Page 1

www.maxim-ic.com

GENERAL DESCRIPTION

The DS25LV02 provides data storage and serial

number identification for battery packs. The lowvoltage Dallas 1-WireÒ interface enables serial

communication on a single battery contact and the

64-bit unique serial number allows multidrop

networking and identification of individual devices.

The 1024-bit EPROM memory is organized as 4

pages of 32 bytes each and supports storage of

battery cell characteristics, charging voltage, current

and temperature parameters, as well as battery pack

manufacturing data. CRC verification provides data

integrity during communication. The EPROM pages

are in-circuit writable and can be individually locked

to protect data. The DS25LV02 is designed to be

completely backward-compatible with the DS2502 for

existing designs.

APPLICATIONS

Cell Phones/Smartphones

Digital Cameras

MP3 Players

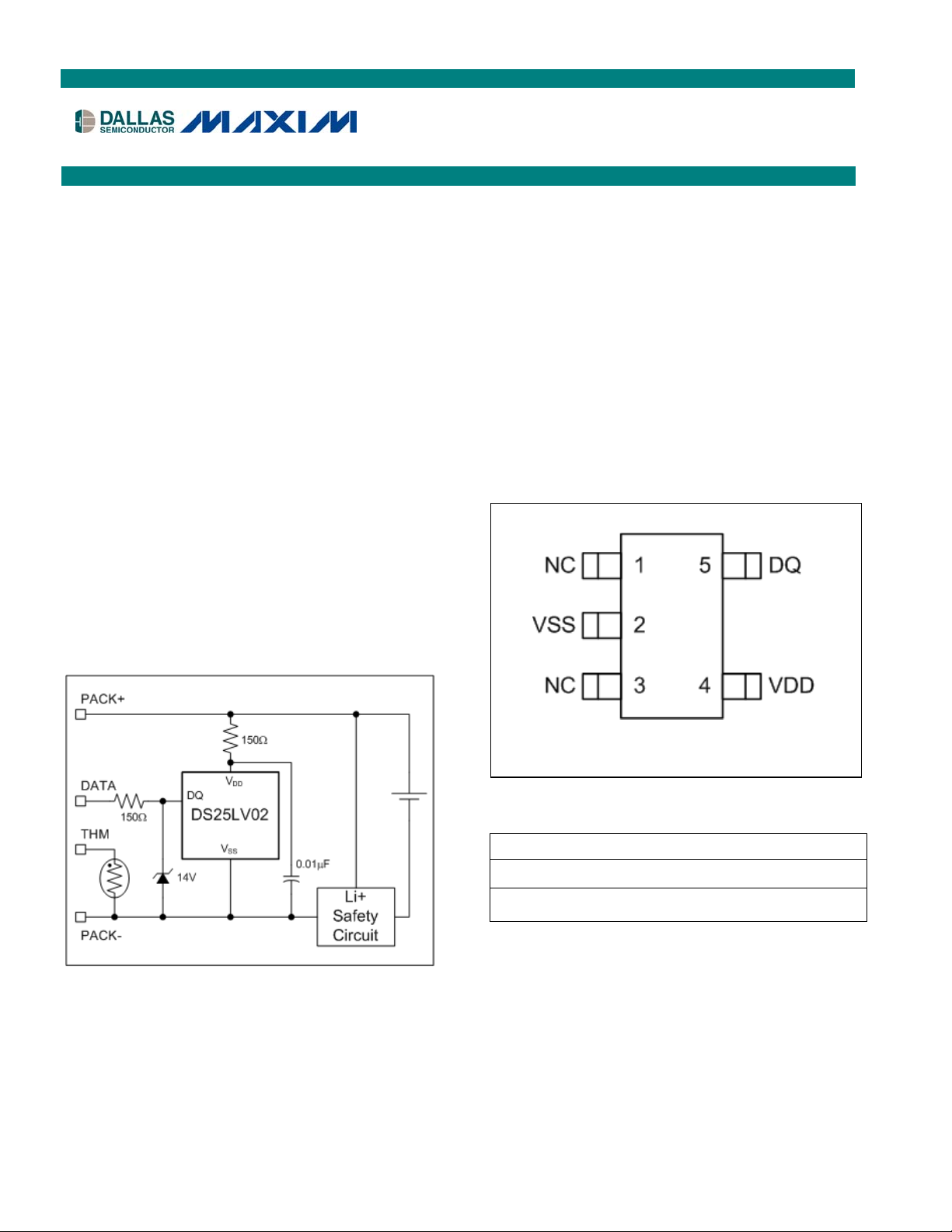

TYPICAL APPLICATION CIRCUIT

DS25LV02

Low-Voltage 1024-Bit EPROM

FEATURES

§ 128 Bytes of EPROM Storage Organized into

Four Separately Lockable Pages

§ Backward-Compatible with DS2502

§ Dallas 1-Wire Interface

§ Input Logic Thresholds Compatible with 1.8V

I/O Supply Rail

§ Unique 64-Bit Serial Number

§ Operates with V

§ Tiny, Thin SOT-23 Package

PIN CONFIGURATION

TOP VIEW

as Low as 2.2V

DD

5-Pin Thin-SOT (TSOT)

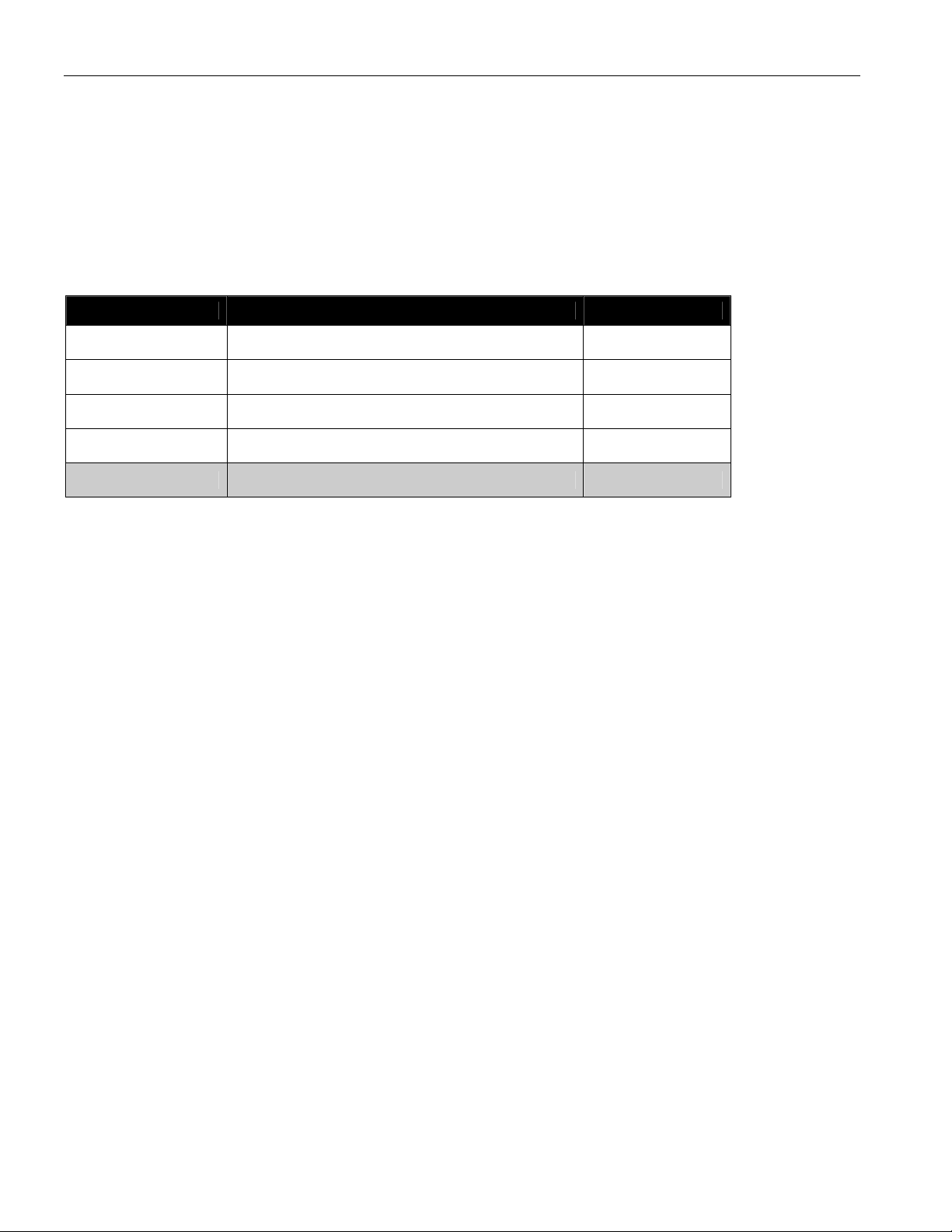

ORDERING INFORMATION

PART TEMP RANGE PIN-PACKAGE

DS25LV02R+U

DS25LV02R+T&

R

+Denotes lead-free package.

1-Wire is a registered trademark of Dallas Semiconductor.

Certain commands, modes, and registers are capitalized for

clarity.

-30°C to +85°C

-30°C to +85°C

5 Thin SOT

5 Thin SOT in

Tape-and-Reel

1 of 17 051106

Page 2

DS25LV02: Low-Voltage 1024-Bit EPROM

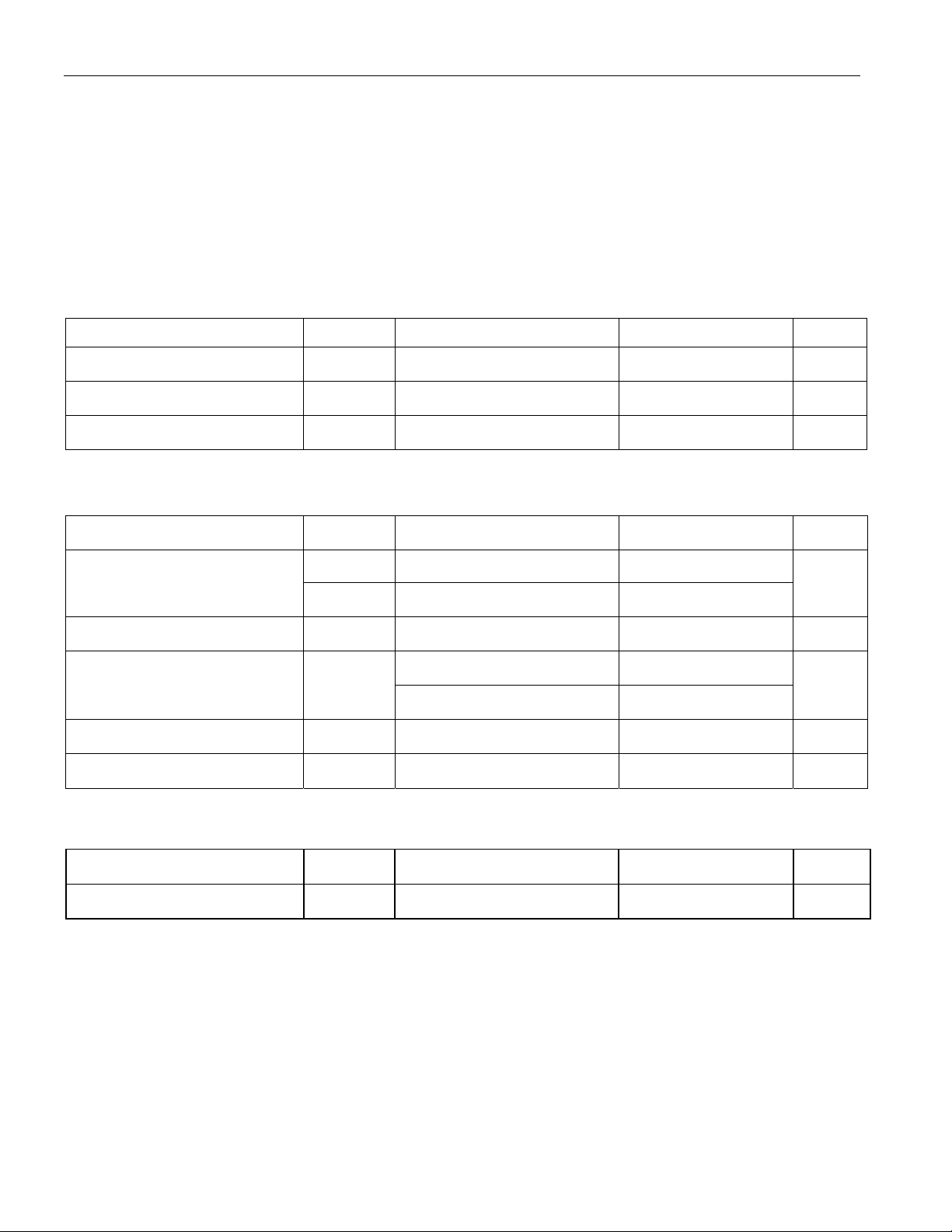

ABSOLUTE MAXIMUM RATINGS

Voltage Range on DQ, Relative to VSS -0.3V to +12V

Voltage Range on V

, Relative to VSS -0.3V to +6V

DD

Operating Temperature Range -30°C to +85°C

Storage Temperature Range -55°C to +125°C

Soldering Temperature See IPC/JEDEC J-STD-020A Specification

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is

not implied. Exposure to the absolute maximum rating conditions for extended periods may affect device.

RECOMMENDED DC OPERATING CONDITIONS

(2.2V £ VDD £ 5.5V, TA = -30°C to +85°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VDD (Notes 1, 2) 2.2 5.5 V

Data Pin Communication Voltage VDQ (Note 1) -0.3 +5.5 V

Data Pin Programming Voltage VPP (Notes 1, 2, 5) 11.5 12.0 V

DC ELECTRICAL CHARACTERISTICS

(2.2V £ VDD £ 5.5V, TA = -30°C to +85°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I

DQ Idle (Note 4) 0.8 2

Supply Current

DD0

I

Communication mode, DQ active 300

DD1

mA

Input-Logic High: DQ VIH (Note 1) 1.5 V

VDD ≥ 2.5V 0.6

Input-Logic Low: DQ (Note 1) VIL

V

0.4

Output-Logic Low: DQ V

OL

Pulldown Current: DQ IPD 0.5

IOL = 4mA (Note 1) 0.4 V

mA

EPROM RELIABILITY SPECIFICATION

(2.2V £ VDD £ 5.5V, TA = -30°C to +85°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Storage t

(Notes 2, 3) 10 Years

EES

2 of 17

Page 3

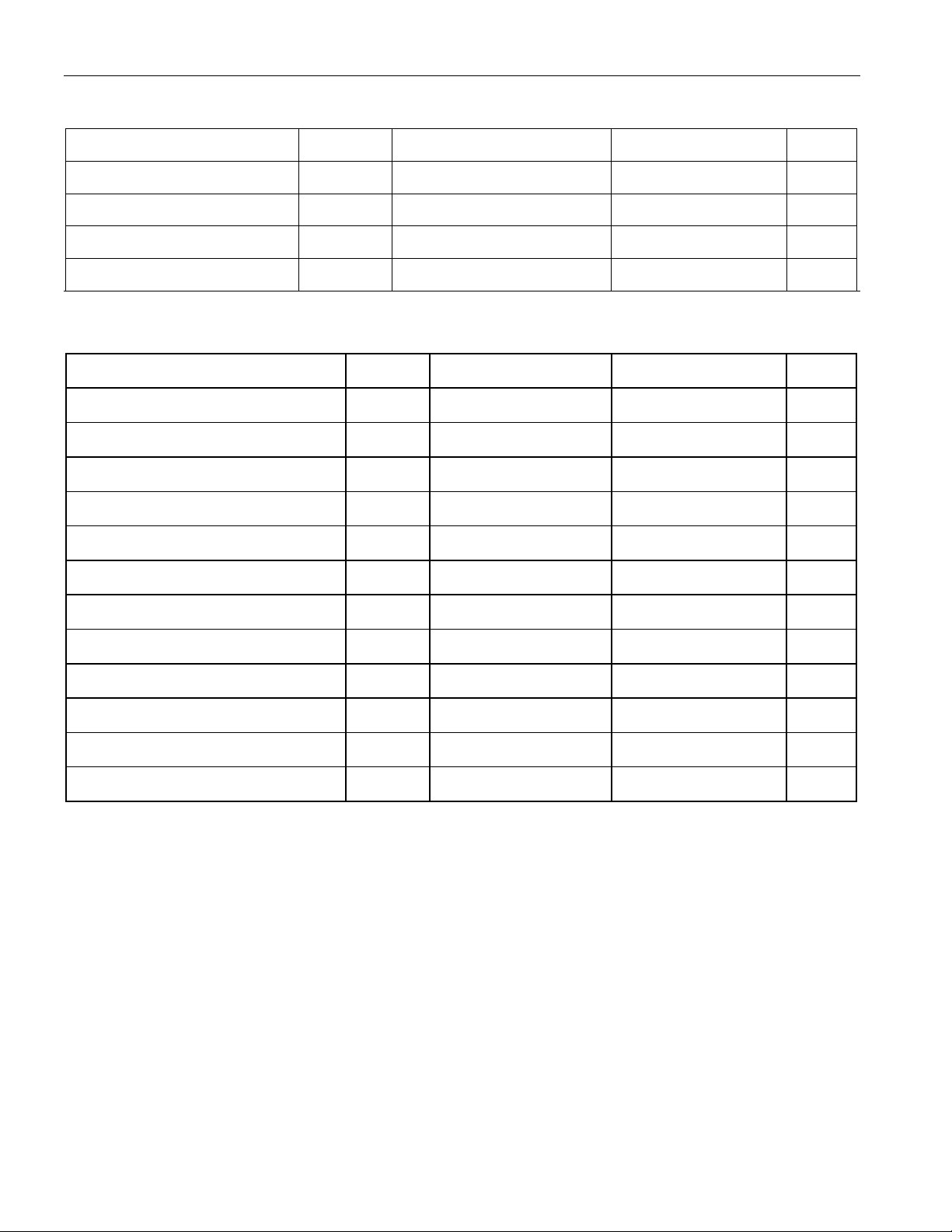

DS25LV02: Low-Voltage 1024-Bit EPROM

AC ELECTRICAL CHARACTERISTICS: EPROM PROGRAMMING

(3.0V £ VDD £ 5.5V, TA = -30°C to +50°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Programming Pulse Width t

Program Voltage Rise Time t

PP

RP

(Notes 1, 2, 5, 6) 480 5000

(Notes 1, 2, 5) 0.5 5.0

Program Voltage Fall Time tFP (Notes 1, 2, 5) 0.5 5.0

Programming Current: DQ Pin I

PP

(Notes 2, 5, 7) 6 10 mA

AC ELECTRICAL CHARACTERISTICS: 1-Wire INTERFACE

(2.2V £ VDD £ 5.5V, TA = -30°C to +85°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Time Slot t

Recovery Time t

Write-0 Low Time t

Write-1 Low Time t

Read-Data Valid t

Reset-Time High t

Reset-Time Low t

60 120

SLOT

1

REC

60 120

LOW0

1 15

LOW1

15

RDV

480

RSTH

480 960

RSTL

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

Presence-Detect High t

Presence-Detect Low t

Delay to Program Pulse tDP 5

Delay to Verify tDV 5

15 60

PDH

60 240

PDL

ms

ms

ms

ms

DQ Capacitance CDQ 50 pF

Note 1:

Note 2:

Note 3:

Note 4:

Note 5:

Note 6:

Note 7:

All voltages are referenced to V

Programming of the EPROM Data and EPROM Status fields require a limited temperature range of 0°C to 50°C and limited V

voltage range of 3.0V to 5.5V.

Storage for t

DQ < V

Programming pulse on DQ pin must be shaped to conform with rise, fall, and width timing specifications. See Figure 7. EPROM

Programming Diagram).

The accumulative duration of all programming pulses for each address must not exceed 5ms.

Specification is guaranteed by design.

at +50°C.

EES

for t > 1.5ms or DQ > VIH for t > 1.5ms [1-Wire oscillator shut down].

IL

.

SS

DD

3 of 17

Page 4

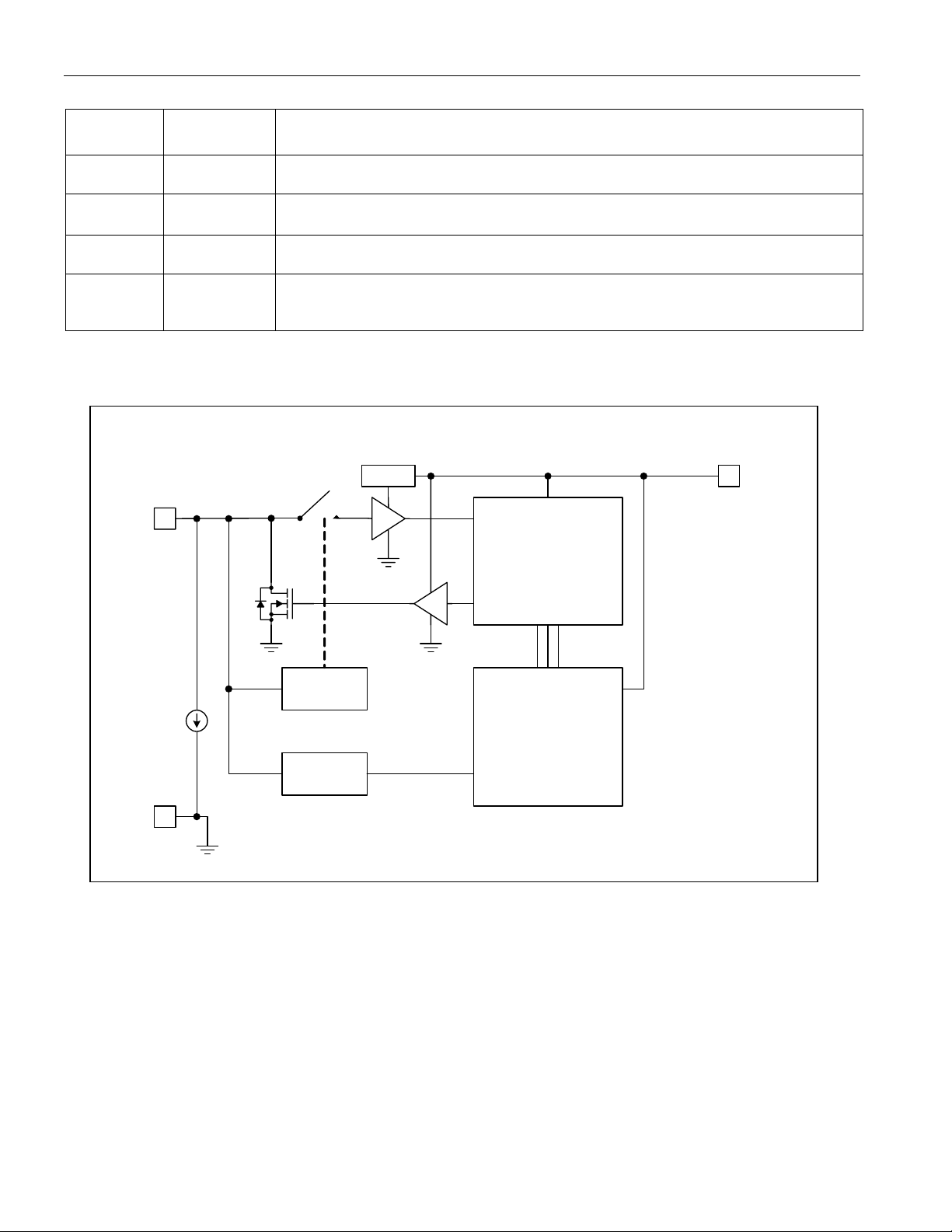

DS25LV02: Low-Voltage 1024-Bit EPROM

PIN DESCRIPTION

PIN NAME FUNCTION

1, 3 N.C. No Connection

2

V

SS

Supply GND and Reference for Serial Communication. Attach

terminal.

V

to battery-pack negative

SS

4

5 DQ

V

DD

Figure 1. Block Diagram

DQ

HV

0.5mA

Supply Input. Bypass to VSS with 0.01mF (typ).

Serial Interface Data I/O Pin. Bidirectional data transmit and receive at 16kbps. Input for

programming voltage pulse during EPROM programming. Internal 0.5mA pulldown ensures

idle mode is entered when no DQ pullup is present.

VDD

HV Detect

Reg.

Vdd_int

DIN

1-Wire I/F

and

Control

DOUT

EPROM Array

HV Shaper

Vpp

VSS

DETAILED DESCRIPTION

The DS25LV02 provides battery-pack identification and data storage. A 128-byte EPROM memory array and an 8

byte status field accessed by a low-voltage 1-Wire interface. Each DS25LV02 has a unique 64-bit Net Address

(ROM ID) for identification.

The EPROM is divided into four 32-byte pages. An additional 8-byte status field provides lock bit and page

redirection information to the user. EPROM writing occurs one byte at a time by supplying a 12V pulse on the DQ

line in-between each byte written. Each page can be individually locked by clearing the appropriate bit in the Status

field. Data is read sequentially from a starting address through the end of the array. CRC verification provides

integrity of all read and written data.

Functional compatibility has been maintained between the DS2502 and DS25LV02 at the Net Address/ROM

Command and Function Command levels for reading and writing the Memory data and Status data fields.

4 of 17

Page 5

DS25LV02: Low-Voltage 1024-Bit EPROM

EPROM MEMORY DATA FIELD

The DS25LV02 has a linear address space for access to the EPROM data field. The EPROM data field is

organized as 4 pages of 32 bytes each as shown in Table 1. The Read Memory and Read Data/Generate CRC

Memory function commands provide read access to the 1024 bits of the EPROM data field. The Write Memory

function command provides write access to the EPROM data field. When received from the factory, the entire

1024-bit EPROM data field is erased and returns logical 1’s when read. Bits within the data field are one time

programmable. Programming changes the bit value to logical zero from the factory default erased value of a logical

1. Once a bit is programmed, it cannot be set back to a logical 1.

Table 1. EPROM Data Field

ADDRESS (HEX) DESCRIPTION READ/WRITE

0000–001F PAGE 0 (32 bytes) R/W*

0020–003F PAGE 1 (32 bytes) R/W*

0040–005F PAGE 2 (32 bytes) R/W*

0060–007F PAGE 3 (32 bytes) R/W*

0080–FFFF Reserved

* One-time write to “0” for each bit.

READ MEMORY [F0h]

The Read Memory command is used to read data from PAGE 0 to PAGE 3 of the 1024-bit EPROM data field. The

bus master follows the command byte with a 2-byte address (TA1 = (T7:T0), TA2 = (T15:T8)) that indicates a

starting byte location within the data field. An 8-bit CRC of the command byte and address bytes is computed by

the DS25LV02 and read back by the bus master to confirm that the correct command word and starting address

were received. If the CRC is deemed to be incorrect by the bus master, the bus master should issue a reset pulse

and repeat the entire sequence. If the CRC is deemed to be correct by the bus master, read time slots can be

issued to receive data from the EPROM data field starting at the initial address. The bus master can issue a reset

pulse at any point or continue to issue read time slots until the end of PAGE 3 of the data field is reached.

If reading continues through the end of PAGE 3, the bus master can issue eight additional read time slots and the

DS25LV02 will respond with a 8-bit CRC of all data bytes read from the initial starting byte through the last byte of

PAGE 3. Terminating the command transaction with a reset pulse prior to reaching the end of PAGE 3 results in a

loss of availability of the 8-bit CRC.

READ DATA/GENERATE 8-BIT CRC [C3h]

The Read Data/Generate 8-bit CRC command is used to read data from PAGE 0 to PAGE 3 of the 1024-bit

EPROM data field. The bus master follows the command byte with a 2-byte address

(TA1 = (T7:T0), TA2 = (T15:T8)) that indicates a starting byte location within the data field. An 8-bit CRC of the

command byte and address bytes is computed by the DS25LV02 and read back by the bus master to confirm that

the correct command word and starting address were received. If the CRC is deemed to be incorrect by the bus

master, the bus master should issue a reset pulse and repeat the entire sequence. If the CRC is deemed to be

correct by the bus master, read time slots can be issued to receive data from the EPROM data field starting at the

initial address. The bus master can issue a reset pulse at any point or continue to issue read time slots until the

end of the 32-byte page is reached. If reading occurs through the end of the 32-byte page, the bus master can

issue eight additional read time slots and the DS25LV02 will respond with an 8-bit CRC of all data bytes read from

the initial starting byte through the last byte of the current page. After the CRC is received, additional read time

slots return data starting with the first byte of the next page. This sequence will continue until the bus master reads

PAGE 3 and its accompanying CRC. Thus each page of data can be considered to be 33 bytes long: the 32 bytes

of user-programmed EPROM data and an 8-bit CRC that gets generated automatically at the end of each page.

The Read Data/Generate 8-Bit CRC command sequence can be exited at any point by issuing a reset pulse.

5 of 17

Page 6

DS25LV02: Low-Voltage 1024-Bit EPROM

WRITE MEMORY [0Fh]

The Write Memory command is used to program the 1024-bit EPROM data field. Programming is performed one or

more bytes at a time, with CRCs of the master-to-slave bit stream provided for data integrity. To begin a memory

write, the bus master issues the Write Memory function command followed by a 2-byte address argument

(TA1 = (T7:T0), TA2 = (T15:T8)) and a 1-byte data argument (D7:D0). The 2-byte address argument sets the

starting byte position in the EPROM data field of the first byte to be written. The data argument provides data for

the first byte to be written. The master must issue 8 read timeslots following the data argument.

An 8-bit CRC of the command byte, address bytes and data byte computed by the DS25LV02 is returned in the 8

timeslots to enable the master to check the integrity of the communication. If the CRC is deemed to be incorrect by

the bus master, the bus master should issue a reset pulse and repeat the entire sequence. If the CRC is deemed to

be correct by the bus master, a programming pulse can be issued to program the byte position within the EPROM

data field pointed to by T15:T0. Following the programming pulse, the bus master must issue 8 read timeslots. The

read timeslots return the EPROM data byte value (least significant bit first) for confirmation by the master.

The bus master can issue a reset pulse at any point after issuing the program pulse to end the write operation, or

continue the write operation with the next byte in the EPROM data field. If a the write operation is continued, the

DS25LV02 automatically increments the internal address pointer to select the next byte in the EPROM data field,

and the new value of T7:T0 is loaded into the 8-bit CRC generator as the starting value. The bus master issues the

next 1-byte data argument followed by 8 read timeslots to return the CRC computed by the DS25LV02. The value

returned is computed with D7:D0, using T7:T0 as the starting value. If the CRC is deemed to be incorrect by the

bus master, the bus master should issue a reset pulse and repeat the entire sequence. If the CRC is deemed to be

correct by the bus master, a programming pulse can be issued to program the byte position pointed to by T15:T0.

Following the programming pulse, the bus master must issue 8 read timeslots. The read timeslots return the

EPROM data byte value (least significant bit first) for confirmation by the master.

The write operation can be continued until the end of the EPROM data field is reached by repeating the sequence

of issuing a 1-byte data argument, 8 read timeslots to return CRC, a programming pulse, and 8 read timeslots to

return EPROM data.

EPROM STATUS

The DS25LV02 has a separate 8-byte linear address space for access to the EPROM STATUS data field using the

Read Status and Write Status function commands.

READ STATUS [AAh]

The Read Status command is used to read data from the EPROM Status data field. The bus master follows the

command byte with a 2-byte address (TA1 = (T7:T0), TA2 = (T15:T8)) that indicates a starting byte location within

the data field. An 8-bit CRC of the command byte and address bytes is computed by the DS25LV02 and read back

by the bus master to confirm that the correct command word and starting address were received. If the CRC is

deemed to be incorrect by the bus master, a reset pulse should be issued and the entire sequence repeated. If the

CRC is deemed to be correct by the bus master, read timeslots can be issued to receive data starting at the initial

address. The bus master can issue a reset pulse at any point or continue to issue read timeslots until the end of

the EPROM Status data field is reached. If reading occurs through the end of the EPROM Status data field, the bus

master can issue 8 additional read timeslots and the DS25LV02 will respond with a 8-bit CRC of all data bytes read

from the initial starting byte through the last byte. Additional read timeslots return logical 1s until the internal

address reaches a multiple of 128. Then data is returned from address 0000h. The Read Status command

sequence can be ended at any point by issuing a reset pulse.

WRITE STATUS [55h]

The Write Status command is used to program the EPROM status field. To begin a status field write, the bus

master issues the Write Status function command followed by a 2-byte address argument

(TA1 = (T7:T0), TA2 = (T15:T8)) and a 1-byte data argument (D7:D0). The 2-byte address argument sets the

starting byte position in the EPROM status field of the first byte to be written. The data argument provides data for

the first byte to be written. The master must issue 8 read timeslots following the data argument.

An 8-bit CRC of the command byte, address bytes, and data byte computed by the DS25LV02 is returned in the 8

timeslots to enable the master to check the integrity of the communication. If the CRC is deemed to be incorrect by

the bus master, the bus master should issue a reset pulse and repeat the entire sequence. If the CRC is deemed to

6 of 17

Page 7

DS25LV02: Low-Voltage 1024-Bit EPROM

be correct by the bus master, a programming pulse can be issued to program the byte position within the EPROM

status field pointed to by T15:T0. Following the programming pulse, the bus master must issue 8 read timeslots.

The read timeslots return the EPROM status byte value (least significant bit first) for confirmation by the master.

The bus master can issue a reset pulse at any point after issuing the program pulse to end the write operation, or

continue the write operation with the next byte in the EPROM status field. If the write operation is continued, the

DS25LV02 automatically increments the internal address pointer to select the next byte in the EPROM status field,

and the new value of T7:T0 is loaded into the 8-bit CRC generator as the starting value. The bus master issues the

next 1-byte data argument followed by 8 read timeslots to return the CRC computed by the DS25LV02. The value

returned is computed with D7:D0, using T7:T0 as the starting value. If the CRC is deemed to be incorrect by the

bus master, the bus master should issue a reset pulse and repeat the entire sequence. If the CRC is deemed to be

correct by the bus master, a programming pulse can be issued to program the byte position pointed to by T15:T0.

Following the programming pulse, the bus master must issue 8 read timeslots. The read timeslots return the

EPROM status byte value (least significant bit first) for confirmation by the master.

The write operation can be continued until the end of the EPROM status field is reached by repeating the sequence

of issuing a 1-byte data argument, 8 read timeslots to return CRC, a programming pulse, and 8 read timeslots to

return EPROM byte value.

Table 2. EPROM Status Field

ADDRESS (HEX) DESCRIPTION READ/WRITE

Write Protect Page bits

B0: Page 0 Write Protect

B1: Page 1 Write Protect

B2: Page 2 Write Protect

0000

B3: Page 3 Write Protect

B4: Reserved for TMEX

B5: Reserved for TMEX

B6: Reserved for TMEX

B7: Reserved for TMEX

R/W*

0001 Page Redirection Byte for Page 0 R/W*

0002 Page Redirection Byte for Page 1 R/W*

0003 Page Redirection Byte for Page 2 R/W*

0004 Page Redirection Byte for Page 3 R/W*

0005-0006 Reserved R

0007 Factory Programmed to 00h R

* One-time write to “0” for each bit.

7 of 17

Page 8

DS25LV02: Low-Voltage 1024-Bit EPROM

Table 3. EPROM Memory and Status Function Commands

COMMAND HEX FUNCTION

Read data from the lower 1024 bits of the 1024-bit EPROM Memory

Read Memory F0

Read Data/Generate CRC C3

Write Memory 0F Write data to the EPROM data field.

data field. Generates a CRC value if a read continues through the

end of the last page.

Read data from the lower 1024 bits of the 1024-bit EPROM Memory

data field. Generates a CRC value of the data if read continues

through the end of the page.

Read Status AA

Write Status 55

Note: The Write Memory, Read Memory, Read Data/Generate CRC, Write Status, and Read Status commands

filter the target address (TA2:TA1) value with a 007Fh AND mask that limits the addressable size of the EPROM

data field and EPROM status field to 1024 bits. Target address values equal to or greater than 0080h (128 decimal)

return data from the lower 128 bytes of the respective data field. The result of the filtering is that the internal

address wraps around every 128 bytes as the external target address increments in multiples of 128. For instance,

each time a read operation crosses a 128-byte boundary (0080h, 0100h, … FF00h, FF80h) data retrieval begins

again at address 0000h. This process repeats until reading occurs through the end of the 64kb memory space

addressable by T15:T0. It is also important to note that the filter is applied prior to calculation of the CRC, so that

target address values that are multiples of 128 return the same CRC. The CRC values should be considered

correct only for T15:T0 in the range of 0000h to 007Fh.

Read data from the 8-byte EPROM status field. Generates a CRC if

read continues through the end of the field.

Write the Page Protection bits and Page Redirection bytes in the

EPROM status field.

1-Wire BUS SYSTEM

The 1-Wire bus is a system that has a single bus master and one or more slaves. A multidrop bus is a 1-Wire bus

with multiple slaves, while a single-drop bus has only one slave device. In all instances, the DS25LV02 is a slave

device. The bus master is typically a microprocessor in the host system. The discussion of this bus system consists

of five topics: 64-bit net address, CRC generation, hardware configuration, transaction sequence, and 1-Wire

signaling.

64-BIT NET ADDRESS (ROM ID)

Each DS25LV02 has a unique, factory-programmed 1-Wire Net Address that is 64 bits in length. The term Net

Address is synonymous with the ROM ID or ROM Code terms used in the DS2502 and older Dallas 1-Wire

documentation. The first 8 bits of the Net Address are the 1-Wire family code (09h for the standard DS25LV02).

The next 48 bits are a unique serial number. The last 8 bits are a cyclic redundancy check (CRC) of the first 56 bits

(see Figure 2). The 64-bit net address and the 1-Wire I/O circuitry built into the device enable the DS25LV02 to

communicate through the 1-Wire protocol detailed in this data sheet.

Figure 2. 1-Wire Net Address Format

8-BIT CRC 48-BIT SERIAL NUMBER

MSb LSb

8-BIT FAMILY

CODE (09H)

8 of 17

Page 9

DS25LV02: Low-Voltage 1024-Bit EPROM

CRC GENERATION

The DS25LV02 has an 8-bit CRC stored in the most significant byte of its 1-Wire net address and generates a CRC

during some command protocols. To ensure error-free transmission of the address, the host system can compute a

CRC value from the first 56 bits of the address and compare it to the CRC from the DS25LV02.

The host system is responsible for verifying the CRC value and taking action as a result. The DS25LV02 does not

compare CRC values and does not prevent a command sequence from proceeding as a result of a CRC mismatch.

Proper use of the CRC can result in a communication channel with a very high level of integrity.

The CRC can be generated by the host using a circuit consisting of a shift register and XOR gates as shown in

Figure 3, or it can be generated in software using the polynomial X

Dallas 1-Wire CRC is available in Application Note 27: Understanding and Using Cyclic Redundancy Checks with

Dallas Semiconductor i

In the circuit in Figure 3, the shift register bits are initialized to 0. Then, starting with the least significant bit of the

family code, one bit at a time is shifted in. After the 8th bit of the family code has been entered, then the serial

number is entered. After the 48th bit of the serial number has been entered, the shift register contains the CRC

value.

ButtonÒ Products (www.maxim-ic.com/appnoteindex).

8

+ X5 + X4 + 1. Additional information about the

Figure 3. 1-Wire CRC Generation Block Diagram

INPUT

MSb

XOR

XOR

LSb

XOR

During some command sequences, the DS25LV02 also generates an 8-bit CRC and provides this value to the bus

master to facilitate validation for the transfer of command, address, and data from the bus master to the

DS25LV02. The DS25LV02 computes an 8-bit CRC for the command and address bytes received from the bus

master for the Read Memory, Read Status and Read/Generate CRC commands to confirm that these bytes have

been received correctly. The CRC generator on the DS25LV02 is also used to provide verification of error-free data

transfer as each EPROM page is sent to the master during a Read Data/Generate CRC command and for the 8

bytes of information in the Status memory field.

In each case where a CRC is used for data transfer validation, the bus master must calculate the CRC value using

the same polynomial function and compare the calculated value to the CRC either stored in the DS25LV02 Net

Address or computed by the DS25LV02. The comparison of CRC values and decision to continue with an

operation are determined entirely by the bus master. There is no circuitry in the DS25LV02 that prevents the

command sequence from proceeding if the stored or calculated CRC from the DS25LV02 and the calculated CRC

from the host do not match.

HARDWARE CONFIGURATION

Because the 1-Wire bus has only a single line, it is important that each device on the bus be able to drive it at the

appropriate time. To facilitate this, each device attached to the 1-Wire bus must connect to the bus with open-drain

or tri-state output drivers. The DS25LV02 uses an open-drain output driver as part of the bidirectional interface

circuitry shown in Figure 4. If a bidirectional pin is not available on the bus master, separate output and input pins

can be connected together.

The 1-Wire bus must have a pullup resistor at the bus-master end of the bus. A value between 2kW and 5kW is

recommended. The idle state for the 1-Wire bus is high. If, for any reason, a bus transaction must be suspended,

the bus must be left in the idle state to properly resume the transaction later. Note that if the bus is left low for more

iButton is a registered trademark of Dallas Semiconductor.

9 of 17

Page 10

than t

, slave devices on the bus begin to interpret the low period as a reset pulse, effectively terminating the

LOW0

transaction.

Figure 4. 1-Wire Bus Interface Circuitry

Vpullup

(1.8 to 5.5V)

DS25LV02: Low-Voltage 1024-Bit EPROM

Bus Master

Rx

Tx

4.7kW

Rx = Receive

Tx = Transmit

Device 1-Wire Port (DQ)

~100 Ohm

MOSFET

~0.5µA

Rx

Tx

TRANSACTION SEQUENCE

The protocol for accessing the DS25LV02 through the 1-Wire port is as follows:

§ Initialization

§ Net Address Command

§ Function Command(s)

§ Data Transfer

All transactions of the 1-Wire bus begin with an initialization sequence consisting of a reset pulse transmitted by the

bus master, followed by a presence pulse simultaneously transmitted by the DS25LV02 and any other slaves on

the bus. The presence pulse tells the bus master that one or more devices are on the bus and ready to operate.

For more details, see below.

NET ADDRESS COMMANDS

Once the bus master has detected the presence of one or more slaves, it can issue one of the net address

commands described in the following paragraphs. The name of each Net Address command (ROM command) is

followed by the 8-bit opcode for that command in square brackets.

Read Net Address [33h]. This command allows the bus master to read the DS25LV02’s 1-Wire net address. The

bus master follows the Read Net Address command with 64 read timeslots allowing the 1-Wire slave to transmit its

address. This command can only be used if there is a single slave on the bus. If more than one slave is present, a

data collision occurs when all slaves try to transmit at the same time (open drain produces a wired-AND result).

Match Net Address [55h]. This command allows the bus master to specifically address one DS25LV02 on the

1-Wire bus. Following this command, the bus master transmits the 64 bit net address of the desired slave device.

Only the addressed DS25LV02 responds to any subsequent function command. All other slave devices ignore the

function command and wait for a reset pulse. This command can be used with one or more slave devices on the

bus.

Skip Net Address [CCh]. This command saves time when there is only one DS25LV02 on the bus by allowing the

bus master to issue a function command without specifying the address of the slave. If more than one slave device

is present on the bus, a subsequent function command can cause a data collision when all slaves transmit data at

the same time.

Search Net Address [F0h]. This command allows the bus master to use a process of elimination to identify the

1-Wire net addresses of all slave devices on the bus. The search process involves the repetition of a simple three-

10 of 17

Page 11

DS25LV02: Low-Voltage 1024-Bit EPROM

step routine: read a bit, read the complement of the bit, then write the desired value of that bit. The bus master

performs this simple three-step routine on each bit location of the net address. After one complete pass through all

64 bits, the bus master knows the address of one device. The remaining devices can then be identified on

additional iterations of the process. Refer to Chapter 5 of the Book of DS19xx i

comprehensive discussion of a net address search, including an actual example (www.maxim-ic.com/iButtonBook

Button Standards for a

).

I/O SIGNALING

The 1-Wire bus requires strict signaling protocols to ensure data integrity. The four protocols used by the

DS25LV02 are as follows: the initialization sequence (reset pulse followed by presence pulse), write 0, write 1, and

read data. The bus master initiates all these types of signaling except the presence pulse.

The initialization sequence required to begin any communication with the DS25LV02 is shown in Figure 5. A

presence pulse following a reset pulse indicates that the DS25LV02 is ready to accept a net address command.

The bus master transmits (Tx) a reset pulse for t

. The bus master then releases the line and goes into receive

RSTL

mode (Rx). The 1-Wire bus line is then pulled high by the pullup resistor. After detecting the rising edge on the DQ

pin, the DS25LV02 waits for t

and then transmits the presence pulse for t

PDH

PDL

.

Figure 5. 1-Wire Initialization Sequence

DQ

LINE TYPE LEGEND:

t

RSTL

t

PDH

t

PDL

t

RSTH

PACK+

PACK-

BOTH BUS MASTER AND

SLAVE ACTIVE LOW

WRITE-TIME SLOTS

A write-time slot is initiated when the bus master pulls the 1-Wire bus from a logic-high (inactive) level to a logic-low

level. There are two types of write-time slots: write 1 and write 0. All write-time slots must be t

a 1ms minimum recovery time, t

and t

LOW0_MIN

after the line falls. If the line is high when sampled, a write 1 occurs. If the line is low when sampled, a

, between cycles. The DS25LV02 samples the 1-Wire bus line between t

REC

in duration with

SLOT

LOW1_MAX

write 0 occurs. The sample window is illustrated in Figure 6. For the bus master to generate a write-1 time slot, the

bus line must be pulled low and then released, allowing the line to be pulled high less than t

after the start of the

RDV

write time slot. For the host to generate a write-0 time slot, the bus line must be pulled low and held low for the

duration of the write-time slot.

READ-TIME SLOTS

A read-time slot is initiated when the bus master pulls the 1-Wire bus line from a logic-high level to a logic-low level.

The bus master must keep the bus line low for at least 1ms and then release it to allow the DS25LV02 to present

valid data. The bus master can then sample the data t

read-time slot, the DS25LV02 releases the bus line and allows it to be pulled high by the external pullup resistor. All

read-time slots must be t

in duration with a 1ms minimum recovery time, t

SLOT

the timing specifications in the Electrical Characteristics table for more information.

from the start of the read-time slot. By the end of the

RDV

, between cycles. See Figure 6 and

REC

11 of 17

Page 12

Figure 6. 1-Wire Write and Read Time Slots

WRITE 0 SLOT WRI TE 1 SLOT

DS25LV02: Low-Voltage 1024-Bit EPROM

V

PULLU P

GND

MODE

Standard

Overdrive

V

PULLU P

15ms

2ms

t

RDV

t

SLOT

t

LOW0

t

Device Sample Window

MIN TYP MAX

15ms 30ms

1ms 3ms

Data = 0

t

SLOT

REC

>1ms

15ms

2ms

READ DATA SLOT

t

REC

t

RDV

t

SLOT

t

LOW1

Device Sample Window

MIN T YP MAX

15ms 30ms

1ms 3ms

Data = 1

t

SLOT

GND

>1ms

Master Sample Window

15ms

MODE

Standard

Overdrive

Master Sampl e Wi ndow

15ms

2ms 2ms

LINE TYPE LEGEND:

Bus Master active LOW Slave Device active LOW

Both Bus Master and Slave Device Resistor pullup

active LOW

12 of 17

Page 13

Figure 7. EPROM Programming Diagram

DS25LV02: Low-Voltage 1024-Bit EPROM

t

RP

VPP Min = 11.5V,

VPP Max = 12.0V

t

DP

1-Wire

Reset

SKIP ROM

Command

Write

Memory

TA1, TA2, Data

and CRC bytes

Programming

Pulse

Command

Presence

Pulse

PACKAGE INFORMATION

(For the latest package outline information, go to www.maxim-ic.com/DallasPackInfo.)

t

PP

t

FP

t

DV

Verification

Read

13 of 17

Page 14

Figure 8. Operational Flow Chart

START

MASTER T x

RESET PULSE

DS25LV02 Tx

PRESENCE PULSE

MASTER Tx

NET ADDRESS

COMMAND

DS25LV02: Low-Voltage 1024-Bit EPROM

33h/39h

READ

DS25LV0 2 Tx

FAMILY CODE

1 BYTE

DS25LV0 2 Tx

SERIAL NUMBER

6 BYTES

DS25LV0 2 Tx

CRC

1 BYTE

NO

55h

MATCH

YES

MAST ER Tx

BIT 0

BIT 0

MATCH?

YES

MAST ER Tx

BIT 1

BIT 1

MATCH?

YES

NO NO

F0h

SEARCH

YESYES

DS25 LV02 Tx BIT 0

DS25 LV02 Tx BIT 0

MASTER Tx BI T 0

NO

NO

BIT 0

MATCH?

DS25 LV02 Tx BIT 1

DS25 LV02 Tx BIT 1

MASTER Tx BI T 1

NO NO

BIT 1

MATCH?

YES

CCh

SKIP

YES

GO TO MEMOR Y

COMMANDS 1

NO

DS25LV02 Tx BIT 63

DS25LV02 Tx BIT 63

MAST ER Tx BIT 63

GO TO MEMORY

COMMANDS 1

YES

MAST ER Tx

BIT 63

BIT 63

MATCH?

NO

GO TO START

14 of 17

Page 15

Figure 8. Operational Flow Chart (Continued)

MEMORY

COMMANDS 1

MASTER Tx MEMORY

FUNCTION COMMAND

DS25LV02: Low-Voltage 1024-Bit EPROM

BUS MASTER Rx 8-BIT CRC OF

COMMAND AND ADDRESS

DS25LV02 INCREMENTS

ADDRESS COUNTER

NO

F0h

READ

MEMORY

?

YES

BUS MASTER T x

TA1 (T7:T0)

BUS MASTER T x

TA2 (T15:T8)

CRC

CORRECT

?

YES

BUS MASTER Rx DATA

FROM DATA MEMORY

BUS MASTER

Tx RESET

?

NO

END

OF D AT A

MEMORY

?

YES

NO

NO

YES

BUS MASTER T x

RESET

AAh

READ

STAT US

?

YES

BUS MASTER T x

TA1 (T7:T0)

BUS MASTER T x

TA2 (T15:T8)

BUS MASTER Rx 8-BIT CRC OF

COMMAND AND ADDRESS

NO

BUS MASTER Rx DATA

FROM STATUS MEMORY

YES

CRC

CORRECT

?

YES

BUS MASTER

Tx RESET

?

NO

END OF

PAGE

?

YES

NO

DS25LV02 INCREMENTS

ADDRESS COUNTER

NO

GO TO MEMORY

COMMANDS 2

BUS MASTER

Tx RESET

?

NO

BUS MASTER Rx 8-BIT

CRC OF DATA

BUS MASTER

Tx RESET

?

NO

BUS MASTER Rx

ALL 1's

YES

YES

DS25LV02 Tx

PRESENCE PULSE

GO TO ST ART

YES

BUS MASTER

Tx RESET

?

NO

BUS MASTER R x 8-BIT

CRC OF STATUS DATA

YES

BUS MASTER

Tx RESET

?

NO

BUS MASTER Rx

ALL 1's

15 of 17

Page 16

Figure 8. Operational Flow Chart (Continued)

DS25LV02: Low-Voltage 1024-Bit EPROM

MEMORY

COMMANDS 2

DS25LV02 INCREMENTS

ADDRESS COUNTER

C3h

READ DAT A

& GENERATE

CRC ?

YES

BUS MASTER Tx

TA1 (T7:T0)

BUS MASTER Tx

TA2 (T15:T8)

BUS MASTER Rx 8-BIT CRC OF

COMMAND AND ADDRESS

CRC

CORRECT

?

BUS MASTER Rx DAT A

FROM DATA MEMORY

BUS MASTER

Tx RESET

?

NO

NO

YES

YES

NO

GO TO MEMORY

COMMANDS 3

BUS MASTER T x

RESET

END OF

NO

NO

PAGE

?

YES

BUS MASTER R x 8-BIT

CRC OF STATUS DATA

CRC

CORRECT

?

YES

END OF

MEMORY

?

YES

BUS MASTER

Tx RESET

?

NO

BUS MASTER Rx

ALL 1's

NO

YES

BUS MASTER T x

RESET

DS25LV02 Tx

PRESENCE PULSE

GO TO START

16 of 17

Page 17

Figure 8. Operational Flow Chart (Continued)

DS25LV02: Low-Voltage 1024-Bit EPROM

MEMORY

COMMANDS 3

0Fh

WRITE

MEMORY

?

BUS MASTER T x

TA1 (T7:T0)

BUS MASTER T x

TA2 (T15:T8)

BUS MASTER T x

DATA BYTE (D7:D0)

BUS MASTER Rx 8-BIT CRC OF

COMMAND, ADDRESS, AND DATA

CRC OF ADDRESS AND DATA

NO

st

PASS )

(1

(SUBSEQU ENT PASSES)

CRC

CORRECT

?

BUS MASTER T x

PROGRAM PULSE

NO

YES

YES

55h

WRITE

STATUS

?

BUS MASTER T x

TA1 (T7:T0)

BUS MASTER T x

TA2 (T15:T8)

BUS MASTER T x

DATA BYTE (D7:D0)

BUS MAST ER R x CRC16 OF

COMMAND, ADDRESS, AND DATA

CRC16 OF ADDRESS AND DATA

NO

st

PASS)

(1

(SUBSEQUENT PASSES)

CRC

CORRECT

?

BUS MASTER T x

PROGRAM PULSE

NO

YES

YES

BUS MASTER

TX RESET

BUS MAST ER

TX RESET

DS25LV02 COPIES

SCRATCHPAD TO DATA EPROM

BUS MAST ER Rx BYTE

NO

YES

DS25LV02 INCREMENTS

ADDRESS COUNTER

DS25LV02 LOADS LSB OF

NEW ADDRESS INTO CRC

NO

FROM EPROM

EPROM BYT E

= CORRECT

?

YES

END OF

DATA

MEMORY

?

NO

GENE RATOR

BUS MAST ER

TX RESET

DS25LV02 COPIES SCRATCHPAD

TO ST ATU S EPROM

BUS MAST ER R x BYTE

NO

YES

DS25LV02 INCREMENTS

ADDRESS COUNTER

DS25LV02 LOADS LSB OF

NEW ADDRESS INTO CRC

NO

FROM EPROM

EPROM BYTE

= CORR ECT

?

YES

END OF

STATUS

MEMORY

?

NO

GENERATOR

DS25LV02 Tx

PRESEN CE PULSE

GO TO ST ART

17 of 17

Loading...

Loading...