Page 1

LM134/LM234/LM334

3-Terminal Adjustable Current Sources

General Description

The LM134/LM234/LM334 are 3-terminal adjustable current

sources featuring 10,000:1 range in operating current, excellent current regulation and a wide dynamic voltage range of

1V to 40V. Current is established with one external resistor

and no other parts are required. Initial current accuracy is

±

3%. The LM134/LM234/LM334 are true floating current

sources with no separate power supply connections. In addition, reverse applied voltages of up to 20V will draw only a

few dozen microamperes of current, allowing the devices to

act as both a rectifier and current source in AC applications.

The sense voltage used to establish operating current in the

LM134 is 64mV at 25˚C and is directly proportional to absolute temperature (˚K). The simplest one external resistor

connection, then, generates a current with ≈+0.33%/˚C temperature dependence. Zero drift operation can be obtained

by adding one extra resistor and a diode.

Applications for the current sources include bias networks,

surge protection, low power reference, ramp generation,

LED driver, and temperature sensing. The LM234-3 and

LM234-6 are specified as true temperature sensors with

guaranteed initial accuracy of

These devices are ideal in remote sense applications because series resistance in long wire runs does not affect

accuracy. In addition, only 2 wires are required.

The LM134 is guaranteed over a temperature range of

−55˚C to +125˚C, the LM234 from −25˚C to +100˚C and the

LM334 from 0˚C to +70˚C. These devices are available in

TO-46 hermetic, TO-92 and SO-8 plastic packages.

Features

n Operates from 1V to 40V

n 0.02%/V current regulation

n Programmable from 1µA to 10mA

n True 2-terminal operation

n Available as fully specified temperature sensor

±

n

3% initial accuracy

March 2000

±

3˚C and±6˚C, respectively.

LM134/LM234/LM334 3-Terminal Adjustable Current Sources

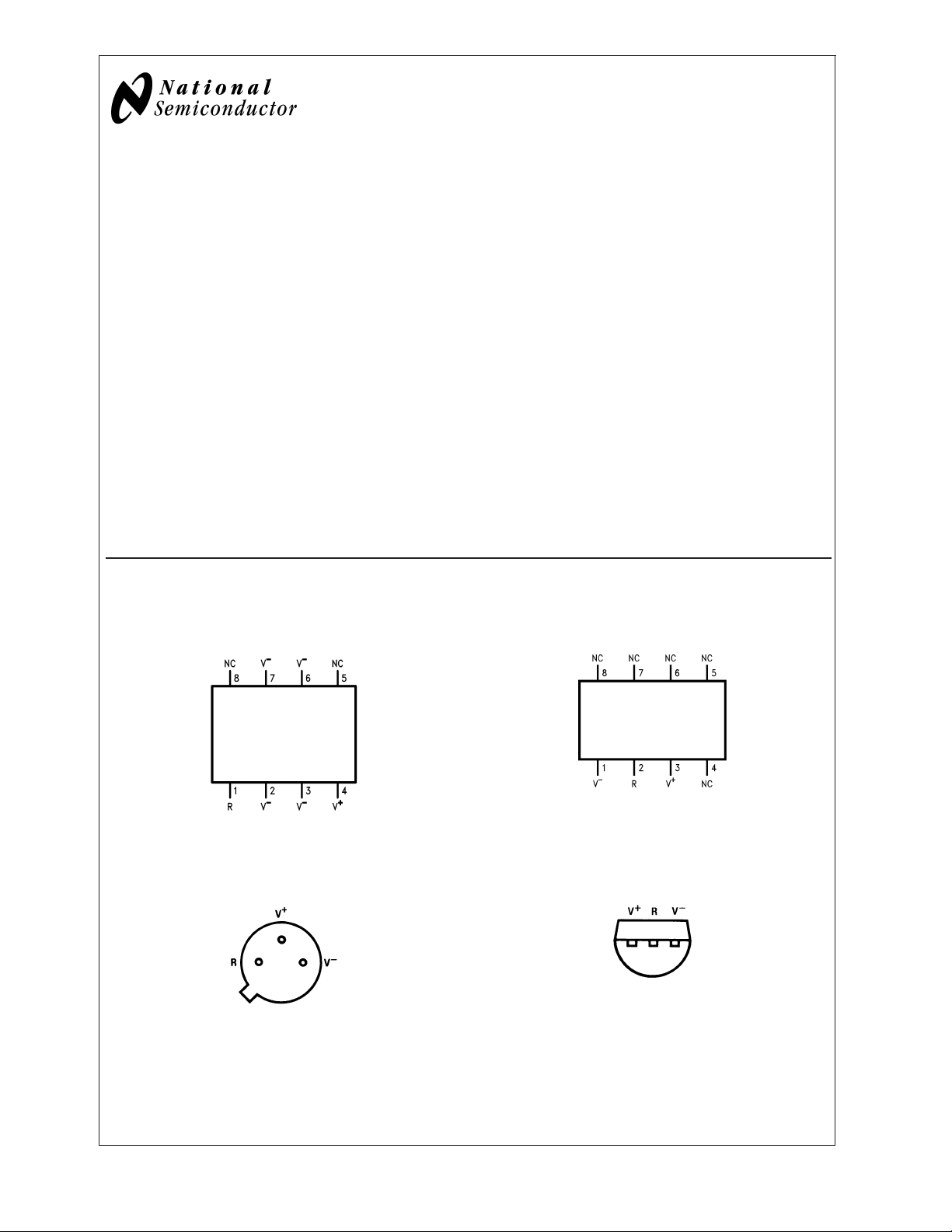

Connection Diagrams

SO-8

Surface Mount Package

Order Number LM334M or LM334MX

See NS Package Number M08A

TO-46

Metal Can Package TO-92 Plastic Package

00569712

V−Pin is electrically connected to case.

Bottom View

Order Number LM134H,

LM234H or LM334H

See NS Package

Number H03H

00569724

SO-8 Alternative Pinout

Surface Mount Package

00569725

Order Number LM334SM or LM334SMX

See NS Package Number M08A

00569710

Bottom View

Order Number LM334Z, LM234Z-3 or LM234Z-6

See NS Package Number Z03A

© 2004 National Semiconductor Corporation DS005697 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

+

to V−Forward Voltage

V

LM134/LM234/LM334 40V

LM134/LM234/LM334

LM234-3/LM234-6 30V

+

V

to V−Reverse Voltage 20V

R Pin to V

−

Voltage 5V

Set Current 10 mA

Power Dissipation 400 mW

LM234/LM234-3/LM234-6 −25˚C to +100˚C

LM334 0˚C to +70˚C

Soldering Information

TO-92 Package (10 sec.) 260˚C

TO-46 Package (10 sec.) 300˚C

SO Package

Vapor Phase (60 sec.) 215˚C

Infrared (15 sec.) 220˚C

See AN-450 “Surface Mounting Methods and Their Effect on

Product Reliability” (Appendix D) for other methods of soldering surface mount devices.

ESD Susceptibility (Note 6) 2000V

Operating Temperature Range (Note

5)

LM134 −55˚C to +125˚C

Electrical Characteristics (Note 2)

Parameter Conditions LM134/LM234 LM334 Units

Set Current Error, V

(Note 3) 1mA

Ratio of Set Current to 100µA ≤ I

Bias Current 1mA ≤ I

Minimum Operating Voltage 2µA ≤ I

Average Change in Set Current 2µA ≤ I

with Input Voltage 1.5 ≤ V

+

=2.5V, 10µA ≤ I

2µA ≤ I

2µA≤I

100µA

1mA

5V ≤ V

1mA

≤ 1mA 3 6 %

SET

<

I

≤ 5mA 5 8 %

SET

<

10µA 8 12 %

SET

≤ 1mA 14 18 23 14 18 26

SET

≤ 5mA 14 14

SET

≤100 µA 18 23 18 26

SET

≤ 100µA 0.8 0.8 V

SET

<

I

≤ 1mA 0.9 0.9 V

SET

<

I

≤ 5mA 1.0 1.0 V

SET

≤ 1mA

SET

+

≤ 5V 0.02 0.05 0.02 0.1 %/V

+

≤ 40V 0.01 0.03 0.01 0.05 %/V

<

I

≤ 5mA

SET

1.5V ≤ V ≤ 5V 0.03 0.03 %/V

5V ≤ V ≤ 40V 0.02 0.02 %/V

Temperature Dependence of 25µA ≤ I

≤ 1mA 0.96T T 1.04T 0.96T T 1.04T

SET

Set Current (Note 4)

Effective Shunt Capacitance 15 15 pF

Note 1: .“Absolute Maximum Ratings” indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits.

Note 2: Unless otherwise specified, tests are performed at T

Note 3: Set current is the current flowing into the V

determined by the following formula: I

0.336%/˚C

@

Tj= 25˚C (227 µV/˚C).

= 67.7 mV/R

SET

= 25˚C with pulse testing so that junction temperature does not change during test

j

+

pin. For the Basic 2-Terminal Current Source circuit shown on the first page of this data sheet. I

(@25˚C). Set current error is expressed as a percent deviation from this amount. I

SET

Min Typ Max Min Typ Max

SET

SET

increases at

is

www.national.com 2

Page 3

Electrical Characteristics (Note 2) (Continued)

Note 4: I

(˚K).

Note 5: For elevated temperature operation, T

Note 6: Human body model, 100pF discharged through a 1.5kΩ resistor.

is directly proportional to absolute temperature (˚K). I

SET

max is:

J

Thermal Resistance TO-92 TO-46 SO-8

θ

(Junction to

ja

Ambient)

(Junction to Case) N/A 32˚C/W 80˚C/W

θ

jc

at any temperature can be calculated from: I

SET

SET=Io

LM134 150˚C

LM234 125˚C

LM334 100˚C

180˚C/W (0.4" leads) 440˚C/W 165˚C/W

160˚C/W (0.125"

leads)

(T/To) where Iois I

measured at T

SET

Electrical Characteristics (Note 2)

Parameter Conditions LM234-3 LM234-6 Units

Set Current Error, V

(Note 3) T

+

=2.5V, 100µA ≤ I

= 25˚

J

SET

≤ 1mA

Equivalent Temperature Error

Ratio of Set Current to 100µA ≤ I

≤ 1mA 14 18 26 14 18 26

SET

Bias Current

Minimum Operating Voltage 100µA I

Average Change in Set Current 100µA ≤ I

with Input Voltage 1.5 ≤ V

5V ≤ V

Temperature Dependence of 100µA ≤ I

≤ 1mA 0.9 0.9 V

SET

≤ 1mA

SET

+

≤ 5V 0.02 0.05 0.02 0.01 %/V

+

≤ 30V 0.01 0.03 0.01 0.05 %/V

≤ 1mA 0.98T T 1.02T 0.97T T 1.03T

SET

Set Current (Note 4) and

Equivalent Slope Error

Effective Shunt Capacitance 15 15 pF

Min Typ Max Min Typ Max

±

1

±

3

±

2

±

±

±

2%

6˚C

3%

LM134/LM234/LM334

o

www.national.com3

Page 4

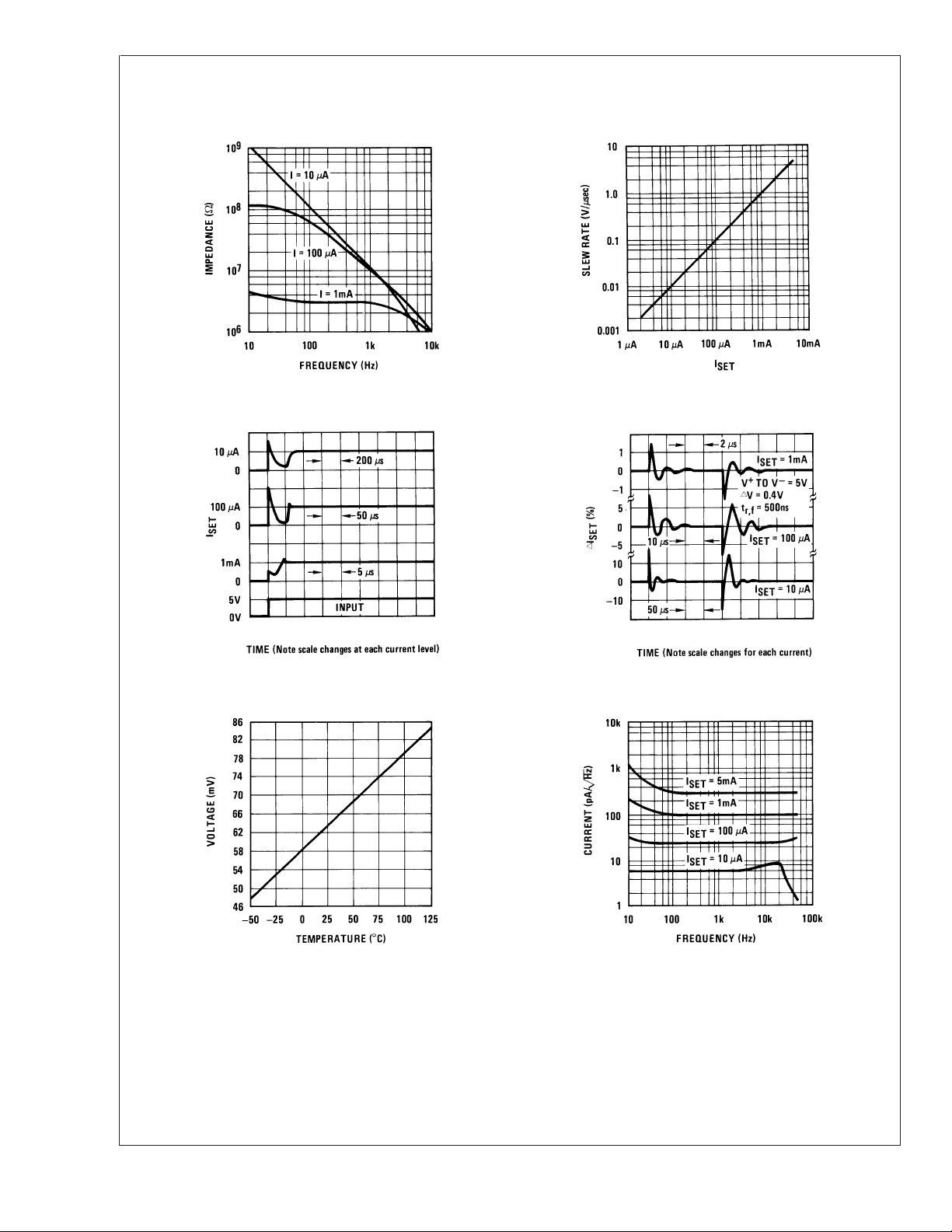

Typical Performance Characteristics

Output Impedance

LM134/LM234/LM334

00569730 00569731

Start-Up Transient Response

Maximum Slew Rate

Linear Operation

Voltage Across R

00569732

) Current Noise

SET(VR

00569734

00569733

00569735

www.national.com 4

Page 5

Typical Performance Characteristics (Continued)

LM134/LM234/LM334

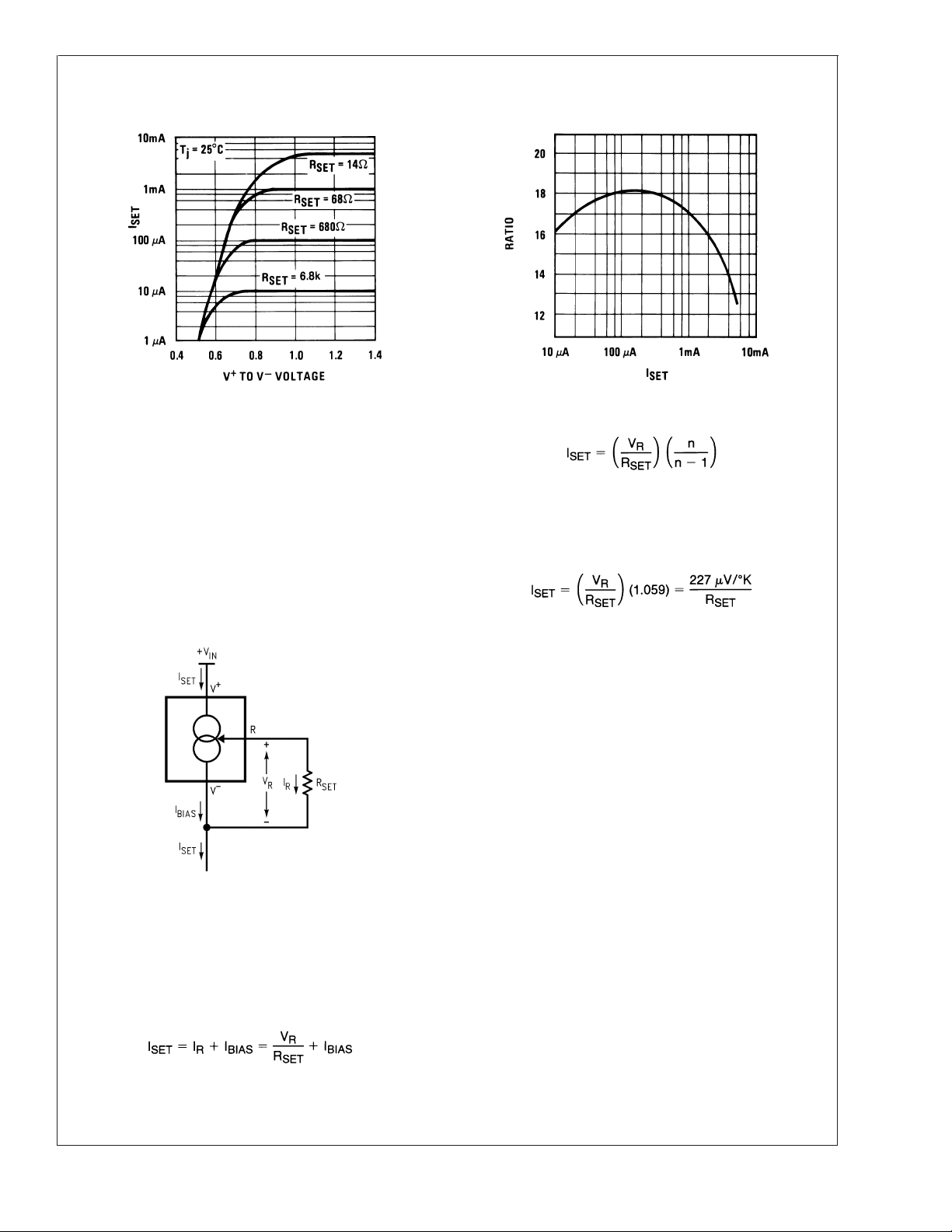

Turn-On Voltage Ratio of I

00569729

Application Hints

The LM134 has been designed for ease of application, but a

general discussion of design features is presented here to

familiarize the designer with device characteristics which

may not be immediately obvious. These include the effects

of slewing, power dissipation, capacitance, noise, and contact resistance.

CALCULATING R

The total current through the LM134 (I

current going through the SET resistor (I

bias current (I

SET

), as shown in Figure 1.

BIAS

) is the sum of the

SET

) and the LM134’s

R

to I

SET

BIAS

00569703

where n is the ratio of I

SET

to I

as specified in the

BIAS

Electrical Characteristics Section and shown in the graph.

Since n is typically 18 for 2µA ≤ I

≤ 1mA, the equation can

SET

be further simplified to

for most set currents.

00569727

FIGURE 1. Basic Current Source

A graph showing the ratio of these two currents is supplied

under Ratio of I

SET

to I

Characteristics section. The current flowing through R

determined by V

, which is approximately 214µV/˚K (64

R

in the Typical Performance

BIAS

SET

mV/298˚K ∼ 214µV/˚K).

Since (for a given set current) I

, the equation can be rewritten

I

SET

is simply a percentage of

BIAS

SLEW RATE

At slew rates above a given threshold (see curve), the

LM134 may exhibit non-linear current shifts. The slewing

rate at which this occurs is directly proportional to I

= 10µA, maximum dV/dt is 0.01V/µs; at I

I

SET

SET

.At

SET

= 1mA, the

limit is 1V/µs. Slew rates above the limit do not harm the

LM134, or cause large currents to flow.

THERMAL EFFECTS

Internal heating can have a significant effect on current

regulation for I

1V increase across the LM134 at I

greater than 100µA. For example, each

SET

= 1 mA will increase

SET

junction temperature by ≈0.4˚C in still air. Output current

) has a temperature coefficient of ≈0.33%/˚C, so the

(I

SET

change in current due to temperature rise will be (0.4)

(0.33) = 0.132%. This is a 10:1 degradation in regulation

compared to true electrical effects. Thermal effects, therefore, must be taken into account when DC regulation is

critical and I

is

package or the TO-92 leads can reduce this effect by more

exceeds 100µA. Heat sinking of the TO-46

SET

than 3:1.

SHUNT CAPACITANCE

In certain applications, the 15 pF shunt capacitance of the

LM134 may have to be reduced, either because of loading

problems or because it limits the AC output impedance of the

current source. This can be easily accomplished by buffering

the LM134 with an FET as shown in the applications. This

can reduce capacitance to less than 3 pF and improve

www.national.com5

Page 6

Application Hints (Continued)

regulation by at least an order of magnitude. DC characteristics (with the exception of minimum input voltage), are not

affected.

NOISE

Current noise generated by the LM134 is approximately 4

times the shot noise of a transistor. If the LM134 is used as

LM134/LM234/LM334

an active load for a transistor amplifier, input referred noise

will be increased by about 12dB. In many cases, this is

acceptable and a single stage amplifier can be built with a

voltage gain exceeding 2000.

LEAD RESISTANCE

The sense voltage which determines operating current of the

LM134 is less than 100mV. At this level, thermocouple or

lead resistance effects should be minimized by locating the

current setting resistor physically close to the device. Sockets should be avoided if possible. It takes only 0.7Ω contact

resistance to reduce output current by 1% at the 1 mA level.

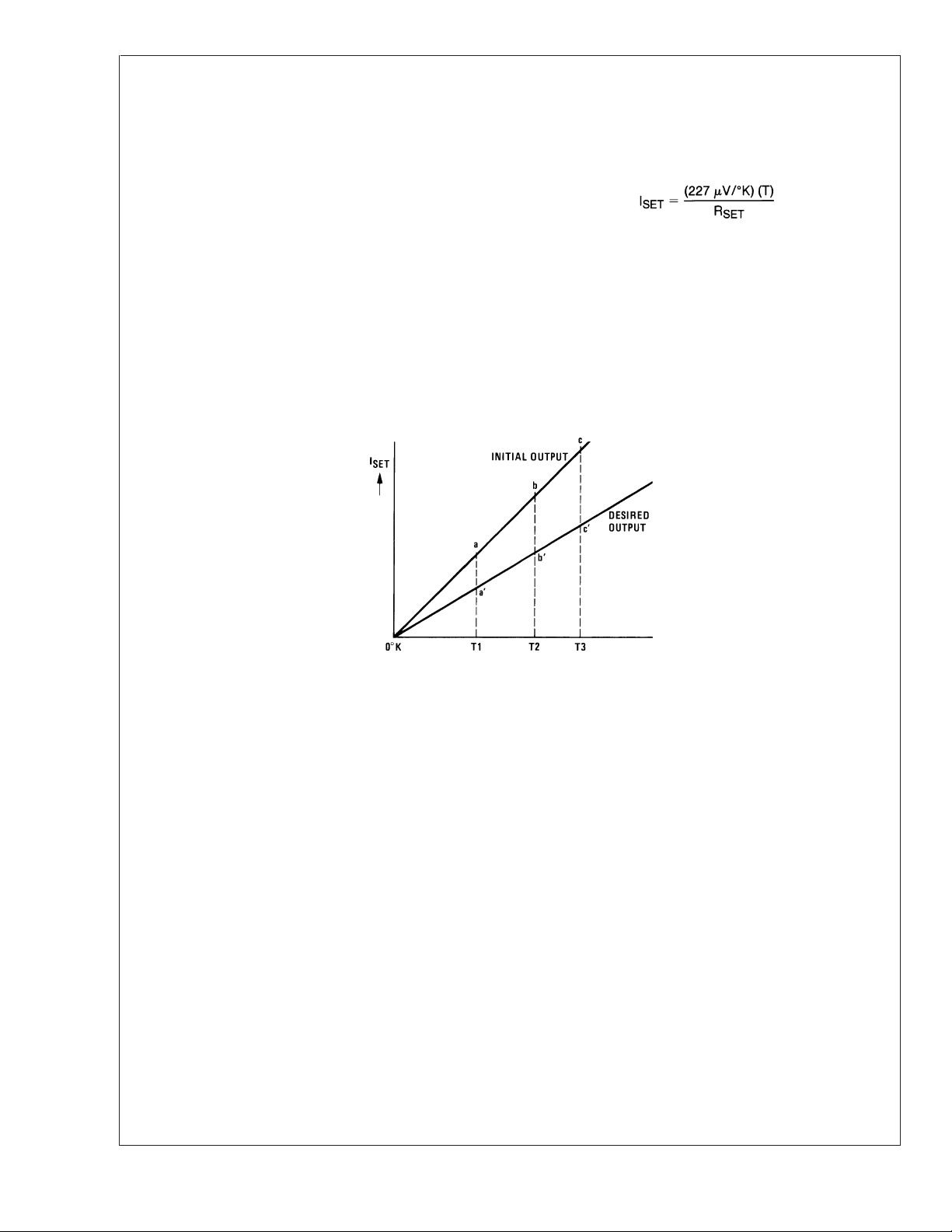

SENSING TEMPERATURE

The LM134 makes an ideal remote temperature sensor because its current mode operation does not lose accuracy

over long wire runs. Output current is directly proportional to

absolute temperature in degrees Kelvin, according to the

following formula:

Calibration of the LM134 is greatly simplified because of the

fact that most of the initial inaccuracy is due to a gain term

(slope error) and not an offset. This means that a calibration

consisting of a gain adjustment only will trim both slope and

zero at the same time. In addition, gain adjustment is a one

point trim because the output of the LM134 extrapolates to

zero at 0˚K, independent of R

or any initial inaccuracy.

SET

FIGURE 2. Gain Adjustment

This property of the LM134 is illustrated in the accompanying

graph. Line abc is the sensor current before trimming. Line

a'b'c' is the desired output. A gain trim done at T2 will move

the output from b to b' and will simultaneously correct the

slope so that the output at T1 and T3 will be correct. This

gain trim can be done on R

or on the load resistor used

SET

to terminate the LM134. Slope error after trim will normally

±

be less than

temperature coefficient resistor must be used for R

A 33 ppm/˚C drift of R

1%. To maintain this accuracy, however, a low

.

SET

will give a 1% slope error because

SET

the resistor will normally see about the same temperature

variations as the LM134. Separating R

from the LM134

SET

requires 3 wires and has lead resistance problems, so is not

00569704

normally recommended. Metal film resistors with less than

20 ppm/˚C drift are readily available. Wire wound resistors

may also be used where best stability is required.

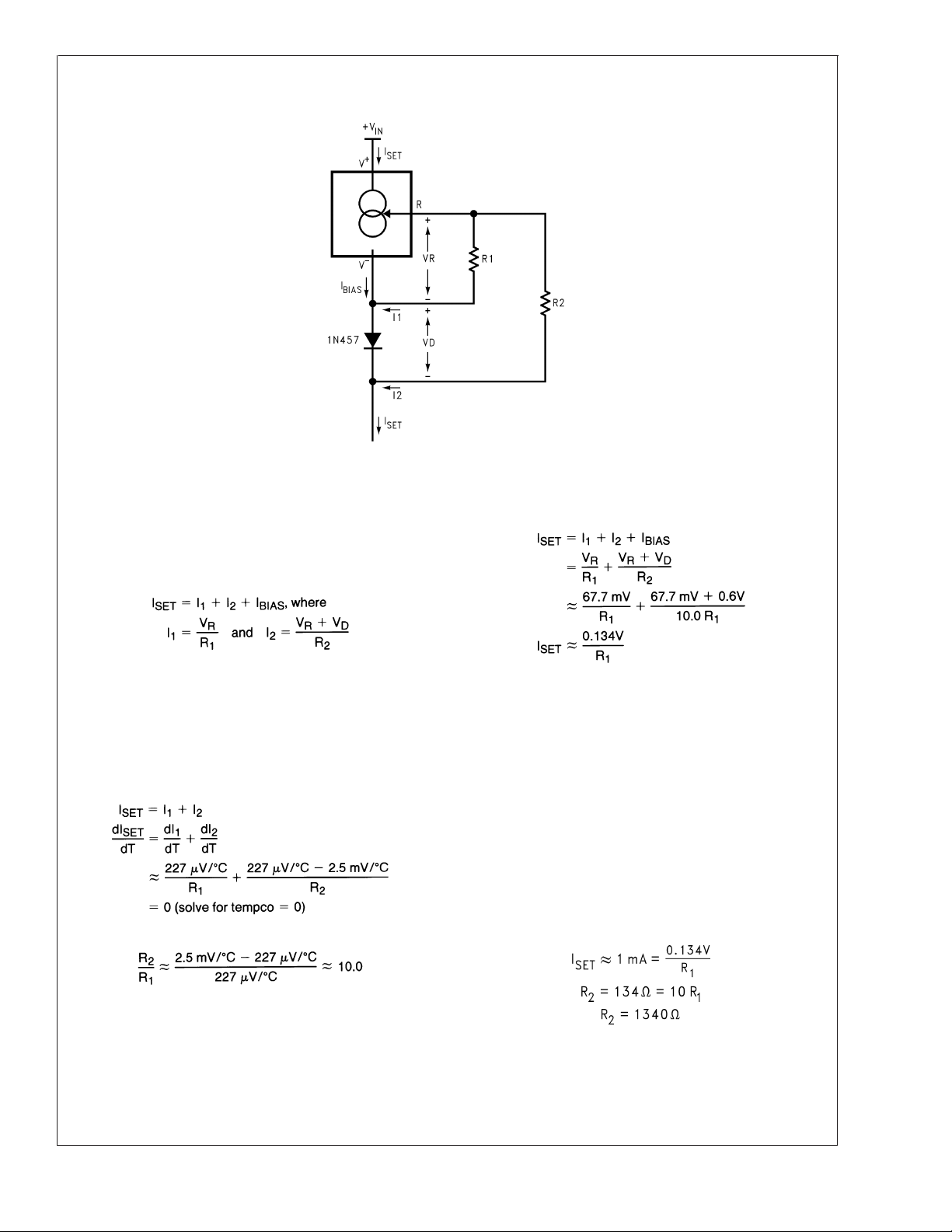

APPLICATION AS A ZERO TEMPERATURE COEFFICENT CURRENT SOURCE

Adding a diode and a resistor to the standard LM134 configuration can cancel the temperature-dependent characteristic of the LM134. The circuit shown in Figure 3 balances

the positive tempco of the LM134 (about +0.23 mV/˚C) with

the negative tempco of a forward-biased silicon diode (about

−2.5 mV/˚C).

www.national.com 6

Page 7

Application Hints (Continued)

LM134/LM234/LM334

00569728

FIGURE 3. Zero Tempco Current Source

The set current (I

uting approximately 50% of the set current, and I

usually included in the I

used for calculations by 5.9%. (See CALCULATING R

) is the sum of I1and I2, each contrib-

SET

term by increasing the VRvalue

1

BIAS.IBIAS

SET

The first step is to minimize the tempco of the circuit, using

the following equations. An example is given using a value of

+227µV/˚C as the tempco of the LM134 (which includes the

component), and −2.5 mV/˚C as the tempco of the

I

BIAS

diode (for best results, this value should be directly measured or obtained from the manufacturer of the diode).

is

.)

This circuit will eliminate most of the LM134’s temperature

coefficient, and it does a good job even if the estimates of the

diode’s characteristics are not accurate (as the following

example will show). For lowest tempco with a specific diode

at the desired I

tested over temperature. If the measured tempco of I

positive, R

negative, R

, however, the circuit should be built and

SET

should be reduced. If the resulting tempco is

2

should be increased. The recommended diode

2

SET

is

for use in this circuit is the 1N457 because its tempco is

centered at 11 times the tempco of the LM134, allowing R

. You can also use this circuit to create a current source

10 R

1

=

2

with non-zero tempcos by setting the tempco component of

the tempco equation to the desired value instead of 0.

EXAMPLE: A 1mA, Zero-Tempco Current Source

First, solve for R

and R2:

1

With the R1to R2ratio determined, values for R1and R

should be determined to give the desired set current. The

formula for calculating the set current at T = 25˚C is shown

below, followed by an example that assumes the forward

voltage drop across the diode (V

across R

and R

is 67.7mV (64 mV + 5.9% to account for I

1

= 10 (from the previous calculations).

2/R1

) is 0.6V, the voltage

D

BIAS

2

The values of R1and R2can be changed to standard 1%

resistor values (R

),

a 0.75% error.

= 133Ω and R2= 1.33kΩ) with less than

1

www.national.com7

Page 8

Application Hints (Continued)

If the forward voltage drop of the diode was 0.65V instead of

the estimate of 0.6V (an error of 8%), the actual set current

will be

LM134/LM234/LM334

an error of less than 5%.

If the estimate for the tempco of the diode’s forward voltage

drop was off, the tempco cancellation is still reasonably

effective. Assume the tempco of the diode is 2.6mV/˚C instead of 2.5mV/˚C (an error of 4%). The tempco of the circuit

is now:

Terminating Remote Sensor for Voltage Output

00569714

Low Output Impedance Thermometer

A 1mA LM134 current source with no temperature compensation would have a set resistor of 68Ω and a resulting

tempco of

So even if the diode’s tempco varies as much as±4% from

its estimated value, the circuit still eliminates 98% of the

LM134’s inherent tempco.

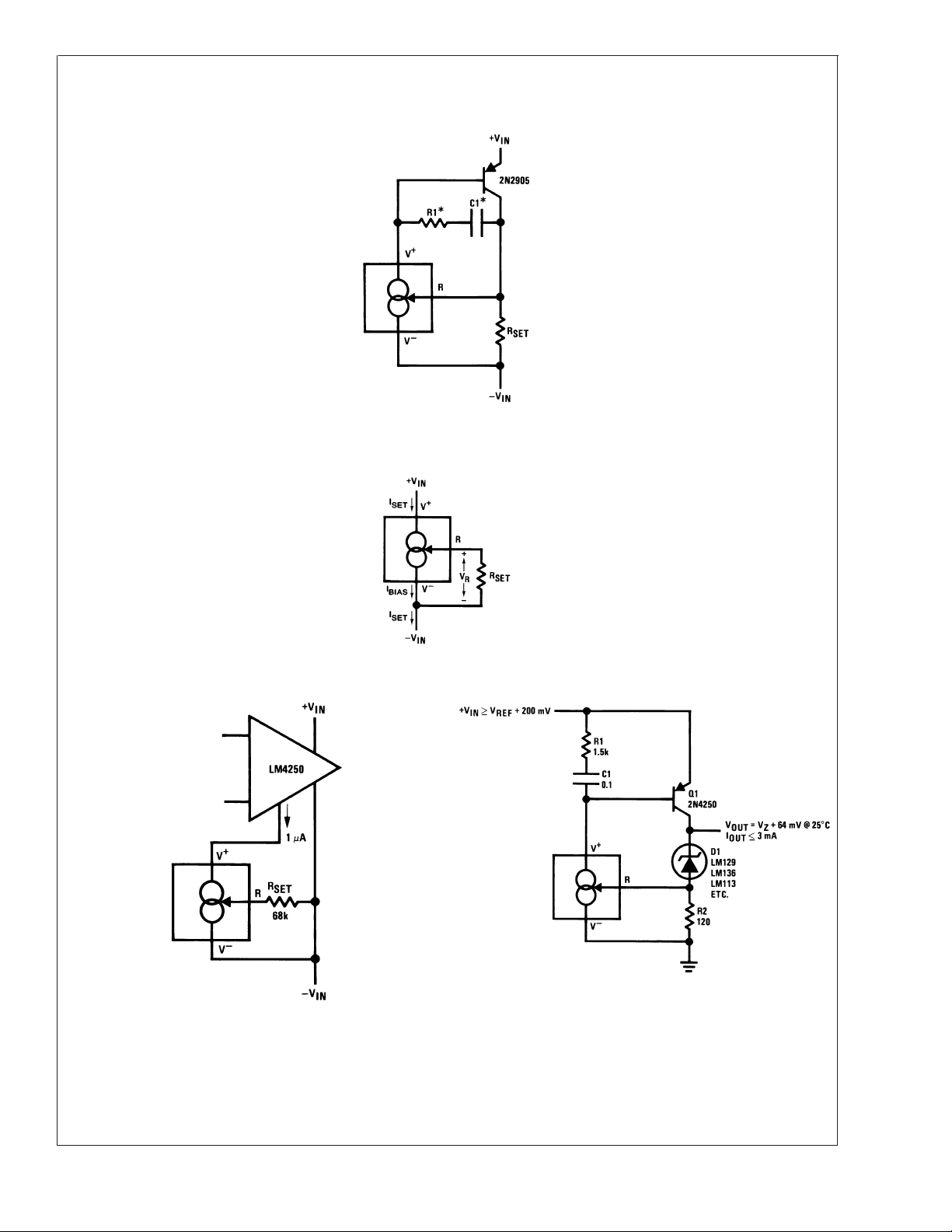

Typical Applications

Ground Referred Fahrenheit Thermometer

*Output impedance of the LM134 at the “R” pin is approximately

where R2is the equivalent external resistance connected from the V−pin

to ground. This negative resistance can be reduced by a factor of 5 or

more by inserting an equivalent resistor R

output.

=(R2/16) in series with the

3

00569706

Low Output Impedance Thermometer

*Select R3 = V

Trim R3 to calibrate

www.national.com 8

/583µA. V

REF

may be any stable positive voltage ≥ 2V

REF

00569715

00569716

Page 9

Typical Applications (Continued)

LM134/LM234/LM334

Higher Output Current

*Select R1 and C1 for optimum stability

Micropower Bias Low Input Voltage Reference Driver

00569705

Basic 2-Terminal Current Source

00569701

00569717

00569718

www.national.com9

Page 10

Typical Applications (Continued)

LM134/LM234/LM334

Ramp Generator

00569719

1.2V Reference Operates on 10 µA and 2V

*Select ratio of R1 to R2 to obtain zero temperature drift

1.2V Regulator with 1.8V Minimum Input

00569720

Zener Biasing

00569749

Alternate Trimming Technique

*Select ratio of R1 to R2 for zero temperature drift

00569707

www.national.com 10

*For±10% adjustment, select R

00569750

10% high, and make R1 ≈ 3R

SET

SET

Page 11

Typical Applications (Continued)

Buffer for Photoconductive Cell

FET Cascoding for Low Capacitance and/or Ultra High Output Impedance

LM134/LM234/LM334

00569751

*Select Q1 or Q2 to ensure at least 1V across the LM134. Vp(1 −

I

) ≥ 1.2V.

SET/IDSS

00569721

Generating Negative Output Impedance

*Z

≈ −16•R1 (R1/VINmust not exceed I

OUT

00569723

)

SET

00569722

FIGURE 4.

In-Line Current Limiter

00569709

*Use minimum value required to ensure stability of protected device. This

minimizes inrush current to a direct short.

Schematic Diagram

www.national.com11

Page 12

Schematic Diagram (Continued)

LM134/LM234/LM334

00569711

www.national.com 12

Page 13

Physical Dimensions inches (millimeters)

unless otherwise noted

LM134/LM234/LM334

Order Number LM134H, LM234H or LM334H

NS Package Number H03H

www.national.com13

Page 14

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LM134/LM234/LM334

SO Package (M)

Order Number LM334M, LM334MX,

LM334SM or LM334SMX

NS Package Number M08A

Order Number LM334Z, LM234Z-3 or LM234Z-6

NS Package Number Z03A

www.national.com 14

Page 15

Notes

LM134/LM234/LM334 3-Terminal Adjustable Current Sources

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products Stewardship

Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain no ‘‘Banned

Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...