Page 1

General Description

The DS2710 is ideal for in-system charging of single-cell

nickel metal hydride (NiMH) cells for low-current

portable applications. Inputs to the DS2710 include USB

voltage sources and 5V regulated adapters.

Temperature, voltage, and charge time are monitored to

provide proper fast-charging control algorithms for

single-cell NiMH or nickel cadmium (NiCd) batteries.

The DS2710 includes battery tests to detect defective or

inappropriate cells such as alkaline primary batteries.

Applications

Small Rechargeable Devices

Voice Recorders

Cordless Mouse

Battery-Powered Toys

Features

♦ Charges Single-Cell NiMH Cells

♦ Switch-Mode Topologies Supported by Hysteretic

Control Technique

♦ Precharges Deeply Depleted Cells

♦ Fast-Charges NiMH with -ΔV Termination

Sensitivity of 2mV (typ)

♦ Monitors Voltage, Temperature, and Time for

Safety and Secondary Termination

♦ Regulates Charge Current

♦ Designed for External pMOS

♦ Rail-to-Rail MOSFET Driver

♦ Tiny 10-Pin TDFN Package (3mm x 4mm)

DS2710

Single-Cell NiMH Charger

________________________________________________________________

Maxim Integrated Products

1

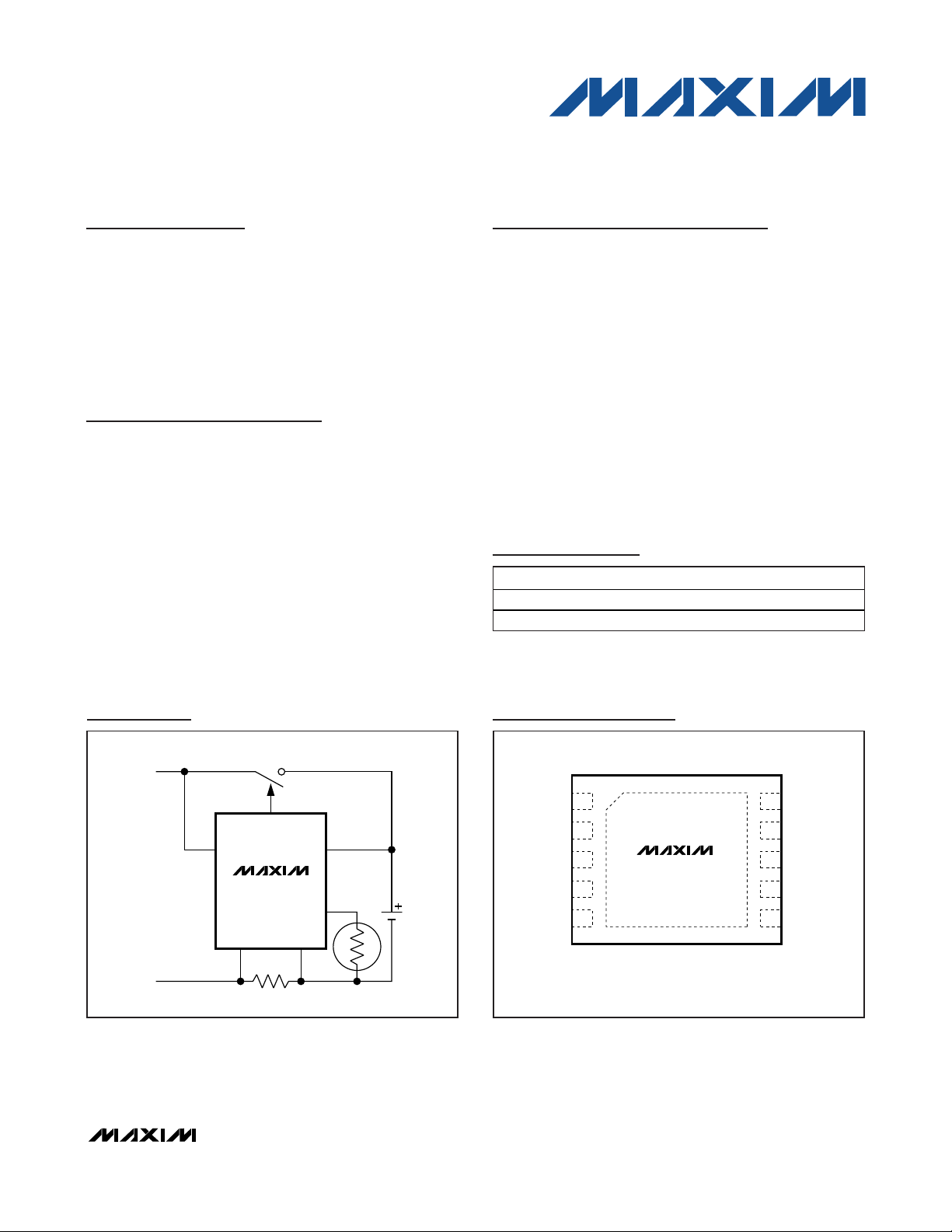

Pin Configuration

Ordering Information

DS2710

V

DD

VP1

THM

CS

VN0 VN1

SENSE

CHARGE

SOURCE

NiMH

CELL

GROUND

Typical Operating Circuit

Rev 0; 4/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead-free/RoHS-compliant package.

T&R = Tape and reel.

*

EP = Exposed pad.

PART PIN-PACKAGE

DS2710G+ 10 TDFN-EP*

DS2710G+T& R 10 TDFN-EP*

TOP VIEW

+

110

SS

2 9 VN1CS

3 8 VN0V

DD

4 7 TMRTHM

*EP

5 6 CTESTSTATUS

*EXPOSED PAD.

DS2710

TDFN

(3mm × 4mm)

VP1V

Page 2

DS2710

Single-Cell NiMH Charger

2 _______________________________________________________________________________________2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED DC OPERATING CONDITIONS

(4.0V ≤ VDD≤ 5.5V, TA= -20°C to +70°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on All Pins Relative to VSS............-0.3V to +6.0V

Continuous Source/Sink Current CS ...................................20mA

Continuous Source Current STATUS ..................................10mA

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature...........................Refer to the IPC/JEDEC

J-STD-020 Specification.

DC ELECTRICAL CHARACTERISTICS

(4.0V ≤ VDD≤ 5.5V, TA= -20°C to +70°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VDD (Note 1) 4.0 5.5 V

Input Voltage Range CTEST, TMR, THM, VP1, VN1 -0.3 VDD V

Supply Current, VDD I

UVLO Threshold V

UVLO Hysteresis V

Output-Voltage Low, CS V

Output-Voltage High, CS V

Output-Voltage Low, STATUS V

Output-Voltage High, STATUS V

Threshold Voltage,

-V Termination

Current-Sense Reference

Voltage

Hysteres is, Current-Sense

Comparator

Propagation Time, Current-Sense

Comparator to Dri ver Output

CS Pin Pul lup Current ICS VDD < V

STATUS Pin Pulldown Current I

Depleted Cell Voltage Thresho ld V

Overcharge Voltage Threshold

Open Socket Voltage Threshold

Offset, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Operating mode (Note 2) 250 1000 μA

DD

VDD rising (Note 1) 3.5 3.9 V

UVLO

VDD falling from above V

UHYS

VDD = 5.0V, IOL = +20mA (Note 1) 1.0 V

OL1

VDD = 5.0V, IOL = -20mA (Note 1) 4.0 V

OH1

VDD = 5.0V, IOL = +2mA (Notes 1, 3) 0.50 V

OL2

VDD = 5.0V, IOH = -2mA (Notes 1, 3) 4.0 V

OH2

V

MAX-O PEN

- V

MAX-CHARGE

After t

-V

V

(Notes 1, 5)

IREF

V

HYS-

COMP

t

PDLY

STAT

LOW

V

MAX-

OPEN

V

MAX-

CHARGE

VOS (Note 7) 98 100 102 mV

Centered ~ 0.113V 18 23 27 mV

2mV overdrive/underdrive at trip thresho ld

(Notes 4, 6)

VDD < V

VP1 - VN1 0.9 1.0 1.1 V

VP1 - VN1, CS = high (Note 7) 1.55 1.65 1.75 V

VP1 - VN1, CS = low (Note 7) 1.64 1.75 1.86 V

(Note 4) 1.0 2.0 3.0 mV

THO

UVLO

UVLO

30 mV

UVLO

125 mV

-6 +6 %

0.1 μs

(Note 4) 2 10 μA

(Note 4) 2 10 μA

Page 3

DS2710

Single-Cell NiMH Charger

_______________________________________________________________________________________ 3

Note 1: Voltages relative to VSS.

Note 2: Specification does not include CS and STATUS pin currents.

Note 3: STATUS pin is active high.

Note 4: Specification is guaranteed by design.

Note 5: Specification applicable during charge cycle with T

A

= 0°C to +70°C.

Note 6: 50mV overdrive while connected to a pMOS transistor (such as ZXM62P02 from Zetex).

Note 7: V

BAT-MAX1

and V

BAT-MAX1

ranges never overlap.

Note 8: VT

HM-MIN

, V

THM-MAX

, and V

THM-STOP

are fixed ratios of VDD. Their ranges never overlap.

Note 9: Maximum allowable leakage on TMR to maintain SUSPEND state.

DC ELECTRICAL CHARACTERISTICS (continued)

(4.0V ≤ VDD≤ 5.5V, TA= -20°C to +70°C, unless otherwise noted.)

ELECTRICAL CHARACTERISTICS: TIMING

(4.0V ≤ VDD≤ 5.5V, TA= -20°C to +70°C, unless otherwise noted.)

Cold Temperature Detect

Threshold

Hot Temperature No-Start

Threshold

Hot Temperature Safety

Shutdown Threshold

SUSPEND Current Threshold I

Presence-Test Current, VP1 VDD 4.0V 1.0 10 15 μA

Reverse-Leakage Current, VP1 V

Impedance-Voltage Test Range V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

THM-MIN

V

THM-MAX

V

THM-ST OP

SUSP END

(Notes 1, 5, 8) 0.73 V

(Notes 1, 5, 8) 0.30 0.33 0.36 V

(Notes 1, 5, 8) 0.29 V

(Note 9) 0.1 0.5 μA

= 0V, VP1 = 1.5V 2 μA

DD

32 400 mV

CTEST

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Internal Time-Base Period t

Internal Time-Base Accuracy -10 +10 %

CS Output Duty Factor

CELL TEST Interval t

PRECHARGE Timeout t

FAST-CHARGE Termination

Hold-Off Period

FAST-CHARGE Flat Voltage

Timeout

Charge-Timer Period t

Charge-Timer Accuracy R

Charge-Timer Range t

CTMR -R ANGE

Toggle Rate, Charging f

Toggle Rate, FAULT State f

0.96 Seconds

BASE

DF1 FAST-CHARGE 96.9

DF2 PRECHARGE/TOP-OFF 25.0

DF3 MAINTENANCE 1.56

31 Seconds

CTST

V

PCHG

t

4 Minutes

THO

V

t

FLAT

R

CTMR

< V

CELL

not increasing 16 Minutes

CELL

= 40k 1.0 Hours

TMR

= 40k -6 +6 %

TMR

34 Minutes

LOW

0.5 5.0 Hours

1 Hz

CHARGE

4 Hz

FAULT

DD

DD

DD

%

Page 4

DS2710

Single-Cell NiMH Charger

4 _______________________________________________________________________________________

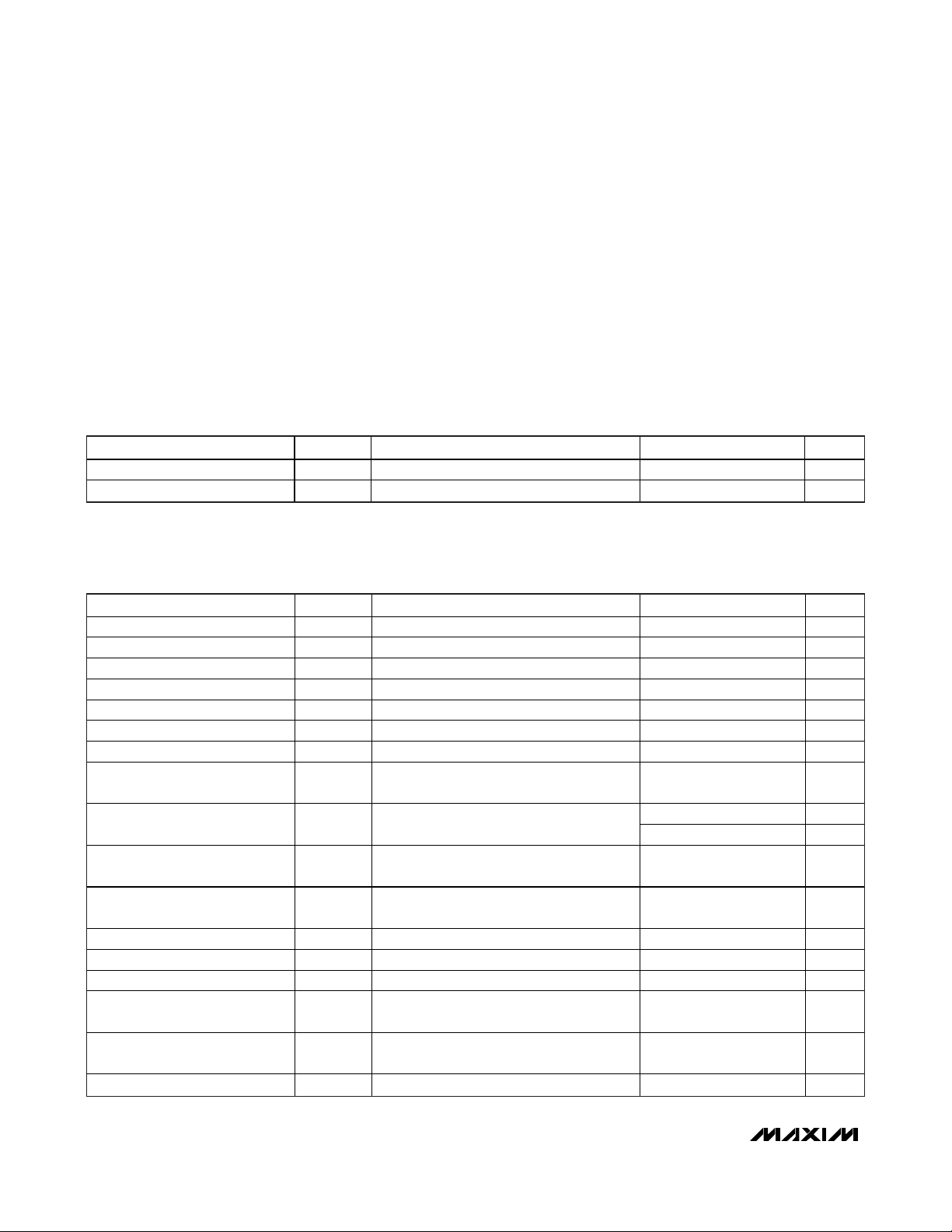

Pin Description

Figure 1. Block Diagram

PIN NAME FUNCTION

1 VSS Device Ground. Connect s directly to the negative terminal of the charge source.

2 CS Charge Source. Feedback control for switching circuitry.

3 V

4 THM Thermistor Input. Connects to a thermistor located near the cell and a resistor-div ider from the VDD pin.

5 STATUS Status Output. Drives an external LED or microprocessor input to indicate charge status.

6 CTEST Impedance Test. Connects to VSS through an external resistor to set the impedance-test threshold.

7 TMR Fast-Charge Timer. Connects to VSS through an external res istor to set the fast-charge timeout period.

8 VN0 Current-Sense Negative Input. Connects to the charge source s ide of the external sense resistor.

9 VN1 Current-Sense Positive Input. Connects to the cell side of the external sense resistor.

10 VP1 Cel l Voltage Sense. The voltage of the cel l is monitored through thi s input pin.

— EP Exposed Pad. Connects to VSS.

Power-Supply Input. Connects to the posit ive terminal of the charge source through a decoupling

DD

network.

V

STATUS

CTEST

TMR

0.1μA

BIAS

UVLO

OSCILLATOR

STATE MACHINE

PRESENSE TEST

PRECHARGE

FAST-CHARGE AND

CELL TESTS

TOP-OFF CHARGE

MAINTENANCE CHARGE

SUSPEND

WATCHDOG

ABORT

0.125V

VOLTAGE

AND

TEMPERATURE

MEASUREMENT

DUTYFACTOR

CONTROL

DS2710

I

PTST

VP1

VN1

THM

VN0

V

SS

CS

DD

3.5V

STATUS

CELL

TEST

CHARGE

TIMER

Page 5

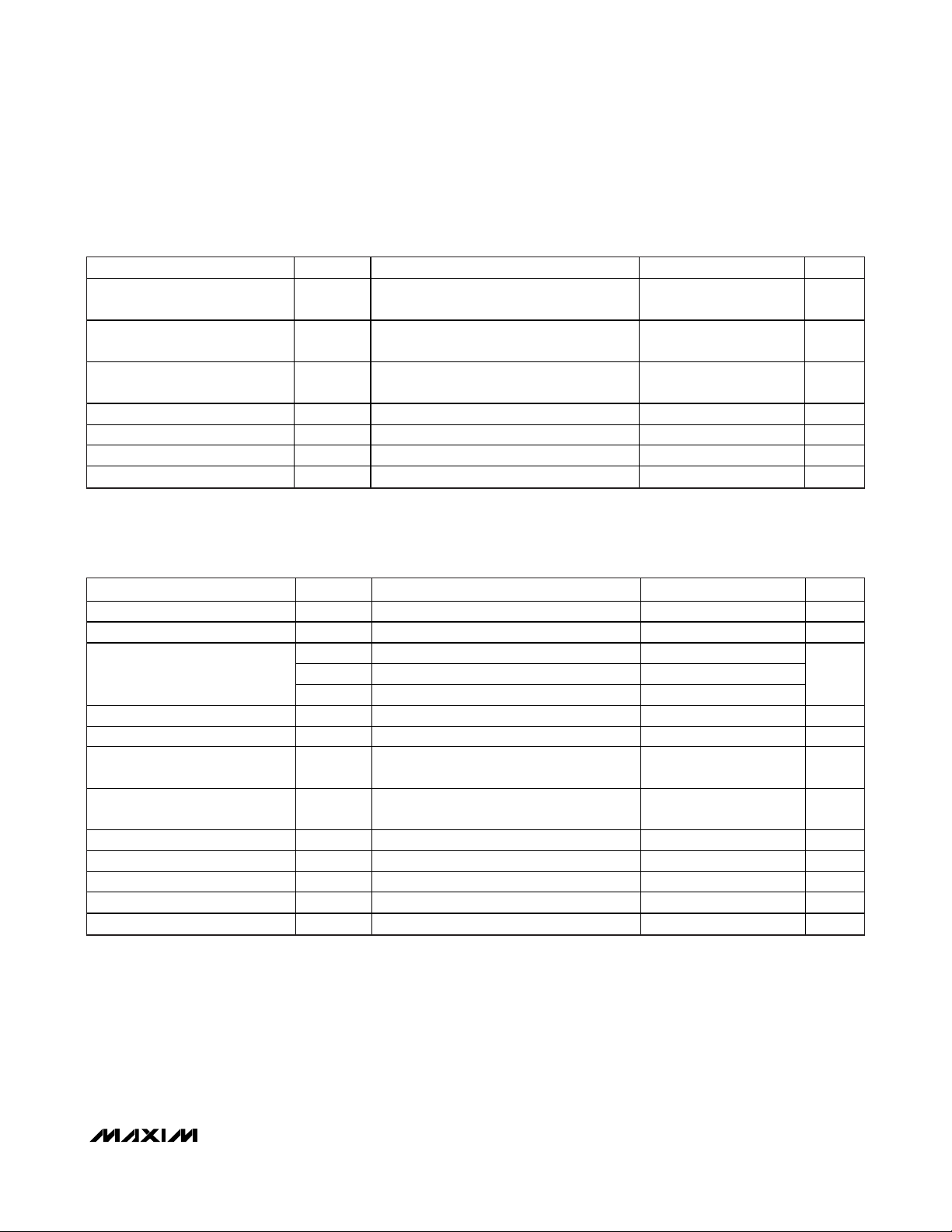

Detailed Description

Charge Algorithm Overview

The DS2710 controls switch-mode topology charging of

a single NiMH cell from a voltage-regulated charge

source. The IC is reset in one of two ways: with the

application of power to the DS2710 or after exiting

SUSPEND state. Once one of these conditions occurs,

the DS2710 enters the PRESENCE state and waits for a

cell to be inserted before starting a charge cycle.

Once a cell is detected, the DS2710 enters PRECHARGE

state and begins qualification to prevent fast charging

of deeply depleted cells or charging under extreme

temperature conditions. Precharging is performed at a

reduced rate until the cell reaches 1V. The algorithm

then proceeds to the FAST-CHARGE state, which

includes cell tests to avoid accidental charging of alkaline cells or NiMH cells that are worn out or damaged.

Fast charging continues as long as all the cell qualification criteria are met. Fast charging terminates by the

-ΔV (negative delta voltage) method. The TOP-OFF

charge phase follows to completely charge the cell.

After the TOP-OFF charge timer expires, the DS2710

enters the MAINTENANCE state to indefinitely keep the

cell at a full state of charge. Maximum voltage, temperature, and charge-time monitoring during all charge

phases act as secondary or safety termination methods

to provide additional protection from overcharge. Any

error condition occurring during charge forces the

DS2710 into the FAULT state and charging terminates.

Charging can be halted at any time by floating the TMR

pin, which forces the DS2710 into SUSPEND state.

Once a charge is complete either normally or by

FAULT, the DS2710 remains in the final state (MAINTENANCE or FAULT) until the cell is removed, the IC is

power cycled, or the IC is forced into SUSPEND state.

Afterwards, the DS2710 returns to PRESENCE state

and the charge cycle begins again.

An internal oscillator provides the main clock source

used to generate timing signals for chip operation. The

PRECHARGE timer, hold-off timers, and timing for CS

operation and cell testing are derived from this time

base. If the internal clock should ever fail, a watchdogdetection circuit halts charging. The watchdog-safety

circuit and charge timer set by the TMR pin are derived

from oscillators other than the main clock source. Figure

1 is the DS2710 block diagram and Figure 2 is the state

diagram.

POWER-ON RESET (POR)

The UVLO circuit serves as a power-up and brownout

detector by monitoring VDDto prevent charging until

V

DD

rises above V

UVLO

, or when VDDdrops below

V

UVLO

- V

UHYS

. If undervoltage lockout is active,

charging is prevented, the state machine is forced to

the POR state, and all charge timers are reset.

PRESENCE

The DS2710 enters the PRESENCE state whenever the

TMR pin is not floating and VDD> V

UVLO

, indicating

that the charge source is present. The DS2710 remains

in the PRESENCE state until a cell is inserted into the

circuit, causing the voltage of VP1 - VN1 to fall below

1.65V (V

MAX-OPEN

) and the cell temperature is inside a

valid charging range between 0°C and +45°C

(T

THM-MIN

and T

THM-MAX

when used with recommended thermistor and resistor values). If both these conditions are met, the DS2710 enters PRECHARGE. If a cell

is inserted but the temperature is outside the valid

charging range, the DS2710 remains in the PRESENCE

state until the cell temperature falls within the valid

charging range.

PRECHARGE

The DS2710 enters the PRECHARGE state when a valid

cell voltage is detected and the cell temperature as

measured by the DS2710 thermistor circuit is within the

valid charging range. The DS2710 precharges the cell

by regulating the voltage drop across the sense resistor to 113mV with a 25% duty cycle. The STATUS output toggles at 1Hz to indicate the cell is being

precharged. Precharging lasts until the measured cell

voltage exceeds 1.0V (V

LOW

), at which time the

DS2710 enters the FAST-CHARGE state. If the cell voltage does not exceed V

LOW

within 30min (t

PCHG

) or if

the cell temperature exceeds +50°C (T

THM-STOP

) at

any time during PRECHARGE, the DS2710 enters the

FAULT state. If at any time during PRECHARGE the cell

voltage exceeds 1.75V (V

MAX-CHARGE

), the DS2710

determines that the cell has been removed and enters

the FAULT state.

FAST-CHARGE

In the FAST-CHARGE state, the DS2710 regulates the

average voltage across the sense resistor to 113mV.

The STATUS output is held high to indicate the cell

pack is being charged. During FAST-CHARGE, the

DS2710 performs a cell test every 31s. The CELL TEST

state is responsible for determining when charge is

complete. As secondary overcharge protection, the

DS2710 terminates FAST-CHARGE and enters TOPOFF based on a time delay set by the external resistor

on the TMR pin. This resistor value can set the secondary charge termination delay to anywhere from

30min up to 5hr. If the cell temperature exceeds +50°C

at any time during FAST-CHARGE, the DS2710 enters

DS2710

Single-Cell NiMH Charger

_______________________________________________________________________________________ 5

Page 6

DS2710

Single-Cell NiMH Charger

6 _______________________________________________________________________________________

Figure 2. State Diagram

> R

R

TMR

SUSPEND

CS = INACTIVE

> 1.0V

V

CELL

t < t

T < +50°C

POR

PRECHARGE

CS = ACTIVE 25% DF

STATUS = 1Hz TOGGLE

AND

PCHG

AND

PASS

31s INTERVAL

(ASYNCHRONOUSLY FROM ANYWHERE)

(ASYNCHRONOUSLY FROM ANYWHERE)

< V

V

- V

DD

UVLO

UHYS

t < t

PCHG

AND

< 1.0V

V

CELL

SUSPEND

CS = INACTIVE

STATUS = LOW

VDD > V

UVLO

V

CELL TEST

CS = INACTIVE

STATUS = HIGH

(3.5V)

V

CELL

t > t

T > +50°C

CELL

< V

MAX-OPEN

PCHG

OR

OR

> V

*

MAX

FAIL: V

OR ΔV > CTEST

R

< R

TMR

CELL

SUSPEND

PRESENCE

CS = INACTIVE

STATUS = LOW

STATUS = 4Hz TOGGLE

> V

MAX-OPEN

> 1.75V

V

CELL

FAULT

CS = INACTIVE

V

> V

CELL

MAX

*

> 1.75V

V

CELL

OR

T < 0°C

OR

T > +45°C

FAST-CHARGE

t < FAST TIMEOUT

CS = ACTIVE

STATUS = HIGH

t > FAST TIMEOUT

-ΔV DETECT

OR

T > +50°C

FLAT VOLTAGE DETECT

MAINTENANCE

CS = ACTIVE 1.56% DF

STATUS = LOW

t < TOP-OFF TIMEOUT

REPRESENTS V

*V

MAX

MAX-CHARGE

TOP-OFF

CS = ACTIVE 25% DF

STATUS = HIGH

WHEN THE CS OUTPUT IS ACTIVE AND V

T > +50°C

OR

t > TOP-OFF TIMEOUT

WHEN THE CS OUTPUT IS INACTIVE.

MAX-OPEN

V

> V

MAX

*

CELL

Page 7

the MAINTENANCE state. If at any time during FASTCHARGE the cell voltage exceeds V

MAX-CHARGE

, the

DS2710 determines that the cell is either overcharged

or has been removed, and enters the FAULT state.

CELL TEST

CELL TEST is performed once every 31s during FASTCHARGE to determine if charging is complete. During

CELL TEST, the CS output is held high to prevent

charging. The cell’s voltage is measured and compared against prior readings. The maximum cell voltage measurement during the charge is retained. If a

cell’s voltage falls more than 2mV (V

-ΔV

) from its peak

reading, the FAST-CHARGE terminates successfully

and moves to TOP-OFF. The DS2710 also moves to

TOP-OFF if the cell’s voltage reading does not exceed

the maximum over a 16min period (t

FLAT

). A hold-off

period for -ΔV and flat voltage detection begins at the

start of fast charging and prevents false termination in

the first 4min of the charge cycle (t

THO

).

The impedance of the cell is also measured during

CELL TEST. The cell’s open-circuit voltage is compared

against the voltage of the cell under charge. The difference is compared against the impedance threshold set

by the CTEST pin. If the difference exceeds the threshold set by CTEST, the cell’s impedance is considered

to be too high for charging and the DS2710 enters the

FAULT state. The DS2710 also enters FAULT state if

any voltage reading in CELL TEST exceeds the

V

MAX-OPEN

threshold.

TOP-OFF

In the TOP-OFF state, the DS2710 charges at 25% the

rate of FAST-CHARGE. The voltage across the sense

resistor is regulated to 113mV with a 25% duty cycle.

The STATUS output is held high to indicate the cell

pack is being charged. The charge timer is reset and

restarted with a timeout period of one-half the

FAST-CHARGE duration. When the charge timer

expires or if the measured temperature exceeds

+50°C, the charger enters the MAINTENANCE state. If

the cell voltage is greater than V

MAX-CHARGE

during

the 25% of time when charge current is applied or

V

MAX-OPEN

during the remaining time, TOP-OFF is exit-

ed early and the DS2710 goes to FAULT.

MAINTENANCE

The DS2710 enters the MAINTENANCE state whenever

the charge completes normally or if the measured cell

temperature exceeds +50°C during the charge. The

STATUS pin is driven low to indicate TOP-OFF has

completed. The cell’s state of charge is maintained

indefinitely by continuing a 1.56% duty-cycle charge of

the cell. The DS2710 remains in the MAINTENANCE

state until the cell is removed, the DS2710 is power

cycled, or the DS2710 is forced into SUSPEND state.

FAULT

The DS2710 can enter FAULT from any charge state if

the cell voltage exceeds V

MAX-CHARGE

any time when

charge current is applied (CS low) or V

MAX-OPEN

at any

time when no charge current is flowing (CS high). In

addition, FAULT can be entered during PRECHARGE if

the cell’s temperature exceeds +50°C or the

PRECHARGE timer expires, or during FAST-CHARGE if

impedance threshold is exceeded. In the FAULT state,

CS is forced high to prevent charging and the STATUS

output toggles at a 4Hz rate to indicate that an error

has occurred. The DS2710 remains in FAULT until a

cell voltage greater than 1.75V (V

MAX-CHARGE

) is

detected, indicating that the cell has been removed.

The DS2710 then enters the PRESENCE state and waits

for the next cell insertion.

SUSPEND

Suspension of charge activity is possible by floating the

TMR pin (R

TMR

> R

SUSPEND

). The CS output is pulled

to VDDto disable the charge control FET to prevent current flow to the cell. When the TMR connection is

restored, charging begins from the PRESENCE state

with all timers reset. The SUSPEND state is useful as a

means to stop charging by the application circuit, such

as with a microcontroller signal.

DS2710

Single-Cell NiMH Charger

_______________________________________________________________________________________ 7

Page 8

DS2710

Charge-Current Regulation

The DS2710 regulates charge current by maintaining a

constant average voltage across an external sense

resistor connected between the VN1 and VN0 pins.

VN1 and VN0 drive an internal comparator in the

DS2710 to switch the CS output ON and OFF to drive a

regulating pnp bipolar or a pMOS transistor. Hysteresis

on the comparator input provides noise rejection. The

DS2710 regulates the charge current during FASTCHARGE to maintain a voltage drop across the sense

resistor as follows:

V

SENSE

= V

IREF

- 0.5 x V

HYS-COMP

= 0.113V (typ)

Figure 3 shows the sense resistor voltage and CS pin

voltage of the regulating circuit during normal operation.

Charging with Load Applied

NiMH cells have a low, but finite, impedance. If load

current is flowing out of the battery, an internal voltage

drop appears at the battery terminals. This can interfere

with the CTEST and -ΔV detection. If the load current is

variable, early termination is more likely than if the load

current is constant. If the load’s ground is connected to

the negative terminal of the cell (VN0), load current

flows through the current-sense resistor, resulting in less

charge current to the battery. The load-current return

path should be to charger ground to reduce the likelihood of false termination or impedance-test errors.

Charging with load applied is not recommended.

Temperature Monitoring

Accurate temperature sensing is needed to detect temperature FAULT conditions. Connecting an external

10kΩ NTC thermistor between THM and VSSand a

10kΩ bias resistor between VDDand THM allows the

DS2710 to sense temperature. To accurately monitor

the cell, the thermistor should make physical contact

either to the cell or cell tabs. Table 1 shows several recommended 10kΩ thermistors.

MIN, MAX Temperature Compare

The voltage thresholds of the THM input (V

THM-MIN

,

V

THM-MAX

) are set to allow charging to start if the thermistor temperature is between 0°C and +45°C when

using the recommended 10kΩ bias resistor and 10kΩ

thermistor circuit. If precharging is in progress and the

voltage on THM reaches V

THM-STOP

, precharging

stops and a FAULT condition is generated. If the voltage on THM reaches V

THM-STOP

during FASTCHARGE or TOP-OFF, charging stops and the DS2710

enters the MAINTENANCE state. FAST-CHARGE and

Single-Cell NiMH Charger

8 _______________________________________________________________________________________

Figure 3. Ideal Comparator Input and Charge Control Output

Waveforms

Figure 4. Ratio of THM Pin to VDDPin Over Temperature

Table 1. THM Thresholds

THM THRESHOLD RATIO OF V

MIN 0.73 27.04 0 +4

MAX 0.33 4.925 +45 +42

STOP 0.29 4.085 +50 +47

NOT DRAWN TO SCALE

V

CS

V

SENSE

TIME

CBIAS

V

V

V

V

V

OH1

OL1

IREF

SENSE

IREF

(DC)

- V

HYS-COMP

THERMISTOR

RESISTANCE

(k)

TEMPERATURE (°C)

Fenwal

Semitec 103AT-2

0.75

0.70

0.65

0.60

0.55

0.50

0.45

VOLTAGE RATIO

0.40

0.35

0.30

0 1020304050

DIVIDER OUTPUT

TEMPERATURE (°C)

197-103LAG-A01,

173-103LAF-301

Page 9

TOP-OFF complete normally if the cell temperature

remains below this threshold.

Used with a 10kΩ resistor, the Semitec 103AT-2 provides approximately 0.9% full scale-per-degree sensitivity. Figure 4 shows this linearity curve. The left axis is

the ratio of the sensed voltage to the divider’s input

voltage (VDD).

Charge-Status Output

The DS2710 indicates the state of charge and the

charge results on the STATUS output pin. When no cell

is present, the output is driven to a logic-low. Any LED

attached to the STATUS pin is off. When a cell is inserted, STATUS oscillates in a 1Hz, 50% duty-cycle pattern

to indicate the cell is precharging. Once the DS2710

transitions to FAST-CHARGE, the STATUS output goes

to logic-high and stays high until the end of TOP-OFF.

STATUS returns to logic-low for MAINTENANCE charge

and remains at logic-low until the cell is removed or the

DS2710 is power cycled. If a FAULT occurs during

charging, STATUS toggles at a fast 4Hz, 50% dutycycle rate until the cell is removed. Table 2 summarizes

the STATUS output and LED operation for each charge

condition.

Charge-Rate Selection

The charge rate is determined by an external sense

resistor connected between the VN1 and VN0 pins. The

DS2710 regulates the charge current to maintain a voltage drop of V

IREF

- 0.5 x V

HYS-COMP

across the sense

resistor during FAST-CHARGE:

V

SENSE

= V

IREF

- 0.5 x V

HYS-COMP

= 0.113V (typ)

The sense resistor can therefore be selected by:

R

SENSE

= 0.113V/Desired FAST-CHARGE Current

The effective FAST-CHARGE rate is equal to 0.969 times

the regulated current limit, TOP-OFF rate is 0.25 times

the regulated current, and MAINTENANCE charge rate

is 0.0156 times the regulated current. Table 3 shows

the charge rates for charging three different cell capacities using a 565mA (0.200Ω sense) current source and

a 1130mA (0.100Ω sense) current source.

DS2710

Single-Cell NiMH Charger

_______________________________________________________________________________________ 9

Table 2. LED Display Patterns Based on Charge State

Table 3. Charge-Rate Examples

CHARGE STATE

NO BATTERY PRECHARGE

STATUS PIN Logic- low

STATUS PIN LED Off 1Hz toggle On Off 4Hz toggle

Oscillates at 1Hz,

50% duty cyc le

FAST-CHARGE/

TOP -OFF

Logic-high Logic-low

MAINTENANCE FAULT

Oscillates at 4Hz,

50% duty cyc le

565mA CHARGE RATE (0.200)

STATE

900mAH 1700mAH 2200mAH 900mAH 1700mAH 2200mAH

FAST-CHARGE C/1.64 C/3.10 C/4.00 C/0.82 C/1.55 C/2.0

PRECHARGE/TOP-OFF C/6.37 C/12.0 C/15.5 C/3.19 C/6.0 C/7.75

MAINTENANCE C/102 C/193 C/249 C/51 C/96 C/125

AT CELL CAPACITY

1130mA CHARGE RATE (0.100)

AT CELL CAPACITY

Page 10

DS2710

Timeout Selection

FAST-CHARGE state normally operates until -ΔV termination. In the event that termination does not occur correctly, a safety timeout is required. This timeout is set

by an external resistor on the TMR pin to VSSand provides secondary protection against significant overcharging. The value of the TMR resistor should be

chosen so that the timeout is greater than the FASTCHARGE time expected in the application, but not so

much greater that its protection is compromised. If the

timer expires during FAST-CHARGE, the timer count is

reset and charging proceeds to the TOP-OFF charge

state. The TMR resistor also sets the timed charge

duration of TOP-OFF state. The TOP-OFF timeout period is fixed at half the FAST-CHARGE timeout period.

When the timer expires in TOP-OFF, the DS2710 enters

the MAINTENANCE state.

Resistors can be selected to support FAST-CHARGE

timeout periods of 0.5hr to 5hr and TOP-OFF timeout

periods of 0.25hr to 2.5hr. The programmed FASTCHARGE time approximately follows the equation:

t(minutes) = 1.5 x R

TMR

(Ω)/1000

Impedance-Test Threshold

Selection

The DS2710 tests the cell impedance every 31s while

in FAST-CHARGE state. Impedance is measured by

comparing the cell voltage during normal charging to

the cell voltage with no charge current (CS output held

high). The resulting voltage difference is compared

against the threshold set by an external resistor from

CTEST to VSS. The detection threshold can be set from

32mV to 400mV. The following formula approximates

the setting for the detection threshold:

V

TEST

= 8000/R

CTEST

(Value in Volts)

Since the charge rate is controlled by the external

sense resistor (R

SENSE

) between VN1 and VN0, the test

threshold can be expressed as impedance as follows:

Impedance Threshold =

( 8000/R

CTEST

)/( 0.113/R

SENSE

) =

70796 x ( R

SENSE/RCTEST

)

For example, an application charging at 1.13A (R

SENSE

= 0.100Ω) would use a 47kΩ resistor on the CTEST pin

to set the impedance threshold to 0.150Ω.

Application Circuit

Figure 5 shows a typical DS2710 application circuit for

charging a NiMH cell from a USB port or other 5V

charge source capable of supplying 0.5A. Q1, L1, C2,

and D2 form a switching buck-regulator circuit controlled by the CS pin of the DS2710. Current is regulated through the current-sense resistor, R9, by switching

Q1 on and off as the sense resistor voltage ramps up

and down toward the preset sense voltage thresholds.

The 0.100Ω sense resistor along with the DC groundreferenced sense threshold level of V

IREF

- 1/2 V

HYS-

COMP

sets the average charge current in the example

to 1.13A. The sense resistor should have a proper

power rating for the chosen charge current.

The TMR resistor is set to 100kΩ for a timeout of 2.5hr.

This is appropriate for cells with a capacity of approximately 2200mAh when charged with the 1.13A charge

current. The CTEST resistor is set to 47kΩ for an impedance-test threshold of approximately 0.150Ω when

charging at 1.13A. Additionally, R6 protects the VP1 pin

from any stress applied to the exposed tabs of a loose

NiMH cell; R3 creates a weak pullup to offset the leakage through D2, which might otherwise cause a false

cell detection; and R1/C1 creates a bypass filter on the

V

DD

pin of the IC.

The value of L1 in Figure 5 represents a moderate

switching speed of ~ 200kHz for FAST-CHARGE state.

L1 can be adjusted to fit specific application goals as

long as the associated change in switching speed

does not exceed the circuit’s ability to maintain proper

regulation of the sense-resistor voltage. All capacitors

should be ceramic surface-mount types of good quality

where possible. The 10µF capacitor can be of any type

that meets the application requirements. All resistors

not previously mentioned are standard surface-mount

types.

Application PCB Layout

Proper layout rules must be followed to ensure a successful application circuit. For all modes of operation,

currents in excess of 1A can flow through the charge

and discharge paths (USB charging is specification limited to 500mA). All these paths should be properly sized

to handle the worst-case current flow, whether from

charging or from powering the load with the battery.

Switch-mode operation presents challenges with fast

voltage and current transients. Proper switch-mode

buck power-supply layout should always be observed.

Single-Cell NiMH Charger

10 ______________________________________________________________________________________

Page 11

DS2710

Single-Cell NiMH Charger

______________________________________________________________________________________ 11

Figure 5. Typical Application Circuit for USB Port Charging

Referring to the example circuit and layout of Figure 6,

the loop labeled as Loop1 encompassing CIN,

Q

SWITCH

, and D

SWITCH

should be kept as small as

possible to minimize the change in loop area that

occurs when switching from the OFF to the ON state

and vice versa. Loop2 should also be minimized as

much as practical, although it contains DC current

components for the most part. The returning ground

currents should be allowed to follow a path on a layer

directly under the outgoing path since the high-frequency components try to follow the path of least

impedance. Low ESR and ESL capacitors should be

used when possible and for all capacitors 10µF and

smaller. Typical surface-mount ceramic types with an

X5R or better dielectric are recommended.

Another important layout detail is the connection of the

sense resistor. Proper Kelvin connection layout should

be used to ensure the signal quality viewed by the

sensing circuit inside the DS2710 is adequate. Figure 7

shows a recommended connection of the sense lines to

the resistor footprint.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

10 TDFN-EP —

56-G0012-001

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

.

R3

270kΩ

+5V

(USB+)

GROUND

(USB-)

1μF

Q1

ZXM62P02E6

R1

150Ω

R4

10kΩ

C1

RT1

103AT-2

10μF

CERAMIC

1kΩ

C2

CS

V

DD

THM

STATUS

R2

TMR CTEST V

D1

GREEN

SMA

R7

100kΩ

L1

15μH

SISCDRH74M-150R

D2

1W B340A-13

SCHOTTKY

DS2710

R8

47kΩ

C3

10μF

CERAMIC

R6

1kΩ

VP1

1S

NiMH

CELL

VN1

R9

0.1Ω

1W

VN0

SS

Page 12

DS2710

Single-Cell NiMH Charger

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Figure 6. Switching Circuit with Example Layout

Figure 7. Sense Resistor Connection Layout

R

GATE

Q

SWITCH

CHARGE SOURCE SIDE

C

IN

LOOP1 LOOP2

CONTROL

D

SWITCH

LOOP AREAS MINIMIZED

L

SWITCH

C

OUT

BATTERY SIDE

CHARGE SOURCE SIDE

CONTROL

C

I

R

G

SENSE TRACES RUN CLOSE

SENSE+ SENSE-

R

SNS

CHARGE SOURCE- CHARGE SOURCE-

BATTERY- BATTERY-

TOGETHER TO MINIMIZE LOOP

Q

S

INDUCTANCE

D

S

L

S

SENSE+

C

O

SENSE-

R

SNS

BATTERY SIDE

BACKSIDE

GROUND PLANE

PROPER KELVIN CONNECTION

AT SENSE RESISTOR

Loading...

Loading...