Page 1

January 2000

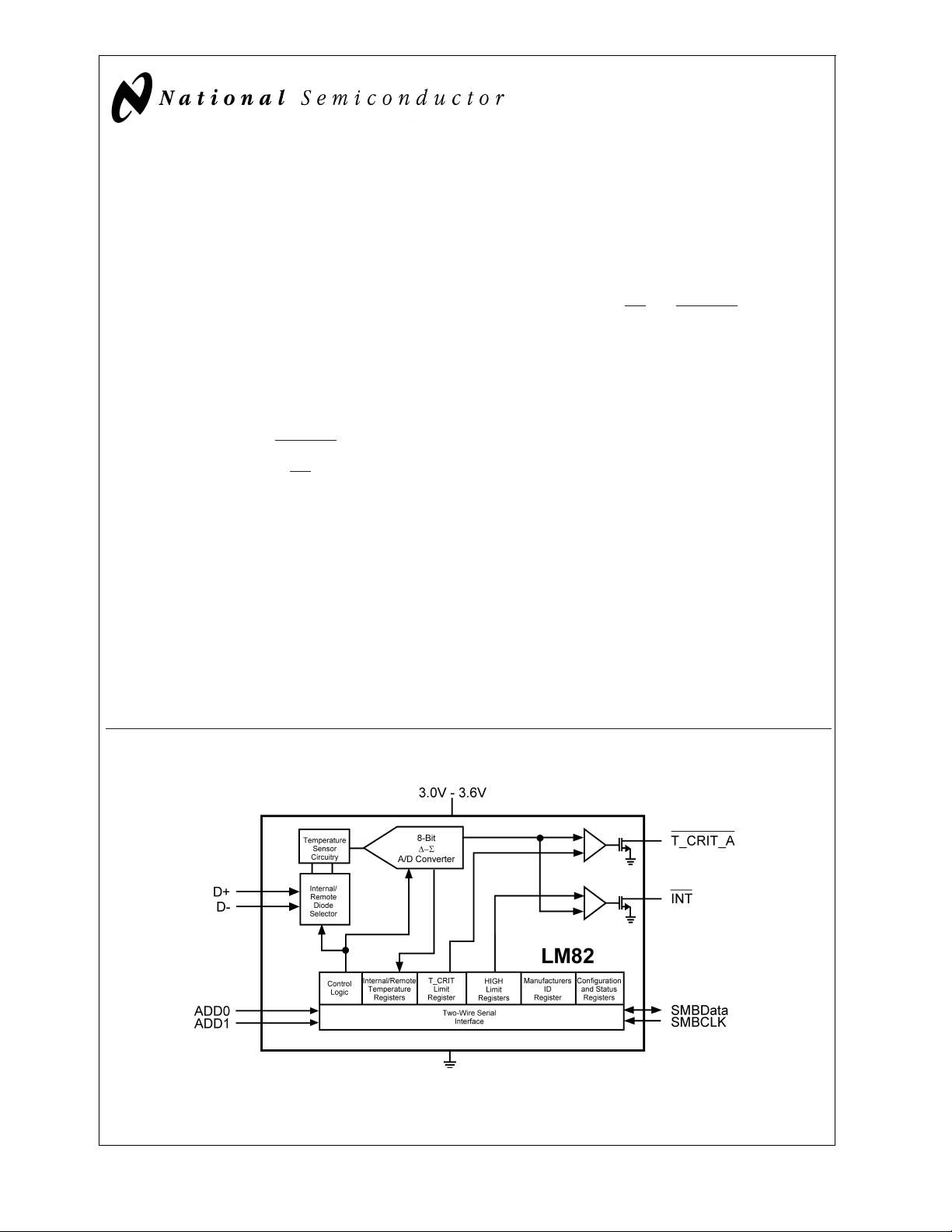

LM82

Remote Diode and Local Digital Temperature Sensor

with Two-Wire Interface

LM82 Remote Diode and Local Digital Temperature Sensor with Two-Wire Interface

General Description

The LM82 is a digital temperature sensor with a 2 wire serial

interface thatsensesthe voltage and thus the temperature of

a remote diode using a Delta-Sigma analog-to-digital converter with a digital over-temperature detector.The LM82 accurately senses its own temperature as well as the temperature of external devices, such as Pentium II

diode connected 2N3904s. The temperature of any ASIC

can be detected using the LM82 as long as a dedicated diode (semiconductor junction) is available on the die. Using

the SMBus interface a host can access the LM82’sregisters

at any time. Activation of a T_CRIT_A output occurs when

any temperature is greater than a programmable comparator

limit, T_CRIT. Activation of an INT output occurs when any

temperature is greater than its corresponding programmable

comparator HIGH limit.

The host can program as well as read back the state of the

T_CRIT register and the 2 T_HIGH registers. Three state

logic inputs allow two pins (ADD0, ADD1) to select up to 9

SMBus address locations for the LM82. The sensor powers

up with default thresholds of 127˚C for T_CRIT and all

T_HIGHs. The LM82 is pin for pin and register compatible

with the LM84, Maxim MAX1617 and Analog Devices

ADM1021.

®

Processors or

Features

n Accurately senses die temperature of remote ICs, or

diode junctions

n On-board local temperature sensing

n SMBus and I

SMBus 1.1 TIMEOUT

n Two interrupt outputs: INT and T_CRIT_A

n Register readback capability

n 7 bit plus sign temperature data format, 1 ˚C resolution

n 2 address select pins allow connection of 9 LM82s on a

single bus

2

C compatible interface, supports

Key Specifications

j

Supply Voltage 3.0V to 3.6V

j

Supply Current 0.8mA (max)

j

Local Temp Accuracy (includes quantization error)

0˚C to +85˚C

j

Remote Diode Temp Accuracy (includes quantization

error)

+25˚C to +100˚C

0˚C to +125˚C

±

3.0˚C (max)

±

3˚C (max)

±

4˚C (max)

Applications

n System Thermal Management

n Computers

n Electronic Test Equipment

n Office Electronics

n HVAC

Simplified Block Diagram

DS101297-1

SMBus™is a trademark of the Intel Corporation.

®

Pentium II

is a registered trademark of the Intel Corporation.

®

I2C

is a registered trademark of the Philips Corporation.

© 2000 National Semiconductor Corporation DS101297 www.national.com

Page 2

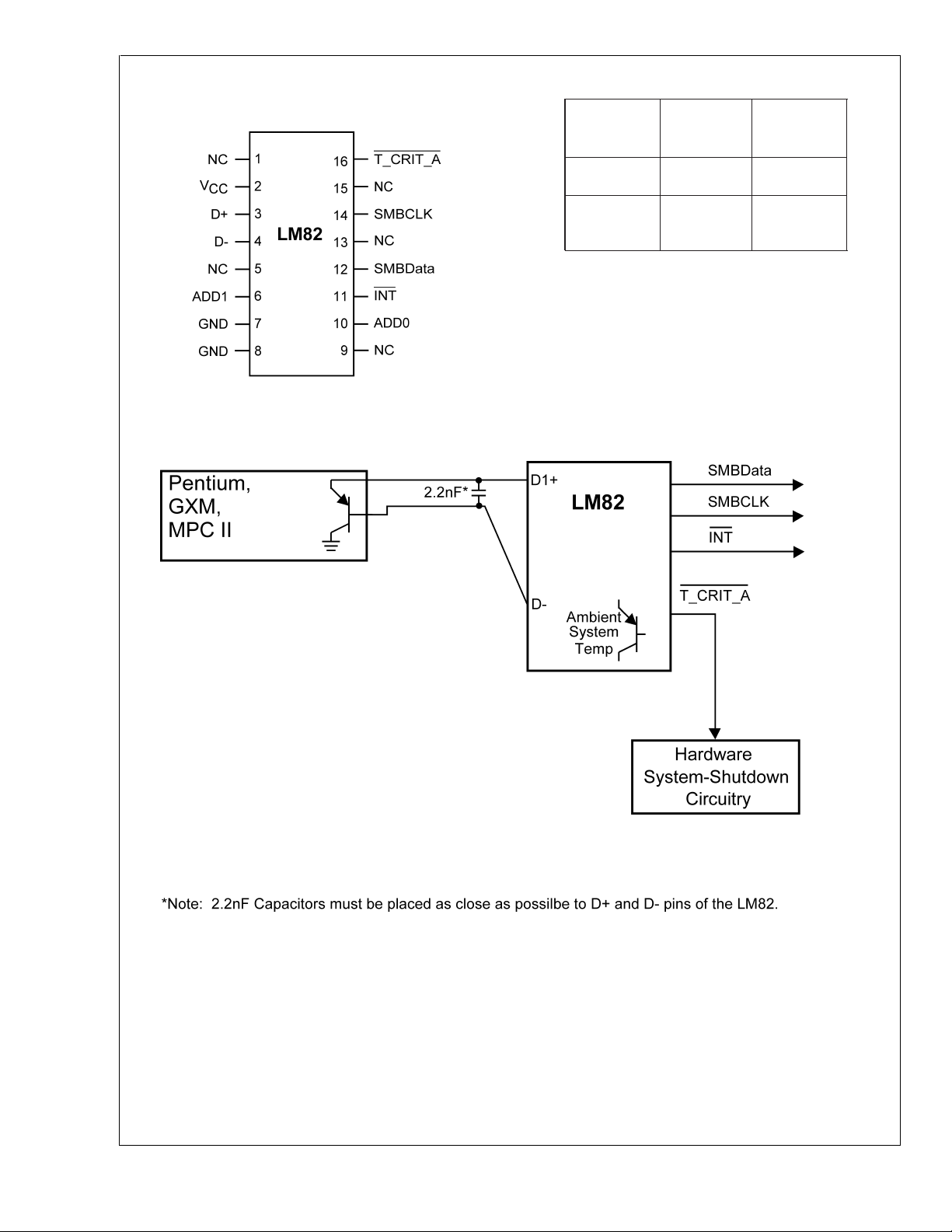

Connection Diagram Ordering Information

LM82

QSOP-16

DS101297-2

TOP VIEW

Order

Number

LM82CIMQA

LM82CIMQAX

Typical Application

NS

Package

Number

MQA16A

(QSOP-16)

MQA16A

(QSOP-16)

Transport

Media

95 Units in

Rail

2500 Units on

Tape and

Reel

www.national.com 2

DS101297-3

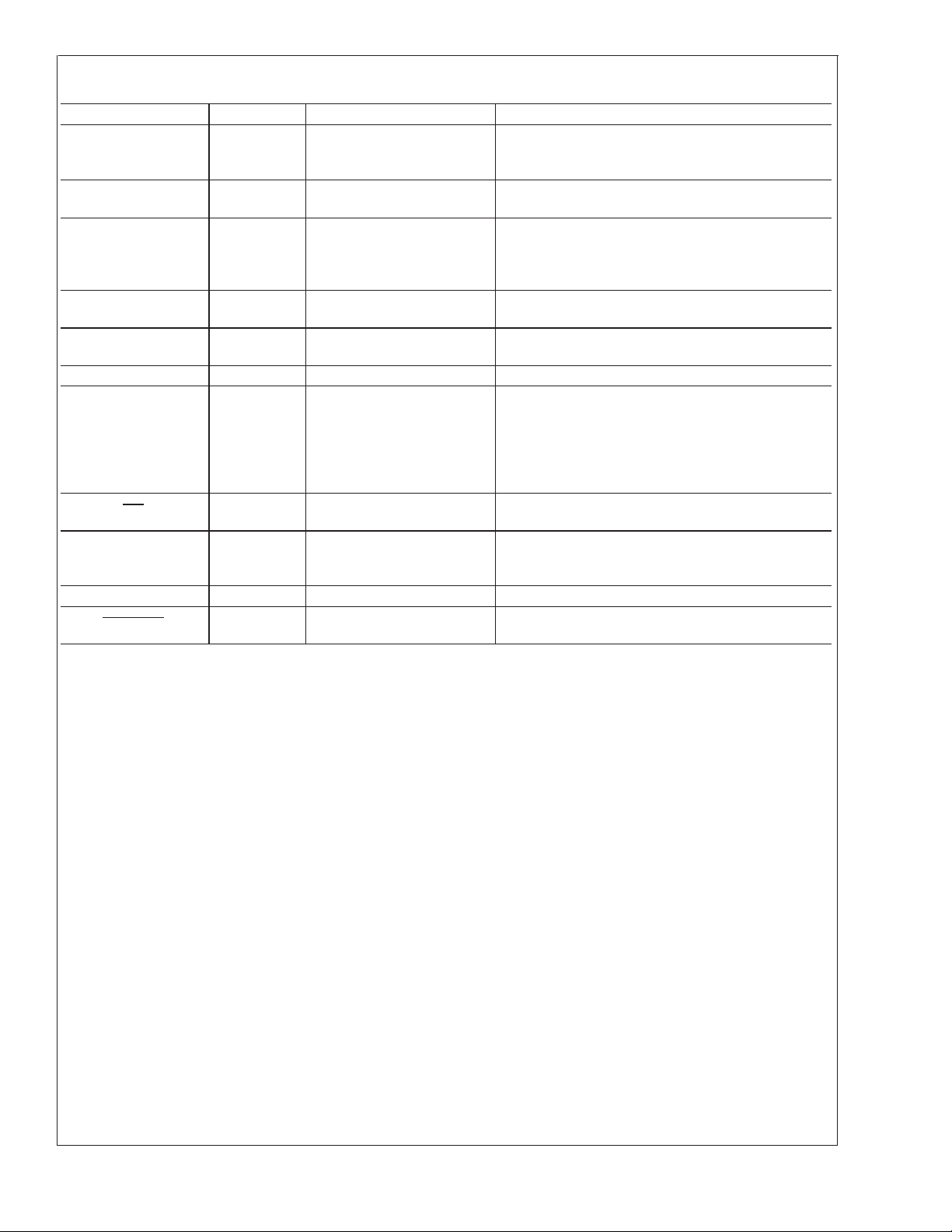

Page 3

Pin Description

LM82

Label Pin

#

Function Typical Connection

floating, unconnected Left floating. PC board traces may be routed

NC 1, 5

V

CC

2

Positive Supply Voltage

Input

Diode Current Source To Diode Anode. Connected to remote discrete

D+ 3

D− 4

ADD0–ADD1 10, 6

Diode Return Current

Sink

User-Set SMBus (I

2

Address Inputs

C)

GND 7, 8 Power Supply Ground Ground

Manufacturing test pins. Left floating. PC board traces may be routed

NC 9, 13, 15

INT

11

SMBData 12

Interrupt Output,

open-drain

SMBus (I

2

C) Serial

Bi-Directional Data Line,

open-drain output

2

SMBCLK 14 SMBus (I

T_CRIT_A

16

Critical Temperature

Alarm, open-drain output

C) Clock Input From Controller, Pull-Up Resistor

through the pads for these pins. No restrictions

applied.

DC Voltage from 3.0 V to 3.6 V

diode junction or to the diode junction on a remote

IC whose die temperature is being sensed. When

not used they should be left floating.

To Diode Cathode. Must float when not used.

Ground (Low, “0”), VCC(High, “1”) or open

(“TRI-LEVEL”)

through the pads for these pins, although the

components that drive these traces should share

the same supply as the LM82 so that the Absolute

Maximum Rating, Voltage at Any Pin, is not

violated.

Pull Up Resistor, Controller Interrupt or Alert Line

From and to Controller, Pull-Up Resistor

Pull Up Resistor, Controller Interrupt Line or

System Shutdown

www.national.com3

Page 4

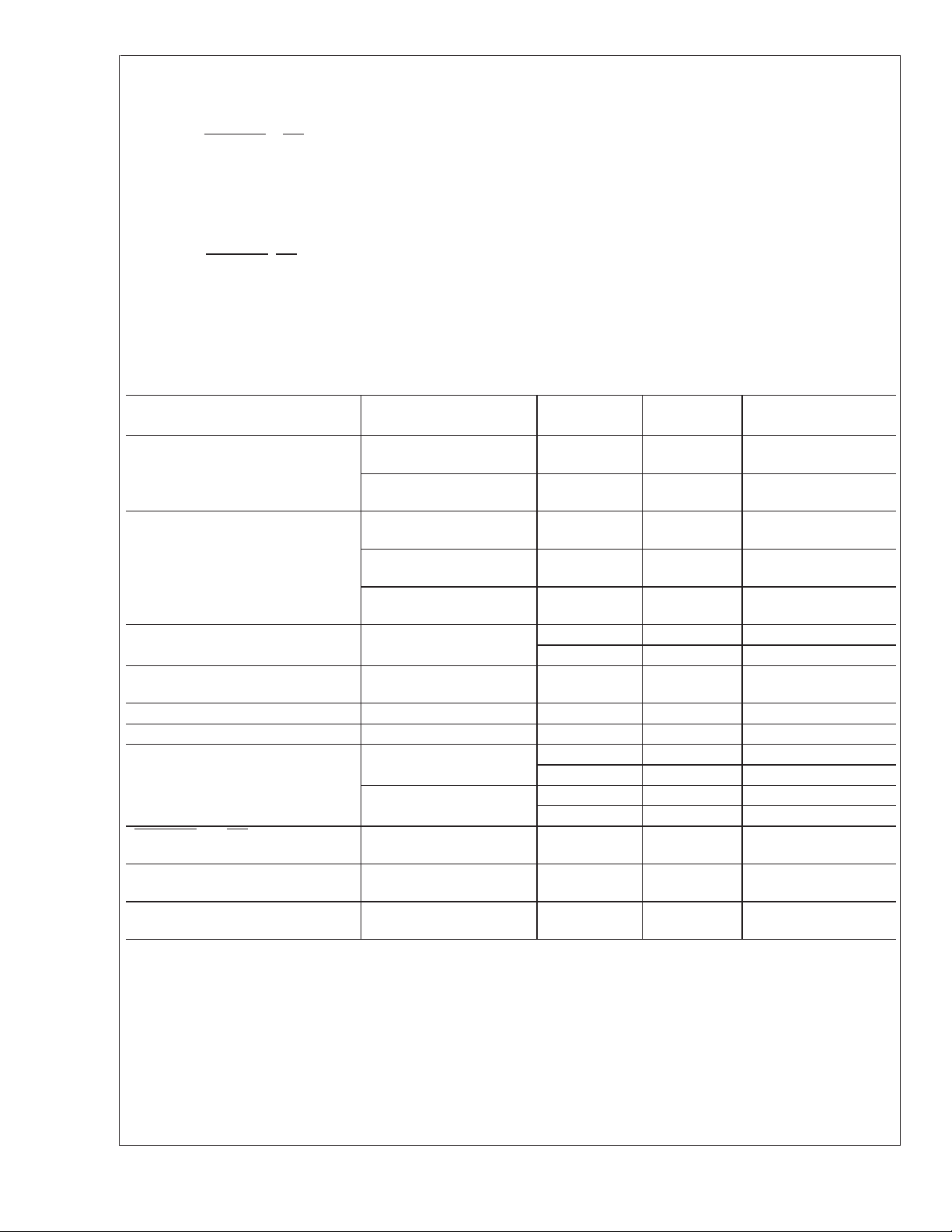

Absolute Maximum Ratings (Note 1)

LM82

Supply Voltage −0.3 V to 6.0 V

Voltage at SMBData,

SMBCLK, T_CRIT_A & INT pins

Voltage at Other Pins −0.3 V to

D− Input Current

Input Current at All Other Pins (Note

2) 5 mA

Package Input Current (Note 2) 20 mA

SMBData, T_CRIT_A, INT Output

Sink Current 10 mA

Storage Temperature −65˚C to +150˚C

−0.5V to 6V

+ 0.3 V)

(V

CC

±

1mA

QSOP Package (Note 3)

Vapor Phase (60 seconds) 215˚C

Infrared (15 seconds) 220˚C

ESD Susceptibility (Note 4)

Human Body Model 2000 V

Machine Model 250 V

Operating Ratings

(Notes 1, 5)

Specified Temperature Range T

LM82 −40˚C to +125˚C

Supply Voltage Range (V

) +3.0V to +3.6V

CC

Soldering Information, Lead Temperature

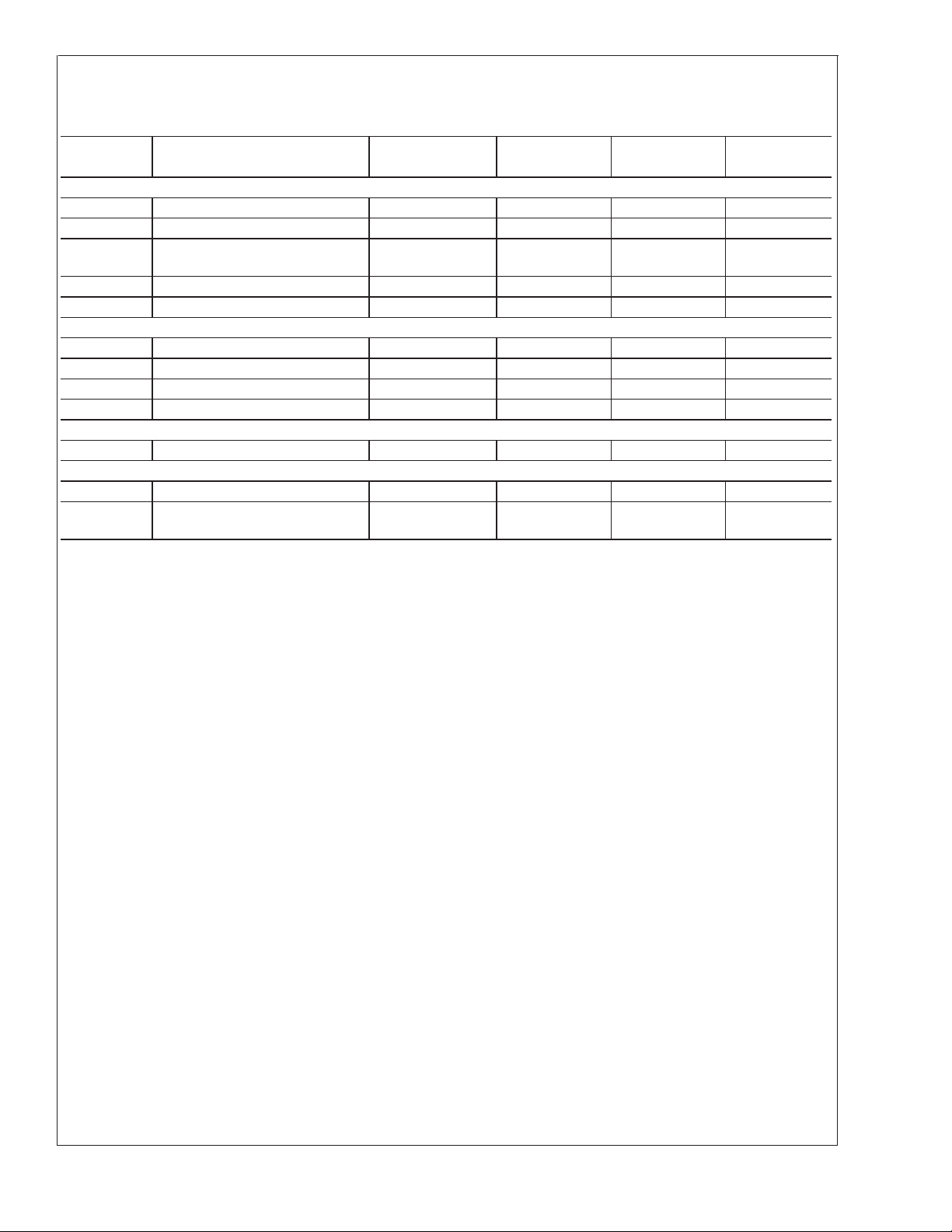

Temperature-to-Digital Converter Characteristics

Unless otherwise noted, these specifications apply for VCC=+3.0 Vdc to 3.6 Vdc. Boldface limits apply for TA=TJ=T

to T

Temperature Error using Local

Diode ((Note 8))

Temperature Error using Remote

Diode ((Note 8))

Resolution 8 Bits

Conversion Time of All

Temperatures

Quiescent Current (Note 9) SMBus (I

D− Source Voltage 0.7 V

Diode Source Current (D+ − D−)=+ 0.65V; high

T_CRIT_A and INT Output

Saturation Voltage

Power-On Reset Threshold On V

Local and Remote T_CRIT and

HIGH Default Temperature settings

; all other limits TA=TJ=+25˚C, unless otherwise noted.

MAX

Parameter Conditions Typical Limits Units

(Note 6) (Note 7) (Limit)

T

= 0 ˚C to +85˚C,

A

=+3.3V

V

CC

T

= −40 ˚C to +125˚C,

A

=+3.3V

V

CC

T

= +60 ˚C to +100˚C,

A

=+3.3V

V

CC

T

= 0 ˚C to +100˚C,

A

=+3.3V

V

CC

T

= 0 ˚C to +125˚C,

A

=+3.3V

V

CC

±

1

±

3 ˚C (max)

±

4 ˚C (max)

±

3

±

3 ˚C (max)

±

4 ˚C (max)

1˚C

(Note 10) 460 600 ms (max)

2

C) Inactive 0.500 0.80 mA (max)

125 µA (max)

level

60 µA (min)

Low level 15 µA (max)

5 µA (min)

I

= 3.0 mA 0.4

OUT

edge

input, falling

CC

2.3

1.8

(Note 11) +127 ˚C

to T

MIN

˚C (max)

V (max)

V (max)

V (min)

MAX

MIN

www.national.com 4

Page 5

Logic Electrical Characteristics

DIGITAL DC CHARACTERISTICS

Unless otherwise noted, these specifications apply for VCC=+3.0 to 3.6 Vdc. Boldface limits apply for TA=TJ=T

T

; all other limits TA=TJ=+25˚C, unless otherwise noted.

MAX

Symbol Parameter Conditions Typical Limits Units

(Note 6) (Note 7) (Limit)

SMBData, SMBCLK

V

V

IN(1)

IN(0)

V

IN(HYST)

Logical “1” Input Voltage 2.1 V (min)

Logical “0”Input Voltage 0.8 V (max)

SMBData and SMBCLK Digital

300 mV

Input Hysteresis

I

I

IN(1)

IN(0)

Logical “1” Input Current VIN=V

CC

0.005 1.5 µA (max)

Logical “0” Input Current VIN= 0 V −0.005 1.5 µA (max)

ADD0, ADD1

V

V

I

I

IN(1)

IN(0)

IN(1)

IN(0)

Logical “1” Input Voltage V

CC

1.5 V (min)

Logical “0”Input Voltage GND 0.6 V (max)

Logical “1” Input Current VIN=V

CC

2 µA (max)

Logical “0” Input Current VIN=0V -2 µA (max)

ALL DIGITAL INPUTS

C

IN

Input Capacitance 20 pF

ALL DIGITAL OUTPUTS

I

OH

V

OL

High Level Output Current VOH=V

SMBus Low Level Output

Voltage

IOL=3mA

=6mA

I

OL

CC

100 µA (max)

0.4

0.6

MIN

V (max)

LM82

to

www.national.com5

Page 6

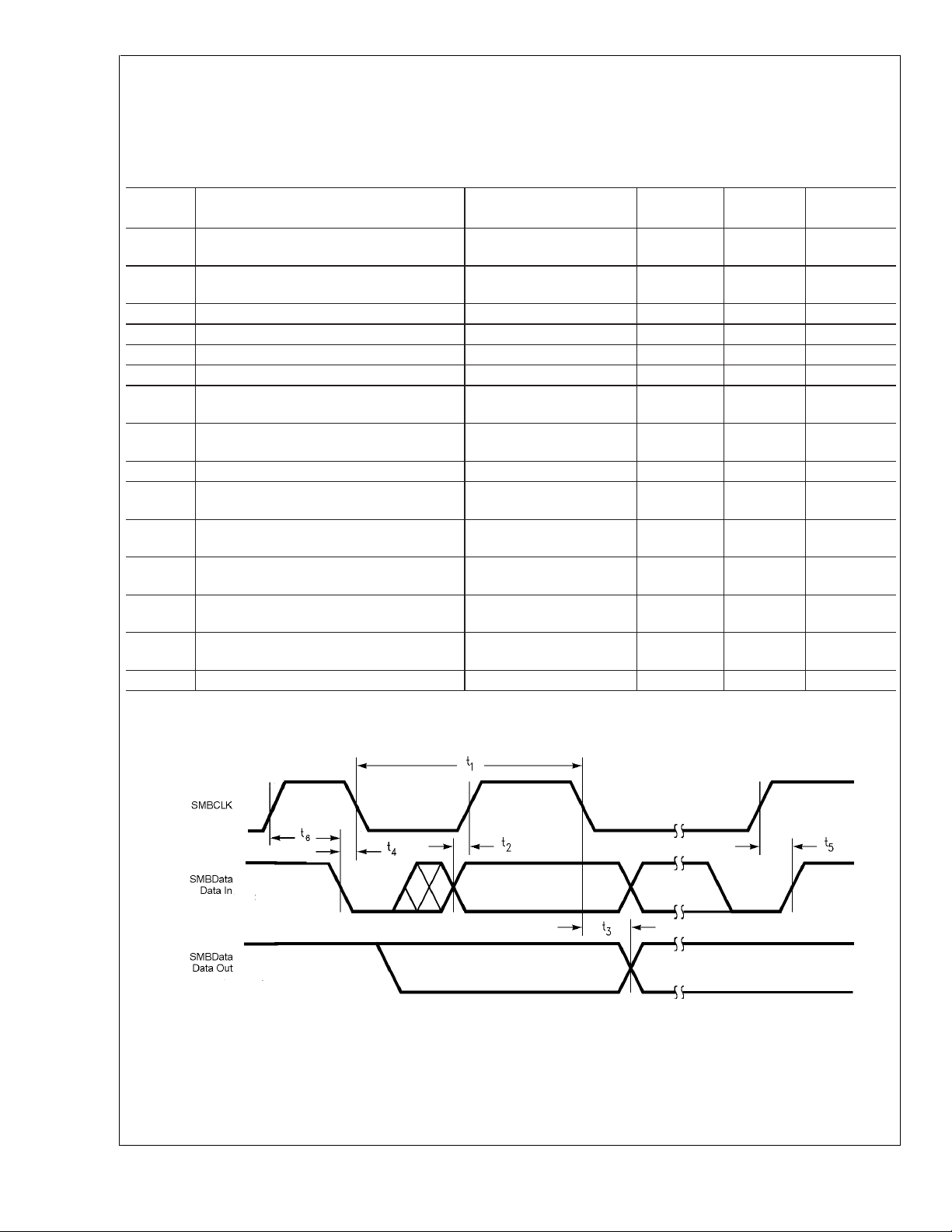

Logic Electrical Characteristics (Continued)

LM82

SMBus DIGITAL SWITCHING CHARACTERISTICS

Unless otherwise noted, these specifications apply for VCC=+3.0 Vdc to +3.6 Vdc, CL(load capacitance) on output lines = 80

pF. Boldface limits apply for T

The switching characteristics of the LM82 fully meet or exceed the published specifications of the SMBus or I2C bus. The following parameters are the timing relationships between SMBCLK and SMBData signals related to the LM82. They are not the

2

I

C or SMBus bus specifications.

A=TJ=TMIN

to T

; all other limits TA=TJ= +25˚C, unless otherwise noted.

MAX

Symbol Parameter Conditions Typical Limits Units

(Note 6) (Note 7) (Limit)

f

SMB

SMBus Clock Frequency 100

10

t

LOW

SMBus Clock Low Time 10 % to 10 % 1.3

25

t

MEXT Cumulative Clock Low Extend Time 10 ms (max)

LOW

t

HIGH

t

R,SMB

t

F,SMB

t

OF

t

TIMEOUT

t

1

t

,

2

t

SU;DAT

t

,

3

t

HD;DAT

t

,

4

t

HD;STA

t

,

5

t

SU;STO

t

,

6

t

SU;STA

t

BUF

SMBus Clock High Time 90 % to 90% 0.6 µs (min)

SMBus Rise Time 10% to 90% 1 µs (max)

SMBus Fall Time 90% to 10% 0.3 ns (max)

Output Fall Time CL= 400 pF,

=3mA

I

O

SMBData and SMBCLK Time Low for

Reset of Serial Interface (Note 12)

250 ns (max)

25

40

SMBCLK (Clock) Period 10 µs (min)

Data In Setup Time to SMBCLK High 100 ns (min)

Data Out Stable after SMBCLK Low 300

TBD

SMBData Low Setup Time to SMBCLK

100 ns (min)

Low

SMBData High Delay Time after

100 ns (min)

SMBCLK High (Stop Condition Setup)

SMBus Start-Condition Setup Time 0.6 µs (min)

SMBus Free Time 1.3 µs (min)

kHz (max)

kHz (min)

µs (min)

ms (max)

ms (min)

ms (max)

ns (min)

ns (max)

SMBus Communication

www.national.com 6

DS101297-4

Page 7

Logic Electrical Characteristics (Continued)

SMBus TIMEOUT

DS101297-7

See drawing DS10129707

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifications do not apply when operating

the device beyond its rated operating conditions.

Note 2: When the input voltage (V

maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of 5 mA to four.

Parasitic components and or ESD protection circuitry are shown in the figure below for the LM82’s pins. The nominal breakdown voltage of the zener D3 is 6.5 V.

Care should be taken not to forward bias the parasitic diode, D1, present on pins: D+, D−,ADD1 andADD0. Doing so by more than 50 mV may corrupt a temperature

or voltage measurement.

) at any pin exceeds the power supplies (V

I

<

GND or V

I

>

VCC), the current at that pin should be limited to 5 mA. The 20 mA

I

LM82

Pin Name D1 D2 D3 D4 Pin Name D1 D2 D3 D4

NC (pins1&5) T_CRIT_A & INT

V

CC

x SMBData x x

x

D+ x x x NC (pins9&15) x x x

D− xxxx SMBCLK x x

ADD0, ADD1 x x x NC (pin 13) x x

Note: An x indicates that the diode exists.

DS101297-13

FIGURE 1. ESD Protection Input Structure

Note 3: See AN-450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in a current National Semicon-

ductor Linear Data Book for other methods of soldering surface mount devices.

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor. Machine model, 200 pF discharged directly into each pin.

Note 5: Thermal resistance of the QSOP-16 package is 130˚C/W, junction-to-ambient when attached to a FR-4 printed circuit board with 1 oz. foil as shown in

.

ure 3

Fig-

www.national.com7

Page 8

Logic Electrical Characteristics (Continued)

LM82

Note 6: Typicals are at TA= 25˚C and represent most likely parametric norm.

Note 7: Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 8: The Temperature Error will vary less than

Note 9: Quiescent current will not increase substantially with an active SMBus.

Note 10: This specification is provided only to indicate how often temperature data is updated. The LM82 can be read at any time without regard to conversion state

(and will yield last conversion result).

Note 11: Default values set at power up.

Note 12: Holding the SMBData and/or SMBCLK lines Low for a time interval greater than t

state of an SMBus communication (SMBCLK and SMBData set High).

±

1.0˚C for a variation in VCCof 3V to 3.6V from the nominal of 3.3V.

will cause the LM82 to reset SMBData and SMBCLK to the IDLE

TIMEOUT

FIGURE 2. Temperature-to-Digital Transfer Function (Non-linear scale for clarity)

FIGURE 3. Printed Circuit Board Used for Thermal Resistance Specifications

1.0 Functional Description

The LM82 temperature sensor incorporates a band-gap type

temperature sensor using a Local or Remote diode and an

8-bit ADC (Delta-Sigma Analog-to-Digital Converter). The

LM82 is compatible with the serial SMBus and I

interfaces. Digital comparators compare Local (LT) and Remote (RT) temperature readings to user-programmable setpoints (LHS, RHS, and TCS).Activation of the INT output indicates that a comparison is greater than the limit preset in a

HIGH register. The T_CRIT setpoint (TCS) interacts with all

the temperature readings. Activation of the T_CRIT_A output

indicates that any or all of the temperature readings have exceed the T_CRIT setpoint.

1.1 CONVERSION SEQUENCE

The LM82 converts its own temperature as well as a remote

diode temperature in the following sequence:

1. Local Temperature (LT)

2. Remote Diode (RT)

2

C two wire

DS101297-5

DS101297-24

This round robin sequence takes approximately 480 ms to

complete.

1.2 INT OUTPUT and T_HIGH LIMITS

Each temperature reading (LT, and RT) is associated with a

T_HIGH setpoint register (LHS, RHS). At the end of a temperature reading a digital comparison determines whether

that reading has exceeded its HIGH setpoint. If the temperature reading is greater than the HIGH setpoint, a bit is set in

one of the Status Registers, to indicate which temperature

reading, and the INT output is activated.

Local and remote temperature diodes are sampled in sequence by the A/D converter. The INT output and the Status

Register flags are updated at the completion of a conversion,

which occurs approximately 60 ms after a temperature diode

is sampled. INT is deactivated when the Status Register,

containing the set bit, is read and a temperature reading is

www.national.com 8

Page 9

1.0 Functional Description (Continued)

less than or equal to it’s corresponding HIGH setpoint, as

shown in

for the INT output and related circuitry.

*

Note: Status Register Bits are reset by a read of Status Register where

bit is located.

Figure 4.Figure 5

shows a simplified logic diagram

DS101297-14

FIGURE 4. INT Temperature Response Diagram

conversion is below the T_CRIT setpoint, as shown in

6

.

Figure 7

shows a simplified logic diagram of the

Figure

T_CRIT_A and related circuitry.

DS101297-6

*

Note: Status Register Bits are reset by a read of Status Register where

bit is located.

FIGURE 6. T_CRIT_A Temperature Response Diagram

LM82

DS101297-21

FIGURE 5. INT output related circuitry logic diagram

The INT output can be disabled by setting the INT mask bit,

D7, of the configuration register. INT can be programmed to

be active high or low by the state of the INT inversion bit, D1,

in the configuration register. A “0” would program INT to be

active low. INT is an open-drain output.

1.3 T_CRIT_A OUTPUT and T_CRIT LIMIT

T_CRIT_A is activated when any temperature reading is

greater than the limit preset in the critical temperature setpoint register (T_CRIT), as shown in

Figure 6

. The Status

Registers can be read to determine which event caused the

alarm. A bit in the Status Registers is set high to indicate

which temperature reading exceeded the T_CRIT setpoint

temperature and caused the alarm, see

Section 2.3

.

Local and remote temperature diodes are sampled in sequence by the A/D converter. The T_CRIT_A output and the

Status Register flags are updated at the completion of a conversion. T_CRIT_A and the Status Register flags are reset

only after the Status Register is read and if a temperature

DS101297-20

FIGURE 7. T_CRIT_A output related circuitry logic

diagram

Located in the Configuration Register are the mask bits for

each temperature reading, see

Section 2.5

. When a mask bit

is set, its corresponding status flag will not propagate to the

T_CRIT_A output, but will still be set in the Status Registers.

Configuration register bits D5 and D3, labled “Remote

T_CRIT_A mask” must be set high before the T_CRIT setpoint is lowered in order for the T_CRIT_A output to function

properly. Setting all four mask bits or programming the

T_CRIT setpoint to 127˚C will disable the T_CRIT_A output.

1.4 POWER ON RESET DEFAULT STATES

LM82 always powers up to these known default states:

1. Command Register set to 00h

2. Local Temperature set to 0˚C

3. Remote Temperature set to 0˚C until the LM82 senses a

diode present between the D+ and D− input pins.

4. Status Register set to 00h.

5. Configuration Register set to 00h; INT enabled and all

T_CRIT setpoints enabled to activate T_CRIT_A.

www.national.com9

Page 10

1.0 Functional Description (Continued)

LM82

6. Local and Remote T_CRIT set to 127˚C

1.5 SMBus INTERFACE

The LM82 operates as a slave on the SMBus, so the

SMBCLK line is an input (no clock is generated by the LM82)

and the SMBData line is bi-directional. According to SMBus

specifications, the LM82 has a 7-bit slave address. Bit 4 (A3)

of the slave address is hard wired inside the LM82 to a 1.

The remainder of the address bits are controlled by the state

of the address select pins ADD1 and ADD0, and are set by

connecting these pins to ground for a low, (0) , to V

high, (1), or left floating (TRI-LEVEL).

Therefore, the complete slave address is:

A6 A5 A4 1 A2 A1 A0

MSB LSB

and is selected as follows:

Address Select Pin State LM82 SMBus

Slave Address

ADD0 ADD1 A6:A0 binary

0 0 001 1000

0 TRI-LEVEL 001 1001

0 1 001 1010

TRI-LEVEL 0 010 1001

TRI-LEVEL TRI-LEVEL 010 1010

TRI-LEVEL 1 010 1011

1 0 100 1100

1 TRI-LEVEL 100 1101

1 1 100 1110

The LM82 latches the state of the address select pins during

the first read or write on the SMBus. Changing the state of

the address select pins after the first read or write to any device on the SMBus will not change the slave address of the

LM82.

Temperature Digital Output

Binary Hex

+125˚C 0111 1101 7Dh

+25˚C 0001 1001 19h

+1˚C 0000 0001 01h

0˚C 0000 0000 00h

−1˚C 1111 1111 FFh

−25˚C 1110 0111 E7h

−55˚C 1100 1001 C9h

for a

CC

1.7 OPEN-DRAIN OUTPUTS

The SMBData, INT and T_CRIT_A outputs are open-drain

outputs and do not have internal pull-ups.A “high” level will

not be observed on these pins until pull-up current is provided from some external source, typically a pull-up resistor.

Choice of resistor value depends on many system factors

but, in general, the pull-up resistor should be as large as

possible. This will minimize any internal temperature reading

errors due to internal heating of the LM82. The maximum resistance of the pull up, based on LM82 specification for High

Level Output Current, to provide a 2.1V high level, is 30kΩ.

Care should be taken in a noisy system because a high impedance pull-up will be more likely to couple noise into the

signal line.

1.8 DIODE FAULT DETECTION

Before each external conversion the LM82 goes through an

external diode fault detection sequence. If D+ input is

shorted to V

be +127 ˚C, and the OPEN bit in the Status Register will be

set. If the T_CRIT setpoint is set to less than +127 ˚C then

the D+ input RTCRIT bit in the Status Register will be set

which will activate the T_CRIT_A output, if enabled. If a D+

is shorted to GND or D−, its temperature reading will be 0 ˚C

and its OPEN bit in the Status Register will not be set.

or floating then the temperature reading will

CC

1.6 TEMPERATURE DATA FORMAT

Temperature data can be read from the Local and Remote

Temperature, T_CRIT, and HIGH setpoint registers; and written to the T_CRIT and HIGH setpoint registers. Temperature

data is represented by an 8-bit, two’s complement byte with

an LSB (Least Significant Bit) equal to 1˚C:

www.national.com 10

Page 11

1.0 Functional Description (Continued)

1.9 COMMUNICATING with the LM82

LM82

There are 13 data registers in the LM82, selected by the

Command Register. At power-up the Command Register is

set to “00”, the location for the Read LocalTemperatureRegister. The Command Register latches the last location it was

set to. Reading the Status Register resets T_CRIT_A and

INT, so long as a temperature comparison does not signal a

fault (see

Sections 1.2 and 1.3

). All other registers are predefined as read only or write only. Read and write registers

with the same function contain mirrored data.

AWrite to the LM82 will always include the address byte and

the command byte. A write to any register requires one data

byte.

Reading the LM82 can take place either of two ways:

1. If the location latched in the Command Register is cor-

rect (most of the time it is expected that the Command

Register will point to one of the Read Temperature Registers because that will be the data most frequentlyread

from the LM82), then the read can simply consist of an

address byte, followed by retrieving the data byte.

2. If the Command Register needs to be set, then an ad-

dress byte, command byte, repeat start, and another address byte will accomplish a read.

The data byte has the most significant bit first. At the end of

a read, the LM82 can accept either Acknowledge or No Acknowledge from the Master (No Acknowledge is typically

used as a signal for the slave that the Master has read its

last byte).

DS101297-9

1.10 SERIAL INTERFACE ERROR RECOVERY

The LM82 SMBus lines will be reset to the SMBus idle state

if the SMBData or SMBCLK lines are held low for 40 ms or

more (t

). The LM82 may or may not reset the state of

TIMEOUT

the serial interface logic if either of the SMBData or SMBCLK

lines are held low between 25 ms and 40 ms. TIMEOUT allows a clean recovery in cases where the master may be reset while the LM82 is transmitting a low bit thus preventing

possible bus lock up.

Whenever the LM82 sees the start condition its serial interface will reset to the beginning of the communication, thus

the LM82 will expect to see an address byte next. This simplifies recovery when the master is reset while the LM82 is

transmitting a high.

www.national.com11

Page 12

1.0 Functional Description (Continued)

LM82

2.0 LM82 REGISTERS

2.1 COMMAND REGISTER

Selects which registers will be read from or written to. Data for this register should be transmitted during the Command Byte of

the SMBus write communication.

P7 P6 P5 P4 P3 P2 P1 P0

0 Command Select

P0-P7: Command Select

Command Se-

lect Address

<

P7:P0>hex

00h 0000 0000 0 RLT Read Local Temperature

01h 0000 0000 0 RRT Read Remote Temperature

02h 0000 0000 0 RSR Read Status Register

03h 0000 0000 0 RC Read Configuration

04h 0000 0000 0 Reserved

05h 0111 1111 127 RLHS Read Local HIGH Setpoint

06h Reserved

07h 0111 1111 127 RRHS Read Remote HIGH Setpoint

08h Reserved

09h 0000 0000 WC Write Configuration

0Ah Reserved

0Bh 0111 1111 127 WRHS Write Local HIGH Setpoint

0Ch Reserved

0Dh 0111 1111 127 WLHS Write Local HIGH Setpoint

0Eh-2Fh Reserved for Future Use

30h-31h 0000 0000 0 Reserved

32h-34h Reserved for Future Use

35h 0000 0000 0 Reserved

36h-37h Reserved for Future Use

38h 0111 1111 127 Reserved

39h Reserved for Future Use

3Ah 0111 1111 127 Reserved

3Bh-41h Reserved for Future Use

42h 0111 1111 127 RTCS Read T_CRIT Setpoint

43h-4Fh Reserved for Future Use

50h 0111 1111 127 Reserved

51h Reserved for Future Use

52h 0111 1111 127 Reserved

53h-59h Reserved for Future Use

5Ah 0111 1111 127 WTCS Write T_CRIT Setpoint

5Ch-6Fh and

F0h-FDh

FEh 0000 0001 1 RMID Read Manufacturers ID

FFh 1 RSR Read Stepping or Die

Power On Default State Register Name Register Function

<

D7:D0>binary<D7:D0>deci-

mal

Reserved for Future Use

Revision Code

www.national.com 12

Page 13

1.0 Functional Description (Continued)

2.2 LOCAL and REMOTE TEMPERATURE REGISTERS (LT, and RT)

(Read Only Address 00h, and 01h):

D7 D6 D5 D4 D3 D2 D1 D0

MSB Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 LSB

D7–D0: Temperature Data. One LSB = 1˚C. Two’s complement format.

2.3 STATUS REGISTER

(Read Only Address 02h):

D7 D6 D5 D4 D3 D2 D1 D0

0 LHIGH 0 RHIGH 0 OPEN RCRIT LCRIT

Power up default is with all bits “0” (zero).

D0: LCRIT: When set to a 1 indicates an Local Critical Temperature alarm.

D1: RCRIT: When set to a 1 indicates a Remote Diode Critical Temperature alarm.

D2: D2OPEN: When set to 1 indicates a Remote Diode disconnect.

D4: D2RHIGH: When set to 1 indicates a Remote Diode HIGH Temperature alarm.

D6: LHIGH: When set to 1 indicates a Local HIGH Temperature alarm.

D7, D5, and D3: These bits are always set to 0 and reserved for future use.

2.4 MANUFACTURERS ID and DIE REVISION(Stepping)

REGISTERS

(Read Address FEh and FFh) Default value 01h for Manufacturers ID(FEh ).

LM82

2.5 CONFIGURATION REGISTER

(Read Address 03h/Write Address 09h):

D7 D6 D5 D4 D3 D2 D1 D0

INT mask

Power up default is with all bits “0” (zero).

D7: INT mask: When set to 1 INT interrupts are masked.

D5: T_CRIT mask, this bit must be set to a 1 before the T_CRIT setpoint is lowered below 127 in order for T_CRIT_A pin to func-

tion properly.

D4: T_CRIT mask for Remote temperature, when set to 1 a remote temperature reading that exceeds T_CRIT setpoint will not

activate the T_CRIT_A pin.

D3: T_CRIT mask, this bit must be set to a 1 before the T_CRIT setpoint is lowered below 127 in order for T_CRIT_A pin to func-

tion properly.

D2: T_CRIT mask for Local reading, when set to 1 a Local temperature reading that exceeds T_CRIT setpoint will not activate

the T_CRIT_A pin.

D1: INT active state inversion. When INT Inversion is set to a 1 the active state of the INT output will be a logical high. Alow would

then select an active state of a logical low.

D6 and D0: These bits are always set to 0 and reserved for future use. A write of 1 will return a 0 when read.

2.6 LOCAL, and REMOTE HIGH SETPOINT REGISTERS (LHS, RHS)

(Read Address 05h, 07h/Write Address 0Bh, 0Dh):

D7 D6 D5 D4 D3 D2 D1 D0

MSB Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 LSB

D7–D0: HIGH setpoint temperature data. Power up default is LHIGH = RHIGH=127˚C.

0 Remote

T_CRIT_A

mask

Remote

T_CRIT_A

mask

Remote

T_CRIT_A

mask

Local

T_CRIT_A

mask

INT Inversion

0

2.7 T_CRIT REGISTER (TCS)

(Read Address 42h/Write Address 5Ah):

D7 D6 D5 D4 D3 D2 D1 D0

MSB Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 LSB

D7–D0: T_CRIT setpoint temperature data. Power up default is T_CRIT = 127˚C.

www.national.com13

Page 14

3.0 SMBus Timing Diagrams

LM82

(a) Serial Bus Write to the internal Command Register followed by a the Data Byte

DS101297-10

DS101297-11

(b) Serial Bus Write to the internal Command Register

DS101297-12

(c) Serial Bus Read from a Register with the internal Command Register preset to desired value.

FIGURE 8. Serial Bus Timing Diagrams

www.national.com 14

Page 15

4.0 Application Hints

The LM82 can be applied easily in the same way as other

integrated-circuit temperature sensors and its remote diode

sensing capability allows it to be used in new ways as well.

It can be soldered to a printed circuit board, and because the

path of best thermal conductivity is between the die and the

pins, its temperature will effectively be that of the printed circuit board lands and traces soldered to the LM82’s pins. This

presumes that the ambient air temperature is almost the

same as the surface temperature of the printed circuit board;

if the air temperature is much higher or lower than the surface temperature, the actual temperature of the of the LM82

die will be at an intermediate temperature between the surface and air temperatures. Again, the primary thermal conduction path is through the leads, so the circuit board temperature will contribute to the die temperature much more

strongly than will the air temperature.

To measure temperature external to the LM82’s die, use a

remote diode. This diode can be located on the die of a target IC, allowing measurement of the IC’s temperature, independent of the LM82’s temperature. The LM82 has been optimized to measure the remote diode of a Pentium II

processor as shown in

used to sense the temperature of external objects or ambient

air.Remember that a discrete diode’s temperature will be affected, and often dominated, by the temperature of its leads.

Figure 9

.A discrete diode can also be

where:

η is the non-ideality factor of the process the diode is

•

manufactured on,

q is the electron charge,

•

k is the Boltzmann’s constant,

•

N is the current ratio,

•

T is the absolute temperature in ˚K.

•

The temperature sensor then measures ∆V

and converts

BE

to digital data. In this equation, k and q are well defined universal constants, and N is a parameter controlled by the temperature sensor. The only other parameter is η, which depends on the diode that is used for measurement. Since

∆V

is proportional to both η andT,the variations in η can-

BE

not be distinguished from variations in temperature. Since

the non-ideality factor is not controlled by the temperature

sensor,it will directly add to the inaccuracy of the sensor.For

the Pentium II Intel specifies a

±

1% variation in η from part

to part. As an example, assume a temperature sensor has

an accuracy specification of

±

3 ˚C at room temperature of 25

˚C and the process used to manufacture the diode has a

non-ideality variation of

±

1%. The resulting accuracy of the

temperature sensor at room temperature will be:

T

=±3˚C+(±1% of 298 ˚K) =±6 ˚C.

ACC

The additional inaccuracy in the temperature measurement

caused by η, can be eliminated if each temperature sensor is

calibrated with the remote diode that it will be paired with.

LM82

DS101297-15

Pentium or 3904 Temperature vs LM82 Temperature

Reading

Most silicon diodes do not lend themselves well to this application. It is recommended that a 2N3904 transistor base

emitter junction be used with the collector tied to the base.

A diode connected 2N3904 approximates the junction available on a Pentium microprocessor for temperature measurement. Therefore, the LM82 can sense the temperature of this

diode effectively.

3.1 ACCURACY EFFECTS OF DIODE NON-IDEALITY

FACTOR

The technique used in today’s remote temperature sensors

is to measure the change in V

at two different operating

BE

points of a diode. For a bias current ratio of N:1, this difference is given as:

3.2 PCB LAYOUT for MINIMIZING NOISE

In a noisy environment, such as a processor mother board,

layout considerations are very critical. Noise induced on

traces running between the remote temperature diode sensor and the LM82 can cause temperature conversion errors.

The following guidelines should be followed:

1. Place a 0.1 µF power supply bypass capacitor as close

as possible to the V

pin and the recommended 2.2 nF

CC

capacitor as close as possible to the D+ and D− pins.

Make sure the traces to the 2.2nF capacitor are

matched.

2. The recommended 2.2nF diode bypass capacitor actu-

ally has a range of 200pF to 3.3nF. The average temperature accuracy will not degrade. Increasing the capacitance will lower the corner frequency where

differential noise error affects the temperature reading

thus producing a reading that is more stable. Conversely, lowering the capacitance will increase the corner frequency where differential noise error affects the

temperature reading thus producing a reading that is

less stable.

3. Ideally, the LM82 should be placed within 10cm of the

Processor diode pins with the traces being as straight,

short and identical as possible. Trace resistance of 1Ω

can cause as much as 1˚C of error.

4. Diode traces should be surrounded by a GND guard ring

to either side, above and below if possible. This GND

guard should not be between the D+ and D− lines. In the

event that noise does couple to the diode lines it would

be ideal if it is coupled common mode. That is equally to

the D+ and D− lines.(See

Figure 10

)

5. Avoid routing diode traces in close proximity to power

supply switching signals or filtering inductors.

www.national.com15

Page 16

4.0 Application Hints (Continued)

LM82

6. Avoid running diode traces close to or parallel to high

speed digital and bus lines. Diode traces should bekept

at least 2cm. apart from the high speed digital traces.

7. If it is necessary to cross high speed digital traces, the

diode traces and the high speed digital traces should

cross at a 90 degree angle.

8. The ideal place to connect the LM82’s GND pin is as

close as possible to the Processors GND associated

with the sense diode.

9. Leakage current between D+ and GND should be kept

to a minimum. One nano-ampere of leakage can cause

as much as 1˚C of error in the diode temperature reading. Keeping the printed circuit board as clean as possible will minimize leakage current.

DS101297-17

FIGURE 10. Ideal Diode Trace Layout

Noise coupling into the digital lines greater than 300mVp-p

(typical hysteresis), overshoot greater than 500mV above

V

, and undershoot less than 500mV below GND, may pre-

CC

vent successful SMBus communication with the LM82. SMBus no acknowledge is the most common symptom, causing

unnecessary traffic on the bus. Although, the SMBus maximum frequency of communication is rather low (100kHz

max) care still needs to be taken to ensure proper termination within a system with multiple parts on the bus and long

printed circuit board traces. An R/C lowpass filter with a 3db

corner frequency of about 40MHz has been included on the

LM82’s SMBCLK input. Additional resistance can be added

in series with the SMBData and SMBCLK lines to further

help filter noise and ringing. Minimize noise coupling by

keeping digital traces out of switching power supply areas as

well as ensuring that digital lines containing high speeddata

communications cross at right angles to the SMBData and

SMBCLK lines.

www.national.com 16

Page 17

Physical Dimensions inches (millimeters) unless otherwise noted

LM82 Remote Diode and Local Digital Temperature Sensor with Two-Wire Interface

16-Lead QSOP Package

Order Number LM82CIMQA or LM82CIMQAX

NS Package Number MQA16

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...