Page 1

www.maxim-ic.com

i

Button DESCRIPTION

The DS1972 is a 1024-bit, 1-Wire® EEPROM

organized as four memory pages of 256 bits each in

a rugged i

byte scratchpad, verified, and then copied to the

EEPROM memory. As a special feature, the four

memory pages can individually be write protected or

put in EPROM-emulation mode, where bits can only

be changed from a 1 to a 0 state. The DS1972

communicates over the single-conductor 1-Wire bus.

The communication follows the standard Dallas

Semiconductor 1-Wire protocol. Each device has its

own unalterable and unique 64-bit ROM registration

number that is factory lasered into the device. The

registration number is used to address the device in

a multidrop 1-Wire net environment.

Button package. Data is written to an 8-

APPLICATIONS

Access Control/Parking Meter

Work-In-Progress Tracking

Tool Management

Inventory Control

Maintenance/Inspection Data Storage

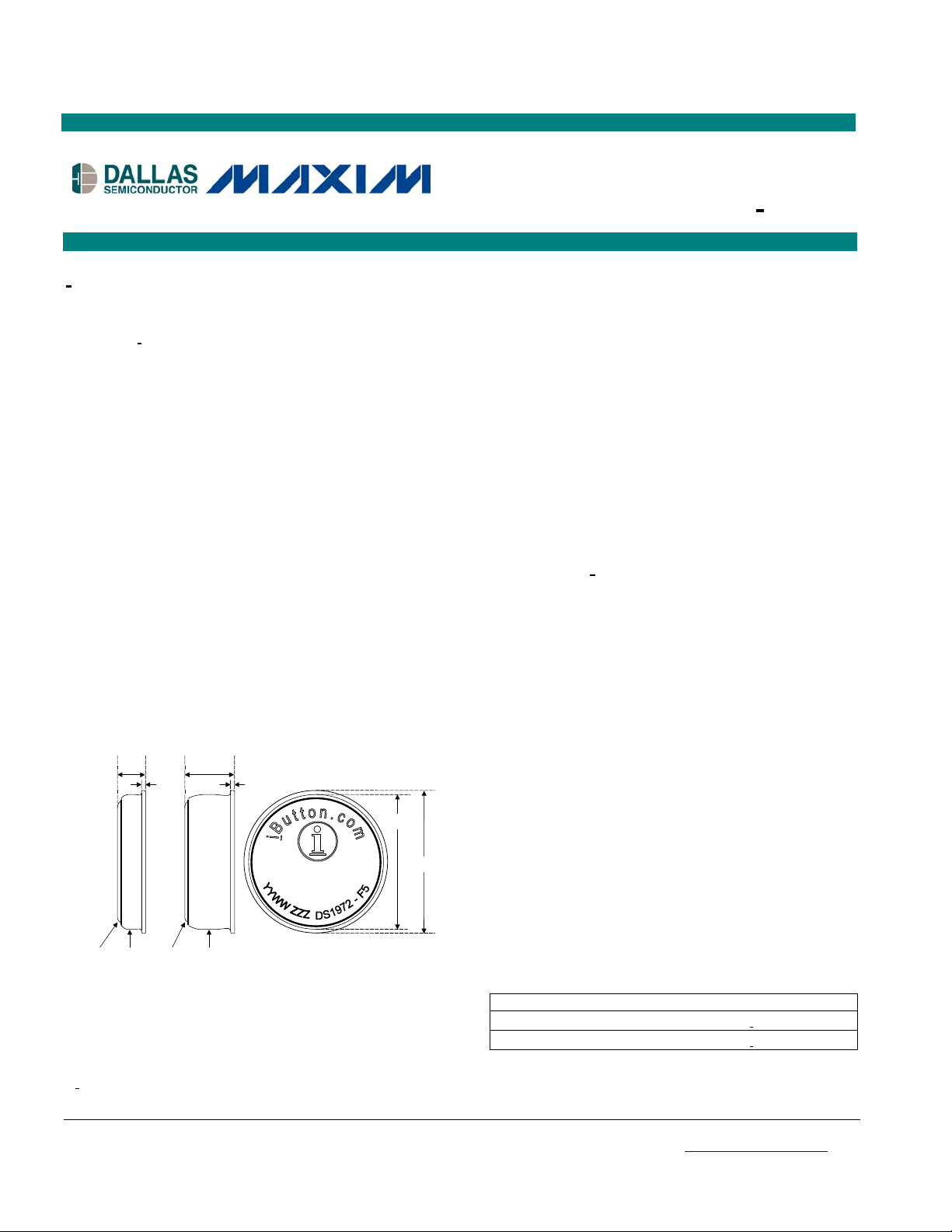

F5 AND F3 MicroCAN

F3 size F5 size Branding

0.51

IO

5.89

GND

0.51

51 2D

0000006234FB

1-Wire

â

â

â

16.25

17.35

3.10

IO GND

Commands, Registers, and Modes are capitalized for

clarity.

Button, 1-Wire, and MicroCAN are registered trademarks of Dallas

I

Semiconductor Corp.

DS1972

1024-Bit EEPROM i

SPECIAL FEATURES

§ 1024 Bits of EEPROM Memory Partitioned into

Four Pages of 256 Bits

§ Individual Memory Pages can be Permanently

Write Protected or Put in EPROM-Emulation

Mode ("Write to 0")

§ Switchpoint Hysteresis and Filtering to Optimize

Performance in the Presence of Noise

§ IEC 1000-4-2 Level 4 ESD Protection (8kV

Contact, 15kV Air, typical)

§ Reads and Writes Over a Wide Voltage Range of

2.8V to 5.25V from -40°C to +85°C

§ Communicates to Host with a Single Digital

Signal at 15.4kbps or 125kbps Using 1-Wire

Protocol

COMMON iButton FEATURES

§ Unique Factory-Lasered 64-Bit Registration

Number Assures Error-Free Device Selection

and Absolute Traceability Because No Two Parts

are Alike

§ Built-In Multidrop Controller for 1-Wire Net

§ Chip-Based Data Carrier Stores Digital Identifi-

cation and Information, Armored in a Durable

Stainless-Steel Case

§ Data can be Accessed While Affixed to Object

§ Button Shape is Self-Aligning with Cup-Shaped

Probes

§ Easily Affixed with Self-Stick Adhesive Backing,

Latched by its Flange, or Locked with a Ring

Pressed onto its Rim

§ Presence Detector Acknowledges when Reader

First Applies Voltage

§ Designed to meet UL#913 (4th Edit.); Intrinsically

Safe Apparatus: Under Entity Concept for use in

Class I, Division 1, Group A, B, C, and D

Locations, contact Dallas Semiconductor for

certification schedule

ORDERING INFORMATION

PART TEMP RANGE PIN-PACKAGE

DS1972-F5# -40°C to 85°C F5 iButton

DS1972-F3# -40°C to 85°C F3 iButton

# indicates RoHS complience

Contact factory lead-free compliance

Button

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, click here: www.maxim-ic.com/errata

1 of 23 REV: 083006

.

Page 2

DS1972: 1024-Bit EEPROM iButton

ABSOLUTE MAXIMUM RATINGS

I/O Voltage to GND -0.5V, +6V

I/O Sink Current 20mA

Operating Temperature Range -40°C to +85°C

Junction Temperature +150°C

Storage Temperature Range -40°C to +85°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is

not implied. Exposure to the absolute maximum rating conditions for extended periods may affect device reliability.

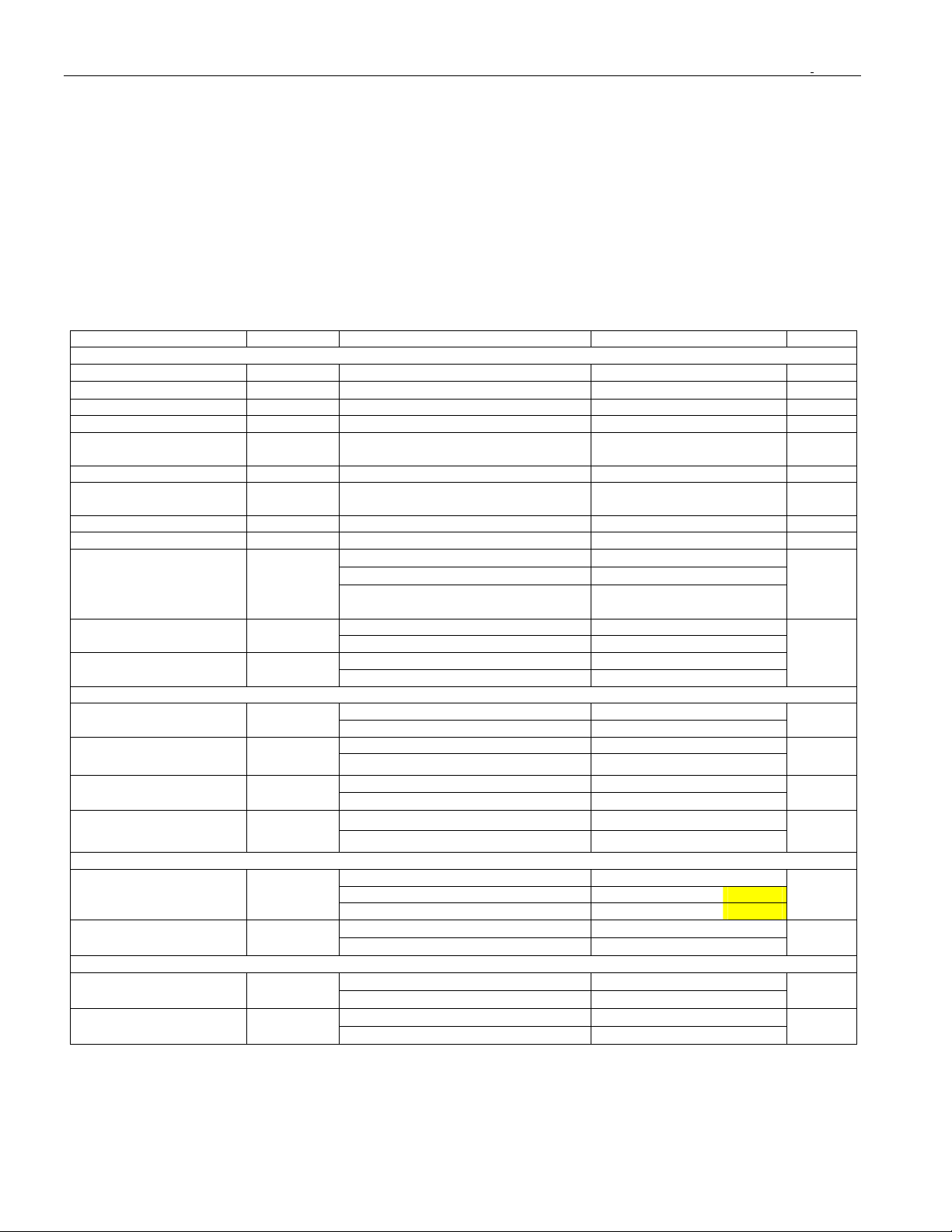

ELECTRICAL CHARACTERISTICS

(TA = -40°C to +85°C; see Note 1.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I/O PIN GENERAL DATA

1-Wire Pullup Voltage V

1-Wire Pullup Resistance

PUP

R

PUP

(Notes 2) 2.8 5.25 V

(Notes 2, 3)

Input Capacitance CIO (Notes 4, 5) 1000 pF

Input Load Current I

High-to-Low Switching

Threshold

Input Low Voltage V

Low-to-High Switching

Threshold

Switching Hysteresis V

Output Low Voltage V

Recovery Time

(Notes 2,12)

(Notes 5, 13)

(Note 2, 14)

t

t

t

L

V

TL

IL

V

TH

HY

OL

REC

REH

SLOT

I/O pin at V

0.05 6.7 µA

PUP

(Notes 5, 6, 7) 0.46 4.4 V

(Notes 2, 8) 0.3 V

(Notes 5, 6, 9) 1.0 4.9 V

(Notes 5, 6, 10) 0.21 1.70 V

At 4mA (Note 11)

Standard speed, R

Overdrive speed, R

PUP

PUP

= 2.2kW

= 2.2kW

Overdrive speed, directly prior to Reset

Pulse; R

PUP

= 2.2kW

Standard speed 0.5 5.0 Rising-Edge Hold-off Time

Overdrive speed Not applicable (0)

Standard speed 65 Timeslot Duration

Overdrive speed 8

I/O PIN, 1-WIRE RESET, PRESENCE DETECT CYCLE

Reset Low Time (Note 2) t

Presence Detect High

Time

Presence Detect Low

Time

Presence Detect Sample

Time (Notes 2, 15)

RSTL

t

PDH

t

PDL

t

MSP

Standard speed 480 640

Overdrive speed 48 80

Standard speed 15 60

Overdrive speed 2 6

Standard speed 60 240

Overdrive speed 8 24

Standard speed 60 75

Overdrive speed 6 10

I/O PIN, 1-Wire WRITE

Write-0 Low Time (Notes

2, 16)

Write-1 Low Time

(Notes 2, 17)

t

W0L

t

W1L

Standard speed 60 120

Overdrive speed, V

> 4.5V 5 15.5

PUP

Overdrive speed 6 15.5

Standard speed 1

Overdrive speed 1

I/O PIN, 1-Wire READ

Read Low Time

(Notes 2, 18)

Read Sample Time

(Notes 2, 18)

t

t

MSR

RL

Standard speed 5

Overdrive speed 1

Standard speed

Overdrive speed

0.3 2.2

0.4 V

kW

5

2

µs

5

µs

µs

µs

µs

µs

µs

µs

15 - e

2 - e

µs

15 - d

2 - d

+ d

t

RL

+ d

t

RL

15

2

µs

µs

2 of 23

Page 3

DS1972: 1024-Bit EEPROM iButton

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

EEPROM

Programming Current I

Programming Time t

durance) (Notes 21, 22)

Data Retention

(Notes 23, 24)

Note 1:

Note 2:

Note 3:

Note 4:

Note 5:

Note 6:

Note 7:

Note 8:

Note 9:

Note 10:

Note 11:

Note 12:

Note 13:

Note 14:

Note 15:

Note 16:

Note 17:

Note 18:

Note 19:

Note 20:

Note 21:

Note 22:

Note 23:

Note 24:

Specifications at T

= -40°C are guaranteed by design only and not production-tested.

A

System requirement.

Maximum allowable pullup resistance is a function of the number of 1-Wire devices in the system and 1-Wire recovery times. The

specified value here applies to systems with only one device and with the minimum 1-Wire recovery times. For more heavily

loaded systems, an active pullup such as that found in the DS2482-x00, DS2480B, or DS2490 may be required.

Maximum value represents the internal parasite capacitance when V

data line, 2.5µs after V

Guaranteed by design, characterization and/or simulation only. Not production tested.

V

, VTH, and V

TL

are a function of the internal supply voltage which is itself a function of V

HY

capacitive loading on IO. Lower V

and V

.

HY

Voltage below which, during a falling edge on IO, a logic 0 is detected.

The voltage on IO needs to be less or equal to V

Voltage above which, during a rising edge on IO, a logic 1 is detected.

After V

is crossed during a rising edge on IO, the voltage on IO has to drop by at least VHY to be detected as logic '0'.

TH

The I-V characteristic is linear for voltages less than 1V.

Applies to a single device attached to a 1-Wire line.

The earliest recognition of a negative edge is possible at t

Defines maximum possible bit rate. Equal to t

Interval after t

is t

PDH(max)

during which a bus master is guaranteed to sample a logic-0 on IO if there is a DS1972 present. Minimum limit

RSTL

; maximum limit is t

Highlighted numbers are NOT in compliance with legacy 1-Wire product standards. See comparison table below.

e represents the time required for the pullup circuitry to pull the voltage on IO up from V

d represents the time required for the pullup circuitry to pull the voltage on IO up from V

master.

Current drawn from IO during the EEPROM programming interval. The pullup circuit on IO during the programming interval

should be such that the voltage at IO is greater than or equal to Vpup(min). If Vpup in the system is close to Vpup(min) then a low

impedance bypass of Rpup which can be activated during programming may need to be added.

Interval begins t

WiLMIN

sequence. Interval ends once the device's self-timed EEPROM programming cycle is complete and the current drawn by the

device has returned from I

Write-cycle endurance is degraded as T

Not 100% production-tested; guaranteed by reliability monitor sampling.

Data retention is degraded as T

Guaranteed by 100% production test at elevated temperature for a shorter time; equivalence of this production test to data sheet

limit at operating temperature range is established by reliability testing.

PROG

PROG

N

CY

t

DR

has been applied the parasite capacitance will not affect normal communications.

PUP

PDH(min)

(Note 5, 19) 0.8 mA

(Note 20) 10 ms

At 25°C 200k Write/Erase Cycles (EnAt 85°C (worst case) 50k

At 85°C (worst case) 10

is first applied. If a 2.2kW resistor is used to pull up the

PUP

, higher R

PUP

+ t

PDL(min)

W0L(min)

.

, shorter t

PUP

IL(MAX)

+ t

, and heavier capacitive loading all lead to lower values of VTL, VTH,

REC

at all times the master is driving IO to a logic-0 level.

after VTH has been reached on the preceding rising edge.

REH

.

REC(min)

after the leading negative edge on IO for the last timeslot of the E/S byte for a valid Copy Scratchpad

to IL.

PROG

A

increases.

A

increases.

---

, R

PUP

to VTH.

IL

to the input high threshold of the bus

IL

, 1-Wire timing, and

PUP

years

LEGACY VALUES DS1972 VALUES

PARAMETER STANDARD SPEED OVERDRIVE SPEED STANDARD SPEED OVERDRIVE SPEED

MIN MAX MIN MAX MIN MAX MIN MAX

t

(incl. t

SLOT

t

RSTL

t

PDH

t

PDL

t

W0L

1)

Intentional change, longer recovery time requirement due to modified 1-Wire front end.

REC)

61µs (undef.) 7µs (undef.) 65µs1) (undef.) 8µs1) (undef.)

480µs (undef.) 48µs 80µs 480µs 640µs 48µs 80µs

15µs 60µs 2µs 6µs 15µs 60µs 2µs 6µs

60µs 240µs 8µs 24µs 60µs 240µs 8µs 24µs

60µs 120µs 6µs 16µs 60µs 120µs 6µs 15.5µs

EXAMPLES OF ACCESSORIES

PART DESCRIPTION

DS9096P Self-Stick Adhesive Pad

DS9101 Multipurpose Clip

DS9093RA Mounting Lock Ring

DS9093A Snap-In Fob

DS9092 iButton Probe

3 of 23

Page 4

DS1972: 1024-Bit EEPROM iButton

DESCRIPTION

The DS1972 combines 1024 bits of EEPROM, an 8-byte register/control page with up to 7 user read/write bytes,

and a fully-featured 1-Wire interface in a rugged i

registration number that is factory lasered to provide a guaranteed unique identity for absolute traceability. Data is

transferred serially via the 1-Wire protocol, which requires only a single data contact and a ground return. The

DS1972 has an additional memory area called the scratchpad that acts as a buffer when writing to the main

memory or the register page. Data is first written to the scratchpad from which it can be read back. After the data

has been verified, a Copy Scratchpad command transfers the data to its final memory location. Applications of the

DS1972 include access control/parking meter, Work-In-Progress tracking, tool management, inventory control, and

maintenance/inspection data storage. Software for communication with the DS1972 is available for free download

from the http://www.maxim-ic.com/products/ibutton/ website.

Button package. Each DS1972 has its own 64-bit ROM

OVERVIEW

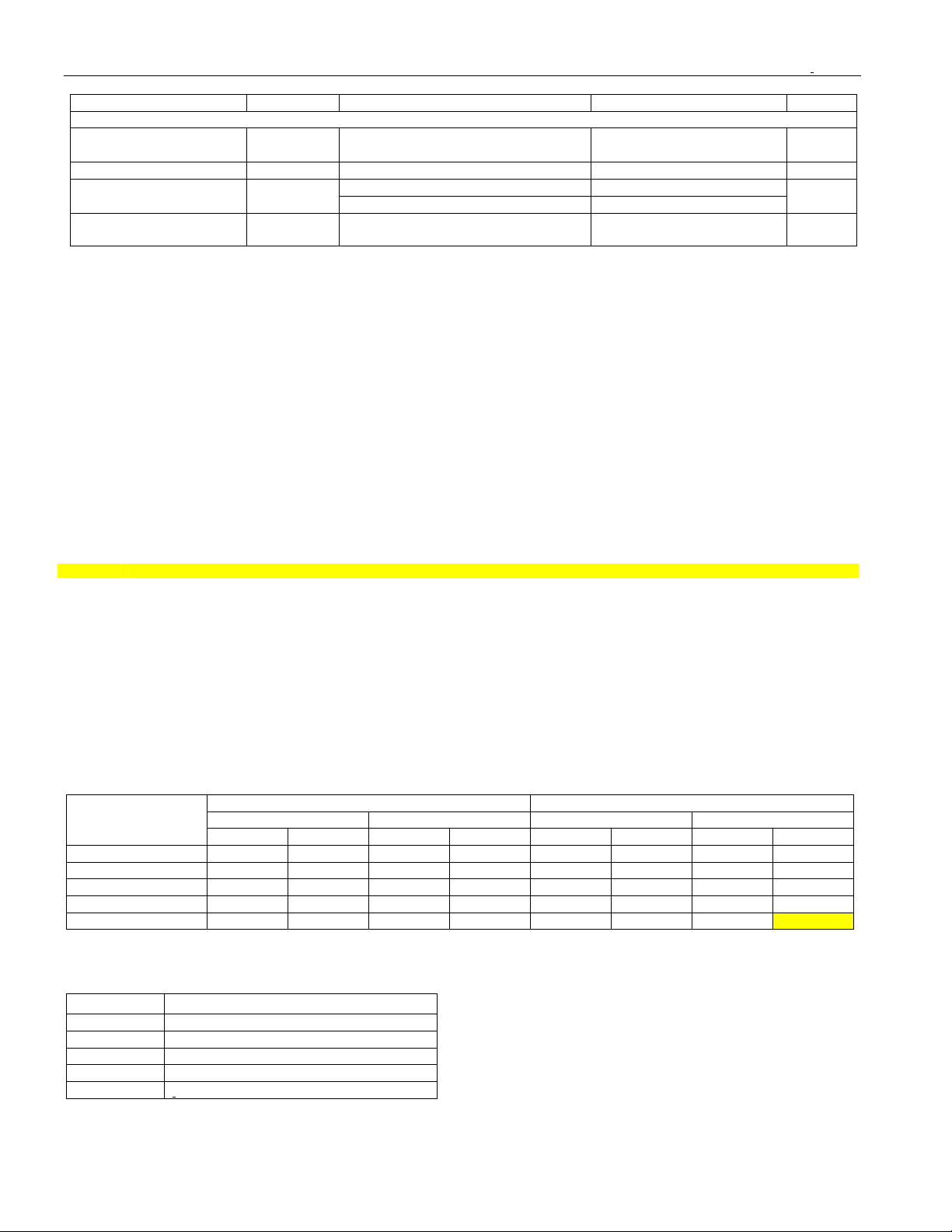

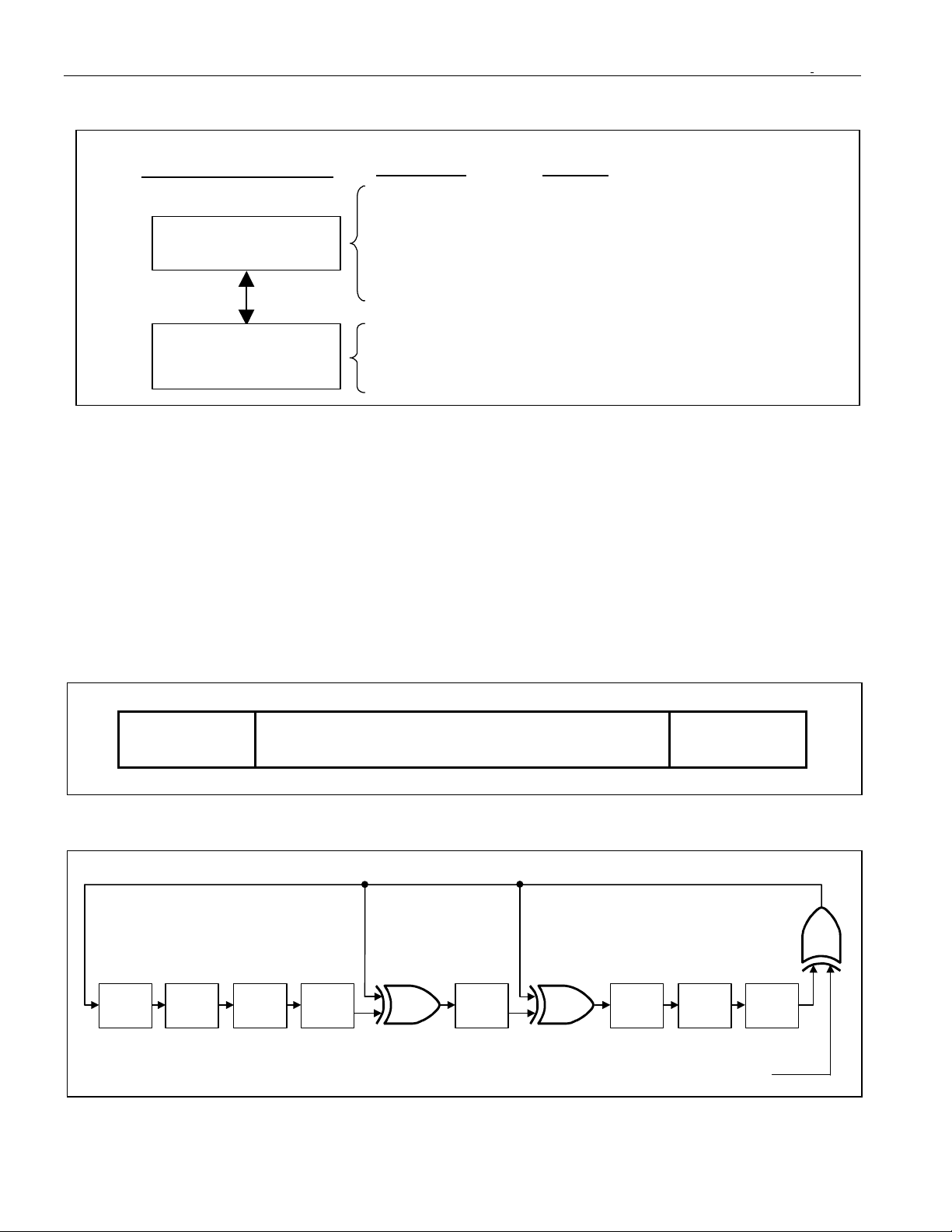

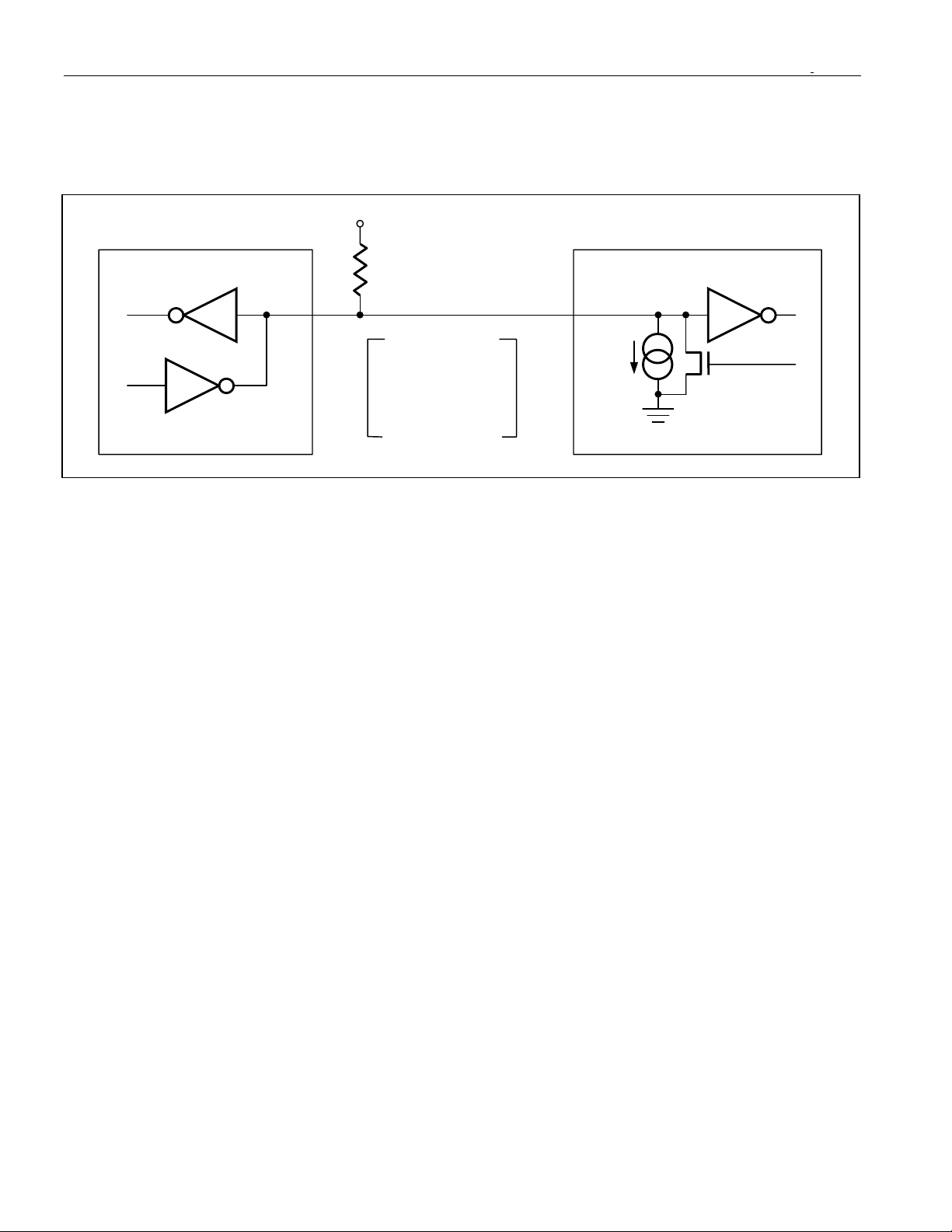

The block diagram in Figure 1 shows the relationships between the major control and memory sections of the

DS1972. The DS1972 has four main data components: 1) 64-bit lasered ROM, 2) 64-bit scratchpad, 3) four 32-byte

pages of EEPROM, and 4) 64-bit register page. The hierarchical structure of the 1-Wire protocol is shown in Figure

2. The bus master must first provide one of the seven ROM Function Commands, 1) Read ROM, 2) Match ROM, 3)

Search ROM, 4) Skip ROM, 5) Resume, 6) Overdrive-Skip ROM or 7) Overdrive-Match ROM. Upon completion of

an Overdrive ROM command byte executed at standard speed, the device enters Overdrive mode where all

subsequent communication occurs at a higher speed. The protocol required for these ROM function commands is

described in Figure 9. After a ROM function command is successfully executed, the memory functions become

accessible and the master may provide any one of the four memory function commands. The protocol for these

memory function commands is described in Figure 7. All data is read and written least significant bit first.

Figure 1. Block Diagram

PARASITE POWER

I/O

Memory

Function

Control Unit

CRC16

Generator

Data Memory

4 Pages of

256 bits each

Register Page

64 bits

1-Wire

Function Control

4 of 23

64-bit

Lasered ROM

DS1972

64-bit

Scratchpad

Page 5

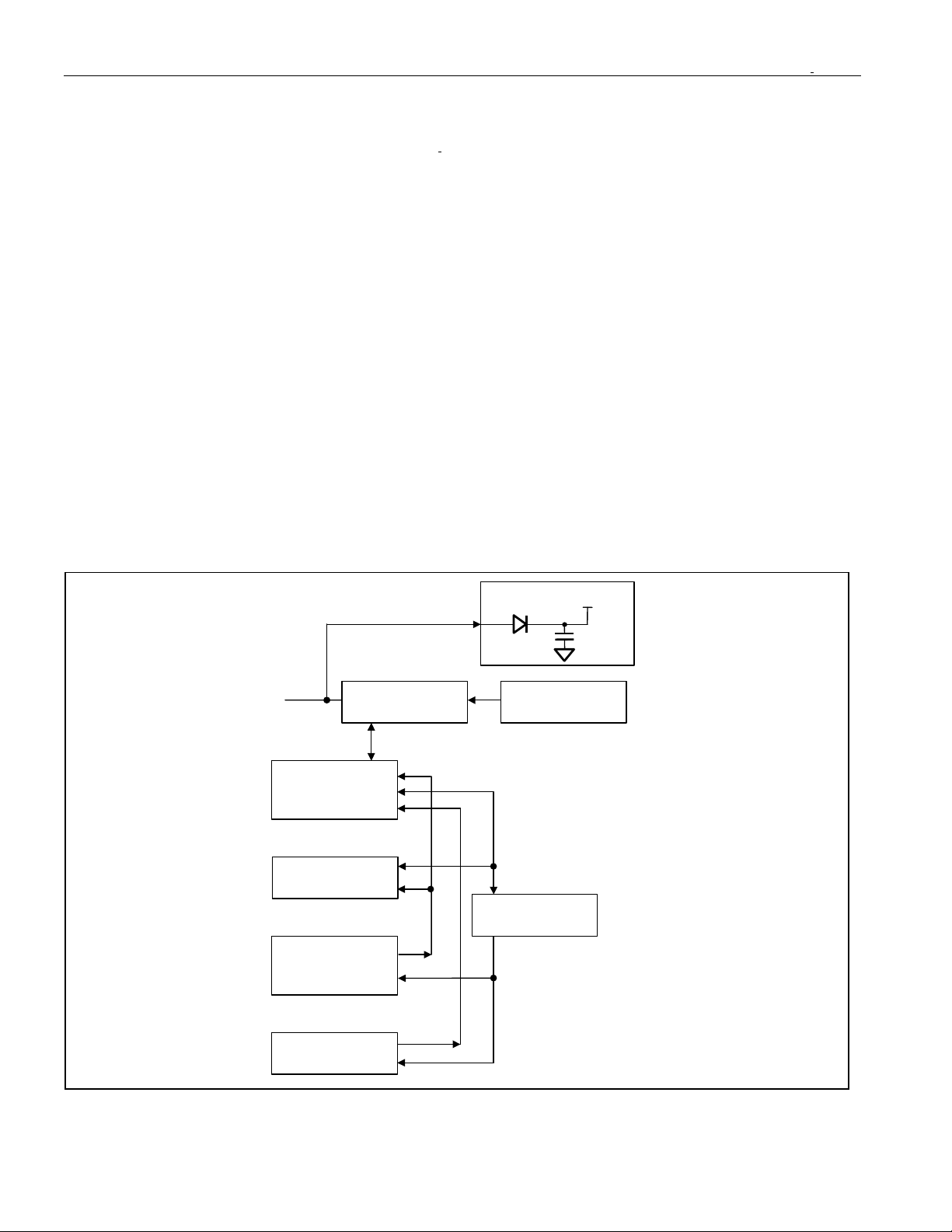

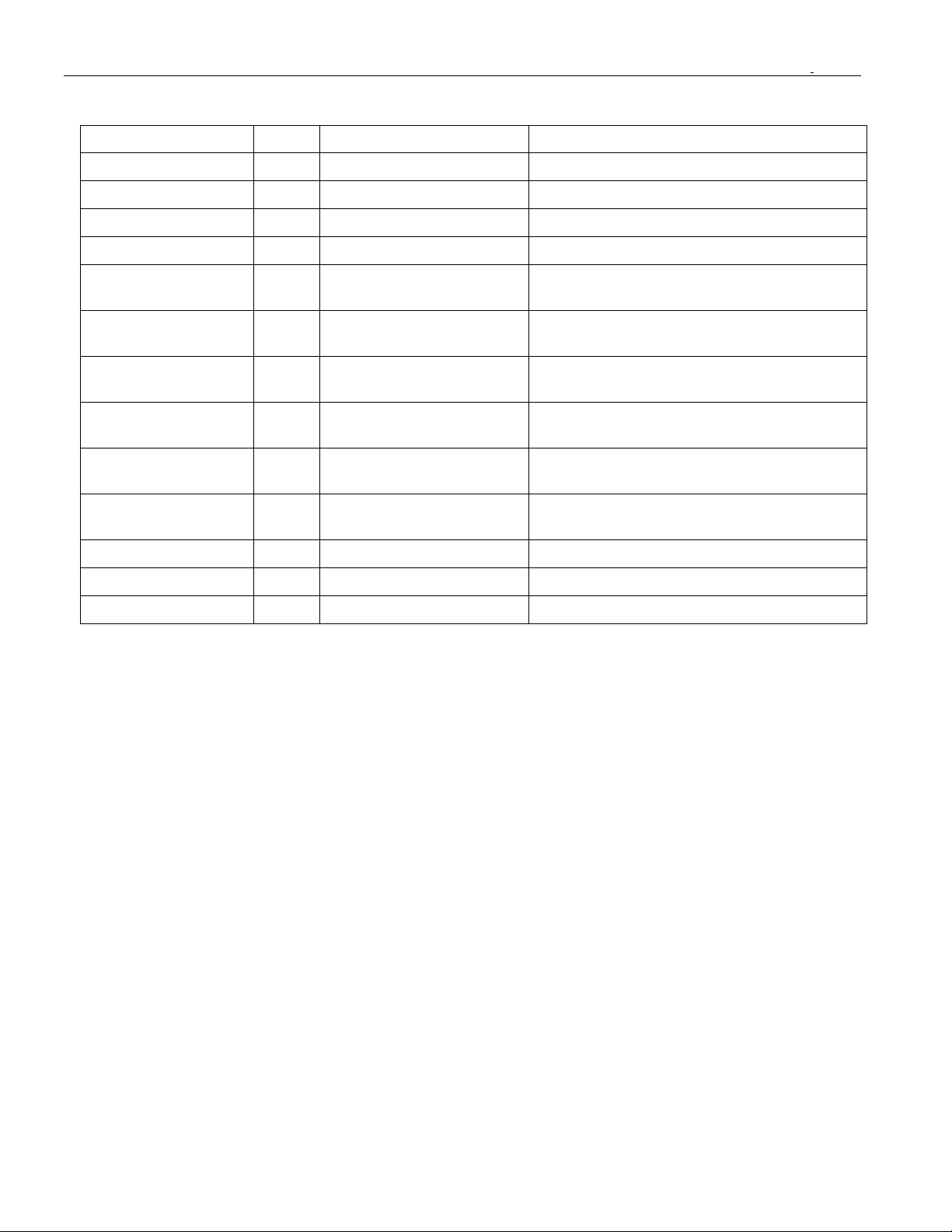

Figure 2. Hierarchical Structure for 1-Wire Protocol

A

A

DS1972 Command Level:

1-Wire ROM Function

Commands (see Figure 9)

vailable

Commands:

Read ROM

Match ROM

Search ROM

Skip ROM

Resume

Overdrive-Skip

Overdrive-Match

DS1972: 1024-Bit EEPROM iButton

Data Field

ffected:

64-bit Reg. #, RC-Flag

64-bit Reg. #, RC-Flag

64-bit Reg. #, RC-Flag

RC-Flag

RC-Flag

RC-Flag, OD-Flag

64-bit Reg. #, RC-Flag, OD-Flag

DS1972-specific

Memory Function

Commands (see Figure 7)

Write Scratchpad

Read Scratchpad

Copy Scratchpad

Read Memory

64-bit Scratchpad, Flags

64-bit Scratchpad

Data Memory, Register Page

Data Memory, Register Page

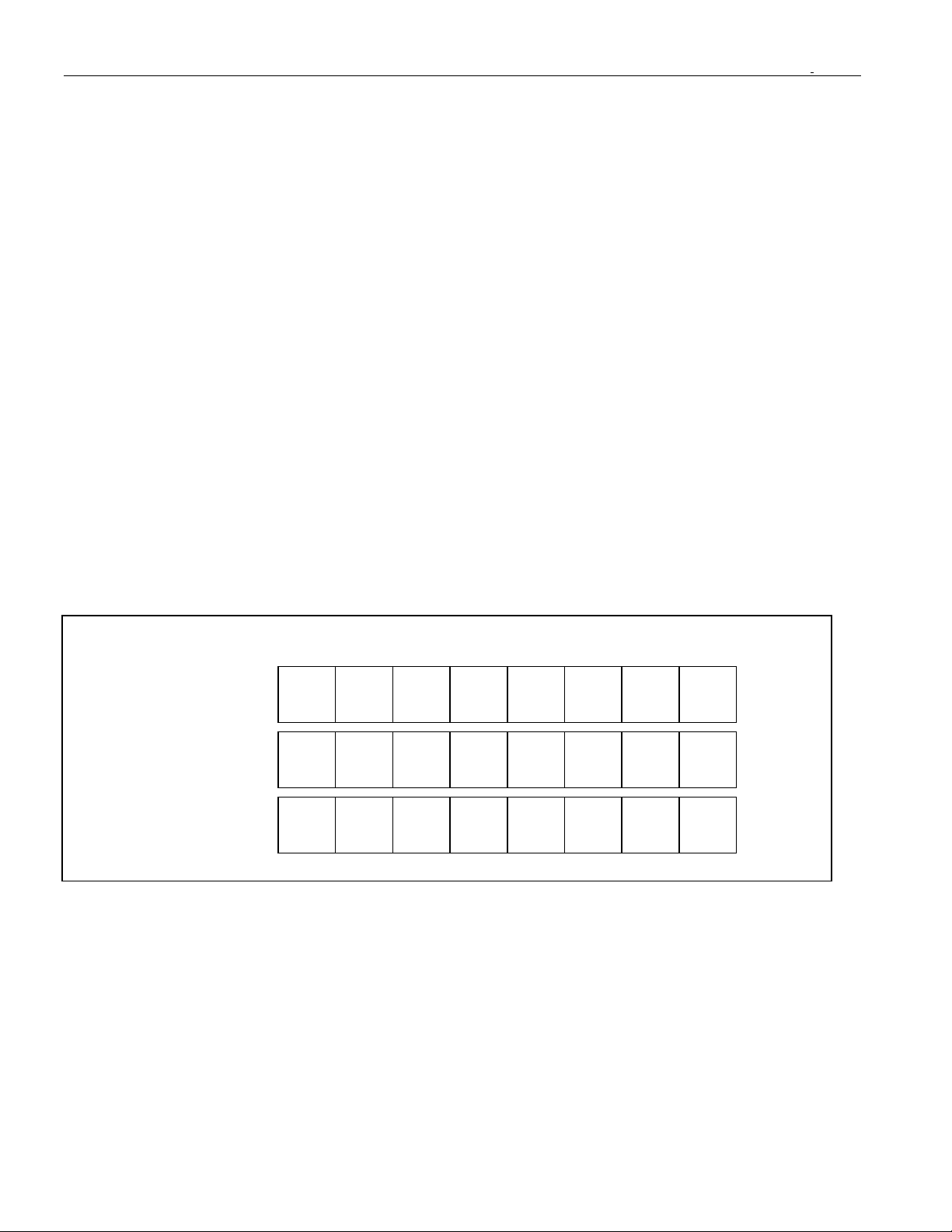

64-BIT LASERED ROM

Each DS1972 contains a unique ROM code that is 64 bits long. The first 8 bits are a 1-Wire family code. The next

48 bits are a unique serial number. The last 8 bits are a CRC (Cyclic Redundancy Check) of the first 56 bits. See

Figure 3 for details. The 1-Wire CRC is generated using a polynomial generator consisting of a shift register and

XOR gates as shown in Figure 4. The polynomial is X

CRC is available in Application Note 27.

The shift register bits are initialized to 0. Then starting with the least significant bit of the family code, one bit at a

time is shifted in. After the 8th bit of the family code has been entered, then the serial number is entered. After the

last bit of the serial number has been entered, the shift register contains the CRC value. Shifting in the 8 bits of the

CRC returns the shift register to all 0s.

Figure 3. 64-Bit Lasered ROM

MSB LSB

8-Bit

CRC Code

MSB LSB MSB LSB MSB LSB

Figure 4. 1-Wire CRC Generator

Polynomial = X8 + X5 + X4 + 1

8

+ X5 + X4 + 1. Additional information about the Dallas 1-Wire

48-Bit Serial Number

8-Bit Family

Code (2Dh)

STAGE

0

X

st

1

STAGE

1

X

nd

2

2

X

rd

3

STAGE

STAGE

3

X

th

4

4

X

th

5

STAGE

5

X

th

6

STAGE

INPUT DATA

6

X

th

7

STAGE

STAGE

7

X

th

8

8

X

5 of 23

Page 6

DS1972: 1024-Bit EEPROM iButton

Figure 5. Memory Map

ADDRESS RANGE TYPE DESCRIPTION PROTECTION CODES

0000h to 001Fh R/(W) Data Memory Page 0

0020h to 003Fh R/(W) Data Memory Page 1

0040h to 005Fh R/(W) Data Memory Page 2

0060h to 007Fh R/(W) Data Memory Page 3

0080h1) R/(W) Protection Control Byte

Page 0

0081h1) R/(W) Protection Control Byte

Page 1

0082h1) R/(W) Protection Control Byte

Page 2

0083h1) R/(W) Protection Control Byte

Page 3

0084h1) R/(W) Copy Protection Byte 55h or AAh: Copy Protect 0080:008Fh, and

0085h R Factory byte. Set at

Factory.

0086h R/(W) User Byte/Manufacturer ID

0087h R/(W) User Byte/Manufacturer ID

0088h to 008Fh N/A Reserved

1)

Once programmed to AAh or 55h this address becomes read-only. All other codes can be stored but will neither

write-protect the address nor activate any function.

55h: Write Protect P0; AAh: EPROM mode

P0; 55h or AAh: Write Protect 80h

55h: Write Protect P1; AAh: EPROM mode

P1; 55h or AAh: Write Protect 81h

55h: Write Protect P2; AAh: EPROM mode

P2; 55h or AAh: Write Protect 82h

55h: Write Protect P3; AAh: EPROM mode

P3; 55h or AAh: Write Protect 83h

any write-protected Pages

AAh:Write Protect 85h, 86h, 87h;

55h: Write Protect 85h, unprotect 86h, 87h

MEMORY

Data memory and registers are located in a linear address space, as shown in Figure 5. The data memory and the

registers have unrestricted read access. The DS1972 EEPROM array consists of 18 rows of 8 bytes each. The first

16 rows are divided equally into 4 memory pages (32 bytes each). These 4 pages are the primary data memory.

Each page can be individually set to Open (unprotected), Write-Protected, or EPROM mode by setting the

associated protection byte in the register row. The last two rows contain protection registers, and reserved bytes.

The register row consists of 4 protection control bytes, a copy protection byte, the factory byte, and two user

byte/manufacture ID bytes. The manufacturer ID can be a customer-supplied identification code that assists the

application software in identifying the product the DS1972 is associated with. Contact the factory to set up and

register a custom manufacturer ID. The last row is reserved for future use. It is undefined in terms of R/W

functionality and should not be used.

In addition to the main EEPROM array, an 8-byte volatile scratchpad is included. Writes to the EEPROM array are

a two-step process. First, data is written to the scratchpad, and then copied into the main array. This allows the

user to first verify the data written to scratchpad prior to copying into the main array. The device only supports full

row (8-byte) copy operations. In order for data in the scratchpad to be valid for a copy operation, the address

supplied with a Write Scratchpad must start on a row boundary, and 8 full bytes must be written into the

scratchpad.

6 of 23

Page 7

DS1972: 1024-Bit EEPROM iButton

The protection control registers determine how incoming data on a Write Scratchpad command is loaded into the

scratchpad. A protection setting of 55h (Write Protect) causes the incoming data to be ingnored and the target

address main memory data to be loaded into the scratchpad. A protection setting of AAh (EPROM mode) causes

the logical AND of incoming data and target address main memory data to be loaded into the scratchpad. Any

other protection control register setting leaves the associated memory page open for unrestricted write access.

Protection control byte settings of 55h or AAh also write protects the protection control byte. The protection-control

byte setting of 55h does not block the copy. This allows write-protected data to be refreshed (i. e., reprogrammed

with the current data) in the device.

The copy protection byte is used for a higher level of security, and should only be used after all other protection

control bytes, user bytes, and write-protected pages are set to their final value. If the copy protection byte is set to

55h or AAh, all copy attempts to the register row and user byte row are blocked. In addition, all copy attempts to

write-protected main memory pages (i. e., refresh) are blocked.

ADDRESS REGISTERS AND TRANSFER STATUS

The DS1972 employs three address registers: TA1, TA2, and E/S (Figure 6). These registers are common to many

other 1-Wire devices but operate slightly differently with the DS1972. Registers TA1 and TA2 must be loaded with

the target address to which the data is written or from which data is read. Register E/S is a read-only transferstatus register, used to verify data integrity with write commands. E/S bits E2:E0 are loaded with the incoming

T2:T0 on a Write Scratchpad command, and increment on each subsequent data byte. This is in effect a byteending offset counter within the 8-byte scratchpad. Bit 5 of the E/S register, called PF, is a logic 1 if the data in the

scratchpad is not valid due to a loss of power or if the master sends less bytes than needed to reach the end of the

scratchpad. For a valid write to the scratchpad, T2:T0 must be 0 and the master must have sent 8 data bytes. Bits

3, 4, and 6 have no function; they always read 0. The highest valued bit of the E/S register, called AA or

Authorization Accepted, acts as a flag to indicate that the data stored in the scratchpad has already been copied to

the target memory address. Writing data to the scratchpad clears this flag.

Figure 6. Address Registers

Bit # 7 6 5 4 3 2 1 0

Target Address (TA1) T7 T6 T5 T4 T3 T2 T1 T0

Target Address (TA2) T15 T14 T13 T12 T11 T10 T9 T8

Ending Address with

Data Status (E/S)

(Read Only)

AA 0 PF 0 0 E2 E1 E0

7 of 23

Page 8

DS1972: 1024-Bit EEPROM iButton

WRITING WITH VERIFICATION

To write data to the DS1972, the scratchpad has to be used as intermediate storage. First the master issues the

Write Scratchpad command to specify the desired target address, followed by the data to be written to the

scratchpad. Note that Copy Scratchpad commands must be performed on 8-byte boundaries, i. e., the 3 LSBs of

the target address (T2..T0) must be equal to 000b. If T2..T0 are sent with non-zero values, the copy function will be

blocked. Under certain conditions (see Write Scratchpad command) the master will receive an inverted CRC16 of

the command, address (actual address sent) and data at the end of the Write Scratchpad command sequence.

Knowing this CRC value, the master can compare it to the value it has calculated itself to decide if the

communication was successful and proceed to the Copy Scratchpad command. If the master could not receive the

CRC16, it should send the Read Scratchpad command to verify data integrity. As a preamble to the scratchpad

data, the DS1972 repeats the target address TA1 and TA2 and sends the contents of the E/S register. If the PF

flag is set, data did not arrive correctly in the scratchpad or there was a loss of power since data was last written to

the scratchpad. The master does not need to continue reading; it can start a new trial to write data to the

scratchpad. Similarly, a set AA flag together with a cleared PF flag indicates that the device did not recognize the

Write command. If everything went correctly, both flags are cleared. Now the master can continue reading and

verifying every data byte. After the master has verified the data, it can send the Copy Scratchpad command, for

example. This command must be followed exactly by the data of the three address registers, TA1, TA2, and E/S.

The master should obtain the contents of these registers by reading the scratchpad.

MEMORY FUNCTION COMMANDS

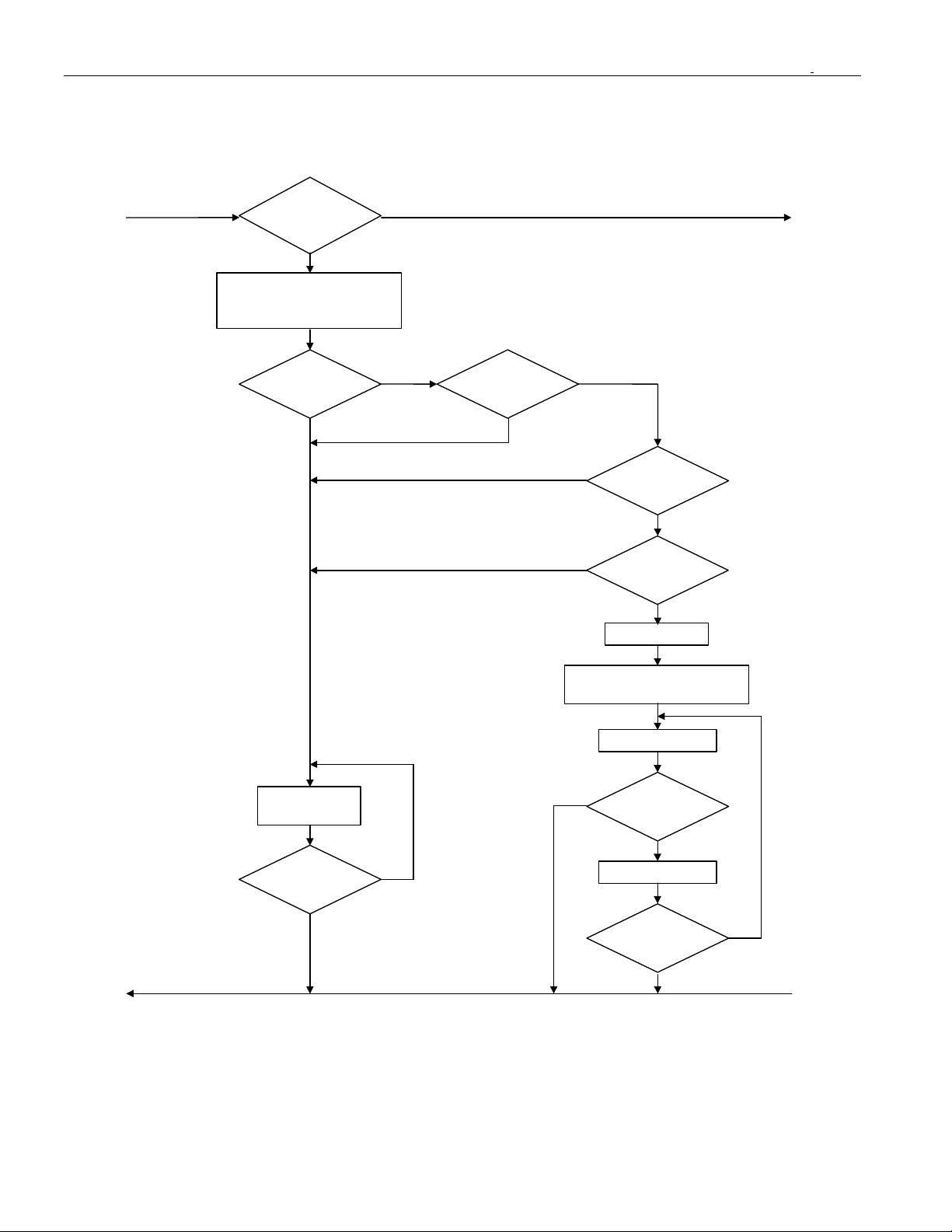

The Memory Function Flow Chart (Figure 7) describes the protocols necessary for accessing the memory of the

DS1972. An example on how to use these functions to write to and read from the device is included at the end of

this document. The communication between master and DS1972 takes place either at regular speed (default, OD =

0) or at Overdrive Speed (OD = 1). If not explicitly set into the Overdrive mode, the DS1972 assumes regular

speed.

WRITE SCRATCHPAD COMMAND [0Fh]

The Write Scratchpad command applies to the data memory, and the writable addresses in the register page. In

order for the scratchpad data to be valid for copying to the array, the user must perform a Write Scratchpad

command of 8 bytes starting at a valid row boundary. The Write Scratchpad command accepts invalid addresses,

and partial rows, but subsequent Copy Scratchpad commands are blocked.

After issuing the Write Scratchpad command, the master must first provide the 2-byte target address, followed by

the data to be written to the scratchpad. The data is written to the scratchpad starting at the byte offset of T2:T0.

The E/S bits E2:E0 are loaded with the starting byte offset, and increment with each susequent byte. Effectively,

E2:E0 is the byte offset of the last full byte written to the scratchpad. Only full data bytes are accepted.

When executing the Write Scratchpad command, the CRC generator inside the DS1972 (Figure 13) calculates a

CRC of the entire data stream, starting at the command code and ending at the last data byte as sent by the

master. This CRC is generated using the CRC16 polynomial by first clearing the CRC generator and then shifting

in the command code (0Fh) of the Write Scratchpad command, the Target Addresses (TA1 and TA2), and all the

data bytes. Note that the CRC16 calculation is performed with the actual TA1 and TA2 and data sent by the

master. The master may end the Write Scratchpad command at any time. However, if the end of the scratchpad is

reached (E2:E0 = 111b), the master may send 16 read-time slots and receive the CRC generated by the DS1972.

If a Write Scratchpad is attempted to a write-protected location, the scratchpad is loaded with the data already in

memory, rather than the data transmitted. Similarly, if the target address page is in EPROM mode, the scratchpad

is loaded with the bitwise logical AND of the transmitted data and data already in memory.

8 of 23

Page 9

Figure 7-1. Memory Function Flow Chart

A

p

Bus Master TX Memory

Function Command

0Fh

Write Scratch-

pad ?

Y

Bus Master TX

TA1 (T7:T0), TA2 (T15:T8)

DS1972 sets

Sets PF = 1

Clears AA = 0

Sets E2:E0 = T2:T0

DS1972: 1024-Bit EEPROM iButton

From ROM Functions

Flow Chart (Figure 9)

To Figure 7

nd

2

N

Part

DS1972

Increments

E2:E0

Master TX Data Byte

To Scratchpad

Master

TX Reset ?

N

E2:E0

N

of Command, Address,

Data Bytes as they were

sent by the bus master

= 7 ?

Y

T2:T0

= 0 ?

Y

PF = 0

DS1972 TX CRC16

pplies only if the

memory area is not

rotected.

Y

N

If write-protected, then

the DS1972 copies the

data byte from the target address into the SP.

If in EPROM mode,

then the DS1972 loads

the bitwise logical AND

of the transmitted byte

and the data byte from

the targeted address

into the SP.

Bus Master

RX “1”s

N

Master

TX Reset ?

Y

To ROM Functions

Flow Chart (Figure 9)

From Figure 7

nd

2

Part

9 of 23

Page 10

Figure 7-2. Memory Function Flow Chart (continued)

y

DS1972: 1024-Bit EEPROM iButton

From Figure 7

st

1

Part

DS1972

Increments

B

te Counter

AAh

Read Scratch-

Pad ?

Y

Bus Master RX

TA1 (T7:T0), TA2 (T15:T8)

and E/S Byte

DS1972 sets Scratchpad

Byte Counter = T2:T0

Bus Master RX

Data Byte from Scratchpad

Master

Y

TX Reset ?

N

N

Byte Counter

= E2:E0 ?

To Figure 7

N

rd

3

Part

To Figure 7

st

1

Part

Bus Master

RX “1”s

Y

Bus Master RX CRC16

of Command, Address,

E/S Byte, Data Bytes as

sent by the DS1972

N

Master

TX Reset ?

Y

From Figure 7

rd

3

Part

10 of 23

Page 11

Figure 7-3. Memory Function Flow Chart (continued)

A

DS1972: 1024-Bit EEPROM iButton

From Figure 7

nd

2

Part

TA1 (T7:T0), TA2 (T15:T8)

55h

Copy Scratch-

Pad ?

Y

Bus Master TX

and E/S Byte

Auth. Code

Match ?

N

To Figure 7

N

4

th

Part

pplicable to all R/W

memory locations.

Y

T15:T0

Y

< 0090h ?

N

N

PF = 0 ?

Y

Y

Copy-

Protected ?

N

AA = 1

Duration: t

Bus Master

RX “1”s

Master

N

TX Reset ?

Y

To Figure 7

nd

2

Part

* 1-Wire idle high for power

11 of 23

PROG

DS1972 copies Scratch-

pad Data to Address

DS1972 TX “0”

Y

Master

TX Reset ?

N

DS1972 TX “1”

Master

TX Reset ?

Y

From Figure 7

th

4

Part

*

N

Page 12

Figure 7-4. Memory Function Flow Chart (continued)

From Figure 7

3

rd

Part

F0h

Read Memory ?

Y

Bus Master TX

TA1 (T7:T0),

TA2 (T15:T8)

N

DS1972: 1024-Bit EEPROM iButton

Address

< 90h ?

N

DS1972

Increments

Address

Y

Counter

DS1972 sets Memory

Address = (T15:T0)

Bus Master RX

Data Byte from

Memory Address

Master

TX Reset ?

N

Y

Address

< 8Fh ?

N

Y

Bus Master

RX “1”s

N

TX Reset ?

To Figure 7

rd

3

Part

Bus Master

RX “1”s

12 of 23

Master

N

Y

Master

TX Reset ?

Y

Page 13

DS1972: 1024-Bit EEPROM iButton

READ SCRATCHPAD COMMAND [AAh]

The Read Scratchpad command allows verifying the target address and the integrity of the scratchpad data. After

issuing the command code, the master begins reading. The first two bytes are the target address. The next byte is

the ending offset/data status byte (E/S) followed by the scratchpad data, which may be different from what the

master originally sent. This is of particular importance if the target address is within the register page or a page in

either Write Protection or EPROM modes. See the Write Scratchpad description for details. The master should

read through the scratchpad (E2:E0 - T2:T0 + 1 bytes), after which it will receive the inverted CRC, based on data

as it was sent by the DS1972. If the master continues reading after the CRC, all data will be logic 1s.

COPY SCRATCHPAD [55h]

The Copy Scratchpad command is used to copy data from the scratchpad to writable memory sections. After

issuing the Copy Scratchpad command, the master must provide a 3-byte authorization pattern, which should have

been obtained by an immediately preceding Read Scratchpad command. This 3-byte pattern must exactly match

the data contained in the three address registers (TA1, TA2, E/S, in that order). If the pattern matches, the target

address is valid, the PF flag is not set, and the target memory is not copy-protected, the AA (Authorization

Accepted) flag is set and the copy begins. All eight bytes of scratchpad contents are copied to the target memory

location. The duration of the device’s internal data transfer is t

not fall below 2.8V. A pattern of alternating 0s and 1s are transmitted after the data has been copied until the

master issues a Reset Pulse. If the PF flag is set or the target memory is copy-protected, the copy will not begin

and the AA flag will not be set. If the copy command was disturbed due to lack of power or for other reasons, the

master will read a constant stream of FFh bytes until it sends a 1-Wire Reset Pulse. In this case the destination

memory may be incompletely programmed requiring a write scratchpad and copy scratchpad be repeated to

ensure proper programming of the EEPROM. This requires careful consideration when designing application

software that writes to the DS1972 in an intermittent contact environment.

during which the voltage on the 1-Wire bus must

PROG

READ MEMORY [F0h]

The Read Memory command is the general function to read data from the DS1972. After issuing the command, the

master must provide the 2-byte target address. After these two bytes, the master reads data beginning from the

target address and may continue until address 008Fh. If the master continues reading, the result will be logic 1s.

The device's internal TA1, TA2, E/S, and scratchpad contents are not affected by a Read Memory command.

1-Wire BUS SYSTEM

The 1-Wire bus is a system that has a single bus master and one or more slaves. In all instances the DS1972 is a

slave device. The bus master is typically a microcontroller. The discussion of this bus system is broken down into

three topics: hardware configuration, transaction sequence, and 1-Wire signaling (signal types and timing). The

1-Wire protocol defines bus transactions in terms of the bus state during specific time slots, which are initiated on

the falling edge of sync pulses from the bus master.

HARDWARE CONFIGURATION

The 1-Wire bus has only a single line by definition; it is important that each device on the bus be able to drive it at

the appropriate time. To facilitate this, each device attached to the 1-Wire bus must have open-drain or tri-state

outputs. The 1-Wire port of the DS1972 is open drain with an internal circuit equivalent to that shown in Figure 8.

A multidrop bus consists of a 1-Wire bus with multiple slaves attached. The DS1972 supports both a Standard and

Overdrive communication speed of 15.4kbps (max) and 125kbps (max), respectively. Note that legacy 1-Wire

products support a standard communication speed of 16.3kbps and Overdrive of 142kbps. The slightly reduced

rates for the DS1972 are a result of additional recovery times, which in turn were driven by a 1-Wire physical

interface enhancement to improve noise immunity. The value of the pullup resistor primarily depends on the

network size and load conditions. The DS1972 requires a pullup resistor of 2.2kW (max) at any speed.

13 of 23

Page 14

DS1972: 1024-Bit EEPROM iButton

The idle state for the 1-Wire bus is high. If for any reason a transaction needs to be suspended, the bus MUST be

left in the idle state if the transaction is to resume. If this does not occur and the bus is left low for more than 16µs

(Overdrive speed) or more than 120µs (standard speed), one or more devices on the bus may be reset.

Figure 8. Hardware Configuration

BUS MASTER DS1972 1-Wire PORT

V

PUP

R

PUP

RX

TX

Open Drain

Port Pin

RX = RECEIVE

TX = TRANSMIT

I

L

100

MOSFET

RXDATA

TX

W

TRANSACTION SEQUENCE

The protocol for accessing the DS1972 through the 1-Wire port is as follows:

§ Initialization

§ ROM Function Command

§ Memory Function Command

§ Transaction/Data

INITIALIZATION

All transactions on the 1-Wire bus begin with an initialization sequence. The initialization sequence consists of a

Reset Pulse transmitted by the bus master followed by Presence Pulse(s) transmitted by the slave(s). The

Presence Pulse lets the bus master know that the DS1972 is on the bus and is ready to operate. For more details,

see the 1-Wire Signaling section.

1-Wire ROM FUNCTION COMMANDS

Once the bus master has detected a presence, it can issue one of the seven ROM function commands that the

DS1972 supports. All ROM function commands are 8 bits long. A list of these commands follows (refer to the flow

chart in Figure 9).

READ ROM [33h]

This command allows the bus master to read the DS1972’s 8-bit family code, unique 48-bit serial number, and 8-bit

CRC. This command can only be used if there is a single slave on the bus. If more than one slave is present on the

bus, a data collision occurs when all slaves try to transmit at the same time (open drain produces a wired-AND

result). The resultant family code and 48-bit serial number result in a mismatch of the CRC.

MATCH ROM [55h]

The Match ROM command, followed by a 64-bit ROM sequence, allows the bus master to address a specific

DS1972 on a multidrop bus. Only the DS1972 that exactly matches the 64-bit ROM sequence responds to the

following memory function command. All other slaves wait for a Reset Pulse. This command can be used with a

single or multiple devices on the bus.

14 of 23

Page 15

DS1972: 1024-Bit EEPROM iButton

SEARCH ROM [F0h]

When a system is initially brought up, the bus master might not know the number of devices on the 1-Wire bus or

their registration numbers. By taking advantage of the wired-AND property of the bus, the master can use a

process of elimination to identify the registration numbers of all slave devices. For each bit of the registration

number, starting with the least significant bit, the bus master issues a triplet of time slots. On the first slot, each

slave device participating in the search outputs the true value of its registration number bit. On the second slot,

each slave device participating in the search outputs the complemented value of its registration number bit. On the

third slot, the master writes the true value of the bit to be selected. All slave devices that do not match the bit

written by the master stop participating in the search. If both of the read bits are zero, the master knows that slave

devices exist with both states of the bit. By choosing which state to write, the bus master branches in the romcode

tree. After one complete pass, the bus master knows the registration number of a single device. Additional passes

identify the registration numbers of the remaining devices. Refer to Application Note 187: 1-Wire Search Algorithm

for a detailed discussion, including an example.

SKIP ROM [CCh]

This command can save time in a single-drop bus system by allowing the bus master to access the memory

functions without providing the 64-bit ROM code. If more than one slave is present on the bus and, for example, a

Read command is issued following the Skip ROM command, data collision occurs on the bus as multiple slaves

transmit simultaneously (open-drain pulldowns produce a wired-AND result).

RESUME [A5h]

To maximize the data throughput in a multidrop environment, the Resume function is available. This function

checks the status of the RC bit and, if it is set, directly transfers control to the memory functions, similar to a Skip

ROM command. The only way to set the RC bit is through successfully executing the Match ROM, Search ROM, or

Overdrive-Match ROM command. Once the RC bit is set, the device can repeatedly be accessed through the

Resume Command function. Accessing another device on the bus clears the RC bit, preventing two or more

devices from simultaneously responding to the Resume Command function.

OVERDRIVE-SKIP ROM [3Ch]

On a single-drop bus this command can save time by allowing the bus master to access the memory functions

without providing the 64-bit ROM code. Unlike the normal Skip ROM command, the Overdrive-Skip ROM sets the

DS1972 in the Overdrive mode (OD = 1). All communication following this command has to occur at Overdrive

speed until a Reset Pulse of minimum 480µs duration resets all devices on the bus to standard speed (OD = 0).

When issued on a multidrop bus, this command sets all Overdrive-supporting devices into Overdrive mode. To

subsequently address a specific Overdrive-supporting device, a Reset Pulse at Overdrive speed has to be issued

followed by a Match ROM or Search ROM command sequence. This speeds up the time for the search process. If

more than one slave supporting Overdrive is present on the bus and the Overdrive-Skip ROM command is followed

by a Read command, data collision occurs on the bus as multiple slaves transmit simultaneously (open-drain

pulldowns produce a wired-AND result).

OVERDRIVE-MATCH ROM [69h]

The Overdrive-Match ROM command followed by a 64-bit ROM sequence transmitted at Overdrive Speed allows

the bus master to address a specific DS1972 on a multidrop bus and to simultaneously set it in Overdrive mode.

Only the DS1972 that exactly matches the 64-bit ROM sequence responds to the subsequent memory function

command. Slaves already in Overdrive mode from a previous Overdrive-Skip or successful Overdrive-Match

command remain in Overdrive mode. All overdrive-capable slaves return to standard speed at the next Reset Pulse

of minimum 480µs duration. The Overdrive-Match ROM command can be used with a single or multiple devices on

the bus.

15 of 23

Page 16

Figure 9-1. ROM Functions Flow Chart

YNY

Y

YNY

Y

YYY

Y

Y

d

Bus Master TX

Reset Pulse

From Memory Functions

Flow Chart (Figure 7)

Reset Pulse ?

OD

N

OD = 0

DS1972: 1024-Bit EEPROM iButton

From Figure 9, 2

n

Part

Bus Master TX ROM

Function Command

33h

Read ROM

Command ?

RC = 0

DS1972 TX

Family Code

(1 Byte)

DS1972 TX

Serial Number

(6 Bytes)

N

55h

Match ROM

Command ?

RC = 0

Master TX Bit 0

Bit 0

Match ?

Master TX Bit 1

Bit 1

Match ?

DS1972 TX

Presence Pulse

N

N

N

F0h

Search ROM

Command ?

RC = 0

DS1972 TX Bit 0

DS1972 TX Bit 0

Master TX Bit 0

Bit 0

Match ?

DS1972 TX Bit 1

DS1972 TX Bit 1

Master TX Bit 1

Bit 1

Match ?

To Figure 9

N

CCh

nd

Part

2

Skip ROM

Command ?

N

RC = 0

DS1972 TX

CRC Byte

Master TX Bit 63

DS1972 TX Bit 63

Master TX Bit 63

DS1972 TX Bit 63

Bit 63

Match ?

RC = 1

N

To Memory Functions

Flow Chart (Figure 7)

Bit 63

Match ?

RC = 1

To Figure 9

nd

Part

2

From Figure 9

nd

Part

2

N

16 of 23

Page 17

Figure 9-2. ROM Functions Flow Chart (continued)

t

DS1972: 1024-Bit EEPROM iButton

To Figure 9, 1

From Figure 9

st

1

Part

s

Part

Resume

Command ?

RC = 1 ?

A5h

Y

Y

N

N

3Ch

Overdrive-

Skip ROM ?

Y

RC = 0 ; OD = 1

Master

TX Reset ?

N

N

69h

N

Overdrive-Match

ROM ?

Y

RC = 0 ; OD = 1

Master TX Bit 0

Y

Bit 0

Match ?

N

OD = 0

Y

From Figure 9

st

Part

1

To Figure 9

st

1

Part

Master

TX Reset ?

N

Master TX Bit 1

Y

Bit 1

Match ?

N

OD = 0

Y

Master TX Bit 63

Bit 63

Match ?

N

OD = 0

Y

RC = 1

17 of 23

Page 18

DS1972: 1024-Bit EEPROM iButton

1-Wire SIGNALING

The DS1972 requires strict protocols to ensure data integrity. The protocol consists of four types of signaling on

one line: Reset Sequence with Reset Pulse and Presence Pulse, Write-Zero, Write-One, and Read-Data. Except

for the Presence Pulse, the bus master initiates all falling edges. The DS1972 can communicate at two different

speeds, standard speed, and Overdrive Speed. If not explicitly set into the Overdrive mode, the DS1972

communicates at standard speed. While in Overdrive mode the fast timing applies to all waveforms.

To get from idle to active, the voltage on the 1-Wire line needs to fall from V

from active to idle, the voltage needs to rise from V

past the threshold VTH. The time it takes for the voltage to

ILMAX

make this rise is seen in Figure 10 as 'e' and its duration depends on the pullup resistor (R

capacitance of the 1-Wire network attached.

The voltage V

is relevant for the DS1972 when determining a

ILMAX

logical level, not triggering any events.

Figure 10 shows the initialization sequence required to begin any communication with the DS1972. A Reset Pulse

followed by a Presence Pulse indicates the DS1972 is ready to receive data, given the correct ROM and memory

function command. If the bus master uses slew-rate control on the falling edge, it must pull down the line for

t

+ tF to compensate for the edge. A t

RSTL

device to standard speed. If the DS1972 is in Overdrive mode and t

in Overdrive mode. If the device is in Overdrive mode and t

duration of 480µs or longer exits the Overdrive mode, returning the

RSTL

is between 80µs and 480µs, the device will reset,

RSTL

is no longer than 80µs. the device remains

RSTL

but the communication speed is undetermined.

Figure 10. Initialization Procedure: Reset and Presence Pulse

MASTER TX “RESET PULSE” MASTER RX “PRESENCE PULSE”

below the threshold VTL. To get

PUP

) used and the

PUP

t

MSP

V

IHMASTER

V

V

PUP

V

TH

V

ILMAX

e

TL

0V

t

F

t

RSTL

t

PDH

t

PDL

t

RSTH

t

REC

RESISTOR MASTER DS1972

After the bus master has released the line it goes into Receive mode. Now the 1-Wire bus is pulled to V

the pullup resistor, or in case of a DS2482-x00 or DS2480B driver, by active circuitry. When the threshold V

crossed, the DS1972 waits for t

Presence Pulse, the master must test the logical state of the 1-Wire line at t

and then transmits a Presence Pulse by pulling the line low for t

PDH

MSP

.

PDL

through

PUP

TH

is

. To detect a

The t

DS1972 is ready for data communication. In a mixed population network, t

window must be at least the sum of t

RSTH

PDHMAX

, t

PDLMAX

, and t

. Immediately after t

RECMIN

should be extended to minimum

RSTH

is expired, the

RSTH

480µs at standard speed and 48µs at Overdrive speed to accommodate other 1-Wire devices.

Read-/Write-Time Slots

Data communication with the DS1972 takes place in time slots, which carry a single bit each. Write-time slots

transport data from bus master to slave. Read-time slots transfer data from slave to master. Figure 11 illustrates

the definitions of the write- and read-time slots.

All communication begins with the master pulling the data line low. As the voltage on the 1-Wire line falls below the

threshold V

a write-time slot and how long data is valid during a read-time slot.

, the DS1972 starts its internal timing generator that determines when the data line is sampled during

TL

18 of 23

Page 19

DS1972: 1024-Bit EEPROM iButton

Master-to-Slave

For a write-one time slot, the voltage on the data line must have crossed the VTH threshold before the write-one

low time t

threshold until the write-zero low time t

data line should not exceed V

the DS1972 needs a recovery time t

Figure 11. Read/Write Timing Diagram

Write-One Time Slot

is expired. For a write-zero time slot, the voltage on the data line must stay below the VTH

W1LMAX

V

IHMASTER

V

V

PUP

V

V

ILMAX

TH

during the entire t

ILMAX

REC

t

W1L

TL

is expired. For the most reliable communication, the voltage on the

W0LMIN

W0L

or t

window. After the V

W1L

threshold has been crossed,

TH

before it is ready for the next time slot.

0V

t

F

e

t

SLOT

Write-Zero Time Slot

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

t

F

Read-Data Time Slot

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

t

F

RESISTOR MASTER

t

W0L

t

SLOT

RESISTOR MASTER

t

RL

t

MSR

Master

Sampling

Window

d

t

SLOT

t

REC

t

REC

RESISTOR MASTER DS1972

19 of 23

Page 20

DS1972: 1024-Bit EEPROM iButton

Slave-to-Master

A read-data time slot begins like a write-one time slot. The voltage on the data line must remain below VTL until the

read low time t

is expired. During the tRL window, when responding with a 0, the DS1972 starts pulling the data

RL

line low; its internal timing generator determines when this pulldown ends and the voltage starts rising again. When

responding with a 1, the DS1972 does not hold the data line low at all, and the voltage starts rising as soon as t

RL

is

over.

The sum of t

the master sampling window (t

most reliable communication, t

later than t

sufficient recovery time t

applies only to a single DS1972 attached to a 1-Wire line. For multidevice configurations, t

+ d (rise time) on one side and the internal timing generator of the DS1972 on the other side define

RL

. After reading from the data line, the master must wait until t

MSRMAX

for the DS1972 to get ready for the next time slot. Note that t

REC

to t

MSRMIN

should be as short as permissible, and the master should read close to but no

RL

) in which the master must perform a read from the data line. For the

MSRMAX

is expired. This guarantees

SLOT

specified herein

REC

needs to be

REC

extended to accommodate the additional 1-Wire device input capacitance. Alternatively, an interface that performs

active pullup during the 1-Wire recovery time such as the DS2482-x00 or DS2480B 1-Wire line drivers can be

used.

IMPROVED NETWORK BEHAVIOR (SWITCHPOINT HYSTERESIS)

In a 1-Wire environment, line termination is possible only during transients controlled by the bus master (1-Wire

driver). 1-Wire networks, therefore, are susceptible to noise of various origins. Depending on the physical size and

topology of the network, reflections from end points and branch points can add up, or cancel each other to some

extent. Such reflections are visible as glitches or ringing on the 1-Wire communication line. Noise coupled onto the

1-Wire line from external sources can also result in signal glitching. A glitch during the rising edge of a time slot can

cause a slave device to lose synchronization with the master and, consequently, result in a Search ROM command

coming to a dead end or cause a device-specific function command to abort. For better performance in network

applications, the DS1972 uses a new 1-Wire front end, which makes it less sensitive to noise.

The 1-Wire front end of the DS1972 differs from traditional slave devices in three characteristics.

1) There is additional low-pass filtering in the circuit that detects the falling edge at the beginning of a time slot.

This reduces the sensitivity to high-frequency noise. This additional filtering does not apply at Overdrive speed.

2) There is a hysteresis at the low-to-high switching threshold V

below V

- VHY, it will not be recognized (Figure 12, Case A). The hysteresis is effective at any 1-Wire speed.

TH

3) There is a time window specified by the rising edge hold-off time t

they extend below V

appear late after crossing the V

- VHY threshold (Figure 12, Case B, tGL < t

TH

threshold and extend beyond the t

TH

taken as the beginning of a new time slot (Figure 12, Case C, t

Devices that have the parameters V

, and t

HY

specified in their electrical characteristics use the improved 1-Wire

REH

front end.

Figure 12. Noise Suppression Scheme

t

V

PUP

REH

. If a negative glitch crosses VTH but does not go

TH

during which glitches are ignored, even if

REH

). Deep voltage droops or glitches that

REH

window cannot be filtered out and are

REH

³ t

REH

).

t

REH

GL

V

TH

V

HY

Case A Case CCase B

0V

t

GL

20 of 23

t

GL

Page 21

DS1972: 1024-Bit EEPROM iButton

A

CRC GENERATION

With the DS1972 there are two different types of CRCs. One CRC is an 8-bit type and is stored in the most

significant byte of the 64-bit ROM. The bus master can compute a CRC value from the first 56 bits of the 64-bit

ROM and compare it to the value stored within the DS1972 to determine if the ROM data has been received errorfree. The equivalent polynomial function of this CRC is X

(noninverted) form. It is computed at the factory and lasered into the ROM.

The other CRC is a 16-bit type, generated according to the standardized CRC16-polynomial function

16

x

+ x15 + x2 + 1. This CRC is used for fast verification of a data transfer when writing to or reading from the

scratchpad. In contrast to the 8-bit CRC, the 16-bit CRC is always communicated in the inverted form. A CRC

generator inside the DS1972 i

Button (Figure 13) calculates a new 16-bit CRC, as shown in the command flow chart

(Figure 7). The bus master compares the CRC value read from the device to the one it calculates from the data,

and decides whether to continue with an operation or to reread the portion of the data with the CRC error.

With the Write Scratchpad command, the CRC is generated by first clearing the CRC generator and then shifting in

the command code, the Target Addresses TA1 and TA2, and all the data bytes as they were sent by the bus

master. The DS1972 transmits this CRC only if E2:E0 = 111b.

With the Read Scratchpad command, the CRC is generated by first clearing the CRC generator and then shifting in

the Command code, the target addresses TA1 and TA2, the E/S byte, and the scratchpad data as they were sent

by the DS1972. The DS1972 transmits this CRC only if the reading continues through the end of the scratchpad.

For more information on generating CRC values, refer to Application Note 27.

Figure 13. CRC-16 Hardware Description and Polynomial

Polynomial = X16+ X15+ X2+ 1

8

+ X5 + X4 + 1. This 8-bit CRC is received in the true

STAGE

0

X

STAGE

8

X

st

1

th

9

STAGE

1

X

STAGE

9

X

2

10

nd

th

11

th

STAGE

10

X

11

X

STAGE

2

X

th

12

STAGE

3

rd

X

3

X

13

STAGE

12

th

4

STAGE

th

X

X

14

STAGE

13

th

5

STAGE

4

th

X

X

15

STAGE

14

6

STAGE

5

th

th

STAGE

6

X

th

7

th

8

STAGE

7

X

th

16

STAGE

15

X

16

X

CRC

OUTPUT

INPUT DAT

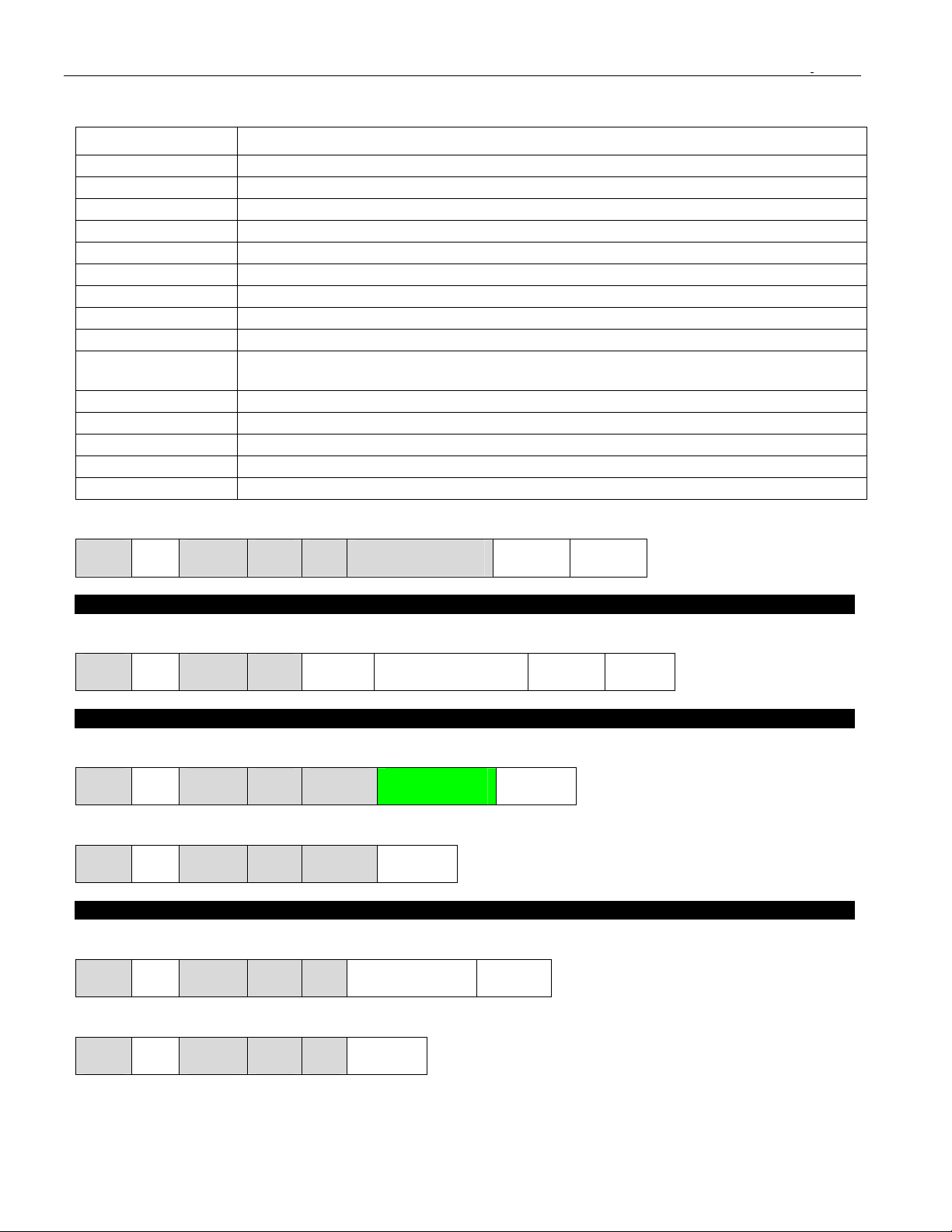

COMMAND-SPECIFIC 1-Wire COMMUNICATION PROTOCOL—COLOR CODES

Master to slave Slave to master Programming

21 of 23

Page 22

DS1972: 1024-Bit EEPROM iButton

COMMAND-SPECIFIC 1-Wire COMMUNICATION PROTOCOL—LEGEND

SYMBOL DESCRIPTION

RST 1-Wire Reset Pulse generated by master.

PD 1-Wire Presence Pulse generated by slave.

Select Command and data to satisfy the ROM function protocol.

WS Command "Write Scratchpad".

RS Command "Read Scratchpad".

CPS Command "Copy Scratchpad".

RM Command "Read Memory".

TA Target Address TA1, TA2.

TA-E/S Target Address TA1, TA2 with E/S byte.

<8 – T2:T0 bytes> Transfer of as many bytes as needed to reach the end of the scratchpad for a given

target address.

<data to EOM> Transfer of as many data bytes as are needed to reach the end of the memory.

CRC16\ Transfer of an inverted CRC16.

FF loop Indefinite loop where the master reads FF bytes.

AA loop Indefinite loop where the master reads AA bytes.

Programming Data transfer to EEPROM; no activity on the 1-Wire bus permitted during this time.

WRITE SCRATCHPAD (CANNOT FAIL)

RST PD Select WS TA <8 – T2:T0 bytes> CRC16\ FF loop

READ SCRATCHPAD (CANNOT FAIL)

RST PD Select RS TA-E/S <8 – T2:T0 bytes> CRC16\ FF loop

COPY SCRATCHPAD (SUCCESS)

RST PD Select CPS TA-E/S Programming AA loop

COPY SCRATCHPAD (INVALID ADDRESS OR PF = 1 OR COPY PROTECTED)

RST PD Select CPS TA-E/S FF loop

READ MEMORY (SUCCESS)

RST PD Select RM TA <data to EOM> FF loop

READ MEMORY (INVALID ADDRESS)

RST PD Select RM TA FF loop

22 of 23

Page 23

DS1972: 1024-Bit EEPROM iButton

MEMORY FUNCTION EXAMPLE

Write to the first 8 bytes of memory page 1. Read the entire memory.

With only a single DS1972 connected to the bus master, the communication looks like this:

MASTER MODE DATA (LSB FIRST) COMMENTS

TX (Reset) Reset Pulse

RX (Presence) Presence Pulse

TX CCh Issue “Skip ROM” command

TX 0Fh Issue “Write scratchpad” command

TX 20h TA1, beginning offset = 20h

TX 00h TA2, address = 0020h

TX <8 data bytes> Write 8 bytes of data to scratchpad

RX <2 bytes CRC16\> Read CRC to check for data integrity

TX (Reset) Reset Pulse

RX (Presence) Presence Pulse

TX CCh Issue “Skip ROM” command

TX AAh Issue “Read scratchpad” command

RX 20h Read TA1, beginning offset = 20h

RX 00h Read TA2, address = 0020h

RX 07h Read E/S, ending offset = 111b, AA, PF = 0

RX <8 data bytes> Read scratchpad data and verify

RX <2 bytes CRC16\> Read CRC to check for data integrity

TX (Reset) Reset Pulse

RX (Presence) Presence Pulse

TX CCh Issue “Skip ROM” command

TX 55h Issue “Copy scratchpad” command

TX 20h TA1

TX 00h TA2 (AUTHORIZATION CODE)

TX 07h E/S

Wait t

¾

RX AAh Read copy status, AAh = success

TX (Reset) Reset Pulse

RX (Presence) Presence Pulse

TX CCh Issue “Skip ROM” command

TX F0h Issue “Read Memory” command

TX 00h TA1, beginning offset = 00h

TX 00h TA2, address = 0000h

RX <144 data bytes> Read the entire memory

TX (Reset) Reset Pulse

RX (Presence) Presence Pulse

<1-Wire idle high>

PROGmax

complete

for the copy function to

23 of 23

Loading...

Loading...