Page 1

SPECIAL FEATURES

www.dalsemi.com

1993

A0

1993

§ Digital thermometer measures temperatures

from -55°C to +100°C in typically 0.2

seconds

§ Zero standby power

§ 0.5°C resolution, digital temperature reading

is two’s complement of °C value

§ Access to internal counters allows increased

resolution through interpolation

§ Reduces control, address, data, and power to

a single data contact

§ 8-bit device-generated CRC for data integrity

§ 8-bit family code specifies DS1920

communications requirements to reader

§ Special command set allows user to skip

ROM section and do temperature

measurements simultaneously for all devices

on the bus

§ 2 bytes of EEPROM to be used either as

alarm triggers or user memory

§ Alarm search directly indicates which device

senses alarming temperatures

COMMON iButton FEATURES

§ Unique, factory-lasered and tested 64-bit

registration number (8-bit family code + 48bit serial number + 8-bit CRC tester) assures

absolute traceability because no two parts are

alike

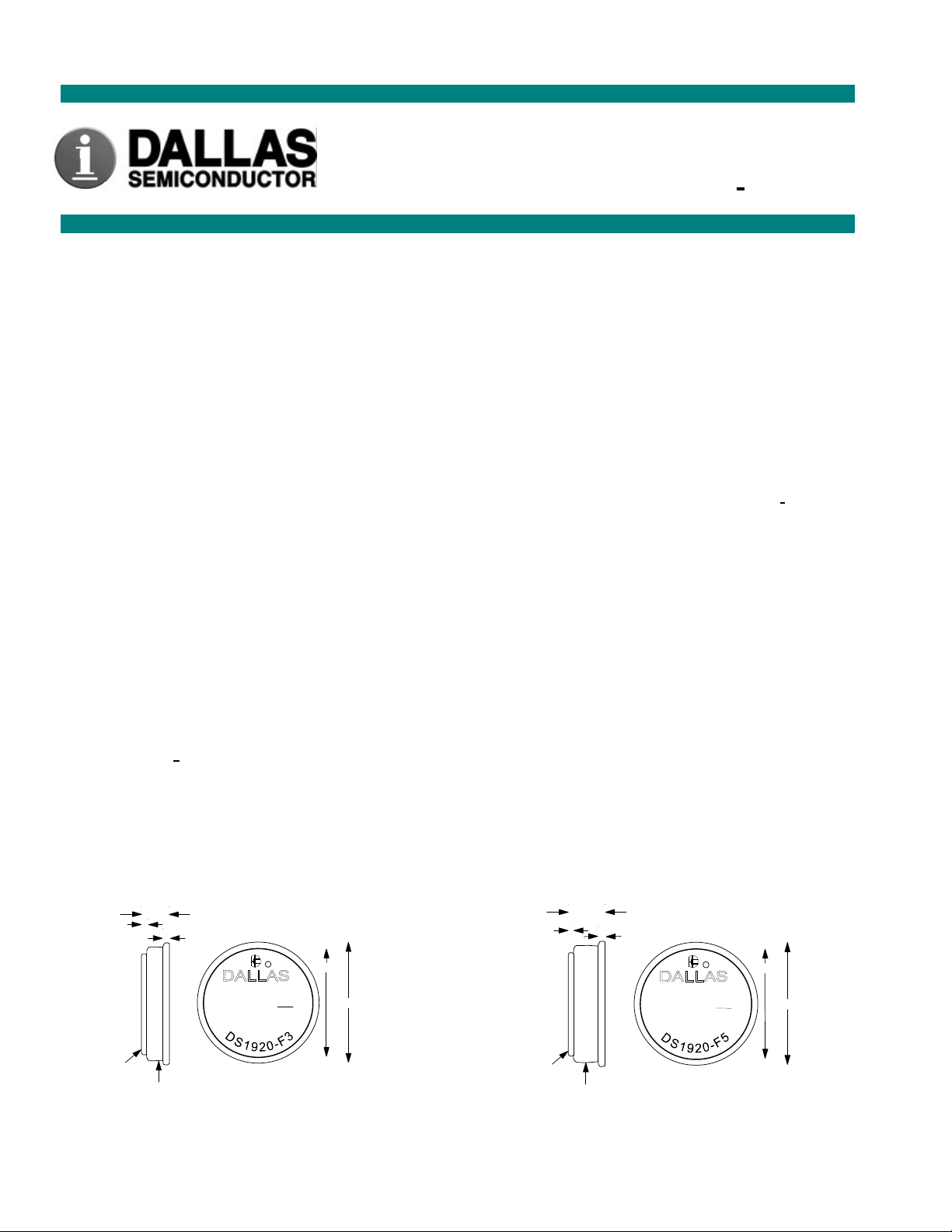

F3 MICROCAN

0.36

TM

3.10

0.51

YYWW REGISTERED RR

000000FBC52B

c

10

16.25

17.35

DS1920

Temperature iButton

§ Multidrop controller for MicroLAN

§ Digital identification and information by

momentary contact

§ Chip-based data carrier compactly stores

information

§ Data can be accessed while affixed to object

§ Economically communicates to bus master

with a single digital signal at 16.3k bits per

second

§ Standard 16 mm diameter and 1-Wire

protocol ensure compatibility with iButton

family

§ Button shape is self-aligning with cup-

shaped probes

§ Durable stainless steel case engraved with

registration number withstands harsh

environments

§ Easily affixed with self-stick adhesive

backing, latched by its flange, or locked with

a ring pressed onto its rim

§ Presence detector acknowledges when reader

first applies voltage

§ Meets UL#913 (4th Edit.); Intrinsically Safe

Apparatus, approved under Entity Concept

for use in Class I, Division 1, Group A, B, C

and D Locations (application pending)

F5 MICROCAN

5.89

0.36

TM

0.51

YYWW REGISTERED RR

20

000000FBD8B3

c

10

TM

16.25

17.35

DATA

GROUND

All dimensions are shown in millimeters

1 of 22 081699

DATA

GROUND

Page 2

DS1920

ORDERING INFORMATION

DS1920-F3 F3 MicroCan

DS1920-F5 F5 MicroCan

EXAMPLES OF ACCESSORIES

DS9096P Self-Stick Adhesive Pad

DS9101 Multi-Purpose Clip

DS9093RA Mounting Lock Ring

DS9093F Snap-In Fob

DS9092 iButton Probe

iButton DESCRIPTION

The DS1920 Temperature iButton provides 9-bit temperature readings which indicate the temperature of

the device. Information is sent to/from the DS1920 over a 1-Wire interface. Power for reading, writing,

and performing temperature conversions is derived from the data line itself. Because each DS1920

contains a unique silicon serial number, multiple DS1920s can exist on the same 1-Wire bus. This allows

for placing temperature sensors in many different places. Applications where this feature is useful include

HVAC environmental controls, sensing temperatures inside buildings, equipment or machinery, and in

process monitoring and control.

OVERVIEW

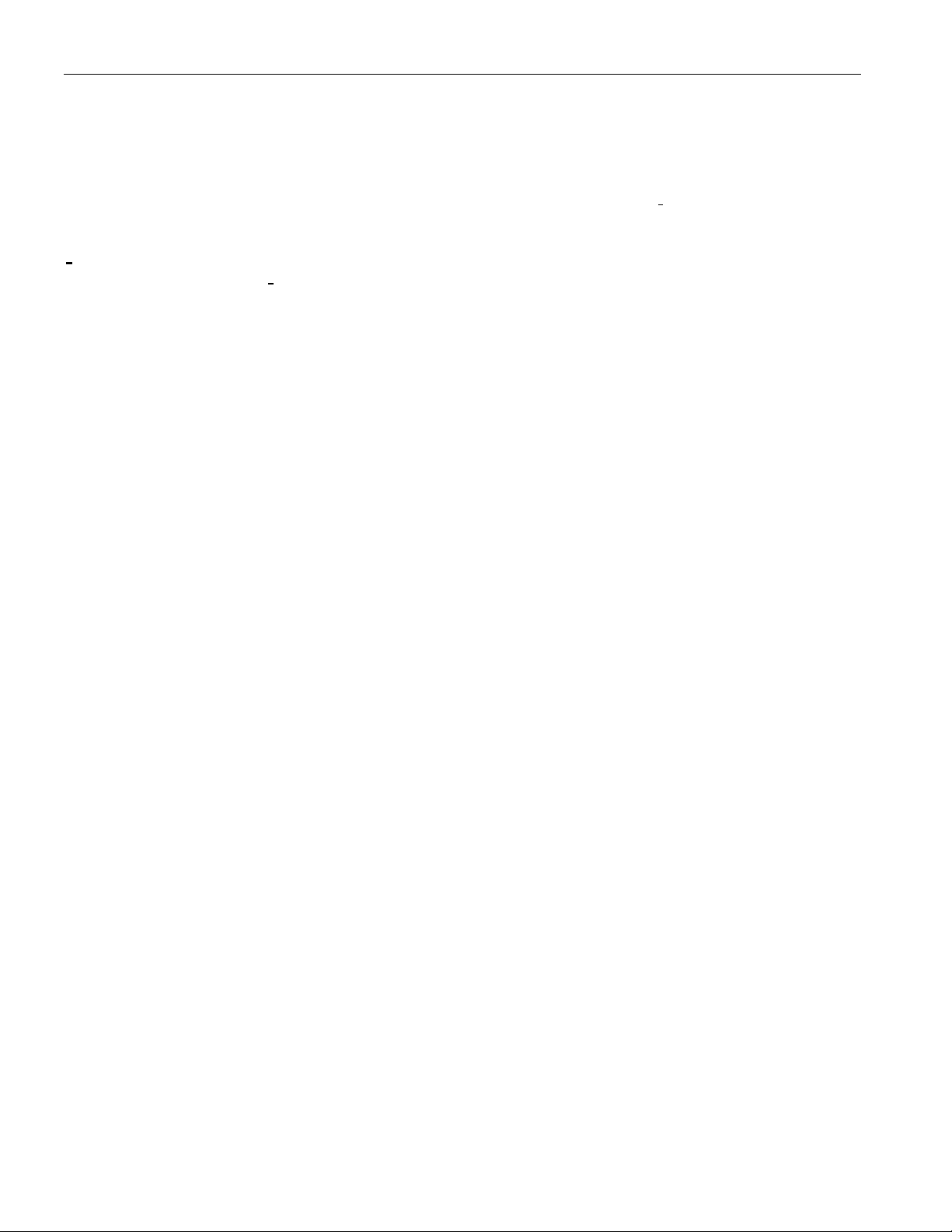

The block diagram of Figure 1 shows the major components of the DS1920. The DS1920 has three main

data components: 1) 64-bit lasered ROM, 2) temperature sensor, and 3) nonvolatile temperature alarm

triggers TH and TL. The device derives its power from the 1-Wire communication line by storing energy

on an internal capacitor during periods of time when the signal line is high and continues to operate off

this power source during the low times of the 1-Wire line until it returns high to replenish the parasite

(capacitor) supply.

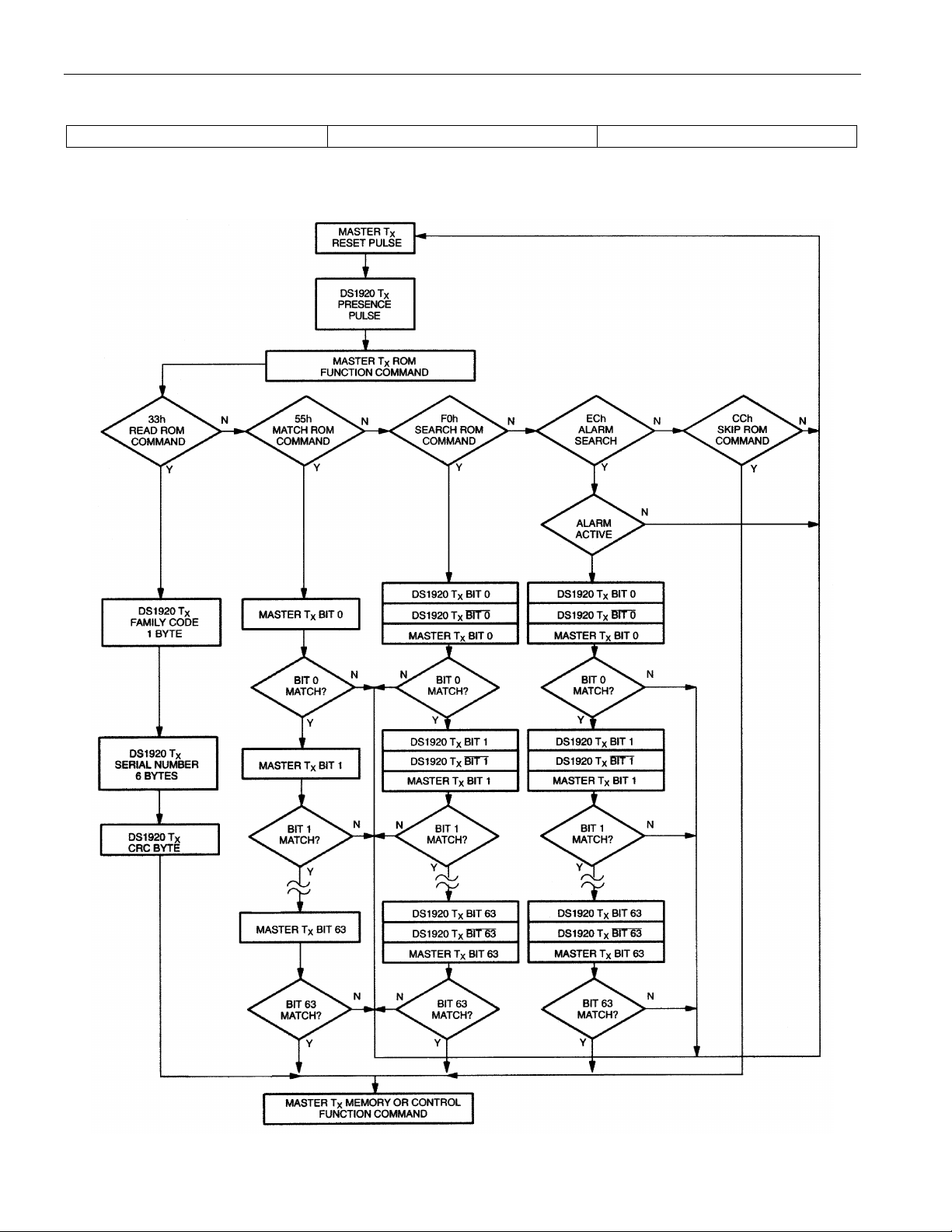

Communication to the DS1920 is via a 1-Wire port. With the 1-Wire port, the memory and control

functions will not be available before the ROM function protocol has been established. The master must

first provide one of five ROM function commands: 1) Read ROM, 2) Match ROM, 3) Search ROM, 4)

Skip ROM, or 5) Alarm Search. These commands operate on the 64-bit lasered ROM portion of each

device and can single out a specific device if many are present on the 1-Wire line as well as indicate to

the bus master how many and what types of devices are present. After a ROM function sequence has been

successfully executed, the memory and control functions are accessible and the master may then provide

any one of the five memory and control function commands.

One control function command instructs the DS1920 to perform a temperature measurement. The result

of this measurement will be placed in the DS1920’s scratchpad memory, and may be read by issuing a

memory function command which reads the contents of the scratchpad memory. The temperature alarm

triggers TH and TL consist of 1 byte of EEPROM each. If the alarm search command is not applied to the

DS1920, these registers may be used as general purpose user memory. Writing TH and TL is done using a

memory function command. Read access to these registers is through the scratchpad. All data is read and

written least significant bit first.

2 of 22

Page 3

DS1920

DS1920 BLOCK DIAGRAM Figure 1

PARASITE POWER

The block diagram (Figure 1) shows the parasite-powered circuitry. This circuitry “steals” power

whenever the data contact is high. Data will provide sufficient power as long as the specified timing and

voltage requirements are met (see the section titled “1-Wire Bus System”). The advantage of parasite

power is that no local power source is needed for remote sensing of temperature.

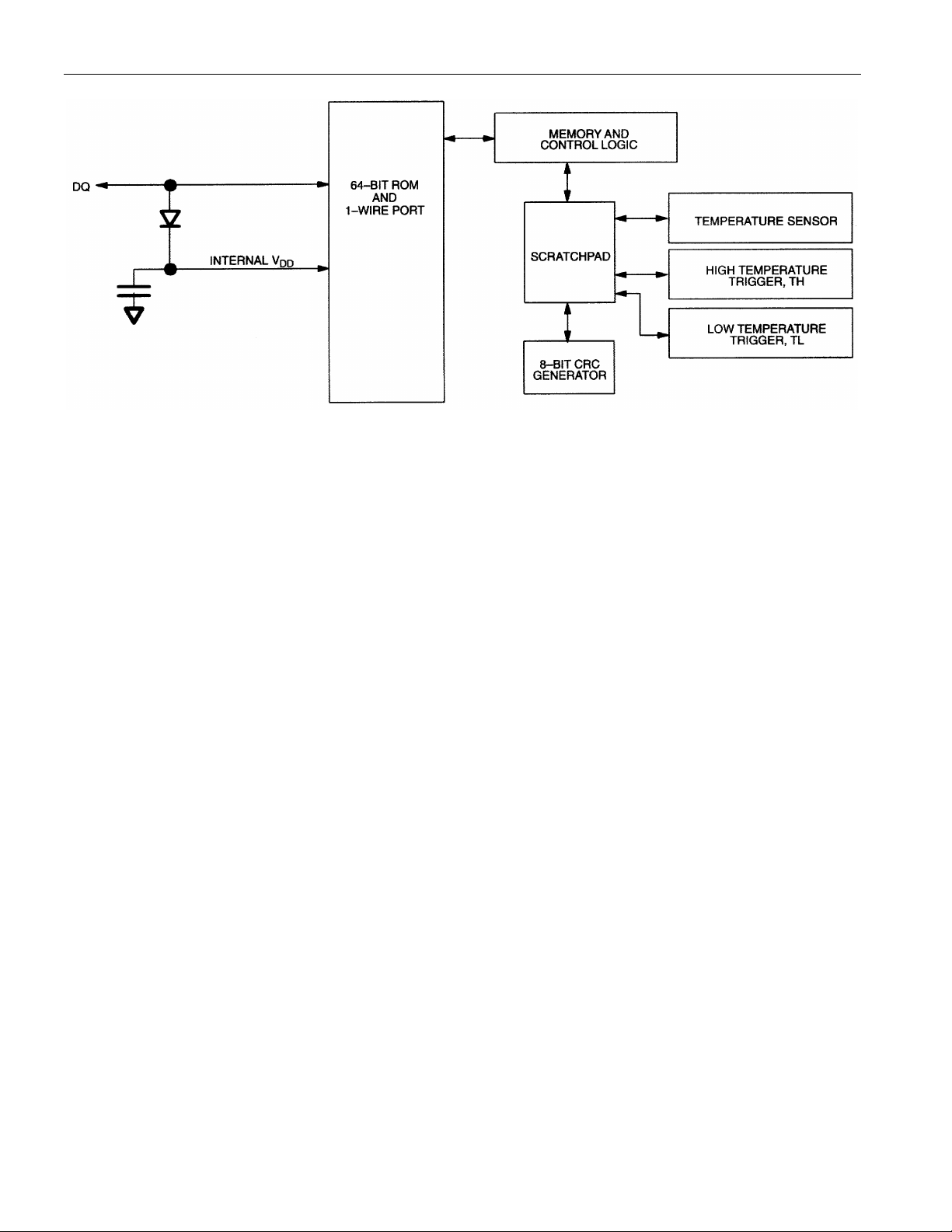

In order for the DS1920 to be able to perform accurate temperature conversions, sufficient power must be

provided over the data line when a temperature conversion is taking place. The DS1920 requires a current

during conversion of up to 1 mA, therefore, the data line will not have sufficient drive due to the 5 kΩ

pullup resistor. This problem is particularly acute if several DS1920s are on the same data line and

attempting to convert simultaneously.

The way to assure that the DS1920 has sufficient supply current is to provide a strong pullup on the data

line whenever temperature conversion or copying to the EEPROM is taking place. This may be

accomplished by using a MOSFET to connect the data line directly to the power supply as shown in

Figure 2. The data line must be switched over to the strong pullup within 10 µs maximum after issuing a

command that involves copying to the EEPROM or initiates a temperature conversion.

3 of 22

Page 4

DS1920

STRONG PULL-UP FOR SUPPLYING DS1920 DURING TEMPERATURE

CONVERSION Figure 2

OPERATION - MEASURING TEMPERATURE

The DS1920 measures temperatures through the use of an on-board proprietary temperature measurement

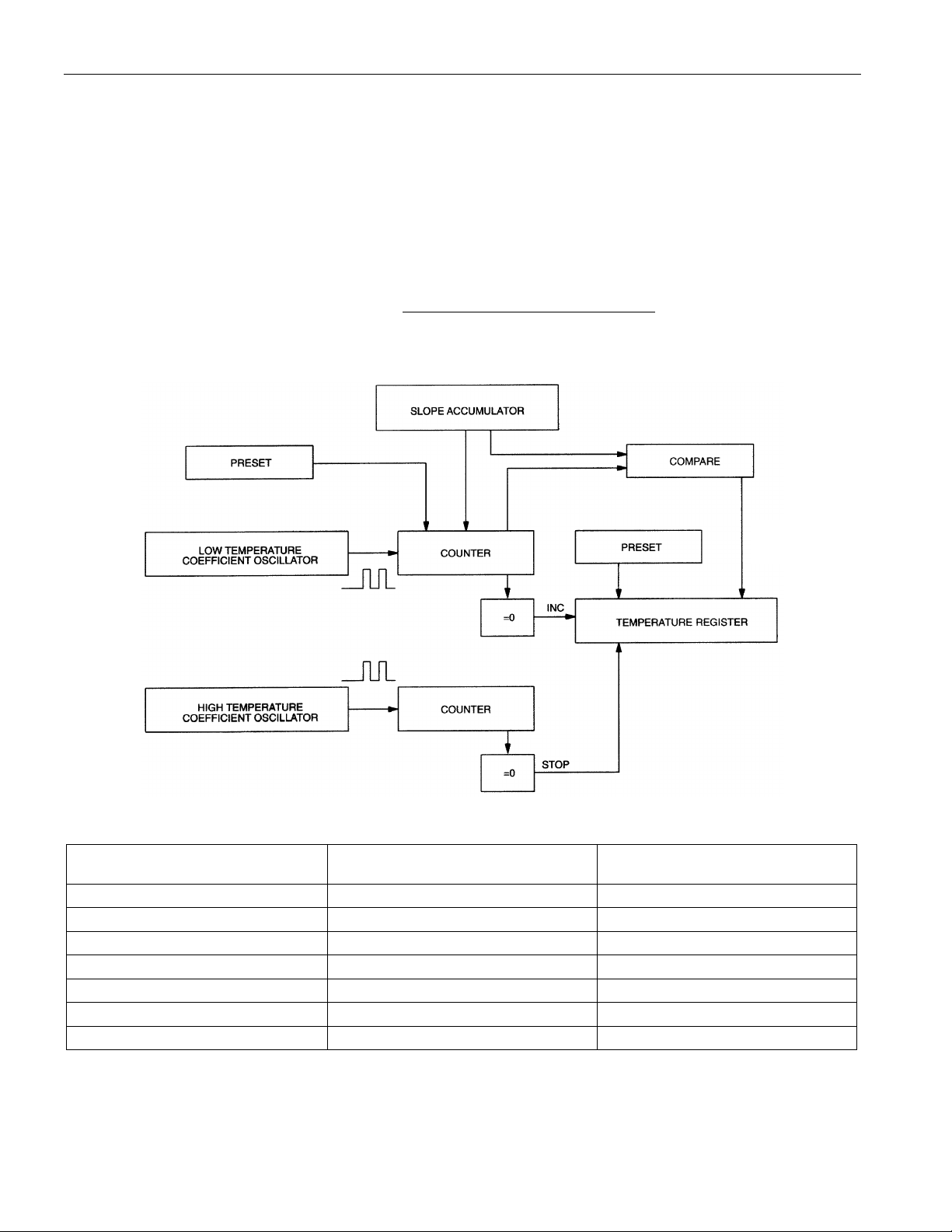

technique. A block diagram of the temperature measurement circuitry is shown in Figure 3.

The DS1920 measures temperature by counting the number of clock cycles that an oscillator with a low

temperature coefficient goes through during a gate period determined by a high temperature coefficient

oscillator. The counter is preset with a base count that corresponds to -55°C. If the counter reaches 0

before the gate period is over, the temperature register, which is also preset to the -55°C value, is

incremented, indicating that the temperature is higher than -55°C.

At the same time, the counter is then preset with a value determined by the slope accumulator circuitry.

The counter is then clocked again until it reaches 0. If the gate period is still not finished, then this

process repeats.

The slope accumulator compensates for the non-linear behavior of the oscillators over temperature,

yielding a high-resolution temperature measurement. This is done by changing the number of counts

necessary for the counter to go through for each incremental degree in temperature. To obtain the desired

resolution, therefore, both the value of the counter and the number of counts per degree C (the value of

the slope accumulator) at a given temperature must be known.

Internally, this calculation is done inside the DS1920 to provide 0.5°C resolution. The temperature

reading is provided in a 16-bit, sign-extended two’s complement reading. Table 1 describes the exact

relationship of output data to measured temperature. The data is transmitted serially over the 1-Wire

interface. The DS1920 can measure temperature over the range of -55°C to +100°C in 0.5°C increments.

For Fahrenheit usage, a lookup table or conversion factor must be used.

Note that temperature is represented in the DS1920 in terms of a ½°C LSB, yielding the following 9-bit

format:

MSB LSB

1 1 1 0 0 1 1 1 0

= -25°C

4 of 22

Page 5

DS1920

The most significant (sign) bit is duplicated into all of the bits in the upper MSB of the 2-byte

temperature register in memory. This “sign-extension” yields the 16-bit temperature readings as shown in

Table 1.

Higher resolutions may be obtained by the following procedure. First, read the temperature, and truncate

the 0.5°C bit (the LSB) from the read value. This value is TEMP_READ. The value left in the counter

may then be read. This value is the count remaining (COUNT_REMAIN) after the gate period has

ceased. The last value needed is the number of counts per degree C (COUNT_PER_C) at that

temperature. The actual temperature may be then be calculated by the user using the following formula:

TEMPERATURE = TEMP_READ - 0.25 +

TEMPERATURE MEASURING CIRCUITRY Figure 3

IN)COUNT_REMA-_C(COUNT_PER

CCOUNT_PER_

SET/CLEAR

LSB

TEMPERATURE/DATA RELATIONSHIPS Table 1

TEMPERATURE

+100°C

+25°C

+½°C

+0°C

-½°C

-25°C

-55°C

DIGITAL OUTPUT

(BINARY)

00000000 11001000 00C8H

00000000 00110010 0032H

00000000 00000001 0001H

00000000 00000000 0000H

11111111 11111111 FFFFH

11111111 11001110 FFCEH

11111111 10010010 FF92H

5 of 22

DIGITAL OUTPUT

(HEX)

Page 6

DS1920

OPERATION - ALARM SIGNALING

After the DS1920 has performed a temperature conversion, the temperature value is compared to the

trigger values stored in TH and TL. Since these registers are 8 bits only, the 0.5°C bit is ignored for

comparison. The most significant bit of TH or TL directly corresponds to the sign bit of the 16-bit

temperature register. If the result of a temperature measurement is higher than TH or lower than TL, an

alarm flag inside the device is set. This flag is updated with every temperature measurement. As long as

the alarm flag is set, the DS1920 will respond to the alarm search command. This allows many DS1920s

to be connected in parallel doing simultaneous temperature measurements. If somewhere the temperature

exceeds the limits, the alarming device(s) can be identified and read immediately without having to read

non-alarming devices.

64-BIT LASERED ROM

Each DS1920 contains a unique ROM code that is 64 bits long. The first 8 bits are a 1-Wire family code

(DS1920 code is 10h). The next 48 bits are a unique serial number. The last 8 bits are a CRC of the first

56 bits. (See Figure 4.) The 64-bit ROM and ROM Function Control section allow the DS1920 to operate

as a 1-Wire device and follow the 1-Wire protocol detailed in the section “1-Wire Bus System.” The

memory and control functions of the DS1920 are not accessible until the ROM function protocol has been

satisfied. This protocol is described in the ROM function protocol flowchart (Figure 5). The 1-Wire bus

master must first provide one of five ROM function commands: 1) Read ROM, 2) Match ROM, 3) Search

ROM, 4) Skip ROM, or 5) Alarm Search. After a ROM function sequence has been successfully

executed, the functions specific to the DS1920 are accessible and the bus master may then provide any

one of the five memory and control function commands.

CRC GENERATION

The DS1920 has an 8-bit CRC stored in the most significant byte of the 64-bit ROM. The bus master can

compute a CRC value from the first 56 bits of the 64-bit ROM and compare it to the value stored within

the DS1920 to determine if the ROM data has been received error-free by the bus master. The equivalent

polynomial function of this CRC is:

CRC = X8 + X5 + X4 + 1

The DS1920 also generates an 8-bit CRC value using the same polynomial function shown above and

provides this value to the bus master to validate the transfer of data bytes. In each case where a CRC is

used for data transfer validation, the bus master must calculate a CRC value using the polynomial

function given above and compare the calculated value to either the 8-bit CRC value stored in the 64-bit

ROM portion of the DS1920 (for ROM reads) or the 8-bit CRC value computed within the DS1920

(which is read as a 9th byte when the scratchpad is read). The comparison of CRC values and decision to

continue with an operation are determined entirely by the bus master. There is no circuitry inside the

DS1920 that prevents a command sequence from proceeding if the CRC stored in or calculated by the

DS1920 does not match the value generated by the bus master.

The 1-Wire CRC can be generated using a polynomial generator consisting of a shift register and XOR

gates as shown in Figure 6. Additional information about the Dallas 1-Wire Cyclic Redundancy Check is

available in the Book of DS19xx iButton Standards.

The shift register bits are first initialized to 0. For the ROM section, starting with the least significant bit

of the family code, 1 bit at a time is shifted in. After the 8th bit of the family code has been entered, then

the serial number is entered. After the 48th bit of the serial number has been entered, the shift register

contains the CRC value. Shifting in the 8 bits of CRC should return the shift register to all 0s.

6 of 22

Page 7

DS1920

64-BIT LASERED ROM Figure 4

8-BIT CRC CODE 48-BIT SERIAL NUMBER 8-BIT FAMILY CODE (10H)

MSB LSB MSB LSB MSB LSB

ROM FUNCTIONS FLOW CHART Figure 5

7 of 22

Page 8

DS1920

1-WIRE CRC CODE Figure 6

MEMORY

The DS1920’s memory is organized as shown in Figure 7. The memory consists of a scratchpad and 2

bytes of EEPROM which store the high and low temperature triggers TH and TL. The scratchpad helps

insure data integrity when communicating over the 1-Wire bus. Data is first written to the scratchpad

where it can be read back. After the data has been verified, a copy scratchpad command will transfer the

data to the EEPROM. This process insures data integrity when modifying the memory.

The scratchpad is organized as 8 bytes of memory. The first 2 bytes contain the measured temperature

information. The 3rd and 4th bytes are volatile copies of TH and TL and are refreshed with every power-on

reset. The next 2 bytes are not used; upon reading back, however, they will appear as all logic 1s. The 7

and 8th bytes are count registers, which may be used in obtaining higher temperature resolution (see

“Operation-Measuring Temperature” section).

th

There is a 9th byte which may be read with a Read Scratchpad command. This byte is a cyclic redundancy

check (CRC) over all of the 8 previous bytes. This CRC is implemented as described in the section titled

“CRC Generation.”

DS1920 MEMORY MAP Figure 7

SCRATCHPAD BYTE EEPROM

TEMPERATURE LSB 0

TEMPERATURE MSB 1

TH/USER BYTE 1 2 TH/USER BYTE 1

TL/USER BYTE 2 3 TL/USER BYTE 2

RESERVED 4

RESERVED 5

COUNT REMAIN 6

COUNT PER °C 7

CRC 8

1-WIRE BUS SYSTEM

The 1-Wire bus is a system which has a single bus master and one or more slaves. The DS1920 behaves

as a slave. The discussion of this bus system is broken down into three topics: hardware configuration,

transaction sequence, and 1-Wire signaling (signal types and timing).

8 of 22

Page 9

DS1920

HARDWARE CONFIGURATION

The 1-Wire bus has only a single line by definition; it is important that each device on the bus be able to

drive it at the appropriate time. To facilitate this, each device attached to the 1-Wire bus must have open

drain or 3-state outputs. The 1-Wire port of the DS1920 (data contact) is open drain with an internal

circuit equivalent to that shown in Figure 8. A multidrop bus consists of a 1-Wire bus with multiple

slaves attached. The 1-Wire bus requires a pull up resistor of approximately 5 kΩ. The idle state for the 1Wire bus is high. If for any reason a transaction needs to be suspended, the bus MUST be left in the idle

state if the transaction is to resume. If this does not occur and the bus is left low for more than 120 ms,

one or more of the devices on the bus will be reset.

HARDWARE CONFIGURATION Figure 8

TRANSACTION SEQUENCE

The protocol for accessing the DS1920 via the 1-Wire port is as follows:

§ Initialization

§ ROM Function Command

§ Memory/Control Function Command

§ Transaction/Data

INITIALIZATION

All transactions on the 1-Wire bus begin with an initialization sequence. The initialization sequence

consists of a reset pulse transmitted by the bus master followed by presence pulse(s) transmitted by the

slave(s).

The presence pulse lets the bus master know that the DS1920 is on the bus and is ready to operate. For

more details, see the “1-Wire Signaling” section.

ROM FUNCTION COMMANDS

Once the bus master has detected a presence pulse, it can issue one of the five ROM function commands.

All ROM function commands are eight bits long. A list of these commands follows (refer to flowchart in

Figure 5):

9 of 22

Page 10

DS1920

Read ROM [33h]

This command allows the bus master to read the DS1920’s 8-bit family code, unique 48-bit serial

number, and 8-bit CRC. This command can only be used if there is a single DS1920 on the bus. If more

than one slave is present on the bus, a data collision will occur when all slaves try to transmit at the same

time (open drain will produce a wired AND result).

Match ROM [55h]

The match ROM command, followed by a 64-bit ROM sequence, allows the bus master to address a

specific DS1920 on a multidrop bus. Only the DS1920 that exactly matches the 64-bit ROM sequence

will respond to the subsequent memory function command. All slaves that do not match the 64-bit ROM

sequence will wait for a reset pulse. This command can be used with a single or multiple devices on the

bus.

Skip ROM [CCh]

This command can save time in a single drop bus system by allowing the bus master to access the

memory functions without providing the 64-bit ROM code. If more than one slave is present on the bus

and a read command is issued following the Skip ROM command, data collision will occur on the bus as

multiple slaves transmit simultaneously (open drain pulldowns will produce a wired AND result). The

Skip ROM command is useful to address all DS1920s on the bus to do a temperature conversion. Since

the DS1920 uses a special command set, other device types will not respond to these commands.

Search ROM [F0h]

When a system is initially brought up, the bus master might not know the number of devices on the 1Wire bus or their 64-bit ROM codes. The search ROM command allows the bus master to use a process

of elimination to identify the 64-bit ROM codes of all slave devices on the bus. The ROM search process

is the repetition of a simple, three-step routine: read a bit, read the complement of the bit, then write the

desired value of that bit. The bus master performs this simple, three-step routine on each bit of the ROM.

After one complete pass, the bus master knows the contents of the ROM in one device. The remaining

number of devices and their ROM codes may be identified by additional passes. See Chapter 5 of the

Book of DS19xx iButton Standards for a comprehensive discussion of a ROM Search, including an actual

example.

Alarm Search [ECh]

The flowchart of this command is identical to the Search ROM command; however, the DS1920 will

respond to this command only if an alarm condition has been encountered at the last temperature

measurement. An alarm condition is defined as a temperature higher than TH or lower than TL. The

alarm condition remains set as long as the DS1920 is powered up or until another temperature

measurement reveals a non-alarming value. For alarming, the trigger values stored in EEPROM are taken

into account. If an alarm condition exists and the TH or TL settings are changed, another temperature

conversion should be done to validate any alarm conditions.

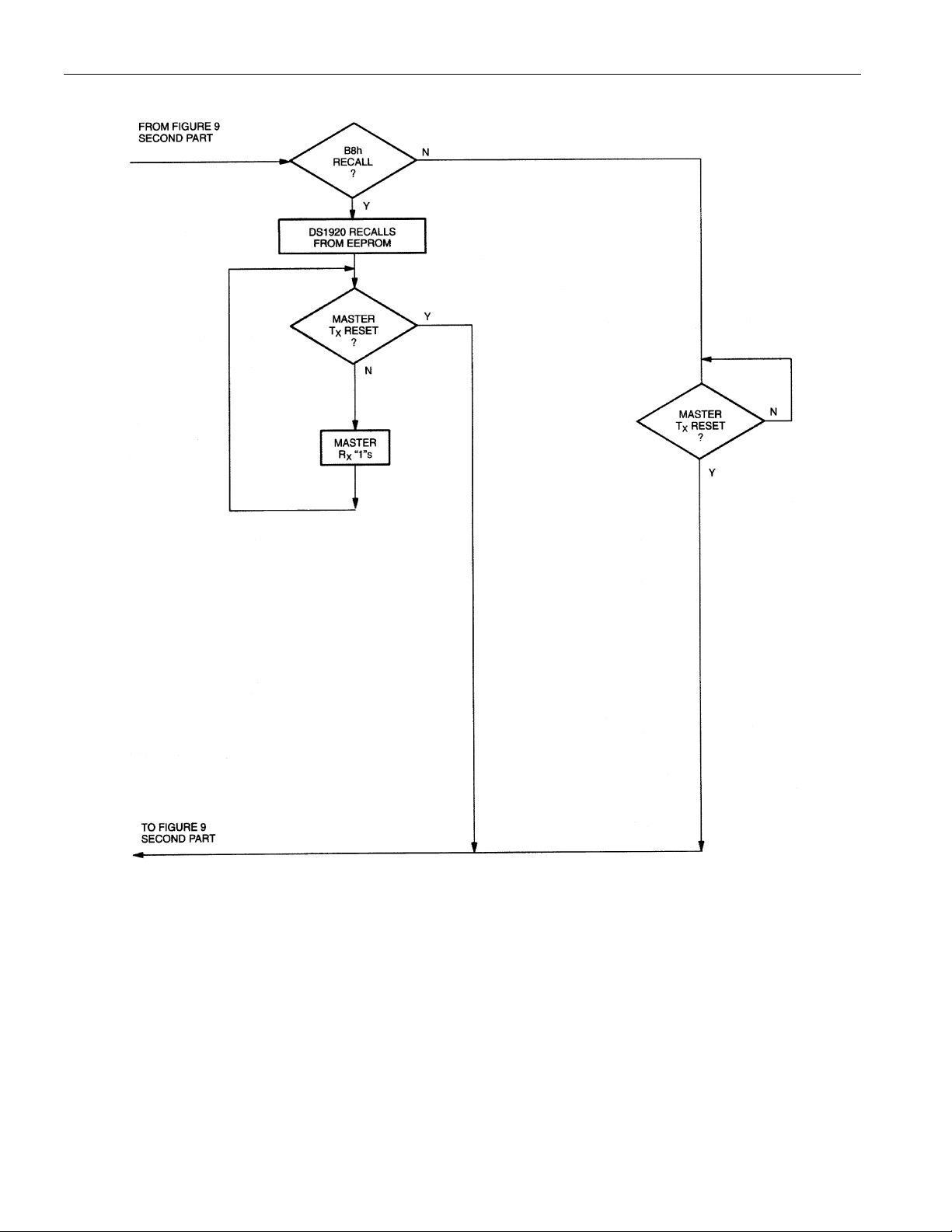

MEMORY AND CONTROL FUNCTION COMMANDS

The following command protocols are summarized in Table 2, and by the flowchart of Figure 9.

Write Scratchpad [4Eh]

This command writes to the scratchpad of the DS1920, starting at address 2. The next 2 bytes written will

be saved in scratchpad memory, at address locations 2 and 3. Writing may be terminated at any point by

issuing a reset. However, if a reset occurs before both bytes have been completely sent, the contents of

these bytes will be indeterminate. Bytes 2 and 3 can be read and written; all other bytes are read only.

10 of 22

Page 11

DS1920

Read Scratchpad [BEh]

This command reads the complete scratchpad. After the last byte of the scratchpad is read, the bus master

will receive an 8-bit CRC of all scratchpad bytes. If not all locations are to be read, the master may issue

a reset to terminate reading at any time.

Copy Scratchpad [48h]

This command copies from the scratchpad into the EEPROM of the DS1920, storing the temperature

trigger bytes in nonvolatile memory. The bus master has to enable a strong pullup for at least 10 ms

immediately after issuing this command.

Convert Temperature [44h]

This command begins a temperature conversion. No further data is required. The bus master has to enable

a strong pullup for 0.5 seconds immediately after issuing this command.

Recall [B8h]

This command recalls the temperature trigger values stored in EEPROM to the scratchpad. This recall

operation happens automatically upon power-up to the DS1920 as well, so valid data is available in the

scratchpad as soon as the device has power applied.

11 of 22

Page 12

MEMORY AND CONTROL FUNCTIONS FLOW CHART Figure 9

DS1920

12 of 22

Page 13

DS1920

13 of 22

Page 14

MEMORY AND CONTROL FUNCTIONS FLOW CHART (cont’d) Figure 9

FIRST PART

DS1920

FROM FIGURE 9

TO FIGURE 9

THIRD PART

14 of 22

Page 15

MEMORY AND CONTROL FUNCTIONS FLOW CHART (cont’d) Figure 9

DS1920

1-WIRE SIGNALING

The DS1920 requires strict protocols to ensure data integrity. The protocol consists of five types of

signaling on one line: Reset Sequence with Reset Pulse and Presence Pulse, Write 0, Write 1, Read Data

and Strong Pullup. All these signals except Presence Pulse are initiated by the bus master. The

initialization sequence required to begin any communication with the DS1920 is shown in Figure 10. A

Reset Pulse followed by a Presence Pulse indicates the DS1920 is ready to accept a ROM command. The

bus master transmits (TX) a Reset Pulse (t

and goes into receive mode (RX). The 1-Wire bus is pulled to a high state via the pullup resistor. After

detecting the rising edge on the 1-Wire line, the DS1920 waits (t

Presence Pulse (t

, 60-240 µs).

PDL

, minimum 480 µs). The bus master then releases the line

RSTL

, 15-60 µs) and then transmits the

PDH

15 of 22

Page 16

DS1920

READ/WRITE TIME SLOTS

The definitions of write and read time slots are illustrated in Figure 11. All time slots are initiated by the

master driving the data line low. The falling edge of the data line synchronizes the DS1920 to the master

by triggering a delay circuit in the DS1920. During write time slots, the delay circuit determines when the

DS1920 will sample the data line. For a read data time slot, if a 0 is to be transmitted, the delay circuit

determines how long the DS1920 will hold the data line low overriding the 1 generated by the master. If

the data bit is a 1, the DS1920 will leave the read data time slot unchanged.

STRONG PULLUP

To provide energy for a temperature conversion or for copying data from the scratchpad to the EEPROM,

a low impedance pullup of the 1-Wire bus to 5V is required just after the corresponding command has

been sent by the master. During temperature conversion or copying the scratchpad, the bus master

controls the transition from a state where the data line is idling high via the pullup resistor to a state where

the data line is actively driven to 5 volts, providing a minimum of 1 mA of current for each DS1920

doing temperature conversion. This low impedance pullup should be active for 0.5 seconds for

temperature conversion or at least 10 ms for copying to the scratchpad. After that, the data line returns to

an idle high state controlled by the pullup resistor. The low-impedance pullup does not affect other

devices on the 1-Wire bus. Therefore it is possible to multidrop other 1-Wire devices with the DS1920.

INITIALIZATION PROCEDURE “RESET AND PRESENCE PULSES” Figure 10

RESISTOR

MASTER

DS1920

480 µs ≤ t

480 µs ≤ t

15 µs ≤ t

60 µs ≤ t

< ∞ ∗

RSTL

< ∞ (includes recovery time)

RSTH

< 60 µs

PDH

< 240 µs

PDL

* In order not to mask interrupt signaling by other devices on the 1-Wire bus, t

be less than 960 µs.

16 of 22

+ tR should always

RSTL

Page 17

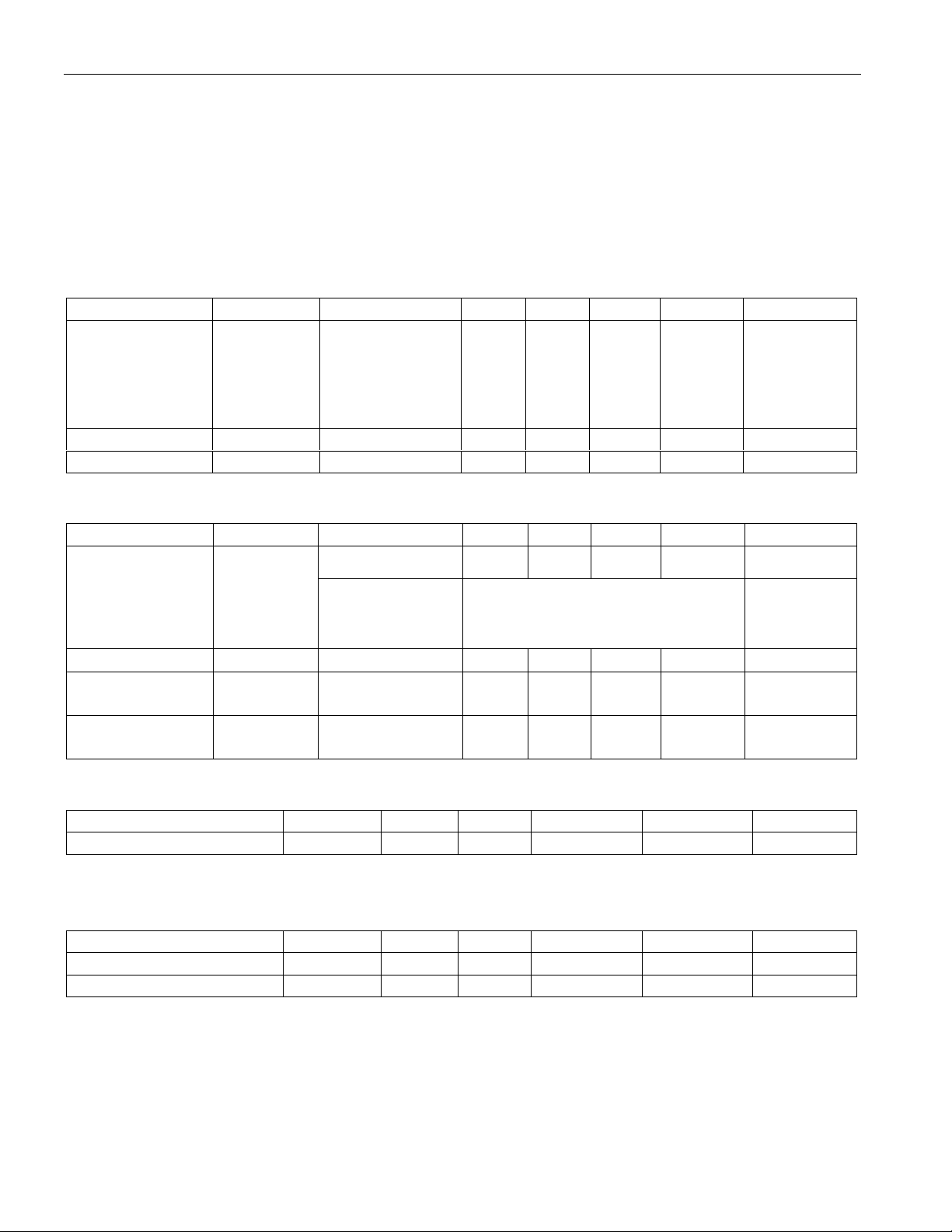

DS1920 MEMORY AND CONTROL FUNCTION COMMANDS Table 2

1-WIRE BUS

AFTER ISSUING

INSTRUCTION DESCRIPTION PROTOCOL

TEMPERATURE CONVERSION COMMANDS

Convert

Temperature

Initiates temperature

conversion

44H strong pullup 1

MEMORY COMMANDS

Read Scratchpad Reads bytes from scratchpad

BEH <read up to 9 data

and reads CRC byte.

Write Scratchpad Writes bytes into scratchpad

4EH <write data into 2

at addresses 2 and 3 (TH and

TL temperature triggers).

Copy Scratchpad Copies Scratchpad into

48H strong pullup 2

nonvolatile memory

(addresses 2 and 3 only).

Recall Recalls values stored in

B8H idle

nonvolatile memory into

scratchpad (temperature

triggers).

PROTOCOL NOTES

bytes>

bytes at addr. 2 and

addr. 3>

DS1920

NOTES:

1. Temperature conversion takes up to 0.5 seconds. After receiving the Convert Temperature command,

the data line for the DS1920 must be held high for at least 0.5 seconds to provide power during the

conversion process. As such, no other activity may take place on the 1-Wire bus for at least this

period after a Convert Temperature command has been issued.

2. After receiving the Copy Scratchpad command, the data line for the DS1920 must be held high for at

least 10 ms to provide power during the copy process. As such, no other activity may take place on

the 1-Wire bus for at least this period after a Copy Scratchpad command has been issued.

READ/WRITE TIMING DIAGRAM Figure 11

Write-1 Time Slot

RESISTOR

MASTER

60 µs ≤ t

1 µs ≤ t

1 µs ≤ t

17 of 22

SLOT

LOW1

REC

< 120 µs

< 15 µs

< ∞

Page 18

READ/WRITE TIMING DIAGRAM (cont’d) Figure 11

Write-0 Time Slot

DS1920

Read-Data Time Slot

RESISTOR

MASTER

DS1920

60 µs ≤ t

1 µs ≤ t

REC

60 µs ≤ t

1 µs ≤ t

0 ≤ t

1 µs ≤ t

t

RDV

LOWR

RELEASE

REC

= 15 µs

tSU < 1 µs

LOW0

< ∞

SLOT

< ∞

< t

SLOT

< 120 µs

< 15 µs

< 45 µs

< 120 µs

18 of 22

Page 19

MEMORY FUNCTION EXAMPLE Table 3

Example: Bus Master initiates temperature conversion, then reads temperature.

MASTER MODE DATA (LSB FIRST) COMMENTS

TX Reset

RX Presence Presence pulse

TX 55H Issue "Match ROM" command

TX <64-bit ROM code> Issue address for DS1920

TX 44H Issue "Convert Temperature" command

TX <DATA LINE HIGH> Data line is held high for at least 0.5 seconds by bus

TX Reset Reset pulse

RX Presence Presence pulse

TX 55H Issue "Match ROM" command

TX <64-bit ROM code> Issue address for DS1920

TX BEH Issue "Read Scratchpad" command.

RX <9 data bytes> Read entire scratchpad plus CRC; the master now

TX Reset Reset pulse

RX Presence Presence pulse, done.

Reset pulse( 480-960 µs)

master to allow conversion to complete.

recalculates the CRC of the eight data bytes received

from the scratchpad, compares the CRC calculated and

the CRC read. If they match, the master continues; if

not, this read operation is repeated.

DS1920

19 of 22

Page 20

DS1920

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground -0.5V to +7.0V

Operating Temperature -55°C to +100°C

Storage Temperature -55°C to +100°C

∗ This is a stress rating only and functional operation of the device at these or any other conditions

above those indicated in the operation sections of this specification is not implied. Exposure to

absolute maximum rating conditions for extended periods of time may affect reliability.

DC ELECTRICAL CONDITIONS (-55°C to +100°C)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS NOTES

Pull up Voltage V

PUP

I/O Functions

2.8

5.0 6.0

V

1,2

+½°C Accurate

4.3

6.0

V

Temperature

Conversions

Logic 1 V

Logic 0 V

IH

IL

DC ELECTRICAL CHARACTERISTICS (-55°C to +100°C; V

2.2 V 2

-0.3 +0.8 V 2, 10

=4.3V to 6.0V)

PUP

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS NOTES

Thermometer

t

ERR

0°C to + 70 °C

+½

°C

11

Error

-55°C to +0°C

and + 70 °C to

SEE TYPICAL CURVE 11

+100 °C

Active Current I

Input Load

Current

Output Logic

Low @ 4 mA

V

DD

I

L

OL

1000 1500

5

0.4 V 2

µA

µA

3,4

CAPACITANCE (TA =25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

I/O (1- Wire) C

IN/OUT

800 pF 9

AC ELECTRICAL CHARACTERISTICS; TEMPERATURE CONVERSION AND

COPY SCRATCHPAD (-55°C to +100°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Temperature Conversion t

Copy Scratchpad t

CONV

COPY

20 of 22

0.2 0.5 seconds

10 ms 5

=4.3V to 6.0V)

PUP

Page 21

AC ELECTRICAL CHARACTERISTICS:

1-WIRE INTERFACE (-55°C to +100°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Time Slot t

Write 1 Low Time t

Write 0 Low Time t

Read Data Valid t

Release Time t

RELEASE

Read Data Setup t

Recovery Time t

Reset Time High t

Reset Time Low t

Presence Detect High t

Presence Detect Low t

PDHIGH

PDLOW

SLOT

LOW1

LOW0

RDV

SU

REC

RSTH

RSTL

60 120

1 15

60 120

exactly 15

0 15 45

1

1

480

480 4800

15 60

60 240

NOTES:

1. Temperature conversion will work with ±2°C accuracy down to V

2. All voltages are referenced to ground.

= 3.4V.

PUP

=2.8V to 6.0V)

PUP

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

DS1920

8

6,7

3. IDD specified with low impedance pull up to 5.0V.

4. Active current refers to temperature conversion.

5. Writing to EEPROM consumes approximately 200 µA.

6. t

may be up to 4800 µs. With longer times, the result of temperature conversion may get lost.

RSTL

7. The reset low time should be restricted to a maximum of 960 ms, to allow interrupt signaling,

otherwise it could mask or conceal interrupt pulses.

8. Read data setup time refers to the time the host must pull the 1-Wire bus low to read a bit. Data is

guaranteed to be valid within 1 µs of this falling edge and will remain valid for 14 µs minimum. (15

µs total from falling edge on 1-Wire bus.)

9. Capacitance on the data contact could be 800 pF when power is first applied. If a 5kΩ resistor is used

to pull up the data line to VCC , 5 µs after power has been applied, the parasite capacitance will not

affect normal communications.

10. Under certain low voltage conditions V

may have to be reduced to as much as 0.5V to always

ILMAX

guarantee a presence pulse.

11. See Typical Curve for specification limits outside the 0°C to 70°C range. Thermometer error reflects

sensor accuracy as tested during calibration.

21 of 22

Page 22

TYPICAL PERFORMANCE CURVE

DS1920 TEMPERATURE iButton

DS1920

TRUE TEMPERATURE (°C)

Error = Reading - True Temperature

When cold, the true temperature is typically colder than the temperature reading

22 of 22

Loading...

Loading...