Page 1

December 2003

LM87

Serial Interface System Hardware Monitor with Remote

Diode Temperature Sensing

General Description

The LM87 is a highly integrated data acquisition system for

hardware monitoring of servers, Personal Computers, or

virtually any microprocessor-based system. In a PC, the

LM87 can be used to monitor power supply voltages, motherboard and processor temperatures, and fan speeds. Actual values for these inputs can be read at any time. Programmable WATCHDOG limits in the LM87 activate a fully

programmable and maskable interrupt system with two out-

#

puts (INT

The LM87 has an on-chip digital output temperature sensor

with 8-bit resolution as well as the capability of monitoring 2

external diode temperatures to 8-bit resolution, an 8 channel

analog input ADC with 8-bit resolution and an 8-bit DAC. A

channel on the ADC measures the supply voltage applied to

the LM87, nominally 3.3 V. Two of the ADC inputs can be

redirected to a counter that can measure the speed of up to

2 fans. A slow speed Σ∆ ADC architecture allows stable

measurement of signals in an extremely noisy environment.

The DAC, witha0to2.5Voutput voltage range, can be

used for fan speed control. Additional inputs are provided for

Chassis Intrusion detection circuits, and VID monitor inputs.

The VID monitor inputs can also be used as IRQ inputs if VID

monitoring is not required. The LM87 has a Serial Bus

interface that is compatible with SMBus

and THERM#).

™

and I2C™.

Features

n Remote diode temperature sensing (2 channels)

n 8 positive voltage inputs with scaling resistors for

monitoring +5 V, +12 V, +3.3 V, +2.5 V, Vccp power

supplies directly

n 2 inputs selectable for fan speed or voltage monitoring

n 8-bit DAC output for controlling fan speed

n Chassis Intrusion Detector input

n WATCHDOG comparison of all monitored values

n SMBus or I

n VID0-VID4 or IRQ0-IRQ4 monitoring inputs

n On chip temperature sensor

2

C Serial Bus interface compatibility

Key Specifications

j

Voltage Monitoring Error

j

External Temperature Error

j

Internal Temperature Error

−40 ˚C to +125 ˚C

j

Supply Voltage Range 2.8 to 3.8 V

j

Supply Current 0.7 mA (typ)

j

ADC and DAC Resolution 8 Bits

j

Temperature Resolution 1.0 ˚C

±

2 % (max)

±

4 ˚C (max)

±

3 ˚C (typ)

Applications

n System Thermal and Hardware Monitoring for Servers,

Workstations and PCs

n Networking and Telecom Equipment

n Office Electronics

n Electronic Test Equipment and Instrumentation

LM87 Serial Interface System Hardware Monitor with Remote Diode Temperature Sensing

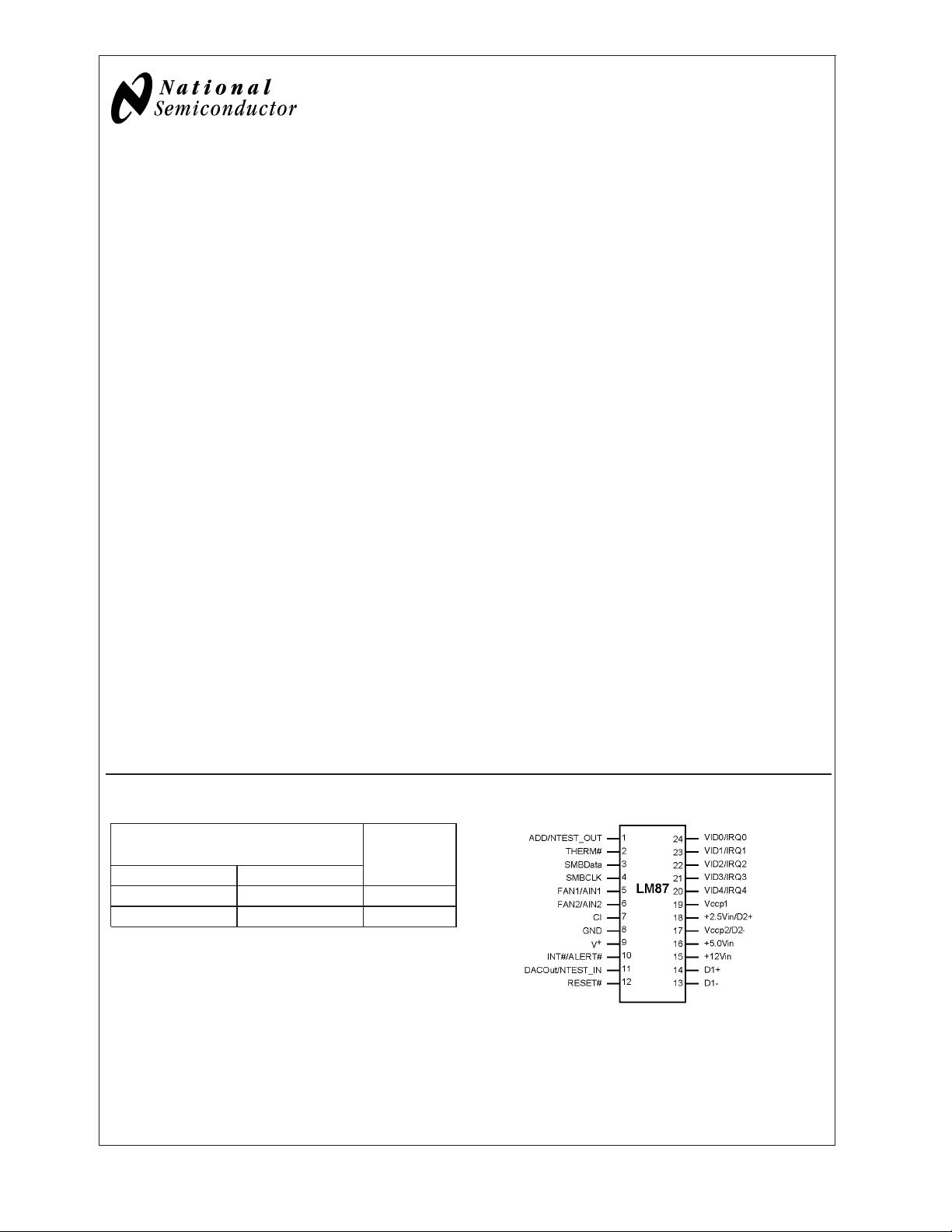

Ordering Information

Temperature Range

−40 ˚C ≤ T

Order Number Device Marking

LM87CIMT

LM87CIMTX

Note:1-Rail transport media, 61 parts per rail

2

-Tape and reel transport media, 2500 parts per reel

SMBus™is a trademark of the Intel Corporation.

© 2003 National Semiconductor Corporation DS100995 www.national.com

1

2

≤ +125 ˚C

A

LM87CIMT MTC24B

LM87CIMT MTC24B

NS Package

Number

Connection Diagram

10099503

Page 2

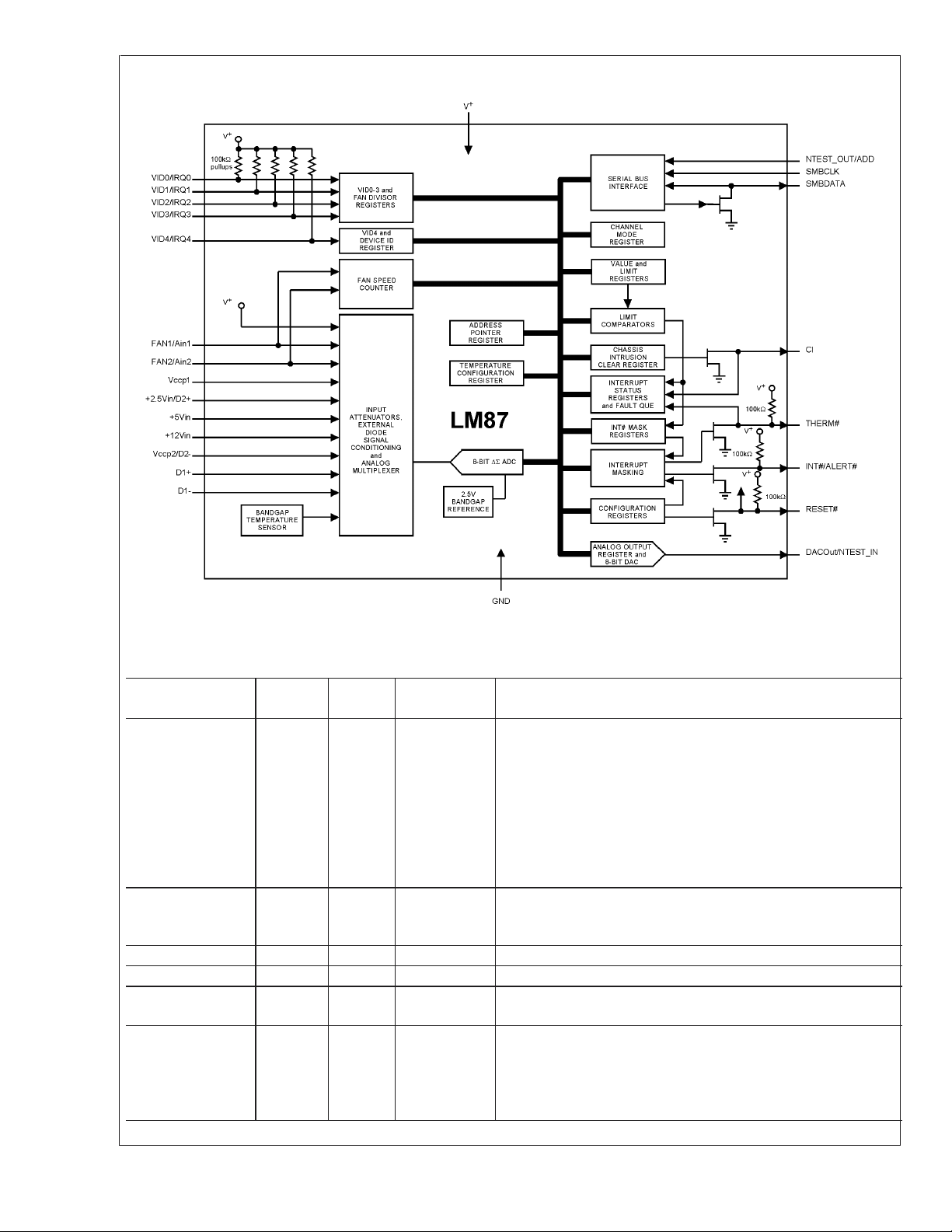

Block Diagram

LM87

10099501

Pin Description

Pin

Name(s)

ADD/NTEST_OUT 1 1 Digital I/0 This pin normally functions as a three-state input that controls the

#

THERM

SMBData 3 1 Digital I/O Serial Bus bidirectional Data. Open-drain output.

SMBCLK 4 1 Digital Input Serial Bus Clock.

FAN1/AIN1FAN2/AIN2

CI 7 1 Digital I/O An active high input from an external circuit which latches a

Pin

Number

2 1 Digital I/O This pin functions as an open-drain interrupt output for temperature

5-6 2 Analog/Digital

Number

of Pins

Type Description

two LSBs of the Serial Bus Address. When this pin is tied to V

the two LSBs are 01. When tied to Ground, the two LSBs are 10. If

this pin is not connected, the two LSBs are 00. This pin also

functions as an output during NAND Tree tests (board-level

connectivity testing). To ensure proper NAND tree function, this pin

should not be tied directly to V

resistor should be used to allow the test output function to work.

Refer to SECTION 11 on NAND Tree testing.

interrupts only, or as an interrupt input for fan control. It has an

on-chip 100 kΩ pullup resistor.

Programmable as analog inputs (0 to 2.5V) or digital Schmitt

Inputs

Trigger fan tachometer inputs.

Chassis Intrusion event. This line can go high without any clamping

action regardless of the powered state of the LM87. There is also

an internal open-drain output on this line, controlled by Bit 7 of the

CI Clear Register (46h), to provide a minimum 20 ms pulse.

or Ground. Instead, a series 5 kΩ

CC

CC

www.national.com 2

Page 3

Pin Description (Continued)

LM87

Pin

Name(s)

GND 8 1 GROUND The system ground pin. Internally connected to all circuitry. The

+

(+2.8 V to

V

+3.8 V)

INT#/ALERT

DACOut/NTEST_IN 11 1 Analog

RESET# 12 1 Digital I/O Master Reset, 5 mA driver (open-drain), active low output with a 20

D1− 13 1 Analog Input Analog input for monitoring the cathode of the first external

D1+ 14 1 Analog Input Analog input for monitoring the anode of the first external

+12Vin 15 1 Analog Input Analog input for monitoring +12 V.

+5Vin 16 1 Analog Input Analog input for monitoring +5 V.

Vccp2/D2− 17 1 Analog Input Digitally programmable analog input for monitoring Vccp2 (0 to 3.6

+2.5Vin/D2+ 18 1 Analog Input Digitally programmable analog input for monitoring +2.5 V or the

Vccp1 19 1 Analog Input Analog input (0 to 3.6 V input range) for monitoring Vccp1, the core

VID4/IRQ4VID0/IRQ0

TOTAL PINS 24

#

Pin

Number

9 1 POWER +3.3 V V+power. Bypass with the parallel combination of 10 µF

10 1 Digital Output Interrupt active low open-drain output. This output is enabled when

20-24 5 Digital Inputs Digitally programmable dual function digital inputs. Can be

Number

of Pins

Type Description

ground reference for all analog inputs and the DAC output. This pin

needs to be connected to a low noise analog ground plane for

optimum performance of the DAC output.

(electrolytic or tantalum) and 0.1 µF (ceramic) bypass capacitors.

Bit 1 in the Configuration Register is set to 1. The default state is

disabled. It has an on-chip 100 kΩ pullup resistor. Alternately used

as an active low output to signal SMBus Alert Response Protocol.

0 V to +2.5 V amplitude 8-bit DAC output. When forced high on

Output/Digital

Input

power up by an external voltage the NAND Tree Test mode is

enabled which provides board-level connectivity testing.

ms minimum pulse width. Available when enabled via Bit 4 in the

Configuration register. It also acts as an active low power on

RESET input. It has an on-chip 100 kΩ pullup resistor.

temperature sensing diode.

temperature sensing diode.

V input range) or the cathode of the second external temperature

sensing diode.

anode of the second external temperature sensing diode.

voltage of processore 1.

programmed to monitor the VID pins of the Pentium/PRO and

Pentium II processors, that indicate the operating voltage of the

processor, or as interrupt inputs. The values are read in the

VID/Fan Divisor Register and the VID4 Register. These inputs have

on-chip 100 kΩ pullup resistors.

#

Indicates Active Low (“Not”)

www.national.com3

Page 4

Absolute Maximum Ratings (Notes 1,

LM87

2)

If Military/Aerospace specified devices are required,

Vapor Phase (60 seconds) 215 ˚C

Infrared (15 seconds) 235 ˚C

Storage Temperature −65 ˚C to +150 ˚C

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

+

Positive Supply Voltage (V

) +6.0 V

Voltage on Any Input or Output Pin:

+12Vin −0.3 V to +18 V

ADD/NTESTOUT,

DACOut/NTEST_IN, AIN1, AIN2

−0.3 V to

+

(V

All other pins −0.3 V to +6 V

Input Current at any Pin (Note 4)

Package Input Current (Note 4)

Maximum Junction Temperature

max) 150 ˚C

(T

J

ESD Susceptibility (Note 6)

Human Body Model 2500 V

Machine Model 150V

Soldering Information

MTC Package (Note 7) :

+ 0.3 V)

±

5mA

±

20 mA

Operating Ratings(Notes 1, 2)

Operating Temperature Range T

LM87 −40 ˚C ≤ TA≤ +125 ˚C

Specified Temperature Range T

LM87 −40 ˚C ≤ TA≤ +125 ˚C

Junction to Ambient Thermal Resistance (θ

NS Package Number: MTC24B 95 ˚C/W

Supply Voltage (V

V

Voltage Range:

IN

+

) +2.8 V to +3.8 V

+12Vin −0.05 V to +15 V

+5Vin −0.05 V to +6.8 V

+3.3Vin −0.05 V to +4.6 V

+2.5Vin −0.05 V to +3.6 V

VID0 - VID4, Vccp −0.05 V to +6.0 V

All other inputs −0.05 V to (V

MIN

MIN

JA

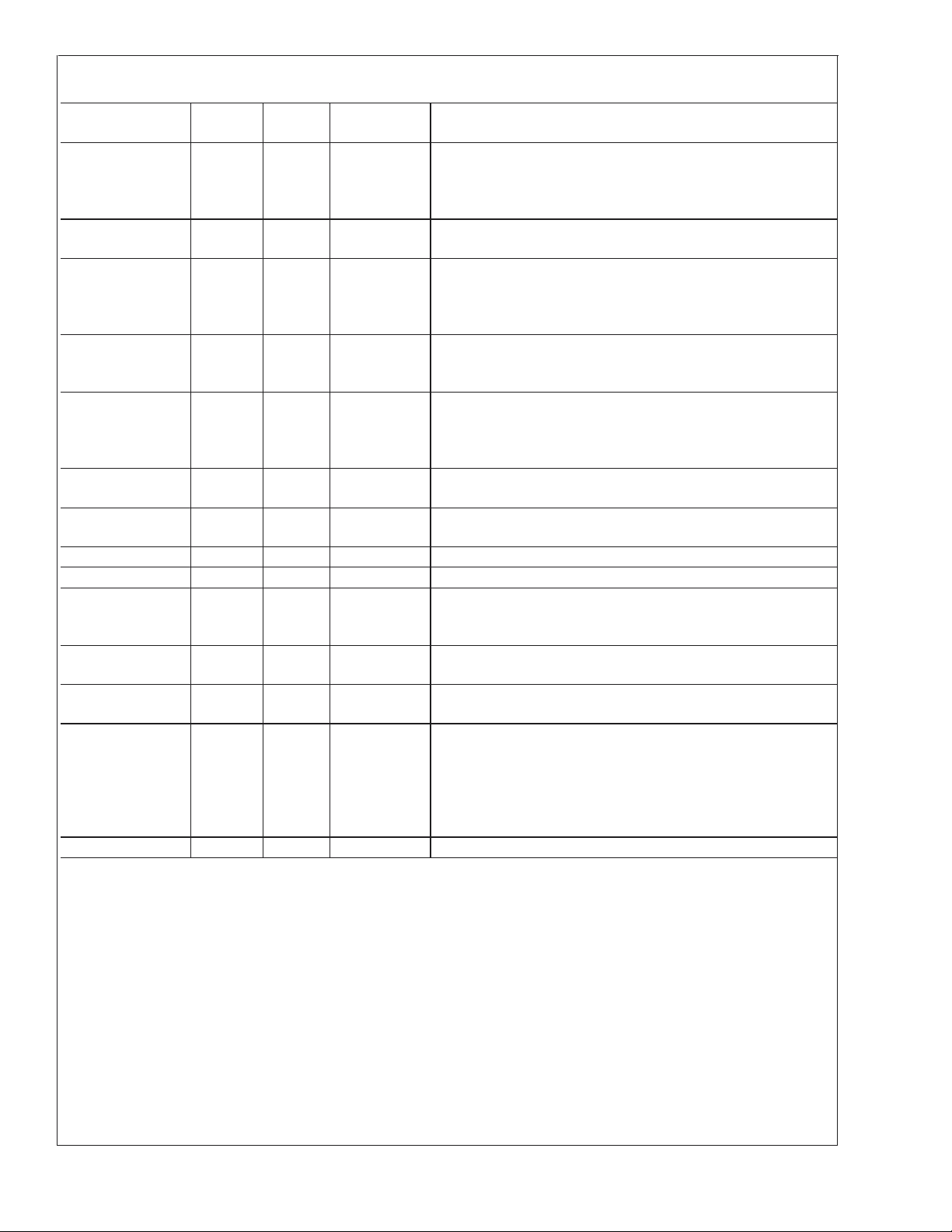

DC Electrical Characteristics

The following specifications apply for +2.8 VDC≤ V+≤ +3.8 VDC, Analog voltage inputs RS= 510 Ω, unless otherwise specified. Boldface limits apply for T

A=TJ=TMIN

to T

Symbol Parameter Conditions Typical Limits Units

POWER SUPPLY CHARACTERISTICS

+

I

Supply Current Normal Mode, Interface

TEMPERATURE-TO-DIGITAL CONVERTER CHARACTERISTICS

Temperature Error using Internal Diode

Temperature Error using Remote Pentium

Diode Sensor (Note 11) and (Note 12)

Temperature Error using Remote 2N3904

Sensor (Note 11) and (Note 12)

Resolution 8 bits 1.0 ˚C (min)

LM87 ANALOG-TO-DIGITAL CONVERTER CHARACTERISTICS

Resolution 8 bits

TUE Total Unadjusted Error (Note 13)

DNL Differential Non-Linearity

t

Total Monitoring Cycle Time (Note 14) 0.28 sec

C

ADC INPUT CHARACTERISTICS

Input Resistance (All analog inputs except

AIN1 and AIN2)

AIN1 and AIN2 DC Input Current 12 µA

DAC CHARACTERISTICS

Resolution 8 Bits

; all other limits TA=TJ= 25 ˚C.(Note 8)

MAX

(Note 9) (Note 10) (Limits)

0.7 2.0 mA (max)

Inactive

Shutdown Mode 0.5 mA

±

3˚C

0˚C≤ T

≤ +125 ˚C, Vcc

A

±

3 ˚C (max)

= 3.3 Vdc

−40 ˚C ≤ T

≤ +125 ˚C,

A

±

4 ˚C (max)

Vcc = 3.3 Vdc

±

2 % (max)

±

1 LSB (max)

130 90 kΩ (min)

≤ TA≤ T

≤ TA≤ T

(Note 5))

+

+ 0.05 V)

MAX

MAX

www.national.com 4

Page 5

DC Electrical Characteristics (Continued)

The following specifications apply for +2.8 VDC≤ V+≤ +3.8 VDC, Analog voltage inputs RS= 510 Ω, unless otherwise specified. Boldface limits apply for T

A=TJ=TMIN

to T

Symbol Parameter Conditions Typical Limits Units

DAC CHARACTERISTICS

DAC Error 0 ˚C ≤ T

Output Load Resistance VO= 2.5 V 1250 Ω (min)

R

L

C

Output Load Capacitance 20 pF (max)

L

FAN RPM-TO-DIGITAL CONVERTER

Fan RPM Error +25 ˚C ≤ T

Full-scale Count 255 (max)

FAN1 and FAN2 Nominal Input

RPM (See Section 6.0)

DIGITAL OUTPUTS (NTEST_OUT)

V

V

OUT(1)

OUT(0)

Logical “1” Output Voltage I

Logical “0” Output Voltage I

OPEN- DRAIN DIGITAL OUTPUTS (SMBData, RESET

V

V

OUT(0)

OUT(0)

Logical “0” Output Voltage (SMBData) I

Logical “0” Output Voltage (Others) I

I

High Level Output Current V

OH

#

RESET

and Chassis Intrusion 45 20 ms (min)

Pulse Width

DIGITAL INPUTS: VID0–VID4, NTEST_IN, ADD/NTEST_OUT, Chassis Intrusion (CI)

V

V

Logical “1” Input Voltage 2.0 V (min)

IN(1)

Logical “0” Input Voltage 0.8 V (max)

IN(0)

SMBus DIGITAL INPUTS (SMBCLK, SMBData)

V

V

V

Logical “1” Input Voltage 2.1 V (min)

IN(1)

Logical “0” Input Voltage 0.8 V (max)

IN(0)

Input Hysteresis Voltage 243 mV

HYST

Tach Pulse Logic Inputs (FAN1, FAN2)

V

V

Logical “1” Input Voltage 0.7xV

IN(1)

Logical “0” Input Voltage 0.3xV

IN(0)

ALL DIGITAL INPUTS

I

I

Logical “1” Input Current VIN=V

IN(1)

Logical “0” Input Current VIN=0V

IN(0)

C

Digital Input Capacitance 20 pF

IN

; all other limits TA=TJ= 25 ˚C.(Note 8)

MAX

(Note 9) (Note 10) (Limits)

≤ +75 ˚C, V+=

A

3.3 V, Code = 255

+

= 3.3 V, 3/4 Scale,

V

code 192

0˚C≤ TA≤ +75 ˚C, V, V

+

= 3.3 V, Code = 8(Note

15)

≤ +75 ˚C

A

−10 ˚C ≤ T

−40 ˚C ≤ T

≤ +100 ˚C

A

≤ +125 ˚C

A

Divisor = 1, Fan Count =

153 (Note 16)

Divisor = 2, Fan Count =

153 (Note 16)

Divisor = 3, Fan Count =

153 (Note 16)

Divisor = 4, Fan Count =

153 (Note 16)

=±3.0 mA at

OUT

+

= +2.8 V

V

=±3.0 mA at

OUT

+

= +3.8 V

V

#

, CI, INT#, THERM#)

= −755 µA 0.4 V (min)

OUT

=−3mA 0.4 V (min)

OUT

OUT

=V

+

+

DC

-3.3 % (min)

+3.7 %

±

3 % (max)

±

10 % (max)

±

15 % (max)

±

20 % (max)

8800 RPM

4400 RPM

2200 RPM

1100 RPM

2.4 V (min)

0.4 V (max)

5 12 µA (max)

+

+

V (min)

V (max)

−12 µA (min)

12 µA (max)

LM87

www.national.com5

Page 6

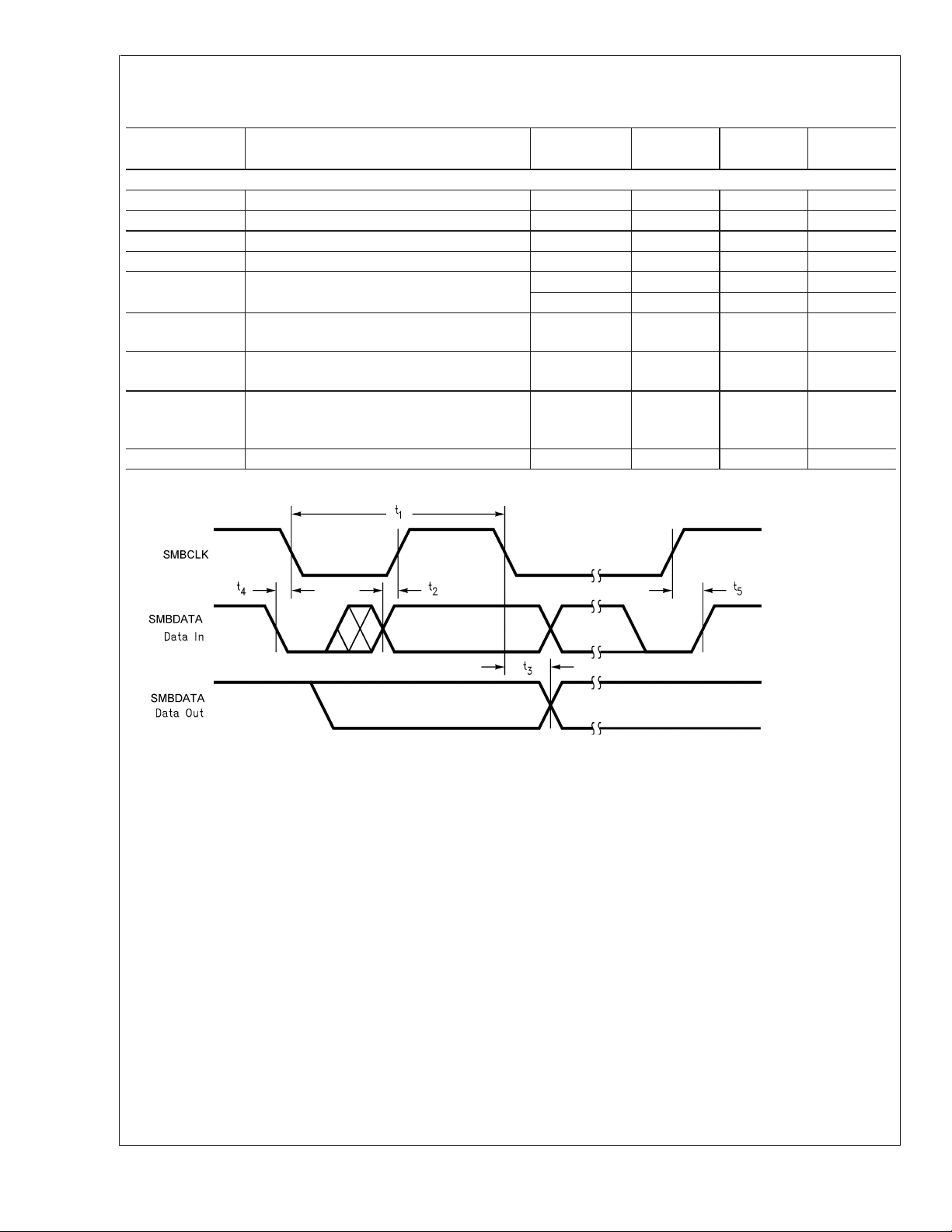

AC Electrical Characteristics

LM87

The following specifications apply for +2.8 VDC≤V+≤ +3.8 VDCon SMBCLK and SMBData, unless otherwise specified. Boldface limits apply for T

A=TJ=TMIN

to T

; all other limits TA=TJ= 25˚C. (Note 17)

MAX

Symbol Parameter Conditions Typical Limits Units

(Note 9) (Note 10) (Limits)

SERIAL BUS TIMING CHARACTERISTICS

t

1

t

rise

t

fall

t

2

t

3

SMBCLK (Clock) Period 2.5 µs (min)

SMBCLK and SMBData Rise Time 1 µs (max)

SMBCLK and SMBData Fall Time 300 ns (max)

Data In Setup Time to SMBCLK High 100 ns (min)

Data Out Stable After SMBCLK Low 100 ns (min)

300 ns (max)

t

4

SMBData Low Setup Time to SMBCLK Low

100 ns (min)

(start)

t

5

SMBData High Hold Time After SMBCLK

100 ns (min)

High (stop)

t

TIMEOUT

SMBCLK low time required to reset the Serial

Bus Interface to the Idle State

31

25

35

C

L

Capacitive Load on SMBCLK and SMBData 80 pF (max)

ms

ms (min)

ms (max)

10099504

FIGURE 1. Serial Bus Timing Diagram

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test

conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise specified.

Note 3: The Absolute maximum input range for :

+2.5Vin -−0.3Vto(1.4xV

+3.3Vin -−0.3Vto(1.8xV

Note 4: When the input voltage (V

maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of 5 mA to four.

Note 5: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

allowable power dissipation at any temperature is P

Note 6: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin.

Note 7: See the section titled “Surface Mount” found in any post 1986 National Semiconductor Linear Data Book for other methods of soldering surface mount

devices.

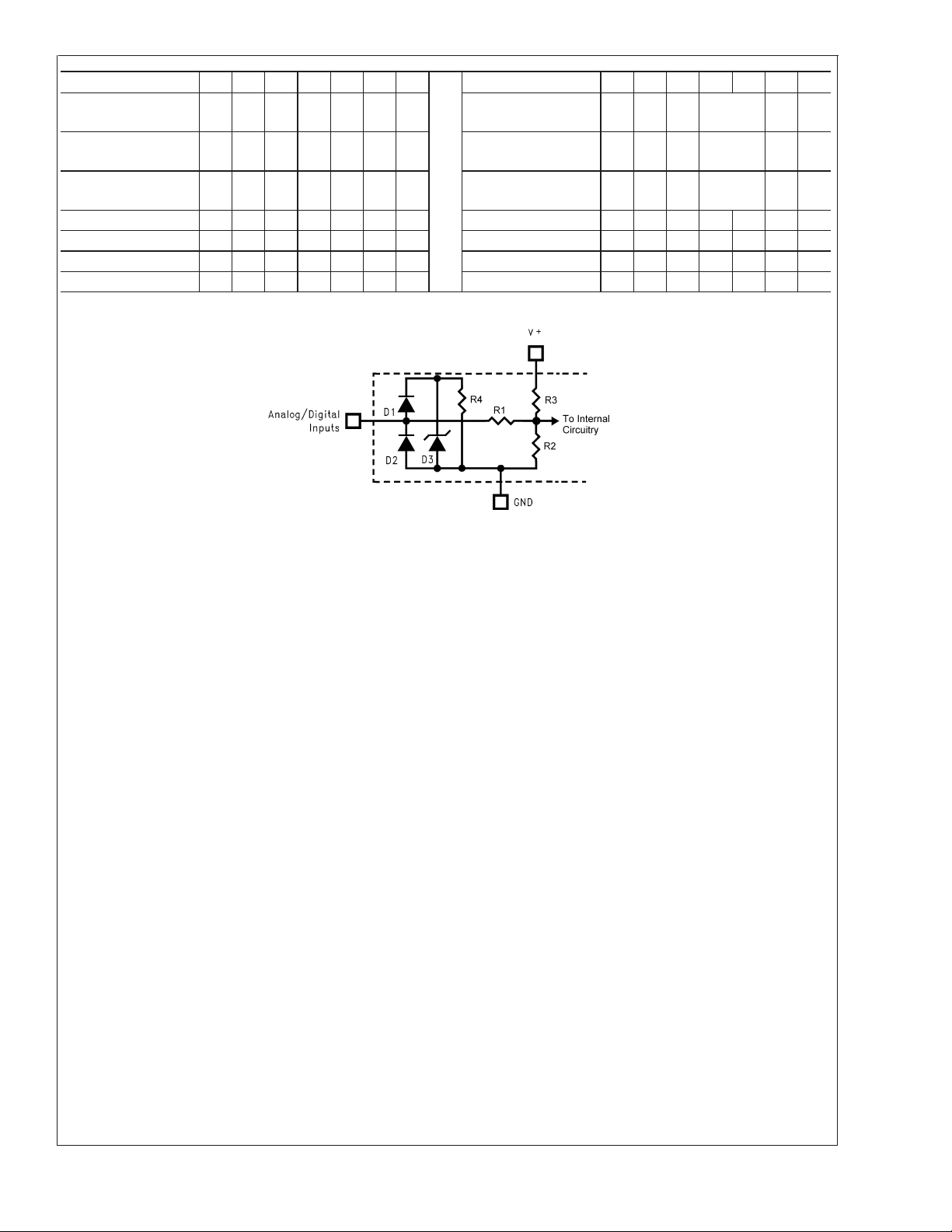

Note 8: Parasitics and or ESD protection circuitry are shown in the figure below for the LM87’s pins. The nominal breakdown voltage of the zener D3 is 6.5 V. Care

should be taken not to forward bias the parasitic diode, D1, present on pins: A0/NTEST_OUT, A1 and DACOut/NTEST_IN. Doing so by more than 50 mV may corrupt

a temperature or voltage measurement.

www.national.com 6

+

+ 0.42 V or 6 V, whichever is smaller

+

+ 0.55 V or 6 V, whichever is smaller.

) at any pin exceeds the power supplies (V

IN

=(TJmax−TA)/θJA.

D

<

IN

GND or V

>

V+), the current at that pin should be limited to 5 mA. The 20 mA

IN

max, θJAand the ambient temperature, TA. The maximum

J

Page 7

Pin Name D1 D2 D3 R1 R2 R3 R4 Pin Name D1 D2 D3 R1 R2 R3 R4

INT

#

xxx0∞100k 1M +12Vin x x R1+R2

∞

≈130k

CI xxx0

∞∞

1M +5Vin x x R1+R2

∞

≈130k

FAN1–FAN2 x x x 0

SMBCLK x x x 0

SMBData x x x 0

#

RESET

xxx0∞100k 1M DACOut/NTEST_IN x x x 0

ADD/NTEST_OUT x x x 0

∞∞

∞∞

∞∞

∞∞

1M +3.3Vin, +2.5Vin,

x x x R1+R2

Vccp1, Vccp2

1M THERM x x x 0

1M VID4–VID0 x x x 0

1M

≈130k

∞

∞

100k 1M

∞

100k 1M

∞∞

1M

1M

LM87

An x indicates that the diode exists.

10099505

FIGURE 2. ESD Protection Input Structure

Note 9: Typicals are at TJ=TA= 25 ˚C and represent most likely parametric norm.

Note 10: Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

±

Note 11: The Temperature Error specification does not include an additional error of

±

Note 12: The Temperature Error will vary less than

Note 13: TUE (Total Unadjusted Error) includes Offset, Gain and Linearity errors of the ADC.

Note 14: Total Monitoring Cycle Time includes all diode checks, temperature conversions and analog input voltage conversions. Fan tachometer readings are

determined separately and do not affect the completion of the monitoring cycle.

Note 15: This is the lowest DAC code guaranteed to give a non-zero DAC output.

Note 16: The total fan count is based on 2 pulses per revolution of the fan tachometer output.

Note 17: Timing specifications are tested at the specified logic levels, V

1˚C over the operating Vcc range of 2.8V to 3.8V.

for a falling edge and VIHfor a rising edge.

IL

1˚C, caused by the quantization error.

www.national.com7

Page 8

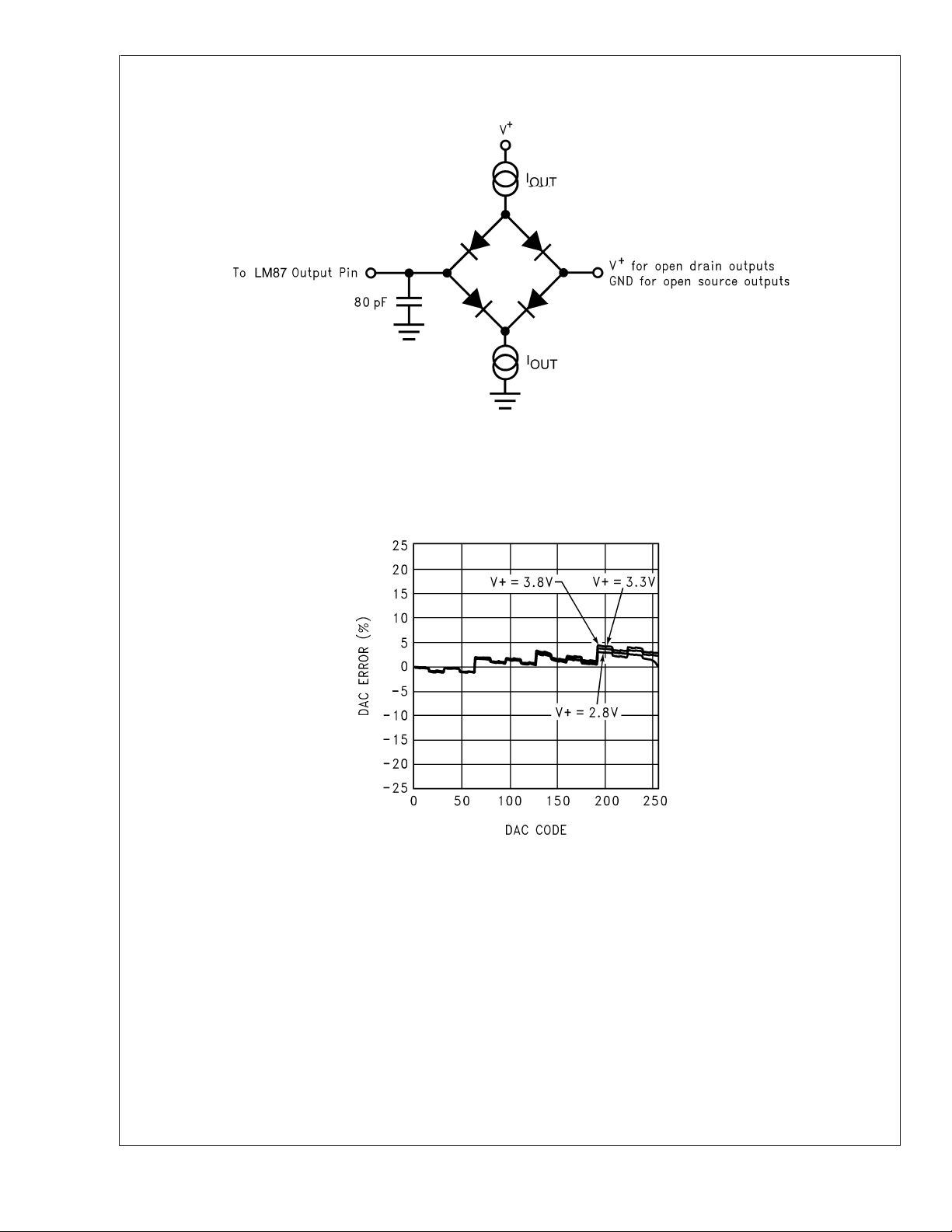

Test Circuit

LM87

FIGURE 3. Digital Output Load Test Circuitry

Typical Performance Characteristics

DAC Power Supply Sensitivity

10099506

Functional Description

1.0 GENERAL DESCRIPTION

The LM87 provides 7 analog inputs, an internal junction type

temperature sensor, two remote junction temperature sensing channels, a Delta-Sigma ADC (Analog-to-Digital Converter), a DAC output, 2 fan speed counters, WATCHDOG

registers, and a variety of inputs and outputs on a single

chip. A two wire SMBus Serial Bus interface is included. The

LM87 performs power supply, temperature, fan control and

fan monitoring for personal computers.

The analog inputs are useful for monitoring several power

supplies present in a typical computer. The LM87 includes

internal resistor dividers that scale external Vccp1, Vccp2,

+2.5V, +5.0 V, +12 V and internal +3.3V power supply volt-

www.national.com 8

10099536

ages to a 3/4 scale nominal ADC output. Two additional

inputs, +AIN1 and +AIN2 (2.5V full scale) are input directly

with no resistive dividers. The LM87 ADC continuously converts the scaled inputs to 8-bit digital words. Measurement of

negative voltages (such as -5 V and -12 V power supplies)

can be accommodated with an external resistor divider applied to the +AIN1 or +AIN2 inputs. Internal and external

temperature is converted to 8-bit two’s-complement digital

words witha1˚CLSB.

Fan inputs measure the period of tachometer pulses from

the fans, providing a higher count for lower fan speeds. The

fan inputs are Schmitt-Trigger digital inputs with an acceptable range of0VtoV

mately V

this represents a stopped or very slow fan. Nominal speeds,

based on a count of 153, are programmable from 1100 to

+

/2. Full scale fan counts are 255 (8-bit counter) and

+

and a transition level of approxi-

Page 9

Functional Description (Continued)

8800 RPM on FAN1 and FAN2. Schmitt-Trigger input circuitry is included to accommodate slow rise and fall times.

An 8 bit DAC with 0 V to 2.5 V output voltage range can be

used for control of fan speed.

The LM87 has several internal registers, as shown in Figure

4, Table 1. The internal registers and their corresponding

internal LM87 addresses are as follows: and Section 13.0.

These include:

Configuration Registers: Provide control and con-

•

figuration.

Channel Mode Register: Controls the functionality of

•

the dual purpose input pins, scaling for internal Vcc measurement, and operation of some IRQ inputs.

Interrupt Status Registers: Two registers to provide

•

status of each WATCHDOG limit or Interrupt event.

Reading the Status Registers clears any active bits.

Interrupt Status Mirror Registers: Two registers to

•

provide status of each WATCHDOG limit or Interrupt

event. Reading the Mirror Registers does not affect the

status bits.

Interrupt Mask Registers: Allows masking of indi-

•

vidual Interrupt sources, as well as separate masking for

each of the two hardware Interrupt outputs.

CI Clear Register: Allows transmitting a 20 ms (mini-

•

mum) low pulse on the chassis intrusion pin (CI).

VID/Fan Divisor Register: This register contains the

•

state of the VID0-VID3 input lines and the divisor bits for

FAN1 and FAN2 inputs.

VID4 Register: Contains the state of the VID4 input.

•

Extended Mode Register: Enable and control the

•

Alert Response operation.

Hardware High Limit Registers: Registers at 13h,

•

14h, 17h and 18h where Internal and External ’Hardware’

WATCHDOG temperature high limits are stored. These

limits have Power On Default settings but can be adjusted by the user. The values stored at 13h and 14h can

be locked down by setting bits 1 and 2 of Configuration

Register 2.

Value and Limit RAM: The DAC digital output, moni-

•

toring results (temperature, voltages, fan counts),

WATCHDOG limits, and Company/Stepping IDs are all

contained in the Value RAM. The Value RAM consists of

a total of 33 bytes, addresses 19h - 3Fh, containing:

— byte 1 at address 19h contains the DAC Data Regis-

ter

— locations 1Ah and 1Bh contain the WATCHDOG low

limits for AIN1 and AIN2

— locations 1Ch - 1Fh are unassigned and do not have

associated registers

— the next 10 bytes at addresses 20h -29h contain all of

the results

— location 2Ah is unassigned and does not have an

associated register

— the next 18 bytes at addresses 2Bh-3Ch are the

remaining WATCHDOG limits

— the last 2 bytes at addresses 3Eh and 3Fh contain the

Company ID and Stepping ID numbers, respectively

When the LM87 is started, it cycles through each measurement in sequence, and it continuously loops through the

sequence approximately once every 0.4 s. Each measured

value is compared to values stored in WATCHDOG, or Hardware High Limit registers. When the measured value violates

the programmed limit the LM87 will set a corresponding

Interrupt in the Interrupt Status Registers. The hardware

#

Interrupt line INT

masking of each Interrupt source. In addition, the Configuration Register has a control bit to enable or disable the

hardware Interrupt. Another hardware Interrupt line available, THERM

Having a dedicated interrupt for these conditions allows

specific actions to be taken for thermal events. This output is

enabled by setting bit 2 of Configuration Register 1.

The Chassis Intrusion input is designed to accept an active

high signal from an external circuit that activates and latches

when the case is removed from the computer.

is fully programmable with separate

#

is used to signal temperature specific events.

LM87

www.national.com9

Page 10

Functional Description (Continued)

LM87

2.0 INTERFACE

FIGURE 4. LM87 Register Structure

www.national.com 10

10099507

Page 11

Functional Description (Continued)

2.1 Internal Registers of the LM87

TABLE 1. The internal registers and their corresponding internal LM87 addresses are as follows:

Register LM87 Internal Hex

Address

Internal Temp. Hardware

High Limit

External Temp. Hardware

High Limit

Test Register 15h 0000 0000

Channel Mode Register 16h 0000 0000

Internal Temp. Hardware

High Limit

External Temp. Hardware

High Limit

Value RAM DAC Data

Register

Value RAM 1Ah-3Fh (See Section 13.18) Contains: monitoring results

Company ID 3Eh 0000 0010 This designates the National Semiconductor LM87.

Revision 3Fh 0000 0110 Revisions of this device will start with 1 and increment

Configuration Register 1 40h 0000 1000

Interrupt Status Register 1 41h 0000 0000

Interrupt Status Register 2 42h 0000 0000

Interrupt Mask Register 1 43h 0000 0000

Interrupt Mask Register 2 44h 0000 0000

CI Clear Register 46h 0000 0000

VID0-3/Fan Divisor Register 47h 0101 XXXX The upper four bits set the divisor for Fan Counters 1

VID4 Register 49h 1000 000X The lower bit reflects the state of VID4 input.

Configuration Register 2 4Ah 0000 0000

Interrupt Status Register 1

Mirror

Interrupt Status Register 2

Mirror

SMBALERT# Enable 80h 0010 0000

13h 0100 0110 70 ˚C Default - User adjustable. Lockable by setting bit

14h 0101 0101 85 ˚C Default - User adjustable. Lockable by setting bit

17h 0100 0110 70 ˚C Default - User adjustable.

18h 0101 0101 85 ˚C Default - User adjustable.

19 h 1111 1111 Defaults to full scale DAC setting.

4Ch 0000 0000

4Dh 0000 0000

Power on

Value

Notes

1 of register 4Ah.

2 of register 4Ah.

(temperature, voltages, fan counts), WATCHDOG

limits, and Company/Stepping IDs

by one.

and 2. The lower four bits reflect the state of the

VID0-VID3 inputs.

LM87

www.national.com11

Page 12

Functional Description (Continued)

LM87

2.2 Serial Bus Interface

(a) Serial Bus Write to the Internal Address Register followed by the Data Byte

10099508

(b) Serial Bus Write to the Internal Address Register Only

10099509

(c) Serial Bus Read from a Register with the Internal Address Register Preset to Desired Location

10099510

FIGURE 5. Serial Bus Timing

The Serial Bus control lines consist of the SMBData (serial

data), SMBCLK (serial clock) and ADD (address) pin. The

LM87 can operate only as a slave. The SMBCLK line only

controls the serial interface, all other clock functions within

LM87 such as the ADC and fan counters are done with a

separate asynchronous internal clock.

When using the Serial Bus Interface, a write will always

consist of the LM87 Serial Bus Interface Address byte, followed by the Internal Address Register byte, then the data

byte. There are two cases for a read:

1. If the Internal Address Register is known to already be at

the desired Address, simply read the LM87 with the

www.national.com 12

Serial Bus Interface Address byte, followed by the data

byte read from the LM87.

2. If the Internal Address Register value is unknown, or if it

is not the desired value, write to the LM87 with the Serial

Bus Interface Address byte, followed by the Internal

Address Register byte. Then restart the Serial Communication with a Read consisting of the Serial Bus Interface Address byte, followed by the data byte read from

the LM87.

The Serial Bus address of the LM87 is set to 010 11(X)(Y).

All bits, except for X and Y, are fixed and cannot be changed.

The values for X and Y are set by the state of theADD pin on

Page 13

Functional Description (Continued)

power up. If ADD is tied to ground the value for XY is 10. If

ADD is tied to Vcc XY will be set to 01. If ADD is not

connected, XY will be 00. XY = 11 is not a possible combination.

All of these communications are depicted in the Serial Bus

Interface Timing Diagrams as shown in Figure 5. The example shown corresponds to the ADD pin tied to Vcc, so

XY=01 and the resulting LM87 address is 0101101.

Serial Bus Timeout can be initiated by holding the SMBCLK

line low for greater than t

Timeout resets the serial bus interface circuitry to the idle

state and readies the LM87 for a new serial bus communication.

3.0 USING THE LM87

3.1 Power On

When power is first applied, the LM87 performs a “power on

reset” on several of its registers. The power on condition of

the LM87’s registers is shown in Table 1. The internal regis-

ters and their corresponding internal LM87 addresses are as

follows: Registers whose power on values are not shown

have power on conditions that are indeterminate (this includes the value RAM ,exclusive of the DAC data, and

WATCHDOG limits). When power is first applied the ADC is

inactive. In most applications, the first action after power on

is to write WATCHDOG limits into the Value RAM.

3.2 Resets

All register values, except the Programmed DAC Output can

be returned to their "power on" default values by taking the

#

RESET

Configuration Register INITIALIZATION. The Value RAM

conversion results, and Value RAM WATCHDOG limits are

not Reset and will be indeterminate immediately after power

on. If the Value RAM contains valid conversion results and/or

Value RAM WATCHDOG limits have been previously set,

they will not be affected by a Configuration Register INITIALIZATION. The Power On Reset, RESET# input, and Configuration Register INITIALIZATION, clear or initialize the following registers (the initialized values are shown on Table I).

Power On Reset also sets the Programmed DAC Output to

full scale (FFh) Hardware High Limit registers 13h, and 14h

will only be returned to default values if the "Write Once" bits

in Configuration Register 2 have not been set:

•

•

•

•

•

•

•

•

•

•

•

•

•

Configuration Register INITIALIZATION is accomplished by

setting Bit 7 of Configuration Register 1 high. This bit automatically clears after being set.

input low for at least TBD ns or by performing a

Configuration Registers 1 and 2

Channel Mode Register

Hardware High Limit Registers

Interrupt Status Register 1

Interrupt Status Register 2

Interrupt Status Mirror Register 1

Interrupt Status Mirror Register 2

Interrupt Mask Register 1

Interrupt Mask Register 2

Chassis Intrusion Clear Register

VID/Fan Divisor Register

VID4 Register

Extended Mode Register

TIMEOUT

(35 ms max). Serial Bus

3.3 Configuration Registers and Channel Mode Register

The Configuration Registers and Channel Mode Register

control the LM87 operation.At power on, the ADC is stopped

and INT_Clear is asserted, clearing the INT

put. These registers start and stop the LM87, enable and

disable interrupt output, configure the operation of dual function inputs, and provide the Reset functions described in

Section 3.2.

Bit 0 of Configuration Register 1 controls the monitoring loop

of the LM87. Setting Bit 0 low stops the LM87 monitoring

loop and puts the LM87 in shutdown mode, reducing power

consumption. Serial Bus communication can take place with

any register in the LM87 although activity on the SMBData

and SMBCLK lines will increase shutdown current, up to as

much as maximum rated supply current, while the activity

takes place. Taking Bit 0 high starts the monitoring loop,

described in more detail subsequently.

Bit 1 of Configuration Register 1 enables the INT

output when this bit is taken high.

Bit 2 of Configuration Register 1 enables the THERM

rupt output when this bit is taken high.

Bit 3 of Configuration Register 1 clears the INT# output when

set high, without affecting the contents of the Interrupt Status

Registers. The LM87 will stop monitoring. It will resume upon

clearing of this bit.

Bit 4 of Configuration Register 1 provides an active low 20

ms (minimum) pulse at the RESET

Bit 6 of Configuration Register 1 clears the THERM# output

when set high, without affecting the contents of the Interrupt

Status Registers.

Bit 7 of Configuration Register 1 (the INITIALIZATION bit)

resets the internal registers of the LM87 as described in

Section 3.2.

Bit 7 of the CI_Clear Register provides an active low 20 ms

(minimum) pulse at the CI

intended for resetting the Chassis Intrusion circuitry.

Bit 0 of Configuration Register 2 enables the INT

output for THERM# events when set low. When this bit is set

high, THERM# error events will not affect the INT# output.

Bit 1 of Configuration Register 2 locks the value set in the

Internal Temperature high limit register at 13h. The value

cannot be changed until a Power On Reset is performed.

Bit 2 of Configuration Register 2 locks the value set in the

External Temperature high limit register at 14h. The value

cannot be changed until a Power On Reset is performed.

Bit 3 of Configuration Register 2 sets the THERM# output

mode. When set to 0, the THERM# output functions in

default mode, when set to 1, THERM# operates in ACPI

mode.

Bit 6 of Configuration Register 2, when set to 1, enables pin

21 as an active high (IRQ3) interrupt input. When set to 0,

this input is disabled as an IRQ interrupt.

Bit 7 of Configuration Register 2, when set to 1, enables pin

20 as an active high (IRQ4) interrupt input. When set to 0,

this input is disabled as an IRQ interrupt.

Bit 0 of the Channel Mode Register, when set to 1, configures pin 5 as AIN1. When set to 0, pin 5 is configured as the

FAN1 input.

Bit 1 of the Channel Mode Register, when set to 1, configures pin 6 as AIN2. When set to 0, pin 6 is configured as the

FAN2 input.

#

#

output pin when set high. This is

#

hardwire out-

#

Interrupt

#

Inter-

output when set high.

#

Interrupt

LM87

www.national.com13

Page 14

Functional Description (Continued)

LM87

Bit 2 of the Channel Mode Register, when set to 0, configures pins 18 and 19 as +2.5V and V

voltage inputs.

CCP2

When set to 1, pins 18 and 19 are configured as a second

remote temperature sensing channel.

Bit 3 of the Channel Mode Register, when set to 0, sets the

nominal voltage for internal V

When set to 1, the nominal V

measurement to 3.3V.

CC

range is 5V.

CC

Bit 4 of the Channel Mode Register, when set to 1, enables

pin 24 as an active low (IRQ0) interrupt input. When set to 0,

this input is disabled as an IRQ interrupt.

Bit 5 of the Channel Mode Register, when set to 1, enables

pin 23 as an active low (IRQ1) interrupt input. When set to 0,

this input is disabled as an IRQ interrupt.

Bit 6 of the Channel Mode Register, when set to 1, enables

pin 22 as an active low (IRQ2) interrupt input. When set to 0,

this input is disabled as an IRQ interrupt.

Bit 7 of the Channel Mode Register, when set to 1, configures pins 20 to 24 as interrupt inputs. When set to 0, pins 20

to 24 are configured as processor voltage ID pins.

3.4 Starting Conversions

The monitoring function (Analog inputs, temperature, and

fan speeds) in the LM87 is started by writing to Configuration

Register 1 and setting INT_Clear (Bit 3) low, and Start (bit 0)

high. The LM87 then performs a “round-robin” monitoring of

all analog inputs, temperature, and fan speed inputs approximately once every 0.3 s. The sequence of items being

monitored is:

1. Check D1 connections

2. Check D2 connections

3. Internal Temperature

4. External D1 Temperature

5. External D2 Temperature

6. +2.5V

7. +Vccp1

8. Vcc 3.3V

9. Vcc 5.0V

10. +5Vin

11. +12Vin

12. +Vccp2

13. AIN1

14. AIN2

15. Fan 1

16. Fan 2

DACOut immediately changes after the DAC Data Register

in the Value RAM has been updated. For a zero to full scale

transition DACOut will typically settle within 100 µsec of the

stop by master in the write to the DAC Data Register Serial

Bus transaction. The DAC Data Register is not reset by the

INITIALIZATION bit found in the Configuration Register.

3.5 Reading Conversion Results

The conversion results are available in the Value RAM.

Conversions can be read at any time and will provide the

result of the last conversion. Because the ADC stops, and

starts a new conversion whenever it is read, reads of any

single value should not be done more often than once every

56 ms. When reading all values, allow at least 0.6 seconds

between reading groups of values. Reading more frequently

than once every 0.6 seconds can also prevent complete

updates of Interrupt Status Registers and Interrupt Output’s.

A typical sequence of events upon power on of the LM87

would consist of:

1. Set WATCHDOG Limits

2. Set Interrupt Masks

3. Start the LM87 monitoring process

4.0 ANALOG INPUTS

All analog input voltages are digitized to 8-bits of resolution.

For safety purposes, and to provide maximum accuracy, a

510 Ω resistor should be placed in series with all analog

voltage inputs. The resistors will limit the possible current

drawn from the power supplies in the event that circuit board

traces are bridged, or accidentally shorted during test. All

analog inputs, except for AIN1 and AIN2, include internal

resistor attenuators. The theoretical LSB size, theoretical

voltage input required for an ADC reading of 192 (3/4 scale)

and 255 (full scale) for each analog input is detailed in the

table below:

Input LSB size Vin for 192 Vin for 255

2.5Vin 13 mV 2.5 V 3.320 V

3.3Vcc 17.2 mV 3.3 V 4.383 V

5Vin/Vcc 26 mV 5 V 6.641 V

12Vin 62.5 mV 12 V 15.93 V

Vccp1, Vccp2 14.1 mV 2.7 V 3.586 V

AIN1/AIN2 9.8 mV 1.875 V 2.49 V

Thus monitoring power supplies within a system can be

easily accomplished by tying the Vccp, +2.5Vin, +5Vin and

+12Vin analog inputs to the corresponding system supply.

Vcc of the LM87 will also be monitored. A digital reading can

be converted to a voltage by simply multiplying the decimal

value of the reading by the LSB size.

For inputs with attenuators the input impedance is greater

than 90 kΩ. AIN inputs do not have resistor attenuators and

are directly tied to the ADC, therefore having a much larger

input impedance.

A negative power supply voltage can be applied to a AIN

input through a resistor divider referenced to a known positive DC voltage as shown in Figure 6. The resistor values

shown in the table below for the circuit of Figure 6 will

provide approximately 1.25 V at the AIN analog inputs of the

LM87 for a nominal reading of 128.

Voltage

Measurements

)

(V

S

R2 R1 V

+

Voltage

at

Analog

Inputs

( ADC code

128)

−12V 20 kΩ 130 kΩ +3.3 V +1.25 V

−5V 20 kΩ 61.0 kΩ +3.3 V +1.25 V

www.national.com 14

Page 15

Functional Description (Continued)

10099530

FIGURE 6. Input Examples. Resistor values shown in

table provide approximately 1.25V at the Vccp inputs.

The resistors were selected by setting R2 = 20 kΩ and then

calculating R1 using the following equation, ( V

maximum negative input voltage, V

+

is the positive pullup

voltage):

R1 = [(1.25V − V

)÷(V+− 1.25V)] x 20 kΩ

S

The maximum R1 can be is restricted by the DC input

current of an AIN input.

Inputs with internal resistor dividers (+2.5Vin, +3.3Vin or

+5Vin, +12Vin) can have voltage applied that exceeds the

power supply up to: 3.6 V for +2.5Vin, 4.6 V for +3.3Vin, 6.8

V for +5Vin, and 15 V for +12Vin. The AIN inputs have a

parasitic diode to the positive supply, so care should be

taken not to forward bias this diode. All analog inputs have

internal diodes that clamp the input voltage when going

below ground thus limiting the negative analog input voltage

range to −50 mV. Violating the analog input voltage range of

any analog input has no detrimental effect on the other

analog inputs. External resistors should be included to limit

input currents to the values given in the ABSOLUTE MAXIMUM RATINGS for Input Current At Any Pin whenever exceeding the analog input voltage range, even on an unpowered LM87. Inputs with external attenuator networks will

usually meet these requirements. If it is possible for inputs

without attenuators (such as AIN1 and AIN2) to be turned on

while LM87 is powered off, additional resistors of about 10

kΩ should be added in series with the inputs to limit the input

current.

4.1 Analog Input Interrupts

A WATCHDOG window comparison on the analog inputs

#

can activate the INT

interrupt output. A converted input

voltage that is above its respective HIGH limit or less than or

equal to its LOW limit will cause a flag to be set in its

Interrupt Status Register. This flag will activate the INT

output when its mask bit is set low. Mask bits are found in the

Interrupt Mask Registers. The Interrupt system is described

in much greater detail in Section 9.0.

S

is the

LM87

5.0 LAYOUT AND GROUNDING

A separate, low-impedance ground plane for analog ground,

which provides a ground point for the GND pin, voltage

dividers and other analog components, will provide best

performance, but is not mandatory. Analog components such

as voltage dividers should be located physically as close as

possible to the LM87.

The power supply bypass, the parallel combination of 10 µF

(electrolytic or tantalum) and 0.1 µF (ceramic) bypass capacitors connected between pin 9 and ground, should also

be located as close as possible to the LM87.

6.0 FAN INPUTS

The FAN1 and FAN2 inputs accept signals from fans

equipped with tachometer outputs. These are logic-level

inputs with an approximate threshold of V

tioning in the LM87 accommodates the slow rise and fall

times typical of fan tachometer outputs. The maximum input

signal range is 0 to V

+

. In the event these inputs are supplied

from fan outputs which exceed 0 to V

division or diode clamping must be included to keep inputs

within an acceptable range, as shown in Figure 7.R2is

selected so that it does not develop excessive voltage due to

input leakage. R1 is selected based on R2 to provide a

minimum input of 2 V and a maximum of V

low as possible to provide the maximum possible input up to

+

for best noise immunity. Alternatively, use a shunt refer-

V

ence or zener diode to clamp the input level.

If fans can be powered while the power to the LM87 is off,

the LM87 inputs will provide diode clamping. Limit input

current to the Input Current at Any Pin specification shown in

the ABSOLUTE MAXIMUM RATINGS section. In most

cases, open collector outputs with pull-up resistors inherently limit this current. If this maximum current could be

exceeded, either a larger pull up resistor should be used or

resistors connected in series with the fan inputs.

The Fan Inputs gate an internal 22.5 kHz oscillator for one

period of the Fan signal into an 8-bit counter (maximum

count = 255). The default divisor, located in the VID/Fan

Divisor Register, is set to 2 (choices are 1, 2, 4, and 8)

providing a nominal count of 153 for a 4400 rpm fan with two

pulses per revolution. Typical practice is to consider 70% of

normal RPM a fan failure, at which point the count will be

219.

Determine the fan count according to:

Note that Fan 1 and Fan 2 Divisors are programmable via

the VID/Fan Divisor Register.

Fan tachometer outputs that provide one pulse per revolution should use a divisor setting twice that of outputs that

provide two pulses per revolution. For example, a 4400 RPM

fan that provides one pulse per revolution should have the

divisor set to 4 such that the nominal counter output is 153.

#

+

/2. Signal condi-

+

, either resistive

+

. R1 should be as

www.national.com15

Page 16

Functional Description (Continued)

LM87

(a) Fan with Tach Pull-Up to +5V

10099512

(b) Fan with Tach Pull-Up to +12V, or Totem-Pole Output

and Resistor Attenuator

(c) Fan with Tach Pull-Up to +12V and Diode Clamp

10099514

(d) Fan with Strong Tach Pull-Up or Totem Pole Output

and Diode Clamp

FIGURE 7. Alternatives for Fan Inputs

Counts are based on 2 pulses per revolution tachometer

outputs.

RPM Time per Revolution Counts for “Divide by 2” Comments

(Default) in Decimal

4400 13.64 ms 153 counts Typical RPM

3080 19.48 ms 219 counts 70% RPM

2640 22.73 ms 255 counts 60% RPM

(maximum counts)

10099513

10099515

Mode Select Nominal RPM Time per Revolution Counts for the 70% RPM Time per Revolution

Given Speed in Decimal for 70% RPM

Divide by 1 8800 6.82 ms 153 6160 9.74 ms

Divide by 2 4400 13.64 ms 153 3080 19.48 ms

Divide by 4 2200 27.27 ms 153 1540 38.96 ms

Divide by 8 1100 54.54 ms 153 770 77.92 ms

drive required by the fan. At power-on the DAC provides full

output, insuring that full fan speed is the default condition.

Care should be taken such that the analog circuitry tied to

this pin does not drive this pin above 2.5 V. Doing so will

place the LM87 in NAND tree test mode which will make all

7.0 DAC OUTPUT

The LM87 provides an 8-bit DAC (Digital-to-Analog Converter) with an output range of 0 to 2.5 volts (9.80 mV LSB).

This DAC can be used in any way, but in most applications of

the LM87 the DAC will be used for fan control. Typically the

pins inputs. After the first SMBus communication with the

LM87, it will leave NAND tree test mode and all inputs/

outputs will function normally.

Fans do not start reliably at reduced voltages, so operation

at a reduced voltage should be preceded by a brief (typically

DAC output would be amplified to provide the up to 12 volt

www.national.com 16

Page 17

LM87

Functional Description (Continued)

1 second) excursion to full operating voltage, then reduce

the voltage. Most fans do not operate at all below 5 to 7

volts. At those lower voltages the fan will simply consume

current, dissipate power, and not operate, and such conditions should be avoided.

The output of the amplifier can be configured to provide a

high or low side pass transistor. A high side pass transistor

simplifies the coupling of tachometer outputs to the tachometer inputs of the LM87 since the fan remains grounded. Low

side drive will require AC coupling along with clamping at the

LM87 input to prevent negative excursions.

A typical circuit for fan drive is shown in Figure 13.

8.0 TEMPERATURE MEASUREMENT SYSTEM

The LM87 temperature sensor(s) and ADC produce 8-bit

two’s-complement temperature data. One internal diode

junction temperature, and up to two external junction temperatures can be monitored. A digital comparator compares

the temperature data to the user-programmable High, Low,

and Hardware Limit setpoints, and Hysteresis values.

Temperature Digital Output

Binary Hex

+0˚C 0000 0000 00h

−1.0˚C 1111 1111 FFh

−25˚C 1110 0111 E7h

−40˚C 1101 1000 D8h

8.2 Internal Temperature Measurement

The LM87 internal temperature is monitored using a junction

type temperature sensor.

8.3 Remote Temperature Measurement

The LM87 monitors the temperature of remote semiconductor devices using the p-n junction temperature sensing principal. Up to two remote IC, diode or bipolar transistor temperatures can be monitored. The remote measurement

channels have been optimized to measure the remote diode

of a Pentium II processor. A discrete diode or bipolar transistor can also be used to sense the temperature of external

objects or ambient air. The 2N3904 NPN transistor base

emitter junction performs well in this type of application.

When using a 2N3904, the collector should be connected to

the base to provide a device that closely approximates the

characteristics of the Pentium II PNP monitoring diode.

When using two external 2N3904 sensors, the D− inputs

should be connected together. This provides the best possible accuracy by compensating for differences between the

2N3904 and Pentium II sensors.

During each conversion cycle, the remote monitoring inputs

perform an external diode fault detection sequence. If the D+

input is shorted to V

or floating then the temperature

CC

reading will be +127˚C, and bit 6 or bit 7 of Interrupt Status

Register 2 will be set. If D+ is shorted to GND or D−, the

temperature reading will be 0˚C and bit 6 or 7 of Interrupt

Status Register 2 will not be set.

(Non-Linear Scale for Clarity)

10099524

FIGURE 8. 8-bit Temperature-to-Digital Transfer

Function

8.1 Temperature Data Format

Temperature data can be read from the Temperature, T

setpoint, T

registers; and written to the T

and Hardware Temperature limit registers. T

setpoint, Hardware Temperature Limit, and Tempera-

T

LOW

setpoint, and Hardware Temperature limit

LOW

HIGH

setpoint, T

LOW

HIGH

HIGH

setpoint,

setpoint,

ture data is represented by an 8-bit, two’s complement word

with an LSB (Least Significant Bit) equal to 1˚C:

Temperature Digital Output

Binary Hex

+125˚C 0111 1101 7Dh

+25˚C 0001 1001 19h

+1.0˚C 0000 0001 01h

8.4 Accuracy Effects of Diode Non-Ideality Factor

The technique used in today’s remote temperature sensors

is to measure the change in V

at two different operating

BE

points of a diode. For a bias current ratio of N:1, this difference is given as:

where:

η is the non-ideality factor of the process the diode is

•

manufactured on,

q is the electron charge,

•

k is the Boltzmann’s constant,

•

N is the current ratio,

•

T is the absolute temperature in ˚K.

•

The temperature sensor then measures ∆V

and converts

BE

to digital data. In this equation, k and q are well defined

universal constants, and N is a parameter controlled by the

temperature sensor. The only other parameter is η, which

depends on the diode that is used for measurement. Since

is proportional to both η and T, the variations in η

∆V

BE

cannot be distinguished from variations in temperature.

Since the non-ideality factor is not controlled by the temperature sensor, it will directly add to the inaccuracy of the

±

sensor. For the Pentium II Intel specifies a

1% variation in

www.national.com17

Page 18

Functional Description (Continued)

LM87

η from part to part. As an example, assume a temperature

sensor has an accuracy specification of

±

3˚C at room tem-

perature of 25˚C and the process used to manufacture the

±

diode has a non-ideality variation of

1%. The resulting

accuracy of the temperature sensor at room temperature will

be:

=±3˚C+(±1% of 298˚K) =±6˚C

T

ACC

.

The additional inaccuracy in the temperature measurement

caused by η, can be eliminated if each temperature sensor is

calibrated with the remote diode that it will be paired with.

8.5 PCB Layout Recommendations for Minimizing Noise

In a noisy environment, such as a processor mother board,

layout considerations are very critical. Noise induced on

traces running between the remote temperature diode sensor and the LM87 can cause temperature conversion errors.

The following guidelines should be followed:

1. Place a 0.1 µF power supply bypass capacitor as close

as possible to the V

pin and the recommended 2.2 nF

CC

capacitor as close as possible to the D+ and D− pins.

Make sure the traces to the 2.2 nF capacitor are

matched.

2. Ideally, the LM87 should be placed within 10 cm of the

Processor diode pins with the traces being as straight,

short and identical as possible.

3. Diode traces should be surrounded by a GND guard ring

to either side, above and below if possible. This GND

guard should not be between the D+ and D− lines. In the

event that noise does couple to the diode lines it would

be ideal if it is coupled common mode. That is equally to

the D+ and D− lines.

4. Avoid routing diode traces in close proximity to power

supply switching or filtering inductors.

5. Avoid running diode traces close to or parallel to high

speed digital and bus lines. Diode traces should be kept

at least 2 cm. apart from the high speed digital traces.

6. If it is necessary to cross high speed digital traces, the

diode traces and the high speed digital traces should

cross at a 90 degree angle.

7. The ideal place to connect the LM87’s GND pin is as

close as possible to the Processors GND associated

with the sense diode. For the Pentium II this would be

pin A14.

FIGURE 9. Recommended Diode Trace Layout

Noise on the digital lines, overshoot greater than V

and

CC

undershoot less than GND, may prevent successful SMBus

communication with the LM87. SMBus no acknowledge is

the most common symptom, causing unnecessary traffic on

the bus. Although, the SMBus maximum frequency of communication is rather low (400 kHz max) care still needs to be

taken to ensure proper termination within a system with

multiple parts on the bus and long printed circuit board

traces. A lowpass filter, in series with the SMBCLK and

10099535

SMBData, has been added internally to the LM87 for noise

immunity. The lowpass filter has a typical cutoff frequency of

20MHz. Additional noise immunity can be achieved by placing a resistor (4.7k to 5.1k Ohms) in series with the SMBCLK

input as close to the LM87 as possible. This resistance, in

conjunction with the IC input capacitance, reduces high frequency noise seen at the SMBCLK input and increases the

reliability of communications.

www.national.com 18

Page 19

Functional Description (Continued)

9.0 WATCHDOG LIMIT COMPARISONS AND INTERRUPT STRUCTURE

LM87

FIGURE 10. Interrupt Structure

Figure 10 depicts the Interrupt Structure of the LM87. The

LM87 can generate Interrupts as a result of each of its

internal WATCHDOG registers on the analog, temperature,

and fan inputs.

External Interrupts can come from the following sources.

While the label suggests a specific type or source of Interrupt, this label is not a restriction of its usage, and it could

come from any desired source:

Chassis Intrusion: This is an active high interrupt from

•

any type of device that detects and captures chassis

intrusion violations. This could be accomplished mechanically, optically, or electrically, and circuitry external

to the LM87 is expected to latch the event. The design of

10099531

the LM87 allows this input to go high even with no power

applied to the LM87, and no clamping or other interference with the line will occur. This line can also be pulled

low for at least 20 ms by the LM87 to reset a typical

Chassis Intrusion circuit. This reset is activated by setting

Bit 7 of CI Clear Register (46h) high. The bit in the

Register is self-clearing.

www.national.com19

Page 20

Functional Description (Continued)

LM87

THERM# Input: This is an active low interrupt that

•

would typically be generated by an external temperature

monitoring system. If the THERM# output is currently

inactive and this input is pulled low by an external circuit,

the THERM# Interrupt Status bit will be set. In addition,

the DAC output will be forced to full scale operation while

THERM# is pulled low by the external source. This allows

a separate thermal sensor to override the current fan

speed setting in an overtemperature situation not sensed

by the LM87. The DAC setting will return to normal when

the THERM# input is deactivated and the DAC setting

register is unaffected by the THERM# input condition.

IRQ0-2: These are active low inputs from any type of

•

external interrupt source. If enabled via the Channel

Mode Register (16h) the INT# output will be activated

whenever these inputs are pulled low. Since there are no

dedicated ISR bits that correspond to the IRQ inputs, the

VID status bits can be read to determine which IRQ input

is active. Similarly, to mask off these inputs as interrupt

sources, they must be disabled via the Channel Mode

Register (16h).

IRQ3-4: These are active high inputs from any type of

•

external interrupt source. If enabled via the Channel

Mode Register (16h) and Configuration Register 2 (4Ah),

the INT# output will be activated whenever these inputs

are driven high. Since there are no dedicated ISR bits

that correspond to the IRQ inputs, the VID status bits can

be read to determine which IRQ input is active. Similarly,

to mask off these inputs as interrupt sources, they must

be disabled via Configuration Register 2 (4Ah).

With the exception of the IRQ inputs and Hardware Temperature errors, all interrupts are indicated in the two Inter-

#

rupt Status Registers. The INT

ters, and individual masks for each Interrupt. As described in

Section 3.3, the hardware Interrupt line can also be enabled/

disabled in the Configuration Register.

#

The THERM

and therefore is only related to internal and external temperature readings, and the Low, High and Hardware temperature limits.

9.1 INT# Interrupts

The INT# system combines several groups of error signals

together into a common output. These groups are; IRQ

inputs, Voltage and Fan inputs, Temperature Values, and the

THERM# input. Each one of these groups or channels functions a little differently.

The IRQ inputs provide the least complicated INT# operation. The IRQ input block is enabled by setting bit 7of the

Channel Mode Register (16h) to 0. Then the individual inputs

are enabled by setting the corresponding IRQ Enable bits to

1. If an IRQ input is enabled, and subsequently an input

signal is asserted on that channel, the INT# output will be

asserted. During the interrupt service routine, the INT# output can be deasserted in a number of ways. The INT#_Clear

bit can be set during the ISR to prevent further interrupts

from occurring. Then the IRQ enable bit for the particular

input can be cleared to prevent that channel from causing

further interrupts. At this point the INT#_Clear bit can be

cleared and no further interrupts would be issued from this

particular IRQ input. Once the signal causing the IRQ has

been removed, the enable bit for that IRQ channel could be

set again.

interrupt output is dedicated to temperature

output has two mask regis-

Voltage, Fan, and Temperature High/Low errors are slightly

more complex in their generation of INT# outputs. All of

these error bits are stored in the Interrupt Status Registers at

43h, 44h and the Interrupt Status Mirror Registers at 4Ch

and 4Dh. These inputs are gated by the Interrupt Mask

Registers and processed by the INT# state machine to generate the INT# output.

Voltage and Fan error conditions are processed as follows.

Every time a round robin conversion cycle is completed, the

high/low limit comparisons for voltage and fan quantities are

updated. If a quantity is outside the limits, the appropriate

Interrupt Status Register bit will be set. If the corresponding

Interrupt Mask Register bit is 0, then the Status Bit will cause

the INT# output to be asserted. Reading the Interrupt Status

register will clear the Status Bit and cause the INT# output to

be deasserted. If the parameter is still outside the limits on

the next conversion, the status bit will again be set and it will

again cause an interrupt. If, on a subsequent conversion

cycle, the parameter returns within the High/Low limits before the Interrupt Status Registers are read, the Interrupt

Status bit will remain set and the INT# output will remain

asserted.

Temperature High/Low errors are somewhat more complicated. The internal temperature value is compared with the

Internal Temperature High and Low Limits in Registers 39h

and 3Ah (and with the Internal Temperature Hardware High

Limit in Registers 13h and 17h, see the next paragraph for

details). We will begin with the temperature value initially

within the High/Low limits and the corresponding Interrupt

Mask Bit = 0. If the temperature value rises above the high

limit, or below the low limit, the corresponding Interrupt

Status Register bit will be set. This will then cause an INT# to

be asserted. Reading the Interrupt Status Register will clear

the status bit and cause INT# to be deasserted. If the temperature value remains above the high limit during subsequent conversion cycles, the Interrupt Status Bit will again be

set, but no new INT# will be generated from this source.

INT# may be reasserted if:

The temperature then transitions up or down through the

•

opposite limit to that originally exceeded.

The original limit crossed is programmed to a new value

•

and on a subsequent conversion cycle, the converted

temperature is outside the new limit. This would cause

the corresponding Interrupt Status Bit to be set, causing

a new INT# event.

An interrupt is generated by any other source, including

•

any other temperature error or the THERM# pin being

pulled low by an external signal.

The third group of signals that will generate INT# outputs are

Hardware Temperature errors, caused by temperatures exceeding the hardware limits stored at 13h, 14h, 17h, and

18h.The internal temperature value is compared with the

Internal Temperature Hardware High Limits in Registers 13h

and 17h. The external temperature values are compared

with the External Temperature Hardware High Limits in Registers 14h and 18h. The limits in Register 14h and 18h apply

equally to the values of both D1 and D2. Both temperature

values are individually compared with both limit values.

The only difference between the different Hardware Limit

registers is that by writing a 1 into Bit 1 of register 4Ah, the

contents of register 13h will be locked and cannot be reprogrammed. Similarly, the contents of register 14h will be

locked by writing a 1 into Bit 2 of register 4Ah. The registers

can only be reprogrammed if Bit 7 of Configuration Register

www.national.com 20

Page 21

Functional Description (Continued)

1 (40h) is written to re-Initialize the chip, or power is removed

and reapplied. This feature is provided to prevent software

from unintentionally overwriting these important limits.

Again, we will assume that the temperature initially is below

the Hardware Temperature setpoints. If the temperature on a

subsequent conversion is above any of the values stored in

the Hardware Temperature Limit registers, the INT# output

will be asserted. Errors caused by exceeding these limits

cannot be cleared by reading the Interrupt Status Registers,

and the INT# condition can only be cleared by clearing the

Thermal INT# Enable bit, by setting the INT#_Clear bit or by

disabling INT# by clearing the INT#_Enable bit.

The final INT# source to consider is the THERM# input/

output. THERM# can be pulled low by an external source to

generate an INT# output. Pulling THERM# low with external

circuitry sets the corresponding THERM# Interrupt Status

Bit. If this bit is not masked, it will cause INT# to be asserted.

Reading the Interrupt Status Registers will clear the status

bit and will cause INT# to be deasserted. If the external

signal continues to pull THERM# low, the Interrupt Status Bit

will be reset at the completion of the next conversion cycle.

This will again assert the INT# output. Note that if the external circuitry pulls THERM# low, but this pin is already low

due to the THERM# output being active, this external signal

cannot be sensed, and the THERM# Interrupt Status Bit will

not be set.

Interrupt Status Registers: Reading a Status Register will

return the contents of the Register, and reset the Register. A

subsequent read done before the analog “round-robin” monitoring loop is complete will indicate a cleared Register. Allow

at least 600 ms to allow all Registers to be updated between

reads. In summary, the Interrupt Status Register clears upon

being read, and requires at least 300 ms to be updated.

When the Interrupt Status Register clears, the hardware

interrupt line will also clear until the Registers are updated by

the monitoring loop.

Interrupt Status Mirror Registers: The Interrupt Status

Mirror Registers provide the same information that the Interrupt Status Registers do. Reading the Status Mirror Registers, however, does not reset the status bits.

Interrupt Mask Registers: All sources which are combined

to form the INT# output can be individually masked via the

two Interrupt Mask Registers at 43h, and 44h. The bits in the

mask registers correspond directly to the bits in the Interrupt

Status Registers. Setting an Interrupt Mask bit inhibits that

Interrupt Status Bit from generating an INT# interrupt. Clearing a mask bit allows the corresponding status bit, if set, to

generate INT# outputs. Interrupt Status Bits will be set and

cleared regardless of the state of corresponding Interrupt

Mask Bits, the mask bits merely allow or prevent the status

bits from contributing to the generation of INT# outputs.

Enabling and Clearing INT#: The hardware Interrupt line

#

) is enabled by setting the INT#_Enable bit at Bit 1 of

(INT

Configuration Register 1. The INT# output can be cleared by

setting the INT#_Clear bit which is Bit 3 of Configuration

Register 1. When this bit is high, the LM87 monitoring loop

will stop. It will resume when the bit is low.

Thermal Interrupt Mask: In some applications, the user

may want to prevent all thermal error conditions from causing INT# interrupts. The Thermal INT# Mask bit (Bit 0 of

Configuration Register 2) is provided for this purpose. The

THERM# output discussed later is not affected by the status

of the Thermal INT# Mask bit and will function normally in

response to temperature error conditions. If the Thermal

LM87

INT# Mask bit is set, the interrupt status for internal and

external temperature, the THERM# input, and the hardware

temperature error comparisons, will continue to be updated

every conversion cycle, but will not have any effect on the

INT# output.

9.2 SMBALERT#

The INT# I/O pin can alternatively be configured as an

SMBALERT# output in conjunction with the SMBALERT#

protocol. In this mode of operation, rather than connecting

the INT# /ALERT# pin to the system interrupt inputs, it will be

connected to the SMBALERT# input pin on the SMBus host.

When an INT#/ALERT# type error condition is detected, this

pin will notify the SMBus host that an SMBus device has an

SMBALERT# condition. The SMBus host will then access

the bus using the Alert Response Address (ARA) which is

0001100b. Only the device asserting the SMBALERT# signal will respond to the ARA, thus providing automatic identification of the device generating the SMBALERT#. After

acknowledging the slave address, the LM87 will disengage

its SMBALERT# output signal. For more information on the

SMBALERT# protocol, please refer to the System Management Bus specification. SMBALERT# is enabled by setting

Bit 6 of the Alert Response Enable register at 80h.

9.3 THERM# Interrupts

The THERM# I/O pin is dedicated to temperature related

error conditions. It includes a built in pull-up resistor to

minimize external components. The THERM# Enable bit, Bit

2 of Configuration Register 1 is used to enable the THERM#

output. The THERM# Clear bit, Bit 6 of Configuration Register 1, when set to 1, clears the THERM# output. TheTHERM# output operates in two different modes when processing thermal error conditions, Default Mode and ACPI Mode,

selected by the state of the THERM# Interrupt Mode bit at Bit

3 of Configuration Register 2 (0 = Default, 1 = ACPI).

Default Mode:The THERM# ouput operates using a simple

comparison of temperature with the corresponding limit values. If any temperature value is outside a corresponding limit

in registers 37h, 39h, 2Bh, 38h, 3Ah, or 2Ch, the THERM#

output will go low. The output will remain asserted until it is

reset by: reading Interrupt Status Register 1, by setting the

THERM#CLR bit, or if the temperature falls below the low

limit for that sensor. When THERM# is cleared by reading

the status register, it may be set again after the next temperature reading, if the temperature is still above the high

limit. When THERM# is cleared by setting THERM#CLR, it

cannot be re-asserted until this bit is cleared. If THERM# is

activated because a temperature value exceeds one of the

hardware limits in registers 13h, 14h, 17h, or 18h, or exceeds 126 degrees C, AOUT will be forced to the full scale

value. In this case, the THERM# output can only be cleared

by setting the THERM#CLR bit or if the temperature returns

to 5 degrees below the hardware limit. Regardless of how

THERM# is cleared, AOUT will be maintained at the full

scale value until the temperature returns to 5 degrees below

the hardware limit that was exceeded.

ACPI Mode: In ACPI mode, THERM# is only activated when

temperatures exceed the high limit settings in registers 13h,

14h, 17h, 18h or the safety limit of 126 degrees C. It will be

de-asserted if the temperature returns at least 5 degrees

below the limit. While THERM# is asserted, AOUT will be

driven to full scale to provide maximum cooling from a variable speed fan.

THERM# also functions as an input. When an external active

low signal is applied to THERM#, it will set the THERM#

www.national.com21

Page 22

Functional Description (Continued)

LM87

input Interrupt Status Bit and will cause AOUT to go to full

scale, regardless of the state of the THERM# Input Interrupt

Mask bit. If the Mask bit is cleared and INT# is enabled, an

INT# will be generated. The THERM# input function is not

affected by the THERM# operating mode.

9.4 Fault Queue

A Fault Queue is incorporated in the external temperature

monitoring sections of the LM87. This serves as a filter to

minimize false triggering caused by short duration or tran-

sient temperature events. The Fault Queue adds a counter

between the comparison logic and the Interrupt Status Register and THERM# output circuitry. The Fault Queue has a

depth of 3, so three consecutive readings outside of limits is

required to set an external temperature Interrupt Status Bit

or generate a THERM# output. When the monitored temperature is returning within limits, only one conversion within

limits is required to clear the status bit. In other words, the

fault queue is only active when travelling outside of the limits,

not when returning back within limits.

FIGURE 11. LM87 Interrupt Structure

#

10.0 RESET

RESET

connected to this line. Setting Bit 4 in Configuration Register

1 high outputs a 20 ms (minimum) low pulse on this line, at

the end of which Bit 4 in the Configuration Register automatically clears. Again, the label for this pin is only its suggested

use. In applications where the RESET

needed it can be used for any type of digital control that

requires a 20 ms (mimimum) active low, open-drain output.

RESET

figuration Register 1. Setting this line low will reset all of the

registers in the LM87 to their power on default state. All

Value RAM locations will not be affected except for the DAC

Data Register.

www.national.com 22

I/O

#

is intended to provide a master reset to devices

#

capability is not

#

operates as an input when not activated by Con-

10099532

11.0 NAND TREE TESTS

A NAND tree is provided in the LM87 for Automated Test

Equipment (ATE) board level connectivity testing. DACOut/

#

NTEST_IN, INT#, THERM

from NAND tree testing. Taking DACOut/NTEST_IN high

during power up activates the NAND Tree test mode. After

the first SMBus access to the LM87 the NAND Tree test

mode is terminated and cannot be reactivated without repeating the power up sequence. To perform a NAND tree

test, all pins included in the NAND tree should be driven to 1

forcing the ADD/NTEST_OUT high. Each individual pin starting with SMBData and concluding with RESET# (excluding

DACOut/NTEST_IN, INT#, THERM

taken low with the resulting toggle observed on the ADD/

NTEST_OUT pin. Allow for a typical propagation delay of

500 ns.

,V+and GND pins are excluded

#

,V+and GND) can be

Page 23

Functional Description (Continued)

FIGURE 12. NAND Tree Test Structure

LM87

10099533

12.0 FAN MANUFACTURERS

Manufacturers of cooling fans with tachometer outputs are

listed below:

NMB Tech

9730 Independence Ave.

Chatsworth, California 91311

818 341-3355

818 341-8207

Model

Number

2408NL 2.36 in sq. X 0.79 in 9-16

2410ML 2.36 in sq. X 0.98 in 14-25

3108NL 3.15 in sq. X 0.79 in 25-42

3110KL 3.15 in sq. X 0.98 in 25-40

Frame Size Airflow CFM

(60 mm sq. X 20 mm)

(60 mm sq. X 25 mm)

(80 mm sq. X 20 mm)

(80 mm sq. X 25 mm)

Mechatronics Inc.

P.O. Box 20