Page 1

General Description

The DS4426 contains four I2C-adjustable current DACs

capable of sinking or sourcing current. External resistors set the full-scale range of each output. Each DAC

output has 127 sink and 127 source steps that are programmed by the I2C interface. Power-supply tracking

functionality is provided for three channels using dedicated control inputs. Once power-supply tracking is

accomplished, the current outputs default to zero. Two

address pins allow up to four DS4426 devices to exist

on the same I2C bus.

Applications

Power-Supply Adjustment

Power-Supply Margining

Power-Supply Tracking

Adjustable Current Sink or Source

Features

♦ Four Current DACs

50µA to 200µA Adjustable Full-Scale Range

127 Settings Each for Sink and Source

♦ Power-Supply Tracking

Power-Supply Sequencing

Ramp-Up and Ramp-Down Tracking Control

Ratiometric Tracking Support

♦ +2.7V to +5.5V Operation

♦ I

2

C-Compatible Serial Interface

♦ Two Address Input Pins Allow Up to Four Devices

on Same I

2

C Bus

♦ Lead-Free, 28-Pin TQFN Package (4mm x 4mm)

with Exposed Pad

♦ Industrial Temperature Range: -40°C to +85°C

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

________________________________________________________________

Maxim Integrated Products

1

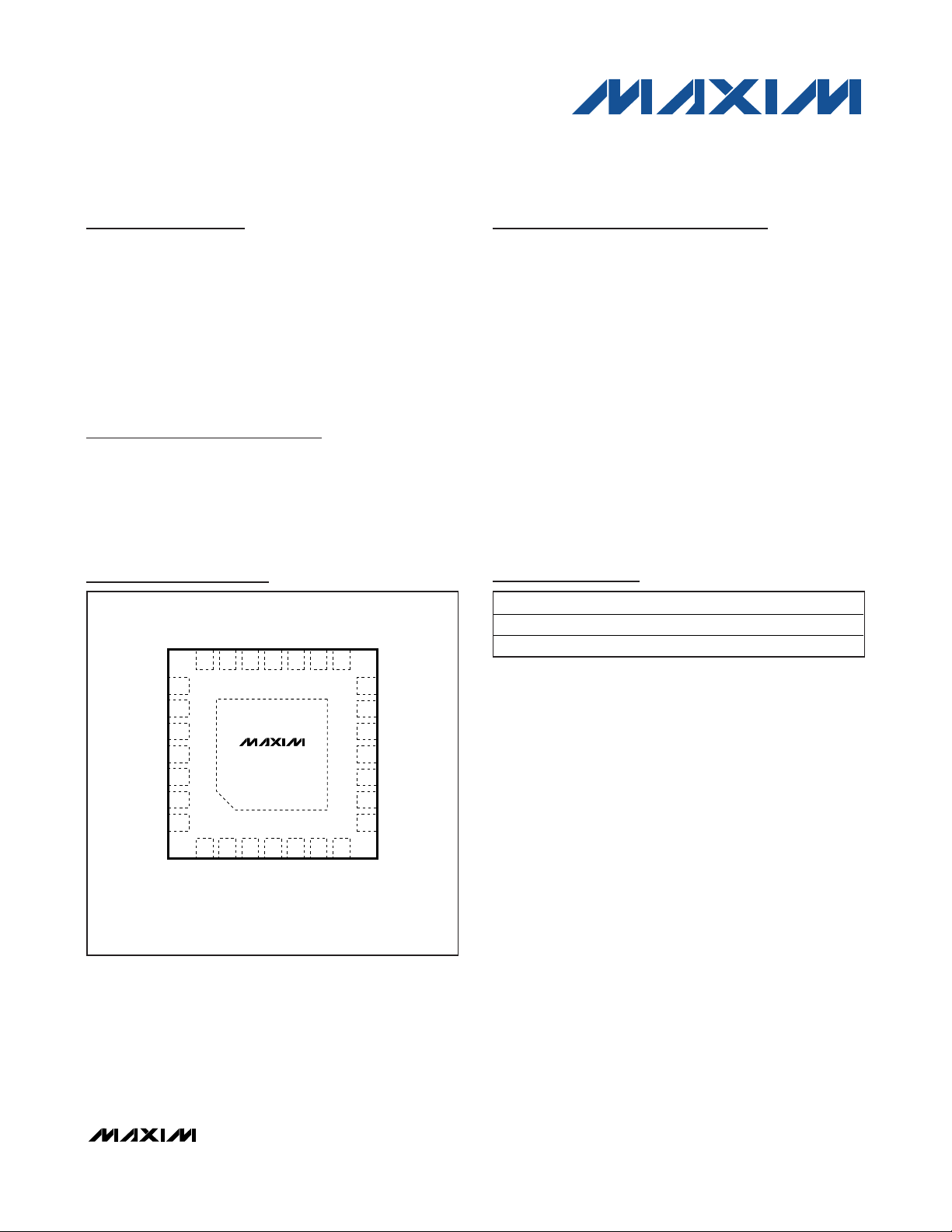

Pin Configuration

Ordering Information

19-4541; Rev 1; 7/09

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

T&R = Tape and reel.

*

EP = Exposed pad.

PART TEMP RANGE PIN-PACKAGE

DS4426T+ -40°C to +85°C 28 TQFN-EP*

DS4426T+T&R -40°C to +85°C 28 TQFN-EP*

Functional Diagram appears at end of data sheet.

TOP VIEW

THR1

DNC

THR3

THR2

18

DS4426

*EP

4567

CC

V

OUT0

OUT1

INN3

OUT2

INP3

OUT3

14

INN2

INP2

13

12

INN1

INP1

11

10

A1

A0

9

8

GND

FS1

22

FS2

23

24

FS3

25

GAIN3

26

GAIN2

27

GAIN1

28

N.C.

*EXPOSED PAD.

FS0

2021 19 17 16 15

+

12

3

SCL

SDA

THIN QFN

(4mm × 4mm)

Page 2

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED OPERATING CONDITIONS

(TA= -40°C to +85°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on SDA, SCL Relative to GND ......-0.5V to +6.0V

Voltage Range on V

CC

Relative to GND ...............-0.5V to +6.0V

Voltage Range on A0, A1, FS[3:0], GAIN[3:1],

INN[3:1], INP[3:1], THR[3:1], and OUT[3:0]

Relative to GND ......................................-0.5V to (V

CC

+ 0.5V)*

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature...........................Refer to the IPC/JEDEC

J-STD-020 Specification.

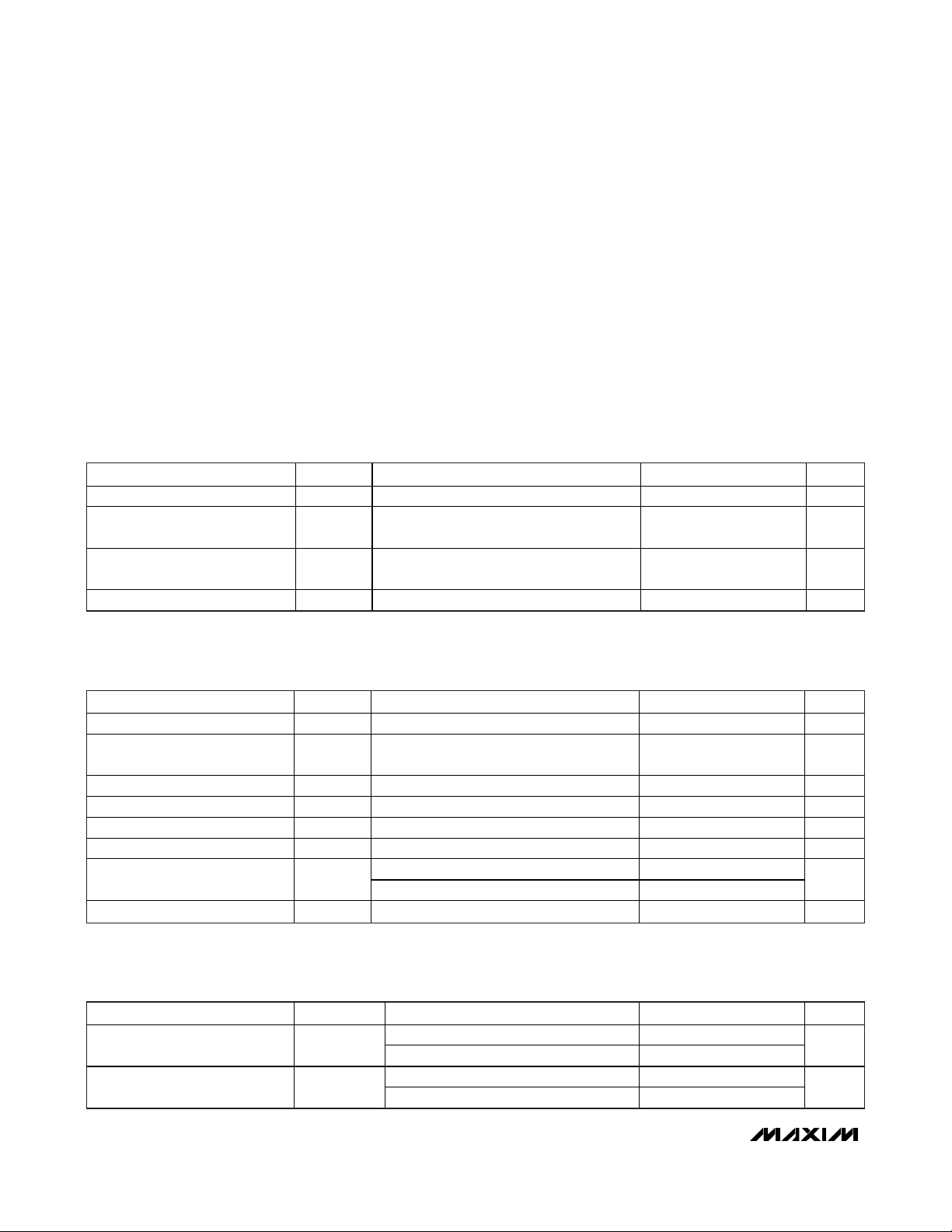

DC ELECTRICAL CHARACTERISTICS

(VCC= +2.7V to +5.5V, TA= -40°C to +85°C.)

DAC OUTPUT CURRENT CHARACTERISTICS

(VCC= +2.7V to +5.5V, TA= -40°C to +85°C.)

*

Not to exceed +6.0V.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VCC (Note 1) 2.7 5.5 V

Input Logic 1

(SDA, SCL, A0, A1)

Input Logic 0

(SDA, SCL, A0, A1)

Full-Scale Resistor Values R

V

IH

V

-0.3

IL

(Note 2) 40 160 k

FS[3:0]

0.7 x

V

CC

VCC+

0.3

0.3 x

V

CC

V

V

PARAMETER S YMBOL CONDITIONS MIN TYP MAX UNITS

Supply Current ICC VCC = +5.5V (Note 3) 0.9 mA

Input Leakage Current

(SDA, SCL)

RFS Voltage V

Reference Voltage V

Temperature Coefficient ±100 ppm/°C

Output Leakage Current (SDA) IL -1 +1 μA

Output-Current Low (SDA) I

I/O Capacitance C

I

VCC = +5.5V -1 +1 μA

IL

TA = +25°C 0.940 0.990 1.040 V

RFS

REF

V

= +0.4V 3

OL

I/O

OL

V

= +0.6V 6

OL

10 pF

1.24 V

mA

PARAMETER S YMBOL CONDITIONS MIN TYP MAX UNITS

Output Current Variation Due to

Power-Supply Change

Output Current Variation Due to

Output-Voltage Change

DC source, V

DC sin k, V

DC source, VCC = +3.6V 0.15

DC sin k, V

measured at +1.2V 0.33

OUT

measured at +1.2V 0.33

OUT

= +3.6V 0.30

CC

%/V

%/V

Page 3

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

_______________________________________________________________________________________ 3

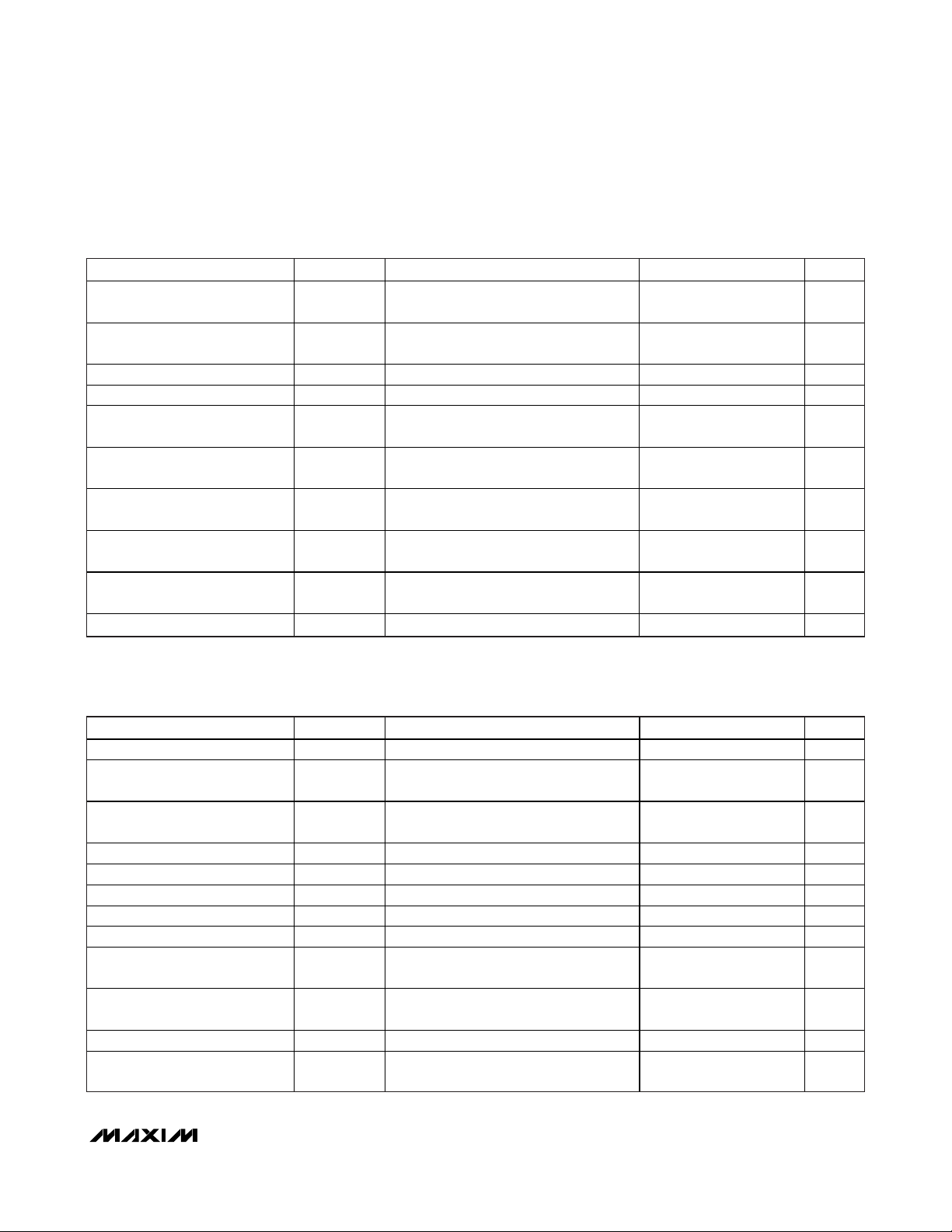

DAC OUTPUT CURRENT CHARACTERISTICS (continued)

(VCC= +2.7V to +5.5V, TA= -40°C to +85°C.)

I2C ELECTRICAL CHARACTERISTICS

(VCC= +2.7V to +5.5V, TA= -40°C to +85°C. Timing referenced to V

IL(MAX)

and V

IH(MIN)

. See Figure 6.)

PARAMETER S YMBOL CONDITIONS MIN TYP MAX UNITS

Output Voltage for Sinking

Current

Output Voltage for Sourcing

Current

Ful l-Scale Sink Output Current I

Ful l-Scale Source Output Current I

Output-Current Full-Scale

Accuracy

Output-Current Temperature

Coefficient

Output-Current Power-Supply

Rejection Ratio

Output-Leakage Current at Zero

Current Setting

Output-Current Differential

Linearity

Output-Current Integral Linearity INL (Note 7) 1 LSB

V

OUT:SINK

V

OUT:SOURCE

OUT:SINK

OUT:SOURCE

I

OUT:FS

I

OUT:TC

0.33 %/V

I

ZERO

DNL (Note 6) 0.5 LSB

(Note 4) 0.5 3.5 V

V

-

(Note 4) 0

(Note 4) 50 200 μA

(Note 4) -200 -50 μA

TA = +25°C ±5 %

(Note 5) ±130 ppm/°C

-1 +1 μA

CC

0.75

V

PARAMETER S YMBOL CONDITIONS MIN TYP MAX UNITS

SCL Clock Frequency f

Bus Free Time Between STOP

and START Condition s

Hold Time (Repeated) START

Condition

Low Period of SCL t

High Period of SCL t

Data Hold Time t

Data Setup Time t

START Setup Time t

SDA a nd SCL Rise Time tR (Note 9)

SDA and SCL Fall Time tF (Note 9)

STOP Setup Time t

SDA a nd SCL Capac it iv e

Loading

(Note 8) 0 400 kHz

SCL

t

1.3 μs

BUF

t

0.6 μs

HD: STA

1.3 μs

LOW

0.6 μs

HIGH

0 0.9 μs

HD:DAT

100 ns

SU:DAT

0.6 μs

SU:STA

0.6 μs

SU:STO

(Note 9) 400 pF

C

B

20 +

0.1C

20 +

0.1C

300 ns

B

300 ns

B

Page 4

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

4 _______________________________________________________________________________________

Note 1: All voltages are referenced to GND. Current entering the IC is specified positive, and current exiting the IC is negative.

Note 2: Input resistors (R

FS[3:0]

) must be between the specified values to ensure the device meets its accuracy and linearity specifi-

cations.

Note 3: Supply current specified with all outputs set to zero current setting and with all inputs at V

CC

or GND. SDA and SCL are

connected to V

CC

. Excludes current through RFSresistors (I

RFS

). Total current including I

RFS

is ICC+ (2 x I

RFS

).

Note 4: The output-voltage full-scale ranges must be satisfied to ensure the device meets its accuracy and linearity specifications.

Only applies to current DAC operation, not power-supply tracking operation.

Note 5: Temperature drift excludes drift caused by external resistors.

Note 6: Differential linearity is defined as the difference between the expected incremental current increase with respect to position

and the actual increase. The expected incremental increase is the full-scale range divided by 127.

Note 7: Integral linearity is defined as the difference between the expected value as a function of the setting and the actual value.

The expected value is a straight line between the zero and the full-scale values proportional to the setting.

Note 8: Timing shown is for fast-mode operation (400kHz). This device is also backward-compatible with I

2

C standard-mode timing.

Note 9: C

B

—Total capacitance of one bus line in pF.

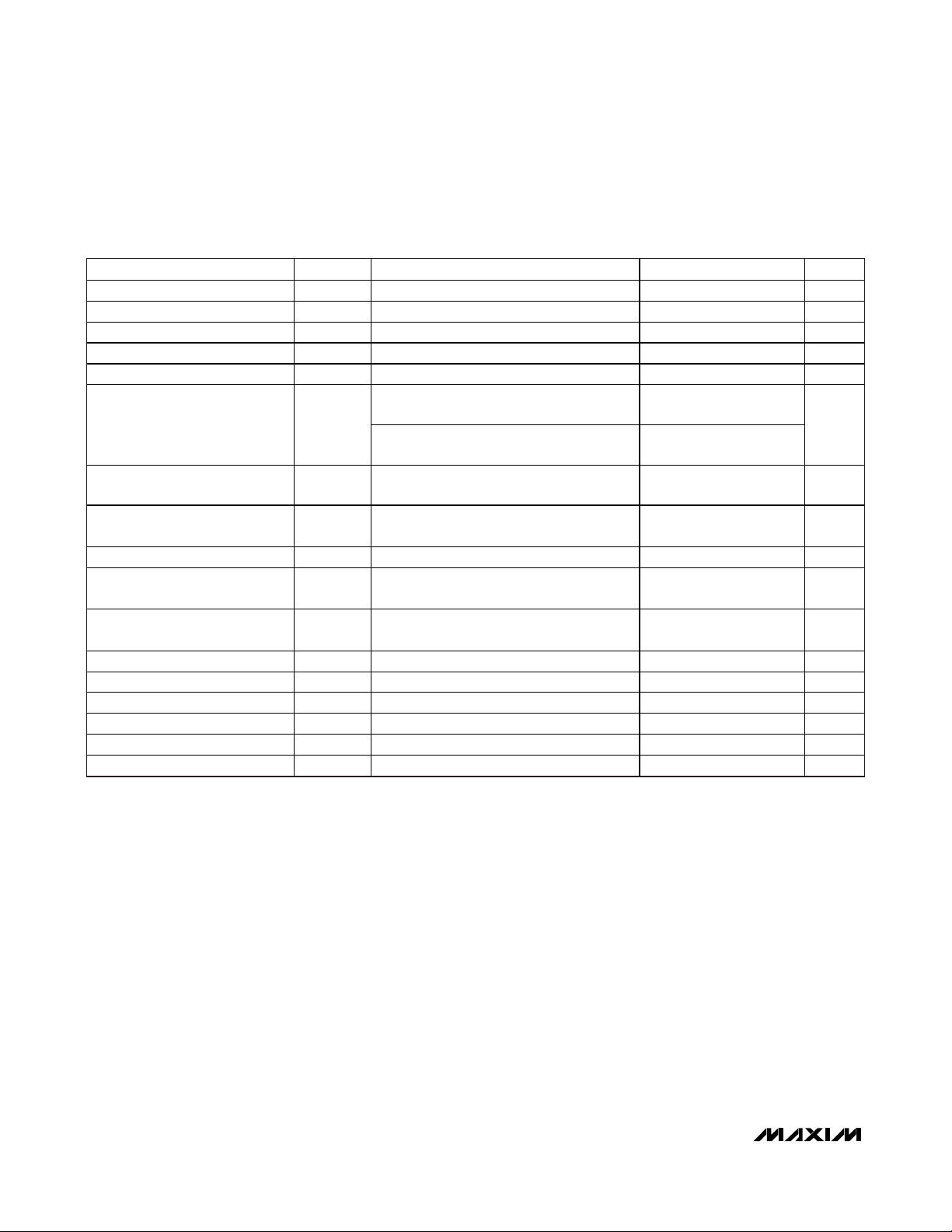

POWER-SUPPLY TRACKING CHARACTERISTICS

(VCC= +2.7V to +5.5V, TA= -40°C to +85°C, see Figure 5.)

PARAMETER S YMBOL CONDITIONS MIN TYP MAX UNITS

Input Divider Ratio R

Output Load R

Feedback Resistor Ratio RF/R

Gain Resistor R

Gain Setting Ratio RL/R

Power-Supply Tracking Gain G

Power-Supply Tracking Input

Bias Current

Power-Supply Tracking Input

Voltage

Unity Gain Bandwidth GBW RL/RG= 1.4; RL= 5k 12 MHz

Output Voltage While Tracking V

Output Current While Track ing I

Tracking Accuracy ±600 mV

Output Leakage I

Comparator Input Bias Current I

Comparator Input Offset V

Swit ch Delay t

Comparator Hysteresis V

DIV

I

V

OUT:TRK

OUT:TRK

BC

OFF

DC

HYS

RA/RB and RC/RD 0.5 1

RL= (RF x RE)/(RF+RE) 1 20 k

L

0.5 4.5

B

0.8 10 k

G

1.4 5

G

RL/RG= 2, RL= 5k, VCC = +3.6V,

T

= +25°C

VI

B

IN

OS

A

RL/RG= 5, RL= 5k, VCC = +3.6V,

= +25°C

T

A

1 μA

INP[3:1] and INN[3:1] 0

Switch closed, VCC = +3.0V, measured at

OUT[3:1], R

RL/RG= 1.4, RG= 1k, V

V

= +0.8V

FB

Switch open 0.5 μA

1 μA

±5 mV

5 μs

12.5 mV

= 5k

L

= +3.0V,

CC

2.4

3.8 6.2 10

V

-

CC

1.4

0 1.5 V

1 mA

mA/V

V

Page 5

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

_______________________________________________________________________________________

5

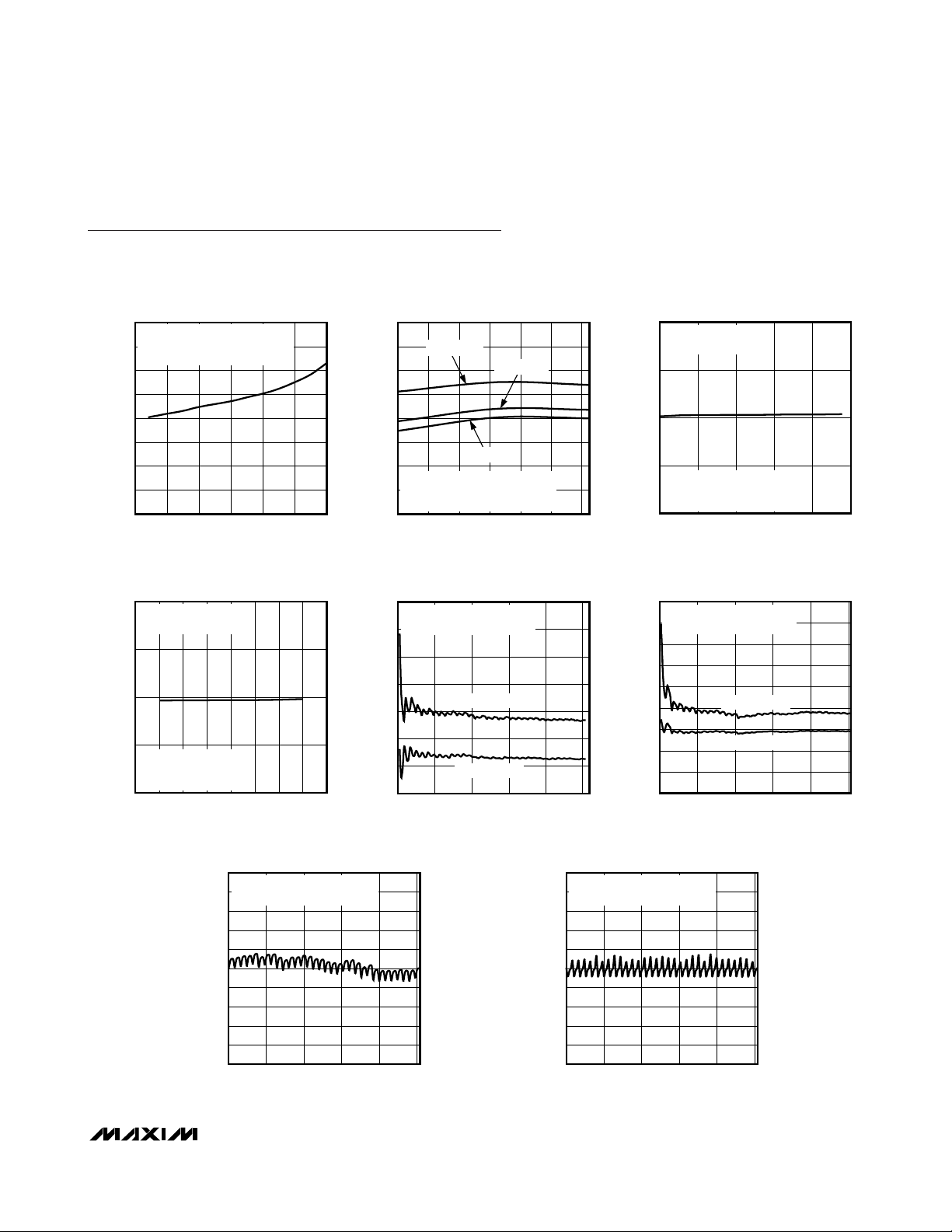

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

600

SDA = SCL = THR[3:1] = V

GAIN[3:1] = FS[3:0] = OUT[3:0] = OPEN

575

INP[3:1] = INN[3:1] = GND

550

525

500

475

SUPPLY CURRENT (μA)

450

425

400

2.5 5.5

SUPPLY VOLTAGE (V)

CC

5.04.53.0 3.5 4.0

VOLTCO (SINK)

250

40kΩ LOAD ON FS[3:0].

= +5.5V

V

CC

225

(μA)

200

OUT

I

175

SDA = SCL = THR[3:1] = V

GAIN[3:1] = OPEN

INP[3:1] = INN[3:1] = GND

150

0 4.0

CC

V

(V)

OUT

SUPPLY CURRENT

vs. TEMPERATURE

DS4426 toc01

600

575

550

525

500

475

SUPPLY CURRENT (μA)

450

425

400

VCC = +5.5V

SDA = SCL = THR[3:1] = V

GAIN[3:1] = FS[3:0] = OUT[3:0] = OPEN

INP[3:1] = INN[3:1] = GND

-40

TEMPERATURE (°C)

VCC = +3.3V

VCC = +2.7V

CC

8060-20 0 20 40

DS4426 toc02

-150

-175

(μA)

-200

OUT

I

-225

-250

05

TEMPERATURE COEFFICIENT

vs. SETTING (SOURCE)

DS4426 toc05

650

550

450

350

250

150

50

-50

TEMPERATURE COEFFICIENT (°C/ppm)

-150

-250

0

300

RANGE FOR THE 50μA TO 200μA

CURRENT SOURCE RANGE

250

DS4426 toc04

200

150

100

50

0

TEMPERATURE COEFFICIENT (°C/ppm)

3.53.02.52.01.51.00.5

-50

0

+25°C TO -40°C

+25°C TO +85°C

125100755025

SETTING (DEC)

VOLTCO (SOURCE)

40kΩ LOAD ON FS[3:0].

= +5.5V

V

CC

SDA = SCL = THR[3:1] = V

GAIN[3:1] = OPEN

INP[3:1] = INN[3:1] = GND

CC

V

(V)

OUT

TEMPERATURE COEFFICIENT

vs. SETTING (SINK)

RANGE FOR THE 50μA TO 200μA

CURRENT SINK RANGE

+25°C TO -40°C

+25°C TO +85°C

SETTING (DEC)

DS4426 toc03

4321

DS4426 toc06

125100755025

1.0

INTEGRAL LINEARITY

RANGE FOR THE 50μA TO 200μA

0.8

CURRENT SOURCE AND SINK RANGE

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0

SETTING (DEC)

125100755025

DS4426 toc07

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

DIFFERENTIAL LINEARITY

RANGE FOR THE 50μA TO 200μA

CURRENT SOURCE AND SINK RANGE

0

SETTING (DEC)

DS4426 toc08

125100755025

Page 6

Detailed Description

The DS4426 contains four I2C-adjustable current

sources that are each capable of sinking and sourcing

current. Three of the current outputs (OUT[3:1]) also

have power-supply tracking circuitry that allows additional current to be sourced during power-up.

Adjustable Current DACs

Each output (OUT[3:0]) has 127 sink and 127 source

settings that are programmed through the I2C interface.

The full-scale current ranges (and corresponding step

sizes) of the outputs are determined by external resistors connected to the corresponding FS pins (see

Figure 1). The formula to determine the external resistor

values (RFS) for each output is given by:

where IFSis the desired full-scale current value, V

RFS

is

the RFSvoltage (see the

DC Electrical Characteristics

table), and RFSis the external resistor value.

To calculate the output-current value (I

OUT

) based on the

corresponding DAC value (see Table 2 for corresponding memory addresses), use the following equation:

On power-up, the DS4426 current DAC outputs are set

to zero current. This is done to prevent the device from

sinking or sourcing an incorrect current before the system host controller has a chance to modify its setting.

Note, however, that if power-supply tracking is enabled

(see the

Power-Supply Tracking Circuit

section), then

the DS4426 can still source current at power-up.

When used in adjustable power-supply applications

(see Figure 8), the DS4426 does not affect the initial

power-up voltage of the supply because it defaults to

providing zero output current on power-up unless

power-supply tracking is enabled. As it sources or

sinks current into the feedback voltage node, it

changes the amount of output voltage required by the

regulator to reach its steady-state operating point.

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

6 _______________________________________________________________________________________

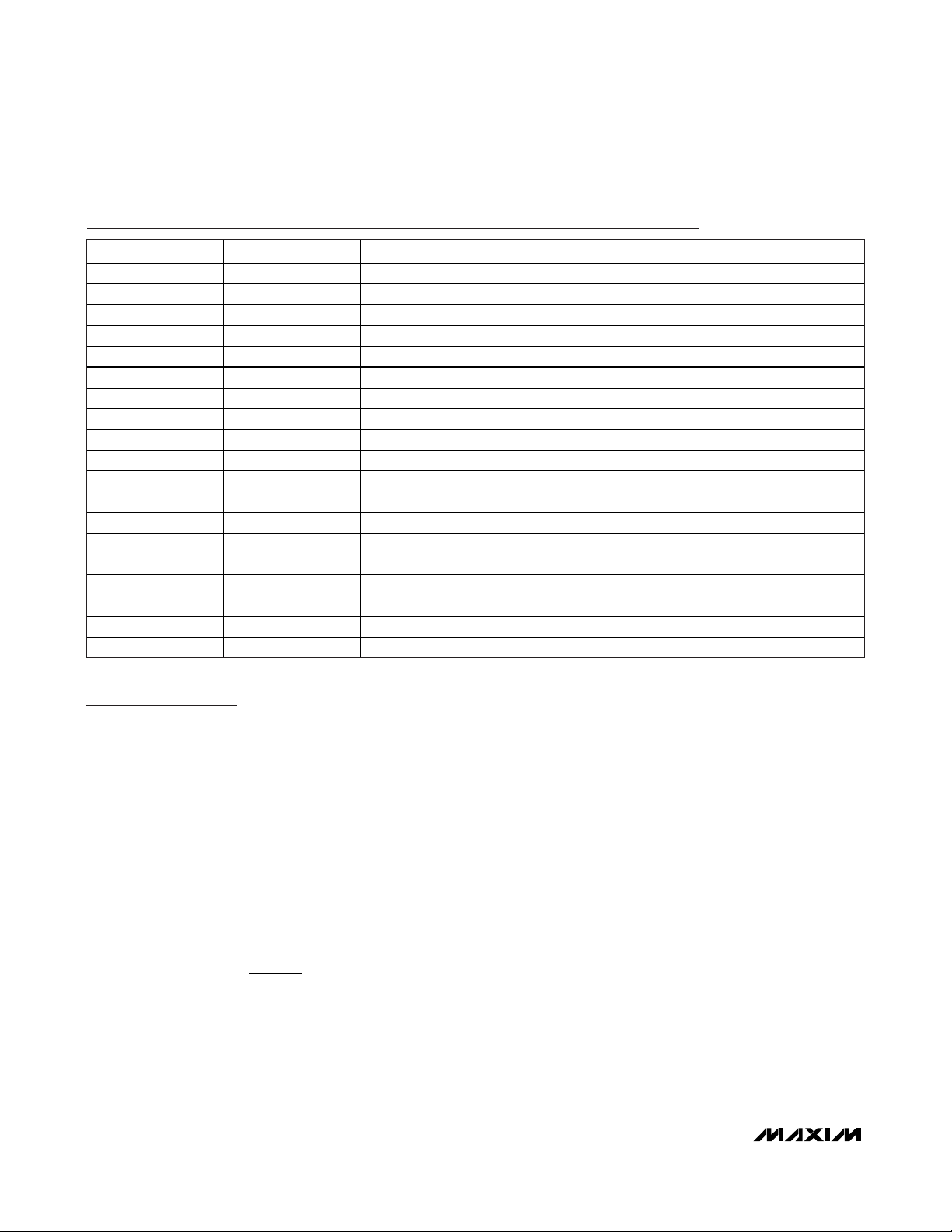

Pin Description

PIN NAME FUNCTION

1 SDA Serial Data Input/Output. I2C data pin.

2 SCL Serial Clock Input. I2C clock input.

3 VCC Voltage Supply

4 OUT0 Current DAC Output

5, 6, 7 OUT1, OUT2, OUT3 Current DAC and Tracking Control Output

8 GND Ground

9 A0 I2C Addre ss Input 0

10 A1 I2C Addre ss Input 1

11, 13, 15 INP1, INP2, INP3 Power-Supply Track ing Pos itive Input

12, 14, 16 INN1, INN2, INN3 Power-Supply Tracking Negati ve Input

17, 19, 20 THR3, THR2, THR1

18 DNC Do Not Connect

21–24 FS0, FS1, FS2, FS3

25, 26, 27

28 N.C. No Connection

— EP Exposed Pad. No connection.

GAIN3, GAIN2,

GAIN1

Threshold Input. Comparator input used to set threshold for tracking

enable/disable based on V

Ful l-Scale Calibration Input. A resistor-to-ground on this input determines fullsca le output current on the associated output.

Gain Adjustment Pin. Connect a resistor between this pin and VCC.

REF

/2.

I

DACValue dec

=×

OUT FS

()

127

V

R

FS

RFS

=

127

I

××16

FS

I

Page 7

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

_______________________________________________________________________________________ 7

Using the external resistors R

FS[3:0]

to set the outputcurrent range, the DS4426 provides some flexibility for

adjusting the impedances of the feedback network or

the range over which the power supply can be controlled or margined.

As a source for biasing instrumentation or other circuits,

the DS4426 provides a simple and inexpensive current

source with an I2C interface for control. The adjustable,

full-scale range allows the application to get the most

out of its 7-bit sink or source resolution.

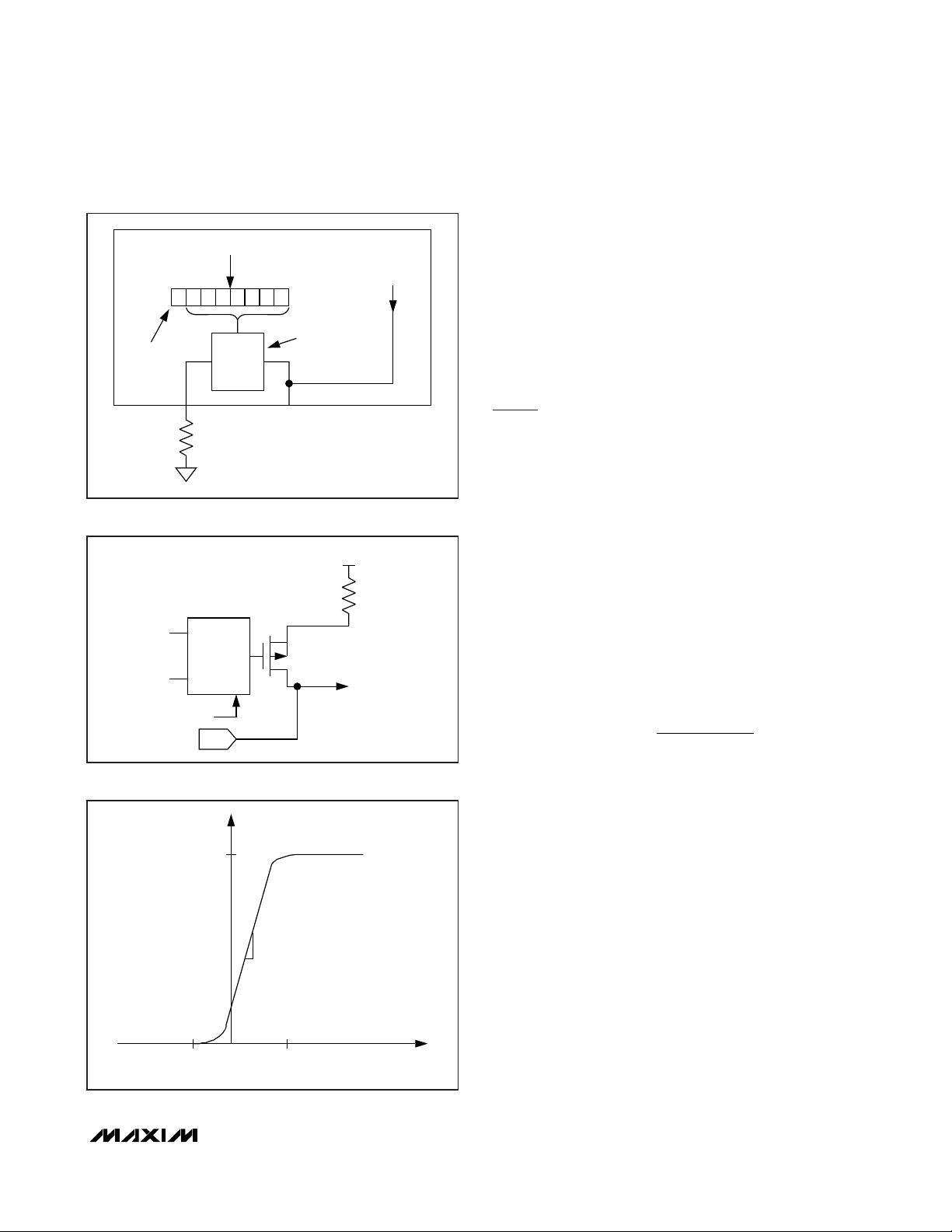

Power-Supply Tracking Circuit

By making use of the power-supply tracking circuitry,

the DS4426 has the ability to source current on powerup. This current is additive with the current DAC

source/sink currents and is determined by the value of

the gain resistor, RG, and the supply voltage, VCC. This

current is controlled by the voltages presented to the

corresponding INP and INN pins, and the voltages presented to the corresponding threshold (THR) pins.

Maximum Source Current

The maximum current the DS4426 can source at

power-up using the power-supply tracking circuitry

depends on the value of the supply voltage, VCC, and

the gain resistor, RG, connected from the corresponding GAIN pin to VCC. The maximum current (I

MAX

) that

can be sourced to the corresponding OUT pin can be

estimated using the following equation:

The power-supply tracking circuit can be estimated

with Figure 2.

Inputs for Power-Supply Tracking:

INP and INN

Each pair of power-supply tracking inputs, INP and

INN, determines if and how much of the I

MAX

current is

sourced when the power-supply tracking circuit is

enabled. When the difference between the voltage presented to INP (V

INP

) and INN (V

INN

) is more than

approximately +0.3V, then the maximum source current, as determined by the value I

MAX

, is sourced into

the OUT pin connection. When the difference between

V

INP

and V

INN

is less than approximately -0.2V, then no

current is sourced into the corresponding OUT pin. The

change in current from no current to I

MAX

can be esti-

mated by the power-supply tracking gain, G

VI

(see the

Power-Supply Tracking Characteristics

table).

Figure 3 shows the typical current behavior of the

power-supply tracking circuit with respect to the voltage difference seen at the INP and INN inputs.

Figure 1. Current DAC Detail

+INP

GAIN

V

CC

DAC

OUT

SLAVE

FEEDBACK

NODE

G

VI

R

G

-INN

SHUTDOWN

Figure 2. Gain Stage

I

-0.2 +0.3

AT V

CC

= +5.0V

I

MAX

G

VI

V

(V

INP

- V

INN

)

Figure 3. INP and INN Differential Inputs

I2C CONTROL

MSB LSB

SOURCE

OR

SINK MODE

R

FS[3:0]

CURRENT

DAC[3:0]

127 POSITIONS

EACH FOR SOURCE

AND SINK MODE

OUT[3:0]FS[3:0]

TRACKING

OUT[3:1] ONLY

VV

−

()

≅

CC OUT

R

G

I

MAX

Page 8

DS4426

THR Inputs for Enabling

Power-Supply Tracking

Comparators are used to individually enable/disable

power-supply tracking based on the voltage presented

to the corresponding THR pin relative to a fixed internal

reference (V

REF

/2 = +0.62V). Figure 4 shows a typical

startup and shutdown plot based on the voltage presented to the THR pin. Tracking can be disabled by

connecting the corresponding THR pin to a voltage

greater than V

REF

/2. Below this threshold, the tracking

circuit is active.

Power-Supply Tracking in DC-DC

Power Applications

The DS4426 provides several options for power-supply

tracking control of DC-DC power supplies. In many

cases, it is desirable to prevent certain DC-DC supplies

from exceeding the voltage of other supplies. This is

often the case with the voltages applied to a digital

core and I/O. Each DS4426 supports one master with

three slave DC-DCs. See Figure 5 for more information.

Loop Bandwidth Consideration

Power-supply tracking is used to override each slave

DC-DC’s feedback loop during power-up and powerdown. Power-supply tracking is capable of slewing at a

much faster rate than most DC-DC converters. Care

must be exercised when selecting the loop bandwidth

of the master DC-DC, slave DC-DC, and power-supply

tracking control loop such that oscillations and overshoot are minimized.

While the slave DC-DC supplies are tracking the master

DC-DC supply, there are three time constants of concern:

1) Master BW. The master DC-DC control loop bandwidth, power-up ramp rate, and power-down ramp

rate.

2) Slave BW. The slave DC-DC supplies control loop

bandwidths.

3) Tracking BW. The DS4426 tracking circuit bandwidth.

To ensure stable operation and minimize peaking, the

bandwidths should follow the following rule:

Master BW and Slave BW < (Tracking BW/10)

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

8 _______________________________________________________________________________________

Figure 4. Enabling Power-Supply Tracking Using the THR Input

V

V

MASTER

V

V

THRESHOLD

SLAVE

GAIN

ERROR

DS4426 TRACKING DISABLED

TRACKING RANGE: DS4426 OVERRIDES SLAVE'S FEEDBACK LOOP

t

Page 9

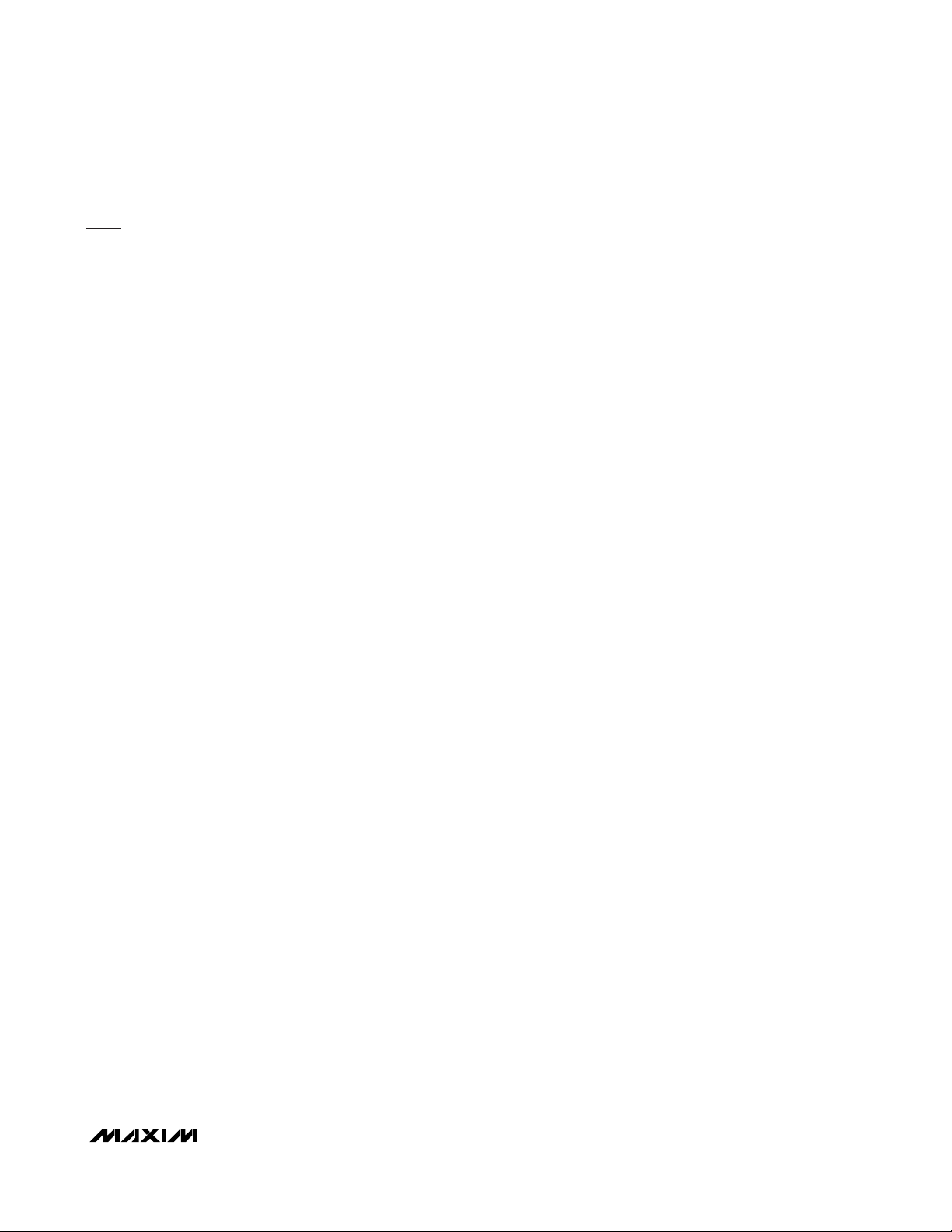

Ratiometric Tracking

The DS4426 can maintain a defined ratio between a

slave voltage and the master voltage where:

KSM= V

SLAVE/VMASTER

.

In Figure 5, this ratio is given by the following:

KSM= [R

B[3:1]

/(R

A[3:1]

+ R

B[3:1]

)]/[R

D[3:1]

/(R

C[3:1]

+ R

D[3:1]

)].

Nonratiometric tracking is the special case where KSM= 1.

Power-Supply Tracking Loop Gain Stability

Slave DC-DC output tracking is controlled by the

DS4426 sourcing current into the slave DC-DC's feedback loop. This changes the stability of the loop during

tracking. The amount of gain used can be adjusted by

changing the ratio of R

L/RG

. If oscillations occur,

increasing RGreduces gain and increases the system’s

phase margin. If the slave DC-DC has a compensation

pin, the RC network connected to this pin can also be

adjusted to improve phase margin. This pin is often

labeled COMP or ITH. A larger compensation time constant (increased R and/or increased C) often increases

the stability of the system during tracking; however, this

also modifies the DC-DC's transient response. In order

to prevent modification of the slave DC-DC’s transient

response after power-supply tracking is complete, R

G

should first be modified before adjusting the compensation network. The higher the gain, the less the gain

error. Reducing the gain increases the gain error during

tracking. See Figure 4 for more information.

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

_______________________________________________________________________________________ 9

Figure 5. Typical DC-DC Power-Supply Tracking Application

5.0V

0.1μF

10kΩ

2

I

C

10kΩ10kΩ

V

SDA

SCL

A0

A1

CC

V

CC

VOUT

MASTER

REF

1.24V

DC-DC

FS0

CONVERTER

R

FS0

FB

2

C CONTROL

I

INTERFACE

V

REF

OUT0

R

F0

R

E0

x3

INP[3:1]

5.0V

INN[3:1]

GAIN[3:1]

THR[3:1]

R

D[3:1]

V

/2

REF

R

A[3:1]

R

B[3:1]

10kΩ

R

THR[3:1]

R

G[3:1]

R

FS[3:1]

OUT[3:1]

DS4426

R

C[3:1]

FS[3:1]

VOUT

SLAVE

DC-DC

CONVERTER

FB

COMP

R

R

F[3:1]

E[3:1]

Page 10

Inputs for Tracking in DC-DC Power

Applications

When enabling/disabling the power-supply tracking, a

resistor-divider connected to the THR input sets the disable threshold (see V

THRESHOLD

in Figure 4). The top

of the resistor-divider must be connected to the master

DC-DC voltage for correct operation. Below this threshold, the tracking circuit is active.

Power-Supply Sequencing

The DS4426 can be used to perform power-supply

sequencing. This is a subset of power-supply tracking

with modifications to the external resistor network. The

basic concept is that the DS4426 sources maximum

current into the slave power supply's feedback node

until a voltage in the system has risen above a specific

voltage level. By sourcing the maximum current into the

feedback node, the power supply's output is held off.

Maximum sourcing current is achieved with two steps:

1) Apply the maximum allowed input voltage across

INP and INN. Connect INP to VCC- 1.4V using a

voltage-divider to ground. Connect INN to ground.

2) Set the gain to the maximum allowed (RL/RG= 5).

The slave power supply is allowed to turn on once the

voltage on THR is greater than V

REF

/2. Use a resistordivider connected to the rising system voltage to scale

the trip point to V

REF

/2.

I2C Slave Address

The DS4426 responds to one of four I2C slave addresses determined by the state of the input on the two

address inputs. The two input states are connected to

VCCor connected to ground.

Memory Organization

The DS4426’s current sources are controlled by writing

to memory addresses listed in Table 2.

The format of each of the output control registers is

given by:

where:

For example:

R

FS0

= 80kΩ and register 0xF8h is written to a value of

0xAAh. Use the following formula to calculate the output current:

I

FS

= (1.0V/80kΩ) x (127/16) = 99.22µA

The MSB of the output register is 1, so the output is

sourcing the value corresponding to position 2Ah (42

decimal). The magnitude of the output current is equal

to the following:

99.22µA x (42/127) = 32.8125µA

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

10 ______________________________________________________________________________________

Table 1. Slave Addresses

Table 2. Memory Addresses

A1 A0 SLAVE ADDRESS (HEX)

GND GND 90h

GND VCC 92h

VCC GND 94h

VCC V

96h

CC

MEMORY ADDRESS (HEX) CURRENT SOURCE

F8h OUT0

F9h OUT1

FAh OUT2

FBh OUT3

BIT 7

(MSB)

BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1

S D6 D5 D4 D3 D2 D1 D

BIT NAME DESCRIPTION

Determines if DAC source s or

Sign

S

DXData

sinks current. For sink, S = 0.

Bit

For source, S = 1.

7-bit data word controlling DAC

output. Setting 0000000b

outputs zero current regardles s

of the state of the sign bit.

BIT 0

(LSB)

0

POWER-ON

DEFAULT

0b

0000000b

Page 11

I2C Serial Interface Description

I2C Definitions

The following terminology is commonly used to

describe I

2

C data transfers:

I2C Slave Address: The slave address of the

DS4426 is determined by the state of the A0 and A1

pins (see Table 1).

Master Device: The master device controls the slave

devices on the bus. The master device generates

SCL clock pulses and START and STOP conditions.

Slave Devices: Slave devices send and receive

data at the master’s request.

Bus Idle or Not Busy: Time between STOP and

START conditions when both SDA and SCL are inactive and in their logic-high states. When the bus is

idle it often initiates a low-power mode for slave

devices.

START Condition: A START condition is generated

by the master to initiate a new data transfer with a

slave. Transitioning SDA from high to low while SCL

remains high generates a START condition. See

Figure 3 for applicable timing.

STOP Condition: A STOP condition is generated by

the master to end a data transfer with a slave.

Transitioning SDA from low to high while SCL

remains high generates a STOP condition. See

Figure 3 for applicable timing.

Repeated START Condition: The master can use a

repeated START condition at the end of one data

transfer to indicate that it will immediately initiate a

new data transfer following the current one.

Repeated STARTs are commonly used during read

operations to identify a specific memory address to

begin a data transfer. A repeated START condition

is issued identically to a normal START condition.

See Figure 6 for applicable timing.

Bit Write: Transitions of SDA must occur during the

low state of SCL. The data on SDA must remain valid

and unchanged during the entire high pulse of SCL,

plus the setup-and-hold time requirements (Figure

6). Data is shifted into the device during the rising

edge of the SCL.

Bit Read: At the end of a write operation, the master

must release the SDA bus line for the proper amount

of setup time (Figure 6) before the next rising edge

of SCL during a bit read. The device shifts out each

bit of data on SDA at the falling edge of the previous

SCL pulse, and the data bit is valid at the rising

edge of the current SCL pulse. Remember that the

master generates all SCL clock pulses, including

when it is reading bits from the slave.

Acknowledgement (ACK and NACK): An

Acknowledgement (ACK) or Not Acknowledge

(NACK) is always the ninth bit transmitted during a

byte transfer. The device receiving data (the master

during a read or the slave during a write operation)

performs an ACK by transmitting a zero during the

ninth bit. A device performs a NACK by transmitting

a 1 during the ninth bit. Timing for the ACK and

NACK is identical to all other bit writes (Figure 6). An

ACK is the acknowledgment that the device is properly receiving data. A NACK is used to terminate a

read sequence or as an indication that the device is

not receiving data.

Byte Write: A byte write consists of 8 bits of information transferred from the master to the slave (most

significant bit first) plus a 1-bit acknowledgement

from the slave to the master. The 8 bits transmitted

by the master are done according to the bit-write definition, and the acknowledgement is read using the

bit-read definition.

Byte Read: A byte read is an 8-bit information transfer from the slave to the master plus a 1-bit ACK or

NACK from the master to the slave. The 8 bits of

information that are transferred (most significant bit

first) from the slave to the master are read by the

master using the bit-read definition, and the master

transmits an ACK using the bit-write definition to

receive additional data bytes. The master must

NACK the last byte read to terminate communication

so the slave returns control of SDA to the master.

Slave Address Byte: Each slave on the I

2

C bus

responds to a slave address byte sent immediately

following a START condition. The slave address byte

contains the slave address in the most significant 7

bits and the R/W bit in the least significant bit. The

DS4426’s slave address is determined by the state

of the A0 and A1 pins (see Table 1). When the R/W

bit is 0 (such as in 90h), the master is indicating it

will write data to the slave. If R/W = 1 (91h in this

case), the master is indicating it wants to read from

the slave. If an incorrect slave address is written, the

DS4426 assumes the master is communicating with

another I2C device and ignores the communication

until the next START condition is sent.

Memory Address: During an I2C write operation,

the master must transmit a memory address to identify the memory location where the slave is to store

the data. The memory address is always the second

byte transmitted during a write operation following

the slave address byte.

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

______________________________________________________________________________________ 11

Page 12

DS4426

I2C Communication

Writing to a Slave: The master must generate a START

condition, write the slave address byte (R/W = 0), write

the memory address, write the byte of data, and generate a STOP condition. Remember that the master must

read the slave’s acknowledgement during all byte-write

operations.

Reading from a Slave: To read from the slave, the

master generates a START condition, writes the slave

address byte with R/W = 1, reads the data byte with a

NACK to indicate the end of the transfer, and generates

a STOP condition.

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

12 ______________________________________________________________________________________

Figure 7. I2C Communication Examples

SCL

NOTE: TIMING IS REFERENCED TO V

IL(MAX)

AND V

IH(MIN)

.

SDA

STOP START REPEATED

START

t

BUF

t

HD:STA

t

HD:DAT

t

SU:DAT

t

SU:STO

t

HD:STA

t

SP

t

SU:STA

t

HIGH

t

R

t

F

t

LOW

Figure 6. I2C Timing Diagram

2

C WRITE TRANSACTION

TYPICAL I

MSB LSB MSB LSB MSB LSB

START

1 0 0 1 0 A1 A0 R/W

SLAVE

b7 b6 b5 b4 b3 b2 b1 b0

ACK

SLAVE

b7 b6 b5 b4 b3 b2 b1 b0

ACK

SLAVE

ACK

STOP

SLAVE

ADDRESS*

2

EXAMPLE I

C TRANSACTIONS (WHEN A0 AND A1 ARE GROUNDED)

SINGLE-BYTE WRITE

A)

-WRITE REGISTER F9h TO 00h

SINGLE-BYTE READ

B)

-READ REGISTER F8h

*THE SLAVE ADDRESS IS DETERMINED BY ADDRESS PINS A0 AND A1.

START

START

READ/

WRITE

90h F9h

10010000 11111 001 00000000

90h

SLAVE

ACK

SLAVE

ACK

REGISTER/MEMORY ADDRESS

F8h

DATA

SLAVE

ACK

SLAVE

ACK

REPEATED

START

SLAVE

STOP

ACK

91h

10010 001

SLAVE

ACK

DATA

MASTER

NACK

STOP10010000 11111 000

Page 13

Applications Information

Example Calculations for an Adjustable

Power Supply

In this example, the circuit shown in Figure 8 is used to

margin a +2.0V supply by ±20%. The margined power

supply has a DC-DC converter output voltage, V

OUT

, of

+2.0V and a DC-DC converter feedback voltage, V

FB

,

of +0.8V. To determine the relationship of R

0A

and R0B,

start with the equation:

Substituting VFB= +0.8V and V

OUT

= +2.0V, the rela-

tionship between R

0A

and R0Bis determined to be:

R0A= 1.5 x R

0B

I

OUT0

is chosen to be 100µA (midrange source/sink

current for the DS4426). Summing the currents into the

feedback node, we have the following:

I

OUT0

= I

R0B

- I

R0A

where:

and

To create a ±20% margin in the supply voltage, the

value of V

OUT

is set to +2.4V. With these values in

place, R0Bis calculated to be 2.67kΩ, and R0Ais

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

______________________________________________________________________________________ 13

Figure 8. Example Typical Application Circuit

R

0

V

=

FB

B

RR

+

00

AB

V

×

OUT

4.7kΩ4.7kΩ

SDA

SCL

GND

V

CC

DS4426

OUT0

V

I

RB

FB

=

R

B00

VV

−

I

RA

OUT FB

=

R

A00

V

CC

DC-DC

CONVERTER

OUT

FB

V

= 2.0V*

OUT

I

I

R0A

R0B

R0A = 4kΩ

VFB = 0.8V*

R0B = 2.67kΩ

*V

AND VFB VALUES ARE DETERMINED BY THE DC-DC CONVERTER AND SHOULD NOT BE CONFUSED WITH V

OUT

FS0

R

FS0

= 80kΩ

I

OUT0

OUT

AND V

OF THE DS4426.

REF

Page 14

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

14 ______________________________________________________________________________________

calculated to be 4.00kΩ. The current DAC in this configuration allows the output voltage to be moved linearly

from +1.6V to +2.4V using 127 settings. This corresponds to a resolution of 6.3mV/step.

V

CC

Decoupling

To achieve the best results when using the DS4426,

decouple the power supply with a 0.01µF (or 0.1µF)

capacitor. Use a high-quality, ceramic, surface-mount

capacitor if possible. Surface-mount components minimize lead inductance, which improves performance.

Ceramic capacitors tend to have adequate high-frequency response for decoupling applications.

DS4426

SDA

V

CC

SCL

A0

A1

FS0

OUT0

I

2

C CONTROL

INTERFACE

V

CC

V

REF

REF

1.24V

INP1

FS1

OUT1

INN1

THR1

GAIN1

V

REF

/2

INP2

FS2

OUT2

INN2

THR2

GAIN2

V

REF

/2

INP3

FS3

OUT3

INN3

THR3

GND

GAIN3

V

REF

/2

Functional Diagram

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

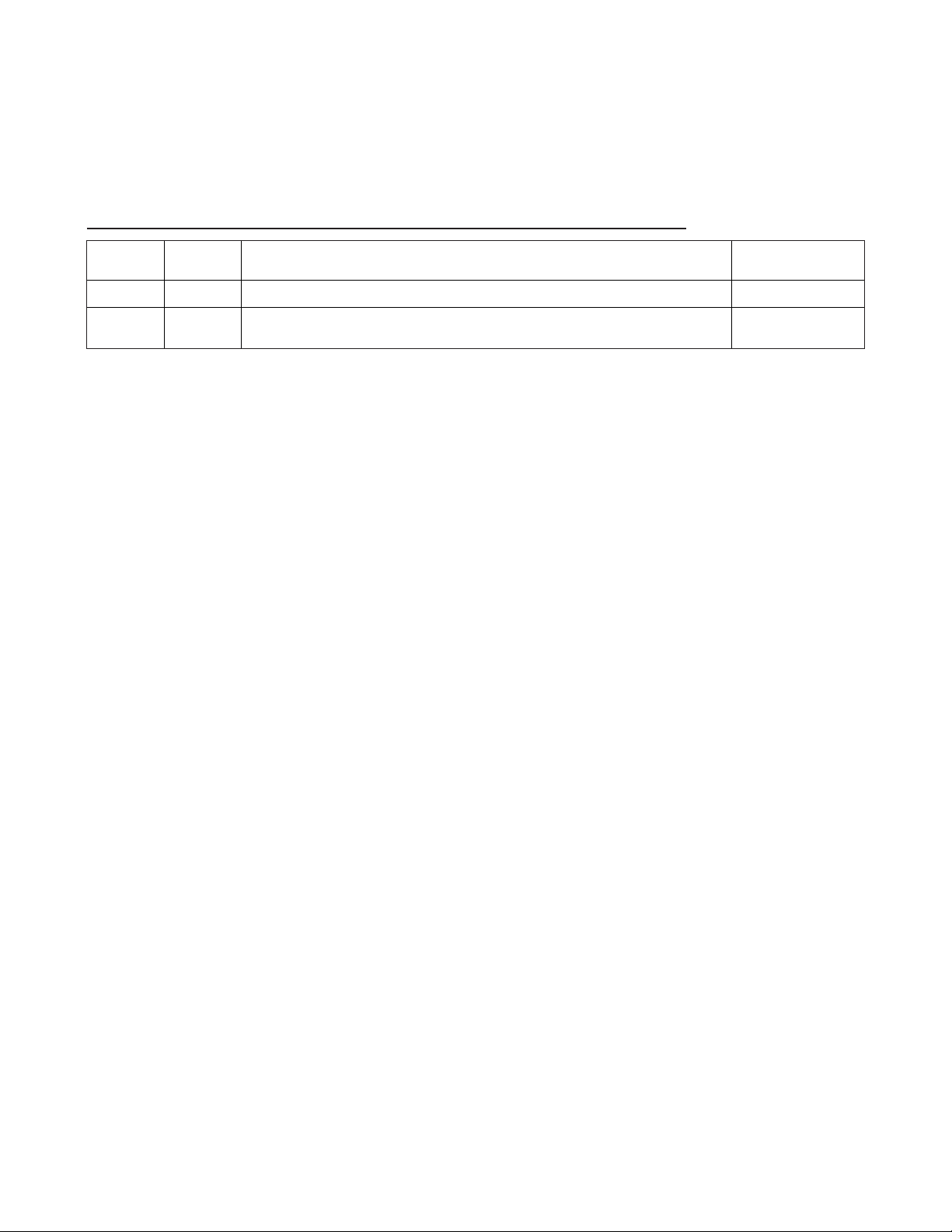

.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

28 TQFN T2844+1

21-0139

Page 15

DS4426

Quad-Channel, I2C-Margining IDACs with

Three Channels of Power-Supply Tracking

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

15

© 2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

0 4/08 Initial release. —

1 7/09

REVISION

DATE

DESCRIPTION

Added OUT[3:0] to the Absolute Maximum Ratings for the following condition:

Voltage Range on A0, A1, FS[3:0], GAIN[3:1], INN[3:1], INP[3:1], and THR[3:1].

PAGES

CHANGED

2

Loading...

Loading...