MHz external clock (50% duty cycle), 24 clocks/conversion (200ksps), external V

REF

= +4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

p

)

TIMING CHARACTERISTICS (Figures 1, 2, 8, and 16)

(AVDD= DVDD= +4.75V to +5.25V, f

SCLK

= 4.8MHz external clock (50% duty cycle), 24 clocks/conversion (200ksps), external

V

REF

= +4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Shutdown Supply Current

Power-Supply Rejection Ratio PSRR

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I

+

AVDD

I

DVDD

CS = DVDD, SCLK = 0, DIN = 0,

DSPR = DV

= DVDD = 4.75V to 5.25V, full-scale

AV

DD

ut (Note 9

in

, full power-down

DD

Acquisition Time t

SCLK to DOUT Valid t

CS Fall to DOUT Enable t

CS Rise to DOUT Disable t

CS Pulse Width t

CS to SCLK Setup t

CS to SCLK Hold t

SCLK High Pulse Width t

SCLK Low Pulse Width t

SCLK Period t

DIN to SCLK Setup t

DIN to SCLK Hold t

CS Falling to DSPR Rising t

DSPR to SCLK Falling Setup t

DSPR to SCLK Falling Hold t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ACQ

DO

DV

TR

CSW

CSS

CSH

CH

CL

CP

DS

DH

DF

FSS

FSH

External clock (Note 6) 729 ns

C

= 30pF 50 ns

DOUT

C

= 30pF 80 ns

DOUT

C

= 30pF 80 ns

DOUT

SCLK rise

SCLK fall (DSP)

SCLK rise

SCLK fall (DSP)

Duty cycle 45% to 55%

Duty cycle 45% to 55%

SCLK rise

SCLK fall (DSP)

SCLK rise

SCLK fall (DSP)

100 ns

100 ns

Conversion 93

Data transfer 50

Conversion 93

Data transfer 50

209 ns

50 ns

100 ns

100 ns

0.6 10 µA

63 dB

0ns

ns

ns

0ns

0ns

Page 6

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

6 _______________________________________________________________________________________

TIMING CHARACTERISTICS (Figures 1, 2, 8, and 16)

(AVDD= +4.75V to +5.25V, DVDD= +2.7V to +5.25V, f

SCLK

= 4.8MHz external clock (50% duty cycle), 24 clocks/conversion

(200ksps), external V

REF

= +4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Note 1: AVDD= DVDD= +5.0V.

Note 2: Relative accuracy is the deviation of the analog value at any code from its theoretical value after full-scale range has been

calibrated.

Note 3: Offset and reference errors nulled.

Note 4: DC voltage applied to on channel, and a full-scale 1kHz sine wave applied to off channels.

Note 5: Conversion time is measured from the rising edge of the 8th external SCLK pulse to EOC transition minus t

ACQ

in 8-bit data-

transfer mode.

Note 6: See Figures 10 and 17.

Note 7: f

SCLK

= 4.8MHz, f

INTCLK

= 4.0MHz. Sample rate is calculated with the formula fs= n1(n2 / f

SCLK

+ n3 / f

INTCLK

)-1where: n

1

= number of scans, n2= number of SCLK cycles, and n3= number of internal clock cycles (see Figures 11–14).

Note 8: Internal reference and buffer are left on between conversions.

Note 9: Defined as the change in the positive full scale caused by a ±5% variation in the nominal supply voltage.

Acquisition Time t

SCLK to DOUT Valid t

CS Fall to DOUT Enable t

CS Rise to DOUT Disable t

CS Pulse Width t

CS to SCLK Setup t

CS to SCLK Hold t

SCLK High Pulse Width t

SCLK Low Pulse Width t

SCLK Period t

DIN to SCLK Setup t

DIN to SCLK Hold t

CS Falling to DSPR Rising t

DSPR to SCLK Falling Setup t

DSPR to SCLK Falling Hold t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ACQ

DO

DV

TR

CSW

CSS

CSH

CH

CL

CP

DS

DH

DF

FSS

FSH

External clock (Note 6) 729 ns

C

DOUT

C

DOUT

C

DOUT

SCLK rise

SCLK fall (DSP)

SCLK rise

SCLK fall (DSP)

Duty cycle 45% to 55%

Duty cycle 45% to 55%

SCLK rise

SCLK fall (DSP)

SCLK rise

SCLK fall (DSP)

= 30pF 100 ns

= 30pF 100 ns

= 30pF 80 ns

100 ns

100 ns

0ns

Conversion 93

Data transfer 93

Conversion 93

Data transfer 93

209 ns

100 ns

0ns

100 ns

100 ns

0ns

ns

ns

Page 7

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

_______________________________________________________________________________________ 7

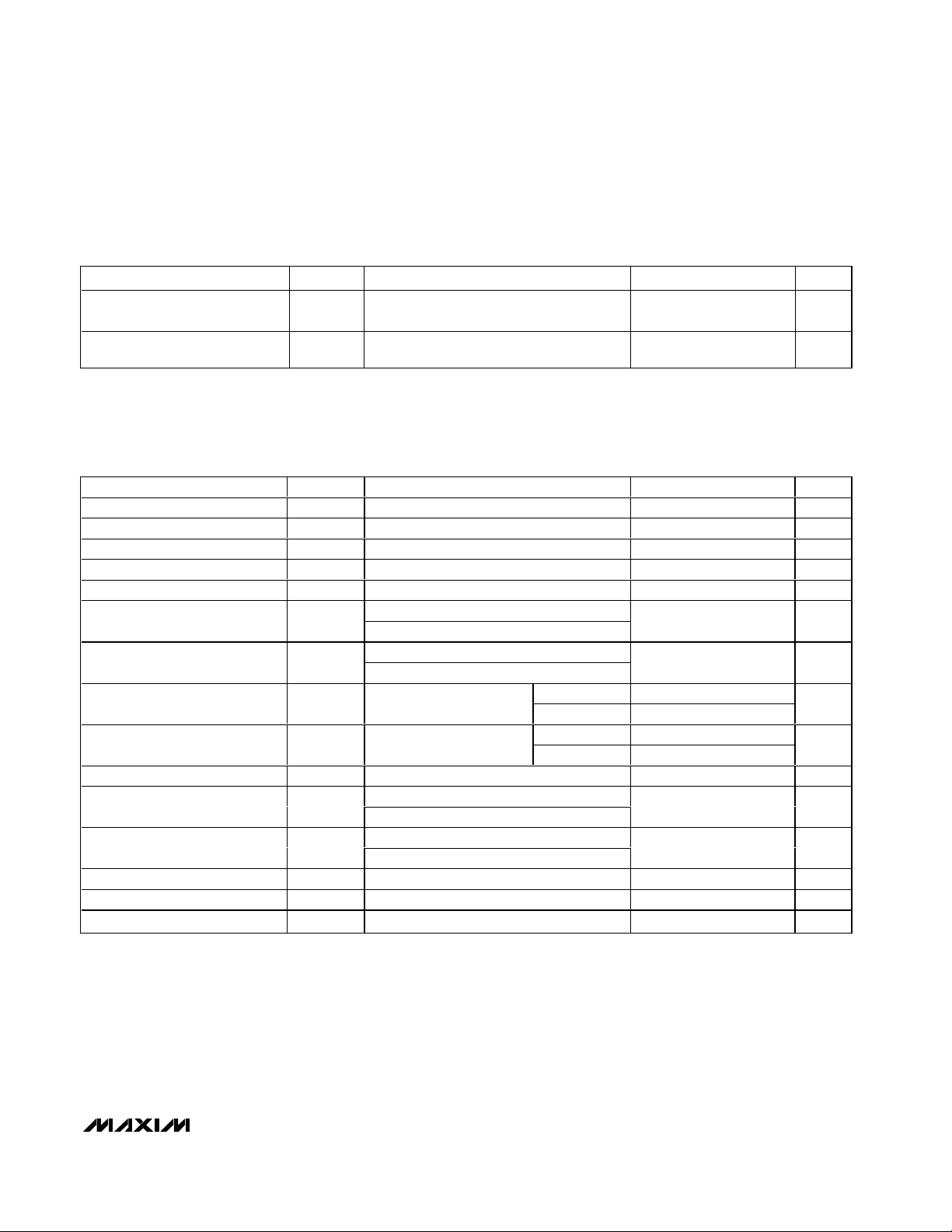

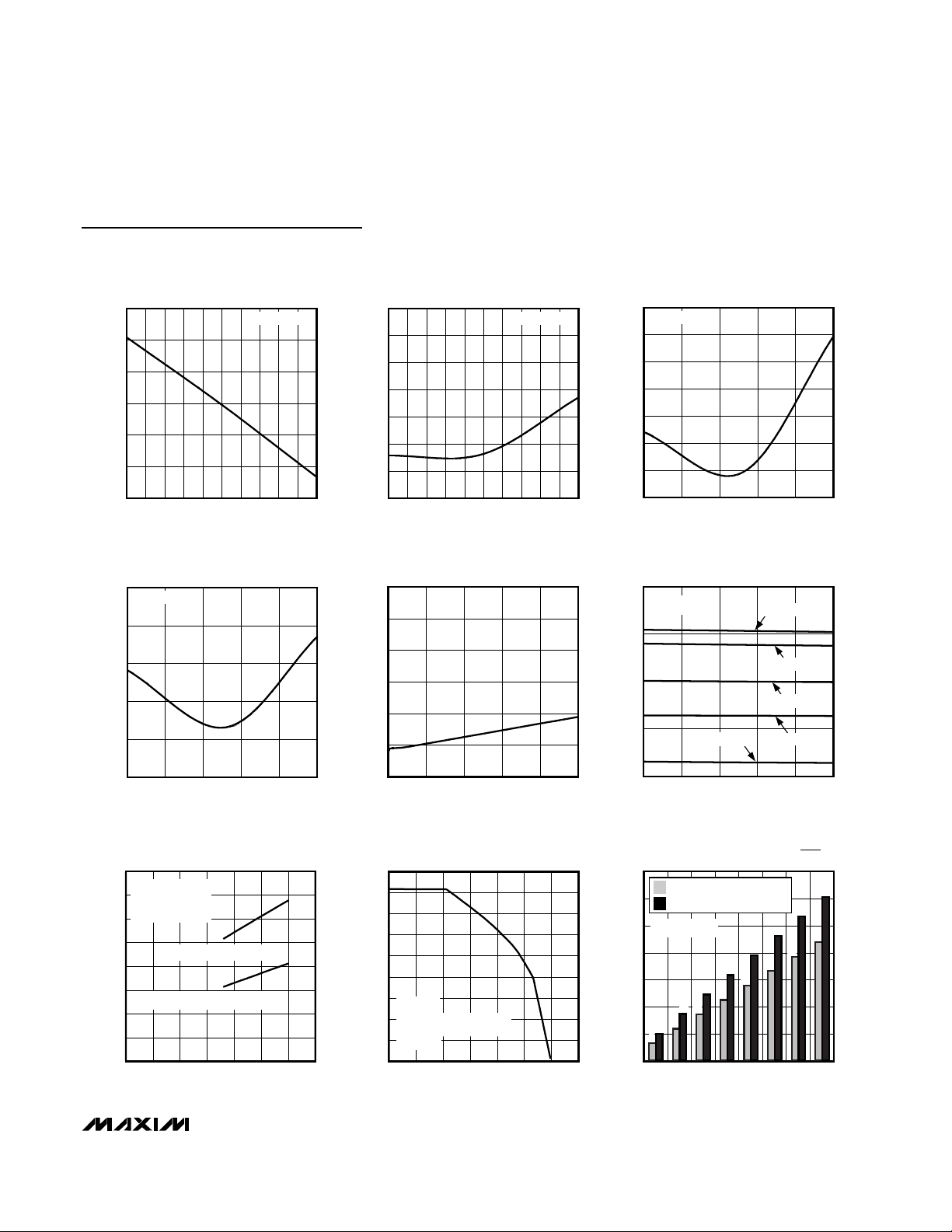

Typical Operating Characteristics

(AVDD= DVDD= +5V, f

SCLK

= 4.8MHz, C

DOUT

= 30pF, external V

REF

= +4.096V, TA= +25°C, unless otherwise noted.)

INL vs. CODE

1.5

1.0

0.5

0

INL (LSB)

-0.5

-1.0

-1.5

0 3276816384 49152 65536

CODE

SINAD vs. FREQUENCY

100

90

80

70

60

50

SINAD (dB)

40

30

20

10

0

0.1 100

FREQUENCY (kHz)

f

= 200kbps

SAMPLE

101

1.5

1.0

MAX1167/68 toc01

0.5

0

DNL (LSB)

-0.5

-1.0

-1.5

120

100

MAX1167/68 toc04

80

60

SFDR (dB)

40

20

0

0.1 100

DNL vs. CODE

0 3276816384 49152 65536

CODE

SFDR vs. FREQUENCY

f

= 200ksps

SAMPLE

101

FREQUENCY (kHz)

MAX1167/68 toc02

MAX1167/68 toc05

20

FFT AT f

0

-20

-40

-60

-80

AMPLITUDE (dB)

-100

-120

-140

-160

0608020 40 100

= 1kHz

AIN

FREQUENCY (kHz)

THD vs. FREQUENCY

0

f

= 200kbps

SAMPLE

-20

-40

-60

THD (dB)

-80

-100

-120

0.1 100

FREQUENCY (kHz)

101

MAX1167/68 toc03

MAX1167/68 toc06

SUPPLY CURRENT vs. CONVERSION RATE

(EXTERNAL CLOCK)

3.0

DVDD = AVDD = +5V

= ALL ZEROS

D

OUT

2.5

EXTERNAL CLOCK

SPI MODE

2.0

1.5

1.0

SUPPLY CURRENT (mA)

0.5

0

-0.5

0200

I

, INT REF

AVDD

I

, EXT REF

AVDD

I

DVDD

CONVERSION RATE (ksps)

MAX1167/68 toc07

(mA)

AVDD

I

18016014012010080604020

vs. ANALOG SUPPLY VOLTAGE

(INTERNAL REFERENCE)

2.95

DVDD = +5V

= 200ksps

f

S

2.90

2.85

2.80

2.75

2.70

4.75 5.25

ANALOG SUPPLY CURRENT

TA = +85°C

AVDD (V)

TA = +70°C

TA = +25°C

TA = 0°C

TA = -40°C

5.155.054.954.85

MAX1167/68 toc08

ANALOG SUPPLY CURRENT

vs. ANALOG SUPPLY VOLTAGE

(EXTERNAL REFERENCE)

2.00

DVDD = +5V

= 200ksps

f

S

1.95

1.90

(mA)

AVDD

I

1.85

1.80

1.75

4.75 5.25

TA = +85°C

TA = +70°C

TA = +25°C

TA = -40°C

AVDD (V)

MAX1167/68 toc09

TA = 0°C

5.155.054.954.85

Page 8

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

8 _______________________________________________________________________________________

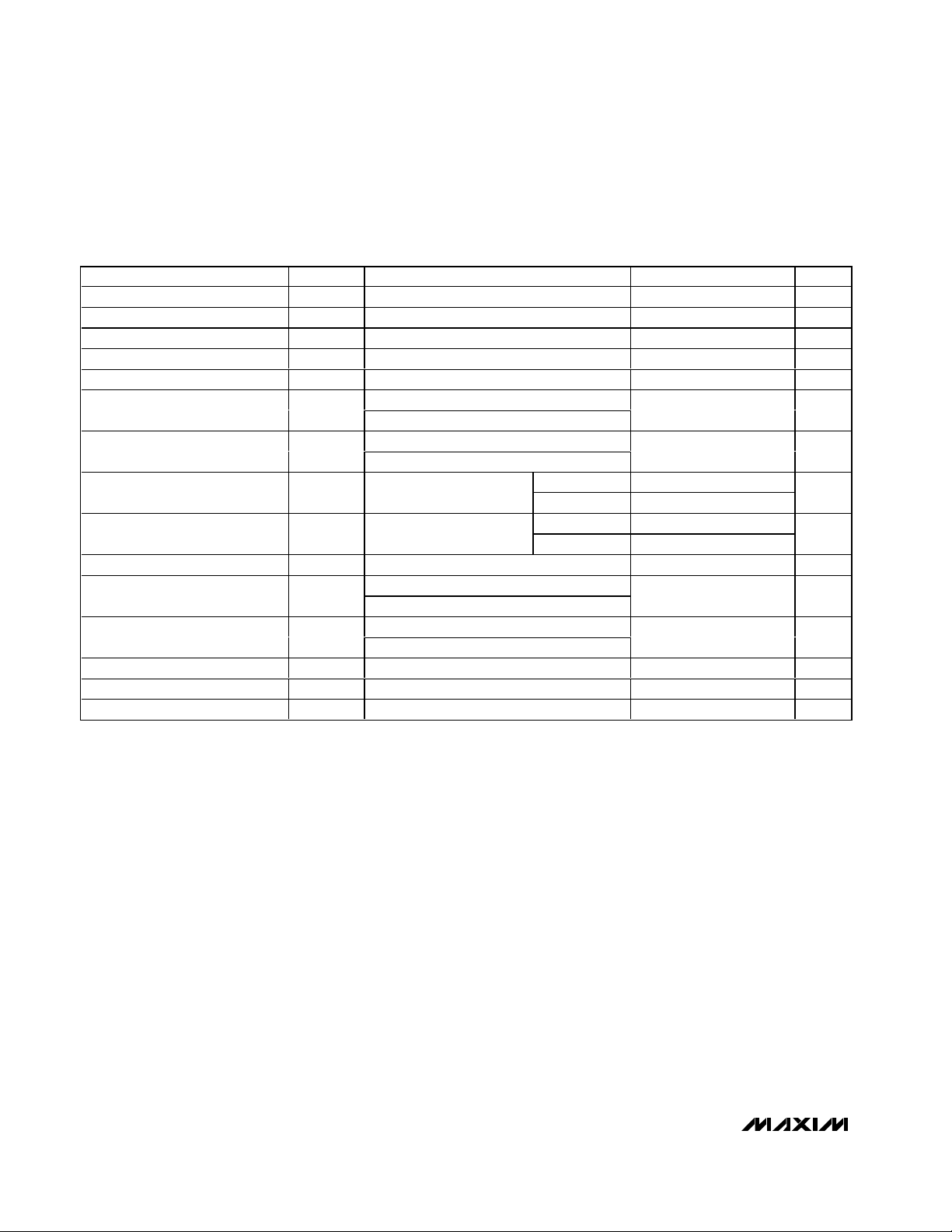

Typical Operating Characteristics (continued)

(AVDD= DVDD= +5V, f

SCLK

= 4.8MHz, C

DOUT

= 30pF, external V

REF

= +4.096V, TA= +25°C, unless otherwise noted.)

DIGITAL SUPPLY CURRENT

vs. DIGITAL SUPPLY VOLTAGE

2.6

AVDD = +5V

= 0

V

IL

2.2

= DV

V

IH

DD

fS = 200ksps

1.8

(mA)

1.4

DVDD

I

1.0

0.6

DOUT = 1010...1010

DOUT = 0000...0000

0.58

0.57

MAX1167/68 toc10

0.56

(µA)

0.55

DVDD

I

0.54

0.53

POWER-DOWN SUPPLY CURRENT

vs. AV

(INTERNAL REFERENCE)

DVDD = +5V

I

DVDD

SUPPLY VOLTAGE

DD

MAX1167/68 toc11

I

AVDD

1.04

1.03

1.02

1.01

1.00

0.99

(mA)

AVDD

I

POWER-DOWN SUPPLY CURRENT

vs. DV

DD

(INTERNAL REFERENCE)

0.7

DVDD = +5VAVDD = +5V

0.6

0.5

(µA)

0.4

DVDD

I

0.3

0.2

I

DVDD

SUPPLY VOLTAGE

MAX1167/68 toc12

I

AVDD

1.03

1.02

1.01

1.00

(mA)

AVDD

I

0.2

2.70 5.25

DVDD (V)

4.744.233.723.21

0.52

4.75 5.25

SHUTDOWN SUPPLY CURRENT

SUPPLY VOLTAGE

vs. AV

DD

(EXTERNAL REFERENCE)

0.58

DVDD = +5V

0.57

0.56

(µA)

I

I

0.55

DVDD

DVDD

0.54

0.53

0.52

4.75 5.25

AVDD (V)

MAX1167/68 toc13

I

AVDD

5.155.054.954.85

POWER-DOWN SUPPLY CURRENT

vs. TEMPERATURE (INTERNAL REFERENCE)

0.58

DVDD = AVDD = +5V

0.57

0.56

(µA)

0.55

DVDD

I

0.54

0.53

MAX1167/68 toc15

I

I

DVDD

AVDD

0.54

0.50

0.46

0.42

0.38

0.34

0.30

1.04

1.03

1.02

1.01

1.00

0.99

(nA)

AVDD

I

(mA)

AVDD

I

AVDD (V)

5.155.054.954.85

0.98

0.1

2.70 5.25

SHUTDOWN SUPPLY CURRENT

vs. DV

SUPPLY VOLTAGE

DD

(EXTERNAL REFERENCE)

0.7

DVDD = +5VAVDD = +5V

0.6

0.5

(µA)

0.4

DVDD

I

0.3

I

0.2

0.1

DVDD

2.70 5.25

DVDD (V)

SHUTDOWN SUPPLY CURRENT

vs. TEMPERATURE (EXTERNAL REFERENCE)

0.58

DVDD = AVDD = +5V

(µA)

DVDD

I

0.57

0.56

0.55

0.54

0.53

I

I

AVDD

DVDD

MAX1167/68 toc14

I

AVDD

4.744.233.723.21

MAX1167/68 toc16

DVDD (V)

0.43

0.42

0.41

0.40

0.39

0.38

0.37

0.45

0.43

0.41

0.39

0.37

(nA)

AVDD

I

(nA)

AVDD

I

4.744.233.723.21

0.99

0.52

-40 85

TEMPERATURE (°C)

603510-15

0.98

0.52

-40 85

TEMPERATURE (°C)

603510-15

0.35

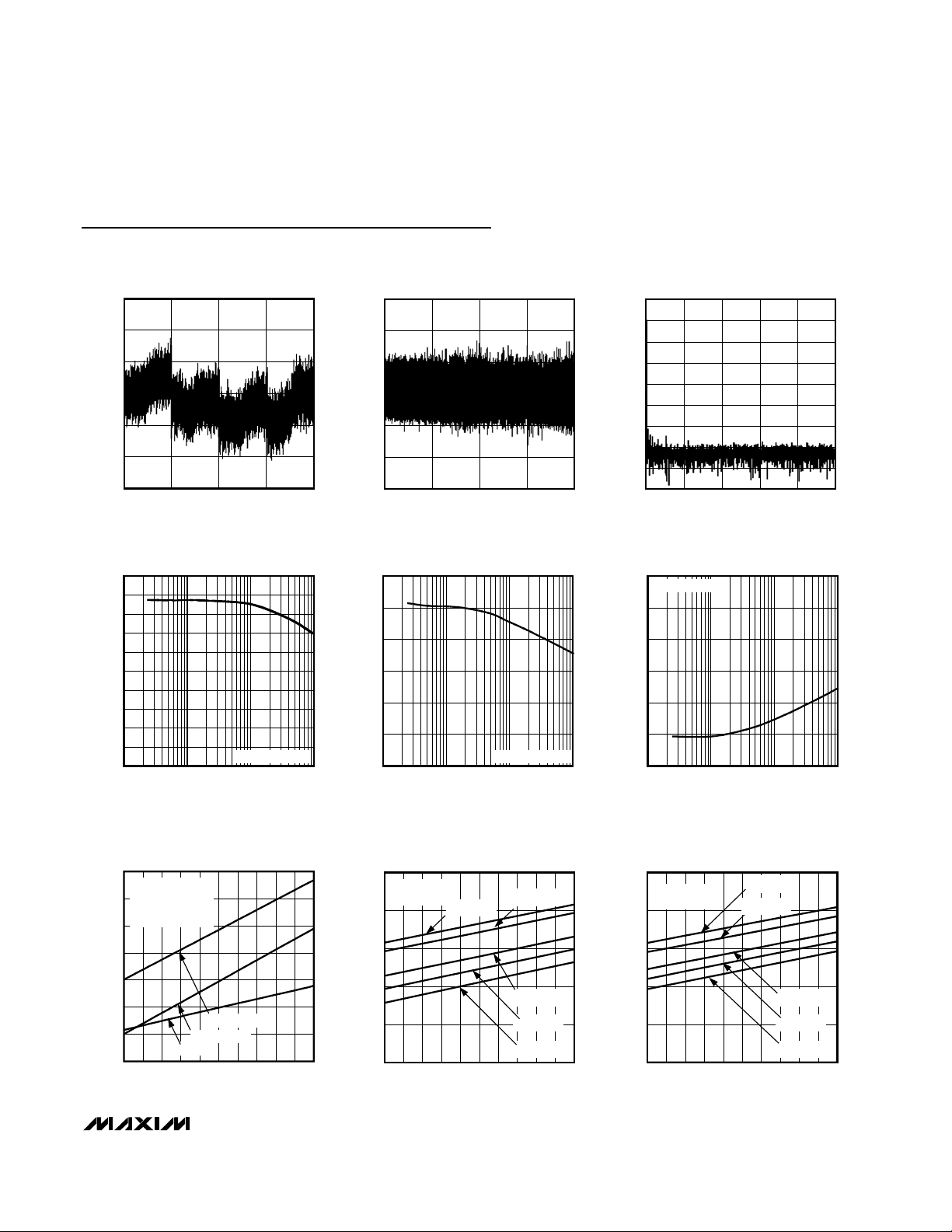

Page 9

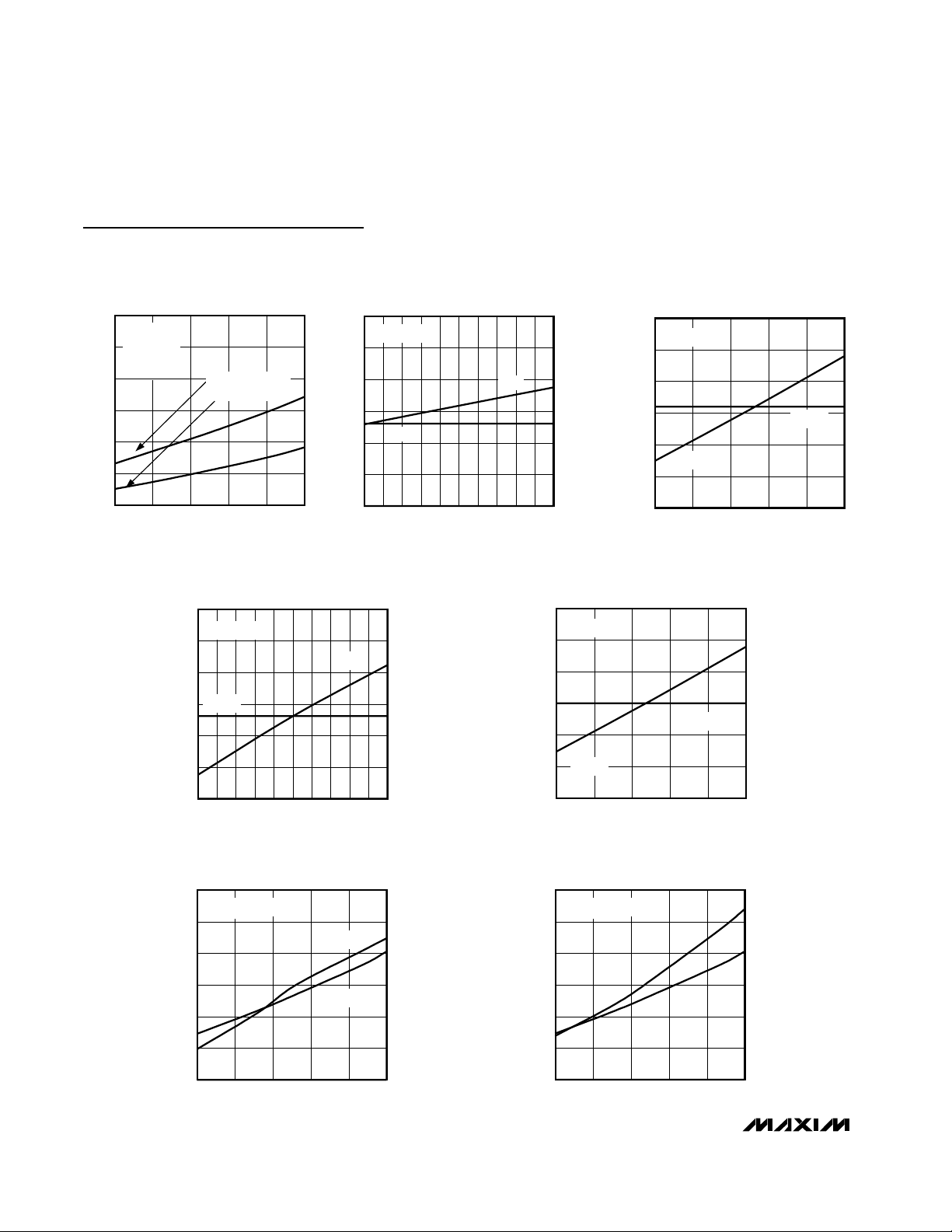

OFFSET ERROR vs. SUPPLY VOLTAGE

MAX1167/68 toc17

AVDD (V)

OFFSET ERROR (µV)

5.154.85 5.054.95

200

100

0

-100

-200

-300

-400

4.75 5.25

V

REF

= +4.096V

GAIN ERROR vs. SUPPLY VOLTAGE

MAX1167/68 toc18

AVDD (V)

GAIN ERROR (%FSR)

5.154.85 5.054.95

0.05

0.04

0.03

0.02

0.01

0

-0.01

-0.02

4.75 5.25

V

REF

= +4.096V

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

_______________________________________________________________________________________ 9

Typical Operating Characteristics (continued)

(AVDD= DVDD= +5V, f

SCLK

= 4.8MHz, C

DOUT

= 30pF, external V

REF

= +4.096V, TA= +25°C, unless otherwise noted.)

GAIN ERROR vs. TEMPERATURE

0

V

= +4.096V

REF

-0.001

-0.002

-0.003

GAIN ERROR (%FSR)

-0.004

0

-20

MAX1167/68 toc20

-40

-60

ISOLATION (dB)

-80

-100

CHANNEL-TO-CHANNEL ISOLATION

OFFSET ERROR vs. TEMPERATURE

200

V

= +4.096V

REF

150

100

50

0

OFFSET ERROR (µV)

-50

-100

-150

-40 85

INTERNAL +4.096V REFERENCE VOLTAGE

vs. FREQUENCY

4.104

MAX1167/68 toc21

4.100

(V)

4.096

REF

V

4.092

vs. ANALOG SUPPLY VOLTAGE

DVDD = +5V

TEMPERATURE (°C)

TA = -40°C

MAX1167/68 toc19

603510-15

TA = +85°C

MAX1167/68 toc22

TA = +70°C

TA = +25°C

TA = 0°C

-0.005

-40 85

EXTERNAL REFERENCE INPUT CURRENT

vs. EXTERNAL REFERENCE VOLTAGE

160

V

= 0

AIN

140

120

100

(µA)

REF

I

= 4.8MHz

f

SCLK

= DV

AV

DD

DD

80

60

40

20

0

199ksps, EXTERNAL CLOCK

87.19ksps, INTERNAL CLOCK

2.0 5.5

4.088

MAX1167/68 toc24

(ms)

CONV

t

4.75 5.25

AVDD (V)

5.155.054.954.85

INTERNAL CLOCK CONVERSION TIME

(8th RISING SCLK TO FALLING EOC)

70

8-BIT DATA-TRANSFER MODE

60

16-BIT DATA-TRANSFER MODE

50

f

= 4.8MHz

SCLK

40

30

20

10

0

17

12

10

6

1

NUMBER OF SCAN-MODE CONVERSIONS

31

24

22

17

46

39

38

33

28

TEMPERATURE (°C)

= +5V

V

(V)

REF

-120

603510-15

0100

FREQUENCY (kHz)

80604020

INTERNAL REFERENCE VOLTAGE

vs. REF LOAD

4.5

4.0

3.5

MAX1167/68 toc23

3.0

(V)

2.5

REF

V

2.0

1.5

f

= 0

SCLK

1.0

INTERNAL REFERENCE MODE

LOAD APPLIED TO REF

0.5

5.04.52.5 3.0 3.5 4.0

= 1µF

C

REF

0

014

(mA)

I

REF

12106 842

60

53

MAX1167/68 toc25

44

8765432

Page 10

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

10 ______________________________________________________________________________________

Pin Description

PIN

MAX1167 MAX1168

1 3 DOUT

2 4 SCLK

35DIN

46EOC

5 7 AIN0 Analog Input 0

6 8 AIN1 Analog Input 1

NAME FUNCTION

Serial Data Output. Data changes state on SCLK’s falling edge in SPI/QSPI/MICROWIRE

mode and on SCLK’s rising edge in DSP mode (MAX1168 only). DOUT is high impedance

when CS is high.

Serial Clock Input. SCLK drives the conversion process in external clock mode and clocks

data out.

Serial Data Input. Use DIN to communicate with the command/configuration/control

register. In SPI/QSPI/MICROWIRE mode, the rising edge of SCLK clocks in data at DIN. In

DSP mode, the falling edge of SCLK clocks in data at DIN.

End-of-Conversion Output. In internal clock mode, a logic low at EOC signals the end of a

conversion with the result available at DOUT. In external clock mode, EOC remains high.

7 9 AIN2 Analog Input 2

8 10 AIN3 Analog Input 3

9 15 REF

10 16 REFCAP

11 17 AGND Analog Ground. Connect to pin 18 (MAX1168) or pin 12 (MAX1167).

Reference Voltage Input/Output. V

with a 10µF capacitor. Bypass with a 1µF (min) capacitor when using internal reference.

Refer ence Byp ass C ap aci tor C onnecti on. Byp ass to AG N D w i th a 0.1µF cap aci tor w hen

usi ng i nter nal r efer ence. Inter nal r efer ence and b uffer sh ut d ow n i n exter nal r efer ence m od e.

sets the analog voltage range. Bypass to AGND

REF

12 18 AGND Primary Analog Ground (Star Ground). Power return for AVDD.

13 19 AV

14 20 CS

15 21 DGND Digital Ground

16 22 DV

— 1 DSPR

— 2 DSEL

— 11 AIN4 Analog Input 4

— 12 AIN5 Analog Input 5

Analog Supply Voltage. Bypass to AGND with a 0.1µF capacitor.

DD

Active-Low Chip-Select Input. Forcing CS high places the MAX1167/MAX1168 in shutdown

with a typical supply current of 0.6µA. In SPI/QSPI/MICROWIRE mode, a high-to-low

transition on CS activates normal operating mode. In DSP mode, after the initial CS

transition from high to low, CS can remain low for the entire conversion process (see the

Operating Modes section).

Digital Supply Voltage. Bypass to DGND with a 0.1µF capacitor.

DD

DSP Frame-Sync Receive Input. A frame-sync pulse received at DSPR initiates a

conversion. Connect to logic high when using SPI/QSPI/MICROWIRE mode.

Data-Bit Transfer-Select Input. Logic low on DSEL places the device in 8-bit-wide datatransfer mode. Logic high places the device in 16-bit-wide data-transfer mode. Do not

leave DSEL unconnected.

Page 11

Detailed Description

The MAX1167/MAX1168 low-power, multichannel, 16-bit

ADCs feature a successive-approximation ADC, automatic power-down, integrated +4.096V reference, and a

high-speed SPI/QSPI/MICROWIRE-compatible interface.

A DSPR input and DSPX output allow the MAX1168 to

communicate with digital signal processors (DSPs) with

no external glue logic. The MAX1167/MAX1168 operate

with a single +5V analog supply and feature a separate

digital supply, allowing direct interfacing with +2.7V to

+5.5V digital logic.

Figures 3 and 4 show the functional diagrams of the

MAX1167/MAX1168, and Figures 5 and 6 show the

MAX1167/MAX1168 in a typical operating circuit. The

serial interface simplifies communication with microprocessors (µPs).

In external reference mode, the MAX1167/MAX1168

have two power modes: normal mode and shutdown

mode. Driving CS high places the MAX1167/MAX1168 in

shutdown mode, reducing the supply current to 0.6µA

(typ). Pull CS low to place the MAX1167/MAX1168 in

normal operating mode. The internal reference mode

offers software-programmable, power-down options as

shown in Table 5.

In SPI/QSPI/MICROWIRE mode, a falling edge on CS

wakes the analog circuitry and allows SCLK to clock in

data. Acquisition and conversion are initiated by SCLK.

The conversion result is available at DOUT in unipolar

serial format. DOUT is held low until data becomes

available (MSB first) on the 8th falling edge of SCLK

when in 8-bit transfer mode, and on the 16th falling

edge when in 16-bit transfer mode (see the Operating

Modes section). Figure 8 shows the detailed SPI/QSPI/

MICROWIRE serial-interface timing diagram.

In external clock mode, the MAX1168 also interfaces

with DSPs. In DSP mode, a frame-sync pulse from the

DSP initiates a conversion that is driven by SCLK. The

MAX1168 formats a frame-sync pulse to notify the DSP

that the conversion results are available at DOUT in

MSB-first, unipolar, serial-data format. Figure 16 shows

the detailed DSP serial-interface timing diagram (see the

Operating Modes section).

Analog Input

Figure 7 illustrates the input-sampling architecture of

the ADC. The voltage applied at REF or the internal

+4.096V reference sets the full-scale input voltage.

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 11

Pin Description (continued)

Figure 1. Load Circuits for DOUT Enable Time and SCLK-toDOUT Delay Time

Figure 2. Load Circuits for DOUT Disable Time

PIN

MAX1167 MAX1168

NAME FUNCTION

— 13 AIN6 Analog Input 6

— 14 AIN7 Analog Input 7

— 23 DSPX

DSP Frame-Sync Transmit Output. A frame-sync pulse at DSPX notifies the DSP that the

MSB data is available at DOUT. Leave DSPX unconnected when not in DSP mode.

— 24 N.C. No Connection. Not internally connected.

DV

DD

1mA

DOUT

1mA

DGND

a) V

C

= 30pF

LOAD

TO V

OL

OH

DOUT

b) HIGH-Z TO V

C

= 30pF

LOAD

DGND

AND V

TO V

OL

OH

OL

1mA

DOUT

C

1mA

DGND

a) V

TO HIGH-Z

OH

LOAD

= 30pF

DOUT

b) V

OL

DV

DD

C

DGND

TO HIGH-Z

LOAD

= 30pF

Page 12

MAX1167/MAX1168

Track/Hold (T/H)

In track mode, the analog signal is acquired on the

internal hold capacitor. In hold mode, the T/H switches

open and the capacitive digital-to-analog converter

(DAC) samples the analog input.

During the acquisition, the analog input (AIN_) charges

capacitor C

DAC

. At the end of the acquisition interval

the T/H switches open. The retained charge on C

DAC

represents a sample of the input.

In hold mode, the capacitive DAC adjusts during the

remainder of the conversion cycle to restore node

ZERO to zero within the limits of 16-bit resolution. At the

end of the conversion, force CS high and then low to

reset the T/H switches back to track mode (AIN_),

where C

DAC

charges to the input signal again.

The time required for the T/H to acquire an input signal

is a function of how quickly its input capacitance is

charged. If the input signal’s source impedance is high,

the acquisition time lengthens and more time must be

allowed between conversions. The acquisition time

(t

ACQ

) is the maximum time the device takes to acquire

the signal. Use the following formula to calculate acquisition time:

t

ACQ

= 11(RS+ RIN+ R

DS(ON)

) ✕ 45pF + 0.3µs

where RIN= 340Ω, RS= the input signal’s source

impedance, R

DS(ON)

= 60Ω, and t

ACQ

is never less

than 729ns. A source impedance of less than 200Ω

does not significantly affect the ADC’s performance.

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

12 ______________________________________________________________________________________

Figure 3. MAX1167 Functional Diagram

REFERENCE

REF

AGND

AIN0

AIN1

AIN2

AIN3

SCLK

CS

ANALOG-INPUT

MULTIPLEXER

OSCILLATOR

BIAS

REFCAP

AZ

RAIL

MULTIPLEXER

CONTROL

BUFFER

SUCCESSIVE-APPROXIMATION

AV

DD

MAX1167

DAC

ANALOG-SWITCH FINE TIMING

REGISTER

COMPARATOR

DV

DD

ACCUMULATOR

MEMORY

OUTPUT DOUT

EOC

DIN

INPUT REGISTER

AGND DGND

Page 13

The MAX1168 features a 16-bit-wide data-transfer

mode that includes a longer acquisition time (11.5

clock cycles). Longer acquisition times are useful in

applications with input source resistances greater than

1kΩ. Noise increases when using large source resistances. To improve the input signal bandwidth under

AC conditions, drive AIN_ with a wideband buffer

(>10MHz) that can drive the ADC’s input capacitance

and settle quickly.

Input Bandwidth

The ADC’s input-tracking circuitry has a 4MHz smallsignal bandwidth, making possible the digitization of

high-speed transient events and the measurement of

periodic signals with bandwidths exceeding the ADC’s

sampling rate by using undersampling techniques. To

avoid aliasing of unwanted, high-frequency signals into

the frequency band of interest, use anti-alias filtering.

Analog Input Protection

Internal protection diodes, which clamp the analog

input to AV

DD

or AGND, allow the input to swing from

(AGND - 0.3V) to (AVDD+ 0.3V) without damaging the

device. If the analog input exceeds 300mV beyond the

supplies, limit the input current to 10mA.

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 13

Figure 4. MAX1168 Functional Diagram

AGND

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

SCLK

DSEL

DSPR

REF

REFCAP

AZ

RAIL

MULTIPLEXER

CONTROL

BUFFER

REFERENCE

ANALOG-INPUT

MULTIPLEXER

BIAS

OSCILLATOR

CS

AV

DD

DAC

ANALOG-SWITCH FINE TIMING

SUCCESSIVE-APPROXIMATION

REGISTER

DV

MAX1168

COMPARATOR

ACCUMULATOR

MEMORY

DD

OUTPUT DOUT

EOC

DSPX

DIN

INPUT REGISTER

AGND DGND

Page 14

MAX1167/MAX1168

Digital Interface

The MAX1167/MAX1168 feature an SPI/QSPI/

MICROWIRE-compatible, 3-wire serial interface. The

MAX1167 digital interface consists of digital inputs CS,

SCLK, and DIN and outputs DOUT and EOC. The

MAX1167 operates in the following modes:

• SPI interface with external clock

• SPI interface with internal clock

• SPI interface with internal clock and scan mode

In addition to the standard 3-wire serial interface modes,

the MAX1168 includes a DSPR input and a DSPX output

for communicating with DSPs in external clock mode and

a DSEL input to determine 8-bit-wide or 16-bit-wide datatransfer mode. When not using the MAX1168 in the DSP

interface mode, connect DSPR to DV

DD

and leave DSPX

unconnected.

Command/Configuration/Control Register

Table 1 shows the contents of the command/configuration/control register and the state of each bit after initial

power-up. Tables 2–6 define the control and configuration

of the device for each bit. Cycling the power supplies

resets the command/configuration/control register to the

power-on-reset default state.

Initialization After Power-Up

A logic high on CS places the MAX1167/MAX1168 in

the shutdown mode chosen by the power-down bits,

and places DOUT in a high-impedance state. Drive CS

low to power up and enable the MAX1167/MAX1168

before starting a conversion. In internal reference

mode, allow 5ms for the shutdown internal reference

and/or buffer to wake and stabilize before starting a

conversion. In external reference mode (or if the internal reference is already on), no reference settling time

is needed after power-up.

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

14 ______________________________________________________________________________________

Figure 5. MAX1167 Typical Operating Circuit

Figure 6. MAX1168 T ypical Operating Circuit

Figure 7. Equivalent Input Circuit

Table 1. Command/Configuration/Control Register

CS

REFCAP

GND

SCLK

DSPX

DOUT

EOC

AGND

AGND

DGND

CS

SCLK

DSPX

DOUT

EOC

0.1µF

ANALOG

INPUTS

+5V

+5V

DIN

1µF

0.1µF

0.1µF

AIN0

AIN1

AIN2

AIN3

DIN

REF

AV

DV

AIN0

0.1µF

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

DIN

DSEL

DSPR

REF

AV

DV

MAX1168

DD

DD

CS

CS

EOC

SCLK

DOUT

EOC

0.1µF

ANALOG

INPUTS

DIN

16

8

+5V

+5V

1µF

0.1µF

SCLK

DOUT

MAX1167

DD

DD

AGND

AGND

DGND

REFCAP

GND

TRACK

HOLD

C

SWITCH

REF

CAPACITIVE

DAC

C

DAC

AGND

HOLD TRACK

ZERO

R

IN

AUTOZERO

RAIL

MUX

R

DSON

AIN_

C

MUX

COMMAND

POWER-UP

STATE

BIT7 (MSB) BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0 (LSB)

CH SEL2 CH SEL1 CH SEL0 SCAN1 SCAN0 REF/PD_SEL1 REF/PD SEL0 INT/EXT CLK

00000110

Page 15

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 15

Table 2. Channel Select

Table 3. MAX1167 Scan Mode, Internal

Clock Only

Table 4. MAX1168 Scan Mode, Internal

Clock Only (Not for DSP Mode)

BIT2 BIT1

SEL1

REF/PD

SEL0

REFERENCE

REFERENCE MODE

(INTERNAL REFERENCE)

TYPICAL

SUPPLY

CURRENT

TYPICAL WAKE-

UP TIME

(C

REF

= 1µF)

0 0 Internal

Internal reference and reference buffer on

between conversions

1mA NA

0 1 Internal

Internal reference and reference buffer off

between conversions

0.6µA 5ms

1 0 Internal

Internal reference on, reference buffer off

between conversions

0.43mA 5ms

1 1 External Internal reference and buffer always off 0.6µA NA

Table 5. Power-Down Modes

Table 6. Clock Modes

BIT7 BIT6 BIT5

CH SEL2 CH SEL1 CH SEL0

000 0

001 1

010 2

011 3

100 4

101 5

110 6

111 7

CHANNEL

AIN_

ACTION

Single channel, no scan 0 0

Sequentially scan channels 0 through N

(N ≤ 7)

Sequentially scan channels 4 through N

(4 ≤ N ≤ 7)

Scan channel N eight times 1 1

BIT4 BIT3

SCAN1 SCAN0

01

10

ACTION

Single channel, no scan 0 0

Sequentially scan channels 0 through N

(N ≤ 3)

Sequentially scan channels 2 through N

(2 ≤ N ≤ 3)

Scan channel N four times 1 1

BIT4 BIT3

SCAN1 SCAN0

01

10

REF/PD_

BIT0

INT/EXT

CLK

0 External clock

1 Internal clock

CLOCK MODE

Page 16

MAX1167/MAX1168

Power-Down Modes

Table 5 shows the MAX1167/MAX1168 power-down

modes. Three internal reference modes and one external reference mode are available. Select power-down

modes by writing to bits 2 and 1 in the command/configuration/control register. The MAX1167/MAX1168

enter the selected power-down mode on the rising

edge of CS.

The internal reference stays on when CS is pulled high,

if bits 2 and 1 are set to zero. This mode allows for the

fastest turn-on time.

Setting bit 2 = 0 and bit 1 = 1 turns both the reference

and reference buffer off when CS is brought high. This

mode achieves the lowest supply current. The reference and buffer wake up on the falling edge of CS

when in SPI/QSPI/MICROWIRE mode and on the falling

edge of DSPR when in DSP mode. Allow 5ms for the

internal reference to rise and settle when powering up

from a complete shutdown (V

REF

= 0, C

REF

= 1µF).

The internal reference stays on and the buffer is shut off

on the rising edge of CS when bit 2 = 1 and bit 1 = 0.

The MAX1167/MAX1168 enter this mode on the rising

edge of CS. The buffer wakes up on the falling edge of

CS when in SPI/QSPI/MICROWIRE mode and on the rising edge of DSPR when in DSP mode. Allow 5ms for

V

REF

to settle when powering up from a complete shut-

down (V

REF

= 0, C

REF

= 1µF). V

REFCAP

is always equal

to +4.096V in this mode.

Set both bit 2 and bit 1 to 1 to turn off the reference and

reference buffer to allow connection of an external reference. Using an external reference requires no extra

wake-up time.

Operating Modes

External Clock 8-Bit-Wide Data-Transfer Mode

(MAX1167 and MAX1168)

Force DSPR high and DSEL low (MAX1168) for SPI/

QSPI/MICROWIRE interface mode. The falling edge of

CS wakes the analog circuitry and allows SCLK to clock

in data. Ensure the duty cycle on SCLK is between 45%

and 55% when operating at 4.8MHz (the maximum

clock frequency). For lower clock frequencies, ensure

the minimum high and low times are at least 93ns.

External-clock-mode conversions with SCLK rates less

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

16 ______________________________________________________________________________________

Figure 8. Detailed SPI Interface Timing

Figure 9. Shutdown Sequence

t

CSW

CS

t

SCLK

DIN

DOUT

CSS

t

DS

t

DH

t

DV

t

CL

CS

COMPLETE CONVERSION SEQUENCE

DOUT

CONVERSION 0

POWERED UP

POWERED DOWN

CONVERSION 1

POWERED UP

• • •

t

t

CH

• • •

• • •

• • •

CP

t

DO

t

CSH

t

TR

Page 17

than 125kHz can reduce accuracy due to leakage of the

sampling capacitor. DOUT changes from high-Z to logic

low after CS is brought low. Input data latches on the

rising edge of SCLK. The first SCLK rising edge begins

loading data into the command/configuration/control

register from DIN. The devices select the proper channel for conversion on the rising edge of the 3rd SCLK

cycle. Acquisition begins immediately thereafter and

ends on the falling edge of the 6th clock cycle. The

MAX1167/MAX1168 sample the input and begin conversion on the falling edge of the 6th clock cycle. Setup

and configuration of the MAX1167/MAX1168 complete

on the rising edge of the 8th clock cycle. The conversion result is available (MSB first) at DOUT on the falling

edge of the 8th SCLK cycle. To read the entire conversion result, 16 SCLK cycles are needed. Extra clock

pulses, occurring after the conversion result has been

clocked out and prior to the rising edge of CS, cause

zeros to be clocked out of DOUT. The MAX1167/

MAX1168 external clock 8-bit-wide data-transfer mode

requires 24 SCLK cycles for completion (Figure 10).

Force CS high after the conversion result is read. For

maximum throughput, force CS low again to initiate the

next conversion immediately after the specified minimum time (t

CSW

). Forcing CS high in the middle of a

conversion immediately aborts the conversion and

places the MAX1167/MAX1168 in shutdown.

External Clock 16-Bit-Wide Data-Transfer Mode

(MAX1168 Only)

Force DSPR high and DSEL high for SPI/QSPI/

MICROWIRE interface mode. Logic high at DSEL allows

the MAX1168 to transfer data in 16-bit-wide words. The

acquisition time is extended an extra eight SCLK cycles

in the 16-bit-wide data-transfer mode. The falling edge of

CS wakes the analog circuitry and allows SCLK to clock

in data. Ensure the duty cycle on SCLK is between 45%

and 55% when operating at 4.8MHz (the maximum clock

frequency). For lower clock frequencies, ensure that the

minimum high and low times are at least 93ns. Externalclock-mode conversions with SCLK rates less than

125kHz can reduce accuracy due to leakage of the sampling capacitor. DOUT changes from high-Z to logic low

after CS is brought low. Input data latches on the rising

edge of SCLK. The first SCLK rising edge begins loading

data into the command/configuration/control register from

DIN. The devices select the proper channel for conversion and begin acquisition on the rising edge of the 3rd

SCLK cycle. Setup and configuration of the MAX1168

completes on the rising edge of the 8th clock cycle.

Acquisition ends on the falling edge of the 14th SCLK

cycle. The MAX1168 samples the input and begins conversion on the falling edge of the 14th clock cycle. The

conversion result is available (MSB first) at DOUT on the

falling edge of the 16th SCLK cycle. To read the entire

conversion result, 16 SCLK cycles are needed. Extra

clock pulses, occurring after the conversion result has

been clocked out and prior to the rising edge of CS,

cause zeros to be clocked out of DOUT.

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________________________ 17

Figure 10. SPI External Clock Mode, 8-Bit Data-Transfer Mode, Conversion Timing

CS

1

SCLK

MSB LSB

DIN

DOUT

DSPR*

DSEL*

ADC

STATE

*MAX1168 ONLY

t

ACQ

8

0

MSB LSB

t

CONV

16

24

IDLE

Page 18

MAX1167/MAX1168

The MAX1168 external clock 16-bit-wide data-transfer

mode requires 32 SCLK cycles for completion (Figure 11).

Force CS high after the conversion result is read. For

maximum throughput, force CS low again to initiate the

next conversion immediately after the specified minimum time (t

CSW

). Forcing CS high in the middle of a

conversion immediately aborts the conversion and

places the MAX1168 in shutdown.

Internal Clock 8-Bit-Wide Data-Transfer and

Scan Mode (MAX1167 and MAX1168)

Force DSPR high and DSEL low (MAX1168) for the SPI/

QSPI/MICROWIRE interface mode. The falling edge of

CS wakes the analog circuitry and allows SCLK to clock

in data (Figure 12). DOUT changes from high-Z to logic

low after CS is brought low. Input data latches on the rising edge of SCLK. The command/configuration/control

register begins reading DIN on the first SCLK rising edge

and ends on the rising edge of the 8th SCLK cycle. The

MAX1167/MAX1168 select the proper channel for conversion on the rising edge of the 3rd SCLK cycle. The

internal oscillator activates 125ns after the rising edge of

the 8th SCLK cycle. Turn off the external clock while the

internal clock is on. Turning off SCLK ensures the lowest

noise performance during acquisition. Acquisition begins

on the 2nd rising edge of the internal clock and ends on

the falling edge of the 6th internal clock cycle. Each bit

of the conversion result shifts into memory as it becomes

available. The conversion result is available (MSB first) at

DOUT on the falling edge of EOC. The internal oscillator

and analog circuitry are shut down on the high-to-low

EOC transition. Use the EOC high-to-low transition as the

signal to restart the external clock (SCLK). To read the

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

18 ______________________________________________________________________________________

Figure 11. SPI External Clock Mode, 16-Bit Data-Transfer Mode, Conversion Timing (MAX1168 Only)

Figure 12. SPI Internal Clock Mode, 8-Bit Data-Transfer Mode, Conversion Timing

CS

SCLK

DIN

DOUT

ADC

STATE

1

MSB

DSPR

DSEL

X = DON,T CARE

LSB

8

0

XX

t

ACQ

X

CS

SCLK

INTERNAL

CLK

DIN

DOUT

1

MSB

8

26 25

LSB

1

16 24 32

XXXXX

MSB

t

CONV

16924

• • •

MSB

LSB

IDLE

LSB

X

EOC

ADC

STATE

X = DON,T CARE

DSPR = DV

DD

, DSEL = GND (MAX1168 ONLY)

t

ACQ

t

CONV

IDLE

POWER-DOWN

Page 19

entire conversion result, 16 SCLK cycles are needed.

Extra clock pulses, occurring after the conversion result

has been clocked out and prior to the rising edge of

CS, cause the conversion result to be shifted out again.

The MAX1167/MAX1168 internal clock 8-bit-wide datatransfer mode requires 24 external clock cycles and 25

internal clock cycles for completion.

Force CS high after the conversion result is read. For

maximum throughput, force CS low again to initiate the

next conversion immediately after the specified minimum time (t

CSW

). Forcing CS high in the middle of a

conversion immediately aborts the conversion and

places the MAX1167/MAX1168 in shutdown.

Scan mode allows multiple channels to be scanned

consecutively or one channel to be scanned eight

times. Scan mode can only be enabled when using the

MAX1167/MAX1168 in the internal clock mode. Enable

scanning by setting bits 4 and 3 in the command/configuration/control register (see Tables 3 and 4). In scan

mode, conversion results are stored in memory until the

completion of the last conversion in the sequence.

Upon completion of the last conversion in the

sequence, EOC transitions from high to low to indicate

the end of the conversion and shuts down the internal

oscillator. Use the EOC high-to-low transition as the signal to restart the external clock (SCLK). DOUT provides

the conversion results in the same order as the channel

conversion process. The MSB of the first conversion is

available at DOUT on the falling edge of EOC (Figure 14).

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 19

Figure 13. SPI Internal Clock Mode,16-Bit Data-Transfer Mode, Conversion Timing (MAX1168 Only)

Figure 14. SPI Internal Clock Mode, 8-Bit Data-Transfer Mode, Scan Mode for Two Conversions, Conversion Timing

CS

1

SCLK

INTERNAL

CLK

DIN

DOUT

EOC

ADC

STATE

X = DON,T CARE

DSPR = DSEL = DV

CS

1

SCLK

INTERNAL

CLK

MSB

DIN

DOUT

89 16

• • • • • •

DATA

X X X X X X X X

CONFIGURATION

DD

21332

t

ACQ

8

2

LSB

1

• • •• • •

t

CONV

6

24

• • • • • •

MSB

3026

POWER-DOWN

48

2417 32

LSB

X

940

MSB

• • •

LSB

• • •

X

EOC

ADC

STATE

CONFIGURATION

X = DON,T CARE

DSPR = DV

DD

, DSEL = GND (MAX1168 ONLY)

t

ACQ

t

CONV

t

ACQ

t

CONV

POWER-DOWN

Page 20

MAX1167/MAX1168

Internal Clock 16-Bit-Wide Data-Transfer and Scan

Mode (MAX1168 Only)

Force DSPR high and DSEL low for the SPI/QSPI/

MICROWIRE interface mode. The falling edge of CS

wakes the analog circuitry and allows SCLK to clock in

data (Figure 13). DOUT changes from high-Z to logic

low after CS is brought low. Input data latches on the

rising edge of SCLK. The command/configuration/control register begins reading DIN on the first SCLK rising

edge and ends on the rising edge of the 8th SCLK

cycle. The MAX1168 selects the proper channel for

conversion on the rising edge of the 3rd SCLK cycle.

The internal oscillator activates 125ns after the rising

edge of the 16th SCLK cycle. Turn off the external clock

while the internal clock is on. Turning off SCLK ensures

lowest noise performance during acquisition.

Acquisition begins on the 2nd rising edge of the internal clock and ends on the falling edge of the 18th internal clock cycle. Each bit of the conversion result shifts

into memory as it becomes available. The conversion

result is available (MSB first) at DOUT on the falling

edge of EOC. The internal oscillator and analog circuitry

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

20 ______________________________________________________________________________________

Figure 15. SPI Internal Clock Mode, 16-Bit Data-Transfer Mode, Scan Mode for Two Conversions, Conversion Timing (MAX1168 Only)

Figure 16. Detailed DSP-Interface Timing (MAX1168 Only)

SCLK

INTERNAL

CLK

DIN

DOUT

EOC

ADC

STATE

CS

1

• • • • • •

DATA

X = DON,T CARE

89 16

X X X X X X X X

2

t

13

ACQ

32 34

• • • • • •• • • • • •

CONV

45

t

ACQ

t

CONV

17

• • •

64

MSB

• • •

POWER-DOWNt

t

CSW

...

...

t

CSH

...

t

DH

...

DSPR

SCLK

CS

t

DF

t

FSS

t

FSH

t

CSS

t

t

CL

CH

t

CP

DIN

t

DS

48

LSB

X

DOUT

t

t

DV

DO

...

t

TR

Page 21

are shut down on the EOC high-to-low transition. Use

the EOC high-to-low transition as the signal to restart

the external clock (SCLK). To read the entire conversion result, 16 SCLK cycles are needed. Extra clock

pulses, occurring after the conversion result has been

clocked out and prior to the rising edge of CS, cause

the conversion result to be shifted out again. The

MAX1168 internal-clock 16-bit-wide data-transfer mode

requires 32 external clock cycles and 32 internal clock

cycles for completion.

Force CS high after the conversion result is read. For

maximum throughput, force CS low again to initiate the

next conversion immediately after the specified minimum time (t

CSW

). Forcing CS high in the middle of a

conversion immediately aborts the conversion and

places the MAX1168 in shutdown.

Scan mode allows multiple channels to be scanned

consecutively or one channel to be scanned eight

times. Scan mode can only be enabled when using the

MAX1168 in internal clock mode. Enable scanning by

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 21

Figure 17. DSP External Clock Mode, 8-Bit Data-Transfer Mode, Conversion Timing (MAX1168 Only)

Figure 18. DSP External Clock Mode, 16-Bit Data-Transfer Mode, Conversion Timing (MAX1168 Only)

CS

DSPR

t

CONV

16

SCLK

DIN

DOUT

DSPX

ADC

STATE

1

MSB

8

LSB

0

MSB LSB

t

ACQ

CS

DSPR

SCLK

DIN

DOUT

1

MSB

8

LSB

0

XX

X

16 24 32

XXXXX

MSB

24

IDLE

LSB

DSPX

ADC

STATE

X = DON,T CARE

t

ACQ

t

CONV

IDLE

Page 22

MAX1167/MAX1168

setting bits 4 and 3 in the command/configuration/control register (see Tables 3 and 4). In scan mode, conversion results are stored in memory until the completion of

the last conversion in the sequence. Upon completion of

the last conversion in the sequence, EOC transitions

from high to low to indicate the end of the conversion

and shuts down the internal oscillator. Use the EOC

high-to-low transition as the signal to restart the external

clock (SCLK). DOUT provides the conversion results in

the same order as the channel conversion process. The

MSB of the first conversion is available at DOUT on the

falling edge of EOC. Figure 15 shows the timing

diagram for 16-bit-wide data transfer in scan mode.

DSP 8-Bit-Wide Data-Transfer Mode (External Clock

Mode, MAX1168 Only)

Figure 16 shows the DSP-interface timing diagram.

Logic low at DSPR on the falling edge of CS enables

DSP interface mode. After the MAX1168 enters DSP

mode, CS can remain low for the duration of the conversion process and each subsequent conversion. Drive

DSEL low to select the 8-bit data-transfer mode. A sync

pulse from the DSP at DSPR wakes the analog circuitry

and allows SCLK to clock in data (Figure 17). The frame

sync pulse alerts the MAX1168 that incoming data is

about to be sent to DIN. Ensure the duty cycle on SCLK

is between 45% and 55% when operating at 4.8MHz

(the maximum clock frequency). For lower clock frequencies, ensure the minimum high and low times are at

least 93ns. External clock mode conversions with SCLK

rates less than 125kHz can reduce accuracy due to

leakage of the sampling capacitor. The input data

latches on the falling edge of SCLK. The command/

configuration/control register starts reading data in on

the falling edge of the first SCLK cycle immediately following the falling edge of the frame sync pulse and

ends on the falling edge of the 8th SCLK cycle. The

MAX1168 selects the proper channel for conversion on

the falling edge of the 3rd clock cycle and begins

acquisition. Acquisition continues until the rising edge

of the 7th clock cycle. The MAX1168 samples the input

on the rising edge of the 7th clock cycle. On the rising

edge of the 8th clock cycle, the MAX1168 outputs a

frame sync pulse at DSPX. The frame sync pulse alerts

the DSP that the conversion results are about to be output at DOUT (MSB first) starting on the rising edge of

the 9th clock pulse. To read the entire conversion

result, 16 SCLK cycles are needed. Extra clock pulses,

occurring after the conversion result has been clocked

out and prior to the next rising edge of DSPR, cause

zeros to be clocked out of DOUT. The MAX1168 external clock, DSP 8-bit-wide data-transfer mode requires

24 clock cycles to complete.

Begin a new conversion by sending a new frame sync

pulse to DSPR followed by new configuration data.

Send the new DSPR pulse immediately after reading

the conversion result to realize maximum throughput.

Sending a new frame sync pulse in the middle of a conversion immediately aborts the current conversion and

begins a new one. A rising edge on CS in the middle of

a conversion aborts the current conversion and places

the MAX1168 in shutdown.

DSP 16-Bit-Wide Data-Transfer Mode (External

Clock Mode, MAX1168 Only)

Figure 16 shows the DSP-interface timing diagram.

Logic low at DSPR on the falling edge of CS enables

DSP interface mode. After the MAX1168 enters DSP

mode, CS can remain low for the duration of the conversion process and each subsequent conversion. The

acquisition time is extended an extra eight SCLK cycles

in the 16-bit-wide data-transfer mode. Drive DSEL high

to select the 16-bit-wide data-transfer mode. A sync

pulse from the DSP at DSPR wakes the analog circuitry

and allows SCLK to clock in data (Figure 18). The

frame sync pulse also alerts the MAX1168 that incoming data is about to be sent to DIN. Ensure the duty

cycle on SCLK is between 45% and 55% when operating at 4.8MHz (the maximum clock frequency). For

lower clock frequencies, ensure the minimum high and

low times are at least 93ns. External-clock-mode conversions with SCLK rates less than 125kHz can reduce

accuracy due to leakage of the sampling capacitor.

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

22 ______________________________________________________________________________________

Figure 19. Unipolar Transfer Function, Full Scale (FS) = V

REF

,

Zero Scale (ZS) = GND

OUTPUT CODE

FULL-SCALE

1111...111

1111...110

1111...101

0000...011

0000...010

0000...001

0000...000

0

123

INPUT VOLTAGE (LSB)

TRANSITION

FS = V

1 LSB =

FS - 3/2 LSB

REF

V

REF

65,536

FS

Page 23

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 23

The input data latches on the falling edge of SCLK. The

command/configuration/control register starts reading

data in on the falling edge of the first SCLK cycle immediately following the falling edge of the frame sync pulse

and ends on the falling edge of the 16th SCLK cycle. The

MAX1168 selects the proper channel for conversion on

the falling edge of the 3rd clock cycle and begins acquisition. Acquisition continues until the rising edge of the

15th clock cycle. The MAX1168 samples the input on the

rising edge of the 15th clock cycle. On the rising edge of

the 16th clock cycle, the MAX1168 outputs a frame sync

pulse at DSPX. The frame sync pulse alerts the DSP that

the conversion results are about to be output at DOUT

(MSB first) starting on the rising edge of the 17th clock

pulse. To read the entire conversion result, 16 SCLK

cycles are needed. Extra clock pulses, occurring after the

conversion result has been clocked out and prior to the

next rising edge of DSPR, cause zeros to be clocked out

of DOUT. The MAX1168 external clock, DSP 16-bit-wide

data-transfer mode requires 32 clock cycles to complete.

Begin a new conversion by sending a new frame sync

pulse to DSPR followed by new configuration data.

Send the new DSPR pulse immediately after reading

the conversion result to realize maximum throughput.

Sending a new frame sync pulse in the middle of a conversion immediately aborts the current conversion and

begins a new one. A rising edge on CS in the middle of

a conversion aborts the current conversion and places

the MAX1168 in shutdown.

Output Coding and Transfer Function

The data output from the MAX1167/MAX1168 is straight

binary. Figure 19 shows the nominal transfer function.

Code transitions occur halfway between successive

integer LSB values (V

REF

= +4.096V, and 1 LSB =

+62.5µV or 4.096V / 65,536V).

Figure 20a. SPI Connections

Figure 20b. MICROWIRE Connections

Figure 20c. SPI/MICROWIRE Interface Timing Sequence (CPOL = CPHA = 0)

I/O

SCK

MISO

SPI

SS

SCLK

CS

DOUT*

*WHEN CS IS HIGH, DOUT = HIGH-Z

V

DD

1ST BYTE READ

CS

SCLK

DOUT

MAX1167

MAX1168

641

8

00000000

3RD BYTE READ

I/O

SK

MICROWIRE

D15 D14 D13 D12 D11 D10 D9 D8 D7

MSB

D1 D0D7 D6 D5 D4 D3 D2

SI

2ND BYTE READ

2420

HIGH-Z

LSB

CS

SCLK

DOUT

MAX1167

MAX1168

1612

Page 24

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

24 ______________________________________________________________________________________

Applications Information

Internal Reference

The internal bandgap reference provides a buffered

+4.096V. Bypass REFCAP with a 0.1µF capacitor to

AGND and REF with a 1µF capacitor to AGND. For best

results, use low-ESR, X5R/X7R ceramic capacitors.

Allow 5ms for the reference and buffer to wake up from

full power-down (see Table 5).

External Reference

The MAX1167/MAX1168 accept an external reference

with a voltage range between +3.8V and AVDD. Connect

the external reference directly to REF. Bypass REF to

AGND with a 10µF capacitor. When not using a low-ESR

bypass capacitor, use a 0.1µF ceramic capacitor in parallel with the 10µF capacitor. Noise on the reference

degrades conversion accuracy.

The input impedance at REF is 37kΩ for DC currents.

During a conversion, the external reference at REF

must deliver 118µA of DC load current and have an output impedance of 10Ω or less.

For optimal performance, buffer the reference through

an op amp and bypass the REF input. Consider the

equivalent input noise (40µV

RMS

) of the MAX1167/

MAX1168 when choosing a reference.

Internal/External Oscillator

Select either an external (0.1MHz to 4.8MHz) or the

internal 4MHz (typ) clock to perform conversions

(Table 6). The external clock shifts data in and out of

the MAX1167/MAX1168 in either clock mode.

When using the internal clock mode, the internal oscillator controls the acquisition and conversion processes,

while the external oscillator shifts data in and out of the

MAX1167/MAX1168. Turn off the external clock (SCLK)

when the internal clock is on to realize lowest noise performance. The internal clock remains off in external

clock mode.

Input Buffer

Most applications require an input-buffer amplifier to

achieve 16-bit accuracy. The input amplifier must have

a slew rate of at least 2V/µs and a unity-gain bandwidth

of at least 10MHz to complete the required output-voltage change before the end of the acquisition time.

At the beginning of the acquisition, the internal sampling capacitor array connects to AIN_ (the amplifier

input), causing some disturbance on the output of the

buffer. Ensure the sampled voltage has settled before

the end of the acquisition time.

Table 7. Detailed SSPCON Register Contents

X = Don’t care.

Figure 21a. QSPI Connections

CONTROL BIT SETTINGS SYNCHRONOUS SERIAL-PORT CONTROL REGISTER (SSPCON)

WCOL BIT7 X Write Collision Detection Bit

SSPOV BIT6 X Receive Overflow Detection Bit

Synchronous Serial-Port Enable Bit:

SSPEN BIT5 1

CKP BIT4 0 Clock Polarity Select Bit. CKP = 0 for SPI master-mode selection.

SSPM3 BIT3 0

SSPM2 BIT2 0

SSPM1 BIT1 0

SSPM0 BIT0 1

0: Disables serial port and configures these pins as I/O port pins.

1: Enables serial port and configures SCK, SDO, and SCI pins as serial

port pins.

Synchronous Serial-Port Mode Select Bit. Sets SPI master mode and

selects f

CLK

= f

OSC

/ 16.

CS

SCK

MISO

QSPI

SS

CS

SCLK

DOUT

V

DD

MAX1167

MAX1168

Page 25

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 25

Digital Noise

Digital noise can couple to AIN_ and REF. The conversion

clock (SCLK) and other digital signals active during input

acquisition contribute noise to the conversion result.

Noise signals, synchronous with the sampling interval,

result in an effective input offset. Asynchronous signals

produce random noise on the input, whose high-frequency components can be aliased into the frequency band

of interest. Minimize noise by presenting a low impedance (at the frequencies contained in the noise signal) at

the inputs. This requires bypassing AIN_ to AGND, or

buffering the input with an amplifier that has a small-signal bandwidth of several megahertz (doing both is preferable). AIN has a typical bandwidth of 4MHz.

Distortion

Avoid degrading dynamic performance by choosing an

amplifier with distortion much less than the total harmonic distortion of the MAX1167/MAX1168 at the frequencies of interest (THD = -100dB at 1kHz). If the

chosen amplifier has insufficient common-mode rejection, which results in degraded THD performance, use

the inverting configuration (positive input grounded) to

eliminate errors from this source. Low-temperaturecoefficient, gain-setting resistors reduce linearity errors

caused by resistance changes due to self-heating. To

reduce linearity errors due to finite amplifier gain, use

amplifier circuits with sufficient loop gain at the frequencies of interest.

DC Accuracy

To improve DC accuracy, choose a buffer with an offset

much less than the MAX1167/MAX1168s’ offset (±10mV

max for +5V supply), or whose offset can be trimmed

while maintaining stability over the required temperature

range.

Figure 21b. QSPI Interface Timing Sequence (External Clock, 8-Bit Data Transfer, CPOL = CPHA = 0)

Table 8. Detailed SSPSTAT Register Contents

X = Don’t care.

Figure 22a. SPI-Interface Connection for a PIC16/PIC17

CONTROL BIT SETTINGS SYNCHRONOUS SERIAL-PORT STATUS REGISTER (SSPSTAT)

SMP BIT7 0

CKE BIT6 1

D/A BIT5 X Data Address Bit

P BIT4 X Stop Bit

S BIT3 X Start Bit

R/W BIT2 X Read/Write Bit Information

UA BIT1 X Update Address

BF BIT0 X Buffer-Full Status Bit

SCLK

CS

DOUT*

*WHEN CS IS HIGH, DOUT = HIGH-Z

SAMPLING INSTANT

SPI Data-Input Sample Phase. Input data is sampled at the middle of

the data output time.

SPI Clock Edge-Select Bit. Data is transmitted on the rising edge of the

serial clock.

1214 86

D15 D14 D13 D12 D11 D10 D9

MSB

D8 D5 D4 D3

D7 D6

D1 D0

LSB

24

HIGH-Z

2016

D2

SCK

SDI

I/O

V

DD

PIC16/17

V

DD

SCLK

DOUT

CS

MAX1167

MAX1168

GND

Page 26

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

26 ______________________________________________________________________________________

Figure 22b. SPI Interface Timing with PIC16/PIC17 in Master Mode (CKE = 1, CKP = 0, SMP = 0, SSPM3 - SSPM0 = 0001)

Serial Interfaces

SPI and MICROWIRE Interfaces

When using the SPI (Figure 20a) or MICROWIRE (Figure

20b) interfaces, set CPOL = 0 and CPHA = 0. Drive CS

low to power on the MAX1167/MAX1168 before starting a

conversion (Figure 20c). Three consecutive 8-bit-wide

readings are necessary to obtain the entire 16-bit result

from the ADC. DOUT data transitions on the serial clock’s

falling edge. The first 8-bit-wide data stream contains all

leading zeros. The 2nd 8-bit-wide data stream contains

the MSB through D6. The 3rd 8-bit-wide data stream contains D5 through D0 followed by S1 and S0.

QSPI Interface

Using the high-speed QSPI interface with CPOL = 0 and

CPHA = 0, the MAX1167/MAX1168 support a maximum

f

SCLK

of 4.8MHz. Figure 21a shows the MAX1167/

MAX1168 connected to a QSPI master, and Figure 21b

shows the associated interface timing.

PIC16 with SSP Module and PIC17

Interface

The MAX1167/MAX1168 are compatible with a

PIC16/PIC17 controller (µC), using the synchronous serial-port (SSP) module.

To establish SPI communication, connect the controller

as shown in Figure 22a and configure the PIC16/PIC17

as system master by initializing its synchronous serialport control register (SSPCON) and synchronous serialport status register (SSPSTAT) to the bit patterns shown

in Tables 7 and 8.

In SPI mode, the PIC16/PIC17 µCs allow 8 bits of data to

be synchronously transmitted and received simultaneously. Three consecutive 8-bit-wide readings (Figure

22b) are necessary to obtain the entire 16-bit result from

the ADC. DOUT data transitions on the serial clock’s

falling edge and is clocked into the µC on SCLK’s rising

edge. The first 8-bit-wide data stream contains all zeros.

The 2nd 8-bit-wide data stream contains the MSB

through D6. The 3rd 8-bit-wide data stream contains bits

D5 through D0 followed by S1 and S0.

Figure 23. DSP Interface Connection

1ST BYTE READ

SCLK

CS

DOUT*

*WHEN CS IS HIGH, DOUT = HIGH-Z

00000000

3RD BYTE READ

20

EXTERNAL

CLOCK

D14 D13 D12 D11 D10 D9 D8

D15

MSB

24

D1 D0D7 D6 D5 D4 D3 D2

LSB

2ND BYTE READ

HIGH-Z

DSP

SCLK

RFS

TFS

DT

DR

FL1

SCLK

DSPR

DSPX

DIN

DOUT

CS

MAX1168

16128641

Page 27

MAX1167/MAX1168

Multichannel, 16-Bit, 200ksps Analog-to-Digital

Converters

______________________________________________________________________________________ 27

DSP Interface