Page 1

LM95010

LM95010 Digital Temperature Sensor with SensorPath Bus in MSOP8 Package

November 2003

Digital Temperature Sensor with SensorPath

MSOP8 Package

General Description

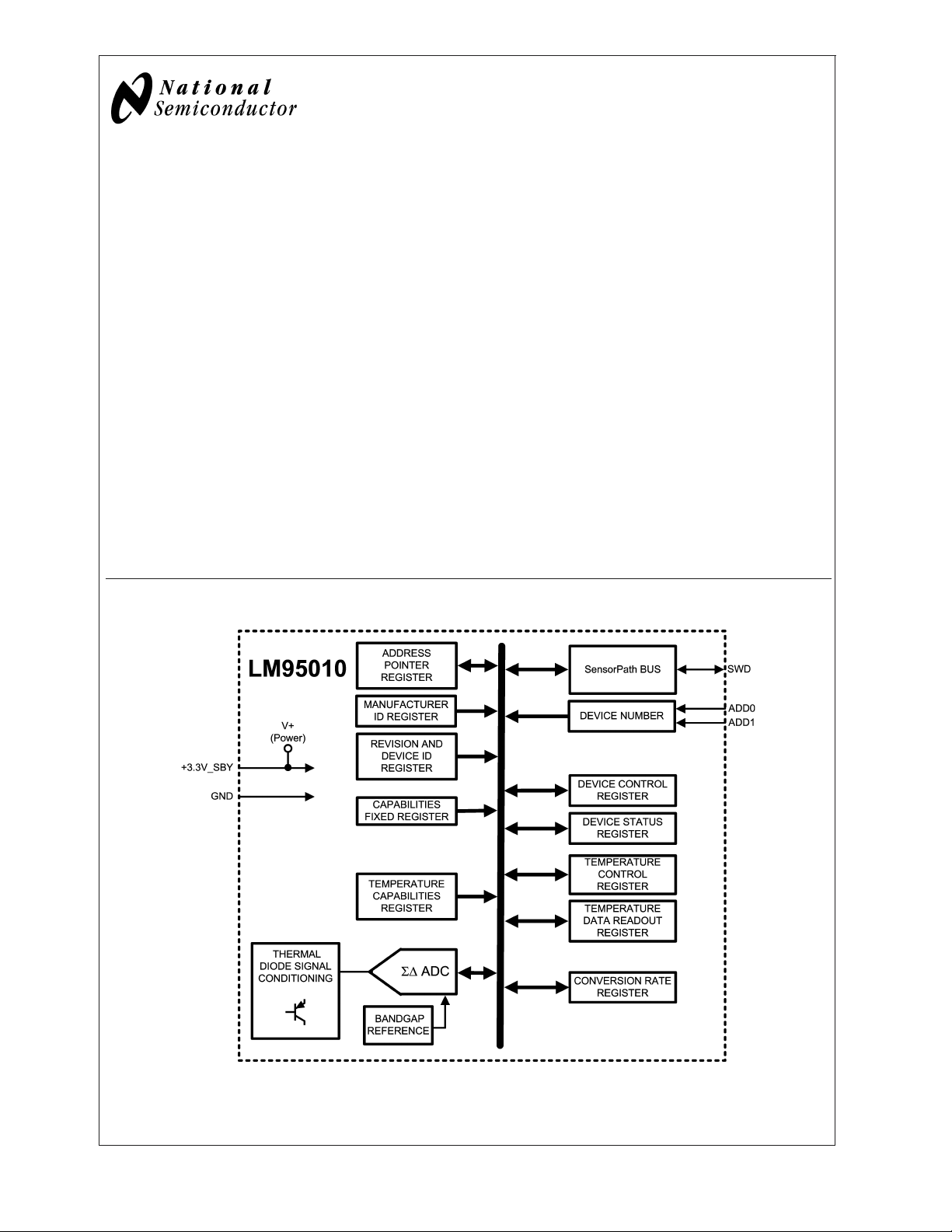

The LM95010 is a digital output temperature sensor that has

single-wire interface compatible with National Semiconductor’s SensorPath interface. It uses a ∆V

ture sensing technique that generates a differential voltage

that is proportional to temperature. This voltage is digitized

using a Sigma-Delta analog-to-digital converter. The

LM95010 is part of a hardware monitor system, comprised of

two parts: the PC System Health Controller (Master), such

as a Super I/O, and up to seven slaves of which four can be

LM95010s. Using SensorPath, the LM95010 will be controlled by the master and report to the master its own die

temperature. SensorPath data is pulse width encoded,

thereby allowing the LM95010 to be easily connected to

many general purpose micro-controllers.

analog tempera-

be

Features

n SensorPath Bus

— 4 hardware programmable addresses

Block Diagram

n Temperature Sensing

— 0.25 ˚C resolution

— 127.75 ˚C maximum temperature reading

n 8-lead MSOP package

Key Specifications

n Temperature Sensor Accuracy

n Temperature Range −20 ˚C to +125 ˚C

n Power Supply Voltage +3.0V to +3.6V

n Power Supply Current 0.5 mA (typ)

n Conversion Time 14 ms to 1456 ms

Applications

n Microprocessor based equipment

— (Motherboards, Base-stations, Routers, ATMs, Point

of Sale, …)

n Power Supplies

™

Bus in

±

2 ˚C (max)

20082001

SensorPath™is a trademark of National Semiconductor Corporation.

© 2003 National Semiconductor Corporation DS200820 www.national.com

Page 2

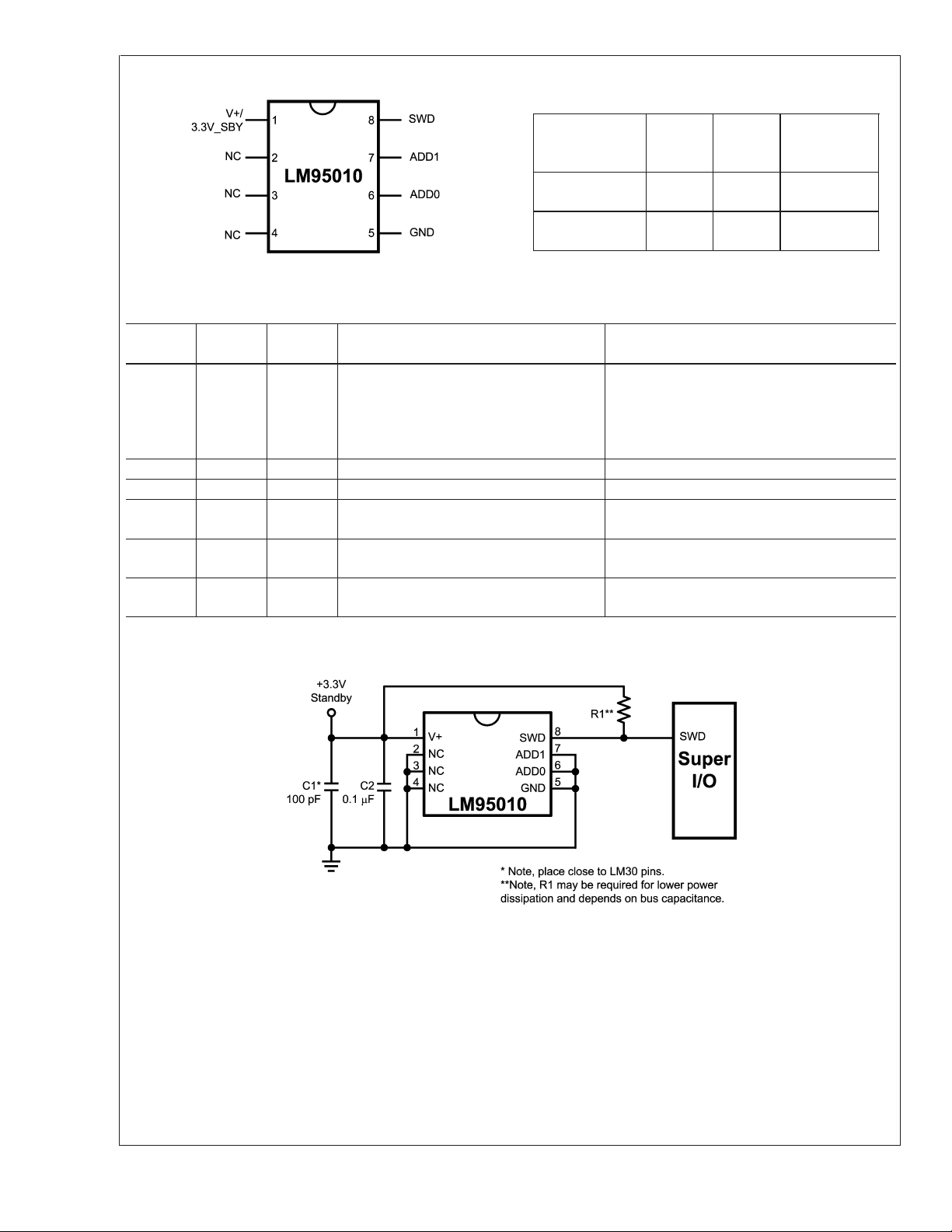

Connection Diagram

Ordering Information

LM95010

Order

Number

LM95010CIMM T19C MUA08A 1000 units in

LM95010CIMMX T19C MUA08A 3500 units in

20082002

Package

Marking

Pin Description

Pin

Number Pin Name Type Description Typical Connection

1 V+/3.3VSBPower Positive power supply pin +3.3V pin. Should be powered by +3.3V Standby power.

This pin should be bypassed with a 0.1 µF

capacitor. A bulk capacitance of approximately

10 µF needs to be in the near vicinity of the

LM95010.

2-4 NC Must be grounded.

5 GND Power Ground System ground

6 ADD0 Input Address select input that assigns the serial

bus device number

7 ADD1 Input Address select input that assigns the serial

bus device number

8 SWD Input/

Output

Single-wire Data, SensorPath serial

interface line; Open-drain output

10k resistor to V+ or GND; must never be left

floating

10k resistor to V+ or GND; must never be left

floating

Super I/O with 1.25k pull-up to 3.3V

NS

Package

Number

Transport

Media

tape and reel

tape and reel

Typical Application

FIGURE 1. LM95010 connection to SensorPath master such as a Super I/O.

20082003

www.national.com 2

Page 3

LM95010

Absolute Maximum Ratings

(Notes 1, 2)

Supply Voltage (V

Voltage on Pin 2 −0.3 V to (V+ + 0.3 V)

+

) −0.5 V to 6.0 V

Soldering Information, Lead Temperature

MSOP-8 Package (Note 6)

Vapor Phase (60 seconds) 215 ˚C

Infrared (15 seconds) 220 ˚C

Voltage on all other Pins −0.5 V to 6.0 V

Input Current per Pin(Note 3) 5 mA

Package Input Current (Note 3) 30 mA

Package Power Dissipation (Note 5)

Output Sink Current 10 mA

Storage Temperature −65 ˚C to +150 ˚C

ESD Susceptibility (Note 4)

Human Body Model 2000 V

Operating Ratings

(Notes 1, 2)

Temperature Range for

Electrical Characteristics T

LM95010CIMM −20 ˚C ≤ TA≤ +125 ˚C

Operating Temperature Range −20 ˚C ≤ T

Supply Voltage Range (V+) +3.0 V to +3.6 V

MIN

≤ TA≤ T

≤ +125 ˚C

A

Machine Model 200 V

DC Electrical Characteristics

The following specifications apply for V+ = 3.0 VDCto 3.6 VDC, unless otherwise specified in the conditions. Boldface limits

apply for T

A=TJ=TMIN

to T

POWER SUPPLY CHARACTERISTICS

Symbol Parameter Conditions

V+ Power Supply Voltage 3.3 3.0

I+

AVG

I+

Peak

Average Power Supply Current SensorPath Bus Inactive (Note

Peak Power Supply Current SensorPath Bus Inactive (Note

Power-On Reset Threshold Voltage 1.6 V (min)

TEMPERATURE-TO-DIGITAL CONVERTER CHARACTERISTICS

Parameter Conditions

Temperature Error T

Temperature Resolution 10 Bits

SWD and ADD DIGITAL INPUT CHARACTERISTICS

Symbol Parameter Conditions

SWD Logical High Input Voltage 2.1 V (min)

SWD Logical Low Input Voltage 0.8 V (max)

ADD Logical High Input Voltage 90%xV+ V (min)

ADD Logical Low Input Voltage 10%xV+ V (max)

SWD Input Hysteresis 300 mV

SWD and ADD Input Leakage

V

V

IH

V

IL

V

IH

V

IL

HYST

I

L

Current

SWD Input Leakage Current with V+

Open or Grounded

; all other limits TA= +25 ˚C.

MAX

= −20 ˚C and +125 ˚C (Note 10)

A

+25 ˚C ≤ T

T

A

GND ≤VIN≤ V+

GND ≤VIN≤ 3.6 V,

and V+ Open or

GND

Typical

(Note 7)

Limits

(Note 8)

Units

(Limit)

V (min)

3.6

V (max)

500 750 µA (max)

9)

1.6 mA

9)

2.8 V (max)

≤ +60 ˚C (Note 10)

A

Typical

(Note 7)

±

1

Limits

(Note 8)

±

3 ˚C (max)

±

2 ˚C (max)

Units

(Limits)

0.25 ˚C

Typical

(Note 7)

Limits

(Note 8)

Units

(Limit)

V+ + 0.5 V (max)

= 0 ˚C to +85 ˚C -0.5 V (min)

-0.3 V (min)

±

0.005

±

0.005 µA

±

10 µA (max)

MAX

www.national.com3

Page 4

SWD and ADD DIGITAL INPUT CHARACTERISTICS

Symbol Parameter Conditions

LM95010

C

IN

Digital Input Capacitance 10 pF

Typical

(Note 7)

Limits

(Note 8)

SWD DIGITAL OUTPUT CHARACTERISTICS

Symbol Parameter Conditions

V

OL

Open-drain Output Logic “Low”

Voltage

I

OH

C

OUT

Open-drain Output Off Current

Digital Output Capacitance 10 pF

IOL=4mA 0.4 V (max)

I

=50µA 0.2 V (max)

OL

Typical

(Note 7)

±

0.005

Limits

(Note 8)

±

10 µA (max)

AC Electrical Characteristics

The following specification apply for V+ = +3.0VDCto +3.6VDC, unless otherwise specified. Boldface limits apply for

T

A=TJ=TMIN

to T

cation. Please refer to that specification for further details.

HARDWARE MONITOR CHARACTERISTICS

Symbol Parameter Conditions

t

CONV

SensorPath Bus CHARACTERISTICS

Symbol Parameter Conditions

t

f

t

r

t

INACT

t

Mtr0

t

Mtr1

t

SFEdet

t

SLout1

t

MtrS

t

SLoutA

t

RST

t

RST_MAX

; all other limits TA=TJ= 25 ˚C. The SensorPath Characteristics conform to the SensorPath specifi-

MAX

Typical

(Note 7)

(Note 8)

Total Monitoring Cycle Time (Note 11) Default 182 163.8 ms (min)

Typical

SWD fall time (Note 12) R

SWD rise time (Note 13) R

= 1.25 kΩ

pull-up

±

30%, CL= 400 pF

=

pull-up

±

= 400 pF

L

30%,

1.25 kΩ

C

(Note 7)

(Note 8)

Minimum inactive time (bus at high level)

guaranteed by the LM95010 before an

Attention Request

Master drive for Data Bit 0 write and for

Data Bit 0-1read

Master drive for Data Bit 1 write 35.4 µs (min)

Time allowed for LM95010 activity

detection

LM95010 drive for Data Bit 1 read by

master

Master drive for Start Bit 80 µs (min)

LM95010 drive for Attention Request 165 µs (min)

Master or LM95010 drive for Reset 354 µs (min)

Maximum drive of SWD by an LM95010,

after the power supply is raised above 3V

Units

(Limit)

Units

(Limit)

Limits

Units

(Limits)

200.2 ms (max)

Limits

Units

(Limits)

300 ns (max)

1000 ns (max)

11 µs (min)

11.8 µs (min)

17.0 µs (max)

48.9 µs (max)

9.6 µs (max)

28.3 µs (min)

38.3 µs (max)

109 µs (max)

228 µs (max)

500 ms (max)

www.national.com 4

Page 5

LM95010

20082004

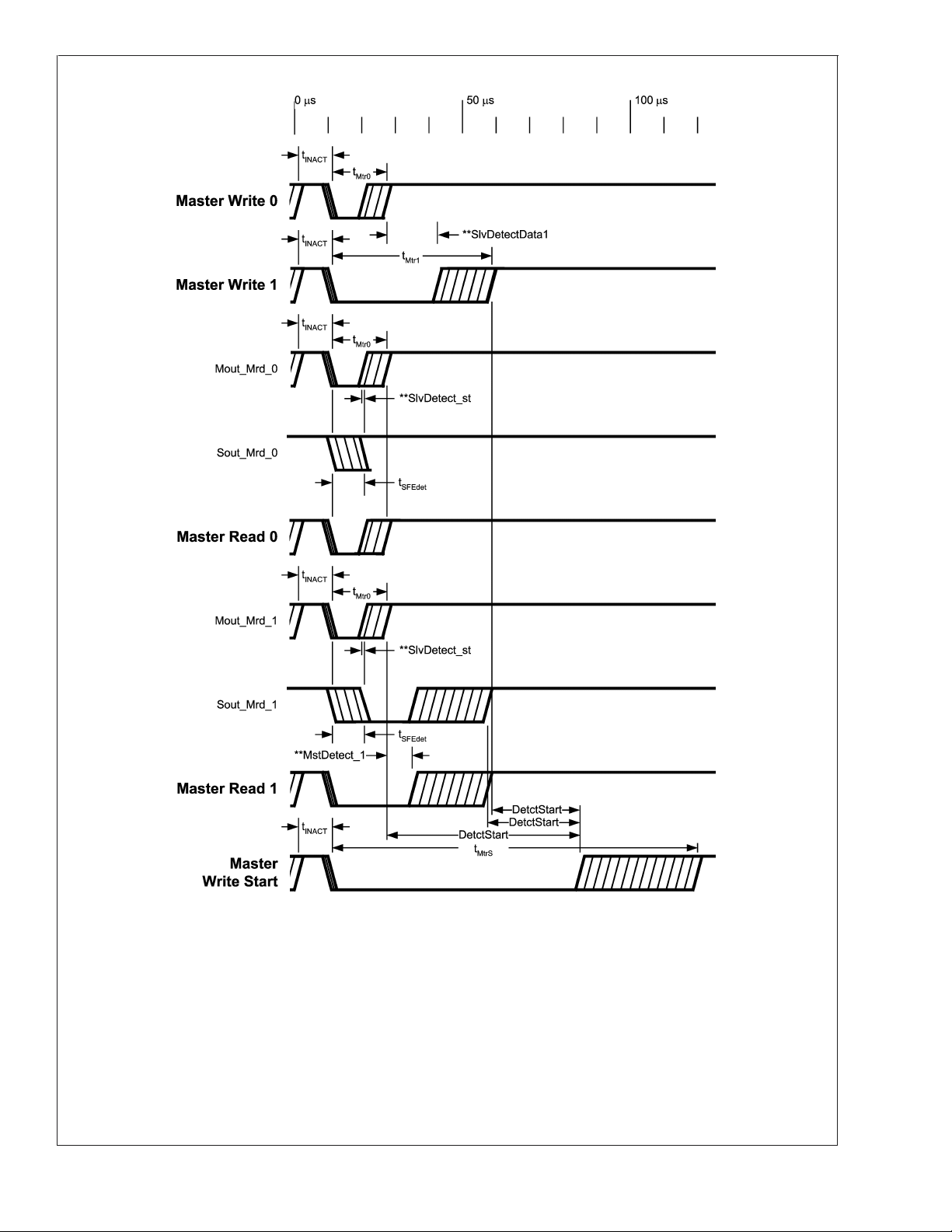

FIGURE 2. Timing for Data Bits 0, 1 and Start Bit. See Section 1.2 "Bit Signaling" for further details.

www.national.com5

Page 6

LM95010

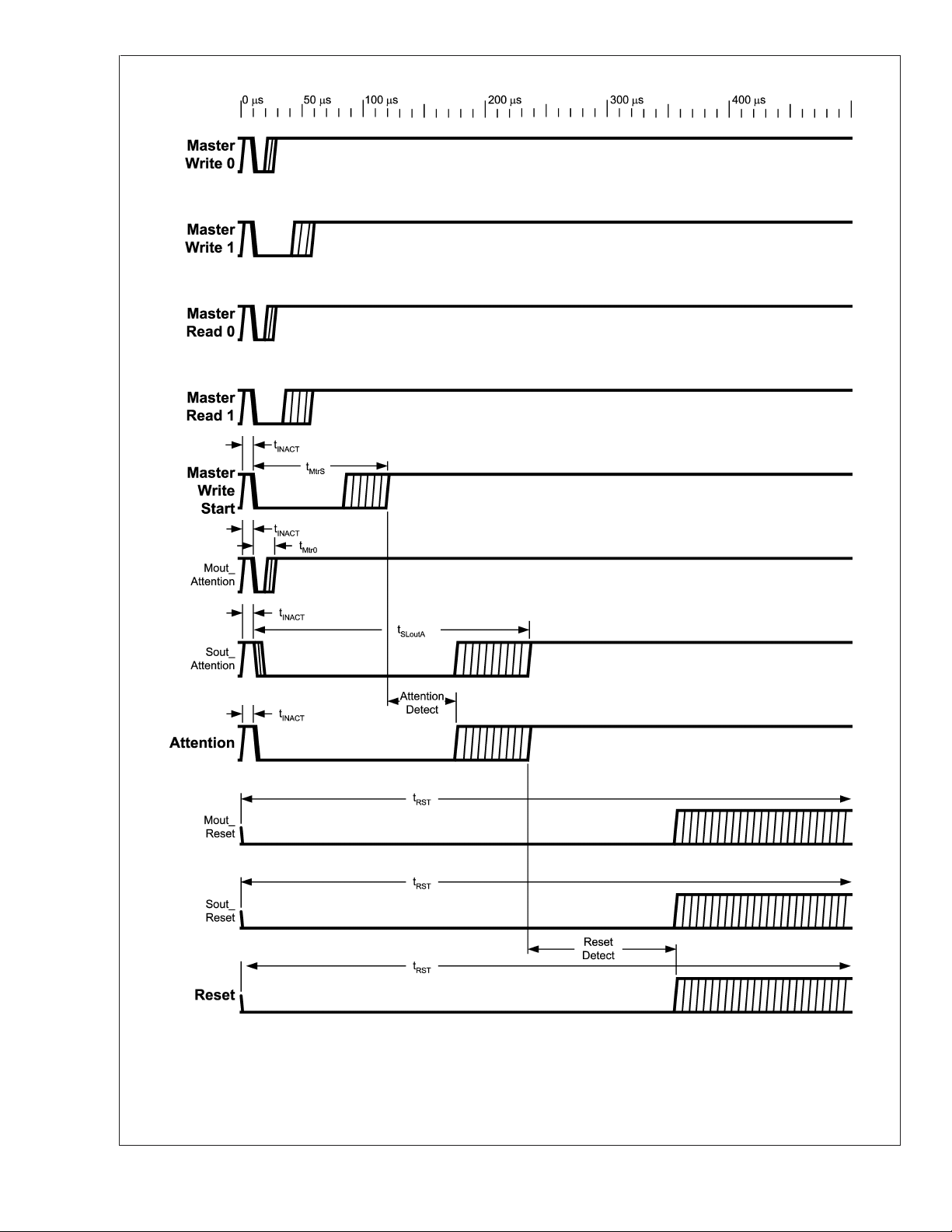

FIGURE 3. Timing for Attention Request and Reset. See Section 1.2 "Bit Signaling" for further details.

www.national.com 6

20082005

Page 7

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test

conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise noted.

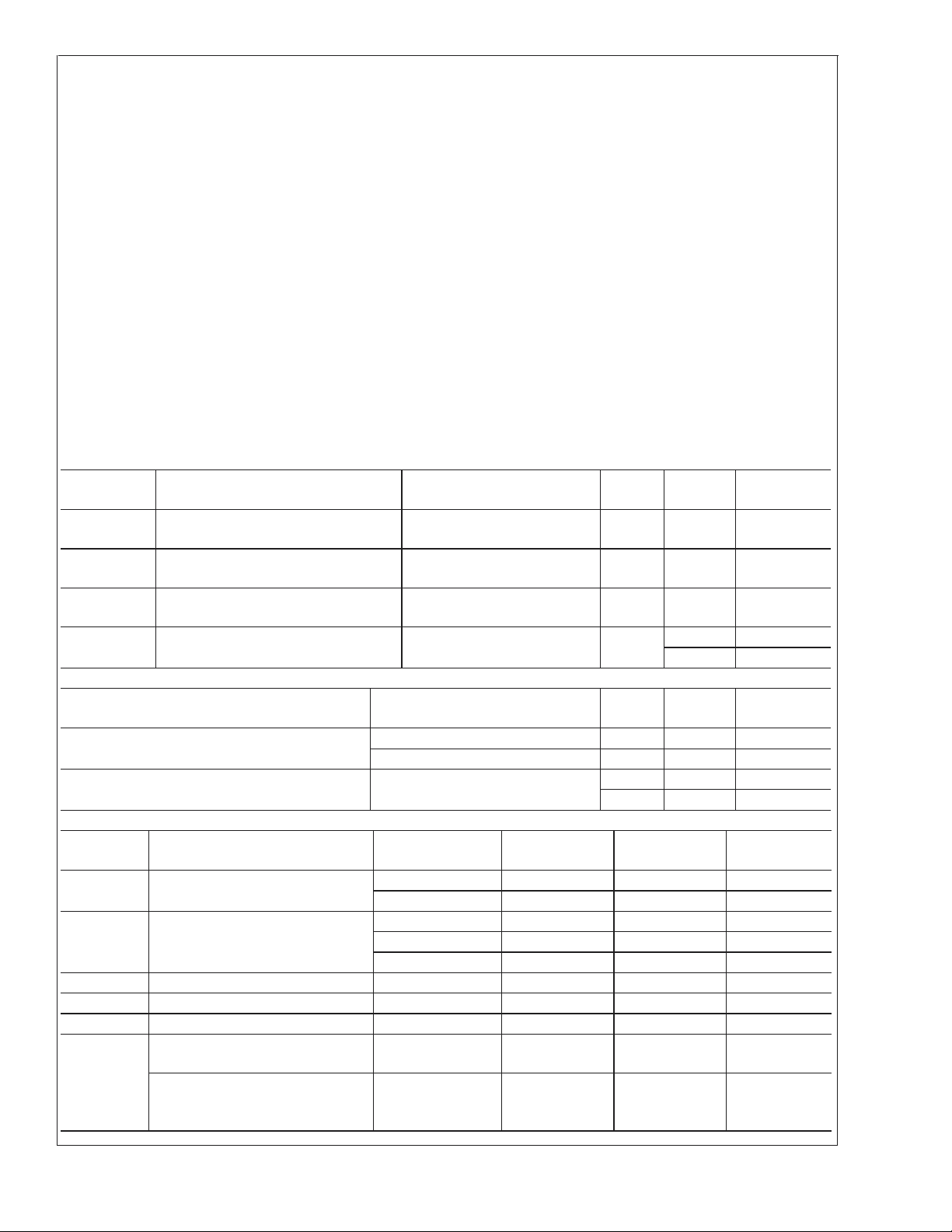

Note 3: When the input voltage (V

components and/or ESD protection circuitry are shown below for the LM95010’s pins. The nominal breakdown voltage of D3 is 6.5 V. SNP stands for snap-back

device. Devices that are connected to a particular pin are marked with a"U" in the table below.

) at any pin exceeds the power supplies (V

IN

<

IN

GND or V

>

V+), the current at that pin should be limited to 5 mA. Parasitic

IN

LM95010

Pin Name PIN

#

D1 D2 D3 D4 D5 R1 SNP ESD CLAMP

V+/3.3V SB 1 UU

NC 2 UUUUUU U

NC 3

NC 4 UU UU U

ADD0 6 UU UU U

ADD1 7 UU U

SWD 8 UU UU U

20082006

FIGURE 4. ESD Protection Input Structure. Devices that are connected to a particular pin are marked with a"U"in

the table above.

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor. Machine model, 200 pF discharged directly into each pin. See Figure 4 above for the ESD

Protection Input Structure.

Note 5: Thermal resistance junction-to-ambient when attached to a printed circuit board with 2 oz. foil is 210 ˚C/W.

Note 6: See the URL “http://www.national.com/packaging/” for other recommendations and methods of soldering surface mount devices.

Note 7: “Typicals” are at T

Note 8: Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 9: The supply current will not increase substantially with SensorPath transactions.

Note 10: Temperature accuracy does not include the effects of self-heating. The rise in temperature due to self-heating is the product of the internal power

dissipation of the LM95010 and the thermal resistance. See (Note 5) for the thermal resistance to be used in the self-heating calculation.

Note 11: This specification is provided only to indicate how often temperature data is updated once enabled.

Note 12: The output fall time is measured from V

Note 13: The output rise time is measured from V

= 25 ˚C and represent most likely parametric norm. They are to be used as general reference values not for critical design calculations.

A

to V

IH min

IL max

. The output fall time is guaranteed by design.

IL max

to V

. The output rise time is guaranteed by design.

IH min

www.national.com7

Page 8

Typical Performance Characteristics

LM95010

Conversion Rate Effect on Power Supply Current

1.0 Functional Description

The LM95010 is based on a ∆Vbetemperature sensing

method. A differential voltage, representing temperature, is

digitized using a Sigma-Delta analog to digital converter. The

digital temperature data can be retrieved over a simple

single-wire interface called SensorPath. SensorPath has

been defined by National Semiconductor and is optimized

for hardware monitoring. National offers a royalty-free license in connection with its intellectual property rights in the

SensorPath bus.

The LM95010 has 2 address pins that allow up to 4

LM95010s to be connected to one SensorPath bus. The

physical interface of SensorPath’s SWD signal is identical to

the familiar industry standard SMBus SMBDAT signal. The

digital information is encoded in the pulse width of the signal

being transmitted. Every bit can be synchronized by the

master simplifying the implementation of the master when

implemented with a microcontroller. For microcontroller’s

with greater functionality an asynchronous attention signal

can be transmitted by the LM95010 to interrupt the microcontroller and notify it that temperature data has been updated in the readout register.

To optimize the LM95010’s power consumption to the system requirements, the LM95010 has a shutdown mode as

well as it supports multiple conversion rates.

1.1 SensorPath BUS SWD

SWD is the Single Wire Data line used for communication.

SensorPath uses 3.3V single-ended signaling, with a pull-up

resistor and open-drain low-side drive (see Figure 5). For

timing purposes SensorPath is designed for capacitive loads

) of up to 400pF. Note that in many cases a 3.3V standby

(C

L

rail of the PC will be used as a power supply for both the

sensor and the master. Logic high and low voltage levels for

SWD are TTL compatible. The master may provide an internal pull-up resistor. In this case the external resistor is not

needed. The minimum value of the pull-up resistor must take

into account the maximum allowable output load current of

4mA.

20082020

20082007

FIGURE 5. SensorPath SWD simplified schematic

1.2 SensorPath BIT SIGNALING

Signals are transmitted over SensorPath using pulse-width

encoding. There are five types of "bit signals":

Data Bit 0

•

Data Bit 1

•

Start Bit

•

Attention Request

•

Reset

•

All the "bit signals" involve driving the bus to a low level. The

duration of the low level differentiates between the different

"bit-signals". Each "bit signal" has a fixed pulse width. SensorPath supports a Bus Reset Operation and Clock Training

sequence that allows the slave device to synchronize its

internal clock rate to the master. Since the LM95010 meets

±

15% timing requirments of SensorPath, the LM95010

the

does not require the Clock Training sequence and does

support this feature. This section defines the "bit signal"

behavior in all the modes. Please refer to the timing diagrams in the Electrical Characteristics section (Figure 2 and

Figure 3) while going through this section. Note that the

timing diagrams for the different types of "bit signals" are

shown together to better highlight the timing relationships

between them. However, the different types of "bit signals"

appear on SWD at different points in time. These timing

diagrams show the signals as driven by the master and the

LM95010 slave as well as the signal as seen when probing

SWD. Signals labels that begin with the label Mout_ depict a

www.national.com 8

Page 9

1.0 Functional Description (Continued)

drive by the master. Signals labels that begin with the label

Slv_ depict the drive by the LM95010. All other signals show

what would be seen when probing SWD for a particular

function (e.g. "Master Wr 0" is the Master transmitting a Data

Bit with the value of 0).

1.2.1 Bus Inactive

The bus is inactive when the SWD signal is high for a period

of at least t

signal".

1.2.2 Data Bit 0 and 1

All Data Bit signal transfers are started by the master. A Data

Bit 0 is indicated by a "short" pulse; a Data Bit 1 is indicated

by a longer pulse. The direction of the bit is relative to the

master, as follows:

Data Write - a Data Bit transferred from the master to the

•

LM95010.

Data Read - a Data Bit transferred from the LM95010 to

•

the master.

A master must monitor the bus as inactive before starting a

Data Bit (read or Write).

A master initiates a data write by driving the bus active (low

level) for the period that matches the data value (t

for a write of "0" or "1", respectively). The LM95010 will

detect that the SWD becomes active within a period of

, and will start measuring the duration of that the SWD

t

SFEdet

is active in order to detect the data value.

A master initiates a data read by driving the bus for a period

. The LM95010 will detect that the SWD have become

of t

Mtr0

active within a period of t

LM95010 will not drive the SWD. For a data read of "1" the

LM95010 will start within t

period of t

the time at which the bus becomes inactive to identify a data

read of "0" or "1".

During each Data Bit, both the master and all the LM95010s

must monitor the bus (the master for Attention Request and

Reset; at the LM95010s for Start Bit, Attention Request and

Reset) by measuring the time SWD is active (low). If a Start

Bit, Attention Requests or Reset "bit signal" is detected, the

current "bit signal" is not treated as a Data Bit.

Note that the bit rate of the protocol varies depending on the

data transferred. Thus, the LM95010 has a value of "0" in

reserved or unused register bits for bus bandwidth efficiency.

1.2.3 Start Bit

A master must monitor the bus as inactive before beginning

a Start Bit.

The master uses a Start Bit to indicate the beginning of a

transfer. LM95010s will monitor for Start Bits all the time, to

allow synchronization of transactions with the master. If a

Start Bit occurs in the middle of a transaction, the LM95010

being addressed will abort the current transaction. In this

case the transaction is not "completed" by the LM95010 (see

Section 1.3 "SensorPath Bus Transactions").

During each Start Bit, both the master and all the LM95010s

must monitor the bus for Attention Request and Reset, by

. The bus is inactive between each "bit

INACT

. For a data read of "0", the

SFEdet

to drive the SWD low for a

. Both master and LM95010 must monitor

SLout1

SFEdet

Mtr0

or t

Mtr1

measuring the time SWD is active (low). If an Attention

Request or Reset condition is detected, the current "bit

signal" is not treated as a Start Bit. The master may attempt

to send the Start Bit at a later time.

1.2.4 Attention Request

The LM95010 may initiate an Attention Request when the

SensorPath bus is inactive.

Note that a Data Bit, or Start Bit, from the master may start

simultaneously with an Attention Request from the

LM95010. In addition, two LM95010s may start an Attention

Request simultaneously. Due to its length, the Attention Request has priority over any other "bit signal", except Reset.

Conflict with Data Bits and Start Bits are detected by all the

devices, to allow the bits to be ignored and re-issued by their

originator.

The LM95010 will either check to see that the bus is inactive

before starting an Attention Request, or start the Attention

Request with the t

active. The LM95010 will drive the signal low for t

time interval after SWD becomes

SFEdet

SLoutA

time.

After this, both the master and the LM95010 must monitor

the bus for a Reset Condition. If a Reset condition is detected, the current "bit signal" is not treated as an Attention

Request.

After Reset, an Attention Request can not be sent before the

master has sent 14 Data Bits on the bus. See Section 1.3.5

for further details on Attention Request generation.

1.2.5 Bus Reset

The LM95010 issues a Reset at power up. The master must

also generate a Bus Reset at power-up for at least the

minimum reset time, it must not rely on the LM95010. SensorPath puts no limitation on the maximum reset time of the

master. Following a Bus Reset, the LM95010 may generate

an Attention Request only after the master has sent 14 Data

Bits on the bus. See section 1.3.5 for further details on

Attention Request generation.

1.3 SensorPath BUS TRANSACTIONS

SensorPath is designed to work with a single master and up

to seven slave devices. Each slave has a unique address.

The LM95010’s supports up to 4 device addresses that are

selected by the state of the address pins ADD0 and ADD1.

The Register Set of the LM95010 is defined in Section 2.0.

1.3.1 Bus Reset Operation

A Bus Reset Operation is global on the bus and affects only

the communication interface of all the devices connected to

it. The Bus Reset operation does not affect either the contents of the device registers, or device operation, to the

extent defined in LM95010 Register Set, see Section 2.0.

The Bus Reset operation is performed by generating a Reset

signal on the bus. The master must apply Reset after powerup, and before it starts operation. The Reset signal end will

be monitored by all the LM95010s on the bus.

After the Reset Signal the SensorPath specification requires

that the master send a sequence of 8 Data Bits with a value

of "0", without a preceding Start Bit. This is required to

enable slaves that "train" their clocks to the bit timing. The

LM95010 does not require nor does it support clock training.

LM95010

www.national.com9

Page 10

1.0 Functional Description (Continued)

LM95010

20082008

FIGURE 6. Bus Reset Transaction

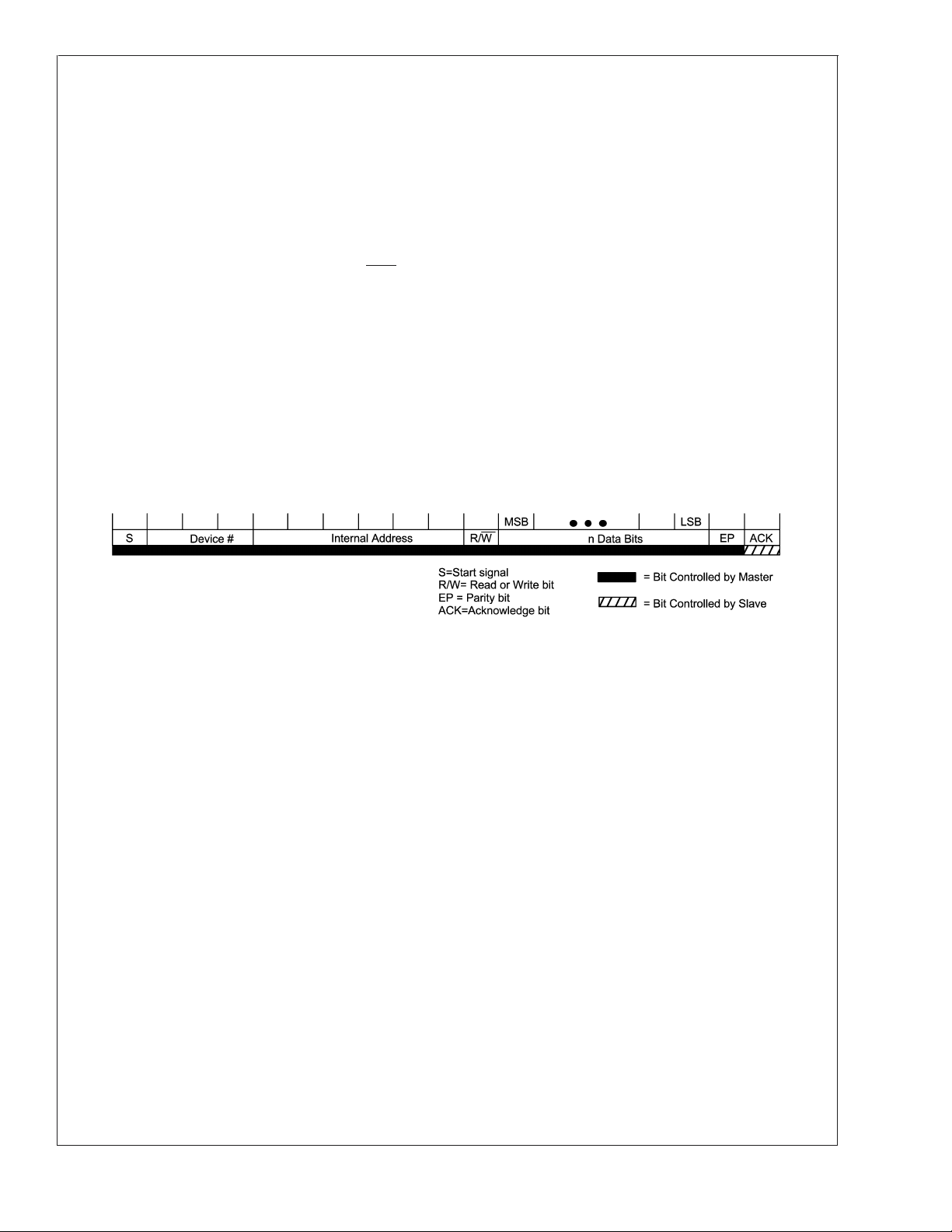

1.3.2 Read Transaction

During a read transaction, the master reads data from a

register at a specified address within a slave. A read transaction begins with a Start Bit and ends with an ACK bit, as

shown in Figure 7.

Device Number This is the address of the LM95010

•

device accessed. Address "000" is a broadcast address

and can be responded to by all the slave devices. The

LM95010 ignores the broadcast address during a read

transaction.

Internal Address The address of a register within the

•

LM95010 that is read.

Read/Write (R/W) A "1" indicates a read transaction.

•

Data Bits During a read transaction the data bits are

•

driven by the LM95010. Data is transferred serially with

the most significant bit first. This allows throughput optimization based on the information that needs to be read.

The LM95010 supports 8-bit or 16-bit data fields, as

described in Section 2.0 "Register Set".

Even Parity (EP) This bit is based on all preceding bits

•

(device number, internal address, read/write and data

bits) and the parity bit itself. The parity -number of 1’s - of

all the preceding bits and the parity bit must be even - i.e.,

the result must be 0. During a read transaction, the EP bit

is sent by the LM95010 to the master to allow the master

to check the received data before using it.

Acknowledge (ACK) During a read transaction the ACK

•

bit is sent by the master indicating that the EP bit was

received and was found to be correct, when compared to

the data preceding it, and that no conflict was detected

on the bus (excluding Attention Request - see Section

1.3.5 "Attention Request Transaction"). A read transfer is

considered "complete" only when the ACK bit is received.

A transaction that was not positively acknowledged is not

considered "complete" by the LM95010 and following are

performed:

— The BER bit in the LM95010 Device Status register is

set

— The LM95010 generates an Attention Request before,

or together with the Start Bit of the next transaction

A transaction that was not positively acknowledged is

also not considered "complete" by the master (i.e. internal operations related to the transaction are not performed). The transaction may be repeated by the master,

after detecting the source of the Attention Request (the

LM95010 that has a set BER bit in the Device Status

register). Note that the SensorPath protocol neither

forces, nor automates re-execution of the transaction by

the master.

The values of the ACK bit are:

— 1: Data was received correctly

— 0: An error was detected (no-acknowledge).

FIGURE 7. Read Transaction, master reads data from LM95010

1.3.3 Write Transaction

In a write transaction, the master writes data to a register at

a specified address in the LM95010. A write transaction

begins with a Start Bit and ends with an ACK Data Bit, as

show in Figure 8.

Device Number This is the address of the slave device

•

accessed. Address "000" is a broadcast address and is

responded to by all the slave devices. The LM95010

responds to broadcast messages to the Device Control

Register.

www.national.com 10

20082009

Internal Address This is the register address in the

•

LM95010 that will be written.

Read/Write (R/W) A "0" data bit directs a write transac-

•

tion.

Page 11

1.0 Functional Description (Continued)

Data Bits This is the data written to the LM95010 regis-

•

ter, are driven by the master. Data is transferred serially

with the most significant bit first. The number of data bits

may vary from one address to another, based on the size

of the register in the LM95010. This allows throughput

optimization based on the information that needs to be

written.

The LM95010 supports 8-bit or 16-bit data fields, as

described in Section 2.0 "Register Set".

Even Parity (EP) This data bit is based on all preceding

•

bits (Device Number, Internal Address, Read/Write and

Data bits) and the Even Parity bit itself. The parity (number of 1’s) of all the preceding bits and the parity bit must

be even - i.e. the result must be 0. During a write transaction, the EP bit is sent by the master to the LM95010 to

allow the LM95010 to check the received data before

using it.

Acknowledge (ACK) During the write transaction the

•

ACK bit is sent by the LM95010 indicating to the master

that the EP was received and was found correct, and that

no conflict was detected on the bus (excluding Attention

Request - see Section 1.3.5 "Attention Request Transac-

LM95010

tion"). A write transfer is considered "completed" only

when the ACK bit is generated. A transaction that was not

positively acknowledged is not considered complete by

the LM95010 (i.e. internal operation related to the transaction are not performed) and the following are performed:

— The BER bit in the LM95010 Device Status register is

set;

— The LM95010 generates an Attention Request before,

or together with the Start Bit of the next transaction

A transaction that was not positively acknowledged is

also not considered "complete" by the master (i.e. internal operations related to the transaction are not performed). The transaction may be repeated by the master,

after detecting the source of the Attention Request (the

LM95010 that has a set BER bit in the Device Status

register). Note that the SensorPath protocol neither

forces, nor automates re-execution of the transaction by

the master.

The values of the ACK bit are:

— 1: Data was received correctly;

— 0: An error was detected (no-acknowledge).

FIGURE 8. Write Transaction, master write data to LM95010

1.3.4 Read and Write Transaction Exceptions

This section describes master and LM95010 handling of

special bus conditions, encountered during either Read or

Write transactions.

If an LM95010 receives a Start Bit in the middle of a transaction, it aborts the current transaction (the LM95010 does

not "complete" the current transaction) and begins a new

transaction. Although not recommend for SensorPath normal

operation, this situation is legitimate, therefore it is not

flagged as an error by the LM95010 and Attention Request is

not generated in response to it. The master generating the

Start Bit, is responsible for handling the not "complete" transaction at a "higher level".

If LM95010 receives more than the expected number of data

bits (defined by the size of the accessed register), it ignores

the unnecessary bits. In this case, if both master and

LM95010 identify correct EP and ACK bits they "complete"

the transaction. However, in most cases, the additional data

bits differ from the correct EP and ACK bits. In this case, both

the master and the LM95010 do not "complete" the transaction. In addition, the LM95010 performs the following:

the BER bit in the LM95010 Device Status register is set

•

the LM95010 generates an Attention Request

•

If the LM95010 receives less than the expected number of

data bits (defined by the size of the accessed register), it

waits indefinitely for the missing bits to be sent by the

20082010

master. If then the master sends the missing bits, together

with the correct EP/ACK bits, both master and LM95010

"complete" the transaction. However, if the master starts a

new transaction generating a Start Bit, the LM95010 aborts

the current transaction (the LM95010 does not "complete"

the current transaction) and begins the new transaction. The

master is not notified by the LM95010 of the incomplete

transaction.

1.3.5 Attention Request Transaction

Attention Request is generated by the LM95010 when it

needs the attention of the master. The master and all

LM95010s must monitor the Attention Request to allow bit

re-sending in case of simultaneous start with a Data Bit or

Start Bit transfer. Refer to the "Attention Request" section,

Section 1.2.4 in the "Bit Signaling" portion of the data sheet.

The LM95010 will generate an Attention Request using the

following rules:

1. A Function event that sets the Status Flag has occurred

and Attention Request is enabled and

2. The "physical" condition for an Attention Request is met

(i.e., the bus is inactive), and

3. At the first time 2 is met after 1 occurred, there has not

been an Attention request on the bus since a read of the

Device Status register, or since a Bus Reset.

OR

www.national.com11

Page 12

1.0 Functional Description (Continued)

1. A bus error event occurred, and

LM95010

2. the "physical" condition for an Attention Request is met

(i.e., the bus is inactive), and

3. At the first time 2. is met after 1 occurred, there has not

been a Bus Reset.

All devices (master or slave) must monitor the bus for an

Attention Request signal. The following notes clarify the

intended system operation that uses the Attention Request

Indication.

Masters are expected to use the attention request as a

•

trigger to read results from the LM95010. This is done in

a sequence that covers all LM95010s. This sequence is

referred to as "master sensor read sequence".

After an Attention Request is sent by an LM95010 until

•

after the next read from the Device Status register the

LM95010 does not send Attention Requests for a function

event since it is guaranteed that the master will read the

Status register as part of the master sensor read sequence. Note that the LM95010 will send an attention for

BER, regardless of the Status register read, to help the

master with any error recovery operations and prevent

deadlocks.

2.0 Register Set

2.1 REGISTER SET SUMMARY

A master must record the Attention Request event. It

•

must then scan all slave devices in the system by reading

their Device Status register and must handle any pending

event in them before it may assume that there are no

more events to handle.

Note: there is no indication of which slave has sent the

request. The requirement that multiple requests are not sent

allows the master to know within one scan of register reads

that there are no more pending events.

1.3.6 Fixed Number Setting

The LM95010 device number is defined by strapping of the

ADD0 and ADD1 pins. The LM95010 will wake (after Device

Reset) with the Device Number field of the Device Number

register set to the address as designated in Section 1.1.1

Device Number. It is the responsibility of the system designer to avoid having two devices with the same Device

Number on the bus.

Devices should be detected by the master by a read operation of the Device Number register. The read returns "000" if

there is no device at that address on the bus (the EP bit must

be ignored).

P

Reg

Register

Add

000 000

000 001 ManufacturerIDR 100Bh 0001000000001011

000 010 Device ID R 21h RevID Device ID

000 011 Capabilities

000 100 Device

000 101 Device

001 000 Temperature

001 001 Temperature

001 010 Temperature

001 011

-011 111

100 000 Conversion

100 001

- 111 111

Name

Device

Number

Fixed

Status

Control

Capabilities

Data

Readout

Control

Reserved R Undefined

Rate

Undefined

Registers

R/

W

R * Not Available

R 1h Reserved Function 1

R 0h Not Available BER 0 0 ERF1 0 0 0 SF1

R/W0h Reserved EnF1 Res Low

R 014Ah Reserved Int

R MSb

R/W0h Reserved EN0 ATE

R/W2h Not Available 000000Conversion

R Undefined

Bit

O

R

Val

Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

15

MSb

Reserved

00000

0000000000100001

0000000000000001

00000000000 0

Rout

Sign 10Bits 0.25˚C

Sens

Size

0000000101001010

64˚C 32˚C 16˚C 8˚C 4˚C 2˚C 1˚C 0.5˚CLSb

Sign

00000000000000

0.25

000000

˚C

Pwr

Reserved

See Table 1

Resolution

1

Shut

down

Bit

0

LSb

Reset

Rate

www.national.com 12

Page 13

2.0 Register Set (Continued)

* Depends on state of ADD pins see Table 1.

2.2 Device Reset Operation

A Device Reset operation is performed in the following conditions:

At device power-up.

•

When the Reset bit in the Device Control register is set to 1 (see Section 2.8 "Device Control").

•

The Device Reset operation performs the following:

Aborts any device operation in progress and restarts device operation.

•

Sets all device registers to their "Reset" (default) value.

•

2.3 DEVICE NUMBER (Addr 00o)

This register is used to specify a unique address for each device on the bus.

P

Reg Add Register Name

000 000 Device Number R 4h-1h

The value of AS2:AS0 is determined by the setting of the ADD0 and ADD1 input pins:

TABLE 1. Device Number Assignment

[ADD1:ADD0] [AS2:AS0]

00 001

01 010

R/

W

O

R

Val

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

Reserved

00000

[ADD1:ADD0] [AS2:AS0]

10 011

11 100

LM95010

Bit 0

LSb

AS2 AS1 AS0

The value of AS2:AS0 will directly change and follow the value determined by ADD1:ADD0. Since this is a read only register the

value of the address cannot be changed by software.

2.4 MANUFACTURER ID (Addr 01o)

P

Reg

Add

000 001

The manufacturer ID matches that assigned to National Semiconductor by the PCI SIG. This register may be used to identify the

manufacturer of the device in order to perform manufacturer specific operations.

2.5 DEVICE ID (Addr 02o)

Reg

Add

000 010 Device ID R 21h

The device ID is defined by the manufacturer of the device and is unique for each device produced by a manufacturer. Bits 15-11

identify the revision number of die and will be incremented upon revision of the device.

Register

Name

Manufacturer

ID

Register

Name

Bit Type Description

10-0 RO DeviceID (Device ID Value) A fixed value that identifies the device.

15-11 RO RevID (Revision ID Value) A fixed value that identifies the device revision.

R/

W

R 100Bh 0001000000001011

R/

W

Bit

O

R

Val

P

O

R

Val

Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

15

MSb

Bit

Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

15

MSb

RevID DeviceID

0000000000100001

1

1

Bit

0

LSb

Bit

0

LSb

www.national.com13

Page 14

2.0 Register Set (Continued)

2.6 CAPABILITIES FIXED (Addr 03o)

LM95010

P

Reg

Register

Add

000 011

The value of this register defines the capabilities of the LM95010. The LM95010 supports only one function, that of Temperature

Measurement type. Please refer to the SensorPath specification for further details on other FuncDescriptor values.

2.7 DEVICE STATUS (Addr 04o)

This register is set to the reset value by a Device Reset.

Reg Add Register Name

Name

Capabilities

Fixed

000 100 Device Status R 0h BER 0 0 ERF1 0 0 0 SF1

Bit Type Description

0ROSF1 (Status Function 1). This bit is set by a Function Event within Function 1. Event details are function

3-1 RO Not supported. Will always read "0".

4ROERF1 (Error Function 1) This bit is set in response to an error indication within Function 1. ERF1 is cleared

6-5 RO Not supported. Will always read "0".

7ROBER (Bus Error). This bit is set when the device either generates, or receives an error indication in the ACK

R/

W

R1h

dependent and are described within the function. SF1 is cleared by Device Reset or by handling the event

within the function (see Section 2.9 for further details).

0: Status flag for Function 1 is inactive (no event).

1: Status flag for Function 1 is active indicating that a Function Event has occurred.

by Device Reset or by handling the error condition within the function (see Section 2.9 for further details).

0: No error occurred in Function 1.

1: Error occurred in Function 1.

bit of the transaction (i.e., no-acknowledge). BER is cleared by Device Reset or by reading the Device Status

register.

0: No transaction error occurred.

1: An ACK bit error (no-acknowledge) occurred during the last transaction.

Bit

O

R

Val

Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

15

MSb

Reserved FuncDescriptor1

0000000000000001

P

R/

W

O

R

Val

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

1

Bit

0

LSb

Bit 0

LSb

2.8 DEVICE CONTROL (Addr 05o)

This register responds to a broadcast write command (DeviceNumber 000). Write using broadcast address is ignored by bits

15-2. This register is set to the reset value by a Device Reset.

P

Reg

Register

Add

000 101

www.national.com 14

Name

Device

Control

Bit Type Description

0 R/W Reset (Device Reset). When set to "1" this bit initiates a Device Reset operation ( See Section 2.2). This bit

R/

W

R/

W

self-clears after the Device Reset operation is completed.

0: Normal device operation. (default)

1: Device Reset

The LM95010 does not require a Device Reset command after power.

Bit

O

R

Val

0h

Bit14Bit13Bit12Bit11Bit

15

MSb

00000000000

10

Reserved

Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

Bit9

EnF1 Res

Low

Pwr

Bit

1

LSb

Shut

downReset

0

Page 15

2.0 Register Set (Continued)

Bit Type Description

1 R/W Shutdown (Shutdown Mode). When set to "1" this bit stops the operation of all functions and places the

device in the lowest power consumption mode.

0: Device in Active Mode. (default)

1: Device in Shutdown Mode.

2 R/W LowPwr (Low-Power Mode). When set to "1" this bit slows the operation of all functions and places the

device in a low power consumption mode. In Low-Power Mode, the conversion rate of the LM95010 is

effected see Section 2.10 for further details.

0: Device in Active Mode. (default)

1: Device in Low-Power Mode.

3RONot supported. Will always read "0".

4 R/W EnF1 (Enable Function 1). When bit is set to "1" this bit Function 1 is enabled for operation. A function may

require setup before this bit is set. The function registers can be accessed even when the function is

disabled.

0: Function 1 is disabled. (default)

1: Function is enabled.

15-5 RO Not supported. Will always read "0".

2.9 TEMPERATURE MEASUREMENT FUNCTION (TYPE - 0001)

This section defines the register structure and operation of a Temperature Measurement function as it applies to the LM95010.

The FuncDescriptor value of this function is ‘0001’.

LM95010

2.9.1 Operation

The Temperature Measurement function as implemented in the LM95010 supports one temperature zone, the LM95010’s internal

temperature (LM95010’s junction temperature). Since the LM95010 only supports one temperature measurement the Sensor

Scan function as defined in the SensorPath specification only applies to one temperature sensor. A temperature scan is enabled

by the SensorEnable bit (EN0). The minimum scan rate is recommended to be 4Hz (i.e. the measurement data is updated at least

once in 250 ms), see Section 2.10 for further details. In Low-Power Mode, the scan rate is four time lower than the scan rate in

Active Mode. The scan rate effects the bus bandwidth required to read the results. The sampling rate of the temperature

measurements can also be controlled via the Conversion Rate register, see Section 2.10 for further details.

Data Readout When a new result is stored in the Readout register a Function Event is generated. Reading the Readout

register clears the Status Function 1 flag (SF1). The result is available in the Readout register waiting for the master to read it

during the master sensor read sequence. If a new result is ready before the previous result has been read, the new result

overwrites the previous result and the Error Function 1 flag (ERF1) is set (indicating an overrun event). Reading the Readout

register clears also the Error Function 1 flag (ERF1). The Readout register contains the temperature data, and the sensor number.

Since the LM95010 only supports one temperature zone the sensor number field will always report zero. Other fields in the

Readout register as defined by the SensorPath specification are not supported.

Readout Resolution The resolution of the readout is defined in the Temperature Capabilities register. The resolution of the

LM95010 is fixed and cannot be modified by software.

Function Event The Temperature Measurement function generates a Function Event whenever a temperature conversion

cycle is completed and new data is stored in the Readout Register. When the new data is stored into the Readout register the SF1

bit in the device Status register is set to "1" and remains set, until it is cleared by reading the Readout register. An Attention

Request is generated on the bus, only if it is enabled by the Attention Enable bit (ATE) in the Temperature Control register.

Setup Before Enabling No setup is required for the Temperature Measurement function before the function is enabled.

2.9.2 Temperature Capabilities (Addr 10o)

P

Reg

Add

001 000

Register

Name

Temperature

Capabilities

R/

W

R 014Ah

Bit

O

R

Val

Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

15

MSb

Int

Reserved

0000000101001010

Sens

Rout

Sign 10Bits

Size

1

0.25˚C

Resolution

Bit

0

LSb

This register defines the format of the temperature data in the readout register. The LM95010 only supports one format as defined

by the values of this register.

www.national.com15

Page 16

2.0 Register Set (Continued)

LM95010

Bit Type Description

2-0 R Resolution. This field defines the value of 1 LSb of the Temperature Readout field in the Readout Register.

The SensorPath specification defines many different weights for the temperature LSb. The LM95010

supports a resolution of 0.25 ˚C and thus a value of 010 for this field. For a full definition of this field please

refer to the SensorPath specification.

5-3 R Number of Bits. This field defines the total number of significant bits of the Temperature Readout field in the

Readout register. The total number of osignificant bits includes the number of bits representing the interger

part of the temperature data and the fractional part of it, as defined by the Resolution field. The LM95010

supports 10 bits and thus a value of 001 for this field. For a full definition of this field please refer to the

SensorPath specification.

6RSign (Signed Data). Defines the type of data in the Temperature Readout field of the Readout register.

0: Unsigned, positive fixed point value.

1: Signed, 2’s complement fixed point value. (value for the LM95010)

7RRoutSize (Readout Register size). Defines the total size of the Readout register.

0: 16 bits. (LM95010 default)

1: 24 bits.

8 R/W IntSens (Internal Sensor Support). Indicates if the device supports internal temperature measurements, as

the LM95010 does.

0: No internal temperature measurement

1: Internal temperature sensor implemented. (value for the LM95010)

15-9 RO Reserved. Will always read "0".

2.9.3 Temperature Data Readout (Addr 11o)

P

Reg

Register

Add

001 001

The LM95010’s temperature data format is two’s complement and has 10-bits of resolution with the LSb having a weight of

0.25 ˚C. The LM95010 can resolve temperature between +127.75 ˚C and -128 ˚C, inclusive. It can measure temperatures

between +127.75 ˚C and −20 ˚C with an accuracy of

Name

Temperature

Data

Readout

R/

W

R

Decimal Binary Hex

+127.75 ˚C 01 1111 1111 1FFh

+100.00 ˚C 01 1001 0000 190h

+1.00 ˚C 00 0000 0100 004h

+0.25 ˚C 00 0000 0001 001h

0 ˚C 00 0000 0000 000h

-0.25 ˚C 11 1111 1111 3FFh

-1.00 ˚C 11 1111 1100 3FCh

-20.00 ˚C 11 1011 0000 3 B0h

-39.75 ˚C 11 0110 0001 361h

-40.00 ˚C 11 0110 0000 360h

-128.00 ˚C 10 0000 0000 200h

O

R

Val

Bit

Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

15

MSb

MSb

64˚C 32˚C 16˚C 8˚C 4˚C 2˚C 1˚C

Sign

±

3.0 ˚C.

Temperature Data Format

0.5

˚C

LSb

0.25

000000

˚C

1

Reserved

Bit

0

LSb

www.national.com 16

Page 17

2.0 Register Set (Continued)

2.9.4 Temperature Control (Addr 12o)

This register is set to the reset value by a Device Reset.

P

Reg

Add

001 010

Bit Type Description

15-2 R Reserved. Will allways read "0".

Register

Name

Temperature

ControlR/W

0RATE (Attention Enable). When set, this bit enables an Attention Request signal to generated by the

1REN0 (Enable Sensor). When this bit is set, the Temperature Sensor is enabled for temperature

R/

W

LM95010, if the EN0 bit is set.

0: Attention Request disabled (from enabled Temperature Sensor- default)

1: Attention Request enabled

measurements.

0: Temperature Sensor disabled (default)

1: Temperature Sensor enabled

Bit

O

R

Val

0h00000000000000

Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit

15

MSb

Reserved

Bit

0

1

LSb

EN0 ATE

LM95010

2.10 CONVERSION RATE (Addr 40o)

P

Reg Add Register Name

100 000 Conversion Rate

LowPwr Conversion Rate[1:0] Typical Conversion Rate (ms)

000 14

100 91

001 91

1 01 364

0 10 182 (default)

1 10 728

0 11 364

1 11 1456

The temperature conversion rate is controlled by this register as well as the Low Power Bit of Device Control Register. This

register is not defined by the SensorPath specification. Therefore, it must be accessed during BIOS run time. The conversion rate

is dependent on system physical requirements and limitations. The thermal response time of the MSOP package is one such

requirement.

R/

W

R/

W

O

R

Val

2h000000Conversion Rate

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

Bit 0

LSb

www.national.com17

Page 18

3.0 Applications Information

3.1 MOUNTING CONSIDERATIONS

LM95010

The LM95010 can be applied easily in the same way as

other integrated-circuit temperature sensors. It can be glued

or cemented to a surface. The temperature that the

LM95010 is reading will typically be within +0.2 ˚C of the

surface temperature to which the LM95010’s leads are attached to.

This presumes that the ambient air temperature is almost the

same as the surface temperature; if the air temperature were

much higher or lower than the surface temperature, the

actual temperature measured would be at an intermediate

temperature between the surface temperature and the air

temperature.

Alternatively, the LM95010 can be mounted inside a sealedend metal tube, and can then be dipped into a bath or

screwed into a threaded hole in a tank. As with any IC, the

LM95010 and accompanying wiring and circuits must be

kept insulated and dry, to avoid leakage and corrosion. This

is especially true if the circuit may operate at cold temperatures where condensation can occur. Printed-circuit coatings

and varnishes such as Humiseal and epoxy paints or dips

are often used to ensure that moisture cannot corrode the

LM95010 or its connections.

The thermal resistance junction to ambient (θ

) is the pa-

JA

rameter used to calculate the rise of a device junction temperature due to its power dissipation. For the LM95010 the

equation used to calculate the rise in the die temperature is

as follows: T

where I

is the quiescent current (500 µA typ.), VOLis the

Q

logic "Low" output level of SWD, and I

+ θJAx [(V+xIQ)+(VOLxIOL)]

J=TA

is the load current

OL

on SWD. Since the LM95010’s junction temperature is the

actual temperature being measured care should be taken to

minimize the load current that the LM95010 is require to

drive. When mounted to a PCB, with 2 oz. copper foil, the

LM95010’s thermal resistance is typically 210 ˚C/W.

www.national.com 18

Page 19

Physical Dimensions inches (millimeters)

unless otherwise noted

LM95010 Digital Temperature Sensor with SensorPath Bus in MSOP8 Package

8-Lead Molded Mini Small Outline Package (MSOP),

JEDEC Registration Number MO-187,

Order Number LM95010CIMM, or LM95010CIMMX,

NS Package Number MUA08A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification

(CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...