Page 1

November 2000

LM3822

Precision Current Gauge IC with Internal Zero Ohm

Sense Element and PWM Output

General Description

The LM3822 Current Gauge provides easy to use precision

current measurement with virtually zero insertion loss (typically 0.003Ω). The LM3822 is used for high-side sensing.

A Delta Sigma analog to digital converter is incorporated to

precisely measure the current and to provide a current averaging function. Current is averaged over 50 msec time

periods in order to provide immunity to current spikes. The

ICs have a pulse-width modulated (PWM) output which indicates the current magnitude and direction. The shutdown pin

can be used to inhibit false triggering during start-up, or to

enter a low quiescent current mode.

The LM3822 is factory-set in two different current options.

The sense range is −1.0A to +1.0A or −2.0A to +2.0A. The

sampling interval for this part is 50ms. If faster sampling is

desired, please refer to the data sheet for the part number

LM3824.

n Low quiescent current in shutdown mode (typically

1.8 µA)

n 50 msec sampling interval

n In MSOP-8 Package

Features

n No external sense element required

n PWM output indicates the current magnitude and

direction

n PWM output is easily interfaced with microprocessors

and controllers

n Precision ∆Σ current-sense technique

n Low temperature sensitivity

n Internal filtering rejects false trips

n Internal Power-On-Reset (POR)

n DC Offset is less than 1 mA for 1A part

LM3822 Precision Current Gauge IC with Internal Zero Ohm Sense Element and PWM Output

Key Specifications

n Ultra low insertion loss (typically 0.003Ω)

n 2V to 5.5V supply range

±

n

2% accuracy at room temperature for the 1A device

(includes accuracy of the internal sense element)

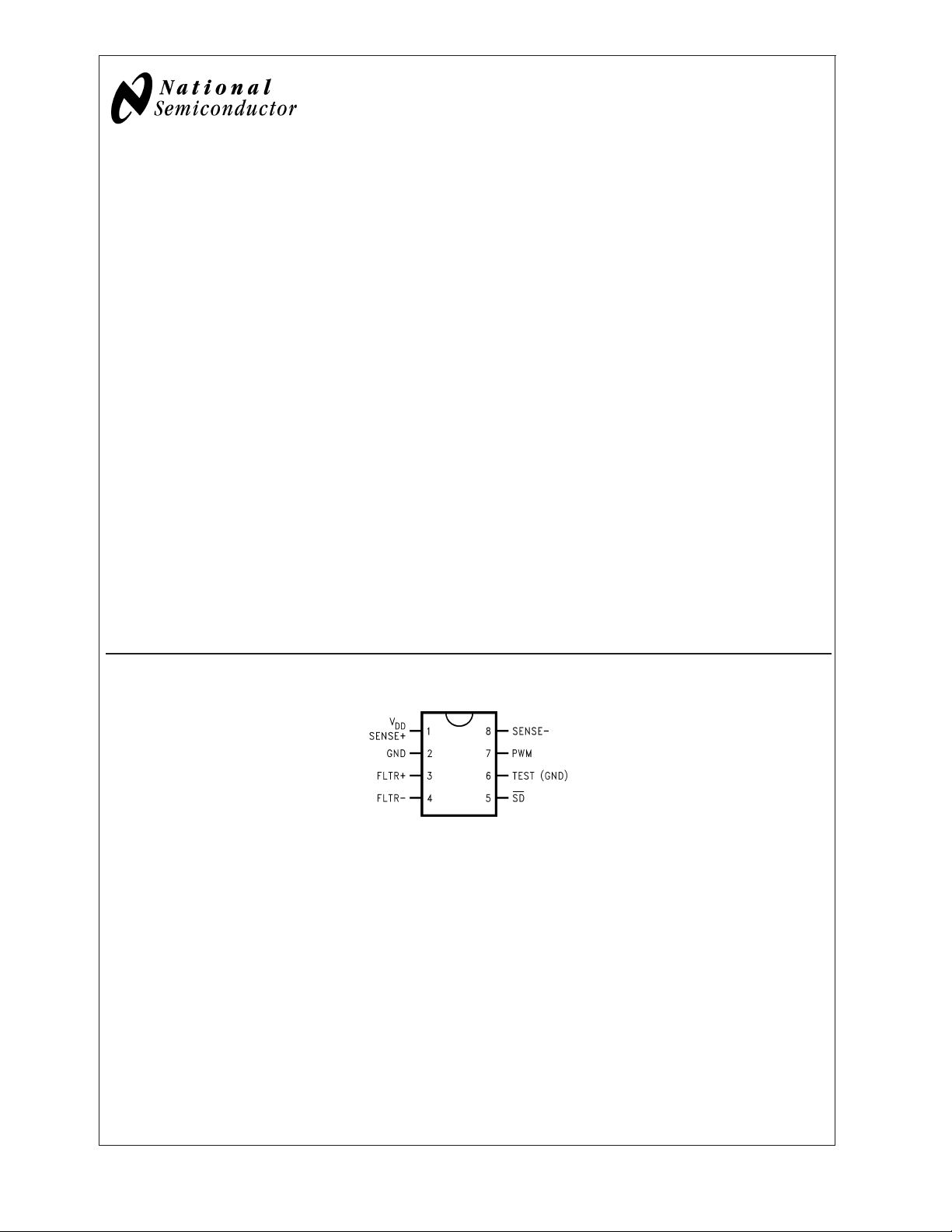

Connection Diagram

LM3822 for High-Side Sensing

Applications

n Battery charge/discharge gauge

n Motion control diagnostics

n Power supply load monitoring and management

n Resettable smart fuse

10124901

Top View

© 2004 National Semiconductor Corporation DS101249 www.national.com

Page 2

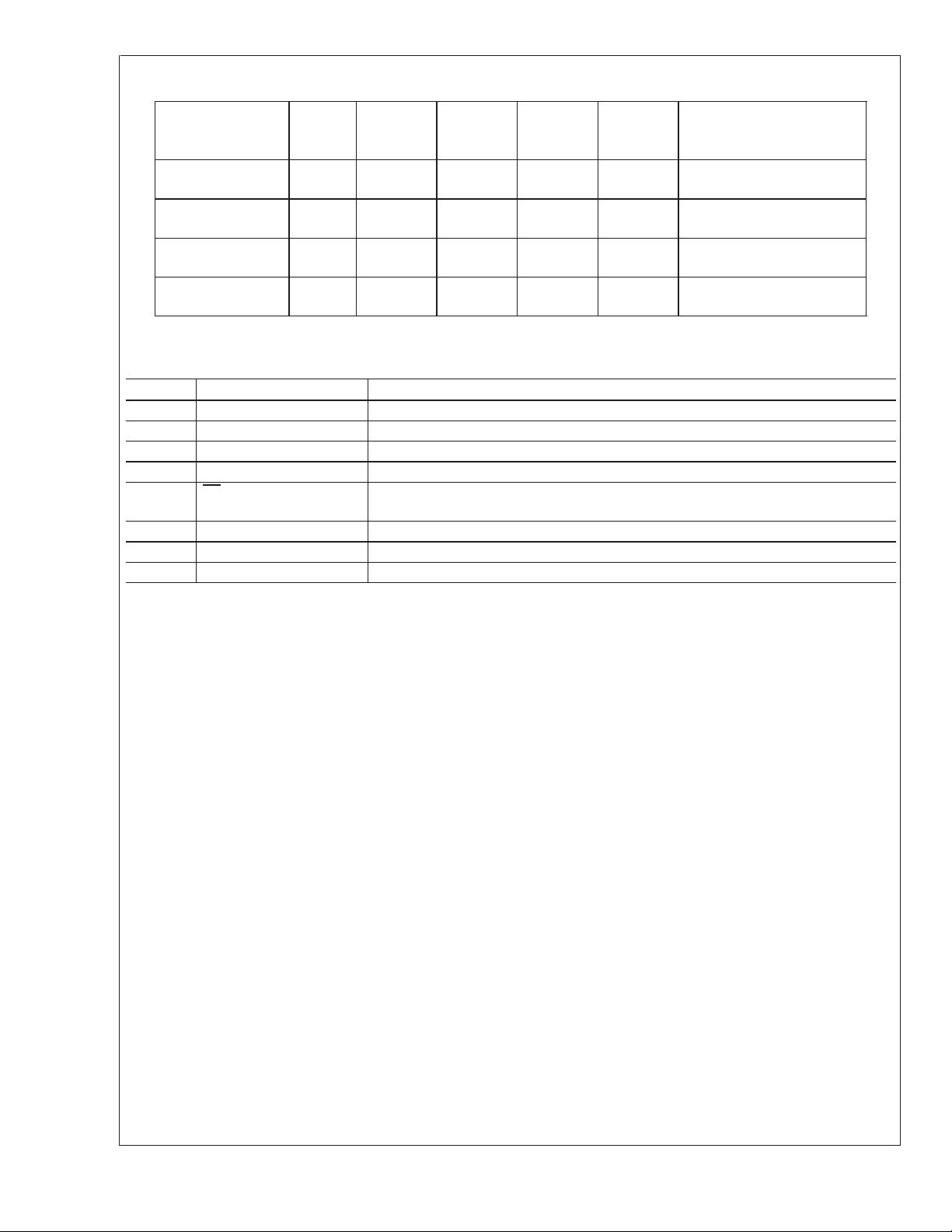

Ordering Information

LM3822

* Current is sampled over a fixed interval. The average current during this interval is indicated by the duty cycle of the PWM output during next interval.

Order No.

LM3822MM-1.0

LM3822MMX-1.0

LM3822MM-2.0

LM3822MMX-2.0

*

Sense

Range

±

1.0A 50 ms High-side MUA08A MSOP-8 Tape and Reel

±

1.0A 50 ms High-side MUA08A MSOP-8 Tape and Reel

±

2.0A 50 ms High-side MUA08A MSOP-8 Tape and Reel

±

2.0A 50 ms High-side MUA08A MSOP-8 Tape and Reel

Sampling

Interval*

Sensing

Method

NS

Package

Number

Pin Description (High-Side, LM3822)

Pin Name Function

1 SENSE+, V

2 GND Supply Ground.

3 FLTR+ Filter input — provides anti-aliasing for delta sigma modulator.

4 FLTR− Filter input.

5SD

6 TEST Connect to GND for normal operation.

7 PWM Digital output indicates the current magnitude and direction.

8 SENSE− Low side of internal current sense.

DD

High side of internal current sense, also supply voltage.

Shutdown input. Connected to VDDthrough a pull-up resistor for normal operation.

When low, the LM3822 is put into a low current mode.

Package

Type

Supplied As:

(1000 units/reel)

(3500 units/reel)

(1000 units/reel)

(3500 units/reel)

www.national.com 2

Page 3

LM3822

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

Storage Temperature −65˚C to +150˚C

Lead Temperature (Soldering, 10 sec) 260˚C

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Operating Ratings (Note 1)

Absolute Maximum Supply Voltage 5.5V

Power Dissipation (Note 2)

ESD Susceptibility (Note 3) 1.5 kV

Sense Current (peak, for 200 msec) (Note 4) 10A

Sink Current for PWM pin 1mA

Maximum Junction Temperature 150˚C

Input Voltage 2.0V to 5.25V

Sense Current (continuous) (Note 4) 5A

Junction Temperature Range −40˚C to +85˚C

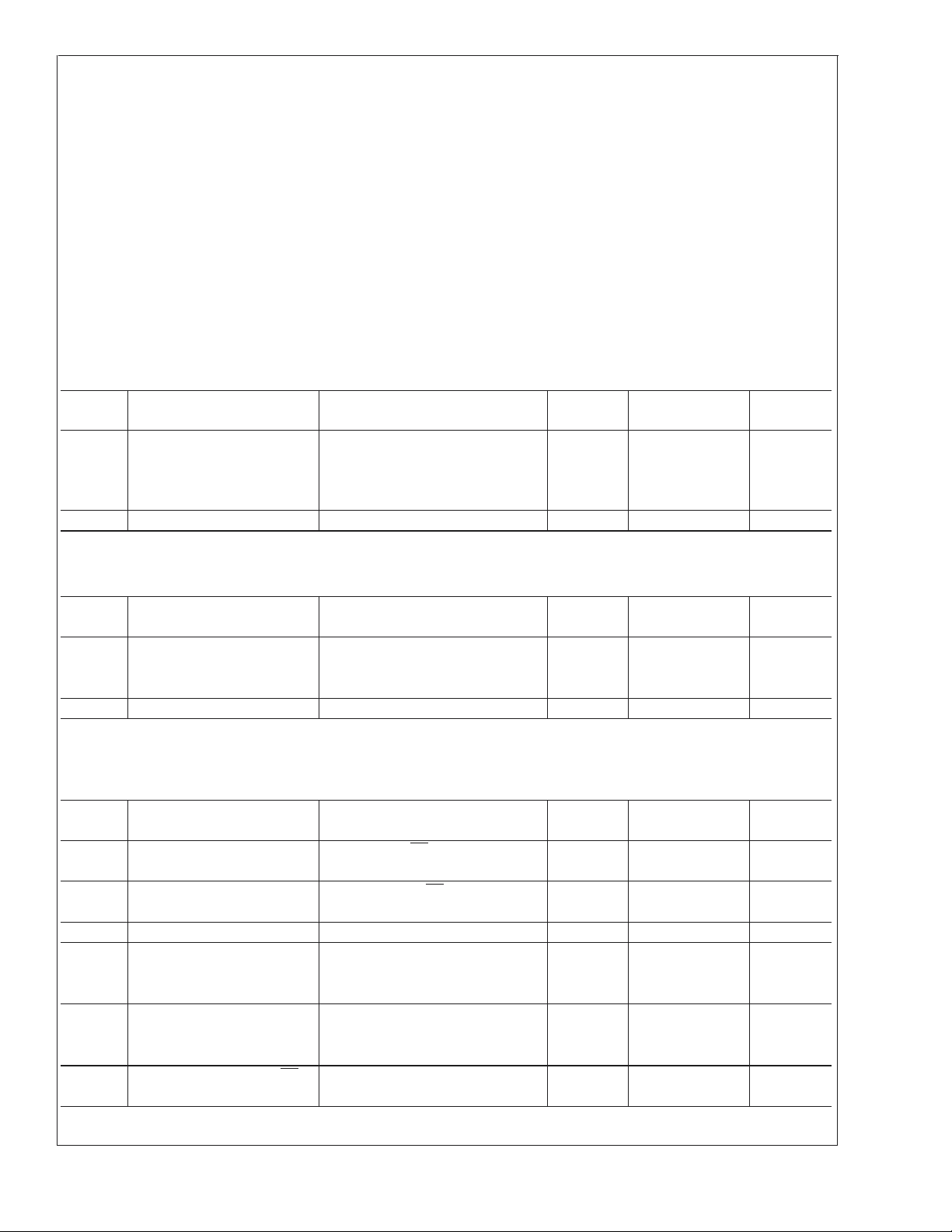

Electrical Characteristics Typical numbers are at 25˚C and represent the most likely parametric norm.

Specifications in standard type face are for T

ranges.

= 25˚C and those with boldface type apply over full operating temperature

J

LM3822-1.0

SENSE+VDD= 3.6V for the following specifications. Supply bypass capacitor is 1 µF and filter capacitor is 0.1 µF.

Symbol Parameter Conditions

I

ACC

Average Current Accuracy

1.0A current 1.0

(Note 7)

e

n

Effective Output Noise (rms) 2 mA

Typ

(Note 5)

Limit

(Note 6)

0.98 / 0.96 A (min)

1.02 / 1.04 A (max)

Units

A

LM3822-2.0

SENSE+VDD= 3.6V for the following specifications. Supply bypass capacitor is 1 µF and filter capacitor is 0.1 µF.

Symbol Parameter Conditions

I

ACC

Average Current Accuracy

2.0A current (Note 8) 2.0 A

(Note 7)

Typ

(Note 5)

Limit

(Note 6)

1.94 / 1.90 A (min)

2.06 / 2.10 A (max)

e

n

Effective Output Noise (rms) 6 mA

Common Device Parameters

Unless otherwise specified, VDD= 3.6V for the following specifications. Supply bypass capacitor is 1 µF and filter capacitor is

0.1 µF.

Symbol Parameter Conditions

I

Q1

I

Q2

D

RES

t

S

f

P

V

TH

Quiescent Current Normal Mode, SD = high 95 µA

Quiescent Current Shutdown Mode, SD = low 1.8 µA

PWM Resolution 0.1 %

Sampling Time 50 ms

Frequency of PWM Waveform 20 Hz

Threshold High Level for SD 1.3 V

Typ

(Note 5)

Limit

(Note 6)

150 µA (max)

10 µA (max)

40 ms (min)

80 ms (max)

12.5 Hz (min)

25 Hz (max)

1.8 V (min)

Units

Units

www.national.com3

Page 4

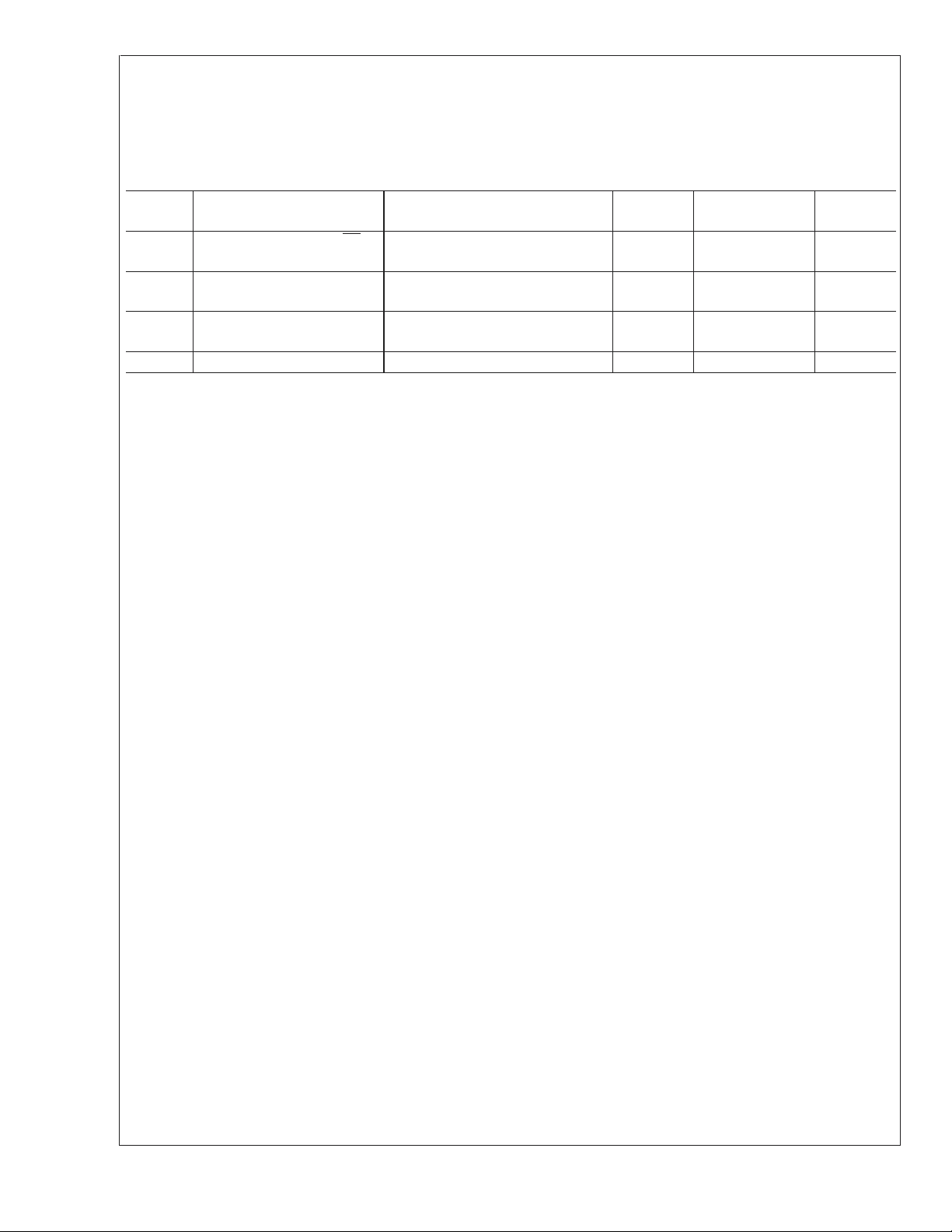

Electrical Characteristics Typical numbers are at 25˚C and represent the most likely parametric norm.

Specifications in standard type face are for T

LM3822

ranges. (Continued)

= 25˚C and those with boldface type apply over full operating temperature

J

Common Device Parameters (Continued)

Unless otherwise specified, VDD= 3.6V for the following specifications. Supply bypass capacitor is 1 µF and filter capacitor is

0.1 µF.

Symbol Parameter Conditions

V

TL

V

OH

Threshold Low Level for SD 1.2 V

Logic High Level for PWM Load current = 1 mA, 2V ≤ VDD≤

Typ

(Note 5)

VDD− 0.05

5.25V

V

OL

Logic Low Level for PWM Sink current = 1 mA, 2V ≤ VDD≤

0.04 V

5.25V

P

I

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see Electrical Characteristics. The

guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed

test conditions.

Note 2: At elevated temperatures, devices must be derated based on package thermal resistance. The device in the surface-mount package must be derated at

θ

JA

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin.

Note 4: The absolute maximum peak and continuous currents specified are not tested. These specifications are dependent on the θ

MSOP-8 package.

Note 5: Typical numbers are at 25˚C and represent the most likely parametric norm. Specifications in standard type face are for T

typeapply over full operating temperature ranges.

Note 6: Limits are 100% production tested at 25˚C. Limits over the operating temperature range are guaranteed through correlation using Statistical Quality Control

(SQC) methods. The limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

Note 7: There is a variation in accuracy over time due to thermal effects. Please refer to the “PWM Output and Current Accuracy” section for more information.

Note 8: This parameter is production tested at 1A and guaranteed by design at 2A.

Note 9: The tolerance of the internal lead frame resistor is corrected internally. The temperature coefficient of this resistor is 2600 ppm/˚C.

Insertion Loss I

= 220˚C/W (typically), junction-to-ambient.

= 1A (Note 9) 0.003 Ω

SENSE

Limit

(Note 6)

0.7 V (max)

− 0.2

V

DD

0.2 V (max)

, which is 220˚C/W for the

JA

= 25˚C and those with boldface

J

Units

V

V (min)

www.national.com 4

Page 5

Typical Performance Characteristics Supply bypass capacitor is 0.1 µF and filter capacitor is

0.1 µF.

Measured Current vs Actual Current

(LM3822-1.0)

10124924 10124925

PWM Frequency vs Supply Voltage PWM Frequency vs Temperature

Measured Current vs Actual Current

(LM3822-2.0)

LM3822

10124933

10124923

Operating Current vs Supply Voltage Shutdown Current vs Supply Voltage

10124918

10124920

www.national.com5

Page 6

Typical Performance Characteristics Supply bypass capacitor is 0.1 µF and filter capacitor is

0.1 µF. (Continued)

LM3822

Operating Current vs Temperature Shutdown Current vs Temperature

10124919

10124921

Current vs PWM Duty Cycle Accuracy vs Supply Voltage

10124922

10124928

Accuracy vs Temperature (LM3822-1.0) Accuracy vs Temperature (LM3822-2.0)

10124936

Note 10: These curves represent a statistical average such that the noise is insignificant.

www.national.com 6

10124935

Page 7

Typical Application Circuits In the application circuits, the 0.1 µF ceramic capacitor between pins 1 and 2

is used for bypassing, and the 0.1 µF ceramic capacitor between pins 3 and 4 is used for filtering. Shutdown (SD) is tied to

VDDthrough a 10 kΩ resistor.

10124905

FIGURE 1. High Side Sense

LM3822

FIGURE 2. Paralleling LM3822 for Higher Load Current

I

TOTAL

= 2.2(D1−0.5)I

+ 2.2(D2−0.5)I

MAX

MAX

where D1is the duty cycle of PWM1 and D2is the duty cycle of PWM2.

Please refer to the Product Operation section for more information.

10124907

www.national.com7

Page 8

Typical Application Circuits In the application circuits, the 0.1 µF ceramic capacitor between pins 1 and 2

is used for bypassing, and the 0.1 µF ceramic capacitor between pins 3 and 4 is used for filtering. Shutdown (SD) is tied to

LM3822

VDDthrough a 10 kΩ resistor. (Continued)

10124908

FIGURE 3. High Voltage Operation — VINGreater Than 5.5V (High Side Sense)

(PWM output is referred to Pin 6)

www.national.com 8

Page 9

Product Operation

The current is sampled by the delta-sigma modulator, as

illustrated in Figure 4. The pulse density output of the deltasigma modulator is digitally filtered. The digital output is then

compared to the output of a digital ramp generator. This

produces a PWM output. The duty cycle of the PWM output

is proportional to the amount of current flowing. A duty cycle

of 50% indicates zero current flow. If the current is flowing in

positive direction, the duty cycle will be greater than 50%.

Conversely, the duty cycle will be less than 50% for currents

flowing in the negative direction. A duty cycle of 95.5%

(−I

MAX

MAX

)

). The IC can

are

MAX

MAX

(4.5%) indicates the current is at I

sense currents from −I

MAX

to +I

MAX

. Options for I

MAX

1.0A or 2.0A. The sense current is given by:

= 2.2 (D−0.5)(I

I

SENSE

where D is the duty cycle of the PWM waveform, and I

the full scale current (1.00A or 2.00A). Similarly, the duty

cycle is given by:

LM3822

SENSE

/(2.2 I

D=[I

For quick reference, see the Conversion Table in Table 1.

In this IC, the current is averaged over 50 msec time slots.

Hence, momentary current surges of less than 50 msec are

tolerated.

This is a sampled data system which requires an antialiasing filter, provided by the filter capacitor.

The delta-sigma modulator converts the sensed current to

the digital domain. This allows digital filtering, and provides

immunity to current and noise spikes. This type of filtering

would be difficult or impossible to accomplish on an IC with

analog components.

The user also needs to specify the full scale value. See the

Ordering Information table for details.

is

MAX

)] + 0.5

FIGURE 4. Functional block diagram of LM3822

10124910

www.national.com9

Page 10

PWM Output and Current Accuracy

LM3822

OFFSET

The PWM output is quantized to 1024 levels. Therefore, the

duty cycle can change only in increments of 1/1024.

There is a one-half (0.5) quantization cycle delay in the

output of the PWM circuitry. That is to say that instead of a

duty cycle of N/1024, the duty cycle actually is (N+

The quantization error can be corrected for if a more precise

result is desired. To correct for this error, simply subtract

1/2048 from the measured duty cycle.

The extra half cycle delay will show up as a DC offset of

bit if it is not corrected for. This is approximately 1.0 mA for

1.0 Amp parts, and 10 mA for 2.0 Amp parts.

JITTER

In addition to quantization, the duty cycle will contain some

jitter. The jitter is quite small (for example, the standard

deviation of jitter is only 0.1% for the LM3822-1.0). Statistically the jitter can cause an error in a current sample. Because the jitter is a random variable, the mean and standard

deviation are used. The mean, or average value, of the jitter

is zero. The standard deviation (0.1%) can be used to define

the peak error caused from jitter.

The “crest factor” has often been used to define the maximum error caused by jitter. The crest factor defines a limit

within which 99.7% of the samples fall. The crest factor is

defined as

Since the jitter is a random variable, averaging multiple

outputs will reduce the effective jitter. Obeying statistical

laws, the jitter is reduced by the square root of the number of

readings that are averaged. For example, if four readings of

the duty cycle are averaged, the resulting jitter (and crest

factor) are reduced by a factor of two.

±

0.3% error in the duty cycle.

1

⁄2)/1024.

Noise will also be reduced by averaging multiple readings,

and follows the statistical laws of a random variable.

ACCURACY VERSUS NOISE

The graph shown in Figure 5 illustrates the typical response

±

of

1 Ampere current gauges. In this graph, the horizontal

axis indicates time, and the vertical axis indicates measured

current (the PWM duty cycle has been converted to current).

The graph was generated for an actual current of 500 mA.

The difference between successive readings manifests itself

as jitter in the PWM output or noise in the current measurement (when duty cycle of the PWM output is converted to

current).

1

⁄

2

The accuracy of the measurement depends on the noise in

the current waveform. The accuracy can be improved by

averaging several outputs. Although there is variation in

successive readings, a very accurate measurement can be

obtained by averaging the readings. For example, on averaging the readings shown in this example, the average

current measurement is 502.3 mA (Figure 5). This value is

very close to the actual value of 500 mA. Moreover, the

accuracy depends on the number of readings that are averaged.

JITTER AND NOISE

Jitter in the PWM output appears as noise in the current

measurement. The Electrical Characteristics show noise

measured in current RMS (root mean square). Arbitrarily one

could specify PWM jitter, as opposed to noise. In either case

the effect results in a random error in an individual current

measurement.

Noise, just like jitter, can be reduced by averaging many

readings. The RMS value of the noise corresponds to one

standard deviation. The “crest factor” can be calculated in

terms of current, and is equal to

noise).

±

3 sigma (RMS value of the

10124926

FIGURE 5. Typical Response of LM3822

LOW CURRENT MEASUREMENTS

The DC offset of the LM3822-1.0 is typically under 1 mA.

This low offset allows accurate low current measurements.

Even currents in the 10 mA range can be measured with

accuracies typically better than

±

5%.

www.national.com 10

Page 11

Look-Up Tables

The following tables show how to convert the duty cycle of

the PWM output to a current value, and vice versa. The

TABLE 1. Current to Duty Cycle Conversion Table

Sense Current

(Imax = 1.0A)

1 2 95.5

0.95 1.90 93.2

0.90 1.80 90.9

0.85 1.70 88.6

0.80 1.60 86.4

0.75 1.50 84.1

0.70 1.40 81.8

0.65 1.30 79.5

0.60 1.20 77.3

0.55 1.10 75.0

0.50 1 72.7

0.45 0.90 70.5

0.40 0.80 68.2

0.35 0.70 65.9

0.30 0.60 63.6

0.25 0.50 61.4

0.20 0.40 59.1

0.15 0.30 56.8

0.10 0.20 54.5

0.05 0.10 52.3

0.00 0.00 50

−0.05 −0.10 47.7

−0.10 −0.20 45.5

−0.15 −0.30 43.2

−0.20 −0.40 40.9

−0.25 −0.50 38.6

−0.30 −0.60 36.4

−0.35 −0.70 34.1

−0.40 −0.80 31.8

−0.45 −0.90 29.5

−0.50 −1 27.3

−0.55 −1.10 25

−0.60 −1.20 22.7

−0.65 −1.30 20.5

−0.70 −1.40 18.2

−0.75 −1.50 15.9

−0.80 −1.60 13.6

−0.85 −1.70 11.4

−0.90 −1.80 9.1

−0.95 −1.90 6.8

−1 −2 4.5

Sense Current

(Imax = 2.0A)

1

quantization error of

Please see the “PWM Output and Current Accuracy” section

for more details.

⁄2bit is not shown in these tables.

Duty Cycle (%)

LM3822

www.national.com11

Page 12

Timing Diagram

LM3822

Duty cycle of the PWM waveform during any sampling interval indicates the current magnitude (average) and direction during the previous sampling interval.

FIGURE 6. Typical Timing Diagram for Mostly Positive Current

10124911

www.national.com 12

Page 13

Physical Dimensions inches (millimeters) unless otherwise noted

LM3822 Precision Current Gauge IC with Internal Zero Ohm Sense Element and PWM Output

8-Lead MSOP

See Ordering Information table for Order Numbers

NS Package Number MUA08A

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products Stewardship

Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain no ‘‘Banned

Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...