Page 1

General Description

The MAX11008 controller biases RF LDMOS power

devices found in cellular base stations and other wireless infrastructure equipment. Each controller includes

a high-side current-sense amplifier with programmable

gains of 2, 10, and 25 to monitor the LDMOS drain current over a range of 20mA to 5A. The MAX11008 supports up to two external diode-connected transistors to

monitor the LDMOS temperatures while an internal temperature sensor measures the local die temperature. A

12-bit successive-approximation register (SAR) analogto-digital converter (ADC) converts the analog signals

from the programmable-gain amplifiers (PGAs), external temperature sensors, internal temperature measurement, and two additional auxiliary inputs. The

MAX11008 automatically adjusts the LDMOS bias voltages by applying temperature, AIN, and/or drain current samples to data stored in lookup tables (LUTs).

The MAX11008 includes two gate-drive channels, each

consisting of a 12-bit DAC to generate the positive gate

voltage for biasing the LDMOS devices. Each gatedrive output supplies up to ±2mA of gate current. The

gate-drive amplifier is current-limited to ±25mA and

features a fast clamp to AGND.

The MAX11008 contains 4Kb of on-chip, nonvolatile

EEPROM organized as 256 bits x 16 bits to store LUTs

and register information. The device operates from

either a 4-wire 16MHz SPI™-/MICROWIRE™-compatible or an I2C-compatible serial interface.

The MAX11008 operates from a +4.75V to +5.25V analog supply with a typical supply current of 2mA, and a

+2.7V to +5.25V digital supply with a typical supply of

3mA. The device is packaged in a 48-pin, 7mm x 7mm,

thin QFN package and operates over the extended

(-40°C to +85°C) temperature range.

Applications

Cellular Base Stations

Microwave Radio Links

Feed-Forward Power Amps

Transmitters

Industrial Process Control

Features

♦ On-Chip 4Kb EEPROM for Storing LDMOS Bias

Characteristics

♦ Integrated High-Side Current-Sense PGA with

Gain of 2, 10, or 25

♦ ±0.75% Accuracy for Sense Voltage Between

+75mV and +1250mV

♦ Full-Scale Sense Voltage

+100mV with a Gain of 25

+250mV with a Gain of 10

+1250mV with a Gain of 2

♦ Common-Mode Range, LDMOS Drain Voltage:

+5V to +32V

♦ Adjustable Low-Noise 0 to AV

DD

Output Gate

Bias Voltage Range

♦ Fast Clamp to AGND for LDMOS Protection

♦ 12-Bit DAC Control of Gate with Temperature

♦ Internal Die Temperature Measurement

♦ 2-Channel External Temperature Measurement

through Remote Diodes

♦ Internal 12-Bit ADC Measurement for

Temperature, Current, and Voltage Monitoring

♦ User-Selectable Serial Interface

400kHz/1.7MHz/3.4MHz I

2

C-Compatible Interface

16MHz SPI-/MICROWIRE-Compatible Interface

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

________________________________________________________________

Maxim Integrated Products

1

19-4371; Rev 0; 11/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

SPI is a trademark of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

Ordering Information

+

Denotes a lead-free/RoHS-compliant package.

*

EP = Exposed pad.

Note: The device is specified over the -40°C to +85°C operating

temperature range.

PART PIN-PACKAGE

MAX11008BETM+ 48 TQFN-EP* ±3

TEMP

ERROR (°C)

Page 2

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

2 _______________________________________________________________________________________

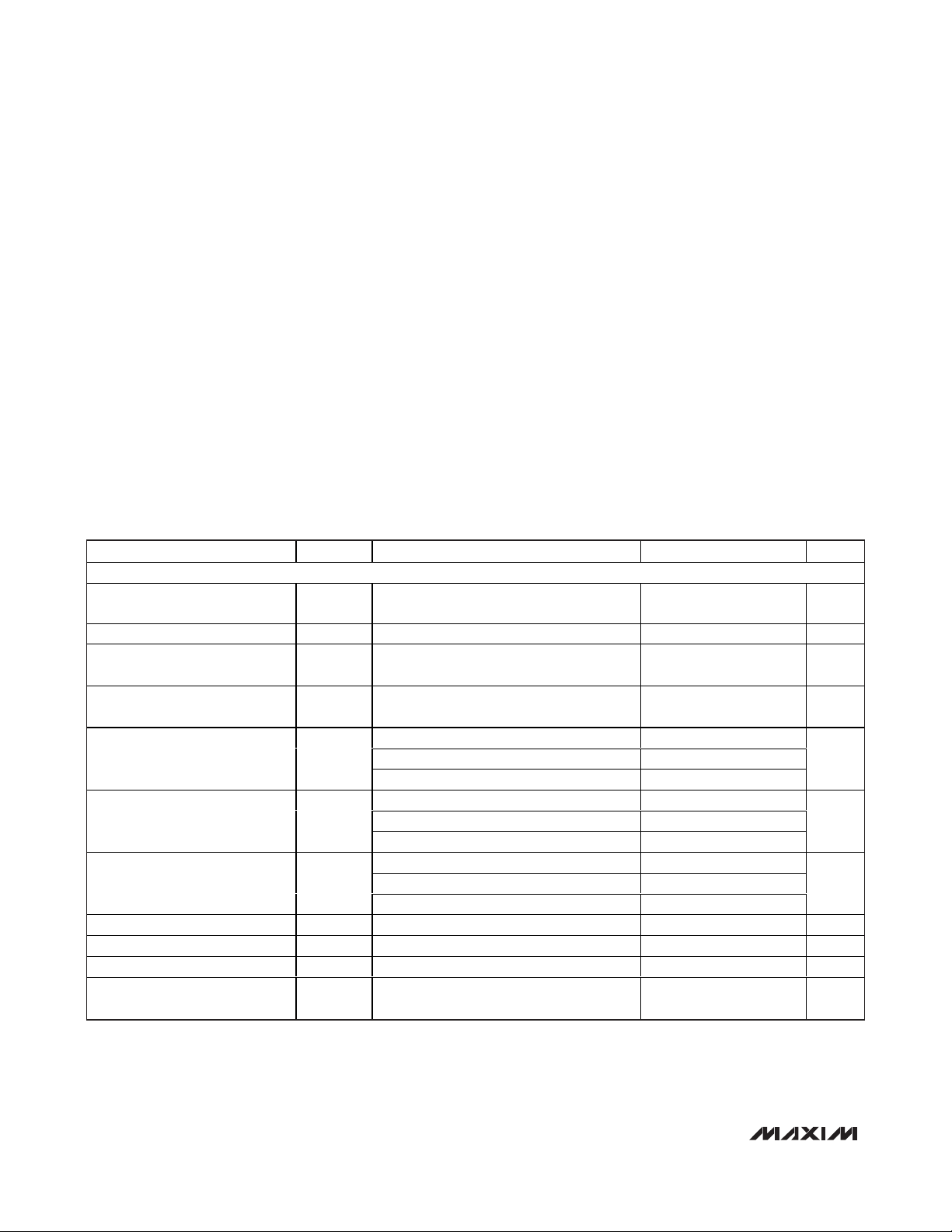

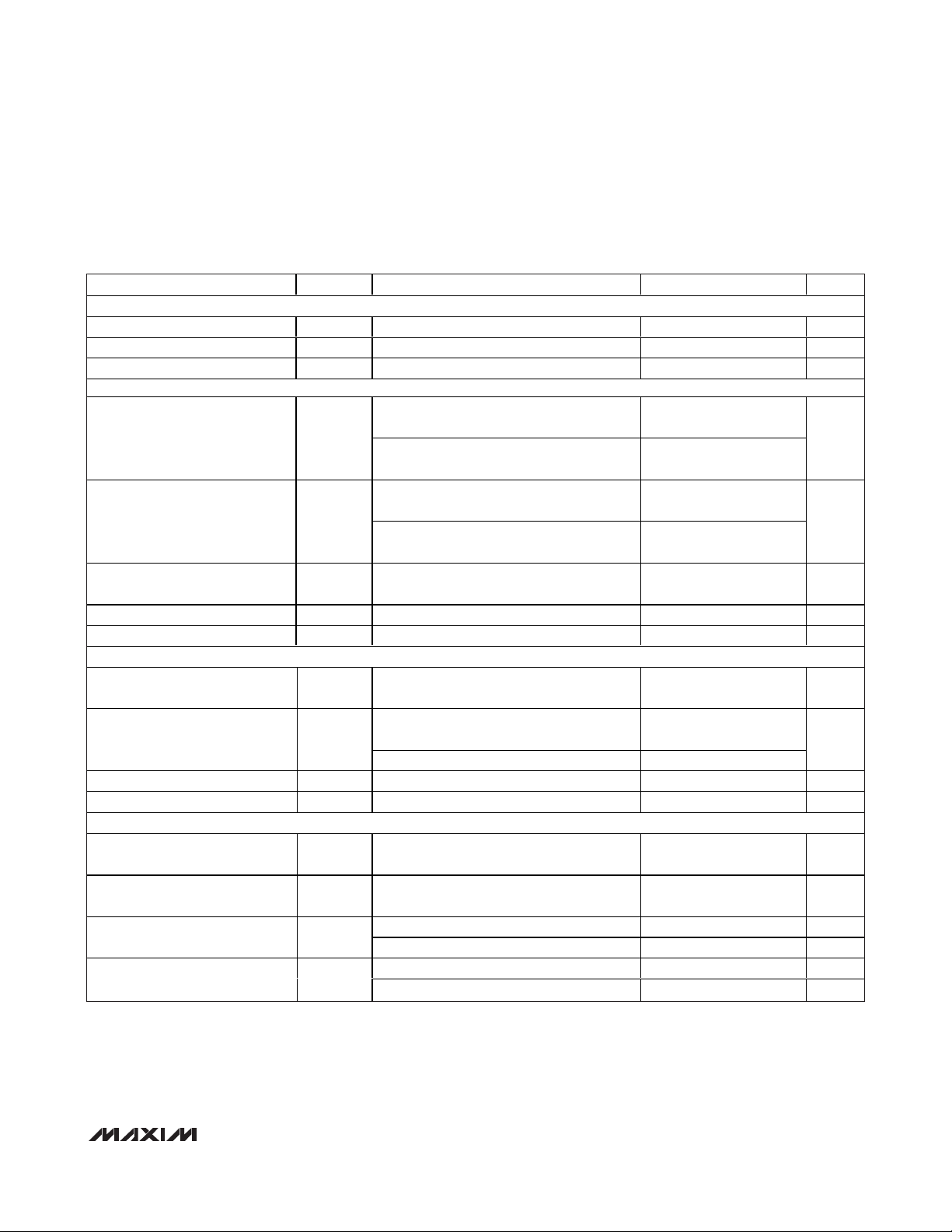

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

CS_+

= +32V, AVDD= DVDD= +5V ±5%, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V, C

REF

= 0.1µF, C

GATE_

= 0.1nF,

V

SENSE

= V

CS_+

- V

CS_-

, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

AVDDto AGND .........................................................-0.3V to +6V

DV

DD

to DGND.........................................................-0.3V to +6V

AGND to DGND.....................................................-0.3V to +0.3V

CS_+, CS_- to AGND .............................................-0.3V to +34V

CS_+ to CS_-

If CS_+ > 6V .........................................................-0.3V to +6V

If CS_+ ≤ 6V .......................................................-0.3V to V

CS_-

Analog Inputs/Outputs to AGND ..................................................

...........................-0.3V to the lower of (AV

DD

+ 0.3V) and +6V

Digital Inputs/Outputs to DGND

(except SDA/DIN and SCL/SCLK)............................................

............................-0.3V to the lower of (DV

DD

+ 0.3V) and +6V

SDA/DIN and SCL/SCLK to DGND ..........................-0.3V to +6V

Continuous Input Current (all terminals)...........................±50mA

Continuous Power Dissipation (T

A

= +70°C)

48-Pin, 7mm x 7mm, TQFN (derate 27.8mW/°C above

+70°C).....................................................................2222.2mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

HIGH-SIDE CURRENT-SENSE PGA

Common-Mode Input Voltage

Range

Common-Mode Rejection Ratio CMRR 5V < V

CS_+ Input Bias Current I

CS_- Input Bias Current I

Minimum Sense Voltage Range

for ±0.75% V

Minimum Sense Voltage Range

for ±2.5% V

Total PGAOUT Voltage Error V

PGAOUT Capacitive Load C

PGAOUT Settling Time t

Saturation Recovery Time

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SENSE

SENSE

V

,

CS1+

V

CS2+

CS_+

CS_-

SENSE

Accuracy

Accuracy

PGAOUT

HSCS

CS_+

< 100mV over the common-mode

V

SENSE

range

< 100mV over the common-mode

V

SENSE

range

Gain = 25 0 100

Gain = 10 0 250Full-Scale Sense Voltage Range V

Gain = 2 0 1250

Gain = 25 75 100

Gain = 10 75 250

Gain = 2 75 1250

Gain = 25 20 100

Gain = 10 20 250

Gain = 2 20 1250

= 75mV ±0.1 ±0.75 %

SENSE

(Note 1) < 25 µs

Settles to within ±0.5% accuracy from

V

= 3 x full scale

SENSE

< 32V 110 dB

532V

135 195 µA

< 45 µs

±1 µA

50 pF

mV

mV

mV

Page 3

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

_______________________________________________________________________________________ 3

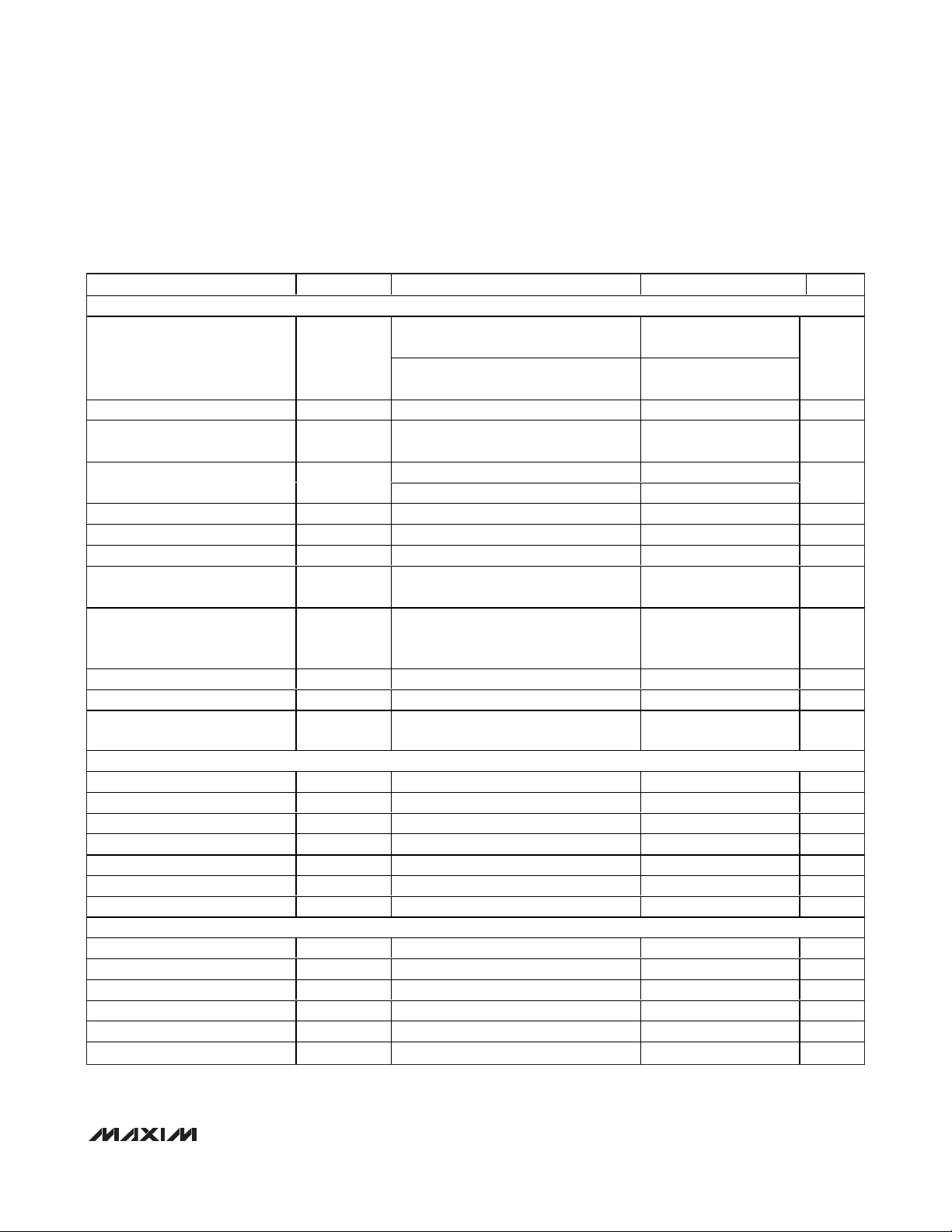

ELECTRICAL CHARACTERISTICS (continued)

(V

CS_+

= +32V, AVDD= DVDD= +5V ±5%, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V, C

REF

= 0.1µF, C

GATE_

= 0.1nF,

V

SENSE

= V

CS_+

- V

CS_-

, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LDMOS GATE DRIVER (Gain = 2)

I

GATE_

Output Gate-Drive Voltage Range V

Output Impedance R

GATE_ Settling Time t

Output Capacitive Load C

GATE_

GATE_

GATE_

GATE_

I

GATE_

Measured at DC 0.1 Ω

R

0.5V to 4.5V (Note 1)

R

R

GATE_ Noise 1kHz to 1MHz 1000 µV

Maximum Power-On Transient ±100 mV

Output Short-Circuit Current Limit I

SC

Total Unadjusted Error TUE

Total Unadjusted Error without

Offset

TUE

NO_OFFSET

1s, sinking or sourcing ±25 mA

Worst case at CODE = 4063, use

external reference (Note 2)

CalCODE = 2457, MaxCODE = 2867,

use external reference, T

(Note 2)

Drift Gain = 2, MaxCODE = 2867 (Note 2) ±15 µV/°C

Clamp to Zero Delay C

Output-Safe Switch OnResistance

R

OPSW

V

MONITOR ADC (DC characteristics)

Resolution N

Differential Nonlinearity DNL

Integral Nonlinearity INL

ADC

ADC

ADC

(Note 5) -2 +2 LSB

Offset Error ±2 ±4 LSB

Gain Error (Note 6) ±2 ±4 LSB

Gain Temperature Coefficient ±0.4 ppm/°C

Offset Temperature Coefficient ±0.4 ppm/°C

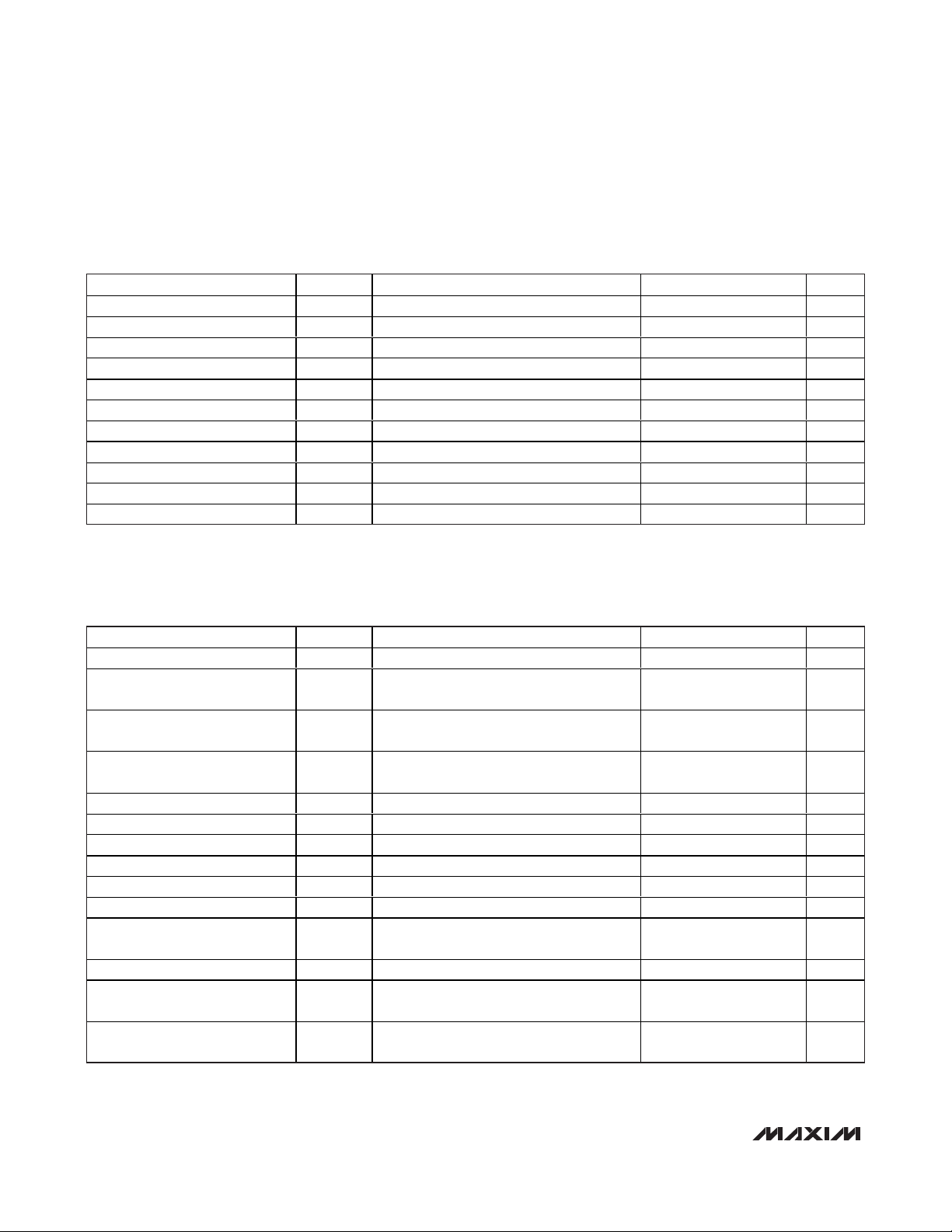

MONITOR ADC DYNAMIC CHARACTERISTICS (1kHz sine-wave input, 2.5V

Signal-to-Noise Plus Distortion SINAD 70 dB

Total Harmonic Distortion THD Up to 5th harmonic -82 dBc

Spurious-Free Dynamic Range SFDR 86 dBc

Intermodulation Distortion IMD f

IN1

Full-Power Bandwidth -3dB 1 MHz

Full-Linear Bandwidth SINAD > 68dB 100 kHz

= ±0.1mA 0.1

= ±2mA 0.75

= 500Ω, C

S

= 0Ω 0 0.5

SERIES

= 500Ω 0 15,000

SERIES

GATE_

= 15µF, V

GATE_

=

AV

AV

45 ms

±7 ±25 mV

= +25°C

A

= 0.5nF (Note 3) 1 µs

GATE_

clamped to AGND (Note 4) 300 Ω

GATE_

12 Bits

, up to 94.4ksps)

P-P

= 0.99kHz, f

= 1.02kHz 76 dBc

IN2

-

DD

0.1

-

DD

0.75

±8 mV

±2 LSB

V

nF

P-P

Page 4

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

4 _______________________________________________________________________________________

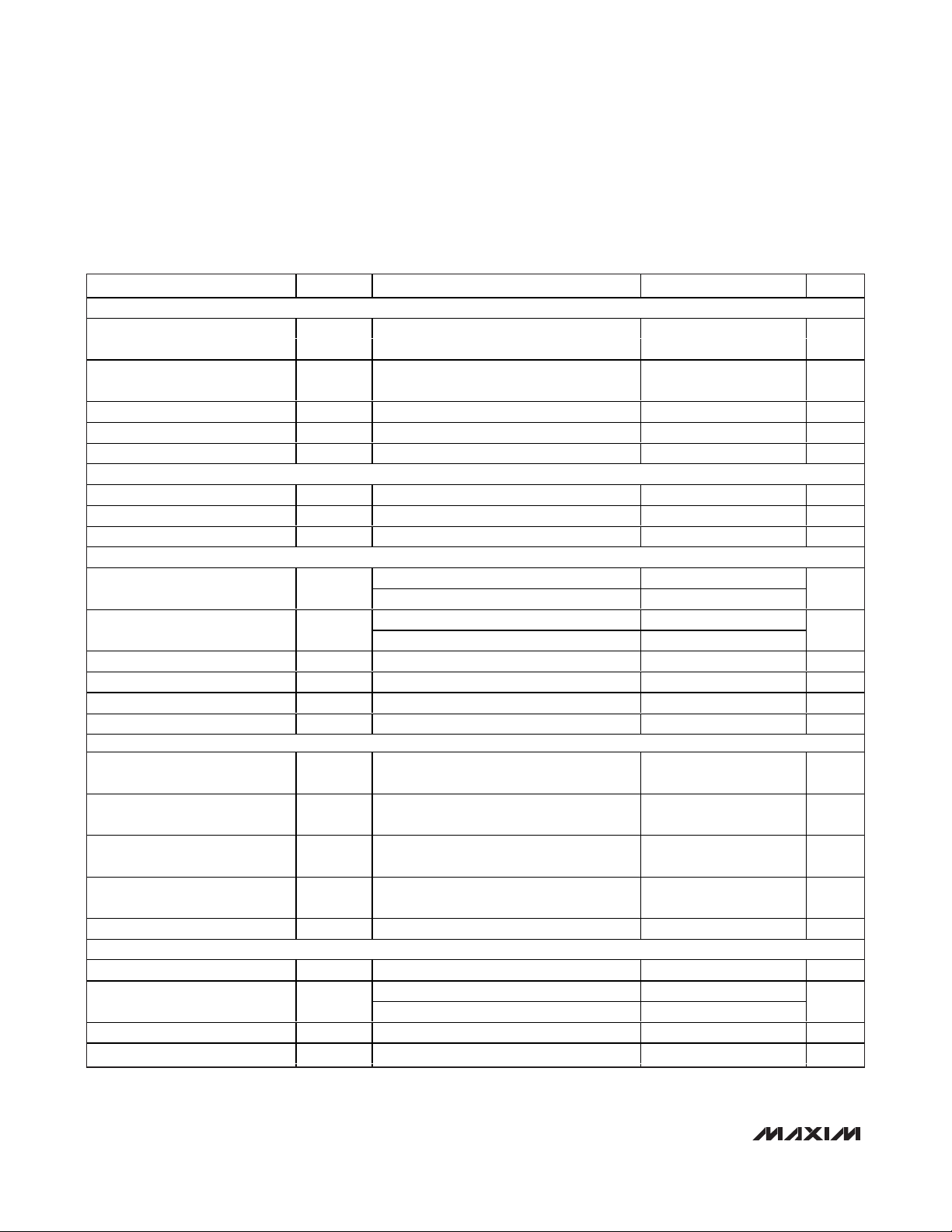

ELECTRICAL CHARACTERISTICS (continued)

(V

CS_+

= +32V, AVDD= DVDD= +5V ±5%, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V, C

REF

= 0.1µF, C

GATE_

= 0.1nF,

V

SENSE

= V

CS_+

- V

CS_-

, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

MONITOR ADC CONVERSION RATE

Power-Up Time (External

Reference)

Power-Up Time (Internal

Reference)

Acquisition Time t

Conversion Time t

Aperture Delay t

t

PUEXT

t

PUINT

ACQ

CONV

AD

Internally clocked, T

MONITOR ADC ANALOG INPUT (ADCIN1, ADCIN2)

Input Voltage Range V

ADCIN

Relative to AGND (Note 7) 0 V

Input Leakage Current VIN = 0 and VIN = V

Input Capacitance C

ADCIN

TEMPERATURE MEASUREMENTS

Internal Sensor Measurement

Error

External Sensor Measurement

Error (Note 9)

TA = +25°C ±0.25

T

= T

A

TA = +25°C ±1

= T

T

A

Relative Temperature Accuracy TA = T

Temperature Resolution 1/8 °C/LSB

E xter nal D i od e D r i ve C ur r ent ( Low ) 3.25 4 µA

E xter nal D i od e D r i ve C ur r ent ( H i g h) 68 75 µA

INTERNAL REFERENCE

REFADC/REFDAC Output

Voltage

REFADC/REFDAC Temperature

Coefficient

V

REFADC

V

REFDAC

TC

REFADC

TC

REFDAC

,

TA = +25°C 2.49 2.50 2.51 V

,

REFADC/REFDAC Output

Impedance

Capacitive Bypass at

REFADC/REFDAC

Power-Supply Rejection Ratio PSRR AVDD = 5V ± 5% 64 dB

EXTERNAL REFERENCE

REFADC Input Voltage Range V

REFADC Input Current I

REFDAC Input Voltage Range V

REFADC

REFADC

REFDAC

V

REFADC

Acquisition/between conversions ±0.01

REFDAC Input Current S tati c cur r ent w hen the D AC i s not cal i b r ated 0.1 µA

to T

MIN

MAX

to T

MIN

MAX

to T

MIN

MAX

= 2.5V, f

1.1 µs

70 µs

0.5 µs

= +25°C 10 µs

A

20 ns

REFADC

AV

DD

±0.01 µA

34 pF

(Note 8) ±1.5 ±3

±3

(Note 9) ±0.4 °C

±15 ppm/°C

6.5 kΩ

270 pF

1.0 AV

= 100ksps 60 80

SAMPLE

0.7 2.5 V

DD

V

°C

°C

V

µA

Page 5

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(V

CS_+

= +32V, AVDD= DVDD= +5V ±5%, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V, C

REF

= 0.1µF, C

GATE_

= 0.1nF,

V

SENSE

= V

CS_+

- V

CS_-

, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

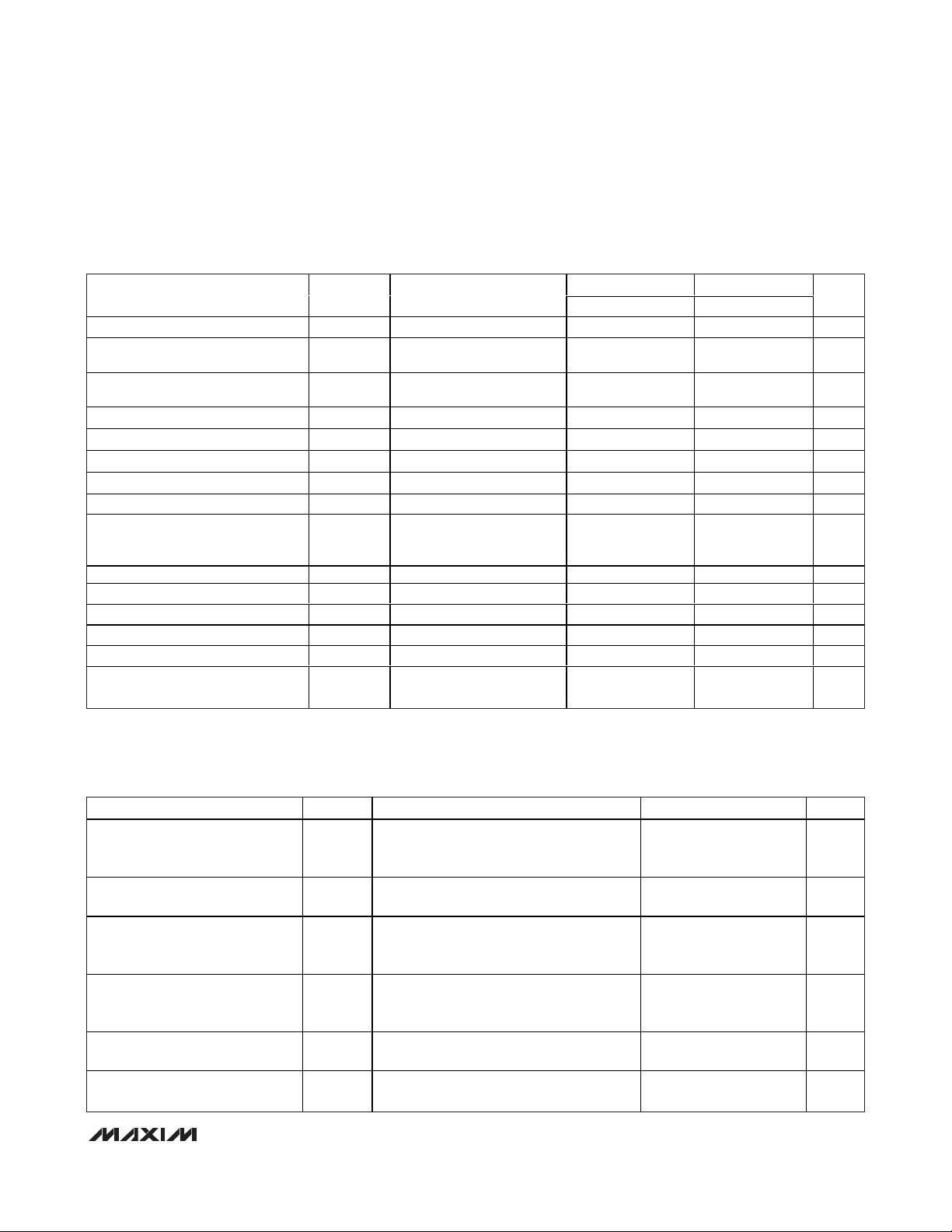

GATE-DRIVER DAC DC ACCURACY

Resolution N

Integral Nonlinearity INL

Differential Nonlinearity DNL

DIGITAL INPUTS (SCL/SCLK, SDA/DIN, A0/CS, A1/DOUT, A2/N.C., CNVST, OPSAFE1, OPSAFE2)

Input High Voltage V

Input Low Voltage V

Input Hysteresis V

Input Leakage Current Digital inputs at 0 or V

Input Capacitance C

DIGITAL OUTPUTS (SDA/DIN, ALARM, BUSY, DOUT)

Output High Voltage V

Output Low Voltage V

Three-State Leakage I

Three-State Capacitance 5pF

POWER SUPPLIES (Note 12)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DAC

DAC

DAC

IH

IL

HYS

IN

OH

OL

IL

Measured at GATE_ ±2 ±4 LSB

Guaranteed monotonic (Note 10) ±1 LSB

SDA/DIN and SCL/SCLK only

A0/CS, A1/DOUT, A2/N.C., CNVST,

OPSAFE1, OPSAFE2 only

SDA/DIN and SCL/SCLK only

A0/CS, A1/DOUT, A2/N.C., CNVST,

OPSAFE1, OPSAFE2 only

SDA/DIN and SCL/SCLK only

ALARM and BUSY only, I

SDA/DIN and A1/DOUT, I

(Note 11)

ALARM and BUSY only, I

Digital inputs at 0 or DV

DVDD

SOURCE

= 3mA,

SINK

= 0.3mA 0.3

SINK

DD

= 0.2mA

0.7 x

DV

2.3

0.08 x

DV

DV

- 0.4V

12 Bits

DD

DD

±0.1 ±1 µA

5pF

DD

±0.1 ±1 µA

0.3 x

DV

0.7

0.4

DD

V

V

V

V

V

Analog Supply Voltage Range AV

Digital Supply Voltage Range DV

Analog Supply Current I

Digital Supply Current I

AVDD

DVDD

DD

DD

AVDD = 5V 2 4 mA

Shutdown (Note 13) 0.4 2 µA

DVDD = 5V 3 6 mA

Shutdown 2 32 µA

4.75 5.25 V

2.7

AV

+ 0.3

DD

V

Page 6

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

6 _______________________________________________________________________________________

SPI TIMING CHARACTERISTICS (Notes 14, 15, Figure 1)

(DVDD= +2.7V to +5.25V, AVDD= +4.75V to +5.25V, V

DGND

= V

AGND

= 0, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V,

C

REF

= 0.1µF, TA= -40°C to +85°C, unless otherwise noted.)

I2C SLOW-/FAST-MODE TIMING CHARACTERISTICS (Notes 14, 15, Figure 4)

(DVDD= +2.7V to +5.25V, AVDD= +4.75V to +5.25V, V

DGND

= V

AGND

= 0, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V,

C

REF

= 0.1µF, TA= -40°C to +85°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCLK Clock Period t

SCLK High Time t

SCLK Low Time t

DIN to SCLK Rise Setup Time t

DIN to SCLK Rise Hold Time t

SCLK Fall to DOUT Transition t

CS Fall to DOUT Enable t

CS Rise to DOUT Disable t

CS Rise or Fall to SCLK Rise t

CS Pulse-Width High t

Last SCLK Rise to CS Rise t

CP

CH

CL

DS

DH

DO

DV

TR

CSS

CSW

CSH

CL = 30pF 20 ns

CL = 30pF 50 ns

CL = 30pF (Note 16) 50 ns

SCL Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated) for START

Condition

Setup Time for a Repeated

START Condition

SCL Pulse-Width Low t

SCL Pulse-Width High t

Data Setup Time t

Data Hold Time t

SDA, SCL Rise Time t

SDA, SCL Fall Time t

SDA Fall Time t

Setup Time for STOP Condition t

Capacitive Load for Each Bus

Line

Pulse Width of Spikes

Suppressed by the Input Filter

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL

t

BUF

t

HD:STA

t

SU:STA

LOW

HIGH

SU:DAT

HD:DAT

SU:STO

C

t

SP

After this period, the first clock pulse is

generated

(Note 17) 0.004 0.9 µs

Receiving (Note 18) 0 300 ns

R

Receiving (Note 18) 0 300 ns

F

Transmitting (Notes 18, 19)

F

(Note 20) 400 pF

B

(Note 21) 50 ns

62.5 ns

25 ns

25 ns

15 ns

0ns

12.5 ns

50 ns

0ns

0 400 kHz

1.3 µs

0.6 µs

0.6 µs

1.3 µs

0.6 µs

100 ns

20 + 0.1

x C

B

0.6 µs

250 ns

Page 7

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

_______________________________________________________________________________________ 7

I2C HIGH-SPEED-MODE TIMING CHARACTERISTICS (Notes 14, 15, Figure 4)

(DVDD= +2.7V to +5.25V, AVDD= +4.75V to +5.25V, V

DGND

= V

AGND

= 0, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V,

C

REF

= 0.1µF, TA= -40°C to +85°C, unless otherwise noted.)

MISCELLANEOUS TIMING CHARACTERISTICS (Note 15)

(DVDD= +2.7V to +5.25V, AVDD= +4.75V to +5.25V, V

DGND

= V

AGND

= 0, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V,

C

REF

= 0.1µF, TA= -40°C to +85°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS

Serial Clock Frequency f

Setup Time (Repeated) START

Condition

Hold Time (Repeated) START

Condition

SCL Pulse-Width Low t

SCL Pulse-Width High t

Data Setup Time t

Data Hold Time t

SCL Rise Time t

SCL Rise Time t

SCL Fall Time t

SDA Rise Time t

SDA Fall Time t

Setup Time for STOP Condition t

Capacitive Load for Each Bus Line C

Pulse Width of Spikes Suppressed

by the Input Filter

SCL

t

SU:STA

t

HD:STA

LOW

HIGH

SU:DAT

HD:DAT

RCL

RCL1

FCL

RDA

FDA

SU:STO

B

t

SP

(Note 17) 4 70 4 150 ns

After a repeated START

condition and after an

acknowledge bit

(Note 20) 100 400 ns

(Note 21) 0 10 0 10 ns

CB = 100pF max CB = 400pF

MIN MAX MIN MAX

0 3.4 0 1.7 MHz

160 160 ns

160 160 ns

160 320 ns

80 120 ns

10 10 ns

10 40 20 80 ns

10 80 20 160 ns

10 40 20 80 ns

10 80 20 160 ns

10 80 20 160 ns

160 160 ns

UNITS

Minimum Time to Wait After a Write

Command Before Reading Back

Data from the Same Location

CNVST Active-Low Pulse Width in

ADC Clock Mode 01

CNVST Active-Low Pulse Width in

ADC Clock Mode 11 to Initiate a

Temperature Conversion

CNVST Active-Low Pulse Width in

ADC Clock Mode 11 for ADCIN1/2

Acquisition

ADC Power-Up Time (External

Reference)

ADC Power-Up Time (Internal

Reference)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

t

RDBK

t

CNV01

t

CNV11

t

ACQ11A

t

APUEXT

t

APUINT

(Note 22) 1 µs

20 ns

20 ns

1.5 µs

1.1 µs

70 µs

Page 8

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

8 _______________________________________________________________________________________

MISCELLANEOUS TIMING CHARACTERISTICS (Note 15) (continued)

(DVDD= +2.7V to +5.25V, AVDD= +4.75V to +5.25V, V

DGND

= V

AGND

= 0, external V

REFADC

= +2.5V, external V

REFDAC

= +2.5V,

C

REF

= 0.1µF, TA= -40°C to +85°C, unless otherwise noted.)

Note 1: Output settles to within ±0.5% of final value.

Note 2: Total unadjusted errors are for the entire gate-drive channel including the 12-bit DAC, and the gate driver is measured at

the GATE1 and GATE2 outputs.

Note 3: V

GATE_

= VDD- 0.1. Measured from when OPSAFE1 or OPSAFE2 is set high.

Note 4: During power-on-reset, the output safe switch is closed. The output safe switch is opened under user software control.

Note 5: Guaranteed to be 11 bits linearly accurate.

Note 6: Offset nulled.

Note 7: The absolute range for analog inputs is from 0 to V

AVDD

.

Note 8: Internal temperature-sensor performance is guaranteed by design.

Note 9: The MAX11008 and the external sensor are at the same ambient temperature. External sensor measurement error is tested

with a diode-connected 2N3904.

Note 10: Guaranteed monotonicity. Accuracy is degraded at lower V

REFDAC

.

Note 11: SDA/DIN is an open-drain output only when in I

2

C mode. A1/DOUT is an open-drain output only when in SPI mode.

Note 12: Supply-current limits are valid only when digital inputs are set to DGND or supply voltage. Timing specifications are only

guaranteed when inputs are driven rail-to-rail.

Note 13: Shutdown supply currents are typically 0.4µA for AV

DD

; maximum specification is limited by automated test equipment.

Note 14: All times are referred to the 50% point between V

IH

and VILlevels.

Note 15: Guaranteed by design. Not production tested.

Note 16: DOUT will go into three-state mode after the CS rising edge. Keep CS low long enough for the DOUT value to be sampled

before it goes to three-state.

Note 17: A master device must provide a hold time of at least 300ns for the SDA signal (referred to V

IL

of the SCL signal) to bridge

the undefined region of SCL’s falling edge.

Note 18: t

R

and tFmeasured between 0.3 x DVDDand 0.7 x DVDD.

Note 19: C

B

= total capacitance of one bus line in pF. For bus loads between 100pF and 400pF, the timing parameters should be

linearly interpolated.

Note 20: An appropriate bus pullup resistance must be selected depending on board capacitance.

Note 21: Input filters on the SDA and SCL inputs suppress noise spikes less than 50ns.

Note 22: When a command is written to the serial interface, the command is passed by the internal oscillator clock and executed.

There is a small synchronization delay before the new value is written to the appropriate register. If the serial interface

attempts to read the new value back before t

RDBK

, the new data is not corrupted; however, the result of the read command

may not reflect the new value.

Note 23: This is the minimum time from the end of a command before CNVST should be asserted. The time allows for the data from

the preceding write to arrive and set up the chip in preparation for the CNVST. The time need only be observed when the

write affects the ADC controls. Failure to observe this time may lead to incorrect conversions (for example, conversion of

the wrong ADC channel).

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DAC Power-Up Time (External

Reference)

DAC Power-Up Time (Internal

Reference)

Acquisition Time (Internally Timed

in ADC Clock Modes 00 or 01)

Conversion Time (Internally

Clocked)

Delay to Start of Conversion Time t

Temperature Conversion Time

(Internally Clocked)

t

DPUEXT

t

DPUINT

t

ACQ

t

CONV

CONVW

t

CONVT

Internally clocked, TA = +25°C 10 µs

(Note 23) 1.3 µs

2µs

70 µs

70 µs

0.6 µs

Page 9

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

_______________________________________________________________________________________ 9

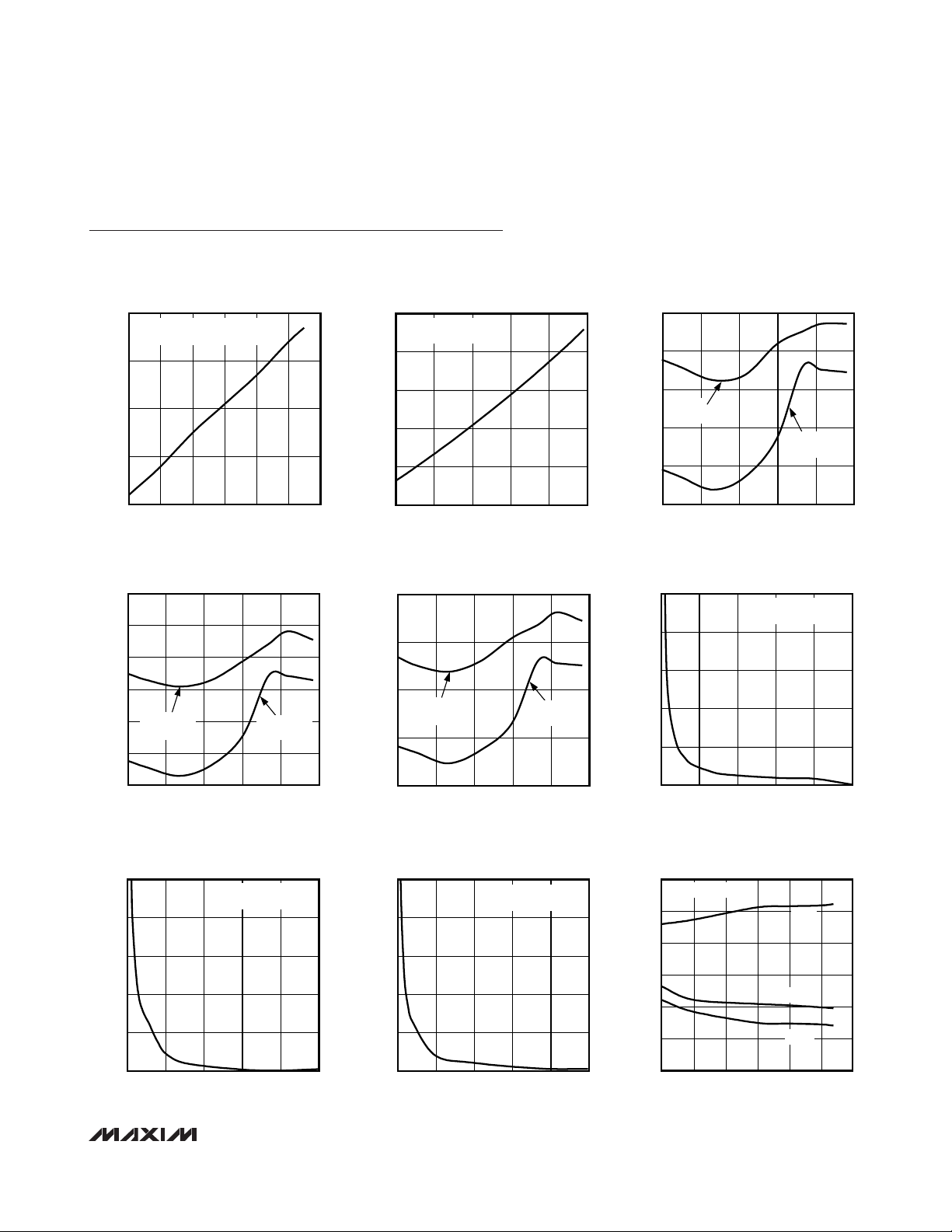

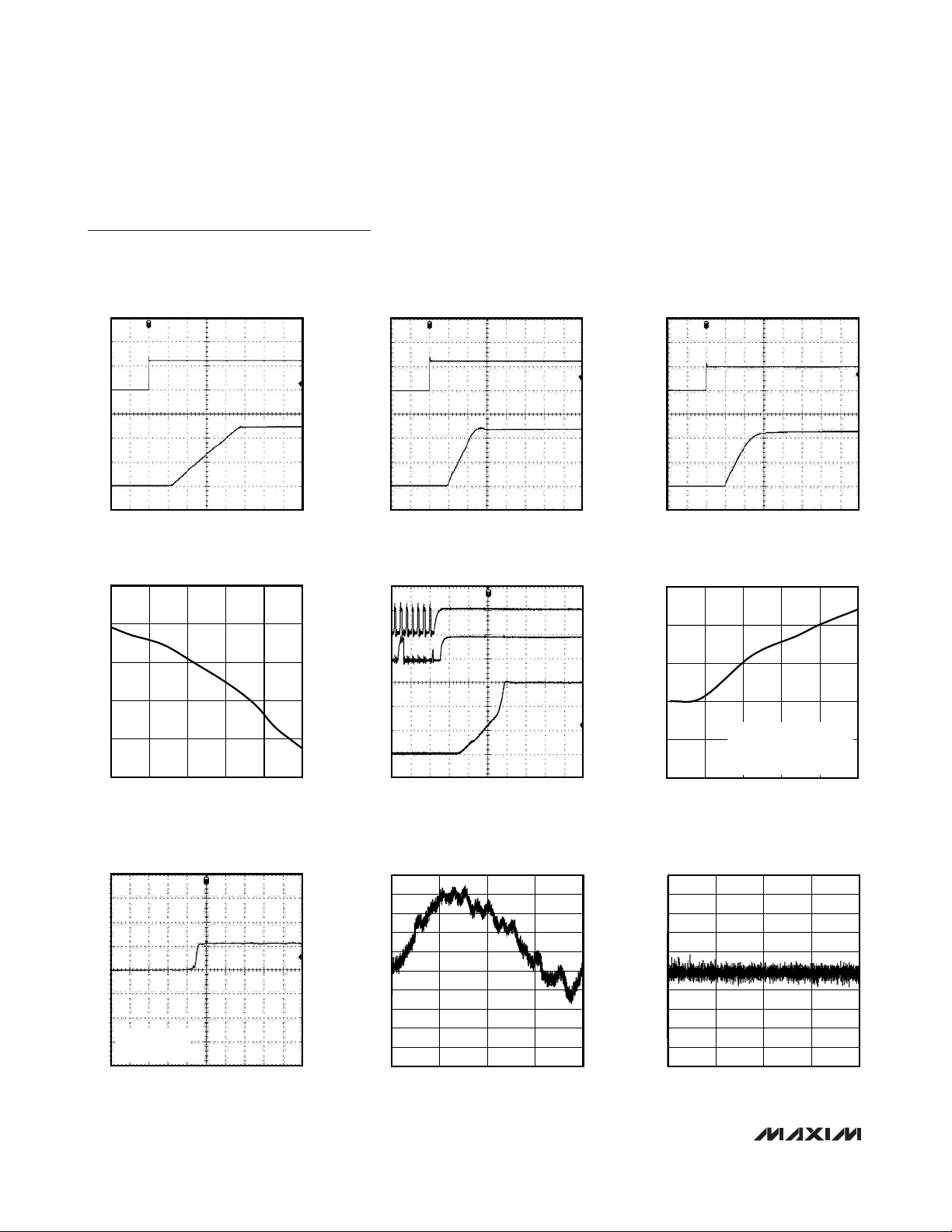

Typical Operating Characteristics

(AVDD= DVDD= 5V, external V

REFADC

= 2.5V, external V

REFDAC

= 2.5V, V

CS_-

= V

CS_+

= 32V, C

REF

= 0.1µF, TA= +25°C, unless oth-

erwise noted.)

2.06

2.07

2.08

2.09

2.10

4.7 4.94.8 5.0 5.1 5.2 5.3

ANALOG SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX11008 toc01

AVDD (V)

I

AVDD

(mA)

DVDD = 5V

INT REF AND DACS TURNED ON

1.0

1.5

2.5

2.0

3.0

3.5

2.70 3.743.22 4.26 4.78 5.30

DIGITAL SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX11008 toc02

DVDD (V)

I

DVDD

(mA)

AVDD = 5V

WD OSC TURNED ON

-0.8

-0.6

-0.2

-0.4

0

0.2

-40 20-10 50 80 110

CURRENT-SENSE AMPLIFIER OUTPUT

ERROR vs. TEMPERATURE (G = 2)

MAX11008 toc03

TEMPERATURE (°C)

PGAOUT_ ERROR (%)

AFTER

CALIBRATION

BEFORE

CALIBRATION

-0.8

-0.4

-0.6

0

-0.2

0.2

0.4

-40 20-10 50 80 110

CURRENT-SENSE AMPLIFIER OUTPUT

ERROR vs. TEMPERATURE (G = 10)

MAX11008 toc04

TEMPERATURE (°C)

PGAOUT_ ERROR (%)

AFTER

CALIBRATION

BEFORE

CALIBRATION

CURRENT-SENSE AMPLIFIER OUTPUT

ERROR vs. TEMPERATURE (G = 25)

MAX11008 toc05

TEMPERATURE (°C)

PGAOUT_ ERROR (%)

805020-10

-0.6

-0.3

0

0.3

-0.9

-40 110

AFTER

CALIBRATION

BEFORE

CALIBRATION

0

0.2

0.6

0.4

0.8

1.0

0500250 750 1000 1250

CURRENT-SENSE AMPLIFIER OUTPUT

ERROR vs. SENSE VOLTAGE (G = 2)

MAX11008 toc06

V

SENSE

(mV)

OUTPUT ERROR (%)

OUTPUT AT PGAOUT_

CMV = 32V

0

0.2

0.6

0.4

0.8

1.0

0 10050 150 200 250

CURRENT-SENSE AMPLIFIER OUTPUT

ERROR vs. SENSE VOLTAGE (G = 10)

MAX11008 toc07

V

SENSE

(mV)

OUTPUT ERROR (%)

OUTPUT AT PGAOUT_

CMV = 32V

0

1

3

2

4

5

04020 60 80 100

CURRENT-SENSE AMPLIFIER OUTPUT

ERROR vs. SENSE VOLTAGE (G = 25)

MAX11008 toc08

V

SENSE

(mV)

OUTPUT ERROR (%)

OUTPUT AT PGAOUT_

CMV = 32V

0

0.10

0.05

0.20

0.15

0.25

0.30

5152010 25 30 35

CURRENT-SENSE AMPLIFIER

OUTPUT ERROR vs. CMV

MAX11008 toc09

COMMON-MODE VOLTAGE (V)

OUTPUT ERROR (%)

V

SENSE

= 75mV

G = 2

G = 25

G = 10

Page 10

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(AVDD= DVDD= 5V, external V

REFADC

= 2.5V, external V

REFDAC

= 2.5V, V

CS_-

= V

CS_+

= 32V, C

REF

= 0.1µF, TA= +25°C, unless oth-

erwise noted.)

2µs/div

CURRENT-SENSE TRANSIENT

RESPONSE (G = 2)

V

SENSE1

1V/div

V

PGAOUT1

1V/div

MAX11008 toc10

0V

0V

1µs/div

CURRENT-SENSE TRANSIENT

RESPONSE (G = 10)

V

SENSE1

200mV/div

V

PGAOUT1

1V/div

MAX11008 toc11

0V

0V

1µs/div

CURRENT-SENSE TRANSIENT

RESPONSE (G = 25)

V

SENSE1

100mV/div

V

PGAOUT1

1V/div

MAX11008 toc12

0V

0V

-4.50

-4.35

-4.05

-4.20

-3.90

-3.75

-40 18-11 47 76 105

GATE VOLTAGE TOTAL UNADJUSTED

ERROR vs. TEMPERATURE

MAX11008 toc13

TEMPERATURE (°C)

V

GATE_

ERROR (mV)

1µs/div

GATE POWER-UP TIME

V

SCL

5V/div

V

SDA

5V/div

V

GATE1

1V/div

MAX11008 toc14

0V

0

0.5

1.5

1.0

2.0

2.5

0200100 300 400 500

GATE_ SETTLING TIME vs. C

GATE

MAX11008 toc16

C

GATE_

(pF)

GATE_ SETTLING TIME (µs)

RS = 500Ω

50% OF SDA STOP EDGE TO

0.5% OF FINAL V

GATE_

4V TRANS ON GATE_ (IODAC_)

10µs/div

MAJOR CARRY TRANSITION GLITCH

V

GATE_

1mV/div

MAX11008 toc17

CODE 7FF TO 800

C

GATE_

= 100pF

-1.0

-0.4

-0.6

-0.8

-0.2

0

0.2

0.4

0.6

0.8

1.0

0 1024 2048 3072 4096

DAC INTEGRAL NONLINEARITY

vs. INPUT CODE

MAX11008 toc18

INPUT CODE

INL (LSB)

-1.0

-0.4

-0.6

-0.8

-0.2

0

0.2

0.4

0.6

0.8

1.0

0 1024 2048 3072 4096

DAC DIFFERENTIAL NONLINEARITY

vs. INPUT CODE

MAX11008 toc19

INPUT CODE

DNL (LSB)

Page 11

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________

11

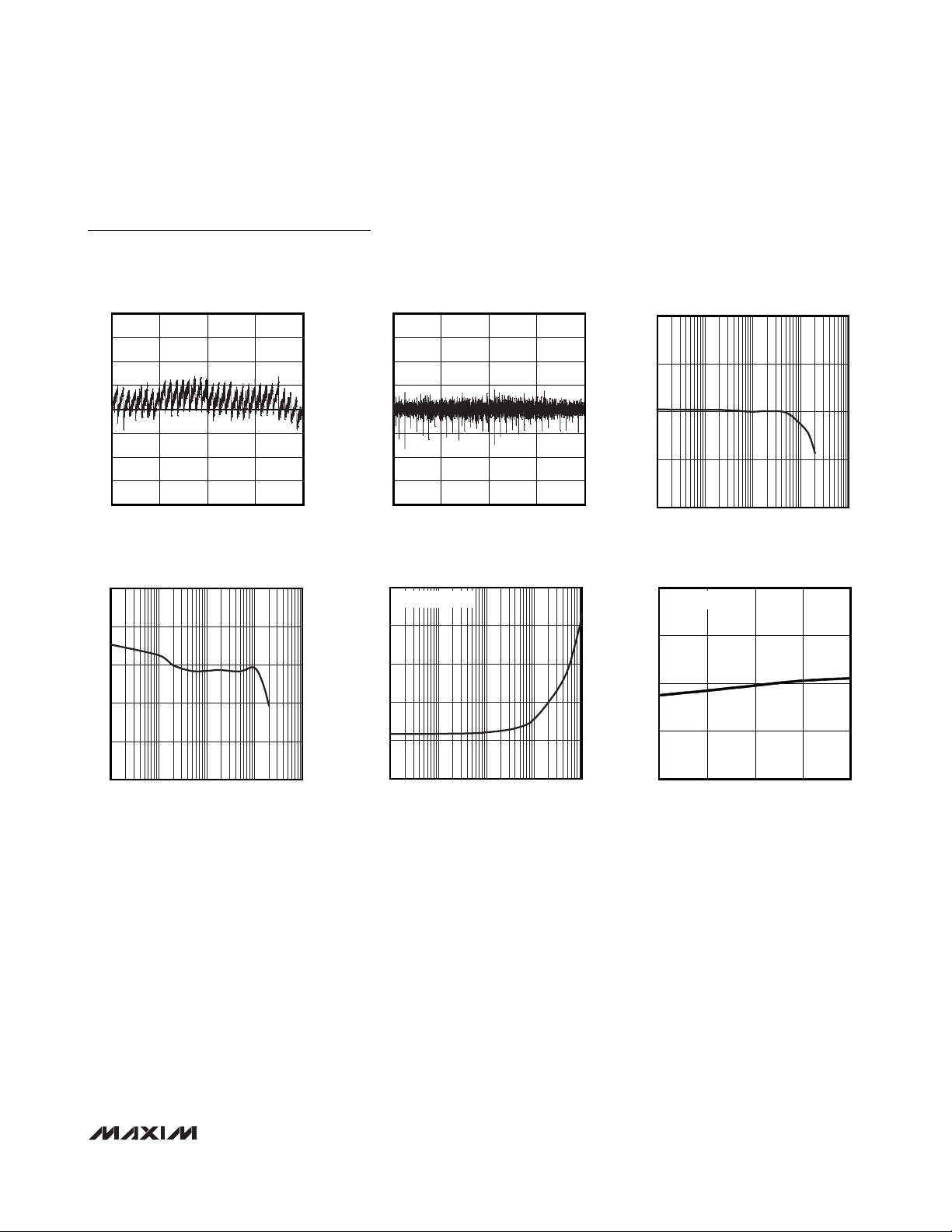

Typical Operating Characteristics (continued)

(AVDD= DVDD= 5V, external V

REFADC

= 2.5V, external V

REFDAC

= 2.5V, V

CS_-

= V

CS_+

= 32V, C

REF

= 0.1µF, TA= +25°C, unless oth-

erwise noted.)

ADC INTEGRAL NONLINEARITY

vs. OUTPUT CODE

1.00

0.75

0.50

0.25

0

ADC INL (LSB)

-0.25

-0.50

-0.75

-1.00

0 1024 2048 3072 4096

OUTPUT CODE

ADC SFDR vs. FREQUENCY

100

90

80

SFDR (dB)

70

60

1.00

MAX11008 toc20

MAX11008 toc23

0.75

0.50

0.25

0

ADC DNL (LSB)

-0.25

-0.50

-0.75

-1.00

0 1024 2048 3072 4096

8

AVDD = DVDD = 5V

7

6

5

SUPPLY CURRENT (mA)

DD

DV

4

ADC DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

OUTPUT CODE

DIGITAL SUPPLY CURRENT

vs. SAMPLING RATE

MAX11008 toc21

80

75

70

SINAD (dB)

65

60

0.1 101 100 1000

ADC INTERNAL REFERENCE VOLTAGE

2.5026

MAX11008 toc24

2.5024

2.5022

2.5020

ADC REFERENCE VOLTAGE (V)

ADC SINAD vs. FREQUENCY

FREQUENCY (kHz)

vs. SUPPLY VOLTAGE

AVDD = DV

DD

MAX11008 toc22

MAX11008 toc25

50

0.1 101 100 1000

FREQUENCY (kHz)

3

0.1 101 100 1000

SAMPLING RATE (ksps)

2.5018

4.750 5.0004.875 5.125 5.250

SUPPLY VOLTAGE (V)

Page 12

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

12 ______________________________________________________________________________________

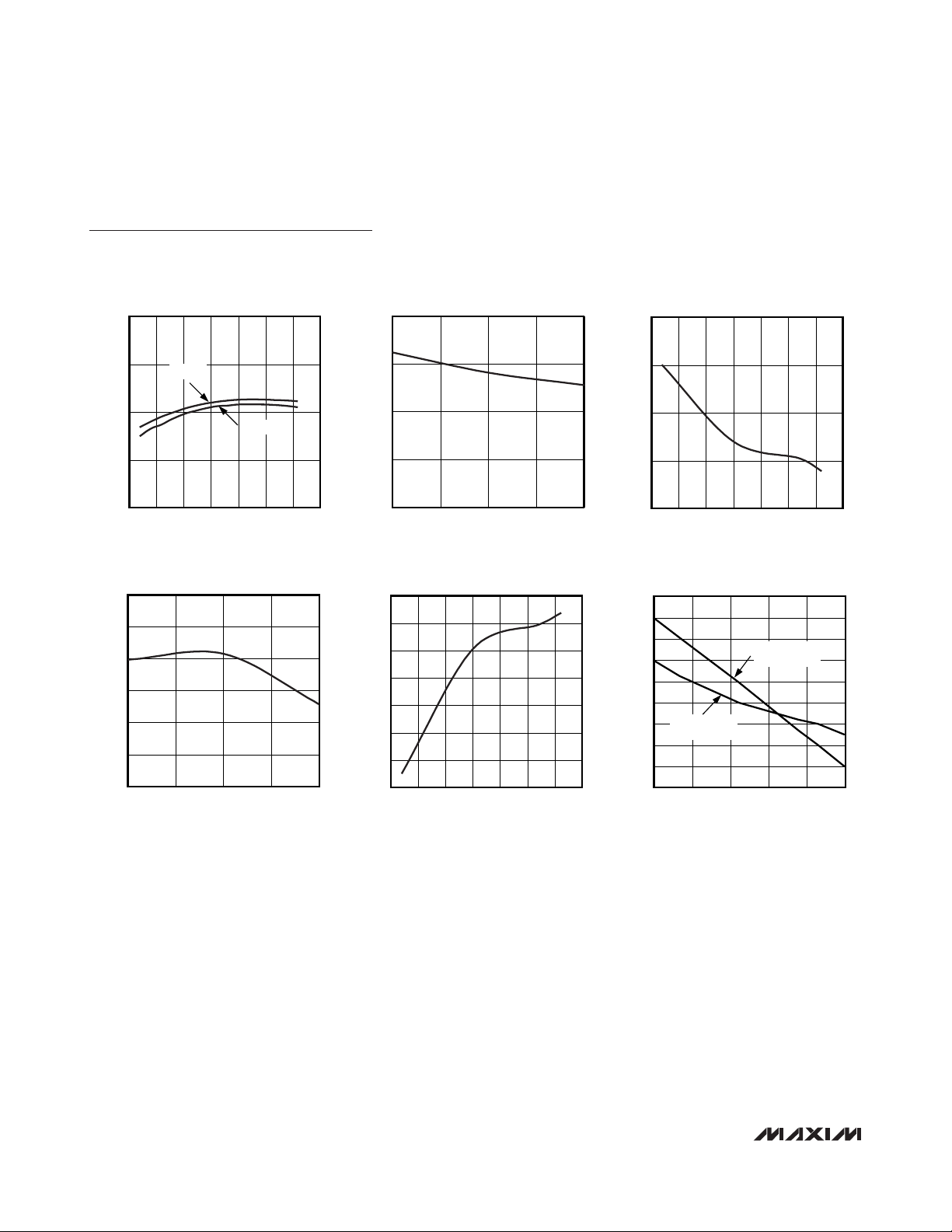

Typical Operating Characteristics (continued)

(AVDD= DVDD= 5V, external V

REFADC

= 2.5V, external V

REFDAC

= 2.5V, V

CS_-

= V

CS_+

= 32V, C

REF

= 0.1µF, TA= +25°C, unless oth-

erwise noted.)

INTERNAL REFERENCE VOLTAGE

vs. TEMPERATURE

2.52

2.0

ADC OFFSET ERROR

vs. ANALOG SUPPLY VOLTAGE

ADC OFFSET ERROR vs. TEMPERATURE

4

2.51

V

REFADC

2.50

REFERENCE VOLTAGE (V)

2.49

2.48

-50 25 50-25 0 75 100 125

TEMPERATURE (°C)

ADC GAIN ERROR

vs. ANALOG SUPPLY VOLTAGE

3.0

2.5

2.0

1.5

1.0

ADC GAIN ERROR (LSB)

0.5

0

4.750 5.0004.875 5.125 5.250

AVDD (V)

V

REFDAC

MAX11008 toc26

1.5

1.0

ADC OFFSET ERROR (LSB)

0.5

0

4.750 5.0004.875 5.125 5.250

4

MAX11008 toc29

3

2

1

0

ADC GAIN ERROR (LSB)

-1

-2

-3

-50 0 25-25 50 75 100 125

AVDD (V)

ADC GAIN EROR vs. TEMPERATURE

TEMPERATURE (°C)

MAX11008 toc27

3

2

ADC OFFSET ERROR (LSB)

1

0

-50 25 50-25 0 75 100 125

0.8

0.6

MAX11008 toc30

0.4

0.2

0

-0.2

EXTERNAL TEMP

-0.4

SENSOR

-0.6

RELATIVE TEMPERATURE ERROR

-0.8

-1.0

-40 18-11 47 76 105

TEMPERATURE (°C)

RELATIVE TEMPERATURE

ERROR vs. TEMPERATURE

INTERNAL TEMP

SENSOR

TEMPERATURE (°C)

MAX11008 toc28

MAX11008 toc31

Page 13

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 13

______________________________________________________________________________________

13

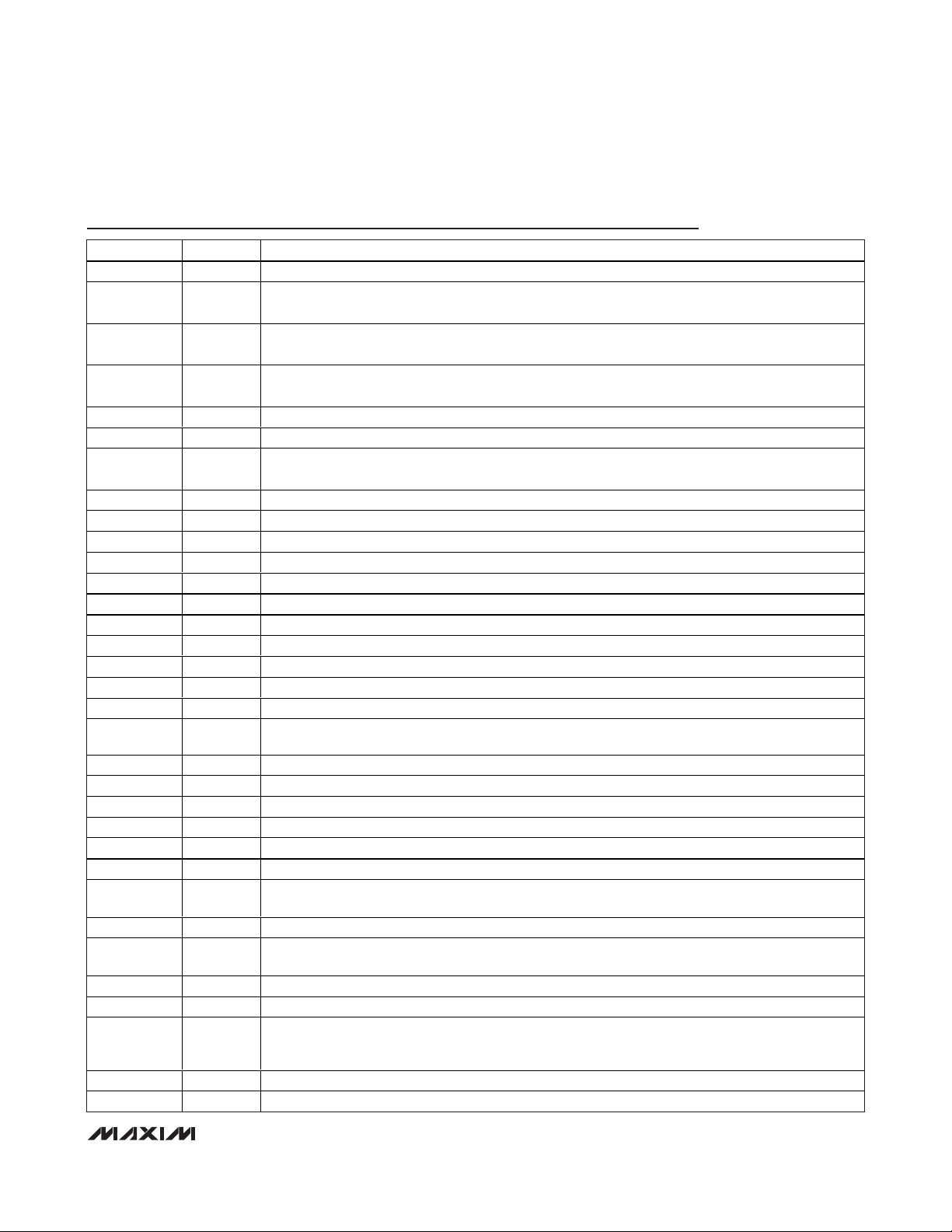

Pin Description

PIN NAME FUNCTION

1, 31 DGND Digital Ground. Connect both DGND inputs to the same potential.

2 OPSAFE1

3 A0/CS

4 CNVST

5 SPI/I2C Interface-Select Input. Connect to DGND for I2C interface. Connect to DVDD for SPI interface.

6 ALARM Alarm Output

7 OPSAFE2

8 REFDAC DAC Reference Input/Output

9 REFADC ADC Reference Input/Output

10 DXP1 Temperature Diode Positive Input 1. Connect DXP1 to the anode of the external diode.

11 DXN1 Temperature Diode Negative Input 1. Connect DXN1 to the cathode of the external diode.

12 DXP2 Temperature Diode Positive Input 2. Connect DXP2 to the anode of the external diode.

13 DXN2 Temperature Diode Negative Input 2. Connect DXN2 to the cathode of the external diode.

14 ADCIN1 ADC Auxiliary Input 1

15 ADCIN2 ADC Auxiliary Input 2

16 PGAOUT2 Programmable-Gain Amplifier Output 2

17 GATE2 Gate-Drive Amplifier Output 2

18 GATE1 Gate-Drive Amplifier Output 1

19, 25, 30,

34–39, 42, 48

20, 24 AV

21, 22, 23 AGND Analog Ground. Connect all AGND inputs to the same potential.

26 CS2+ C ur r ent- S ense P osi ti ve Inp ut 2. C S 2+ i s the exter nal sense- r esi stor connecti on to the LD M OS 2 sup p l y.

27 CS2- Current-Sense Negative Input 2. CS2- is the external sense-resistor connection to the LDMOS 2 drain.

28 CS1- Current-Sense Negative Input 1. CS1- is the external sense-resistor connection to the LDMOS 1 drain.

29 CS1+ C ur r ent- S ense P osi ti ve Inp ut 1. C S 1+ i s the exter nal sense- r esi stor connecti on to the LD M OS 1 sup p l y.

32, 33, 47 DV

40 PGAOUT1 Programmable-Gain Amplifier Output 1

41 A2/N.C.

43 SCL/SCLK Serial-Clock Input. SCL is the I2C-compatible clock input. SCLK is the SPI-compatible clock input.

44 SDA/DIN S er i al - D ata Inp ut/Outp ut. S D A i s the I2C- com p ati b l e i np ut/outp ut. D IN i s the S P I- com p ati b l e d ata i np ut.

45 A1/DOUT

46 BUSY Busy Output. BUSY goes high to indicate activity.

— EP Exposed Pad. Connect EP to AGND. Internally connected to AGND.

N.C. No Connection. Not internally connected. Leave unconnected.

Output Safe Switch Logic Input 1. Drive OPSAFE1 high to close the output safe switch and clamp

GATE1 to AGND. Drive OPSAFE1 low to open the switch.

Address-Select Input 0/Chip-Select Input. In I

1. In SPI mode, this is the chip-select input.

Active-Low Conversion Start Input. Drive CNVST low to begin a conversion when in clock modes 01

and 11.

Output Safe Switch Logic Input 2. Drive OPSAFE2 high to close the output safe switch and clamp

GATE2 to AGND. Drive OPSAFE2 low to open the switch.

Analog-Supply Input. Connect both AVDD inputs to the same potential.

DD

Digital-Supply Input. Connect all DVDD inputs to the same potential. Connect a 0.1µF capacitor to

DD

.

DV

DD

Address-Select Input 2/N.C. In I

mode, this is a no connection pin.

Address-Select Input 1/Data Out. In I

mode, this is the serial-data output. Data is clocked out on the falling edge of SCLK. DOUT is a highimpedance output when CS is driven high.

2

C mode, this pin is the address-select input 2. See Table 1. In SPI

2

2

C mode, this is the address-select input 0. See Table

C mode, this is the address-select input 1. See Table 1. In SPI

Page 14

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

14 ______________________________________________________________________________________14 ______________________________________________________________________________________

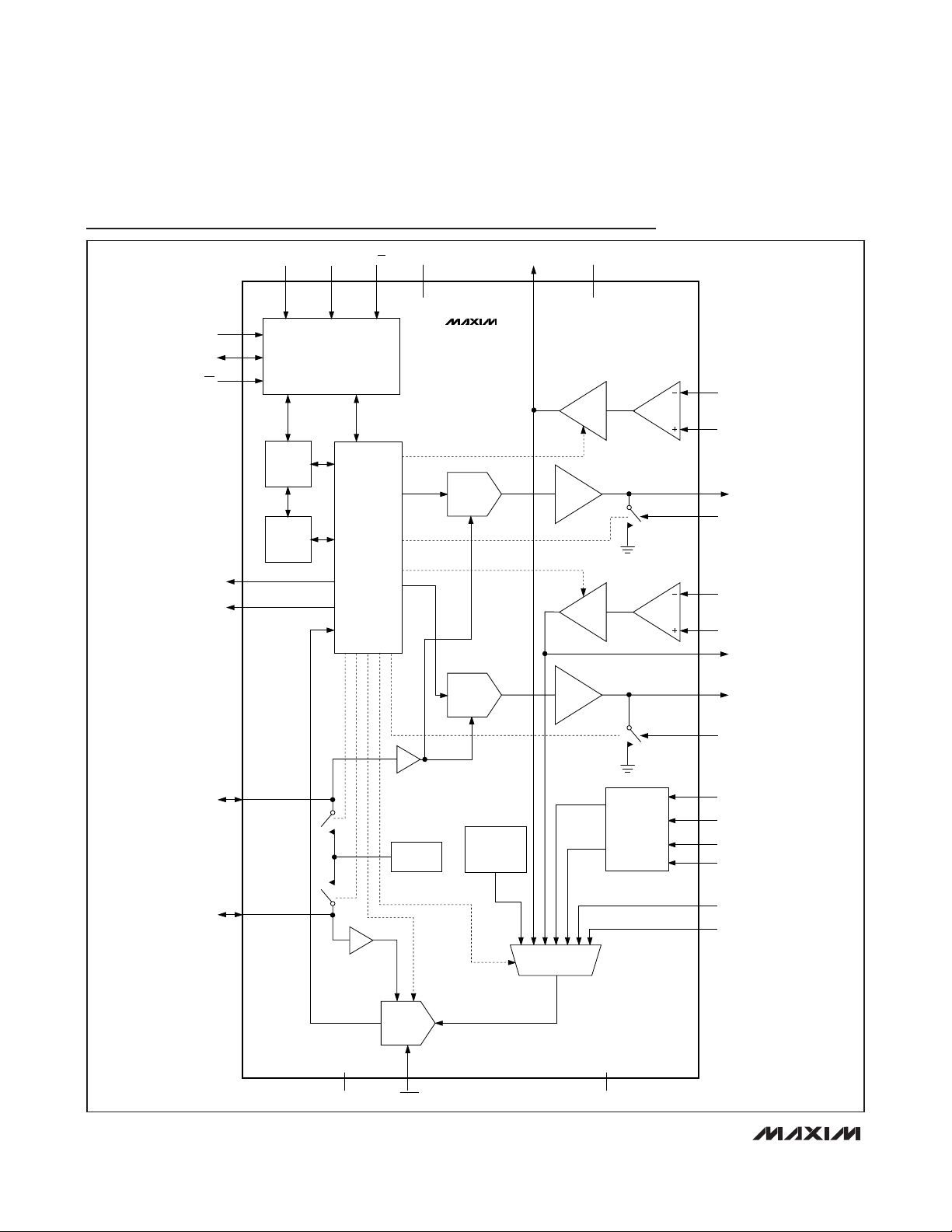

Functional Diagram

A1/DOUTA2/N.C.

A0/CS

DV

DD

PGAOUT1

AV

DD

SCL/SCLK

SDA/DIN

SPI/I2C

ALARM

BUSY

FIFO

EEPROM

SERIAL INTERFACE

REGISTER MAP

AND DIGITAL

CONTROL

MAX11008

12-BIT DAC1

12-BIT DAC 2

CS1+

PGA 1

CS1-

= 2

A

V

PGA 2

= 2

A

V

GATE1

OPSAFE1

CS2+

CS2-

PGAOUT2

GATE2

OPSAFE2

REFDAC

REFADC

2.5V

REFERENCE

12-BIT ADC

CNVST

INTERNAL

TEMPERATURE

SENSOR

MUX

AGNDDGND

EXTERNAL

TEMPERATURE

SENSOR

PROCESSING

DXP1

DXN1

DXP2

DXN2

ADCIN1

ADCIN2

Page 15

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 15______________________________________________________________________________________ 15

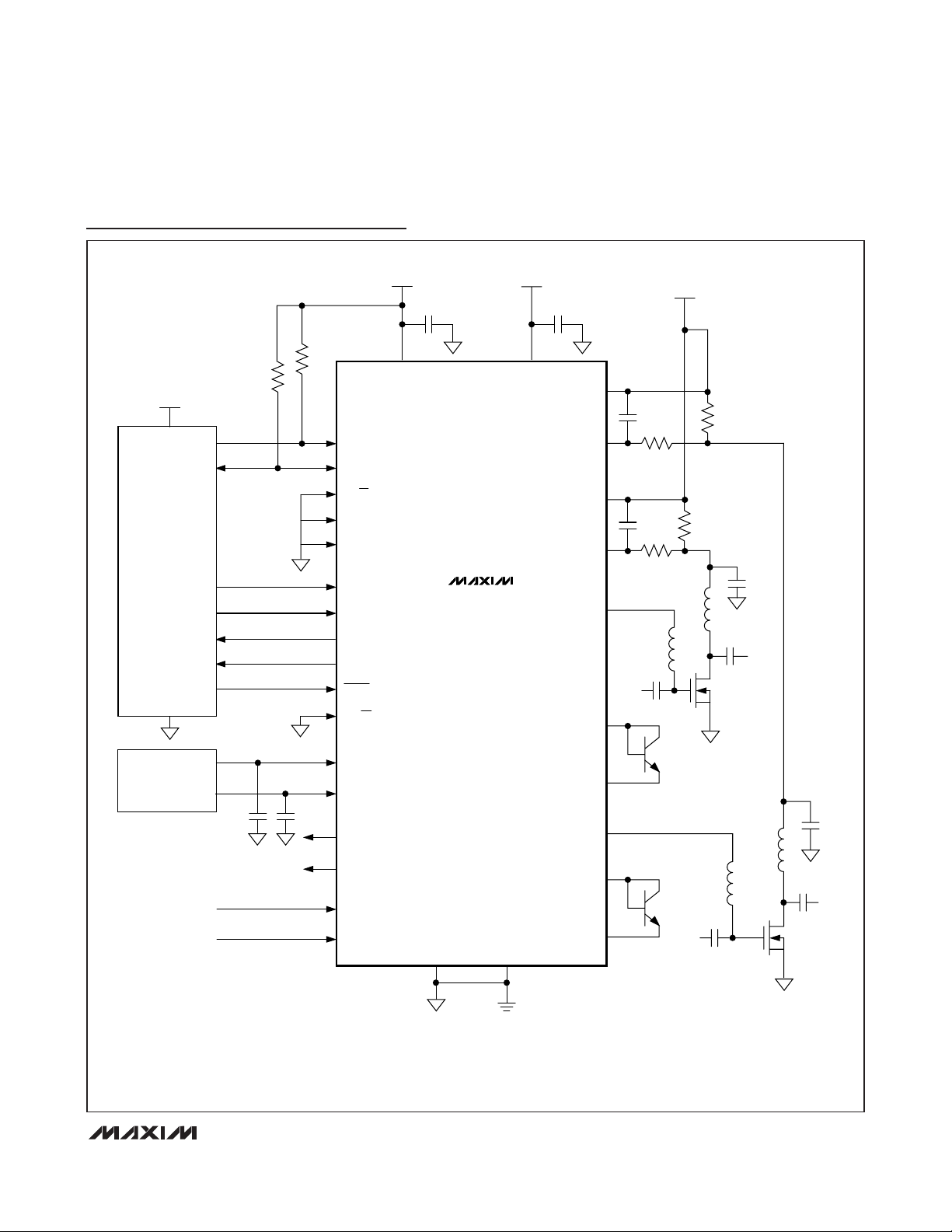

Typical Application Circuits—I2C Interface

DV

DD

0.1µF

4.7kΩ

DV

4.7kΩ

5V

SCL/SCLK

SDA/DIN

A0/CS

A1/DOUT

A2/N.C.

µC

OPSAFE1

OPSAFE2

ALARM

BUSY

CNVST

SPI/I2C

DD

MAX11008

AV

DD

0.1µF

AV

DD

CS1+

CS1-

CS2+

CS2-

GATE2

RF IN

DXP2

32V

*

C

F

R

*

F

*

C

F

*

R

F

R

SENSE

R

SENSE

LDMOS 1

RF OUT

EXTERNAL

2.5V

REFERENCE

REFADC

DXN2

GATE1

DXP1

DXN1

I2C SERIAL INTERFACE

= 1/(2 π RFCF).

CUTOFF

SECTION.

RF IN

RF OUT

LDMOS 2

0.1µF 0.1µF

*SDA RESISTOR VALUE VARIES WITH LOAD AND SCL FREQUENCY. SEE THE

*SELECT RF AND CF BASED ON DESIRED FILTER CUTOFF FREQUENCY WHERE f

LIMIT R

REFDAC

PGAOUT1

PGAOUT2

ADCIN1

ADCIN2

DGND AGND

TO 100Ω TO MINIMIZE OFFSET ERRORS.

F

Page 16

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

16 ______________________________________________________________________________________

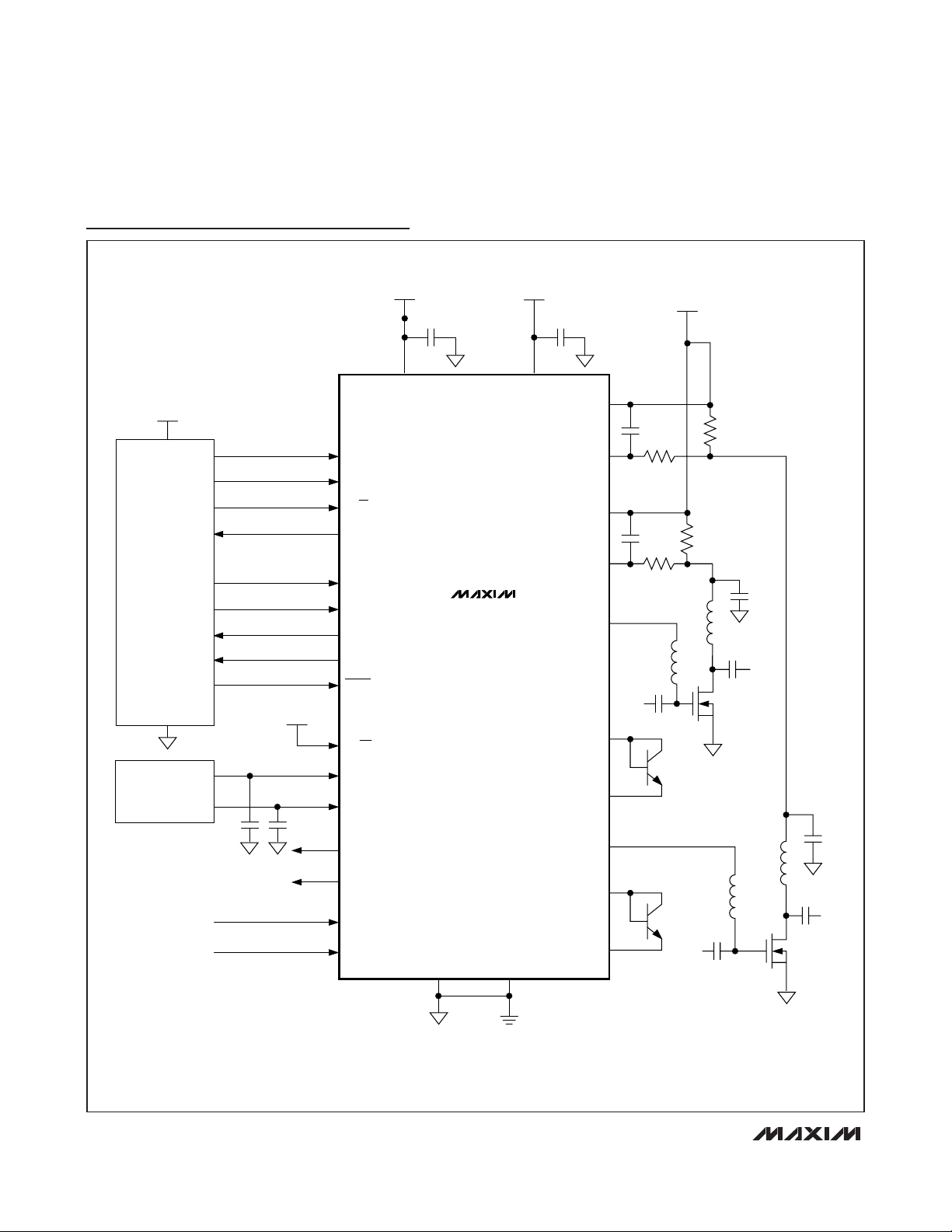

Typical Application Circuits—SPI Interface

5V

µC

DV

DD

0.1µF

DV

DD

SCL/SCLK

SDA/DIN

A0/CS

A1/DOUT

OPSAFE1

OPSAFE2

ALARM

BUSY

CNVST

DV

DD

SPI/I2C

MAX11008

AV

DD

0.1µF

AV

DD

CS1+

CS1-

CS2+

CS2-

GATE2

RF IN

DXP2

32V

C

*

F

RF*

C

*

F

RF*

R

SENSE

R

SENSE

LDMOS 1

RF OUT

EXTERNAL

2.5V

REFERENCE

0.1µF

0.1µF

*SELECT RF AND CF BASED ON DESIRED FILTER CUTOFF FREQUENCY WHERE f

LIMIT R

REFADC

REFDAC

PGAOUT1

PGAOUT2

ADCIN1

ADCIN2

DGND AGND

TO 100Ω TO MINIMIZE OFFSET ERRORS.

F

GATE1

CUTOFF

DXN2

DXP1

DXN1

= 1/(2 π RFCF).

RF IN

RF OUT

LDMOS 2

Page 17

Detailed Description

The MAX11008 sets and controls the bias conditions

for dual RF LDMOS power devices found in cellular

base-station power amps. Each device includes two

high-side current-sense amplifiers with programmable

gains of 2, 10, and 25 to monitor the LDMOS transistor

drain current over the 20mA to 5A range. Two external

diode-connected transistors monitor the LDMOS transistor temperatures while an internal temperature sensor measures the local die temperature of the

MAX11008. The 12-bit ADC is interfaced to a 7:1 multiplexer and converts the signals from the PGA outputs,

internal and external temperature readings, or the two

auxiliary analog inputs into digital data results that can

be stored in the FIFO.

On the control side, two gate-drive channels, driven

from two 12-bit DACs and a gain stage of 2, generate a

positive gate voltage bias for the LDMOS. Each gatedrive output supports up to ±2mA of gate current. The

gate-drive amplifier is current-limited to ±25mA and

features a fast clamp to analog ground that operates

independently of the serial interface.

The MAX11008 includes an on-chip, nonvolatile

EEPROM that stores LUTs and register information. The

LUTs are designed to store gate voltage vs. temperature

curves for the LDMOS FET. The data is used for temperature compensation of the LDMOS FET’s bias point.

The LUTs can also contain compensation data for another independent parameter: either sense voltage or

AIN voltage.

Digital Serial Interface

The MAX11008 features both an I2C and an SPI-compatible serial interface. Connect SPI/I2C to DGND to

select the I2C serial-interface operation, or to DVDDto

select the SPI serial-interface operation. Do not alter

interface mode during operation.

SPI Serial Interface

Connect SPI/I2C to DVDDto select the SPI interface.

The SPI serial interface consists of a serial data input

(DIN), a serial clock line (SCLK), a chip select (CS),

and a serial data output (DOUT). The use of serial data

output (DOUT) is optional and is only required when

data is to be read back by the master device. The

MAX11008 is SPI compatible within the range of VDD=

+2.7V to +5.25V. DIN, SCLK, CS, and DOUT facilitate

bidirectional communication between the MAX11008

and the master at rates up to 20MHz.

Figure 1 illustrates the 4-wire interface timing diagram.

The MAX11008 is a transmit/receive slave-only device,

relying upon a master to generate a clock signal. The

master initiates data transfer on the bus and generates

the SCLK signal to permit data transfer.

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 17

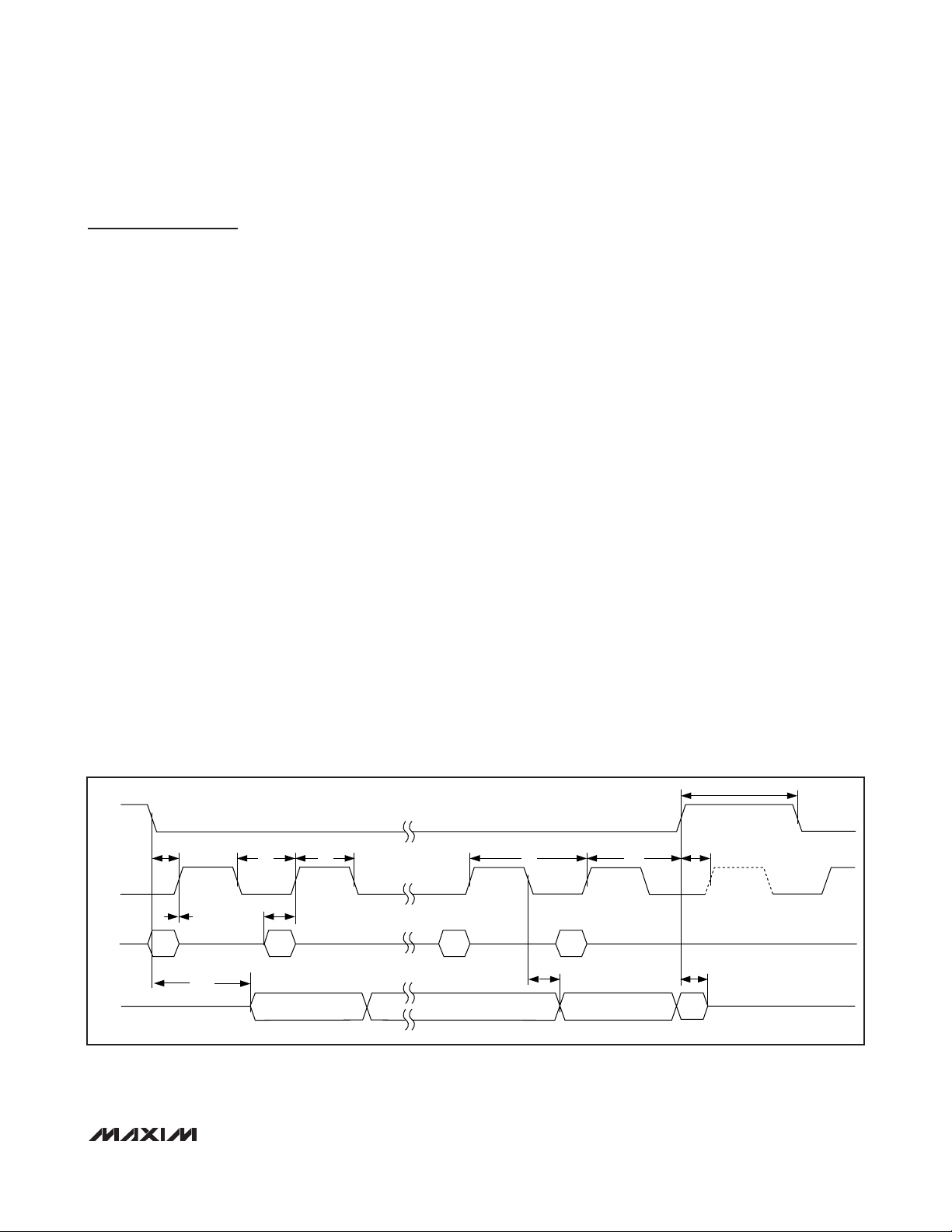

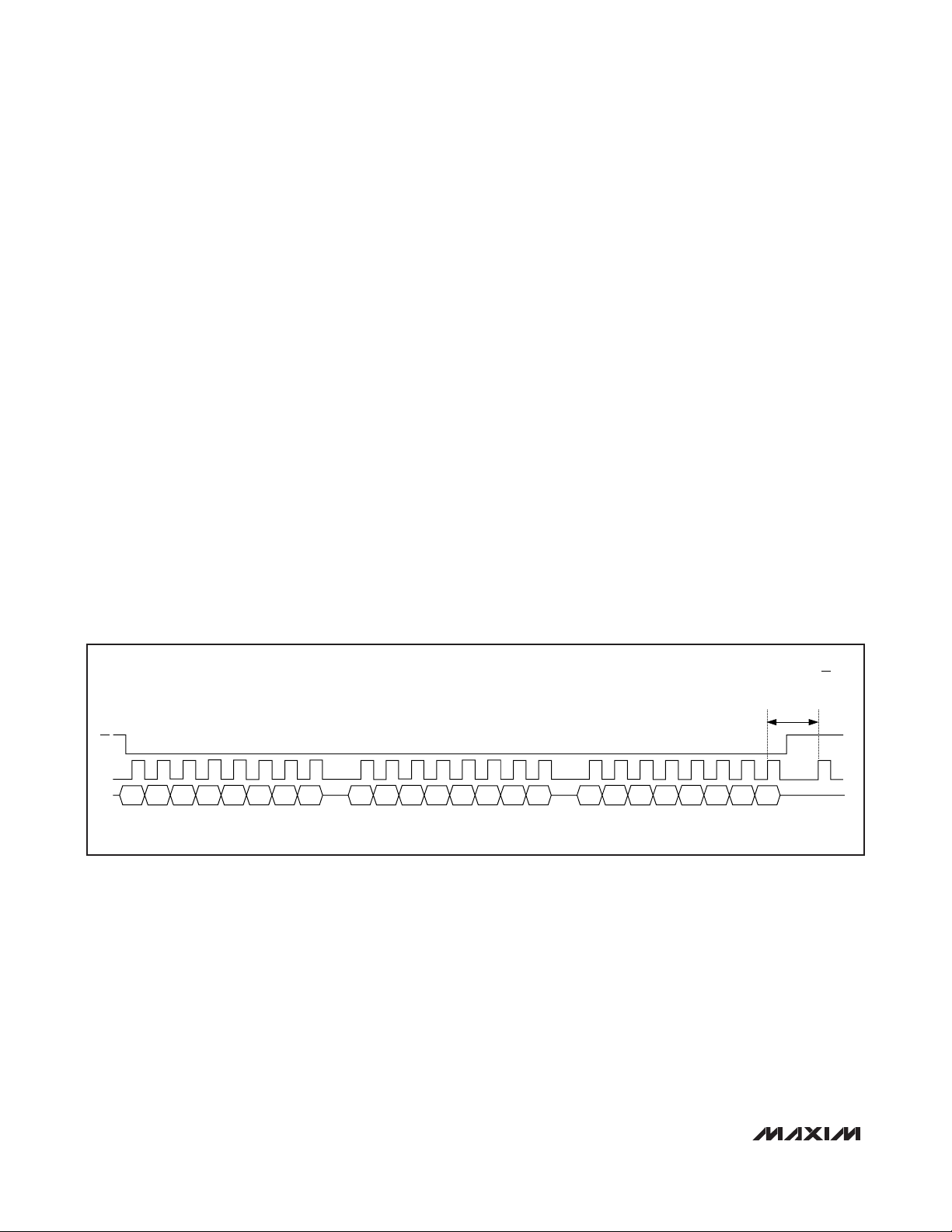

Figure 1. SPI Serial-Interface Timing

CS

t

CSS

SCLK

t

DH

DIN

DOUT

D23

t

DV

t

CL

t

DS

D22 D1 D0

t

CSW

t

t

CH

t

CP

t

DO

t

CSH

CSS

t

TR

Page 18

MAX11008

The SPI bus cycles are 24 bits long. Data can be supplied as three 8-bit bytes or as a continuous 24-bit

stream. CS must remain low throughout the 24-bit

sequence. The first 8-bit byte is a command byte

C[7:0]. The next 16 bits are data bits D[15:0]. Clock

signal SCLK can idle low or high, but data is always

clocked in on the rising edge of SCLK (CPOL = CPHA).

SPI data transfers begin with the falling edge of CS.

Data is clocked into the device on the rising edges of

SCLK and clocked out of the device on the falling

edges of SCLK. For correct bus cycles, CS should

frame the data and should not return to a 1 until after

the last active rising clock edge. See Figure 2 for timing

details. A rising edge of CS causes DOUT to threestate and data reads should be performed accordingly.

See Figures 1 and 3.

When writing instructions to the MAX11008, 24 clock

cycles must be completed before CS is driven high.

The MAX11008 executes the instruction only after the

24th clock cycle has been received and CS is driven

high. To abort unwanted instructions, CS can be driven

high at any time before the 23rd rising clock edge.

When reading data from the MAX11008, 24 clock

cycles must be completed before CS is driven high. If

CS is driven high before the completion of the 24th

falling edge, DOUT immediately three-states, the interface resets in preparation for the next command, and

the data being read is lost.

Write Format

Use the following sequence to write 16 bits of data to a

MAX11008 register (see Figure 2):

1) Drive CS low to select the device.

2) Send the appropriate write command byte (see

Table 6 for the register address map). The command byte is clocked in on the rising edge of SCLK.

3) Send 16 bits of data D[15:0] starting with the most

significant bit (MSB). Data is clocked in on the rising

edges of SCLK.

4) Drive CS high to conclude the command.

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

18 ______________________________________________________________________________________

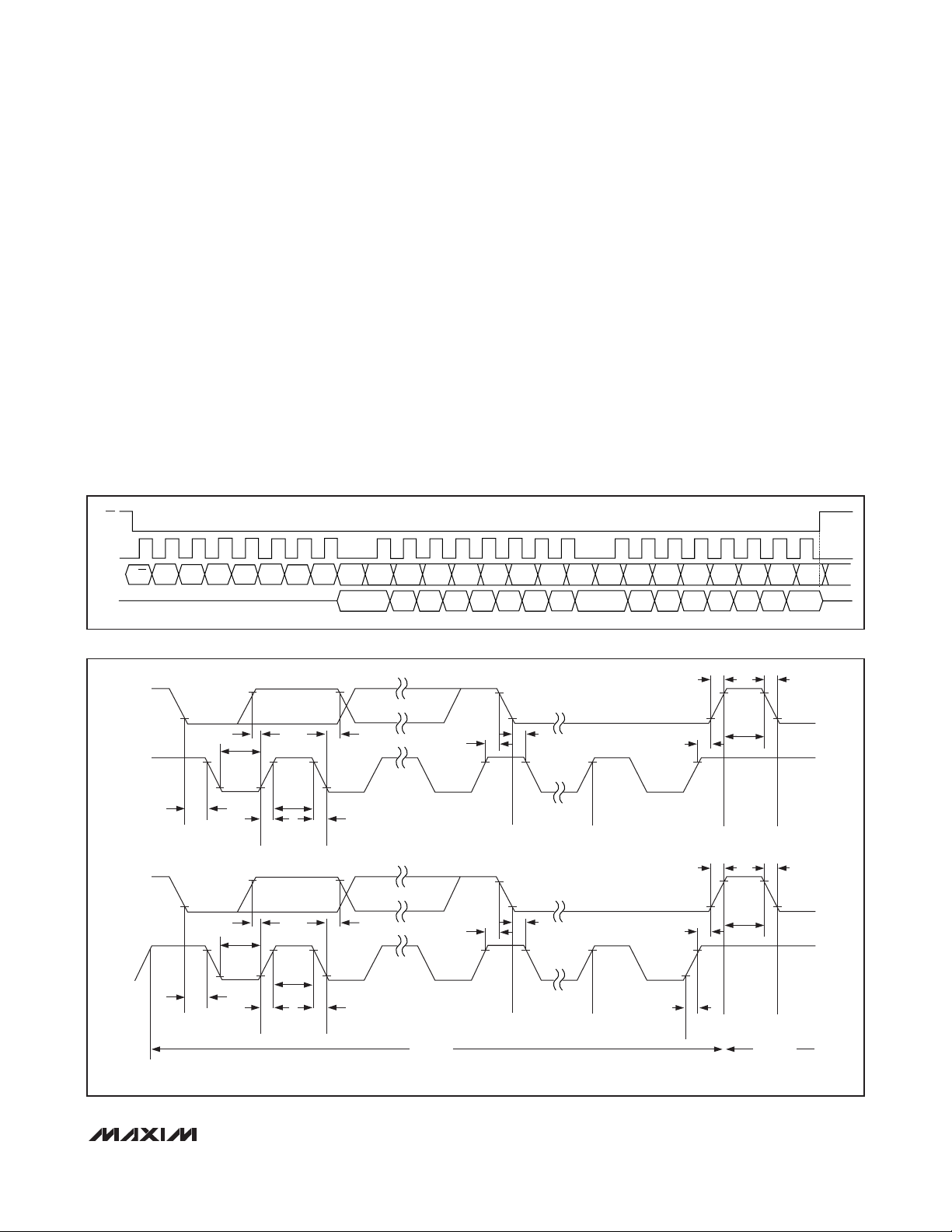

Figure 2. SPI Write Sequence

A RISING EDGE OF CS

DURING THIS PERIOD

COMPLETES A VALID WRITE

COMMAND

CS

SCLK

DIN

C6CR/W- C4C5 C2C3 C0C1

D15D14D13D12D11D10D9D8 D7D6D5D4D3D2D1D0

Page 19

Read Format

Use the following sequence to read 16 bits of data from

a MAX11008 register (see Figure 3):

1) Drive CS low to select the device.

2) Send the appropriate read command byte (see

Table 6 for the register address map). The command byte is clocked in on the rising edges of

SCLK.

3) Receive 16 bits of data. The first 4 bits of data are

always high. Data is clocked out on the falling edges

of SCLK.

4) Drive CS high.

I2C Serial Interface

Connect SPI/I2C to DGND to select the I2C interface. The

I2C serial interface consists of a serial data line (SDA)

and a serial clock line (SCL). The MAX11008 is I2C compatible within the DV

DD

= 2.7V to 5.25V range. SDA and

SCL facilitate bidirectional communication between the

MAX11008 and the master at rates up to 400kHz for fast

mode and up to 3.4MHz for high-speed mode (HS

mode). See the

Bus Timing

and

HS I2C Mode

sections

for more information on data-rate configurations.

Figure 4 shows the 2-wire interface timing diagram. The

MAX11008 is a transmit/receive slave-only device, relying upon a master to generate a clock signal. The master (typically a microcontroller) initiates data transfers

on the bus and generates the SCL signal to permit data

transfer.

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 19

Figure 3. SPI Read Sequence

Figure 4. I2C Serial-Interface Timing Diagram

CS

SCLK

DIN

DOUT

C6R/W C4C5 C2C3 C0C1

a) F/S-MODE I

SDA

2

C SERIAL INTERFACE TIMING

t

SU, DAT

t

LOW

XXXXXXXXXXXX XXXXX

D14 D13 D12 D11 D10 D9 D8 D6 D5 D4 D3 D2 D1D15 D7 D0

t

HD, DAT

t

SU, STA

X

t

HD, STA

t

SU, ST0

t

R

t

F

t

BUF

SCL

t

t

HD, STA

S

2

b) HS-MODE I

SDA

PARAMETERS ARE MEASURED FROM 30% TO 70%.

C SERIAL INTERFACE TIMING

t

SU, DAT

t

LOW

SCL

t

HD, STA

t

S Sr A

RCL

HIGH

t

R

t

HIGH

t

F

Sr A

t

HD, DAT

t

RCL

t

SU, STA

t

HD, STA

t

SU, ST0

t

RCL

PS

t

RDA

P

t

RDA

t

BUF

S

F/S MODEHS MODE

Page 20

MAX11008

A master device communicates to the MAX11008 by

transmitting the proper slave address followed by a

command and/or data words. Each transmit sequence

is framed by a START (S) or repeated START (Sr) condition and a STOP (P) condition. Each word transmitted

over the bus is 8 bits long and is always followed by an

acknowledge clock pulse.

The MAX11008 SDA and SCL drivers are open-drain

outputs, requiring a pullup resistor (750Ω or greater) to

generate a logic-high voltage (see the

Typical

Application Circuits

). Series resistors are optional for

noise filtering. These series resistors protect the input

stages of the MAX11008 from high-voltage spikes on

the bus line, and minimize crosstalk and undershoot of

the bus signals.

Bit Transfer

One data bit is transferred during each SCL clock

cycle. The data on SDA must remain stable during the

high period of the SCL clock pulse. Changes in SDA

while SCL is high are control signals (see the

START

and STOP Conditions

section). Both SDA and SCL idle

high when the I2C bus is not busy.

START and STOP Conditions

The master initiates a transmission with a START condition (S), which is a high-to-low transition on SDA while

SCL is high. The master terminates a transmission with

a STOP condition (P), which is a low-to-high transition

on SDA while SCL is high (see Figure 5). A repeated

START condition (Sr) can be used in place of a STOP

condition to leave the bus active and the mode

unchanged (see the

HS I2C Mode

section).

Acknowledge Bits and Not-Acknowledge Conditions

Data transfers are framed with an acknowledge bit

(ACK) or a not-acknowledge bit (NACK). Both the master and the MAX11008 (slave) generate acknowledge

bits. To generate an acknowledge, the receiving device

must pull SDA low before the rising edge of the

acknowledge-related clock pulse (ninth clock pulse)

and keep it low during the high period of the clock

pulse (see Figure 6).

To generate a not-acknowledge condition, the receiver

allows SDA to be pulled high before the rising edge of

the acknowledge-related clock pulse, and leaves SDA

high during the high period of the clock pulse.

Monitoring the acknowledge bits allows for detection of

unsuccessful data transfers. An unsuccessful data

transfer happens if a receiving device is busy or if a

system fault has occurred. In the event of an unsuccessful data transfer, the bus master reattempts communication at a later time.

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

20 ______________________________________________________________________________________

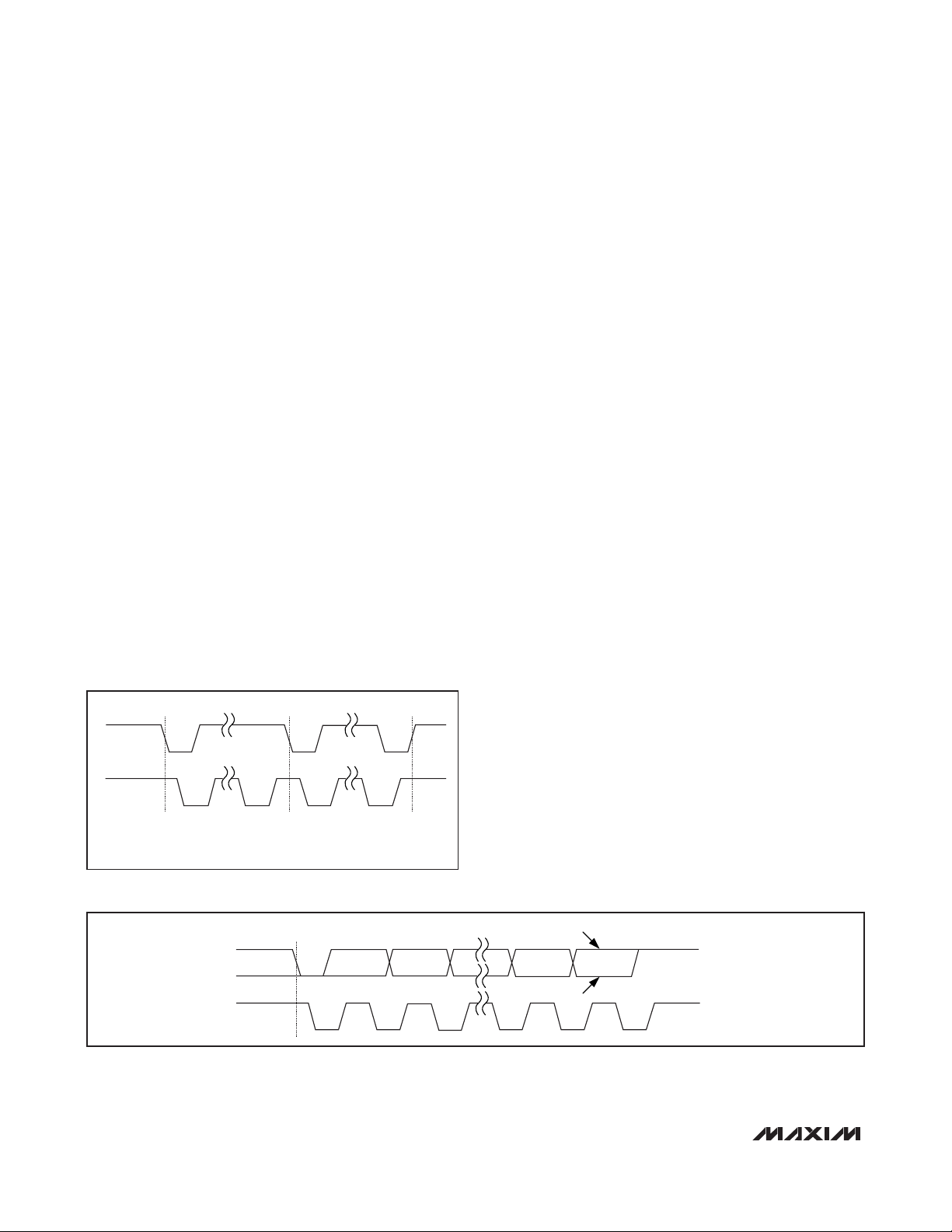

Figure 5. START and STOP Conditions

Figure 6. Acknowledge Bits

SSrP

SDA

SCL

S = START.

Sr = REPEATED START.

P = STOP.

S

SDA

SCL

12 8

NOT ACKNOWLEDGE

ACKNOWLEDGE

9

Page 21

Slave Address

A bus master initiates communication with a slave

device by issuing a START condition followed by the 7bit slave address and a read/write (R/W) bit (see Figure

7). When the device recognizes its slave address, it is

ready to accept or send data depending on the R/W

bit. When the MAX11008 recognizes its slave address,

it issues an ACK by pulling SDA low for one clock cycle

and is ready to accept or send data depending on the

R/W bit that was sent.

The MAX11008 has eight user-selectable slave addresses, which are set through inputs A0, A1, and A2 (see

Table 1). This feature allows up to eight MAX11008

devices to share the same bus inputs. The 4 MSBs D[7:4]

are factory set, and the 3 LSBs are user-selectable.

Bus Timing

At power-up, the bus timing is set for I2C fast-mode

(F/S mode), which allows I2C clock rates up to 400kHz.

The MAX11008 can also operate in high-speed mode

(HS mode) to achieve I

2

C clock rates up to 3.4MHz.

See Figure 4 for I2C bus timing.

HS I2C Mode

Select HS mode by addressing all devices on the bus

with the HS-mode master code 0000 1XXX (X = don’t

care). After successfully receiving the HS-mode master

code, the MAX11008 issues a NACK, allowing SDA to

be pulled high for one clock cycle (see Figure 8). After

the NACK, the MAX11008 operates in HS mode. The

master must then send a repeated START (Sr) followed

by a slave address to initiate HS-mode communication.

If the master generates a STOP condition, the

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 21

Figure 7. Slave Address Bits

Figure 8. F/S-Mode to HS-Mode Transfer

Table 1. Slave Address Select

A2 A1 A0 ADDRESS

0 0 0 0101000

0 0 1 0101001

0 1 0 0101010

0 1 1 0101011

1 0 0 0101100

1 0 1 0101101

1 1 0 0101110

1 1 1 0101111

S

SDA

SCL

SDA

0 0 A2 A1 A0

12

0000

1234

1

1

34 5 67 89

1XXX9A

5678

F/S MODE

R/W A

Sr

HS MODE

Page 22

MAX11008

MAX11008 returns to F/S mode. Use a repeated START

condition in place of a STOP condition to leave the bus

active and the mode unchanged. Figure 9 summarizes

the data bit transfer format for HS-mode communication.

Register Address/Data Bytes (Write Cycle)

A write cycle begins with the bus master issuing a

START condition followed by 7 address bits (see Figure

5 and Table 1) and a write bit (R/W = 0). Once the

slave address is recognized and the write bit is

received, the MAX11008 (I2C slave) issues an ACK by

pulling SDA low for one clock cycle. The master then

sends the register address byte (command byte) to the

slave. The MSB of the register address byte is the

read/write bit for the destination register address of the

slave and must be set to 0 for a write cycle (see the

Register Address Map

section). After receiving the

byte, the slave issues another acknowledge, pulling

SDA low for one clock cycle. The master then writes

two data bytes, receiving an ACK from the slave after

each byte is sent. The master ends the write cycle by

issuing a STOP condition. When operating in HS mode,

a STOP condition returns the bus into F/S mode (see

the

HS I2C Mode

section). Figure 10 shows a complete

write cycle.

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

22 ______________________________________________________________________________________

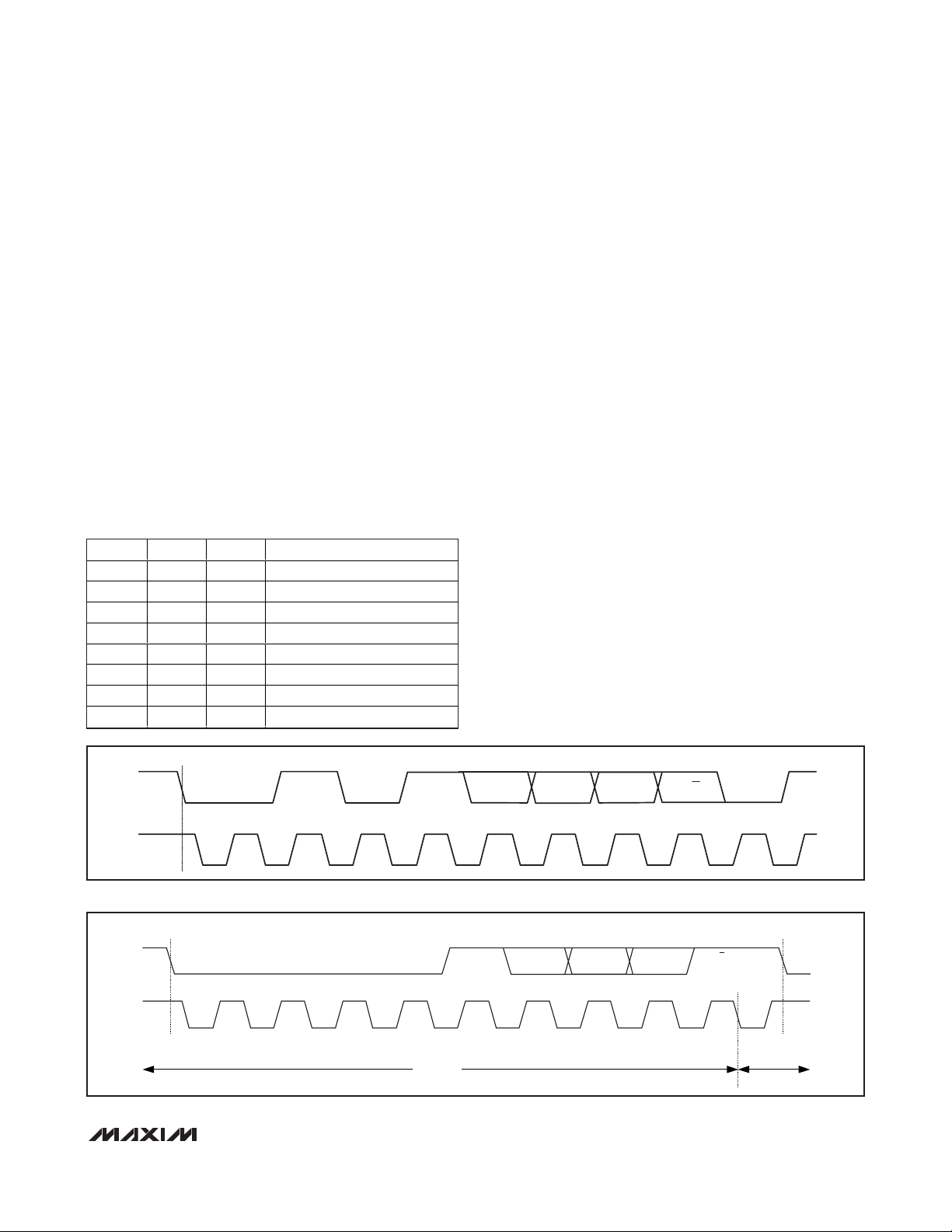

Figure 9. Data-Transfer Format in HS Mode

Figure 10. Write Cycle

MASTER TO SLAVE

SLAVE TO MASTER

F/S MODE HS MODE

S

MASTER CODE

N Sr SLAVE ADDRESS R/W A DATA A P

F/S MODE

N BYTES + ACK

HS MODE CONTINUES

MASTER TO SLAVE

SLAVE TO MASTER

4-BYTE WRITE CYCLE

1

S

711

SLAVE

ADDRESS

A

W

8

REGISTER ADDRESS

BYTE

WHETHER TO READ OR WRITE TO

A1DATA BYTE

MSB DETERMINES

REGISTERS

Sr SLAVE ADD

8

A1DATA BYTE

8

1

A

P OR Sr

1

NUMBER OF BITS

Page 23

Register Address/Data Bytes (5-Byte Read Cycle)

A read cycle begins with the master issuing a START

condition followed by a 7-bit address, (see Figure 5

and Table 1) and a write bit (R/W = 0) to instruct the

MAX11008 interface that it is about to receive data.

Once the slave address is recognized and the write bit

is received, the MAX11008 (I2C slave) issues an ACK

by pulling SDA low for one clock cycle. The master

then sends the register address byte (command byte)

to the slave. The MSB of the register address byte is

the read/write bit for the destination register address of

the slave and must be set to 1 for a read cycle (see the

Register Address Map

section). After this byte is

received, another acknowledge bit is sent to the master

from the slave. The master then issues a repeated

START (Sr) condition. Following a repeated START (Sr),

the master writes the slave address byte again with a

read bit (R/W = 1). After a third acknowledge signal

from the slave, the data direction on the SDA bus

reverses and the slave writes the 2 data bytes (the

contents of the register that was addressed in the previous command byte) to the master. Finally, the master

issues a NACK followed by a STOP condition (P), ending the read cycle. Figure 11 shows a complete 5-byte

read cycle.

Default Read Cycle (3-Byte Read Cycle)

The MAX11008 2-wire interface has a unique feature for

read commands. To avoid the necessity of sending 2

slave address bytes in one read cycle (see the 5-byte

read cycle in Figure 11), the MAX11008 2-wire interface

recognizes a single slave address byte with a read bit

(R/W = 1). In this case, the interface outputs the contents of the last read device register. This default read

feature is useful when the master must perform multiple

consecutive reads from the same device register.

Figure 11 shows a complete 3-byte read cycle.

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 23

Figure 11. 5-Byte and 3-Byte Read Cycle

MASTER TO SLAVE

SLAVE TO MASTER

5-BYTE READ CYCLE

1

S

3-BYTE READ CYCLE

1

711

SLAVE

ADDRESS

71

SLAVE

ADDRESS

RS

8

A

W COMMAND BYTE

1

A

8

DATA BYTE DATA BYTE

1

ASr

18

A

711

SLAVE

ADDRESS

81

DATA BYTE

AA

R

1

1

N

P OR Sr

NUMBER OF BITS

81

DATA BYTE

N

1

P OR Sr

NUMBER OF BITS

Page 24

MAX11008

12-Bit ADC

The MAX11008 12-bit ADC uses a SAR conversion

technique and on-chip track-and-hold (T/H) circuitry to

convert the PGA outputs (PGAOUT1 and PGAOUT2),

temperature measurements, and single-ended auxiliary

input voltages (ADCIN1 and ADCIN2) into 12-bit digital

data when in ADC monitor mode (see the

Hardware

Configuration Register (HCFIG) (Read/Write)

section).

All nontemperature measurements are converted using

a unipolar transfer function (see Figure 13), and all temperature measurements are converted using a bipolar

transfer function (see Figure 14).

Analog Input T/H

Figure 12 shows the equivalent circuit for the ADC input

architecture of the MAX11008. In track mode, an input

capacitor is connected to the input signal (ADCIN1,

ADCIN2, PGAOUT1, PGAOUT2, or temperature sensor

processor output). Another input capacitor is connected to AGND. After the T/H enters hold mode, the difference between the sampled positive and negative input

voltages is converted. The charging rate of the input

capacitance determines the time required for the T/H to

acquire an input signal. If the input signal’s source

impedance is high, the required acquisition time

lengthens accordingly.

Any source impedance below 300Ω does not affect the

ADC’s AC performance. A high-impedance source can

be accommodated either by lengthening t

ACQ

or by

placing a 1µF capacitor between the positive and negative analog inputs. The combination of the analoginput source impedance and the capacitance at the

analog input creates an RC filter that limits the analog

input bandwidth.

Input Bandwidth

The ADC’s input-tracking circuitry has a 1MHz smallsignal bandwidth, to digitize high-speed transient

events and measure periodic signals with bandwidths

exceeding the ADC’s sampling rate by using undersampling techniques. Anti-alias filtering of the input signals is necessary to prevent high-frequency

components from aliasing into the frequency band of

interest.

Analog Input Protection

Internal electrostatic-discharge (ESD) protection diodes

clamp all analog inputs to AVDDand AGND, allowing

the inputs to swing from (AGND - 0.3V) to (AVDD+

0.3V) without damage. However, for accurate conversions near full scale, the inputs must not exceed AV

DD

by more than 50mV or be lower than AGND by 50mV. If

an analog input voltage exceeds the supplies, limit the

input current to 2mA.

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

24 ______________________________________________________________________________________

Figure 12. Analog Input Track and Hold

REFADC

ADCIN1

ADCIN2

PGAOUT1

PGAOUT2

TEMP SENSOR READING

AGND

ALL SWITCHES SHOWN IN TRACK MODE.

HOLD

TRACK

TRACK

CIN+

CIN-

HOLD

/2

AV

DD

CAPACITIVE

DAC

TRACK

COMPARATOR

HOLD

Page 25

ADC Transfer Functions

Figure 13 shows the unipolar transfer function for nontemperature measurements, and Figure 14 shows the

bipolar transfer function used for temperature measurements. Code transitions occur halfway between successive-integer LSB values. Output coding is binary,

with 1 LSB = V

REFADC

/4096 for nontemperature measurements, and 1 LSB = +0.125°C for temperature

measurements. All signed binary results use two’s complement format.

ADC Conversion Scheduling

The MAX11008 ADC multiplexer scans and converts

the selected inputs in the order shown in Table 2 (see

the

ADC Conversion Register (ADCCON) (Write Only)

section) when more than one channel is selected. The

results are stored in the FIFO when in ADC monitoring

mode. The BUSY signal is set at the start and reset at

the end of a scan except when the continuous convert

bit is set at which time BUSY does not then respond to

ADC conversions.

Writing a conversion command before a conversion is

complete cancels the pending conversion. Avoid

addressing the device using the serial interface while

the ADC is converting.

ADC Clock Modes

The MAX11008 offers three conversion/acquisition

modes (known as clock modes) selectable through

configuration register bits CKSEL1 and CKSEL0.

If the ADC conversion requires the internal reference

(temperature measurement or voltage measurement with

internal reference selected) and the reference has not

been previously forced on (FBGON = 1), the device

inserts a typical delay of 72µs, for the reference to settle,

before commencing the ADC conversion. The reference

remains powered up while there are pending conversions. If the reference is not forced on, it automatically

powers down at the end of a scan or when CONCONV in

the ADC Conversion register is set back to 0.

Internally Timed Acquisitions

and Conversions

Clock Mode 00

In clock mode 00, power-up, acquisition, conversion,

and power-down are all initiated by writing to the ADC

Conversion register and performed automatically using

the internal oscillator. This is the default clock mode.

The ADC sets the BUSY output high, powers up, and

scans all requested channels storing the results in the

FIFO if the ADCMON bit has been set. After the scan is

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 25

Figure 13. ADC Transfer Function

Figure 14. Temperature Transfer Function

Table 2. Order of ADC Conversion Scan

V

REFADC

1111 1111 1111

1111 1111 1110

1111 1111 1101

1111 1111 1100

BINARY OUTPUT CODE

0000 0000 0011

0000 0000 0010

0000 0000 0001

0000 0000 0000

0

0111 1111 1111

0111 1111 1110

0111 1111 1101

0000 0000 0001

OUTPUT CODE

0000 0000 0000

1111 1111 1111

1000 0000 0010

1000 0000 0001

1000 0000 0000

-256 +2550

FULL-SCALE TRANSITION

1 LSB = V

1 2 3 4093 4095

1 LSB = +0.125°C

/4096

REFADC

INPUT VOLTAGE (LSB)

TEMPERATURE (°C)

V

REFADC

ORDER OF SCAN DESCRIPTION OF CONVERSION

1 Internal device temperature

2 External diode 1 temperature

3 Output of PGA 1 for current sense

4 Auxiliary input 1 (ADCIN1)

5 External diode 2 temperature

6 Output of PGA 2 for current sense

7 Auxiliary input 2 (ADCIN2)

Page 26

MAX11008

complete the ADC powers down, BUSY is pulled low,

and the results for all of the selected channels are

available in the FIFO.

The duration of the BUSY pulse is additive, depending

on the channel conversion sequence selected. The

BUSY pulse is set typically for 72µs by temperature

conversions; 52µs by PGAOUT conversions, and 7µs

by ADCIN conversions.

Clock Mode 01

In clock mode 01, power-up, acquisition, conversion,

and power-down are all initiated through a single pulse

on CNVST and performed automatically using the inter-

nal oscillator. Initiate a scan by writing to the ADC conversion register and setting CNVST low for at least

20ns. The ADC sets the BUSY output high, powers up,

and scans all requested channels storing the results in

the FIFO if the ADCMON bit has been set. After the

scan is complete, the ADC powers down, BUSY is

pulled low, and the results for all of the selected channels are available in the FIFO. The BUSY pulse behavior is identical to that of clock mode 00.

Externally Timed

Acquisitions and Conversions

Clock Mode 10

Clock mode 10 is reserved. Do not use this clock

mode.

Clock Mode 11

In clock mode 11, set the FBGON bit. Conversions are

initiated one at a time through CNVST and performed

using the internal oscillator. In this mode, the acquisition

time is controlled by the time CNVST is low. CNVST is

resynchronized by the internal oscillator, resulting in a

one-clock cycle (typically 320ns) uncertainty in the exact

sampling instant. Different timing parameters apply

depending if the conversion is temperature, from ADCIN,

or from PGAOUT (as specified in the

Clock Mode 00

section). Figure 15 shows a conversion time example.

Both internal and external temperature conversions are

internally timed. Pull CNVST low for a minimum of 20ns

(t

CNV11

) to trigger a temperature conversion. The BUSY

output goes high and the temperature conversion result

is available in the FIFO (if the ADCMON bit is set) 72µs

(typ) after BUSY goes low again.

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

26 ______________________________________________________________________________________

Figure 15. ADC Clock Mode 11 Example

INTERNAL TEMPERATURE READING, PGA1 OUTPUT, AND ADCIN1 CONVERSION TIMING IN CLOCK MODE 11

t

= 20ns (typ)

CNV

CNVST

= 1.5µs (typ)

t

= 30µs (typ)

t

ACQ

ACQ

BUSY

INTERNAL

OPERATIONS

WRITE TO ADC

CONVERT REGISTER TO

SET UP ADC SCAN

FBGON = 1,

ADCMON = 1

TEMPERATURE

CONVERSION

70µs (typ)

CONVERSION RESULT

AVAILABLE IN FIFO

IDLE MODE,

POWERED

TEMPERATURE

REF AND

TEMP

SENSOR

PGA 1

ACQUISITION

PGA 1

CONVERSION

22µs (typ)

RESULT AVAILABLE

IDLE MODE,

REF AND

SENSOR

POWERED

PGA 1 OUTPUT

CONVERSION

IN FIFO

TEMP

ADCIN1

ADCIN1

CONVERSION

ACQUISITION

ADCIN 1

CONVERSION

RESULT AVAILABLE

IN FIFO

7µs (typ)

END OF

SCAN

Page 27

For a PGAOUT conversion, set CNVST low for a minimum of 30µs or maximum of 40µs. The BUSY output

goes high at the start of the CNVST pulse and the

PGAOUT conversion result is available in the FIFO (if the

ADCMON bit has been set) 52µs (typ) after BUSY goes

low again.

For an ADCIN conversion, set CNVST low for at least

1.5µs. The BUSY output goes high at the end of the

CNVST pulse and the ADCIN conversion result is available in the FIFO (if the ADCMON bit is set) 7µs (typ) after

BUSY goes low again.

For ease of operation, all CNVST pulses can use a 30µs

width irrespective of the source being converted. In the

case of ADC conversions, the BUSY pulse width is

extended accordingly. For clock modes 00 and 01, the

BUSY pulse width duration depends on the channel conversion sequence selected.

Continuous conversion is not supported in this clock

mode (see Table 20 for the ADC Conversion register).

Changing Clock Modes During ADC Conversions

If a change is made to the clock mode in the configuration register while the ADC is already performing a conversion (or series of conversions), the following

describes how the MAX11008 responds:

• When CKSEL = 00 and is then changed to another

value, the ADC completes the already triggered series

of conversions and then goes idle. The BUSY output

remains high until the conversions are completed. The

MAX11008 then responds in accordance with the new

CKSEL mode.

• When CKSEL = 01 and is then changed to another

value and if the device is waiting for the initial external

trigger, the MAX11008 immediately exits clock mode

01, powers down the ADC, and goes idle. The BUSY

output stays low and the new clock mode is observed.

If a conversion sequence has started, the ADC completes the requested conversions and then goes idle.

The BUSY output remains high until the conversions

are completed. The MAX11008 then responds in

accordance with the new CKSEL mode.

• When CKSEL = 11 and is then changed to another

value and if the device is waiting for an external trigger, the MAX11008 immediately exits clock mode 11,

powers down the ADC, and goes idle. The BUSY output stays low and the new clock mode is observed.

Turning the Continuous Conversion Bit

(CONCONV) On and Off

When switching between continuous and single conversion modes, the clock mode requires resetting to avoid

hanging the ADC sequencing routine.

For example, the following is the command sequence to

switch from continuous to single conversion and revert to

continuous conversion:

1) Write ADCCON (00000000 10110111).

2) Turn off the selected channels, but leave the continuous convert bit asserted. Write ADCCON (00000000

10000000).

3) Turn off the continuous convert bit. Write ADCCON

(00000000 00000000).

4) Change from the current clock mode (00 in this case)

to any other one. Write HCFIG (00000100 00011000).

5) Change the clock mode back. Write HCFIG

(00000100 00001000).

6) Clear the FIFO. Write SCLR (00000000 00000100).

7) Perform the single conversion. Write ADCCON

(00000000 00110111).

8) Read the FIFO five times to capture the results of the

single conversions. Read FIFO.

9) Turn continuous convert back on. Write ADCCON

(00000000 10110111).

The alternative to this command sequence is to leave

continuous conversion on and just read the FIFO. When

using this method, decode the channel tag to determine

which channel has been read.

12-Bit DACs

In addition to the 12-bit ADC, the MAX11008 also

includes two voltage-output, 12-bit, monotonic DACs

with typically less than ±2 LSB integral nonlinearity

error and less than ±1 LSB differential nonlinearity

error. Each DAC also has a 45ms settling time and

ultra-low glitch energy (4nV·s). The 12-bit DAC codes

are unipolar binary with 1 LSB = V

REFDAC

/4096.

MAX11008

Dual RF LDMOS Bias Controller with

Nonvolatile Memory

______________________________________________________________________________________ 27

Page 28

MAX11008

Figure 16 shows the functional diagram of the

MAX11008 DACs. Each DAC includes an input and

output register. The input registers hold the result of the

most recent write operation, and the output registers

hold the current output code for the respective DAC.

Data written to a DAC input register is transferred to its

output register by writing to the Load DAC register (see

Table 22). Alternatively, write data directly to the output

register using the DAC Input and Output Data register.

The analog output voltages of the DACs (before amplification by the gate-drive amplifiers) are calculated with

the following equation:

where V

DACREF

is the value of the internal or external

reference voltage and CODE is the decimal value of the

12-bit code contained in the output register.

Gate-Drive Amplifiers

The gate-drive amplifiers are proportional to the analog

outputs of the 12-bit DACs and provide the necessary

gate voltage to drive the external LDMOS transistors.

Both amplifiers have a fixed gain of 2V/V and are capable of sourcing or sinking up to 2mA of current. Output

short-circuit protection prevents output currents from

exceeding ±25mA.

The gate output is equal to the DAC output voltage

amplified by 2.

V

GATE_

= 2 x V

DAC

See the

Software Configuration Registers

and

Temperature/APC LUT Configuration Registers

sections

for information on how the gate voltages are controlled

by temperature and APC samples.

Output Clamp

The MAX11008 features an output clamp mode that

protects the external LDMOS transistors by connecting

the gate-drive amplifier outputs (GATE_) to AGND. The

clamp mode can be controlled by the OPSAFE_ digital

inputs or by setting the appropriate ALMCLMP[1:0] bits

in the Alarm Hardware Configuration register (see

Table 14). When using the OPSAFE_ digital inputs, pull

OPSAFE_ high to enter clamp mode and pull OPSAFE_

low to exit clamp mode. The clamp can also be activated automatically from the alarm trip point setting registers; see the

Alarm Software Configuration Register

(ALMSCFIG) (Read/Write)

section.

Self-Calibration

Calibrate channel 1 and channel 2 by writing to the

PGA Calibration Control register. The MAX11008 functions after power-up without a calibration. Command a

calibration after powering up the device by setting the

TRACK bit to 0 and the DOCAL bit to 1 (see Table 19).

Subsequently, set the TRACK, DOCAL, and SELFTIME