Page 1

CMOS 8K 2-Wire Serial EEPROM

Features

·

Operating voltage: 2.2V~5.5V

·

Low power consumption

-

Operation: 5mA max.

-

Standby: 5mA max.

·

Internal organization: 1024´8

·

2-wire Serial Interface

·

Write cycle time: 5ms max.

·

Automatic erase-before-write operation

General Description

The HT24LC08 is an 8K-bit serial read/write non-volatile

memory device using the CMOS floating gate process.

Its 8192 bits of memory are organized into 1024 words

and each word is 8 bits. The device is optimized for use

in many industrial and commercial applications where

Block Diagram Pin Assignment

·

Partial page write allowed

·

16-byte Page Write Mode

·

Write operation with built-in timer

·

Hardware controlled write protection

·

40-year data retention

·

106rewrite cycles per word

·

Commerical temperature range (0°Cto+70°C)

·

8-pin DIP/SOP package

low power and low voltage operation are essential. Up

to two HT24LC08 devices may be connected to the

same 2-wire bus. The HT24LC08 is guaranteed for 1M

erase/write cycles and 40-year data retention.

HT24LC08

S C L

S D A

W P

A 0 ~ A 2

V C C

V S S

I / O

C o n t r o l

L o g i c

M e m o r y

C o n t r o l

L o g i c

A d d r e s s

C o u n t e r

H V P u m p

X

D

E E P R O M

A r r a y

E

C

P a g e B u f f e r

Y D E C

S e n s e A M P

R / W C o n t r o l

Pin Description

Pin Name I/O Description

A0~A2

SDA

SCL

WP

VSS

VCC

I Address input

I/O Serial data

I Serial clock input

I Write protect

¾

¾

Negative power supply, ground

Positive power supply

A 0

1

A 1

2

3

A 2

4

V S S

H T 2 4 L C 0 8

8 D I P - A / S O P - A

V C C

8

W P

7

6

S C L

5

S D A

Rev. 1.20 1 November 4, 2002

Page 2

HT24LC08

Absolute Maximum Ratings

Operating Temperature (Commercial) ........................................................................................................ 0°Cto70°C

Storage Temperature ............................................................................................................................ -50°Cto125°C

Applied VCC Voltage with Respect to VSS ............................................................................................... -0.3V to 6.0V

Applied Voltage on any Pin with Respect to VSS

........................................................................................................

Note: These are stress ratings only. Stresses exceeding the range specified under ²Absolute Maximum Ratings² may

cause substantial damage to the device. Functional operation of this device at other conditions beyond those

listed in the specification is not implied and prolonged exposure to extreme conditions may affect device reliabil

ity.

-0.3V to VCC+0.3V

-

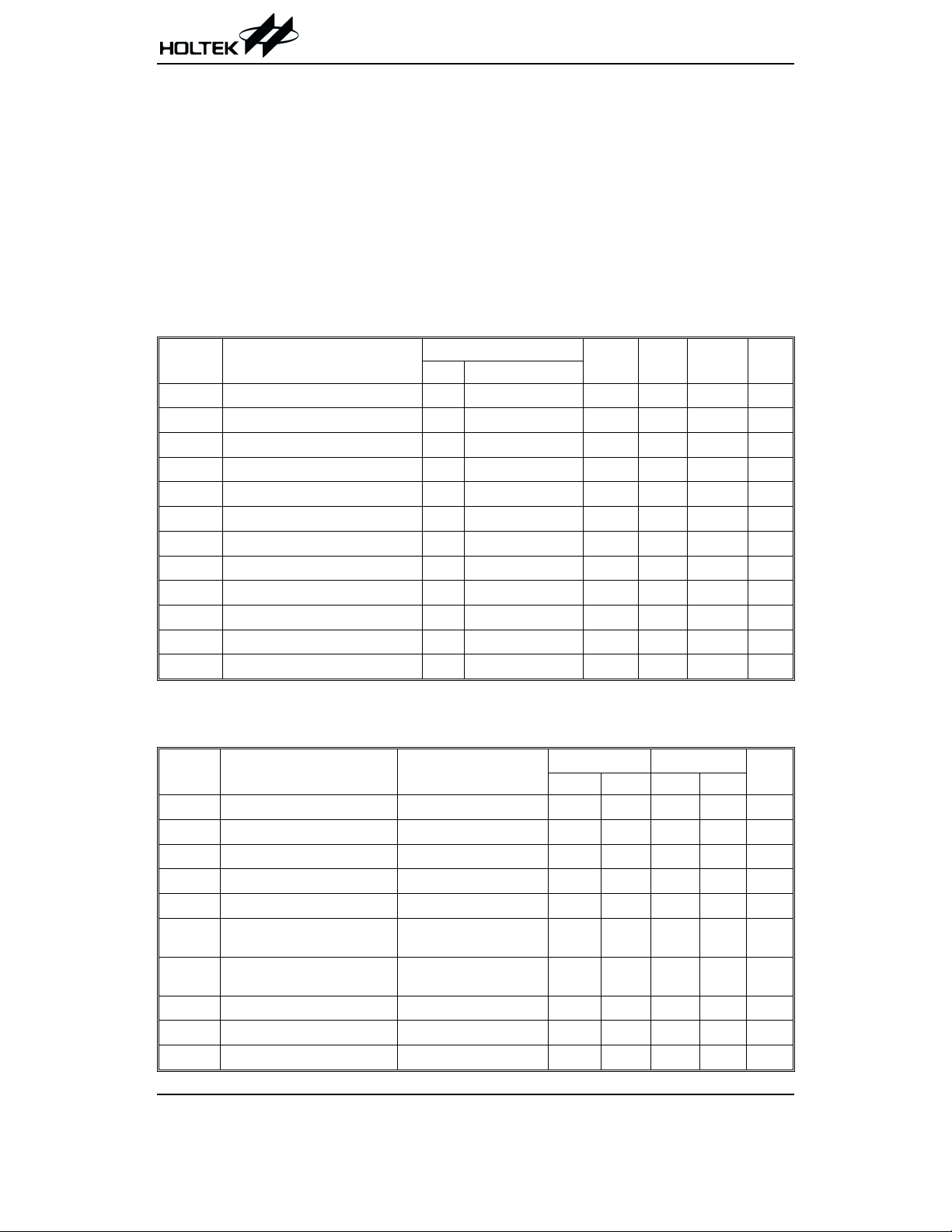

D.C. Characteristics

Symbol Parameter

V

I

CC1

I

CC2

V

V

V

I

LI

I

LO

I

STB1

I

STB2

C

C

CC

IL

IH

OL

IN

OUT

Operating Voltage

Operating Current 5V Read at 100kHz

Operating Current 5V Write at 100kHz

Input Low Voltage

Input High Voltage

Output Low Voltage 2.4V

Input Leakage Current 5V

Output Leakage Current 5V

Standby Current 5V

Standby Current 2.4V

Input Capacitance (See Note)

Output Capacitance (See Note)

Note: These parameters are periodically sampled but not 100% tested

Test Conditions

V

CC

Conditions

¾¾

¾¾ -1 ¾

¾¾

=2.1mA

I

OL

=0 or V

V

IN

V

OUT

V

IN

V

IN

=0 or V

=0 or V

=0 or V

CC

CC

CC

¾ f=1MHz 25°C ¾¾

¾ f=1MHz 25°C ¾¾

A.C. Characteristics

Symbol Parameter Remark

f

SK

t

HIGH

t

LOW

t

R

t

F

t

HD:STA

t

SU:STA

t

HD:DAT

t

SU:DAT

t

SU:STO

Clock Frequency

Clock High Time

Clock Low Time

SDA and SCL Rise Time Note

SDA and SCL Fall Time Note

START Condition Hold Time

START Condition Setup Time

After this period the first

clock pulse is generated

Only relevant for repeated

START condition

Data Input Hold Time

Data Input Setup Time

STOP Condition Setup Time

¾¾

¾

¾

¾

¾

¾

Min. Typ. Max. Unit

2.2

¾

¾¾

¾¾

0.7V

CC

¾

¾¾

¾¾

CC

¾¾

¾¾

¾¾

Standard Mode*

V

CC

Min. Max. Min. Max.

4000

4700

¾

¾

4000

4000

0

200

4000

100

¾

¾

1000

300

¾

¾

¾

¾

¾

¾

600

1200

¾

¾

600

600

0

100

600

Ta=0°Cto70°C

5.5 V

2mA

5mA

0.3V

CC

V

+0.5

CC

0.4 V

1

1

5

4

6pF

8pF

Ta=0°Cto70°C

=5V±10%

400 kHz

¾

¾

300 ns

300 ns

¾

¾

¾

¾

¾

V

V

mA

mA

mA

mA

Unit

ns

ns

ns

ns

ns

ns

ns

Rev. 1.20 2 November 4, 2002

Page 3

HT24LC08

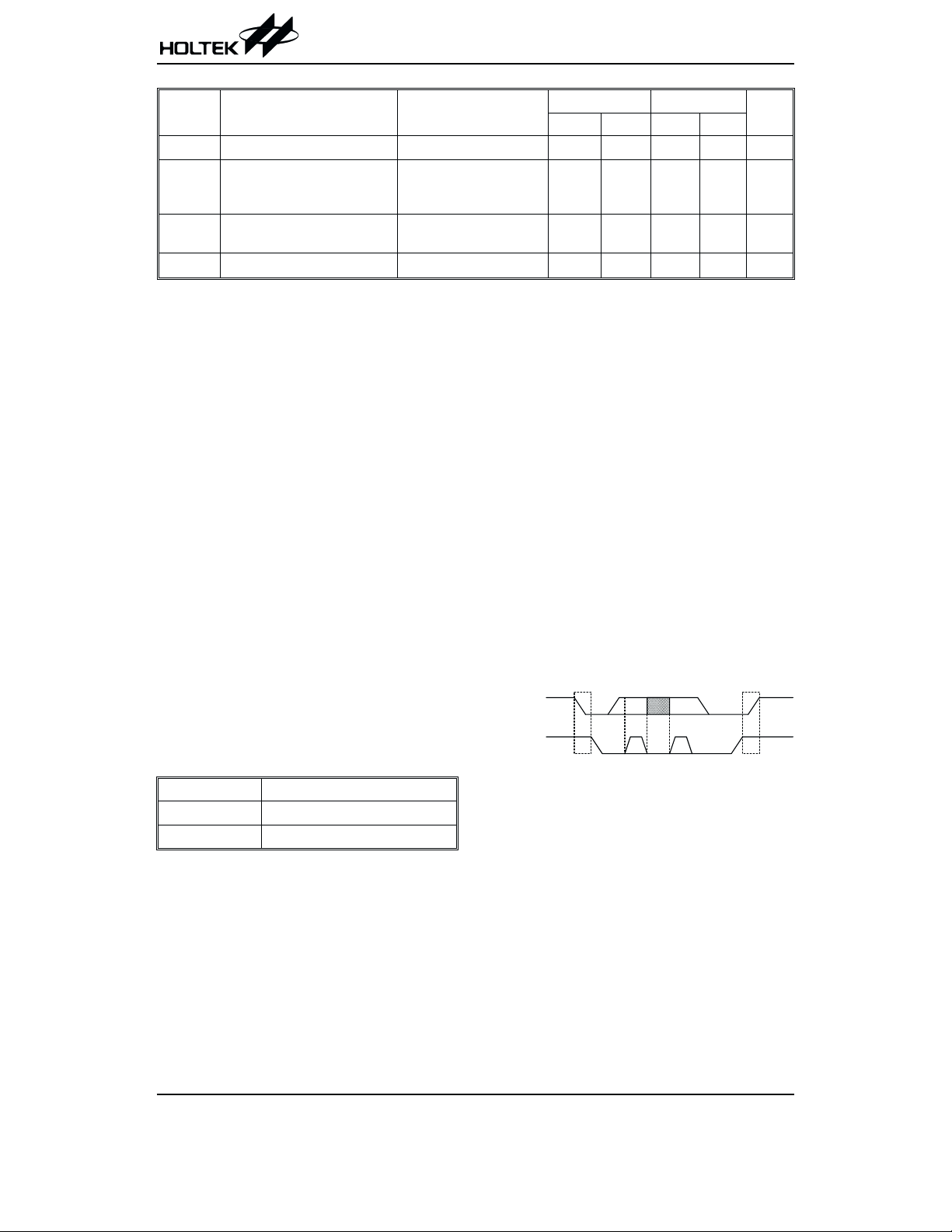

Symbol Parameter Remark

t

AA

Output Valid from Clock

¾¾

Time in which the bus

t

BUF

Bus Free Time

must be free before a new

transmission can start

t

t

SP

WR

Input Filter Time Constant

(SDA and SCL Pins)

Write Cycle Time

Noise suppression time

¾¾5¾

Notes: These parameters are periodically sampled but not 100% tested

* The standard mode means V

=2.2V to 5.5V

CC

For relative timing, refer to timing diagrams

Functional Description

·

Serial clock (SCL)

The SCL input is used for positive edge clock data into

each EEPROM device and negative edge clock data

out of each device.

·

Serial data (SDA)

The SDA pin is bidirectional for serial data transfer.

The pin is open drain driven and may be wired-OR

with any number of other open drain or open collector

devices.

·

A0, A1, A2

The HT24LC08 uses the A2 input for hard wire addressing and a total of two 8K devices may be addressed on a single bus system. The A0 and A1 pins

have no connection.

·

Write protect (WP)

The HT24LC08 has a write protect pin that provides

hardware data protection. The write protect pin allows

normal read/write operations when the connection is

grounded. When the write protect pin is connected to

V

, the write protection feature is enabled and oper

CC

ates as shown in the following table.

WP Pin Status Protect Array

At V

At V

CC

SS

Full Array (8K)

Normal Read/Write Operations

Memory organization

Internally organized with 1024 8-bit words, the 8K re

quires a 10-bit data word address for random word ad

dressing.

Device operations

·

Clock and data transition

Data transfer may be initiated only when the bus is not

busy. During data transfer, the data line must remain

stable whenever the clock line is high. Changes in

data line while the clock line is high will be interpreted

as a START or STOP condition.

·

Start condition

A high-to-low transition of SDA with SCL high is a start

condition which must precede any other command

(refer to Start and Stop Definition Timing diagram).

·

Stop condition

A low-to-high transition of SDA with SCL high is a stop

condition. After a read sequence, the stop command

will place the EEPROM in a standby power mode (re

fer to Start and Stop Definition Timing Diagram).

·

Acknowledge

All addresses and data words are serially transmitted

to and from the EEPROM in 8-bit words. The

EEPROM sends a zero to acknowledge that it has received each word. This happens during the ninth clock

cycle.

S D A

-

S C L

Device addressing

The 8K EEPROM device requires an 8-bit device ad

dress word following a start condition to enable the chip

for a read or write operation. The device address word

-

consist of a mandatory one, zero sequence for the first

-

four most significant bits (refer to the diagram showing

the Device Address). This is common to all the

EEPROM device.

The 8K EEPROM uses the A2 device address bit with

the next two bits for memory page addressing. The A2

bit must compare its corresponding hard-wired input

pin. The A1 and A0 pins have no connection.

These page addressing bits on the 8K device should be

considered the most significant bits of the data word ad

Standard Mode*

V

CC

=5V±10%

Min. Max. Min. Max.

4700

¾

S t a r t

c o n d i t i o n

3500

¾

100

¾

1200

¾

D a t a a l l o w e d

t o c h a n g e

A d d r e s s o r

a c k n o w l e d g e

v a l i d

Unit

900 ns

ns

¾

50 ns

5ms

S t o p

c o n d i t i o n

-

-

-

Rev. 1.20 3 November 4, 2002

Page 4

HT24LC08

dress which follows. The A0, A1 and A2 pins have no

connection.

The 8th bit device address is the read/write operation

select bit. A read operation is initiated if this bit is high

and a write operation is initiated if this bit is low.

If the comparison of the device address succeed the

EEPROM will output a zero at ACK bit. If not, the chip will

return to a standby state.

1 0

D e v i c e A d d r e s s

R / W1 0 A 2 A 1 A 0

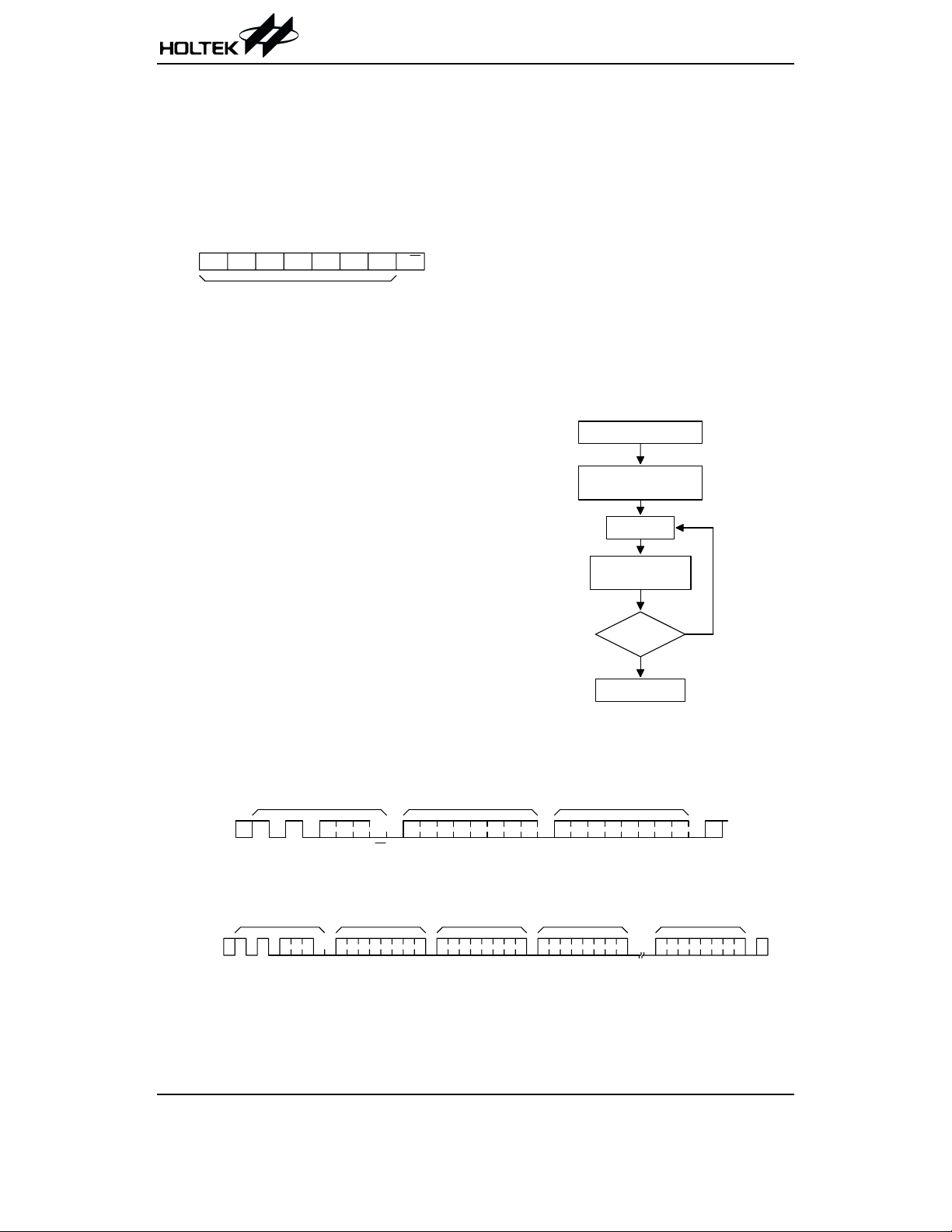

Write operations

·

Byte write

A write operation requires an 8-bit data word address

following the device address word and acknowledg

ment. Upon receipt of this address, the EEPROM will

again respond with a zero and then clock in the first

8-bit data word. After receiving the 8-bit data word, the

EEPROM will output a zero and the addressing de

vice, such as a microcontroller, must terminate the

write sequence with a stop condition. At this time the

EEPROM enters an internally-timed write cycle to the

nonvolatile memory. All inputs are disabled during this

write cycle and EEPROM will not respond until write is

complete (refer to Byte write timing).

·

Page write

The 8K EEPROM is capable of a 16-byte page write.

A page write is initiated in the same way as a byte

write, but the microcontroller does not send a stop condition after the first data word is clocked in. Instead, after the EEPROM acknowledges the receipt of the first

data word, the microcontroller can transmit up to 15

more data words. The EEPROM will respond with a

zero after each data word received. The

microcontroller must terminate the page write sequence

with a stop condition (refer to Page write timing).

The data word address lower four bits are internally in

cremented following the receipt of each data word.

The higher data word address bits are not incre

-

mented, retaining the memory page row location.

·

Acknowledge polling

Since the device will not acknowledge during a write

cycle, this can be used to determine when the cycle is

complete (this feature can be used to maximize bus

throughput). Once the stop condition for a write com

mand has been issued from the master, the device ini

-

tiates the internally timed write cycle. ACK polling can

be initiated immediately. This involves the master

sending a start condition followed by the control byte

for a write command (R/W=0). If the device is still busy

with the write cycle, then no ACK will be returned. If

the cycle is completed, then the device will return the

ACK and the master can then proceed with the next

-

read or write command.

S e n d W r i t e C o m m a n d

-

S e n d S t o p C o n d i t i o n

t o I n i t i a t e W r i t e C y c l e

S e n d S t a r t

S e n d C o n t r o l B y t e

w i t h R / W = 0

( A C K = 0 ) ?

N e x t O p e r a t i o n

N o

Y e s

Acknowledge polling flow

-

W o r d a d d r e s s D A T A

A C K A C K

P

S t o p

S D A

S

S t a r t

D e v i c e a d d r e s s

A 2 A 1 A 0

R / W

A C K

Byte write timing

D e v i c e a d d r e s s W o r d a d d r e s s D A T A n

S

S D A

S t a r t

A C K

A C K

D A T A n + 1 D A T A n + x

A C K

P

A C K

S t o p

Page write timing

Rev. 1.20 4 November 4, 2002

Page 5

HT24LC08

·

Write protect

The HT24LC08 can be used as a serial ROM when

the WP pin is connected to VCC . Programming will be

inhibited and the entire memory will be

write-protected.

·

Read operations

Read operations are initiated in the same way as write

operations with the exception that the read/write se

lect bit in the device address word is set to one. There

are three read operations: current address read, ran

dom address read and sequential read.

·

Current address read

The internal data word address counter maintains the

last address accessed during the last read or write op

eration, incremented by one. This address stays valid

between operationsas long as the chip power is main

tained. The address roll over during read from the last

byte of the last memory page to the first byte of the first

page. The address roll over during write from the last

byte of the current page to the first byte of the same

page. Once the device address with the read/write se

lect bit set to one is clocked in and acknowledged by

the EEPROM, the current address data word is seri

ally clocked out. Themicrocontroller does not respond

with an input zero but does generate a following stop

condition (refer to Current read timing).

·

Random read

A randomread requires a dummy byte write sequence

to load in the data word address which is then clocked

in and acknowledged by the EEPROM. The

microcontroller must then generate another start con

dition. The microcontroller now initiates a current ad

-

dress read by sending a device address with the

-

-

read/write select bit high. The EEPROM acknowl

edges the device address and serially clocks out the

data word. The microcontroller does not respond with

a zero but does generate a following stop condition

-

(refer to Random read timing).

·

Sequential read

-

-

Sequential reads are initiated by either a current ad

dress read or a random address read. After the

microcontroller receives a data word, it responds with

an acknowledgment. As long as the EEPROM re

ceives an acknowledgment, it will continue to incre

-

-

ment the data word address and serially clock out

sequential data words. When the memory address

-

-

limit is reached, the data word address will roll over

and the sequential read continues. The sequential

read operation is terminated when the microcontroller

does not respond with a zero but does generate a fol

lowing stop condition.

S D A

S

S t a r t

D e v i c e a d d r e s s

S D A

S D A

S

S t a r t

S

S t a r t

A 2 A 1 A 0

D e v i c e a d d r e s s D A T A n

D e v i c e a d d r e s s D A T A

A 2 A 1 A 0

A C K

Current read timing

W o r d a d d r e s s

A C K

A C K

S

S t a r t

D e v i c e a d d r e s s

Random read timing

D A T A n + 1 D A T A n + x

A C K

A C K

Sequential read timing

A C K

S t o p

P

N o A C K

D A T A

S t o p

P

N o A C K

P

A C K

S t o p

Rev. 1.20 5 November 4, 2002

Page 6

Timing Diagrams

S C L

S D A

S D A

O U T

S C L

t

S U : S T A

HT24LC08

t

t

F

t

L O W

t

H D : S T A

t

S P

t

A A

H I G H

t

R

t

t

H D : D A T

S U : D A T

V a l i d V a l i d

t

S U : S T O

t

B U F

S D A

W o r d n

8 t h b i t

A C K

S t o p

c o n d i t i o n

t

W R

S t o p

c o n d i t i o n

Note: The write cycle time tWRis the time from a valid stop condition of a write sequence to the end of the valid start con

dition of sequential command.

-

Rev. 1.20 6 November 4, 2002

Page 7

Package Information

8-pin DIP (300mil) outline dimensions

B

C

D

HT24LC08

A

8

5

4

1

H

I

G

E

F

=

Symbol

Min. Nom. Max.

A 355

B 240

C 125

D 125

E16

F50

G

¾

H 295

I 335

Dimensions in mil

¾

¾

¾

¾

¾

¾

100

¾

¾

a 0°¾15°

375

260

135

145

20

70

¾

315

375

Rev. 1.20 7 November 4, 2002

Page 8

8-pin SOP (150mil) outline dimensions

5

8

A

1

B

4

C

HT24LC08

C '

D

E

F

Symbol

Min. Nom. Max.

A 228

B 149

C14

C¢

189

D53

E

¾

F4

G22

H4

G

H

=

Dimensions in mil

¾

¾

¾

¾

¾

50

¾

¾

¾

a 0°¾10°

244

157

20

197

69

¾

10

28

12

Rev. 1.20 8 November 4, 2002

Page 9

Product Tape and Reel Specifications

Reel dimensions

HT24LC08

T 2

A

B

T 1

D

SOP 8N

Symbol Description Dimensions in mm

A Reel Outer Diameter

B Reel Inner Diameter

C Spindle Hole Diameter

D Key Slit Width

T1 Space Between Flange

T2 Reel Thickness

330±1.0

62±1.5

13.0+0.5

2.0±0.15

12.8+0.3

18.2±0.2

C

-0.2

-0.2

Rev. 1.20 9 November 4, 2002

Page 10

Carrier tape dimensions

HT24LC08

D

E

F

PD 1

P 1P 0

W

A 0

B 0

C

SOP 8N

Symbol Description Dimensions in mm

W Carrier Tape Width

P Cavity Pitch

E Perforation Position

F Cavity to Perforation (Width Direction)

D Perforation Diameter

12.0+0.3

8.0±0.1

1.75±0.1

5.5±0.1

1.55±0.1

D1 Cavity Hole Diameter 1.5+0.25

P0 Perforation Pitch

P1 Cavity to Perforation (Length Direction)

A0 Cavity Length

B0 Cavity Width

K0 Cavity Depth

t Carrier Tape Thickness

4.0±0.1

2.0±0.1

6.4±0.1

5.20±0.1

2.1±0.1

0.3±0.05

C Cover Tape Width 9.3

t

K 0

-0.1

Rev. 1.20 10 November 4, 2002

Page 11

HT24LC08

Holtek Semiconductor Inc. (Headquarters)

No.3, Creation Rd. II, Science-based Industrial Park, Hsinchu, Taiwan

Tel: 886-3-563-1999

Fax: 886-3-563-1189

http://www.holtek.com.tw

Holtek Semiconductor Inc. (Sales Office)

11F, No.576, Sec.7 Chung Hsiao E. Rd., Taipei, Taiwan

Tel: 886-2-2782-9635

Fax: 886-2-2782-9636

Fax: 886-2-2782-7128 (International sales hotline)

Holtek Semiconductor (Shanghai) Inc.

7th Floor, Building 2, No.889, Yi Shan Rd., Shanghai, China

Tel: 021-6485-5560

Fax: 021-6485-0313

http://www.holtek.com.cn

Holtek Semiconductor (Hong Kong) Ltd.

RM.711, Tower 2, Cheung Sha Wan Plaza, 833 Cheung Sha Wan Rd., Kowloon, Hong Kong

Tel: 852-2-745-8288

Fax: 852-2-742-8657

Holmate Semiconductor, Inc.

48531 Warm Springs Boulevard, Suite 413, Fremont, CA 94539

Tel: 510-252-9880

Fax: 510-252-9885

http://www.holmate.com

Copyright Ó 2002 by HOLTEK SEMICONDUCTOR INC.

The information appearing in this Data Sheet is believed to be accurate at the time of publication. However, Holtek as

sumes no responsibility arising from the use of the specifications described. The applications mentioned herein are used

solely for the purpose of illustration and Holtek makes no warranty or representation that such applications will be suitable

without further modification, nor recommends the use of its products for application that may present a risk to human life

due to malfunction or otherwise. Holtek reserves the right to alter its products without prior notification. For the most

up-to-date information, please visit our web site at http://www.holtek.com.tw.

-

Rev. 1.20 11 November 4, 2002

Loading...

Loading...