Page 1

N

www.maxim-ic.com

DS2404

EconoRAM Time Chip

FEATURES

§ 4096 bits of nonvolatile dual-port memory

including real time clock/calendar in binary

format, programmable interval timer, and

programmable power-on cycle counter

®

§ 1-Wire

interface for MicroLAN

communication at 16.3kbits/s

§ 3-wire host interface for high-speed data

communications at 2Mb/s

§ Unique, factory-lasered and tested 64-bit

registration number (8-bit family code +

48-bit serial number + 8-bit CRC tester)

assures absolute traceability because no two

parts are alike

§ Memory partitioned into 16 pages of 256-bits

for packetizing data

§ 256-bit scratchpad with strict read/write

protocols ensures integrity of data transfer

§ Programmable alarms can be set to generate

interrupts for interval timer, real time clock,

and/or cycle counter

§ 16-pin DIP, SO, and SSOP packages

§ Operating temperature range from -40°C to

+85°C

§ Operating voltage range from 2.8V to 5.5V

ORDERING INFORMATION

DS2404-001 16-pin DIP

DS2404S-001 16-pin SO

DS2404B 16-pin SSOP

DS2404S-001/T&R Tape and Reel of S2404S-001

DS2404B/T&R Tape and Reel of DS2404B

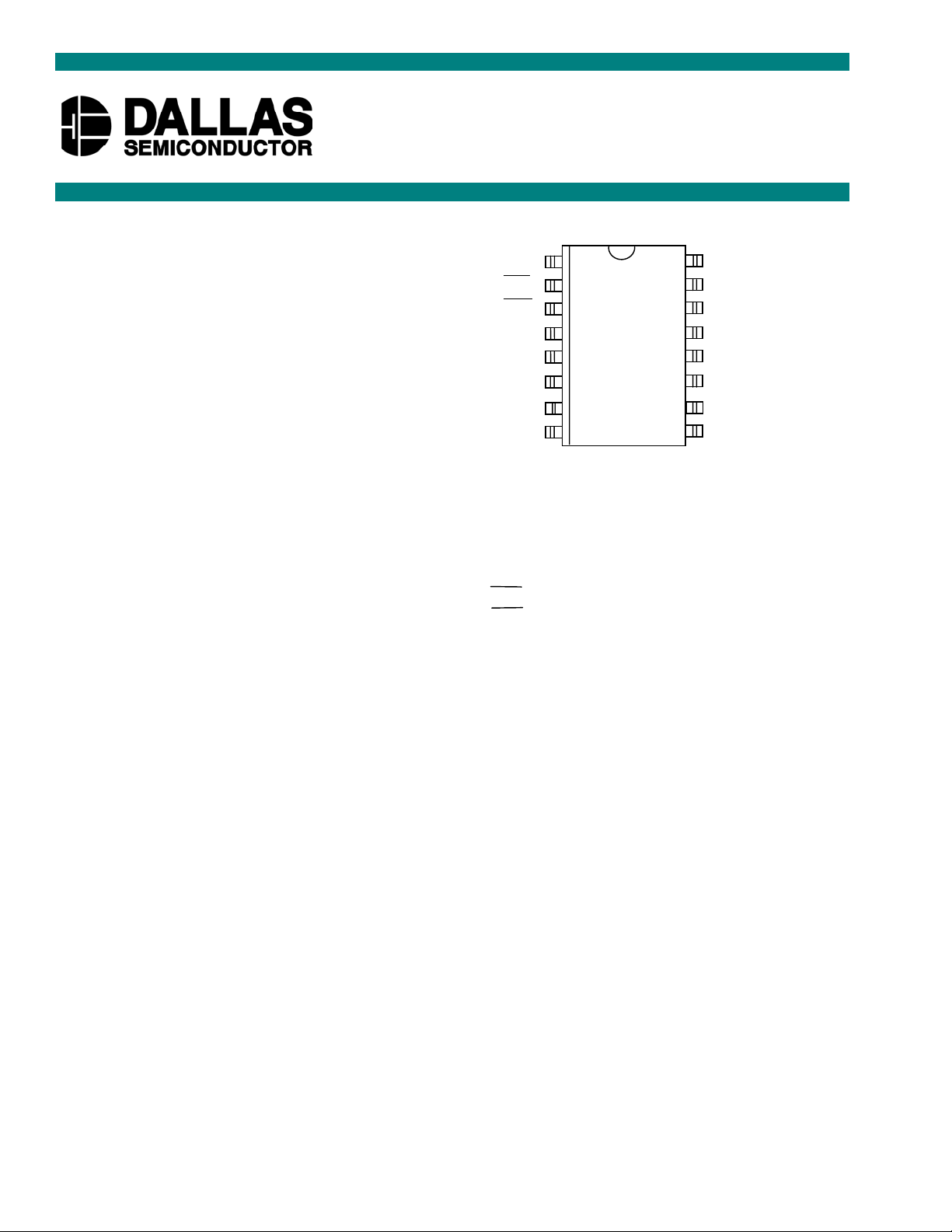

PIN ASSIGNMENT

VCC 1 16 VCC

IRQ 2 15 X1

RST 3 14 X2

DQ 4 13 GND

I/O 5 12 NC

CLK 6 11 1HZ

C 7 10VBATO

GND 8 9 VBATB

16-PIN DIP (300 MIL)

16-PIN SO (300 MIL)

16-PIN SSOP (208 MIL)

See Mechanical Drawings Section

PIN DESCRIPTION

VCC – 2.8 to 5.5V

IRQ – Interrupt Output

RST – 3-Wire Reset Input

DQ – 3-Wire Input/Output

I/O – 1-Wire Input/Output

CLK – 3-Wire Clock Input

NC – No Connection

GND – Ground

V

– Battery Backup Input

BATB

V

1Hz – 1Hz Output

X1, X2 – Crystal Connections

– Battery Operate Input

BATO

DESCRIPTION

The DS2404 EconoRAM Time Chip offers a simple solution for storing and retrieving vital data and time

information with minimal hardware. The DS2404 contains a unique lasered ROM, real-time

clock/calendar, interval timer, cycle counter, programmable interrupts, and 4096-bits of SRAM. Two

separate ports are provided for communication: 1-Wire and 3-wire. Using the 1-Wire port, only one pin is

required for communication, and the lasered-ROM can be read even when the DS2404 is without power.

The 3-wire port provides high-speed communication using the traditional Dallas Semiconductor 3-wire

interface. With either interface, a strict protocol for accessing the DS2404 ensures data integrity. Utilizing

backup energy sources, the data is nonvolatile (NV) and allows for stand-alone operation.

1 of 29 110501

Page 2

DS2404

The DS2404 features can be used to create a stopwatch, alarm clock, time and date stamp, logbook, hour

meter, calendar, system power-cycle timer, expiration timer, and event scheduler.

DETAILED PIN DESCRIPTION

PIN SYMBOL DESCRIPTION

1,16 V

2

3

CC

IRQ

RST

4DQData input/output pin for 3-wire operation.

5I/OData input/output for 1-Wire operation: Open drain. (See “Parasite

6CLKClock input pin for 3-wire operation.

7,12 NC

8,13 GND Ground pin. Either pin can be used for ground.

9V

10 V

BATB

BATO

11 1Hz 1Hz square wave output: Open drain.

14,15 X1,X

2

Power input pins for V

one can be used for V

V

pin description and “Power Control” section).

BATO

operate mode. 2.8V to 5.5V operation. Either

CC

Only one is required for normal operation. (See

CC.

Interrupt output pin. Open drain.

Reset input pin for 3-wire operation. (See “Parasite Power” section.)

Power” section.)

No connection pins.

Battery backup input pin. Battery voltage can be 2.8V to 5.5V. (See

V

Battery operate input pin for 2.8V to 5.5V operation. The V

V

pin description and “Power Control” section.)

BATO

pins must be grounded when this pin is used to power the chip.

BATB

CC

&

(See “Power Control” section.)

Crystal pins. Connections for a standard 32.768kHz quartz crystal,

EPSON part number C-002RX or C-004R (be sure to request 6pF load

capacitance).

NOTE: X1 and X2 are very high impedance nodes. It is recommended

that they and the crystal be guard-ringed with ground and that high

frequency signals be kept away from the crystal area. See Figure 18 and

Application Note 58 for details.

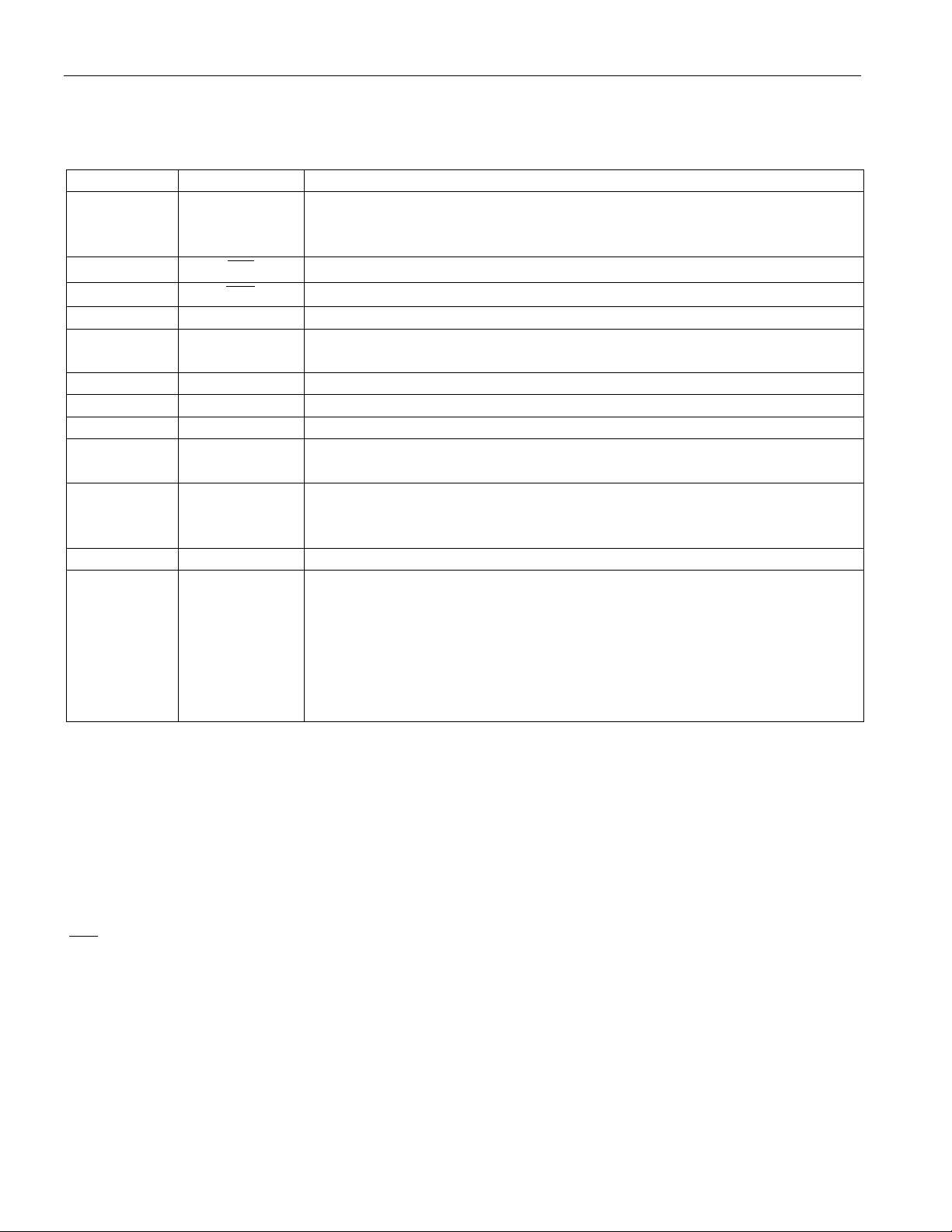

OVERVIEW

The DS2404 has four main data components: 1) 64-bit lasered ROM, 2) 256-bit scratchpad, 3) 4096-bit

SRAM, and 4) timekeeping registers. The timekeeping section utilizes an on-chip oscillator that is

connected to an external 32.768kHz crystal. The SRAM and timekeeping registers reside in one

contiguous address space referred to hereafter as memory. All data is read and written least significant bit

first.

Two communication ports are provided a 1-Wire port and a 3-wire port. A port selector determines which

of the two ports is being used. The communication ports and the ROM are parasite-powered via I/O,

RST , or V

through the 1-Wire port. The scratchpad and memory are accessible via either port.

If the 3-wire port is used, the master provides one of four memory function commands: 1) read memory,

2) read scratchpad, 3) write scratchpad, or 4) copy scratchpad. The only way to write memory is to first

write the scratchpad and then copy the scratchpad data to memory. (See Figure 6.)

If the 1-Wire port is used, the memory functions will not be available until the ROM function protocol

has been established. This protocol is described in the ROM functions flow chart (Figure 9). The master

must first provide one of five ROM function commands: 1) read ROM, 2) match ROM, 3) search ROM,

. This allows the ROM to be read in the absence of power. The ROM data is accessible only

CC

2 of 29

Page 3

DS2404

4) skip ROM or 5) search interrupt. After a ROM function sequence has been successfully executed, the

memory functions are accessible and the master may then provide any one of the four memory function

commands (Figure 6).

The “Power Control” section provides for two basic power configurations: battery operate mode and V

operate mode. The battery operate mode utilizes one supply connected to V

may utilize two supplies; the primary supply connects to VCC and a backup supply connects to V

. The VCC operate mode

BATO

BATB

.

DS2404 BLOCK DIAGRAM Figure 1

CC

COMMUNICATION PORTS

Two communication ports are provided: a 1-Wire and a 3-wire port. The advantages of using the 1-Wire

port are as follows: 1) provides access to the 64-bit lasered ROM, 2) consist of a single communication

signal (I/O), and 3) multiple devices may be connected to the 1-Wire bus. The 1-Wire bus has a

maximum data rate of 16.3kbits/s and requires one 5kW external pull-up.

The 3-wire port consists of three signals: RST , CLK, and DQ. RST is an enable input, DQ is bidirectional

serial data, and the CLK input is used to clock in or out the serial data. The advantages of using the

3-wire port are 1) high data transfer rate (2MHz), 2) simple timing, and 3) no external pull-up required.

3 of 29

Page 4

DS2404

Port selection is accomplished on a first-come, first-serve basis. Whichever port comes out of reset first

will obtain control. For the 3-wire port, this is done by bringing RST high. For the 1-Wire port, this is

done on the first falling edge of I/O after the reset and presence pulses. (See “1-Wire Signaling” section.)

More information on how to arbitrate port access is found in section “Device Operation Modes” later in

this document.

PARASITE POWER

The block diagram (Figure 1) shows the parasite-powered circuitry. This circuitry “steals” power

whenever the I/O, RST , or VCC pins are high. When using the 1-Wire port in battery operate mode,

RST and V

provide no power since they are low. However, I/O will provide sufficient power as long as

CC

the specified timing and voltage requirements are met. The advantages of parasite power are two-fold:

1) by parasiting off these pins, battery power is conserved and 2) the ROM may be read in absence of

normal power. For instance, in battery-operate mode, if the battery fails, the ROM may still be read

normally.

In battery-backed mode, if VCC fails, the port switches in the battery but inhibits communication. The

ROM may still be read normally over the 1-Wire port if RST is low.

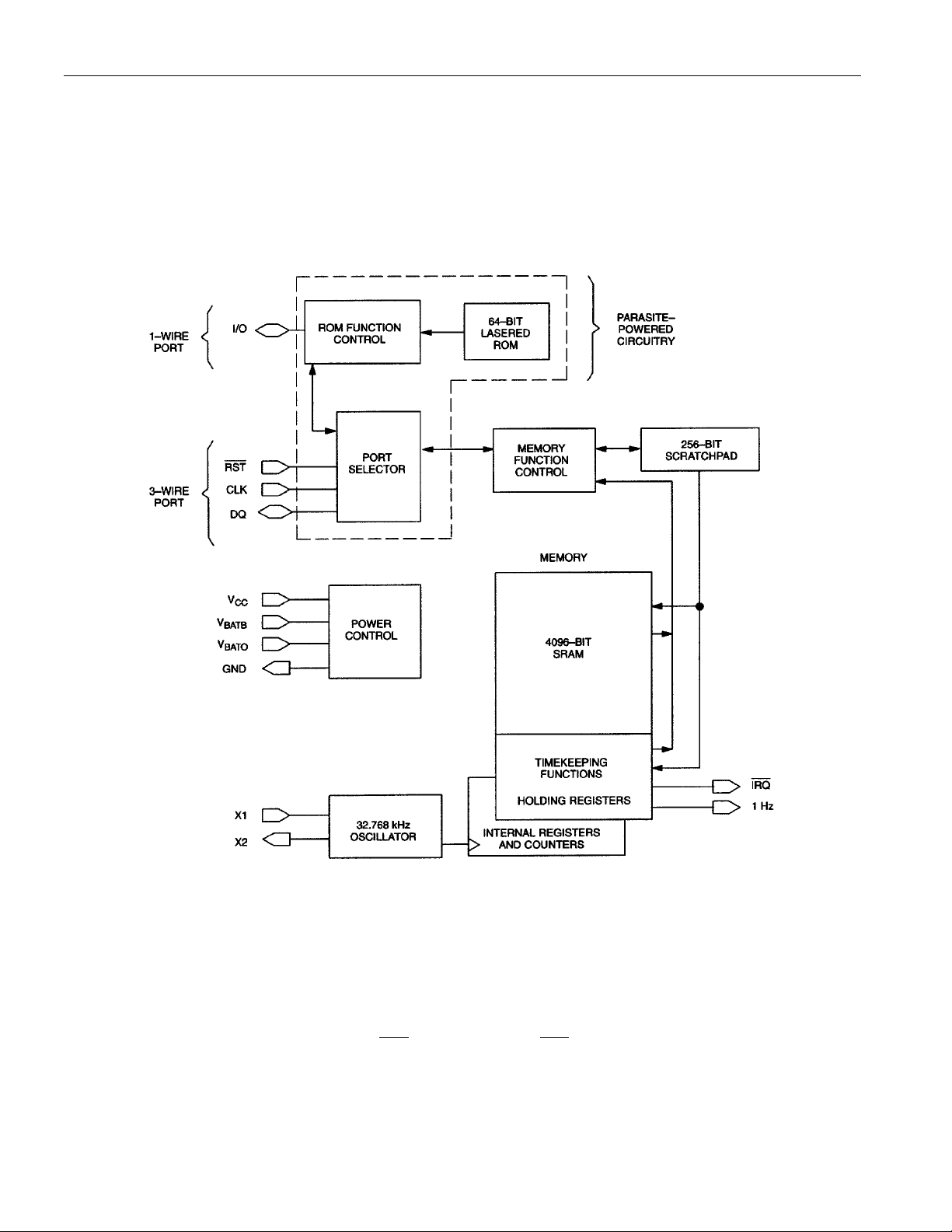

64-BIT LASERED ROM

Each DS2404 contains a unique ROM code that is 64 bits long. The first eight bits are a 1-Wire family

code (DS2404 code is 04h). The next 48 bits are a unique serial number. The last eight bits are a CRC of

the first 56 bits. (See Figure 2.)

The 1-Wire CRC is generated using a polynomial generator consisting of a shift register and XOR gates

as shown in Figure 3. The polynomial is X8 + X5 + X4 + 1. Additional information about the Dallas

1-Wire Cyclic Redundancy Check is available in Application Note 27, “Understanding and Using Cyclic

Redundancy Checks with Dallas Semiconductor iButton Products”.

The shift register bits are initialized to zero. Then starting with the least significant bit of the family code,

one bit at a time is shifted in. After the 8th bit of the family code has been entered, then the serial number

is entered. After the 48th bit of the serial number has been entered, the shift register contains the CRC

value. Shifting in the eight bits of CRC should return the shift register to all zeros.

64-BIT LASERED ROM Figure 2

CRC SERIAL NUMBER DS2404 FAMILY CODE

8 BITS 48-BIT UNQUE NUMBER 04h

MSB LSB

1-WIRE CRC CODE Figure 3

4 of 29

Page 5

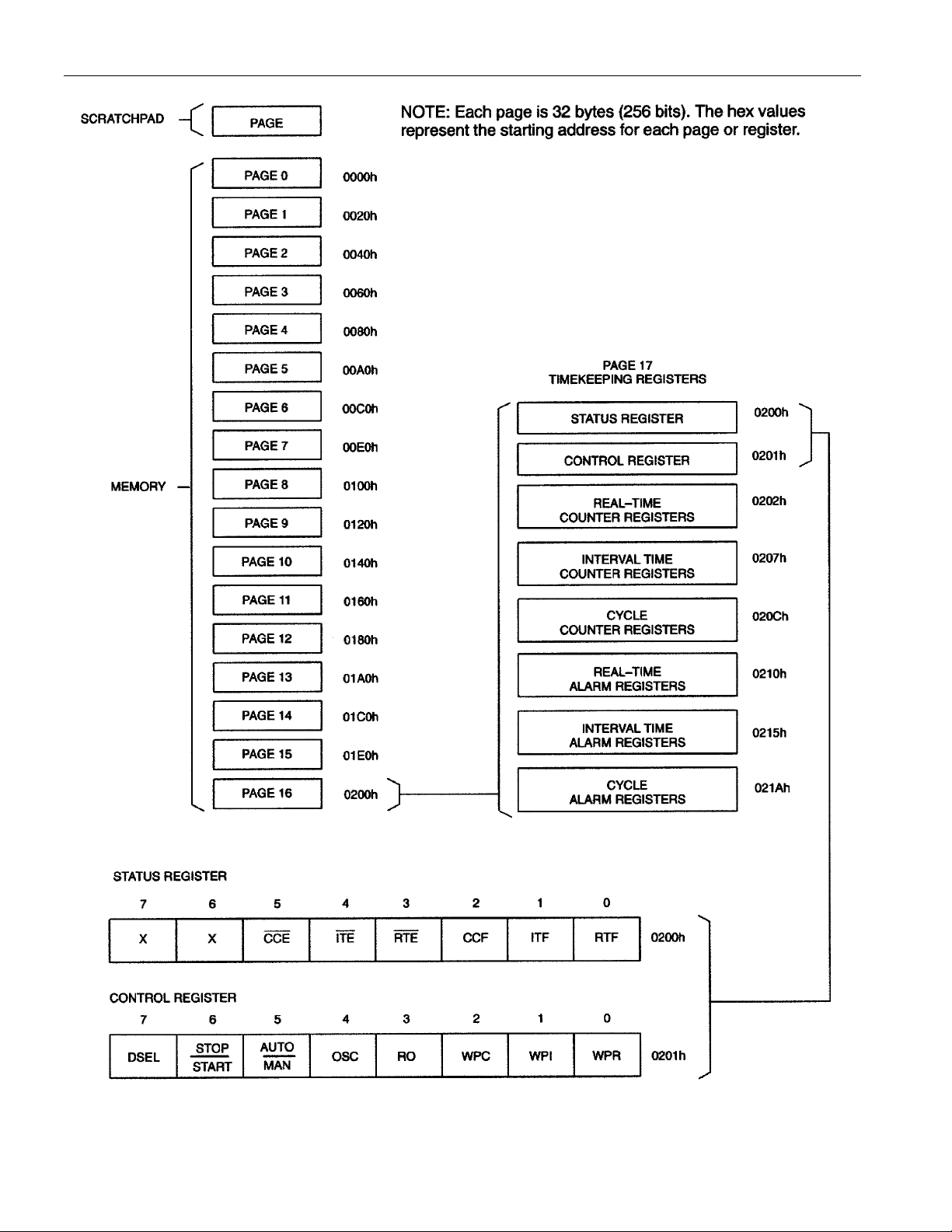

MEMORY MAP Figure 4

DS2404

5 of 29

Page 6

DS2404

MEMORY

The memory map in Figure 4 shows a page (32 bytes) called the scratchpad and 17 pages called memory.

Pages 0 through 15 each contain 32 bytes which make up the 4096-bit SRAM. Page 16 has only 30 bytes

which contain the timekeeping registers.

The scratchpad is an additional page of memory that acts as a buffer when writing to memory. Data is

first written to the scratchpad where it can be read back. After the data has been verified, a copy

scratchpad command will transfer the data to memory. This process ensures data integrity when

modifying the memory.

TIMEKEEPING

A 32.768kHz crystal oscillator is used as the time base for the timekeeping functions. The oscillator can

be turned on or off by an enable bit in the control register. The oscillator must be on for the real-time

clock, interval timer, cycle counter and 1Hz output to function.

The timekeeping functions are double buffered. This feature allows the master to read time or count

without the data changing while it is being read. To accomplish this, a snapshot of the counter data is

transferred to holding registers which the user accesses. This occurs after the eighth bit of the Read

Memory Function command.

Real-Time Clock

The real-time clock is a 5-byte binary counter. It is incremented 256 times per second. The least

significant byte is a count of fractional seconds. The upper four bytes are a count of seconds. The realtime clock can accumulate 136 years of seconds before rolling over. Time/date is represented by the

number of seconds since a reference point which is determined by the user. For example, 12:00A.M.,

January 1, 1970 could be a reference point.

Interval Timer

The interval timer is a 5-byte binary counter. When enabled, it is incremented 256 times per second. The

least significant byte is a count of fractional seconds. The interval timer can accumulate 136 years of

seconds before rolling over. The interval timer has two modes of operation which are selected by the

MANAUTO/ bit in the control register. In the auto mode, the interval timer will begin counting after the

I/O line has been high for a period of time determined by the DSEL bit in the control register. Similarly,

the interval timer will stop counting after the I/O line has been low for a period of time determined by the

DSEL bit. In the manual mode, time accumulation is controlled by the STARTSTOP/ bit in the control

register.

NOTE: For auto mode operation, the high level on the I/O pin must be greater than or equal to 70% of

V

CC

or V

BATO

.

Cycle Counter

The cycle counter is a 4-byte binary counter. It increments after the falling edge of the I/O line if the

appropriate I/O line timing has been met. This timing is selected by the DSEL bit in the control register.

(See “Status/ Control” section).

NOTE: For cycle counter operation, the high level on the I/O pin must be greater than or equal to 70% of

V

CC

or V

BATO

.

6 of 29

Page 7

DS2404

Alarm Registers

The alarm registers for the real-time clock, interval timer, and cycle counter all operate in the same

manner. When the value of a given counter equals the value in its associated alarm register, the

appropriate flag bit is set in the status register. If the corresponding interrupt enable bit(s) in the status

register is set, an interrupt is generated. If a counter and its associated alarm register are write protected

when an alarm occurs, access to the device becomes limited. (See “Status/Control”, “Interrupts”, and the

“Programmable Expiration” sections.)

STATUS/CONTROL REGISTERS

The status and control registers are the first two bytes of page 16 (see “Memory Map”, Figure 4).

Status Register

76543210

XX

CCE

ITE RTE

CCF ITF RTF 0200h

Don’t care bits Read Only

RTF Real-time clock alarm flag

0

ITF Interval timer alarm flag

1

CCF Cycle counter alarm flag

2

When a given alarm occurs, the corresponding alarm flag is set to a logic 1. The alarm flag(s) is cleared

by reading the status register.

RTE

3

4

ITE

5

CCE

Real-time interrupt enable

Interval timer interrupt enable

Cycle counter interrupt enable

Writing any of the interrupt enable bits to a logic 0 will allow an interrupt condition to be generated when

its corresponding alarm flag is set (see “Interrupts” section).

Control Register

76543210

DSEL

WPR Write protect real-time clock/alarm registers

0

WPI Write protect interval timer/alarm registers

1

WPC Write protect cycle counter/alarm registers

2

STOP

START

AUTO

MAN.

OSC RO WPC WPI WPR 0201h

7 of 29

Page 8

DS2404

Setting a write protect bit to a logic 1 will permanently write protect the corresponding counter and alarm

registers, all write protect bits, and additional bits in the control register. The write protect bits can not be

written in a normal manner (see “Write Protect/Programmable Expiration” section).

RO Read Only

3

If a programmable expiration occurs and the read only bit is set to a logic 1, then the DS2404 becomes

read only. If a programmable expiration occurs and the read only bit is a logic 0, then only the 64-bit

lasered ROM can be accessed (see “Write Protect/Programmable Expiration” section).

OSC Oscillator enable

4

This bit controls the crystal oscillator. When set to a logic 1, the oscillator will start operation. When the

oscillator bit is a logic 0, the oscillator will stop.

5

AUTO/ MAN Automatic/ Manual Mode

When this bit is set to a logic 1, the interval timer is in automatic mode. In this mode, the interval timer is

enabled by the I/O line. When this bit is set to a logic 0, the interval timer is in manual mode. In this

mode the interval timer is enabled by the STOP/START bit.

6

STOP/START

Stop/Start (in Manual Mode)

If the interval timer is in manual mode, the interval timer will start counting when this bit is set to a logic

0 and will stop counting when set to a logic 1. If the interval timer is in automatic mode, this bit has no

effect.

DSEL Delay Select Bit

7

This bit selects the delay that it takes for the cycle counter and the interval timer (in auto mode) to see a

transition on the I/O line. When this bit is set to a logic 1, the delay time is 123 + 2 ms. This delay allows

communication on the I/O line without starting or stopping the interval timer and without incrementing

the cycle counter. When this bit is set to a logic 0, the delay time is 3.5 ±0.5 ms.

MEMORY FUNCTION COMMANDS

The “Memory Function Flow Chart” (Figure 6) describes the protocols necessary for accessing the

memory. Two examples follow the flowchart. Three address registers are provided as shown in Figure 5.

The first two registers represent a 16-bit target address (TA1, TA2). The third register is the ending

offset/data status byte (E/S).

The target address points to a unique byte location in memory. The first five bits of the target address

(T4:T0) represent the byte offset within a page. This byte offset points to one of 32 possible byte

locations within a given page. For instance, 00000b points to the first byte of a page where as 11111b

would point to the last byte of a page.

8 of 29

Page 9

DS2404

The third register (E/S) is a read only register. The first five bits (E4: E0) of this register are called the

ending offset. The ending offset is a byte offset within a page. Bit 5 (PF) is the partial byte flag. Bit 6

(OF) is the overflow flag. Bit 7 (AA) is the authorization accepted flag.

ADDRESS REGISTERS Figure 5

76543210

TARGET ADDRESS (TA1) T7 T6 T5 T4 T3 T2 T1 T0

TARGET ADDRESS (TA2) T15 T14 T13 T12 T11 T10 T9 T8

ENDING ADDRESS WITH

DATA STATUS (E/S)

(READ ONLY)

AA OF PF E4 E3 E2 E1 E0

Write Scratchpad Command [0Fh]

After issuing the write scratchpad command, the user must first provide the 2–byte target address,

followed by the data to be written to the scratchpad. The data will be written to the scratchpad starting at

the byte offset (T4:T0). The ending offset (E4: E0) will be the byte offset at which the host stops writing

data. The maximum ending offset is 11111b (31d). If the host attempts to write data past this maximum

offset, the overflow flag (OF) will be set and the remaining data will be ignored. If the user writes an

incomplete byte and an overflow has not occurred, the partial byte flag (PF) will be set.

Read Scratchpad Command [AAh]

This command may be used to verify scratchpad data and target address. After issuing the read scratchpad

command, the user may begin reading. The first two bytes will be the target address. The next byte will

be the ending offset/data status byte (E/S) followed by the scratchpad data beginning at the byte offset

(T4: T0). The user may read data until the end of the scratchpad after which the data read will be all logic

1’s.

Copy Scratchpad [55h]

This command is used to copy data from the scratchpad to memory. After issuing the copy scratchpad

command, the user must provide a 3-byte authorization pattern. This pattern must exactly match the data

contained in the three address registers (TA1, TA2, E/S, in that order). If the pattern matches, the AA

(Authorization Accepted) flag will be set and the copy will begin. At this point, the part will go into a T

mode, transmitting a logic 1 to indicate the copy is in progress. A logic 0 will be transmitted after the data

has been copied. Any attempt to reset the part will be ignored while the copy is in progress. Copy

typically takes 30 ms.

The data to be copied is determined by the three address registers. The scratchpad data from the

beginning offset through the ending offset, will be copied to memory, starting at the target address.

Anywhere from 1 to 32 bytes may be copied to memory with this command. Whole bytes are copied even

if only partially written. The AA flag will be cleared only by executing a write scratchpad command.

X

9 of 29

Page 10

MEMORY FUNCTION FLOW CHART Figure 6

DS2404

10 of 29

Page 11

DS2404

Read Memory [F0h]

The read memory command may be used to read the entire memory. After issuing the command, the user

must provide the 2-byte target address. After the two bytes, the user reads data beginning from the target

address and may continue until the end of memory, at which point logic 1’s will be read. It is important to

realize that the target address registers will contain the address provided. The ending offset/data status

byte is unaffected.

The hardware of the DS2404 provides a means to accomplish error-free writing to the memory section.

To safeguard reading data in the 1-Wire environment and to simultaneously speed up data transfers, it is

recommended to packetize data into data packets of the size of one memory page each. Such a packet

would typically store a 16-bit CRC with each page of data to ensure rapid, error-free data transfers that

eliminate having to read a page multiple times to determine if the received data is correct or not. (See the

Book of DS19xx iButton Standards, Chapter 7 for the recommended file structure to be used with the 1Wire environment.)

MEMORY FUNCTION EXAMPLES

Example 1: Write one page of data to page 15

Read page 15 (3-wire port)

MASTER MODE DATA(LSB FIRST) COMMENTS

TX Reset

TX 0Fh Issue “write scratchpad” command

TX E0h TA1, beginning offset=0

TX 01h TA2, address=01E0h

TX <32 data bytes> Write 1 page of data to scratchpad

TX Reset

TX AAh Issue “read scratchpad” command

RX E0h Read TA1, beginning offset=0

RX 01h Read TA2, address=01E0h

RX 1Fh Read E/S, ending offset=31d, flags=0

RX <32 data bytes> Read scratchpad data and verify

TX Reset

TX 55h Issue “copy scratchpad” command

TX E0h

TX 01h

TX 1Fh

RX <busy indicator>

TX Reset

TX F0h Issue “read memory” command

TX E0h TA1, beginning offset=0

TX 01h TA2, address=01E0h

RX <32 data bytes> Read memory page 15 and verify

TX Reset

Master pulses RST low

Master pulses RST low

Master pulses RST low

TA1

TA2 AUTHORIZATION CODE

E/S

Wait until DQ=0 (~30 ms typical)

Master pulses

Master pulses

RST low

RST low, done

NOTE: The ROM function commands do not apply to the 3-wire port. After RST is at a high level, the

device expects to receive a memory function command.

11 of 29

Page 12

DS2404

Example 2: Write two data bytes to memory locations 0026h and 0027h (the seventh and eighth byte of

page 1). Read entire memory (1-Wire port).

MASTER MODE DATA(LSB FIRST) COMMENTS

TX Reset

reset pulse (480–960 ms)

RX Presence presence pulse

TX CCh Issue “skip ROM” command

TX 0Fh Issue “write scratchpad” command

TX 26h TA1, beginning offset=6

TX 00h TA2, address=0026h

TX <2 data bytes> Write 2 bytes of data to scratchpad

TX Reset reset pulse

RX Presence presence pulse

TX CCh Issue “skip ROM” command

TX AAh Issue “read scratchpad” command

RX 26h Read TA1, beginning offset=6

RX 00h Read TA2, address=0026h

RX 07h Read E/S, ending offset=7, flags=0

RX <2 data bytes> Read scratchpad data and verify

TX Reset reset pulse

RX Presence presence pulse

TX CCh Issue “skip ROM” command

TX 55h Issue “copy scratchpad” command

TX 26h

TX 00h

TX 07h

TA1

TA2 AUTHORIZATION CODE

E/S

TX Reset reset pulse

RX Presence presence pulse

TX CCh Issue “skip ROM” command

TX F0h Issue “read memory” command

TX 00h TA1, beginning offset=0

TX 00h TA2, address=0000h

RX <542 bytes> Read entire memory

TX Reset reset pulse

RX Presence presence pulse, done

WRITE PROTECT/PROGRAMMABLE EXPIRATION

The write protect bits (WPR, WPI, WPC) provide a means of write protecting the timekeeping data and

limiting access to the DS2404 when an alarm occurs (programmable expiration).

The write protect bits may not be written by performing a single copy scratchpad command. Instead, to

write these bits, the copy scratchpad command must be performed three times. Please note that the AA bit

will be set, as expected, after the first copy command is successfully executed. Therefore, the

authorization pattern for the second and third copy command should have this bit set. The read

scratchpad command may be used to verify the authorization pattern.

12 of 29

Page 13

DS2404

The write protect bits, once set, permanently write protects their corresponding counter and alarm

registers, all write protect bits, and certain control register bits as shown in Figure 7. The time/count

registers will continue to count if the oscillator is enabled. If the user wishes to set more than one write

protect bit, the user must set them at the same time. Once a write protect bit is set it cannot be undone,

and the remaining write protect bits, if not set, cannot be set.

The programmable expiration takes place when one or more write protect bits have been set and a

corresponding alarm occurs. If the RO (read only) bit is set, only the read scratchpad and read memory

function commands are available. If the RO bit is a logic “0”, no memory function commands are

available. The ROM functions are always available.

WRITE PROTECT CHART Figure 7

WRITE PROTECT BIT SET: WPR WPI WPC

Data Protected from

User Modification:

* Becomes write “1” only, i.e., once written to a logic “1”, may not be written back to a logic “0”.

** Forced to a logic “0”.

Real Time Clock

Real Time Alarm

WPR

WPI

WPC

RO

OSC *

Interval Timer

Interval Time Alarm

WPR

WPI

WPC

RO

OSC *

STOP/START **

AUTO/ MAN

Cycle Counter

Cycle Counter Alarm

WPR

WPI

WPC

RO

OSC *

DSEL

1-WIRE BUS SYSTEM

The 1-Wire bus is a system which has a single bus master and one or more slaves. In most instances the

DS2404 behaves as a slave. The exception is when the DS2404 generates an interrupt due to a

timekeeping alarm. The discussion of this bus system is broken down into three topics: hardware

configuration, transaction sequence, and 1-Wire signaling (signal types and timing). The 1-Wire protocol

defines bus transactions in terms of the bus state during specific time slots that are initiated on the falling

edge of sync pulses from the bus master. For a more detailed protocol description, refer to Chapter 4 of

the Book of DS19XX iButton Standards.

HARDWARE CONFIGURATION

The 1-Wire bus has only a single line by definition; it is important that each device on the bus be able to

drive it at the appropriate time. To facilitate this, each device attached to the 1-Wire bus must have open

drain or 3-state outputs. The 1-Wire port of the DS2404 (I/O pin 5) is open drain with an internal circuit

equivalent to that shown in Figure 8. A multidrop bus consists of a 1-Wire bus with multiple slaves

attached. The 1-Wire bus has a maximum data rate of 16.3k bits per seconds. Depending on 1-Wire

communication speed and bus load characteristics, the optimal pull-up resistor value will be in the 1.5 kW

to 5 kW range.

The idle state for the 1-Wire bus is high. If for any reason a transaction needs to be suspended, the bus

MUST be left in the idle state if the transaction is to resume. If this does not occur and the bus is left low

for more than 120 ms, one or more of the devices on the bus may be reset.

13 of 29

Page 14

DS2404

HARDWARE CONFIGURATION Figure 8

See

Note

NOTE:

Depending on 1-Wire communication speed and bus load characteristics, the optimal pull-up resistor

value will be in the 1.5 kW range to 5 kW range.

TRANSACTION SEQUENCE

The protocol for accessing the DS2404 via the 1-Wire port is as follows:

§ Initialization

§ ROM Function Command

§ Memory Function Command

§ Transaction/Data

INITIALIZATION

All transactions on the 1-Wire bus begin with an initialization sequence. The initialization sequence

consists of a reset pulse transmitted by the bus master followed by presence pulse(s) transmitted by the

slave(s). The presence pulse lets the bus master know that the DS2404 is on the bus and is ready to

operate. For more details, see the “1-Wire Signaling” section.

ROM FUNCTION COMMANDS

Once the bus master has detected a presence, it can issue one of the five ROM function commands. All

ROM function commands are eight bits long. A list of these commands follows (refer to flowchart in

Figure 9):

Read ROM [33h]

This command allows the bus master to read the DS2404’s 8-bit family code, unique 48-bit serial

number, and 8-bit CRC. This command can only be used if there is a single DS2404 on the bus. If more

than one slave is present on the bus, a data collision will occur when all slaves try to transmit at the same

time (open drain will produce a wired-AND result). The resultant family code and 48-bit serial number

will usually result in a mismatch of the CRC.

14 of 29

Page 15

DS2404

Match ROM [55h]

The match ROM command, followed by a 64-bit ROM sequence, allows the bus master to address a

specific DS2404 on a multidrop bus. Only the DS2404 that exactly matches the 64-bit ROM sequence

will respond to the following memory function command. All slaves that do not match the 64-bit ROM

sequence will wait for a reset pulse. This command can be used with a single or multiple devices on the

bus.

Skip ROM [CCh]

This command can save time in a single drop bus system by allowing the bus master to access the

memory functions without providing the 64-bit ROM code. If more than one slave is present on the bus

and a read command is issued following the Skip ROM command, data collision will occur on the bus as

multiple slaves transmit simultaneously (open drain pulldowns will produce a wired-AND result).

Search ROM [F0h]

When a system is initially brought up, the bus master might not know the number of devices on the

1-Wire bus or their 64-bit ROM codes. The search ROM command allows the bus master to use a process

of elimination to identify the 64-bit ROM codes of all slave devices on the bus. The search ROM process

is the repetition of a simple 3-step routine: read a bit, read the complement of the bit, then write the

desired value of that bit. The bus master performs this simple, 3-step routine on each bit of the ROM.

After one complete pass, the bus master knows the contents of the ROM in one device. The remaining

number of devices and their ROM codes may be identified by additional passes. See Chapter 5 of the

Book of DS19xx iButton Standards for a comprehensive discussion of a search ROM, including an actual

example.

Search Interrupt [ECh]

This ROM command works exactly as the normal ROM Search, but it will identify only devices with

interrupts that have not yet been acknowledged.

15 of 29

Page 16

ROM FUNCTIONS FLOW CHART (1-WIRE PORT ONLY) Figure 9

DS2404

(See Figure 8)

16 of 29

Page 17

DS2404

1-WIRE SIGNALING

The DS2404 requires strict protocols to ensure data integrity. The protocol consists of five types of

signaling on one line: Reset Sequence with reset pulse and presence pulse, write 0, write 1, Read Data

and interrupt pulse. All these signals except presence pulse and interrupt pulse are initiated by the bus

master.

The initialization sequence required to begin any communication with the DS2404 is shown in Figure 10.

A reset pulse followed by a presence pulse indicates the DS2404 is ready to send or receive data given the

correct ROM command and memory function command.

The bus master transmits (TX ) a reset pulse (t

, minimum of 480 ms). The bus master then releases the

RSTL

line and goes into receive mode (RX ). The 1-Wire bus is pulled to a high state via the pull-up resistor.

After detecting the rising edge on the date line, the DS2404 waits (t

presence pulse (t

, 60 - 240 ms). There are special conditions if interrupts are enabled where the bus

PDL

, 15-60 ms) and then transmits the

PDH

master must check the state of the 1-Wire bus after being in the RX mode for 480 ms. These conditions

will be discussed in the “Interrupt” section.

READ/WRITE TIME SLOTS

The definitions of write and read time slots are illustrated in Figure 11. All time slots are initiated by the

master driving the data line low. The falling edge of the data line synchronizes the DS2404 to the master

by triggering a delay circuit in the DS2404. During write time slots, the delay circuit determines when the

DS2404 will sample the data line. For a read data time slot, if a “0” is to be transmitted, the delay circuit

determines how long the DS2404 will hold the data line low overriding the 1 generated by the master. If

the data bit is a “1”, the device will leave the read data time slot unchanged.

INITIALIZATION PROCEDURE “RESET AND PRESENCE PULSES” Figure 10

RESISTOR

MASTER

DS2404

480 ms £ t

480 ms £ t

15 ms £ t

60 ms £ t

< ¥ *

RSTL

< ¥ (includes recovery time)

RSTH

< 60 ms

PDH

< 240 ms

PDL

* In order not to mask interrupt signaling by other devices on the 1-Wire bus, t

be less than 960 ms.

17 of 29

+ tR should always

RSTL

Page 18

READ/WRITE TIMING DIAGRAM Figure 11

Write-one Time Slot

DS2404

Write-zero Time Slot

Read-data Time Slot

60ms < t

1ms £ t

1ms £ t

60ms £ t

1ms £ t

SLOT

LOW1

REC

LOW0

REC

< 120ms

< 15ms

< ¥

< t

< ¥

SLOT

< 120ms

RESISTOR

MASTER

DS2404

60ms £ t

1ms £ t

0 £ t

RELEASE

1ms £ t

= 15ms

t

RDV

t

< 1ms

SU

18 of 29

SLOT

LOWR

REC

< 120ms

< 15ms

< 45ms

< ¥

Page 19

DS2404

Interrupts

If the DS2404 detects an alarm condition, it will automatically set the corresponding alarm flag (CCF,

ITF or RTF) in the Status Register. If the flag’s corresponding interrupt bit ( RST , ITE or RTE ) is enabled

(logic 0) an interrupt condition begins as the alarm goes off. The DS2404 signals the interrupt condition

by pulling the open drain IRQ output low. The interrupt condition ceases when the alarm flags are cleared

(i.e., the interrupt is acknowledged by reading the Status Register, address 200H) or if the corresponding

interrupt enable bit is disabled (set to logic 1).

Interrupts can also be generated on the 1-Wire port. Since communication and interrupt signaling share

the same pin, one has to distinguish between two types of interrupts: spontaneous interrupts, called type

1, and delayed interrupts type 2. Spontaneous interrupts that have not yet occurred need to be (re-) armed

by a reset pulse after all communication on the 1-Wire bus has finished. A single falling slope on the

1-Wire bus will disarm this type of interrupt. If an alarm condition occurs while the device is disarmed, at

first a type 2 interrupt will be produced.

Spontaneous interrupts are signaled by the DS2404 by pulling the data line low for 960 to 3840 ms as the

interrupt condition begins (Figure 12). After this long low pulse a presence pulse will follow. If the alarm

condition occurs just after the master has sent a reset pulse, i.e., during the high or low time of the

presence pulse, the DS2404 will not assert its Interrupt Pulse until the presence pulse is finished

(Figure 13).

If the DS2404 cannot assert a spontaneous interrupt, either because the data line was not pulled high,

communication was in progress, or the interrupt was not armed, it will extend the next reset pulse to a

total length of 960 to 3840 ms (delayed interrupt). If the alarm condition occurs during the reset low time

of the reset pulse, the DS2404 will immediately assert its interrupt pulse; thus the total low time of the

pulse can be extended up to 4800 ms (Figure 14). If a DS2404 with a not previously signaled alarm

detects a power-on cycle on the 1-Wire bus, it will send a presence pulse and wait for the reset pulse sent

by the master to extend it and to subsequently issue a presence pulse (Figure 15). As long as an interrupt

has not been acknowledged by the master, the DS2404 will continue sending interrupt pulses.

The interrupt signaling discussed so far is valid for the first opportunity the device has to signal an

interrupt. It is not required for the master to acknowledge an interrupt immediately. If an interrupt is not

acknowledged, the DS2404 will continue signaling the interrupt with every reset pulse. To do so, DS2404

devices of Revision B4 (earlier production parts) will always use the waveform of the Type 2 Interrupt

(Figure 14). Devices of Revision B5 (current production) will either use the waveform of the Type 2

Interrupt (Figure 14) or the waveform of the Type 1A Interrupt (Figure 13). The waveform of the Type 2

Interrupt will be observed after a communication to a device other than the interrupting one; after

successful communication to the interrupting device (without acknowledging the interrupt) the waveform

of the Type 1A Interrupt will be found. The revision code of the DS2404 is appended to the

manufacturing date code, which is printed on the top of the package right below the part number.

19 of 29

Page 20

TYPE 1 INTERRUPT Figure 12

TYPE 1A INTERRUPT (SPECIAL CASE) Figure 13

DS2404

DS2404

TYPE 2 INTERRUPT Figure 14

20 of 29

Page 21

DS2404

TYPE 2 INTERRUPT (SPECIAL CASE) Figure 15

3-WIRE I/O COMMUNICATIONS

The 3–wire bus is comprised of three signals. These are the RST (reset) signal, the CLK (clock) signal,

and the DQ (data) signal. All data transfers are initiated by driving the RST input high. Driving the RST

input low terminates communication. (See Figures 19 and 20.)

A clock cycle is a sequence of a falling edge followed by a rising edge. For data inputs, the data must be

valid during the rising edge of a clock cycle. Command bits and data bits are input on the rising edge of

the clock and data bits are output on the falling edge of the clock. When reading data from the DS2404,

the DQ pin goes to a high impedance state while the clock is high. Taking RST low will terminate any

communication and cause the DQ pin to go to a high impedance state.

POWER CONTROL

There are two methods of supplying power to the DS2404, VCC Operate mode with battery backup and

Battery Operate mode. If the DS2404 is used in an application where battery backup is not desired, the

part must be wired for Battery Operate mode.

21 of 29

Page 22

V

Operate Mode (Battery-Backed)

CC

Figure 16 shows the necessary connections for operating the DS2404 in VCC Operate mode.

VCC OPERATE MODE Figure 16

DS2404

VCC Pin 1 & 16 2.8V to 5.5V

V

Pin 9 2.8V to 5.5V

BATB

V

Pin 10 must be unconnected

BATO

To always allow communication through the 1-Wire or wire port, the voltage on VCC must be

approximately 3-wire port, the voltage on VCC must be approximately 0.2V above the voltage on V

BATB

Otherwise the DS2404 will retain data, but will not allow any access.

The V

below V

functionality and data retention. No communication can take place while V

During power-up, when VCC reaches a value of approximately 0.2V above V

circuit connects VCC and disconnects V

VCC has stayed approximately 0.2V above V

must pass the range from V

pin is normally connected to any standard 3V lithium cell or other energy source. As VCC falls

BATB

, the power switching circuit allows V

BATB

. If the oscillator is on, no communication can take place until

BATB

to 0V in no less than 100ns for the power switching circuit to function

BATB

for 123 ± 2ms. During power-down, the falling V

BATB

to provide energy for maintaining clock

BATB

is greater than VCC.

BATB

, the power switching

BATB

CC

properly.

.

22 of 29

Page 23

Battery Operate Mode

Figure 17 shows the necessary connections for operating the DS2404 in Battery Operate mode.

BATTERY OPERATE MODE Figure 17

DS2404

The V

V

CC

V

Pin 9 Ground

BATB

V

Pin 10 2.8 to 5.5V

BATO

pin is normally connected to any standard 3 V lithium cell or other energy source. The Battery

BATO

Pin 1 & 16 Ground

Operate mode also minimizes the power-consumption in applications where battery backup is not

required and the V

lead is directly connected to the system’s 5V supply.

BATO

NOTE:

In Battery Operate mode, the voltage on DQ must never exceed the voltage on V

interface is used. This restriction does not apply to the 1-Wire interface.

if the 3-wire

BATO

DEVICE OPERATION MODES

With its two ports and two power modes the DS2404 can be operated in several ways. While the

maximum voltage on the 1-Wire port (I/O) is always 6V, the maximum voltage on the 3-wire port (DQ)

depends on the power mode and actual operating voltage. A particular port is selected by setting the

control lines to a state that makes the other port inactive. See Table 1 for details.

When using the 3-wire port only and the DS2404 is wired for V

1 Wire I/O pin can be used as counter input. This mode requires that the I/O lead is connected to V

through a 5kW (typical) resistor. To enable communication through the 3-wire port a reset/presence

sequence has to be performed on the 1-Wire port after the system has powered up.

Operate Mode (Battery Backed) the

CC

CC

23 of 29

Page 24

DS2404

OPERATION MODES AND CONDITIONS Table 1

PORT USAGE BATTERY OPERATE MODE V

1-Wire only

3-Wire only

DQ Voltage (3-wire) £ V

Float RST , DQ, CLK or tie to GND

BATO

If unused: float I/O (1-Wire) or tie to GND; if used as counter input: see text

1-Wire and 3-wire

Dual Port Operation

DQ Voltage (3-wire) £ V

BATO

1-Wire Port: finish each communication with a reset/presence sequence: when

idle: either keep I/O pulled high through a resistor or pull it low;

3-wire Port: when idle: keep

RST and CLK low, keep DQ high or low or

floating

OPERATE MODE (BATTERY BACKED)

CC

DQ Voltage (3-wire) £ V

DQ Voltage (3-wire) £ V

CC

CC

+0.3V

+0.3V

DUAL PORT OPERATION

The on-chip arbitration logic works on a first-come, first serve principle. Assuming that at one time both

ports are idle, the one port that becomes active prior to the other one is granted access. Activity on the

3-wire port begins as the voltage level on the RST input changes from low to high. The 1-Wire port is

considered active with the first falling edge detected after the presence pulse.

Attempting to communicate with the device through the port that temporarily has no access does not

affect communication through the other port. If communication on the 1-Wire port is initiated while the

3-wire port is active, the device will still respond to the reset pulse, but any subsequently transmitted

1-Wire command will be ignored. When reading the ROM or memory, for example, the response will

always be 1’s, indicating that access was denied. While the 1-Wire port is active, the 3-wire data line DQ

is in tristate mode. The always present resistor of approximately 60kW pulls DQ low. The micro

connected to the 3-wire port will fight against this weak pulldown and, depending on its port

characteristics, possibly dominate the logical value on DQ.

Since writing to the memory of the DS2404 requires multiple steps with short periods where both ports

are inactive, additional measures are required. To avoid one port overwriting actions initiated by the other

port one should do the following:

Allow the microcontroller operating the 3-wire port to monitor the activity on the 1-Wire port. This could

be done by means of a retriggerable one-shot, for example. The microcontroller should wait for a break of

several milliseconds on the 1-Wire port before attempting communication through the 3-wire port.

In addition, data should be organized as data packets with a length byte at the beginning and a CRC check

at the end. Whenever one side has finished communication with the DS2404 it should write a token such

as a “null-packet” into the scratchpad. A null-packet consists of three bytes that represent a zero length

followed by a valid 16-bit CRC. As one port tries to communicate with the device, the first memory

function command should be a Read Scratchpad. Communication should only proceed if the null-packet

is found. Otherwise communication through the other port is not yet finished and one is likely to interfere

if one does not immediately release the port for the communication on the other port to resume. For

details on recommended data structures please refer to chapters 7 or 10 of the “Book of DS19xx iButton

Standards”.

24 of 29

Page 25

CRYSTAL PLACEMENT ON PCB Figure 18

3-WIRE WRITE DATA TIMING DIAGRAM Figure 19

DS2404

3-WIRE READ DATA TIMING DIAGRAM Figure 20

25 of 29

Page 26

DS2404

ABSOLUTE MAXIMUM RATINGS*

Voltage on DATA to Ground -0.5V to +7.0V

Operating Temperature Range -40°C to +85°C

Storage Temperature Range -55°C to +125°C

Soldering Temperature See J-STD-020A Specification

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time may affect reliability.

RECOMMENDED OPERATING CONDITIONS (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Logic 1 V

Logic 0 V

RST Logic 1

Supply V

Battery V

V

IH3

IL3

CC

BATB

BATO

,

2.2 V

+0.3 V 1

CC

-0.3 +0.8 V 1

2.8 5.5 V 1

2.8 5.5 V 1

2.8 3.0 5.5 V 1,6

DC ELECTRICAL CHARACTERISTICS

(1-WIRE PORT) (-40°C to +85°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Logic 1 V

Logic 0 V

Output Logic Low @ 4mA V

Output Logic High V

Input Load Current I

IH1

IL1

OL

OH

L

2.2 6.0 V 1,9

-0.3 +0.8 V 1,16

0.4 V 1

V

PUP

5

= 5V+ 10%)

CC

V 1,12

mA

13

DC ELECTRICAL CHARACTERISTICS

OP. MODE) (-40°C to +85°C; VCC = 5V+ 10%)

(V

CC

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Output Leakage I

Output Current @ 2.4V on DQ I

Output Current @ 0.4V on DQ I

Active Current I

Standby Current I

LO

OH

OL

CC1

CC2

3mA18

1

mA

17

-3 mA 19

2mA5

500

mA

11

DC ELECTRICAL CHARACTERISTICS

(BATT. OP. MODE) (-40°C to +85°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Output Leakage I

Output Current @ 2.4V on DQ I

Output Current @ 0.4V on DQ I

I/O Operate Charge Q

Battery Current (OSC On) I

Battery Current (OSC Off) I

LO

OH

OL

BATO

BAT1

BAT2

1mA18

1

mA

-1 mA 19

200 nC 10

350 nA 7

200 nA 7,21

BATO

= 3.0V)

17

26 of 29

Page 27

DS2404

CAPACITANCE (t

= 25°C)

A

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

Output Capacitance C

I/O (1-Wire) I

IN/OUT

IN

OUT

100 800 pF 8

10 pF

15 pF

RESISTANCES (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

RST Resistance to Ground

Z

DQ Resistance to Ground Z

CLK Resistance to Ground Z

RST

DQ

CLK

65

65

65

kW

kW

kW

AC ELECTRICAL CHARACTERISTICS:

3-WIRE PORT (-40°C to +85°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Data to CLK Setup t

CLK to Data Hold t

CLK to Data Delay t

CLK Low Time t

CLK High Time t

CLK Frequency t

DC

CDH

CDD

CL

CH

CLK

CLK Rise and Fall tR,t

RST to CLK Setup

CLK to RST Hold

RST Inactive Time

CLK or RST to DQ High Z

t

t

CCH

t

CWH

t

CDZ

CC

F

35 ns 2

40 ns 2

100 ns 2,3,4

250 ns 2

250 ns 2

DC 2.0 MHz 2

500 ns 2

1

40 ns 2

250 ns 2

50 ns 2

= 5V+ 10%)

CC

ms

2

AC ELECTRICAL CHARACTERISTICS:

1-WIRE PORT (-40°C to +85°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Time Slot t

Write 1 Low Time t

Write 0 Low Time t

Read Low Time t

Read Data Valid t

Release Time t

RELEASE

Read Data Setup t

Recovery Time t

Interrupt t

Reset Time High t

Reset Time Low t

Presence Detect High t

Presence Detect Low t

SLOT

LOW1

LOW0

LOWR

RDV

SU

REC

INT

RSTH

RSTL

PDH

PDL

60 120

115ms23

60 120

115ms23

15

01545

1

1

960 4800

480

480 960

15 60

60 240

=2.8 to 5.5V)

CC

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

22

15

14

20

27 of 29

Page 28

NOTES:

1. All voltages are referenced to ground.

DS2404

2. V

3. V

= 2.0V or VIL = 0.8V with 10ns maximum rise and fall time.

IH

= 2.4V and V

DQH

= 0.4V, respectively.

DQL

4. Load capacitance = 50pF.

5. Measured with outputs open.

6. When battery is applied to V

7. V

BATB

, or V

= 3.0V; all inputs inactive state.

BATO

input, VCC and V

BATO

must be 0V.

BATB

8. Capacitance on the I/O pin could be 800pF when power is first applied. If a 5kW resistor is used to

pull-up the I/O line to V

, 5ms after power has been applied, the parasite capacitance will not affect

PUP

normal communications.

9. For auto-mode operation of the interval timer, the high level on the I/O pin must be greater than or

equal to 70% of V

CC

or V

BATO

.

10. Read and write scratchpad (all 32 bytes) at 3.0V.

11. All other inputs at CMOS levels.

12. V

= external pull-up voltage.

PUP

13. Input load is to ground.

14. An additional reset or communication sequence cannot begin until the reset high time has expired.

15. Read data setup time refers to the time the host must pull the I/O line low to read a bit. Data is

guaranteed to be valid within 1ms of this falling edge.

16. Under certain low voltage conditions V

may have to be reduced to as much as 0.5V to always

IL1MAX

guarantee a presence pulse.

17. Applies to 1 Hz and IRQ pins only.

18. Applies to DQ pin only.

19. Applies to DQ, 1Hz and IRQ pins only.

28 of 29

Page 29

20. The reset low time (t

) should be restricted to a maximum of 960ms, to allow interrupt signaling,

RSTL

otherwise, it could mask or conceal interrupt pulses.

21. When the battery is attached, the oscillator powers up in the off state.

DS2404

22. The optimal sampling point for the master is as close as possible to the end time of the 15ms t

period without exceeding t

. For the case of a Read-one time slot, this maximizes the amount of

RDV

RDV

time for the pull-up resistor to recover the line to a high level. For a Read-zero time slot it ensures

that a read will occur before the fastest 1-Wire device(s) release the line (t

RELEASE

= 0).

23. The duration of the low pulse sent by the master should be a minimum of 1µs with a minimum value

as short as possible to allow time for the pull-up resistor to recover the line to a high level before the

1-Wire device samples in the case of a Write 1 Low Time or before the master samples in the case of

a Read Low Time.

29 of 29

Loading...

Loading...