Page 1

www.maxim-ic.com

DS2431

1024-Bit 1-Wire EEPROM

GENERAL DESCRIPTION

The DS2431 is a 1024-bit, 1-Wire® EEPROM chip

organized as four memory pages of 256 bits each.

Data is written to an 8-b yte scratchpad, verif ied, and

then copied to the EEPROM memory. As a special

feature, the four memory pages can individually be

write protected or put in EPROM-emulation mode,

where bits can only be changed from a 1 to a 0 stat e.

The DS2431 communicates over the singleconductor 1-Wire bus. The communication follows

the standard Dallas Semiconductor 1-Wire protocol.

Each device has its own unaltera ble and unique 64bit ROM registration number that is factory lasered

into the chip. The registration number is used to

address the device in a multidrop 1-Wire net

environment.

APPLICATIONS

Accessory/PC Board Ident if ic ati on

Medical Sensor Calibration Data Storage

Analog Sensor Calibration Including IEEEP1451.4 Smart Sensors

Ink and Toner Print Cartridge Identification

After-Market Management of Consumables

FEATURES

!

1024 Bits of EEPROM Memory Partitioned into

Four Pages of 256 Bits

!

Individual Memor y Pages can be Permanently

Write Protected or Put in EPROM-Emulation

Mode ("Write to 0")

!

Switchpoint Hysteresis and Filtering to Optimize

Performance in the Presence of Noise

!

IEC 1000-4-2 Level 4 ESD Protection (8kV

Contact, 15kV Air)

!

Reads and Writes Over a Wide Voltage Range of

2.8V to 5.25V from -40°C to +85°C

!

Communicates to Host with a Single Digital

Signal at 15.4kbps or 111kbps Using 1-Wire

Protocol

ORDERING INFORMATION

PART TEMP RANGE PIN-PACKAGE

DS2431 -40°C to 85°C TO-92

DS2431/T&R -40°C to 85°C TO-92, tape & reel

DS2431P -40°C to 85°C TSOC

DS2431P/T&R -40°C to 85°C TSOC, tape & reel

DS2431X -40°C to 85°C CSP, tape & reel

TYPICAL OPERATING CIRCUIT

V

CC

R

PUP

µC

I/O

DS2431

GND

Commands, Registers, and Modes ar e capita li ze d for

clarity.

PIN CONFIGURATION

1

TO-92

1 2 3

1 2 3

2

3

TSOC, TO-92 pi nout:

Pin 1 ------------- GND

Pin 2 ------------- I/O

All other pins -- NC

2

1

A B

CSP, approx. 68 × 68 mil

TSOC, Top View

A1 = NC

A2 = I/O

B1 = NC

B2 = GND

6

5

4

Top view, bumps not visible

1-Wire is a registered trademark of Dallas Semiconductor Corp.

Note: Some revisions of this device may incorporate deviations from published spec ifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For informati on about device errata, click here: www.maxim-ic.com/errata.

1 of 23

REV: 050704

Page 2

DS2431: 1024-Bit, 1-Wire EEPRO M

ABSOLUTE MAXIMUM RATINGS

I/O Voltage to GND -0.5V, +6V

I/O Sink Current 20mA

Operating Temperature Range -40°C to +85°C

Junction Temperature +150°C

Storage Temperature Range -40°C to +85°C

Soldering Temperature See IPC/JEDEC J-STD-020A

Stresses beyond those listed under “Absolute Maximum Ratings” may caus e permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of t he specifications is

not implied. Exposure to the absolute maximum rating conditions for extended periods may affect device rel i abili ty .

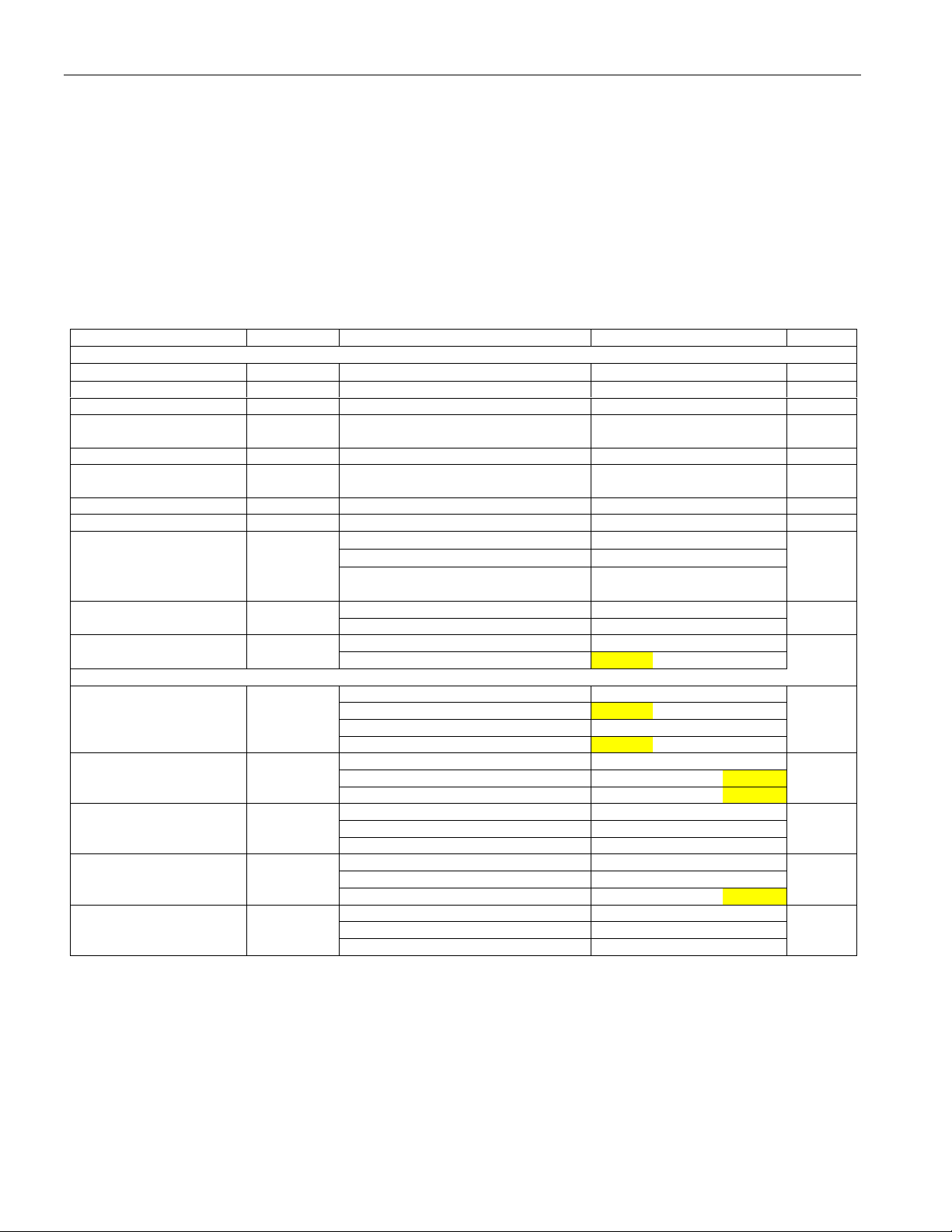

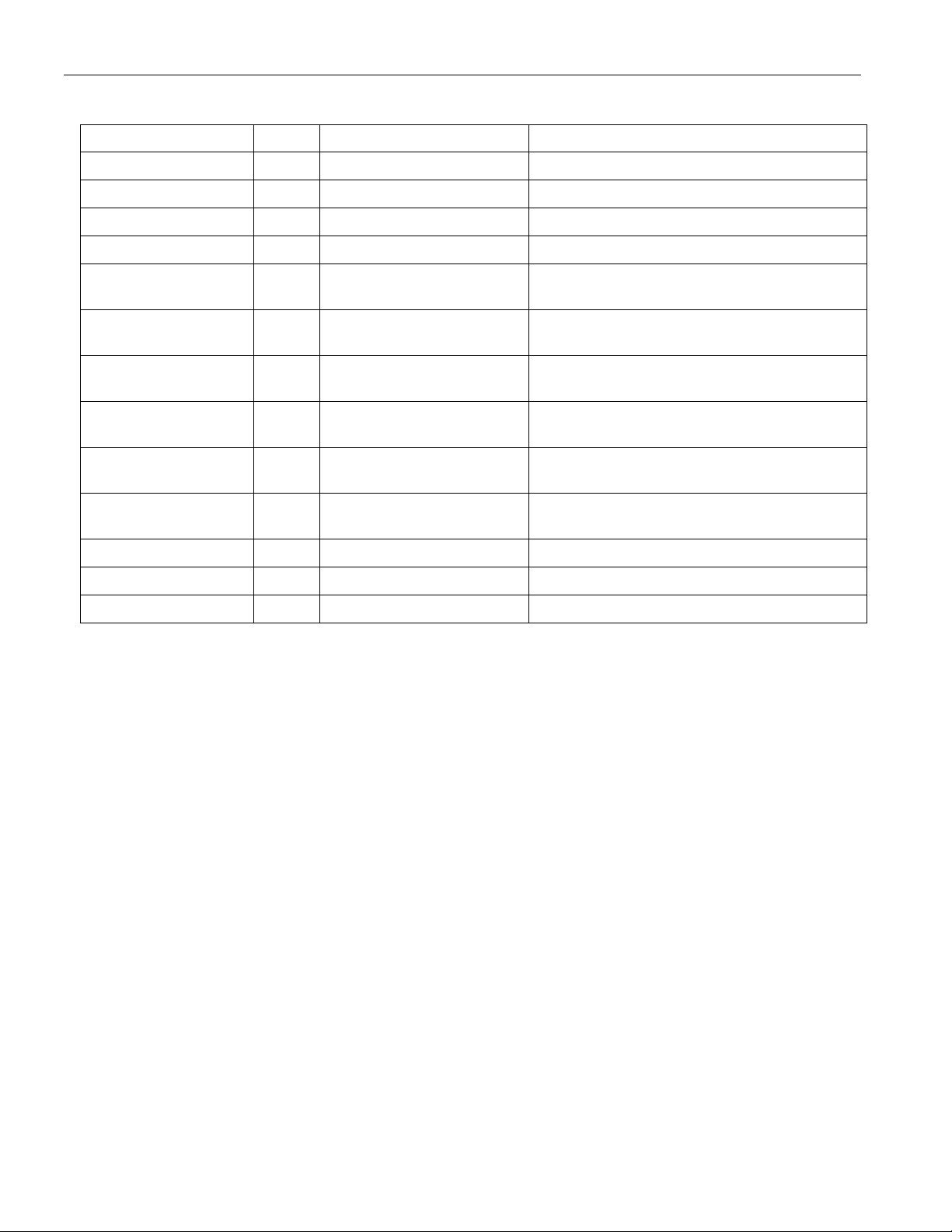

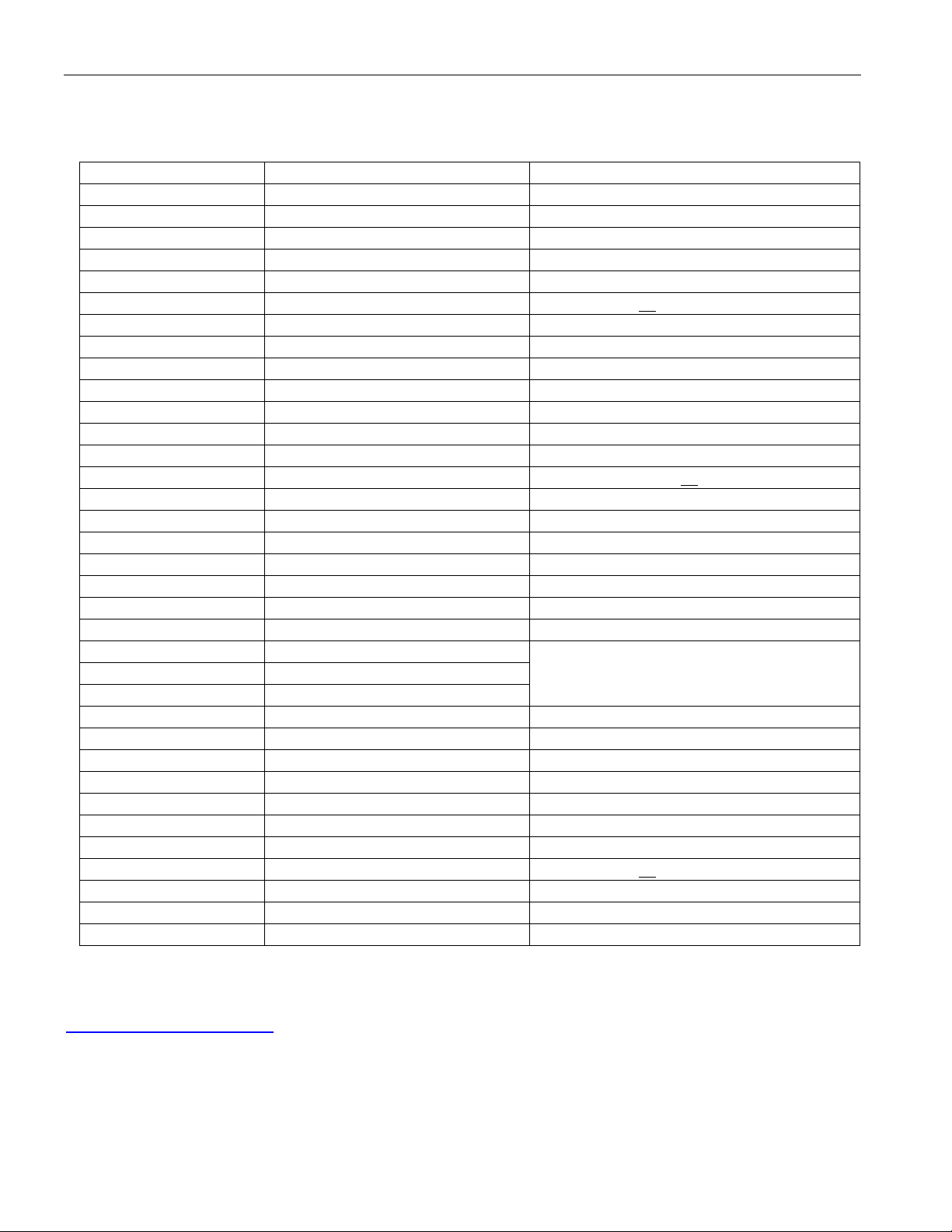

ELECTRICAL CHARACTERISTICS

(V

= 2.8V to 5.25V, TA = -40°C to +85°C.)

PUP

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I/O PIN GENERAL DATA

1-Wire Pullup Resistance

Input Capacitance C

Input Load Current I

High-to-Low Switching

Threshold

Input Low Voltage V

Low-to-High Switching

Threshold

Switching Hysteresis V

Output Low Voltage V

Recovery Time

(Notes 1,11)

Rising-Edge Hold-off Time t

Timeslot Duration (Note 1) t

R

V

V

t

REC

REH

SLOT

PUP

IO

L

TL

IL

TH

HY

OL

I/O PIN, 1-WIRE RESET, PRESENCE DETECT CYCLE

Reset Low Time (Note 1) t

Presence Detect High

Time

Presence Detect Fall Time

(Notes 4, 14)

Presence Detect Low

Time

Presence Detect Sample

Time (Note 1)

RSTL

t

PDH

t

FPD

t

PDL

t

MSP

(Notes 1, 2)

0.3 2.2

kΩ

(Notes 3, 4) 100 800 pF

I/O pin at V

PUP

0.05 2.2 µA

(Notes 4, 5, 6) 0.5 4.1 V

(Notes 1, 7) 0.3 V

(Notes 4, 5, 8) 1.0 4.9 V

(Notes 4, 5, 9) 0.22 1.70 V

At 4mA (Note 10) 0.4 V

Standard speed, R

Overdrive speed, R

PUP

PUP

= 2.2kΩ

= 2.2kΩ

Overdrive speed, directly prior to reset

pulse; R

PUP

= 2.2kΩ

Standard speed (Note 12) 0.5 5.0

Overdrive speed Not applicable (0)

Standard speed 65

Overdrive speed (Note 13) 9

Standard speed, V

> 4.5V 480 640

PUP

Standard speed (Note 12) 504 640

Overdrive speed, V

> 4.5V 48 80

PUP

5

2

µs

5

µs

µs

µs

Overdrive speed (Note 13) 53 80

Standard speed, V

Standard speed (Note 13) 15 63

> 4.5V 15 60

PUP

µs

Overdrive speed (Note 13) 2 7

Standard speed, V

Standard speed 1.1 7

> 4.5V 1.1 3.75

PUP

µs

Overdrive speed 1.1

Standard speed 60 240

Overdrive speed, V

> 4.5V 8 24

PUP

µs

Overdrive speed (Note 13) 8 26

Standard speed, V

Standard speed 70 75

> 4.5V 64 75

PUP

µs

Overdrive speed 8.1 10

2 of 23

Page 3

DS2431: 1024-Bit, 1-Wire EEPRO M

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I/O PIN, 1-Wire WRITE

Write-0 Low Time (Note 1) t

Write-1 Low Time

(Notes 1, 15)

I/O PIN, 1-Wire READ

Read Low Time

(Notes 1, 16)

Read Sample Time

(Notes 1, 16)

EEPROM

Programming Current I

Programming Time t

Write/Erase Cycles

(Endurance)

Data Retention t

W0L

t

W1L

t

RL

t

MSR

PROG

PROG

N

CY

DR

Standard speed 60 120

Overdrive speed (Note 13) 716

Standard speed 5

Overdrive speed 1

Standard speed 5

Overdrive speed 1

Standard speed

Overdrive speed

tRL + δ

tRL + δ

15 - ε

2 - ε

15 - δ

2 - δ

15

(Note 17) 1 mA

(Note 18) 12.5 ms

At 25°C 200k

At 85°C (worst case) 50k

At 85°C (worst case) 10 years

µs

µs

µs

2

µs

---

Note 1:

Note 2:

Note 3:

Note 4:

Note 5:

Note 6:

Note 7:

Note 8:

Note 9:

Note 10:

Note 11:

Note 12:

Note 13:

Note 14:

Note 15:

Note 16:

Note 17:

Note 18:

System requirement.

Maximum allowable pullup resistance is a function of the number of 1-Wire devices in the system and 1-Wire recovery times. The

specified value here applies to systems with only one device and with the minimum 1-Wire recovery times. For more heavily

loaded systems, an active pullup such as that found in the DS2482-x00, DS2480B, or DS2490 may be required.

Capacitance on the data pin could be 800pF when V

after V

Guaranteed by design, simulation only. Not production tested.

V

Voltage below which, during a falling edge on I/O, a logic 0 is detected.

The voltage on I/O needs to be less or equal to V

Voltage above which, during a rising edge on I/O, a logic 1 is detected.

After V

The I-V characteristic is linear for voltages less than 1V.

Applies to a single DS2431 attached to a 1-Wire line.

The earliest recognition of a negative edge is possible at t

Highlighted numbers are NOT in compliance with legacy 1-Wire product standards. See comparis on table bel ow.

Interval during the negative edge on I/O at the beginning of a Presence Detect pulse between the time at which the voltage is

80% of V

ε represents the time required for the pullup circuitry to pull the voltage on I/O up from V

δ represents the time required for the pullup circuitry to pull the voltage on I/O up from V

master.

Current drawn from I/O during the EEPROM programming interval. The pullup circuit on I/O during the programming interval

should be such that the voltage at I/O is greater than or equal to Vpup(min). If Vpup in the system is close to Vpup(min) then a

low impedance bypass of Rpup which can be activated during programming may need to be added.

Interval begins t

sequence. Interval ends once the device's self-timed EEPROM programm ing cycle is complete and the current drawn by the

device has returned from I

has been applied the parasite capacitance will not affect normal communications.

PUP

, VTH, and V

TL

TH

are a function of the internal supply voltage.

HY

is crossed during a rising edge on I/O, the voltage on I/O has to drop by at least VHY to be detected as logic '0'.

and the time at which the voltage is 20% of V

PUP

after the leading negative edge on IO for the last timeslot of the E/S byte for a valid Copy Scratchpad

WiLMIN

to IL.

PROG

is first applied. If a 2.2kΩ resistor is used to pull up the data line, 2.5µs

PUP

whenever the master drives the line low.

ILMAX

after VTH has been previously reached.

REH

.

PUP

to VTH.

IL

to the input high threshold of the bus

IL

LEGACY VALUES DS2431 VALUES

PARAMETER STANDARD SPEED OVERDRIVE SPEED STANDARD SPEED OVERDRIVE SPEED

MIN MAX MIN MAX MIN MAX MIN MAX

t

(incl. t

SLOT

t

RSTL

t

PDH

t

PDL

t

W0L

1)

Intentional change, longer recovery time requirement due to modified 1-Wire front end.

) 61µs (undef.) 7µs (undef.) 65µs

REC

480µs (undef.) 48µs 80µs 504µs 640µs 53µs 80µs

15µs 60µs 2µs 6µs 15µs 63µs 2µs 7µs

60µs 240µs 8µs 24µs 60µs 240µs 8µs 26µs

60µs 120µs 6µs 16µs 60µs 120µs 7µs 16µs

1)

(undef.) 9µs (undef.)

PIN DESCRIPTION

NAME FUNCTION

I/O 1-Wire Bus Interface. Open drain, requires external pullup resistor.

GND Ground Reference

N.C. Not Connected

3 of 23

Page 4

DS2431: 1024-Bit, 1-Wire EEPRO M

DESCRIPTION

The DS2431 combines 1 024 bits of EEPROM, an 8-byte register/control page with up to 7 user read/write bytes,

and a fully-featured 1-Wire interface in a single c hip. Each DS2431 has its own 64-bit ROM registration number

that is factory lasered into the chip to provide a guaranteed unique identity for absolute traceability. Data is

transferred serially via the 1-Wire protocol, which requires only a single data lead and a ground return. The DS2431

has an additional mem ory area ca lled the sc ratchpad t hat acts as a buff er when writing to t he main m emor y or the

register page. Data is first written to the scratchpad from which it can be read back. After the data has been

verified, a cop y scratchpad command transf ers the data to its final memory location. Applications of the DS2431

include accessory/PC board identification, medical sensor calibration data storage, analog sensor calibration

including IEEE-P1451.4 Sm art Sensors, ink and toner pr int cartridge identif ication, and after-m arket management

of consumables.

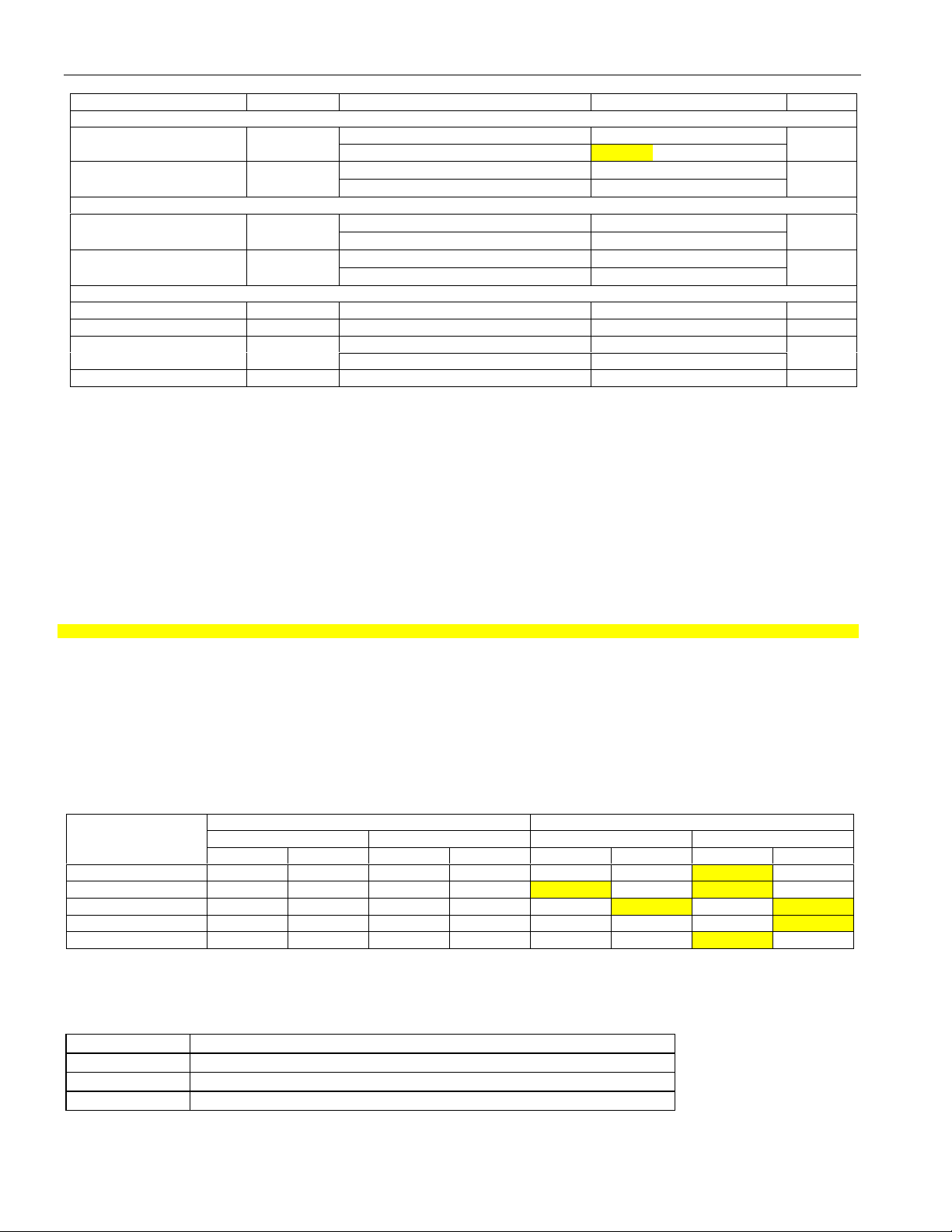

OVERVIEW

The block diagram in Figure 1 shows the relationships between the major control and memory sections of the

DS2431. The DS2431 has four main data components: 1) 64-bit lasered ROM, 2) 64-bit scratchpad, 3) four 32-byte

pages of EEPROM, and 4) 6 4- bit r egis t er pa ge. The hierarchical str uc ture of the 1-Wire protocol is shown i n Fig ur e

2. The bus master must first provide one of the seven ROM Function Commands, 1) Read ROM, 2) Match ROM, 3)

Search ROM, 4) Skip ROM, 5) Resum e, 6) Overdrive- Skip ROM or 7) Overdrive-Matc h ROM. Upon c ompletion of

an Overdrive ROM command byte executed at standard speed, the device enters Overdrive mode where all

subsequent comm unication occurs at a higher sp eed. The protoc ol requir ed for thes e ROM function c ommands is

described in Figure 9. After a ROM function command is successfully executed, the memory functions becom e

accessible and the master m ay provide any one of the four m emory function commands. The protoc ol for these

memory function commands is described in Figure 7. All data is read and written least significant bit first.

Figure 1. Block Diagram

I/O

Function Control

Memory

Function

Control Unit

CRC16

Generator

Data Memory

4 Pages of

256 bits each

1-Wire

PARASITE POWER

64-bit

Lasered ROM

DS2431

64-bit

Scratchpad

Register Page

64 bits

4 of 23

Page 5

Figure 2. Hierarchical Structure for 1-Wire Protocol

DS2431: 1024-Bit, 1-Wire EEPRO M

DS2431 Co m m a nd Level:

1-Wire ROM Function

Commands (see Figure 9)

DS2431-specific

Memory Function

Commands (see Figure 7)

Available

Commands:

Read ROM

Match ROM

Search ROM

Skip ROM

Resume

Overdrive Skip

Overdrive Match

Write Scratchpad

Read Scratchpad

Copy Scratchpad

Read Memory

Data Field

Affected:

64-bit Reg. #, RC-Flag

64-bit Reg. #, RC-Flag

64-bit Reg. #, RC-Flag

RC-Flag

RC-Flag

64-bit Reg. #, RC-Flag, OD-Flag

64-bit Reg. #, RC-Flag, OD-Flag

64-bit Scratchpad, Flags

64-bit Scratchpad

Data Memory, Register Page

Data Memory, Register Page

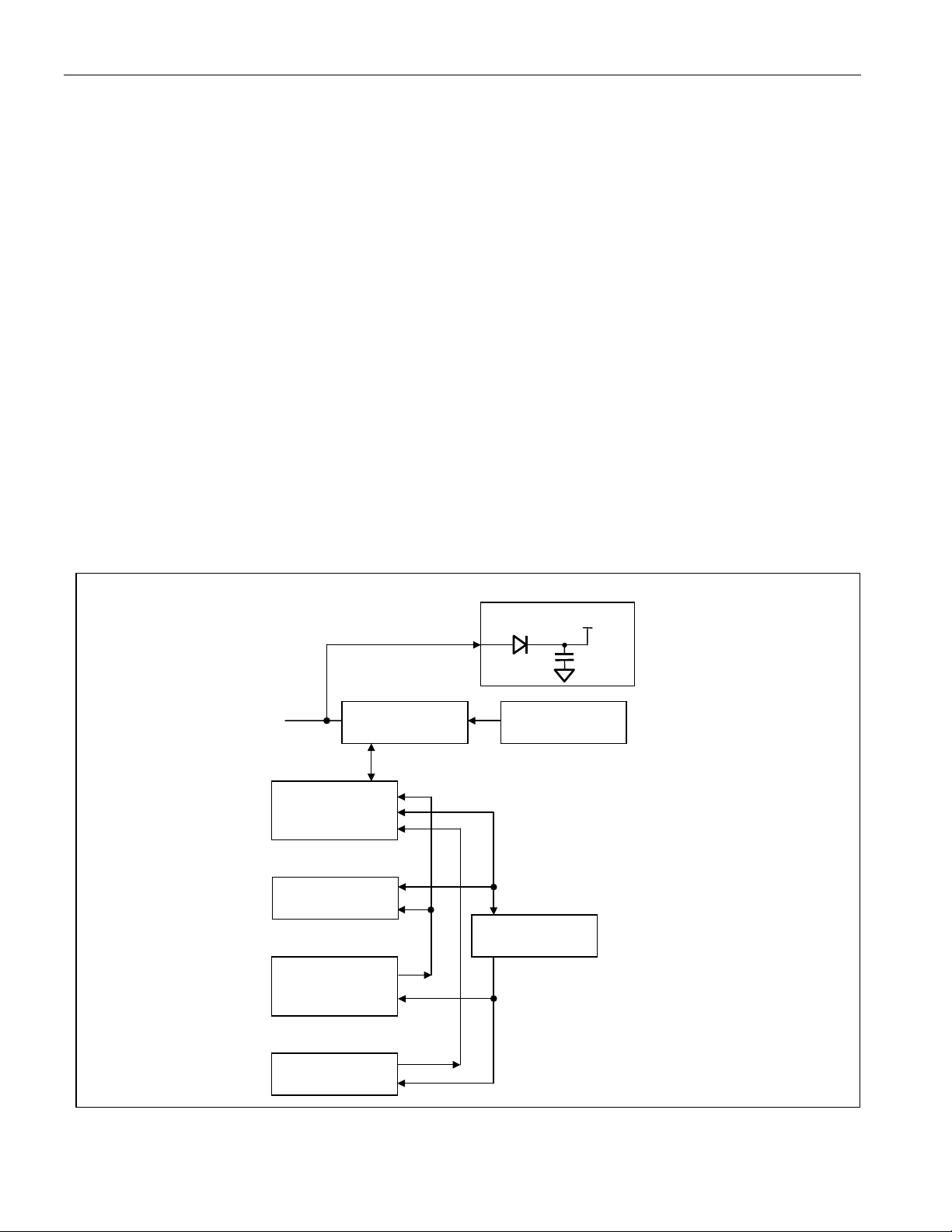

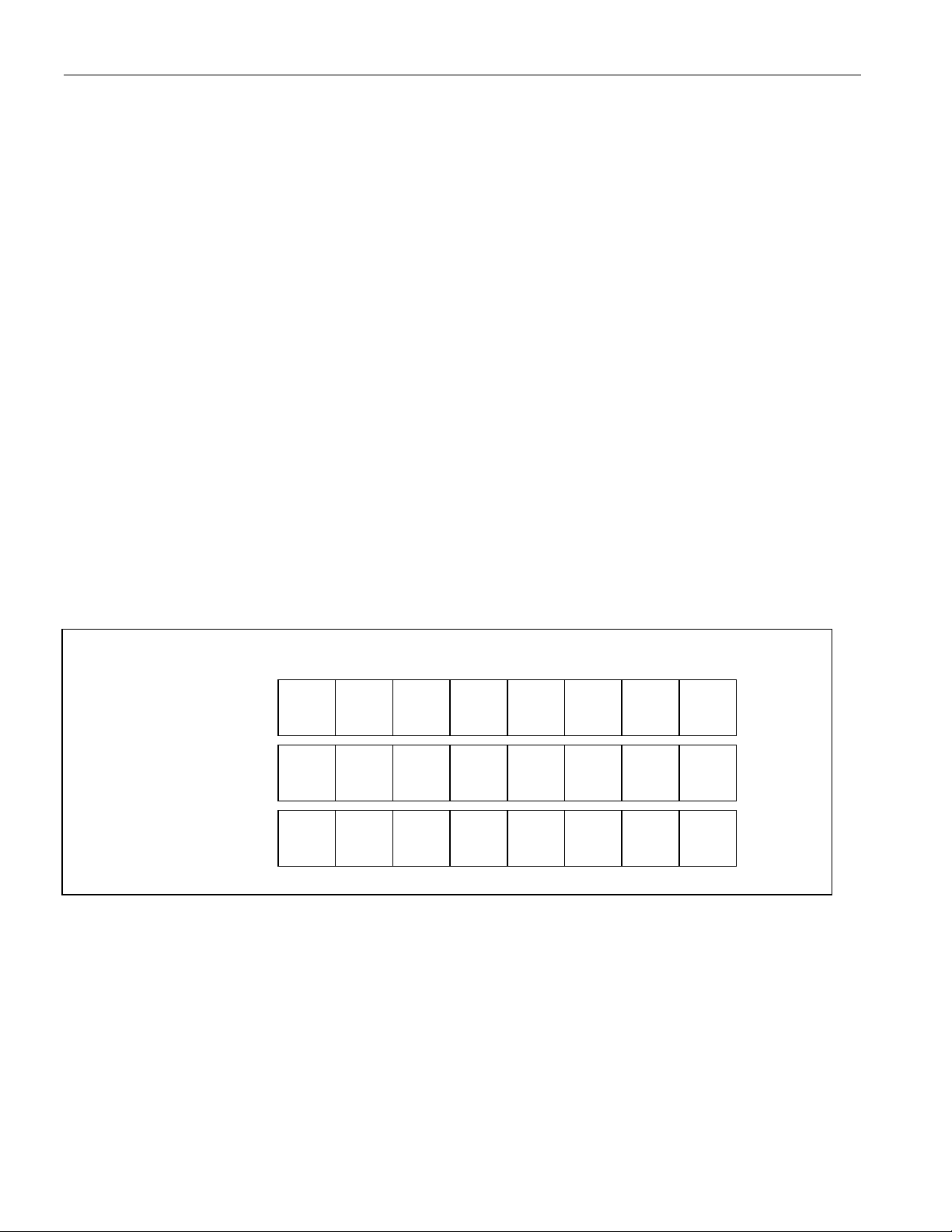

64-BIT LASERED ROM

Each DS2431 contains a uniqu e ROM code that is 6 4 bits long. T he f irst 8 bits ar e a 1-W ire f amily code. T he next

48 bits are a unique serial number. The last 8 bits are a CRC (Cyclic Redundanc y Check) of the f irst 56 bits. See

Figure 3 for details. T he 1-Wire CRC is generated using a polynomial generator cons isting of a shift register and

XOR gates as shown in Figure 4. The polynomial is X

CRC is available in Application Note 27.

The shift register b its are initial ized to 0. Then s tarting with the least sig nificant bit of the f amily code, one bit at a

time is shifted in. Af ter the 8t h bit of the fam ily code has b een enter ed, then th e serial number is entered. After the

last bit of the serial number has been entered, the shift register contai ns the CRC value. Shifting i n the 8 bits of the

CRC returns the shift register to all 0s.

8

+ X5 + X4 + 1. Additional infor mation about the Dall as 1- Wire

Figure 3. 64-Bit Lasered ROM

MSB LSB

8-Bit

CRC Code

MSB LSB MSB LSB MSB LSB

Figure 4. 1-Wire CRC Generator

STAGE

0

X

st

1

STAGE

1

X

nd

2

2

X

rd

3

STAGE

STAGE

3

X

th

4

48-Bit Serial Number

Polynomial = X8 + X5 + X4 + 1

th

5

STAGE

4

X

STAGE

5

X

th

6

STAGE

6

X

INPUT DATA

8-Bit Family

Code (2Dh)

th

7

STAGE

7

X

8

th

8

X

5 of 23

Page 6

DS2431: 1024-Bit, 1-Wire EEPRO M

Figure 5. Memory Map

ADDRESS RANGE TYPE DESCRIPTION PROTECTION CODES

0000h to 001Fh R/(W) Data Memory Page 0

0020h to 003Fh R/(W) Data Memory Page 1

0040h to 005Fh R/(W) Data Memory Page 2

0060h to 007Fh R/(W) Data Memory Page 3

1)

0080h

0081h

0082h

0083h

0084h

1)

1)

1)

1)

R/(W) Protection Control Byte

Page 0

R/(W) Protection Control Byte

Page 1

R/(W) Protection Control Byte

Page 2

R/(W) Protection Control Byte

Page 3

55h: Write Protect P0; AAh: EPROM mode

P0; 55h or AAh: Write Protect 80h

55h: Write Protect P1; AAh: EPROM mode

P1; 55h or AAh: Write Protect 81h

55h: Write Protect P2; AAh: EPROM mode

P2; 55h or AAh: Write Protect 82h

55h: Write Protect P3; AAh: EPROM mode

P3; 55h or AAh: Write Protect 83h

R/(W) Copy Protecti on B yte 55h or AAh: Copy Protect 008 0:00 8Fh, and

any write-protected Pages

0085h R Factory byte. Set at

Factory.

AAh:Write Protect 85h, 86h, 87h;

55h: Write Protect 85h, unprotect 86h, 87h

0086h R/(W) User Byte/Manufacturer ID

0087h R/(W) User Byte/Manufacturer ID

0088h to 008Fh N/A Reserved

1)

Once programm ed to AAh or 5 5h this a ddress bec omes read-onl y. All oth er c odes can be s tored but will neith er

write-protect the address nor activate any function.

MEMORY

Data memory and regist ers are loc ated in a linear addres s spac e, as show n in Fi gure 5. T he data m emor y and t he

registers have unrestrict ed r e ad acc es s . T he DS 243 1 EE P RO M ar ra y co nsis ts of 18 rows of 8 bytes each. T he f irs t

16 rows are divided equally into 4 m emory pages (32 bytes each). These 4 pages ar e the primary data m emory.

Each page can be individually set to open (unprotected), write protected, or EPROM mode by setting the

associated protectio n byte in the regist er row. The last two r ows contain protect ion registers, an d reserved bytes .

The register row consists of 4 protection control bytes, a copy protection byte, the factory byte, and two user

byte/manufacture ID bytes. The m anufacturer ID can be a customer-suppl ied identification code that assists the

application software in identifying the product the DS2431 is associated with. Contact the f actory to set up and

register a custom manufacturer ID. The last row is reserved for future use. It is undefined in terms of R/W

functionality and should not be use d.

In addition to the main EEPROM array, an 8-byte vo latile s cratchpa d is inc luded. Writes to the EEPROM arr ay are

a two-step process. First, da ta is written to the scratchpa d, and then copied into the m ain array. This allows the

user to first verif y the data written to s cratchpad pr ior to c opying into the m ain arra y. The device on ly supports full

row (8-byte) copy operations. In order for data in the scratchpad to be valid for a copy operation, the address

supplied with a Write Scratchpad must start on a row boundary, and 8 full bytes must be written into the

scratchpad.

6 of 23

Page 7

DS2431: 1024-Bit, 1-Wire EEPRO M

The protection contr ol registers determine ho w incoming data on a write-scratchpad com mand is loaded into the

scratchpad. A protection setting of 55h (W rite Protect) causes the incoming data to be ingnored and t he target

address main memory data to be loaded into the scratchpad. A pr otection setting of AAh (EPROM Mode) c auses

the logical AND of incoming data and target address main memory data to be loaded into the scratchpad. Any

other protection control register setting leaves the associated m emory page open for unrestricted write access.

Protection control b yte settings of 55h or AAh also wr ite protect the protection control b yte. The prot ection-contro l

byte setting of 55h does n ot block the cop y. This allows write-protected data t o be refreshed ( i. e., reprogramm ed

with the current data) in the device.

The copy protection b yte is used for a higher level of security, and should only be used after all other protection

control bytes, user bytes, and writ e-protected pag es are set to their fin al value. If t he copy protec tion b yte is set to

55h or Aah, all copy attem pts to the register row and user byte row are block ed. In addition, all copy attem pts to

write-protected main memory pages (i. e., refresh) are blocked.

ADDRESS REGISTERS AND TRANSFER STATUS

The DS2431 employs three address register s: T A1, TA2, and E/S (Figure 6) . T hes e r egist er s are c om mon to man y

other 1-Wire devices but operate slig htly differ ently with the D S2431. Register s TA1 and T A2 must be lo aded with

the target address to which the data is written or from which data is re ad. Register E/S is a read-only tr ansferstatus register, used to verify data integrity with write commands. ES bits E2:E0 are loaded with the incoming

T2:T0 on a write-scratchpad command, and increment on each subsequent data byte. This is in effect a byteending offset counter within the 8-b yte scratchpad. Bit 5 of the E/S register, cal led PF, is a logic 1 if the data in the

scratchpad is not va li d du e to a los s of po wer or if the master sends l es s b ytes tha n n eed ed to reach the end of the

scratchpad. For a valid wr ite to the s cratchpa d, T2:T 0 must be 0 and t he m aster mus t have sent 8 da ta bytes . Bits

3, 4, and 6 have no function; they always read 0. The highest valued bit of the E/S register, called AA or

Authorization Accepted, ac ts as a flag to indicat e that the data stor ed i n the sc ratchpa d has alre ad y been copi ed to

the target memory address. Writing data to the scratchpad clears this flag.

Figure 6. Address Registers

Bit #76543210

Target Address (TA1)T7T6T5T4T3T2T1T0

Target Address (TA2) T15 T14 T13 T12 T11 T10 T9 T8

Ending Address with

Data Status (E/S)

(Read Only)

AA 0 PF 0 0E2E1E0

7 of 23

Page 8

DS2431: 1024-Bit, 1-Wire EEPRO M

WRITING WITH VERIFICATION

To write data to the DS2431 , the scratchpad has to b e used as intermediat e storage. First the master issues the

Write Scratchpad command to specify the desired target address, followed by the data to be written to the

scratchpad. Note that Copy Scratchpad com mands must be perf ormed on 8-byte bo undaries, i. e., the 3 L SBs of

the target address (T2..T0) mus t be equal to 000b. If T 2..T 0 ar e sent with no n- zero v alu es, the copy function wil l be

blocked. Under certai n conditions (see Write Scr atchpad comm and) the master will receive an inverte d CRC16 of

the command, address (actual addres s sent) and data at the end of the Write Scr atchpad command sequence.

Knowing this CRC value, the master can compare it to the value it has calculated itself to decide if the

communication was s ucces sf ul and proc eed to the Copy Scra tchpa d com m and. If the m as ter could no t r eceive the

CRC16, it should send t he Read Scratchpad comm and to verify data integrit y. As a preamble t o the scratchpad

data, the DS2431 repeats the target addres s TA1 and TA2 and sends th e contents of the E/S regis ter. If the PF

flag is set, data did n ot arr i ve c orr ectly in the scratchpad or th er e was a loss of po wer s ince dat a was last wr itten to

the scratchpad. The master does not need to continue reading; it can start a new trial to write data to the

scratchpad. Similarl y, a set AA flag to gether with a c leared PF flag in dicates that the device did n ot recognize the

Write command. If everything went correctly, both flags are cleared. Now the master can continue reading and

verifying every dat a byte. After the master has verified the data, it can sen d the Copy Scratc hpad command, f or

example. This comm and must be followed exactl y by the data of the three address registers, TA1, TA2, and E/S.

The master should obtain the contents of these registers by reading the scratchpad.

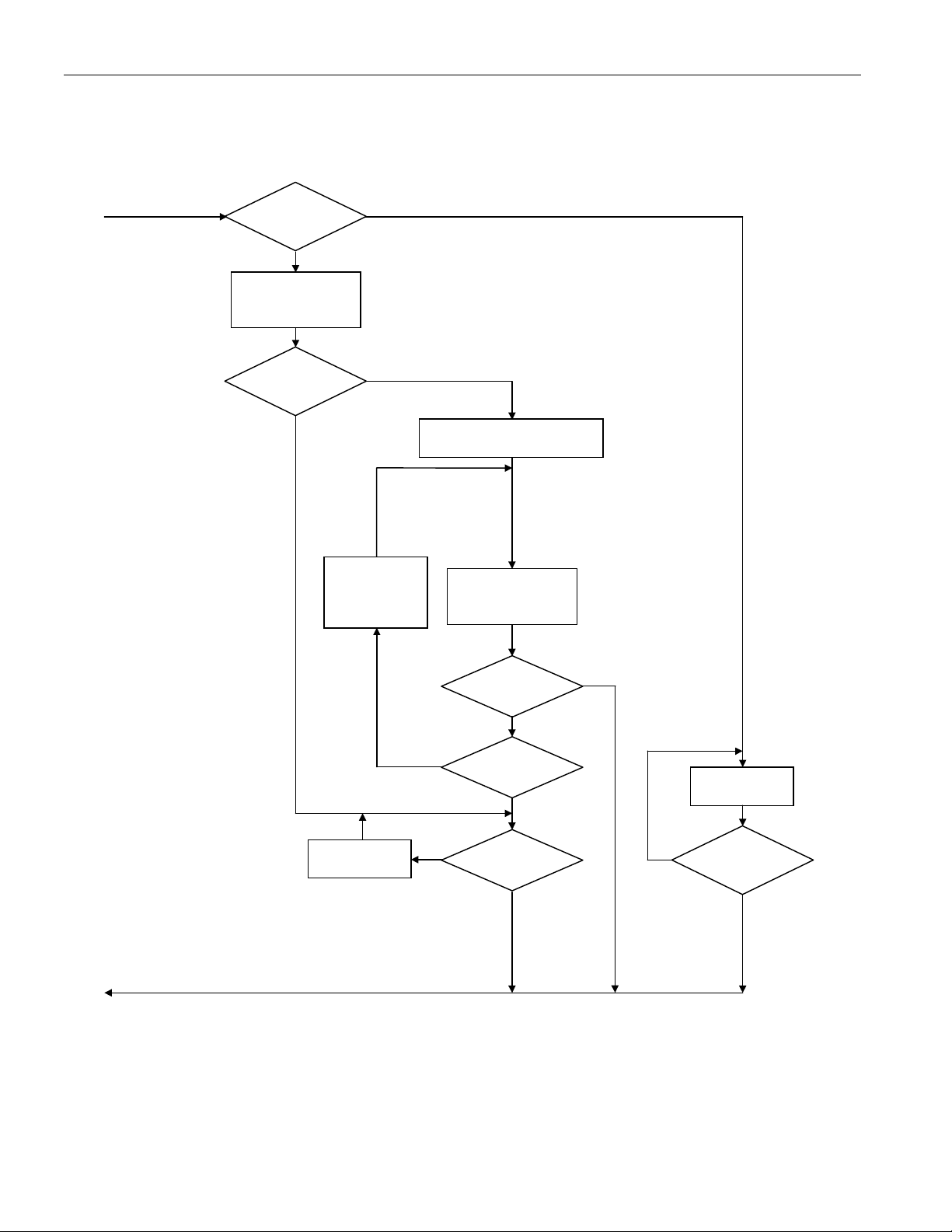

MEMORY FUNCTION COMMANDS

The Memory Funct ion Flow Chart (Figure 7) describes th e protocols necessary for ac cessing the memory of the

DS2431. An example on how to use these func tions to write to a nd read from the device is incl uded at the end of

this document. The communic ation bet wee n m as ter and DS2431 t akes place either at regul ar s pee d (def au lt, O D =

0) or at Overdrive Speed (OD = 1). If not explicitly set into the Overdrive Mode, the DS2431 assumes regular

speed.

WRITE SCRATCHPAD COMMAND [0Fh]

The Write Scratchpad comm and applies to the data mem ory, and the writable addresses i n the register page. In

order for the scratchpad data to be valid for copying to the array, the user must perform a Write Scratchpad

command of 8 bytes starting at a valid row bou ndary. The W rite Scratchpad com mand accepts in valid addres ses,

and partial rows, but subsequent Copy Scratchpad commands are blocked.

After issuing the Write Scratchp ad command, the master must first provide th e 2-byte target a ddress, followed b y

the data to be written to the scratchpad. T he data is written to th e scratchpad startin g at the byte off set of T2:T0.

The ES bits E2:E0 ar e loaded with the starting b yte offset, and increment with eac h susequent byte. Effec tively,

E2:E0 is the byte offset of the last full byte written to the scratchpad. Only full data bytes are accepted.

When executing the Write Sc ratchpad command, the CRC gener ator inside the DS2431 (Figure 13) c alculates a

CRC of the entire data stream, starting at the command code and ending at the last data byte as sent by the

master. This CRC is generat ed using the CRC16 p olynomial b y first clearing the CRC generat or and then shif ting

in the command code ( 0FH) of the W rite Scratchpad com mand, the Tar get Addresses ( TA1 and TA2), and all the

data bytes. Note that the CRC16 calculation is performed with the actual TA1 and TA2 and data sent by the

master. The master may end the W rite Scratc hpad com mand at an y time. Howev er, if th e end of the scratchpad is

reached (E2:E0 = 111b), the master may send 16 read-time slots and receive the CRC generated by the DS2431.

If a Write Scratchpad is attempted to a write- protected location, the sc ratchpad is loaded with the data already in

memory, rather than the data transm itted. Similarl y, if the target ad dress page is in EPRO M mode, the sc ratchpad

is loaded with the bitwise logical AND of the transmitted data and data already in memory.

8 of 23

Page 9

Figure 7-1. Memory Function Flow Chart

(

)

(Fig

)

(Fig

)

p

DS2431: 1024-Bit, 1-Wire EEPRO M

DS2431

Increments

E2:E0

Bus Master TX Memory

Function Command

0Fh

Write Scratch-

pad ?

Y

Bus Master TX

T7:T0), TA2 (T15:T8

TA1

DS2431 sets

Sets PF = 1

Clears AA = 0

Sets E2:E0 = T2:T0

Master TX Data Byte

To Scratch

ad

Master

TX Reset ?

N

E2:E0

N

= 7 ?

Y

T2:T0

= 0 ?

Y

From ROM Functions

Flow Chart

N

ure 9

To Figure 7

nd

Part

2

Applies only if the

memory area is not

protected.

Y

If

write-protected

, then

the DS2431 copies the

data byte from the target address into the SP.

If in

EPROM mode

,

then the DS2431 loads

the bitwise logical AND

of the transmitted byte

and the data byte from

N

the targeted address

into the SP.

Bus Master

RX “1”s

PF = 0

DS2431 TX CRC16

of Command, Address,

Data Bytes as th e y we r e

sent by the bus master

N

Master

TX Reset ?

Y

To ROM Functions

Flow Chart

9 of 23

ure 9

From Figure 7

nd

Part

2

Page 10

Figure 7-2. Memory Function Flow Chart (continued)

y

y

y

y

y

DS2431: 1024-Bit, 1-Wire EEPRO M

From Figure 7

st

Part

1

DS2431

Increments

B

te Counter

AAh

Read Scratch-

Pad ?

Y

Bus Master RX

TA1 (T7:T0), TA2 (T15:T8)

and E/S B

te

DS2431 sets Scratchpad

B

te Counter = T2:T0

Bus Master RX

Data B

te from Scratchpad

Master

Y

TX Reset ?

N

N

Byte Counter

= E2:E0 ?

To Figure 7

N

rd

Part

3

To Figure 7

st

1

Part

Bus Master

RX “1”s

Y

Bus Master RX CRC16

of Command, Address,

E/S Byte, Data Bytes as

the DS2431

sent b

N

Master

TX Reset ?

Y

From Figure 7

rd

3

Part

10 of 23

Page 11

Figure 7-3. Memory Function Flow Chart (continued)

y

p

DS2431: 1024-Bit, 1-Wire EEPRO M

From Figure 7

nd

Part

2

TA1 (T7:T0), TA2 (T15:T8)

55h

Copy Scratch-

Pad ?

Y

Bus Master TX

and E/S B

te

Auth. Code

Match ?

N

To Figure 7

N

4

th

Part

Applicable to all R/W

memory locations.

Y

T15:T0

Y

< 0090h ?

N

N

PF = 0 ?

Y

Y

Copy-

Protected ?

N

AA = 1

To Figure 7

nd

2

Part

Bus Master

RX “1”s

Master

TX Reset ?

Y

* 1-Wire idle high for power

DS2431 copies Scratch-

*

ad Data to Address

DS2431 TX “0”

Y

Master

TX Reset ?

N

N

DS2431 TX “1”

Master

N

TX Reset ?

Y

From Figure 7

th

4

Part

11 of 23

Page 12

Figure 7-4. Memory Function Flow Chart (continued)

(

)

(

)

y

From Figure 7

3

rd

Part

F0h

Read Memory ?

Y

Bus Master TX

TA1 (T7:T0),

TA2

T15:T8

N

DS2431: 1024-Bit, 1-Wire EEPRO M

Address

< 90h ?

N

DS2431

Increments

Address

Y

Counter

DS2431 sets Memory

Address =

T15:T0

Bus Master RX

Data Byte from

Memor

Address

Master

TX Reset ?

N

Y

Address

< 8Fh ?

N

Y

Bus Master

RX “1”s

N

Master

TX Reset ?

Y

To Figure 7

rd

3

Part

Bus Master

RX “1”s

N

Master

TX Reset ?

Y

12 of 23

Page 13

DS2431: 1024-Bit, 1-Wire EEPRO M

READ SCRATCHPAD COMMAND [AAh]

The Read Scratchpad c ommand allo ws verifying the t arget address and t he integrity of the scratchpa d data. After

issuing the command code, the m aster begins reading. The f irst two b ytes are the tar get addres s. The nex t byte is

the ending offset/data status byte (E/S) followed by the scratchpad data, which may be different from what the

master originally sent. This is of particular importanc e if the target address is within the regis ter page or a pag e in

either Write Protection or EPROM modes. See the Write Scratchpad description for details. The master should

read through the scratc hpad (E2: E0 – T 2:T 0 + 1 bytes) , after which it will rece ive t he in verted CRC, bas ed on data

as it was sent by the DS2431. If the master continues reading after the CRC, all data will be logic 1s.

COPY SCRATCHPAD [55h]

The Copy Scratchpad command is used to copy data from the scratchpad to writable memory sections. After

issuing the Copy Sc ratc hp ad c om mand, the master must provide a 3-byte authorization patter n , which should have

been obtained by an immediatel y preceding Read Scratchpad comm and. This 3-byte pattern must ex actly match

the data contained in the three address reg isters (TA1, TA2, E/S, in that order). If the pattern matches, the tar get

address is valid, the PF flag is not set, and the target memory is not copy-protected, the AA (Authorization

Accepted) flag is set and the cop y begins. All eight b ytes of scratchpad co ntents are copie d to the target m emory

location. The devic e ’s in ter na l d ata trans f er takes 13ms maximum during which the volt ag e on the 1- Wire bus m ust

not fall below 2.8V. A pattern of alternating 0s and 1s are transmitted after the data has been copied until the

master issues a reset pulse. If the PF f lag is s et or t he ta r get memory is copy-protec ted, t he c opy will not begin and

the AA flag will not be set.

READ MEMORY [F0h]

The Read Memory command is th e ge ner a l f unction to read data from the DS2431. After is suin g th e c om mand, the

master must provide the 2-byte targ et address. After these two b ytes, the master reads data beg inning from the

target address and may continue unti l address 008Fh. If the master continues reading, the res ult will be logic 1s.

The device's internal TA1, TA2, E/S, and scratchpad contents are not affected by a Read Memory command.

1-Wire BUS SYSTEM

The 1-Wire bus is a system that has a s ingle b us mas ter and one or m ore s laves. In all instances the DS24 31 is a

slave device. The bus m aster is t ypically a micr ocontroller. The d iscussion of this bus system is broken down into

three topics: hardware configuration, transaction sequence, and 1-Wire signaling (signal types and timing). The

1-Wire protocol def ines bus transact ions in term s of the bus state d uring specific time slots, whic h are initiat ed on

the falling edge of sync pulses from the bus master.

HARDWARE CONFIGURATION

The 1-Wire bus has only a sin gle line b y definit ion; it is important that each device on the bus be able to dr ive i t at

the appropriate time. To facilitat e this, each device attached to the 1-W ire bus must have open-drain or tr i-state

outputs. The 1-Wire port of the DS2431 is open drain with an internal circuit equivalent to that shown in Figure 8.

A multidrop bus co nsists of a 1- Wire bus with multiple sl aves att ached . T he DS2431 sup ports bot h a St andar d a nd

Overdrive communication speed of 15.4kbps (max) and 111kbps (max), respectively. Note that legacy 1-Wire

products support a st andard communication speed of 16. 3kbps and Overdrive of 142kbps. T he slightly reduced

rates for the DS2431 are a result of additional recovery times, which in turn were driven by a 1-Wire physical

interface enhancement to improve noise immunity. The value of the pullup resistor primarily depends on the

network size and load conditions. The DS2431 requires a pullup resistor of 2.2kΩ (max) at any speed.

The idle state for th e 1-W ire bus is hi gh. If for any reason a transac tion needs t o be sus pended, th e bus MUST be

left in the idle sta te if the tr ansac tion is to resum e. If this does not occur and the bus is lef t low for more than 16µs

(Overdrive speed) or more than 120µs (standard speed), one or more devices on the bus may be reset.

13 of 23

Page 14

Figure 8. Hardware Configuration

BUS MASTER DS2431 1-Wire PORT

DS2431: 1024-Bit, 1-Wire EEPRO M

V

PUP

R

PUP

RX

TX

Open Drain

Port Pin

RX = RECEIVE

TX = TRANSMIT

2.2µA

Max.

100

MOSFET

RXDATA

TX

Ω

TRANSACTION SEQUENCE

The protocol for accessing the DS2431 through the 1-Wire port is as follows:

! Initialization

! ROM Function Command

! Memory Function Command

! Transaction/Data

INITIALIZATION

All transactions on the 1-W ire bus begin with an initialization sequ ence. The initialization s equence consists of a

reset pulse transmitted by the bus mas ter followed b y presence pulse( s) transm itted b y the slave(s ). The pres ence

pulse lets the bus master know that the DS2431 is on the bus and is ready to operate. For more details, see the

1-Wire Signaling section.

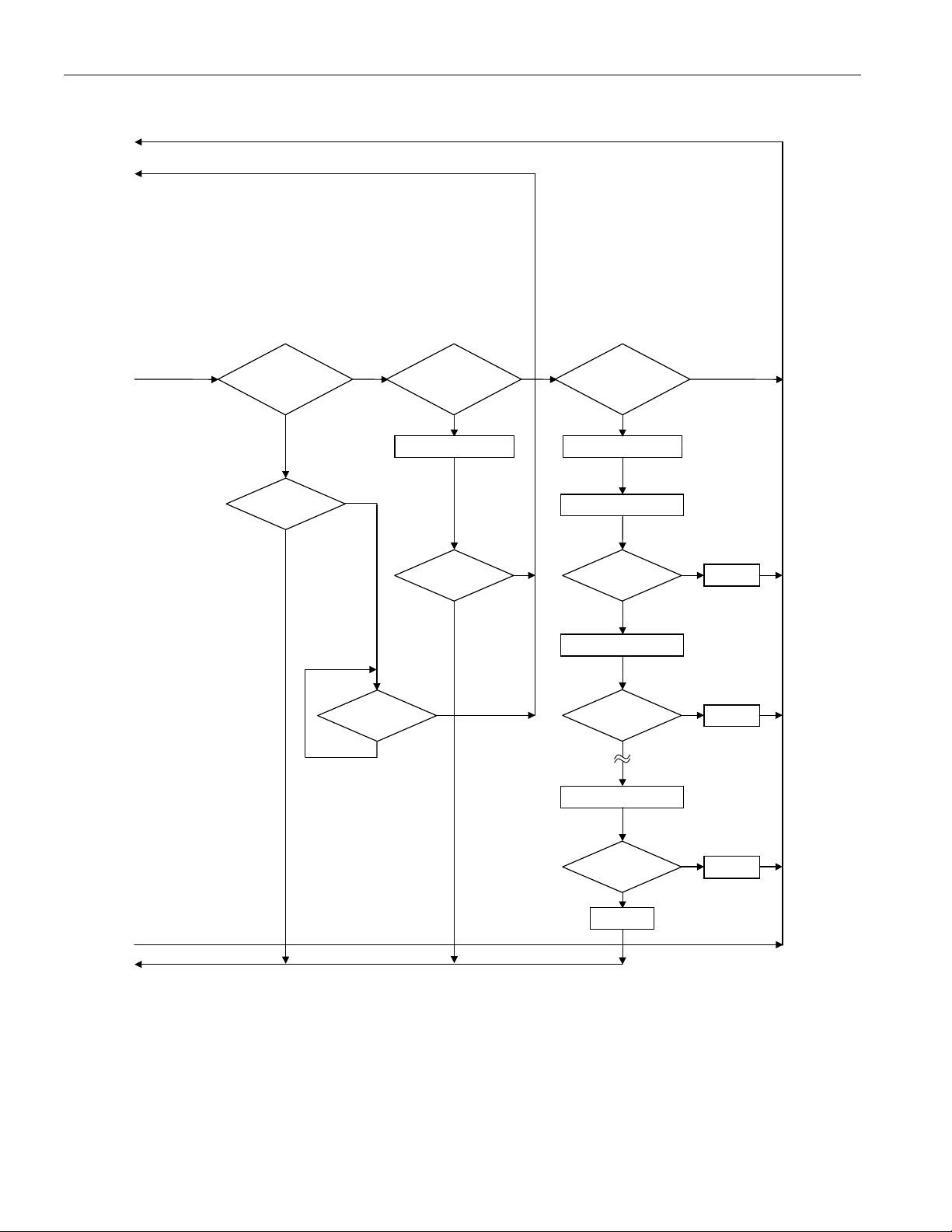

1-Wire ROM FUNCTION COMMANDS

Once the bus mas ter has detected a presence, it can issue one of the seven ROM f unction commands that th e

DS2431 supports. Al l ROM functio n comm ands are 8 bits lon g. A list of these com mands follo ws (refer to the flow

chart in Figure 9).

READ ROM [33h]

This command allows the bus m aster to read the DS2431’s 8-bit famil y code, u ni que 48- bit s eri al number, and 8-bit

CRC. This command can only be used if there is a single slave on the bus. If more than one slave is present on the

bus, a data collision occurs when all slaves try to transm it at the same time (open drain produces a wired-AND

result). The resultant family code and 48-bit serial number result in a mismatch of the CRC.

MATCH ROM [55h]

The Match ROM command, followed by a 64-bit ROM sequence, allows the bus master to address a specific

DS2431 on a multidrop bus. Only the DS2431 that exactly matches the 64-bit ROM sequence responds to the

following mem ory function command. All other sla ves wait for a reset pulse. This command can be used with a

single or multiple devices on the bus.

14 of 23

Page 15

DS2431: 1024-Bit, 1-Wire EEPRO M

SEARCH ROM [F0h]

When a system is initiall y brought up, the b us mas ter might not k now the n umber of devices on th e 1-W ire bus or

their registration numbers. By taking advantage of the wired-AND property of the bus, the master can use a

process of elimination to identify the registration numbers of all slave devices. For each bit of the registration

number, starting with the l east significant bit, the bus m aster issues a triplet of tim e slots. On the first slot, each

slave device participating in the search outputs the true val ue of its registration number bit. On the second slot,

each slave device par tic ipating in the s earc h outputs the c om plem ented val ue of its r egistrat ion num ber bit. On t he

third slot, the master writes the true value of the bit to be selected. All slave devices that do not m atch the bit

written by the master s top participat ing in th e search. If b oth of the read bits ar e zero, th e mas ter knows that s lave

devices exist with both states of the bit. By choos ing whic h state to wr ite, the bus mas ter branches in the rom code

tree. After one com plete pass, th e bus m aster k nows the regis tration num ber of a single d evice. Addition al pass es

identify the registr ation num bers of the rem aining dev ices. Refer to Appl ication N ote 187: 1-Wir e Search Algor ithm

for a detailed discussion, including an example.

SKIP ROM [CCh]

This command can save time in a single-drop bus system by allowing the bus master to access the memory

functions without providing the 64- bit ROM code. If more than one s lave is presen t on the bus and, for exam ple, a

Read command is issued follo wing the Skip ROM command, data collis ion occurs on the bus as m ultiple slaves

transmit simultaneously (open-drain pulldowns produce a wired-AND result).

RESUME [A5h]

To maximize the data throughput in a multidrop environment, the Resume function is available. This function

checks the status of the RC bit and, if it is set, directly transfers control to the Memory functions, similar to a Skip

ROM command. The only way to set the RC bit is t hr oug h suc c ess f ull y exec uting th e Matc h ROM, Search ROM, or

Overdrive Match ROM command. Once the RC bit is set, the device can repeatedly be accessed through the

Resume Command function. Accessing another device on the bus clears the RC bit, preventing two or more

devices from simultaneously responding to the Resume Command function.

OVERDRIVE SKIP ROM [3Ch]

On a single-drop bus this comm and can save time b y allowing the bus master to access the memor y functions

without providing the 64-bit ROM c ode. Unlike the nor mal Skip ROM c ommand, the O verdrive Sk ip ROM sets the

DS2431 in the Overdr ive mode (OD = 1). All comm unication following this c ommand has to occur at Overdrive

speed until a reset pulse of minimum 480µs duration resets all devices on the bus to standard speed (OD = 0).

When issued on a multidrop bus, this command sets all Overdrive-supporting devices into Overdrive mode. To

subsequently address a specific Overdrive- supporting device, a res et pulse at Overdrive speed has to be issued

followed by a Match ROM or Search ROM comm and sequence. T his spee ds up the tim e f or the search pr ocess. If

more than one slave supporting Overdr i ve is present on the bus and the O verdri ve Skip ROM command is f oll owe d

by a Read command, data collision occurs on the bus as multiple slaves transmit simultaneously (open-drain

pulldowns produce a wired-AND result).

OVERDRIVE MATCH ROM [69h]

The Overdrive Match RO M command follo wed by a 64-bit ROM sequ ence transmitted at O verdrive Speed a llows

the bus master to address a specific DS2 431 on a multidrop b us and to simultaneous ly set it in Overdrive mode.

Only the DS2431 that exac tly matches the 64-bit ROM sequence res ponds to the subsequent m emory function

command. Slaves already in Overdrive mode from a previous Overdrive Skip or successful Overdrive Match

command remain in Overdrive mode. All overdrive-capable slaves return to standard speed at the next Reset Pulse

of minimum 480µs duration. The Overdri ve Match ROM com m and can be used with a sing le or m ulti ple dev ices on

the bus.

15 of 23

Page 16

Figure 9-1. ROM Functions Flow Chart

)

y

(Fig

)

Bus Master TX

From Memory Functions

Flow Chart

ure 7

Reset Pulse ?

Reset Pulse

OD

Y

DS2431: 1024-Bit, 1-Wire EEPRO M

From Figure 9, 2nd Part

N

OD = 0

Bus Master TX ROM

Function Command

33h

Read ROM

Command ?

RC = 0

DS2431 TX

Family Code

(1 Byte)

DS2431 TX

Serial Number

(6 Bytes)

DS2431 TX

Presence Pulse

N

55h

Match ROM

Command ?

RC = 0

Master TX Bit 0

Bit 0

Match ?

Master TX Bit 1

Bit 1

Match ?

N

N

N

Y

N

N

Y

F0h

Search ROM

Command ?

YY YY

RC = 0

DS2431 TX Bit 0

DS2431 TX Bit 0

Master TX Bit 0

Bit 0

Match ?

Y

DS2431 TX Bit 1

DS2431 TX Bit 1

Master TX Bit 1

Bit 1

Match ?

Y

N

CCh

Skip ROM

Command ?

RC = 0

To Figure 9

2nd Part

N

DS2431 TX

CRC B

te

Master TX Bit 63

Bit 63

Match ?

Y

RC = 1

N

To Memory Functions

Flow Chart (Figure 7

DS2431 TX Bit 63

DS2431 TX Bit 63

Master TX Bit 63

N

Bit 63

Match ?

RC = 1

Y

To Figure 9

2nd Part

From Figure 9

nd

Part

2

16 of 23

Page 17

Figure 9-2. ROM Functions Flow Chart (continued)

To Figure 9, 1st Part

From Figure 9

1

st

Part

A5h

Resume

Command ?

N

3Ch

Overdrive

Skip ROM ?

DS2431: 1024-Bit, 1-Wire EEPRO M

N

69h

Overdrive Match

ROM ?

N

From Figure 9

st

1

Part

RC = 1 ?

Y

Y

N

Master

TX Reset ?

N

Y

RC = 0 ; OD = 1

Master

TX Reset ?

N

Y

Y

RC = 0 ; OD = 1

Master TX Bit 0

Y

Bit 0

Match ?

N

OD = 0

Y

Master TX Bit 1

Bit 1

Match ?

N

OD = 0

Y

Master TX Bit 63

Bit 63

Match ?

N

OD = 0

Y

RC = 1

To Figure 9

st

1

Part

17 of 23

Page 18

DS2431: 1024-Bit, 1-Wire EEPRO M

1-Wire SIGNALING

The DS2431 requires strict pr otocols to ensure data integr ity. The protocol consists of four types of signaling on

one line: Reset Sequence with Reset Puls e and Presence Pulse, Wr ite-Zero, Write-One, and Read-Dat a. Except

for the Presence pu lse, the bus master initiates all falling edges. The D S2431 can communicate at t wo different

speeds, standard speed, and Overdrive Speed. If not explicitly set into the Overdrive mode, the DS2431

communicates at standard speed. While in Overdrive Mode the fast timing applies to all waveforms.

To get from idle to ac tive, the voltage on the 1- Wire line needs to fall from V

from active to id le, the vo ltage nee ds to rise from V

past the threshold VTH. The time it takes for the voltage to

ILMAX

make this rise is seen in Figure 10 as 'ε' and its duration depends on the pullup resistor (R

capacitance of the 1-W ire network attached.

The voltage V

is relevant for the DS2431 when determining a

ILMAX

below the threshold VTL. To get

PUP

) used and the

PUP

logical level, not triggering any events.

Figure 10 shows the init ialization sequence re quired to be gin any comm unication with the DS243 1. A Reset Pul se

followed by a Prese nce Pulse in dicates the DS 2431 is read y to receive data, g iven the correct RO M and mem ory

function comm and. If the bus master uses slew-r ate c ontro l o n th e falling edge, it must pull do wn t he line for t

t

to compensate for the edg e. A t

F

standard speed. If the DS2431 is in Overdrive Mode and t

duration of 480µs or longer exits t he Overdr iv e Mode, re turn ing the devic e to

RSTL

is no longer than 80µs. the device remains in

RSTL

RSTL

+

Overdrive Mode.

Figure 10. Initialization Procedure: Reset and Presence Pulse

MASTER TX “RESET PULSE” MASTER RX “PRESENCE PULSE”

t

t

PDH

MSP

t

PDL

t

RSTH

t

REC

V

IHMASTER

V

V

PUP

V

TH

V

ILMAX

0V

ε

TL

t

F

t

RSTL

RESISTOR MASTER DS2431

After the bus master has release d the line it goes in to rece ive m ode. Now the 1- W ire bus is pulled to V

the pullup resistor, or in case of a DS2482-x 00 or DS2480B driver, b y active circuitry. W hen the thresho ld V

crossed, the DS2431 wa its f or t

presence pulse, the master must test the logical state of the 1-Wire line at t

The t

window must be at leas t the sum of t

RSTH

DS2431 is ready for da ta communication. In a mixed population network, t

and then transm its a Pr esence Puls e b y pullin g the l ine lo w for t

PDH

PDHMAX

, t

PDLMAX

, and t

RECMIN

.

MSP

. Immediately after t

should be extended to m inimum

RSTH

PDL

is expired, the

RSTH

through

PUP

TH

is

. To detect a

480µs at standard speed and 48µs at Overdrive speed to accommodate other 1-Wire devices.

Read-/Write-Time Slots

Data communication with the DS2431 takes place in time slots, which carry a single bit each. Write-time slots

transport data from bus master to s lave. Read-time slots transf er data from slave to master. F igure 11 illustrates

the definitions of the write- and read-time slots.

All communication begins with the m aster pulling the data line lo w. As the voltage on t he 1- Wire line falls below the

threshold V

a write-time slot and how long data is valid during a read-time slot.

, the DS2431 starts its intern al tim ing generat or that deter mines whe n the da ta line is s ampled during

TL

18 of 23

Page 19

DS2431: 1024-Bit, 1-Wire EEPRO M

Master-to-Slave

For a write-one time slot, the voltage on the data line must have crossed the VTH threshold befor e the write-one

low time t

threshold until the write-zero low time t

data line should not ex ceed V

the DS2431 needs a recovery time t

Figure 11. Read/Write Timing Diagram

Write-One Time Slot

is expired. For a write-zero time slot, the voltage on the data line must stay below the V

W1LMAX

is expired. For the m ost reliable comm unication, the voltage on the

V

IHMASTER

V

V

PUP

V

TH

V

ILMAX

W0LMIN

during the entire t

ILMAX

t

W1L

TL

before it is ready for the next time slot.

REC

W0L

or t

window. After the VTH threshold has been c rossed,

W1L

0V

t

F

ε

t

SLOT

RESISTOR MASTER

TH

Write-Zero Time Slot

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

t

F

Read-Data Time Slot

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

t

F

t

W0L

t

SLOT

RESISTOR MASTER

t

t

RL

MSR

Master

Sampling

Window

δ

t

SLOT

t

REC

t

REC

RESISTOR MASTER DS2431

19 of 23

Page 20

DS2431: 1024-Bit, 1-Wire EEPRO M

Slave-to-Master

A read-data time slot begins lik e a write- on e t ime slot. The voltage o n th e d ata li ne must remain below VTL until the

read low time t

line low; its internal timing generat or deter m ines when this pulld own ends and the vo ltage st arts r ising ag ain. W hen

responding with a 1, the DS2431 does not hold the data line low at all, and the voltage starts rising as soon as t

over.

is expired. During th e tRL window, when resp onding with a 0, the D S2431 starts pull ing the data

RL

RL

is

The sum of t

the master sampling window (t

most reliable c ommunication, t

later than t

sufficient recovery time t

applies only to a single DS2431 attached to a 1-Wire line. For multidevice configurations, t

+ δ (rise time) on one side and the in ternal t iming gener ator of the DS2431 on the oth er side def ine

RL

. After reading from the data line, the m aster must wait until t

MSRMAX

for the DS2431 to get ready for the next time slot. Note that t

REC

to t

MSRMIN

should be as short as permissible, and the m aster should read clos e to but no

RL

) in which the master must perf orm a r ead f r om the data l ine. F or the

MSRMAX

is expired. This guarantees

SLOT

specified herein

REC

REC

needs to be

extended to accommodate the addit ional 1-W ire device input c apacitance. A lternatively, a n interf ace that perf orms

active pullup during the 1-Wire recovery time such as the DS2482-x00 or DS2480B 1-W ire line drivers can be

used.

IMPROVED NETWORK BEHAVIOR (SWITCHPOINT HYSTERESIS)

In a 1-Wire environment, line term ination is possible only during transients contro lled by the bus master (1-W ire

driver). 1-W ire networks , therefore, ar e suscept ible to no ise of various or igins. De pending o n the p hysical si ze and

topology of the net work, reflections fr om end points and bra nch points can add up, or cancel each other to some

extent. Such reflec tions ar e vis ible as glitc hes or ringi ng on t he 1-Wire communication li ne. Noise c oupled on to t he

1-Wire line from external sourc es can als o res ult in s igna l gl itchi ng. A g li tc h d uring th e r isin g e dge of a time slot can

cause a slave device to lose synchroni zation with the m as ter and, co nsequ entl y, result i n a se arch ROM c omm and

coming to a dead end or cause a device-specific f unction command to abort. For be tter performance in network

applications, the DS2431 uses a new 1-Wire front end, which m akes it les s sens itive to no ise an d also r educ es th e

magnitude of noise injected by the slave device itself.

The 1-Wire front end of the DS2431 differs from traditional slave devices in four characteristics.

1) The falling edge of the presence pulse has a controlled slew rate. This provides a better match to the line

impedance than a digitally switched transistor, converting the high-frequency ringing known from traditional

devices into a smoother low-bandwidth transition. The slew-rate control is specified by the parameter t

which has different values for standard and Overdrive speed.

2) There is additional low-pas s filtering in the cir cuit that detects the f alling edge at the begi nning of a time slot.

This reduces the sensitivity to high-frequency noise. This additional filtering does not apply at Overdrive speed.

3) There is a hysteresis at the low-to-high switching threshold V

below V

- VHY, it will not be recognized (Figure 12, Case A). The hysteresis is effective at any 1-Wire speed.

TH

4) T here is a tim e windo w spec ified by th e risin g edge hold- off tim e t

they extend below V

appear late after cr ossing the V

- VHY threshold (Figure 12, Cas e B, tGL < t

TH

threshold and extend be yond the t

TH

taken as the beginning of a new time slot (Figure 12, Case C, t

Only devices that have the parameters t

, VHY, and t

FPD

REH

. If a negative g litc h cr os s es VTH but does not go

TH

during which glit ches ar e ign ored, even if

REH

). Deep voltage dr oops or glitches that

REH

window cannot be filtered out and are

REH

≥ t

REH

).

GL

specified in their electrical characteristics use the

improved 1-Wire front end.

FPD

,

Figure 12. Noise Suppression Scheme

V

PUP

V

TH

V

HY

Case A Case CCase B

0V

t

REH

t

GL

20 of 23

t

REH

t

GL

Page 21

DS2431: 1024-Bit, 1-Wire EEPRO M

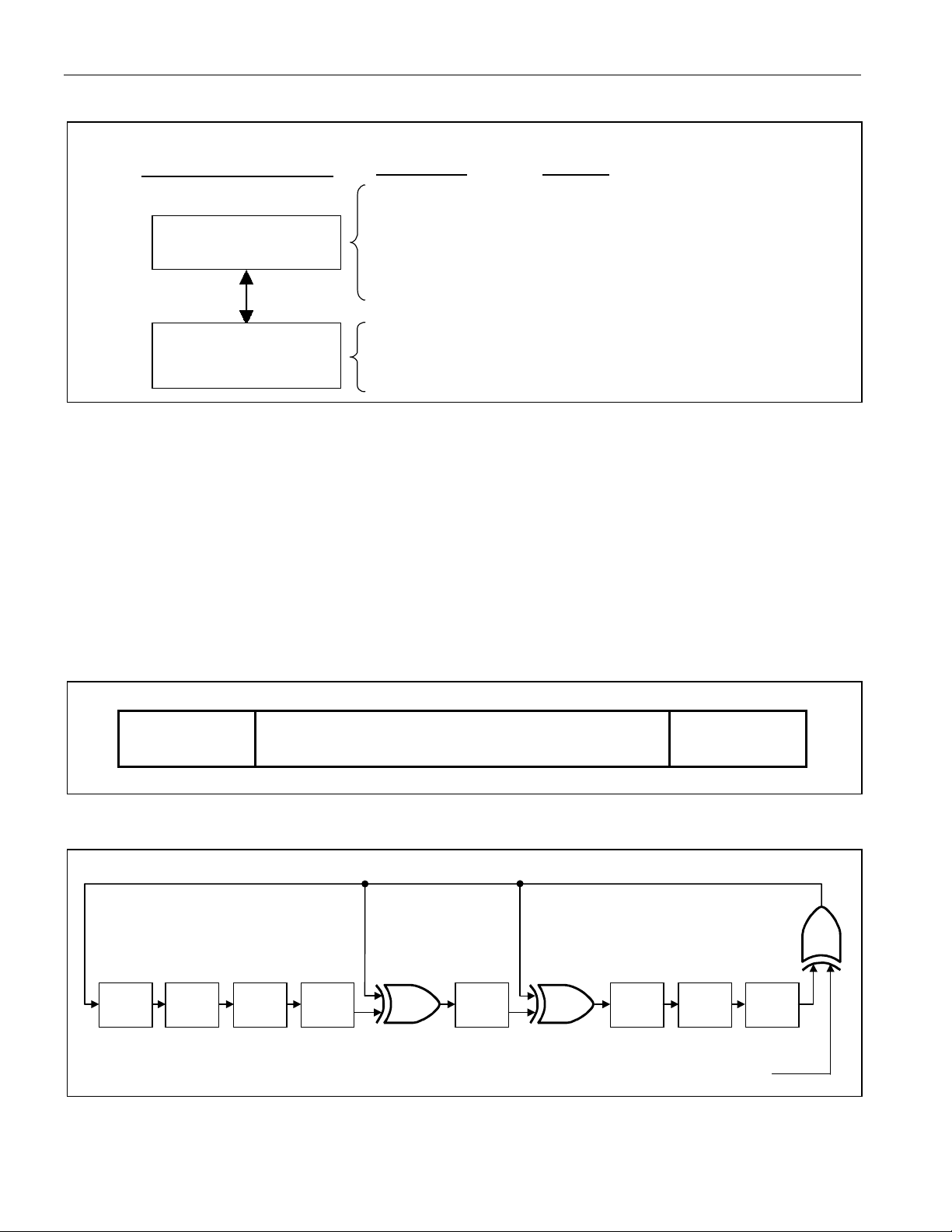

CRC GENERATION

With the DS2431 there are two different types of CRCs. One CRC is an 8-bit type and is stored in the most

significant byte of the 64-bit ROM. The bus master can compute a CRC value f rom the first 56 bits of the 64-bit

ROM and compare it t o the val ue store d with in t he DS24 31 to d eterm ine if the ROM data has b een recei ved er rorfree. The equivalen t polynomial function of this CRC is X

(noninverted) form. It is computed at the factory and lasered into the ROM.

8

+ X5 + X4 + 1. This 8-bit CRC is received i n the true

16

The other CRC is a 16-b it type, g enerated accordin g to the s tandardize d CRC 16-polynom ial f unction x

+ x15 + x

+ 1. This CRC is use d for fast verification of a data tra nsfer when writing to or reading f rom the scratchpad. In

contrast to the 8-bit CRC, the 16-bit CRC is always communicated in the inverted form . A CRC gen erator inside the

DS2431 chip (Figure 13) calcul ates a new 16-bit CRC, as shown in the command flow c hart (Figure 7). The bus

master compares the CRC value read f rom the dev ice to the one it calculat es from the data, an d decides whether

to continue with an operation or to reread the portion of the data with the CRC error.

With the Write Scratchpad command, the CRC is generate d by first clearing the CRC gen erator and the n s hif tin g in

the command code, the Target Addresses TA1 and TA2, and all the data bytes as they were sent by the bus

master. The DS2431 transmits this CRC only if E2:E0 = 111b.

With the Read Scratchpad command, the CRC is gen erate d by first clearing the CRC gener ator a nd t hen shif tin g i n

the Command code, the Tar get Addres ses T A1 and T A2, th e E/S byte, and the s cratchp ad data as the y were se nt

by the DS2431. The DS 2431 transmits this CRC on ly if the reading cont inues through the end of the scratchpad.

For more information on generating CRC values, refer to

Application Note 27

.

Figure 13. CRC-16 Hardware Description and Polynomial

Polynomial = X16 + X15 + X2 + 1

st

1

STAGE

nd

2

STAGE

rd

3

STAGE

th

4

STAGE

th

5

STAGE

th

6

STAGE

th

7

STAGE

th

8

STAGE

2

0

X

8

X

9

STAGE

1

X

th

STAGE

9

X

10

th

11

th

STAGE

10

X

STAGE

11

X

2

X

th

12

STAGE

12

X

3

X

th

13

13

X

4

X

th

14

STAGE

14

X

5

X

th

15

STAGE

6

X

7

X

th

16

STAGE

15

X

16

X

CRC

OUTPUT

INPUT DATA

COMMAND-SPECIFIC 1-Wire COMMUNICATION PROTOCOL—COLOR CODES

Master to slave Slave to master Programming

21 of 23

Page 22

DS2431: 1024-Bit, 1-Wire EEPRO M

COMMAND-SPECIFIC 1-Wire COMMUNICATION PROTOCOL—LEGEND

SYMBOL DESCRIPTION

RST 1-Wire Reset Pulse generated by master.

PD 1-Wire Presence Pulse generated by slave.

Select Command and data to satisfy the ROM function protocol.

WS Command "Write Scratchpad".

RS Command "Read Scratchpad".

CPS Command "Copy Scratchpad".

RM Command "Read Memory".

TA Target Address TA1, TA2.

TA-E/S Target Address TA1, TA2 with E/S byte.

<8 – T2:T0 bytes>

<data to EOM> Transfer of as many data bytes as are needed to reach the end of the memory.

CRC16\ Transfer of an inverted CRC16.

FF loop Indefinite loop where the master reads FF bytes.

AA loop Indefinite loop where the master reads AA bytes.

Programming Data transfer to EEPROM; no activity on the 1-Wire bus permitted during this time.

Transfer of as many bytes as needed to reach the end of the scratchpad for a given

target address.

WRITE SCRATCHPAD (CANNOT FAIL)

RST PD Select WS TA <8 – T2:T0 bytes> CRC16\ FF loop

READ SCRATCHPAD (CANNOT FAIL)

RST PD Select RS TA-E/S <8 – T2:T0 bytes> CRC16\ FF loop

COPY SCRATCHPAD (SUCCESS)

RST PD Select CPS TA-E/S Programming AA lo op

COPY SCRATCHPAD (INVALID ADDRESS OR PF = 1 OR COPY PROTECTED)

RST PD Select CPS TA-E/S FF loop

READ MEMORY (SUCCESS)

RST PD Select RM TA <data to EOM> FF loop

READ MEMORY (INVALID ADDRESS)

RST PD Select RM TA FF loop

22 of 23

Page 23

DS2431: 1024-Bit, 1-Wire EEPRO M

MEMORY FUNCTION EXAMPLE

Write to the first 8 bytes of memory page 1. Read the entire memory.

With only a single DS2431 connected to the bus master, the communication looks like this:

MASTER MODE DATA (LSB FIRST) COMMENTS

TX (Reset) Reset pulse

RX (Presence) Presence pulse

TX CCh Issue “Skip ROM” command

TX 0Fh Issue “Write scratchpad” command

TX 20h TA1, beginning offset=20h

TX 00h TA2, address=0020h

TX <8 data bytes> Write 8 bytes of data to scratchpad

RX <2 bytes CRC16\> Read CRC to check for data integrity

TX (Reset) Reset pulse

RX (Presence) Presence pulse

TX CCh Issue “Skip ROM” command

TX AAh Issue “Read scratchpad” command

RX 20h Read TA1, beginning offset=20h

RX 00h Read TA2, address=0020h

RX 07h Read E/S, ending offset=111b, AA, PF = 0

RX <8 data bytes> Read scratchpad data and verify

RX <2 bytes CRC16\> Read CRC to check for data integrity

TX (Reset) Reset pulse

RX (Presence) Presence pulse

TX CCh Issue “Skip ROM” command

TX 55h Issue “copy scratchpad” command

TX 20h TA1

TX 00h TA2 (AUTHORIZATION CODE)

TX 07h E/S

---- <1-Wire idle high> Wait 13 ms for the copy function to complete

RX AAh Read copy status, AAh = success

TX (Reset) Reset pulse

RX (Presence) Presence pulse

TX CCh Issue “Skip ROM” command

TX F0h Issue “Read Memory” command

TX 00h TA1, beginning offset=00h

TX 00h TA2, address=0000h

RX <144 data bytes> Read the entire memory

TX (Reset) Reset pulse

RX (Presence) Presence pulse

PACKAGE INFORMATION

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information, go to

www.maxim-ic.com/DallasPackInfo

Maxim/Dallas Semiconductor cannot assume responsibility for use of any circuitry other than circuitry entirely embodied

in a Maxim/Dallas Semiconductor product. No circuit patent licenses are implied. Maxim/Dallas Semiconductor reserves the

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

MAXIM

is a registered trademark of Maxim Integrated Products, Inc.

right to change the circuitry and specifications without notice at any time.

.)

23 of 23

© 2004 Maxim Integrated Products • Printed USA

DALLAS

is a registered trademark of Dallas Semiconductor Corporati on.

Loading...

Loading...