Page 1

DS2172

DS2172

Bit Error Rate Tester (BERT)

FEATURES

• Generates/Detects digital bit patterns for analyzing,

evaluating and troubleshooting digital communications systems

• Operates at speeds from DC to 52 MHz

• Programmable polynomial length and feedback taps

for generation of any other pseudorandom pattern up

to 32 bits in length including: 26–1, 29–1, 211–1,

15

2

–1, 220–1, 223–1, and 232–1

• Programmable user–defined pattern and length for

generation of any repetitive pattern up to 32 bits in

length

• Large 32–bit error count and bit count registers

• Software programmable bit error insertion

• Fully independent transmit and receive sections

• 8–bit parallel control port

• Detects test patterns with bit error rates up to 10

DESCRIPTION

The DS2172 Bit Error Rate T ester (BERT) is a software

programmable test pattern generator, receiver, and

analyzer capable of meeting the most stringent error

performance requirements of digital transmission facilities. Two categories of test pattern generation (Pseudorandom and Repetitive) conform to CCITT/ITU O.151,

O.152, O.153, and O.161 standards. The DS2172

operates at clock rates ranging from DC to 52 MHz. This

wide range of operating frequency allows the DS2172 to

be used in existing and future test equipment, transmission facilities, switching equipment, multiplexers,

DACs, Routers, Bridges, CSUs, DSUs, and CPE equipment.

The DS2172 user programmable pattern registers provide the unique ability to generate loopback patterns

required for T1, Fractional–T1, Smart Jack, and other

–2

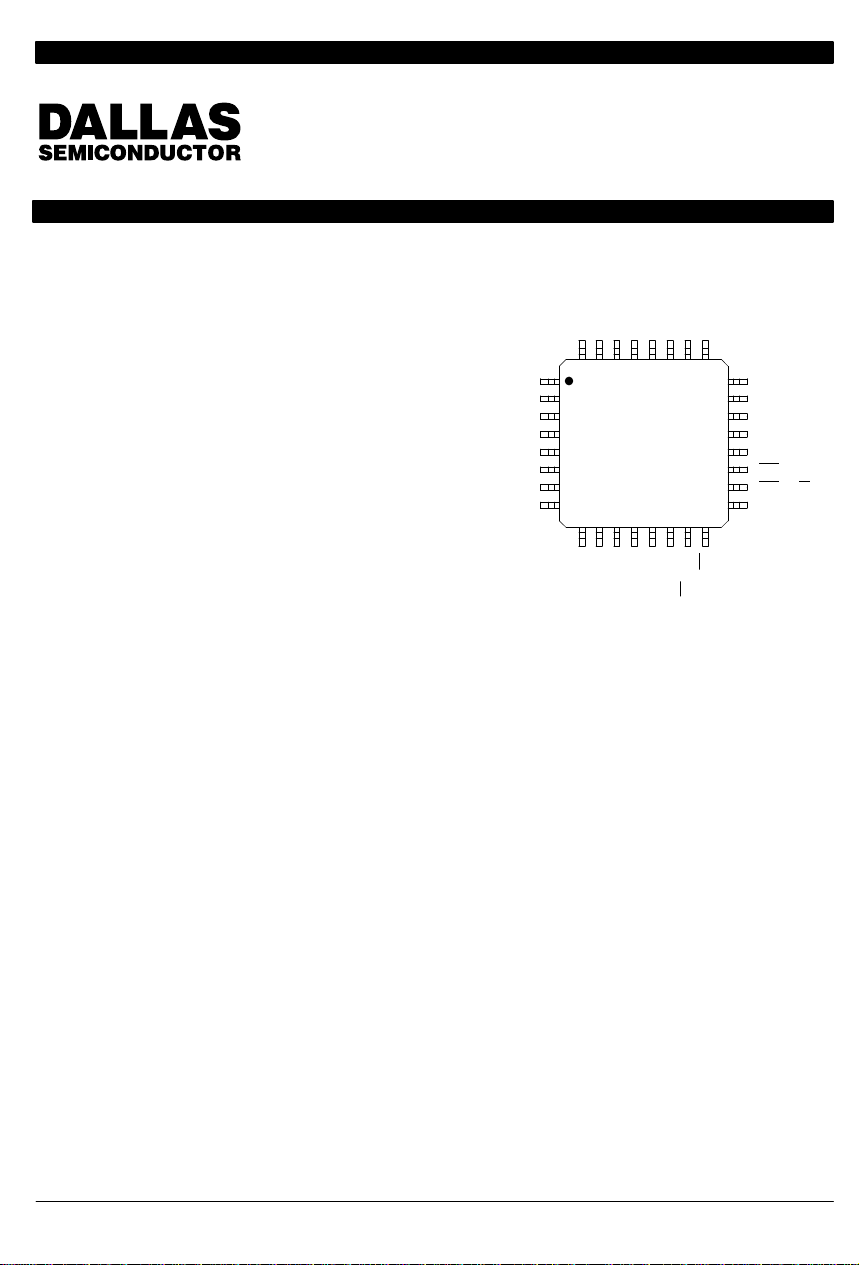

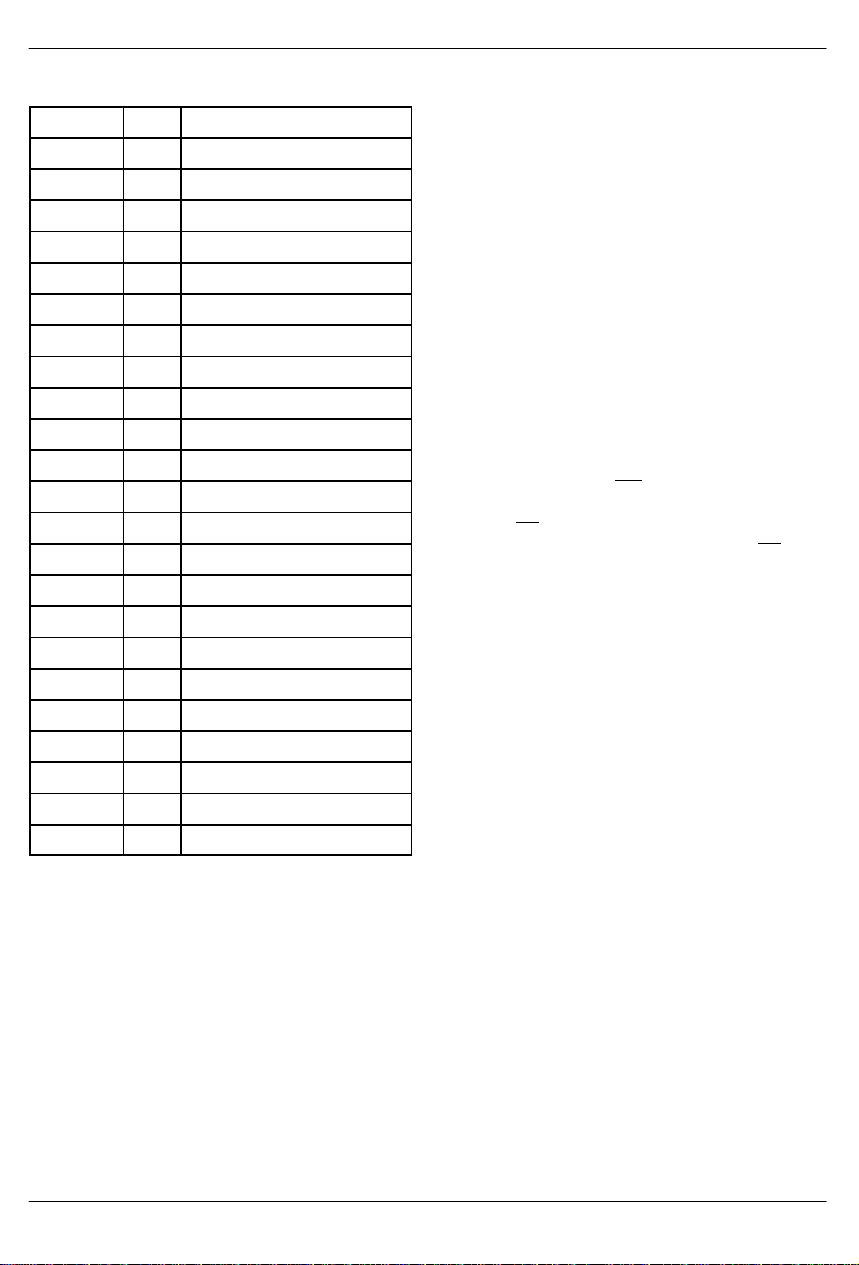

PIN ASSIGNMENT

TDATA

TDIS

TCLK

VSS

VDD

RCLK

RDIS

RDATA

32 31 30 29 28 27 26 25

TL

AD0

AD1

TEST

VSS

AD2

AD3

AD4

1

2

3

4

DS2172

32–PIN TQFP

5

6

7

8

9 101112131415 16

AD5

AD6

AD7

BTS

VSS

VDD

RD (DS)

test procedures. Hence the DS2172 can initiate the

loopback, run the test, check for errors, and finally deactivate the loopback.

The DS2172 consists of four functional blocks: the pattern generator, pattern detector , error counter , and control interface. The DS2172 can be programmed to generate any pseudorandom pattern with length up to 2

bits (See T able 5, Note 9) or any user programmable bit

pattern from 1 to 32 bits in length. Logic inputs can be

used to configure the DS2172 for applications requiring

gap clocking such as Fractional–T1, Switched–56,

DDS, normal framing requirements, and per–channel

test procedures. In addition, the DS2172 can insert

single or 10

–1

to 10–7 bit errors to verify equipment

operation and connectivity .

RL

24

23

RLOS

LC

22

21

VSS

20

VDD

19

INT

WR (R/W)

18

17

ALE (AS)

CS

32–1

Copyright 1997 by Dallas Semiconductor Corporation.

All Rights Reserved. For important information regarding

patents and other intellectual property rights, please refer to

Dallas Semiconductor data books.

031197 1/20

Page 2

DS2172

1.0 GENERAL OPERATION

1.1 Pattern Generation

The DS2172 is programmed to generate a particular

test pattern by programming the following registers:

– Pattern Set Registers (PSR)

– Pattern Length Register (PLR)

– Polynomial Tap Register (PTR)

– Pattern Control Register (PCR)

– Error Insertion Register (EIR)

Please see Tables 4 and 5 for examples of how to program these registers in order to generate some standard test patterns. Once these registers are programmed, the user will then toggle the TL (Transmit

Load) bit or pin to load the pattern into the onboard pattern generation circuitry and the pattern will begin

appearing at the TDATA pin.

1.2 Pattern Synchronization

The DS2172 expects to receive the same pattern that it

transmitted. The synchronizer examines the data at

RDATA and looks for characteristics of the transmitted

pattern. The user can control the onboard synchronizer

with the Sync Enable and Resync bits in the Pattern

Control Register.

In pseudorandom mode, the received pattern is tested

to see if it fits the polynomial generator as defined in the

transmit side. For pseudorandom patterns, only the

original pattern and an all ones pattern or an all zeros

pattern will satisfy this test. Synchronization in pseudorandom pattern mode should be qualified by using the

RA1 and RA0 indicators in the Status Register. Once in

synchronization (SR0. = 1) any deviation from this pattern will be counted by the Bit Error Count Register.

In repetitive pattern mode a received pattern of the

same length as being transmitted will satisfy this test.

Synchronization in repetitive pattern mode should be

qualified by using the RA1 and RA0 indicators in the

Status Register and examining the Pattern Receive

Register (PRR0––3). See section 10 for an explanation

of the Pattern Receive Register. Once in synchronization (SR.0 = 1) any deviation from this pattern will be

counted by the Bit Error Count Register.

1.3 BER Calculation

Users can calculate the actual Bit Error Rate (BER) of

the digital communications channel by reading the bit

error count out of the Bit Error Count Register (BECR)

and reading the bit count out of the Bit Count Register

(BCR) and then dividing the BECR value with the BCR

value. The user has total control over the integration

period of the measurement. The LC (Load Count) bit or

pin is used to set the integration period.

1.4 Generating Errors

Via the Error Insertion Register (EIR), the user can

intentionally inject a particular error rate into the transmitted data stream. Injecting errors allows users to

stress communication links and to check the functionality of error monitoring equipment along the path.

1.5 Power–Up Sequence

On power–up, the registers in the DS2172 will be in a

random state. The user must program all the internal

registers to a known state before proper operation can

be insured.

031197 2/20

Page 3

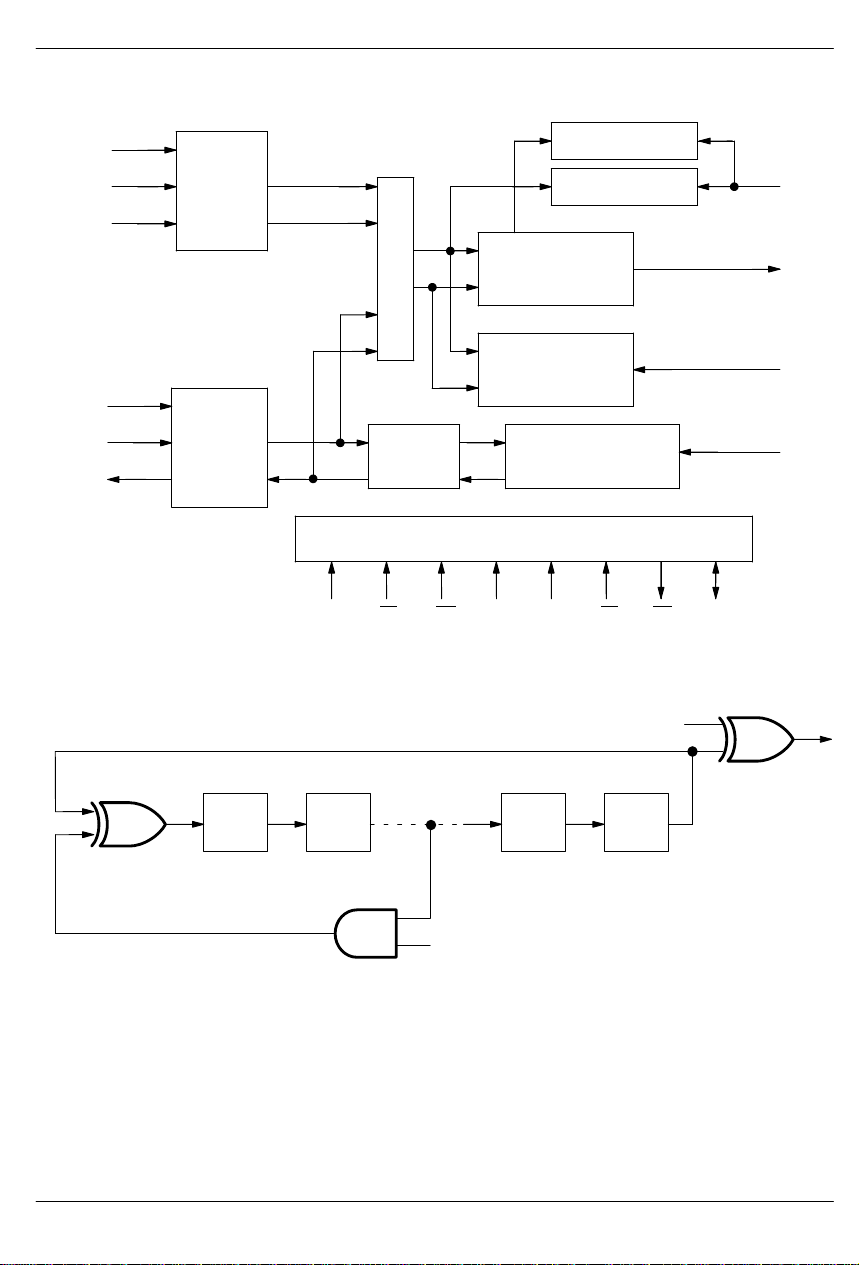

DS2172 FUNCTIONAL BLOCK DIAGRAM Figure 1

DS2172

RDIS

RCLK

RDATA

TDIS

TCLK

TDATA

RECEIVE

RATE

CONTROL

TRANSMIT

RATE

CONTROL

DETECTOR

LOOPBACK MUX

RECEIVE PATTERN

REGISTERS

ERROR

INSERTION

PARALLEL CONTROL PORT

BTS RD WR TEST ALE CS INT AD0–AD7

DS2172 PATTERN GENERATION BLOCK DIAGRAM Figure 2

TAP A FEEDBACK

BIT ERROR COUNTER

BIT COUNTER

PATTERN

PATTERN

GENERATOR

LC

SYNC

RL

TL

EIR.5

XOR

XOR DFF DFF DFF DFF

0 1 N–2 N–1

TAP B FEEDBACK

PCR.5

NOTES:

1. Tap A always equals length (N–1) of pseudorandom or repetitive pattern.

2. Tab B can be programmed to any feedback tap for pseudorandom pattern generation.

031197 3/20

Page 4

DS2172

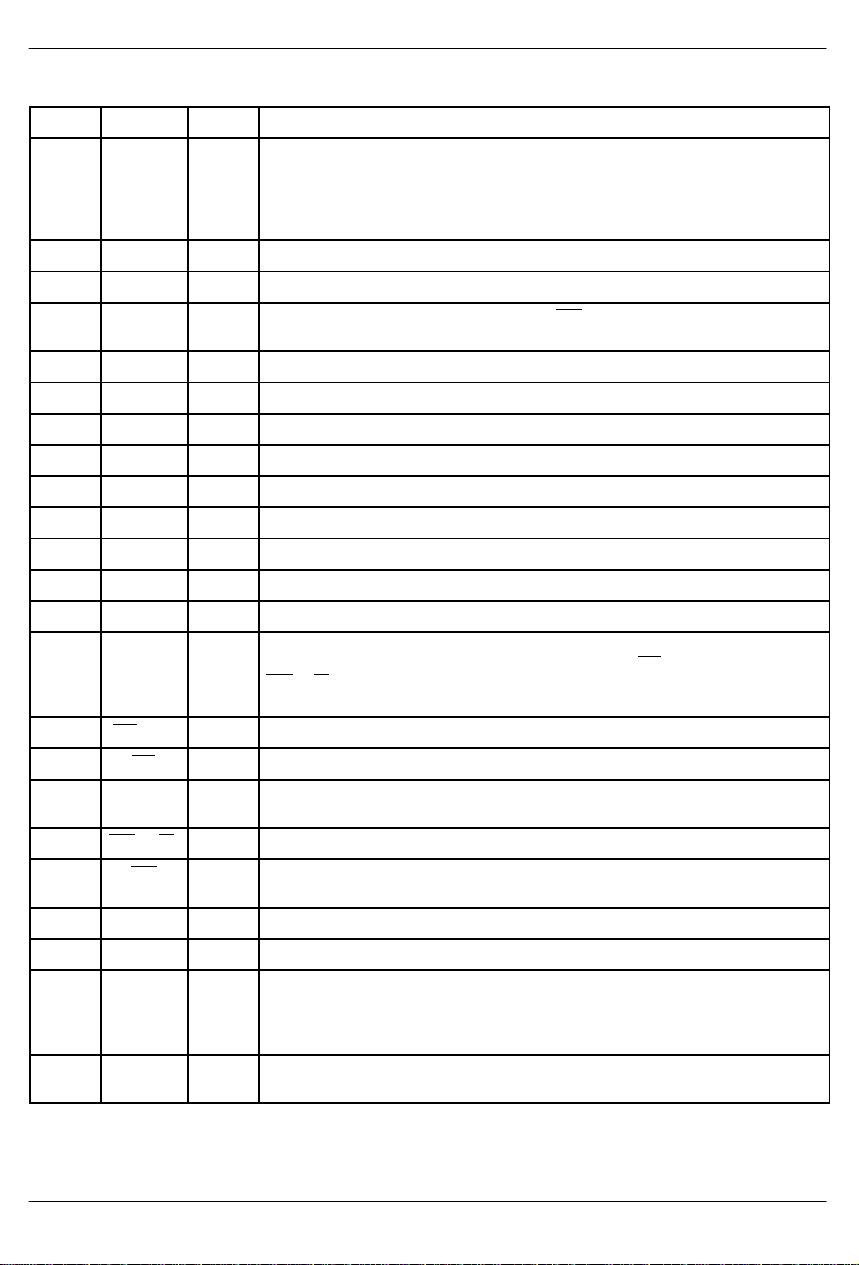

DETAILED PIN DESCRIPTION Table 1

PIN SYMBOL TYPE DESCRIPTION

1 TL I Transmit Load. A positive–going edge loads the pattern generator with the

2 AD0 I/O Data Bus. A 8–bit multiplexed address/data bus.

3 AD1 I/O Data Bus. A 8–bit multiplexed address/data bus.

4 TEST I Test. Set high to 3–state all output pins (INT, ADx, TDATA, RLOS). Should

5 V

SS

6 AD2 I/O Data Bus. A 8–bit multiplexed address/data bus.

7 AD3 I/O Data Bus. A 8–bit multiplexed address/data bus.

8 AD4 I/O Data Bus. A 8–bit multiplexed address/data bus.

9 AD5 I/O Data Bus. A 8–bit multiplexed address/data bus.

10 AD6 I/O Data Bus. A 8–bit multiplexed address/data bus.

11 AD7 I/O Data Bus. A 8–bit multiplexed address/data bus.

12 V

13 V

SS

DD

14 BTS I Bus Type Select. Strap high to select Motorola bus timing; strap low to select

15 RD (DS) I Read Input (Data Strobe).

16 CS I Chip Select. Must be low to read or write the port.

17 ALE (AS) I Address Latch Enable (Address Strobe). A positive going edge serves to

18 WR (R/W) I Write Input (Read/Write).

19 INT O Alarm Interrupt. Flags host controller during conditions defined in Status

20 V

21 V

DD

SS

22 LC I Load Count. A positive–going edge latches the current bit and bit error count

23 RLOS O Receive Loss Of Sync. Indicates the real time status of the receive synchro-

contents of the Pattern Set Registers. The MSB of the repetitive or pseudorandom pattern appears at TDATA after the third positive edge of TCLK from

asserting TL. TL is logically OR’ed with PCR.7 and should be tied to V

not used. See Figure 8 for timing information.

be tied to V

to enable all outputs.

SS

– Signal Ground. 0.0 volts. Should be tied to local ground plane.

– Signal Ground. 0.0 volts. Should be tied to local ground plane.

– Positive Supply. 5.0 volts.

Intel bus timing. This pin controls the function of the RD

(R/W) pins. If BTS = 1, then these pins assume the function listed in

WR

(DS), ALE(AS), and

parenthesis ().

demultiplex the bus.

Register. Active low, open drain output.

– Positive Supply. 5.0 volts.

– Signal Ground. 0.0 volts. Should be tied to local ground plane.

into the user accessible BCR and BECR registers and clears the internal

count registers. LC is logically OR’ed with control bit PCR.4. Should be tied

if not used.

to V

SS

nizer. Active high output; transitions low after receiving 32 matching bits.

SS

if

031197 4/20

Page 5

PIN DESCRIPTIONTYPESYMBOL

24 RL I Receive Load. A positive–going edge loads the previous 32 bits of data

received at RDATA into the Pattern Receive Registers. RL is logically OR’ed

with control bit PCR.3. Should be tied to V

if not used.

SS

25 RDATA I Receive Data. Received NRZ serial data, sampled on the rising edge of

RCLK.

26 RDIS I Receive Disable. Set high to prevent the data at RDATA from being

sampled. Set low to allow bits at RDATA to be sampled. Should be tied to V

if not used. See Figure 6 for timing information. All receive side operations

are disabled when RDIS is high.

27 RCLK I Receive Clock. Input clock from transmission link. 0 to 52 MHz. Can be a

gapped clock. Fully independent from TCLK.

28 V

29 V

DD

SS

– Positive Supply. 5.0 volts.

– Signal Ground. 0.0 volts. Should be tied to local ground plane.

30 TCLK I Transmit Clock. Transmit demand clock. 0 to 52 MHz. Can be a gapped

clock. Fully independent of RCLK.

31 TDIS I Transmit Disable. Set high to hold the current bit being transmitted at

TDATA. Set low to allow the next bit to appear at TDATA. Should be tied to

if not used. See Figure 7 for timing information. All transmit side opera-

V

SS

tions are disabled when TDIS is high.

32 TDATA O Transmit Data. Transmit NRZ serial data, updated on the rising edge of

TCLK.

DS2172

SS

031197 5/20

Page 6

DS2172

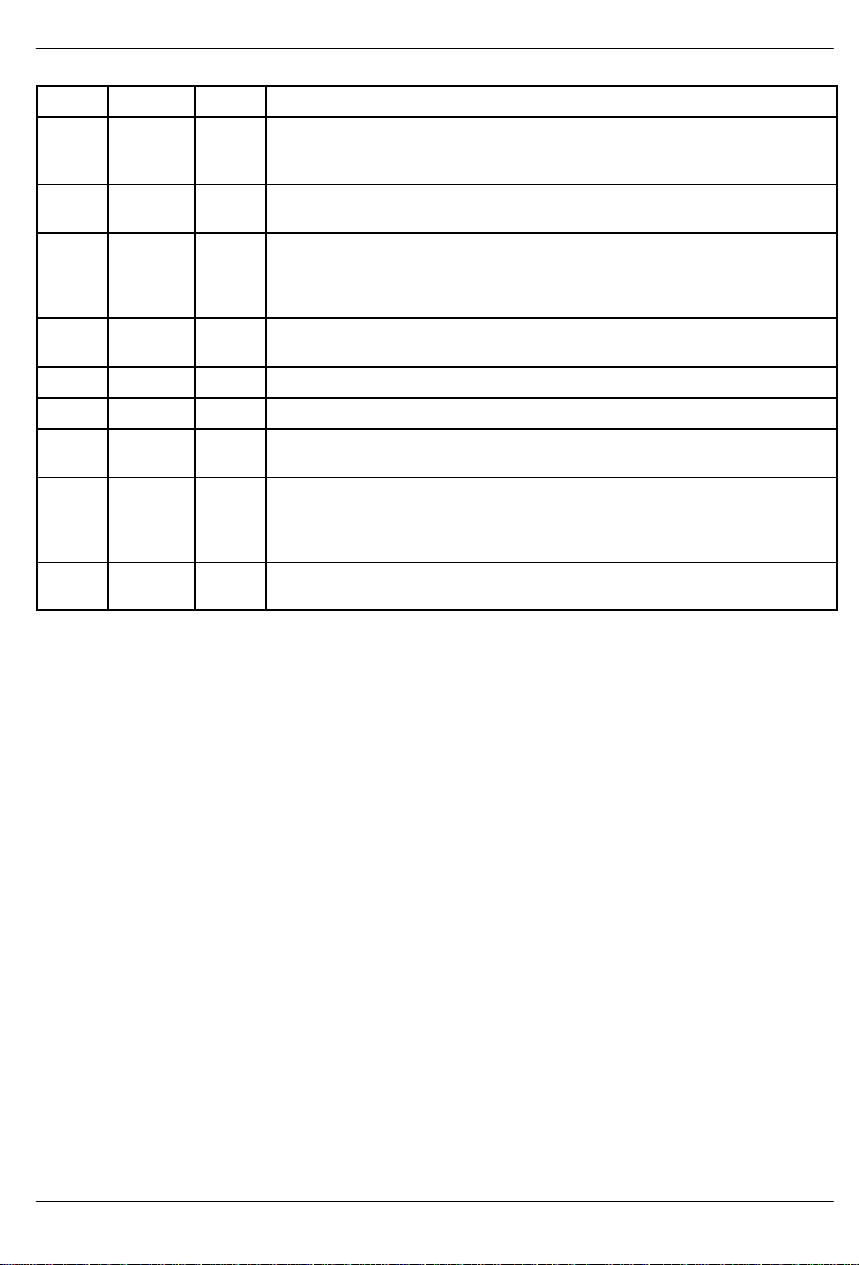

DS2172 REGISTER MAP Table 2

ADDRESS R/W REGISTER NAME

00 R/W Pattern Set Register 3.

01 R/W Pattern Set Register 2.

02 R/W Pattern Set Register 1.

03 R/W Pattern Set Register 0.

04 R/W Pattern Length Register.

05 R/W Polynomial Tap Register.

06 R/W Pattern Control Register.

07 R/W Error Insert Register.

08 R Bit Counter Register 3.

09 R Bit Counter Register 2.

0A R Bit Counter Register 1.

0B R Bit Counter Register 0.

0C R Bit Error Counter Register 3.

0D R Bit Error Counter Register 2.

0E R Bit Error Counter Register 1.

0F R Bit Error Counter Register 0.

10 R Pattern Receive Register 3.

11 R Pattern Receive Register 2.

12 R Pattern Receive Register 1.

13 R Pattern Receive Register 0.

14 R Status Register.

15 R/W Interrupt Mask Register.

1C R/W Test Register (see note 1)

NOTE:

1. The Test Register must be set to 00 hex to insure

proper operation of the DS2172.

2.0 PARALLEL CONTROL INTERFACE

The DS2172 is controlled via a multiplexed bi–directional address/data bus by an external microcontroller

or microprocessor. The DS2172 can operate with either

Intel or Motorola bus timing configurations. If the BTS

pin is tied low, Intel timing will be selected; if tied high,

Motorola timing will be selected. All Motorola bus signals are listed in parenthesis (). See the timing diagrams in the A.C. Electrical Characteristics for more

details. The multiplexed bus on the DS2172 saves pins

because the address information and data information

share the same signal paths. The addresses are presented to the pins in the first portion of the bus cycle and

data will be transferred on the pins during second portion of the bus cycle. Addresses must be valid prior to

the falling edge of ALE(AS), at which time the DS2172

latches the address from the AD0 to AD7 pins. Valid

write data must be present and held stable during the

later portion of the DS or WR

DS2172 outputs a byte of data during the latter portion of

the DS or RD pulses. The read cycle is terminated and

the bus returns to a high impedance state as RD transitions high in Intel timing or as DS transitions low in Motorola timing. The DS2172 can also be easily connected

to non–multiplexed buses. RCLK and TCLK are used to

update counters and load transmit and receive pattern

registers. At slow clock rates, sufficient time must be

allowed for these port operations.

pulses. In a read cycle, the

3.0 PATTERN SET REGISTERS

The Pattern Set Registers (PSR) are loaded each time a

new pattern (whether it be pseudorandom or repetitive)

is to be generated. When a pseudorandom pattern is

generated, all four PSRs must be loaded with FF Hex.

When a repetitive pattern is to be created, the four PSRs

are loaded with the pattern that is to be repeated.

Please see Tables 4 and 5 for some programming

examples.

031197 6/20

Page 7

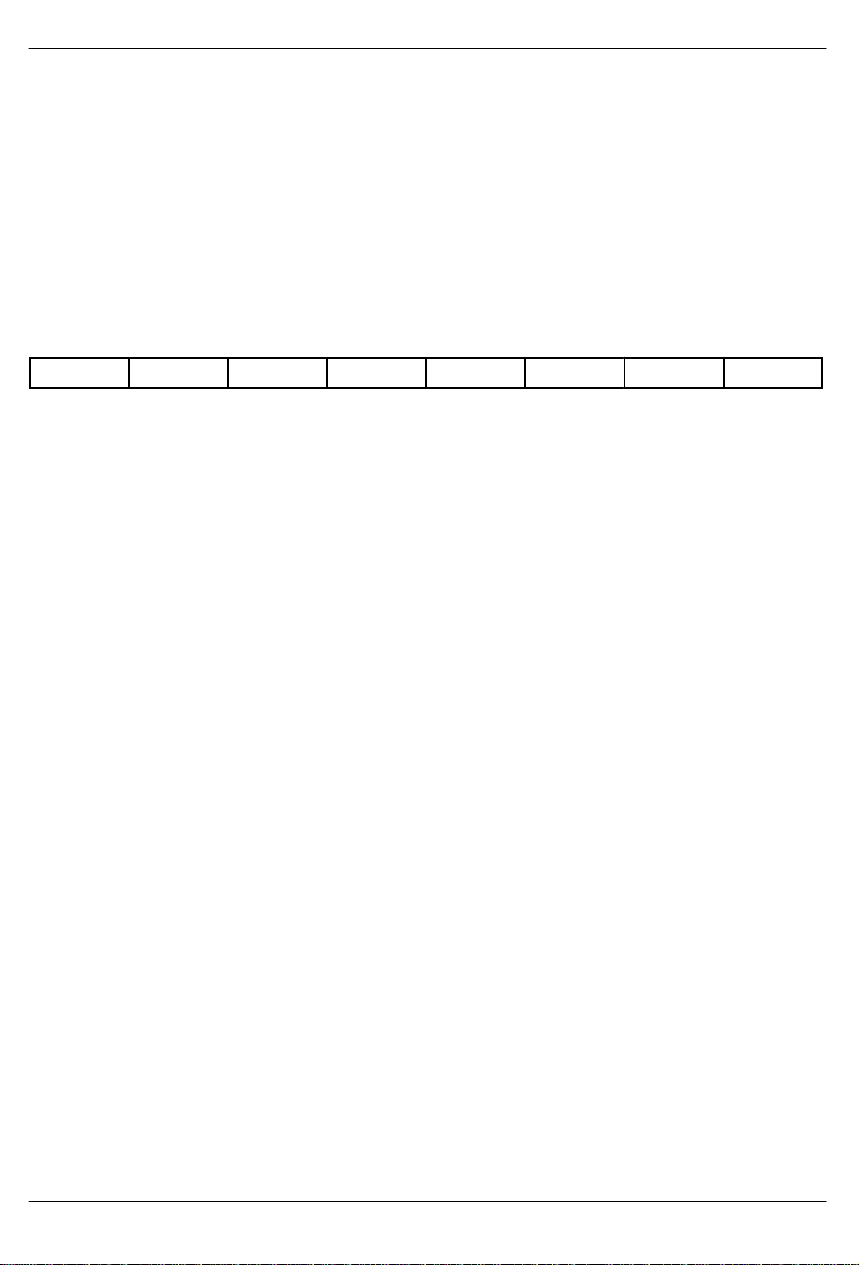

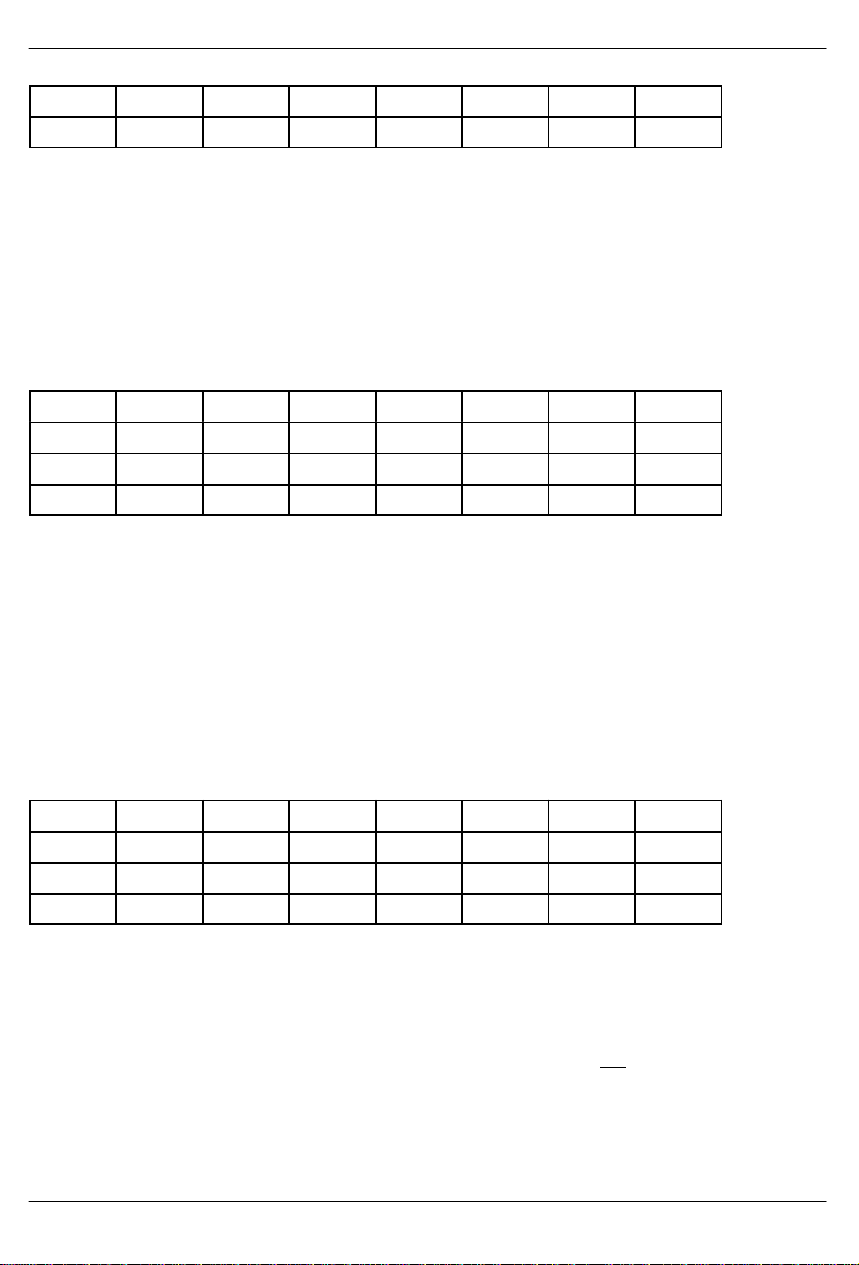

PATTERN SET REGISTERS

(MSB) (LSB)

PS31

PS23 PS22 PS21 PS20 PS19 PS18 PS17 PS16

PS15 PS14 PS13 PS12 PS11 PS10 PS9 PS8

PS7 PS6 PS5 PS4 PS3 PS2 PS1 PS0

PS30 PS29 PS28 PS27 PS26 PS25 PS24

DS2172

PSR3

(addr.=00 Hex)

PSR2

(addr.=01 Hex)

PSR1

(addr.=02 Hex)

PSR0

(addr.=03 Hex)

4.0 PATTERN LENGTH REGISTER

Length Bits LB4 to LB0 determine the length of the

pseudorandom polynomial or programmable repetitive

pattern that is generated and detected. With the

pseudorandom patterns, the “Tap A” feedback position

of the pattern generator is always equal to the value in

the Pattern Length Register (PLR). Please refer to Figure 2 for a block diagram of the pattern generator and to

Tables 4 and 5 for some programming examples.

PLR: PATTERN LENGTH REGISTER (Address=04 Hex)

(MSB) (LSB)

–

SYMBOL POSITION NAME AND DESCRIPTION

– PLR1.7 Not Assigned. Should be set to 0 when written to.

– PLR1.6 Not Assigned. Should be set to 0 when written to.

– PLR1.5 Not Assigned. Should be set to 0 when written to.

LB4 PLR1.4 Length Bit 4.

LB3 PLR1.3 Length Bit 3.

LB2 PLR1.2 Length Bit 2.

LB1 PLR1.1 Length Bit 1.

LB0 PLR1.0 Length Bit 0.

5.0 POLYNOMIAL TAP REGISTER

Polynomial T ap Bits PT4 – PT0 determine the feedback

position of T ap B connected to the XOR input of the pattern generator. Feedback Tap B provides one of two

– – LB4 LB3 LB2 LB1 LB0

feedback paths within the pattern generator. Please

refer to Figure 2 for a block diagram of the pattern generator and to Tables 4 and 5 for register programming

examples.

PTR: POLYNOMIAL TAP REGISTER (Address=05 Hex)

(MSB) (LSB)

– – – PT4 PT3 PT2 PT1 PT0

SYMBOL POSITION NAME AND DESCRIPTION

– PTR.7 Not Assigned. Should be set to 0 when written to.

– PTR.6 Not Assigned. Should be set to 0 when written to.

– PTR.5 Not Assigned. Should be set to 0 when written to.

PT4 PTR.4 Polynomial Tap Bit 4.

031197 7/20

Page 8

DS2172

PT3 PTR.3 Polynomial Tap Bit 3.

PT2 PTR.2 Polynomial Tap Bit 2.

PT1 PTR.1 Polynomial Tap Bit 1.

PT0 PTR.0 Polynomial Tap Bit 0.

6.0 PATTERN CONTROL REGISTER

The Pattern Control Register (PCR) is used to configure

the operating parameters of the DS2172 and to control

the patterns being generated and received. Also the

PCR is used to control the pattern synchronizer and the

error and bit counters.

PCR: PATTERN CONTROL REGISTER (Address=06 Hex)

(MSB) (LSB)

TL QRSS PS LC RL SYNCE RESYNC LPBK

SYMBOL POSITION NAME AND DESCRIPTION

TL PCR.7 Transmit Load. A low to high transition loads the pattern generator with

QRSS PCR.6 Zero Suppression Select. Forces a “one” into the pattern whenever the

PS PCR.5 Pattern Select.

LC PCR.4 Latch Count Registers. A low to high transition latches the bit and error

RL PCR.3 Receive Data Load. A transition from low to high loads the previous 32 bits

SYNCE PCR.2 SYNC Enable.

RESYNC PCR.1 Initiate Manual Resync Process. A low to high transition will force the

LPBK PCR.0 Transmit/Receive Loopback Select. When enabled, the RDA T A input is

the contents of the Pattern Set Registers. PCR.7 is logically ORed with the

input pin TL. Must be cleared and set again for subsequent loads.

next 14 bit positions are all “zeros”. Should only be set when using the

QRSS pattern.

0 = Zero suppression disabled

1 = Zero suppression enabled

0 = Repetitive Pattern

1 = Pseudorandom Pattern

counts into the user accessible registers BCR and BECR and clears the

internal register count. PCR.4 is logically OR’ed with input pin LC. Must be

cleared and set again for subsequent loads.

of data received at RDATA into the Pattern Receive Registers (PRR).

PCR.3 is logically OR’ed with input pin RL. Must be cleared and set again

for subsequent latches.

0 = auto resync is enabled.

1 = auto resync is disabled.

DS2172 to resynchronize to the incoming pattern at RDATA. Must be

cleared and set again for a subsequent resync.

disabled; TDATA continues to output data as normal. See Figure 1.

0 = loopback disabled

1 = loopback enabled

031197 8/20

Page 9

DS2172

7.0 ERROR INSERT REGISTER

The Error Insertion Register (EIR) controls circuitry

within the DS2172 that allows the generated pattern to

automatically at regular intervals by properly programming the EIR0 to EIR2 bits or bit errors can be inserted at

random (under microcontroller control) via the EIR.3 bit.

be intentionally corrupted. Bit errors can be inserted

EIR: ERROR INSERT REGISTER (Address=07 Hex)

(MSB) (LSB)

–

SYMBOL POSITION NAME AND DESCRIPTION

– EIR.7 Not Assigned. Should be set to 0 when written to.

– EIR.6 Not Assigned. Should be set to 0 when written to.

TINV EIR.5 Transmit Data Inversion Select.

RINV EIR.4 Receive Data Inversion Select.

SBE EIR.3 Single Bit Error Insert. A low to high transition will create a single bit error.

EIB2 EIR.2 Error Insert Bit 2. See Table 3.

EIB1 EIR.1 Error Insert Bit 1. See Table 3.

EIB0 EIR.0 Error Insert Bit 0. See Table 3.

– TINV RINV SBE EIR2 EIR1 EIR0

0 = do not invert data to be transmitted at TDATA

1 = invert data to be transmitted at TDATA

0 = do not invert data received at RDATA

1 = invert data received at RDATA

Must be cleared and set again for a subsequent bit error to be inserted. Can

be used to accomplish rates not addressed in Table 3 (e.g., BER of less

–7

than 10

).

ERROR BIT INSERTION Table 3

EIB2 EIB1 EIB0 ERROR RATE INSERTED

0 0 0 no errors automatically inserted

0 0 1 10

0 1 0 10

0 1 1 10

1 0 0 10

1 0 1 10

1 1 0 10

1 1 1 10

–1

–2

–3

–4

–5

–6

–7

031197 9/20

Page 10

DS2172

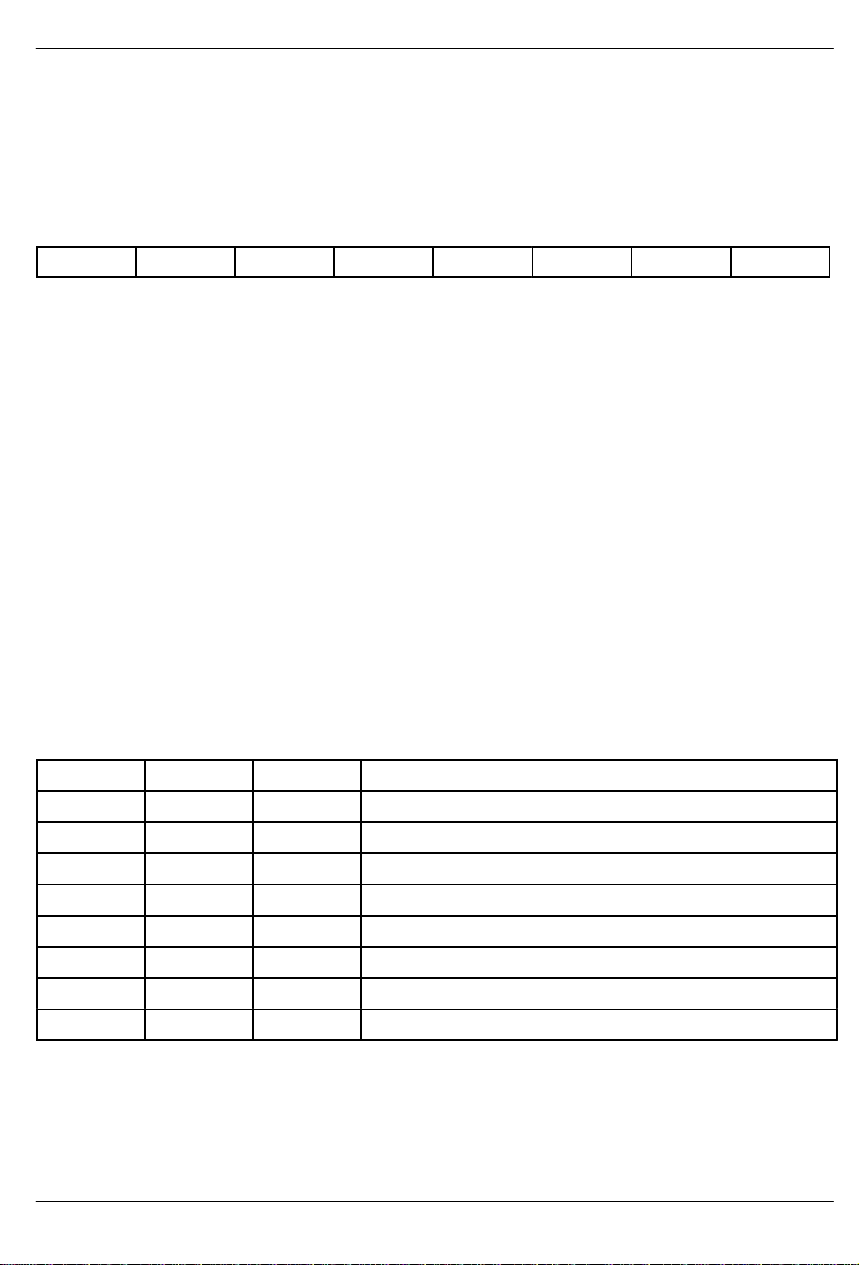

PSEUDORANDOM PATTERN GENERATION (PCR.5=1) Table 4

PATTERN TYPE PTR PLR PSR3 PSR2 PSR1 PSR0 TINV RINV

23 – 1 00 02 FF FF FF FF 0 0

24 – 1 00 03 FF FF FF FF 0 0

25 – 1 01 04 FF FF FF FF 0 0

26 – 1 04 05 FF FF FF FF 0 0

27 – 1 00 06 FF FF FF FF 0 0

27 – 1 Fractional T1 LB Activate 03 06 FF FF FF FF 0 0

27 – 1 Fractional T1 LB Deactivate 03 06 FF FF FF FF 1 1

29 – 1 O.153 (511 type) 04 08 FF FF FF FF 0 0

210 – 1 02 09 FF FF FF FF 0 0

211 – 1 O.152 and O.153 (2047 type) 08 0A FF FF FF FF 0 0

215 – 1 O.151 0D 0E FF FF FF FF 1 1

217 – 1 02 10 FF FF FF FF 0 0

218 – 1 06 11 FF FF FF FF 0 0

220 – 1 O.153 02 13 FF FF FF FF 0 0

220 – 1 O.151 QRSS (PCR.6=1) 10 13 FF FF FF FF 0 0

221 – 1 01 14 FF FF FF FF 0 0

222 – 1 00 15 FF FF FF FF 0 0

223 – 1 O.151 11 16 FF FF FF FF 1 1

225 – 1 02 18 FF FF FF FF 0 0

228 – 1 02 1B FF FF FF FF 0 0

229 – 1 01 1C FF FF FF FF 0 0

231 – 1 02 1E FF FF FF FF 0 0

232 – 1 (see note below) 10 1F FF FF FF FF 0 0

031197 10/20

Page 11

DS2172

REPETITIVE PATTERN GENERATION (PCR.5=0) Table 5

PATTERN TYPE PTR PLR PSR3 PSR2 PSR1 PSR0 TINV RINV

all ones 00 00 FF FF FF FF 0 0

all zeros 00 00 FF FF FF FE 0 0

alternating ones and zeros 00 01 FF FF FF FE 0 0

double alternating ones and zeros 00 03 FF FF FF FC 0 0

3 in 24 00 17 FF 20 00 22 0 0

1 in 16 00 0F FF FF 00 01 0 0

1 in 8 00 07 FF FF FF 01 0 0

1 in 4 00 03 FF FF FF F1 0 0

D4 Line Loopback Activate 00 04 FF FF FF F0 0 0

D4 Line Loopback Deactivate 00 02 FF FF FF FC 0 0

NOTES FOR TABLES 4 AND 5:

1. PTR = Polynomial Tap Register (address = 05)

2. PLR = Pattern Length Register (address = 04)

3. PSR3 = Pattern Set Register 3 (address = 00)

4. PSR2 = Pattern Set Register 2 (address = 01)

5. PSR1 = Pattern Set Register 1 (address = 02)

6. PSR0 = Pattern Set Register 0 (address = 03)

7. TINV = Transmit Data Inversion Select Bit (EIR.5)

8. RINV = Receive Data Inversion Select Bit (EIR.4)

32

9. For the 2

–1 pattern, the random pattern actually repeats every (4093 x 220 ) + 1046529 bits instead of 232 – 1.

8.0 BIT COUNT REGISTERS

The Bit Count Registers (BCR3 to BCR0) comprise a

32–bit count of bits (actually RCLK cycles) received at

RDATA. BC31 is the MSB of the 32 bit count. The bit

counter increments for each cycle of RCLK when input

pin RDIS is low. The bit counter is disabled during loss

of SYNC. The Status Register bit BCOF is set when this

the user must clear the BCR by either toggling the LC bit

or pin. The DS2172 latches the bit count into the BCR

registers and clears the internal bit count when either

the PCR.4 bit or the LC input pin toggles from low to

high. The bit count and bit error count (available via the

BECRs) are used by an external processor to compute

the BER performance on a loop or channel basis.

32–bit register overflows. Upon an overflow condition,

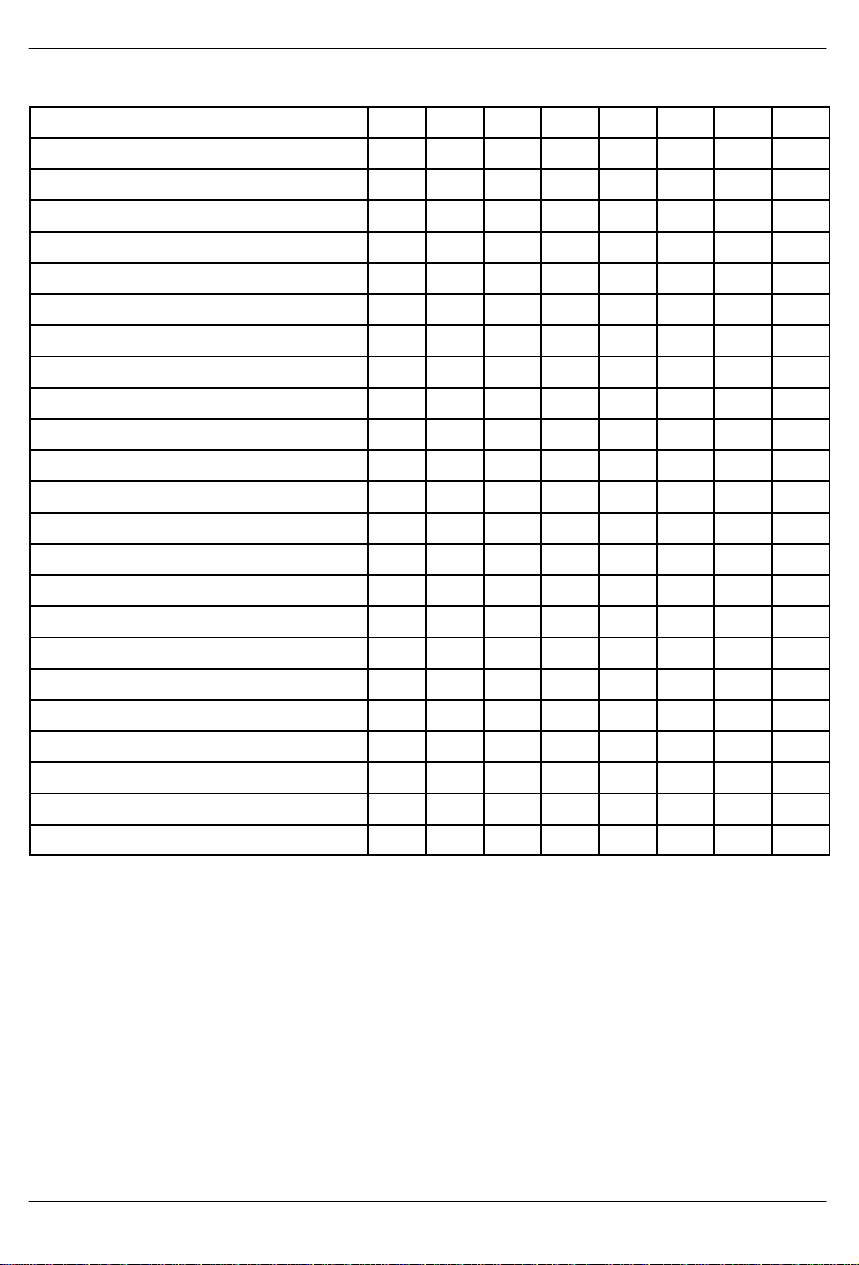

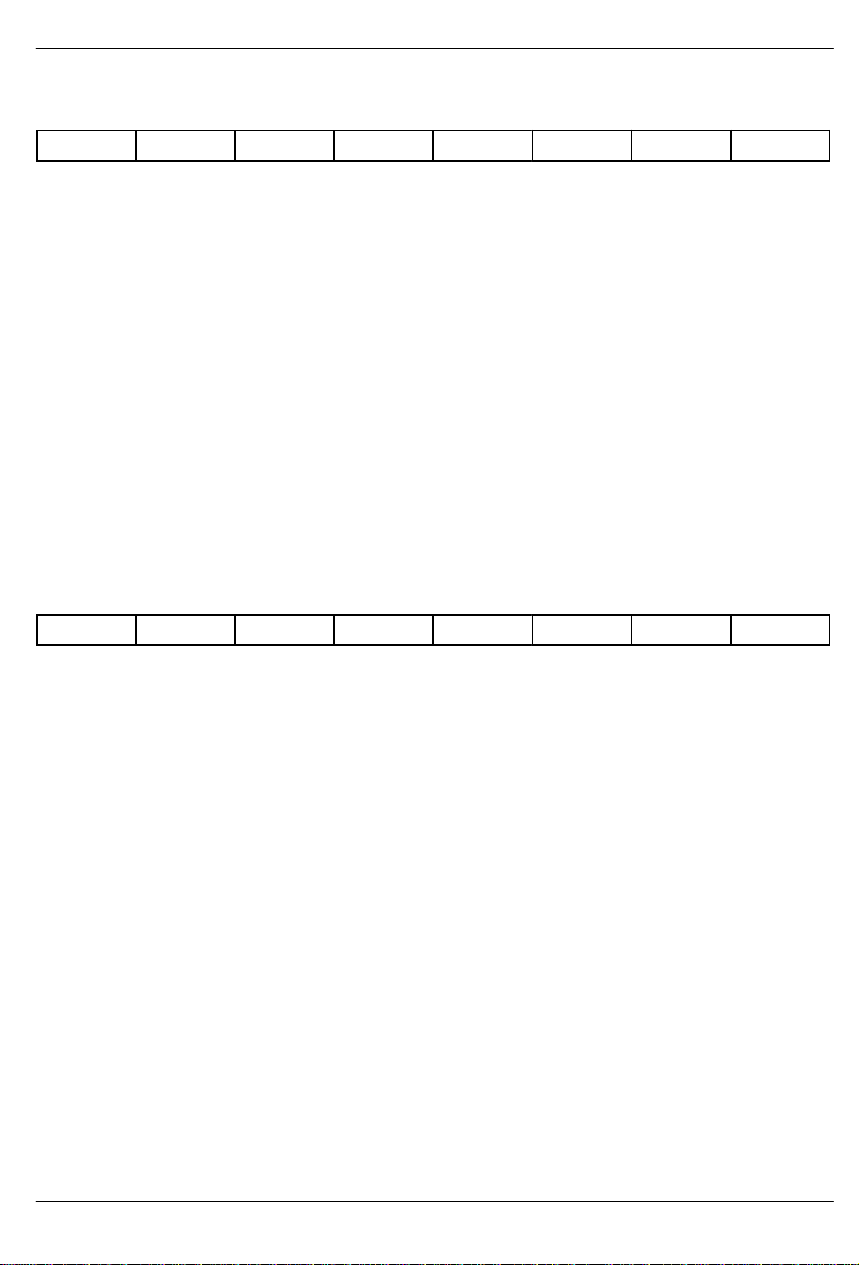

BIT COUNT REGISTERS

(MSB) (LSB)

BC31 BC30 BC29 BC28 BC27 BC26 BC25 BC24

BC23 BC22 BC21 BC20 BC19 BC18 BC17 BC16

BCR3

(addr.=08 Hex)

BCR2

(addr.=09 Hex)

BCR1

(addr.=0A Hex)

BCR0

(addr.=0B Hex)

031197 11/20

Page 12

DS2172

BC15 BC14 BC13 BC12 BC11 BC10 BC9 BC8

BC7 BC6 BC5 BC4 BC3 BC2 BC1 BC0

9.0 BIT ERROR COUNT REGISTERS

The Bit Error Count Registers (BECR3 to BECR0) comprise a 32–bit count of bits received in error at RDATA.

The bit error counter is disabled during loss of SYNC.

BEC31 is the MSB of the 32 bit count. The Status Register bit BECOF is set when this 32–bit register overflows.

Upon an overflow condition, the user must clear the

BECR by either toggling the LC bit or pin. The DS2172

latches the bit error count into the BECR registers and

clears the internal bit error count when either the PCR.4

bit or the LC input pin toggles from low to high. The bit

count (available via the BCRs) and bit error count are

used by an external processor to compute the BER performance on a loop or channel basis.

BIT ERROR COUNT REGISTERS

(MSB) (LSB)

BEC31

BEC23 BEC22 BEC21 BEC20 BEC19 BEC18 BEC17 BEC16

BEC15 BEC14 BEC13 BEC12 BEC11 BEC10 BEC9 BEC8

BEC7 BEC6 BEC5 BEC4 BEC3 BEC2 BEC1 BEC0

10.0 PATTERN RECEIVE REGISTERS

The Pattern Receive Register (PRR) provide access to

the data patterns received at RDA T A. The operation of

these registers depends on the synchronization status

of the DS2172. Asserting the RL bit (PCR.3) or pin during an out–of –sync condition (SR.0 = 0) will latch the

previous 32 bits of data received at RDAT A into the PRR

registers. When the DS2172 is in sync (SR.0 = 1)

asserting RL will latch the pattern that to which the

BEC30 BEC29 BEC28 BEC27 BEC26 BEC25 BEC24

device has established synchronization. Since the

receiver has no knowledge of the start or end of the pattern, the data in the PRR registers will have no particular

alignment. As an example, if the receiver has synchronized to the pattern 00100110, PRR1 may report

1001 1000, 11000100 or any rotation thereof. Once synchronization is established, bit errors cannot be viewed

in the PRR registers.

BECR3

(addr.=0C Hex)

BECR2

(addr.=0D Hex)

BECR1

(addr.=0E Hex)

BECR0

(addr.=0F Hex)

PATTERN RECEIVE REGISTERS

(MSB) (LSB)

PR31 PR30 PR29 PR28 PR27 PR26 PR25 PR24

PR23 PR22 PR21 PR20 PR19 PR18 PR17 PR16

PR15 PR14 PR13 PR12 PR11 PR10 PR9 PR8

PR7 PR6 PR5 PR4 PR3 PR2 PR1 PR0

11.0 STATUS REGISTER AND INTERRUPT

MASK REGISTER

The Status Register (SR) contains information on the

current real time status of the DS2172. When a particular event has occurred, the appropriate bit in the register

will be set to a one. All of the bits in these registers

(except for the SYNC bit) operate in a latched fashion.

This means that if an event occurs and a bit is set to a

one in any of the registers, it will remain set until the user

reads that bit. For the BED, BCOF, and BECOF status

031197 12/20

bits, they will be cleared when read and will not be set

again until the event has occurred again. For RLOS,

RA0, and RA1 status bits, they will be cleared when

read if the condition no longer persists.

The SR register has the unique ability to initiate a hardware interrupt via the INT

events in the SR can be either masked or unmasked

from the interrupt pins via the Interrupt Mask Register

(IMR).

pin. Each of the alarms and

PRR3

(addr.=10 Hex)

PRR2

(addr.=11 Hex)

PRR1

(addr.=12 Hex)

PRR0

(addr.=13 Hex)

Page 13

SR: STATUS REGISTER (Address=14 Hex)

(MSB) (LSB)

–

RA1 RA0 RLOS BED BCOF BECOF SYNC

SYMBOL POSITION NAME AND DESCRIPTION

– SR.7 Not Assigned. Could be any value when read.

RA1 SR.6 Receive All Ones. Set when 32 consecutive ones are received; allowed to

be cleared when a zero is received.

RA0 SR.5 Receive All Zeros. Set when 32 consecutive zeros are received; allowed

to be cleared when a one is received.

RLOS SR.4 Receive Loss Of Sync. Set when the device is searching for synchroniza-

tion. Once sync is achieved, will remain set until read.

BED SR.3 Bit Error Detection. Set when bit errors are detected.

BCOF SR.2 Bit Counter Overflow. Set when the 32–bit BCR overflows.

BECOF SR.1 Bit Error Count Overflow. Set when the 32–bit BECR overflows.

SYNC SR.0 Sync. Real time status of the synchronizer (this bit is not latched). Will be

set when the incoming pattern at RDATA matches for 32 consecutive bit

positions. Will be cleared when 6 or more bits out of 64 are received in error

(if PCR.2 = 0).

IMR: INTERRUPT MASK REGISTER (Address=15 Hex)

(MSB) (LSB)

– RA1 RA0 RLOS BED BCOF BECOF SYNC

DS2172

SYMBOL POSITION NAME AND DESCRIPTION

– IMR.7 Not Assigned. Should be set to zero when written to.

RA1 IMR.6 Receive All Ones.

0 = interrupt masked

1 = interrupt enabled

RA0 IMR.5 Receive All Zeros.

0 = interrupt masked

1 = interrupt enabled

RLOS IMR.4 Receive Loss Of Sync.

0 = interrupt masked

1 = interrupt enabled

BED IMR.3 Bit Error Detection.

0 = interrupt masked

1 = interrupt enabled

BCOF IMR.2 Bit Counter Overflow.

0 = interrupt masked

1 = interrupt enabled

BECOF IMR.1 Bit Error Count Overflow.

0 = interrupt masked

1 = interrupt enabled

SYNC IMR.0 Sync.

0 = interrupt masked

1 = interrupt enabled

031197 13/20

Page 14

DS2172

12.0 AC TIMING AND DC OPERATING CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground –1.0V to +7.0V

Operating Temperature 0°C to 70°C

Storage Temperature –55°C to +125°C

Soldering Temperature 260°C for 10 seconds

* This is a stress rating only and functional operation of the device at these or any other conditions above those

indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (0°C to 70°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Logic 1 V

Logic 0 V

Supply V

IH

IL

DD

2.0 VDD+0.3 V

–0.3 +0.8 V

4.50 5.50 V

CAPACITANCE (tA=25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

Output Capacitance C

IN

OUT

5 pF

7 pF

DC CHARACTERISTICS (0°C to 70°C; VDD=5V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Current @ 5V I

Input Leakage I

Output Leakage I

Output Current @ 2.4V I

Output Current @ 0.4V I

DD

LO

OH

OL

IL

–1.0 +1.0 µA 2

–1.0 mA

+4.0 mA

10 mA 1

1.0 µA 3

NOTES:

1. TCLK = RCLK = 1.544 MHz; outputs open circuited.

2. 0.0V < V

3. Applies to INT when tri–stated.

031197 14/20

< V

IN

DD

Page 15

DS2172

AC CHARACTERISTICS – PARALLEL PORT (0°C to 70°C; VDD=5V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Cycle Time t

CYC

Pulse Width, DS Low or RD High PW

Pulse Width, DS High or RD Low PW

Input Rise/Fall Times tR, t

R/W Hold Time t

R/W Setup Time Before DS High t

CS Setup Time Before DS, WR or

Active

RD

CS Hold Time t

Read Data Hold Time t

Write Data Hold Time t

Mux’ed Address Valid to AS or

ALE Fall

Mux’ed Address Hold Time t

Delay Time DS, WR or RD to AS

or ALE Rise

RWH

RWS

t

CS

CH

DHR

DHW

t

ASL

AHL

t

ASD

Pulse Width AS or ALE High PW

Delay Time, AS or ALE to DS,

or RD

WR

Output Data Delay Time from DS

or RD

Data Setup Time t

t

ASED

t

DDR

DSW

EL

EH

F

ASH

200 ns

100 ns

100 ns

20 ns

10 ns

50 ns

20 ns

0 ns

5 50 ns

0 ns

15 ns

10 ns

20 ns

30 ns

10 ns

5 50 ns

50 ns

031197 15/20

Page 16

DS2172

INTEL BUS READ AC TIMING (BTS=0) Figure 3

PW

ALE

t

ASD

ASH

t

CYC

WR

RD

t

ASD

PW

EL

t

CS

CS

t

ASL

AD0–AD7

t

AHL

INTEL BUS WRITE AC TIMING (BTS=0) Figure 4

PW

PW

ASH

t

EL

t

CS

t

ASL

ALE

WR

RD

CS

t

ASD

t

ASD

t

ASED

ASED

PW

EH

t

CH

t

DDR

t

CYC

PW

EH

t

t

DHR

t

DHW

CH

AD0–AD7

031197 16/20

t

t

AHL

DSW

Page 17

MOTOROLA BUS AC TIMING (BTS=1) Figure 5

PW

ASH

AS

DS

R/W

AD0–AD7

(READ)

CS

AD0–AD7

(WRITE)

t

ASD

t

ASL

t

ASL

PW

t

t

AHL

AHL

t

ASED

EL

t

RWS

t

CS

t

DDR

DS2172

PW

EH

t

CYC

t

DSW

t

RWH

t

DHR

t

CH

t

DHW

031197 17/20

Page 18

DS2172

AC CHARACTERISTICS – RECEIVE SIDE (0°C to 70°C; VDD=5V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

RCLK Period t

RCLK Pulse Width t

RDATA Set Up to RCLK Rising t

RDATA Hold from RCLK Rising t

RDIS Set Up to RCLK Rising t

RDIS Hold from RCLK Rising t

RL and LC Pulse Width t

CP

CH

t

SU1

HD1

SU2

HD2

WRL

RLCK Rise and Fall Times tR, t

CL

F

19 ns

8

8

ns

ns

4 ns

0 ns

4 ns

0 ns

25 ns

10 ns 1

AC CHARACTERISTICS – TRANSMIT SIDE (0°C to 70°C; VDD=5V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

TCLK Period t

TCLK Pulse Width t

TDATA Delay from TCLK Rising t

TDIS Set Up to TCLK Rising t

TDIS Hold from TCLK Rising t

TL Pulse Width t

TL Set Up to TCLK Rising t

TL Hold Off from TCLK Rising t

CP

CH

t

DD

SU

HD

WTL

STL

HTL

TCLK Rise and Fall Time tR, t

CL

F

19 ns

8

8

ns

ns

9 ns

4 ns

0 ns

15 ns

4 ns

0 ns

10 ns 1

NOTE:

1. The maximum rise and fall time is either 10 ns or 10% of tCP whichever is less.

031197 18/20

Page 19

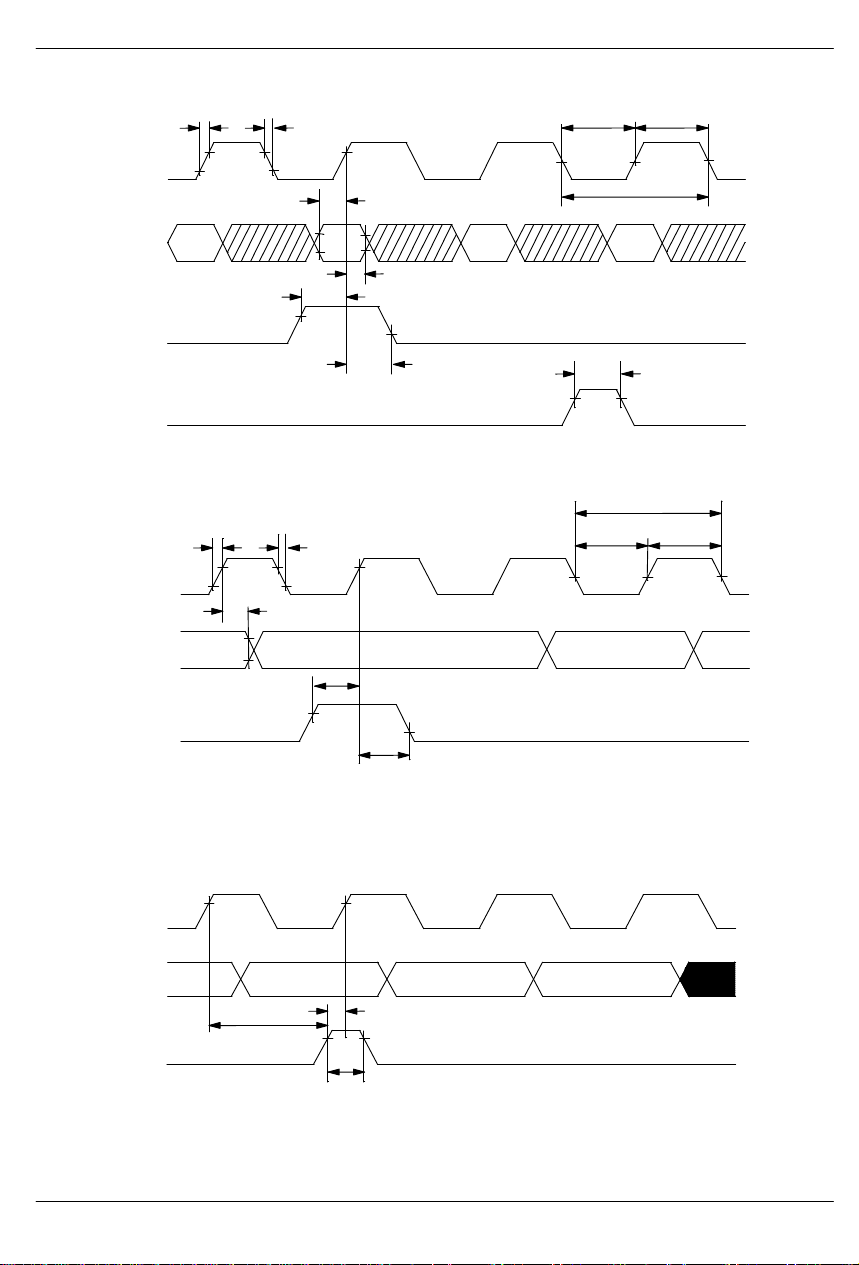

RECEIVE AC TIMING Figure 6

t

R

DS2172

t

t

F

CL

t

CH

RCLK

t

SU1

RDATA

t

SU2

RDIS

RL/LC

TRANSMIT AC TIMING Figure 7

t

R

TCLK

TDATA

TDIS

t

DD

t

CP

t

HD1

t

HD2

t

F

t

WRL

t

CP

t

CL

t

CH

SEE NOTE BELOW

t

SU

t

HD

NOTE: When TDIS is high about the rising edge of TCLK, TDAT A will not be updated and will be held with the previous

valve until TDIS is low about the rising edge of TCLK.

TRANSMIT AC TIMING FOR THE TL INPUT Figure 8

TCLK

TDATA

t

t

HTL

TL

NOTE: The rising edge of TL causes the internal pattern generation circuitry to be reloaded; the first bit of the new

pattern (the shaded one) will appear after two TCLK periods.

STL

t

WTL

031197 19/20

Page 20

DS2172

DS2172 32–PIN TQFP

031197 20/20

GAUGE

Loading...

Loading...